Page 1

ICD-ST25

SERVICE MANUAL

Ver 1.0 2004.03

SPECIFICATIONS

Recording media Built-in flash memory 32MB,

Recording time See page 11.

Frequency range • ST: 80 Hz - 13,500 Hz

Speaker Approx. 28 mm (1

Power output 300 mW

Input/Output • Microphone jack (minijack, stereo)

Playback speed control +100% to -50% (DPC)

Power requirements Two LR03 (size AAA) alkaline batteries: 3 V DC

Dimensions (w/h/d)

Mass (incl. batteries) 75 g (2.65 oz)

Supplied accessories Stereo Ear Receiver × 1

Design and specifications are subject to change without notice.

Stereo/Monaural recording

• SP: 80 Hz - 7,000 Hz

• LP: 80 Hz - 3,500 Hz

– input for plug in power, minimum input level

0.6 mV, 3 kilohms or lower impedance microphone

• Headphones jack (minijack, stereo)

output

for 8 - 300 ohms ear receiver

–

• USB connector

•

DC IN 3V jack (excluding the Korean and the

People’s Republic of China models)

(not incl. projecting parts and controls)

41.5 × 103.6 × 13.3 mm (1 11/16 × 4 1/8 × 17/

USB Connecting cable × 1

Application Software (CD-ROM) × 1

Carring Case x 1

LR03 (size AAA) alkaline batteries × 2*

*For the United States model only

1

/8 in.) dia.

US Model

Canadian Model

AEP Model

UK Model

Korea Model

Tourist Model

in.)

32

9-877-590-01

2004C1678-1

© 2004.03

IC RECORDER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

Page 2

ICD-ST25

TABLE OF CONTENTS

1. GENERAL ·········································································· 3

2. DISASSEMBLY

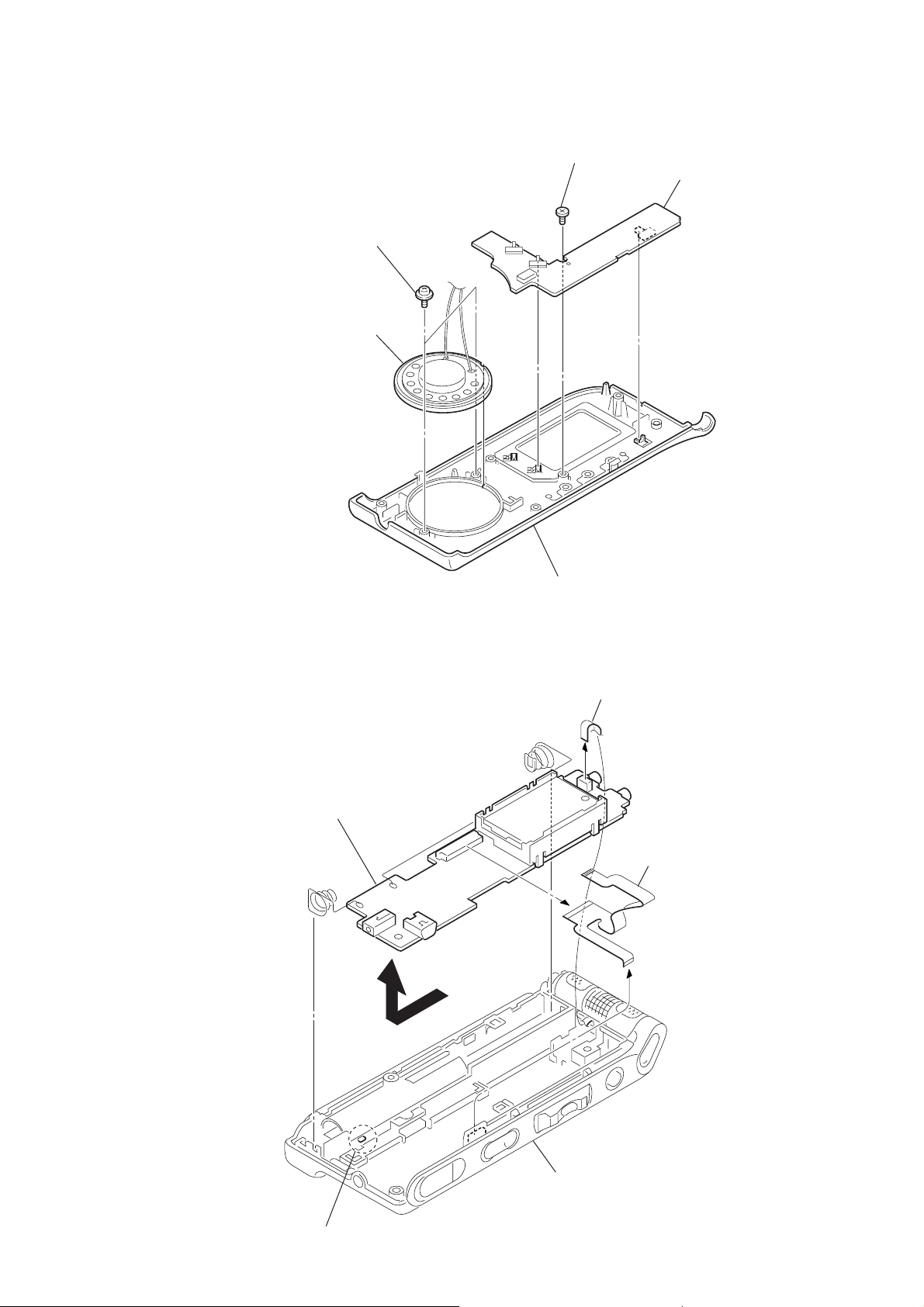

2-1. Case Block Assy ··························································· 4

2-2. F-SW Board ·································································· 5

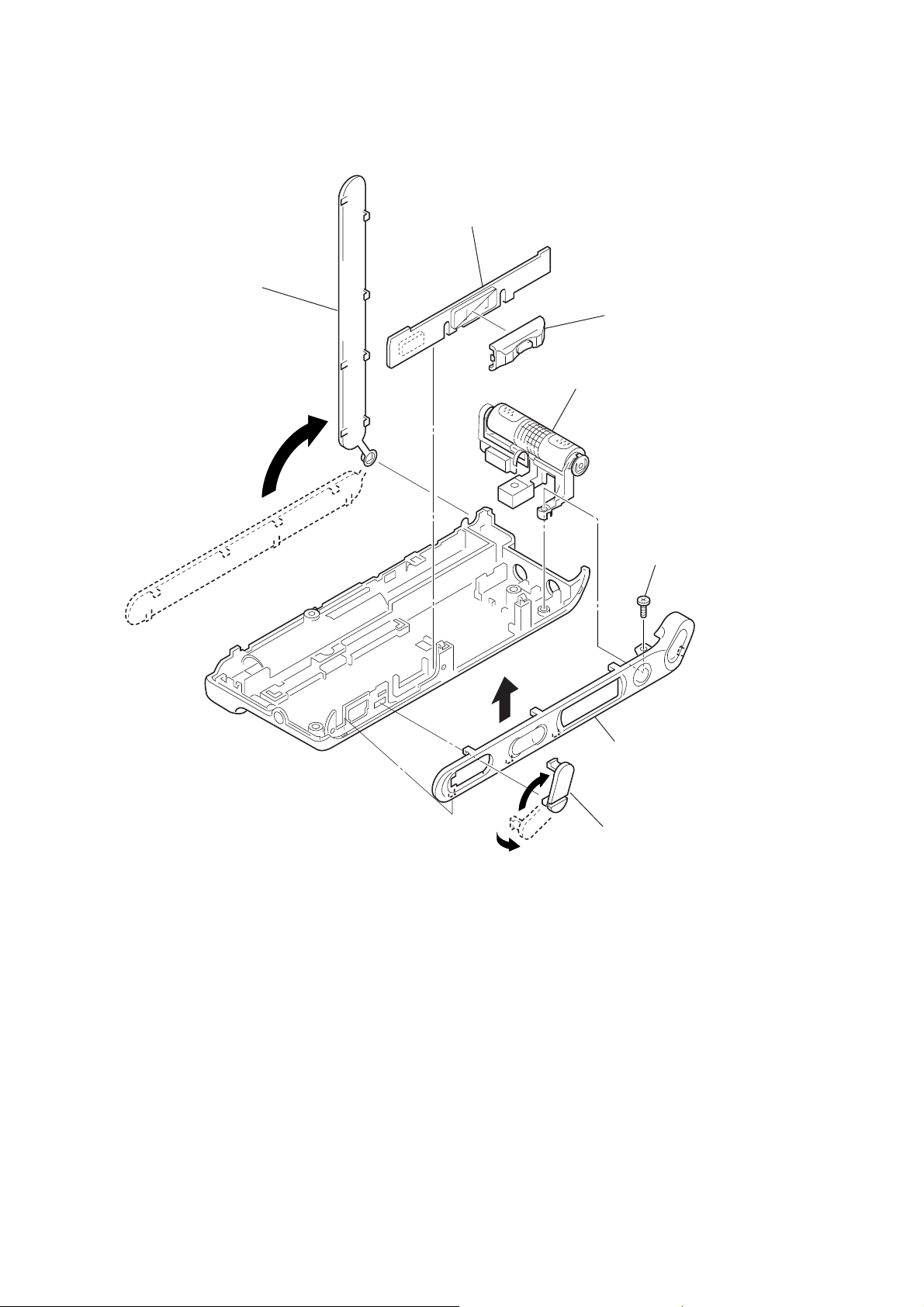

2-3. MAIN Board ································································· 5

2-4. S-SW Board, Microphone Block Assy ························· 6

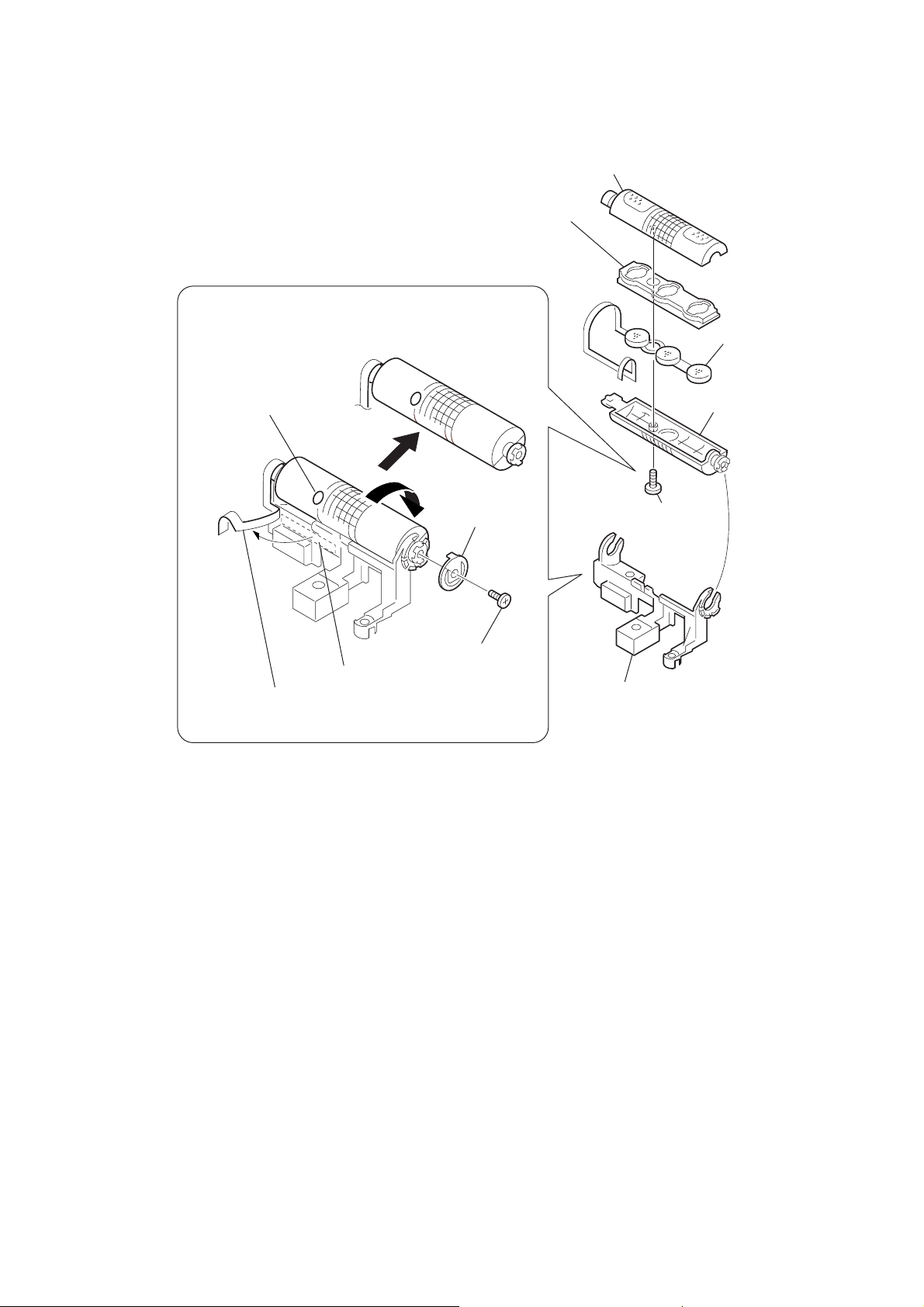

2-5. Microphone Unit··························································· 7

