Sony GDM-F500 Service Manual

HISTORY

When clicking an item, it’s detail is displayed.

Model Name: GDM-F500

Part No. : 9-978-620-11

Date SUP/COR No. Description of SUP/COR

1999.01 COR-1

CORRECTED PART NO. OF TRANFORMER ASSY,

FLYBACK

Change of

main text

Yes

GDM-F500

SERVICE MANUAL

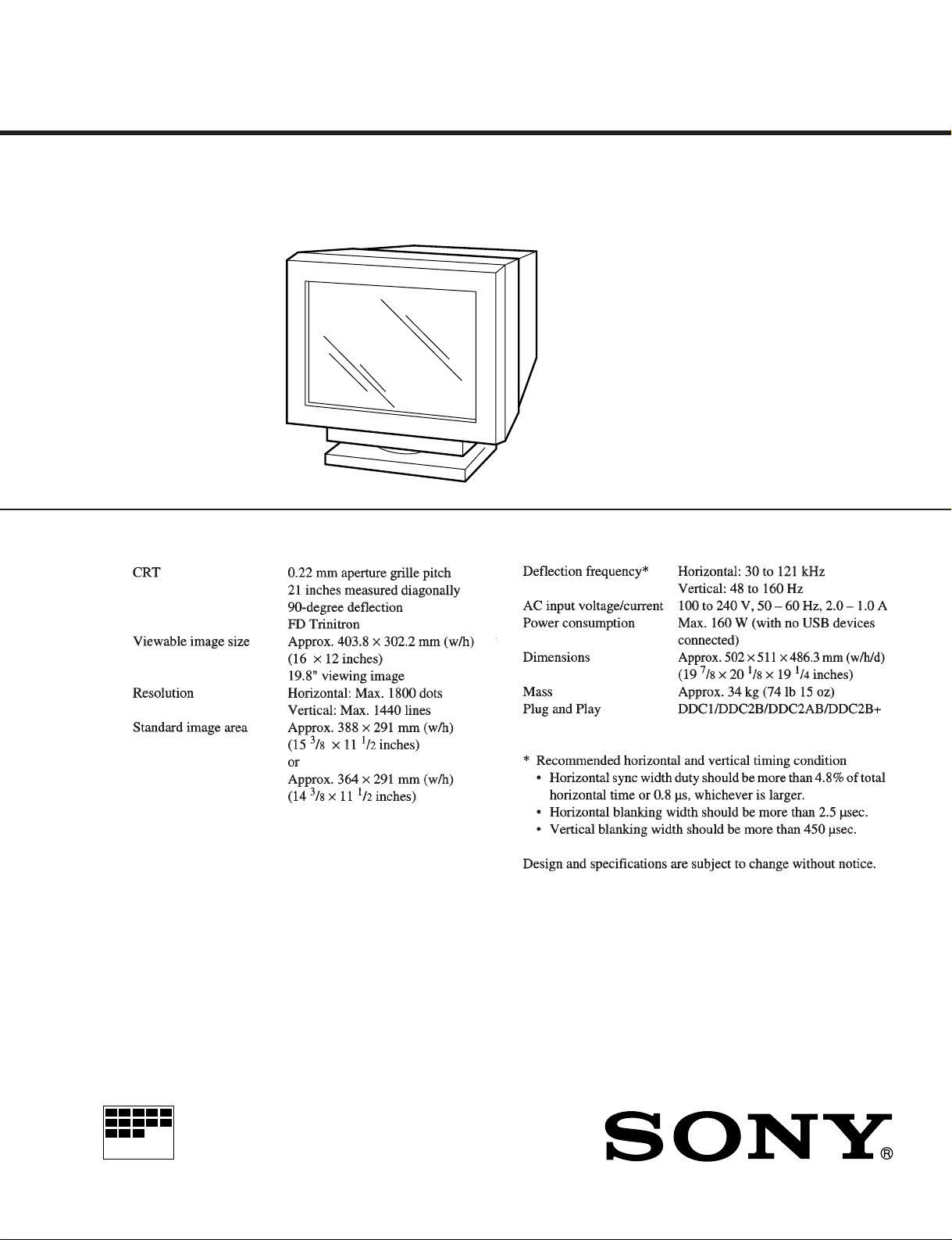

SPECIFICATIONS

US Model

Canadian Model

AEP Model

Chassis No. SCC-L03C-A

N3P

CHASSIS

MICROFILM

TRINITRON

®

COLOR GRAPHIC DISPLAY

GDM-F500

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps,

and mounting hardware have been replaced. Be absolutely

certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious

signs of deterioration. Point them out to the customer and

recommend their replacement.

6. Check the line cords for cracks and abrasion. Recommend

the replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specified values.

Make sure your instruments are accurate; be suspicious of

your HV meter if sets always have low HV.

8. Check the antenna terminals, metal trim, “metallized”

knobs, screws, and all other exposed metal parts for AC

Leakage. Check leakage as described below.

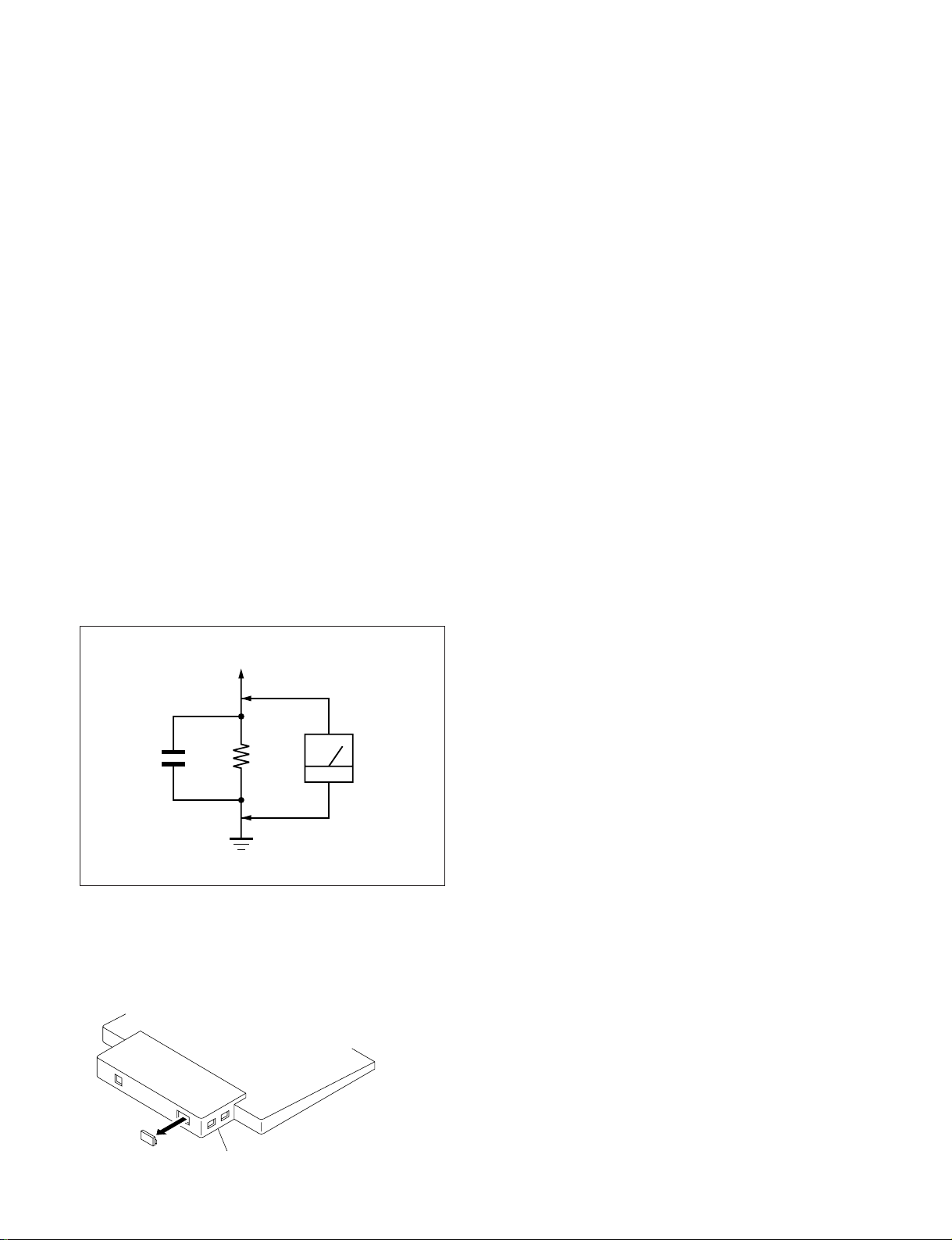

To Exposed Metal

Parts on Set

AC

0.15 µF

1.5 k

Ω

Voltmeter

(0.75 V)

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part having a return to chassis, must not exceed 0.5 mA (500

microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to

use these instruments.

