Sony ICDP-28 Service manual

ICD-P28

SERVICE MANUAL

Ver 1.0 2004.03

SPECIFICATIONS

Recording media Built-in flash memory, Monaural recording

Recording time SP: 9 hours 40 minutes

LP: 15 hours 45 minutes

Frequency response 180 Hz - 3,500 Hz

Speaker approx. 3.2 cm (1 5/16 in.) dia.

Power output 250 mW

Input/Output • Earphone jack (minijack) for 8 - 300 ohms

ear receiver/headphones

• Microphone jack (minijack, monaural)

Plug in power

Minimum input level 0.6 mV

3 kilohms or lower impedance microphone

Power requirements Tw o LR03 (size AAA) alkaline batteries: 3 V DC

Dimensions (w/h/d) (not incl. projecting parts and controls)

44.5 × 105.3 × 14.0 mm (1 13/16 × 4 1/4 × 9/16 in.)

Mass (incl. batteries) 71 g (2.5 oz)

Supplied accessories LR03 (size AAA) alkaline batteries (2) (For the

US only)

USB connecting cable (1)

Application software (CD-ROM) (1)

US Model

Canadian Model

AEP Model

Tourist Model

Korean Model

9-877-649-01

2004C04-1

© 2004.03

Design and specifications are subject to change without notice.

IC RECORDER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

1

ICD-P28

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

UNLEADED SOLDER

•

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

TABLE OF CONTENTS

1. SERVICE NOTE ................................................................ 3

2. GENERAL

Index to Parts and Controls ..................................................... 4

3. DISASSEMBLY

3-1. Case (Upper) Assy .............................................................. 5

3-2. F-SW Board, P-SW Board .................................................. 6

3-3. Main Board ......................................................................... 6

3-4. PC Board ............................................................................. 7

4. TEST MODE .......................................................................8

5. DIAGRAMS

5-1. IC Pin Description.............................................................11

5-2. Block Diagram .................................................................. 13

5-3. Printed Wiring Board – Main Section – ............................ 15

5-4. Printed Wiring Board – F-SW Section – ........................... 16

5-5. Printed Wiring Board – P-SW, PC Section – .................... 17

5-6. Schematic Diagram – Main Section (1/2) – ...................... 18

5-7. Schematic Diagram – Main Section (2/2) – ...................... 19

5-8. IC Block Diagrams............................................................20

6. EXPLODED VIEWS

6-1. Case Section ...................................................................... 21

6-2. Main Board Section .......................................................... 22

7. ELECTRICAL PARTS LIST ........................................23

2

SECTION 1

R105

SERVICE NOTE

1-1. CAUTIONS OF FLASH MEMORY (IC701)

EXCHANGE

[Precaution when the flash memory (IC701) is replaced]

When the flash memory (IC701) is replaced, be sure to perform the

BAD BLOCK check* and writing of the model code. If they are not

completed, the unit will not operate normally.

* BAD BLOCK check is to check the flash ROM memory

area (the BAD BLOCK area) where data cannot be

guaranteed. The resultant information of this check is stored

in the TOC-AREA so that the BAD BLOCK area should

not be used.

[BAD BLOCK Check Procedure]

1. When the power is turned on after the flash memory (IC701) is

replaced, the BAD BLOCK check starts automatically and the

OPR (D701) lights in orange.

2. In about 30 seconds after start of the check, the OPR (D701)

changes the color to green indicating that the check is

completed.

