Sony J-MECH Service Manual

DV MECHANICAL ADJUSTMENT MANUAL VI

Ver 1.0 2000. 3

J MECHANISM

Please use this manual with the service manual of the respective models.

MECHANISM DECK

TABLE OF CONTENTS

1. Preparations for Check, Adjustment and

Replacement of Mechanism Block

1-1. Cassette Compartment Assy, Damper Assy ······················· 3

2. Periodic Inspection and Maintenance

2-1. Rotary Drum Cleaning ······················································· 4

2-2. Tape Path System Cleaning ················································ 4

(Refer to Fig. 2-1.)······························································4

2-3. Periodic Inspection List······················································5

2-4. Service Jigs and Tools ························································ 6

2-5. Mode Selector II Operating Procedure······························· 8

4. Tape Path Adjustment

4-1. Adjustment Preparation ···················································· 32

4-2. Tracking Adjustment ························································ 33

4-3. TG3 Guide Adjustment ····················································33

4-4. TG7 Guide Adjustment ····················································34

4-5. Check upon Completion of Adjustment ··························· 34

5. Exploded View

5-1. Cassette Compartment Block Assy, Drum Assy Block ···· 36

5-2. LS Chassis Block Assy····················································· 37

5-3. Mechanism Chassis Block Assy······································· 38

3. Check, Adjustment and Replacement of

Mechanical Parts

3-1. Drum················································································· 12

3-2. L. Motor Holder Block Assy (Loading) and

FP-228 Flexible Wiring Board (DEW Sensor)················· 13

3-3. Retainer Plate Assy, LED Retainer···································14

3-4. Brake-T Block Assy, T-reel Table Assy,

Gooseneck Gear Assy·······················································15

3-5. TG1 Assy, Tension Coil Spring (Tension Regulator) ······· 16

3-6. TG1 FWD Position Adjustment ······································· 17

3-7. FWD Back-tension Adjustment········································ 18

3-8. Reel Torque Check ··························································· 18

3-9. TG3 Guide Zenith Adjustment········································· 18

3-10. TG6 Guide Zenith Adjustment········································· 19

3-11. LS Cam Plate Position Adjustment ·································· 19

3-12. LS Chassis Block Assy, LS Guide Retainer····················· 20

3-13. LS Cam Plate, Tension Coil Spring (Brake-S), Brake-S,

Torsion Coil Spring (Brake Arm), Cassette Position Set-S,

Brake-S Driving Arm Assy··············································· 21

3-14. TG7 Block Assy, Torsion Coil Spring

(TG7 Return, Pinch Return), Pinch Arm Assy ················· 22

3-15. Layout Diagram of FP-102 Flexible Wiring Board·········· 23

3-16. TG1 Cam Slider, LS Arm, LS Roller,

Mode Gear Assy, LS Guide Roller··································· 24

3-17. Guide Rail········································································· 25

