SONY HCD-XGV50 Service Manual

HCD-XGV50

SERVICE MANUAL

Ver 1.0 2003.08

• HCD-XGV50 is the Amplifier,

CD player, tape deck and tuner

section in LBT-XGV50.

Model Name Using Similar Mechanism

CD CD Mechanism Type CDM37B-30BD62

Section Base Unit Name BU-30BD62

Optical Pick-up Name A-MAX.3

TAPE Model Name Using Similar Mechanism HCD-XGV80

Section Tape Mechanism Type CWM43RR23

Mexican Model

HCD-XGV80

SPECIFICATIONS

The following measured at AC 127 V, 60 Hz

DIN power output (rated): 135 + 135 watts

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference):

165 + 165 watts

(6 ohms at 1 kHz, 10% THD)

Inputs

PHONO IN (phono jacks): sensitivity 3 mV,

impedance 47 kilohms

MD (VIDEO) IN L/R (phono jacks):

sensitivity 450 mV(250 mV),

impedance 47 kilohms

Outputs

PHONES (stereo phone jack): accepts headphones of 8 ohms or more

MD (VIDEO) OUT L/R (phono jacks):

voltage 250 mV, impedance 1 kilohms

VIDEO OUT (phono jack): max. output level 1Vp-p,

load impedance 75 ohms

FRONT SPEAKER: accepts of 6 to 16 ohms

VIDEO CD/CD player section

System Compact disc digital audio system

Laser Semiconductor laser

(λ=795 nm)

Emission duration: continuous

Frequency response 2 Hz – 20 kHz (±0.5 dB)

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

Video color system format NTSC, PAL

Tape deck section

Recording system 4-track 2-channel, stereo

Frequency response 50 – 13,000 Hz (±3 dB),

using Sony TYPE I cassettes

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz (50 kHz step)

Antenna FM lead antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range 530 – 1,710 kHz

(with the tuning interval set at 10 kHz)

531 – 1,602 kHz

(with the tuning interval set at 9 kHz)

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

— Continued on next page —

9-961-115-01

2003H02-1

© 2003.08

COMPONENT Hi-Fi STEREO SYSTEM

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

HCD-XGV50

General

Power requirements

Mexican models: 120 V or 127 V AC, 60 Hz

Power consumption 150 watts

Dimensions (w/h/d) (Main Unit) Approx. 355 x 425 x 451 mm

Mass (Main Unit) Approx. 13.0 kg

Design and specifications are subject to change without notice.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

2

HCD-XGV50

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and

check that the S curve waveforms is output three times.

TABLE OF CONTENTS

1. SERVICING NOTE

·························································· 4

2. GENERAL ·········································································· 5

3. DISASSEMBLY ································································ 7

4. TEST MODE ···································································· 16

5. MECHANICAL ADJUSTMENTS ····························· 18

6. ELECTRICAL ADJUSTMENTS ······························· 18

7. DIAGRAMS

7-1. Circuit Board Location ······················································ 22

7-2. Block Diagram – CD Servo Section – ······························· 24

Block Diagram – Tuner/Tape Deck Section – ··················· 25

Block Diagram – Main Section – ······································ 26

Block Diagram

– Display/Key Control/Power Supply Section – ·········· 27

7-3. Printed Wiring Board – BD Section – ······························· 28

7-4. Schematic Diagram – BD Section – ·································· 29

7-5. Printed Wiring Board – Video Section – ··························· 30

7-6. Schematic Diagram – Video Section – ······························ 31

7-7. Printed Wiring Board – Motor LED Section – ·················· 32

7-8. Schematic Diagram –Motor LED Section – ······················ 32

7-9. Schematic Diagram – Main (1/4) Section – ······················ 33

7-10. Schematic Diagram – Main (2/4) Section – ······················ 34

7-11. Schematic Diagram – Main (3/4) Section – ······················ 35

7-12. Schematic Diagram – Main (4/4) Section – ······················ 36

7-13.Printed Wiring Board – Main Section – ····························· 37

7-14. Printed Wiring Board – CD-L, CD-R Section – ················ 38

7-15. Schematic Diagram – CD-L, CD-R Section – ··················· 39

7-16. Printed Wiring Board – TC-A, TC-B Section – ················ 40

7-17. Schematic Diagram – TC-A, TC-B Section – ··················· 41

7-18.Printed Wiring Board – Panel VR, Key Section – ············· 42

7-19. Schematic Diagram – Panel VR, Key Section –················ 43

7-20.Printed Wiring Board – Panel FL Section – ······················· 44

7-21. Schematic Diagram – Panel FL Section – ························· 45

7-22. Printed Wiring Board – Power Amp Section – ·················· 46

7-23. Schematic Diagram – Power Amp Section – ····················· 47

7-24. Printed Wiring Board – Power Supply Section –·············· 48

7-25. Schematic Diagram – Power Supply Section – ················· 48

7-26. IC Pin Function Description ············································· 49

7-27. IC Block Diagram ····························································· 56

8. EXPLODED VIEWS

8-1. Case, Back Panel Section ·················································· 59

8-2. Front Panel Section-1 ························································ 60

8-3. Front Panel Section-2 ························································ 61

8-4. Chassis Section ·································································· 62

8-5. CD Mechanism Deck Section (CDM37B-30BD62) ········· 63

8-6. Base Unit Section (BU-30BD62) ······································ 64

9. ELECTRICAL PARTS LIST ······································· 65

3

HCD-XGV50

SECTION 1

SERVICING NOTE

SERVICE POSITION FOR BD BOARD AND OPTICAL PICK-UP BLOCK

BD board

3

Bottom plate

1

2

4

BU fitting screw

Tw o screws (+BVTP 3 x 8)

