Sony KD-55XD9305, KD-65XD9305 Schematic

SERVICE MANUAL

ORIGINAL MANUAL ISSUE DATE: 2/2016

Version Date Subject

1.0 2/2016 Original manual issue.

GN2SK CHASSIS

Segment: QF

LCD TV

9-888-588-01

MODEL LIST

MODEL COLOR COMMANDER DEST.

KD-55XD9305 Black RMF-TX200E CEI/UKA/RU3

KD-65XD9305 Black RMF-TX200E CEI/UKA/RU3

MODEL COLOR COMMANDER DEST.

KD-55/65XD9305

2

WARNINGS AND CAUTIONS - ENGLISH

CAUTION

These servicing instructions are for use by qualified service personnel only.

To reduce the risk of electric shock, do not perform any servicing other than that contained in the operating instructions unless you are qualified to do so.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis.

The chassis of this receiver is directly connected to the ac power line.

CARRYING THE TV

Be sure to follow these guidelines to protect your property and avoid causing serious injury.

• Carry the TV with an adequate number of people; larger size TVs require two or more people.

• Correct hand placement while carrying the TV is very important for safety and to avoid damages.

SAFETY-RELATED COMPONENT WARNING!!

Components identified by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe operation. Replace these components with Sony

parts whose part numbers appear as shown in this manual or in supplements published by Sony. Circuit adjustments that are critical for safe operation are identified in this manual.

Follow these procedures whenever critical components are replaced or improper operation is suspected.

CAUTION ABOUT THE LITHIUM BATTERY

• Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type.

• Outer case broken battery should not contact to water.

KD-55/65XD9305

3

WARNINGS AND CAUTIONS - FRENCH

ATTENTION!!

Ces instructions de service sont à l’usage du personnel de service qualifi é seulement.

Pour prévenir le risque de choc électrique, ne pas faire l’entretien autre que celui contenu dans le Mode d’emploi à moins que vous soyez qualifi é faire ainsi.

WARNING!!

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout dépannage. Le chássis de ce récepteur est

directement raccordé à l’alimentation du secteur.

POUR TRANSPORTER LE TÉLÉVISEUR

Tenez compte de ce qui suit pendant l’installation du téléviseur :

• Débranchez tous les câbles avant de transporter le téléviseur.

• Transportez le téléviseur avec le nombre de personnes approprié ; un téléviseur de grande taille doit être transporté par au moins deux personnes.

• Lors du transport du téléviseur, l’emplacement des mains est très important pour votre sécurité, ainsi que pour éviter de causer des dommages.

ALERTE!!

Afi n d’eviter tout risque d’electrocution provenant d’un chassis sous tension, un transformateur d’isolement doit etre utilise lors de tout depannage. Le chassis de ce recepteur est

directement raccorde a l’alimentation du secteur.

ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque sur les schemas de principe, les vues explosees et les listes de pieces sont d’une importance critique pour la securite

du fonctionnement. Ne les remplacer que par des composants Sony dont le numero de piece est indique dans le present manuel ou dans des supplements publies par Sony. Les

reglages de circuit dont l’importance est critique pour la securite du fonctionnement sont identifi es dans le present manuel. Suivre ces procedures lors de chaque remplacement de

composants critiques, ou lorsqu’un mauvais fonctionnement suspecte.

KD-55/65XD9305

4

USE CAUTION WHEN HANDLING THE LCD PANEL

When repairing the LCD panel, be sure you are grounded by using a wrist band.

When repairing the LCD panel on the wall, the LCD panel must be secured using the 4 mounting holes on the rear cover.

1) Do not press on the panel or frame edge to avoid the risk of electric shock.

2) Do not scratch or press on the panel with any sharp objects.

3) Do not leave the module in high temperatures or in areas of high humidity for an extended period of time.

4) Do not expose the LCD panel to direct sunlight.

5) Avoid contact with water. It may cause a short circuit within the module.

6) Disconnect the AC power when replacing the backlight (CCFL) or inverter circuit. (High voltage occurs at the inverter circuit at 650Vrms.)

7) Always clean the LCD panel with a soft cloth material.

8) Use care when handling the wires or connectors of the inverter circuit. Damaging the wires may cause a short.

9) Protect the panel from ESD to avoid damaging the electronic circuit (C-MOS).

10) It is recommended not to exceed 1 hour of Power-On nor Burn-in period with LCD panel face down condition, in repair activity.

WARNINGS AND CAUTIONS

KD-55/65XD9305

5

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered connections. Check the entire board surface for solder splashes and bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and mounting hardware have been replaced. Be absolutely certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them out to the customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of deterioration. Point them out to the customer and recommend their replacement.

6. Check the line cords for cracks and abrasion. Recommend the replacement of any such line cord to the customer.

7. Check the antenna terminals, metal trim, “metallized” knobs, screws, and all other exposed metal parts for AC leakage. Check leakage as described below.

8. For safety reasons, repairing the Power board and/or Inverter board is prohibited.

KD-55/65XD9305

6

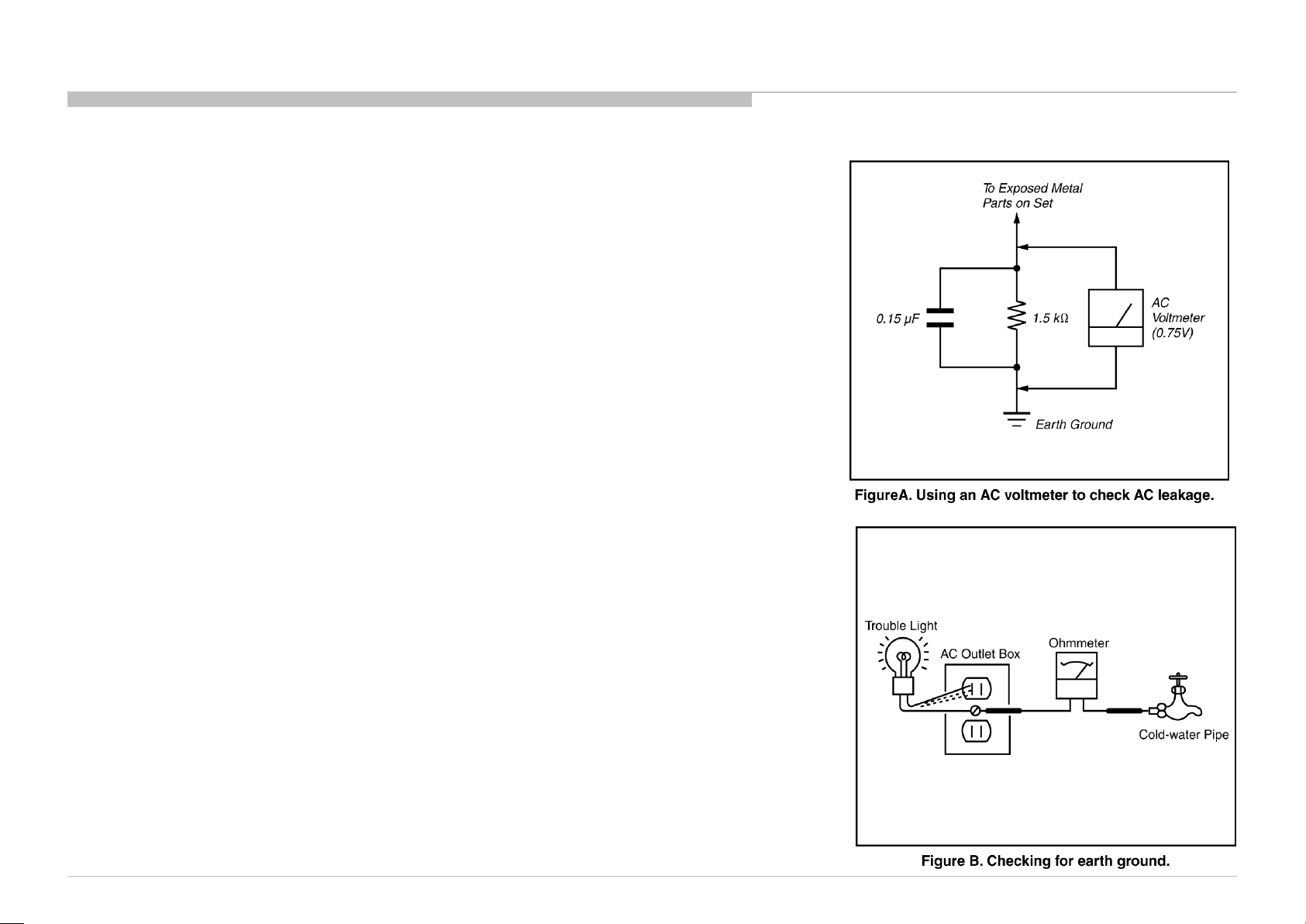

Leakage Test

The AC leakage from any exposed metal part to earth ground and from all exposed metal parts to any exposed

metal part having a return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA WT-540A. Follow the manufacturers’

instructions to use these instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245 digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM or battery-operated AC voltmeter. The

“limit” indication is 0.75 V, so analog meters must have an accurate low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of passive VOMs that are suitable. Nearly all

battery-operated digital multimeters that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate retaining screw on most AC outlet boxes is also

at earth ground.

If the retaining screw is to be used as your earth ground, verify that it is at ground by measuring the resistance

between it and a cold-water pipe with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt trouble- light (not a neon lamp) between the hot

side of the receptacle and the retaining screw. Try both slots, if necessary, to locate the hot side on the line; the

lamp should light at normal brilliance if the screw is at ground potential (see Figure B).

