Sony kdf 37h1000 schematic

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KDF-37H1000

RM-YD014 US/CND

LA-5

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 4/2007

:UPDATED ITEM

☛

REVISION DATE SUBJECT

4/2007 No revisions or updates are applicable at this time.

4/2007 Corrected Reference numbers for Fan and Fan Damper. Replaced page 71.

5/2007 Updated Self Diagnostic displays to include Lamp error. Replaced pages 8 & 9.

Added PN for 2P Connector Assembly (Thermal Fuse). Replaced pages 15 & 72.

LCD PROJECTION TELEVISION

9-883-746-03

Self Diagnosis

Supported model

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KDF-37H1000

RM-YD014 US/CND

LA-5

CHASSIS

9-883-746-03

KDF-37H1000 RM-YD014

LCD PROJECTION TELEVISION

KDF-37H1000

TABLE OF CONTENTS

SECTION TITLE PAGE SECTION TITLE PAGE

Specifi cations ................................................................................. 4

Warnings and Cautions .................................................................. 6

Safety Check-Out ........................................................................... 7

Self-Diagnostic Function ................................................................. 8

SECTION 1: DISASSEMBLY ............................................................... 10

1-1. Overview .............................................................................. 10

1-2. HAM Board Removal ............................................................11

1-3. Screen Frame Removal ........................................................11

1-3-1. Rear Cover Removal ..................................................11

1-3-2. Diffusion Plates (Screens) and

Screen Frame Assembly Removal .......................... 12

1-3-3. Diffusion Plates (Screens) Tape Method ................. 12

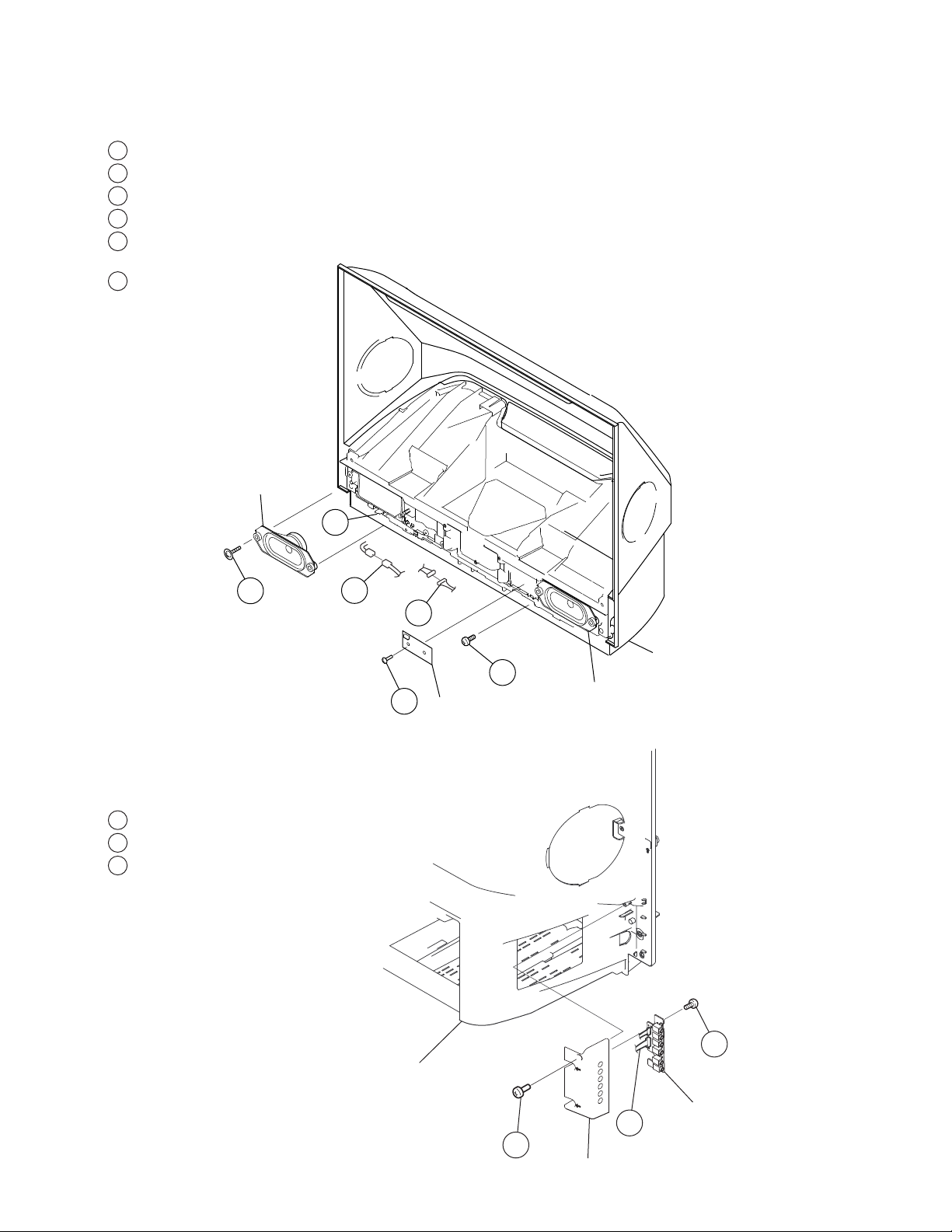

1-4. HB Board and Speaker Removal ......................................... 13

1-5. HCM Board Removal ........................................................... 13

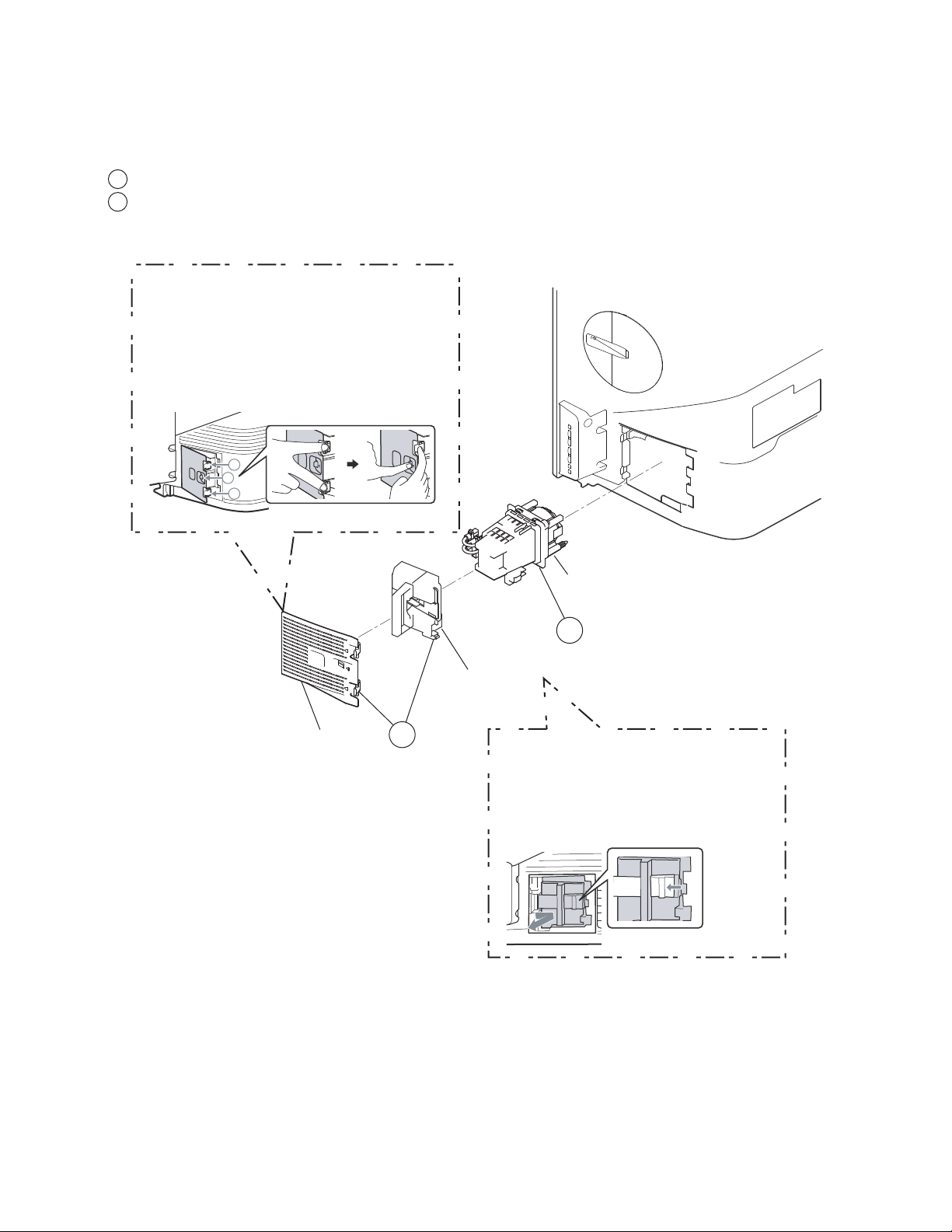

1-6. Lamp Removal ..................................................................... 14

1-7. Lamp Duct Removal ............................................................. 15

1-8. Fan Exhaust Duct Removal ................................................. 16

1-9. Optical Unit Block Removal .................................................. 17

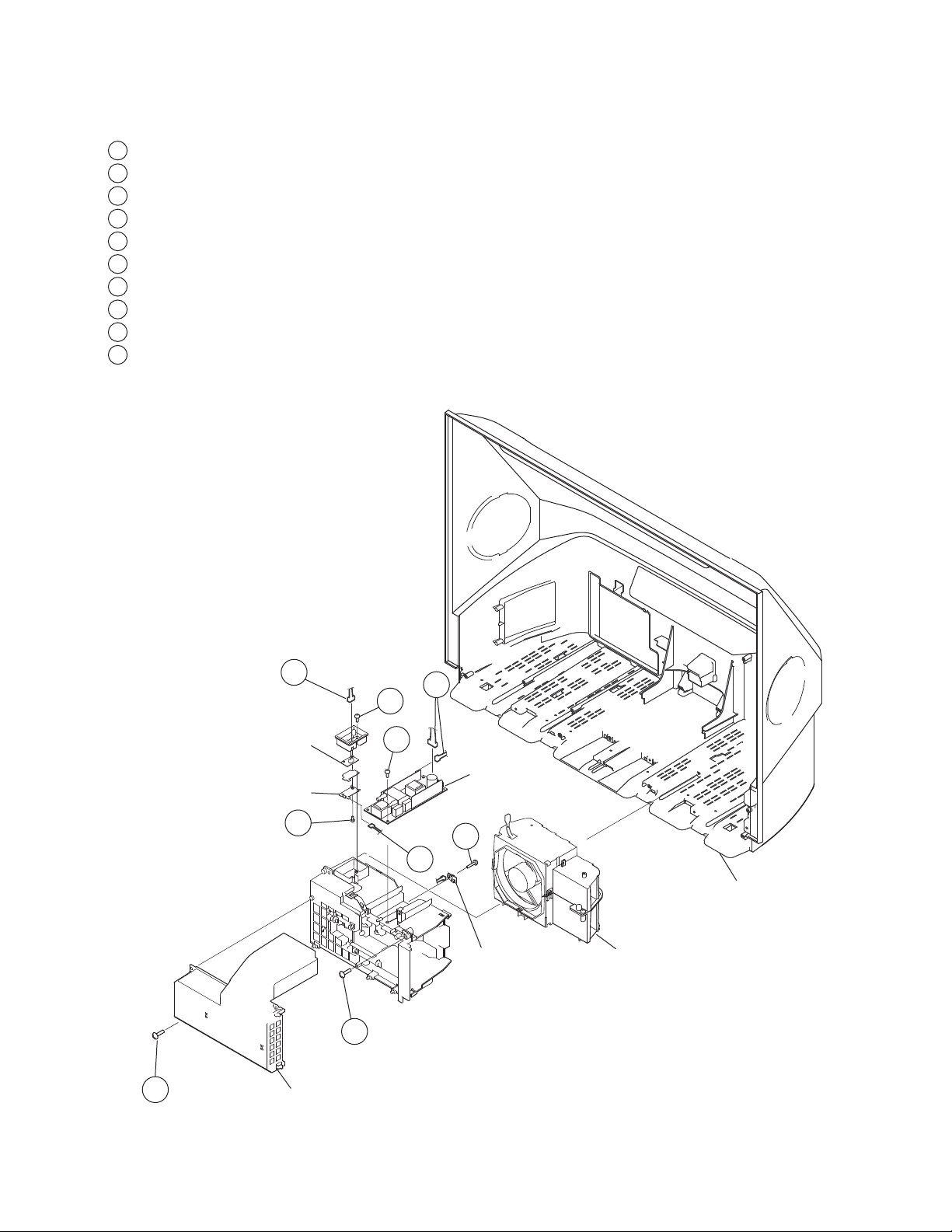

1-10. Chassis Remvoal ................................................................. 18

Wire Dressing ....................................................................... 19

SECTION 2: CIRCUIT ADJUSTMENTS .............................................. 32

2-1. Using the Remote Commander for Electrical Adjustments .. 32

2-2. Accessing Service Adjustment Mode ................................... 32

2-3. Viewing the Service Menus .................................................. 32

2-4. Using the Remote Commander to View Service Data ......... 33

2-4-1. Changing Service Data ............................................ 33

2-4-2. Exiting Service Mode ............................................... 33

2-5. Updating the Model Information when

Replacing the BM Board ...................................................... 33

2-5-1. Verifying Model Information ..................................... 34

2-6. Adjusting the Horizontal and vertical Settings ...................... 34

2-7. Resetting the Lamp .............................................................. 34

2-8. Verifying Service Data Changes .......................................... 34

2-9. Resetting to Factory Defaults ............................................... 35

SECTION 3: DIAGRAMS ..................................................................... 36

3-1. Circuit Boards Location ........................................................ 36

3-2. Printed Wiring Boards and

Schematic Diagrams Information ......................................... 36

3-3. Block Diagrams .................................................................... 38

Signal Flow Block Diagram .................................................. 38

Connection Diagram ............................................................ 39