5

Optical pick-up block

4

Main unit

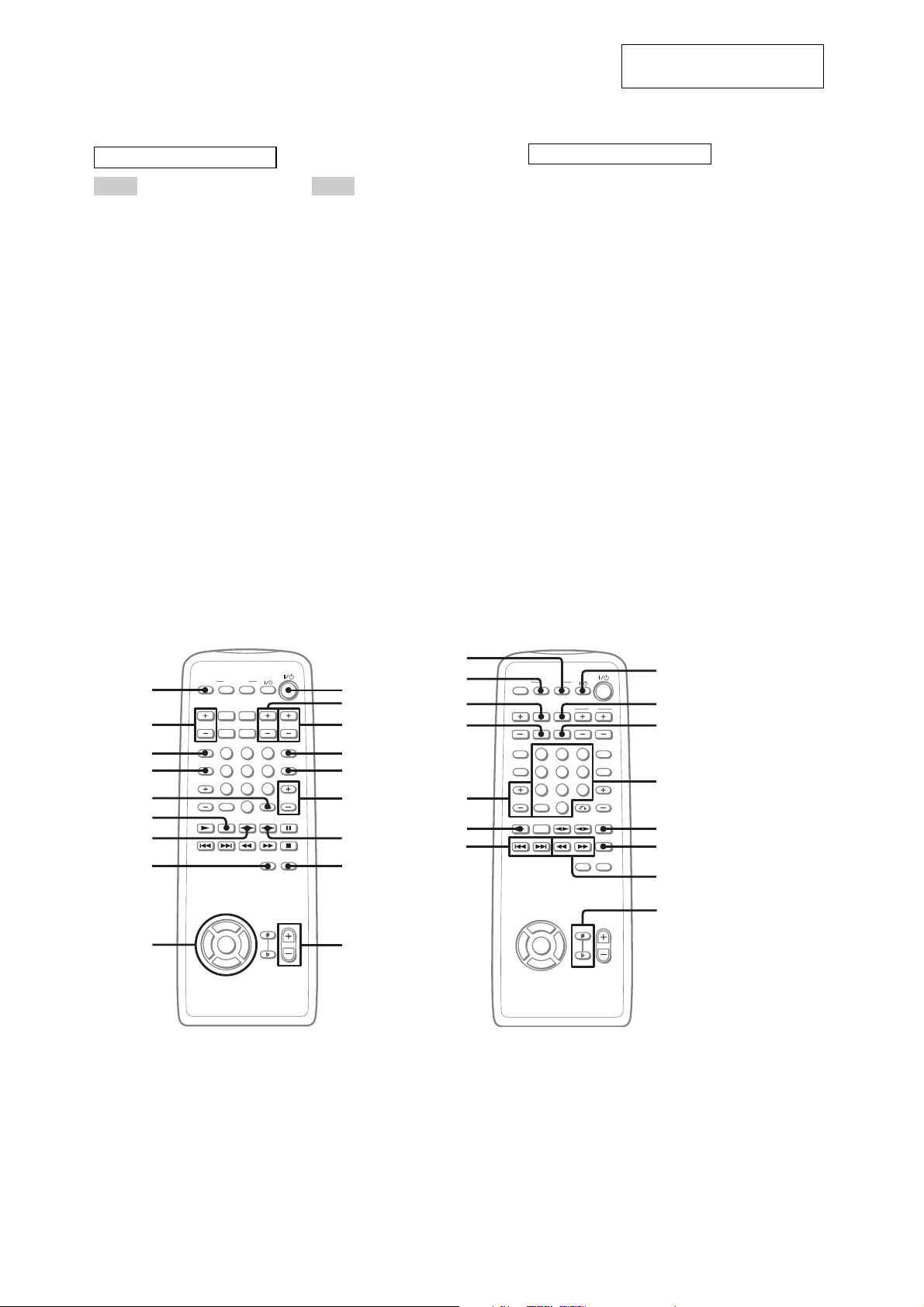

ALBUM +/– qh

CD SYNC qf

Deck A ws

Deck B w;

Direct equalizer ef

SALSA/REGGAE/TANGO/

MOVIE/GAME/SAMBA/

ROCK/JAZZ/DANCE/POP

DIRECTION wk

DISC 1 – 5 ek

DISC SKIP ek

Disc tray wd

DISPLAY 2

Display window 7

EDIT wf

EFFECT ej

ENTER eg

FM MODE qs

FUNCTION qa

MD (VIDEO) ea

MEMORY qs

P FILE eh

PHONES jack qg

PHONO e;

PLAY MODE wf

Power illuminator 5

PUSH OPEN wd

Remote sensor 3

REPEAT wf

ALPHABETICAL ORDER

A – D E – J K – R

qlwa w;wswd

e;

ea

wf

wl

wk

qd

qf

qg

23 745 8690qa1

elek

ed ef eg ehej

qs

qh

qj

SLEEP 9

SPECTRUM ANALYZER 4

SURROUND ed

TIMER SELECT 8

TUNER ENTER qs

TUNER/BAND qs

TUNING MODE qs

TUNING +/– qs

VOLUME control 6

X-GROOVE ql

S – Z

?/1 (power) 1

c

/CLOCK SET 0

X (pause) qd

h/H (play) qd wl

x (stop) qd wl

.m/M> (rewind/fast

forward) qd wl

z REC qf

./> (go back/go forward)

qj

M/m/</, (cursor) eg

m/M (rewind/fast forward)

el

NX (play/pause) el

x (stop) el

A EJECT Z/Z B EJECT (eject)

w;

BUTTON DESCRIPTIONS

SECTION 2

GENERAL

HCD-XGV50

This section is extracted from

instruction manual.

5

HCD-XGV50

Remote control

This section is extracted from

instruction manual.

ALPHABETICAL ORDER

A – N O – Z

ALBUM +/– qj

CLEAR wa

CLOCK/TIMER SELECT es

CLOCK/TIMER SET ed

DISC SKIP e;

DISPLAY ea

EFFECT 8

ENTER 0

FILE SELECT +/– 6

FUNCTION +/– wl

NEXT wj

Number buttons ws

ON SCREEN w;

PLAY MODE qh

PRESET +/– wj

PREV wj

REPEAT qg

SELECT wk

SLEEP qk

SPECIAL MENU 5

SURROUND qa

TUNER/BAND qd

TUNING +/– wg

TV CH +/– 3

TV/VIDEO 4

TV VOL +/– 2

VOL +/– 9

BUTTON DESCRIPTIONS

?/1 (power) 1

M/m/</, (cursor) 0

X (pause) wd

x (stop) wf

m/M (rewind/fast forward)

./> (go back/go forward)

