Sony HCD-XG500 - Bookshelf, HCD-XG60 System Service Manual

SERVICE MANUAL

COMPACT DISC DECK RECEIVER

US Model

Canadian Model

AEP Model

UK Model

HCD-XG500

E Model

HCD-XG60

SPECIFICATIONS

HCD-XG60/XG500

Photo: HCD-XG60

Ver 1.0 2001.02

9-929-577-11 Sony Corporation

2001B0500-1 Audio Entertainment Group

C 2001.2 General Engineering Dept.

HCD-XG60/XG500 is the amplifier, CD

player, tape deck and tuner section in

LBT-XG60/XG500.

Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol ; are trademarks of Dolby Laboratories Licensing Corporation.

Model Name Using Similar Mechanism HCD-LX6/LX50/LX70

CD

CD Mechanism Type CDM37M-5BD32L

Section

Base Unit Name BU-5BD32L

Optical Pick-up Name KSS-213DH

TAPE

Model Name Using Similar Mechanism NEW

Section

T ape Tr ansport Mechanism Type TCM-230PWR42

AUDIO POWER SPECIFICATIONS:

(US model only)

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION

With 6 ohm loads both channels driven, from

120-10,000 Hz; rates 140 watts per channel

minimum RMS power, with no more than 10%

total harmonic distortion.

Amplifier section

Canadian model:

Continuous RMS power output (reference)

160 + 160 watts (6 ohms at

1 kHz, 10% THD)

Total harmonic distortion less than 0.07%

(6 ohms at 1 kHz, 70 W)

AEP, UK models:

DIN power output (rated) 110 + 110 watts

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference)

140 + 140 watts

(6 ohms at 1 kHz, 10% THD)

Music power output (reference)

240 + 240 watts

(6 ohms at 1 kHz, 10% THD)

Other models:

The following measured at AC 120/220/240V, 50 Hz

DIN power output (rated) 150 + 150 watts

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference)

200 + 200 watts

(6 ohms at 1 kHz, 10% THD)

Inputs

DJ MIX*:

(phono jacks) sensitivity 250 mV,

impedance 47 kilohms

GUITAR IN:

(phone jack) sensitivity 75 mV,

impedance 470 kilohms

PHONO IN:

(phono jacks) sensitivity 3 mV,

impedance 47 kilohms

MIX MIC:

(phone jack) sensitivity 1 mV,

impedance 10 kilohms

VIDEO IN:

(phono jacks) sensitivity 250 mV,

impedance 47 kilohms

GAME IN:

(phono jacks) sensitivity 250 mV,

impedance 47 kilohms

MD IN:

(phono jack) sensitivity 450 mV,

impedance 47 kilohms

Outputs

DJ MIX*:

(phono jacks) sensitivity 250 mV,

impedance 1 kilohms

PHONES:

(stereo phone jack) accepts headphones of 8

ohms or more

VIDEO OUT:

(phono jack) voltage 250 mV

impedance 1 kilohm

MD OUT:

(phono jacks) voltage 250 mV

impedance 1 kilohm

FRONT SPEAKER:

accepts impedance of 6 to

16 ohms

* US, Canadian, AEP, UK, and Mexican models

only

CD player section

System Compact disc and digital

audio system

Laser Semiconductor laser

(λ=780nm), Emission

duration: continuous

Wavelength 780 – 790 nm

Frequency response 2 Hz – 20 kHz (±0.5 dB)

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

CD OPTICAL DIGITAL OUT

(Square optical connector jack, rear panel)

Wavelength: 660 nm

Output level –18 dBm

– Continued on next page –

2

HCD-XG60/XG500

Tape player section

Recording system 4-track 2-channel stereo

Frequency response 40 – 13,000 Hz (±3 dB),

(DOLBY NR OFF)

using Sony TYPE I cassette

40 – 14,000 Hz (±3 dB),

using Sony TYPE II cassette

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range

US, Canadian models: 87.5 – 108.0 MHz (100

kHz step)

Other models: 87.5 – 108.0 MHz

(50 kHz step)

Antenna FM lead antenna

Antenna terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

US, Canadian, Mexican, Argentina models:

530 – 1,710 kHz

(with the interval set at 10

kHz)

531 – 1,710 kHz

(with the interval set at 9

kHz)

Other models:

531 – 1,602 kHz

(with the interval set at 9

kHz)

Singapore model: 531 – 1,602 kHz

(with the interval set at 9

kHz)

530 – 1,710 kHz

(with the interval set at 10

kHz)

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

General

Power requirements

US, Canadian models: 120 V AC, 60 Hz

AEP, UK models: 230 V AC, 50/60 Hz

Mexican model: 120 V AC, 50/60 Hz

Other models: 120 V, 220 V or 230 – 240

V AC, 50/60 Hz

Adjustable with voltage

selector

Power consumption

US model:

240 watts

Canadian model:

320VA

AEP, UK models: 220 watts

0.6 watts (at the power

saving mode)

Other models:

180 watts

Dimensions (w/h/d) Approx. 355 x 425 x 450

mm

Mass :

HCD-XG500 Approx. 13.5 kg

HCD-XG60 Approx. 15.0 kg

Supplied accessories: AM loop antenna (1)

FM lead antenna (1)

Speaker cords (2)

Speaker pads (8)

Remote commander (1)

Batteries (2)

Design and specifications are subject to change

without notice.

3

HCD-XG60/XG500

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 5

2. GENERAL

Location of Controls ....................................................... 6

Setting the Time .............................................................. 7

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 8

3-2. Case ................................................................................. 8

3-3. Front Panel Section......................................................... 9

3-4. Cover (TC), Tape Mechanism Deck

(TCM-230PWR42) ......................................................... 9

3-5. MAIN Board, Fan, D.C. (M901)

(Except AEP, UK Models).............................................. 10

3-6. MAIN Board (AEP, UK Models) ................................... 10

3-7. CD Mechanism Deck (CDM37M-5BD32L).................. 11

3-8. Base Unit (BU-5B32L) ................................................... 12

3-9. Disc Table........................................................................ 12

4. TEST MODE.............................................................. 13

5. MECHANICAL ADJUSTMENTS....................... 15

6. ELECTRICAL ADJUSTMENTS

Deck section .................................................................... 15

CD Section ...................................................................... 18

7. DIAGRAMS

7-1. Block Diagram – CD SERVO Section – ....................... 19

7-2. Block Diagram – TUNER/TAPE DECK Section – ...... 20

7-3. Block Diagram – MAIN Section – ................................ 21

7-4. Block Diagram – DISPLAY/KEY CONTROL/

POWER SUPPLY Section – ........................................... 22

7-5. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 23

7-6. Printed Wiring Board – BD Board – ............................. 24

7-7. Schematic Diagram – BD Board – ................................ 25

7-8. Printed Wiring Boards – CD MOTOR Section – .......... 26

7-9. Schematic Diagram – CD MOTOR Section – .............. 27

7-10. Printed Wiring Board – A UDIO Board – ...................... 28

7-11. Schematic Diagram – AUDIO Board – ......................... 29

7-12. Printed Wiring Board – LEAF SW Board –.................. 30

7-13. Schematic Diagram – LEAF SW Board –..................... 30

7-14. Schematic Diagram – MAIN Board (1/3) – .................. 31

7-15. Schematic Diagram – MAIN Board (2/3) – .................. 32

7-16. Schematic Diagram – MAIN Board (3/3) – .................. 33

7-17. Printed Wiring Board – MAIN Board – ........................ 34

7-18. Printed Wiring Board – PA Board – .............................. 36

7-19. Schematic Diagram – PA Board – ................................. 37

7-20. Printed Wiring Boards – MIC/FRONT INPUT/

HEADPHONES Boards –............................................... 38

7-21. Schematic Diagram – MIC/FRONT INPUT/

HEADPHONES Boards – ............................................. 39

7-22. Printed Wiring Board – PANEL FL Board – ................ 40

7-23. Schematic Diagram – PANEL FL Board – ................... 41

7-24. Printed Wiring Boards

– PANEL VR/ILLUMINATION Boards –..................... 42

7-25. Schematic Diagram

– PANEL VR/ILLUMINATION Boards –..................... 43

7-26. Printed Wiring Boards – TC-A/TC-B/CD-L/

CD-R (1)/CD-R (2) Boards – ......................................... 44

7-27. Schematic Diagram – TC-A/TC-B/CD-L/

CD-R (1)/CD-R (2) Boards – ......................................... 45

7-28. Printed Wiring Board – TRANSFORMER Section–.... 46

7-29. Schematic Diagram – TRANSFORMER Section–....... 46

7-30. IC Pin Function Description ........................................... 50

8. EXPLODED VIEWS

8-1. Case, Back Panel Section................................................ 55

8-2. Front Panel Section-1...................................................... 56

8-3. Front Panel Section-2...................................................... 57

8-4. Chassis Section ............................................................... 58

8-5. Tape Mechanism Deck Section-1

(TCM-230PWR42) ......................................................... 59

8-6. Tape Mechanism Deck Section-2

(TCM230PWR42)........................................................... 60

8-7. CD Mechanism Deck Section (CDM37M-5BD32L) .... 61

8-8. Base Unit Section (BU-5BD32L)................................... 62

9. ELECTRICAL PARTS LIST ............................... 63

4

HCD-XG60/XG500

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

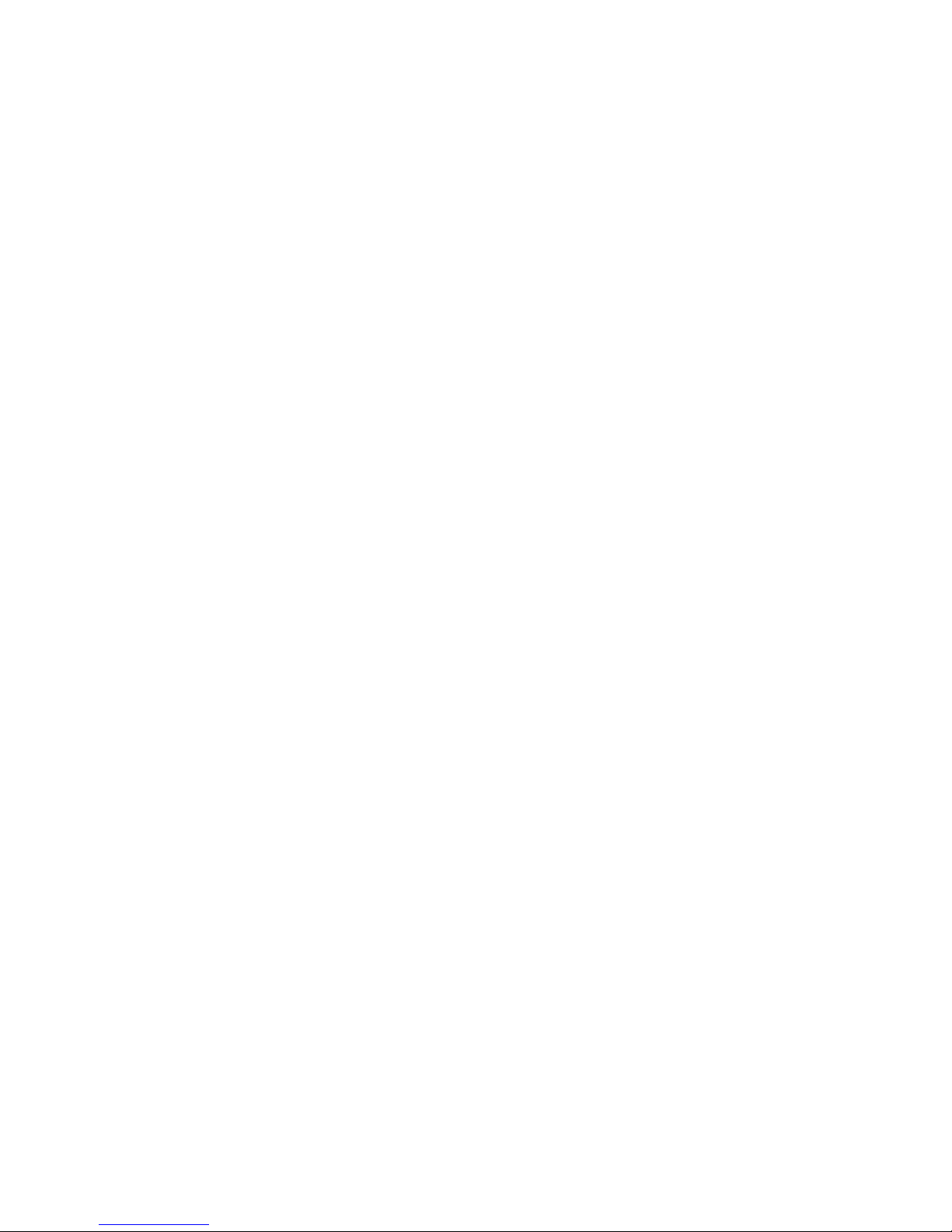

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63T rd are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

Fig. A. Using an AC voltmeter to check AC leakage.

1.5 k

Ω

0.15 µF

AC

voltmete

r

(0.75 V)

To Exposed Metal

Parts on Set

Earth Ground

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMA TIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

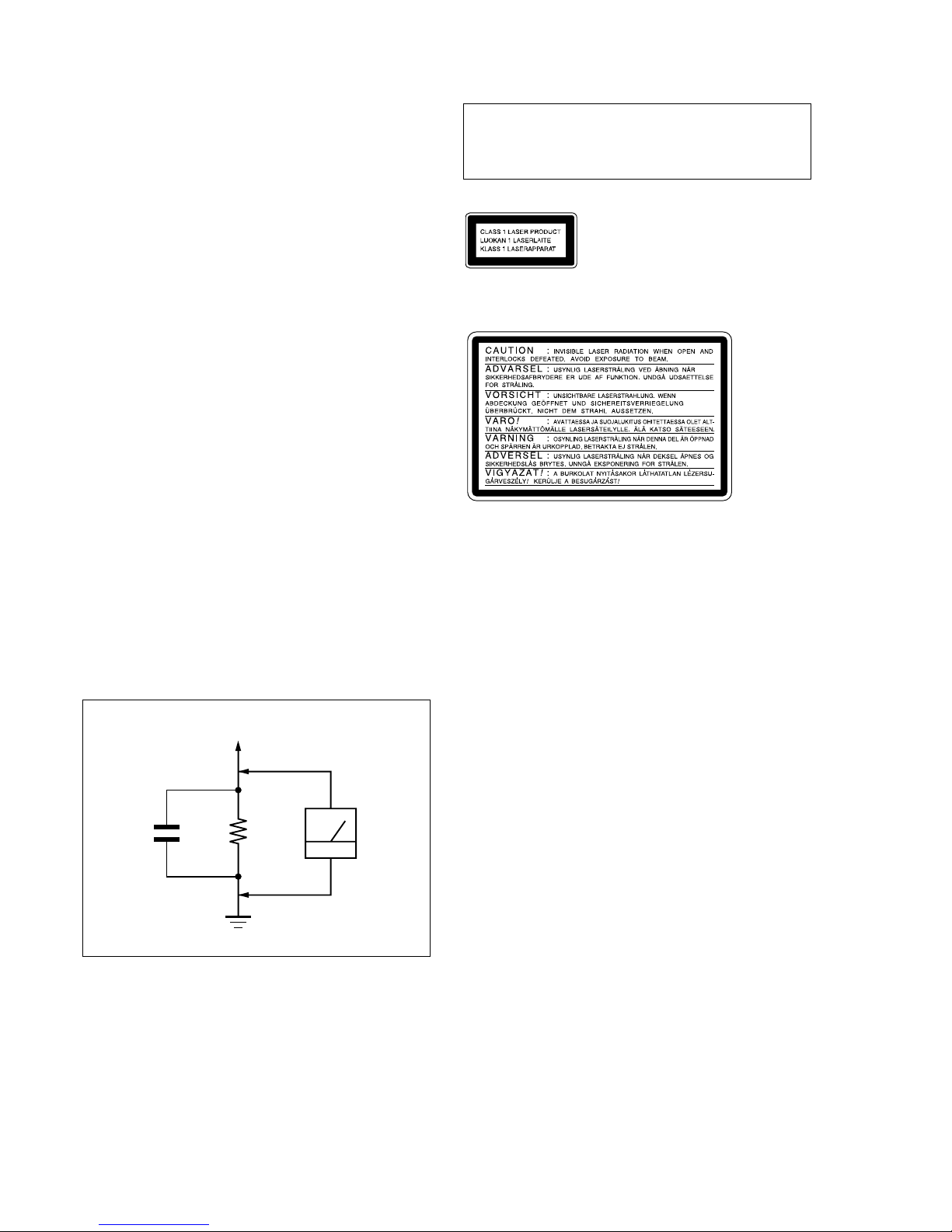

The following caution label is located inside the unit.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

5

HCD-XG60/XG500

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and

check that the S curve waveforms is output three times.

