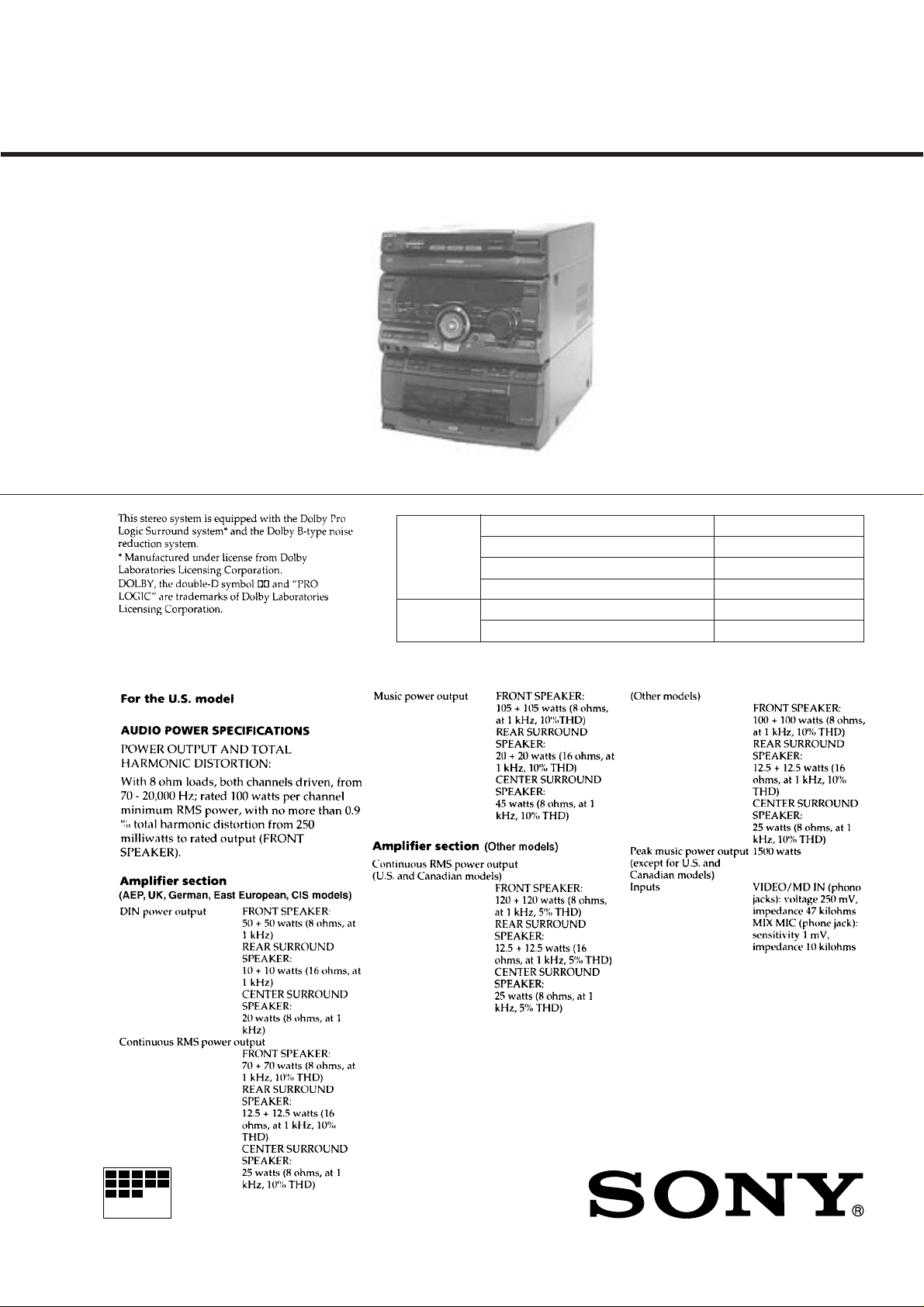

HCD-D90A V/GR10AV/

RX100A V

SERVICE MANUAL

HCD-D90AV/GR10AV/RX100AV is the

tuner, deck, CD and amplifier section in

MHC-D90AV/GR10AV/RX100AV.

Photo : HCD-RX100AV : US model

Model Name Using Similar Mechanism HCD-H991AV

CD

SECTION

TAPE

DECK

SECTION

CD Mechanism Type CDM38L-5BD29AL

Base Unit Type BU-5BD29AL

Optical Pick-up Type KSS-213D/Q-NP

Model Name Using Similar Mechanism HCD-H991AV

Tape Transport Mechanism Type TCM-220WR2

US Model

HCD-D90AV/RX100AV

Canadian Model

AEP Model

UK Model

HCD-RX100AV

E Model

Australian Model

Tourist Model

HCD-GR10AV

SPECIFICATIONS

COMPACT DISC DECK RECEIVER

— Continued on next page —

MICROFILM

— 1 —

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS

SONT DONNÉS DANS CE MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS PAR SONY.

— 2 —

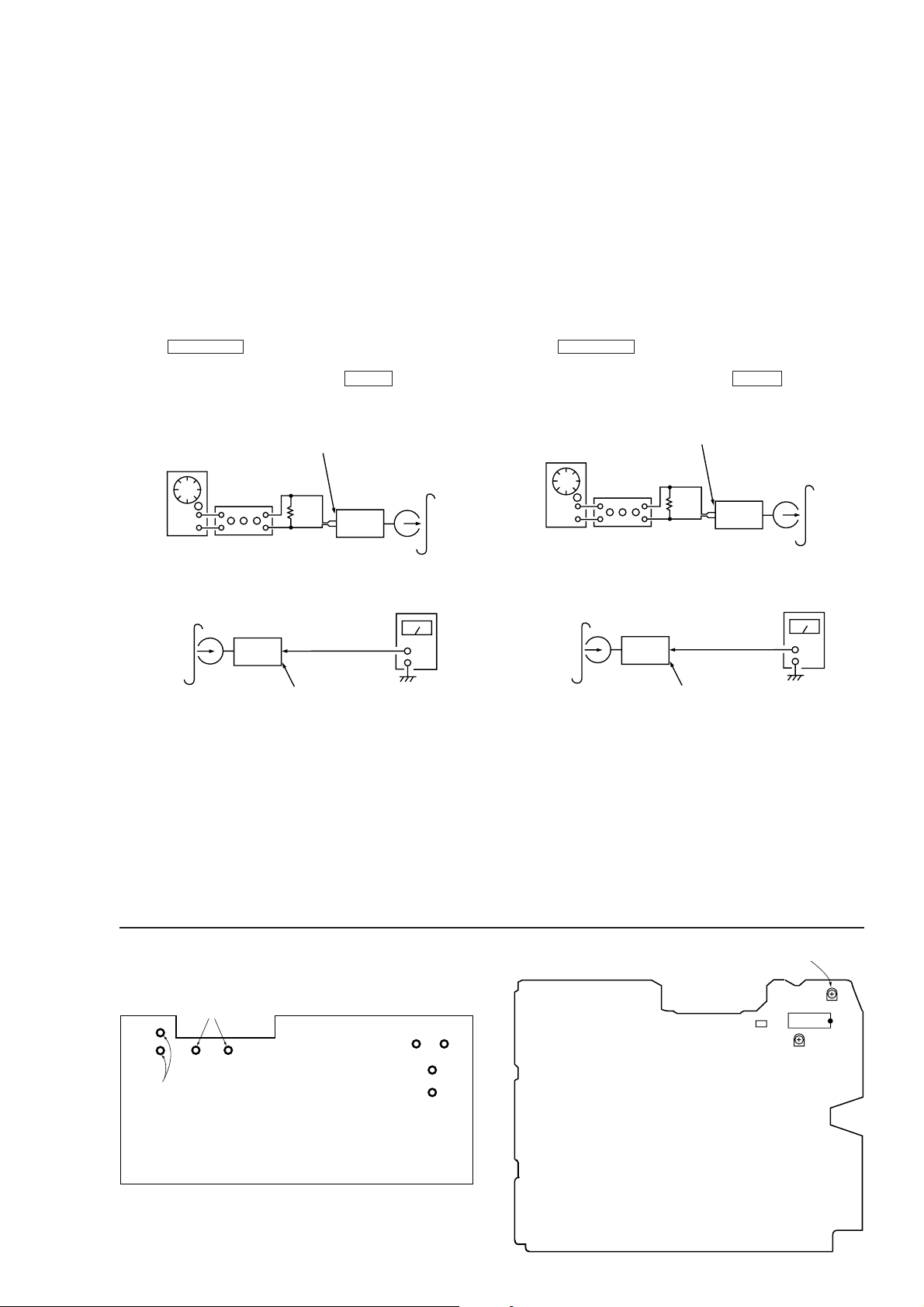

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a V OM

or battery-operated A C v oltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

This caution

label is located

inside the unit.

0.15µF

Ω

1.5k

Earth Ground

AC

voltmeter

(0.75V)

Fig. A. Using an AC voltmeter to check AC leakage.

— 3 —

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repain parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output three times.

MODEL IDENTIFICATION

— BACK PANEL —

• Abbreviation

CND:Canadian model

G :German model

EE :East European model

EA :Saudi Arabia model

HK :Hong Kong model

SP :Singapore model

JE :Tourist model

MY :Malaysia model

AUS:Australian model

TH :Thailand model

IA :Indonesian model

E2 :Without SW tuner E model

E3 :With SW tuner E model

PRODUCT

COUNTRY

INDONESIA

INDONESIA

INDONESIA

INDONESIA

INDONESIA

INDONESIA

INDONESIA

INDONESIA

INDONESIA

INDONESIA

INDONESIA

THAILAND

MALAYSIA

MALAYSIA

MALAYSIA

PARTS No.

