Sony ICDMS-515 Service manual

ICD-MS515

SERVICE MANUAL

Ver 1.0 2002. 02

SPECIFICATIONS

Recording media “Memory Stick“, Monaural recording

Recording time

Maximum recording time of a “ Memory Stick “ *

Mode** 4MB 8MB 16MB 32MB 64MB 128MB

SP 30 min. 64 min. 130 min. 264 min. 532 min. 1,067 min.

LP 82 min. 171 min. 347 min. 705 min. 1,418 min. 2,846 min.

* When using each “Memory Stick“ for use with ICD-MS515 only and by the

initial setting with three folders.

**The initial setting is SP mode.

Frequency response SP: 250 Hz - 7,300 Hz

Speaker approx. 23 mm (

Power output 200 mW

Input/Output • Earphone jack (minijack) for 8 - 300 ohms

Playback speed control +100% to -50% (DPC)

Power requirements Two size AAA (LR03) alkaline batteries: 3 V DC

Dimensions 34.4 x 106.3 x 18 mm (1

Mass 75 g (2.7 oz) (incl. batteries and a “Memory Stick“)

Supplied accessories “Memory Stick“ x 1

LP: 250 Hz - 3,500 Hz

earphone/headphones

• Microphone jack (minijack, monaural)

Plug in power

Minimum input level: 0.7 mV 3 kilohms or

lower impedance microphone

• USB connector

(w/h/d) (not incl. projecting parts and controls)

“Memory Stick Voice Editor“ (CD-ROM) x 1

Carrying case x 1

Size AAA (LR03) alkaline battery x 2 (U.S.A. and

tourist models only)

29

/

32

in.) dia.

3

/8 x 4 1/4 x 23/

(min.: minutes)

in.)

32

US Model

Canadian Model

AEP Model

UK Model

E Model

Tourist Model

9-873-547-01

2002B1600-1

© 2002.02

Design and specifications are subject to change without notice.

IC RECORDER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

ICD-MS515

TABLE OF CONTENTS

1. GENERAL ··········································································3

2. DISASSEMBLY ································································4

2-1. Front Cabinet Section, Lid (M) Section ······················· 4

2-2. LCD Block Assy···························································5

2-3. Eject Mecha Block Assy, MAIN Board························6

2-4. Speaker Assy (SP3201), Microphone Unit (MIC3201),

AUDIO Board-1···························································· 7

2-5. Speaker Assy (SP3201), Microphone Unit (MIC3201),

AUDIO Board-2···························································· 8

2-6. SWITCH Board ····························································8

2-7. Liquid Crystal Indicator Unit········································9

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

3. TEST MODE ···································································· 10

4. DIAGRAMS ······································································12

4-1. Block Diagrams ··························································13

4-2. Printed Wiring Board – AUDIO Board –···················· 15

4-3. Schematic Diagram – AOUDIO Board (1/2) –··········· 16

4-4. Schematic Diagram – AOUDIO Board (2/2) –··········· 17

4-5. Printed Wiring Board – MAIN Board – ····················· 18

4-6. Schematic Diagram – MAIN Board (1/2) – ··············· 19

4-7. Schematic Diagram – MAIN Board (2/2) – ··············· 20

4-8. Printed Wiring Board – SWITCH Board – ················· 21

4-9. Schematic Diagram – SWITCH Board –···················· 22

4-10. IC Block Diagrams ····················································· 23

4-11. IC Pin Function Descriptions······································ 25

5. EXPLODED VIEWS ······················································ 30

5-1. Front Cabinet Section ················································· 30

5-2. Rear Cabinet Section ·················································· 31

5-3. Case Section································································ 32

6. ELECTRICAL PARTS LIST ······································· 33

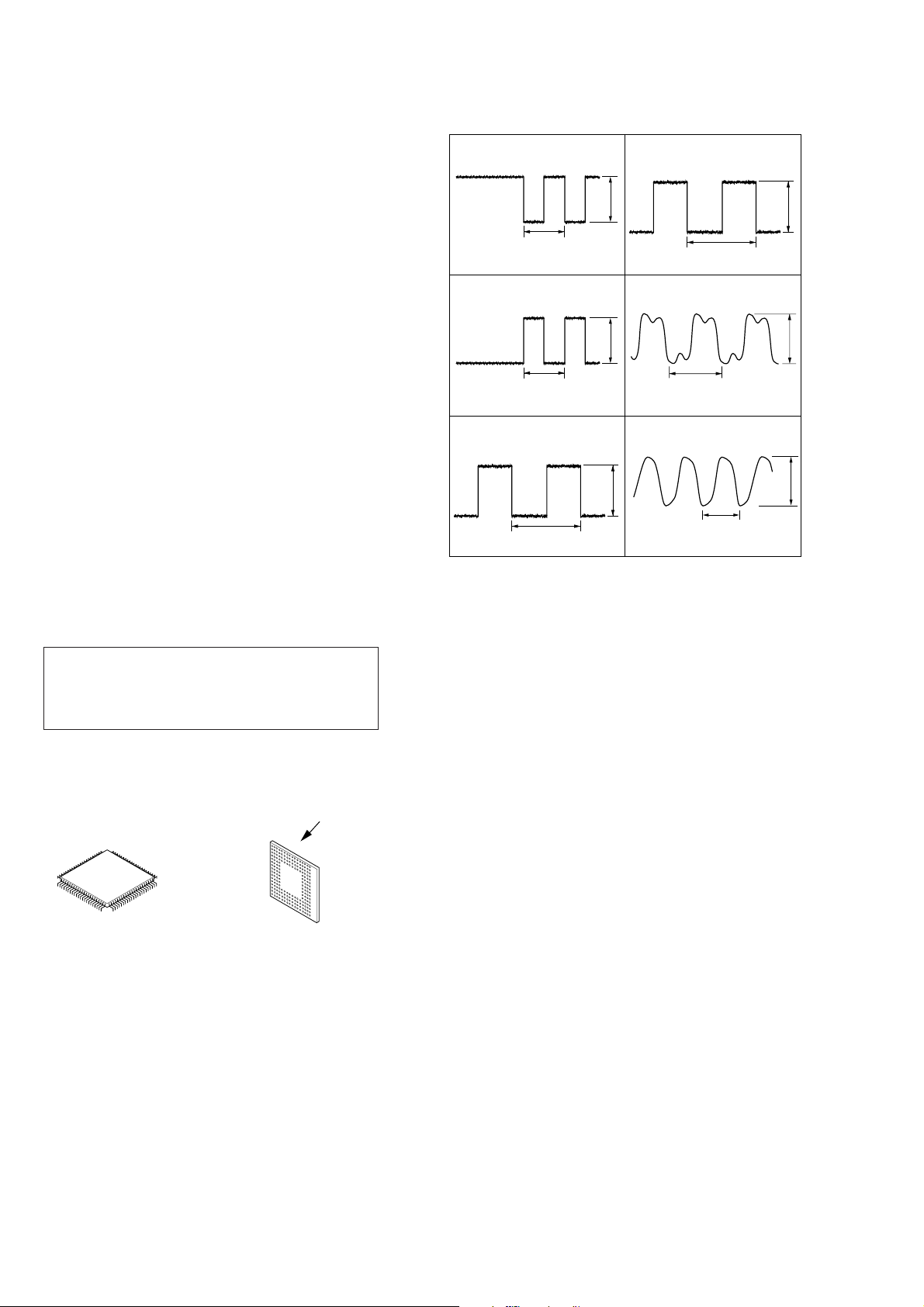

* Replacement of IC6201, IC7102 used in this set requires a special

tool.