3-4. Schematics and Supporting Information .............................. 40

BM Board Schematic Diagram (1 of 12) .............................. 40

BM Board Schematic Diagram (2 of 12) .............................. 41

BM Board Schematic Diagram (3 of 12) .............................. 42

BM Board Schematic Diagram (4 of 12) .............................. 43

BM Board Schematic Diagram (5 of 12) .............................. 44

BM Board Schematic Diagram (6 of 12) .............................. 45

BM Board Schematic Diagram (7 of 12) .............................. 46

BM Board Schematic Diagram (8 of 12) .............................. 47

BM Board Schematic Diagram (9 of 12) .............................. 48

BM Board Schematic Diagram (10 of 12) ............................ 49

BM Board Schematic Diagram (11 of 12) ............................. 50

BM Board Schematic Diagram (12 of 12) ............................ 51

G Board Schematic Diagram (1 of 2) ................................... 54

G Board Schematic Diagram (2 of 2) ................................... 55

HAM Board Schematic Diagram .......................................... 58

HB Board Schematic Diagram ............................................. 60

HCM Board Schematic Diagram .......................................... 62

S Board Schematic Diagram ................................................ 64

T Board Schematic Diagram ................................................ 65

U Board Schematic Diagram ................................................ 66

3-5. Semiconductors ................................................................... 69

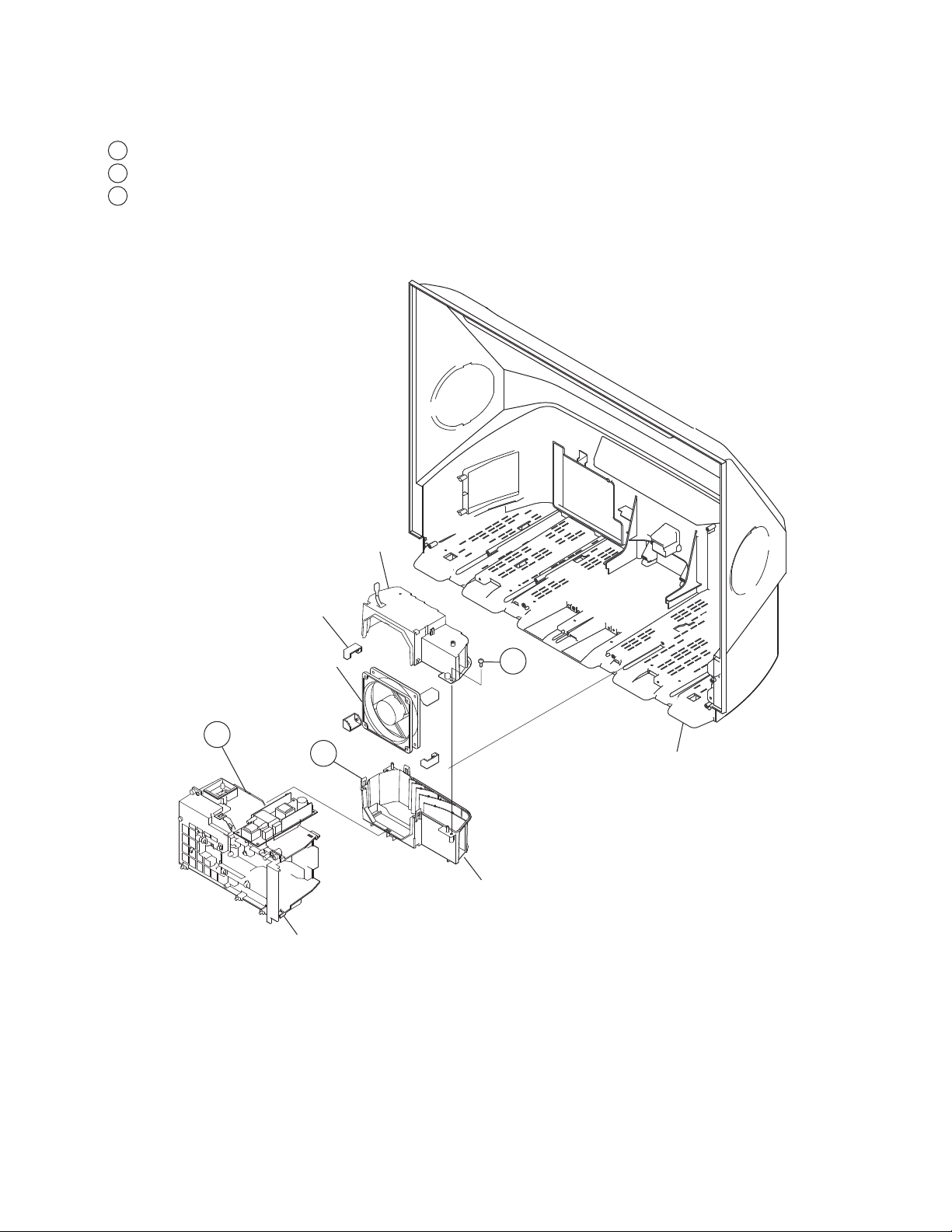

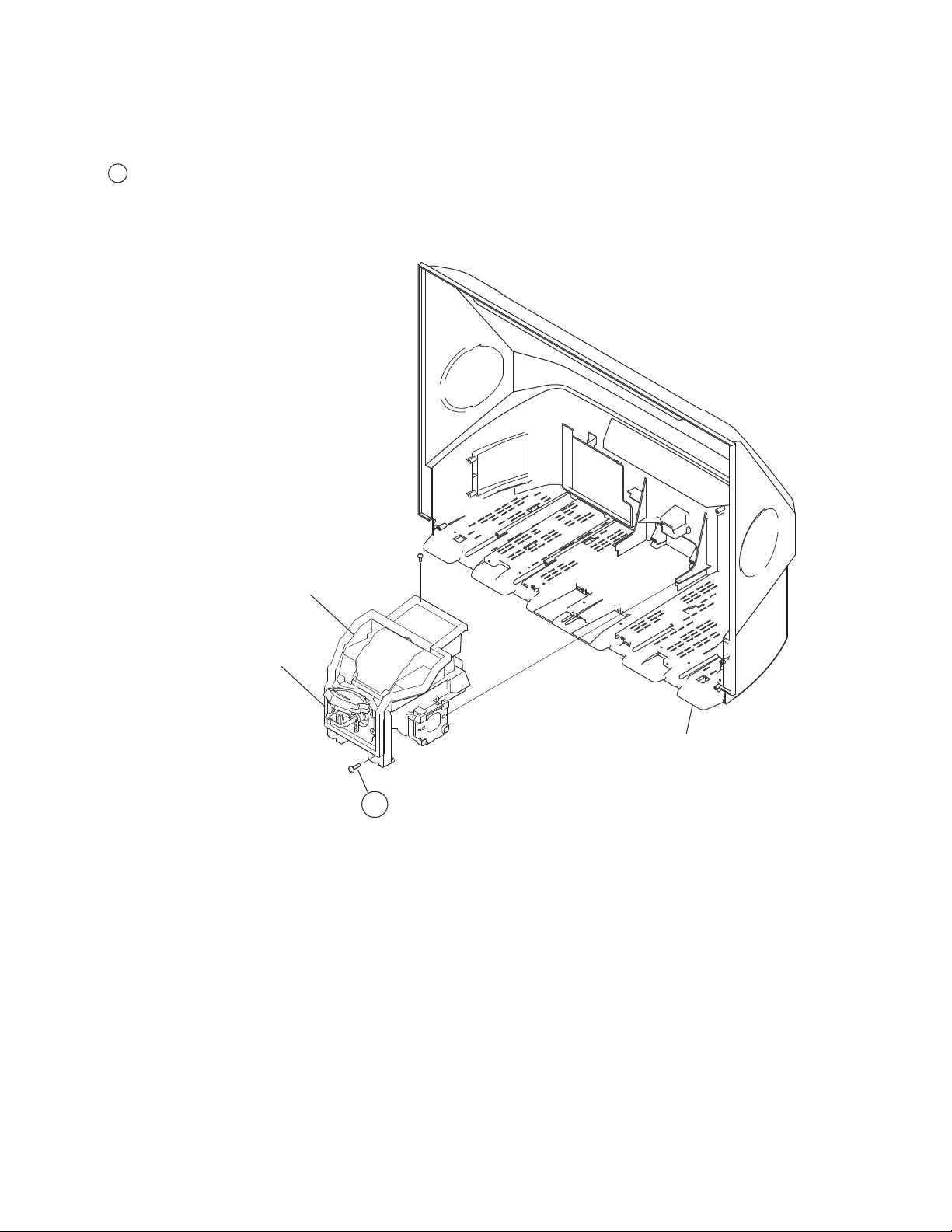

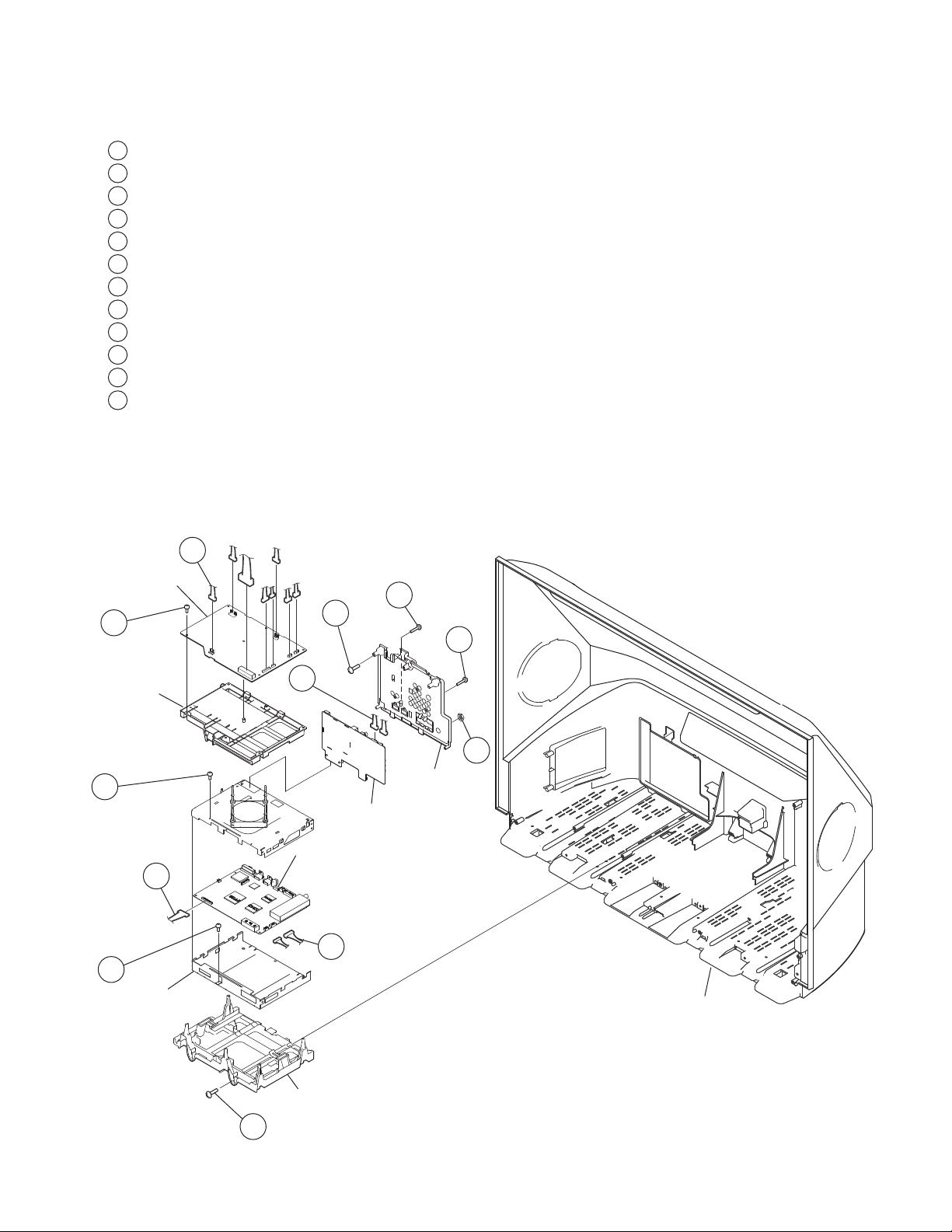

SECTION 4: EXPLODED VIEWS ........................................................ 70

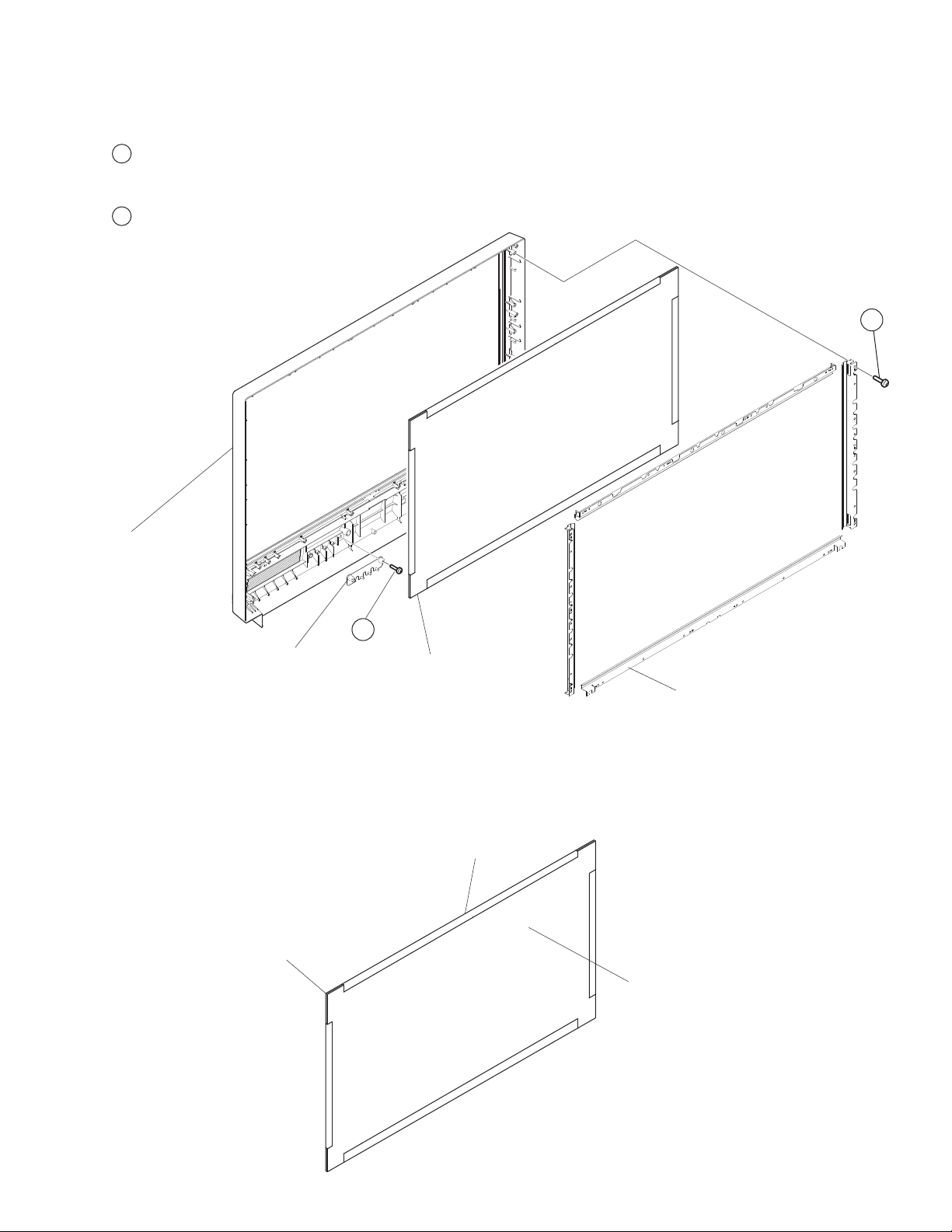

4-1. Screen Frame and Mirror Assemblies .................................. 70

4-2. Chassis and Optical Block Assembly ................................... 71

4-3. Connectors ........................................................................... 72

