Sony HCD-ZT4 Service Manual

HCD-ZT4

SERVICE MANUAL

Ver. 1.0 2008.06

• HCD-ZT4 is the amplifi er, USB, CD player, tape

deck and tuner section in LBT-ZT4.

CD

Section

Tape deck

Section

Model Name Using Similar Mechanism

Mechanism Type

Optical Pick-up Block Name

Model Name Using Similar Mechanism

Tape Transport Mechanism Type

US Model

NEW

CDM88A-K6BD93-WOD

KSM-213DCP

NEW

TCM-J1 or CS-21SC-900TP

AUDIO POWER SPECIFICATION

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION:

With 6 ohm loads, both channels driven,

from 120Hz – 10kHz; rated 110wattsper

channel minimum RMS power, with no

more than 0.7% total harmonic distortion

from 250 miliwatts to rated output.

Amplifier section

The following are measured at AC 120 V

60 Hz

Front speaker

RMS output power (reference):

180W+180W(perchannelat67,

1 kHz, 10% THD)

Subwoofer

RMS output power (reference): 180 W

(at 6 7, 100Hz,10%THD)

Inputs

AUDIO INPUT:sensitivity

800 mV, impedance 47 kilohms

MIC: sensitivity 1 mV, impedance

10 kilohms

(USB) port: Type A

DMPORT

Outputs

PHONES: accepts headphones of 8 7 or

more

FRONT SPEAKER: accepts impedance of

6 7

SUBWOOFER: accepts impedance of 6 7

SPECIFICATIONS

USB section

Supported bit rate

MP3 (MPEG 1 Audio Layer-3):

32 – 320 kbps, VBR

WMA: 32 – 192 kbps, VBR

AAC: 48 – 320 kbps

Sampling frequencies

MP3 (MPEG 1 Audio Layer-3):

32/44.1/48 kHz

WMA: 44.1 kHz

AAC: 44.1 kHz

Transfer speed

Full-Speed

Supported USB device

Mass Storage Class

Maximum current

500 mA

CD player section

System: Compact disc and digital audio

system

Laser Diode Properties

Emission Duration: Continuous

Laser Output*: Less than 44.6 MW

* This output isthe value measurement

at a distance of 200 mm from the

objective lens surface on the Optical

Pick-up Block with 7 mm aperture.

Frequency response: 20 Hz – 20 kHz

Signal-to-noise ratio: More than 90 dB

Dynamic range: More than 88 dB

Tape deck section

Recording system: 4-track 2-channel, stereo

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range:

87.5 – 108.0 MHz (100 kHz step)

Antenna: FM lead antenna

Antenna terminals: 75 ohms unbalanced

Intermediate frequency: 10.7 MHz

AM tuner section

Tuning range

530 – 1,710 kHz (with 10 kHz tuning

interval)

531 – 1,710 kHz (with 9 kHz tuning

interval)

Antenna: AM loop antenna,externalantenna

terminal

Intermediate frequency: 450 kHz

General

Power requirements

AC 120 V,60 Hz

Power consumption

225 W

Dimensions (w/h/d) (excl. speakers)

Approx. 231 × 361 × 437.5 mm

(91/8×141/4×171/4inch)

Mass (excl. speakers)

10.0 kg (22 lb 1 oz)

Design and specifications are subject to

change without notice.

9-889-196-01

2008F05-1

2008.06

©

COMPACT DISC DECK RECEIVER

Sony Corporation

Audio Business Group

Published by Sony Techno Create Corporation

HCD-ZT4

NOTES ON CHIP COMPONENT REPLACEMENT

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

FLEXIBLE CIRCUIT BOARD REPAIRING

• Keep the temperature of soldering iron around 270 °C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specifi ed herein may result in hazardous radia-

tion exposure.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

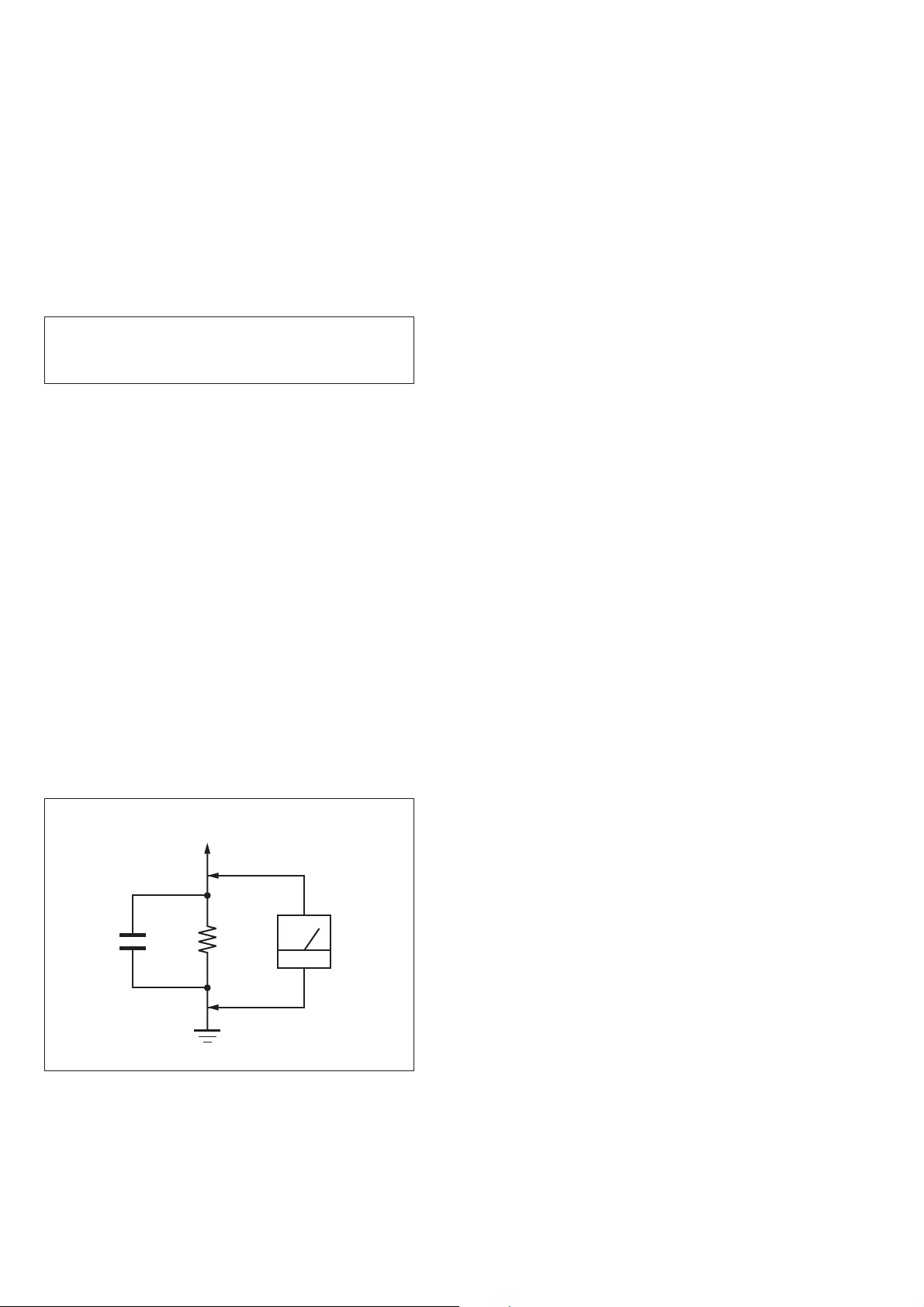

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

AC

1.5 kΩ0.15 μF

voltmeter

(0.75 V)

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONET WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

TABLE OF CONTENTS

HCD-ZT4

1. SERVICING NOTES ............................................. 4

2. GENERAL .................................................................. 8

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 10

3-2. Side-L/R Case ................................................................. 11

3-3. Top Panel Block .............................................................. 11

3-4. Tape Mechanism Deck .................................................... 12

3-5. Front Panel Block ........................................................... 12

3-6. DC FAN (M102), Back Panel ......................................... 13

3-7. MAIN Board ................................................................... 13

3-8. CD Mechanism Block ..................................................... 14

3-9. DC Fan (M101), POWERAMP Board ........................... 14

3-10. Base Unit ......................................................................... 15

3-11. OP Base Assy (KSM-213D) ........................................... 15

3-12. Belt (DLM3A) ................................................................ 16

4. TEST MODE ............................................................ 17

5. MECHANICAL ADJUSTMENTS ...................... 20

6. ELECTRICAL ADJUSTMENTS ........................ 21

7. DIAGRAMS

7-1. Block Diagram - CD SERVO, USB Section - ................ 23

7-2. Block Diagram - MAIN Section - ................................... 24

7-3. Block Diagram - AMP Section - ..................................... 25

7-4. Block Diagram

- PANEL, POWER SUPPLY Section - ........................... 26

7-5. Schematic Diagram - CD Board (1/2) - .......................... 28

7-6. Schematic Diagram - CD Board (2/2) - .......................... 29

7-7. Printed Wiring Board - CD Board - ................................ 30

7-8. Printed Wiring Board - TC Board - ................................. 31

7-9. Schematic Diagram - TC Board - ................................... 31

7-10. Printed Wiring Board - USB Board - .............................. 32

7-11. Schematic Diagram - USB Board - ................................. 33

7-12. Printed Wiring Board - DMPORT Board - ..................... 34

7-13. Schematic Diagram - DMPORT Board - ........................ 34

7-14. Printed Wiring Board - MAIN Board - ........................... 35

7-15. Schematic Diagram - MAIN Board (1/4) - ..................... 36

7-16. Schematic Diagram - MAIN Board (2/4) - ..................... 37

7-17. Schematic Diagram - MAIN Board (3/4) - ..................... 38

7-18. Schematic Diagram - MAIN Board (4/4) - ..................... 39

7-19. Printed Wiring Board - POWERAMP Board - ............... 40

7-20. Schematic Diagram - POWERAMP Board - .................. 41

7-21. Printed Wiring Boards - JACK Section - ........................ 42

7-22. Schematic Diagram - JACK Section - ............................ 42

7-23. Printed Wiring Boards - REG Section - .......................... 43

7-24. Schematic Diagram - REG Section - .............................. 43

7-25. Printed Wiring Boards - DISPLAY Board - .................... 44

7-26. Schematic Diagram - DISPLAY Board - ........................ 45

7-27. Printed Wiring Boards - PANEL Section - ..................... 46

7-28. Schematic Diagram - PANEL Section - .......................... 47

7-29. Printed Wiring Board - TRANS2 Board - ....................... 48

7-30. Schematic Diagram - TRANS2 Board - ......................... 49

8. EXPLODED VIEWS

8-1. Case Section .................................................................... 58

8-2. Loading Panel Section .................................................... 59

8-3. DISPLAY Board Section ................................................ 60

8-4. Front Panel Section ......................................................... 61

8-5. Meter Display Assy ......................................................... 62

8-6. Top Panel Section ........................................................... 63

8-7. Back Panel Section ......................................................... 64

8-8. MAIN Board Section ...................................................... 65

8-9. Chassis Section ............................................................... 66

8-10. CD Mechanism Section (CDM88A-K6BD93-WOD) .... 67

9. ELECTRICAL PARTS LIST .............................. 68

3

HCD-ZT4

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The fl exible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc refl ective surface by the objective lens in the optical

pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

RELEASING THE DISC TRAY LOCK

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Releasing Procedure:

1. Press [I/1] button to turn the power on.

2. Press the [CD] button to select CD function.

3. While pressing the [

seconds).

4. The message “UNLOCKED” is displayed and the disc tray is

unlocked.

] button, press the [Z] button for more 5

x

Note: When “LOCKED” is displayed, the slot lock is not released by

turning power on/off with the [I/1] button.

4

HOW TO OPEN THE TRAY WHEN POWER SWITCH TURN OFF

lever

HCD-ZT4

Turn a gear by

a driver till a lever

falls down to the

position of the figure.

Pull the tray by the hand.

hole

HOW TO REMOVE THE KNOB VOLUME

knob volume

hole

gear

front panel block

(back view)

Push the knob volume by the flat head driver.

5

HCD-ZT4

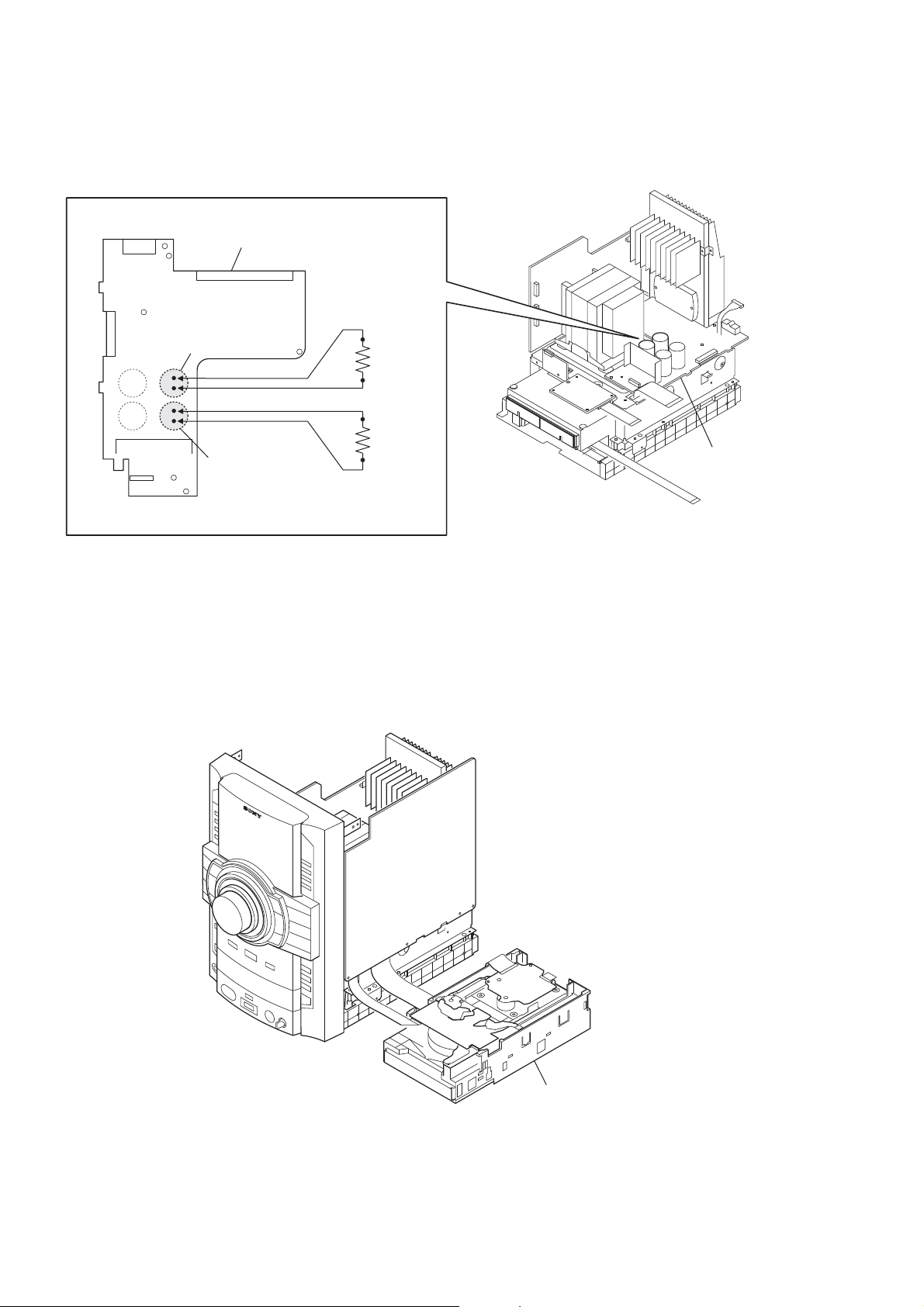

CAPACITOR DISCHARGE FOR ELECTRIC SHOCK PREVENTION

In checking the MAIN board, make a capacitor discharge

of C803 and C804 for electric shock prevention.

