Page 1

HISTORY INFORMA TION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

ORIGINAL MANUAL ISSUE DATE: 4/2013

Version Date Subject

1.0 4/2013 Original manual issue.

RB1FS CHASSIS

Segment: FS-L/FS-M

LCD TV

9-888-529-01

Page 2

SERVICE MANUAL

Segment: FS-L/FS-M

RB1FS CHASSIS

LCD TV

9-888-529-01

Page 3

MODEL LIST

MODEL COLOR COMMANDER DEST.

KD-55X9000A Black RM-SD017 CHINA

RMF-SD004

KD-65X9000A Black RM-SD017 CHINA

RMF-SD004

MODEL COLOR COMMANDER DEST.

KD-55/65X9000A(CH)

3

Page 4

WARNINGS AND CAUTION S - ENGLISH

CAUTION

These servicing instructions are for use by qualified service personnel only.

To reduce the ri sk o f ele ct ri c sho c k, d o not perfo r m a ny se rvi ci ng other than tha t c ont ai ned in t he o p er at ing ins tr ucti o ns unless you are qualified to do so.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis.

The chassis of this receiver is directly connected to the ac power line.

CARRYING THE TV

Be sure to follow these guidelines to protect your pro perty and avoid causing serious injury.

• Carry the TV with an adequate number of people; larger size TVs require two or more people.

• Correct hand placement while carrying the TV is very important for safety and to avoid damages.

SAFETY-RELATED COMPONENT WARNING!!

Components identified by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe operation. Replace these components with Sony

parts whose part numbers appear as shown in this manual or in supplements published by Sony. Circuit adjustments that are critical for safe opera tion are identified in this manual.

Follow these procedures whenever critical components are replaced or improper operation is suspected.

KD-55/65X9000A(CH)

4

Page 5

USE CAUTION WHEN HANDLING T HE LCD PANEL

When repa ir ing the LCD p a nel, b e sure you ar e gro und ed b y using a wrist b and .

When repa ir ing the LCD p a nel o n the wall, the LCD panel must b e sec ure d using the 4 mounting ho le s o n the re ar c ove r .

1) Do not press on the panel or frame edge to avoid the risk of electric shock.

2) Do not scratch or press on the panel with any sharp objects.

3) Do not leave the module in high temper atures or in areas of high humidity for an extended p eriod of time.

4) Do not expose the LCD panel to direct sunlight.

5) Avoid contact with water. It may cause a short circuit within the module.

6) Disconnect the AC power when replacing the backlight (CCFL) or inverter circuit. (High voltage occurs at the inverter circuit at 650Vrms.)

7) Always clean the LCD panel with a soft cloth material.

8) Use care when handling the wires or connectors of the inverter circuit. Damaging the wires may cause a short.

9) Protect the panel from ESD to avoid damaging the electronic circuit (C-MOS).

10) It is recommended not to exceed 1 hour of Power-On nor Burn-in period with LCD panel face do wn condition, in repair activity.

WARNINGS AND C AUT IO NS

KD-55/65X9000A(CH)

5

Page 6

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered connections. Check the entire board surface for solder splashes and bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and mounting hardware have been replaced. Be absolutely certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them out to the customer and recommend their replacement.

5. Look for par ts which, though functio ning, show ob vio us signs of d e ter io r at io n. P oi nt them out to the custo mer and recommend their replacement.

6. Check the line cords for cracks and abrasion. Recommend the replacement of any such line cord to the customer.

7. Check the antenna terminals, metal trim, “metallized” knobs, screws, and all other exposed metal parts for AC leakage. Check leakage as described below.

8. For safety reasons, repairing the Power board and/or Inv ert er board is prohibited.

KD-55/65X9000A(CH)

6

Page 7

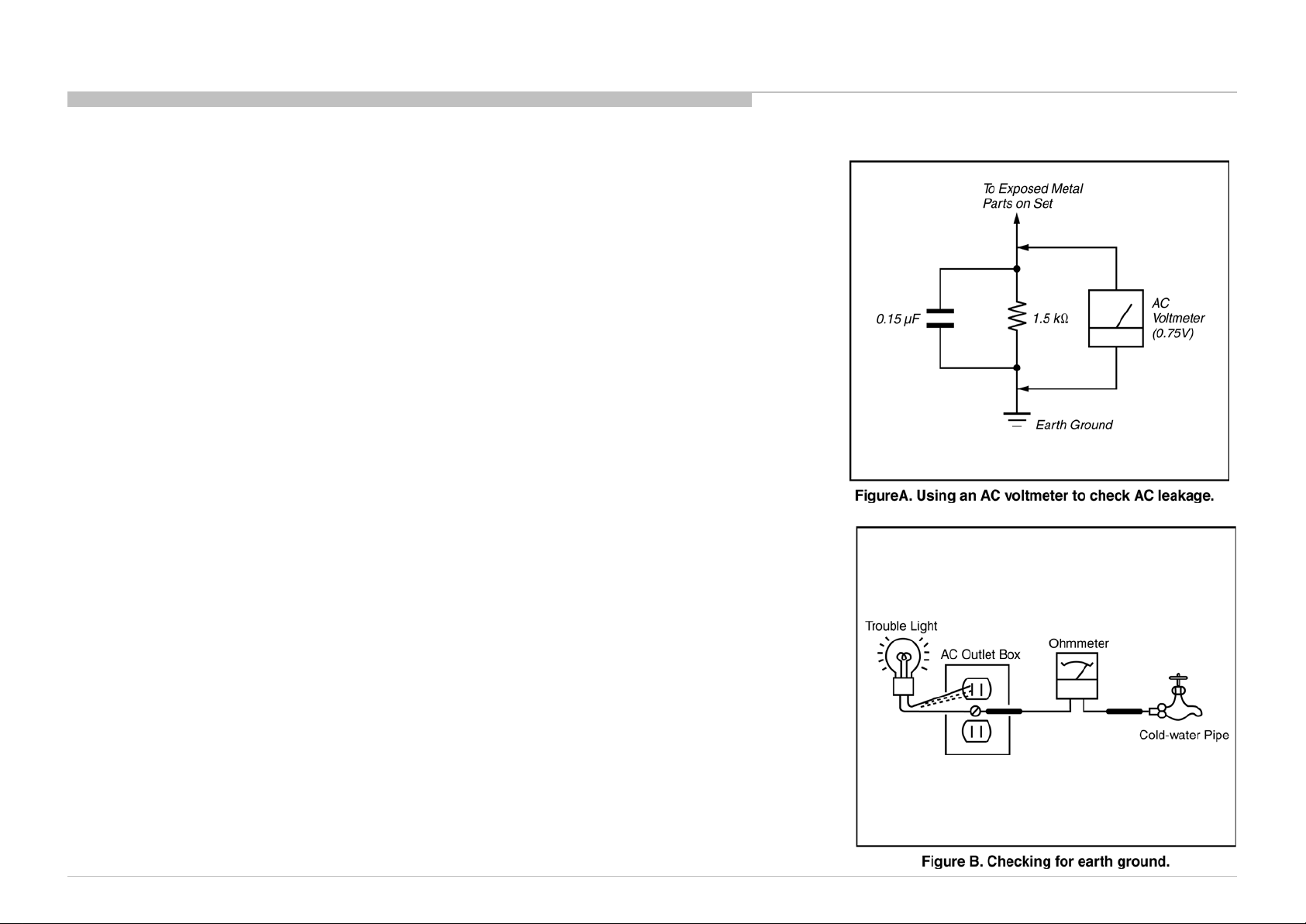

Leakage Test

The AC leakage from any exposed metal part to earth ground and from all exposed m etal parts to any exposed

metal part having a return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be m easured by any one of three m ethod s.

1. A commercial leakag e tester, such as the Simpson 229 o r RC A WT-540A. Follow the manufacturers’

instructions to use these instructions.

2. A battery-operated AC milliampm ete r. The Data Precision 245 digital m ultim eter is suitable fo r this job.

3. Measuring the voltage d rop across a resistor by means of a VOM or battery -operated AC voltmeter. The

“limit” indication is 0.75 V, so analog meters must have an accurate low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of passive VO Ms that are suita bl e. Nearly all

battery-operated dig ital multim eters that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate retaining screw on most AC outlet boxes is also

at earth ground.

If the retaining screw is to be used as your earth ground, verify that it is at ground by measuring the resistance

between it and a cold-water pipe with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt trouble- light (not a neon lamp) between the hot

side of the receptacle and the retaining screw. Try both slots, if necessary, to locate the hot side on the line; the

lamp should light at normal brilliance if the screw is at ground potential (see Figure B).

SAFETY CHECK-OUT

KD-55/65X9000A(CH)

7

Page 8

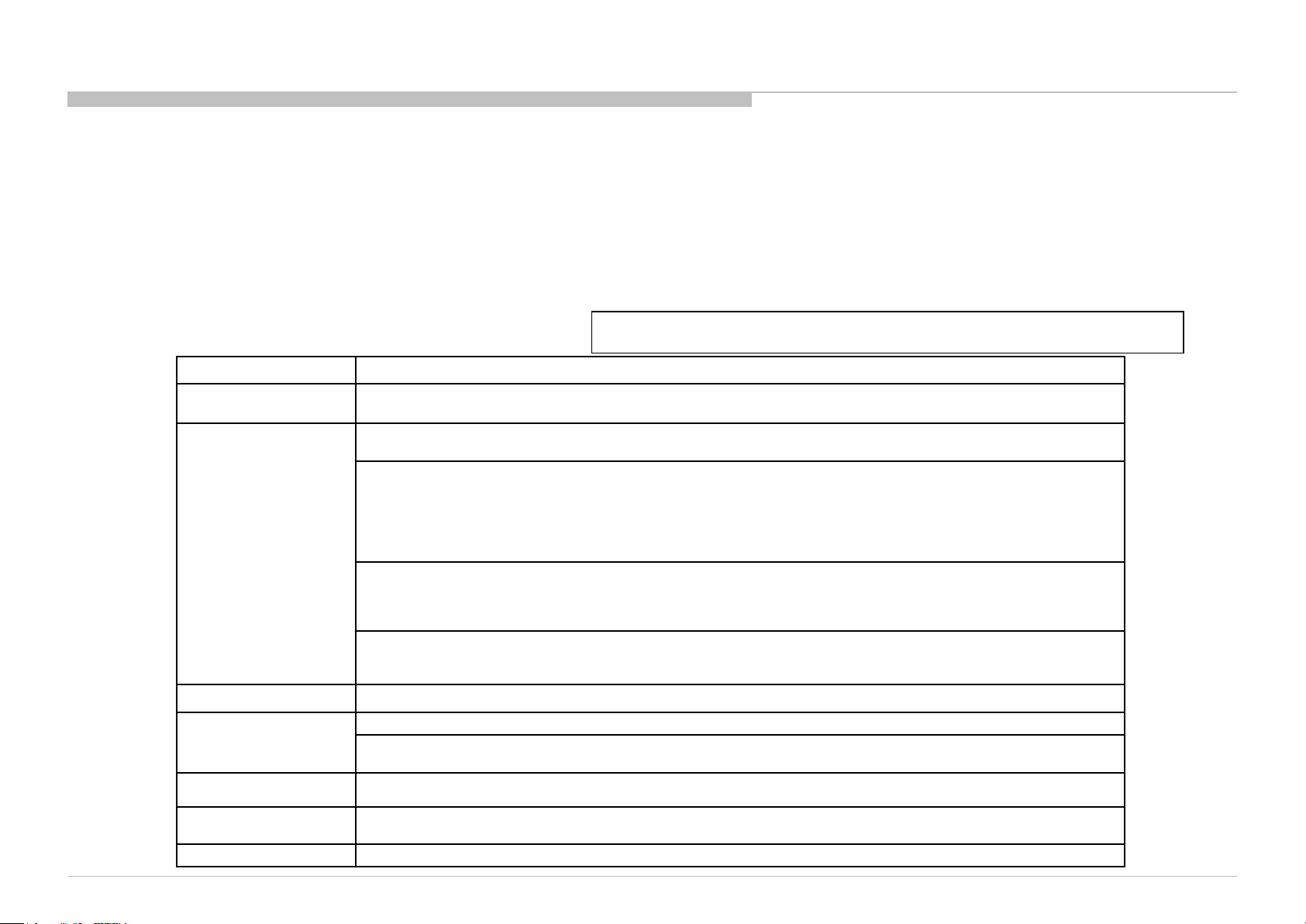

SELF DIAGNOSIS FUNCTION

The units in this manual c ontain a self-diagnostic function. If an error occ urs, the Smart Core Red LED will automatically b egin to flash.

The number of times the LED flashes translates to a probable source of the problem.

A definition of the Smart Core Red LED flash indicators is listed in the instruction manual for the user’s knowledge and reference.

If an error symptom cannot be reproduced, the remote commander can be used to review the failure occurrence data stored in memory to reveal past problems and how often these

problems occur.

DIAGNOSTIC TEST INDICATORS

When an error occurs, the Smart Core Red LED will flash a set number of times to indicate the possible cause of the problem.

If there is more than one error, the LED will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen.

If the screen displays a “0”, no error has occurred .

RED LED blinking count Detection Items

2x

3x

4x <L/P> LED driver failure/LED voltage protection [LD_ERR]

5x

<G/B> Main 12V failure [MAIN_POWE]

* This failure is not saved.

<B> Main 5.0/3.3/1.8/1.0/ 1.1V failure [DC_ALERT]

* 5.0/1.0V failures are not saved.