SECTION 5: ELECTRICAL PARTS LIST ............................................ 73

KDF-37H1000

APPENDIX A: ENCRYPTION KEY COMPONENTS ..........................A-1

APPENDIX A: REPLACING THE LAMP ............................................B-1

3

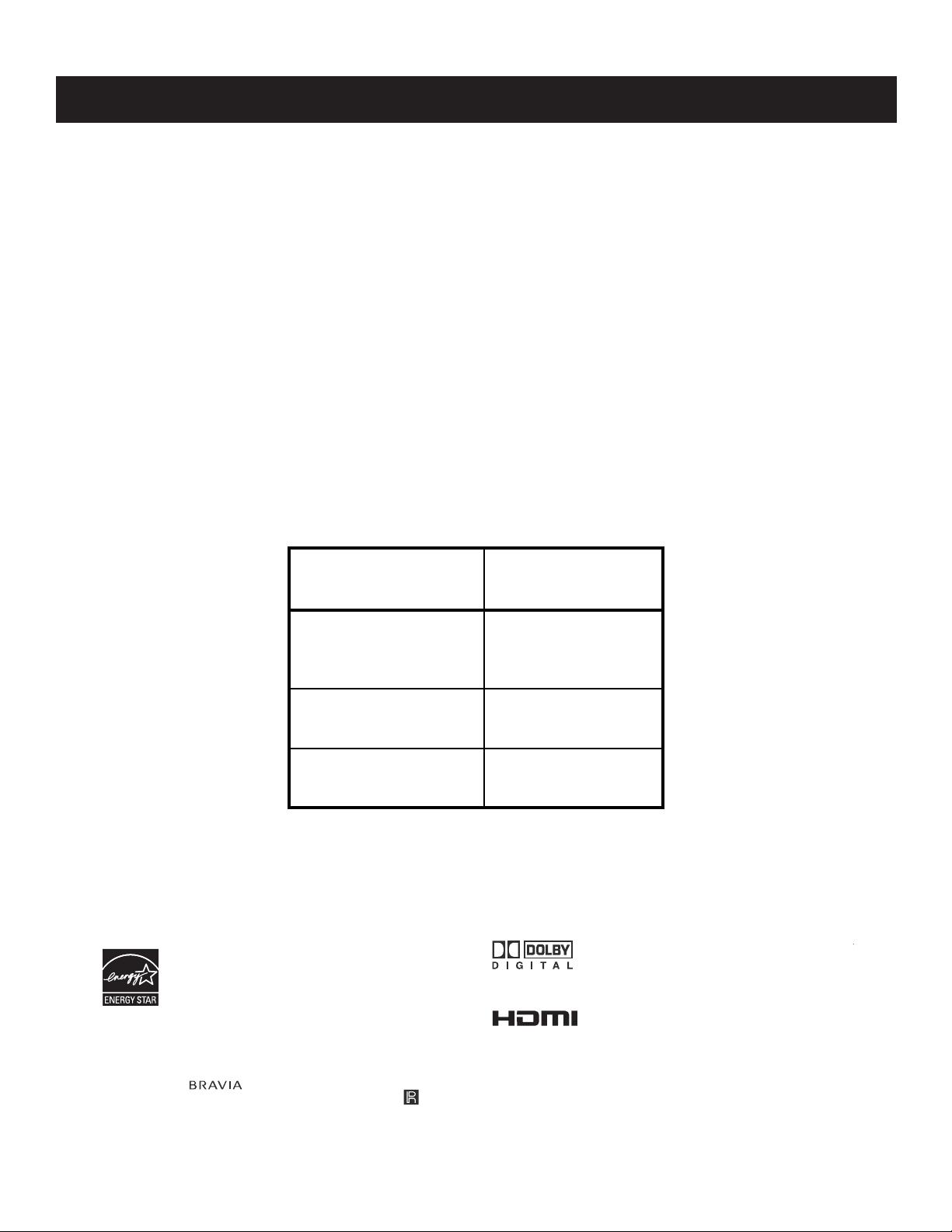

SPECIFICATIONS

p

)

p

b

a

KDF-37H1000

Power Requirements

Power Consumption (W)

In Use (Max)

In Standby

Inputs/Outputs

120V, 60Hz

200W

Less than 0.8W

HDMI IN 1/2

Video - 480i, 480p, 720p, 1080i, 1080p, PC timing

Audio - Two channel linear PCM 32, 44.1 and 48 kHz,

16, 20, and 24 bit

Audio - (HDMI IN 2 only) 500 mVrms

(100% modulation) Impedance:47 kilo ohms

Video (IN) 1/2/3

Video

1 total Y: 1.0 Vp-p, 75ohms unbalanced,

sync negative

S Video (IN)

1 total (4-pin mini DIN)

Y: 1Vp-p, 75ohms unbalanced, sync negative

C: 0.286Vp-p (Burst signal), 75ohms

Audio (IN)

500 mVrms (100% modulation)

Impedance:47 kilo ohms

Component In 1/2/3

) (Component Video)

(Y, P

B/CB

Y: 1.0 Vp-p, 75 ohms unbalanced, sync negative

:

0.7 Vp-p, 75 ohms;

P

B

PR: 0.7 Vp-p, 75 ohms

Audio (IN)

500 mVrms (100% modulation)

Impedance:47 kilo ohms

Audio Out

500 mVrms (100% modulation) Up to 2 Vrms at the

maximum volume setting (Varies with input level)

Digital Audio Optical Output (PCM/Dolby Digital)

Optical Rectangular

KDF-37H1000

eaker Output(W

S

S

eaker Dimension

Dimensions (W x H x D)

Mass

Trademark Information

As an ENERGY STAR® Partner, Sony

Corporation has determined that this product

meets the ENERGY STAR

®

guidelines for

energy efficiency.

ENERGY STAR

®

is a U.S. registered mark.

Blu-ray Disc is a trademark.

“BRAVIA” and , BRAVIA ENGINE EX, “XMB”

and “XrossMediaBar”, S-Force, BRAVIA Theatre Sync, , DM

BRAVIA Internet Video Link Ready and “PS3” are trademarks

or registered marks of Sony Corporation and/or

Sony Computer Entertainment Inc.

KDF-37H1000

12W + 12W

mm 65 x 130 mm

in

2

9/16

x 5

1/8

in

mm 899 x 663 x 342 mm

in

35

7/16

x 26

1/8

x 13

1/2

in

kg 20 kg

lbs 44.2 lbs

This TV is manufactured under license from Dol

Laboratories. “Dolby” and the double-D symbol

trademarks of Dolby Laboratories.

This TV incorporates High-

™

(HDMI

) technology. HDMI, the HDMI logo and HighDefinition Multimedia Interface are trademarks or

registered trademarks of HDMI Licensing LLC.

x

,

Macintosh is a trademark licensed to Apple Computer, Inc.,

registered in the U.S.A and other countries.

Definition Multimedia Interface

Design and specifi cations are subject to change without notice.

4

Television system

American TV standard, NTSC

ATSC Compliant 8VSB, ATSC (8VSB terrestrial)

ANSI/SCTE 07 2000, QAM on cable

Channel coverage

Terrestrial 2-69/ Cable TV: 1-125 (analog)

Terrestrial 2-69/ Cable TV: 1-135 (digital)

Screen Size (measured diagonally)

37 inches

Antenna

75-ohm external antenna terminal for VHF/UHF

Projection System

3 LCD Panels, 1 lens projection system

LCD Panel System

LCD (Liquid Crystal Display) Panel

KDF-37H1000

LCD Panel

0.73 inch TFT LCD panel (1,280 x 720 pixels)

Projection Lens

High Performance, large diameter hybrid lens F2.4

Lamp

100W, XL-2500 Ultra High Pressure Lamp

Supplied Accessories

Remote Commander RM-YD014

Two Size AA (R6) Batteries

Operating Instructions

Quick Setup Guide

Warranty Card

Online Registration Card

Optional Accessories

Connecting Cables

Lamp

XL-2500 Ultra High Pressure Lamp

KDF-37H1000

5

KDF-37H1000

WARNINGS AND CAUTIONS

CAUTION

These servicing instructions are for use by qualifi ed service personnel only. To reduce the risk of electric shock, do not perform any servicing other

than that contained in the operating instructions unless you are qualifi ed to do so.

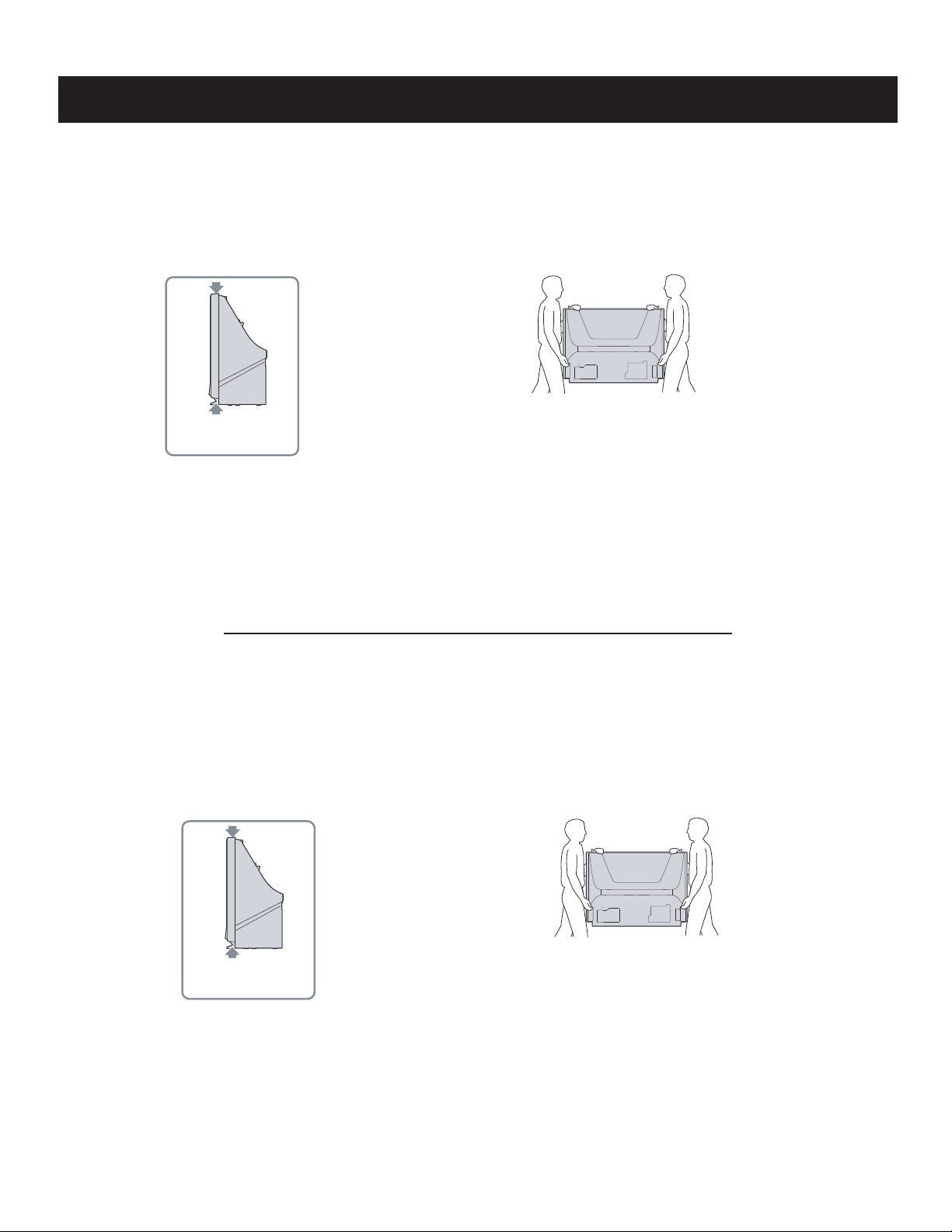

CARRYING THE TV

Carrying the TV requires at least two people. Do not hold

by the pedestal or the front panel of the TV. Doing so may

cause these parts to break off.

When moving the TV, place one hand in the hole on the

lower portion of the TV while grasping the top with the other

hand, as shown in the illustration below.

Do not grasp the

pedestal or the front

panel of the TV.

If you have connected cables and cords, be sure to

unplug them before moving the TV.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of this receiver is

directly connected to the AC power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe operation. Replace

these components with Sony parts whose part numbers appear as shown in this manual or in supplements published by Sony. Circuit adjustments that

are critical for safe operation are identifi ed in this manual. Follow these procedures whenever critical components are replaced or improper operation is

suspected.

ATTENTION!!

Ces instructions de service sont à l’usage du personnel de service qualifi é seulement. Pour prévenir le risque de choc électrique, ne pas faire

l’entretien autre que celui contenu dans le Mode d’emploi à moins que vous soyez qualifi é faire ainsi.

TRANSPORTER LE TÉLÉVISEUR

Le transport du téléviseur doit être effectué par au

moins deux personnes. Ne tenez pas le téléviseur

par son socle ni par le panneau avant. Ces pièces

risqueraient de se détacher.

