Page 1

HCD-EC68USB

SERVICE MANUAL

Ver. 1.1 2008.06

• HCD-EC68USB is the amplifi er, USB, CD player

and tuner section in MHC-EC68USB.

SPECIFICATIONS

Model Name Using Similar Mechanism

Mechanism Type

Base Unit Name

Optical Pick-up Block Name

AEP Model

E Model

NEW

CDM88A-K6BD91UR-WOD

BU-K6BD91UR-WOD

KSM-213DCP

European model:

Power output (rated):

70 W + 70 W (at 6 Ω, 1 kHz,

1% THD)

RMS output power (reference):

90 W + 90 W (per channel at 6 Ω,

1 kHz, 10% THD)

Other models:

220, 240 V, 50/60 Hz

Power output (rated):

50 W + 50 W (at 6 Ω, 1 kHz,

1% THD)

RMS output power (reference):

70 W + 70 W (per channel at 6 Ω,

1 kHz, 10% THD)

Inputs

AUDIO IN (stereo mini jack):

Sensitivity 800 mV, impedance 22 kilohms

(USB) port: Type A

Outputs

PHONES (stereo mini jack): accepts

headphones with an impedance of 8 Ω or

more

SPEAKER: impedance

6 Ω

USB section

Supported bit rate

MP3 (MPEG 1 Audio Layer-3):

32 − 320 kbps, VBR

Sampling frequencies

MP3 (MPEG 1 Audio Layer-3):

32/44.1/48 kHz

Transfer speed

Full-Speed

Supported USB device

Mass Storage Class

Maximum current

500 mA

CD player section

System: Compact disc and digital audio

system

Laser: Semiconductor laser (λ=770 −

810 nm)

Emission duration: continuous

Frequency response: 20 Hz − 20 kHz

Signal-to-noise ratio: More than 90 dB

Dynamic range: More than 88 dB

Tuner section

FM stereo, FM/AM superheterodyne tuner

Antenna:

FM lead antenna

AM loop antenna

FM tuner section:

Tuning range:

87.5 − 108.0 MHz (50 kHz step)

Intermediate frequency: 10.7 MHz

AM tuner section:

Tuning range

European mo del:

531 − 1,602 kHz

(with 9 kHz tuning interval)

Other models:

530 − 1,710 kHz

(with 10 kHz tuning interval)

531 − 1,710 kHz

(with 9 kHz tuning interval)

Intermediate frequency: 450 kHz

General

Power requirements

European model:

AC 230 V, 50/60 Hz

Mexican model: AC 127 V, 60 Hz

Argentine model: AC 220 V, 50/60 Hz

Other models: AC 120, 220 or 230 – 240 V,

50/60 Hz, adjustable with voltage selector

Power consumption

European model:

130 W

0.5 W (in Power Saving Mode)

Other models: 110 W

Dimensions (w/h/d) (excl. speakers)

Approx. 200 × 306 × 415 mm

Mass (excl. speakers)

European model:

6.0 kg

Other models:

5.6 kg

change without notice.

COMPACT DISC RECEIVER

9-889-055-02

2008F05-1

2008.06

©

Sony Corporation

Audio Business Group

Published by Sony Techno Create Corporation

Page 2

HCD-EC68USB

Ver. 1.1

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270 °C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures other than

those specifi ed herein may result in hazardous radiation exposure.

This appliance is

classified as a CLASS 1

LASER product. This

marking is located on the

rear exterior.

TABLE OF CONTENTSNotes on chip component replacement

1. SERVICING NOTES ............................................. 3

2. GENERAL .................................................................. 7

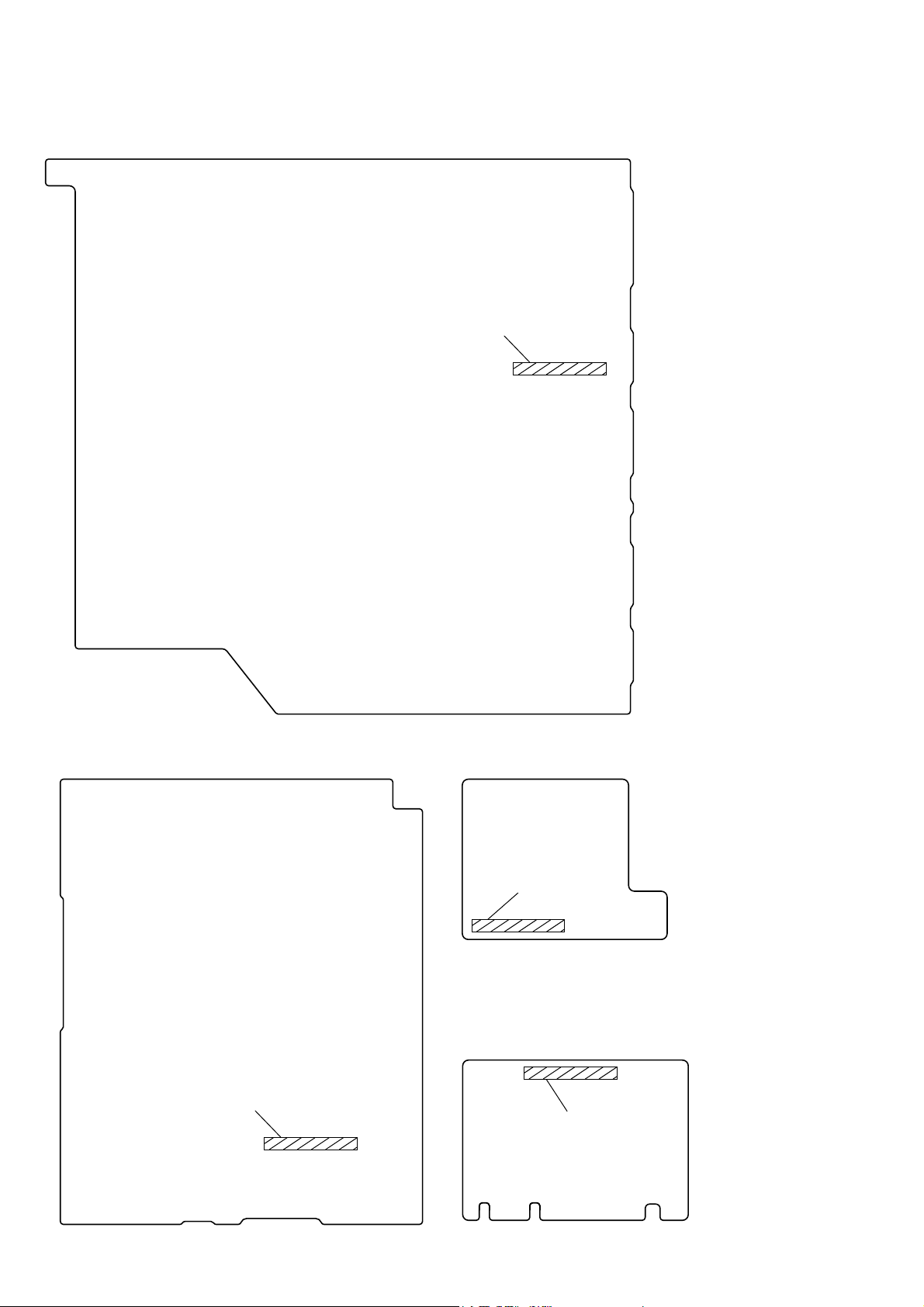

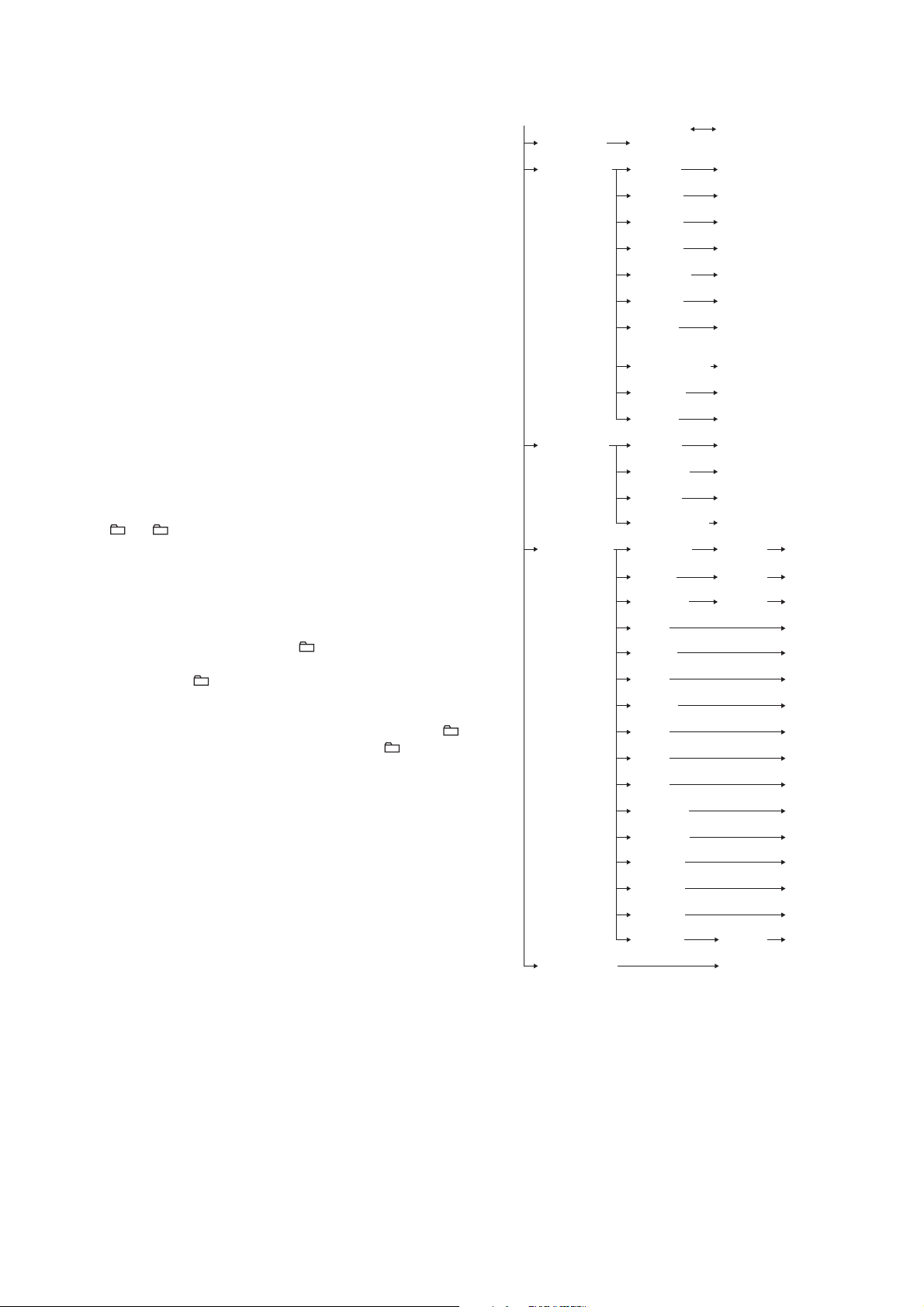

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 8

3-2. Side Panel (L)/(R) ........................................................... 9

3-3. Panel (Top) ...................................................................... 9