SAFETY CHECK-OUT

KD-55/65XD9305

7

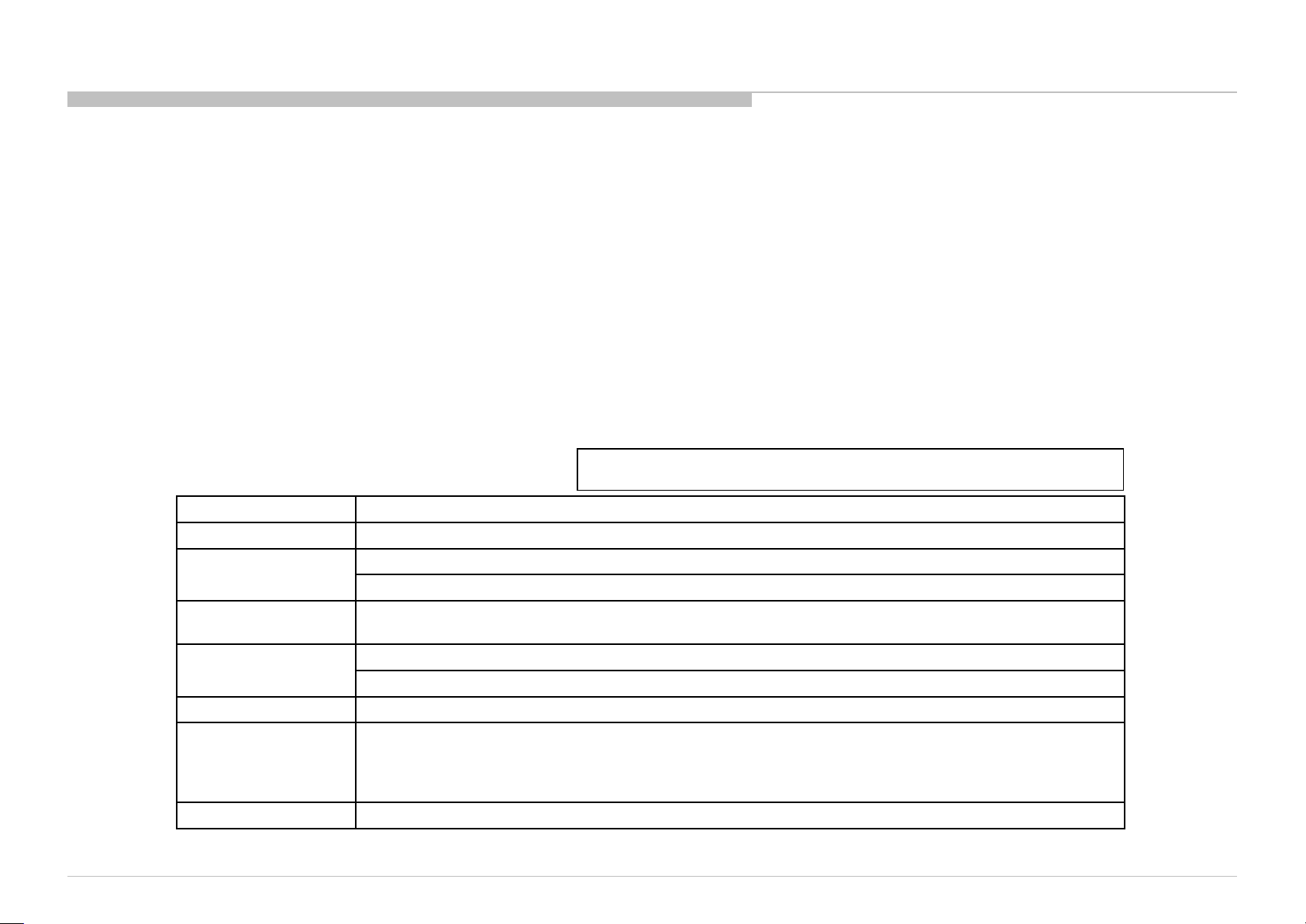

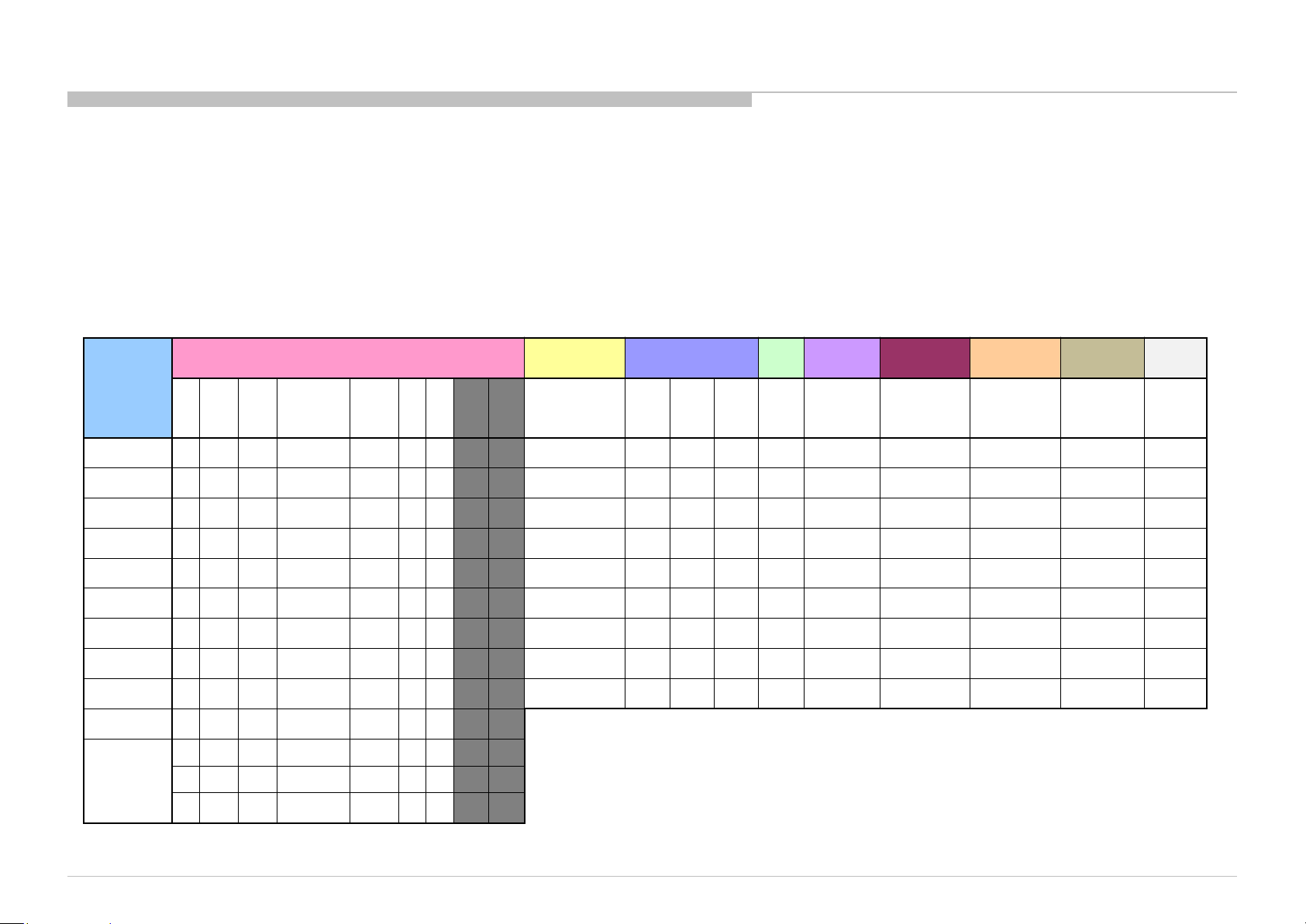

SELF DIAGNOSIS FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the Smart Core Red LED will automatically begin to flash.

The number of times the LED flashes translates to a probable source of the problem.

A definition of the Smart Core Red LED flash indicators is listed in the instruction manual for the user’s knowledge and reference.

If an error symptom cannot be reproduced, the remote commander can be used to review the failure occurrence data stored in memory to reveal past problems and how often these

problems occur.

DIAGNOSTIC TEST INDICATORS

When an error occurs, the Smart Core Red LED will flash a set number of times to indicate the possible cause of the problem.

If there is more than one error, the LED will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen.

If the screen displays a “0”, no error has occurred .

<G>: Power supply board, <B>: Main board, <T>: Tcon board, (LD) board,<P>: Panel module,

<S>: Speaker, <A>: Power Adapter, <D>: DPS 4K BE board, <T>: Temperature Board

RED LED blinking count Detection Items

2x <G/B/A> Main 12V over voltage [MAIN_POWER]

3x

4x

5x

6x <G/P/B/LD/D> Backlight failure [BACKLIGHT]

7x

8x <B/D> Software error [SW_ERR]

<B> Main 5.0V failure [DC_ALERT]

<B/S> Audio amp. protection [AUD_ERR]

<LD/P/D> LED driver failure/LED voltage protection [LD_ERR]

<LD/P/D>Error detection of the I2C communication between the Main device and the LD IC.[BCM_ERR]

<P/T/G/B> Panel ID EEPROM I2C No ACK (Also panel power failure is a suspect) [P_ID_ERR]

<T> Tcon IC I2C communication error [TCON_ERR]

Over temperature protection [TEMP_ERR]

<B/T> Temp. sensor I2C No ACK [TEMP_ERR]

<B/D> V By One lock error between Main device and 4KBE device [4KBE_ERR]

<B>4KBE device UART communication error detection.

KD-55/65XD9305

Red italic: detect at startup sequence only.

8

SELF DIAGNOSIS FUNCTION

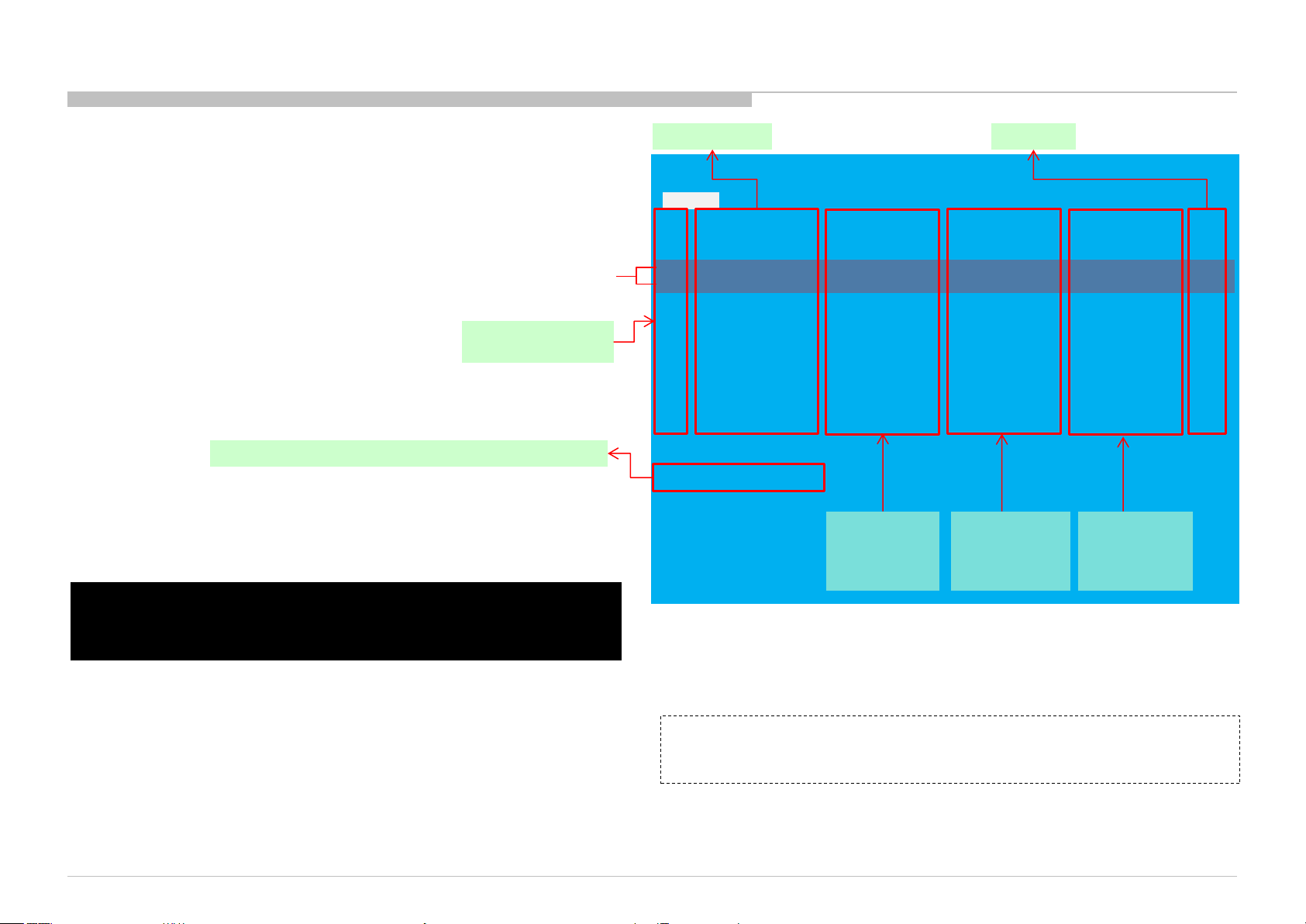

[SELF DIAGNOSTIC SCREEN DISPLAY]

Format of error timestamps

YYMMDDhh mmss (in UTC)

Example :

120823132523 -> Aug 23 2012 13:25:23 UTC

* On ly whe n time is set, an err or tim estamp

is save d.

• Panel Ope rat ion Ti me is recorded ever y 30 min,

but Total Operation Ti me is recorded eve ry 1 h r .

Ther efo re, the panel op. time might bec ome l arg er t han th e total op. tim e.

Total Operation Time [hr] – Boot Count – Panel Operation Time [hr]

" These error item

does not work."

Smart Core Red LED

blinking count

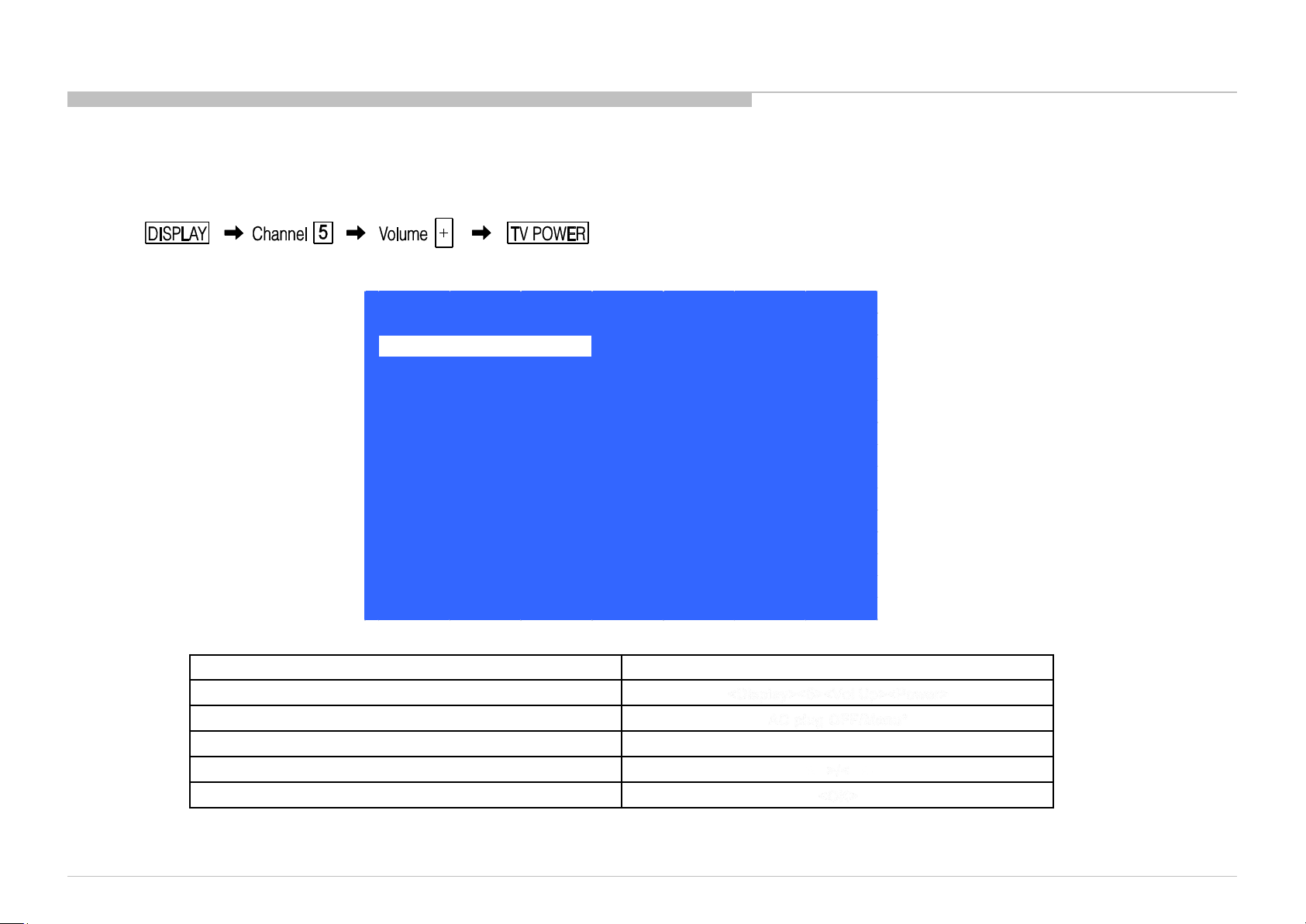

For errors with symptoms such as “power sometimes shuts off” or

“screen sometimes goes out” that cannot be confirmed,

it is possible to bring up past occurrences of failure for confirmation on the screen:

In standby mode, press buttons on the remote commander sequentially in rapid

succession as shown below:

Error Naming

SELF CHECK

Back

<<

002 MAIN_POWER 000000000000 000000000000 000000000000 000

003 DC_ALERT 000000000000 000000000000 000000000000 000

003 AUD_ERR 150101000018 150101000018 150101000018 003

003 HDMI_EQ 150101000123 150101000045 150101000045 003

003 TU_DEMOD 150101000218 150101000223 150101000105 003

004 LD_ERR 000000000000 000000000000 000000000000 000

004 BCM_ERR 000000000000 000000000000 000000000000 000

005 TCON_ERR 150101000504 000000000000 000000000000 001

005 P_ID_ERR 000000000000 000000000000 000000000000 000

006 BACKLIGHT ERR 000000000000 000000000000 000000000000 000

007 TEMP_ERR 150101000200 150101000002 000000000000 002

007 4KBE_ERR 000000000000 000000000000 000000000000 000

008 SW_ERR 000000000000 000000000000 000000000000 000

00005 00414 00002

[Home]Exit

Error

timestamp for

last recorded

error

Error count

Error

timestamp for

second last

recorded error

Error

timestamp for

3rd last

recorded error

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen.

After you have completed the repairs, clear the result display to “0”.

Clearing the Self Check Diagnostic List

Panel operation time : Press the Channel 7 => Channel 0 .

NOTE:

This model does not have the function to clear the error history of self-diagnostic screen

by remote such as press the Channel 8 => Channel 0.

To exit the Self Diagnostic screen...

*If you want to finish service mode app, do AC OFF/ON

→Service mode app is disable perfectly

*if you want to move home menu, push <HOME>button

→Service mode app do background(not disable perfectly)

KD-55/65XD9305

9

ADJUSTMENT

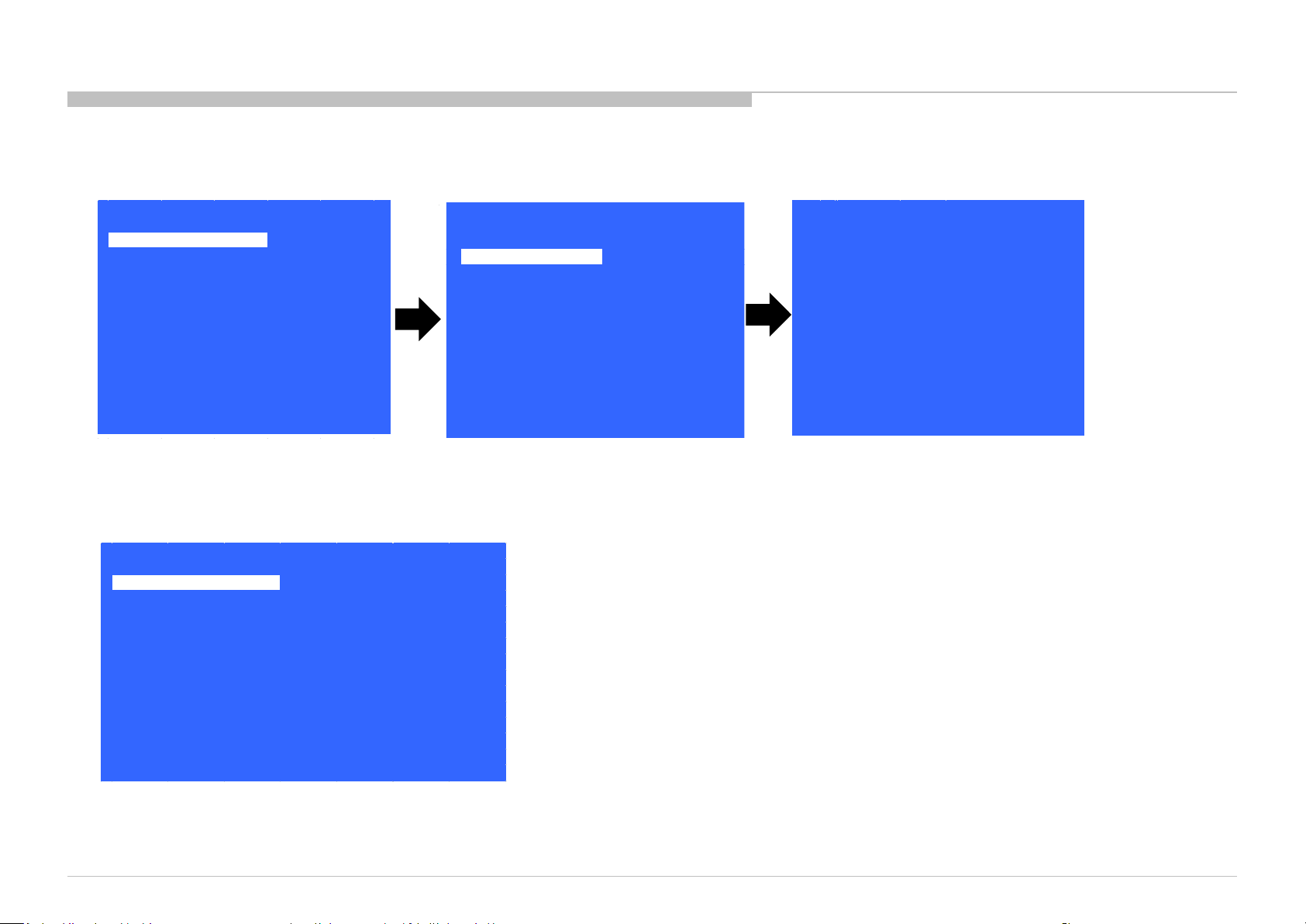

HOW TO ENTER SERVICE MODE

1) Turn on the main power switch to place the set in standby mode.

2) Press the buttons on the remote commander as follows, and entering service mode.

3) Service mode display.

Service Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wifi

>>

>>

>>

>>

>>

>>

>>

4) How to use the remote commander.

*When finished the operation of service mode , please AC Plug OFF/ON the TV set.

If you don’t do AC plug OFF/ON, remain the Service Mode App and User can see the Service Mode after RC ON.

(Refer the previous page.)

KD-55/65XD9305

[</>] Set [Home]Exit

Function The flow of control

Service mode on <Display><5><V ol Up><Powe r>

Service mode off AC plug OF F/Menu*

Item up / down <↑>/ <↓ >

Item select left/right

Execute <OK>

<←>/<→>

10

SOFTWARE VERSION

>>

Model Information

>>

Model Number Setting

>>

SERIAL NUMBER EDIT

[</> ] Set [Home]Exit

Model

Status Information

1) In Service Mode, select “Model Information”, press “Enter” or “→” button to enter Status Information.

ADJUSTMENT

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wifi

Service Mode

>>

>>

>>

>>

>>

>>

>>

[</>] Set [Home]Exit

2) Press “Enter” or “Return” button to return to Service Mode.

Service Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wifi

>>

>>

>>

>>

>>

>>

>>

>>

Main Micro

SW Version:

NVM Version:

Boot Version:

PQ Version:

AQ Version:

<Ext>

exFRC:

CameraVID:

CameraPIC:

CameraFW:

4k BE

MLFW:

MAFW:

ADSP

NDAT

PDAT

BDAT

BCM

FDAT

UDAT

BDIX

PKG2.011.0010NAB

0001 UC2

V1.000

102100006

AQ1.100

00.00.00.00

0

0

0

SF1.002

SF0.360

SF0.501

SD0.370

SD0.370

SD1.011

SD------SD0.002

SD0.000

SD0.370

KD-55/65XD9305

[</>] Set [Home]Exit

11

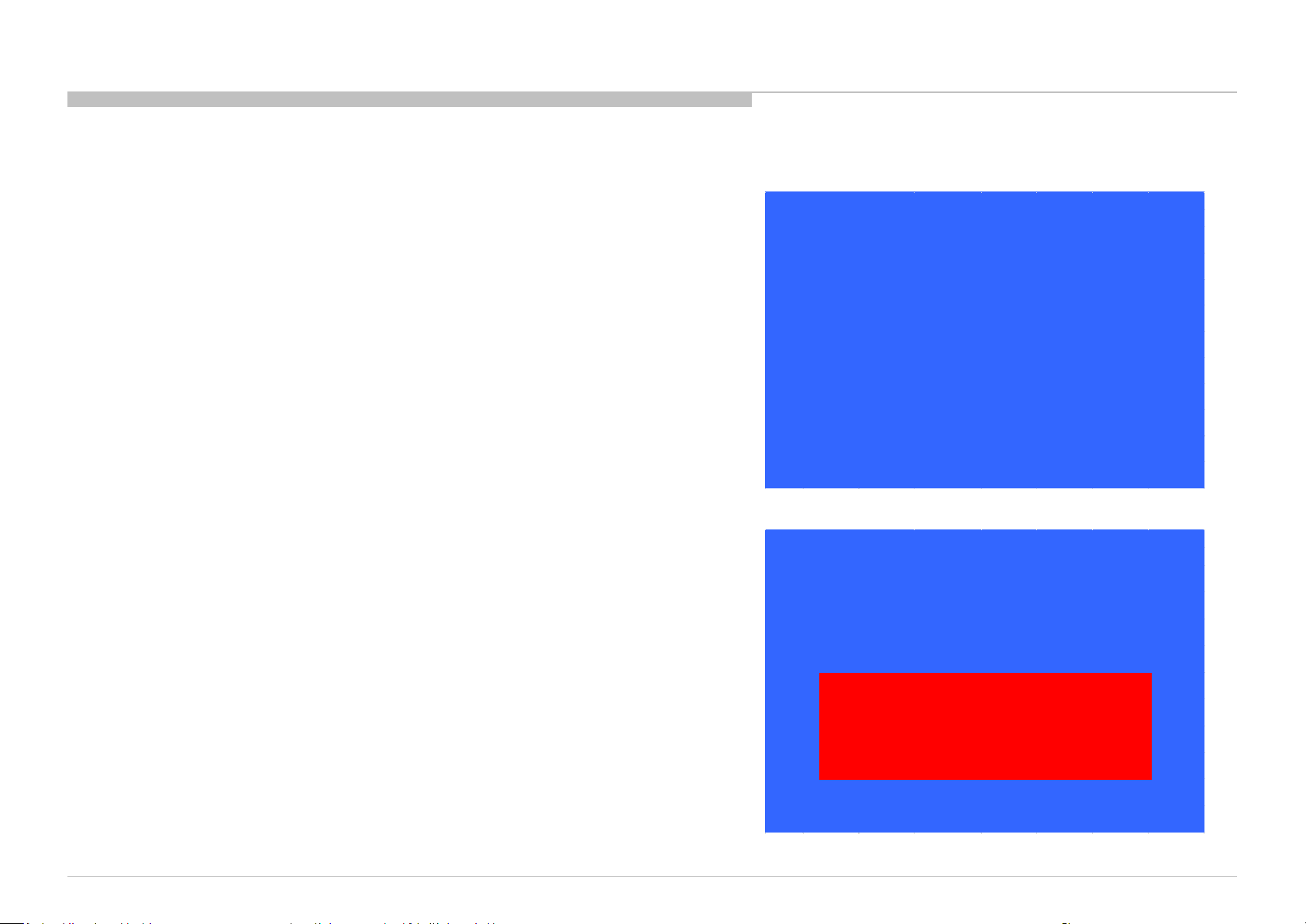

SERIAL NUMBER EDIT (1)

ADJUSTMENT

1) In “Service Mode”, select “Model Information” by pressing “↑” or “↓” then pressing “Enter” or

“→” button to enter inside.

2) Select “Serial Number Edit” by pressing “↑” or “↓” button then pressing “→” button.

3) Press “↑” or “↓” to input numbers.

4) After user input data , press <Enter> .

• Pop-up dialog appear to confirm input data correct

• Serial Number can be set ONLY ONCE

5) Press “→” or “←” button to select YES or NO.

Select YES if input data is correct.

Select NO if input data is incorrect.

Press <Enter> to save answer.

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wifi

Status Information

Model Information

Model Number Setting

Serial Number Edit

Status Information

Model Information

Model Number Setting

Serial Number Edit

Service Mode

>>

>>

>>

>>

>>

>>

>>

[</>] Set [Home]Exit

Service Mode

Service Mode

>>

>>

>>

_ _ _ _ _ _ _

>>

>>

>>

9 9 9 9 9 9 9

KD-55/65XD9305

Input Data correct?

