Page 1

HCD-DX30/RG40

SERVICE MANUAL

Ver 1.0 2001. 05

• HCD-DX30/RG40 is the tuner,

deck, CD and amplifier section in

MHC-DX30/RG40.

Photo : HCD-DX30

CD CD Mechanism Type CDM58B-K6BD38

Section Base Unit Name BU-K2BD38

Tape deck

Section

US Model

Canadian Model

AEP Model

HCD-RG40

E Model

Australian Model

HCD-DX30

Model Name Using Similar Mechanism NEW

Optical Pick-up Name KSM-213DCP

Model Name Using Similar Mechanism NEW

AUDIO POWER SPECIFICATIONS:

(HCD-RG40 USA models only)

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION:

with 6 ohm loads both channels driven, from

120 – 10,000 Hz; rates 100 watts per channel

minimum RMS power, with no more than 10%

total harmonic distortion from 250 milliwatts to

rated output.

Total harmonic distortion less than 0.07%

(6 ohms at 1 kHz, 50 W)

Amplifier section

US, Canadian models:

HCD-RG40

Continuous RMS power output (reference)

100 + 100 watts (6 ohms

at 1 kHz, 10% THD)

Total harmonic distortion less than 0.07%

(6 ohms at 1 kHz, 50 W)

AEP models:

HCD-RG40

DIN power output (rated) 65 + 65 watts

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference)

80 + 80 watts (6 ohms at

1 kHz, 10% THD)

Music power output (reference)

160 + 160 watts (6 ohms

at 1 kHz, 10% THD)

SPECIFICATIONS

Other models:

HCD-DX30

The following measured at AC 120, 220, 240 V

50/60 Hz

DIN power output (rated) 100 + 100 watts

(6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference)

120 + 120 watts (6 ohms

at 1 kHz, 10% THD)

Inputs

MD/VIDEO (AUDIO) IN (phono jacks):

voltage 450/250 mV,

impedance 47 kilohms

GAME (AUDIO) IN (phono jack):

voltage 450 mV,

impedance 47 kilohms

MIC (mini jack): sensitivity 1 mV,

impedance 10 kilohms

Outputs

PHONES (stereo mini jack):

accepts headphones of

8 ohms or more

FRONT SPEAKER: accepts impedance of 6 to

16 ohms

SURROUND SPEAKER (MHC-RG60 only):

accepts impedance of 6 to

16 ohms

COMPACT DISC DECK RECEIVER

CD player section

System Compact disc and digital

audio system

Laser Semiconductor laser

(λ=780 nm)

Emission duration:

continuous

Laser output Max. 44.6 µW*

*This output is the value

measured at a distance of

200 mm from the

objective lens surface on

the Optical Pick-up Block

with 7 mm aperture.

Frequency response 2 Hz – 20 kHz (±0.5 dB)

Wavelength 780 – 790 nm

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

CD OPTICAL DIGITAL OUT

(Square optical connector jack, rear panel)

Wavelength 660 nm

Output Level –18 dBm

— Continued on next page —

9-873-149-01

2001E1600-1

© 2001.5

Sony Corporation

Home Audio Company

Shinagawa Tec Service Manual Production Group

Page 2

HCD-DX30/RG40

Tape deck section

Recording system 4-track 2-channel stereo

Frequency response 40 – 13,000 Hz (±3 dB),

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

US, Canadian, Mexican, Argentina models:

European and Middle Eastern models:

Other models: 531 – 1,602 kHz (with the

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

General

Power requirements

US, Canadian models: 120 V AC, 60 Hz

European models: 230 V AC, 50/60 Hz

Australian models: 230 – 240 V AC,

Mexican models: 120 V AC, 50/60 Hz

Other models: 120 V, 220 V or

Power consumption

USA models:

HCD-RG40: 140 watts

Canadian models:

HCD-RG40: 140 watts

European models:

HCD-RG40: 140 watts

HCD-RG40: 0.5 watts (at the Power

Other models:

HCD-DX30: 175 watts

Dimensions (w/h/d)

using Sony TYPE I

cassette

530 – 1,710 kHz (with the

interval set at 10 kHz)

531 – 1,710 kHz (with the

interval set at 9 kHz)

531 – 1,602 kHz (with the

interval set at 9 kHz)

interval set at 9 kHz)

530 – 1,710 kHz (with the

interval set at 10 kHz)

50/60 Hz

230 – 240 V AC,

50/60 Hz

Adjustable with voltage

selector

Saving Mode)

Approx. 280 × 325 × 421 mm

SAFETY CHECK-OUT

After correcting the original service problem, perform the

following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

LEAKAGE

The A C leakag e from any exposed metal part to earth g round and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated A C voltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are e xamples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

AC

0.15 µF

Fig. A. Using an AC voltmeter to check AC leakage.

1.5 kΩ

Earth Ground

Voltmeter

(0.75 V)

Mass

North American models:

HCD-RG40: Approx. 9.0 kg

European models:

HCD-RG40: Approx. 9.0 kg

Other models:

HCD-DX30: Approx. 10.0 kg

Design and specifications are subject to change

without notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

2

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Page 3

HCD-DX30/RG40

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

TABLE OF CONTENTS

1. SERVICE NOTE ······························································· 4

2. GENERAL ··········································································5

3. DISASSEMBLY ································································ 7

4. TEST MODE ···································································· 12

5. ELECTRICAL ADJUSTMENTS ······························· 16

6. DIAGRAMS······································································ 19

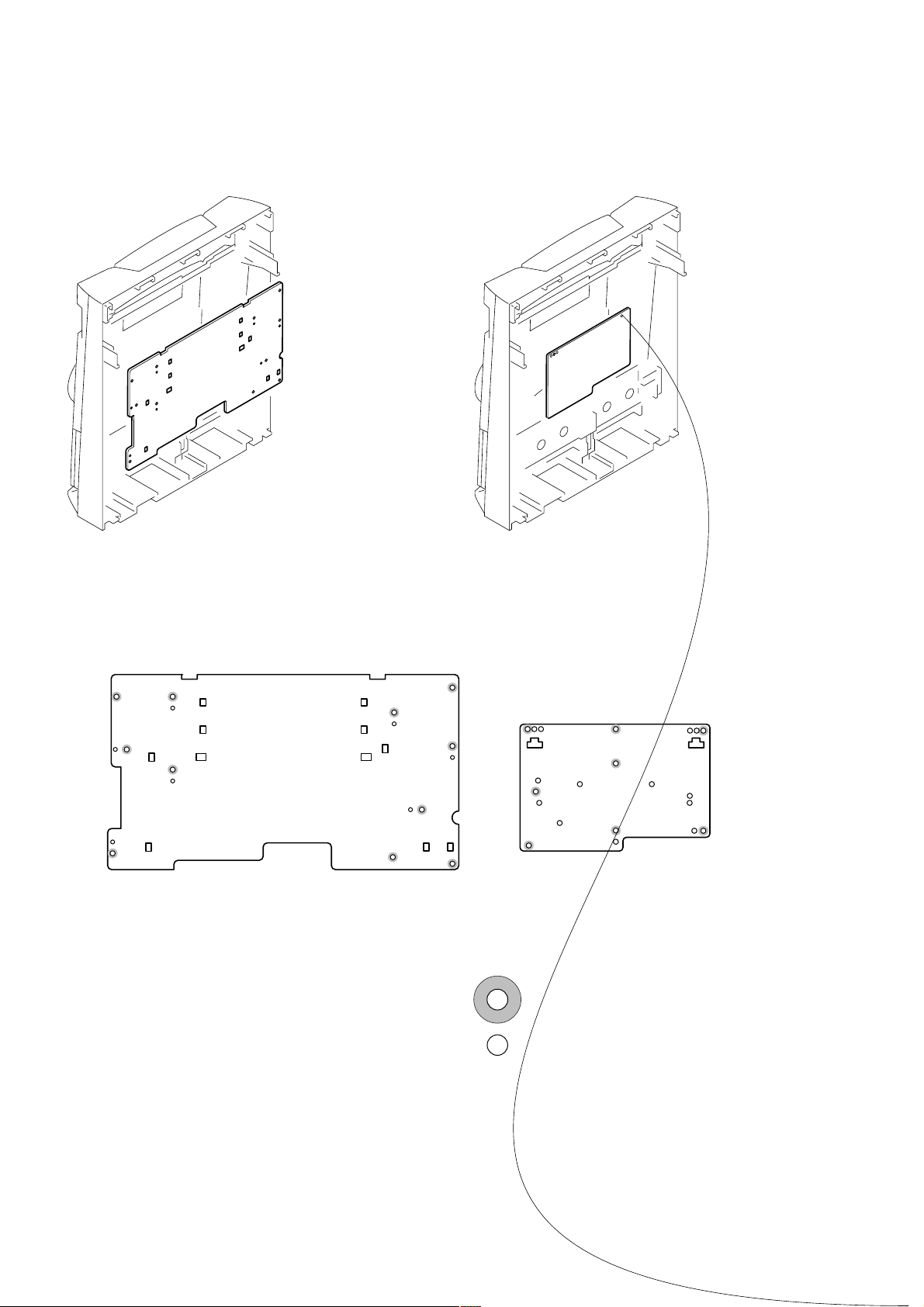

6-1. Circuit Board Location ················································ 20

6-2. Block Diagrams Tuner/CD Section ···························· 21

Main Section ······························································· 22

6-3. Schematic Diagram Main Section (1/4) ···················· 23

6-4. Schematic Diagram Main Section (2/4) ···················· 24

6-5. Schematic Diagram Main Section (3/4) ···················· 25

6-6. Schematic Diagram Main Section (4/4) ···················· 26

6-7. Printed Wiring Board Main Section ·························· 27

6-8. Printed Wiring Board BD Section ····························· 28

6-9. Schematic Diagram BD Section ································ 29

6-10.Printed Wiring Board Power AMP Section ··············· 30

6-11.Schematic Diagram Power AMP Section·················· 31

6-12.Printed Wiring Board Panel Section·························· 32

6-13.Schematic Diagram Panel Section ···························· 33

6-14.Printed Wiring Board Key Section ···························· 34

6-15.Schematic Diagram Key Section ······························· 35

6-16.Printed Wiring Board Driver Section ························ 36

6-17.Schematic Diagram Driver Section ··························· 37

6-18.Printed Wiring Board Trans Section·························· 38

6-19.Schematic Diagram Trans Section ···························· 39

6-20.IC Pin Function Description ········································ 40

6-21.IC Block Diagrams ······················································ 42

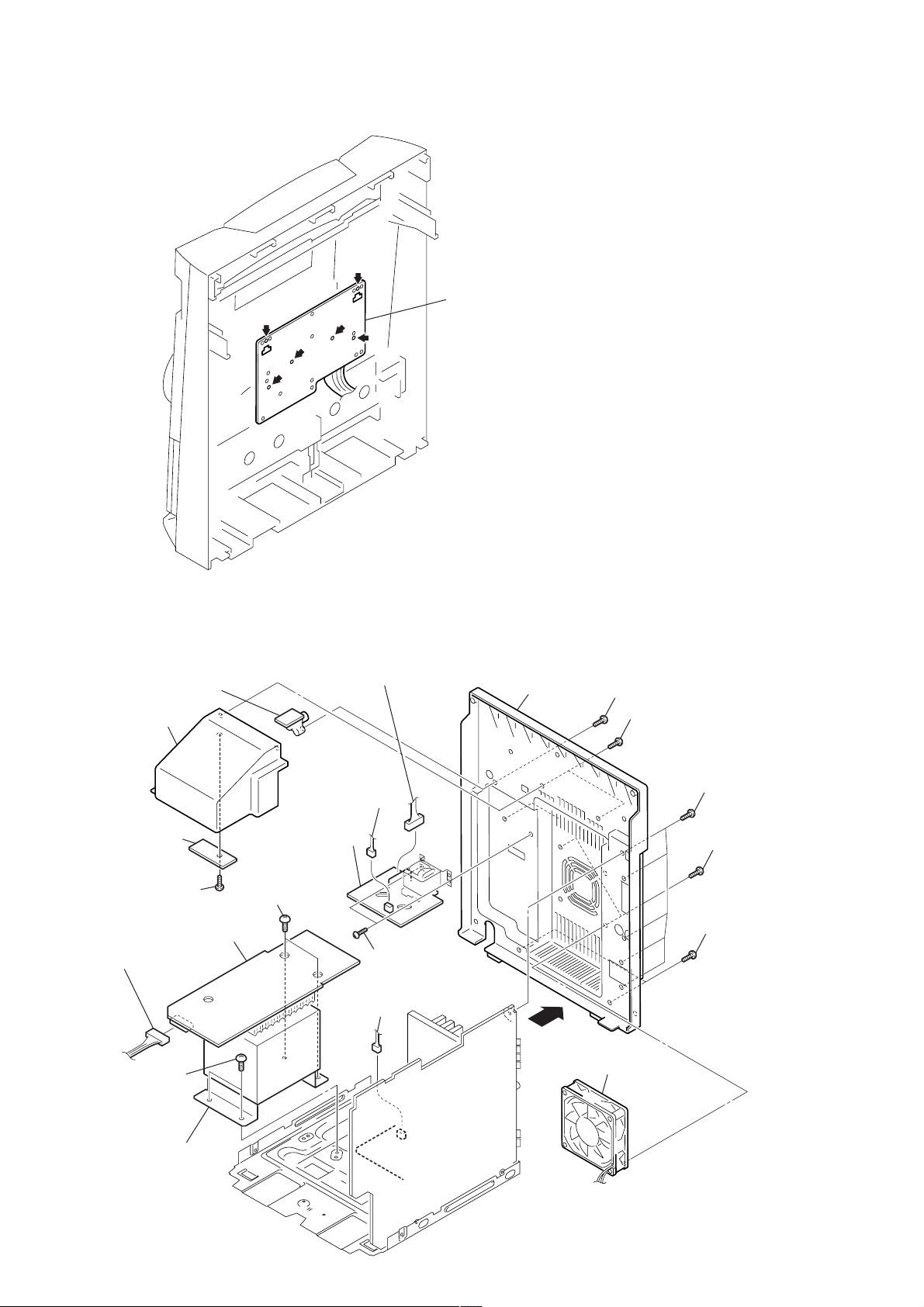

7. EXPLODED VIEWS

7-1. Main Section ······························································· 45

7-2. Front Panel Section ····················································· 46

7-3. Main Board Section ····················································· 47

7-4. CD Mechanism Deck Section ····································· 48

8. ELECTRICAL PARTS LIST ······································· 49

MODEL IDENTIFICATION

— BACK PANEL —

PARTS No.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

MODEL

AR, E, E51, SP models

AUS, KR, MX, TH models

• Abbreviation

CND : Canadian model

AUS : Australian model

SP : Singapore model

TH : Thai model

PARTS No.

4-234-091-1s

4-234-091-7s

KR : Korea model

MX : Mexican model

AR : Argentina model

E51 : Chilean and Peruvian model

3

Page 4

HCD-DX30/RG40

SECTION 1

SERVICE NOTE

4

Page 5

Main unit

1234 6589q;qaqs7

eg

ef

ed

es

ea

e;

HCD-DX30/RG40

SECTION 2

GENERAL

This section is extracted

from instruction manual.

qd

qf

qg

qh

qj

qk

wl

AUDIO jacks ed

CD qs

CD SYNC wf

Deck A wl

Deck B w;

DIRECTION*

DISC 1 – 3 wa

DISC SKIP EX-CHANGE ea

Disc tray 8

DISPLAY 7

EDIT 7

EFFECT ON/OFF 4

ENTER 0

GAME eg

GAME EQ 2

GROOVE 3

KARAOKE PON*

1

7

2

es

MD (VIDEO) qg

MIC jack*

MIC LEVEL co ntrol*

MOVIE EQ 9

MUSIC EQ 6

P FILE qa

PHONES jack qk

PLAY MODE 7

PTY/DIRECTION 7

REC PAUSE/START wd

REPEAT 7

SPECTRUM 7

STEREO/MONO 7

TAPE A/B qf

TUNER MEMORY 7

TUNER/BAND qd

VIDEO jack ef

VOLUME control qh

2

e;

2

wj

ql

w;

wawswdwfwgwhwj wk

BUTTON DESCRIPTIONS

v/V/b/B 5

Z (deck A) wk

Z (deck B) ql

M (fast forward) ws

. (go back) wg

Z OPEN/CLOSE qj

?/1 (power) 1

x (stop) wg

nN (play) wg

X (pause) wg

> (go forward) wg

m (rewind) wh

1

*

PTY/DIRECTION for

European model

2

HCD-DX30 only

*

5

Page 6

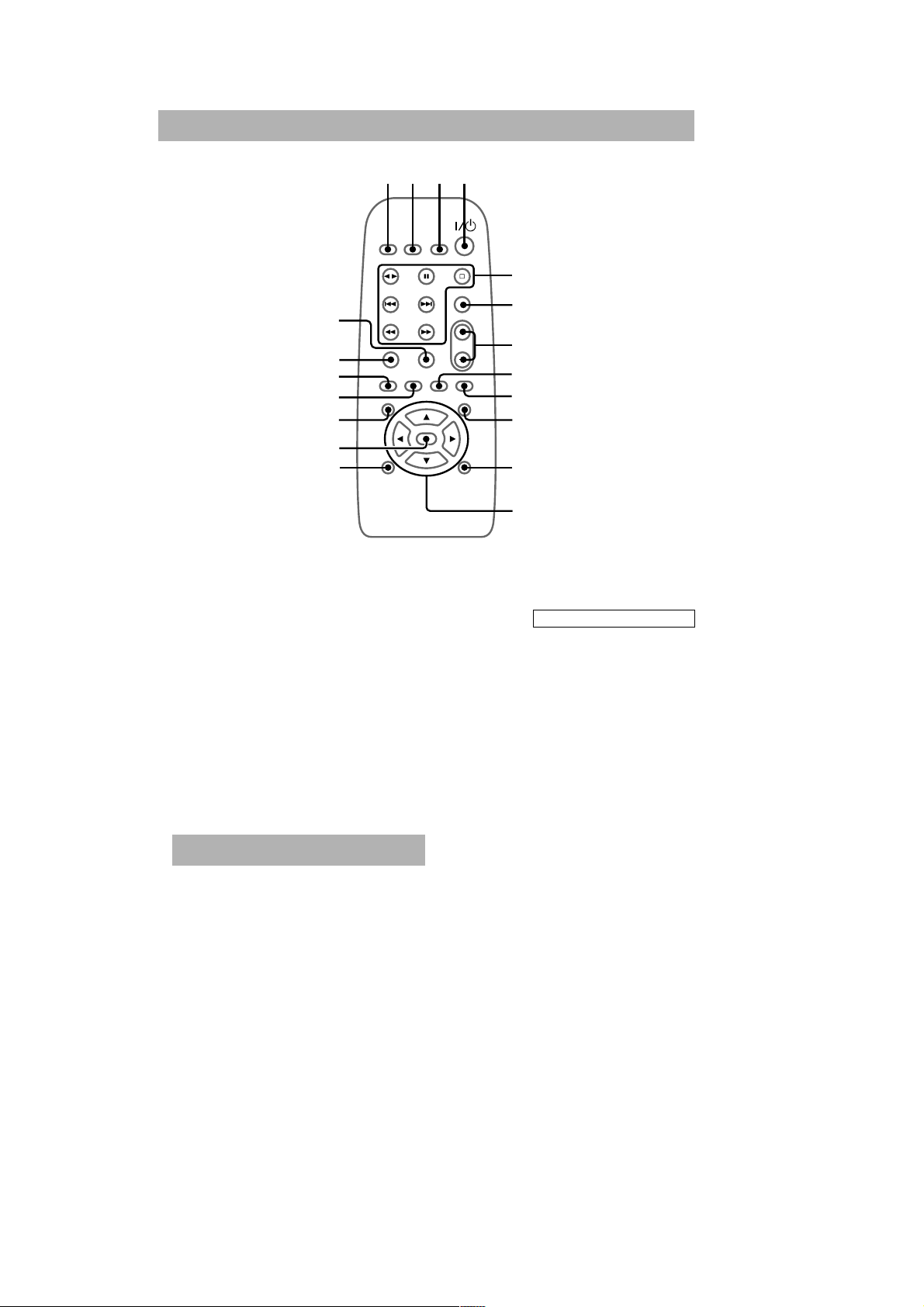

HCD-DX30/RG40

Remote Control

ql

qk

qj

qh

qg

qf

qd

12 34

5

6

7

8

9

0

qa

CD qj

CLEAR 6

CLOCK/TIMER SELECT 2

CLOCK/TIMER SET 3

D.SKIP ql

EFFECT ON/OFF qa

ENTER qf

GAME qk

MD (VIDEO) 9

P FILE qd

PRESET EQ qg

SLEEP 1

SURROUND 0

TAPE A/B 8

TUNER/BAND qh

VOL +/– 7

Setting the time

1 Turn on the system.

2 Press CLOCK/TIMER SET on the

remote.

Proceed to step 5 when “CLOCK” appears

in the display.

3 Press v or V repeatedly to select “SET

CLOCK”.

4 Press ENTER.

5 Press v or V repeatedly to set the hour.

qs

BUTTON DESCRIPTIONS

v/V/b/B qs

M (fast forward)/TUNING

+ 5

. (go back)/PRESET

– 5

?/1 (power) 4

x (stop) 5

nN (play) 5

X (pause) 5

> (go forward)/PRESET

+ 5

m (rewind)/TUNING – 5

6 Press B.

The minute indication flashes.

7 Press v or V repeatedly to set the

minute.

8 Press ENTER.

Tip

If you made a mistake or want to change the time,

start over from step 1.

Note

The clock settings are canceled when you disconnect

the power cord or if a power failure occurs.