POWERAMP board

C803

800 Ω/2W

800 Ω/2W

C804

POWERAMP board

CD MECHANISM BLOCK SERVICE POSITION

CD mechanism block

(bottom view)

6

POWERAMP BOARD SERVICE POSITION

POWERAMP board

TRANS2 board

HCD-ZT4

MAIN board

front panel block

CD mechanism block

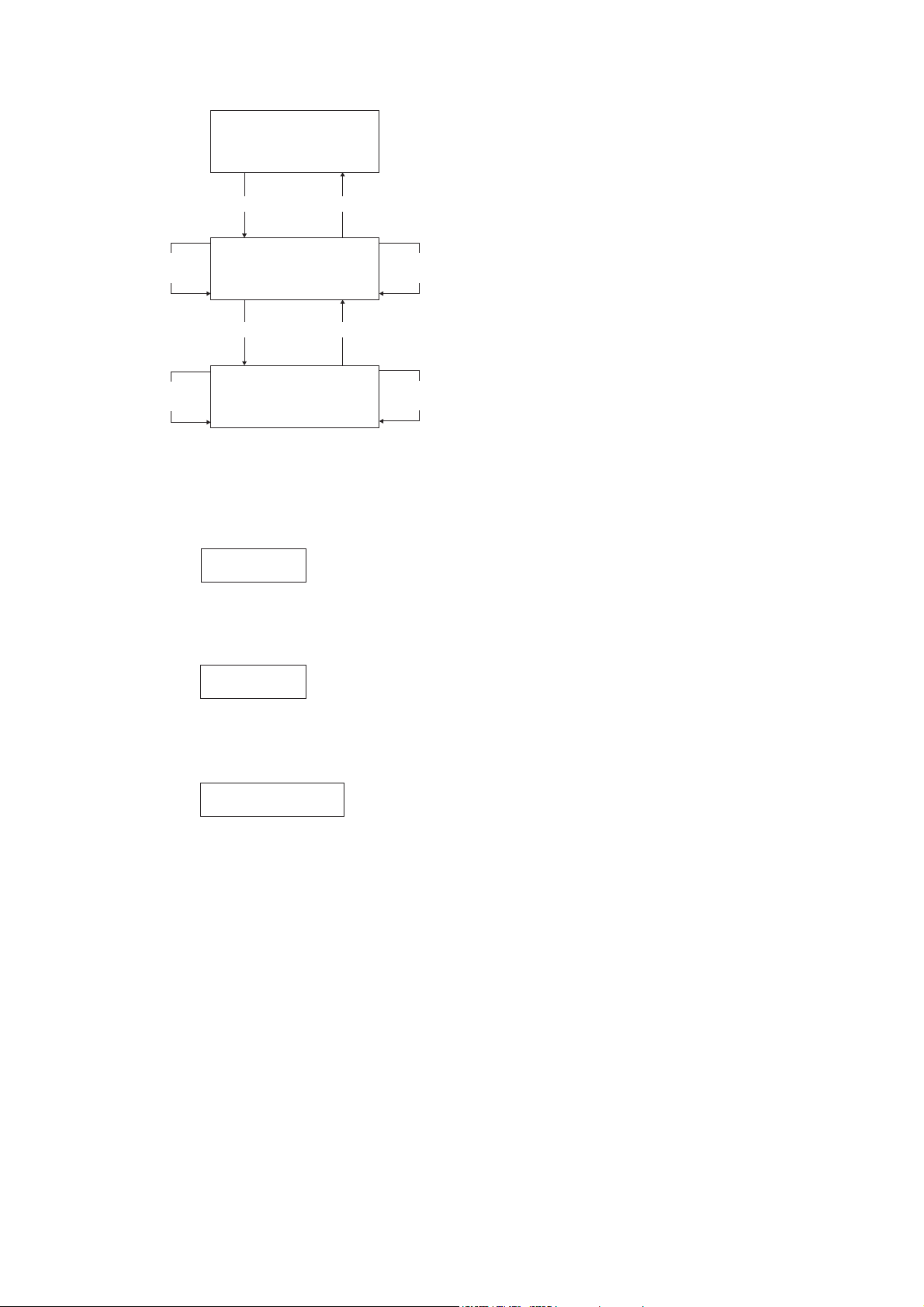

HOW TO DISTINGUISH TAPE MECHANISM DECK

Two kinds of tape mechanism decks installed by this set exist.

Please do the repair exchange after confi rming which tape mechanism deck set of the repair according to how to distinguish the fi gure

below.

Tape Deck Name Tape Deck Part No. Belt Part No.

2-670-389-01 BELT (1)

3-214-817-01 BELT (FR)

2-688-621-01 BELT (R/F)

2-688-622-01 BELT (MAIN)

motor

Metal part: TCM-J1

Mold part: CS-21SC-900TP

tape deck

TCM-J1

CS-21SC-900TP

A-1527-851-A

1-797-575-11

7

HCD-ZT4

SECTION 2

GENERAL

This section is extracted

from instruction manual.

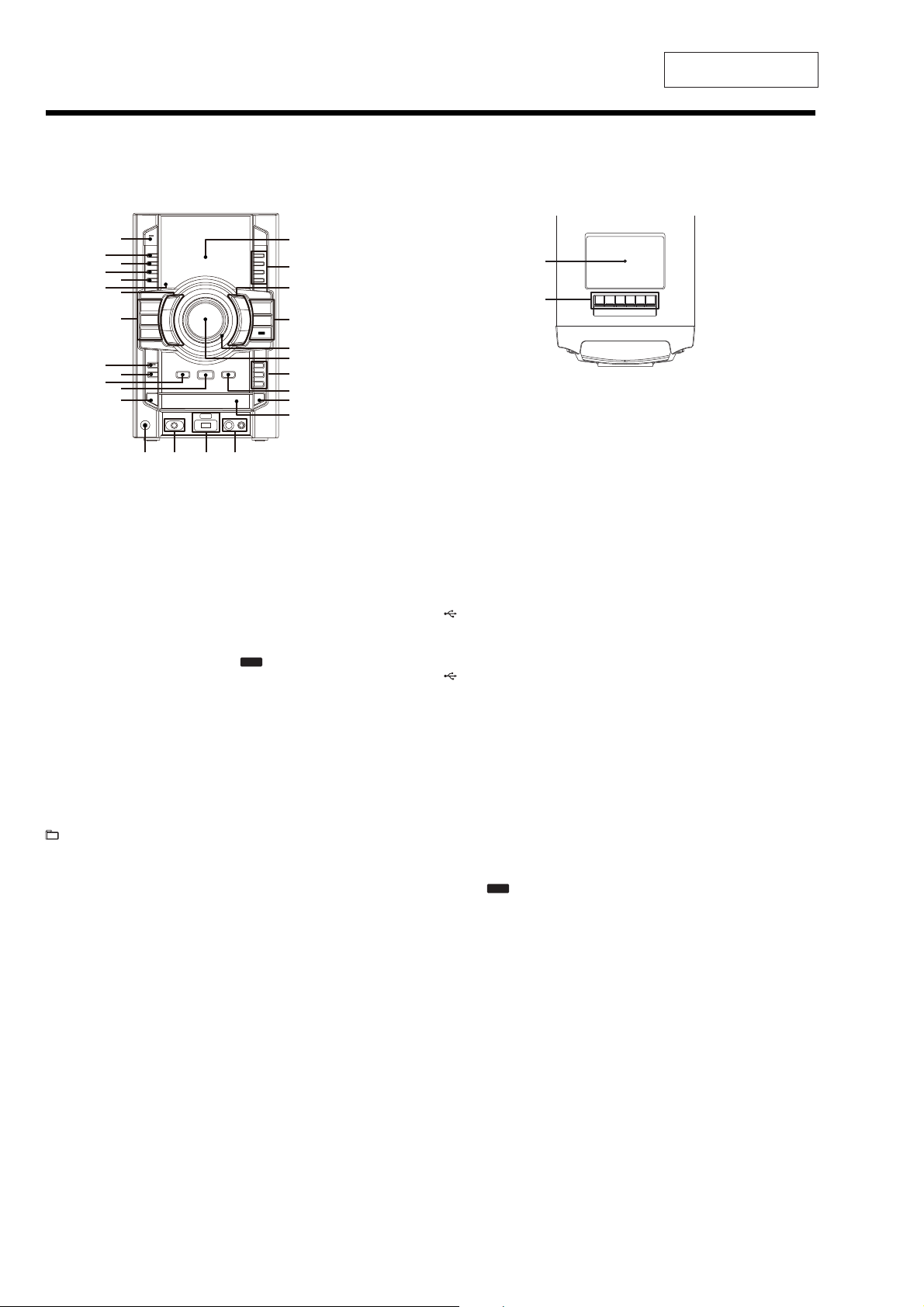

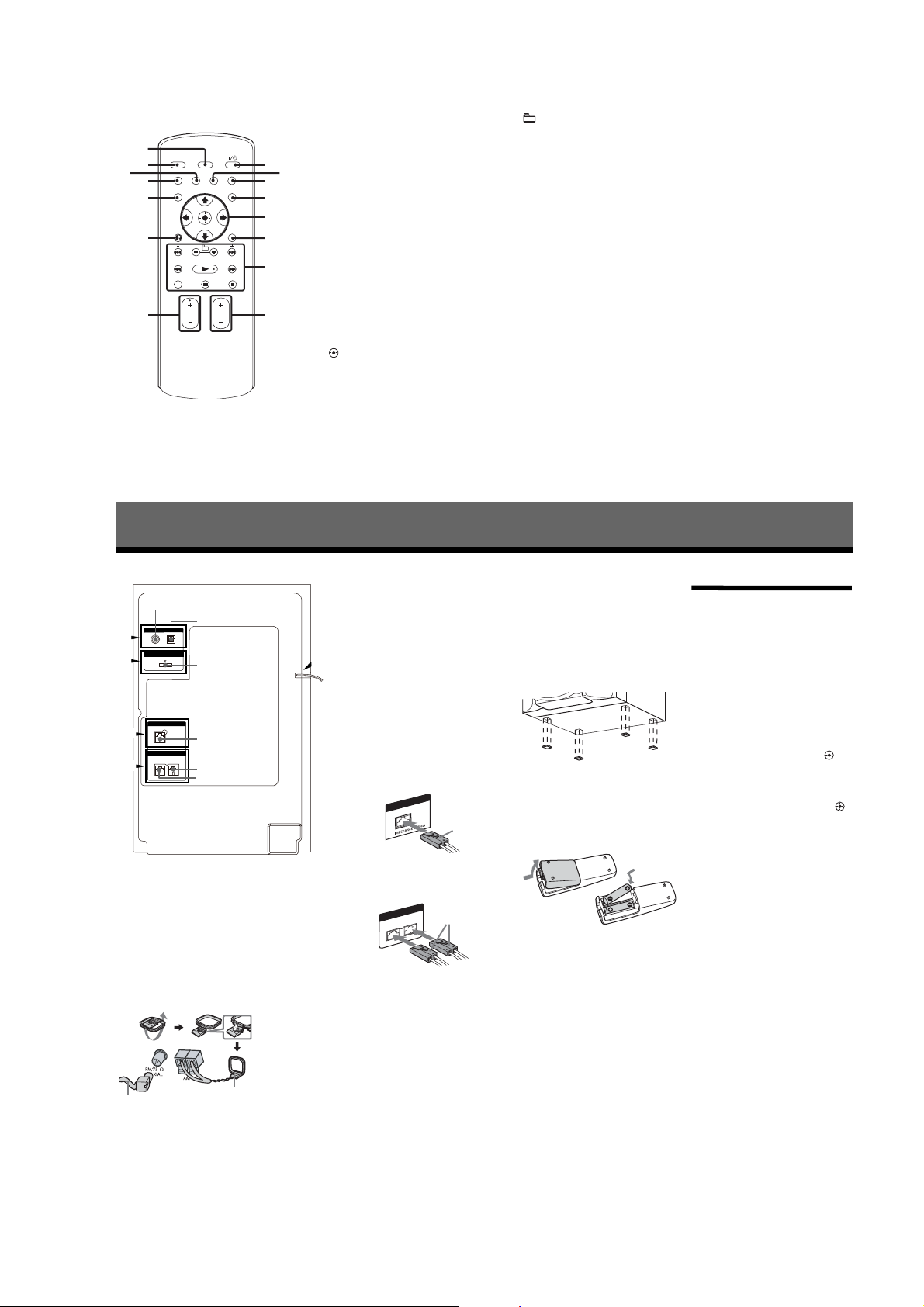

Guide to parts and controls

This manual mainly explains operations using the remote, but the same operations can also be performed using the buttons on the unit having the same or similar names.

Unit

Front view

Top view

CD

TUNER/

BAND

TAPE

*

R

RB

RT

RE

RH

RG

(on/standby)

Press to turn on the system.

The STANDBY indicator lights up when

the system is turned off.

#

DISPLAY

Press to change the information on the

display.

$

METER MODE

Press to select the preset meter display.

%

OPTIONS

Press to change the display, USB and

MP3 BOOSTER+ settings.

&

ERASE

Press to eraseaudio files and folders from

the connected optional USB device.

'

Remote sensor

(

+/– (select folder)

Press to select a folder.

N.(rewind/fast forward)

Press to find a point in a track.

/9(play/pause)

Press to start or pause playback.

Y (stop)

Press to stop playback.

TUNING +/–

Press to tune in the station you want.

(go back/go forward)

Press to select a track or file.

XH

XG

AUDIO

DMPORT

USB

XE

XT

XB

X

RM

RL

RKRI

)

CD

Press to select the CD function.

TUNER/BAND

Press to select the TUNER function.

Press to select the FM or AM band.

TAPE

Press to select the TAPE function.

AUDIO

Press to select the AUDIO function.

USB

Press to select the USB function.

DMPORT

Press to select the DMPORT function.

*

SUBWOOFER

Press to turn on and off the subwoofer.

The SUBWOOFER indicator lights up

when the subwoofer is turned on.

+

REC TIMER

Press to set the Recording Timer.

,

RETURN

Press to return to the parent folder.

Presstoexitsearchmode.

-

NTER

E

Press to enter the settings.

.

DISC SKIP/EX-CHANGE

Press to select a disc. Press to exchange a

disc while playing.

XI

XK

/

PHONES jack

Connect the headphones.

0

AUDIO INPUT jack

Connect to an audio component

(Portable audio player, etc.).

1

(USB) indicator

Lights up in red when transferring to the

connected optional USB device or when

erasing audio files or folders.

(USB) port

Connect an optional USB device.

2

MIC jack

Connect an optional microphone.

MIC LEVEL

Turn to adjust the microphone volume.

3

Disc tray

4

; OPEN/CLOSE

Press to insert or eject a disc.

5

REC TO

Press to transfer onto the connected

optional USB device.

6

DISC 1 – 3

Press toselect a disc.Pressto switch tothe

CD function from other function.

USB

7

MASTER VOLUME

Turn to adjust the volume.

8

OPERATION DIAL

Turn to select a setting in the OPTIONS

menu.

Turn to select a track, file or folder.

9

PRESET EQ

GROOVE, SURROUND

Press to select a sound effect.

EQ BAND

Press to select the frequency band.

:

Display

;

Tape deck

XK

[ (record)

Press to record onto a tape.

# (play)

Press to start tape playback.

*The# button has a tactile dot. Use the tactile

dot as a reference when operating the system.

N.(rewind/fast forward)

Press to rewind/fast forward a tape.

Y; (stop/eject)

Press to stop tape playback.

Press to insert or eject a tape.

9 (pause)

Press to pause tape playback.

8

HCD-ZT4

Remote RM-AMU008

RH

RG

RE

RT

RB

R

Getting Started

(on/standby)

Press to turn on the system.

#

CLEAR

Press to delete the last step from the

program list.

$

EQ

Press to select a sound effect.

%

TIMER MENU

Press to set the clock and the timers.

&

7WC#

Press to select the settings.

Press to enter the selection.

'

TOOL MENU

Press to select themenu of the component

connected to the DIGITAL MEDIA

PORT adapter.

(

(go back/go forward)

Press to select a track or file.

+/– (select folder)

Press to select a folder.

+/– (tuning)

Press to tune in the station you want.

N.(rewind/fast forward)

Press to find a point in a track or file.

/(play)

Press to start playback.

DISC SKIP

Press to select a disc.

9 (pause)

Press to pause playback.

Y (stop)

Press to stop playback.

)

FUNCTION +/–

Press to select a function.

*

VOLUME +/–*

Press to adjust the volume.

* The VOLUME + button has a tactile dot. Use

the tactile dot as a reference when operating

the system.

+

0 RETURN

Press to return to the parent folder.

Press to exit search mode.

,

TUNER MEMORY

Press to preset the radio station.

-

PLAY MODE/TUNING MODE

Press to select the play mode of an

AUDIOCD,MP3discor anoptional

USB device.

Press to select the tuning mode.

.

REPEAT/FM MODE

Presstolistentoadisc,anUSBdevice,a

single track or file repeatedly.

Press to select the FM reception mode

(monaural or stereo).

/

SLEEP

Press to set the Sleep Timer.

0

DISPLAY

Press to change the information on the

display.