<B/S> Audio amp. protection [AUD_PROT]

<B> HDMI equalizer/switch I2C NACK [HDMI_EQ] * There is Temp. sensor on the same I2C bus

<C> HDMI switch/equalizer I2C communication monitoring. [HDMI_EQCX]

<B> Tuner or demodulator I2C NACK [TU_DEMOD]

<B> AFE device I2C NACK [AFE_I2C]

<B> AFE device SPI NACK [AFE_SPI] * only for AEP,CH

<B> Scorpio VBO Tx Lock monitoring. [SC_OUT_ERR]

<B> VBO Lock monitoring between Ayu2 and Scorpio. [SC_ERR]

<B> Scorpio SPI Flash read error detection. [SC_ERR]

<B> Scorpio device I2C communication error detection. [SC_ERR]

<B> DDR-PHY DLL ready error detection for FRC. [FRCD_I2C]

<B> DRAM initial sequence done error detection for FRC. [FRCD_I2C]

<B> FRC device I2C communication error detection. [FRCD_I2C]

<P/T/G/B> Panel ID EEPROM I2C NACK (Also panel power failure is a suspect) [P_ID_ERR]

<T> TCON device I2C NACK [TCON_ERR]

<T> TCON device Initialization failure [TCON_ERR]

<G>: Power supply board, <B>: Main board, <T>: Tcon board, <L>: LED driver (LD) board

<P>: Panel module , <S>: Speaker, <A>: Power Adapter, <C>: CX board

KD-55/65X9000A(CH)

6x <G/T/P/B> Backlight converter OVP[BACKLITE]

7x

8x Software Error (Also the main board’s memory or CAM module is a suspect)

Over temperature protection [TEMP_ERR]

<B> Temp. sensor I2C NACK [TEMP_ERR] * There is HDMI Eq on the same I2C bus.

8

Page 9

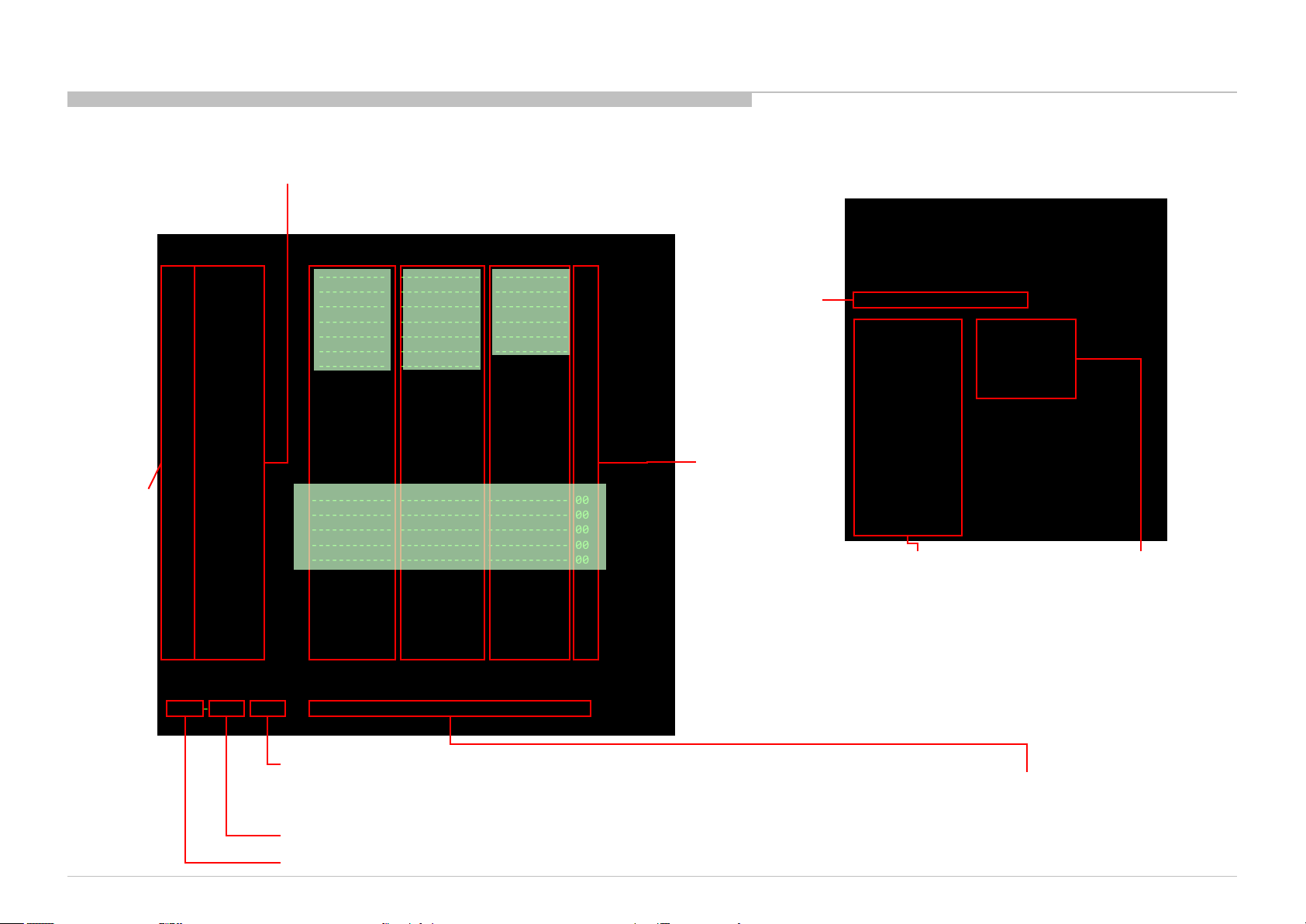

[SELF DIAGNOSTIC SCREEN DISPL AY]

SELF DIAGNOSIS FUNCTION

Smart Core

Red LED

blinking count

Error item name

SELF CHECK

002 MAIN_POWE ------------ ------------ ------------ 00

003 AFE_I2C ------------ ------------ ------------ 00

003 DC_ALERT ------------ ------------ ------------ 00

003 AUD_PROT ------------ ------------ ------------ 00

003 HDMI_EQ ------------ ------------ ------------ 00

003 TU_DEMOD ------------ ------------ ------------ 00

003 AFE_SPI ------------ ------------ ------------ 00

003 SC_OUTERR ------------ ------------ ------------ 00

003 SC_ERR ------------ ------------ ------------ 00

003 FRCD_I2C ------------ ------------ ------------ 00

003 HDMI_EQCX ------------ ------------ ------------ 00

004 VLED ------------ ------------ ------------ 00

004 LD_ERR ------------ ------------ ------------ 00

005 TCON_ERR 120823132523 ------------ ------------ 01

005 P_ID_ERR ------------ ------------ ------------ 00

005 PCON_ERR ------------ ------------ ------------ 00

005 TG_ERR ------------ ------------ ------------ 00

006 BACKLITE ------------ ------------ ------------ 00

007 TEMP_ERR ------------ ------------ ------------ 00

007 FAN_ERR ------------ ------------ ------------ 00

008 VPC_WDT ------------ ------------ ------------ 00

008 MEPS_WDT ------------ ------------ ------------ 00

008 HOST_WDT ------------ ------------ ------------ 00

008 STBY_WDT ------------ ------------ ------------ 00

008 AFE_WDT ------------ ------------ ------------ 00

010 EMIT_ERR ------------ ------------ ------------ 00

00081-00671-00088 00000000000000000570-00000000000000000132

Format of error timestamps

YYMMDDhhmmss (in UTC)

Example:

120823132523 -> Aug 23 2012 13:25:23 UTC

* Only when time is set, an error timestamp is saved.

*Following error is invalid in FSML.

FAN_ERR

EMIT_ERR

PCON_ERR

Error

timestamp

for last

recorded

error

Error

timestamp

for second

last

recorded

error

Error

timestamp

for 3rd last

recorded

error

Error count

MAC address

of Wi-Fi USB

dongle*1.

*1

1. When no Wi-Fi USB dongle is connected, NA is displayed.

2. If you insert/disconnect Wi-Fi USB Dongle during Self Diagnosis

- Alternatively, you can re-display Self D iagnosis D isplay t o update the

Model Name :

Serial Number :

Package Number : PKG0.651JPA

Device ID : B0:00:01:67:BB:33

Wired Mac : 3C:07:71:46:86:6D

Wireless Mac : N/A

USB dongle : N/A

<MAIN> <EXT>

DM0.651JPA WF:3.0.0.1023

WF0.430W00AA WF:--------

DF3.011W00AA FD:-.--YM1.010W00AA BT:1.2.14.940

M5.001C

(DM0.651JPA) <FS>

DD2.050W00AA EFR:03.00.00.14

PK2.050W00AA DNC:----------AM0.650JP DNI:---------- DNF:----MID:072DB8A1

PID:0F060040 SCF:20.01

PNL:T550QVD02.0 SYE:

Main CPU

information

External module

information

Display, press <1> -> <4> on remote commander to refresh Mac

address displayed on “USB dongle”.

information.

KD-55/65X9000A(CH)

Panel operation time by hour

Panel Operation Time is recorded every 30 min, but T otal Oper ation Time is recorded every 1 hr.

Therefore, the panel op. time might become lar ger t han the total op. time.

Boot count

Total operation time by hour

Count of writing to NAND device:

As vfat partition– As ext4 partition

9

Page 10

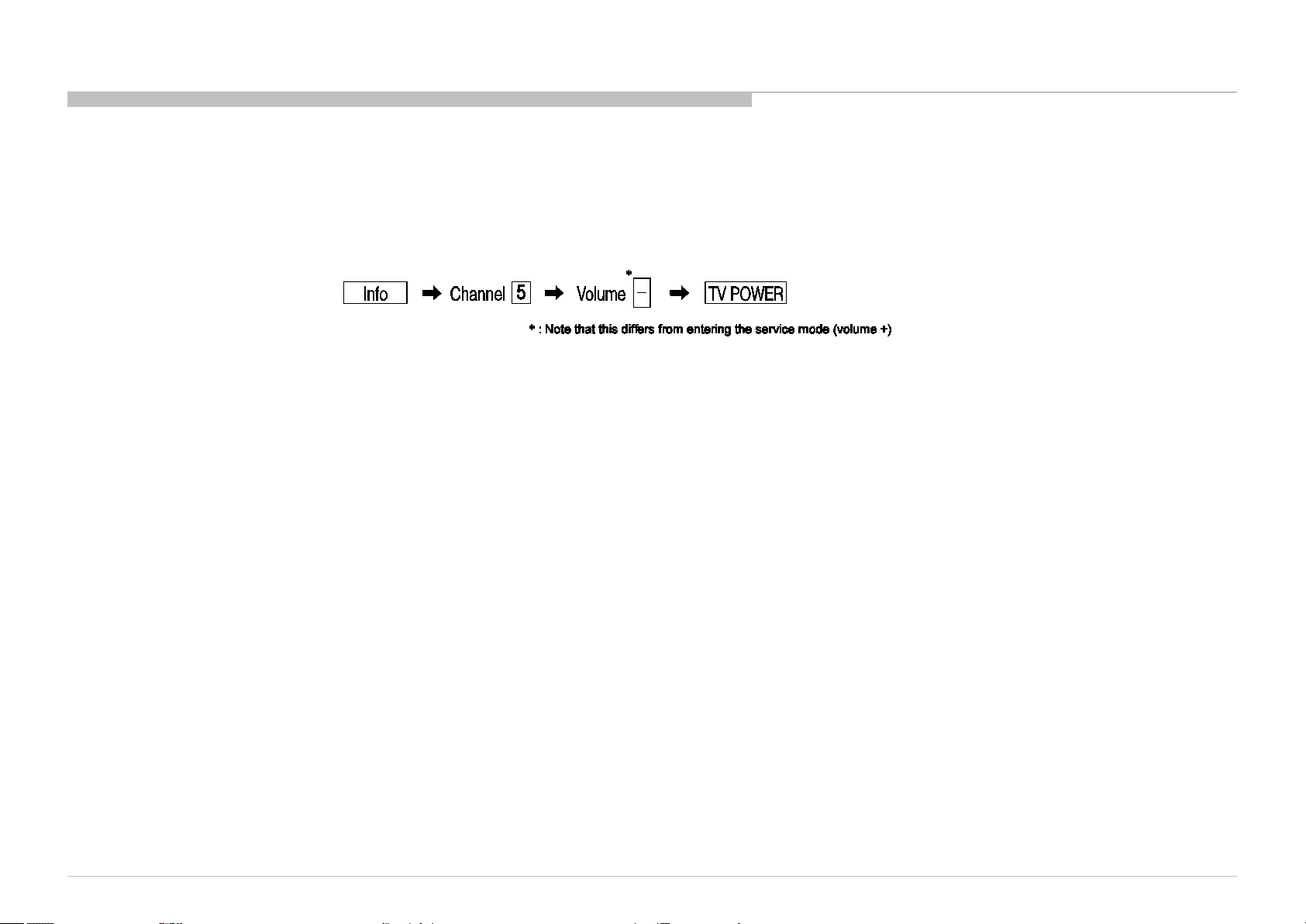

SELF DIAGNOSIS FUNCTION

SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it is possible to bring up past occurrences of failure for

confirmation on the screen:

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen.

After you have completed the repairs, clear the result display to “0”.

Clearing the Self Check Diagnostic List

1. Error history and Error count : Press the Channel 8 => Channel 0 .

2. Panel operation time : Press the Channel 7 => Channel 0 .

Exiting the Self-diagnostic screen

To exit the Self Diagnostic screen, turn off the power to the TV by pressing the POWER button on the remote or the POWER button on the TV.