ICD-P28

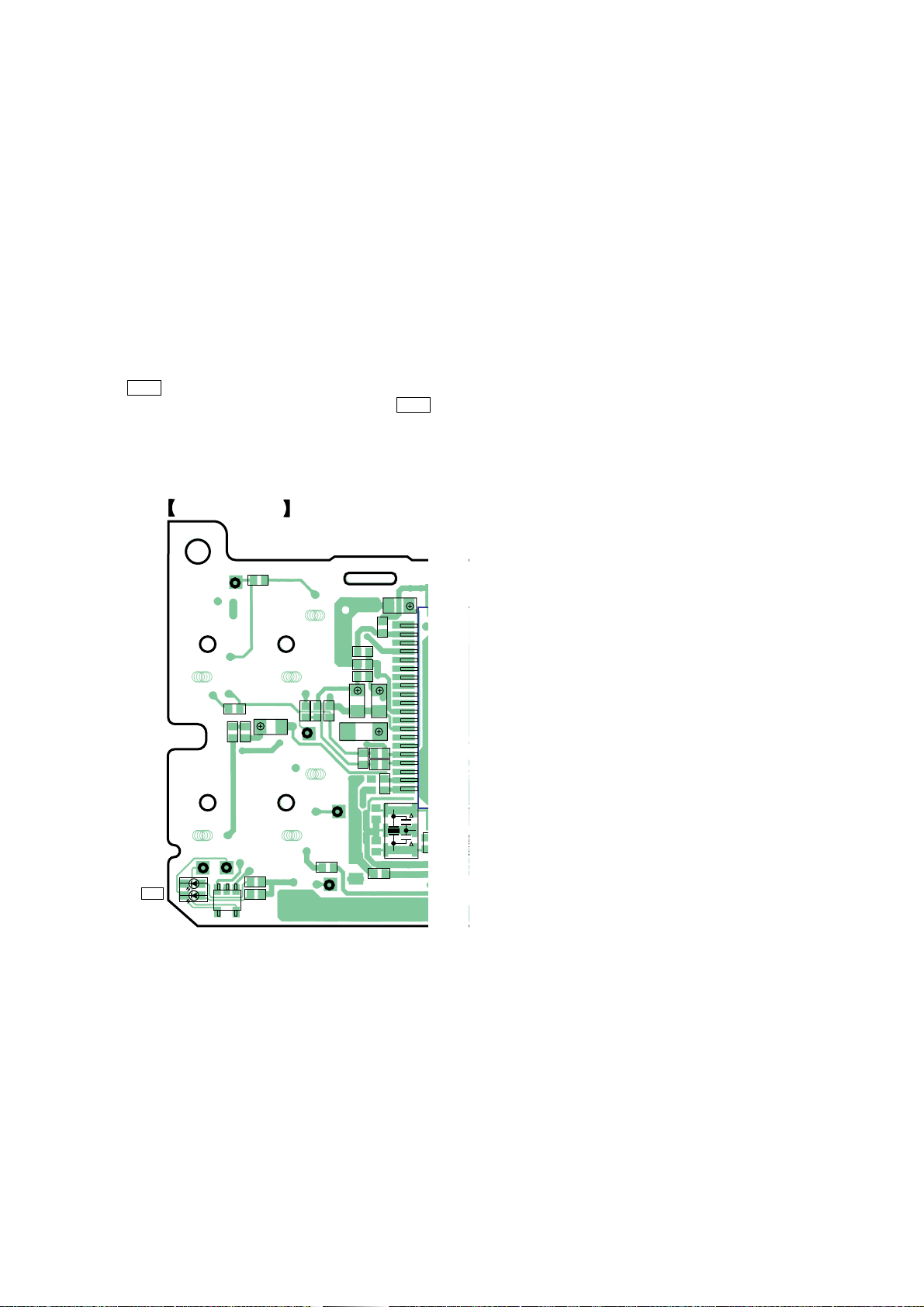

MAIN BOARD (SIDE B)

R101

TP102

FB102

C125

R128

FB104

TP714 TP715

RED

(REC)

D701

D701

OPR

GRN

(PLAY)