4-986-846-0

4-986-846-1

4-986-846-2

4-986-846-3

4-986-846-4

4-988-023-0

4-988-023-1

4-988-023-2

4-988-023-3

4-988-023-4

4-988-023-5

4-988-023-7

4-988-275-0

4-988-275-1

4-988-275-2

Parts No.

MODEL

RX100AV: US model

RX100AV: CND model

RX100AV: AEP, UK, G model

RX100AV: EE, CIS model

D90AV : US model

GR10AV : E3, IA model

GR10AV : E2 model

GR10AV : SP model

GR10AV : JE model

GR10AV : HK model

GR10AV : AUS model

GR10AV : TH model

RX100AV: AEP model

GR10AV : EA model

GR10AV : MY model

TABLE OF CONTENTS

1. SERVICING NOTE

.......................................................... 5

2. GENERAL .......................................................................... 6

3. DISASSEMBLY

3-1. Loading Panel ....................................................................... 8

3-2. Front Panel ........................................................................... 8

3-3. TC Mechanism Deck and Deco Board (Except US, CND) .. 9

3-4. HP/MIC Board, Display Board and TC SW Board .............. 9

3-5. Disc Tray ........................................................................... 10

4. SERVICE MODE ............................................................11

5. MECHANICAL ADJUSTMENTS .......................... 13

6. ELECTRICAL ADJUSTMENTS ............................... 13

7. DIAGRAMS

7-1. Circuit Boards Location ...................................................... 19

7-2. Brock Diagrams

• Tuner Section (AEP, UK, German model).......................21

• Tuner Section (East European, CIS model).....................23

• CD Section ....................................................................... 25

• Deck Section .................................................................... 27

• Main Section .................................................................... 29

• Power Section .................................................................. 31

7-3. Printed Wiring Board — CD Section —.............................33

7-4. Schematic Diagram — CD Section — ............................... 35

7-5. Printed Wiring Board

—Tuner (AEP, UK, German model) Section — .................38

7-6. Schematic Diagram

—Tuner (AEP, UK, German model) Section — .................39

7-7. Schematic Diagram

—Tuner (East European, CIS model) Section — ............... 41

7-8. Printed Wiring Board

—Tuner (East European, CIS model) Section — ............... 43

7-9. Printed Wiring Board — Main Section —.......................... 44

7-10. Schematic Diagram — Main Section — .......................... 47

7-11. Schematic Diagram — Deck Section — .......................... 51

7-12. Printed Wiring Board — Deck Section — ....................... 55

7-13. Schematic Diagram — Panel Section — ......................... 58

7-14. Printed Wiring Board — Panel Section —....................... 61

7-15. Schematic Diagram — Power Section — ........................ 65

7-16. Printed Wiring Board — Power Section — ..................... 69

7-17. Schematic Diagram — CD Motor Section — .................. 72

7-18. Printed Wiring Board — CD Motor Section —...............73

7-19. IC Block Diagrams ........................................................... 75

7-20. IC Pin Functions ............................................................... 82

8. EXPLODED VIEWS

8-1. Case Section........................................................................91

8-2. Main Board Section ............................................................ 92

8-3. Panel Board Section ............................................................ 94

8-4. Front Panel Section ............................................................. 96

8-5. TC Mechanism Section 1 (TCM-220WR2)........................ 97

8-6. TC Mechanism Section 2 (TCM-220WR2)........................ 98

8-7. CD Mechanism Section 1 (CDM38L-5BD29AL) .............. 99

8-8. CD Mechanism Section 2 (CDM38L-5BD29AL) ............ 100

8-9. Base Unit Section (BU-5BD29AL) .................................. 101

9. ELECTRICAL PARTS LIST ...................................... 102

— 4 —

SECTION 1

SERVICING NOTE

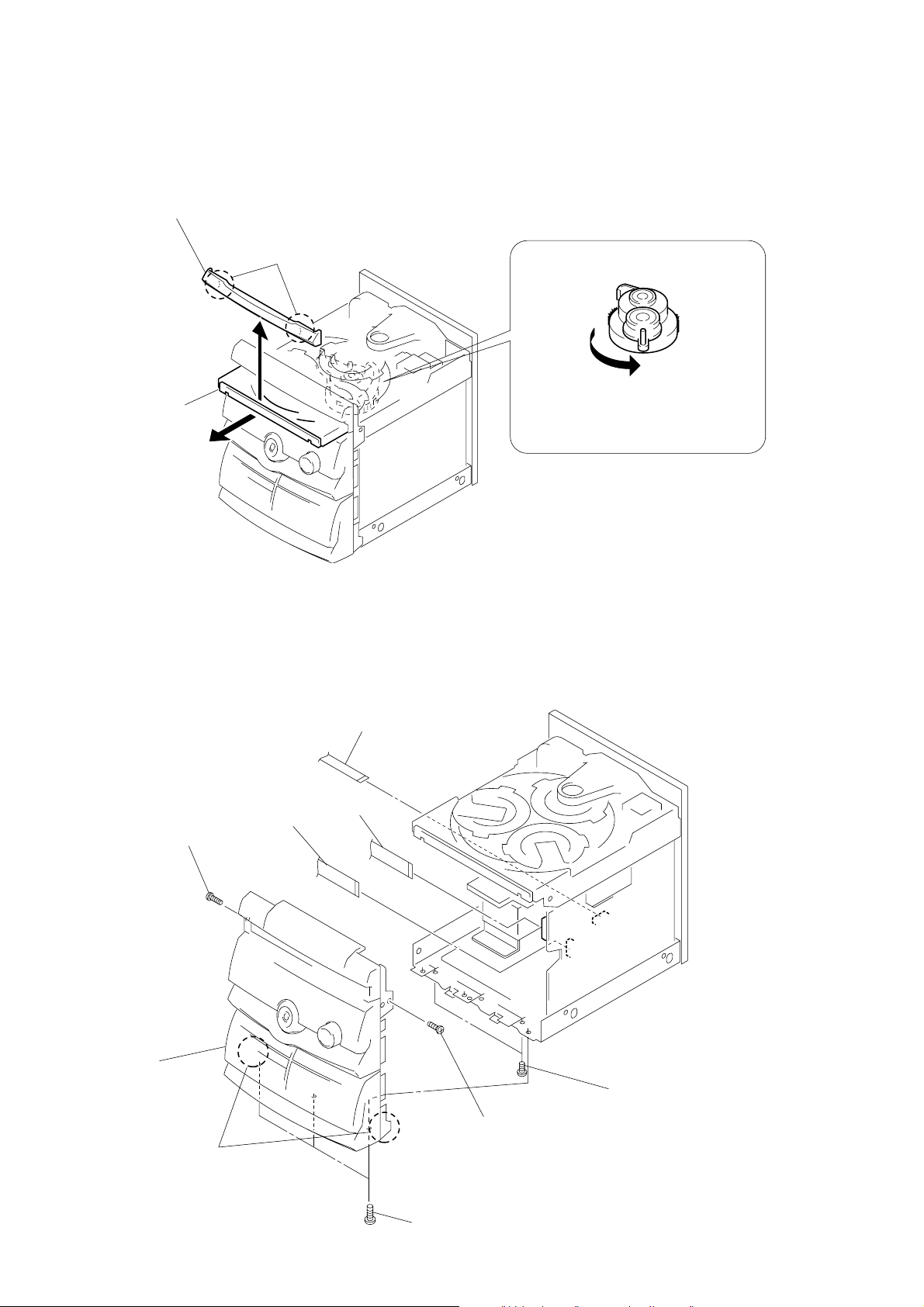

HOW TO OPEN THE DISC TRAY WHEN POWER SWITCH

TURNS OFF

1

Remove the Case.

3

Pull-out the disc tray.

2

Turn the cam to the

direction of arrow.

