Sony HCDDX-170 Service manual

HCD-DX150/DX170/

AUDIO POWER SPECIFICATIONS

for the US model

POWER OUTPUT AND

TOTAL HARMONIC

DISTORTION: With 3 ohm loads, both

channels driven, from

200 – 20,000 Hz; rated

55 watts per channel

minimum RMS power,

with no more than 0.7 %

total harmonic distortion

from 250 milli watts to

rated output.

Amplifier section

North American model:

Surround mode (reference) music power ou tput

Front: 133 W + 133 W

(with SS-TS31)

Center*: 133 W

(with SS-CT31)

Surround*: 133 W + 133

W

(with SS-TS31B)

Subwoofer*: 135 W

(with SS-WS31)

Other models:

Stereo mode (rated)

Surround mode (reference) music power ou tput

DX150

55 W + 55 W (3 ohms at 1

kHz, DIN)

Front: 133 W + 133 W

(with SS-TS31)

Center*: 133 W

(with SS-CT31)

Surround*: 133 W + 133

W

(with SS-TS31B)

Subwoofer*: 135 W

(with SS-WS31)

DX170

Surround m ode (reference) music power output

Front: 143 W + 143 W

(with SS-TS31)

Center*: 143 W

(with SS-CT31)

Surround*: 143 W + 143

W

(with SS-TS31B)

Subwoofer*: 285 W

(with SS-WS32)

Depending on the sound field settings and the source,

there may be no sound output.

Inputs

VIDEO/SAT (AUDIO IN) Sensitivity: 250/450 mV

Phones

DX250

Surround mode (reference) music powe r output

Impedance: 50 kilohms

Accepts low-and highimpedance headphones.

Front: 143 W + 143 W

(with SS-TS41)

Center*: 143 W

(with SS-CT31)

Surround*: 143 W + 143

W

(with SS-TS31B)

Subwoofer*: 285 W

(with SS-WS32)

Central/South American models

Stereo mode (rated)

Surround mode (reference) music power ou tput

55 W + 55 W (DIN)

Front: 120 W + 120 W

Center*: 120 W

Surround*: 120 W + 120

W

Subwoofer*: 120 W

DX250

SERVICE MANUAL

Ver. 1.3 2005.11

HCD-DX150/DX170/DX250 are the amplifier, DVD/

CD and tuner section in DA V -DX150/DX170/DX250.

This system incorporates with Dolby* Digital and Dolby

Pro Logic (II) adaptive matrix surround decoder and the

DTS** Digital Surround System.

* Manufactured under license from Dolby Laboratories.

"Dolby", "Pro Logic" and the double-D symbol are

trademarks of Dolby Laboratories.

** Manufactured under license from Digital Theater

Systems, Inc. "DTS" and "DTS Digital Surround" are

trademarks of Digital Theater Systems, Inc.

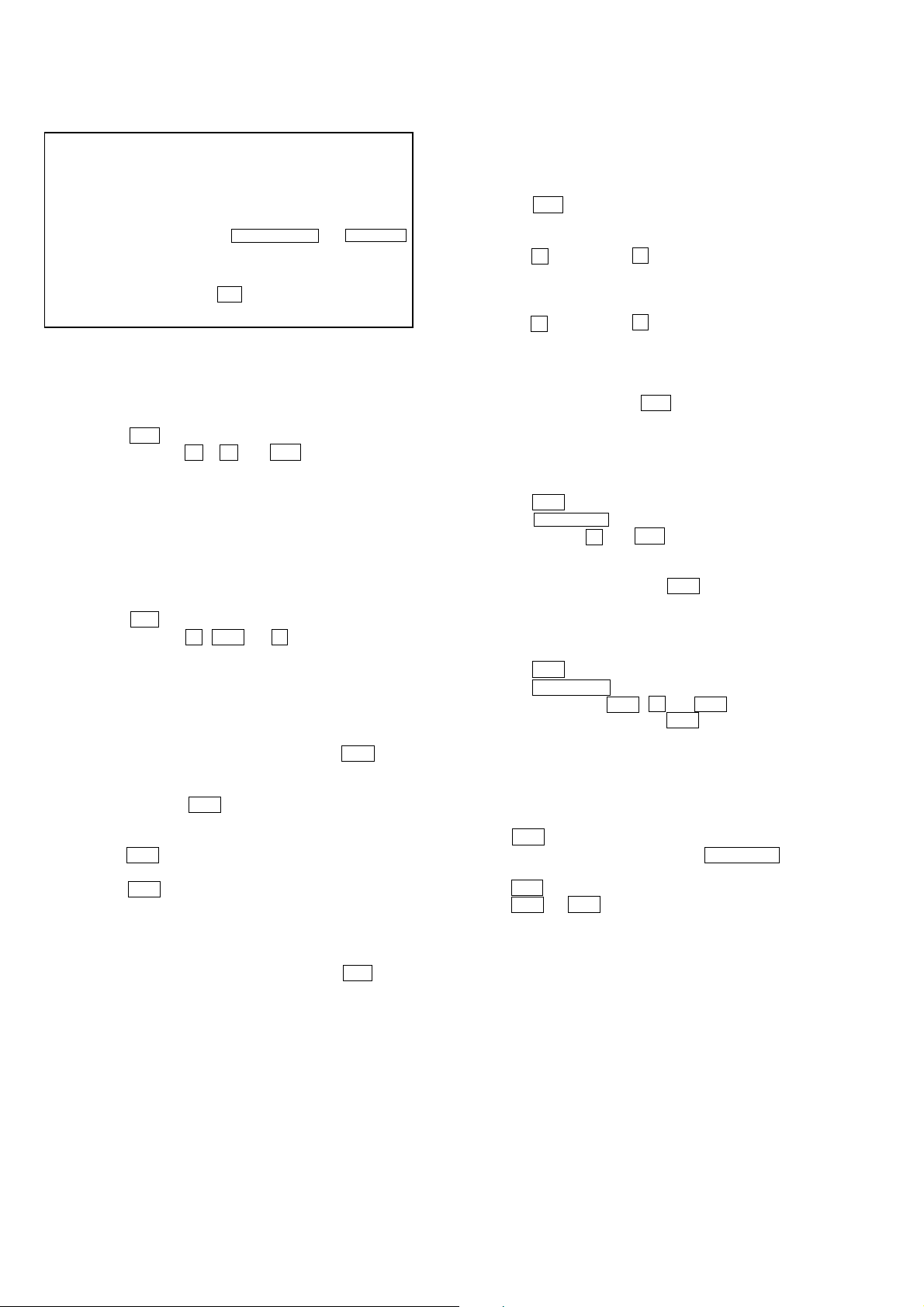

Photo: HCD-DX150

US Model

Canadian Model

HCD-DX150/DX170/DX250

E Model

Australian Model

HCD-DX150

Model Name Using Similar Mechanism NEW

Mechanism T ype CDM81C-DVBU101

Optical Pick-up Name

KHM-310CAB/C2NP

9-879-398-04

2005K16-1

© 2005.11

Sony Corporation

Home Audio Division

Published by Sony Engineering Corporation

SPECIFICATIONS

— Continued on next page —

DVD RECEIVER

HCD-DX150/DX170/DX250

DVD system

Laser Semiconductor laser

(DVD: λ = 650 nm)

(CD: λ = 790 nm)

Emission duration:

continuous

Signal format system

North American, Latin, and Mexican models:

NTSC

Other models:

NTSC/PAL

Frequency response (at 2 CH STEREO mode)

DVD (PCM): 2 Hz to 22

kHz (±1.0 dB)

CD: 2 Hz to 20 kHz (±1.0

dB)

Tuner section

System

PLL quartz-locked digital

synthesizer system

FM tuner section

Tuning range

North American models:

87.5 – 108.0 MHz

(100 kHz step)

Other models:

87.5 – 108.0 MHz

(50 kHz step)

Antenna (aerial)

Antenna (aerial) terminals

Intermediate frequency

FM wire antenna (aerial)

75 ohms, unbalanced

10.7 MHz

AM tuner section

Tuning range

North American, Latin, and Mexican models:

530 – 1,710 kHz (with the

interval set at 10 kHz)

531 – 1,710 kHz (with the

interval set at 9 kHz)

Middle eastern models:

531 – 1,602 kHz (with the

interval set at 9 kHz)

Other models:

530 – 1,710 kHz (with the

interval set at 10 kHz)

531 – 1,602 kHz (with the

interval set at 9 kHz)

Antenna (aerial)

Intermediate frequency

AM loop antenna (aerial)

450 kHz

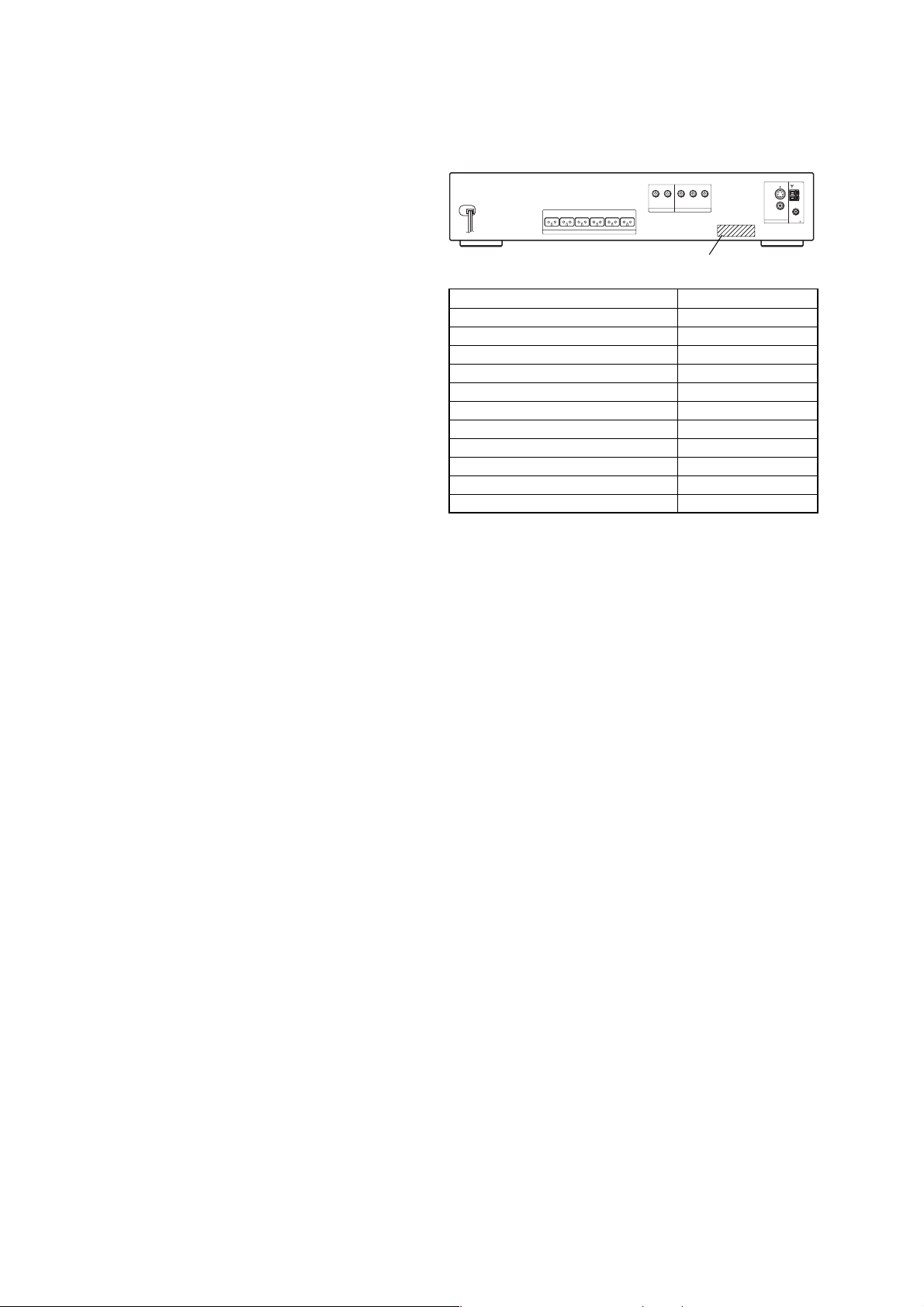

MODEL IDENTIFICATION

– Rear Panel –

Y

AUDIO IN

PB/CBPR/C

DVD ONLY

COMPONENT VIDEO OUT

Part No.

R

R L

FRONT R FRONT L SURR R SURR L CENTER WOOFER

SPEAKER

VIDEO/SAT

Model Part No.

HCD-DX150 US 2-541-507-0[]

HCD-DX150 CND 2-541-507-1[]

HCD-DX150 AUS 2-541-507-2[]

HCD-DX150 MX 2-541-507-3[]

HCD-DX150 EA 2-541-507-4[]

HCD-DX150 E32 2-541-507-5[]

HCD-DX150 SP 2-541-507-6[]

HCD-DX170 US 2-588-786-0[]

HCD-DX170 CND 2-588-786-1[]

HCD-DX250 US 2-588-786-2[]

HCD-DX250 CND 2-588-786-3[]

•Abbreviation

AUS: Australian model.

CND : Canadian model.

E32 : 110 – 240 V AC Area in E model.

EA : Saudi Arabia model.

MX : Mexican model.

SP : Singapore model.

VIDEOS(DVD ONLY)

MONITOR OUT

AM

VIDEO

COAXIAL

75

FM

Video section

Outputs

Video: 1 Vp-p 75 ohms

S video:

Y: 1 Vp-p 75 ohms

C: 0.286 Vp-p 75 ohms

COMPONENT:

Y: 1 Vp-p 75 ohms

PB/CB, PR/CR: 0.7 Vp-p

75 ohms

General

Power requirements

North American and Mexican models:

120 V AC, 60 Hz

Central/South American models:

110 – 240 V AC, 50/60 Hz

Other models:

Power consumption

220 – 240 V AC, 50/60 Hz

On: 145 W (DAV-DX150)

On: 160 W (DAV-DX170/DX250)

Standby: 0.3 W (at the

Power Saving Mode)

Dimensions (approx.)

430 × 88 × 415 mm

1

/2 × 16 3/8 inches)

(17 × 3

(w/h/d) incl. pr ojecting

parts

Mass (approx.)

4.9 kg (10 lb 13 oz) (DAV-DX150)

5.0 kg (11 lb 1 oz) (DAV-DX170/DX250)

Design and specifications are subject to change

without notice.

2

HCD-DX150/DX170/DX250

r

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

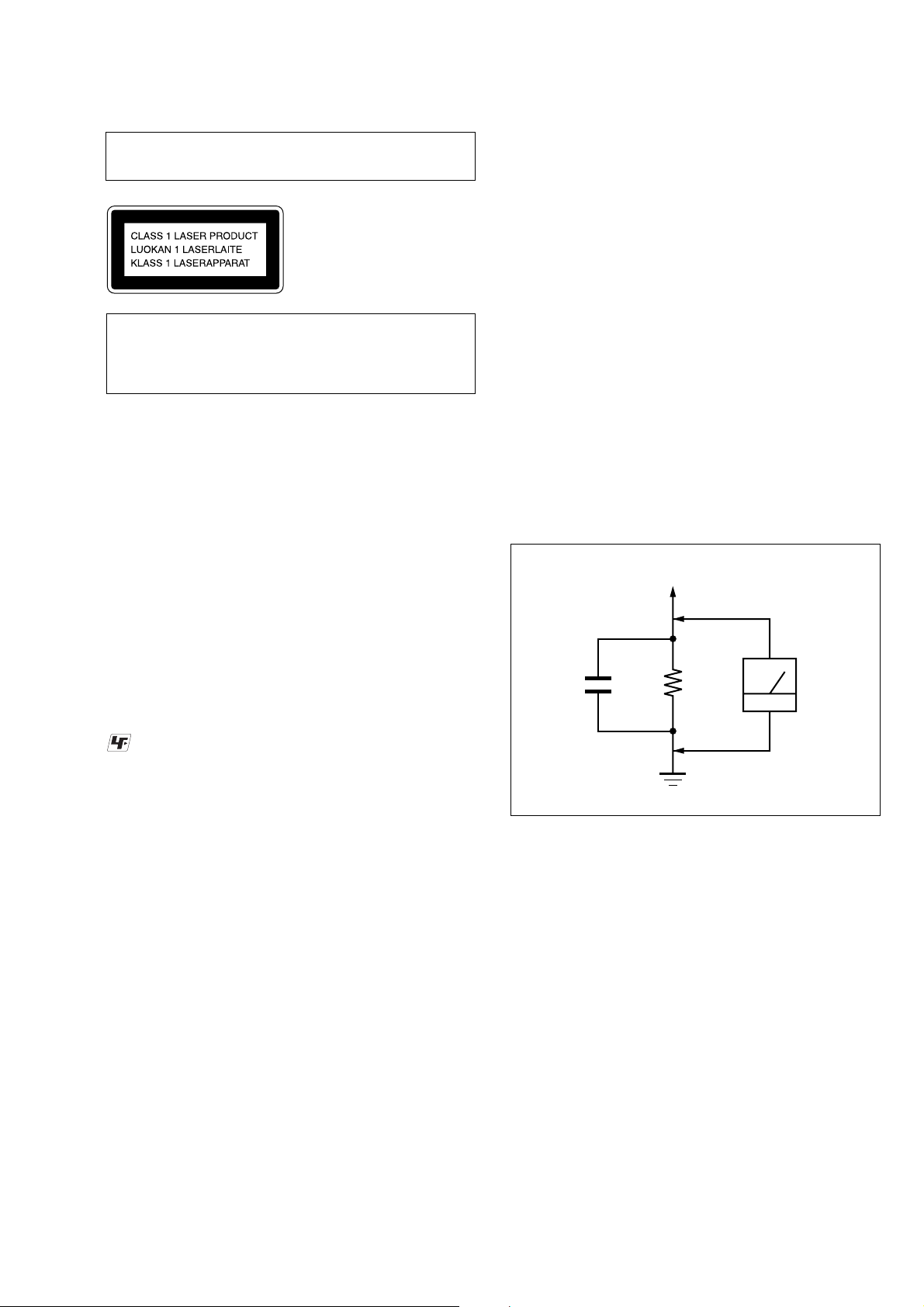

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the manuf acturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter . The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate lo w-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

AC

0.15 µF

1.5 k

Ω

Earth Ground

voltmete

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COM- POSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU D ANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

3

HCD-DX150/DX170/DX250

Ver. 1.2

TABLE OF CONTENTS

1. SERVICING NOTE ................................................... 5

2. GENERAL ................................................................... 8

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 10

3-2. Case, Front Panel Assy .................................................... 11

3-3. FL Board, H/P Board....................................................... 12

3-4. STBY Board, LED Board, KEY Board .......................... 12

3-5. IO Board, DC Fan ........................................................... 13

3-6. DMB10 Board ................................................................. 13

