GV-D300/D300E/D900/D900E

SERVICE MANUAL

Ver 1.6 2003.06

With SUPPLEMENT-1 (9-974-068-81)

With SUPPLEMENT-2 (9-974-068-82)

With CORRECTION-2 (9-974-068-92)

With SUPPLEMENT-3 (9-974-068-83)

Photo: GV-D900E

GV-D300/D900: NTSC

GV-D300E/D900E: PAL

Function difference table

Model

Function

LCD

GV-D300/300E

—

GV-D900/D900E

5.5 inches

For MECHANISM ADJUSTMENTS, refer to the “DV MECHANICAL

ADJUSTMENT MANUAL D MECHANISM ” (original: 9-973-815-11),

supplement: 9-973-815-81) and “DV MECHANICAL ADJUSTMENT

MANUAL

SPECIFICATIONS

D200 MECHANISM ” (original: 9-973-981-11).

US Model

Canadian Model

GV-D300/D900

AEP Model

UK Model

E Model

GV-D300E/D900E

D200 MECHANISM

MICROFILM

DIGITAL VIDEO CASSETTE RECORDER

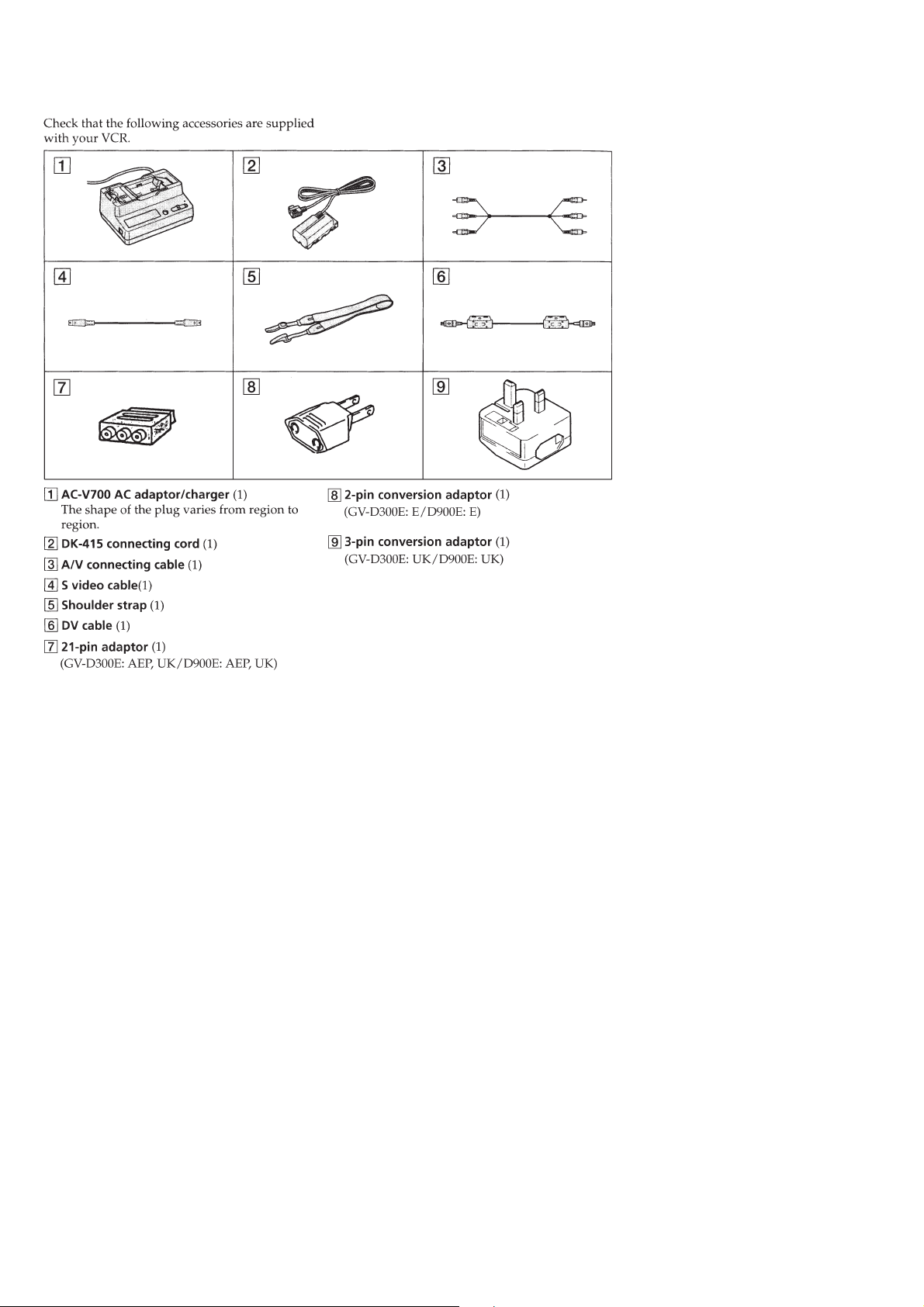

Supplied Accessories

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

— 2 —

TABLE OF CONTENTS

SERVICE NOTE

1. Power Supply During Repairs ............................................ 5

2. How to Take a Cassette Out When the Main Power Cannot

Be Turned ON (Forced Ejected) ......................................... 5

3. Warning Indicators .............................................................5

2-8. IR-29, IO-62 Boards........................................................2-4

2-9. EX-34 Board....................................................................2-5

2-10. Cabinet (Upper) Assembly ..............................................2-5

2-11. LCD Display Module (GV-D900/D900E) ......................2-5

2-12. Circuit Boards Location ..................................................2-6

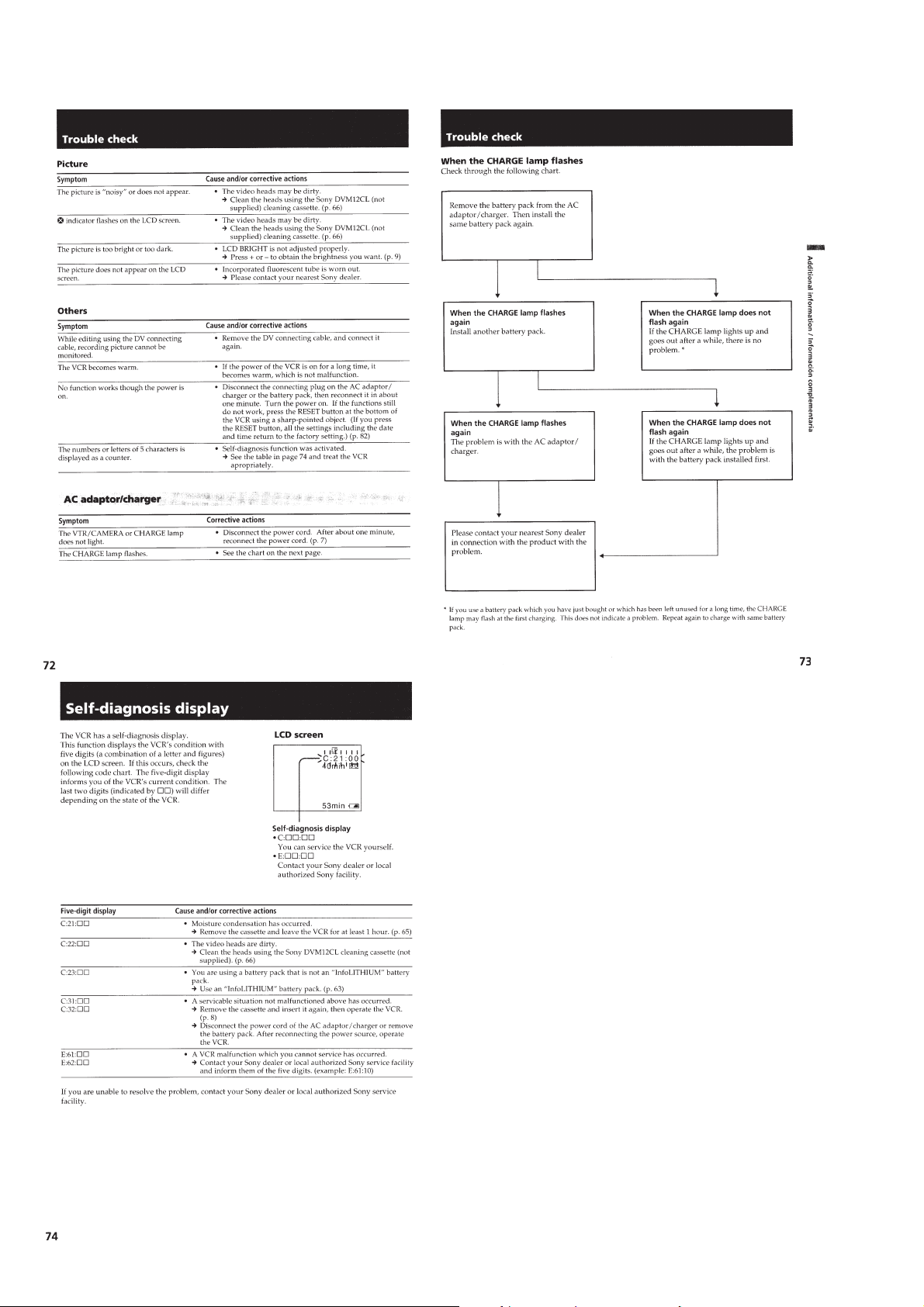

SELF-DIAGNOSIS FUNCTION

1. Self-Diagnosis Function ..................................................... 6

2. Self-Diagnosis Display....................................................... 6

3. Service Mode Display ........................................................ 6

3-1. Display Method .................................................................. 6

3-2. Switching of Backup No. ................................................... 6

3-3. End of Display.................................................................... 6

4. Self-Diagnosis Code Table ................................................. 7

1. GENERAL

This section is extracted from

instruction manual. (GV-D900)

Before you begin

Using this manual ..................................................................1-1

Basic operations

Installing the AC adaptor/charger ..........................................1-1

Inserting a cassette .................................................................1-2

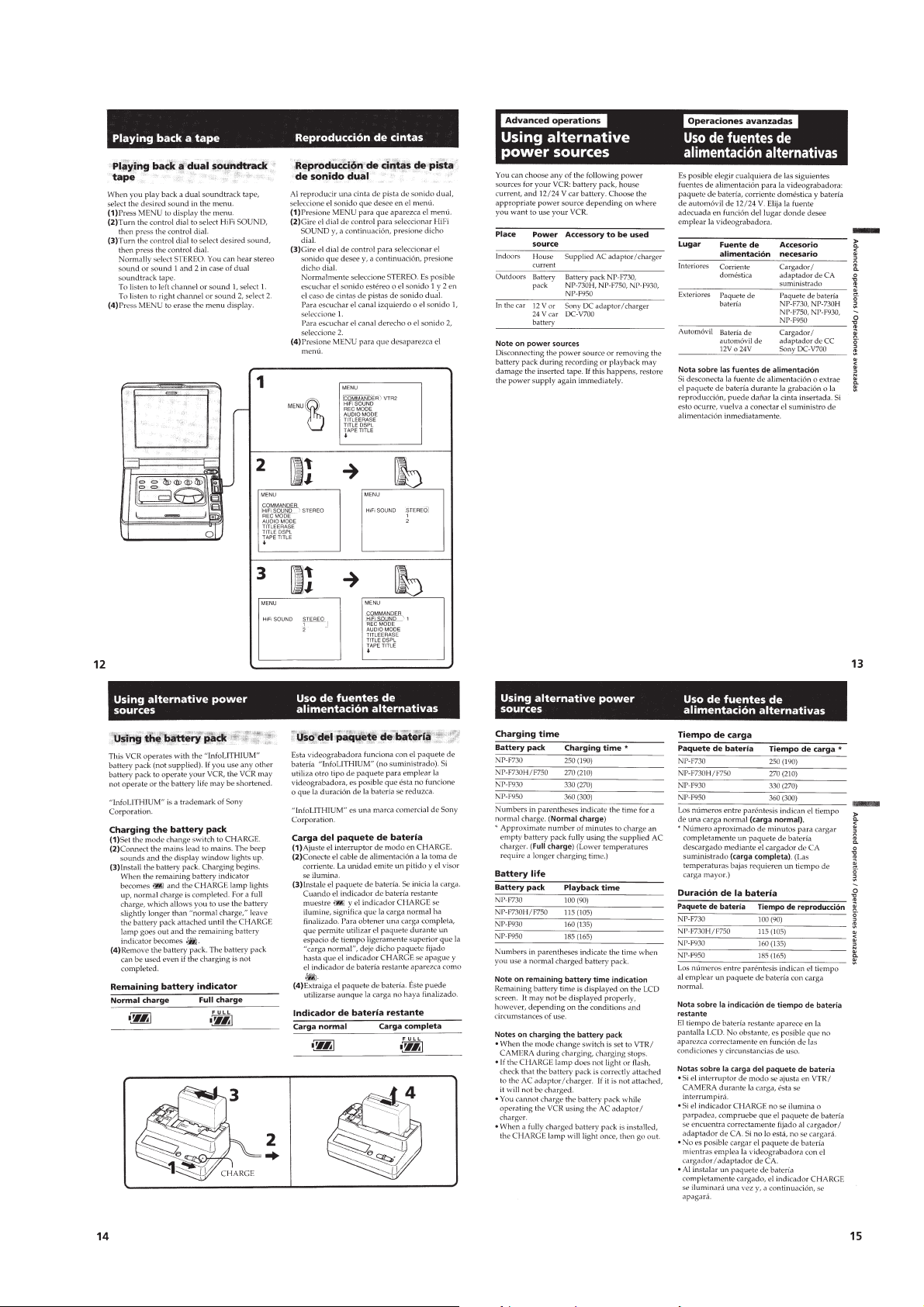

Playing back a tape ................................................................1-2