— 5 —

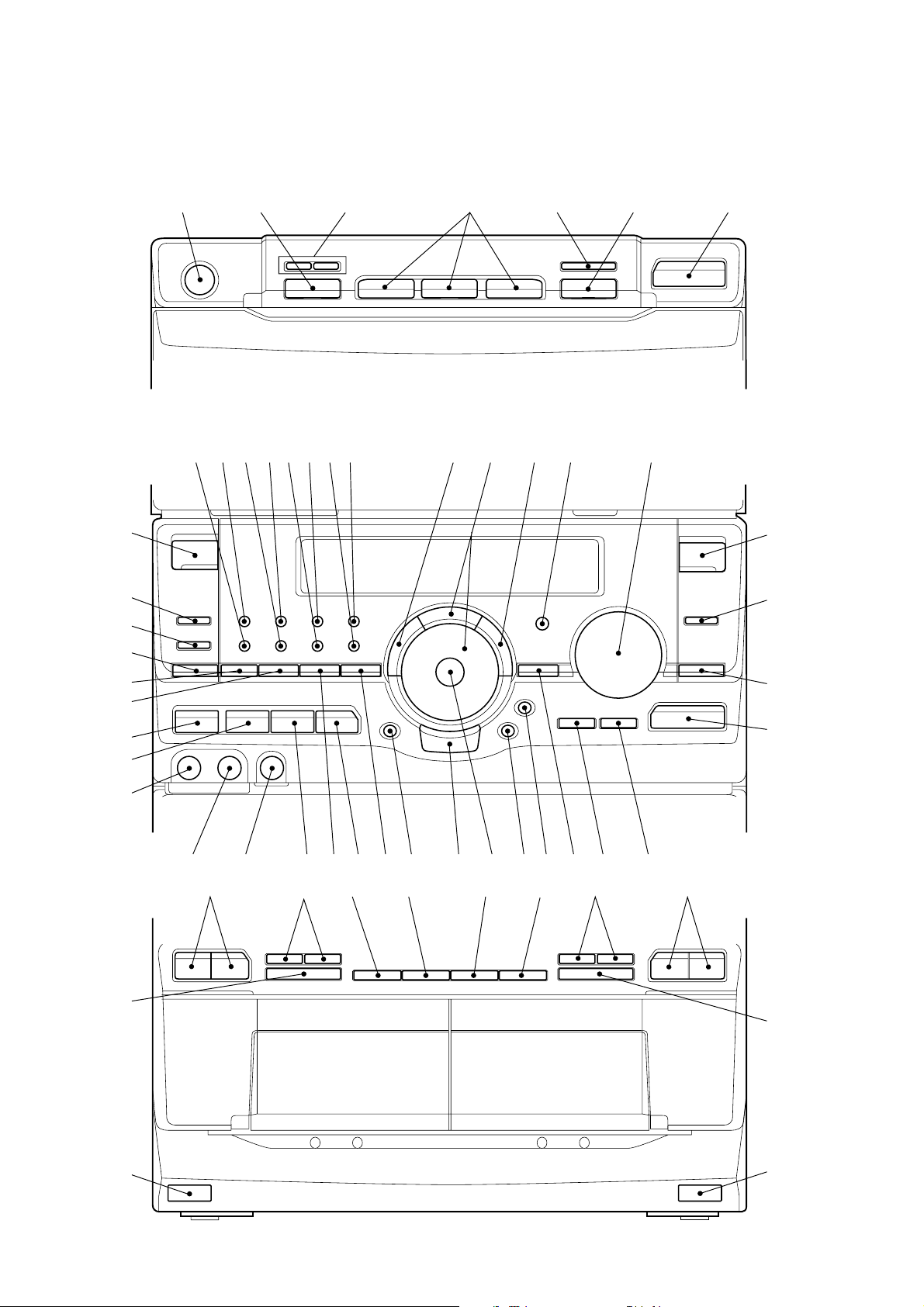

Front Panel

SECTION 2

GENERAL

8

9

!º

1

!ª

2

@º @¡ @™@£@∞@¢ @§ @¶ @• @ª

3

4

5

#º

6

7

#¡

#™

#£

!¡

!™

!£

!¢

!∞

!§

%ª

!¶

$•

!•

#• #ª

$ª

%º

$º

$¡

$™

%¡

$¢

%™

$£

$∞

$§

%£

$¶

%∞

#¶

#¢

#∞

#§

%§

%¢

%¶

%•

— 6 —

LOCATION OF PARTS AND CONTROLS

1 POWER button

2 DISC SKIP EX-CHANGE button

3 CD 0, ) button

4 DISC1-DISC3 buttons

5 CD p button

6 § OPEN/CLOSE button

7 CD ·∏ button

8 TIMER SELECT button

9 CLOCK/TIMER SET button

0 SLEEP button

!¡ P FILE MEMORY button

!™ P FILE button

!£ MUSIC button

!¢ NON-STOP button

!∞ WAVE button

!§ PHONES jack

!¶ MIX MIC jack

!• MIC LEVEL knob

!ª 1/ALL DISCS button

@º DISPLAY/DEMO button

@¡ PLAY MODE button

@™ SPECTRUM ANALYZER button

@£ REPEAT button

@¢ DOLBY NR button

@∞ EDIT button

@§ DIRECTION button

@¶ LOW FREQUENCY button

@• JOG dial, indicator

@ª HIGH FREQUENCY button

#º KARAOKE PON/MPX button

#¡ VOLUME control

#™ FUNCTION button

#£ PTY button (AEP, UK, German)

#¢ TUNER MEMORY button

#∞ TUNER/BAND button

#§ STEREO/MONO button

#¶ TUNING MODE button

#• LOOP button

#ª MOVIE button

$º FLASH button

$¡ GAME button

$™ GROOVE button

$£ ENTER/NEXT button

$¢ PRO LOGIC button

$∞ DSP button

$§ DBFB button

$¶ EFFECT ON/OFF button

$• Deck A ª, · button

$ª Deck A 0, ) button

%º HIGH SPEED DUBBING button

%¡ CD SYNCHRO button

%™ r REC button

%£ P button

%¢ Deck B p button

%∞ Deck B 0, ) button

%§ Deck B ª, · button

%¶ Deck A 6 button

%• Deck B 6 button

%ª Deck A p button

— 7 —

SECTION 3

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

3-1. LOADING PANEL

3

Loading panel

Claws

2

Pull-out the disc tray.

1

Turn the cam to the direction

of arrow.

3-2. FRONT PANEL

1

Remove the connectors.

(Main board : CN401, CN402, CN701)

5

Screw (+BVTP3x10)

7

Front panel

assembly

CN701

CN402

CN401

2

Two screws (+BVTT3x6)

6

Claws

4

Screw (+BVTP3x10)

3

Three screws (+BVTT3x6)

— 8 —

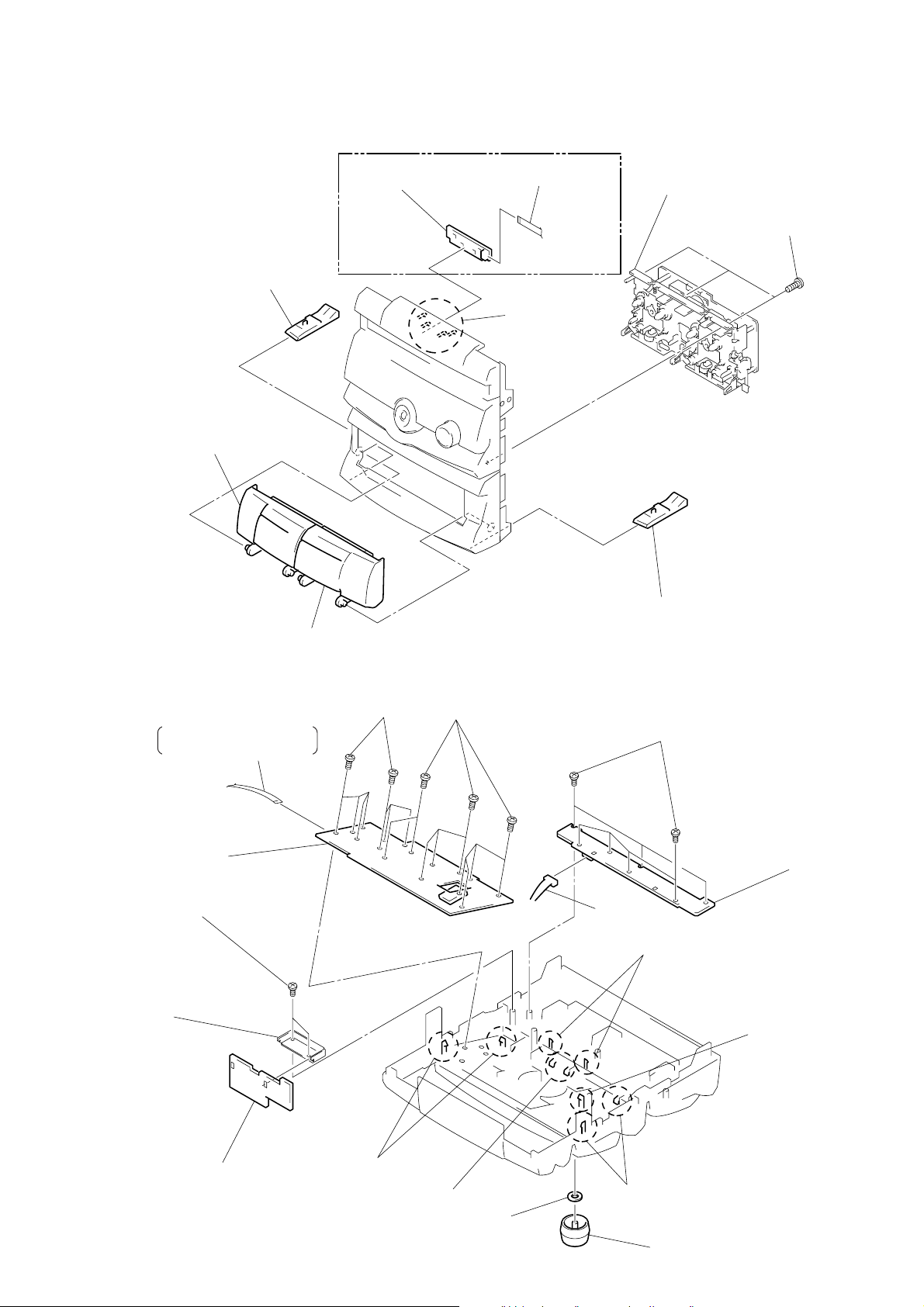

3-3. TC MECHANISM DECK AND DECO BOARD (Except US, CND)

1

Push the buttons (EJECT) 4 and 5.

5

Button (EJECT)

6

Cassette lid (A)

assembly

8

DECO board

9

Flat type wire (5 core)

Except US, CND

Claws

3

TC mechanism deck

2

Three screws

(+BVTP2.6x8)

7

Cassette lid (B) assembly

3-4. HP/MIC BOARD, DISPLAY BOARD AND TC SW BOARD

7

6

Flat type wire

8 core : US, CND

10 core : Except : US, CND

!£

Display board

1

Two screws

(+BVTP2.6x8)

2

Bracket (HP)

Seven screws

(+BVTP2.6x8)

8

Nine screws

(+BVTP2.6x8)

!¢

!¶

Connector

(CN607)

4

Button (EJECT)

Seven screws

(+BVTP2.6x8)

!∞

Claws

!§

TC SW board

!™

Claw

3

HP/MIC board

• Abbreviation

CND: Canadian model

9

Claws

0

Claws

5

Nut

— 9 —

!¡

Claws

4

Knob (Vol)

3-5. DISC TRAY

(Perform after removing the front panel.)

