Page 1

HCD-SV2D

Amplifier section

AUDIO POWER SPECIFICATIONS

(USA model only)

POWER OUTPUT AND TOTAL HARMONIC

DISTORTION:

With 6 ohm loads, both channels dr i ven, from

120 – 10,000 Hz: rated 50 watts per channel

minimum RMS power, with no more than 10%

total harmonic distortion from 250 milliwatts to

rated output.

North American model:

Front speaker

Continuous RMS power output (reference):

50 + 50 watts (6 ohms at

1kHz, 10% THD)

Total harmonic distortion less than 0.07% (6 ohms at

1kHz, 25 W)

Other models:

The following measured at AC 120 V, 240 V, 50/60 Hz

DIN power output (rated) 40 + 40 watts

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (refe r en ce)

50 + 50 watts

(6 ohms at 1 kHz, 10%

THD)

MIC (phone jack)(Asian models only):

sensitivity 1 mV,

impedance 10 kilohms

Inputs

TV IN (phono jacks): voltage 1 V,

impedance 47 kilohms

Outputs

VIDEO OUT (phono jack):

max. output level

1 Vp-p, unbalanced, Sync

negative, load impedance

75 ohms

DIGITAL OUT (OPTICAL) (Square optical connector

jack, rear panel)

Wavelength 660 nm

PHONES (stereo mini jack):

accepts headphones of

8ohms or more

SPEAKER: accepts impedance of

6ohms

Disc player section

System Compact disc and dig it a l

audio and video system

Laser Semiconductor laser

(DVD: λ=650 nm,

CD: λ=780 nm)

Emission duration:

continuous

Frequency response DVD (PCM 48 kHz):

2 Hz – 22 kHz (±1 dB)

CD: 2 Hz – 20 kHz (±1 dB)

Video color system format

Pan-American models:

NTSC

Other models: NTSC, PAL

Tape deck section

Recording system 4-track 2-channel stereo

Frequency response 40 – 13,000 Hz,

using Sony TYPE I

cassette

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

(50 kHz step)

Antenna FM lead antenna

Antenna terminals 75 ohms unbalanced

Intermediate frequency 10.7 MHz

SERVICE MANUAL

Ver. 1.1 2005.08

HCD-SV2D is the Amplifier, DVD player, Tape

Deck and Tuner section in CMT-SV2D.

This system incorporates Dolby1) Digital and DTS2) Digital

Surround System.

1)

Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic”, and the double-D symbol are trademarks

of Dolby Laboratories.

2)

Manufactured under license from Digital Theater Systems,

Inc. “DTS” and “DTS 2.0 + Digital Out” are trademarks of

Digital Theater Systems, Inc.

SPECIFICATIONS

DVD

Section

TAPE Model Name Using Similar Mechanism HCD-DV2D

Section Tape Transport Mechanism T ype CMAL5Z220C

US Model

E Model

Model Name Using Similar Mechanism HCD-DV2D

DVD Mechanism Type KDA898ST

Traverse Mechanism Name 1ADOMEZ0412

9-879-645-02

2005H16-1

© 2005.08

Sony Corporation

Audio Group

Published by Sony Engineering Corporation

DVD DECK RECEIVER

— Continued on next page —

Page 2

HCD-SV2D

r

AM tuner section

Tuning range

Pan-American models: 530 – 1,710 kHz

(with the tuning interval

set at 10 kHz)

531 – 1,710 kHz

(with the tuning interval

set at 9 kHz)

Other models: 530 – 1,710 kHz

(with the interval set at

10 kHz)

531 – 1,602 kHz

(with the interval set at

9kHz)

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

General

Power requirements

North American model: 120 V AC, 60 Hz

Other models: 110 – 120 V, 220 – 240 V

AC, 50/60 Hz

Adjustable with voltage

selector

Power consumption

USA model: 110 watts

Other models: 120 watts

Dimensions (w/h/d) (excl. speakers)

Approx. 191 × 255 ×

310 mm

Mass (excl. speakers) Approx. 6.5 kg

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

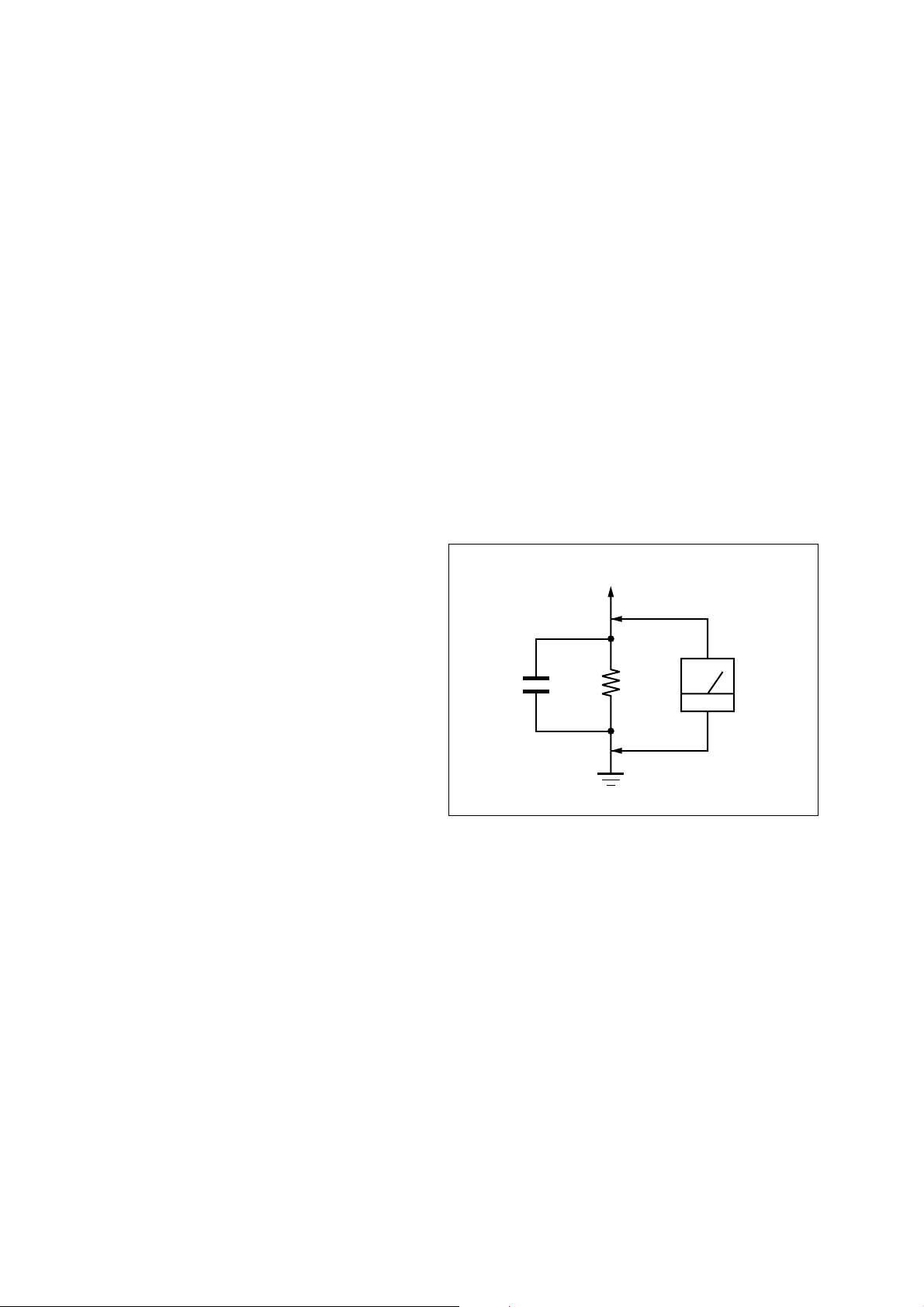

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the manuf acturers’ instructions to use these

instruments.

2. A battery-operated A C milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC v oltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V A C range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

Design and specifications are subject to change

without notice.

AC

0.15 µF

1.5 k

Ω

Earth Ground

voltmete

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

Page 3

HCD-SV2D

Ver. 1.1

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

• Abbreviation

E3 : 240 V AC area in E model.

SP : Singapore model.

TH : Thai model.

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 4

2. GENERAL ................................................................... 5

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 8

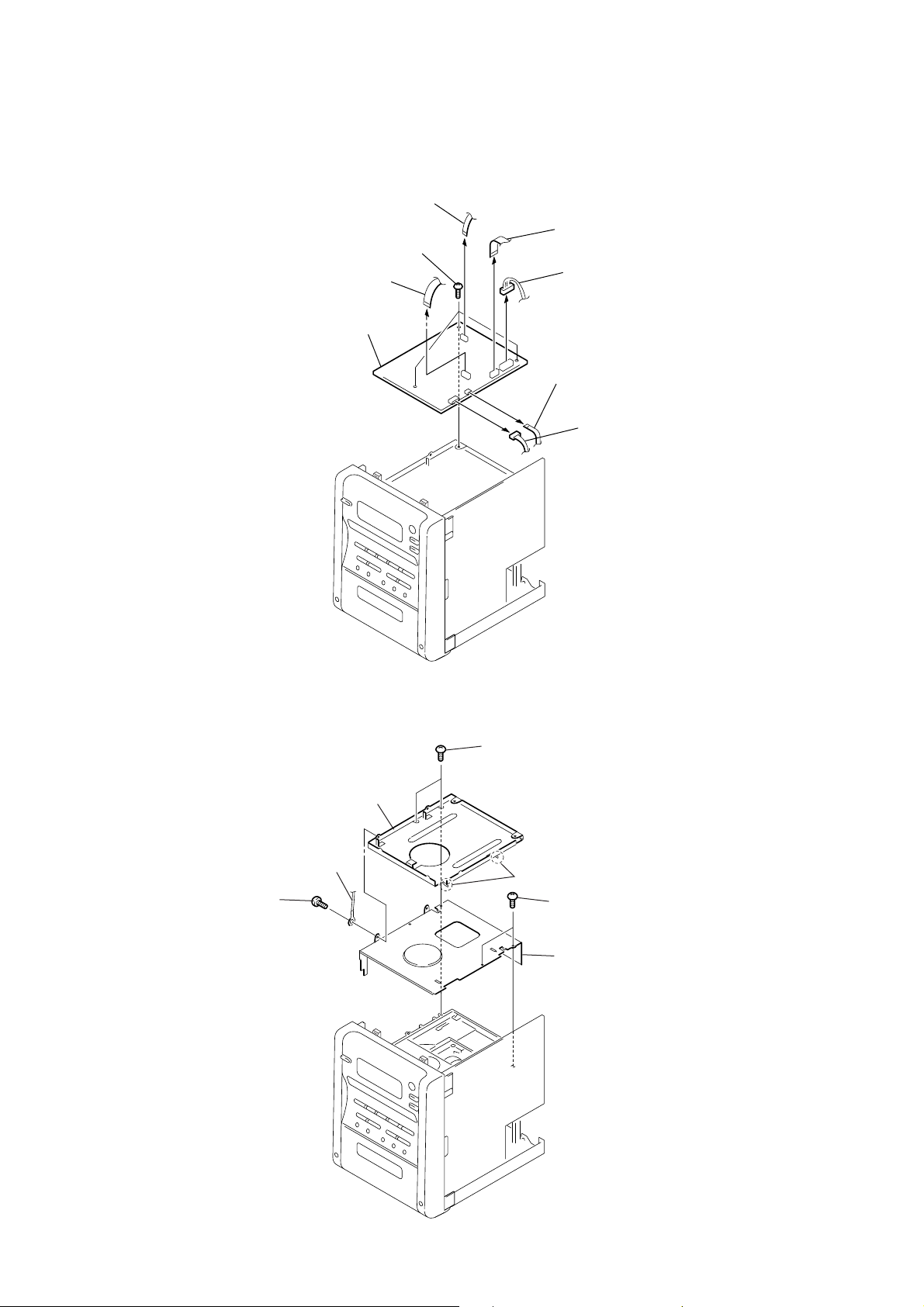

3-2. Cover Top, DC Fan .......................................................... 9

3-3. AMP Board, AV Board, Tuner (FM/AM) ....................... 9

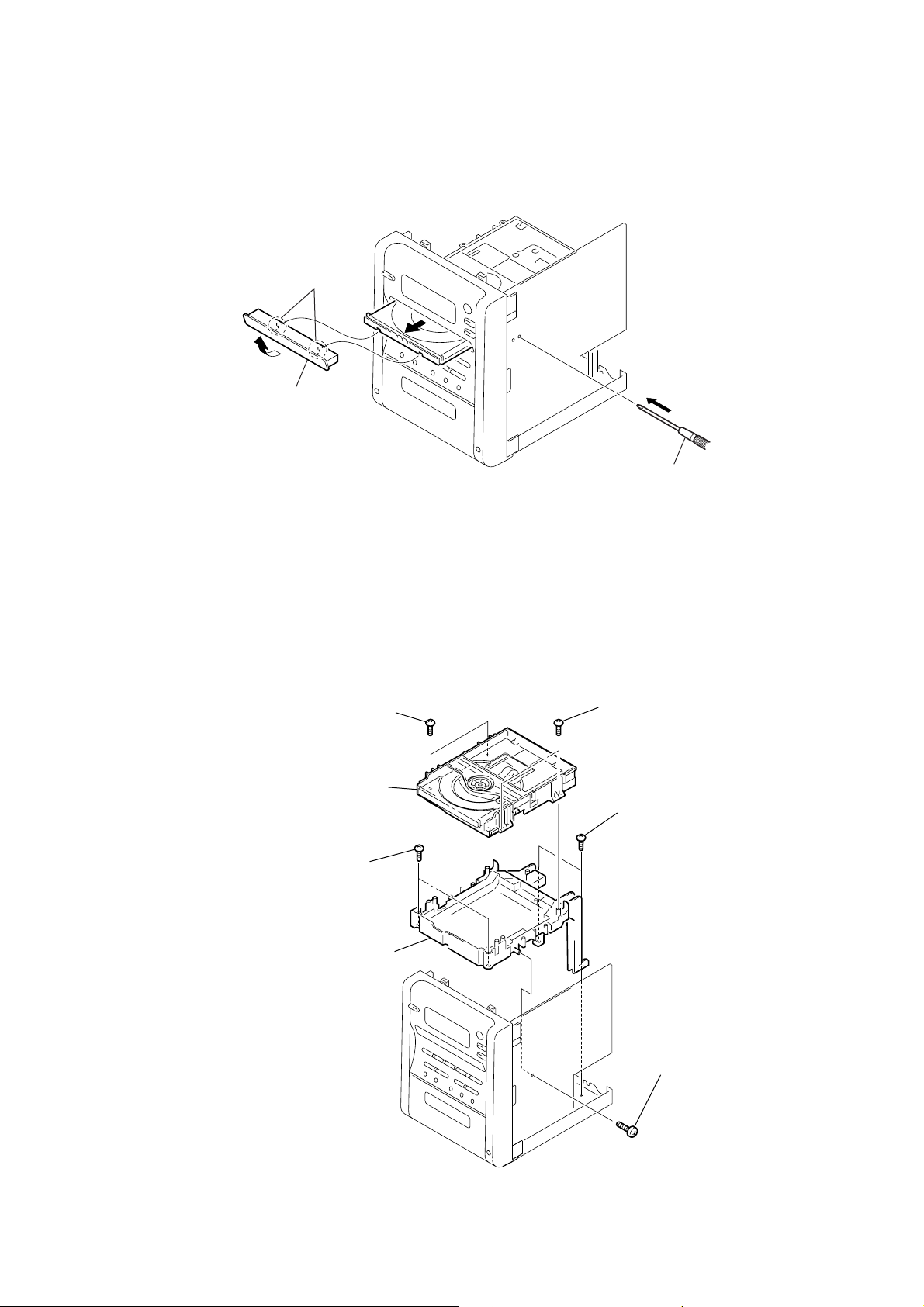

3-4. MPEG Board ................................................................... 10

3-5. DVD Mech Cover A/B .................................................... 10

3-6. Panel (DVD) .................................................................... 11