B E B

C C

Q701

R717

R716

FB101

TP101

R102

TP719

FB103

TP718

R103

R110

C114

R104

C110

C102

C101

C106

C105

R133

C104

C112

C116

C111

X101

30

31

50

51

R135

C107

3

ICD-P28

SECTION 2

GENERAL

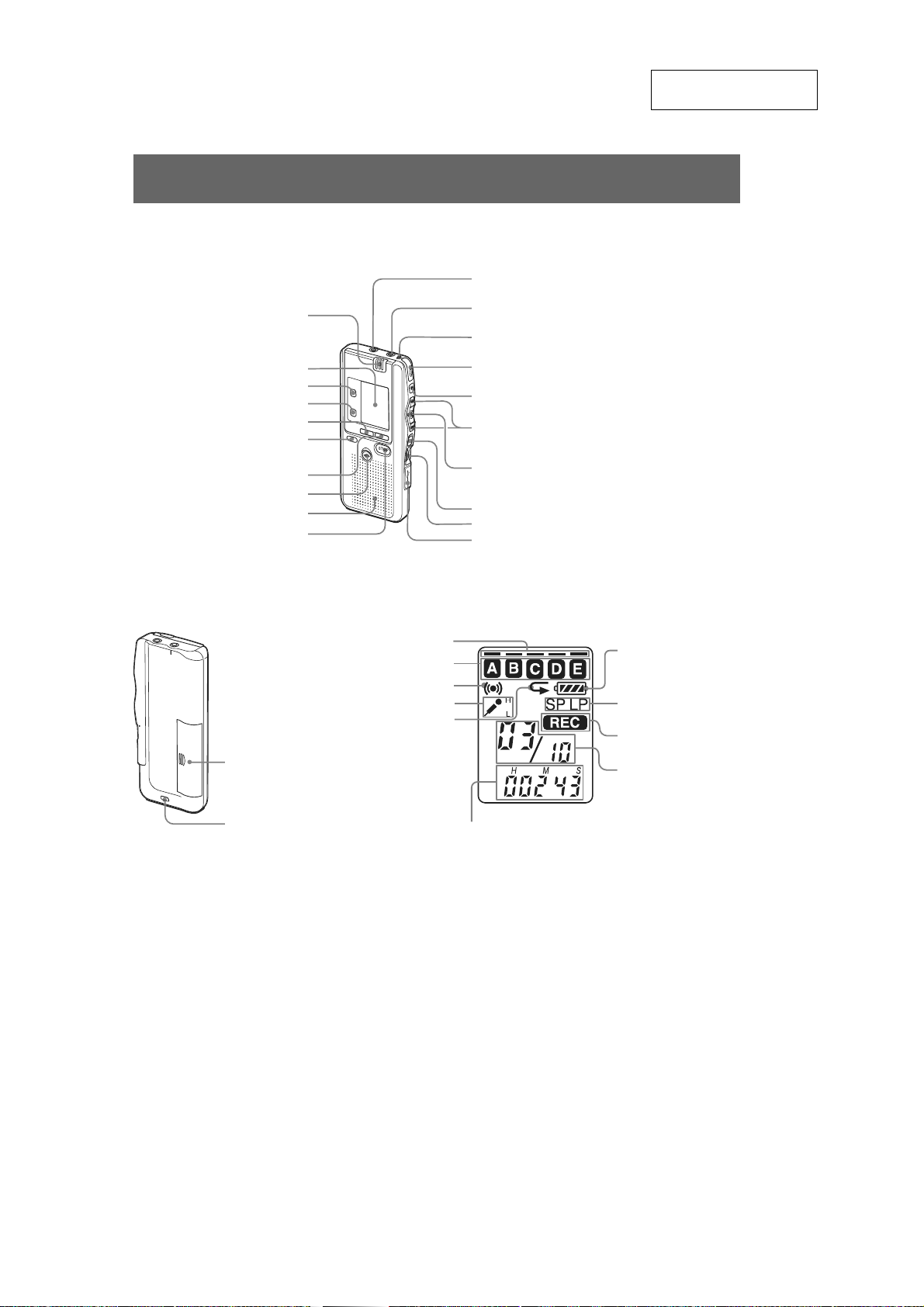

Index to Parts and Controls

Main unit

MIC jack

(PLUG IN POWER)

(built-in microphone)

MIC

EAR (earphone) jack

OPR (operation) indicator

This section is extracted

from instruction manual.

Rear

Display window

FOLDER

DIVIDE

DISPLAY

MIC SENS

(microphone sensitivity)

MENU

ERASE

Speaker

STOP

Battery

compartment

Display window

Remaining memory indicator

Folder indication

Alarm indicator

Microphone sensitivity indication

Repeat play indicator

zREC (record) /STOP

X PAUSE

– ./ >+ SELECT

(ENTER)

NxPLAY/STOP

(ENTER)

HOLD

VOL (volume)

USB connector

Remaining battery

indicator

Recording mode

indication

REC (recording)

indicator

Selected message

number/number of

messages in a folder

Hook for handstrap

(not supplied)

Counter /Remaining time indication /Recording date and

time indication /Current time indication (15:30, etc.) /Menu

indication (ALARM, BEEP, etc.) /Mode indication of the

menu (ON, OFF, etc.) /Messages (ERASE, HOLD, etc.)