• The voltage and waveform of CSP (chip size package) cannot be

measured, because its lead layout is different from that of conventional IC.

• Lead layouts

surface

Lead layout of

conventional IC

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

CSP (chip size package)

2

SECTION 1

Jog lever

Press the

center

Press up

Press down

Step 2: Setting the Clock

You need to set the clock to use the alarm function or record the date and

time.

Clock setting display appears when you insert battery for the first time, or

when you insert battery after the unit has been without battery for a

certain period of time. In this case, proceed from step 4.

1

Turn the jog lever toward MENU.

The menu mode will be displayed in the

display window.

2

Press the jog lever up (>) four times

to select “DATE&TIME”.

3

Press the jog lever (x•B).

The date and time setting window is

displayed. The year digits will flash.

Turn

toward

MENU

Turn

toward

FOLDER

4

Set the date and time.

1 Press the jog lever up or down (>/

.)to select the digits of the year.

2 Press the jog lever (x•B).

The month digits will flash.

3 Set the month, day, and the time in

sequence, then press the jog lever

(x•B).

The menu mode will be displayed again.

5

Turn the jog lever toward MENU.

The window will return to normal display.

To display the current time

Press x STOP button during the sleep display mode (page 53).

The current time will be displayed for three seconds.

GENERAL

Front Rear

ICD-MS515

This section is extracted from

instruction manual.

1 ERASE button (25)

2 EAR (earphone) jack (19, 22)

3 OPR (operation) indicator

(17, 22)

4 Built-in microphone (17, 31)

5 Display window (93)

6 zREC (record) /REC

PAUSE button (17, 31)

7 xSTOP button (17, 22, 27)

8 Jog lever

FOLDER/MENU/

.(review/fast backward)/

> (cue/fast forward)/

x• B (play/stop•enter) (12,

16, 21, 28, 58)

9 INDEX/BOOKMARK

button (29, 33)

0 A-B REPEAT/PRIORITY

button (30, 40)

qa EJECT lever (15)

qs Memory Stick slot (14)

qd HOLD switch (52)

qf Speaker

qg VOL (volume) +/– buttons

(22)

qh Slit for the supplied

handstrap

qj MIC (PLUG IN POWER)

jack (20)

qk USB connector (70)

ql Battery compartment (10)

3

ICD-MS515

)

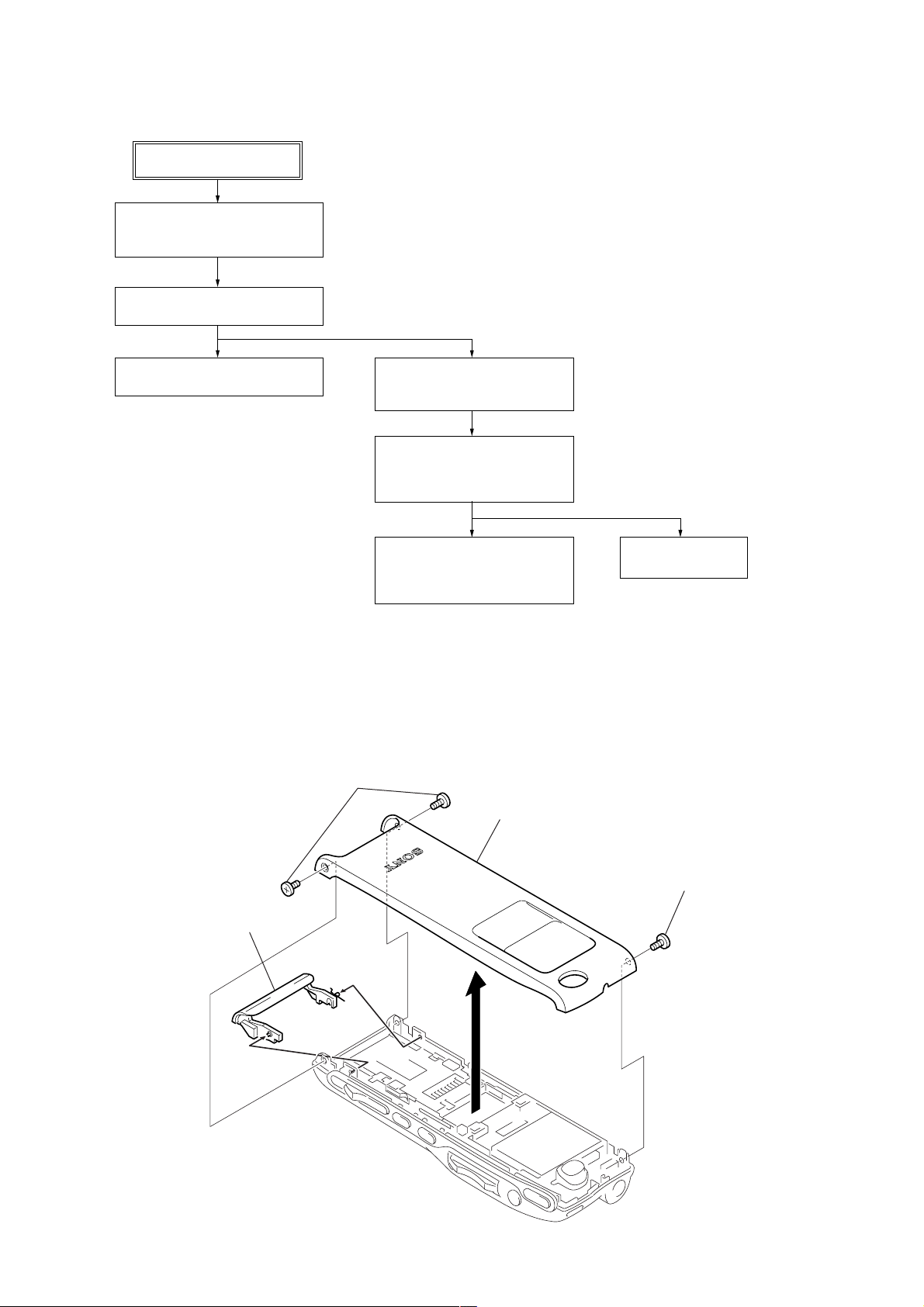

Note : Disassemble the unit in the order as shown below.

