Sony HCD-EC59 Service Manual

HCD-EC59

SERVICE MANUAL

Ver. 1.0 2010.06

• HCD-EC59 is the amplifi er , USB, CD player and

tuner section in MHC-EC59.

• MPEG Layer-3 audio coding technology and patents licensed from Fraunhofer IIS and Thomson.

• Windows Media is either a registered trademark or trademark of Microsoft Corporation in the

United States and/or other countries.

• This product is protected by certain intellectual property rights of Microsoft Corporation. Use or

distribution of such technology outside of this product is prohibited without a license from Microsoft or an authorized Microsoft subsidiary.

SPECIFICATIONS

Main unit

Amplier section

e following measured at AC 127 V, 60 Hz

(Mexican model)

e following measured at AC 220 V,

50/60 Hz (Argentine model)

e following measured at AC 120 V, 220 V,

240 V, 50/60 Hz (Other models)

Power output (rated):

25 W + 25 W (at 6 Ω, 1 kHz, 1%

THD)

RMS output power (reference):

60 W + 60 W (per channel at 6 Ω,

1 kHz)

Inputs

PC IN (stereo mini jack):

Sensitivity 800 mV, impedance

22 kilohms

Outputs

PHONES (stereo mini jack):

accepts headphones with an

impedance of 8 Ω or more

SPEAKERS: impedance: 6 Ω

USB section

Supported bit rate:

MP3 (MPEG 1 Audio Layer-3):

32 kbps – 320 kbps, VBR

WMA: 48 kbps – 192 kbps

AAC: 48 kbps – 320 kbps

Sampling frequencies:

MP3 (MPEG 1 Audio Layer-3):

32/44.1/48 kHz

WMA: 44.1 kHz

AAC: 44.1 kHz

(USB) port:

Maximum current:

500 mA

CD player section

System:

Compact disc and digital audio

system

Laser Diode Properties

Emission Duration: Continuous

Laser Output*: Less than 44.6μW

* is output is the value

measurement at a distance of

200mm from the objective lens

surface on the Optical Pick-up Block

with 7mm aperture.

Frequency response: 20 Hz – 20 kHz

Signal-to-noise ratio: More than 90 dB

Dynamic range: More than 88 dB

Tuner section

FM stereo, FM/AM superheterodyne tuner

Antenna:

FM lead antenna

AM loop antenna

FM tuner section:

Tuning range:

87.5 MHz – 108.0 MHz (50 kHz step)

Intermediate frequency: 225 kHz

AM tuner section:

Tuning range

Latin American models:

530 kHz – 1,710 kHz (10 kHz step)

531 kHz – 1,710 kHz (9 kHz step)

Other models:

531 kHz – 1,602 kHz (9 kHz step)

530 kHz – 1,610 kHz (10 kHz step)

Intermediate frequency: 53 kHz

E Model

Model Name Using Similar Mechanism HCD-EX6/EX6T

Base Unit Name BU-D1BD74UR

Optical Pick-up Block Name DA11MMVGP

General

Power requirements

Mexican model:

AC 127 V, 60 Hz

Argentine model:

AC 220 V, 50/60 Hz

Other models:

AC 120 V, 220 V or 230 V 240 V,

50/60 Hz, adjustable with voltage

selector

Power consumption: 85 W

(0.5 Wat the Power Saving Mode)

Dimensions (W/H/D) (excl. speakers)

Approx. 200 mm × 306 mm ×

305 mm

Mass (excl. speakers): Approx. 3.8 kg

Design and specications are subject to

change without notice.

Standby power consumption: 0.5 W

Halogenated ame retardants are not used

in the certain printed wiring boards.

COMPACT DISC RECEIVER

9-889-885-01

2010F05-1

2010.06

©

Sony Corporation

Audio&Video Business Group

Published by Sony Techno Create Corporation

HCD-EC59

NOTES ON CHIP COMPONENT REPLACEMENT

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

FLEXIBLE CIRCUIT BOARD REPAIRING

• Keep the temperature of soldering iron around 270 °C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

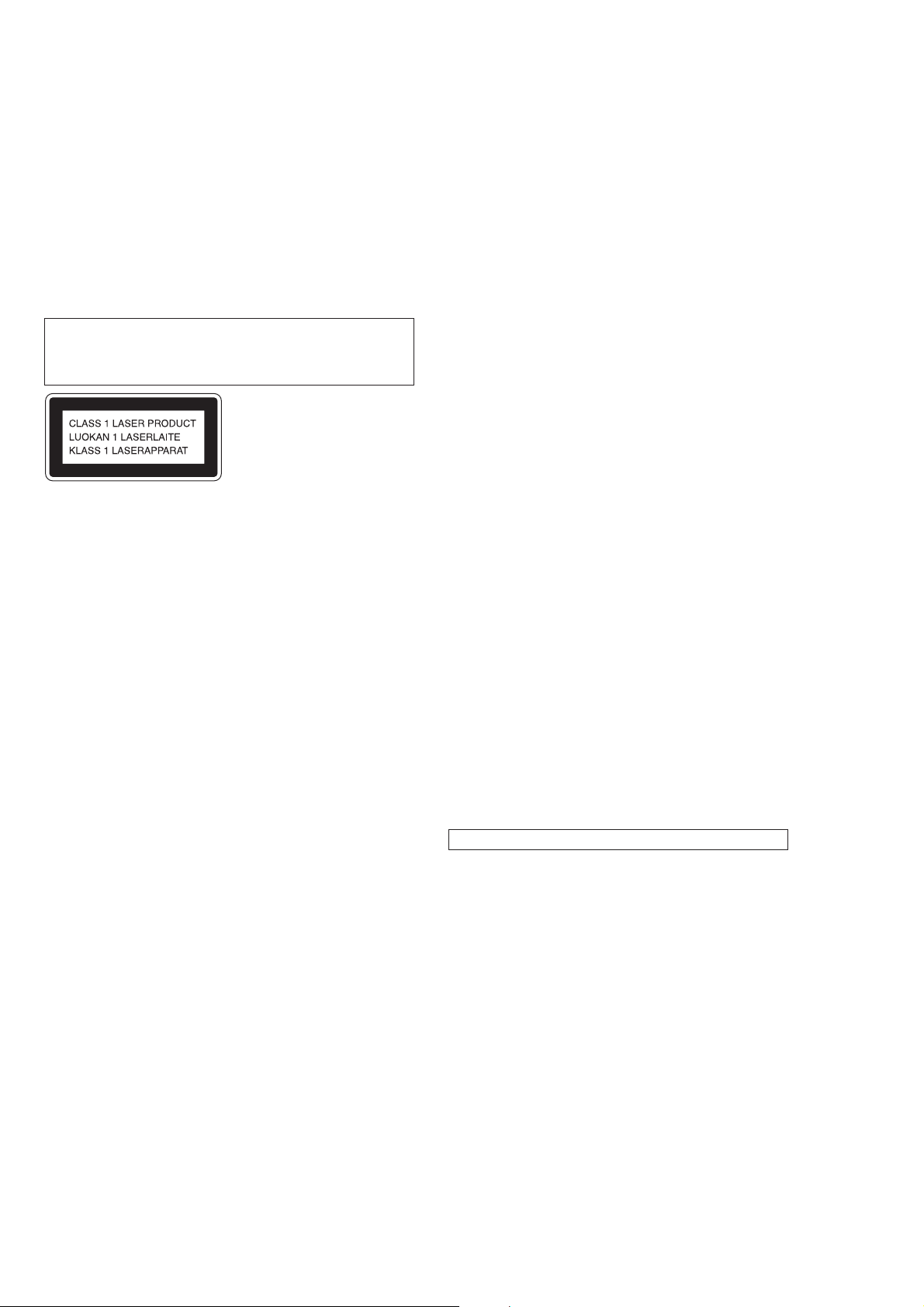

CAUTION

Use of controls or adjustments or performance of procedures

other than those specifi ed herein may result in hazardous radia-

tion exposure.