4

SECTION 3

y

DISASSEMBLY

Note : This set can be disassemble according to the following sequence.

SET

3-1. CASE (UPPER) ASSY

(Page 5)

3-2. F-SW BOARD,

P-SW BOARD

(Page 6)

3-3. MAIN BOARD

(Page 6)

3-4. PC BOARD

(Page 7)

ICD-P28

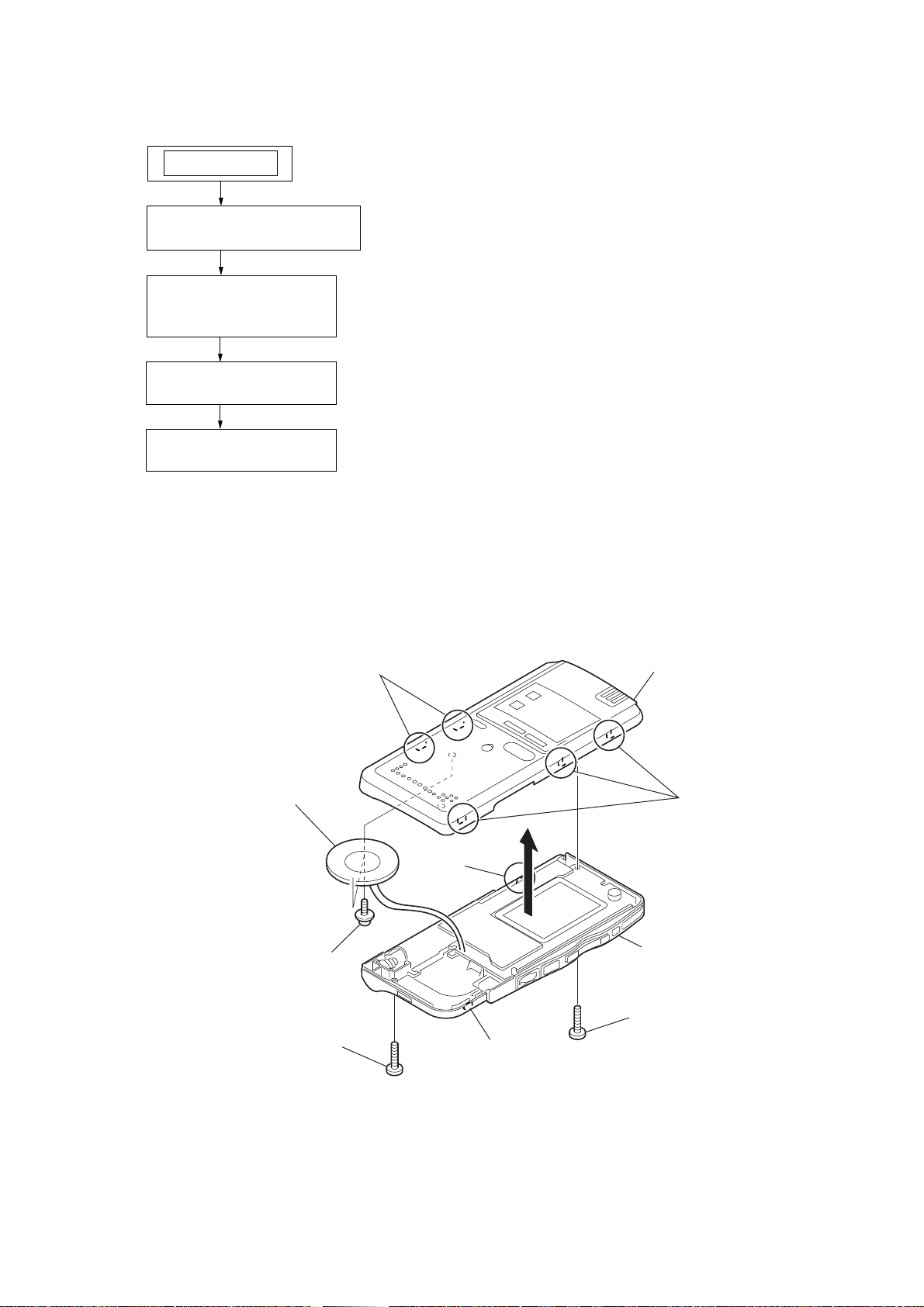

Note : Follow the disassembly procedure in the numerical order given.