Advanced operations

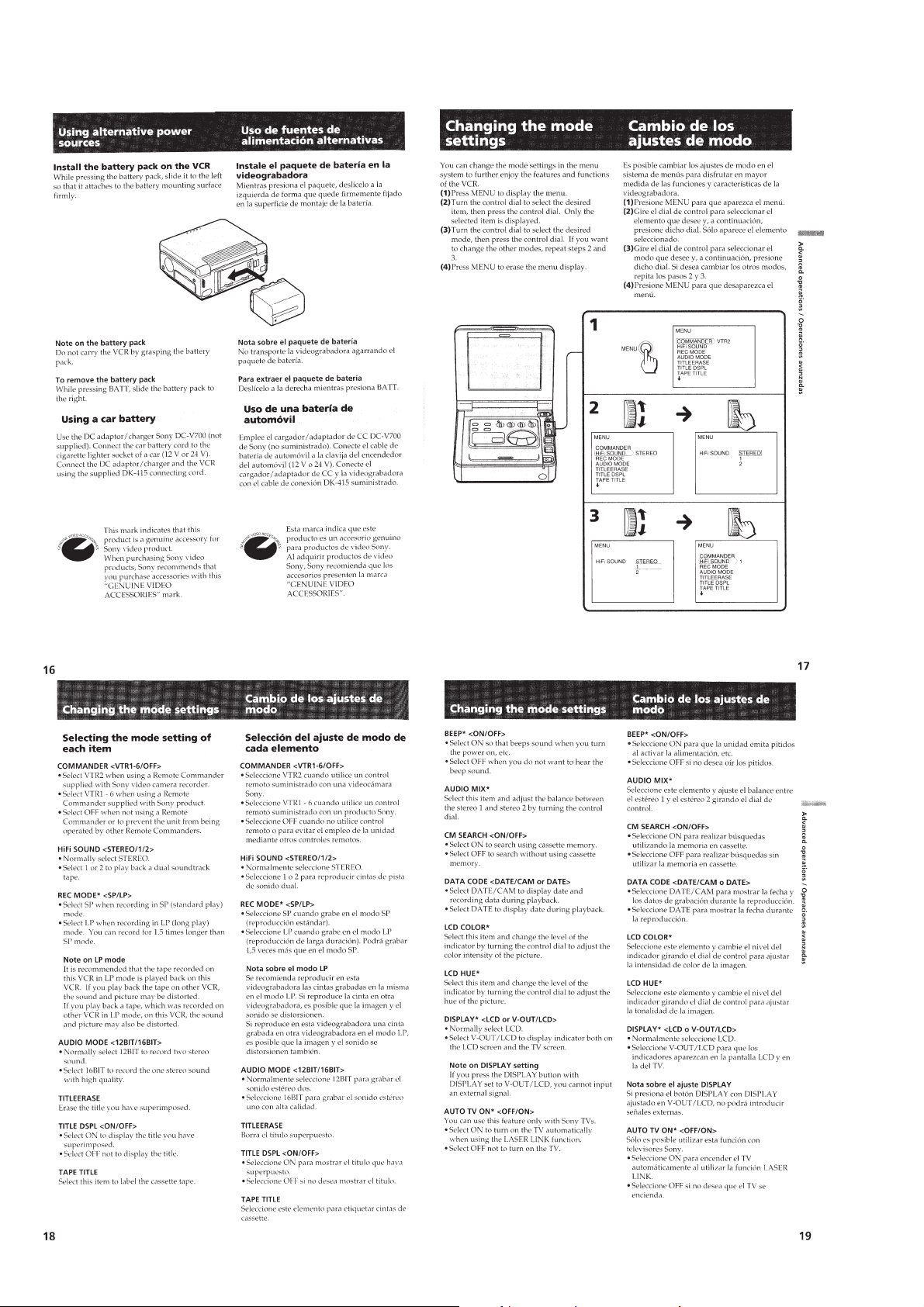

Using alternative power sources ............................................1-3

Changing the mode setting ....................................................1-4

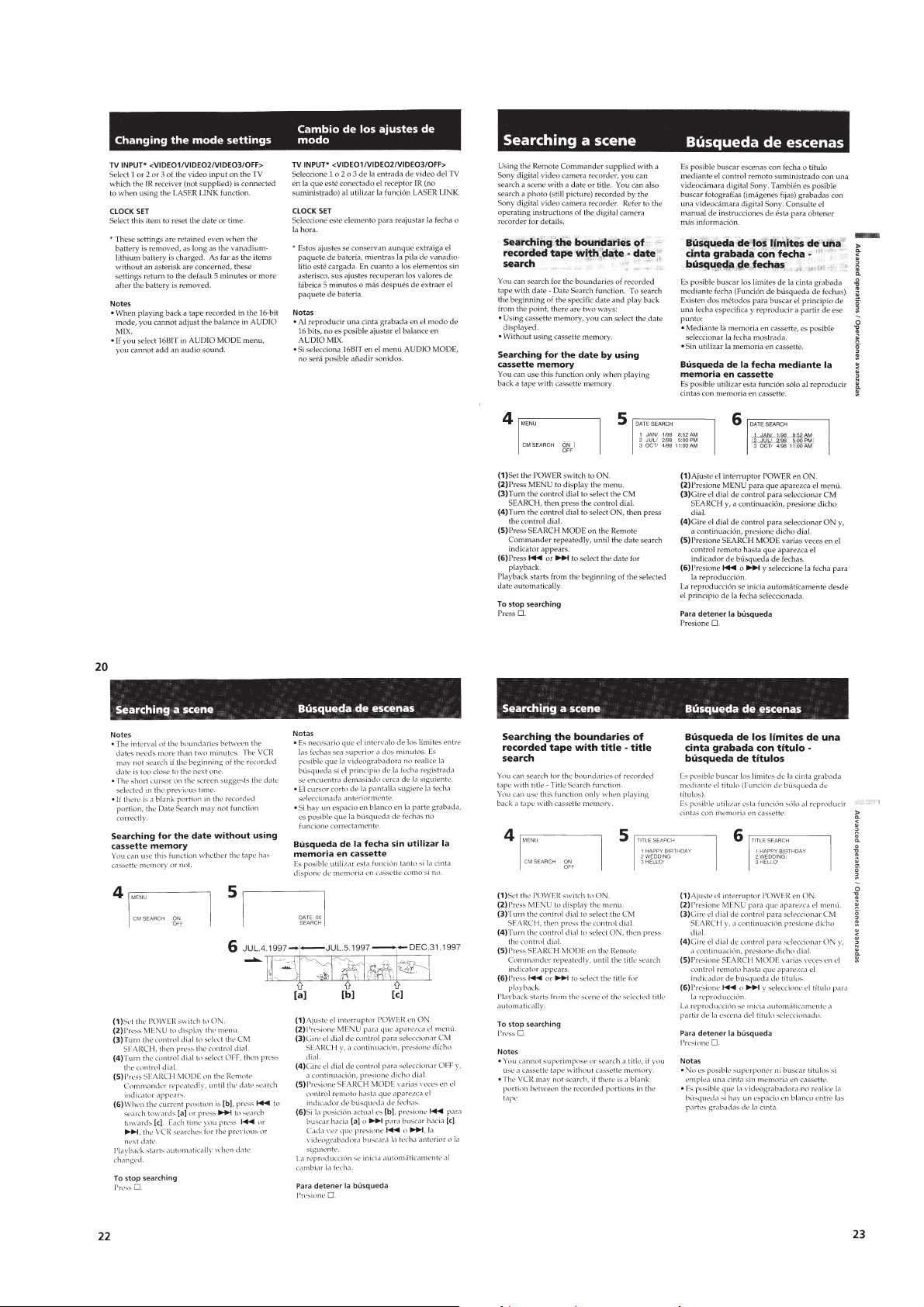

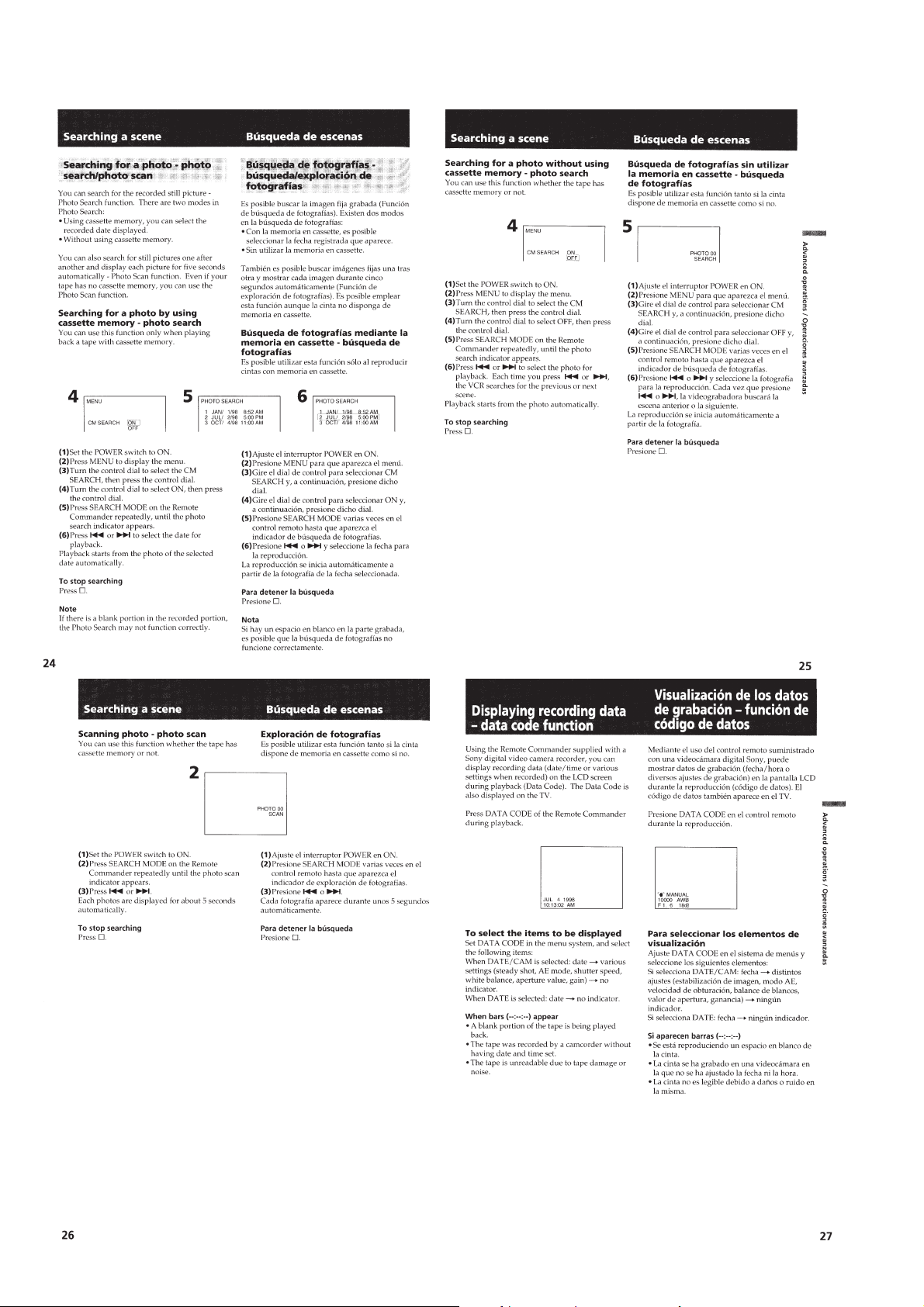

Searching a scene...................................................................1-5

Displaying recording data - data code function .....................1-6

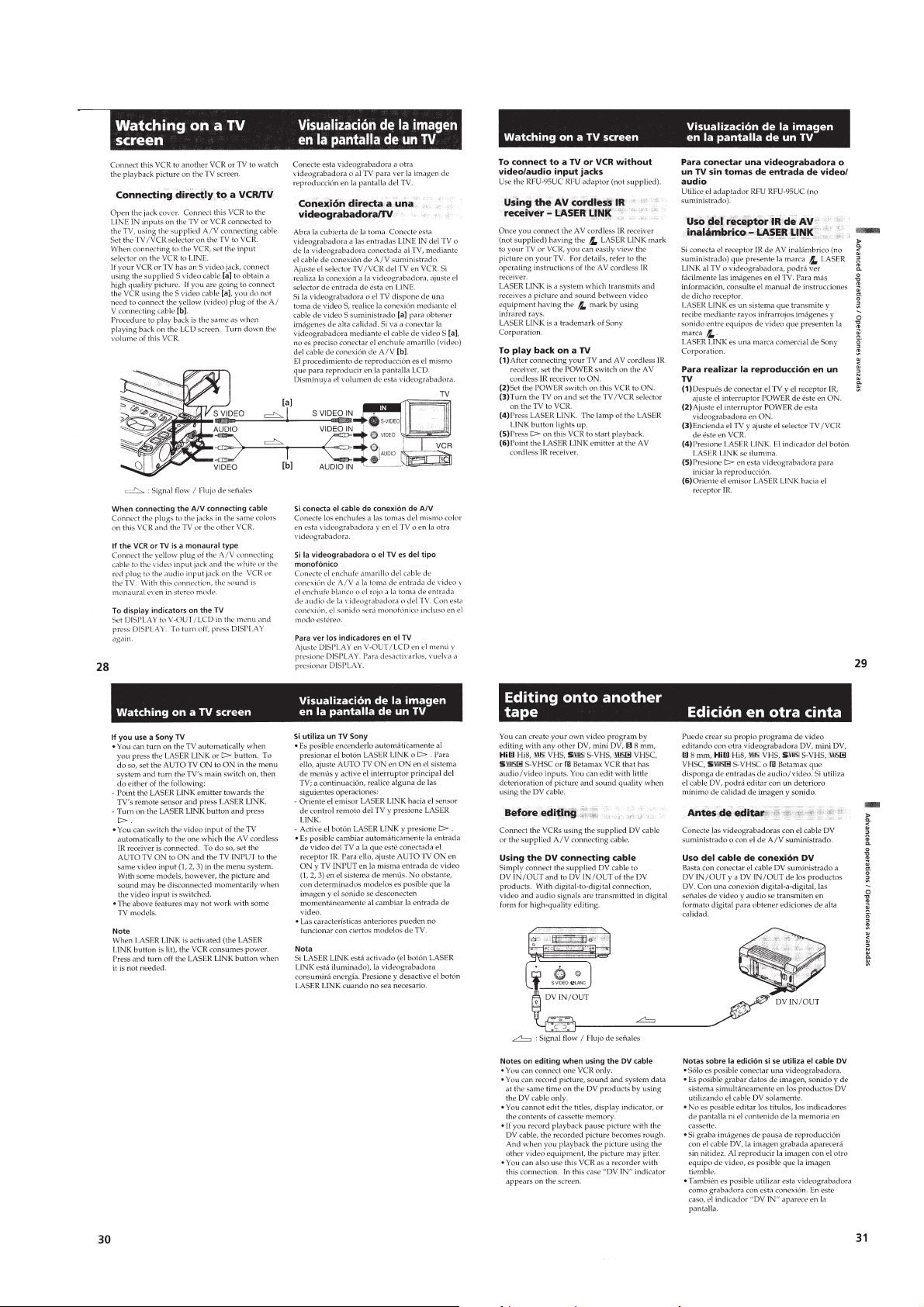

Watching on a TV screen .......................................................1-7

Editing onto another tape.......................................................1-7

