Page 1

KDE55XBR950

UC Model

PANEL MODULE SERVICE MANUAL

PDP Module Name

FPF55C17196UA

FLAT PANEL COLOR TV

Page 2

CONTENTS

1 OUTLINE ..................................................................................................................................1

1.1 Panel Dimension ................................................................................................................1

1.2 Feature...............................................................................................................................1

1.3 Specification .......................................................................................................................2

1.3.1 Functional specification ...............................................................................................2

1.3.2 Display quality specification.........................................................................................3

1.3.3 I/O Interface Specification............................................................................................ 4

2 SAFETY HANDLING of THE PLASMA DISPLAY ..................................................................... 8

2.1 Notes to Follow During Servicing ....................................................................................... 8

3 NAME and FUNCTION .............................................................................................................9

3.1 Configuration ......................................................................................................................9

3.2 Block Diagrams ................................................................................................................10

3.2.1 Signal Diagrams ........................................................................................................10

3.2.2 Power Diagrams ........................................................................................................ 11

3.3 Function............................................................................................................................12

3.3.1 Logic board Function .................................................................................................12

3.3.2 Function of X-SUS Board ..........................................................................................13

3.3.3 Function of Y-SUS Board........................................................................................... 13

3.4 Protection function............................................................................................................14

4 PROBLEM ANALYSIS ............................................................................................................15

4.1 Outline of Repair Flow......................................................................................................15

4.2 Outline of PDP Module Repair Flow.................................................................................16

4.3 Checking the Product Requested for Repair....................................................................19

4.4 Operation Test Procedure ................................................................................................20

4.5 Fault Symptom .................................................................................................................22

4.6 Problem Analysis Procedure ............................................................................................ 25

4.6.1 "The entire screen does not light.(Main power is turned off)” Problem analysis

procedure............................................................................................................................25

4.6.2 "Vertical line/Vertical bar" Problem analysis procedure.............................................. 31

4.6.3 "Horizontal bar" Problem analysis procedure.............................................................35

4.7 Problem Analysis Using a Personal Computer................................................................. 36

4.7.1 Connecting a computer..............................................................................................36

4.7.2 Preparing a computer ................................................................................................36

4.7.3 Problem Analysis Procedure...................................................................................... 37

5 Disassembling and Reassembling..........................................................................................40

5.1 Exploded View..................................................................................................................40

5.2 X-SUS Circuit Board Removal/Installation Procedure......................................................41

Page 3

5.3 Y-SUS Circuit Board Removal/Installation Procedure................................................................43

5.4 ABUS-U1 Circuit Board Removal/Installation Procedure.......................................................... 45

5.5 ABUS-U2 Circuit Board Removal/Installation Procedure.......................................................... 47

5.6 ABUS-U3 Circuit Board Removal/Installation Procedure .......................................................... 49

5.7 ABUS-U4 Circuit Board Removal/Installation Procedure .......................................................... 51

5.8 ABUS-D1 Circuit Board Removal/Installation Procedure..........................................................53

5.9 ABUS-D2 Circuit Board Removal/Installation Procedure..........................................................55

5.10 ABUS-D3 Circuit Board Removal/Installation Procedure........................................................ 57

5.11ABUS-D4 Circuit Board Removal/Installation Procedure.........................................................59

5.12 LOGIC Board Removal/Installation Procedure......................................................................... 61

5.13 Complete Panel Chassis Removal/Installation Procedure......................................................63

6 Operation Check and Adjustment Method..........................................................................................66

6.1 List of Check and Adjustment Items.............................................................................................66

6.2 Check and Adjustment Method.....................................................................................................67

6.2.1 Check and adjustment procedure.........................................................................................67

6.2.2 Parameter adjustment............................................................................................................68

6.2.3 Operation performance check items.....................................................................................70

6.2.4 Heat Run Test...........................................................................................................................72

6.2.5 Logic board parameter forwarding .......................................................................................74

6.2.6 Accumulation time reset.........................................................................................................76

6.2.7 Setup before shipment...........................................................................................................77

7 The parts information .............................................................................................................................78

7.1 FPF55C17196UA-53 configuration list.......................................................................................78

8 packing Procedure................................................................................................................................79

8.1 Single packing................................................................................................................................ 79

Page 4

Caution

Scope; 55P1 series

(Model name; FPF55C17196UA)

Before doing the service operation please be sure to read this service

analysis manual. This module has a lot of devices to secure the safety

against the fire, electric shock, injury and harmful radiation.

To maintain the safety control, please follow the instructions and remarks

described in this service analysis manual.

Page 5

)

1 OUTLINE

The module is a plasma display module which can be designed in there is no fan in addition to a

general feature of the plasma display such as a flat type, lightness, and high-viewing-angle and

terrestrial magnetism.

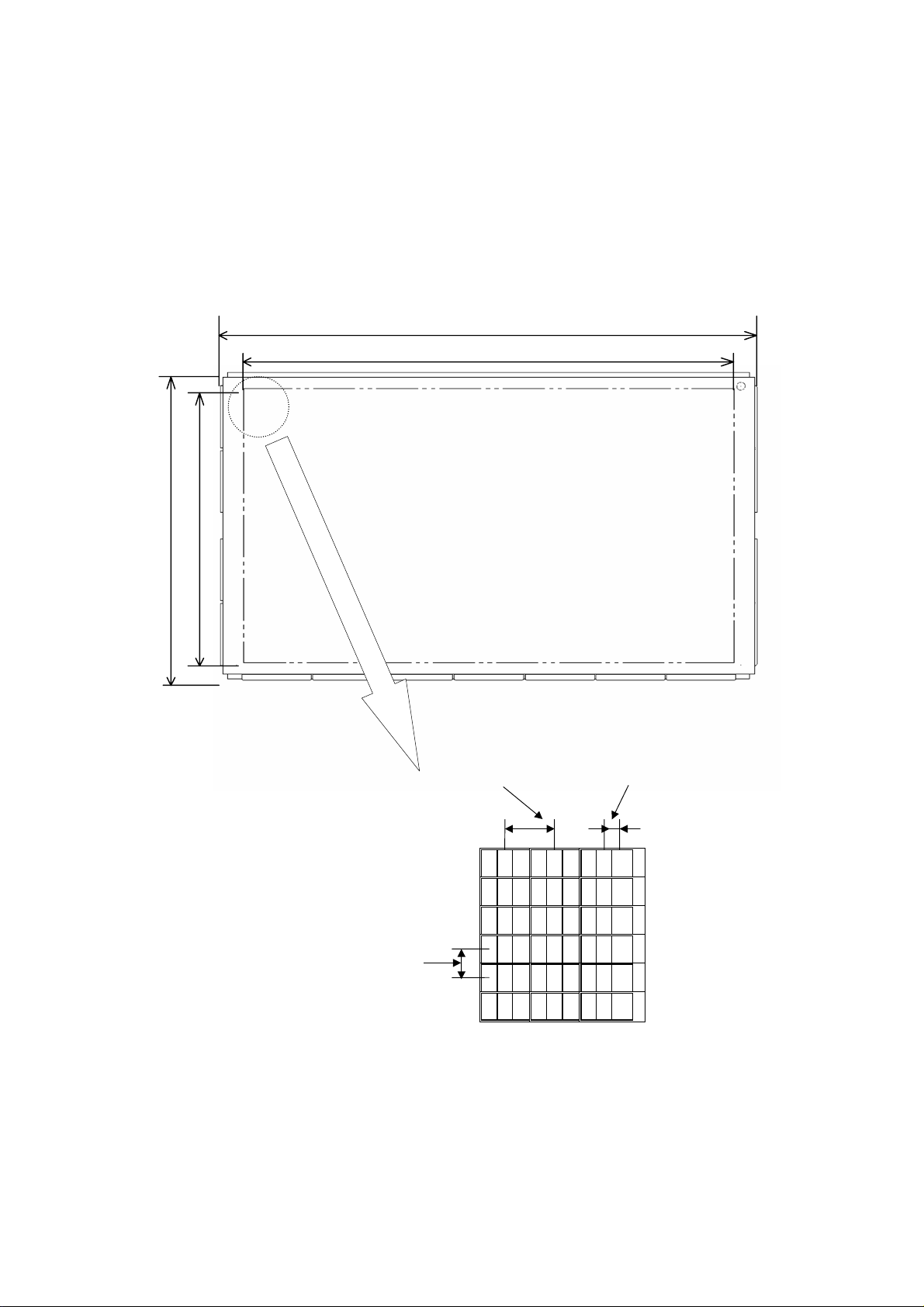

1.1 PANEL DIMENSION

1340(Glass

1229.4

691.2

750(Glass)

Pixel pitch(horizontal)

Pixelpitch(Vertical)

0.90mm

RGB

RGB

RGB

RGB

RGB

RGB

0.90 mm

RGB

RGB

RGB

RGB

RGB

RGB

1.2 FEATURE

1. For high definition television and monitor by Progressive method

2. For FAN Less design(Low consumption electric power)

3. Flat type・Lightness

4. Customizing of module equipped with communication function

-1-

Sub- pixel pitch(horizontal)

0.30mm

RGB

RGB

RGB

RGB

RGB

RGB

Page 6

1.3 SPECIFICATION

1.3.1 Functional specification

Item NO

Specification

UA-5*

Externals

Display panel

Color Grayscale(standard)

BrightNess

Chromaticity

Coordinates

Contrast Contrast in Darkroom(60Hz)

Data signal

Module size

Weight

Display size

Resolution

Pixel pitch

Sub pixel pitch

White(display load Ratio 1%,standard)

(x,y)、white 10%

Video signal (RGB each color)

1 1340 × 760 × 66mm

2 30kg

3 1229.4 × 691.2mm

(55inch: 16:9)

4 1366 × 768 pixel

5 0.90(H) × 0.90(V)mm

6 0.30(H) × 0.90(V)mm

9 RGB each color 256 Grayscale

11 1000cd/ m2

14 (0.290,0.290)

15 900:1

16 LVDS(10bit)X1 or LVDS(10bit)X2

Dot clock(max)

Sync Signal

Powersupply

Noise Shade noise at 18dB(A) or less

Guarantee

environment

Horizontal Sync Signal(max)

Vertical Sync Signal

Input voltage/current

Standby electric power(max)

Temperature(operation)

Temperature(storage)

Humidity(operation)

Humidity(storage)

17 85MHz

18 50KHz(LVDS)

19 50Hz ± 1.9 / 60 ± 1.7Hz (LVDS)

20 +3.3/+5/+75-90/+50-65V

21 1W

22 25dB(A) or less

23

24

25 20 ~ 85 %RH (no condensation)

26 20 ~ 80 %RH (no condensation)

0 ~ 45 °C

0 ~ 45 °C

*It is made to give priority when there is a delivery specification according to the customer.