3-1. CASE (UPPER) ASSY

3

two claws

9

speaker (SP101)

6

claw

8

two

screws

x

(1.7

2.5)

7

0

case (upper) ass

5

three claws

case block assy

2

screw

(B 1.7x7)

4

claw

1

screw

(B 1.7x10)

5

ICD-P28

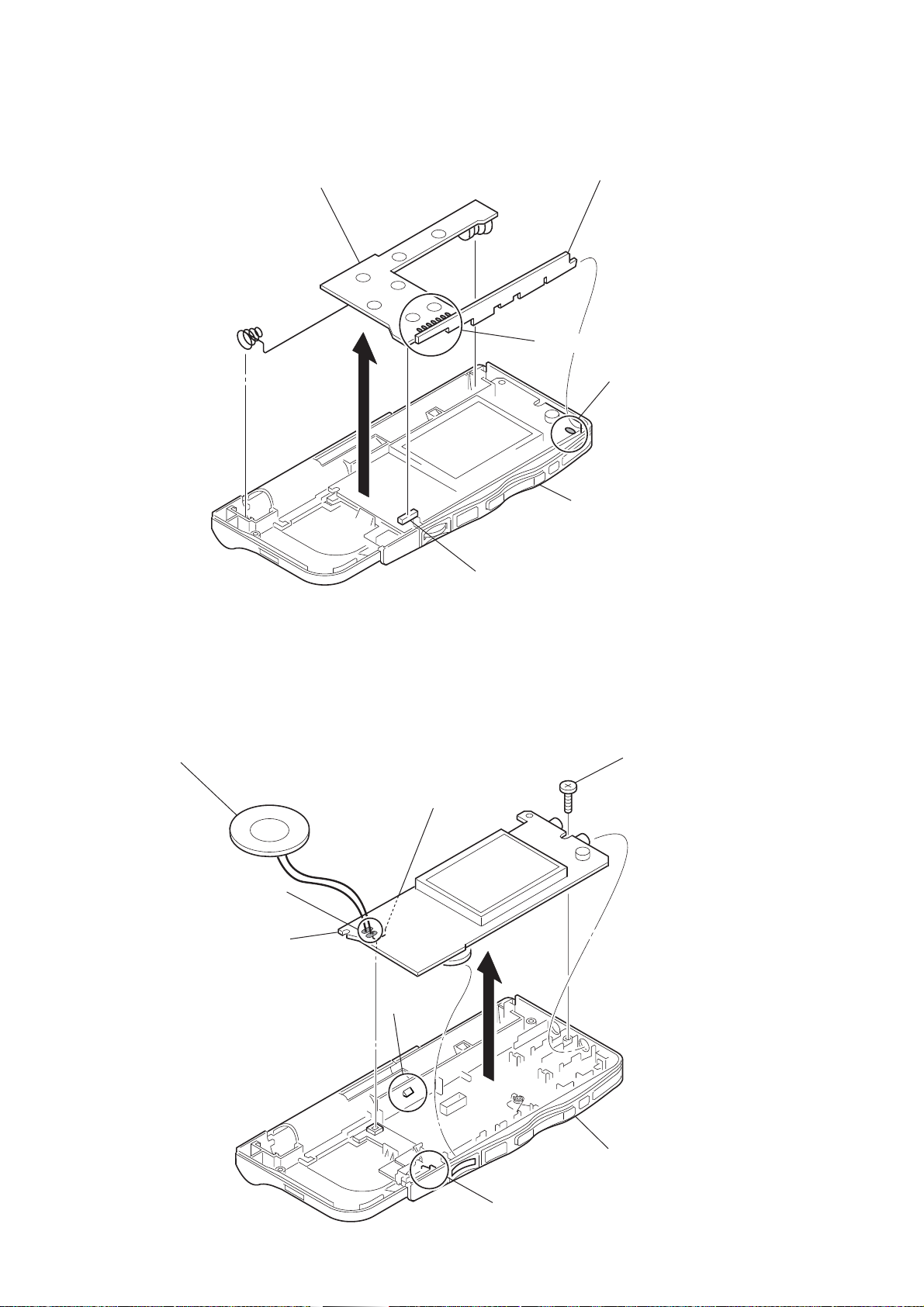

3-2. F-SW BOARD, P-SW BOARD

6

F-SW board

5

P-SW board

3-3. MAIN BOARD

2

speaker (SP101)

3

2

CN703

4

Removal the seven solders.