This appliance is classifi ed as

a CLASS 1 LASER product.

This marking is located on the

rear exterior.

TABLE OF CONTENTS

1. SERVICING NOTES ............................................. 3

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 6

2-2. Side Panel (L)/(R) ........................................................... 7

2-3. Top Panel Assy ................................................................ 7

2-4. Front Panel Block ........................................................... 8

2-5. Knob (VOL) .................................................................... 8

2-6. MAIN Board ................................................................... 9

2-7. Base Unit (BU-D1BD74UR) .......................................... 10

2-8. Optical Pick-up Block (DA11MMVGP) ........................ 10

3. TEST MODE ............................................................ 11

4. ELECTRICAL CHECKS ...................................... 13

5. DIAGRAMS

5-1. Printed Wiring Board - CD Section - .............................. 18

5-2. Schematic Diagram - CD Section - ................................. 19

5-3. Printed Wiring Board - USB Section - ............................ 20

5-4. Schematic Diagram - USB Section - .............................. 21

5-5. Printed Wiring Boards - MAIN Section - ....................... 22

5-6. Schematic Diagram - MAIN Section - ........................... 23

5-7. Printed Wiring Boards

- 2CH AMP/USB-JACK/JACK Boards - ....................... 24

5-8. Schematic Diagram

- 2CH AMP/USB-JACK/JACK Boards - ....................... 25

5-9. Printed Wiring Board - PANEL Board - ......................... 26

5-10. Schematic Diagram - PANEL Board - ............................ 27

5-11. Printed Wiring Board - PT-SWITCH Board - ................. 28

5-12. Schematic Diagram - PT-SWITCH Board - ................... 29

SAFETY-RELATED COMPONENT WARNING!

6. EXPLODED VIEWS

6-1. Overall Section ............................................................... 32

6-2. Front Panel Section ......................................................... 33

6-3. Chassis Section ............................................................... 34

6-4. Top Panel Section ........................................................... 35

7. ELECTRICAL PARTS LIST .............................. 36

Accessories are given in the last of the electrical parts list.

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

SECTION 1

SERVICING NOTES

HCD-EC59

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body .

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The fl exible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc refl ective surface by the objective lens in the optical

pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

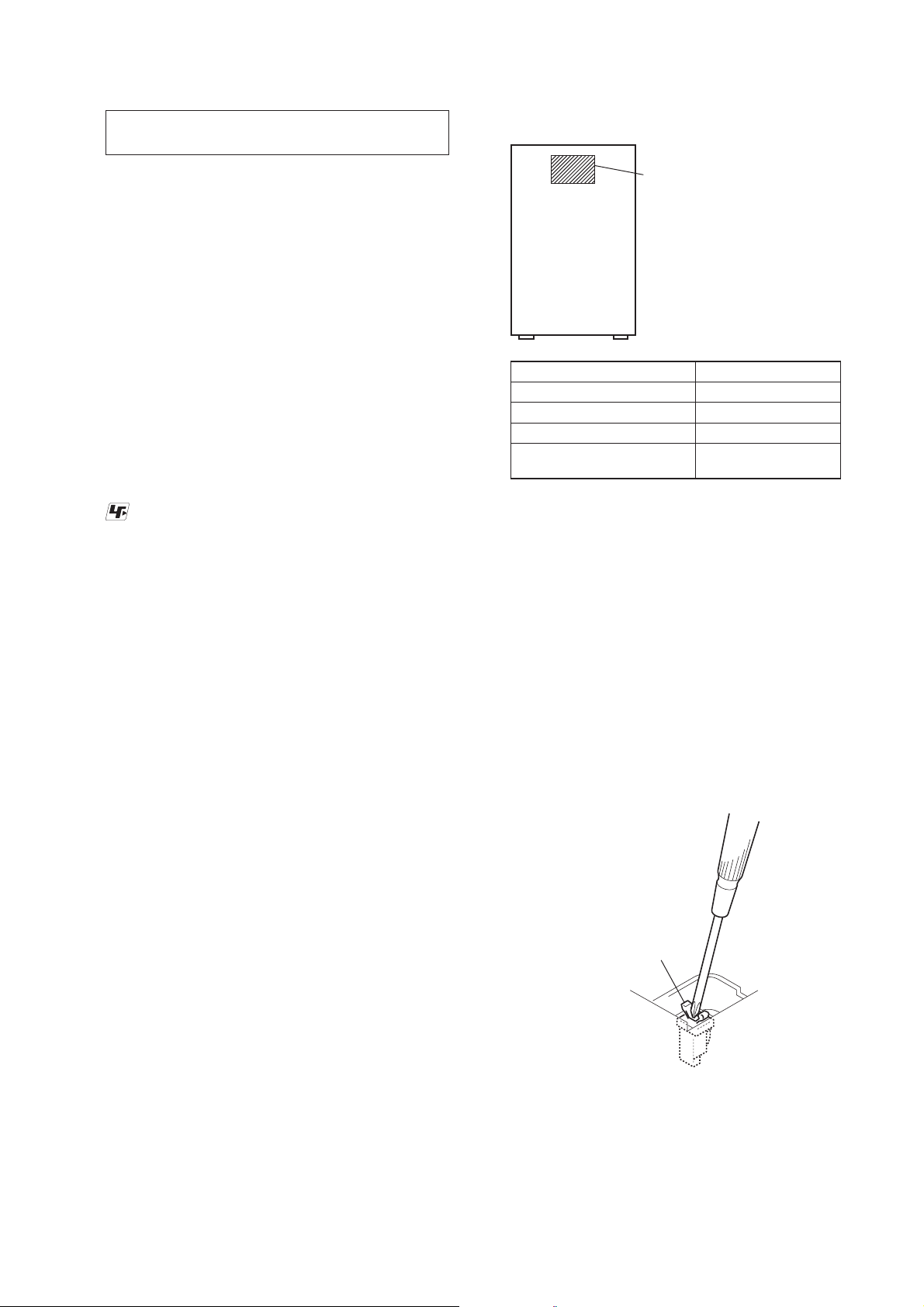

MODEL IDENTIFICATION

- Back Panel -

Model

Number

Label

Model Part No.

Argentina model

Mexican model

African model

120V AC area in E model,

Chilean and Peruvian models

4-184-199-0[]

4-184-200-0[]

4-184-201-0[]

4-187-950-0[]

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

During normal operation of the equipment, emission of the laser

diode is prohibited unless the upper lid is closed while turning on

the SW305 (push switch type).

The following checking method for the laser diode is operable.

• Method

Emission of the laser diode is visually checked.