3-7. MAIN Board.................................................................... 14

3-8. MD COVER .................................................................... 14

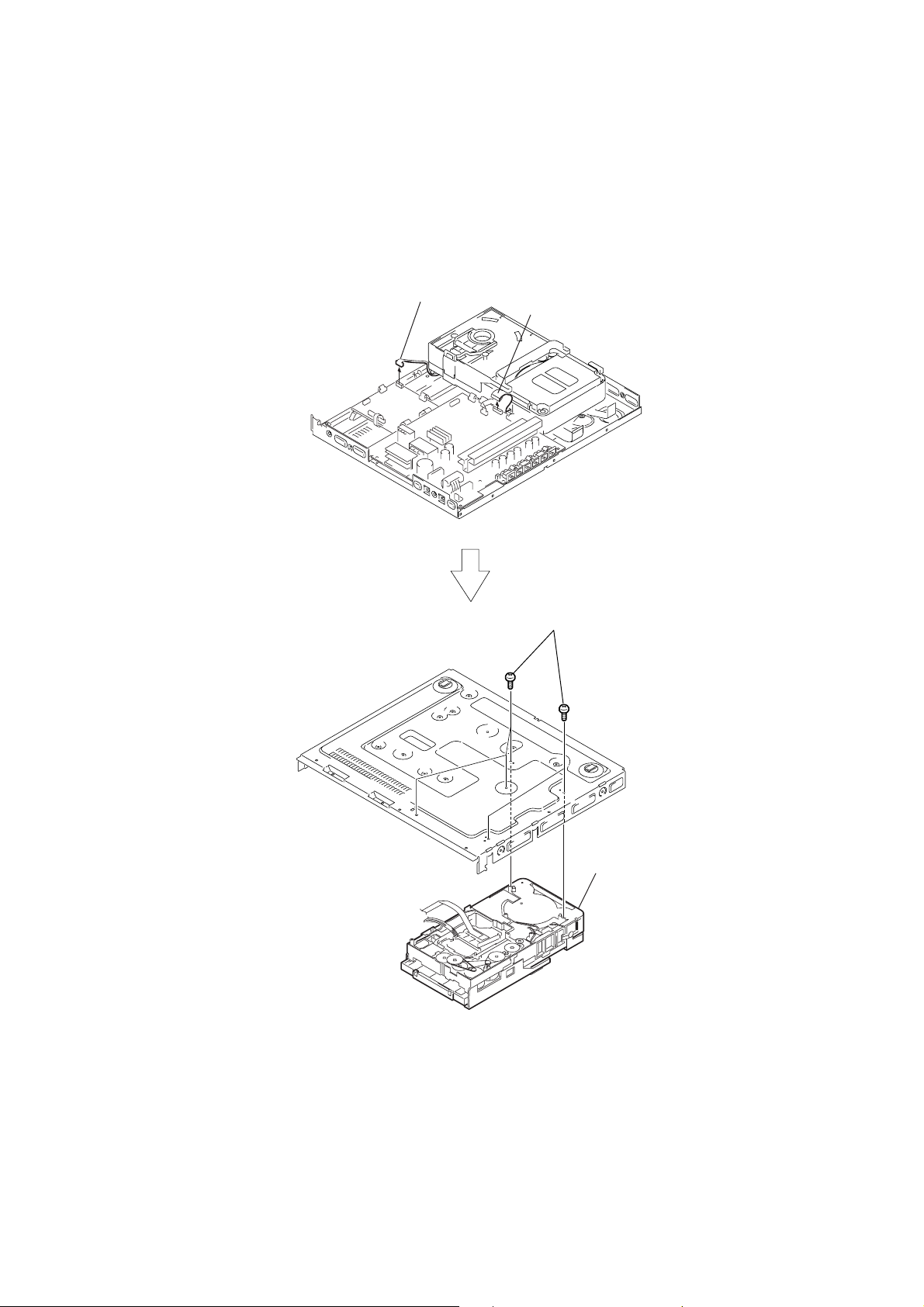

3-9. DVD Mechanism Deck (CDM81C-DVBU101) ............. 15

3-10. Tray.................................................................................. 16

3-11. MOTOR Board, M761 (LD/ST MOTOR),

M762 (BU U/D MOTOR) ............................................... 16

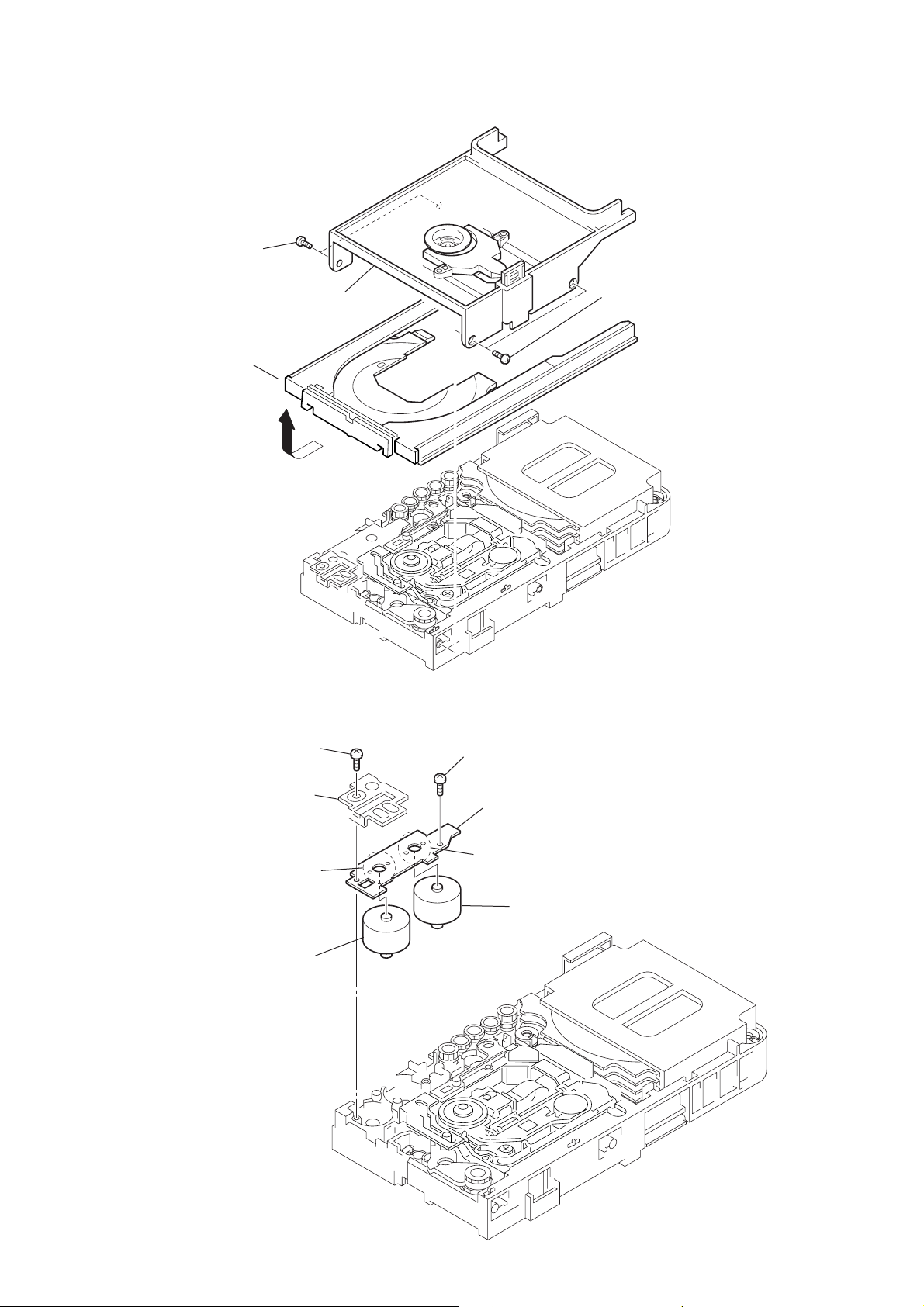

3-12. Base Unit (DVBU101) .................................................... 17

3-13. Optical Pick-up (KHM-310CAB/C2NP) ........................ 17

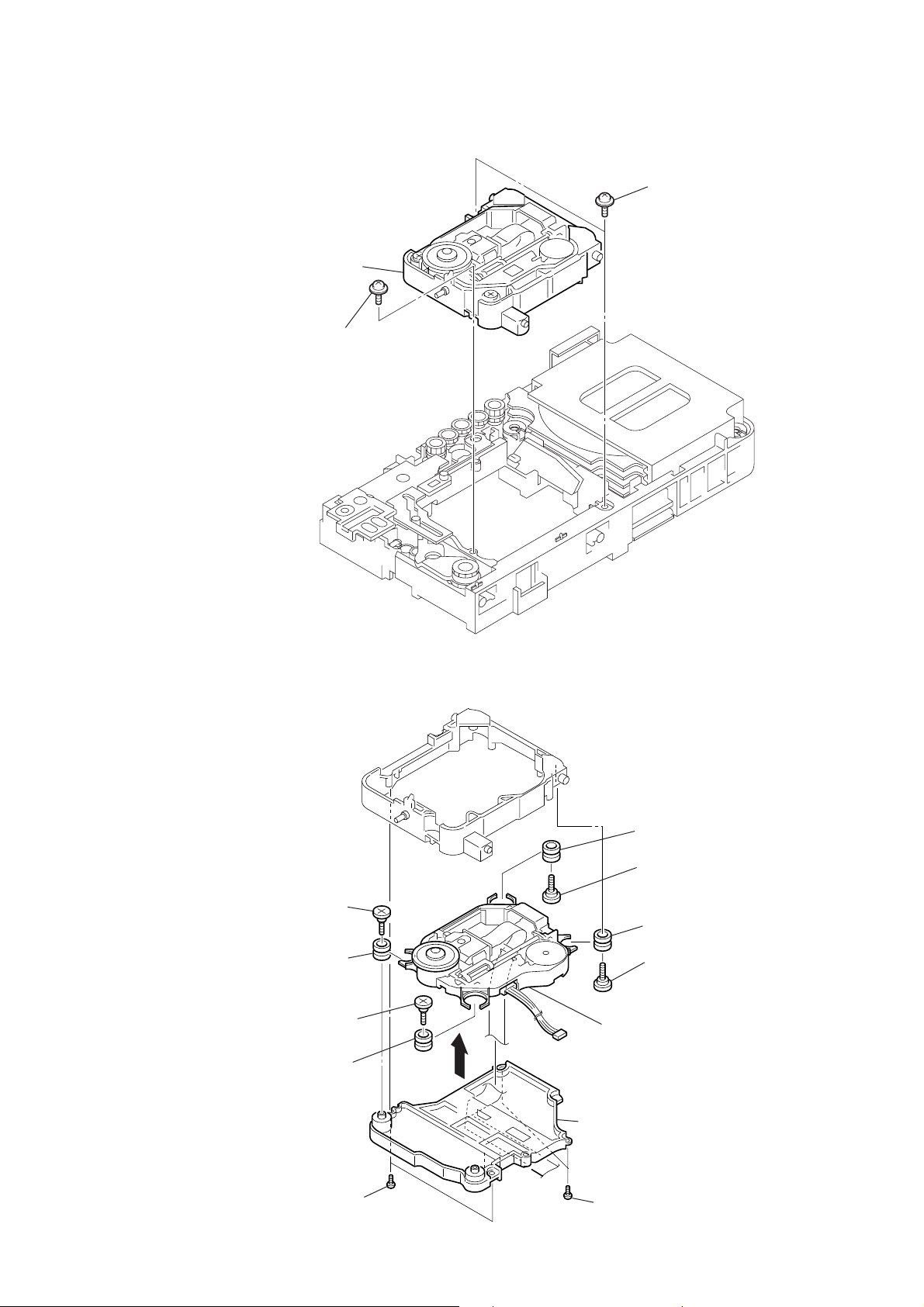

3-14. Gear (Sub Tray 1), Gear (Sub Tray 2) ............................. 18

3-15. Lever Assy ....................................................................... 18

3-16. Stocker Section ................................................................ 19

3-17. Cam (Stocker).................................................................. 19

3-18. Gear (Stocker 3) .............................................................. 20

3-19. Rotary Encoder (MD)...................................................... 20

3-20. Gear (BU1) ...................................................................... 21

4. TEST MODE ............................................................... 22

5. DIAGRAMS

5-1. Block Diagram – RF/SERVO Section –......................... 28

– VIDEO Section –.......................................................... 29

– AMP Section –.............................................................. 30

– AUDIO Section –.......................................................... 31

– POWER Section – ........................................................ 32

5-2. Printed Wiring Board – DVD Mechanism Section – ...... 33

5-3. Schematic Diagram – DVD Mechanism Section – ........ 34

5-4. Printed Wiring Board – DMB10 Section (Side A) – ...... 35

5-5. Printed Wiring Board – DMB10 Section (Side B) – ...... 36

5-6. Schematic Diagram – DMB10 Section (1/4) – .............. 37

5-7. Schematic Diagram – DMB10 Section (2/4) – .............. 38

5-8. Schematic Diagram – DMB10 Section (3/4) – .............. 39

5-9. Schematic Diagram – DMB10 Section (4/4) – .............. 40

5-10. Printed Wiring Board – MAIN Section (Side A) – ......... 41

5-11. Printed Wiring Board – MAIN Section (Side B) – ......... 42

5-12. Schematic Diagram – MAIN Section (1/7) – ................. 43

5-13. Schematic Diagram – MAIN Section (2/7) – ................. 44

5-14. Schematic Diagram – MAIN Section (3/7) – ................. 45

5-15. Schematic Diagram – MAIN Section (4/7) – ................. 46

5-16. Schematic Diagram – MAIN Section (5/7) – ................. 47

5-17. Schematic Diagram – MAIN Section (6/7) – ................. 48

5-18. Schematic Diagram – MAIN Section (7/7) – ................. 49

5-19. Printed Wiring Board – PANEL Section – ...................... 50

5-20. Schematic Diagram – PANEL Section –........................ 51

5-21. Printed Wiring Board – IO Section – .............................. 52

5-22. Schematic Diagram – IO Section – ................................ 53

6. EXPLODED VIEWS

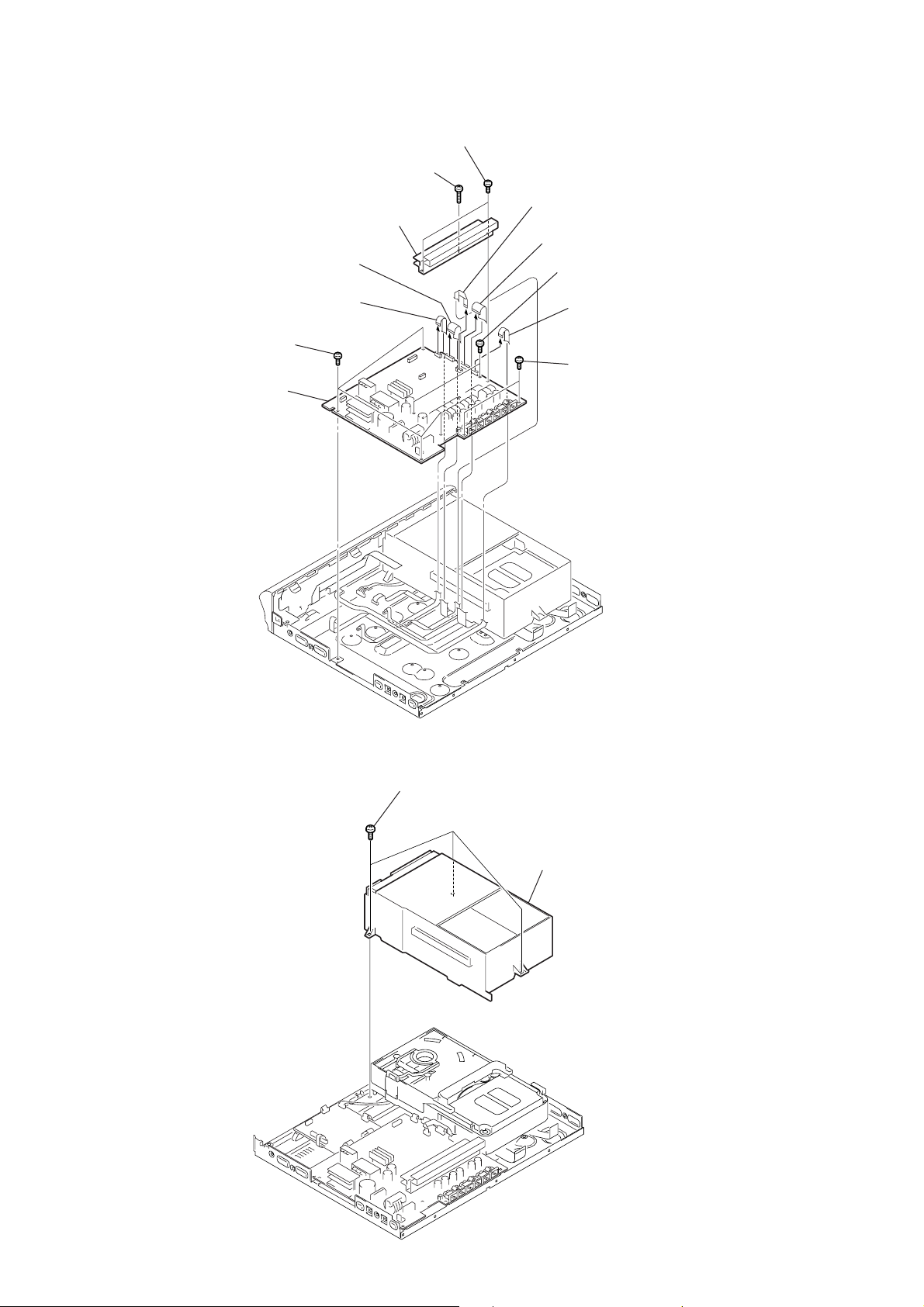

6-1. Overall Section ................................................................ 66

6-2. Front Panel Section ......................................................... 67

6-3. Chassis Section................................................................ 68

6-4. DVD Mechanism Deck Section-1

(CDM81C-DVBU101) .................................................... 69

6-5. DVD Mechanism Deck Section-2

(CDM81C-DVBU101) .................................................... 70

6-6. DVD Mechanism Deck Section-3

(CDM81C-DVBU101) .................................................... 71

6-7. Base Unit (DVBU101) .................................................... 72

7. ELECTRICAL PARTS LIST .................................. 73

4

SECTION 1

SERVICING NOTE

HCD-DX150/DX170/DX250

Ver. 1.2

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output several times.