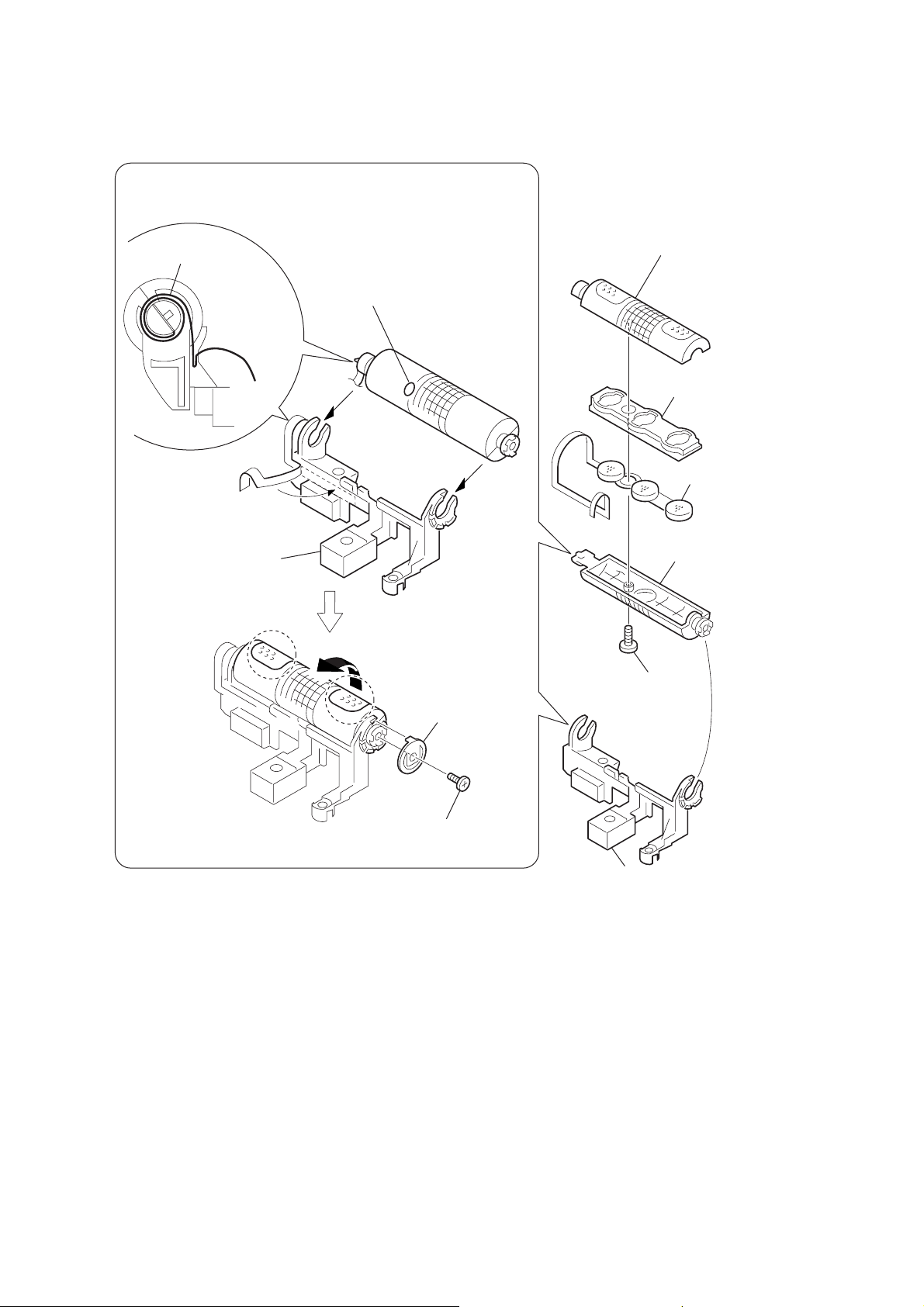

2-6. The Cautions At The Time Of A Microphone

Block Assy··································································· 8

3. TEST MODE······································································ 9

4. DIAGRAMS

4-1. Block Diagrams

– MAIN Section -1 – ·················································· 13

– MAIN Section -2 – ·················································· 14

– PANEL/POWER Section –······································ 15

4-2. Printed Wiring Board – MAIN Board (Side A) – ······· 16

4-3. Printed Wiring Board – MAIN Board (Side B) – ······· 17

4-4. Printed Wiring Board – F-SW Board –······················· 18

4-5. Printed Wiring Board – S-SW Board –······················· 19

4-6. Schematic Diagram – MAIN Board (1/5) – ··············· 20

4-7. Schematic Diagram – MAIN Board (2/5) – ··············· 21

4-8. Schematic Diagram – MAIN Board (3/5) – ··············· 22

4-9. Schematic Diagram – MAIN Board (4/5) – ··············· 23

4-10. Schematic Diagram – MAIN Board (5/5) – ··············· 24

4-11. IC Pin Function Descriptions······································ 29

5. EXPLODED VIEWS

5-1. Upper Lid Block ························································· 34

5-2. Case Block ·································································· 35

6. ELECTRICAL PARTS LIST······································· 36

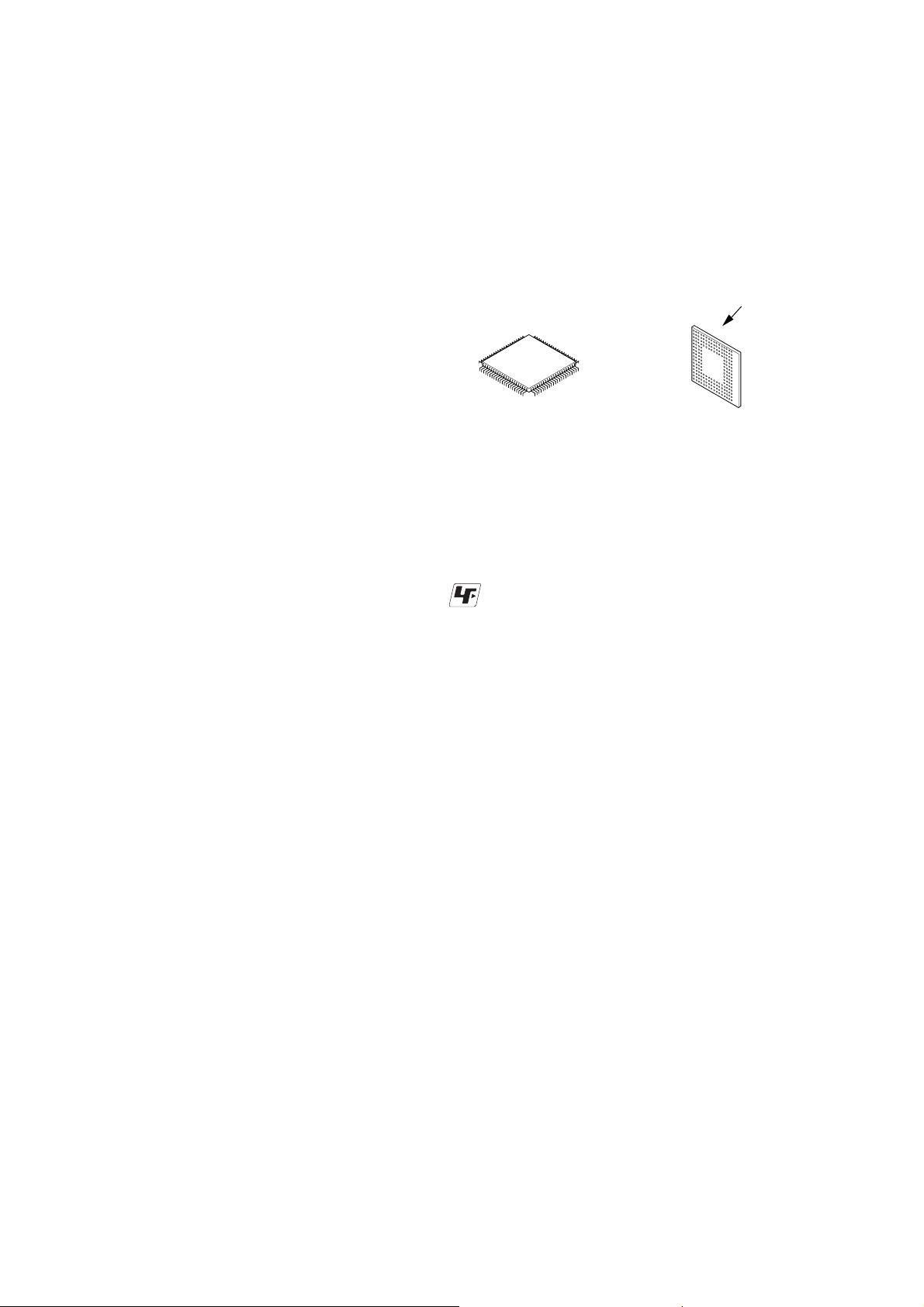

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

✩Replacement of IC6001 used in this set requires a special tool.

• The voltage and waveform of CSP (chip size package) cannot be

measured, because its lead layout is different from that of con ventional IC.

• Lead layouts

surface

Lead layout of

conventional IC

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky , less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

CSP (chip size package)

2

Page 3

Index to Parts and Controls

2 Press the jog lever (x•B).

The month digits will flash.

3 Set the month and day in

sequence, then press the jog lever

(x•B).

The hour digits will flash.

5

Set the time.

1 Press the jog lever up or down

(>/.) to select the digits of

the hour.

2 Press the jog lever (x•B).

The minute digits will flash.

3 Set the minute.

4 Press the jog lever (x•B).

The menu mode will be

displayed again.

Note

If you do not press the jog lever

(x•B) for more than one minute,

the clock setting mode is cancelled

and the window will return to

normal display.

6

Turn the jog lever toward

MENU.

The window will return to normal

display.

1 If the unit is left unused for more than 3

seconds in the stop mode after the clock

is set, the display will show the current

time (page 27).

v

Refer to the pages indicated in parentheses for details.

Front

SECTION 1

GENERAL

Rear

ICD-ST25

This section is extracted from

instruction manual.

qj

qk

ql

wa

1 Built-in microphone (12, 14)

2 Built-in microphone (12, 14)

3 OPR (operation) indicator

(12, 20)

4 DIRECTNL (directional)

switch (14)

5 ERASE button (37)

6 A-B

button (34, 44)

7 DIVIDE/

button (33, 40)

8 Display window (24)

9 DPC ON/OFF switch (31)

Step 2: Setting the Clock

You need to set the clock to use the alarm function or record the date and

time.

Clock setting display appears when you insert batteries for the first time,

or when you insert batteries after the unit has been without batteries for a

certain period of time. In this case, proceed from step 4.

1

Turn the jog lever toward

MENU.

The menu mode will be displayed in

the display window.

2

Press the jog lever up or down

(>/.) to select “SET DATE”.

(repeat)/PRIORITY

(bookmark)

Jog lever

Press down (.).

0 Speaker

K zREC (record) /REC

PAUSE button (12, 35)

L xSTOP button (13, 21)

M Jog lever

FOLDER/MENU/

.(review/fast backward)/

> (cue/fast forward)/

x• B (play/stop•enter)

N VOICE UP (Digital Voice

Up) switch (30)

O VOL (volume) +/– buttons

(20)

Press up (>).

Turn toward MENU.

Press the center

(x•B).

w;

qh USB connector (56)

qj m (microphone) jack (17)

qk i (headphones) jack (18, 20)

ql HOLD switch (29, 51)

w;

DC IN 3V jack (6)

For Korean and the People’s

(

Republic of China Models,

this jack does not exist.)

wa

Battery compartment (6)

3

Press the jog lever (x•B).

The date and time setting window is

displayed. The year digits will flash.

4

Set the date.

1 Press the jog lever up or down

>/.

(

the year.

) to select the digits of

3

Page 4

ICD-ST25

Note : Disassemble the unit in the order as shown below.

SET

2-1.

CASE BLOCK ASSY

(Page 4)

SECTION 2

DISASSEMBLY

2-3.

MAIN BOARD

(Page 5)

2-4.

S-SW BOARD,

MICROPHONE BLOCK ASSY

(Page 6)

2-5.

MICROPHONE UNIT

(Page 7)

Note : Follow the disassembly procedure in the numerical order given.

2-1. CASE BLOCK ASSY

1

two screws

(+B 1.7

×

7)

2-2.