1. Open the upper lid.

2. Push the SW305 as shown in Fig. 1.

Note: Do not push the detection lever strongly, or it may be bent or

damaged.

3. Check the object lens for confi rming normal emission of the

laser diode. If not emitting, there is a trouble in the automatic

power control circuit or the optical pick-up.

In this operation, the object lens will move up and down 2

times along with inward motion for the focus search.

SW305

Fig. 1. Method to push the SW305

3

HCD-EC59

–

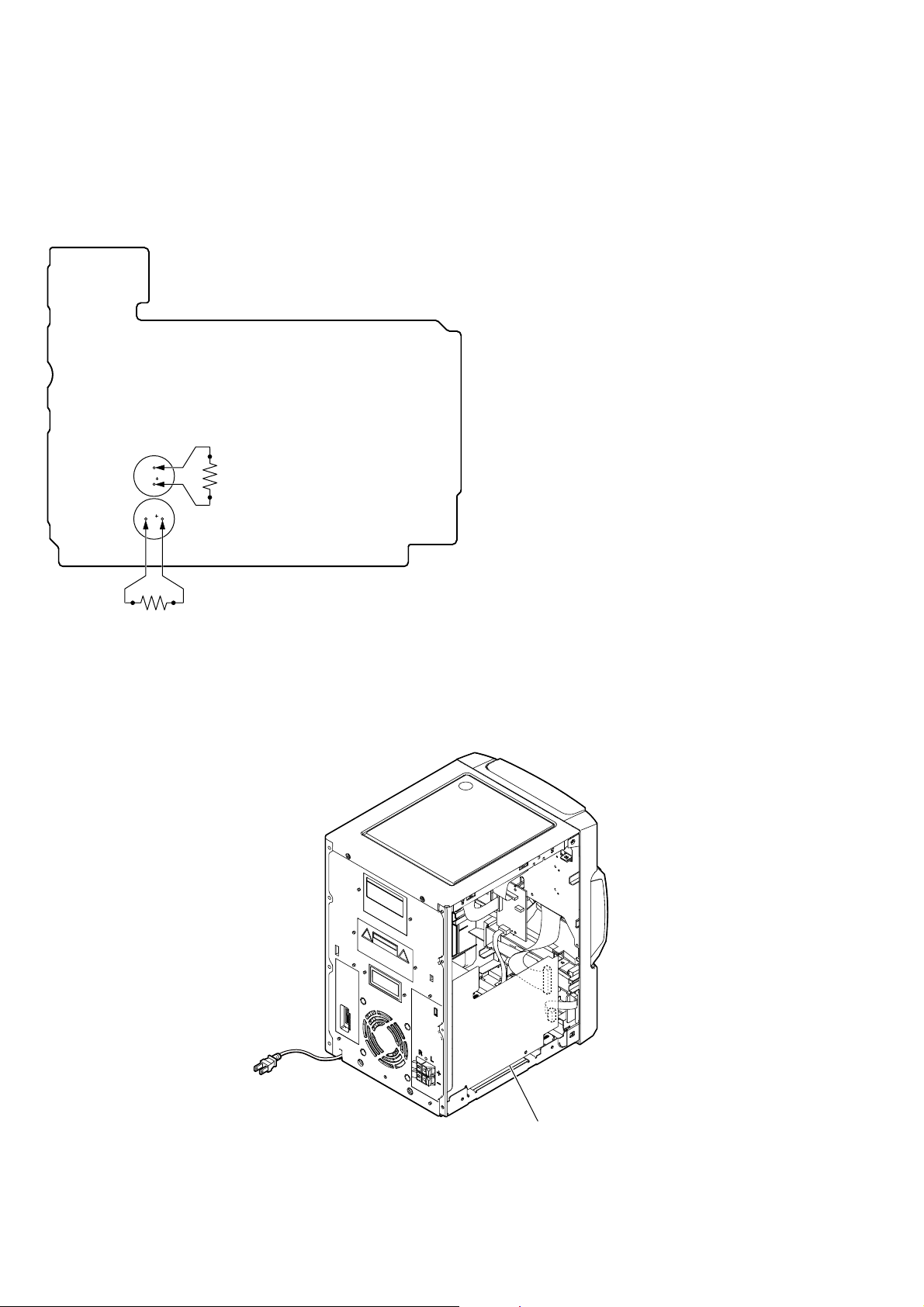

CAPACITOR ELECTRICAL DISCHARGE PROCESSING

When checking the board, the electrical discharge is necessary for the electric shock prevention.

Connect the resistors referring to the fi gure below.

• MAIN board (C622, C626)

Both ends of respective capacitors.

