Sony HCDSLK-1-I, HCDSLK-2-I Service manual

HCD-SLK1i/SLK2i

SERVICE MANUAL

Ver. 1.0 2010.06

Photo: HCD-SLK1i

• HCD-SLK1i is the amplifi er, USB, memory card, disc player and tuner section in WHG-SLK1i.

• HCD-SLK2i is the amplifi er, USB, memory card, disc player and tuner section in WHG-SLK2i.

Model Name Using Similar Mechanism NEW

Mechanism Type CDM86B-DVBU101

Optical Pick-up Name KHM-313CAB

SPECIFICATIONS

Main unit

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION:

(HCD-SLK1i e United States model

only)

With 8 ohm loads, both channels driven,

10,000 Hz; rated 35 watts per

from 120

channel minimum RMS power, with no

more than 1% total harmonic distortion

from 800 milliwatts to rated output.

Amplier section

e following measured at AC 120 V, 60 Hz

(North American model)

e following measured at AC 127 V, 60 Hz

(Mexican model)

e following measured at AC 127 V

240 V, 60 Hz (Brazilian model)

e following measured at AC 220 V

240 V, 50/60 Hz (European, Korean,

Argentine and ai models)

e following measured at AC 120 V

240 V, 50/60 Hz (Other models)

HCD-SLK2i

Brazilian model:

Power output (rated):

85 W + 85 W (at 6 , 1 kHz,

1% THD)

RMS output power (reference):

100 W + 100 W (per channel at 6 ,

1 kHz, 10% THD)

Other models:

Power output (rated):

85 W + 85 W (at 6 , 1 kHz,

1% THD)

RMS output power (reference):

120 W + 120 W (per channel at 6 ,

1 kHz)

HCD-SLK1i

e United States model:

RMS output power (reference):

65 W + 65 W (per channel at 8 ,

1 kHz)

Other models:

Power output (rated):

40 W + 40 W (at 8 , 1 kHz,

1% THD)

RMS output power (reference):

65 W + 65 W (per channel at 8 ,

1 kHz)

Inputs

VIDEO/SAT VIDEO IN:

1 Vp-p, 75

VIDEO/SAT AUDIO IN:

voltage 250/450 mV, impedance

47 k

Outputs

DVD VIDEO OUT:

max. output level 1 Vp-p, unbalanced,

Sync negative, load impedance 75

PHONES:

accepts headphones of 8 or more

SPEAKERS:

Use only the supplied speakers

SS-SLK2i (WHG-SLK2i) or SS-SLK1i

(WHG-SLK1i).

USB section

(USB) port: Type A

Maximum current: 500 mA

Memory card section

Multi memory card slot:

Compatible with “Memory Stick”

media (page 110), SD memory cards

(page 111)

Disc player section

System:

Compact disc and digital audio and

video system

Laser Diode Properties

Emission duration: Continuous

Laser Output*: Less than 44.6 µW

* is output is the value measurement

at a distance of 200mm from the

objective lens surface on the Optical

Pick-up Block with 7mm aperture.

Frequency response

DVD (PCM 48 kHz): 2 Hz

(±1 dB)

20 kHz (±0.5 dB)

CD: 2 Hz

Video color system format

North American and Latin American

models: NTSC

Other models: NTSC and PAL

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range

North American and Brazilian

models:

108.0 MHz (100 kHz

87.5 MHz

step)

Other models:

108.0 MHz (50 kHz step)

87.5 MHz

22 kHz

Antenna:

FM lead antenna

Antenna terminals:

75 Ω unbalanced

Intermediate frequency:

10.7 MHz

AM tuner section

Tuning range

European and Saudi Arabian models:

1,602 kHz (9 kHz step)

531 kHz

North American and Latin American

models:

1,710 kHz (10 kHz step)

530 kHz

1,710 kHz (9 kHz step)

531 kHz

Other models:

1,602 kHz (9 kHz step)

531 kHz

1,610 kHz (10 kHz step)

530 kHz

Antenna:

AM loop antenna

Antenna terminals:

External antenna terminal

Intermediate frequency:

450 kHz

General

Power requirements

North American model:

AC 120 V, 60 Hz

Mexican model:

AC 127 V, 60 Hz

Brazilian model:

240 V, 60 Hz

AC 127 V

European, Korean, Argentine and

ai models:

240 V, 50/60 Hz

AC 220 V

Other models:

240 V, 50/60 Hz

AC 120 V

Power consumption

HCD-SLK2i:

80 W

HCD-SLK1i:

60 W

Dimensions (W/H/D) (excl. speakers)

HCD-SLK2i:

Approx. 330 mm × 203 mm ×

141 mm

HCD-SLK1i:

Approx. 330 mm × 203 mm ×

138 mm

Mass (excl. speakers)

HCD-SLK2i:

Approx. 3.7 kg

HCD-SLK1i:

Approx. 3.6 kg

Design and specications are subject to

change without notice.

iPod models

You can use the following iPod models on this system. Update your iPod with the latest

soware before using it.

iPod nano

5th generation

(video camera)

iPod classic

160 GB (2007)

iPod nano

2nd generation

(aluminum)

US Model

Canadian Model

AEP Model

Chinese Model

Saudi Arabia Model

Singapore Model

Korean Model

Thai Model

HCD-SLK1i

Mexican Model

Brazilian model

Argentina model

HCD-SLK2i

E Model

HCD-SLK1i/SLK2i

iPod touch

2nd generation

iPod touch

1st generation

iPod classic

120 GB

160 GB (2009)

iPod nano

3rd generation

(video)

iPod nano

4th generation

(video)

iPod classic

80 GB

DVD RECEIVER

9-889-894-01

2010F05-1

2010.06

©

Sony Corporation

Audio&Video Business Group

Published by Sony Techno Create Corporation

HCD-SLK1i/SLK2i

Manufactured under license from Dolby

Laboratories. “Dolby” and the doubleD symbol are trademarks of Dolby

Laboratories.

“DVD+RW,” “DVD-RW,” “DVD+R,” “DVD

VIDEO,” and the “CD” logos are trademarks.

DivX® is a video le compression

technology, developed by DivX, Inc. DivX,

DivX Certied, and associated logos are

trademarks of DivX, Inc. and are used under

license.

is product is an ocial DivX

product.

MPEG Layer-3 audio coding technology and

patents licensed from Fraunhofer IIS and

omson.

iPod is a trademark of Apple Inc., registered

in the U.S. and other countries.

“Made for iPod” means that an electronic

accessory has been designed to connect

specically to iPod and has been certied by

the developer to meet Apple performance

standards.

Apple is not responsible for the operation of

this device or its compliance with safety and

regulatory standards.

, “Memory Stick,” ,

“Memory Stick Duo,”

“MagicGate Memory Stick,” “Memory Stick

PRO,”

Stick PRO Duo,”

“Memory Stick PRO-HG Duo,”

Micro,”

Stick-ROM,”

“MagicGate,” and

trademarks or registered trademarks of Sony

Corporation.

SDHC Logo is a trademark of SD-3C, LLC.

Windows Media is either a registered

trademark or trademark of Microso

Corporation in the United States and/or

other countries.

is product is protected by certain

intellectual property rights of Microso

Corporation. Use or distribution of such

technology outside of this product is

prohibited without a license from Microso

or an authorized Microso subsidiary.

certied

®

, “Memory

, “Memory Stick

, , “Memory

,

are

THIS PRODUCT IS LICENSED UNDER

THE MPEG-4 VISUAL PATENT

PORTFOLIO LICENSE FOR THE

PERSONAL AND NON-COMMERCIAL

USE OF A CONSUMER FOR

(i) ENCODING VIDEO IN COMPLIANCE

WITH THE MPEG-4 VISUAL STANDARD

(“MPEG-4 VIDEO”)

AND/OR

(ii) DECODING MPEG-4 VIDEO THAT

WAS ENCODED BY A CONSUMER

ENGAGED IN A PERSONAL AND NONCOMMERCIAL ACTIVITY AND/OR WAS

OBTAINED FROM A VIDEO PROVIDER

LICENSED BY MPEG LA TO PROVIDE

MPEG-4 VIDEO.

NO LICENSE IS GRANTED OR SHALL

BE IMPLIED FOR ANY OTHER

USE. ADDITIONAL INFORMATION

INCLUDING THAT RELATING TO

PROMOTIONAL, INTERNAL AND

COMMERCIAL USES AND LICENSING

MAY BE OBTAINED FROM MPEG LA,

LLC. SEE http://www.mpegla.com/

All other trademarks and registered

trademarks are of their respective holders.

In this manual,

specied.

,

,

TM

and ® marks are not

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range are suitable. (See

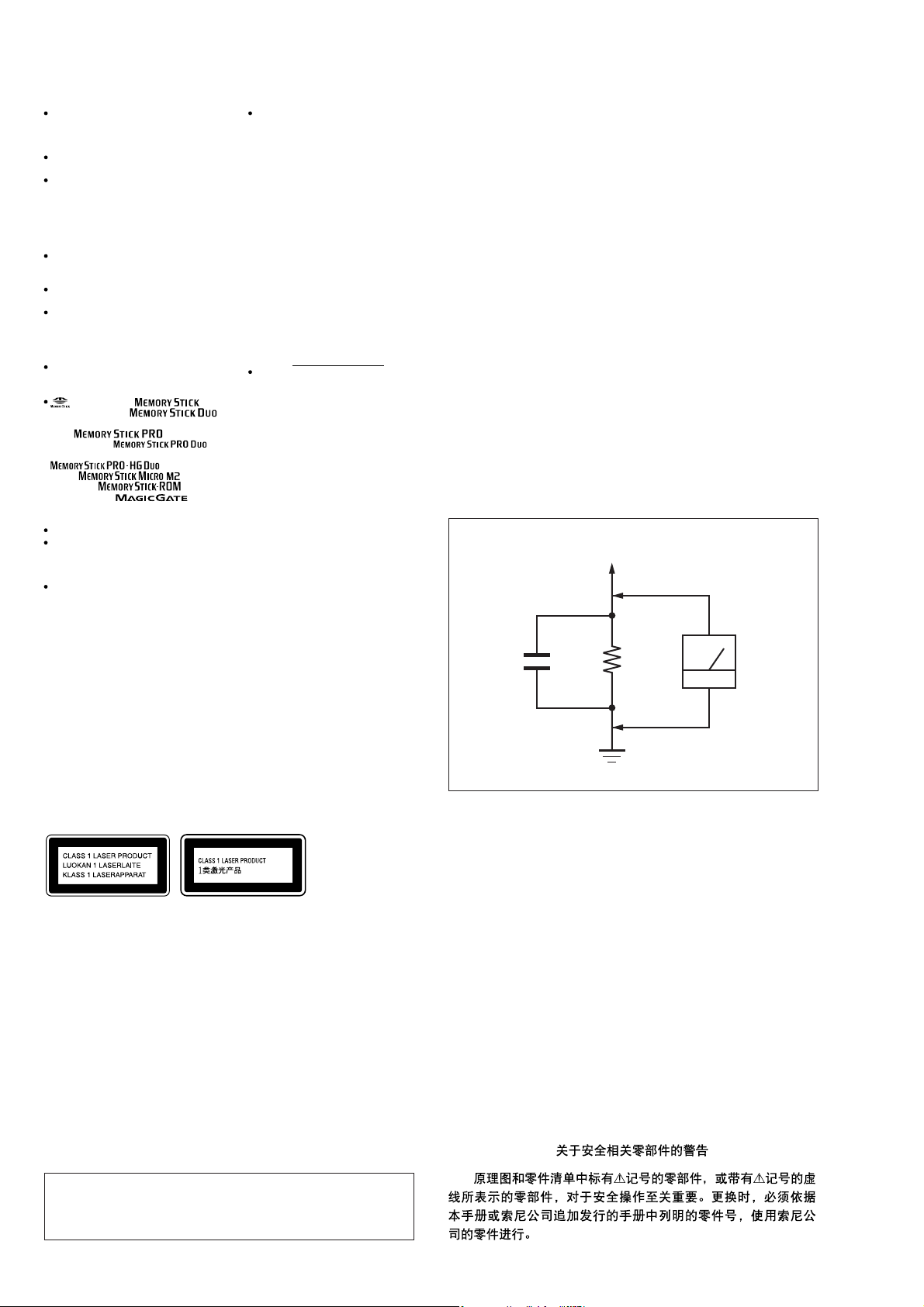

Fig. A)

To Exposed Metal

Parts on Set

AC

1.5 kΩ0.15 μF

voltmeter

(0.75 V)

is appliance is classied as a CLASS 1

LASER product. is marking is located

on the rear exterior.

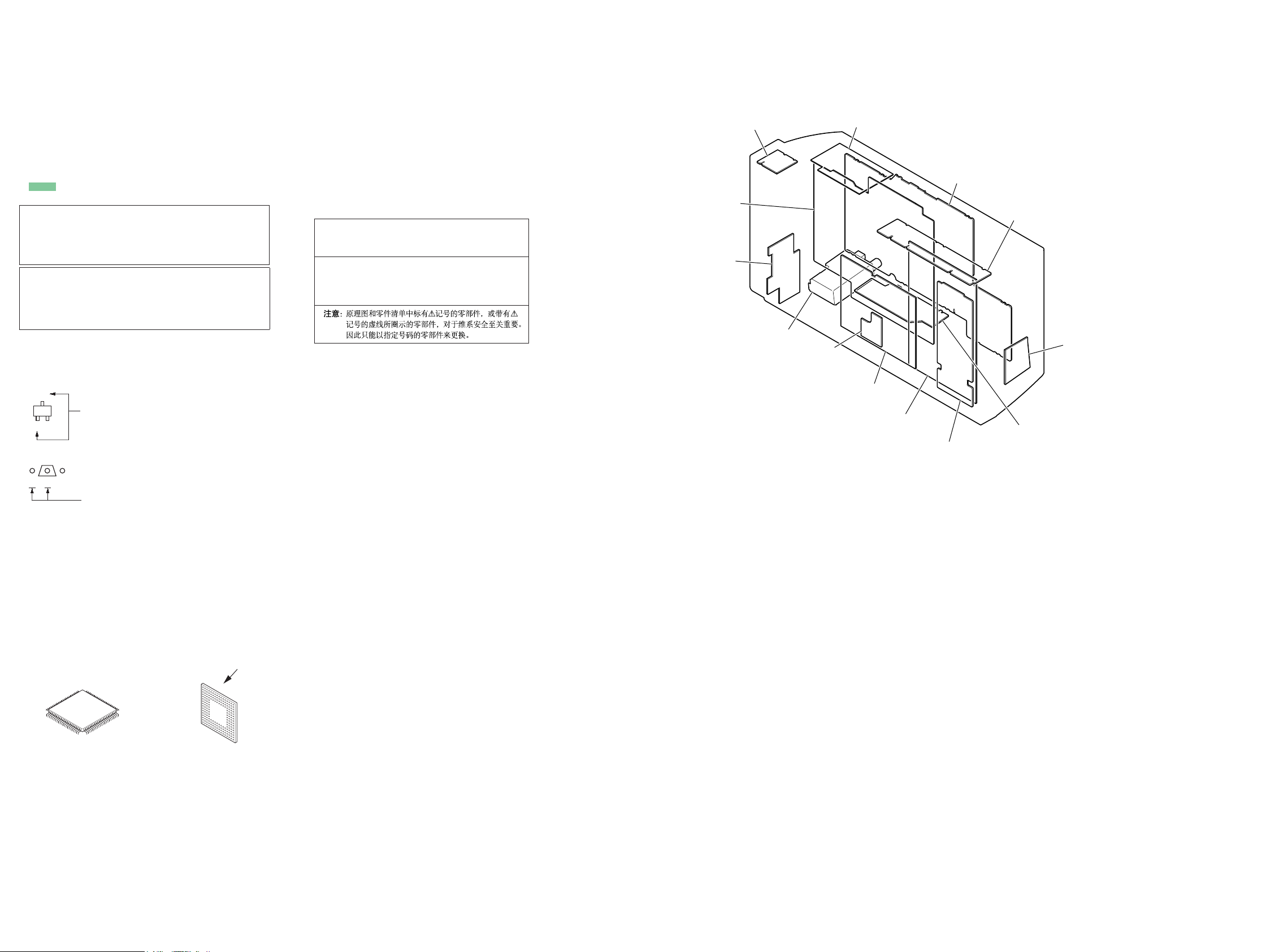

NOTES ON CHIP COMPONENT REPLACEMENT

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

FLEXIBLE CIRCUIT BOARD REPAIRING

• Keep the temperature of soldering iron around 270 °C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specifi ed herein may result in hazardous radia-

tion exposure.