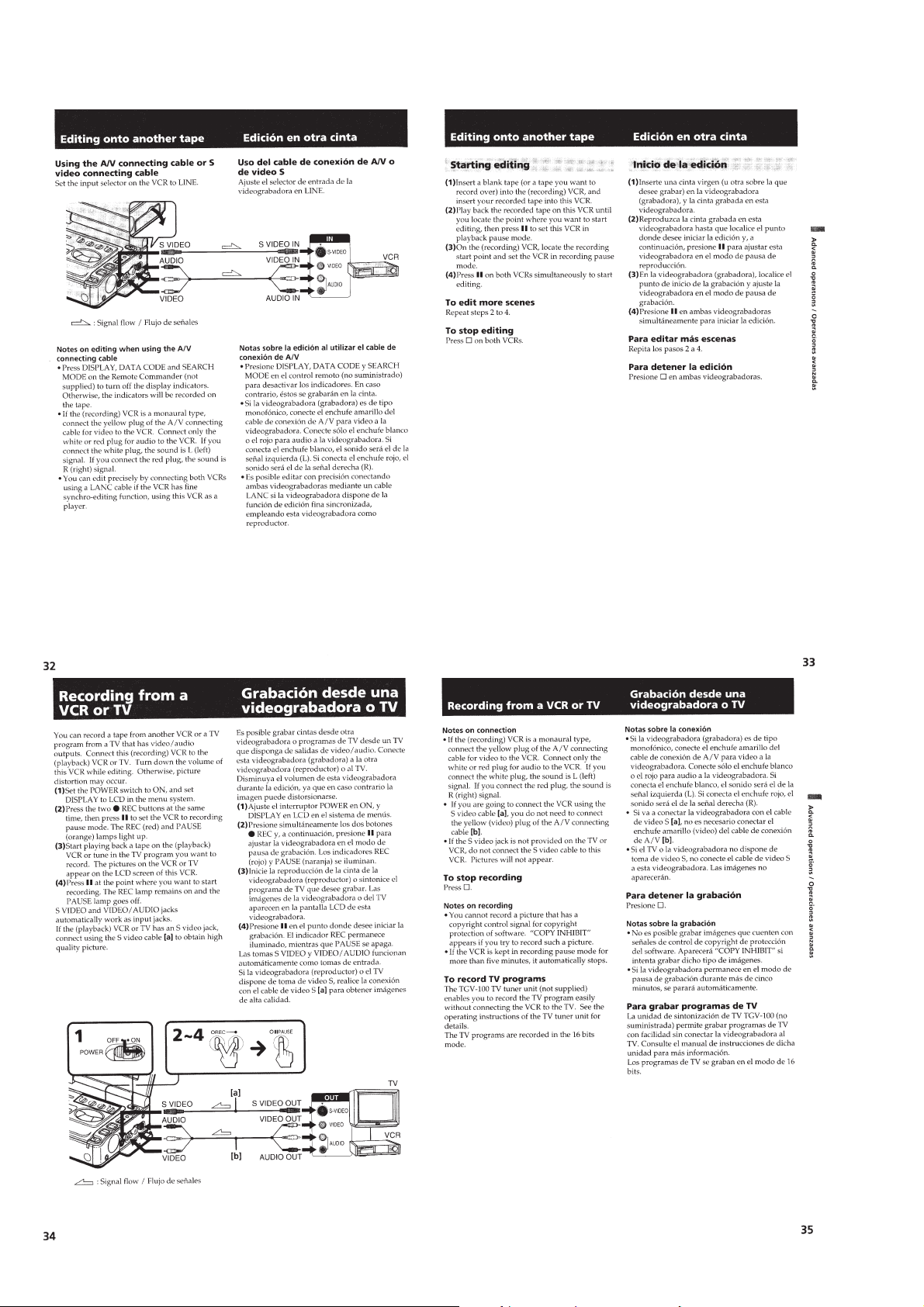

Recording from a VCR or TV ...............................................1-8

Audio dubbing .......................................................................1-9

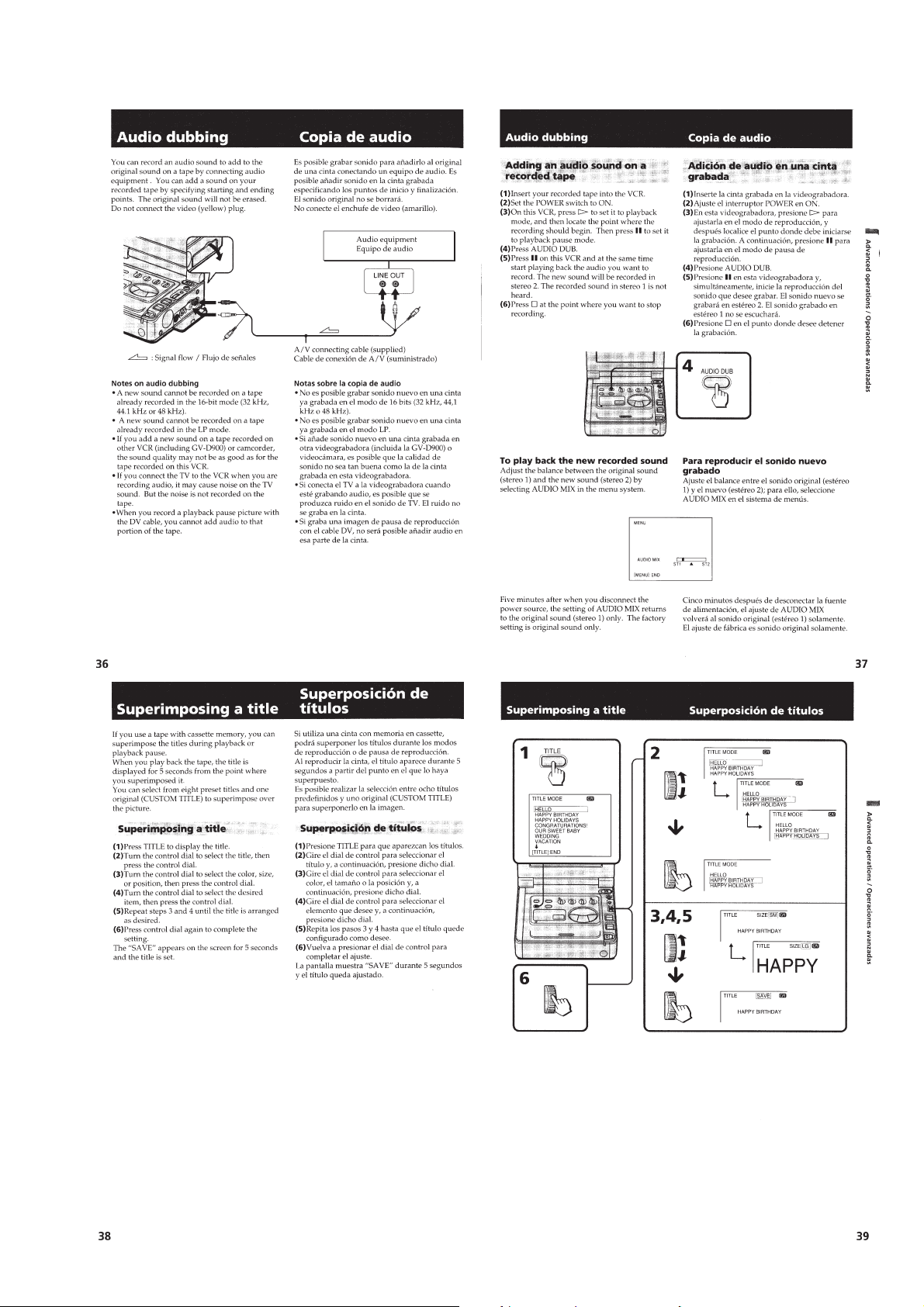

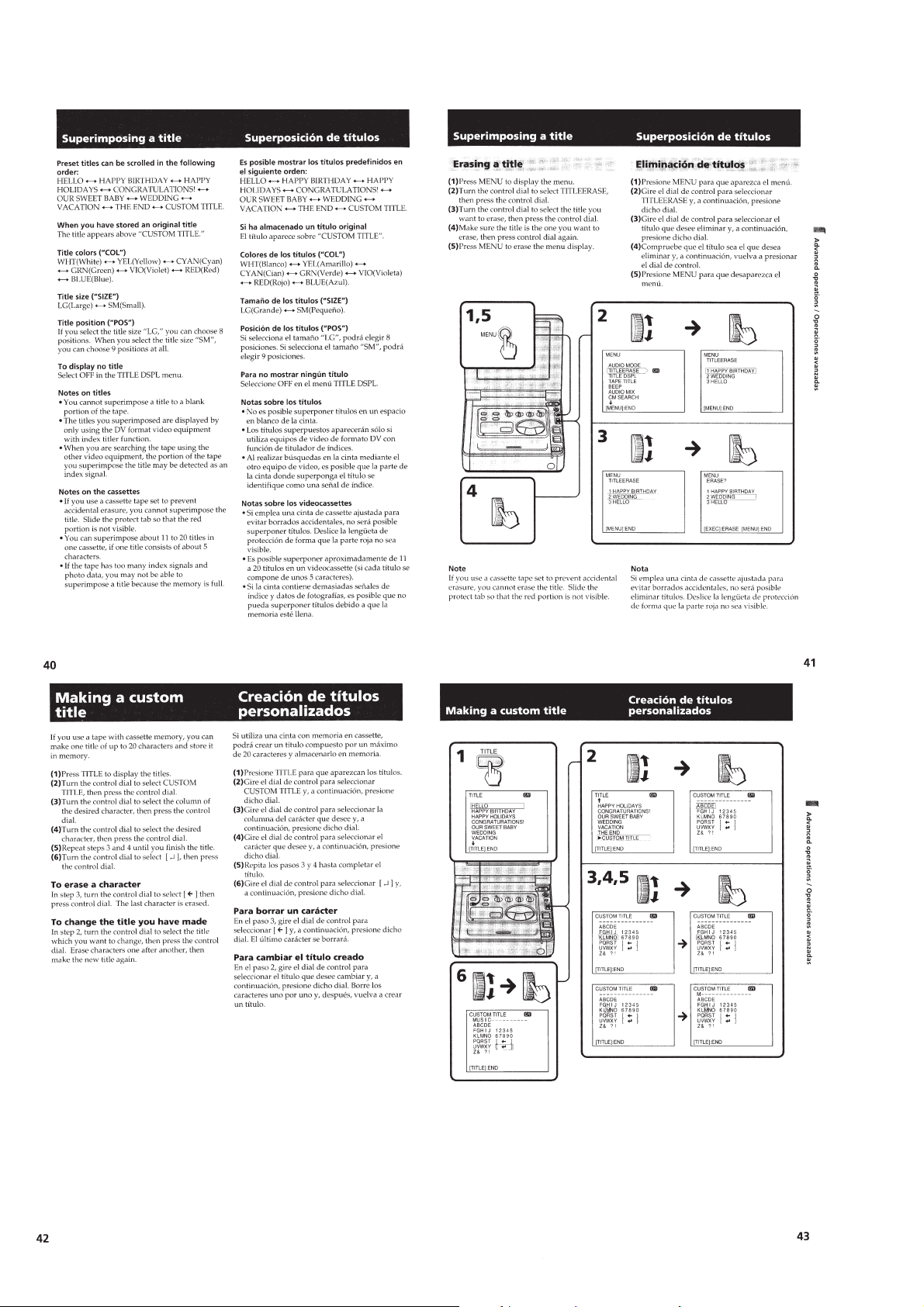

Superimposing a title .............................................................1-9

Making a custom title ..........................................................1-10

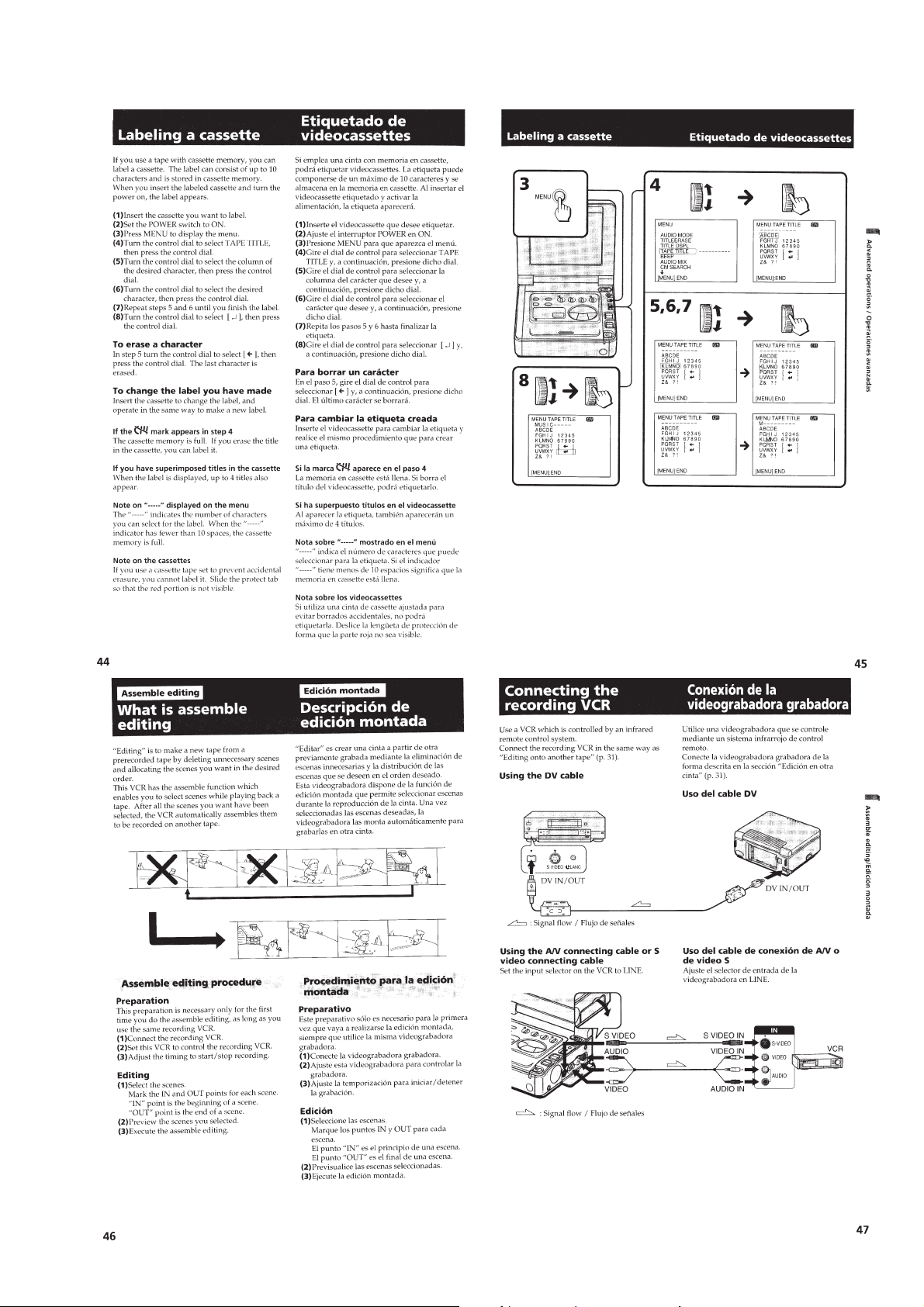

Labeling a cassette ...............................................................1-11