SET

FRONT CABINET SECTION,

LID (M) SECTION

(Page 4)

LCD BLOCK ASSY

(Page 5)

SECTION 2

DISASSEMBLY

LIQUID CRYSTAL INDICATOR UNIT

(Page 9)

EJECT MECHA BLOCK ASSY,

SPEAKER ASSY (SP3201),

MICROPHONE UNIT (MIC3201),

AUDIO BOARD-1

SPEAKER ASSY (SP3201),

MICROPHONE UNIT (MIC3201),

AUDIO BOARD-2

Note : Follow the disassembly procedure in the numerical order given.

2-1. Front Cabinet Section, Lid (M) Section

2

two screws (M 1.4)

MAIN BOARD

(Page 6)

(Page 7)

(Page 8)

3

front cabinet section

SWITCH BOARD

(Page 8)

1

screw (M 1.4

4

lid (M), spring (Lid)

4

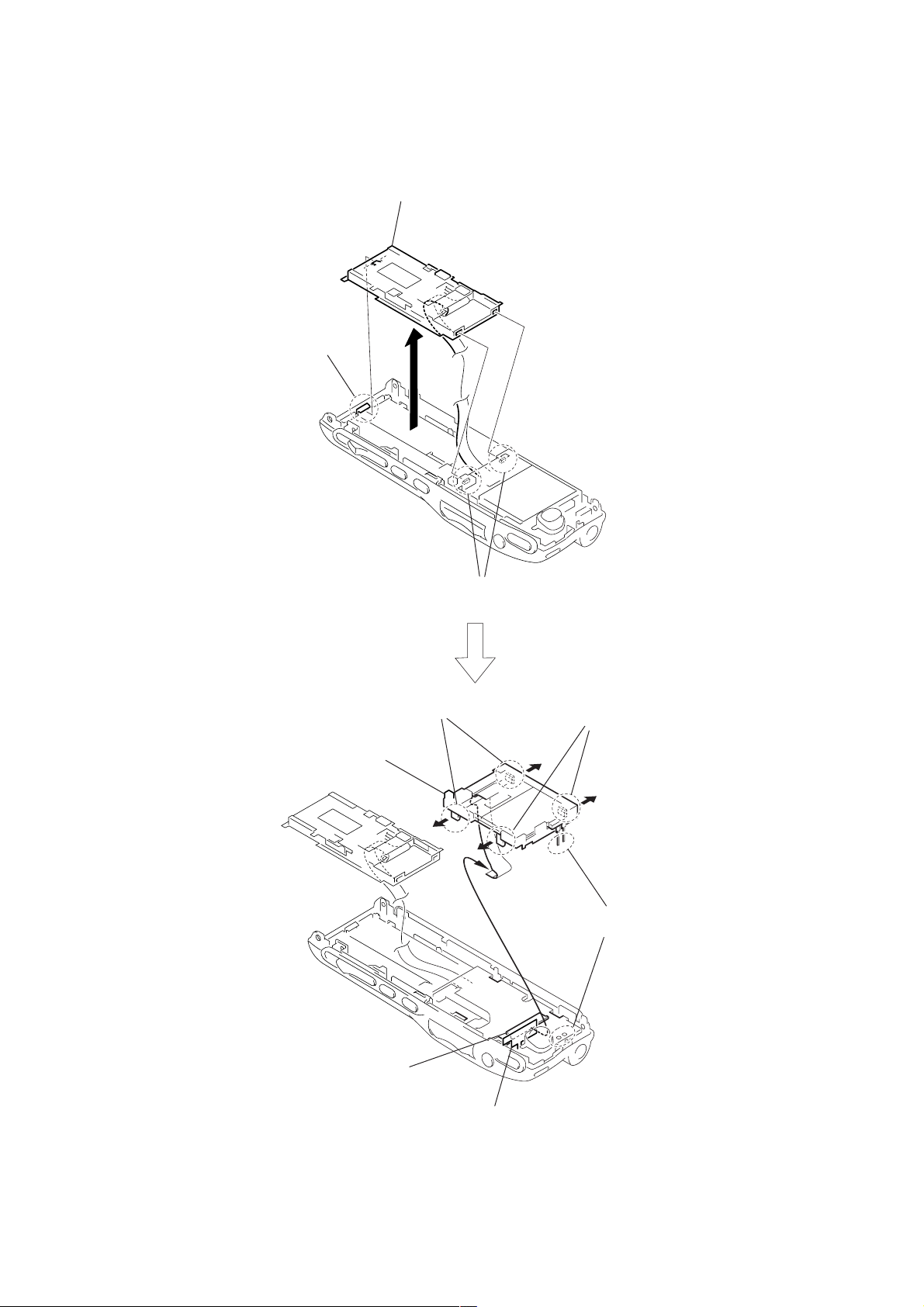

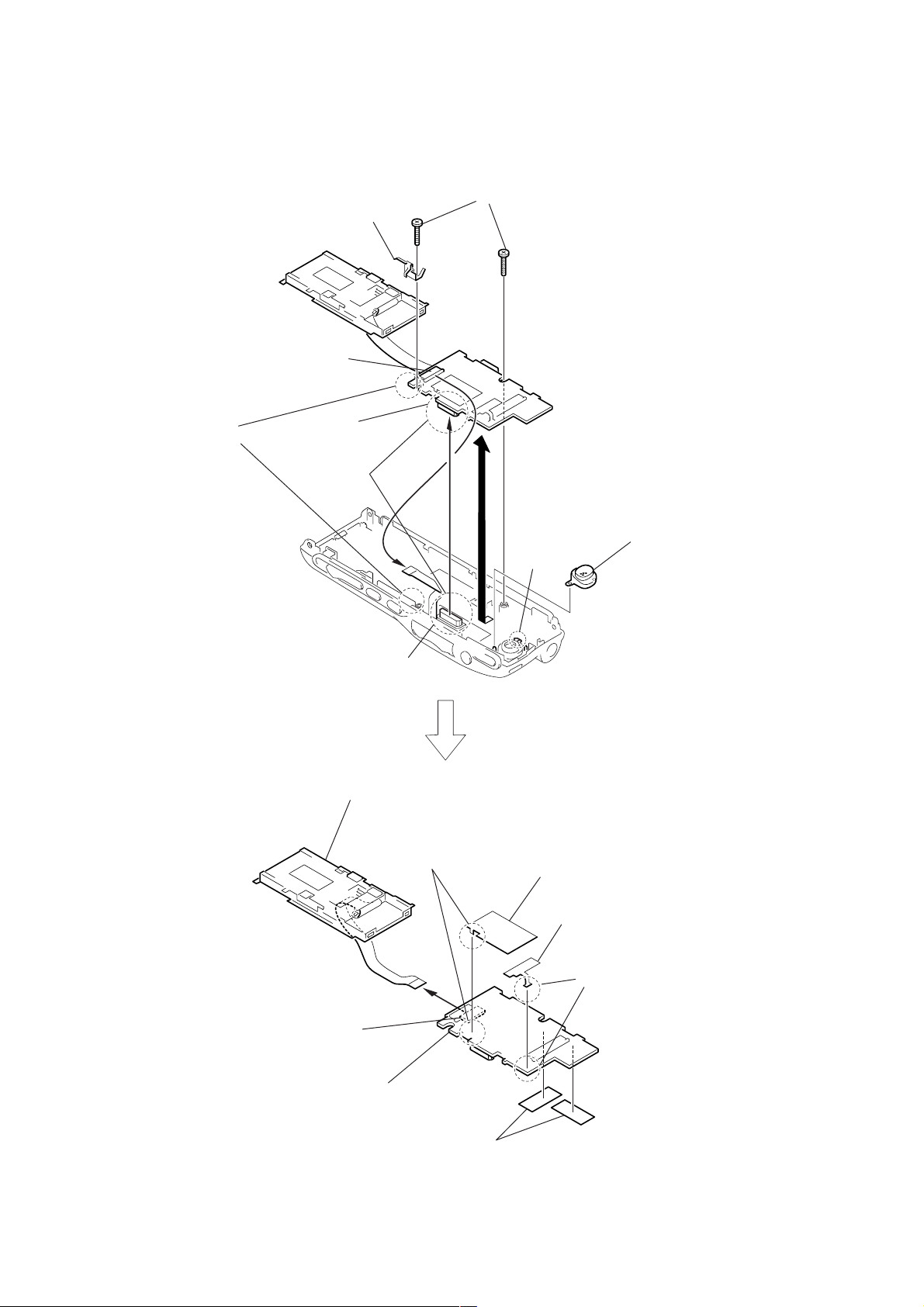

2-2. LCD Block Assy

2

claw

3

eject mecha block assy

ICD-MS515

9

LCD block assy

6

two claws

1

two claws

7

two claws

5

Remove soldering

from the two points of el element.

8

connector

(CN7102) (22 core)

4

shield paper (E)

5

ICD-MS515

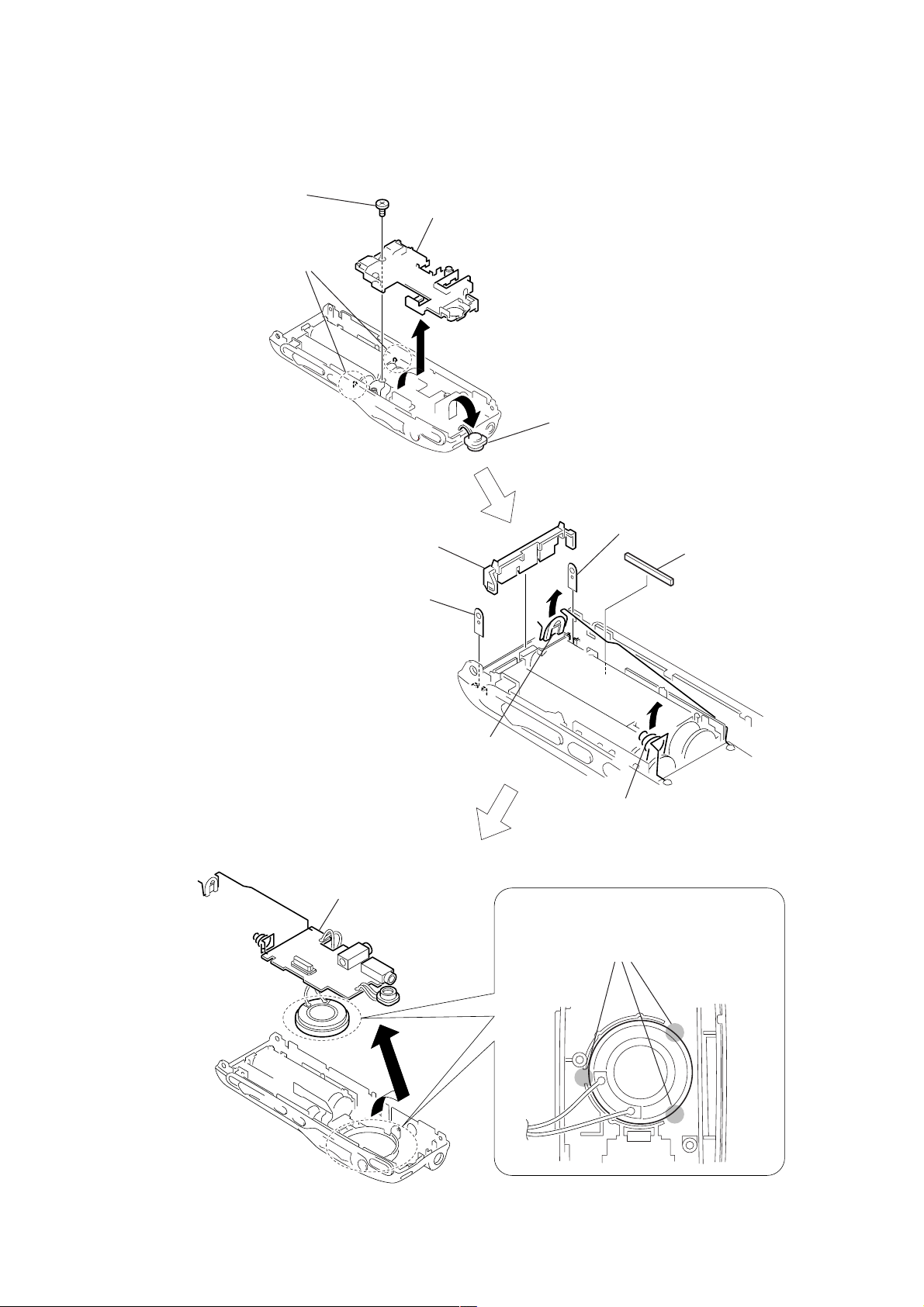

2-3. Eject Mecha Block Assy, MAIN Board

3

ground plate

4

connector

(CN7104) (8 core)

2

two screws (B 1.7

×

8)

5

Remove the soldering.