KD-55/65X9000A(CH)

10

Page 11

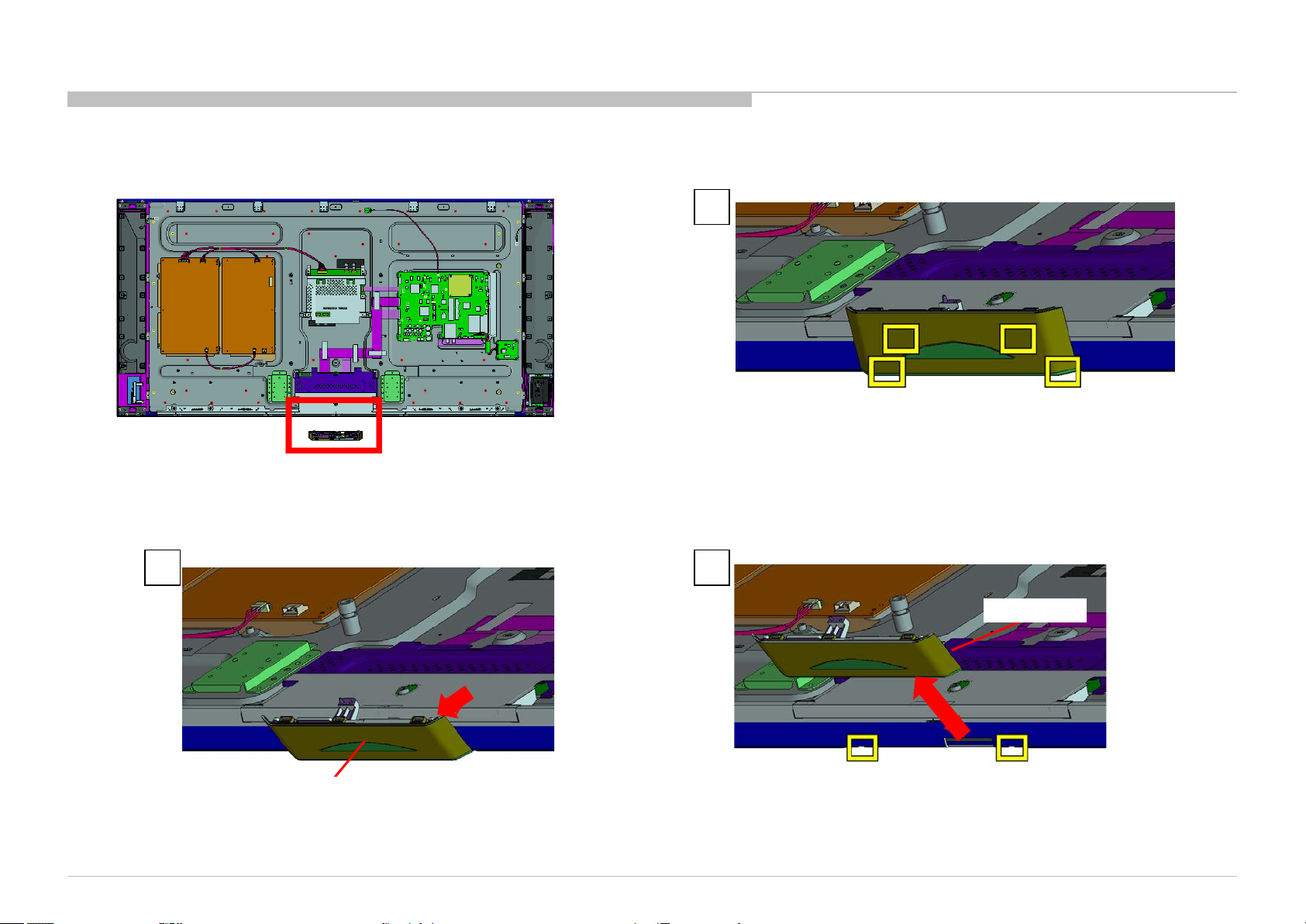

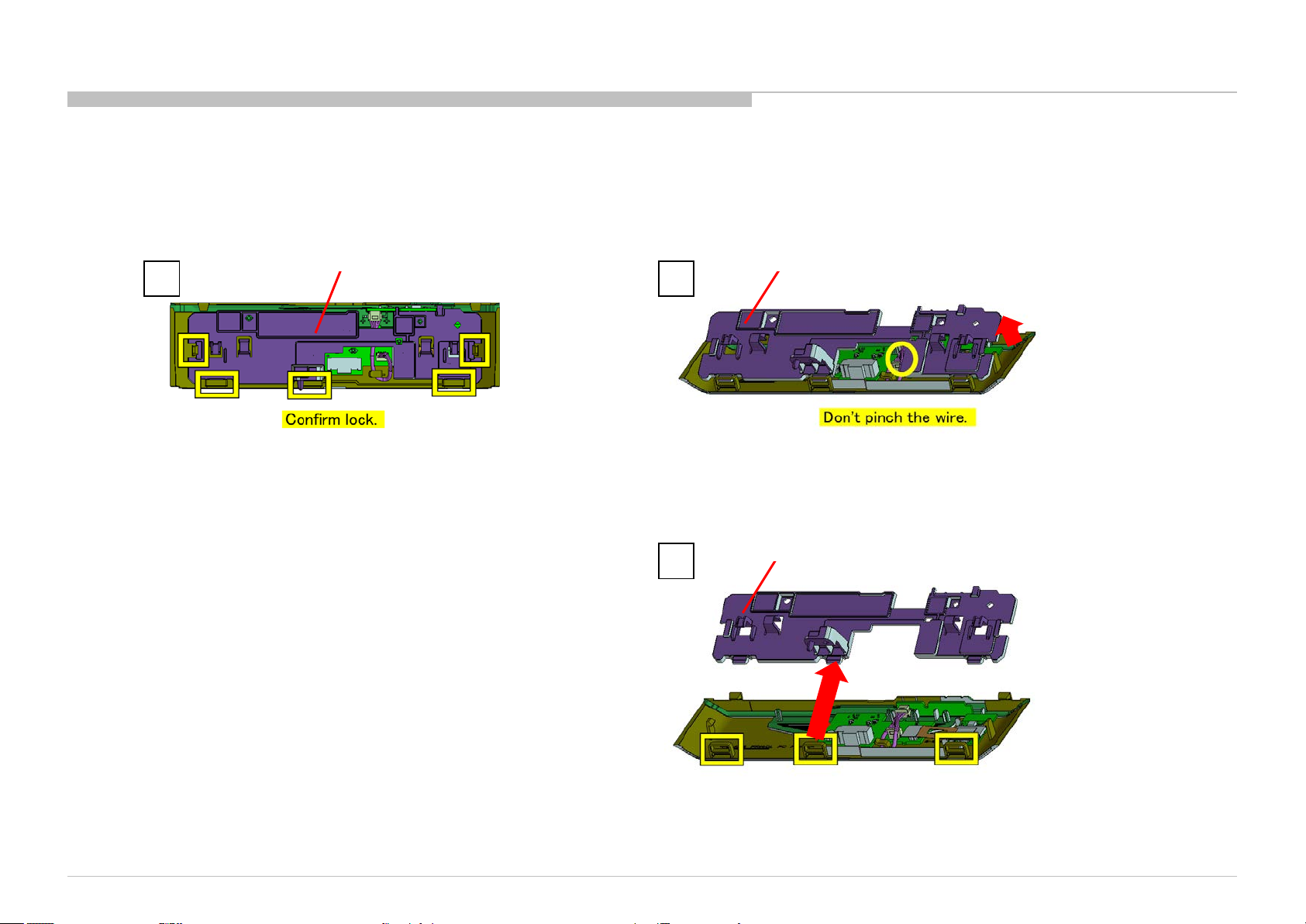

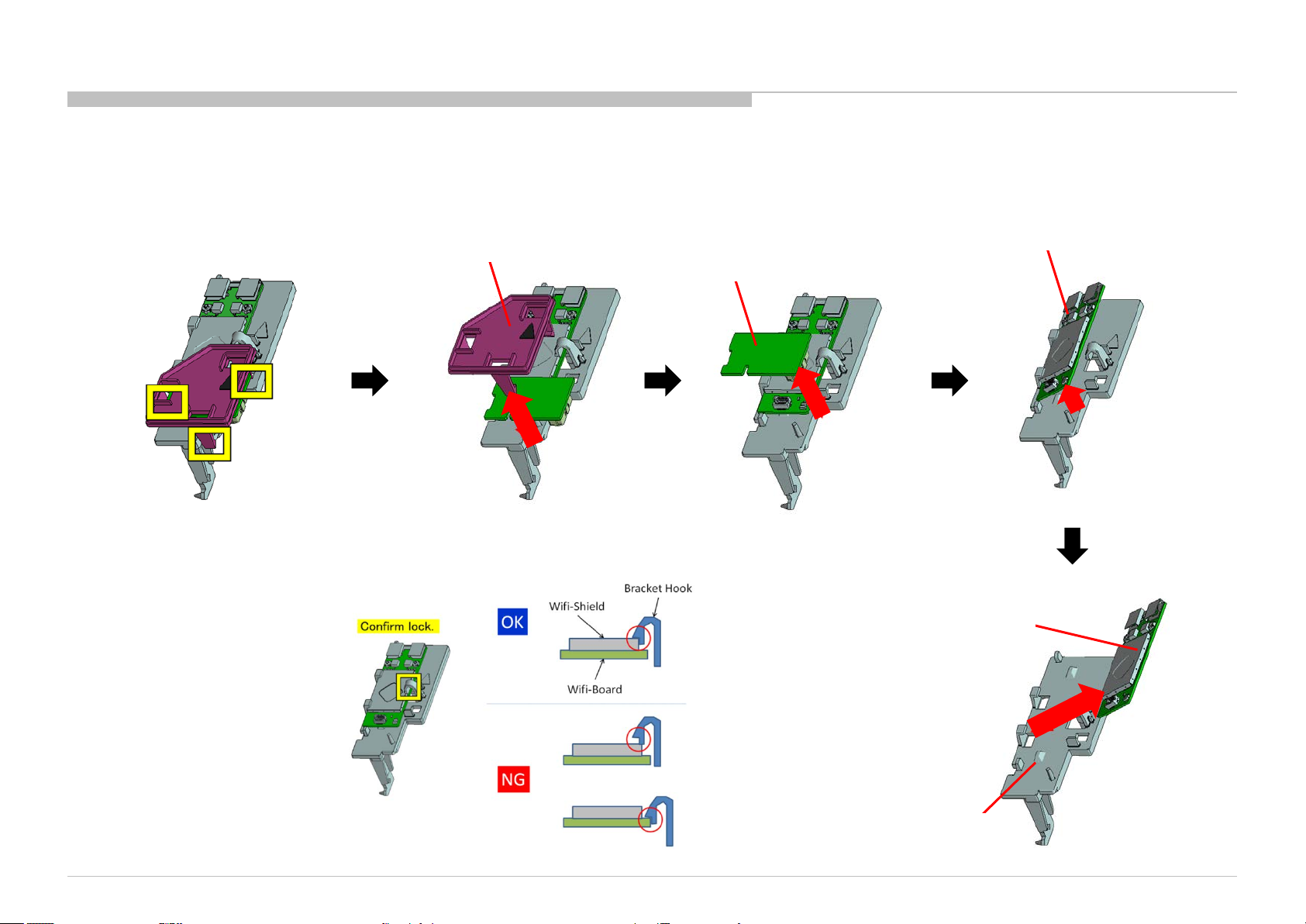

SEC 1. DISASSEMBLY

• There are clutch in the yellow frame[ ]. Therefore please be careful in the case of the disassembly or assembly of parts.

KD-55/65X9000A(CH)

11

Page 12

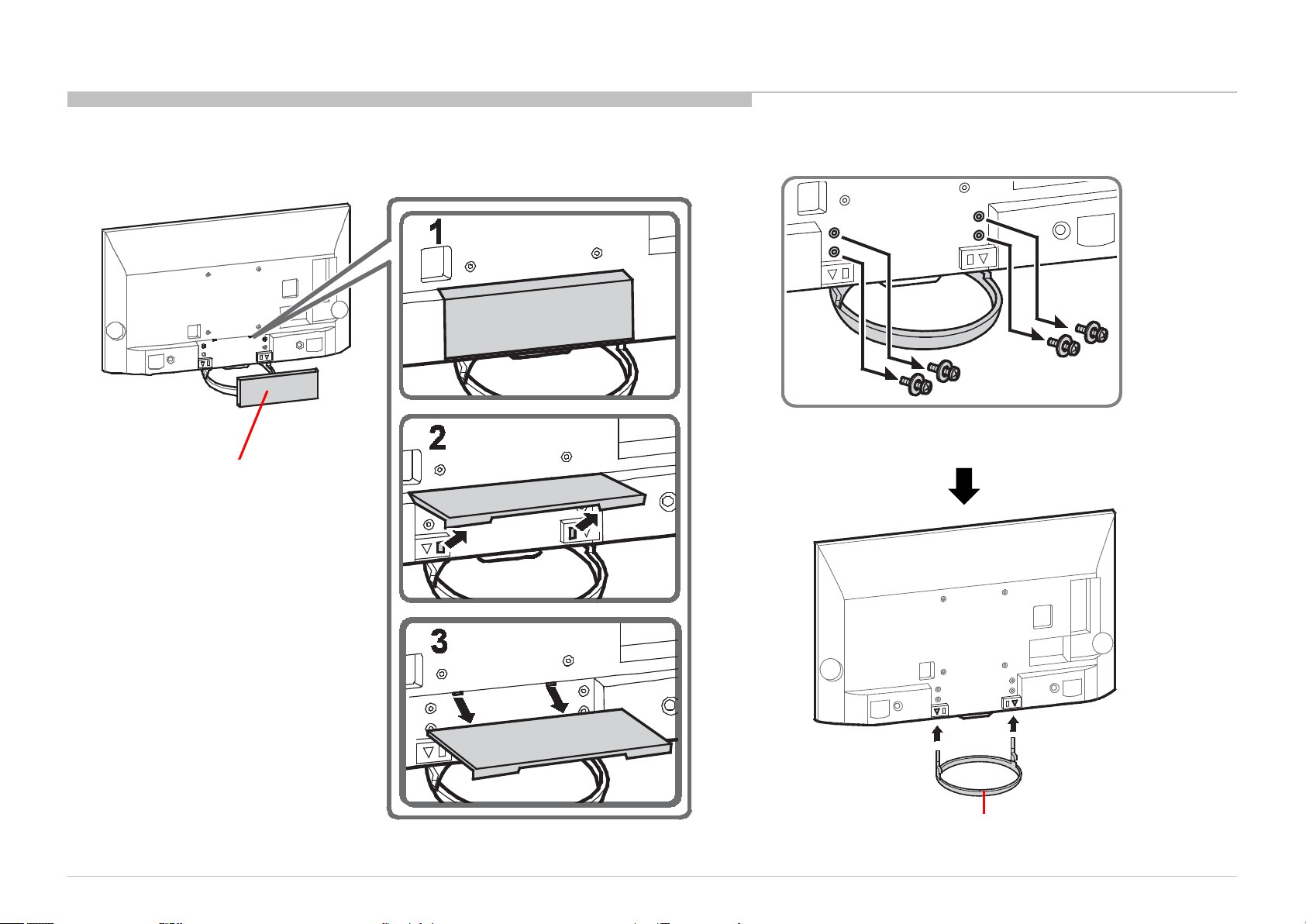

1-1. KD-55X9000A

COVER, UNDER (L CCT) AND STAND BLOCK

COVER, UNDER (L CCT)

