Sony KDF 55WF655K, KDF 60WF655K Service Manual

HISTORY

When clicking an item, it’s detail is displayed.

Model Name: KDF-55WF655K/60WF655K

SERVICE MANUAL

Part No. : 9-872-748-01

Date SUPP./CORR. Description of SUP/COR

2005.3 – NEW –

Change of

main text

SERVICE MANUAL

LA-3

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

KDF-55WF655K

KDF-60WF655K

RM- KD001

RM- KD001

Korea

Korea

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

KDF-55WF655K

RM-KD001

LCD PROJECTION TV

Specifications

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

Power Requirements 220V AC, 60Hz

Power Consumption (W)

In Use (Max) 250W

In Standby Under 20W Less than 1w

Inputs/Outputs HDMI IN

Video - 1080i, 720p, 480p, 480i

Audio - Two channel linear PCM

32, 44.1 and 48 kHz, 16, 20, and

24 bit

Video (IN)

4 total (1 on front panel)

1Vp-p, 75ohms unbalanced, sync

negative

S Video (IN)

4 total (1 on front panel)

Y: 1Vp-p, 75ohms unbalanced,

sync negative

C: 0.286Vp-p (Burst signal),

75ohms

Audio (IN)

7 total (1 on front panel)

500 mVrms (100% modulation)

Impedance:47 kilo ohms

Audio (VAR/FIX) Out

1 total

500 mVrms at the maximum vol

ume setting (Variable)

500 mVrms (Fixed)

Impedance (Output):2 kilo ohm

Note: Audio Out jacks are opera

ble only when the TV’s speaker

is set to Off.

Control S (IN)

1 total

Minijack

Control S (OUT)

1 total

Minijack

Component Video Input

, PR)

2 (Y, P

B

Y : 1.0 Vp-p, 75 ohms unbalanced, sync negative

: 0.7 Vp-p, 75 ohms;

P

B

: 0.7 Vp-p, 75 ohms

P

R

RF Inputs

2 total

Digital Audio Optical Output

(PCM/Dolby Digital)

1 total

Optical Rectangular (1)

Speaker Output (W)

L/R 5W x 2

Woofer 20W

Dimensions (W x H x D)

mm 1,456 x 943 x 491 mm 1,574 x 1,005 x 518 mm

in 57

Mass

kg 46 kg 50.5 kg

lbs 101 lbs 7 oz 111 lbs 5 oz

TruSurround, SRS and the (z)® symbol are trademarks

of SRS Labs, Inc.

TruSurround technology is incorporated under license

from SRS Labs, Inc.

BBE and BBE Symbol are trademarks of BBE Sound,

Inc. and are licensed by BBE Sound, Inc. under U.S.

Patent No. 4,638,258 and 4,482,866.

Manufactured under license from

Dolby Laboratories Licensing

Corporation. Dolby and the double-D

symbol are trademarks of Dolby

Laboratories Licensing Corporation.

KDF-55WF655K KDF-60WF655K

3/8

1/4

x 37

3/8

x 19

in 62 x 39

5/8

x 20

1/2

This TV incorporates High-Definition

Multimedia Interface (HDMI™)

technology. HDMI, the HDMI logo

and High-Definition Multimedia

Interface are trademarks or registered

trademarks of HDMI Licensing LLC.

WEGA, Steady Sound, Digital Reality Creation,

CineMotion, Memory Stick, Memory Stick Duo,

Memory Stick PRO, Memory Stick PRO Duo,

MagicGate, MID and Twin View are trademarks of Sony

Corporation.

in

Design and specifi cations are subject to change without notice.

– 2 –

Television system

(Digital signal with Atsc compliant 8USB is only supported)

American TV standard, NTSC

ATSC compliant 8VSB, ATSC (8VSB terrestrial)

Channel coverage

Terrestrial 2-69/ Cable TV: 1-125 (analog)

Terrestrial: 2-69/ Cable TV: 1-135 (digital)

Screen Size (measured diagonally)

55 inches (KDF-55WF655 Only)

60 inches (KDF-60WF655 Only)

Antenna

75-ohm external antenna terminal for VHF/UHF

Projection System

3 LCD Panels, 1 lens projection system

LCD Panel

0.87 inch TFT LCD panel Approx. 3.28 million dots

(1,042,168 pixels)

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

Projection Lens

High Performance, large diameter hybrid lens F2.4

Lamp

UHP lamp, 120W, XL-2300

Supplied Accessories

Remote Commander RM-KD001

Two Size AA (R6) Batteries

– 3 –

WARNING!!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECElVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PAR TS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESECOMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL TO SAFEOPERATION ARE IDENTIFIED IN THIS

MANUAL. FOLLOW THESE PROCEDURES WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

– 4 –

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

Section Title Page

–––––– –––– ––––

1. SELF DIAGNOSIS FUNCTION ................................... 6

2. DISASSEMBLY

2-1. REAR COVER.......................................................... 11

2-2. OU BRACKET ......................................................... 11

2-3. CHASSIS ASSEMBLY AND FAN........................... 12

2-4. SERVICE POSITION ............................................... 12

2-5. POWER SUPPLY BLOCK(LAMP DRIVE UNIT),

OPTICS UNIT BLOCK, T BOARD......................... 13

2-6. RF ANTENNA SWITCH AND P BOARD .............. 13

2-7. U AND H4 BOARDS ............................................... 14

2-8. F BOARD AND G1 BOARD ................................... 14

2-9. A BOARD AND KD BOARD .................................. 15

2-10. Q BOX ASSEMBLY AND B BOARD ..................... 15

2-11. G2 BOARD ............................................................... 16

2-12. WOOFER .................................................................. 16

2-13. D.C. FAN................................................................... 17

2-14. FRONT COVER ASSEMBLY ................................. 17

2-15. HM BOARD AND H2 BOARD ............................... 18

2-16. H1 BOARD ............................................................... 18

2-17. SCREEN MIRROR BLOCK ASSEMBLY .............. 19

2-18. MIRROR COVER ASSEMBLY, H3 BOARD

AND SPEAKER ....................................................... 19

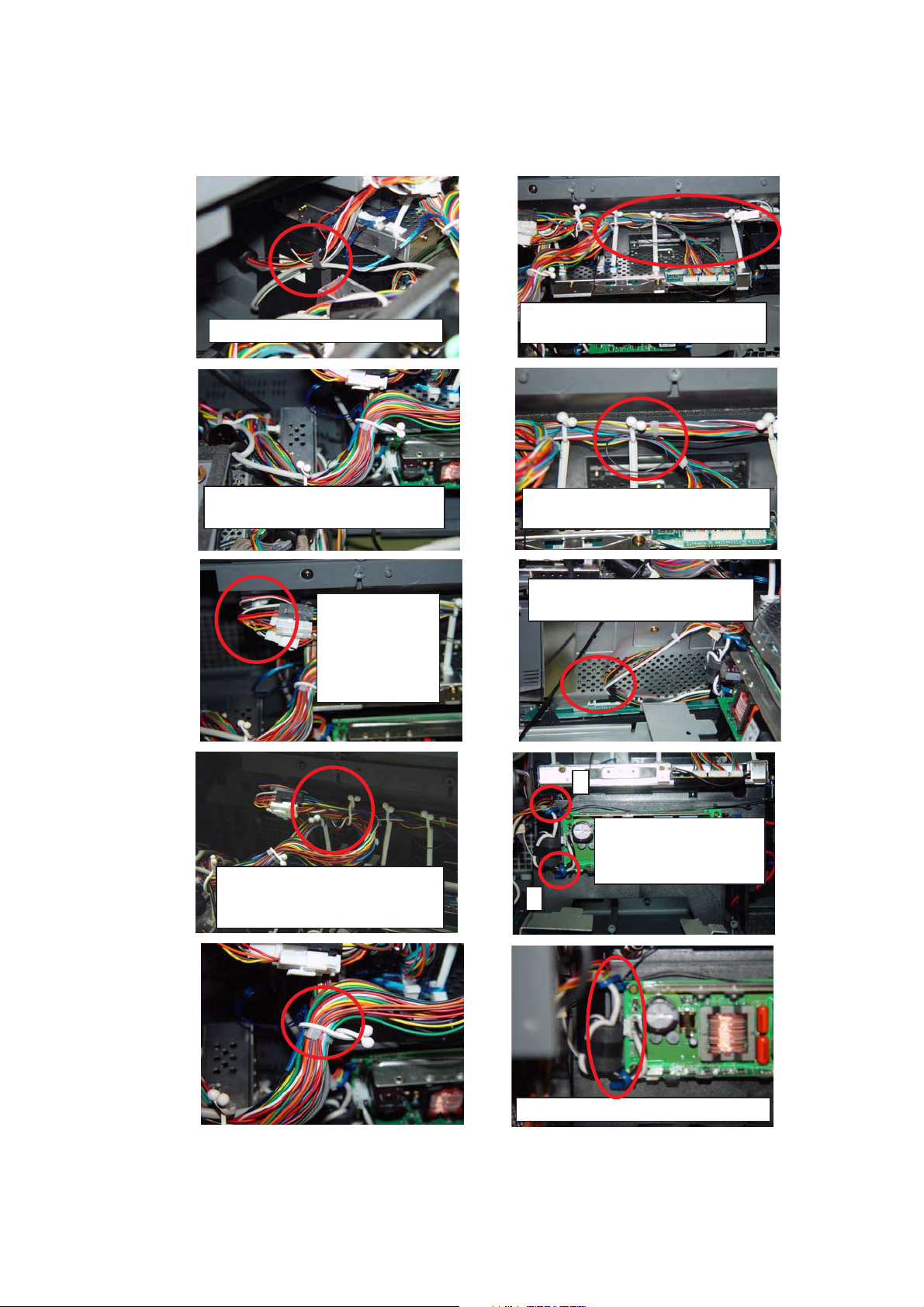

3. WIRE DRESSING ........................................................... 20

4. CIRCUIT ADJUSTMENTS

4-1. SETTING THE SERVICE ADJUSTMENT MODE 24

4-2. SERVICE ADJUSTMENT MODE MEMORY ........ 24

4-3. MEMORY WRITE CONFIRMATION METHOD .. 25

4-4. REMOTE ADJUSTMENT BUTTONS

AND INDICATORS ................................................. 25

4-5. H/V CENTER CONFIRMATION AND

ADJUSTMENT ......................................................... 26

4-6. SERVICE DATA ....................................................... 27

4-7. ID MAP TABLE........................................................ 27

Section Title Page

–––––– –––– ––––

5. DIAGRAMS

5-1. CIRCUIT BOARDS LOCATION ................................. 27

5-2. SCHEMATIC DIAGRAMS AND

PRINTED WIRINGS INFORMATION ........................ 27

5-3. BLOCK DIAGRAM ................................................. 28

5-4. SCHEMATIC DIAGRAMS .......................................... 29

(1) Schematic Diagram of A (1/3) Board ................ 29

(2) Schematic Diagram of A (2/3) Board ............... 30

(3) Schematic Diagram of A (3/3) Board ............... 31

(4) Schematic Diagram of F Board ........................ 32

(5) Schematic Diagram of G1 (1/2) Board ............. 33

(6) Schematic Diagram of G1 (2/2) Board ............. 34

(7) Schematic Diagram of G2 (1/2) Board ............. 35

(8) Schematic Diagram of G2 (2/2) Board ............. 36

(9) Schematic Diagram of H1, H2 Boards ............. 37

(10) Schematic Diagram of H3, H4, HM Boards ..... 38

(11) Schematic Diagram of KD Board ..................... 39

(12) Schematic Diagram of P, T Boards ................... 40

(13) Schematic Diagram of U Board ....................... 41

5-5. PRINTED WIRING BOARDS...................................... 42

• A Board (Component Side) ................................... 42

• A Board (Conductor Side) .................................... 43

• F Board ................................................................. 44

• G1 Board (Component Side) ................................ 45

• G1 Board (Conductor Side) .................................. 46

• G2 Board (Component Side) ................................ 47

• G2 Board (Conductor Side) .................................. 48

• H1, H2, H3 Boards ............................................... 49

• H4, HM Boards ..................................................... 50

• KD Board .............................................................. 51

• P, T, U Boards ....................................................... 52

5-6. SMICONDUCTORS ..................................................... 53

6. EXPLODED VIEWS

6-1. SCREEN MIRROR BLOCK, COVERS .................. 54

6-2. BOTTOM BLOCK ................................................... 55

6-3. MAIN BRACKET-1 ................................................. 56

6-4. MAIN BRACKET-2 ................................................. 57

6-5. OPTICS UNIT BLOCK ............................................ 58

7. ELECTRICAL PARTS LIST ........................................ 59

• A Board ............................................................................... 59

• F Board ............................................................................... 65

• G1 Board ............................................................................. 66

• G2 Board ............................................................................. 69

• HM Board ........................................................................... 72

• H1 Board ............................................................................. 73

• H2 Board ............................................................................. 73

• H3 Board ............................................................................. 74

• H4 Board ............................................................................. 74

• KD Board ............................................................................ 74

• P Board ................................................................................ 77

• T Board ............................................................................... 80

• U Board ............................................................................... 80

APPENDIX ........................................................................... 1

– 5 –

KDF-55WF655K/60WF655K

SECTION 1

RM-KD001 RM-KD001

SELF DIAGNOSIS FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the /STANDBY or LED will automatically begin

to flash.

