Page 1

HCD-XB8

SERVICE MANUAL

HCD-XB8 is the tuner, deck, CD and

amplifier section in LBT-XB8AV.

Photo : AEP model

CD

SECTION

TAPE

DECK

SECTION

Model Name Using Similar Mechanism HCD-D670AV/N555AV

CD Mechanism Type CDM37L-5BD29AL

Base Unit Type BU-5BD29AL

Optical Pick-up Type KSS-213D/Q-NP

Model Name Using Similar Mechanism HCD-D670AV/N555AV

Tape Transport Mechanism Type TCM-220WR2

AEP Model

UK Model

E Model

Australian Model

PX Model

SPECIFICATIONS

— Continued on next page —

MICROFILM

COMPACT DISC DECK RECEIVER

— 1 —

Page 2

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

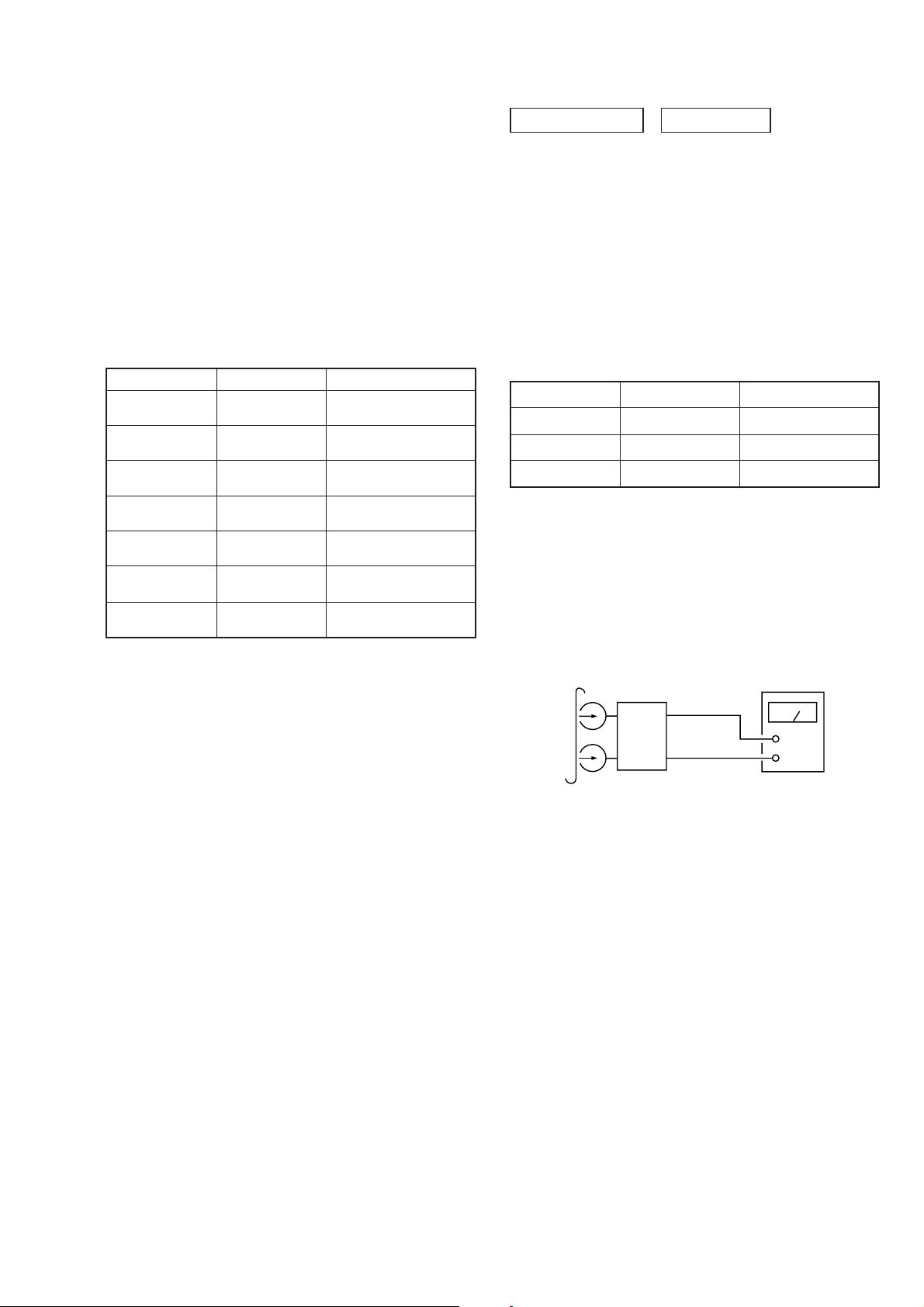

MODEL IDENTIFICATION

— BACK PANEL —

Parts No.

• Abbreviation

AUS: Australian model

AR : Argentine model

SAF: South Africa model

MX : Mexican model

EE : East European model

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

This caution

label is located

inside the unit.

— 2 —

MODEL

AEP, UK model

EE, CIS model

E, AR, SAF model

AUS model

PX model

MX model

PARTS No.

4-987-045-0

4-987-045-2

4-988-222-0

4-988-222-1

4-988-222-2

4-988-222-3

Page 3

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repain parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

TABLE OF CONTENTS

1. GENERAL

.......................................................................... 4

2. DISASSEMBLY

2-1. Front Panel ........................................................................... 5

2-2. Main Board ........................................................................... 6

2-3. Tape Mechanism Deck .......................................................... 6

2-4. Cassette Lid Assembly.......................................................... 7

2-5. CD Lid assembly................................................................... 7

2-6. CD Mechanism Deck ............................................................ 8

2-7. Base Unit ............................................................................. 8

2-8. Disc Table ............................................................................. 8

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output three times.

3. SERVICE MODE ........................................................9

4. MECHANICAL ADJUSTMENTS .......................... 11

5. ELECTRICAL ADJUSTMENTS ...............................11

6. DIAGRAMS

6-1. Circuit Boards Location ...................................................... 18

6-2. Brock Diagrams

• Tuner Section (AEP, UK model) ..................................... 19

• Tuner Section (East European, CIS model)..................... 21

• CD Section ....................................................................... 23

• Deck Section .................................................................... 25

• Main Section .................................................................... 27

• Power Section .................................................................. 29

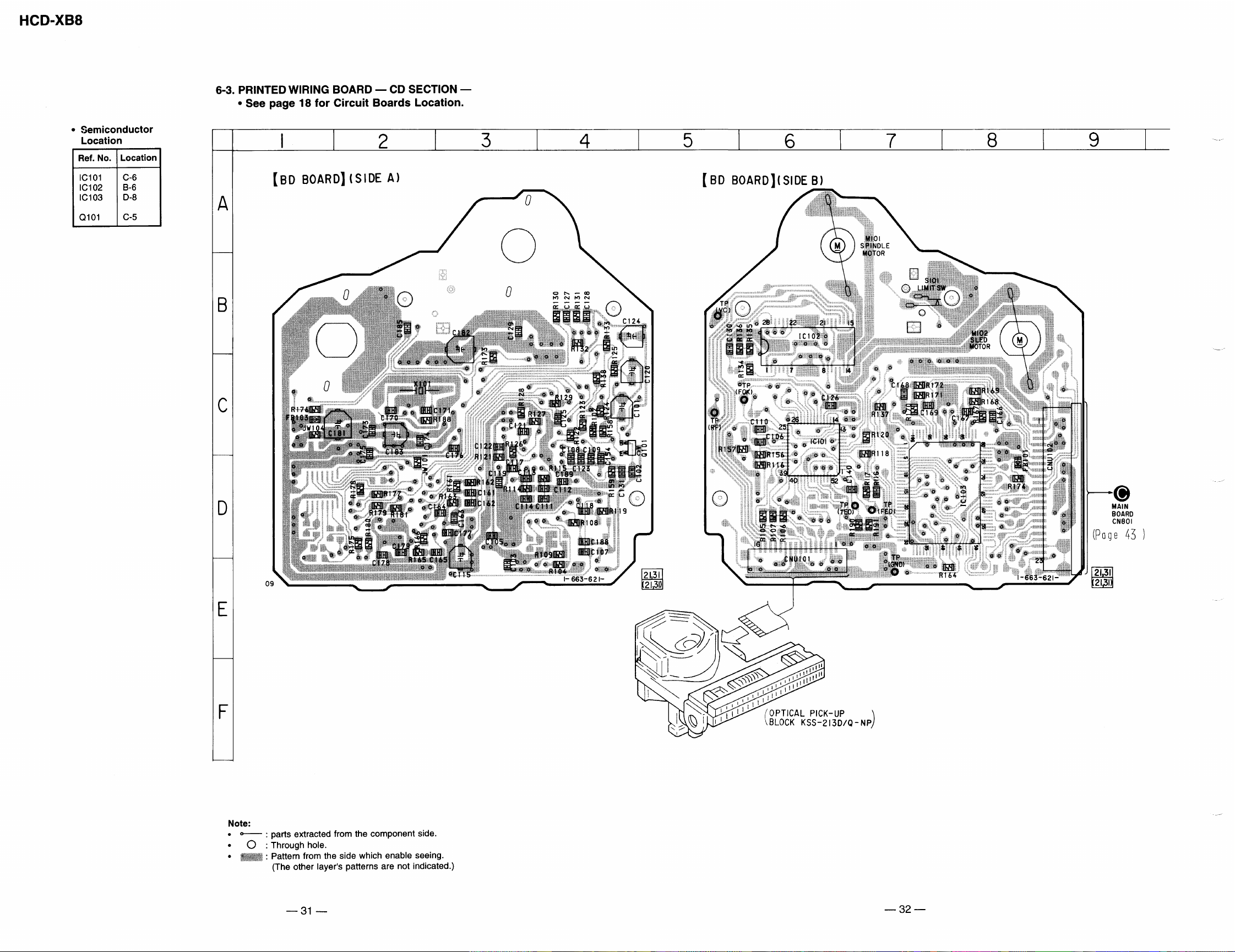

6-3. Printed Wiring Board —CD Section —.............................. 31

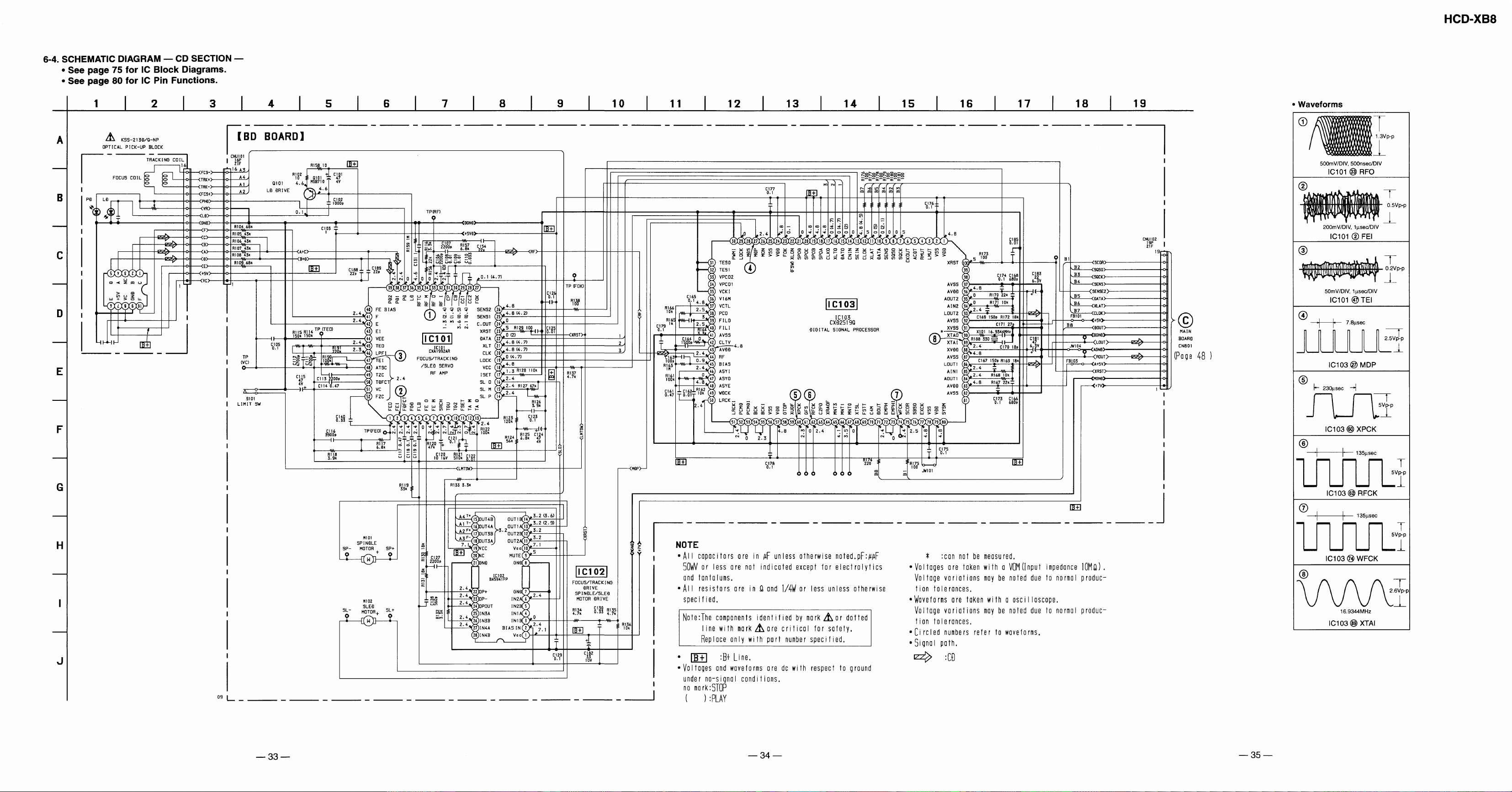

6-4. Schematic Diagram — CD Section — ............................... 33

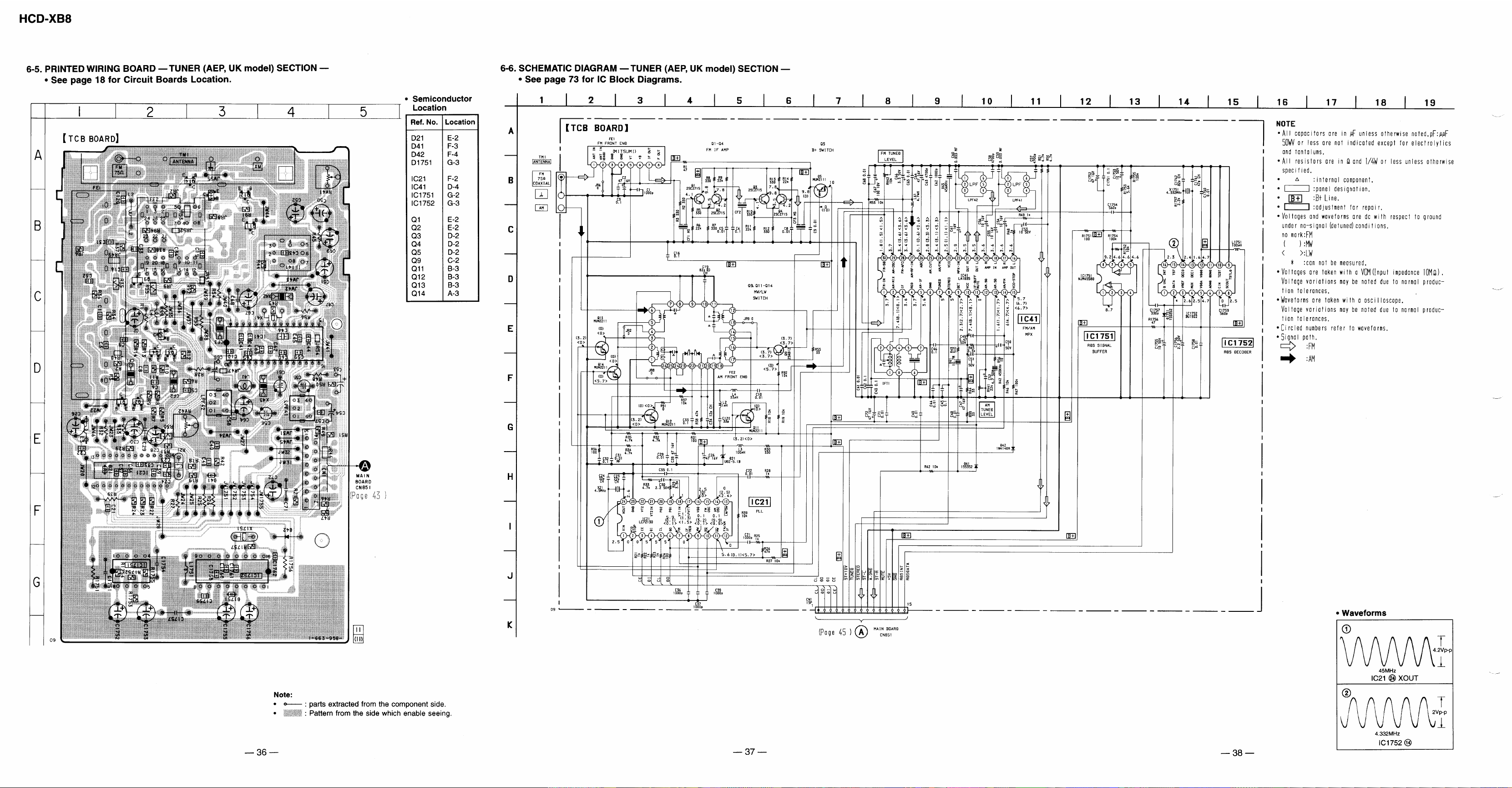

6-5. Printed Wiring Board

—Tuner (AEP, UK model) Section —................................ 36

6-6. Schematic Diagram

—Tuner (AEP, UK model) Section —................................ 37

6-7. Schematic Diagram

—Tuner (East European, CIS model) Section — ............... 39

6-8. Printed Wiring Board

—Tuner (East European, CIS model) Section — ............... 41

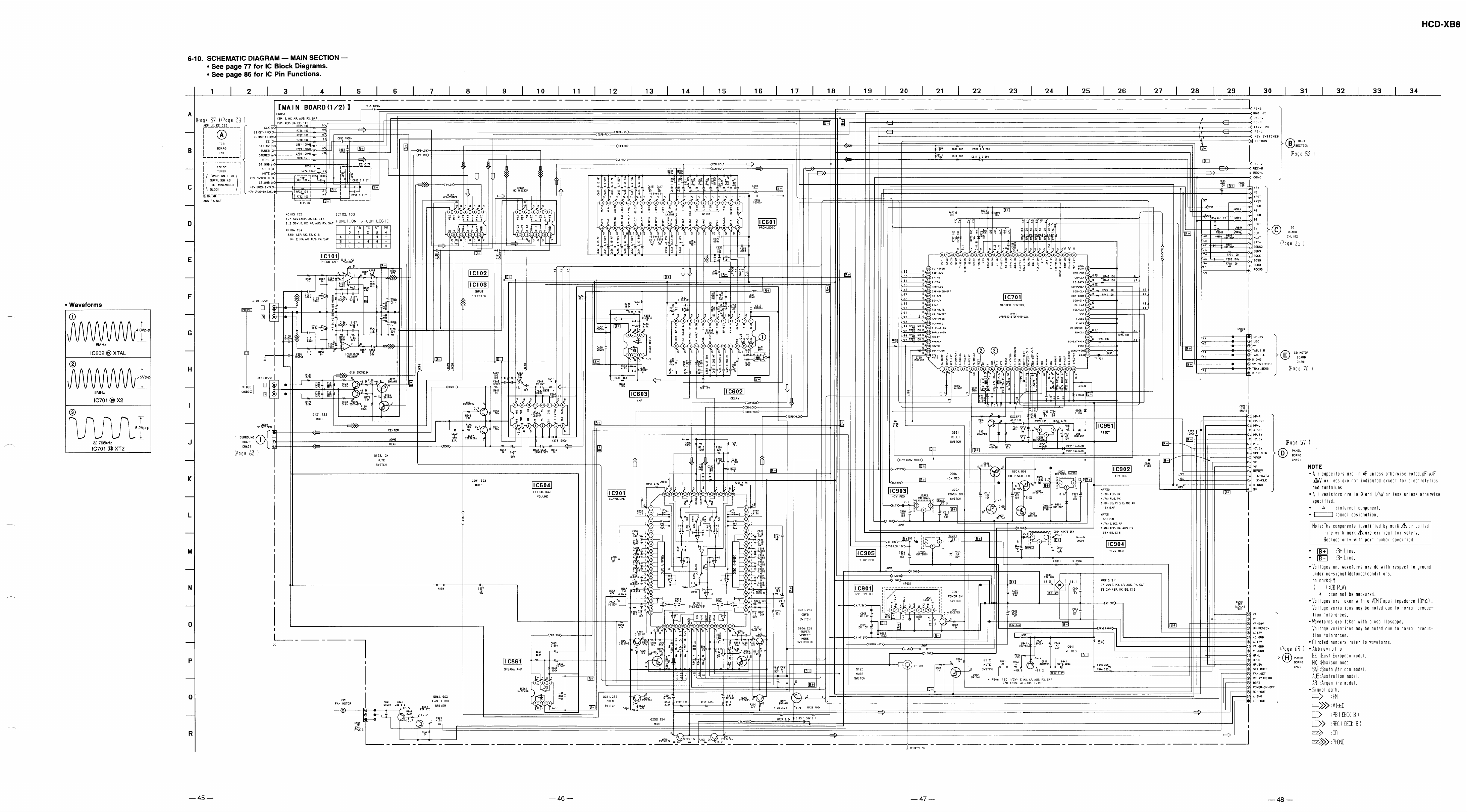

6-9. Printed Wiring Board — Main Section —.......................... 42

6-10. Schematic Diagram — Main Section — .......................... 45

6-11. Schematic Diagram — Deck Section — .......................... 49

6-12. Printed Wiring Board — Deck Section — ....................... 53

6-13. Schematic Diagram — Panel Section — ......................... 56

6-14. Printed Wiring Board — Panel Section —.......................59

6-15. Schematic Diagram — Power Section — ........................ 63

6-16. Printed Wiring Board — Power Section — ..................... 67

6-17. Schematic Diagram — CD Motor Section —.................. 70

6-18. Printed Wiring Board — CD Motor Section — ...............71

6-19. IC Block Diagrams ........................................................... 73