CN7101

7

connector

CN7201

9

eject mecha block assy

qs

Remove the soldering.

6

claw

qd

1

ornament (MIC)

sheet (SD-A)

qa

shield paper (E)

q;

Remove the soldering.

8

connector

(CN7103) (10 core)

qg

MAIN

board

qf

insulating sheet (JACK)

6

2-4. Speaker Assy (SP3201), Microphone Unit (MIC3201), AUDIO Board-1

)

1

screw (B 1.7

×

3

two claws

4)

4

chassis (PWB)

2

Turn over the Microphone unit (MIC3201

in the direction of the arrow.

ICD-MS515

6

cover (battery terminal)

5

bracket

8

Pull up the Cap (terminal).

q;

AUDIO board

microphone unit (MIC3201)

, speaker

assy (SP3201),

5

bracket

9

Pull up the Battery terminal (-).

Remove soldering from the three points of

speaker assy (SP3201).

7

insulating sheet

7

ICD-MS515

)

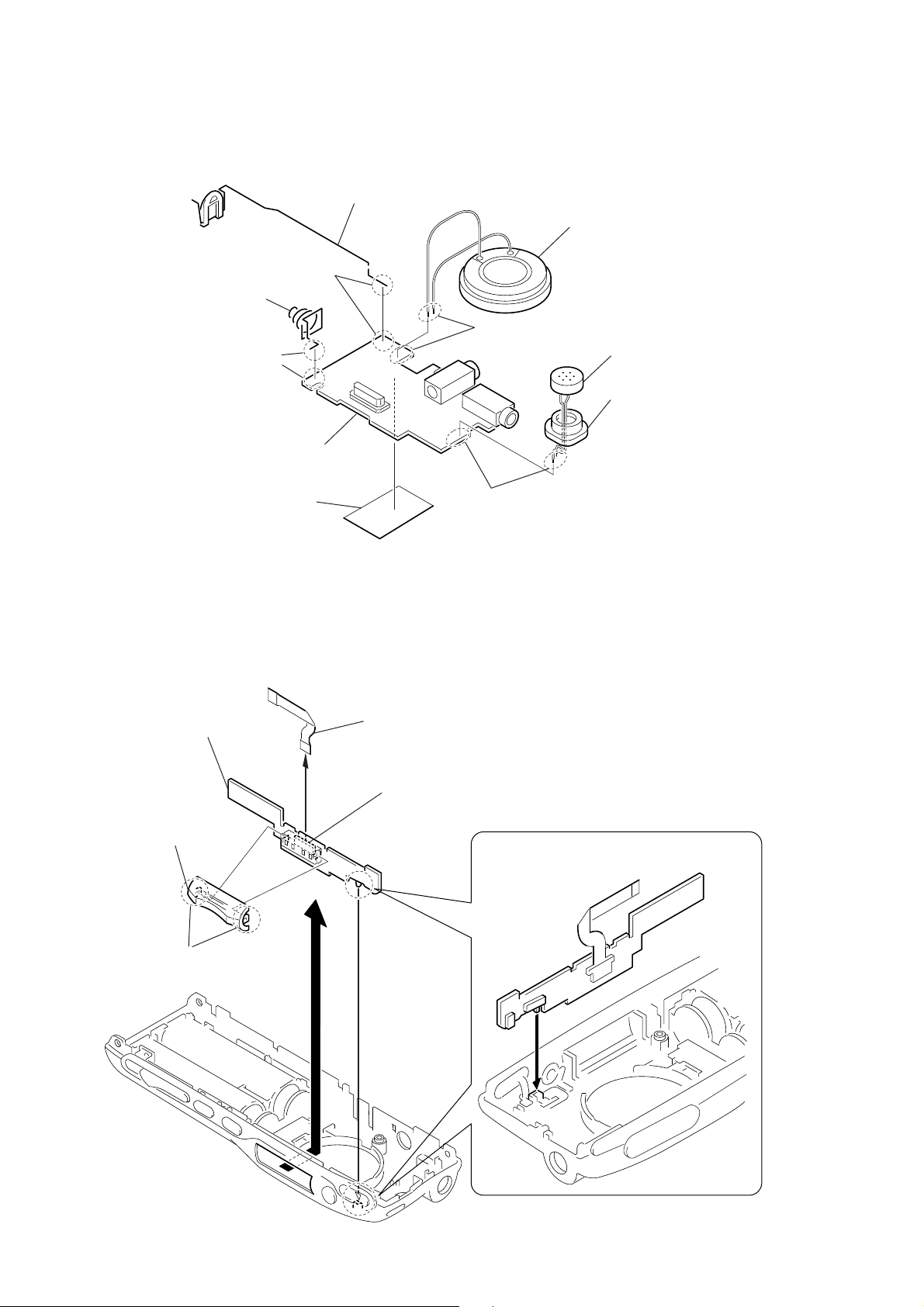

2-5. Speaker Assy (SP3201), Microphone Unit (MIC3201), AUDIO Board-2

2

1

Remove the soldering.

4

battery Terminal

3

Remove the soldering.

qa

terminal

(-)

AUDIO board

(+) block assy

9

8

Remove soldering from the two points.

7

microphone unit (MIC3201

speaker

assy (SP3201)

6

microphone cushion

q;

2-6. SWITCH Board

6

SWITCH

5

button (5D)

i

nsulating sheet (SPK)

board

1

3

connection flexible

2

connector

(CN901) (8 core)

5

Remove soldering from the two points.

board

To attach, align the switch position as shown.