The number of times the LED fl ashes translates to a probable source of the problem. A defi nition of the /STANDBY or LED

flash indicators is listed in the instruction manual for the user’s knowledge and reference. If an error symptom is diffi cult to reproduced

use the Remote

Commander to display the record that is stored at the internal NVM to specify the cause of the failure.

Diagnostic Test Indicators

When an error occurs, the /STANDBY or LED will fl ash a set number of times to indicate the possible cause of the problem.

If there is more than one error, the LED will identify the fi rst of the problem areas. If the errors occur simultaneously, the one that

corresponds to the fewest flashes is identifi ed fi rst.

Results for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

Diagnostic Item Number of times

Description /STANDBY or LED Probable Cause Detected Symptoms

lamp flashes

Lamp cover error 3 times

Fan error 4 times - Fan connector is not seated securely - No picture/No sound

Temp error 4 times - IIC-E line connector is not seated properly - No picture/No sound

Lamp driver error 5 times - Lamp driver defect - No picture/No sound

Low B error 6 times -No “DD 6V “ output (G1 board) - No picture/No sound

Audio error 7 times

D-OVP error 8 times

ATSC-OVP error 10 times

Lamp error

-LED is ON. - Lamp is dead - No picture/No sound

- Lamp cover is not fastened securely

- Fan1-4 Power is not supplied.(G2 board)

- Fan caught wires or harnesses

- Internal temperature is too high

(WE:H3 board, WF/XS:H4 board)

- Short-circuit of Audio power supply line

(KD board, G1 board)

- Blowout of a fuse

(PS4702,PS4703,PS4704 on KD board)

- IC failure

(IC4703,IC4708,IC4710 on KD board)

- Overvoltage of +3.3V or +2.5V

(A board, B board)

-No “DTL MODULE 5V “ output

(G1 board, G2 board)

- No picture/No sound

- No picture/No sound

- No picture/No sound

- No picture/No sound

– 6 –

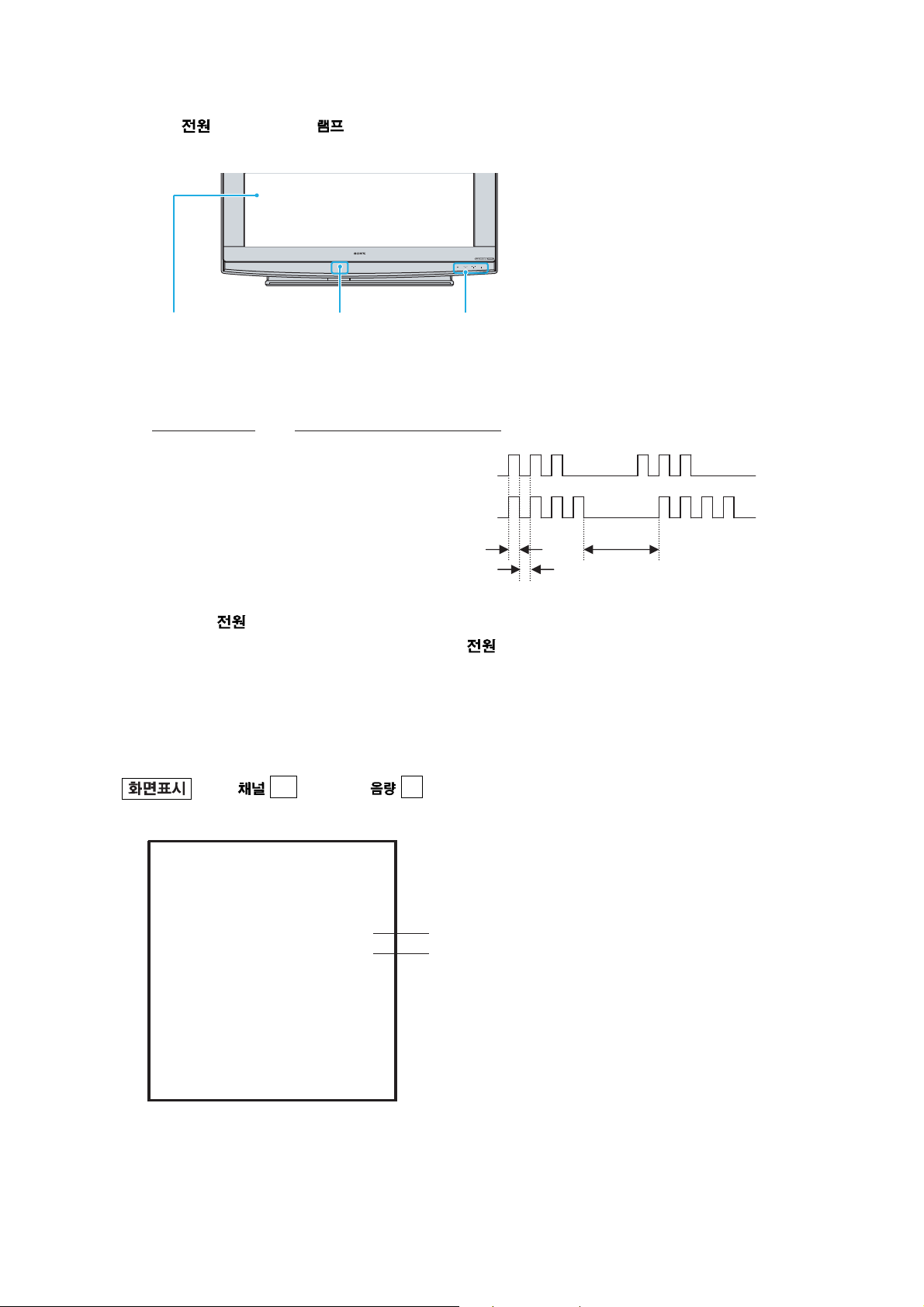

Display of /STANDBY or LED Flash Count

LAMP TIMER POWER/STANDBY

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

POWER

PRO

STD/DUO

Screen

Proj ection l amp

Indicators

-Oneflash is notusedfor self-diagnosis.

-Example

Diagnosis

Number of times LED Flash

Lamp cover 3 times

Fan 4 times

LED ON : 0.3sec

LED OFF : 0.3sec

LED OFF

3.0sec

Releasing the /STANDBY LED Flash

Unplug the power cord from the outlet to temporarily stop the /STANDBY lamp from flashing.

Self-Diagnosis Screen Display

For failures that are diffi cult to reproduce, or accompany occasional power off and/or picture mute, the Self-Diagnosis screen display is

useful to specify the cause.

To Bring Up Screen Test

In standby mode, press the buttons on the Remote Commander sequentially, in rapid succession, as shown below:

1.

Self-Diagnostic Screen Display

t 5 t - t Power ON

SELFCHECK

1:LAMP ERR 0

3:

LAMP COVER 0

FAN-E/TEMP-E 1

4:

5:LAMP DRIVER

0

"1" is displayed when a failure is detected one or more times

"0" is displayed when no failure has been detected

6:LowB-ERR 0

7:Audio-Prot

1

8:D-OVP 0

10 : ATSC_OVP 0

101 : WDT 0

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen during repairs.

When you have completed the repairs, clear the result display to “0”.

Note: The self-diagnostic function will not be able to detect any subsequent faults after completion of the repairs unless the result

display is cleared to “0”.

– 7 –

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

Clearing the Result Display

To clear the result display to “0”, press the buttons on the Remote Commander sequentially when the diagnostic screen is displayed, as

shown below:

1. If the screen is already displayed, proceed to step 3. If not, Power off (Set to Standby model).

2. Press

3. Press

Clearing the Self-Diagnostic Screen

The self diagnosis screen display is cleared by turning off the set using the Remote Commander or the power switch.

Self-Diagnostic Circuit

Self-Diagnosis Function Operation

3 : Lamp cover The rib at the back of the lamp cover closes the SW on the T board to ground pin 3 of

4 : Fan Fan rotation is detected by “FAN-PROT” and the DE-micro (pin 92 of IC6902) turns off the

4 : Temp When the temperature sensor on the H3 board (WE models) or H4 board (WF/XS models)

5 : Lamp driver When the “LAMP-PROT” (pin 95) is low, the lamp is not turned on. If the “LAMP-HV-

6 : Low B error When no “DD 6V “ is detected, pin 129 of TV-micro is low and it turns off the main power.

7 : Audio When DC voltage is detected at the speaker or woofer outputs, pin 128 of TV-micro is low

8 : D-OVP When overvoltage of “+3.3V” or “+2.5V” is detected, pin 126 of TV-micro is low and it

10 : ATSC-OVP When no “Digital Module 5V” is detected, pin 127 of TV-micro is low and it turns off the

LAMP : Lamp When the “LAMP-PROT” (pin 95) is low, the lamp is not turned on. If the “LAMP-HV-

t 5 t – t 1 ON

8 t ENTER

CN8001.

It is monitored by the DE-micro (pin 94 of IC6902) and turns off the lamp when it is opened.

lamp when it is “high”.

detects high temperature, or IIC-E line connector (CN6022:G2 board, CN44:H3board/

H4board) is not seated securely, the DE-micro turns off the lamp.

DET”(pin 96) is low at the same time, it is classified as no high voltage of the lamp driver.

and it turns off the main power.

turns off the main power.

main power.

DET” (pin96) is high at the same time, it is classified as no lamp or a dead lamp.

– 8 –

Self-Diagnosis Block Diagram

H4 board

IC41

Temp

4:Temp

sensor

KD board

Audio

amp

A board

+3.3V

7:Audio

8:D-OVP

+2.5V

G1 board

DD6V

6:LowB

error

DTL5

IC6902

Display Engine u-com

IIC-E

LAMP-COVER

LAMP-PROT

LAMP-HV-DET

CN6029

23

CN6020

C26

CN6029

23

CN6006

G2 board

FAN PROT

IIC-WE

92

94

95

96

CN6017

4:Fan

11

14

13

14

A8

A14

B14

16

CN6000

2

5

8

CN6022

8

CN6019

12:ATSC

CN6023

515

FAN1-PRT

FAN2-PRT

FAN3-PRT

FAN4-PRT

3:Lamp cover

5:Lamp

driver

OVP

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

Fan1

Fan2

Fan3

Fan4

T board

S8001

SW

Lamp driver

HV-DET

B

IC3801 WE u-com

IIC-WE

IIC-TV

IC3604 TV u-com

IIC-TV

SP_DC_PROT

128

126

D_OVP

LB_ERROR

129

127

ATSC_OVP

Digital Box

DTL MDL5V

Lamp

– 9 –

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

Reading Lamp and Panel time

Use the following to determine the lamp and panel time of a set.

Screen Display Method

In standby mode, press the buttons on the Remote Commander sequentially, in rapid succession, as shown below:

+

1. Press

2. To enter the DE-micro service menu, press

3. To display the Lamp time, press

5

2

ex am ple

PANEL NVM OK 9 OPTION_E

0 LAMP 0 Diff

Lam pTM 14 Lam pCT 71

The screen displays:

“T

otal lamp time is 14 hours” and “T

9 times.

otal lamp ON/OFF cycle is 71 times”

3 times.

1

Power ON

To reset the lamp time press

WRI-EXE(Character color is Red) is momemtarily displayed and LampTM is

reset to “0”.

4. To display the Panel time, press

3

1

7 times

.

ex am ple

PANEL NVM OK 9 OPT ION_E

7 SH SFT1 10 Diff 1

PanelTM 14h

The screen displays:

“T

NOTE: You cannot reset the Panel time with the Service menu.

otal Panel time is 14 hours”

Exiting Service Mode

After completing the changes exit service mode by turning off the set using the Remote Commander or the power switch.