SECTION 1

SERVICING NOTES

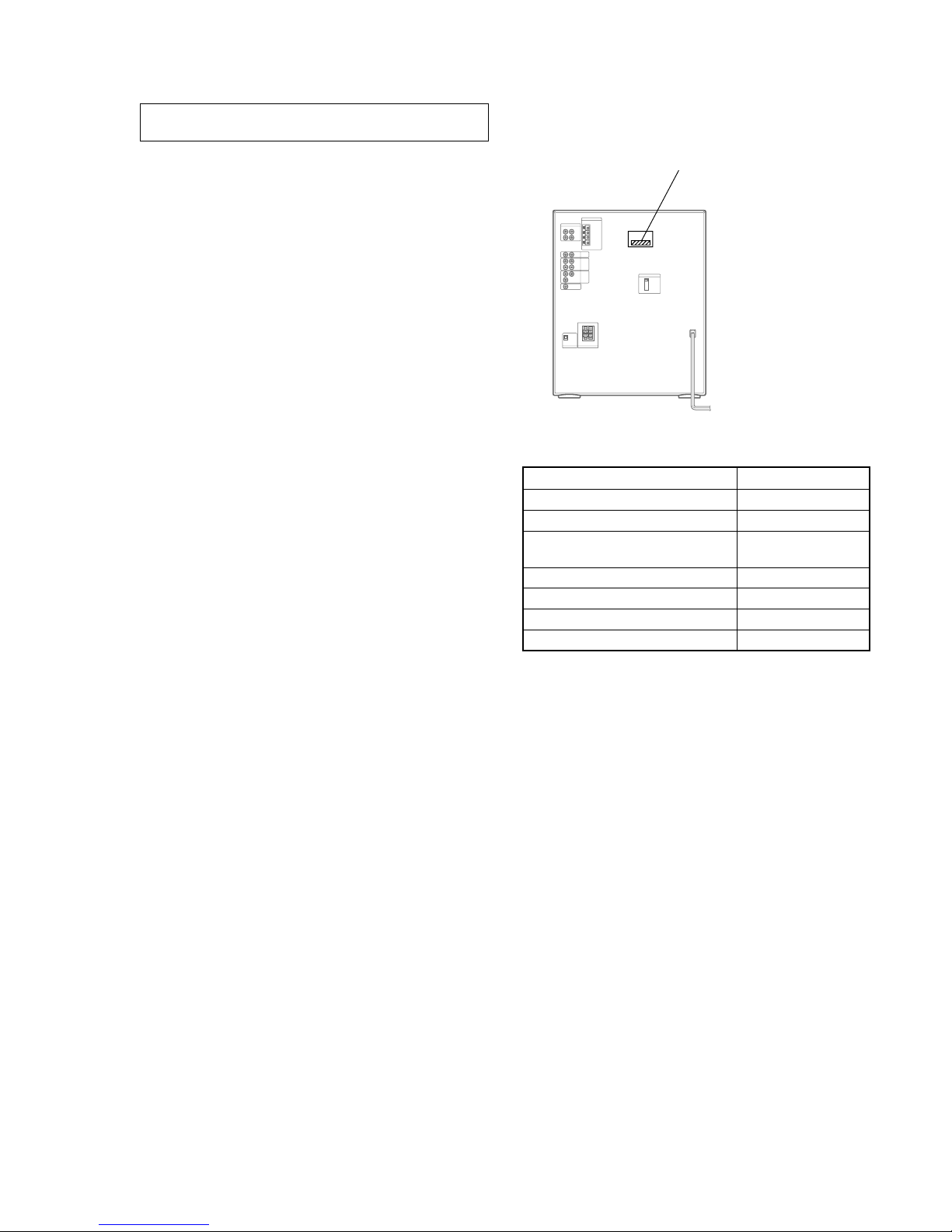

• MODEL IDENTIFICATION

– Rear Panel –

PART No.

MODEL PART No.

US model 4-232-087-0

[]

AEP and UK models 4-232-087-1

[]

120 V AC area in E and

Argentina models

4-232-087-2

[]

Singapore model 4-232-087-3

[]

Mexican model 4-232-087-4

[]

Saudi Arabia model 4-232-087-5

[]

Canadian model 4-232-087-6

[]

6

HCD-XG60/XG500

SECTION 2

GENERAL

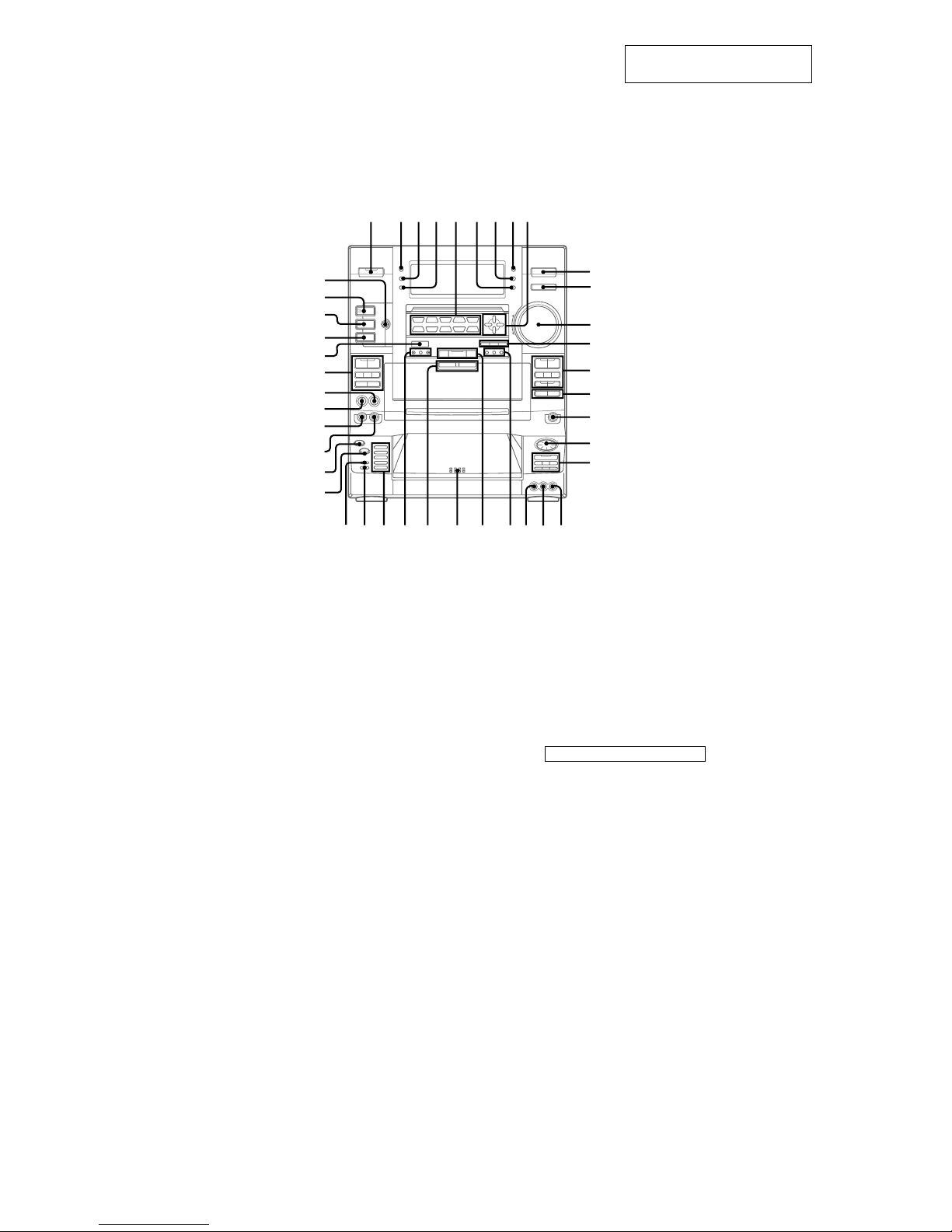

This section is extracted from

instruction manual.

CD SYNC qg (16,17)

DIRECT EQUALIZER 5 (18)

SALSA

REGGAE

SAMBA

TANGO

MOVIE

GUITAR

ROCK

JAZZ

DANCE

GAME

DIRECTION eh (15,16,17)

DISC SKIP qk (9,10,17)

DISC 1~5 wj (9)

DISPLAY 3 (8,11,13)

DOLBY NR eh (15,16)

EDIT wl (17)

ENTER wh (12,27)

ENTER/NEXT qd (8,14,17,19,22)

FLAT qd (18)

FLASH e; (11)

FUNCTIONq; (7,9,10,16,17,23,24)

GAME qa (21)

AUDIO L w; (23)

AUDIO R ql (23)

VIDEO wa (23)

GROOVE r; (18)

GUITAR DISTORTION wh (21)

GUITAR jack es (21)

GUITAR LEVEL eg (21)

H SPEED DUB qg (16)

Jog dial (AMS./>) qj

(9,10,11,17)

LOOP ea (7,11)

MIC LEVEL ef (20)

MIX GUITAR/KARAOKE ej (20,21)

MIX MIC jack ed (20)

NON STOP wk (10)

P.FILE qd (18,19)

PLAY MODE qk (9,10,17)

PHONES jack qh

POWER SAVE/DEMO

(STANDBY) 2 (8)

PTY ws (14) (AEP, UK models)

PUSH OPEN wf (9)

REPEAT qk (9)

SPECTRUM ANALYZER 4 (20)

SLEEP 7 (21)

STEREO/MONO ws (13)

SUPER WOOFER el (18)

SUPER WOOFER MODE ek (18)

SURROUND ra(16,18)

TUNER/BAND wd(12,13,16)

TUNER MEMORY wh (12)

TIMER SELECT 8 (22)

TUNING MODE ws (12,13)

VOLUME control qs (9,13,15)

BUTTON DESCRIPTIONS

@/1 1

c/CLOCK SET 6

v/V/b/B 9

z REC qf

X qf

m /M, AMS./> qfeh

h,H qfeh

x qfqkeh

HX qk

+/– wd

A EJECT Z/Z B EJECT wg

wawswdwfwgwjwkwl

e;

ea

es

ed

ef

eg

ej

el

ek

r;

ra

eh

wh w; ql

qd

qs

qa

234 5 6 789

q;

qf

qg

qh

qj

qk

1

LOCATION OF CONTROLS

– Front Panel –

7

HCD-XG60/XG500

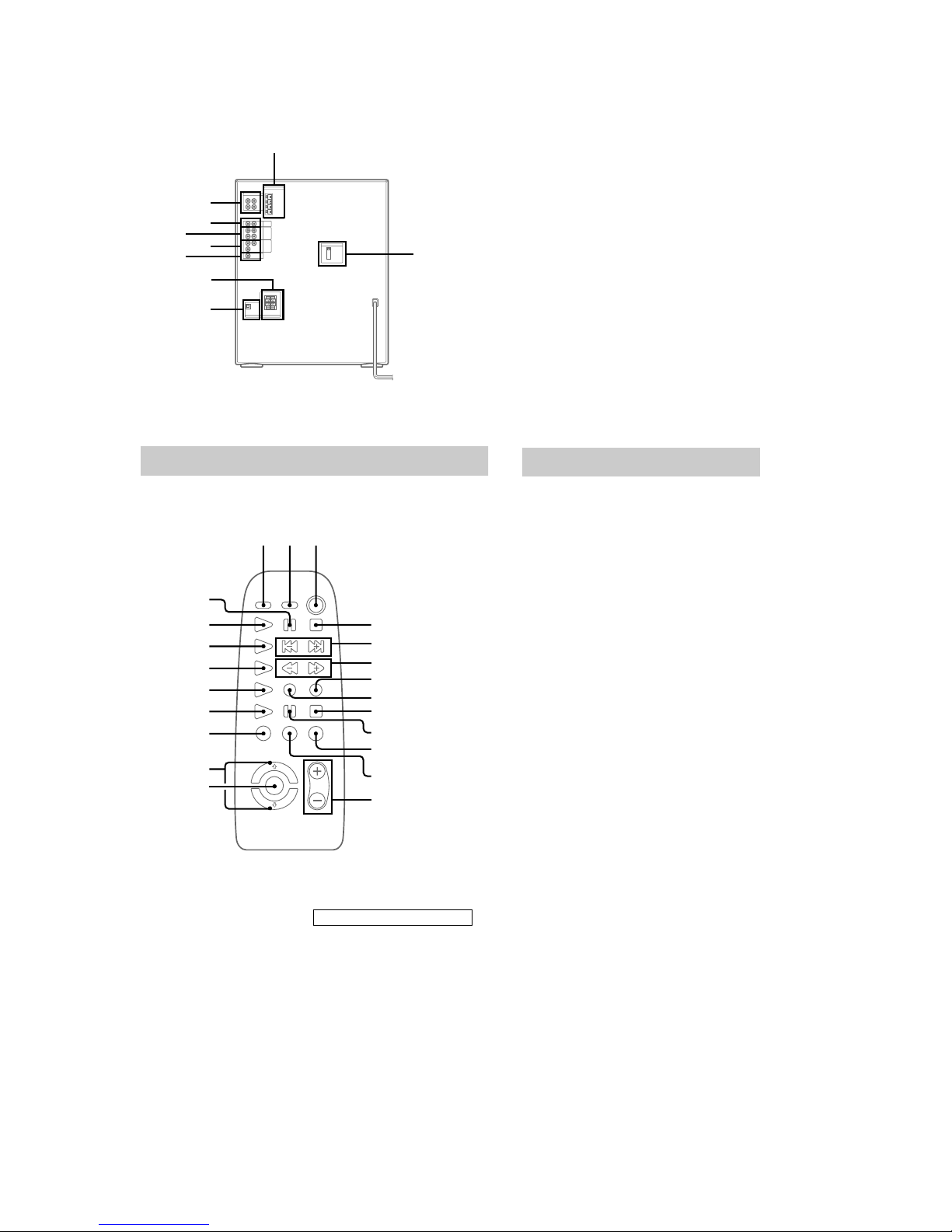

1 ANTENNA terminal

2 DJ MIX RETURN/SEND jack

(US, Canadian, AEP, UK Mexican models)

3 PHONO IN jack

4 MD IN/OUT jack

5 VIDEO/AUDIO IN jack

6 VIDEO OUT jack

7 FRONT SPEAKER terminal

8 CD DIGITAL OUT OPTICAL terminal

9 VOLTAGE SELECTOR switch

(120 V AC area in E, Saudi Arabia, Singapore, Argentina models)

– Rear Panel –

2

1

3

5

8

9

7

4

6

Setting the time

1

Turn on the system.

