Page 1

HCD-GRX9900/RXD9

SERVICE MANUAL

HCD-GRX9900/RDX9 are the Amplifier,

CD player, Tape Deck and Tuner section

in MHC-GRX9900/RXD9.

Dolby noise reduction manufactured under license

from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks of Dolby Laboratories Licensing Corporation.

Photo: HCD-RXD9 (US model)

CD

Section

Tape deck

Section

US Model

AEP Model

UK Model

HCD-RXD9

E Model

HCD-GRX9900

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM38LH-5BD32L

Base Unit Name BU-5BD32L

Optical Pick-up Name KSS-213D/Q-NP

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type TCM-230AWR2

Amplifier section

US model:

AEP and UK models:

DIN power output (rated) 120 + 120 watts

(8 ohms at 1 kHz, DIN)

Continuous RMS power output (reference)

150 + 150 watts

(8 ohms at 1 kHz, 10% THD)

Music power output (reference)

275 + 275 watts

(8 ohms at 1 kHz, 10% THD)

SPECIFICATIONS

E models:

The following measured at AC 120, 220, 240 V 50/60 Hz

DIN power output (rated) 200 + 200 watts

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference)

250 + 250 watts

(6 ohms at 1 kHz, 10% THD)

– Continued on next page –

MICROFILM

MINI Hi-Fi COMPONENT SYSTEM

Page 2

Specifications (continued)

Inputs

MD/VIDEO (AUDIO) IN: voltage 450 mV/250mV,

(phono jacks) impedance 47 kilohms

MIX MIC: (phone jack) sensitivity 1 mV, impedance 10

kilohms

Outputs

MD OUT: voltage 250 mV,

(phono jacks) impedance 1 kilohms

PHONES: accepts headphones of 8 ohms

(stereo phone jack) or more

SPEAKER:

E models: accepts impedance of 6 to 16 ohms

Other models: accepts impedance of 8 to 16 ohms

SUPER WOOFER (GRX9900/RXD9: US models):

Voltage 1 V, impedance 1 kilohm

CD player section

System Compact disc and digital audio system

Laser Semiconductor laser (λ=780nm)

Emission duration: continuous

Laser output Max. 44.6 µW*

*This output is the value measured at

distance of 200 mm from the objective

lens surface on the Optical Pick-up

Block with 7 mm aperture.

Frequency response 2 Hz - 20 kHz (±0.5 dB)

Wavelength 780 -790 nm

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

CD OPTICAL DIGITAL OUT

(Square optical connector jack, rear panel)

Wavelength 600 nm

Output Level -18 dBm

Tape player section

Recording system 4-track 2-channel stereo

Frequency response 40 - 13,000 Hz (±3 dB),

(DOLBY NR OFF) using Sony TYPE I cassette

40 - 14,000 Hz (±3 dB),

using Sony TYPE II cassette

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 - 108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

3 Band type:

Saudi Arabia model:

MW: 531 - 1,602 kHz

(with the interval set at 9 kHz)

SW: 5.95 - 17.90 MHz

(with the interval set at 5 kHz)

Other models:

MW: 531 - 1,602 kHz

(with the interval set at 9 kHz)

530 - 1,710 kHz

(with the interval set at 10 kHz)

SW: 5.95 - 17.90 MHz

(with the interval set at 5 kHz)

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

General

Power requirements

US model: 120 V AC, 60 Hz

AEP and UK models: 230 V A C, 50/60 Hz

Mexican model: 120 V AC, 50/60 Hz

Other models: 120 V, 220 V, or 230 - 240 V AC,

50/60 Hz

Adjustable with voltage selector

Power consumption

US model: 170 watts

AEP and UK models: 180 watts

Other models: 240 watts

Dimensions (w/h/d) Approx. 280 × 360 × 395 mm

(131/8 × 141/4 × 155/8 in.)

Mass

US model: Approx. 10.6 kg (23 lb 6 oz.)

AEP and UK models: Approx. 10.8 kg

Other models: Approx. 12.2 kg

Supplied accessories: AM loop antenna (1)

Remote Commander (1)

Batteries (2)

FM lead antenna (1)

Speaker cords (2)

Front speaker pads (8)

Design and specifications are subject to change without notice.

UKV tuner section (3 band (FM-AM-UKV) models only)

Tuning range 65.0 - 74.0 MHz

Stereo Plus

AM tuner section

Tuning range

2 Band type:

US model: 530 - 1,710 kHz

(with the interval set at 10 kHz)

531 - 1,710 kHz

(with the interval set at 9 kHz)

AEP and UK models:

531 - 1,602 kHz

(with the interval set at 9 kHz)

Other models: 531 - 1,602 kHz

(with the interval set at 9 kHz)

530 - 1,710 kHz

(with the interval set at 10 kHz)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

Page 3

TABLE OF CONTENTS

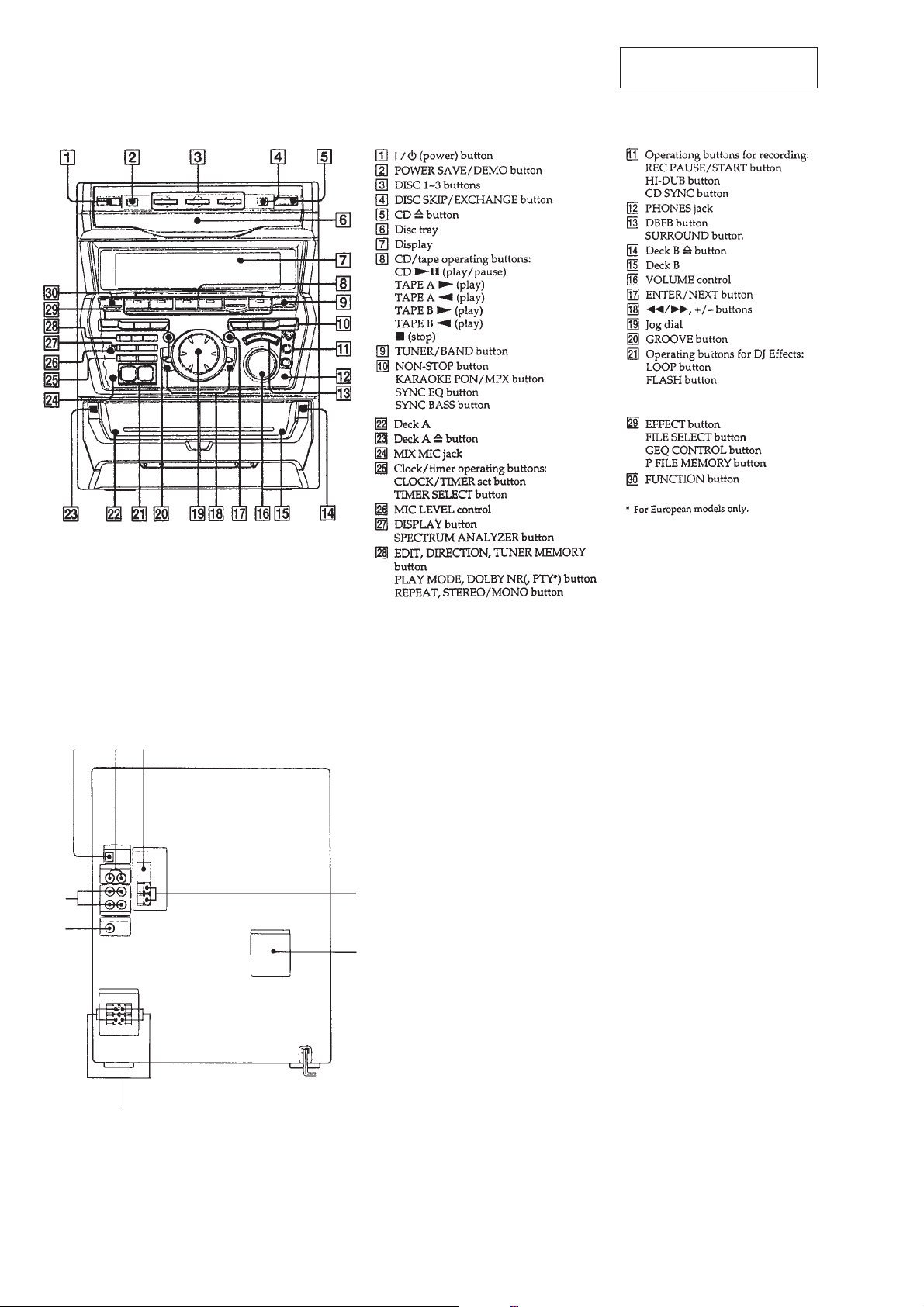

SECTION 1

SERVICING NOTES

1. SERVICING NOTES............................................... 3

2. GENERAL

Location of Controls ....................................................... 6

Setting the Time .............................................................. 7

3. DISASSEMBLY ......................................................... 8

4. TEST MODE.............................................................. 11

5. MECHANICAL ADJUSTMENTS....................... 14

6. ELECTRICAL ADJUSTMENTS

DECK Section ................................................................. 14

CD Section ...................................................................... 17