– 10 –

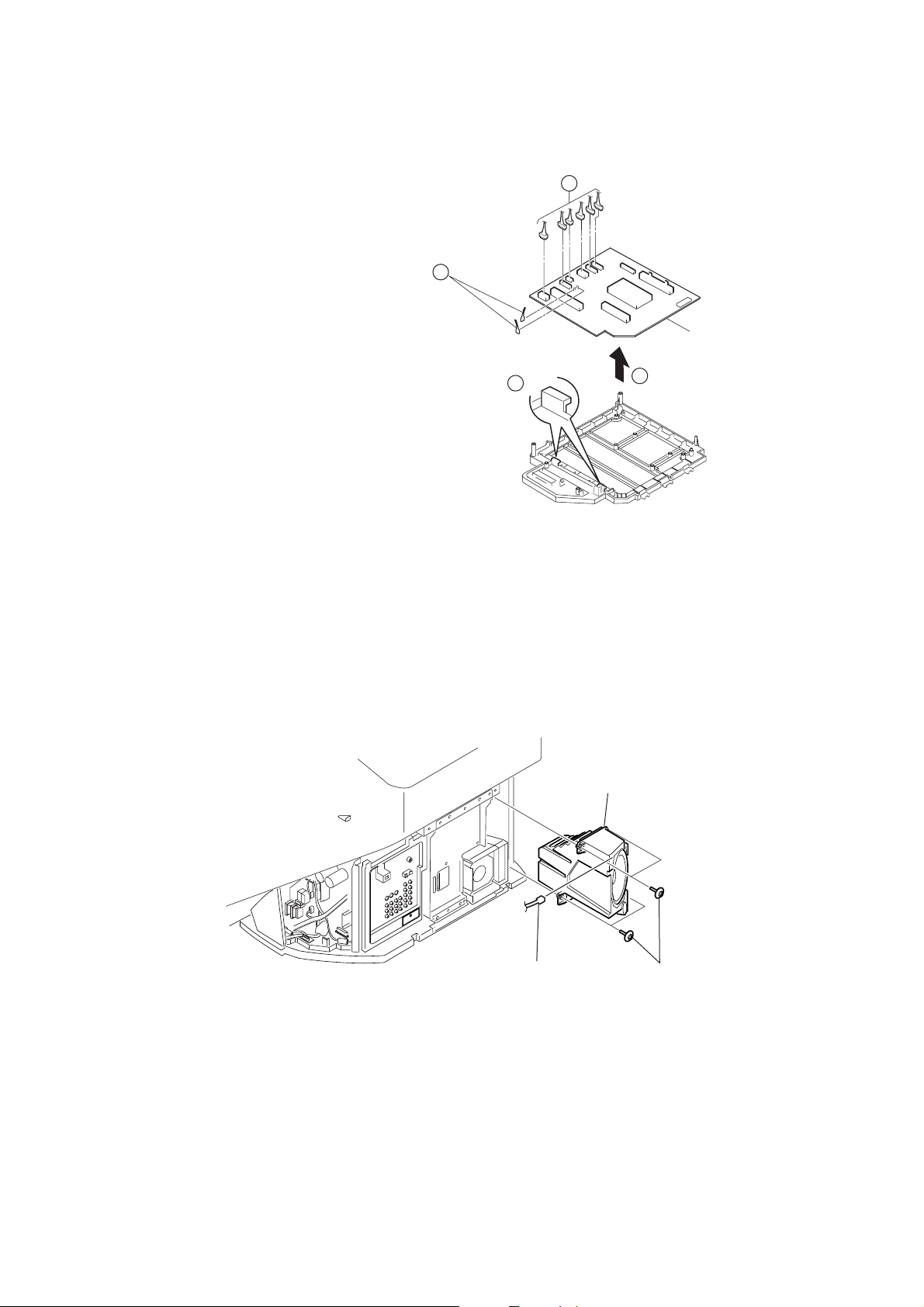

2-1. REAR COVER

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

SECTION 2

DISASSEMBLY

Rear cover

2-2. OU BRACKET

4

6 OU bracket

1

Thirteen screws

(+BVTP 4x16)

1 Screw

(+BVTP 4x16)

2 Two screws

(+BVTP 4x16)

5 Three

fasten tags

– 11 –

3 Two screws

(+BVTP 4x16)

2-3. CHASSIS ASSEMBLY AND FAN

4 Chassis assembly

3

2 Side stay (R)

6 Fan bracket (chassis)

with DC fan

1 Screw

(+BVTP 4x16)

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

5 Three screws

(+PTPWH 4x16)

2-4. SERVICE POSITION

Chassis assembly

Pull back on claw, then gently pull out chassis assembly

1

– 12 –

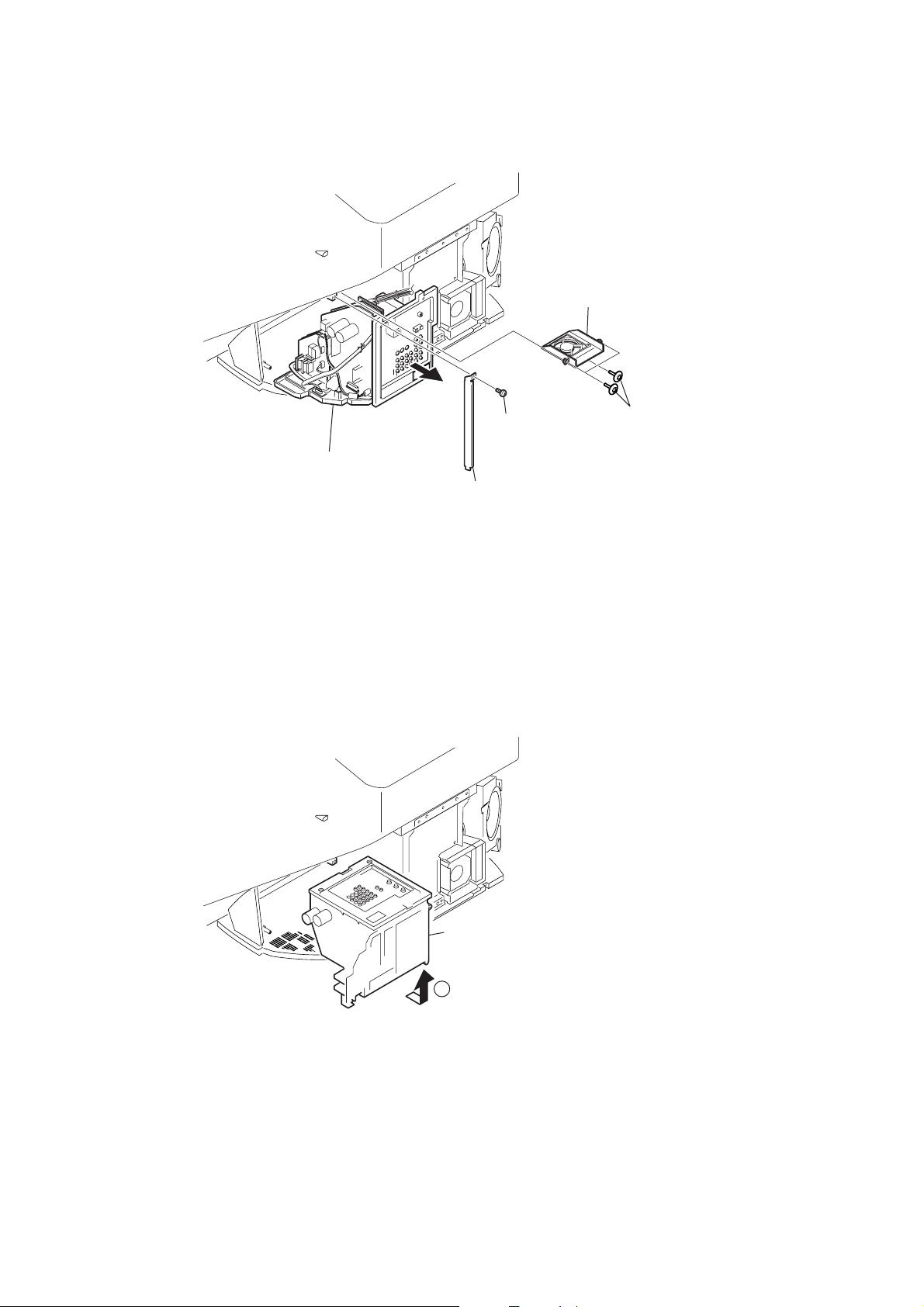

KDF-55WF655K/60WF655K

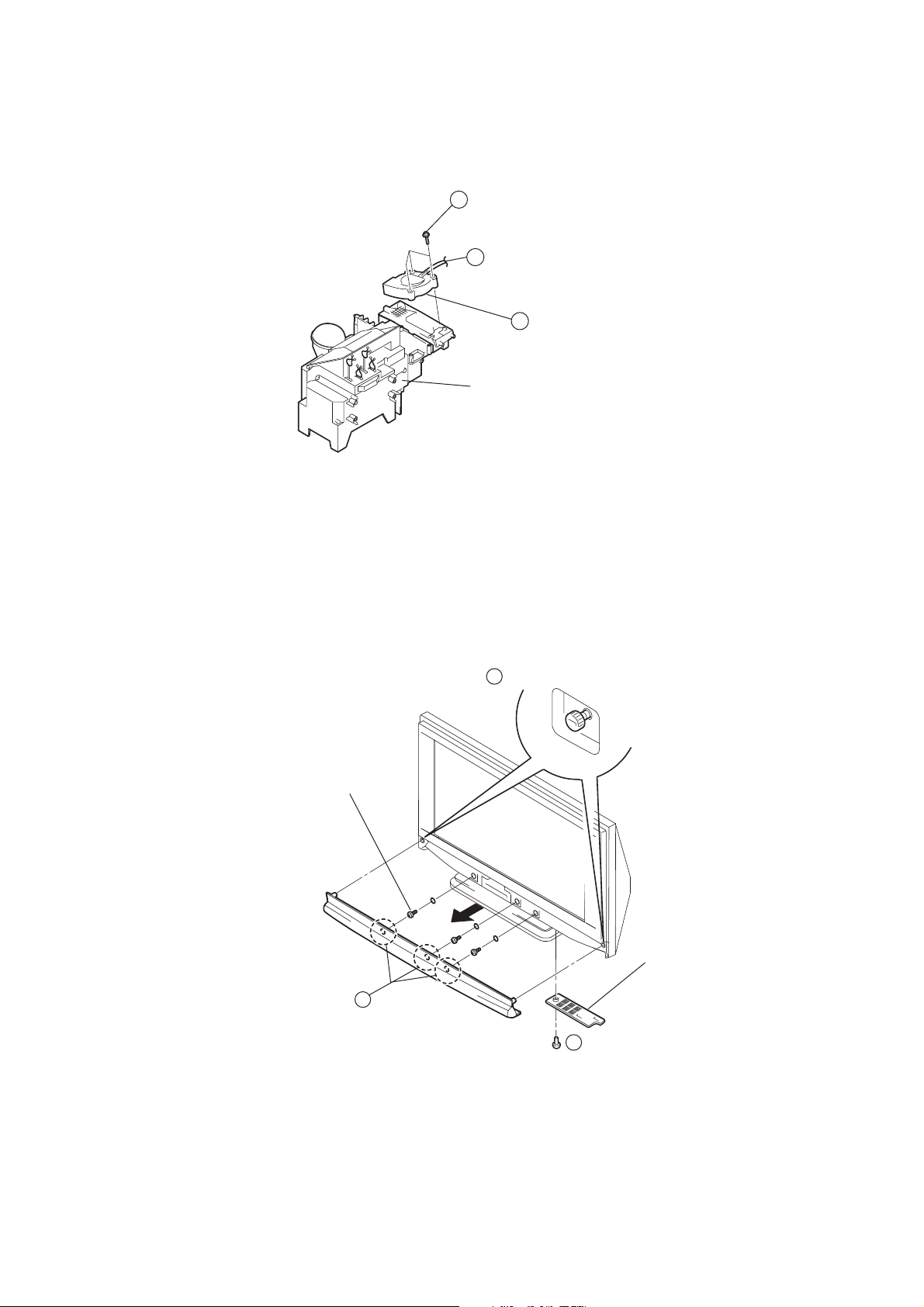

2-5. POWER SUPPLY BLOCK (LAMP DRIVE UNIT), OPTICS UNIT BLOCK, T BOARD

CAUTION: When removing the Power Supply Block be careful not to move the Optics Unit Block

RM-KD001 RM-KD001

qa T board

CAUTION: When removing the Power Supply Block

be careful not to move

the Optics Unit Block

1 Remove the duct fan bracket with DC fan

3 Two screws (+PWH 4x16)

4 Unhook the

antenna cable

7 Power

supply

block

2 Disconnect two connectors

(to detach the cables from the

Optics Unit Block Assembly)

6

5 Four screws

(+BVTP 3x12)

2

5

6 Optics unit block assembly

(with power supply block)

0 Screw

(+BVTP 3x12)

9 Duct fan bracket 2

8

7 Two screws

(+BVTP 4x16)

3 Duct fan bracket

with DC fan

1 Screw

(+BVTP 4x16)

4 Loosen two screws

2-6. RF ANTENNA SWITCH AND P BOARD REMOVAL

Disconnect one connector

and the ground wire

Two screws

7

6

(+BVTP 3x12)

P board

4

U bracket

5

RF antenna switch

Two hexagonal nuts

1

Screw (+PSWM 3x8)

2

Six Screws (+BVTP

3

3x12)

– 13 –

2-7. U AND H4 BOARDS

9

4

G1 board

5

Gently pull back on the three clips

on the pin connection slots

while slowly lifting the G1 Board.