2

Press c/CLOCK SET.

When you set the time for the first time,

skip to the step 5.

3

Press v/V repeatedly to select SET

CLOCK.

4

Press ENTER/NEXT.

5

Press v/V repeatedly to set the hour.

6

Press ENTER/NEXT.

The minute indication flashes.

7

Press v/V repeatedly to set the minute.

8

Press ENTER/NEXT.

The clock starts working.

Tip

If you’ve made a mistake or want to change the time,

start over from step 1.

Note

The clock settings are canceled when you disconnect

the power cord or if a power failure occurs.

Remote control

AMS ./>, PRESET+/– 5

(9,13,14,15)

CD N wa (9)

CHECK 8 (10)

CLEAR 7 (10)

DECK A N ql (15)

DECK B N qk (15)

DISC SKIP 1 (9,10,17)

FILE SELECT ON/OFF qf (18)

FILE SELECT F/f qg (11)

FLASH qs (11)

FUNCTION qa

(7,9,10,16,17,23,24)

LOOP qh (11)

MD N qj

MD X 0

MD x 9

SLEEP 2 (21)

TUNER/BAND w;(12,16)

VOL +/– qd (9,13,15)

BUTTON DESCRIPTIONS

@/1 3

x 4

m/M 6

X ws

ql

qk

qj

qh

qg

qf

ws

wa

w;

6

7

8

9

q;

4

5

qd

qs

qa

123

8

HCD-XG60/XG500

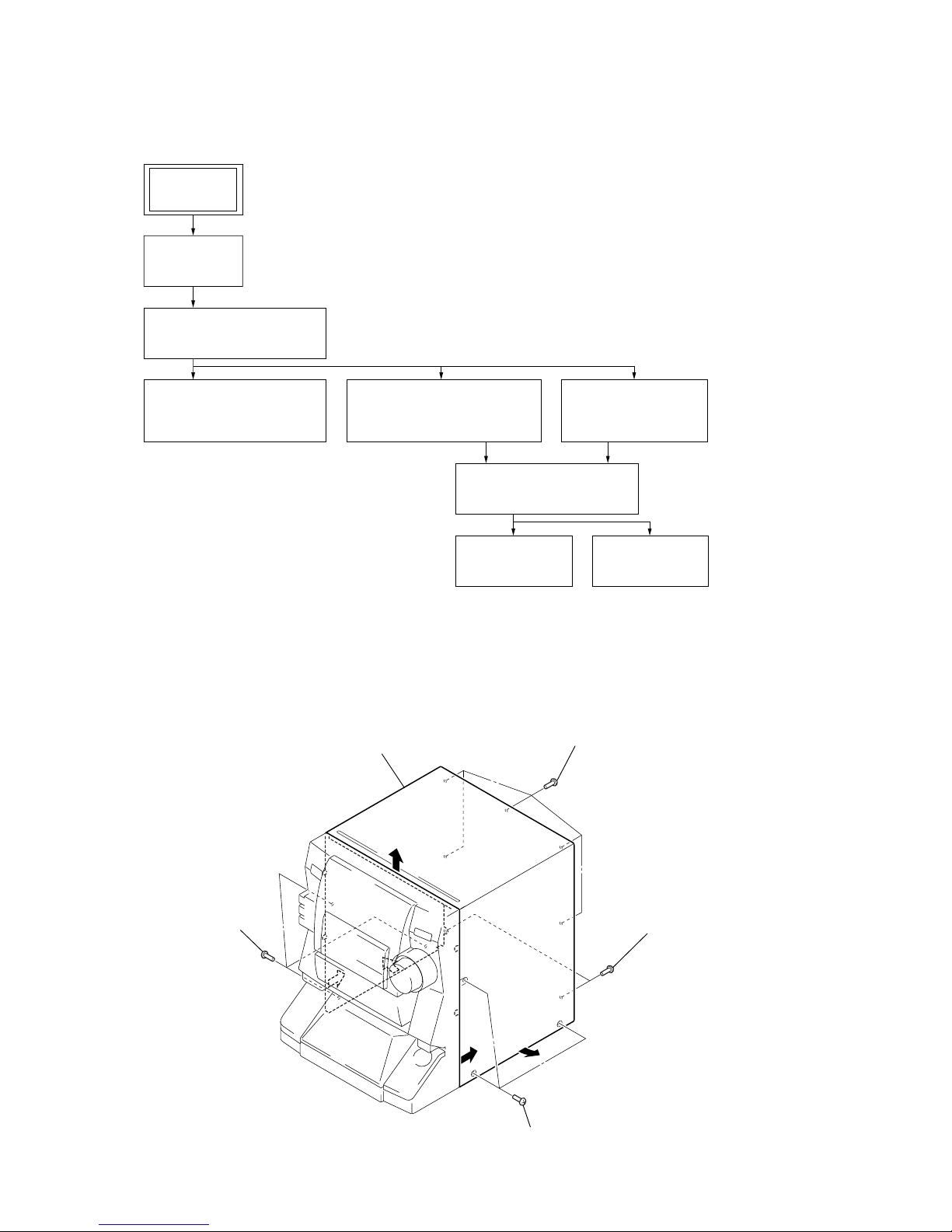

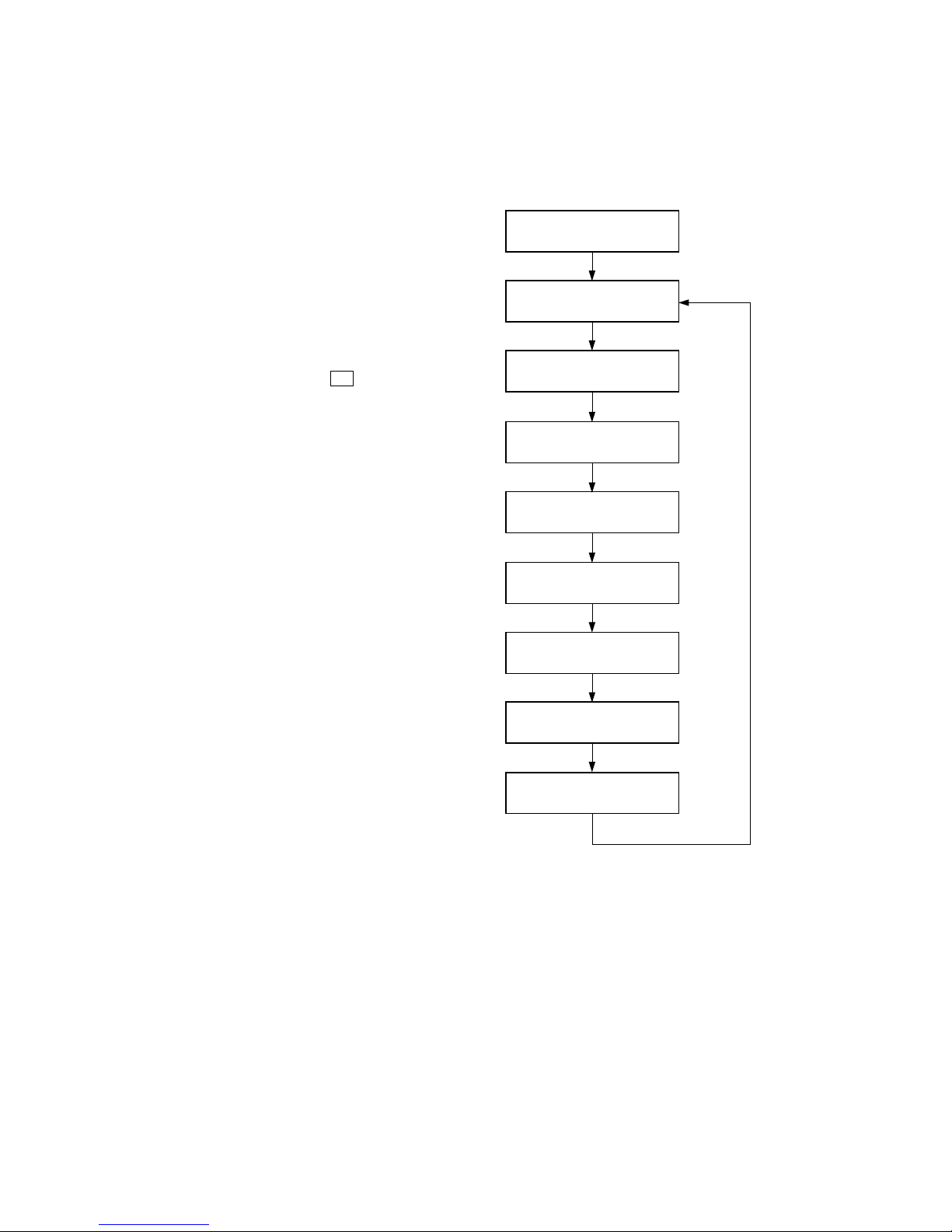

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SECTION 3

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

3-2. CASE

3-2. CASE

(Page 8)

3-3. FRONT PANEL SECTION

(Page 9)

3-4. COVER (TC),

TAPE MECHANISM DECK

(TCM-230PWR42)

(Page 9)

3-7. CD MECHANISM DECK

(CDM37M-5BD32L)

(Page 11)

3-8. BASE UNIT

(BU-5BD32L)

(Page 12)

3-9. DISC TABLE

(Page 12)

3-6. MAIN BOARD

(AEP, UK MODELS)

(Page 10)

3-5. MAIN BOARD,

FAN, D.C. (M901)

(EXCEPT AEP, UK MODELS)

(Page 10)

SET

1

three screws

(CASE3 TP2)

1

three screws

(CASE3 TP2)

2

five screws

(BVTT3

×

6)

3

two screws

(BVTP3

×

8

)

4

4

5

5

6

case

9

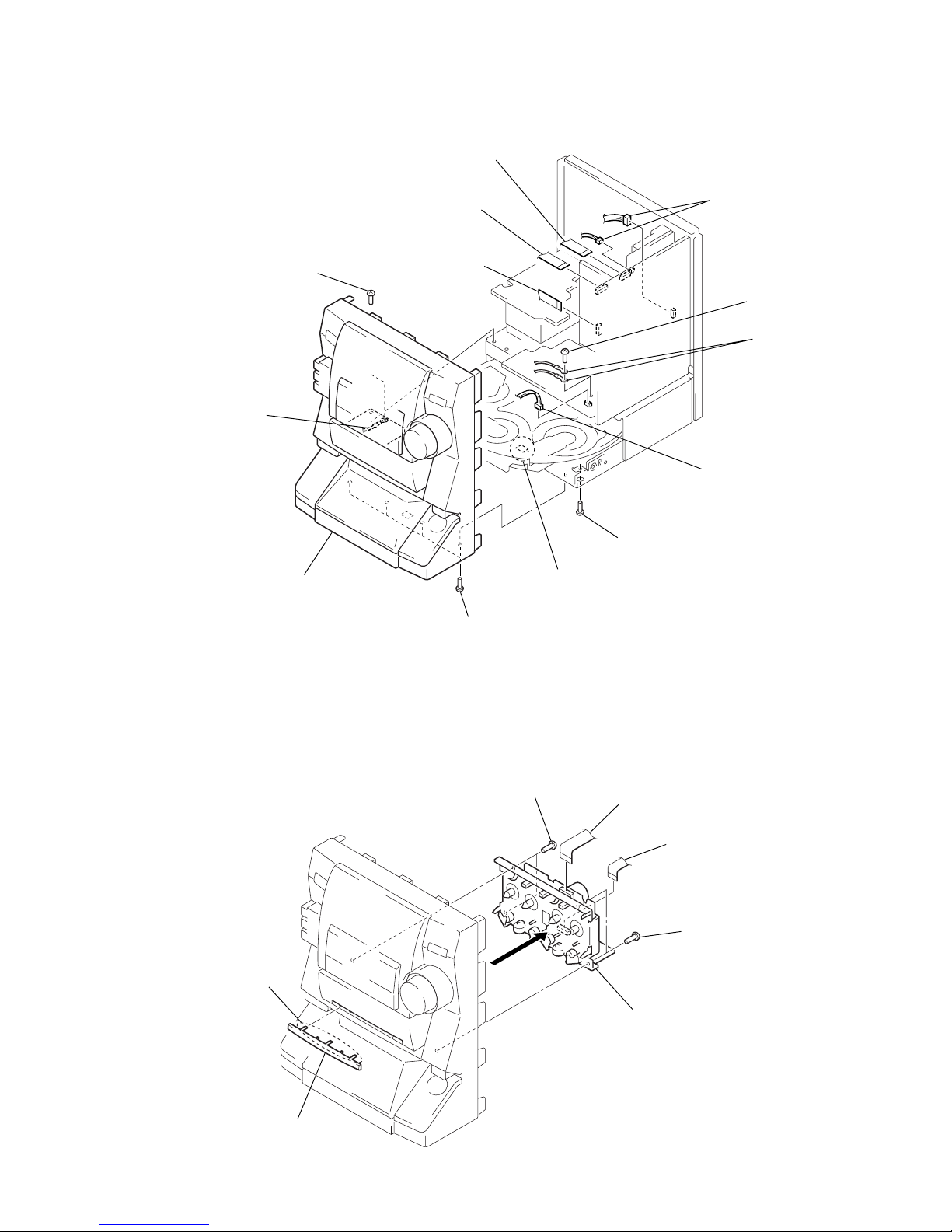

HCD-XG60/XG500

3-3. FRONT PANEL SECTION

3-4. COVER (TC), TAPE MECHANISM DECK (TCM-230PWR42)

1

wire (flat type)

(15 core) (CN303)

2

two connectors

(CN452, 702)

1

wire (flat type)

(17 core) (CN304)

1

wire (flat type)

(13 core) (CN431)

3

screw

(BVTP3

×

8

)

4

two lugs

4

lug

2

connector

(CN806)

5

screw

(BVTP3

×

8)

6

claw

5

four screws

(BVTP3

×

8)

7

front panel section

3

two screws

(BVTP3

×

8)

1

five claws

2

cover (TC)

4

two screws

(BVTP3

×

8)

3

wire (flat type) (17 core)

(CN1001)

3

wire (flat type) (15 core

)

(CN601)

4

two screws

(BVTP3

×

8)

5

tape mechanism deck

(TCM-230PWR42)