7. DIAGRAMS

7-1. Block Diagram – CD SERVO Section – ........................ 19

7-2. Block Diagram – TAPE DECK Section – ...................... 21

7-3. Block Diagram – MAIN Section –................................. 23

7-4. Block Diagram – DISPLAY/KEY CONTROL/

POWER SUPPLY Section – ........................................... 25

7-5. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 27

7-6. Printed Wiring Board – BD Board – .............................. 29

7-7. Schematic Diagram – BD Board – ................................ 31

7-8. Printed Wiring Boards – CD MOTOR Section –.......... 33

7-9. Schematic Diagram – CD MOTOR Section – .............. 35

7-10. Pr inted Wiring Board – AUDIO Board – ...................... 37

7-11. Schematic Diagram – AUDIO Board – ......................... 39

7-12. Printed Wiring Board – LEAF SW Board –.................. 41

7-13. Schematic Diagram – LEAF SW Board – ..................... 41

7-14. Pr inted Wiring Board – MAIN Board – ........................ 43

7-15. Schematic Diagram – MAIN Board (1/4) – .................. 45

7-16. Schematic Diagram – MAIN Board (2/4) – .................. 47

7-17. Schematic Diagram – MAIN Board (3/4) – .................. 49

7-18. Schematic Diagram – MAIN Board (4/4) – .................. 51

7-19. Printed Wiring Board – PANEL/CD SW Board – ........ 53

7-20. Schematic Diagram

– PANEL (1/3)/CD SW Board –..................................... 55

7-21. Schematic Diagr am – PANEL (2/3) Board – ................ 57

7-22. Schematic Diagram – PANEL (3/3) Board – ................ 59

7-23. Pr inted Wiring Board – TRANS Board –....................... 61

7-24. Schema tic Diagr am – TRANS Board –......................... 62

7-25. Printed Wiring Board

– SUB TRANS Board (RXD9) –.................................... 63

7-26. Schematic Diagram

– SUB TRANS Board (RXD9) –.................................... 64

7-27. IC Pin Function Description ........................................... 69

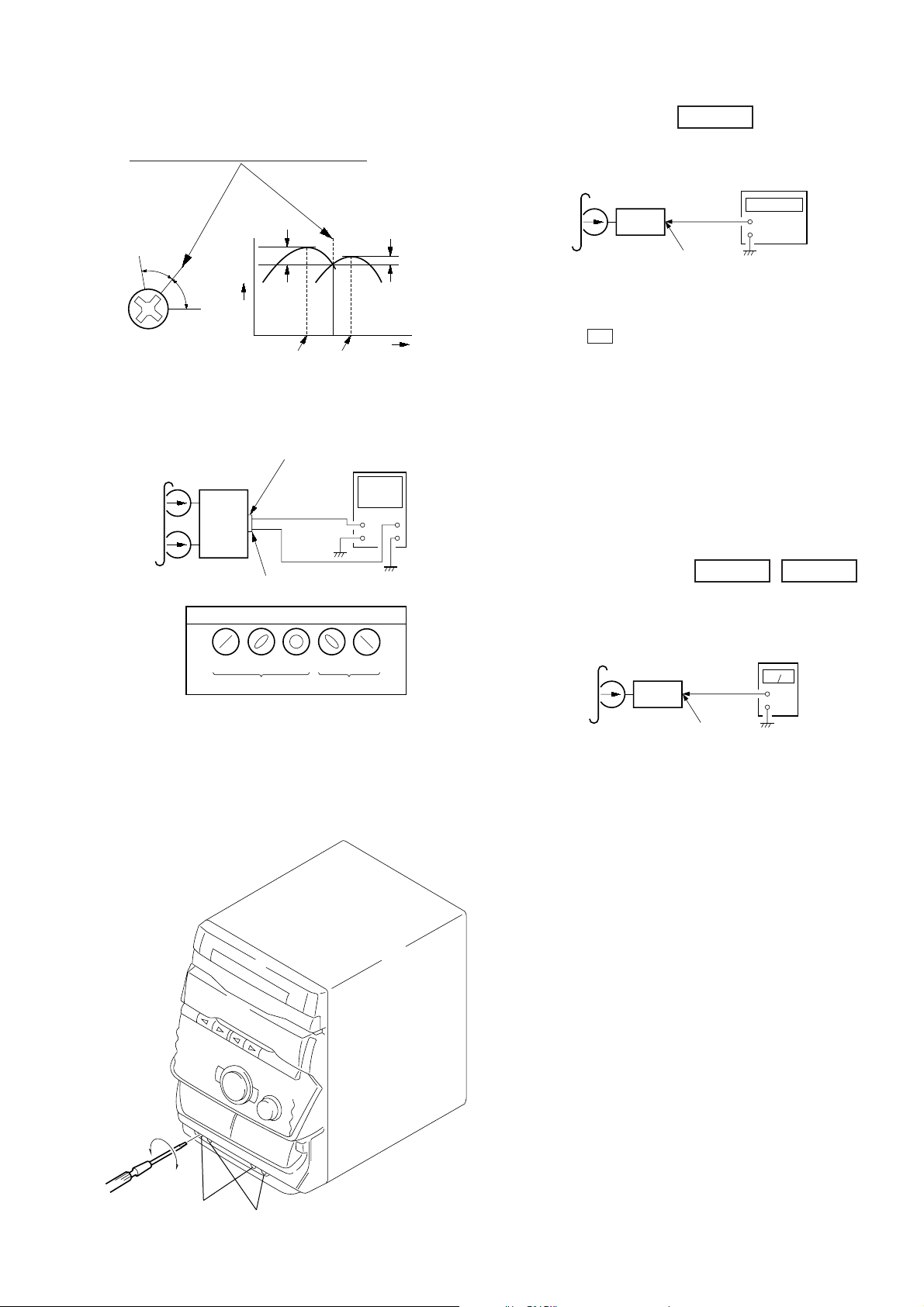

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The A C leaka ge from an y e xposed metal part to earth g round and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63T rd are e xamples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

AC

1.5 k

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

Ω

Earth Ground

voltmeter

(0.75 V)

8. EXPLODED VIEWS ................................................ 7 4

9. ELECTRICAL PARTS LIST ............................... 83

– 3 –

Page 4

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

MODEL IDENTIFICATION

– Rear Panel –

PART No.

CAUTION :

INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

ADVARSEL :

SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION. UNDGÅ UDSAETTELSE

FOR STRÅLING.

VORSICHT :

ABDECKUNG GEÖFFNET UND SICHEREITSVERRIEGELUNG

ÜBERBRÜCKT. NICHT DEM STRAHL AUSSETZEN.

VARO!:

TIINA NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VARNING :

OCH SPÄRREN ÄR URKOPPLAD. BETRAKTA EJ STRÅLEN.

ADVERSEL :

SIKKERHEDSLÅS BRYTES. UNNGÅ EKSPONERING FOR STRÅLEN.

VIGYAZAT!:

GÁRVESZÉLY

INVISIBLE LASER RADIATION WHEN OPEN AND

USYNLIG LASERSTRÅLING VED ÅBNING NÅR

UNSICHTBARE LASERSTRAHLUNG, WENN

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALT-

OSYNLING LASERSTRÅLING NÄR DENNA DEL ÄR ÖPPNAD

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG

A BURKOLAT NYITÁSAKOR LÁTHATATLAN LÉZERSU-

!

KERÜLJE A BESUGÁRZÁST!

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

MODEL PART No.

Argentine and 120 V AC Area in E models 4-214-457-0π

Saudi Arabia model 4-214-457-1π

Singapore and Malaysia models 4-214-457-2π

Mexican model 4-214-457-3π

AEP, UK, German and

North European models

4-214-457-5π

CIS model 4-214-457-6π

US model 4-214-457-7π

240 V AC Area in E model 4-214-457-8π

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

– 4 –

Page 5

HOW TO OPEN THE DISC TRAY WHEN POWER SWITCH TURNS OFF.

e

1

Remove the Cover. (Refer to page 8)

3

Pull-out the disc tray.

2

Turn the cam to the

direction of arrow.

NOTE FOR INSTALLATION (ROTARY ENCODER)

BU cam

Groove

Note:When attaching the Base unit, Insert th

section A into the groove of BU cam.

Section A

Note:When attaching the BU cam,

engage the Rotary encoder

switch as shown in the figure.

– 5 –

Page 6

LOCATION OF CONTOROLS

– Front Panel –

SECTION 2

GENERAL

This section is extracted from

instruction manual.

– Rear Panel –

123

4

5

6

7

8

1 CD DIGITAL OUT terminal

2 VIDEO (AUDIO) IN jack

3 FM COAXIAL ANTENNA terminal

(RXD9: AEP and UK models)

FM ANTENNA terminal

(GRX9900/RXD9: US models)

4 MD IN/OUT jack

5 SUPER WOOFER jack

(GRX9900/RXD9: US models)

6 SPEAKER terminal

7 AM ANTENN A terminal

8 VOLTAGE SELECTOR switch

(GRX9900: 120 V AC Area in E, 240 V AC Area in E, Saudi

Arabia, Singapore, Malaysia, Argentine models)

– 6 –

Page 7

– 7 –

Page 8

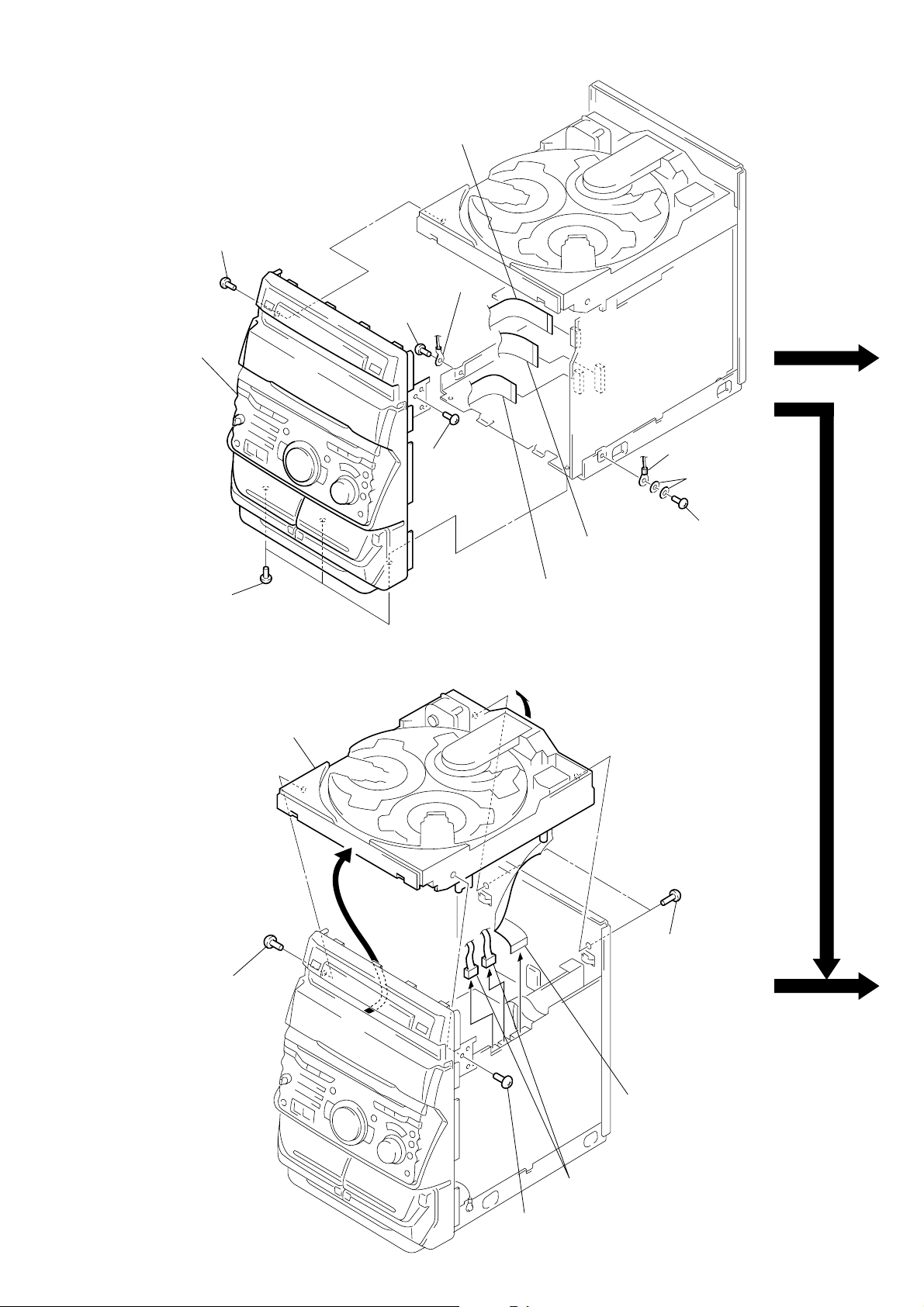

SECTION 3

)

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

CASE

6

case

2

screw

(case3 TP2) (3 × 12)

3

two screws

(case3 TP2) (3 × 8)

5

4

4

1

five screws

(BVTT3 × 8)

2

screw

(case3 TP2) (3 × 12)

3

two screws

(case3 TP2) (3 × 8

LOADING PANEL ASS’Y

A

1

Turn the cam-in the

direction of the arrow A.