6-20. IC Pin Functions ............................................................... 80

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

7. EXPLODED VIEWS

7-1. Case and Back Panel Section .............................................. 89

7-2. Front Panel Section 1 .......................................................... 90

7-3. Front Panel Section 2 .......................................................... 91

7-4. Chassis Section ................................................................... 92

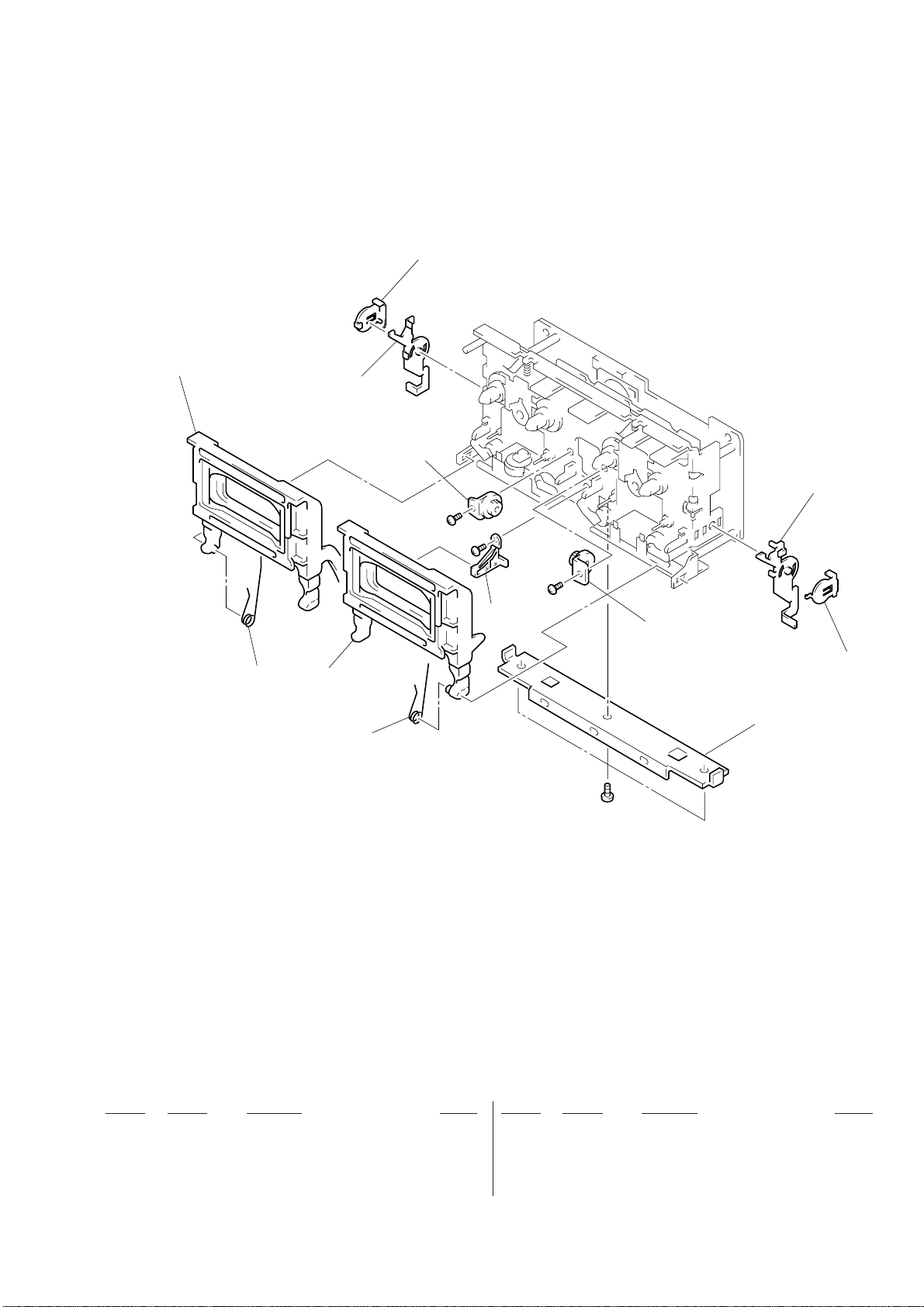

7-5. TC Mechanism Section 1 (TCM-220WR2)........................ 93

7-6. TC Mechanism Section 2 (TCM-220WR2)........................ 94

7-7. TC Mechanism Section 3 (TCM-220WR2)........................ 95

7-8. CD Mechanism Section (CDM37L-5BD29AL) ................. 96

7-9. Base Unit Section (BU-5BD29AL) .................................... 97

8. ELECTRICAL PARTS LIST ........................................ 98

— 3 —

Page 4

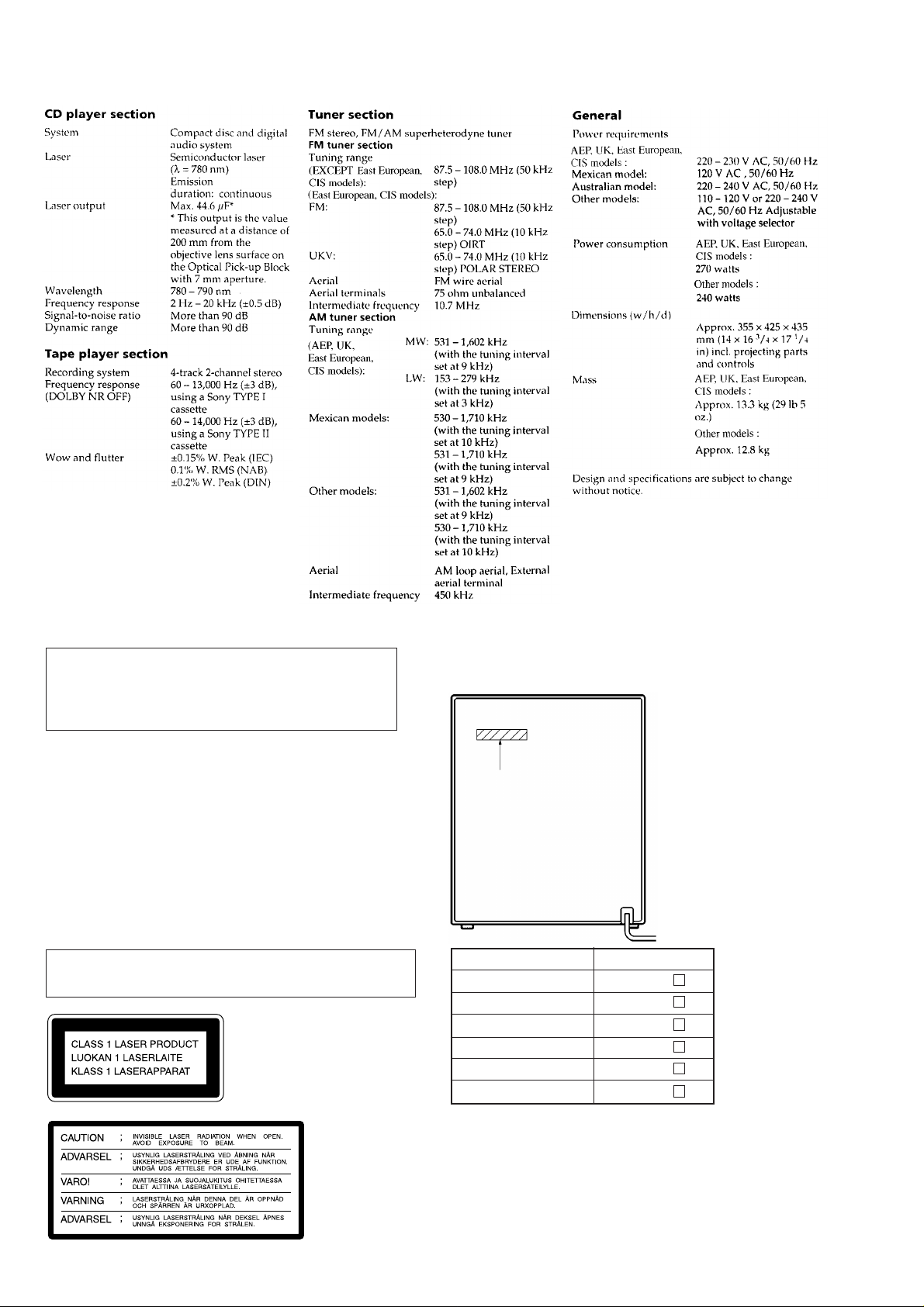

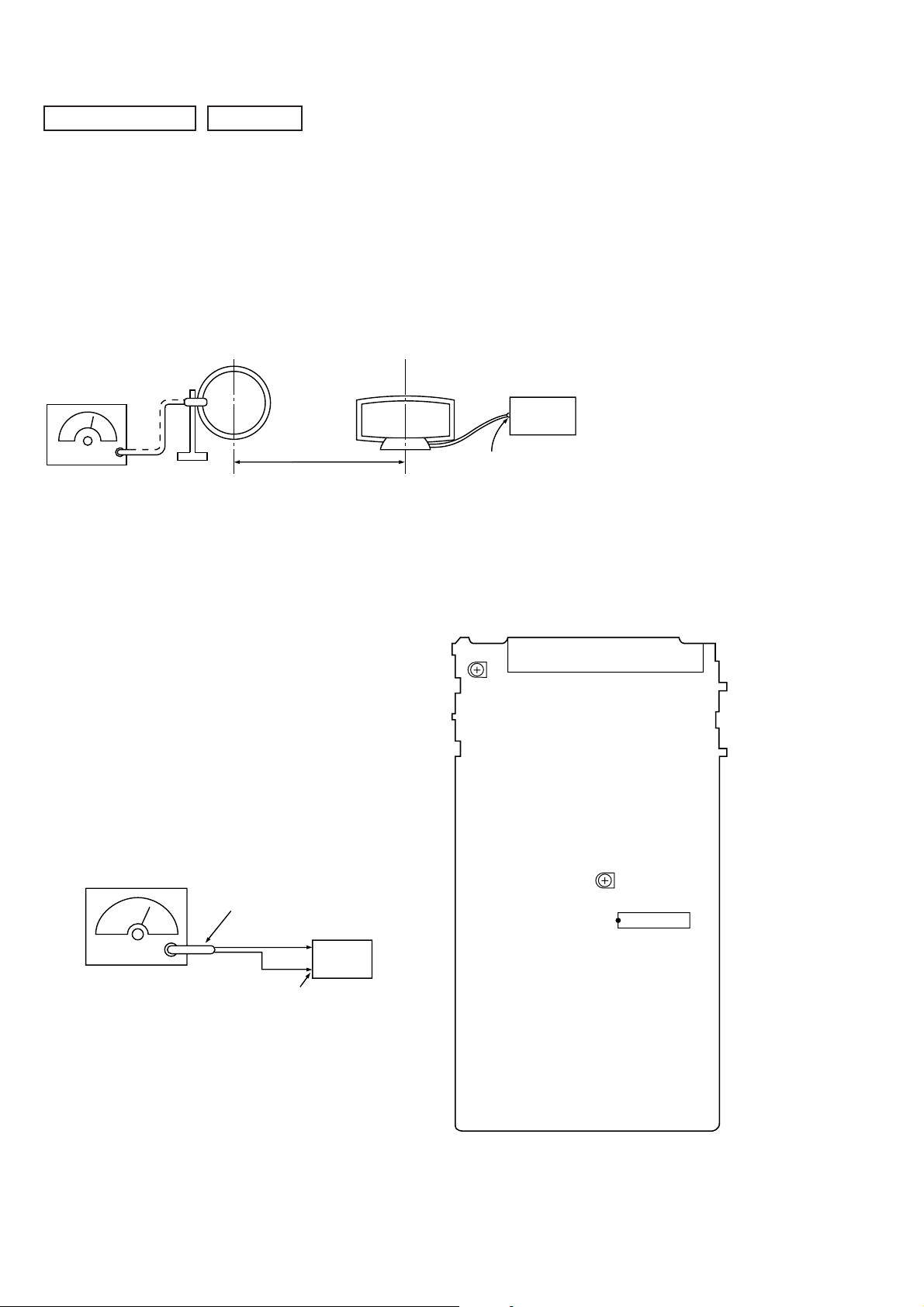

Front Panel

SECTION 1

GENERAL

2

3

4

5

6

!•

!ª

@¡

@∞

#∞

#§

1

7

8

!¶

@º @™@£ @¢

#¢

9

#™

!¡ !£

!º

@§

#¡

!™

@•

!∞

!¢

!§

@¶

@ª

#º

#£

$™

$£

#¶

#•

$º

%¢

%∞

%§

#ª

$¡

$¶

%•

$¢

$∞

$§

$•

$ª

%º

%¡

%™

%£

^º

%ª

^¡

%¶

^™ ^£

— 4 —

Page 5

LOCATION OF PARTS AND CONTROLS

1 POWER button

2 REC button

3 t/CLOCK SET button

4 DAILY 1 button

5 DAILY 2 button

6 SLEEP button

7 DISPLAY/DEMO button

8 SPECTRUM ANALYZER button

9 Display Window

!º ENTER/NEXT button

!¡ TUNER MEMORY button

!™ TUNING MODE button

!£ TUNER/BAND button

!¢ TUNING (+/-) button

!∞ PTY button

(AEP, UK)

!§ STEREO/MONO button

!¶ Equalizer indicators

!• MIC LEVEL knob

!ª MIC jack

@º DSP button

@¡ WAVE button

@™ PROLOGIC button

@£ KARAOKE PON/MPX button

@¢ P FILE MEMORY button

@∞ PHONES jack

@§ EFFECT button

@¶ FUNCTION button

@• GROOVE button

@ª VOLUME control

#º SUPER WOOFER button

#¡ GEQ control buttons

#™ GEQ CONTROL button

#£ SUPER W MODE button

#¢ ENTER button

#∞ Deck A ª, · button

#§ Deck A p button

#¶ DIRECTION button

#• DOLBY NR button

#ª Deck A 0, ) button

$º Deck A 6 EJECT button

$¡ Deck B p button

SECTION 2

DISASSEMBLY

$™ Deck B ª, · button

$£ Deck B 0, ) button

$¢ Deck B r REC button

$∞ Deck B P button

$§ CD SYNC button

$¶ H SPEED DUB button

$• Deck B 6 EJECT button

$ª 6 OPEN button

%º CD · button

%¡ CD p button

%™ CD P button

%£ DISC SKIP button

%¢ DISC1-DISC5 buttons

%∞ NON-STOP button

%§ LOOP button

%¶ FLASH button

%• 1/ALL DISCS button

%ª PLAY MODE button

^º CD 0, ) button

^¡ REPEAT button

^™ EDIT button

^£ ≠ AMS ± dial

Note: Follow the disassembly procedure in the numerical order given.