DC, 0.05/7.5/7.5/6A

-2-

Page 7

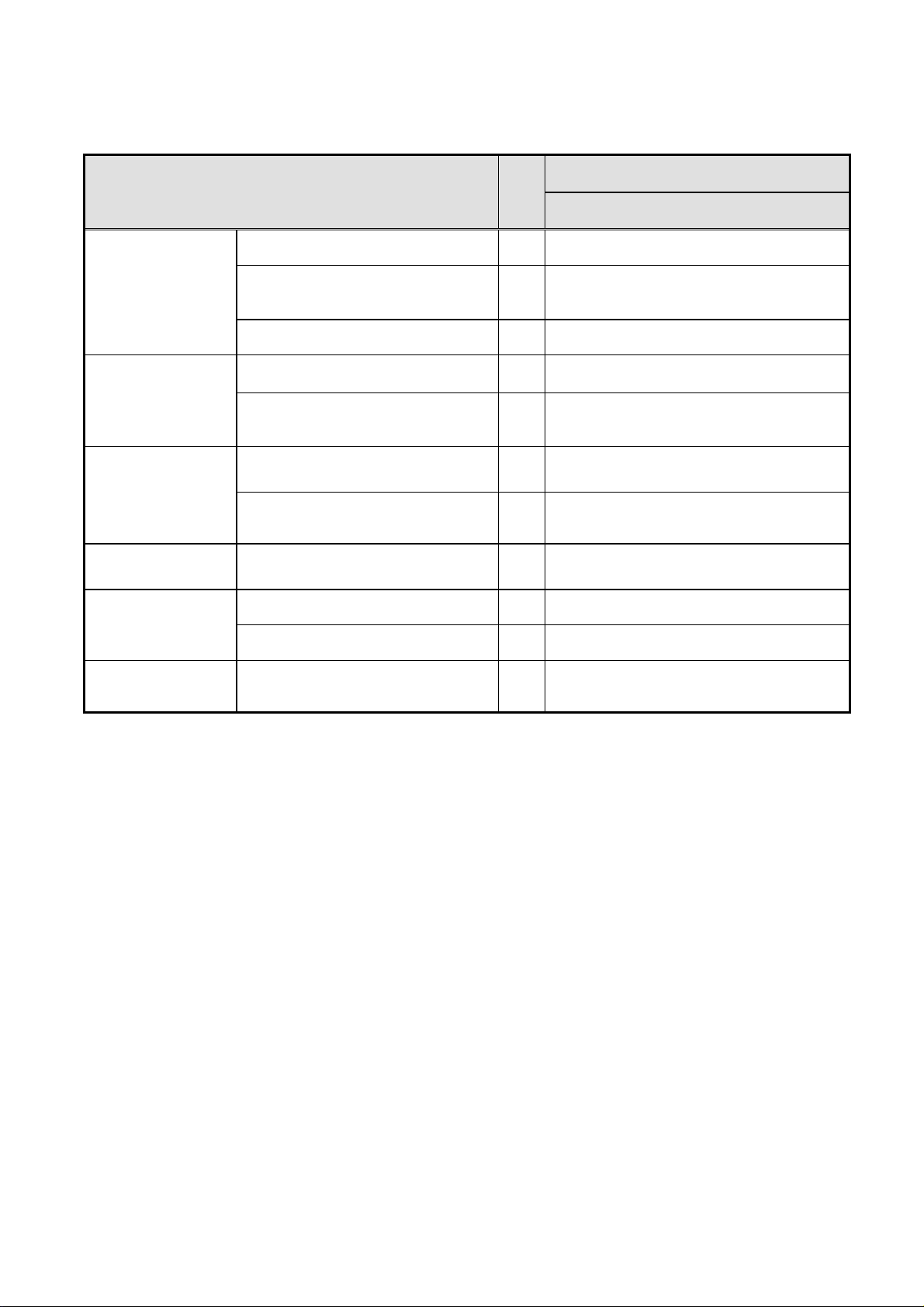

1.3.2 Display quality specification

Specification

Item NO

UC-5*

Non-lighting cell

defect

Non-extinguishing

cell defect

Flickering cell defect

High intensity cell

defect

Brightness variation

Color variation White block of 10% load [9 point]

Total number (subpixel)

Density (subpixel/cm2)

Size (H x V) (subpixel)

Total number (subpixel)

Density (subpixel/ cm

Flickering lighting cell defect

(sub pixel/cm

Flickering non-extinguishing cell defect

Twice or more bright point

White block of 10% load [9 point] (%)

In area adjacent 20mm [White] (%)

2

)

2

)

1 15 or less

2 2 or less

(However,1 continuousness or less)

3 1x2 or less, Or 2x1 or less

4

5 Each color 2 cells max

6 5 or less

7 Number on inside of

8 0

9 20 or less

10 10 or less

11 X: Average ± 0.020

6 or less(each color 2 or less)

(However,1 continuousness or less)

Non-extinguishing cell defect

y: Average ± 0.020

*It is made to give priority when there is a delivery specification according to the customer.

-3-

Page 8

A

1.3.3 I/O Interface Specification

(1) LVDS Signal Definition and Function

A video signal (display data signal and control signal) is converted from parallel data to serial

data with the LVDS transmitter and further converted into four sets of differential signals before

input to this product. These signals are transmitted seven times faster than dot clock signals.

The dot clock signal is converted into one set of differential signals by the transmitter before

input to this product. The LVDS signal definition and function are summarized below:

No. Item Signal Name

Number

of

signals

I/O Form Content of definition

1

Video Signal

Timing Signal

(ODD)

2

Video Signal

Timing Signal

(EVEN)

Display signal

3

4

5

6 SDA 1 I/O

Clock (ODD)

Clock (EVEN)

Power down

Signal

Communication

7

RA0RA0+

RA1RA1+

RA2RA2+

RA3RA3+

RA4R

4+

RB0RB0+

RB1RB1+

RB2RB2+

RB3RB3+

RB4RB4+

RACLKINRACLKIN+

RACLKINRACLKIN+

PDWN 1 Input LVTTL

SCL 1 I/O

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Input

Input

Input

Input

LVDS

Differential

LVDS

Differential

LVDS

Differential

LVDS

Differential

LVTTL

2

(I

C)

Differential serial data signal.

Input video and timing signals after

differential serial conversion using a

dedicated transceiver.

The serial data signal is transmitted

seven times faster than the base

signal.

Differential serial data signal.

Input video and timing signals after

differential serial conversion using a

dedicated transceiver.

The serial data signal is transmitted

seven times faster than the base

signal.

Input the clock signal after

differential conversion using a

dedicated transceiver.

The clock signal is transmitted at

the same speed as the base signal.

Low :LVDS receiver outputs are all

“L”.

High: Output signals are active.

2

I

C bus serial data communication

signal.

Communication with the control

MPU of this product is enabled.

“High”: Low power consumption

8

9

10

Control

MPU Communication / Control

CPUGO 1 Input LVTTL

PDPGO 1 Input LVTTL

IRQ 1

Outpu

t

LVTTL

mode of the control MPU of this

product is released.

“High”: This product is started.

(CPUGO=“High” Effective)

It changes into "Low" → "High"

when this product enters the

undermentioned state.

1. Vcc/Va/Vs output decrease

2. Circuit abnormality detection

-4-

Page 9

A

B

(2) Video Signal Definition and Function

The table below summarizes the definitions and functions of input video signals before LVDS

conversion.

Item Signal name

Original

Display signal

(before LVDS

transmittance)

Video signal

(ODD)

Video signal

(EVEN)

Clock

Horizontal

sync signal

Vertical sync

signal

Blanking

signal

DATA-RA

DATA-GA

DATA-BA

DATA-RB

DATA-GB

DATA-BB

DCLK

DCLK

Hsync

Vsync

BLANKA

BLANKB

Number

of signals

Input/

output

10

10

10

10

10

10

2 Input

1 Input

1 Input

2 Input

Input

Input

Display data signal

RA9/GA9/BA9 is the highest intensity bit.

RA0/GA0/BA0 is the lowest intensity bit.

Display data signal

RB9/GB9/BB9 is the highest intensity bit.

RB0/GB0/BB0 is the lowest intensity bit.

Video signal timing: These signals

continuously input are necessary. Data are

read when these signals are fallen.

Regulates one horizontal line of data: Begins

control of the next screen when

fallen.

Screen starts up control timing signal: Begins

control of the next screen when

fallen.

Input the same frequency in both

odd-numbered and even-numbered fields.

Display period timing signal.

H indicates the display period and L indicates

the non display period.

Note:

Set this timing properly like followings, as is

used internally for signal processing.

・Set the blanking period so that the number of

effective display data items in one horizontal

period is 1366.

・Set the number of blanking signals in one

vertical period to 384, which is one half the

number of effective scan lines.

Signal definition and function

Hsync is

Vsync is

If the

BLANK changes when the Vsync

frequency is switched, the screen display may

be disturbed or brightness may change.

The screen display is restored to the normal

state later when the

constant again.

BLANK length is

-5-

Page 10

)

)

(3) Connector Specification

The connector specification is shown below. Please do not connect anything with the terminal NC.

(3-1) Signal connector [CN1]

Pin No. Signal name Pin No. Signal name

1 RA0- 2 GND(LVDS

3 RA0+ 4 SCL

5 RA1- 6 GND

7 RA1+ 8 SDA

9 RA2- 10 GND(LVDS)

11 RA2+ 12 CPUGO

13 RACLK- 14 PDPGO

15 RACLK+ 16 IRQ

17 RA3- 18 PDWN

19 RA3+ 20 GND(LVDS)

21 RA4- 22 GND

23 RA4+ 24 GND

25 GND 26 GND

27 GND 28 GND

29 GND 30 GND

DF13-30DP-1.25 V (tin-plated) (Maker: HIROSE DENKI)

[Conforming connector] Housing: DF13-30DS-1.25C Contact: DF13-2630SCF

(3-2) Signal connector [CN2]

Pin No. Signal name Pin No. Signal name

1 RA0- 2 GND(LVDS

3 RA0+ 4 SCL

5 RA1- 6 GND

7 RA1+ 8 SDA

9 RA2- 10 GND(LVDS)

11 RA2+ 12 CPUGO

13 RACLK- 14 PDPGO

15 RACLK+ 16 IRQ

17 RA3- 18 PDWN

19 RA3+ 20 GND(LVDS)

21 RA4- 22 GND

23 RA4+ 24 GND

25 GND 26 GND

27 GND 28 GND

29 GND 30 GND

DF13-30DP-1.25 V (tin-plated) (Maker: HIROSE DENKI)

[Conforming connector] Housing: DF13-30DS-1.25C Contact: DF13-2630SCF

-6-

Page 11

(3-3) Power Source Connectors (PSU only is used on repair working)

(a) Power input / Signal control connector [CN3]

Pin No. Symbol

1 N.C.

2 VSAGO

3 VCEGO

4 Vrs

5 Vra

6 GND

7 GND

8 GND

9 Vpr2

10 Vcc

11 Vcc

B11B-PH-SM3-TB (Maker: JST)

[Conforming connector]

Housing: PHR-11

Contact: SPH-002T-P0.5L

(b) Power supply output connector for system [CN21]

Pin No. Symbol

1 Va

2 Va

3 Vcc

4 Vcc

5 Vcc

6 GND

7 GND

8 GND

9 Vs

10 Vs

11 Vs

B10P-VH (Maker: JST)

[Conforming connector]

Housing: VHR-10N

Contact: SVH-21T-P1.1

-7-

Page 12

2 SAFETY HANDLING of THE PLASMA DISPLAY

2.1 NOTES TO FOLLOW DURING SERVICING

The work procedures shown with the Note indication are important for ensuring the

safety of the product and the servicing work. Be sure to follow these instructions.