MAIN Board (Conductor Side) –

C626

C622

800 :/2 W

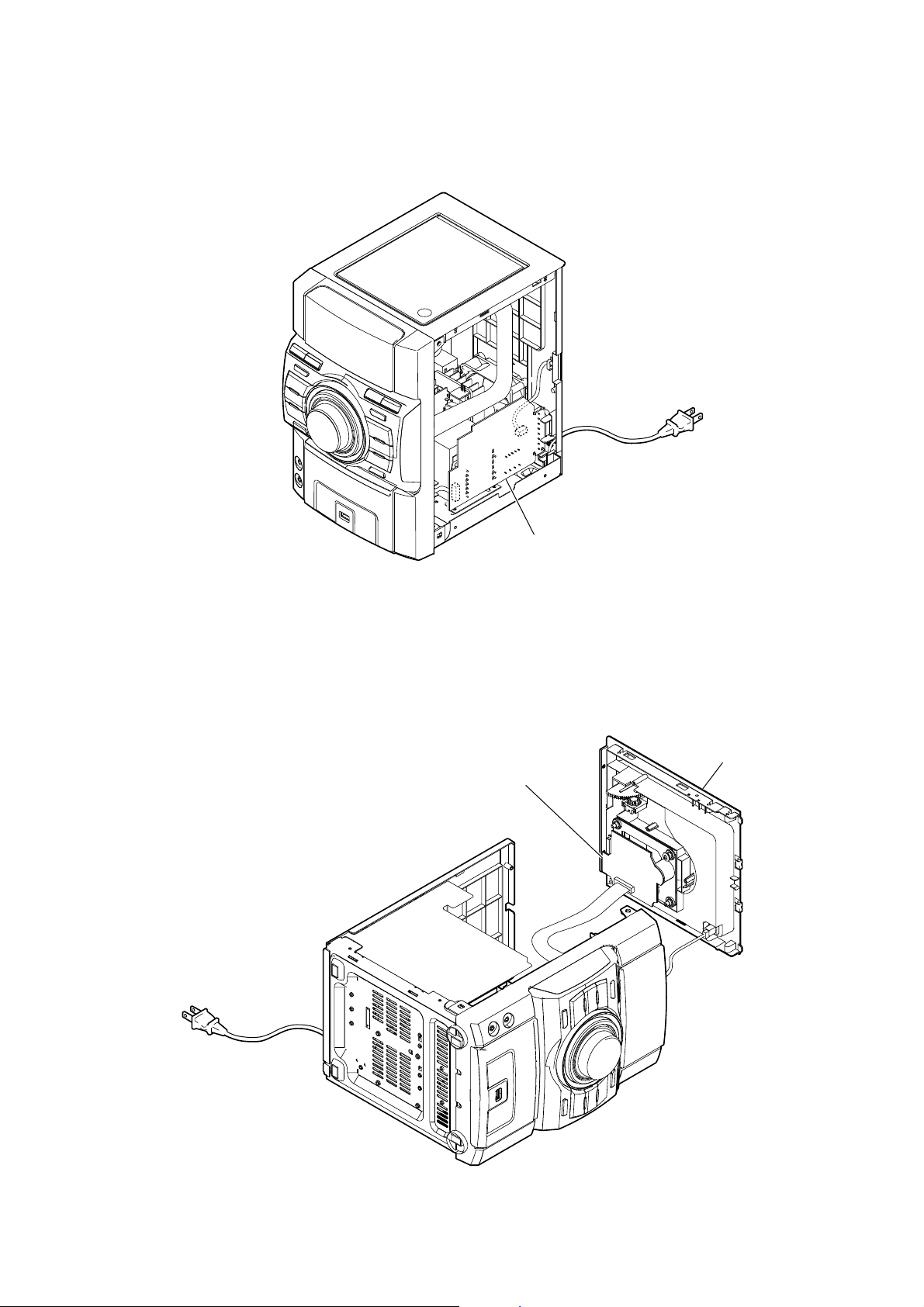

MAIN BOARD SERVICE POSITION

• SIDE PANEL (L) was removed.

800 :/2 W

MAIN board

– Rear side view –

4

PT-SWITCH BOARD SERVICE POSITION

• SIDE PANEL (R) was removed.

HCD-EC59

BD74UR BOARD SERVICE POSITION

• SIDE PANEL (L) and (R) are removed, and the set is laid.

PT-SWITCH board

top panel block

BD74UR board

5

HCD-EC59

DISASSEMBLY

• This set can be disassembled in the order shown below.

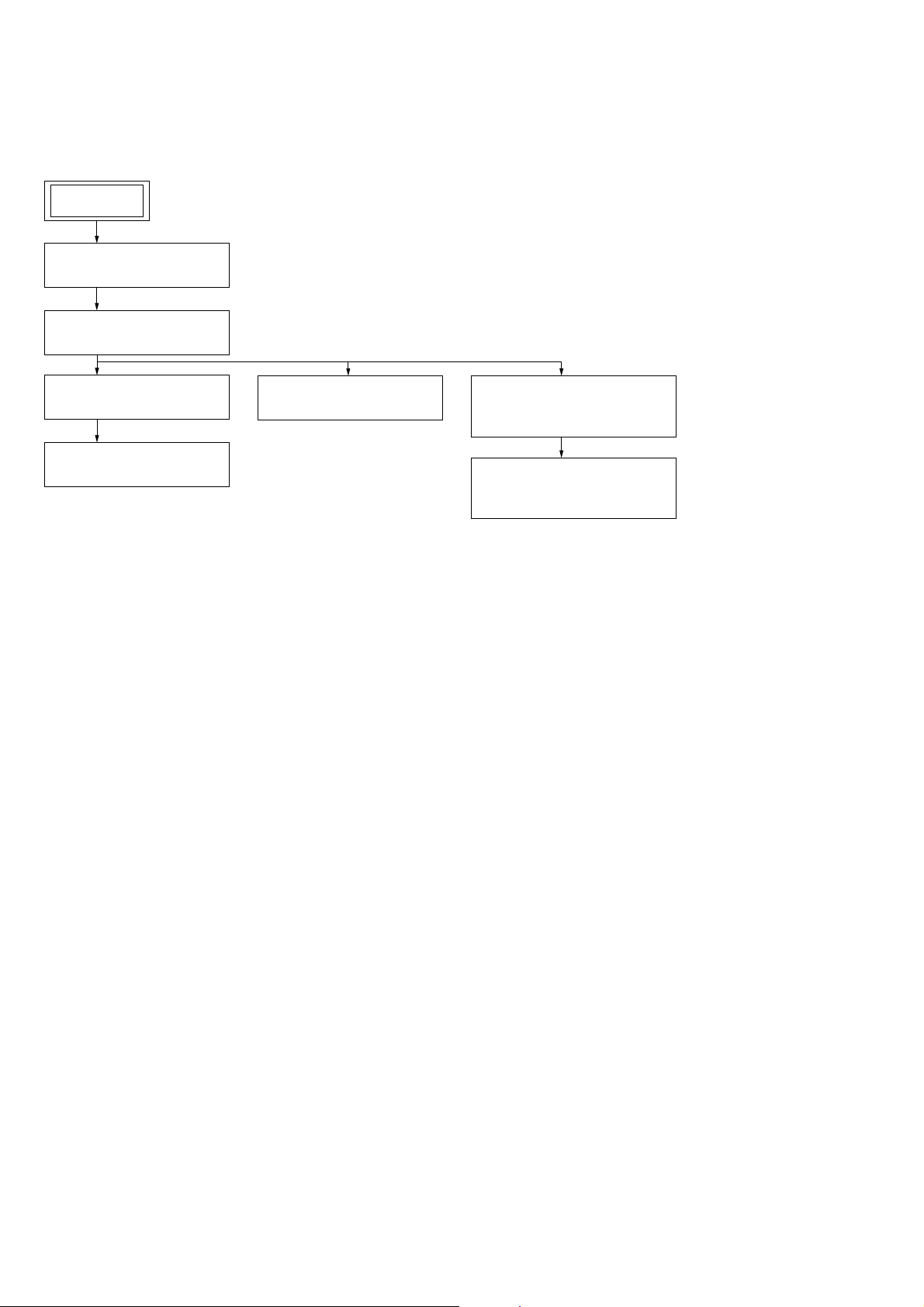

2-1. DISASSEMBLY FLOW

SET

2-2. SIDE PANEL (L)/(R)

(Page 7)

2-3. TOP PANEL ASSY

(Page 7)

SECTION 2

2-4. FRONT PANEL BLOCK

(Page 8)

2-5. KNOB (VOL)

(Page 8)

2-6. MAIN BOARD

(Page 9)

2-7. BASE UNIT

(BU-D1BD74UR)

(Page 10)

2-8. OPTICAL PICK-UP BLOCK

(DA11MMVGP)

(Page 10)