Assemble editing

What is assemble editing .....................................................1-11

Connecting the recording VCR............................................1-11

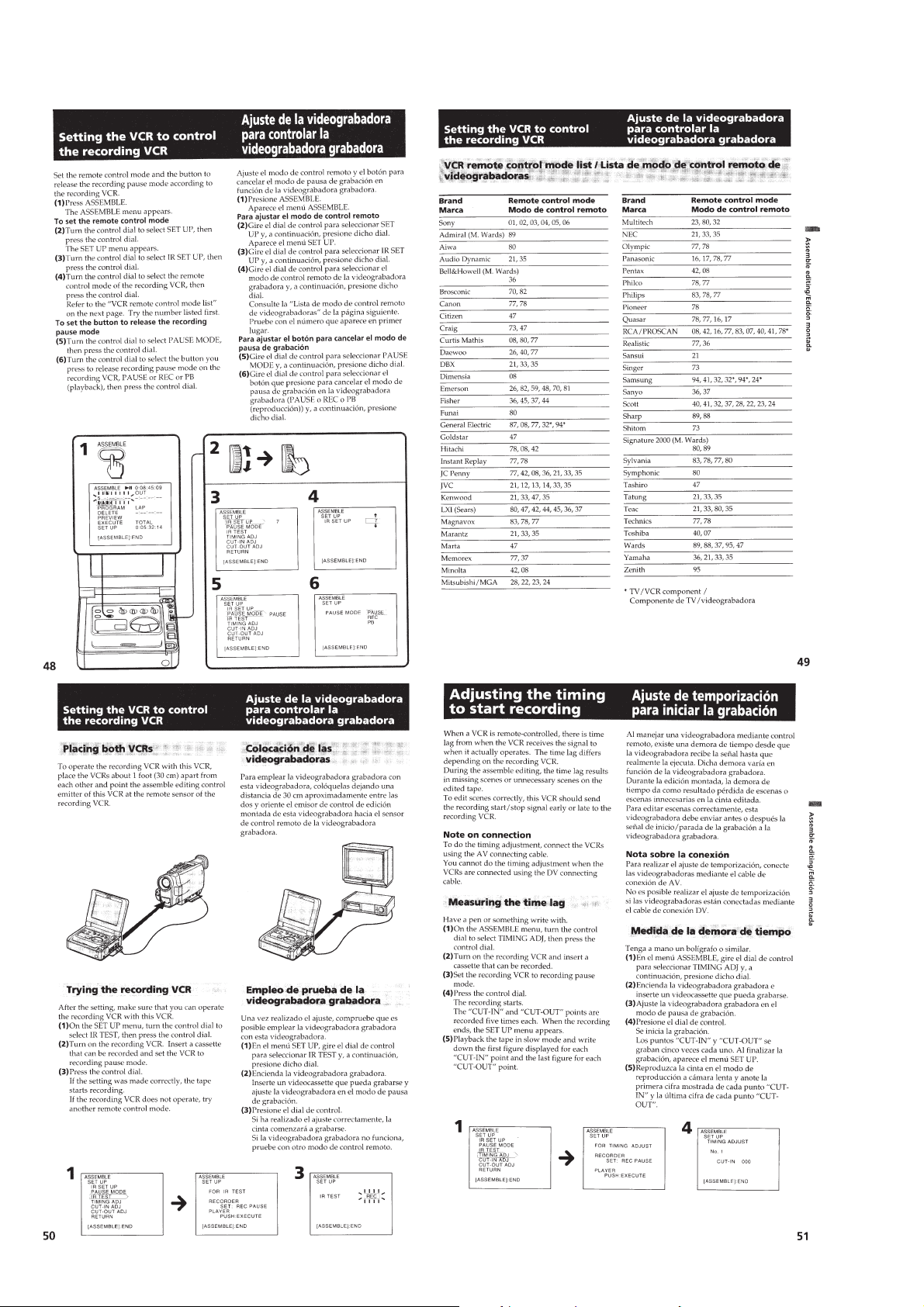

Setting the VCR to control the recording VCR ................... 1-12

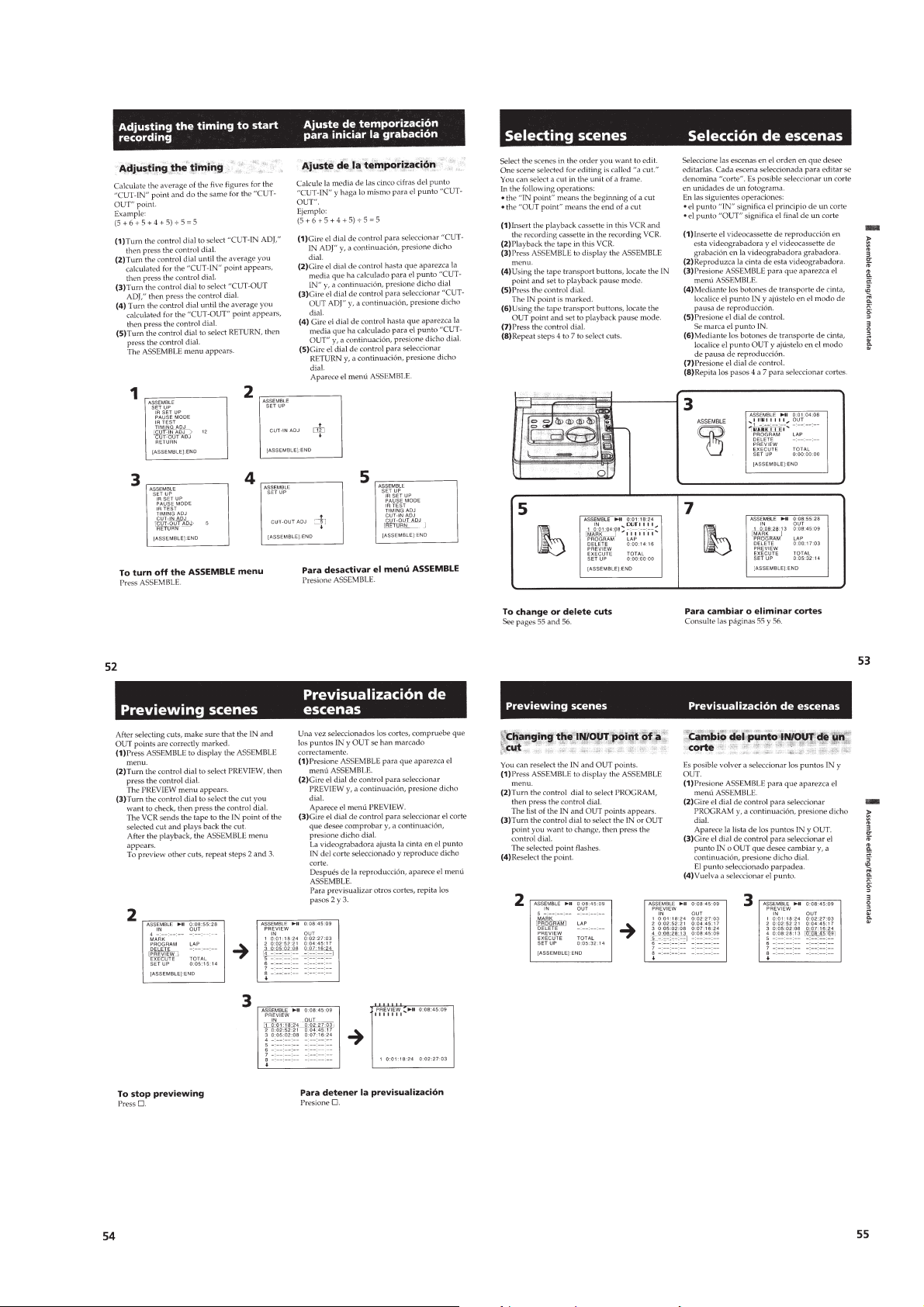

Adjusting the timing to start recording ................................1-12

Selecting scenes ...................................................................1-13

Previewing scenes................................................................1-13

Executing the assemble editing ........................................... 1-14

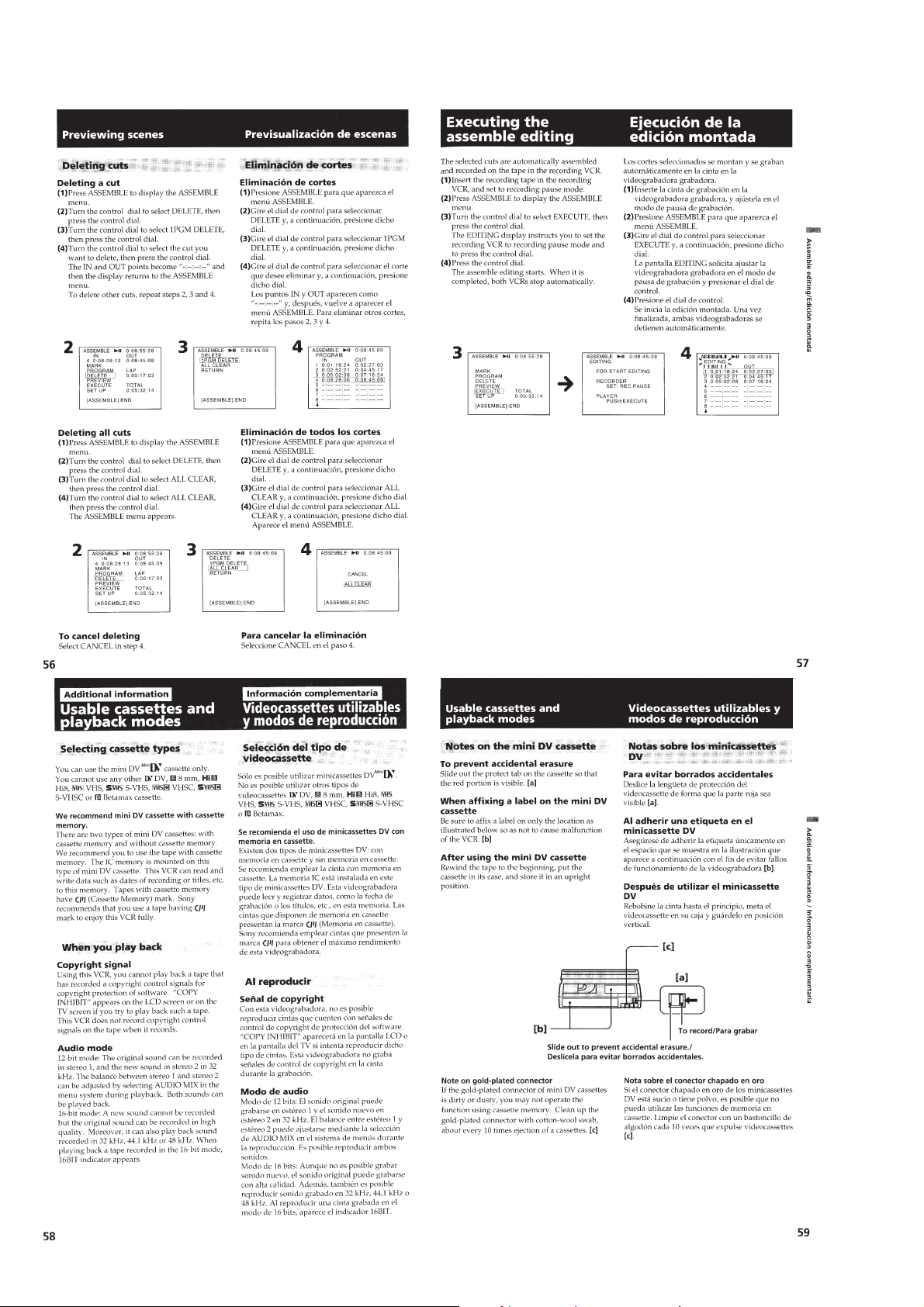

Additional information

Usable cassettes and playback modes..................................1-14

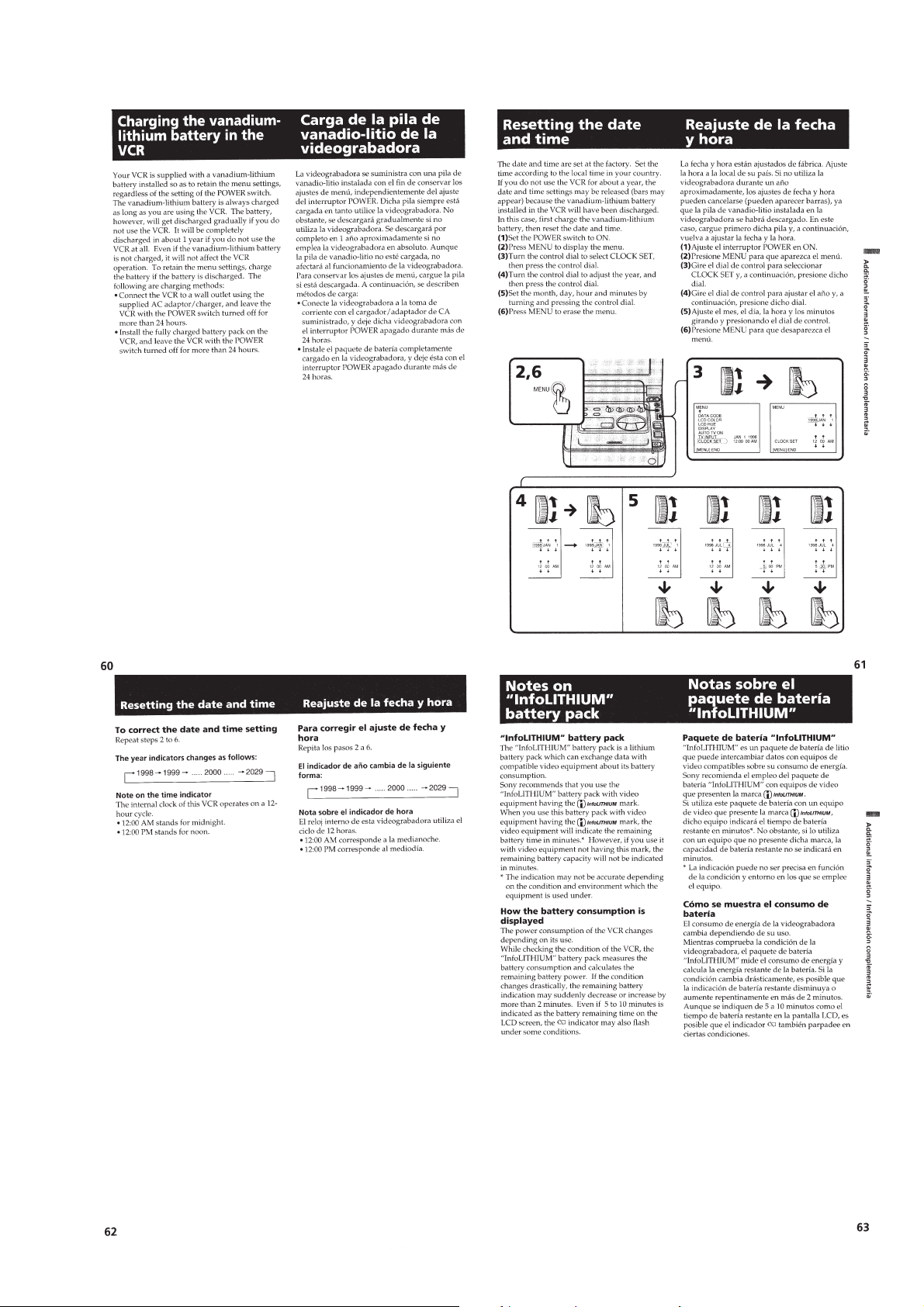

Charging the vanadium-lithium battery in the VCR ............1-15

Resetting the date and time..................................................1-15