Before starting the work, secure a sufficient working space.

At all times other than when adjusting and checking the product, be sure to turn OFF the

main POWER switch and disconnect the power cable from the power source of the display

(jig or the display itself) during servicing.

To prevent electric shock and breakage of PC board, start the servicing work at least 30

seconds after the main power has been turned off. Especially when installing and removing

the power supply PC board and the SUS PC board in which high voltages are applied, start

servicing at least 4 minutes after the main power has been turned off.

While the main power is on, do not touch any parts or circuits other than the ones specified.

The high voltage power supply block within the PDP module has a floating ground. If any

connection other than the one specified is made between the measuring equipment and

the high voltage power supply block, it can result in electric shock or activation of the

leakage-detection circuit breaker.

When installing the PDP module in, and removing it from the packing carton, be sure to

have at least two persons perform the work while being careful to ensure that the flexible

printed-circuit cable of the PDP module does not get caught by the packing carton.

When the surface of the panel comes into contact with the cushioning materials, be sure to

confirm that there is no foreign matter on top of the cushioning materials before the surface

of the panel comes into contact with the cushioning materials. Failure to observe this

precaution may result in the surface of the panel being scratched by foreign matter.

When handling the circuit PC board, be sure to remove static electricity from your body

before handling the circuit PC board.

Be sure to handle the circuit PC board by holding the such large parts as the heat sink or

transformer. Failure to observe this precaution may result in the occurrence of an

abnormality in the soldered areas.

Do not stack the circuit PC boards.

Failure to observe this precaution may result in problems resulting from scratches on the

parts, the deformation of parts, and short-circuits due to residual electric charge.

Routing of the wires and fixing them in position must be done in accordance with the

original routing and fixing configuration when servicing is completed.

All the wires are routed far away from the areas that become hot (such as the heat sink).

These wires are fixed in position with the wire clamps so that the wires do not move,

thereby ensuring that they are not damaged and their materials do not deteriorate over

long periods of time. Therefore, route the cables and fix the cables to the original position

and states using the wire clamps.

Perform a safety check when servicing is completed.

Verify that the peripherals of the serviced points have not undergone any deterioration

during servicing. Also verify that the screws, parts and cables removed for servicing

purposes have all been returned to their proper locations in accordance with the original

setup.

-8-

Page 13

3 NAME and FUNCTION

4

ABUS

ABUS

ABUS

e

M

e

4

e

e

C

A

3.1 CONFIGURATION

DM

-U1

Signal Cable

Serial ID Label

-U2

Product Label

Signal Cable

P.S. Cabl

-U3

ABUS-U

Signal Cable

P.S. Cable

XBB

SD

ABUS-D1

Y- S U S

ABUS-D2

Signal Cabl

ABUS-D3

LOGI

Signal Cabl

X-SUS

ABUS-D

P.S. Cabl

-9-

Page 14

3.2 Block Diagrams

γ

U

YYYY

S

S

X

X

-

-

S

S

C

C

A

L

L

A

3

A

4

A

5

A

6

A

7

A

8

A

9

A

0

A

A

3

A

4

A

5

A

6

A

7

A

8

A

9

A

0

A

3.2.1 Signal Diagrams

----SU

SUS B.

B.

B. B.

SUSSU

Y-SUS

Y-SUS

MMMM

MMMM

SSSS

DDDD

SSSS

DDDD

EVEN SW

Y- S C A N

EVEN SW

ODD SW

Y-SC AN

ODD SW

POS /NEG

RESET SW

ABUS U1

ABUS U1....

ABUS U1ABUS U1

DMU1

DMU2 ADMU

ABUS U2

ABUS U2

ABUS U2ABUS U2

DMU

DMU

DMU

ABUS U3

ABUS U3

ABUS U3ABUS U3

DMU

DMU

CNU3-8CNU3-7

DMU

ABUS U4

ABUS U4....

ABUS U4ABUS U4

DMU1

DMU11

XXXX

BBBB

BBBB

XXXX

BBBB

BBBB

X

-SU

SUS B.

B.

-

SUSSU

B. B.

X

X-SUS

EVEN SW

X-SCAN

EVEN SW

X-SUS

ODD SW

X-SCAN

ODD SW

POS

RESET SW

SIGNA

SIGNAL

SIGNALSIGNA

INPUT

INPUT

INPUT INPUT

CN1

CN2

Isk

Iak

Thermistors

CN4

CN31

LVD S

Analog Sw

OSC

10MHz

LVD S

I2C

DML1 ADML2 ADML

ABUS D1

ABUS D1....

ABUS D1ABUS D1

comp.

V-S YN C c ont.

SCI.

Failure DET.

FLASH MEMORY

CND2-6

DML

DML

DML

DML

ABUSD2

ABUSD2

ABUSD2ABUSD2

ABUS D3

ABUS D3

ABUS D3ABUS D3

CND3-8

CND3-9

SCAN CONTROLLER

DATA PROCESSOR ×2

RGB

GAIN

DITHER

/ERR DIF.

MP

APC cont.

I/O

DML

DML

CND3-10

TIMMING ROM

SUB FIELD

PRC.

12.75MHz

OSC

12.75MHz

EEPROM

D/A

DML1

DML11

ABUS D4

ABUS D4....

ABUS D4ABUS D4

25.5MHz

MEMORY

CONTROLLER

51MHz

×4

Vrs

Vra

Vrw

Vrx

Vq

Vu

LOGI

LOGIC B.

LOGICLOGI

B.

B. B.

FRAME

MEMORY

CN21

CN3

CN7

CN8

CN5

CN6

-10-

Page 15

3.2.2 Power Diagrams

YYYY

S

S

X

X

-

-

S

S

C

C

V

V

0

9

A

w

4

6

3

4

-

5

0

----SU

SUS B.

B.

B. B.

SUSSU

Y-SUS

Y-SUS

SSSS

DDDD

MMMM

SSSS

DDDD

MMMM

CN3

CN31

EVEN SW

Y- S C A N

EVEN SW

ODD SW

Y-SC AN

ODD SW

POS/NEG

RESET SW

Vcc 5V

Vs 85V

Vx 40V

Vw 190

CNU

ABUS U1

ABUS U1....

ABUS U1ABUS U1

ADMU1

ADMU2 ADMU3 ADMU4 ADMU5 ADMU6 ADMU7 ADMU8 ADMU9 ADMU10 ADMU11

ABUS U2

ABUS U2

ABUS U2ABUS U2

ABUS U3

ABUS U3

ABUS U3ABUS U3

ABUS U4

ABUS U4....

ABUS U4ABUS U4

XXXX

BBBB

BBBB

XXXX

BBBB

BBBB

ADML1 ADML2 ADML3 ADML4 ADML5 ADML6 ADML7 ADML8 ADML9 ADML10 ADML11

ABUS D1

ABUS D1....

ABUS D1ABUS D1

ABUSD2

ABUSD2

ABUSD2ABUSD2

ABUS D3

ABUS D3

ABUS D3ABUS D3

ABUS D4

ABUS D4....

ABUS D4ABUS D4

CN22

Vcc 5V

Va 6 3V

Vcc 5V

Va 6 3V

X

-SU

SUS B.

B.

-

SUSSU

CN2

EVEN SW

EVEN SW

ODD SW

ODD SW

POS/NEG

RESET SW

Vcc 5V

Vs 85V

Vx 40V

Vw 190V

B. B.

X-SUS

X-SCAN

X-SUS

X-SCAN

X

CN2

DC/DC

CONVERTER

Vu 35V

Vq -40V

YFVE Vy VE

18V 18V 17V

DC/DC

CONVERTER

CN3

Vpr2 3.3V

CPUgo

PDPgo

from PSY(+5V/+3.3V)

from EXT.CONT.

D/

MPU

rst

LOGI

LOGIC B.

LOGICLOGI

CN

Vra

Vrs

Vr

Vrx

Vu

Vq

YSTBY

B.

B. B.

XFVE Vxx VE

18V 20V 17V

DC/DC

CONVERTER

Vcc 5V

CN21

xvxwgo

RST

CN2

from PSY(+5V/+63V/+85V)

Vs 85V

Vs 85V

-11-

Page 16

3.3 FUNCTION

3.3.1 Logic board Function

(1) Data Processor

- γ adjustment(1 / 2.2 / 2.4 / 2.6 / 2.8)

- NTSC/EBU format(Color matrix) Switch

- RGB gain Control(White balance adjustment, Amplitude limitation)

- Error Diffusion Technology(Grayscale adjustment)

- Dither(Grayscale adjustment)

- Burn-in Pattern generation

(2) Data Converter

- Quasi out-line adjustment (luminous pattern control)

(3) Scan Controller

- Address driver control signal generator (ADM)

- scan driver control signal generator (SDM)

- X/Y sustain control signal generator

(4) Waveform ROM

- Waveform Pattern for drive / Timing memory

(5) MPU

- Synchronous detection

- System control

- Driving voltage(Va, Vs, Vr, Vw, Vu, Vq) Minute adjustment

- Abnormal watch (breakdown detection)/abnormal processing

- Is(sustain) current control (sustain pulse control)

- Ia(address) current control (sub-field control)

- External communication control

- Flash memory (firmware)

(6) EEPROM

- Control parameter memory

- The accumulation energizing time (Every hour).

- Abnormal status memory (16 careers)

-12-

Page 17

3.3.2 Function of X-SUS Board

(1) DC/DC power supply block

Vs (+85V) Æ Vw (+190V) / Vx (+40V) / Vu (+35V) / Vq (-40V)

Vcc (+5V) Æ Vex (+16V) / XFve (+18V, floating)

(2) X switching block

Switching during address period

Switching during sustain period

Switching during reset period

(3) Current detector block

Isx (sustain) current detection

Ia (address) current detection

(4) Voltage detector block

Vs (sustain) voltage detection

Va (address) voltage detection

3.3.3 Function of Y-SUS Board

(1) DC/DC power supply block

Vcc (+5V) Æ Vey (+16V) / YFve (+18V, floating)

(2) Y Switching block

Switching during address period

Switching during sustain period

Switching during reset period

(3) Current detector block

Isy (sustain) current detection

-13-

Page 18

3.4 PROTECTION FUNCTION

State of protection operation

(√:State change、、、、There is no change at the blank.)