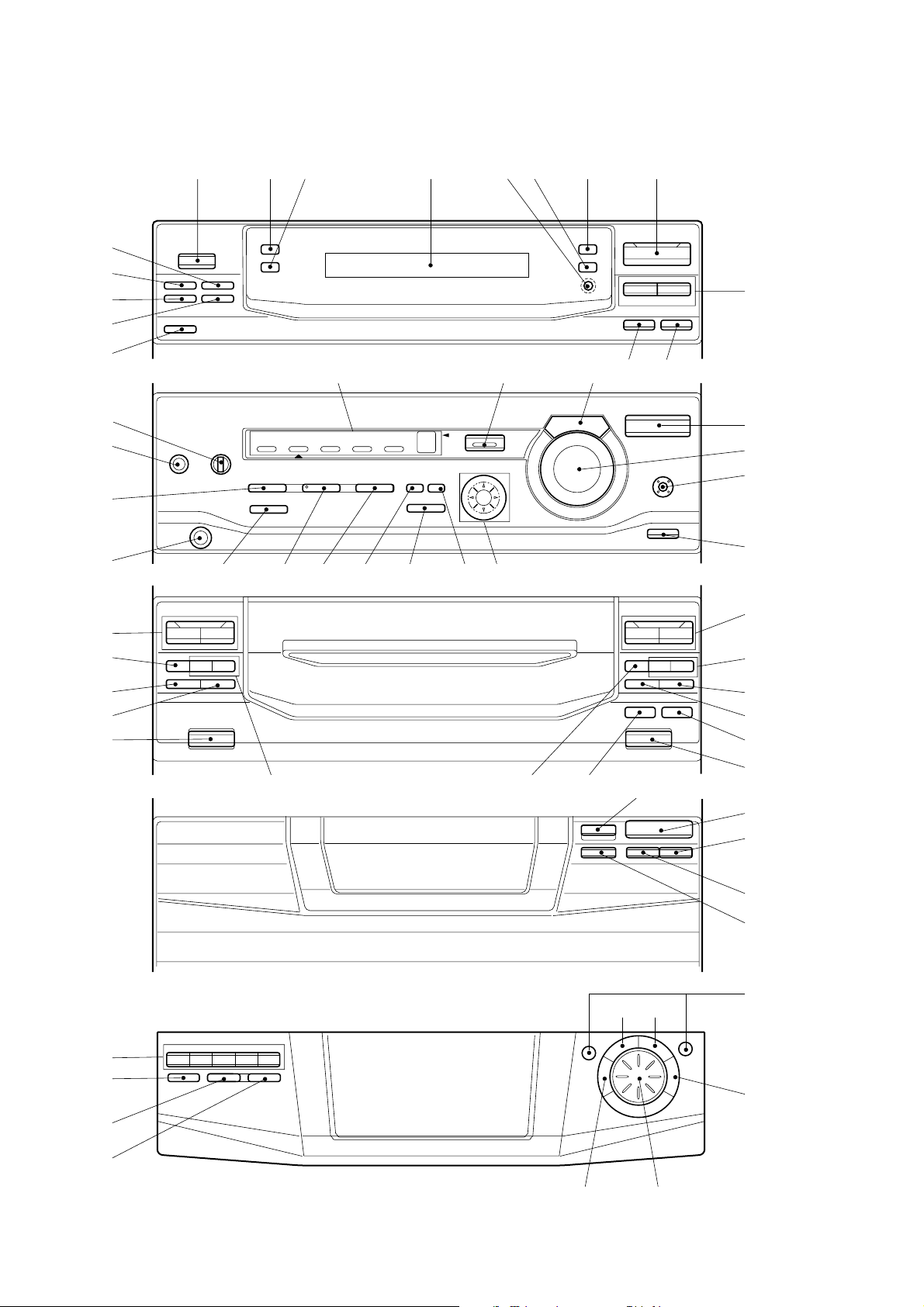

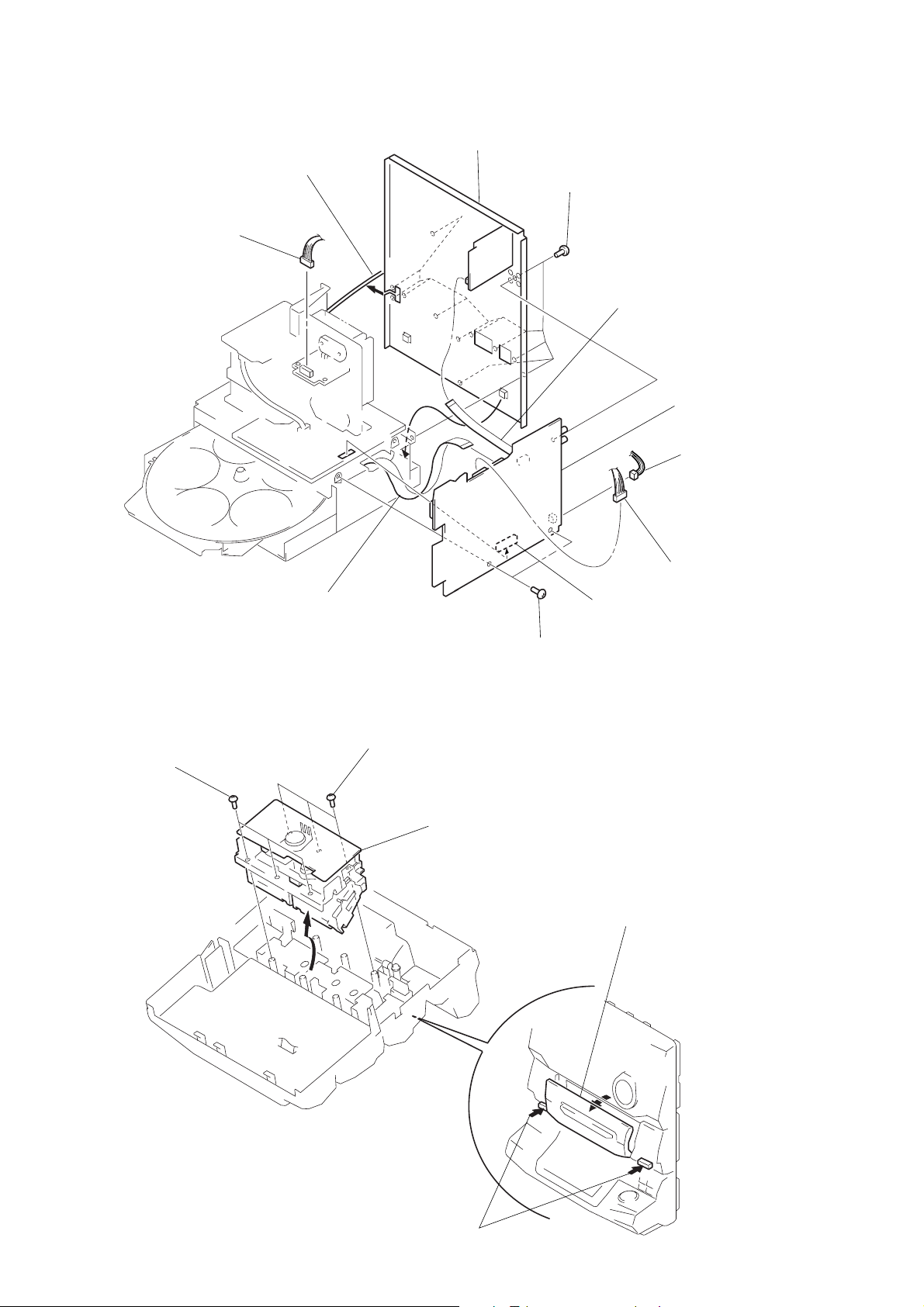

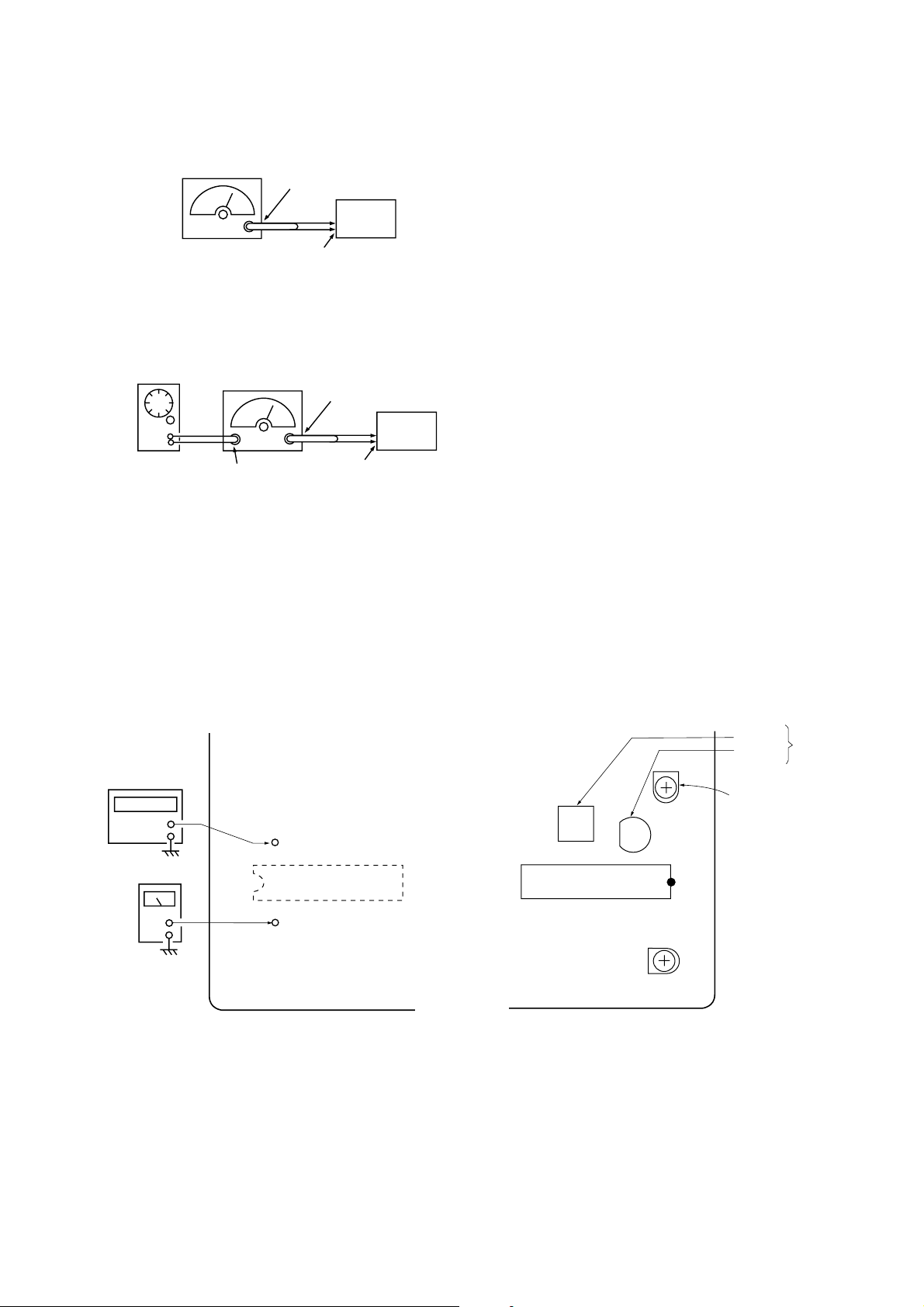

2-1. FRONT PANEL

1

Three flat type wires

(CN401, CN402, CN701)

3

Front panel

2

Four screws (BVTP3x8)

— 5 —

Page 6

2-2. MAIN BOARD

7

Connector

(CN601)

3

Power cord

4

Back panel

2

Twelve screws (BVTP3x8)

Flat type wire (CN1)

1

!¡

6

Main board

!™

Connector (CN961)

Connector (CN830)

2-3. TAPE MECHANISM DECK

3

Three screws

(BVTP2.6x8)

5

Flat type wire (CN801)

A

4

Three screws (BVTP2.6x8)

5

Remove the tape mechanism deck

section to direction of the arrow

9

Connector (CN901)

8

Two screws (BVTP3x8)

A

2

.

Open the cassette lids.

1

Push the two buttons.

— 6 —

Page 7

2-4. CASSETTE LID ASSEMBLY

1

Two springs

4

Cassette lid assembly

3

Two bracket

2

Two screws (BVTP2.6x8)

2-5. CD LID ASSEMBLY

2

Connector (CN671)

1

Four screws (BVTP2.6x8)

3

Connector (CN661)

4

CD lid assembly

— 7 —

Page 8

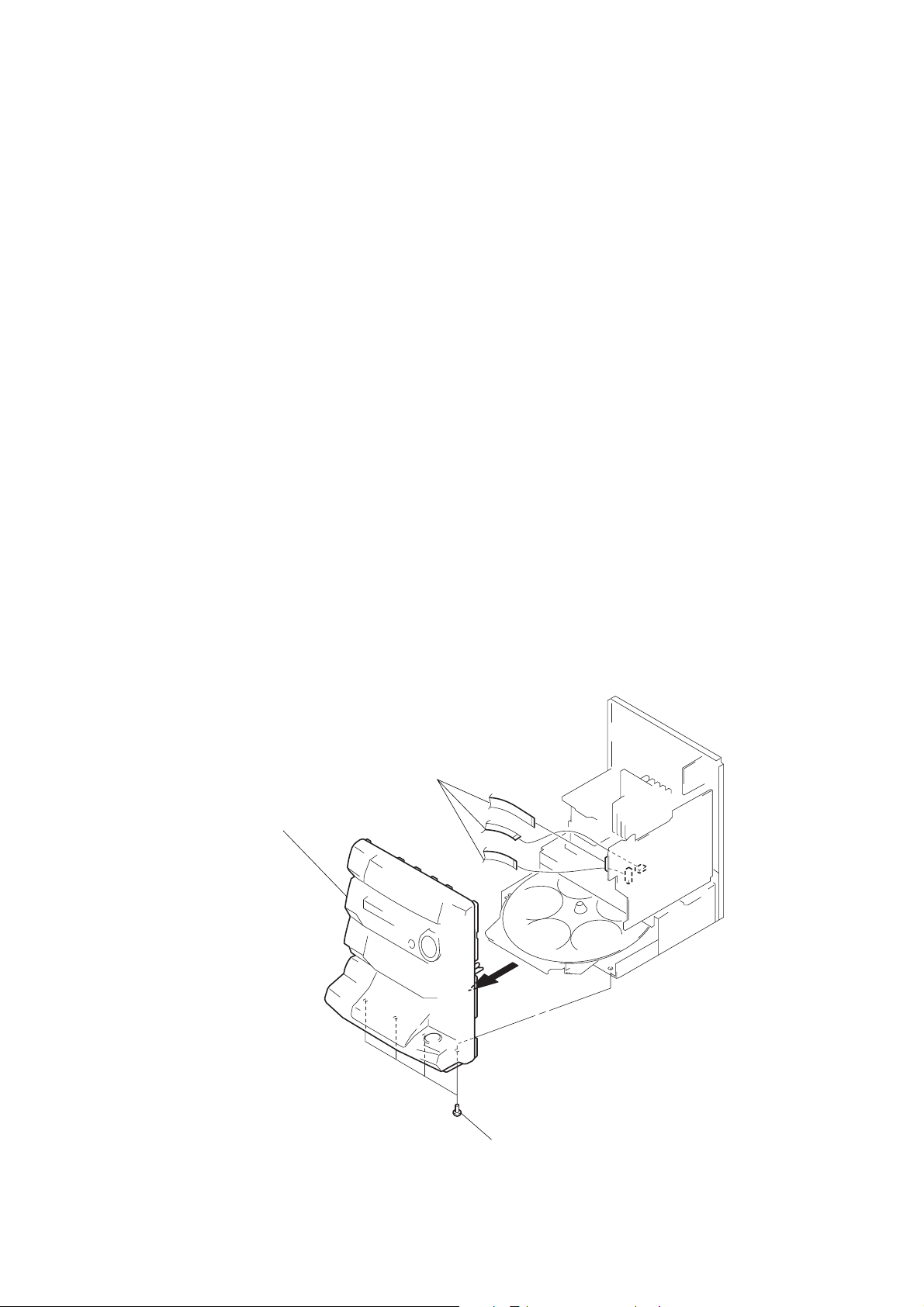

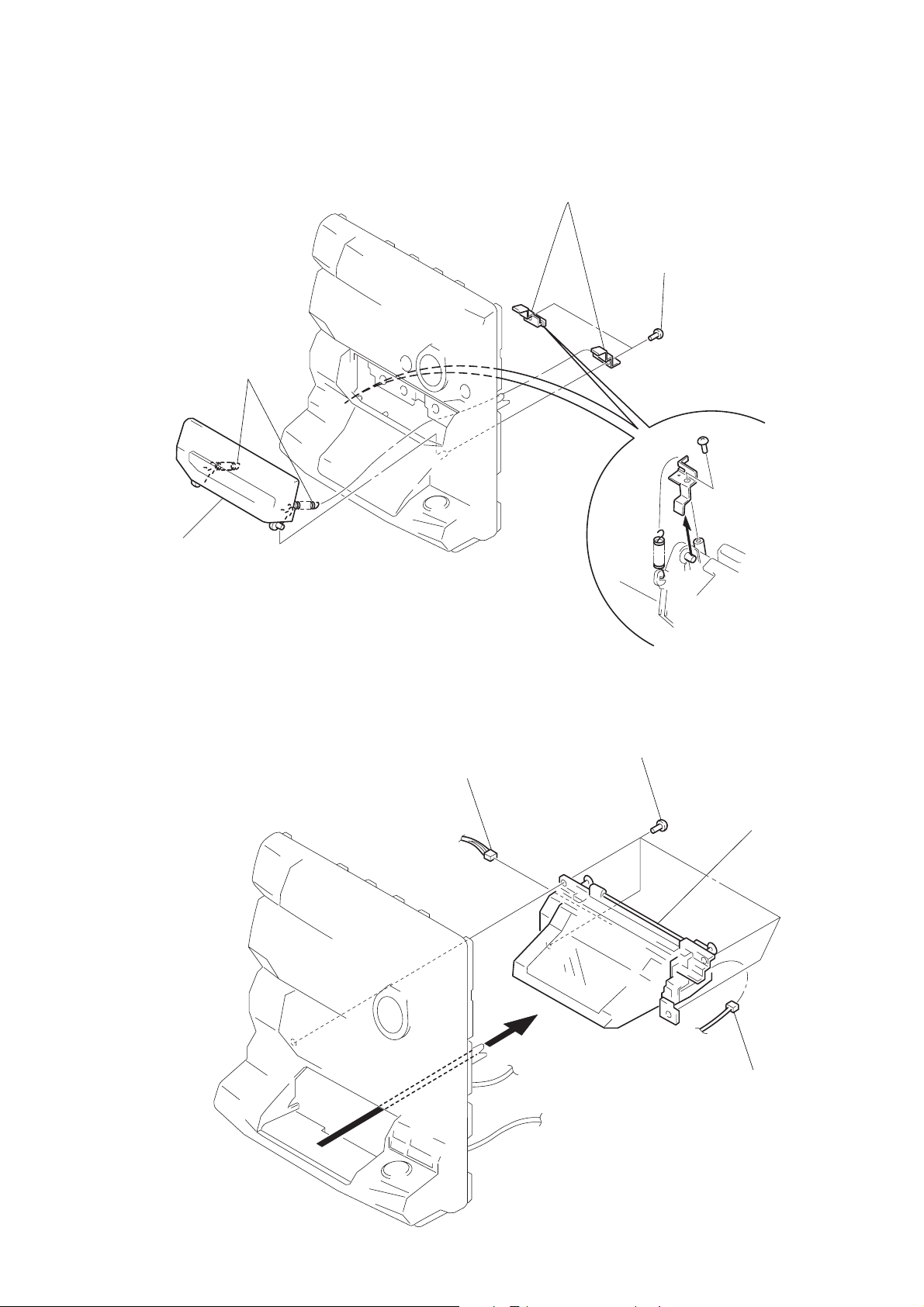

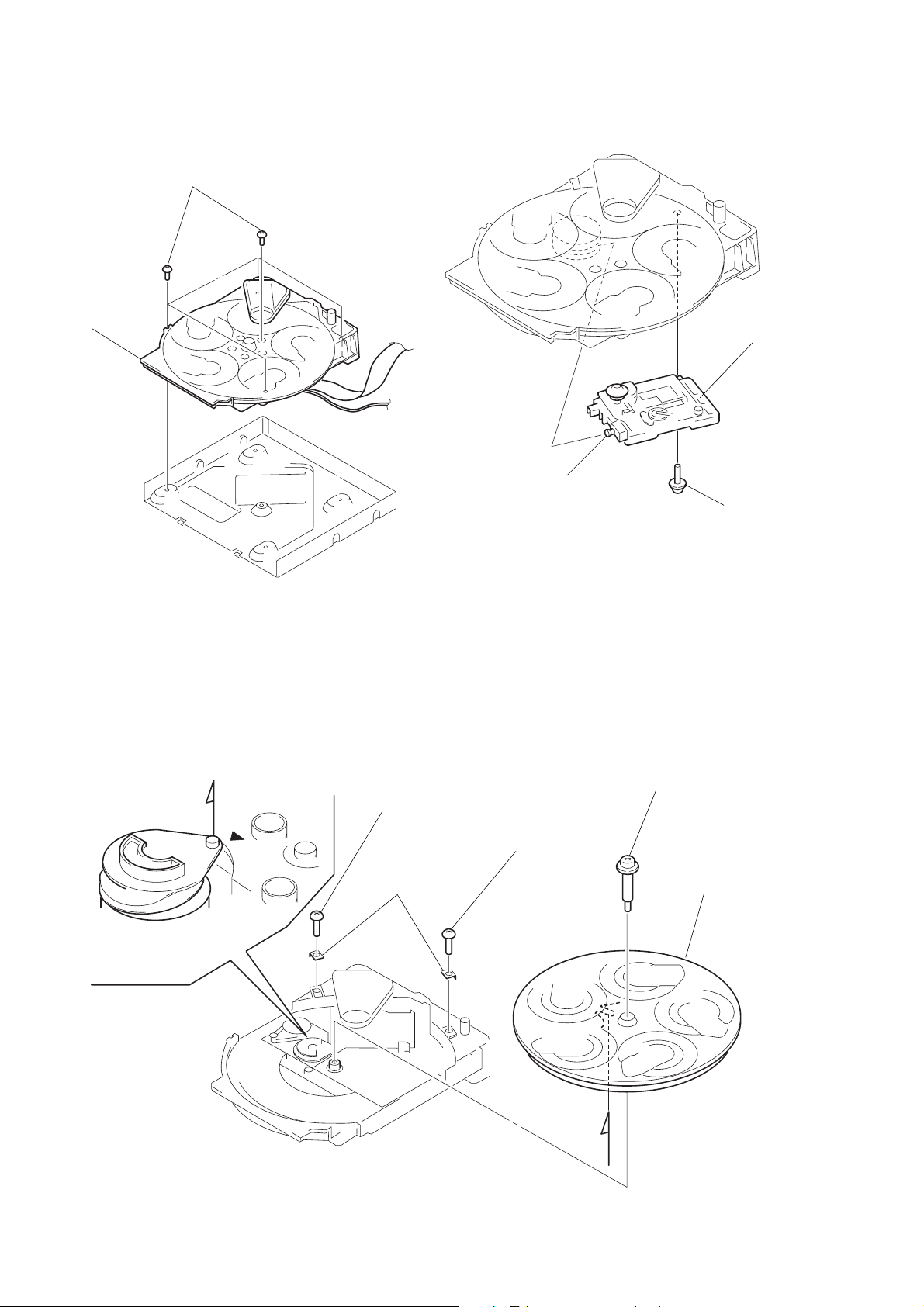

2-6. CD MECHANISM DECK

1

Five screws

(BVTP3x8)

2

CD mechanism

deck

2-7. BASE UNIT

2

Boss

1

Yoke bracket

3

Bass unit

2-8. DISC TABLE

Note:

When the disc table is installed, adjust the positions of

roller cam and mark ” as shown in the figure, then set to

the groove of disc table.