6

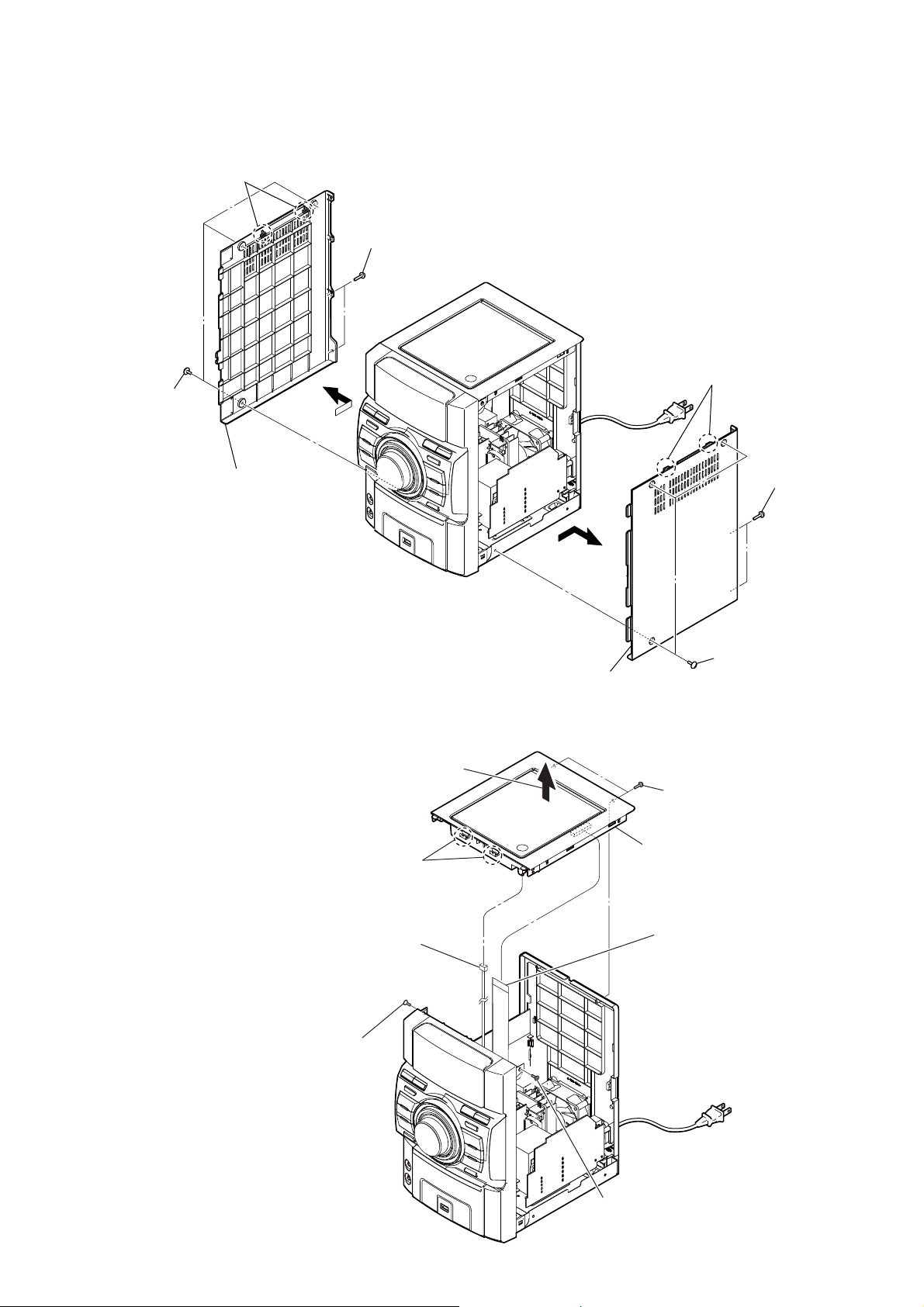

Note: Follow the disassembly procedure in the numerical order given.

2-2. SIDE PANEL (L)/(R)

two claws

4

two screws

2

(BVTP3 u 10)

three screws

1

(case 3 TP2)

side panel (L)

5

3

two claws

4

HCD-EC59

two screws

2

(BVTP3 u 10)

2-3. TOP PANEL ASSY

Lift up the side of the top panel assy in the back and

6

remove the two claws in front of the top panel assy.

two claws

5

connector

3

(SW305)

3

side panel (R)

5

three screws

1

(case 3 TP2)

two screws

2

(BVTP3 u 10)

top panel assy

7

4 flexible flat cable (25 core)

(CN403)

screw

1

(KTP3 u 10)

screw

1

(KTP3 u 10)

7

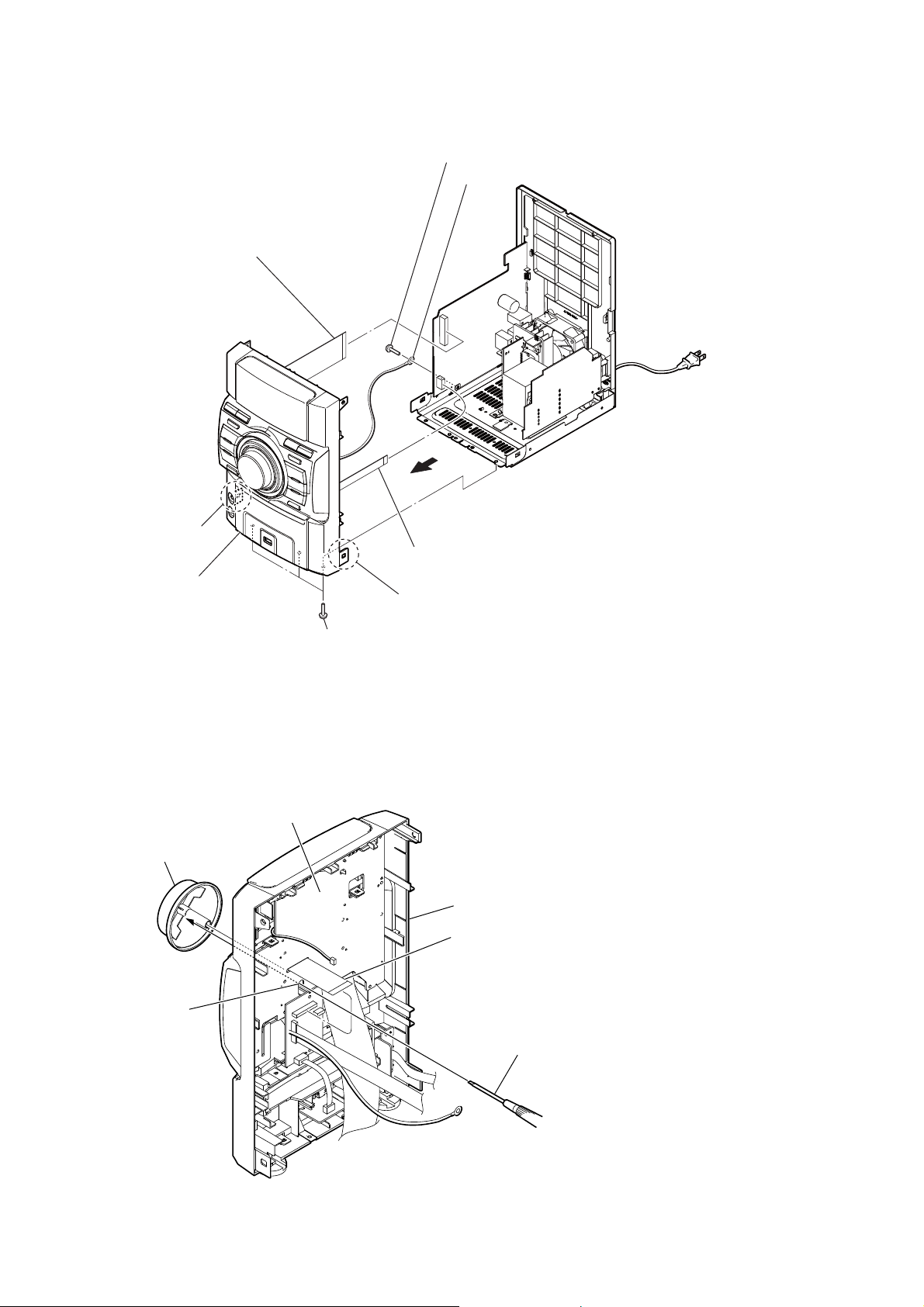

HCD-EC59

2-4. FRONT PANEL BLOCK

1 flexible flat cable (25 core)

(CN607)

3 screw (BVTP3 u 10)

4 lead wire (from USB board)

7

claw

6

front panel block

8

5 three screws

(BVTT3 u 8)

6

2-5. KNOB (VOL)

Note: This illustration sees the front panel block from PANEL board side.