F-SW BOARD

(Page 5)

two claws

claw

3

Remove two solders

of the MAIN board.

two claws

claw

4

case block assy

2

claw

flexible board

4

Page 5

2-2. F-SW BOARD

d

1

two screws

(1.7 × 2.5)

2

speaker (2.8cm)(SP3001)

3

tapping screw

(1.7 × 2.5)

4

F-SW boar

ICD-ST25

2-3. MAIN BOARD

5

MAIN board

4

5

upper lid block assy

1

flexible board of

microphone unit

2

flexible board

3

case assy

claw

5

Page 6

ICD-ST25

y

2-4. S-SW BOARD, MICROPHONE BLOCK ASSY

6

ornament (L)

5

S-SW board

4

button (5D)

7

microphone block assy

2

tapping pan screw

(M1.4

3

ornament (R) block ass

1

×

3)

lid (connector)

6

Page 7

2-5. MICROPHONE UNIT

t

4

Microphone part is turned in the direction of arrow A,

and it removes in the direction of arrow

screw hole part

B

8

microphone cushion

B

.

7

microphone cover

9

microphone uni

0

microphone case

ICD-ST25

adhesive sheet

3

Microphone unit flexible

board is removed.

A

2

1

pan

tapping screw

(M1.4

click plate

×

2)

6

pan

(M1.4

5

microphone base

tapping screw

×

4.5)

7

Page 8

ICD-ST25

2-6. THE CAUTIONS AT THE TIME OF A MICROPHONE BLOCK ASSY

microphone unit

flexible board

microphone base

2

It inserts in a microphone base.

screw hole part

3

It turns in the direction of an arrow.

click plate

microphone cover

1

pan

tapping screw

(M1.4

microphone cushion

microphone unit

microphone case

×

4.5)

4

pan

tapping screw

(M1.4

×

2)

microphone base

8

Page 9

SECTION 3

DSP STEREO through mode / MIC : L / MUTE : ON / VOL-LEVEL : 12

t "L / on / 12 / DSP ST"

DSP MONO through mode / MIC : H / MUTE : OFF / VOL-LEVEL : 23

t "H / oF / 23 / DSP MO"

1k sine wave output mode / MUTE : ON / VOL-LEVEL : 06 t "on / 06 / SIN"

:

:

DSP MO

SIN

DSP ST

AU IO DSP ST

23

DSP MO

oF

H

m

12

DSP ST

on

L

m

06

SIN

on

.

>

(select), (set)

x

x x x

x B

x B

TEST MODE

ICD-ST25

[Setting Method of the Test Mode]

To enter the test mode, turn on the HOLD . switch while pressing

the x key and VOL+ key at the same time with the power on.

[Exiting Method of the Test Mode]

Exit the test mode by turning off the power.

[Initial Status of the Test Mode]

When the test mode is set, the LCD display appears as shown below .

LCD display (Example)

69

101

01ST25

69

101

01

ST25

Iris(DSP) version : 69

SakuraR(CPU) version : 1.01

LPEC ST version : 01

Model code : ST25

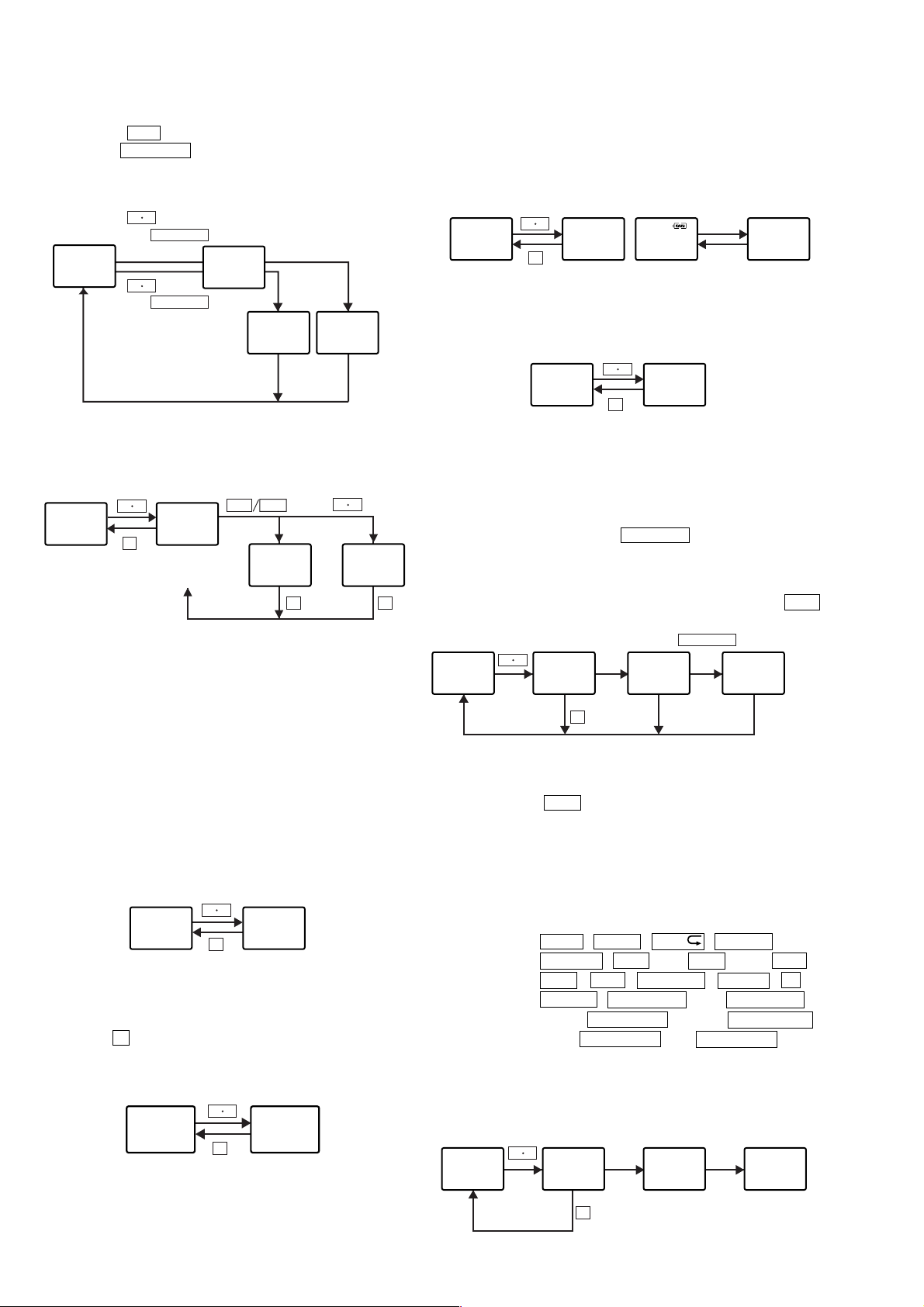

[Flow Chart of the Test Mode]

START

TEST MODE

>

.

.

>

>

>

>

>

RST

MENU

.

KEY

COUNT

.

USB

.

LED

.

BATTKEY

.

.

AU IO

.

.

.

LCD

SLEEP

BEEP

RTC

>

>

>

>

Initial status of test mode

Model code, LPEC ST,

>

F/W version display

>

.

[Operation in the Test Mode]

After entering the test mode, you can move within the test menu by

pressing the . / > key. You can move to the submenu by

pressing the x•B key. Then each test mode can be executed.

1. LCD test

• LCD is tested of all light-on and all light-off.

x B x B

LCD

x

ALL

LCD

:

OFF LCD

CHK LCD

ALL LCD

:

>

.

CBA

H

STSP

M

m

L

★

★

88

★

YM

888888

D E

REC

888

MM DS

LP

(select), (set)

(LCD off)

x x x

CHK

START

.

CHK

END

>

2. Audio test

Perform the through-playback and sine wave output.

• Contents of the submenu

DSP ST: DSP STEREO through mode

DSP MO: DSP MONO through mode

SIN: 1 kHz sine wave output mode

• Select the microphone sensitivity with the A-B

HtLtHtLtHt

...

switch.

•The VOR detection operation can be checked by the LED.

Sound: The red LED is turned on. No sound: The red LED is

turned off.

• MUTE can be set to “ON” or “OFF” with the ERASE key.

•The sound volume can be adjusted with the VOL+ key or

VOL- key during the audio test except the MUTE mode.

• In the directional microphone selection, ON/OFF of the

DIRECTNL switch is performed with the DIVIDE key.

DIRECTNL switch ON : The green LED is turned on.

OFF : The green LED is turned off.

• In the audio test mode the operation is performed according to

JACK detection.

•The microphone sensitivity, sound volume and MUTE (on/off)

are displayed on the LCD.

•The microphone sensitivity selection and the VOR test are

effective in the through-playback mode.

•The directional microphone selection is effective in the DSP

MONO through mode.

Turn off the power

(Extract the batteries or DC jack)

END

TEST MODE

9

Page 10

ICD-ST25

ON

LED

LED

x

x B

USB

OFF

VBUS

ON

VBUS

PC

LINK

HOLD.

ON

x

Suspend

mode

cut Vbuscut Vbus

Vbus

on

x B

RST

MENU

KEY

PUSH INIT

OK

ALL

x

All keys

are entered

In the case that

the initialization

and reset operation

end correctly.

(blinking)

x B

3. Sleep test

•Pressing the x•B key causes the set to enter the sleep state.

•When the HOLD . switch is ON, the LCD is turned off.

When OFF, the LCD is turned on.

•Press any keys to exit the sleep state.

x B

(with HOLD.

OFF status)

SLEEP

x B

(with HOLD.

ON status)

SOON

INSLEEP

(LCD OFF)

any keys any keys

4. Beep test

• Beep sound of 1.3 kHz or 2 kHz is output.

>

x B

BEEP 1.3K

x

2.0K

1.3K

:

:

.

(select), (set)

x B

1.3K 2.0K

x x

7. Battery remaining power and DC IN test

•The detected A/D value (hexadecimal) of the battery remaining

power is displayed. When DC jack is inserted, the battery mark

on the LCD is turned off.

DC jack

x B

x

FF

BATTBATT BATTBATT

is inserted

DC jack

is extracted

8. LED test

• LEDs (OPR: red and green, BL: green) are all turned on.

9. USB test

• When the menu starts the USB self-check, either presence or

absence of the Vbus is judged.

(Vbus is present: “ON VBUS”, Vbus is absent: “OFF VBUS”)

•The USB driver always works re gardless of presence or absence

of the USB signal only when Vbus is available during the USB

test. At this time, turning on HOLD . causes the set to mov e

to the suspend state. Turning of f the Vb us causes the set to return

to the test menu.

• In the menumode if the Vbus is supplied, any key will not w ork.

Therefore the Vbus will be supplied after surely pressing the x•B

key.

5. RTC test

•Perform the function test of the RTC and EEPROM.

(1) RTC EEPROM test

Confirmation of writing, reading (verifying) and erasing of

arbitrary data with the specified registers.

(2) RTC clock function test

Confirmation that RTC updates the time to the microcomputer

at one second interval.

• OK, NG judgement is performed to the test result.

When NG, it is displayed which device RTC or EEPROM

becomes NG.

(All OK : "RTC OK" / RTC NG : "RTC BAD" / EEPROM NG

: "EEP BAD")

x B

OK

RTC

x

RTC

6. Key entry test

•When the any key is pressed, the entry ke y and the A/D converted

value (hexadecimal) of the three channel keys are displayed.

•When the x key is pressed, the A/D value of the ke y is displayed

while the key is depressed. When the key is released, the screen

returns to the test menu.

x B

oFFFF

KEYiFFKEY

x

10. Menu reset

•Pressing the x•B key causes the set to enter the menu

initialization standby state.

•When the following keys are all entered, the EEPROM

initialization (returning setting in the menu and user name to

default value) and formatting process (deleting all message files

in the flash memory) are executed. At the same time, the W ak eUp

signal is checked, too.

Check keys: VOL- , VOL+ , A-B , ERASE ,

DIVIDE , DPC ON , DPC OFF , . ,

x•B , > , FOLDER , MENU , x ,

z REC , HOLD

OFF ,

DIRECTNL ON

.

ON , HOLD

, and DIRECTNL

.

OFF, VOICE UP ON, VOICE UP OFF

• If all tests end in success, “-ALLOK-” is displayed. If initialization

in the EEPROM is NG, “INIT. NG” appears.

•Turn off the power to exit the test mode.

10

Page 11

11. Key durable test

•Pressing the x•B key makes the count to "------" and sets test

standby status.

Once more pressing the x•B key mak es the count to "000000"

and sets the key durable test.

In this mode any key input and slide switch operation are counted

and the number is displayed.

Turn off the power to exit this mode.

any keys or slide

switches operation

x B x B

KEY

COUNT

KEY

------

x

KEY

000000

Key durable

test

KEY

000001

ICD-ST25

11

Page 12

ICD-ST25

SECTION 4

DIAGRAMS

Note on Schematic Diagrams:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• C : panel designation.

• A : B+ Line.

•Power voltage is dc 3V and fed with regulated dc power

•Voltages and waveforms are dc with respect to ground

•Voltages are taken with a VOM (Input impedance 10 MΩ).

•Wav eforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

✩Replacement of IC6001 used in this set requires a spe-

• The voltage and waveform of CSP (chip size package)

: internal component.

supply from DC IN jack (J5001).

under no-signal (detuned) conditions.

no mark : PB

[]: REC

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

F : PB

L : REC

cial tool.

cannot be measured, because its lead layout is different

from that of conventional IC.