3-4. MAIN Board ................................................................... 10

3-5. Front Panel Block ........................................................... 10

3-6. Back Panel Block ............................................................ 11

3-7. 3 CD Mechanism Block .................................................. 11

3-8. Base Unit ......................................................................... 12

3-9. OP Base Assy (KSM-213D) ........................................... 12

3-10. Belt (DLM3A) ................................................................ 13

4. TEST MODE ............................................................ 14

5. ELECTRICAL ADJUSTMENTS ........................ 18

6. DIAGRAMS

6-1. Block Diagram - CD SERVO, TUNER Section - ........... 20

6-2. Block Diagram - USB Section - ..................................... 21

6-3. Block Diagram - MAIN Section - ................................... 22

6-4. Printed Wiring Board - CD Board - ................................ 24

6-5. Schematic Diagram - CD Board - ................................... 25

6-6. Printed Wiring Boards - USB Section - .......................... 26

6-7. Schematic Diagram - USB Section - .............................. 27

6-8. Printed Wiring Board

- MAIN Board (Suffi x-12/-13) - ..................................... 28

6-9. Printed Wiring Board - MAIN Board (Suffi x-14) - ........ 29

6-10. Schematic Diagram - MAIN Board (1/2) - ..................... 30

6-11. Schematic Diagram - MAIN Board (2/2) - ..................... 31

6-12. Printed Wiring Board - LOW AMP Board - ................... 32

6-13. Schematic Diagram - LOW AMP Board - ...................... 32

6-14. Printed Wiring Boards - KEY Section - .......................... 33

6-15. Schematic Diagram - KEY Section - .............................. 33

6-16. Printed Wiring Board - PANEL Board (Suffi x-12) - ...... 34

6-17. Printed Wiring Board - PANEL Board (Suffi x-13) - ...... 35

6-18. Printed Wiring Board - PANEL Board (Suffi x-14) - ...... 36

6-19. Schematic Diagram - PANEL Board - ............................ 37

6-20. Printed Wiring Board - PT Board - ................................. 38

6-21. Schematic Diagram - PT Board - .................................... 39

7. EXPLODED VIEWS

7-1. Panel Section ................................................................... 48

7-2. Front Panel Section ......................................................... 49

7-3. Chassis Section ............................................................... 50

7-4. Main Section ................................................................... 51

7-5. 3 CD Mechanism Section

(CDM88A-K6BD91UR-WOD) ...................................... 52

SAFETY-RELATED COMPONET WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

8. ELECTRICAL PARTS LIST .............................. 53

Note: Refer to “Suffi x-14” for DIAGRAMS of 120V AC area in E

model.

Page 3

SECTION 1

SERVICING NOTES

HCD-EC68USB

Ver. 1.1

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The fl exible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc refl ective surface by the objective lens in the optical

pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

MODEL IDENTIFICATION

– Back Panel –

Model Part No.

AEP model

120V AC area in E, Chilean and Peruvian

models

Mexican model

Argentina model

MODEL

NUMBER

LABEL

3-398-095-0[]

3-398-096-0[]

3-398-097-0[]

3-398-098-0[]

RELEASING THE DISC TRAY LOCK

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Releasing Procedure:

1. Press [

] button to turn the power on.

?/1

2. Press the [FUNCTION] button to select CD function.

3. While pressing the [

] button, press the [Z] button for more 5

x

seconds).

4. The message “UNLOCKED” is displayed and the disc tray is

unlocked.

Note: When “LOCKED” is displayed, the slot lock is not released by

turning power on/off with the [

?/1

] button.

3

Page 4

HCD-EC68USB

SUFFIX-12/-13/-14 DISCRIMINATION OF PRINTED WIRING BOARDS

– MAIN Board (Component Side) –

Suffix-12 : 1-875-488-12

Suffix-13 : 1-875-488-13

Suffix-14 : 1-875-488-14

– PANEL Board (Component Side) –

Suffix-12 : 1-875-490-12

Suffix-13 : 1-875-490-13

Suffix-14 : 1-875-490-14

– USB CONN Board (Component Side) –

Suffix-12 : 1-875-497-12

Suffix-13 : 1-875-497-13

Suffix-14 : 1-875-497-14

– JACK Board (Component Side) –

Suffix-12 : 1-875-493-12

Suffix-13 : 1-875-493-13

Suffix-14 : 1-875-493-14

4

Page 5

HOW TO OPEN THE TRAY WHEN POWER SWITCH TURN OFF

HCD-EC68USB

pull the tray by the hand.

HOW TO REMOVE THE KNOB (VOL)

knob (VOL)

gear

front panel block

(back view)

lever

Turn a gear by a driver

till a lever falls down

to the position of the figure.

hole

Push the knob (VOL) by the flat head driver.

5

Page 6

HCD-EC68USB

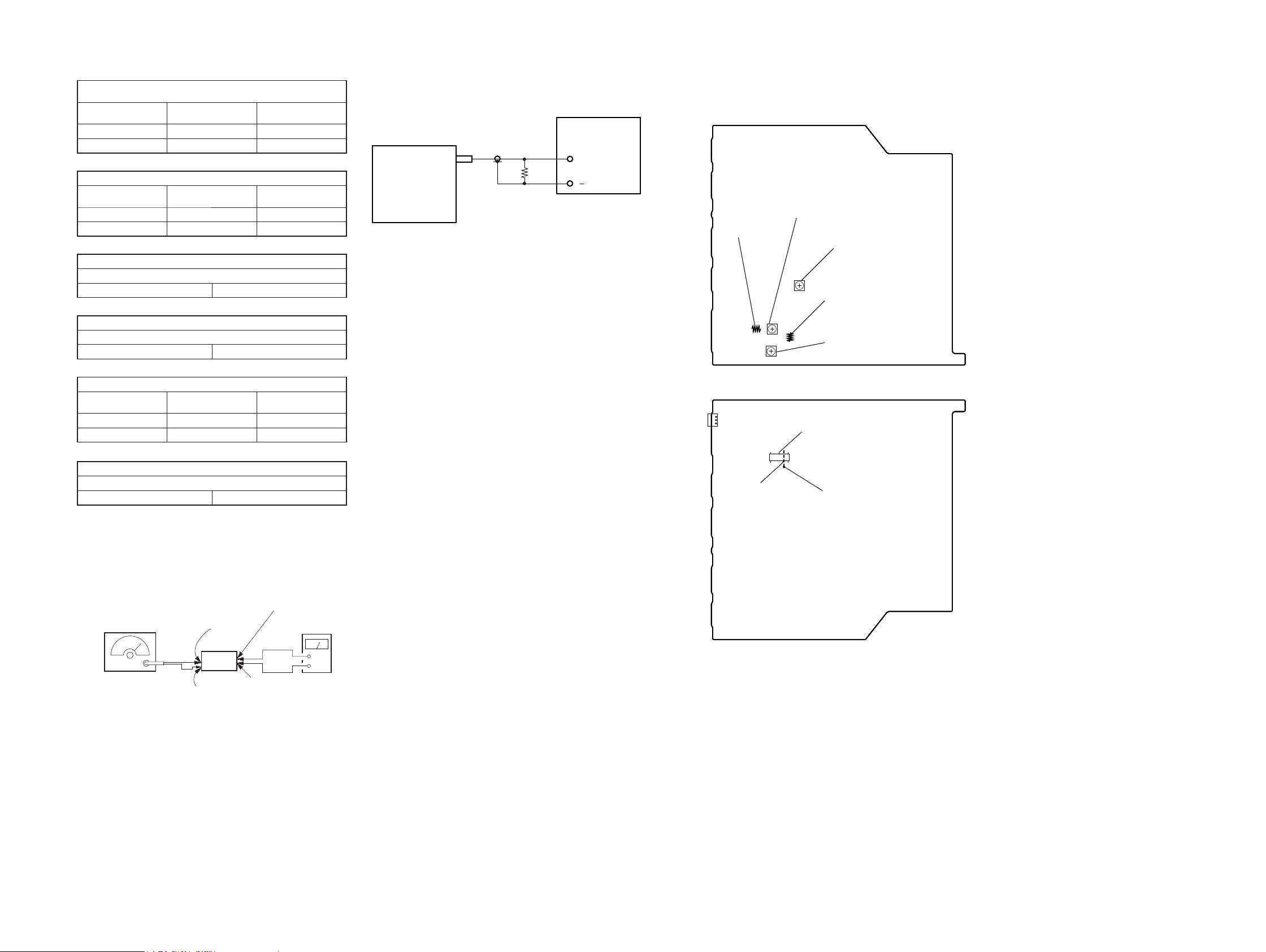

CAPACITOR DISCHARGE FOR ELECTRIC SHOCK PREVENTION

In checking the MAIN board, make a capacitor discharge

of C622 and C626 for electric shock prevention.

800 Ω/2W

MAIN board

800 Ω/2W

C626

C622

MAIN board

6

Page 7

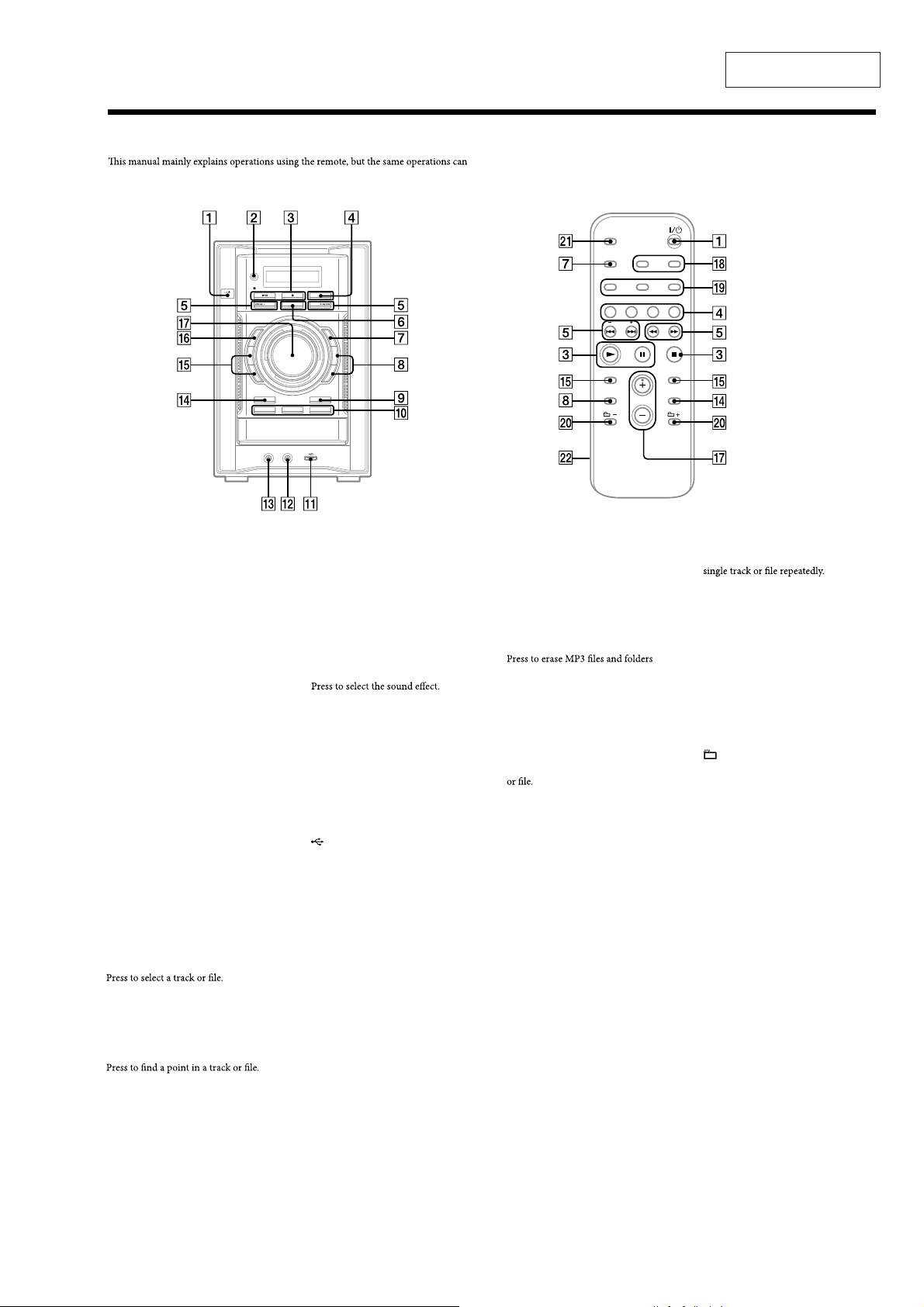

Guide to parts and controls

SECTION 2

GENERAL

also be performed using the buttons on the unit having the same or similar names.