Hooking up the system securely

Notes

ANTENNA

"

DMPORT

#

$

%

To FM lead antenna

To AM loop antenna

To DIGITAL MEDIA PORT adapter

To subwoofer

To front speaker (left)

To front speaker (right)

SUBWOOFER

FRONT SPEAKER

V

" Antennas

Find a location and an orientation that

provide good reception, and then set up

the antennas.

Extend the FM lead

antenna horizontally

Keep the antennas away from the speaker

cords, the power cord and the USB cable

to avoid picking up noise.

# DMPORT (DIGITAL MEDIA PORT)

Connect the DIGITAL MEDIA PORT

adapter. You need to connect the

DIGITAL MEDIA PORT adapter to an

optional audio device (portable audio

player, etc.).

AM loop antenna

• The DIGITAL MEDIA PORT adapters are

• Do not connect an adapter other than the

• When connecting the DIGITAL MEDIA

&

• Do not connect or disconnect the DIGITAL

• When using a DIGIT AL MEDIA PORT

$ Subwoofer

Be sure to insert the connector straight

into the terminals.

% Front speakers

Be sure to insert the connector straight

into the terminals.

& Power

Connect the power cord to a wall socket.

The demonstration appearsin the display.

If the plug does not fit the wall socket,

detach the supplied plug adaptor (only for

models equipped with an adaptor).

When carrying this system

Use the buttons on the unit for this

operation.

1

2

3

4

available for purchase depending on the area.

DIGITAL MEDIA PORT adapter.

PORT adapter, be sure the connector is

inserted with the arrow mark facing towards

the arrow mark on the DMPORT jack.

MEDIA PORTadapter to/from theDMPORT

jack while the system is turned on.

adapter that has video output function,

connect the video output of the adapter

directly to the TV.

SUBWOOFER

Purple

FRONTSPEAKER

R

EDANCE

P

IM

Remove all discs to protect the CD

mechanism.

White

L

6Ω

USE

Press CD to select the CD function.

Hold down DISC SKIP/

EX-CHANGE, and press until

“STANDBY” appears.

After “MECHA LOCK” appears,

unplug the power cord.

Speaker pads

Attach the supplied speaker pads to the

bottom of the front speakers and

subwoofer to prevent slipping.

Front speakers:

4 pads for each speaker

Subwoofer:

4 pads

To use the remote

Slide and remove the battery

compartment lid, then, insert the two

supplied R6 (size AA) batteries, & side

first, matching the polarities shown

below.

Notes

• With normal use, the batteries should l ast for

about six months.

• Do not mix an old battery with a new on e or

mix different types of batteries.

• If you do not use the remote for a long period

of time, remove thebatteries to avoid damage

from battery leakage and corrosion.

Setting the clock

You cannot set the clock in PowerSaving

Mode.

Use the buttons on the remote for this

operation.

1 Press to turn on the system.

2 Press TIMER MENU (RM-AMU008).

If “PLAY SET” appears on the

display, press

(RM-AMU008) repeatedly to select

“CLOCK SET” and then press

(RM-AMU008).

3 Press

7W(RM-AMU008) repeatedly to

set the hour, and then press

(RM-AMU008).

4 Use the same procedure to set

the minutes.

The clock settings are lost when you

disconnect the power cord or if a

power failure occurs.

To display the clock when the

system is turned off

Press DISPLAYrepeatedly until theclock

is displayed. The clock is displayed for

about 8 seconds.

7W.

9

HCD-ZT4

DISASSEMBLY

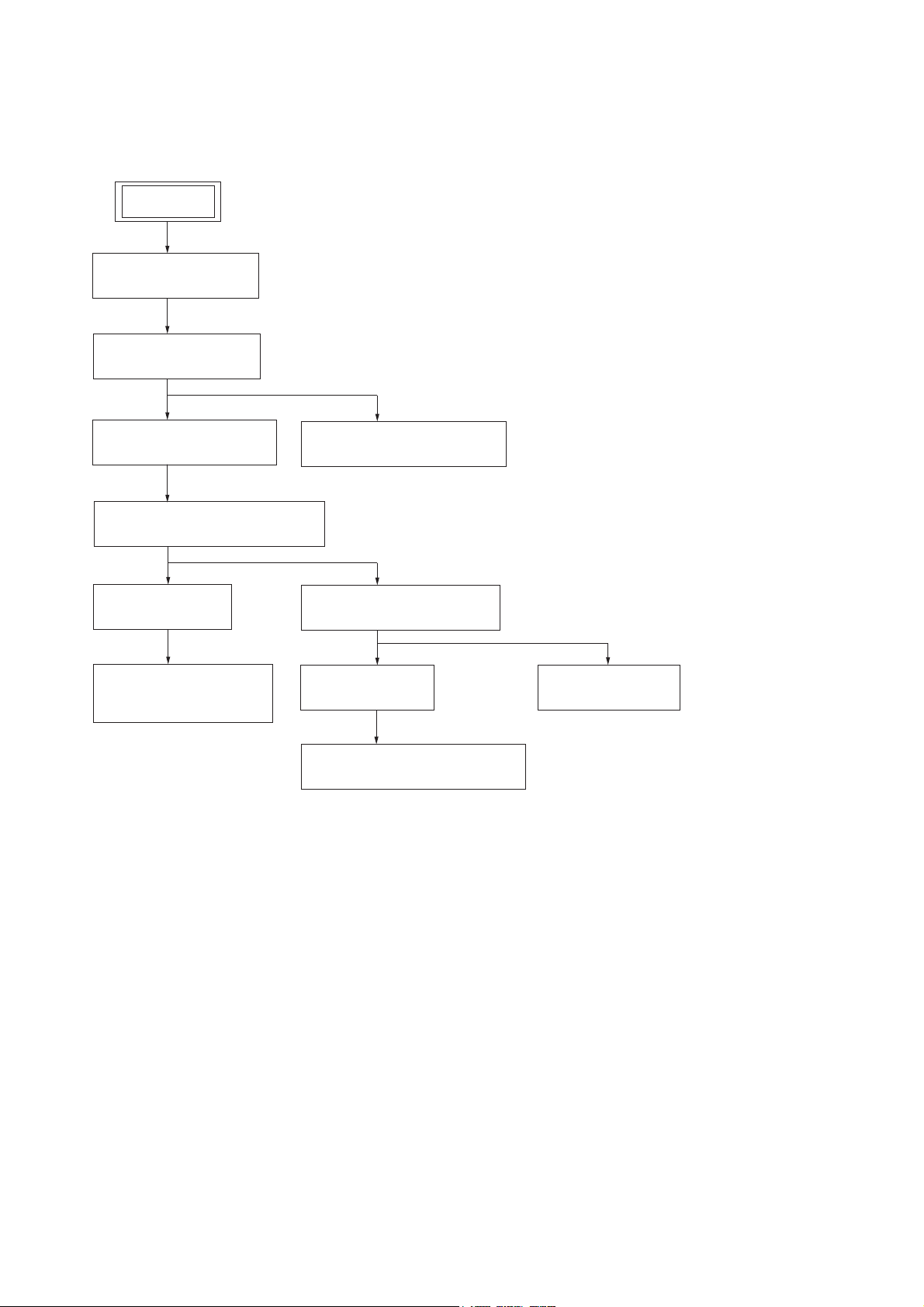

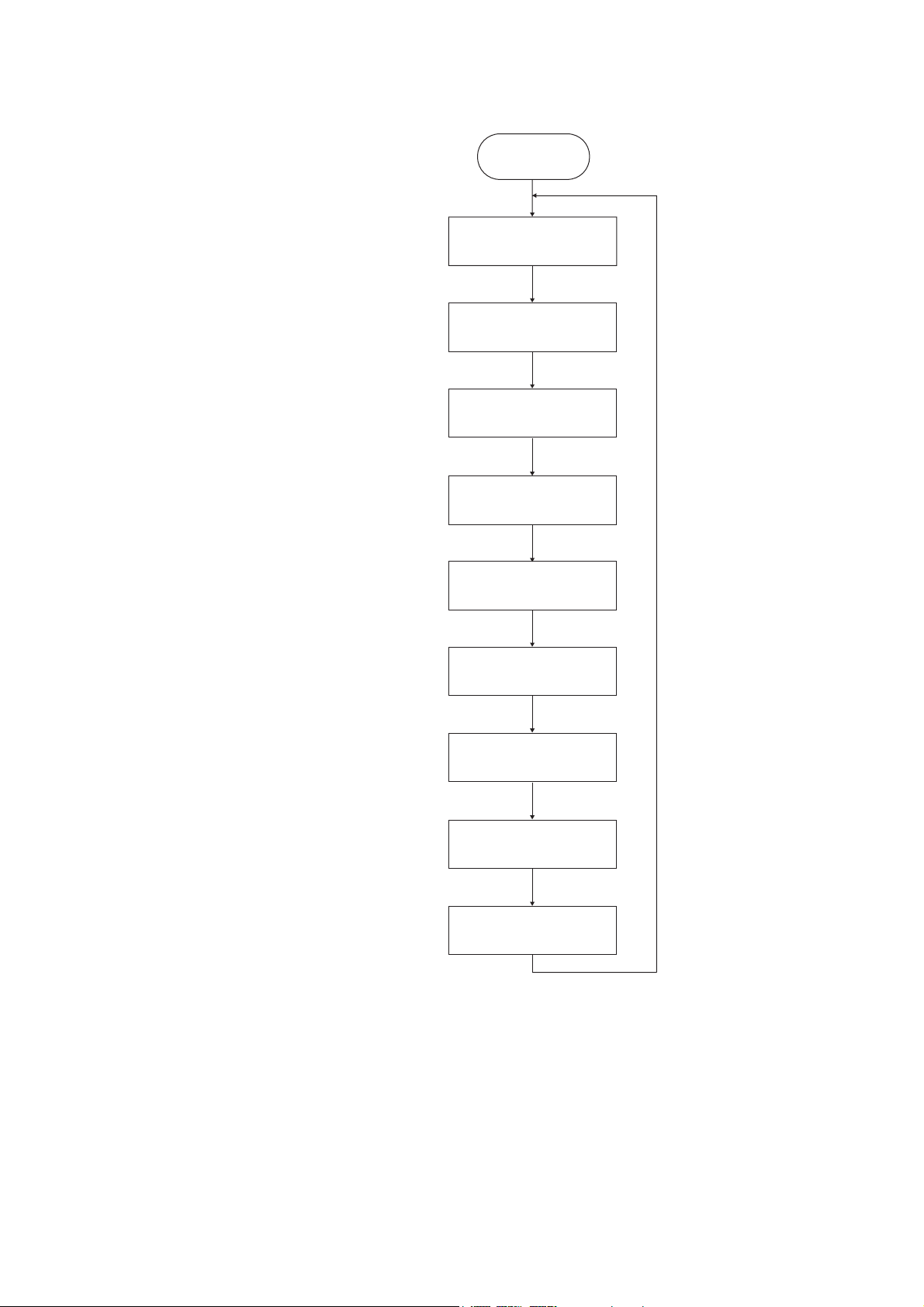

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. SIDE-L/R CASE

(Page 11)

3-3. TOP PANEL BLOCK

(Page 11)

SECTION 3

3-5. FRONT PANEL BLOCK

(Page 12)

3-6. DC FAN (M102), BACK PANEL

(Page 13)

3-7. MAIN BOARD

(Page 13)

3-9. DC FAN (M101),

POWERAMP BOARD

(Page 14)

3-4. TAPE MECHANISM DECK

(Page 12)

3-8. CD MECHANISM BLOCK

(Page 14)

3-10. BASE UNIT

(Page 15)

3-11. OP BASE ASSY (KSM-213D)

(Page 15)

3-12. BELT (DLM3A)

(Page 16)

10

Note: Follow the disassembly procedure in the numerical order given.