CD N (play) wk

KEY CONTROL

RETURN O qf

TAPE A nN (play) qs

TAPE B nN (play) 7

TV ?/1 ql

#/2 wh

wg

wj

qk

qj

qh

qg

qf

qd

qs

qa

q;

ed

1

2

3

es

ea

e;

ql

w;

wa

4

5

6

7

wl

wk

wj

8

V

bB

v

9

V

bB

v

ws

wd

wf

wg

wh

6

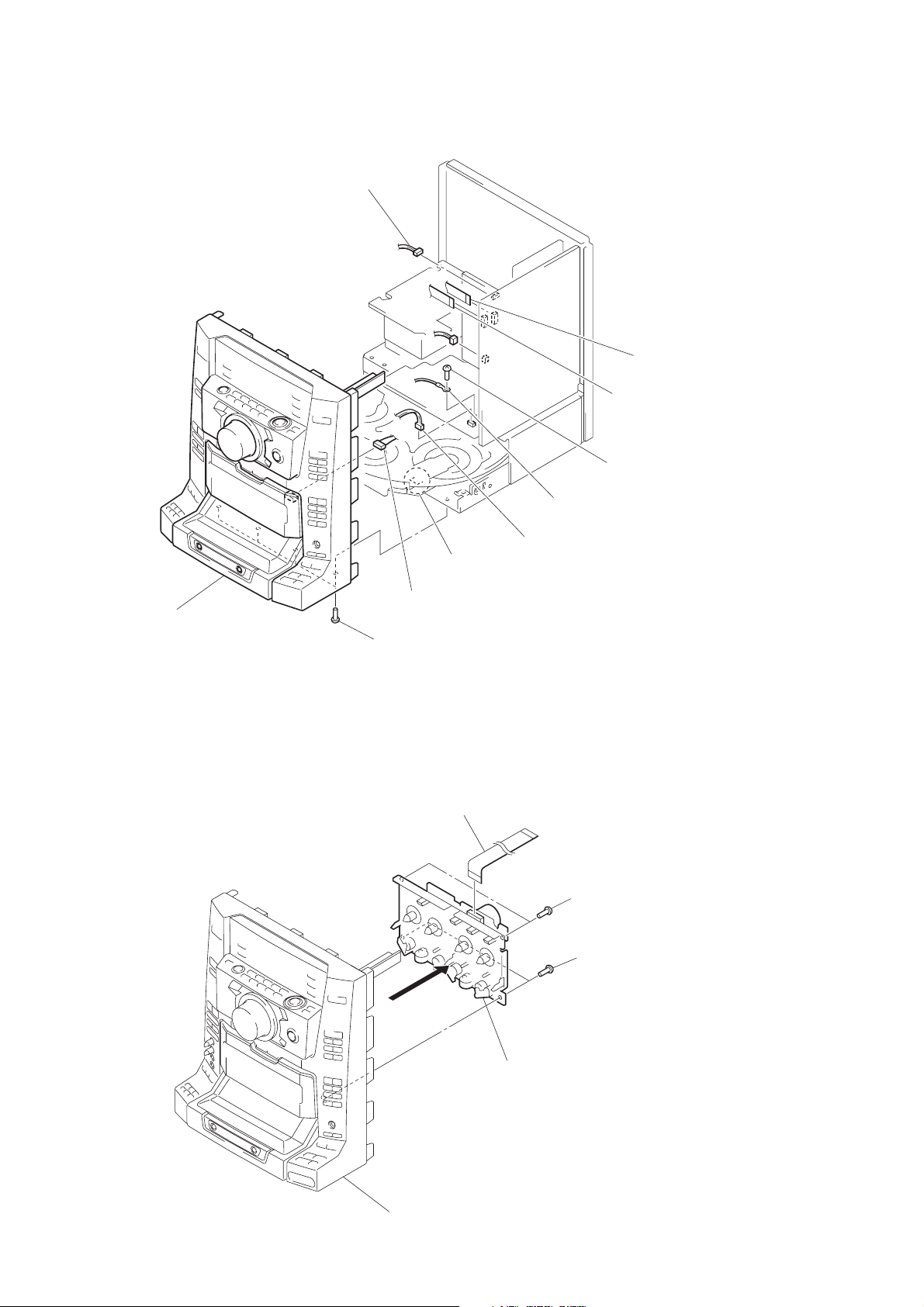

SECTION 3

)

DISASSEMBLY

• The equipment can be removed using the following procedure.

Set Case Front panel section Tape mechanism deck (CWM43RR23)

PANEL FL board, GAME board, TC-A board,

TUNER board, TC-B board

KEY board

PANEL VR board

HEADPHONE board, ALBUM board, Bumper ASSY

CD-L board, DOOR SW board, CD-R board

VIDEO board

Back panel, DC fan, MAIN board

CD mechanism deck (CDM37B-30BD62)

HCD-XGV50

Base unit-1 (BU-30BD62)

Disc table

Note : Follow the disassembly procedure in the numerical order given.

3-1. CASE

8

Case

7

1

Three screws (CASE3 TP2)

Base unit-2 (BU-30BD62) BD board

3

Five screws (BVTT 3x6)

6

5

6

4

Tw o screws (BVTP 3x8

5

2

Three screws (CASE3 TP2)

7

HCD-XGV50

)

)

3-2. FRONT PANEL SECTION

3

Connector (CN311)

1

Flat type wire (CN371

2

Flat type wire (CN431)

5

Screw (BVTP 3x8)

q;

Front panel section

3-3. TAPE MECHANISM DECK (CWM43RR23)

9

Claw

7

Connector (B deck)

8

Four screws (BVTP 3x8)

1

Flat type wire (13 core)

6

Lug

4

Connector (CN806)

2

Tw o screws (BVTP 2.6x8)

3

Tw o screws (BVTP 2.6x8

4

Front panel

5

Tape mechanism deck

(CWM43RR23)

8

3-4. PANEL FL BOARD, GAME BOARD, TC-A BOARD, TUNER BOARD, TC-B BOARD

)

)

Five screws (BVTP 2.6x8)

qa

7

(CN601)

qf

2

Bracket (TA)

ql

Two claws

1

Screw (BVTP 2.6x8)

qh Two

w;

claws

qs

(BVTP 2.6x8)

GAME board

ws

TC-A board

Four screws

qj

qd

Four screws

(BVTP 2.6x8)

5

Connector

(CN700)

wd

Three claws

qk

PANEL FL

board

HCD-XGV50

Flat type wire

8

Screw (BVTP 2.6x8)

9

Bracket (MAIN)