Disconnect two connectors

(CN1601 and CN1602)

and one ground wire (CN1607)

Remove one screw

(+BVTP 3X12 TYPE2)

Disconnect two connectors

(CN1908 and CN1909)

and two ground wires

(CN1902 and CN1903)

Disconnect two connectors (CN1603 & CN1604)

8

Unfasten three Circuit Board Supports

Remove wires from purse locks

2

Disconnect the Power cord

from CN1900 connector.

7

3

1

6

Pull F Bracket out

and up to remove

Claw

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

One screw

(+BVTP 3X12)

2-8. F BOARD AND G1 BOARD

Gently pull back on tab to

release U board

2

3

Gently pull back on tabs

to release H4 board

1

U board

– 14 –

2-9. A BOARD AND KD BOARD

Disconnect three connectors

(CN4701, CN4705, and CN4702)

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

5

Disconnect three connectors

3

(CN8003, CN8004, and CN8008)

and coax cable from tuner

Unfasten two Circuit Board Supports

Gently pull back

4

2

on the three clips

on the Pin Connection slots

while slowly lifting the A board

A board

Remove cables

1

from purse locks

2-10. Q BOX ASSEMBLY AND B BOARD

KD board

Gently pull back

6

on the two clips

on the Pin Connection slots

while slowly lifting the KD board

Disconnect six connectors

Unplug two coax cables

connected to the antenna switch

Remove four screws

(+BVTP 3X12)

6

Remove two screws

8

(+BVTP

7

3X12 TYPE2)

Remove cables from purse locks

5

Q Box Assembly

Remove two connectors

9

2

(CN3501 and CN3502)

1

Remove cables from purse

B board

Remove two screws

3

(3X12), + BVWHTP

Gently pull back

4

on the two clips

on the Pin Connection slots

while slowly lifting the B board

– 15 –

2-11. G2 BOARD

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

Disconnect 6 connectors

(CN6000, CN6024,

CN6028, CN6021,

CN6023, and CN6022)

Disconnect 2 ground wires

(CN6013 and CN6015)

Gently pull back on the two clips

while slowly lifting the G2 Board.

2

1

G2 board

3

3

2-12. WOOFER

3 Woofer block assembly

1 Connector

2 Four screws

(+PTPWH 4x16)

– 16 –

2-13. D.C. FAN

KDF-55WF655K/60WF655K

2

Three screws

(+BVTP 3x12)

1

Disconnect two connectors

3

D.C. Fan

Optics Unit block assembly

RM-KD001 RM-KD001

2-14. FRONT COVER ASSEMBLY

Three screws

(+BVTP 3X12 TYPE2)

Gently pull the

Front cover assembly forward.

Note the area of the 3 magnets

holding the cover

1 Two ornamental screws

Cable Cover

2

3

One screw

(+BVTP 3X12)

2-14-2. REPLACING THE LAMP

For detailed instructions on replacing the lamp, see

Page 16 of the Operating Instructions manual.

– 17 –

2-15. HM BOARD AND H2 BOARD

1

Two screws

(+BVTP 3X12 TYPE2)

Two screws

(+BVTP 3X12 TYPE2)

Pull back on the clip

while lifting the HM board up

HM board

Disconnect one connector

(CN7301)

One screw

(+BVTP 3x12)

Disconnect one connector

(CN4502)

2

3

5

6

Disconnect USB cable

4

6

H2 board

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

2-16. H1 BOARD REMOVAL

Disconnect one connector

Screen mirror block assembly

3

H1 board

H1 board

H1 button

H1 bracket

– 18 –

Gently pull back on the bottom tab

4

of the H1 bracket then slide out the H1 board

One screw

2

(+BVTP 4x16)

1

Using tweezers gently detach the

H1 Bracket Cap

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

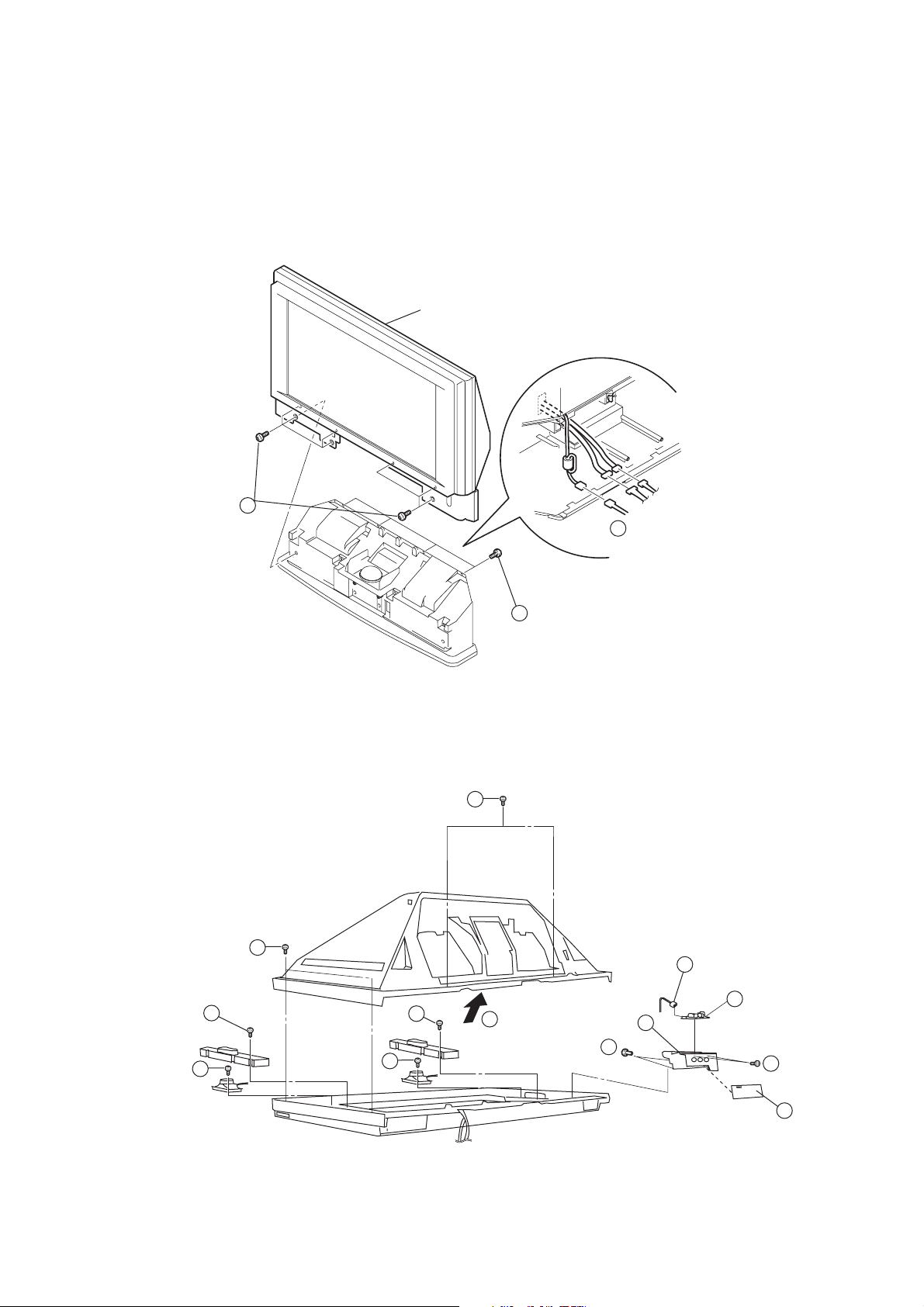

2-17. SCREEN MIRROR BLOCK ASSEMBLY

Caution:

When repairing anything inside the Screen Mirror Block Assembly be sure to clean the mirror and Diffusion Plate

to remove any dust particles.

Note: Be sure to remove the screws that secure

the reinfocement plates (R)/(L).

Screen mirror block assembly

Seven screws

(+BVTP 4x16)

3

2

Four screws

(+BVTP 4x16)

2-18. MIRROR COVER ASSEMBLY, H3 BOARD AND SPEAKER

Four screws

2

(+BVTP 4X16)

Sixteen screws

(+BVTP

4X16)

1

1

Disconnect three connectors

11

Disconnect one connector

Eight screws

(+BVTP

4X16)

Four screws

(+BVTP 4X16)

10

4

5

4

5

3

Lift bracket out

Two screws

(+BVTP 4x16)

7

6

Lift H3 board up,

then pull back to remove

from bracket

9

Two screws

(+BVTP 4x16)

8

Remove H3

Bracket door

– 19 –

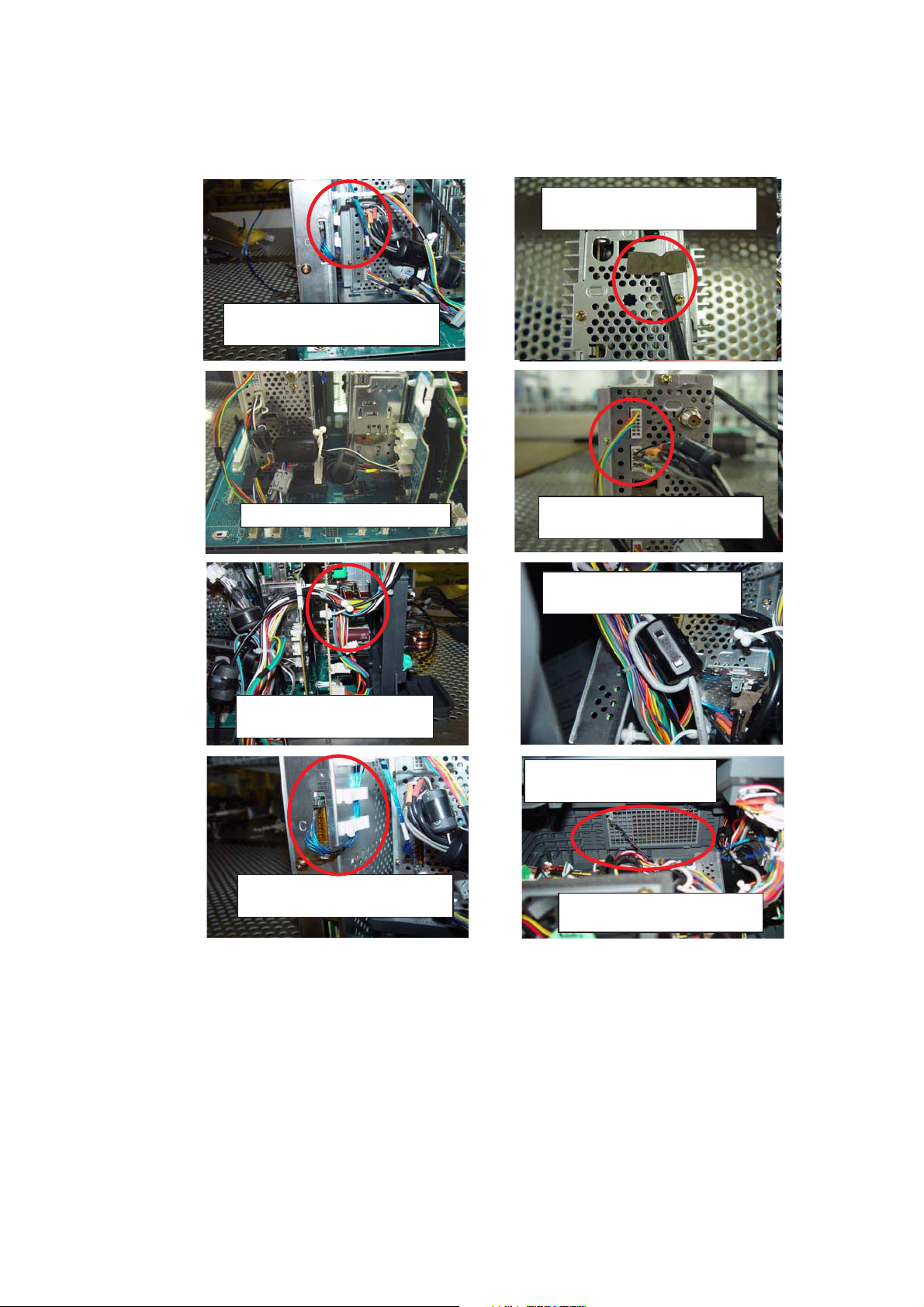

[F] EMI Shield wire around

2nd post

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

SECTION 3

WIRE DRESSING

Make sure purse lock is

completely seated to [G1]