Lorsque vous déplacez le téléviseur, placez une

main dans l’orifice de la partie inférieure du

téléviseur tout en tenant la partie supérieure de

l’autre main, comme illustré ci-dessous.

Ne tenez pas le

téléviseur par son socle

ni par le panneau avant.

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout dépannage. Le

chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

Si vous avez branché les câbles et les cordons

d’alimentation, veillez à les débrancher avant de

déplacer le téléviseur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque ! sur les schemas de principe, les vues explosees et les listes de pieces sont d’une

importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants Sony dont le numero de piece est indique dans le

present manuel ou dans des supplements publies par Sony. Les reglages de circuit dont l’importance est critique pour la securite du fonctionnement

sont identifi es dans le present manuel. Suivre ces procedures lors de chaque remplacement de composants critiques, ou lorsqu’un mauvais

fonctionnement suspecte.

KDF-37H1000

6

SAFETY CHECK-OUT

KDF-37H1000

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if sets

always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

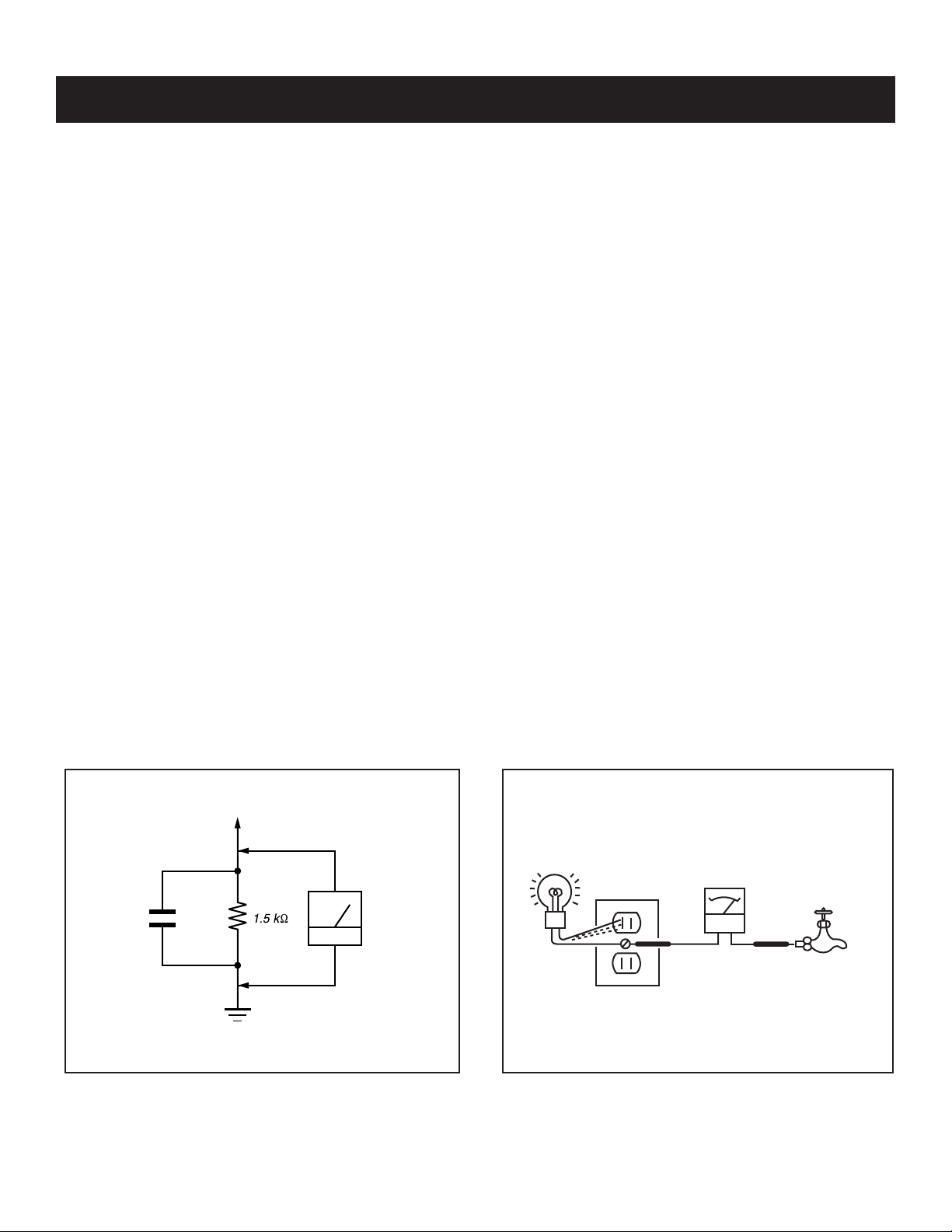

Leakage Test

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of

passive VOMs that are suitable. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable (see Figure A).

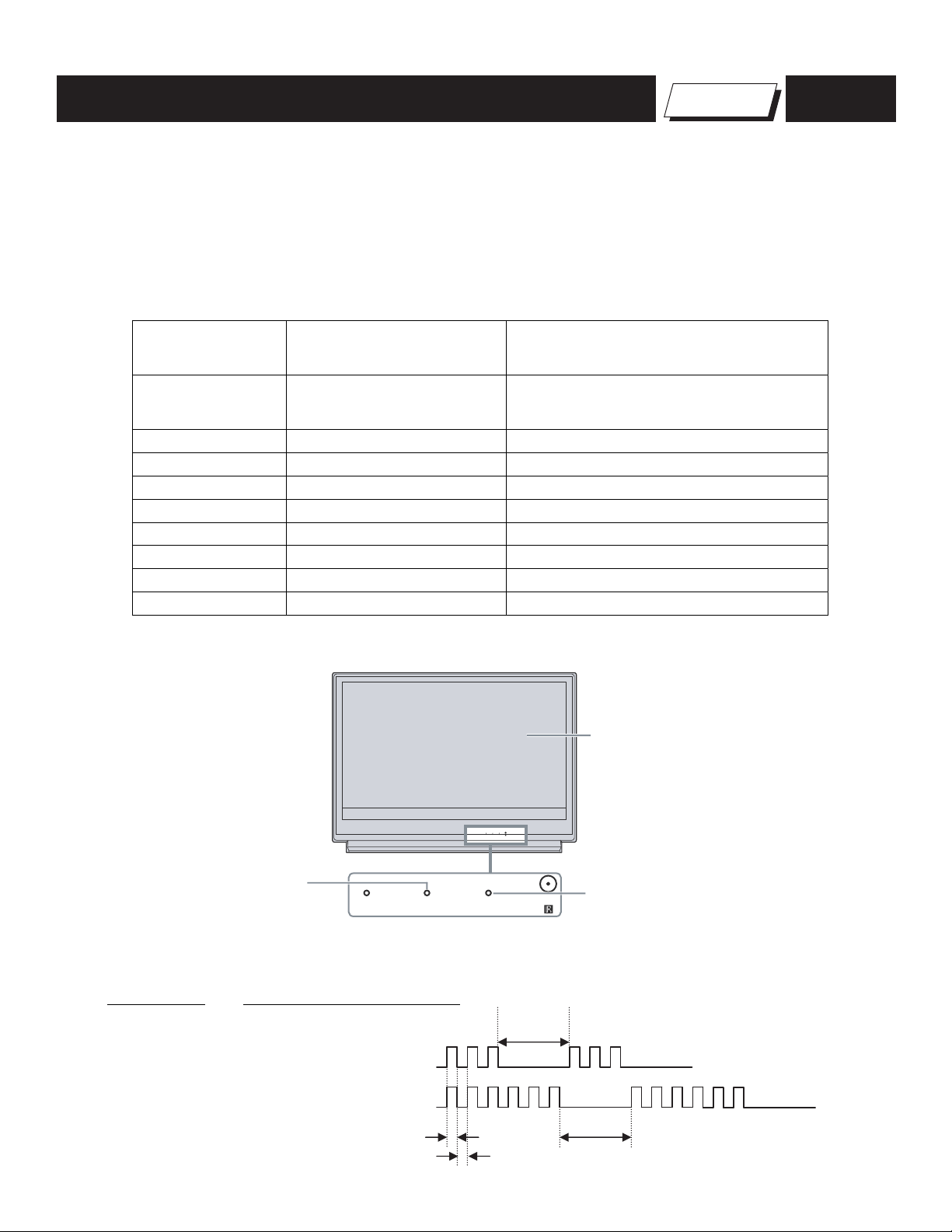

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground. If the

retaining screw is to be used as your earth ground, verify that it is at

ground by measuring the resistance between it and a cold-water pipe

with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt

trouble- light (not a neon lamp) between the hot side of the receptacle

and the retaining screw. Try both slots, if necessary, to locate the hot

side on the line; the lamp should light at normal brilliance if the screw

is at ground potential (see Figure B).

0.15 μF

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

KDF-37H1000

To Exposed Metal

Parts on Set

Earth Ground

AC

Voltmeter

(0.75V)

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

7

KDF-37H1000

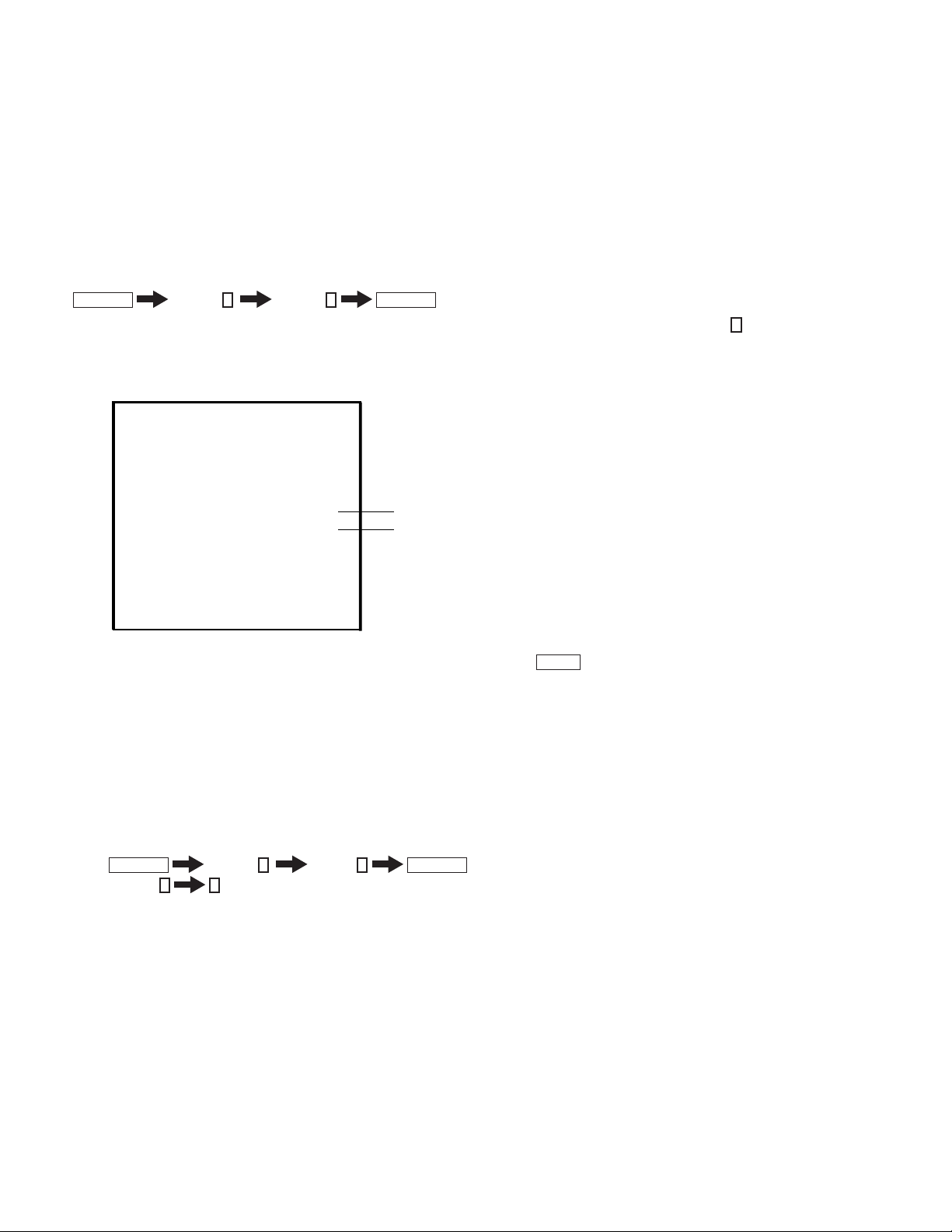

SELF-DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the POWER/STANDBY will automatically begin to fl ash. The number of

times the LED fl ashes translates to a probable source of the problem. A defi nition of the POWER/STANDBY fl ash indicators is listed in the instruction

manual for the user’s knowledge and reference. If an error symptom is diffi cult to reproduced use the Remote Commander to display the record that is

stored at the internal NVM to specify the cause of the failure.

Diagnostic Test Indicators

When an error occurs, the POWER/STANDBY will fl ash a set number of times to indicate the possible cause of the problem. If there is more than

one error, the POWER/STANDBY will identify the fi rst of the problem areas. If the errors occur simultaneously, the one that corresponds to the fewest

fl ashes is identifi ed fi rst.

Results for all of the following diagnostic items are displayed on screen. (No error has occurred if the screen displays a “0”.)

Self Diagnosis

Supported model

Number of times

LED indicator

flashes Diagnosis Item Probable Cause

Lamp not seated properly

☛

1 Lamp Error

(Note: The lamp LED will flash red when

this error occurs, not the Power LED)

2 OVP 10.5V is high on B Board

3 LowB Error 10.5V is low on B Board

4 Not Used in this model

5 HV Detect Ballast is not working

6 Lamp Cover/ Lamp Position The Lamp cover is not closed securely.

7 Temp Error High Temperature or sensor connection

8 Audio Error DC error on U Board

9 Fan Error Fan is not working properly

DISPLAY OF POWER/STANDBY OR LAMP LED FLASH COUNT

Screen

TIMER LAMP POWER

Flashes red for Lamp error

TIMER LAMP POWER

Flashes red for all except Lamp error

- 4 Flash is not used for self-diagnosis

-Example

Diagnosis

LowB Error

Number of times LED Flashes

LED OFF

3.0sec

3 times

Lamp Cover 6 times

KDF-37H1000

LED ON : 0.3sec

LED OFF : 0.3sec

LED OFF

3.0sec

8

KDF-37H1000

RELEASING THE POWER/STANDBY LED FLASH

Unplug the power cord from the outlet to temporarily stop the POWER/STANDBY lamp from fl ashing.