0

Four screws (BVTP 2.6x8

Four screws (BVTP 2.6x8)

wf

TUNER board

qg

Four screws

(BVTP 2.6x8)

wa

Three claws

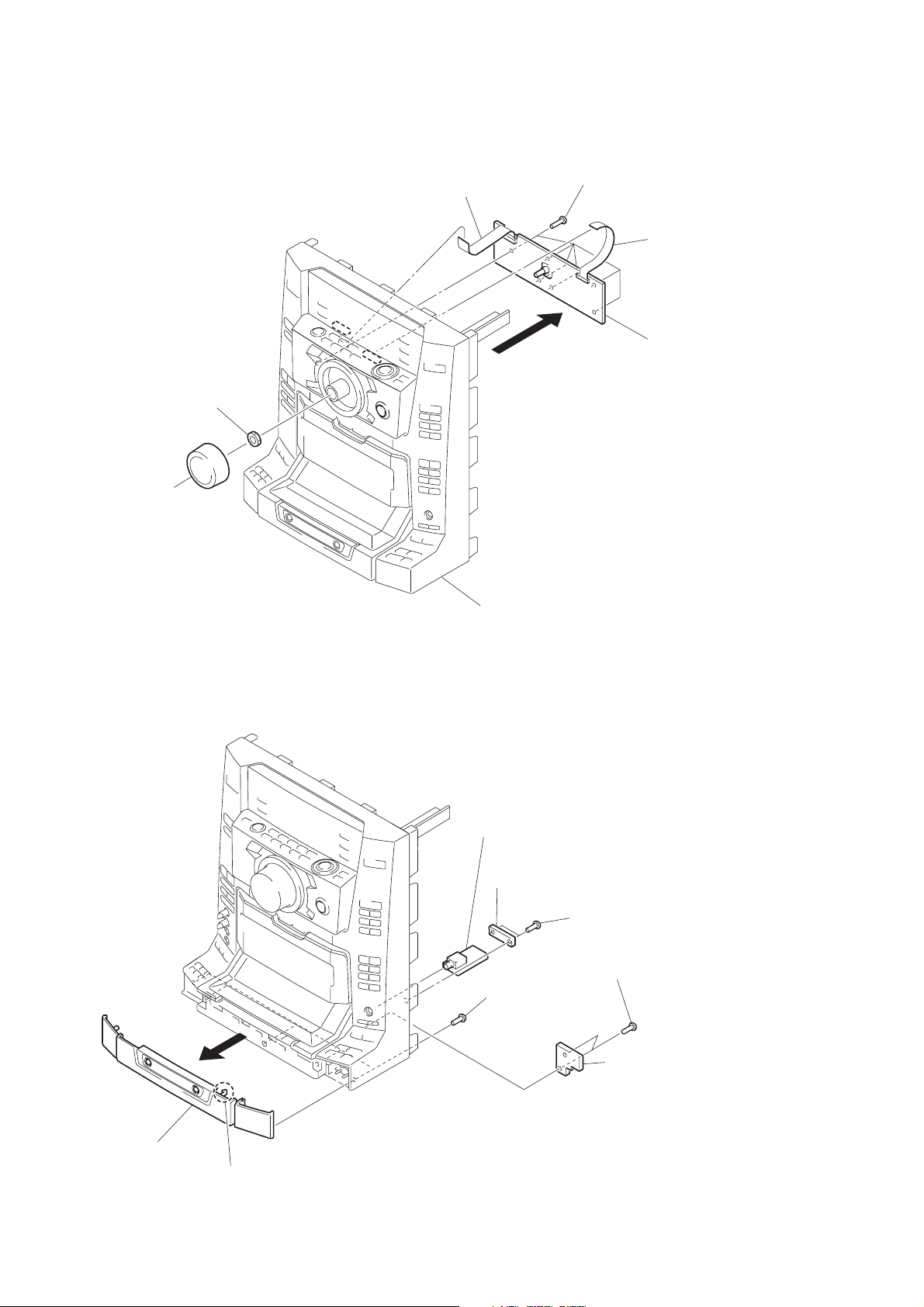

3-5. KEY BOARD

6

Three claws

Front panel

7

wg

Three claws

3

Screw (BVTP 2.6x8)

4

Bracket (TA)

wh

TC-B board

6

Connector (CN600)

1

Three screws (BVTP 2.6x8

2

OPERATION PANEL ASSY

8

KEY board

4

Cursor

5

Five screws (BVTP 2.6x8)

3

Flat type wire (CN801)

Front panel

9

HCD-XGV50

)

3-6. PANEL VR BOARD

2

Nut (Supplied with S700)

1

Volume knob

3

Flat type wire (CN601)

6

5

Six screws (BVTP 2.6x8)

4

Flat type wire (CN801

7

PANEL VR board

3-7. HEADPHONE BOARD, ALBUM BOARD, BUMPER ASSY

8

Front panel

3

HEADPHONE board

2

Bracket HP PWB

6

Five screws

(BVTP 2.6x8)

1

To w screws (BVTP 2.6x8)

4

To w screws (BVTP 2.6x8)

5

ALBUM board

10

9

Bumper ASSY

7

Claw

HCD-XGV50

)

)

3-8. CD-L BOARD, DOOR SW, CD-R BOARD

3

8

Sub panel CD ASSY

qf

DOOR SW

board

qd

Froating screw

(DIA.12)

qs

CD-L board

0

BRACKET (S/P) (L)

5

Five claws

6

Connector (CN700)

7

qk

CD-R board

Front panel

1

4

Connector (CN600)

2

Four screws (BVTP 2.6x8)

Five screws (BVTP 2.6x8

9

Screw (BVTP 2.6x8)

3-9. VIDEO BOARD

qa

Four screws

(BVTP 2.6x8)

qj

Four screws (BVTP 2.6x8)

qh

BRACKET (S/P) (R)

qg

Screw (BVTP 2.6x8)

1

Two screws

(BVTP 3 X 8)

4

Flat type wire

(CN201)

7

2

VIDEO board

5

Connector (CN301)

3

Flat type wire (CN101

6

Two screws

(BVTP 3 X 8)

11

HCD-XGV50

3-10. BACK PANEL, DC FAN (M901), MAIN BOARD

7

Back panel

0

DC FAN

(M901)

qa

Flat type wire

(CN401)

6

1

Flat type wire (CN441)

2

Seven screws

(BVTP 3 X 8)

3

Two screws

(BVTP 3 X 8)

9

Two screws

(BVTP 3 X 8)

5

Tow screws

(BVTP 3 X 8)

4

Three screws

(BVTP 3 X 8)

qd

Connector

(CN721)

8

Connector (CN961)

qs

Connector (CN441)

qh

MAIN board

qf

Two screws

(BVTP 3 X 8)

qg

Two connectors

(CN901, 902)

12

3-11. CD MECHANISM DECK (CDM37B-30BD62)

1

Flat type wire

(CN401)

4

Three screws

(BVTP 3 X 8)

7

2

Connector

(CN411)

6

Two screws (BVTP 3 X 8)

8

7

3

Four screws (BVTP 3 X 8)

Wire holder

5

Two screws

(BVTP 3 X 8)

HCD-XGV50

qa

CD mechanism deck

(CDM37B-30BD62)

0

Five screws

(BVTP3 × 8)

9

Remove two cables from

wire holder.