6

Page 7

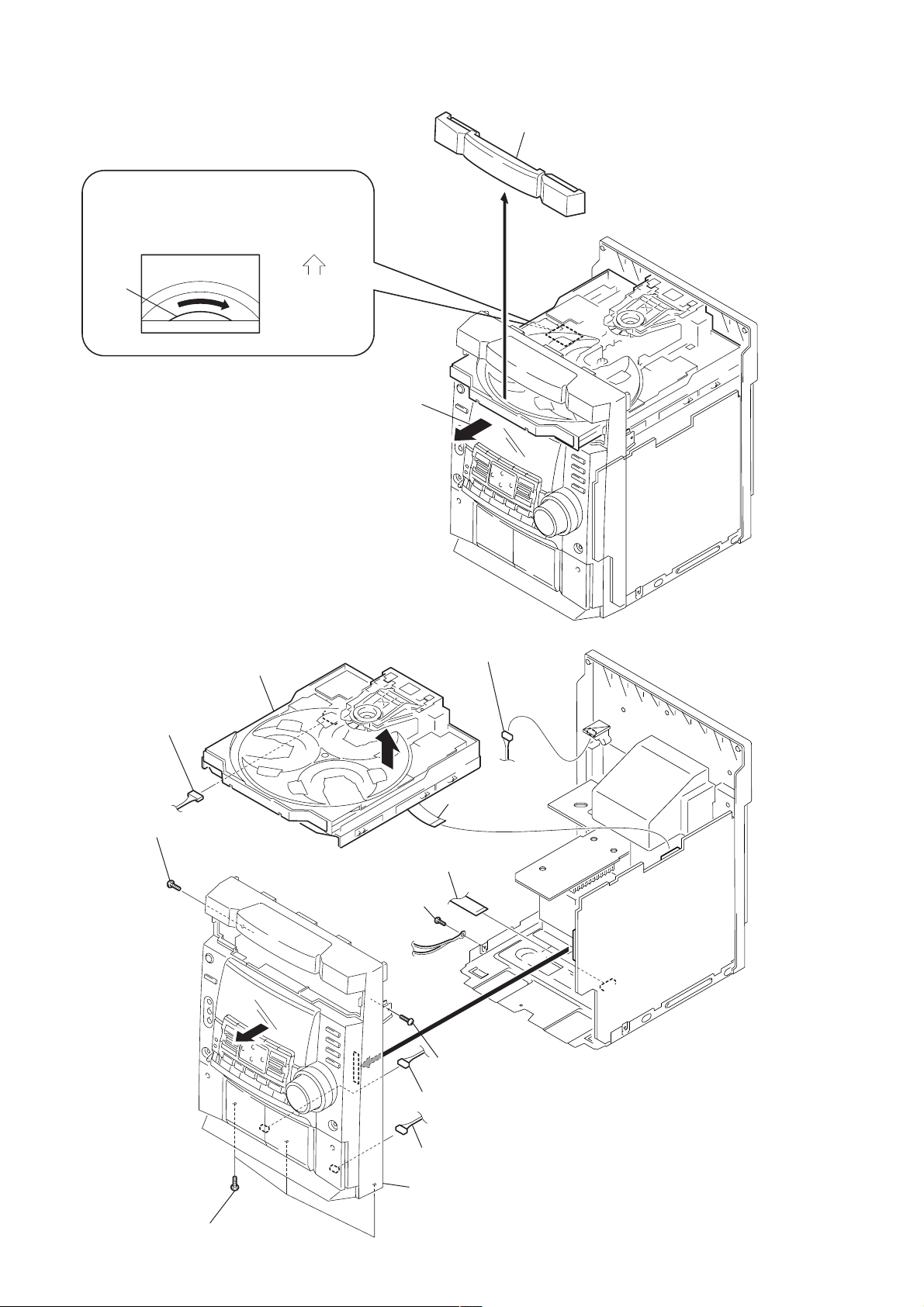

Note : Disassemble the unit in the order as shown below.

d

)

Case (Top)

Set

CD door

HCD-DX30/RG40

SECTION 3

DISASSEMBLY

Front panel section

Base unit

Sub trans board, Trans board, Sensor board and Video out board

Main board and Power board

Driver board, Moter board and Address sensor boar

Note : Follow the disassembly procedure in the numerical order given.

3-1. CASE (TOP)

qs

Case (Top)

qd

6

Two screws (Case 3 TP2)

Case (Side-L)

8

Screw

(+BVTP 3

×

10)

Key boardPanel boardTape mechanism deck

qa

Four screws (+BVTP 3

qs

×

10)

7

Screw (Case 3 TP2)

9

(+BVTT 3

Screw

×

q;

Case (Side-R)

5

3

Screw

(+BVTP 3

1

8)

2

Two screws

(Case 3 TP2)

4

Screw

(+BVTT 3

Screw (Case 3 TP2)

×

×

10

8)

7

Page 8

HCD-DX30/RG40

3-2. CD DDOR

CD mechanism deck (CDM58B)

1

Turn the pulley to the direction of arrow.

pulley

Front panel side

2

Pull-out the disc tray.

CD door

3

3-3. FRONT PANEL SECTION

CD mechanism deck (CDM58B)

2

Connector

10p (CN701)

4

Screw (+BVTP 3

×

qd

10)

5

6

Wire (flat type) 17p (CN2)

8

Screw

(+BVTP 3

qs

×

10)

9

7

Connector

2p (CN714)

1

Wire (flat type)

19p (CN102)

3

Screw

(+BVTP 3

Connector 3p

×

10)

q;

Connector 7p

Front panel section

qa

Three screws (+BVTP 3

× 6

)

8

Page 9

3-4. TAPE MECHANISM DECK

)

2

Tape mechanism deck

HCD-DX30/RG40

1

Six

screws

(+BVTP 2.6

×

8

3-5. PANEL BOARD

1

Volume knob

2

Vol knob ring

3

6

Panel board

4

Connector

13p (CN712)

5

Cut the seven melted-connection points with a cutting plier.

Note: When attching the panel board,

refer to "Service Note" on page 4.

9

Page 10

HCD-DX30/RG40

3-6. KEY BOARD

2

Key board

1

Cut the six melted-connection points with a cutting plier.

Note: When attching the Key board,

refer to "Service Note" on page 4.

3-7. SUB TRANS BOARD, TRANS BOARD, SENSOR BOARD AND VIDEO OUT BOARD

1

Connector 2p (CN2) (EXCEPT:SP,E51,E2,AR)

w;

Video out board

qs

Cover (Duct)

qd

Sensor board

qa

Screw

(+BVTP 3

5

Connector 13P (CN915)

×

10)

Trans board

Connector 4p (CN2) (SP,E51,E2,AR)

2

Connector 3p

(CN903)

4

Sub trans

board

6

Two screws

(+BVTT 4

×

6)

9

(CN504)

3

Tw o

(+BVTP 3

Connector 2p

screws

×

10)

Back panel

qh

ql

Screw (+BVTP 3

q;

Two screws

(+BVTP 3

×

10)

×

10)

qf

Five screws

(+BVTP 3

qj

Two screws

(+BVTP 3

qg

Two screws

(+BVTT 3

×

×

×

10)

10)

6)

10

7

Two screws

(+BVTT 4

8

Power

(T911)

×

6)

transformer

qk

DC fan (M961)

Page 11

3-8. MAIN BOARD AND POWER BOARD

d

6

Two screws (+BVTT 3

4

Three screws (+BVTT 3

5

Power

3

Two screws (+BVTP 3

board

×

16)

×

6)

×

HCD-DX30/RG40

7

6)

Heat sink

Main board

2

Main boar

3-9. BASE UNIT

qs

Two insulators

8

Two stoppers (BU)

2

Holder (BU) assy

Base unit

qa

1

Two screws (+BVTT 3

1

Screw (+PTPWH M2.6)

q;

Screw (DIA. 12)

qs

Two insulators

9

Tw o

screws (+PTPWH M2.6)

×

6)

7

Two screws (+BVTP 2.6

6

BD board

5

Screw (+BVTP 2.6

×

8)

4

Wire (flat type) 16p (CN102)

Wire (flat type) 19p (CN101)

×

3

8)

11

Page 12

HCD-DX30/RG40

3-10. DRIVER BOARD, MOTOR BOARD AND ADDRESS SENSOR BOARD

q;

qa

Tray

3

Wire (flat type)

8p (CN702)

2

Driver board

Screw (+PTPWH 2.6

qs

Screw (+BVTP 2.6

8

×

Motor board

×

8)

8)

4

Two screws (+BVTP 2.6

6

Wire (flat type) 8p (CN721)

5

Remove the two solderings of motor.

qd

Address sensor board

7

×

8)

Connector 4p (CN722)

1

Screw (+BVTP 2.6

9

Pull-out the disc tray.

×

8)

12

Page 13

SECTION 4

TEST MODE

HCD-DX30/RG40

[MC Cold Reset]

• The cold reset clears all data including preset data stored in the

RAM to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. Press three buttons x , ENTER , and ?/1 simultaneously.

2. The fluorescent indicator tube displays “COLD RESET” and

the set is reset.

[CD Ship Mode]

• This mode moves the pickup to the position durable to vibration. Use this mode when returning the set to the customer after

repair.

Procedure:

1. Press 1/u button to turn the set ON until “STANDBY”

appears.

2. Press CD button and 1/u button simultaneously.

3. When you releaset he buttons, a message “LOCK” is displayed

on the fluorescent indicator tube, and the CD ship mode is set.

[MC Hot Reset]

• This mode resets the set with the preset data kept stored in the

memory. The hot reset mode functions same as if the power

cord is plugged in and out.

Procedure:

1.

Press three buttons x , ENTER , and DISPLAY simultaneously.

2. The fluorescent indicator tube becomes blank instantaneously,

and the set is reset.

[CD Service Mode]

• This mode can run the CD sled motor freely. Use this mode, for

instance, when cleaning the pickup.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “CD”.

3. Press three buttons x , ENTER , and OPEN/CLOSE simul-

taneously.

4. The CD service mode is selected.

5. With the CD in stop status, turn the shuttle knob clockwise to

move the pickup to outside track, or turn the shuttle knob

counter-clockwise to inside track.

6. To exit from this mode, perform as follows:

1) Move the pickup to the most inside track.

2) Press three buttons in the same manner as step 2.

Note: • Always move the pickup to most inside track when exiting from

this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear can be

chipped.

[Change-over of AM Tuner Step between 9 kHz and

10 kHz]

• A step of AM channels can be changed over between 9 kHz and

10 kHz.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “TUNER”, and press TUNER/BAND

button to select the BAND “MW”.

3. Press ?/1 button to turn the set OFF.

4. Press ENTER and ?/1 buttons simultaneously, and the display

of fluorescent indicator tube changes to “AM 9 k STEP” or

“AM 10 k STEP”, and thus the channel step is changed over.

[GC Test Mode]

• This mode is used to check the software version, FL tube, LED,

keyboard, headphone and volume.

Procedure:

1. Press three buttons x , ENTER and DISC 2 simultaneously.

2. LEDs and fluorescent indicator tube are all turned on.

3. When ENTER and DISC2 are pressed at the same time, the

key number check mode starts up. In this mode, the key numbers

of each key series are displayed.

4. In the key check mode, the fluorescent indicator tube displays

“KEY 000”. Each time a button is pressed.

5. When ENTER and DISC2 are pressed at the same time, the

key count check mode starts up. In this mode, the message “KEY

CNT @@” is displayed on the FL display tube. When each

button is pressed, the key row number is incremented first. Then

the key value is then incremented. However, one the button is

pressed, the key value cannot be counted.

6. When ENTER and DISC2 are pressed at the same time, the

headphones check mode starts up. In this mode, the message

“H_P ON” is displayed when the headphones are inserted. When

the headphones are not inserted. the message “H_P OFF” is

displayed.

7. When ENTER and DISC2 are pressed at the same time, the

volume check mode starts up. In this mode, the message

“VOLUME FLAT” is displayed on the FL display tube. When

the volume control knob is rotated in the positive (+) direction,

the message “VOLUME UP” is displayed. When the volume

control knob is rotated in the negative (-) direction, the message

“VOLUME DOWN” is displayed.

8. In order to quit the mode, either press ENTER and DISC2 at

the same time or press the three buttons at the same time as in

step 1.

9. To exit from this mode, press three buttons in the same manner

as step 1, or disconnect the power cord.

13

Page 14

HCD-DX30/RG40

[MC Test Mode]

• This mode is used to check operations of the respective sections

of Amplifier, TUNER, CD and Tape.

Procedure:

1. Press the ?/1 button to turn on the set.

2. Press the three buttons of x , ENTER and DISC 3

simultaneously.

3. A message “TEST MODE” appears on the FL display tube.

• The messages VACS1 to VACS5 are displayed when the VACS

is changed in this mode.

• The number of repeats of TAPE and CD is set to the infinite

number as the default setting.

4 When v (CURSOR UP) button is pressed, GEQ increases to

its maximum and a message “GEQ MAX” appears.

5. When V (CURSOR DOWN) button is pressed, GEQ decreases

to its minimum and a message “GEQ MIN” appears.