A

2

Screw (BVTP3x8)

3

Bracket (BU)

1

Screw (BVTP3x8)

4

Stop screw

5

Disc table

— 8 —

A

Page 9

SECTION 3

SERVICE MODE

MC Cold Reset

• The cold reset clears all data including preset data stored in the RAM to initial conditions. Execute this mode when returning the set to the

customer.

Procedure:

1. Press three buttons SPECTRUM ANALYZER , ENTER , and DISC 1 simultaneously.

2. The fluorescent indicator tube becomes blank instantaneously, and the set is reset.

CD Delivery Mode

• This mode moves the pick-up to the position durable to vibration. Use this mode when returning the set to the customer after repair.

Procedure:

1. Press POWER button to turn the set ON.

2. Press PLAY MODE button and POWER button simultaneously.

3. A message “LOCK” is displayed on the fluorescent indicator tube, and the CD delivery mode is set.

MC Hot Reset

• This mode resets the set with the preset data kept stored in the memory . The hot reset mode functions same as if the po wer cord is plugged

in and out.

Procedure:

1. Press three buttons SPECTRUM ANALYZER , ENTER , and DISC 2 simultaneously.

2. The fluorescent indicator tube becomes blank instantaneously, and the set is reset.

Sled Servo Mode

• This mode can run the CD sled motor freely. Use this mode, for instance, when cleaning the pick-up.

Procedure:

1. Select the function “CD”.

2. Press three buttons SPECTRUM ANALYZER , ENTER , and FUNCTION simultaneously.

3. The Sled Servo mode is selected, if “CD” is blanking on the fluorescent indicator tube.

4. With the CD in stop status, press ) button in CD section to move the pick-up to outside track, or 0 button to inside track.

5. To exit from this mode, perform as follows:

1) Move the pick-up to the most inside track.

2) Press three buttons in the same manner as step 2.

Note:

• Always move the pick-up to most inside track when exiting from this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear can be chipped.

Change-over of FUNCTION Name

• The FUNCTION name of external input terminal can be changed over to VIDEO or MD. With the FUNCTION selected to “MD”, about

5dB mute is applied to the input gain.

Procedure:

1. Press POWER button to turn the set OFF.

2. Press POWER button together with FUNCTION button, and the power is turned on, the display of fluorescent indicator tube changes

to “MD” or “VIDEO” instantaneously, and thus the FUNCTION is changed over.

Change-over of AM Tuner Step between 9kHz and 10kHz

• A step of AM channels can be changed over between 9kHz and 10kHz.

Procedure:

1. Press POWER button to turn the set ON.

2. Select the function “TUNER”, and press TUNER/BAND button to select the BAND “AM”.

3. Press POWER button to turn the set OFF.

4. Press ENTER/NEXT and POWER buttons simultaneously, and the display of fluorescent indicator tube changes to “AM 9k STEP” or

“AM 10k STEP”, and thus the channel step is changed over.

LED and Fluorescent Indicator Tube All Lit, Key Check Mode

Procedure:

1. Press three buttons SPECTRUM ANALYZER , ENTER , and DISC 3 simultaneously.

2. LEDs and fluorescent indicator tube are all turned on.

Press DISC 2 button, and the key check mode is activated.

3. In the key check mode, the fluorescent indicator tube displays “K 1 V0 J0”. Each time a b utton is pressed, “K”value increases. Ho we ver ,

once a button is pressed, it is no longer taken into account.

“J” Value increases like 1, 2, 3 ... if rotating JOG knob in “+” direction, or it decreases like 0, 9, 8 ... if rotating in “-” direction.

“V” Value increases like 1, 2, 3 ... if rotating VOLUME knob in “+” direction, or it decreases like 0, 9, 8 ... if rotating in “-” direction.

4. To exit from this mode, press three buttons in the same manner as step 1, or disconnect the power cord.

— 9 —

Page 10

Aging Mode

This mode can be used for operation check of CD section and tape deck section.

• If an error occurred:

The aging operation stops.

• If no error occurs:

The aging operation continues repeatedly.

1. Aging Mode in CD Section

1-1. Operating procedure of Aging Mode

1. Set discs in DISC 1 and DISC 3 trays.

2. Select the function “CD”.

3. Press three buttons SPECTRUM ANALYZER , ENTER , and KARAOKE PON/MPX simultaneously.

4. The aging mode is activated, if a roulette mark on the fluorescent indicator tube is blinking.

5. In the aging mode, the aging is executed in a sequence given in “1-2. Operation during Aging Mode”.

The aging continues unless an alarm occurred.

6. To exit from the aging mode, press POWER button to turn the set OFF.

• If a button other than buttons In CD section is pressed during aging, the aging in the CD section is finished.

• To execute aging to the tape deck section successively, press · button in the deck A.

“AGING” is displayed on the fluorescent indicator tube. (For the aging in tape deck, see “2. Aging Mode in Tape Deck Section”.

1-2. Operation during aging Mode

In the aging mode, the program is executed in the following sequence.

1. The disc tray turns to select a disc. (For a disc selection sequence, see Section 1-3.)

2. TOC of disc is read.

3. The pick-up accesses to the last track.

4. Steps 1 through 3 are repeated.

1-3. Disc Selection Sequence

• During the aging mode, discs are selected in the following sequence:

Disc 1 → Disc 3

↑↓

Disc 3 ← Disc 1

2. Aging Mode in Tape Deck Section

2-1. Operating procedure of Aging Mode

1. Load a commercially available 10-minute tape into the decks A and B respectively.

(If a 10-minute tape is not available, another tape may be used but a cycle time will be longer.)

2. Select the function “TAPE”.

3. Rewind tapes in advance by pressing 0 button respectively on decks A and B.

4. Press three buttons SPECTRUM ANALYZER , ENTER , and KARAOKE PON/MPX simultaneously.

5. Press · button on deck A. (This button triggers the aging mode.)

6. The aging mode is activated if “AGING A” is displayed on the fluorescent indicator tube.

7. In the aging mode, the aging is executed in a sequence given in “2-2. Operation during Aging Mode”.

The aging continues unless an alarm occurred.

8. To exit from the aging mode, press POWER button to turn the set OFF.

2-2. Operation during Aging Mode

In the aging mode, the program is executed in the following sequence.

1. A tape on FWD side is played for one minute.

2. PAUSE STOP is made.

3. Recording is made for 3 minutes. (For the deck not having the record function, the play is executed.)

4. FF is executed up to the end of tape.

5. A tape is reversed, and the tape on REV side is played for one minute.

6. PAUSE STOP is made.

7. Recording is made for 3 minutes. (For the deck not having the record function, the play is executed.)

8. FF is executed up to the end of tape.

9. Steps 1 through 8 are executed for the other deck.

10. Steps 1 through 9 are repeated unless an alarm occurred.

2-3. Deck Selection Sequence

• During the aging mode, decks are selected in the following sequence:

Deck A (FWD) → Deck A (REV)

↑↓

Deck B (REV) ← Deck B (FWD)

— 10 —

Page 11

SECTION 4

MECHANICAL ADJUSTMENTS

SECTION 5

ELECTRICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

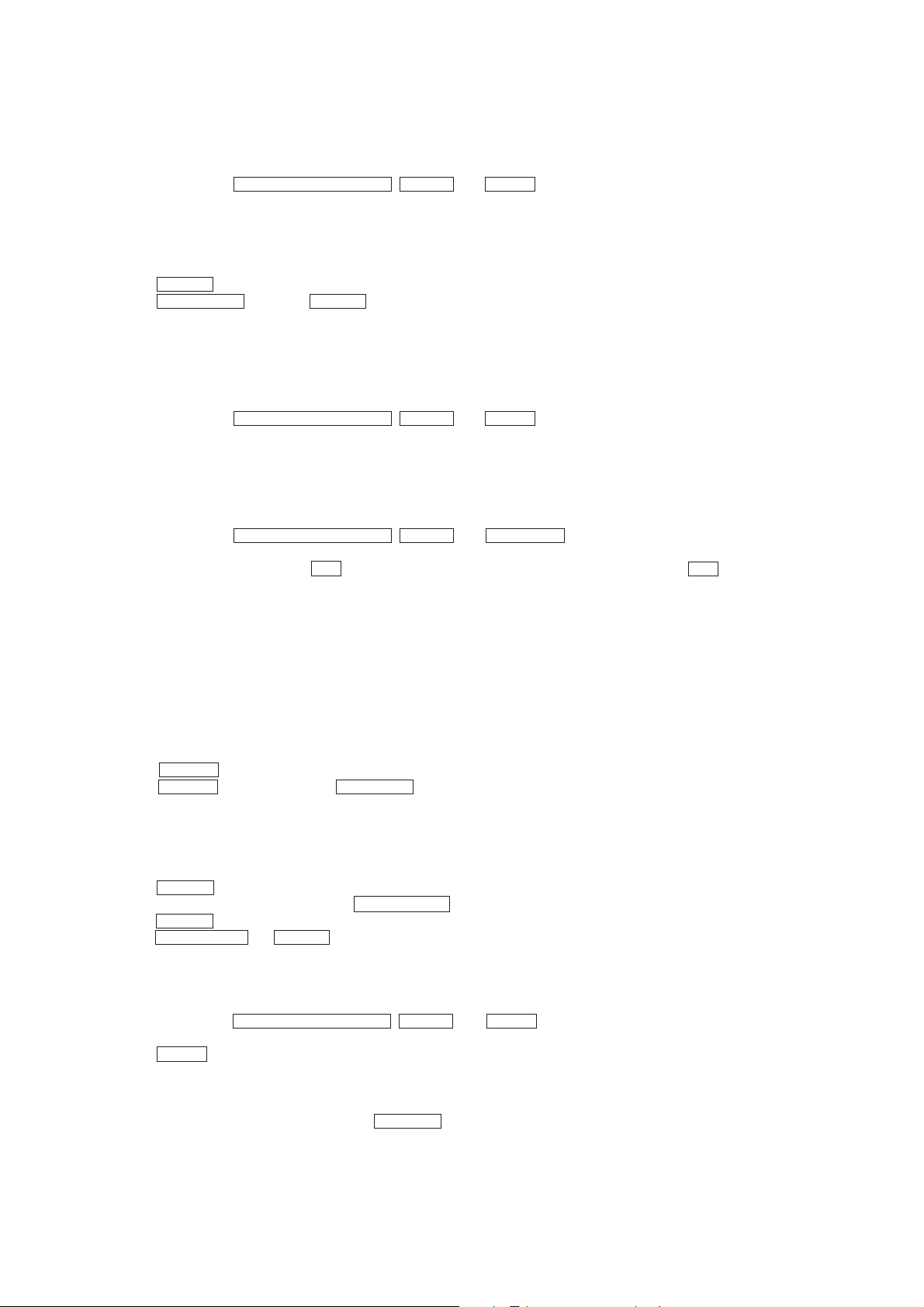

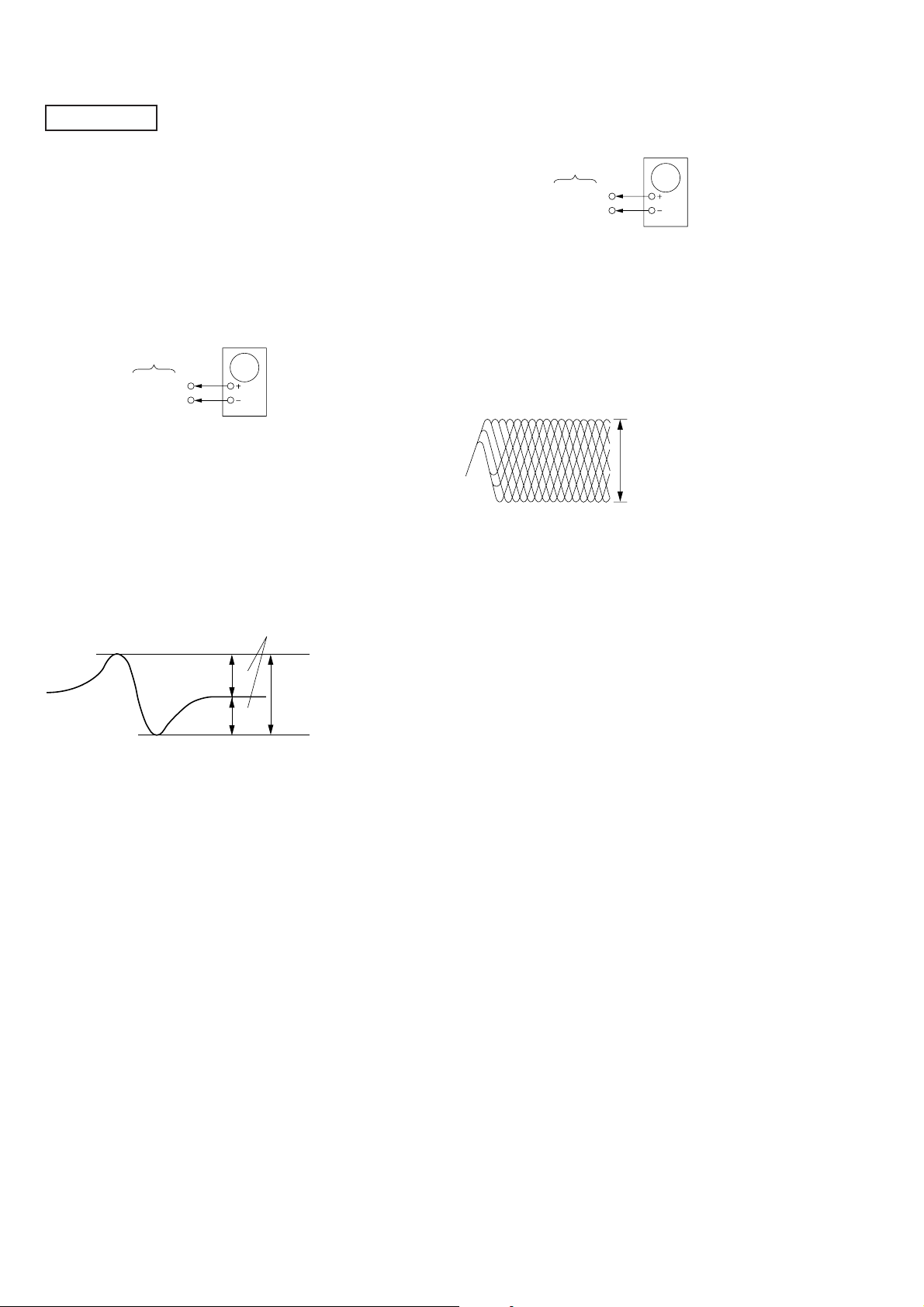

Torque Measurement

Torque

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

Torque meter

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

Meter reading

36 to 61 g • cm

(0.5 - 0.84 oz • inch)

2 to 6 g • cm

(0.02 - 0.08 oz • inch)

36 to 61 g • cm

(0.5 - 0.84 oz • inch)

2 to 6 g • cm

(0.02 - 0.08 oz • inch)

61 to 143 g • cm

(0.85 - 1.99 oz • inch)

100 g or more

(3.53 oz or more)

100 g or more

(3.53 oz or more)

DECK SECTION 0 dB=0.775V

1. Demagnetize the record/playback head with a head damagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjusted.

4. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit adjustment.)

6. The adjustments should be performed for both L-CH and R-CH.

7. Switches and controls should be set as follows unless otherwise

specified.

Signal

P-4-A100

WS-48B

P-4-L300

10 kHz, –10 dB

3 kHz, 0 dB

315 Hz, 0 dB

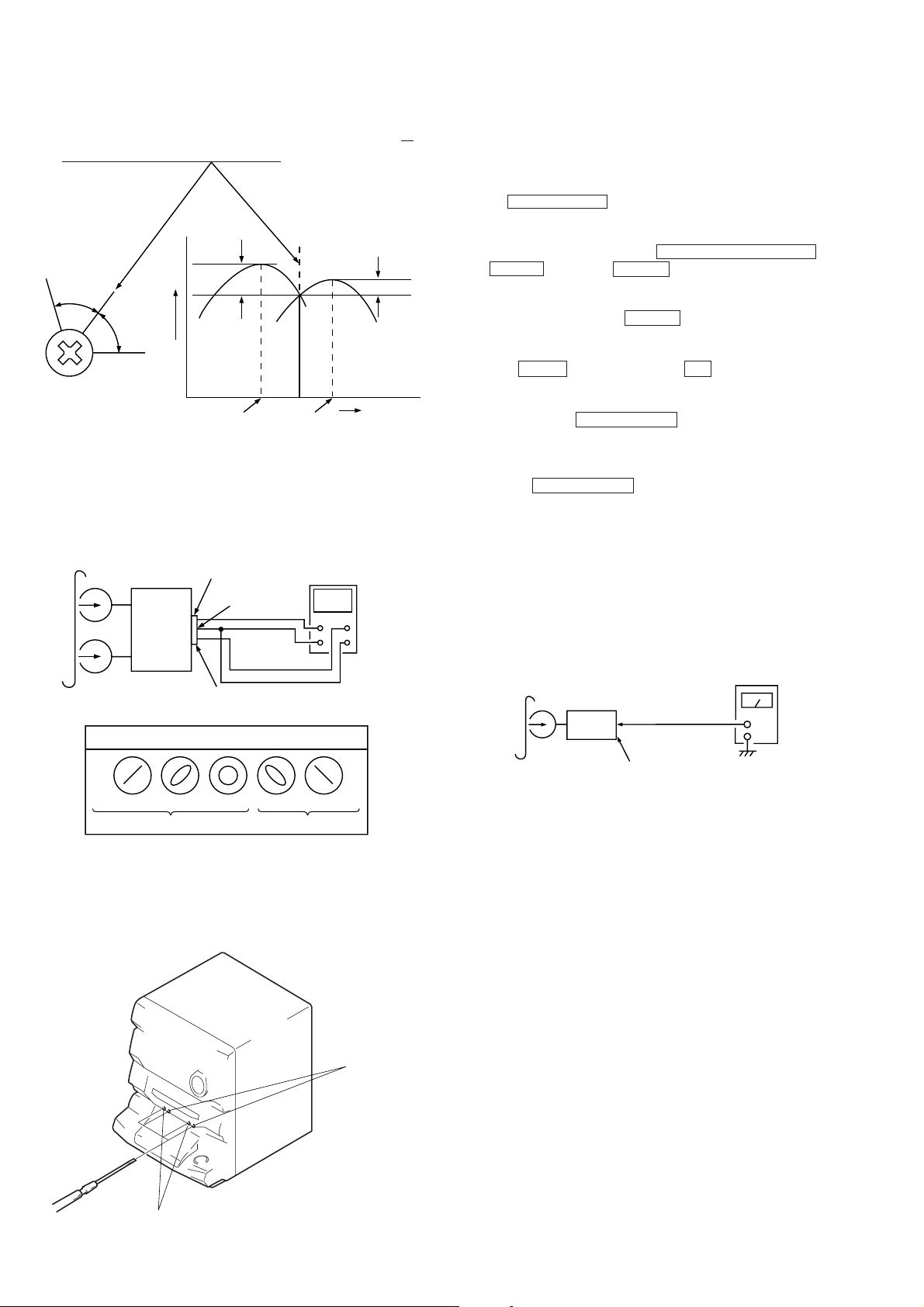

Record/Playback Head Azimuth Adjustment

(Deck A, Deck B)

Note: Perform this adjustments for both decks.