PANEL board

knob (VOL)

3

2 flexible flat cable (9 core)

(CN605)

claw

front panel block

1 flexible flat cable (25 core)

(CN901)

hole

Push the knob (VOL) by flat-head screwdriver.

2

8

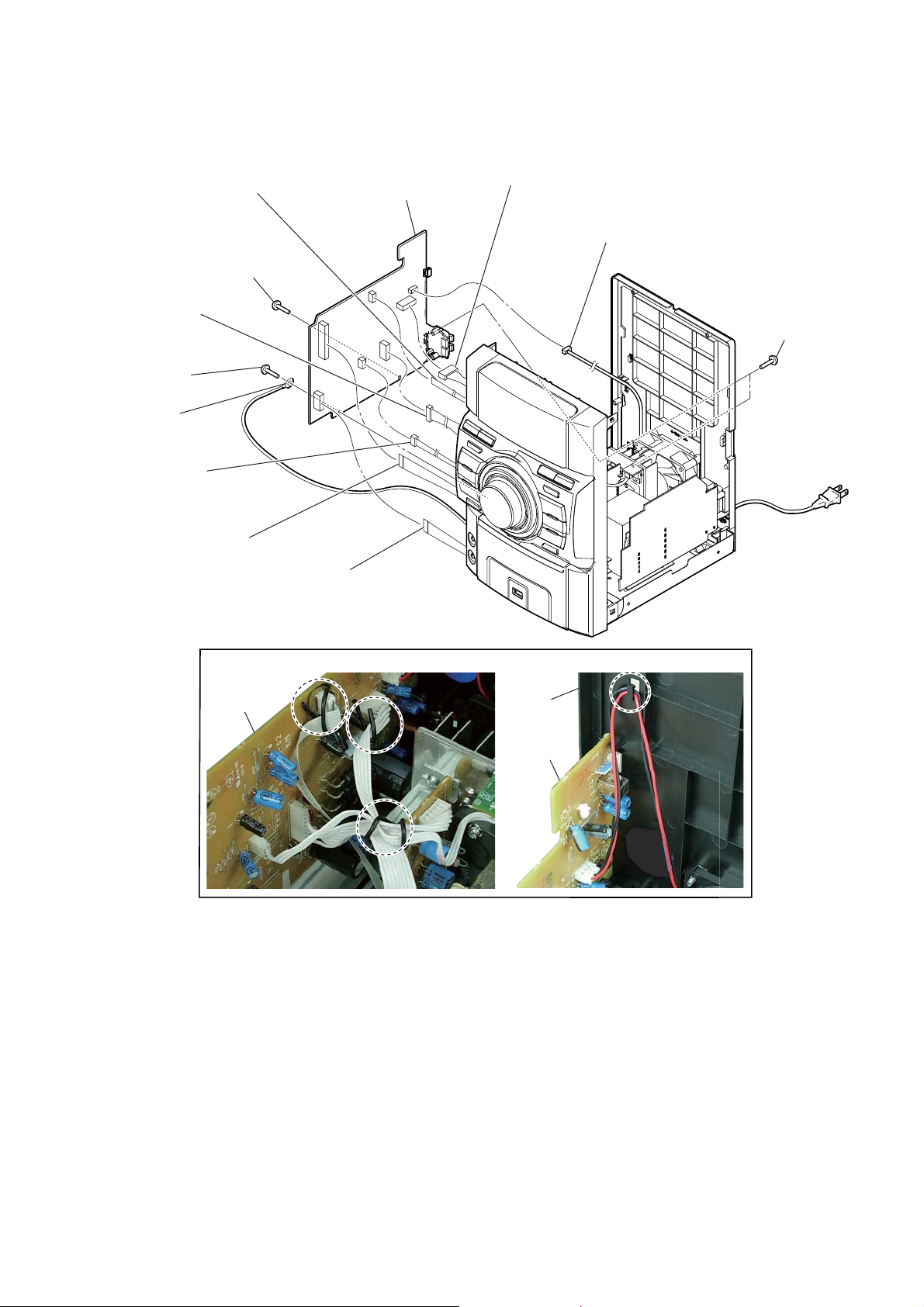

2-6. MAIN BOARD

HCD-EC59

8 screw

(BVTP3 u 10)

4 connector

(CN604)

8 screw

(BVTP3 u 10)

9 lead wire

(from USB board)

3 connector

(CN609)

1 flexible flat cable (25 core)

(CN607)

5 flexible flat cable (5 core)

(CN603)

2 flexible flat cable

(9 core) (CN605)

0 MAIN board

6 connector

(CN633)

7 fan motor connector

(CN601)

8 two screws

(BVTP3 u 10)

:LUHVHWWLQJ

MAIN board

back

panel

MAIN

board

9

HCD-EC59

2-7. BASE UNIT (BU-D1BD74UR)

Note 1: This illustration sees the top panel assy from base unit side.

two insulators

4

(blue)

four floating screws

1

(PTPWHM2.6)

base unit

7

(BU-D1BD74UR)

2

two insulators

3

(gray)

four claws

5

Note 2: Four claws might be fixed by bond.

Please fix four claws by the bond

when you replace the cover (D1).

cover (D1)

6

2-8. OPTICAL PICK-UP BLOCK (DA11MMVGP)

Note 1: When disconnecting the wire (fl at type) (16 core) of optical pick-up block, solder the short-land.

tapping screw (P2)

5

optical pick-up block

7

(DA11MMVGP)

Note 2: When assembling the optical pick-up block,

remove the solder of short-land after

connecting the wire (flat type) (16 core).

shaft (support)

6

wire (flat type) (16 core) (optical pick-up)

3

Solder the short-land.

2

10

Remove four solders.

1

BD74UR board block

4

SECTION 3

TEST MODE

HCD-EC59

COLD RESET

The cold reset clears all data including preset data stored in the

memory to initial conditions. Execute this mode when returning

the set to the customer.

Procedure:

1. In the standby status, press the [

] button to turn the power

?/1

on.

2. Press three buttons of [

], [FUNCTION] and [

x

] simultane-

?/1

ously.

3. When “RESET” appears, the set enters standby status.

PANEL TEST MODE

Enter The Panel Test Mode

Procedure:

1. In the standby status, press the [

] button to turn the power

?/1

on.

2. Press three buttons of [DSGX], [x] and [

] simultaneously.

?/1

3. When the panel test mode is activated, LEDs and segments of

the liquid crystal display are all turned on.

Version Check

Procedure:

1. In the panel test mode (all LEDs and segments of the liquid

crystal display are turned on), press the [FUNCTION] button.

2. On the liquid crystal display, date and version are displayed

“xxxxxxxx”.

3. From this status, press the [u] button, and the destination and

model name are displayed.

4. T o release from this mode, press three buttons of [DSGX], [

and [

] simultaneously.

?/1

x

Key Test Mode

Procedure:

1. In the panel test mode (all LEDs and segments of the liquid

crystal display are turned on), press the [x] button.