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE

PAR DES PIÈCES SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

2

TABLE OF CONTENTS

HCD-SLK1i/SLK2i

1. SERVICING NOTES ............................................. 4

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 9

2-2. Top Panel Block .............................................................. 10

2-3. Rear Case Block .............................................................. 10

2-4. Main Chassis Block ........................................................ 11

2-5. MAIN Board ................................................................... 12

2-6. Switching Regulator Block ............................................. 12

2-7. Cover (CDM) Block ....................................................... 13

2-8. DVD Mechanism Deck Block ........................................ 13

2-9. DISPLAY Board ............................................................. 14

2-10. Optical Pick-up Block (KHM-313CAB) ........................ 15

2-11. Belt (MOT) ..................................................................... 15

2-12. LCD Board ...................................................................... 16

2-13. LCD Module ................................................................... 16

3. TEST MODE ............................................................ 17

4. DIAGRAMS

4-1. Block Diagram - SERVO Section - ................................ 21

4-2. Block Diagram - AUDIO INPUT Section - .................... 22

4-3. Block Diagram - AUDIO OUTPUT Section - ................ 23

4-4. Block Diagram - VIDEO Section - ................................. 24

4-5. Block Diagram

- PANEL, POWER SUPPLY Section - ........................... 25

4-6. Schematic Diagram - DISPLAY Section (1/7) - ............. 27

4-7. Schematic Diagram - DISPLAY Section (2/7) - ............. 28

4-8. Schematic Diagram - DISPLAY Section (3/7) - ............. 29

4-9. Schematic Diagram - DISPLAY Section (4/7) - ............. 30

4-10. Schematic Diagram - DISPLAY Section (5/7) - ............. 31

4-11. Schematic Diagram - DISPLAY Section (6/7) - ............. 32

4-12. Schematic Diagram - DISPLAY Section (7/7) - ............. 33

4-13. Printed Wiring Board - DISPLAY Section (1/2) - .......... 34

4-14. Printed Wiring Boards - DISPLAY Section (2/2) - ......... 35

4-15. Printed Wiring Board - LCD Board - .............................. 36

4-16. Schematic Diagram - LCD Board - ................................ 37

4-17. Printed Wiring Boards - AUDIO IN/OUT Section - ....... 38

4-18. Schematic Diagram - AUDIO IN/OUT Section - ........... 39

4-19. Printed Wiring Boards - KEY Section - .......................... 40

4-20. Schematic Diagram - KEY Section - .............................. 41

4-21. Printed Wiring Board

- MAIN Board (Component Side) (SUFFIX-11) - ......... 42

4-22. Printed Wiring Board

- MAIN Board (Conductor Side) (SUFFIX-11) - ........... 43

4-23. Printed Wiring Board

- MAIN Board (Component Side) (SUFFIX-12) - ......... 44

4-24. Printed Wiring Board

- MAIN Board (Conductor Side) (SUFFIX-12) - ........... 45

4-25. Schematic Diagram - MAIN Board (1/4) - ..................... 46

4-26. Schematic Diagram - MAIN Board (2/4) - ..................... 47

4-27. Schematic Diagram - MAIN Board (3/4) - ..................... 48

4-28. Schematic Diagram - MAIN Board (4/4) - ..................... 49

5. EXPLODED VIEWS

5-1. Top Panel, Rear Case Section ......................................... 64

5-2. Switching Regulator Section .......................................... 65

5-3. MAIN Board Section ...................................................... 66

5-4. DISPLAY Board Section ................................................ 67

5-5. Front Panel Section ......................................................... 68

5-6. DVD Mechanism Deck Section

(CDM86B-DVBU101) ................................................... 69

6. ELECTRICAL PARTS LIST .............................. 70

Accessories are given in the last of the electrical parts list.

Note: Refer to the servicing notes “MAIN BOARD

DISCRIMINATION” (page 4) for how to

distinguish SUFFIX-11 and SUFFIX-12.

3

HCD-SLK1i/SLK2i

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The fl exible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc refl ective surface by the objective lens in the optical

pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

RELEASING THE DISC SLOT LOCK

The disc slot lock function for the antitheft of an demonstration

disc in the store is equipped.

Releasing Procedure:

1. Press the [

] button to turn on the system.

?/1

2. Touch the [HOME] sensor.

3. Touch the [M], [m], [<] and [,] sensors to select the “CD/

DVD”, and touch the [ENTER] sensor.

4. Press two buttons of [x] and [Z] simultaneously, and hold for

more than fi ve seconds.

5. The message “UNLOCKED” is displayed on the liquid crystal

display module and the disc slot is unlocked.

Note: When “LOCKED” is displayed, the disc slot lock is not released by

turning power on/off with the [

?/1

] button.

NOTE FOR REPLACEMENT OF THE MS-214 BOARD

When the MS-214 board is defective, exchange the entire MD

(AU) ASSY.

NOTE FOR REPLACEMENT OF THE TOUCH PANEL

BOARD

When the TOUCH PANEL board is defective, exchange the entire

mounted board.

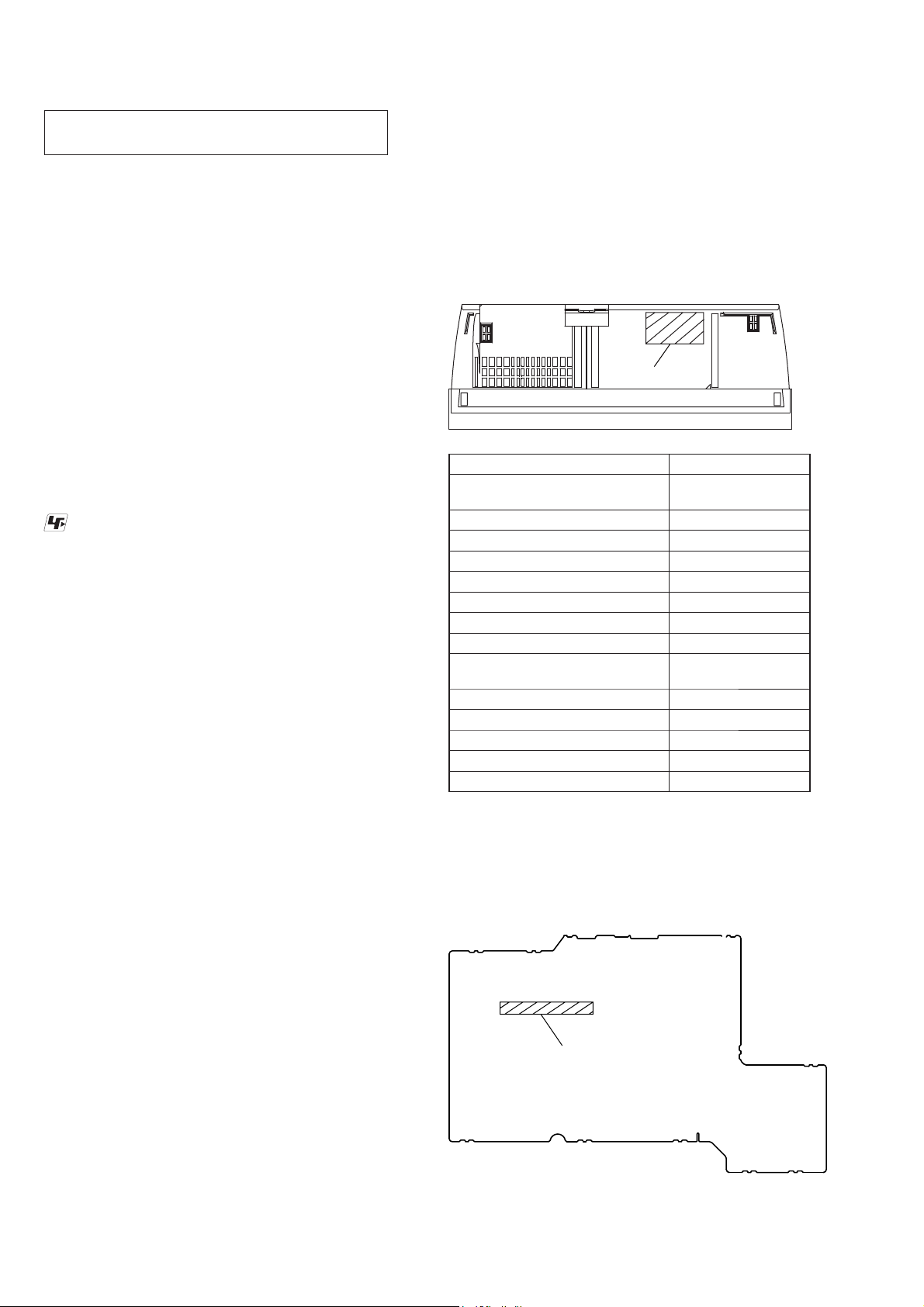

MODEL IDENTIFICATION

– Bottom view –

Model

Number

Label

Model Part No.

SLK1i: US model

SLK1i: 240V AC area in E model

SLK2i: 240V AC area in E model

SLK1i: Singapore model

SLK1i: Canadian model

SLK1i: AEP model

SLK1i: Saudi Arabia model

SLK1i: Korean model

SLK2i: 120V AC area in E, Chilean

and Peruvian models

SLK2i: Brazilian model

SLK2i: Argentina model

SLK2i: Mexican model

SLK1i: Thai model

SLK1i: Chinese model

Model number label is

marked on the panel.

4-189-097-0[]

4-189-097-1[]

4-189-098-0[]

4-189-100-0[]

4-189-102-0[]

4-189-103-0[]

4-189-104-0[]

4-189-105-0[]

4-189-106-0[]

4-189-107-0[]

4-189-108-0[]

4-189-309-0[]

4-191-613-0[]

MAIN BOARD DISCRIMINATION

In this set, the MAIN board has been changed in the midway of

production.

Repair after distinguishing each type set to doing the repair referring to the following.

– MAIN Board (Component Side) –

SUFFIX-11 : 1-881-738-11

SUFFIX-12 : 1-881-738-12

4

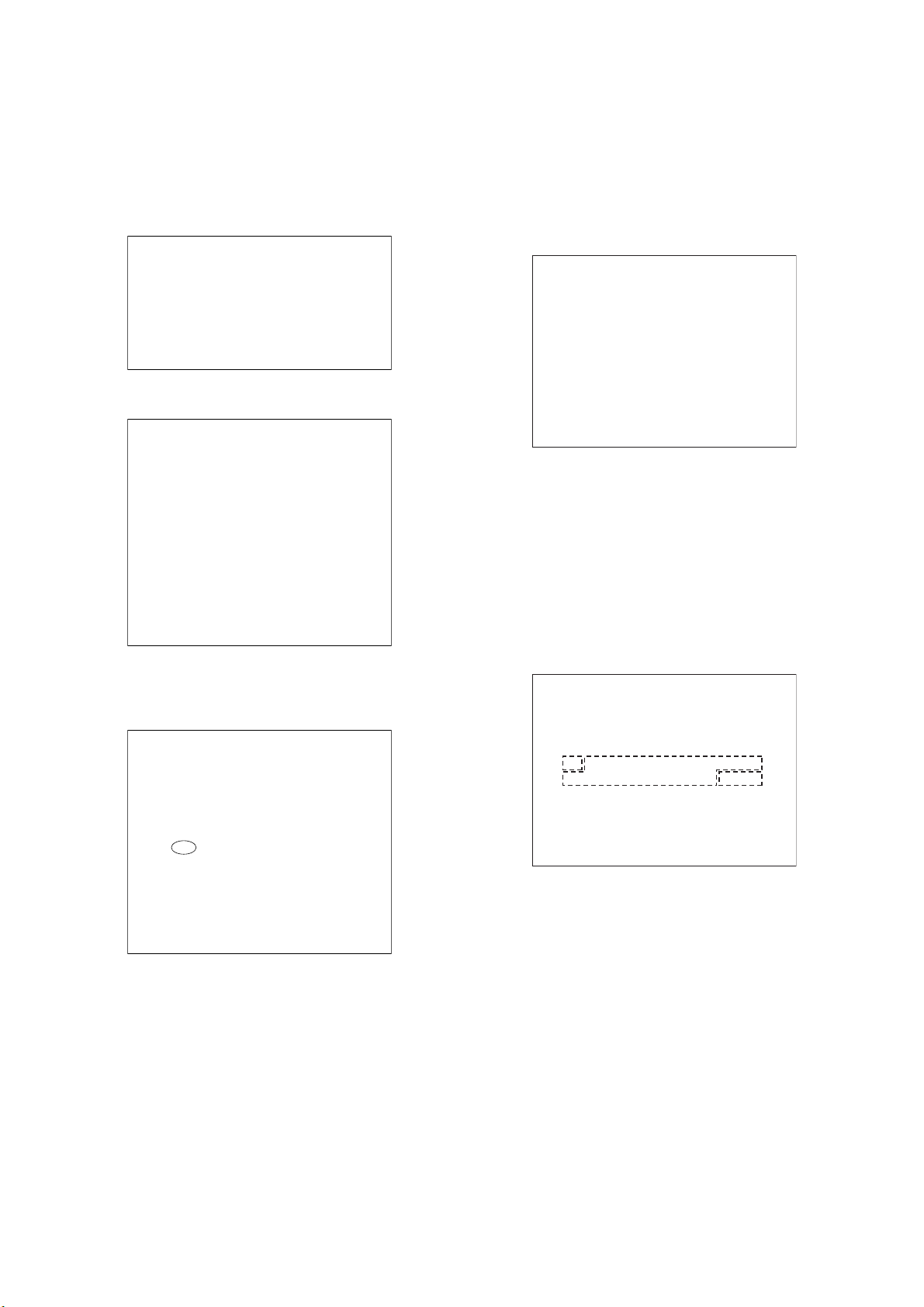

CAPACITOR ELECTRICAL DISCHARGE PROCESSING

When checking the board, the electrical discharge is necessary for

the electric shock prevention.

Connect the resistors referring to the fi gure below.

• Switching regulator (C201, C202) (for HCD-SLK1i)

Both ends of respective capacitors.