13

HCD-XGV50

)

w

3-12. BASE UNIT-1 (BU-30BD62)

2

Boss

3

Base unit

(BU-30BD62)

1

BU fitting scre

3-13. BASE UNIT-2 (BU-30BD62)

1

Two floating screws (DIA.12)

4

Two coil springs

(insulator)

6

Base unit (BU-30BD62)

2

Two screws

(BVTP 2.6 X 8)

3

Two stoppers

(BU)

14

5

Two coil

springs

(insulator

Holder (BU30) assy

3-14. BD BOARD

e

4

BD board

BU-30BD62

3

Flat type wire (CN102)

HCD-XGV50

3-15. DISC TABLE

Note: When the disc table is installed, adjust the positions of roller cam

and mark B as shown in the figure, then set to the groove of disc

table.

Cam (holder)

A

Roller cam

1

Remove the two solders.

2

Remove the two solders.

3

Step screw

1

Screw (BVTP 3

×

8)

2

Bracket (BU)

4

Disc tabl

A

15

HCD-XGV50

B

SECTION 4

TEST MODE

[MC Cold Reset]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Turn the power ON or set to the DEMO mode.

2. Press three buttons of x (TC-B) , TUNER ENTER , and \/1

simultaneously.

3. The set is reset, and displays “COLD RESET”, then becomes

DEMO mode.

[Change-over the AM Tuning Interval]

• The AM tuning interval can be changed over 9 kHz or 10 kHz.

Procedure:

1. Press the \/1 button to turn the power ON.

2. Select the function “TUNER”, and press the TUNER/BAND

button to select the BAND “AM”.

3. Press the \/1 button to turn the power OFF.

4. Press the TUNER ENTER and \/1 buttons simultaneously,

and the display on the fluorescent indicator tube changes to

“AM 9 K STEP” or “AM 10 K STEP”, and thus the tuning

interval is changed over.

[CD Ship Mode] (No memory clear)

• This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the \/1 button to turn the power ON.

2. Press the EDIT and

3. A message “LOCK” is displayed on the fluorescent indicator

tube, and the CD delivery mode is set.

[LED and Fluorescent Indicator Tube All Lit, Key Check

Mode]

Procedure:

1. Press three buttons of x (TC-B) , TUNER ENTER ,and

DISC 2 simultaneously.

2. LEDs and fluorescent indicator tube are all turned on.

3. Press the DISC 1 button, the MODE and DESTINATION are

displayed fluorescent indicator tube.

4. Each time the DISC 1 button is pressed, the MC/GC category

version is displayed in the following order.

NR MC GC CD CDDM CDMA

5. Press the DISC 2 button, and the key check mode is acti-vated.

6. In the key check mode, the fluorescent indicator tube displays

“K 0 J0 V0”. Each time a button is pressed, “K” value in-creases

to “K69”call the button is pressed. However, once a button is

pressed, it is no longer taken into account.

“V” value increases like 1, 2, 3 ... if turn the VOLUME dial

clockwise (“+” direction), or it decreases like 0, 9, 8 ... if turn

the VOLUME dial counterclockwise (“–” direction).

7. To release from this mode, press three buttons in the same

manner as step 1, or disconnect the power cord.

buttons simultaneously.

\/1

BDABDBSTTATMTC

CDM

[Sled Servo Mode] (CD service mode)

• This mode can run the CD sled motor freely. Use this mode, for

instance, when cleaning the pick-up.

Procedure:

1. Select the function “CD”.

2. Press three buttons x (TC-B) , TUNER ENTER , and

DISC 5 simultaneously.

3. The Sled Servo mode is selected, if “CD” is blanking on the

fluorescent indicator tube.

4. With the CD in stop status, press M button in CD section to

move the pick-up to outside track, or m button to inside track.

5. To exit from this mode, press

OFF.

Note:

• Always move the pick-up to most inside track when exiting from

this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear can

be chipped.

[Change-over of FUNCTION Name]

• The FUNCTION name of external input terminal can be changed

over to VIDEO or MD. With the FUNCTION selected to “MD”,

about 5dB mute is applied to the input gain.

Procedure:

1. Press \/1 button to turn the power OFF.

2. Press

several seconds, and the power is turned on, the display of

fluorescent indicator tube changes to “MD” or “VIDEO”

instantaneously, and thus the FUNCTION is changed over.

[Aging Mode]

This mode can be used for operation check of tape deck section.

Tape deck section work in parallel.

• If an error occurred:

The aging operation stops and display then status.

• If no error occurs:

The aging operation continues repeatedly.

Procedure:

1. Load the tapes into the decks A and B respectively.

2. Press the FUNCTION button to select the function “CD”.

3. Press the PLAY MODE button to set the “ALL DISCS” mode,

and press the REPEAT button to “REPEAT” off.

4. Press three buttons of x (TC-B) , TUNER ENTER ,and

DISC 4 simultaneously.

5. The aging mode is activated, if the indicator of disc tray number on the fluorescent indicator tube is blinking.

6. To release from the aging mode, press the \/1 button to turn

the power OFF and operate the cold reset. (Refer to the “MC

Cold Reset”)

1. Display at the Aging Mode

• Display operating state of tape deck section alternately.

• If an error occurred, stop display.

[Changeover the color system]

The color system can be changed over PAL, NTSC or AUTO.

Procedure:

The color system can be changed over PAL, NTSC or AUTO by

pressing \/1 button while pressing followings and indication on

display changes to “COLOR PAL”, “COLOR NTSC” or “COLOR

AUTO”.

button together with FUNCTION button for

\/1

button turn to the power

\/1

16

PA L: REGGAE + \/1

NTSC : MOVIE + \/1

AUTO : TANGO + \/1

HCD-XGV50

2. Tape Deck Section

• The sequence during the aging mode is following as below.

• If an error occurred, stop display that step.

Aging mode sequence (Tape deck section):

Rewind the tape A

“TAPE A AG-1”

Shut off

FWD the tape A

“TAPE A AG-2”

2 minutes

Fast forward the tape A

“TAPE A AG-3”

Shut off or 20 seconds

RVS the tape A

“TAPE A AG-4”

2 minutes

Rewind the tape A

“TAPE A AG-5”

Shut off

3. CD Section

• The sequence during the aging mode is following as below.

• If an error occurred, stop display that step.