3-7. DVD Loader (KDA898ST) ............................................. 11

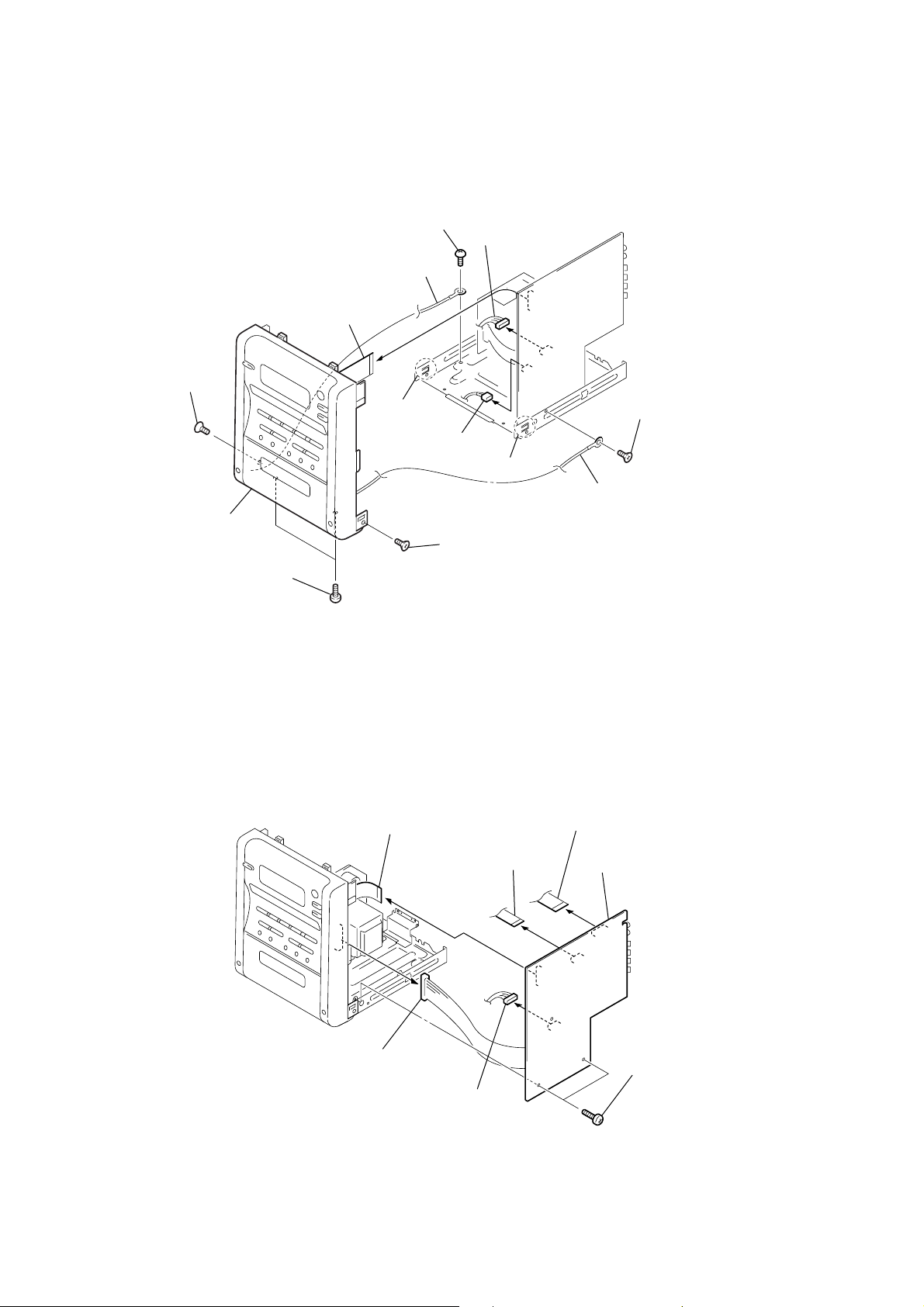

3-8. Front Panel Section ......................................................... 12

3-9. MAIN Board.................................................................... 12

3-10. Cassette Deck Mechanism (CMAL5Z220C) .................. 13

3-11. KEY Board...................................................................... 13

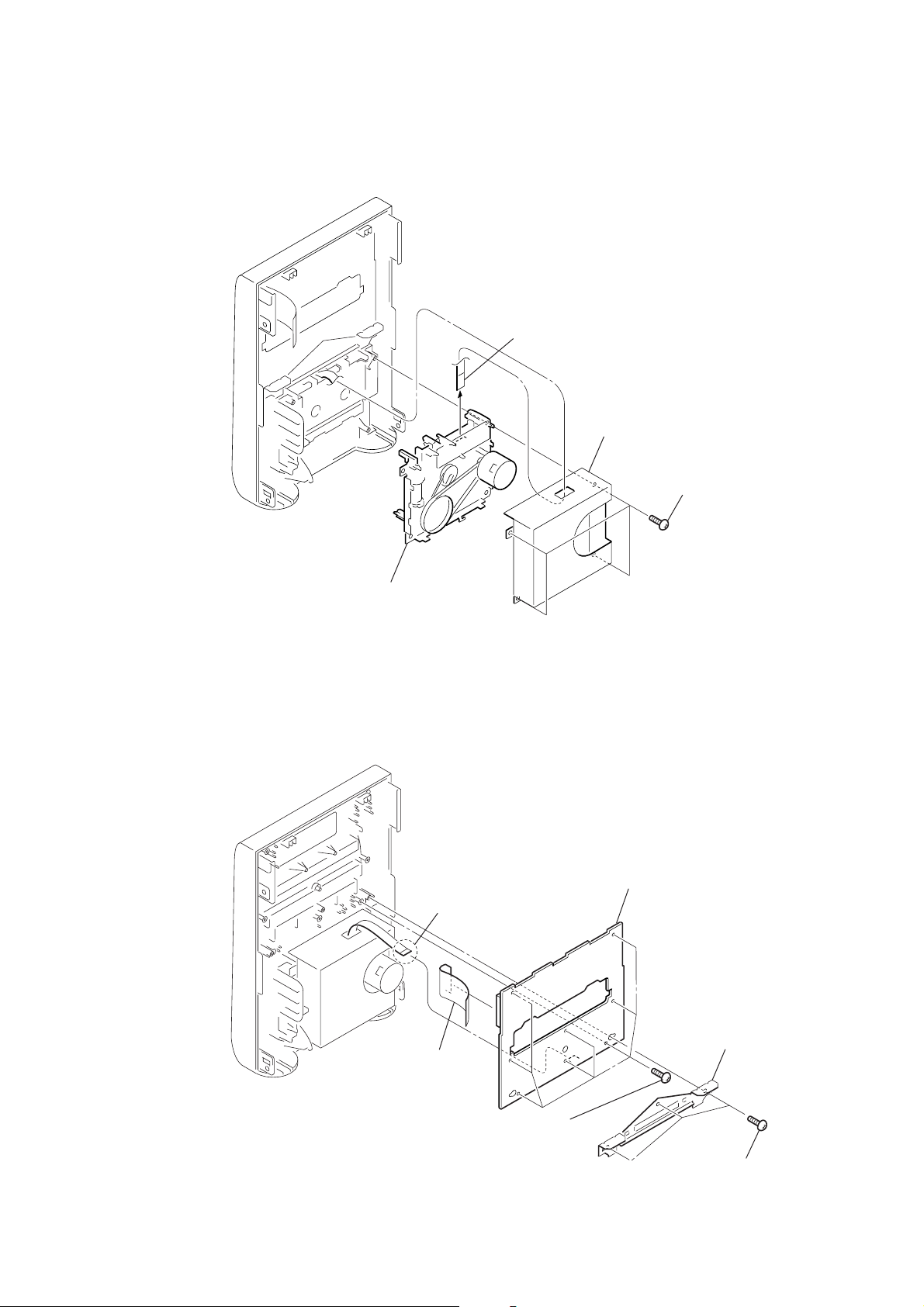

3-12. Traverse Mech (1ADOMEZ0412) .................................. 14

3-13. Lid TC ............................................................................. 14

4. TEST MODE ............................................................... 15

5. MECHANICAL ADJUSTMENTS......................... 19

6. ELECTRICAL ADJUSTMENTS .......................... 19

7. DIAGRAMS

7-1. Block Diagrams — MPEG-1 Section — ....................... 22

— MPEG-2 Section —.................................................... 23

— AUDIO Section —...................................................... 24

— PANEL/POWER Section — ...................................... 25

7-2. Printed Wiring Board — MAIN Section-1 —................ 26

7-3. Printed Wiring Board — MAIN Section-2 —................ 27

7-4. Schematic Diagram — MAIN Section —...................... 28

7-5. Printed Wiring Board — MPEG Section-1 — ............... 29

7-6. Printed Wiring Board — MPEG Section-2 — ............... 30

7-7. Schematic Diagram — MPEG Section — ..................... 31

7-8. Printed Wiring Board — KEY Section — ..................... 32

7-9. Schematic Diagram — KEY Section — ........................ 33

7-10. Printed Wiring Board — AV Section —......................... 34

7-11. Schematic Diagram — AV Section — ........................... 34

7-12. Printed Wiring Board — AMP/POWER Section — ...... 35

7-13. Schematic Diagram — AMP Section — ........................ 36

7-14. Schematic Diagram

— POWER Section (E3, SP, TH Model) — ................... 37

7-15. Schematic Diagram

— POWER Section (US Model) —................................ 38

8. EXPLODED VIEWS

8-1. Overall Section................................................................ 54

8-2. Front Panel Section ......................................................... 55

8-3. Chassis Section................................................................ 56

8-4. DVD Mechanism Deck Section ...................................... 57

9. ELECTRICAL PARTS LIST .................................. 58

3

Page 4

HCD-SV2D

Ver. 1.1

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveforms is output three times.

DISC TRA Y LOCK

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Procedure :

1. Press the ?/1 button to turn the set ON.

2. Press the DVD u button to select “DVD”

3. Set disc on the tray, press the x button and the Z button

simultaneously for five seconds.

4. The message “LOCKED” is displayed the tray is locked.

5. To release from this mode, press the x button and the Z

button simultaneously for five seconds again.

6. The message “UNLOCKED” is displayed and the tray is

unlocked.

Note: When “LOCKED” is displayed, the slot lock is not released by

turning power on/off with the ?/1 button.

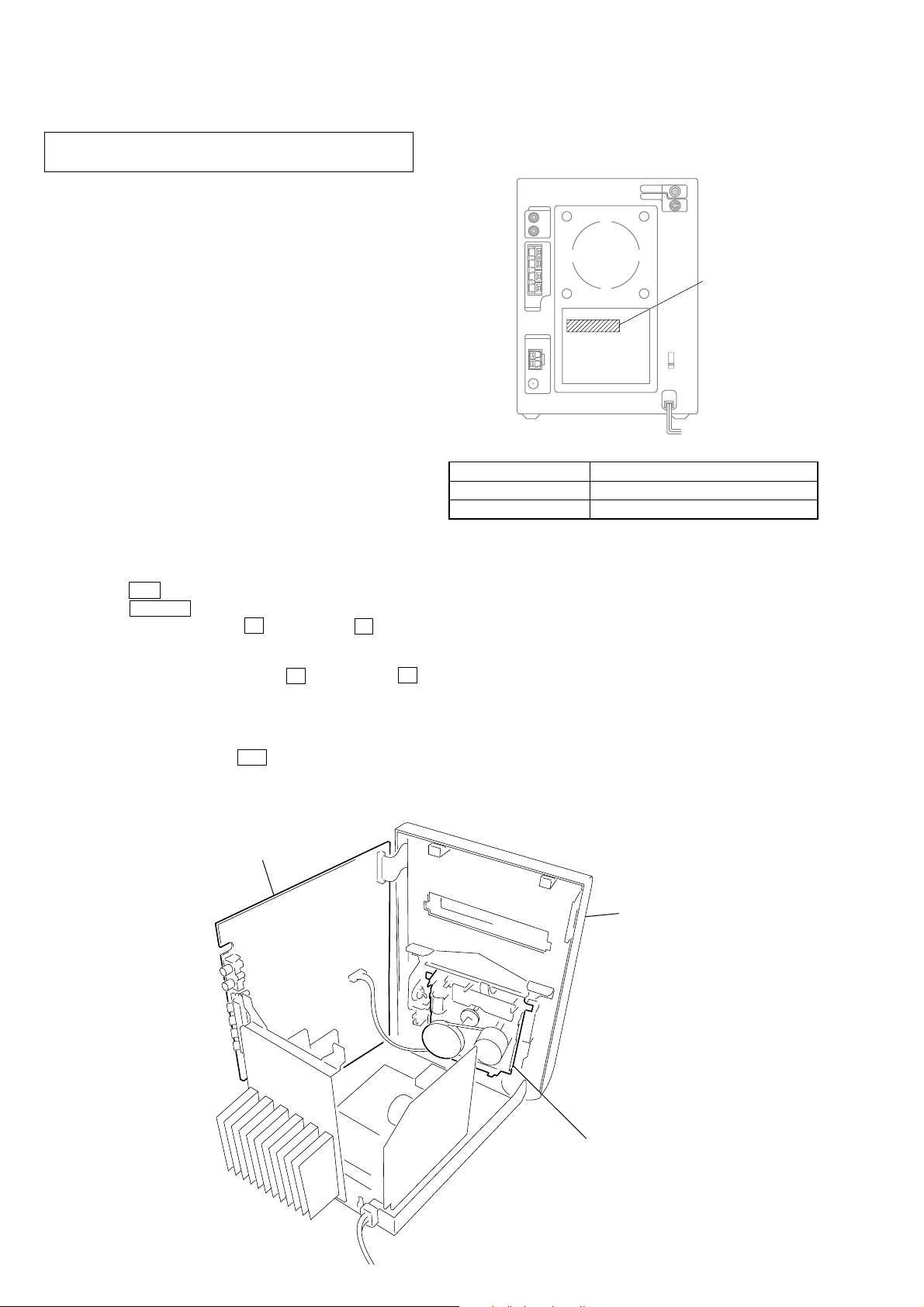

MODEL IDENTIFICATION

– Back Panel –

Power requirement

indication

Model Power V oltage Indication

US model 120 V AC, 60 Hz

E3, SP, TH models 110 – 120 V/220 – 240V AC, 50/60 Hz

•Abbreviation

E3 : 240 V AC area in E model.

SP : Singapore model.

TH : Thai model.

• SERVICE POSITION OF THE TAPE CASSETTE MECHANISM DECK

MAIN board

Front Panel

Tape Cassette Mechanism Deck

(CMAL5Z220C)

4

Page 5

SECTION 2

GENERAL

List of button locations and reference pages

HCD-SV2D

This section is extracted

from instruction manual.

How to use this page

Use this page to find the lo ca tion of buttons and other

parts of the system that are mentioned in the text.

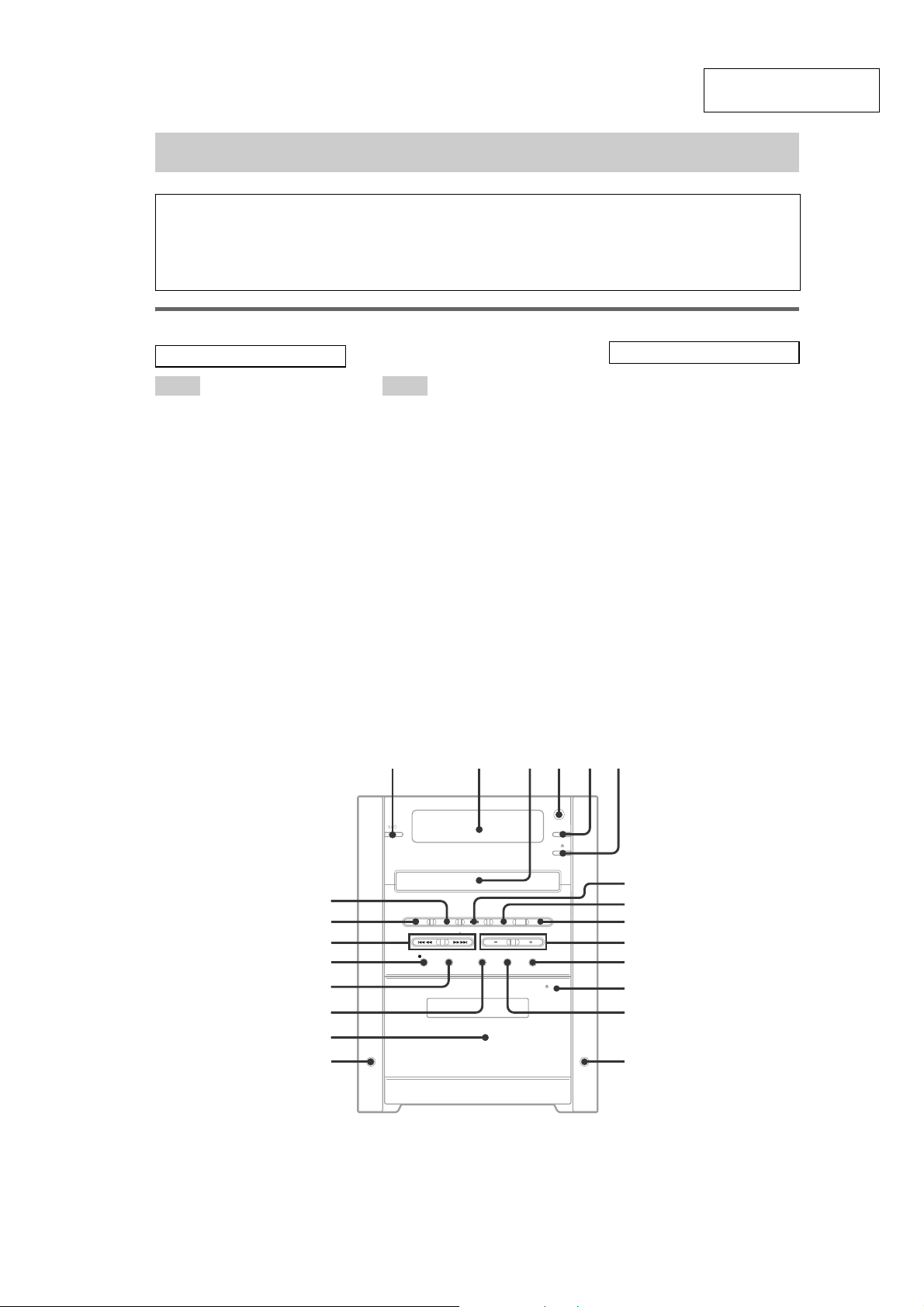

Main unit

ALPHABETICAL ORDER

A – O P – Z

Cassette compartment qh (28)