2. The message “KEY0 0 0” displayed. Whenever any buttons

are pressed, the value is changed.

3. T o release from this mode, press three buttons of [DSGX], [x]

and [

] simultaneously.

?/1

CHANGE-OVER THE AM TUNING INTERVAL

The AM tuning interval can be changed over 9 kHz or 10 kHz.

Procedure:

1. Press the [

] button to turn the power on.

?/1

2. Press the [FUNCTION] button to select TUNER AM function.

3. Press the [

] button again to turn the power off (standby).

?/1

4. After pressing the [DISPLAY] button, while pressing the

[TUNING +

M L

] button, press the [

?/1

] button.

5. It turns power on and display “9k STEP” or “10k STEP”, and

thus the tuning interval is changed over.

CD SERVICE MODE

This mode can move the SLED of the optical pick-up, and also can

turn the optical pick-up laser power on and off.

Procedure:

1. Press the [

2. Press three buttons of [u], [ENTER] and [

] button to turn the power on.

?/1

?/1

ously.

3. Press the [FUNCTION] button to select CD function.

4. It enters the CD service mode and displays “SERVICE”.

5. To release from this mode, press three buttons of [u], [ENTER] and [

] simultaneously.

?/1

Key Operation:

[TUNING +

M L

], [– TUNING

l m

]:

Use these keys to move the SLED. When [TUN-

ING +

M L

] is pressed in this mode, the SLED

moves to outer circumference and the message

]

When [– TUNING

“SLED OUT” is displayed.

l m

] is pressed in this

mode, the SLED moves to inner circumference and

the message “SLED IN” is displayed.

[CD]:

Use this key to turn the optical pick-up laser power

on and off. When the laser power is turned on, the

message “LD ON” is displayed. When the laser

power is turned off, the message “LD OFF” is displayed.

] simultane-

CD POWER MANAGE

This mode is for switch the CD power supply on/off. Even if this

state pulls out AC plug, it is held.

Procedure:

1. Press the [

] button to turn the power on.

?/1

2. Press the [FUNCTION] button to select CD function.

3. Press the [

] button again to turn the power off (standby).

?/1

4. After pressing the [DISPLAY] button, while pressing the [x]

button, press the [

?/1

] button.

5. It turns power on and display “CD/USB”, then display “PWR

ON” or “PWR OFF”.

11

HCD-EC59

CD FACTORY MODE

Note 1: Do not enter the this mode while any other test mode is in prog-

ress.

Note 2: Do not enter any other test mode while the this mode is in prog-

ress.

Procedure:

1. Press the [

2. Press the [FUNCTION] button to select CD function

3. Press three buttons of [u], [USB] and [

4. It enters the CD factory mode and the message “FACTORY”

is displayed. When the [CD] button is pressed, the following

message (initial display) is displayed.

– ON

S character mode setting

Tracking servo setting

RF gain setting

Key Operation:

[CD]:

The display changes in the following order when-

] button to turn the power on.

?/1

ever the button is pressed.

] simultaneously.

?/1

(Initial display)

FCSAG ** (**: Focus AGC value)

TRKAG ** (**: Track AGC value)

RF_AG ** (**: RF AGC value)

[DSGX]:

RF gain setting changes whenever the button is

pressed.

“–”: No gain fi xation.

“AL”: Fix to the gain for AL disc.

“RW”: Fix to the gain for RW disc.

[FUNCTION]:

S character mode setting changes whenever the but-

ton is pressed.

“ ”: S character mode OFF.

“S”: S character mode ON.

5. To release from this mode, press three buttons of [u], [USB]

and [

] simultaneously.

?/1

12

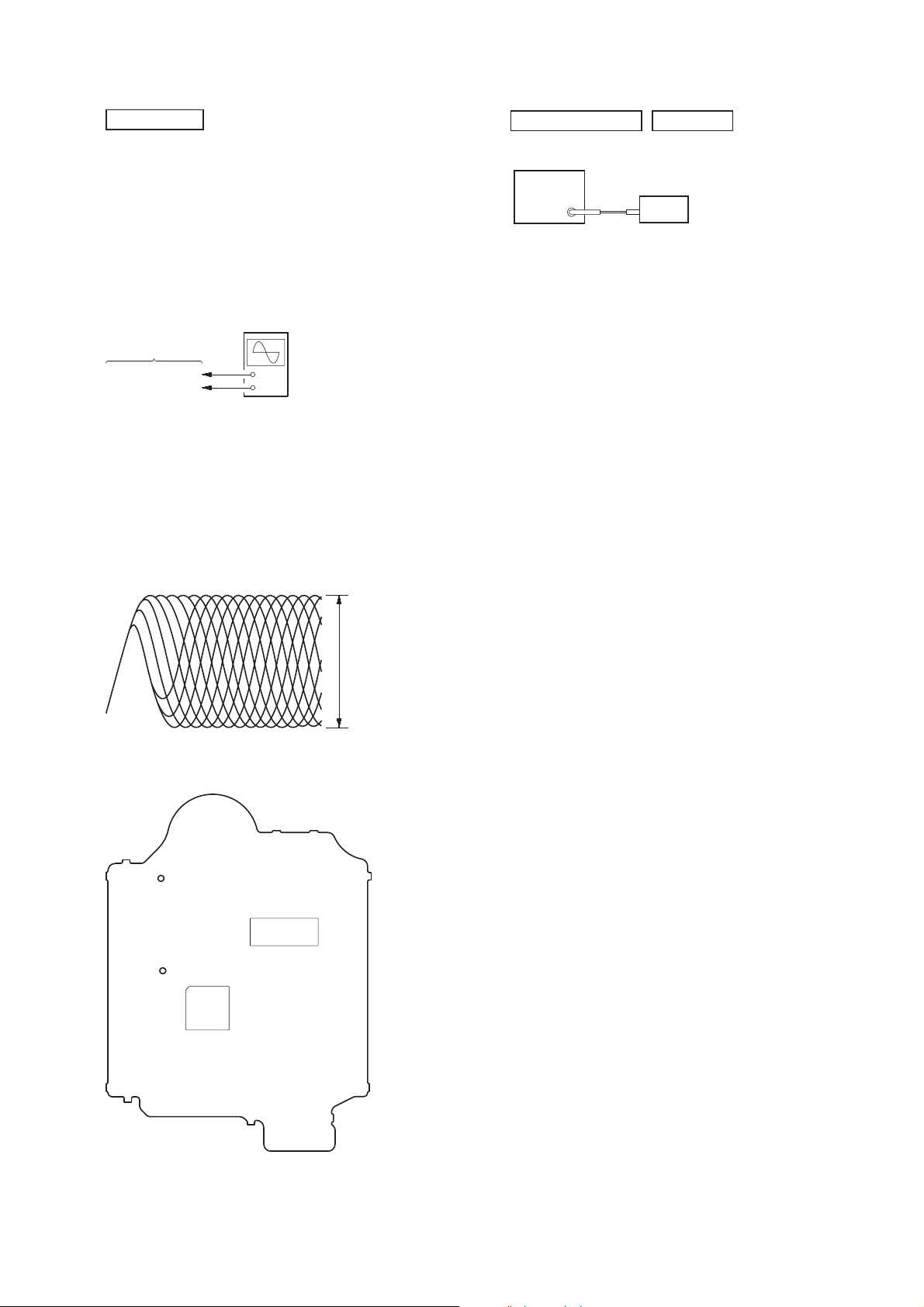

SECTION 4

ELECTRICAL CHECKS

HCD-EC59

CD SECTION

Note:

1. CD Block is basically constructed to operate without adjustment.

2. Use YEDS-18 disc (Part No. 3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10 MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specifi ed value with the following checks.