3-18. Gear Cover B, GL Driving Gear ······································ 26

3-19. Drum Base Block Assy, Coaster-S Block Assy,

Coaster-T Block Assy·······················································27

3-20. DC Motor (Capstan), Conversion Gear, Relay Gear ········ 28

3-21. Gear Cover C, Pinch Driving Arm Assy, Cam Gear B····· 29

3-22. Gear Cover A, FP-100 Flexible Wiring Board ················· 30

3-23. Deceleration Gear, Mode Gear Assy,

FP-100 Flexible Wiring Board, Cam Gear A ··················· 31

6. Printed Wiring Boards and

Schematic Diagrams ·············································· 39

7. Electrical Parts List················································· 41

— 2 —

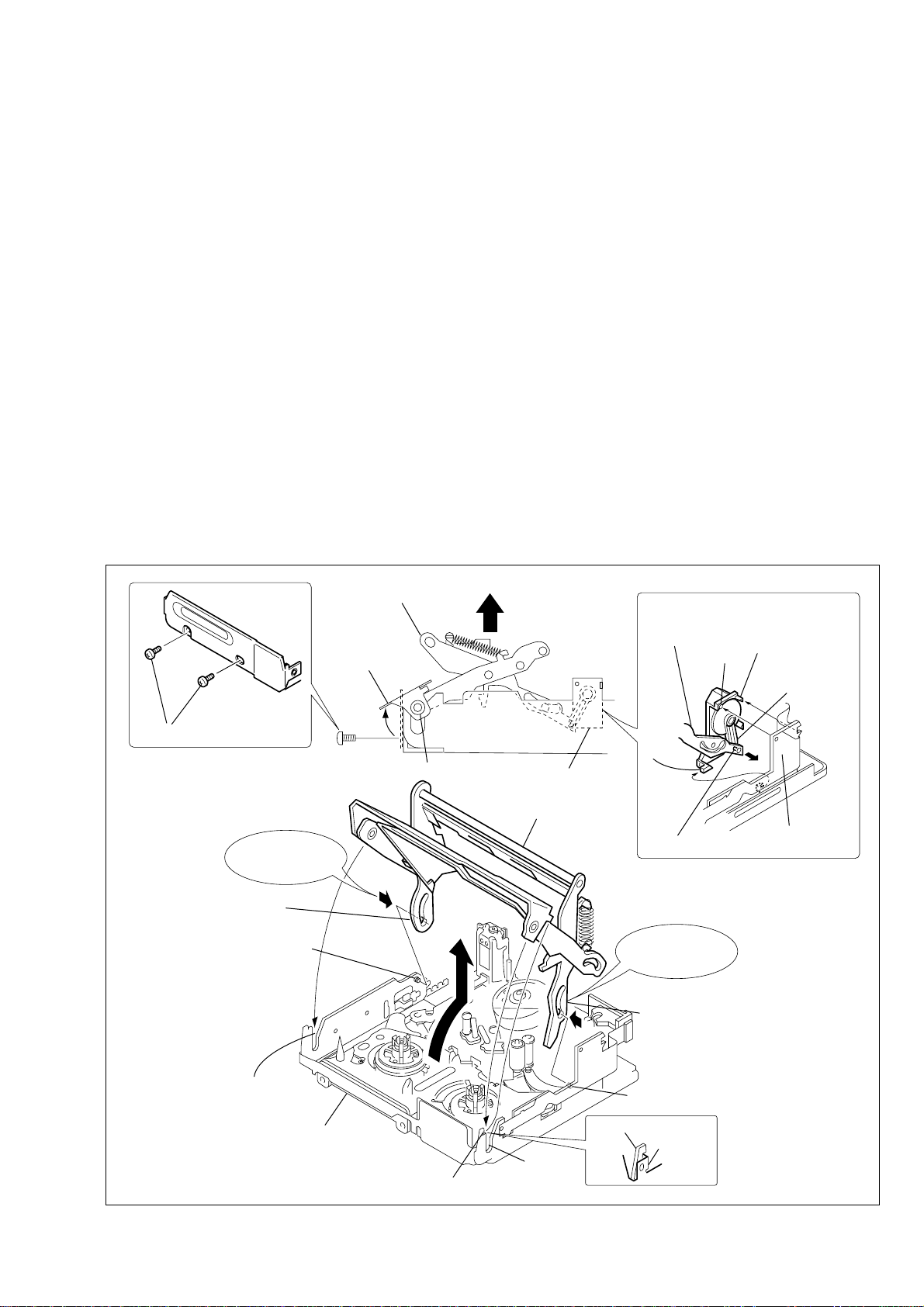

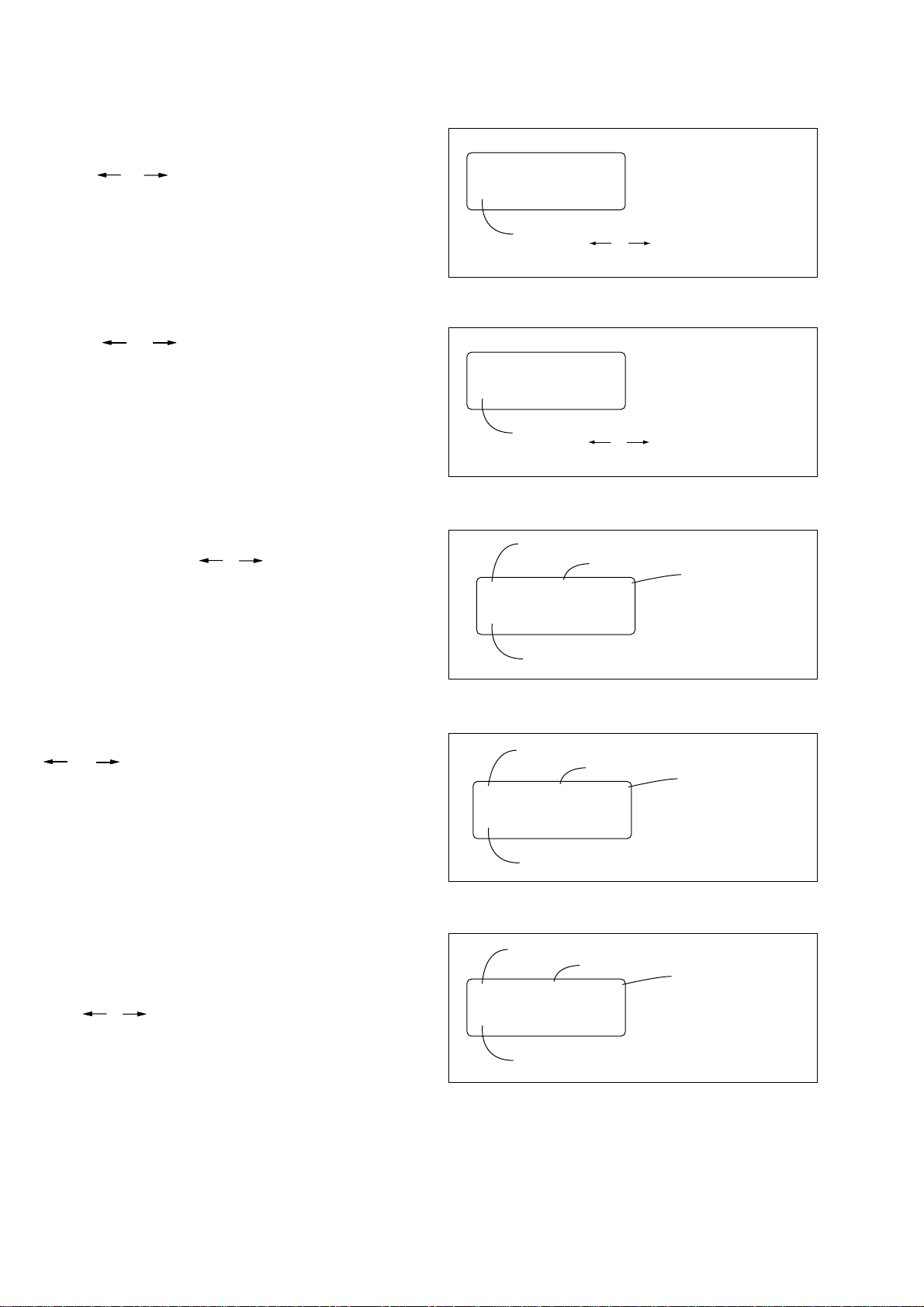

1. Preparations for Check, Adjustment and Replacement of Mechanism Block

Removal method of

damper assy

1 Claw

1 Claw

Damper assy

Holder arm

Damper shaft

Holder arm

While pressing

toward the inside

Cassette compartment

slide shaft

Cassette compartment

slide shaft

D Groove

Holder arm

LS chassis block assy

LS frame pivots

(two pivots in the right and left)

LS chassis block assy

LS chassis block assy

Cassette compartment

block assy

D Groove

F Notch

While pressing

toward the inside

Cassette compartment

block assy

LS frame

2 Two screws (M1.4 × 2)

Dowel

Slot of damper arm

A

C

B

E

E

* Be careful not to

deform here.

* Be careful not to

deform here.

LS chassis block assy

LS frame

• Refer to the “DISASSEMBLY” section of the SERVICE MANUAL of the respective models for details of removing cabinets and

printed wiring boards.

• When making any adjustment to a mechanism or r eplacing mechanical parts, be sure to use the Mode Selector II and select the appropriate

status of the mechanical deck such that the mechanical status is suitable for the desired work. Refer to section “2-5. Mode Selector II”

for details on how to enter the mode shown in a rectangle [ ] mode in subsequent paragraphs of this manual.

1-1. Cassette Compartment Assy, Damper Assy

1. Removal Procedure

1) Set the [EJ] mode.

2) When the cassette compartment moves up in the direction of

the arrow B, establish the [ULE] mode.

3 Release the two claws 1 and dowel of the damper assy and

remove the damper assy.

4) Remove the shaft of the holder arm from the damper arm.

5) Remove the two screws (M1.4 × 2) 2.

6) Lift up the LS frame in the direction of the arrow C.

7) Lift up the cassette compartment block assy in the direction of

the arrow A. While pushing the holder arm in the direction of

the inside arrow E, remove the cassette compartment block

assy.

2. Attachment procedure

1) Set the [ULE] mode.

2) Attach the holder arm of the cassette compartment block assy

to the cassette compartment slide shaft on both sides of the LS

chassis block assy from inside.

3) Install the LS frame pivot into the groov e D of the LS chassis.

Drop down the LS frame in the direction opposite to C.

4) Hook the LS frame T -side bent portion on the LS chassis notch

F.

5) Attach the LS frame with two screws (M1.4 × 2) 2.

Tightening torque: 0.054 ± 0.01 N•m (0.6 kg•cm).

6) While inserting the damper shaft of the cassette compartment

block assy into slot of the damper arm, engage the two claws

1 with the notch of the LS chassis block assy, and fix the

dowel to the corresponding hole of the LS chassis block assy

respectively.

Note: Check that the two claws 1 and dowel do not come off.