CD SYNC qk (28)

Disc tray 3 (12)

DISPLAY 5 (27, 34, 35, 36)

Display window 2

MIC jack

MIC/ECHO

MIC/ECHO LEVEL +/–

(30)

1)

qf (30)

1)

qa (30)

1)

w;

PHONES jack qg

PLAY MODE qj (13, 16, 44)

PRESET EQ qd (30)

Remote sensor 4

REPEAT

TUNER/BAND ws (25, 26, 29)

TUNING +/– w; (25, 27)

TV wa (29, 38)

VOLUME +/– 0 (13, 27, 28)

2)

qa (15)

Illustration number

r

TUNER/BAND ws (25, 26, 29)

Name of button/part Reference page

RR

BUTTON DESCRIPTIONS

?/1 (power) 1 (10, 44)

Z (open/close) 6 (12)

DVD NX (play/pause) 7 (10,

12, 23, 28, 39, 44)

TAPE N (play) 8 (28)

x (stop) 9 (10, 12, 26, 28, 31,

39, 44)

Z PUSH OP E N (eject) qs (28)

z REC PAUSE/START (record)

ql (28, 31)

m/M (rewind/fast forward)

w; (13, 28)

./> (go back/forward) w;

(12, 28)

1)

HCD-SV2D Asian model only

2)

Except for HCD-SV2D Asian

model

ws

wa

w;

ql

qk

qj

qh

qf

123546

7

8

9

0

qa

qs

qd

qg

5

Page 6

HCD-SV2D

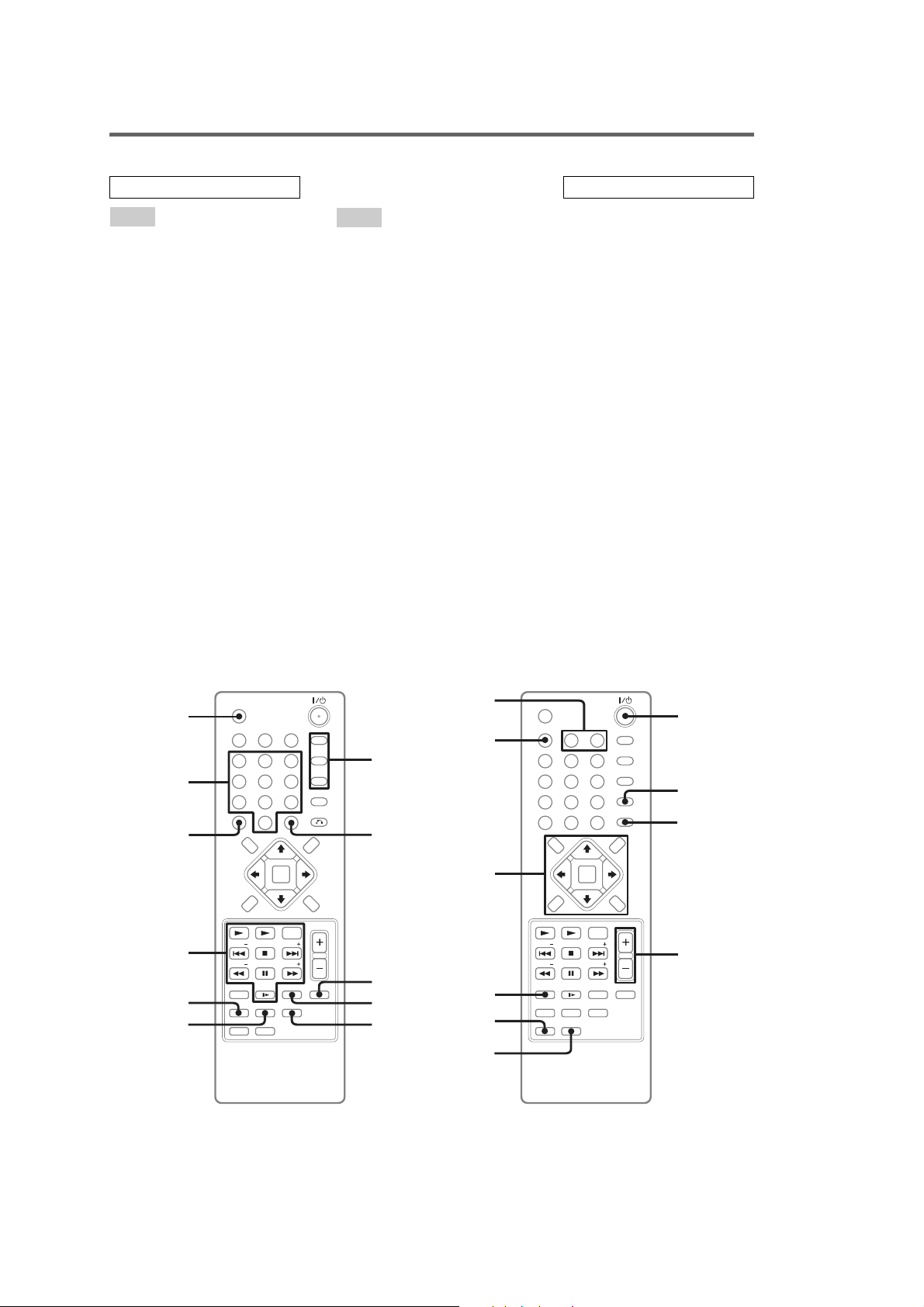

Remote control

ALPHABETICAL ORDER

A – J

ANGLE qa (20)

AUDIO qa (19, 31)

CLEAR ql (16, 17, 23)

CLOCK/TIMER SELECT 0

(33, 34)

CLOCK/TIMER SET 0 (11, 32,

33)

DIMMER 6 (34)

DISPLAY 8 (34, 35, 36)

DVD MENU 8 (14, 15)

DVD SETUP 8 (11, 20, 21, 22,

24, 38, 44)

DVD TOP MENU 8 (14)

ENTER 8 qs (11, 14, 15, 17, 20,

21, 22, 25, 32, 33, 38, 44)

FM MODE qh (27)

K – Z

KARAOKE PON qg (30)

MUTING 9 (13, 27, 28)

Number buttons* w; (14, 15, 16,

17, 22)

PLAY MODE 7 (13, 16)

PRESET +/– qk (25, 26)

PRESET EQ qf (30)

REPEAT qj (15)

SLEEP wa (32)

SUBTITLE qa (20)

TIME SEARCH 2 (17)

TUNER BAND qk (25, 26)

TUNER MEMORY 5 (25)

TUNING +/– qk (25, 27)

TV qd

VOLUME +/– 4 (13, 27, 28, 32)

BUTTON DESCRIPTIONS

?/1 (power) 1 (10, 32, 44)

O RETURN 3 (15)

M/m/</

TAPE N (play) qk (28)

DVD N (play) qk (10, 12, 23,

./> (go back/forward) qk

x (stop) qk (10, 12, 28, 39)

m/M (rewind/fast forward)

DVD X (pause) qk (12)

SLOW y qk (13)

*The number 5 button has a

, 8 (11, 13, 20, 38,

44)

39)

(11, 12, 32)

qk (13, 28)

tactile dot. Use the tactile dot as

a reference when operating the

system.

wa

w;

ql

qk

qj

qa

qs

qd

qf

qgqh

0

1

9

2

3

8

4

7

6

5

6

Page 7

Setting the clock

Use buttons on the remote for the operation.

1

Press ?/1 to turn on the system.

2

Press CLOCK/TIMER SET.

3

Press . or > repeatedly to set the

hour.

4

Press ENTER.

5

Press . or > repeatedly to set the

minute.

6

Press ENTER.

The clock starts working.

To adjust the clock

1

Press CLOCK/TIMER SET.

2

Press . or > to select “CLOCK SET”,

then press ENTER.

3

Do the same procedures as step 3 to 6

above.

HCD-SV2D

Notes

The clock settings are canceled when you disconnect

the power cord or if a power failure occurs.

You cannot set the clock in Powe r Sa ving Mode

(page 34).

7

Page 8

HCD-SV2D

Ver. 1.1

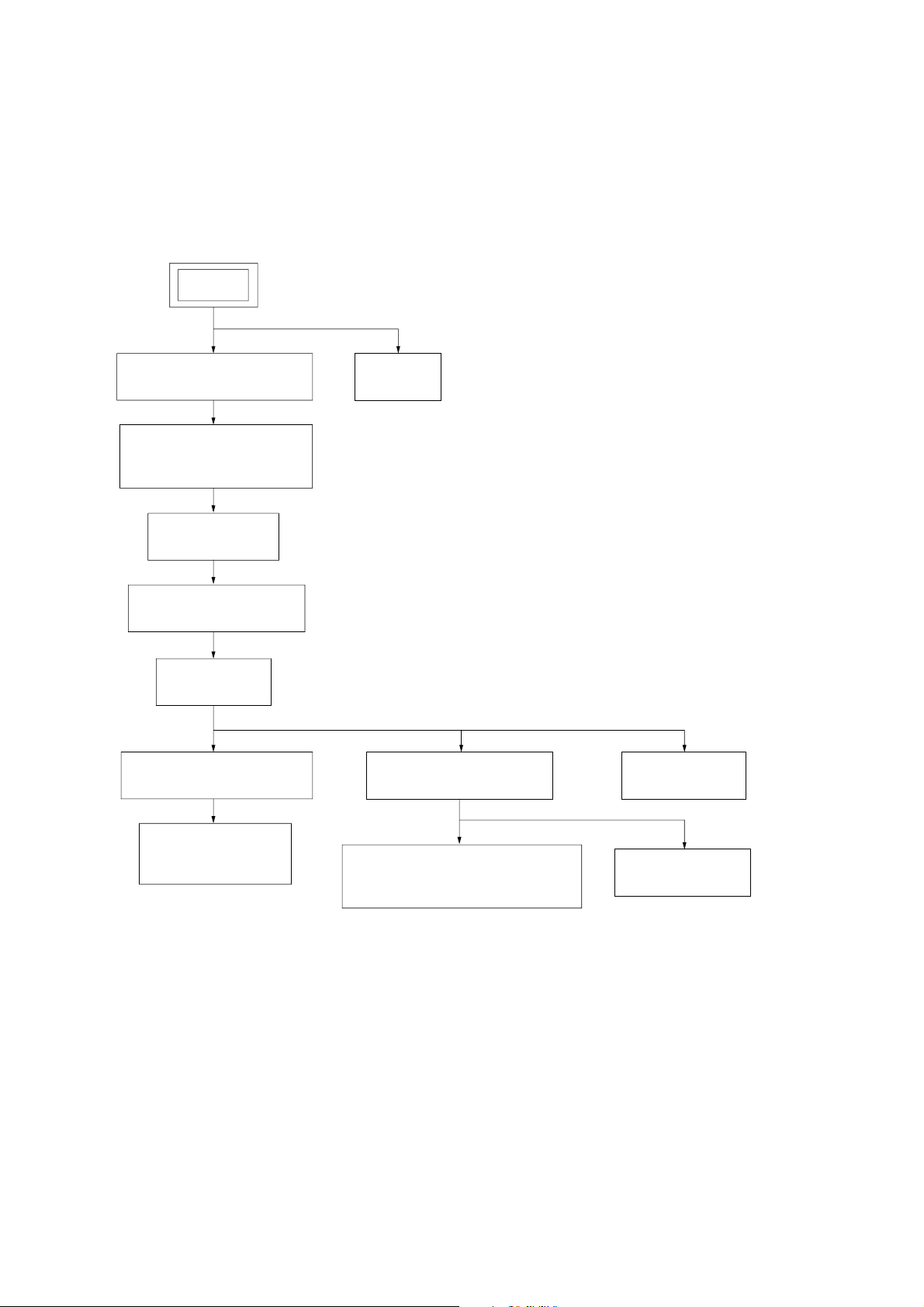

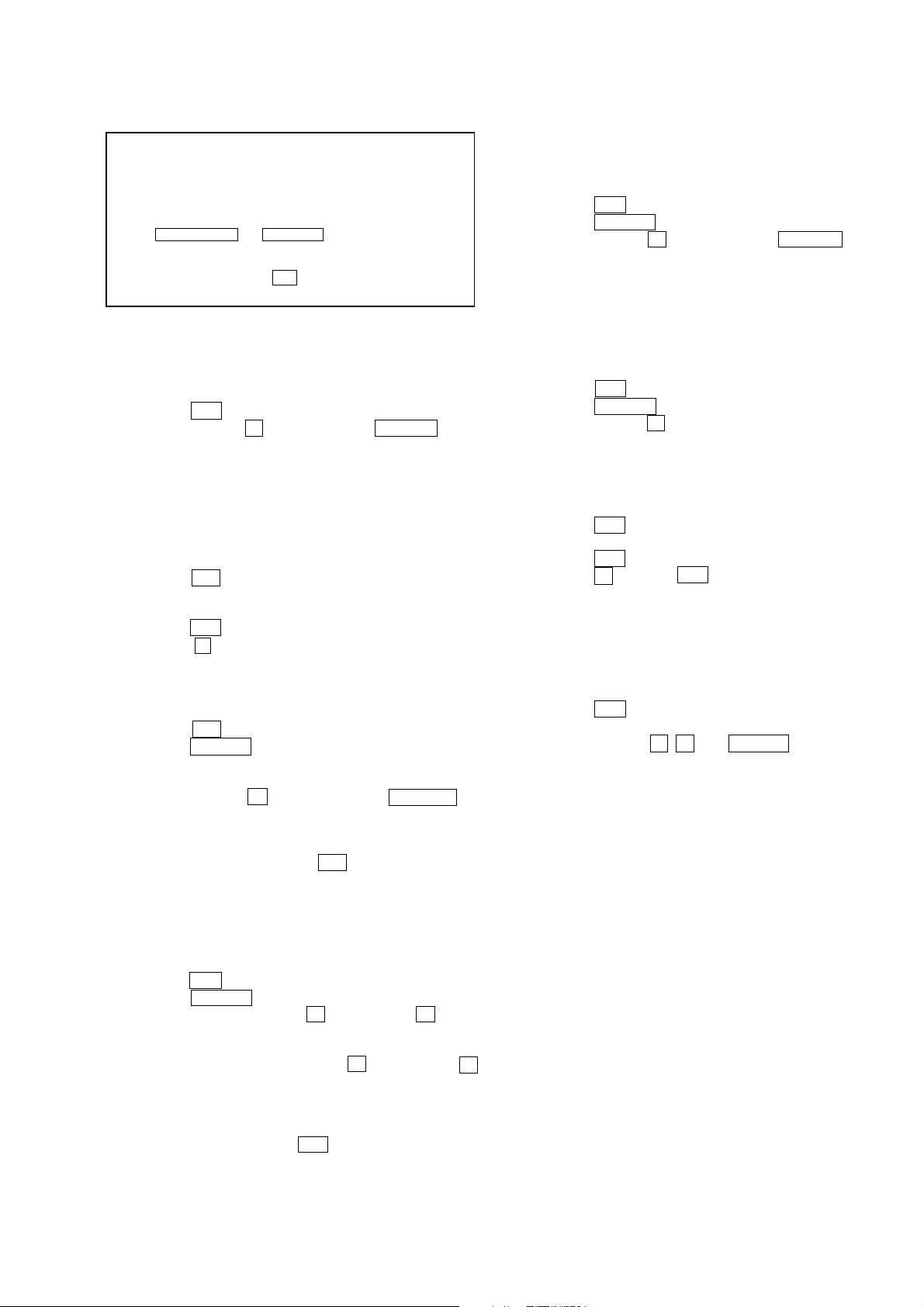

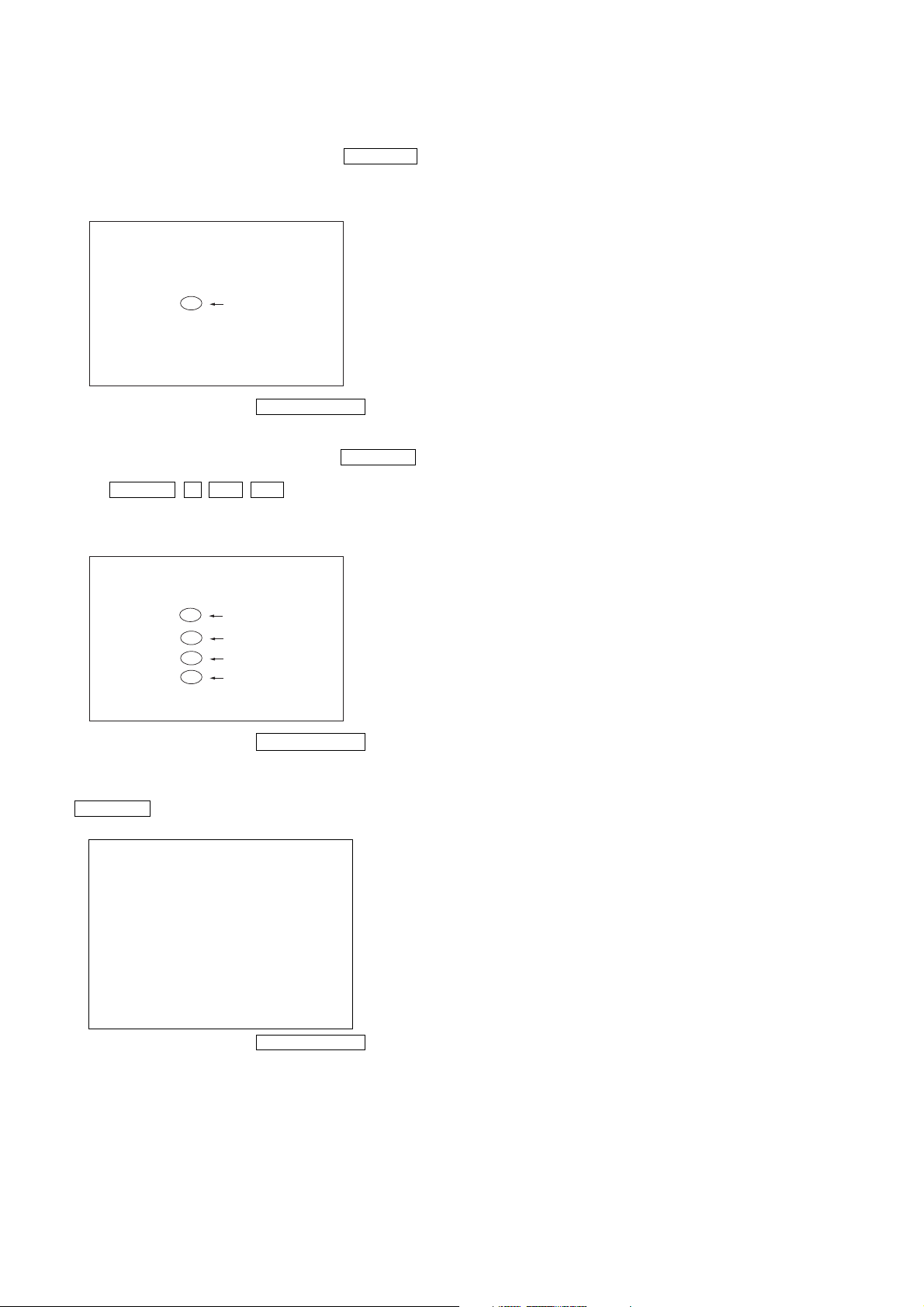

3-1. DISASSEMBLY FLOW

•This set can be disassembled in the order shown below.