Self-Diagnostic Screen Display

For failures that are diffi cult to reproduce, or accompany occasional power off and/or picture mute, the Self-Diagnostic screen display is useful to

specify the cause.

VIEWING THE SELF-DIAGNOSTIC SCREEN

1. TV must be in standby mode. (Power off).

2. Press the following buttons on the Remote Commander within a second of each other:

DISPLAY

NOTE: This differs from the method of accessing service mode which is Volume

Sample Self-Diagnostic Screen Display

☛

Channel

1 : LAMP_ERR 0

2 : OVP 0

3 : LowB-ERROR 0

5:

6:

7 : TEMP-ERROR

8 : AUDIO-ERROR 0

9 : FAN-ERROR 0

5

Volume -

SELF CHECK

HV DETECT

LAMP_COVER 1

0

0

POWER

+

"1" is displayed when an error is detected one or more times

"0" is displayed when no error has been detected

Name: KDF-37H1000

Serial: XXXXXXXXXX

NOTE: To refresh the Self Check menu when all the items are not displayed, press

3. Proceed to Viewing the Self-Diagnostic Errors.

JUMP

on the Remote Commander.

CLEARING THE SELF-DIAGNOSTIC SCREEN

The self-diagnostic results displayed on the screen are not cleared automatically, therefore you should always check the self-diagnostic screen during

repairs. When you have completed the repairs, clear the self-diagnostic screen to reset the results to “0”.

Note: The self-diagnostic function will not be able to detect any subsequent faults after completion of the repairs unless the Self-Diagnostic

result display is cleared to reset the results to “0”.

1. If the Self-Diagnostic screen is already displayed, proceed to step 3. If not, Power off (Set to Standby mode).

2. Press

3. Press Channel 8

The status resets to 0.

4. To exit the Self-Diagnostic screen, turn the power off.

DISPLAY

Channel

0

5

Volume -

POWER

KDF-37H1000

9

1-1. OVERVIEW

TOOLS NEEDED

Long Phillips Screwdriver

Needle Nose Pliers

Small Flathead Screwdriver or Jewelers Screwdriver

The connectors in this chassis have been redesigned to ensure they are securely fasten to the boards. Please review the illustrations below.

Use caution not to rock the Type 2 or Type 3 connectors when removing or reinstalling to avoid breaking the solder leads off the

Printed Circuit Boards.

KDF-37H1000

SECTION 1: DISASSEMBLY

TYPE 1

LIFT ONE SIDE AT A TIME

BY PUSHING TAB IN WITH

SMALL SCREWDRIVER

TYPE 2

SQUEEZE DOWN ON

TAB TO RELEASE

TYPE 3

SQUEEZE LOCKING TAB

TOWARDS CONNECTOR

BEFORE PULLING FREE

CAUTION! IF THE TYPE 2 FEMALE

CONNECTOR HAS A SLOT (AS SHOWN)

MAKE SURE THE LOCK TAB SEATS INSIDE

THIS SLOT.

KDF-37H1000

10

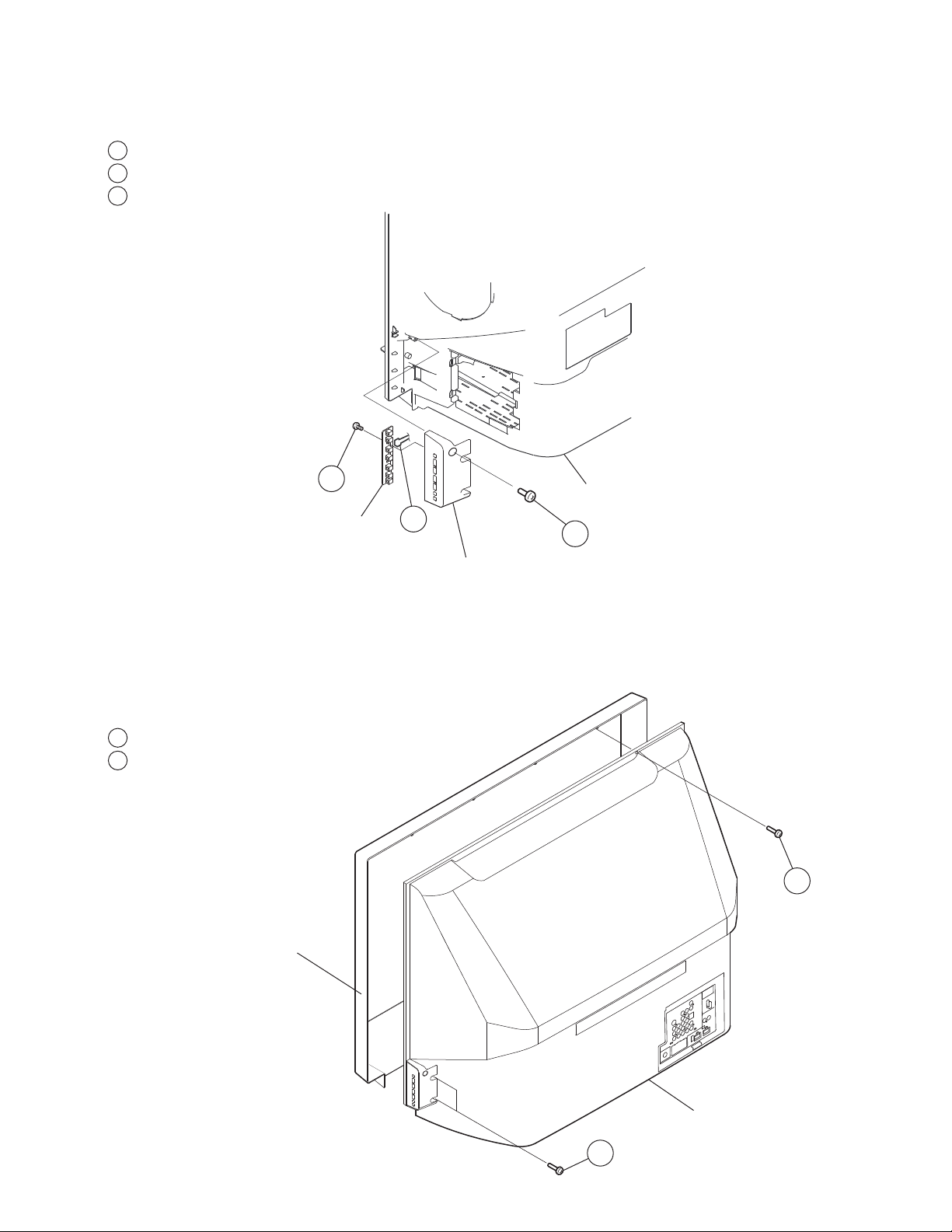

1-2. HAM BOARD REMOVAL

1

Remove one screw, +BVTP2 4X16

2

Disconnect a connector from HAM board

3

Remove 2 screws for HAM board removal,

+BVTP 3x12 TYPE2

KDF-37H1000

3

HAM PWB

1-3. SCREEN FRAME REMOVAL

All of the components of this model can be reached by removing the Screen Frame Assembly.

Caution:

When removing the Rear Cover or the Screen Frame

dust particles.

1-3-1. REAR COVER REMOVAL

1

Remove 10 screws, +BVTP2 4x16

2

Remove 4 screws from side brackets, +BVTP2 4x16

Rear Cover

2

1

Control Botton

Bracket

Assembly, be sure to clean the mirror and Diffusion Plate(s) to remove any

1

Screen Frame Assembly

KDF-37H1000

Rear Cover

2

11

KDF-37H1000

1-3-2. DIFFUSION PLATES (SCREENS) AND SCREEN FRAME ASSEMBLY REMOVAL

1

Remove 4 screws, +BVTP2 4x16

(3 screws on each side to remove the side brackets,

and 4 screws on the top and bottom brackets.)

2

Remove 1 screw, +BVTP 3x12, to remove Light Guide.

NOTE: The Light Guide is not included with the

Screen Frame Assembly.

1

Screen Frame Assembly

1-3-3. DIFFUSION PLATES (SCREENS) TAPE METHOD

NOTE: The following diagram illustrates the taping method when replacing the diffusion Plates.

For Part Numbers refer to the Exploded View section of this manual.

Light Guide

Diffusion Plate

(Lenticular - Front side)

2

Diffusion Plates

Screen Holder

Black Acetate Tape

Diffusion Plate

(Frensnel - Rear side)

KDF-37H1000

12

1-4. HB BOARD AND SPEAKER REMOVAL

1

Remove 5 screws from separator, +BVTP2 4x16

2

Disconnect connectors from HB board

3

Disconnect connectors from Speakers

4

Lift tabs and slide out separator unit.

5

Remove 2 screws for HB board removal,

+BVTP 3x12 TYPE2 IT-3

6

Remove 4 screws from speakers,

+BWTP2 4x16

Speaker

KDF-37H1000

6

1-5. HCM BOARD REMOVAL

1

Remove one screw, +BVTP2 4X16

2

Disconnect connectors from HCM board

3

Remove 2 screws for HCM board removal,

+BVTP 3x12 TYPE2

4

3

2

Rear Cover

1

HB PWB

5

Speaker

KDF-37H1000

3

Rear Cover

HC PWB

2

1

HC Bracket

13

1-6. LAMP REMOVAL

For detailed instructions, refer to “Replacing the Lamp” in the Appendix section of this manual

1

Remove the Lamp Door and the Lamp Cover

2

Pull the lamp out of the TV

Using equal force, press both hooks (marked

by 1) towards the TV screen in the direction

the arrows are pointing.

While pressing the two hooks (marked by 1),

push the center lever (marked by 2) towards

the TV screen and pull the Lamp Cover towards

you. The lamp cover should come off easily.

1

2

1

KDF-37H1000

Lamp Cover

Lamp Block

2

Lamp Door

1

Remove the Lamp Door.

Holding the door knob, press the door lever

toward the door knob in the direction the

arrow is pointing. Then, pull the lamp door

out of the TV towards you.

KDF-37H1000

14

1-7. LAMP DUCT REMOVAL

1

Disconnect 4 connector joints (not shown)

2

Remove 2 screws, +BVTP2 4x16

3

Disconnect a connector from fuse box

4

Remove one screw, +BVTP 3x12 TYPE2 IT-3

5

Remove one screw, +BVTP 3x12 TYPE2 IT-3

6

Remove one screw, +BVTP 3x12 TYPE2 IT-3

7

Remove one screw, +BVTP 3x12 TYPE2 IT-3

8

Disconnect 2 connectors

9

Disconnect 2 connectors

10

☛

Disconnect 1 connector (Thermal Fuse)

KDF-37H1000

3

8

4

S PWB

Fuse Sheet

Fuse Plate

7

Power Board

5

9

10

☛

T PWB

Rear Cover

Fan and Exhaust ducts

6

2

Duct, Intake

KDF-37H1000

15

1-8. FAN EXHAUST DUCT REMOVAL

1

Release hook from Lamp Duct

2

Remove 2 screws, +BVTP2 4X16

3

Release three hooks to separate upper and lower duct

Caution:

When replacing the DC Fan be sure to remove any dust particles.

KDF-37H1000

Fan Cushion

1

Exhaust Duct(U)

Fan

3

Lamp Duct

2

Rear Cover

Exhaust Duct(L)

KDF-37H1000

16

1-9. OPTICAL UNIT BLOCK REMOVAL

Use caution not to damage the lens when removing the Optical Unit Block Assembly

1

Remove 2 screws, +BVTP2 4x16

Caution:

When replacing the Optics Unit Block

Assembly be sure to remove any dust particles.

KDF-37H1000

Optical Unit

Block Assembly

If necessary,

gently cut the foam

above the connector cable

to detach from the

Optical Unti Block

Assembly.

NOTE: The connector is

NOT included with the

Optical Block Assembly.

Rear Cover

1

KDF-37H1000

17

1-10. CHASSIS REMVOAL

1

Disconnect 8 connectors from G board

2

Disconnect a lead wire connector from B board

3

Disconnect 2 connectors from B board

4

Remove 2 screws, +BVTP2 4x16

5

Remove one screw, +BVTP 3x12 TYPE2 IT-3

6

Remove 3 screws, +PSW M3X8

7

Remove 6 screws, +BVTP 3x12 TYPE2 IT-3

8

Disconnect 2 connectors from U board

9

Remove 2 screws, SPECIAL (+PW 4X30)

10

Remove2 screws, +PSW M3X8

11

Remove 2 screws, +BVTP 3x12 TYPE2 IT-3

12

Remove 1 washer hexagon nut from tuner

Caution:

When replacing any part of the chassis be sure to remove any dust particles and clean the mirror

KDF-37H1000

.