2. A battery-operated AC milliammeter. The Data Precision

245 digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are

examples of a passive VOMs that are suitable. Nearly all

battery operated digital multimeters that have a 2 V AC

range are suitable. (See Fig. A)

WARNING!!

NEVER TURN ON THE POWER IN A CONDITION IN

WHICH THE DEGAUSS COIL HAS BEEN REMOVED.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK

¡ ON THE SCHEMATIC DIAGRAMS, EXPLODED

VIEWS AND IN THE PARTS LIST ARE CRITICAL FOR

SAFE OPERATION. REPLACE THESE COMPONENTS

WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE CRITICAL FOR SAFE OPERATION

ARE IDENTIFIED IN THIS MANUAL. FOLLOW THESE

PROCEDURES WHENEVER CRITICAL COMPONENTS

ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

CAUTION ON DAS (ECS) CONNECTOR

• The connector for DAS (ECS) adjustment is provided inside

the cover shown below. Be careful with an electrical shock

when connecting the connector with the power supplied. Also,

return the removed cover to the home position.

STAND

AVERTISSEMENT!!

NE JAMAIS METTRE SOUS TENSION QUAND LA

BOBINE DE DEMAGNETISATION EST ENLEVÉE.

ATTENTION AUX COMPOSANTS RELATIFS À LA

SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE TRAME ET

UNE MARQUE

¡ SONT CRITIQUES POUR LA SÉCURITÉ.

NE LES REMPLACER QUE PAR UNE PIÈCE PORTANT LE

NUMÉRO SPECIFIÉ. LES RÉGLAGES DE CIRCUIT DONT

L’IMPORTANCE EST CRITIQUE POUR LA SÉCURITÉ DU

FONCTIONNEMENT SONT IDENTIFIÉS DANS LE

PRÉSENT MANUEL. SUIVRE CES PROCÉDURES LORS

DE CHAQUE REMPLACEMENT DE COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS FONCTIONNE-MENT

EST SUSPECTÉ.