Aging mode sequence (CD section):

Tray Turn

DISC 1

chucking

TOC Read

Track 1 Play

2 seconds

Last Track Play

2 seconds

FWD the tape B

“TAPE B AG-2”

2 minutes

Fast forward the tape B

“TAPE B AG-3”

Shut off or 20 seconds

RVS the tape B

“TAPE B AG-4”

2 minutes

Rewind the tape B

“TAPE B AG-5”

Shut off

Note: “TAPE * AG- * ” is display of each step.

Tray Tun

DISC 4

Chucking

TOC Read

Track 1 Play

2 seconds

Last Track play

[VACS ON/OFF]

• The volume control by VACS is turned ON/OFF.

Procedure:

1. Press the \/1 button to turn the power ON.

2. Press the PLAY MODE and \/1 buttons simultaneously.

3. The reaction display appears when switcing ON/OFF.

17

HCD-XGV50

SECTION 5

MECHANICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

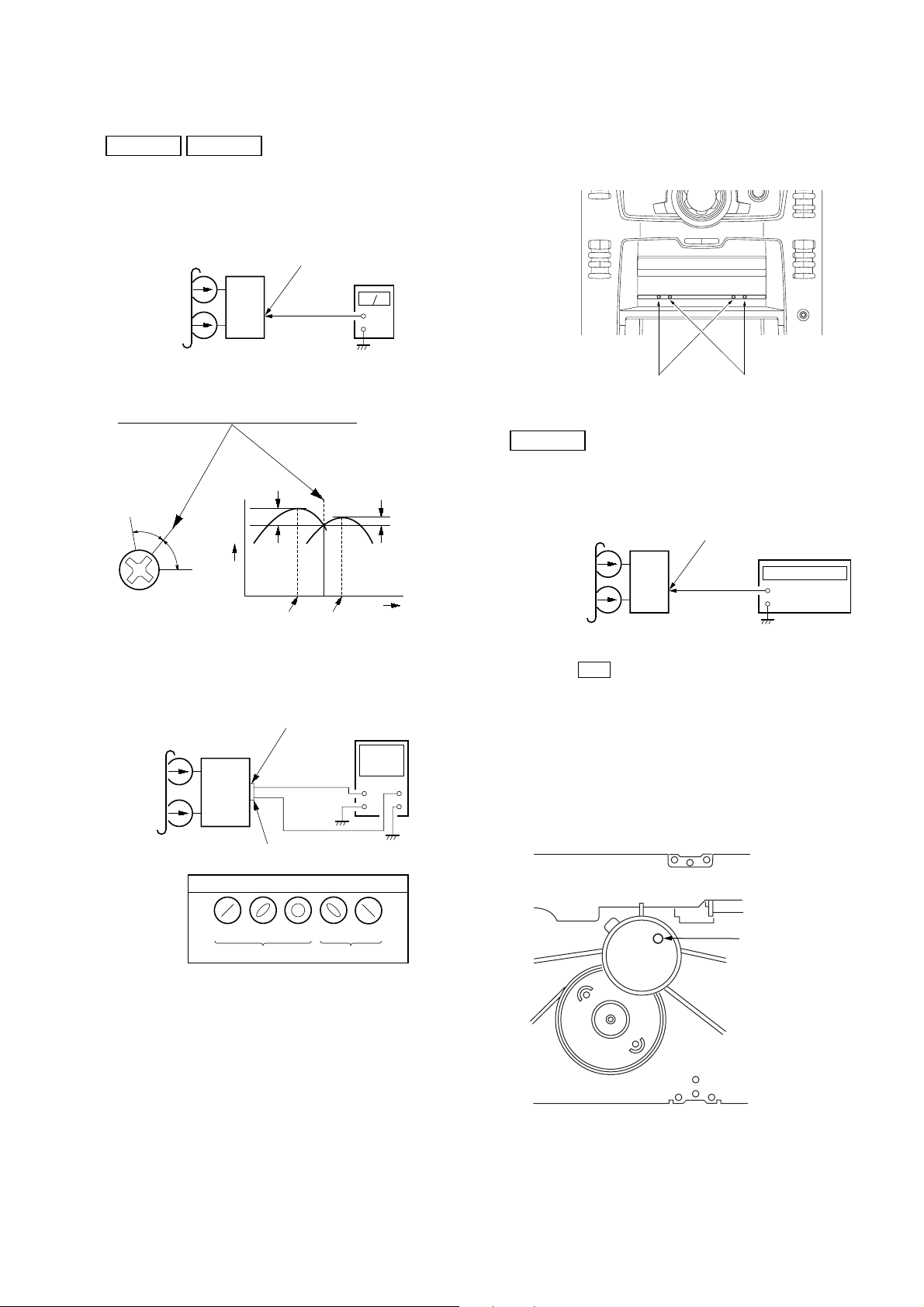

Torque Measurement

Mode Torque Meter Meter Reading

2.9~6.9 mN•m

FWD CQ-102C (30 to 70 g•cm)

(0.42 – 0.97 oz•inch)

FWD 0.19~0.59 mN•m

back tension CQ-102C (2 to 6 g•cm)

(0.03 – 0.08 oz•inch)

7.8~16.7 mN•m

FF/REW CQ-201B (80 to 170 g•cm)

(1.11 – 2.36 oz • inch)

SECTION 6

ELECTRICAL ADJUSTMENTS

DECK SECTION 0 dB = 0.775 V

Precaution

1. Demagnetize the record/playback head with a head demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in

this service manual. (As a general rule, playback circuit

adjustment should be completed before performing recording

circuit adjustment.)

6. The adjustments should be performed for both L-CH and R-CH.

7. Switches and controls should be set as follows unless otherwise specified.

8. Set to the test mode.

(1) Press the \/1 button to turn the power ON.

(2) Select the function “TAPE A or B”.

(3) Press the button of x (TC-B) , TUNER ENTER ,and DISC

3 simultaneously, to set the tape deck test mode

and displays “TEST MODE” on the fluorescent indicator

tube.

(4) To release from the test mode, press the \/1 button.

• Test Tape

Tape Signal Used for

P-4-A100 10 kHz, – 10 dB Azimuth Adjustment

WS-48B 3kHz, 0dB Tape Speed Adjustment

18

HCD-XGV50

)

set

MAIN board

MD (VIDEO) OUT jack (J701)

L-CH, R-CH

+

–

frequency counter

test tape

WS-48B

(3 kHz, 0 dB)

Tape speed adjustment

control inside motor

Record/Playback Head Azimuth Adjustment

DECK A DECK B

Note: Perform this adjustments for both decks

Procedure:

1. Mode: Playback (FWD)

test tape

P-4-A100

(10 kHz, – 10 dB)

MAIN board

MD (VIDEO) OUT jack (J701

L-CH, R-CH

level meter

set

+

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

Output

level

within

1dB

within

1dB

L-CH

peak

Adjustment Location: Playback Head (Deck A).