G Board

7

G Bracket

6

5

B-Shield

1

10

9

11

8

12

Terminal

Bracket

U Board

B Board

2

3

Rear Cover

KDF-37H1000

Main Base

4

18

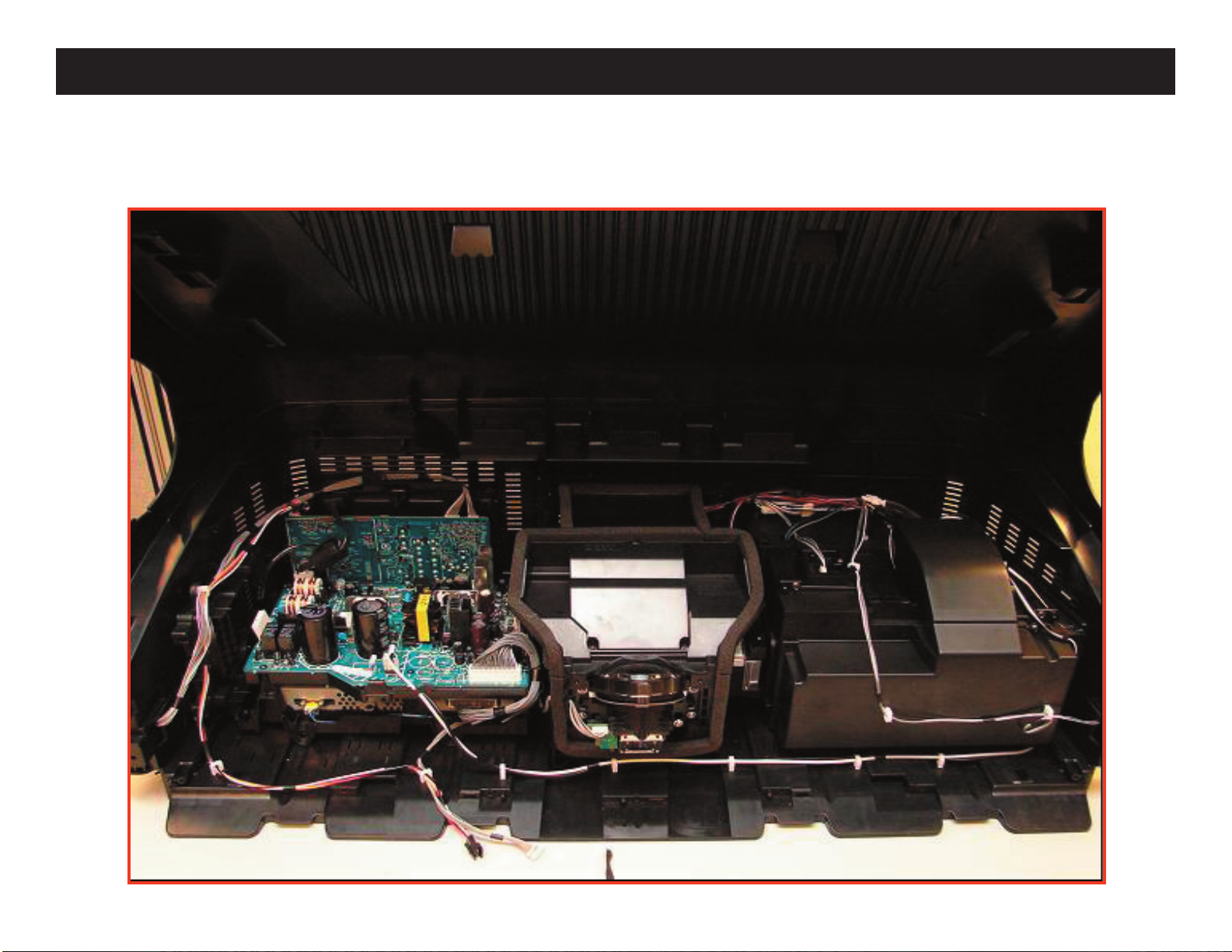

WIRE DRESSING

COMPLETE INTERNAL WIRE DRESSING

KDF-37H1000

KDF-37H1000

19

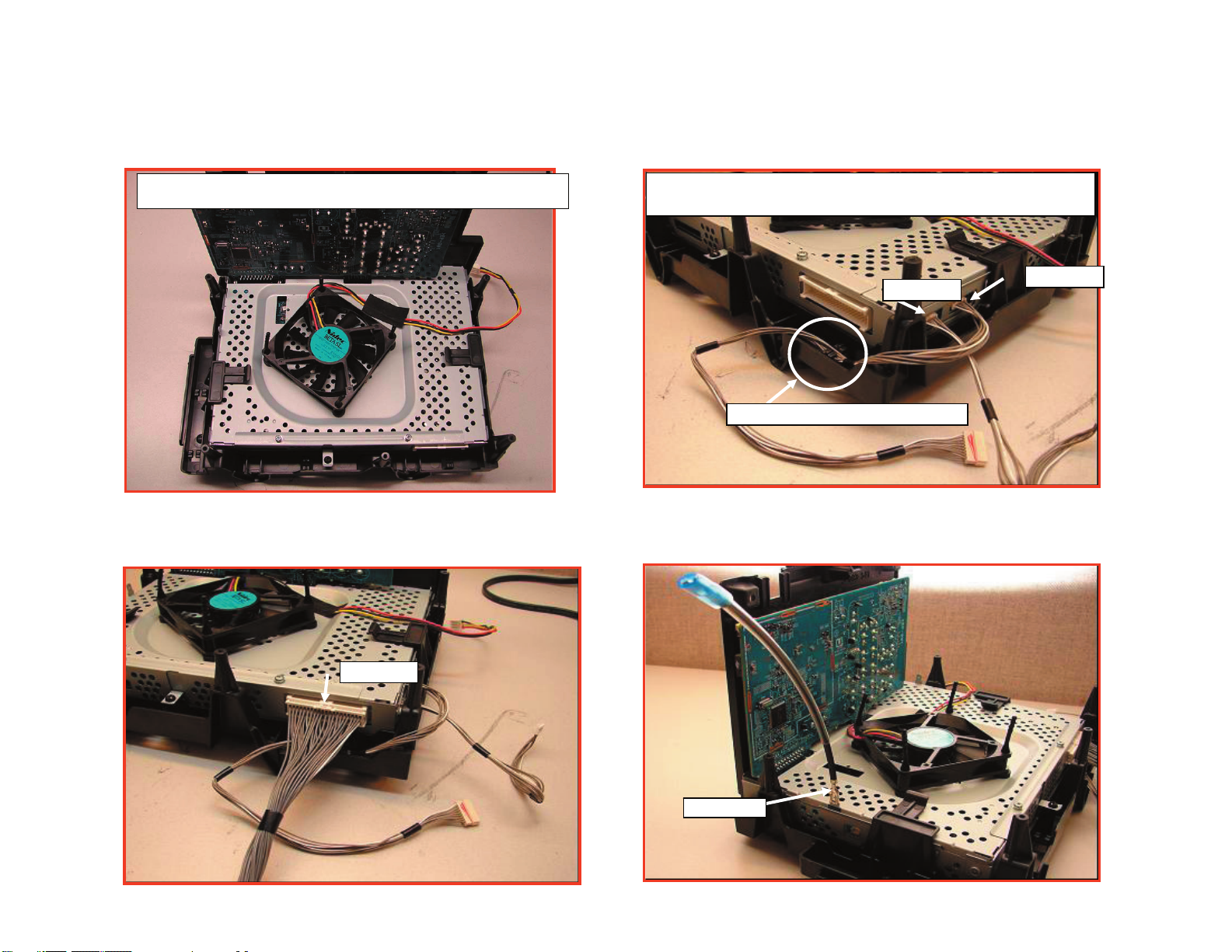

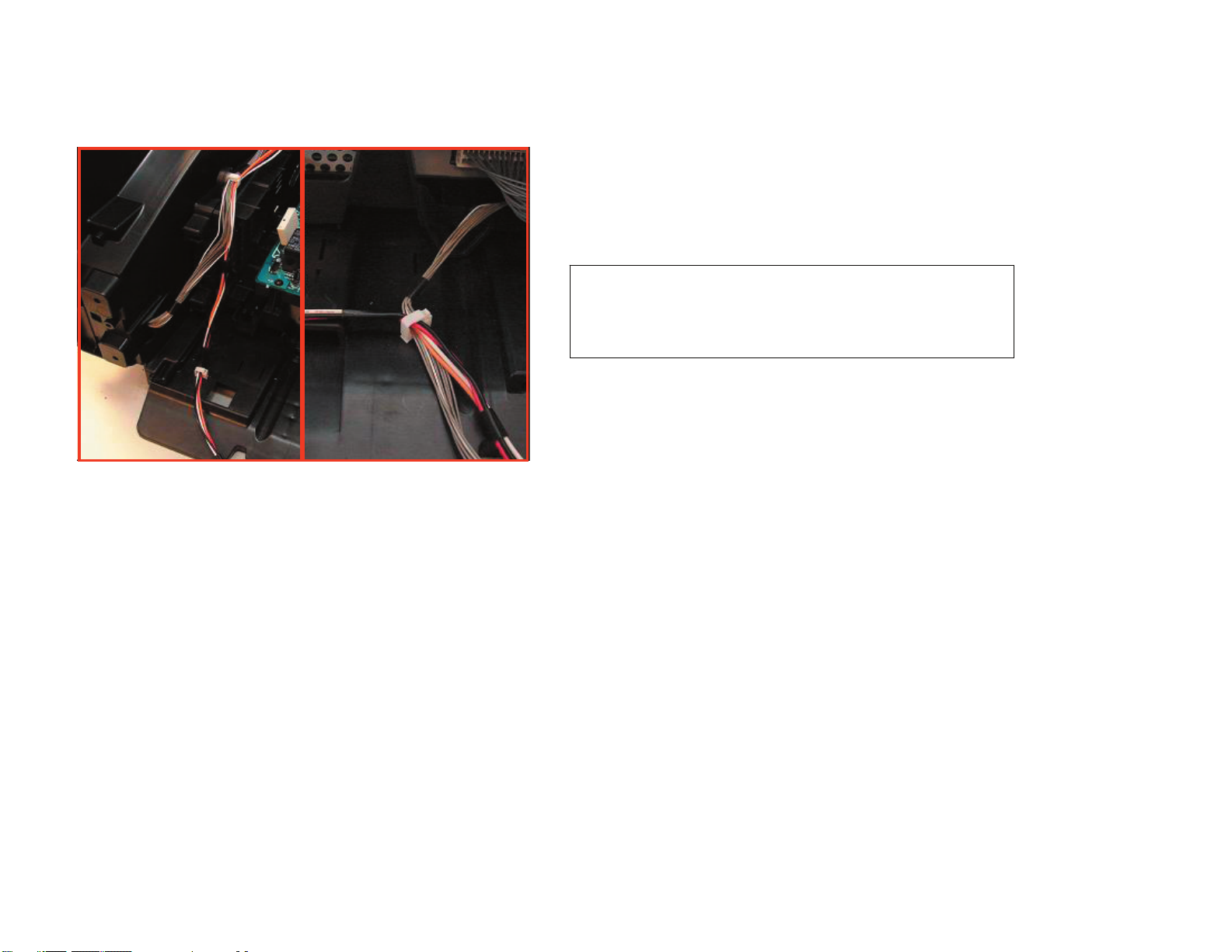

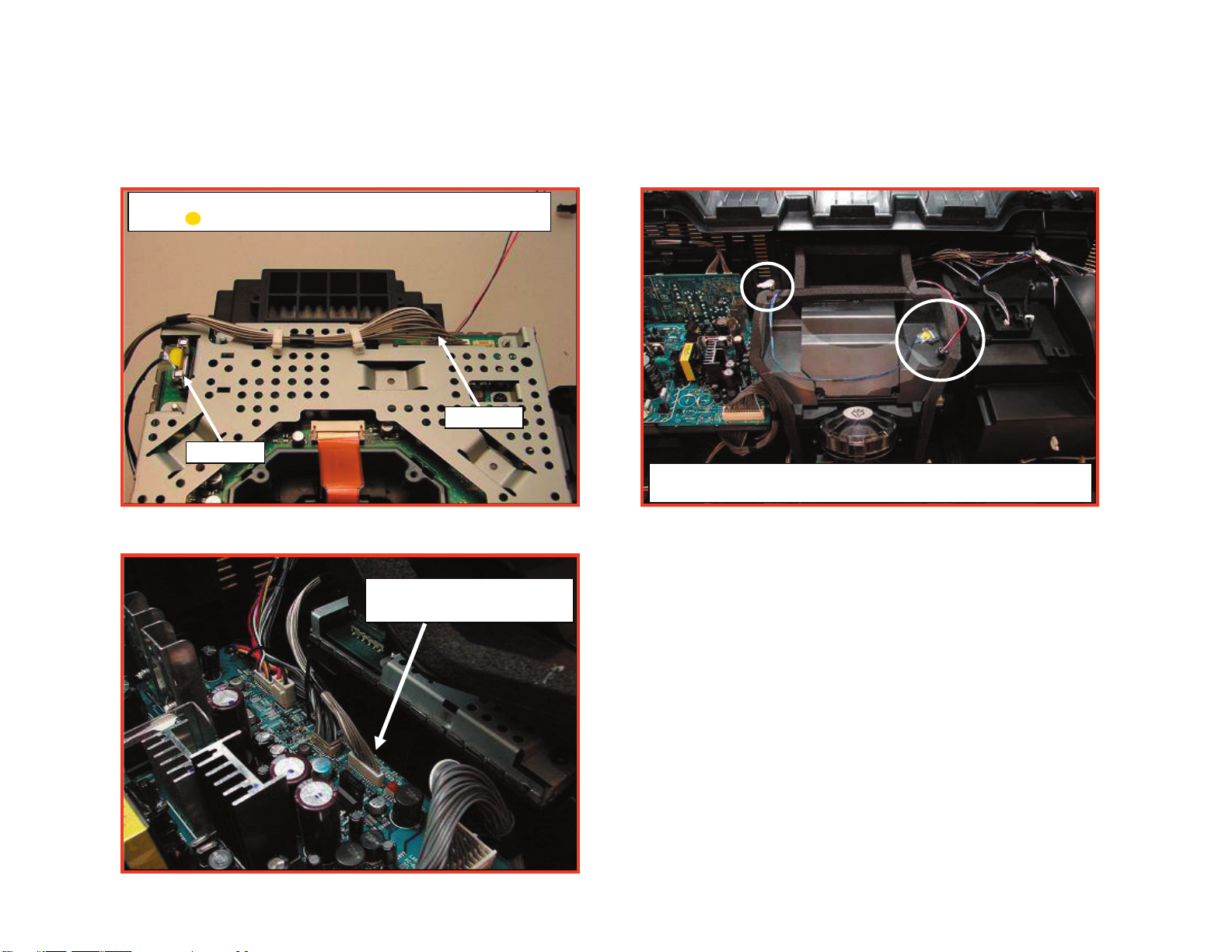

B BLOCK ASSEMBLY

KDF-37H1000

After installing Fan add Himelon Tape as shown below

Install 8P IRIS and 9P HB joint connector assy and wire dress

as shown

191003515

191003514

Wire dress into hook on Main Bracket

KDF-37H1000

191003507

191003507

20

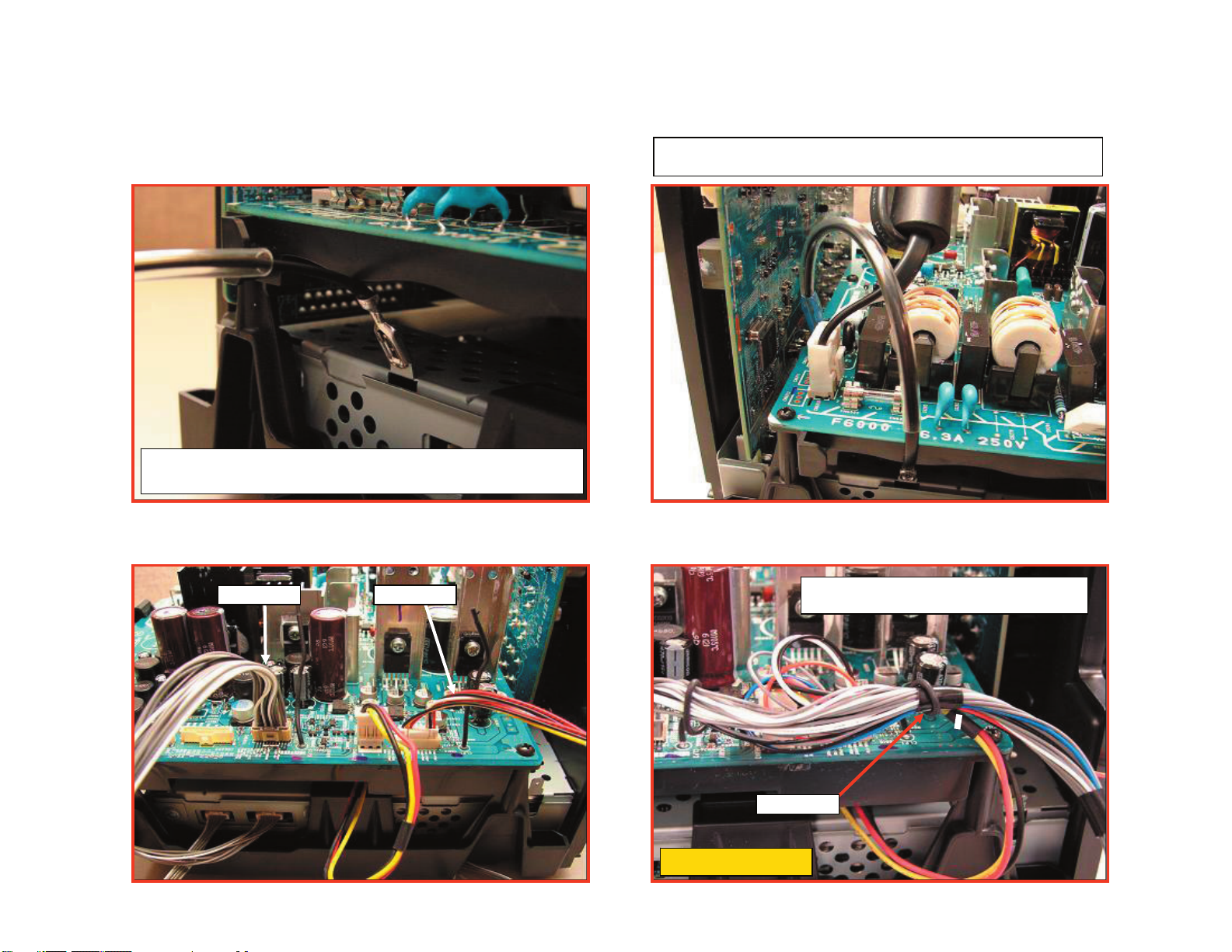

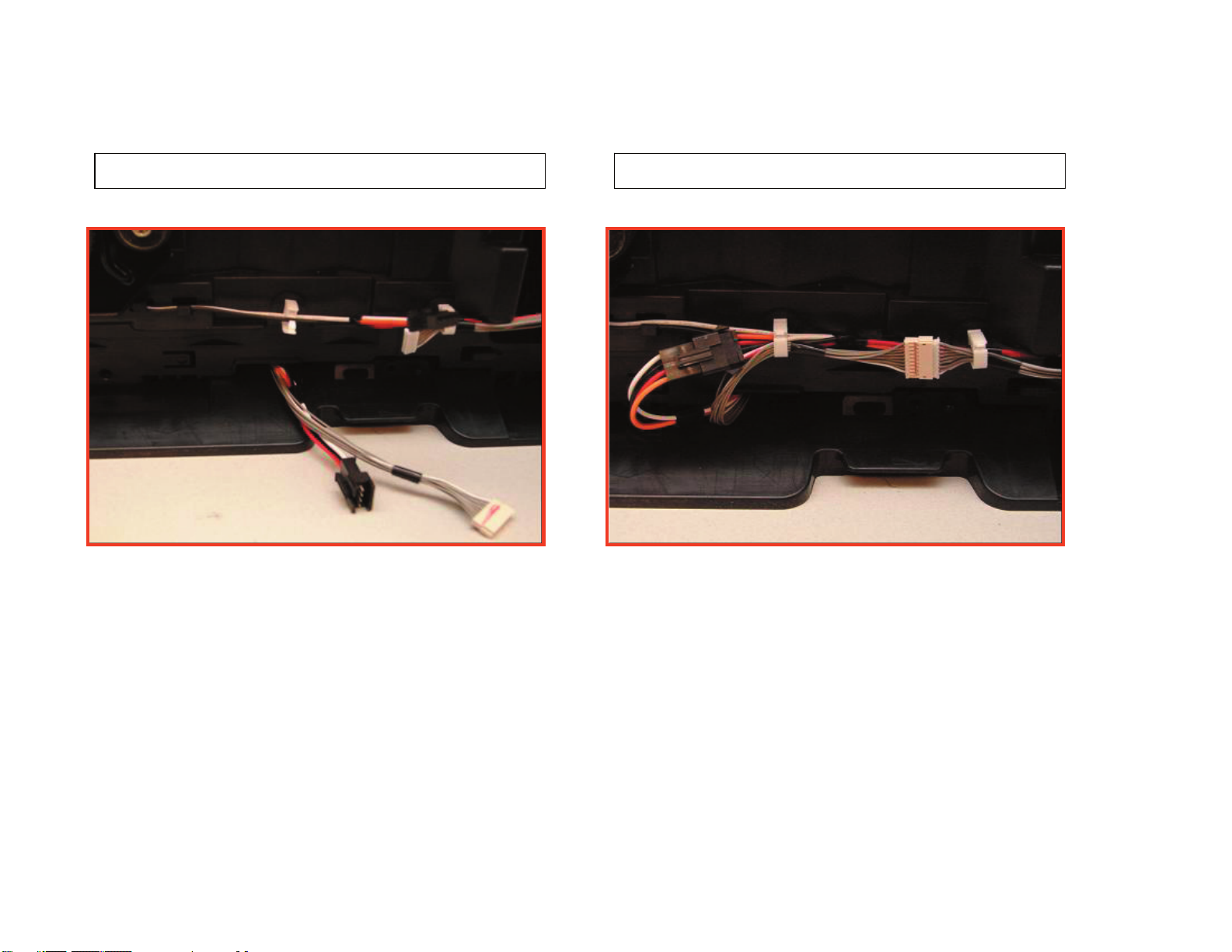

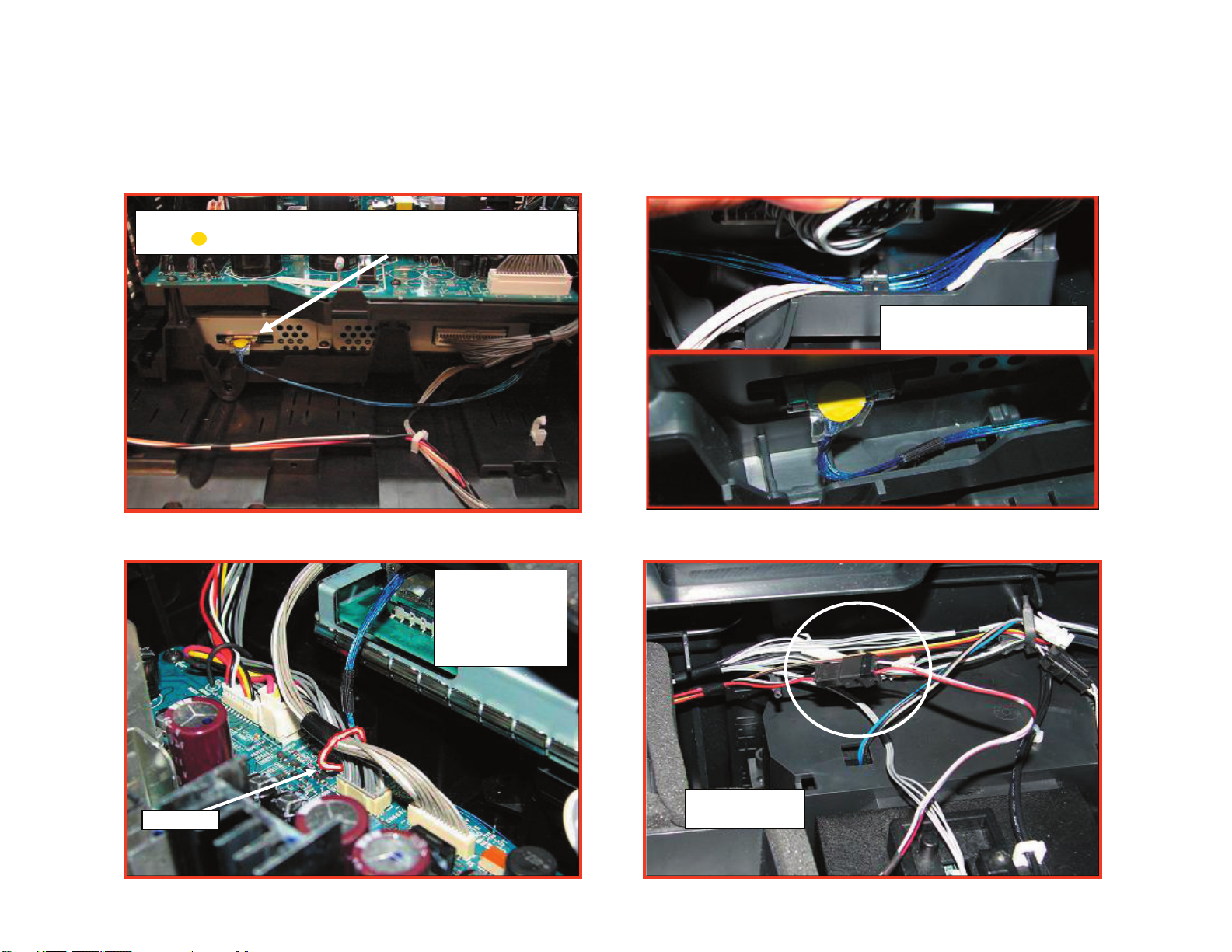