6. When b (CURSOR LEFT) or B (CURSOR RIGHT) button

is pressed, GEQ is set to flat and a message “GEQ FLAT”

appears.

7. In the test mode, the default-preset channel is called even when

the TUNER is selected and an attempt is made to call the preset

channel that has been stored in memory, by operating the Shuttle

knob. (It means that the memory is cleared.)

8. When a tape is inserted in the Deck B and the TAPE B function

is selected, and when the REC PAUSE/START button is

pressed twice, recording starts.

The VIDEO function is selected automatically as the input

source.

9. Select the desired loop by pressing the PLAY MODE button

in the TAPE B function. Insert a test tape AMS-110A or AMSRO to Deck A.

10. Press the SPECTRUM button to enter the AMS test mode.

11. After a tape is rewound first, the FF AMS is checked, and the

mechanism is shut off after detecting the AMS signal twice.

12. Then the REW AMS is checked and the mechanism is shut off

after detecting the AMS signal twice.

13. When the check is complete, a message of either OK or NG

appears.

14. When the two buttons of SPECTRUM and DISC1 are pressed

at the same time in any function modes, either the “VACS ON”

display to enable the VACS function or the “VACS OFF” display

to disable the VACS function can be selected.

15. When you want to exit this mode, press the ?/1 button twice.

The cold reset is enforced at the same time.

[Microprocessor version display]

• If the following operation is performed during the POWER OFF

in the modes other than the POWER SAVE mode (i.e., while the

Demo display shows the watch time),

1. When three buttons of STOP , ENTER , V (CUSOR DOWN)

are pressed at the same time, the MC and the GC microprocessor

version numbers are displayed as “M1.00 G1.00”.

2. When three buttons of STOP , ENTER , v (CUSOR UP) are

pressed at the same time, the model name and destination are

displayed as “BG1 AS1A3”.

14

Page 15

[Aging Mode]

This mode can be used for operation check of CD section and tape deck section.

• If an error occurred:

The aging operation stops and display status.

• If no error occurs:

The aging operation continues repeatedly.

1. Operating method of Aging Mode

Turn on the main power and select “CD” of the function.

1) Set a disc in DISC1 tray. Select ALL DISC CONTINUE, and REPEAT OFF.

2) Load the tapes recording use into the decks A and B respectively.

3) Press three buttons x , ENTER , and

DISC SKIP EX-CHANGE simultaneously.

4) Aging operations of CD and tape are started at the same time.

5) To exit the aging mode, perform [MC Cold Reset].

3. Aging Mode in CD section

1) Display state

• No error occurs

Display

AGING[*][*][*][*]

HCD-DX30/RG40

Note:

[*][*][*][*]

Error display

E ** s ## $$ %%

1234 5

1 **

2 s

3 ##

4 $$

5 %%

: Number of aging operations

The error No. 00 indicates the newest error. As the error No. increases, it means the older error.

When you want to retrieve the error history, press the PLAY MODE button in the case of mechanism error.

Or press the REPEAT button in the case of NO DISC error.

M: Mechanism error

Don’t care

High order digits only

D: Stopped during closing due to problems other than mechanism.

E: Stopped during opening due to problems other than mechanism.

C: Stopped during chucking due to problems other than mechanism.

F: Stopped during EX-opening due to problems other than mechanism.

Emergency related errors (High order digits only)

1: Stopped during chuck-up

2: Stopped during chuck-down

3: Time out by EX-OPEN

5: Time out by EX-CLOSE

D: No disc error

01: FOCUS ERROR

02: GFS ERROR

03: SETUP ERROR

01: NO DISC judgment without chucking retry

02: NO DISC judgment after chucking retry

Status at the time of NO DISC judgment

(High order digits only)

1: STOP

2: SETUP

3: TOC READ

4: ACCESS

5: PLAY BACK

6: PAUSE

7: MANUAL SEARCH (PLAY)

8: MANUAL SEARCH (PAUSE)

• When the buttons x , ENTER and DISC 1 are pressed simultaneously, number of time of the mechanism error and the NO DISC error

can be checked.

Display: EMC**EDC** **: Number of times of error (Maximum three times)

EMC: Mechanism error

EDC: NO DISC error

• When aging operation is complete, be sure to perform the MC Cold Reset to reset the error history.

15

Page 16

HCD-DX30/RG40

2) Operation during aging mode

In the aging mode, the program is executed in the following

sequence.

(1) The disc tray opens and closes.

(2) The mechanism accesses DISC 2 and makes an attempt to

read TOC. However, since there are no discs, a message

“CD2 NO DISC” appears.

(3) The mechanism accesses DISC 3 and a message “CD3 NO

DISC” appears.

(4) The disc tray turns to select a disc1.

(5) A disc is chucked.

(6) TOC of disc is read.

(7) The pickup accesses to the track 1, and playing 2 seconds.

(8) The pickup accesses to the last track, and playing 2 seconds.

(9) Every time when an aging operation of step 1 to step 8 is

complete, the display “AGING[*][*][*][*]” value increases

as the number of aging operations is counted up.

(10) Returns to step 1.

3. Aging Mode in Tape Deck section

1) Display state

• No error occurs

Display action now

• Error occurred

Display action last time

NO. Display action Action contents Final timing

TAPE A AG-6 Rewind the TAPE A

1

TAPE B AG-1 Rewind the TAPE B

2 TAPE A AG-2 FWD play the TAPE A 2 minutes playing

3 TAPE A AG-3 F.F. the TAPE A

4 TAPE A AG-4 REV play the TAPE A 2 minutes playing

5 TAPE A AG-5 Rewind the TAPE A The top of tape

6 TAPE B AG-2 FWD play the TAPE B 2 minutes playing

7 TAPE B AG-3 F.F. the TAPE B

8 TAPE B AG-4 REV play the TAPE B 2 minutes playing

9 TAPE B AG-5 Rewind the TAPE B The top of tape

The top of tape

20 second FF or the end

of tape

20 second FF or the end

of tape

2) Operation during aging mode

In the aging mode, the program is executed in the following

sequence.

(1) Rewind is executed up to the top of tape A and B.

(2) A tape on FWD side is played for 2 minutes.

(3) FF is executed up to either made for 20 second or the end of

tape.

(4) A tape is reversed, and the tape on REV side is played for 2

minutes.

The tape on the REV side is played in both A and B.

(5) Rewind is executed up to the top of tape.

(6) Returns to step 2, and repeat steps from 2 to 5.

[Function Change Mode]

* elect either VIDEO or MD of the external FUNCTION input.

Procedure:

1. Turn on the power.

2. Press the two buttons MD (VIDEO) and ?/1 at the same

time.

The main power is turned on and the other function of the

previous function is selected and displayed. “MD” or

“VIDEO”.

16

Page 17

SECTION 5

ELECTRICAL ADJUSTMENTS

HCD-DX30/RG40

FM Tuned Level Adjustment

FM RF Signalgenerator

75

Ω

coaxial

set

Carrier frequency : 98 MHz

Modulation : AUDIO 1 kHz, 75 kHz

deviation (100%)

Output level : 28 dB (at 75

Ω

open)

FM ANTENNA terminal

(TM101)

Procedure:

1. Supply a 98 MHz signal at 28 dB from the ANTENNA terminal.

2. Tune the set to 98 MHz.

3. Adjust RV101 to the point (moment) when the TUNED

indicator will change from going off to going on.

Adjustment Location: MAIN board

Null Adjustment

FM RF Signalgenerator

75

Ω

coaxial

set

Carrier frequency : 98 MHz

Modulation : AUDIO 1 kHz, 75 kHz

deviation (100%)

Output level : 60 dB (at 75

Ω

open)

FM ANTENNA terminal

(TM101)

CD SECTION

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

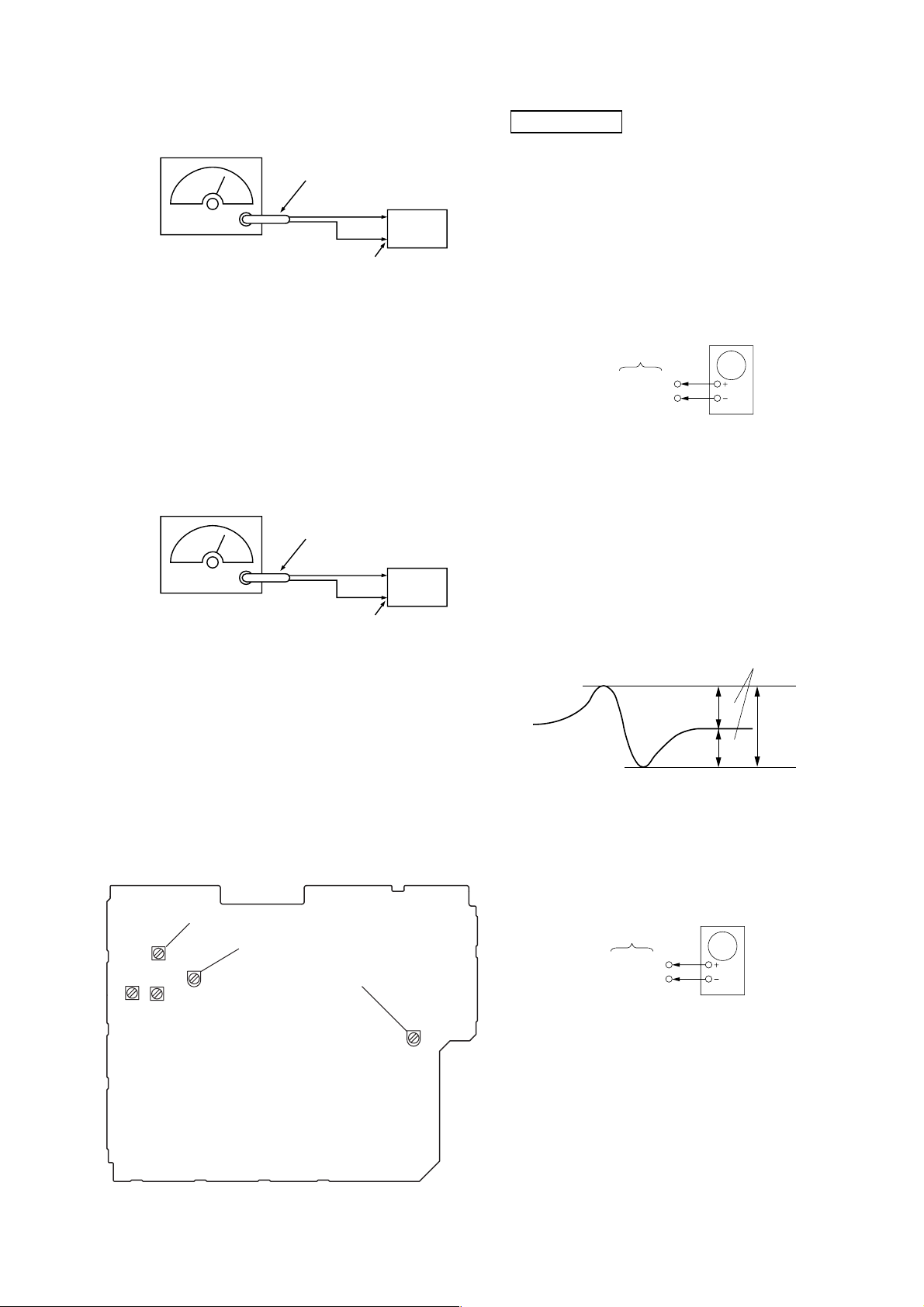

S-Curve Check

Oscilloscope

BD board

TP(FEO)

TP(VC)

Procedure :

1. Connect oscilloscope to TP (FEO).

2. Connect between TP (FEI) and TP (VC) by lead wire.

3. Connect between TP (AGCCON) and TP (D GND) by lead wire.

4. Turn Power switch on.

5. Load a disc (YEDS-18) and actuate the focus search. (In

consequence of open and close the disc tray, actuate the focus

search)

6. Confirm that the oscilloscope waveform (S-curve) is

symmetrical between A and B. And confirm peak to peak level

within 4 ±1 Vp-p.