– Switching Regulator (Conductor Side) –

800 :/2 W

T101

C201

C202

HCD-SLK1i/SLK2i

800 :/2 W

• Switching regulator (C201) (for HCD-SLK2i)

Both ends of respective capacitor.

– Switching Regulator (Conductor Side) –

800 :/2 W

C201

T101

5

HCD-SLK1i/SLK2i

HOW TO EJECT THE DISC WHEN POWER SWITCH TURNS OFF

Note: Please take out the DVD mechanism block from a set referring to “SECTION 2 DISASSEMBLY”.

disc

– DVD mechanism block bottom view –

Please rotate the pully in the direction of the arrow after removing mechanism deck,

and eject the disc.

IP BOARD SERVICE POSITION

DISPLAY board

Note: Neither the wire from switching regulator

nor the fan cable must loosen.

wire from switching regulator fan cable

fan motor

IP board

6

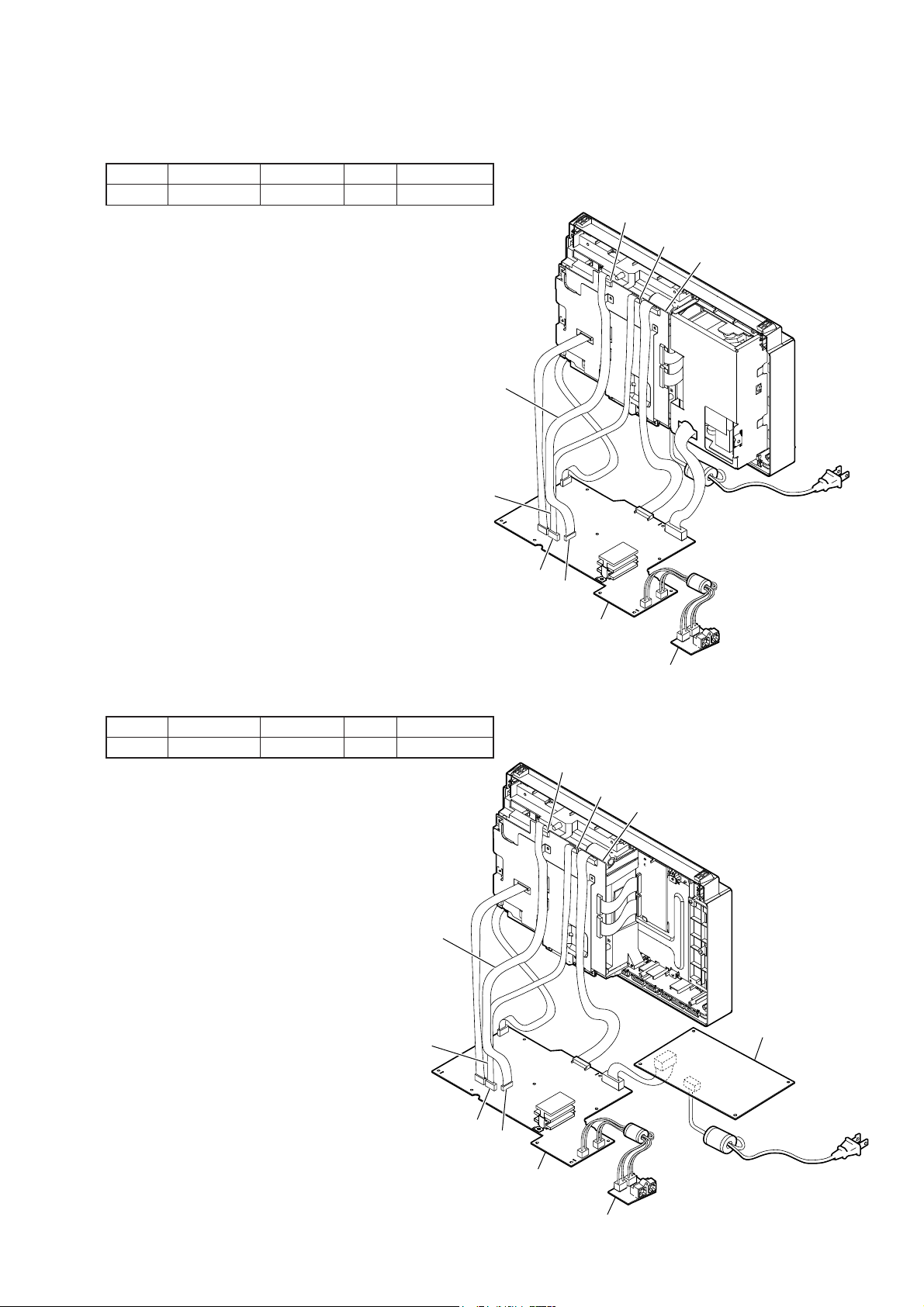

MAIN BOARD SERVICE POSITION

• Please connect following extension jig.

Jig No. Part No. Pitch (mm) Cores Length (mm)

J-2501-102-A 1 13 300

1

Please do not make a mistake when you install the extention jig

Note:

because CN101 and CN301 on MAIN board and CN302 and

CN408 on DISPLAY board are all thirteen pins.

Connect extension jig 1

to the MAIN board (CN301) and DISPLAY board (CN302)

Connect extension jig 1

to the MAIN board (CN101) and DISPLAY board (CN408)

HCD-SLK1i/SLK2i

CN302

CN408

DISPLAY board

SWITCHING REGULATOR SERVICE POSITION

• Please connect following extension jig.

Jig No. Part No. Pitch (mm) Cores Length (mm)

J-2501-102-A 1 13 300

1

Please do not make a mistake when you install the extention jig

Note:

because CN101 and CN301 on MAIN board and CN302 and

CN408 on DISPLAY board are all thirteen pins.

Connect extension jig 1

to the MAIN board (CN301) and DISPLAY board (CN302)

CN101

CN301

MAIN board

TERMINAL board

CN302

CN408

DISPLAY board

Connect extension jig 1

to the MAIN board (CN101) and DISPLAY board (CN408)

SWITCHING REGULATOR

CN101

CN301

MAIN board

TERMINAL board

7

HCD-SLK1i/SLK2i

DISPLAY BOARD SERVICE POSITION

• Please connect following extension jig.

Jig No. Part No. Pitch (mm) Cores Length (mm)

1

2

3

J-2501-102-A 1 13 300

J-2501-245-A 1 23 300

J-2501-248-A 1 27 300

Please do not make a mistake when you

Note:

install the extention jig because CN101

and CN301 on MAIN board and CN302

and CN408 on DISPLAY board are all

thirteen pins.

Connect extension jig 1

to the MAIN board (CN301)

and DISPLAY board (CN302)

DISPLAY board

CN302

Connect extension jig 2

to the DISPLAY board (CN407)

and LCD board (CN904)

CN904

CN903

CN408

LCD board

CN407

Connect extension jig 3

to the DISPLAY board (CN406)

and LCD board (CN903)

Connect extension jig 1

to the MAIN board (CN101)

and DISPLAY board (CN408)

CN101

CN301

MAIN board

TERMINAL board

CN406

DVD MECHANISM DECK, LCD AND JACK BOARDS SERVICE POSITION

• Please connect following extension jig.

Jig No. Part No. Pitch (mm) Cores Length (mm)

1

2

3

4

J-2501-102-A 1 13 300

J-2501-245-A 1 23 300

J-2501-248-A 1 27 300

J-2501-241-A 1 7 300

Connect extension jig 2

to the DISPLAY board (CN407)

and LCD board (CN904)

LCD board

SWITCHING REGULATOR block

CN904

CN903

DVD mechanism deck

8

Connect extension jig 1

to the MAIN board (CN301)

and DISPLAY board (CN302)

DISPLAY board

JACK board

CN705

Connect extension jig 4

to the JACKboard (CN705)

and DISPLAY board (CN604)

Connect extension jig 1

to the MAIN board (CN101)

and DISPLAY board (CN408)

CN302

CN101

CN408

CN604

CN301

MAIN board

TERMINAL board

CN406

Connect extension jig 3

to the DISPLAY board (CN406)

and LCD board (CN903)

CN407

SWITCHING REGULATOR block

Please do not make a mistake when you

Note:

install the extention jig because CN101

and CN301 on MAIN board and CN302

and CN408 on DISPLAY board are all

thirteen pins.