5. Check the focus bias check when optical pick-up block is replaced.

FOCUS BIAS CHECK

oscilloscope

(DC range)

BD74UR board

CL102 (RFOUT)

CL117 (VREF)

+

–

Procedure :

1. Connect the oscilloscope to CL102 (RFOUT) and CL117

(VREF) on the BD74UR board.

2. Press the [

] button to turn the power on, and press the

?/1

[FUNCTION] button to select CD function.

3. Set disc (YEDS-18) and press the [u] button to playback.

4. Confi rm that oscilloscope waveform is as shown in the fi gure

below (eye pattern).

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

TUNER SECTION

0 dB = 1 μV

FM AUTO STOP CHECK

signal

generator

set

Procedure :

1. Turn the power on.

2. Input the following signal from Signal Generator to FM antenna input directly.

Carrier frequency : A = 87.5 MHz, B = 98 MHz, C = 108 MHz

Deviation : 75 kHz

Modulation : 1 kHz

ANT input : 35 dBu (EMF)

Note: Please use 75 ohm “coaxial cable” to connect SG and the set. You

cannot use video cable for checking.

Please use SG whose output impedance is 75 ohm.

3. Set to FM tuner function and scan the input FM signal with

automatic scanning.

4. Confi rm that input Frequency of A, B and C detected and auto-

matic scanning stops.

The stop of automatic scanning means “The station signal is received in good condition”.

Checking Location:

– BD74UR Board (Conductor Side) –

CL117

(VREF)

IC301

CL102

(RFOUT)

IC101

level:

1.1 ± 0.4 Vp-p

13

HCD-EC59

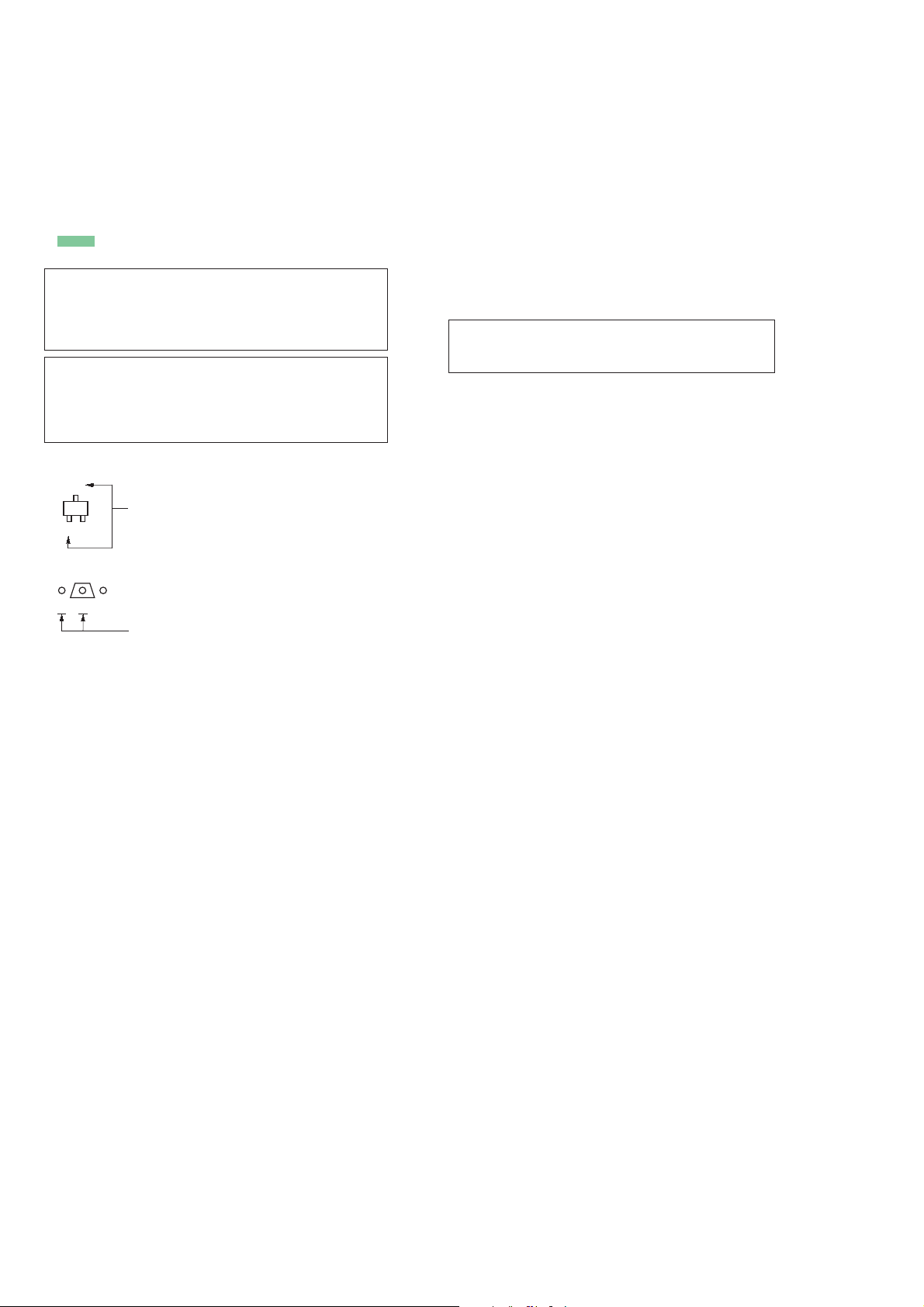

SECTION 5

DIAGRAMS

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For Printed Wiring Boards.

Note:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• W : indicates side identifi ed with part number.

•

(The other layers' patterns are not indicated.)

• Indication of transistor.

• Abbreviation

AR : Argentina model

E2 : 120V AC area in E model

E4 : African model

E51 : Chilean and Peruvian models

MX : Mexican model

: Pattern from the side which enables seeing.

Caution:

Pattern face side:

(Conductor Side)

Parts face side:

(Component Side)

Caution:

Pattern face side:

(SIDE B)

Parts face side:

(SIDE A)

C

Q

B

E

Q

B

CE

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

These are omitted.

These are omitted.

For Schematic Diagrams.

Note:

• All capacitors are in μF unless otherwise noted. (p: pF) 50

WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and 1/4 W or less unless otherwise

specifi ed.

• f : internal component.

• 2 : nonfl ammable resistor.

• C : panel designation.

Note: The components identifi ed by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specifi ed.

• A : B+ Line.

• B : B– Line.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

– BD74UR Board –

no mark : CD PLAY

– Other Boards –

no mark : TUNER (FM/AM)

• Voltages are taken with VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : TUNER (FM/AM)

J : CD PLAY

E : USB

f : PC IN

• Abbreviation

AR : Argentina model

E2 : 120V AC area in E model

E4 : African model

E51 : Chilean and Peruvian models

MX : Mexican model

14

Loading...

Loading...