– 2 –

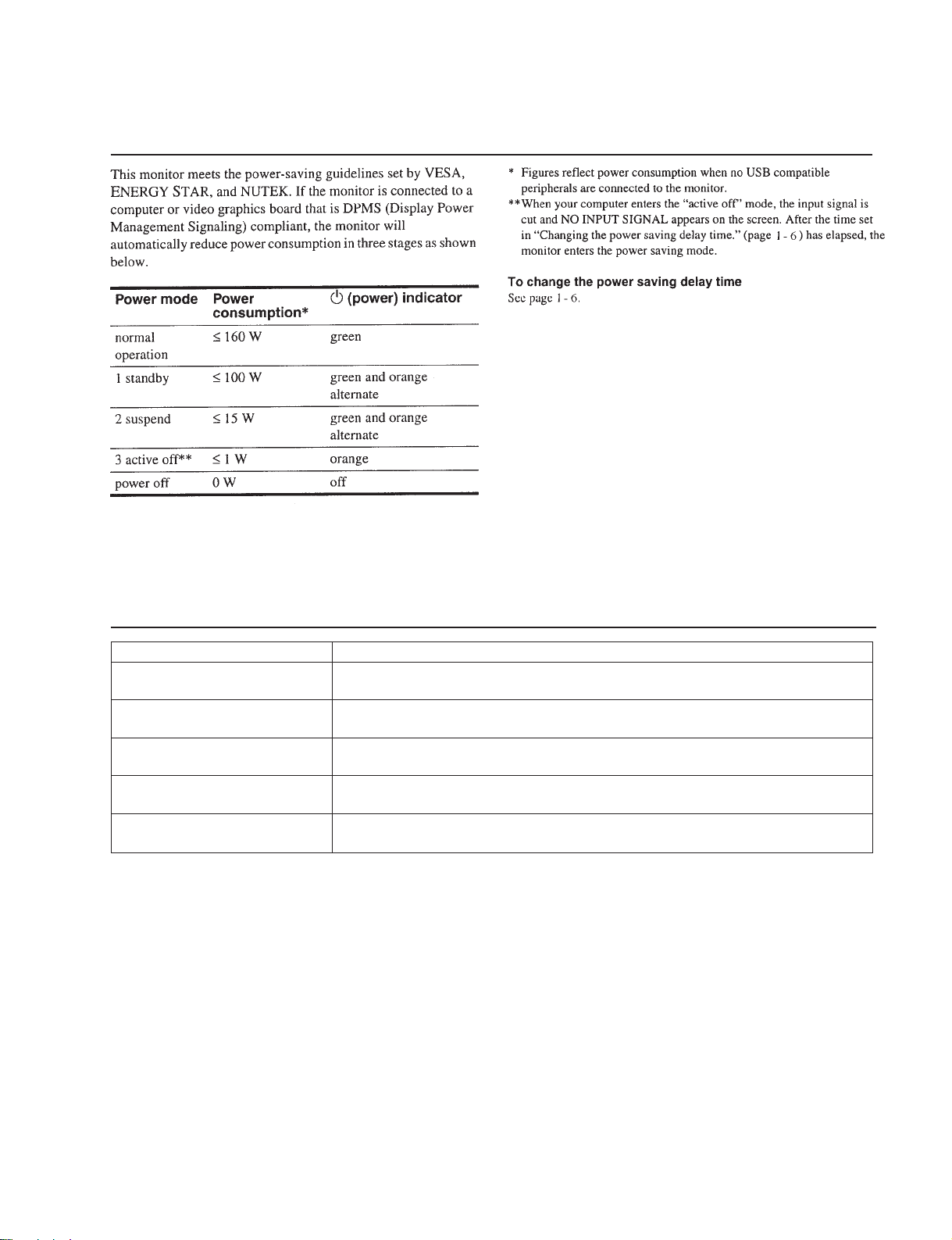

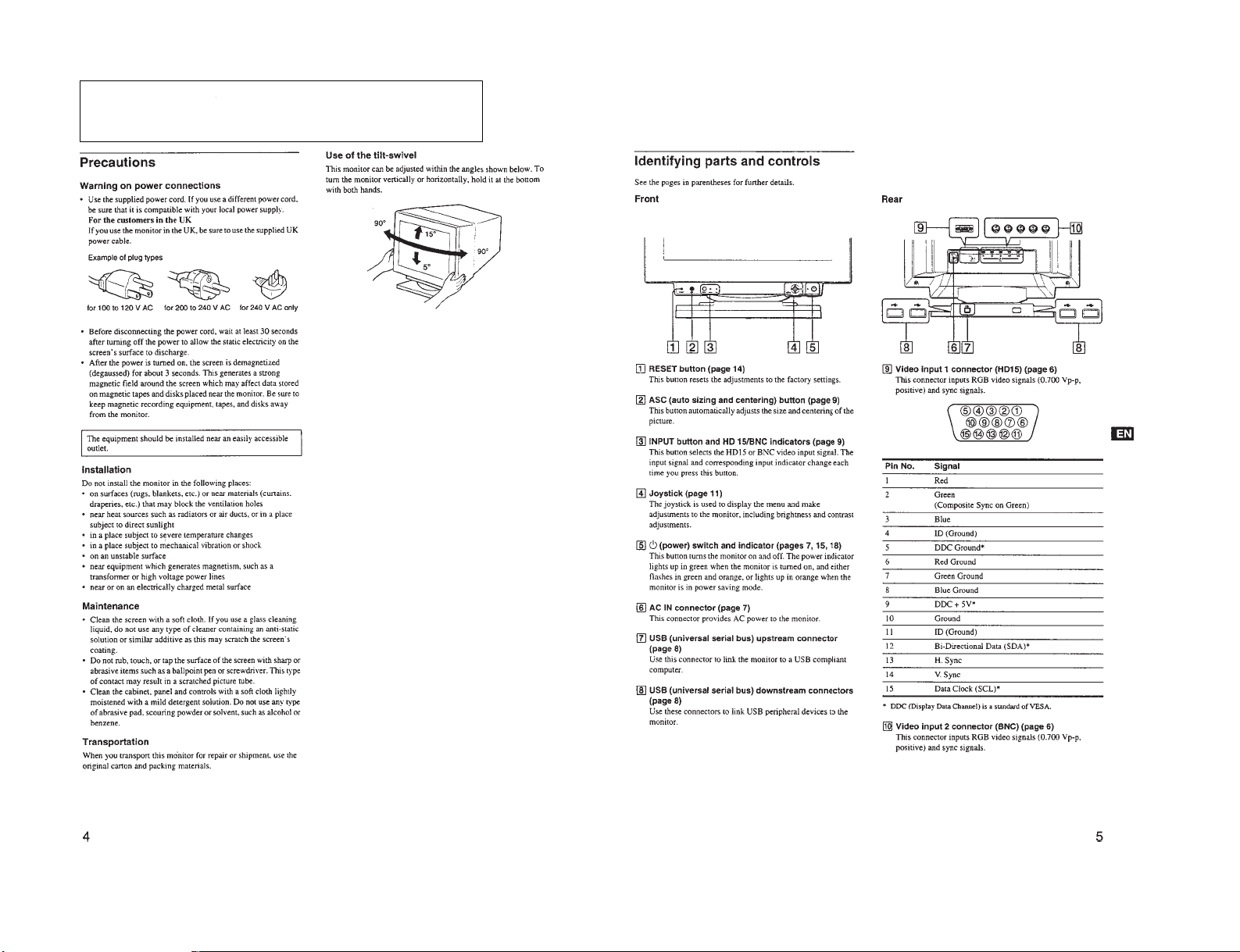

POWER SAVING FUNCTION

GDM-F500

DIAGNOSIS

Failre

+B failure

Horizontal / Vertical Deflection

failure, Thermal protector

ABL protector

HV failure

Aging / Self Test

Aging Mode (Video Aging) : During Power Save, press “MENU” key for longer than 2 second.

Self Test (OSD Color Bar) : During Power Save, press “CONTRAST” + (/) key for longer than 2 second.

Reliability Check Mode : During Power Save, press “CONTRAST” – (?) key for longer than 2 second.

Orange → Off

(0.5 sec) (0.5 sec)

Orange → Off

(1.5 sec) (0.5 sec)

Orange → Off

(0.5 sec) (1.5 sec)

Orange → Off → Orange → Off

(0.25 sec) (0.25 sec) (0.25 sec) (1.25 sec)

Orange → Off → Green → Off

(0.5 sec) (0.5 sec) (0.5 sec) (0.5 sec)

Power LED

– 3 –

GDM-F500

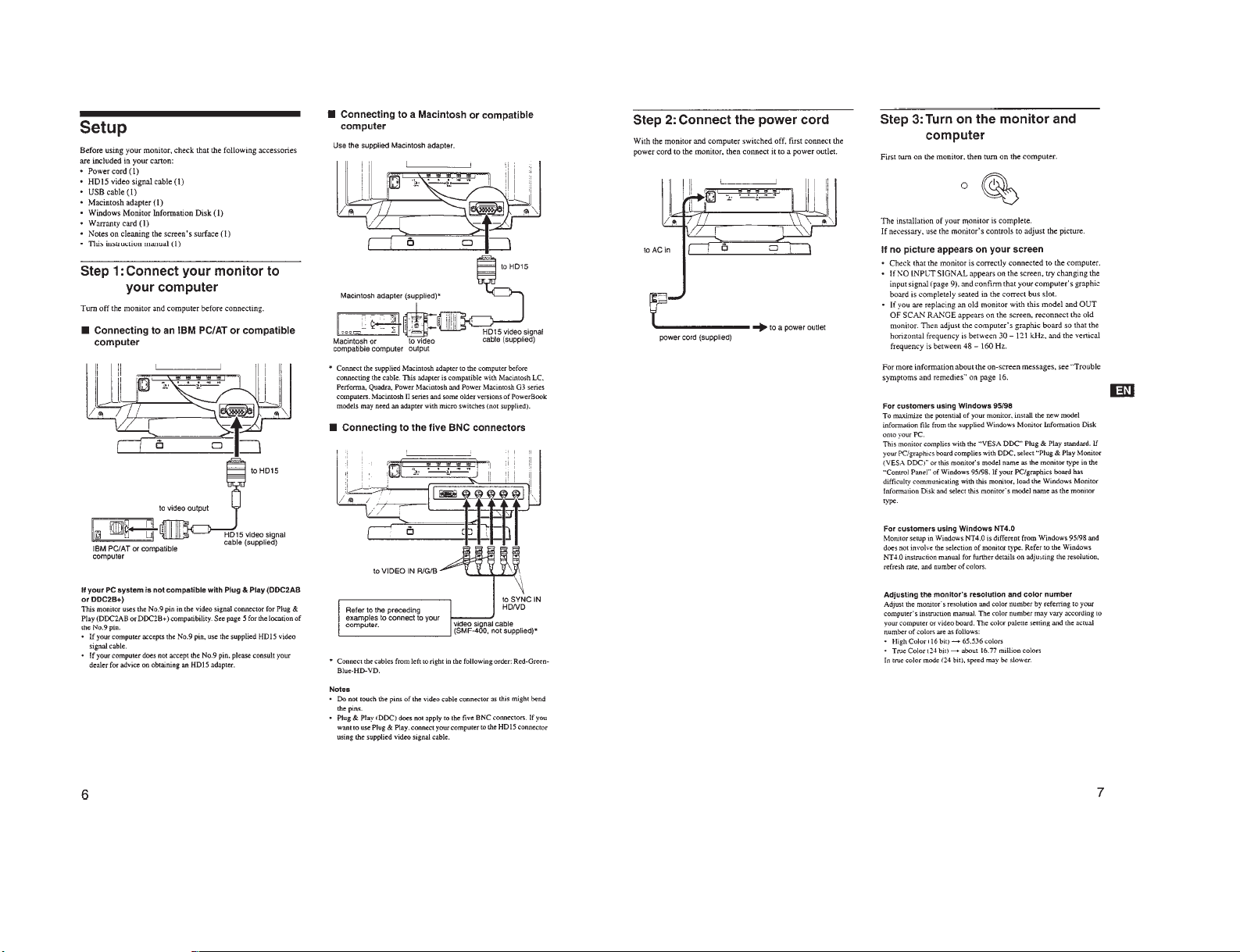

TIMING SPECIFICATION

MODE AT PRODUCTION MODE 1 MODE 2 MODE 3 MODE 4 MODE 5

RESOLUTION 738 X 414 1600 X 1200 1800 X 1440 1800 X 1350 1364 X 1201

CLOCK 28.322 MHZ 229.500 MHZ 299.436 MHZ 299.000 MHZ 195.500 MHZ

— HORIZONTAL —

H-FREQ 31.469 kHz 106.250 kHz 120.740 kHz 120.565 kHz 106.250 kHz

usec usec usec usec usec

H. TOTAL 31.777 9.412 8.282 8.294 9.412

H. BLK 5.720 2.440 2.271 2.274 2.435

H. FP 0.318 0.279 0.668 0.669 0.276

H. SYNC 3.813 0.837 0.481 0.482 0.839

H. BP 1.589 1.325 1.122 1.124 1.320

H. ACTIV 26.057 6.972 6.011 6.020 6.977

— VERTICAL —

V. FREQ(HZ) 70.087 Hz 85.000 Hz 80.120 Hz 85.084 Hz 85.000 Hz

lines lines lines lines lines

V. TOTAL 449 1250 1507 1417 1250

V. BLK 35 50 67 67 49

V. FP 5 1 1 1 1

V. SYNC 2 3 3 3 3

V. BP 28 46 63 63 45

V. ACTIV 414 1200 1440 1350 1201

— SYNC —

INT(G) NO NO NO NO NO

EXT(H/V)/POLARITY YES N/P YES P/P YES P / P YES P / P YES P/P

EXT(CS) /POLARITY NO NO NO NO NO

INT/NON INT NON INT NON INT NON INT NON INT NON INT

SIZE (21") 388 X 291mm 388 X 291mm 364 X 291mm 388 X 291mm 388 X 291 mm

98. 4.27 VER.