Abnormality part

Reactivation

condition when

abnormal content

is excluded

Vw

Vx

Vs

Va

Vex

Vey

State Vw, Vx Vs Va Vex Vey Vcc Vpr

Overvoltage Stop(no latch)

Overcurrent Delay Latch

Overvoltage Stop(no latch)

Overcurrent Delay Latch

Overvoltage Latch

Low voltage Latch

Overcurrent Delay Latch

Overvoltage Latch

Low voltage Latch

Overcurrent Delay Latch

Overvoltage Stop(no latch)

Voltage

Overcurrent

pendency(no

latch)

Va

ux

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √

AC

Re-turn

ing on

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Vcc

Vpr2

Overvoltage Latch

Overcurrent Delay Latch

Overcurrent Delay Latch

√ √ √ √ √ √ √

√ √ √ √ √ √ √

√ √ √ √ √ √ √ √ √

-14-

Yes

Yes

Yes

Page 19

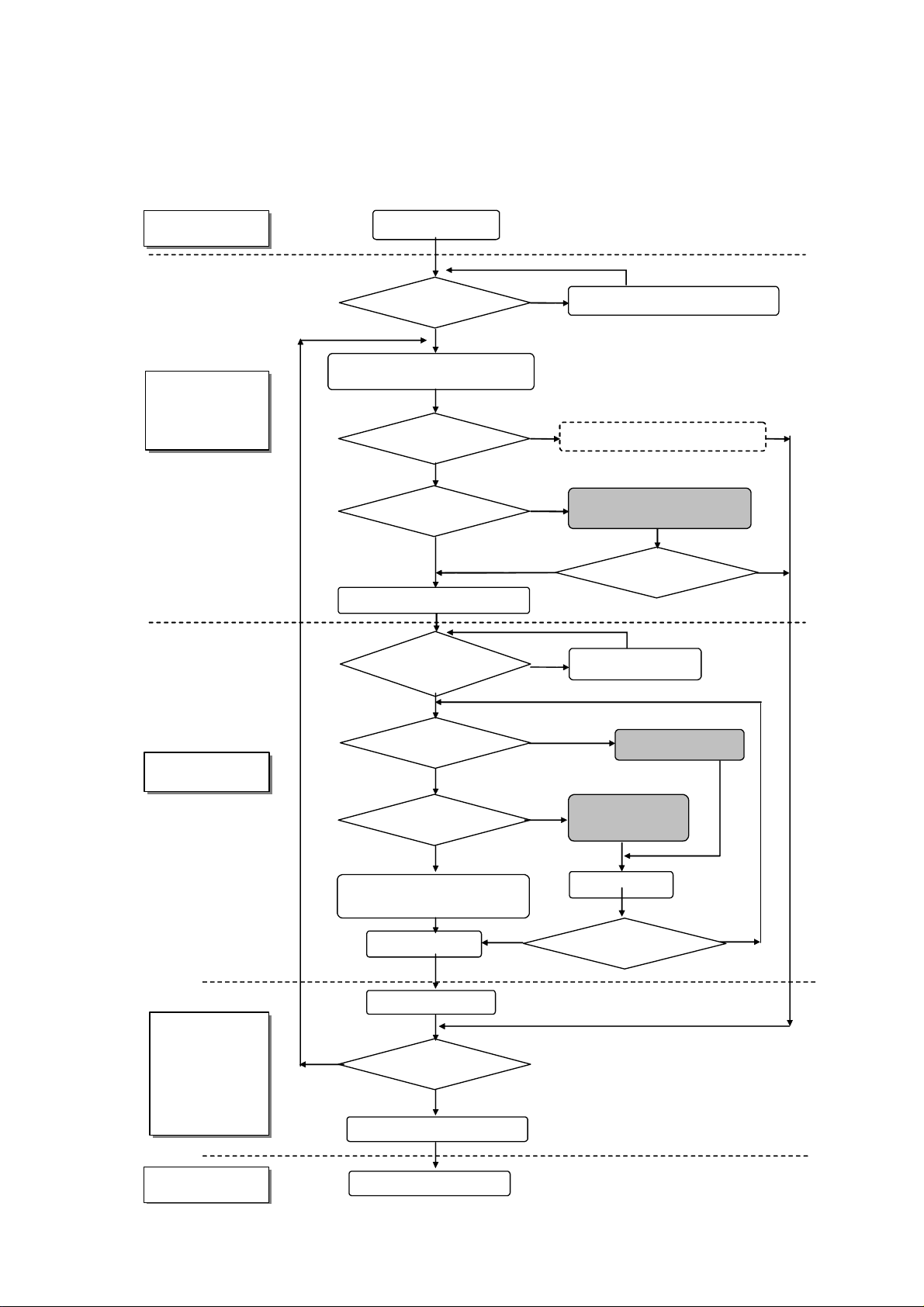

4 PROBLEM ANALYSIS

Y

Y

YNY

YYY

Y

4.1 OUTLINE OF REPAIR FLOW

Client

Product

manufacturer

(Repair center)

Client claim

Repair product

and Claim contents match

Product block/PDP module block

Locating cause of problem

Is PDP module block

Defective ?

Is the Panel defective ?

PDP module sent to factory

Repair product and

claim contents match

Recheck the problem description

N

Product problem analysis/Repair

PC board replacement/Parts

N

N

replacement

Operation normal ?

Recheck problem

description

Y

Repair center

Product

manufacturer

(Repair center)

Client

Is the panel faulty?

PC board

unacceptable (NG) ?

Processing to prevent

recurrence

Packing/Shipment

Installation in product

N

Product runs normally ?

Return of repaired product

End of repair

Panel replacement/IC

module replacement

N

PC board

replacement/Parts

replacement

N

Heat run

Operation normal ?

N

-15-

Page 20

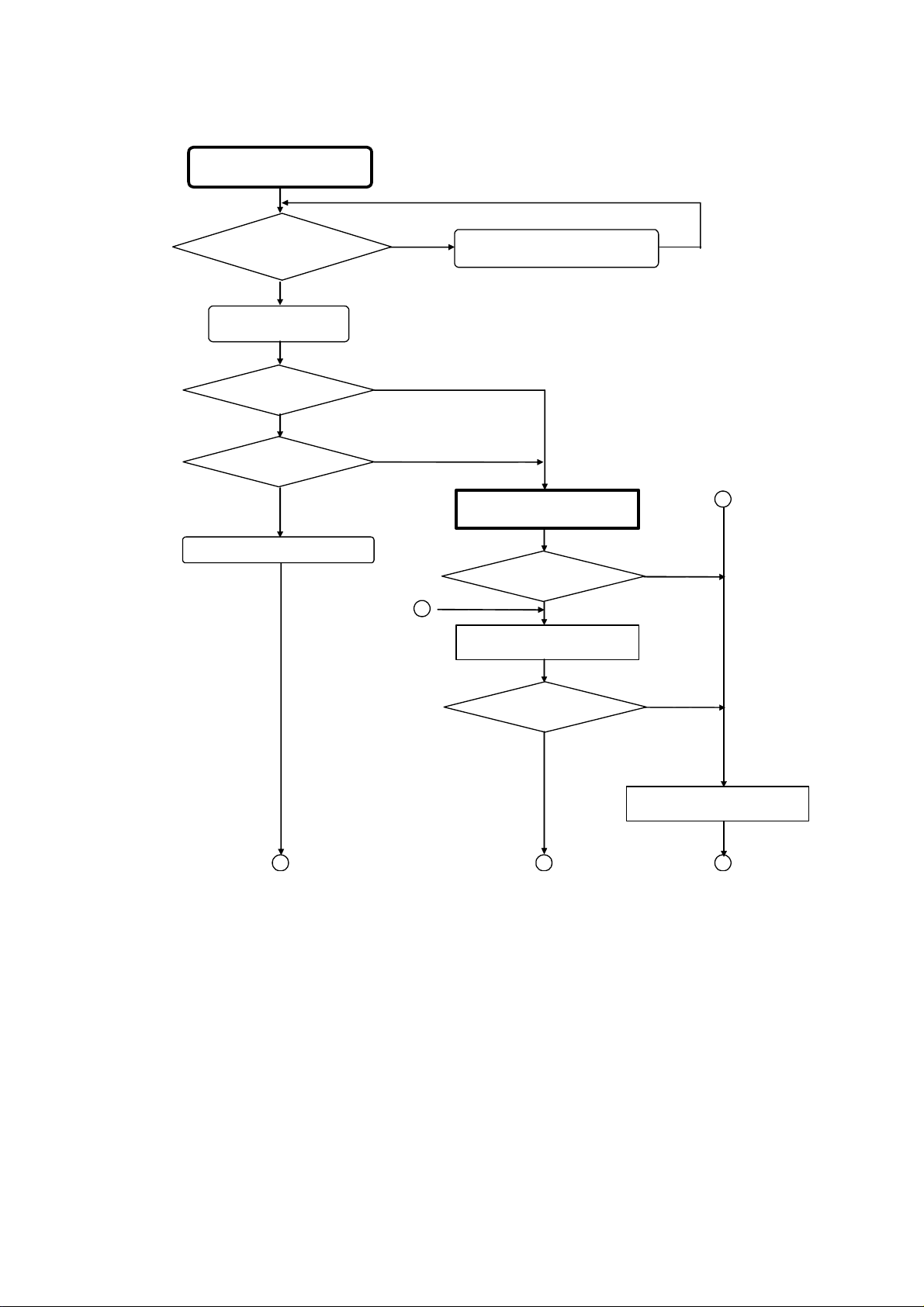

4.2 OUTLINE OF PDP MODULE REPAIR FLOW

Receipt of returned product

(Chapter 4.3)

returned product agree with ID

Does ID of

of actual

Yes

Appearance check

Yes

Appearance unacceptable

(NG) ?

Yes

Repair of appearance

requested ?

Yes

Repair defective spots

No

No

No

Repair description and returned

product rechecked.

Perform operation test

(Chapter 4.4).

Problem recurred ?

2

Check description of

repair request.

4

No

Yes

Contents match ?

Yes

13 5

No

Problem symptom

nonrecurrence analysis mode

-16-

Page 21

1

Fault mode classification (Chapter 4.5)

Fault analysis (Chapter 4.6)

Repair of faulty spots (Chapter 5)

Replace LOGIC PC board or

panel chassis ?

No

3

Perform operation test (Chapter 4.4)

Problem repaired?

Yes

Warranty test (Running)

End of repair

Yes

Adjustment (Chapter 6)

No

Shipment

-17-

Page 22

Problem symptom nonrecurrence

5

analysis mode/Shipment process mode

Implement module tapping

Problem recurs ?

No

Yes

Turn off the main power

2

Perform running test (Burn-in pattern)

No

Problem recurs ?

Yes

3

-18-

Page 23

4.3 CHECKING THE PRODUCT REQUESTED FOR REPAIR

Check the serial ID number of the product requested for repair before starting the problem

analysis and repair. Structure of serial ID number is shown below.