Notes on “InfoLITHIUM” battery pack ..............................1-15

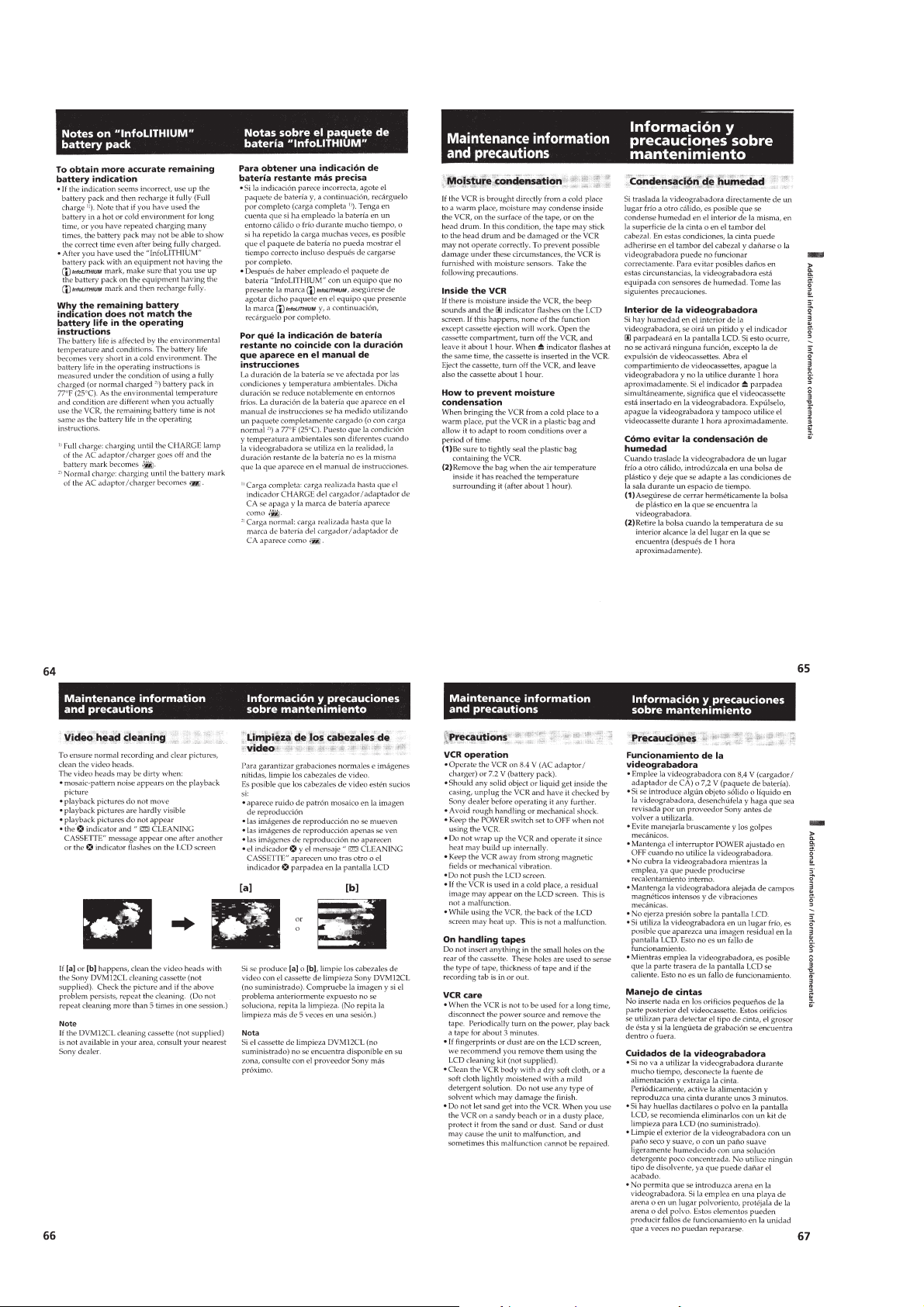

Maintenance information and precautions...........................1-16

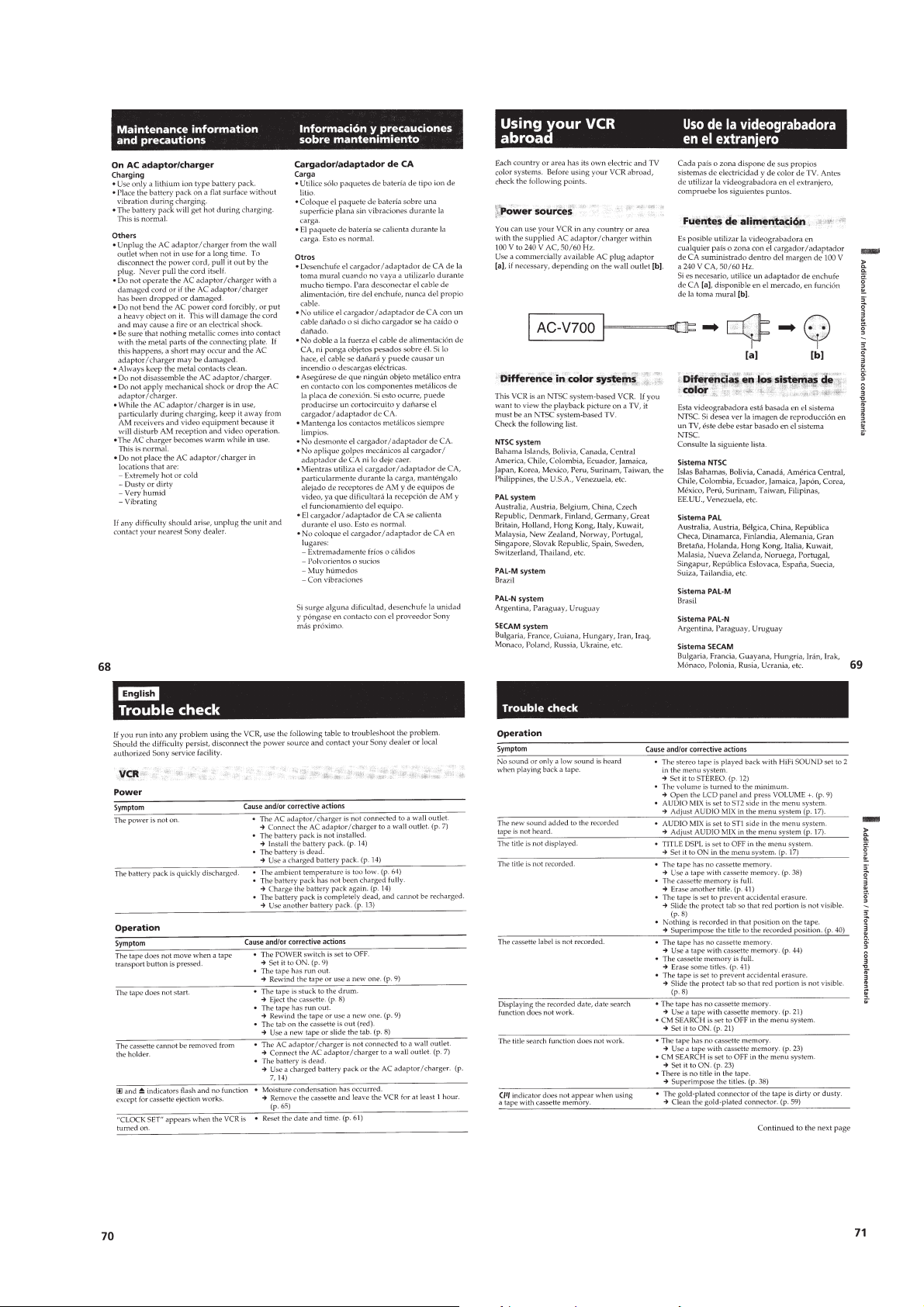

Using your VCR abroad ......................................................1-17

Trouble check ......................................................................1-17

Self-diagnosis display ..........................................................1-18

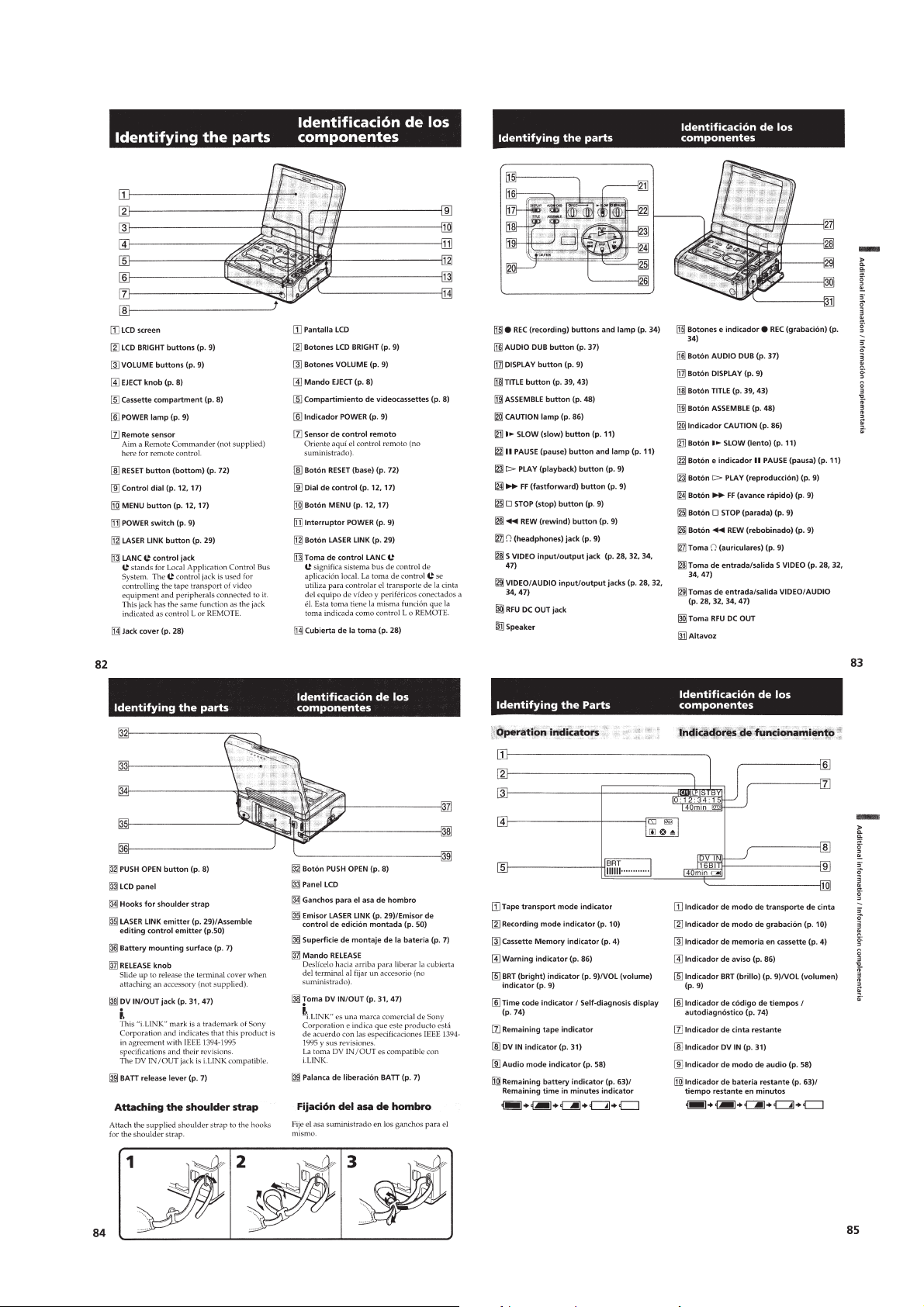

Identifying the parts .............................................................1-19

Warning indicators ...............................................................1-20

2. DISASSEMBLY

2-1. Cassette Lid Assembly .................................................... 2-1

2-2. Cabinet (Bottom) Assembly,

FP-571 (Lithium Battery) ................................................2-2

2-3. MD Block Assembly,

Battery Panel Assembly...................................................2-2

2-4. CB-61, RJ-77 Boards ......................................................2-3