10

HCD-XG60/XG500

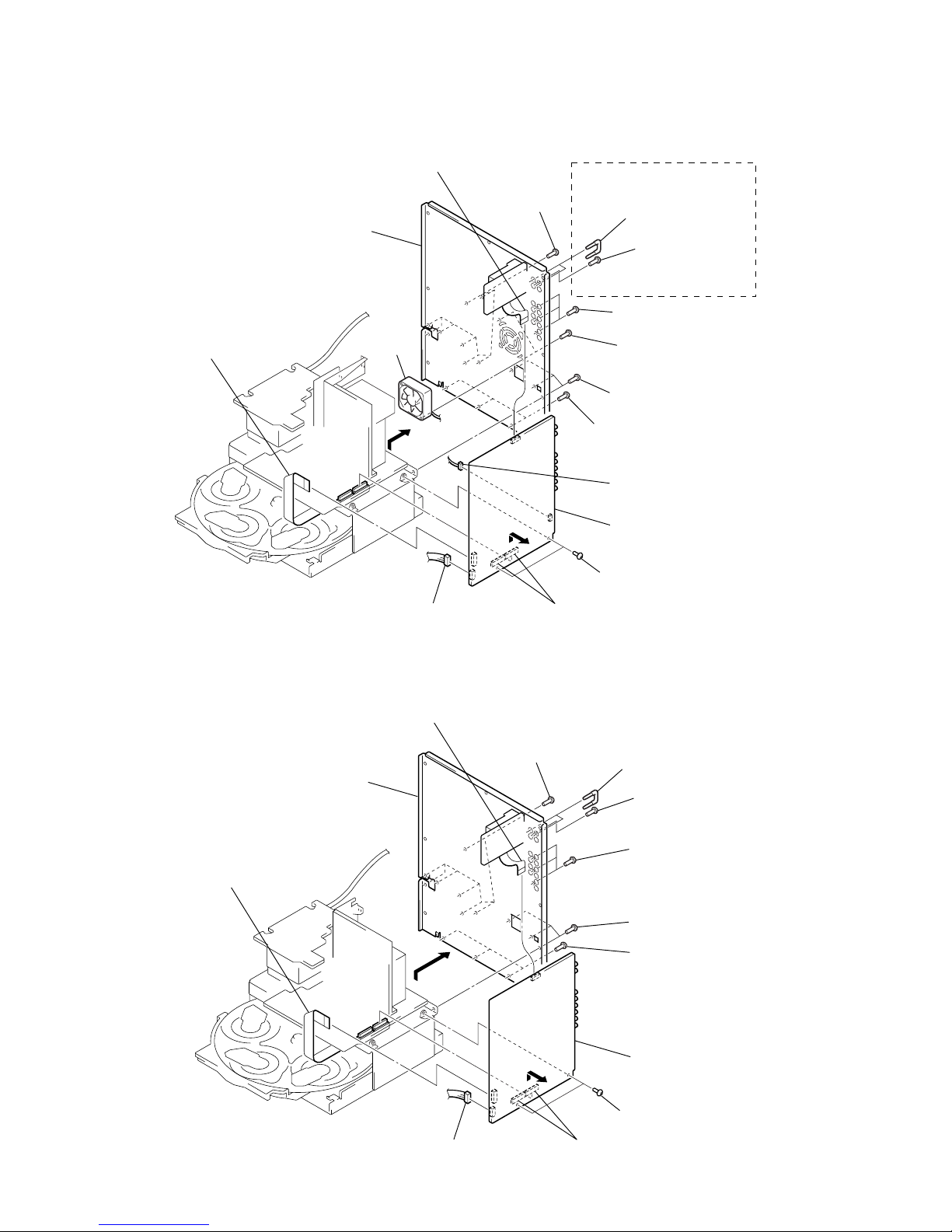

3-5. MAIN BOARD, FAN, D.C. (M901) (EXCEPT AEP, UK MODELS)

3-6. MAIN BOARD (AEP, UK MODELS)

9

wire (flat type) (19 core)

(CN411)

7

fan, D.C.

(M901)

8

back panel

1

wire (flat type)

(13 core) (CN441)

3

eight screws

(BVTP3

×

8)

3

three screws

(BVTP3

×

8)

3

three screws

(BVTP3

×

8)

6

two screws

(BVTP3

×

8)

3

screw

(BVTP3

×

8)

2

jumper plug

US, Canadian, Mexican models

3

three screws

(BVTP3

×

8)

qa

two screws

(BVTP3

×

8)

qs

two connectors

(CN803, 804)

0

connector

(CN412)

4

5

connector (CN903)

qd

MAIN board

6

wire (flat type) (19 core)

(CN411)

5

back panel

1

wire (flat type)

(15 core) (CN441)

3

seven screws

(BVTP3

×

8)

3

three screws

(BVTP3

×

8)

3

three screws

(BVTP3

×

8)

3

screw

(BVTP3

×

8

)

2

jumper plug

3

three screws

(BVTP3

×

8)

8

two screws

(BVTP3

×

8)

9

two connectors

(CN803, 804)

7

connector

(CN412)

4

0

MAIN board

11

HCD-XG60/XG500

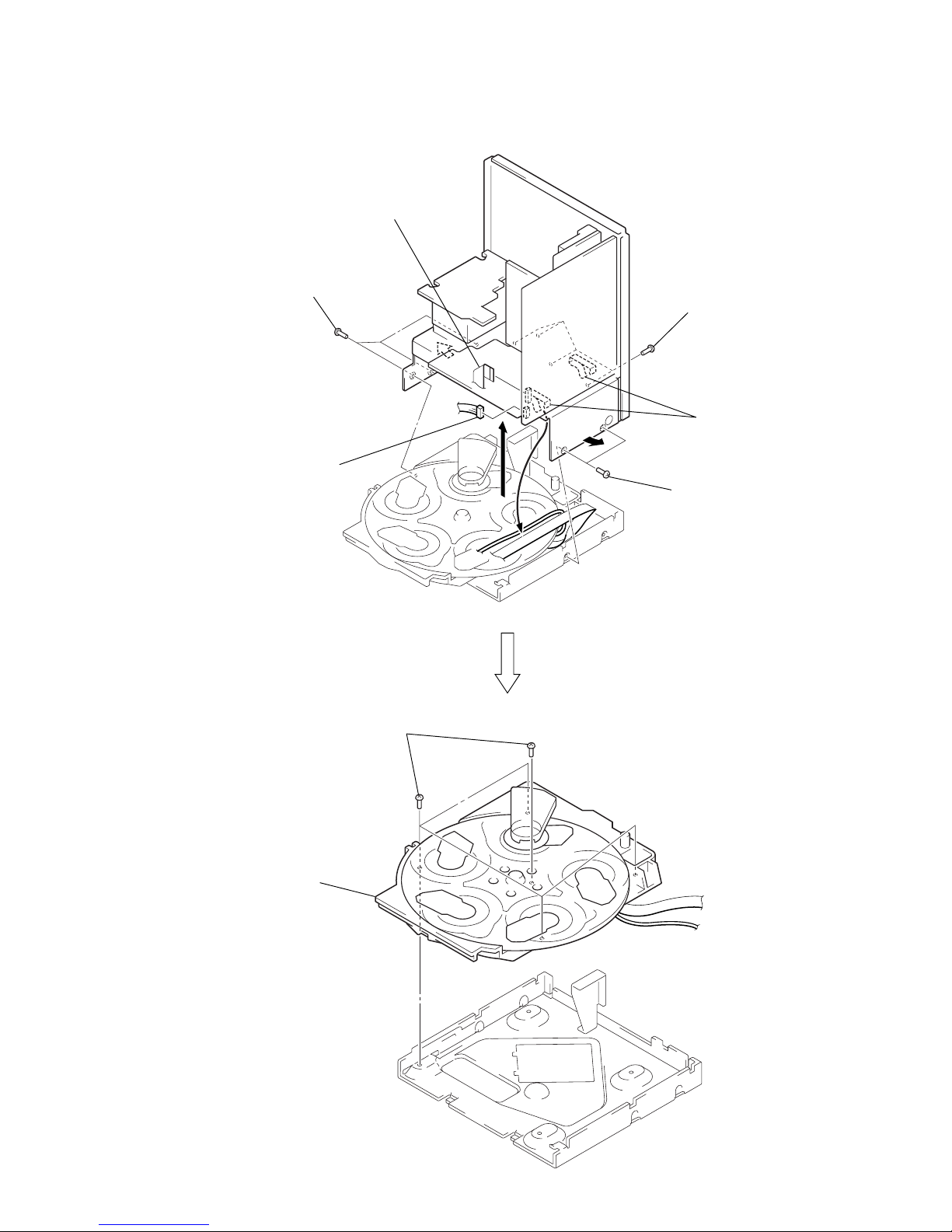

3-7. CD MECHANISM DECK (CDM37M-5BD32L)

2

connector

(CN412)

4

three screws

(BVTP3

×

8)

5

6

5

1

wire (flat type)

(19 core) (CN411)

3

four screws

(BVTP3

×

8)

4

two screws

(BVTP3

×

8)

7

Open the cable clamp.

9

CD mechanism deck

(CDM37M-5BD32)

8

five screws

(BVTP3 × 8)

12

HCD-XG60/XG500

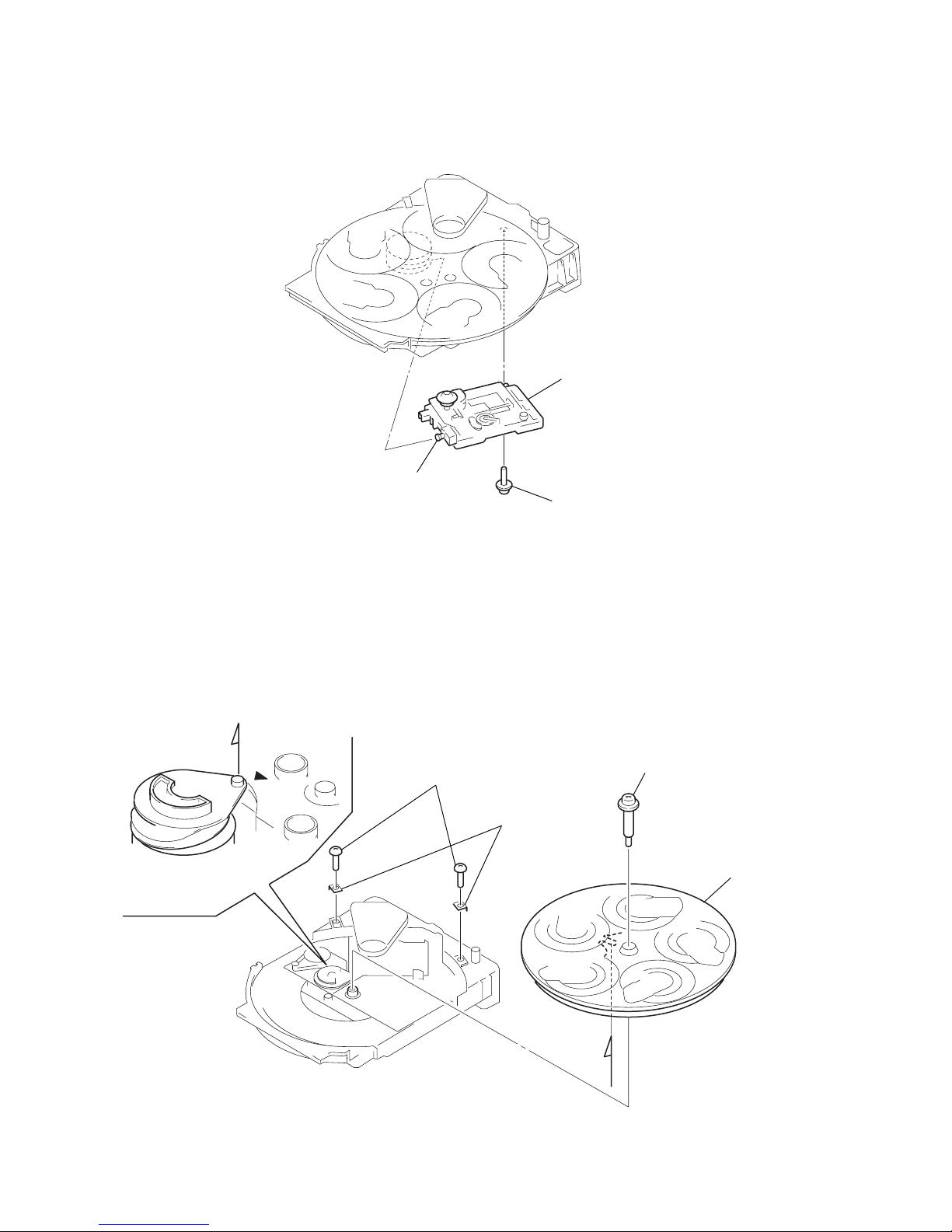

3-8. BASE UNIT (BU-5BD32L)

3 base unit

(BU-5BD32L)

1 BU fitting scre

w

2 boss

3-9. DISC TABLE

Note: When the disc table is installed, adjust the positions of roller cam

and mark B as shown in the figure, then set to the groove of disc

table.

1 two screws

(BVTP3 × 8)

A

2 two brackets (BU)

3 step screw

4 disc tabl

e

A

13

HCD-XG60/XG500

[CD Delivery Mode]

• This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the ?/1 button to turn the power ON.

2. Press the [LOOP] and ?/1 buttons simultaneously.

3. A message “LOCK” is displayed on the fluorescent indicator

tube, and the CD delivery mode is set.

[LED and Fluorescent Indicator Tube All Lit, Key Check

Mode]

Procedure:

1. Press three buttons of [ /CLOCK SET], [ENTER/NEXT],

and [DISC 2] simultaneously.

2. LEDs and fluorescent indicator tube are all turned on.

Press the [DISC 2] button, and the key check mode is activated.

3. In the ke y check mode, the fluorescent indicator tube displays

“K 0 J0 V0”. Each time a button is pressed, “K” value increases. However , once a button is pressed, it is no longer taken

into account.

“J” value increases like 1, 2, 3 ... if turn the JOG dial clockwise, or it decreases like 0, 9, 8 ... if turn the JOG dial counterclockwise.

“V” value increases like 1, 2, 3 ... if turn the [VOLUME] dial

clockwise, or it decreases like 0, 9, 8 ... if turn the JOG dial

counterclockwise.

4. To release from this mode, press three buttons in the same

manner as step 1, or disconnect the power cord.

c

[MC Cold Reset]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Turn the power ON or set to the DEMO mode.

2. Press three buttons of [ /CLOCK SET], [ENTER/NEXT], and

?/1 simultaneously.

3. The set is reset, and displays “COLD RESET”, then becomes

DEMO mode.

[MC Hot Reset]

• This mode resets the set with the preset data kept stored in the

memory. The hot reset mode functions same as if the power

cord is plugged in and out.

Procedure:

1. Turn the power ON or set to the DEMO mode.

2. Press three buttons of [ /CLOCK SET], [ENTER/NEXT],

and [DISC 1] simultaneously.

3. The set is reset, and becomes standby state.

[Change-over the AM Tuning Interval]

(EXCEPT AEP, UK, and Saudi Arabia models)

• The AM tuning interval can be changed over 9 kHz or 10 kHz.

Procedure:

1. Press the ?/1 button to turn the power ON.

2. Select the function “TUNER”, and press the [TUNER/BAND]

button to select the BAND “AM”.