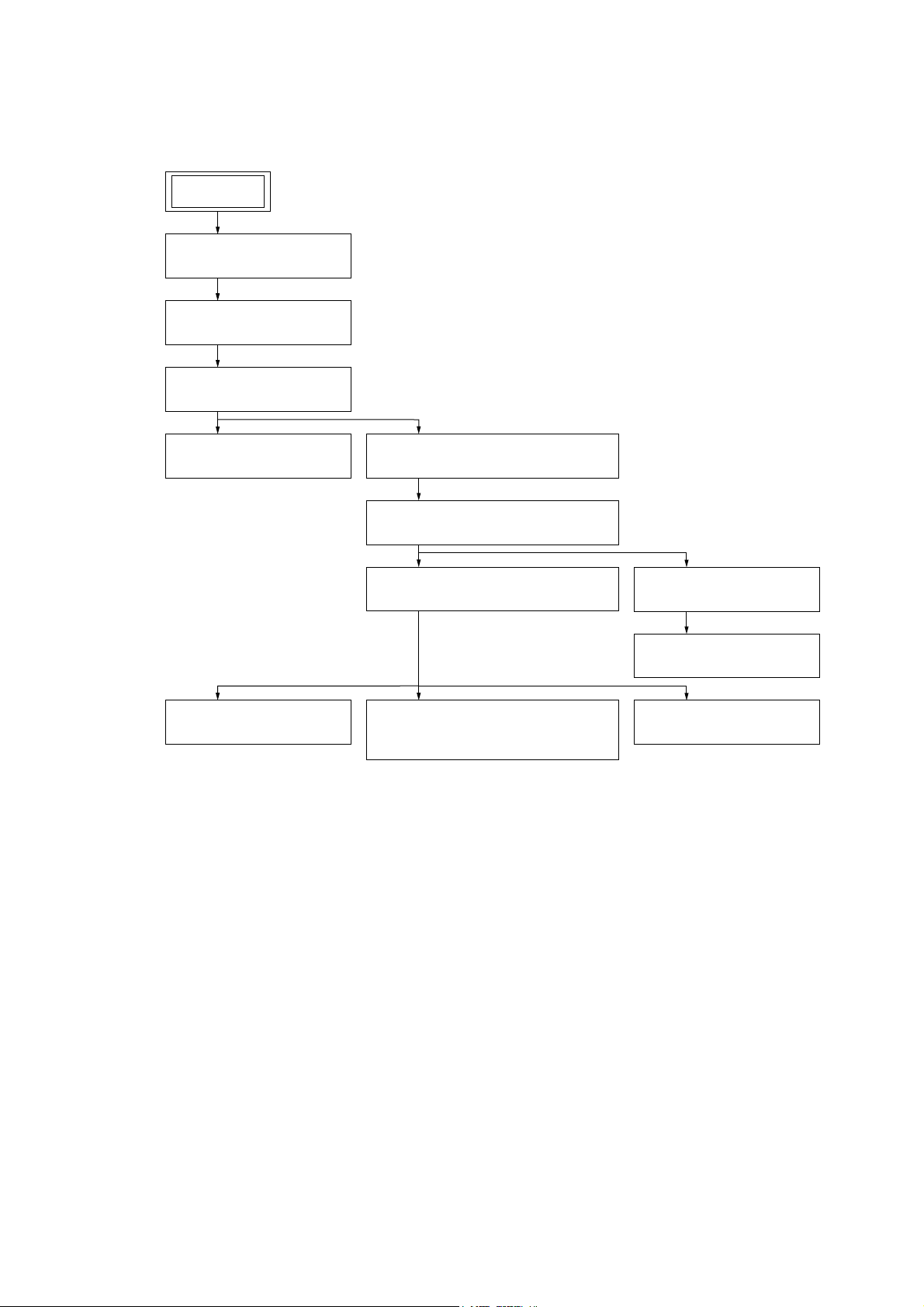

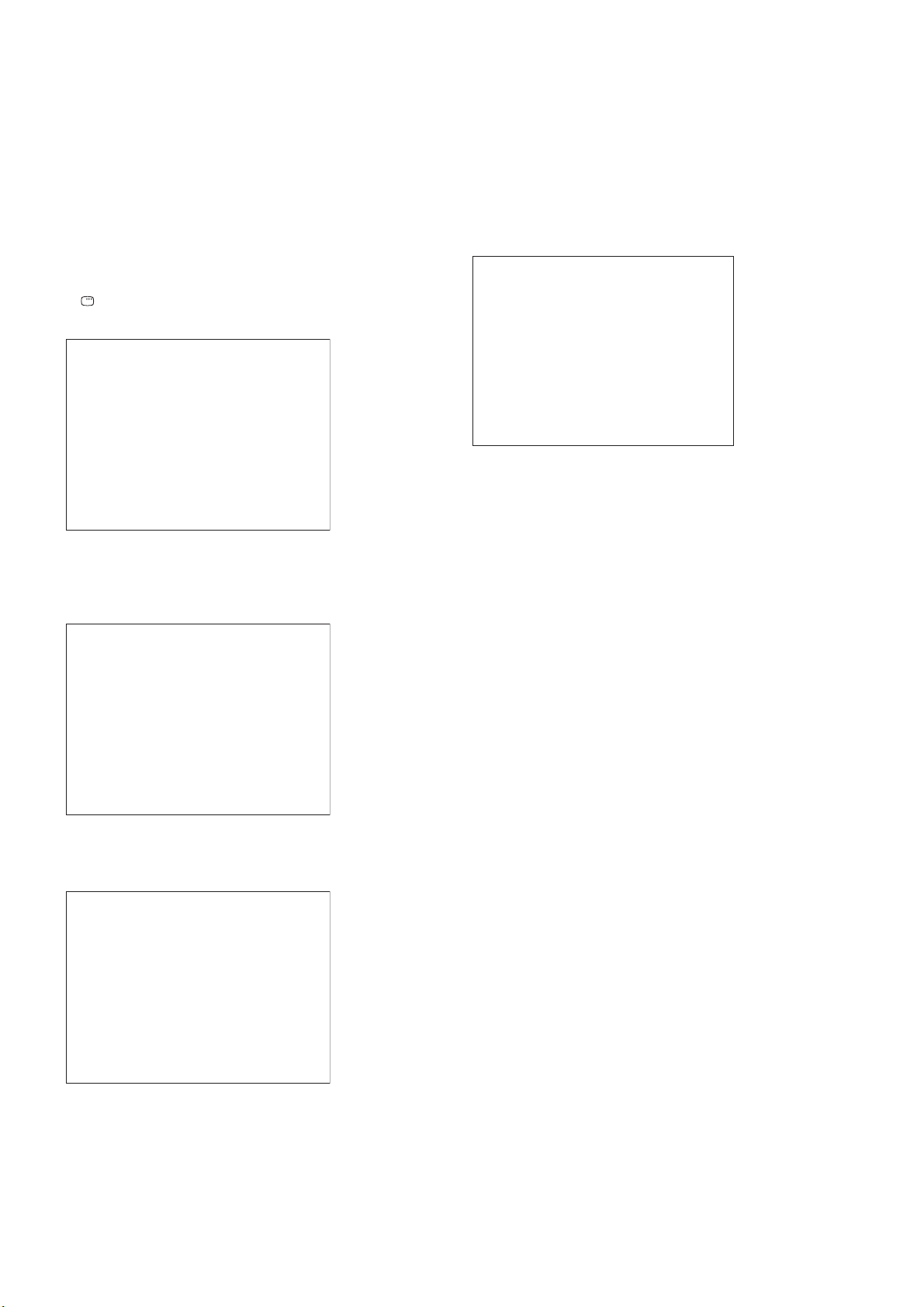

DISASSEMBLY

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

SET

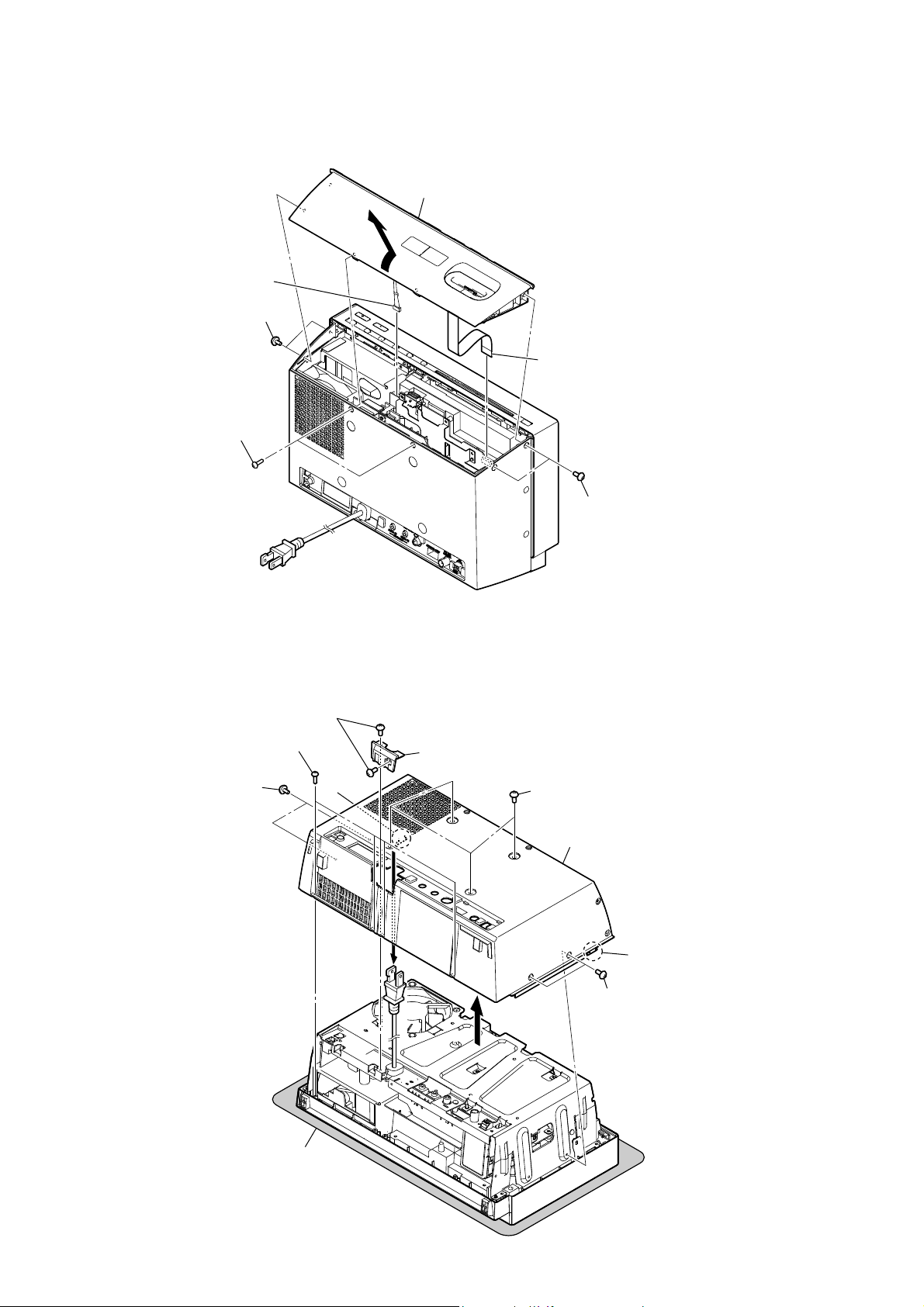

2-2. TOP PANEL BLOCK

(Page 10)

2-3. REAR CASE BLOCK

(Page 10)

2-4. MAIN CHASSIS BLOCK

(Page 11)

HCD-SLK1i/SLK2i

SECTION 2

2-5. MAIN BOARD

(Page 12)

2-9. DISPLAY BOARD

(Page 14)

2-6. SWITCHING REGULATOR BLOCK

(Page 12)

2-7. COVER (CDM) BLOCK

(Page 13)

2-8. DVD MECHANISM DECK BLOCK

(Page 13)

2-10. OPTICAL PICK-UP BLOCK

(KHM-313CAB)

(Page 15)

2-12. LCD BOARD

(Page 16)

2-13. LCD MODULE

(Page 16)

2-11. BELT (MOT)

(Page 15)

9

HCD-SLK1i/SLK2i

Note: Follow the disassembly procedure in the numerical order given.

2-2. TOP PANEL BLOCK

3

connector

5

(CN405)

two flat head screws

2

(TP)

two flat head screws

1

(TP)

top panel block

6

wire (flat type) (11 core)

4

(CN404)

2-3. REAR CASE BLOCK

5

(BVTP2.6)

two flat head screws

3

(TP)

four screws

– Rear view –

two flat head screws

1

(TP)

claw

6

support (bushing)

2

two flat head screws

2

(TP)

four screws

4

(SLK1i: BTT4 u 8/SLK2i: hook)

rear case block

9

10

Note: Please spread a sheet under a set

sheet

not to injure front panel.

8

– Rear bottom view –

7

claw

6

two flat head screws

3

(TP)

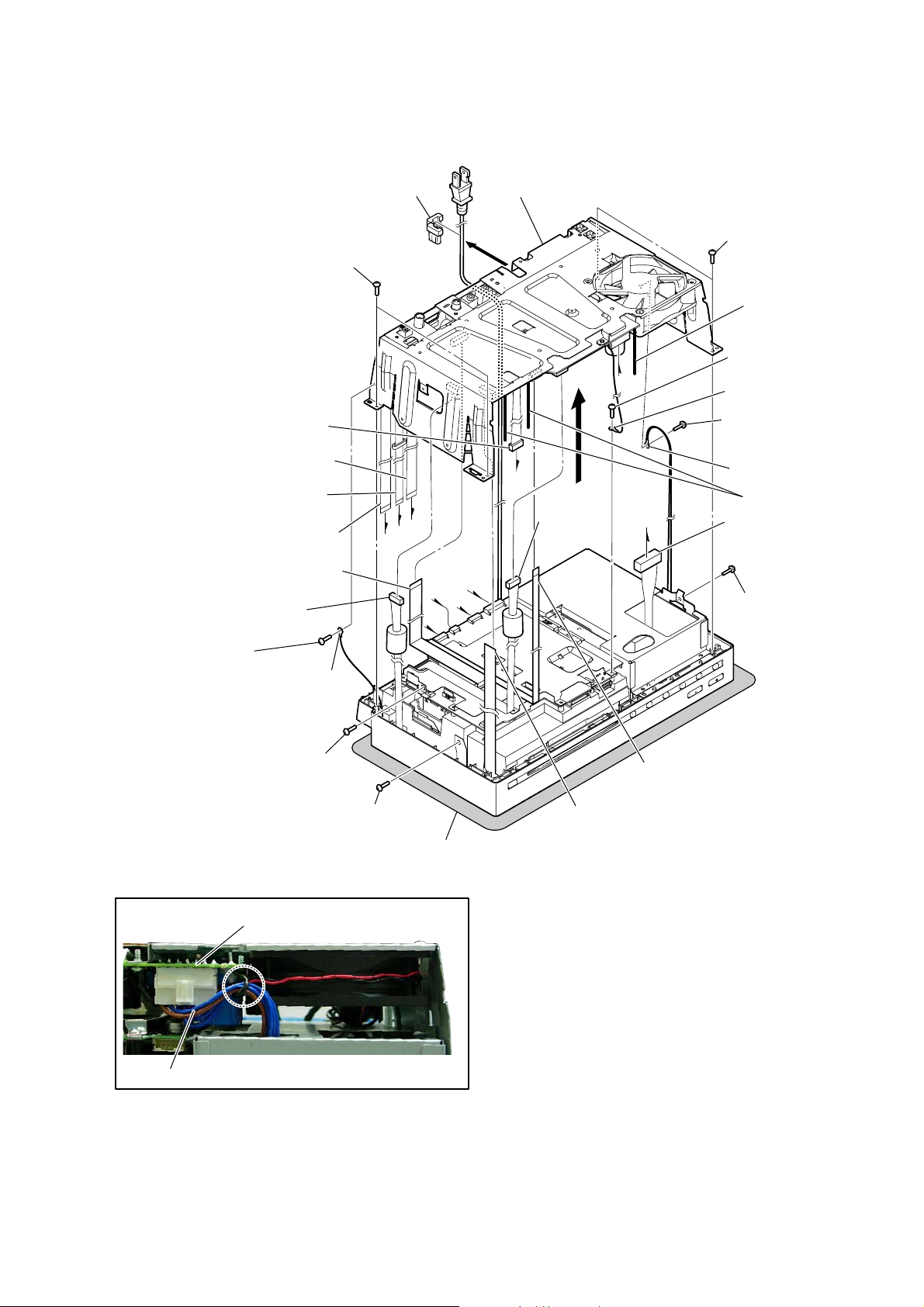

2-4. MAIN CHASSIS BLOCK

two screws

qh

(BVTP2.6)

Please do not make a mistake when you

Note 2:

install the wire (flat type) (13 core)

because CN302 and CN408 are both

thirteen pins.

connector

9

(CN602)

wire (flat type) (13 core)

0

(CN408)

wire (flat type) (7 core)

qa

(CN604)

wire (flat type) (13 core)

qs

(CN302)

wire (flat type) (15 core)

ql

(CN102)

connector

w;

(CN304)

screw

qd

(BVTP3 u 8)

qg

wire

cord bushing

2

D

E

C

– Rear top view –

1

B

D

C

E

main chassis block

wa

B

connector

6

(CN901)

qk

A

A

HCD-SLK1i/SLK2i

two screws

qh

(BVTP2.6)

Lift up the lead pin.

3

screw (BVTP2.6)

qh

wire

qj

screw

qd

(BVTP3 u 8)

wire (GND)

qf

Lift up two lead pins.

5

connector

4

(CN900)

screw

qd

(BVTP3 u 8)

:ire VettiQJ

wire from switching regulator

MAIN board

screw

qd

(BVTP3 u 8)

screw

qd

(BVTP3 u 8)

8

(CN103)

sheet

Note 1:

Please spread a sheet under a set

not to injure front panel.

wire (flat type) (11 core)

7

(CN104)

wire (flat type) (13 core)

11

HCD-SLK1i/SLK2i

2-5. MAIN BOARD

:LUHVHWWLQJ

fan cable

Please let me crawl the side of the fan motor about the cable

Note 1:

because the cable is drawn in to the fan motor.

wire (flat type) (11 core) (CN302) (AEP)/

5

wire (flat type) (9 core) (CN303) (except AEP)

connector

6

(CN902)

DC fan connector

1

(CN600)

MAIN board

MAIN board

qf

three screws

7

(BVTP3 u 8)

wire (flat type) (13 core)

0

(CN101)

screw

7

(BVTP3 u 8)

heat sink (AMP)

qd

wire (flat type) (13 core)

qa

(CN301)

fan motor

wire

8

2-6. SWITCHING REGULATOR BLOCK

9

4

(CN105)

three screws

qs

(BVTP3 u 8)

three screws

7

(BVTP3 u 8)

two screws

2

(BVTP2.6)

wire (flat type) (9 core)

Note 2:

wire (flat type) (13 core) because CN101 and CN301

are both thirteen pins.

switching regulator block

3

connector

2

(CN601)

connector

3

(CN602)

Please do not make a mistake when you install the

two screws

2

(BVTP2.6)

12

power cord

Release the power cord

1

flom the coating clip.

– Rear top view –

sheet

Note: Please spread a sheet under a set

not to injure front panel.

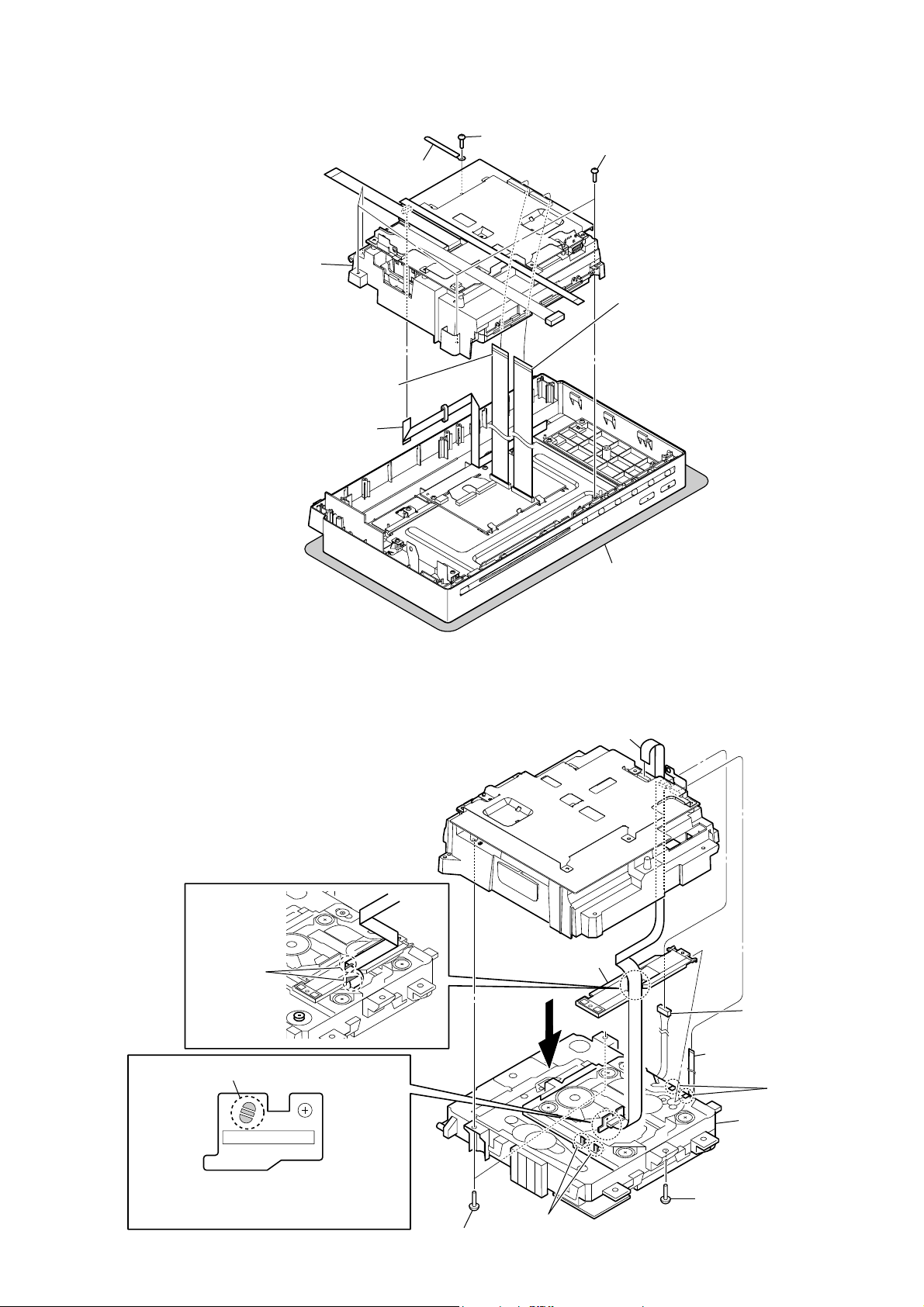

2-7. COVER (CDM) BLOCK

6 cover (CDM) block

wire (flat type) (23 core)

3

(CN407)

wire (flat type) (11 core)

1

(CN412)

5 coating clip

4 screw

(BVTP2.6)

4 four screws

(BVTP2.6)

wire (flat type) (27 core)

2

(CN406)

HCD-SLK1i/SLK2i

sheet

Note: Please spread a sheet under a set

not to injure front panel.