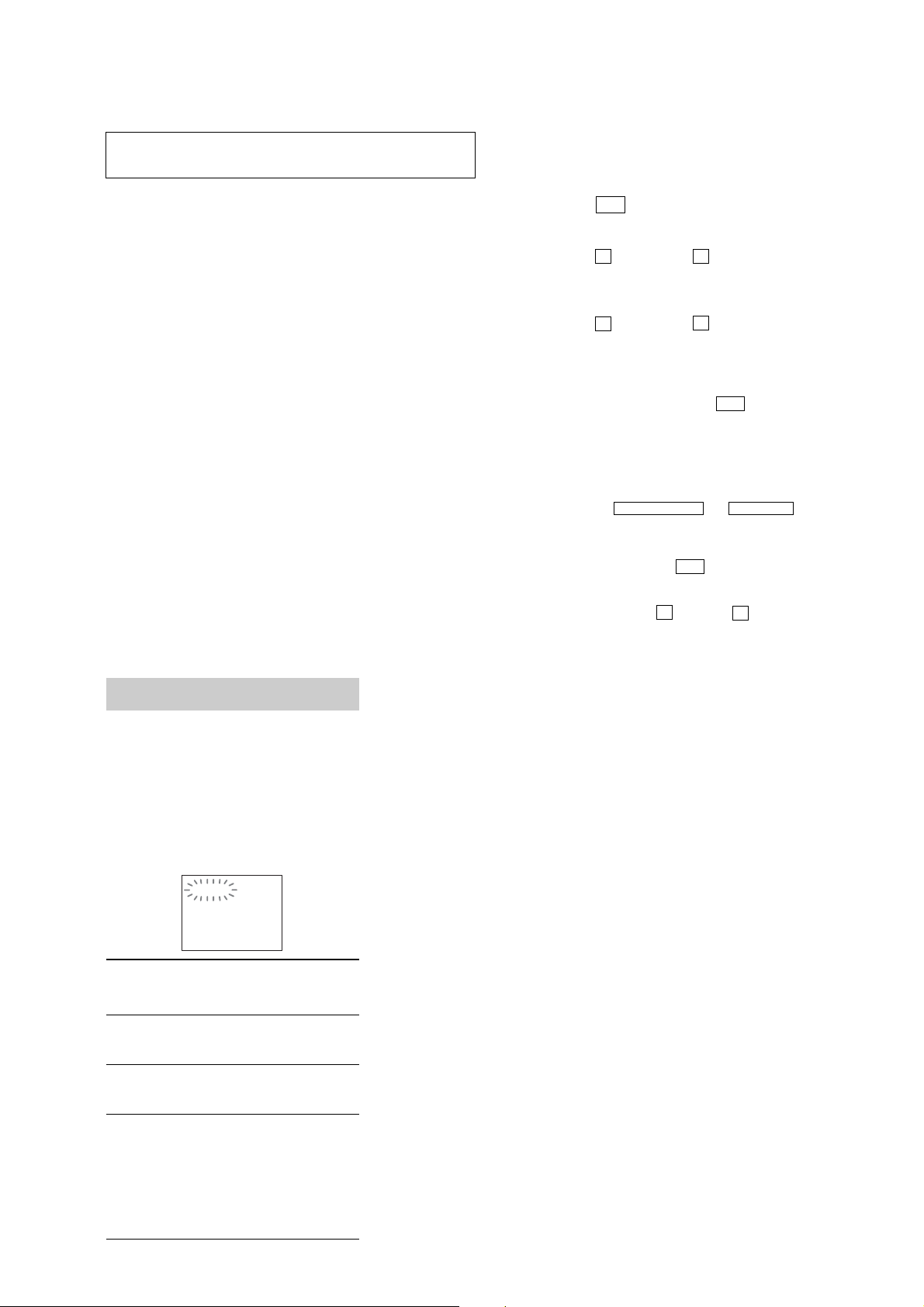

Self-diagnosis Function

(When letters/numbers appear in the

display)

When the s elf-diagnosis function is activated to

prevent the system from malfunctioning, a 5character service number (e.g., C 13 50) with a

combination of a letter and 4 digits appears on

the screen and the front pa nel display. In this

case, check the following table.

DISC SLOT LOCK

The disc slot lock function for the antitheft of an demonstration

disc in the store is equipped.

Setting Procedure :

1. Press the ?/1 button to turn the set on.

2. Press the [FUNCTION] button to set DVD function.

3. Insert a disc.

4. Press the

x stick and the A button simultaneously for five

seconds.

5. The message “LOCKED” is displayed and the slot is locked.

Releasing Procedure :

1. Press the x stick and the A button simultaneously for five

seconds again.

2. The message “UNLOCKED” is displayed and the slot is

unlocked.

Note: When “LOCKED” is displayed, the slot lock is not released by

Note 1: Regarding the notification symbol “R”

Note 2: Incorrect operations may be performed if the test mode ia not

Note 3: If the disc tray does not open and the message “LOCKED”

turning power on/off with the ?/1 button.

Because the number of the operating buttons of this product

are limited, some operations require use of the operating

buttons of the remote commander, When a specific operation

requires use of the operating buttons of the remote commander,

“R” is added to the specific operating procedure in this manual.

Example MENU/NO “R” The MENU/NO button of remote

commander.

entered properly.

In this case, press the ?/1 button to turn the power off, and

retry to enter the test mode.

appears, press the x tick and the A button simultaneously for

5 seconds or longer.

Then remove your fingers from the above stick and the button.

The message “UNLOCKED” appears for 2 seconds and the disc

tray opens.

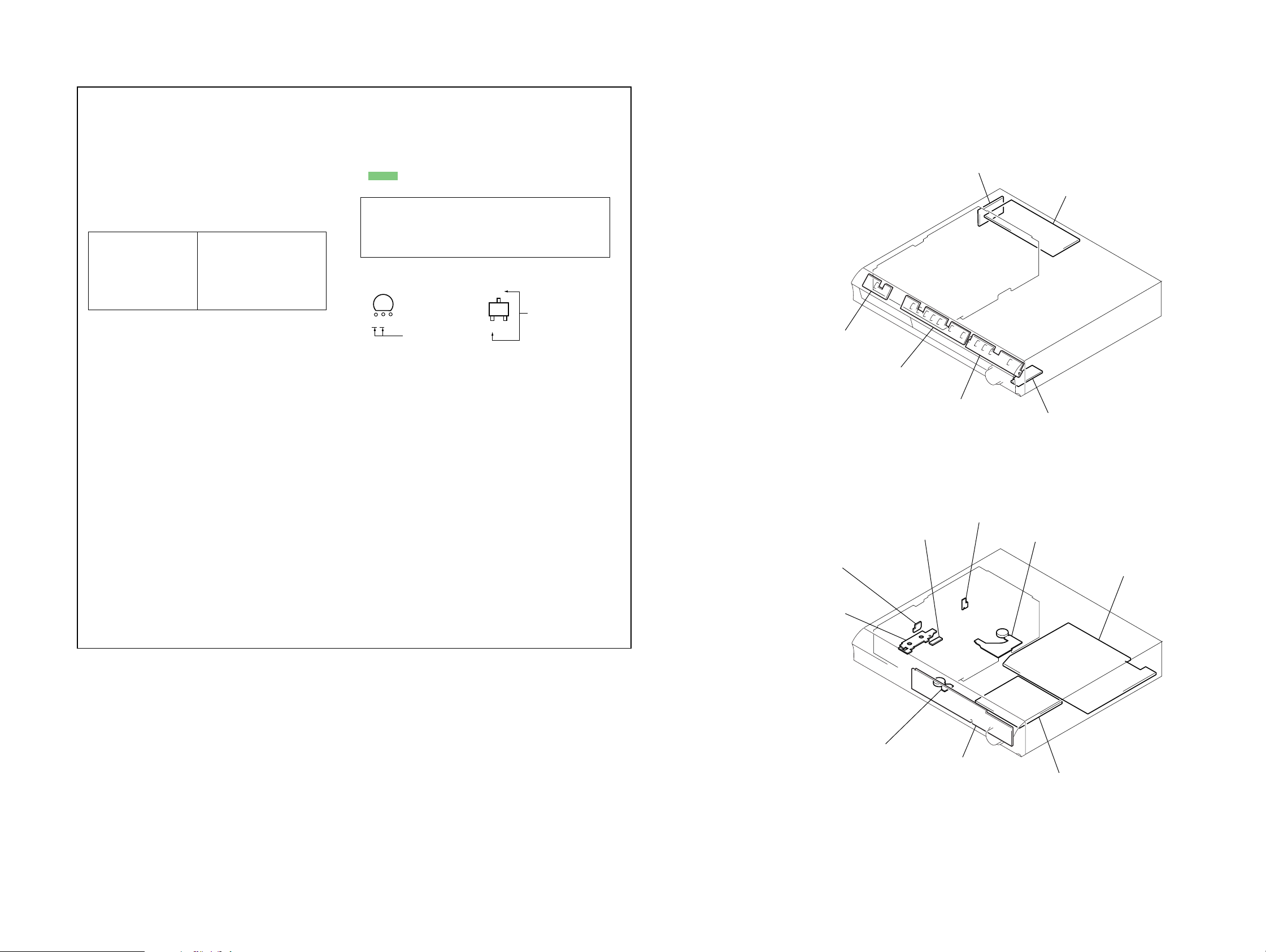

Note on DMB10 board or DMB11 board replacement

New part of EEP ROM (IC103) on the DMB10 board or DMB11

board cannot be used. Therefore, if the mounted DMB10 board

(A-1088-070-A, etc.) is replaced, exchange new EEP R OM (IC103)

with that used before the replacement.

C:13:50

First 3

characters of

the service

number

C 13 The disc is dirty.

C 31 The disc is not inserted correctly.

E XX

(xx is a number)

Cause and/or corrective action

,Clean the disc with a soft cloth

(page 80).

,Restart the system, then re-insert

the disc correctly.

To prevent a malfunction, the

system has performed the selfdiagnosis function.

,Contact your nearest Sony

dealer or local authorized Sony

service facility and giv e the 5character service number.

Example: E 61 10

5

HCD-DX150/DX170/DX250

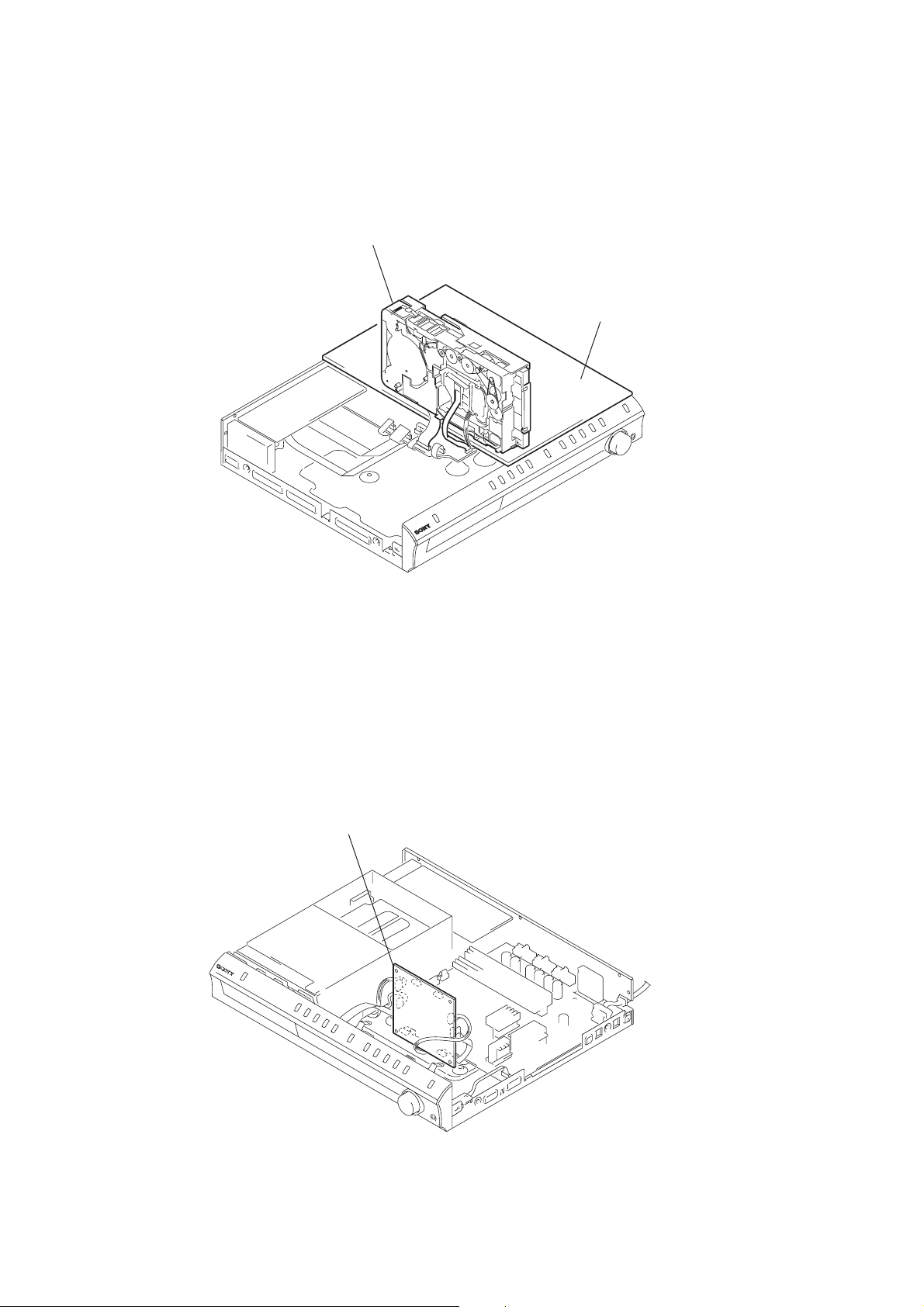

• SERVICE POSITION-1 (DVD MECHANISM DECK)

DVD MECHANISM DECK

Insulation seat

• SERVICE POSITION-2 (DMB10 BOARD)

DMB10 board

6

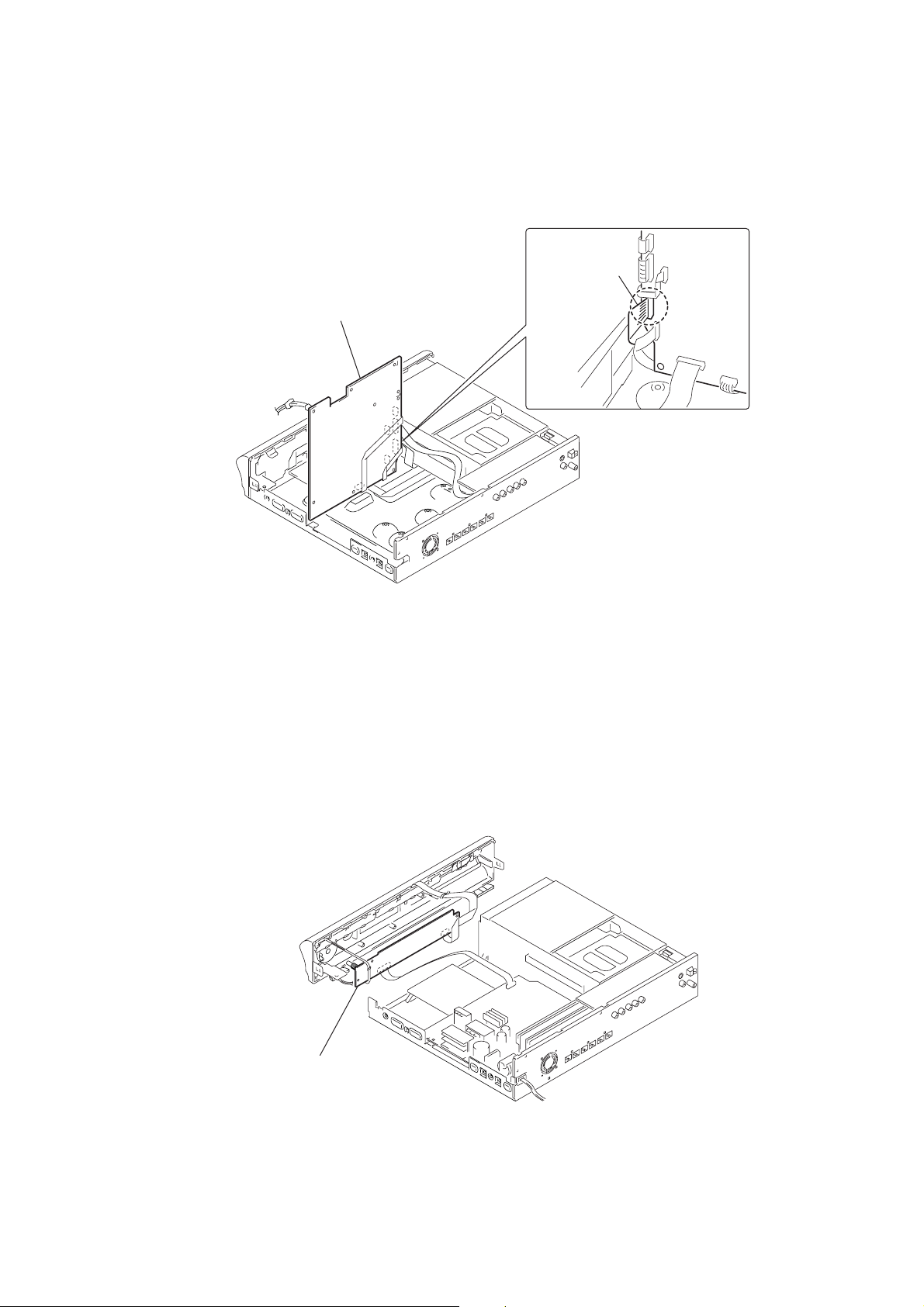

• SERVICE POSITION-3 (MAIN BOARD)

MAIN board

HCD-DX150/DX170/DX250

Extension cable

(J-2501-244-A 21p)

• SERVICE POSITION-4 (FL BOARD)