: Impossible to measure

∗

4

W or less unless otherwise

Note on Printed Wiring Boards:

• Y : parts extracted from the conductor side.

• b : Pattern from the side which enables seeing.

The other layers’ patterns are not indicated.

Caution:

Pattern face side: Parts on the pattern face side seen from

(SIDE B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(SIDE A) the parts face are indicated.

• MAIN board is multi-layer printed board. However, the

patterns of intermediate-layer have not been included in

the diagram.

✩Replacement of IC6001 used in this set requires a spe-

cial tool.

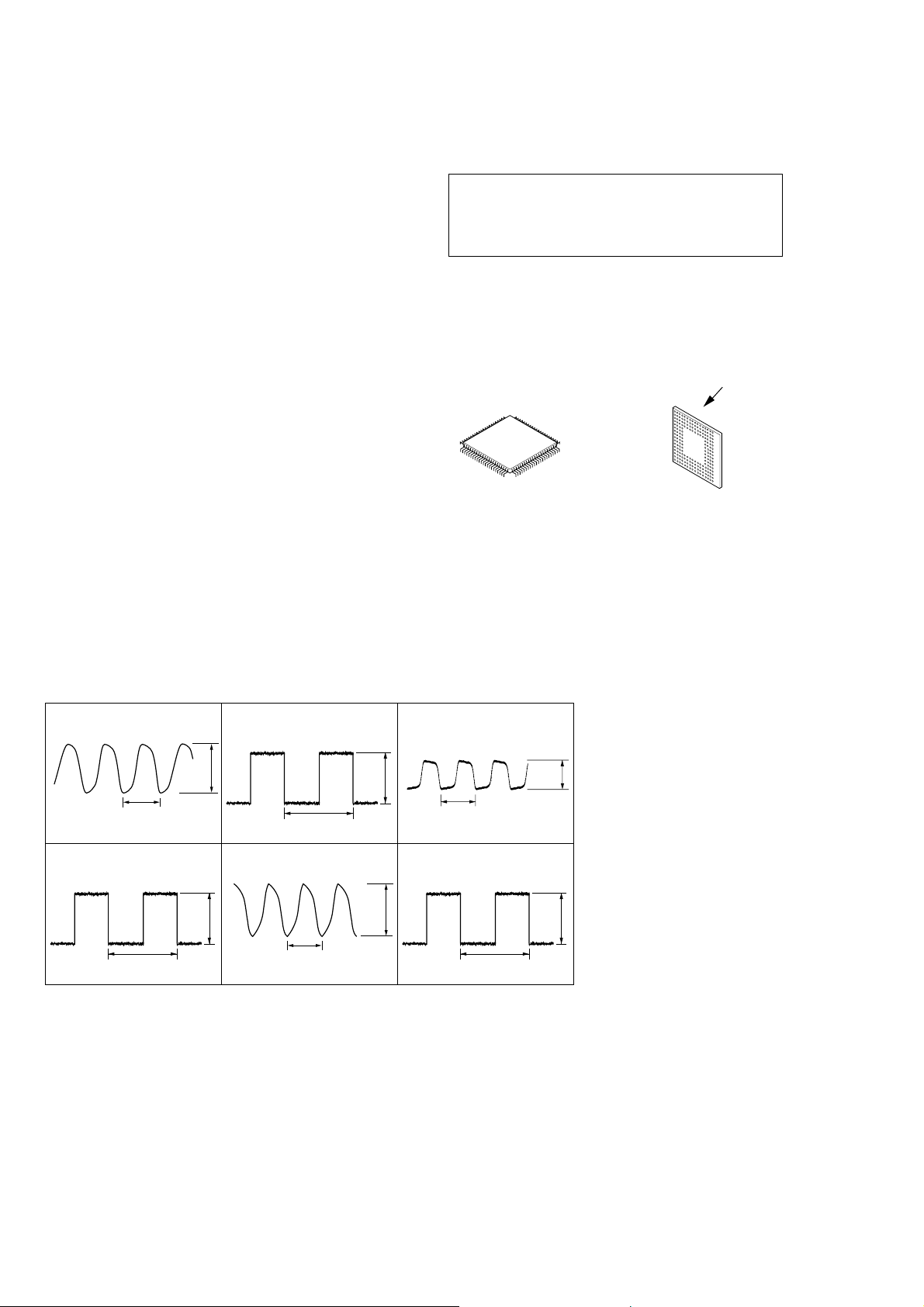

• Lead layouts

surface

Lead layout of

conventional IC

CSP (chip size package)

• WA VEFORMS

1

IC6003 3 (XXT)

88.5 ns

1 V/DIV, 40 ns/DIV

2

IC6003 1 (FOUT)

1 V/DIV, 40 ns/DIV

88.5 ns

3.3 Vp-p

4.1 Vp-p

3

IC3004 6 (MCLK)

1 V/DIV, 40 ns/DIV

4

IC7003 <z/, (XTAL)

1 V/DIV, 100 ns/DIV

88.5 ns

244 ns

4.1 Vp-p

3.4 Vp-p

5

IC8001 qd (X OUT)

(When the USB is connected)

8.33 ns

1 V/DIV, 40 ns/DIV

6

IC7004 5 (FOUT)

1 V/DIV, 10 µs/DIV

3.7 Vp-p

3.2 Vp-p

30.5 ns

12

Page 13

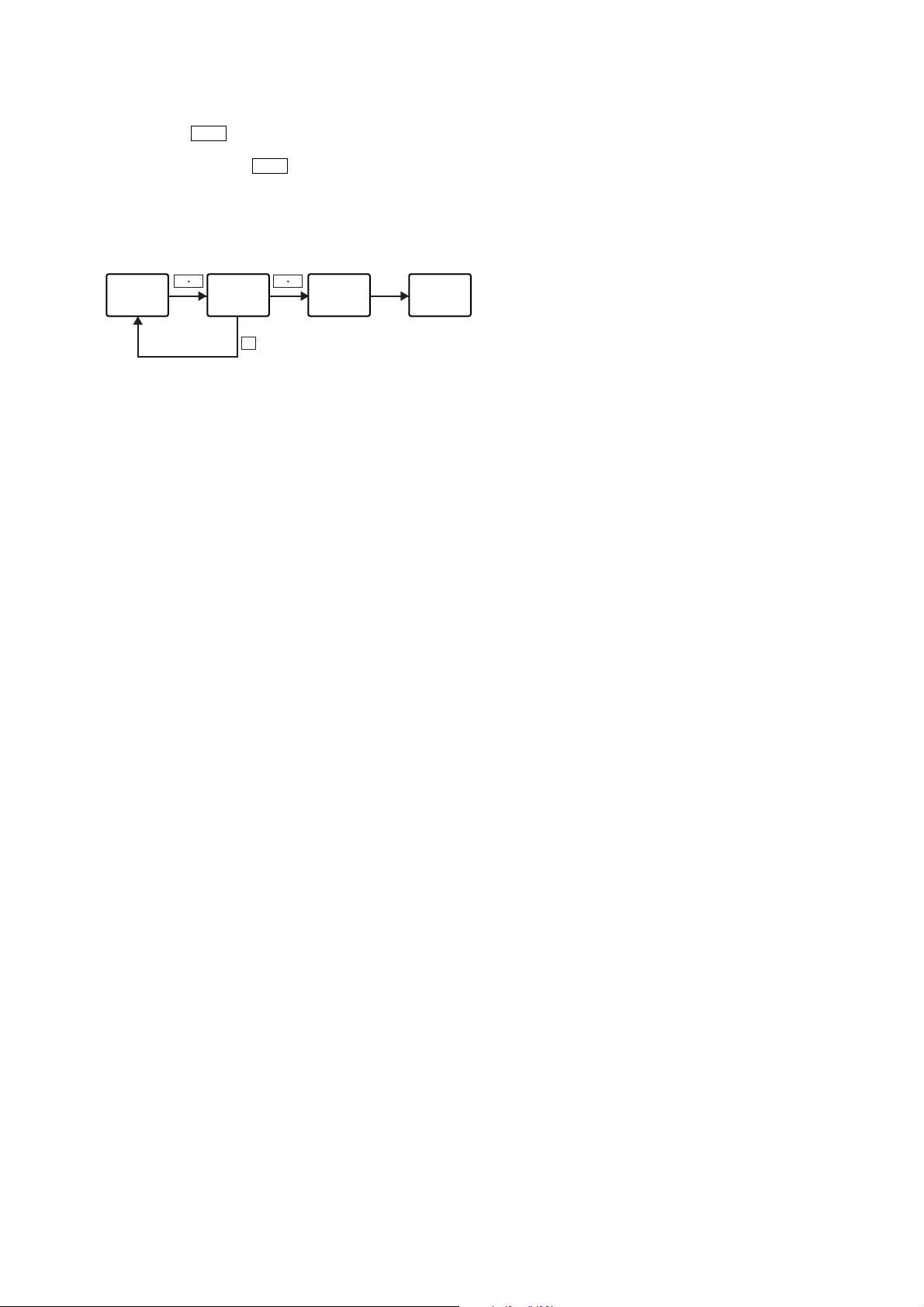

4-1. BLOCK DIAGRAMS – MAIN SECTION -1 –

MIC1

(ZOOM)

MIC2

(L-CH)

MIC3

(R-CH)

J3001

m

PLUG IN POWER

Q3002

Q3004

4

2

IC3002

MIC AMP

IN+

REG

OUT

STBY

ICD-ST25

6

3

26

6

24

29

2

1

MICVCC

INTINL

INTINR

EXTINR

EXTINL

CTL1

IC3001

MIC AMP

OUTL

OUTR

INT/EXT

VCC

IC3004

ADC, DAC, HEADPHONE AMP

AINR2

25

STDO

BICK

LRCK

SDTI

9

7

5

8

AINL2

26

13

17

Q3001

16

Q5008

7

B+ SWITCH

AVDD

AINL1

28

AINR1

27

STDO

BCLK

LRCK

A

SO

XRST

J3002

SP3001

(SPEAKER)

B

POWER AMP

5

VO1

8

VO2

D902

(OPR)

(REC/PB)

XBATTEN

IC3003

XSHUT-

DOWN

4

-IN

1

RED(REC)

GREEN(PB)

13

8

6

5

12

3

2

SI/PO DRIVER

MONOMIC

SPAMP

XREDLED

XGRLED

XBATTEN

CLK

DATA

IC7001

XADAPDN

XDSPRST

Q3003

MUTE

HPMUTE

XSTMIC

XLIGHT1

XLIGHT2

MCLK

CDTI

CCLK

MIN

CSN

IC6003

CLOCK GEN

XT

FOUT

XXT

XCONT

6

4

3

18

2

1

HPR

14

HPL

15

MOUT

17

PDN

1

X6001

11.2896MHz

5

15

7

9

11

4

14

D7002

(LCD PANEL LIGHT)

D7003

3

4

MCLK

IC7004

REAL TIME CLOCK

CLK

9

XIRQ

DI

7

DO

8

FOUT

CE

10

Signal path

: PB

: REC

3

5

46

HPJACK

115

SPICLK

45

SPIDATA

IC7003 (1/3)

CPU

XMICJACK

DSPSYSCLK

102

18

XADACS

BEEP

100

AUSCK

99

AUSOT

98

10112116

AUSIN

RTCCS

13

X0A32K

111

XRTCINTR

1313

Page 14

ICD-ST25

– MAIN SECTION -2 –

DSPCVDD

A

STDO

BCLK

LRCK

SO

XRST

MCLK

IC5005

VOLTAGE

DETECT

IC6001

DSP

ADASI

45

40

BCLK

LRCLK

47

SO

35

138

XRST

MCLK

46

150

CLKIN

12

TSO

TSCK

TSOEN

TSIEN

TSIOEN

TSI

FMSDIO

FMSCK

XFMWP

XFMCS

48

49

50

55

158

52

160

157

11

12

IC6004

4

FLASH MEMORY

5

2

6

3

1

2

IC6002

SDI

SDO

SCK

XWP

XCS

119

1

118

120

IC7003 (2/3)