SET

SECTION 3

DISASSEMBLY

3-2. COVER TOP, DC FAN

(Page 9)

3-3. AMP BOARD, AV BOARD,

TUNER (FM/AM)

(Page 9)

3-4. MPEG BOARD

(Page 10)

3-5. DVD MECH COVER A/B

(Page 10)

3-6. PANEL (DVD)

(Page 11)

3-7. DVD LOADER (KDA898ST)

(Page 11)

3-13. LID TC

(Page 14)

3-8. FRONT PANEL SECTION

(Page 12)

3-9. MAIN BOARD

(Page 12)

3-12. TRA VERSE MECH

(1ADOMEZ0412)

(Page 14)

3-10. CASSETTE DECK MECHANISM

(CMAL5Z220C)

(Page 13)

3-11. KEY BOARD

(Page 13)

8

Page 9

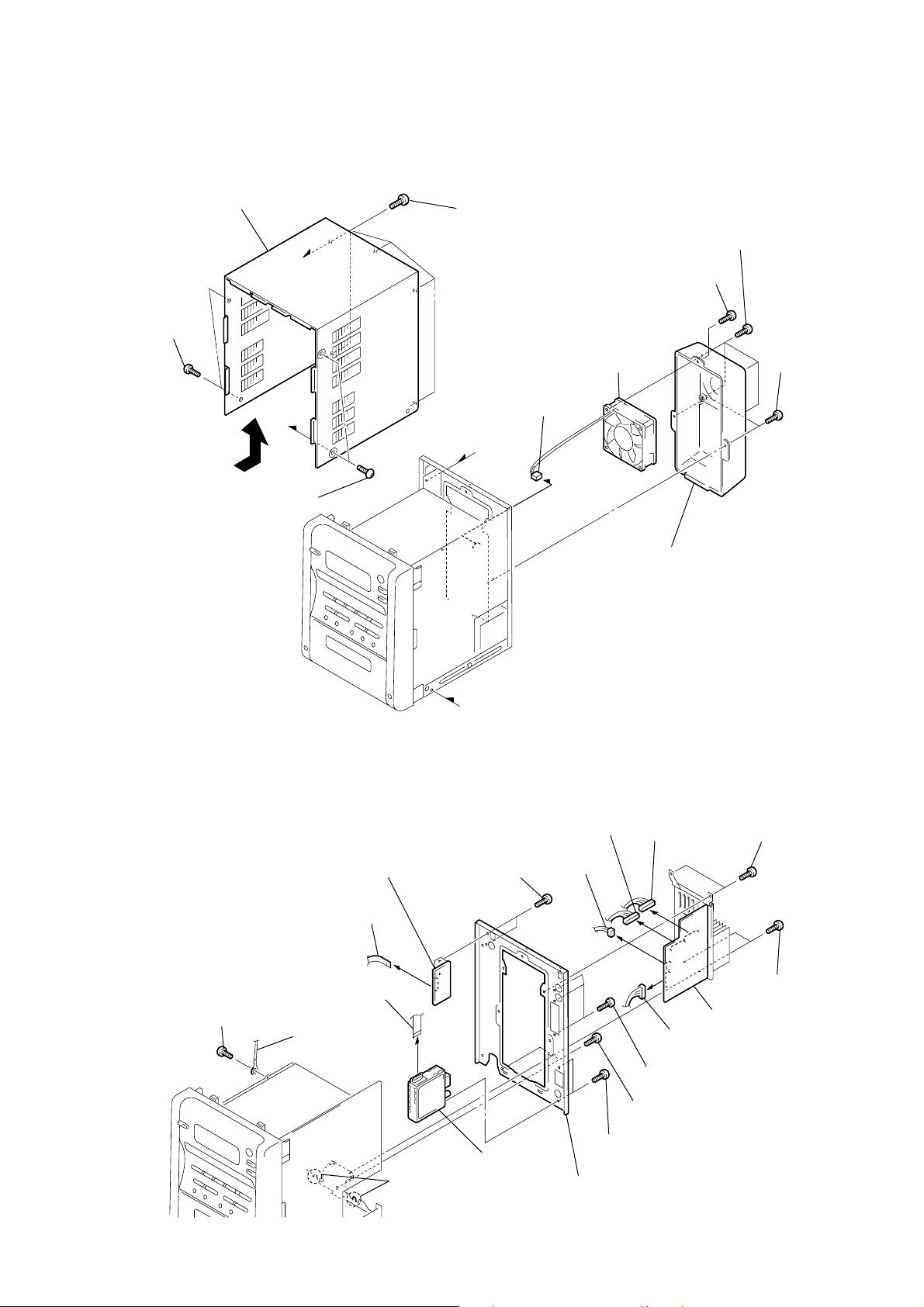

Note: Follow the disassembly procedure in the numerical order given.

3-2. COVER TOP, DC FAN

5

cover top

a

2

two s

crews

×

(+BTP 3

8)

b

4

3

five s

(+BTP 3

crews

8

connector

(3P)(CN350)

a

HCD-SV2D

×

8)

q;

7

s

(+BVTP 3

DC fan

9

four s

crew

crews

×

(+BVTP 3

×

8)

8)

6

two s

crews

×

(+BVTP 3

8)

1

two s

(+BTP 3

crews

×

8)

3-3. AMP BOARD, AV BOARD, TUNER (FM/AM)

qh

qj

AV board

qs

wire (flat type)

(5core) (CN851)

two s

(+BVTP 3

b

crews

5

connector

(3P) (CN106)

×

10)

4

connector

(7P) (CN102)

qa

cover HT-SINK

3

connector

(10P) (CN108)

1

two s

(+BVTP 3

crews

×

10)

q;

s

crew

(+BTP 3

2

two s

qf

wire (flat type)

×

8)

(11core)

qa

earth wire

qk

two claws

qg

tuner

qd

(+BVTP 3

ql

panel back

6

connector

(5P) (CN101)

9

three s

(+BVTP 3

8

two s

(+BVTP 3

two s

crews

×

crews

8)

(+BVTP 3

7

AMP board

crews

×

10)

×

8)

crews

×

10)

9

Page 10

HCD-SV2D

)

3-4. MPEG BOARD

7

wire (flat type)

(5core) (J703)

1

three s

(+BTP 3

4

wire (flat type)

(24core) (J705)

8

MPEG board

crews

×

8)

5

wire (flat type)

(9core) (J701)

6

connector

(9P) (J702)

3

wire (flat type)

(6core) (J706)

2

connector

(5P) (J707

3-5. DVD MECH COVER A/B

1

s

crew

(+BTP 3

5

DVD mech cover A

2

earth wire

×

8)

3

two s

(+BTP 3

crews

×

4

two hooks

6

(+BVTP 3

7

8)

two s

crews

×

8)

DVD mech cover B

10

Page 11

3-6. PANEL (DVD)

3

two

HCD-SV2D

claws

2

4

panel (DVD)

3-7. DVD LOADER (KDA898ST)

1

two s

(+BVTP 3

3

DVD loader (KDA898ST)

crews

× 10

1

screwdriver

2

two s

)

(+BVTP 3

crews

× 10

5

two s

(+BVTP 3

crews

)

×

10)

4

two s

(+BVTP 3

crews

7

holder mecha

× 10

)

6

s

crew

×

(+BVTP 3

10)

11

Page 12

HCD-SV2D

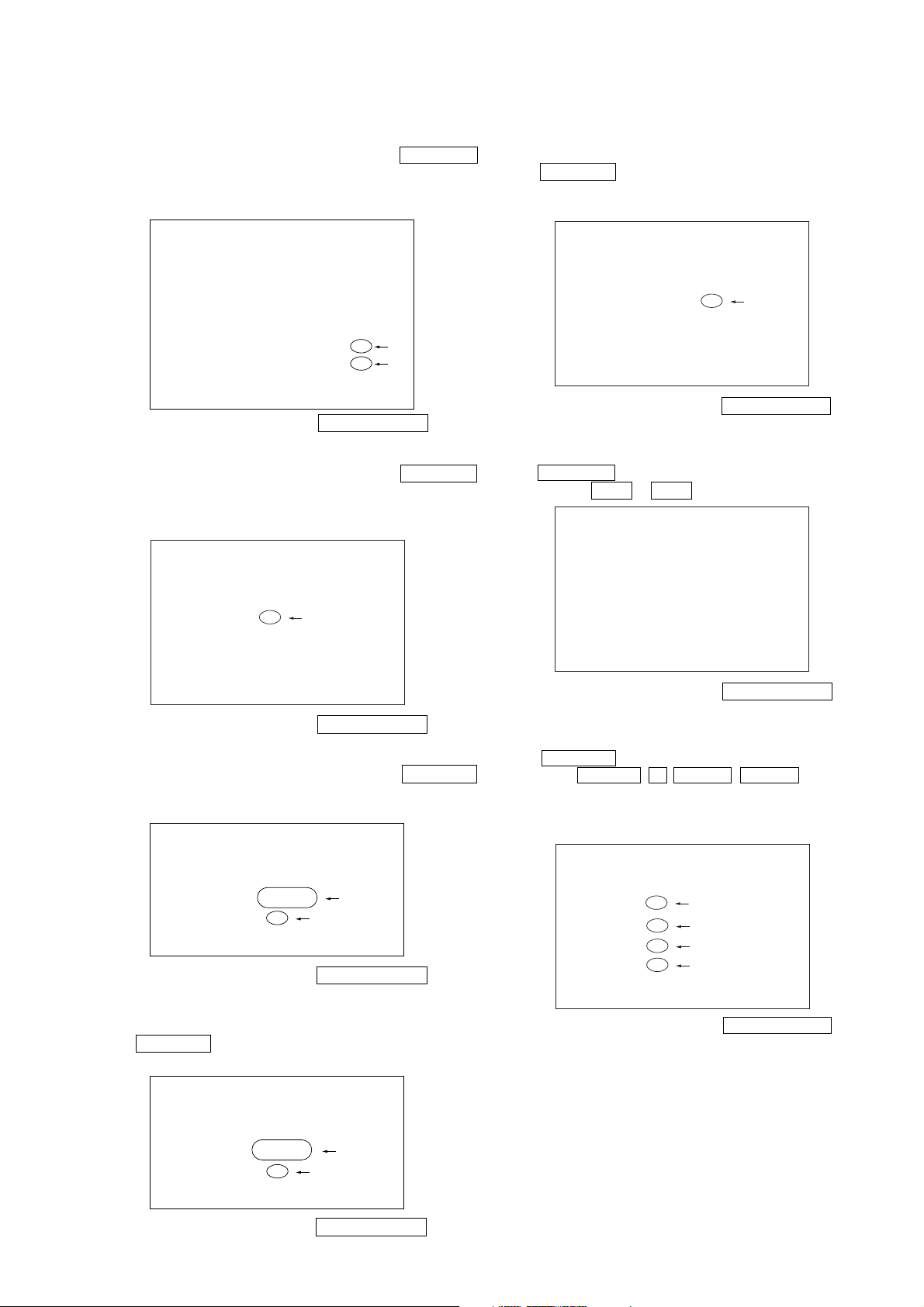

3-8. FRONT PANEL SECTION

3

screw

(+KTP 3

×

8)

6

(+BVTP

8

wire (flat type)

(21core) (CN501)

two s

crews

3 × 8

7

earth wire

qs

claw

q;

connector

(4P) (CN401)

)

9

connector

(8P) (CN201)

qa

claw

5

earth wire

4

screw

(+KTP 3

×

8)

qd

front panel section

3-9. MAIN BOARD

1

two screws

(+BVTP 3

×

10)

2

2

wire (flat type)

(21core) (CN501)

6

(9core) (CN503)

screw

(+KTP 3

wire (flat type)

×

8)

7

wire (flat type)

(11core) (CN203)

8

MAIN board

12

5

connector

(11P) (FW901)

3

connector

(8P) (CN201)

1

two s

(+BVTP 3

crews

×

10)

Page 13

3-10. CASSETTE DECK MECHANISM (CMAL5Z220C)

1

wire (flat type)

(7core)

3

shield cover

2

four screws

(+BVTP 3

×

HCD-SV2D

Ver. 1.1

10)

3-11. KEY BOARD

4

cassette deck mechanism

(CMAL5Z220C)

5

w

ire (flat type)

(21core) (CN601)

4

w

ire (flat type)

(7core) (CN602)

6

KEY board

2

bracket

3

eight screws

(+BVTP 3

×

10)

1

three screws

(+BVTP 3

×

10)

13

Page 14

HCD-SV2D

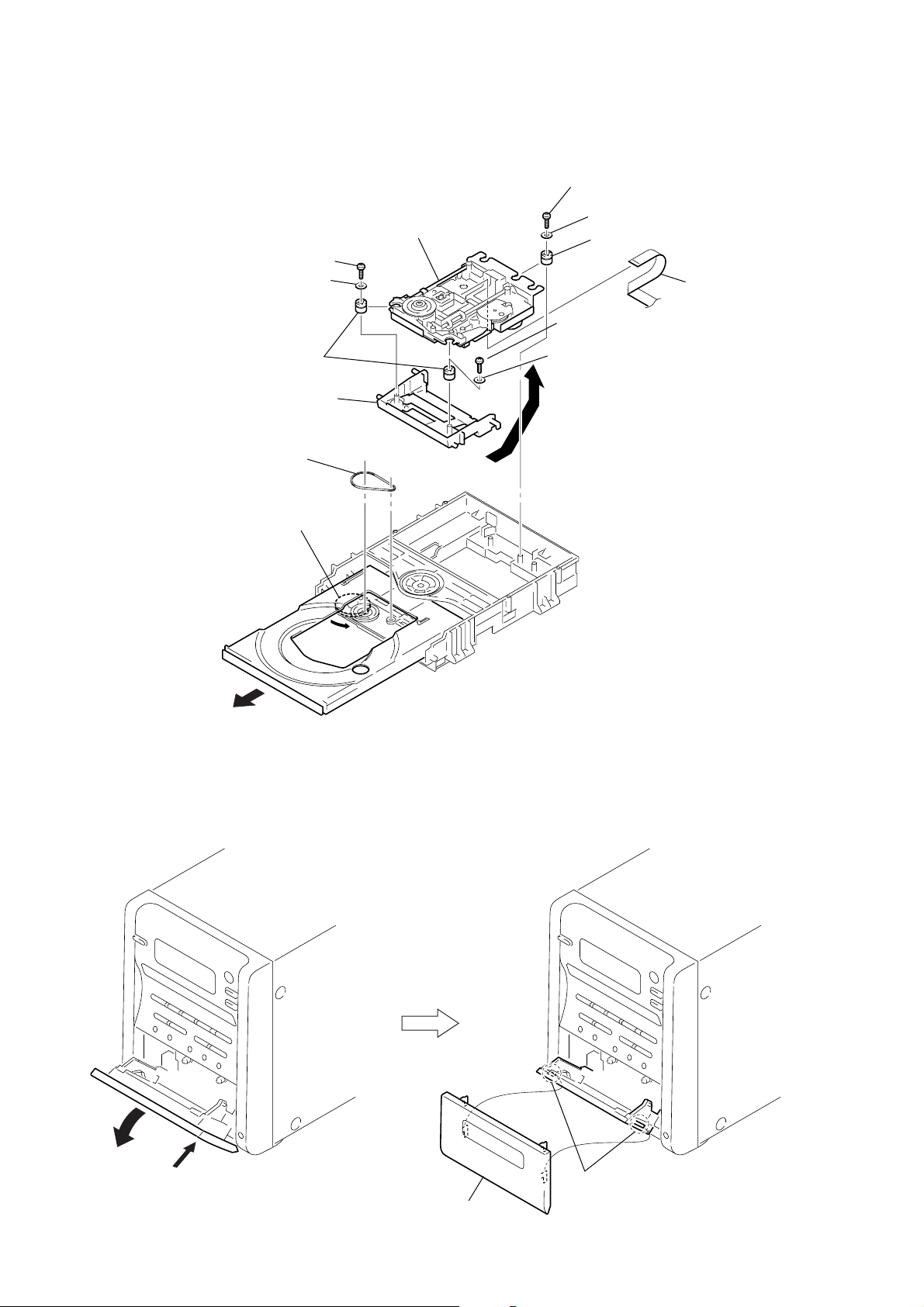

3-12. TRAVERSE MECH (1ADOMEZ0412)

7

screw

8

washer

qs

two dumpers

(traverse mech)

qg

traverse mech

(1ADOMEZ0412)

9

q;

4

screw

5

washer

qd

dumper (traverse mech)

screw

washer

qf

w

ire (flat type)

24core

3-13. LID TC

qa

holder(traverse mech)

3

belt (pulley)

Turn round the gear in the

1

direction of the arrow.