Yes No

12

SERIAL NUMBER EDIT (2)

Yes No

Input Data correct?

ADJUSTMENT

If YES is selected, the input data is saved into EEPROM.

SERIAL NUMBER EDIT is greyed out and the serial number that has been input is displayed.

User will not able to edit anymore.

If NO is selected, the input data is not saved into EEPROM.

The serial number that has been input is displayed.

User can still edit the Serial Number.

Status Information

Model Information

Model Number Setting

Serial Number Edit

Status Information

Model Information

Model Number Setting

Serial Number Edit

Service Mode

>>

>>

>>

9 9 9 9 9 9 9

Service Mode

>>

>>

>>

9 9 9 9 9 9 9

KD-55/65XD9305

13

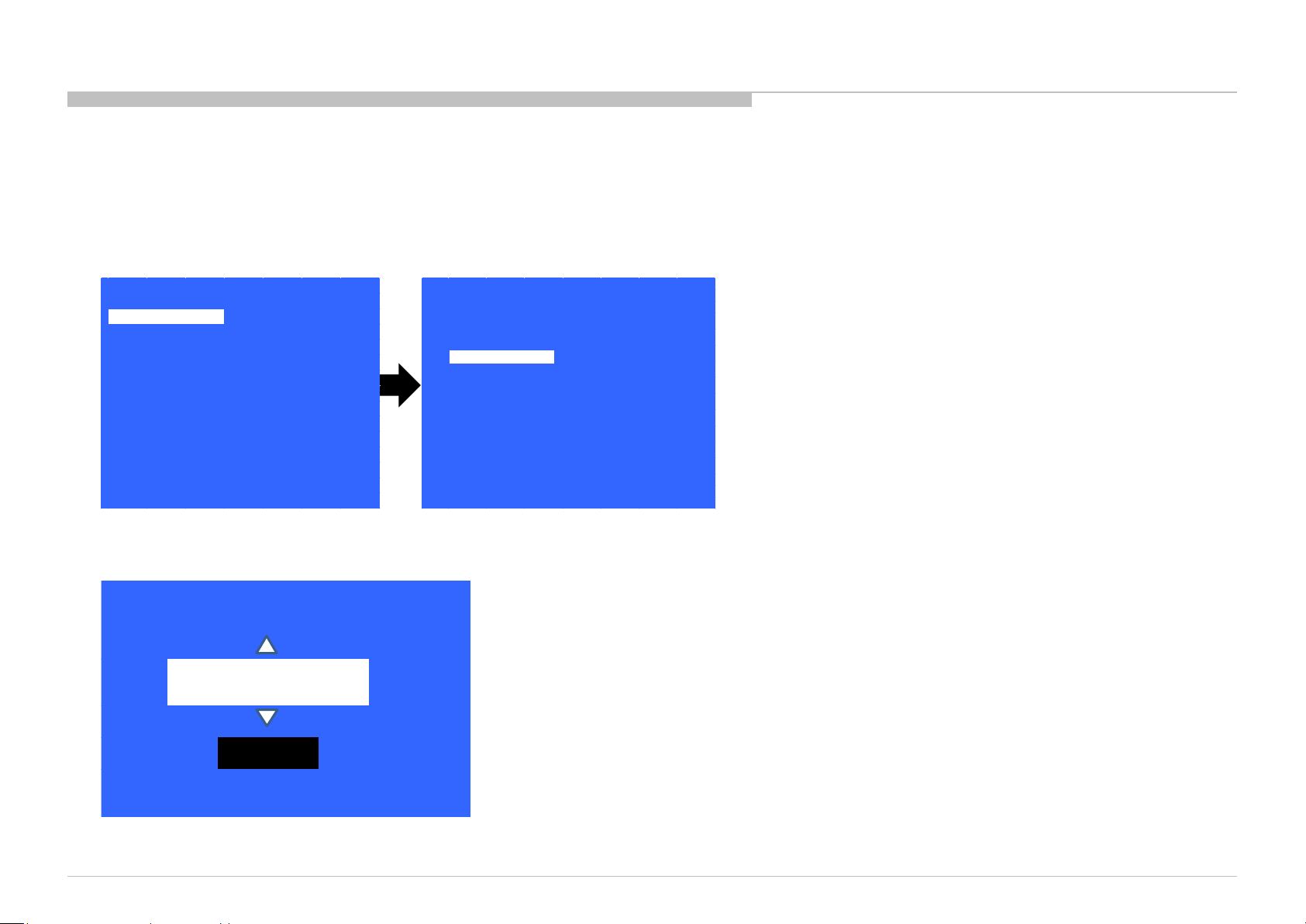

MODEL NUMBER SETTING

_ _ _ _ _ _ _ _ _ _ _ _

OK

[MODEL_NUMBER_SETTING]

1) In “Service Mode”, select “Model Information” by pressing “↑” or “↓” then pressing “Enter” or “→” button to enter inside.

2) Select “Model Number Setting” by pressing “↑” or “↓” button then pressing “Enter” or “→” button.

3) Press “↑” or “↓” arrow key to scroll Product Name Candidate.

(e.g. KDL-40X500B CO1,KDL-40X500C BR6)

ADJUSTMENT

Service Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Tuner

Wifi

>>

>>

>>

>>

>>

>>

>>

Status Information

Model Information

Model Number Setting

Serial Number Edit

Service Mode

>>

>>

>>

>>

[</>] Set [Home]Exit

4) Select one Product Name from the list, press <Enter> will pop dialog to inform user to confirm data. Model dependent settings will be overwritten into EEPROM.

KD-55/65XD9305

14

ADJUSTMENT

Back

R WB Gain

<[ 0 ]>

G WB Gai n

<[ 0 ]>

B WB Gain

<[ 0 ]>

R WB Offs et

<[ 0 ]>

G WB Offs et

<[ 0 ]>

B WB Offs et

<[ 0 ]>

<<

[</>] Set [Home]Exit

>>

>>

>>

>>

>>

>>

>>

Service Mode

[</>] Set [Home]Exit

Tuner

Wifi / BT

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

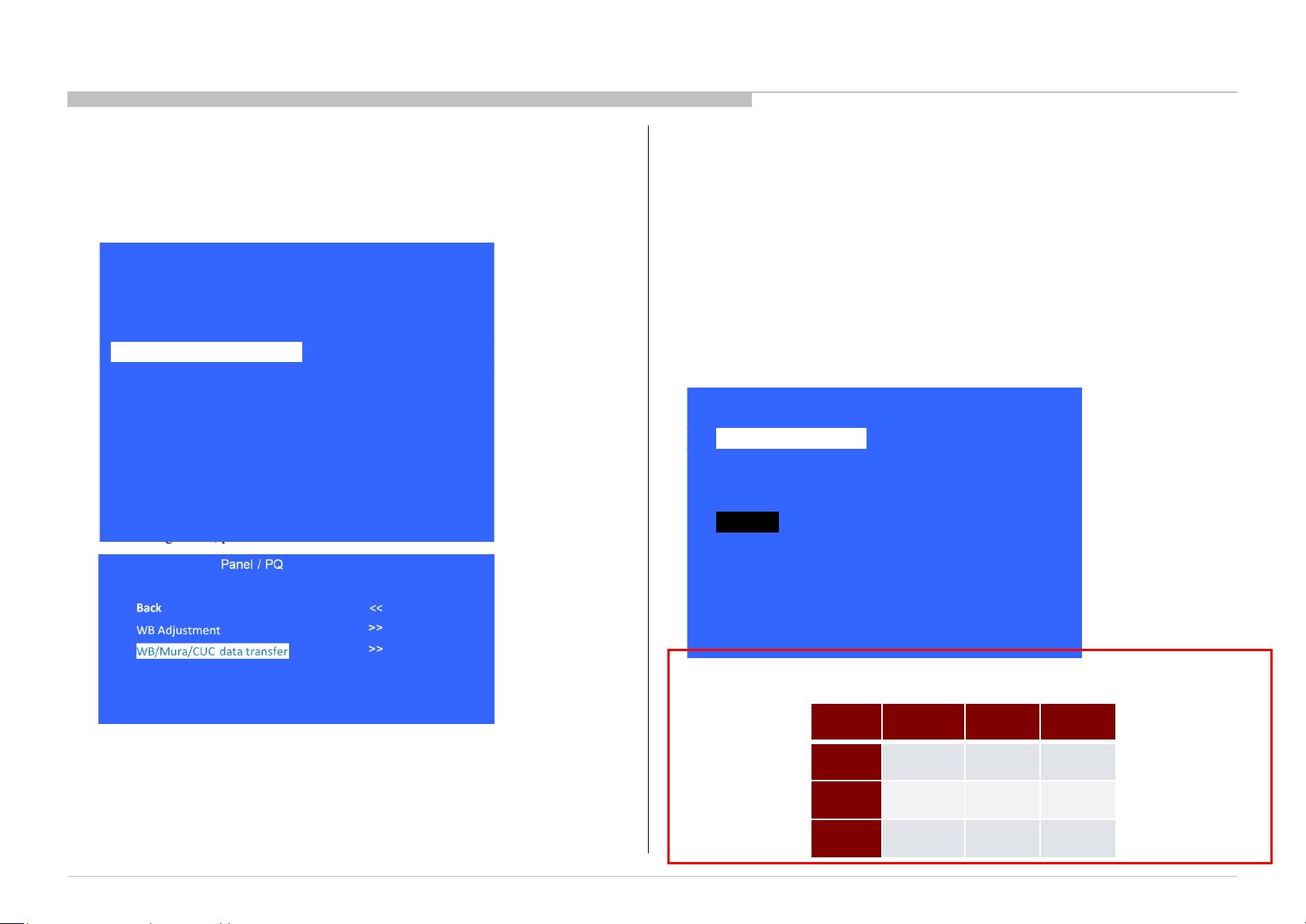

WB ADJUSTMENT

(Please apply when the Main board or panel is replaced.)

In “Panel/PQ” service mode.

a. Go to “WB Adjustment” category by “↑” or “↓”.

b. To select “WB Adjustment”, press “→” button.

c. To change data , press “←” or “→” on remote commander.

KD-55/65XD9305

15

ADJUSTMENT

>>

>>

>>

>>

>>

>>

>>

Service Mode

[</>] Set [Home]Exit

Tuner

Wifi / BT

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

General Setting

Back

<<

<[ 0. SoC to T-con ]>

Mura data transfer

<[ 0. SoC to T-con ]>

CUC data trans fer

<[ 0. SoC to T-con ]>

[Start]

[</>] Set [Home]Exit

WB/Gamma data trans fer

WB/MURA/CUC DATA TRANSFER

(Please apply when the Main board or panel is replaced.)

1. In “Panel/PQ” service mode.

a. Go to “WB/Mura/CUC data transfer” category by “↑” or “↓”.

b. To select “WB/Mura/CUC data transfer”, press “→” button.

c. To change data , press “←” or “→” on remote commander.

2. In “WB/Mura/CUC data transfer”.

a. Select “WB/Gamma data transfer” by pressing “↑” or “↓” on remote commander.

b. To change the items, press “←” or “→” on remote commander and press “Enter”

button.

Selectable items are:

0. SoC to T-con

1. T-con to SoC

2. Not action

c. Select “[start]” and press “Enter” button to start transfer.

KD-55/65XD9305

*Please refer to another manual “Service Procedure for Panel, Board and Software Change /

Upgrade(P/N:98881800x)” for details. GN2SK chassis is the same as GN1T chassis basically.

WB/

Gamma

Mura

CUC

B-board

replace

1.T-con to

Soc

1.T-con to

Soc

1.T-con to

Soc

T-con

replace

0.SoC to

T-con

0.SoC to

T-con

0.SoC to

T-con

Panel

replace

0.SoC to

T-con

1.T-con

to Soc

1.T-con

to Soc

16

HDD PERFORMANCE CHECK

>>

>>

>>

>>

>>

>>

>>

[</>] Set [Home]Exit

General Setting

Tuner

Wifi / BT

Service Mode

Model Information

Self diagnos is History

Video / Audio

Panel / PQ

Service Mode

Please wait…

<[ NG ]>

Back <<

HDD Performace Check

Result

ADJUSTMENT

1. In “Service Mode”, select “General Setting” by pressing “↑” or “↓” then

pressing “Enter” or “→” button to enter inside.

2. Select “HDD Performance check ” by pressing “↑” or “↓” then pressing

“Enter” or “→” button to enter inside.

General Setting

Back <<

Aging mode <[On/Off]>

HDD Performance Check

AAA

Update CI+ Credentials >>

Boot count reset >>

ECS Enable <[On/Off]>

3. A message "Please wait ..." is displayed during performance check processing.

4. Result OK or NG will be displayed after performance of HDD is checked.

HDD Performance Check

>>

>>

[</>] Set [Home]Exit

KD-55/65XD9305

17

HDD RE-REGISTRATION

>>

>>

>>

>>

>>

>>

>>

[</> ] Set [Home]Exit

General Setting

Tuner

Wifi / B T

Servic e Mode

Model Information

Self diagnosis History

Video / Audio

Panel / PQ

<[ NG ]>

Back <<

HDD Re-Register

Result

1) In “Service Mode”, select “General Setting” by pressing “↑” or “↓” then pressing “Enter” or “→” button to enter inside.