2

Pull-out

the disc tray.

3

loading panel ass’y

– 8 –

Page 9

FRONT PANEL SECTION

)

5

screw

(BVTT3

×

10)

7

front panel section

1

wire (flat type)

(15 core) (32 cm) (CN303)

2

screw

(BVTT2.6

5

×

5)

screw

(BVTP3

4

lug

×

10)

1

wire (flat type)

(23 core) (CN501)

4

lug

3

two washers

2

screw

(BVTT2.6

×

5

6

three screws

×

(BVTT3

6)

CD MECHANISM DECK SECTION (CDM38LH-5BD32L)

3

Remove the CD mechanism

deck (CDM38LH-5BD32L)

in the direction of arrows

A

– B.

B

1

screw

×

(BVTP3

10)

1

wire (flat type) (17 core)

(CN304)

A

2

two screws

(BVTP3

×

8)

– 9 –

1

4

screw

(BVTP3

5

wire (flat type) (19 core)

(CN391)

two connectors

(CN392, 393)

×

10)

Page 10

)

TAPE MECHANISM DECK SECTION (TCM-230AWR2)

2

Open two

cassette lids.

1

Push the cassette lid.

3

three screws

(BVTP2.6

×

8)

3

two screws

(BVTP2.6

4

tape mechanism deck

section (TCM-230AWR2)

×

8)

1

Push the cassette lid.

MAIN BOARD

• Abbreviation

AR: Argentine model

E2 : 120 V AC Area in E model

E3 : 240 V AC Area in E model

EA : Saudi Arabia model

1

wire (flat type)

13 core: GRX9900: E2, MX, AR/RXD9: US

15 core: GRX9900: E3, EA, MY, SP/

()

(CN371)

RXD9: AEP, UK

2

connector

(CN13)

(RXD9)

MX: Mexican model

MY: Malaysia model

SP : Singapore model

3

two screws

(BVTP3

×

8)

3

five screws

(BVTP3

×

8

2

connector

(CN901)

4

Remove the MAIN board

in the direction of the arrow.

– 10 –

3

two screws

(BVTP3

5

connector

(CN403)

×

8)

Page 11

SECTION 4

TEST MODE

[MC Cold Reset]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Turn the power ON or set to the DEMO mode.

2. Press three buttons of p , [ENTER/NEXT], and 1/u simulta-

neously.

3. The set is reset, and displays “COLD RESET”, then becomes

DEMO mode.

[MC Hot Reset]

• This mode resets the set with the preset data kept stored in the

memory. The hot reset mode functions same as if the power

cord is plugged in and out.

Procedure:

1. Turn the power ON or set to the DEMO mode.

2. Press three buttons of p , [ENTER/NEXT], and [DISC1] si-

multaneously.

3. The set is reset, and becomes standby state.

[Change-over the AM Tuning Interval]

(EXCEPT AEP, UK, and Saudi Arabia models)

• The AM tuning interval can be changed over 9 kHz or 10 kHz.

Procedure:

1. Press the 1/u button to turn the power ON.

2. Select the function “TUNER”, and press the [TUNER/BAND]

button to select the BAND “AM”.

3. Press the 1/u button to turn the power OFF.

4. Press the [ENTER/NEXT] and 1/u buttons simultaneously,

and the display on the fluorescent indicator tube changes to

“AM 9 k STEP” or “AM 10 k STEP”, and thus the tuning

interval is changed over.

[CD Service Mode]

• This mode can run the CD sled motor optionally. Use this mode,

for instance, when cleaning the optical pick-up.

Procedure:

1. Press the 1/

2. Select the function “CD”.

3. Press three buttons of p , [ENTER/NEXT], and § simulta-

neously.

4. Set to the Sled Servo mode.

5. With the CD in stop status, turn the JOG dial clockwise to

move the optical pick-up to outside track, or turn it counterclockwise to inside track.

6. To exit from this mode, perform as follows.

1) Move the optical pick-up to the most inside track.

2) Disconnect the power cord.

Notes: • Always move the optical pick-up to most inside track when

u button to turn the power ON.

exiting from this mode. Otherwise, a disc will not be unloaded.

• Do not r un the sled motor excessively, otherwise the gear can

be chipped.

[CD Delivery Mode]

• This mode moves the optical pick-up to the position durable to

vibration. Use this mode when returning the set to the customer

after repair.

Procedure:

1. Press the 1/

2. Press the [LOOP] and 1/u buttons simultaneously.

3. A message “LOCK” is displayed on the fluorescent indicator

tube, and the CD delivery mode is set.

[LED and Fluorescent Indicator Tube All Lit, Key Check

Mode]

Procedure:

1. Press three buttons of p , [ENTER/NEXT], and [DISC2] si-

multaneously.

2. LEDs and fluorescent indicator tube are all turned on.

Press the [DISC2] button, and the key check mode is activated.

3. In the key check mode, the fluorescent indicator tube displays

“K 0 J0 V0”. Each time a button is pressed, “K” value increases. However , once a button is pressed , it is no longer taken

into account.

“J” value increases like 1, 2, 3 ... if turn the JOG dial clockwise, or it decreases like 0, 9, 8 ... if turn the JOG dial counterclockwise.

“V” value increases like 1, 2, 3 ... if turn the [VOLUME] dial

clockwise, or it decreases like 0, 9, 8 ... if turn the JOG dial

counterclockwise.

4. To exit from this mode, press three buttons in the same man-

ner as step 1, or disconnect the power cord.

u button to turn the power ON.

– 11 –

Page 12

[Aging Mode]

This mode can be used for operation check of CD section and tape

deck section.

CD section and tape deck section work in parallel.

• If an error occurred:

The aging operation stops only an error occurred sections and

display then status.

• If no error occurs:

The aging operation continues repeatedly.

Procedure:

1. Set disc in DISC1 tray.

2. Load the tapes into the decks A and B respectively.

3. Press the [PLAYMODE] button to set the “ ALL DISCS” mode,

and press the [REPEAT] button to “REPEAT” off.

4. Press the [FUNCTION] button to select the function “CD”.

5. Press three buttons of p , [ENTER/NEXT], and [DISCSKIP/

EX-CHANGE] simultaneously.

6. The aging mode is activated, if the indicator of disc tray num-

ber on the fluorescent indicator tube is blinking.

7. To exit from the aging mode, press the 1/u button to turn the

power OFF and operate the cold reset. (Refer to the “MC Cold

Reset”)

• Display at an error occurred

1) Display of the error count

(1) Press three buttons of p , [ENTER/NEXT], and [CDSYNC]

simultaneously.

(2) Display of the error count following as below.

Display

EMC**EDC

Notes:

EMC**: The number of mechanical error.

EDC**: The number of no disc error after chucking the disc.

**

2) Display of mechanical error

Display

E**M##$$&&

1. Display at the Aging Mode

• Display operating state of CD section and tape deck section alternately.

• If an error occurred, stop display which that section.

2. CD Section

• Display at the aging mode is the same as the normal operation.

• T he sequence during the aging mode is following as below.

Aging mode sequence (CD section) :

Turn the disc tray

Disc1 chucking

TOC read

Play track1 for 2 seconds

Play last track for 2 seconds

Notes:

: The number of mechanical error.(“00” is latest one)

**

(Press the [PLAYMODE] button to changes next error display)

## : Not used.

$$ : Loading error. (Second figure is not used)

D: The error in the midst of close at the except mechanical trouble.

E : The error in the midst of open at the except mechanical trouble.

C : The error in the midst of chuck up at the except mechanical

trouble.

F : The error in the midst of EX-open at the except mechanical

trouble.

&&: Loading error. (Second figure in not used)

1:The error in the midst of chuck up.

2:The error in the midst of chuck down.

3:Time up of EX-open

4:Time up of EX-close.

3) Display of no disc error

Display

E**D##$$&&

Notes:

: The number of mechanical error.(“00” is latest one)

**

(Press the [REPEAT] button to changes next error display)

##:

01:Focus error

02:GFS error

03:Set up error

$$:

00:No disc error when does not chucking retry.

02:No disc error when chucking retry to completion.

&&: The state when judged no disc error. (Second figure is not used)

1: Stop

2: Set up

3: TOC read

4: Access

5: Play

6: Pause

7: Manual search (Play)

8: Manual search (Pause)

– 12 –

Page 13

3. Tape Deck Section

• The sequence during the aging mode is following as below.

• If an error occurred, stop display that step.

Aging mode sequence (Tape deck section) :

Rewind the tape A and B

“TAPE A AG-1”

Shut off

FWD play the tape A

“TAPE A AG-2”

2 minutes

Fast forward the tape A

“TAPE A AG-3”

Shut off or 20 seconds

REV play the tape A

“TAPE A AG-4”

2 minutes

Rewind the tape A

“TAPE A AG-5”

Shut off

FWD play the tape B

“TAPE B AG-2”

2 minutes

Fast forward the tape B

“TAPE B AG-3”

Shut off or 20 seconds

REV play the tape B

“TAPE A AG-4”

2 minutes

Rewind the tape B

“TAPE B AG-5”

Shut off

Note: “TAPE * AG-*” is display of each step.

– 13 –

Page 14

SECTION 5

r

MECHANICAL ADJUSTMENTS

SECTION 6

ELECTRICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

Torque Measurement

Mode

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

Torque meter

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

Meter reading

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

2 to 6 g • cm

(0.03 – 0.08 oz • inch)

31 to 71 g • cm

(0.43 – 0.98 oz • inch)

2 to 6 g • cm

(0.03 – 0.08 oz • inch)

71 to 143 g • cm

(0.99 – 1.99 oz • inch)

100 g or more

(3.53 oz or more)

100 g or more

(3.53 oz or more)

DECK SECTION

0 dB=0.775 V

1. Demagnetize the record/playback head with a head demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in

this service manual. (As a general rule, playback circuit adjustment should be completed before performing recording

circuit adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

7. Switches and controls should be set as follows unless otherwise specified.

8. Set to the DOLBY NR OFF.

9. Set to the test mode.

(1) Press the 1/u button to turn the power ON.