Fig. 1-1

— 3 —

2. Periodic Inspection and Maintenance

t

• Be sure to perform the following maintenance and inspection so

that the machine delivers its full performance and functions, and

to protect the machine and tape. Also, perform the following

maintenance items after completing the repair work, regardless

of the number of hours the machine has been operated by the

user.

2-1. Rotary Drum Cleaning

1) Press a wiping cloth (Ref. No. J-2) moistened with cleaning

fluid (Ref. No. J-1) lightly against the rotary drum. Rotate the

upper drum with a super-fine applicator slowly in the counter clockwise direction to clean the rotary drum.

Caution: Never rotate the rotary drum by turning on the main power of

the motor or rotate it in the clockwise direction. Never move the

cloth vertically against the head tip, as this will surely damage

the video head; the video head must not be cleaned by any other

different methods.

TG2

TG1

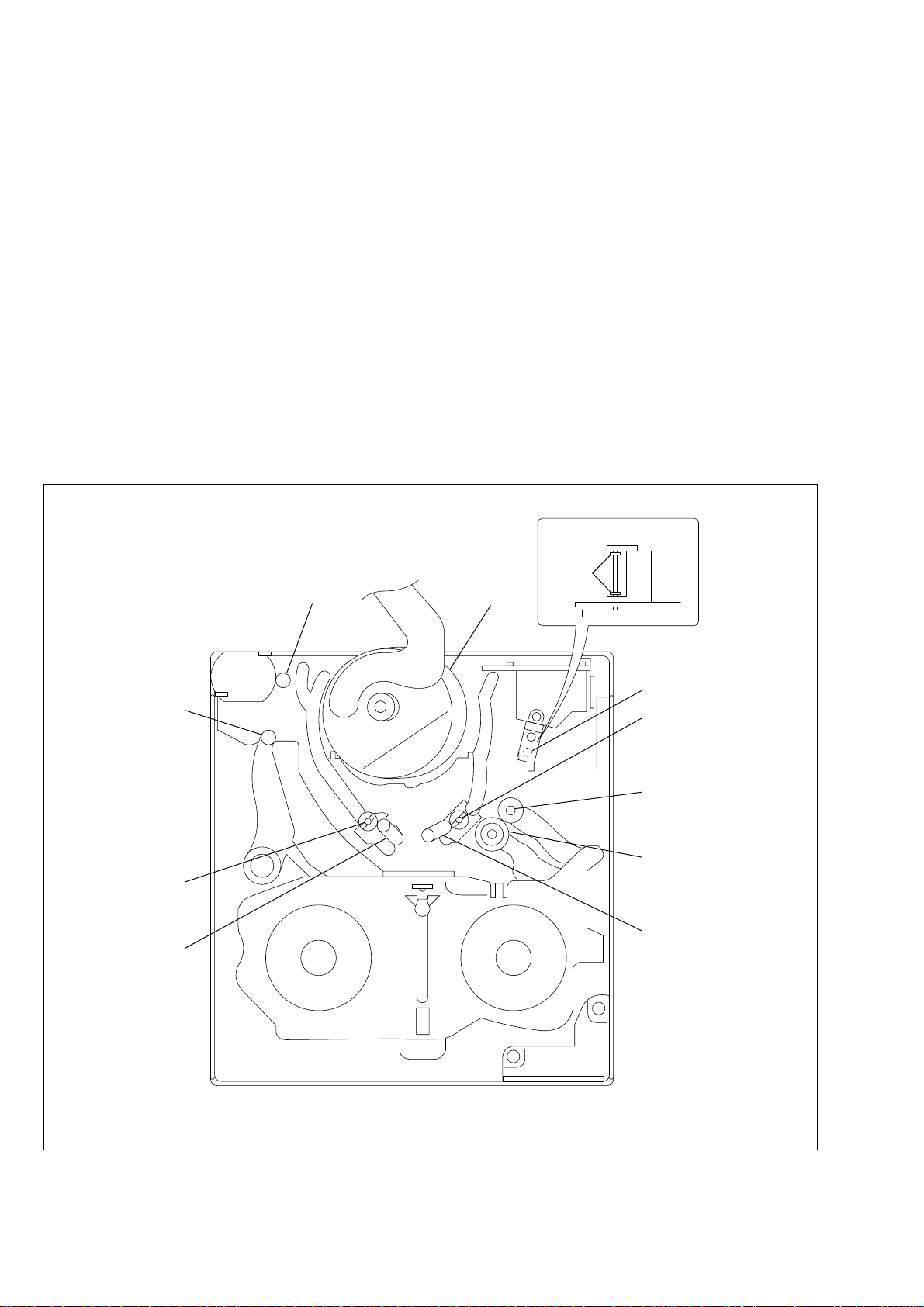

2-2. Tape Path System Cleaning

(Refer to Fig. 2-1.)

1) Set the EJECT state. Clean the tape running path (TG-1, -2, 3, -4, -5, -6 and -7, pinch roller and capstan shaft) and lower

drum with a super-fine applicator (Ref. J-3) moistened with

cleaning fluid.

Note 1: Be careful not to allow oil or grease of the various link mechanisms

to get on the super-fine applicator (Ref. J-3).

Note 2: Once the super-fine applicator has been moistened with alcohol,

do not use it to clean other mechanical parts such as the tape guide.

However, the pinch roller is cleaned with alcohol.

Note 3: When cleaning the capstan shaft, be carefull not to move the oil

seal. If the oil seal is moved, oil will leak.