2) Select “AAA” by pressing “↑” or “↓” then pressing “Enter” or “→” button to enter inside.

Back <<

Aging mode <[On/Off]>

HDD Performance Check >>

AAA >>

Update CI+ Credentials >>

Boot count reset >>

ECS Enable <[On/Off]>

General Setting

ADJUSTMENT

3) Result OK or NG will be displayed after HDD re-registration is succeed/failed.

[</>] Set [Home]Exit

KD-55/65XD9305

18

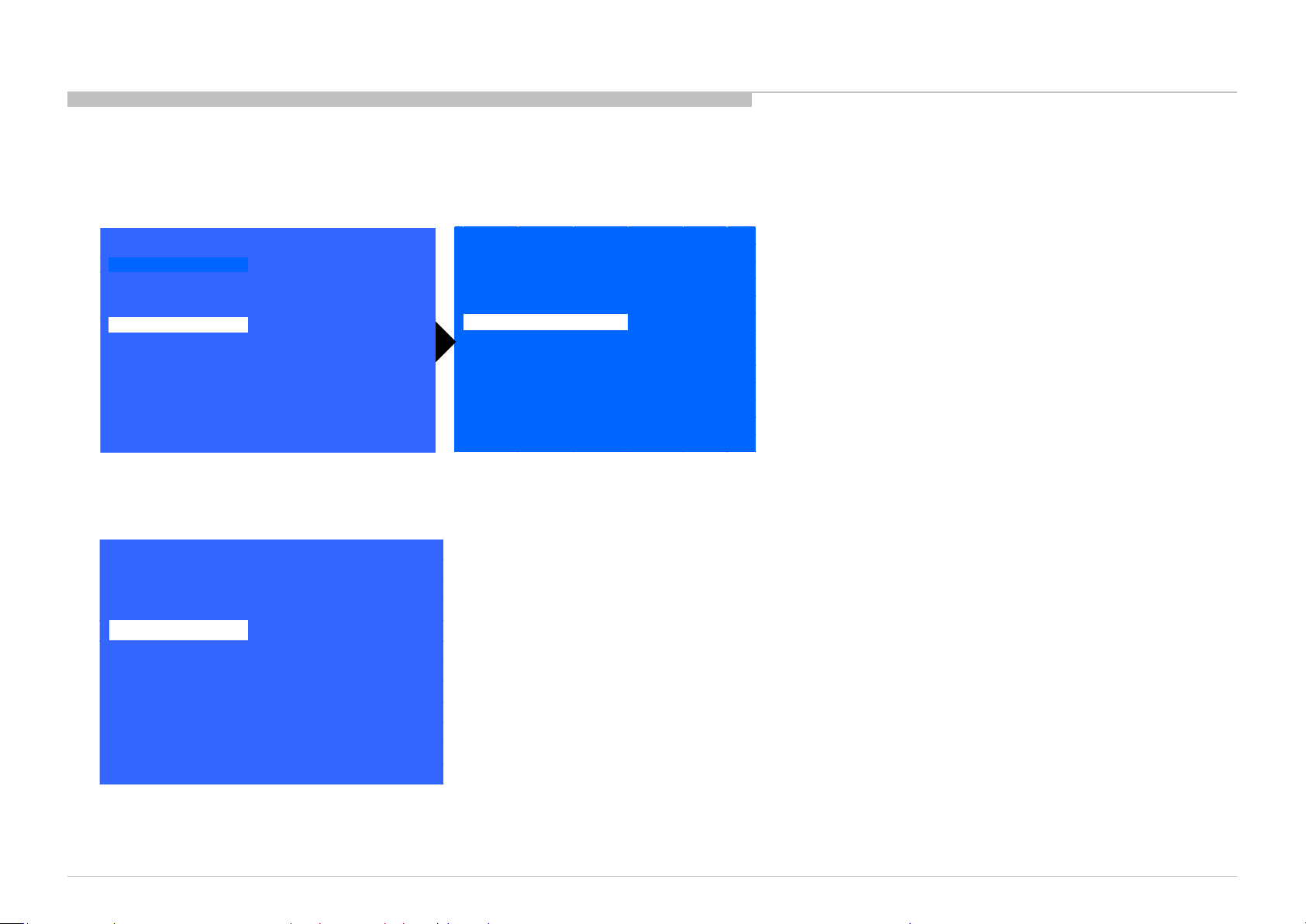

USB UPDATE

1:Download USB image and unzip file.

2: copy unzip file to USB memory root folder.

3: USB memory insert TV.

*Please refer to another manual “Service Procedure for Panel, Board

and Software Change / Upgrade(P/N:98881800x)” for details.

GN2SK chassis is the same as GN1T chassis basically.

4:USB image is newer soft version.

Automatically show message and start update.

Please follow directions.

System software update

Copying USB update file. Please wait…

Preparing for system software update. During the system software update, the TV will automatically restart.

Please do not remove the USB device until an update complete message is displayed . The update may take up to

30 minutes to complete.

System software update

The system software update is complete .

Some user settings may have changed during the update.

Please remove the USB device and select ”OK” to exit

5: finished

OK

46%

4:USB image is not newer soft version.

Automatically show message and start update.

Please follow directions.

System software update

Your software is up to date

Please remove the USB device and select [OK] to exit

5: finished

OK

KD-55/65XD9305

19

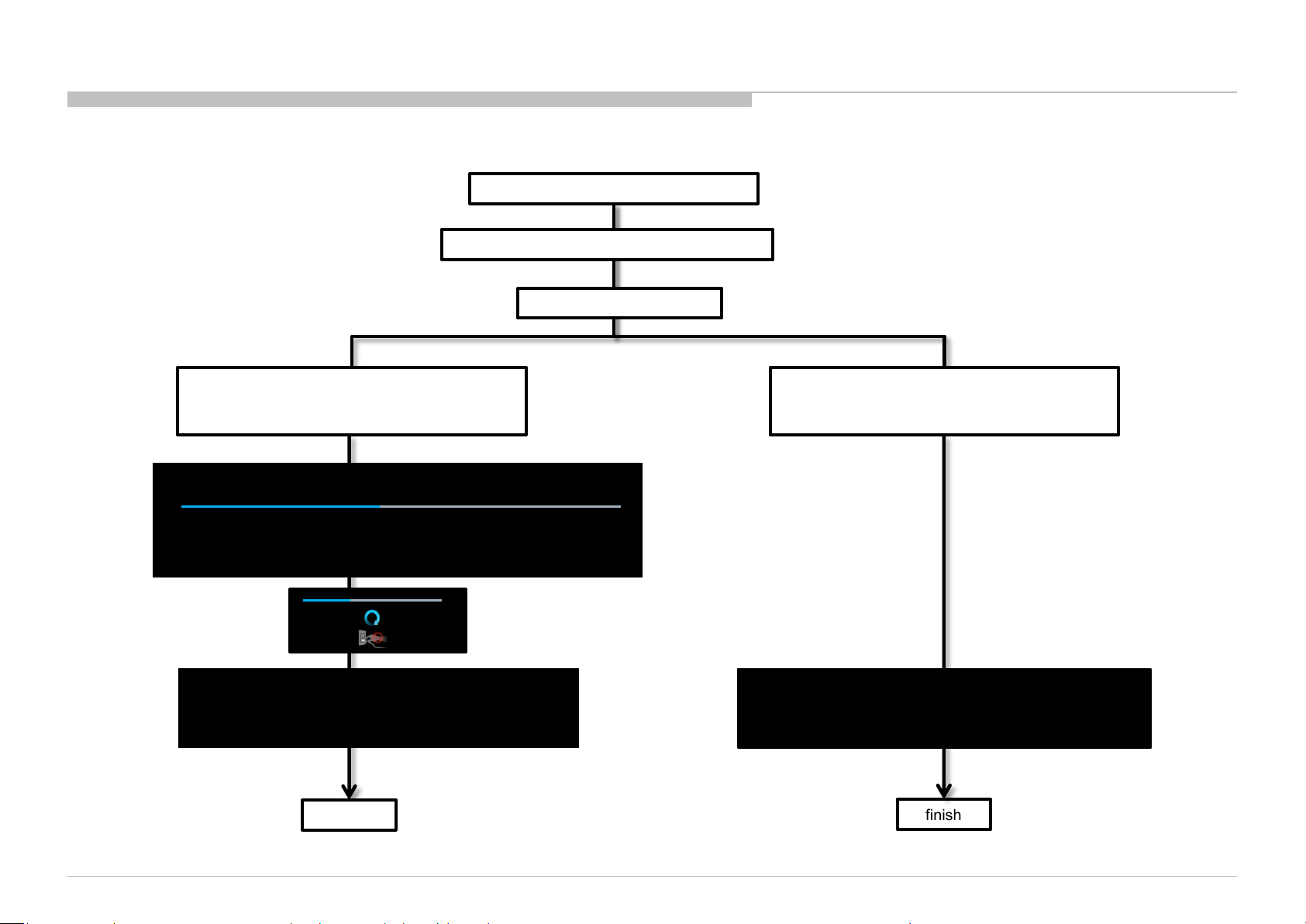

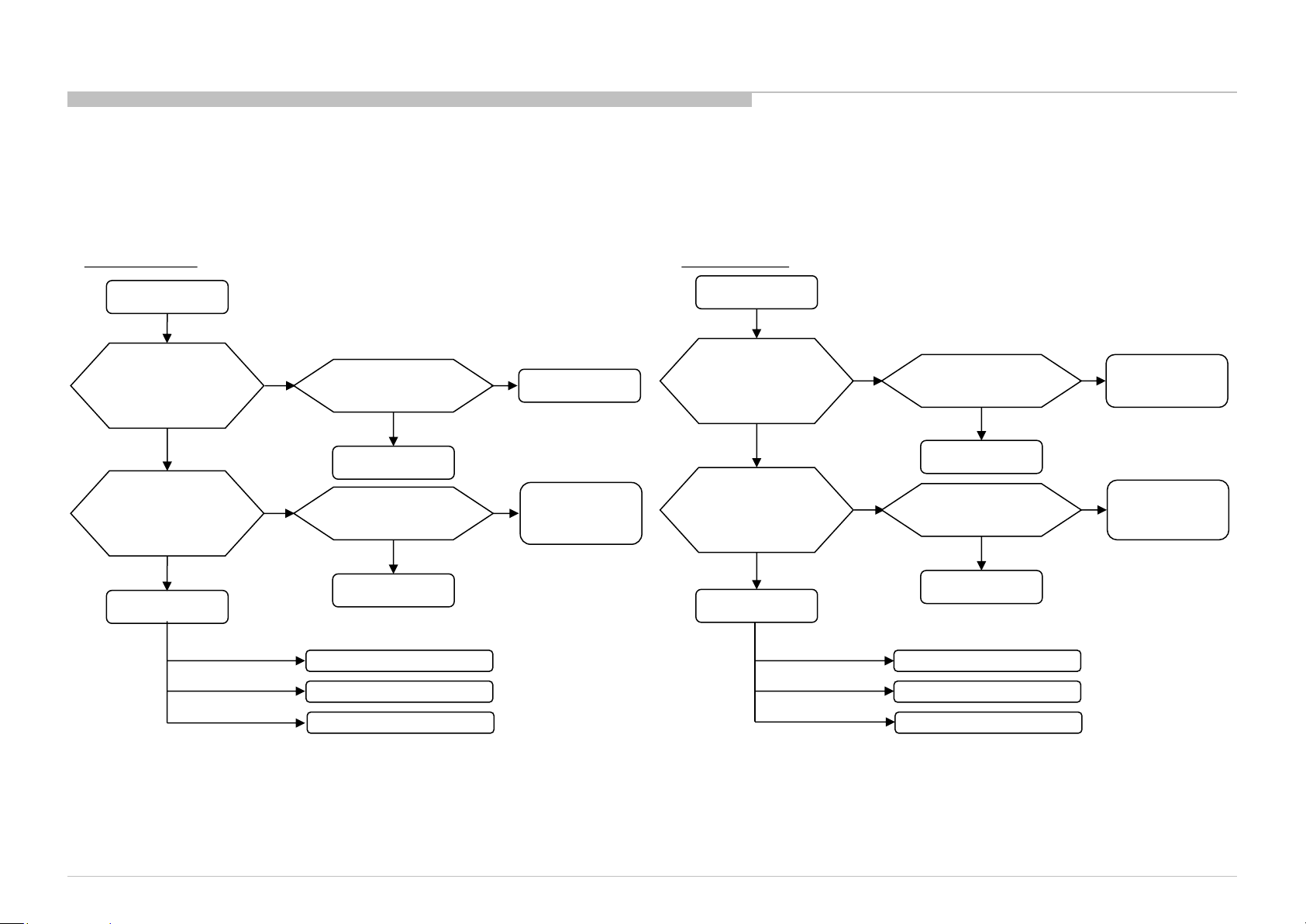

TROUBLE SHOOTING

Remote

Bluetooth

No White Power LED &

Stationary

dots

No video

No video

all Inputs

No Remote

Smart Core no LED

Bluetooth / One

Step Remote

Power

(Communication)

(Backlight)