HCD-EC68USB

This section is extracted

from instruction manual.

Unit

/ (on/standby)

Press to turn on the system.

Remote sensor

Unit: (play/pause)

Remote: (play)

(pause)

Presstostartorpauseplayback.

(stop)

Presstostopplayback.

FUNCTION

Presstoselectthefunction.

CD

Press to select the CD function.

TUNER/BAND

Press to select the TUNER function.

Press to select FM or AM reception

mode.

USB

Press to select the USB function.

/ (go back/go forward)

Unit: TUNING +/−

Remote: +/− (tuning)

Press to tune in the desired station.

/ (rewind/fast forward)

Unit: USB

Press to select the USB function.

DISPLAY

Presstochangethe informationonthe

display.

Unit: DSGX, EQ

Remote: EQ

(open/close)

Press to insert and eject a disc.

R

Unit: DISC 1 − 3

Press to select a disc. Press to switch to

the CD function from other function.

RB

(USB) port

Connect an optional USB device (Digital

music player or USB storage media).

RT

AUDIO INPUT jack

Connect to an audio component

(Portable audio player, etc.).

PHONES jack

Connect the headphones.

Remote

RG

Unit: DISC SKIP/EX-CHANGE

Press to select a disc. Press to exchange a

disc while playing.

Remote: DISC SKIP

Press to select a disc.

RH

Unit: ERASE

from the connected optional USB device

(Digital music player or USB storage

media).

ENTER

Press to enter the settings.

Remote: CLEAR

Press to delete a pre-programmed track

RI

USB SYNC REC/REC1

Press to record from a disc onto the

connected optional USB device (Digital

music player or USB storage media).

RK

Unit: MASTER VOLUME

Turn to adjust the volume.

Remote: VOLUME +/−

Pressto adjustthevolume.

RL

CLOCK/TIMER SET

Presstosettheclockandthetimers.

RM

REPEAT/FM MODE

Press to listen to a disc, an USB device, a

Press to select the FM reception mode

(monaural or stereo).

TUNER MEMORY

Press to preset the radio station.

PLAY MODE/TUNING MODE

Press to select the play mode of a CD,

MP3 disc or an optional USB device

(Digital music player or USB storage

media).

Press to select the tuning mode.

X

+/− (select folder)

Press to select a folder.

XB

SLEEP

Press to set the Sleep Timer.

Battery compartment lid

7

Page 8

HCD-EC68USB

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. SIDE PANEL (L)/(R)

(Page 9)

3-3. PANEL (TOP)

(Page 9)

SECTION 3

DISASSEMBLY

3-5. FRONT PANEL BLOCK

(Page 10)

3-7. 3 CD MECHANISM BLOCK

(Page 11)

3-8. BASE UNIT

(Page 12)

3-9. OP BASE ASSY

(KSM-213D)

(Page 12)

3-4. MAIN BOARD

(Page 10)

3-10. BELT (DLM3A)

(Page 13)

3-6. BACK PANEL BLOCK

(Page 11)

8

Page 9

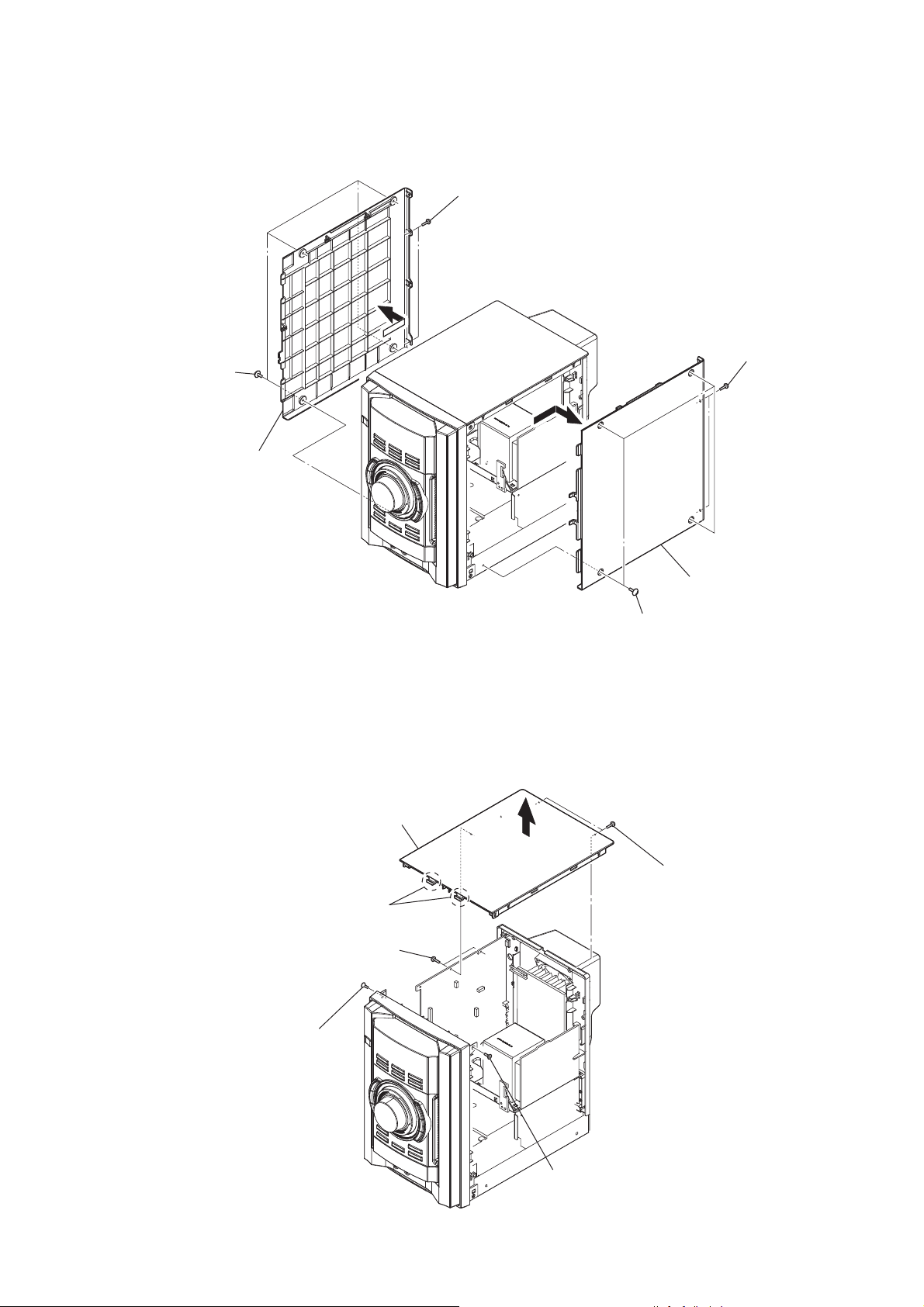

Note: Follow the disassembly procedure in the numerical order given.

3-2. SIDE PANEL (L)/(R)

four screws

(case3 TP)

side panel (L)

two screws

(B3)

HCD-EC68USB

two screws

(B3)

3-3. PANEL (TOP)

(KTP3 × 10)

screw

panel (top)

two claws

two screws

(BVTP3 × 10)

four screws

(case3 TP)

two screws

(B3)

side panel (R)

screw

(KTP3 × 10)

9

Page 10

HCD-EC68USB

3-4. MAIN BOARD

MAIN board

RT

two screws

RB

(BVTP3 × 6)

screw

(BVTP3 × 10)

flexible flat cable (27 core)

(CN607)

flexible flat cable (9 core)

(CN605)

connector (CN613)

flexible flat cable (21 core)

(CN608)

connector (CN604)

flexible flat cable (5 core)

(CN603)

connector (CN633)

connector (CN601)

two screws

R

(B3)

3-5. FRONT PANEL BLOCK

screw (BVTP3 × 10)

flexible flat cable (27 core)

(CN607)

flexible flat cable (21 core)

(CN608)

front panel

RE

block

door (CD)

connector (CN613)

harness

RB

(9 core) (CN605)

flexible flat cable

pull the tray by hand.

two screws

RT

(BVTP3 × 10)

gear

flexible flat cable (13 core)

(CN302)

flexible flat cable (27 core)

(CN906)

lever

Turn a gear by a driver

till a lever falls down

to the position of the figure.

10

Page 11

3-6. BACK PANEL BLOCK

connector (power cord)

(CN053)

screw

(BVTP3 × 10)

connector (CN601)

two screws

(B3)

four screws

(B3)

two screws

(B3)

back panel block

HCD-EC68USB

3-7. 3 CD MECHANISM BLOCK

flexible flat cable (27 core)

(CN202)

3 CD mechanism block

Cut the clamp.

Note: Please do not forget fixation by clamping

when you install the power cord.

flexible flat cable (13 core)

four screws

(BVTP3 × 10)

two tapes

Note: When installing the CD mechanism section,

install two tapes for prevention of noise.

11

Page 12

HCD-EC68USB

3-8. BASE UNIT

two screws (PTPWHM2.6)

two screws (PTPWHM2.6)

insulator

two springs

(insulator)

insulator

two springs (insulator)

insulator

– Bottom view –

3-9. OP BASE ASSY (KSM-213D)

insulator

CD mechanism block

base unit

Remove four solders.

OP base assy

(KSM-213D)

flexible flat cable (16 core)

(CD board: CN301/optical pick-up block)

CD board

12

Page 13

3-10. BELT (DLM3A)

position of belt

belt

HCD-EC68USB

cover

belt

two belts (DLM3A)

four screws

13

Page 14

HCD-EC68USB

SECTION 4

TEST MODE

COLD RESET

The cold reset clears all data including preset data stored in the

memory to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. In the standby status, press the [

on.

2. Press three buttons of [x], [USB] and at last [

ously.