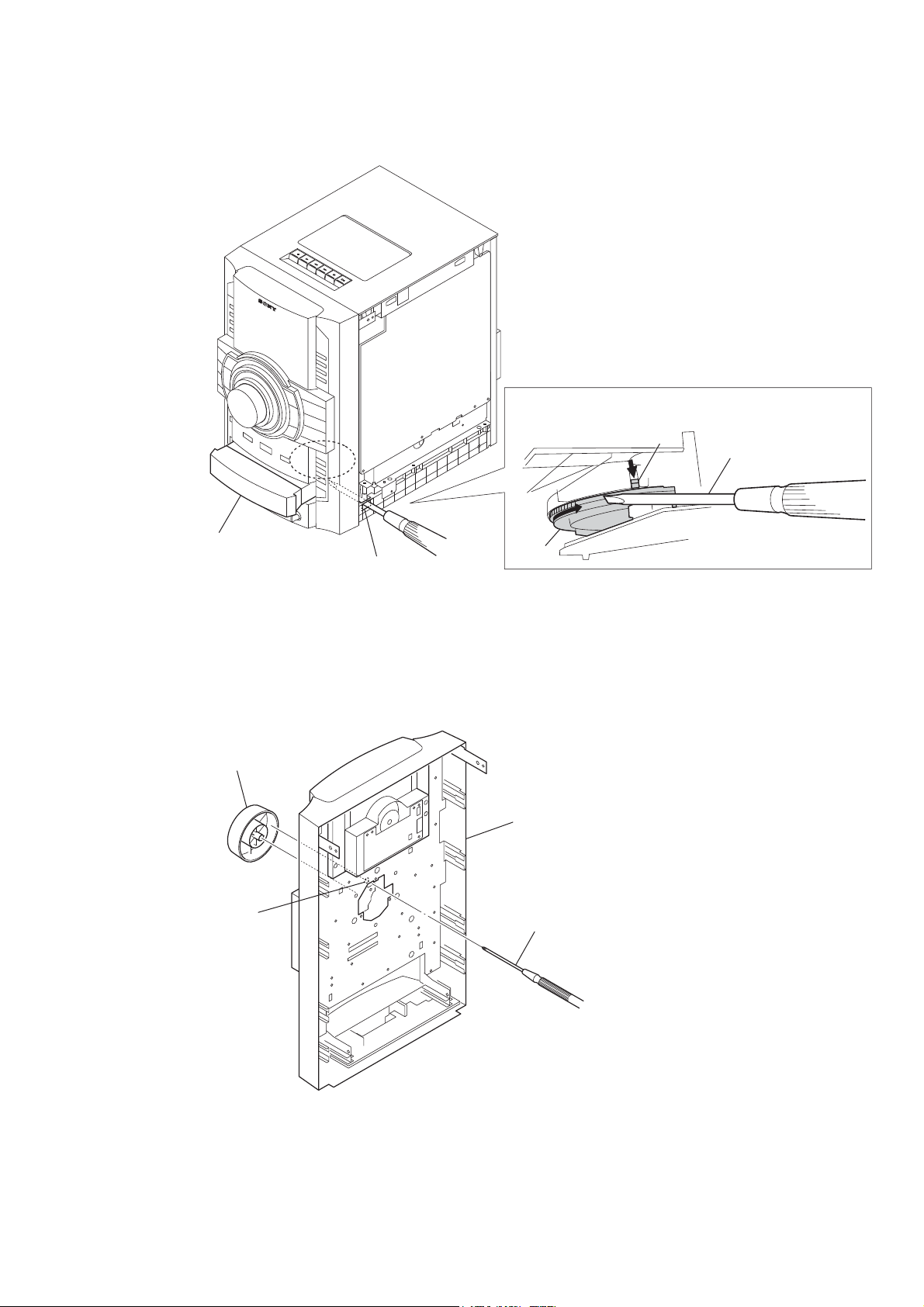

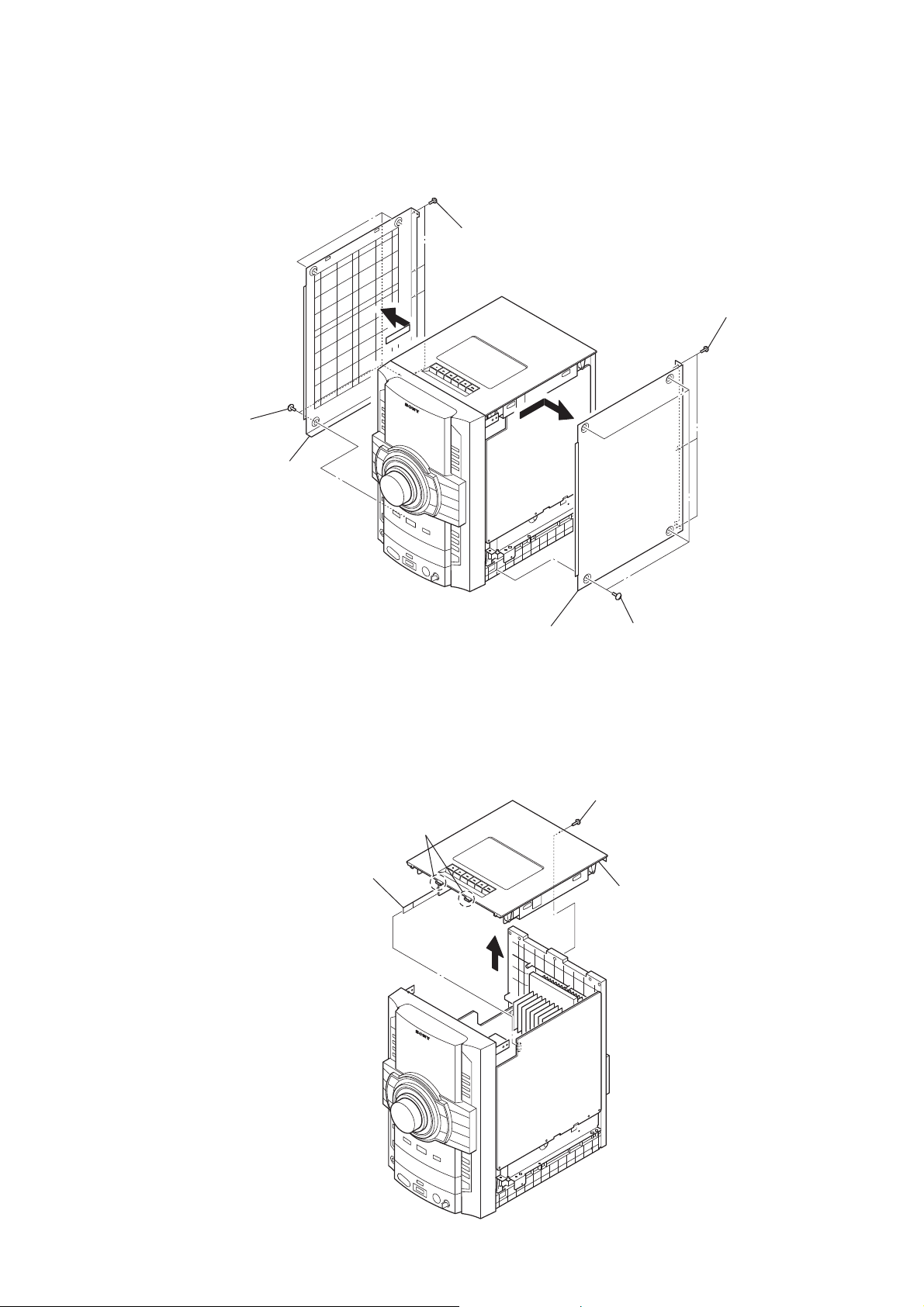

3-2. SIDE-L/R CASE

four screws

(case 3 TP2)

side-L case

four screws

(BVTP3 × 10)

HCD-ZT4

three screws

(BVTP3 × 10)

3-3. TOP PANEL BLOCK

flexible flat cable

(CN450)

two claws

side-R case

four screws

(case 3 TP2)

screw

(BVTP3 × 10)

top panel block

11

HCD-ZT4

3-4. TAPE MECHANISM DECK

Note: This illustration is seeing top panel block from inside.

two screws

(BVTP2.6 × 8)

two screws

(BVTP2.6 × 8)

tape mechanism deck

bracket (deck)

connector (CN501)

Cut the two clamps.

TC board

two screws

(BVTP3 × 8)

Open the cassette box.

3-5. FRONT PANEL BLOCK

RT

(BVTP3 × 10)

connector (CN470)

screw

(BVTP3 × 10)

two harness

RB

screw

(BVTP3 × 10)

panel loading

screw

two harnesses

RE

Pull the

tray by hand.

connector (CN488)

connector (CN903)

flexible flat cable (CNCN403)

top panel block

hole

Turn a gear by

a driver till a lever

falls down to the

position of the figure.

lever

12

two screws

(BVTP3 × 10)

screw (BVTP3 × 10)

front panel block

RG

gear

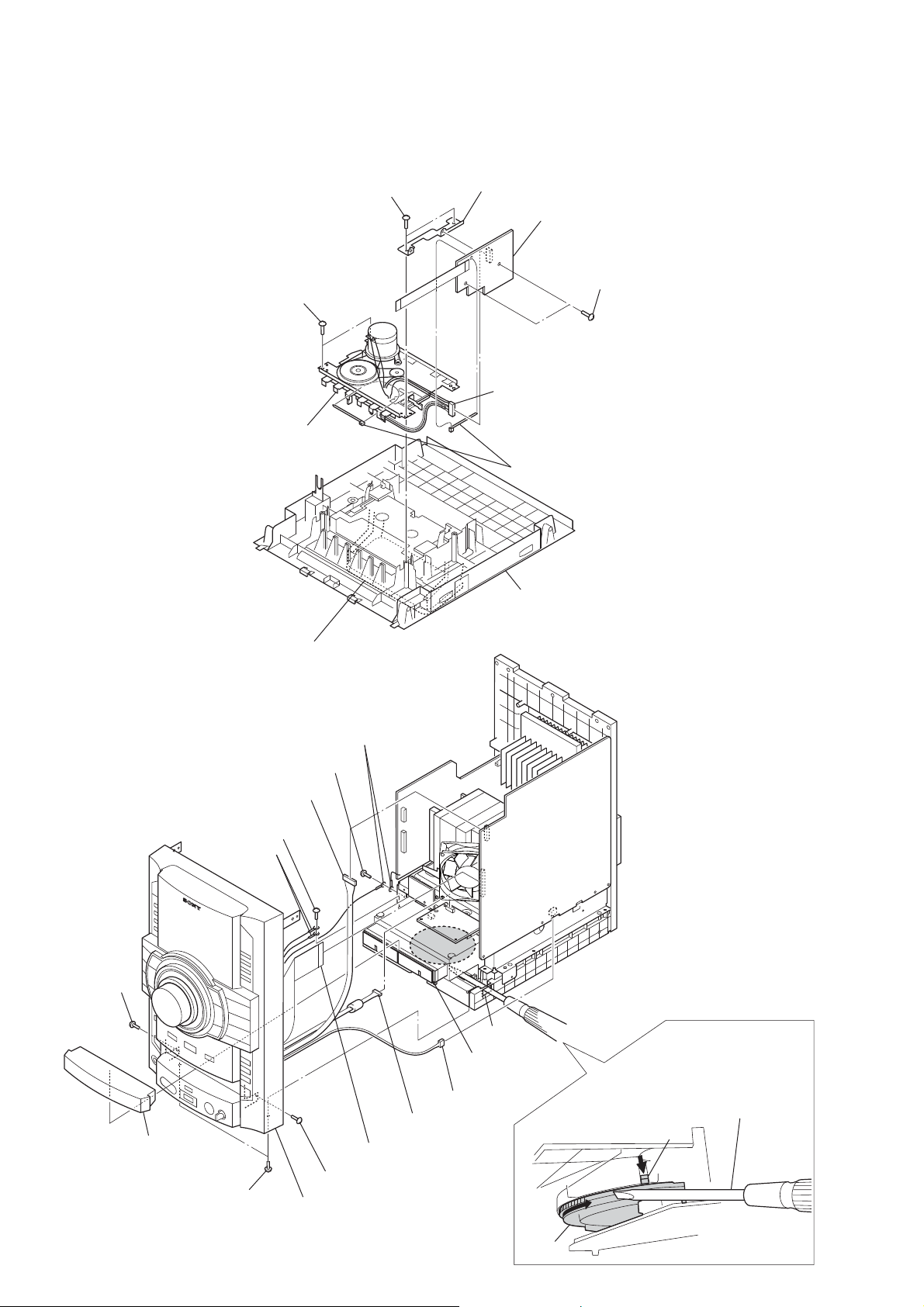

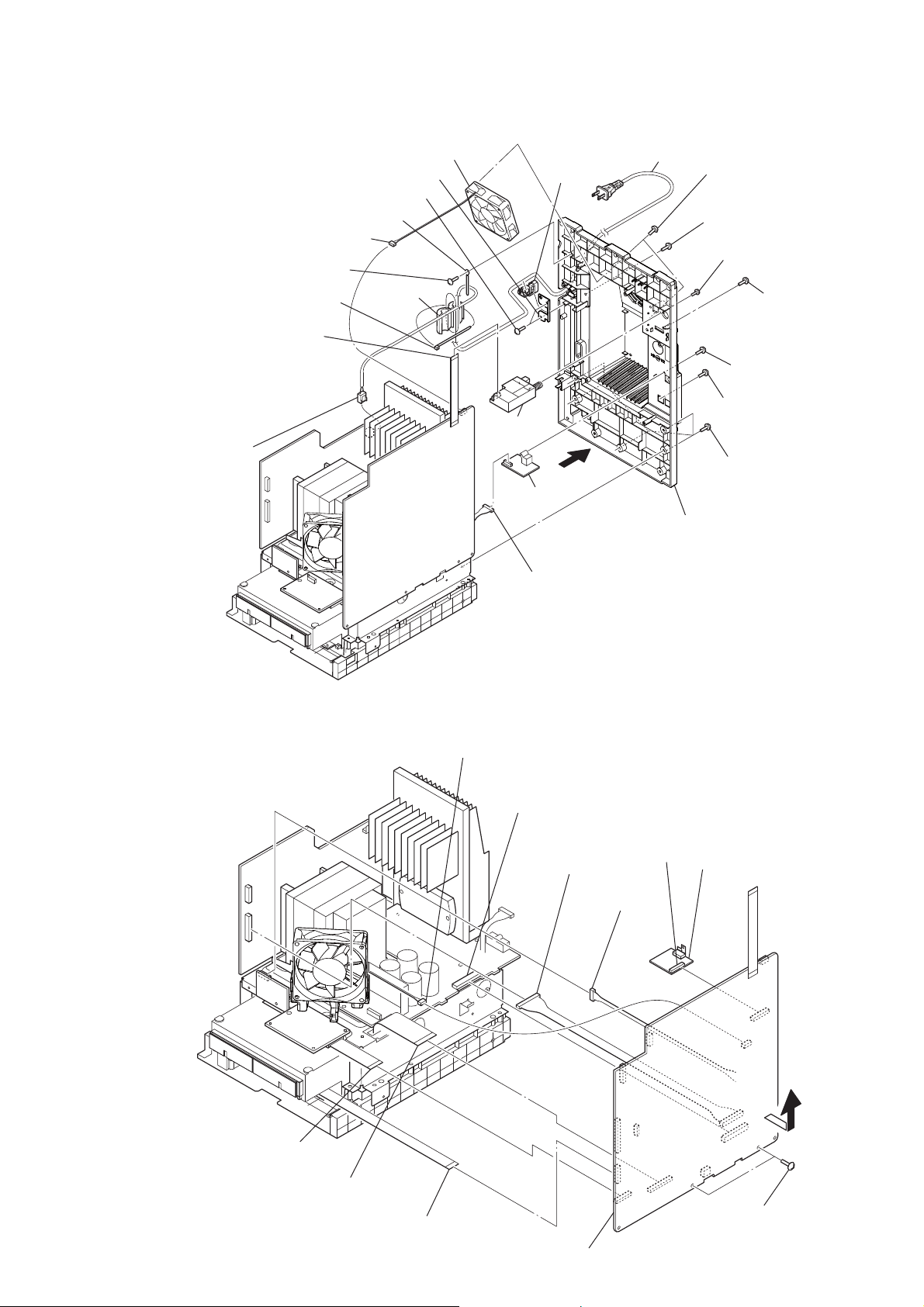

3-6. DC FAN (M102), BACK PANEL

RH

bushing bracket

two screws (BVTP3 × 10)

X

XB

DC fan (M102)

cord

XT

bushing

power cord

XE

two screws

RG

(BVTP3 × 12)

HCD-ZT4

RI

flexible flat cable

(9 core)

power cord connector

(CN901)

RK

fan connector (CN690)

screw (BVTP3 × 10)

Cut the clamp.

RL

coating clip

ferrite core

RM

tuner

RE

(FM/AM)

SW JACK

RB

board

connector

(CN890)

R

back panel

XG

screw

(BVTP3 × 8)

two screws

RT

(BVTP3 × 10)

(BVTP3 × 10)

screw

(BVTP3 × 10)

screw

(BVTP3 × 10)

five screws

(BVTP3 × 10)

screw

3-7. MAIN BOARD

flexible flat cable (21 core)

(CN420)

wire (flat type) (31 core)

(CN430)

wire (flat type) (13 core)

(CN410)

fan connector

(CN110)

connector

(CN801)

connector

(CN907)

MAIN board

RT

R

(CN1301)

connector

(CN055)

connector

DMPORT board

RB

two screws

(BVTP3 × 10)