TEMP

Software

4KBE

TRIAGE

1. Confirm the symptom from the customer.

2. Select that symptom from the chart.

3. Bring all the boards and cables listed for that symptom.

4. Follow the troubleshooting charts in the technical guides to isolate the board.

5. Chart Color Code.

RED DOT: Most likely defective part

BLUE TRIANGLE: Secondary possible defective part

BLACK TEXT: Board that may correct the symptom

KD-55/65XD9305

Reference

B* Board

G* Board/ADP

H* Board

Speaker

Wifi & BT

Module

LD* Board

V By One FFC

Tcon

LCD Panel

Temp Board

Problem

Symptoms - Shutdown. Power LED

blinking red diagnostics sequences

2 3 4 5 6 7 8 9 10

p l p

l p p

p

p p l l

p l

l p l p l

Power LD

Audio

p

p

l

l l

l

Panel

Panel

does not response to

remote (Dead Set)

No

Power

Video

- missing or distorted

colored

One of

lines or

Inputs

Network Audio Skype Smart Core

Wireless

can't connect

No Audio

Skype

Can't Work

(Set is still alive)

(OSR) can't

p p l l p p l p p p

l

p

l

p

p

l

p

p

p

p

l

l

p

l

p

p

l

(BT)

connect

l

20

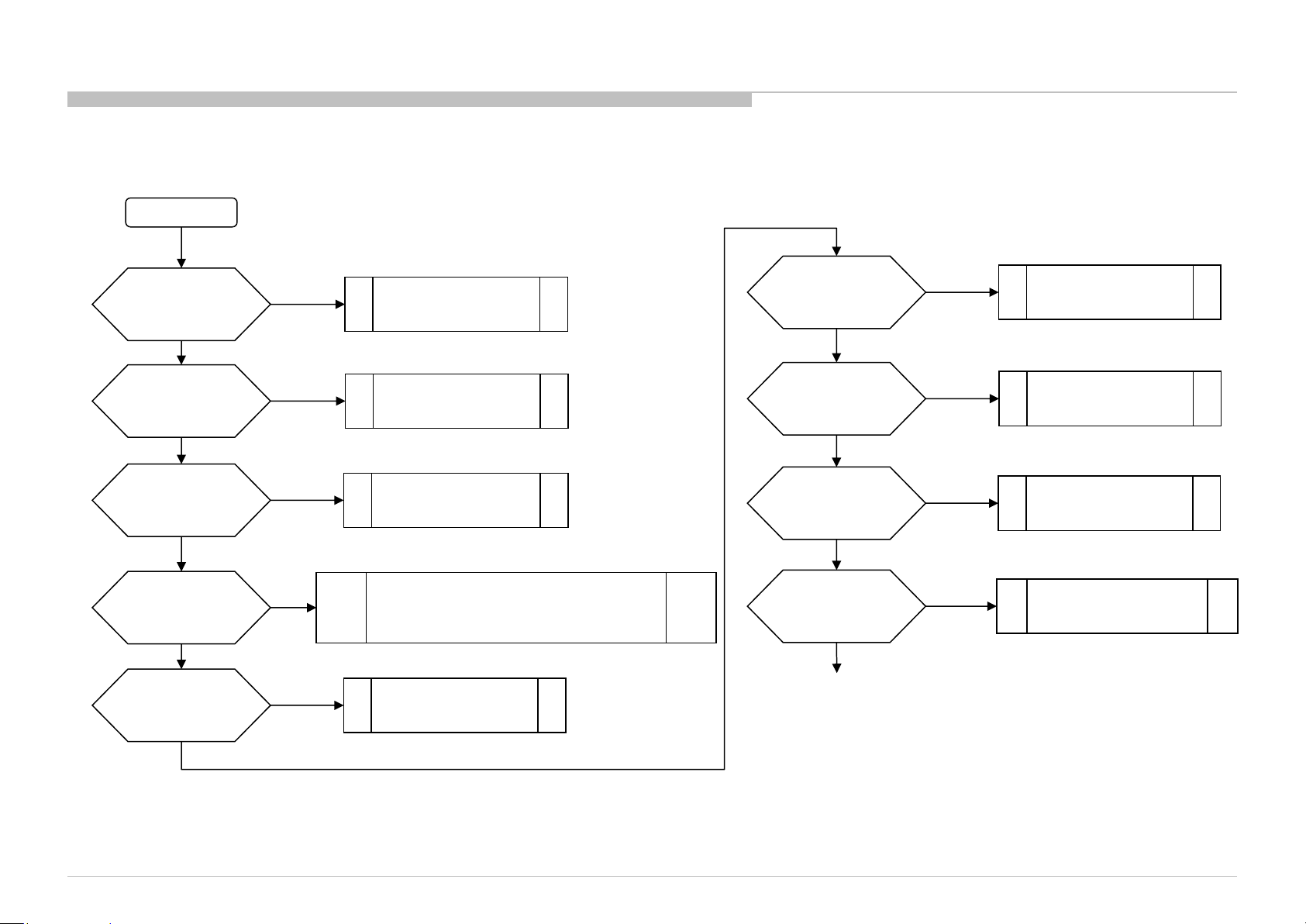

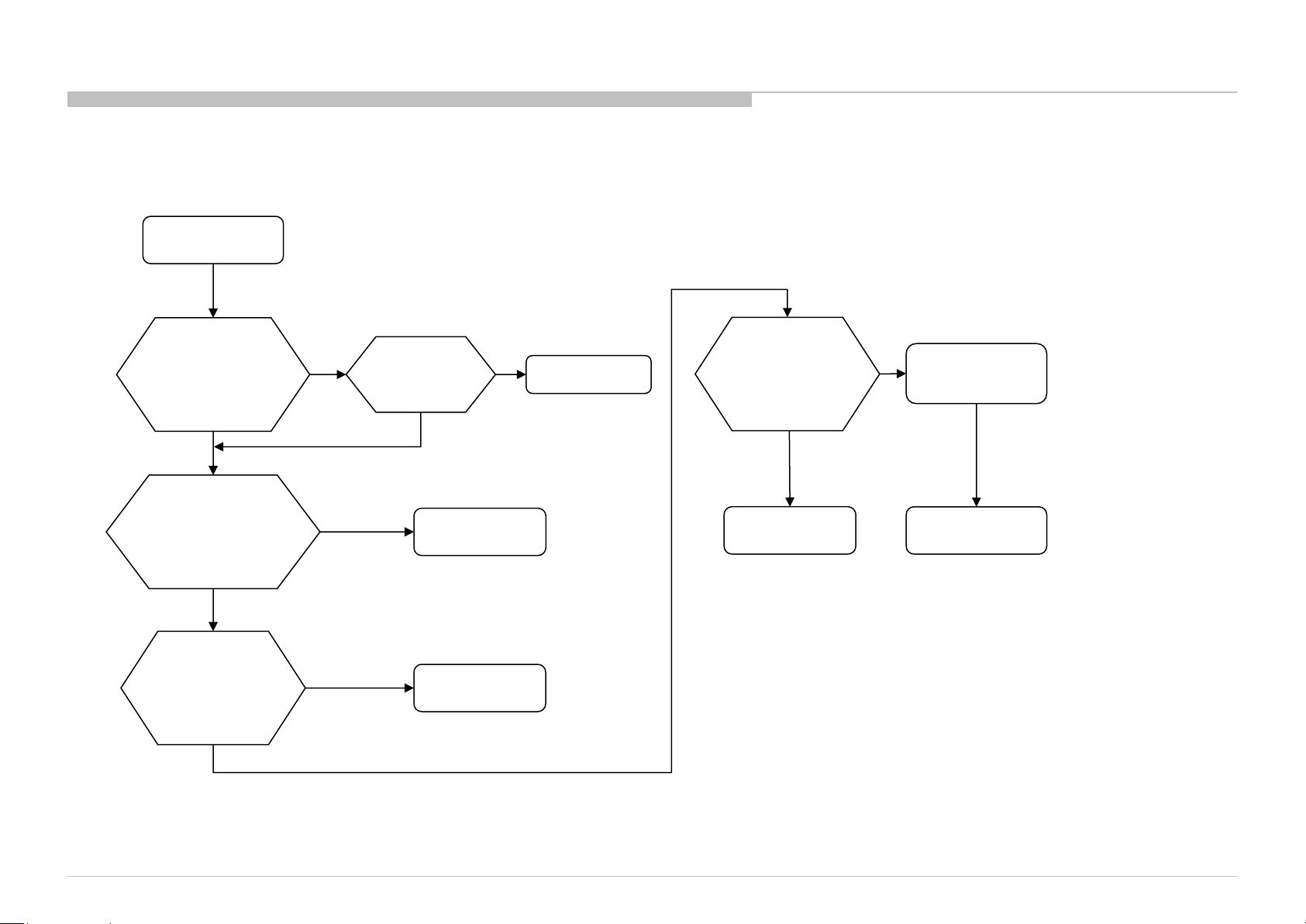

FLOW

1-1. NO POWER

TROUBLE SHOOTING

with G* board

No Power

Check STBY 3.3V

C484

near CN401

on DPS board

OK

Check STBY 3.3V

C9006

near CN9000

on BM1 board

OK

B* Board

NG

NG

Replace

Between G* Board to

DPS Board Harness

OK

Harness

Replace

Between DPS Board to

BM1 Board Harness

OK

Harness

u-Com Failure

DDCON/LDO

NG

NG

G* Board

DPS Board /

R407, R408

on DPS Board

with AC-ADP

No Power

Check 24V

C485

near CN401

on DPS board

OK

Check STBY 3.3V

C9006

near CN9000

on BM1 board

OK

B* Board

NG

NG

Replace

Between LD Board to

DPS Board Harness

OK

Harness

Replace

Between DPS Board to

BM1 Board Harness

OK

Harness

u-Com Failure

DDCON/LDO

NG

NG

LD Board

or

AC Adaptor

DPS Board /

IC408

on DPS Board

KD-55/65XD9305