3. When “RESET” appears, the set enters standby status.

] button to turn the power

?/1

] simultane-

?/1

PANEL TEST MODE

Enter The Panel Test Mode

Procedure:

1. In the standby status, press the [

on.

2. Press three buttons of [DISPLAY], [x], and [USB] simultaneously.

3. When the panel test mode is activated, LEDs and segments of

the liquid crystal display are all turned on.

Version Check

Procedure:

1. In the panel test mode (all LEDs and segments of the liquid

crystal display are turned on), press the [FUNCTION] button.

2. On the liquid crystal display, date and version are displayed

“xxxxxxxx”. For example, “1114V102”.

3. From this status, press the [USB] button, and the destination and

model name are displayed. For example, “CE2” and “ESLO–”.

4. To release from this mode, press three buttons of [DISPLAY],

[x], and [USB] simultaneously.

Key Test Mode

Procedure:

1. In the panel test mode (all LEDs and segments of the liquid

crystal display are turned on), press the [DISPLAY] button.

2. The message “KEY0 0 0”displayed. Whenever any buttons

are pressed and the [VOLUME] dial is turned, the value is

changed.

3. To release from this mode, press three buttons of [DISPLAY],

[

], and [FUNCTION] simultaneously.

x

] button to turn the power

?/1

CD REPEAT 5 LIMIT CANCEL MODE

Number of repeats for CD playback is 5 times when the repeat

mode is “REPEAT”. This mode enables CD to repeat playback for

limitless times.

Procedure:

1. Press the [

2. Press the [FUNCTION] button to select CD function.

3. Press three buttons of [DISPLAY], [

ING] simultaneously.

4. It enters the CD repeat 5 limit cancel mode and displays “NO

LIMIT”

5. To release this mode, press the [

off.

] button to turn the power on.

?/1

?/1

], and [

x

l m

] button to turn the power

– TUN-

CD SHIP MODE

This mode can run the CD sled motor optionally. Use this mode,

for instance, when cleaning the optical pick-up.

Procedure:

1. Press the [

2. Confi rm there is no disc in all trays.

3. Press the [FUNCTION] button to select CD function.

4. Press two buttons of [u] and [

5. Set to the CD ship mode. (chucking on)

6. After blink “STANDBY”, “LOCK” is displayed, disconnect

the AC plug.

] button to turn the power on.

?/1

?/1

] simultaneously.

CD TRAY LOCK

This mode is for the antitheft of CD disc in shop. (not for transport)

Procedure:

1. Press the [

2. Press the [FUNCTION] button to select CD function.

3. Insert a disc.

4. While pressing the [

seconds.

5. The message “LOCKED” is displayed and the disc tray is

locked. (Even if exiting from this mode, the disc tray is still

locked)

6. If press the [Z] button to eject the disc, the message “LOCKED”

is displayed and can not eject the disc.

7. To release this lock, while pressing the [

] button for 5 seconds again.

[

Z

8. The message “UNLOCKED” is displayed and the disc tray is

unlocked.

] button to turn the power on.

?/1

] button, press the [Z] button for more 5

x

] button, press the

x

CD POWER MANAGE

This mode is for switch the CD power supply on/off. Even if this

state pulls out AC plug, it is held.

Procedure:

1. Press the [

2. Press the [FUNCTION] button to select CD function.

3. Press the [

4. After pressing the [DISPLAY] button, while pressing the [

button, press the [

5. It turns power on and display “CD POWER”, then display

“ON” or “OFF”.

] button to turn the power on.

?/1

] button again to turn the power off (standby).

?/1

] button.

?/1

x

CHANGE-OVER THE AM TUNING INTERVAL

(Except AEP model)

The AM tuning interval can be changed over 9 kHz or 10 kHz.

Procedure:

1. Press the [

2. Press the [TUNER/BAND] button to select TUNER (AM)

function.

3. Press the [

4. After pressing the [DISPLAY] button, while pressing the

[TUNING +

5. It turns power on and display “9k STEP” or “10k STEP”, and

thus the tuning interval is changed over.

] button to turn the power on.

?/1

] button again to turn the power off (standby).

?/1

M L

] button, press the [

?/1

] button.

CD SHIP AND COLD RESET

Procedure:

1. Press the [

2. Confi rm there is no disc in all trays.

3. Press the [FUNCTION] button to select CD function.

4. Press three buttons of [USB SYNC REC/REC 1], [

– TUNING] and [

5. After blink “STANDBY”, “RESET” is displayed, disconnect

the AC plug.

] button to turn the power on.

?/1

] simultaneously.

?/1

l m

COMMON TEST MODE

Procedure:

1. Press the [

2. Press three buttons of [USB SYNC REC/REC 1], [TUNING +

M L

3. It enters the common test mode and displays “COMMON”.

4. Each time the [VOLUME] dial is turned, “VOL MIN”, “VOL

16”, and “VOL MAX” are displayed.

5. To release from this mode, press three buttons of [USB SYNC

REC/REC 1], [TUNING +

taneously.

] button to turn the power on.

?/1

], and [DISPLAY] simultaneously.

M L

], and [DISPLAY] simul-

]

14

Page 15

HCD-EC68USB

[CD SERVO TEST MODE]

This mode can check the servo system operations of the optical

pick-up system (= optical unit + CD board).

Note1: Do not enter the [CD SERVO TEST MODE] while any other test

mode is in progress.

Note2: Do not enter any other test mode while the [CD SERVO TEST

MODE] is in progress.

How to Enter the CD Servo Test Mode

Procedure:

1. Press the [

2. Press the [FUNCTION] button to select CD function.

3. Press three buttons of [u], [

[DISPLAY] simultaneously.

4. It enters the CD servo test mode and displays “BDT S CU”.

How to Exit from the CD Servo Test Mode

Procedure:

1. Press three buttons of [u], [

[DISPLAY] simultaneously.

2. It releases from the CD Servo Test Mode and returns to the

ordinary CD function.

Key Operation:

[

+], [ –]:

Use these keys to move between the fi ve modes

[DSGX] , [EQ]:

Use these keys to move between the different layers

[TUNING +

Use these keys to move the cursor to the right digit

Press [TUNING +

] button to turn the power on.

?/1

l m

l m

– TUNING] and

– TUNING] and

contained in the CD Servo Test Mode, that are the

S-Curve Mode, the RAM Read Mode, the RAM

Write Mode, the Command Out Mode and the Error

Rate Mode as described below. Also, use these keys

to move between the menus within the respective

fi ve modes. When [

+] is pressed, the screen advances to the next menu or to the next mode. When

[ –] is pressed, the screen returns back to the

previous menu or to the previous mode. Use these

keys also to increase or decrease the numeric value

when changing the numeric value. Pressing [ +]

increases the value and pressing [ –] decreases

the value.

of the hierarchy of the CD Servo Test Mode shown

below. Press [DSGX] to move down to the lower

layer, and press [EQ] to move up to the higher layer.

M L

], [

l m

– TUNING]:

or to the left digit in the six-digit number, when

changing the numeric value.

M L

to the right, and press [

] to move the cursor

l m

– TUNING] to

return the cursor to the left.

CD Servo Test Mode Tree:

S Curve Mode LD ON

(BDT S CU) (LD ON)

RAM Read Mode

(BDTRAM R) (DISCTYPE) (AL: 0000, RW: 0001)

Gain Index value indication

(GAININDX) (0001)

RFO GAIN value indication

(RFO_GAIN) (0009)

FEO GAIN value indication

(FEO_GAIN) (0005)

SBAD GAIN value indication

(SBAD_GAI) (0007)

TEO GAIN value indication

(TEO_GAIN) (000A)

Disc Size value indication

(DISCSIZE) (0000: Non disc, 0001: 8cm,

0002: 12cm)

(OPABRKER) (0000)

SBBT Data value indication

(SBBT DAT) (006C)

FEOOCD value indication

(FEOOCD) (0440)

RAM Write Mode

(BDTRAM W) (00 SPG) (Non mask:00, Mask:01)

Fix RF Gain value edit

(00 FIX) (Non Fix:00, AL Fix:01, RW Fix:02)

TMAX ON value edit

(00 TMA)

Driver Mute OFF value edit

(00 D_M) (Normal:00, Forced OFF:01)

Command Out Mode

(BDT COMO) (COMOUT6X) (000000) (OK)

READ2X value edit command out

(READ2X) (60) (50)

REG READ value edit command out

(REG_READ) (00) (0000)

FEBC? command out

(FEBC?) (00)

FGADD? command out

(FGADD?) (10)

TEBC? command out

(TEBC?) (00)

TGADD? command out

(TGADD?) (00)

RFGC? command out

(RFGC?) (00)

FEOF? command out

(FEOF?) (FFC0)

TEOF? command out

(TEOF?) (FFC0)

TEIOCD1? command out

(TEIOCD1?) (FE80)

TEIOCD2? command out

(TEIOCD2?) (FF40)

TEIOCD3? command out

(TEIOCD3?) (FFC0)

TEOOCD? command out

(TEOOCD?) (FD00)

FEOOCD? command out

(FEOOCD?) (F780)

MONITOR value edit command out

(MONITOR) (570A00) (OK)

Error Rate Mode Error rate indication

(BDT ERR) (00000000)

Higher layer Lower layer of menu hierarchy

Disc Type value indication

Op ABRAKE Error

SPG Mask value edit

COMOUT6X value edit command out

value indication

[FUNCTION]:

Use this key to execute Command Out in the Com-

mand Out Mode.

15

Page 16

HCD-EC68USB

CD SERVICE MODE

This mode can move the SLED of the optical pick-up, and also can

turn the optical pick-up laser power on and off.

Procedure:

1. Press the [

2. Press three buttons of [u], [TUNING +

DISPLAY simultaneously.

3. Press the [FUNCTION] button to select CD function.

4. It enters the CD service mode and displays “SERVICE”.

5. To exit from this mode, press three buttons of [u], [TUN-

ING +

Key Operation:

[TUNING +

Use these keys to move the SLED. When [TUN-

When [

[DISPLAY]:

Use this key to turn the optical pick-up laser power

] button to turn the power on.

I/1

M L

M L

] and DISPLAY simultaneously.

M L

], [

l m

ING +

M L

moves to outer circumference and the message

“SLED OUT” is displayed.

l m

mode, the SLED moves to inner circumference and

the message “SLED IN” is displayed.

on and off. When the laser power is turned on, the

message “LD ON” is displayed. When the laser

power is turned off, the message “LD OFF” is displayed.

– TUNING]:

] is pressed in this mode, the SLED

– TUNING] is pressed in this

], and

CD ERROR CODE

The past errors of the CD mechanism (CDM) are displayed as the

CDM Errors, and those of the optical pick-up system (= optical

unit + CD board) are displayed as the BD Errors as shown below.

Procedure:

1. Press the [

2. Press the [FUNCTION] button to select CD function.

3. Press three buttons of [TUNING +

PLAY] simultaneously.

4. Then, the CDM error code is displayed as “M0xxxxxx” (x

means hexadecimal number) on the liquid crystal display as

shown below.

5. Every pressing of the [TUNING +

mode increments the number after “M” starting from “M0” up

to “M9”, and then returns to “M0”. Every pressing of the [

m

– TUNING] button in this mode decrements the number

after “M”. The smaller the error code number is, the newer the

error content is.