(2) Select the function “TAPE A or B”.

(3) Press the button of p , [ENTER/NEXT], and [DISC3]

simultaneously, to set the tape deck test mode and blink

the indicator of disc tray number on the fluorescent indicator tube.

(4) To exit from the test mode, press the 1/u button.

• Test Tape

Tape Signal Used for

P-4-A100 10 kHz, –10 dB Azimuth Adjustment

WS-48B 3 kHz, 0 dB Tape Speed Adjustment

P-4-L300 315 Hz, 0 dB Level Adjustment

Record/Playback Head Azimuth Adjustment

DECK A DECK B

Note: Perform this adjustments for both decks

Procedure:

1. Mode: Playback

test tape

P-4-A100

(10 kHz, –10 dB)

MAIN board

MD OUT jack (J101)

L-CH, R-CH

set

level mete

+

–

– 14 –

Page 15

2. T urn the adjustment scre w and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

Tape Speed Adjustment

Mode: Playback

test tape

WS-48B

(3 kHz, 0 dB)

DECK B

frequency counter

Output

level

within

1dB

L-CH

peak

R-CH

peak

within

1dB

Screw

position

L-CH

peak

Screw

position

R-CH

peak

3. Mode: Playback

MAIN board

test tape

P-4-A100

(10 kHz, –10 dB)

L-CH

R-CH

in phase 45°90°135°180

MD OUT jack (J101)

L-CH

R-CH

waveform of oscilloscope

good

oscilloscope

wrong

H

V

°

4. Repeat step 1 to 3 in playback (REV) mode.

5. After the adjustments, apply suitable locking compound to the

pats adjusted.

set

MAIN board

MD OUT jack (J101)

L-CH, R-CH

+

–

1. Insert the WS-48B into the deck B.

2. Press the ( button on the deck B.

3. Press the [HI-DUB] button in playback mode.

Then at HIGH speed mode.

4. Adjust RV1001 on the LEAF SW board do that frequency

counter reads 6,000 ± 180 Hz.

5. Press the [HI-DUB] button.

Then back to NORMAL speed mode.

6. Adjust RV1002 on the LEAF SW board so that frequency

counter reads 3,000 ± 90 Hz.

Adjustment Location: LEAF SW board

Sample value of Wow and Flutter: 0.3% or less W.RMS (JIS)

(WS-48B)

Playback level Adjustment DECK A DECK B

Procedure:

Mode: Playback

test tape

P-4-L300

(315 Hz, 0 dB)

set

MAIN board

MD OUT jack (J101)

L-CH, R-CH

level meter

+

–

Adjustment Location:Playback Head (Deck A).

Record/Playback/Earth Head (Deck B).

forward

reverse

Deck A is RV311 (L-CH) and RV411 (R-CH), Deck B is RV301

(L-CH) and RV401 (R-CH) so that adjustment within adjustment

level as follows.

Adjustment Level:

J101 PB level: 301.5 to 338.3 mV (–8.2 to –7.2 dB) level

difference between the channels: within ±0.5 dB

Adjustment Location: AUDIO board

– 15 –

Page 16

REC Bias Adjustment DECK B

Procedure:

1. Mode: Record

FUNCTION: VIDEO

MAIN board

VIDEO (AUDIO) IN jack (J101)

L-CH, R-CH

50 mV (–23.8 dB)

600

Ω

AF OSC

1) 315 Hz

2) 10 kHz

attenuator

2. Mode: Playback

set

blank tape

CN-123

Specification values:

J101 PB level: 47.2 to 53.0 mV (–24.3 to –23.3 dB)

Adjustment Location: MAIN board

– MAIN BOARD (Conductor Side) –

RV301

L

IC301

RV351

R

REC LEVEL

VIDEO (AUDIO) IN

J101

MD OUT

(L/R)

(L/R)

recorded

portion

set

MAIN board

MD OUT jack (J101)

L-CH, R-CH

level meter

+

–

3. Confirm playback the signal recorded in step 1 become specification values as follows.

If these values are out of specification values, adjust the R V341

(L-CH) and RV441 (R-CH) on the AUDIO board to repeat

steps 1and 2.

Specification values: Playback output of 315 Hz to playback

output of 10 kHz: ± 0.5 dB

Adjustment Location: AUDIO board

REC Level Adjustment DECK B

Procedure:

1. Mode: Record

FUNCTION: VIDEO

MAIN board

VIDEO (AUDIO) IN jack (J101)

L-CH, R-CH

AF OSC

315 Hz, 50 mV (–23.8 dB)

Ω

attenuator

600

blank tape

CS-123

set

– AUDIO BOARD (Component Side) –

RV441

RV401

RV301

LR

PB LEVEL

– DECK B –

– LEAF SW BOARD (Component Side) –

TAPE SPEED

(NORMAL) (HIGH)

RV1002

RV1001

IC602

RV341

RL

REC BIAS

CN601

CN1001

RV311

LR

PB LEVEL

– DECK A –

RV411

2. Mode: Playback

recorded

portion

set

MAIN board

MD OUT jack (J101)

L-CH, R-CH

level meter

+

–

3. Confirm playback the signal recorded in step 1 become specification values as follows.

If these values are out of specification values, adjust the R V301

(L-CH) and R V351 (R-CH) on the MAIN board to repeat steps

1 and 2.

– 16 –

Page 17

CD SECTION

V

+

–

BD board

TP (TE)

TP (VC)

oscilloscope

)

Note:

1. CD Block is basically designed to operate without adjustment. Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10 MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specified value with the following checks.

S-Curve Check

oscilloscope

BD board

TP (FE)

TP (VC)

+

–

E-F Balance (1 Track Jump) Check

Procedure :

1. Connect oscilloscpe to TP (TE) and TP (VC).

2. Turn the power ON.

3. Load a disc (YEDS-18) and playback the number five track.

4. Press the ^ (CD) button. (Becomes the 1 track jump mode)

5. Confirm that the level B and A (DC voltage) on the oscilloscope waveform.

Procedure:

1. Connect oscilloscope to TP (FE).

2. Connect between TP (FE1) and TP (VC) by lead wire.

3. Connect between TP (AGCCON) and TP (GND) by lead wire.

4. Turn the power ON.

5. Load a disc (YEDS-18) and actuate the focus search. (In consequence of open and close the disc tray, actuate the focus

search)

6. Cofirm that the oscilloscope waveform (S-curve) is symmetrical between A and B. And confirm peak to peak level within

4 ± 1 Vp-p.

S-curve waveform

symmetry

A

B

within 4

±

1 Vp-p

7. After check, remove the lead wire connected in step 2 and 3.

Note: • Try to measure several times to make sure than the ratio of A : B

or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the brightness

to obtain best waveform.

RF Level Check

oscilloscope

BD board

1 track jump waveform

B

0V

level = 1.3

Specified level: × 100 = less than ± 22%

±

0.6 Vp-p symmetry

A

B

A (DC voltage

6. After check, remove the lead wire connected in step 1.

center of

waveform

TP (RF)

TP (VC)

+

–

Procedure:

1. Connect oscilloscope to TP (RF).

2. Connect between TP (AGCCON) and TP (GND) by lead wire.

3. Turn the power ON.

4. Load a disc (YEDS-18) and playback.

5. Confirm that the oscilloscope waveform is clear and check RF

signal level is correct or not.

6. After check, remove the lead wire connected in step 2.

Note: Clear RF signal waveform means that the shape “≈” can be clearly

distinguished at the center of the waveform.

VOLT/DIV: 200 m

TIME/DIV: 500 ns

level:

±

0.3 Vp-p

1.45

– 17 –

Page 18

Checking Location:

– BD BOARD (Side B) –

TP (VC)

TP (RF)

IC103

IC102

TP (TE)

TP (GND)

TP

(AGCCON)

TP (FE)

TP (FE1)

– 18 –

Page 19

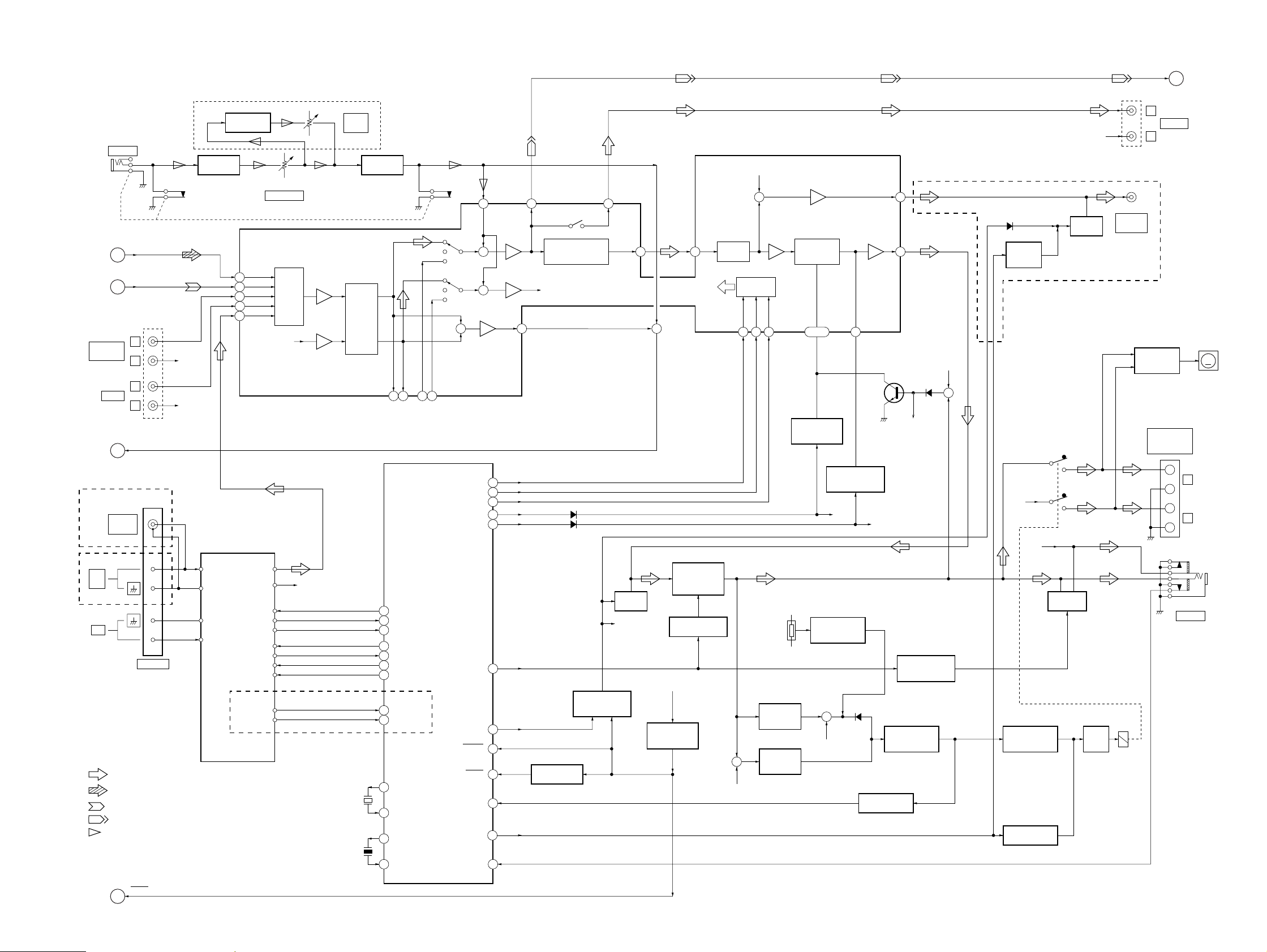

SECTION 7

DIAGRAMS

7-1. BLOCK DIAGRAM – CD SERVO Section –

HCD-GRX9900/RXD9

DETECTOR

A

B

C

D

F

E

OPTICAL PICK-UP

(KSS-213D/Q-NP)