3. Press the ?/1 button to turn the power OFF.

4. Press the [ENTER/NEXT] and ?/1 buttons simultaneously,

and the display on the fluorescent indicator tube changes to

“AM 9 K STEP” or “AM 10 K STEP”, and thus the tuning

interval is changed over.

c

SECTION 4

TEST MODE

c

14

HCD-XG60/XG500

[Aging Mode]

This mode can be used for operation check of tape deck section.

Tape deck section work in parallel.

• If an error occurred:

The aging operation stops and display then status.

• If no error occurs:

The aging operation continues repeatedly.

Procedure:

1. Load the tapes into the decks A and B respectively.

2. Press the [FUNCTION] button to select the function “CD”.

3. Press the [PLAY MODE] button to set the “ALL DISCS” mode,

and press the [REPEAT] button to “REPEAT” off.

4. Press three buttons of [ /CLOCK SET], [ENTER/NEXT],

and [DISC 4] simultaneously.

5. The aging mode is activated, if the indicator of disc tray num-

ber on the fluorescent indicator tube is blinking.

6. To release from the aging mode, press the ?/1 button to turn

the power OFF and operate the cold reset. (Refer to the “MC

Cold Reset”)

1. Display at the Aging Mode

• Display operating state of tape deck section alternately.

• If an error occurred, stop display.

2. Tape Deck Section

• The sequence during the aging mode is following as below.

• If an error occurred, stop display that step.

Aging mode sequence (Tape deck section) :

Rewind the tape A and B

“TAPE A AG-1”

Shut off

FWD play the tape A

“TAPE A AG-2”

2 minutes

Fast forward the tape A

“TAPE A AG-3”

Shut off or 20 seconds

REV play the tape A

“TAPE A AG-4”

2 minutes

Rewind the tape A

“TAPE A AG-5”

Shut off

FWD play the tape B

“TAPE B AG-2”

2 minutes

Fast forward the tape B

“TAPE B AG-3”

Shut off or 20 seconds

REV play the tape B

“TAPE B AG-4”

2 minutes

Rewind the tape B

“TAPE B AG-5”

Shut off

Note: “TAPE * AG-*” is display of each step.

c

15

HCD-XG60/XG500

SECTION 5

MECHANICAL ADJUSTMENTS

SECTION 6

ELECTRICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

Torque Measurement

Mode Torque Meter Meter Reading

3.1~6.96 mN•m

FWD CQ-102C (31 to 71 g•cm)

(0.43 – 0.98 oz•inch)

FWD

0.20~0.58 mN•m

back tension

CQ-102C (2 to 6 g•cm)

(0.03 – 0.08 oz•inch)

3.1~6.96 mN•m

REV CQ-102RC (31 to 71 g•cm)

(0.43 – 0.98 oz • inch)

REV

0.20~0.58 mN•m

back tension

CQ-102RC (2 to 6 g•cm)

(0.03 – 0.08 oz • inch)

6.97~14.02 mN•m

FF/REW CQ-201B (71 to 143 g•cm)

(0.99 – 1.99 oz • inch)

9.80 mN•m

FWD tension CQ-403A (100 g or more)

(3.53 oz or more)

9.80 mN•m

REV tension CQ-403A (100 g or more)

(3.53 oz or more)

Precaution

1. Demagnetize the record/playback head with a head demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in

this service manual. (As a general rule, playback circuit adjustment should be completed before performing recording

circuit adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise specified.

8. Set to the DOLBY NR OFF.

9. Set to the test mode.

(1) Press the ?/1 button to turn the power ON.

(2) Select the function “TAPE A or B”.

(3) Press the button of [ /CLOCK SET], [ENTER/NEXT],

and [DISC 3] simultaneously, to set the tape deck test mode

and displays “TEST MODE” on the fluorescent indicator

tube.

(4) To release from the test mode, press the ?/1 button.

• Test Tape

Tape Signal Used for

P-4-A100 10 kHz, – 10 dB Azimuth Adjustment

WS-48B 3 kHz, 0 dB Tape Speed Adjustment

P-4-L300 315 Hz, 0 dB Playback Level Adjustment

0 dB = 0.775 V

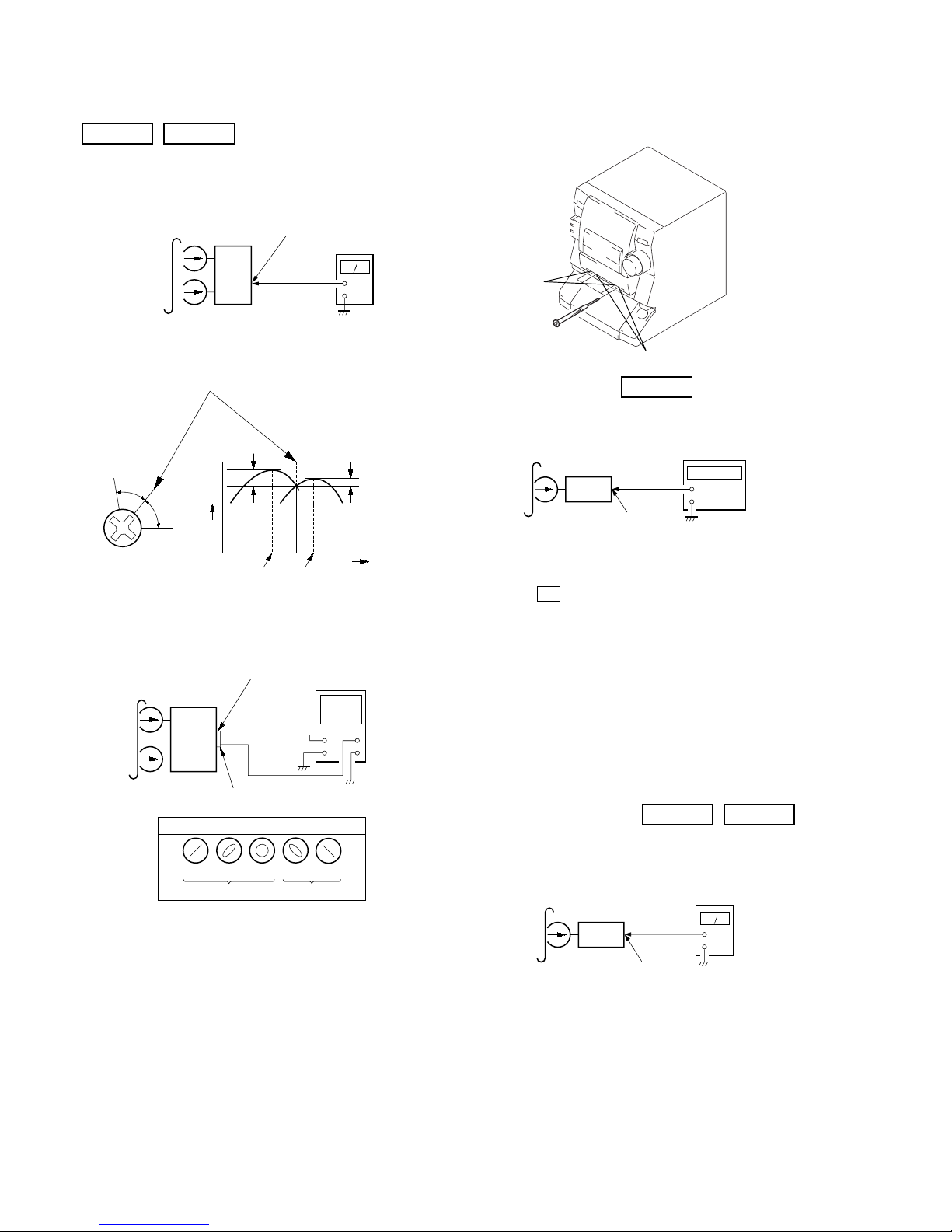

DECK SECTION

c

16

HCD-XG60/XG500

Tape Speed Adjustment DECK B

Mode: Playback

1. Insert the WS-48B into the deck B.

2. Press the H button on the deck B.

3. Press the [H SPEED DUB] button in playback mode.

Then at HIGH speed mode.

4. Adjust RV1001 on the LEAF SW board do that frequency

counter reads 6,000 ± 180 Hz.

5. Press the [H SPEED DUB] button.

Then back to NORMAL speed mode.

6. Adjust RV1002 on the LEAF SW board so that frequency

counter reads 3,000 ± 90 Hz.

Adjustment Location: LEAF SW board

Sample value of Wow and Flutter: 0.3% or less W.RMS (JIS)

(WS-48B)

Playback Level Adjustment DECK A DECK B

Procedure:

Mode: Playback

Deck A is RV311 (L-CH), Deck B is RV301 (L-CH) so that adjustment within specification values as follows.

Specification V alues:

J101 PB level: 301.5 to 338.3 mV (– 8.2 to – 7.2 dB) level

difference between the channels: within ± 0.5 dB

Adjustment Location: AUDIO board

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

3. Mode: Playback

4. Repeat step 1 to 3 in playback (REV) mode.

5. After the adjustments, apply suitable locking compound to the

pats adjusted.

Screw

position

L-CH

peak

within

1dB

Output

level

L-CH

peak

R-CH

peak

within

1dB

Screw

position

R-CH

peak

set

test tape

P-4-A100

(10 kHz, – 10 dB)

R-CH

oscilloscope

L-CH

R-CH

V

H

waveform of oscilloscope

in phase 45 ° 90 ° 135° 180°

good

wrong

MAIN board

MD OUT jack (J701)

L-CH

+

–

set

test tape

WS-48B

(3 kHz, 0 dB)

MAIN board

MD OUT jack (J701)

L-CH, R-CH

frequency counter

+

–

set

test tape

P-4-L300

(315 Hz, 0 dB)

MAIN board

MD OUT jack (J701)

L-CH

level mete

r

Record/Playback Head Azimuth Adjustment

Note: Perform this adjustments for both decks

Procedure:

1. Mode: Playback (FWD)

DECK A DECK B

set

MAIN board

MD OUT jack (J701)

L-CH, R-CH

+

–

level mete

r

test tape

P-4-A100

(10 kHz, – 10 dB)

Adjustment Location:Playback Head (Deck A).

Record/Playback/Erase Head (Deck B).

reverse

forward

17

HCD-XG60/XG500

REC Bias Adjustment DECK B

Procedure:

1. Mode: Record

FUNCTION: VIDEO

2. Mode: Playback

3. Confirm playback the signal recorded in step 1 become specification values as follows.

If these values are out of specification values, adjust the RV341

(L-CH) and RV441 (R-CH) on the AUDIO board to repeat

steps 1and 2.

Specification values: Playback output of 315 Hz to playback

output of 10 kHz: ± 0.5 dB

Adjustment Location: AUDIO board

REC Level Adjustment DECK B

Procedure:

1. Mode: Record

FUNCTION: VIDEO

2. Mode: Playback

3. Confirm playback the signal recorded in step 1 become specification values as follows.

If these values are out of specification values, adjust the RV301

(L-CH) and RV351 (R-CH) on the MAIN boar d to repeat steps

1 and 2.

Specification values:

J101 PB level: 47.2 to 53.0 mV (– 24.3 to – 23.3 dB)

Adjustment Location: MAIN board

attenuator

set

MAIN board

VIDEO AUDIO IN jack (J701)

L-CH, R-CH

1) 315 Hz

2) 10 kHz

50 mV (– 23.8 dB)

600

Ω

blank tap

e

CN-123

AF OSC

+

–

set

recorded

portion

MAIN board

MD OUT jack (J701)

L-CH, R-CH

level mete

r

set

MAIN board

VIDEO AUDIO IN jack (J701)

L-CH, R-CH

315 Hz, 50 mV (– 23.8 dB)

blank tape

CS-123

600

Ω

attenuator

AF OSC

+

–

set

recorded

portion

MAIN board

MD OUT jack (J701)

L-CH, R-CH

level mete

r

RV301

RV341

RV311

IC602

CN601

RL

RV441

PB LEVEL

(L)

– DECK B –

REC BIAS

PB LEVEL (L)

– DECK A –

– AUDIO BOARD (Component Side) –

TAPE SPEED

RV1002

RV1001

(NORMAL) (HIGH)

CN1001

– LEAF SW BOARD (Component Side) –

MD OUT

L/R

IC301

REC LEVEL

RV301

L-CH

RV351

R-CH

VIDEO

AUDIO IN

L/R

J701

– MAIN BOARD (Conductor Side) –

18

HCD-XG60/XG500

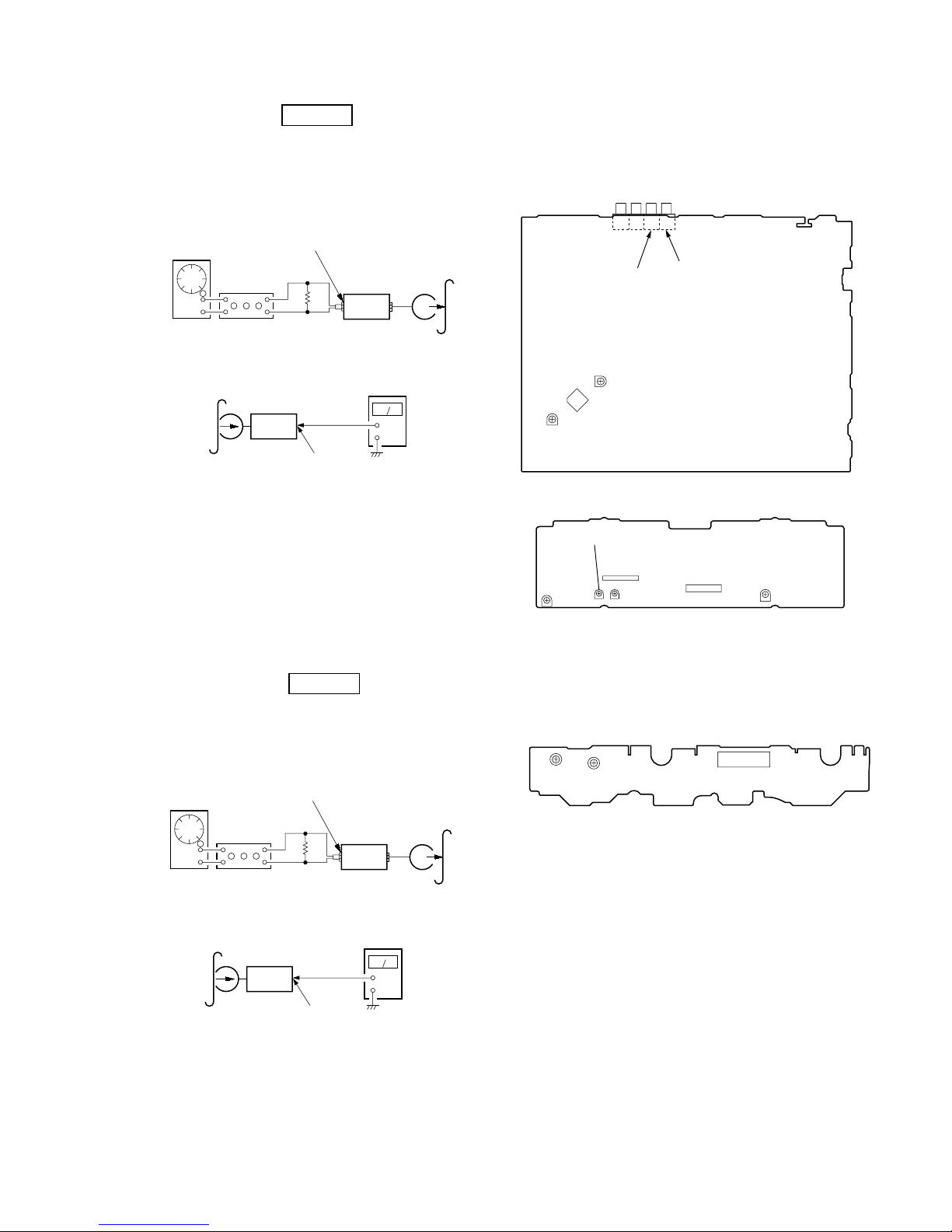

Note:

1. CD Block is basically designed to operate without adjustment. Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10 MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specified value with the following checks.