Tie btwn 1st & 2nd posts

Blk/Wht to the right

Use Coated Lead Pin to keep

wires from migrating into

Primary Ckt

Make sure Coated Lead

Pin does not touch

[G1] heat sink

USB cable must stay to right

side of [B]

[KD] wires are secured to free

purse lock, not ATSC Box

Make sure 8 pin connector is

fully seated

– 20 –

LVDS Cables dresses behind

purse lock

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

Emi Tape added to Sub Tuner

cable

Detail of front side ATSC Box

Detail of front side [G1] All wires through purse lock

Detail of front side ATSC Box [C1] LVDS dressing

Top connector wires must be to

the left of lower wires

Detail of USB around ATSC

Box Area

Bend GND tab after wire is

installed

USB Cable must not touch

metal grill for EMI issue

– 21 –

Tape must avoid OP Block Label

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

Sensor wire should be in left

three purse locks

Purse Lock must be to the right of

the cable tie position

Front side

harnesses

dressed

through bottom

block purse lock

Front side harnesses dressed

behind the 1st [C1] purse lock &

secured with free purse lock

Loop sensor wire at the 2nd purse

lock position

Clip position move to avoid wire

touching Emi Shield

2

Dress Drvr harness

through bottom coated

lead pin then the top

1

Left Side Coated Lead Pins details

– 22 –

Right Side Coated Lead Pins

details

Twist Coated Lead inward to

avoid contact with fan assembly

after installation

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

– 23 –

SECTION 4

CIRCUIT ADJUSTMENTS

4-1. SETTING THE SERVICE ADJUSTMENT

MODE

To adjust various set features, use the Remote Commander to put the

set into service mode to display the service menus.

1. TV must be in standby mode. (Power off).

2. Press the following buttons on the Remote Commander within a

second of each other:

The first service menu (TV) displays.

3. To display the service menu that contains the category you want

to adjust, press on the Remote Commander.

(Refer to Service Menus)

Service Menu

t 5 t + t 1 .

Category

Ircnmetne

ste sp

TV

VERSION

CXA2209Q

AP

DLBY

BUSSW

CXA2103

CXA2163

2DCOMB

Q BOX

QM

QT

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

SERVICE MENUS

(CATEGORIES ONLY)

WEM 2

(WEGA ENGINE)

DCP-INT

DCP-OSD

DCP-BLK

DCP-ADJ1

DCP-ADJ2

DCP-USER

DCP-AVP

MID-1-9

PANEL

(DISPLAY ENGINE)

OP

A7001R

A7001G

A7001B

GB_RGB

FAN_CNT1

FAN_CNT2

TEMP

PANEL NVM OK 1 5D089T9PN

41RLVL_

Item #

H

4590

Data value

D

i ff1

Adjustment

item

Sample Panel (Display Engine) Service Menu

4-2. SERVICE ADJUSTMENT MODE MEMORY

The screen displays the • rst category in the selected service menu.

4. To change the category, press 2 or 5 on the Remote Com-

mander.

Note: Pressing 2 or 5 only changes the categories within the

service menu displayed. To change a category on one of the other

service menus, press the

menu is displayed.

5. To change the adjustment item, press 1 or 4 on the Remote

Commander.

6. To change the data value, press 3 or 6 on the Remote Com-

mander.

Note: To go back to the last saved data value, press - then

on the Remote Commander to read the memory.

7. To write into memory, press

Remote Commander.

8. To exit service mode, turn the power off.

button until the correct service

then on the

TELETEXT

MSP SIZE

MSPMD

MSPSEL

MSPFNC

MSP3714G

CCPS (1-11)

DELAY (1-2)

OSD

CC M

CC S

CC T

ID

OPB GA

OP GA

OP US

SNNR

SNSS

DRCVR

USER-NR

LPFC

CCPM-1 (1-12)

OVSN

OP

OSD_E

OPTION_E

S_MAS_M

S_MAS_S

J_L004

D9809_1

D9809PIC

D9809TPN

D9809CUR

D9809TG1

D9809 OSD

D9809HPF

D9809CSC

D9809CGA

D9809HUE

IMG_SHFT

PROT_CNT

– 24 –

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

4-3. MEMORY WRITE CONFIRMATION METHOD

1. After completing all adjustments turn the set off with the Remote Commander and WAIT for the fans to turn off before proceeding to the

next step.

Note: It may take up to two minutes for the fans to stop.

Caution: To avoid over heating the lamp, do not unplug the set until the fans have stopped.

2. After the fans have stopped, unplug the set from the AC outlet, then plug the set back in the AC outlet.

3. To verify the changes repeat steps 2 through 5 from sections 2-1. Setting the Service Adjustment Mode and 2-2. Service Adjustment Mode

Memory.

4. To exit service mode, turn the power off.

Note: To restore the User Controls and Channel Memory settings to the preset factory conditions, put the set into service mode (step

2 from 2-1. Setting the Service Adjustment Mode), then press 8 then

display the initial setup screen.

4-4. REMOTE ADJUSTMENT BUTTONS AND INDICATORS

Write into

memory

Adjustment

item up

1

on the Remote Commander. The set will restart and

1

3

Data value up

Category up

Adjustment

item down

Restore User Control

and Channel Memory

2

4

8

(+)

6 Data value down

5 Category down

Display Service Menue

RM-KD001

– 25 –

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

4-5. H/V CENTER CONFIRMATION AND ADJUSTMENTS

Please check the picture horizontal/vertical center after the replacement of the Optics Unit Block Assembly or any part of the Top assembly.

1. Check the H/V center with 480i monoscope signal in “Full” mode.

2. If the center is shifted, adjust using the following service items:

NOTE: Please record the steps shifted as MDHP and MDVP .

MID-X1 9 MDHP (for H center)

10 MDVP (for H center)

MDVP

MDHP

3. Change the WIDE mode to “Normal” and change the register data as follows:

MID-X1 9 MDHP + MDHP

(Don’t change the MDVP data)

4. Display the Twin Picture with the “split” button of the remote commander and change the registers data as follows:

MID-X1 9 MDHP + MDHP

10 MDVP +

5. Press “Favorites” button and change the registers data as follows:

MID-X1 9 MDHP +

10 MDVP +

MDVP

MDHP

MDVP

6. OSD horizontal position must be adjusted as follows:

If above sum exceeds 255, set 1 to “16 RP1H” and set the “sum-256” to “17 RP1L”.

Since the registers are different from other cases, be careful to follow complete instructions, and write the data before changing the

display/ wide mode .

4-6. SERVICE DATA

Please refer to the appendix for details.

– 26 –

SECTION 5

(

)

DIAGRAMS

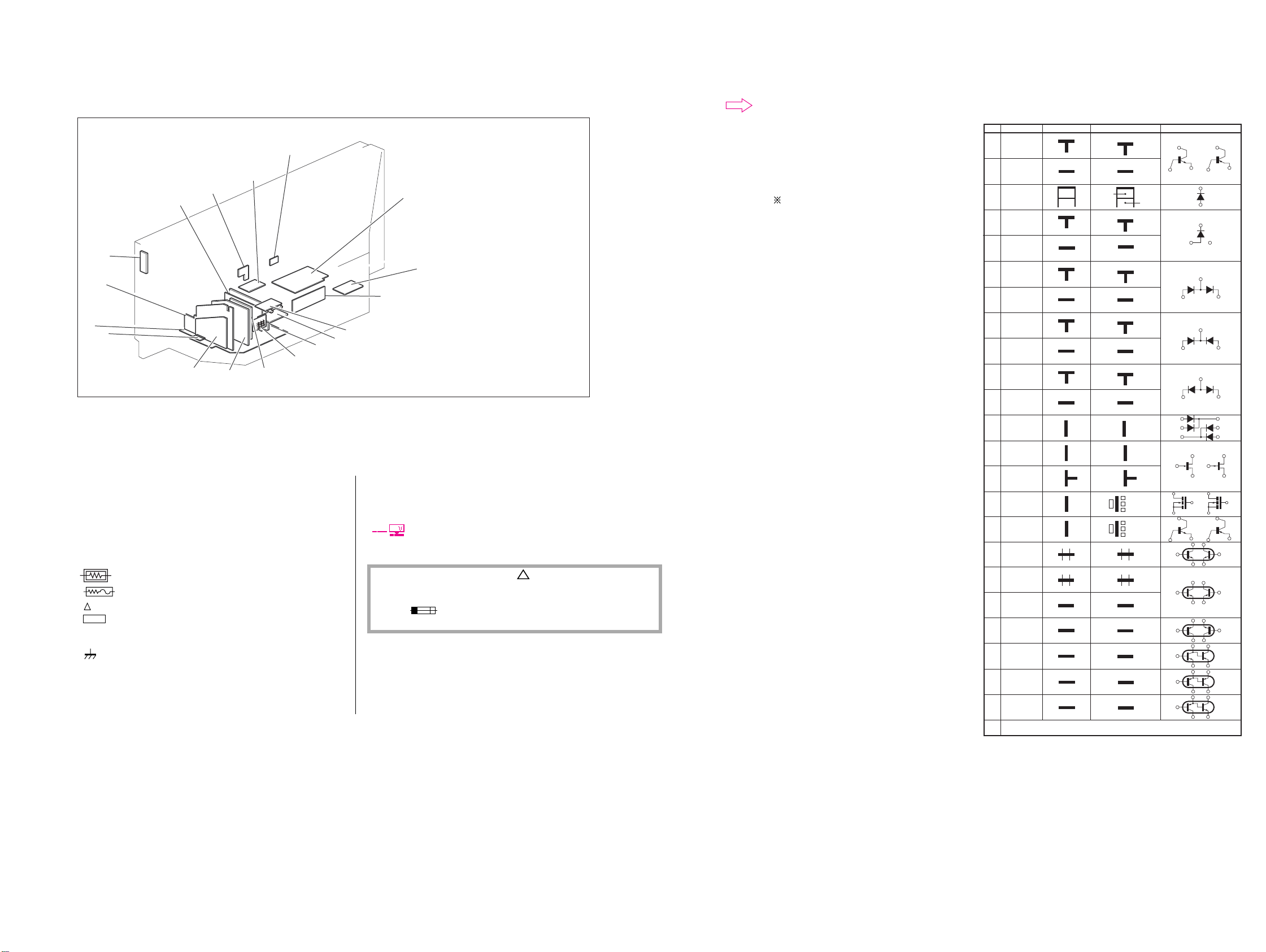

5-1. CIRCUIT BOARDS LOCATION

T

Q Box

H2

Assembly

H1

G1

G2

H4

F

5-2. SCHEMATIC DIAGRAMS AND PRINTED WIRINGS INFORMATION

Note:

• The parts marked “#” on schematic diagrams are not mounted.

• All capacitors are in µF unless otherwise noted. pF : µµF 50WV or

less are not indicated except for electrolytics and tantalums.

• All electrolytics are in 50V unless otherwise specifi ed.

• All resistors are in ohms. kΩ=1000Ω, MΩ=1000kΩ

Indication of resistance, which does not have one for rating

electrical power, is as follows: Pitch : 5mm

• 1/ 4 W in resistance, 1/10 W and 1/16 W in chip resistance.

•

: nonflammable resistor.

•

•

•

: fusible resistor.

: internal component.

: panel designation and adjustment for repair.

• All variable and adjustable resistors have characteristic curve B, unless otherwise noted.

•

: earth-chassis.

• Readings are taken with a PAL color-bar signal input.

• Readings are taken with a 10MΩ digital multimeter.

•Voltages are dc with respect to ground unless otherwise noted.

Rating electrical power :

HM

C (Part of Optics Unit Block Assembly

Cannot be ordered separately)

H3

Power supply

bloc k

RF antenna switch

P

B

U

A

KD

1

/ 4 W

•Voltage variations may be noted due to normal production tolerances.

• All voltages are in V.

: Measurement impossibillity.

S

• Circled numbers are waveform references.

• A : B+line.

• : B-line (Actual measured value may be different).

The components identifi ed by shading and

only with part number specifi ed.

The symbol indicates a fast operating fuse and is displayed on the component

side of the board. Replace only with fuse of the same rating as marked.