LASER DIODE

PD

7

4

2

1

5

I-V AMP

10

6

LD

CD D+5V

10

11

AUTOMATIC

POWER

CONTROL

Q101

FOCUS/TRACKING ERROR AMP

A

5

B

6

C

7

D

8

F

F I-V AMP

E

E I-V AMP

LD

3

RF AMP,

SUMMING

APC LD

AMP

IC103

RF

AMP

RF EQ

AMP

FOCUS

ERROR AMP

TRACKING

ERROR AMP

APC PD

AMP

RFO

HOLD SW

LDON

FILTER

53

54 56

FILO

PCO

CLTV

RFAC

ASYI

ASYO

DIGITAL

CLV

MDP

26

ASYMMETRY

CORRECTION

XRST

3

16

FE

14

TE

13

21

22

PD

4

51

49

48

DIGITAL

SUBCODE

PROCESSOR

XLON

XLAT

DATA

14 5 6

PLL

CPU INTERFACE

CLOK

SENS

8

7

DIGITAL SIGNAL PROCESSOR,

DIGITAL FILTER, D/A CONVERTER

55

FILI

EFM

DEMODULATOR

SERVO AUTO

SEQUENCER

SQSO

SCOR

20

1 2

16K

RAM

SQCK

IC101 (1/2)

CORRECTOR

SERVO

INTERFACE

SCLK

COUT

9 21

D/A

INTERFACE

INTERNAL BUS

ERROR

SSTP

EMPH

WFCK

GFS

64 15

27

ON :

18

S101

(LIMIT)

When the optical pick-up

is inner position.

PCMD

BCK

LRCK

C2PO

SERIAL

IN

INTERFACE

DIGITAL

62

63

61

19

OUT

DOUT

60

DIGITAL

FILTER,

NOISE SHAPER

TO MIRR/DFCT/

FOK DETECTOR

PWM

&

INTEGRATOR

AOUT1

AOUT2

70

77

CLOCK

GENERATOR

X101

CD DIGITALOUT

OPTICAL

OPTICAL

TRANSCEIVER

CD-L

IC381

IC381

A

(Page 23)

BUFFER

TIMING

LOGIC

LOUT1

LOUT2

XTAI

XTAO

72

75

R-CH

66

67

16.9344MHz

AIN1

71

AIN2

76

(TRACKING)

(FOCUS)

05

2-AXIS

DEVICE

M101

(SPINDLE)

M102

(SLED)

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

IC102

CH4OUTF

15

M

M

16

17

18

12

11

14

13

CH4OUTR

CH3OUTF

CH3OUTR

CH2OUTF

CH2OUTR

CH1OUTF

CH1OUTR

MOTOR

DRIVE

MOTOR

DRIVE

COIL

DRIVE

COIL

DRIVE

CH4SIN

CH3FIN

CH3RIN

CH2FIN

CH2RIN

CH1FIN

CH1RIN

MUTE

25

43

39

40

41

FE

TE

SE

24

23

SFDR

28

SRDR

29

5

6

2

3

20

TFDR

30

TRDR

31

FFDR

32

33

FRDR

FOCUS/TRACKING/SLED

RFDC

A/D

CONVERTER

PWM GENERATOR

SERVO DSP

FOCUS/TRACKING/SLED

DIGITAL SERVO

PROCESSOR

IC101 (2/2)

MIRR/DFCT/

FOK

DETECTOR

TO SERVO INTERFACE

FOK

MIRR

DFCT

24

22

23

33

SQ-CLK

32

SQ-DATA

19

SCOR

56

SENSE

37

CD-CLK

58

XLT

CD-DATA

35

HOLD

57

SYSTEM CONTROLLER

(CD MECHANISM CONTROL)

IC501 (1/4)

59

XRST

DISC-SENS

TBL-SENS

OUT-OPEN

ENC1

ENC2

ENC3

LOAD-OUT

LOAD-IN

TBL-L

TBL-R

60

61

71

69

68

66

67

63

65

LEVEL SHIFT

Q701

(OPEN/CLOSE DET)

470

ROTARY

2

ENCODER

S811

3

DISC TRAY SLIDE MOTOR DRIVE

FIN

10

RIN

2

DISC TRAY TURN MOTOR DRIVE

IN1

3

IN2

6

DISC TRAY SENSOR

S801

CLOSE

OPEN

IC801

MOTOR

DRIVE

IC701

MOTOR

DRIVE

DISC IN DETECT

SENSOR

IC703

IC702

DISC TRAY

ADDRESS DETECT

OUT1

7

OUT2

4

OUT1

7

OUT2

2

M

(DISC TRAY SLIDE)

M

(DISC TRAY TURN)

M801

M701

– 19 – – 20 –

• SIGNAL PATH

: CD PLAY (ANALOG OUT)

: CD PLAY (DIGITAL OUT)

Page 20

HCD-GRX9900/RXD9

7-2. BLOCK DIAGRAM – TAPE DECK Section –

L-CH

R-CH R-CH

(RECORD/PLAYBACK)

L-CH

R-CH R-CH

HP101

(PLAYBACK)

HRPE101 (1/2)

DECK PROCESS

DECK A/B SELECT, PB/REC EQ AMP,

DOLBY NR AMP, ALC, AMS

IC301

DOLBY PASS

NORM/HIGH

PB A/B

70

120

R-CH

NR ON/OFF

BIAS ON/OFF

RM ON/OFF

L.P.F.

BUFFER

AMS

CIRCUIT

REC/PB/PASS

LM ON/OFF

+

28

27

26

MAOUT

MSIN

MSOUT

RIN (L)

43

ALC (L)

44

DOLBY NR

ALC

ALC

ROUT (L)

35 34

AMP

CIRCUIT

IN (L)

REC OUT (L)

39

RV301

REC LEVEL (L)

(DECK B)

EQ IN (L)

38

PB EQ AMP

(DECK A)

IC611

PB EQ AMP

(DECK B)

IC601

REC/PB SWITCHING

IC602

1

3

R-CH

R-CH

RV311

PB LEVEL (L)

(DECK A)

RV301

PB LEVEL (L)

(DECK B)

4

AIN (L)

48

BIN (L)

46

BIAS (N)

33

BIAS (C)

32

BIAS (M)

31

S1004

(DECK A 120/70)

S1008

(DECK B 120/70)

BIAS

CONTROL

CIRCUIT

B NORM/CROM

ALC ON/OFF

A 120/70

1516182022 23242517

19

REC

EQ AMP

PB OUT (L)

EQ OUT

40

(L)

36

PB-L

REC-L

B

(Page 23)

C

(Page 24)

• SIGNAL PATH

: PLAYBACK (DECK A)

: PLAYBACK (DECK B)

: RECORD

RV441

REC BIAS (R)

(DECK B)

HRPE101 (2/2)

(ERASE)

R-CH

05

2

RV341

REC BIAS (L)

(DECK B)

BIAS OSC

T621

BIAS OSC

Q621, 622

REC BIAS

SWITCH

Q623

C331, L331

BIAS

TRAP

B+

(A+7V)

D+5V

100

TC-RELAY

(DECK A PLAY)

8584838281 807978

PB-A/B

EQ-H/N

ALC-ON/OFF

A-PLAY-SW

87

S1001

S1002

(DECK B PLAY)

BIAS

REC-MUTE

B-PLAY-SW

86

TC-MUTE

R/P-PASS

NR-ON/OFF

(DECK A HALF)

S1003

77

AMS-IN

88

DETECT SENSOR

A-HALF

(DECK B HALF)

(DECK A REC)

ROTATION

(DECK A)

IC1001

91

A-SHUT

S1006

S1005

S1009

(DECK B REC)

ROTATION

DETECT SENSOR

(DECK B)

IC1002

90

B-SHUT

SYSTEM CONTROLLER

B-HALF

89

IC501 (2/4)

TRIGGER PLUNGER

DECK A

TRIGGER

PLUNGER DRIVE

(DECK A)

Q333, 334

73

A-TRG

TRIGGER PLUNGER

DECK B

TRIGGER

PLUNGER DRIVE

(DECK B)

Q331, 332

72

B-TRG

Q335

76

CAP-M-H/L

RV1001

TAPE SPEED

(HIGH)

CAPM-CNT1

CAPM-CNT2

CAPSTAN MOTOR

CONTROL SWITCH

Q1001

75

MOTOR DRIVE

74

RV1002

TAPE SPEED

(NORMAL)

CAPSTAN

Q336 – 343

M

M1

(CAPSTAN)

– 21 –

– 22 –

Page 21

7-3. BLOCK DIAGRAM – MAIN Section –

HCD-GRX9900/RXD9

J711

MIX MIC

VIDEO

MD IN

A

B

D

FM 75Ω

COAXIAL

CD-L

PB-L

SPEANA

(Page 20)

(Page 22)

(AUDIO) IN

(Page 25)

(RXD9: AEP, UK)

(GRX9900/RXD9: US)

FM

75Ω

AM

• SIGNAL PATH

: TUNER (FM/AM)

: CD PLAY

: TAPE PLAY

: RECORD

: MIC INPUT

(Page 25)

RESET

E

J101 (1/2)

L

R

L

R

ANTENNA

R-CH

R-CH

MIC AMP

IC712 (1/2)

(GRX9900: Saudi Arabia)

DIGITAL ECHO

IC711

IN E2

65

IN D2

66

IN B2

68

IN A2

69

IN C2

67

GRAPHIC EQUALIZER CONTROL,

FM/AM TUNER UNIT

FM ANT

FM ANT

AM ANT

AM ANT

ST-L

ST-R

ST-MUTE

STEREO

TUNED

ST-DIN

ST-DOUT

ST-CLK

ST-CE

RDS-DATA

RDS-INT

RV712

MIC LEVEL

INPUT

SELECT

SWITCH

R-CH

INPUT SELECT SWITCH,

ELECTRICAL VOLUME

IC101

R-CH

(RXD9: AEP, UK)

05

RV711

ECHO

LEVEL

SOUND

CONTROL

CIRCUIT

X601

32.768kHz

X613

16MHz

MIC AMP

IC712 (2/2)

49

50

51

53

54

55

52

21

20

11

10

13

15

KEY IN2

KEY IN1

KEY OUT 2

60 5 59 6

SYSTEM CONTROLLER

ST-MUTE

STEREO

TUNED

ST-DOUT

ST-DIN

ST-CLK

ST-CE

RDS-DATA

RDS-INT

XC-OUT

XC-IN

X-OUT

X-IN

KEY OUT 1

IC501 (3/4)

PROTECTOR

2 58 57

MIC IN

REC A2

+

+

L+R

+

493-DATA

493-CLK

493-LATCH

DBFB-H/L

BASS FREQ.