S-curve waveform

symmetry

Procedure:

1. Supply a 98 MHz signal at 60 dB from the ANTENNA terminal.

2. Tune the set to 98 MHz.

3. Measure voltage between pin 21 and pin 23 of IC 101. Adjust

T101 ubtil the voltage becomes 0 V.

Adjustment Location: MAIN board

Adjustment Location

[MAIN BOARD] Component side

T101:NULL

T101

IFT101

RV101

T102

RV101:FM TUNED LEVEL

RV661:TAPE SPEED

RV661

A

within 4 ±1Vp-p

B

7. After check, remove the lead wire connected in step 2 and 3.

Note : • Try to measure several times to make sure than the ratio

of A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

RF Level Check

oscilloscope

BD board

TP(RF)

TP(VC)

Procedure :

1. Connect oscilloscope to TP (RF).

2. Connect between TP (AGCCON) and TP (D GND) by lead wire.

3. Turned Power switch on.

4. Load a disc (YEDS-18) and playback.

5. Confirm that oscilloscope waveform is clear and check RF signal

level is correct or not.

6. After check, remove the lead wire connected in step 2.

17

Page 18

HCD-DX30/RG40

e

)

r

Note : Clear RF signal waveform means that the shape “ ◊ ” can be clearly

distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500ns

level : 1.45 ± 0.3Vp-p

E-F Balance (1 Track jump) Check

oscilloscop

BD board

TP(TEO)

TP(VC)

Procedure :

1. Connect oscilloscope to TP (TEO) and TP (VC).

2. Turned Power switch on.

3. Load a disc (YEDS-18) and playback the number five track.

4. Press the gG button. (Becomes the 1 track jump mode.)

5. Confirm that the level B and A (DC voltage) on the oscilloscope

waveform.

1 track jump waveform

center of

waveform

Adjustment Location:

[BD BOARD] (Conductor Side)

TP

TP

(AGCCON)

IC103

TP

(RF)

24

TP

(FEI)

1

40

41

12

TP

(TEO)

(FEO)

TP

(VC)

(XPCK)

2021

IC101

61

60

TP

(DGND)

TP

1

80

B

0V

level=1.3±0.6Vp-p

Specified level: –– × 100=less than ±22%

A

B

symmetry

A (DC voltage

6. After check, remove the lead wire connected in step 1.

RF PLL Free-run Frequency Check

Procedure :

1. Connect frequency counter to test point (XPCK) with lead wire.

BD board

TP (XPCK)

frequency counte

2. Turned Power switch on.

3. Put the disc (YEDS-18) in to play the number five track.

Confirm that reading on frequency counter is 4.3218MHz.

18

Page 19

SECTION 6

C

B

These are omitted.

E

Q

DIAGRAMS

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

HCD-DX30/RG40

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

• C : panel designation.

• A : B+ Line.

• B : B– Line.

• H : adjustment for repair.

• Voltages and waveforms are dc with respect to ground

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

• Abbreviation

: internal component.

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

under no-signal (detuned) conditions.

Voltage variations may be noted due to normal production tolerances.

no mark : FM

( ) : CD

[ ] : TAPE

Voltage variations may be noted due to normal production tolerances.

F : FM

f : AM

E : PB (DECK A)

d : PB (DECK B)

G : REC (DECK B)

J : CD

c : digital out

CND : Canadian model

AUS : Australian model

SP : Singapore model

KR : Korea model

MX : Mexican model

AR : Argentina model

TH : Thai model

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• b : Pattern from the side which enables seeing.

• Indication of transistor.

Q

B

CE

These are omitted.

• Abbreviation

CND : Canadian model

AUS : Australian model

SP : Singapore model

KR : Korea model

MX : Mexican model

AR : Argentina model

TH : Thai model

19

Page 20

HCD-DX30/RG40

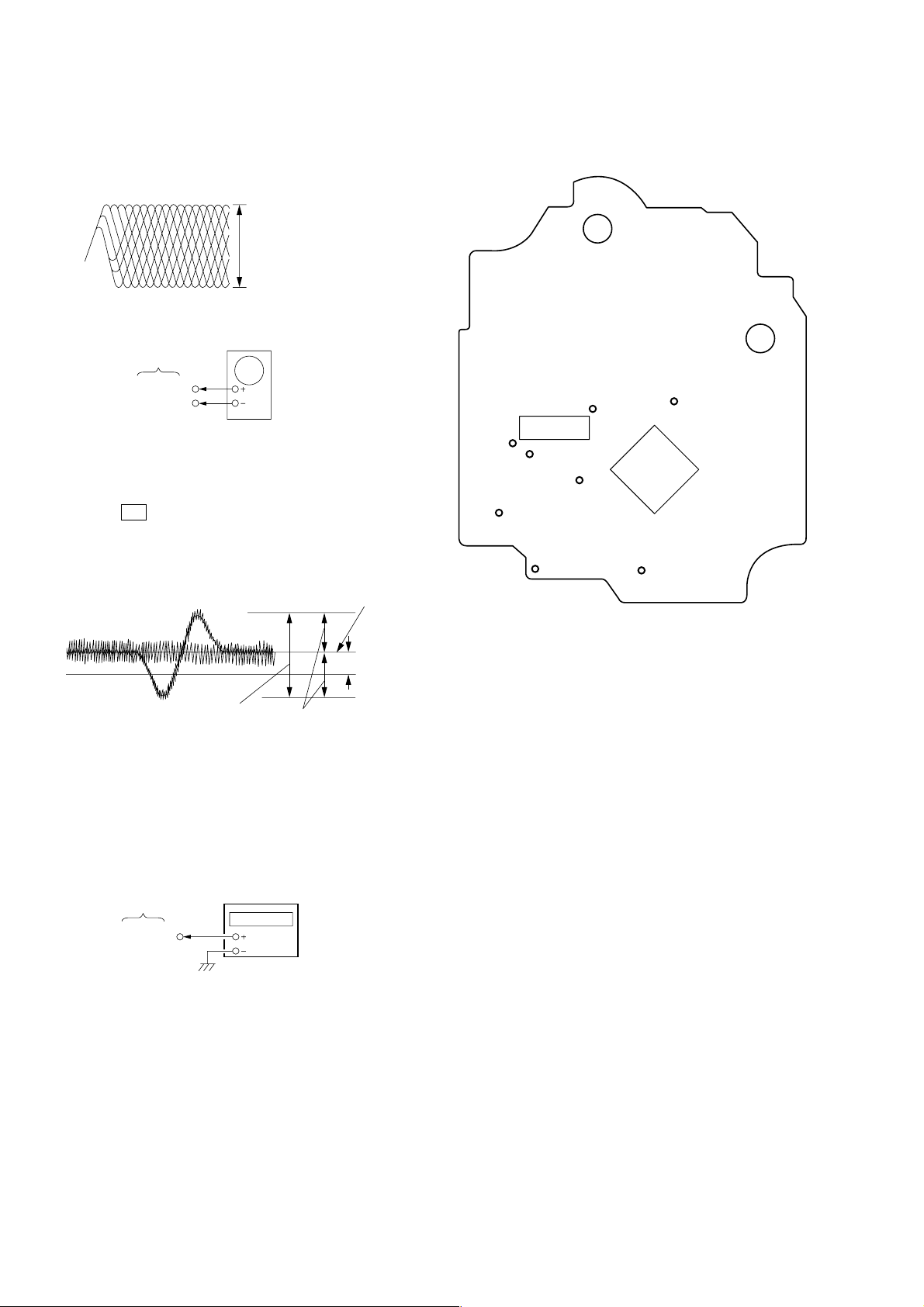

6-1. CIRCUIT BOARD LOCATION

MOTOR board

DRIVER board

SUB TRANS board

TRANS board

PANEL board

KEY board

ADDRESS SENSOR board

VIDEO OUT board

BD board

SENSOR board

MAIN board

POWER AMP board

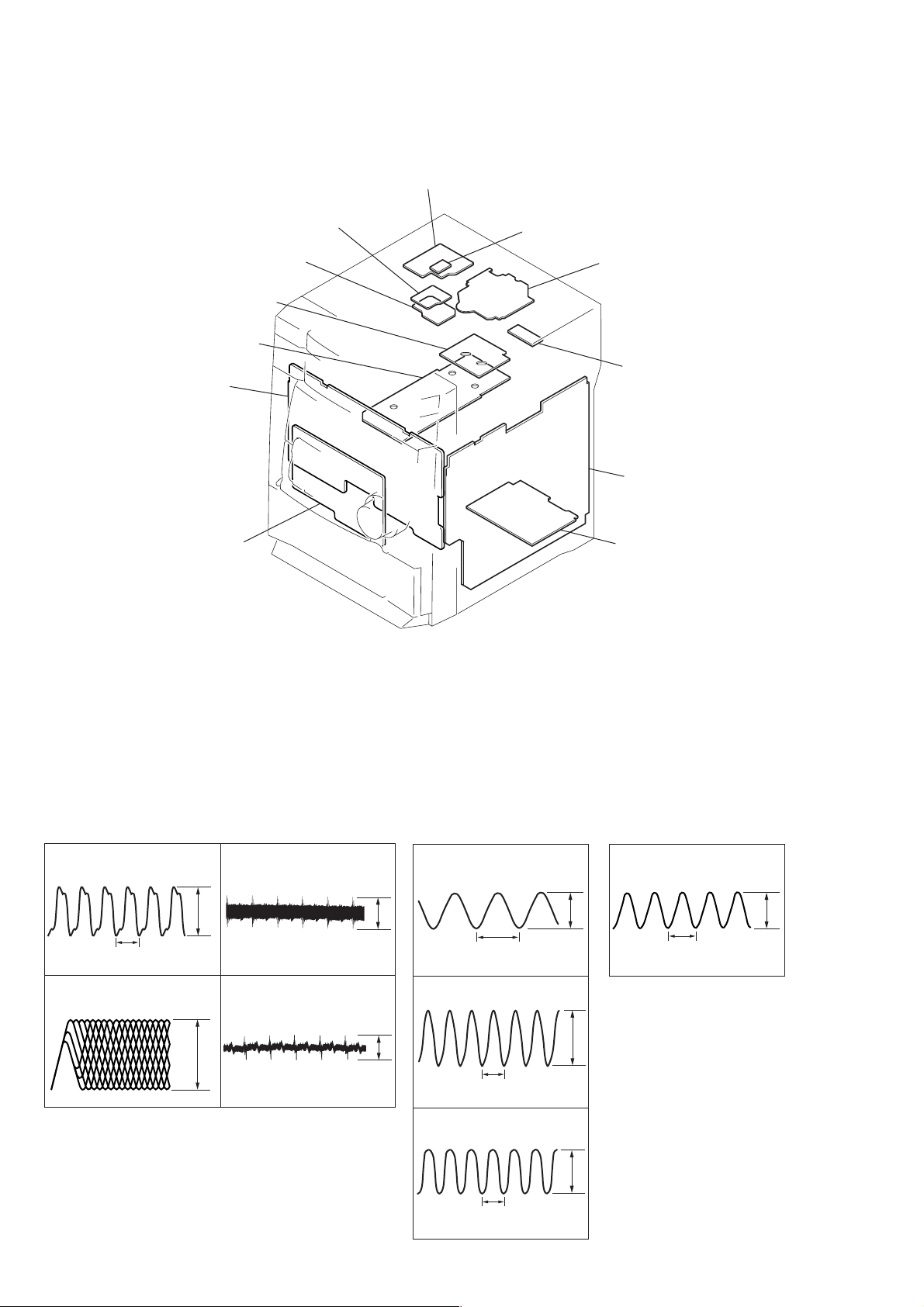

• WAVEFORMS

– BD BOARD –

1

IC101 yj

CD PLAY MODE

59ns

(16.9344MHz)