Main Device Failure

Main Device Failure

21

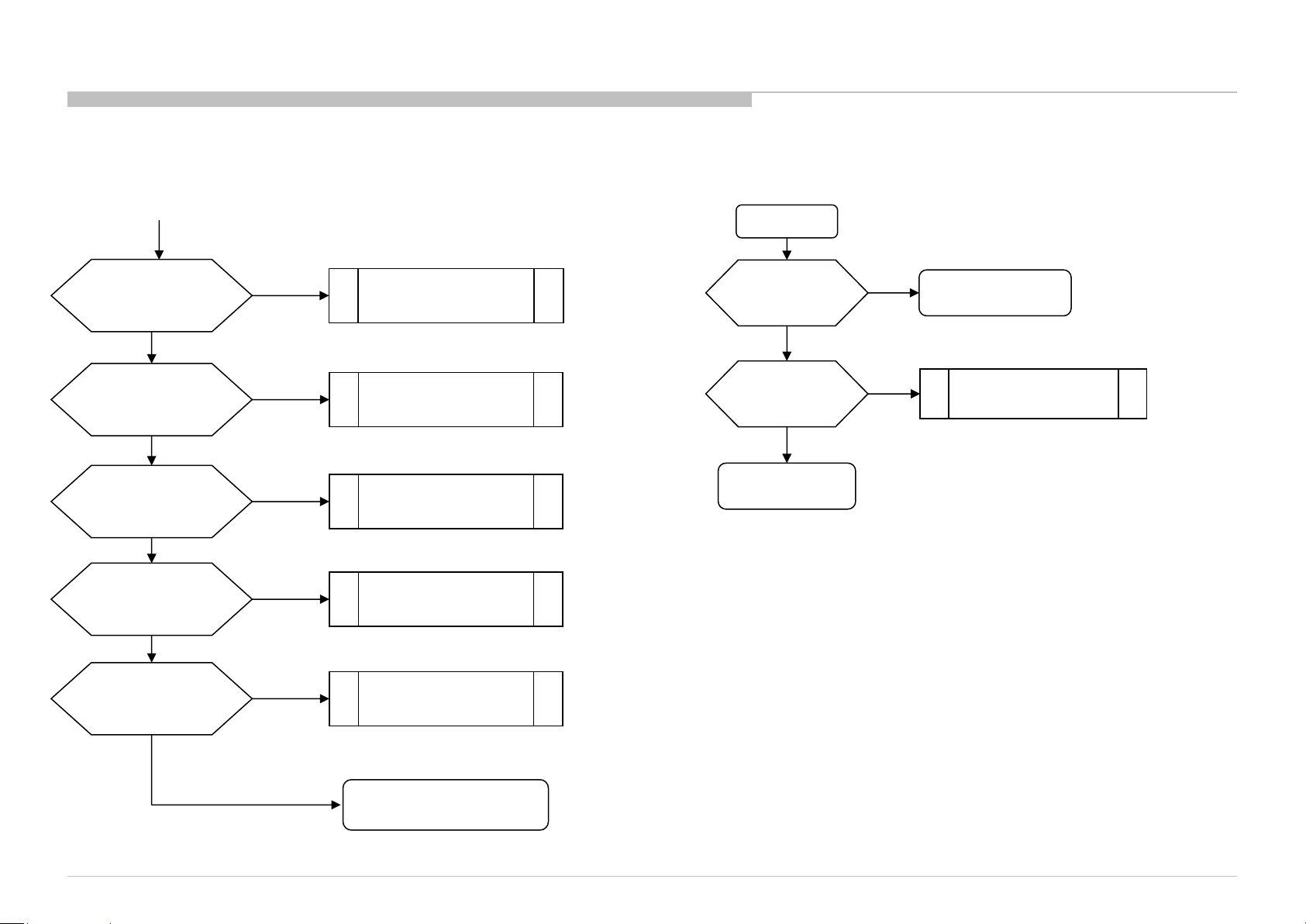

FLOW

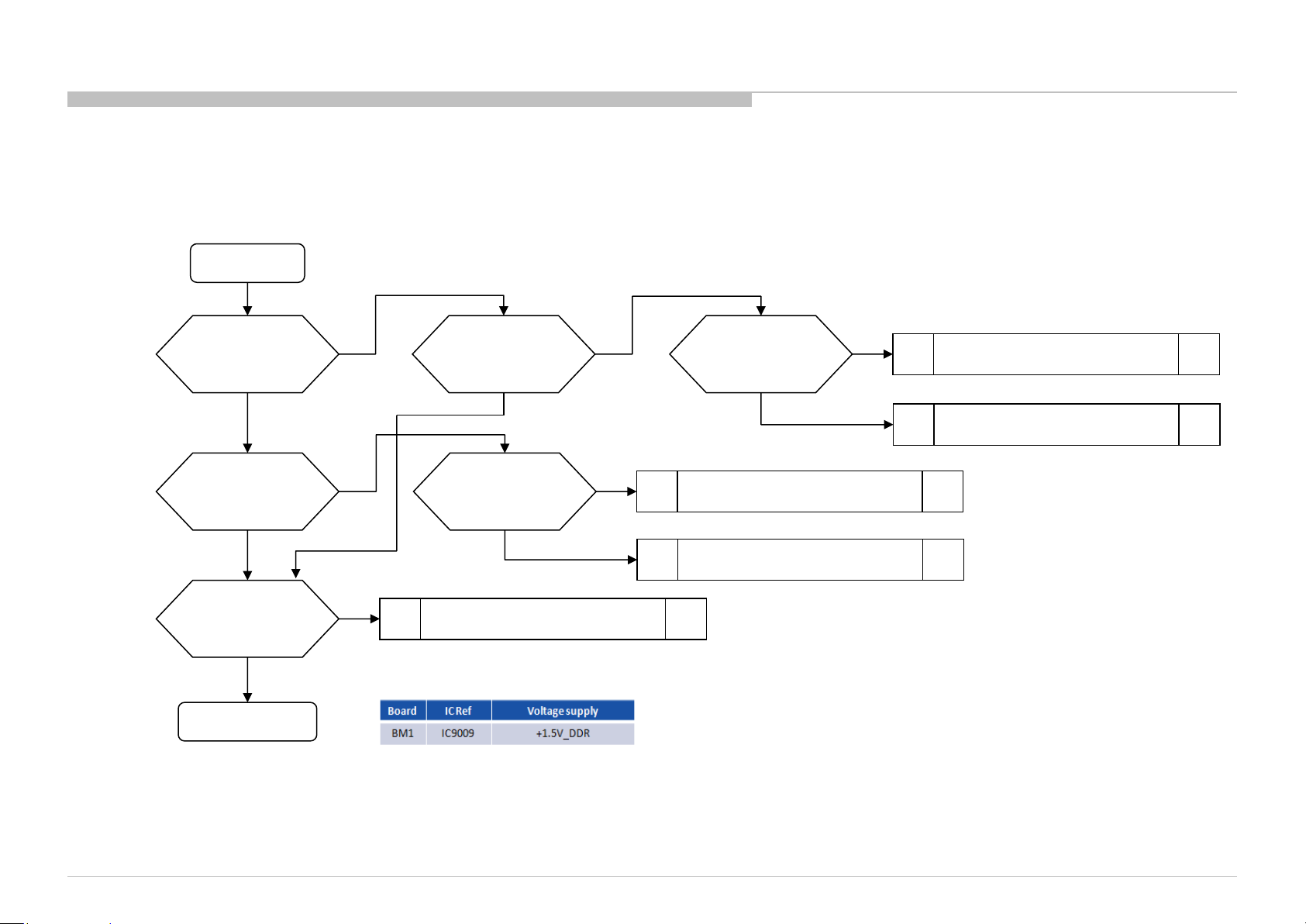

1-2-1. NO POWER U-COM FAILURE

START

TROUBLE SHOOTING

Check C9117 Voltage.

Is the voltage >3.0V?

yes

Check C9129 Voltage.

Is the voltage >3.0V?

yes

Check OPWRSB

R9179 Voltage.

Is the voltage 0V?

yes

Check POWER_ON

IC9017 #pin19

Is the voltage >3.0V?

yes

Check P_ON_LNB

IC9017 #pin15

Is the voltage >3.0V?

no

no

no

no

no

Check +3.3V_STBY

C9006, CN9000 #24pin

Check DC_OFF_DET

IC9000

SOC

Muffin

problem

Try AC Off and On after few minutes.

If #pin19 keep Low, change IC9017.

If #pin19 goes High few seconds and downs to Low,

Check 12.5V Line (G board or IC403 on DPS).

Change IC9017

Check MAIN_VCC

R9175 Voltage.

Is the voltage >1.6V?

yes

Check P_ON_VBUS

IC9017 #pin11

is >3.0V?

yes

Check P_ON_#1

IC9017 #pin13

is >3.0V?

yes

Check PGOOD_1

R9173 Voltage.

Is the voltage >3.0V?

yes

Continue next page…

no

no

no

no

Check 12.5V Line

(G board or IC403 on DPS).

Change IC9017

Change IC9017

1-3 No POWER - DDCON/LDO

Check 1.0V DDCON (IC9008)

KD-55/65XD9305

yes

22

FLOW

1-2-1. NO POWER U-COM FAILURE

from the previous page

TROUBLE SHOOTING

1-2-2. NO POWER DC_OFF_DET CHECK

START

Check P_ON_#2

IC9017 #pin14

Is the voltage >3.0V?

yes

Check ORESETB

IC9017 #pin12

Is the voltage >3.0V?

yes

Check X_SYSTEM_RST

IC9017 #pin16

Is the voltage >3.0V?

yes

If PANEL_PWER_ON

(R9172) is 0V

Check XRST

IC9017 #pin17

Is the voltage >3.0V?

yes

If BL_MUTE

(R9090) is 0V

Check BL_ON

IC9017 #pin18

Is the voltage >3.0V?

yes

no

no

no

no

no

Change IC9017

Change IC9017

Change IC9017

Change IC9017

Change IC9017

Check DC_OFF_DET

R9035

Is voltage < 3V?

yes

Check Vdd

C9024

Is voltage < 5V?

yes

END

( IC9000 is working OK )

no

( IC9000 is working OK )

no

END

Change IC9000

KD-55/65XD9305

( IC9017 is working OK )