Record/Playback/Erase Head (Deck B).

forward

reverse

Tape Speed Adjustment

DECK B

Procedure:

Mode: Playback

R-CH

Screw

position

peak

L-CH

peak

R-CH

peak

Screw

position

3. Mode: Playback

MAIN board

test tape

P-4-A100

(10 kHz, – 10 dB)

L-CH

set

R-CH

in phase 45°90°135°180

MD (VIDEO) OUT jack (J701)

L-CH

R-CH

waveform of oscilloscope

good

oscilloscope

wrong

H

V

°

4. Repeat step 1 to 3 in playback (REV) mode.

5. After the adjustments, apply suitable locking compound to the

pats adjusted.

1. Insert the WS-48B into the deck B.

2. Press the H button on the deck B.

3. Adjust the tape speed adjustment control inside motor so that

frequency counter reads 3,000 ± 90Hz.

Sample value of wow and flutter : W.RMS (JIS) less than 0.3%

WS-48B

Adjustment Location:

Tape speed Adjustment

19

HCD-XGV50

e

)

CD SECTION

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use LUV-P01 (4-999-032-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

S-Curve Check

Oscilloscope

BD board

TP(FE)

TP(DVC)

Procedure :

1. Connect oscilloscope to TP (FE).

2. Connect between TP (FE) and TP (DVC ( 1.65 V)) by lead

wire.

3. Press the \/1 button to turn the power ON.

4. Load a disc (LUV-P01) and actuate the focus search. (In consequence of open and close the disc tray, actuate the focus search)

5. Confirm that the oscilloscope waveform (S-curve) is symmetrical between A and B. And confirm peak to peak level within 2

±0.5 Vp-p.

S-curve waveform

symmetry

A

within 4

±

1Vp-p

B

Note: Clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

VOLT/DIV : 200mV

TIME/DIV : 500ns

level : 1.45

±

0.3Vp-p

E-F Balance (1 Track jump) Check

oscilloscop

BD board

TP(TE)

TP(DVC)

Procedure:

1. Connect oscilloscope to TP (TE) and TP (DVC) board.

2. Press the \/1 button to turn the power ON.

3. Load a disc (LUV-P01) and playback the number nine track.

4. Press the bB button. (Becomes the 1track jump mode.)

5. Confirm that the level B and A (DC voltage) on the oscilloscope waveform.

center of

waveform

B

0V

B=1.3 ± 0.6Vp-p

Specified level: × 100=less than – 22%

A

B

symmetry

A (DC voltage

6. After check, remove the lead wire connected in step 2.

Note : • Try to measure several times to make sure than the ratio

of A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

RF Level Check

oscilloscope

BD board

TP(RFDC)

TP(RFAC)

Procedure :

1. Connect oscilloscope to TP (RFDC) and TP (RFAC).

2. Press the \/1 button to turn the power ON.

3. Load a disc (LUV-P01) and playback.

4. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

Checking Location:

[BD BOARD] (SIDE B)

DVC

SE

FE

TE

RFDC

RFAC

DVC

20

VIDEO SECTION

e

p

Note :

1. VIDEO board is basically designed to operate without adjustment. Therefore, check each item in order given.

2. Use HLV-402 (8-909-870-00) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

Video Level Check (VIDEO BOARD)

Purpose

This adjustment is made to satisfy the NTSC standard, and if not

adjusted correctly, the brightness will be too large or small.

Oscilloscop

75

Ω

set

HCD-XGV50

J721

VIDEO OUTPUT

Procedure:

1. Connect oscilloscope to VIDEO output.

2. Load a disc HLV-402 (8-909-870-00) playback.

3. Check that the video level is 1.0 ± 0.1 Vp-p.

(WHITE 100%)

1.0 ± 0.1 Vp-

21

HCD-XGV50

Five screws (BVTT 3x6)

7-1. CIRCUIT BOARD LOCATION

SECTION 7

DIAGRAMS

GAME board

TC-A board

CD-L board

ALBUM board

PANEL FL board

TRANS board

SUB TRANS board

TUNER PACK (FM/AM TUNER UNIT)

MAIN board

PA board

TUNER board

TC-B board

KEY board

PANEL VR board

DOOR SW board

HEADPHONE board

CD-R board

SENSOR board

VIDEO board

22

BD board

MOTOR board

LED board

r

WAVEFORMS

HCD-XGV50

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

2

•

• 5 : fusible resistor.

Note:

The components identified by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specified.

• C : panel designation.

• A : B+ Line.

• B : B– Line.

• H : adjustment for repair.

•Voltages and waveforms are dc with respect to ground

•Voltages are taken with a VOM (Input impedance 10 MΩ).

•Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: nonflammable resistor.

under no-signal conditions.

BD board section and VIDEO board section.

no mark: CD PLAY

Other board section

no mark: TUNER (FM/AM)

( ): TAPE PLAY

< >: TAPE REC

[ ]: CD PLAY

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

F : TUNER (FM/AM)

E : TAPE PLAY (DECK A)

d : TAPE PLAY (DECK B)

G : RECORD

J : CD PLAY

g : VIDEO

4

W or less unless otherwise

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• : Pattern from the side which enables seeing.

(The other layers´ Patterns are not indicated.)

• Indication of transistor.

C

Q

B

B

B

E

Q

CE

These are omitted.

These are omitted.

Q

CE

These are omitted.