2-5. Control Switch Block (FK-71) ........................................2-3

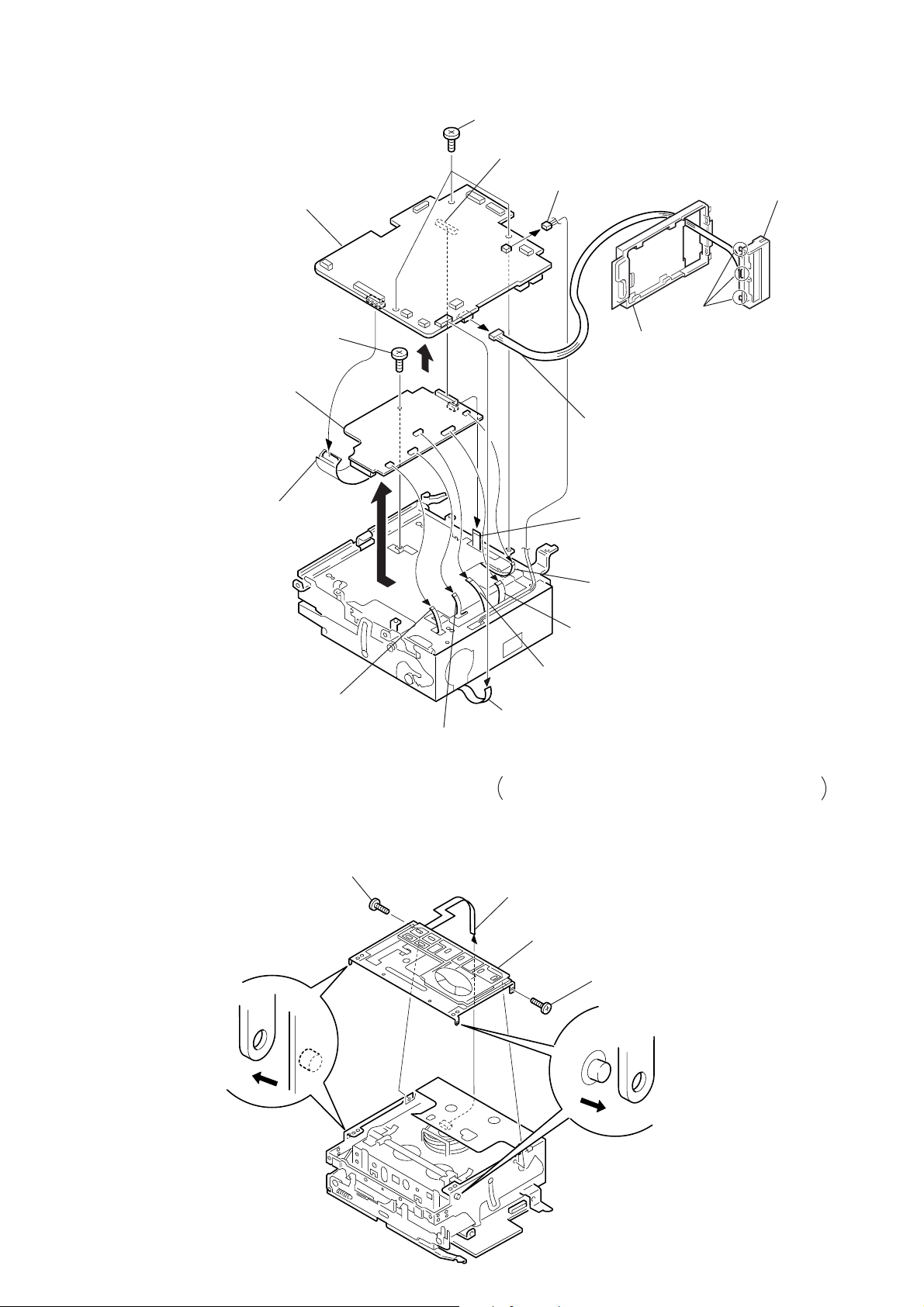

2-6. MD Block ........................................................................2-4

2-7. Cabinet (R) Assembly .....................................................2-4

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram (1) ..............................................3-1

3-2. Overall Block Diagram (2) ..............................................3-4

3-3. Power Block Diagram .....................................................3-7

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagram ..............................................4-1

4-2. Printed Wiring Boards and

Schematic Diagrams........................................................4-5

• CB-61 (Chroma Process, SYNC SEP, SIG Interface,

RGB Decoder, Audio, Mode Control, DC-DC Converter)

Printed Wiring Board ......................................4-7

• CB-61 (Signal Processor)(1/10)

Schematic Diagram .......................................4-14

• CB-61 (Video Input)(2/10)

Schematic Diagram .......................................4-17

• CB-61 (Chroma Process)(3/10)

Schematic Diagram .......................................4-21

• CB-61 (SYNC SEP, EVR, SIG Interface)(4/10)

Schematic Diagram .......................................4-23

• CB-61 (RGB Decoder)(5/10)

Schematic Diagram .......................................4-26

• CB-61 (Audio 1)(6/10) Schematic Diagram .............. 4-29

• CB-61 (Audio 2)(7/10) Schematic Diagram .............. 4-32

• CB-61 (IR Block)(8/10) Schematic Diagram.............4-35

• IR-29 (IR Transmitter)

Printed Wiring Board and

Schematic Diagram .......................................4-37

• CB-61 (Mode Control)(9/10)

Schematic Diagram .......................................4-40

• CB-61 (DC-DC Converter)(10/10)

Schematic Diagram .......................................4-43

• RJ-77 (REC/PB Process, RF Interface, Blocking,

Mecha Con/Servo, Audio Signal Process, Mode Control)

Printed Wiring Board .................................... 4-47

• RJ-77 (REC/PB Processor)(1/9)

Schematic Diagram .......................................4-51

• RJ-77 (RF Interface)(2/9)

Schematic Diagram .......................................4-56

• RJ-77 (DV Signal Process)(3/9)

Schematic Diagram .......................................4-59

• RJ-77 (Blocking, DRAM)(4/9)

Schematic Diagram .......................................4-63

• RJ-77 (ECC, TBC, CHCD)(5/9)

Schematic Diagram .......................................4-67

• FP-242, FP-584 (Tape Sensors)

Flexible Boards ............................................. 4-70

• RJ-77 (Audio Signal Process)(6/9)

Schematic Diagram .......................................4-72

• RJ-77 (Mecha Con/Servo)(7/9)

Schematic Diagram .......................................4-75

• Rj-77 (Audio Display)(8/9)

Schematic Diagram .......................................4-78

• Rj-77 (Mode Control)(9/9)

Schematic Diagram .......................................4-81

• IO-62 (AV In/Out)

Printed Wiring Board .................................... 4-83

• IO-62 (AV In/Out, Customer Control)

Schematic Diagram .......................................4-85

— 3 —

• EX-34 (DC-AC Inverter)

Schematic Diagram .......................................4-89

• EX-34 (Multi Connector, Back Light Power)

Printed Wiring Board .................................... 4-93

• FK-71 (Control Switch Block) ...................................4-95

5. ADJUSTMENTS

5-1. Adjustment Preparations .................................................5-1

1-1. Preparations Before Adjustment......................................5-1

1-1-1.List of Service Tools ........................................................5-1

5-2. Mechanism Section Adjustment...................................... 5-2

2-1. Operating Without Cassette .............................................5-2

2-2. Tape Path Adjustment......................................................5-2

1. Preparations for Adjustment............................................ 5-2

5-3. Electrical Adjustments.....................................................5-3

3-1. Preparations Before Adjustments ....................................5-3

3-1-1.Equipment Required ........................................................5-3

3-1-2.Precautions on Adjusting.................................................5-4

3-1-3.Adjusting Connectors ......................................................5-4

3-1-4.Connecting the Equipment ..............................................5-5

3-1-5.Checking the Input Signals..............................................5-6

3-1-7.Input/Output Level and Impedance .................................5-6

3-1-6.Alignment Tape ...............................................................5-6

3-2. Initialization of D, C Page Data ......................................5-7

1. Initializing the D Page Data ............................................5-7

2. Modification of D Page Data...........................................5-7

3. D Page Table.................................................................... 5-7

4. Initializing the C Page Data.............................................5-9

5. Modification of C Page Data...........................................5-9

6. C Page Table ....................................................................5-9

3-3. System Control System Adjustment..............................5-11

1. Battery End Adjustment (CB-61 Board) .......................5-11

3-4. Servo System Adjustments ............................................5-12

1. T Reel FG Duty Adjustment (RJ-77 Board)..................5-12

2. Switching Position Adjustment (RJ-77 Board) .............5-12

3-5. Video System Adjustments............................................5-13

3-5-1.RF Block Adjustments...................................................5-13

1. Recording Current Adjustment (RJ-77 Board)..............5-13

2. PLL F

3. CLK DELAY Adjustment (RJ-77 Board) .....................5-14

4. AGC Center Level Adjustment (RJ-77 Board)..............5-14

5. AEQ Adjustment (RJ-77 Board) ................................... 5-15

6. PLL Capture Range Adjustment (RJ-77 Board)............ 5-15

3-5-2. Clock Adjustments........................................................5-16

1. IC1900 27MHz XTAL F0 Adjustment (RJ-77 Board)...5-16

2. IC1900 VCO Operation Check (RJ-77 Board).............. 5-16

3. IC6101 41.85MHz VCO Operation Check

3-5-3. Base Band Block Adjustments......................................5-17

1. NPS PLL Adjustment (CB-61 Board)...........................5-17

2. NPS Y Level Adjustment (CB-61 Board)...................... 5-17

3. VIDEO Output Y Level Adjustment (CB-61 Board) ....5-18

4. S VIDEO Output Y Level Adjustment

5. AGC Adjustment (CB-61 Board) ..................................5-19

6. NPS B-Y Level Adjustment (CB-61 Board) .................5-19

7. NPS R-Y Level Adjustment For PAL Model

8. VIDEO Output Burst Level Adjustment

9. NPS R-Y Level Adjustment For NTSC Model

10. S VIDEO Output Chroma Level Adjustment

11. AFC TC Adjustment (CB-61 Board).............................5-21

12. AFC F0 Adjustment (CB-61 Board) ..............................5-22

13. Decoder APC Adjustment (CB-61 Board) ....................5-22

0 Adjustment (RJ-77 Board) ................................5-13

(RJ-77 Board) ................................................................5-16

(CB-61 Board) ...............................................................5-18

(CB-61 Board) ...............................................................5-20

(CB-61 Board) ...............................................................5-20

(CB-61 Board) ...............................................................5-20

(CB-61 Board) ...............................................................5-21

14. Decoder ACC Adjustment (CB-61 Board) ....................5-22

15. Decoder HUE Adjustment (CB-61 Board)....................5-23

16. Y AD Clamp Adjustment (CB-61 Board) .....................5-23

17. CR AD Clamp Adjustment (CB-61 Board) ...................5-24

18. CB AD Clamp Adjustment (CB-61 Board) ...................5-24

19. Y AD Level Adjustment (CB-61 Board) .......................5-25

20. CR AD Adjustment (CB-61 Board)...............................5-25

21. CB AD Level Adjustment (CB-61 Board).....................5-26

3-5-4.BIST Check ...................................................................5-27

1. Playback System Check ................................................5-27

2. Recording System Check ..............................................5-28

3-6. IR Transmitter Adjustments...........................................5-29

1. IR Video Carrier Frequency Adjustment

(CB-61 Board) ..............................................................5-29

2. IR Video Deviation Adjustment (CB-61 Board) ...........5-29

3. IR Audio Deviation Adjustment (CB-61 Board) ...........5-30

3-7. Audio System Adjustments ...........................................5-31

1. Playback Level Check ...................................................5-31

2. Overall Level Characteristics Check .............................5-31

3. Overall Separation Check.............................................. 5-31

4. Overall Noise Level Check............................................5-32

3-8. LCD System Adjustment (GV-D900/D900E) ...............5-33

1. LCD Initial Data Input ..................................................5-33

2. PANEL –19V Adjustment (CB-61 Board) ....................5-34

3. Horizontal Position Adjustment (CB-61 Board) ...........5-34

4. Bright Adjustment (CB-61 Board) ................................5-35

5. Contrast Adjustment (CB-61 Board).............................5-35

6. Color Adjustment for NTSC Model (CB-61 Board).....5-36

7. HUE Adjustment for NTSC Model (CB-61 Board)......5-36

8. Burst Cleaning Adjustment For PAL Model

(CB-61 Board) ...............................................................5-37

9. Color Adjustment For PAL Model (CB-61 Board) .......5-37

10. V-COM Adjustment (CB-61 Board) .............................5-38

11. White Balance Adjustment (CB-61 Board)...................5-38

5-4. Service Mode.................................................................5-39

4-1. Adjustment Remote Commander .................................. 5-39

1. Using the Adjustment Remote Commander..................5-39

2. Precautions Upon Using the

Adjustment Remote Commander .................................. 5-39

4-2. Data Process ..................................................................5-40

4-3. Service Mode.................................................................5-41

1. Setting the Test Mode ....................................................5-41

2. Emergence Memory Address ........................................5-41

2-1. EMG Code (Emergency Code) .....................................5-41

2-2. MSW Code ....................................................................5-42

3. Bit Value Discrimination ...............................................5-43

4. Switch Check (1) ...........................................................5-43

5. Switch Check (2) ...........................................................5-44

6. Record of Use Check..................................................... 5-44

6. REPAIR PARTS LIST

6-1. Exploded Vie ws ...............................................................6-1

6-1-1.Cabinet Assembly ............................................................6-1

6-1-2.LCD Window Cabinet, Cabinet (Upper) Assembly ........6-2

6-1-3.Mechanism Deck Assembly ............................................6-3

6-1-4.Cassette Compartment and Drum Assembly...................6-4

6-1-5.LS Chassis Block Section................................................6-5

6-1-6.Mechanism Chassis Block Section-1 ..............................6-6

6-1-7.Mechanism Chassis Block Section-2 ..............................6-7

6-2. Electrical Parts List .........................................................6-8