13

HCD-ZT4

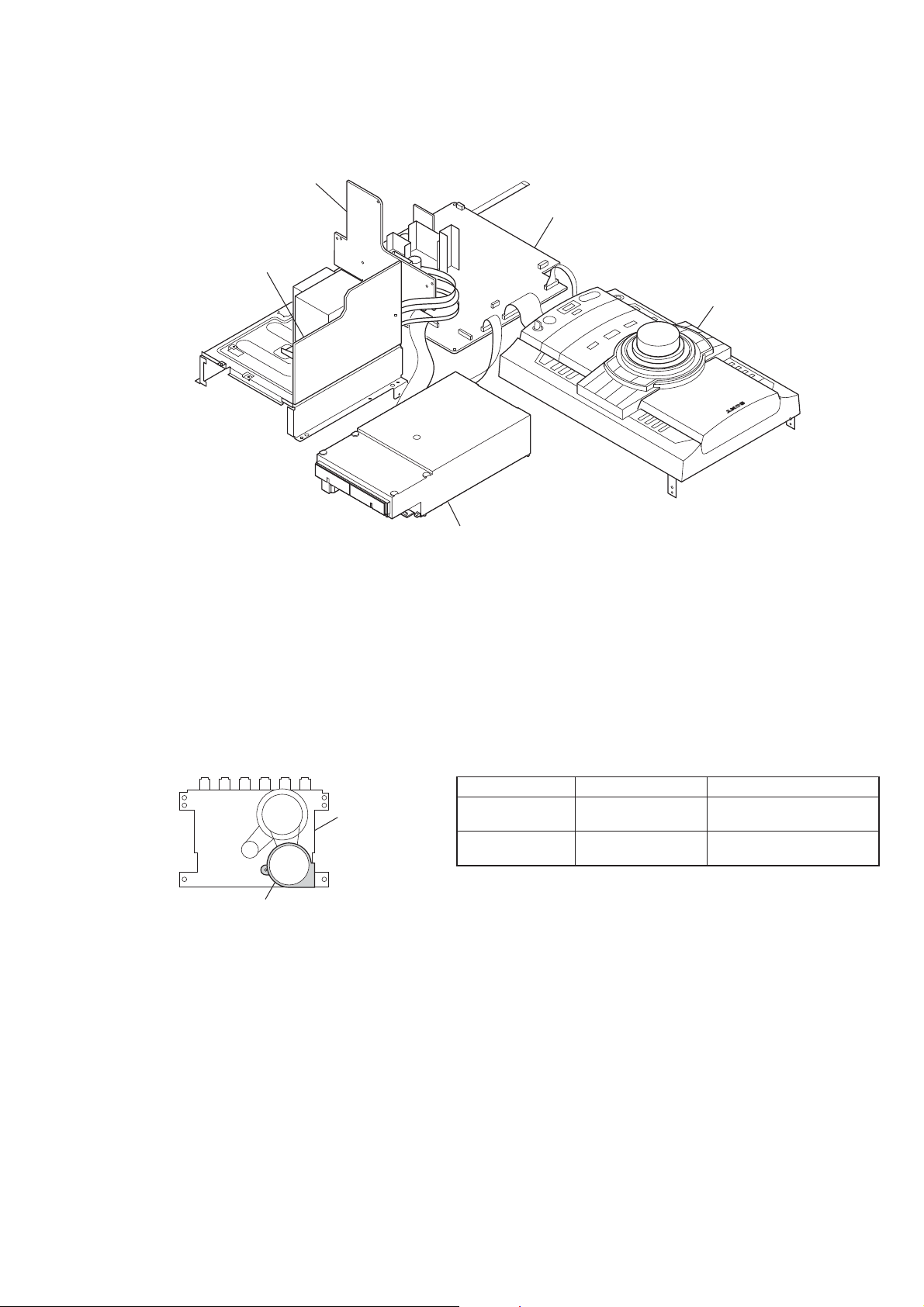

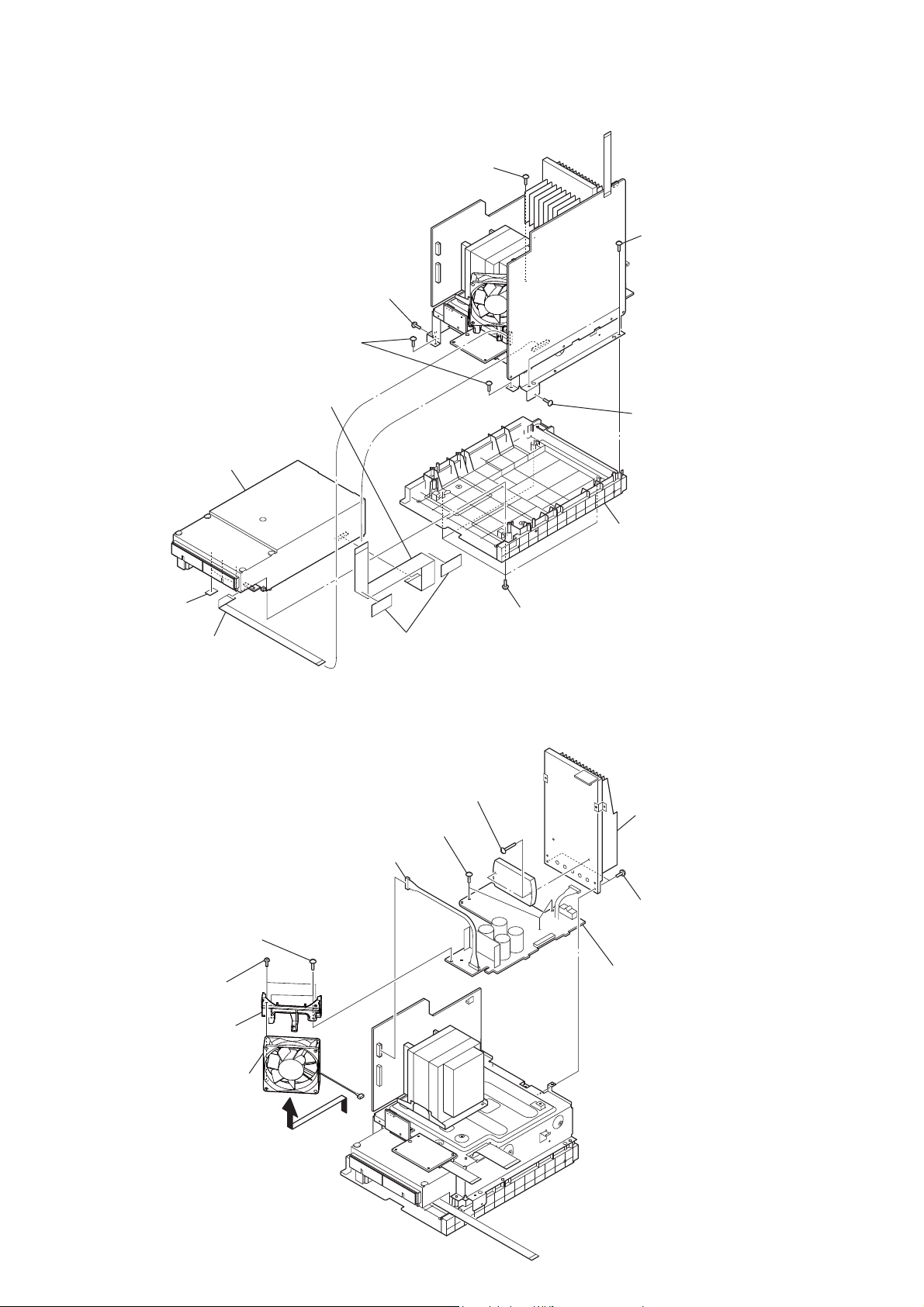

3-8. CD MECHANISM BLOCK

wire (flat type) (31 core)

(MAIN board: CN430/

CD board: CN201)

CD mechanism block

RT

screw

(BVTP3 × 10)

two screws

(BVTP3 × 10)

screw

(BVTP3 × 10)

two screws

(BVTP3 × 10)

screw

(BVTP3 × 10)

three sheets

RB

wire (flat type) (13 core)

(MOTOR board/

MAIN board: CN410)

Note: When installing the CD mechanism section,

install two tapes for prevention of noise.

3-9. DC FAN (M101), POWERAMP BOARD

connector (CN903)

two screws

(BVTP3 × 10)

two screws

(BVTP3 × 12)

two saranet cushions

two screws

(transistor)

three screws

(BVTP3 × 10)

four screws

(BVTP3 × 10)

chassis

heat sink block

two screws

(BVTP3 × 10)

POWERAMP board

RB

14

bracket (fan)

DC fan (M101)

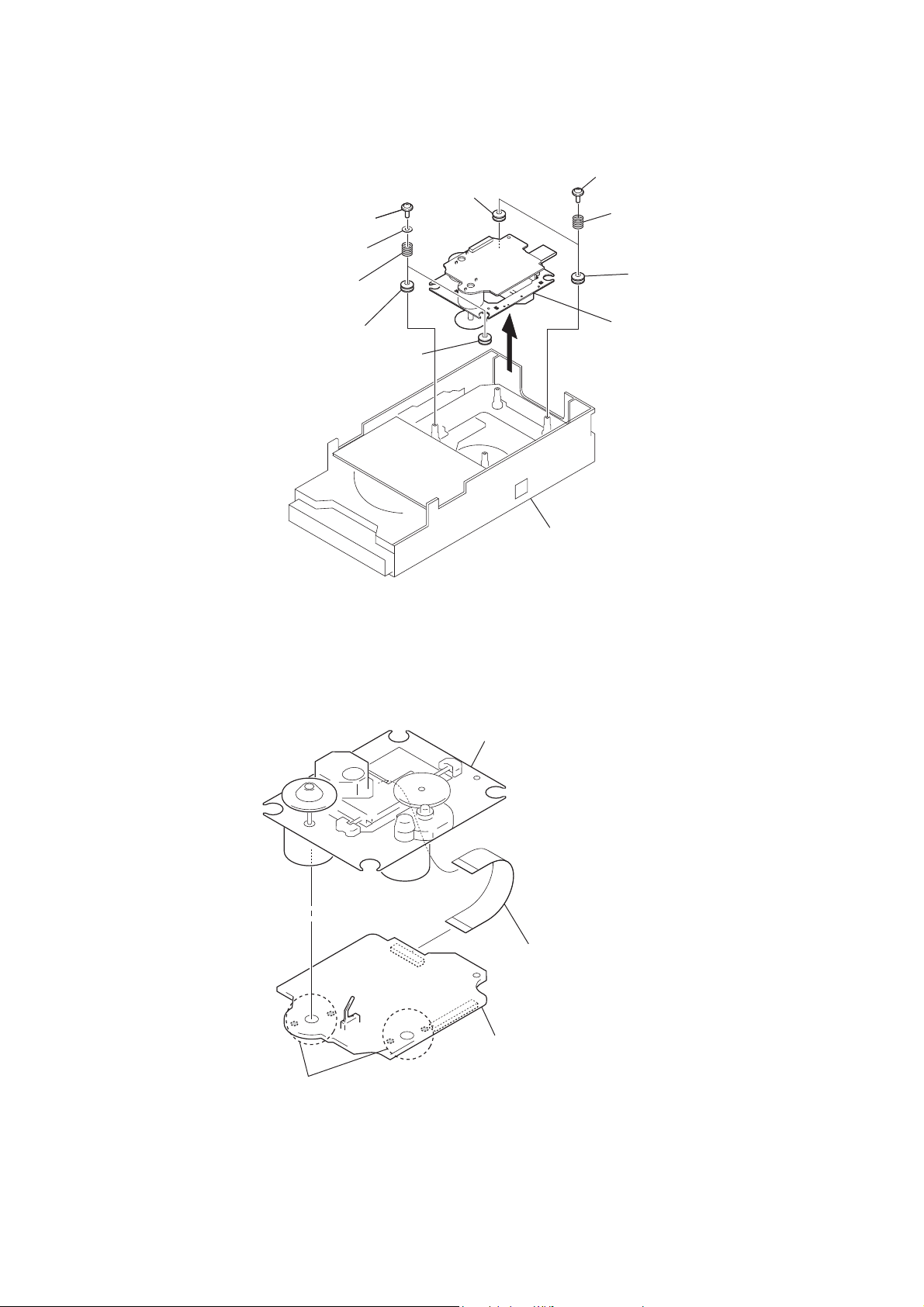

3-10. BASE UNIT

two screws (PTPWHM2.6)

two polyethylene washers

HCD-ZT4

two screws (PTPWHM2.6)

insulator

two springs

(insulator)

insulator

two springs (insulator)

insulator

insulator

– Bottom view –

3-11. OP BASE ASSY (KSM-213D)

CD mechanism block

OP base assy

(KSM-213D)

base unit

Remove four solders.

flexible flat cable (16 core)

(CD board: CN301/optical pick-up block)

CD board

15

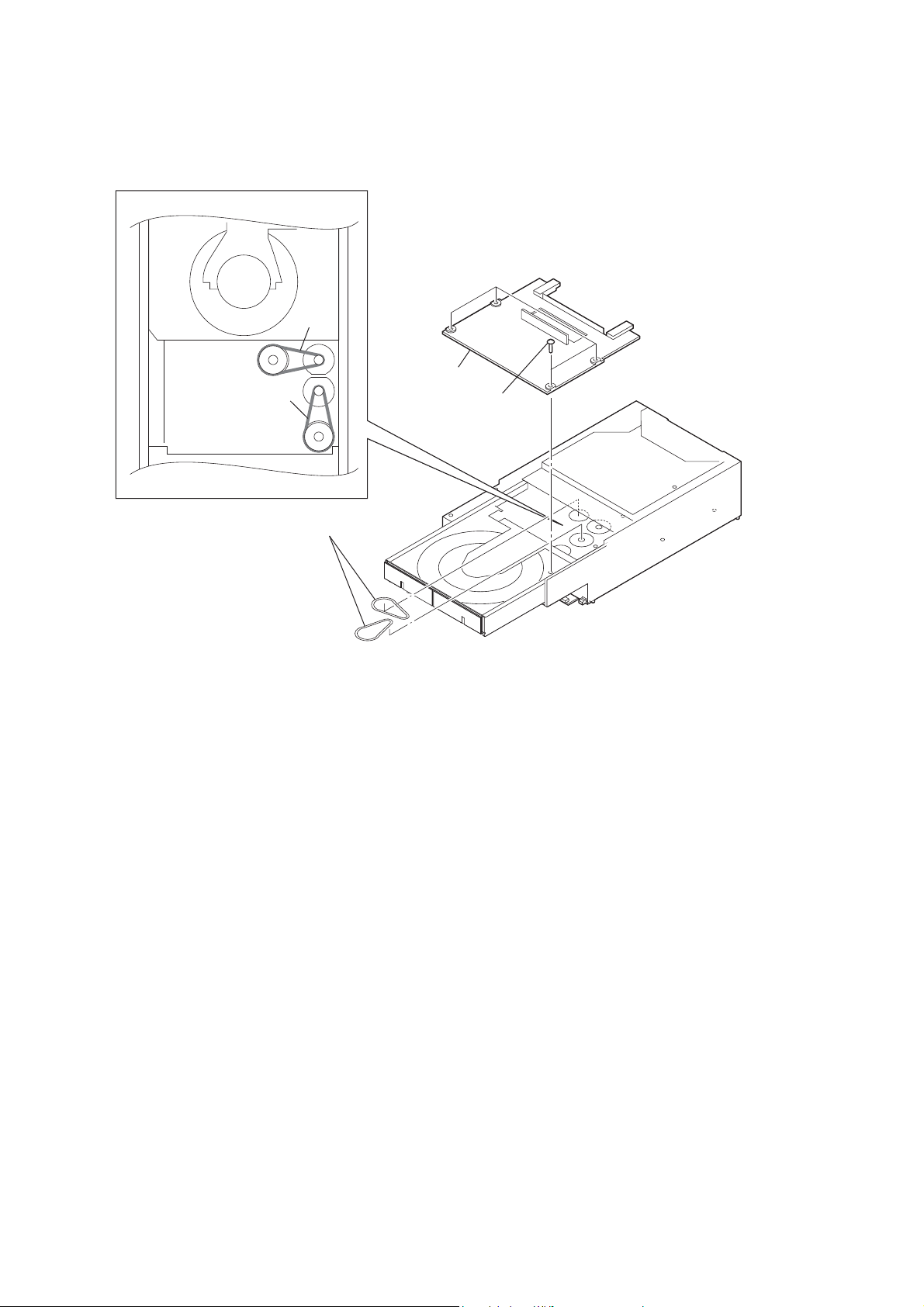

HCD-ZT4

3-12. BELT (DLM3A)

position of belt

belt

cover

belt

two belts (DLM3A)

four screws

16

SECTION 4

TEST MODE

HCD-ZT4

PANEL TEST MODE

This mode is used to check the fl uorescent indicator tube, LEDs,

keys, [MASTER VOLUME] jog, [OPERATION DIAL] jog, model, destination and software version.

Procedure:

1. Press [x] button, [METER MODE] button and [DISC 2] button simultaneously.

2. All LEDs and segments in fl uorescent indicator tube are lighted

up. The POWER LED is lighted up in red color if the system is

turned off and POWER LED is turn off if the system is turned

on.

3. When you want to enter to the software version display mode,

press [DISC 1] button. The model information appears on the

fl uorescent indicator tube. The message “GSL 2RS” appears

on the fl uorescent indicator tude. Press [DISC 1] button again

to view the destination information.

4. During the destination information display, press [DISC 1]

button. Each time [DISC 1] button is pressed, the fl uorescent

indicator tube shows the version of each category software in

the following sequence: SC, GC, SYS, CD, CDDM, CDMA,

CDMB, BDA, BDB, ST, TC, TA, TM, MM1, MM2 (USB

Micro computer) , MTR (METER) and return back to model

information display.

5. When [DISC 3] button is pressed while the version numbers

are being displayed except model and destination, the date

of the software creation appears. When [DISC 3] button is

pressed again, the display returns to the software version display. When [DISC 1] button is pressed while the date of the

software creation is being displayed, the date of the software

creation is displayed in the same order of software version display.

6. Press [DISC 2] button, the key check mode is activated.

7. In the key check mode, the fl uorescent indicator tube displays

“K 0 J0 V0”.

Each time a button is pressed, “K” value increases. However,

once a button has been pressed, it is no longer taken into account.

“V” value increases in the manner of 0,1, 2, 3 ... if [MASTER

VOLUME] knob is turned clockwise, or it decreases in the

manner of 0, 9, 8,7 ... if [MASTER VOLUME] knob is turned

counterclockwise.

“J” value increases in the manner of 0,1, 2, 3 ... if [OPERA-

TION DIAL] knob is turned clockwise, or it decreases in the

manner of 0, 9, 8,7 ... if [OPERATION DIAL] knob is turned

counterclockwise.

8. When [DISC SKIP/EX-CHANGE] button is pressed after all

LEDs and segments in fl uorescent indicator tube light up, al-

ternate segments in fl uorescent indicator tube and LEDs would

light up. If you press [DISC SKIP/EX-CHANGE] button

again, another half of alternate segments in fl uorescent indica-

tor tube and LEDs would light up. Pressing [DISC SKIP/EXCHANGE] button again would cause all segments in fl uores-

cent indicator tube and LEDs light up.

9. To release from this mode, press three buttons in the same

manner as step 1, or disconnect the power cord.

COMMON TEST MODE

This mode is used to check operations of the respective sections of

Amplifi er and Tape.

To enter Common Test Mode

Procedure:

1. Press [x] button, [METER MODE] button and [DISC 3] button simultaneously.

2. The CD ring indicators fl ash on the fl uorescent indicator tube.

The function is changed to AUDIO and the volume is changed

to VOLUME MIN.

Check of Amplifi er

Procedure:

1. Press [EQ BAND] button repeatedly until a message “GEQ

MAX” appears on the fl uorescent indicator tube. GEQ increas-

es to its maximum.

2. Press [EQ BAND] button repeatedly until a message “GEQ

MIN” appears on the fl uorescent indicator tube. GEQ decreas-

es to its minimum.

3. Press [EQ BAND] button repeatedly until a message “GEQ

FLAT” appears on the fl uorescent indicator tube. GEQ is set to

fl at.

4. When the [MASTER VOLUME] knob is turned clockwise

even slightly, the sound volume increases to its maximum and

a message “VOLUME MAX” appears on the fl uorescent indi-

cator tube.

5. When the [MASTER VOLUME] knob is turned counterclockwise even slightly, the sound volume decreases to its minimum

and a message “VOLUME MIN” appears on the fl uorescent

indicator tube.

Tape function

When a tape is inserted in deck and recording is started, the function is changed to AUDIO.

To release from Common Test mode

Procedure:

1. To release from this mode, press [

2. The cold reset is enforced at the same time.

?/1

] button.