6

2

14

2

1

4

lid TC

3

two claws

Page 15

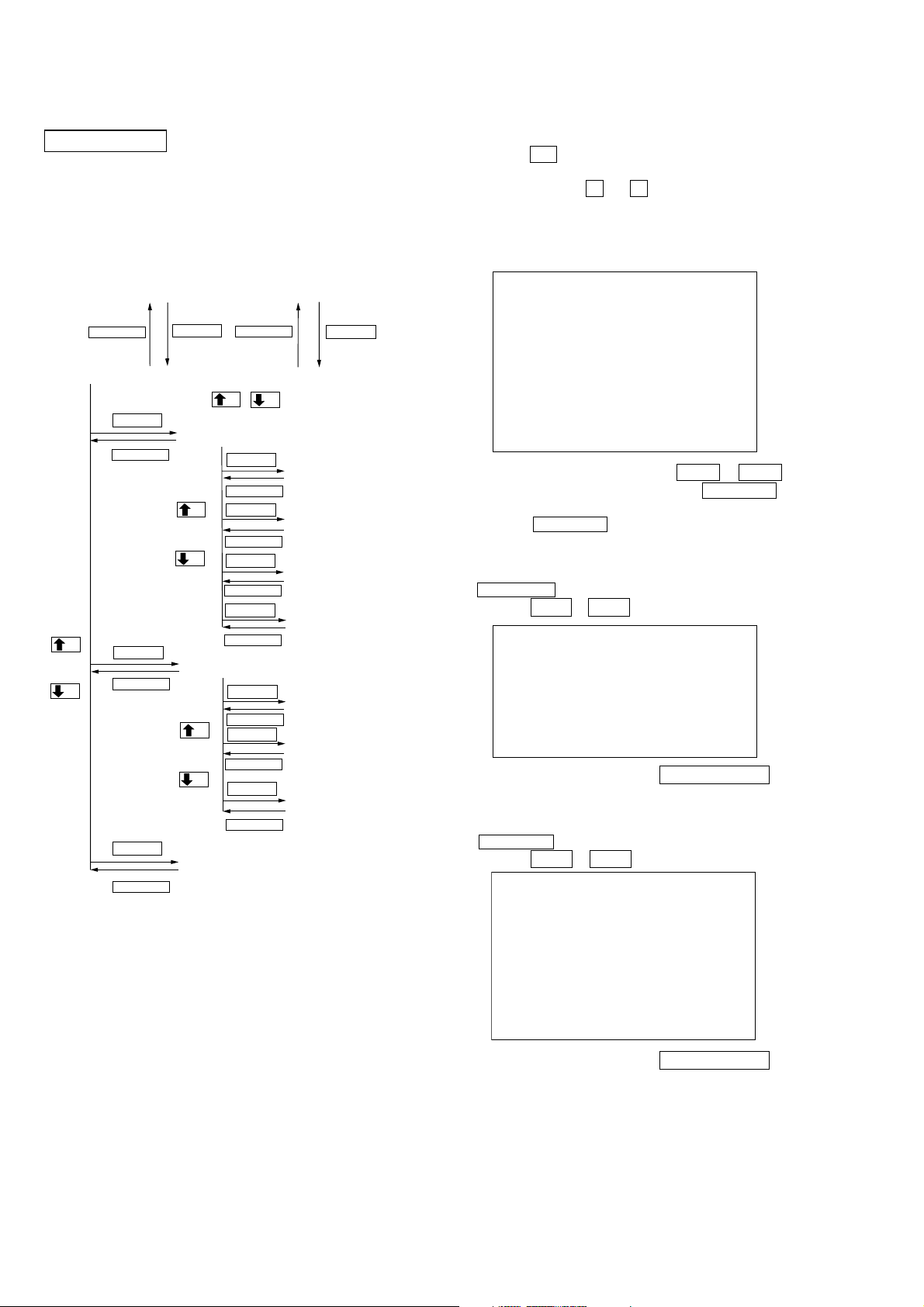

SECTION 4

TEST MODE

HCD-SV2D

Note 1:Regarding the notification symbol “R”

Because the number of the operating buttons of this product are

limited, some operations require use of the operating buttons of

the remote commander. W hen a specific operation requires use

of the operating buttons of the remote commander, “R” is added

to the specific operating procedure in this manual. Example

MENU/NO “R” The MENU/NO button of remote commander .

Note 2:Incorrect operations may be performed if the test mode is not

entered properly.

In this case, press the ?/1 button to turn the power off, and

retry to enter the test mode.

COLD RESET

• The cold reset clears all data including preset data stored in

the RAM to initial conditions. Execute this mode when

returning the set to the customers.

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Press three buttons x , [PLAY MODE] and DVD u simul-

taneously.

3. The message “COLD RESET” is displayed and the set is reset.

TUNER STEP CHANGE

(EXCEPT FOR AEP, UK, RUSSIAN models)

•A step of AM channels can be changed over between 9 kHz

and 10 kHz.

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Select the function “TUNER”, and press [TUNER/BAND]

button to select the BAND “AM”.

3. Press the ?/1 button to turn the set OFF.

4. Press the x and [TUNER/BAND] buttons simultaneously,

and thus the channel step is changed over.

SHIP RESET

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Press the DVD u button to select “DVD”

3. Remove the disc.

4. The message “NO DISC” is displayed.

5. Press three buttons x , [PLAY MODE] and TAPE N si-

multaneously.

6. The message “SHIP RESET” is displayed and the set is reset.

The DVD function is activated.

7. T o exit from this mode, press the ?/1 button and pull out the

AC plug.

PANEL TEST MODE

•This mode is used to check the software version, LCD, LED

and keyboard.

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Press the DVD u button to select “DVD”

3. Press three bottons x , [PRESET EQ] and T APE N simul-

taneously.

4. When the panel test mode is activated, all se gments are turned

on.

VERSION DISPLAY

•This mode is used check the model, destination, software

version.

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Press the DVD u button to select “DVD”

3. Press three buttons x , [PRESET EQ] and [TV] simultaneous-

ly, the model and destination are displayed.

DVD COLOR SYSTEM CHANGE OVER

•The color system can be changed over NTSC or PAL.

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Set the function to “DVD”.

3. Press the ?/1 button to turn the set OFF.

4. Press the x button and ?/1 button simultaneously. The set

will power on automatically.

5. The message “COLOR PAL” or “COLOR NTSC” will be

displayed on the fluorescent indicator tube. The color system

is changed over.

CD Repeat 5 Times Limit Release Mode

Procedure:

1. Press the ?/1 button to turn the set ON.

2. Set the function to “DVD”.

3. Press three buttons x , Z , and DVD u simultaneously.

4. The repeat all mark blinks and then repeat 5 times limit is

released.

DISC TRA Y LOCK

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Procedure :

1. Press the ?/1 button to turn the set ON.

2. Press the DVD u button to select “DVD”

3. Set disc on the tray, press the x button and the Z button

simultaneously for five seconds.

4. The message “LOCKED” is displayed the tray is locked.

5. To release from this mode, press the x button and the Z

button simultaneously for five seconds again.

6. The message “UNLOCKED” is displayed and the tray is

unlocked.

Note: When “LOCKED” is displayed, the slot lock is not released by

turning power on/off with the ?/1 button.

15

Page 16

HCD-SV2D

DVD SECTION

[GENERAL DESCRIPTION]

The T est Mode allows you to make dia gnosis and adjustment easily

using the remote commander and monitor TV. The instructions,

diagnostic results, etc. are given on the on-screen display (OSD).

[Configuration of Test Mode]

[ SERVICE MODE TEST SEQUENCE ]

RETURN "R"

ENTER "R"

[SYSCON Diagnosis ]

ENTER "R"

RETURN "R"

ENTER "R"

[Version Information ]

"R"

"R"

[MPEG Test]

RETURN "R"

ENTER "R"

[Check DSP]

RETURN "R"

"R"

ENTER "R"

[Check Flash]

RETURN "R"

"R"

ENTER "R"

RETURN "R"

ENTER "R"

[Check SDRAM]

[Check EEPROM]

"R"

ENTER "R"

RETURN "R"

[FRONT PANEL Test]

"R"

RETURN "R"

"R"

ENTER "R"

RETURN "R"

ENTER "R"

[Panel Key Test]

[VFD Test]

RETURN "R"

"R"

ENTER "R"

[Remote Key Test]

RETURN "R"

ENTER "R"

[SERVO Test]

RETURN "R"

1. STARTING TEST MODE

1. Press the ?/1 button to turn the power on, and set the function

to DVD.

2. While pressing the x and Z button at the same time, rotate

the [VOLUME+] knob clockwise to enter the test mode.

3. The message “SERVICE IN” appears on the fluorescent

indicator tube, and the message Test Mode Menu appears on

the monitor screen as follows.

SERVICE MODE TEST SEQUENCE

DVD Service Mode

SYSCON Diagnosis

Version Information

Reset And Exit

1. T o e xecute each function, press the m “R” or M “R” button

to select the desired menu.Then press the ENTER “R” button.

2. T o exit the Test Mode, select the menu “Reset And Exit” and

press the ENTER “R” button.

2. SYSCON Diagnosis

1. Select the menu “SYSCON Diagnosis” and press the

ENTER “R” button.

2. Press the m “R” or M “R” button to select the desired menu.

SYSCON Diagnosis

MPEG T

est

SERVO T

FRONT PANEL

est

Test

3. To exit the Test Mode, press the O RETURN “R” button.

2-1. MPEG Test MENU

1. Select the menu “MPEG Test Menu” and press the

ENTER “R” button.

2. Press the m “R” or M “R” button to select the desired menu.

MPEG Test Menu

16

Check DSP

Check Flash

Check SDRAM

Check EEPROM

3. To exit the Test Mode, press the O RETURN “R” button.

Page 17

HCD-SV2D

2-1-1. Check DSP

1. Select the menu “Check DSP” and press the ENTER “R”

button, then execute this mode.

2. When the check is completed with success, “OK” appears.

When the check finds any failure, “fail” appear.

Check DSP

MCU comm access

Register access

... ok

... ok

3. To exit the Test Mode, press the O RETURN “R” button.

2-1-2. Check Flash

1. Select the menu “Check Flash” and press the ENTER “R”

button, then execute this mode.

2. When the check is completed with success, “OK” appears.

When the check finds any failure, “fail” appears.

Check Flash

2-2. SERVO Test MENU

1. Select the menu “SERVO Test Menu” and press the

ENTER “R” button, then execute this mode.

2. When the check is completed with success, “OK” appears.

When the check finds any failure, “fail” appears.

SERVO Test Menu

Check Motor Driver

... ok

3. To exit the Test Mode, press the O RETURN “R” button.

2-3. FRONT PANEL Test MENU

1. Select the menu “FRONT PANEL Test Menu” and press the

ENTER “R” button, then execute this mode.

2. Press the m “R” or M “R” b utton to select the desired menu.

FRONT PANEL Test Menu

Status

... ok

3. To exit the Test Mode, press the O RETURN “R” button.

2-1-3. Check SDRAM

1. Select the menu “Check SDRAM” and press the ENTER “R”

button, then execute this mode.

2. If error is detected, the “ Address” and the “Error” count appear.

Check SDRAM

Address

Error

X x XXXX

X

3. To exit the Test Mode, press the O RETURN “R” button.

2-1-4. Check EEPROM

1. Select the menu “Check EEPROM” and press the

ENTER “R” button, then execute this mode.

2. If error is detected, the “ Address” and the “Error” count appear.

Panel Key Test

VFD Test

Remote Key Test

3. To exit the Test Mode, press the O RETURN “R” button.

2-3-1. Panel Key Test

1. Select the menu “PANEL KEY Test” and press the

ENTER “R” button, then execute this mode.

2. Press TAPE N , x , M > , .m button on the

Front panel in this order.

3. When the check is completed with success, “OK” appears.

When the check finds any failure, “fail” appears.

Panel Key Test

... ok

PLAY

Stop

Next

Prev

... ok

... ok

... ok

4. To exit the Test Mode, press the O RETURN “R” button.

Check EEPROM

Address

Error

X x X X

X

3. To exit the Test Mode, press the O RETURN “R” button.

17

Page 18

HCD-SV2D

2-3-2. VFD Test MENU

1. Select the menu “VDF Test Men u” and press the ENTER “R”

button, then execute this mode.

2. When the check is completed with success, “OK” appears.

When the check finds any failure, “fail” appears..

VFD Test

... ok

Status

3. To exit the Test Mode, press the O RETURN “R” button.

2-3-3. IR Remote Test

1. Select the menu “IR Remote T est” and press the ENTER “R”

button, then execute this mode.

2. Press TAPE N , x , > , . button on the remote

commander in this order.

3. When the check is completed with success, “OK” appears.

When the check finds any failure, “FAIL” appears.

IR Remote Test

... ok

PLAY

Stop

Next

Prev

... ok

... ok

... ok

4. To exit the Test Mode, press the O RETURN “R” button.

3. Version Information

1. Select the menu “Version Information” and press the

ENTER “R” button, then execute this mode.

2. The “Version” appears.

Version Information

MPEG Version

: XXX.XX.XX.XX.X

3. To exit the Test Mode, press the O RETURN “R” button.

18

Page 19

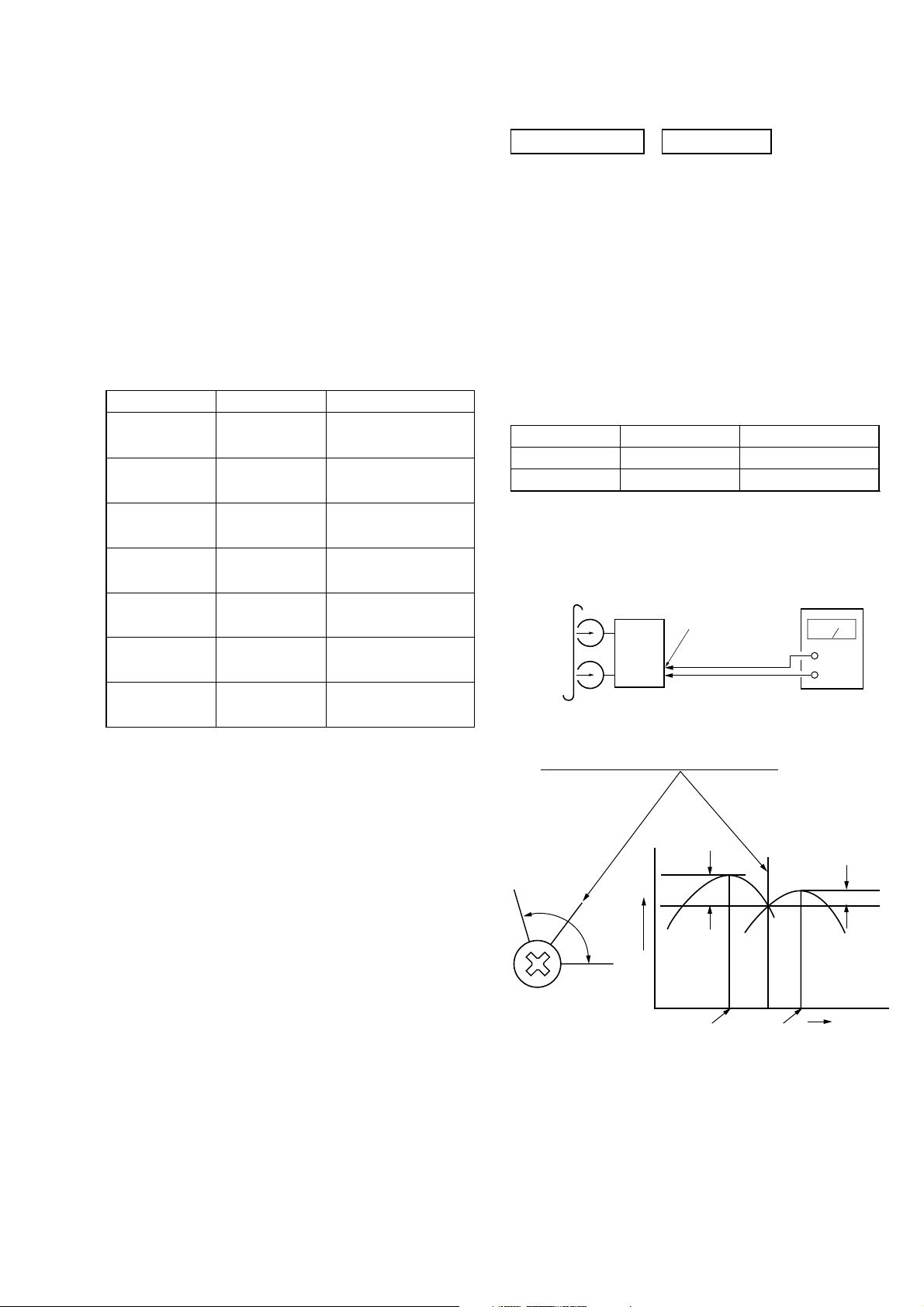

SECTION 5

test tape

P-4-A100

(10kHz, –10dB)

MAIN board

JK102

speaker terminal

level meter

set

+

–

MECHANICAL ADJUSTMENTS

HCD-SV2D

SECTION 6

ELECTRICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to

the parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

Torque Measurement

Mode

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

Torque meter Meter reading

2.94 – 7.84 mN • m

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

(31 to 71 g • cm)

(0.43 – 0.98 oz • inch)

0.15 – 0.59 mN • m

(2 to 6 g • cm)

(0.02 – 0.08 oz • inch)

2.94 – 7.84 mN • m

(30 to 79 g • cm)

(0.42 – 1.11 oz • inch)

0.15 – 0.59 mN • m

(2 to 6 g • cm)

(0.03 – 0.08 oz • inch)

6.86 – 17.64 mN • m

(71 to 143 g • cm)

(0.98 – 2.49 oz • inch)

9.8 mN • m or more

(100 g • cm or more)

(1.4 oz • inch or more)

9.8 mN • m or more

(100 g • cm or more)

(1.4 oz • inch or more)

DECK SECTION 0 dB=0.775V

1. Demagnetize the record/playback head with a head

demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to

the parts adjusted.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in

this service manual. (As a general rule, playback circuit

adjustment should be completed before performing recording

circuit adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise

specified.