(1) Checking serial ID number of PDP module (14 digits)

The serial ID number of the product that is brought in for service and that of the

completed panel chassis has the structure as shown below.

The serial ID number is shown on the bar code label that is attached to the rear of the

chassis (aluminum).

N9A 4 01 001A1 01A

Version No.: 01 ~ 99

A ~ Z (excluding I and O)

Lot No.: 001 ~ 999

A ~ Z (excluding I and O)

1 ~ 3

Production week code: 01 ~ 53

Production year (low digit): 0 ~ 9

Product code: N9A- model 55 type

Module product label Serial ID label of panel chassis

* The module serial ID number and the serial ID number of the completed chassis are usually the same

when the product is brought in for repair for the first time.

(2) Checking serial ID number of constituent PC boards (12 digits)

The serial ID number of the module constituent PC boards has the following structure.

The serial ID number is shown on the bar code label that is attached to each PC board.

CP 1 01 00001 1A

Version No.: 1 ~ 9 , a~z

A ~ Z (excluding I and O)

Lot No.: 00001 ~ Z9999

Production week code: 01 ~ 53

Production year (low digit): 0 ~ 9

Product code: Different 2 digits for each board

-19-

Page 24

4.4 OPERATION TEST PROCEDURE

d

f

Five screws

Photp 4.1 Photo 4.2

(1) Prepare the test equipment.

(2) Set the PSU board (PS-jig) by five M3X8 screw on the module o

requestedfor repair. (photo4.1)

(3) Connect the cable connector from PSU board to CN9 on logic boar

and CN21 on XSUS board. (photo4.2)

(4) Set the module of requested repair to a stand.

(5) Connect between the CN1/CN2 on the logic board and the CN5/CN7

on the interface board (I/F-jig) by particular cable. (photo4.3)

(6) Turn on the AC power to the interface board (I/F-jig).

(7) Select the signal used when a problem occurs, or full white pattern.

(8) Turn on the PDP go switch on the interface board (I/F-jig). (Then, the main

power of the module is turned on.)

Check Fault Symptom

CN21

X-SUS

CN9

LOGIC

-20-

Page 25

F

Photo 4.3

< State of initialization>

CN7 CN5

CN2

CN1

PDPgo switch

ON

OF

Select switch of Display size,

Synchronous, and Clock signal

-21-

Page 26

4.5 FAULT SYMPTOM

NO Fault

contents

Entire screen

1 After momentarily going on, the

does not light.

2

3 Single vertical line (of different

Vertical line

4 Single vertical line (of different

screen becomes black

immediately or after a few

seconds. (Main power is turned

off.)

Screen lights dimly even on the

back screen.

color) start point at center of

screen

color) start point exclude at

center of screen

Fault status Suspected

5

Single full vertical line (of different

color)

Analysis

fault location

X-SUS,Y-SUS

PSU, Panel

chassis, Logic

ABUSL or R

Logic Replace

procedure

and

measure

Refer to

Chapter

4.6.1

Logic

board

Panel chassis

Logic, ABUS,

ADM

Refer to

Chapter

4.6.2

Panel chassis Replace

Panel

chassis

Logic Replace

Logic

board

6

Vertical bar Bar width of 1/33 of horizontal

7 Abnormal display at bar width of

8 Abnormal display at bar width of

9 Abnormal display at bar width of

10 Abnormal display at bar width of

11 Abnormal display at upper side

size or abnormal display in

multiples of 1/33.

1/11 of horizontal size or

multiples of 1/11

.

1/11 of horizontal size (Vertical

bar of different color)

2/11 of horizontal size (Vertical

bar of different color)

2/11 of horizontal size (Vertical

bar of different color)

or lower side of horizontal size

(Vertical bar of different color)

Panel chassis

(ADM)

Panel chassis

ABUS

Connection of

above boards.

Connection of

ADM,

ABUS

Connection of

ABUS

Connection of

ABUS

Connection of

ABUS and

Logic or

X-SUS and

ABUS

Refer to

Chapter

4.6.2

Refer to

Chapter

4.6.2

-22-

Page 27

NO Fault contents Fault status Suspected

A

fault location

12 One hall horizontal line

Horizontal line

does’nt light or one horizontal

line does not light from the

effective scan area.

13

Horizontal bar

14 Abnormal display (or no

15

16 Image sticking Fixed display contents are

17 Stains Oval-shaped points having

18 Twinkle The entire screen

19 Flicker The entire screen flickers

20 Luminance is

abnomal

21 Chrominance is

abnomal

22 Synchronization

is disturbed

Every other line does’nt light

on entire screen.

display) at bar width of 1/12 of

vertical size or multiples of

1/12

Abnormal display (or no

display) at bar width of 1/2 of

vertical size or multiples of

1/2

always displayed.

abnormal luminance are

scattered in the upper or

lower part of screen

momentarily becomes

brighter or darker

continuously

Screen is too dark or too

bright (out of specifications)

Colors cannot be displayed

correctly

Panel chassis

(SDM)

X-SUS

Y-SUS

ABUS-D2

ABUS-D3

BCDEFG

Panel chassis

(SDM)

Panel chassis

Y-SUS

X-SUS

Connection of

board

Panel chassis Judge after

Panel chassis Judge after

Poor

connector

contact

(CN1,2)

Logic

Logic

Analysis

procedure and

measure

Replace Panel

chassis

Replace

X-SUS/Y-SUS

ABUS-D2

ABUS-D3

Replace Panel

chassis

Refer to

Chapter 4.6.3

operating test

on full white

display,

Replace Panel

chassis

operating test

on full white

display,

Replace Panel

chassis

Connector /

cable

re-connection

or cable

exchange

Replace logic

board

Replace logic

board

-23-

Page 28

NO Fault contents Fault status Suspected

fault

location

23

Picture

distorted

Logic

24

Steps of

gradarion are

skipped

Luminance linearity is

poor

Logic

25

Abnormal

sound

26

External

communication

Adjustment and γ

cannrot be changed

PSU

X-SUS

Y- SU S

Panel

Logic

is abnormal

27

No light after

abnormal

display

Brightly and random

display, and it becomes

no light afterwards.

Y-SUS

Analysis

procedure and

measure

Replace logic

board

Replace logic

board

Abnormal

locations are

exchanged

Replace logic

board

Replace Y-SUS

board

-24-

Page 29

4.6 PROBLEM ANALYSIS PROCEDURE

p

(

p

4.6.1. "The entire screen does not light (Main power is turned off)” Problem analysis procedure

The entire screen does not light.

(Main power is turned off.)

PC for analysis

Connected?

N

Y

Analysis using PC

Chapter 4.7

Remove CN9 (LOGIC)

Turn on AC power.

PSU board

r2 (3.3V)

V

N

PSU board is

defective.

Turn off AC power.

Connect CN 9 (LOGIC).

Turn on AC power

Y

STANDBY power

supply has defect

Remove the following power connectors

PSU board

r2 (3.3V) exists?

V

Y

Turn off the AC power.

(4 locations):

CN 21 (X-SUS)

CN 31 (Y-SUS)

CN 4-5 (ABUS-U4)

CN 24

ABUS-D4)

N

LOGIC board is

defective.

STANDBY power supply

(MPU power supply) system

has short-circuited.

Turn off the AC

power.

End of analysis

(1)

-25-

Page 30

A

p

(1)

CN21

(3)(4) : Vcc

(5)(6)(7)’: GND

(8)(9)(10) : Vs

X-SUS board

CN21 (3)-(5) pins or

CN21 (7)-(8) pins

are shorted.

N

Y

X-SUS board is

defective.

Switching circuit (power supply)

has short-circuit.

CN31

(2)(3)(4): Vs

(7) : Vcc

(6)(8) : GND

CNU4-5

(1)(2): Va

(4)(5) : Vcc

(6)(7): GND

Y-SUS board

CN31 (4)-(6) pins or

CN31 (7)-(8) pins

are shorted.

N

ABUSU4 board

CNU4-5 (1)-(7) or

CNU4-5 (5)-(7) short

N

Y

Remove SDM from the

following (2) connectors.*

CN 32

CN 33

Y-SUS board

CN31 (4)-(6) pins or

CN32 (7)-(8) pins

are shorted.

Y

Y

Disconnect the following (3)

connectors.*

CNU2-4(ABUS-U2)

CNU3-5(ABUS-U3)

CNU3-10(ABUS-U3)

* Refer to Chapter 5.3 for

SDM removal procedure.

SDM is

defective

(Panel chassis

is defective.)

SDM chip/Flexible shorted

Y-SUS board is

defective.

Switching circuit

(power supply) has

CNU4-5

1

in

(2)

Each ABUS-U* board

CNU1-4(1)-(7) or (5)-(7)

CNU2-7(1)-(7) or (5)-(7)

CNU3-10(1)-(7) or 5)-(7)

CNU4-3(1)-(7) or (5)-(7)

short

Y

Power supply circuit has short-circuited.

N

ADM is defective

(Panel chassis is

defective.)

DM chip/Flexible shorted

ABUS-U* board

is defective.

End of analysis

-26-

Page 31

p

(2)

CND4-5

(1)(2): Va

(4)(5): Vcc

(6)(7): GND

Re-connect the following (4)

Power supply connectors.

ABUSD4 board

CND4-5 (1)-(7) or

CND4-5 (5)-(7)

short.

N

CN21 (X-SUS)

CN31 (Y-SUS)

CNU4-5 (ABUS-U4)

CN24 (ABUS-D4)

Y

Disconnect the following (3)

connectors.*

CND2-4(ABUS-D2)

CND3-5(ABUS-D3)

CND3-10(ABUS-D3)

Each ABUS-D* board

CND2-4 (1)-(7) or (5)-(7)

CND2-9 (1)-(7) or (5)-(7)

CND3-12 (1)-(7) or (5)-(7)

CND4-3 (1)-(7) or (5)-(7)

short.

Y

Power supply circuit has short-circuited.

CND4-5

N

ADM is defective

(Panel chassis is

defective.)

ADM chip/Flexible shorted

ABUS-D* board is

defective.

1

in

End of analysis

Turn on AC power.

Turn on the PDP go switch on the

interface board jig.

PSU board

Vcc (5V) exist?

Y

(3)

N

LOGIC board is

defective.

Control logic power system has short-circuited.

Turn off the AC

power.

End of analysis

-27-

Page 32

(

(3)

Turn on AC power.

PSU board

Va (63V) exist?

N

Turn off the AC power.

Disconnect

CNU4-5(ABUSU4).

Turn on AC power.

PSU board

Va (63V) exist?

N

Turn off the AC power.

Disconnect

CND4-5(ABUSD4).

Turn on AC power.

Y

ADM is defective.

ADM chip has abnormality.

Y

ABUSU1-4 boards

are defective.

Power supply line has abnormality.

Ex. capacitor)

PSU board

Va (63V) exist?

N

PSU board

Vs (85V) exist?