– Rear top view –

2-8. DVD MECHANISM DECK BLOCK

Note 1: When disconnecting the wire (fl at type) (24 core) of optical pick-up block, solder the short-land.

9 wire (flat type) (24 core)

(CN001)

5 two claws

Solder the short-land.

8

7 FFC holder

4

2 connector

(CN202)

1 wire (flat type) (7 core)

(CN201)

6 two claws

Note 2: When assembling the optical pick-up block,

remove the solder of short-land after

connecting the wire (flat type) (24 core).

3 two screws

(BVTP2.6)

0 DVD mechanism

deck block

3 screw

6 two claws

– DVD mechanism deck block bottom view –

(BVTP2.6)

13

HCD-SLK1i/SLK2i

2-9. DISPLAY BOARD

ferrite core

2

(US, Canadian)

connector

1

(CN301)

wire (flat type) (11 core)

4

(CN411)

wire (flat type) (15 core)

3

(CN002)

5 eight screws

(BVTP2.6)

8 cover (CDM)

0 radiation sheet

7

6 shield (MS)

qa DISPLAY board

9 ground plate (USB)

14

2-10. OPTICAL PICK-UP BLOCK (KHM-313CAB)

four insulator screws

1

insulator

5

optical pick-up block

6

(KHM-313CAB)

2

insulator

5

5

3

4

insulator

connector

insulator

5

wire (flat type) (24 core)

HCD-SLK1i/SLK2i

2-11. BELT (MOT)

– DVD mechanism deck block bottom view –

1 belt (MOT)

– DVD mechanism deck block bottom view –

15

HCD-SLK1i/SLK2i

s

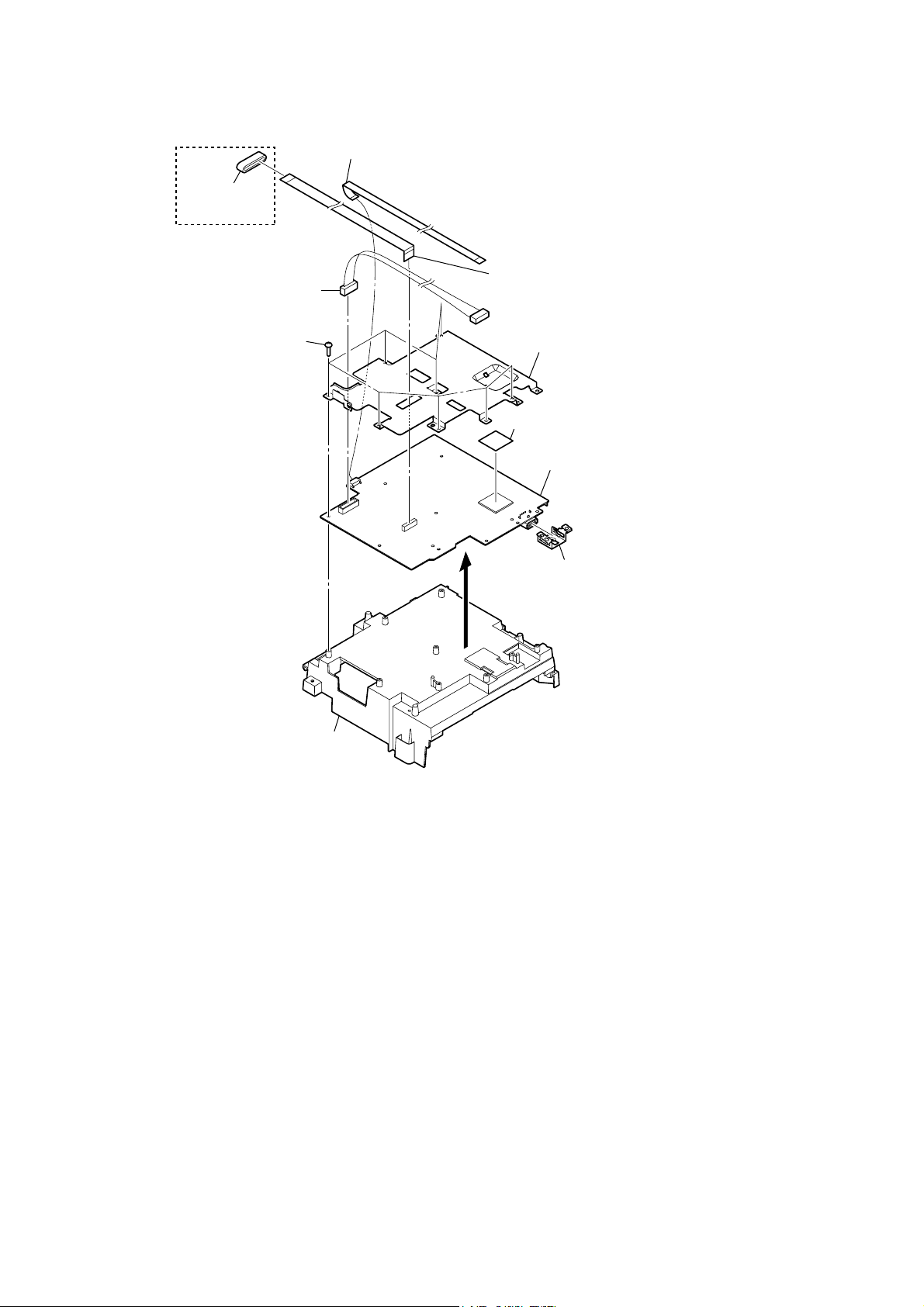

2-12. LCD BOARD

wire (flat type) (23 core)

8

(CN904)

4 two screws

(BVTP2.6)

wire (flat type) (27 core)

7

(CN903)

2 LCD module flexible flat cable

(CN901)

2-13. LCD MODULE

LCD board

9

Note: Please spread a sheet under a set

not to injure front panel.

6 two screws

(BVTP2.6)

sheet

1 LCD module connector

(CN905)

6

5 two claw

– Rear bottom view –

3 LCD module flexible flat cable

(CN902)

wire (flat type) (11 core)

1

(KEY-RIGHT board: CN263, KEY-LEFT board: CN262)

2 three screws

(BVTP2.6)

8 wire (GND)

9 bracket (LCD)

qa LCD module

sheet

Note: Please spread a sheet under a set

not to injure front panel.

– Rear bottom view –

0

3

5 ornament (CDM) assy

6 four screws

(BVTP2.6)

7 ground plate (LCD)

4 two bosses

16

SECTION 3

TEST MODE

HCD-SLK1i/SLK2i

COLD RESET

Reset the system to its factory default settings.

Procedure:

1. Press the [

] button to turn on the system.

?/1

2. Touch the [M], [m], [<] and [,] sensors to select the “Settings”, and touch the [ENTER] sensor.

3. Touch the [M], [m], [<] and [,] sensors to select the “Reset

all settings”, and touch the [ENTER] sensor.

4. Touch the [<] and [,] sensors to select the “Yes”, and touch

the [ENTER] sensor.

5. All the settings are reset and returned to the default settings,

then become standby mode.

VERSION DISPLAY

Each version, destination and model name are displayed.

Procedure:

1. Press the [

] button to turn on the system.

?/1

2. Press two buttons of [x] and [VOL –] and touch the [OPTIONS] sensor simultaneously.

3. The system version, GUI version, DVD version, destination

and model name are displayed on the liquid crystal display

module.

• Screen display

Settings

System Information

Software version

1

System

GUI

DVD

Dest.

Model

:

2

:

3

:

4

:

5

:

COMMON TEST

The test of each category is executed.

Procedure:

1. Press the [

] button to turn on the system.

?/1

2. Press two buttons of [x] and [VOL –] and touch the [ENTER]

sensor simultaneously, then become common test mode.

3. When the [VOL +] button is pressed, the sound volume increases to its maximum and the message “Max.” appears on

the liquid crystal display module.

4. When the [VOL –] button is pressed, the sound volume decreases to its minimum and the message “Min.” appears on the

liquid crystal display module.

Releasing method:

Press the [

] button to turn off the system.

?/1

VACS DISPLAY

The test of each category is executed.

Procedure:

1. Press the [

] button to turn on the system.

?/1

2. Press two buttons of [x] and [VOL +] and touch the [ENTER]

sensor simultaneously.

3. The [AUTO STANDBY] indicator repeats on and off, then become VACS display mode.

4. Press two buttons of [x] and [>] buttons and touch the [ENTER] sensor simultaneously.

5. The [AUTO STANDBY] indicator blinks corresponding to the

VACS level at that time.

Blinking frequency: VACS level (0 to 5).

Releasing method:

Press two buttons of [x] and [VOL +] buttons and touch the [ENTER] sensor simultaneously.

1 System version

2 GUI version

3 DVD version

4 Destination:

00: Singapore or Thai model

02: 240V AC area in E model

04: Saudi Arabia model

09: Brazilian model

10: US or Canadian model

11: Korean model

12: 120V AC area in E, Chilean, Peruvian or Argentina model

13: Mexican model

14: Chinese model

16: AEP model

5 Model name:

00: HCD-SLK1i

16: HCD-SLK2i

Releasing method:

Press the [

] button to turn off the system.

?/1

DVD SHIP MODE AND COLD RESET

Cold reset is executed at the same time with DVD ship

mode.

Procedure:

1. Press the [

] button to turn on the system.

?/1

2. Touch the [HOME] sensor.

3. Touch the [M], [m], [<] and [,] sensors to select the “CD/

DVD”, and touch the [ENTER] sensor.

4. Conrm there is no disc in the disc slot.

5. Press three buttons [x], [.] and [

] simultaneously.

[/1

6. Become standby mode, then become DVD ship mode.

Releasing method:

Pull out the power code.

VIDEO/SAT CHANGE

This mode changes external video source.

Procedure:

1. Press the [

] button to turn on the system.

?/1

2. Touch the [M], [m], [<] and [,] sensors to select the “Settings”, and touch the [ENTER] sensor.

3. Touch the [M], [m], [<] and [,] sensors to select the “External Video Source”, and touch the [ENTER] sensor.

4. Touch the [M] and [m] sensors to select the “Video” or “Satellite”, and touch the [ENTER] sensor.

5. The external video source changed.

17

HCD-SLK1i/SLK2i

DISC ANTITHEFT LOCK

This mode is used to unable to take sample disc out of disc slot in

the shop.

Procedure:

1. Press the [

] button to turn on the system.

?/1

2. Touch the [HOME] sensor.

3. Touch the [M], [m], [<] and [,] sensors to select the “CD/

DVD”, and touch the [ENTER] sensor.

4. Press two buttons of [x] and [Z] simultaneously, and hold for

more than ve seconds.

5. The message “LOCKED” is displayed on the liquid crystal

display module and the disc slot is locked (Even if pressing the

[Z] button, the message “LOCKED” is displayed on the liquid

crystal display module and the disc slot is locked).

Releasing method:

1. Press two buttons of [x] and [Z] buttons simultaneously, and

hold for more than ve seconds.

2. The message “UNLOCKED” is displayed on the liquid crystal

display module and the disc slot is unlocked.

DVD COLOR SYSTEM CHANGE (SLK1i: 240V AC area

in E, Saudi Arabia, Singapore, Korean, Thai, Chinese/

SLK2i: 120V AC area in E and 240V AC area in E models

only)

This mode let you change the color system of the video output

from PAL to NTSC or vice-versa.

Procedure:

1. Press the [

] button to turn on the system.

?/1

2. Touch the [HOME] sensor.

3. Touch the [M], [m], [<] and [,] sensors to select the “CD/

DVD”, and touch the [ENTER] sensor.

4. Press the [

5. Press two buttons of [X] and [

] button to turn off the system.

?/1

] simultaneously.

?/1

6. The message “DVD COLOR NTSC” or “DVD COLOR PAL”

displayed on the liquid crystal display module and thus the

color system is changed.

MTK REBOOT PREVENT

This mode is setting that MTK is not rebooted.

Procedure:

1. Press the [

] button to turn on the system.

?/1

2. Touch the [HOME] sensor.

3. Touch the [M], [m], [<] and [,] sensors to select the “CD/

DVD”, and touch the [ENTER] sensor.

4. Press three buttons [x], [>] and [Z] simultaneously.

5. The rebooting prevention setting was completed (there is no

change in the display).

REMOTE DISABLE MODE

This mode disable the remote commander reception.

Procedure:

1. Press the [

] button to turn on the system.

?/1

2. Press two buttons [x] and [VOL +] and touch the [OPTIONS]

sensor simultaneously.

3. The remote commander reception is invalidated (there is no

change in the display).

Releasing method:

Press two buttons [x] and [VOL +] and touch the [OPTIONS]

sensor simultaneously.

DVD SECTION

GENERAL DESCRIPTION

The IOP measurement allows you to make diagnosis and adjustment simply by using the remote commander . The instructions,

diagnosis results, etc. are given on the on-screen display (OSD).

Be sure to execute the IOP measurement when a BU (Base Unit)

is replaced.

DVD SERVICE MODE

It changes to the DVD service mode. Remote commander is necessary for the operation.

1. HOW TO ENTER THE DVD SERVICE MODE

Procedure:

1. Press the [

2. Touch the [HOME] sensor.

3. Touch the [M], [m], [<] and [,] sensors to select the “CD/

DVD”, and touch the [ENTER] sensor.

4 Press three buttons of [x], [VOL +] and [Z] simultaneously.

5. The DVD service mode starts.

The menu shown below will be displayed on the liquid crystal

display module.

0. Ex ter nal Chi p Ch eck

1. Se rvo Par ame ter Che ck

2. Dr ive Man ual Ope rat ion

3. Em erg ency Hi stor y

4. Ve rsi on Info rmat ion

EE PRO M NO CL EAR

Mo del Na me

IF -co n : Ver . XX .XX (XX XX)

Sy sco n : Ver . X. XXX

] button to turn on the system.

?/1

Re moc on Diag nos is Menu

: XXX XXX XX

Releasing method:

Press the [

] button to turn off the system.