STK-MUTE

LINE-MUTE

AC-CUT

RESET

F-RELAY

RY-SW

30

47

48

38

7

44

1

6

22

12

27

3

36

RESET SWITCH

GRAPHIC EQUALIZER

CONTROL CIRCUIT

R-CH

D607

D644

MUTING CONTROL

SWITCH

Q508, 509

Q501

REC B2

F OUT2

42 41

MUTING

Q113

R-CH

COMMAND

+

POWER AMP

STANDBY SWITCH

Q803, 804, 881

+5V

RESET SIGNAL

GENERATOR

IC502

IC801

VOL

IN2

VOLUME

CONTROL

+

R-CH

R-CH

+

CPU

INTERFACE

DATA

CLOCK

LATCH

34

TH831

OVER LOAD

DETECT

Q801

DC DETECT

SWITCH

Q433, 434

BASS BOOST

CONTROL

CIRCUIT

BB B2,

BB A2

38, 39

DBFB CONTROL

SWITCH

Q111

CONTROL SWITCH

TEMPERATURE

DETECT SWITCH

Q831, 832

+

R-CH

SUPER

WOOFER

BUF IN2

373233

BASS FREQUENCY

Q201

R-CH

D803

PROTECT SWITCH

BUF

OUT2

FEED BACK

SWITCH

Q112

R-CH

OVER LOAD

DETECT SWITCH

Q439

72

36

D141

R-CH

MUTING CONTROL

SWITCH

Q412

Q432

R-CH

+

D191

PROTECT

SWITCH

Q192

–1

–2

R-CH

R-CH

OVER LOAD

DETECT SWITCH

Q437

PROTECT SWITCH

Q435, 436

MUTING

Q411, 471

R-CH

MUTING

Q191

(GRX9900/RXD9: US)

RELAY

DRIVE

Q431

J101 (2/2)

J191

SUPER

WOOFER

RY401

REC-L

L

MD OUT

R

FAN MOTOR

DRIVE

Q401, 402

TM401

SPEAKER

IMPEDANCE

USE 6 – 16Ω

+

–

+

–

C

PHONES

(Page 22)

L

R

J701

M501

(FAN)

M

– 23 –

– 24 –

Page 22

HCD-GRX9900/RXD9

7-4. BLOCK DIAGRAM – DISPLAY/KEY CONTROL/POWER SUPPLY Section –

D

FLUORESCENT INDICATOR TUBE DRIVER,

KEY CONTROL

IC601

BAND-PASS FILTER

IC603

SPEANA

(Page 23)(Page 23)

E

RESET

(RXD9)

+5V REGULATOR

IC11

SUB POWER TRANSFORMER

RECT

D12 – 15

T11

GRID DRIVE

Q611 – 616

FL601

FLUORESCENT INDICATOR TUBE

GRID DRIVE

Q610

S611 – 630,

S637 – 650, 801 – 807

REMOTE CONTROL

RECEIVER

IC602

LED DRIVE

Q607

LED DRIVE

Q608

D608, 609

ROTARY

ENCODER

S601

ROTARY

ENCODER

S602

S601

(JOG DIAL)

S602

VOLUME

D609

(RIGHT)

D608

(LEFT)

(FOR ILLUMINATION DISPLAY)

46 – 67

S1 – S22

32 – 27

G13 – G18

G2 – G12

44 – 42, 40 – 33

45

G1

11 – 14

KEY0 – KEY3

1

SIRCS

2

JOG-A

8

JOG-B

VOL-A

9

10

VOL-B

22

GRADATION R/WAKE UP

15

GRADATION L

05

S LOW FREQ (BPF0)

ALL BAND (L+R)

RESET

L SEL

LED DATA

LED SCK

LED LAT

I2C DATA

I2C CLK

XOUT

XIN

72

70

X601

12.5MHz

BPF1

BPF2

BPF3

BPF4

16

17

18

19

20

21

73

7

5

3

4

78

79

F01

17

F02

16

F04

14

DET

F05

13

F06

12

L+R

11

DET

LED DRIVER

IC604

DATA

13

14

CLK

15

STB

SYSTEM CONTROLLER

IC501 (4/4)

IIC-DATA

30

IIC-CLK

29

WAKE UP

18

LINE

B.P.F.

17, 19 – 23, 2, 3, 5, 7, 10, 11

P1 – P6, P8, P9, P11, P12, P15, P16

FL SW

STBY RELAY

CD-POWER

POWER

STBY LED

TIMER LED

IN

REC IN

42

43

5

2

39

26

LED DRIVE

Q604, 620

LED DRIVE

4

6

B+ SWITCH

Q601, 602

D611 – 615, 619,

D620, 622 – 626,

D631 – 634, 801 – 803

(RXD9)

Q605

LED +5V

Q603

D804

I/u

D636

TIMER SELECT

+5V

SYSTEM CONTROLLER

(IC501) B+

+5V (STBY)

(PANEL SECTION B+)

CD D+5V, CD A+5V

CD MECHANISM DECK

SECTION B+

D+5V

M62493FP (IC101),

CD SENSOR CIRCUIT B+

(RXD9)

D501, 502

D509

B+ SWITCH

Q907, 908

B+ SWITCH

Q904, 905

D+5V

(TAPE DECK SECTION B+)

LED +5V

(PANEL SECTION B+)

(GRX9900)

(RXD9)

D925

(GRX9900)

(RXD9)

D923

(GRX9900)

(RXD9)

D922

(GRX9900)

(RXD9)

D924

(GRX9900)

–26V

(FL DRIVER (IC601) B–)

REGULATOR

TC, PANEL,

REGULATOR

CONTROL SWITCH

Q903, 923

CD M+7V

(CD MOTOR SECTION B+)

TC M+12V

(TC MOTOR SECTION B+)

ST +10V

(FM/AM TUNER UNIT B+)

(RXD9)

+5V

IC902

AUDIO

–26V REGULATOR

POWER AMP (IC801),

PROTECTOR CIRCUIT

(GRX9900)

+7V

–7V

FAN MOTOR B–

+10V

REGULATOR

Q909

Q13

TO FLUORESCENT

INDICATOR TUBE

(FL601)

REGULATOR

Q901, 902, 913

REGULATOR

Q914, 951, 952

FL ON/OFF

SWITCH

Q12, 17

FL ON/OFF

SWITCH

Q14 – 16

VF1

VF2

B+

B–

B+

B–

–26V REGULATOR

Q971

+7V

–7V

D405 – 407

+7V

REGULATOR

IC901

+12V

REGULATOR

IC903

RECT

D17 – 20

(GRX9900)

RECT

D832

RECT

D831

RECT

D971

RECT

D901 – 904

RECT

D907 – 910

RELAY DRIVE

Q11

POWER TRANSFORMER

T951

RY11

(GRX9900: Mexican/RXD9)

VOLTAGE

SELECTOR

S951

(EXCEPT GRX9900: Mexican/RXD9)

AC IN

(GRX9900)

AC IN

– 25 –

– 26 –

Page 23

7-5. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

CONNECTOR board

SENSOR board

MOTOR (TURN) board

MOTOR (SLIDE) board

LEAF SW board

AUDIO board

BD board

(In addition to this, the necessary note is printed in each block)

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• p : parts mounted on the conductor side.

¢

•

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

• Indication of transisitor.

: internal component.

Q

B

CE

These are omitted.

Q

B

CE

These are omitted.

C

Q

B

E

These are omitted.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

• 2 : nonflammable resistor.

• 5 : fusible resistor.

• C : panel designation.

• U : B+ Line.

• V : B– Line.

• H : adjustment for repair.

• V oltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

• Abbreviation

: internal component.

Note: The components identified by mark ! or

dotted line with mark ! are critical for safety .

Replace only with part number specified.

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

F : TUNER (FM/AM)

E : PLAYBACK (DECK A)

d : PLAYBACK (DECK B)

G : RECORD

J : CD PLAY (ANALOG OUT)

c : CD PLAY (DIGITAL OUT)

N : MIC INPUT

AED : North European model

AR : Argentine model

E2 : 120 V AC Area in E model

E3 : 240 V AC Area in E model

EA : Saudi Arabia model

G : German model

MY : Malaysia model

MX : Mexican model

SP : Singapore model

4

W or less unless otherwise

• Circuit Boards Location

CD SW board

PANEL board

TRANS board

SUB TRANS board

(RXD9)

TUNER PACK

MAIN board

– 27 –

– 28 –

Page 24

HCD-GRX9900/RXD9

7-6. PRINTED WIRING BOARD – BD Board – • See page 28 for Circuit Boards Location.

)(

TP(GND)

TP(VC)

TP(RF)

TP

(AGCCON)

TP(FE)

TP(TE)

TP(FE1)

21

31

31,,

21

05

05

)(

)(

(Page 43)

19

21

21

31

31,,

• Semiconductor

Location

(Side A)

Ref. No. Location

Q101 C-3

– 29 –

KSS-213D/Q-NP

• Semiconductor

Location

(Side B)

Ref. No. Location

IC101 C-2

IC102 B-1

IC103 B-1

– 30 –

Page 25

7-7. SCHEMATIC DIAGRAM – BD Board – • See page 65 for Waveforms. • See page 66 for IC Block Diagrams.

HCD-GRX9900/RXD9

(Page 45)

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark : CD STOP

( ) : CD PLAY

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

– 31 –

– 32 –

Page 26

HCD-GRX9900/RXD9

7-8. PRINTED WIRING BOARDS – CD MOTOR Section – • See page 28 for IC Circuit Boards Location.