– 4 –

TABLE OF CONTENTS

Section Title Page

1. GENERAL ................................................................. 1-1

2. DISASSEMBLY

2-1. Cabinet Removal ............................................... 2-1

2-2. D Board Removal .............................................. 2-1

2-3. G Board Removal .............................................. 2-2

2-4. A Board Removal .............................................. 2-2

2-5. L Board Removal .............................................. 2-3

2-6. Service Position.................................................. 2-3

2-7. H1, H2 and J Boards Removal .......................... 2-4

2-8. US Board Removal............................................. 2-4

2-9. Picture Tube Removal ....................................... 2-5

2-10. Harness Location................................................ 2-6

3. SAFETY RELATED ADJUSTMENT............. 3-1

GDM-F500

4. ADJUSTMENTS ..................................................... 4-1

5. DIAGRAMS

5-1. Block Diagrams .................................................. 5-1

5-2. Frame Shcematic Diagram................................. 5-7

5-3. Circuit Boards Location ..................................... 5-9

5-4. Schematic Diagrams and Printed Wiring

Boards ................................................................. 5-9

(1) Schematic Diagrams of D (1/2, 2/2) Board ...... 5-13

(2) Schematic Diagrams of G, H1, H2, J and

L Boards ............................................................ 5-17

(3) Schematic Diagram of A Board ........................ 5-24

(4) Schematic Diagram of US Board ...................... 5-29

5-5. Semiconductors ................................................. 5-32

6. EXPLODED VIEWS

6-1. Chassis ............................................................... 6-1

6-2. Picture Tube ...................................................... 6-2

6-3. Packing Materials .............................................. 6-3

7. ELECTRICAL PARTS LIST ............................ 7-1

Note: Hand degauss must be used on stand-by or power-off condition.

This model has an automatic earth magnetism correction function by using an earth

magnetism sensor and a LCC coil. When using a hand degauss while monitor (LCC

coil) is being operated, it sometimes gets magnetized, and the system may not work

properly as a result.