S-Curve Check

Procedure:

1. Connect oscilloscope to TP (FE) and TP (VC).

2. Connect between TP (FE1) and TP (VC) by lead wire.

3. Connect between TP (AGCCON) and TP (GND) by lead wire.

4. Turn the power ON.

5. Load a disc (YEDS-18) and actuate the focus search. (In con-

sequence of open and close the disc tray, actuate the focus

search)

6. Cofirm that the oscilloscope waveform (S-curv e) is symmetri-

cal between A and B. And confirm peak to peak level within

4 ± 1 Vp-p.

S-curve waveform

7. After check, remove the lead wire connected in step 2 and 3.

Note: • Try to measure sev eral times to make sure than the ratio of A : B

or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the brightness

to obtain best waveform.

RF Level Check

Procedure:

1. Connect oscilloscope to TP (RF) and TP (VC).

2. Connect between TP (AGCCON) and TP (GND) b y lead wire.

3. Turn the power ON.

4. Load a disc (YEDS-18) and press the H X button to play.

5. Confirm that the oscilloscope waveform is clear and check RF

signal level is correct or not.

6. After check, remove the lead wire connected in step 2.

Note: Clear RF signal waveform means that the shape “ ” can be clearly

distinguished at the center of the waveform.

CD SECTION

+

–

BD board

TP (FE)

TP (VC)

oscilloscop

e

A

B

symmetry

within 4 ± 1 Vp-p

+

–

BD board

TP (RF)

TP (VC)

oscilloscop

e

(AC range)

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

(with the 10: 1 probe

in use)

level:

1.45 ± 0.3 Vp-p

E-F Balance (1 Track Jump) Check

Procedure :

1. Connect oscilloscpe to TP (TE) and TP (VC).

2. Turn the power ON.

3. Load a disc (YEDS-18) and playback the number five track.

4. Press the H X button. (Becomes the 1 track jump mode)

5. Confirm that the level B and A (DC voltage) on the oscilloscope waveform.

1 track jump waveform

Specified level: × 100 = less than ± 22%

6. After check, remove the lead wire connected in step 1.

Checking Location:

A

B

+

–

BD board

TP (TE)

TP (VC)

oscilloscope

(DC range)

A (DC voltage

)

center of

waveform

B

0V

level = 1.3 ± 0.6 Vp-p symmetry

– BD BOARD (Side B) –

TP (VC)

TP (FE)

TP (FE1)

TP (TE)

TP (RF)

TP (AGCCON)

TP (GND)

IC102

IC103

HCD-XG60/XG500

1919

SECTION 7

DIAGRAMS

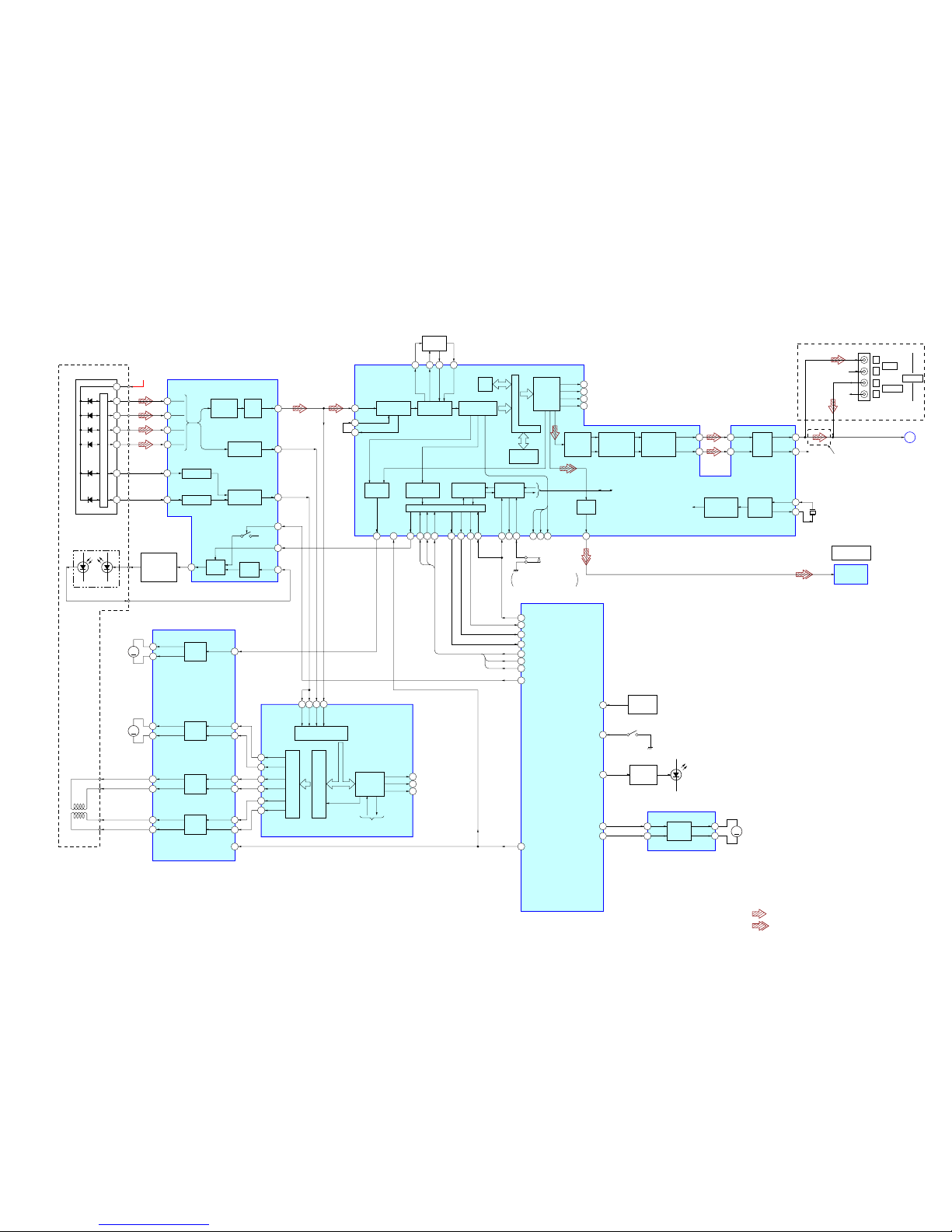

7-1. BLOCK DIAGRAM – CD SERVO Section –

SQSO

SQCK

A/D

CONVERTER

CH1OUTF

CH1OUTR

5

4

7

2

1

5

10

6

6

7

8

16

14

13

10

11

22

4

3

51

49

48

43

24

41

40

39

64 15

28

29

30

31

32

33

24

25

23

5

6

2

3

17

18

15

16

E

B

C

D

A

CD D+5V

F

DETECTOR

A

B

C

D

RF

SUMMING

AMP

FOCUS

ERROR AMP

RF EQ

AMP

TRACKING

ERROR AMP

RFO

FE

RF AMP,

FOCUS/TRACKING ERROR AMP

IC103

TE

E

F

F I-V AMP

E I-V AMP

AUTOMATIC

POWER

CONTROL

Q101

APC LD

AMP

APC PD

AMP

LD

LD

PD

LASER DIODE

RFAC

ASYO

ASYI

ASYMMETRY

CORRECTION

DIGITAL

PLL

DIGITAL SIGNAL PROCESSOR,

DIGITAL FILTER, D/A CONVERTER

IC101 (1/2)

DATA

XLAT

CLOK

14 5 6

MDP

26

7

8

XLON

3

XRST

DIGITAL

CLV

D/A

INTERFACE

SE

TE

FE

RFDC

FOCUS/TRACKING/SLED

SERVO DSP

FOCUS/TRACKING/SLED

PWM GENERATOR

SFDR

CH3FIN

CH4SIN

CH3RIN

CH3OUTF

CH3OUTR

CH2FIN

CH2RIN

CH1FIN

CH1RIN

20

MUTE

SRDR

TFDR

TRDR

FFDR

FRDR

S101

(LIMIT)

EMPH

WFCK

GFS

MIRR/DFCT/

FOK

DETECTOR

SERVO AUTO

SEQUENCER

SERVO

INTERFACE

CPU INTERFACE

18

63

62

61

19

SENS

20

35

57

58

37

56

19

SCOR

SQ-DATA

SQ-CLK

CD-DATA

XLT

CD-CLK

SENS

SCOR

1 2

32

33

SCLK

COUT

9 21

SSTP

27

FOK

22

23

MIRR

DFCT

TO SERVO INTERFACE

CH4OUTF

CH4OUTR

M101

(SPINDLE)

MOTOR

DRIVE

MOTOR

DRIVE

COIL

DRIVE

CH2OUTF

CH2OUTR

COIL

DRIVE

M

M

M102

(SLED)

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

IC102

2-AXIS

DEVICE

(TRACKING)

(FOCUS)

DIGITAL SERVO

PROCESSOR

IC101 (2/2)

OPTICAL PICK-UP BLOCK

(KSS-213DH)

LDON

21

HOLD SW

PD

I-V AMP

12

11

13

14

54 565355

FILTER

FILO

PCO

CLTV

FILI

EFM

DEMODULATOR

SERIAL

IN

INTERFACE

DIGITAL

FILTER,

NOISE SHAPER

PWM

&

INTEGRATOR

BUFFER

CLOCK

GENERATOR

OPTICAL

TRANSCEIVER

IC781

IC781

CD DIGITALOUT

OPTICAL

TIMING

LOGIC

DIGITAL

OUT

INTERNAL BUS

16K

RAM

ERROR

CORRECTOR

SUBCODE

PROCESSOR

60

HOLD

59

XRST

XTAI

X101

16.9344MHz

AIN1

AIN2

R-CH

CD-L

AOUT1

AOUT2

TO MIRR/DFCT/

FOK DETECTOR

PCMD

BCK

LRCK

C2PO

DOUT

66

XTAO

67

70

77

LOUT1

LOUT2

72

75

71

76

: CD PLAY (ANALOG OUT)

: CD PLAY (DIGITAL OUT)

SYSTEM CONTROLLER

(CD MECHANISM CONTROL)

IC501 (1/4)

When the optical pick-up

is inner position.

ON :

(Page 21)

A

• SIGNAL PATH

• R-ch is omitted due to same as L-ch.

TBL-L

TBL-R

M

TABLE MOTOR DRIVER

IC201

OUT1

OUT2

IN1

IN2

M201

(TABLE)

DISC TABLE

SENSOR

IC202

ENC3/UP-SW

S201

(UP)

T-SENS

MOTOR

DRIVE

61

68

65

63

ENC2/DISC-LED

69

9

1

7

3

LED DRIVE

Q201

D201

(DISC No.)

J705

L

R

L

R

SEND

RETURN

DJ MIX

R-CH

R-CH

(EXCEPT XG60 : Mexican/XG500)

(XG60 : Mexican/XG500)

HCD-XG60/XG500

2020

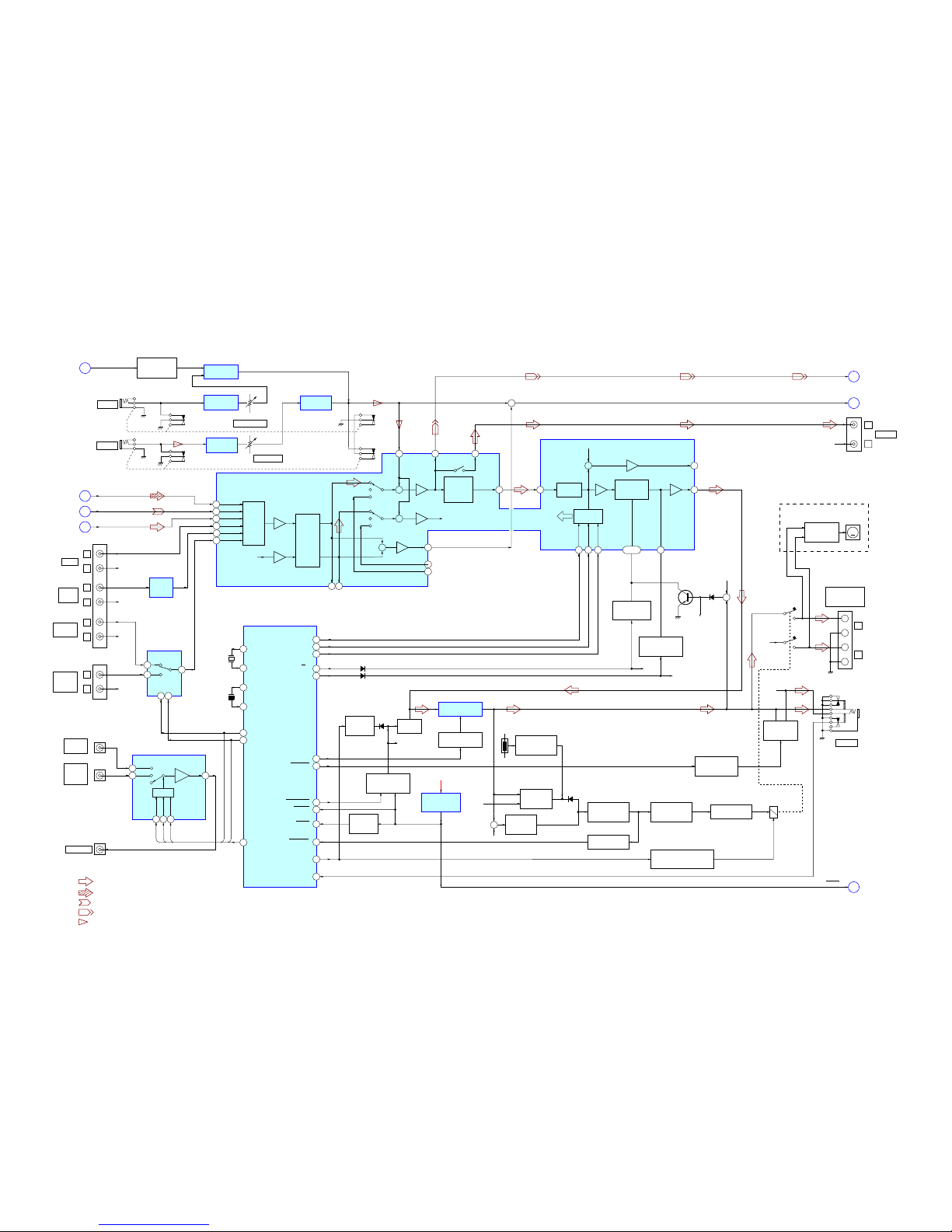

7-2. BLOCK DIAGRAM – TUNER/TAPE DECK Section –

PB EQ AMP

(DECK A)

IC611 (2/2)

PB LEVEL (L)

(DECK A)

REC-L

PB-L

CAPSTAN MOTOR

CONTROL SWITCH

Q1001

CAPSTAN

MOTOR DRIVE

Q336, 339

1

B

(Page 21)

(Page 21)

L-CH

R-CH

HP101

(PLAYBACK)

PB EQ AMP

(DECK B)

IC601 (2/2)

L-CH

R-CH

R-CH

R-CH

R-CH

HRPE101 (1/2)

(RECORD/PLAYBACK)

ALC

REC

EQ AMP

AMS

CIRCUIT

DOLBY NR

AMP

CIRCUIT

BIAS

CONTROL

CIRCUIT

DOLBY PASS

R-CH

R-CH

L.P.F.