4

Two claws

2

5

3

Flat type wire (8 core)

Pull-out the disc tray.

Remove the disc tray.

Note: When installing the Disc tray, pull around the flat type wire to

pass through the claw

A

and claw B, as shown in the figure.

Claw

A

1

Turn the cam to the

direction of arrow.

Claw

B

— 10 —

SECTION 4

SERVICE MODE

MC Cold Reset

• The cold reset clears all data including preset data stored in the RAM to initial conditions. Execute this mode when returning the set to the

customer.

Procedure:

1. Press three buttons SPECTRUM ANALYZER , ENTER/NEXT , and DISC 1 simultaneously.

2. The fluorescent indicator tube becomes blank instantaneously, and the set is reset.

CD Delivery Mode

• This mode moves the pick-up to the position durable to vibration. Use this mode when returning the set to the customer after repair.

Procedure:

1. Press POWER button to turn the set ON.

2. Press PLAY MODE button and POWER button simultaneously.

3. A message “LOCK” is displayed on the fluorescent indicator tube, and the CD delivery mode is set.

MC Hot Reset

• This mode resets the set with the preset data kept stored in the memory. The hot reset mode functions same as if the power cord is plugged

in and out.

Procedure:

1. Press three buttons SPECTRUM ANALYZER , ENTER/NEXT , and DISC 2 simultaneously.

2. The fluorescent indicator tube becomes blank instantaneously, and the set is reset.

Sled Servo Mode

• This mode can run the CD sled motor freely. Use this mode, for instance, when cleaning the pick-up.

Procedure:

1. Select the function “CD”.

2. Press three buttons SPECTRUM ANALYZER , ENTER/NEXT , and FUNCTION simultaneously.

3. The Sled Servo mode is selected, if “CD” is blanking on the fluorescent indicator tube.

4. With the CD in stop status, press ) button in CD section to move the pick-up to outside track, or 0 button to inside track.

5. To exit from this mode, perform as follows:

1) Move the pick-up to the most inside track.

2) Press three buttons in the same manner as step 2.

Note:

• Always move the pick-up to most inside track when exiting from this mode. Otherwise, a disc will not be unloaded.

• Do not run the sled motor excessively, otherwise the gear can be chipped.

Change-over of FUNCTION Name

• The FUNCTION name of external input terminal can be changed over to VIDEO or MD. With the FUNCTION selected to “MD”, about

5dB mute is applied to the input gain.

Procedure:

1. Press POWER button to turn the set OFF.

2. Press POWER button together with FUNCTION button, and the power is turned on, the display of fluorescent indicator tube changes

to “MD” or “VIDEO” instantaneously, and thus the FUNCTION is changed over.

Change-over of AM Tuner Step between 9kHz and 10kHz

• A step of AM channels can be changed over between 9kHz and 10kHz.

Procedure:

1. Press POWER button to turn the set ON.

2. Select the function “TUNER”, and press TUNER/BAND button to select the BAND “AM”.

3. Press POWER button to turn the set OFF.

4. Press ENTER/NEXT and POWER buttons simultaneously, and the display of fluorescent indicator tube changes to “AM 9k STEP” or

“AM 10k STEP”, and thus the channel step is changed over.

LED and Fluorescent Indicator Tube All Lit, Key Check Mode

Procedure:

1. Press three buttons SPECTRUM ANALYZER , ENTER/NEXT , and DISC 3 simultaneously.

2. LEDs and fluorescent indicator tube are all turned on.

Press DISC 2 button, and the key check mode is activated.

3. In the key check mode, the fluorescent indicator tube displays “K 1 V0 J0”. Each time a b utton is pressed, “K”value increases . Howe ver ,

once a button is pressed, it is no longer taken into account.

“J” Value increases like 1, 2, 3 ... if rotating JOG knob in “+” direction, or it decreases like 0, 9, 8 ... if rotating in “-” direction.

“V” Value increases like 1, 2, 3 ... if rotating VOLUME knob in “+” direction, or it decreases like 0, 9, 8 ... if rotating in “-” direction.

4. To exit from this mode, press three buttons in the same manner as step 1, or disconnect the power cord.

— 11 —

Aging Mode

This mode can be used for operation check of CD section and tape deck section.

• If an error occurred:

The aging operation stops.

• If no error occurs:

The aging operation continues repeatedly.

1. Aging Mode in CD Section

1-1. Operating procedure of Aging Mode

1. Set discs in DISC 1 and DISC 2 trays.

2. Select the function “CD”.

3. Press three buttons SPECTRUM ANALYZER , ENTER/NEXT , and KARAOKE PON/MPX simultaneously.

4. The aging mode is activated, if a roulette mark on the fluorescent indicator tube is blinking.

5. In the aging mode, the aging is executed in a sequence given in “1-2. Operation during Aging Mode”.

The aging continues unless an alarm occurred.

6. To exit from the aging mode, press POWER button to turn the set OFF.

• If a button other than buttons In CD section is pressed during aging, the aging in the CD section is finished.

• To execute aging to the tape deck section successively, press · button in the deck A.

“AGING” is displayed on the fluorescent indicator tube. (For the aging in tape deck, see “2. Aging Mode in Tape Deck Section”.

1-2. Operation during aging Mode

In the aging mode, the program is executed in the following sequence.

1. The disc table is ejected.

2. The disc tray turns to select a disc. (For a disc selection sequence, see Section 1-3.)

3. TOC of disc is read.

4. The pick-up accesses to the last track.

5. Disc table is ejected.

6. Steps 2 through 5 are repeated.

1-3. Disc Selection Sequence

• During the aging mode, discs are selected in the following sequence:

Disc 1 → Disc 2

↑↓

Disc 2 ← Disc 1

2. Aging Mode in Tape Deck Section

2-1. Operating procedure of Aging Mode

1. Load a commercially available 10-minute tape into the decks A and B respectively.

(If a 10-minute tape is not available, another tape may be used but a cycle time will be longer.)

2. Select the function “TAPE”.

3. Rewind tapes in advance by pressing 0 button respectively on decks A and B.

4. Press three buttons SPECTRUM ANALYZER , ENTER/NEXT , and KARAOKE PON/MPX simultaneously.

5. Press · button on deck A. (This button triggers the aging mode.)

6. The aging mode is activated if “AGING A” is displayed on the fluorescent indicator tube.

7. In the aging mode, the aging is executed in a sequence given in “2-2. Operation during Aging Mode”.

The aging continues unless an alarm occurred.

8. To exit from the aging mode, press POWER button to turn the set OFF.

2-2. Operation during Aging Mode

In the aging mode, the program is executed in the following sequence.

1. A tape on FWD side is played for one minute.

2. PAUSE STOP is made.

3. Recording is made for 3 minutes. (For the deck not having the record function, the play is executed. In this case, · LED does not

light up.)

4. FF is executed up to the end of tape.

5. A tape is reversed, and the tape on REV side is played for one minute.

6. PAUSE STOP is made.

7. Recording is made for 3 minutes. (For the deck not having the record function, the play is executed. In this case, ª LED does not

light up.)

8. FF is executed up to the end of tape.

9. Steps 1 through 8 are executed for the other deck.

10. Steps 1 through 9 are repeated unless an alarm occurred.

2-3. Deck Selection Sequence

• During the aging mode, decks are selected in the following sequence:

Deck A (FWD) → Deck A (REV)

↑↓

Deck B (REV) ← Deck B (FWD)

— 12 —

SECTION 5

MECHANICAL ADJUSTMENTS

SECTION 6

ELECTRICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

Torque Measurement

Torque

FWD

FWD

back tension

REV

REV

back tension

FF/REW

FWD tension

REV tension

Torque meter

CQ-102C

CQ-102C

CQ-102RC

CQ-102RC

CQ-201B

CQ-403A

CQ-403R

Meter reading

36 to 61 g • cm

(0.5 - 0.84 oz • inch)

2 to 6 g • cm

(0.02 - 0.08 oz • inch)

36 to 61 g • cm

(0.5 - 0.84 oz • inch)

2 to 6 g • cm

(0.02 - 0.08 oz • inch)

61 to 143 g • cm

(0.85 - 1.99 oz • inch)

100 g or more

(3.53 oz or more)

100 g or more

(3.53 oz or more)

DECK SECTION 0 dB=0.775V

1. Demagnetize the record/playback head with a head damagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjusted.

4. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit adjustment.)

6. The adjustments should be performed for both L-CH and R-CH.

7. Switches and controls should be set as follows unless otherwise

specified.

Signal

P-4-A100

WS-48B

P-4-L300

10 kHz, –10 dB

3 kHz, 0 dB

315 Hz, 0 dB

Record/Playback Head Azimuth Adjustment

(Deck A, Deck B)

Note: Perform this adjustments for both decks.

Procedure:

1. Mode : Playback

test tape

P-4-A100

(10kHz, –10dB)

main board

CN403

3

(L-CH)

Pin

1

(R-CH)

Pin

Used forTape

Azimuth Adjustment

Tape Speed Adjustment

Level Adjustment

level meter

set

main board

CN403

2

(GND)

Pin

+

–

— 13 —

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw so

that outputs match within 1 dB of peak.