!

symbol are critical for safety . Replace

•

: signal path.(RF)

Reference information

RESISTOR : RN METAL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RW NONFLAMMABLE WIREWOUND

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

ADJUSTMENT RESISTOR

:

COIL : LF-8L MICRO INDUCTOR

CAPACITOR : TA TANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

Terminal name of semiconductors in silk screen

printed circuit ( )

Device Printed symbol Terminal name

Transistor

1

Transistor

2

3

Diode

4

Diode

Diode

5

Diode

6

Diode

7

8

Diode

Diode

9

Diode

0

Diode

qa

Diode

qs

Transistor

qd

(FET)

Transistor

qf

(FET)

Transistor

qg

(FET)

Transistor

qh

Transistor

qj

Transistor

qk

Transistor

ql

Transistor

w;

Transistor

wa

Transistor

ws

Transistor

wd

Discrete semiconductot

–

Chip semiconductors that are not actually used are included.

*

Collector

Base

Collector

Base

Cathode

Cathode

Anode

Cathode

Anode

Common

Anode

Common

Anode Cathode

Common

Anode

Common

Anode Anode

Common

Cathode

Common

Cathode

Anode

Anode

Cathode

Drain

Drain

B1 E1C2

B2 C1

E2

B2 E2C1

B1 C2

E1

B2 E2

C1

B1 C2

E1

B2 E2

C1

B1 C2

E1

E2

B1 E1

C2

(B2)

E1

B1

C1

(B2)

E1

E2

C2

Emitter

Emitter

Anode

(NC)

(NC)

Cathode

Anode

Cathode

Cathode

Cathode

Anode

Anode

Source

Gate

Source

Gate

Source

Drain

Gate

Emitter

Collector

Base

C1(B2)

E2

C2

B1

C1

Circuit

D

G

D

S

B1

B1

B1

B1

B1

B1

D

G

S

S

D

G

C1

E1

C1

E1

E1

C1

E2

C1

C1

G

S

C2

B2

E2

C2

B2

E2

E2

B2

C2

C2C1(B2)

E2

E2E1(B2)

C2

C2E1(B2)

C2

Ver.1.5

– 27 –

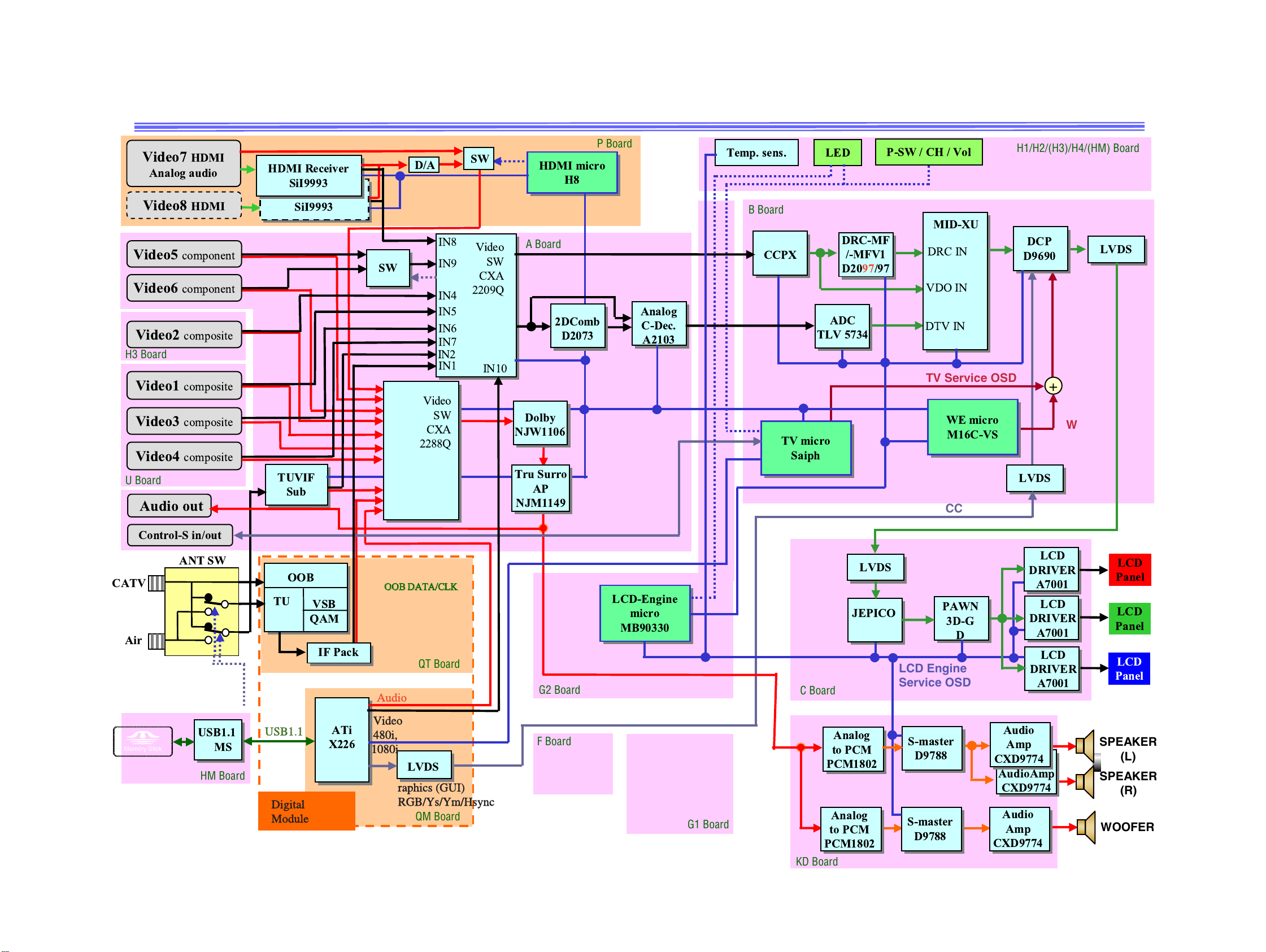

5-3. BLOCK DIAGRAM

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

$

H3 Board

"

#

U Board

/

&'(

&'(

)))"

)))"

&'(

&'(

)))"

)))"

%

%

+

!

%

!

*(

*(

A Board

,*

8

-7% 1

( ((

-7 #)

$

$

1"

P Board

,0!

1"

B Board

,,

.4*3! 22!

&,0

+0

1)+)

,

. "#

*(

*(

35

35

GUI Graphics / Analog CC

0% + , +

0

TV Service OSD

%4 *(

%4 *(

,0

,0

H1/H2/(H3)/H4/(HM) Board

,

))1

.

.

+

WE

Service OSD

.

.

,/(0 +/

,

(

Memory Stick

- %

!

h

HM Board

USB1.1

Digital

Module

" #$%

QT Board

Audio

Video

480i, 480p, 720p,

1080i

.

raphics (GUI)

RGB/Ys/Ym/Hsync

QM Board

G2 Board

F Board

.,04

.,04

*(

*(

)1""1

)1""1

G1 Board

C Board

, $1

, $1

KD Board

.

74,

/ ,

/ ,

.

%-

"06

LCD Engine

Service OSD

0*2/(

)$$

0*2/(

)$$

&4&

&4&

&4&

*3

,)#

*3

,)#

*3

,)#

.,

11

.,

11

.,

11

.,

.,

.,

SPEAKER

(L)

SPEAKER

(R)

WOOFER

– 28 –

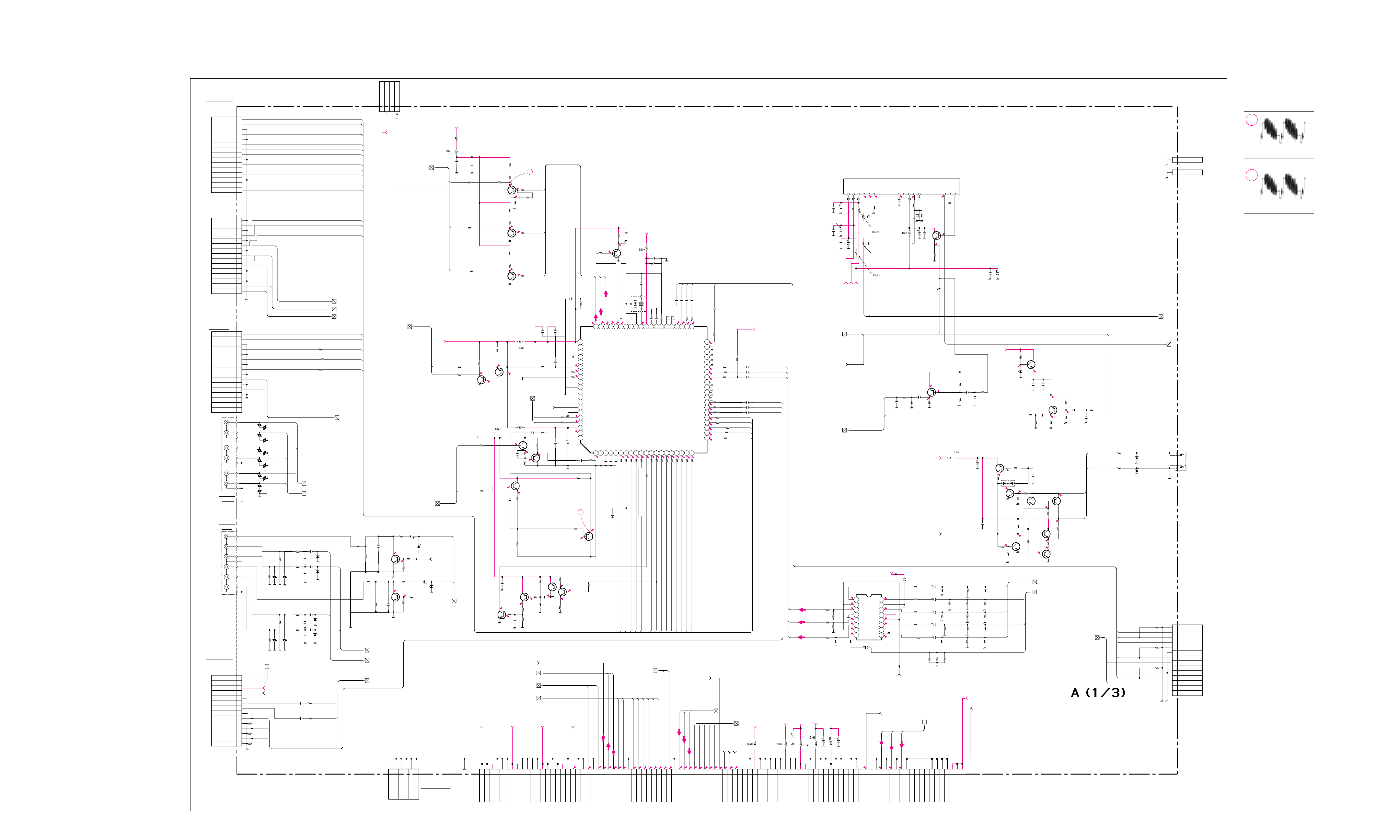

5-4. SCHEMATIC DIAGRAMS

(1) Schematic Diagram of A (1/3) Board

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23

TO U:CN9401

CN8002

B-TO-B

B-TO-B

15P

TO U:CN9402

CN8001

15P

Y1

C1

GND

Y3

GND

C3

S3

Y4

GND

C4

S4

V1-S2

GND

V3-S2

V4-S2

GND

V1

GND

V3

GND

V4

GND

L1

L3

L4

GND

R1

GND

R3

R4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

A

—

B

—

C

—

D

—

E

—

CN8003

B16B-XADSS-N-A

F

—

G

—

H

—

I

—

TO H3:CN43

J8002

6P

V2-SW

V2-S2

E

V2-C

E

V2-Y

E

V2-V

E

V2-L

V2-R

E

VIDEO 56

SIGNAL

1

2

3

4

5

6

7

8

9

10

E

11

12

13

14

15

16

L1

R1

L2

R2

VD8013

VD8017

VD8014

VD8018

VD8015 R8190

VD8016

VD8024

J

VIDEO 56

AUDIO

—

K

R1

R2

—

J8004

6P

L

—

M

TO P:CN9504

—

N

—

O

CN8004

B14B-XADSS-N-A

SCLK

SDAT

9V

HDMI-RESET

A-GND

R

L

GND

PR

GND

PB

GND

Y

GND

IIC-TV

SCL

1

SDA

2

3

4

5

6

7

8

9

10

11

12

13

14

R8033

75

1/10W

:RN-CP

—

P

R8005

470k

1/10W

:CHIP

R8004

470k

1/10W

:CHIP

L4

R4

L2

R2

HDMI-RESET

PR

PB

Y

KDF-55WF655K/60WF655K

RM-KD001 RM-KD001

V

CN8009

i

d

4P

e

9

G

G

WHT

o

V

N

N

D

D

:S-MICRO

O

u

t

2

3

1

4

Y1

C1

Y3

C3

S3

Y4

C4

S4

S2-1

S2-3

S2-4

V1

V3

V4

L1

L3

R1

R3

V1LR

(P3)