— 4 —

SERVICE NOTE

k

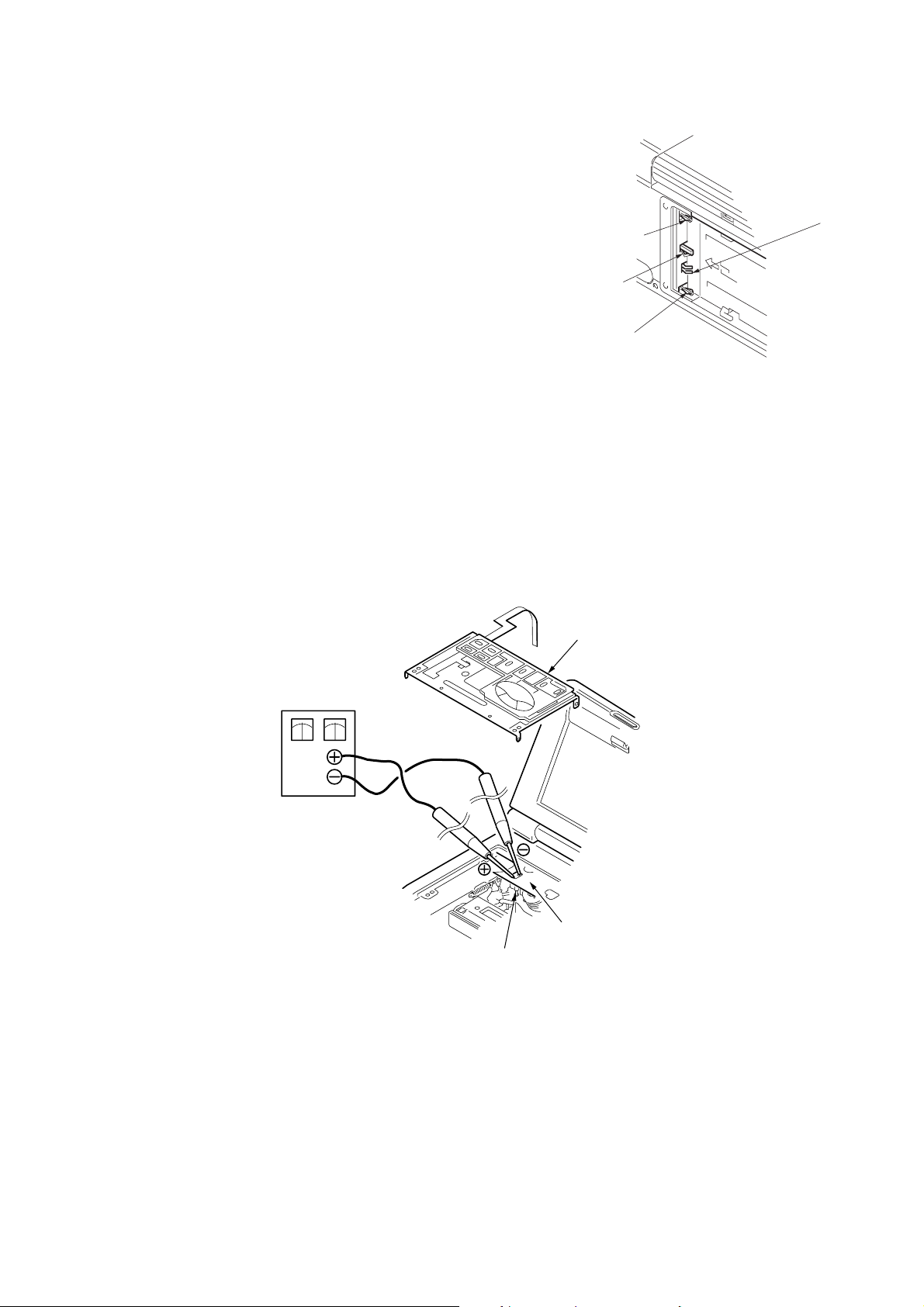

1. POWER SUPPLY DURING REPAIRS

In this unit, about 5 seconds after power is supplied (8.4V) to the

battery terminal using the service power cord (J-6082-223-A), the

power is shut off so that the unit cannot operate.

This following two methods are av ailable to prev ent this. Take note

of which to use during repairs.

Method 1.

Connect the servicing remote commander RM-95 (J-6082-053-B)

to the LANC jack, and set the remote commander switch to the

“ADJ” side.

Battery terminal

Battery switch

Battery sig terminal

‘

Method 2.

Press the following battery switch using adhesive tape, etc.

Battery terminal

’

2. HOW TO TAKE A CASSETTE OUT WHEN THE MAIN POWER

CANNOT BE TURNED ON (FORCED EJECTED)

Procedure:

1. Remove the cassette lid referring to the section “2. DISASSEMBLY, 2-1”.

2. Remove the operation switch block (FK-71 board) referring to the section “2. DISASSEMBLY, 2-5”.

3. Remove the CB-61 board referring to section “2. DISASSEMBLY, 2-4”, and remove the FP-586 flexible board from CN3140 (4P) on

the RJ-77 board.

4. Apply +4.5 V from the regulated power supply to the loading motor terminal as shown below and remove the cassette.

CAUTION: Be careful not contact with the lid frame assembly when applying +4.5 V.

Control switch bloc

Regulated power supply

4.5V

GND

Lid frame assembly

Loading motor

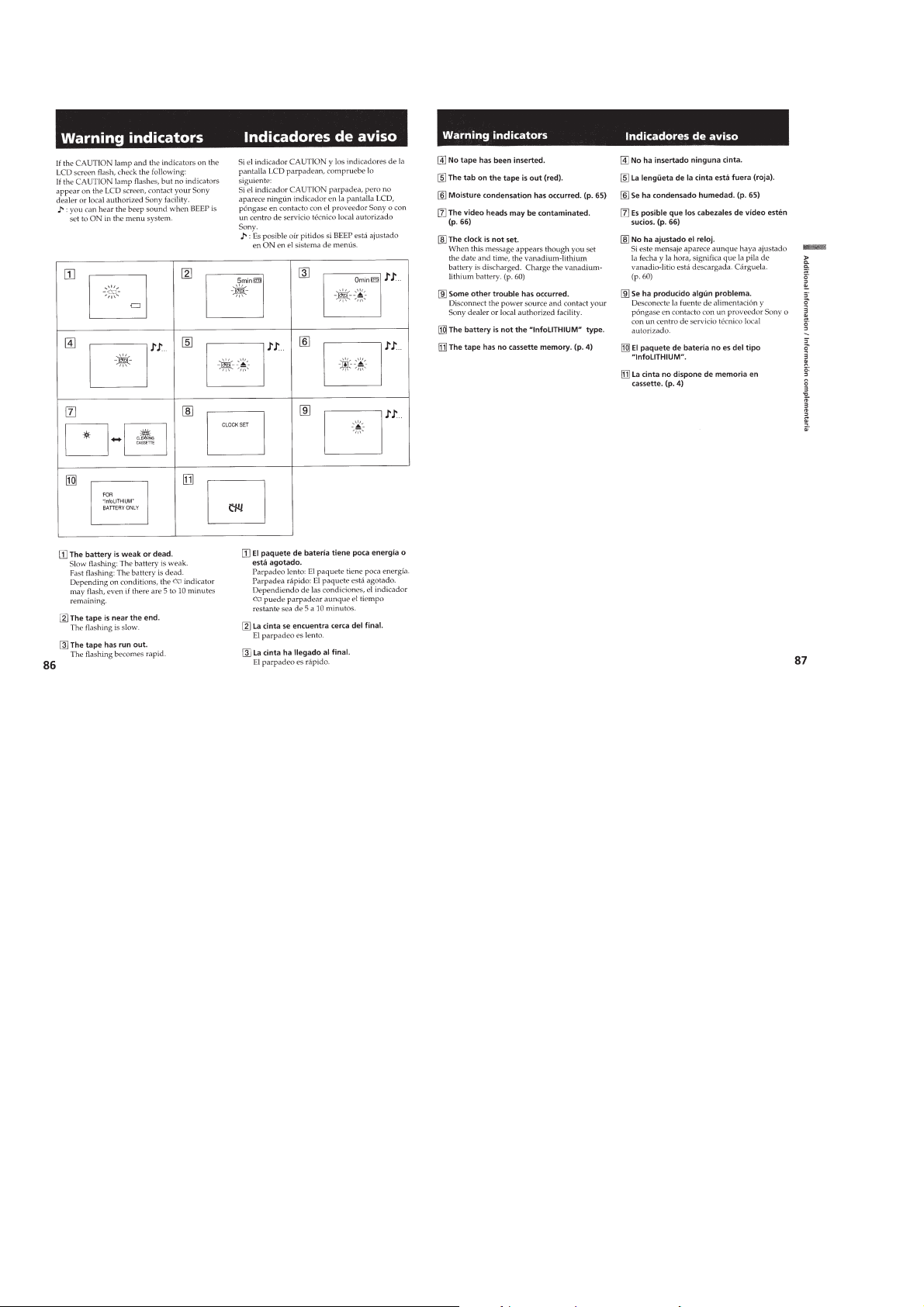

3. WARNING INDICATORS

If the CAUTION lamp flashes, b ut no indicators appear on the LCD screen or on the monitor TV screen, it means tha t an error occurs either

in the fan motor or in the fan motor drive circuit. Refer to the schematic diagram on page 4-43 for repair.

— 5 —

SELF-DIAGNOSIS FUNCTION

1. SELF-DIAGNOSIS FUNCTION

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the LCD screen or monitor

TV (Note) what to do. This function consists of two display; selfdiagnosis display and service mode display.

Details of the self-diagnosis functions are provided in the Instruction

manual.

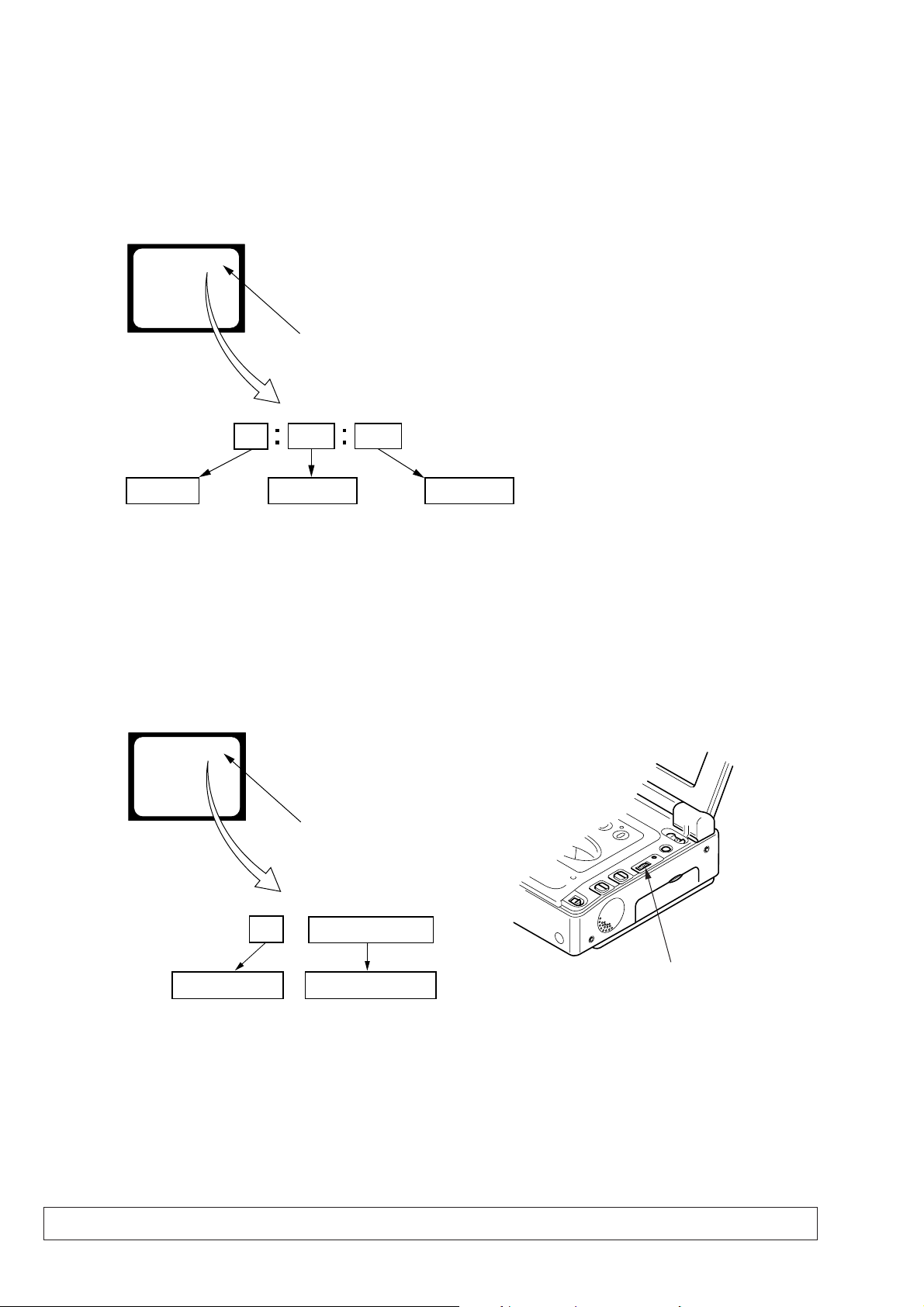

LCD screen or monitor TV

C : 3 1 : 1 1

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

Blinks at 3.2Hz

3 1C

Block

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Tur n o n power again.

1 1

2. SELF-DIAGNOSIS DISPLAY

When problems occur while the unit is operating, the counter of the

viewfinder shows a 4-digit display consisting of an alphabet and

numbers, which blinks at 3.2 Hz. This 5-character display indicates

the “repaired by:”, “block” in which the problem occurred, and

“detailed code” of the problem.

Note: Set the DISPLAY in the menu system to V-OUT/LCD only for the

model with LCD screen, and press the DISPLAY button.

Detailed Code

Refer to page 7.

Self-diagnosis Code Table.

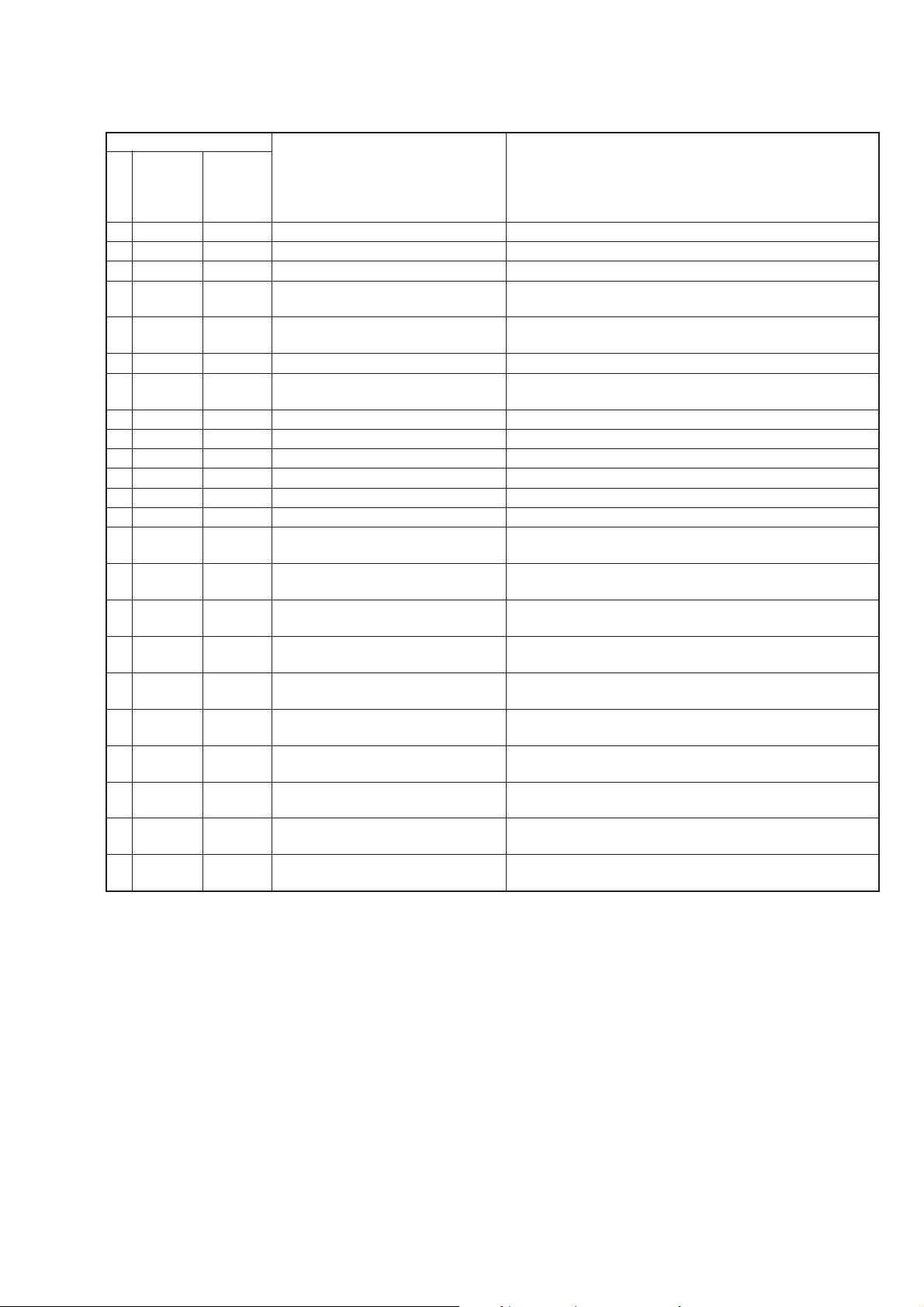

3. SER VICE MODE DISPLAY

The service mode display shows up to six self-diagnosis codes shown in the past.