CPU

DSPSIN

DSPSCK

DSPSIOEN

DATA0-DATA7

DSPSOT

USBADR0 - USBADR6

FLMRB

FLMCLE

XFLMALE

XFLMRE

22

2

21

11

20

19

3-10

24-30

IC7002

FLASH MEMORY

R/B

7

CLE

16

ALE

17

XCEXFLMCS0

9

RE

8

WEXFLMWE

18

WPXFLMWP

1923

29-32,

I/O1-I/O8

41-44

IC8001

USB CONTROLLER

D0 - D7

23-30

40,

A0 - A6

17-22

D8002

Q7002

SWITCH

IC8003

+3.5V

REG

CN7001

USB

KEYINH

23

DDCOUT

VBUS

C

D

E

Signal path

: PB

: REC

REQ

159

X7001

4.096MHz

104

107

108

DSPIFREQ

XTALIN

XTAL

XUSBCS

XINTUSB

XUSBVBUS

XUSBLWR

XUSBRD

XUSBRST

RX

TX

WAKEUP

31

109

110

34

32

33

95

96

103

Q7003

WAKEUP

SWITCH

CS

45

INT0

42

INT1

11

LWR

44

RD

43

46

RST

VBUS

D+

TRON

XIN

XOUT

5

3

D-

4

6

14

13

X8001

12MHz

1

VBUS

2

D-

3

D+

WAKEUP

F

1414

Page 15

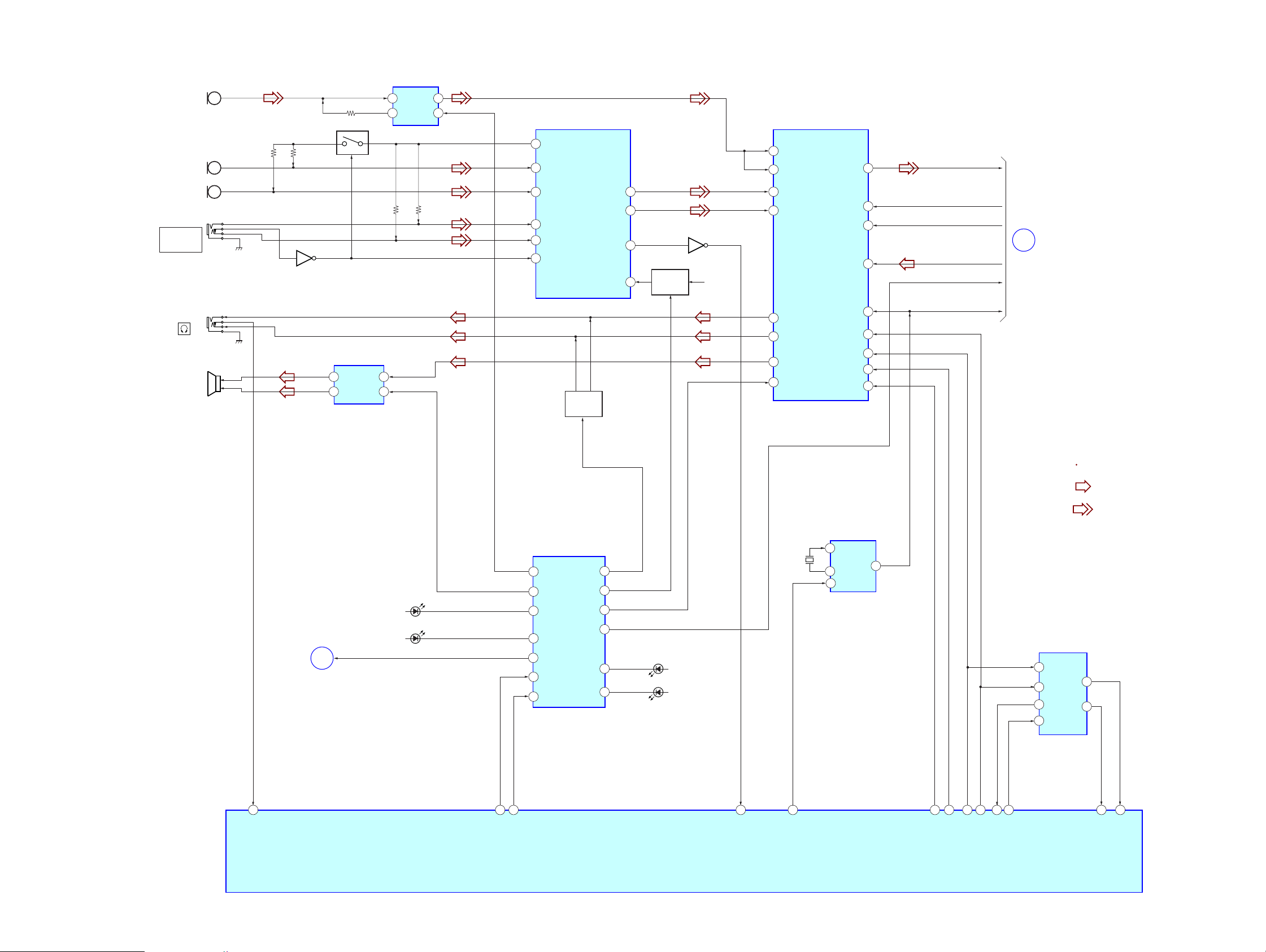

– PANEL/POWER SECTION –

S903,904,

906,907

FUNCTION

KEY

S910

SEESAW

KEY

LIQUID

CRYSTAL

DISPLAY

MODULE

49-74,

77-82

83-86

40

SEG0 - SEG31

COM0 - COM3

KEYIN0

IC7003(3/3)

CPU

XCPURST

XFLMPWR

ICD-ST25

DDCOUT

D

IC7005

90

97

RESET

32

Q7001

FLMVCC

(IC7002)

B+

SWITCH

DIRECTNL

S7001

HOLD

S901

S902

DPC

S905,

908,909

FUNCTION

KEY

WAKEUP

F

KEYINH

C

ON

OFF

ON

OFF

ON

OFF

41

42

44

112

KEYIN1

MICSEL

XDPCSW

HOLDSW

DSPPWR

BATT

XDCINDET

117

113

DSPEVDD

(IC6001, 6002, 6003)

VBUS

E

39

XBATTEN

B

Q5006,5007

B+

SWITCH

Q5001

SWITCH

DDCOUT(3.1V)

AVDD(2.9V)

SWITCH

Q5012

IC5001

+2.9V

REG

4

DSPCVDD(1.6V)

IC3003 VDD

DDCOUT

(3.1V)

15

3

4

6

IC5003

DC/DC CONV.

FB1

EXT1

PWM1

EN2

FB2

EXT2

L5002

D5004

D5003

Q5002

SWITCH

1

108

Q5003

SWITCH

L5001

VBATT

Q5005

DC DET

IC5004

B+

SWITCH

IC5002

VOLTAGE

DETECT

Q5010, 5011

SWITCH

31

D5005

Q5009

DRY BATTERY

SIZE "AAA"

(IEC DESIGNATION LR03)

2PCS, 3V

J5001

DC IN 3V

1515

Page 16

ICD-ST25

4-2. PRINTED WIRING BOARD – MAIN BOARD (SIDE A) –

12

S

(SIDE A)

S

45

1

2

IC5002

3

A

MAIN BOARD

B

J5001

C

3

8

E

1

D

E

14

85

Q5013

F

• : Uses unleaded solder.

3456789

IC5005

4

3

5

IC5001

1

C5012

R5012

3

IC6001

CSP(Chip Size Package)

IC5003

S

C6002

1

3

S

IC6002

IC6003

4

6

S

HOLD

OFF

ON

IC3003

C1008

IC3001

IC3004

E

S

S

45

13

C2009

IC3002

2

1

4

IC6004

E

L

SW

S

L

SW

R

R

1-687-788-

GND

GND

13

(13)

J3002

i

J3001

mPLUG IN POWER

• Semiconductor Location

Ref. No. Location

D5002 C-2

D5003 D-3

D5004 D-3

D5005 D-2

D5007 E-2

D5009 E-2

IC3001 D-7

IC3002 E-7

IC3003 C-6

IC3004 D-6

IC5001 C-3

IC5002 B-2

IC5003 C-3

IC5005 B-4

IC6001 C-5

IC6002 E-5

IC6003 E-5

IC6004 F-7

Ref. No. Location

Q3001 D-7

Q3002 B-8

Q3004 E-8

Q5001 C-5

Q5002 D-3

Q5003 E-3

Q5005 C-1

Q5006 E-6

Q5007 E-6

Q5008 B-6

Q5009 C-1

Q5010 B-2

Q5011 C-1

Q5012 C-3

Q5013 E-2

Q5014 B-3

VDR5002 B-1

1616

Page 17

ICD-ST25

4-3. PRINTED WIRING BOARD – MAIN BOARD (SIDE B) –

12

A

B

MAIN BOARD

SP3001

(SPEAKER)

(SIDE B)

DRY BATTERY

(IEC DESIGNATION LR 03)

SIZE "AAA"

2PCS,3V

C

D

IC8001

E

1

F

5

1

2

IC8003

3

R7048

• : Uses unleaded solder.

3456789

IC7001

R7047

TO

F-SW

A

BOARD

CN901

(Page 18) (Page 19)

181

S

S

R7011

IC7002

TO

S-SW

B

BOARD

CN902

4

3

2

1

MICROPHONE

IC7003

1

2

IC7005

IC7004

3

(LCD PANEL LIGHT)

S

E

(LCD PANEL LIGHT)

E

136

1

5

1

8

45

1-687-788-

2

4

13

(13)

UNIT

MIC2

MIC1

ZOOM

MIC3

Lch

Rch

• Semiconductor

Location

Ref. No. Location

D7002 C-9

D7003 E-9

D7004 C-8

D8001 F-3

D8002 E-2

IC7001 E-3

IC7002 E-5

IC7003 D-7

IC7004 C-8

IC7005 E-8

IC8001 D-2

IC8003 F-3

Q3003 E-9

Q7001 D-3

Q7002 D-3

Q7003 D-8

Q7004 E-8

Q7005 E-8

USB

LCD

TO

1717

Page 18

ICD-ST25

4-4. PRINTED WIRING BOARD – F-SW BOARD –

• : Uses unleaded solder.

F-SW BOARD

(SIDE A)

ON

OFF

DIRECTION ON/OFF

F-SW BOARD

(SIDE B)

OPR

VOICE UP

OFF

ERASE

DPC ON/OFF

ON

OFF

ON

10

A-B /

DIVIDE/

PRIORITY

bookmark

12

1-687-789-

(12)

1-687-789-

12

(12)

A

TO

MAIN

BOARD

CN7001

(Page 17)

1

1818

Page 19

ICD-ST25

4-5. PRINTED WIRING BOARD – S-SW BOARD –

• : Uses unleaded solder.

S-SW BOARD

(SIDE A)

S-SW BOARD

REC/REC PAUSE

(SIDE B)

STOP

B

TO

MAIN

BOARD

CN7001

(Page 17)

18

1-687-790-

12

(12)

VOL

VOL

1-687-790-

FOLDER

12

(12)

MENU

PUSH PLAY/STOP(ENTER)

1919

Page 20

ICD-ST25

4-6. SCHEMATIC DIAGRAM – MAIN BOARD (1/5) –

Q3004

3LP01S-K-TL-E

R2001

R3027

1M

R2002

4.7k

MIC2

LCH

MIC1

ZOOM

MIC4

2.2k

2.2k

R1016

W3001

5P

TP1003

TP3005

TP3003

TP2003

RCH

R2016

C3009

0.1

2.2k

R3012

C3007

R3003

2.2k

C3001

0.01

R1002

2.2k

2.2k

0.1

C2016

4.7k

R1001

0.1

C1016

C1001

C2004

220k

C2003

0.47

0.01

0.01

C2001

0.01

0.01

C1002

R2003

R2013

10k

C2002

0.1

0.001

C2015

R2015

22k

R3004

100k

0.1

C2005

R2004 C2009

1k 0.022

C2007

R2005

0.047

4.7k

0.047

C2008

4.7k

R2006

C2006

0.047

R2007

10k

Q3001

UN9214J-(K8).SO

R3007

R3009

22k

C3005

100k

R3008

1

47k

R3010

C3008

0.1

R3022

IC3002

0.1

10k

NJM2781RB1

100

C3030

C3027

10 6.3V

C3010

1

1

(Page 24)

J3001

PLUG IN POWER

J3002

SP3001

TP3002

TP3001

FB1001

FB2002

FB3002

JC3001

FB2001

FB3001

FB3004

FB1002

TP3004

R1009

IC3001

LA7473V-TLM-E

R1013

10k

Q3002

R2010

R1010

R3005

C1015

0.001

100k

4.7

4.7

IC3003

C1003

0.1

C1012

UN9214J-(K8).SO

47 6.3V

R2012R1012R2009

1k1k1k

C2012

47

6.3V

1k

OUTVDD

GND

OUT+

C3011

C3012

6.3V

0.1

10

C3013

220p

R3013

220k

R1015

MM3111XWLE

ININ+

BIAS

SHUT

R3014

100k

10k

C1004

0.47

6.3V

10

C3003

Q5008

3LP01S-K-TL-E

R3030

100k

6.3V

10

C3028

C3015

1

C1005

0.047

0.1

R1006

10k

C1006

4.7k

4.7k

R1003

R1005

C1008

C1007

R3015

R1004

22k

R5018

C3004

0.022

0.022

C1011

10

6.3V

C2013

0.1

0.1

C1013

4.7k

0.047

0.047

1M

C3016

2.2 6.3V

C3017

C3018

C3019

0.1

0.1

C3020

10 6.3V

C3022C3021

0.10.1

IC3004

AK4566VN-L

C3023

0.01

R3018

100k

R3016

220

R3017

100k

C3024

0.1

0.1

R3020

C3025

10

C3026

0.001

(Page 21)

Q3003

NTHD4508NTIG

R3024

470k

R7003

R7002

100

100

C7023

0.01

D7003

CL-196SYG-CD-T

D7002

CL-196SYG-CD-T

470k

R7043

(Page 24)