Part Number: 4-454-665-01

DISASSEMBLY

4 Screws (SCREW, +PSW M5X12) P/N: 2-580-607-01

KD-55/65X9000A(CH)

STAND BLOCK

12

Page 13

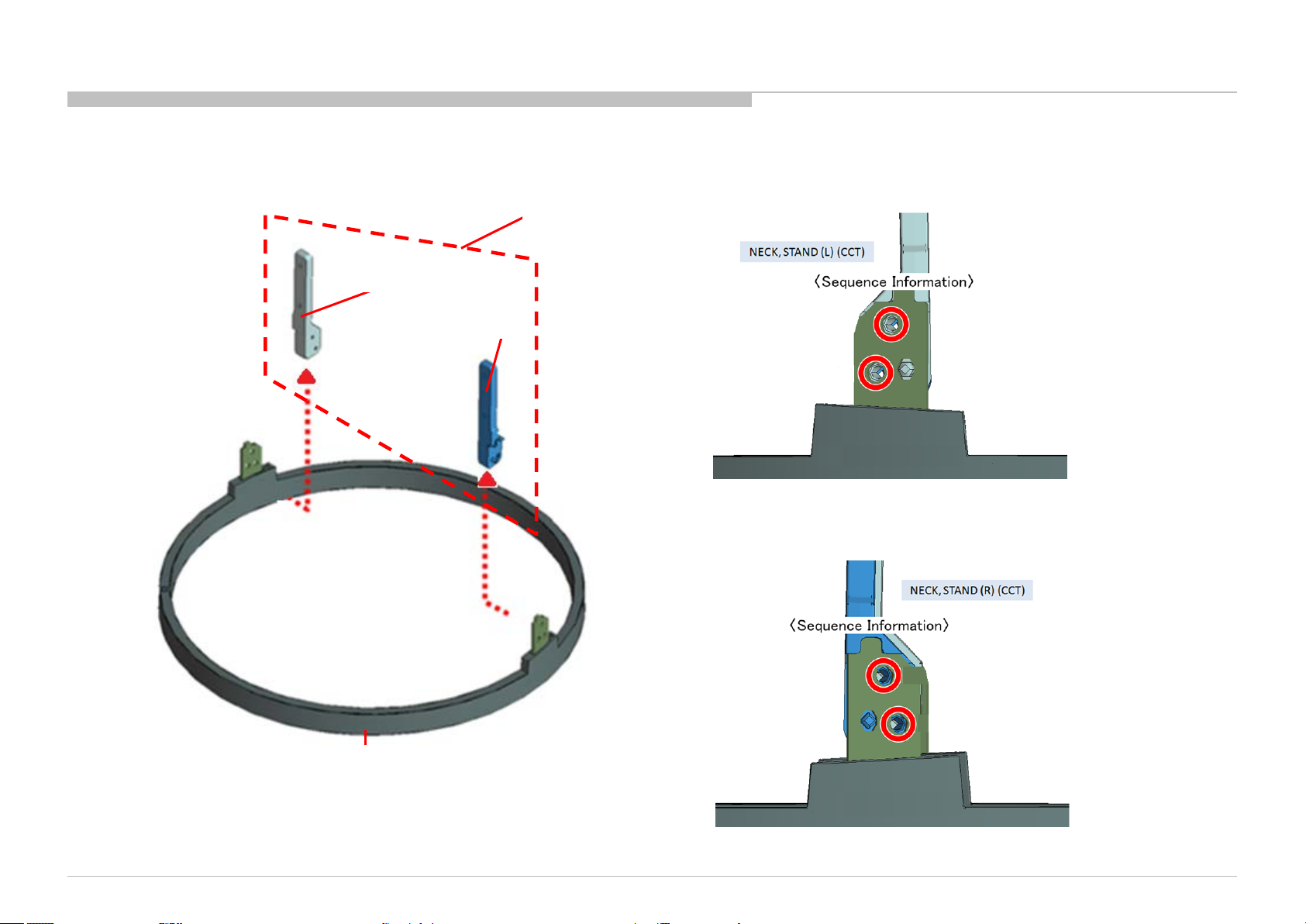

1-1. KD-55X9000A

NECK, STAND (CCT) A AND STAND (CCT) A

NECK, STAND (L) (CCT)

NECK, STAND (R) (CCT)

DISASSEMBLY

NECK, STAND (CCT) A

Part Number: 4-462-872-01

2 Screws (SCREW, +PSW M5X12) P/N: 2-580-607-01

KD-55/65X9000A(CH)

STAND (CCT) A

Part Number: 4-454-672-01

2 Screws (SCREW, +PSW M5X12) P/N: 2-580-607-01

13

Page 14

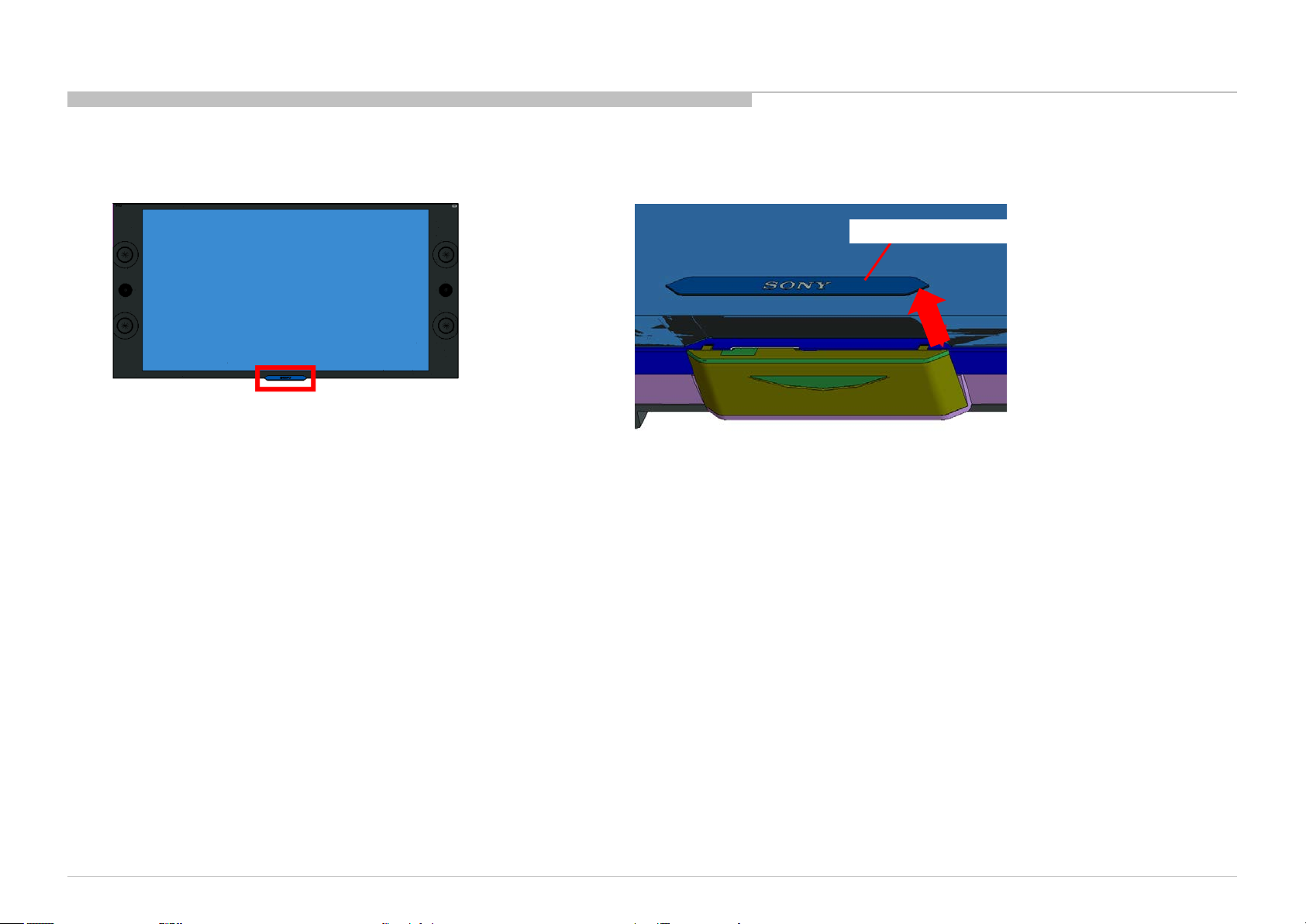

1-1. KD-55X9000A

PANEL ORNAMENT, SC (CCT ) A

DISASSEMBLY

PANEL ORNAMENT, SC (CCT) A

KD-55/65X9000A(CH)

14

Page 15

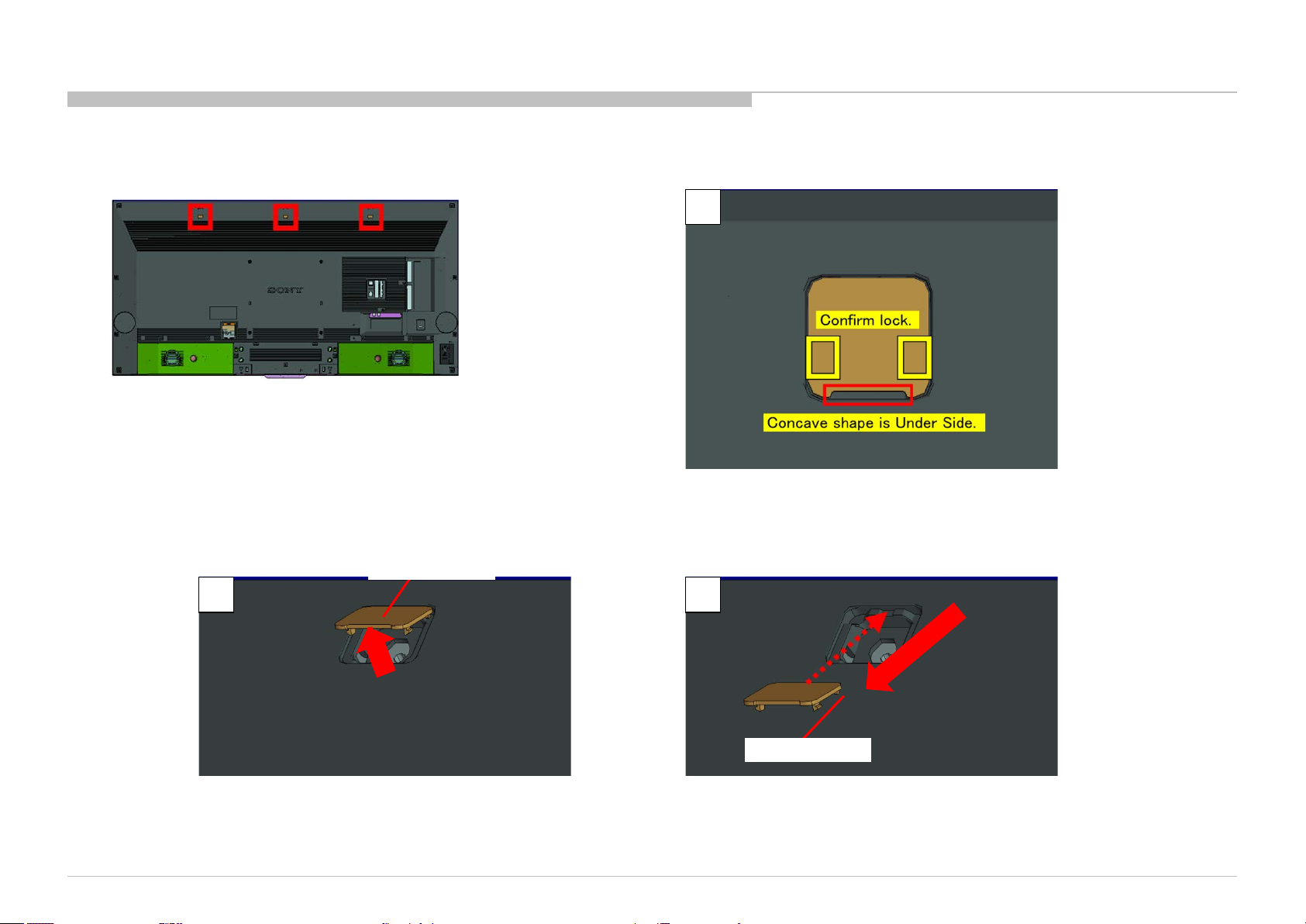

1-1. KD-55X9000A

AC COVER

DISASSEMBLY

AC COVER

1 Screw (SCREW, +PSW M3X6 W12) P/N: 4-256-393-01

KD-55/65X9000A(CH)