Tape Speed Adjustment (Deck A)

Note: Set the test mode using the following method and begin tape

speed adjustment.

In the test mode, the tape will move at double speed while

the HIGH SPEED DUBBING button is pressed.

L-CH

peak

R-CH

screw

position

peak

3. Mode: Playback

test tape

P-4-A100

(10kHz, –10dB)

output

within

level

1dB

L-CH

peak

main board

CN403

3

(L-CH)

Pin

L

set

R

Pin

1

(R-CH)

Waveform of oscilloscope

Pin

2

(GND)

R-CH

peak

oscilloscope

within 1dB

screw

position

Procedure:

With the power turned ON, press the SPECTRUM ANALYZER

button, ENTER/NEXT button, and EFFECT ON/OFF button

simultaneously.

(The “VOLUME” on the fluorescent display tube will blink while

in the test mode.)

To exit the test mode, press the POWER button.

1. Load WS-48B into deck A and a recordable tape into deck B.

2. Press the r REC button, and press the · button of deck B to

set deck B into the recording state.

3. Play deck A.

4. While pressing the HIGH SPEED DUBBING button, set double

speed play.

5. Adjust RV652 of the AUDIO board so that the reading of the

frequency counter becomes 6000 ± 30 Hz.

6. Release the HIGH SPEED DUBBING button to set normal

speed play.

7. Adjust RV651 of the AUDIO board so that the reading of the

frequency counter becomes 3000 ± 15 Hz.

Adjustment Location: AUDIO board

Playback Level Adjustment (Deck A, Deck B)

Procedure:

Mode: Playback

test tape P-4-L300

(315Hz, 0dB)

set

level meter

in phase

45˚

90˚

135˚ 180˚

wronggood

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

Adjustment Location: Playback Head (Deck A)

Record/Playback/Erase Head (Deck B)

foward

reverse

main board

CN403 Pin

Pin

3

(L-CH)

1

(R-CH)

Deck A is RV311 (L-CH) and RV411 (R-CH), deck B is RV301

(L-CH) and RV401 (R-CH)

so that adjustment within the following adjustment level.

Adjustment level:

CN403 playback level: 301.5 to 338.3 mV (–8.2 to –7.2 dB)

level difference between the channels: within ± 0.5 dB

Adjustment Location: AUDIO board

— 14 —

Record Bias Adjustment (Deck B)

Record Level Adjustment (Deck B)

Procedure:

INTRODUCTION

When set to the test mode performed in Tape Speed Adjustment, when the tape is rewound after recording, the “REC memory

mode” which rewinds only the recorded portion and playback is

set.

This “REC memory mode” is convenient for performing this adjustment. During recording, the input signal FUNCTION will automatically switch to VIDEO.

1. Press FUNCTION button to select VIDEO. (This step is not

necessary if the above test mode has already been set.)

2. Load a tape into deck B, and press the r REC button.

3. Mode: Record

VIDEO/MD (AUDIO) IN

1) 315Hz

2) 10kHz

AF OSC

attenuator

} 50 mV (–23.8 dB)

Ω

600

blank tape

CS-123

set

4. Mode: Playback

recorded

position

level meter

Procedure:

INTRODUCTION

When set to the test mode performed in Tape Speed Adjustment, when the tape is rewound after recording, the “REC memory

mode” which rewinds only the recorded portion and playback is

set.

This “REC memory mode” is convenient for performing this

adjustment. During recording, the input signal FUNCTION will

automatically switch to VIDEO.

1. Press FUNCTION button to select VIDEO. (This step is not

necessary if the above test mode has already been set.)

2. Load a tape into deck B, and press the r REC button.

3. Mode: Record

VIDEO/MD (AUDIO) IN

315 Hz 50 mV (–23.8 dB)

AF OSC

attenuator

Ω

set

blank tape

CS-123600

4. Mode: Playback

recorded

position

level meter

set

main board

CN403 Pin

Pin

3

(L-CH)

1

(R-CH)

5. Confirm playback the signal recorded in step 2 become adjustment level as follows.

If these levels do not adjustment level, adjust the RV341 (LCH) and RV441 (R-CH) on the AUDIO board to repeat steps 3

and 4.

Adjustment level: The playback output of 10 kHz le vel dif ference

against 315 Hz reference should be ± 1.0 dB.

Adjustment Location: AUDIO board

Adjustment Location

[AUDIO BOARD] (Conductor Side)

RV341(Lch),R V441(Rch)

Record Bias

RV301

RV401

RV441 R V341

RV301(Lch),RV401(Rch)

Playback Level (Deck B)

RV651 (Normal Speed)

RV652 (High Speed)

Tape Speed

RV311(Lch),RV411(Rch)

Playback Level (Deck A)

RV652RV651

RV311

RV411

set

main board

CN403 Pin

Pin

3

(L-CH)

1

(R-CH)

5. Confirm playback the signal recorded in step 2 become adjustment level as follows.

If these levels do not adjustment level, adjust the RV301 (LCH) and RV351 (R-CH) on the MAIN board to repeat steps 3

and 4.

Adjustment level:

CN403 playback level: 47.2 to 53.0 mV (–24.3 to –23.3 dB)

Adjustment Location: MAIN board

RV301

[MAIN BOARD] (Component Side)

Record Level (L CH)

13

CN403

IC401

RV351

Record Level

(R CH)

— 15 —

TUNER SECTION 0dB=1µV

Note 1: As a front-end (FE1) is difficult to r epair if faulty, replace

it with new one.

Note 2: No adjustment is needed due to a tuner pack for except

AEP, UK, German, East European, CIS models.

AM Tuned Level Adjustment

Note: FM Tuned Level adjustment should be performed after this

AM Tuned Level Adjustment.

Setting:

Band: MW

loop antenna

AM RF SSG

loop antenna

(Supplied accessories)

set

30% amplitude

modulation by

400Hz signal

Modulation: 999 kHz (at 9 kHz step)

1,050 kHz (at 10 kHz step)

Field strength dB (µV/m) = SSG output level dB (µV/m) –26dB.

60cm

Procedure:

1. Set the output of SSG so that the input level of the set becomes

55 dB or 58 dB. (55 dB: Except East European, CIS model, 58

dB: East European, CIS model)

2. Tune the set to 999 kHz or 1,050 kHz.

3. Adjust RV41 to the point (moment) when the TUNED indicator

will change from going off to going on.

Adjustment Location: TCB board

FM Tuned Level Adjustment

Note: This adjustment should be performed after the AM Tuned

Level Adjustment.

Setting:

FM RF SSG

75

Ω

coaxial

set

Carrier frequency: 98MHz

Modulation: AUDIO 1kHz, 75kHz

Output level: 25dB (at 75

deviation (100%)

23dB (at 75

Ω

open) (Except East European, CIS model)

Ω

open) (East European, CIS model)

FM ANTENNA terminal (TM1)

AM antenna

terminal (TM1)

Adjustment Location

[TCB BOARD] (Component Side)

TM1

RV41

AM Tuned Level

RV42

FM T uned

Level

IC21

Band: FM

Procedure:

1. Supply a 25 dB or 23 dB 98 MHz signal from the ANTENNA

terminal.

2. Tune the set to 98 MHz.

3. Adjust R V42 to the point (moment) when the TUNED indicator

will change from going off to going on.

Adjustment Location: TCB board

— 16 —

FM Polar Adjustment (East European, CIS model only)

Connection 1 :

FM RF SSG

Carrier frequency: 69 MHz

Output level: 1 mV (60 dBµ) (at 75

Modulation: AUDIO 1 kHz, 10 kHz deviation

75

Ω

coaxial

FM antenna

terminal (75

Ω

open)

set

Ω

)

Connection 2 :

AF OSC

FM RF SSG

75 Ω coaxial

set

Procedure :

1. Set the modulation of FM RF SSG to AUDIO 1 kHz, 10 kHz

deviation according to “Connection 1”.

2. Tune the set to 69 MHz.

3. Adjust the R V1702 so that the reading of frequency counter connected to TP1702 (VCO) becomes within 31.25 kHz ± 0.05 kHz.

(VCO adjustment)

4. Then record the reading of the level meter connected to TP1701.

5. Set the modulation of FM RF SSG to AUDIO 31.25 kHz, 10

kHz deviation according to “Connection 2”.