Procedure:

1. Mode : Playback

test tape

P-4-A100

(10kHz, –10dB)

main board

CN403

Pin

3

(L-CH)

Pin

1

(R-CH)

Used forTape

Azimuth Adjustment

Tape Speed Adjustment

Level Adjustment

level meter

set

main board

CN403

Pin

2

(GND)

+

–

— 11 —

Page 12

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw so

that outputs match within 1 dB of peak.

Tape Speed Adjustment (Deck A)

Note: Set the test mode using the following method and begin tape

speed adjustment.

In the test mode, the tape will move at double speed while

the H SPEED DUB. button is pressed.

L-CH

peak

R-CH

screw

position

peak

3. Mode: Playback

test tape

P-4-A100

(10kHz, –10dB)

output

level

within

1dB

L-CH

peak

main board

CN403

Pin

3

(L-CH)

L

set

R

Pin

1

(R-CH)

Waveform of oscilloscope

Pin

2

(GND)

R-CH

peak

oscilloscope

within 1dB

screw

position

Procedure :

With the power turned ON, press the SPECTRUM ANALYZER

button, ENTER button, and EFFECT button simultaneously.

(The “VOLUME” on the fluorescent display tube will blink while

in the test mode.)

To exit the test mode, press the POWER button.

1. Load WS-48B into deck A and a recordable tape into deck B.

2. Press the r REC button, and press the · button of deck B to

set deck B into the recording state.

3. Play deck A.

4. While pressing the H SPEED DUB. button, set double speed

play.

5. Adjust RV652 of the AUDIO board so that the reading of the

frequency counter becomes 6000 ± 30 Hz.

6. Release the H SPEED DUB. button to set normal speed play.

7. Adjust RV651 of the AUDIO board so that the reading of the

frequency counter becomes 3000 ± 15 Hz.

Adjustment Location: AUDIO board

Playback Level Adjustment (Deck A, Deck B)

Procedure:

Mode: Playback

test tape P-4-L300

(315Hz, 0dB)

set

level meter

in phase

45˚

90˚

135˚ 180˚

wronggood

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

Adjustment Location: Playback Head (Deck A)

Record/Playback/Erase Head (Deck B)

reverse

forward

main board

CN403 Pin

Pin

3

(L-CH)

1

(R-CH)

Deck A is RV311 (L-CH) and RV411 (R-CH), deck B is RV301

(L-CH) and RV401 (R-CH)

so that adjustment within the following adjustment level.

Adjustment level:

CN403 playback level: 301.5 to 338.3 mV (–8.2 to –7.2 dB)

level difference between the channels: within ± 0.5 dB

Adjustment Location: AUDIO board

— 12 —

Page 13

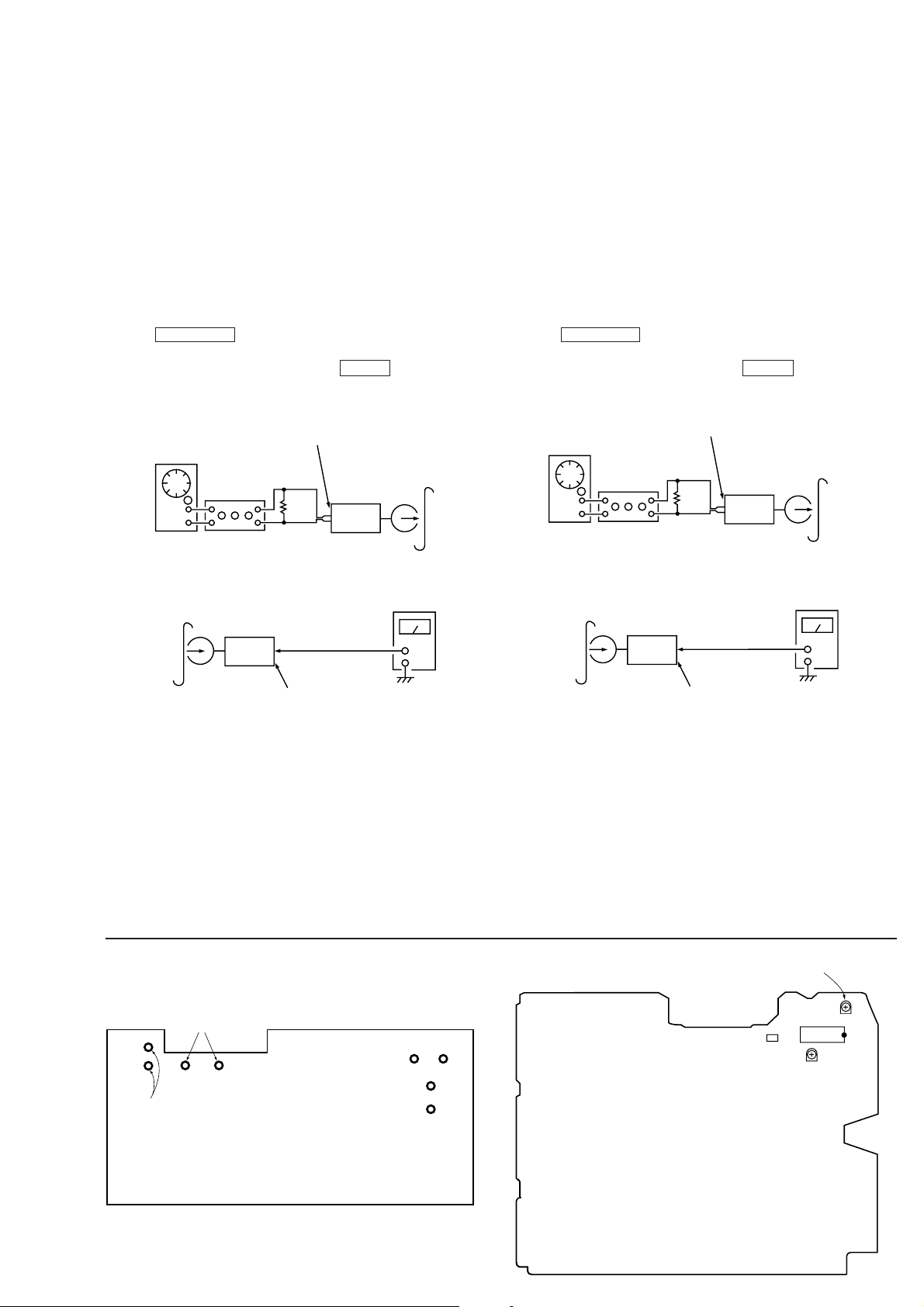

Record Bias Adjustment (Deck B)

Record Level Adjustment (Deck B)

Procedure:

INTRODUCTION

When set to the test mode performed in Tape Speed Adjustment, when the tape is rewound after recording, the “REC memory

mode” which rewinds only the recorded portion and playback is

set.

This “REC memory mode” is convenient for performing this adjustment. During recording, the input signal FUNCTION will automatically switch to VIDEO.

1. Press FUNCTION button to select VIDEO. (This step is not

necessary if the above test mode has already been set.)

2. Load a tape into deck B, and press the r REC button.

3. Mode: Record

VIDEO (AUDIO) IN

1) 315Hz

2) 10kHz

AF OSC

attenuator

} 50 mV (–23.8 dB)

Ω

600

blank tape

CS-123

set

4. Mode: Playback

recorded

position

level meter

Procedure:

INTRODUCTION

When set to the test mode performed in Tape Speed Adjustment, when the tape is rewound after recording, the “REC memory

mode” which rewinds only the recorded portion and playback is

set.

This “REC memory mode” is convenient for performing this

adjustment. During recording, the input signal FUNCTION will

automatically switch to VIDEO.

1. Press FUNCTION button to select VIDEO. (This step is not

necessary if the above test mode has already been set.)

2. Load a tape into deck B, and press the r REC button.

3. Mode: Record

VIDEO (AUDIO) IN

315 Hz 50 mV (–23.8 dB)

AF OSC

attenuator

Ω

set

blank tape

CS-123600

4. Mode: Playback

recorded

position

level meter

set

main board

CN403 Pin

Pin

3

(L-CH)

1

(R-CH)

5. Confirm playback the signal recorded in step 2 become adjustment level as follows.

If these levels do not adjustment level, adjust the RV341 (LCH) and RV441 (R-CH) on the AUDIO board to repeat steps 3

and 4.

Adjustment level: The playback output of 10 kHz le vel dif ference

against 315 Hz reference should be ± 0.5 dB.

Adjustment Location: AUDIO board

Adjustment Location

[AUDIO BOARD] (Conductor Side)

RV341(Lch),R V441(Rch)

Record Bias

RV301

RV401

RV441 RV341

RV301(Lch),RV401(Rch)

Playback Level (Deck B)

RV651 (Normal Speed)

RV652 (High Speed)

Tape Speed

RV311(Lch),RV411(Rch)

Playback Level (Deck A)

RV652RV651

RV311

RV411

set

main board

CN403 Pin

Pin

3

(L-CH)

1

(R-CH)

5. Confirm playback the signal recorded in step 2 become adjustment level as follows.

If these levels do not adjustment level, adjust the RV301 (LCH) and RV351 (R-CH) on the MAIN board to repeat steps 3

and 4.

Adjustment level:

CN403 playback level: 47.2 to 53.0 mV (–24.3 to –23.3 dB)

Adjustment Location: MAIN board

RV301

[MAIN BOARD] (Component Side)

Record Level (L CH)

13

CN403

IC401

RV351

Record Level

(R CH)

— 13 —

Page 14

TUNER SECTION 0dB=1µV

Note 1: As a front-end (FE1) is diff icult to repair if faulty, replace

it with new one.

Note 2: No adjustment is needed due to a tuner pack for except

AEP, UK, East European, CIS models.

AM Tuned Level Adjustment

Note: FM Tuned Level adjustment should be performed after this

AM Tuned Level Adjustment.

Setting:

Band: MW

loop antenna

AM RF SSG

loop antenna

(Supplied accessories)

set

30% amplitude

modulation by

400Hz signal

Modulation: 999 kHz (at 9 kHz step)

1,050 kHz (at 10 kHz step)

Field strength dB (µV/m) = SSG output level dB (µV/m) –26dB.

60cm

Procedure:

1. Set the output of SSG so that the input level of the set becomes

55 dB or 58 dB. (55 dB : Except East European, CIS model, 58

dB : East European, CIS model)

2. Tune the set to 999 kHz or 1,050 kHz.

3. Adjust R V41 to the point (moment) when the TUNED indicator

will change from going off to going on.

Adjustment Location: TCB board

FM Tuned Level Adjustment

Note: This adjustment should be performed after the AM Tuned

Level Adjustment.

Setting:

Band: FM

FM RF SSG

75

Ω

coaxial

AM antenna

terminal (TM1)

Adjustment Location

[TCB BOARD] (Component Side)

TM1

RV41

AM Tuned Level

RV42

FM T uned

Level

IC21

set

Carrier frequency: 98MHz

Modulation: AUDIO 1kHz, 75kHz

Output level: 25dB (at 75

deviation (100%)

(EXCEPT East European, CIS model)

23dB (at 75

(East European, CIS model)

Ω

open)

Ω

open)

FM ANTENNA terminal

(TM1)

Procedure:

1. Supply a 25 dB or 23 dB 98 MHz signal from the ANTENNA

terminal.

2. Tune the set to 98 MHz.

3. Adjust RV42 to the point (moment) when the TUNED indicator

will change from going off to going on.

Adjustment Location: TCB board

— 14 —

Page 15

FM Polar Adjustment (East European, CIS model only)

Connection 1 :

FM RF SSG

Carrier frequency: 69 MHz

Output level: 1 mV (60 dBµ) (at 75

Modulation: AUDIO 1 kHz, 10 kHz deviation

75

Ω

coaxial

FM antenna

terminal (75

Ω

open)

set

Ω

)

Connection 2 :

AF OSC

FM RF SSG

75 Ω coaxial

set

Procedure :

1. Set the modulation of FM RF SSG to AUDIO 1 kHz, 10 kHz

deviation according to “Connection 1”.

2. Tune the set to 69 MHz.

3. Adjust the RV1702 so that the reading of frequency counter connected to TP1702 (VCO) becomes within 31.25 kHz ± 0.05 kHz.

(VCO adjustment)

4. Then record the reading of the level meter connected to TP1701.

5. Set the modulation of FM RF SSG to AUDIO 31.25 kHz, 10

kHz deviation according to “Connection 2”.

6. Tune the set to 69 MHz.

7. Set the CT1701 to be mechanical center.

8. Adjust the L1701 so that the reading of the level meter connected to TP1701 (FILTER) becomes maximum.

Then adjust the CT1701 so that the reading of the level meter

connected to TP1701 (FIL TER) becomes maximum. (SUB CARRIER PEAK Adjustment)

9. Adjust the RV1701 so that the level at the moment becomes 14

dB higher value than the level recorded in step 4. (SUB CARRIER LEVEL Adjustment)

Audio 31.25kHz

Carrier frequency: 69 MHz

Output level: 1 mV (60 dBµ) (at 75

Modulation: AUDIO 31.25 kHz, 10 kHz deviation

external

modulation

terminal

(EXTERNAL MODULATION)

Ω

open)

FM antenna

terminal (75

Adjustment Location

[TCB BOARD] (Conductor Side)

frequency counter

+

_

level meter

TP1701

(FILTER)

IC1701

Ω

)

[TCB BOARD] (Component Side)

L1701

CT1701

RV1701

Sub Carrier

Level

IC1701

Sub Carrier Peak

TP1702

(VCO)

RV1702

VCO

— 15 —

Page 16

CD SECTION

RF Level Check

Note:

1. CD Block is basically constructed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10M impedance.

4. Clean the object lens by an applicator with neutral detergent when

the signal level is low than specified value with the following

checks.

S Curve Check

oscilloscope

BD board

TP (FEO)

TP (VC)

Procedure :

1. Connect oscilloscope to test point TP (FEO).

2. Connect between test point TP (FOK) and Ground by lead wire.

3. Turn Power switch on.

4. Put disc (YEDS-18) in and turned Power switch on again and

actuate the focus search. (actuate the focus search when disc

table is moving in and out.)

5. Check the oscilloscope waveform (S-curve) is symmetrical between A and B. And confirm peak to peak le vel within 3 ± 1Vp-p.

oscilloscope

BD board

TP (RF)

TP (VC)

Procedure :

1. Connect oscilloscope to test point TP (RF) on BD board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Confirm that oscilloscope waveform is clear and check RF signal level is correct or not.

Note: Clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 nS

level: 1.3 ± 0.3 Vp-p

S-curve waveform

symmetry

A

B

within 3 ± 1 Vp-p

6. After check, remove the lead wire connected in step 2.

Note: • Try to measure several times to make sure than the ratio of

A : B or B : A is more than 10 : 7.

• T ake sweep time as long as possible and light up the brightness to obtain best waveform.

— 16 —

Page 17

E-F Balance (1 Track Jump) check

BD board

TP (TEO)

TP (VC)

Procedure:

1. Connect oscilloscope to test point TP (TEO) on BD board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in to play the number five track.

4. Press the “P (Pause)” button.

5. Check the level B of the oscilloscope's waveform and the A (DC

voltage) of the center of the Traverse waveform.

Confirm the following:

A – B

• x 100 = less then ± 7 (%)

2 (A + B)

oscilloscope

• A + B = 500 ± 100 mVp-p

1 track jump waveform

0V

level : 500 mV ± 100 mVp-p

Center of the waveform

B

A (DC voitage)

Symmetry

Adjustment Location:

[BD BOARD] (Conductor Side)

CN101

TP

(GND)

TP

(TEO)

IC103

TP (RF)

TP

(FEO)

IC101

TP

(FOK)

TP

(VC)

IC102

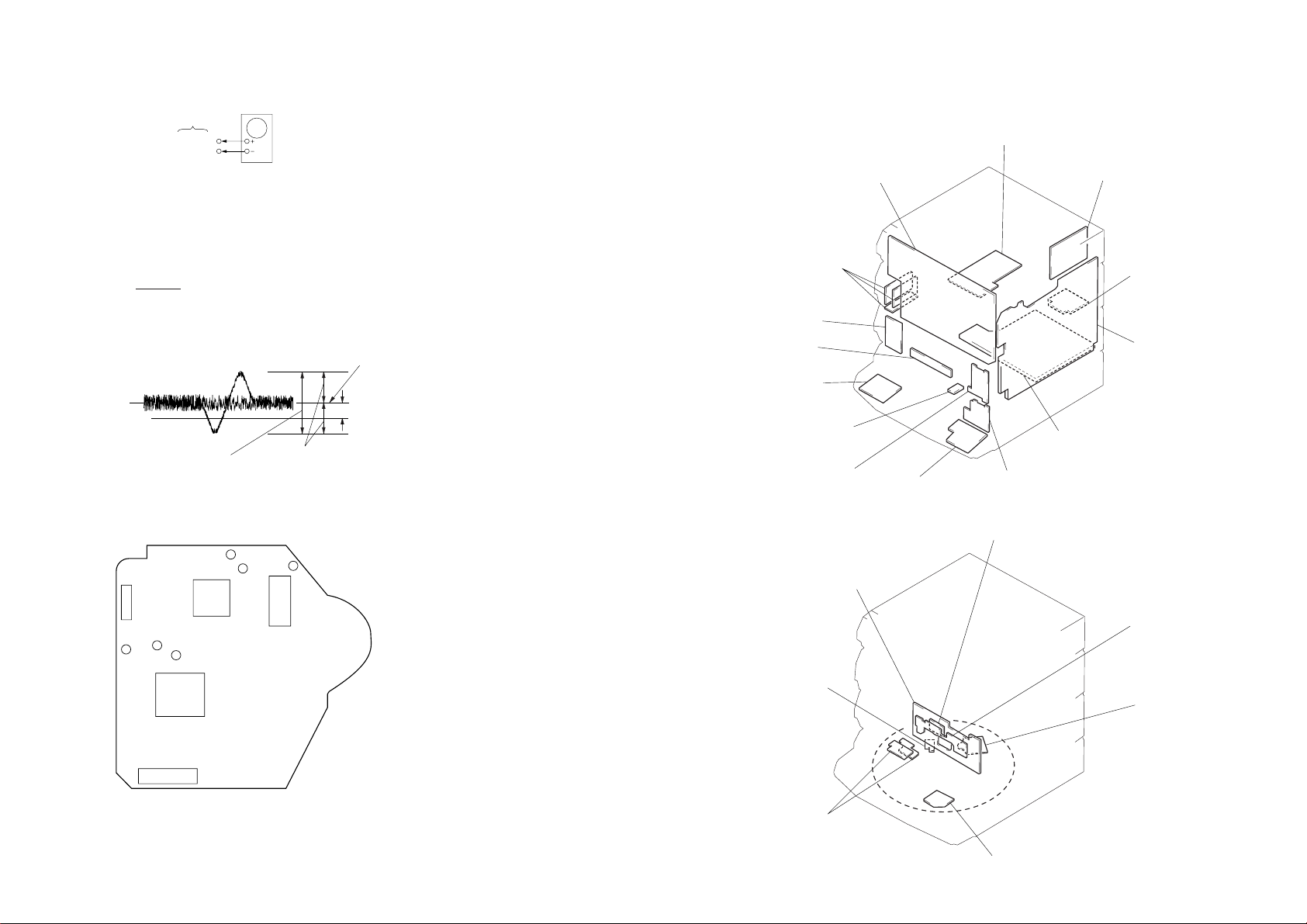

6-1. CIRCUIT BOARDS LOCATION

PANEL board

HP/MIC board

TC-A SW board

CD-LED board

CD-A SW board

DOOR SW board

TC-B SW board

Note: pA is including in AUDIO board.