FL board

7

HCD-DX150/DX170/DX250

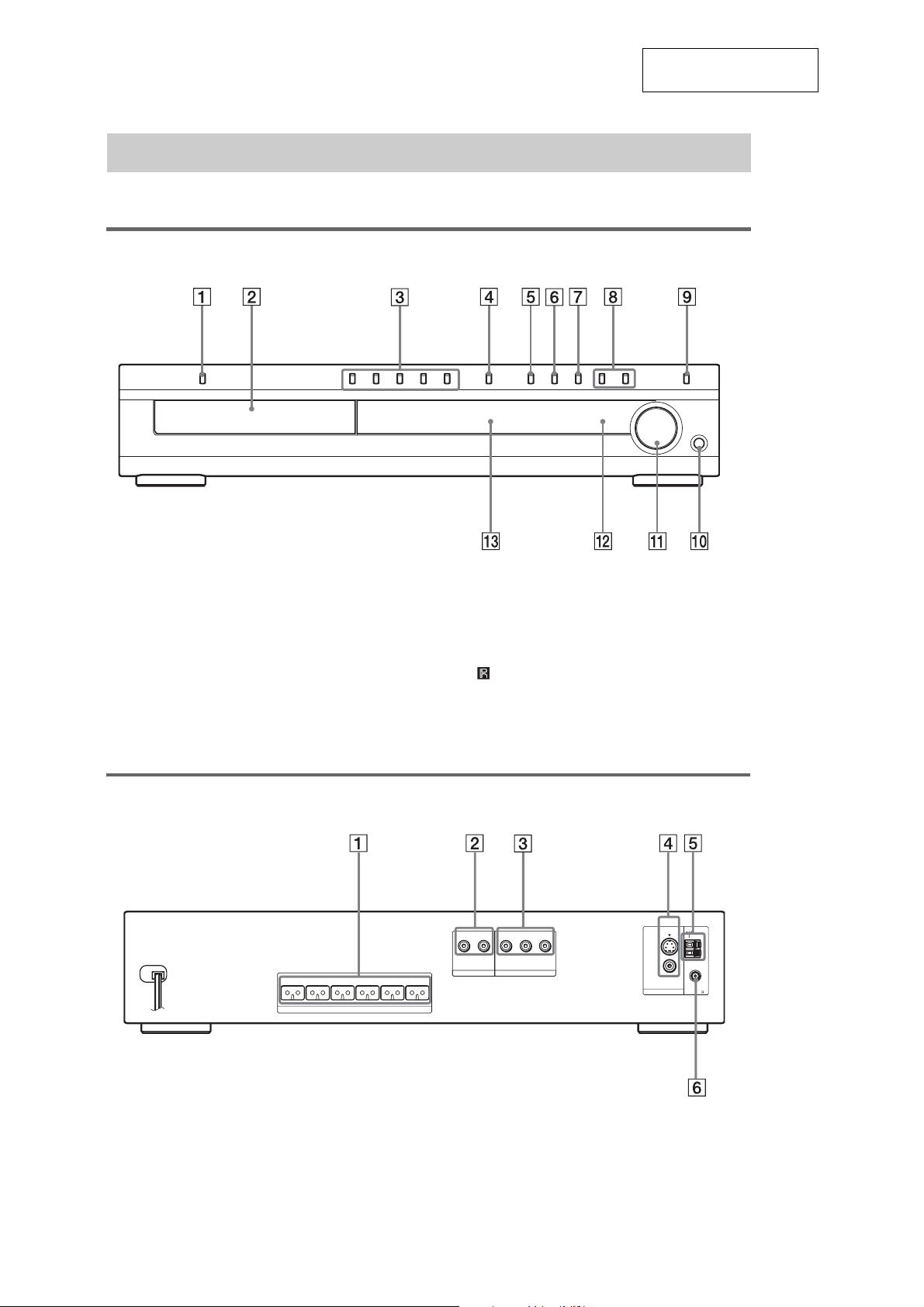

Index to Parts and Controls

For more in formation, refer to the pages in dicated in pare ntheses.

Front panel

SECTION 2

GENERAL

This section is extracted

from instruction manual.

A "/1 (on/standby) (25, 29, 70)

B Disc tray (29)

C DISC 1-5 (29)

D A (open/close) (29, 70)

E H (play) (29)

F X (pause) (30)

G x (stop) (30, 70)

Rear panel

FRONT R FRONT L SURR R SURR L CENTER WOOFER

SPEAKER

H ./> (30)

I FUNCTION (29)

J PHONES jack (29)

K VOLUME (29)

L (remote sensor) (12)

M Front panel display (91)

Y

AUDIO IN

R L

VIDEO/SAT

PB/CBPR/C

DVD ONLY

COMPONENT VIDEO OUT

R

VIDEOS(DVD ONLY)

VIDEO

MONITOR OUT

AM

COAXIAL

FM

75

A SPEAKER jacks (14)

B VIDEO/SAT AUDIO IN jacks (21, 23)

C COMPONENT VIDEO OUT jacks (19)

D MONITOR OUT (VIDEO / S VIDEO) jacks

(19)

E AM terminal (18)

F FM 75 COAXIAL jack (18)

8

HCD-DX150/DX170/DX250

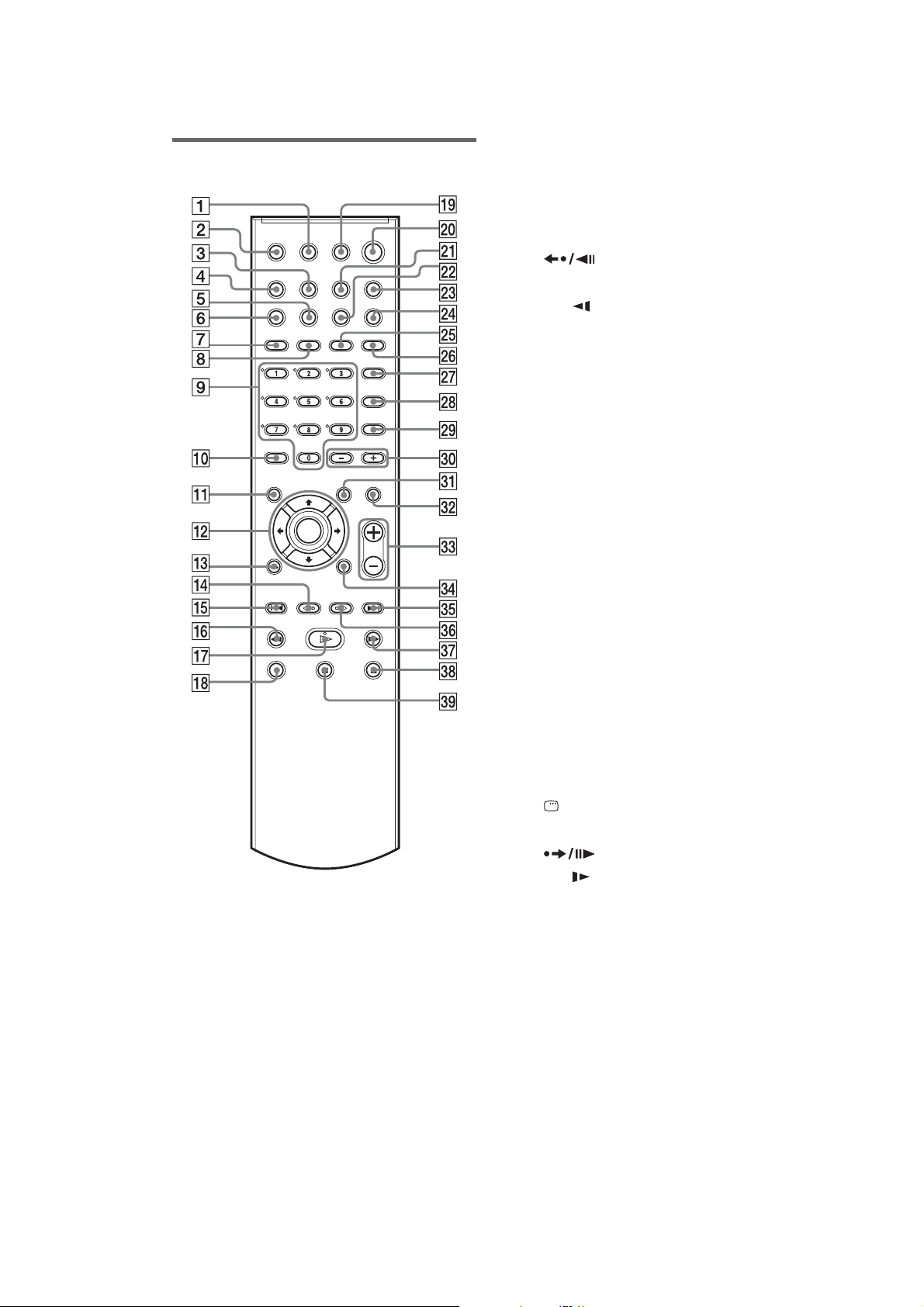

Remote

A TV [/1 (on/standby) (64)

B TV/VIDEO (64)

C TUNER MENU (67)

D SLEEP (69)

E DISC SKIP (29)

F PROGRESSIVE (20)

G REPEAT/FM MODE (33, 68)

H TUNER/BAND (68)

I Number buttons (34, 60, 64)

The number 5 button has a tactile dot.*

J CLEAR, - (26, 31, 65)

K TOP MENU (34)

L C/X/x/c/ENTER (25, 31, 55, 60, 66, 70,

71)

M O RETURN (35)

N REPLAY, STEP (30)

O . PRESET –, TV CH – (26, 30, 64, 68)

P m/ SLOW, TUNING – (45, 67)

Q H (play) (29)

The H button has a tactile dot.*

R TV (64)

S THEATRE SYNC (65)

T "/1 (on/standby) (25, 29, 68)

U AMP MENU (25, 66, 70)

V DSGX (58)

W FUNCTION (20, 29, 57, 66)

X SOUND FIELD (55)

Y DISPLAY (68)

Z PICTURE NAVI (39)

wj AUDIO (53)

wk SUBTITLE (59)

wl ANGLE (59)

e; ALBUM –/+ (30, 65)

ea MENU (34)

es MUTING (30)

ed VOLUME, TV VOL +/– (29, 64, 68)

The VOLUME, TV VOL + button has a

tactile dot.*

ef DISPLAY (9, 26, 31, 60, 71)

eg > PRESET +, TV CH + (26, 30, 64, 68)

eh ADVANCE, STEP (30)

ej M/ SLOW, TUNING + (45, 67)

ek x (stop) (30, 60, 68)

el X (pause) (30)

The X button has a tactile dot . *

*Use the tactile dot as a ref erence when operat ing the

system.

9

HCD-DX150/DX170/DX250

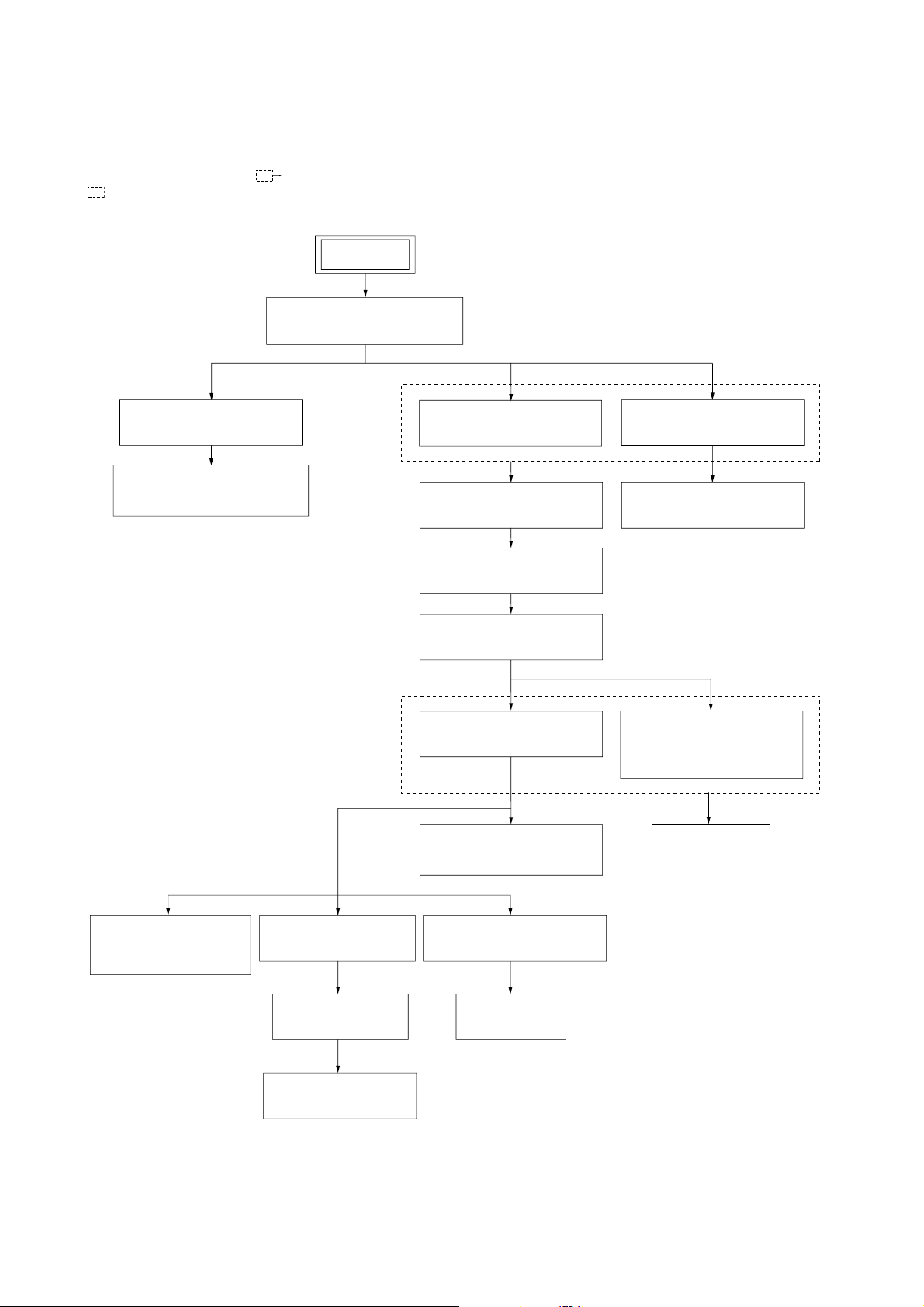

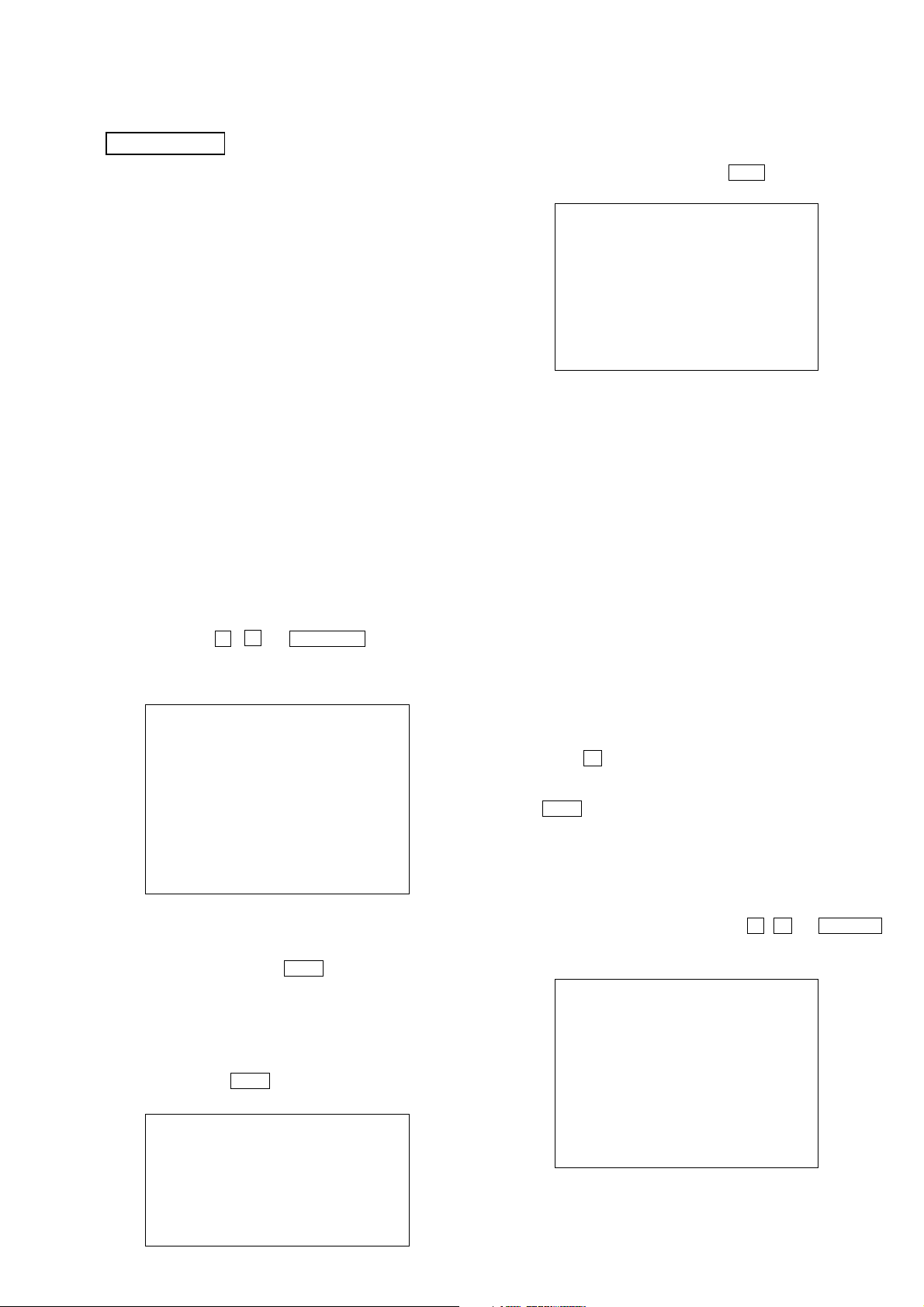

3-1. DISASSEMBLY FLOW

•This set can be disassembled in the order shown below.

•The dotted square with arrow (

) are completed.

(

) prompts you to move to the next job when all of the works within the dotted square

SECTION 3

DISASSEMBLY

SET

3-2.CASE, FRONT PANEL ASSY

3-3.FL BOARD, H/P BOARD

(Page 12)

3-4.STBY BOARD, LED BOARD,

KEY BOARD

(Page 12)

(Page 11)

3-5.IO BOARD, DC FAN

(Page 13)

3-8.MD COVER

(Page 14)

3-9.DVD MECHANISM DECK

(CDM81C-DVBU101)

(Page 15)

3-10.TRAY

(Page 16)

3-12.BASE UNIT (DVBU101)

(Page 17)

3-6.DMB10 BOARD

(Page 13)

3-7.MAIN BOARD

(Page 14)

3-11.MOTOR BOARD

M761 (LD/ST MOTOR),

M762 (BU U/D MOTOR)

(Page 16)

10

3-14.GEAR (SUB TRAY 1),

GEAR (SUB TRAY 2)

(Page 18)

3-16.STOCKER SECTION

(Page 19)

3-17.CAM (STOCKER)

(Page 19)

3-18.GEAR (STOCKER 3)

(Page 20)

3-13.OPTICAL PICK-UP

(KHM-310CAB/C2NP)

(Page 17)

3-19.ROTARY ENCODER (MD)

(Page 20)

3-20.GEAR (BU1)

(Page 21)

3-15.LEVER ASSY

(Page 18)

Note: Follow the disassembly procedure in the numerical order given.