Capstan shaft cleaning

Oil seal

Drum

Capstan shaf

TG6

TG3

TG4

TG7

Pinch roller

TG5

Fig. 2-1

— 4 —

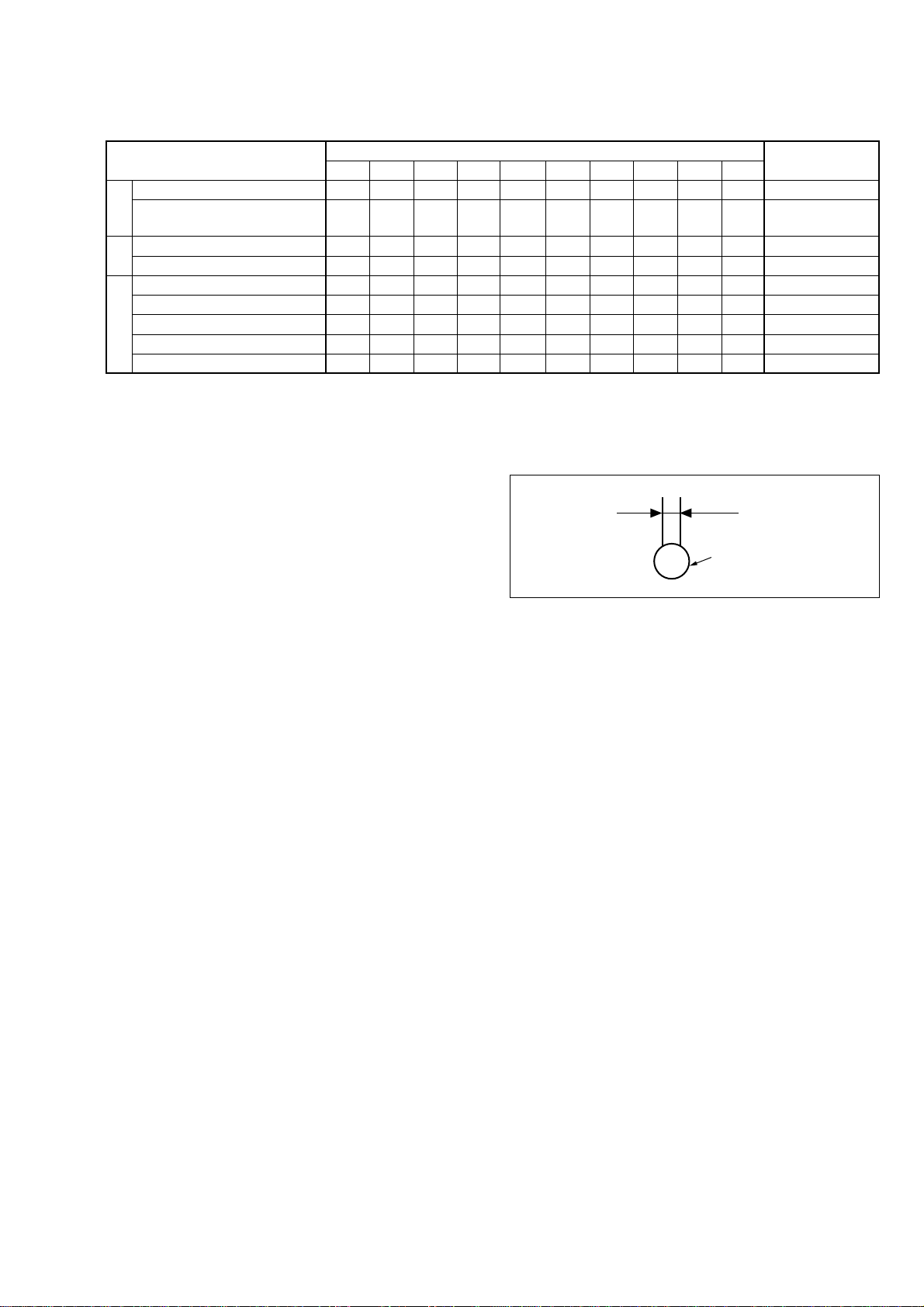

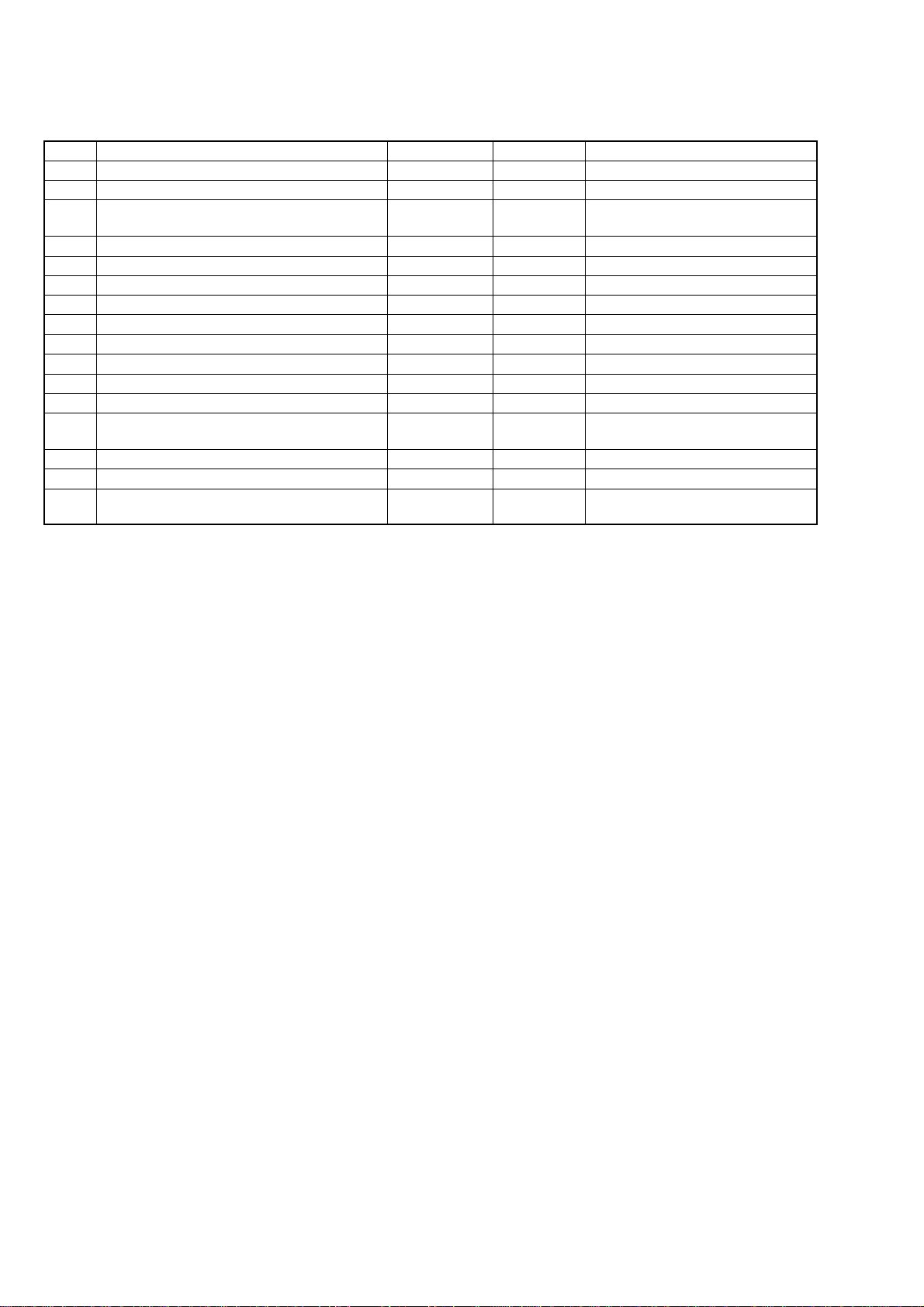

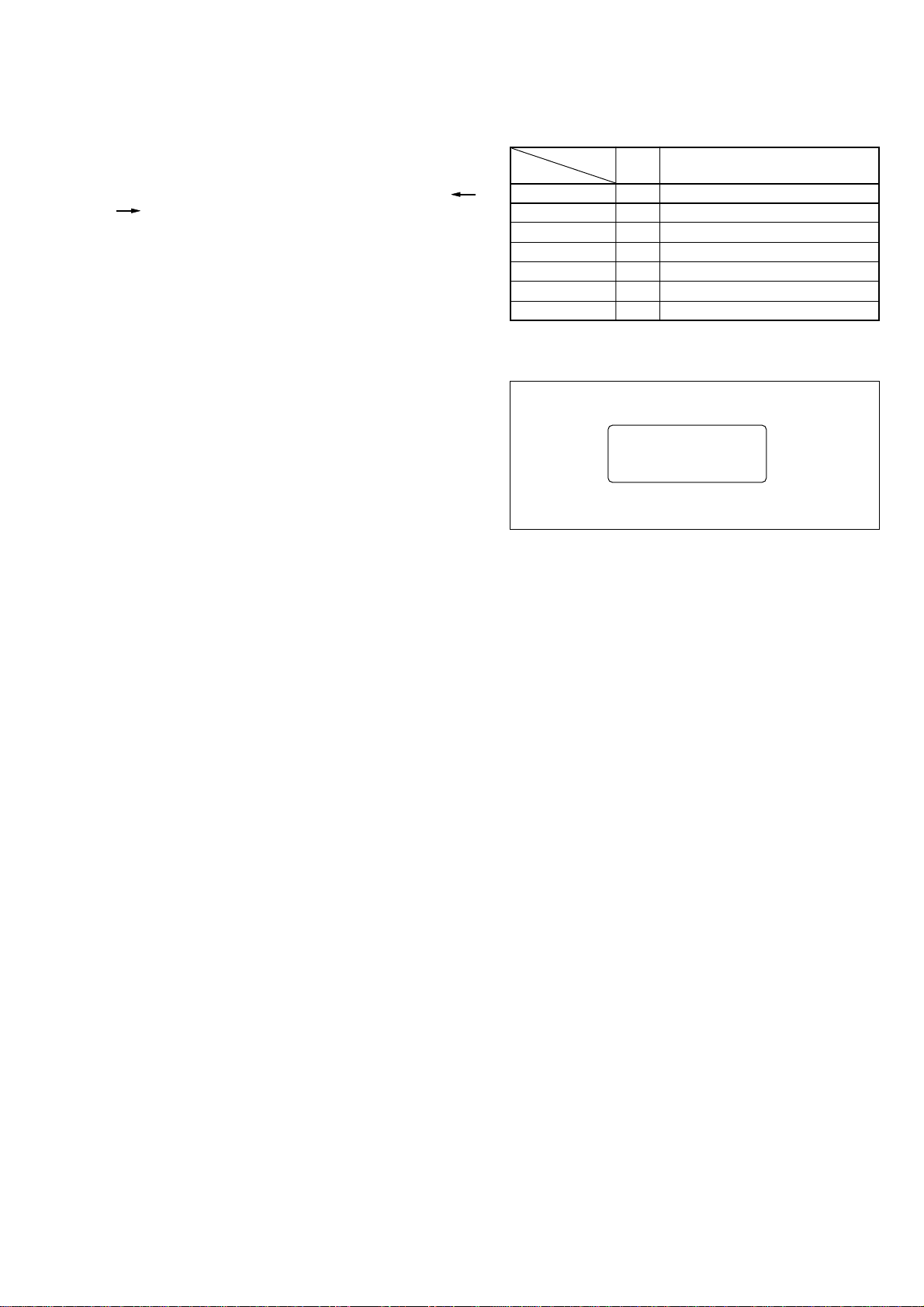

2-3. Periodic Inspection List

r

Maintenance and inspection item

Tape running surface cleaning

Rotary drum cleaning and

degaussing

Capstan bearing

Loading motor

Drive

mechanism

Abnormal sound

Back-tension measurement

Brake system

Brake system

FWD/RVS torque measurement

Performance check

Note 1: When the machine is overhauled, replace the parts referring to the

Note 2: Grease

above list.

• Be sure to use the specified grease only. (If grease of different

viscosity is used, it can cause various troubles.)

• The grease used for bearings must not contain any dust or other

matter, otherwise excessive abr asion and seizure of the bearing

could occur.

• A drop of grease means the amount of grease as shown in the

illustration, which is the amount that is attracted to the tip of a

rod of 2 mm diameter.

• FLOIL grease (SG-941): Part No. 7-662-001-39

500

a

a

—

—

✩

—

—

—

—

1000

a

a

✩

✩

✩

✩

✩

✩

✩

1500

a

a

—

—

✩

—

—

—

—

Operating hours (H)