COLD RESET

The cold reset clears all data including preset data stored in the

EEPROM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Press [

2. Press [x] button, [ENTER] button, and [

neously.

3. “COLD RESET” appears on the fl uorescent indicator tube.

After that, the fl uorescent indicator tube becomes blank for a

while, and the system is reset.

] button to turn on the system.

?/1

] button simulta-

?/1

VACS ON/OFF

This mode is used to switch ON and OFF the VACS (Variable Attenuation Control System).

Procedure:

1. Press [

2. Press [x] button, [DISC 2], and [DISPLAY] button simultaneously. The message “VACS OFF” or “VACS ON” appears on

the fl uorescent indicator tube.

] button to turn on the system.

?/1

17

HCD-ZT4

TUNER STEP CHANGE

The step interval of AM channels can be toggled between 9 kHz

and 10 kHz. This mode is not available for Saudi Arabian, European and Russian models.

Procedure:

1. Press [

] button to turn on the system.

?/1

2. Press [TUNER/BAND] button repeatedly to select the “AM”.

3. Press [

4. Press [ENTER] button and [

] button to turn off the system.

?/1

?/1

] button simultaneously. The

system turns on automatically. The message “AM 9K STEP”

or “AM 10K STEP” appears on the fl uorescent indicator tube

and thus the channel step is changed.

CD SERVICE MODE

This mode let you move the CD sled motor freely. Use this mode

when you want to clean the optical pick-up.

Procedure:

1. Press [

2. Press [CD] button to select CD function.

3. Press [x] button, [METER MODE] button, and [OPEN/

CLOSE] button simultaneously.

4. The CD service mode is activated. The message “SERVICE

MODE” appears on the fl uorescent indicator tube.

5. With the disc in stop status, press [M] to move the optical

pick-up to outside track, or press [m] to move to inside track.

The message “SLED OUT” or “SLED IN” appears on the fl uo-

rescent indicator tube.

6. To turn on or off the laser, press [>] button. The message

“LD ON” or “LD OFF” appears on the fl uorescent indicator

tube.

7. To release from this mode, press [

] button to turn on the system.

?/1

?/1

] button.

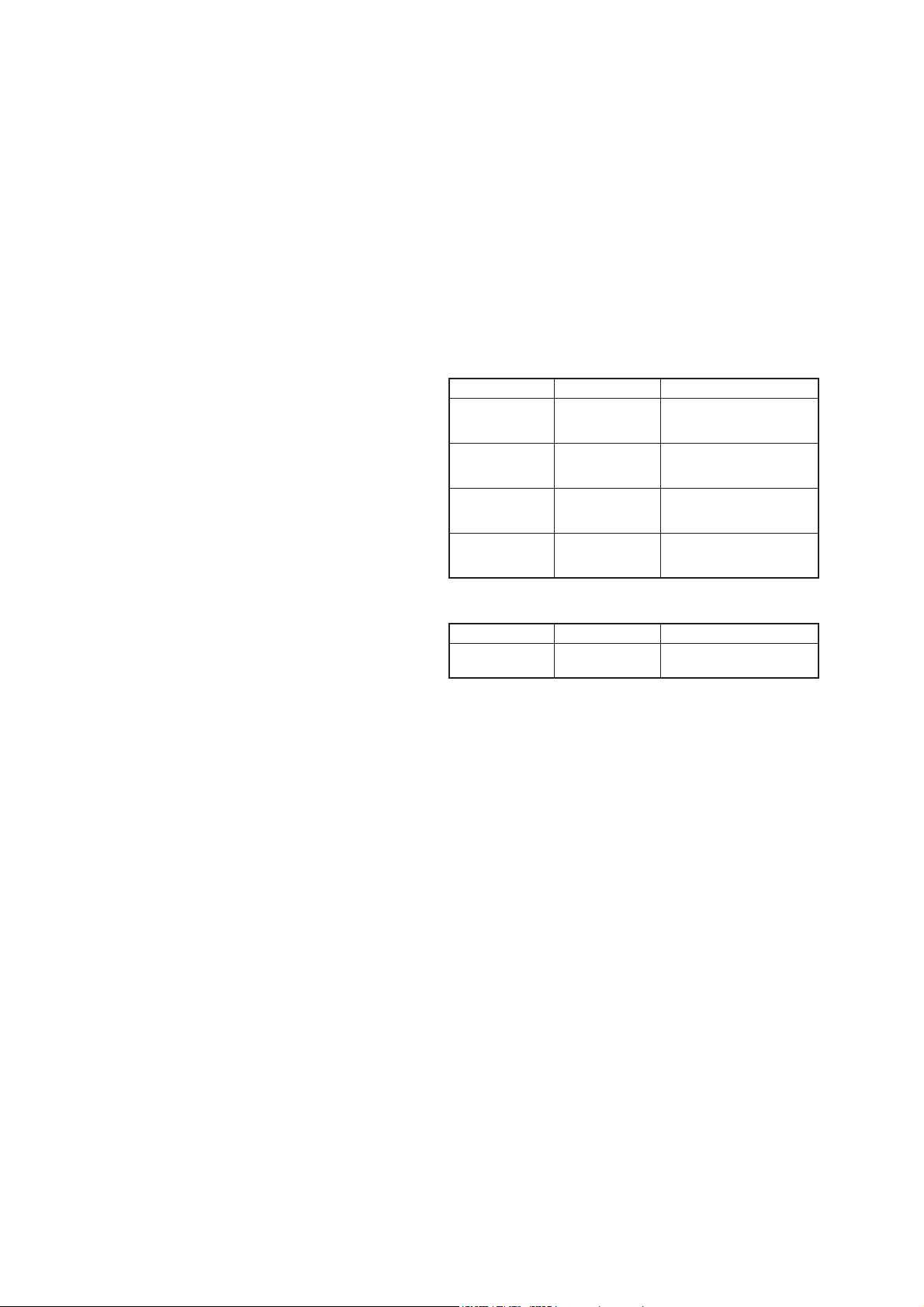

• Aging mode sequence:

START (from

Disc 1)

Disc Chucking

TOC Reading

Play first track for 2

seconds

Play last track for 2

seconds

EX-CHANGE open/

close

CD AGING MODE

This mode can be used for operation check of CD section.

If an error occurs, the aging operation would stops and the status is

displayed. If there were no error occurs, the aging operation would

continue repeatedly.

Procedure:

1. Press [

2. Select CD function.

3. Load three discs on the disc tray.

4. Press [PLAY MODE/TUNING MODE] button on the remote

repeatedly to select the “ALL DISCS” mode, and press the

[REPEAT/FM MODE] button on the remote repeatedly to select “REPEAT OFF” mode.

5. Press [x] button, [METER MODE] button and [DISC SKIP/

EX-CHANGE] button simultaneously.

6. Aging operation is started.

7. To release from this mode, press [

power cord to turn off the system.

] button to turn on the system.

?/1

] button or disconnect the

?/1

Open the disc tray

Disc skip

Close the disc tray

Change the disc tray

CD ERROR CODE MODE

Display the CD error code when an error occurred

Procedure:

1. Press [x] button, [METER MODE] button and [DISC 1] button simultaneously to enter the error code display mode.

2. The fl uorescent indicator tube displays the number of total er-

ror.

3. Each time [m] or [M] button is pressed, display change as

below.

18

HCD-ZT4

Display of

Total Error

FF button FR button

AMS (+)

button

FF button

AMS (+)

button

Display of

Mechanical

Errors

Display of

No Disc

Errors

AMS (–)

button

FR button

AMS (–)

button

4. To clear the error record, operate the cold reset. (Refer to the

“COLD RESET”)

5. To release from this mode, press the [

] button or disconnect

?/1

the power plug to turn off the system.

• Display of total error

EM**ED**

EM** : The number of mechanical errors.

ED** : The number of no disc errors after chucking the disc.

• Display of mechanical errors

M*

M* : The number of mechanical error (“0” is latest one)

(Press [>] button to display the next error)

• Display of no disc errore

CD REPEATS 5 LIMIT OFF MODE

The number of repeat for CD playback is 5 times when the repeat

mode is “REPEAT ALL”. This mode enables CD to repeat playback for limitless times.

Procedure:

1. Press [

] button to turn on the system.

?/1

2. Select CD function.

3. Press [x] button, [CD] button and [DISC 1] button simultane-

ously to enter the CD repeat 5 limit off mode and the fl uores-

cent indicator tube displays “LIMIT OFF”.

4. To release from this mode, operate the cold reset. (Refer to the

“COLD RESET”)

CD SHIP MODE (WITH MEMORY CLEAR)

This mode moves the optical pick-up to the position durable to

vibration and clears all data including preset data stored in the EEPROM to initial conditions during the next AC-In. Use this mode

when returning the set to the customer after repair.

Procedure:

1. Press [

] button to turn on the system.

?/1

2. Select CD function.

3. Press [x] button, [DISC 1] button and [

] button simultane-

?/1

ously. The system turns off automatically.

4. After the “STANDBY” blinking display fi nishes, a message

“MECHA LOCK” is displayed on the fl uorescent indicator

tube and the CD ship mode is set.

CD SHIP MODE (WITHOUT MEMORY CLEAR)

This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press [

2. Select CD function.

3. Press [DISC SKIP/EX-CHANGE] button and [

multaneously. The system turns off automatically.

4. After the “STANDBY” blinking display fi nishes, a message

“MECHA LOCK” is displayed on the fl uorescent indicator

tube and the CD ship mode is set.

] button to turn on the system.

?/1

] button si-

?/1

D*$$%%&&##00

D* : The number of no disc error (“0” is latest one)

(Press [>] button to display next error)

$$ : Error type

01 : Focus error

02 : GFS error

03 : Setup error

%% : Not used

&& :

00 : No disc judgment without chucking retry.

01 : No disc judgment after chucking retry.

## : The state when judged as no disc

01 : Stop

02 : Setup

03 : TOC reading

04 : Access

05 : Playback

06 : Pause

07 : Manual search (Play)

08 : Manual search (Pause)

CD TRAY LOCK MODE

This mode let you lock the disc tray. When this mode is activated,

the disc tray will not open when [OPEN/CLOSE] button or [DISC

SKIP/EX-CHANGE] button is pressed. The message “LOCKED”

will be displayed on the fl uorescent indicator tube.

Procedure:

1. Press [

] button to turn on the system.

?/1

2. Select CD function.

3. Press [x] button and [OPEN/CLOSE] button simultaneously

and hold down until “LOCKED” or “UNLOCKED” displayed

on the fl uorescent indicator tube (around 5 seconds).

FACTORY PRESET

This mode is use to load all the factory use preset frequencies into

FM 1-FM 20 and AM 1-AM 10. Originally, frequency of FM 1FM 20 and AM 1-AM10 are set to the minimum frequency.

Procedure:

1. Press [

2. Press [TUNER/BAND] button, [x] button, and [DISC 1] button simultaneously and the message “FACTORY” appears

on the fl uorescent indicator tube. The function is changed to

TUNER automatically.

] button to turn on the system.

?/1

19

HCD-ZT4

SECTION 5

MECHANICAL ADJUSTMENTS

VACS DISPLAY

This mode is used to check the VACS level.

Procedure:

1. Press [

] button to turn on the system.

?/1

2. Press [ERASE] button, [x] button and [ENTER] button si-

multaneously.

3. The fl uorescent indicator tube displays “VACSA”. “A” repre-

sents Conventional VACS (Triggered by signal level)

4. To release from this mode, do the step 2 again.

METER SWITCH TOUCH COUNT DISPLAY

This mode is used to display the total count of meter pointer touch

initial switch and max switch.

Procedure:

1. Press [

] button to turn on the system.

?/1

2. Press [x] button, [ENTER] button and [DISPLAY] button simultaneously.

3. The fl uorescent indicator tube displays “IxxxxxMyyyyy”.

“I” represents the Initial Switch touch.

“xxxxx” represents the total count of Initial Switch touch.

(Maximum Value of “xxxxx” = 65535)

“M” represents the Max Switch touch.

“yyyyy” represents the total count of Max Switch touch.

(Maximum Value of “yyyyy” = 65535)

4. To release from this mode, do the step 2 again. The fl uorescent

indicator tube displays “MODE OUT”.

METER TEST MODE

This mode is used to check the meter device.

Procedure:

1. Press [

2. Press [x] button, [ENTER] button and [METER MODE] button simultaneously and the message “TST MODE IN” appears

on the fl uorescent indicator tube.

3. Meter Backlight LEDs, Meter Pointer LEDs, Power Illuminator LEDs and fl uorescent indicator tube are lighted up.

4. When you want to perform count total step from Initial Switch

to Max Switch operation mode, press [M] button. The meter pointer will move from Initial Switch to Max Switch and

fi nally move back to the middle position. The total step count

information appears on the fl uorescent indicator tube. “xxx

STP yy” is shown.

“xxx” represents the total step.

(Value of “xxx” should between 430 steps to 470 steps)

“yy” represents the status of total step count.

(If total step between 430 steps to 470 steps, “yy” is OK, Else

“yy” is NG)

5. When you want to perform count total step from Max Switch

to Initial Switch operation mode, press [m] button. The meter pointer will move from Max Switch to Initial Switch and

fi nally move back to the middle position. The total step count

information appears on the fl uorescent indicator tube. “xxx

STP yy” is shown.

“xxx” represents the total step.

(Value of “xxx” should between 430 steps to 470 steps)

“yy” represents the status of total step count.

(If total step between 430 steps to 470 steps, “yy” is OK, else

“yy” is NG).

6. To release from this mode, do the step 2 again. The fl uorescent

indicator tube displays “TST MODE OUT”.

] button to turn on the system.

?/1

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback head pinch roller

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer. (Do not bring the head magnetizer close to the erase

head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, appiy suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

• Torque Measurement

Mode Torque Meter Meter Reading

FWD CQ-102AS

FWD

Back Tension

FF CQ-201AS

REV CQ-201B

CQ-102C

2.0 – 8.0 mN • m

(20 to 80 g • cm)

(0.28 – 1.12 oz • inch)

0.15 – 0.6 mN • m

(1.5 to 6 g • cm)

(0.021 – 0.083 oz • inch)

5 – 17.7 mN • m

(50 to 177 g • cm)

(0.7 – 2.48 oz • inch)

5 – 17.7 mN • m

(50 to 177 g • cm)

(0.7 – 2.48 oz • inch)

• Tape Tension Measurement

Mode Tension Meter Meter Reading

FWD CQ-403A

more than 80 g

(more than 2.82 oz)

20

SECTION 6

ELECTRICAL ADJUSTMENTS

HCD-ZT4

DECK SECTION 0 dB = 0.775V

1. Demagnetize the record/playback head with a head demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

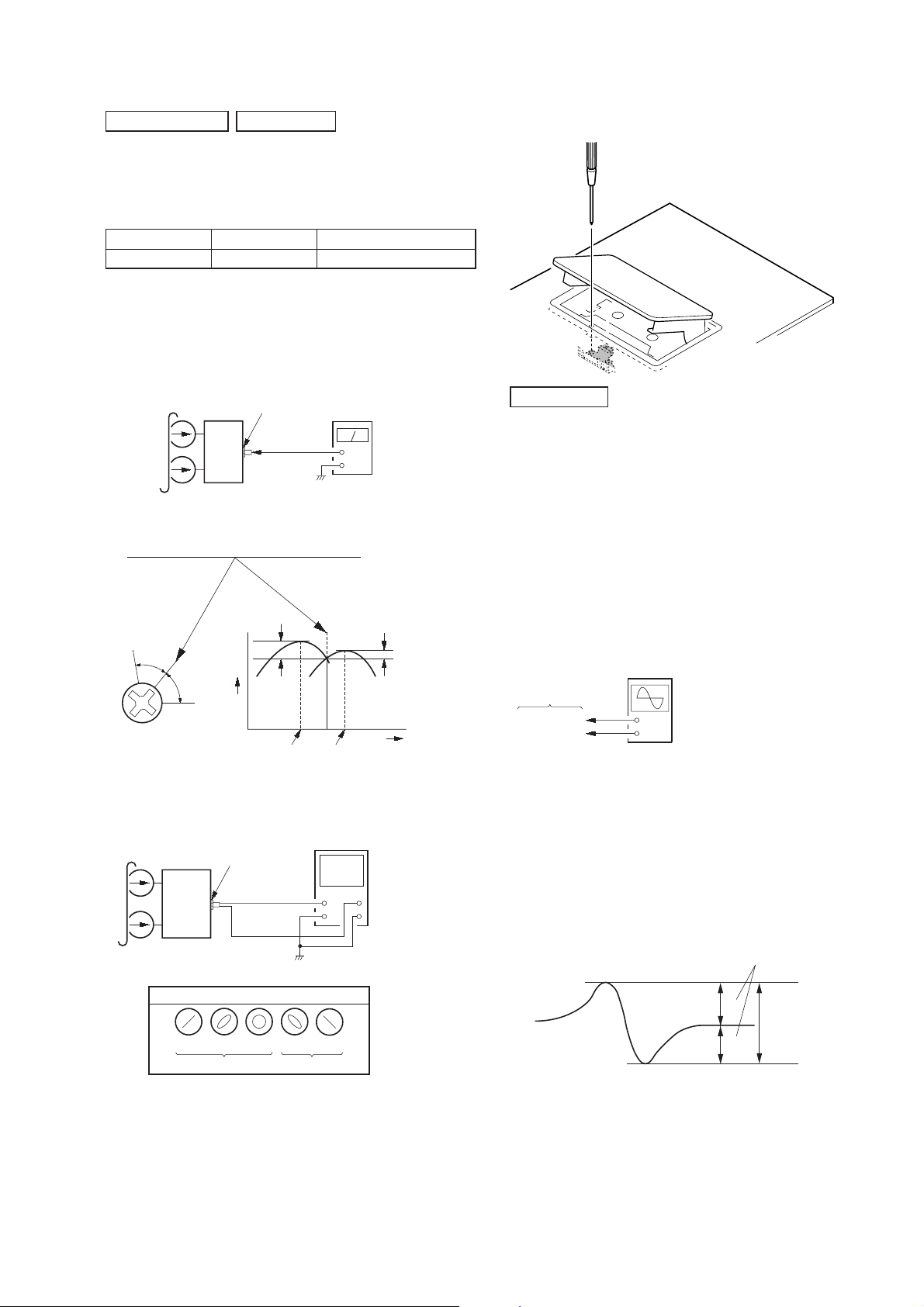

TEST TAPE

Tape Signal Used for

P-4-A063 6.3 kHz, -10 dB Azimuth Adjustment

RECORD/PLAYBACK HEAD AZIMUTH ADJUSTMENT

Procedure:

1. Mode: Playback

test tape

P-4-A063

(6.3 kHz, −10 dB)

MIC board

PHONES jack

(J702)

set

level meter

+

–

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

Output

level

within

1 dB

L-CH

peak

R-CH

peak

within

1 dB

Screw

position

L-CH

peak

Screw

position

R-CH

peak

3. Mode: Playback

test tape

P-4-A063

(6.3 kHz, −10 dB)

set

MIC board

PHONES jack

(J702)

oscilloscope

H

V

Adjustment Location: Record/Playback/Erase Head

CD SECTION

Note:

1. CD Block is basically designed to operate without adjustment. Therefore, check each item in order given.

2. Use YEDS-18 (PART No. 3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specifi ed value with the following checks.

TEST DISC LIST

Use the following test disc on electrical checks.

YEDS-18 (PART No. 3-702-101-01) or

PATD-012 (PART No. 4-225-203-01)

S-CURVE CHECK

oscilloscope

(DC range)

CD board

TP106 (FE)

TP124 (VC)

+

–

Procedure:

1. Connect an oscilloscope to TP106 (FE) and TP124 (VC).

2. Turn the power ON.

3. Load a disc (YEDS-18) and actuate the focus search. (In consequence of open and close the disc tray, actuate the focus

search)

4. Confi rm that the oscilloscope waveform (S-curve) is symmet-

rical between A and B. And confi rm peak to peak level within

1.8 ± 0.5 Vp-p.

waveform of oscilloscope

in phase 45° 90° 135° 180°

good

wrong

4. After the adjustments, apply suitable locking compound to the

pats adjusted.

S-curve waveform

symmetry

A

within 1.8 ± 0.5 Vp-p

B

Note:

• Try to measure several times to make sure than the ratio of A : B or B

: A is more than 10 : 7.

• Take sweep time as long as possible and light up the brightness to

obtain best waveform.

21

HCD-ZT4

RF LEVEL CHECK

oscilloscope

CD board

TP123 (RFO)

TP124 (VC)

Procedure:

1. Connect an oscilloscope to TP123 (RFO) and TP124 (VC).

2. Turn the power ON.

3. Load a disc (YEDS-18) and playback.

4. Confi rm that oscilloscope waveform is clear and check if RF

signal level is correct or not.

Note: Clear RF signal waveform means that the shape “◊” can be clearly

distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200 mV

TIME/DIV : 500 ns

level : 1.3 ± 0.3 Vp-p

Connecting Location: CD board

– CD Board (Conductor Side) –

TUNER SECTION

FM TUNE LEVEL CHECK

signal

generator

set

Procedure:

1. Turn on the set.

2. Input the following signal from signal generator to FM antenna

input directly.

Carrier Freq : A = 87.5 MHz, B = 98 MHz, C = 108 MHz

Deviation : 75 kHz

Modulation : 1 kHz

ANT input : 35 dBu (EMF)

Note: Use 75 ohm coaxial cable to connect signal generator and the set.

You cannot use video cable for checking.

Use signal generator whose output impedance is 75 ohm.

3. Set to FM tuner function and tune A, B and C signals.

4. Confi rm “TUNED” is lit on the display for A, B and C sig-

nals.

When the selected station signal is received in good condition,

“TUNED” is displayed.

TP124 (VC)

TP123 (RFO)

TP106 (FE)

IC101

22

HCD-ZT4

HCD-ZT4

2323

SECTION 7

DIAGRAMS

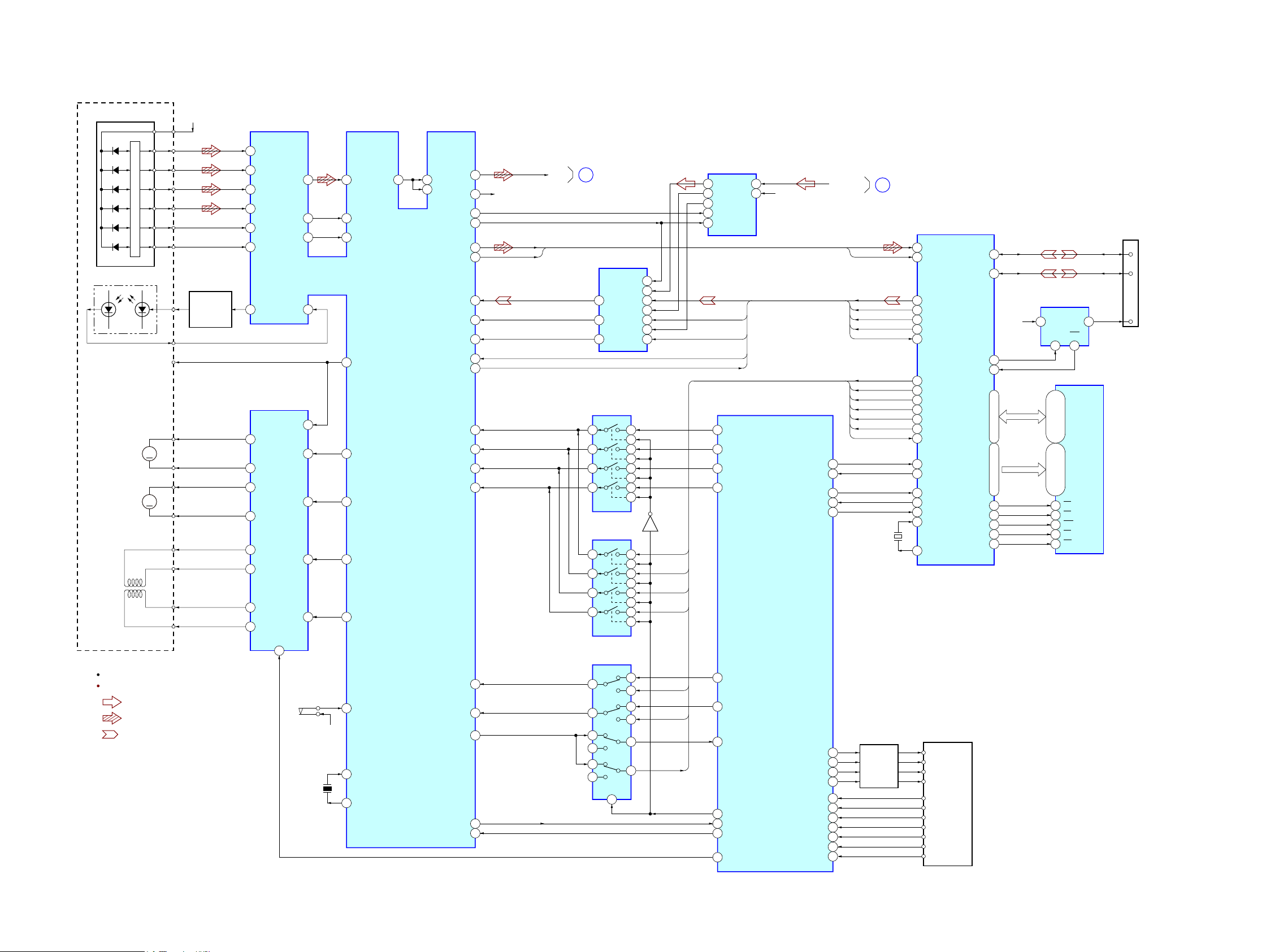

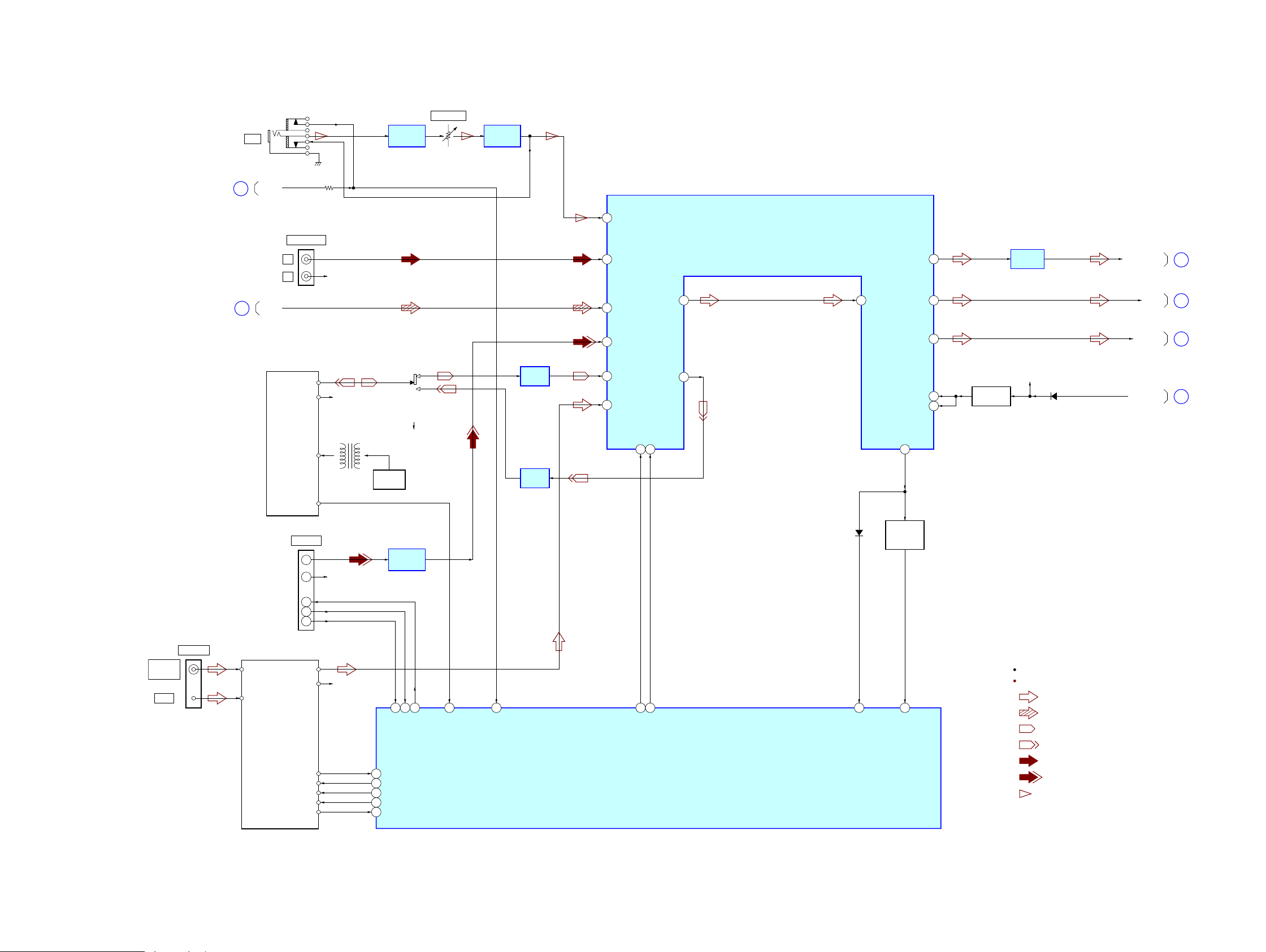

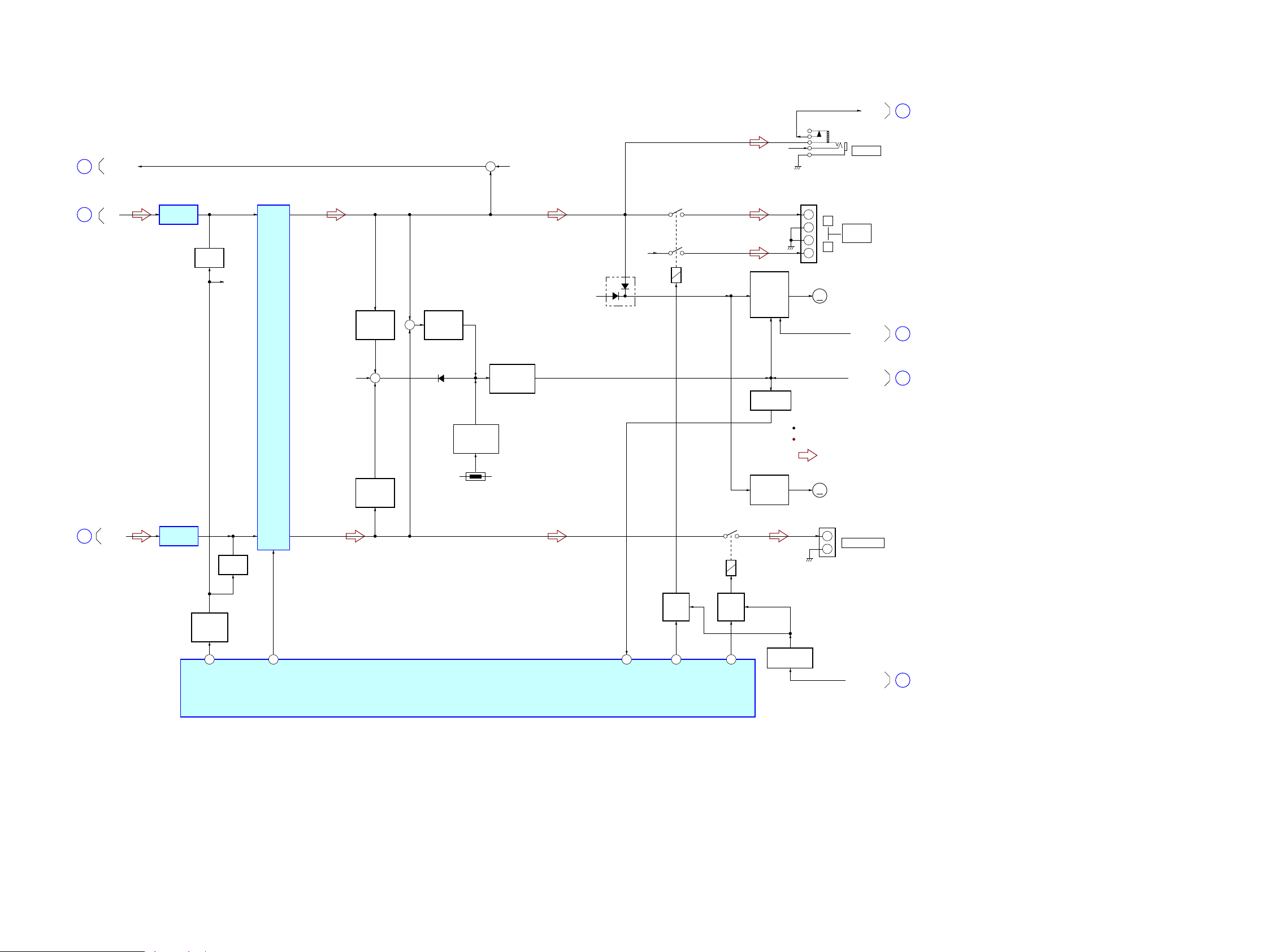

7-1. BLOCK DIAGRAM - CD SERVO, USB Section -

SYSTEM CONTROLLER

IC401 (1/4)

CD-MP3 PROCESSOR

IC101

MUTE

2-AXIS

DEVICE

(TRACKING)(FOCUS)

95

89

A

+3.3V

DETECTOR

FNi1 (A)

RFo

97 FPi1 (B)

88

2

AGCi

3RFRP RFZi

76TEi TEZi

83RFEQo 81 RFi

82 RFRPi

30LO

27RO

46AoUT3 (PO4)

50PIO2

65AIN (PI4)

66BCKi (PI5)

BCK

A-IN

BUS1-U

BUS0-U

BUS2-U

BUS3-U

BUCK-U

67LRCKi (PI6)

LRCK

51PIO3

GATE

49PIO1

ST-REQ

38BUS0

R-CH

94 FNi2 (C)

96 FPi2 (D)

100 TNi (E)

98 TPi (F)

91 LDo 92MDi

2VO1+

1VO1–

13 DMo

LD

PD

LASER DIODE

OPTICAL PICK-UP

BLOCK

(KSM-213DCP)

B

C

D

E

F

12 FMo

10 TRo

9FOo

20 IO0 (/HSO)

I-V AMP

M401

(SPINDLE)

M402

(SLED)

12 VO2–

11 V O2+

18 VO3+

17 VO3–

26 VO4+

27

7

IN4’

24

IN3’ 20

IN2’

9

IN1

3

BIAS

23

84 VRo

VO4–

M

M

FOCUS/TRACKING COIL DRIVE,

SLED/SPINDLE MOTOR DRIVE

IC401

S201

(LIMIT)

+3.3V

24 XO

23 XI

X102

16.9344MHz

47 CD-MMUTE

CD-L

R-CH

USB_REC-L

: CD PLAY

SIGNAL PATH

R-ch is omitted due to same as L-ch.