– 5 –

1-1

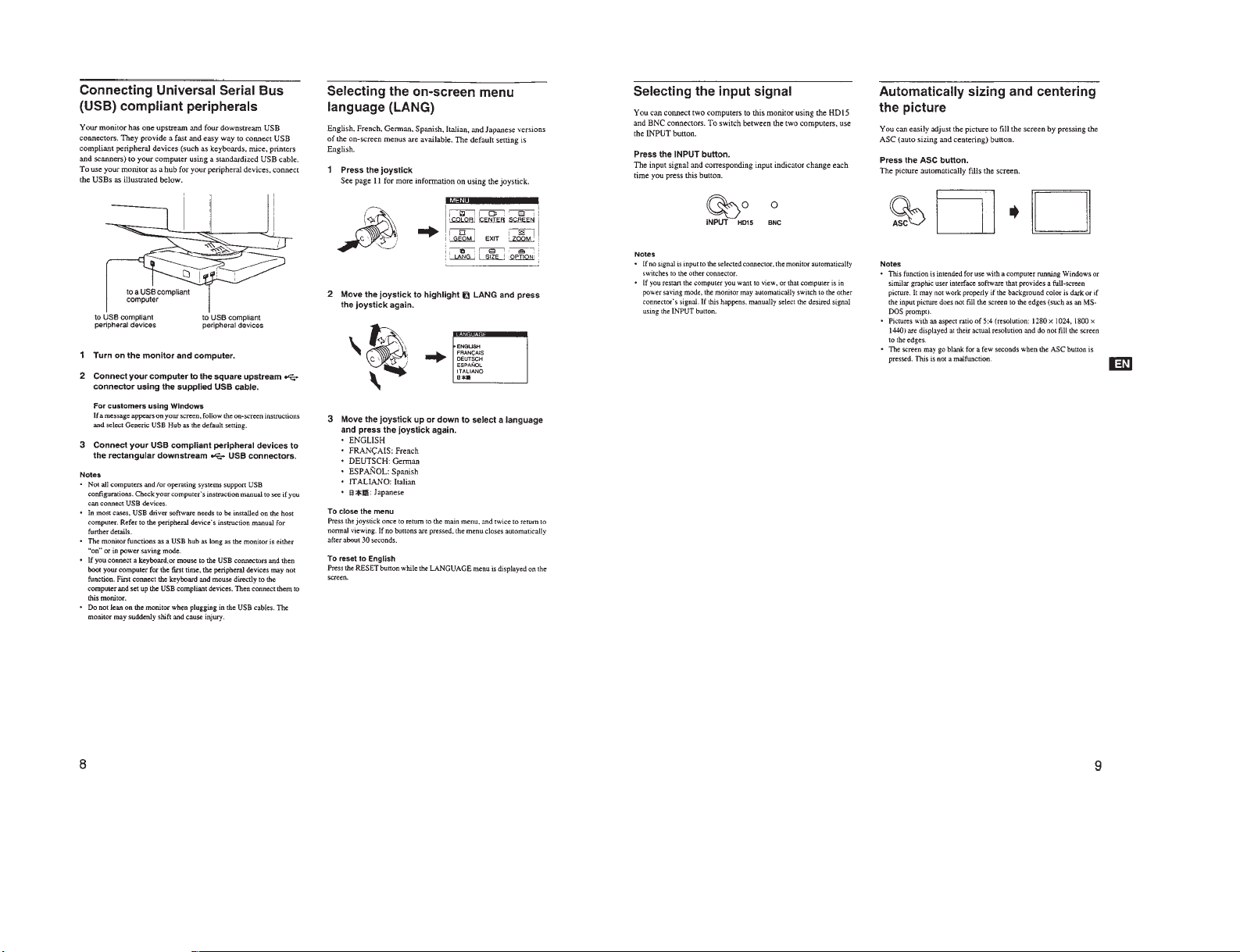

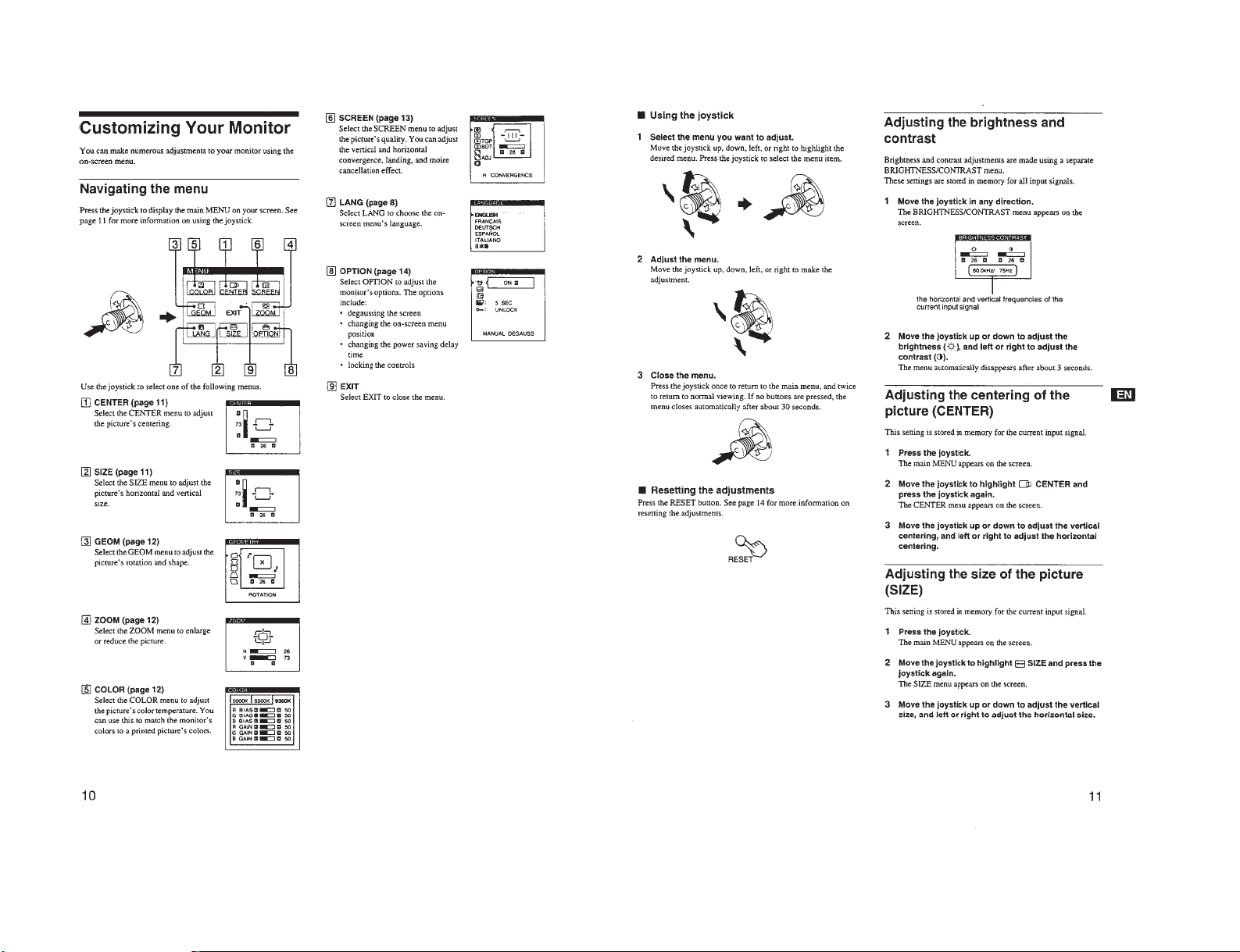

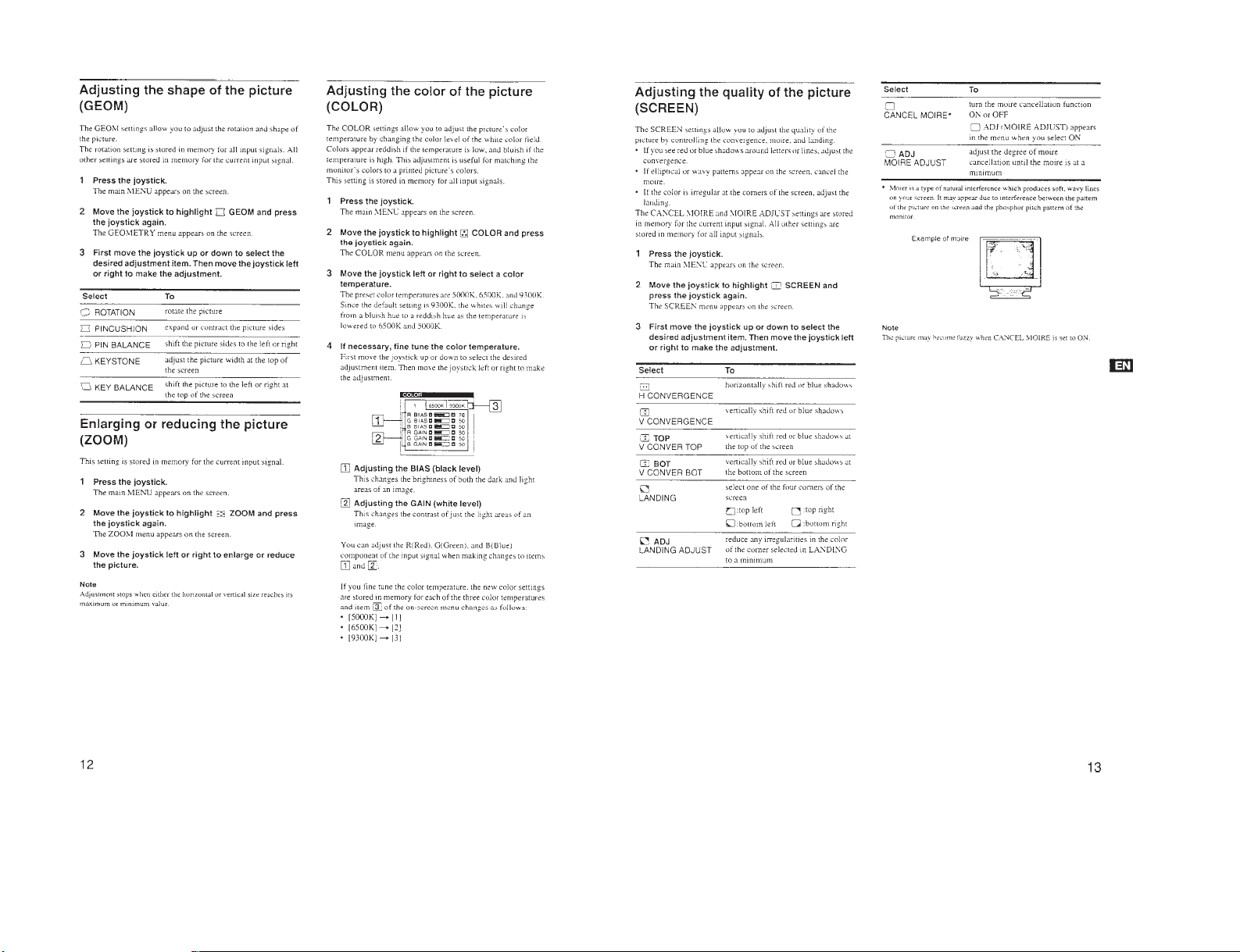

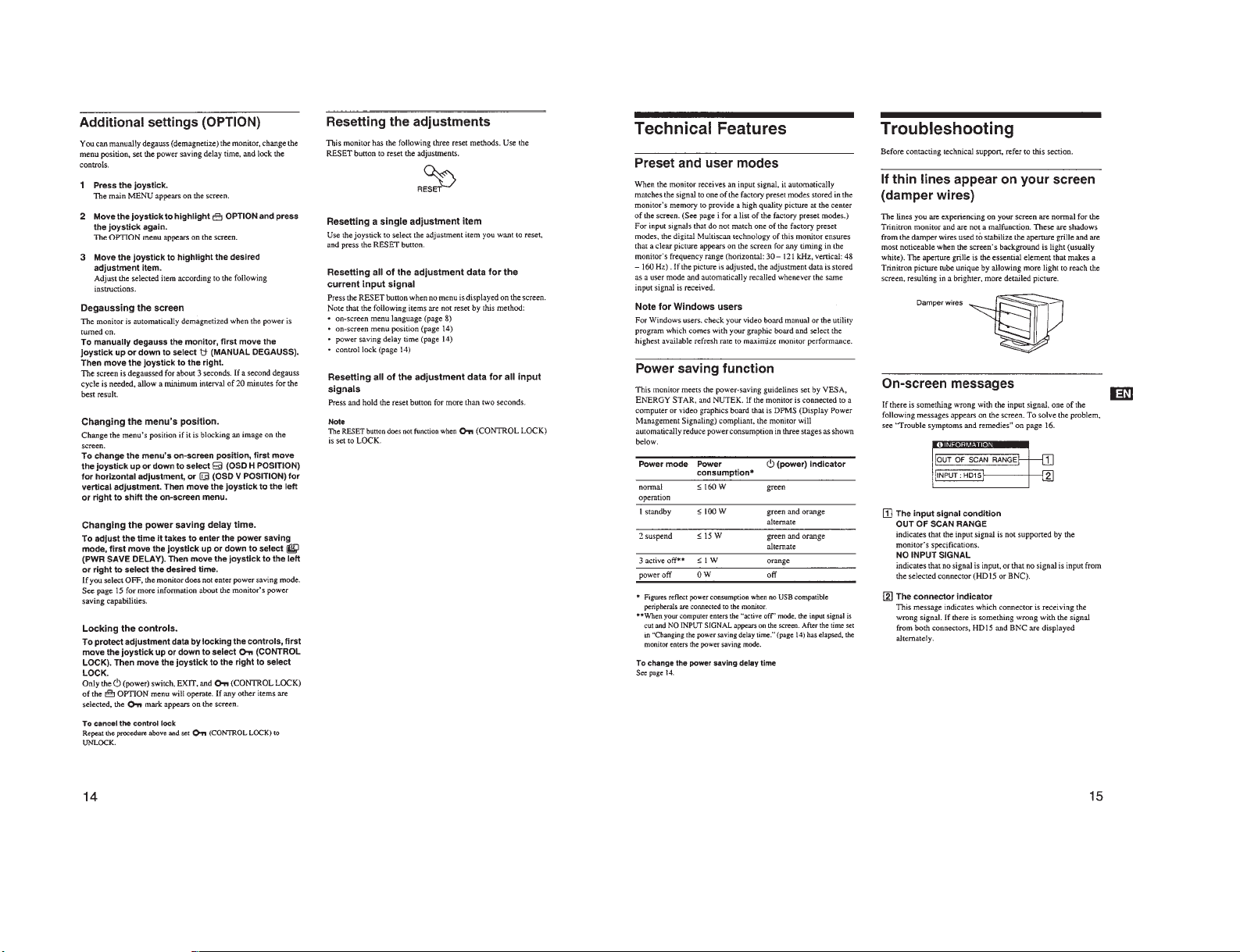

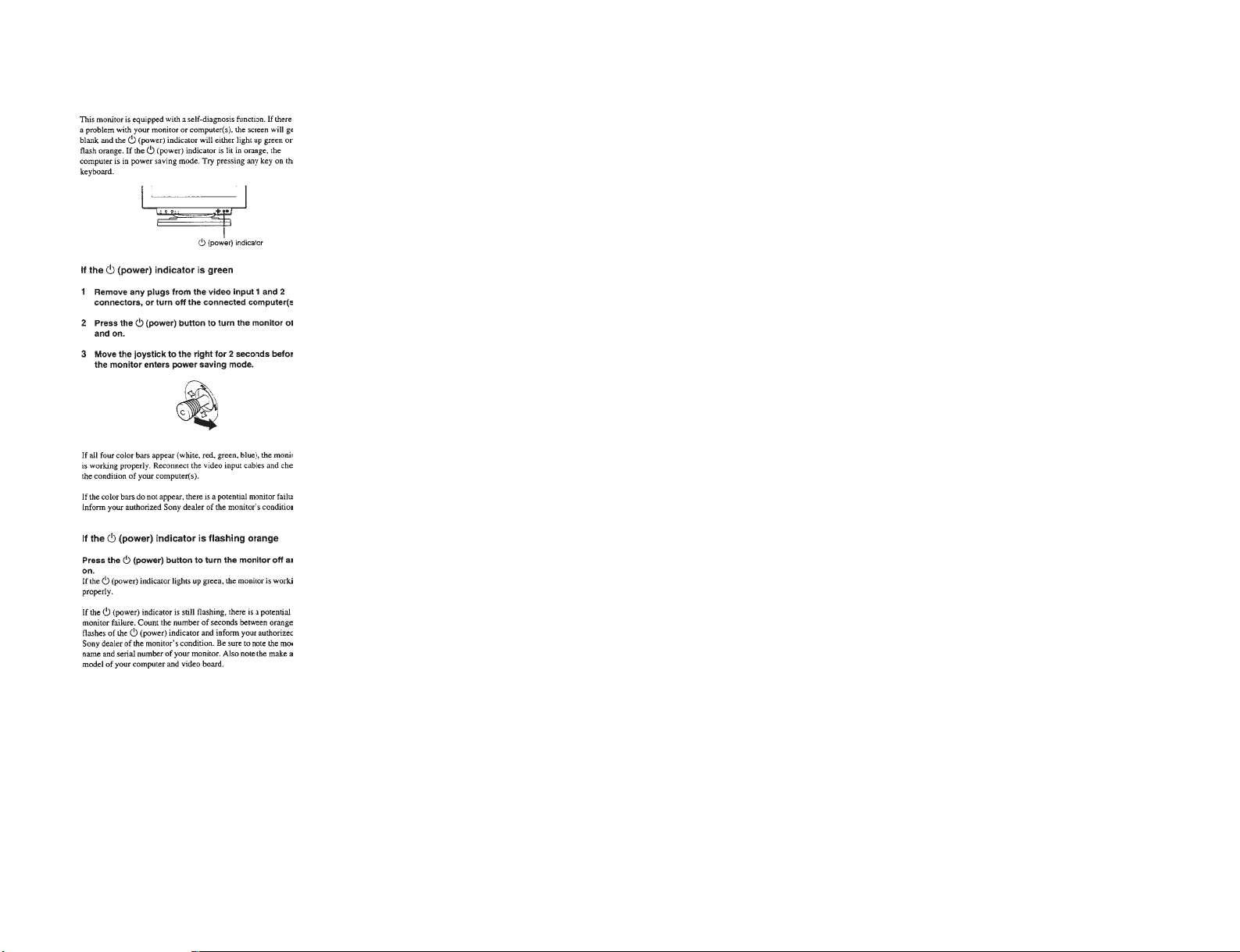

The operating instructions mentioned here are partial abstracts

from the Operating Instruction Manual. The page numbers of

the Operating Instruction Manual remain as in the manual.