6. Tune the set to 69 MHz.

7. Set the CT1701 to be mechanical center.

8. Adjust the L1701 so that the reading of the level meter connected to TP1701 (FILTER) becomes maximum.

Then adjust the CT1701 so that the reading of the level meter

connected to TP1701 (FIL TER) becomes maximum. (SUB CARRIER PEAK Adjustment)

9. Adjust the RV1701 so that the level at the moment becomes 14

dB higher value than the level recorded in step 4. (SUB CARRIER LEVEL Adjustment)

Audio 31.25kHz

Carrier frequency: 69 MHz

Output level: 1 mV (60 dBµ) (at 75

Modulation: AUDIO 31.25 kHz, 10 kHz deviation

external

modulation

terminal

(EXTERNAL MODULATION)

Ω

open)

FM antenna

terminal (75

Adjustment Location: TCB board

Adjustment Location

[TCB BOARD] (Conductor Side)

frequency counter

+

_

level meter

TP1701

(FILTER)

IC1701

TP1702

(VCO)

Ω

)

[TCB BOARD] (Component Side)

L1701

CT1701

RV1701

Sub Carrier

Level

IC1701

RV1702

VCO

Sub Carrier Peak

— 17 —

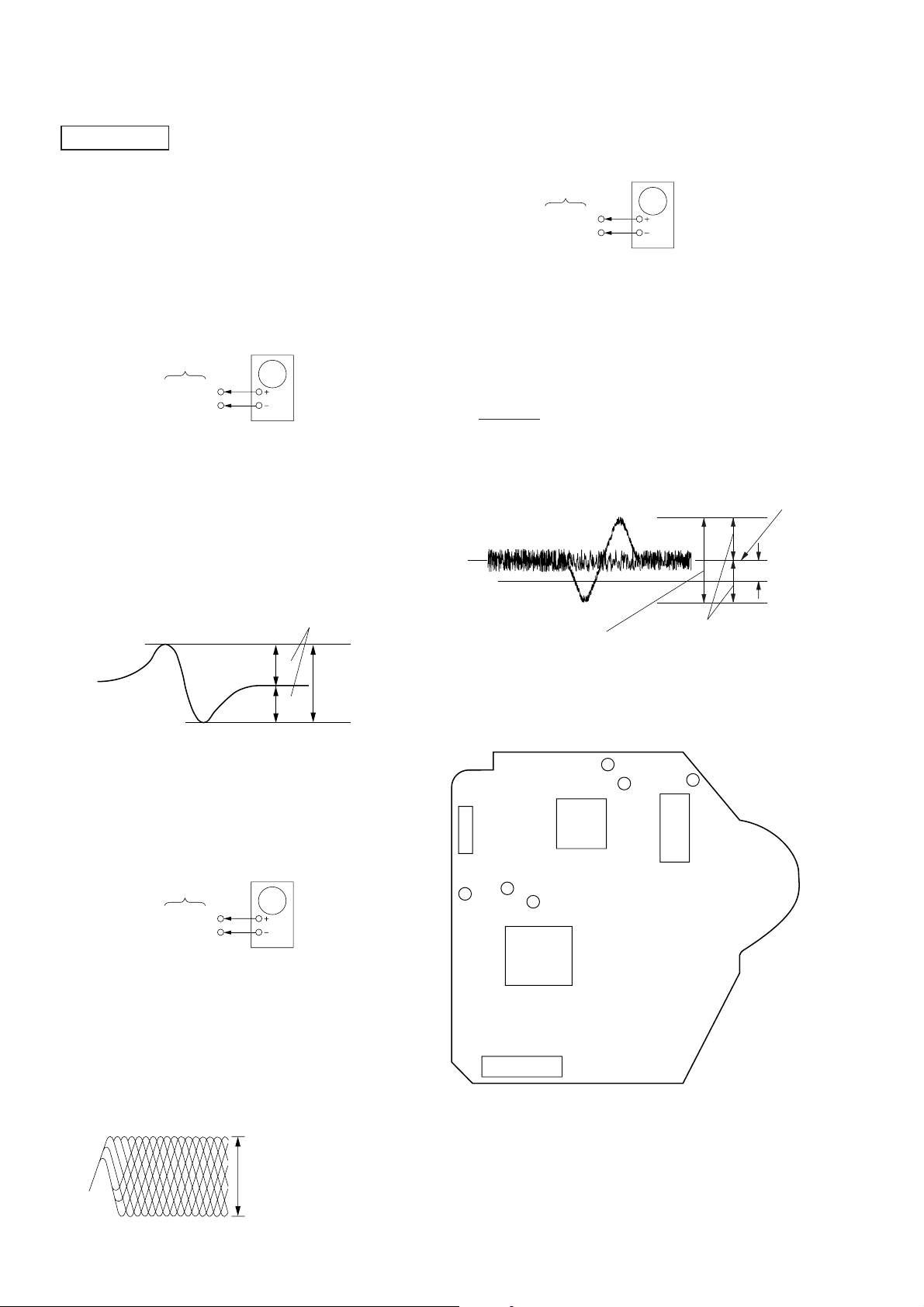

CD SECTION

E-F Balance (1 Track Jump) check

Note:

1. CD Block is basically constructed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10M impedance.

4. Clean the object lens by an applicator with neutral detergent when

the signal level is low than specified value with the following

checks.

S Curve Check

oscilloscope

BD board

TP (FEO)

TP (VC)

Procedure :

1. Connect oscilloscope to test point TP (FEO).

2. Connect between test point TP (FOK) and Ground by lead wire.

3. Turn Power switch on.

4. Put disc (YEDS-18) in and turned Power switch on again and

actuate the focus search. (actuate the focus search when disc

table is moving in and out.)

5. Check the oscilloscope waveform (S-curve) is symmetrical between A and B. And confirm peak to peak le vel within 3 ± 1Vp-p.

S-curve waveform

symmetry

oscilloscope

BD board

TP (TEO)

TP (VC)

Procedure:

1. Connect oscilloscope to test point TP (TEO) on BD board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in to play the number five track.

4. Press the “P (Pause)” button.

5. Check the level B of the oscilloscope's wav eform and the A (DC

voltage) of the center of the Traverse waveform.

Confirm the following:

A – B

• x 100 = less then ± 7 (%)

2 (A + B)

• A + B = 500 ± 100 mVp-p

1 track jump waveform

0V

level : 500 mV ± 100 mVp-p

Center of the waveform

B

A (DC voitage)

Symmetry

A

within 3 ± 1 Vp-p

B

6. After check, remove the lead wire connected in step 2.

Note: • Try to measure several times to make sure than the ratio of

A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the brightness to obtain best waveform.

RF Level Check

oscilloscope

BD board

TP (RF)

TP (VC)

Procedure :

1. Connect oscilloscope to test point TP (RF) on BD board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Confirm that oscilloscope waveform is clear and check RF signal level is correct or not.

Note: Clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

Adjustment Location:

[BD BOARD] (Conductor Side)

TP (RF)

TP

(FOK)

IC101

CN101

TP

(TEO)

TP

TP

(GND)

(FEO)

IC103

IC102

TP

(VC)

IC102

RF signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 nS

level: 1.3 ± 0.3 Vp-p

— 18 —

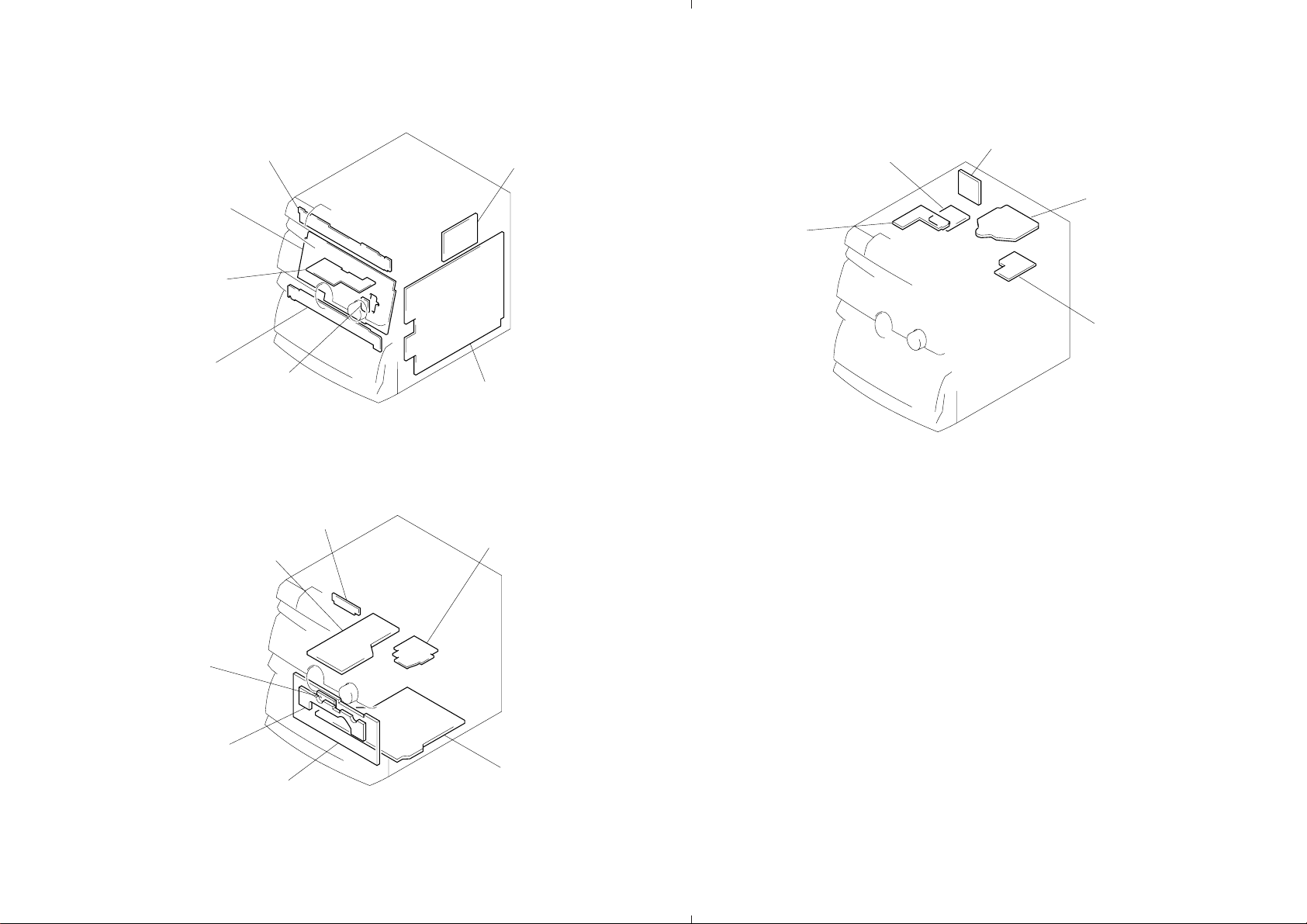

7-1. CIRCUIT BOARDS LOCATION

DIAGRAMS

PANEL board

(including

HP/MIC board

TC SW board

CD SW board

p

B)

p

B

DECO board

(Exept D90AV/RX100AV: US, CND)

TRANS board

ENCAPSULATED COMPONENT

(Except AEP, UK, G, EE, CIS)

TCB board (AEP, UK, G, EE, CIS)

MAIN board

Note:pA is including in AUDIO board.

pB is including in PANEL board.