C7001

0.1

(Page 23)

IC7001

BU2090FS-E2

(Page 23)(Page 23) (Page 22)(Page 22)

2020

Page 21

4-7. SCHEMATIC DIAGRAM – MAIN BOARD (2/5) –

IC7002

K9F5608U0C-PCB0T00

0.1

C8002

C8003

ICD-ST25

X8001

C8005

12MHz

8p

1M

R8006

R8009

R8022

8p

470

220

IC8003

XC62FP3502MR

(Page 20)

R7009

1M

R7044

TP7014

1k

C7022

Q7001

NDS356AP

R7010

10k

C8006

0.1

R8007

470k

R8010

R7040

470k

C7003

0.1

1

R7011

470k

C7004

0.1

C8001

0.1

IC8001

M66291GP-2

100k

100k

R8003

R8004

C8004

0.001

R8005

R8002R8001

470k470k

470k

100k

C8007

0.1

R8011

R8012

R8013

R8015

22

R8016

100k

100k

2.2k

22

D8001

RB520S-30TE61

R8021

C8009

4.7 10V

D8002

1SS352

R8020

1

4.7k

C8010

1

R7039

TP7002

FB7001

FB7002

1k

R7047

R7048

1k

1k

CN7001

1

VBUS

2

D–

3

D+

4

IN

5

GND

6

GND

7

GND

8

GND

9

GND

39

16

(Page 24)

(Page 23)

2121

Page 22

ICD-ST25

4-8. SCHEMATIC DIAGRAM – MAIN BOARD (3/5) –

CRS02(TE85L)

Q5003

XP152A12C0MR

IC5003

L5001

C5007

1

D5004

XC9502B092AR

D5003

CRS02

(TE85L)

Q5002

XP151A12A2MR

L5002

C5011

22p

R5007 R5008

470k 680k

R5006

680k

R5009

470k

C5012

100p

R5026

100k

C5026

0.1

(Page 20)

R5012

330k

R5010

150k

R5025

R5024

1M

Q5014

3LN01S-K-TL-E

Q5013

NTHS2101PT1G

2.2M

C5009

0.1

C5014

6.3V

47

C5005

10

6.3V

IC5001

R1160N291B-TR-FA

0.6

Q5012

3LN01S-K-TL-E

TP5006

TP5004

C5020

0.1

IC5005

XC61CS23XXNR

C5016

10V

(Page 20)

Q5007

R5017

1M

NDS356AP

TP5005

Q5006

3LN01S-K-TL-E

33

R5016

470k

R5015

470k

C5021

0.1

C5022

4.7

10V

TP5010

(Page 23)

J5001

W5001

W5002

D5009

MAZS120008S0

D5007

MAZS120008S0

TP5001

C5003

47 10V

TP5008

TP5002

C5004

0.1

C5006

TH5001

THERMISTOR

MA2ZD02001SO

S1F77600Y0A000L

0.1

TP5003

D5002

IC5002

R5005

470k

D5005

MA2ZD02001SO

T5001

3LP01S-K-TL-E

C5010

Q5011

R5021

Q5009

0.1

470k

NTHD4508NT1G

R5022

470k

Q5010

3LN01S-K-TL-E

2SC4617R

R5011

2.2k

C5017

47

10V

Q5005

1k

R5013

C5018

10V

TP5009

47

TP5007

R5014

10k

VDR5002

(Page 24)

(Page 23)

2222

Page 23

ICD-ST25

4-9. SCHEMATIC DIAGRAM – MAIN BOARD (4/5) / SWITCH SECTION –

(Page 20)

TP6012

6T

N

470k

25P10-AVM

M

R6004

IC6002

TP6013

R3028

TP6011

100k

R6009

220

R6003

R6026

R6027

100k

100k

RB6002

100k

100k

R6006

100k

R6007

RB6001

100k

R6005

100k

R6001

R6002

0.1

C6003

470k

C6001

1

C6002

1

470k

470k

(Page 20)

(Page 22)

(Page 20)

TP7006

7007

TP

• See page 29 for IC Pin Function Description.

TP6001

TP6002

00k

TP6004TP6003

IC6001

µPD77213F1-101-DA2

470k

R6010R6008

R6011

470k100k

470k

R6012

1

R6014R6013

6016

100k100k

R

2/5

(Page 21)

R6015

C6007

100k

0.001

TP6005

TP6006

C6014

0.1

TP6007

R6019

100p

100k

C6010

TP6008

TP6009

TP6010

R6025

11.2896MHz

C6009

C6006

0.1

100k

R6020

100k

R6021

IC6004

TC7S04FU(TE85R)

6366AFT(TE1)

NJU

IC6003

470

X6001

5p

C6008

R7008

R6022

47

(Page 24)

C901

0.0047

S918 R911

5p

CN7001

18P

R7006

2.2k

R7007

1k

1k

CN902

CN901

33k

8P

R910

CL-165HR/YG-D-T

10P

R909

22k

22k

R908

R904

R903

4.7k

3.3k

D902

OPR

R918

220k

C902

0.0047

FOLDER

MENU

PUSH

PLAY/STOP(ENTER)

33k

S909

REC/REC PAUSE

ERASE

S908

STOP

S907

VOL

S906

VOL

S905

(book mark)

DIVIDE

S904

S903

PRIORITY

S911

VOICE UP

S902

S901

DIRECTNL

R907

R906

4.7k

3.3k

R905

2.2k

R913

4.7k

R912

R919

1k

100k

100k

R6017

R6018

100k

(Page 22)

(Page 24)

2323

Page 24

ICD-ST25

4-10. SCHEMATIC DIAGRAM – MAIN BOARD (5/5) –

(Page 20)

(Page 20)

(Page 23)

(Page 22)

• See page 32 for IC Pin Function Description.

S7001

HOLD

R7012

470k

TP7010

R7015

1k

X7001

R7019

(Page 21)

Q7004

UN9214J-(K8).SO

R7027 100k

R7028

1SS352

D7004

JP

R7030

100

10V

C7016

47

C7017

R7025

470k

RX-4591CF

IC7004

0.1

TP7001

TP7003

R7038

100k

C7019

100p

4.096MHz

C7009

100p

0

R7023

470k

C7010

0.1

R7041

0

0

R7042

0

R7026

R7029 R7031 R7034

100k 100k 100k

UN9214J-(K8).SO

IC7005

R3130N28EA-TR

Q7005

C7021

0.1

(Page 23)

TP7012

R7001

C7005

0.1

R7046 100k

R7045 100k

Q7002

3LP01S-K-TL-E

TP7013

C7020

0.001

TP7004

36P

CN7002

1M

IC7003

MB91F233

1k

R7022

C7012

C7013

C7011

C7014

0.1

0.1

0.1

0.1

R7032

100k

R7050

1k

C7015

0.001

R7033

100k

R7014

R7013

C7006

0.1

C5001

0.1

R5001

100k

R5002

33k

Q5001

3LP01S-K-TL-E

R5003

470k

220k

R7016

10k

TP7008

10k

TP7009

1k

R7020

Q7003

3LP01S-K-TL-E

C7018

0.1

2424

Page 25

• IC BLOCK DIAGRAMS

CTL-2

EXTNF1R

EXT IN-R

EXT MIC

DET

EXTNF2R

EXT MIC

AMP R

IC3001 LA7473V-TLM-E (MAIN BOARD)

MIC VCC

HPFSW

INT IN-R

MIC

VCC

INTNFR

INT MIC

AMP R

GND

INTOUTR

MIXINL

AMP R

MIXOUTR

192021222324252627282930

MIX

OFF

HPF IN-R

ON

EXT

INT

OUTPUT

AMP R

ICD-ST25

OUT-R

INT/EXT

161718

EXT MIC

AMP L

RIPPLE

FILTER

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

CTL-1

EXT IN-L

EXTNF1L

RF

EXTNF2L

VCC

INT IN-L

INT MIC

INTNFL

AMP L

MIXINR

INTOUTL

MIX

AMP L

OFF

MIXOUTL

ON

HPF IN-L

EXT

INT

OUTPUT

AMP L

BIAS

OUT-L

BIAS

IC3002 NJM2781RB1 (MAIN BOARD)

SIT/MONO

NOISE

REG

STBY

IN+

1

2

3

4

REG

8

GND

7

V+

6

OUT

5

IN-

25

Page 26

ICD-ST25

IC3003 MM3111XWLE (MAIN BOARD)

HPL

MUTET

MOUT

MIN

SHUT

BIAS

IN+

IN-

1

BIAS

2

3

4

20k

20k

8

OUT-

7

GND

6

VDD

5

OUT+

IC3004 AK4566VN-L (MAIN BOARD)

SDTI

SDTO

DVDD

DVSS

HVSS

HVDD

HPR

814 13 12 11 10 9

BOOST

IPGA & ADC

HPF

DATT

DAC

AUDIO I/F

CONTROLLER

15

16

17

18

AINL1

AINL2

AINR1

AINR2

IPGA

ADC

DAC

7

BICK

6

MCLK

5

LRCK

4

CDTI

26

RIN

VREF

LIN

19

20

21

VREF

VCOM

VCOM

HP AMP

MOUT

AVSS

AVDD

AINR2

AINL2

AINR1

2822 23 24 25 26 27

AINL1

CONTROL

REGISTER

3

CCLK

2

CSN

1

PDN

Page 27

IC5003 XC9502B092AR (MAIN BOARD)

ICD-ST25

EXT1

VDD

FB1

PWM1

EN1

1

2

3

4

5

PWM/PFM

CONTROLLER1

PWM

COMPARATOR1

ERROR AMP1 ERROR AMP2

VREF1=0.9V

WITH SOFT START1,

EN1

EN1 TO

INTERNAL CIRCUIT

RAMP WAVE

GENERATOR1

RAMP WAVE

GENERATOR2

OSC

GENERATOR

PWM/PFM

CONTROLLER2

IC6003 NJU6366AF1(TE1) (MAIN BOARD)

XXT

VDD

PWM

COMPARATOR2

VREF1=0.9V

WITH SOFT START2,

EN2

EN2 TO

INTERNAL CIRCUIT

FOUT

13 2

10

EXT2

9

GND

8

FB2

7

PWM2

6

EN2

RF

1/2 1/2 1/2

CG CD

ABC D

XT

XCONT

IC7001 BU2090FS-E2 (MAIN BOARD)

VDD

HPMUTE

XLIGHT2

MONOMIC

XBATTEN

OUTPUT

BUFFER

(OPEN DRAIN)

CONTROL

CIRCUIT

12 BIT

SHIFT

REGISTER

12 BIT

STORAGE

REGISTER

16 15 14 13 12

3-STATE

BUFFER

64 5

VSS

XDSPRST

10

11

XFLMPWR9XADAPDN

2 3 5 6 7 8

1

CLK

VSS

DATA

4

XLIGHT1

XGRLED

XSTMIC

XREDLED

SPAMP

27

Page 28

ICD-ST25

IC7004 RX-4591CF (MAIN BOARD)

VDD

FOE

XIRQ

FOUT

32.768kHz

1

OSC

2

3

DI

4

T1

5

DO

CLK

CE

DIVIDER

FOUT

CONTROLLER

INTERRUPTS

CONTROLLER

BUS

INTERFACE

CIRCUIT

CLOCK

AND

CALENDAR

TIMER

REGISTER

ARARM

REGISTER

CONTROL

REGISTER

AND

SYSTEM

CONTROLLER

CE

CLK

DO

DI

10

CE

9

CLK

8

DO

7

DI

6

GND

IC8001 M66291GP-2 (MAIN BOARD)

CVDD

GND

VBUS

TRON

TEST

DACK1

DREQ1

TC1

INT1

IVDD

D15/A0

HWR/BYTE

INT0

RD

LWR

CS

RST

DREQ0

DACK0

41

ENDPOINT

FIFO MEMORY

40

39

48

1

2

3

D-

4

D+

5

6

7

8

9

10

11

12

14

13

5

6

4

3

I/O BLOCK

OSCILLATION

BUFFER

/48MHzPLL

VBUS

INPUT CIRCUIT

D+ PIN PULLUP

CIRCUIT

USB

TRANSCEIVER

46

47

45

USB-IP

TRANSFER

CONTROLLER

INTERFACE

INTERRUPT CONTROLLER

SERIAL

ENGINE

(SIE)

42

4344

CONTROLLER

FIFO MEMORY CONTROLLER

D12

3738

INTERFACE

UNIT

(BIU)

8-10

BUS

36

GND

IVDD

35

34

D11

D10

33

32

D9

31

D8

D7

30

29

D6

D5

28

D4

27

26

D3

11

D2

25

D13

D14

28

13 14 15 16 17 18 19

A1

XOUT

XIN

GND

CVDD

A2

20

21 22 23 24

A3

A4

A5

A6

D0

D1

Page 29

4-11. IC PIN FUNCTION DESCRIPTIONS

• IC6001 uPD77213F1-101-DA2 (DSP) (MAIN BOARD)

ICD-ST25

Pin No.