)

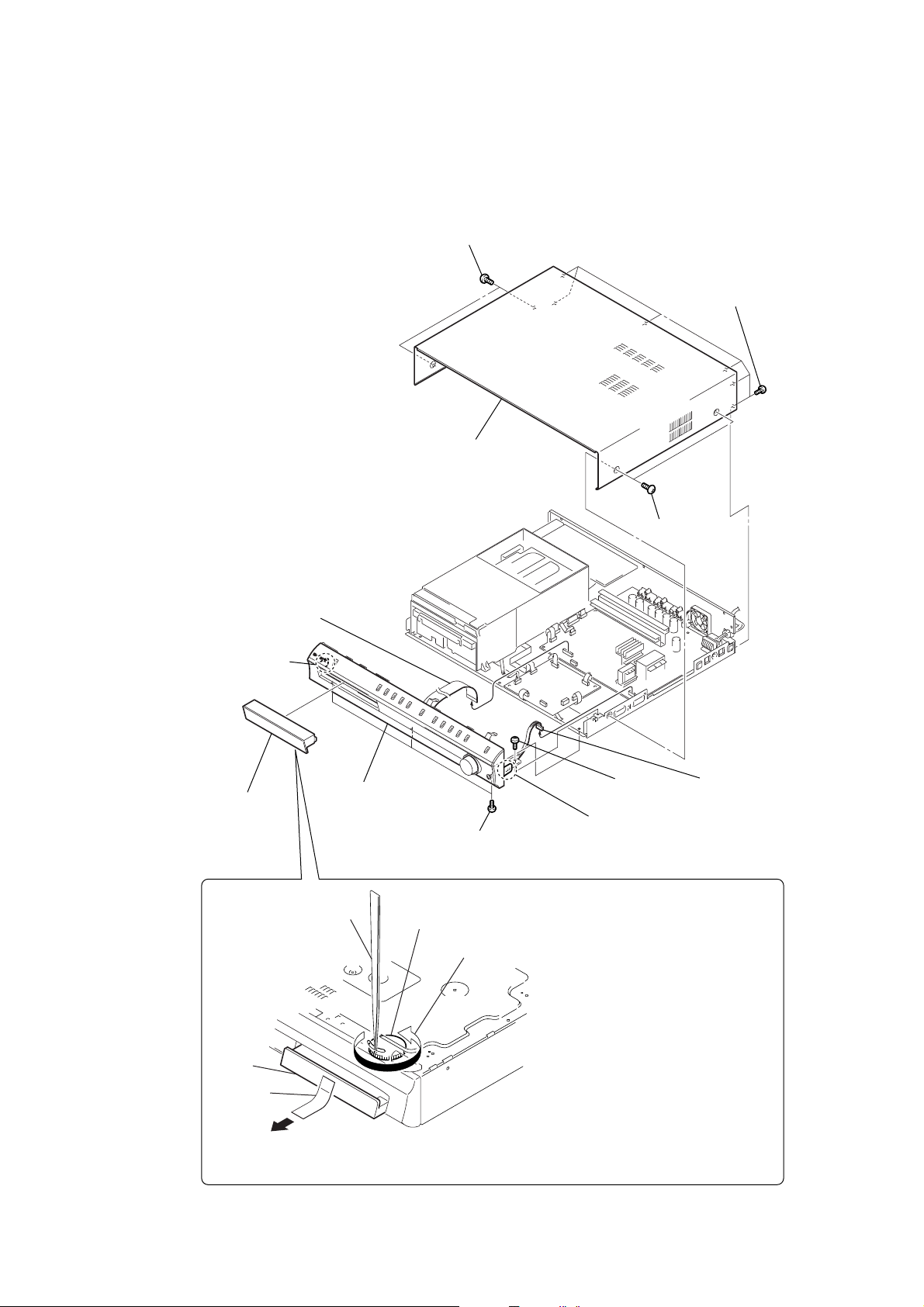

3-2. CASE, FRONT PANEL ASSY

4

two screws (CASE3 TP2)

7

case

HCD-DX150/DX170/DX250

6

six screws (+BV 3

8

19p(CN509)

qs

3

DVD lid assy

w

ire (flat type)

claw

qf

front panel assy

tweezers

qa

three screws (+BV 3)

gear

1 Insert tip of tweezers through the hole of bottom plate,

and roate the gear in the counter-clockwise direction.

0

screw (+BV 3)

qd

claw

5

two screws

(CASE3 TP2)

9

connector

(CNP903)

DVD lid

tape

2 Attach an adhesive tape on the DVD LID and draw it out.

11

HCD-DX150/DX170/DX250

t

)

)

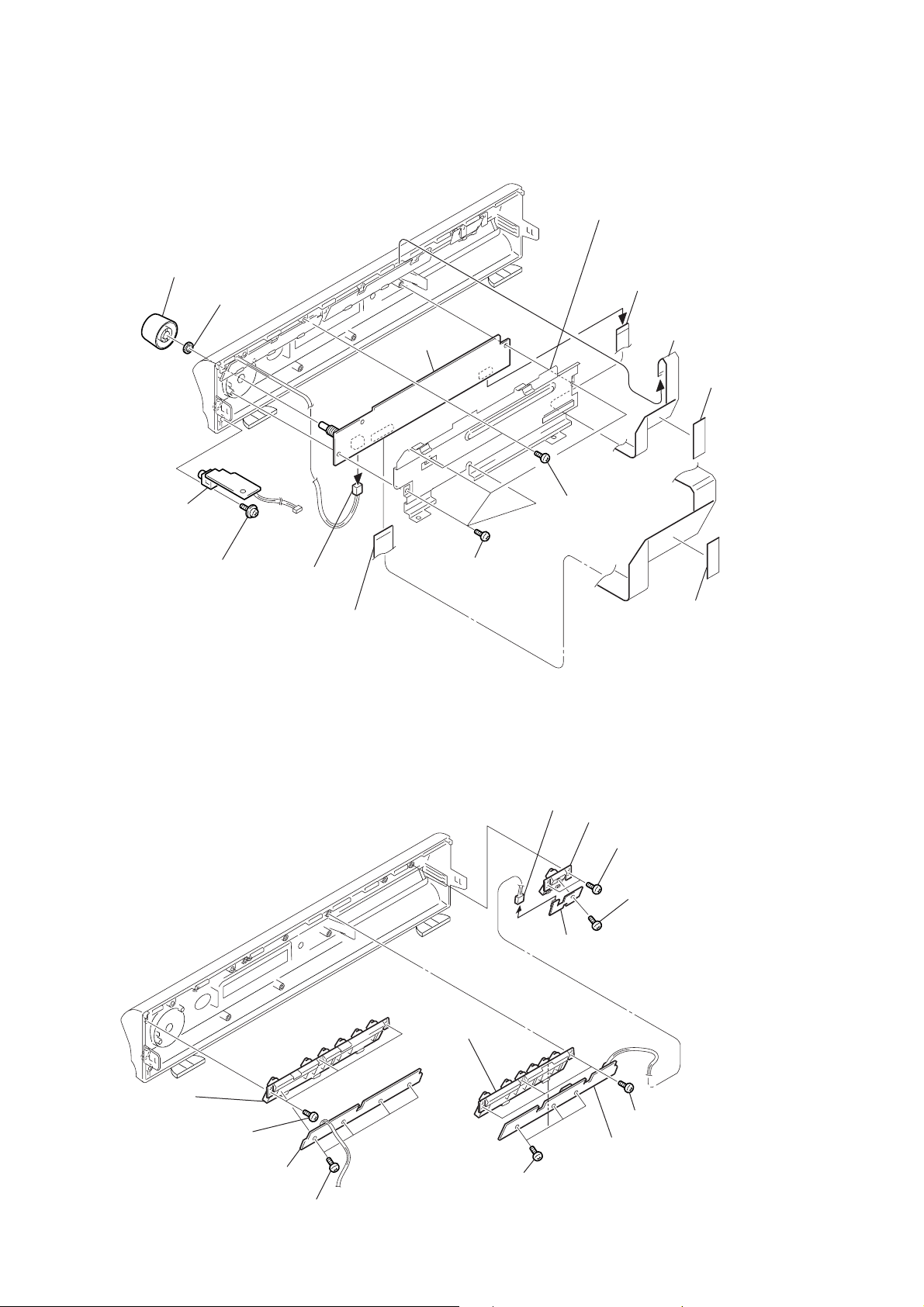

3-3. FL BOARD, H/P BOARD

3

knob (vol)

4

nut

qf

FL board

0

shield (front)

qa

wire (flat type)

9p(CN802)

9

wire (flat type

9p(CN803)

6

shee

2

H/P board

1

froating screw

(PTPWHM 2.6)

qd

connector

(CN805)

qs

19p(CN801)

wire (flat type)

3-4. STBY BOARD, LED BOARD, KEY BOARD

8

four

screws (+BV 3)

qa

(CN804)

7

two tapping screws

(+P2.6

connector

qd

qs

STBY board

×

6)

5

sheet

button (power)

9

two screws (+BV 2.6)

0

screw (+BV 2.6)

12

4

button (play)

1

three

screws (+BV 2.6)

3

KEY board

2

four

screws (+BV 2.6)

8

button (disc) assy

6

three

screws (+BV 2.6)

7

LED board

5

three screws (+BV 2.6

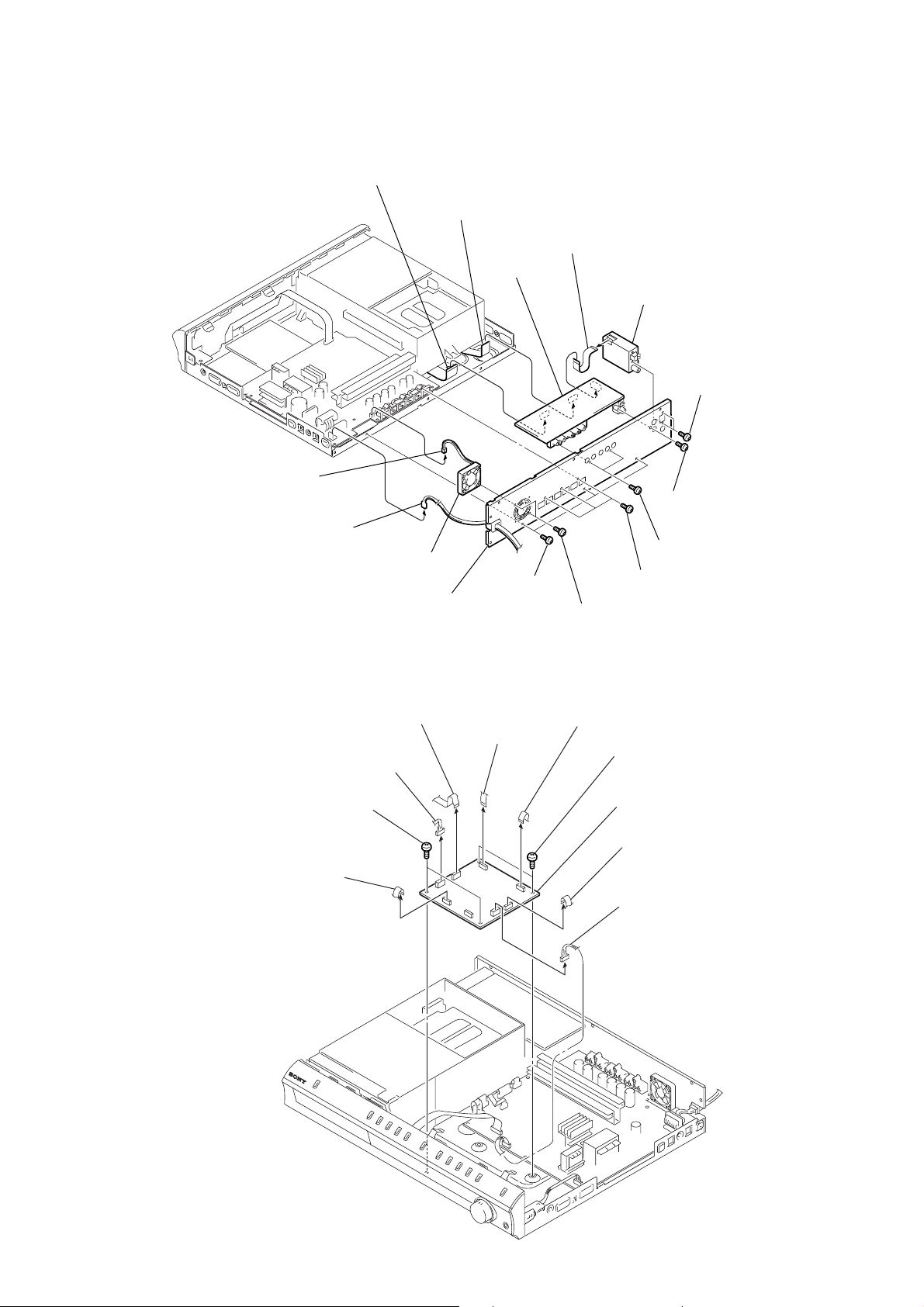

3-5. IO BOARD, DC FAN

)

)

2

connector

(CN300)

5

wire (flat type)

23p(CN601)

6

wire (flat type)

13p(CN201)

qf

IO board

0

wire (flat type)

11p(CN101)

HCD-DX150/DX170/DX250

qa

tuner

9

two screws (+BV 2.6 × 6

qs

screw (+BV 3)

3-6. DMB10 BOARD

1

connector

(CN901)

8

two screws (+BV 3)

1

wire (flat type)

13p(CN106)

3

wire (flat type)

24p(CN101)

2

connector

(CN201)

8

DC fan

back panel

3

three

(+BV 3)

4

wire (flat type)

13p(CN4802)

screws

qd

two

4

three

screws (+BV 3)

7

two screws (BVTT 4 × 8)

5

wire (flat type)

7p(CN302)

9

two screws (+BV 3

0

DMB10 board

6

wire (flat type)

11p(CN4501)

7

connector

(CN401)

screws (+BV 3)

13

HCD-DX150/DX170/DX250

)

R

3-7. MAIN BOARD

5

21p(CN508)

4

11p(CN505)

9

four screws (+BV 3)

qs

MAIN board

2

screw (BVTP 3 × 12)

3

heat sink (AMP)

wire (flat type)

wire (flat type)

1

two screws (+BV 3)

6

wire (flat type)

7p(CN503)

7

wire (flat type)

23p(CN507)

0

two screws (+BV 3)

8

11p(CN504)

qa

wire (flat type)

two screws (+BV 3

3-8. MD COVER

1

t

hree screws (+BV 3)

2

MD COVE

14

3-9. DVD MECHANISM DECK (CDM81C-DVBU101)

k

1

connector

(CN201)

2

w

ire (flat type)

21p(CN508)

HCD-DX150/DX170/DX250

3

five

screws (+BV 3)

4

DVD mechanism dec

(CDM81C-DVBU101)

15

HCD-DX150/DX170/DX250

3-10. TRAY

2

two

screws

×

5

8)

tray

4

(+BTP 2.6

3

bracket

1

two

screws

(+BTP 2.6

×

8)

3-11. MOTOR BOARD, M761 (LD/ST MOTOR), M762 (BU U/D MOTOR)

1

screw

(+BTP 2.6

7

Remove soldering from the two points.

8

M762 (BU U/D MOTOR)

2

bracket

×

8)

3

screw

(+BTP 2.6 × 8)

4

MOTOR board

5

Remove soldering from the two points.

6

M761 (LD/ST MOTOR)

16

3-12. BASE UNIT (DVBU101)

s

w

3

base unit (DVBU101)

2

floating

(+PTPWH2.6)

screw

HCD-DX150/DX170/DX250

1

two floating

(+PTPWH2.6)

screw

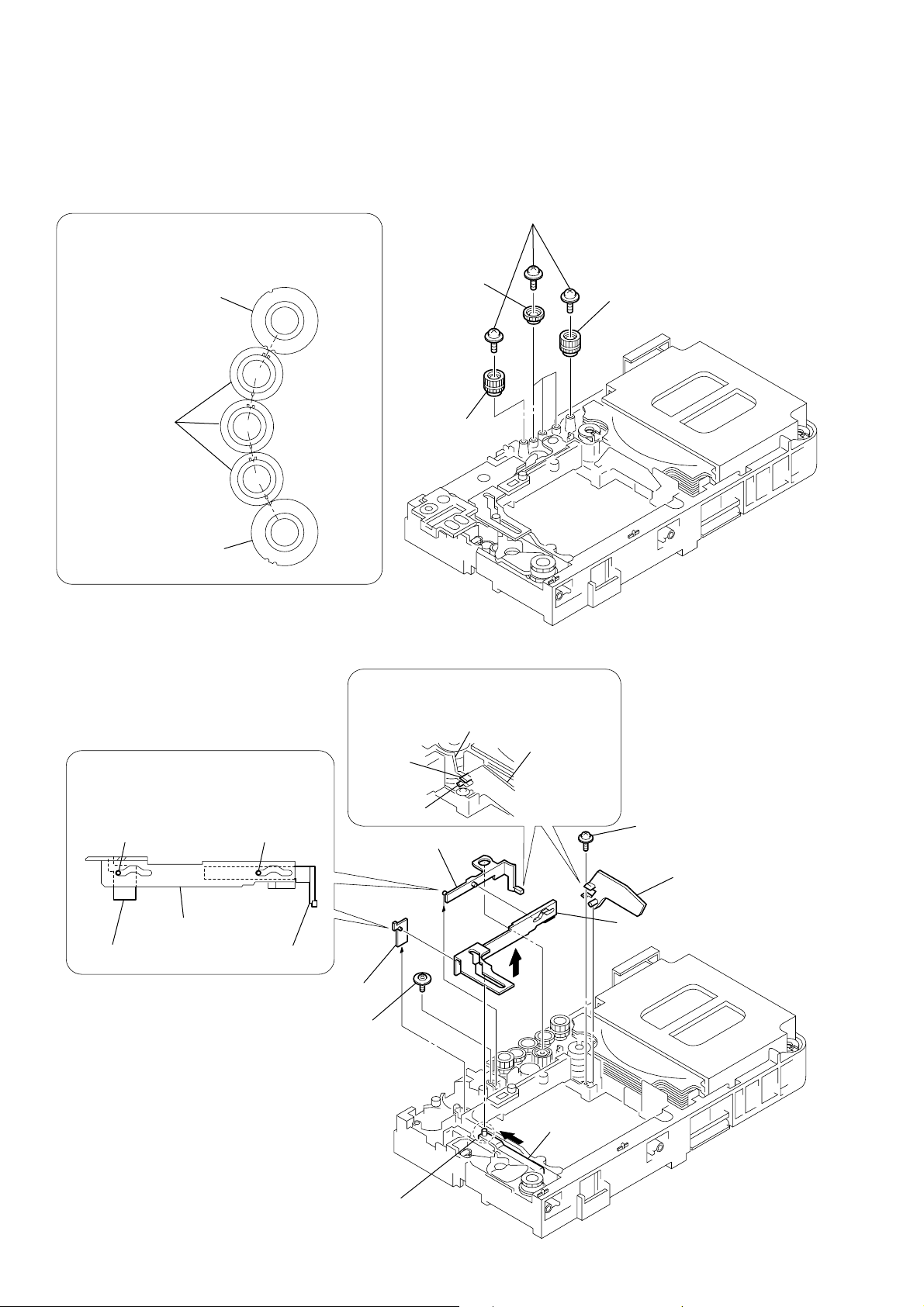

3-13. OPTICAL PICK-UP (KHM-310CAB/C2NP)

3

insulator

4

9

insulator

insulator

0

insulator

screw

screw

5

qa

insulator

6

7

insulator

qs

8

qd

optical pick-up

(KHM-310CAB/C2NP)

holder (310) assy

insulator

insulator

screw

scre

2

two

screws

(+BTP 2.6

×

8

)

1

two

screws

(+BTP 2.6

×

8

)

17

HCD-DX150/DX170/DX250

3-14. GEAR (SUB TRAY 1), GEAR (SUB TRAY 2)

PRECAUTION DURING GEAR (SUB TRAY 1/2) INSTALLATION

Align the marks of the gears as shown in the illustration.