15

Page 16

1-1. KD-55X9000A

CCT CAP SCREW

DISASSEMBLY

1

KD-55/65X9000A(CH)

CCT CAP SCREW

2 3

CCT CAP SCREW

16

Page 17

1-1. KD-55X9000A

REAR COVER (L CCT) A

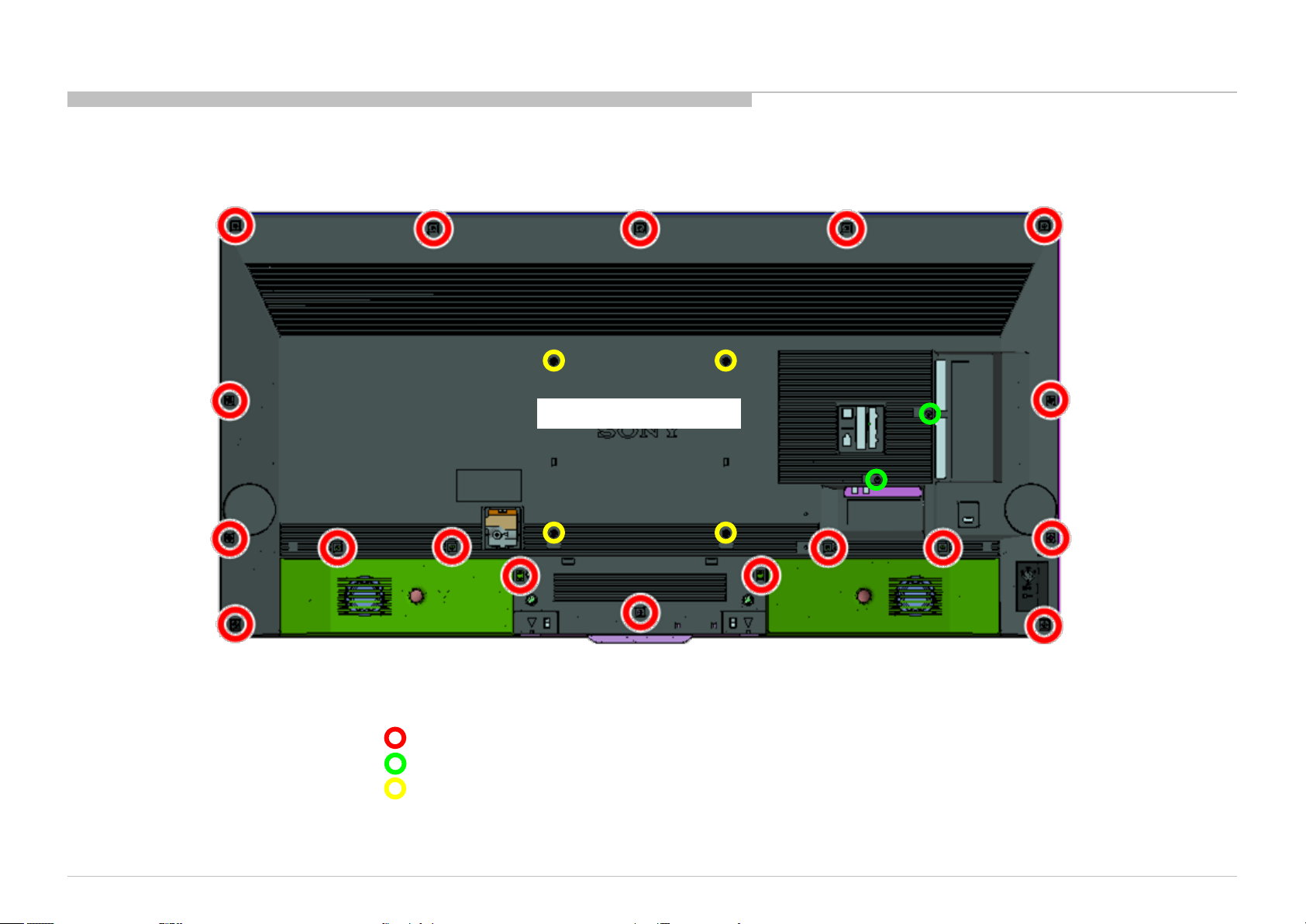

DISASSEMBLY

REAR COVER (L CCT) A

KD-55/65X9000A(CH)

18 Screws (SCREW, +PSW M3X 6 STEP) P/N: 4-457-815-02

2 Screws (SCREW +BVTP 3X10 TYPE2 IT-3) P/N: 7-685-647-79

4 Screws (SCREW, ORNAMENTAL M6X12) P/N: 4-268-126-02

17

Page 18

1-1. KD-55X9000A

COVER, WOOFER (L) (CCT)

DISASSEMBLY

1

COVER, WOOFER (L) (CCT)

1 Screw (SCREW, +PSW M3X6 W12) P/N: 4-256-393-01

COVER, WOOFER (L) (CCT)

2

KD-55/65X9000A(CH)

18

Page 19

1-1. KD-55X9000A

COVER, WOOFER (R) (CCT)

DISASSEMBLY

1

COVER, WOOFER (R) (CCT)

1 Screw (SCREW, +PSW M3X6 W12) P/N: 4-256-393-01

COVER, WOOFER (R) (CCT)

KD-55/65X9000A(CH)

2

19

Page 20

1-1. KD-55X9000A

BRACKET, NECK (CCT)

DISASSEMBLY

1

6 Screws (SCREW, +PSW M4X10) P/N: 4-159-298-01

2

KD-55/65X9000A(CH)

BRACKET, NECK (CCT)

20

Page 21

1-1. KD-55X9000A

BRACKET, UNDER (CCT)

DISASSEMBLY

1

1 Screw (SCREW +BVTP 3X10 TYPE2 IT-3) P/N: 7-685-647-79

KD-55/65X9000A(CH)

2

BRACKET, UNDER (CCT)

21

Page 22

1-1. KD-55X9000A

CONNECTOR ASSY AND FFC

CONNECTOR ASSY 28P

Part Number: 1-910-107-75

FLEXIBLE FLAT CABLE 20P

Part Number: 1-910-107-78

DISASSEMBLY

FLEXIBLE FLAT CABLE 41P (FSL)

Part Number: 1-846-699-11

KD-55/65X9000A(CH)

HARNESS ASSY (MAIN)

Part Number: 1-910-107-76

LEAD WIRE WITH CONNECTOR 51P

Part Number: 1-846-697-11

CONNECTOR ASSY 3P

Part Number: 1-910-107-83

FLEXIBLE FLAT CABLE 51P (FSL)

Part Number: 1-846-698-11

22

Page 23

1-1. KD-55X9000A

SP BOX ASSY

DISASSEMBLY

1

SP BOX ASSY

5 Screws (SCREW, +PSW M3X6 W12) P/N: 4-256-393-01

2 3

5 Screws (SCREW, +PSW M3X6 W12) P/N: 4-256-393-01

KD-55/65X9000A(CH)

SP BOX ASSY

SP BOX ASSY

SP BOX ASSY

23

Page 24

1-1. KD-55X9000A

SMART CORE

DISASSEMBLY

1

KD-55/65X9000A(CH)

3 2

SMART CORE

SMART CORE

24

Page 25

1-1. KD-55X9000A

LID,SC(CCT) A

1 2

DISASSEMBLY

LID,SC(CCT) A LID,SC(CCT) A

KD-55/65X9000A(CH)

3

LID,SC(CCT) A

25

Page 26

1-1. KD-55X9000A

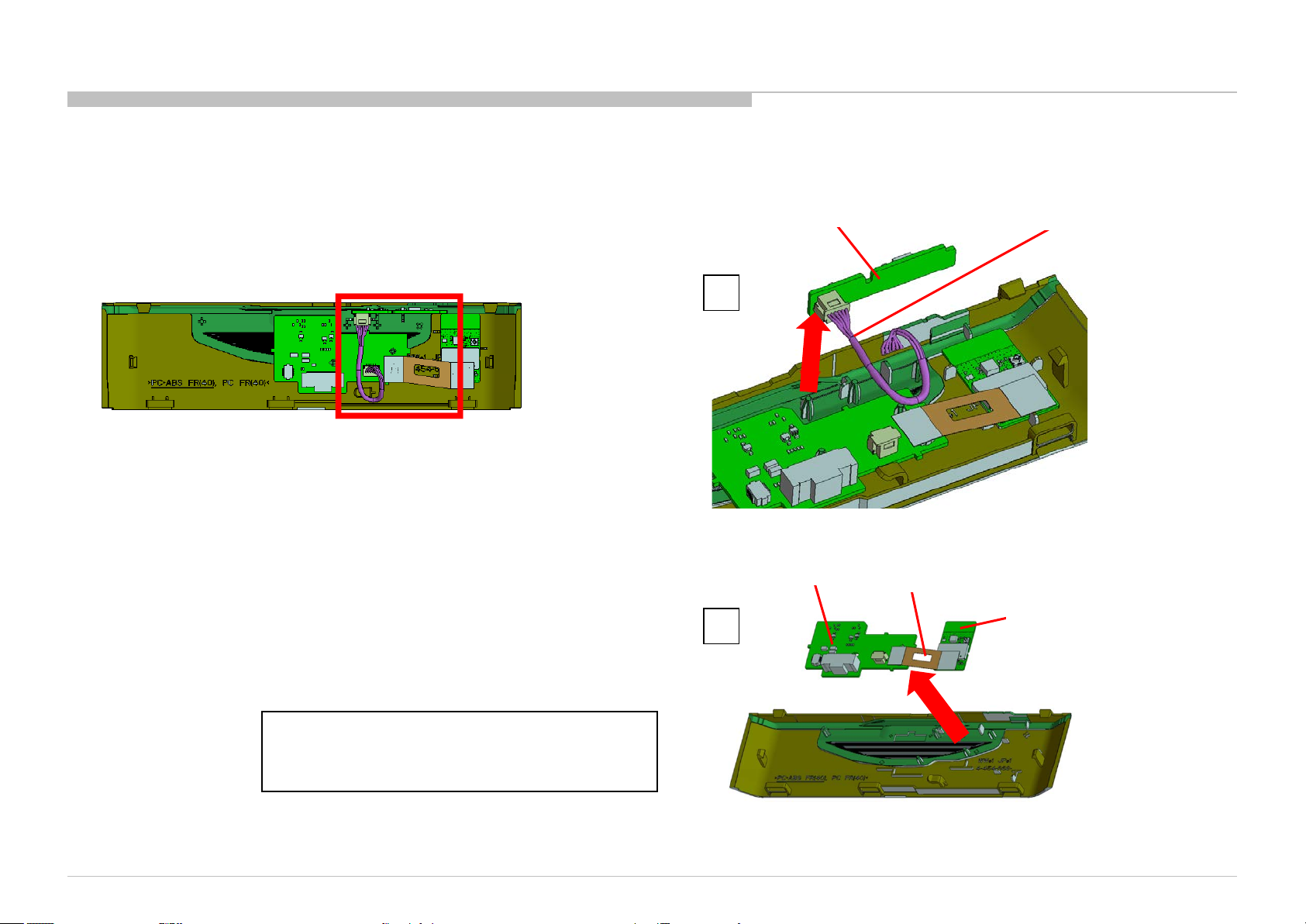

HIF BOARD, HSF-LM BOARD, BLUETOOTH MODULE AND FPC-BT

DISASSEMBLY

1

HSF-LM BOARD

2

HIF BOARD

CONNECTOR ASSY 5P

Part Number: 1-910-107-74

FPC-BT

BLUETOOTH MODULE

KD-55/65X9000A(CH)

Note:

FPC-BT is not reusable.

Please replace FPC-BT to new one if FPC-BT is removed

from HSF-LM BOARD or BLUETOOTH MODULE.