SECTION 1

GENERAL

1-2

1-3

1-4

1-5

1-6

1-7

1-8

GDM-F500

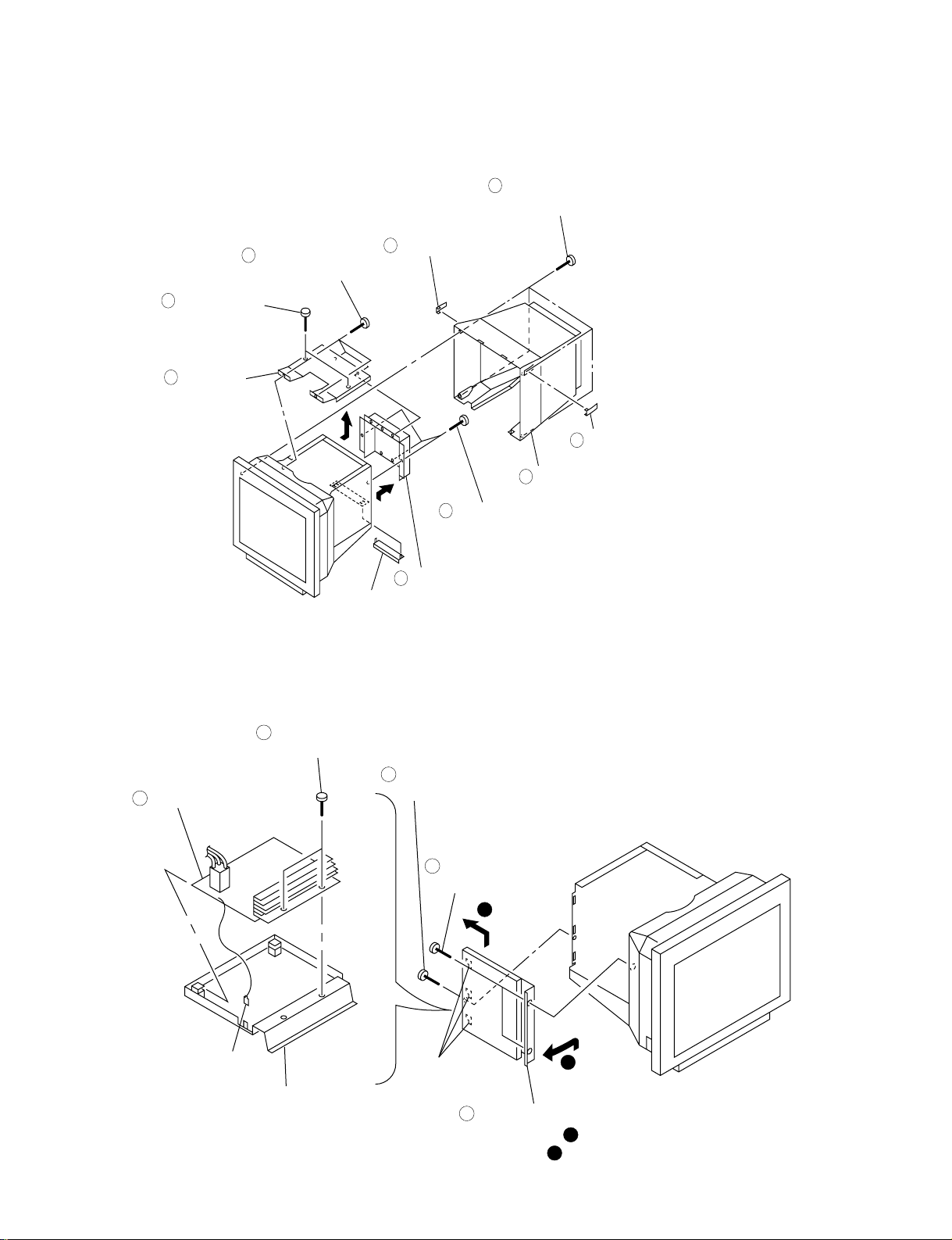

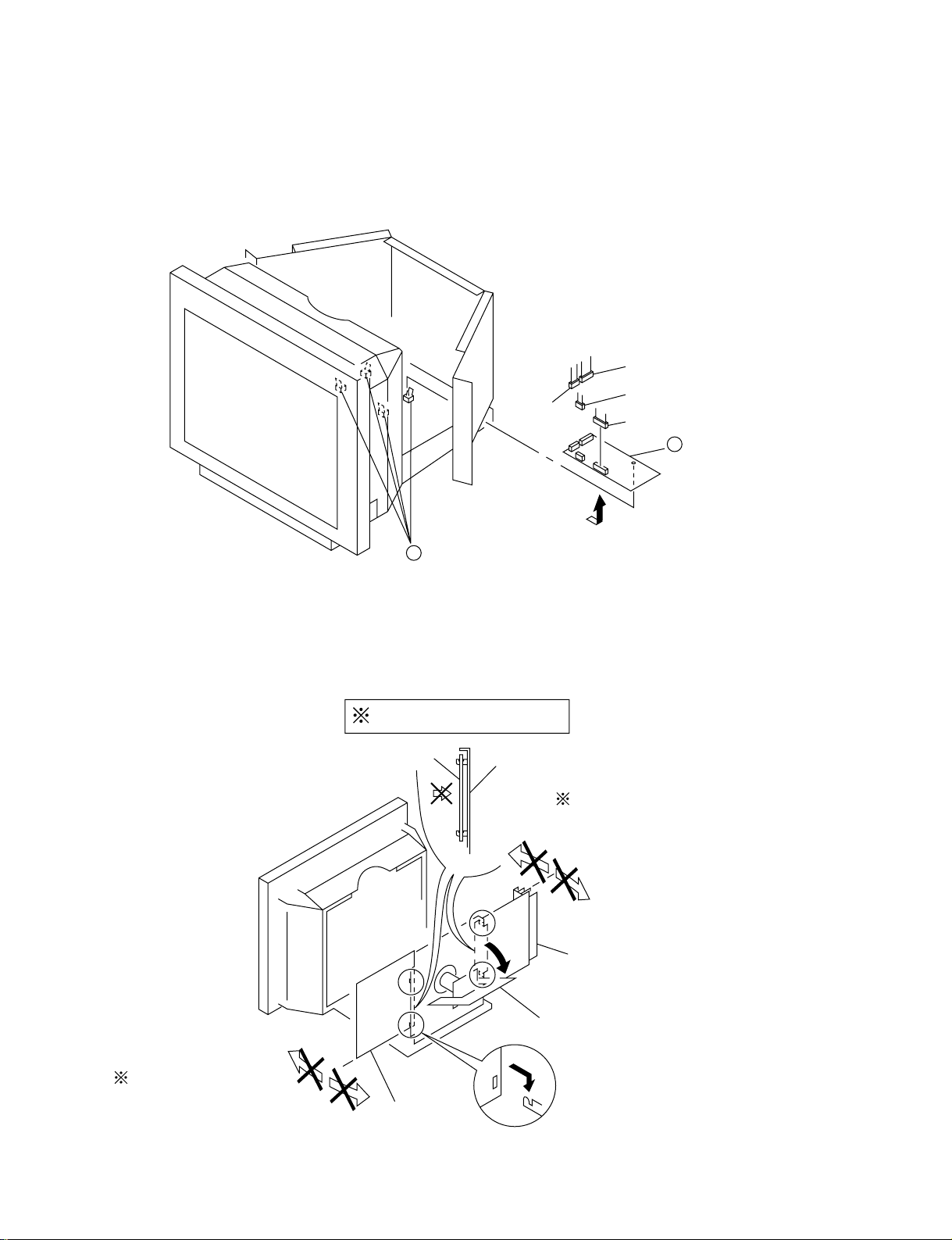

2-1. CABINET REMOVAL

6

Two screws

(+ BVTT 4 x 8)

7

Top cover

5

Four screws

(+ BVTT 4 x 8)

SECTION 2

DISASSEMBLY

3

Four screws

(+ BVTP 4 x 16)

1

Screw cover

4

Cabinet

2

Screw cover

2-2. D BOARD REMOVAL

4

Two screws

(+ BVTP 3 x 10)

5

D board

Attachment

1

Three screws

8

(+ BVTT 4 x 8)

9

Video shield

Screw

(+ BVTT 4 x 8)

2

Two screws

(+ BVTT 4 x 8)

B

GND

Side cover (D) assembly

Three hooks

3

Open the D block in the direction

of the arrow and remove of

the arrow .