4

(sub tray 1)

gear (sub tray 2)

gear (sub tray 1)

gear (sub tray 2)

3

1

(+PTPWH 2.6

three gears

gear (sub tray 2)

five screws

×

8)

2

gear (sub tray 2)

3-15. LEVER ASSY

Before re-assembling, align the lever (release)

and the lever (sub tray) with the lever (mode)

as shown in the illustration.

dowel dowel

lever (mode)

lever (release)

lever (sub tray)

When re-assembling, insert the lever (sub tray)

between the bosses of the shutter (tray).

5

lever (sub tray)

6

lever (release)

3

floating screw

(+PTPWH M2.6)

boss

boss

shutter (tray)

lever (sub tray)

4

1

screw

(+PTPWH 2.6 × 8)

2

shutter (tray)

7

lever (mode)

18

cam (BU)

Before re-assembling, slide the cam (BU)

in the direction of the arrow.

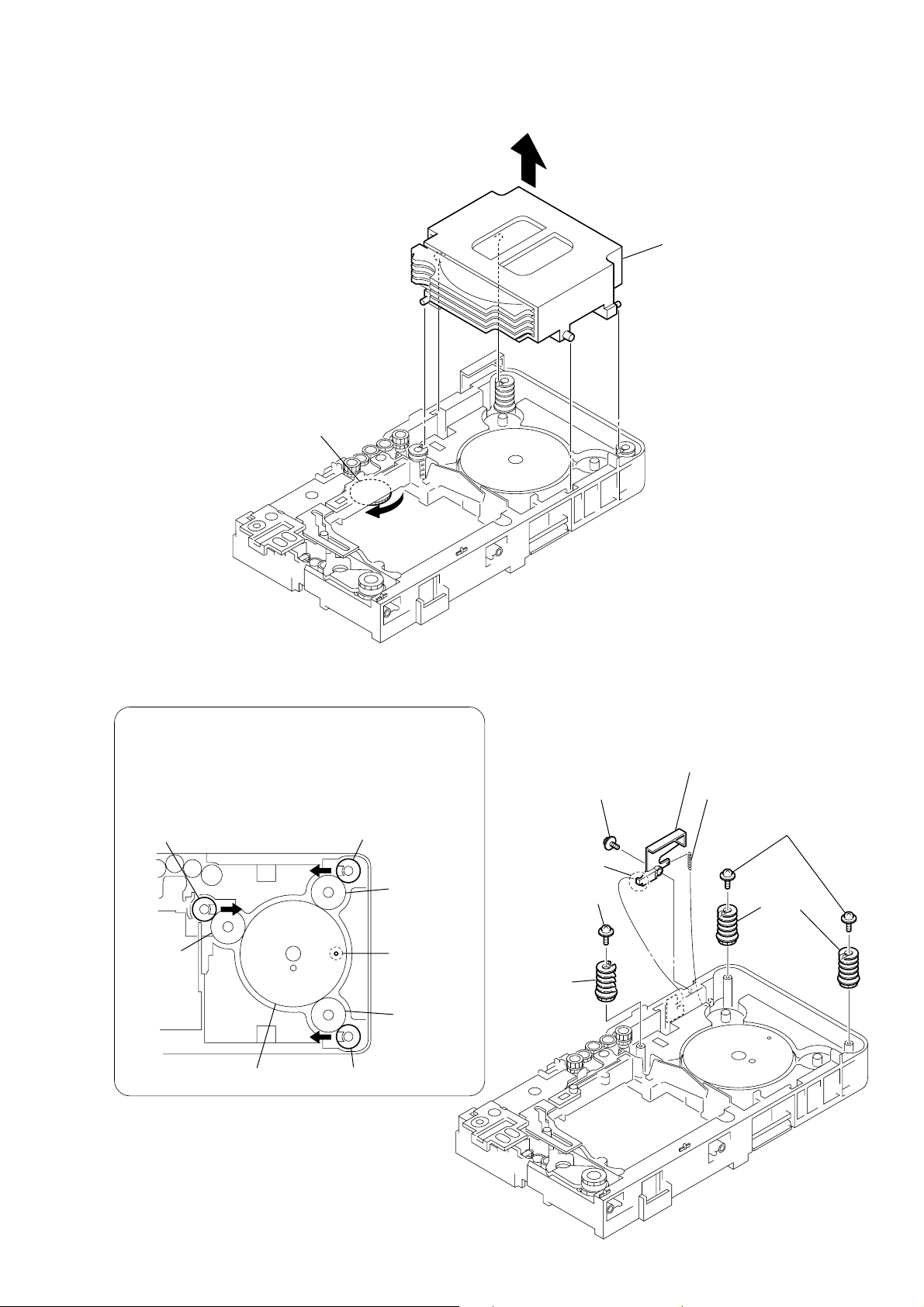

3-16. STOCKER SECTION

5

two screws

(+PTPWH 2.6 × 8)

6

two cams

(stocker)

8

cam

(stocker)

cam (stocker)

cam (stocker)

cam (stocker)

hole

gear

(stocker 2)

gear

(stocker 2)

gear

(stocker 2)

gear (stocker 3)

2

tension spring (SW)

4

lever (SW)

1

screw

(+PTPWH 2.6 × 8)

7

screw

(+PTPWH 2.6 × 8)

3

hook

PRECAUTION DURING CAM (STOCKER) INSTALLATION

Before installing the cams (stocker), fix the gear (stocker 3) in

the manner so that the hole of the gear (stocker 3) should be

aligned with the hole of the chassis located beneath

the gear (stocker 3). Be sure to install the cams (stocker) in

such a way that the grooves of the cams (stocker) face

the direction of the arrows.

1

Rotate the gear (SS3) in the

direction of the arrow.

HCD-DX150/DX170/DX250

2

stocker section

3-17. CAM (STOCKER)

19

HCD-DX150/DX170/DX250

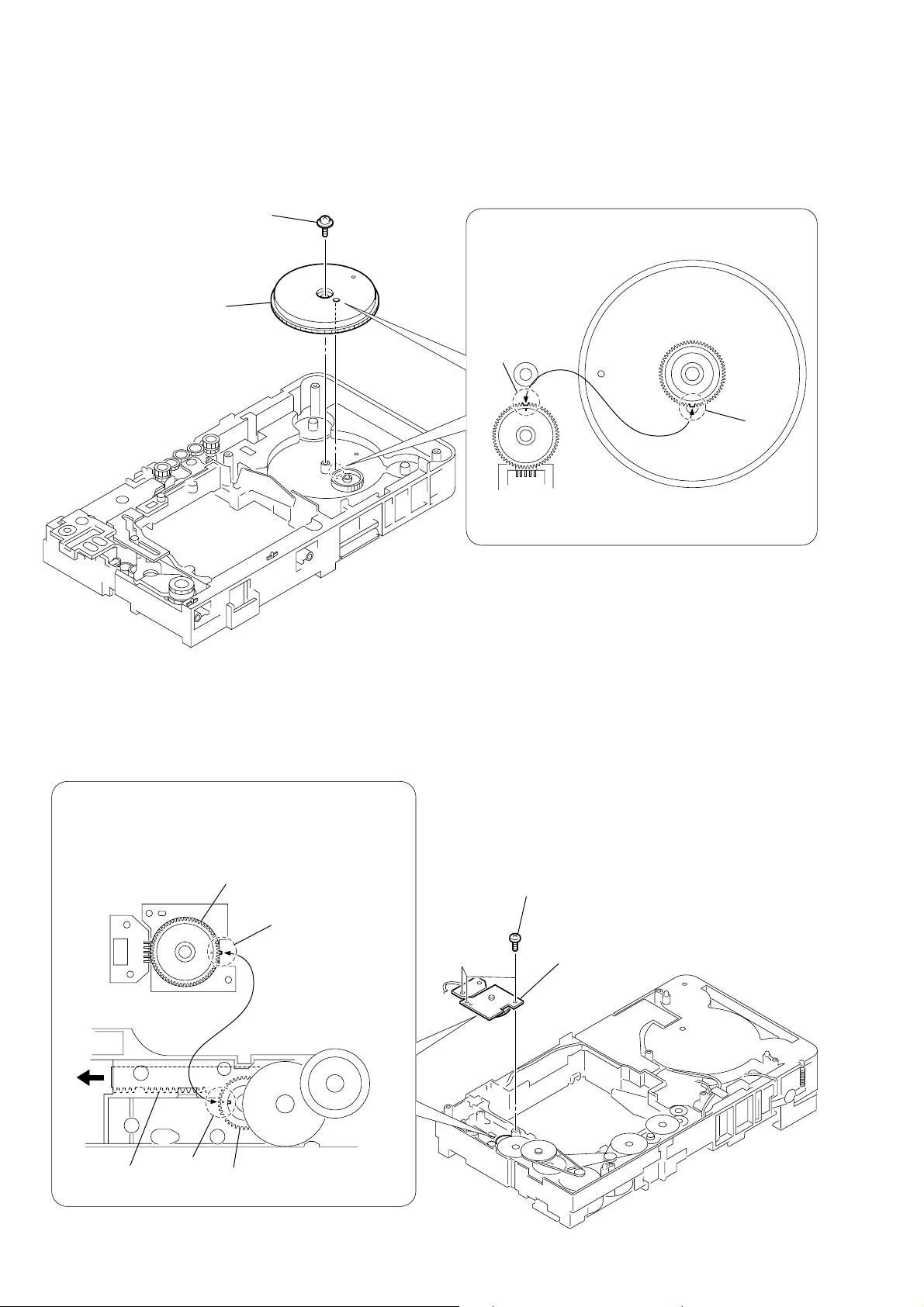

3-18. GEAR (STOCKER 3)

1

screw

(+PTPWH 2.6

2

gear (stocker 3)

PRECAUTION DURING GEAR (STOCKER 3) INSTALLATION

×

8)

Be sure to align the rib of the gear (stocker 3) with the groove

of the rotary encoder.

groove

rib

rotary encoder

(ST U/D encoder)

gear (stocker 3)

(reverse-side)

3-19. ROTARY ENCODER (MD)

PRECAUTION DURING ROTARY ENCODER (MD) INSTALLATION

Slide the cam (BU) in the direction of the arrow so that the mark

of the gear (BU1) can be seen. Engage the gears while aligning

the mark of the gear (BU1) with the protruding part of the

rotary encoder.

rotary encoder (MD)

protruding part

1

three screws

(+BTP 2.6

2

×

8)

rotary encoder (MD)

20

cam (BU)

mark

gear (BU1)

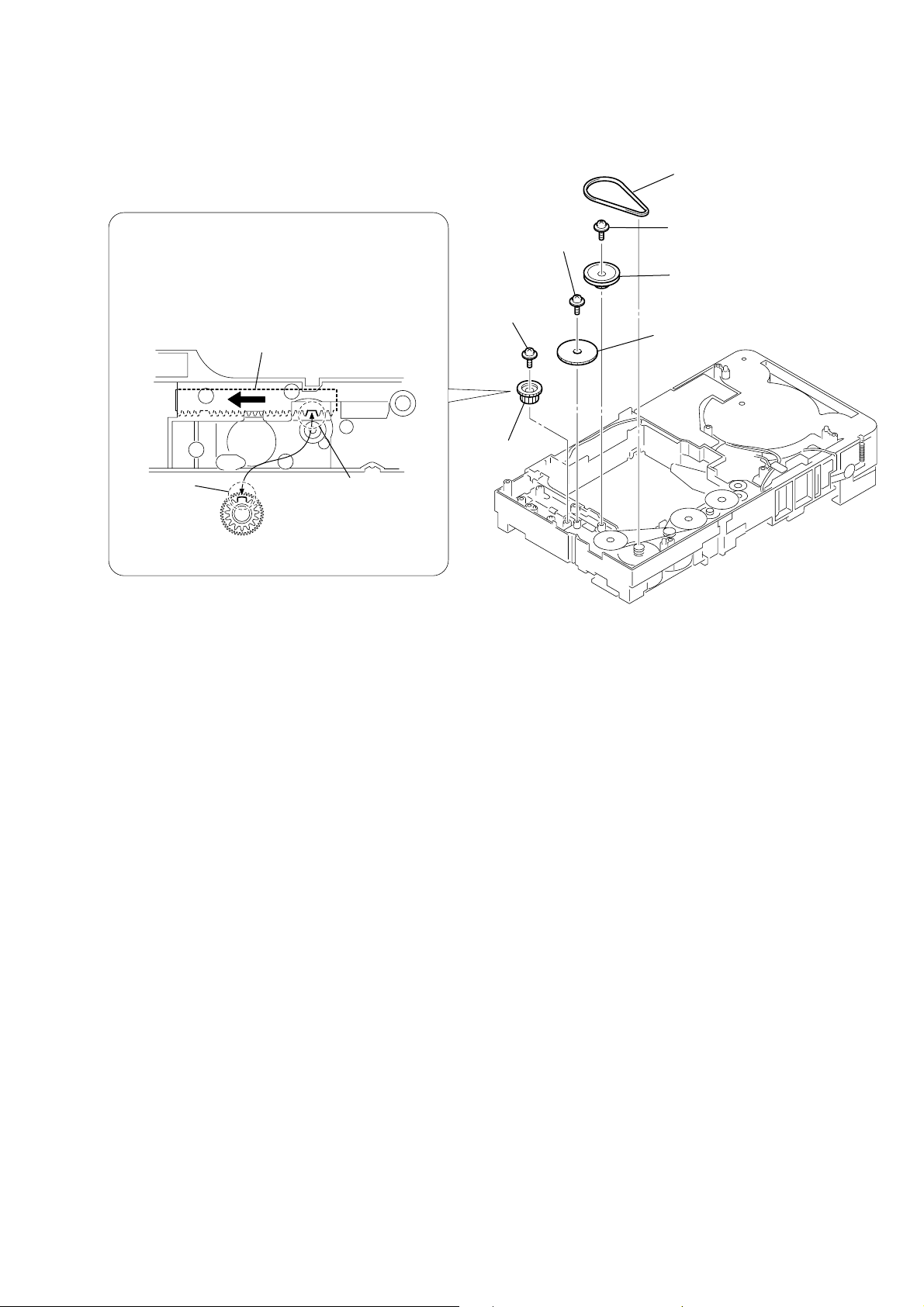

3-20. GEAR (BU1)

PRECAUTION DURING GEAR (BU1) INSTALLATION

Before re-assembling, slide the cam (BU) in the direction of

the arrow.

Assemble the gear (BU1) in such a manner that the groove

of the cam (BU) is aligned with the rib of the gear (BU1).

cam (BU)

4

screw

(+PTPWH 2.6 × 8)

6

screw

(+PTPWH 2.6

7

gear (BU1)

HCD-DX150/DX170/DX250

1

belt (sub tray)

2

screw

(+PTPWH 2.6 × 8)

3

pulley (BU)

×

8)

5

gear (BU2)

rib

groove

gear (BU1)

21

HCD-DX150/DX170/DX250

SECTION 4

TEST MODE

Note 1: Regarding the notification symbol “R”

Because the number of the operating buttons of this product

are limited, some operations require use of the operating

buttons of the remote commander, When a specific operation

requires use of the operating buttons of the remote

commander, “R” is added to the specific operating procedure

in this manual. Example MENU/NO “R” The MENU/NO

button of remote commander.

Note 2: Incorrect operations may be performed if the test mode is

not entered properly.

In this case, press the ?/1 button to turn the power off, and

retry to enter the test mode.

1. Cold Reset

• The cold reset clears all data including preset data stored in

the RAM to initial conditions. Execute this mode when

returning the set to the customers.

Procedure:

1. Press the ?/1 button to turn the power on.

2. Press three buttons x , A and ?/1 simultaneously.

3. When this button is operated, display as “COLD RESET” for

a while and all of the settings are reset.

2. Panel Test Mode

•This mode is used to check the software version, LCD, LED

and keyboard.

2-1. DVD LED Test Mode

Procedure:

1. Press the ?/1 button to turn on the power.

2. Press three bottons X , . and A simultaneously.

3. When the display LED test mode is activated, all segments

are turned on.

4. To exit from this mode, pull out the AC plug.

2-2. V ersion T est Mode

Procedure:

1. When the panal test mode is activated, press the . button

and the message “DC1***” is displayed, the version test mode

is activated.

2. Whenever press the . button, the version is displayed in

order of NA, MC, SYS, UI, DVD, CDMA, CDMB , ST005,

TA, TM and DC1.

3. Press the > button and the date of the softwafe production

is displayed.

4. Press the > button again and the version is displayed.

5. To exit from this mode, pull out the AC plug.

2-3. Key Test Mode

Procedure:

1. When the panel test mode is activated, press the H button,

to select the key test mode.

2. To enter the KEY test mode, the fluorecent indicator displays

“K0 VO”. Each time a button is pressed, “KEY” value

increases. However, once a button is pressed, it is no longer

taken into account. When all keys are pr essed correctly , “K13

VO” is displayed.

3. To exit from this mode, pull out the AC plug.

3. Disc Tray Lock

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Setting Procedure :

1. Press the ?/1 button to turn the set on.

2. Press the FUNCTION button to set DVD function.

3. Insert a disc.

4. Press the x button and the A button simultaneously for fi ve

seconds.

5. The message “LOCKED” is displayed and the tray is locked.

Releasing Procedure :

1. Press the x button and the A button simultaneously for fi ve

seconds. again.

2. The message “UNLOCKED” is displayed and the tray is

unlocked.

Note: When “LOCKED” is displayed, the slot lock is not released by

turning power on/off with the ?/1 button.

4. DVD Ship Mode

• Use this mode when returning the set to the customer after

repair.

Procedure:

1. Press the ?/1 button to turn the set on.

2. Press the FUNCTION button to set the function “DVD”.

3.