?/1

TUNER STEP CHANGE (SLK1i: US, Canadian, 240V AC

area in E, Singapore, Korean, Thai, Chinese/SLK2i only)

The step interval of AM channels can be toggled between 9 kHz

and 10 kHz.

Procedure:

1. Press the [

] button to turn on the system.

?/1

2. Touch the [M], [m], [<] and [,] sensors to select the “Settings”, and touch the [ENTER] sensor.

3. Touch the [M], [m], [<] and [,] sensors to select the “AM

Step Change”, and touch the [ENTER] sensor.

4. Touch the [M] and [m] sensors to select the “9kHz” or “10kHz”,

and touch the [ENTER] sensor.

5. The step interval of AM channels changed.

18

6. The menu above is the Remocon Diagnosis Menu screen

which consists of ve main functions. At the bottom of the

menu screen, the model name, IF-con version and Syscon version.

Releasing method:

Press the [

] button to turn off the system.

?/1

HCD-SLK1i/SLK2i

1-1. EXECUTING IOP MEASUREMENT

In order to execute IOP measurement, the following standard procedures must be followed.

Procedure:

1. Enter the DVD service mode.

2. Select “2. Drive Manual Operation” by pressing the [2] button

on the remote commander. The screen will appear as shown.

Drive Manual Operation

1. Servo Control

2. Track/Layer Jump

3. Manual Adjustment

4. Tray Aging Mode

5. MIRR time Adjust

0. Return to Top Menu

3. Select “3. Manual Adjustment” by pressing the [3] button on

the remote commander. The screen will appear as shown.

Manual Adjust

1. Track Balance Adjust:

2. Track Gain Adjust:

3. Focus Balance Adjust:

4. Focus Gain Adjust:

5. Eq Boost Adjust:

6. Iop:

7. TRV. Level:

8. S curve(FE) Level:

9. RFL(PI) Level:

0. MIRR Time:

[ M ] [ m ] Change Value

[RETURN] Return to previous menu

4. Select “6. IOP” by pressing the [6] button on the remote commander.

5. Wait until a hexadecimal number appear.

Manual Adjust

1. Track Balance Adjust:

2. Track Gain Adjust:

3. Focus Balance Adjust:

4. Focus Gain Adjust:

5. Eq Boost Adjust:

6. Iop. 51:

7. TRV. Level:

8. S curve(FE) Level:

9. RFL(PI) Level:

0. MIRR Time:

[ M ] [ m ] Change Value

[RETURN] Return to previous menu

6. Convert each data from hexadecimal to decimal using conversion table.

7. Please fi nd the label on the rear of the BU (Base Unit).

The default IOP value is written in the label.

8. Subtract between these two values.

9. If the remainder is smaller than 93 (decimal), then it is OK.

However if the value is higher than 93, then the BU is defective and need to be change.

10. Press the [RETURN] button on the remote commander to return back to previous menu.

11. Press the [0] button on the remote commander to return to Top

Menu.

1-2. EMERGENCY HISTORY

To check the emergency history, please follow the following procedure.

Procedure:

1. From the Top Menu of Remocon Diagnosis Menu, select “3.

Emergency History Check” by pressing the [3] button on the

remote commander. The following screen appears on the onscreen display.

Emg. History Check

Laser Hours CD 999h 59min

01. 01 05 04 04

00 00 00 00 00 00 23 45

02. 02 02 01 01 00 A9 4B 00

00 00 00 00 00 00 23 45

[Next] Next Page [Prev] Prev Page

[O] Return to Top Menu

DVD 999h 59min

00 92 46 00

2. You can check the total time when the laser is turned on during

playback of DVD and CD from the above menu. The maximum time, which can be displayed are 999h 59min.

3. You can check the error code of latest 10 emergency history

from the above menu. To view the previous or next page of

emergency history, press [.] or [>] button on the remote

commander. The error code consists of the following three

blocks. The fi rst block indicates the error code. The second

block indicates the parameter and the third block indicates the

time of error code as shown below.

• Error Code

Emg. History Check

Laser Hours CD 999h 59min

*1 *2

01. 01 05 04 04

00 00 00 00 00 00 23 45

02. 02 02 01 01 00 A9 4B 00

00 00 00 00 00 00 23 45

[Next] Next Page [Prev] Prev Page

[O] Return to Top Menu

DVD 999h 59min

00 92 46 00

*3

*1 : Error Code

*2 : Parameter of error code

*3 : Time of error code

The meaning of error code is as below:

01: Communication error (No reply from syscon)

02: Syscon hung up

03: Power OFF request when syscon hung up

19: Thermal shutdown

24: MoveSledHome error

25: Mechanical move error (5 Changer)

26: Mechanical move stack error

30: DC motor adjustment error

31: DPD offset adjustment error

32: TE balance adjustment error

33: TE sensor adjustment error

34: TE loop gain adjustment error

35: FE loop gain adjustment error

36: Bad jitter after adjustment

40: Focus NG

42: Focus layer jump NG

19

HCD-SLK1i/SLK2i

52: Open kick spindle error

51: Spindle stop error

60: Focus on error

61: Seek fail error

62: Read Q data/ID error

70: Lead in data read fail

71: TOC read time out (CD)

80: Can’t buffering

81: Unknown media type

1-2-1. Clear the Laser Hour

Press [

DISPLAY] button and then press [CLEAR] button on the

remote commander. The data for both CD and DVD data are reset.

Emg. History Check

Laser Hours CD 0h 0min

01. 01 05 04 04

00 00 00 00 00 00 23 45

02. 02 02 01 01 00 A9 4B 00

00 00 00 00 00 00 23 45

[Next] Next Page [Prev] Prev Page

[O] Return to Top Menu

DVD 0h 0min

00 92 46 00

1-2-2. Clear the Emergency History

Press [DVD TOP MENU] button and then press [CLEAR] button

on the remote commander. The error code for all emergency history would be reset.

1-3. CHECK VERSION INFORMATION

To check the version information, please follow the following procedure.

1. From the Top Menu of Remocon Diagnosis Menu, select “4.

Version Information” by pressing the [4] button on the remote

commander. The following screen appears on the on-screen

display.

Version information

Firm (Main) : Ver. x.xxx

Firm (Sub) : xx.xx

RISC : xxxxxx

8032 : xxxxxx

Audio DSP : xx.xx.xx.xx

Servo DSP : xx.xx.xx.xx

[0] Return to Top Menu

To return to the Top Menu of Remocon Diagnosis Menu, press

[0] button on the remote commander.

Emg. History Check

Laser Hours CD 999h 59min

01. 00 00 00 00

00 00 00 00 00 00 00 00

02. 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00

[Next] Next Page [Prev] Prev Page

[O] Return to Top Menu

DVD 999h 59min

00 00 00 00

1-2-3. Clear the Initialize Setup Data

Press [DVD MENU] button and then press [CLEAR] button on the

remote commander.

Emg. History Check

Laser Hours CD 999h 59min

[Next] Next Page [Prev] Prev Page

[O] Return to Top Menu

DVD 999h 59min

initialize setup data...

1-2-4. Return to the Top Menu of Remocon Diagnosis

Menu

Press [0] button on the remote commander.

20

HCD-SLK1i/SLK2i

HCD-SLK1i/SLK2i

2121

SECTION 4

DIAGRAMS

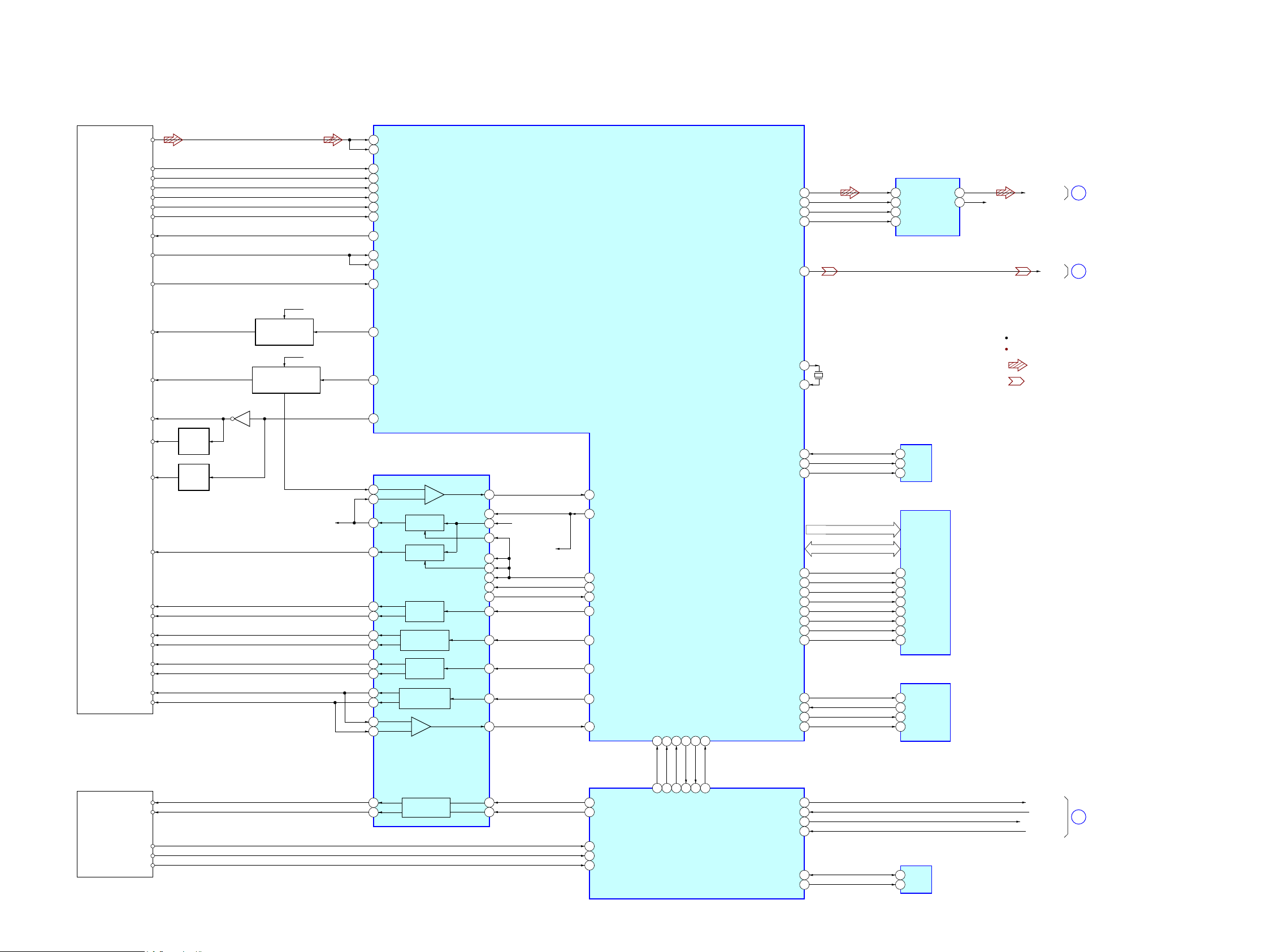

4-1. BLOCK DIAGRAM - SERVO Section -

RF

OPTICAL PICK-UP

BLOCK

(KHM-313CAB)

MS-214 BOARD

AUTO POWER

CONTROL (FOR CD)

Q003 (1/2)

RFIP

RFIN

RF_C

VOA/A

VOB/B

VOC/C

VOD/D

VOF/F+H

VOE/E+G

VC

LIMIT

PD

LD (780)

3

RF_B

2

RF_A

1

RF_D

4

RF_F

6

RF_E

5

V2O

LIMITSW

12

LDO1

17

MDI1

15

MDI2

16

AUTO POWER

CONTROL (FOR DVD)

Q003 (2/2)

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED/LOADING MOTOR DRIVE

IC201

VREF

MUTE123

MUTE4

TSD_M

PS

RF AMP, SERVO DSP,

DVD/CD DECODER

IC005

SYSTEM CONTROLLER

IC100 (1/3)

VR (650)

VR (780)

MSW

Q002

VCC

LD (650)

LDO2

MSW

18

VM9V

OCSW1

43

FMO

FOO

DMO

TRO

VREFO

FWD

45

REV

44

IOPMON

SPFG

MUTE123

MUTE4

TSD_M

42

25

21

22

20

19

45

6

7

17

40

16

13

10

4

1

43

39

24

41

23

REG01

REG02

REG02

REG02

FCS+

FCS-

TRK+

TRK–

SP–

SP+

SL–

SL+

46

47

REGULATOR

32

31

30

REGULATOR

29

SPINDLE MOTOR

DRIVE

27

28

SLED MOTOR

DRIVE

FOCUS COIL

DRIVE

36

37

TRACKING COIL

DRIVE

35

34

DVD ON

SWITCH

Q001 (2/2)

DVD_SCO

23

DVD_SID

22

DVD_SOD

24

XIFCS

27

XSYSRST

21

DVD_XIFBUSY

25

IFSCK

IFCS#

IFSDO

IFBSY

IFSDI

PRST#

35 40 4341

88

87

25

94

20

21

24

13

22

116

EEPROM

IC002

WP

EEWP

SCL

SDA

SCL

SDA

SD-RAM

IC008

FLASH ROM

IC003

UDQM

LDQM

CAS

RAS

WE

CLK

BA1

BA0

DQM1

DQM0

CAS#

RAS#

RWE#

RCLK

BA1

RD0 - RD15

RA0 - RA11

BA0

SF_CK

SF_DI

SF_DO

SF_CS#

SI

SO

_CS

SCK

6

5

2

136

37

38

39

RD0 - 15

DQ0 - DQ15

A0 - A11

RA0 - 11

AML RXD IN

AML TXD OUT

AML BUSY

AML RESET

37

38

35

36

78

80

66

75

77

76

55

65

ASDATA0

ALRCK

ACLK

ABCK

39

15

17

18

16

38

21

20

7

6

5

CD ON

SWITCH

Q001 (1/2)

126

125

118

127

115

119

120

114

CVBS

CVBS

AML RXD IN

AML TXD OUT

AML BUSY

AML RESET

128

CKSW1

42

TRG-SW

6

LDM+

LDM–

TRG-SW

CKSW1

OCSW1

26

33

34

EEPROM

IC150

EEPROM-CLK

EEPROM-DATA

SCL

SDA

6

5

50

49

99

R-CH

5AOUT-R

AUDIO

D/A CONVERTER

IC301

8AOUT-L

1SDATA

4MCLK

2SCLK

3 LRCK

A

DVD_L_OUT

B

C

VREFO1.4V

X001

27MHz

XTALO

XTALI

10

9

: DISC PLAY

SIGNAL PATH

R-ch is omitted due to same as L-ch.