6. When the [USB SYNC REC/REC 1] button is pressed then,

the BD error code is displayed as “D0xxxxxx” (x means hexadecimal number) on the liquid crystal display as shown below.

In the same way as the CDM error code, use of the [TUNING

+

M L

mode enables tracing of the error history.

7. To release from this mode, press the [

power off.

] button to turn the power on.

I/1

] and the [

l m

– TUNING] buttons in this

M L

M L

], [x] and [DIS-

] button in this

] button to turn the

I/1

l

Contents of “CDM Errors”

Error display example

M 0 FF 11 42

1 2 3 4

1 It indicates the error history number

0 to 9: The error code number 0 indicates the newest error.

2 It indicates whether the CDM error occurs in the normal opera-

tions or during the initialization operation.

FF : The error has occurred in the normal opera-

tions.

Other than FF : The error has occurred during the initialization

operation.

3 It indicates the processing during which the trouble has oc-

curred.

01: The disc EJECT processing is in progress.

02: The disc INSERTION-WAITING processing is in prog-

ress.

03: Processing of the disc INSERTION-REQUEST for the up-

per CD tray is in progress.

04: Processing of the disc EJECTION-REQUEST for the up-

per CD tray is in progress.

05: The disc pulling-in operation is in progress.

06: The disc chucking processing is in progress.

07: The disc re-chucking processing is in progress.

08: The disc chucking-release completion operation is in prog-

ress.

4 It indicates the operation during which the trouble has oc-

curred.

00 : Waiting for the operation.

10 to 13 : The disc EJECT operation is in progress.

20 : The disc pulling-in operation is in progress.

30 : The disc chucking-release operation is in progress.

40 to 43 : The disc EJECT operation due to error is in prog-

ress.

Contents of “BD Errors”

Error display example

0 02 09

D

1 2 3 4

1 It indicates the error history number

0 to 9: The error code number 0 indicates the newest error.

2 It indicates the error content

01: The focus servo cannot lock-in.

02: GFS is no good (NG).

03: The startup time exceeds the specifi ed period of time (time

over)

04: The focus servo is unlocked continuously.

05: Q code cannot be obtained within the specifi ed period of

time.

06: The tracking servo cannot lock-in.

07: Blank disc

01

16

Page 17

HCD-EC68USB

3 It indicates the on-going processing of optical pick-up system

(= optical unit + BD board) when the trouble has occurred.

01: The CD SHIP mode processing is in progress.

02: The POWER OFF processing is in progress.

03: The INITIALIZE processing is in progress.

04: The optical pick-up system (= optical unit + BD board) is

in the stop state.

05: The STOP operation is in progress.

06: The startup processing is in progress.

07: The TOC read-in processing is in progress.

08: The SEARCH operation is in progress.

09: The PLAY operation is in progress.

0A: The PAUSE operation is in progress.

0B: The PLAY – MANUAL SEARCH operation is in prog-

ress.

0C: The PAUSE – MANUAL SEARCH operation is in prog-

ress.

4 It indicates the operation that is being processed when the trou-

ble has occurred.

It indicates the step number of each processing specifi ed by 3.

Because the numbers of steps are different in each processing,

this number is different in each processing.

CD FACTORY MODE

Note1: Do not enter the [CD FACTORY MODE] while any other test-

mode is in progress.

Note2: Do not enter any other test mode while the [CD FACTORY

MODE] is in progress.

Key Operation:

[DISPLAY]:

The display changes in the following order when-

ever the button is pressed.

[DSGX]:

RF gain setting changes whenever the button is

“–”: No gain fi xation.

“AL”: Fix to the gain for AL disc.

“RW”: Fix to the gain for RW disc.

[EQ]:

Tracking servo setting changes whenever the but-

“ON”: Tracking servo ON.

“OFF”: Tracking servo OFF.

[FUNCTION]:

S character mode setting changes whenever the but-

“ ”: S character mode OFF.

“S”: S character mode ON.

(Initial display)

fcsAG ** (**: Focus AGC value)

trkAG ** (**: Track AGC value)

RF-AG ** (**: RF AGC value)

pressed.

ton is pressed.

ton is pressed.

Procedure:

1. Press the [

2. Press the [FUNCTION] button to select CD function

3. Press three buttons of [u], [USB], and [DISPLAY] simulta-

neously.

4. It enters the CD factory mode and displays the following message.

] button to turn the power on.

?/1

–X1ON

S character mode setting

Tracking servo setting

RF gain setting

5. To release from this mode, press the [

power off.

] button to turn the

?/1

17

Page 18

HCD-EC68USB

SECTION 5

ELECTRICAL ADJUSTMENTS

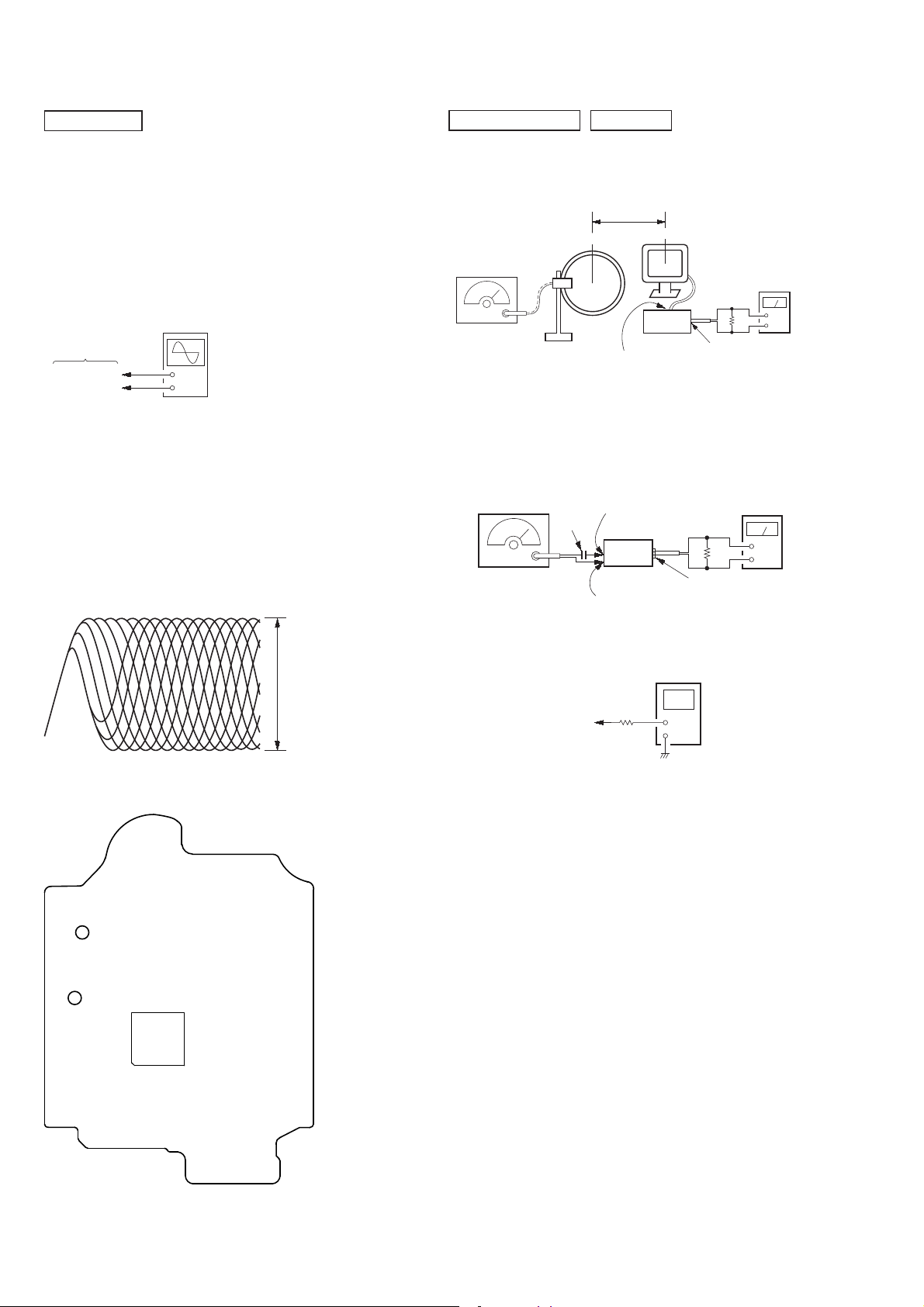

CD SECTION

Note:

1. CD Block is basically constructed to operate without adjustment.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10 MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specifi ed value with the following checks.

5. Check the focus bias check when optical pick-up block is replaced.

FOCUS BIAS CHECK

oscilloscope

(DC range)

CD board

TP121 (RFI)

TP124 (VC)

+

–

Procedure :

1. Connect the oscilloscope to TP121 (RFI) and TP124 (VC) on

the CD board.

2. Press the [

] button to turn the power ON, and press the [Z]

?/1

button to open the CD disc tray.

3. Set disc (YEDS-18) on the trey and press the [u] button to

playback.

4. Confi rm that oscilloscope waveform is as shown in the fi gure

below. (eye pattern)

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

TUNER SECTION

0 dB = 1 μV

[AM]

Setting:

FUNCTION: AM

loop antenna A

AM RF signal

generator

30% amplitude

modulation by

400 Hz signal

Output level: 54 dBuV

MAIN board

ANTENNA

CN801 pin

[FM]

Setting:

FUNCTION: FM

FM RF signal

generator

0.01 F

75kHz frequency

deviation by 1K Hz

signal

Output level: as low as possible

(8dBuV)

MAIN board

ANTENNA

CN801 pin

60 cm

loop antenna B

set

MAIN board

ANTENNA

CN801 pin

set

level meter

32 Ω

JACK board

PHONES jack (J492)

32 Ω

JACK board

PHONES jack (J492)

+

–

level meter

+

–

Checking Location:

– CD Board (Conductor Side) –

TP124

(VC)

TP121

(RFI)

IC101

level:

1.2 ± 0.3 Vp-p

digital voltmeter

MAIN board

IC801 pin XL (TUNER VT)

100 kΩ

• Repeat the procedures in each adjustment several times.

18

Page 19

HCD-EC68USB

HCD-EC68USB

1919

AM FREQUENCY COVERAGE ADJUSTMENT

(Except AEP model)

Adjustment Part Frequency Display

Reading on Digital

Voltmeter

L801 530 kHz 1.5 ± 0.1 V

Confi rmation 1,710 kHz 8 ± 0.5 V

AM FREQUENCY COVERAGE ADJUSTMENT (AEP model)

Adjustment Part Frequency Display

Reading on Digital

Voltmeter

L801 531 kHz 1.5 ± 0.1 V

Confi rmation 1,602 kHz 7.2 ± 0.5 V

AM TRACKING ADJUSTMENT (Except AEP model)

Adjust for a maximum reading on level meter

L805 530 kHz

AM TRACKING ADJUSTMENT (AEP model)

Adjust for a maximum reading on level meter

L805 531 kHz

FM FREQUENCY COVERAGE ADJUSTMENT

Adjustment Part Frequency Display

Reading on Digital

Voltmeter

L803 87.5 kHz 1.75 ± 0.1 V

Confi rmation 108 kHz 6.2 ± 0.5 V

FM TRACKING ADJUSTMENT

Adjust for a minimum reading on level meter

L804 98 MHz

Adjustment Location: MAIN board

FM DETECTOR ADJUSTMENT

Setting:

FUNCTION: FM

1. Turn the set to 98 MHz.

2. Adjust L802 so that modulation distortion may become the

best in the vicinity of the maximum value where the tuner out

level becomes –15dBuV or more.