3-1. Display Method

While pressing the “STOP” key, set the switch from OFF to ON, and continue pressing the “STOP” key for 10 seconds continuously. The

service mode will be displayed, and the counter will show the backup No. and the 5-character self-diagnosis codes.

LCD screen or monitor TV

[3] C : 3 1 : 1 1

Lights up

[3]

Backup No.

Order of previous errors

3-2. Switching of Backup No.

By rotating the control dial, past self-diagnosis codes will be shown in order. The backup No. in the [] indicates the order in which the

problem occurred. (If the number of problems which occurred is less than 6, only the number of problems which occurred will be shown.)

[1] : Occurred first time [4] : Occurred fourth time

[2] : Occurred second time [5] : Occurred fifth time

[3] : Occurred third time [6] : Occurred the last time

C : 3 1 : 1 1

Control dial

self-diagnosis codes

3-3. End of Display

Turning OFF the power supply will end the service mode display.

Note: The “self-diagnosis displa y” data will be backed up by the coin-type lithium battery of FP-571 flexible board. When this coin-type lithium ba ttery

is removed, the “self-diagnosis display” data will be lost by initialization.

— 6 —

4. SELF-DIAGNOSIS CODE TABLE

Self-diagnosis Code

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

Block

Function

21

22

23

31

31

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

Detailed

Code

00

00

00

10

11

20

21

22

23

24

30

40

42

10

11

20

21

22

23

24

30

40

42

Symptom/State

Condensation.

Video head is dirty.

Non-standard battery is used.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum

FG fault during normal drum

operations

Correction

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Use the info LITHIUM battery.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

— 7 —

SECTION 1

GENERAL

GV-D300/D300E/D900/D900E

This section is extracted from

instruction manual. (GV-D900)

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

1-11

1-12

1-13

1-14

1-15

1-16

1-17

1-18

1-19

1-20E

SECTION 2

DISASSEMBLY

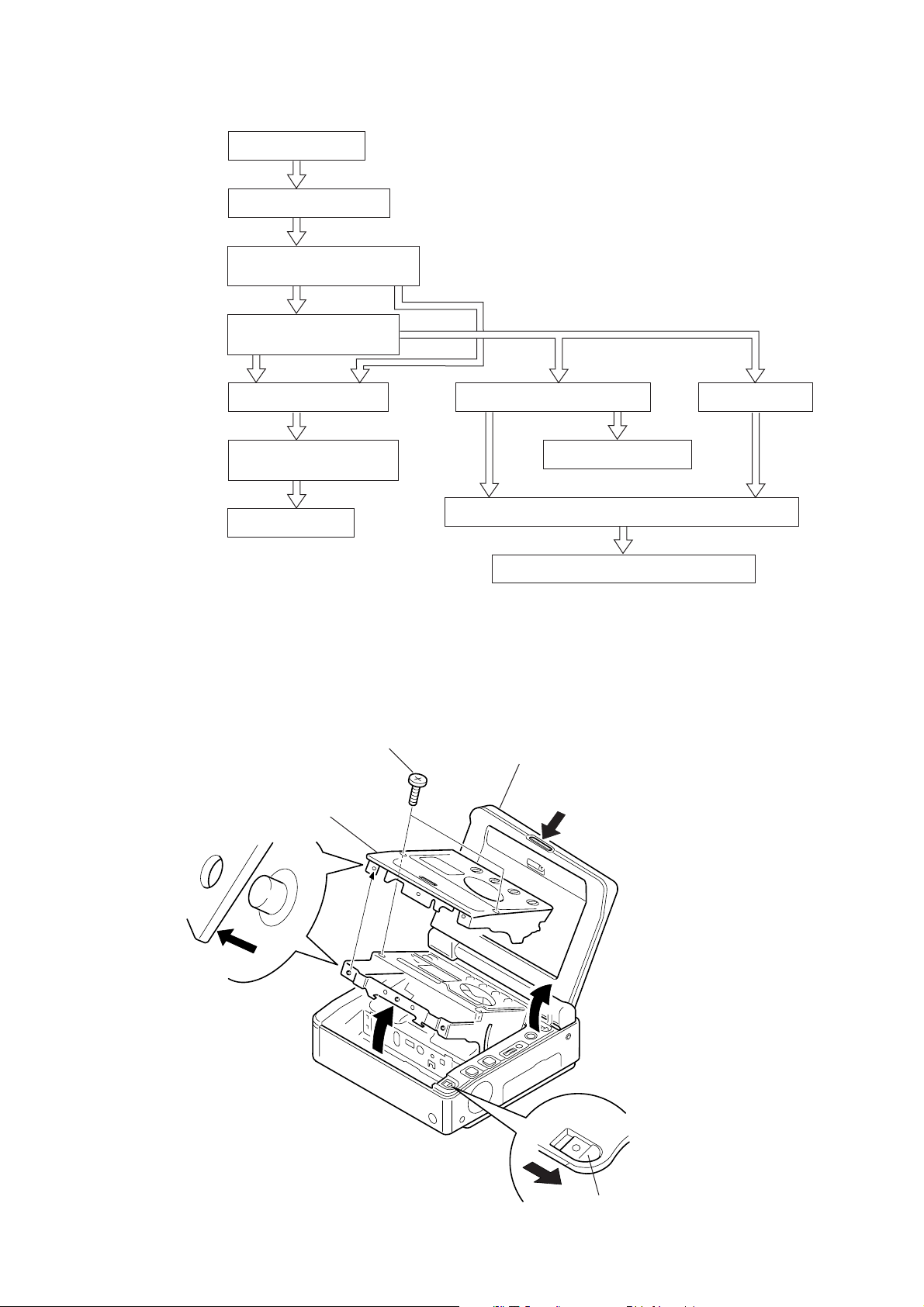

NOTE: Follow the disassembly procedure in the numerical order given.

Video WALKMAN

2-1. Cassette lid assembly

2-2. Cabinet (bottom) assembly

FP-571 (lithium battery)

2-3. MD block assembly

Battery panel assembly

GV-D300/D300E/D900/D900E

2-4. CB-61, RJ-77 boards

2-5. Control switch block

(FK-71)

2-6. MD block

2-1. CASSETTE LID ASSEMBLY

2

Two screws (M2)

4

Remove the cassette

lid assembly

2-7. Cabinet (R) assembly

2-8. IR-29, IO-62 boards

2-10. Cabinet (upper) assembly

2-11. LCD display module (GV-D900/D900E)

1

Open the LCD window cabinet

assembly in the direction of the

arrow A. (only D900/D900E)

Push here.

2-9. EX-34 board

2-1

A

3

knob to open the cassette

compartment.

Press the cassette EJECT

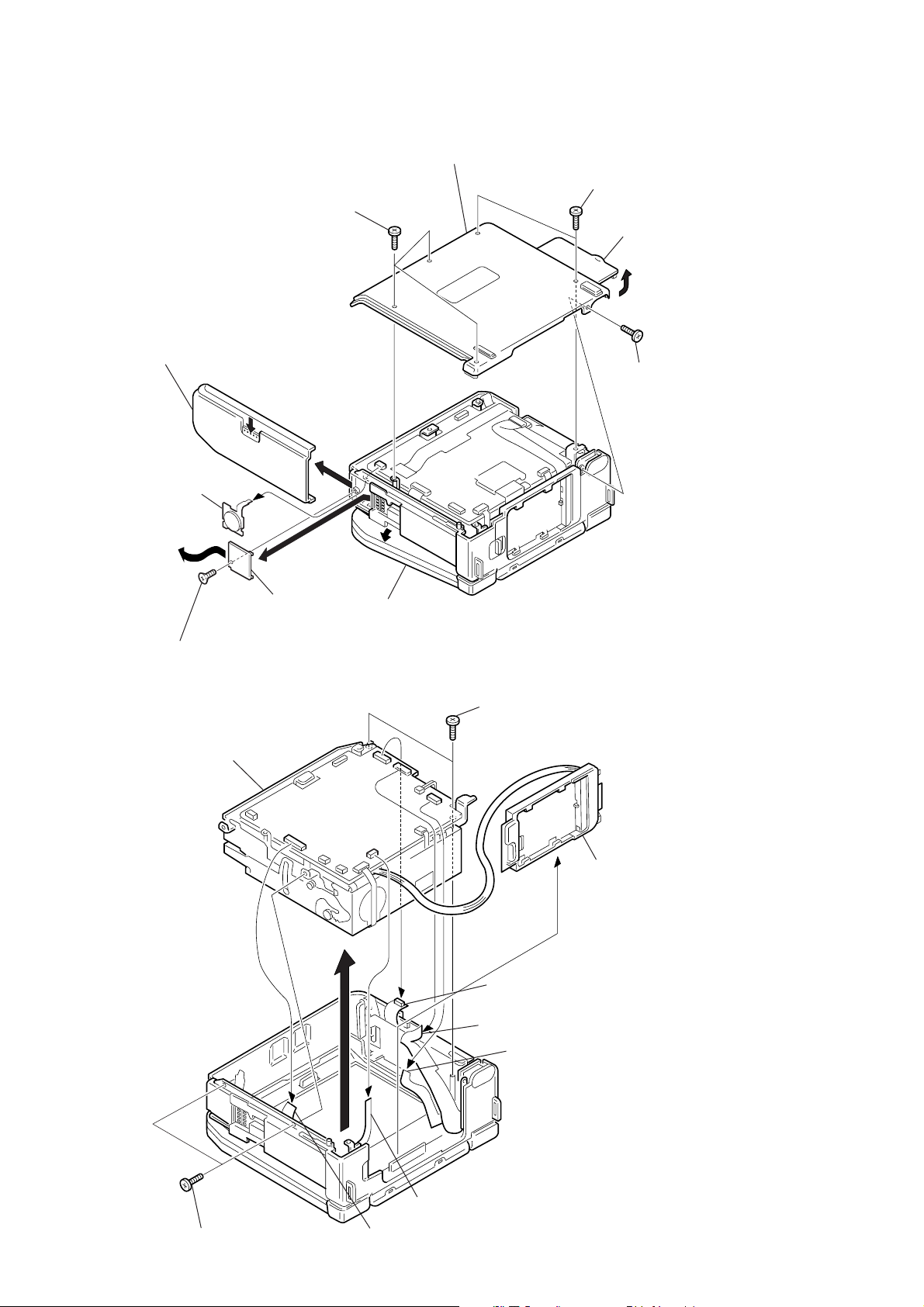

2-2. CABINET (BOTTOM) ASSEMBLY, FP-571(LITHIUM BATTERY)

)

Open the Jack lid in the direction of the

4

3

Three screws (M2)

2

Press the release button to remove

the cabinet (bottom) assembly in the

direction of the arrow

A

.

arrow

assembly.

B

and remove the cabinet (bottom)

3

Two screws (M2)

Jack lid

3

B

Screw (M2

C

A

ARD

CB-61

BO

1

Open the LCD panel a little.

.

7

FP-571 flexible board

CB-61 board CN9926 4P

C

6

lid in the direction

of the arrow

5

Tapping screw (+K2 × 5)

Remove the lithium

2-3. MD BLOCK ASSEMBLY, BATTERY PANEL ASSEMBLY

7

Two screws (M2)

8

Remove the MD block assembly.

CB-61

BOARD

6

Remove the battery

panel assembly.

7

Two screws (M2 black)

2

FP-602 flexible board

1

FP-570 flexible board

CB-61 board CN9931 40P

2-2

5

FP-598 flexible board

3

FP-569 flexible board

4

FP-572 flexible board

2-4. CB-61, RJ-77 BOARDS

4

Remove the CB-61 board.

8

Screw (M2)

!∞

Remove the RJ-77 board

in the direction of the arrow

5

FP-599 flexible board

CN9930 50P

A

.

CB-61

BOARD

RJ-77

BOARD

A

3

Three screws (M2)

Board to board connector

1

DC fan cable

2

6

CN3900 5P

!¢

CN3100 18P (from capstan motor)

!£

CN3101 6P (from the mode switch)

3

7

Remove the battery

terminal.

Claws

Battery panel

Battery panel assembly cable

Flexible board

9

FP586 flexible board

CN3104 4P

(from loading motor)

0

Flexible board

CN2708 10P

(from video head)

2-5. CONTROL SWITCH BLOCK (FK-71)

2

Screw (M1.4 × 2.5)

!™

FP-538 flexible board

CN3102 17P (from S reel/ T reel)

Flexible board

!¡

CN3103 11P (from drum motor)

1

2

Control switch block (FK-71) CN9927 10P

The numbers in square

when removing the battery terminal board only.

1

Remove the flexible board from the CB-61 board CN9927 (10P).

3

Remove the Control switch block (FK-71)

`

show the order of disassembly

2

Screw (M1.4 × 2.5)

2-3

Loading...

Loading...