2000

2500

3000

a

a

a

a

a

a

✩

—

✩

✩

—

✩

✩

✩

✩

✩

—

✩

✩

—

✩

✩

—

✩

✩

—

✩

3500

a

a

—

—

✩

—

—

—

—

4000

a

a

✩

✩

✩

✩

✩

✩

✩

4500

a

a

—

—

✩

—

—

—

—

2 mm diamete

Fig. 2-2

5000

a

a

Remarks

Be careful not to attach oil

Be careful not to attach oil

✩

✩

✩

✩

✩

✩

✩

a: Cleaning, ✩: Check

Grease

— 5 —

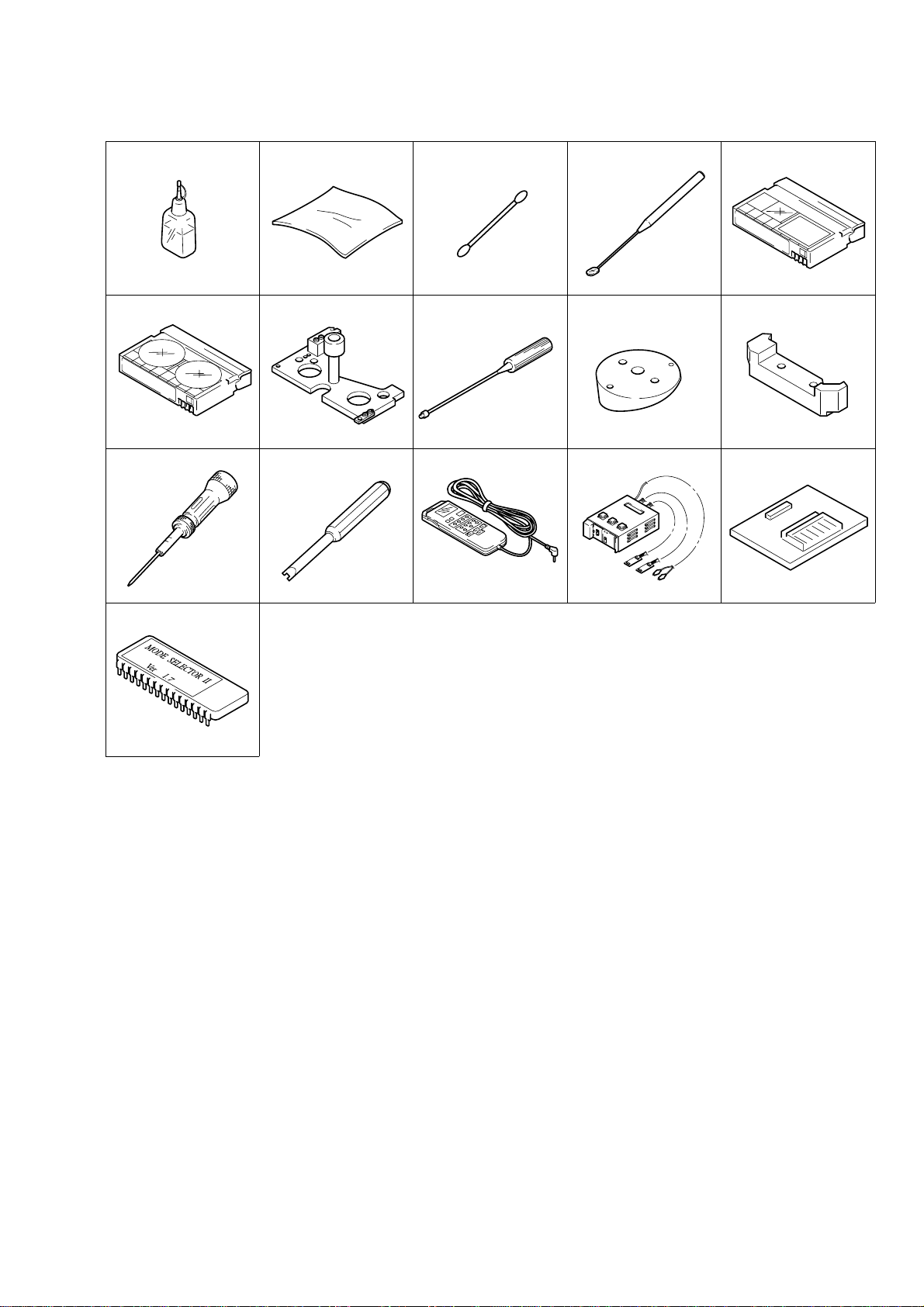

2-4. Service Jigs and Tools

Ref. No.

J-1

Cleaning fluid

J-2

Wiping cloth

Super-fine applicator

J-3

(made by Nippon Applicator (P752D))

J-4

Mirror (small oval type)

J-5

Tracking tape (XH2-1) (NTSC, PAL)

J-6

Mini DV torque cassette

J-7

TG1 adjustment jig (FWD position adjustment)

J-8

TG1 FWD adjustment screwdriver

J-9

Dummy drum (for TG36) (J mechanism)

J-10

TG36 gauge

J-11

Torque screwdriver

J-12

Tape path screwdriver

Adjustment remote commander

J-13

(RM-95 upgraded) * Note 1

J-14

Mode Selector II

J-15

Mode Selector II conversion board (J)

Mode Selector II ROM (supporting J mechanism)

J-16

* Note 2

Other required equipment: Oscilloscope

Note 1: If the microprocessor in the adjustment remote commander is not

the new one (UPD7503G-C56-12), the pages cannot be switched.

In this case, replace it with the new microprocessor (8-759-148-

35).

Name

Y-2031-001-0

7-741-900-53

J-6080-840-A

8-967-997-01

J-6082-360-A

J-6082-492-A

J-6082-364-A

J-6082-490-A

J-6082-491-A

J-9049-330-A

J-6082-026-A

J-6082-053-B

J-6082-282-B

J-6082-493-A

J-6082-314-E

Part code

—

Jig inscription

GD-2038

Used for

Tape path

Tape path

For TG1 FWD position adjustment

For tape path adjustment

General adjustment (ROM version 1.7)

ROM for Mode Selector II

Note 2: This is the ROM used for upgrading the version of Mode Selector

II to enable it to be used for the J mechanism.

— 6 —

J-1 J-2 J-3 J-4 J-5

J-6 J-7 J-8 J-9 J-10

J-11 J-12 J-13 J-14 J-15

J-16

Fig. 2-3

— 7 —

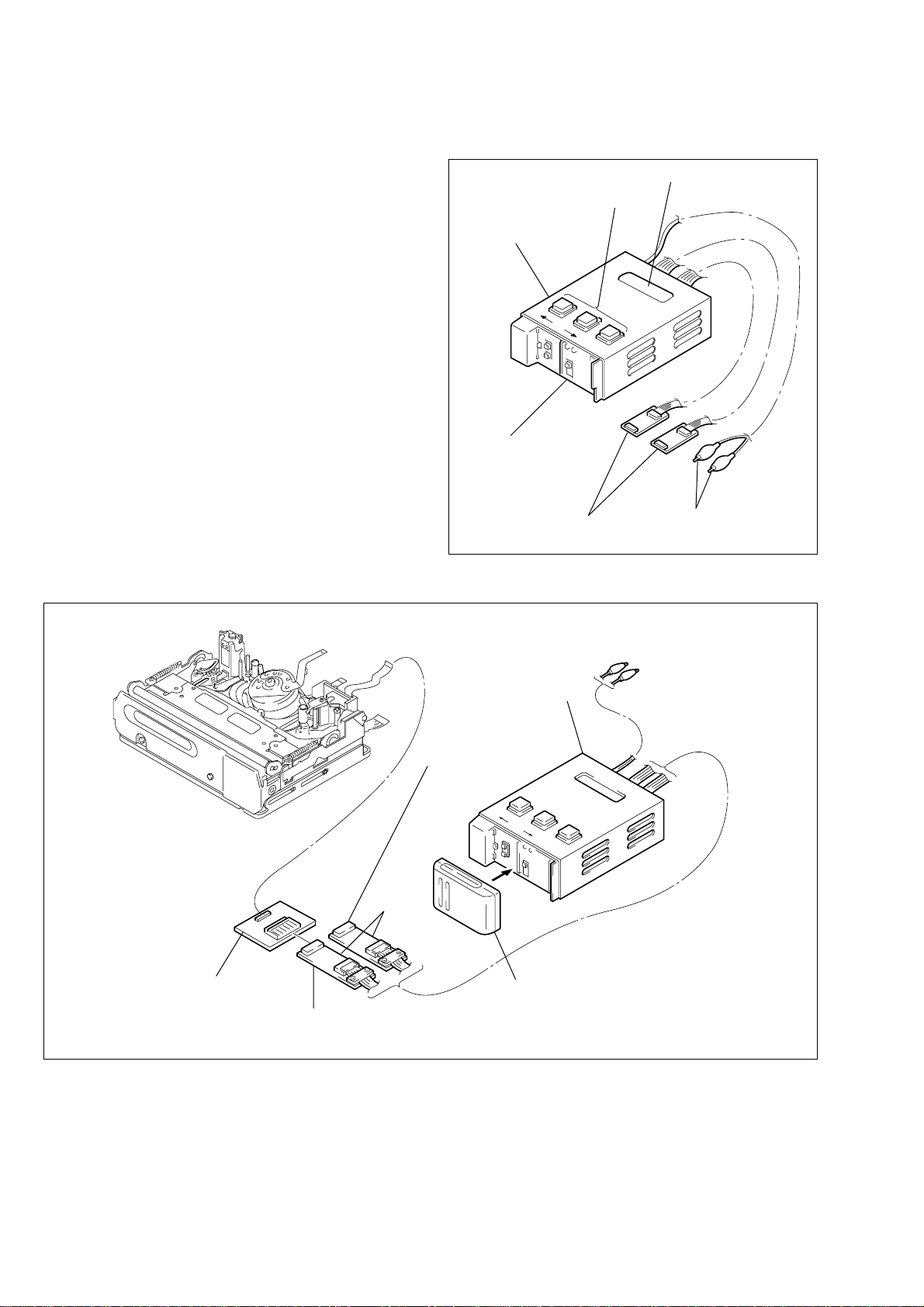

2-5. Mode Selector II Operating Procedure

2-5-1. Introduction

The Mode Selector II is a mechanism drive tool that assists

maintenance work of the various mechanism decks. It has the

following functions.