FM AUTO STOP CHECK

generator

SET

+

75 Ω

Procedure :

1. Turn the power on.

2. Input the following signal from Signal Generator to FM antenna input directly.

* Carrier Freq : A = 87.5 MHz, B = 98 MHz, C = 108 MHz

Deviation : 75 kHz

Modulation : 1 kHz

ANT input : 35 dBu (EMF)

Note: Please use 75 ohm “coaxial cable” to connect SG and the set. You

cannot use video cable for checking.

Please use SG whose output impedance is 75 ohm.

3. Set to FM tuner function and scan the input FM signal with

automatic scanning.

4. Confi rm that input Frequency of A, B and C detected and auto-

matic scanning stops.

The stop of automatic scanning means “The station signal is received in good condition”.

Adjustment Location and Connecting Points:

– MAIN Board (Component Side) –

L801

L804

AM Tracking

Adjustment

FM Frequency

Coverage Adjustment

L802

FM Detector

Adjustment

L803

FM Frequency

Coverage Adjustment

L805

AM Tracking

Adjustment

– MAIN Board (Conductor Side) –

3

CN801

ANTENNA

1

36

IC801

1

IC801 pin RT

(TUNER OUT L-ch)

IC801 pin XL

(TUNER VT)

19

18

JW801

(TUNER-GND)

FM RF signal

generator

Carrier frequency: 98MHz

Modulation:

deviation by FM 75 kHz

Output level: 60 dBuV

MAIN board

ANTENNA

CN801 pin

set

MAIN board

ANTENNA

CN801 pin

MAIN board

IC801 pin RT

(TUNER OUT L-ch)

level meter

+

–

MAIN board

JW801 (TUNER-GND)

Page 20

HCD-EC68USB

HCD-EC68USB

2020

6-1. BLOCK DIAGRAM - CD SERVO, TUNER Section -

SECTION 6

DIAGRAMS

OPTICAL PICK-UP BLOCK

(KSM-213DCP)

B

C

D

E

A

F

SP+

SP-

LD

PD

VC

AUTOMATIC

POWER

CONTROL

Q301

FOCUS/TRACKING COIL DRIVE,

SLED/SPINDLE MOTOR DRIVE

IC401

CD-MP3 PROCESSOR

IC101

VO1+2

VO1-

1

IN1

3

SL+

SL-

VO2-

12

VO2+

11

IN2’

9

T+

T-

VO3+

18

VO3-

17

IN3’

20

F+

F-

CD MECHANISM

DECK

M1-

M2+

M2-

M1+

VO4+

26

VO4-

27

IN4’

24

MUTE 7

97 FPi1 (B)

94 FNi2 (C)

96 FPi2 (D)

100

TNi (E)

95 FNi1 (A)

98 TPi (F)

91 LDo

MDi

84 VRo

13 DMo

92

12 FMo

10 TRo

9FOo

XO

XI

X102

16.9344MHz

S201

(LIMIT)

24

23

IO0 (/HSO)

20

LO CD-L30

RO R-CH

27

BUS0 38

BUS1

39

I/O-CD-BUS0

17

I/O-CD-BUS1

18

BUS2 (SO)

40

BUS3 (SI)

41

I/O-CD-BUS2

19

I/O-CD-BUS3

20

O-CD-BUCK

25

O-CD-CCE

26

XRST

37 O-CD-RST27

O-DR-MUTE

23

I-REQ

24

SBSY

54

O-3CD-M1+/O-CDM-M1+

8

O-3CD-M1-/O-CDM-M1- 10

O-3CD-M2+/NC

11

O-3CD-M2-/NC 12

O-CD-SBSY

43

B

A

MOTOR

DRIVE

Q311 - 318

SW3

SW2

I-CHACK

SW1

I-3CD-SW1/O-CDM-OPEN

7

I-3CD-SW3/O-CDM-CLOSE

5

I-3CD-SW2/NC

6

I-3CD-CHACK

21

I-STOCK

I-OPEN

I-CLOSE

I-3CD-STOCK

22

I-1CD-CLOSE_OPEN/NC 48

AM/FM-DET, OSC, MIX, PLL, IF AMP

IC801

36

FM RF-IN

8

FM IF-IN

22

MPX-IN

1

AM RF-IN

31

AM-OSC

33

I-TU-DO

56

O-TU-CLK

55

O-TU-CE

57

O-TU-DI

39

I-TU-ANSD

X801

75kHz

2019

XIN

XOUT

16DI17CL15

CE

18DO25

AGC

3

CN801

ANTENNA

FM/AM

1

BAND-PASS

FILTER

FL803

AM

TRACKING

L805

AM FREQUENCY

COVERAGE

L801

D801

7

AM IF-IN

T801

AM IF

34

FM RF-OUT

FM

TRACKING

L804

32

FM-OSC

FM FREQUENCY

COVERAGE

L803

+9V

11

FM-DET

FM

DETECTOR

L802

3FM-MIX 23FM DET-OUT 12L-OUT

13

R-OUT R-CH

TUNER-L

5

AM-MIX

24

AM DET-OUT

CF801

• SIGNAL PATH

: AM

: CD PLAY

• R-ch is omitted due to same as L-ch.

: FM

SYSTEM CONTROLLER

IC301 (1/3)

Q301

40 O-USB-SEL1_2/O-SW-ON/I-TP-STATE

BUS1

BUS0

BUS2

BUS3

BUCK

BUS0 – BUS3,

BUCK, CCE, REQ

DATA SELECTOR

IC303

SELECT

42BUCK (CLK) 4

2

3

CCE

43XCCE

48PIO0

7

5

REQ

6

12

14

13

9

10

11

1

BUS

SWITCH

IC301

BUS

SWITCH

IC302

D

65AIN (PI4)

66BCKi (PI5)

BCK

A-IN

67LRCKi (PI6)

LRCK

51PIO3

GATE

49PIO1

ST-REQ

C

DATA, CLOCK,

A-IN, BCK, LRCK,

GATE, ST-REQ

47AOUT2 (PO5)

63BCK (PO8)

CLOCK

DATA

(Page

22)

(Page 21)

(Page 21)

(Page 22)

Page 21

HCD-EC68USB

HCD-EC68USB

2121

6-2. BLOCK DIAGRAM - USB Section -

BUS1

BUS0

BUS2

BUS3

BUCK

CCE

REQ

LB

I/O0 – I/O15

D0 – D15

S-RAM

IC921

39

UB

40

OE

41

WE

17

CE

6

79 D+

80 D–

77 USBOC

USB CONTROLLER

IC901

31 O-USB-RXD/O-DMP-RXD

SYSTEM CONTROLLER

IC301 (2/3)

CN902

(USB)

3

2

1

D+

D–

78 USBPON

70 CS2

64

RD

65 WR

66 SRLLB

67 SRLUB

VBUS

DATA, CLOCK,

A-IN, BCK, LRCK,

GATE, ST-REQ

BUS0 – BUS3,

BUCK, CCE, REQ

VBUS POWER

ON/OFF SWITCH

IC915

5

1

4OUT

EN

3

FLG

IN

VBUS

+5V

93DATA

92BCK

BCK

A-IN

LRCK

GATE

ST-REQ

71LRCK

94GATE

97ST-REQ

55BUS0

56BUS1

88RXD1

29 I-USB-TXD/I-DMP-TXD87TXD1

34 O-USB-DI/5V-ON/O-TP-REC-MUTE2DI

30 I-USB-DO/I-DMP-5V-DET84DO

45 I-DMP-DET/O-USB-RST1/RESET

57BUS2

58BUS3

59/BUCK

60/CCE

96REQ

7 – 10, 13 – 16,

29 – 32, 35 – 38

18 – 25, 28 – 35

A0 – A15

A1 – A16

44 – 42, 27 – 24,

21 – 18, 5 – 1

37 – 43, 46 – 54

73

X2

75

X1

X901

9MHz

: USB

CLOCK

DATA

85DATA

86CLOCK

: CD PLAY

SIGNAL PATH

R-ch is omitted due to same as L-ch.

C

D

(Page 20)

(Page 20)

Page 22

HCD-EC68USB

HCD-EC68USB

2222

SYSTEM CONTROLLER

IC301 (3/3)

INPUT SELECTOR,

ELECTRICAL VOLUME

IC602

4 19TUNER-L OUT-L

9SEL-L

12VOL-L

TUNER-L

A

6 CD-L

8 AUDIO-L

CD-L

B

M601

(FAN)

I-RST

54

I-HOLD

42

49

I/O-I2C-DATA

50

I/O-I2C-CLK

26

SDATA25SCLK

3O-POWER

• SIGNAL PATH

: CD PLAY

• R-ch is omitted due to same as L-ch.

: FM

: AUDIO IN

FAN M OTOR

DRIVE

Q601, 602

PROTECT

DETECT

Q603

4O-CD-ON

RELAY

DRIVE

Q619

PROTECT

DETECT

Q611, 612

PROTECT

DETECT

Q605, 606

OVER LOAD

DETECT

Q101, 102

D103

POWER AMP

IC101

+1.5V

REGULATOR

IC201

CD +1.5V

+9V

REGULATOR

IC601

+9V

+5V

REGULATOR

IC701

VBUS +5V

RELAY B+

+3.3V

REGULATOR

Q624

REGULATOR

CONTROL

Q622

VO LTAGE

DETECT

Q305, 306

+4V

REGULATOR

Q302 - 304

D631

+9V

CD +3.3V

+3V

REGULATOR

Q801

TUNER +3V

+5V

REGULATOR

Q802

TUNER +5V

SYSTEM +3.3V

D601

R-CH

D303

D055

D617

D628

D602, 606

MM

DC DETECT

Q618

STANDBY

SWITCH

Q608

J492

RY602

R-CH

PHONES

J491

AUDIO IN

SPEAKER

IMPEDANCE

USE 6Ω

+

–

–

+

R

L

TB602

R-CH

R-CH

2

O-AMP-ON

RY001 (AEP)

RY002 (EXCEPT AEP)

PT001 (AEP)

PT002 (EXCEPT AEP)

SUB POWER TRANSFORMER

PT003 (EXCEPT AEP)

PT004 (AEP)

MAIN POWER

TRANSFORMER

VSTBY

+VH

-VH

(AC IN)

RECT

D051, 052

RECT

D607 - 610

RECT

D629, 630

I-P-MONI

36

RELAY

DRIVE

Q604

• Abbreviation

AR : Argentina model

E2 : 120V AC area in E model

E51 : Chilean and Peruvian model

MX : Mexican model

X302

6MHz

X1

X0

92

93

X301

32.768kHz

X1A

X0A

14

13

I-RMC

9

REMOTE CONTROL

RECEIVER

IC302

LED DRIVE

Q301

LED301

O-LED-STBY

28

LCD301

LIQUID

CRYSTAL

DISPLAY

ROTARY

ENCODER

S301

VOLUME

SW301, 303 - 308,

SW309, 310

SW311 - 319

(FRONT PANEL KEYS)

I-KEY1, I-KEY2, I-KEY-WAKEUP/VOL

37, 38, 41

COM0 - COM1

59 - 62

SEG0 - SEG32

63, 64, 67 - 89, 94 - 100, 1

I/

STANDBY

VOLTAGE

SELECTOR

S001

(E2, E51)

(AEP, MX, AR)

(Page 20)

(Page 20)

6-3. BLOCK DIAGRAM - MAIN Section -

Ver. 1.1

Page 23

HCD-EC68USB

HCD-EC68USB

2323

For Schematic Diagrams.