1 to 3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41 to 44

45

46

47

48

49

50

51

52

53

54

55

56

57

Pin Name

NC

EVDD

XADACS

ADACCLK

ADACDTI

ADACDTO

MICPWR

GND

XFMWP

XFMCS

MICSENSE

GND

NC

EVDD

HD1

HD2

HD0

HD3

HD5

HD4

GND

IVDD

HD7

HD6

GND

EVDD

XHCS

HA1

XHWR

HA0

XHRD

TIMOUT

SO

XHWE

XHRE

GND

EVDD

BCLK

NC

ADASI

MCLK

LRCLK

TSO

TSCK

TSOEN

GND

TSI

TSIAK

TSORQ

TSIEN

EVDD

MA1

I/O

—

Not used

—

I/O power supply (3.1V)

O

AD/DA chip select (Not used) (fixed at “L”)

I/O

AD/DA clock (Not used) (fixed at “L”)

I

AD/DA data input (Not used) (fixed at “L”)

O

AD/DA data output (Not used) (fixed at “L”)

O

Microphone power supply control (Not used) (fixed at “L”)

—

Ground terminal

O

Boot flash ROM write protect

O

Boot flash ROM chip select

O

Micropone sensitivity select (H: Conference, L: Dictation) (Not used) (fixed at “L”)

—

Ground terminal

—

Not used

—

I/O power supply (3.1 V)

I/O

Host data bus (Not used)

I/O

Host data bus (Not used)

I/O

Host data bus (Not used)

I/O

Host data bus (Not used)

I/O

Host data bus (Not used)

I/O

Host data bus (Not used)

—

Ground terminal

—

Core power supply (1.6 V)

I/O

Host data bus (Not used)

I/O

Host data bus (Not used)

—

Ground terminal

—

I/O power supply (3.1 V)

I

Host chip select (Pull-up) (fixed at “H”)

I

Host data access 1 (Pull-down) (fixed at “L”)

I

Host write (Pull-up) (fixed at “H”)

I

Host data access 0 (Pull-down) (fixed at “L”)

I

Host read (Pull-up) (fixed at “H”)

O

Not used

O

Serial data output

O

Host write enable (Not used)

O

Host read enable (Not used)

—

Ground terminal

—

I/O power supply (3.1 V)

I/O

Bit clock

—

Not used

I

ADA serial data input

I

Master clock

I/O

Clock for L-ch and R-ch (H: L-ch, L: R-ch)

O

Time sharing serial data output

I

Time sharing serial clock input

I

Time sharing serial output enable

—

Ground terminal

I

Time sharing serial data input

O

Time sharing serial input response (Not used)

O

Time sharing serial output request (Note used)

I

Time sharing serial input enable

—

I/O power supply (3.1 V)

O

Memory address bus 1 (Not used)

Description

29

Page 30

ICD-ST25

Pin No.

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81 to 84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

Pin Name

MA0

GND

IVDD

MA2

MA4

GND

MA3

MA7

MA5

MA8

MA6

MA9

MA10

GND

EVDD

MA11

MA12

MA14

MA13

MA16

MA15

EVDD

MA17

NC

EVDD

MA18

MA19

XMHOLDAK

XMRD

XMHOLDRQ

GND

EVDD

XMWAIT

XMWR

GND

IVDD

XMBSTB

MD0

GND

MD3

MD1

MD4

MD5

MD6

MD2

MD8

GND

EVDD

MD7

MD13

MD10

MD11

I/O

O

Memory address bus 0 (Not used)

—

Ground terminal

—

Core power supply (1.6 V)

O

Memory address bus 2 (Not used)

O

Memory address bus 4 (Not used)

—

Ground terminal

O

Memory address bus 3 (Not used)

O

Memory address bus 7 (Not used)

O

Memory address bus 5 (Not used)

O

Memory address bus 8 (Not used)

O

Memory address bus 6 (Not used)

O

Memory address bus 9 (Not used)

O

Memory address 10 (Not used)

—

Ground terminal

—

I/O power supply (3.1 V)

O

Memory address 11 (Not used)

O

Memory address 12 (Not used)

O

Memory address 14 (Not used)

O

Memory address 13 (Not used)

O

Memory address 16 (Not used)

O

Memory address 15 (Not used)

—

I/O power supply (3.1 V)

O

Memory address 17 (Not used)

—

Not used

—

I/O power supply (3.1 V)

O

Memory address 18 (Not used)

O

Memory address 19 (Not used)

O

Memory bus hold response (Not used)

O

Memory read-out (Not used)

I

Memory bus hold request (Pull-up) (fixed at “H”)

—

Ground terminal

—

I/O power supply (3.1 V)

I

Memory access weight (Pull-up)

O

Memory write (Not used)

—

Ground terminal

—

Core power supply (1.6 V)

O

Memory bus strobe (Not used)

I/O

Memory data bus (Not used)

—

Ground terminal

I/O

Memory data bus (Not used)

I/O

Memory data bus (Not used)

I/O

Memory data bus (Not used)

I/O

Memory data bus (Not used)

I/O

Memory data bus (Not used)

I/O

Memory data bus (Not used)

I/O

Memory data bus (Not used)

—

Ground terminal

—

I/O power supply (3.1 V)

I/O

Memory data bus (Not used)

I/O

Memory data bus (Not used)

I/O

Memory data bus (Not used)

I/O

Memory data bus (Not used)

Description

30

Page 31

ICD-ST25

Pin No.

113

114

115

116

117

118

119

120

121

122

123 to 126

127

128

129

130

131

132

133

134

135

136, 137

138

139

140

141

142

143

144, 145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161 to 164

Pin Name

MD9

MD14

GND

MD15

MD12

TICE

TMS

EVDD

GND

TDO

NC

XTRST

TCK

EVDD

IC

TDI

STOPS

CSTOP

IC

GND

PLL0,PLL1

XRST

GND

IVDD

PLL3

HALTS

GND

IVDD

PLL2

GND

EVDD

CLKOUT

CLKIN

BOOT1

GND

BOOT3

BOOT0

GND

BOOT2

FMSCK

TSIOEN

REQ

FMSDIO

NC

I/O

I/O

Memory data bus (Not used)

I/O

Memory data bus (Not used)

—

Ground terminal

I/O

Memory data bus (Not used)

I/O

Memory data bus (Not used)

O

Test ICE

I

Test mode selection

—

I/O power supply (3.1 V)

—

Ground terminal

O

Test data output

—

Not used

I

Test reset

I

Test clock input

—

I/O power supply (3.1 V)

—

Internal connection (Not used)

I

Test data input

O

Stop (Open)

I

Clear stop mode (Pull-down) (fixed at “L”)

—

Internal connection (Not used)

—

Ground terminal

I

PLL rate setting 0 and 1

I

Reset

—

Ground terminal

—

Core power supply (1.6 V)

I

PLL rate setting 3

O

HALT

—

Ground terminal

—

Core power supply (1.6 V)

I

PLL rate setting 2

—

Ground terminal

—

I/O power supply (3.1 V)

O

Clock output

I

Clock input

I

Boot mode 1 (fixed at “H”)

—

Ground terminal

I

Boot mode 3 (fixed at “H”)

I

Boot mode 0 (fixed at “L”)

—

Ground terminal

I

Boot mode 2 (fixed at “H”)

I/O

Boot flash ROM serial clock

I

SIO enable

O

Request

I/O

Boot flash ROM serial data

—

Not used

Description

31

Page 32

ICD-ST25

• IC7003 MB91F233 (CPU) (MAIN BOARD)

Pin No.

1

2

3 to 10

11

12

13

14

15

16

17

18

19

20

21

22

23

24 to 30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49 to 74

75

76

77 to 82

83 to 86

87

88

89

90

91 to 94

95

96

97

98

99

100

101

Pin Name

DSPSCK

FLMCLE

DAT A0 to 7

XFLMCS0

DSPSYSCK

X0A32k

X1A32k

VCC3BCK

VSS

VCC3LGC

BEEP

XFLMWE

XFLMRE

XFLMALE

FLMRB

XFLMWP

USBADR0 to 6

XUSBCS

XUSBRD

XUSBRST

XUSBLWR

XFLMCS1

AVCC

AVREF

AVSS

BATT

KEYIN0

KEYIN1

MICSEL

NC

VUPDPC

XMICJACK

HPJACK

VSS

AVCC3IO

SEG0 to 25

DVCC

DVSS

SEG26 to 31

COM0 to 3

MOD2

MOD1

MOD0

XCPURST

LCDV0 to 3

RX

TX

XFLMPWR

AUSIN

AUSOT

AUSCK

RTCCS

I/O

O

Serial clock output for DSP

O

Command latch enable signal output for FLASH

I/O

Data input/output to FLASH and USB

O

Chip enable signal output for FLASH

O

System clock control signal output for DSP

I

32KHz vibration terminal (input)

—

32KHz vibration terminal (input)

—

Internal logic backup voltage terminal

—

Ground terminal

—

Internal logic voltage terminal

O

Beep output

O

Write enable signal output for FLASH

O

Read enable signal output for FLASH

O

Address latch enable signal output for FLASH

I

Ready/Busy signal input from FLASH

O

Write protect signal output to FLASH

O

Address signal output to USB control

O

Chip select signal output to USB control

O

Read strobe signal output to USB control

O

Reset signal output to USB control

O

Low write strobe signal output to USB control

O

Chip enable signal output for FLASH (Not used)

—

Analog power supply

—

Reference voltage terminal

—

Ground (Analog) terminal

I

Battery voltage detect signal input

I

Key 0 A/D input

I

Key 1 A/D input

I

Directivity microphone switch signal input

—

Not used

I

DPC switch signal input

I

External microphone detect signal input

I

Headphone detect signal input

—

Ground terminal

—

Voltage terminal

O

LCD segment output terminal

—

Voltage terminal

—

Ground terminal

O

LCD segment output terminal

O

LCD common output terminal

I

Mode input terminal

I

Mode input terminal (fixed at “L”)

I

Mode input terminal (fixed at “L”)

I

CPU external reset signal input

—

LCD reference voltage terminal

I

FLASH overwrite RX

O

FLASH overwrite TX

O

FLASH power supply control signal output (L:ON)

I

Serial data input from RTC

O

Serial data output to RTC, ADC and DAC

O

Serial clock output to RTC, ADC and DAC

O

Chip select signal output to RTC

Description

32

Page 33

ICD-ST25

Pin No.

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

Pin Name

XADACS

WAKEUP

DSPIFREQ

DVCC

DVSS

XTALIN

XTAL

XINTUSB

XUSBVBUS

XRTCINTR

HOLDSW

XDCINDET

DMUTEIN

SPIDATA

XSPICLK

DSPPWR

DSPSIOEN

DSPSIN

DSPSOT

I/O

O

Chip select signal output to ADC, DAC

I

WAKE UP interrupt input

I

DSP I/F interrupt request

—

Voltage terminal

—

Ground terminal

I

Main vibration terminal (input)

O

Main vibration terminal (input)

I

USB driver interrupt request input (L:active)

I

USB driver VBUS detect interrupt request input

I

RTC interrupt input

I

Hold switch input (interrupt:on)

I

AC adaptor detect input (interrupt:on)

I

DIN MUTE interrupt (Not used)

O

Data output to IC7001

O

Clock output to IC7001

O

DSP power supply circuit control output

O

DSP SIO enable output

I

DSP serial data input

O

DSP serial data output

Description

33

Page 34

ICD-ST25

NOTE:

• -XX, -X mean standardized parts, so they may

have some differences from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

5-1. UPPER LID BLOCK

SECTION 5

EXPLODED VIEWS

• The mechanical parts with no reference number

in the exploded views are not supplied.

10

9

not

supplied

8

SP3001

7

5

6

not

supplied

4

3

cover assy

1

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 3-318-203-81 SCREW (B1.7X7), TAPPING

* 3 A-4547-174-A MAIN BOARD, COMPLETE

4 X-3383-280-2 HOLDER (LCD) ASSY

5 1-687-791-21 PWB, FLEXIBLE

6 4-973-264-02 SCREW (1.7X2.5)

7 3-318-382-91 SCREW (1.7X2.5), TAPPING

* 8 A-4547-169-A F-SW BOARD, COMPLETE

9 X-2022-142-1 LID SUB ASSY, UPPER (EXCEPT AEP)

9 X-2022-143-1 LID SUB ASSY, UPPER (AEP)

10 3-266-210-11 WINDOW (LCD)

SP3001 1-529-276-22 SPEAKER (2.8cm)

34

Page 35

5-2. CASE BLOCK

ICD-ST25

70

69

72

62

not

supplied

60

63

64

a

56

67

55

68

57

66

a

65

61

not

supplied

59

58

52

51

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

51 X-3385-109-1 CASE ASSY

52 3-250-038-31 LID, BATTERY CASE

53 3-250-039-01 KNOB (HOLD)

54 3-250-049-11 LID (CONNECTOR)

55 3-250-046-12 ORNAMENT (R)

56 3-250-048-11 BUTTON (VOL)

57 3-250-047-11 BUTTON (RS)

58 3-348-998-41 SCREW (M1.4X3), TAPPING, PAN

59 3-250-050-21 BUTTON (5D)

60 3-253-571-01 SHEET, ADHESIVE

* 61 A-4547-170-A S-SW BOARD, COMPLETE

53

54

62 3-250-051-11 ORNAMENT (L)

63 3-250-042-01 BASE, MICROPHONE

64 3-348-998-71 SCREW (M1.4X4.5), TAPPING, PAN

65 3-348-998-21 SCREW (M1.4X2), TAPPING, PAN

66 3-250-045-01 PLATE, CLICK

67 3-250-043-11 COVER, MICROPHONE

68 1-477-825-21 MICROPHONE UNIT

69 3-250-044-01 CUSHION, MICROPHONE

70 3-250-052-11 CASE, MICROPHONE

72 3-255-085-01 CUSHION (BATTERY)

35

Page 36

ICD-ST25

SECTION 6

F-SW MAIN

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when

ordering these items.