Signal Used forTape

P-4-A100

WS-48B

[Record/Playback Head Azimuth Adjustment]

Procedure:

1. Mode : Playback

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1 dB of peak.

10 kHz, –10 dB

3 kHz, 0 dB

Azimuth Adjustment

Tape Speed Adjustment

L-CH

peak

screw

position

R-CH

peak

output

level

within

1 dB

L-CH

peak

R-CH

peak

within 1dB

screw

position

19

Page 20

HCD-SV2D

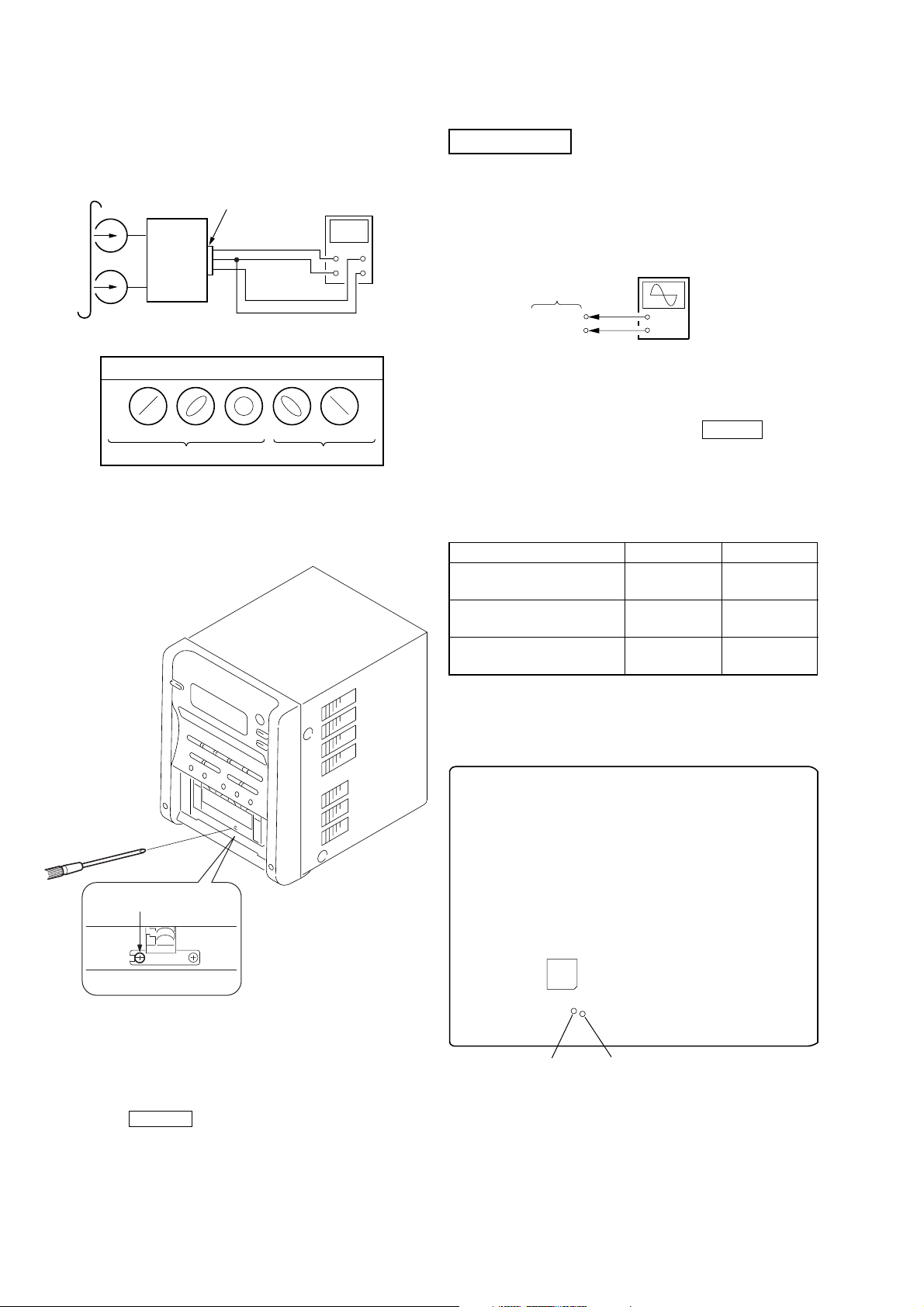

3. Mode: Playback

test tape

P-4-A100

(10kHz, –10dB)

set

in phase 45

MAIN board

JK102

speaker terminal

L

R

Waveform of oscilloscope

°

90

°

good

135

oscilloscope

°

wrong

180

°

4. After the adjustments, apply suitable locking compound to

the parts adjusted.

Adjustment Location: Record/Playback/Erase Head

DVD SECTION

[RF Level Check]

Check the RF level when optical pick-up block (TRAVERSE

MECH) is replaced.

Connection:

oscilloscope

MPEG board

TP (RF)

TP (VC)

Procedure:

1. Connect an oscilloscope to TP (RF) and TP (VC) on the MPEG

board.

2. Turn the power on.

3. Set the test disc on the tray and press DVDu button to

playback.

4. Observe the waveform of the oscilloscope, and check that the

RF level is satisfied to specified value.

[Test Disc List and Specified Value]

Use the following test disc on adjustment.

TEST DISC Specified Value Deviation

CD (YEDS-18)

PART No. :3-702-101-01

DVD Single Layer (HLX-504)

PART No. :J-6090-088-A

DVD Dual Layer (HLX-505)

PART No. :J-6090-089-A

+

–

310 mV +30 mV/–50 mV

290 mV +25 mV/–40 mV

120 mV +20 mV/–30 mV

adjustment screw

Note: Refer to “ 3-13. LID TC ” (see page 14)

[Tape Speed Check]

Procedure:

1. Turn the power on.

2. Insert the WS-48B into deck.

3. Press the TAPE N button of deck.

4. Check the reading of frequency counter becomes 3000 ± 90

Hz.

Note: Do not use existing test disc for DVD.

Checking Location: MPEG board

[MPEG BOARD]

U709

TP (RF) TP (VC)

Sample Value of Wow and flutter

W.RMS (JIS) less than 0.3%

(test tape: WS-48B)

20

Page 21

SECTION 7

DIAGRAMS

HCD-SV2D

Ver. 1.1

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For Schematic Diagrams.

Note:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except f or electrolytics and

tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

• C : panel designation.

Note: The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

• A : B+ Line.

•Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

– MPEG Section –

No mark: DVD STOP

– Other Section –

No mark: FM

< > : T APE REC

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

d : TUNER

E : PB(TAPE)

a : REC(TAPE)

J : DVD (AUDIO)

c : DVD (RF)

I : DVD (DIGITAL)

h : TV IN

L : VIDEO

N : MIC

•Abbreviation

E3 : 240 V AC area in E model.

SP : Singapore model.

TH : Thai model.

4

W or less unless otherwise

For Printed Wiring Boards.

Note:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• f : internal component.

• : Pattern from the side which enables seeing.

Caution:

Pattern face side: P arts on the pattern face side seen from

(Side A) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side B) the parts face are indicated.

• Indication of transistor.

C

Q

B

B

B

E

Q

CE

These are omitted.

CE

These are omitted.

These are omitted.

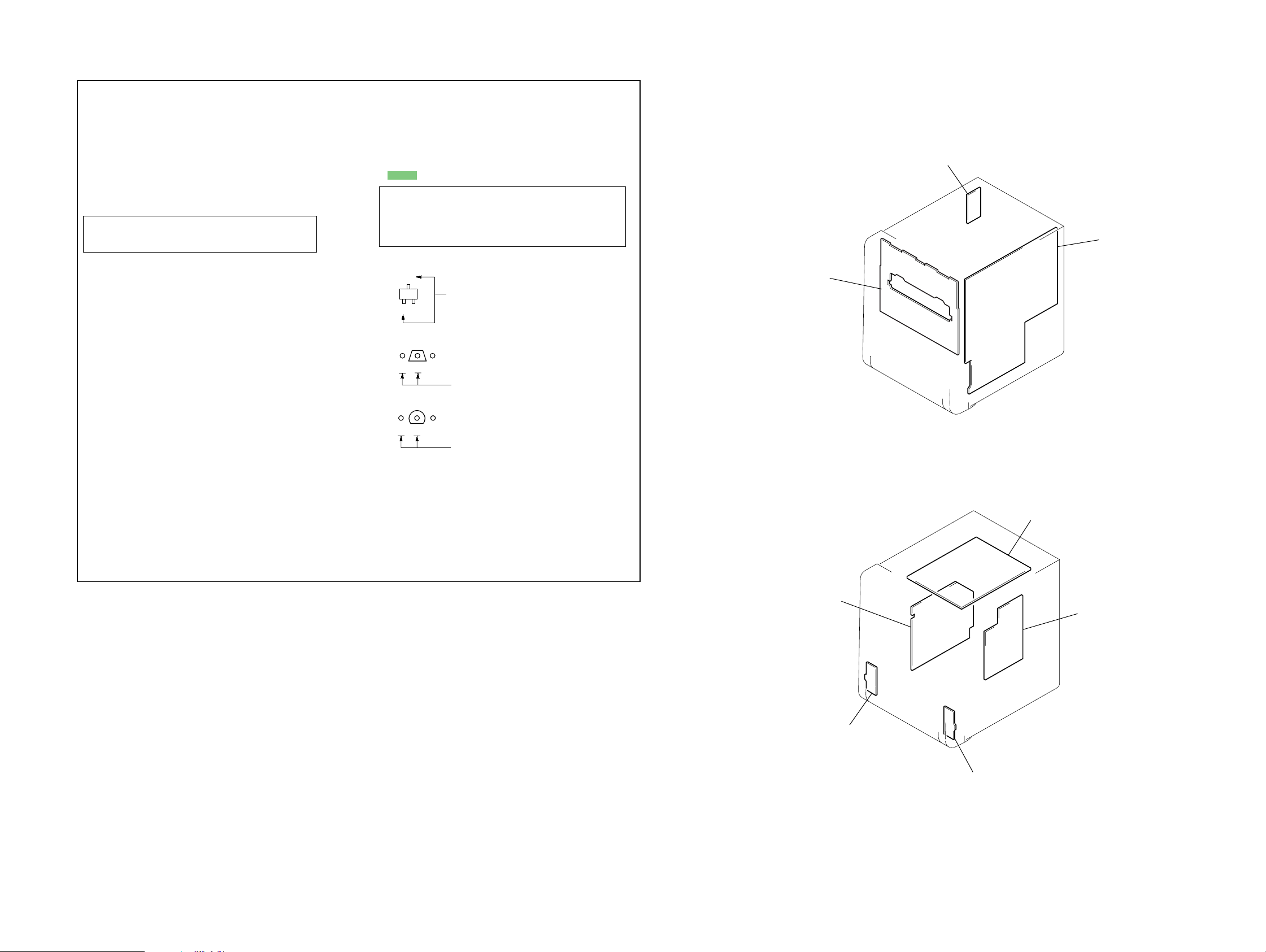

• Circuit Boards Location

AV board

MAIN board

KEY board

MPEG board

HCD-SV2D

POWER board

AMP board

MIC board

(E3, SP and TH models only)

HP board

2121

Page 22

HCD-SV2D

7-1. BLOCK DIAGRAMS — MPEG-1 SECTION —

OPTICAL

PICK-UP

CD/DVD

VR-CD

VR-DVD

MD

LD-DVD

LD-CD

F-

F+

T+

T-

A

B

C

D

E

F

F-

F+

T+

T-

VR CONTROLLER

VR CONTROLLER

Q710

CD/DVD

SELECTOR

Q711,712

(CD)

Q713

(DVD)

Q714

POWER

CONTROLLER

(DVD)

Q715

POWER

CONTROLLER

(CD)

RFN

55

CAP

1

CAO

62

PD2

5

PD1

4

PD4

7

PD3

6

TIN2

14

TIN1

13

FIN1

9

FIN2

10

DVD/CD

26

DPD/TE

27

LDS1

16

LDS2

18

LDD1

15

LDD2

17

U709

RF AMP

FOCUS/TRACKING

ERROR AMP

59

PFP

55

61

RFOP

RFON

LDON2

LDON1

RREC

WO

LDON1

LDON2

XHTR

RST

TEBL

FEBL

SGC

DVD/CD

DVD/TE

GU

55

54

22

21

38

PH

47

BH

46

TE

40

FE

39

41

21

22

31

FC

34

33

TH

30

36

CP

37

35

32

26

27

25

EFNINP

10

EFNINN

12

LDON2

172

LDON1

171

PREC

4

RFPH

5

RFBH

6

BHC

19

TE

7

TEC

21

FE

8

WO

20

LDON1

171

LDON2

172

XHTR

170

FO

25

RST

26

DEFECTO

168

TBAL

27

FBAL

28

SGC

29

TSTD1

23

TSTDO

24

DVD CD

167

AD11VREF22AD02SLCO30SPDO31TDO

XIN

134

XOUT

135

145-148

MD8-15

150-153

156-159

MD0-7

161-164

MWEB

60

MRAS1B

61

62-65

MA0-8

68-72

MCASUB

77

U707

AV DECODER

SERVO CONTROLLER

HOST INTERFACE

HDAT1-7

HADR0-12

54-59,78-83

FG (PP1)

HIROB37HWAITB38HRESB39HRDB40HWRD41HCSB42HDATO

36

SDO

32

33

46-53

MA10

MOEB

AVD0-7

DO0T

AVERRB

AVSCTB

AVDACK

AVACKO

AVRAOI

LRSY

ROMCK

ROMXA

C2F

X16MIO

75

76

96

-

103

142

95

94

93

92

91

87

86

85

84

137

43

16.9344MHz

DFFR

DBGN

DCLK

DACK

DRFO

LRCK

BCK

CD DATA

C2F

AMCLK

Y701

31-34,

36-39

2-5,

7-10

13

14

16-19

22-26

29

27

28

WE

RAS

A0-8

CASL

OE

CASH

DO0T

U708

S-RAM

IO8-15

IO0-7

H

E

MPEG2

SECTION

MPEG2

SECTION

OPEN SW

CLOSE SW

MLD2

MLD1

SLED+

SLED-

PANEL POWER

SECTION

PANEL POWER

SECTION

HCD-SV2D

SP+

SP-

SPD FG

INT DEC

RDY

LSI RSTRDWR

HA0-12

HA0-7

DATA&ADDRESS BUS

F-

F+

T+

TOP

TCL

D

C

T-

U705(1/2)

AMP

2

1

3

OPN

CLS

VOL3+

8

VOL3-

9

VOL4+

7

VOL4-

6

VOL0+

5

VOL0-

4

VOL1-

13

VOL1+

12

VOL2+

10

VOL2-

11

FWD

1

REW

2

U706

MOTOR

DRIVER

VIN4+

VREF-IN

VIN3+

VIN2+

VIN1+B

VIN1+A

VIN1-B

VIN2-

VIN4-

VIN3-

31

30

25

22

19

17

18

21

32

24

U705(2/2)