26

Page 27

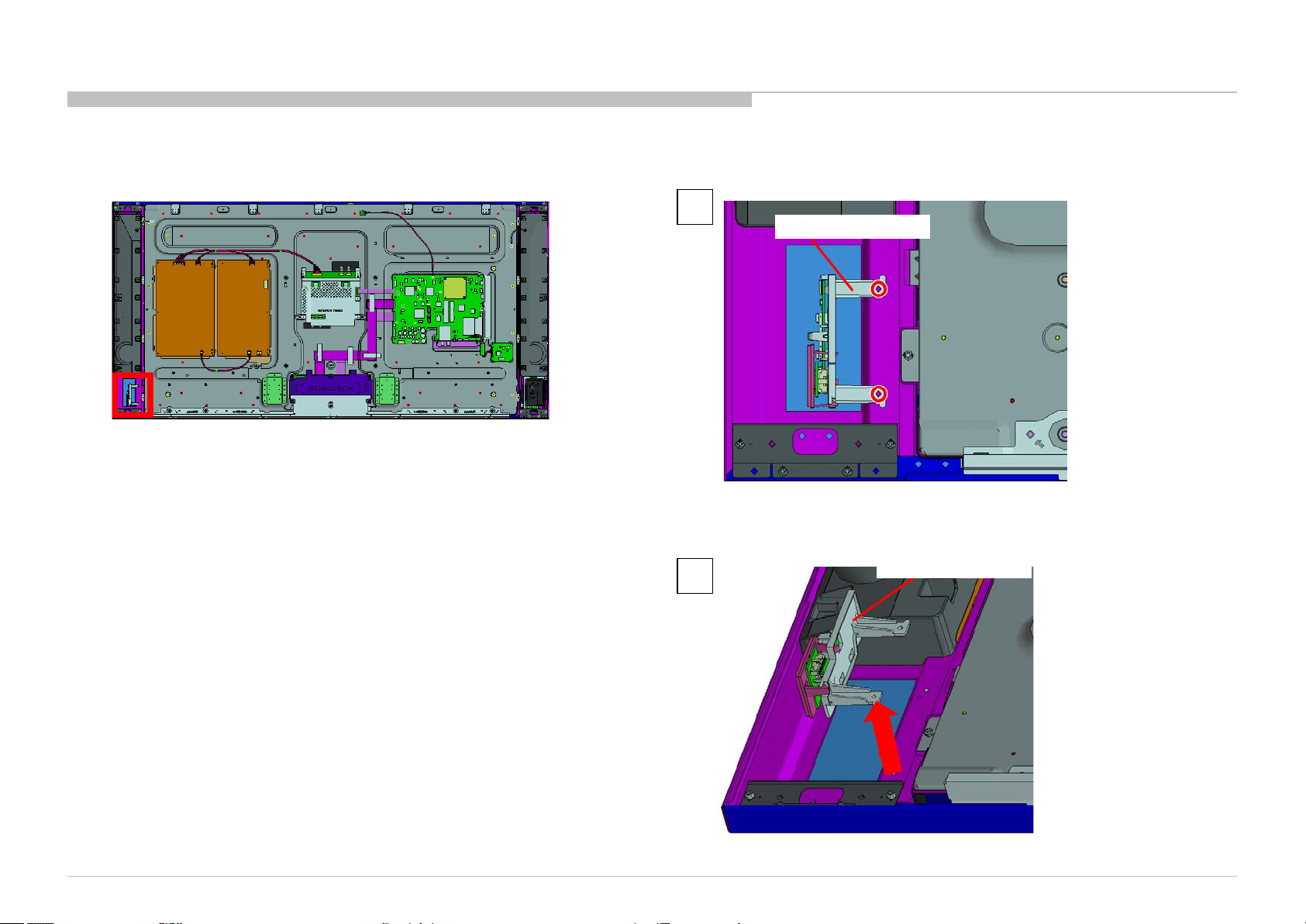

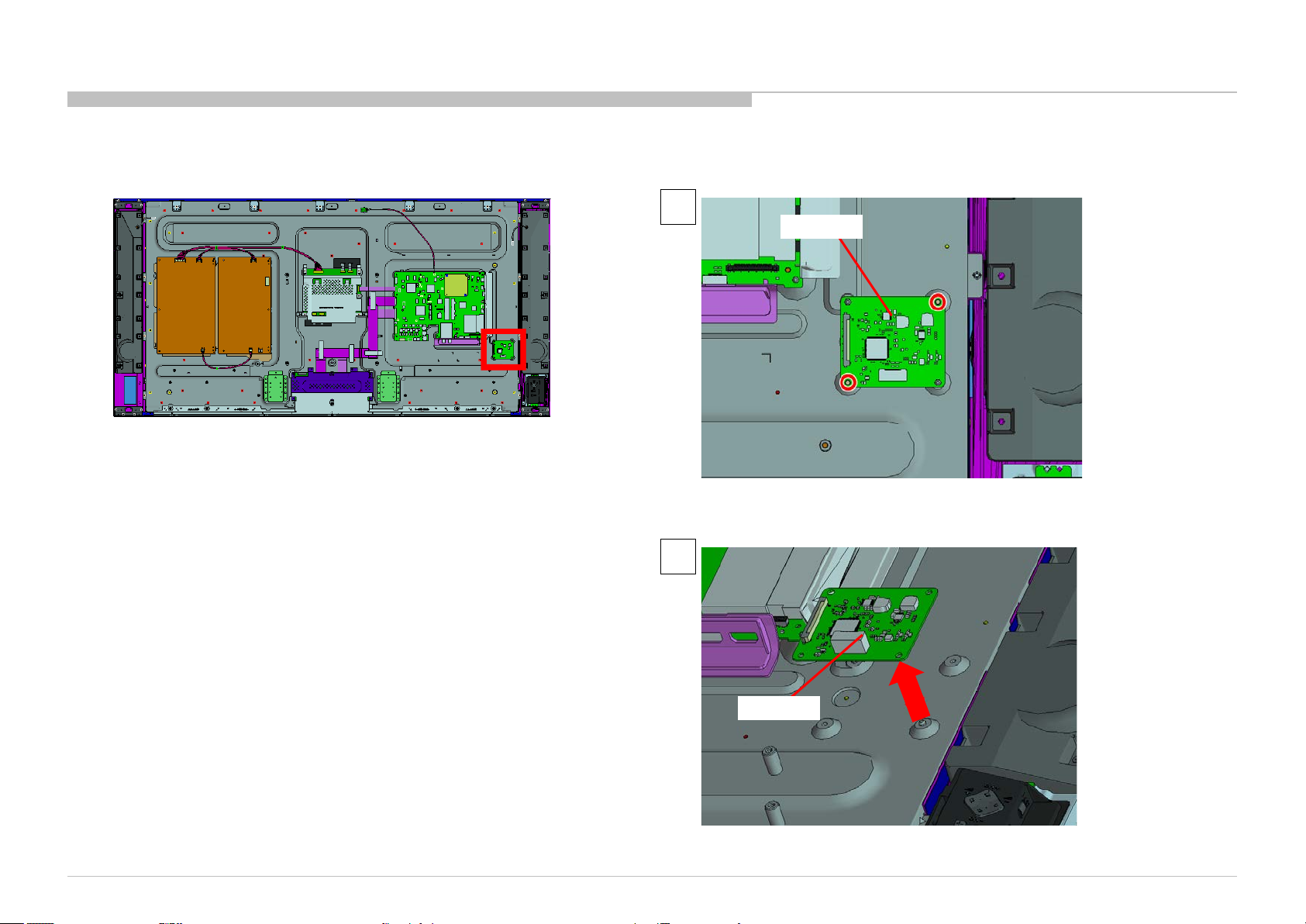

1-1. KD-55X9000A

WLAN MODULE ASS Y

DISASSEMBLY

1

WLAN MODULE ASSY

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

KD-55/65X9000A(CH)

2

WLAN MODULE ASSY

27

Page 28

1-1. KD-55X9000A

COVER,MODULE(CCT) A, HW BOARD, WLAN MODULE AND BRACKET, MODULE (CCT)

DISASSEMBLY

COVER,MODULE(CCT) A

WLAN MODULE

HW BOARD

WLAN MODULE

KD-55/65X9000A(CH)

BRACKET, MODULE (CCT)

28

Page 29

1-1. KD-55X9000A

CX BOARD

DISASSEMBLY

1

CX BOARD

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

KD-55/65X9000A(CH)

2

CX BOARD

29

Page 30

1-1. KD-55X9000A

SWITCH UNIT (HUS -F WW) AND BRACKET, HUS(CCT)

SWITCH UNIT (HUS-F WW)

DISASSEMBLY

1

SWITCH UNIT (HUS-F WW)

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

BRACKET, HUS(CCT)

2 3 4

KD-55/65X9000A(CH)

BRACKET, HUS(CCT)

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

30

Page 31

1-1. KD-55X9000A

BRACKET, UNDER (MOLD) AND BRACKET SIDE (MOLD CCT)

DISASSEMBLY

KD-55/65X9000A(CH)

BRACKET SIDE (MOLD CCT)

BRACKET, UNDER (MOLD)

31

Page 32

1-1. KD-55X9000A

BAF BOARD

DISASSEMBLY

1

13 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

BAF BOARD

2

KD-55/65X9000A(CH)

BAF BOARD

32

Page 33

1-1. KD-55X9000A

SHEET, THERMAL (BAF) AND GASKET(BAF)

DISASSEMBLY

KD-55/65X9000A(CH)

SHEET, THERMAL (BAF)

33

Page 34

1-1. KD-55X9000A

TS BOARD

DISASSEMBLY

1

TS BOARD

1 Screw (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

TS BOARD

KD-55/65X9000A(CH)

2

34

Page 35

1-1. KD-55X9000A

CONNECTOR ASSY AND HERNESS ASSY

DISASSEMBLY

CONNECTOR ASSY, 3P

Part Number: 1-846-714-11

HARNESS ASSY (G-LD)

Part Number: 1-910-107-77

KD-55/65X9000A(CH)

35

Page 36

1-1. KD-55X9000A

G7 BOARD AND G6 BOARD

DISASSEMBLY

1

2

G7 BOARD

5 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

G6 BOARD

G6 BOARD

G7 BOARD

KD-55/65X9000A(CH)

G6 BOARD

5 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

36

Page 37

1-1. KD-55X9000A

SHEET, INSULATION (CCT L)

DISASSEMBLY

1

SHEET, INSULATION (CCT L)

2

KD-55/65X9000A(CH)

SHEET, INSULATION (CCT L)

37

Page 38

1-1. KD-55X9000A

TAPE 95

DISASSEMBLY

KD-55/65X9000A(CH)

38

Page 39

1-1. KD-55X9000A

COVER, SP (L) (CCT) ASSY

DISASSEMBLY

1

COVER, SP (L) (CCT) ASSY

12 Screws (SCREW +PSW 3X10) P/N: 7-682-949-09

2 Screws (SPACER(SP-RC), HEX) P/N: 4-457-814-02

COVER, SP (L) (CCT) ASSY

KD-55/65X9000A(CH)

2 3

COVER, SP (L) (CCT) ASSY

39

Page 40

1-1. KD-55X9000A

COVER, SP (R) (CCT) ASSY

DISASSEMBLY

1

12 Screws (SCREW +PSW 3X10) P/N: 7-682-949-09

2 Screws (SPACER(SP-RC), HEX) P/N: 4-457-814-02

3 2

COVER, SP (R) (CCT) ASSY

COVER, SP (R) (CCT) ASSY

COVER, SP (R) (CCT) ASSY

KD-55/65X9000A(CH)

40

Page 41

1-1. KD-55X9000A

LOUD SPEAKER (80MM)

DISASSEMBLY

LOUD SPEAKER (80MM)

KD-55/65X9000A(CH)

41

Page 42

1-1. KD-55X9000A

LOUD SPEAKER (18MM)

1 2

DISASSEMBLY

KD-55/65X9000A(CH)

LOUD SPEAKER (18MM)

LOUD SPEAKER (18MM)

2 Screws (SCREW +BVTP 3X10 TYPE2 IT-3) P/N: 7-685-647-79

42

Page 43

1-1. KD-55X9000A

BRACKET,TW (CCT)

DISASSEMBLY

1 2

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

KD-55/65X9000A(CH)

BRACKET,TW (CCT)

BRACKET,TW (CCT)

43

Page 44

1-1. KD-55X9000A

MOUNTED PWB (NETWORK)

DISASSEMBLY

1

MOUNTED PWB (NETWORK)

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

MOUNTED PWB (NETWORK)

2 3

KD-55/65X9000A(CH)

MOUNTED PWB (NETWORK)

44

Page 45

1-1. KD-55X9000A

LOUD SPEAKER (80MM)

DISASSEMBLY

LOUD SPEAKER (80MM)

KD-55/65X9000A(CH)

45

Page 46

1-1. KD-55X9000A

LOUD SPEAKER (18MM)

1 2

DISASSEMBLY

LOUD SPEAKER (18MM)

2 Screws (SCREW +BVTP 3X10 TYPE2 IT-3) P/N: 7-685-647-79

KD-55/65X9000A(CH)

LOUD SPEAKER (18MM)

46

Page 47

1-1. KD-55X9000A

BRACKET,TW (CCT)

DISASSEMBLY

1 2

KD-55/65X9000A(CH)

BRACKET,TW (CCT)

BRACKET,TW (CCT)

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

47

Page 48

1-1. KD-55X9000A

MOUNTED PWB (NETWORK)

DISASSEMBLY

1

MOUNTED PWB (NETWORK)

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

MOUNTED PWB (NETWORK)

2 3

KD-55/65X9000A(CH)

MOUNTED PWB (NETWORK)

48

Page 49

1-1. KD-55X9000A

LOUD SPEAKER( P ASS IVE RADI AT O R )

LOUD SPEAKER(PASSIVE RADIATOR)

DISASSEMBLY

KD-55/65X9000A(CH)

49

Page 50

1-1. KD-55X9000A

BRACKET,SP (CCT)

2 3

DISASSEMBLY

1

BRACKET,SP (CCT)

BRACKET,SP (CCT)

BRACKET,SP (CCT)

KD-55/65X9000A(CH)

50

Page 51

1-1. KD-55X9000A

ORNAMENT,SP (CCT)

DISASSEMBLY

KD-55/65X9000A(CH)

1 2

ORNAMENT,SP (CCT)

ORNAMENT,SP (CCT)

51

Page 52

1-1. KD-55X9000A

ORNAMENT,SP (CCT)

DISASSEMBLY

ORNAMENT,SP (CCT)

KD-55/65X9000A(CH)

1 2

ORNAMENT,SP (CCT)

52

Page 53

1-1. KD-55X9000A

LCD PANEL

DISASSEMBLY

LCD PANEL

6 Screws (SCREW, +PSW M4X10) P/N: 4-159-298-01

KD-55/65X9000A(CH)