CHASSIS ASSEMBLY

Before Installing [G] Board it may be necessary to bend tab slightly in

order to properly install [G] board.

KDF-37H1000

Lighting ground should be behind AC cord. UL Tube should be located

on [G] board side of connection as shown below

KDF-37H1000

191003519 191003520

ONLY Wire dress 3P Fan Connector to wire

holder on (1) side of wire as shown below.

Wire Pin

CRITICAL FOR EMI

21

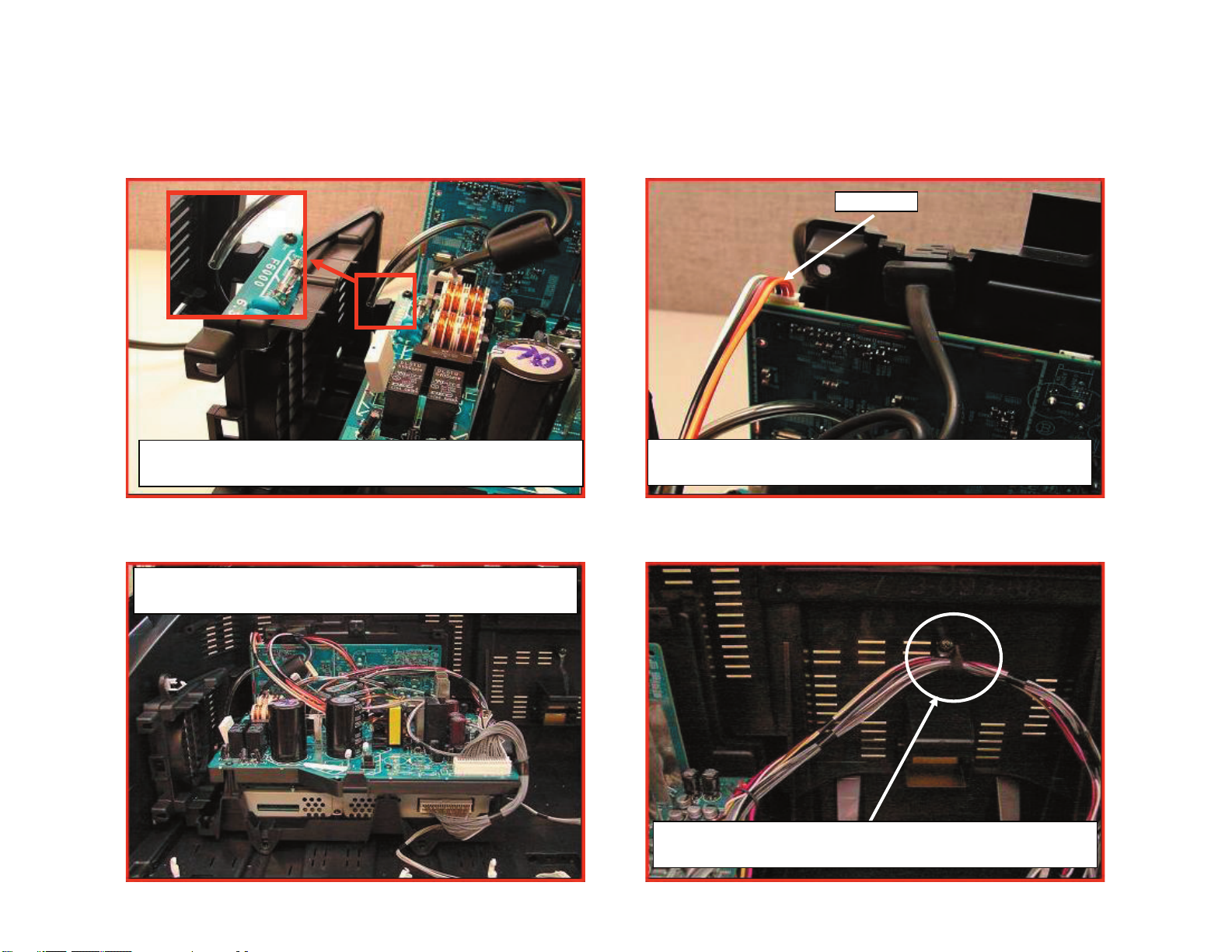

CHASSIS ASSEMBLY (CONTINUED)

KDF-37H1000

191003512

Lighting Ground should be inside of Fan Bracket as shown

Install Chassis Assy to Rear Cabinet

KDF-37H1000

Install 4P Speaker Connector Assy to [U]

Route and Dress 9P and 20P Connecto r Assy to Rear Cabinet as

shown above.