1

Removal the solder.

case block assy

3

screw

(1.7x4)

1

Removal the two solders.

8

MAIN board

4

claw

6

CN801

5

7

case (lower) assy

claw

6

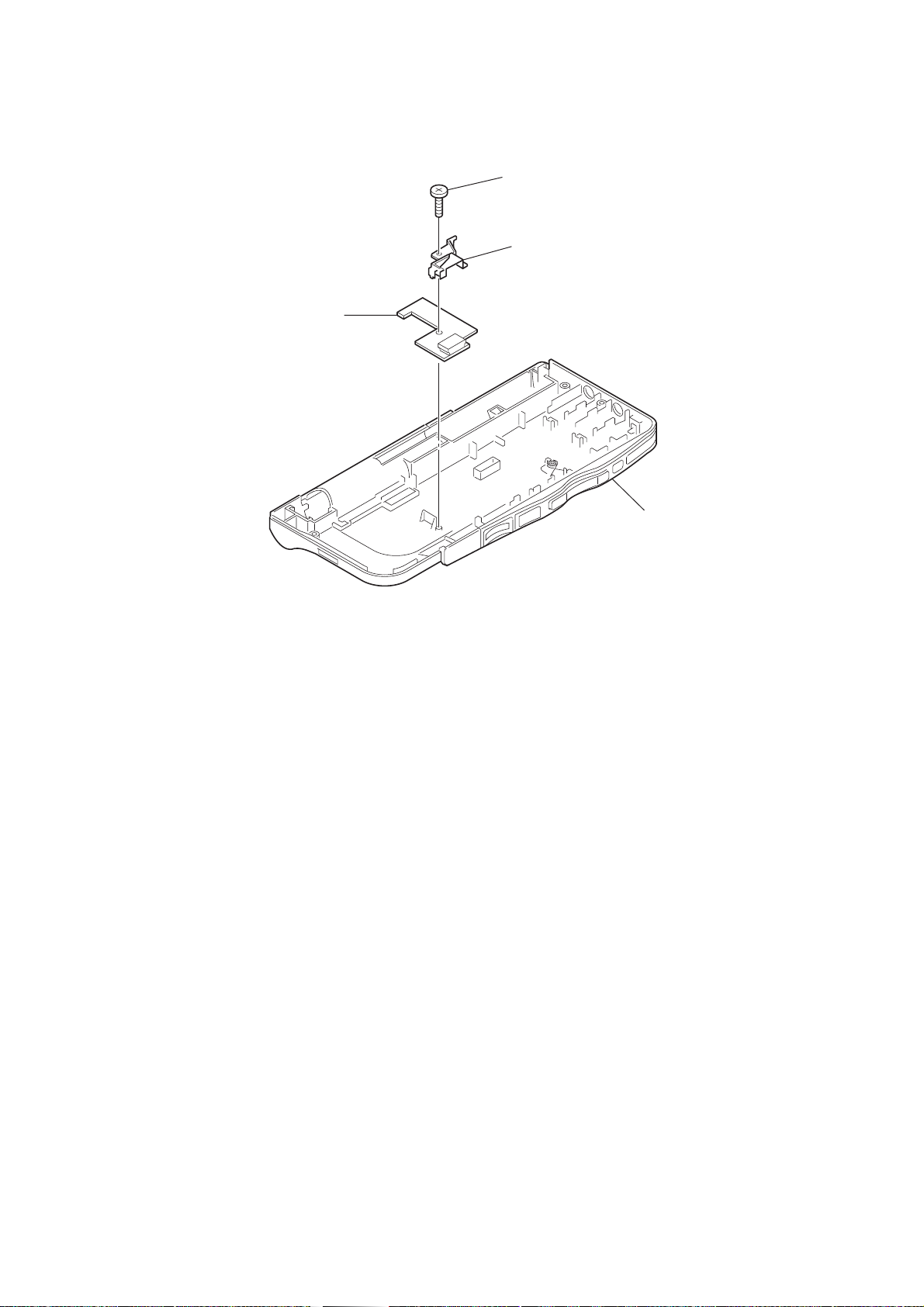

3-4. PC BOARD

y

2

PC board

1

screw

(1.7

x

3

holder (jack)