4

two claws

8

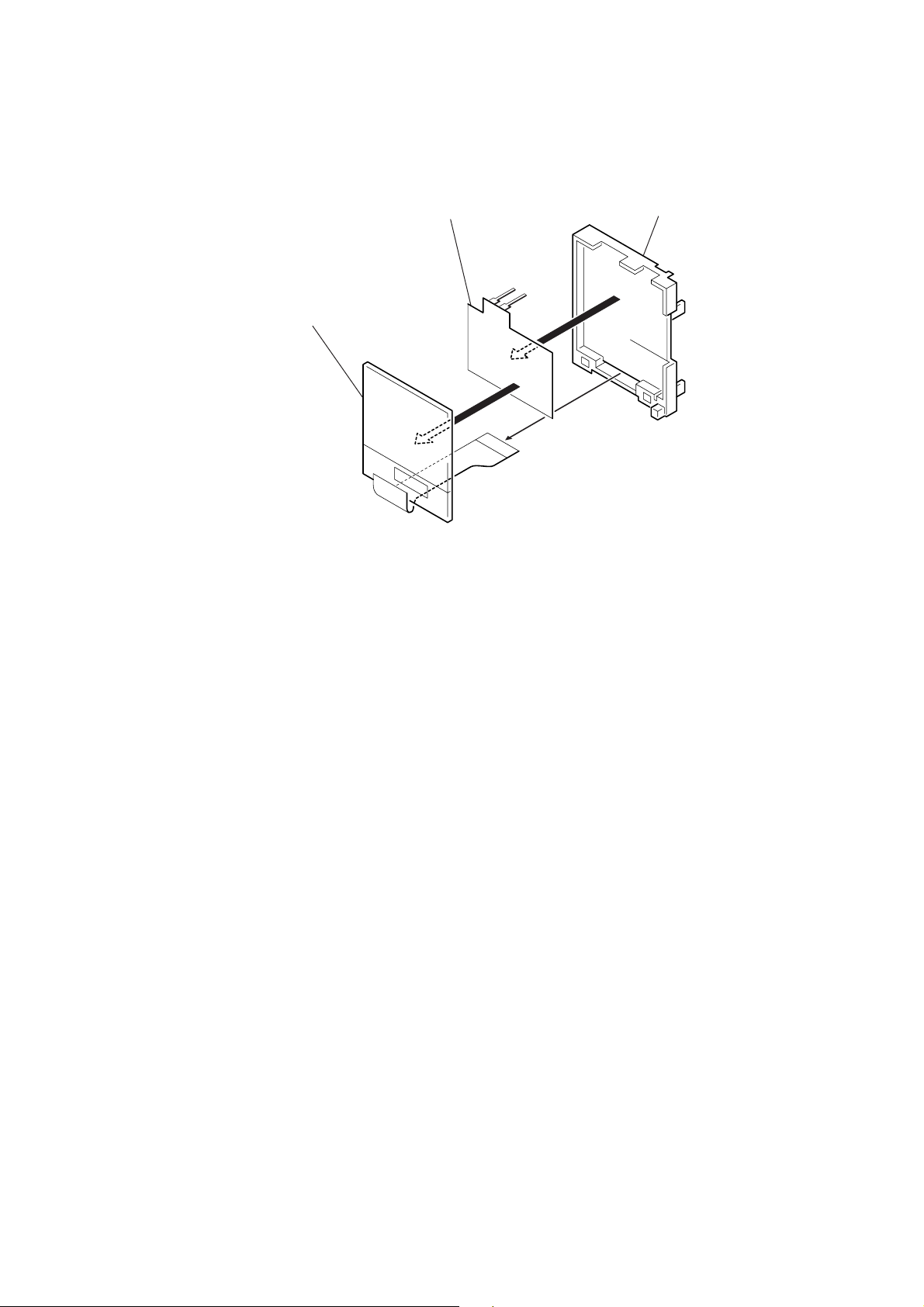

2-7. Liquid Crystal Indicator Unit

1

liquid crystal indicator unit (LCD1)

2

el element

3

holder (LCD)

ICD-MS515

9

ICD-MS515

SECTION 3

TEST MODE

[Setting Method of the Test Mode]

There are two different methods to enter the test mode:

(1) T o enter the test mode, turn on the HOLD switch while pressing

the STOP key and VOLUME+ key at the same time with the

power on.

(2) While pressing the VOLUME- key, turn on the power in state

that the test land (TP7105) on the main board (side A) is shorted

to GND.

[Exiting Method of the Test Mode]

Exit the test mode by turning off the power.

[Initial Status of the Test Mode]

When the test mode is set, the LCD display appears as shown below .

LCD display

Cliché-2.

Iris-**/L-

WORLD USB

**

**

Cliché (CPU) version are displayed.

Iris (DSP) version/LPEC version are displayed.

Destination setting/USB installation information are displayed.