2

IC101 ta

CD PLAY MODE

400nsec/div

6.4Vp-p

1.2Vp-p

3

IC101 ra

CD PLAY MODE

approx 200mVp-p

4

IC101 el

CD PLAY MODE

approx 170mVp-p

– MAIN BOARD –– PANEL BOARD –

1

IC102 wf STOP MODE

222ns

(4.5MHz)

2

IC401 qd STOP MODE

63ns

(16.0MHz)

3

IC401 qa STOP MODE

31µs

(32.768kHz)

4.1Vp-p

4.0Vp-p

3.0Vp-p

1

IC701 4 STOP MODE

200ns

(5MHz)

5.3Vp-p

20

Page 21

6-2. BLOCK DIAGRAMS

TUNER/CD SECTION

TM101

FM 75Ω

G

AM

EXCEPT US,CND,AEP MODEL

FE101

1

US,CND MODEL ONLY

8

1

1

3

IF OUT

ANT IN

OSC OUT

FE101

IF OUT

ANT IN

AEP MODEL ONLY

ANT IN

RB101

F OUT

FE101

13

VT

VT

4

HCD-DX30/RG40

1

FM IF

9

IF OUT

12

AM/IF

24

AM OSC

13

VCO STOP

8

IF REQ MUTE

20

AM RF IN

22

AM OSC

23

V REG

AM/FM IF MPX

IC101

AM MIX OUT

FM SD ADJ

FM/AM DET

TUNED

STEREO

L OUT

R OUT

R-CH

RV101

X102

4.332MHz

IFT101

Q105

RDS

AMP

BUFFER

Q103

AEP ONLY

RDS

IC103

4

MUX

DATA

14

XO

INT

13

XI

11

10

18AM IF IN

19

3

16

6

17

L-CH

A

MAIN

SECTION

MASTER CONTROL

IC401(1/2)

2

16

21

20

24

23

RDS DATA

RDS INT

TUNED

STEREO

• RCH is omitted

• Signal Path

: FM

: CD

: DIGITAL OUT

X101

Q102

Q101

RF IF

AMP

10

1

24

15

18

17

19

FM

XIN

XOUT

FM OSC

VT1 IN

VT1

PD1

PLL

IC102

FM/AM IF

AM OSC

12

FM

7

14

2VCO STOP

8IF REQ

DO

6DO

DI

DI

4DI

CL

CL

5

CE

CE

3

7

8

5

1

3

4

7IF OUT

8OSC OUT

5VT

55

JR109

14

1511

67

US,CND

MODEL

EXCEPT

US,CND

R107

9

CF101 CF102

+B TU+12V

JR609

4.5MHz

OPTICAL PICK-UP

BLOCK

(KSM-213DCP)

VC

A

B

C

D

E

F

LD

GND

PD

VR

F+

FOCUS

COIL

F-

COIL

T+

T-

TRACKING

+5V

Q101

LD

DRIVE

122

RF AMP

IC103

VC

12

A

5

B

6

C

7

D

8

E

11

F

10

LD

3

PD

4

IC102

MOTOR/COIL DRIVE

CH1RO

13

CH1FO

14

CH2RO

11

CH2FO

12

RFO

RFI

FE

TE

CH1RI

CH1FI

CH2RI

CH2FI

ST MUTE

22

DO

DI

CL

CE

DIGITAL SERVO

DIGITAL SIGNAL PROC.

D/A CONV.

IC101

D OUT

60

16

17

14

13

22LD ON

21HOLD SW

3

2

6

5

RFAC

51

RFDC

43

39

41

40

14

32

33

30

31

FE

TE

SE

XLON

FFDR

FRDR

TFDR

TRDR

L OUT

R OUT

SCLK

SCOR

SQSO

SSTP

XTAI

XTAO

72

75

20

27

66

67

R-CH

5DATA

7CLOK

6XLAT

2SQCK

9

1

X101

16.9344MHz

S101

LIMIT

IN SW

PH671

OPTICAL

DIGITAL

OUT

CD

DIGITAL OUT

L OUT

B

MAIN

SECTION

ST DIN

27

ST DOUT

26

ST CLK

28

ST CE

25

CD DATA

33

CD CLK

37

XLT

42

SQ CLK

33

SCOR

19

SQ DATA

32

BU UP/DOWN SW

MTR CNT2

T SENS

IC701

44

45MTR CNT1

49

46OPEN SW

47CLOSE SW

48

9

MOTOR

DRIVE

7

TBL ADDRESS

4

2

IC711

SENSOR

M

S701

OPEN/CLOSE

S711

BU UP/

DOWN

M721

TURN

MOTOR

SLED

MOTOR

SPINDLE

MOTOR

CH3RI

CH3RO

18

23

SRDR

29

M

CH3FO

17

CH4RO

16

24CH3FI

25CH4INS

SFDR

28

MDP

26

3XRST

43

XRST

M

CH4FO

15

MUTE

20

41

HOLD

2121

Page 22

HCD-DX30/RG40

MAIN SECTION

L

R

L

TC BLOCK

A

B

JK301

JK705

CN713

J704

DECK-A

DECK-B

A MODE

B MODE

A HALF

B HALF

REC(FWD)

REC(REW)

A PHOTO

B PHOTO

A SOL

B SOL

CAP M+

MOTOR H

MOTOR L

L-CH

LOUT

L-CH

R-CH

US,CND,AEP

MODEL

IC702

3

2

Q711

LIMITER

1

RV661

GAME

J702

TUNER

SECTION

CD

SECTION

MD IN

VIDEO

OUT

VIDEO

IN

VIDEO

AUDIO

MIC

JW710

RV709

MIC

LEVEL

Q601,602

Q603,604

Q605,606

CAP MOTOR

L201

BIAS

Q220,221

PLAY/REC

CONTROL

A TRIG

DRIVE

B TRIG

DRIVE

DRIVE

INPUT SELECT

TONE/VOL CONT

IC301

TUNER/L

43

OUT L

32

OUT R

CD/L

42

MD/L

47

INLE GAME

49

MIC

56

TAPE/L

80

SP LAT A81SP LAT B82SP LAT C

45

DPLL1

57

DPLR1

59

SI

34

SCK

35

A

36

B

37

C

38

X501

32.768kHz

10

XC IN

11

BP OUT

16MHz

15

XC OUT

VIDEO AMP

IC704

1

3

5

2

R-CH

BIAS

OSC

Q223

PLAY/REC

SWITCH

60

61

65

4

Q217

MUTE

Q227

A TRIG

B TRIG

CAP M CONT

7

Q224,228

SWITCH

BIAS

90

B SHUT89A SHUT

IC702

6

5

1

2

9

67

B REC REW66B REC FWD

7

PB/REQ EQ AMP

IC201

CH1/A

CH1/B

REC OUT

Q222,225

SWITCH

71

69

B HALF68A HALF

PRE OUT

REC IN

MIX OUT

TAPE A/B

B PLAY70A PLAY

5

11

6

19

77

47

TC PLAY

73

BIAS

Q214

MUTE

Q210,211

AMS

72

76

PB A/B

AMS IN

74

S726 S701

DISPLAY

Q226

79

REC MUTE

POWER

78

PB MUTE

Q229

MUTE

5

VIDEO SW2

6

7

LAT

CLK

DATA

MASTER CONTROL

IC401(2/2)

95

VACS

97

LED

DRIVE

94

Q701

D701

X602

X IN

R-CH

31

39

91

83

13

X OUT

SP/VACS

LINE MUTE

Q361,362

MUTE

CONT

Q301

MUTE

Q503,504

MUTE

CONT

84

88

STK MUTE

FRONT RELAY

STBY RELAY86RESET

4

85

PROTECT

REMOTE

12

IC501

1

6

POWER

AMP

12

Q581

MUTE

100

S-IN

18

1

S-OUT

ACCUT

2

S-CLK3S-BSY

SWITCH

41

38

M-RESET

CD POWER

Q661 IC661

RESET

Q365

MUTE

CONT

TH501

RESET

3

SENS701

REMOTE

Q363

MUTE

Q501

OVER LOAD

DETECTOR

CD D+5V

CD A+5V

FAN +B

PANEL +5V

TC D+5V

µCOM +B

µCOM +B

RDS D+5V

TC A+12V

MIC A+12V

TU +12V

TC M+9V

1

Q582,583

OVER HEAT

DETECTOR

D664

D691-693

Q381,382

PROTECT

DETECTOR

1

D670

D667

D668

D661

D662

D686

D502

PROTECT

Q584

FAN ON

SWITCH

SP MODEL ONLY

IC681 Q681,682

CD POWER

+5V

3

REG

SWITCH

1

1

1

Q383

CONT

IC682

+5V

REG

IC683

+12V

REG

IC684

+9V

REG

3

3

3

Q384,385

RELAY

DRIVE

Q386,387

PROTECT

SWITCH

D383

POWER

AMP

D543 D542

+B

-B

EVER +5.6V

RY371

D681-684

D687-690

S713-725

FUCTION

S727-738

FUCTION

S702-712

FUCTION

VR701

VOLUME

Q911

-V

REG

D541

KEY

KEY

KEY

F1

F2

IC901

+5.6V

3

REG

R CH

R CH

T911

MAIN TRANS

D902-905

1

CN301

Q371,373

FAN

DRIVE

EXCEPT AEP

DISPLAY CONTROL

17

HEADPHONE

22

KEY0

21

KEY1

20

KEY2

VOL A

13

VOL B

14

S-OUT

9

S-IN

8

S-CLK

7

S-BSY

10

RESET

6

VP

60

(SP,E,AR,E51,AUS)

(AEP,KR,SP,E,AR,E51)

SP,E,AR,E51

Q907

RELAY

DRIVE

L

SPEAKER

R

FAN

IC701

MO/VIDEO LED

TAPE LED

REC LED

ENTER LED

DVD5.1 LED

PRO LED

JW911

JW912

JW913

(MX)

JW911

JW912

JW913

F919

US,CND

T901

SUB TRSNS

RY901

S29

G11

S0

G0

J701

PHONS

68

61

.

58

37

80

69

31

32

33CD LED

34TUNER LED

30GAME LED

29

28

26

27

35GROOVE LED

3X1

4X2

220/230

EXCEPT

SP,E,AR,E51

SP,E,AR,E51

F1 F2

Q707-710,712

RES701

5MHz

JW3

JW1

JW4

Q702-706

LED

DRIVER

LED

DRIVER

240

120

• RCH is omitted

• Signal Path

: PB (DECK A)

: PB (DECK B)

: REC (DECK B)

: FM

: CD

FLD1

FLOURESCENT

INDICATOR TUBE

D702-706

D716-720

D707-711

JW7

JW6

JW5

AUS

AEP,KR

US,CND,MX

S901

VOLTAGE

SELECTOR

SP,E,AR,E51

AC

IN

2222

Page 23

HCD-DX30/RG40

6-3. SCHEMATIC DIAGRAM MAIN SECTION (1/4)

DX30

• See page 20 for Wavefoms. • See page 42 for IC Block Diagrams.

(Page 24)

IC B/D

IC B/D

(Page 25)

2323

Page 24

HCD-DX30/RG40

6-4. SCHEMATIC DIAGRAM MAIN SECTION (2/4)

• See page 43 for IC Block Diagrams.