1. Manual Test

In this mode, the motor of the mechanism deck is powered only

during the period while the switch is turned on manually. Using the

Manual Test, the operator can freely control the motor of the

mechanism deck.

2. Step Test

In this mode, the motor of the mechanism deck is kept turned on

until the mechanical status is changed from the present mechanical

status that is obtained from the sensor information. The Step T est is

used to confirm a series of movements of the mechanism deck.

LCD display screen

Selector button

Mode Selector II

(Ref. No. J-14)

RVS

FF

SEL

3. Auto Test

The Mode Selector II stores the status transition table in its memory

as data indicating the respective modes of the mechanism deck.

The status transition table can be used to confirm whether a

mechanism deck is operating normally or has abnormality from a

series of movements of a mechanism deck. If an abnormal status

transition is detected during operation, the “NG” indication appears

and the mechanism stops moving.

Mode Selector II (J-6082-282-B) connection diagram

J mechanism

External battery is

connected here as

a power supply

Relay board

(already connected)

Mode Selector II

Connector (black) 6-pin

(not used in J mechanism)

Alligator clip

Fig. 2-4

Alligator clip

(not used in J mechanism)

Mode Selector II

conversion board (J)

(Ref. No. J-15)

Relay board

Battery such as NP-55, NP-77

(power supply)

Connector (white) 6-pin

Fig. 2-5

— 8 —

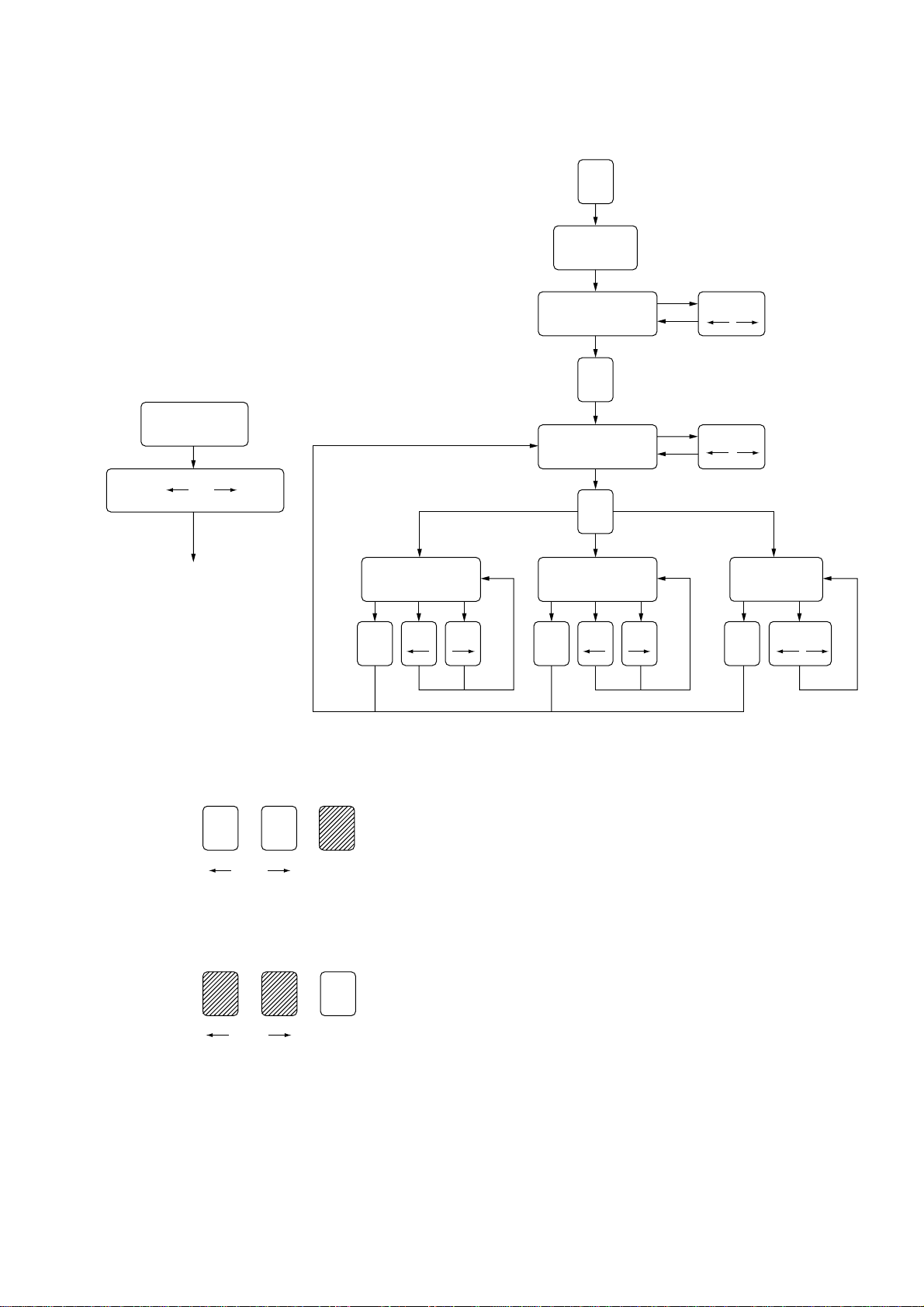

2-5-2. Operation

SEL

SEL

SEL

STEP TEST

MANUAL TEST

AUT O TEST

POWER ON

MECHA SELECT

MODE SELECT

From any status

Press RVS and FF for

2 sec. simultaneously

Main power is

turned off

RVS, FF

RVS, FF

RVS, FFSELRVS FFSELRVS FFSEL

1. Operation Flow Chart

Note: The ROM in the Mode Selector II supports the J mechanism.

2. Mode Selector II Power On

Turn on the main power of the Mode Selector II as follows.

Press the SEL button.

3. Mode Selector II Power Off

Turn off the main power of the Mode Selector II as follows.

Press the RVS and FF buttons at the same time for 2 seconds or

longer while the power is on.

RVS FF SEL

RVS FF SEL

— 9 —

4. Mecha Select

)

)

)

When the main power is turned on, the MECHA SELECT display

appears on the LCD screen. Select the desired mechanism name

using the R VS and FF buttons. Selection is complete when the SEL

button is pressed. (Fig. A shows the J mechanism.)