(Page 43)

B

DISC TRAY

SLIDE

DISC TRAY

TURN

1-658-577-

(DISC TRAY ADDRESS DETECT)

– 33 –

05

C

(Page 43)

– 34 –

Page 27

7-9. SCHEMATIC DIAGRAM – CD MOTOR Section – • See page 67 for IC Block Diagrams.

DISC TRAY

ADDRESS DETECT

DISC TRAY SLIDE

CLOSE

OPEN

HCD-GRX9900/RXD9

DISC IN DETECT

SENSOR

DISC TRAY

SENSOR

MTZJ-T-72

(DISC TRAY SLIDE)

DISC

TRAY

TURN

DISC TRAY TURN

MOTOR DRIVER

B

(Page 45)

MTZJ-T-72

C

(Page 45)

– 35 –

LEVEL SHIFT

• Voltages are dc with respect to ground under no-signal

conditions.

no mark : CD STOP

– 36 –

Page 28

HCD-GRX9900/RXD9

7-10. PRINTED WIRING BOARD – AUDIO Board – • See page 28 for Circuit Boards Location.

(

)

05

D

(Page 43)

– 37 –

– 38 –

Page 29

7-11. SCHEMATIC DIAGRAM – AUDIO Board – • See page 68 for IC Block Diagram.

HCD-GRX9900/RXD9

(PLAYBACK)

PB EQ AMP

(DECK A)

PB EQ AMP

(DECK B)

PB LEVEL (L)

(DECK A)

PB LEVEL (R)

(DECK A)

PB LEVEL (L)

(DECK B)

PB LEVEL (R)

(DECK B)

D

(Page 49)

REC BIAS (R)

(DECK B)

BIAS OSC

REC BIAS (L)

(DECK B)

SWITCHING

REC BIAS

-6.8

– 39 –

• Voltages are dc with respect to ground under no-signal

conditions.

no mark : TAPE PLAY

( ) : RECORD

– 40 –

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

Page 30

HCD-GRX9900/RXD9

7-12. PRINTED WIRING BOARD – LEAF SW Board – • See page 28 for Circuit Boards Location.

DECK A

PLUNGER

4

3

1

2

(DECK A PLAY)

05

(DECK A HALF)

(DECK A 120/70)

(

)

(DECK A REC)

7-13. SCHEMATIC DIAGRAM – LEAF SW Board –

(CAPSTAN)

DECK B

PLUNGER

DECK A

PLUNGER

(DECK A 120/70)

(DECK A HALF)

(DECK A REC)

(DECK B HALF)

ROTATION DETECT SENSOR

(DECK A)

CONTROL SWITCH

ROTATION DETECT

SENSOR (DECK B)

E

(Page 43)

(DECK B PLAY)

4

1

(DECK B HALF)

DECK B

PLUNGER

3

2

(DECK B 120/70)

(DECK B REC)

21

21

• Semiconductor Location

Ref. No. LocationRef. No. Location

D141 E-10

D191 E-12

D331 E-1

D333 F-1

D334 E-1

D335 F-1

D401 G-11

D403 F-12

D405 H-6

D406 J-4

D407 I-2

D411 G-3

D501 D-7

D502 E-6

D503 D-6

D504 D-7

D505 D-7

D506 D-7

D509 F-2

D607 E-5

D644 C-8

D801 J-11

D802 G-9

D803 G-11

D831 I-6

D832 J-7

D851 J-10

D852 G-9

D881 H-9

D901 J-4

D902 J-4

D903 J-4

D904 I-4

D905 I-1

D906 H-1

D907 J-5

D908 I-5

D909 J-5

D910 J-5

D915 I-4

D921 H-4

D922 G-4

D923 G-4

D924 F-2

D925 G-4

Q113 E-9

Q161 C-9

Q162 C-9

Q163 E-9

Q191 E-12

Q192 E-10

Q201 D-9

Q251 C-9

Q331 C-1

Q332 C-2

Q333 C-2

Q334 C-2

Q335 D-1

Q336 F-1

Q337 F-1

Q338 F-1

Q339 F-1

Q340 E-1

Q341 E-1

Q342 F-1

Q343 E-1

Q401 F-12

Q402 E-12

Q411 G-2

Q412 G-3

Q431 G-12

Q432 G-11

Q433 F-11

Q434 F-11

Q435 F-11

Q436 F-11

Q437 G-12

Q439 F-12

Q471 F-2

Q501 D-7

Q508 D-7

Q509 E-7

Q801 H-10

Q803 G-10

Q804 G-9

Q831 G-10

Q832 G-10

Q851 J-10

Q881 I-9

Q901 H-2

Q902 I-1

Q903 H-1

Q904 G-4

Q905 G-4

Q907 G-5

Q908 G-4

Q909 I-4

Q913 H-1

Q914 G-2

Q923 H-1

Q951 G-2

Q952 H-1

E

(Page 49)

IC101 C-10

IC301 B-3

IC381 A-12

IC501 D-5

IC502 D-7

IC801 H-10

IC901 G-6

IC902 G-4

IC903 H-4

Q111 D-10

Q112 D-10

(DECK B REC)

(DECK B 120/70)

• Voltages are dc with respect to ground under no-signal

conditions.

no mark : TAPE PLAY

( ) : RECORD

: Impossible to measure

∗

– 41 –

(DECK A PLAY)

(DECK B PLAY)

– 42 –

Page 31

7-14. PRINTED WIRING BOARD – MAIN Board – • See page 28 for Circuit Boards Location.

HCD-GRX9900/RXD9

(Page 38)

(Page 41)

(Page 33)(Page 33)

(Page 30)

(Page 53)

(Page 61)

(GRX9900)

(RXD9)

(Page 63)

(Page 61)

– 43 – – 44 –

Page 32

HCD-GRX9900/RXD9

7-15. SCHEMATIC DIAGRAM – MAIN Board (1/4) –

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : TUNER (FM/AM)

( ) : CD PLAY

(Page 31)

(Page 36)

(Page

47)

(Page

51)

(Page 36)

– 45 –

(Page 50)

– 46 –

Page 33

7-16. SCHEMATIC DIAGRAM – MAIN Board (2/4) –

HCD-GRX9900/RXD9

(Page

46)

(Page

50)

(Page 61)

(Page 52)

– 47 –

• Voltages are dc with respect to ground under no-signal

(detuned) conditions.

no mark : FM

– 48 –

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

Page 34

HCD-GRX9900/RXD9

7-17. SCHEMATIC DIAGRAM – MAIN Board (3/4) –

(Page 46)

(Page 47)

(Page 51)

(Page 62)

(Page 64)

(Page 40)

(Page 58)

(Page 51)

• Voltages are dc with respect to ground under nosignal (detuned) conditions.

no mark : TUNER (FM/AM)

( ) : CD PLAY

{ } : TAPE PLAYBACK (DECK A)

[ ] : TAPE PLAYBACK (DECK B)

〈〈 〉〉 : RECORD

– 49 –

(Page 42)

– 50 –

Page 35

7-18. SCHEMATIC DIAGRAM – MAIN Board (4/4) – • See page 65 for Waveforms.

(Page

46)

(Page

50)

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : TUNER (FM/AM)

( ) : CD PLAY

{ } : TAPE PLAYBACK (DECK A)

[ ] : TAPE PLAYBACK (DECK B)

〈〈 〉〉 : RECOARD

(Page 48)

HCD-GRX9900/RXD9

(Page

50)

– 51 –

– 52 –

Page 36

HCD-GRX9900/RXD9

• Semiconductor

Location

Ref. No. Location

D601 F-6

D608 C-9

D609 C-2

D611 C-6

D612 C-7

D613 C-5

D614 C-4

D615 E-4

D619 D-3

D620 E-1

D621 G-6

D622 G-4

D623 G-7

D624 E-5

D625 E-4

D626 E-7

D631 D-6

D632 D-5

D633 D-8

D634 D-7

D636 F-8

IC601 B-5

IC602 B-9

IC603 B-7

IC604 F-5

IC711 E-8

IC712 G-8

(Page 43)

7-19. PRINTED WIRING BOARDS – PANEL/CD SW Board – • See page 28 for Circuit Boards Location.

Q601 F-6

Q602 F-6

Q603 F-6

Q604 A-10

Q605 A-10

Q607 B-2

Q608 C-9

Q610 B-7

Q611 B-7

Q612 B-7

Q613 B-7

Q614 B-7

Q615 B-8

Q616 B-8

Q620 A-10

• Semiconductor

Location

Ref. No. Location

D801 A-7

D802 A-6

D803 A-4

D804 A-10

– 53 –

– 54 –

Page 37

7-20. SCHEMATIC DIAGRAM – PANEL (1/3)/CD SW Board– • See page 68 for IC Block Diagrams.

HCD-GRX9900/RXD9

– 55 –

• Voltages and waveforms are dc with respect to ground

(Page 57)(Page 59)(Page 59)

under no-signal (detuned) conditions.

no mark : TUNER (FM/AM)

– 56 –

Page 38

HCD-GRX9900/RXD9

7-21. SCHEMATIC DIAGRAM – PANEL (2/3) Board– • See page 65 for waveform.

(Page 56)

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : TUNER (FM/AM)

(Page 59)

(Page 50)

(Page 60)

– 57 –

– 58 –

Page 39

7-22. SCHEMATIC DIAGRAM – PANEL (3/3) Board– • See page 68 for IC Block Diagrams.

HCD-GRX9900/RXD9

(Page 57)

(Page 58)

(Page 55)

(Page 55)

– 59 –

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : TUNER (FM/AM)

– 60 –

Page 40

HCD-GRX9900/RXD9

7-23. PRINTED WIRING BOARD – TRANS Board –

• See page 28 for Circuit Boards Location.

7-24. SCHEMATIC DIAGRAM – TRANS Board –

(Page 63)

(Page 48)

(Page 50)

(Page 64)

• Voltages are dc with respect to ground under no-signal

(detuned) conditions.

no mark : TUNER (FM/AM)

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

(Page 43)

(Page 43)

– 61 –

• Semiconductor

Location

Ref. No. Location

D971 G-2

D972 G-1

D973 G-1

Q971 G-1

– 62 –

Page 41

HCD-GRX9900/RXD9

7-25. PRINTED WIRING BOARD – SUB TRANS Board (RXD9) –

• See page 28 for Circuit Boards Location.