V3LR

(P3)

V4LR

(P3)

(P3)

S2

R8007

0 1/10W :1608

R8008

0 1/10W :1608

R8006

0 1/10W :1608

VD8023

R8029

1/10W

:RN-CP

R8030

1/10W

:RN-CP

Y6

Y5

PB6

PB5

PR6

PR5

VD8011

VD8006

75

75

R8016

1k

1/10W

:CHIP

R8015

1k

1/10W

:CHIP

C8087

0.001

B:1608

R8014

1k

1/10W

:CHIP

R8013

1k

1/10W

:CHIP

C8090

1

10V

B:1608

C8018 R8018

1

10V

B:1608

C8021

1

10V

B:1608

B:1608

B:1608

C8086

0.001

C8089

0.001

V6V

V5V

C8084

1

10V

B:1608

C8085

1

10V

B:1608

D8008

UDZSTE-1710B

C8088

1

10V

B:1608

UDZSTE-1710B

C8091

0.001

B:1608

D8011

UDZSTE-1710B

1k

1/10W

:CHIP

R8017

1k

1/10W

:CHIP

UDZSTE-1710B

D8010

D8009

R

R7

L7

VD8019

VD8020

VD8021

VD8022

R8010

470k

1/10W

:CHIP

VD8012

R8009

470k

1/10W

:CHIP

VD8007

+9V

S2-2

C2

Y2

V2

V2LR

R8019

0

1/10W

:1608

L

R8020

0

1/10W

:1608

R

R8021

470k

1/10W

:CHIP

V5LR

V6LR

V7LR(HDMI)

+9V

Q8033

MSD601-RT1

MUTE

C8083

0.0047

B:1608

R8022

470k

1/10W

:CHIP

C8082

0.0047

B:1608

(P3)

(P3)

SUB-CV/YC-OUT

R8023

1/10W

:CHIP

0.0

R8024

1k

1/10W

:CHIP

0.0

1k 1/10W :CHIP

Q8034

MSD601-RT1

MUTE

(P3)

1

2

D

D

N

N

G

G

MAINCOMP

(P2)

TUNERV

C8081

10

1k

16V

:AL-CP

D8006

R8027

1/10W

:CHIP

7

.

0

0.7

3

D

N

G

UDZSTE-1710B

5

D

N

G

C8080

10

16V

:AL-CP

6

CN8006

B TO B

D

N

TO G2:CN6033

G

PROTECT

D8007

UDZSTE-1710B

PROTECT

6P

1k

R8026

10k

1/10W

:CHIP

R8028

R8025

10k

1/10W

:CHIP

4

D

N

G

+5V

SUB_Y/CV

SUB_C

L-MUTE

+9V

FB8003

BK1608HS601

C8007

Y

PB

PR

0

(P3)

R8035

68

1/10W

:CHIP

R8031

0

1/10W

:1608

STCV

MTCV(DBOX)

100 1/10W :CHIP

0.1

16V

F:1608

R8034

82

1/10W

:CHIP

R8036

100

1/10W

:CHIP

R8040

680

1/10W

:CHIP

Q8009

MSB709-RT1

BUFF

+9V

R8039

100 1/10W :CHIP

R8037

MSD601-RT1

+3.3V

2SA1226-T1-E3E4

2SA1226-T1-E3E4

R8047

1/10W

:CHIP

2.9

2.3

Q8032

2

2

3

3

C

B

V

V

3

3

.

.

3

3

+

+

R8049

1/10W

:1608

Q8015

BUFF

Q8017

BUFF

680

L8016

Q8011

MSD601-RT1

C8066

0.1

16V

B:1608

2

3

A

V

3

.

3

+

0

R8053

1k

1/10W

:CHIP

R8052

0

1/10W

:CHIP

R8051

1k

1/10W

:CHIP

R8050

0

1/10W

:CHIP

Q8022

2SA1226-T1-E3E4

BUFF

3.3

C8004

8p

3.9

C8065

8p

Q8031

MSB709-RT1

R8048

100k

2.3

1/10W

:CHIP

0.0

C8003

0.1

16V

B:1608

1

1

1

3

3

3

B

C

A

D

D

D

N

N

N

G

G

G

R8055

470

1/10W

:CHIP

R8054

150

1/10W

:CHIP

2.1

R8275

1/10W

:CHIP

3.0

3.0

L8015

Q8008

MSB709-RT1

BUFF

2.8

3.3

R8060

2.2k

1/10W

:CHIP

R8056

2.2k

1/10W

:CHIP

0.0

+2.5V

0

3

C

V

5

.

2

+

2

R8066

100

1/10W

:RN-CP

1.3

0.3

R8276

2.2k

C8107

1/10W

10p

:CHIP

CH:1608

33

2.3

R8064

100

1/10W

:RN-CP

2.3

R8063

100

1/10W

:RN-CP

C8064

0.1

16V

B:1608

IIC-TV

C8005

4.7

F:CHIP

1.8k

1/10W

:CHIP

2.7

1.5

Q8013

MSD601-RT1

3.3

R8057

1.8k

1/10W

:CHIP

R8074 R8077

56k

1/10W

:RN-CP

R8069

10k

1/10W

:CHIP

8.4

R8059

1k

1/10W

:CHIP

R8058

10k

1/10W

:CHIP

MTCV(DBOX)

TUNERLR

0

0

9

9

3

3

2

2

B

A

C

B

D

D

D

N

N

N

V

G

G

G

5

.

2

+

Y

PB

PR

C8099

B:1608

C8010

470

16V

:AL-CP

0.1

16V

B:1608

R8072

68k

1/10W

:CHIP

R8081

100 1/10W :CHIP

R8080

100 1/10W :CHIP

COMP-SW

R8079

SCL

22 1/10W :CHIP

R8078

SDA

22 1/10W :CHIP

R8071

100

1/10W

:CHIP

R8070R8061

1k

1/10W

:CHIP

C8008

0.1

16V

2.1

B:1608

Q8012

MSB709-RT1

Q8028

220

MSB709-RT1

1/10W

:CHIP

8.7

1.2

R8075C8067

1.2

4.7k

0.1

1/10W

16V

:CHIP

B:1608

R8073

1M

1/10W

:CHIP

(P3)

MSLR

(P3)

TUCONT

DD 6V DD OVP

9

8

8

8

7

2

2

A

C

D

N

V

G

6

D

D

7

2

2

2

2

B

A

C

B

D

N

V

V

V

G

6

6

6

D

D

D

D

D

D

0.1

16V

B:1608

R8076

1/10W

:CHIP

C8012C8009

0.1

16V

1k

F:CHIP

7

2

A

D

N

G

2.8

2.7

2.3

4.4

4.3

2.2

C8011

:AL-CP

C8013

4.7

R8269

1/10W

:CHIP

1.8

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

470

16V

R8083

100

1/10W

:CHIP

R8068

1k

1/10W

:CHIP

1

100

1.8

Q8026

MSD601-RT1

0

.

0

6

6

2

2

C

B

D

P

N

V

G

O

D

D

R8043

100

1/10W

1.0

:CHIP

Q8010

MSB709-RT1

SYNC-BUF

Y

B

R

P

P

R8084

68k

PB

1/10W

:CHIP

PR

3

3

.

.

2

2

1

T

1

1

U

T

T

O

U

U

R

O

O

C

B

Y

C

VCC_OUT

SEL_HOUT2

SEL_VOUT2

SYNC_IN2

SEL_OUT2

Y_PH2

CV/YOUT2

C/CBOUT2

CROUT2

GND_OUT

CVOUT3

YOUT3

COUT3

DC_OUT

ADR

SCL

SDA

VCC_IN

IN1_CV

NC

6

2

A

D

N

G

/

/

V

C

C

V

N

V

C

I

C

_

_

_

2

D

3

N

N

N

I

G

I

1 2 3 4 5 6 7 8 9

9

.

2

C8068 C8069

0.1

16V

B:1608

B:1608

C8109

47p

CH:1608

2.5

Q8024

MSB709-RT1

R8082

10k

1/10W

:CHIP

)

X

O

B

R

D

L

(

R

T

M

V

1

U

T

T

D

R

1

U

T

T

D

1

1

9

.

.

.

4

4

3

5

5

5

4

2

2

2

2

C

B

A

C

D

R

L

N

-

-

V

G

S

S

U

M

M

T

T

D

R8044 C8019

1k

1/10W

:CHIP

3

.

1

0.1

16V

4

2

B

R

U

T

T

D

Y

C8070

B:1608

B:1608

1.7

X8001

C8063

1

8

0

3

.

.

.

10V

2

1

2

B:1608

1

1

1

1

T

H

T

N

U

P

U

I

O

_

O

_

V

Y

_

C

_

L

N

L

E

Y

E

S

S

S

V

Y

C

S

C

_

_

_

_

3

3

4

4

N

N

N

N

I

I

I

I

9

3

.

.

2

1

P

P

I

I

H

H

C

C

:

:

W

W

0

0

1

1

/

/

0.1

1

1

16V

0

0

0

0

1

1

6

5

8

8

0

0

8

8

R

R

2

2

V

S

)

X

O

B

D

(

L

T

M

C

C

N

N

Y

Y

S

S

H

H

-

M

S

L

1

U

T

T

D

0

0

1

1

.

.

.

.

4

0

0

4

4

3

3

3

2

2

2

2

A

C

B

A

S

H

L

-

U

D

S

N

T

N

H

I

G

A

T

B

M

D

U

S

+5V

0.1

16V

C8045

L8002

0.1

16V

B:1608

C8062

B:1608

4M

1

T

U

O

H

_

L

E

S

Y

_

4

N

I

P

I

H

C

:

W

0

1

/

1

0

0

1

7

8

0

8

R

2

Y

T

F

A

M

C8101

0.1

470

16V

16V

C8046 C8048 C8049 C8050

:AL-CP

0.1

16V

B:1608

C8051

0.01

25V

B:1608

C8061

1

10V

R8095

B:1608

10k

1/10W

:CHIP

8

.

2

F

L

H

H

F

F

F

A

F

I

T

I

D

X

D

_

/

_

D

K

C

N

L

C

C

G

V

_

T

X

E

IC8001

CXA-2209Q

VIDEO SW

2

C

S

S

_

_

_

4

5

4

N

N

N

I

I

I

10 11 12 13 14 15 16 17 18 19 20

1

3

9

.

.

.

0

2

1

P

P

I

I

H

H

C

C

:

:

W

#

0

P

1

I

/

9

H

1

8

C

0

:

8

0

R

0

1

W

0

1

/

8

1

8

0

8

k

R

1

1

9

0

8

R

2

2

2

S

C

IIC-TV

C

T

G

F

A

A

S

0

9

4

.

.

.

0

1

1

2

2

2

2

2

2

C

B

A

T

T

T

F

T

F

A

A

A

-

-

C

B

N

G

U

I

A

S

A

M

W

P

P

E

S

_

_

R

_

V

H

I

0

1

N

I

V

2

C

Y

C

S

_

_

_

_

5

5

5

5

N

N

N

N

I

I

I

I

9

3

9

3

.

.

.

.

1

2

1

2

P

P

P

P

I

I

I

I

H

H

H

H

C

C

C

C

:

:

:

:

W

W

W

W

0

0

0

0

1

1

1

1

/

/

/

/

1

1

1

1

0

0

0

0

0

0

0

0

1

1

1

1

2

4

3

6

9

9

9

9

0

0

0

0

8

8

8

8

R

R

R

R

1

2

1

1

1

S

V

Y

C

A

D

S

O

P

P

N

A

A

O

S

S

M

-

-

F

O

I

2

0

0

3

.

.

.

.

0

0

0

4

1

1

1

0

2

2

2

2

C

B

A

C

V

T

T

P

P

A

O

A

A

D

N

S

S

S

O

-

-

M

O

I

F

CN8041

1P

1

FB8004 FB8005 FB8006

0

1/10W

:2012

V

V

0

9

3

100

16V

V

V

5

3

+

3

+

5.2

0.0

4.3

4.3

0.0

5.2

R8282 C8097

47

1/10W

:CHIP

8

8

C

B

V

D

5

N

+

G

V

9

+

1

2

3

4

5

6

7

8

8

A

D

N

G

0

1/10W

:2012

L

C

V

S

5

L

C

S

)

X

O

B

D

(

V

C

T

M

IC8002

TL52055DR

YUV SW

IN1B

SW1

OUT1

E

OUT2

OUT3

SW3

IN3A

100

16V

:AL-CP

2

.