SURROUND board

SENSOR board

•Abbreviation

CND:Canadian model

G :German model

EE :East European model

CONNECTOR board

MOTOR (TURN) board

BD board

MOTOR (SLIDE) board

p

A

MOTOR board

LEAF SWITCH board

AUDIO board

(including

p

POWER board

A)

— 19 —

— 20 —

HCD-D90AV/GR10AV/RX100AV

7-2. BLOCK DIAGRAMS

— TUNER SECTION — (AEP, UK, German model)

TM1

ANTENNA

FM 75Ω

COAXIAL

AM

09

ST +10V

Q5

FE1

FM FRONT END

ANT IN

VT

1710

FM

VT1

IF OUT

Q13

MW

SW

9

MW

6

5

3

2

26 25 24 23 22 21

Q14

LW SW

CF1

10.7MHz

FE2

MW/LW FRONTEND

Q12

MW

SW

IF AMP

Q1, 2

12

13

14

15

16

20

PLL

IC21

17

Q11

MW

SW

LW SW

Q9

11

IF AMP

Q3, 4

RV42

TUNED

LEVEL

MW

CF2

10.7MHz

CF3

10.7MHz

4

REG

29

AM OSC

AM RF IN

27

FM SD

30 14

FM

AM OSC

7

AM/FM

15

2

FM

AM MIX

IF BUFF

VCO STOP

11

1214

8

FM/AM IF

VCO STOP

1 FM IN

FM/AM MPX

AM

SD

AM

MUTE

SD

D41

IF REQ

IC41

12

13

2

RV41

X42

450kHz

1 24

AM

TUNED

LEVEL

XIN

AM IF

IFT1

XOUT

X21

4.5MHz

X41

10.7MHz

X43

456kHz

24 22

AM/FM

5

AM IF

8

STEREO

9

DET

7

TUNED

VCO

23

3 ST-CE

CE

4

DI

5

CL

DO

6

OUT L

MPX IN

OUT R

IC1751

57

ST L

RDS INT

RDS DATA

STEREO

TUNED

MUTE

COM-DIN

COM-CLK

COM-DATA

RDS DECODER

4

13 14

20

LPF

RCH

21

IC1752

X1751

4.332MHz

• R CH: Same as L ch

• SIGNAL PATH

: FM

: MW

A

MAIN

SECTION

(Page 29)

18

2

16

AMP IN L

AMP

16

OUT

L

— 21 —

— 22 —

— TUNER SECTION — (East European, CIS model)

ST +10V

Q5

TM1

ANTENNA

FM 75Ω

COAXIAL

ANT IN

AM

1710

FM

VT1

09

FE1

FM FRONT END

IF OUT

VT

LW SW

Q13

MW

SW

9

MW

6

5

3

2

26 25 24 23 22 21

Q14

CF1

10.7MHz

MW/LW FRONTEND

Q12

MW

SW

HCD-D90AV/GR10AV/RX100AV

CF3

10.7MHz

IF AMP

Q1-4

FE2

12

LW SW

13

14

15

16

20

PLL

IC21

17

Q11

MW

SW

4

Q9

11

REG

29

AM OSC

27

AM RF IN

FM SD

30 14

RV42

FM

TUNED

LEVEL

MW

AM OSC

7

AM/FM

15

FM

VCO STOP

11

2

1214

VCO STOP

AM MIX

MUTE

IF BUFF

8

IF REQ

FM/AM IF

1 FM IN

FM/AM MPX

IC41

2

AM

12

SD

AM

13

SD

D41

RV41

X42

450kHz

TUNED

1 24

XIN

LEVEL

AM

AM IF

XOUT

IFT1

X21

4.5MHz

X41

10.7MHz

X43

456kHz

5

9

23

AM IF

DET

VCO

D42 D43

AM/FM

STEREO

TUNED

13

LW/SW

MPX IN

22

24

SUB CARRIER

PEAK

L1701CT1701

TP1701

CE

DI

CL

DO

RV1701

SUB CARRIER

LEVEL

3

4

5

6

8

7

POLAR

DECODER

IC1701

2

IN

L OUT

3

POUT

R OUT

MON

SUB IN

20

18 17

TP1702

VCO

VCO

RV1702

20OUT L

POLAR/PILOT

SWITCH

IC1702

C0

5

C. COM

CA

SWITCH

Q1702

9 11

D1704

A. COM

D1701

D1702

4

14

SWITCH

Q1703

D1703

ST IND

910

C1

3

VCO

STOP

7

6

R CH

R CH

SWITCH

LPF 18

Q1701

AMP

AMP

IN

16

OUT

L

L

• R CH: Same as L ch

• SIGNAL PATH

: FM

: MW

ST-L

STEREO

TUNED

MUTE

ST-CE

COM-DIN

COM-CLK

COM-CLK

A

MAIN

SECTION

(Page 29)

— 23 —

— 24 —

HCD-D90AV/GR10AV/RX100AV

— CD SECTION —

OPTICAL PICK-UP BLOCK

B+

K

DETECTOR

E

A

D

A

D

C

B

C

B

F

LASER

DIODE

FOCUS

COIL

SLED/SPINDLE

MOTOR DRIVE

IC102 (2/2)

11

M102

SLED MOTOR

M101

SPINDLE

MOTOR

09

M

M

12

13

14

•

•

SLED MOTOR

SPINDLE MOTOR

TRACKING

COIL

2-AXIS

DEVICE

DRIVE

DRIVE

IC841

1

D.OUT

FOCUS/TRACKING SERVO.

RF AMP

IC101 (1/2)

1

4

2

5

10

6

LD DRIVE

T+

–

T

–

F

F+

6

3

Q101

15

16

18

17

38

PD1

39

PD2

41

F

42

E

2

FEI

1

FEO

TEO

45

47

TEI

3637LD

PD

TRACKING

COIL DRIVE

FOCUS/TRACKING

COIL DRIVE

IC102 (1/2)

COIL DRIVE

IC101 (2/2)

SL O

XRST

MUTE

FOCUS

SLED

SERVO

LOCK

C.OUT

SENS1

SENS2

DATA

23

9

FE M

TA M

RF O

33

19

24

25

26

6

FE O

7

12

TA O

13

22

21

XLT

CLK

20

27

FOK

27

26

1416

SL P

44

29

14

15

RF

LOCK

CNIN

SEIN

DATAO

15 16 17

XLTO

CLKO

71

DOUT

FOK

MDP

23

27

CD DIGITAL

OPTICAL

DIGITAL SIGNAL PROCESSOR

SPOD

21

S101

LIMIT

OUT

IC103

CLOK

XLAT

DATA

10 11 12 75

M701

TURN

M

MOTOR

M801

SLIDE

M

MOTOR

SQCK

SENS

SCOR

SQSO

8

79 100

MOTOR DRIVER

7

OUT1

2

OUT2

MOTOR DRIVER

4

OUT2

7

OUT1

TURN

IC701

SLIDE

IC801

X101

16.9344MHz

89 • 90

•

XTAI

XTAO

L-CH

86

LOUT1

LOUT2

93

R-CH

XRST

CD CLK

CD DATA

SENS2

SCOR

SQ DATA

SQ CLK

SENS

XRST

IN1

IN2

S801

OPEN/CLOSE

3

6

XLAT

TABLE

SENSOR

IC702

DISC

SENSOR

IC703

ROTARY

ENCODER

S811

DET

Q701

T. SENS

DISC SENS

ENC 1

ENC 2

ENC 3

OPEN

TBL.L

TBL.R

C

MAIN

SECTION

(Page 29)

• R CH: Same as L ch

2

RIN

10

FIN

LOAD IN

LOAD OUT

• SIGNAL PATH

: CD

: Digital out

— 25 —

— 26 —

— DECK SECTION —

HCD-D90AV/GR10AV/RX100AV

HP101

PB HEAD

(DECK A)

REC/PB HEAD

(DECK B)

HRPE101

ERASE HEAD

S1008

S1004

B CrO

13

2

DOLBY NR

RECOUT

NORM

24 25

15

B 120/70

BIAS SW

CROM

2

PAS

DOL

M1

CAPSTAN

MOTOR

DOLBY

TYPE B

CN403

3

R CH

1

PB OUT

8

LM ON/

20

OFF

NORM/

14

HIGH

NR ON/

18

OFF

19

PB

RIN

6

BIAS ON/OFF

16

17

RM ON/OFF

CAP M SWITCH

Q405, 407

SPEED

RV651

NORMAL

SPEED

CONTROL

Q651

RV652

HIGH

SPEED

M

+5V

S1003

(A HALF)

SWITCH

Q406

REEL

DETECT

Q1001

REEL

DETECT

Q1002

S1001 (A PLAY)

S1002 (B PLAY)

+5V

A CrO

RV311

PLAYBACK

IC601

1

IC602

R

4

REC/PB

• R CH : Same as L ch

• SIGNAL PATH

: PB (DECK A)

: PB (DECK B)

: REC (DECK B)