: VIDEO

LOADING

MOTOR DRIVE

(Page 22)

(Page 23)

(Page 24)

HCD-SLK1i/SLK2i

HCD-SLK1i/SLK2i

2222

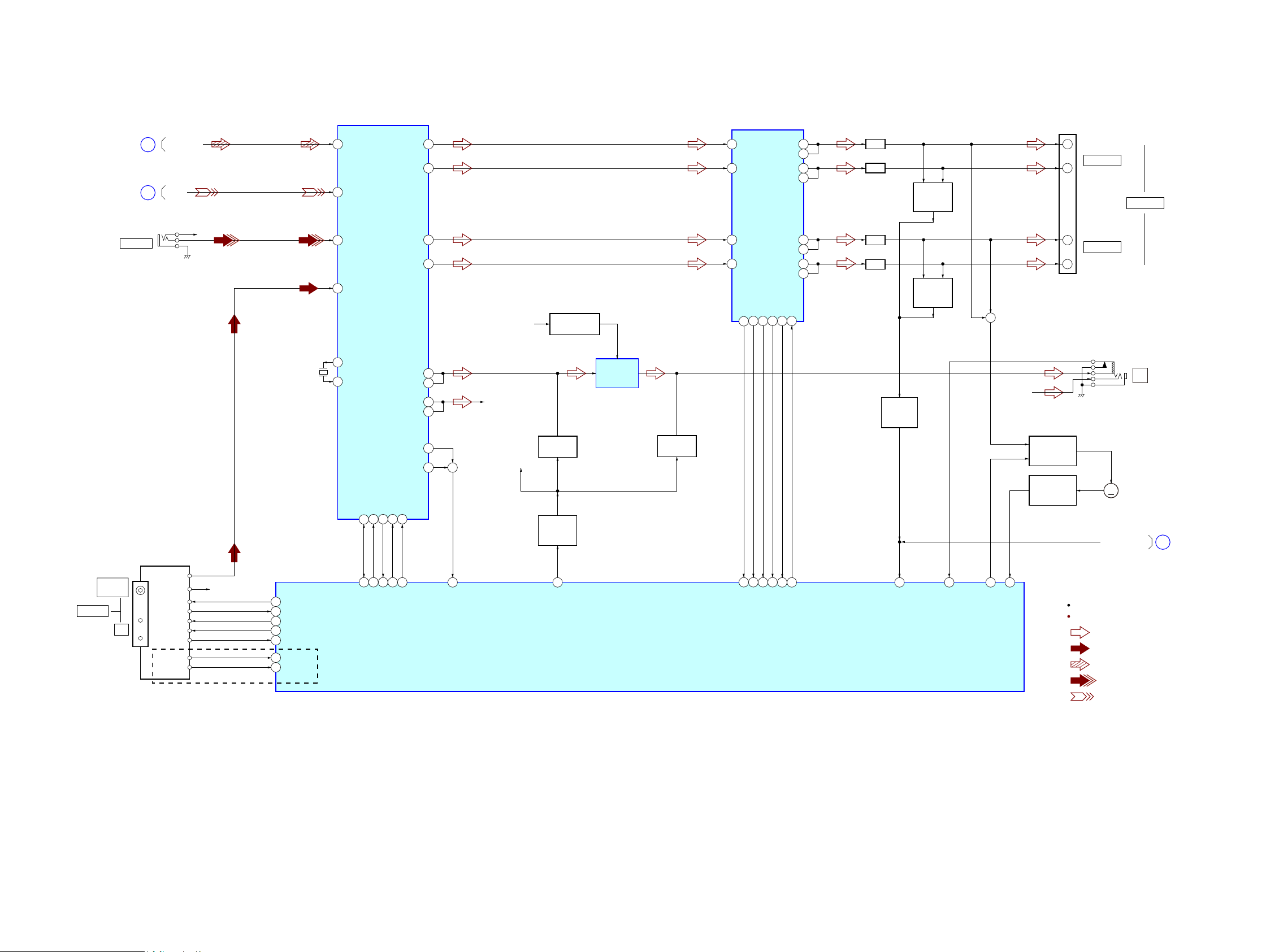

4-2. BLOCK DIAGRAM - AUDIO INPUT Section -

AUDIO DSP

IC401 (1/2)

CN1003

(iPod Dock)

27

28

R-CH

R-CH

4

6

30

LINE-OUT-L

LINE-OUT-R

23

iPod_VIDEO

I2CSDA

I2CSCK

Composite Video

8

iPod+5V

VBUS

USB D+

USB D–

iPod Detect

13

Acc PWR

32 iPod DET

iPod CP RESET

I2C SDA

I2C SCK

33 iPod Acc Power

14 USBB D–

13 USBB D+

11 USBB VBUS

WAKE UP

Q402

12I2C SCL

13I2C SDA

EEPROM

IC405

4RESET

CN401

3

2

1

VBUS5V

VBUS

D+

D–

5 USBA D–

4 USBA D+

2 USBA VBUS

CN402

4

11

8

VCC

SD/MMC-4 (VCC)

PRO/SD

INS

SD/MS INS

CARD VCC ENABLE

34 Card Vcc OverCurrent DET

1

10

SD-9 (DAT2)

DATA2

205

206

182

3

EN

DC_3.3V

4/OC

B+ SWITCH

IC406

1Vin

5VOUT

215

SD/MS DAT2

184

3

7

SD/MMC-1 (DAT3)

DATA3

SD/MS DAT3

183

15

6

BS

SD/MMC-2 (CMD)

SD CMD/MS BS

180

5

14

SCLK

SD/MMC-5 (CLK)

SD/MS CLK

181

12

18

SDIO/DATA0

SD/MMC-7 (DAT0)

SD/MS DAT0

187

13

19

DATA1

SD-8 (DAT1)

SD/MS DAT1

186

175

17

SD/MMC#CD

SD CARD DET

177

20

SD#WP

SD WP

176

BCK

MCLK

MDATA

212

LRCK

213

DAC SMUTE

178

IPOD USB SEL

211

214

UART Rx

AML BUSY

RESET

203

UART Tx

204

197

216

5

92

RSTN

10OUTR

AUDIO

D/A CONVERTER

IC606

11OUTL

3SDTI

1MCLK

2 BICK

4 LRCK

6SMUTE

iPod LINE AMP

IC612

iPod/USB

SELECT

SWITCH

IC613

SWITCH

CONTROL

Q610, 613

E

AML-L

SD-RAM

IC404

FLASH ROM

IC403

UDQM

LDQM

CAS

RAS

WE

CLK

BA1

BA0

M1 DQM1

M1 DQM0

M1 CAS n

M1 RAS n

M1 WE n

M1 CLKO

M1 BA1

M1 BA0

SPI C/M1 D0

SPI D/M1 D1

SPI Q/M1 D2

M1_DQ0

M1_DQ1

M1_DQ2

SPI CS

SI (D)

SQ (Q)

CS (S)

SCLK (C)

6

5

2

136

40

39

38

M1_DQ3 - 7, M1_D8 - 15

M1_DQ0 - M1_DQ2

M1_A0 - 12

76

77

60

71

73

72

48

58

39

15

17

18

CSM1 SCS0 n

75 19

16

38

21

20

D

AML RXD IN

AML TXD OUT

AML BUSY

AML RESET

C

: iPod

SIGNAL PATH

R-ch is omitted due to same as L-ch.

: MEMORY CARD

: USB

: VIDEO

M1 A0 - M1 A12

SPI WP/M1 D3, M1 D4 - M1 D15

DQ3 - DQ15

DQ0 - DQ2

A0 - A12

(Page

21)

(Page 23)

(Page 24)

HCD-SLK1i/SLK2i

HCD-SLK1i/SLK2i

2323

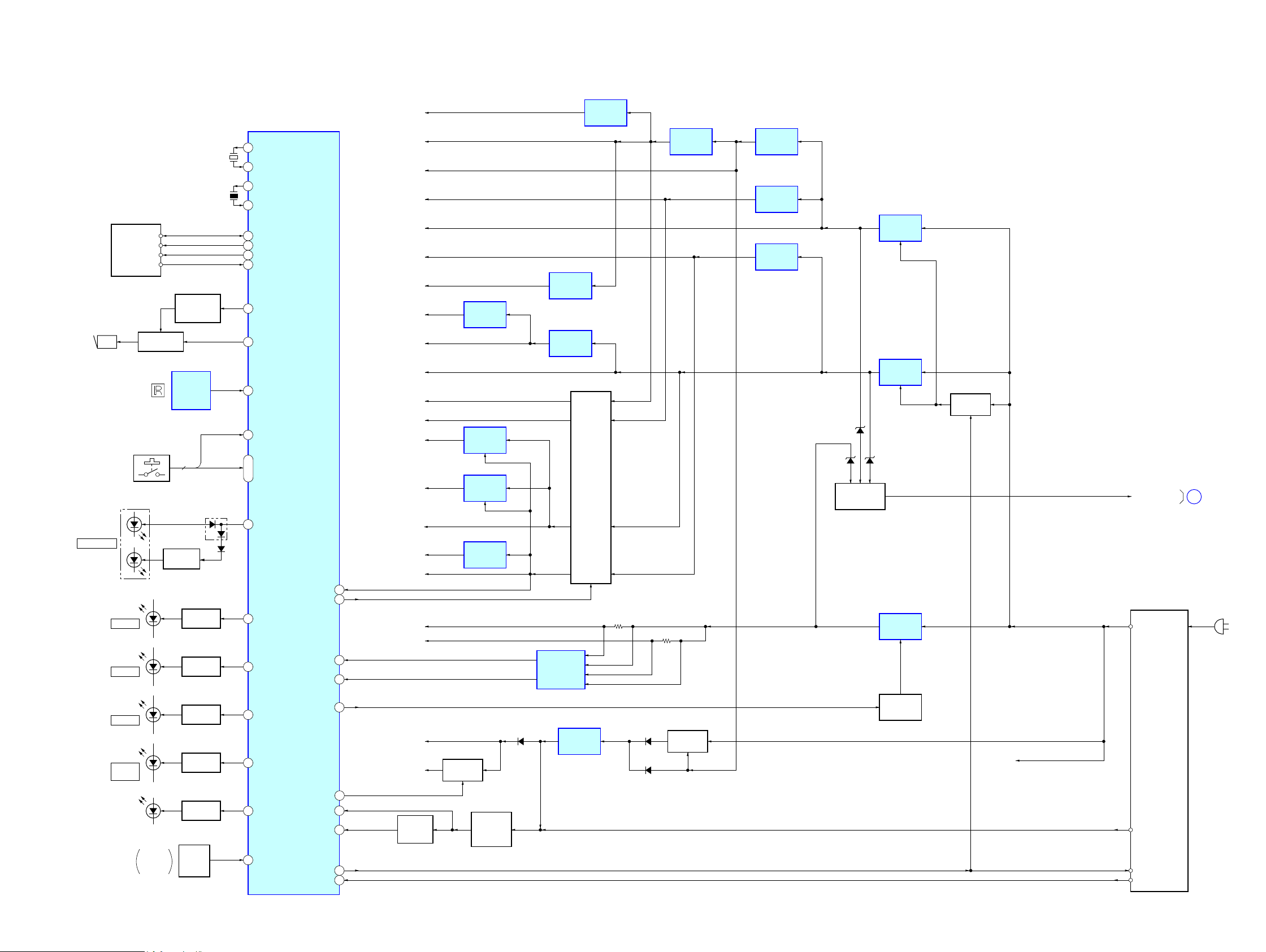

4-3. BLOCK DIAGRAM - AUDIO OUTPUT Section -

R-CH

J703

AUDUO IN

E

AML-L

A

DVD_L_OUT

TU1

TUNER (FM)

TUNER-L

PLL_DO

PLL_CE

TUNED

PLL_DI

PLL_CLK

TUNER-R R-CH

SYSTEM CONTROLLER

IC100 (2/3)

ST-CE

69

ST-CLK

RDS_INT

RDS_DATA

RDS-INT

18

RDS DATA

7

ST-DIN

72

71

ST-DOUT

70

ST-TUNED

68

(AEP)

FM 75:

COAXIAL

AM

ANTENNA

A/D CONVERTER,

DIGITAL AUDIO PROCESSOR

IC300

60 LINEIN7L

63 LINEIN8L

66 LINEIN9L

69 LINEIN10L

RIPPLE FILTER

Q401

MUTING

Q403

MUTING

Q412

PWM1_LD 92

PWM1_RD 96

PWM1_LI

93

LINEOUT1L

76

LINEOUT1R

77

PWM1_RI

97

J241

R-CH

R-CH

HEADPHONE

AMP

IC401

MUTING

CONTROL

Q404

R-CH

A+9V

HP DET

2

FAN-CONTROL

61

PROTECT FAN

63

HP MUTE

1

PROTECT AMP

54

PWM3_LI 5

PWM3_LD 4

PWM3_RI 9

PWM3_RD 8

i

OVER LOAD

DETECT

Q608, 609

OVER LOAD

DETECT

Q606, 607

L.P.F.

L.P.F.

L.P.F.

L.P.F.

SPEAKERS

FRONT R

TB601

+

+

FRONT L

DIGITAL POWER AMP

IC500

4 INPUT_A OUT_A

5 INPUT_B OUT_B

11 INPUT_D

10

52

44

INPUT_C

OUT_D

28

36OUT_C

OUT_A

OUT_B

53

45

OUT_D

29

37OUT_C

DSP-MUTE

80

DSP-VALID

79

DSP-CLK

78

DSP-DATA

77

DSP-RESET

81

/MUTE

I2C_SDA1

VAL ID

I2C_SCL1

/RESET

VAC S

92

34 38 3910

33

/CLIP

56

/OTW2

53

/OTW1

52

/SD

73

READY

55

/CLIP

/SD

/OTW2

/OTW1

READY

16 18 1917

15

/D-AMP-RESET

51

/RESET

2

+

+

M601

(FAN)

FAN M OTOR

DRIVE

Q600 - 602, 613

FAN PROTECT

DETECT

Q610 - 612

MM

PROTECT

DETECT

Q620

F

PROTECT_AMP

X385

24.576MHz

XTAL_OUT

XTAL_IN

86

87

: AUDIO

: DISC PLAY

SIGNAL PATH

R-ch is omitted due to same as L-ch.

: TUNER

: AUDIO IN

: USB

(Page 21)

(Page 22)

(Page 25)

HCD-SLK1i/SLK2i

HCD-SLK1i/SLK2i

2424

4-4. BLOCK DIAGRAM - VIDEO Section -

J702

VIDEO IN

B

CVBS

VIDEO SELECTOR

IC602

VIDEO A/D CONVERTER

IC605

DISPLAY CONTROLLER

IC401 (2/2)

12 D3 (DVD)

1AIP1A

13 D0 (iPod)

14 D1 (input)

22 SDA

21 SCL

VIDEO AMP

IC604

VIDEO AMP

IC1001

VIDEO AMP

IC603

COM 3

LCD SCL(SPI)

LCD B0 -

LCD B7

LCD G0 - LCD G7

LCD R0 - LCD R7

YOUT0 - 7

11 – 18

21 – 23, 25 – 27, 29, 30

136 – 139, 141 – 144145 – 149, 151 – 153155 – 162

SEL A

11

SEL B

10

J701

DVD VIDEO OUT

8 8

8 8

8 8

8 8

iPod_VIDEO

I2CSDA

I2CSCK

D

LCD901

LIQUID CRYSTAL

DISPLAY MODULE

DR0 - 7

DB0 - 7

DG0 - 7

SCL

165

193

LCD DCLK

DCLK

166

LCD HSYNC

HSYNC

167

LCD DE

DE

168

LCD VSYNC

VSYNC

169

LCD CS(SPI)

CS

170

LCD SDA(SPI)

SDA

171

LCD GBR

GBR

VDPA

VDNA

VGL

VGH

LED OUT

LED_I_SENCE

173

VGH10VCTL

VGHL CS0

118

VGHL CS1

119

LCD PWM

LED PWM

LED CS1

110

LED CS0

109

DC/DC

CONVERTER

Q604,

D601, 605 - 607, 615

B+ SWITCH

Q606, 607

DC/DC

CONVERTER

Q603,

D608, 609, 616, 617

+5.5V

REGULATOR

Q605, D612

DC/DC

CONVERTER

Q602, D618

–5.5V

REGULATOR

D613

VCOM

14

V1 - 14

NDAVO

PDAVO

BIAS

CIRCUIT

D+5V

HP–5V

91

85

87

RESETB 8 Video Dec RESET

656D0 - 656D7

194

AVI D 26 Video Dec AVID

195

INTREQ/GPCL 27 Video Dec INTREQ/GPCL

196

PDN 28 Video Dec PDN

199

SCLK 9 Video Dec PCLK

200

VSYNC 24 Video Dec VSYNC

201

HSYNC 25 Video Dec HSYNC

202

FID/GLCO 23 Video Dec FID/GLCO

188

SELB

190

SELA

192

Video AMP B MUTE

191

209

210

Video AMP A MUTE

X601

14.31818MHz

XTAL2

XTAL1/OSC

6

5

X401

24MHz

OSCOUT

OSCIN

SIGNAL PATH

R-ch is omitted due to same as L-ch.