ICD-P28

3.7)

case (lower) ass

7

ICD-P28

SECTION 4

TEST MODE

[Setting Method of the Test Mode]

(1) To enter the test mode , turn on the HOLD switch while

pressing the STOP key and MENU key at the same time with

the power on.

[Exiting Method of the Test Mode]

Exit the test mode by turning off the power.

[Initial Status of the Test Mode]

When the test mode is set, the LCD display appears as shown

below.

LCD display

/091

P17

091tIC702 version

(Displayed to A or B folder

when version a or b.)

P17tSet code

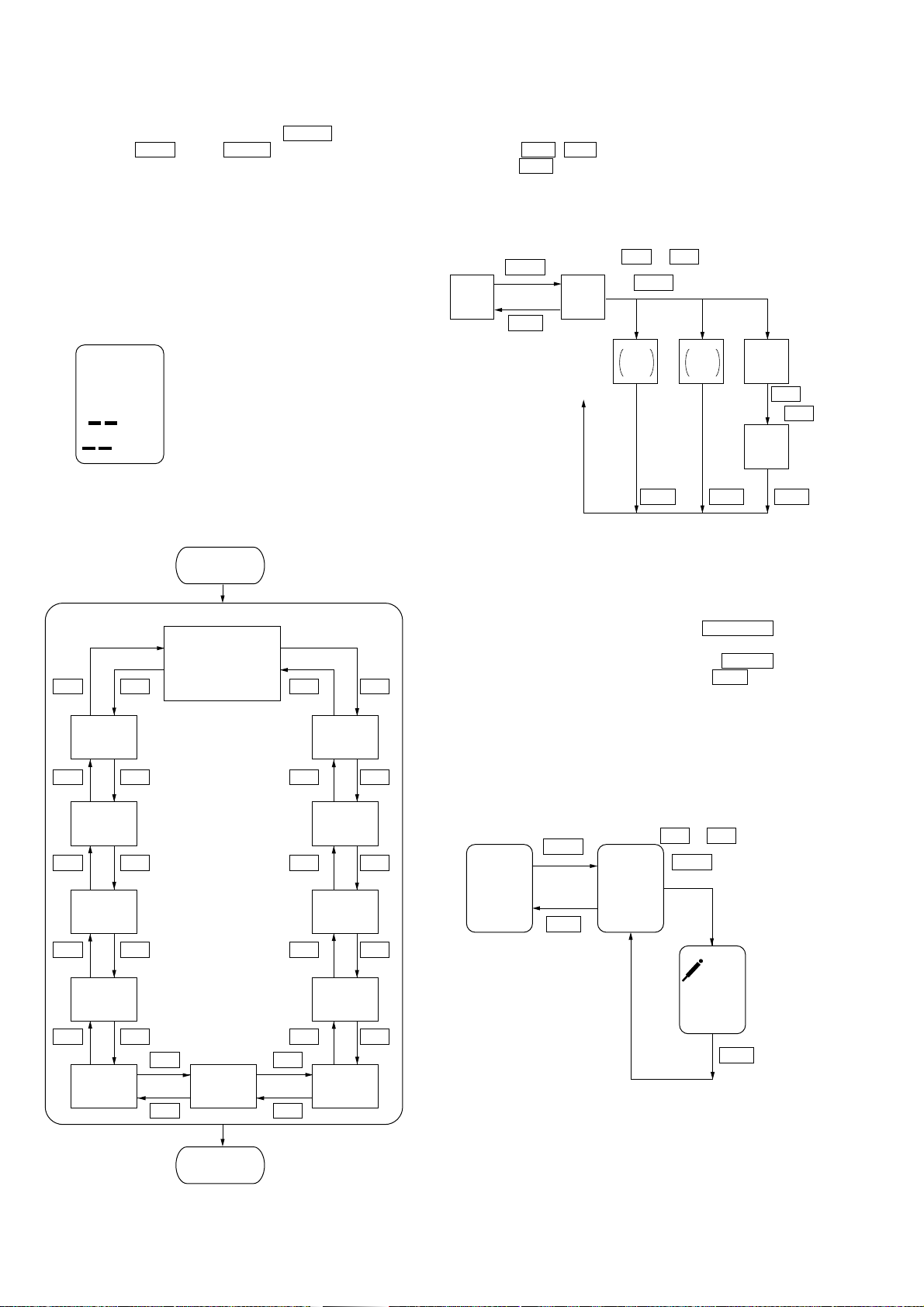

[Flow Chart of the Test Mode]

START

TEST MODE

Initial status of

Test mode.

Set code,LPEC ST,

.>

F/W version display

LCD

.>

.>

RST

MENU

.>

[Operation in the Test Mode]

After entering the test mode, you can move within the test menu by

pressing the . / > key. You can move to the submenu by

pressing the x•B key. Then each test mode can be executed.

1. LCD test

• LCD is tested all light-on and all light-off.

x • B

LCD LCD

STOP

ALL

•

•

•

OFF LCD

CHK LCD

ALL LCD

•

•

•

. / >

x • B

LCD

ON

(SET)

LCD

OFF

(SELECT)

CHK

START

.

/ .

CHK

END

STOP STOP STOP

2. Audio test

Perform the through-playback.

• Contents of the submenu

DSPLOP: DSP through mode.

• Select the microphone sensitivity with the MIC SENS switch.

HtLtHtLt

……

• MUTE can be set to “ON” or “OFF” with the ERASE key.

•The sound volume can be adjusted with the VOL volume key

during the audio test except the MUTE mode.

•This test operates in accordance with to the JA CK detection test.

It displays the current mode, microphone sensitivity and mute

on the LCD display.

[Example of LCD display]

DSP through mode/MIC: H/MUTE: OFFtH/OF/DSPLOP

AUDIO

.>

SLEEP

.>

BEEP

.>