Note:

• All capacitors are in μF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/4 W or less unless otherwise

specifi ed.

• f : internal component.

• 2 : nonfl ammable resistor.

• C : panel designation.

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

• A : B+ Line.

• B : B– Line.

• C : adjustment for repair.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

– CD Board –

no mark

: CD PLAY

– Other Boards –

no mark

: TUNER (FM/AM)

• Voltages are taken with a VOM (Input impedance 10

MΩ).

Voltage variations may be noted due to normal production

tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : FM

f : AM

J : CD PLAY

i : AUDIO IN

d : USB

• Abbreviation

AR : Argentina model

E2 : 120V AC area in E model

E51 : Chilean and Peruvian models

MX : Mexican model

For Printed Wiring Boards.

Note:

• X : Parts extracted from the component side.

• Y : Parts extracted from the conductor side.

• W : indicated side identifi ed with part number.

• f : Internal component.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

• Indication of transistor.

• Circuit Boards Location

The components identifi ed by mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specifi ed.

Caution:

Pattern face side:

(SIDE B)

Parts face side:

(SIDE A)

Parts on the pattern face side seen from

the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

Caution:

Pattern face side:

(Conductor Side)

Parts face side:

(Component Side)

Parts on the pattern face side seen from

the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

Ver. 1.1

C

Q

B

E

Q

B

CE

These are omitted.

These are omitted.

KEY POWER board

USB board

KEY CD board

MAIN board

PANEL board

LOW AMP board

PT board

CD board

JACK board

REG board

USB CONN board

Page 24

HCD-EC68USB

6-4. PRINTED WIRING BOARD - CD Board -

12345678910

A

CD BOARD (COMPONENT SIDE)

C401

B

C405

C

R213

C202

C201

R216

R121

R211

C206

R201

C212

C207

135

4

C205

C204

D

IC201

E

R212

R214

R112

R111

C115

X102

F

• See page 23 for Circuit Boards Location.

R415

R118

C153

R114

C108

R119

C133

R155

C130

C128

C112

X102

C309

Q301

R303

R302

E

R304

R301

C307

1-872-620-

• : Uses unleaded solder.

CD BOARD (CONDUCTOR SIDE)

M401

(SLED)

C125

C124

TP124(VC)

C122

R140

C123

R142

R143

(RFI)

C143

C141

C144

C148

C137

C138

C139

C140

C142

R144

C146

C147

C149

R148

C150

R151

TP121

C106

C306

11

(11)

R135

R146

R136

C145

R134

C118

R139

R145

R147

R149

R150

R130

C105

C104

CN301

R129

R128

C100

C117

C136

C135

C120

C107

C119

M

IC101

C102

C101

C103

R101

C126

C127

C113

R109

C303

R108

R102

R106

C301

R402

R105

C302

R414

C109

C110

R104

C132

S201

(LIMIT)

R154

R405

C404

C403

IC401

M

R408

R224

R210

R209

R110

R218

R219

R220

R221

R153

R222

C116

R223

R157

R156

C217

R208

R207

R206

R205

R204

R203

CN202

C151

C152

R202

M402

(SPINDLE)

S

USB BOARD

CN906

(Page 26)

HCD-EC68USB

OPTICAL PICK-UP

BLOCK

(KSM-213DCP)

1-872-620-

11

(11)

G

2424

Page 25

HCD-EC68USB

HCD-EC68USB

2525

IC B/D

S

USB

BOARD

CN906

2

1

IC B/D

OPTICAL

PICK-UP

BLOCK

(KSM-213DCP)

M

M

CLOCK

GATE

ST_REQ

GPIN/AIN

SF SY/BCKIN

ZDET/LRCKIN

M-MUTE

MGND

VM (7V)

DVDD (3.3V)

D-OUT

DGND

SBSY

REQ

BUCK

BUS3

BUS2

BUS1

BUS0

AGND

DACGND

AVDD (3.3V)

L-OUT

R-OUT

CCE

DATA

R224 100

R121

100

R108

R109 100

R154

R153

C201

R304

R201

R110

R303

R203

R204

R205

R206

R207

R208

R209

R210

R219

R223

R222

R221

R218

R112

R202

R211

Q301

R301

C202

R157

TP121 (RFI)

TP124 (VC)

R156

CN301

R101

C401

R415

R102

R128

R129

R143

R142 R139

R114

R140

R151

R220

R150

R212

IC101

R105

R106

IC201

X102

C301

C307

C309

C100

C138

C153

C151

C204

C130

C128

C113

C127

C126

C103

C102

C120

C118

C117

C101

C124

C125

R145

R146

R147

R148

R149

C149

C105

C143

C146

C145

C148

C104

C405

C404

C403

C205

C116

C133

CN202

C110

R111

C115

R155

C109

C132

R104

C123

C122

C139

C150

R136 R135

R134

C112 C108

R119

R118

C136

C107

R130

R144

C144

C147

C140

C137

C141

C142

C106

R302

C306

C303C302

R405

R402

R408

R414

C207

C152

C206

IC401

1M

1M

100

10V

2.2

0

10k

C212

100k

2.2

100

100

100

100

100

100

100

100

100k

100k

100k

100k

100k

100

0

100

2SA2119K

100k

100

10V

100

100

16P

220

220

10V

47k

10k

470k

1k

47k

22k 47k

10k

0

0

100k

0

TK63115SCL-G@GT

0.1

1

0.001

0.1

470p

0.0022

0.1

0.1

0.0022

0.1

0.1

0.1

0.01

0.01

0.022

C119

0.022

0.1

0.0047

0.0047

0

0

0

0

0

22p

0.1

0.01

470p

0.01

47p

0.1

0.1

0.1

0.1

0.1

0.1

0.1

0.1

100

22

6.3V

47

0.1

0.1

0

470p

470p

0.01

0.001

22k 470k

1M

0.1 0.1

47p

0.1

4.7k

22k

0.1

0.1

0.01

0.01

0.0022

0.1

100

10V

0

100

10V

1010

10k

2.2k

2.2k

4.7k

1

0.0022

1

BA5826SFP-E2

SP-

SP+

SL+

SL-

100

R213 100

R214 100

R216

100

1M

1k

16.9344MHz

TC94A70FG-008 (S, D)

5p

5p

27P

0

100k

IC101

CD-MP3 PROCESSOR

IC401

FOCUS/TRACKING COIL DRIVE,

SLED/SPINDLE MOTOR DRIVE

IC201

+1.5V REGULATOR

SP-

SP+

SL+

SL-

M401

(SPINDLE)

M402

(SLED)

AUTOMATIC POWER

CONTROL

S201

(LIMIT)

0.1

C217

100k

RST

(Page 27)

6-5. SCHEMATIC DIAGRAM - CD Board -

• See page 40 for waveforms. • See page 40 for IC Block Diagrams. • See page 42 for IC Pin Function Description.

Page 26

HCD-EC68USB

• Semiconductor

Location

Ref. No. Location

D903 C-1

D904 C-1

D951 A-4

D952 A-4

IC301 D-3

IC302 D-2

IC303 D-2

IC901 C-2

IC915 C-1

IC921 C-3

Q301 D-3

6-6. PRINTED WIRING BOARDS - USB Section -

123456 7

USB CONN BOARD

A

C951

ET951

CN951

1

2

6

7

C950

CN950

(USB)

JR951

14

1-875-497-

B

(CHASSIS)

USB BOARD (COMPONENT SIDE)

• See page 23 for Circuit Boards Location.

(SUFFIX-12/-13)

USB CONN BOARD

CN951

1

2

6

7

C951

ET951

12, 13

(12, 13)

(CHASSIS)

JR951

• : Uses unleaded solder.

D903

C950

D951

D952

14

CN950

(USB)

1-875-497-

USB BOARD (CONDUCTOR SIDE)

(SUFFIX-14)

14

(14)

R1

MAIN

BOARD

CN613

R2

(SUFFIX-14)(SUFFIX-12/-13)

(Page 29)(Page 28)

MAIN

BOARD

CN613

C

D

E

R979

R976

TP942

TP941

TP915

C918

TP900

TP903

TP904

TP906

C936

TP966

TP968

TP967

TP938

TP940

TP935

TP939

R932

TP937

TP907

TP908

TP965

TP964

TP927

R978

TP936

D903

D904

TP926

IC915

TP914

5

1

34

R921

R934

TP928

R310

R361

R362

TP929

TP933

R920

R925

R933

16

C363

R926

R947

R945

9

TP934

R922

R938

C912

C914

R923

R924

R916

C909

C913

R928

100

8

IC303

1

TP925

C910

76

TP924

R919

C908

75

IC901

1

IC302

87

14

C362

TP917

TP921

TP922

TP923

TP919

TP918

R944

R943

TP911

51

25

1

TP916

R942

50

26

TP912

R941

C907

R957

R956

R954

R952

TP909

R958

R953

IC301

1

7

C361

TP963

R955

R951

TP930

23

IC921

44

R959

R960

R961

R963

R991

Q301

14

BE

8

R988

TP950

R962

TP952

22

1

R964

R965

TP953

TP951

TP910

C922

TP913

R966

R977

TP954

TP949

1-875-503-

TP955

11

(11)

C905

2

R913

R903

C903

1

M2

R902

R975

C904

MAIN BOARD

(Page 29)

R904

R905

R972

R974

C906

C902

CN608

(SUFFIX-14)

R907

R973

R906

R971

R970

R950

R305

R917

C915

R304

R306

R307

1

2

X901

R983

C901

R901

R937

R915

C921

20

21

CN907

M1

MAIN BOARD

CN608

(Page 28)

(SUFFIX-12/-13)

R308

R312

R981

S

CN901

12

C916

C920

R985

R986

R984

R309

CN906

R989

C923

W901

R982

CD BOARD

CN202

(Page 24)

CN902

1-875-503-

2

4

C937

2

6

1

5

R990

1

CN903

7

27

26

(CHASSIS)

T1

T2

T3

11

(11)

(SUFFIX-12)

PANEL

BOARD

CN307

(Page 34)

PANEL

BOARD

CN307

(Page 35)

PANEL

BOARD

CN307

(Page 36)

(SUFFIX-14)

(SUFFIX-13)

HCD-EC68USB

Note: Refor to “SUFFIX-12/-13/-14 DISCRIMINATION OF PRINTED WIRING

BOARDS” (page 4) of the servicing notes for suffi x-12/-13/-14.