AUDIO board

p

(including

TABLE SENSOR board

A)

SECTION 6

DIAGRAMS

CD-B2 SW board

TRANS board

CD-B1 SW board

p

A

MOTOR board

TCB board (AEP, UK, East European, CIS)

FM/AM TUNER PACK

(ENCAPSLATED COMPONENT)

(EXCEPT AEP , UK, East European,

CIS)

SURROUND board

MAIN board

POWER board

LEAF SWITCH board

BD board

IC102

— 17 —

CD MOTOR board

LED board

— 18 —

Page 18

HCD-XB8

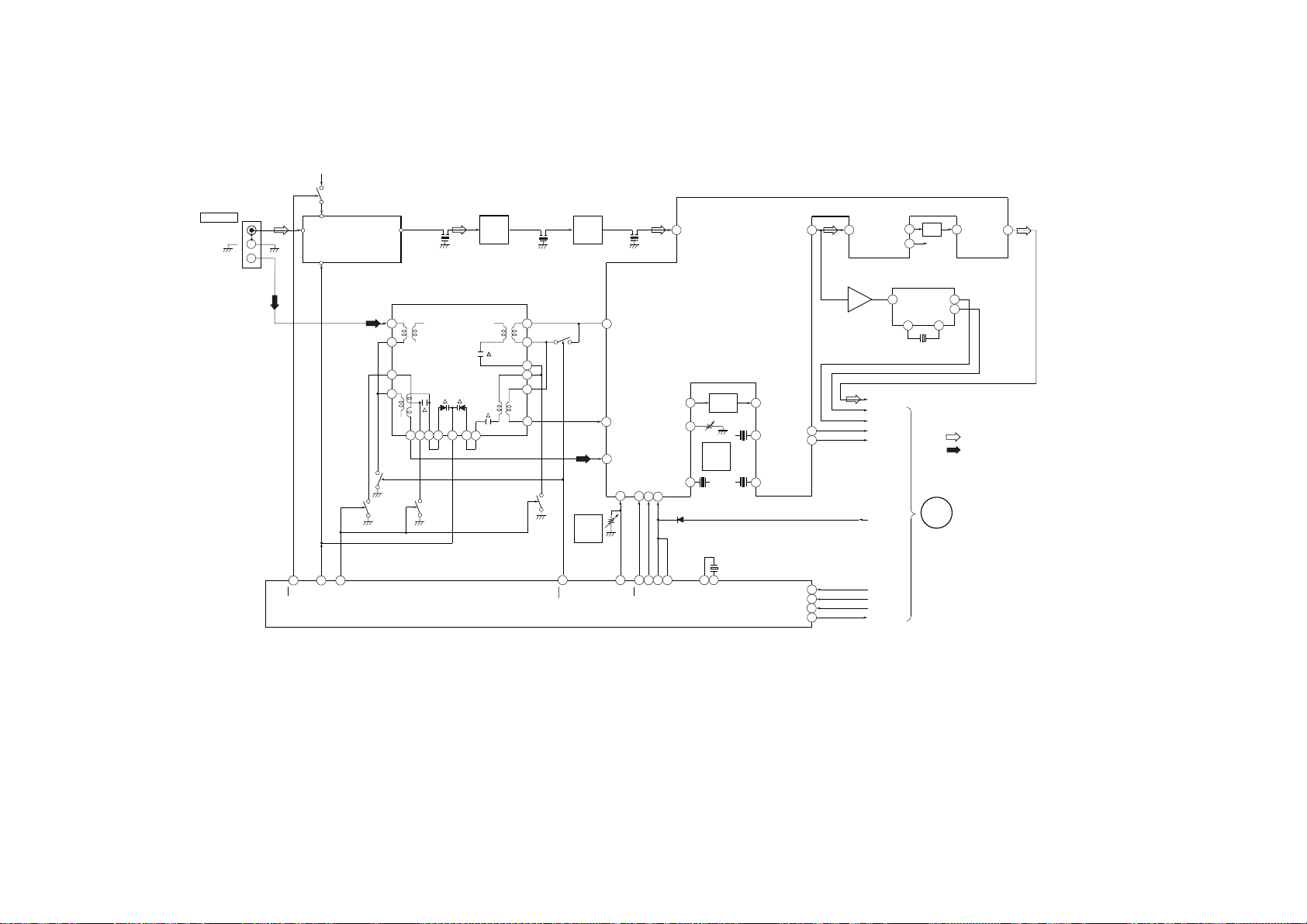

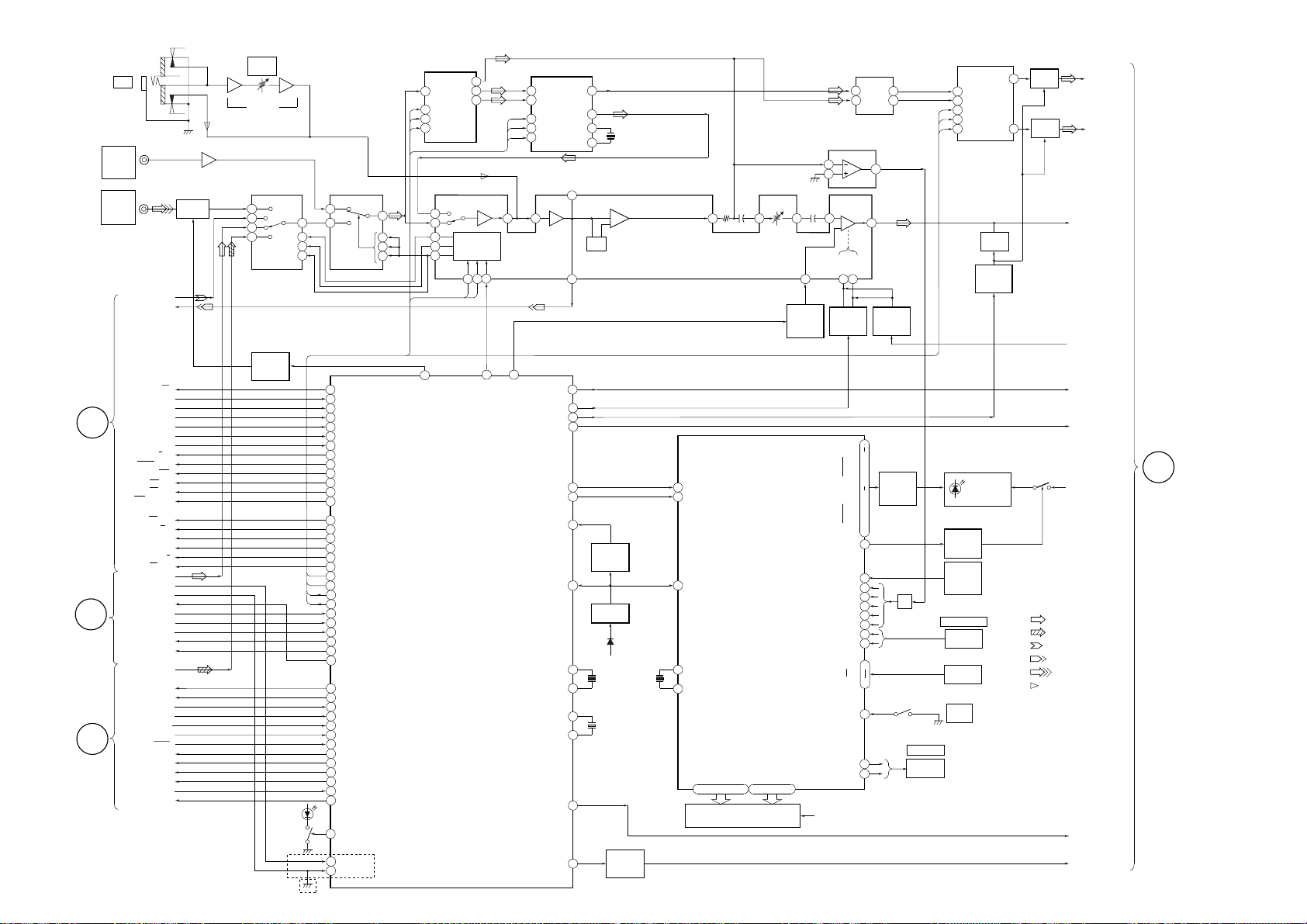

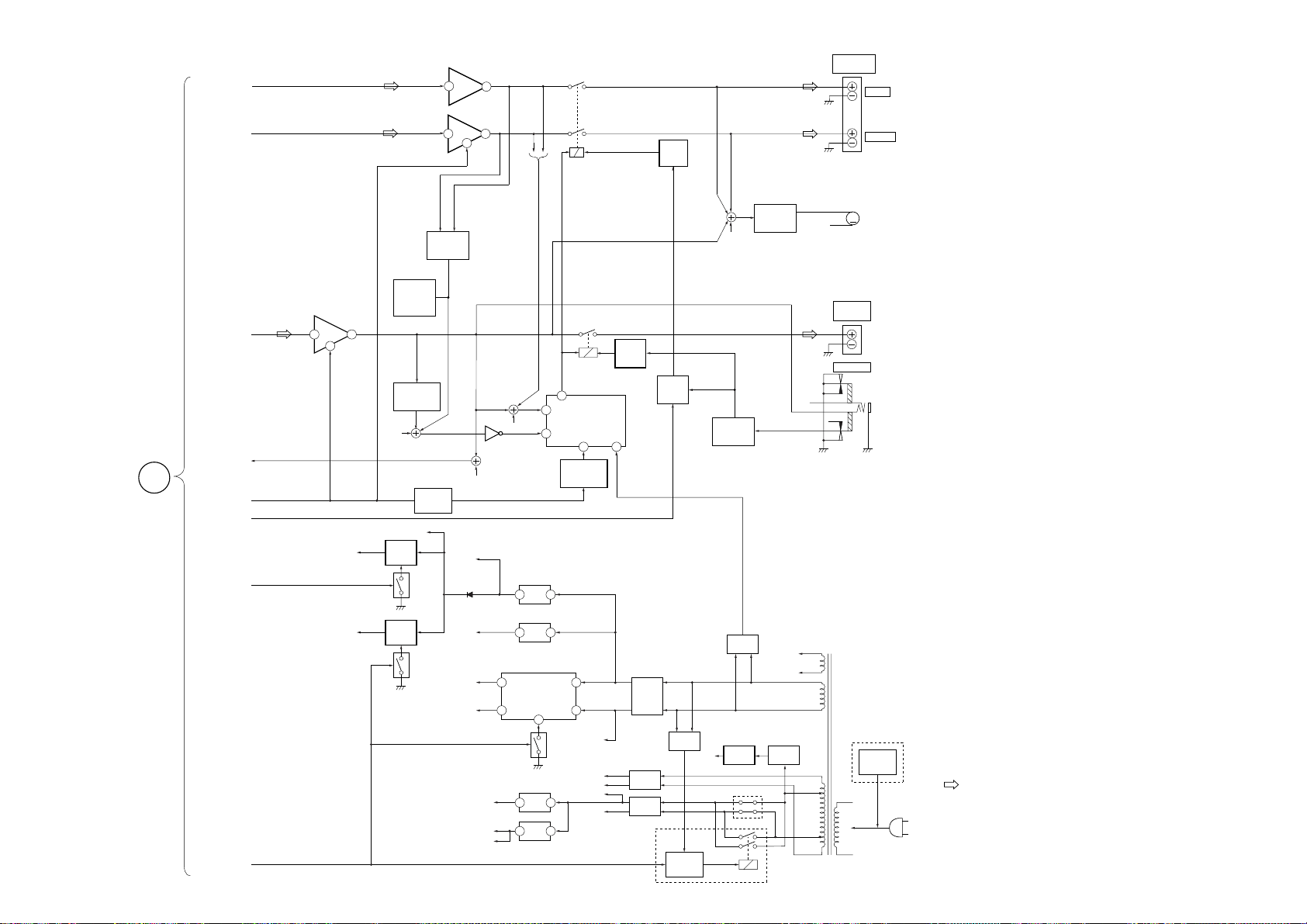

6-2. BLOCK DIAGRAMS

— TUNER SECTION — (AEP, UK model)

TM1

ANTENNA

FM 75Ω

COAXIAL

AM

ST +10V

Q5

FE1

FM FRONT END

ANT IN

VT

1710

FM

VT1

09

IF OUT

LW SW

Q13

MW

SW

9

MW

6

5

3

2

26 25 24 23 22 21

Q14

CF1

10.7MHz

FE2

MW/LW FRONTEND

Q12

MW

SW

29

27

4

10.7MHz

REG

AM OSC

AM RF IN

FM SD

30 14

AM OSC

CF3

7

AM/FM

15

2

FM

AM MIX

IF BUFF

VCO STOP

11

1214

8

FM/AM IF

VCO STOP

MUTE

IF REQ

1 FM IN

AM

SD

AM

SD

D41

FM/AM MPX

IC41

2

12

RV41

13

X42

450kHz

1 24

AM

TUNED

LEVEL

XIN

AM IF

IFT1

XOUT

X21

4.5MHz

X41

10.7MHz

X43

456kHz

5

9

23

AM IF

DET

VCO

24 22

AM/FM

8

STEREO

7

TUNED

3 ST-CE

CE

4

DI

5

CL

DO

6

OUT L

MPX IN

OUT R

IC1751

ST L

RDS INT

RDS DATA

STEREO

TUNED

MUTE

COM-DIN

COM-CLK

COM-DATA

4

57

20

LPF

RCH

21

RDS DECODER

IC1752

13 14

X1751

4.332MHz

MAIN

SECTION

(Page 27)

A

• R CH: Same as L ch

• SIGNAL PATH

: FM

: MW

16

18

2

AMP IN L

AMP

OUT

16

L

IF AMP

Q1, 2

12

13

14

15

16

20

PLL

IC21

17

Q11

MW

SW

LW SW

Q9

11

IF AMP

Q3, 4

RV42

FM

TUNED

LEVEL

MW

CF2

10.7MHz

— 19 —

— 20 —

Page 19

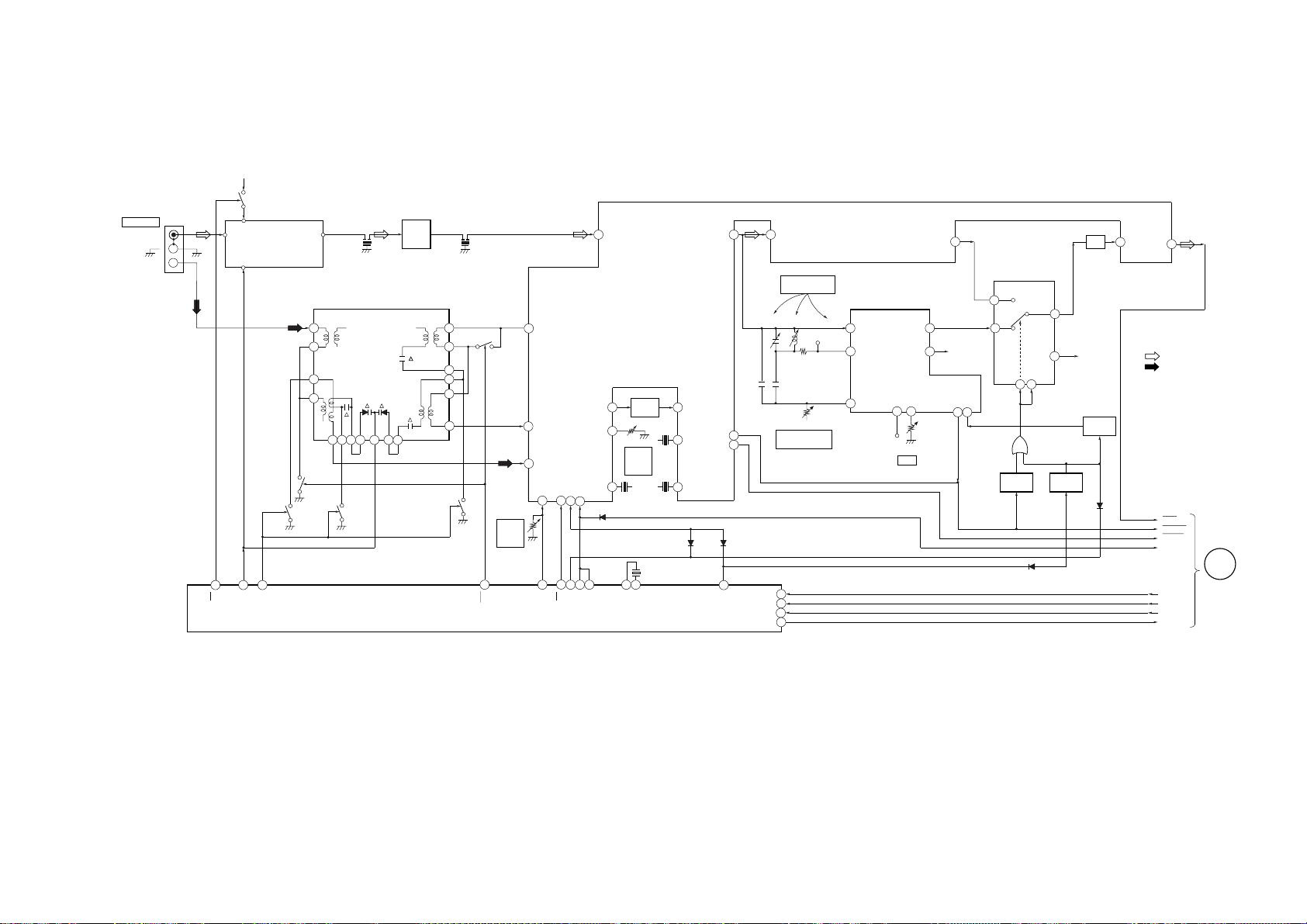

— TUNER SECTION — (East European, CIS model)

ST +10V

HCD-XB8

TM1

ANTENNA

FM 75Ω

COAXIAL

Q5

ANT IN

AM

09

VT

1710

FM

VT1

9

MW

FE1

FM FRONT END

IF OUT

Q13

MW

SW

6

5

3

2

26 25 24 23 22 21

Q14

LW SW

CF1

10.7MHz

FE2

MW/LW FRONTEND

Q12

MW

SW

IF AMP

Q1-4

12

LW SW

Q9

13

14

15

16

20

PLL

IC21

17

Q11

MW

SW

11

4

REG

29

AM OSC

27

AM RF IN

FM SD

30 14

RV42

FM

TUNED

LEVEL

MW

AM OSC

7

AM/FM

15

2

FM

AM MIX

IF BUFF

VCO STOP

11

1214

8

FM/AM IF

VCO STOP

1 FM IN

FM/AM MPX

AM

SD

AM

MUTE

SD

D41

IF REQ

24

AM/FM

IC41

AM IF

2

12

RV41

TUNED

LEVEL

13

X42

450kHz

1 24

XIN

5

AM IF

IFT1

X41

10.7MHz

AM

456kHz

X21

4.5MHz

XOUT

STEREO

9

DET

TUNED

VCO

23

X43

D42 D43

13

LW/SW

MPX IN

22

SUB CARRIER

PEAK

L1701CT1701

TP1701

CE

DI

CL

DO

RV1701

SUB CARRIER

LEVEL

3

4

5

6

8

7

POLAR

DECODER

IC1701

2

IN

L OUT

3

POUT

R OUT

MON

SUB IN

20

18 17

TP1702

VCO

VCO

RV1702

20OUT L

POLAR/PILOT

SWITCH

IC1702

C0

5

C. COM

CA

9 11

Q1702

D1704

A. COM

D1701

D1702

4

14

SWITCH

R CH

Q1703

D1703

ST IND

910

C1

3

VCO

STOP

SWITCH

7

6

R CH

LPF 18

SWITCH

Q1701

AMP

AMP

IN

16

OUT

L

L

• R CH: Same as L ch

• SIGNAL PATH

: FM

: MW

ST-L

STEREO

TUNED

MUTE

ST-CE

COM-DIN

COM-CLK

COM-CLK

A

MAIN

SECTION

(Page 27)