(Page 23)

(Page 25)

IC B/D

(Page 26)

2424

Page 25

6-5. SCHEMATIC DIAGRAM MAIN SECTION (3/4)

HCD-DX30/RG40

(Page 23)

(Page 24)

(Page 26)

(Page 31)

2525

Page 26

HCD-DX30/RG40

6-6. SCHEMATIC DIAGRAM MAIN SECTION (4/4)

• See page 20 for Wavefoms. • See page 40 for IC Pin Function Description.

(Page 24)

(Page 33)

(Page 25)

(Page 37)

(Page 29)

(Page 31)

2626

Page 27

HCD-DX30/RG40

6-7. PRINTED WIRING BOARD MAIN SECTION

MAIN BOARD

A

B

IC401

C

D

TO

PANEL

D

BOARD

CN711

(Page 32)

E

TAPE DECK BLOCK

F

G

RECORD/PLAYBACK/ERASE

H

I

ERASE

J

12

SUPPLIED WITH

THE ASSEMBLED

BLOCK

A DECK

PLAYBACK

L-CH

R-CH

B DECK

L-CH

R-CH

E

E

E

E

34567891011121314

E

E

E

E

E

E

E

E

E

E

• See page 20 for Circuit Boards Location.

DX30

3

IC661

E

1

AEP

E

DX30

E

DX30

E

E

IC201

E

DX30

E

E

E

E

E

E

E

E

E

E

IC684

123

E

IC682

E

TO

DRIVER

BOARD

CN701

(Page 36)

IC301

123

• Semiconductor Location

TO

BD BOARD

CN101

(Page 28)

A

IC102

19

E

PH671

1

CD DIGITAL

2

3

OUT

OPUTICAL

D101 D-13

D104 C-11

D108 C-10

D203 F-6

D204 F-6

D205 G-6

D206 F-3

D207 I-6

D301 E-8

D302 C-5

D303 B-8

D361 G-10

D371 G-13

Ref. No. Location

IC681

123

TM101

FM

E

IC101

75

D372 H-12

D374 H-12

D383 F-11

D601 E-3

D602 E-3

D661 B-5

E

ANTENNA

E

E

E

E

AEP,UK

AM

D662 B-4

D663 B-6

D664 B-5

D665 B-5

D666 B-5

D667 A-5

D668 A-5

D669 B-5

D670 A-7

IC103

D681 H-11

D682 H-10

D683 H-11

D684 H-10

D685 H-8

AEP

D686 G-8

D687 H-11

IC683

123

AEP,UK

E

E

E

E

E

E

E

E

E

E

E

E

AEP

R

L

M961

JK302

SPEAKER

+

MD/VIDEO

(AUDIO)

-

L ch

R ch

D688 H-11

D689 H-11

D690 H-11

D691 G-7

D692 G-7

D693 G-8

D694 I-13

D695 I-13

IC101 C-11

IC102 A-11

IC201 G-4

IC301 D-8

IC401 C-3

IC661 B-6

IC681 C-9

IC682 H-8

IC683 H-8

IC684 H-7

E

AEP

TO

POWER AMP BOARD

C

CN503

(Page 30)

TO

B

POWER AMP BOARD

CN502

(Page 30)

EXCEPT

AEP

AEP

1-681-440-

11

(11)

Ref. No. Location

Q101 C-11

Q102 A-12

Q103 D-11

Q104 D-11

Q210 F-5

Q211 F-6

Q212 H-4

Q213 F-4

Q214 G-6

Q215 H-5

Q216 H-4

Q217 G-4

Q218 H-3

Q219 H-4

Q220 H-4

Q221 H-3

Q222 G-6

Q223 I-4

Q224 I-5

Q225 G-6

Q226 F-5

Q227 I-6

Q228 I-5

Q229 F-4

Q230 H-5

Q301 I-7

Q302 I-8

Q361 D-4

Q362 D-4

Q363 G-12

Q364 G-11

Q365 G-11

Q371 G-13

Q373 G-12

Q381 G-12

Q382 G-12

Q383 G-12

Q384 F-12

Q385 F-12

Q386 F-11

Q387 F-11

Q601 D-3

Q602 E-3

Q603 D-3

Q604 E-3

Q605 D-3

Q606 D-3

Q661 B-5

Q681 C-9

Q682 D-9

2727

Page 28

HCD-DX30/RG40

6-8. PRINTED WIRING BOARD BD SECTION

• Semiconductor

Location

Ref. No. Location

IC101 B-2

IC102 C-3

IC103 B-2

TP

(RF)

TP(D GND)

TP

(VC)

TP(FE0)

TP(FE1)

TP(TE0)

IC101

IC103

TP(AGC CON)

TP

(XPCK)

Q101 A3

M

IC102

18

19

2

1

A

CN102

(Page 27)

2828

Page 29

HCD-DX30/RG40

6-9. SCHEMATIC DIAGRAM BD SECTION

• See page 20 for Wavefoms. • See page 43, 44 for IC Block Diagrams.

IC B/D

A

CN102

(Page 26)

IC B/D

IC B/D

(4/4)

2929

Page 30

HCD-DX30/RG40

6-10. PRINTED WIRING BOARD POWER AMP SECTION

POWER AMP BOARD

A

B

DX30

B

C

TO

MAIN

BOARD

CN402

(Page 27)

13

• See page 20 for Circuit Boards Location.

AEP,KR

E

IC501

E

E

E

E

DX30

• Semiconductor

SENSOR BOARD

1-681-442-

1

E

E

E

Location

Ref. No. Location

D501 C-7

D502 C-5

D541 D-6

D542 B-3

11

D543 B-3

D551 C-5

(11)

IC501 A-6

Q501 B-7

Q503 C-7

Q504 C-6

Q551 B-5

Q581 B-6

Q582 C-7

Q583 C-8

Q584 C-8

D

E

F

C

TO

MAIN

BOARD

CN403

(Page 27)

12

13

+

_

AEP,KR

13

F

11

1-681-448-

(11)

TO

TRANS

BOARD

CN915

(Page 38)

345678910

3030

Page 31

6-11. SCHEMATIC DIAGRAM POWER AMP SECTION

2 : C502,552

470p : RG40

1000p : DX30

2

HCD-DX30/RG40

D5SBA204101

3

DX30

RG40

DX30

AEP,KR

F

AEP,KR

2

3 : R504,554

33k : RG40

56k : DX30

DX30

3

DX30

Q582,583

OVER HEAT DETECTOR

Q584 : FAN ON SWITCH

DX30

CN915

(Page 39)

CN506

CN403

(Page 26)

(4/4)

C544

1000

25V

(3/4)

CN402

(Page 25)

3131

Page 32

HCD-DX30/RG40

6-12. PRINTED WIRING BOARD PANEL SECTION

PANEL BOARD

A

B

E

E

C

E

E

D

30

29

• See page 20 for Circuit Boards Location.

80

1

IC701

(FLUORESCENT INDCATOR TUBE)

61

60

41

40

20 21

E

DX30

DX30

SENS701

13

DX30

E

• Semiconductor

Location

Ref. No. Location

D701 A-12

D702 C-2

E

D703 B-2

D704 A-2

D705 B-2

D706 C-12

D713 D-5

D716 C-2

D717 B-2

D718 A-2

D719 B-2

D720 C-12

D721 E-4

IC701 C-6

IC702 E-10

Q701 B-11

Q702 C-4

Q703 C-4

Q704 B-4

Q705 C-4

Q706 C-11

Q711 C-8

E

F

G

H

I

D

TO

MAIN BOARD

CN701

(Page 27)

IC702

2

1

J701,702

S701,702,722-725

13

TO

KEY BOARD

CN715

(Page 34)

DX30

DX30

G

1

11

(11)

1-681-446-

VIDEO OUT BOARD

VIDEO

OUT

11

(11)

12

345678910111213

3232

Page 33

HCD-DX30/RG40

6-13. SCHEMATIC DIAGRAM PANEL SECTION

• See page 20 for Wavefoms. • See page 41 for IC Pin Function Description.

3 .1

0

4 .9

(Page 26)

(Page 35)

3333

Page 34

HCD-DX30/RG40

6-14. PRINTED WIRING BOARD KEY SECTION

KEY BOARD

A

E

B

E

• See page 20 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

D707 D-1

D708 B-3

D709 C-7

D710 B-7

Q707 B-1

Q708 B-1

Q709 C-6

Q710 C-6

C

D

E

G

13

TO

PANEL BOARD

CN712

(Page 32)

E

E

1-681-447-

S704-721,726-738

DX30

11

(11)

12

34567

3434

Page 35

6-15. SCHEMATIC DIAGRAM KEY SECTION

HCD-DX30/RG40

(Page 33)

3535

Page 36

HCD-DX30/RG40

6-16. PRINTED WIRING BOARD DRIVER SECTION

12

A

B

• See page 20 for Circuit Boards Location.

3456

IC711

4

C

D

E

14

14

14

14

IC701

F

G

14

14

E

CN1

(Page 27)

3636

Page 37

HCD-DX30/RG40

6-17. SCHEMATIC DIAGRAM DRIVER SECTION

• See page 43 for IC Block Diagrams.

IC B/D

AC

EK

E

(4/4)

CN1

(Page 26)

3737

Page 38

HCD-DX30/RG40

6-18. PRINTED WIRING BOARD TRANS SECTION

TRANS BOARD

4

A

VOLTAGE

B

C

D

SELECTOR

220V

230-240V

SP,E,AR,E51

AUS

120V

AEP

AEP,SP,E,AR,E51

SP,E,AR,E51,AUS

• See page 20 for Circuit Boards Location.

EXCEPT

1

SP,E,AR,E51

US,CND,MX,KR

MX,KR

US,CND,SP,E,AR,E51

SP,E,AR,E51

POWER TRANSFORMER

US,CND

C

E

B

1-681-444-

F

TO

POWER AMP

BOARD

CN501

(Page 30)

11

(11)

E

F

G

H

SUB TRANS BOARD

2

3

1

IC901

E

EXCEPT

SP,E,AR,E51

SP,E,AR,E51

1

I

POWER

TRANSFORMER

SP,E,AR,E51

4

EXCEPT

SP,E,AR,E51

1-681-445-

11

(11)

AC

IN

12

3456789101112

3838

Page 39

6-19. SCHEMATIC DIAGRAM TRANS SECTION

(Page 31)

HCD-DX30/RG40

3939

Page 40

HCD-DX30/RG40

6-20. IC PIN FUNCTION DESCRIPTION

• MAIN BOARD IC401 M30622MCA-B23FP (MASTER CONTROL)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Pin Name

S-OUT

S-CLK

S-BSY

REMOTE IN

3878-DAT

3878-LAT

3848-CLK

BYTE

CN VSS

XC IN

XC OUT

RESET

X OUT

VSS

X IN

VCC

NMI

AC-CUT

RCOR

RDS-INT

RDS-DATA

ST-MUTE

SSTEREO(IN)

TUNER

ST-CE

ST-DOUT

ST-DIN

ST-CLK

VCD

VCD

NO USE

SQ-DAT IN

SQ-CLK

SENS

CD-DAT OUT

CAN’T-USE

CD-CLK

CD-POWER

CLOCK-OUT

HOLD

M-RESET

XLT

XRST

LOAD-IN

LOAD-OUT

OPEN

CLOSE

UP/DOWN

T-SENS

GAME/DVD

I/O

O

Serial data output the display control.

O

Serial clock output from main controller.

I

Busy signal input from the display control. “L” : busy

I

Pemoto commander input.

O

Data signal output for IC301(BH3878KS2)

O

Latch signal output for IC301(BH3878KS2)

O

Clock signal output for IC301(BH3878KS2)

—

Connected to ground.

—

Connected to ground.

I

SUB SYSTEM CLOCK input.(32.768MHz)

O

SUB SYSTEM CLOCK output.(32.768MHz)

I

System reset input.