Press three buttons x

4. After a message “MECHA LOCK” is displayed on the

fluorescent indicator tube, pull out the AC plug.

5. To exit from this mode, press the ?/1 button to turn the set

on.

5. DVD Debug In Mode

Procedure:

1. Press the ?/1 button to turn the set on.

2. Press the FUNCTION button to set the function “DVD”.

3. Press the three buttons . , A and > simultaneously.

4. To exit from this mode, press the ?/1 button to turn the set

on.

6. AM Step Change

•A step of AM channels can be changed over between 9 kHz

and 10 kHz.

Procedure:

1. Press ?/1 button to turn the set ON.

2. Select the function “TUNER”, and press FUNCTION button

to select the BAND “AM”.

3. Press ?/1 button to turn the set OFF.

4. Press > and ?/1 buttons simultaneously, and the display

of fluorescent indicator tube changes to “AM 9 k STEP” or

“AM 10 k STEP”, and thus the channel step is changed over.

,

and

?/1

simultaneously.

22

HCD-DX150/DX170/DX250

Ver. 1.3

DVD SECTION

[TEST DISC LIST]

Be sure to use the DVD disc that matches the signal standards of

your region.

• CD

YEDS-18 (Part No.: 3-702-101-01)

PATD-012 (Part No.: 4-225-203-01)

• DVD SL (Single Layer)

NTSC : HLX-503 (Part No.: J-6090-069-A)

HLX-504 (Part No.: J-6090-088-A)

PAL : HLX-506 (Part No.: J-6090-077-A)

• DVD DL (Dual Layer)

NTSC : HLX-501 (Part No.: J-6090-071-A)

HLX-505 (Part No.: J-6090-089-A)

PAL : HLX-507 (Part No.: J-6090-078-A)

4-1. GENERAL DESCRIPTION

The Mirror Time and IOP measurement allows you to make

diagnosis and adjustment simply by using the remote commander

and monitor TV. The instructions, diagnosis results, etc. are given

on the on screen display (OSD).

The Mirror Time and IOP measurement is required is such events

where servicing a DVD-Player includes changing the Base Unit

(BU). For each new BU to be used with a certain MV-044 board,

Mirror Time and IOP measurement need to be carried out.

4-2. STARTING TEST MODE

Press three buttons x , A and VOLUME + simultaneously

with the DVD player in standby mode.

The Test Mode starts, then the menu shown below will be

displayed on the TV screen.

Remocon Diagnosis Menu

0. External Chip Check

1. Servo Parameter Check

2. Drive Manual Operation

3. Emergency History

4. Version Information

5. Video Level Adjustment

Model Name : DC1_XX

IF-con : V

Syscon : Ver.

The menu above is the Remocon Diagnosis Menu screen which

consists of six main function. At the bottom of the menu screen,

the model name and IF-con version. To enter Mirror Time

Adjustment menu, press button 2 “R” on the remote commander

to enter Drive Manual Operation menu. To exit from the T est Mode,

press the power button on the remote commander.

4-3. DRIVE MANUAL OPERATION

The Drive Manual Operation menu consists of five main

function. By pressing 2 “R” button on the remote commander in

the Remocon Diagnosis Menu, the screen will appear as below.

er. xx.xx (xxxx)

x.xxx

4-4. MIRROR TIME ADJUSTMENT

To enter Mirror Time Adjustment, press 5 “R” button on the remote

commander. The screen will appear as below.

MIRR time Adjust Menu

1. CD MIRR time Check:

2. DVD MIRR time Check:

3. Threshold:

4. Save to EEPROM

5. Default set MIRR time

[Open] Tray open [Close] Tray close

[0] Return to previous menu

There are five main commands in the Mirr time Adjust menu as

shown in the figure above. The functions of each command are

described in the following page.

1. CD MIRR time Check

This command checks the Mirror time value for CD disc.

2. DVD MIRR time Check

This command checks the Mirror time value for DVD disc.

3. Threshold

This command displays the threshold value between CD and DVD

mirror time.

4. Save to EEPROM

This command saves an adjusted mirror time value to the EEPR OM.

5. Default set MIRR time

This command will set CD and DVD mirror time to fir mware default

value.

[Open] / [Close]

Pressing the A button controls the tray for disc change

during mirror time adjustment.

[0] Return to previous menu

Press 0 “R” button to return to previous menu.

4-4-1. EXECUTING MIRROR TIME ADJUSTMENT

In order to execute mirror time adjustment, the following standard

procedures must be followed.

(1) In standby mode, press three buttons x , A and VOLUME

+ simultaneously.

(2) Select “2. Drive Manual Operation”.

Remocon Diagnosis Menu

0. External Chip Check

1. Servo Parameter Check

2. Drive Manual Operation

3. Emergency History Check

4. Version information

5. Video Level Adjustment

Drive Manual Operation

1. Servo Control

2. Track/Layer Jump

3. Manual Adjustment

4. Mecha t est mode

5. MIRR time Adjust

0. Return to Top Menu

Model : DC1_xx

IF-con : Ver. xx.xx (xxxx)

Syscon : Ver. x.xxx

23

HCD-DX150/DX170/DX250

(3) Select “5. MIRR time Adjust”.

Drive Manual Operation

1. Servo Control

2. Track/Layer Jump

3. Manual Adjustment

4. Mecha test mode

5. MIRR time Adjust

0. Return to Top Menu

(4) Select “5. Default set MIRR time”.

MIRR time Adjust Menu

1. CD MIRR time Check:

2. DVD MIRR time Check:

3. Threshold:

4. Save to EEPROM:

5. Default set MIRR time:

[Open] Tray open [Close] Tray close

[0] Return to previous menu

(5) Select “3. Threshold”.

(6) Confirm the number. If it is 75, go to next step. If it is any

other value, return to step 4.

MIRR time Adjust Menu

(14) Confirm the same values are displayed. If it is not same,

return to step 7.

MIRR time Adjust Menu

1. CD MIRR time Check:

2. DVD MIRR time Check: XX XX

3. Threshold:

4. Save to EEPROM:

5. Default set MIRR time:

[Open] Tray open [close] Tray close

[0] Return to previous menu

(15) Push A button to eject tray.

(16) Take out HLX-504 and insert Test Disc YEDS-18 into

tray.

(17) Push A button to close tray.

(18) Push “1. CD MIRR time check”.

(19) Wait for HEX number to display.

(20) Confirm the number, if YY is 5A ~ E8, proceed with next

step. If no, return to 15.

MIRR time Adjust Menu

1. CD MIRR time Check:

2. DVD MIRR time Check:

3. Threshold: 75

4. Save to EEPROM:

5. Default set MIRR time:

[Open] Tray open [Close] Tray close

[0] Return to previous menu

(7) Push A button to eject tray.

(8) Insert Test Disc HLX-504 into tray.

(9) Push A button to close tray.

(10) Push “2. DVD MIRR time Check”.

(11) Wait for HEX number to display.

(12) Confirm the number, if XX is 28 ~ 70, proceed with next

step. If no, return to 8.

MIRR time Adjust Menu

1. CD MIRR time Check:

2. DVD MIRR time Check: xx xx

3. Thereshold:

4. Save to EEPROM:

5. Default set MIRR time:

[Open] tray open [close] Tray close

[0] Return to previous menu

1. CD MIRR time Check: yy YY

2. DVD MIRR time Check: XX XX

3. Threshold:

4. Save to EEPROM:

5. Default set MIRR time:

[Open] Tray open [close] Tray close

[0] Return to previous menu

(21) Push “4. Save to EEPROM”.

(22) Confirm the same values are displayed. If it is not the

same, return to step 15.

MIRR time Adjust Menu

1. CD MIRR time check: YY YY

2. DVD MIRR time check: XX XX

3. Threshold:

4. Save to EEPROM:

5. Default set MIRR time:

[Open] Tray open [close] Tray close

[0] Return to previous menu

(23) Push A button to eject tray.

(24) Remove Test Disc YEDS-18 from tray.

(25) Push A button to close tray.

(26) Press 0 “R” button to the Drive Manual Operation menu.

(13) Push “4. Save to EEPROM”.

24

(27) Press 0 “R” button to return to the Remocon Diagnosis

Menu.

(28) Press the ?/1 button to switch OFF set.

HCD-DX150/DX170/DX250

4-5. EXECUTING IOP MEASUREMENT

In order to execute mirror time adjustment, the following standard

procedures must be followed.

(1) In standby mode, press three buttons x , A and VOLUME

+ simultaneously.

Remocon Diagnosis Menu

0. External Chip Check

1. Servo Parameter Check

2. Drive Manual Operation

3. Emergency History Check

4. Version information

5. Video Level Adjustment

Model : DC1 XX

IF-con Ver : XX.XX (XXXX)

Syscon Ver : X.XX

(2) Select “2. Drive Manual Operation” by pressing the 2 “R”

button on the remote commander. The screen will appear as

below.

Drive Manual Operation

1. Servo Control

2. Track/Layer Jump

3. Manual Adjustment

4. Tray Aging Mode

5. MIRR time adjust

0. Return to top Menu

(5) Wait until a hexadecimal number appear.

Manual Adjust

1. Track Balance Adjust:

2. Track Gain Adjust:

3. Focus Balance Adjust:

4. Focus Gain Adjust:

5. Eq Boost Adjust:

6. Iop. ED 9E:

7. TRV. Level:

8. S curve(FE) Level:

9. RFL(PI) Level:

0. MIRR Time:

Change Value

[0] Return to previous menu

(6) Convert each data from hexadecimal to decimal using

conversion table.

(7) Substract between these two values.

(8) If the remainder is smaller than 93 (decimal), then it is

OK. However if the value is higher than 93, then the BU

is defective and need to be change.

(9) Press RETURN “R” button to return back to previous menu.

(10) Press 0 “R” button to return to Top Menu and power OFF

the DVD Player.

(3) Select “3. Manual Adjustment” by pressing the 3 “R” b utton

on the remote commander. The screen will appear as below.

Manual Adjust

1. Track Balance Adjust:

2. Track Gain Adjust:

3. Focus Balance Adjust:

4. Focus Gain Adjust:

5. Eg boost Adjust:

6. Iop:

7. TRV. Level:

8. S curve(FE) Level:

9. RFL(PI) Level:

0. MIRR Time:

o O Change Value

[RETURN] Return to previous menu

(4) Select Iop by pressing 6 “R” button on the remote commander .

25

HCD-DX150/DX170/DX250

)

Ver. 1.3

ELECTRICAL ADJSTMENT

DVD SECTION

When the base unit is replaced, perform the adjustment and the

measurement as shown below in this order.

1) MIRROR TIME ADJUSTMENT (See page 23)

2) EXECUTING IOP MEASUREMENT (See page 25)

[TEST DISC LIST]

Be sure to use the DVD disc that matches the signal standards of

your region.

• CD

YEDS-18 (Part No.: 3-702-101-01)

PATD-012 (Part No.: 4-225-203-01)

• DVD SL (Single Layer)

NTSC : HLX-503 (Part No.: J-6090-069-A)

HLX-504 (Part No.: J-6090-088-A)

PAL : HLX-506 (Part No.: J-6090-077-A)

• DVD DL (Dual Layer)

NTSC : HLX-501 (Part No.: J-6090-071-A)

HLX-505 (Part No.: J-6090-089-A)

PAL : HLX-507 (Part No.: J-6090-078-A)

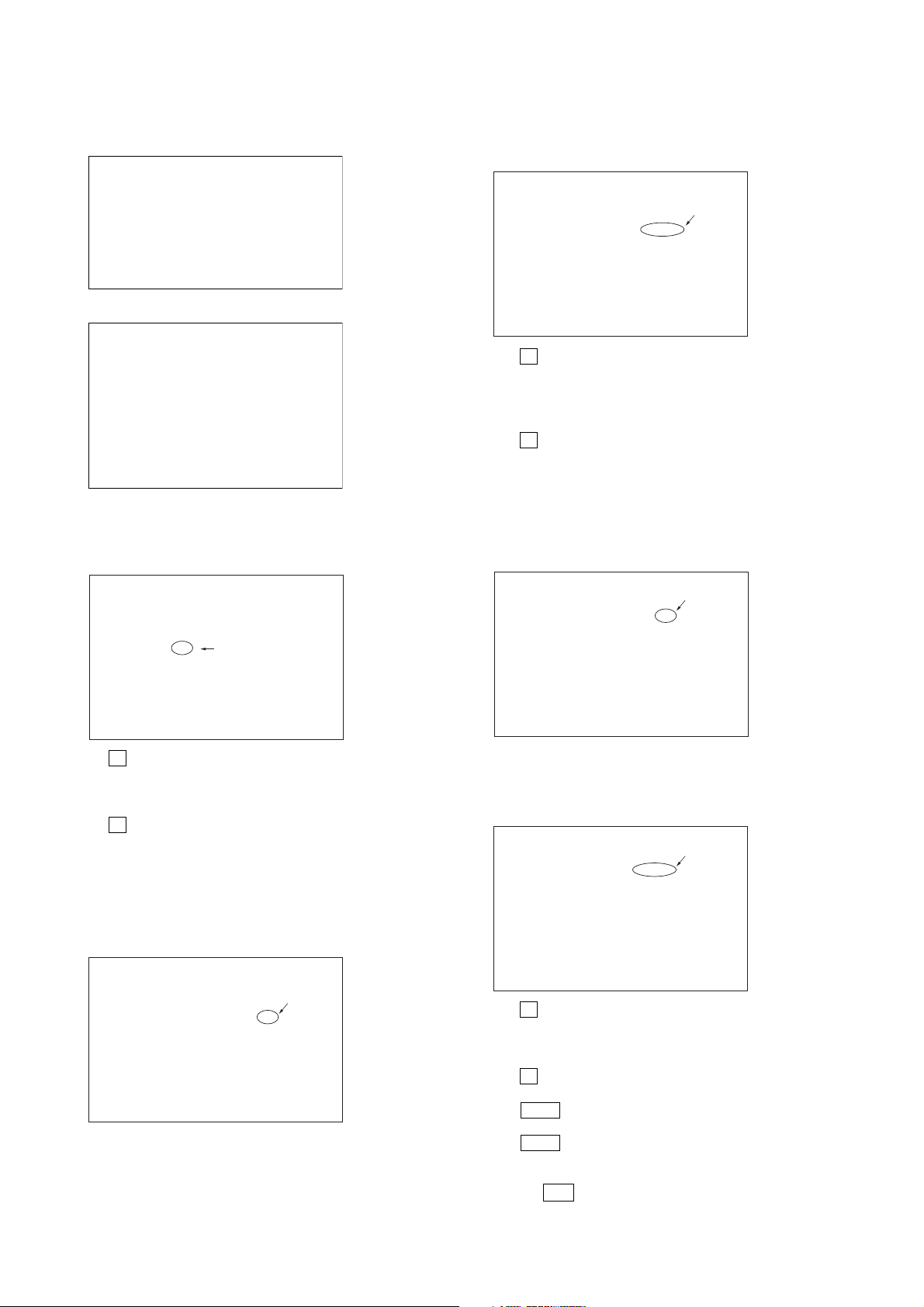

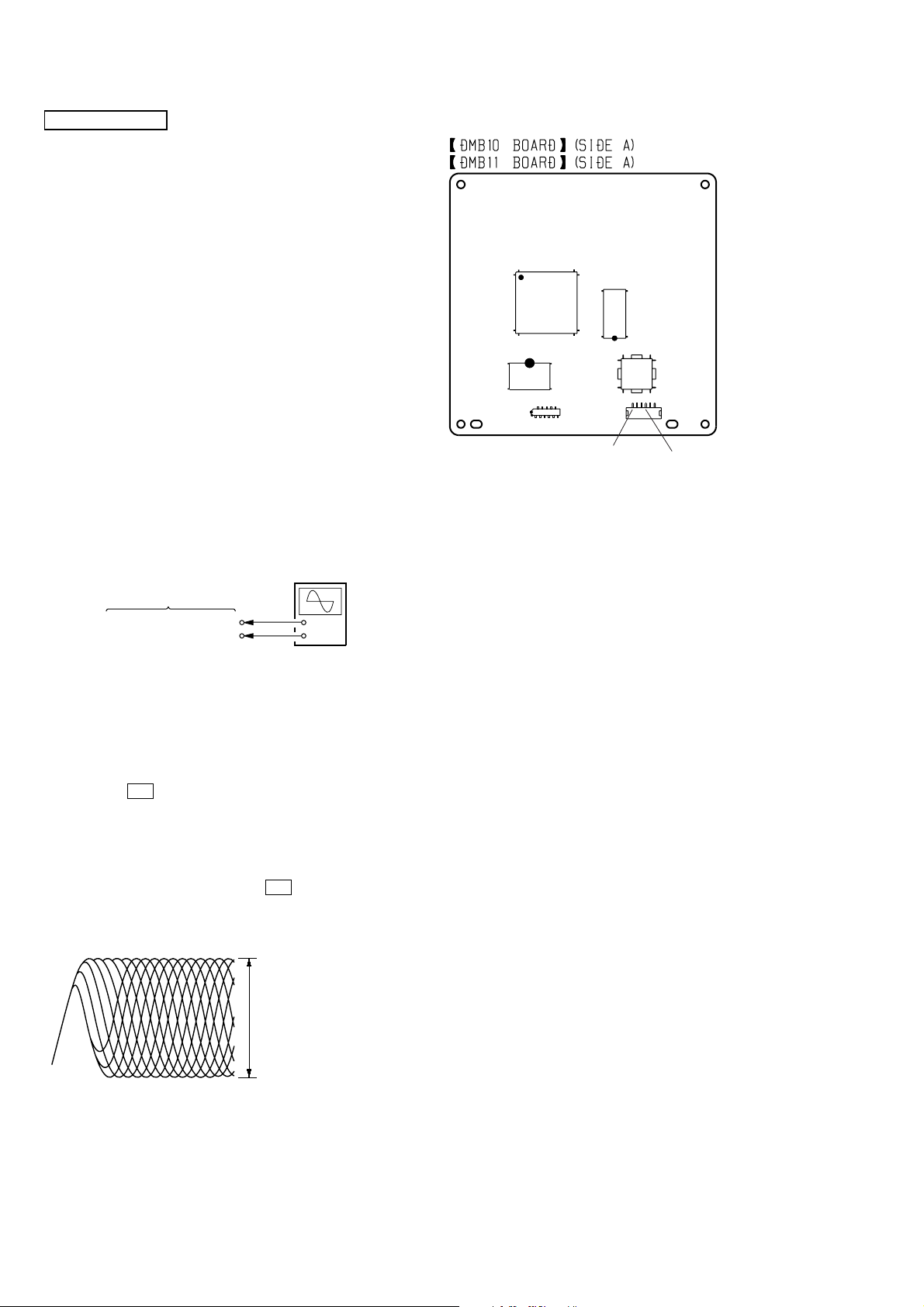

[RF Level Check]

Connection:

Checking Location: DMB10 board or DMB11 board (Side A)

IC104

IC102

CN105

IC201

6

1

CN105 pin 3 (GND

IC101

CN106

CN105 pin 6 (RFMON)

DMB10 board

DMB11 board

CN105 pin 6 (RFMON)

CN105 pin

3

(GND)

oscilloscope

+

–

Procedure:

1. Conect an oscilloscope to CN105 pin 6 (RFMON) and CN105

pin 3 (GND) on the DMB10 or DMB11 board.