CF3

10.7MHz

— 21 —

— 22 —

Page 20

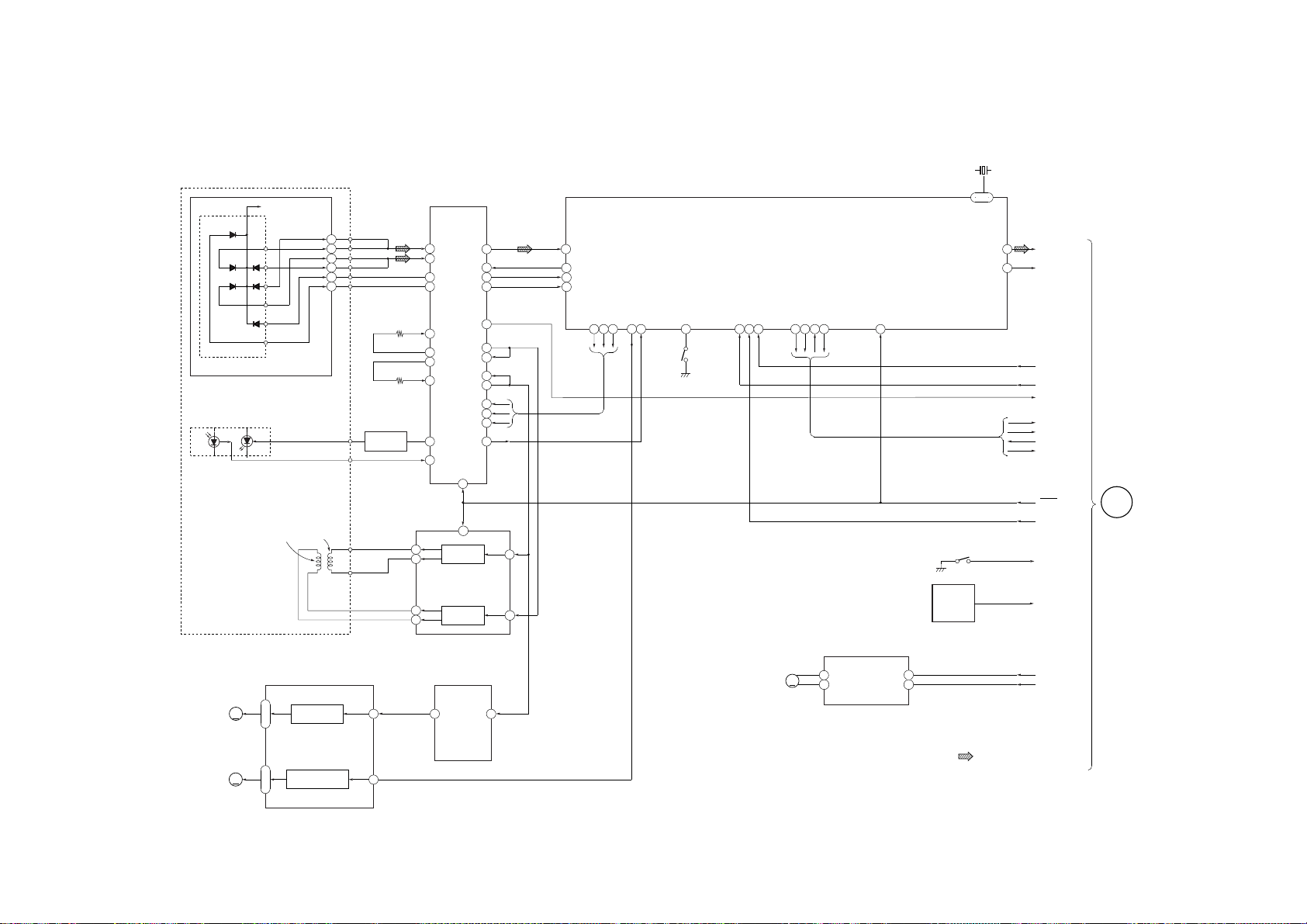

HCD-XB8

— CD SECTION —

OPTICAL PICK-UP BLOCK

DETECTOR

E

A

B

LASER

DIODE

M102

M

SLED MOTOR

M101

M

SPINDLE

MOTOR

09

X101

FOCUS/TRACKING SERVO.

RF AMP

15

16

18

17

IC101 (1/2)

38

PD1

39

PD2

41

F

42

E

2

FEI

1

FEO

TEO

45

47

TEI

3637LD

PD

TRACKING

COIL DRIVE

FOCUS/TRACKING

COIL DRIVE

IC102 (1/2)

COIL DRIVE

IC101 (2/2)

SL O

XRST

23

MUTE

FOCUS

SLED

SERVO

RF O

LOCK

C.OUT

SENS1

SENS2

FE M

TA M

DATA

9

FE O

TA O

CLK

33

19

24

25

26

6

7

12

13

22

21

XLT

20

27

FOK

27

26

1416

SL P

RF

44

LOCK

29

14

CNIN

15

SEIN

DATAO

CLKO

FOK

XLTO

MDP

23

15 16 17

27

DIGITAL SIGNAL PROCESSOR

SPOD

21

S101

LIMIT

IC103

CLOK

XLAT

DATA

10 11 12 75

M201

TABLE

MOTOR

SQCK

SCOR

SQSO

8

79 100

M

SENS

7

3

MOTOR DRIVER

OUT1

OUT2

IC201

XRST

DISC

TABLE

SENSOR

IC202

9

IN1

1

IN2

B+

K

TRACKING

COIL

2-AXIS

DEVICE

SLED/SPINDLE

MOTOR DRIVE

IC102 (2/2)

SLED MOTOR

DRIVE

1

4

2

5

10

6

LD DRIVE

Q101

T+

–

T

–

F

F+

6

A

D

D

C

C

B

F

FOCUS

COIL

11

•

12

16.9344MHz

89 • 90

•

XTAI

XTAO

86

LOUT1

LOUT2

93

S201

UP SW

• R CH: Same as L ch

L-CH

R-CH

CD CLK

CD DATA

SENS2

SCOR

SQ DATA

SQ CLK

SENS

XRST

XLAT

UP SW

T.SENS

TBL.L

TBL.R

C

MAIN

SECTION

(Page 27)

• SIGNAL PATH

: CD

13

14

•

SPINDLE MOTOR

DRIVE

3

— 23 —

— 24 —

Page 21

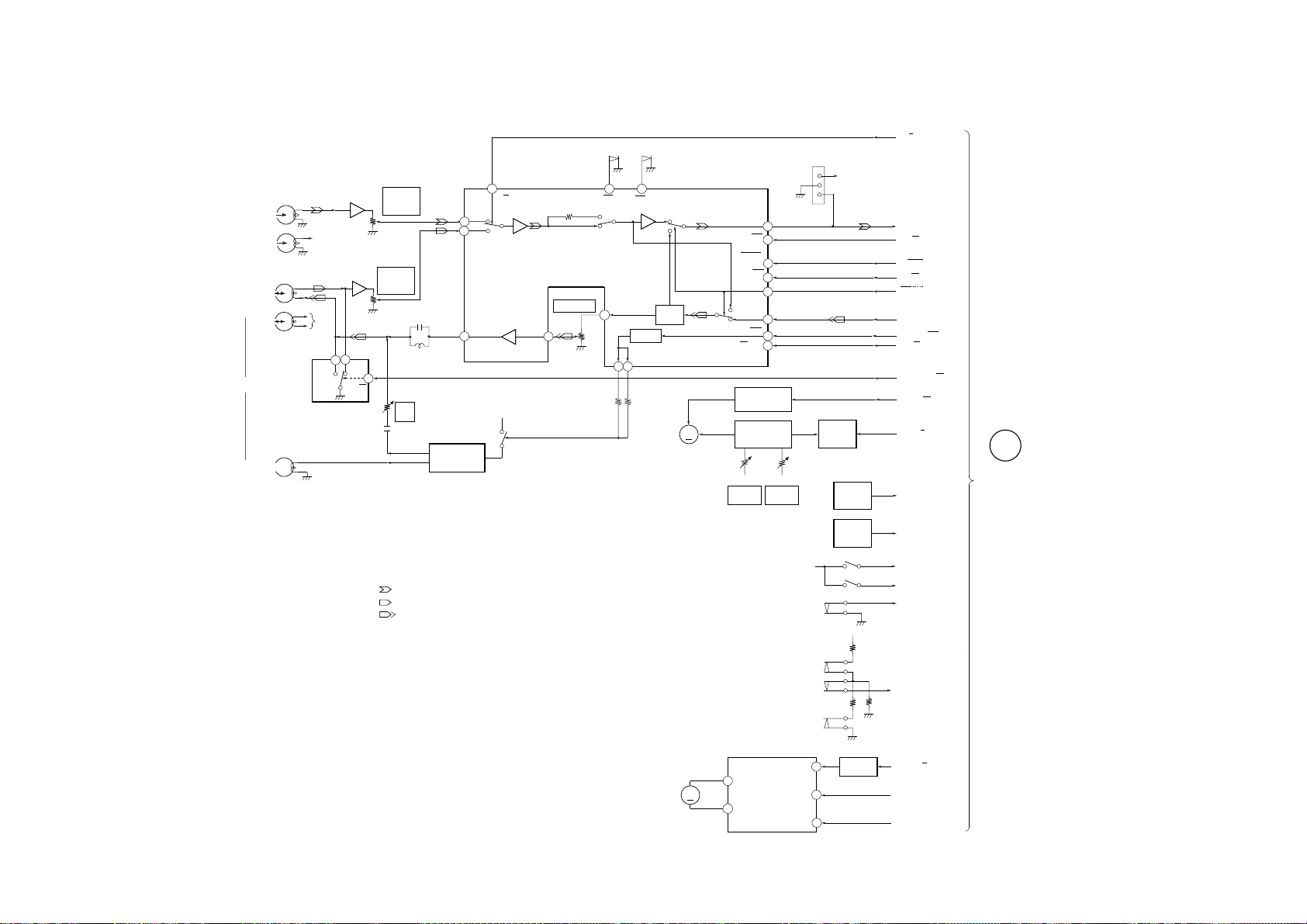

— DECK SECTION —

HCD-XB8

HP101

PB HEAD

(DECK A)

REC/PB HEAD

(DECK B)

HRPE101

ERASE HEAD

S1008

S1004

B CrO

2

DOLBY NR

RECOUT

NORM

24 25

15

B 120/70

BIAS SW

CROM

2

PAS

DOL

M1

CAPSTAN

MOTOR

DOLBY

TYPE B

CN403

3

R CH

1

PB OUT

8

LM ON/

20

OFF

NORM/

14

HIGH

NR ON/

18

OFF

19

PB

RIN

6

BIAS ON/OFF

16

17

RM ON/OFF

CAP M SWITCH

Q405, 407

SPEED

RV651

NORMAL

SPEED

CONTROL

Q651

RV652

HIGH

SPEED

M

+5V

S1003

(A HALF)

SWITCH

Q406

REEL

DETECT

Q1001

REEL

DETECT

Q1002

S1001 (A PLAY)

S1002 (B PLAY)

+5V

A CrO

RV311

RV301

PLAYBACK

IC601

DECK B

1

IC602

R

4

REC/PB

• R CH : Same as L ch

• SIGNAL PATH

: PB (DECK A)

: PB (DECK B)

: REC (DECK B)

PLAYBACK

LEVEL

DECK A

LEVEL

RV341

REC

BIAS

REC BIAS

T621, Q621, 622

IC611

L

R

L

R

R CH

R CH

3

P

ERASE BIAS

X

BIAS OSC

12

PB-A/B

A IN

2

B IN

4

+7.5V

Q623, 901

EQIN

10

EQOUT

11

RV301

REC LEVEL

13

A 120/70

70

120

DECK PROCESS

IC401

10

PB A/B

PB L

LM ON/OFF

NORM/HIGH

NR ON/OFF

REC/PB/PASS

REC L

BIAS ON/OFF

RM ON/OFF

RELAY REC/PB

CAP M ON/OFF

CAP M H / L

A SHUT

B SHUT

A PLAY

B PLAY

A HALF

B

MAIN

SECTION

(Page 27)

S1005

TRIGGER

MOTOR

DRIVE

IC402

(REC A)

S1006

(B HALF)

S1009

(REC B)

VZ

IN2

IN1

BHALF

SWITCH

4

Q408, 409

6

5

TRIG H / L

B TRIG

A TRIG

— 26 —

09

2

M2

TRIGGER

MOTOR

M

OUT1

10

OUT2

— 25 —

Page 22

HCD-XB8

— MAIN SECTION —

J761

MIC

J101

PHONO

IN

L

J101

VIDEO

(AUDIO)

IN

L

REC L

RELAY REC/PB

A SHUT

B SHUT

B HALF

B

DECK

SECTION

(Page 26)

A

TUNER

SECTION

(Page 20,

22)

C

CD

SECTION

(Page 24)

09

A HALF

A PLAY

B PLAY

PB A / B

NORM/HIGH

BIAS ON/OFF

RM ON/OFF

NR ON/OFF

REC/PB PASS

LM ON/OFF

CAP M H/L

TRIG H/L

CAP M ON/OFF

RDS DATA

RDS INT

COM DIN

COM DATA

STEREO

TUNED

T. SENS

SENS 2

CD CLK

CD DATA

UP SW

SQ CLK

SQ DATA

PB L

A TRG

B TRG

ST L

ST CE

MUTE

L CH

TBL. L

TBL. R

SCOR

SENS

X RST

X LAT

31

PHONO EQ AMP

IC101

MUTE

Q121

31

MIC AMP

V

1

TC

2

ST

4

CD

5

RV760

MIC

LEVEL

67

IC760

INPUT SELECT

IC102

MUTE

CONTROL

Q123,124

(DISC No.)

EXCEPT

AEP,UK

D201

INH

A

B

D+5V

10

3

9

6

1

2

3

4

Q201

— 27 —

3

5

96

26

27

28

97

94

95

87

88

89

90

91

92

93

82

83

84

85

86

41

42

44

45

66

70

69

68

72

67

60

61

18

76

73

74

57

48

47

77

36

34

58

62

22

21

INPUT SELECT

IC103

RELAY

A SHUT

B SHUT

B HALF

A HALF

A PLAY SW

B PLAY SW

PB A/B

EQ H//N

BIAS

REC MUTE

NR ON/OFF

R/P PASS

TC MUTE

CAP H/N

A TRG

B TRG

TRG LOW

CAP M ON/OFF

VOL LAT

PL LAT

COM DOUT

COM CLK

ST DIN

STEREO

TUNED

ST CE

ST MUTE

ST DOUT

TBL L

TBL R

SCOR

T SENS

SENS 2

SENS

XRST

CD CLK

CD DATA

UP SW

SQ CLK

SQ DATA IN

XLT

TRAY LED

RDS DATA

RDS INT

4

9

10

11

AEP,UK

DOLBY PRO LOGIC

9

LIN

3

41

DATA

4

42

CLK

2

40

EN

69

71

28

29

30

54

INPUT CHANGE

MASTER CONTROL

IC601

IC701

C-OUT

S-OUT

L-OUT

34

35

37

MICON

INTERFACE

34

32 33

3

4

LATCH

3

427 LAT SW F CON

CENTER

REAR

FRONT

3

4

2

65 64

99

10

8

3

2

4

CD POWER

STK MUTE

S-IN

L-IN

DATA

CLK

EN

POWER

DBFB H/L

TA MUTE

R RELAY

IIC DATA

IIC CLK

RESET

AC CUT

DELAY

IC602

XT1

XT2

FRONT

X1

X2

S-OUT

L-MIX

OUT

XTAL

XTAL

61

REC 2A

62

98

55

56

15

20

11

10

14

13

46

100

VOLUME

3

IN

14

IN

4

8

CLK

3

9

DATA

1

10

PANEL LED

LED

CONTROL

Q601

REMOTE

CONTROL

RECEIVER

IC602

S711

= AMS +

ROTARY

ENCODER

KEY

MATRIX

S681

6

OPEN

IC604

SWITCH

MUTE

Q254

MUTE

Q120

2

OUT

15

OUTLATCH

IC603

REAR

CENTER

6

5

LED SELECT

SPEANA 1

SPEANA 2

SPEANA 3

SPEANA 4

DOOR SW

VF

40

SWITCH

LED1

LED13

LED15

LED18

SIRCS

JOG A

JOG B

KEY 1

VOL A

VOL B

DBFB

Q201

•

L+R

AMP

IC861

BB22

3

1

AMP

7

5

7

FRONT

38

BB12

41

DBFB

SWITCH

Q202

3

10

•

15

•

16

•

18

LED

SWITCH

20

•

22

•

23

•

25

•

47

29

39

42

43

D/A

44

45

46

26

41

3733KEY 5

38

S701

24

40

VOLUME

ROTARY

ENCODER

13

FRONT

16

23

X601

8MHz

24

45 44 43 42

+ +

EQ

2

1

7

RESET

SWITCH

Q951

RESET

IC951

D951

+5V

X601

X701

8MHz

5MHz

X702

32.768KHz

MUTE

SWITCH

Q912

EQUALIZER / VOLUME

IC201

DATA

28

CLOCK

27

14

RESET

12

XOUT

13

XIN

SEG1-35

67 - 100 • 1

FLUORESCENT INDICATOR TUBE

DISPLAY CONTROL

IC601

GR1-16

51 - 66

FL601

39

S.WOOFER

MODE

SWITCH

Q206

REAR

MUTE

Q602

MUTE

Q601

Q602,603

CENTER

FRONT

DBFB

POWER ON/OFF

R RELAY

D+5V

REAR

CENTER

• R CH: Same as L ch

• SIGNAL PATH

: FM

: CD

: PB

: REC

: VIDEO

: MIC

CD POWER

STK MUTE

D

POWER

SECTION

— 28 —

Page 23

HCD-XB8

D

MAIN

SECTION

(Page 28)

09

— POWER SECTION —

REAR

CENTER

FRONT

FRONT

DBFB

STK MUTE

R RELAY

CD POWER

POWER ON/OFF

POWER AMP

IC201

1 10

6

AU/D5V SW

D5V

SW

REAR

CENTER

Rch

CD REG

+5V REG

— 29 —

THERMAL

DET

Q670,671

THP670

OVER LOAD

DET

Q201

D5V

SWITCHED

Q904

Q906

Q905

Q907

OVER LOAD

MUTE

SWITCH

Q331

1

DET

Q601,651

POWER AMP

IC601

6

Rch

+5V

D905

D7V

A+7.5V

A–7.5V

+12V

ST10V

PRO-LOG 10V

TM402

SURROUND

UNREG

–12V

FRONT

Rch

TRANSFORMER

T501

POWER

SPEAKER

TM401

FRONT

SPEAKER

J760

PHONES

M

MOTOR

E,AR,PX,SAF

SELECTOR

REAR

CENTER

M901

FAN

VOLTAGE

S501

• R CH : Same as L ch

• SIGNAL PATH

: FM

• Abbreviation

EE: East European model.

AC

MX: Mexican model.

IN

AR: Argentine model.

AUS: Australian model.

SAF: South African model.