2-1

A

A

B

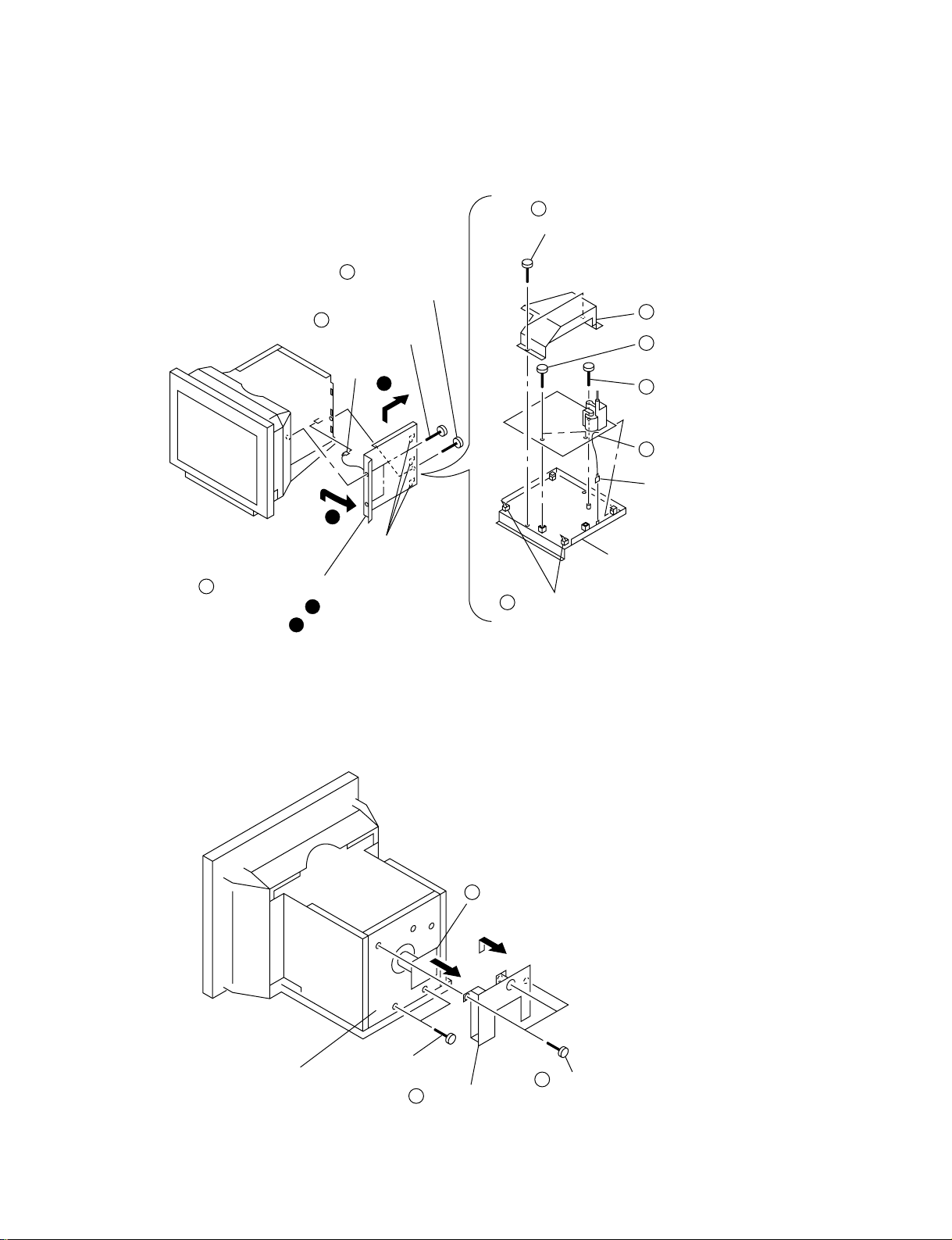

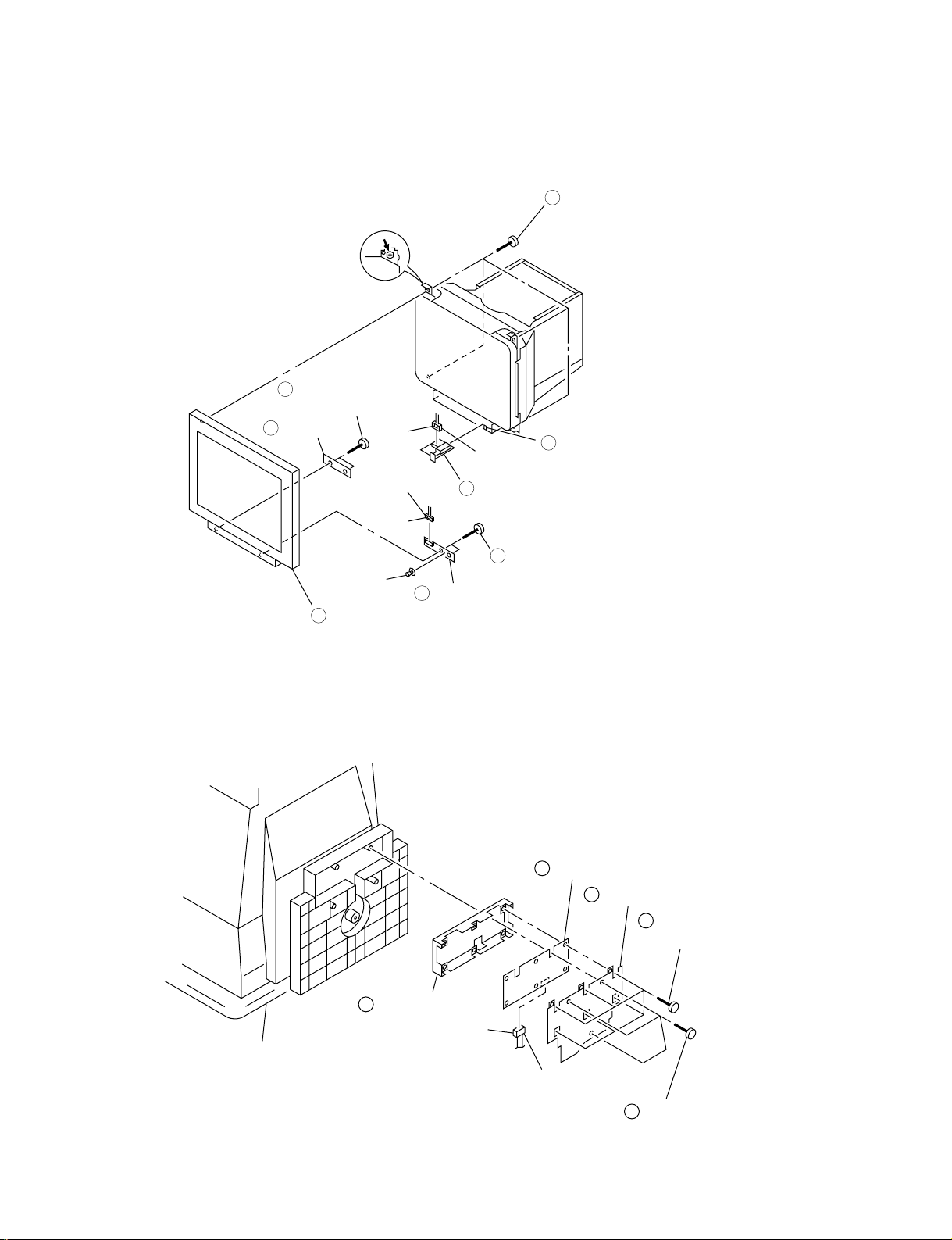

2-3. G BOARD REMOVAL

2

1

Screw

(+ BVTT 4 x 8)

Two screws

(+ BVTT 4 x 8)

GND

B

4

Two screws

(+ BVTP 3 x 10)

5

G shield

6

Two screws

(+ BVTP 3 x 10)

7

Screw

(+ P 3.5 x 20)

9

G board

GND

GDM-F500

3

Open the G block in the direction

of the arrow and remove of

the arrow .

A

B

2-4. A BOARD REMOVAL

A

Three hooks

8

Two printed circuit board holders

3

A board (2/2)

Side cover (G) assembly

Rear shield assembly

Two screws

(+BVTT 4 x 8)

2

A board (1/2)

2-2

1

Three screws

(+BVTT 4 x 8)

GDM-F500

2-5. L BOARD REMOVAL

CN5002

CN5001

CN5004

CN5003

2

L board

2-6. SERVICE POSITION

1

Four printed circuit board holders

CAUTION : SHORT

D,G boards

Rear shield

If the claw is hooked,

opening and closing the

board is impossible.

Do not try to do it by force.

D board (Refer to 2-2. )

If the claw is hooked,

opening and closing the

board is impossible.

Do not try to do it by force.

A board (Refer to 2-4. )

G board

(Refer to 2-3.)

2-3

2-7. H1, H2 AND J BOARDS REMOVAL

5

Two screws

(+ BVTP 3 x 10)

6

H2 board

Claw

CN801

CN891

8

J board

1

Four screws

(Tapping screw 5)

7

Claw

GDM-F500

2

Bezel assembly

2-8. US BOARD REMOVAL

Knob

Claw

4

H1 board

3

Two screws

(+ BVTP 3 x 10)

5

US board

2

Stand cover

3

Six screws

(+ BVTP 3 x 10)

Cushion

4

Shield case

Claw

2-4

CN2601

1

Three screws

(+ BVTP 3 x 10)

Loading...

Loading...