2. Turn the power on.

3. Insert the CD test disc (refer to the TEST DISC LIST), and

press the H button to play the disc back.

4. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

Note: A clear RF signal wav eform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

5. Eject the CD disc, and insert the DVD SL test disk (refer to the

TEST DISC LIST), and press the H button to play the disc

back.

RF signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

level: 0.57 ± 1.1 Vp-p (CD)

0.58 ± 1.23 Vp-p (DVD)

26

SECTION 6

d

d

DIAGRAMS

HCD-DX150/DX170/DX250

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For Schematic Diagrams.

Note:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

• C : panel designation.

Note:

The components identified by mark 0 or dotted

line with mark 0 are criti-

cal for safety.

Replace only with part

number specified.

• A : B+ Line.

• B : B– Line.

•Voltages and waveforms are dc with respect to ground under no-signal (detuned) conditions.

•Voltages and waveforms are dc with respect to ground in

service mode.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

no mark : DVD STOP

•Voltages are taken with VOM (Input impedance 10 MΩ).

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

J : CD PLAY

c : DVD PLAY

d : TUNER

L : VIDEO

E : Y

a : CHROMA

r : COMPONENT VIDEO

q : R, G, B

e : AUDIO IN

• Abbreviation

AUS : Australian model.

CND : Canadian model.

E32 : 110 – 240 V AC Area in E model.

EA : Saudi Arabia model.

MX : Mexican model.

SP : Singapore model.

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

For Printed Wiring Boards.

Note:

• X : parts extracted from the component side.

• a : Through hole.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(SIDE A) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(SIDE B) the parts face are indicated.

• Indication of transistor.

C

Q

CEB

These are omitte

These are omitte

EB

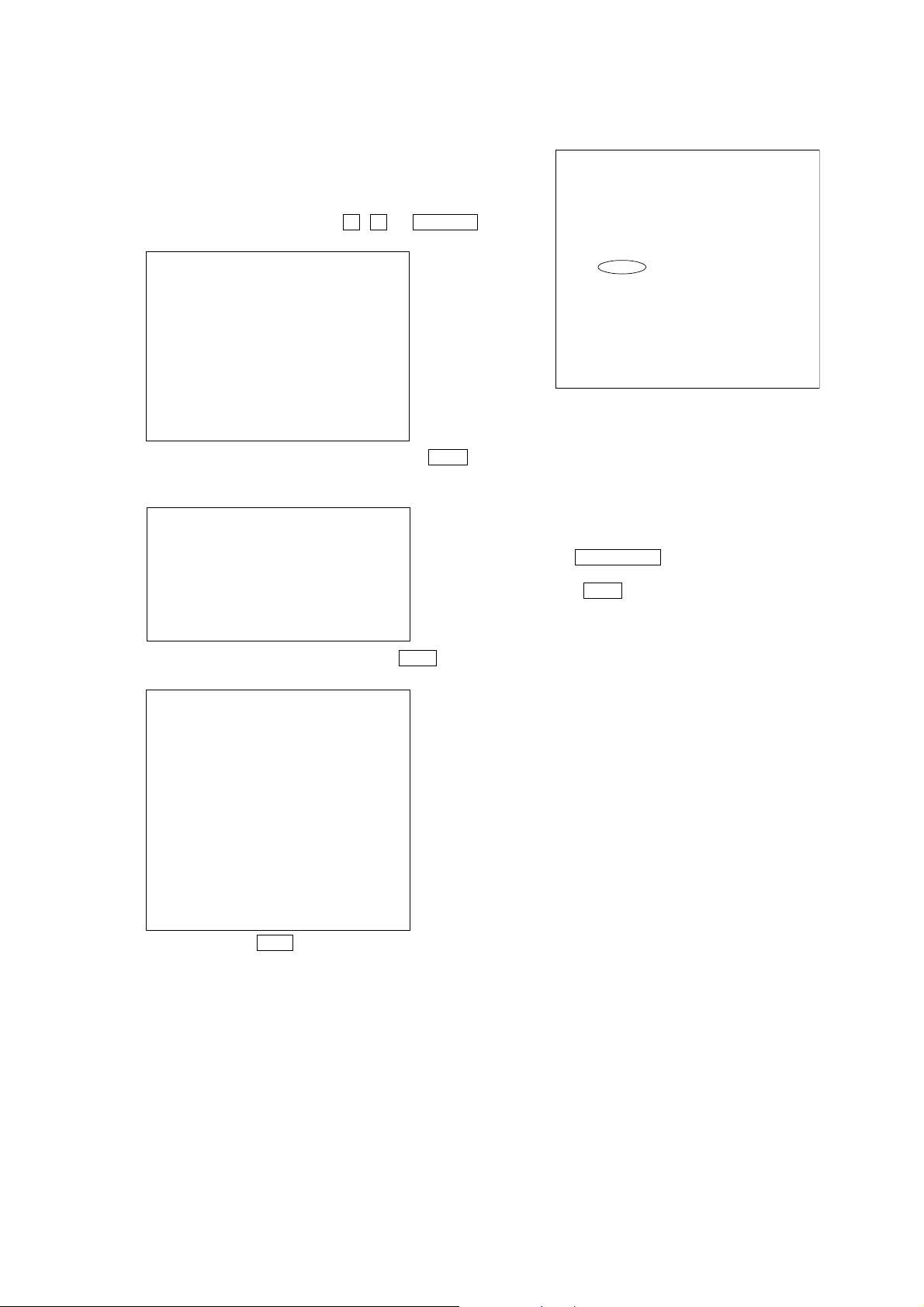

• Circuit Boards Location

STBY board

SW(1) board

MOTOR board

LED board

SENSOR board

TUNER unit

IO board

KEY board

H/P board

SW(2) board

TRANSLATION board

MAIN board

HCD-DX150/DX170/DX250

ENCODER board

FL board

DMB10 board

2727

HCD-DX150/DX170/DX250

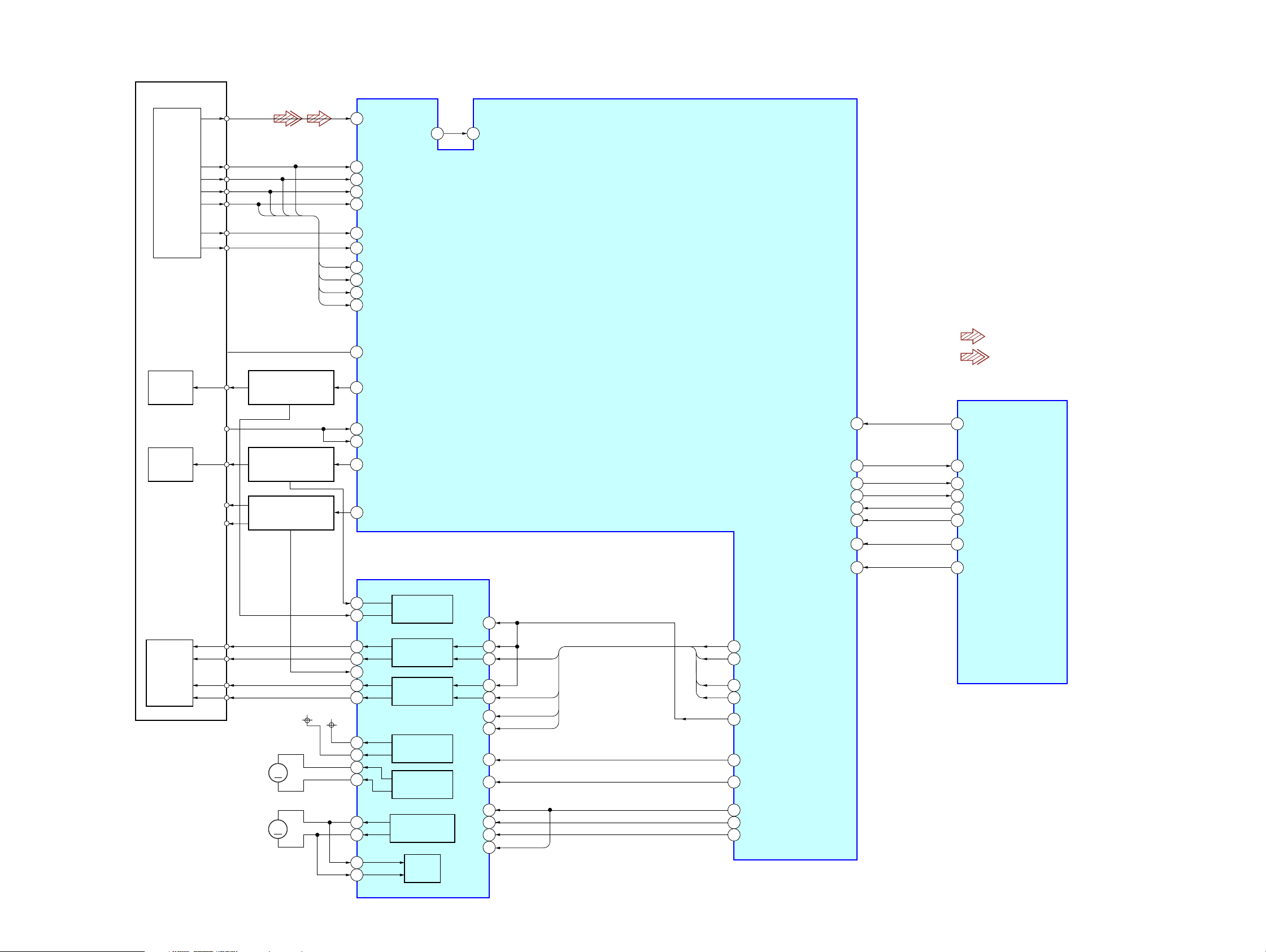

6-1. BLOCK DIAGRAM – RF/SERVO SECTION –

DETECTOR

OPTICAL PICK-UP

BLOCK

(KHM-310CAB)

LASER

DIODE

(FOR CD)

LASER

DIODE

(FOR DVD)

CD LD

DVD LD

WR650

VR780

RF

PD

DVDRFIP

6

OSP

252 253

A

B

C

D

F

E

B

A

C

D

A

B

D

C

DVDA

2

DVDB

3

DVDC

4

DVDD

5

19

TPI

18

TNI

8

NA

9

NB

10

MD

11

MC

OSN

IC102 (1/3)

CD/DVD RF AMP,

FOCUS/TRACKING ERROR AMP

DVD SYSTEM PROCESSOR

DIGITAL SERVO PROCESSOR

• Signal Path

: CD PLAY

176

Q102 (1/2)

AUTOMATIC POWER

CONTROL (FOR CD)

Q102 (2/2)

AUTOMATIC POWER

CONTROL (FOR DVD)

Q101, Q103

VOLUME CONTROL

23

20

21

22

187

LI M SW

LD01

MD12

MD11

LD02

MSW

PRST

IFCK

MAMUTE

IFSDO

IFSDI

XIFCS

110

99

51

98

101

100

43

33

25

32

31

39

: DVD PLAY

MTK_XRST

DVD_SCO/CLK1

MAMUTE

DVD_SOD/RXD1

DVD_SID/TXD1

DVD_XIFCS

2AXIS

DEVICE

FOCUS/

TRACKING

COIL

FCS+

FCS–

TRK+

TRK–

M2

(SLED)

M1

(SPINDLE)

MM

MM

+3.3V

SP+

SP–

SL–

SL+

FOCUS/TRACKING COIL DRIVER,

SPINDLE, SLED MOTOR DRIVER

42

41

36 48

37 1

32

35 3

34 4

VCC

32

31

30

29

27

28

47

46

IC201

BUFFER

FOCUS COIL

DRIVE

TRACKING COIL

DRIVE

SLED MOTOR

DRIVE

SLED MOTOR

DRIVE

SPINDLE MOTOR

DRIVE

BUFFER

177

OCSW

105

IFBSY

43

10

13

40

45

19

20

22

21

V1P4

FOO

TRO

FMO

DMO

V1P4

FMO

FOO

DMO

TRO

38

42

37

41

30

40

47

184

183

181

FMO

FOO

DND

TRO

V REFO

IOPMON

SPFG

MUTE123

MUTE

TSDM

42

SEN

34

DVD_IFBUSY/RST1

IC509 (1/4)

SYSTEM

CONTROLLER

HCD-DX150/DX170/DX250

2828

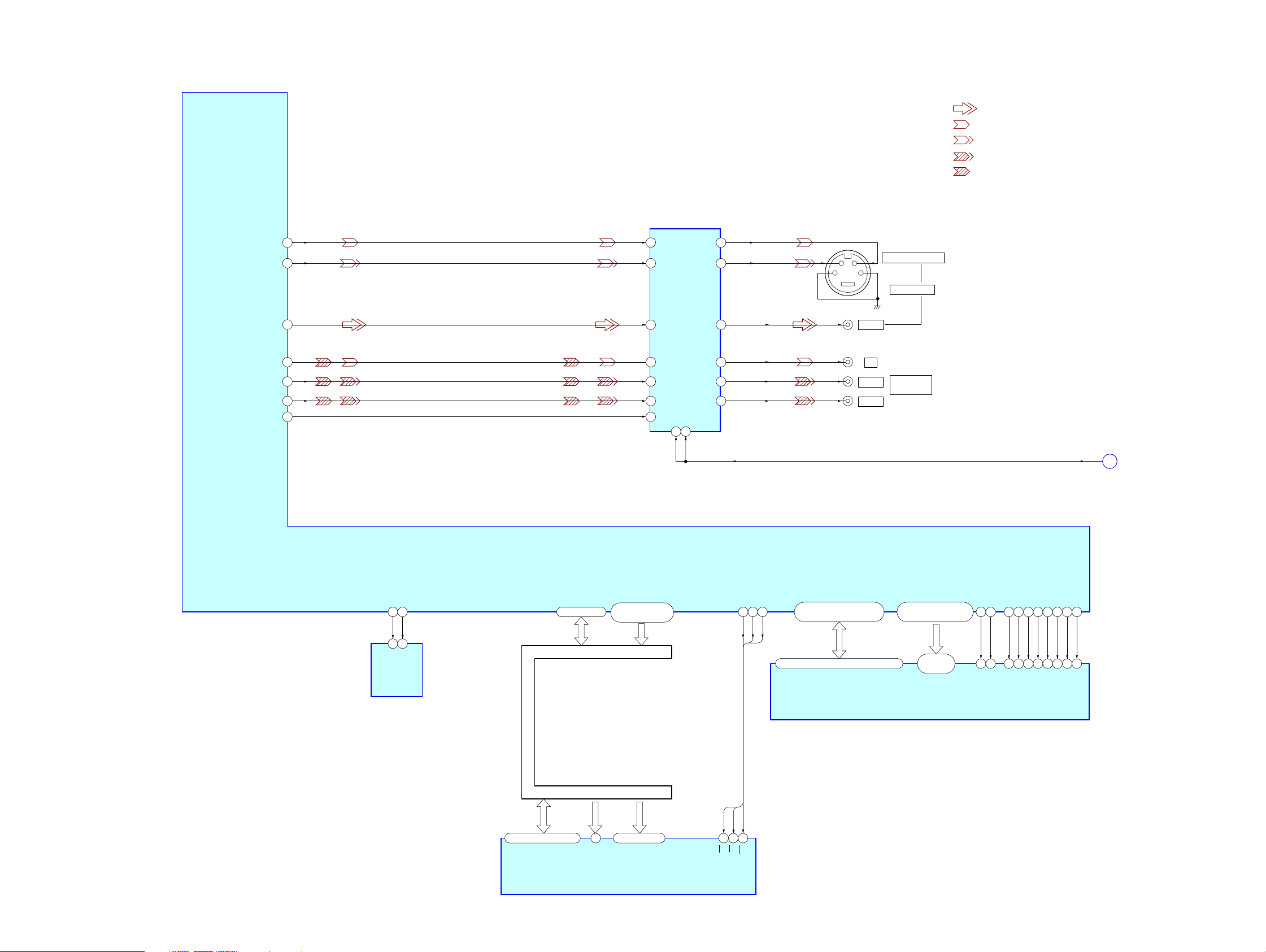

– VIDEO SECTION –

IC201

VIDEO AMP, 75Ω DRIVER

HCD-DX150/DX170/DX250

• Signal Path

: VIDEO

: Y

: CHROMA

: COMPONENT VIDEO

: R, G, B

YUV1

YUV2

YUY3

YUY4

YUY5

YUV6

WODE

194

196

198

200

202

203

171

IC102(2/3)

DVD SYSTEM PROCESSOR

SCL

102

103

6 5

SCL

IC103

EEPROM

SDA

SPA

AB0 – AB7

81-84,86-88,91

HD0 – HD7 A0 – A21

DATA & ADDRESS BUS

53-61, 67-72, 74-76,

6

YIN

2

CIN

4

CVBSIN

10

CYIN

12

CBIN

14

CRIN

25

SI

HIGHA0-7

IOA0-7, IOA18-IOA20

A16, A17

78, 89, 92, 93

MUTE1

3

13

YOUT

COUT

VOUT

CYOUT

CBOUT

CROUT

MUTE2

21

26

23

20

18

16

VOUT

CYOUT

CBOUT

CROUT

AV SEL1

77

CEWEOE

IOCS

79

IOWA

IOUE

66

2,4,5,7,8,10,11,13,42,44,45,47,48,50,51,53

RD0 – RD15

125-123, 121, 120, 118,

117, 115, 135, 133-128, 126

RD0 – RD15

21

43

VIDEO

Y

PB/C

PR/C

S VIDEO(DVD ONLY)

J201

MONITOR OUT

J202

COMPONENT

B

VIDEO OUT

R

146, 147, 149-151,

158-160, 162, 164-166

RA0 – RA11

22-26,

29-35

RA0 – RA11

IC104

SDRAM

RCLK

RCS

RWE

MRAS

BA0

BA1

143

20

142

145 156 113 137 157

38

19

21

BS0

BS1

DRCLK

138

RCS

CAS

140

139

16

18

17

CAS

RAS

RWE

MDQM0

15

DQM0

MDQM1

39

DQM1

AV SEL1

CLE

37

DRCLE

B

AMP

SECTION

HCD-DX150/DX170/DX250

DATA & ADDRESS BUS

HD0 – HD7

29,31,33,35,38,40,42,44 25-16, 9-1, 48

DQ0 – DQ7

A0

IC101

FLASH ROM

A0 – A19DQ15/A-1

A1-A20

CE

OE

WE

2645

28OE11

CE

WE

2929

Loading...

Loading...