7-26. SCHEMATIC DIAGRAM – SUB TRANS Board (RXD9) –

(Page 62)

(Page

50)

K

(Page 61)

• Semiconductor

Location

Ref. No. Location

D11 C-2

D12 C-2

D13 C-1

D14 C-2

D15 C-2

D16 E-3

D17 D-2

D18 D-2

D19 D-2

D20 D-2

D21 D-2

D22 D-1

D23 D-1

• Voltages are dc with respect to ground under no-signal

(detuned) conditions.

no mark : TUNER (FM/AM)

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

(Page 43)

– 63 –

IC11 D-3

Q11 E-2

Q12 D-2

Q13 D-2

Q14 D-1

Q15 D-1

Q16 D-1

Q17 D-1

– 64 –

Page 42

• Waveforms

– BD Board –

1 IC101 ^¶ (XTAO)

5 IC101 @§ (MDP)

– MAIN Board –

1 IC501 0 (XC-IN)

• IC Block Diagrams

– BD Board –

IC101 CXD2587Q

3.1 Vp-p

16.9344 MHz

2 IC101 %¡ (RF AC) (CD Play Mode)

3 IC101 $¡ (TE) (CD Play Mode)

1.2 Vp-p

2.5 Vp-p

7.8 µs

32.768 kHz

6 IC102 !§ (RFO) (CD Play Mode) 2 IC501 !∞ (XIN)

1.3 Vp-p

16 MHz

– PANEL Board –

1 IC601 &™ (XOUT)

1.8 Vp-p

2.2 Vp-p

LRCK

PCMD

BCK

EMPH

XVDD

XTAI

XTAO

XVSS

AVDD1

AOUT1

AIN1

LOUT1

AVSS1

AVSS2

LOUT2

AIN2

AOUT2

AVDD2

RMUT

LMUT

VDD

AVDD3

DOUT

60

DIGITAL

OUT

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

D/A

INTERFACE

TIMING

LOGIC

OVER SAMPLING

PWM

3rd ORDER

NOISE SHAPER

DIGITAL FILTER

SERIAL IN

INTERFACE

59

58

INTERNAL BUS

PWM

VSS

57

ERROR

CORRECTOR

16K

RAM

SUBCODE

PROCESSOR

FILO

FILI

PCO

54

56

55

DIGITAL

PLL

EFM

DEMODULATOR

SERVO

INTERFACE

SERVO AUTO

SEQUENCER

AVSS3

CLTV

52

53

ASYI

BIAS

RFAC

51

49

50

ASYMMETRY

CORRECTION

48

ASYO

47

AVDD0

46

IGEN

45

AVSS0

ADIO

44

SERVO DSP

FOCUS

SERVO

TRACKING

SERVO

SLED

SERVO

CE

TE

RFDC

43

41

42

OPERATIONAL

AMPLIFIER

ANALOG SWITCH

A/D

CONVERTER

PWM GENERATOR

CLOCK

GENERATOR

FOCUS PWM

GENERATOR

TRACKING

PWM GENERATOR

SLED PWM

GENERATOR

DIGITAL

CLV

MIRR, DFCT,

FOK

DETECTOR

SE

40

FE

39

VC

38

XTSL

37

TES1

36

TEST

35

VSS

34

33

FRDR

32

FFDR

TRDR

31

TFDR

30

SRDR

29

28

SFDR

SSTP

27

MDP

26

25

LOCK

FOK

24

DFCT

23

22

MIRR

4 IC101 #ª (FE) (CD Play Mode)

0.2 Vp-p

0.5 Vp-p

12.5 MHz

4.7 Vp-p

1

2

SQSO

SQCK

3

XRST

4

SYSM

CPU

INTERFACE

7

5

6

XLAT

DATA

8

CLOK

SENS

9

10

SCLK

11 12

VDD

ATSK

13

SPOA

14

SPOB

1516171819

XUGF

XPCK

XLON

WFCK

GFS

20

C2PO

SCOR

COUT

21

– 65 –

– 66 –

Page 43

IC103 CXA2568M-T6

HOLD

AGC VTH

VEE

+

–

VC

VC

VCC

APC LD AMP

50µA

+

–

+

–

VEE

RF SUMMING AMP

+

–

FOCUS ERROR AMP

+

–

VCC

+

–

VCC

+

–

VC

+

–

VC

RF EQ AMP

+

–

1

VEE

2

LD

3

4

PD

5

A

6

B

7

C

D

8

9

VC

10

F

APC PD AMP

+

–

+

–

VEE

–

+

VC

VEE

VC

+

–

24

23

22

21

20

19

18

17

16

15

14

VCC

LC/PD

LD ON

HOLD SW

AGC CONT

RF BOT

RFTC

RF I

RF O

RFE

FE

VC BUFFER

VC

–

+

+

–

E

11

VC

12

VC

– MOTOR (TURN) Board –

IC701 M54641L

VCC

1

2

OUT2

REG

IN1

GND

INPUT

3

AMP.

CONTROL

INPUT

AMP.

4

POWER AMP.

POWER AMP.

VC

VCC

8

OUT1

7

IN2

6

REFERENCE

5

VEE

VCC

VC

–

+

TRACKING

ERROR AMP

TE

13

– MOTOR (SLIDE) Board –

IC801 BA6286N

TSD

POWER

SAVE

CONTROL

LOGIC

GND

RIN

VREF

OUT2

RNF

GND

OUT1

VM

VCC

FIN

1

2

3

4

5

6

7

8

9

10

– 67 –

Page 44

– AUDIO Board –

IC602 µPC1330HA

2

1

SW R1 GND SW P1

3

– PANEL Board –

IC603 BA3830F

4

CONT

INVERTER

COMPARATER

5

VCC

GND

6

SW P2 GND

7 8 9

SW R2

IC604 NJU3716M-T2

R02

R01

LINE NF

LINE IN

REC NF

REC IN

RESET C

BIAS C

GND

2

3

4

5

7

8

9

6

CURRENT

REFERENCE

CURRENT

–

+

–

+

REFERENCE

1

IC711 M65850FP

BAND

PASS

FILTER

RESET

DET

18

17

16

15

14

13

12

11

10

RESET

F01

F02

F03

F04

F05

F06

REC LEVEL

VCC

VDDP6P5P4P3P2VSSP1CLR

2021 192324 22 18 17 16 15 14 13

CONTROL

CIRCUIT

SHIFT REGISTER

LATCH CIRCUIT

OUTPUT CIRCUIT

P11

8

6

7

P12

P13

VSS

21

P7P8P9

43

P10

STB

CLK

DATA

9

11

10

125

P15

P16

SO

P14

1

LPF1IN

VCC

1/2 VCC

AUTO

RESET

LPF1

OSCILLATOR

CLOCK

RESET

2 3

LPF1OUT

CLOCK

REF

DO1

MAIN

CONTROL

D1

DO0

A/D

5 6 7

4

CC1

OP1IN

OP1OUT

OP2IN

D/A

MO

MI

OP2OUT

LPF2IN

20KBIT

CC2

LPF2OUT

891014 13 12 11

LPF2

SRAM

GND

– 68 –

Page 45

7-27. IC PIN FUNCTION DESCRIPTION

• MAIN BOARD IC501 M30622MA-A07FP (SYSTEM CONTROLLER (CD MECHANISM CONTROL))

Pin No. Pin Name I/O Description

1 STK-MUTE O

2 POWER O

3 F-RELAY O

4 R-RELAY O

5 CD-POWER O

6 LINE-MUTE O

7 DBFB-H/L O

8

9 CNVSS —

10 XC-IN I

11 XC-OUT O

12 RESET I

13 X-OUT O

14 VSS —

15 X-IN I

16 VCC —

17

18 WAKE UP I

19 SCOR

20 RDS-INT I

21 RDS-DATA I

22 AC-CUT I

23 PL-CLK O

24 PL-DATA O

25 PL-LAT O

26 TIMER LED O

27 PROTECTOR I

28

29 IIC-CLK I/O

30 IIC-DATA I/O

31 NCO O

32

33

34 SW MODE O

35

36 RY-SW I

37 CD-CLK O

38 493-LATCH O

BYTE

NMI

V MUTE

SQ-DATA

SQ-CLK

CD-DATA

Power amplifier on/off selection signal output terminal “L”: standby mode, “H”: on

Power on/off control signal output for the audio system (+5V) and deck, panel, audio system

(+7V) “L”: standby mode, “H”: power on

Relay drive signal output for the speaker protect “H”: relay on

Relay drive signal output for the speaker protect “H”: relay on Not used (open)

Power on/off control signal output for the CD mechanism deck section

“L”: standby mode, “H”: power on

Line muting on/off control signal output terminal “L”: muting on

DBFB normal/high selection signal output to the M62493FP (IC101)

“L”: DBFB high, “H”: DBFB low

I

External data bus line byte selection signal input terminal Fixed at “L” in this set

Ground terminal

Sub system clock input terminal (32.768 kHz)

Sub system clock output terminal (32.768 kHz)

System reset signal input from the reset signal generator (IC502) “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

Main system clock output terminal (16 MHz)

Ground terminal

Main system clock input terminal (16 MHz)

Power supply terminal (+5V)

I

Non-maskable interrupt input terminal Fixed at “H” in this set

Wakeup control signal input from the fluorescent indicator tube driver (IC601) “H” active

I Subcode sync (S0+S1) detection signal input from the CXD2587Q (IC101) on the CD block

RDS serial data transfer clock signal input from the FM/AM tuner unit (Used for the AEP, UK,

German and North European models only)

RDS serial data input from the FM/AM tuner unit (Used for the AEP, UK, German and North

European models only)

AC off detection signal input from the reset signal generator (IC502) “L”: AC cut checked

Serial data transfer clock signal output to the pro-logic circuit Not used (open)

Serial data output to the pro-logic circuit Not used (open)

Serial data latch pulse output to the pro-logic circuit Not used (open)

LED drive signal output of the TIMER SELECT indicator (D636) “H”: LED on

Protect on/off detection signal input from the speaker protect circuit

“L”: protect on, “H”: protect off

O

Muting on/off control signal output terminal “L”: muting off Not used (open)

Communication data reading clock signal input or transfer clock signal output with the fluo-

rescent indicator tube driver (IC601)

Communication data bus with the fluorescent indicator tube driver (IC601)

Not used (open)

I

Subcode Q data input from the CXD2587Q (IC101) on the CD block

O

Subcode Q data reading clock signal output to the CXD2587Q (IC101) on the CD block

Not used (open)

O

Serial data output to the CXD2587Q (IC101) on the CD block

Connection detect signal input of the headphone jack (J701)

“L”: no connected, “H”: headphone connected

Serial data transfer clock signal output to the CXD2587Q (IC101) on the CD block

Serial data latch pulse output to the M62493FP (IC101)

– 69 –

Page 46

Pin No. Pin Name I/O Description

*2 Disc tray slide motor (M801) control

39 STBY LED O

40 VC L+R/L–R O

41 VC BYPASS O

42 FL SW O

43 STBY RELAY O

44 BASS FREQ. O

45 FUNC SEL1 O

46 FUNC SEL0 O

47 493-DATA O

48 493-CLK O

49 ST-MUTE O