5. Test Type Select

Using the RVS and FF buttons, select a desired test type from the

three types of “MANUAL”, “STEP” and “AUTO”. Selection is

complete when the SEL button is pressed.

6. Manual Test

In this test, the motor of the mechanism deck is turned on only

during the period while the RVS or FF button is pressed manually.

MECHA SELECT

J

Pressing the RVS or FF button

changes the mechanism name.

Fig. a

TEST TYPE SELECT

MANUAL

Pressing the RVS or FF button cycles

among MANUAL, STEP, AUTO in this order.

Fig. b

Mechanism name

Present mode

Motor ON/OFF

J MANUAL OFF

STATUS

7. Step Test

In this test, the direction of motor movement is determined by the

RVS and FF buttons. The motor of the mechanism deck is kept

turned on until the mechanical status is changed from the present

mechanical status that is obtained from the sensor information.

8. Auto Test

In this test, the mechanism deck is tested as to whether it performs

a series of movements correctly in accordance with the operation

sequence that is memorized earlier for each type of deck, by checking

the output signals from sensors with the stored memory. Turning

on the RVS or FF button performs the same operation.

Present status of sensor appears. (example: EJ

Fig. c

Mechanism name

Present mode

Motor ON/OFF

J STEP OFF

STATUS

Present status of sensor appears. (example: EJ

Fig. d

Mechanism name

Present mode

Motor ON/OFF

J AUTO OFF

STATUS

Present status of sensor appears. (example: EJ

Fig. e

— 10 —

2-5-3. Mechanism Status (Position) Transition Table Using Mode Selector II

After selecting a mechanism deck, select either the MANUAL or

STEP test (not AUTO) using the Mode Selector II. The desired

mechanism status (position) can be specified by pressing the RVS

or FF button. (The selected status appears on STATUS.)

EJyULEySRyGLySTOPyRP

2-5-4. Battery Alarm Indication

When the level of the battery used to supply power to this system

decreases, this display appears asynchronously . When this happens,

all operations are disabled and the battery must be replaced.

MD name

Code

ABC

001

101

100

110

010

011

J Mechanism

1

EJ

2

ULE

3

SR

4

GL

5

STOP

6

RP

BATT DOWN

CHANGE PLEASE

Fig. f

— 11 —

3. Check, Adjustment and Replacement of Mechanical Parts

y

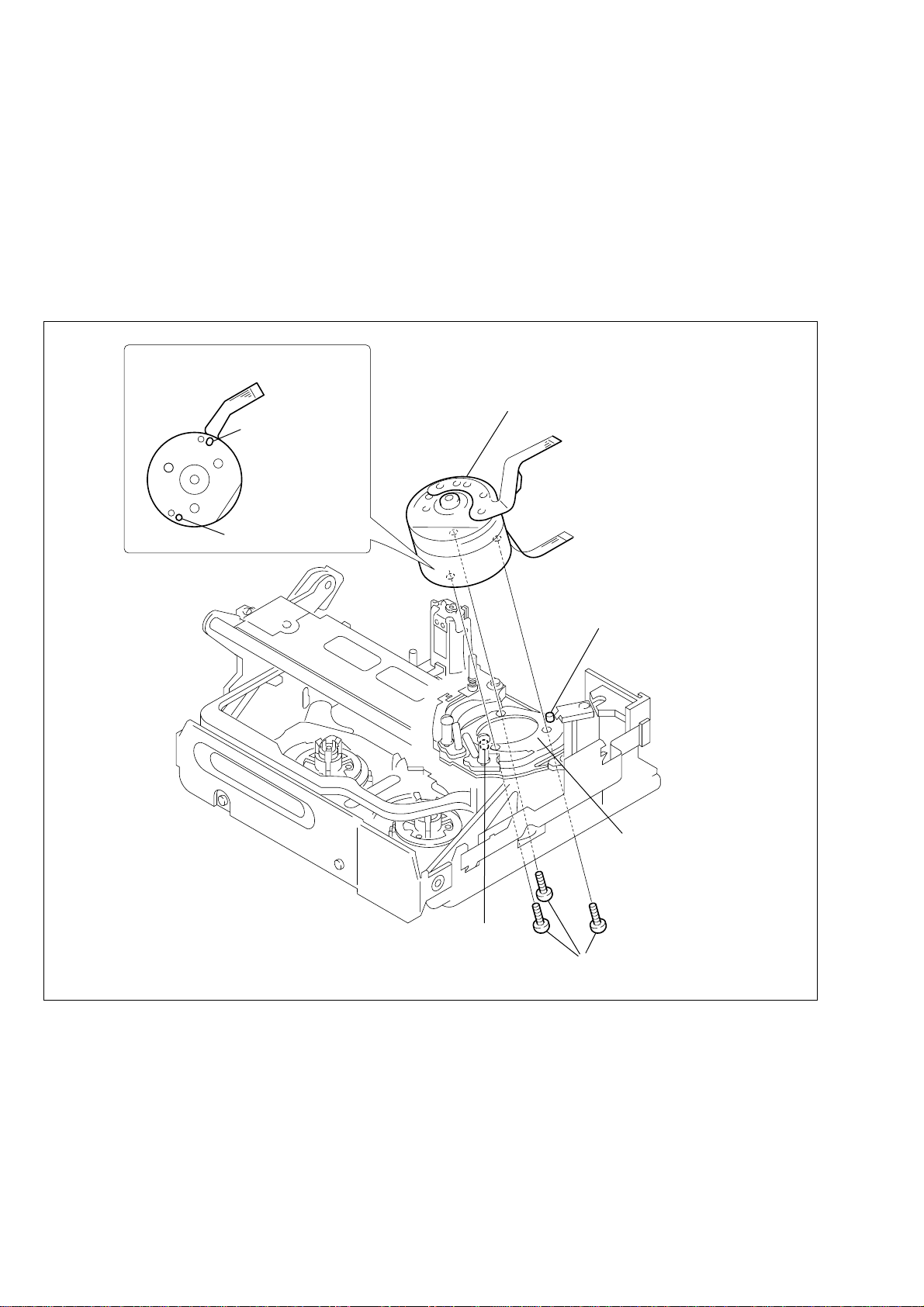

3-1. Drum

1. Removal procedure

1) Loosen the three screws (M1.4 × 2) 1 fixing the drum and

remove the drum.

Drum (rear view)

Slot (reference hole A)

Hole (reference hole B)

2. Attachment procedure

1) Align the two reference holes A and B on the rear of the drum

with the position setting reference pins A and B of the drum

base assy.

2) Install the drum with the three screws (M1.4 × 2) 1 and tighten

the screws in order from A, then B and finally C.

Tightening torque: 0.059 ± 0.01 N•m (0.6 kg•cm)

3) Clean the drum referring to section 2-1.

4) Perform the tape path adjustment. (Refer to section 4, “Tape

Path Adjustment”.)

Drum

Reference pin B

Fig.3-1

Reference pin A

Drum base block ass

C

A

B

1 Three screws (M1.4 × 2)

— 12 —

Loading...

Loading...