BUFFER

Q335

M

M1

(CAPSTAN)

HRPE101 (2/2)

(ERASE)

BIAS OSC

T621

A+7V

R-CH

3

28

36

40

35 34

39

26

77

19

1516182022 23242517

8584838281 807978

31

33

32

+

48

4

2

RV311

PB LEVEL (L)

(DECK B)

RV301

TAPE SPEED

(NORMAL)

RV1002

TAPE SPEED

(HIGH)

RV1001

REC LEVEL (L)

(DECK B)

RV301

REC BIAS (R)

(DECK B)

RV441

REC BIAS (L)

(DECK B)

BIAS OSC

Q621, 622

REC BIAS

SWITCH

Q623

ROTATION

DETECT SENSOR

(DECK A)

IC1001

RV341

BIAS

TRAP

C331, L331

REC/PB SWITCHING

IC602

SYSTEM CONTROLLER

(CD MECHANISM CONTROL)

IC501 (2/4)

DECK PROCESS,

DECK A/B SELECT, PB/REC EQ AMP,

DOLBY NR AMP, ALC, AMS

IC301

A IN (L)

B IN (L)

A IN (R)

B IN (R)

MAOUT

PB OUT (L)

EQ OUT

(L)

MSIN

MSOUT

BIAS ON/OFF

70

120

BIAS (N)

BIAS (C)

BIAS (M)

S1004

A 120/70

B NORM/CROM

ALC ON/OFF

PB A/B

NORM/HIGH

NR ON/OFF

RM ON/OFF

REC/PB/PASS

LM ON/OFF

(DECK A 120/70)

88

S1003

(DECK A HALF)

S1001

(DECK A PLAY)

S1002

(DECK B PLAY)

S1008

(DECK B 120/70)

27

REC OUT (L)

R OUT (L)

R IN (L)

ALC (L)

EQ IN (L)

ALC

IN (L)

44

38

100

AMS-IN

91

A-SHUT

ROTATION

DETECT SENSOR

(DECK B)

IC1002

90

B-SHUT

TRIGGER

PLUNGER DRIVE

(DECK A)

Q333, 334

73

A-TRG

TC-MUTE

R/PB/PAS

NR-ON/OFF

REC-MUTE

BIAS

EQ-H/N

PB-A/B

ALC

TC-RELAY

A-PLAY-SW

B-PLAY-SW

A-HALF

89

S1006

(DECK B HALF)

S1009

(DECK B REC)

S1005

(DECK A REC)

B-HALF

TRIGGER PLUNGER

DECK A

TRIGGER

PLUNGER DRIVE

(DECK B)

Q331, 332

72

B-TRG

76

74

CAP-M-H/L

CAPM-CNT2

TRIGGER PLUNGER

DECK B

87

86

C

• SIGNAL PATH

: PLAYBACK (DECK A)

: PLAYBACK (DECK B)

: RECORD

: TUNER (FM/AM)

D+5V

(UNSW)

R-CH

FM/AM TUNER UNIT

ANTENNA

ST-L

FM ANT

FM ANT

AM ANT

AM ANT

ST-R

ST-MUTE

STEREO

TUNED

ST-DIN

ST-DOUT

ST-CLK

ST-CE

FM

75Ω

AM

COAXIAL

FM 75Ω

(AEP, UK)

(EXCEPT AEP, UK)

RDS-DATA

RDS-INT

49 50 51 54 53 55 52 21 20

RDS-INT

RDS-DATA

ST-CE

ST-CLK

ST-DOUT

ST-DIN

TUNED

STEREO

ST-MUTE

RDS-INT

RDS-DATA

ST-CE

ST-CLK

ST-DOUT

ST-DIN

TUNED

STEREO

ST-MUTE

(AEP, UK)

(Page 21)

D

CT-L

• R-ch is omitted due to same as L-ch.

46

51

53

43

ST-MUTE

STEREO

TUNED

ST-DIN

ST-DOUT

ST-CLK

ST-CE

RDS-DATA

RDS-INT

(AEP, UK)

PB EQ AMP

(DECK A)

IC611 (1/2)

PB EQ AMP

(DECK B)

IC601 (1/2)

HCD-XG60/XG500

2121

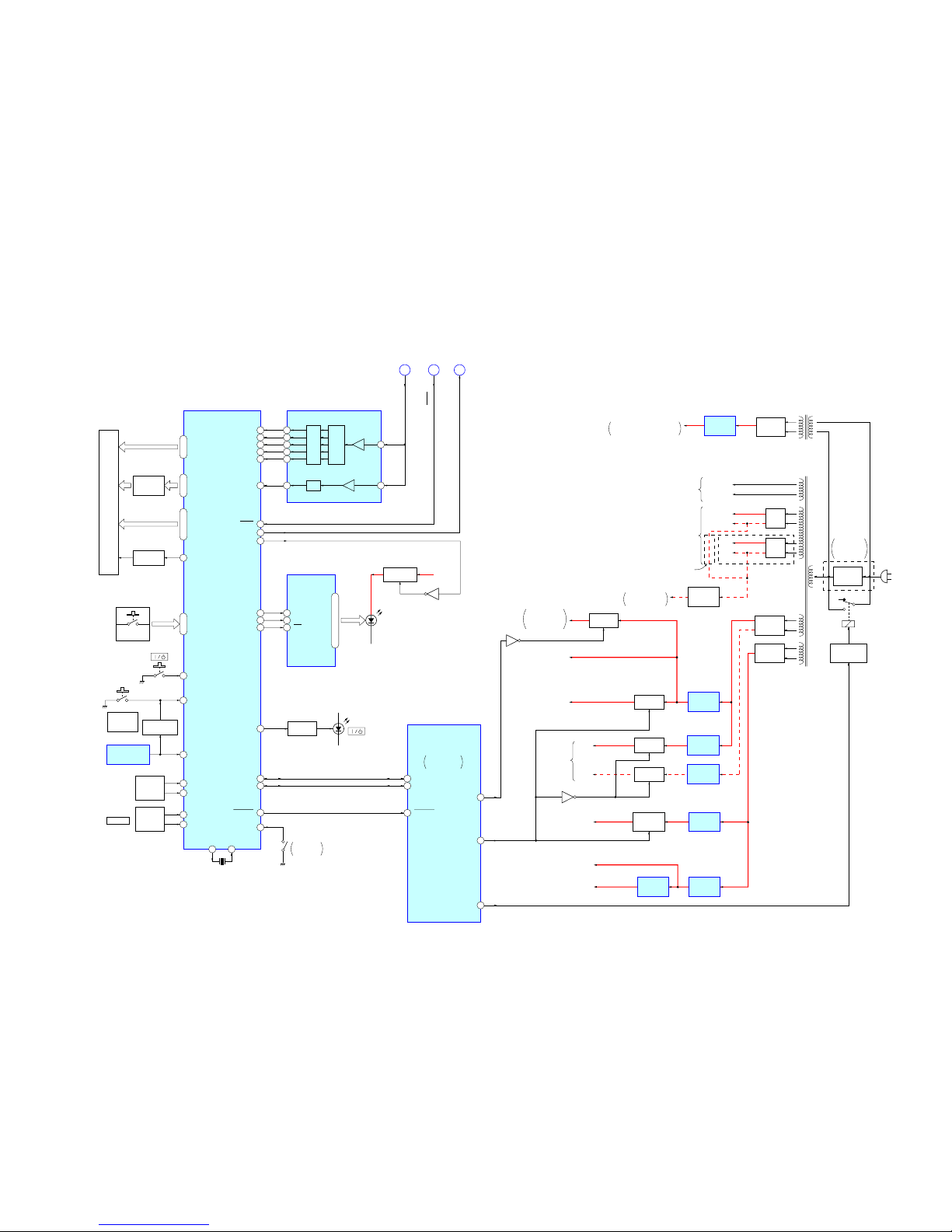

7-3. BLOCK DIAGRAM – MAIN Section –

DBFB CONTROL

SWITCH

Q111

BASS WOOFER

CONTROL SWITCH

Q115

PROTECT

SWITCH

Q804

RESET

SWITCH

Q801

PHONO

EQ AMP

IC601

POWER AMP

IC801

CD-L

J701 (1/2)

A

(Page 19)

(Page 20)

C

(Page 20)

(Page 22)

PB-L

B

SPEANA

F

R-CH

FUNCTION SELECT

SWITCH

IC181

R-CH

VOLUME

CONTROL

CPU

INTERFACE

BASS BOOST

CONTROL

CIRCUIT

INPUT

SELECT

SWITCH

SOUND

CONTROL

CIRCUIT

GRAPHIC

EQUALIZER

CONTROL

CIRCUIT

R-CH

FEED BACK

SWITCH

Q112

R-CH

COMMAND

F OUT2

BUF

OUT2

VOL

IN2

+

+

R-CH

R-CH

R-CH

R-CH

EVER +5V

D803

R-CH

+

+

RV601

MIC AMP

IC850 (2/2)

MUTING

Q113

OVER LOAD

DETECT

Q801, 851

TEMPERATURE

DETECT SWITCH

Q831, 832

DC DETECT

SWITCH

Q433, 434

INPUT SELECT SWITCH,

GRAPHIC EQUALIZER CONTROL,

ELECTRICAL VOLUME

IC101

IN D2

IN C2

IN E2

IN A2

IN F2

KEY IN2

KEY IN1

KEY OUT 2

KEY OUT 1

L+R

DATA

CLOCK

LATCH

493-DATA

493-CLK

493-LAT

SW-MODE

BB B2,

BB A2

MIC IN

SUPER

WOOFER

REC A2

REC-L

REC B2

R-CH

R-CH

X0

X

AB

X1

TH831

R-CH

R-CH

+

R-CH

M901

(FAN)

(US, Canadian, E)

R-CH

–1

–2

FAN MOTOR

DRIVE

Q961, 962

R-CH

R-CH

OVER LOAD

DETECT SWITCH

Q432

PROTECT SWITCH

Q439

OVER LOAD

DETECT SWITCH

Q437

FRONT SPEAKER PROTECT

RELAY DRIVE

Q401, 402

STANDBY SWITCH

Q803, 804, 834

MUTING CONTROL

SWITCH

Q802, 803

MUTING CONTROL

SWITCH

Q833

HEADPHONE

MUTING

Q805, 855

TM401

J802

J801

L

L

R

R

PHONO

IN

L

R

VIDEO

AUDIO IN

GAME

INPUT

AUDIO

MD IN

J701 (2/2)

L

R

MD OUT

38, 39

D501

D534

D807

D401

RY401

J803

PHONES

+

–

–

+

SYSTEM CONTROLLER

(CD MECHANISM CONTROL)

IC501 (3/4)

+

GUITAR AMP

IC853

27

F-RELAY

3

7

34

STK-POWER

1

HP MUTE

93

LINE-MUTE

RESET

6

12

AC-CUT

22

HP-IN

36

47

48

38

60 5

59

6

2 58 57

42 41

72

36

34

BUF IN2

373233

66

67

65

69

64

IN B2

68

M

L

R

30

+

XC-OUT

X502

16MHz

X501

32.768kHz

XC-IN

X-OUT

X-IN

FUNC SEL0

FUNC SEL1

V MUTE

11

10

13

46

14

13

10 9

12

15

J804 (2/2)

L

R

45

28

PROTECT

DBFB-H/L

GUITAR

MIX MIC

DISTORTION

E

(Page 22)

DISTORTION

ON/OFF SWITCH

Q880 – 883

GUITAR AMP

IC852

MIC AMP

IC850 (1/2)

MIC LEVEL

RV602

GUITAR LEVEL

ST-L

D

(Page 20)

1

6

IN1

IN3

10

VOUT

532

CTLA

CTLB

CTLC

LOGIC

J804 (1/2)

J702 (1/2)

J702 (2/2)

CBACBA

VIDEO SELECT

SWITCH,

VIDEO AMP

IC191

GAME

INPUT

VIDEO

VIDEO

AUDIO IN

VIDEO OUT

• SIGNAL PATH

: TUNER (FM/AM)

: CD PLAY

• R-ch is omitted due to same as L-ch.

: TAPE PLAY

: RECORD

: MIC INPUT

G

(Page 22)

RESET

RESET SIGNAL

GENERATOR

IC801

PROTECT SWITCH

Q431

FRONT SPEAKER

IMPEDANCE

USE 4 – 16Ω

HCD-XG60/XG500

2222

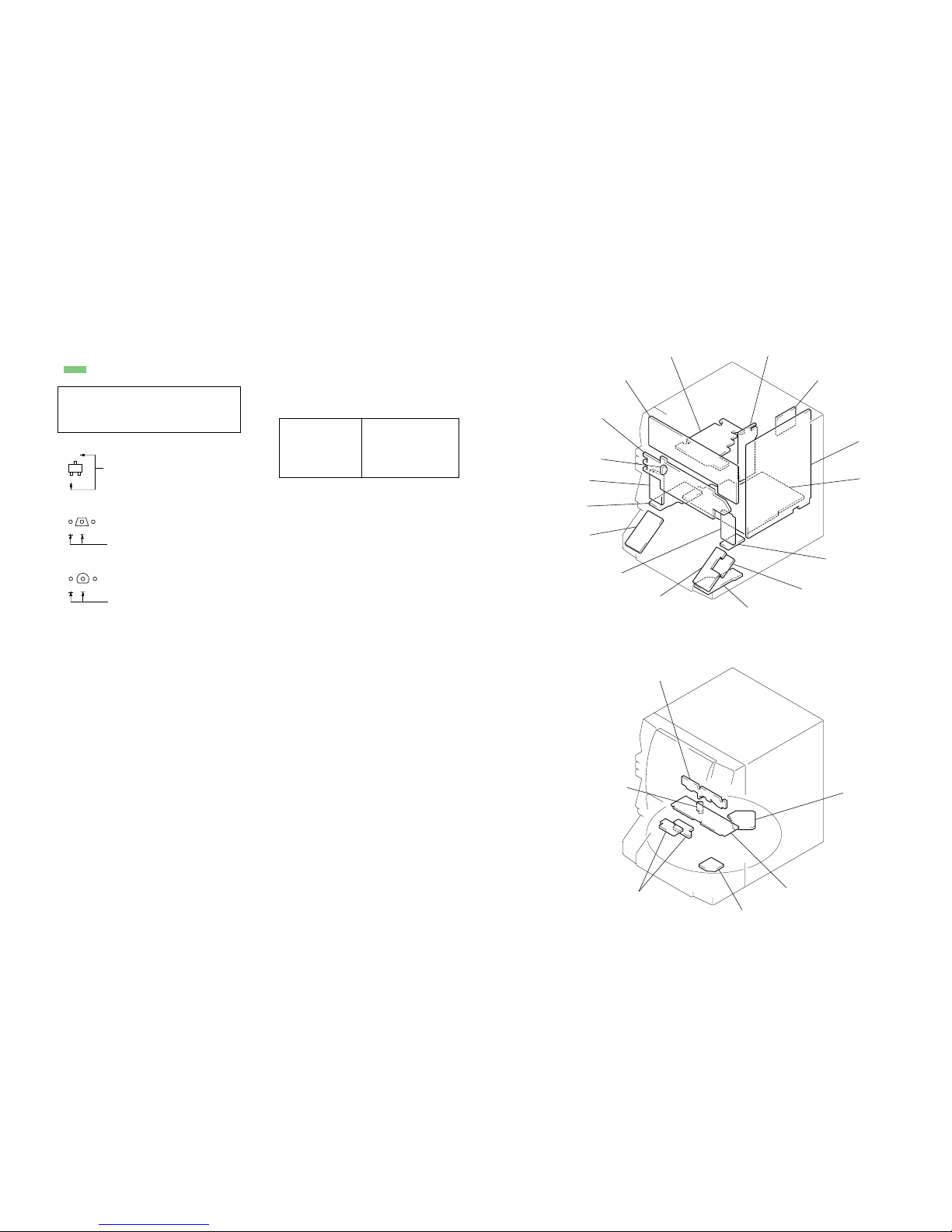

7-4. BLOCK DIAGRAM – DISPLAY/KEY CONTROL/POWER SUPPLY Section –

+10V

REGULATOR

IC931

TUNER

B+ SWITCH

Q931, 932

+12V

REGULATOR

IC932

+7V

REGULATOR

IC933

+7V

REGULATOR

IC901

–7V

REGULATOR

IC951

ST +10V

(FM/AM TUNER UNIT B+)