O

MAIN SYSTEM CLOCK output.(16MHz)

—

Connected to ground.

I

MAIN SYSTEM CLOCK input.(16MHz)

—

Power supply.(+5V)

I

PULL UP.(EVER+5V)

I

AC CUT ON(L)/OF(H) CHECK.

I

CD Q-data request signal input.

I

RDS interrupt signal input.

I

RDS data signal input.

O

Tuner mute signal output.

I

STEREO detect signal input.L=ON,H=OFF

I

TUNER detect signal input.L=ON,H=OFF

O

TUNER chip eneble output.

O

TUNER data output.

I

TUNER data input.

O

TUNER clock signal output.

—

Not used.

—

Not used.

—

Not used.

I

Subcode Q data input(CD data).

I

Subcode Q data input(CD clock).

I

BD condition signal input.

O

CD data output.

—

Not used.

O

CD clock output.

O

CD-POWER ON/OFF signal output.H=ON,L=OFF

—

Not used.

O

MODE signal input.

O

Micom reset signal output to the display control. “L” : reset

O

CD latch signal output.

O

CD reset signal output.

I

Loading motor control signal input.

O

Loading motor control signal output.

I

Tray open detect signal input.

I

Tray close detact signal input.

I

Pick-up up/down detect signal input.

I

CD table detect signal input.

—

Not used.

Description

Pin No.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Pin Name

NO USE

CENT-MUTE

REAR-MUT

494-DAT

494-CLK

494-LT

SUR1

SUR2

SUR3

A-TRG

B-TRG

VDD

SOFT TEST

VSS

CAMP-CONT

B-REC FWD

B-REC REW

A-HAFE

B-HAFE

A-PLAY

B-PLAY

AMS-IN

DISPLAY KEY

POWER-KEY

BIAS

PB-A/B

TC-RELAY

PB-MUT

REC-MUT

SP-LATA

SP-LATB

SP-LATC

LINE-MUT

STK-MUT

PROTECT

STB-RELAY

REAR-RELAY

FRONT-RELAY

A-SHUT

B-SHUT

SP/VACS

MODE IN

SPEC-IN

VIDEO SW2

VA C S

AVSS

POWER-KEY

AV-REF

AVCC

S-IN

I/O

—

Not used.

—

Not used.

—

Not used.

—

Not used.

—

Not used.

—

Not used.

—

Not used.

—

Not used.

—

Not used.

O

A deck trigger control signal output.H=ON,L=OFF

O

B deck trigger control signal output.H=ON,L=OFF

—

Power supply.(+5V)

—

Not used.

—

Connected to ground.

O

Capstan motor REV/FWD/STOP control signal output.H=REV,L=FWD/STOP

I

Detection input from the deck-B rec forward detect switch. “L” : rec

I

Detection input from the deck-B rec reverse detect switch. “L” : rec

I

A deck hafe detect signal input.

I

B deck hafe detect signal input.

I

A deck play detect signal input.

I

B deck play detect signal input.

I

AMS signal input.L=ON,H=OFF

O

DISPLAY KEY control signal output.

O

POWER KEY control signal output.

O

BIAS ON/OFF signal output.H=ON,L=OFF

O

Playback deck A/B select signal output.H=High,L=Normal

O

Tape deck relay ON/OFF signal output.H=ON,L=OFF

O

PB mute ON/OFF signal output .H=ON,L=OFF

O

REC mute ON/OFF signal output .H=ON,L=OFF

O

Serial data latch pulse output to BH3878KS2 (IC301)

O

Serial data latch pulse output to BH3878KS2 (IC301)

O

Serial data latch pulse output to BH3878KS2 (IC301)

O

Line mute signsl output.L=ON,H=OFF

O

Power amplifier mute ON/OFF signal output.H=ON,L=OFF

I

Speaker protect signal input.L=ON,H=OFF

O

STANDBY relay control signal output.

O

Rear speaker relay control output.

O

Front speaker relay control output.

O

A deck reel pulse detect signal output.

O

B deck reel pulse detect signal output.

I

MODEL

I

Version select signal input.

—

Connected to ground.

O

POWER ON/OFF signal output.H=ON,L=OFF

—

Analog reference voltage.

—

Power supply.(+5V)

Description

4040

Page 41

• PANEL BOARD IC701 UPD780232GC-031-8BT (DISPLAY CONTROL)

HCD-DX30/RG40

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

Pin Name

VDD

VSS

X1

X2

IC

RESET

S-CLK

S-IN

S-OUT

SBSY

NO USE

NO USE

VOL-A

VOL-B

NO USE

NO USE

HEADHONE

AVSS

NO USE

KEY2-KEY0

VSS

AVDD

VDD

DV5.1-LED

PRO-LED

ENTER-LED

REC-LED

GAME-LED

MO/VIDEO-LED

TAPE-LED

CD-LED

TUNER-LED

GROOVE

NO USE

S29-S8

VDD2

VLOOD

S7-S0

G11-G0

I/O

—

Power supply.(+5V)

—

Connected to ground.

O

System clock output terminal.(5MHz)

I

System clock input terminal.(5MHz)

I

Reset signal input from main controller.

I

Serial clock input from main controller.

I

I

—

Not used.

—

Not used.

I

VOLUME A signal input.

I

VOLUME B signal input.

—

Not used.

—

Not used.

I

Headphone detect signal input. H=ON,L=OFF

—

Connected to ground.

—

Not used.

I

KEY input.(AD)

—

Connected to ground.

—

Power supply.(+5V)

—

Power supply.(+5V)

O

DV5.1 LED driver output.

O

GROOVE LED driver output.

O

ENTER LED driver output.

O

REC LED driver output.

O

GAME LED driver output.

O

MO(VIDEO) LED driver output.

O

TAPE LED driver output.

O

CD LED drover output.

O

TUNER LED driver output.

—

Not used.

—

Not used.

O

FL segment signal output.

—

Power supply.(+5V)

O

FL segment signal output.

O

FL gride output.

Description

41

Page 42

HCD-DX30/RG40

2

6-21. IC BLOCK DIAGRAMS

IC101 BA1450 (MAIN BOARD)

AM OSC OUT

24

VREG

FM

IF

1 2 3 4 5 6 7 8 9 10 11 12

FM IN

V . REG

VCC

AM OSC

AM

OSC

SD

DET

FM SD ADJ

FM BAND WIDTH

GND

IC102 LC72130 (MAIN BOARD)

AM

MIX

FM

DET

20212223

AM RF IN

FM DET

AM MIX OUT

19

LED

DRIVER

TUNED

AM IF

AM

DET

AM IF IN

STEREO

AM AGC

AGC

COMP

IN REQ MUTE

FM/AM DET OUT

161718

IF OUT

AM MPX IN

15

DECODER

R OUT

FM MPX IN

14 13

SW

L OUT

VCO STOP

SD

1/2

1/2

PD

VCO

AM/FM

24

XOUT

VSS

22

23

AOUT

REFERENCE

DIVIDER

2

C B

I / F

AIN2

21

SWALLOW COUNTER

20

PD2

19

1/16.1/17 4bits

REFERENCE

DIVIDER

DATA SHIFT REGISTER

PD1

AIN1

18

SWALLOW COUNTER

1/16.1/17 4bits

PHASE DETECTOR

CHARGE PUMP

LATCH

17

AOUT1

16

VDD

POWER

ON

RESET

FMIN

AMIN

I02

13

14

15

1/2

C B

I / F

42

3

1

2

XIN

B05

4

CE

D1

6

5

CL

D0

8

7

B01

B02

10

9

B04

B03

12

11

I01

IFIN

Page 43

HCD-DX30/RG40

IC201 TA8189N (MAIN BOARD) IC701 BA6956AN (DRIVER BOARD)

METAL

PRE

CH2/A CH2/B NF VCC CG NF ALC

24 23 22 21 20 19 18 17

OUT

OUT

TAPE A

/TAPE B

REC

OUT

16

REC

IN

15 14 13

TSD

REC

OUT

CH2

CH1

–

+

+

–

CH2

–

+

A/B

IREF

VREF1

CH1

+

–

123456789101112

PRE

CH1/A CH1/B NF GND1 M/H NF

OUT

OUT

MIX

OUT

VREF2

M/N

IC101 CXD2587Q (BD BOARD)

VDD

60

DOUT

AVDD3

VSS

59

57

58

FILO

CLTV

FILI

PCO

56

55

52

54

53

REC

IN

AVSS3

51

ALC

GNDGND

GNDMETAL

RFAC

CONTROL LOGIC

1 2 3 4 5 6 7 8 9

OUT2

43

RFDC

42

RNF

CE

TE

41

VREF

ASYI

BIAS

50

AVDD0

ASYO

47

49

48

46

IGEN

45

AVSS0

ADIO

44

OUT1

VM

VCC

FIN

GND

RIN

LRCK

PCMD

BCK

EMPH

XVDD

XTAI

XTAO

XVSS

AVDD1

AOUT1

AIN1

LOUT1

AVSS1

AVSS2

LOUT2

AIN2

AOUT2

AVDD2

RMUT

LMUT

SE

DIGITAL

OUT

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

D/A

INTERFACE

TIMING

LOGIC

OVER SAMPLING

PWM

PWM

3rd ORDER

NOISE SHAPER

DIGITAL FILTER

SERIAL IN

INTERFACE

INTERNAL BUS

ERROR

CORRECTOR

16K

RAM

SUBCODE

PROCESSOR

DIGITAL

PLL

EFM

DEMODULATOR

SERVO

INTERFACE

SERVO AUTO

SEQUENCER

ASYMMETRY

CORRECTION

SERVO DSP

FOCUS

SERVO

TRACKING

SERVO

SLED

SERVO

OPERATIONAL

AMPLIFIER

ANALOG SWITCH

A/D

CONVERTER

PWM GENERATOR

CLOCK

GENERATOR

FOCUS PWM

GENERATOR

TRACKING

PWM GENERATOR

SLED PWM

GENERATOR

DIGITAL

CLV

MIRR, DFCT,

FOK

DETECTOR

40

FE

39

VC

38

XTSL

37

TES1

36

TEST

35

VSS

34

33

FRDR

32

FFDR

TRDR

31

TFDR

30

SRDR

29

28

SFDR

SSTP

27

MDP

26

25

LOCK

FOK

24

DFCT

23

22

MIRR

1

2

SQSO

SQCK

3

XRST

4

SYSM

CPU

INTERFACE

7

5

6

XLAT

DATA

CLOK

8

SENS

9

10

SCLK

11 12

VDD

ATSK

13

SPOA

14

SPOB

1516171819

XUGF

XPCK

XLON

WFCK

GFS

20

C2PO

SCOR

COUT

21

43

Page 44

HCD-DX30/RG40

IC102 BA5974P (BD BOARD)

PRFVCC

1 2 3 4 5 6 7 8 9 10 11 12 13 14

VREFOUT

CH4BIN

INTERFACE

CH1FIN

CH4SIN'

RF

CH1RIN

F

R

CH4SIN

CAPAIN1

CH3FIN

F

INTERFACE

INTERFACE

CH2FIN

CH3RIN

R

RF

CH2RIN

R

F

F

R

CAPAIN3

MUTE

CAPAIN2

MUTE

POWVCC

POWVCC

CH3OUTR

CH2OUTR

THERMAL

SHUTDOWN

GND

202122232425262728 19 18 17 16 15

GND

VREFIN

IC103 CXA2568M-T (BD BOARD)

CH3OUTF

CH2OUTF

CH4OUTR

LEVEL SHIFT

CH1OUTR

CH4OUTF

CH1OUTF

HOLD

AGCVTH

LD

PD

VEE

VC

A

B

C

D

F

E

1

2

3