5

6

AMP

7

SC DVD

BE01

• Signal Path

MPEG2

I

SECTION

MPEG2

J

SECTION

MPEG2

G

SECTION

: DVD(RF)

: DVD(DIGITAL)

2222

Page 23

— MPEG-2 SECTION —

HCD-SV2D

PANEL POWER

SECTION

MPEG1

SECTION

MPEG1

SECTION

MPEG1

SECTION

MPEG1

SECTION

F

G

H

I

MRST

DSSTB

DSCK

DSDA

DRFO

DACK

DFFR

DBGN

DCLK

C2F

LRCK

BCK

CD DATA

AMCLK

SPD FG

RDY

INTDET

LSI RST

DATA& ADDRESS BUS

WE12RST

11 28

WR

BEO1

105

129

MEMWR

MEMDAO

7

SSCRRO/CPCIO11

8

SSCRRO/CPCIO10

49

SSCRXD/GPCI08

51

SSCRXD/GPCI09

34

ATDA2

9

14

ATDD4-11

16

18

ATDD11

19

ATDD13

20

ATDD12

21

ATDD2

22

ATDD1

23

ATDA1

36

ATDA0

37

ATCS1

38

ATCS0

39

AMCLK

179

GPCI07

47

ATIORD

31

GPCIO1

41

GPCIO14

4

RD

128

OE

123

MEMRD

SCDVD

147-150,152

MFWOS2

RAMADD0

53-55,57-60,

62-64,67

A13

3-1,48,

17,16,9

154,155

MEMAD13

RAMADD11

68

FLASH MEMORY

A19

MEMAD19

RAMBA0

UD707

DO8

30,32,34,36,

39,41,43,45

115,118,120,

122,106,108,

110,112

MEMDA8

RAMBA166PCLK78RASWE75RASCAS74RAMRAS72RADOM

A0

DO14

4-8,

18-25

131,133-138

140,142-146

MEMAD0

MEMDA15

UD705

VIDEO DAC ENCODER

76

A12

HA0-12

HA0-12

MEMAD12

DO0

DO7

29,31,33,35,

38,40,42,44

HA0-7

HA0-7

105,107,109,

111,113,

117,119,121

MEMDA0

MEMDA7

RAMDAT0-15

80,82,84,86,87,89,

90,92,93,95,96,98,

99,101,102,104

UD708

EEPROM

SDA

SCL

5 6

196

195

GCLKP

CPCIO16

CPCIO17

CVBS/C

ALR CLK

AOUT O

AMCLK

JTMS/CPCIO47

GPC106

GPC105

XO

160

161

162GCLKA

170

177GPCIO18

181SPDIF/AOUT3

190AB CLK

188

184

179

203

46

45

YD701

27MHz

VIDEO1

MPEG1

R-CH

JK1

VIDEO OUT

• R-CH is omitted due to same as L-CH.

• Signal Path

UD701

BUFFER

2

SEL

VIN2

3

DOUT

E

VOUT

VIN1

1

UD709

2 1

BUFFER

7

JK801A

B

AUDIO

SECTION

DIGITAL OUT

OPTICAL

: DVD(AUDIO)

: DVD(RF)

: DVD(DIGITAL)

: VIDEO

VOUT

2

1

SCK16

15

ML

14

MC

MD

13

DATA3LRCK

U704

AUDIO DAC

BCK

VOUTL

VOUTR

SECTION

7

8

J

HCD-SV2D

20-24,

27-32

19

A0-A10

18 35 15 16 17 14 36

CS

WE

A11

CLK

CAS

RAS

UD706

DRAM

LDOM

UDOM

2,3,5,6,8,9,11,

12,39,40,42,43,

45,46,48,49

D0-D15

2323

Page 24

HCD-SV2D

Ver. 1.1

— AUDIO SECTION —

E3,SP,TH

MIC

JK202

ANTENNA

TV IN

FM 75Ω

COAXIAL

AM

IC402(1/2)

6

MIC AMP

7

5

JK201

L

R

TUNER PACK

L-CH

R-CH

D OUT

D IN

CL

CE

TUNED

MUTE

STEREO

RDDA

ROCK

R-CH

R-CH

IC401

ECHO

DISK

SLT4SDI

5

23

SYSTEM CONTROLLER

E-DATA

58

E-STB

52

E-CLK

57

TUDO

19

TUDI

18

TUCK

20

TUCE

12

TUND

13

RMUTE

1

STE

11

RDDA

21

RDCK

46

RMUT

2

RPHD

3

BIAS

4

MIC IN

31

SCK

3

IC402(2/2)

2

3

IC501(1/2)

SDAT/ROMDA

SCK/ROM CK

MIC AMP

7

Q401,402

MIC MUTE

AMUTE

TMOT

HDPN

MPEG2

SECTION

TSOL

TCNT

REPT

Q403-405

BUFFER

2

3

B

53

54

59

5

6

7

31

30

IC102

MIXER AMP

IC101

SOUND PROCESSOR

VARL

IN4

LINT2

LINT3

LINT1

BASSOL

SDA

RECOUTL

SCL

SCL

SDA

Q105

MUTE CONT

LOUT

6

28

30

29

31

7

21

22

6

5

IC503

EPROM

IC103

POWER AMP

CH1

25

Q102

MUTE

R-CH

27

Q319

A

PANEL

POWER

SECTION

MUTE

SWITCH

Q314,317

CURRENT

DETECT

11 4

13

IN

STBY

INVERTER

OUT+

Q199

CH1

Q308

PROTECT

SWITCH

Q104,301

OVER LOAD

DETECT

R-CH

Q303,304,354

DC PROTECT

R-CH

R-CH

R-CH

Q350-352

FAN CONT

L

R

JK103

PHONES

JK102

SPEAKER

IMPEDANCE

USE 6Ω

FAN

TAPE

MECHANISM

DECK

L-CH

REC/PB

HEAD

R-CH

ERASE

PACK

RECF

RECR

HDPLY

TCNT

MOT

R-CH

R-CH

Q209

MUTE

Q653,654

MOTOR DRIVER

Q202,207

REC/PB SWITCH

Q201,204,206

REC/PB SWITCH

Q212

Q213

BIAS

USC

+VM

Q214

IC201

TAPE REC/PB AMP

CH I/A

1

PREO

REC IN

RECO

14

3

16

16

Q215

REC DETECT

Q210

MUTE

+10V +VDD

Q313

+10V REG

• R-CH is omitted due to same as L-CH.

• Signal Path

: AUDIO

: PB(TAPE)

: REC(TAPE)

: TUNER

: DVD(AUDIO)

: TV IN

: MIC

Q353,355

FAN CURRENT

DETECT

HCD-SV2D

SOL

Q651,652

SOL DRIVER

2424

Page 25

— PANEL/POWER SECTION —

TRANSFORMER(MAIN)

VF

VF

PT901

POWER

HCD-SV2D

Ver. 1.1

S658,S651-654

FUNCTION

KEY

S665,S666,S656,S657,S659

FUNCTION

KEY

S655,S660-664

FUNCTION

KEY

REMOTE

CONTROL

RECEIVER

IR651

1

32.768kHz

X501

X502

8.38MHz

IC501 (2/2)

SYSTEM CONTROLLER

KEY1

26

KEY2

27

KEY3

28

REM

45

37

XT2

38

XT1

40

X2

41

X1

VFSTB

VFCK

VEDA

LED

PCON

INH

TUON

CD ON

-33V(VPP)

Q306

SWITCH

IC651

FL DRIVER

GRID1-4

I/

14-29,

31-38

42-39

30

-33V(VPP)VEE

17

16

15

Q502

LED

60

DRIVE

64

44

61

62

SEG1-SEG24

9

STB

8

CLK

7

DIN

D652

VFD651

FLUORESCENT

INDICATOR

TUBE

AUDIO

VF

VF

SECTION

+9V (TU)

Q196,197

SWITCH

A

Q318

SWITCH

Q305,Q320

POWER

CONTROL

Q309,310

SWITCH

Q198

+9V

REG

D309

D324

D +5V

+12V(VM)

+9V

+1.8V

+3.3V

+2.5

+3.3V

Q315

-33V

REG

POWER AMP B+

POWER AMP B-

+VDD

IC301

+5V

2

REG

5

Q311,312

+12V

REG

Q316

+9V

REG

UD703

+1.8V

3

REG

UD702

+3.3V

3

REG

UD704

+2.5V

REG

U702

+3.3V

REG

D306

D301

D302

1

1

1

12

12

D+5V

MPEG1

SECTION

MPEG1

SECTION

MPEG2

SECTION

HCD-SV2D

RY901

C

D

F

CLS

OPN

TOP

TCL

DSCK

DSSTB

DSDA

MRST

CLS

56

OPN

55

14

TOP

35

TCL

DSCK

50

DSSTB

49

DSDA

48

MRST

47

RLY

FPON

RST

AVR

SFTY

63

Q504-506

+5V

REG

+12V(VM)

D501

D901-904

Q507

SWITCH

22

IC502

RESET

36

SWITCH

34

29

+5V

D906

Q307

RELAY

DRIVE

TRANSFORMER

D907

PT902

POWER

(SUB)

E3,SP,TH

SW901

VOLTAGE

SELECTOR

US

AC IN

2525

Page 26

HCD-SV2D

Ver. 1.1

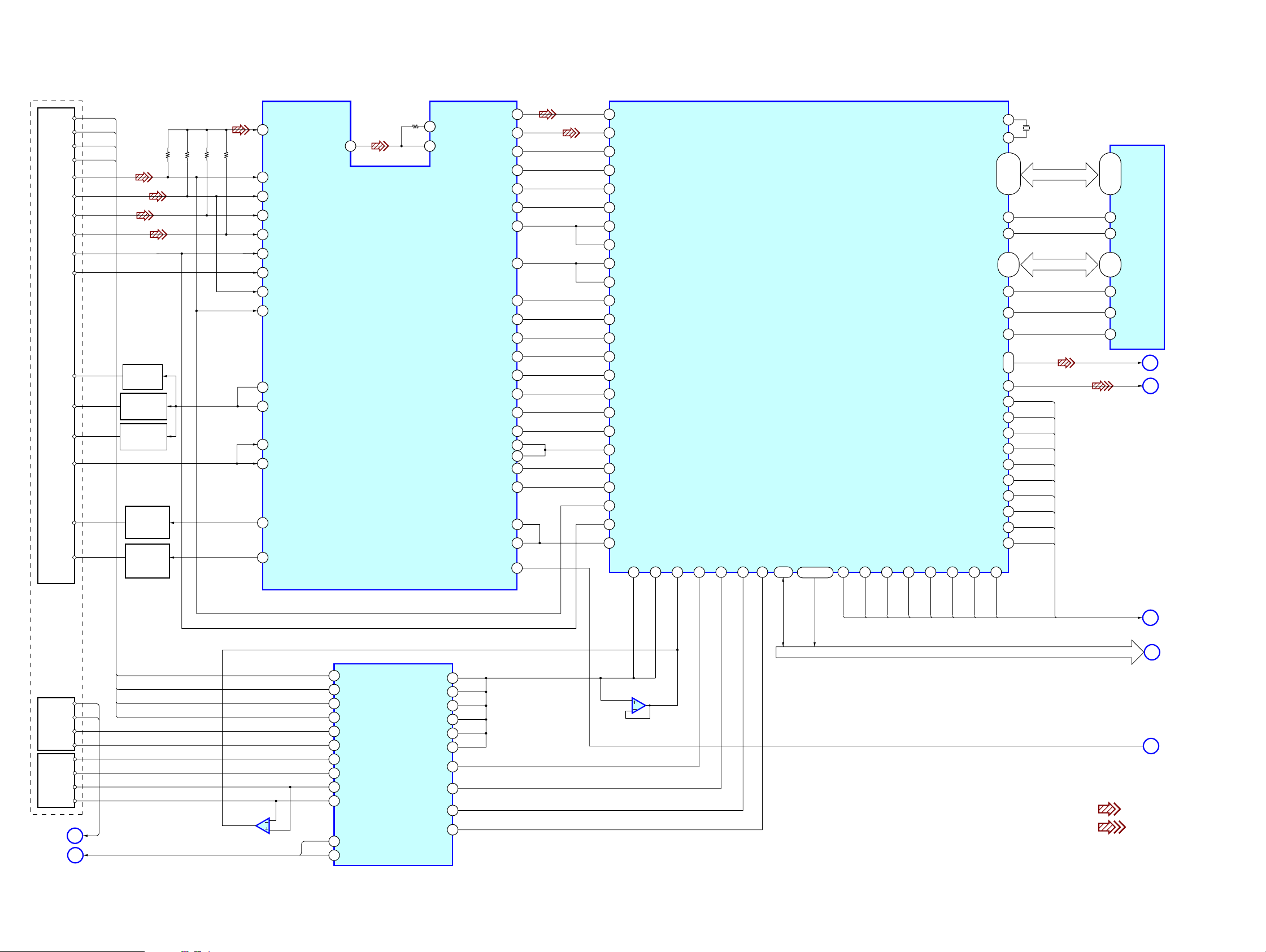

7-2. PRINTED WIRING BOARD — MAIN SECTION-1 —

• See page 21 for Circuit Boards Location. :Uses unleaded solder.

A

B

C

D

E

F

G

12

MAIN BOARD

L

TV

IN

R

+

L

–

SPEAKER

IMPEDANCE USE 6Ω

–

R

+

H

AMP BOARD

CN108

(Page 35)

345678910

TUNER

PACK

MPEG BOARD

C

J702

(Page 29)

B

MPEG BOARD

J701

(Page 29)

DOWN LOAD PORT

A

KEY BOARD

CN601

(Page 32)

HEAD

(PLAYBACK/ERASE)

L-CH

REC/PB

HEAD

R-CH

ERASE

HEAD

IC201

E3,SP,TH

CN401

G

MIC

BOARD

CN401

(Page 32)

• Semiconductor

Location

Ref. No.

D105 G-2

D196 B-2

D197 B-3

D198 B-3

D199 B-3

D201 E-7

D301 I-6

D302 I-8

D306 I-8

D307 I-9

D308 I-8

D310 H-9

D312 G-2

D314 H-2

D317 G-2

D319 G-4

D320 F-4

D321 F-4

D322 F-4

D323 H-5

D401 H-7

D501 E-9

D502 C-9

D503 D-8

D505 D-8

D507 G-6

D508 H-8

IC201 E-8

IC301 H-6

Q198 B-3

Q212 F-9

Q213 F-9

Q214 F-9

Q215 D-8

Q313 G-3

Q315 I-9

Q316 H-8

Q504 C-8

Location

HCD-SV2D

H

IC301

E

AMP BOARD

CN106

I

J

K

(Page 35)

I

AMP BOARD

CN102

(Page 35)

POWER BOARD

D

FW901

(Page 35)

2626

Page 27

7-3. PRINTED WIRING BOARD — MAIN SECTION-2 —

HCD-SV2D

Ver. 1.1

• See page 21 for Circuit Boards Location. :Uses unleaded solder.

C

D

E

F

G

12

A

MAIN BOARD

B

IC502

E3,SP,TH

IC402

345678

IC501

IC503

IC101

IC102

IC401

• Semiconductor

Location

Ref. No.

D106 C-8

D107 C-8

D309 I-3

D313 G-4

IC101 D-5

IC102 E-5

IC401 G-3

IC402 G-2

IC501 B-3

IC502 C-2

IC503 C-3

Q196 B-7

Q197 B-7

Q199 B-7

Q201 F-3

Q202 D-3

Q203 F-3

Q204 F-3

Q205 F-3

Q206 E-4

Q207 E-4

Q208 D-3

Q209 D-3

Q210 D-2

Q211 E-2

Q305 I-3

Q306 I-1

Q307 H-2

Q317 G-4

Q318 G-4

Q319 I-2

Q401 G-2

Q402 G-2

Q403 F-4

Q404 E-4

Q405 E-4

Q502 B-2

Q505 C-2

Q506 C-2

Q507 B-2

Location

HCD-SV2D

H

I

2727

Page 28

HCD-SV2D

Ver. 1.1

7-4. SCHEMATIC DIAGRAM — MAIN SECTION —

TO TUNER PACK

MAIN BOARD

A

(Page 33)

DOWNLOAD

PORT

B

HEAD

(PLAYBACK/ERASE)

L-CH

REC/PB

HEAD

R-CH

ERASE

HEAD

KEY

BOARD

CN601

MPEG

BOARD

J701

(Page 31)

SWITCH

2.6

<-7.0>

2.9<-11.1>

4.9

4.2

REC/PB SWITCH

2.6<-7.0>

2.6

<-7.0>

REC/PB SWITCH

Q201-Q205

0<-14.9>

2.9

<0>

4.9

0<0>

0<-14.9>

2.9

<0>

REC/PB SWITCH

Q212, Q213

BIAS OSC

9.6

<9.0>

0<0>

0<0>

0<0>

0<-14.9>

0<0>

9.6

<9.0>

2.9

<-0.7>

9.5

<2.3>

9.6<2.7>

0<-0.7>

0<-0.7>

3

9.6<2.2>

9.5 <0.4>

0<0.8>

R5811*

US:4.7k

E3:15k

SP,TH:91k

5.0

• See page 41, 42 for IC Block Diagrams. • See page 39 for Waveforms. • See page 45 for IC Pin Function Description.