2626

Page 27

HCD-EC68USB

HCD-EC68USB

2727

BOARD

S

CD

CN202

BOARD

CN608

M

MAIN

(2/2)

BOARD

T

PANE L

CN307

BOARD

CN613

R

MAIN

(1/2)

IC B/D

IC B/D

11

00

00

00

00

0.2 0.2

3.1

3.1

0.2 0.2

0.2 0.2

0.2 0.2

0.2 0.2

0.2 0.2

0.2 0.2

0.2 0.2

3.1 3.1

3.1 0

3.1 0

00

00

00

3.1

3.1

2.9

2.9

2.9

2.9

3.1

3.1

3.1

3.1

2.9

2.9

2.9

2.9

3.1

0

2.9

2.9

3.1

2.9

3.1

3.1

2.9 3.1

3.1

2.9

2.9

2.9

2.9

0

0

0

0

3.1

3.1

3.1

3.1

3.1

3.1

3.1

3.1

0

0

0

0

0

3.1

0

0

0

0

0

0

0

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

3.1

3.1

0

0

0

0

0

0

0

3.1

3.1

3.1

3.1

1.6

3.1

3.1

3.1

3.1

3.1

3.1

1.43.1

1.6

00002.9

2.9

2.9

2.9

3.1

3.1

3.1

3.1

3.1

3.1

3.1

0.1

3.103.1

3.1

0

3.1

3.1

3.1

0

0

0

0

0.2

0.2

0.2

0.2

0.2

0.2

0.2

0.2

5

5

3.1

3

16

15

14

13

12

11

10

98

7

6

5

4

3

2

1

TC74VHC157FT(EKJ)

IC303

SELECT

1A

1B

1Y

2A

2B

2Y

GND

3Y

3B

3A

4Y

4B

4A

ST

VCC

14

13

12

11

10

9

87

1

2

3

4

5

6

TC74HC4066AFT(EL)

IC302

GND

VCC

10k

R362

14

13

12

11

10

9

87

1

2

3

4

5

6

TC74HC4066AFT(EL)

IC301

GND

VCC

10k

R361

0.1C363

0.1C362

0.1C361

22pC910

0.1

C916

0R916

TP907

16V10C904

TP903

27R924

16V

10

C902

100

R919

27R923

0.1C907

0.1

C906

10kR920

4.7kR903

16V

10

C903

0.1C921

15kR925

10k

R901

0.1

C901

100k

R921

4.7kR907

0R928

0.1C908

4.7kR906

4.7kR902

0.1C905

4.7kR904

15kR926

4.7kR905

0R933

144

43

42

41

40

39

38

2

3

4

5

6

7

37

36

35

34

33

8

9

10

11

12

32

31

30

29

28

27

13

14

15

16

17

18

1926

25

24

23

20

21

22

IS61LV6416-10TLT

IC921

A15

A14

A13

A12

A11

CE

I/O0

I/O1

I/O2

I/O3

VDD

GND

I/O4

I/O5

I/O6

I/O7

WE

A10

A9

A8

A7

NC

NC

A6

A5

A4

A3

NC

I/O8

I/O9

I/O10

I/O11

VDD

GND

I/O12

I/O13

I/O14

I/O15

CB

UB

OE

A2

A1

A0

TP904

0.1C914

0.1C915

TP908

0R917

100R986

100R985

100R983

100R981

100R932

100R979

100R978

100

R977

100R938

100R937

100R976

4.7kR950

10k

R934

4.7k

R947

4.7kR945

22pC909

100kR944

100kR943

100kR942

100kR941

TP914

TP915

100k

R922

0.1

C920

10k

R991

10k

R988

2SC3052EF-T1-LEF

Q301

100R304

100R309

100R306

100R310

100R308

100R305

100R307

100k

R312

100R972

100R974

100R973

100R971

100R975

100R970

100R982

100R984

TP916

TP917

TP919

TP921

TP922

TP923

TP924

TP925

TP927

TP926

TP928

TP929

TP930

TP918

TP933

TP934

TP935

TP936

TP937

TP938

TP939

TP940

TP941

TP942

TP949

TP950

TP951

TP952

TP953

TP954

TP955

TP963

TP966

TP965

TP964

TP967

TP968

TP906

TP912

TP911

TP910

TP909

TP913

54

321

R5523N001B-TR-F

IC915

EN

GND

FLG IN

OUT

R915 10k

100kR913

0

R989

0

R990

C918 0.1

C912 10p

9MHz

X901

0.1C913

0.1C922

1

2

3

4

5

6

7

7P

CN903

GND

GND

GND

D+

D-

VBUS

VBUS

1

2

3

4

5

5P

CN902

USB-SO

USB-SI

USB-DO

USB-DI

SEL1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

21P

CN907

USB-RST

M-MUTE

M-GND

VM+7V

DVDD

D-OUT

D-GND

SBSY

REQ

CCE

BUCK

BUS3

BUS2

BUS1

BUS0

RST

A-GND

L-OUT

DAC-GND

R-OUT

AVDD+3.3V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

27P

CN906

1

2

2P

CN901

VBUS-5V

VBUS-GND

47R951

47R952

47R953

47R954

47R955

47R956

47R957

47R958

47R959

47R960

47R961

47R962

47R963

47R964

47R965

47R966

TP900

C923

0.047

1 2 3 4 5 6 7 8 9 10111213141516171819202122232425

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51525354555657585960616263646566676869707172737475

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

TMP92CD28AFG-6UJ5

IC901

USB-RST

I-USB-DI

INT1

INT2

INT3

DVCC3B

XT1

XT2

PWE

DVSS1B

DVCC1B

RVOUT1

RVIN

RVIN

RVOUT2

DVCC1A

DVSS1AD0D1D2D3D4D5D6D7

DVSS

DVCC

D8

D9

D10

D11

D12

D13

D14

D15

A0

A1

A2

A3

A4

A5

A6

A7

DVSS

DVCC3A

A8

A9

A10

A11

A12

A13

A14

A15

A16

BUS0-U

BUS1-U

BUS2-U

BUS3-U

BUCK-U

CCE-U

A23

DVSS

DVCC3A

RD

SRWR

SRLLB

SRLUB

TA0IN

BOOT

SRAM-CS

LRCK

AM1

X2

DVSS

X1

DVCC3A

USBOC

USBPON

D+

D-

AM0

X1USB

DVSS

O-USB-DO

DATA

CLK

O-USB-SO

I-USB-SI

SPCLK

SO0

SI0

BCK

A-IN

GATE

DVCC3A

REQ-U

ST-REQ

PG1

PG0

DVSS

100pC936

100pC937

MAZ8051GMLS0

D904

MAZ8051GMLS0

D903

MAZ8051GMLS0

D952

(SUFFIX-14)

MAZ8051GMLS0

D951

10V

220

C950

0.1

C951

4P

CN950

1

2

3

4

1

2

3

4

5

6

7

7P

CN951

VBUS

VBUS

D-

D+

GND

GND

GND

E

ET951

BUS2-Z

BUS1

BUS0

CCE-U

BUS0-U

BUS1-U

BUS2-U

CCE-Z

BUS3-U

REQ

CCE

BUS0-Z

BUCK

BUS1-Z

D7

A7

D6

LB

A8

UB

A1

RD

A9

A4

A5

A5

A8

WR

SRAM-CS

A4

A12

A13

BCK

A3

REQ-U A14

A15

D5

A16

GATE

A2

D4A9D3

A12

A10

A1

D2

A11

A7

D1

A11

D0

A6

A3

A2

DATA

A10

A6

LRCK

CLK

I-USB-DI

I-USB-SI-RXD

A-IN

GATE

REQ

ST-REQ

USB-RST

O-USB-DO

D8

D9

D10

D11

D12

D13

D15

D14

BUS3

BUS2

BUCK-Z

I-USB-DI

I-USB-SI-RXD

LRCK

BUS0-Z

BUS1-Z

BUS2-Z

BUS3-Z

BUCK-Z

CCE-Z

REQ-Z

BUS3-U

BUS0-U

BUS2-U

BUS1-U

BUCK-U

CCE-U

BCK

O-USB-SO-TXD

O-USB-DO

SEL-U

REQ-U

BUS3-Z

BUCK-U

D8

D9

D10

D11

D12

D13

D14

D15

D7

D6

D5

D4

D3

D2

D1

D0

A13

A14

A15

A16

DATA

CLK

ST-REQ

BUS0

BUS1

BUS2

BUS3

BUCK

CCE

USB-RST

A-IN

REQ-Z

SEL-U

RD

WR

LB

UB

SRAM-CS

O-USB-SO-TXD

S-RAM

IC921

USB CONTROLLER

IC901

VBUS POWER

IC915

BUS SWITCH

IC301

BUS SWITCH

IC302

DATA SELECTOR

IC303

W901

(CHASSIS)

USB BOARD

INVERTER

ON/OFF SWITCH

D-

(CHASSIS)

VBUS

USB CONN BOARD

GND

(USB)

D+

B

K

208

E

71221 9

A

F

21156

I

1814

G

10

C

34 16

D

13 17 19

J

H

511

CLOCK

GATE

ST_REQ

GPIN/AIN

SF SY/BCKIN

ZDET/LRCKIN

M-MUTE

MGND

VM (7V)

DVDD (3.3V)

D-OUT

DGND

SBSY

REQ

BUCK

BUS3

BUS2

BUS1

BUS0

AGND

DACGND

AVDD (3.3V)

L-OUT

R-OUT

CCE

DATA

RST

(Page 30)

(Page 25)

(Page 37)

6-7. SCHEMATIC DIAGRAM - USB Section -

(Page 31)

• See page 40 for waveforms. • See page 40 for IC Block Diagrams. • See page 42 for IC Pin Function Description.

Note: Refor to “SUFFIX-12/-13/-14 DISCRIMINATION OF PRINTED WIRING

BOARDS” (page 4) of the servicing notes for suffi x-14.

Page 28

HCD-EC68USB

• Semiconductor

Location

Ref. No. Location

D601 E-2

D602 E-6

D604 G-3

D605 D-5

D606 E-6

D607 G-5

D608 F-5

D609 G-5

D610 F-5

D611 H-6

D612 H-6

D614 B-6

D615 D-7

D617 D-6

D618 E-6

D619 E-6

D620 E-7

D621 D-5

D622 D-5

D628 D-7

D629 H-6

D630 H-6

D631 E-7

D701 F-7

D704 G-7

D791 E-5

D801 B-3

D802 A-4

D803 B-4

D804 B-3

D805 B-2

D806 A-2

IC602 B-7

IC701 F-7

IC801 C-4

Q601 D-4

Q602 D-5

Q603 D-5

Q604 G-3

Q605 D-6

Q606 D-5

Q608 B-6

Q611 D-5

Q612 D-6

Q618 D-7

Q619 G-6

Q622 E-6

Q624 E-7

Q801 B-5

Q802 B-5

6-8. PRINTED WIRING BOARD - MAIN Board (Suffi x-12/-13) -

12345678910

MAIN BOARD

A

FL803

JW743

D804

L804

C847

R846

C846

JW739

JW729

JW728

JW726

T801

R832

JR602

JW725

D806

CN801

ANTENNA

FM/AM

13

D805

B

JW682

C848

C

CF801

D

JW650

JW652

E

JW651

JW662

D601

F

TB602

L

SPEAKER

IMPEDANCE

G

USE 6Ω

R

R611

C609

C610

R612

H

R609

JW654

L603

JW653

L604

ET601

(CHASSIS)

R610

JW659

JW660

R639

R640

C617

C618

R647

JW672

JW657

JW658

JW661

RY602

C607

C608

R615

C620

RY601,RY602

L805

JW744

R847

JW742

D801

R838

R843

TP690

C836

C819