PLAYBACK

LEVEL

DECK A

RV301

LEVEL

DECK B

RV341

REC

BIAS

REC BIAS

T621, Q621, 622

IC611

L

R CH

R

L

R

R CH

3

P

ERASE BIAS

X

BIAS OSC

12

PB-A/B

A IN

2

B IN

4

+7.5V

Q623, 901

EQIN

10

EQOUT

11

RV301

REC LEVEL

A 120/70

70

120

DECK PROCESS

IC401

10

PB A/B

PB L

LM ON/OFF

NORM/HIGH

NR ON/OFF

REC/PB/PASS

REC L

BIAS ON/OFF

RM ON/OFF

RELAY REC/PB

CAP M ON/OFF

CAP M H / L

A SHUT

B SHUT

A PLAY

B PLAY

A HALF

B

MAIN

SECTION

(Page 29)

S1005

TRIGGER

MOTOR

DRIVE

IC402

(REC A)

S1006

(B HALF)

S1009

(REC B)

VZ

IN2

IN1

BHALF

SWITCH

4

Q408, 409

6

5

TRIG H / L

B TRIG

A TRIG

— 28 —

09

2

M2

TRIGGER

MOTOR

OUT1

M

10

OUT2

— 27 —

HCD-D90AV/GR10AV/RX100AV

— MAIN SECTION —

B

DECK

SECTION

(Page 28)

A

TUNER

SECTION

(Page 22, 24)

C

CD

SECTION

(Page 26)

09

J751

MIX MIC

OUT L

VIDEO/MD

(AUDIO)

IN L

J101

REC L

RELAY REC/PB

A SHUT

B SHUT

B HALF

A HALF

A PLAY

B PLAY

PB A / B

NORM/HIGH

BIAS ON/OFF

RM ON/OFF

NR ON/OFF

REC/PB PASS

LM ON/OFF

CAP M H/L

A TRG

B TRG

TRIG H/L

CAP M ON/OFF

RDS DATA

RDS INT

COM DIN

COM DATA

STEREO

TUNED

ST CE

MUTE

TBL. L

TBL. R

SCOR

T. SENS

SENS 2

SENS

X RST

CD CLK

CD DATA

DISC SENS

SQ CLK

SQ DATA

X LAT

OPEN

ENC-1

ENC-2

ENC-3

LOAD IN

LOAD OUT

PB L

ST L

L CH

MUTE

Q121

31

MIC AMP

V

TC

ST

CD

RV750

MIC

LEVEL

IC750

INPUT SELECT

1

2

4

5

MUTE

CONTROL

Q123,124

EXCEPT

RX100AV:

AEP,UK,G

67

IC102

3

A

10

9

B

6

INH

96

26

27

28

97

94

95

87

88

89

90

91

92

93

82

83

84

85

86

1

41

2

42

3

44

4

45

66

70

69

68

72

67

60

61

18

76

73

74

57

48

47

75

36

34

58

81

80

79

78

64

63

22

21

— 29 —

RELAY

A SHUT

B SHUT

B HALF

A HALF

A PLAY SW

B PLAY SW

PB A/B

EQ H//N

BIAS

REC MUTE

NR ON/OFF

R/P PASS

TC MUTE

CAP H/N

A TRG

B TRG

TRG LOW

CAP M ON/OFF

VOL LAT

PL LAT

COM DOUT

COM CLK

ST DIN

STEREO

TUNED

ST CE

ST MUTE

ST DOUT

TBL L

TBL R

SCOR

T SENS

SENS 2

SENS

XRST

CD CLK

CD DATA

DISC SENS

SQ CLK

SQ DATA IN

XLT

OUT OPEN

ENC1

ENC2

ENC3

LOAD IN

LOAD OUT

RDS DATA

RDS INT

RX100AV:

AEP,UK,G

DOLBY PRO LOGIC

9

LIN

3

41

DATA

4

42

CLK

2

40

EN

69

71

28

29

30

54

INPUT CHANGE

MASTER CONTROL

IC601

IC701

C-OUT

S-OUT

L-OUT

34

35

37

MICON

INTERFACE

32 33

3

4

427 LAT

34

LATCH

3

CENTER

REAR

FRONT

3

4

2

65 64

10

8

3

2

4

CD POWER

DELAY

IC602

S-IN

L-IN

DATA

CLK

EN

POWER

DBFB H/L

TA MUTE

R RELAY

IIC DATA

IIC CLK

RESET

AC CUT

STK MUTE

XT1

XT2

FRONT

X1

X2

S-OUT

L-MIX

XTAL

61

62

98

55

56

11

10

14

13

46

100

OUT

XTAL

REC 2A

2

1

7

15

20

13

16

23

24

EQ

D951

FRONT

RESET

SWITCH

Q951

RESET

IC951

+5V

X701

5MHz

X702

32.768KHz

SWITCH

X601

8MHz

MUTE

Q912

GR10AV/RX100AV

Rch

X601

8MHz

45 44 43

EQUALIZER / VOLUME

SUPER WOOFER

AMP

IC105

DATA

28

CLOCK

27

14

RESET

12

XOUT

13

XIN

SEG1-35

67 - 100 • 1

FLUORESCENT INDICATOR TUBE

D90AV

+ +

IC201

MUTE

Q130

DISPLAY CONTROL

IC601

GR1-16

51 - 66

FL601

J102

SUPER

WOOFER

REAR

CENTER

6

5

42

LED SELECT

SPEANA 1

SPEANA 2

SPEANA 3

SPEANA 4

DOOR SW

VF

SWITCH

LED1

LED8

LED10

LED15

SIRCS

JOG A

JOG B

KEY 1

VOL A

VOL B

40 41

DBFB

Q201

•

L+R

AMP

IC861

BB22

VOLUME

4

3

1

RECEIVER

3

14

8

9

10

LED

CONTROL

Q603

REMOTE

CONTROL

IC602

S601

(JOG)

ROTARY

ENCODER

KEY

MATRIX

S681

6

OPEN

IN

IN

CLK

DATA

PANEL LED

IC604

SWITCH

MUTE

Q254

MUTE

Q120

2

OUT

15

OUTLATCH

IC603

3

1

AMP

7

5

7

FRONT

38

BB12

DBFB

SWITCH

Q202

3

10

•

16

LED

•

SWITCH

18

22

•

47

29

39

42

43

D/A

44

45

46

26

41

3733KEY 5

38

S602

24

40

VOLUME

ROTARY

ENCODER

REAR

MUTE

Q602

MUTE

Q601

Q601,602

CENTER

FRONT

DBFB

POWER ON/OFF

R RELAY

D+5V

REAR

CENTER

• R CH: Same as L ch

• SIGNAL PATH

: FM

: CD

: PB

: REC

: VIDEO

: MIC

• Abbreviation

G: German model.

CD POWER

STK MUTE

D

POWER

SECTION

(Page 31)

— 30 —

— POWER SECTION —

REAR

REAR

1

POWER AMP

IC601

10

RY401

HCD-D90AV/GR10AV/RX100AV

TM402

SURROUND

–1

REAR

SPEAKER

REAR

D

MAIN

SECTION

(Page 30)

09

CENTER

FRONT

DBFB

STK MUTE

R RELAY

CD POWER

POWER ON/OFF

D90AV/GR10AV/RX100AV:

US,CND

POWER AMP

RX100AV: AEP,UK,G,EE,CIS

POWER AMP

FRONT

IC201

3 12

8

IC201

1 10

6

D5V

SW

AU/D5V SW

CENTER

Rch

SWITCHED

CD REG

Q904

+5V REG

Q906

— 31 —

THERMAL

DET

Q670,671

THP670

OVER LOAD

DET

Q201

D5V

Q905

Q907

MUTE

SWITCH

Q331

OVER LOAD

DET

Q601,651

6

Rch

+5V

D905

D7V

A+7.5V

A–7.5V

+12V

ST10V

PRO-LOG 10V

Q941

RECT

RY101

FAN MOTOR

DRIVER

Q961, 962

D104,105

CENTER

RECT

Rch

VF

VF

UNREG

–12V

FRONT

POWER

TRANSFORMER

T501

M

TM401

FRONT

SPEAKER

J750

PHONES

GR10AV : E,EA,SP,

JE,HK,IA

CENTER

M901

FAN

MOTOR

VOLTAGE

SELECTOR

S501

• R CH : Same as L ch

• SIGNAL PATH

: FM

• Abbreviation

: Canadian model.

CND

: German model.

G

: East European model.

EE

: Saudi Arabia model.

EA

AC

IN

: Singapore model.

SP

: Tourist model.

JE

: Hong Kong model.

HK

: Indonesian model.

IA

1318

Rch

Q323

+5V REG

IC902

3 1

+7V REG

IC903

3 1

+7V, –7V REG

IC901

+7.5

1

–7.5 EN

10

4

+12V REG

IC904

3 1

3 1

+10V REG

IC905

–2

RY402

–1

6

2

PROTECTOR

IC301

1

V

CC

V

EE

Q901

7

PROTECT

SWITCH

Q301

2

9

UNREG

–12V

POWER B+

POWER B–

SURR B+

SURR B–

4

RELAY

DRIVE

Q403

RECT

D901

RECT

D101

RECT

D102

RX100AV: AEP,UK,G,EE,CIS

RELAY

DRIVE

Q404

RELAY

CONTROL

Q402

RECT

D110,111

VFDP

D90AV/GR10AV/RX100AV : US,CND

RELAY

DRIVER

Q111-113

Rch

HP / SP

SWITCHING

Q401,405

D302,303

VF REG

— 32 —

Loading...

Loading...