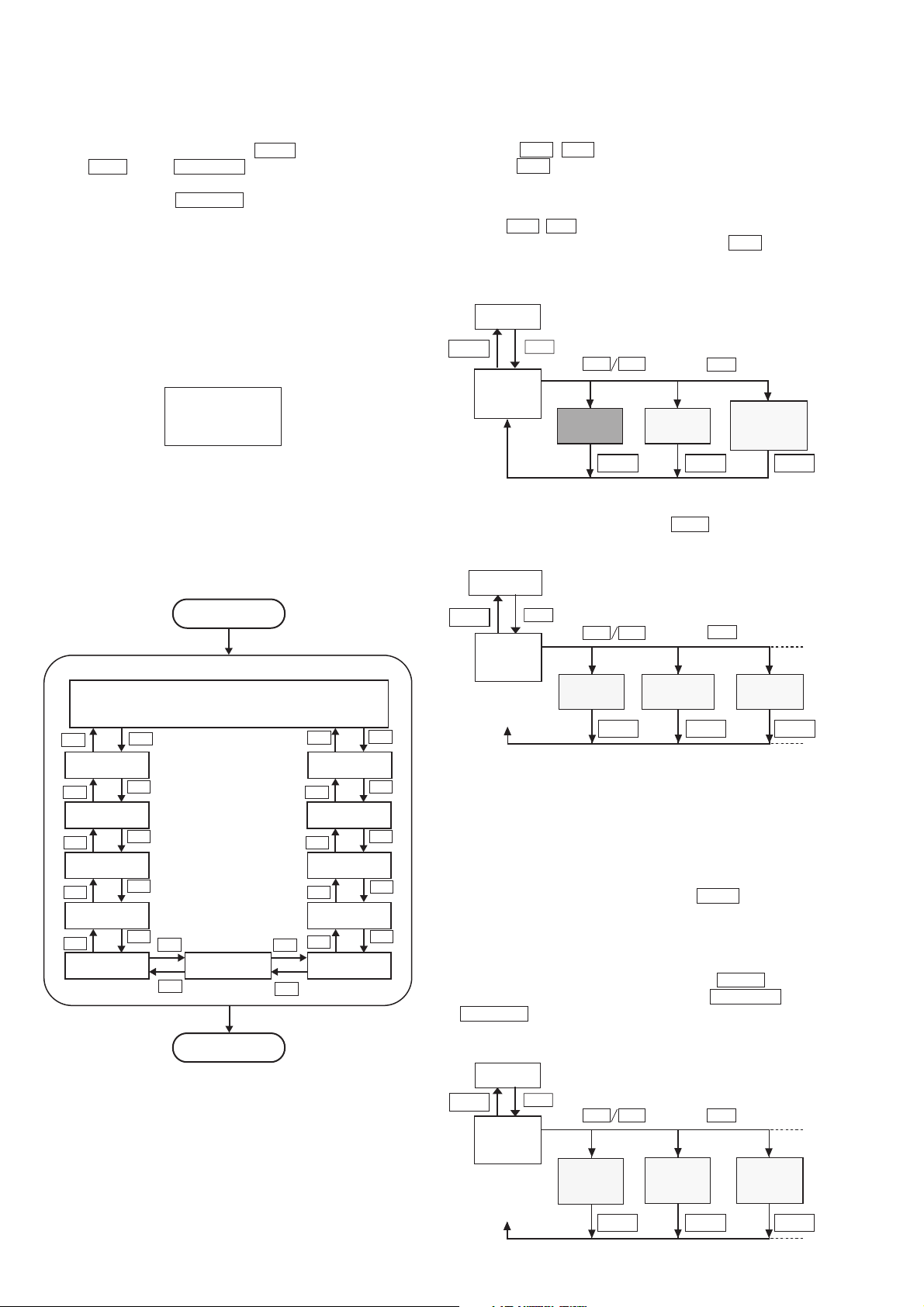

[Flow Chart of the Test Mode]

START

TEST MODE

Initial status of test mode

Version display

Destination setting information display

.

LCD TEST

.

SETTING:AREA

.

AUDIO TEST

.

SLEEP TEST

.

BEEP TEST

>

>

>

>

>

>

.

SIO TEST

END

TEST MODE

>

.

>

RESET MENU

.

USB TEST

.

LED TEST

>

BATT TEST

>

KEY TEST

.

>

>

.

.

[Operation in the Test Mode]

After entering the test mode, you can move within the test menu by

pressing the . / > key. You can move to the submenu by

pressing the x•B key. Then each test mode can be executed.

1. LCD test

• CD is tested of all light-on and all light-off.

• Use the . / > key to adjust the contrast of the LCD. The

setting value is written in the EEPROM with the x•B ke y. If the

LCD test ends with OK, “**** OK ****” is displayed. If the

LCD test ends with NG, “****NG****” is displayed.

The default value is “0x12”.

LCD TEST

LCD OFF

CONTROL

x•B

.

LCD

ALL ON

>

STOP

(select), (set)

ALL OFF

x•B

LCD

STOP STOP

LCD ALL ON

LcdCont.0x12

## SETTING ###

STOP

LCD ALL ON

2. Setting destination

• After selecting the destination with the submenu, the set value is

saved in the EEPROM with the x•B key. If it is OK,

“****OK****” is displayed. If it is NG, “****NG****” is

displayed.

SETTING:AREA

STOP

WORLD

JAPAN USB

x•B

JAPAN USB

JAPAN

WORLD USB

:

:

>

.

>>JAPAN

∗∗∗∗

OK

∗∗∗∗

STOP STOP STOP

(select), (set)

>>WORLD USB

∗∗∗∗ OK ∗∗∗∗

x•B

>>WORLD

∗∗∗∗

OK

∗∗∗∗

3. Audio test

Perform the through-playback and sine wave output.

• Contents of the submenu

ADA SP: AD/DA-through-SP mode

ADA LP: AD/DA-through-LP mode

DSP SP: DSP-through-SP mode

DSP LP: DSP-through-LP mode

1 kHz SIN: 1 kHz sine wave output mode

• Select the microphone sensitivity with the HOLD switch.

ON: High sensitivity OFF: Low sensitivity

• The VOR detection operation can be checked by the LED.

Sound: The red LED is turned on. No sound: The red LED is

turned off.

• MUTE can be set to “ON” or “OFF” with the ERASE key.

• The sound volume can be adjusted with the VOLUME+ key or

VOLUME- key during the audio test except the MUTE mode.

• The microphone sensitivity, sound volume and MUTE (on/off)

are displayed on the bottom of the LCD.

AUDIO TEST

ADA LP

ADA SP

1KHz SIN

:

DSP LP

DSP SP

ADA LP

:

x•B

>

.

ADA LOOP

SP MODE

H/VOL10/Moff

STOP STOP STOP

(select), (set)

1KHz SinWave

H/VOL10/Moff

x•B

- -

ADA LOOP

SP MODE

H/VOL10/Moff

STOP

10

ICD-MS515

4. Sleep test

• Pressing the x•B key causes the set to enter the sleep state.

• When the HOLD switch is ON, the LCD is turned off. When

OFF , the LCD is turned on.

• Press any key to exit the sleep state.

x•B

(with HOLD off status)

SLEEP TEST

x•B

(with HOLD on status)

LCD OFF

SLEEP TEST

SLEEP!. Zzz..

any key any key

5. Beep test

• Beep sound of 1.3 kHz or 2 kHz is output.

BEEP TEST

STOP

>>1.3KHzBEEP

2.0KHzBEEP

x•B

.

>

(select), (set)

BEEP

1.3KHz

STOP STOP

x•B

2.0KHz

BEEP

9. LED/EL test

• LED (red and green) and EL are all turned on.

x•B

LED TEST

STOP

LED/EL ON

10. Rest menu

• Pressing the x•B key causes the set to enter the menu

initialization standby state.

• When the following keys are all entered and the x•B key is

pressed, the initialization is executed. At the same time, the

WakeUp signal is checked, too.

Check keys: VOLUME+ , VOLUME– , A-B REPEAT ,

INDEX , STOP , zREC , ERASE , . ,

x•B , > , MENU , FOLDER

and check states of Memory Stick insert and

outsert ( EJECT ).

• If all tests end in success, “**ALLOK**” is displayed. If the key

entry is NG or if any of the keys is not pressed yet, “**KEYNG**”

x•B

RESET MENU

In the case that the key entry and saving

in the EEPROM end correctly, after the check

key is entered.

x•B

6. SIO test

• Perform the connection test of the RTC, EEPROM and serial to

parallel conversion IC.

• As to the test result, if all of the connection test are OK,

“****OK****” is displayed. If the connection test of the RTC is

NG, “**RTCNG**” is displayed. If the EEPROM is NG,

“**EEPNG**” is displayed.

x•B

SIO TEST

STOP

SIO TEST

∗∗∗∗

OK

∗∗∗∗

7. Key entry test

• When the any ke y is pressed, the entry key and the A/D con verted

value (hexadecimal) of the two channel keys are displayed.

• When the STOP key is pressed, the A/D value of the key is

displayed while the key is depressed. When the key is released,

the screen returns to the test menu.

-- : not input yet

x•B

KEY TEST

STOP

-KEY-AD0:0x FF

KEY-AD1:0xFF

8. Battery remaining power test

• The detected A/D value (hexadecimal) of the battery remaining

power is displayed.