22

()

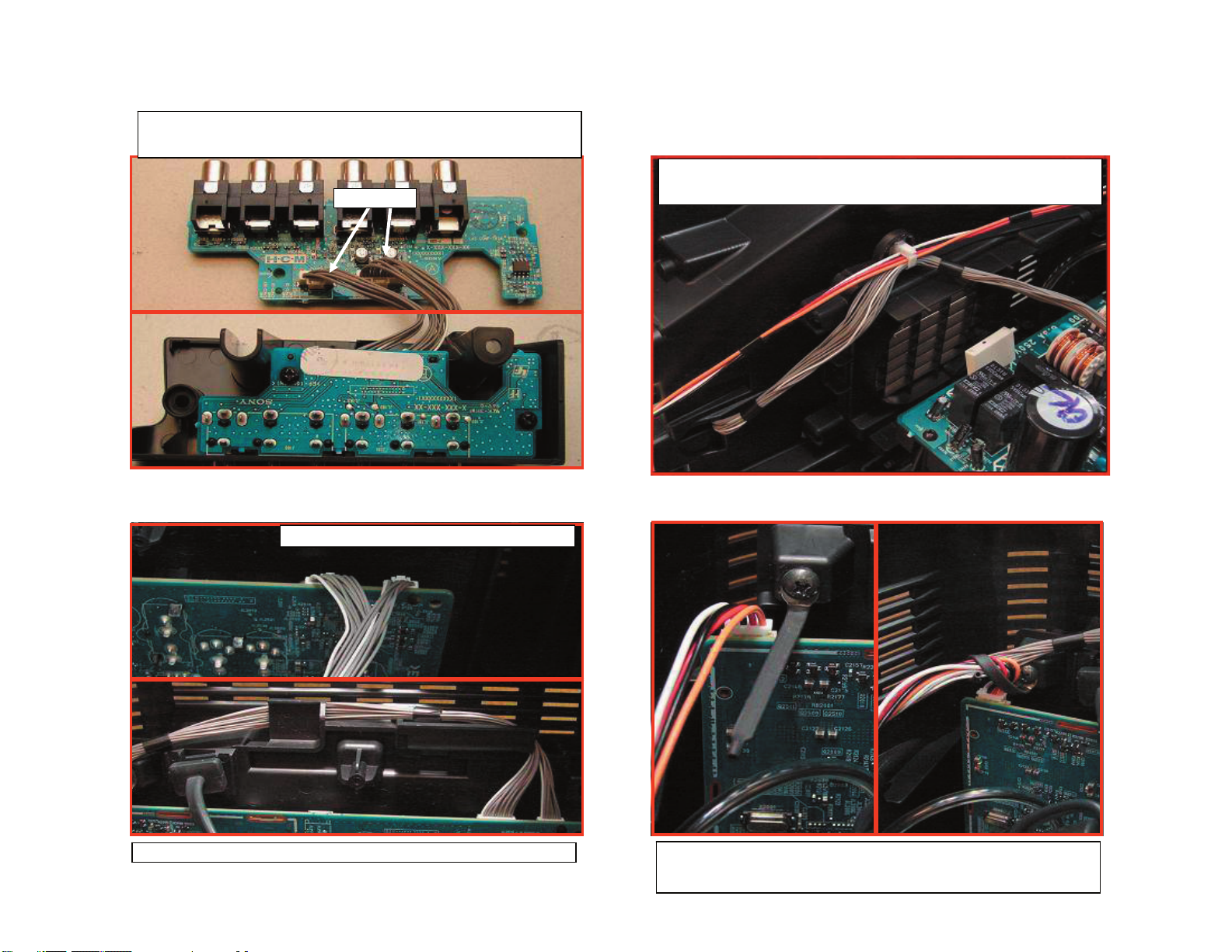

CHASSIS ASSEMBLY (CONTINUED)

HCM connector assy must be installed to [HCM] board before

installing board to HC Bracket

191003507

KDF-37H1000

After Installing HC Bracket w/ [HCM] board to Rear Cabinet Route

HCM connector Assy and 4P Speaker Conn Assy to Fan Bracket.

After Installing Route above terminal bracket as shown above.

KDF-37H1000

Install 8P/12P Connector from [HCM] to [U]

Wire Dress 4P Speaker Connector and 12P/8P HC connector assy to

wire holder. Bend wire Holder as necessary to take up "slack" in

cables.

23

SPEAKER WIRE ASSEMBLY

Fig. 1 Fig. 2

KDF-37H1000

Route 4P Speaker to Wire Holder as shown in Fig 1.

Then Route 4P Speaker and 9P [HB] connectors to wire holder shown

in fig.2

KDF-37H1000

24

SPEAKER WIRE ASSEMBLY AND HB BOARD

KDF-37H1000

When Installing Seperator Block Assy ensure that the Speaker and

[HB] Connectors are not pinched and routed as below.

After connecting 9P[HB] and 4P Speaker Connector wire dress to

Holder Wire as shown below

KDF-37H1000

25

FERRITE CORE INSTALLATION

KDF-37H1000

Install Ferrite Core ZCAT2017-0930 Sony P/N 1-500-484-21 to the

following connector assys as shown below

Ferrite Core

p/n 1-500-484-21

KDF-37H1000

CRITICAL FOR EMI

26

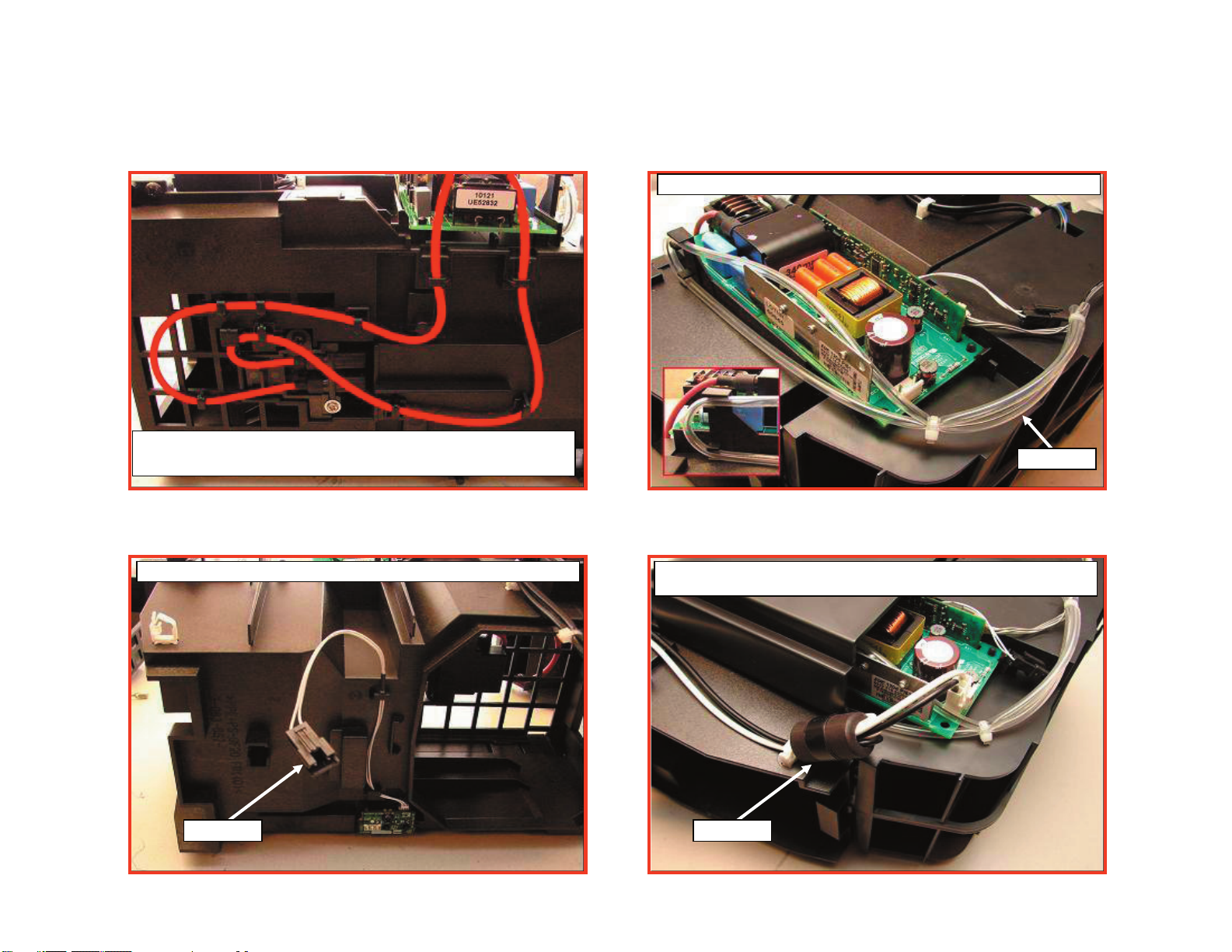

POWER SUPPLY BLOCK (BALLAST)

Lamp Connector from Ballast MUST be kept from Crossing. Please

follow above wire dressing.

KDF-37H1000

Route 7P Ballast Control Conn Assy as shown below.

191003518

T BOARD

Route 7P Ballast Control Conn Assy as shown below.

KDF-37H1000

S BOARD

Install 3P Ballast Power as shown below and wire dress to Holder

Wire.

191003517 191003509

27

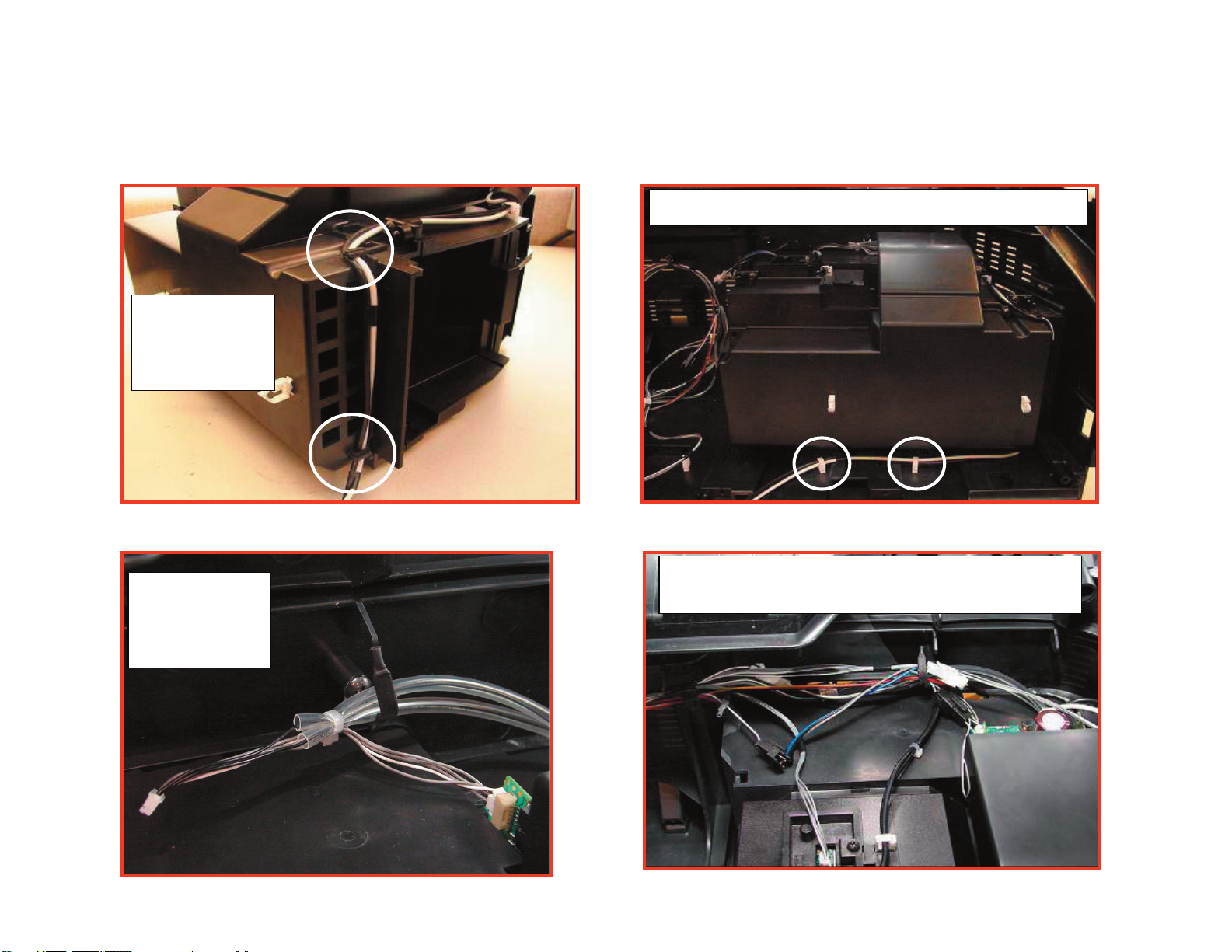

DUCT BLOCK ASSEMBLY

Wired Dress 3P

Ballast Power to

hooks on Duct Block

as shown to the right.

KDF-37H1000

Install Duct Block Assy to Rear Cabinet and Route 3P Ballast power

Connector as shown to Holder Wire on Rear Cabinet

Ensure 9P ballast

Connector is wire

dressed as shown to

the right

KDF-37H1000

Connect 9P Ballast/2P thermal sensor/3P [T] and 3P Duct Blk Fan

Connector and dress to wire holders as shown. Do Not close

Completely wire holders.

28

OPTICAL UNIT BLOCK ASSEMBLY

Install 21P LVDS and 15P[C] to [G] as shown below. Yellow

Sticker should be facing towards center of [C] board.

183391311

KDF-37H1000

191003517

When Installing Optical Block use caution not to pinch 15P, 21P LVDS

and 3P Fan Connector.

KDF-37H1000

Install 15P Connector from

Optical Blk to [G]

29

OPTICAL UNIT BLOCK ASSEMBLY (CONTINUED)

Install 21P LVDS Connector from Optical Blk to [BM]. Yellow Sticker

should be facing Up.

KDF-37H1000

Wire Dress LVDS Cable to

bottom hooks of Main Bracket

Wire PIn

KDF-37H1000

Dress 15P/21P

LVDS and 20P

Connectors using

Wire Pin on [G]

board as shown

Install 3P Optical

Block Fan

30

Loading...

Loading...