53

Page 54

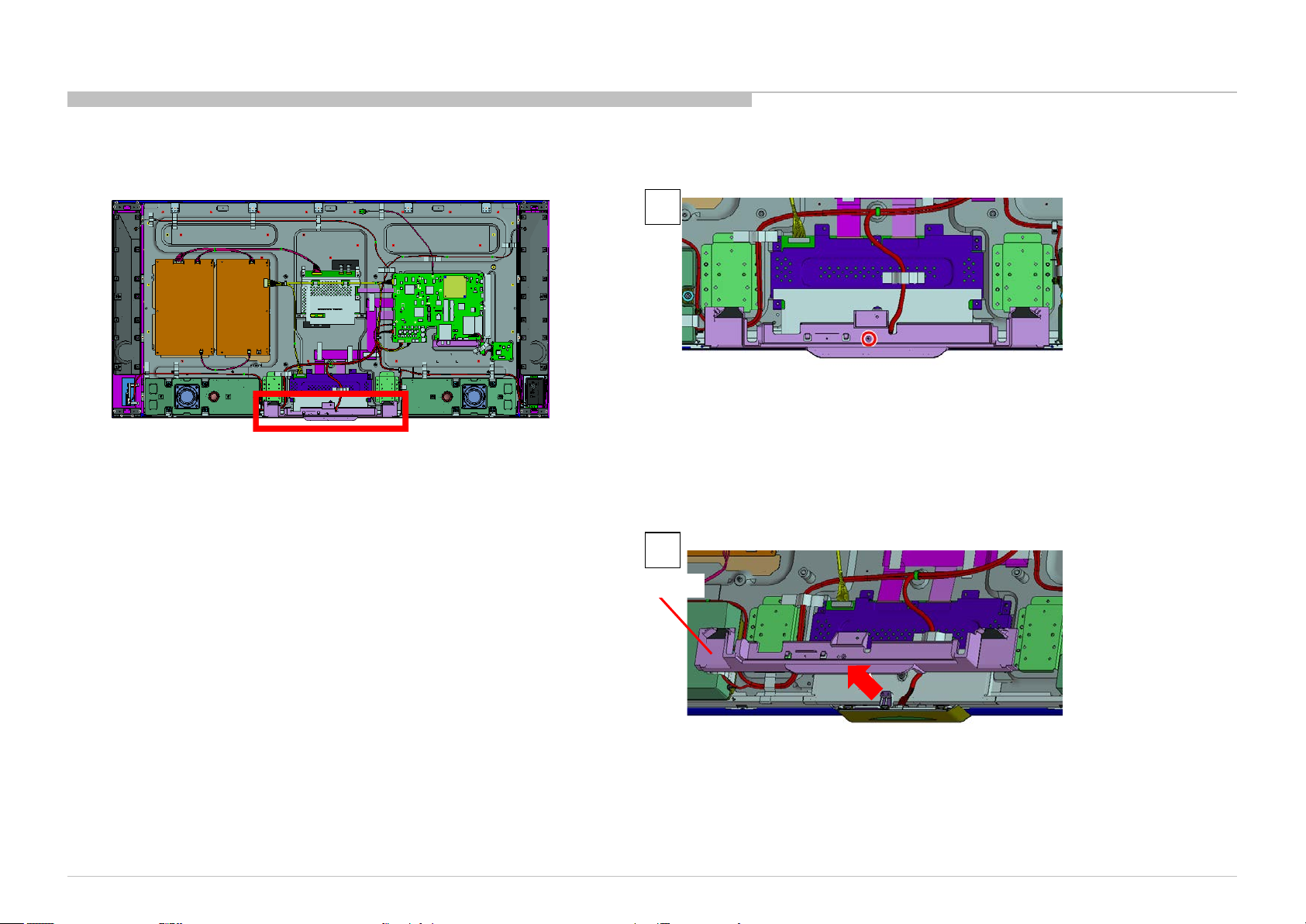

1-1. KD-55X9000A

WIRE DRESSING-1

2

3

DISASSEMBLY

1 2

1

3

KD-55/65X9000A(CH)

54

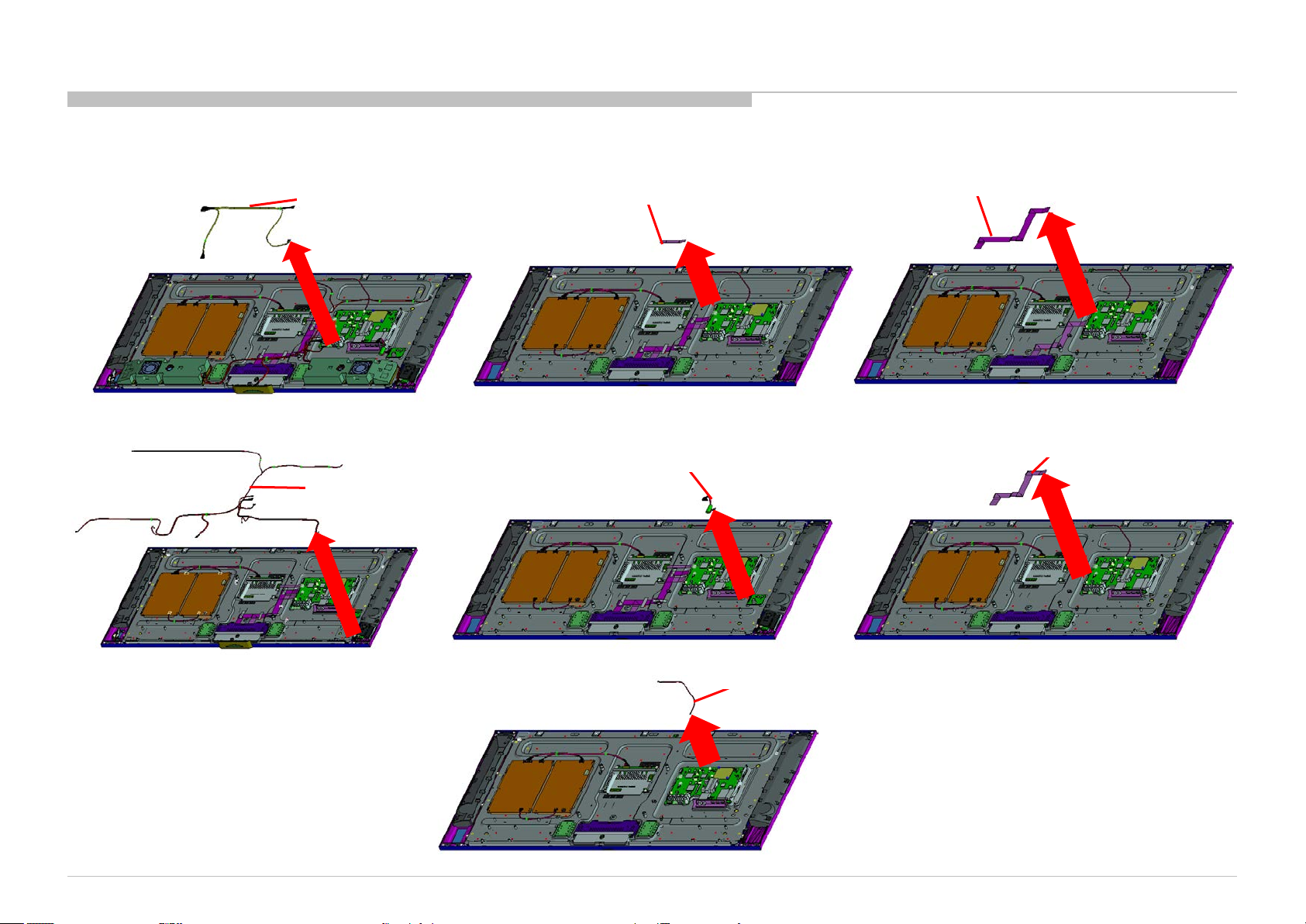

Page 55

1-1. KD-55X9000A

WIRE DRESSING-2

DISASSEMBLY

KD-55/65X9000A(CH)

55

Page 56

1-1. KD-55X9000A

WIRE DRESSING-3

BAF Board

DISASSEMBLY

CX Board

BAF Board

KD-55/65X9000A(CH)

CX Board

56

Page 57

1-2. KD-65X9000A

COVER, UNDER (M CCT) AND STAND BLOCK

COVER, UNDER (M CCT)

Part Number: 4-454-666-01

DISASSEMBLY

KD-55/65X9000A(CH)

STAND BLOCK

57

Page 58

1-2. KD-65X9000A

NECK, STAND (CCT) A AND STAND (CCT) A

NECK, STAND (L) (CCT)

NECK, STAND (R) (CCT)

DISASSEMBLY

NECK, STAND (CCT) A

Part Number: 4-462-872-01

2 Screws (SCREW, +PSW M5X12) P/N: 2-580-607-01

KD-55/65X9000A(CH)

STAND (CCT) A

Part Number: 4-454-672-01

2 Screws (SCREW, +PSW M5X12) P/N: 2-580-607-01

58

Page 59

1-2. KD-65X9000A

PANEL ORNAMENT, SC (CCT ) A

DISASSEMBLY

PANEL ORNAMENT, SC (CCT) A

KD-55/65X9000A(CH)

59

Page 60

1-2. KD-65X9000A

AC COVER

DISASSEMBLY

AC COVER

1 Screw (SCREW, +PSW M3X6 W12) P/N: 4-256-393-01

KD-55/65X9000A(CH)

60

Page 61

1-2. KD-65X9000A

CCT CAP SCREW

DISASSEMBLY

1

KD-55/65X9000A(CH)

3 2

CCT CAP SCREW

CCT CAP SCREW

61

Page 62

1-2. KD-65X9000A

REAR COVER (M CCT) A

DISASSEMBLY

REAR COVER (M CCT) A

KD-55/65X9000A(CH)

18 Screws (SCREW, +PSW M3X 6 STEP) P/N: 4-457-815-02

2 Screws (SCREW +BVTP 3X10 TYPE2 IT-3) P/N: 7-685-647-79

4 Screws (SCREW, ORNAMENTAL M6X12) P/N: 4-268-126-02

62

Page 63

1-2. KD-65X9000A

COVER, WOOFER (L) (CCT)

DISASSEMBLY

1

COVER, WOOFER (L) (CCT)

1 Screw (SCREW, +PSW M3X6 W12) P/N: 4-256-393-01

KD-55/65X9000A(CH)

2

COVER, WOOFER (L) (CCT)

63

Page 64

1-2. KD-65X9000A

COVER, WOOFER (R) (CCT)

DISASSEMBLY

1

COVER, WOOFER (R) (CCT)

1 Screw (SCREW, +PSW M3X6 W12) P/N: 4-256-393-01

KD-55/65X9000A(CH)

2

COVER, WOOFER (R) (CCT)

64

Page 65

1-2. KD-65X9000A

BRACKET, NECK (CCT)

DISASSEMBLY

1

6 Screws (SCREW, +PSW M4X10) P/N: 4-159-298-01

KD-55/65X9000A(CH)

2

BRACKET, NECK (CCT)

65

Page 66

1-2. KD-65X9000A

BRACKET, UNDER (CCT)

DISASSEMBLY

1

1 Screw (SCREW +BVTP 3X10 TYPE2 IT-3) P/N: 7-685-647-79

KD-55/65X9000A(CH)

2

BRACKET, UNDER (CCT)

66

Page 67

1-2. KD-65X9000A

CONNECTOR ASSY AND FFC

CONNECTOR ASSY 28P

Part Number: 1-910-107-79

HARNESS ASSY (MAIN)

Part Number: 1-910-107-80

FLEXIBLE FLAT CABLE 20P

Part Number: 1-910-107-82

LEAD WIRE WITH CONNECTOR 51P

Part Number: 1-846-697-11

DISASSEMBLY

FLEXIBLE FLAT CABLE 41P (FSM)

Part Number: 1-846-701-11

FLEXIBLE FLAT CABLE 51P (FSM)

Part Number: 1-846-700-11

KD-55/65X9000A(CH)

CONNECTOR ASSY 3P

Part Number: 1-910-107-84

67

Page 68

1-2. KD-65X9000A

SP BOX ASSY

DISASSEMBLY

1

SP BOX ASSY

5 Screws (SCREW, +PSW M3X6 W12) P/N: 4-256-393-01

2 3

5 Screws (SCREW, +PSW M3X6 W12) P/N: 4-256-393-01

KD-55/65X9000A(CH)

SP BOX ASSY

SP BOX ASSY

SP BOX ASSY

68

Page 69

1-2. KD-65X9000A

SMART CORE

DISASSEMBLY

1

KD-55/65X9000A(CH)

3 2

SMART CORE

SMART CORE

69

Page 70

1-2. KD-65X9000A

LID,SC(CCT) A

1 2

DISASSEMBLY

LID,SC(CCT) A LID,SC(CCT) A

KD-55/65X9000A(CH)

LID,SC(CCT) A

3

70

Page 71

1-2. KD-65X9000A

HIF BOARD, HSF-LM BOARD, BLUETOOTH MODULE AND FPC-BT

DISASSEMBLY

1

2

HSF-LM BOARD

HIF BOARD

CONNECTOR ASSY 5P

Part Number: 1-910-107-74

FPC-BT

BLUETOOTH MODULE

KD-55/65X9000A(CH)

Note:

FPC-BT is not reusable.

Please replace FPC-BT to new one if FPC-BT is removed

from HSF-LM BOARD or BLUETOOTH MODULE.