>

RTC

.

END

TEST MODE

COUNT

>

.

Turning off the power.

USB

LED

BATTKEY

KEY

.>

.>

.>

x • B

AUDIO DSPLOP

STOP

. / >

(SET)

x • B

H

OF

DSPLOP

(SELECT)

STOP

8

ICD-P28

3. Sleep test

•Pressing the x•B key causes the set to enter the sleep state.

•Press any keys to exit the sleep state.

x • B

with

off

HOLD

SLEEP SOON

SLEEP

any keys

4. Beep test

• Beep sound of 1.3 kHz or 2 kHz is output.

x • B

. / >

x • B

(SELECT)

(SET)

6. Key entry test

•When the any key is pressed, the entry key and the A/D

converted value (hexadecimal) of the two channel keys are

displayed.

KEY IN0 is displayed on the upper side and KEY IN1 on the

lower side.

•When the STOP key is pressed, the A/D value of the key is

displayed while the key is depressed. When the key is released,

the screen returns to the test menu.

x • B

OFF

KEY KEY,OFF

STOP

7. Battery remaining power test

•The detected A/D value (hexadecimal) of the battery remaining

power is displayed.

x • B

BATT BATT

STOP

u

AA

BEEP 1.3k

STOP

•

•

•

2.0k

1.3k

•

•

•

1.3k 2.0k

STOP

5. RTC test

•Perform the connection test of the RTC, EEPROM.

x • B

ON

RTC RTC

STOP

(1) RTC EEPROM test

This test checks that any data is written and read to and from

specific registers (verify check) and that data is cleared.

(2) RTC clock function test

This test checks that the time is updated at intervals of 1 second

in the micro processor by the RTC.

• It determines whether a test result is OK or NG.

If NG, it indicates that either device of R TC or EEPR OM was

found to be NG.

(All OKs: RTC OK/R TC NG: R TC B AD/EEPR OM NG: EEP

BAD)

ONON

STOP

8. LED test

• LED ( OPR : orange) are all turned on.

x • B

LED LED

STOP

ON

9

Loading...

Loading...