FAN MOTOR B+

TC M+12V

(TC MOTOR SECTION B+)

CD M+7V

(CD MOTOR SECTION B+)

B+ SWITCH

Q911, 912

B+ SWITCH

Q901, 902

B– SWITCH

Q903 – 905

+5V

REGULATOR

IC911

RECT

D833 – 836

RECT

D841 – 844

POWER AMP (IC801),

PROTECT CIRCUIT

POWER

TRANSFORMER

T951

RECT

D832

RECT

D831

–35V

REGULATOR

Q903, 908

AC IN

TC, PANEL,

AUDIO

A+7V

A–7V

VF

TO FLUORESCENT

INDICATOR TUBE

(FL601)

VF

+VL

–VL

+VH

–VH

REMOTE CONTROL

RECEIVER

IC702

GRID DRIVE

Q605, 606

FLUORESCENT INDICATOR TUBE DRIVER,

KEY CONTROL

IC601

SYSTEM CONTROLLER

CD MECHANISM

CONTROL

IC501 (4/4)

LED DRIVER

IC701

BAND-PASS FILTER

IC602

Q604

+5V (LED)

BPF 0

19

BPF 2

20

BPF 3

21

BPF 4

GRID DRIVE

Q607

DET

DET

B.P.F.

22

ALL BAND

REC IN

LINE

IN

1

SIRCS

ROTARY

ENCODER

S763

ROTARY

ENCODER

S736

74

JOG A

9

VOL A

75

JOG B

10

72 70

VOL B

XOUT

XIN

B+ SWITCH

Q602, 603

KEY 0 – KEY 4

BPF 1

F02

F04

F05

F06

F03

GR-1

(Page 21)(Page 21)

F

D611 – 614, 621, 622,

D700 – 710, 713 – 719,

D741, 791

SPEANA

LED SEL

7

LED DAT

5

LED SCK

3

LED LATCH

DATA

CLK

6

13

14

15

43

I2C DATA

I2C CLK

IIC-DATA

IIC-CLK

RESET

RESET

18

79

78

29

WAKE UP

WAKE UP

8

D-SW

S742

80

18

30

CD-POWER

5

POWER

Q906

2

73

17

14

13

12

REC

LEVEL

11

15

16

4

6

11 – 15

SEG-1 – SEG-23

44 – 46

GR-15, GR-16

28 , 27

GR-2 – GR-14

42, 40 – 29

17, 19 – 23, 1 – 4, 7 – 11

P1 – P6, P7 – P10, P12 – P16

S763

(JOG DIAL)

S601 – 607, 611 – 619, 621 – 627,

S701 – 710, 712 – 732, 741, 743 – 757

(S632 : AEP, UK)

S736

VOLUME

X601

12.5MHz

G

STB

LED DRIVE

Q601

LED STANDBY

77

+5V (LED)

(PANEL SECTION B+)

D+5V (UNSW)

(RDS SECTION B+)

FLUORESCENT INDICATOR TUBE

FL601

D601

LID (CD)

OPEN/CLOSE

–35V

FL DRIVER (IC601)

B–

CD A+5V (SW) ,

CD D+5V (SW)

CD MECHANISM

DECK SECTION

B+

Q914

VOLTAGE

SELECTOR

S901

AU D+5V

M62493FP (IC101) B+

D+5V (SW)

(CD SENSOR SECTION B+)

4

KEY POWER ON/OFF

KEY POWER

SAVE/DEMO

2

SIRCS BUFFER

Q608, 609

S608

POWER

SAVE/DEMO

(STANDBY)

S609

(Page 21)

E

GUITAR DISTORTION

16

DISTORTION

B+ SWITCH

Q913

RECT

D902 – 905

+5V

REGULATOR

IC901

EVER +5V

SYSTEM CONTROLLER (IC501) ,

FL DRIVER (IC601) B+

(XG60)

(XG500)

RY901

STBY RELAY

43

EXCEPT

XG60 : Mexican

/XG500

SUB POWER

TRANSFORMER

T901

POWER ON/OFF

RELAY DRIVE

Q901

HCD-XG60/XG500

2323

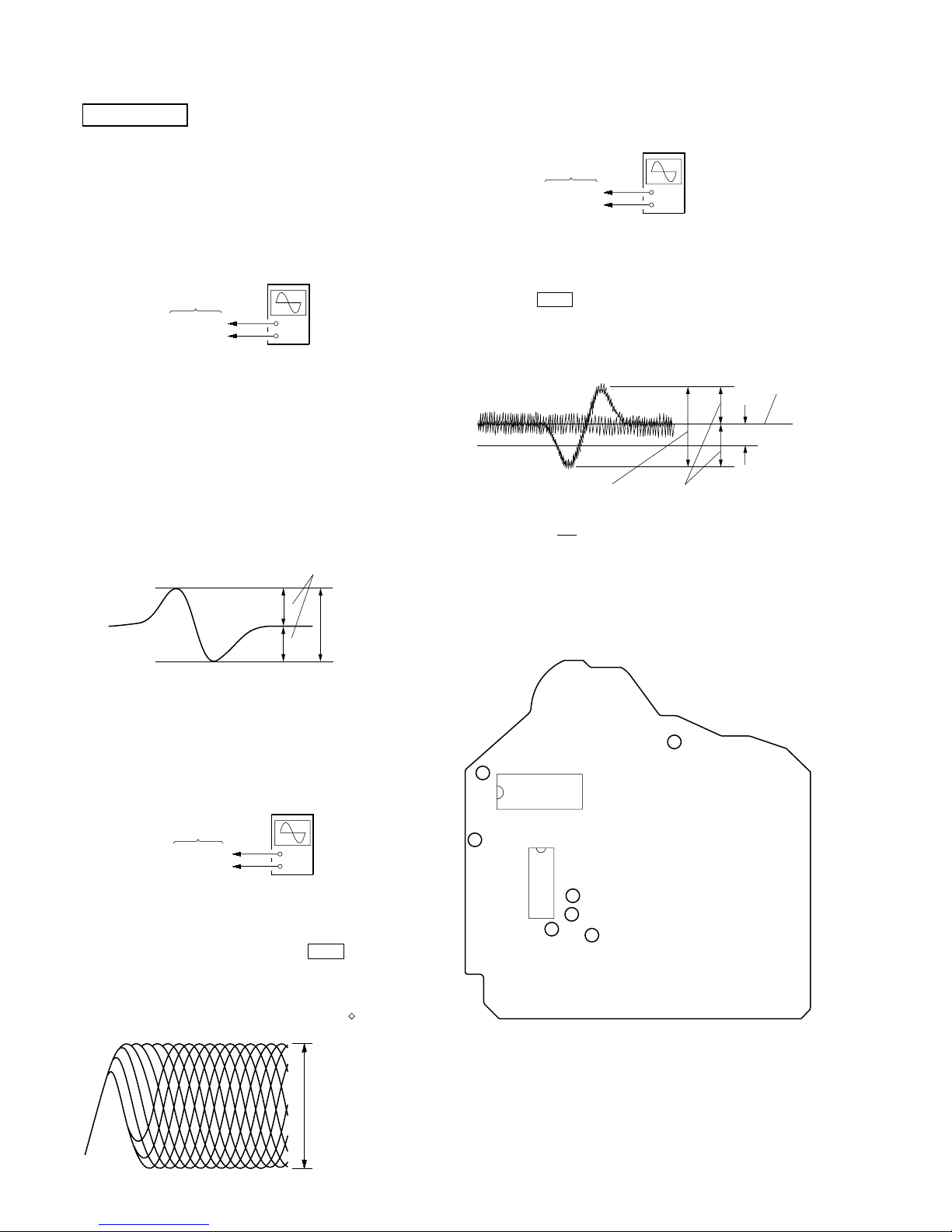

7-5. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

• Indication of transistor.

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

C

B

These are omitted.

E

Q

B

These are omitted.

CE

Q

B

These are omitted.

CE

Q

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

4

W or less unless otherwise

specified.

• 2 : nonflammable resistor.

• 5 : fusible resistor.

• C : panel designation.

• A : B+ Line.

• B : B– Line.

• H : adjustment for repair.

• Voltages are taken with a V OM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : TUNER (FM/AM)

E : TAPE PLAY (DECK A)

d : TAPE PLAY (DECK B)

G : RECORD

J : CD PLAY (ANALOG OUT)

c : CD PLAY (DEGITAL OUT)

N : MIC INPUT

• Abbreviation

AR : Argentina model

CND : Canadian model

E2 : 120 V AC area in E model

EA : Saudi Arabia model

MX : Mexican model

SP : Singapore model

Note:

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specified.

Note:

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro

spécifié.

CD-R (1) board

TC-B board

CD-L board

TC-A board

MIC board

ILLUMINATION board

PANEL VR board

PANEL FL board

TRANS board SUB TRANS board

TUNER PACK

(FM/AM TUNER UNIT)

MAIN boar

d

PA board

HEADPHONES board

CD-R (2) board

FRONT INPUT board

LEAF SW board

TABLE SENSOR board

CD MOTOR board

LED board

AUDIO board

BD board

• Circuit Boards Location

HCD-XG60/XG500

2424

KSS-213DH

19

)(

)(

)(

TP(VC)

TP(RF)

TP(TE)

TP(FE1)

TP(FE)

TP

(AGCCON)

TP(GND)

21

21

31

31,,

21

21

31

31,,

MAIN BOARD

CN411

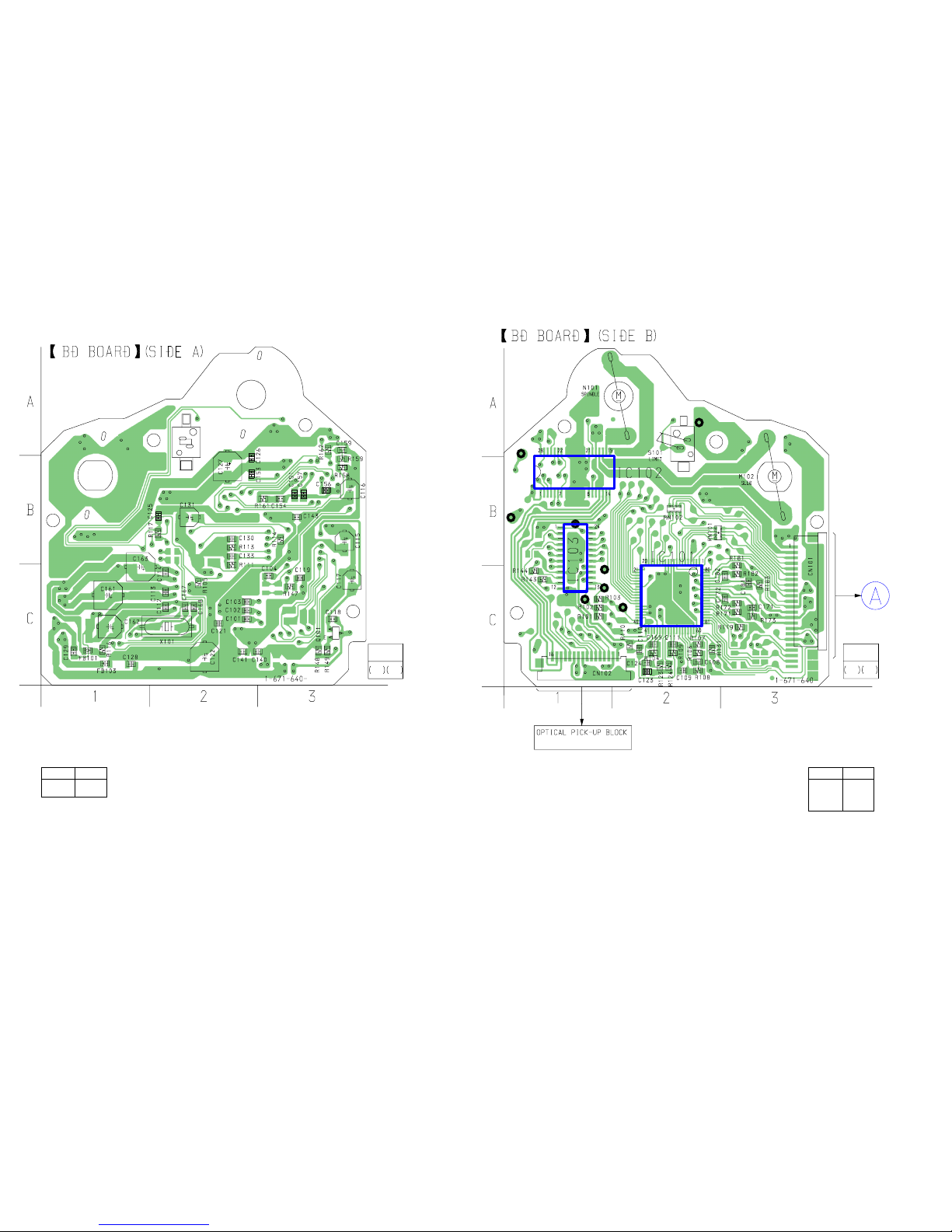

7-6. PRINTED WIRING BOARD – BD Board – • See page 23 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

Q101 C-3

• Semiconductor

Location

Ref. No. Location

IC101 C-2

IC102 B-1

IC103 B-1

(Page 34)

Loading...

Loading...