– MAIN BOARD – – BD BOARD –

1

IC501 qa (XC-OUT)

3.0Vp-p

32KHz

VOL/DIV : 1V AC

2

IC501 qd (X-OUT)

16MHz

3

CN321 2

TAPE REC only

µ

sec

18

4

CN321 3

TAPE REC only

18

µ

sec

TIME/DIV : 10

VOL/DIV : 1V AC

TIME/DIV : 50nsec

VOL/DIV : 10V AC

TIME/DIV : 5

VOL/DIV : 10V AC

TIME/DIV : 5

2.0Vp-p

24Vp-p

36Vp-p

µ

sec

µ

sec

µ

sec

– VIDEO BOARD –

1 IC505 (XTAO)

2 IC505 (CLKB)

3 IC505 (RFAC)

150

33.8688 MHz

207

27 MHz

173

VOL/DIV : 0.2V AC

TIME/DIV : 0.5

4 IC505 6 (EPSIG)

H

2.5 Vp-p

VOL/DIV : 1V AC

TIME/DIV : 20nsec

2.8 Vp-p

VOL/DIV : 1V AC

TIME/DIV : 20nsec

0.8 Vp-p

µ

sec

0.8 Vp-p

VOL/DIV : 0.5V AC

TIME/DIV : 20

µ

sec

1

IC103 qg (RFAC)

2

IC103 qh (FE)

3

IC103 qk (TE)

5 Q301 E

– PANEL FL BOARD –

0.8 Vp-p

VOL/DIV : 0.2V AC

TIME/DIV : 0.5

VOL/DIV : 0.2V AC

TIME/DIV : 0.2msec

VOL/DIV : 1V AC

TIME/DIV : 0.2msec

µ

sec

0.15 Vp-p

0.7 Vp-p

1

IC601 is (X OUT)

4MHz

3.0Vp-p

VOL/DIV : 1V AC

TIME/DIV : 0.2

H

0.8 Vp-p

VOL/DIV : 0.5V AC

TIME/DIV : 20

µ

sec

6 IC307 6 (VOUT)

µ

sec

H

1.0 Vp-p

VOL/DIV : 0.5V AC

TIME/DIV : 20

µ

sec

23

23

HCD-XGV50

7-2. BLOCK DIAGRAMS

– CD SERVO SECTION –

+2.5V

VCC

+4.5V

VCC

A

PD1

B

PD2

C

D

I-V AMP

F

I1-6

E

I5-10

OPTICAL PICK-UP BLOCK

(A-MAX.3)

LASER DIODE

LD

LD

PD

PD

SPINDLE

MOTOR

MOTOR

COIL

FOCUS

COIL

S101

(LIMIT)

T+

T-

F+

F-

(

TRACKING

ON: when the optical pick-up

(

is inner position.

M101

M102

SLED

11

10

LD

DRIVE

Q101

M

M

FOCUS/TRACKING ERROR AMP

22

VCC

VCC

13

A

6

B

7

C

8

D

9

F

F I-V AMP

E

E I-V AMP

LD

1

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

VO4+

5

VO4

10

VO3+

1

VO3

2

VO2

56

VO2+

55

VO1

52

VO1+

47

-

-

-

-

RF AMP,

IC103

SUMMING

APC LD

AMP

RF

AMP

∑

A-D

IC102

MOTOR

DRIVE

MOTOR

DRIVE

COIL

DRIVE

COIL

DRIVE

FOCUS

ERROR AMP

TRACKING

ERROR AMP

APC PD

AMP

VREF

IN3+

IN3

IN2+

IN2

IN1+

IN1

STBY

IN4

-

-

-

4 3

23

22

27

26

32

31

35

34

8

EQ_IN

RF EQ

DC

AMP

VDC

BUFFER

DATA DECODERR,

D/A CONVERTOR

IC506

RST

AMP

26

RFC

RFACAC_SUM

RFDCO

RFDCI

VDC

SW

FE

FEI

TE

PD

15

28

29

16

17

18

14

12

2

TE

Q102

LD-ONFERFDC

5 9 346

AO4

AO6

AO3

RST

RST

AO5

CLK

• R-ch is omitted due to same as L-ch.

• Signal Path

: CD PLAY (ANALOG)

RFAC

173

RFDC

160

201

CD-DSP,

IC505

GPIO2

SRQ

GPIO3

SOK

AUDXCLKO

DRDAT0

DRDAT15

DRADR0

DRADR10

GPIO4

GPIO5

SCS

AUDDTO0

AUDLRCK

AUDBCK

GPIO11

CPSIG

NVOEL

DRDQM1

DRDQM0

DRCK

DRBS

DRRAS

DRCAS

DRWEL

I

I

SYS RST

81

RST

204

203

26

205

6

74

78

77

70

76

72

68

73

49-56,

59-66

34-37,

39-45

Y

164

FE

TE

162

163

SE

CLKA

CLK

206

207

149

150

189

133

161

165

137

138

140

141

142

143

135

30

29

28

CLKB

XTAI

XTAO

GPIO9

24

XTSL

MDP

CE

VC

SFDR

SRDR

TFDR

TRDR

FFDR

FRDR

SSTP

GPIO14

GPIO13

GPIO12

DIGITAL SERVO,

MPEG DECODER, DAC

GPIO0

GPIO1

13 14 15 16 18 19

SI

SO

SCK

X502

27MHz

X501

33.8688MHz

12

DI

11

10

LD

DATA

DATA

CLK

LAT

MCLK

A+5V

(SW)

16

2

3

1

13

14

15

16

WE

+3.3V

REG

Q581

6 5

VCC

DATA

I/F

LRCK

BLK

CONTROL

17 18 20 38 15 39

BA0

CLK

CAS

RAS

LDQM

D/A

CONVERTOR

IC504

VDD

LOUT CD-L

DAC

DAC

UDQM

7

ROUT

8

24

DE

A0-A16 DQ0-DQ7

2-12,23,

25-31

2,4,5,7,8,10,11,13,

23-26,

42,44,45,47,48,50,51,53

29-34

A0-A9

SDRAM

IC507

ROM

IC508

8-15

0-15

DQ0-DQ15

13-15,

7-21

0-7

5

3

LPF

IC102

7

1

: VIDEO

A

R-ch

LPF

Q302

SYSTEM CONTROLLER

(CD MECHANISM CONTROL)

CD-DATA

XLT

35

SI

SO

To MAIN

SECTION

(Page 26)

VIDEO AMP

IC307

IN

3 6

2

STB

+4.5V

(IC103)

Q370

3

+2.5V

+3.3V

V-MUTE

33

SQ-CLK

TBL-SENS

BU UP/DW SW

LED-DISK

IC501 (1/4)

MTR-CTRL1

MTR-CTR2

SQ-DATA

CD-CLK

SCOR

HOLD

XRST

4036 37 193243

RST

SCS

SCK

SOK

SRQ

OUT

RIPPLE FILTER

Q201

+2.5V REG

IC201

+3.3V REG

IC202

49

48

(UP SWITCH)

LED DRIVE

47

Q412

44

45

Q411

5

DISC TABLE

S201

Q201

VCD-VIDEO

1

SENSOR

IC202

TABLE MOTOR DRIVER

IN2

1

IN1

9

B

D+5V

(SW)

(DISC No.)

IC201

MOTOR

DRIVE

D201

To MAIN

SECTION

(Page 26)

OUT2

OUT1

3

7

M201

M

(TABLE)

24

24

Loading...

Loading...