: TUNER (FM/AM)

: USB

VCC

A

B

C

D

E

F

LD

PD

SP+

VC

SP–

SL+

SL–

T+

T–

F+

F–

47AoUT2 (PO5)

63BCK (PO8)

CLK

DATA

2 1 41 CD BUS0

13

39BUS1 3 4 42 CD BUS1

5

40BUS2 (SO) 9 8 43 CD BUS2

45 CD CLK

6

41BUS3 (SI) 10 11 44 CD BUS3

12

BUS SWITCH

IC670

2 1

13

3 4

5

9 8

6

10 11

12

BUS SWITCH

IC672

Q671

DATA SELECTOR

IC673

SELECT

42BUCK (CLK) 4

2

3

CCE-U

46 CD CCE

43XCCE

54SBSY

48PIO0

7

40 MP3 IREQ

37 USB SEL-SW

19 SBSY

37XRST

48 CD-XRST

5

REQ-U

6

12

14

13

9

10

11

1

CLK

DATA

LB

I/O0 – I/O15

D0 – D15

S-RAM

IC921

39

UB

40

OE41

WE

17

CE

6

79D+

80D–

77USBOC

USB CONTROLLER

IC901

CN1000

(USB)

3

2

1

D+

D–

78USBPON

70CS2

64

RD

65WR

66SRLLB

67SRLUB

VBUS

VBUS POWER

ON/OFF SWITCH

IC915

5

1

4OUT

EN

3

FLG

IN

VBUS

+5V

93

DATA

92

BCK

85 DATA

86 CLOCK

71

LRCK

94

GATE

97

ST-REQ

55 BUS0

56 BUS1

88 RXD1

87 TXD1

2DI

84 DO

1 /RESET

57 BUS2

58 BUS3

59 /BUCK

60 /CCE

96 REQ

7 – 10, 13 – 16,

29 – 32, 35 – 38

18 – 25, 28 – 35

A0 – A15

A1 – A16

44 – 42, 27 – 24,

21 – 18, 5 – 1

37 – 43, 46 – 54

73 X2

75 X1

X901

9MHz

AUTOMATIC

POWER

CONTROL

Q301

BCK

A-IN

LRCK

GATE

ST-REQ

BUS1-U

BUS0-U

BUS2-U

BUS3-U

BUCK-U

CCE-U

REQ-U

35USB TXD0

36USB RXD0

38USB RTS0

34USB CTS0

33USB RESET

A/D CONVERTER

IC501

STDO

SCLK

AINL

2

AINR

1

9

12

LRCK

MCLK

10

11

PDN

13

DATA SELECTOR

IC502

3Y

3B

10

SELECT

1

3A

11

1B

3

1A

2

2B

6

2A

5

9

1Y

4

2Y

7

A

B

CD MECHANISM

DECK

M1-

M2+

M2-

M1+

M1+

21

M1-

18

M2+

7

M2-

6

MOTOR

DRIVE

Q640, 641,

Q643 - 648

SW3

SW2

SW7-CHACK

SW1

SW1

23

SW3

22

SW2 25

SW-CHUCK

24

SW5-STOCK

SW8-OPEN

SW6-CLOSE

SW-STOCK

27

SW-CLOSE

26

SW-OPEN

28

(Page 24)

(Page 24)

HCD-ZT4

HCD-ZT4

2424

7-2. BLOCK DIAGRAM - MAIN Section -

R-CH

L501

BIAS OSC

S501

(REC/PB)

PB

REC

REC AMP

IC502

PB AMP

IC501

OSC

Q501, 502

TUNER (FM/AM)

TAPE MECHANISM

DECK

AM

FM ANT

AM ANT

ST-L

ST-R

ST-DOUT

R-CH

LCH

RCHEHR-CH

ST-DIN

ST-CLK

ST-CE

FM75Ω

COAXIAL

ANTENNA

AUDIO INPUT

L

R

J703

R-CHRch+

Lch+

TXD

DET

RXD

DMPORT

CN1302

TUNED

61 ST-TUNED

45 TAPE-L

43 ST-L

21

DATA22CLK

42

30

AUX-L

46 MIC

29 VOLINLTONEOUTL 26OUTL

44 CD-L

41 DMPORT-L

DMPORT DET

TC-TAPE STATE

67 ST-DOUT

66 ST-CLK

63 ST-CE

57

MC RXD

32

MC TXD

31 82

13

14

5

6

7

R2A15216FP-DATA

60

9

SA2POWER ILLUMINETOR

68

VACS IN

89

R2A15216FP-CLK

59

MIC/HP DET

71

23SWOUT

28BB1L

36RECBL

37RECAL

BAND-PASS

FILTER

Q115, 116

R-CH

27BB2L

BASS AGC

Q128

D630

D201

INPUT SELECTOR,

ELECTRICAL VOLUME

IC407

SYSTEM CONTROLLER

IC401 (2/4)

: TUNER (FM/AM)

: CD PLAY

SIGNAL PATH

R-ch is omitted due to same as L-ch.

: TAPE PLAY

: TAPE REC

: AUDIO IN

: MIC

: DMPORT

J700

MIC

RV700

MIC LEVEL

MIC AMP

IC700 (1/2)

LINE AMP

IC1300

MIC AMP

IC700 (2/2)

SW

C

HP IN

A

CD-L

B

USB_REC-L

E

SW OUT

F

BASS AGC

D

OUT

LINE AMP

IC251

65 ST-DIN

(Page 25)

(Page 23)

(Page 23)

(Page 25)

(Page 25)

(Page 25)

HCD-ZT4

HCD-ZT4

2525

7-3. BLOCK DIAGRAM - AMP Section -

OUT

LINE AMP

IC252

D

BASS AGC

F

SW OUT

E

POWER

AMP

IC800

MUTING

Q402

OVER LOAD

DETECT

Q801

OVER LOAD

DETECT

Q802

R-CH

MUTING

Q430

LINE AMP

IC253

+

R-CH

R-CH

R-CH

MUTING

CONTROL

Q670

LINE MUTE

58

STK MUTE

51

SW SPK RELAY

52

+

R-CH

PROTECT

DETECT

Q806, 809, 811

FAN M OTOR

DRIVE

Q690, 691,

Q693 -695,

Q697

RY800

+

–

–

+

RY890

D632

D807

TH801

M

M102

(FAN)

FAN M OTOR

DRIVE

Q110 - 113

M

M101

(FAN)

PHONES

+

–

SUBWOOFER

JK890

RELAY

DRIVE

Q805

FR SPK RELAY

53

PROTECT

50

RELAY

DRIVE

Q804

R-CH

J702

SYSTEM CONTROLLER

IC401 (3/4)

: TUNER (FM/AM)

SIGNAL PATH

R-ch is omitted due to same as L-ch.

+

OVER LOAD

DETECT

Q803

R

L

FRONT

SPEAKER

JK800

PROTECT

G

DC DETECT

H

STBY LED

J

HP IN

C

DC DETECT

Q815

LEVEL SHIFT

Q447

TEMPERATURE

DETECT

Q807, 808

(Page 24)

(Page 24)

(Page 24)

(Page 24)

(Page 26)

(Page 26)

(Page 26)

HCD-ZT4

HCD-ZT4

2626

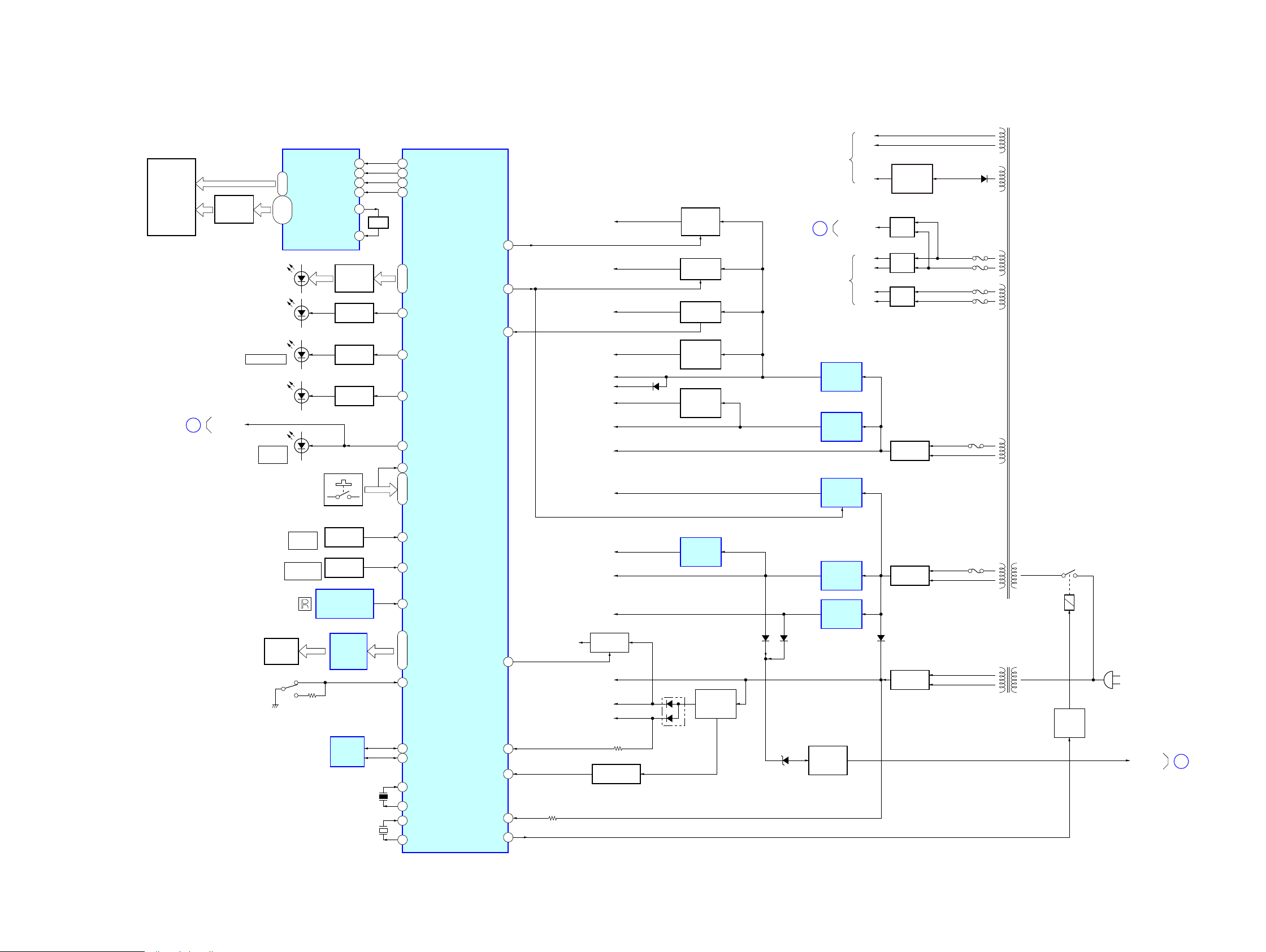

7-4. BLOCK DIAGRAM - PANEL, POWER SUPPLY Section -

REMOTE CONTROL

RECEIVER

IC1102

FL1101

FLUORESCENT

INDICATOR

TUBE

MOTOR

ASSY

S031

(METER POSITION DETECT)

3 SW LED

AD-KEY0 AD-KEY2

FLUORESCENT INDICATOR

TUBE DRIVER

IC1101

SYSTEM CONTROLLER

IC401 (4/4)

F907

RECT

D911, 912

PROTECT

DETECT

Q606

RECT

D602

D006

LED-VOL1. 2 LED-VOL5. 6

S1165 - 1195

54STBY RELAY

20AC-CUT

RESET SWITCH

Q214, 215

D213

+3.3V

UNREG +16V

VBUS+5V

EVER +10V

83OVERVOLTAGE

12RESET

91 MASTER VOL

2 – 13,

15, 16

DR35 - DR16

38 – 19

DR0 - DR13

79 - 77

METER IN1 METER IN4

100, 84, 1, 2 97, 95, 94

LED DRIVE

Q1139, 1141,

Q1143

GRID DRIVE

Q1102 - 1113,

Q111 5, 1116

D1124 - 1129

(STREAM)

LED DRIVE

Q1205

70 USB-BLUE LED

LED DRIVE

Q1190

D1205

SUBWOOFER

72 STBY LED

KEY0

4 SIRCS

D1196

I/

STANDBY

ROTARY

ENCODER

MASTER

VOLUME

OPERATION

DIAL

S1052

90 OPERATION DIAL

ROTARY

ENCODER

S1051

13 X-OUT

15 X-IN

METER SW

X402

5MHz

11 XC-OUT

10 XC-IN

X401

32.768kHz

SI FL-DRIVER-DATA

49 86

SCK FL-DRIVER-CLK

48 85

EEP-SDA

55

EEP-SCL

56

CSB FL-DRIVER-CS

51 87

RSTB FL-DRIVER-RESET

52 88

74 POWER/DISPLAY-KEY

(AC IN)

RY901

RELAY

DRIVE

Q903

D+1.5V

+1.5V

REGULATOR

IC201

DMPORT+5V

D605 D055

D623, 624

D908

A+9V

M+9V

M+7V

F906

RECT

D601

F904

F905

RECT

D801

F908

F909

RECT

D800

RECT

D812

D608

+9V

REGULATOR

IC080

+9V

REGULATOR

IC602

A/D CONVERTER +5V

+5V

REGULATOR

Q696

M+5V

+5V

REGULATOR

Q1220

+3.3V

REGULATOR

IC603

+5V

REGULATOR

IC050

+5V

REGULATOR

IC055

+4V

REGULATOR

Q210 - 212

SEL A, SEL B

CD MECHANISM

MOTOR B+

REGULATOR

Q655 - 658

73LED CTRL

5CDM-SD

TAPE +9V

B+ SWITCH

Q681, 684

49TC_M+9V SW

JOG B+

39AD SUPPLY SW

B+ SWITCH

Q627, 628

–32V

REGULATOR

Q902

AMP

SECTION

B+

FOR

FLUORESCENT

INDICATOR

TUBE

–VFL

VF

VF

PT902

SUB POWER

TRANSFORMER

PT901

MAIN POWER

TRANSFORMER

45

46

XT

XTB

OSC

VDD+3.3V

D+3.3V,

VREF+3.3V

+VH

–VH

+VL

–VL

D1000, 1003

(USB)

80 METER LED

LED DRIVE

Q010

D011 - 015

(ILLUMINATION)

B+ SWITCH

Q1114, 1117,

Q1120, 1122

MOTOR

DRIVE

IC001

EEPROM

IC675

81

PROTECT

G

DC DETECT

H

STBY LED

J

(Page 25)

(Page 25)

(Page 25)

Loading...

Loading...