RY401

Q901

6

PROTECTOR

PROTECT

V

CC

V

EE

RY402

IC301

7

SWITCH

Q301

2

9

UNREG

–12V

POWER B+

POWER B–

SURR B+

SURR B–

–1

–2

RELAY

DRIVE

Q404

Rch

–1

RELAY

DRIVE

Q403

RELAY

CONTROL

Q402

HP / SP

SWITCHING

RECT

RELAY

Q401,405

VFDP

E,MX,AR,PX,AUS,SAF

RECT

D302,303

VF REG

Q941

RY101

4

RECT

D901

D110,111

RECT

D101

RECT

D102

DRIVER

Q111-113

AEP,UK,EE,CIS

10

1318

2

Rch

+7.5

1

–7.5 EN

10

+5V REG

IC902

3 1

+7V REG

IC903

3 1

+7V, –7V REG

IC901

4

+12V REG

IC904

3 1

3 1

+10V REG

IC905

1

Q323

FAN MOTOR

DRIVER

Q961, 962

RECT

D104,105

REAR

CENTER

VF

VF

— 30 —

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

6-19. IC BLOCK DIAGRAMS

2

• Tuner section

IC21 LC72130

24

XOUT

VSS

22

23

AOUT

REFERENCE

DIVIDER

2

C B

I / F

AIN2

21

SWALLOW COUNTER

20

PD2

19

1/16.1/17 4bits

REFERENCE

DIVIDER

DATA SHIFT REGISTER

PD1

AIN1

18

SWALLOW COUNTER

1/16.1/17 4bits

PHASE DETECTOR

CHARGE PUMP

LATCH

17

AOUT1

16

VDD

POWER

ON

RESET

FMIN

AMIN

I02

13

14

15

1/2

C B

I / F

1

2

XIN

B05

IC41 LA1835

FM-SD

AM-OSC

ALC

AM

OSC

BUFF

S METER

LEVEL

DET

S-CURVE

FM

IF

1

2

FM-IN

AM-MIX

DET

3

4 5

CE

D1

AM-RF-IN

FM-AFC

AM

AM

RF.AMP

MIX

AM

IF

AM/FM

IF

BUFF

FM

REG GND

3

4 5

IF

REG

CL

AGC

COMP

TUNING

DRIVE

AGC

AM-IF

AM

DET

6

D0

AM.CUT

AM

FM

6

GND

7

B01

AM/FM

24252627282930

7

TU-LED

8

B02

23

AM/FM

SW

8

VCO

ST-LED

9

B03

MPX-IN

22

9

DET

VCO

10

B04

OUT R

21

DECODER

ANTI BIRDIE

STEREO

DRIVE

FFFFFF

PHASE

DET

VCC

10

VCC

11

20

11

I01

OUT L

STEREO

PILOT

DET

IF-BUFF

SW

TRIG

12

IFIN

AMP-IN R

19

12

AM.SD

AMP-IN L

18

13

AM.SD

MUTE

17

14

R

AM/FM

L

16

15

CO-STOP

— 73 —

Page 38

IC1701 IR3R42

D

SUBIN

SUBOUT

AMP

1

VCC

MON

1/2

PHASE

AMP

2 3

IN

WAVEFORM

SEP.

GATE

POUT

20 19 18 17 16 15 14 13 12 11

REGULATOR

VCO

OSC

1/2

SAMPLE

& HOLD

BUFFER

4

RHC

LPF1A

LPF1B

DETIN

LPF2A

AMP

PHASE

COMPARATOR

5 6 7 8 9 10

ROUT

LOUT

ST

LHC

PHASE

COMPARATOR 2

MUTE

VCO STOP

IC1752 BU1922

FILTER

DDD

V

RDCL

TS7

QUALITY BIT

GENERATOR

OSCO

141516 13 12 11 10 9

OSCILLATOR

AND

DIVIDER

OSCI

RECONSTRUCTION

LPF2B

TRIGGER

GND

LAMP

57kHz

BANDPASS

(8th ORDER)

SSD

V

TEST

TEST LOGIC AND OUTPUT

SELECTOR SWITCH

ANTI-

ALIASING

FILTER

TSTL

QUAL

DEFFERENTIAL

DECODER

RDDA

BIPHASE

SYMBOL

DECODER

321 4 5 6 7 8

Vref

MUX

CONTAS LOOP

VARIABLE AND

FIXED DIVIDER

CLOCK REGENERATION

AND SYNC

REFERENCE

VOLTAGE

DDA

V

SSA

V

VP1

CLOCKED

COMPARATOR

CIN

SCOUT

— 74 —

Page 39

• CD section

IC101 CXA1992AR

+

PD2 IV

AMP

FE_BIAS

40

VEE

BAL1

TOG2

TOG1

–

+

–

+

VCC

FZC COMP.

–

+

F IV AMP

–

+

E IV AMP

BAL2

BAL3

TOG4

TOG3

+

–

ATSC

WINDOW

COMP.

–

+

TZC COMP.

+

–

+

–

BAL4

VCC

VEE

TEO

LPFI

ATSC

TDFCT

F

41

E

42

43

EI

44

VEE

45

46

47

TEI

48

49

TZC

50

51

VC

FZC

52

PD2

–

1

FEO

–

+

PD1 IV

AMP

TGFL

–

+

+

–

E-F BALANCE

WINDOW COMP.

+

–

DFCT

2 3

PD1

FEI

VCC

VCC

TM1

CB

RF_O

PD

LD

RFTC

RF_M

RF_I

CP

CC1

FOK

CC2

27282930313233343536373839

VEE

–

+

–

+

–

+

RF SUMMING

AMP

FOH

FOL

TGH

TGL

BALH

BALL

ATSC

TZC

FZC

+

–

–

+

–

+

–

–

+

VEE

MIRR

VCC

–

+

–

+

+

–

–

+

VEE

LEVEL S

VCC

–

+

FOK

LDON

LPCL

LPC

TGFL

IIL DATA REGISTER

INPUT SHIFT REGISTER

ADDRESS DECODER

SENS SELECTOR

OUTPUT DECODER

DFCTO

IFB1-6

BAL1-4

TOG1-4

+

+

–

VCC

–

+

VEE

+

–

+

DFCT

–

+

MIRR

IIL

↓

TTL

DFCT1

CC1

FS1-4 TG1-2 TM1-7 PS1-4

SENS2

26

IIL

↓

TTL

–

TTL

↓

IIL

VCC

ISET

VCC VCC

SENS1

25

C. OUT

24

XRST

23

DATA

22

XLT

21

CLK

20

LOCK

19

VCC

18

ISET

17

SL_O

16

TM4 TM6

SL_M

VCC

FS1

FS2

Charge

up

TM7

TM3

TM5

VEEVEE

FSET

TG2

–

+

15

–

SL_P

14

+

TM2

+

–

–

+

+

–

APC

VEE

LASER POWER CONTROL

FE AMP

IFB4

IFB5

IFB2

IFB3

IFB1

IFB6

VEE

+

–

+

TRK. GAIN

–

WINDOW COMP.

+

–

TG1

FOCUS

PHASE COMPENSATION

–

+

+

–

FO. BIAS

WINDOW

COMP.

TRACKING

PHASE COMPENSATION

DFCT

FS4

VEE

FDFCT

4

5 6 7 8 9 10

FGD

FLB

FE_O

FE_M

SRCH

TGU

TG2

FSET

TA_M

131211

TA_O

— 75 —

Page 40

IC102 BA5941FP

IN4B

IN4A

27

28

IN3B

IN3A

OP OUT

OP IN (–)

OP IN (+)

26

24

25

22

23

GND

21 20

NC

VCC

OUT3A

18

19

OUT3B

1617

OUT4A

OUT4B

15

NC

+

–

Vcc

–

+

–

+

–

+

–

+

1 2

VCC

BIAS IN

3

IN1B

IC103 CXD2519Q

80

–

+

+

–

SYSM

4

VDD

79 78

IN1A

VSS

EXCK

77

5

IN2B

SBSO

SCOR

76 75 74

6

WFCK

73 72

IN2A

EMPHI

–

+

+

–

EMPH

LEVEL SHIFT

LEVEL SHIFT

LEVEL SHIFT

LEVEL SHIFT

+

PCMD

LRCKI

+

–

14

OUT1B

+

XUGF

+

12 13

GTOP

VDD

VSS

56 55 54

57

–

OUT2B

MUTE

7

GND

DOUT

71

8

GND

C4M

FSTT

XTSL

MNT0

67

MNT1

66 65 64

69 68

70

9

MNT3

MUTE

XROF

VccVcc

C2PO

63 62

–

11

10

VCC

OUT2A

RFCK

GFS

XPCK

59 58

60

61

BCKI

BCK

PCMDI

53 52 51

–

OUT1A

AVSS

AVDD

AOUT1

AIN1

LOUT1

AVSS

XVDD

XTAI

XTAO

XVSS

AVSS

LOUT2

AIN2

AOUT2

AVDD

AVSS

XRST

OSC

50

LRCK

WDCK

49

48

ASYE

47

ASYO

46

ASYI

45

BIAS

44

RF

43

AVDD

42

CLTV

AVSS

41

40

FILI

39

FILO

38

PCO

37

VCTL

36

V16M

35

VCKI

34

VPCO1

33

VPCO2

32

TES1

31

TES0

81

NC

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

NC

99

NC

100

–

+

–

+

SERIAL-IN

INTERFACE

1 234

VDD

VSS

LMUT

–

+

–

+

OVER SAMPLING

DIGITAL FILTER

TIMING

LOGIC

RMUT

PWMPWM

3RD-ORDER NOISE SHAPER

CPU

INTERFACE

56789 10

TES2

CKOUT

SQCK

SQSO

SENS

11

DATA

DEMODURATOR

SUB CODE

PROCESSOR

12 13

XLAT

CLOK

SEIN

EFM

14

CNIN

SEQUENCER

15 16 17

XLTO

DATO

SERVO

AUTO

18 19

CLKO

SPOA

ERROR

CORRECTOR

16K RAM

21

20

SPOB

SPOC

SPOD

22 23

XLON

24

FOK

D / A

INTERFACE

DIGITAL OUT

25 26 27

VSS

VDD

DIGITAL CLV

28 29 30

MDP

MON

MDS

LOCK

PWMI

ASYMMETRY

CORRECTOR

DIGITAL

PLL

CLOCK

GENERATOR

— 76 —

Page 41

• Main section

IC102 MC14052BCP

IC103, 1702 MC14053BCP

VDD2

12 3 456 78

0

1

141516 13 12 11 10 9

2

COMMON30

COMMON

3

1

INHIBIT

IC602 LV1016

VDD

DEC

OSC

22

2324

VDD

A

B

IN-FILTER

(40kHz)

20 19 18 17 16 15 14 13

21

ADM

ADM-CONT SRAM

A

B

A

OSC

SEL.A

EE

V

–

L–R

B

B

SEL.B

DECODER

SS

V

A

+

L+R

(–6dB)

DC-CUT

A

VREF

A

16

15

14

13

12

11

10

9

VOL/MUTE

S-TRIM

B

VDD

B.COM

A.COM

A1

A0

A

B

C

S-OUT

1

B1

B0

2

C1

3

C.COM

4

5

CO

6

INH

7

VEE

8

VSS

A.GND

L-OUT

A

B

+

L+DELAY

OUT-FILTER

(7k/5k)

B-NR

B

A

+

R+DELAY

OPEN

OPEN

OPEN

R-OUT

B

DC-OUT

INV-PHASE

1

D.GND

2 3

CLK

DATA

4

ENABLE

5 6

NR-DET

NR-IREF

7

VCC

8

L-IN

9 10 12

R-IN

S-IN

11

DC-CUT

DELAY-OUT

— 77 —

Page 42

IC601 LA2786

BPF1

BPF2

VREF

S-CH DC OUT

C-CH DC OUT

L-CH DC OUT

R-CH DC OUT

VREF

L-IN

R-IN

V

L-BPF1

L-BPF2

L-BPF3

1

NOISE

FILTER

2

3

V REF

4

5

6

7

8

9

10

SS

11

12

13

14

BALANCE

CONTROL

CONTROL

VR

P. S.P. S.

NOISE

CH

VR

VR

VCAVCA

VCAVCA

VCAVCA

VCAVCA

LPF

LPF

LPF

+

GENERATOR

DIVIDER

CMODE

NOISE

MUTE

+

OSC

CTRIM

CONTROL

CLK

42

41

DATA

ENABLE

40

OSC1

39

38

V

CC

L-OUT

37

R-OUT

36

S-OUT

35

34

C-OUT

CMODE-CAP.

33

C-TRIM DC CUT

32

R-BPF1

31

R-BPF2

30

R-BPF3

29

DC CUT

DC CUT

R RECT

L RECT

VLR-TH

VLR-1

VLR-2

IC604 TC9210P

1

V

SS

OUT

2

3

INL-CH

4

A-GND

5

NC

6

CS1

GND

7

8

CK

15

16

17

18

19

20

21

RECT RECT RECT RECT

LOG

DIFF

DUAL T

CONTROL

LOG

DIFF

28

27

26

25

24

23

22

DC CUT

DC CUT

L-R RECT

L+R RECT

VCS-TH

VCS-1

VCS-2

IC901 LA5617

16

V

LEVEL

SHIFT

CIRCUIT

L-CH

DATA

LATCH

CIRCUIT

SHIFT RESISTER

(13bit)

STROBE OSC

CIRCUIT

R-CH

DATA

LATCH

CIRCUIT

LEVEL

SHIFT

CIRCUIT

DD

OUT

15

14

13

12

11

10

9

IN

A-GND

NC

CS2

STB

DATA

R-CH

ERROR

AMP

2 3

1

VO1

VCC

ON/OFF

VREF

CN1

CURRENT

LIMITER

VMUTE VCC

VCC

4

EN

CURRENT

LIMITER

5 6 7 8 9 10

GND

ON/OFF

140uA

~_

COMPARATER

VREF

~_

1.8V

NC

CN2

ERROR

AMP

START

CIRCUIT

VREF

OVER HEAT

PROTECT

VEE

VO2

— 78 —

EN DISPLAY

Page 43

• CD motor sectoin

IC201 TA8409S

STANDBY

BLOCK

HEAT

CUT OFF

BLOCK

2 3

1

VCC OUT2 NC GND

IN2

• Power sectoin

IC301 uPC1237HA

VREF

BLOCK

5 6

4

7

VS

OUT1 VREF IN1

8

9

OVER LOAD DET

CC

ON

V

F/F

OFFSET DET

LATCH/

AUTORESET

1 2 3

AC OFF

DET

4 5 6 7 8

MUTE

V

CC

• Deck sectoin

IC402 LB1641

T.S.D O.C.P

MOTOR

DRIVE

FWD/REV/STOP

CONTROL LOGIC

MOTOR

DRIVE

IC602 uPC1330HA

2

1

SW R1 GND SW P1

3

4

CONT

INVERTER

COMPARATER

5

VCC

GND

6

SW P2 GND

7 8 9

SW R2

2 3

1

GND

DRIVE

MOTOR

NOISE

FILTER

5 6 7 8 9 10

4

VCC 1

FWD.IN

REV.IN

CLAMP

VCC 2

NOISE

FILTER

DRIVE

MOTOR

— 79 —

Page 44

6-20. IC PIN FUNCTIONS

• IC101 FOCUS/TRACKING/SLED SERVO RF AMP (CXA1992AR)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

FEO

FEI

FDFCT

FGD

FLB

FE O

FE M

SRCH

TGU

TG2

FSET

TA M

TA O

SL P

SL M

SL O

ISET

CC

V

LOCK

CLK

XLT

DA TA

XRST

C.OUT

SENS1

SENS2

FOK

CC2

CC1

CB

CP

RF I

RF O

Pin Name

I/O Function

Focus error amplifier output

O

Connected internally to the window comparator input for bias adjustment

Focus error input

I

Capacitor connection pin for defect time constant

I

Ground this pin through a capacitor for cutting the focus servo high-frequency gain

I

External time constant setting pin for boosting the focus servo low-frequency

I

Focus drive output

O

Focus amplifier inverted input

I

External time constant setting pin for generating focus search waveform

I

External time constant setting pin for switching tracking high-frequency gain

I

External time constant setting pin for switching tracking high-frequency gain

I

Peak frequency setting pin for focus and tracking phase compensation amplifier

I

Tracking amplifier inverted input

I

Tracking drive output

O

Sled amplifier non-inverted input

I

Sled amplifier inverted input

I

Sled drive output

O

Connect an external capacitance to set the current which determines the Focus search,

I

Track jump, and Sled kick heights

Positive power supply

I

The sled overrun prevention circuit operates when this pin is Low (No pull-up resistance)

I

Serial data transfer clock input from CPU (No pull-up resistance)

I

Lach input from CPU (No pull-up resistance)

I

Serial data input from CPU (No pull-up resistance)

I

Reset input; resets at Low (No pull-up resistance)

I

Track number count signal output

O

Outputs FZC, DFCT1, TZC, BALH, TGH, FOH, ATSC, and others according to the com-

O

mand from CPU

Outputs DFCT2, MIRR, BALL, TGL, FOL,and others according to the command from

O

CPU

Focus OK comparator output

O

Input for the defect bottom hold output with capacitance coupled

I

Defect bottom hold output

O

Connected internally to the interruption comparator input

Connection pin for defect bottom hold capacitor

I

Connection pin for MIRR hold capacitor

I

MIRR comparator non-inverted input

Input for the RF summing amplifier output with capacitance coupled

I

RF summing amplifier output

O

Eye-pattern check point

• Abbreviation

FZC : Focus zero-cross

DFCT : Defect

TZC : Tracking zero-cross

BALH : E-F Balance (High)

TGH : Tracking Gain (High)

FOH : Focus Bias (High)

A TSC : Auti Shock

MIRR : Mirror

BALL : E-F Balance (Low)

TGL : Tracking Gain (LOW)

FOL : Foucas Bias (LOW)

— 80 —

Page 45

Pin No. Pin Name I/O Function

RF summing amplifier inverted input

The RF amplifier gain is determined by the resistance connected between this pin and

34

RF M

I

RFO pin

External time constant setting pin during RF level control

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

RFTC

LD

PD

PD1

PD2

FE BIAS

F

E

EI

VEE

TEO

LPFI

TEI

ATSC

TZC

TDFCT

VC

FZC

I

APC amplifier output

O

APC amplifier input

I

RF I-V amplifier inverted input

I

Connect these pins to the photo diode A+C and B+D pins

I

Bias adjustment of focus error amplifier

I

Leave this pin open for automatic adjustment

F I-V and E I-V amplifier inverted input

I

Connect these pins to photo diodes F and E

I

I-V amplifier E gain adjustment

–

(When not using automatic balance adjustment)

Negative power supply

–

Tracking error amplifier output

O

E-F signal is output

Comparator input for balance adjustment

I

(Input from TEO through LPF)

Tracking error input

I

Window comparator input for ATSC detection

I

Trackig zero-cross comparator input

I

Capacitor connection pin for defect time constant

I

CC + VEE)/2 direct voltage output

(V

O

Focus zero-cross comparator input

I

• Abbreviation

APC : A uto Power Control

— 81 —

Page 46

• IC103 DIGITAL SIGNAL PROCESSOR (CXD2519Q)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Pin Name I/O Function

–

VDD

VSS

LMUT

RMUT

ACDT

CKOUT

SQCK

SQSO

SENS

DATA

XLAT

CLOK

SEIN

CNIN

DATO

XLTO

CLKO

SPOA

SPOB

SPOC

SPOD

XLON

FOK

VDD

VSS

MON

MDP

MDS

LOCK

PWMI

TES0

TES1

VPCO2

VPCO1

VCKI

V16M

VCTL

PCO

FILO

FILI

+5V power supply

–

Ground

O

Lch “L” detection flog (Not used)

O

Rch “L” detection flog (Not used)

O

Test output (Not used)

O

Master clock divider output (Not used)

I

Clock input for SQSO read out

O

Serial output for Sub-Q 80bit

O

SENS signal output to CPU

I

Serial data input, supplied from CPU

I

Latch input, supplied from CPU

I

Serial data transfer clock input, supplied from CPU

I

SENS input from IC101

I

Numbers of track jump counted signal input

O

Serial data output to IC101

O

Serial data latch output to IC101

O

Serial data transfer clock output to IC101

I

Micro computer demodulation interface (Input A)

I

Micro computer demodulation interface (Input B)

I

Micro computer demodulation interface (Input C)

I

Micro computer demodulation interface (Input D)

O

Micro computer demodulation interface (Output)

I

Focus OK input

–

+5V power supply

–

Ground

O

Output to control ON/OFF of spindle motor (Not used)

O

Output to control spindle motor servo

O

Output to control spindle motor servo (Not used)

O

GFS is sampled by 460Hz

I

Input to control the outside spindle motor

I

Test pin (Connected to ground)

I

Test pin (Connected to ground)

O

Charge-pump output (Not used)

O

Charge-pump output (Not used)

I

VCO2 oscillator input (Not used)

O

VCO2 oscillator output (Not used)

I

VCO2 control voltage input

O

Charge-pump output to master PLL

O

Filter output to master PLL

I

Filter input for master PLL

• Abbreviation

GFS : Guarded Frame Sync

PLL : Phase Locked Loop

— 82 —

Page 47

Pin No.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71