: VIDEO

(Page 21)

(Page 22)

HCD-SLK1i/SLK2i

HCD-SLK1i/SLK2i

2525

4-5. BLOCK DIAGRAM - PANEL, POWER SUPPLY Section -

D908

(AC IN)

D909

SWR1

SWITCHING REGULATOR

PVDD

AC-DET

P. CONT

PROTECT

+12V

REGULATOR

IC901

+5V

REGULATOR

IC900

+5V

REGULATOR

IC902

SOFT START

Q903, 904

REGULATOR

CONTROL

Q918, 919

OVER VOLTAGE

DETECT

Q910 - 912

D910 D912

D913

OVER CURRENT

DETECT

IC611

+3.3V

REGULATOR

IC906

+9V

REGULATOR

IC903

+3.3V

REGULATOR

IC907

+5V

REGULATOR

IC905

+9V

REGULATOR

IC904

A+3.3V

+1.8V

REGULATOR

IC610

DC_1.8V

+3.3V

REGULATOR

IC609

DC_3.3V

+1.2V

REGULATOR

IC601

DC_1.2V

+1.8V

REGULATOR

IC004

DVD+1.8V

+3.3V

REGULATOR

IC007

DVD A+3.3V

+3.3V

REGULATOR

IC001

RF+3.3V

A+5V

A+9V

LED+9V

D+12V

D+3.3V

D+5V

B+ SWITCH

Q914 - 917,

920 - 923

IC301_+5V

VM9V

DVD D+3.3V

DVD+5V

iPod+5V

VBUS5V

EVER+3.3V

AD-LINE_PULL-UP

D200

B+ SWITCH

Q905 - 907

+4V

REGULATOR

IC908

SYSTEM CONTROLLER

IC100 (3/3)

SIRCS IN

REMOTE

CONTROL

RECEIVER

IC242

PHOTO

DIODE

PH901

4

TP INT

75

TP RESET

76

TP SCL

48

TP SDA

47

POWER-KEY

74

LUX-SENSOR

94

AD-KEY-0 - 2

X110

32.768kHz

XCout

XCIN

11

10

X114

5MHz

XOUT

XIN

13

15

SONYLOGO LED28

D901, 902

(SONY LOGO)

LED DRIVE

Q901

BUZZER CONT3

BUZZER LEVEL

CONTROL

Q103

TP BUZZER26

BUZZER DRIVE

Q104

S261 - 269

KEY0

83 – 85

3

12RESET

60P. CONT

19PROTECT-INT

66USB POWER

57USB OC

58IPOD OC

67MTK POWER

RESET

SWITCH

Q202

RESET

SIGNAL

GENERATOR

Q201

PLAY LED

89

LED DRIVE

Q262

D267

PAUSE LED

90

LED DRIVE

Q263

D264

TIMER LED

87

LED DRIVE

Q264

D265

A. STBY LED

88

LED DRIVE

Q265

D266

LED DRIVE

Q261

D262

59

STBY-LED

D270

D261

TIMER

PAU SE

PLAY

ON/STANDBY

AUTO

STANDBY

F

PROTECT_AMP

TOUCH SENSOR

BOARD

BZ701

TP SDA

TP RESET

TP INT

TP SCL

B+ SWITCH

Q198, 199

AD-SWTICH

100

82DVD 3.3V MONITOR

20/AC-CUT

PVDD

AMBIENT

LIGHT

SENSOR

(Page 23)

HCD-SLK1i/SLK2i

HCD-SLK1i/SLK2i

2626

For Schematic Diagrams.

Note:

• All capacitors are in μF unless otherwise noted. (p: pF) 50

WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and 1/4 W or less unless otherwise

specifi ed.

• f : internal component.

• C : panel designation.

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

• A : B+ Line.

• B : B– Line.

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark : TUNER

• Voltages are taken with VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

E : VIDEO

J : DISC PLAY

f : TUNER

p : USB

g : iPod

l : MEMORY CARD

i : AUDIO IN

• Abbreviation

AR : Argentina model

BR : Brazilian model

CH : Chinese model

CND : Canadian model

E2 : 120 V AC area in E model

E3 : 240 V AC area in E model

E51 : Chilean and Peruvian models

EA : Saudi Arabia model

KR : Korean model

MX : Mexican model

SP : Singapore model

TH : Thai model

• The voltage and waveform of CSP (chip size package)

cannot be measured, becaise its lead layout is different

from that of conventional IC.

For Printed Wiring Boards.

Note:

• X : Parts extracted from the component side.

• Y : Parts extracted from the conductor side.

• x : Parts mounted on the conductor side.

• f : Internal component.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

• Indication of transistor.

• Abbreviation

AR : Argentina model

BR : Brazilian model

CH : Chinese model

CND : Canadian model

E2 : 120 V AC area in E model

E3 : 240 V AC area in E model

E51 : Chilean and Peruvian models

EA : Saudi Arabia model

KR : Korean model

MX : Mexican model

SP : Singapore model

TH : Thai model

• Lead layouts

Caution:

Pattern face side:

(Conductor Side)

Parts face side:

(Component Side)

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

• DISPLAY board is multi-layer printed board. However, the

patterns of intermediate-layers have not been included in

this diagrams.

• Circuit Boards Location

Caution:

Pattern face side:

(SIDE B)

Parts face side:

(SIDE A)

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

Note: The components identifi ed by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specifi ed.

Note: Les composants identifi és par une marque

0 sont critiques pour la sécurité.

Ne les remplacer que par une piéce portant

le numéro spécifi é.

C

Q

B

E

Q

B

CE

These are omitted.

These are omitted.

surface

CSP (Chip Size Package) Lead layout of conventional IC

KEY-LEFT board

DISPLAY board

HP board

TUNER (FM/AM)

MS-214 board

IP board

MAIN board

KEY-RIGHT board

TERMINAL board

LCD board

SWITCHING REGULATOR

JACK board

TOUCH PANEL board

HCD-SLK1i/SLK2i

HCD-SLK1i/SLK2i

2727

4-6. SCHEMATIC DIAGRAM - DISPLAY Section (1/7) -

• See page 50 for Waveforms. • See page 50 for IC Block Diagrams. • See page 55 for IC Pin Function Description.

DISPLAY

(2/7)

2

BOARD

(2/7)

3

DISPLAY

BOARD

1

BOARD

DISPLAY

(2/7)

8

(3/7)

DISPLAY

BOARD

BOARD

5

(4/7)

DISPLAY

BOARD

DISPLAY

7

(4/7)

IC B/D

1

1.2

3.3

3.3

1.6

2.6

3.3

3.3

3.3

3.3

3.3

3.3

0

3.3

3.3

3.3

3.3

3.3

3.3

1.2

3.3

3.3

3.3

3.3

0

0

3.3

3.3

0.6

3.3

0

3.3

1.6

0

0

3.1

2.5

3.3

3.3

3.3

3.3

1.6

1.6

0

3.3

0

0

3.3

3.3

0

5

3.3

000

3.3

0

5

3.3

000

3.3

3.3

0.3

0.3

0.3

3.3

0.3

0.3

0.3

1.2

0.3

0.3

3.3

3.3

3.3

3.3

1.5

1.5

1.5

1.7

3.3

1.7

1.6

1.6

1.601.6

1.6

1.6

1.7

1.7

3.3

1.7

1.7

1.7

0

1.7

0

0

0

0

0.6

2.8

2.8

2.8

3.3

3.3

3.3

3.3

1.2

0.5

0

2.7

2.7

2.8

0.5

3.3

1.4

0

3.3

3.3

3.3

0.6

0.2

0.2

0.3

0.6

0.6

0.6

0.8

0.8

0.2

0.2

0.3

3.3

0.6

0.6

0.6

0.8

0.8

0.2

0.2

0.3

0.6

0.6

0.6

0.8

0.8

3.3

1.2

3.3

0

0

0.5

0.5

0

0

0.5

0.4

3.3

3.3

3.3

3.3

0

R403

1k

R404

22

R407

22

R408

22

R409

22

R410

0.1

R411

0.1

R412

0.1

R413

0.1

R414

0

R415

1k

R416

FB403

0.1

C417

0.1

C418

0.1

C419

0.1

C420

0.1

C421

0.1

C422

0.1

C423

0.1

C424

0.1

C425

0.1

C426

0.1

C427

0.1

C428

0.1

C429

0.1

C430

0.1

C431

0.1

C432

0.1

C434

0.1

C435

0.1

C436

LCDPWB

LEDPWM

LEDCS0

LEDCS1

VGHLCS0

100R440

100R441

100R445

100R446

10k

R451

180

R452

180

R453

180R454

180R455

180R456

180R457

0

R460

10k

R461

100

R463

4.7k

R464

100

R465

100

R468

0.1

C443

FB410

FB411

10kR478

10kR479

100

R481

100R482

100R483

100R484

100

R485

100

R486

100

R487

100

R488

100

R489

100

R490

100

R491

100

R492

100

R493

100

R494

100

R495

100

R496

0.1

C449

0.1

C450

0.1

C451

0.1

C452

R498

4.7k

4.7k

R500

4.7k

R510

4.7k

R513

4.7k

R515

4.7k

R517

R519

4.7k

R521

4.7k

4.7k

R523

R525

4.7k

100R526

100

R527

100

R528

100

R529

100

R530

100

R532

10V

100

C453

10V

100

C455

10V

100

C456

10V

100

C458

SELA

SELB

VideoAMP_A_MUTE

VideoAMP_B_MUTE

VideoDecRESET

VideoDecPDN

VideoDecPCLK

VideoDecAVID

VideoDecINTREQ/GPCL

VideoDecVSYNC

VideoDecHSYNC

VideoDecFID/GLCO

656D0

656D1

656D2

656D3

656D4

656D5

656D6

656D7

DACS-MUTE

JTAGTMS/I2SMCLK

JTAGTDI/I2SBCK

JTAGTCK/I2SLRCK

JTAGTDO/I2SMDATA

VGH10VCTL

100

R536

10

R542

10

R545

10

R547

0.047

C465

0.047

C466

0.047

C469

0.047

C470

10

R548

JL471

JL472

JL473

JL474

JL475

JL476

JL477

JL478

JL479

JL487

JL489

JL490

JL491

JL493

JL494

JL495

JL496

JL497

JL498

JL530

JL531

JL532

JL534

1

23

4

L401

10k

R447

1 2 3 4 5 6 7 8 91011 12131415161718192021222324252627282930313233343536373839404142434445464748495051525354

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

11311 411511 6117118119120121122123124125126127128129130131132133134135136137138139140141142143144145146147148149150151152153154155156157158159160161162

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

56

55

110 109112 111

165

164

163

167

168

166

AML6226D

IC401

USBA ID

USBA VBUS

USB VDD3.3

USBA D+

USBA D-

USBA VSS3.3

USBA txrtune

USBA VSS3.3

USBA VDD3.3

USBB ID

USBB VBUS

USBB VDD3.3

USBB D+

USBB D-

USBB VSS

USBB txrtune

USBB VSS3.3C

USBB VDD3.3

PLL VDD3.3

PLL VSS

656D0

656D1

656D2

VDD3.3

656D3

656D4/MDATA

656D5

VDD1.2

656D6

656D7

DVSS

iPod DET

iPod Acc Power

Card Vcc OverCurrent DET

SPI CSNCSPI HOLD

SPI C/M1 D0

SPI D/M1 D1

SPI Q/M1 D2

SPI WP/M1 D3

VDD3.3

M1 D4

M1 D5

DVSS

M1 D6

M1 D7

M1 DQM0

M1 D15

M1 D14

M1 D13

M1 D12

M1 D11

VDD3.3

M1 D8

M1 DQM1

DVSS

M1 CLK0

M1 CKE

M1 A12

M1 A11

M1 A9

M1 A8

M1 A7

M1 A6

M1 A5

M1 A4

VDD3.3

M1 WE n

M1 CAS n

M1 RAS n

VDD1.2

M1 SCS0 n

M1 BA0

M1 BA1

DVSS

M1 A10

M1 A0

M1 A1

M1 A2

M1 A3

LCD PWM180

LCD PWM

VDD3.3

LED PWM

LED PWM180

Remote Input

LED BackLightIC Cont

VGH10VCTL

IPOD USB SEL

TADC AV3.3

TADC CH11

TADC CH10

TADC CH9

TADC CH8

TADC CH7

TADC CH6

TADC CH5

TADC CH4

TADC CH3

TADC CH2

TADC CH1

TADC CH0

TADC CAP+

TADC CAP-

TADC AGND

RTC XOUT

RTC XIN

RTC PDAC GND

REF12 VX

VREF12 FB

VGHL CS0

VGHL CS1

AOUT SPRC

AOUT SPR

AOUT HPR

AOUT HPRC

AOUT AVSS3.3

AOUT REFN

AOUT VCM

AOUT REFP

AOUT AVDD3.3

AOUT HPLC

AOUT HPL

AOUT SPL

AOUT SPLC

NC

VDD1.2

VDD3.3

LCD R0

LCD R1

LCD R2

LCD R3

DVSS

LCD R4

LCD R5

LCD R6

LCD R7

LCD G0

LCD G1

LCD G2

LCD G3

LCD G4

VDD3.3

LCD G5

LCD G6

LCD G7

DVSS

LCD B0

LCD B1

LCD B2

LCD B3

LCD B4

LCD B5

LCD B6

LCD B7

LCD VSYNC

LCD CS(SPI)

LCD SDA(SPI)

DVSS

LCD GBR

iPod LINE MUTE

SD/MS INS

SD WP

SD CARD DET

DAC SMUTE

VDD3.3

SD CMD/MS BS

SD/MS CLK

iPod CP RESET

SD/MS DAT3

SD/MS DAT2

VDD1.2

SD/MS DAT1

SD/MS DAT0

SELB

DVSS

SELA

Video AMP A MUTE

Video AMP B MUTE

Video Dec RESET

Video Dec AVID

Video Dec INTREQ/GPCL

Video Dec PDN

AML BUSY

VDD3.3

Video Dec PCLK

Video Dec VSYNC

Video Dec HSYNC