N

Turn off the AC power.

(4)

Y

ABUSD1-4 boards

are defective.

Turn off the AC power.

Power supply line has abnormality.

(Ex. capacitor)

End of analysis

Y

PSU board is

defective (Vs).

Turn off the AC power.

End of analysis

-28-

Page 33

A

(4)

Disconnect between

SDM and Y-SUS

Measure of SDM power line

resistor (A1-A2, B1-B2,

C1-C2, D1-D2)

Does SDM power

supply line short?

N

Y

SDM is defective.

(Panel chassis is

defective.)

SDM chip operation is abnormal.

Turn on AC power.

Y

Turn off the

AC power.

N

PSU board

Vs (85V) and Vcc

(5V) exist?

(5)

Turn off the AC

power.

1

A2

B1

B2

C1

C2

D1

D2

-29-

Page 34

X

X

A

A

A

A

(5)

Disconnect between

XBB and X-SUS

Measure of XBB line resistor

(A1-B1, B1-A2, A2-B2, B2-A3,

A3-B3, B3-A4, A4-B4)

Does XBB line

short?

Y-SUS board is defective.

-SUS board is defective.

XBB is defective. (Panel

chassis is defective.)

-SUS board is defective.

Turn off the AC power.

End of analysis

1

B1

2

B2

3

B3

4

B4

-30-

Page 35

4.6.2 "Vertical line/Vertical bar" Problem analysis procedure

A

j

Vertical line/Vertical bar

LOGIC ~ ABUS board signal

cable has abnormal appearance?

N

Y

Signal cable is

defective.

ADM flexible has abnormal

appearance?

N

Turn on the power.

One vertical line?

N

Y

Y

Tap lightly on ADM flexible

heat-melted junction.

ny changes

phenomena?

N

ADM is defective.

(Panel chassis is

defective.)

Y

Heat-melted

unction is defective

(Panel chassis is

defective.)

End of analysis

Turn off the

power.

Panel address has open

circuit or ADM IC chip is

(Panel chassis is defective.)

(1)

defective.

End of analysis

-31-

Page 36

N

(1)

Bar of 1/2 width on

the upside does

not light?

Bar of 1/2 width on

the downside does

not light?

N

N

Y

Voltage exists at

ABUSU4 board

CN U4-5.

N

Turn off the power.

Disconnect CNU4-5 on the

ABUSU4 board.

Turn on the power.

Voltage exists

at PSU Side?

N

Y

Voltage exists at

ABUSD4 board

CND4-5?

N

Y

Y

Y

LOGIC board is

defective.

ABUSU* board is

defective.

PSU cable is

defective. Connector

has poor connection

(LOGIC board is

defective.)

LOGIC board is

defective.

(2)

Turn off the power.

Disconnect CND4-5 on the

ABUSD4 board.

Turn on the power.

Voltage exists

at PSU Side?

N

-32-

Y

ABUSD board is

defective.

PSU cable is defective. Connector

has poor connection.

(PSU board is defective.)

Turn off the power.

End of analysis

Page 37

p

(2)

Vertical line of

different color

does appear?

Y

N

Exists on half

upside?

Y

N

Turn off the power.

Replace ABUSU board

(Backup part).

Turn on the main power.

Normal?

Y

ABUSU board is

defective.

N

Replace LOGIC board (Backup part)

Turn off the power.

Turn on the power.

Y

Normal?

LOGIC board is

defective.

N

Turn off the power.

Replace signal cable between

LOGIC and ABUSU.

Turn on the

Normal?

ower.

Y

N

Signal cable is

defective.

ADM is defective.

(Panel chassis is

defective.)

Turn off the power.

End of analysis

(3)

(4)

-33-

Page 38

(3)

(4)

Replace ABUSD board (Backup part).

Turn off the power.

Turn on the power.

Normal?

Y

ABUSD board is

defective.

N

Replace LOGIC board (Backup part).

Turn off the power.

Turn on the power.

Normal?

N

Y

LOGIC board is

defective.

Replace signal cables between LOGIC

Turn off the power.

and ABUS.

Turn on the power.

Panel is defective.

(Panel chassis is

defective.)

Normal?

N

Y

Signal cable is

defective.

ADM is defective.

(Panel chassis is

defective.)

Turn off the main power.

End of analysis

-34-

Page 39

4.6.3 "Horizontal bar" Problem analysis procedure

Replace Y-SUS board (Backup part).

Horizontal bar

Turn off the power.

Turn on the power.

Normal?

Replace Y-SUS board (Defective product).

Replace X-SUS board (Backup part)

Turn off the power.

Turn on the power.

N

Y

Y-SUS board is

defective.

Normal?

N

Y

X-SUS board is

defective.

Replace X-SUS board (Defective product).

Replace ABUS-D2 and D3 board (Backup part)

Turn off the power.

Turn on the power.

Normal?

N

Y

ABUS-D2 and D3 board

are defective.

Panel chassis is

defective.

Turn off the power.

End of analysis

-35-

Page 40

4.7 PROBLEM ANALYSIS USING A PERSONAL COMPUTER

4.7.1 Connecting a computer

(1) Set the module in accordance with Chapter 4.4.

(2) Connect the RS-232C terminal of the computer to the RS-232C terminal of the interface

board.

(3) Turn on the main power to the interface board. (Red LED goes on.)

POWER indicator (red LED)

4.7.2 Preparing a computer

(1) Turn on the main power to the computer.

(2) Set the PDPgo switch on the interface board to ON and turn on the main power to the

module.

(3) For computer running MS-DOS:

C: \ >FHPP1<ENTER>

For computer running WINDOWS:

Start menu → Run → FHPP1<ENTER>

(4) The following menu screen appears.

Main menu

*1: Use COM1: for the computer's communication port.

*2: Set the communication setup as follows.

Speed: 9600 bps

Data: 7 bits

Parity: none

In Windows, restart the computer after setting the communication setup.

*3: If the program starts up while the module standby power is not yet turned on, the menu

screen will not be displayed.

Stop bit: 1 bit

-36-

Page 41

4.7.3 Problem Analysis Procedure

(1) Select the problem analysis menu from the main menu using the ↑key or ↓key and press

<ENTER> key to start the program.

Main menu

(2) Check the error code (hexadecimal number) from the Latest error code read-out menu and

locate the faulty position from the following table.

Problem analysis menu

The state of the module

The latest error code

A past error code is shown in

new the order.

All error code is cleared to 0.

Example of displaying breakdown analysis

(3) Confirm the latest error code, and then the faulty point is specified from the Error code table.

(4) Select RETURN using the ↑key or ↓key and press <ENTER> key to start the program, then

the screen returns to the menu screen.

* When EXIT is selected, the screen returns to the WINDOWS or DOS screen.

-37-

Page 42

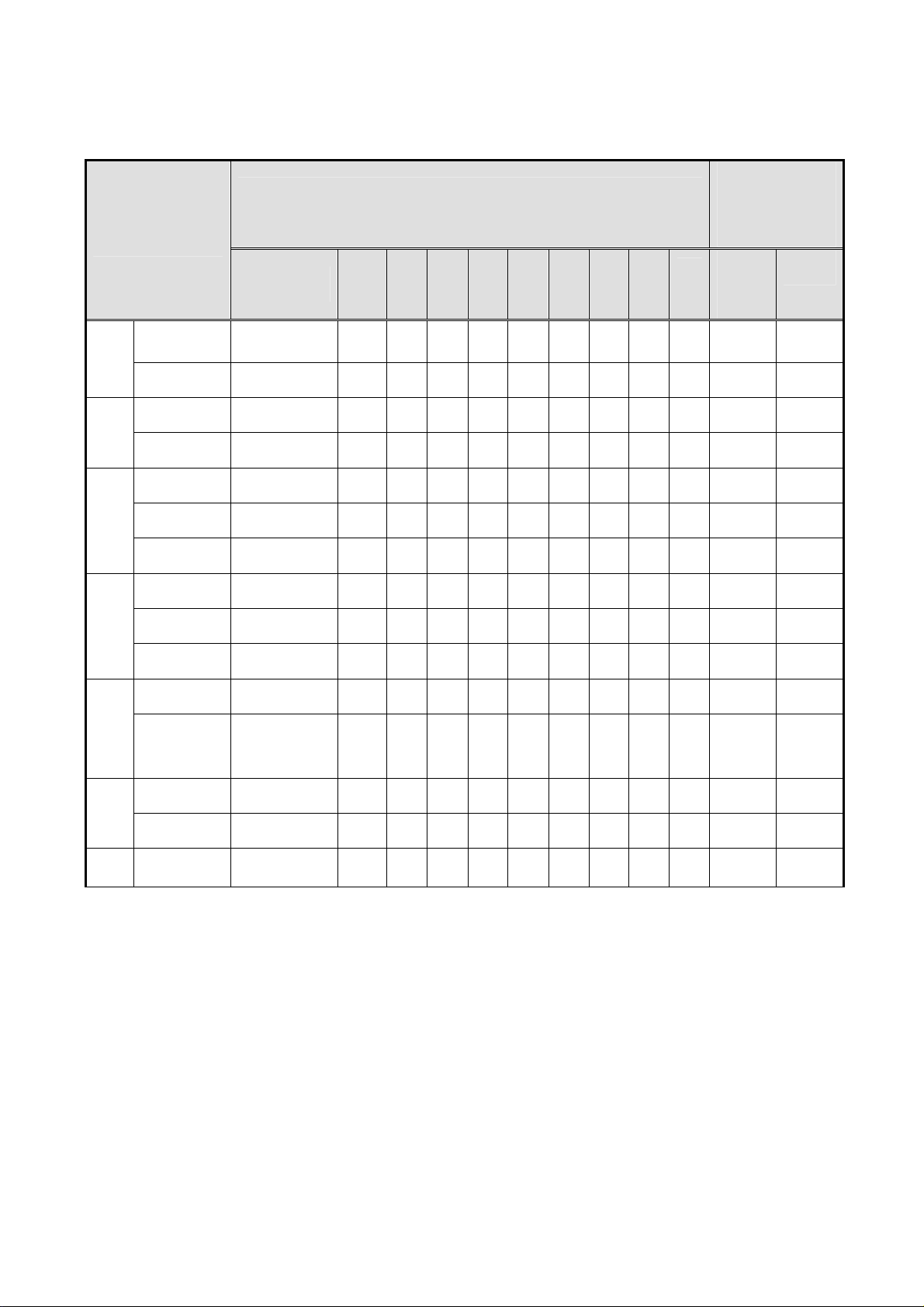

Error code table

Detect

ERR

code

position

(board)

Contents

(In the order of higher probability of defect)

(1) (2) (3) (4) (5) (6) (7)