RESET MENU

KEY?

STOP STOP

RESET MENU

∗∗

ALL OK

∗∗

11. USB test

• When the menu starts the USB self-check, either presence or

absence of the Vbus is judged.

(Vbus is present: “VBUS: ON”, Vbus is absent: “VBUS: OFF”)

• The USB driver al wa ys works re gardless of presence or absence

of the USB signal only when Vbus is available during the USB

test. At this time, turning on HOLD causes the set to mo ve to the

suspend state. Turning of f the Vb us causes the set to return to the

test menu.

USB TEST

x•B

USB TEST

VBUS : ON

STOP

or cut Vbus

When Vbus is on, HOLD key turns on.

USB TEST

Suspend

cut Vbus

BATT TEST

x•B

BATT TEST

BATT 0x9C

STOP

11

ICD-MS515

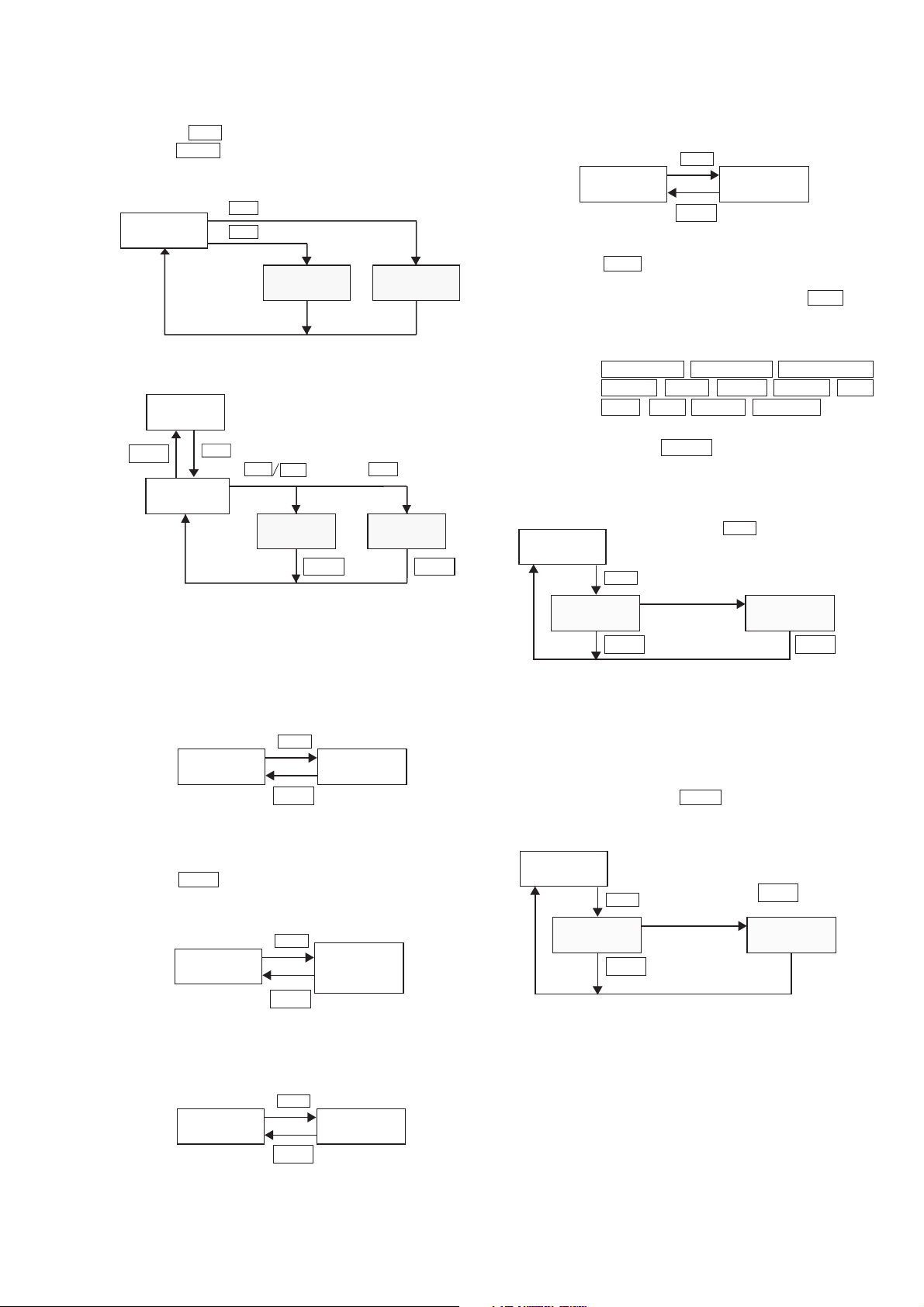

1 IC7101 wd (SCK1)

2 IC7101 wl (SIPCLK)

3 IC7101 es

(DSPSYSCK)

4 IC7101 ef (FSCLK)

5 IC7101 ej (MSCLK)

6 IC7101 yd (CF2)

2 V/DIV, 4 µs/DIV

2 V/DIV, 10 µs/DIV

2 V/DIV, 40 ns/DIV2 V/DIV, 4 µs/DIV

2 V/DIV, 200 ns/DIV

1 V/DIV, 40 ns/DIV

31 µs

5.7

µ

s

567 ns

3.0 Vp-p

3.0 Vp-p

3.9 Vp-p

70 ns

3.1 Vp-p

3.9 Vp-p

71 ns

5.1 µs

3.1 Vp-p

SECTION 4

DIAGRAMS

Note on Schematic Diagrams:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and

specified.

f

•

• C : panel designation.

• A : B+ Line.

• Power voltage is dc 3V and fed with regulated dc power

• Voltages and waveforms are dc with respect to ground

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

* Replacement of IC6201, IC7102 used in this set requires

• The voltage and waveform of CSP (chip size package)

: internal component.

supply from battery terminal.

under no-signal (detuned) conditions.

no mark : REC

[ ] : PB

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

F : PB

L : REC

a special tool.

cannot be measured, because its lead layout is different

from that of conventional IC.

: Impossible to measure

∗

1

4

/

W or less unless otherwise

• WAVEFORMS

Note on Printed Wiring Boards:

• Y : parts extracted from the conductor side.

• b : Pattern from the side which enables seeing.

Caution:

Pattern face side: Parts on the pattern face side seen from

(SIDE B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(SIDE A) the parts face are indicated.

* Replacement of IC6201, IC7102 used in this set requires

a special tool.

• Lead layouts

Lead layout of

conventional IC

CSP (chip size package)

surface

12

Loading...

Loading...