END

23

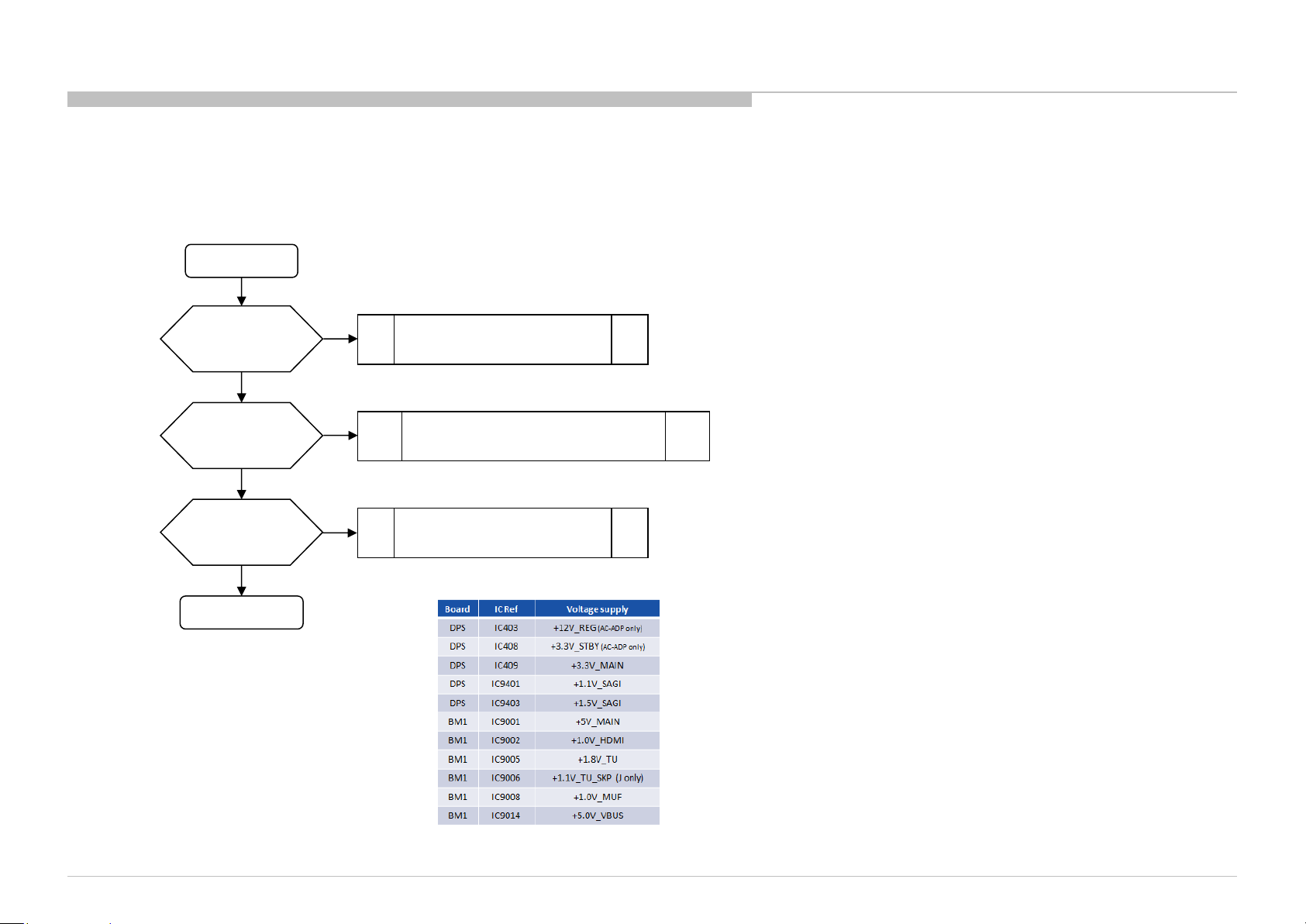

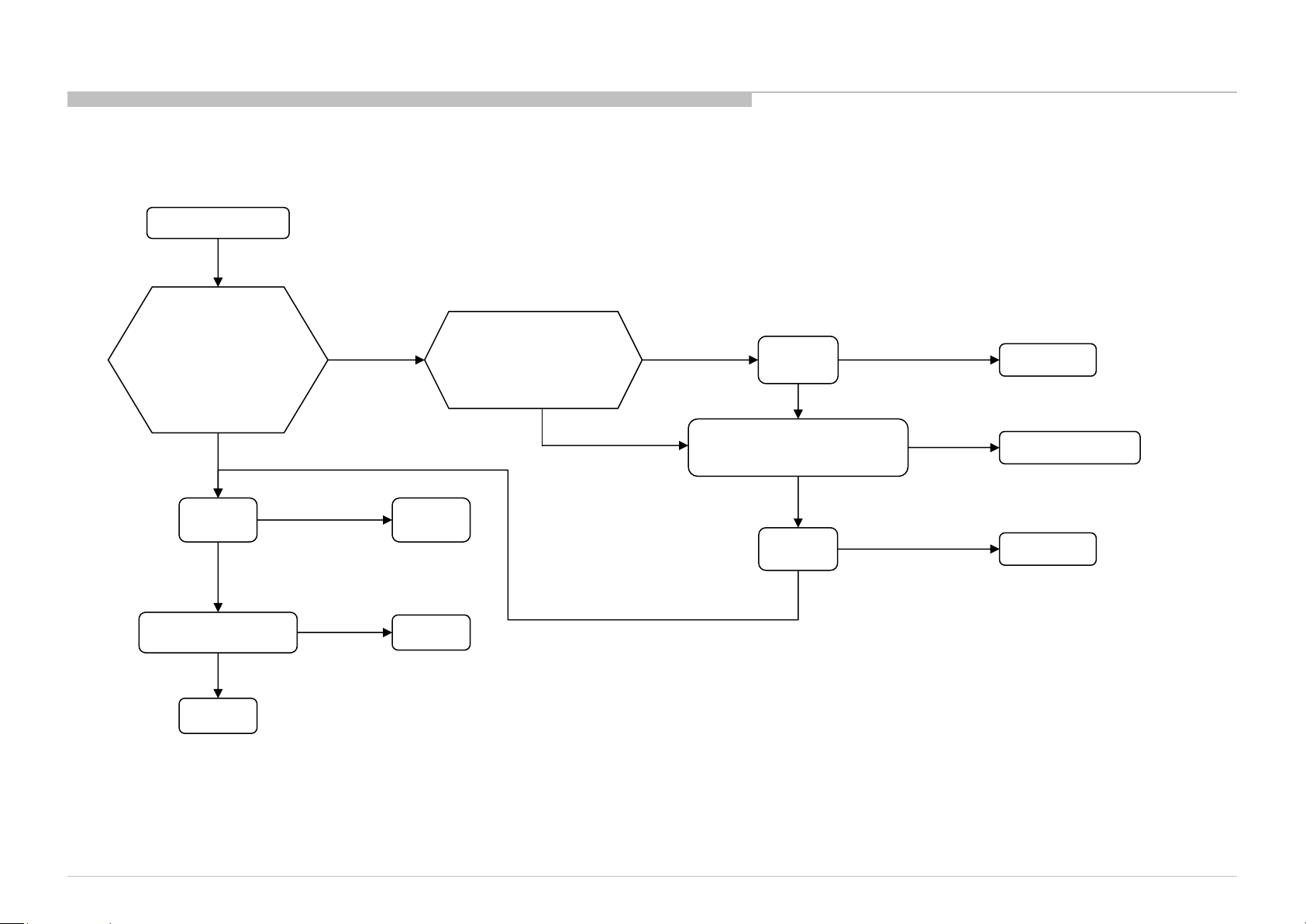

FLOW

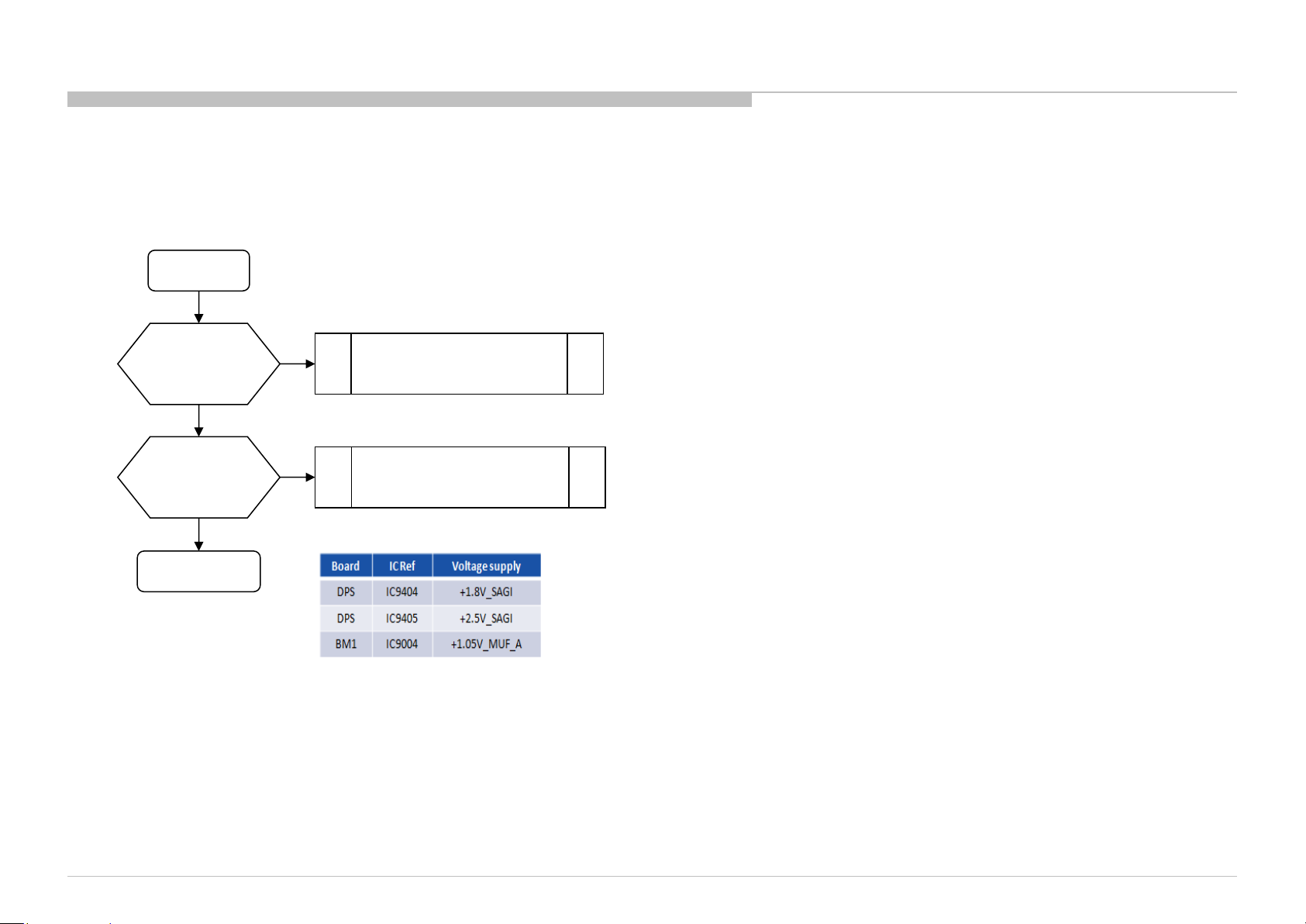

1-3. NO POWER DDCON/LDO

DDCONs check

START

TROUBLE SHOOTING

Check fuse

F9xxx / F4xx

Is fuse OK?

yes

Check Vcc voltage

C9xxx / C4xx

Is voltage >12.0V?

yes

Check Enable pin

voltage

Is voltage >2.5V?

yes

Change DDCON IC

no

no

no

Change Fuse

Check POWER_ON IC9017 #pin19

(Refer 1-2 No Power U-Com Failure)

1-2 No Power U-Com Failure

or

Enable source

KD-55/65XD9305

24

FLOW

1-3. NO POWER DDCON/LDO

DDCON check

START

TROUBLE SHOOTING

Check IC9001 Vcc voltage

C9033

Is voltage >12V?

yes

Check Vcc voltage

C9061

Is voltage >4V?

yes

Check Enable

IC9010 #pin1

Is voltage >2.5V?

yes

Change DDCON

IC9009

no

no

no

Check Vcc voltage

C9061

Is voltage >3V?

yes

Check

D9001

Is diode ?

yes

Change IC9010

no

no

Check

D9000

Is diode ?

no

yes

Change D9001

Check +5V_MAIN DDCON (IC9001)

Change D9000

Check +3.3V_STBY.

G board or IC408 on DPS

KD-55/65XD9305

25

FLOW

1-3. NO POWER DDCON/LDO

LDOs check

START

yes

TROUBLE SHOOTING

Check Vcc voltage

C9xxx

Is voltage >3V?

yes

Check Enable pin

voltage

Is voltage >3V?

yes

Change LDO IC

no

Check +3.3V_DDC_OUT

DDCON (IC409)

no

1-2 No Power U-Com Failure

KD-55/65XD9305

26

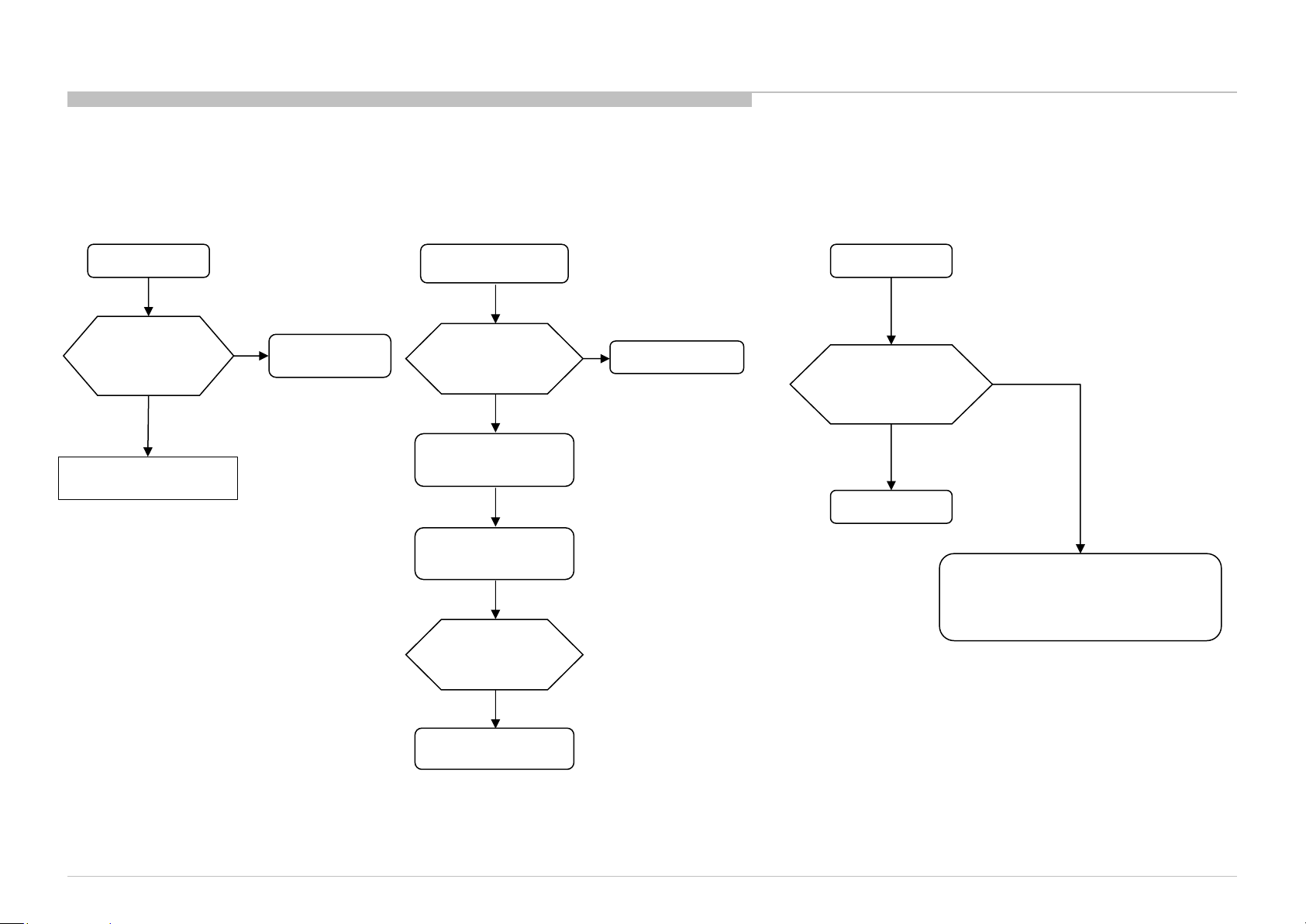

FLOW

2-1. LED BLINKING 2X (MAIN POWER ERROR)

TROUBLE SHOOTING

with G* board

2-time blinking

Check +12V_REG

at pin 11/13 of on B Board

(CN9000 BM1),

Voltage > 13.2V ?

No

BM1 Board

Yes

G* Board

with AC-ADP

2-time blinking

Check +12V_REG

at pin 11/13 of on B Board

(CN9000 BM1),

Voltage > 13.2V ?

No

BM1 Board

Yes

DPS Board /

IC403 on DPS

KD-55/65XD9305

27

FLOW

2-2. LED BLINKING 3X

TROUBLE SHOOTING

2-3. LED BLINKING 4X (LED VOLTAGE ERROR)

AUDIO ERROR DC_ALERT

LED 3x blinking

Check +5.0V_VBUS

at pin1 in IC8001, 4.959V

<Voltage<5.285V?

OK

Audio check point

Go to Audio Error

NG

IC9014,etc

(B* Board)

LED 3x blinking

Audio Error ?

Yes

Go to

3-3 Power Off Checking

Go to

3-4 Power On Checking

Replace B Board

No

See other flow

4-time blinking

Check

BMFW2: CN9000 21Pin

BM1: CN7704 29Pin

on the B* Board

Under0.897V or less

B* Board

Change LD board or G* board/Adapter.

Between 0.898V to 2.997V

LED driver or G* board/Adapter

KD-55/65XD9305

Finish

28

FLOW

2-4. LED BLINKING 5X (PANEL COMMUNICATION ERROR)

5-times blinking

TROUBLE SHOOTING

Check

“+12.5V_TCON” at

CN401 #4 (or C493)

on the DPS-Board

OK

Replace the Harness

Between G-Board

and DPS

NG

Replace

the V-By-One FFC

NG

NG

Replace G-Board

Symptom

improve

Symptom

improve

OK

NG

Harness is

suspicious

V-By-One FFC

is suspicious

G-Board is

suspicious

Change

DPS

Symptom

improvement

DPS is

suspicious

NG

Change

Panel (or T-con)

Symptom

improvement

Panel (or T-Con) is

suspicious

KD-55/65XD9305

29

FLOW

2-5. LED BLINKING 6X (BACKLIGHT ERROR)

6-times blinking

Check Voltage of

BL_ERR_DET

on 21pin of CN401

on DPS

Voltage < 1.85 V

Voltage ≥ 1.85 V

Check

harness/connection

G/LD* board to DPS Board

Harness /

Connection OK

Harness /

Connection

broken

Change

harness

No

improvement

LED driver or G board

Change LD board or G board.

TROUBLE SHOOTING

Symptom

Improvement

Harness

Symptom

Improvement

LD board / G board

No

Improvement

between DPS and BM1

No

Improvement

KD-55/65XD9305

Change

DPS

Change 30P FFC

BM1 Board

Symptom

Improvement

Symptom

Improvement

DPS Board

30P FFC

No

improvement

Change

No

Improvement

Panel

Symptom

Improvement

Panel

30

Loading...

Loading...