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

* A-4547-169-A F-SW BOARD, COMPLETE

*********************

< CONNECTOR >

CN901 1-816-935-21 CONNECTOR, FFC/FPC 10P

< DIODE >

D902 8-719-073-33 DIODE CL-165HR/YG-D-T (OPR)

< RESISTOR >

R903 1-208-695-11 METAL CHIP 3.3K 0.5% 1/16W

R904 1-208-699-11 METAL CHIP 4.7K 0.5% 1/16W

R912 1-218-953-11 RES-CHIP 1K 5% 1/16W

R913 1-218-961-11 RES-CHIP 4.7K 5% 1/16W

R918 1-218-981-11 RES-CHIP 220K 5% 1/16W

R919 1-218-977-11 RES-CHIP 100K 5% 1/16W

< SWITCH >

S901 1-786-436-21 SWITCH, SLIDE (DIRECTNL)

S902 1-572-922-11 SWITCH, SLIDE (DPC)

S903 1-771-844-11 SWITCH, TACTILE (SMD)

S904 1-771-844-11 SWITCH, TACTILE (SMD) (ERASE)

S905 1-771-844-11 SWITCH, TACTILE (SMD)

S911 1-572-922-11 SWITCH, SLIDE (VOICE UP)

************************************************************

* A-4547-174-A MAIN BOARD, COMPLETE

*********************

3-250-040-11 TERMINAL (+), BATTERY

3-250-041-11 TERMINAL (-), BATTERY

3-251-177-01 SPACER (JACK)

3-250-332-01 CAP (TERMINAL)

ELECTRICAL PARTS LIST

• CAPACITORS:

uF: µF

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F: nonflammable

• COILS

uH: µH

•Abbreviation

CND : Canadian model

JE : Tourist model

KR : Korea model

C1013 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C1015 1-164-937-11 CERAMIC CHIP 0.001uF 10% 50V

C1016 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C2001 1-164-943-11 CERAMIC CHIP 0.01uF 10% 16V

C2002 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C2003 1-125-891-11 CERAMIC CHIP 0.47uF 10% 10V

C2004 1-164-943-11 CERAMIC CHIP 0.01uF 10% 16V

C2005 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C2006 1-119-923-11 CERAMIC CHIP 0.047uF 10% 10V

C2007 1-119-923-11 CERAMIC CHIP 0.047uF 10% 10V

C2008 1-119-923-11 CERAMIC CHIP 0.047uF 10% 10V

C2009 1-107-819-11 CERAMIC CHIP 0.022uF 10% 16V

C2012 1-110-569-11 TANTAL. CHIP 47uF 20% 6.3V

C2013 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C2015 1-164-937-11 CERAMIC CHIP 0.001uF 10% 50V

C2016 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C3001 1-164-943-11 CERAMIC CHIP 0.01uF 10% 16V

C3003 1-117-919-11 TANTAL. CHIP 10uF 20% 6.3V

C3004 1-117-919-11 TANTAL. CHIP 10uF 20% 6.3V

C3005 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C3007 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C3008 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

(z A-B / PRIORITY)

(z DIVIDE/ bookmark)

C3009 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C3010 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C3011 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C3012 1-117-919-11 TANTAL. CHIP 10uF 20% 6.3V

C3013 1-164-933-11 CERAMIC CHIP 220PF 10% 50V

C3015 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C3016 1-107-819-11 CERAMIC CHIP 0.022uF 10% 16V

C3017 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C3018 1-113-600-11 TANTAL. CHIP 2.2uF 20% 6.3V

C3019 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C3020 1-117-919-11 TANTAL. CHIP 10uF 20% 6.3V

C3021 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C3022 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , uPC... , µPC... ,

uPD..., µPD...

• Accessories are given in the last of this parts

list.

When indicating parts by reference number,

please include the board name.

< CAPACITOR >

C1001 1-164-943-11 CERAMIC CHIP 0.01uF 10% 16V

C1002 1-164-943-11 CERAMIC CHIP 0.01uF 10% 16V

C1003 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C1004 1-125-891-11 CERAMIC CHIP 0.47uF 10% 10V

C1005 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C1006 1-119-923-11 CERAMIC CHIP 0.047uF 10% 10V

C1007 1-119-923-11 CERAMIC CHIP 0.047uF 10% 10V

C1008 1-119-923-11 CERAMIC CHIP 0.047uF 10% 10V

C1011 1-107-819-11 CERAMIC CHIP 0.022uF 10% 16V

C1012 1-110-569-11 TANTAL. CHIP 47uF 20% 6.3V

36

C3023 1-164-943-11 CERAMIC CHIP 0.01uF 10% 16V

C3024 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C3025 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C3026 1-164-937-11 CERAMIC CHIP 0.001uF 10% 50V

C3027 1-117-919-11 TANTAL. CHIP 10uF 20% 6.3V

C3028 1-117-919-11 TANTAL. CHIP 10uF 20% 6.3V

C3030 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C5001 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C5003 1-137-934-11 TANTAL. CHIP 47uF 20% 10V

C5004 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C5005 1-117-919-11 TANTAL. CHIP 10uF 20% 6.3V

Page 37

ICD-ST25

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

C5006 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C5007 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C5009 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C5010 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C5011 1-164-858-11 CERAMIC CHIP 22PF 5% 50V

C5012 1-164-931-11 CERAMIC CHIP 100PF 10% 50V

C5014 1-110-569-11 TANTAL. CHIP 47uF 20% 6.3V

C5016 1-135-993-11 TANTAL. CHIP 33uF 20% 10V

C5017 1-137-934-11 TANTAL. CHIP 47uF 20% 10V

C5018 1-137-934-11 TANTAL. CHIP 47uF 20% 10V

C5020 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C5021 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C5022 1-131-860-11 TANTAL. CHIP 4.7uF 20% 10V

C5026 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C6001 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C6002 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C6003 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C6006 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C6007 1-164-937-11 CERAMIC CHIP 0.001uF 10% 50V

C6008 1-164-845-11 CERAMIC CHIP 5PF 0.25PF 50V

C6009 1-164-845-11 CERAMIC CHIP 5PF 0.25PF 50V

C6010 1-164-931-11 CERAMIC CHIP 100PF 10% 50V

C6014 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C7001 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C7003 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C7004 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C7005 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C7006 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C7009 1-164-931-11 CERAMIC CHIP 100PF 10% 50V

C7010 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C7011 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C7012 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C7013 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C7014 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C7015 1-164-937-11 CERAMIC CHIP 0.001uF 10% 50V

C7016 1-137-934-11 TANTAL. CHIP 47uF 20% 10V

C7017 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C7018 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C7019 1-164-931-11 CERAMIC CHIP 100PF 10% 50V

C7020 1-164-937-11 CERAMIC CHIP 0.001uF 10% 50V

C7021 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C7022 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C7023 1-164-943-11 CERAMIC CHIP 0.01uF 10% 16V

C8001 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C8002 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C8003 1-164-848-11 CERAMIC CHIP 8PF 0.5PF 50V

C8004 1-164-937-11 CERAMIC CHIP 0.001uF 10% 50V

C8005 1-164-848-11 CERAMIC CHIP 8PF 0.5PF 50V

C8006 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

CN7004 1-816-276-11 CONNECTOR, FPC (ZIF) 18P

< DIODE >

D5002 8-719-075-93 DIODE MA2ZD02001SO

D5003 8-719-074-47 DIODE CRS02 (TE85L)

D5004 8-719-074-47 DIODE CRS02 (TE85L)

D5005 8-719-075-93 DIODE MA2ZD02001SO

D5007 8-719-056-59 DIODE MAZS120008SO

D5009 8-719-056-59 DIODE MAZS120008SO

D7002 6-500-594-01 DIODE CL-196SYG-CD-T

D7003 6-500-594-01 DIODE CL-196SYG-CD-T

D7004 8-719-016-74 DIODE 1SS352

D8001 8-719-069-29 DIODE RB520S-30TE61

D8002 8-719-016-74 DIODE 1SS352

< FERRITE BEAD >

FB1001 1-469-084-21 FERRITE 0mH

FB1002 1-469-084-21 FERRITE 0mH

FB2001 1-469-084-21 FERRITE 0mH

FB2002 1-469-084-21 FERRITE 0mH

FB3001 1-469-084-21 FERRITE 0mH

FB3002 1-469-084-21 FERRITE 0mH

FB3004 1-469-084-21 FERRITE 0mH

FB7001 1-414-593-21 INDUCTOR, FERRITE BEAD

FB7002 1-414-593-21 INDUCTOR, FERRITE BEAD

< IC >

IC3001 8-759-380-80 IC LA7473V-TLM-E

IC3002 6-703-863-01 IC NJM2781RB1

IC3003 6-705-850-01 IC MM3111XWLE

IC3004 6-703-859-01 IC AK4566VN-L

IC5001 6-703-864-01 IC R1160N291B-TR-FA

IC5002 6-703-869-01 IC S1F77600Y0A000L

IC5003 6-703-860-01 IC XC9502B092AR

IC5005 6-703-865-01 IC XC61CS23XXNR

✩ IC6001 6-803-583-01 IC uPD77213F1-101-DA2

IC6002 6-703-866-01 IC M25P10-AVMN6T

IC6003 6-703-867-01 IC NJU6366AF1 (TE1)

IC6004 8-759-058-58 IC TC7S04FU (TE85R)

IC7001 8-759-670-89 IC BU2090FS-E2

IC7002 6-705-077-01 IC K9F5608U0C-PCB0T00 (ICD-ST25)

IC7002 6-705-675-01 IC K9F1G08U0M-PCB0T (ICD-ST45)

IC7003 6-703-868-01 IC MB91F233

IC7004 6-703-861-01 IC RX-4591CF

IC7005 6-701-736-01 IC R3130N28EA-TR

IC8001 6-702-098-01 IC M66291GP-2

IC8003 6-704-146-01 IC XC62FP3502MR

< JACK >

C8007 1-125-777-11 CERAMIC CHIP 0.1uF 10% 10V

C8009 1-131-860-11 TANTAL. CHIP 4.7uF 20% 10V

C8010 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

< CONNECTOR >

* CN3001 1-817-347-21 CONNECTOR, FFC/FPC 5P

CN7001 1-816-036-31 CONNECTOR (SQUARE TYPE) (USB) 5P

J3001 1-817-346-11 JACK (PLUG IN POWER)

J3002 1-817-346-21 JACK (i)

J5001 1-794-615-11 JACK, DC (POLARITY UNIFIED TYPE)

(DC IN 3V)

< SHORT >

JC3001 1-218-990-11 SHORT CHIP 0

✩ Replacement of IC6001 used in this set requires a

special tool.

37

Page 38

ICD-ST25

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

< COIL >

L5001 1-456-159-11 INDUCTOR 22uH

L5002 1-456-159-11 INDUCTOR 22uH

< TRANSISTOR >

Q3001 8-729-042-72 TRANSISTOR UN9214J-(K8).SO

Q3002 8-729-042-72 TRANSISTOR UN9214J-(K8).SO

Q3003 6-550-859-01 TRANSISTOR NTHD4508NT1G

Q3004 6-550-747-01 TRANSISTOR 3LP01S-K-TL-E

Q5001 6-550-747-01 TRANSISTOR 3LP01S-K-TL-E

Q5002 8-729-053-03 TRANSISTOR XP151A12A2MR

Q5003 8-729-051-50 TRANSISTOR XP152A12C0MR

Q5005 8-729-927-99 TRANSISTOR 2SC4617R

Q5006 6-550-746-01 TRANSISTOR 3LN01S-K-TL-E

Q5007 8-729-041-23 TRANSISTOR NDS356AP

Q5008 6-550-747-01 TRANSISTOR 3LP01S-K-TL-E

Q5009 6-550-859-01 TRANSISTOR NTHD4508NT1G

Q5010 6-550-746-01 TRANSISTOR 3LN01S-K-TL-E

Q5011 6-550-747-01 TRANSISTOR 3LP01S-K-TL-E

Q5012 6-550-746-01 TRANSISTOR 3LN01S-K-TL-E

Q5013 6-550-861-01 TRANSISTOR NTHS2101PT1G

Q5014 6-550-746-01 TRANSISTOR 3LN01S-K-TL-E