4

7

C

E

T

U

M

P

.

H

FB8012 FB8013

BK2125HS601 BK2125HS601

A

D

S

S

A

0

3

4

.

.

.

4

0

4

R8130

0

1/10W

:1608

L8004

:LHLZ06

R8128

22

1/10W

:CHIP

R8127

22

1/10W

:CHIP

L8008

:LHLZ06

A

D

S

S-HSYNC

C8056

100p

CH:1608

M-HSYNC

5.1

6

IN1A

1

5

E

1

5.2

4

IN2B

1

3

VCC

1

0.0

2

SW2

1

5.1

1

IN2A

1

0

E

1

9

IN3B

5.2

SUB-VIDEO

F

W

R

1

.

4

6

6

7

6

7

B

A

A

C

B

W

D

D

-

W

O

U

N

N

S

E

A

G

G

-

D

P

I

.

V

H

_

B

U

S

:AL-CP

8

.

3

C

G

A

F

R

C8014

10

16V

FB8007

C8022

B:1608

L8006

:LHLZ06

R8137

1/10W

:CHIP

+9V

R8131

100

1/10W

:CHIP

COMP-SW

(P2)

D

F

T

T

N

V

I

F

U

G

9

V

A

O

33k

10V

R8277

1/10W

:CHIP

R8278

1/10W

:CHIP

R8279

1/10W

:CHIP

R8280

1/10W

:CHIP

:RN-CP

R8264

1/10W

1

47

47

47

47

R8281

1/10W

:CHIP

220

C8033

0.0022

B:1608

0.7

47

AUDIO OUT

R8140

22k

1/10W

:CHIP

R8143

2.2k

1/10W

:CHIP

STBY5V

(P3)

2PD601AR

TP8001

SIRCS

C8092

:AL-CP

C8093

:AL-CP

C8094

:AL-CP

C8096

:AL-CP

100

16V

:AL-CP

:RN-CP

Q8023

3.3

R8142

1/10W

:CHIP

100

16V

100

16V

C8095

100

16V

R8144

1/10W

3.0

R8141

150k

1/10W

:CHIP

INV

10k

100

16V

270

4

R8139

2

.

.

7

5

1/10W

0

:CHIP

1/10W

:2012

0.01

25V

C8032

100

16V

:AL-CP

Q8029

2PB709AR

INVERTER

C8054

4.7k

F:1608

R8138

10k

1/10W

:CHIP

C8108

470

16V

:AL-CP

T

U

M

O

E

E

-

T

T

T

E

U

E

U

D

O

D

M

3.9

3.8

V

C

T

S

R

L

T

S

R8151

150k

C8053

1/10W

0.047

:CHIP

16V

3.2

B:1608

R8150

1M

1/10W

:CHIP

L8001

:GLF2012

C8044

100

16V

:AL-CP

R8147

270

1/10W

:RN-CP

R8256 R8257

220

1/10W

:RN-CP

R8146

270

1/10W

:RN-CP

R8260 R8261

1/10W

:RN-CP

R8145

270

1/10W

:RN-CP

R8265

220

1/10W

:RN-CP

:RN-CP

220

:RN-CP

+1.8V

C8041

0.0022

B:1608

R8152

1.5k

1/10W

:CHIP

C8055

330p

B:1608

Q8001

MSB709-RT1

SW

R8153

2.2k

1/10W

:CHIP

Q8003

MSD601-RT1

BUFF

C8043

0.1

25V

F:1608

R8156

220k

1/10W

:CHIP

R8254 R8255

220

220

1/10W

1/10W

:RN-CP

:RN-CP

R8149

270

1/10W

1/10W

:RN-CP

:RN-CP

R8258 R8259

220

1/10W

R8148

1/10W

:RN-CP

270

R8262 R8263

220

1/10W

:RN-CP

:RN-CP

:RN-CP

220

1/10W

(P2)

DD GND

(P2)

220

1/10W

1/10W

220

220

C8042

:AL-CP

+5V

RD3.9SB2-TI

4.6

4.5

MSD601-RT1

0.5

R8155

100k

1/10W

:CHIP

Y6

PB6

PR6

100

16V

D8023

Q8002

R8162

220

1/10W

:CHIP

3.9

Q8030

2PB709AR

INVERTER

R8168

4.7k

1/10W

:CHIP

R8161

220k 1/10W :CHIP

4.5

D8003

DAN202K

0.0

47k 1/10W :CHIP

R8159

220k

1/10W

:CHIP

R8158

10k

1/10W

:CHIP

0.0

INV

Y5

PB5

PR5

C8052

:CHIP

0.1

25V

3.3

C8002

B:1608

R8165

MSB709-RT1

Q8006

MSD601-RT1

R8163

100k

1/10W

:CHIP

0.5

Q8027

2PD601AR

C8058

10V

F:1608

R8167

10k

1/10W

:CHIP

0.1

16V

Q8004

SW

5.0

BUFF

0.0

0.0

V6V

V5V

C8047

:AL-CP

1

MSB709-RT1

47

10V

R8173

10k

1/10W

:CHIP

Q8007

R8172

100k

1/10W

:CHIP

0.0

R8171

1/10W

:CHIP

3.3

0.5

SW

10k

Q8005

MSD601-RT1

IIC-TV

TUNERLR

)

X

O

B

D

(

V

C

T

M

R8179

150k

1/10W

:CHIP

C8057

R8182

0.047

2.2k

16V

1/10W

B:1608

:CHIP

3.3

R8178

1M

1/10W

:CHIP

0.0

R8176

0

1/10W

:1608

S OUT

C8059

220p

:CHIP

R8191

100

D8002

1/10W

UDZSTE-1710B

S OUT

S IN

S IN

:CHIP

100

D8001

1/10W

UDZSTE-1710B

:CHIP

SW

R8041

75

1/10W

:RN-CP

HS

DBOXLR

(P3)

PR

VS

R8042

75

1/10W

:RN-CP

PB

R

R8046

75

Y

L

:RN-CP

1/10W

TERMINAL BLOCK

L

8

.

3

5

5

5

4

4

4

3

3

C

B

A

C

B

H

C

R

D

D

H

D

E

C

N

N

V

G

L

G

R

E

S

E

R

3

A

C

B

A

K

W

L

T

S

D

B

T

_

N

_

A

C

G

T

_

P

X

O

A

E

T

1

2

2

2

C

D

N

G

1

1

C

B

A

B

A

CN8005

V

V

V

D

D

N

N

G

G

96P

8

8

8

.

.

.

:B TO B

1

1

1

+

+

+

TO G2: CN6020

TUNER

9-965-972-01<LA3>A P1 OF 3

0

1/10W

:2012

TU8001

BTF-FA421

SUB TU

C8016

100

C8015

16V

0.0022

B:1608

:AL-CP

C8031

0.0022

R8126

B:1608

2.2k

1/10W

C8030

:CHIP

47

:AL-CP

C8037

C8036

0.0022

:AL-CP

B:1608

0.1

16V

B:1608

S

V

3

V

L

/

_

2

0

L

1

_

N

0

I

1

N

I

V

S

C

_

_

6

6

N

N

I

I

1

3

.

.

0

2

P

P

I

I

H

H

C

C

:

:

W

#

0

1

/

8

1

9

0

8

0

R

0

1

7

9

0

8

R

3

3

S

V

L

C

S

R

P

4

.

4

0

0

2

2

B

A

V

T

D

N

L

G

C

S

2.2

2.2

16V

16V

F:CHIP

F:CHIP

R

S

B

P

H

P

P

I

H

C

:

1

0

W

1

0

8

1

R

/

1

R8103

8

8

3

3

.

.

.

.

0

2

2

1/10W

0

2

2

1

:CHIP

4142434445464748495051525354555657585960

R

B

H

C

C

/

_

_

1

0

0

L

1

1

_

IN10_Y

N

N

0

I

I

1

N

I

IN9_SW

IN9_L3

IN9_L2

IN9_L1

IN9_CR

IN9_CB

IN9_Y

IN8_SW

IN8_L3

IN8_L2

IN8_L1

IN8_CR

IN8_CB

IN8_Y

IN7_S2

IN7_C

IN7_Y

IN7_CV

IN7_S

2

C

Y

S

_

_

_

6

6

6

N

N

N

I

I

I

1

9

9

3

.

.

.

.

0

1

1

2

P

P

P

I

I

I

H

H

H

C

C

C

:

:

:

W

W

#

0

0

1

1

/

/

2

1

1

0

1

8

0

0

R

0

0

1

1

0

9

0

9

1

0

8

8

R

R

3

2

3

3

S

Y

C

SUB_BLK

Y

C8100

4.7

F:CHIP

100

40

2.0

39

38

37

36

35

2.3

34

2.3

33

2.1

32

31

30

29

28

2.3

27

2.3

26

2.1

25

0.1

24

2.3

23

1.9

22

1.9

21

2.3

R8115

100

1/10W

:CHIP

R8117

2.2M

1/10W

:CHIP

R8110

100 1/10W :CHIP

R8109

100

R8108

100

R8107

100 1/10W :CHIP

R8106

100 1/10W :CHIP

R8105

100 1/10W :CHIP

R8114

#

:CHIP

R8113

100 1/10W :CHIP

100 1/10W :CHIP

100 1/10W :CHIP

R8111

100

+5V

C8071

2.2 16V F:CHIP

2.2 16V F:CHIP

C8073

4.7 F:CHIP

C8074

2.2 16V F:CHIP

C8075

2.2 16V F:CHIP

C8076

2.2 16V F:1608

S2-4

C4

R8112

Y4

R8104

V4

S4

PR

C8072

PB

Y

PR

PB

Y

Y

PB

PR

TUNERV

MTCV(DBOX)

TUCONT

R8121

0

1/10W

:1608

R8120

0

1/10W

:1608

R8119

0

1/10W

:1608

4.3

R8123

1k

1/10W

:CHIP

R8122

1k

1/10W

:CHIP

R8124

1k

1/10W

:CHIP

(P2)

MAINCOMP

V

5

SUBCOMP

Y

D

R

P

B

P

Y

0

0

1

.

.

.

3

3

2

9

9

9

1

1

1

C

B

A

B

R

Y

P

P

-

-

N

N

N

I

I

I

A

A

A

M

M

M

D

B

H

V

P

7

6

2

6

.

.

.

.

2

2

0

2

8

8

8

7

1

C

R

P

B

U

S

7

1

1

1

1

B

A

C

B

Y

H

V

B

-

-

-

P

B

B

B

U

U

U

B

S

S

S

U

S

(P2)

T

E

S

E

E

T

R

U

-

S

M

C

I

-

M

R

R

D

I

A

H

S

V

6

0

6

0

.

.

.

.

4

0

0

0

6

7

6

6

1

1

1

1

A

C

B

A

K

S

T

E

L

C

S

T

B

R

R

U

_

I

-

M

B

S

I

-

U

M

R

S

D

A

H

V

Y

B

T

S

0

.

2

5

5

5

4

1

C

F

P

A

D

S

4

1

1

1

1

B

A

C

B

F

P

D

D

V

N

N

5

L

G

G

Y

C

B

S

T

S

V

3

3

+

L8018L8019

C8077

470

16V

:AL-CP

4

3

3

3

2

1

1

A

C

D

D

N

N

G

G

2

1

1

1

1

B

A

C

B

V

D

3

D

D

N

3

N

N

G

+

G

G

V

V

9

+

L8017

L8011

2

1

1

1

1

1

A

C

B

V

9

V

D

+

9

N

+

G

V

1

5

1

+

+

C8078

0

1

470

0

8

16V

L

C8098

470

16V

:AL-CP

1

0

0

1

1

1

A

C

B

D

D

V

N

N

1

G

G

1

+

:AL-CP

0

9

9

9

1

C

B

A

A

D

V

D

D

N

5

N

N

G

+

G

G

GND

CN8039

#

1

GND

(P3)

CONTROL S OUT

J8001

CONTROL S IN

CN8008

TO D BOX

14P

GND(PR)

1

H

2

PR

3

V

4

GND(PB)

5

GND(R)

6

PB

7

R

8

GND(Y)

9

GND(L)

10

Y

11

L

12

NC

13

NC

14

L8003

:FLR50

C8006

10

25V

:CHIP

R8032

1/10W

:1608

L

R

VAR/FIXLR

A BOARD WAVEFORMS

1

1.21 Vp-p (H)

1

2.13 Vp-p (H)

– 29 –

Loading...

Loading...