MIC

BOARD

G

CN401

(Page 33)

5.2

0

0

0

Q401, Q402

MIC MUTE

9.2

Q403

BUFFER

5.3

4.7

222

222

2.7K

0.18

0.18

2.7K

0.18

BUFFER

9.9

0.18

4.7

4.1

5.0

IC102

MIXER AMP

9.9

9.6

0

SWITCH

MUTE SWITCH

4.9

5.2

0

2.6

0

0

5.0

VOLTAGE CHART

IC501

IC502

RESET SWITCH

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

VOLT

4.9

4.9

4.9

0

0

0

0

0

–

5.0

0

0

0

4.8

0

0

0

4.9

IC501

SYSTEM CONTROLLER

12

IC B/D

0

1.2

2.0

1.4

7.1

2.0

1.2

0

NO.

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

INVERTER

0

TAPE REC/PB AMP

VOLT

4.9

0

0.3

0

0.2

4.9

0.2

5.1

–

5.0

5.0

5.0

2.8

3.8

3.8

0.4

IC201

0.7

TV IN

0.3

+9V REG

12.4

0

12.4

0

SWITCH

12.3

12.4

50V

5.0

Q504-506

LED DRIVE

0

0.3

4.9

5.0

4.9

EPROM

IC503

Q210, Q211

0

1.2

2.2

1.7

1.7 <0.8>

2.3

0

1.2

00

0

Q215

REC DETECT

MUTE

0.7

MUTE

0

NO.

VOLT

NO.

49

4.9

33

50

5.0

34

51

0

35

52

5.0

36

53

3.3

37

54

2.4

38

55

0

39

56

3.0

40

57

2.8

41

58

–

42

59

0

43

60

4.9

44

61

4.9

45

62

0

46

63

4.9

47

64

3.2

48

VOLT

0

0.7

<0>

0

3.4

4.8

0.3

0

4.9

4.9

0

0

4.9

0

4.9

0

0

4.9

4.9

4.9

0.7<0>

0.6

+5V REG

5.7

0.7

0

0.7

0.2

10.6

10.3

11.3

MUTE

0

0

C

MPEG BOARD J702

(Page 31)

IC401

ECHO

2.3

2.5

2.5

2.5

2.6

2.5

2.5

2.6

2.6

2.5

2.5

2.6

2.5

IC101

IC B/D

2.5

IC301

+5V REG

2.6

2.5

2.5

2.5

2.6

2.5

4.3

4.3

4.3

4.3

4.9

4.9

5.0

5.0

5.0

5.0

5.0

4.1

4.7

9.9

BUFFER

5.1

5.1

17.8

0

0

0.7

SWITCH

5.2

0

0

4.9

5.2

4.9

5.0

5.0

0

5.0

5.0

5.0

0

SOUND PROCESSOR

9.6

5.1

5.2

E3,SP,TH

5.2

0

5.2

IC402

MIC AMP

AMP BOARD

CN108(Page 36)

H

POWER

0

CONTROL

0.6

0

0.6

POWER

CONTROL

9.9

11.0

+10V REG

16.3

18.0

CURRENT

DETECT

17.8

0

17.0

+9V REG

8.8

10.8

AMP BOARD

I

CN102(Page 36)

-32.4

-32.9

-33V REG

-38.6

E

AMP BOARD

CN106

(Page 36)

+

L

SPEAKER

–

IMPEDANCE

–

USE 6Ω

R

+

D

POWER BOARD

FW901

(Page 37):E3,SP,TH

(Page 38):US MODEL

RELAY DRIVE

0

4.5

NO MARK : FM

< > :TAPE REC

HCD-SV2D

2828

Page 29

HCD-SV2D

7-5. PRINTED WIRING BOARD — MPEG SECTION-1 —

12

A

MPEG BOARD

34567891011121314

B

C

D

U708

E

F

• See page 21 for Circuit Boards Location. :Uses unleaded solder.

U707

UD706

UD707

UD705

MONITOR DEBUGGER DEBUG TERMINAL

U704

UD708

UD701

F

AV BOARD

CN851A

(Page 34)

• Semiconductor

Location

Ref. No.

D701 G-2

D702 G-6

D703 G-7

D704 I-13

D705 J-8

D706 C-12

DD702 H-10

DD703 H-10

DD709 F-13

DD710 F-6

Q710 G-6

Q711 G-6

Q712 G-6

Q713 G-7

Q714 G-5

Q715 G-5

U702 J-8

U704 D-11

U705 H-2

U706 I-3

U707 D-4

U708 D-2

U709 H-5

UD701 B-12

UD702 I-10

UD703 G-9

UD704 G-8

UD705 D-9

UD706 D-6

UD707 F-8

UD708 C-11

UD709 H-12

Location

G

H

K

UD703

UD704

U705

U709

I

U706

UD702

UD709

U702

J

DVD

MECHANISM

BLOCK

DVD

MECHANISM

BLOCK

DVD

MECHANISM

BLOCK

B

MAIN

BOARD

CN503

(Page 26)

C

MAIN

BOARD

CN302

(Page 26)

HCD-SV2D

2929

Page 30

HCD-SV2D

7-6. PRINTED WIRING BOARD — MPEG SECTION-2 —

12

A

B

C

D

MPEG BOARD

34567891011121314

• See page 21 for Circuit Boards Location. :Uses unleaded solder.

G

E

F

H

I

J

K

HCD-SV2D

3030

Page 31

7-7. SCHEMATIC DIAGRAM — MPEG SECTION —

HCD-SV2D

Ver. 1.1

• See page 42, 43 and 44 for IC Block Diagrams. • See page 39 for Waveforms. • See page 47, 51 for IC Pin Function Description.

(Page 28)

AV

CN851A

(Page 34)

5

4

3

2

1

FFC/FPC-11P/1.25

J703

DGND

VIDEO OGND

SV

DIGITAL OUT

DGND

(Page 28)

BF33

CVBS1

FB

FB708

+5V

FBD716

FB

DGND

BF33

*1

*1 UD707

SST39VF00/TSOP-102:US

SST39VF00/TSOP-105:SP,TH

SST39VF00/TSOP-107:E3

HCD-SV2D

3131

Page 32

HCD-SV2D

Ver. 1.1

7-8. PRINTED WIRING BOARD — KEY SECTION —

• See page 21 for Circuit Boards Location. :Uses unleaded solder.

12

A

HP BOARD

345678910111213141516

E3,SP,TH

HP BOARD

PHONES

MIC BOARD

JK202

MIC

MIC BOARD

• Semiconductor

Location

B

Ref. No.

D651 F-3

D652 E-7

15

41

D654 E-3

IC651 H-10

C

KEY BOARD

AMP

K

BOARD

CN101(Page 35)

KEY BOARD

MAIN

G

BOARD

CN401(Page 26)

IR651 K-7

Q651 E-3

Q652 F-14

Q653 D-4

Q654 D-14

Location

D

E

E

F

REC

PAUSE/START

E

?/1

(FLUORESCENT INDICATOR TUBE)

TV

M>

TUNING -

MIC/ECHO

LEVEL -

M>

TUNING +

MIC/ECHO

LEVEL +

EXCEPT US

E3,SP,TH

IC651

BX

G

TAPE

MECHANISM

DECK

H

PLAY MODE

I

-

VOLUME

US

J

REPEAT

MIC/ECHO

E3,SP,TH

+

K

B

IR651

L

HCD-SV2D

Z

DISPLAY

A

MAIN

BOARD

CN501

(Page 26)

3232

Page 33

7-9. SCHEMATIC DIAGRAM — KEY SECTION —

HCD-SV2D

Ver. 1.1

• See page 40 for IC Block Diagram.

KEY BOARD

VOLUME+

REC

PAUSE/START

IR651

REMOTE CONTROL

RECEIVER

TV

B

US

MIC/ECHO

4.9

4.9

VOLUME–REPEAT

E3,SP,TH

BX

S667

DISPLAY

-29.2

-29.2

-29.2

-29.2

-29.2

-29.2

-29.2

-29.2

-29.2

(FLUORESCENT INDICATOR TUBE)

Q651, Q652

SOL DRIVER

-26.5

-24.0

-29.0

-29.0

-29.0

-31.5

-29.0

-32.1

-29.2

-29.2

-29.2

-26.5

-29.0

-29.0

-31.5

uPD16315GB-3BS

IC651

FL DRIVER

1.8

IC B/D

0

4.9

4.9

0

4.9

4.9

-29.0

-29.0

-29.0

-29.0

-26.5

4.9

0

0

9.0

0

9.4

9.0

Q653, Q654

MOTOR DRIVER

9.5

9.5

9.5

8P

9.4

9.5

TAPE

MECHANISM

DECK

J

K

AMP

BOARD

CN101

(Page 36)

E3,SP,TH

G

MAIN

BOARD

CN401

(Page 28)

PLAY MODE

MIC/ECHO LEVEL

HP BOARD

MIC BOARD

M>

.m

MIC/ECHO LEVEL

+

+

E3,SP,TH

Z

–

?/1

–

C166

C203

NO MARK : FM

A

MAIN BOARD CN501

(Page 28)

HCD-SV2D

3333

Page 34

HCD-SV2D

7-10. PRINTED WIRING BOARD — AV SECTION —

12

3456

A

AV BOARD

B

C

DIGITAL OUT

OPTICAL

JK802

VIDEO OUT

• See page 21 for Circuit Boards Location.

:Uses unleaded solder.

F

MPEG

BOARD

J703

(Page 29)

7-11. SCHEMATIC DIAGRAM — AV SECTION —

AV BOARD

Vcc

JK801A3P

IN

C851A

JK802

JK801A

DIGITAL OUT

OPTICAL

JK802

VIDEO OUT

GND

0.1

L851A 10uH

R851

1K

FB851A

CN851A 5P

GND

OPT

+5V

VIDEO

GND

F

MPEG

BOARD

J703

(Page 31)

D

E

F

G

AV BOARD

HCD-SV2D

3434

Page 35

7-12. PRINTED WIRING BOARD — AMP/POWER SECTION —

• See page 21 for Circuit Boards Location.

HCD-SV2D

Ver. 1.1

:Uses unleaded solder.

A

B

C

D

E

12

FAN

AMP BOARD

MAIN

I

BOARD

CN103

(Page 26)

MAIN

BOARD

H

CN107

(Page 26)

E

3456789101112

MAIN

BOARD

CN105

(Page 26)

AMP BOARD

HP

E

K

BOARD

CW101

(Page 32)

E

IC103

• Semiconductor

Location

Ref. No.

D101 C-3

D102 C-4

D103 C-4

D104 C-4

D311 D-3

D351 C-6

IC103 D-4

Q101 C-10

Q102 C-10

Q103 C-9

Q104 C-9

Q105 C-10

Q301 C-9

Q303 C-9

Q304 B-10

Q308 C-10

Q309 D-11

Q310 D-11

Q311 E-3

Q312 D-2

Q314 C-11

Location

F

G

H

(E3,SP,TH MODELS)

AC IN

POWER BOARDPOWER BOARD

(US MODEL)

(E3, SP, TH MODELS)

AC IN

• Semiconductor

Location

Ref. No.

1

2

1

2

D901 G-2

D902 H-2

D903 G-2

9

4

9

4

D904 G-2

D905 F-3

D906 G-2

D907 H-2

5

POWER TRANSFORMER(SUB)

1

* Not replaceable : Built in transformer

SW901

VOLTAGE

I

D

MAIN

BOARD

CN301

(Page 26)

*

J

SELECTOR

110 - 120V

220 - 240V

D

MAIN

BOARD

CN301

(Page 26)

5

POWER TRANSFORMER(SUB)

1

* Not replaceable : Built in transformer

*

(US

• Semiconductor

Location

Ref. No.

D901 G-8

D902 H-8

D903 G-8

D904 G-8

D905 F-8

D906 G-8

D907 H-8

MODEL

Location

)

Location

HCD-SV2D

PT901

POWER TRANSFORMER(MAIN)

PT901

POWER TRANSFORMER(MAIN)

3535

Page 36

HCD-SV2D

Ver. 1.1

7-13. SCHEMATIC DIAGRAM — AMP SECTION —

• See page 44 for IC Block Diagram.

H

MAIN

BOARD

CN107

(Page 28)

AMP BOARD

IC103

POWER AMP

070

IC B/D

0

0

0

0

0

0

0

0

2.6

31.6

0

32.9

-32.8

-31.3

K

HP BOARD

CW101

(Page 33)

E

MAIN

0

0

0.7

0.7

0

MUTE

MUTE CONT

0

1.0

OVER LOAD

DETECT

0

4.9

0

0

-1.0

0

Q103, Q104

OVER LOAD

0

-1.0

DETECT

E3,SP,TH

Q350-Q352

FAN CONT

6.0

12.3

12.3

12.3

1.0

1.0

0

0

MUTE

BOARD

CN105

(Page 28)

(TO FAN)

I

MAIN

BOARD

CN103

(Page 28)

HCD-SV2D

12.3

+12V REG

0

FAN CU RRENT

DETECT

US

FAN CURRENT

DETECT

0.7

0

0.6

NO MARK : FM

4.9

+12V REG

12.3

12.9

17.2

16.7

SWITCH

12.9

13.0

0

SWITCH

0

4.5

PROTECT SWITCH

4.9

0

17.2

DC PROTECT

4.9

16.8

0

-5.2

0

DC PROTECT

-5.2

DC PROTECT

0

0

4.9

3636

Page 37

7-14. SCHEMATIC DIAGRAM — POWER SECTION (E3, SP, TH MODEL) —

HCD-SV2D

Ver. 1.1

D

MAIN

BOARD

CN301

(Page 28)

POWER BOARD

FW901

(E3,SP,TH MODEL)

POWER TRANS FORMER (MAIN)

*

Not replaceable : Built in transformer

*

VOLTAGE SELECTOR

POWER TRANS FORMER (SUB)

AC IN

HCD-SV2D

3737

Page 38

HCD-SV2D

Ver. 1.1

7-15. SCHEMATIC DIAGRAM — POWER SECTION (US MODEL) —

D

MAIN

BOARD

CN301

(Page 28)

POWER BOARD

FW901

(US MODEL)

1.6A / 250V

POWER TRANS FORMER (MAIN)

*

Not replaceable : Built in transformer

*

R902

3.3M

POWER TRANS FORMER (SUB)

AC IN

JW903

HCD-SV2D

3838

Page 39

•Waveforms

4

U707 <zcv (XIN)

58.9 ns

3.9 Vp-p

1 V/DIV, 25 ns/DIV

5

UD705 <zn/ (XO)

37 ns

3.5 Vp-p

1 V/DIV, 10 ns/DIV

6

UD705 <zm/ (CVBS/C)

H

950 mVp-p

500 mV/DIV, 10

µ

s/DIV

– MAIN Board –

1

IC501 ej (XT2)

HCD-SV2D

– MPEG Board –

30.5 µs

1 V/DIV, 10

2

1 V/DIV, 50 ns/DIV

3

20 V/DIV, 5

µ

s/DIV

IC501 r; (X2)

120 ns

Q212 (collector)(TAPE REC)

10.7 µs

µ

s/DIV

5.3 Vp-p

5.0 Vp-p

91.2 Vp-p

39

Page 40

HCD-SV2D

Ver. 1.1

• IC Block Diagrams

– KEY Board –

IC651 uPD16315GB-3BS

VSS

VDD

GRID1

GRID2

GRID3

394041424344

GRID4

SEG23/GRID6

SEG24/GRID5

SEG21/GRID8

SEG22/GRID7

SEG20/GRID9

3435363738

LED1

LED2

LED3

LED4

OSC

DOUT

DIN

CLK

STB

KEY1

KEY2

Grid driver

Command decoder

1

2

3

4

5

6

7

8

9

10

11

OSC

Serial

interface

4-bit latch

Display memory

24 bits x 12 words

Timing generator

key scan

Key data memory

(2 x 16 bits)

12-bit shift register

24-bit output latch

Data selector

Multiplexed driver

segment driver

SEG19/GRID10

33

32

SEG18/GRID11

SEG17/GRID12

31

30

VEE

SEG16/KS16

29

SEG15/KS15

28

27

SEG14/KS14

SEG13/KS13

26

SEG12/KS12

25

SEG11/KS11

24

SEG10/KS10

23

12 13 14 15 16 17 18 19 20 21 22

VSS

VDD

SEG1/KS1

SEG2/KS2

SEG3/KS3

SEG4/KS4

SEG5/KS5

SEG6/KS6

SEG7/KS7

SEG8/KS8

SEG9/KS9

40

Page 41

– MAIN Board –

IC101 TDA7464

DIG_GND

2324252627282930313233

R_OUT

L_OUT

N.B.SW

SCL

22

SDA

AGND

20

21

ATT

SPRK

79dB control

TREBLE_L

19

MUTE

TREBLE_R

18

TREBLE_RI

MIDDLE_R0

16

17

RM

MIDDLE_L1

15

RM

MIDDLE_L0

14

79dB control

SPRK

HCD-SV2D

BASS_RI

13

ATT

MUTE

BASS_R0

12

RB

BASS_L1

119

RB

BASS_L0

N.B.SW

RECOUT_R

RECOUT_L

L_IN4

L_IN3

L_IN2

L_IN1

VREFOUT

R_IN1

RPS4

RPS3

RPS2

RPS1

30K

FIX

MIX SW

SURR

79dB

control

FIX

PS4

400Hz

PS3

400Hz

PS2

4KHz

PS1

90Hz

REC

SURR

SRS

MIDDLE

TREBLE

AMP

MIXING