00 LOGIC STANDBY power is stopped PSU PSU temperature

LOGIC

02 ROM data of waveform is abnormal LOGIC

04 3.3V power voltage has dropped LOGIC PSU

06 3.3V power startup is faulty X-SUS Y-SUS

08 1V power voltage has dropped LOGIC PSU

0A 1V power startup is faulty X-SUS Y-SUS ADM1-22 PSU ABUS LOGIC

18 Internal I2C_SCL1_LOW level LOGIC

19 Internal I2C_ACK does not respond LOGIC

1C EEPROM initial setting is defective LOGIC

1D EEPROM write-down is defective LOGIC

1E EEPROM user initial setting is

LOGIC

defective

1F

EEPROM factory setting reading is

LOGIC

defective

X-SUS

24 Vex power voltage has decreased X-SUS LOGIC

25 Vex power voltage is excessive X-SUS

26 Vex power startup is faulty. X-SUS LOGIC

28 Vx power voltage has dropped X-SUS LOGIC

29 Vx power voltage is excessive X-SUS

2A Vx power startup is faulty. X-SUS LOGIC

39 Vs power current is excessive

X-SUS Panel LOGIC

(during operation)

3B Vs power current is excessive

X-SUS Panel LOGIC

(during startup)

3C Vq power voltage has dropped X-SUS

3D Vq power voltage is excessive X-SUS

3E

44 Vey power voltage has dropped Y-SUS LOGIC

Y-SUS

Vq power startup is faulty. X-SUS

45 Vey power voltage is excessive Y-SUS

46 Vey power startup is faulty. Y-SUS LOGIC

48 Vu power voltage has dropped Y-SUS

49 Vu power voltage is excessive Y-SUS

4A Vu power startup is faulty. Y-SUS

59 Vs power current is excessive

Y-SUS Panel LOGIC

(during operation)

5B Vs power current is excessive

Y-SUS Panel LOGIC

(during startup)

5D

X-SUS

61 Vs power voltage is excessive PSU X-SUS LOGIC

Y-SUS

62 Vs power startup is faulty. X-SUS Y-SUS PSU LOGIC

64 Ve power voltage has dropped LOGIC X-SUS Y-SUS

SDM current is excessive SDM Y-SUS Panel LOGIC

65 Ve power voltage is excessive X-SUS Y-SUS

66 Ve power startup is faulty. LOGIC X-SUS Y-SUS

68 Vw power voltage has dropped Y-SUS X-SUS LOGIC

69 Vw power voltage is excessive X-SUS

6A

ABUS

81 Va power voltage is excessive PSU X-SUS LOGIC

82 Va power startup is faulty.

99 Va power current is excessive

9B

Vw power startup is faulty. Y-SUS X-SUS LOGIC

(during operation)

Va power current is excessive

(during startup)

ADMU1-U11

ADND1-D11

ADMU1-U11

ADND1-D11

ADMU1-U11

ADND1-D11

PSU X-SUS LOGIC ABUS

ABUS X-SUS PSU LOGIC

ABUS X-SUS PSU LOGIC

Suspected faulty board

ADMU1-U11

ADND1-D11

PSU

ABUSU1-U4

ABUSD1-D4

Remarks

has probably

increased

LOGIC

-38-

Page 43

Detect

ERR

position

code

(board)

9D Va power current is excessive (during

A5 ADM-D1 ADM-D1 has abnormal heat generation. ADM-D1 PSU LOGIC

A7 ADM-U1 ADM-U1 has abnormal heat generation. ADM-U1 PSU LOGIC

A9 ADM-D2 ADM-D2 has abnormal heat generation. ADM-D2 PSU LOGIC

AB ADM-U2 ADM-U2 has abnormal heat generation. ADM-U2 PSU LOGIC

AD ADM-D3 ADM-D3 has abnormal heat generation. ADM-D3 PSU LOGIC

AF ADM-U3 ADM-U3 has abnormal heat generation. ADM-U3 PSU LOGIC

B1 ADM-U4 ADM-U4 has abnormal heat generation. ADM-U4 PSU LOGIC

B3 ADM-D4 ADM-D4 has abnormal heat generation. ADM-D4 PSU LOGIC

B5 ADM-U5 ADM-U5 has abnormal heat generation. ADM-U5 PSU LOGIC

B7 ADM-D5 ADM-D5 has abnormal heat generation. ADM-D5 PSU LOGIC

B9 ADM-U6 ADM-U6 has abnormal heat generation. ADM-U6 PSU LOGIC

BB ADM-D6 ADM-D6 has abnormal heat generation. ADM-D6 PSU LOGIC

BD ADM-U7 ADM-U7 has abnormal heat generation. ADM-U7 PSU LOGIC

BF ADM-D7 ADM-D7 has abnormal heat generation. ADM-D7 PSU LOGIC

C5 ADM-U8 ADM-U8has abnormal heat generation. ADM-U8 PSU LOGIC

C7 ADM-D8 ADM-D8 has abnormal heat generation. ADM-D8 PSU LOGIC

C9 ADM-U9 ADM-U9has abnormal heat generation. ADM-U9 PSU LOGIC

CB ADM-D9 ADM-D9 has abnormal heat generation. ADM-D9 PSU LOGIC

CD ADM-U10 ADM-U10has abnormal heat

CF ADM-D10 ADM-D10 has abnormal heat

D1 ADM-U11 ADM-U11has abnormal heat

D3 ADM-D11 ADM-D11 has abnormal heat

E2 LOGIC 5V power startup is faulty. X-SUS Y-SUS PANEL PSU ABUS LOGIC

FC PSU Detection error of Vs and Va voltage. PSU LOGIC

operation)

generation.

generation.

generation.

generation.

Contents

Contents

(In the order of higher probability of defect)

(1) (2) (3) (4) (5) (6) (7)

ADM1-8 ABUS PSU LOGIC Excess current is

ADM-U10 PSU LOGIC

ADM-D10 PSU LOGIC

ADM-U11 PSU LOGIC

ADM-D11 PSU LOGIC

Suspected faulty board

Remarks

detected in ACCC

operation.

It can possibly

occur depending

on screen display.

-39-

Page 44

5 DISASSEMBLING AND REASSEMBLING

⑬

③

④

⑤

⑥⑦⑧

⑫① ⑭⑮⑯ ⑱

⑰

⑲

Unless otherwise specified, use the torque screwdriver for screw tightening, following the

tightening torques.

Screw size Tightening torque

M 3 0.69±0.049Nm (7±0.5kg·cm)

M 4 1.18±0.098Nm (12±1.0kg·cm)

5.1 Exploded View

②

⑲

⑲

⑨

⑩

⑲

⑪

⑲

⑲

-40-

Page 45

5.2 X-SUS Circuit Board Removal/Installation Procedure

(4)

When removing the circuit board after the main power is turned on/off, wait for at

Note

CN22

(5)

least four minutes before starting to remove the circuit board.

If the circuit board removal is started immediately after turning off the main power, it

can result in electric shock or damage to the circuit due to residual electric charge.

Remove the circuit board following the steps below. To install the circuit board, reverse the removal

procedure.

(1) Remove the fixing screws (M3x8) fixing XBB at 4 locations.

(2) Pull out the XBB board horizontally and disconnect the connectors (CN26, CN27).

(3) Release the lock of the FPC connector (CN20) and disconnect the signal cable.

(4) Disconnect the cables from the VH connectors (CN22, CN23, CN24).

(5) Remove the fixing screws (M3x8) fixing XSUS at 7 locations.

(6) Release the space holder (rod) at the 3 locations.

(7) Remove the X-SUS board.

(1)

(4)CN23

(6)

(2)CN26

(5)

Pull out

(5)

(5)

(5)

(5)

(3)CN20

(5)

Pull out

(6)

Note

(4)CN24

*

On handling the FPC connector

To release the lock, release it by gently flipping it with the nail of the

thumb or forefinger. Never pinch the lock lever with fingers or hook

on it (especially with a fingernail). Doing so might damage the lock

lever.

(1)

(1)

(2)CN27

(6)

(1)

-41-

Page 46

p

y

③

Note

Pick up and release upper the lock of space

holder (rod). Moreover, confirm the lock surel

combines intuition when you install the board.

Space holder (rod)

Pick up Pick u

PCB

-42-

Page 47

5.3 Y-SUS Circuit Board Removal/Installation Procedure

3

When removing the circuit board after the main power is turned on/off, wait for at

Note

(1)

(1)

least four minutes before starting to remove the circuit board.

If the circuit board removal is started immediately after turning off the main power, it

can result in electric shock or damage to the circuit due to residual electric charge.

Remove the circuit board following the steps below. To install the circuit board, reverse the removal

procedure.

(1) Remove the fixing screws (M3x8) fixing SDM at 6 locations.

(2) Pull out the SDM board horizontally and disconnect the connectors (CN32, CN33).

(3) Release the lock of the FPC connector (CN30) and disconnect the signal cable.

(4) Disconnect the power supply connectors (CN31).

(5) Remove the fixing screws (M3x8) fixing YSUS at 6 locations.

(6) Release the space holder (rod) at the 4 locations.

(7) Remove the Y-SUS board.

(6)

(4)CN31

(2)CN32

(5)

(1)

Pull out

(5)

(1)

(5)

Pull out

(2)CN3

(1)

(6)

(1)

Note

* On handling the FPC connector

To release the lock, release it by gently flipping it with the nail of the

thumb or forefinger. Never pinch the lock lever with fingers or hook

on it (especially with a fingernail). Doing so might damage the lock

lever.

(3)CN30

(6)

(5)

(5)

(5)

(6)

-43-

Page 48

y

p

④

Note

Pick up and release upper the lock of space

holder (rod). Moreover, confirm the lock surel

combines intuition when you install the board.

Space holder (rod)

Pick up Pick u

PCB

-44-

Page 49

5.4 ABUS-U1 Circuit Board Removal/Installation Procedure

3

When removing the circuit board after the main power is turned on/off, wait for at

Note

least four minutes before starting to remove the circuit board.

If the circuit board removal is started immediately after turning off the main power, it

can result in electric shock or damage to the circuit due to residual electric charge.

Remove the circuit board following the steps below. To install the circuit board, reverse the removal

procedure.

(1) Release the lock of CNU1-3 and then reconnect the signal cable (FPC).

(2) Release the lock of CNU1-1, CNU1-2 by lifting the lock and then reconnect flexible cable of ADM.

(3) Release the power supply connector CNU2-4 on the ABUS-U2 board.

(4) Remove the fixing screws (M3x8) fixing ADM at 4 locations.

(5) Remove the fixing screws (M3x8) fixing ABUS-U1 at 1 location.

(6) Release the space holder (rod) at the 1 location.

(7) Remove the ABUS-U1 board.

(2)CNU1-1

(2)CNU1-2

(3)CNU2-4

(4)

(4)

(4)

(6)

(2)CN3

(5)

(1)CNU1-3

Note

(4)

* On handling the FPC connector

To release the lock, release it by gently flipping it with the nail of the

thumb or forefinger. Never pinch the lock lever with fingers or hook

on it (especially with a fingernail). Doing so might damage the lock

lever.