71

Page 72

1-2. KD-65X9000A

WLAN MODULE ASS Y

DISASSEMBLY

1

WLAN MODULE ASSY

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

KD-55/65X9000A(CH)

WLAN MODULE ASSY

2

72

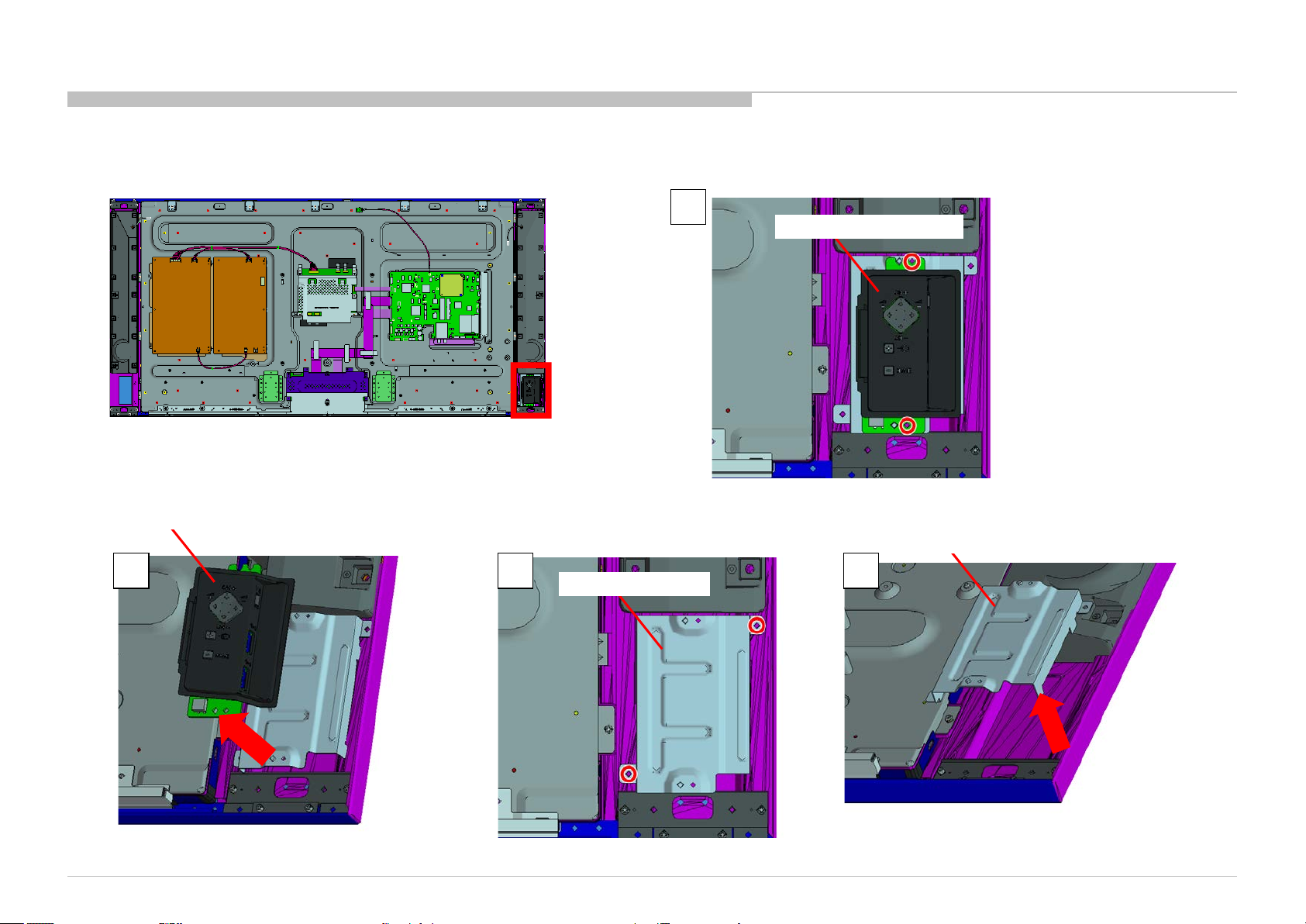

Page 73

1-2. KD-65X9000A

COVER,MODULE(CCT) A, HW BOARD, WLAN MODULE AND BRACKET, MODULE (CCT)

DISASSEMBLY

COVER,MODULE(CCT) A

WLAN MODULE

HW BOARD

WLAN MODULE

KD-55/65X9000A(CH)

BRACKET, MODULE (CCT)

73

Page 74

1-2. KD-65X9000A

CX BOARD

DISASSEMBLY

1

CX BOARD

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

KD-55/65X9000A(CH)

2

CX BOARD

74

Page 75

1-2. KD-65X9000A

SWITCH UNIT (HUS -F WW) AND BRACKET, HUS(CCT)

DISASSEMBLY

1

SWITCH UNIT (HUS-F WW)

2 3 4

BRACKET, HUS(CCT)

SWITCH UNIT (HUS-F WW)

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

BRACKET, HUS(CCT)

KD-55/65X9000A(CH)

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

75

Page 76

1-2. KD-65X9000A

BRACKET, UNDER (MOLD) AND BRACKET SIDE (MOLD CCT)

DISASSEMBLY

KD-55/65X9000A(CH)

BRACKET SIDE (MOLD CCT)

BRACKET, UNDER (MOLD)

76

Page 77

1-2. KD-65X9000A

DISASSEMBLY

BAF BOARD

BAF BOARD

1

13 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

2

KD-55/65X9000A(CH)

BAF BOARD

77

Page 78

1-2. KD-65X9000A

SHEET, THERMAL (BAF) AND GASKET(BAF)

DISASSEMBLY

KD-55/65X9000A(CH)

SHEET, THERMAL (BAF)

78

Page 79

1-2. KD-65X9000A

TS BOARD

1 1

DISASSEMBLY

TS BOARD

1 Screw (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

KD-55/65X9000A(CH)

TS BOARD

2

79

Page 80

1-2. KD-65X9000A

CONNECTOR ASSY AND HERNESS ASSY

DISASSEMBLY

CONNECTOR ASSY, 3P

Part Number: 1-846-714-11

HARNESS ASSY (G-LD)

Part Number: 1-910-107-81

KD-55/65X9000A(CH)

80

Page 81

1-2. KD-65X9000A

G8 BOARD AND G6 BOARD

DISASSEMBLY

1

2

G8 BOARD

5 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

G6 BOARD

G6 BOARD

G8 BOARD

KD-55/65X9000A(CH)

G6 BOARD

5 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

81

Page 82

1-2. KD-65X9000A

SHEET, INSULATION (CCT M)

DISASSEMBLY

1

SHEET, INSULATION (CCT M)

KD-55/65X9000A(CH)

2

SHEET, INSULATION (CCT M)

82

Page 83

1-2. KD-65X9000A

TAPE 95

DISASSEMBLY

KD-55/65X9000A(CH)

83

Page 84

1-2. KD-65X9000A

COVER, SP (L) (CCT) ASSY

DISASSEMBLY

1

COVER, SP (L) (CCT) ASSY

12 Screws (SCREW +PSW 3X10) P/N: 7-682-949-09

2 Screws (SPACER(SP-RC), HEX) P/N: 4-457-814-02

COVER, SP (L) (CCT) ASSY

KD-55/65X9000A(CH)

3 2

COVER, SP (L) (CCT) ASSY

84

Page 85

1-2. KD-65X9000A

COVER, SP (R) (CCT) ASSY

DISASSEMBLY

1

12 Screws (SCREW +PSW 3X10) P/N: 7-682-949-09

2 Screws (SPACER(SP-RC), HEX) P/N: 4-457-814-02

3 2

COVER, SP (R) (CCT) ASSY

COVER, SP (R) (CCT) ASSY

COVER, SP (R) (CCT) ASSY

KD-55/65X9000A(CH)

85

Page 86

1-2. KD-65X9000A

LOUD SPEAKER (80MM)

DISASSEMBLY

LOUD SPEAKER (80MM)

KD-55/65X9000A(CH)

86

Page 87

1-2. KD-65X9000A

LOUD SPEAKER (18MM)

1 2

DISASSEMBLY

KD-55/65X9000A(CH)

LOUD SPEAKER (18MM)

LOUD SPEAKER (18MM)

2 Screws (SCREW +BVTP 3X10 TYPE2 IT-3) P/N: 7-685-647-79

87

Page 88

1-2. KD-65X9000A

BRACKET,TW (CCT)

DISASSEMBLY

1 2

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

KD-55/65X9000A(CH)

BRACKET,TW (CCT)

BRACKET,TW (CCT)

88

Page 89

1-2. KD-65X9000A

MOUNTED PWB (NETWORK)

DISASSEMBLY

1

MOUNTED PWB (NETWORK)

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

MOUNTED PWB (NETWORK)

MOUNTED PWB (NETWORK)

2 3

KD-55/65X9000A(CH)

89

Page 90

1-2. KD-65X9000A

LOUD SPEAKER (80MM)

DISASSEMBLY

LOUD SPEAKER (80MM)

KD-55/65X9000A(CH)

90

Page 91

1-2. KD-65X9000A

LOUD SPEAKER (18MM)

1 2

DISASSEMBLY

LOUD SPEAKER (18MM)

2 Screws (SCREW +BVTP 3X10 TYPE2 IT-3) P/N: 7-685-647-79

KD-55/65X9000A(CH)

LOUD SPEAKER (18MM)

91

Page 92

1-2. KD-65X9000A

BRACKET,TW (CCT)

DISASSEMBLY

BRACKET,TW (CCT)

1

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

KD-55/65X9000A(CH)

2

BRACKET,TW (CCT)

92

Page 93

1-2. KD-65X9000A

MOUNTED PWB (NETWORK)

DISASSEMBLY

1

MOUNTED PWB (NETWORK)

2 Screws (SCREW (+PSW) (M3X6)) P/N: 2-990-421-41

MOUNTED PWB (NETWORK)

2 3

KD-55/65X9000A(CH)

MOUNTED PWB (NETWORK)

93

Page 94

1-2. KD-65X9000A

LOUD SPEAKER( P ASS IVE RADI AT O R )

LOUD SPEAKER(PASSIVE RADIATOR)

DISASSEMBLY

KD-55/65X9000A(CH)

94

Page 95

1-2. KD-65X9000A

DISASSEMBLY

BRACKET,SP (CCT)

2 3

BRACKET,SP (CCT)

1

BRACKET,SP (CCT)

BRACKET,SP (CCT)

KD-55/65X9000A(CH)

95

Page 96

1-2. KD-65X9000A

ORNAMENT,SP (CCT)

DISASSEMBLY

KD-55/65X9000A(CH)

1 2

ORNAMENT,SP (CCT)

ORNAMENT,SP (CCT)

96

Page 97

1-2. KD-65X9000A

ORNAMENT,SP (CCT)

DISASSEMBLY

ORNAMENT,SP (CCT)

KD-55/65X9000A(CH)

1 2

ORNAMENT,SP (CCT)

97

Page 98

1-2. KD-65X9000A

WIRE DRESSING-1

DISASSEMBLY

1 2

1

3

2

3

KD-55/65X9000A(CH)

98

Page 99

1-2. KD-65X9000A

WIRE DRESSING-2

DISASSEMBLY

KD-55/65X9000A(CH)

99

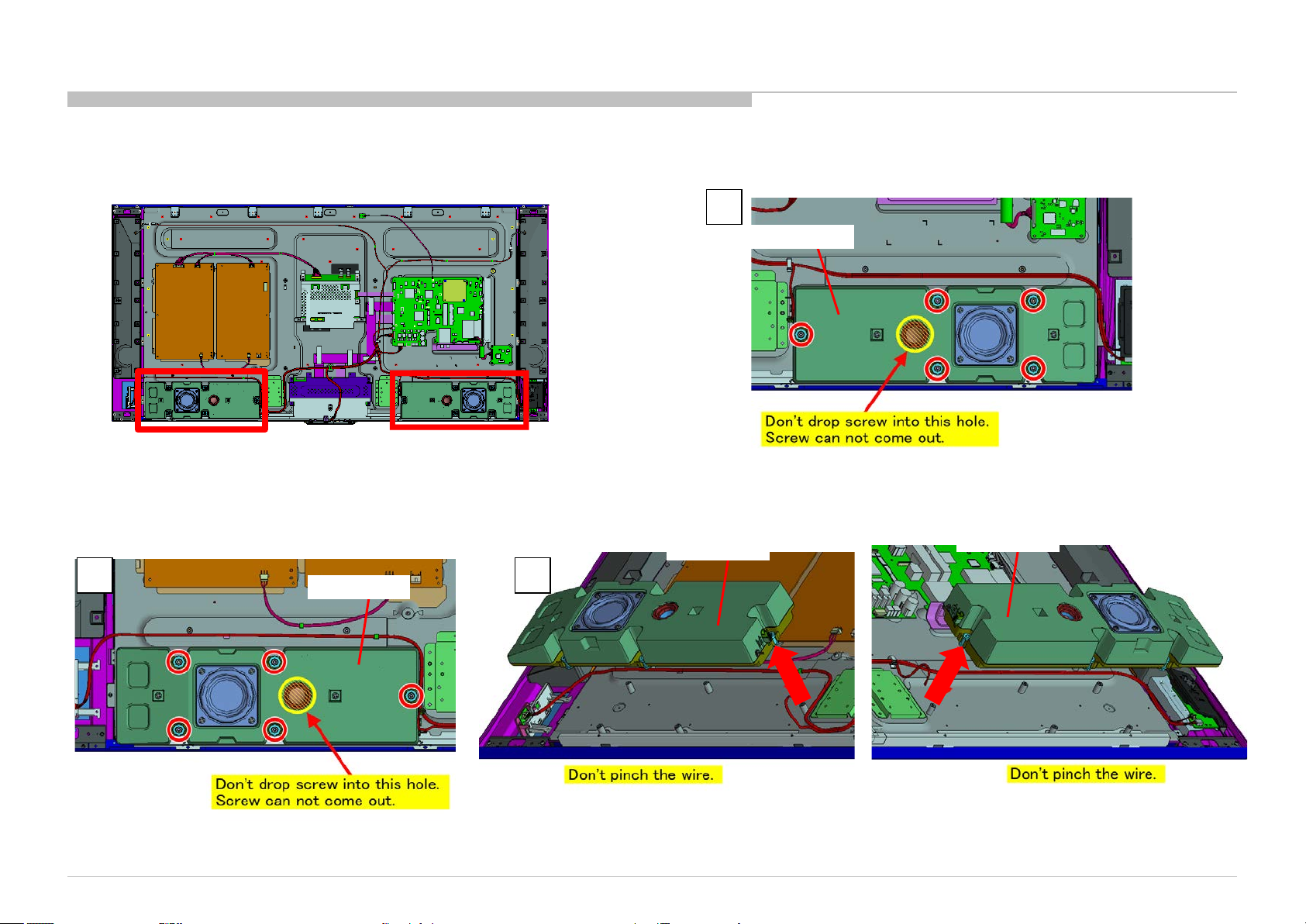

Page 100

1-2. KD-65X9000A

WIRE DRESSING-3

BAF Board

DISASSEMBLY

CX Board

BAF Board

KD-55/65X9000A(CH)

CX Board

100

Loading...

Loading...