-45-

Page 50

y

p

⑤

Note

Pick up and release upper the lock of space

holder (rod). Moreover, confirm the lock surel

combines intuition when you install the board.

Pick up Pick u

Space holder (rod)

PCB

-46-

Page 51

5.5 ABUS-U2 Circuit Board Removal/Installation Procedure

3

When removing the circuit board after the main power is turned on/off, wait for at

Note

least four minutes before starting to remove the circuit board.

If the circuit board removal is started immediately after turning off the main power, it

can result in electric shock or damage to the circuit due to residual electric charge.

Remove the circuit board following the steps below. To install the circuit board, reverse the removal

procedure.

(1) Release the lock of CNU2-5, CNU2-6 and then reconnect the signal cable (FPC).

(2) Release the lock of CNU2-1, CNU2-2, CNU2-3

(3) Release the CNU2-4 and power supply connector CNU3-5 on the ABUS-U3 board.

(4) Remove the fixing screws (M3x8) fixing ADM at 6 locations.

(5) Remove the fixing screws (M3x8) fixing ABUS-U2 at 2 locations.

(6) Release the space holder (rod) at the 1 location.

(7) Remove the ABUS-U2 board.

(2)CNU2-3

(2)CNU2-1

(2)CNU2-2

by lifting the lock and then reconnect flexible cable of ADM.

(3)CNU3-5

(3)CNU2-4

(4)

(4)

(4)

(5)

(2)CN3

(1)CNU2-5

Note

* On handling the FPC connector

To release the lock, release it by gently flipping it with the nail of the

thumb or forefinger. Never pinch the lock lever with fingers or hook

on it (especially with a fingernail). Doing so might damage the lock

lever.

(4)

(4)

(6)

(1)CNU2-6

(4)

(5)

-47-

Page 52

y

p

⑥

Note

Pick up and release upper the lock of space

holder (rod). Moreover, confirm the lock surel

combines intuition when you install the board.

Space holder (rod)

Pick up Pick u

PCB

-48-

Page 53

5.6 ABUS-U3 Circuit Board Removal/Installation Procedure

When removing the circuit board after the main power is turned on/off, wait for at

Note

(2)CNU3-4

least four minutes before starting to remove the circuit board.

If the circuit board removal is started immediately after turning off the main power, it

can result in electric shock or damage to the circuit due to residual electric charge.

Remove the circuit board following the steps below. To install the circuit board, reverse the removal

procedure.

(1) Release the lock of CNU3-6, CNU3-7, CNU3-8, CNU3-9 and then reconnect the signal cable (FPC).

(2) Release the lock of CNU3-1, CNU3-2, CNU3-3, CNU3-4

of ADM.

(3) Release the power supply connector CNU3-5, CNU3-10 on the ABUS-U3 board.

(4) Remove the fixing screws (M3x8) fixing ADM at 8 locations.

(5) Remove the fixing screws (M3x8) fixing ABUS-U3 at 2 locations.

(6) Release the space holder (rod) at the 1 location.

(7) Remove the ABUS-U3 board.

by lifting the lock and then reconnect flexible cable

(2)CNU3-3

(2)CNU3-2

(2)CNU3-1

(4)

(4)

(4)

(4)

(6)

(4)

(4)

(4)

(5)

(5)

(1)CNU3-6(3)CNU3-5

Note

* On handling the FPC connector

To release the lock, release it by gently flipping it with the nail of the

thumb or forefinger. Never pinch the lock lever with fingers or hook

on it (especially with a fingernail). Doing so might damage the lock

lever.

(4)

(1)CNU3-10

(1)CNU3-9

(1)CNU3-8(1)CNU3-7

-49-

Page 54

y

p

⑦

Note

Pick up Pick u

Pick up and release upper the lock of space

holder (rod). Moreover, confirm the lock surel

combines intuition when you install the board.

Space holder (rod)

PCB

-50-

Page 55

5.7 ABUS-U4 Circuit Board Removal/Installation Procedure

When removing the circuit board after the main power is turned on/off, wait for at

Note

(3)CNU3-10

least four minutes before starting to remove the circuit board.

If the circuit board removal is started immediately after turning off the main power, it

can result in electric shock or damage to the circuit due to residual electric charge.

Remove the circuit board following the steps below. To install the circuit board, reverse the removal

procedure.

(1) Release the lock of CNU4-4 and then reconnect the signal cable (FPC).

(2) Release the lock of CNU4-1, CNU4-2

(3) Release the CNU4-5 and power supply connector CNU3-10 on the ABUS-U3 board.

(4) Remove the fixing screws (M3x8) fixing ADM at 8 locations.

(5) Remove the fixing screws (M3x8) fixing ABUS-U3 at 2 locations.

(6) Release the space holder (rod) at the 1 location.

(7) Remove the ABUS-U3 board.

by lifting the lock and then reconnect flexible cable of ADM.

(4)

(2)CNU4-2

(2)CNU4-1

(4)

(5)

(4)

(5)

(6)

(1)CNU4-4 (3)CNU4-5

Note

* On handling the FPC connector

To release the lock, release it by gently flipping it with the nail of the

thumb or forefinger. Never pinch the lock lever with fingers or hook

on it (especially with a fingernail). Doing so might damage the lock

lever.

(4)

-51-

Page 56

e

y

p

⑧

Note

Pick up and release upper the lock of spac

holder (rod). Moreover, confirm the lock surel

combines intuition when you install the board.

Space holder (rod)

-52-

Pick up Pick u

PCB

Page 57

5.8 ABUS-D1 Circuit Board Removal/Installation Procedure

When removing the circuit board after the main power is turned on/off, wait for at

Note

least four minutes before starting to remove the circuit board.

If the circuit board removal is started immediately after turning off the main power, it

can result in electric shock or damage to the circuit due to residual electric charge.

Remove the circuit board following the steps below. To install the circuit board, reverse the removal

procedure.

(1) Release the lock of CND1-3 and then reconnect the signal cable (FPC).

(2) Release the lock of CND1-1, CND1-2 by lifting the lock and then reconnect flexible cable of ADM.

(3) Release the power supply connector CND2-4 on the ABUS-U3 board.

(4) Remove the fixing screws (M3x8) fixing ADM at 4 locations.

(5) Remove the fixing screws (M3x8) fixing ABUS-D1 at 1 location.

(6) Release the space holder (rod) at the 1 location.

(7) Remove the ABUS-D1 board.

(1)CND1-3

(5)

(6)

(4)

(4)

(4)

(4)

(2)CND1-1 (2)CND1-2

Note

* On handling the FPC connector

To release the lock, release it by gently flipping it with the nail of the

thumb or forefinger. Never pinch the lock lever with fingers or hook

on it (especially with a fingernail). Doing so might damage the lock

lever.

(3)CND2-4

-53-

Page 58

⑨

e

y

p

Note

Pick up and release upper the lock of spac

holder (rod). Moreover, confirm the lock surel

combines intuition when you install the board.

Space holder (rod)

Pick up Pick u

PCB

-54-

Page 59

5.9 ABUS-D2 Circuit Board Removal/Installation Procedure

When removing the circuit board after the main power is turned on/off, wait for at

Note

(1)CND2-6 (1)CND2-7

least four minutes before starting to remove the circuit board.

If the circuit board removal is started immediately after turning off the main power, it

can result in electric shock or damage to the circuit due to residual electric charge.

Remove the circuit board following the steps below. To install the circuit board, reverse the removal

procedure.

(1) Release the lock of CND2-5, CND2-6, CND2-7, CND2-8 and then reconnect the signal cable (FPC).

(2) Release the lock of CND2-1, CND2-2, CND2-3

(3) Release the power supply connector CND2-4 on the ABUS-D2 board and CND3-5 on the ABUS-D3 board.

(4) Remove the fixing screws (M3x8) fixing ADM at 6 locations.

(5) Remove the fixing screws (M3x8) fixing ABUS-D2 at 2 locations.

(6) Release the space holder (rod) at the 2 locations.

(7) Remove the ABUS-D2 board.

by lifting the lock and then reconnect flexible cable of ADM.

(1)CND2-8

(1)CND2-5

(3)CND2-4

(2)CND2-3

Note

(5)

(4)

(5)

(4)

(4)

(6)

(4)

(4)

(6)

(4)

(2)CND2-2 (2)CND2-1

(3)CND2-9

* On handling the FPC connector

To release the lock, release it by gently flipping it with the nail of the

thumb or forefinger. Never pinch the lock lever with fingers or hook

on it (especially with a fingernail). Doing so might damage the lock

lever.

-55-

Page 60

⑩

p

e

y

Note

Pick up and release upper the lock of spac

holder (rod). Moreover, confirm the lock surel

combines intuition when you install the board.

Space holder (rod)

Pick up Pick u

PCB

-56-

Page 61

5.10 ABUS-D3 Circuit Board Removal/Installation Procedure

When removing the circuit board after the main power is turned on/off, wait for at

Note

least four minutes before starting to remove the circuit board.

If the circuit board removal is started immediately after turning off the main power, it

can result in electric shock or damage to the circuit due to residual electric charge.

Remove the circuit board following the steps below. To install the circuit board, reverse the removal

procedure.

(1) Release the lock of CND3-6, CND3-7, CND3-8, CND3-9, CND3-10, CND3-11 and then reconnect the signal

cable (FPC).

(2) Release the lock of CND3-1, CND3-2, CND3-3, CND3-4

of ADM.

(3) Release the power supply connector CND3-4,CND 3-12 .

(4) Remove the fixing screws (M3x8) fixing ADM at 8 locations.

(5) Remove the fixing screws (M3x8) fixing ABUS-D3 at 2 locations.

(6) Release the space holder (rod) at the 2 locations.

(7) Remove the ABUS-D3 board.

by lifting the lock and then reconnect flexible cable

(1)CND3-9 (1)CND3-8

(1)CND3-7

(1)CND3-6

(3)CND3-5

(4)

Note

(5)

(4)

(4)

(6)

(6)

(4)

(4)

(1)CND3-10

(5)

(1)CND3-11

(3)CND3-12

(4)

(4)

(4)

(2)CND3-2 (2)CND3-3 (2)CND3-4

(2)CND3-1

* On handling the FPC connector

To release the lock, release it by gently flipping it with the nail of the

thumb or forefinger. Never pinch the lock lever with fingers or hook

on it (especially with a fingernail). Doing so might damage the lock

lever.

-57-

Page 62

⑪

e

y

p

Note

Pick up and release upper the lock of spac

holder (rod). Moreover, confirm the lock surel

combines intuition when you install the board.

Space holder (rod)

Pick up Pick u

PCB

-58-

Page 63

5.11 ABUS-D4 Circuit Board Removal/Installation Procedure

When removing the circuit board after the main power is turned on/off, wait for at

Note

least four minutes before starting to remove the circuit board.

If the circuit board removal is started immediately after turning off the main power, it

can result in electric shock or damage to the circuit due to residual electric charge.

Remove the circuit board following the steps below. To install the circuit board, reverse the removal

procedure.