Page 1

FST-GTK11iP/GTK33iP/

RDH-GTK11iP/GTK33iP

SERVICE MANUAL

Ver. 1.0 2012.03

Photo: RDH-GTK33iP

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION:

(e United States model only)

With 3.5 ohm loads, both channels driven, from 120

50 watts per channel minimum RMS power, with no more than 0.7% total

harmonic distortion from 250 milliwatts to rated output.

Amplier section (US model)

RMS output power (reference):

210 W + 210 W (per channel at 3.5 Ω, 1 kHz)

Amplier section (Except US model)

e following are measured at AC 120 V 240 V, 50/60 Hz (Latin American

models (except for Mexican and Argentine models))

e following are measured at AC 127 V, 60 Hz (Mexican model)

e following are measured at AC 220 V

Russian, Australian and Argentine models)

e following are measured at AC 120 V

FST-GTK33iP/RDH-GTK33iP

Power output (rated):

100 W + 100 W (at 3.5 Ω, 1 kHz, 1% THD)

RMS output power (reference):

210 W + 210 W (per channel at 3.5 Ω, 1 kHz)

FST-GTK11iP/RDH-GTK11iP

Power output (rated):

55 W + 55 W (at 3 Ω, 1 kHz, 1% THD)

RMS output power (reference):

115 W + 115 W (per channel at 3 Ω, 1 kHz)

Speaker section

Speaker system: 2 way speaker system, Bass reex

Speaker units:

FST-GTK33iP/RDH-GTK33iP:

Woofer: 200 mm, cone type

Tweeter: 66 mm, cone type

FST-GTK11iP/RDH-GTK11iP:

Woofer: 160 mm, cone type

Tweeter: 40 mm, cone type

Rated impedance:

FST-GTK33iP/RDH-GTK33iP: 3.5 Ω

FST-GTK11iP/RDH-GTK11iP: 3.0 Ω

Input

DVD/PC IN (audio in L/R):

FST-GTK33iP/RDH-GTK33iP: Sensitivity 1,000 mV, impedance 47 kΩ

FST-GTK11iP/RDH-GTK11iP: Sensitivity 1,500 mV, impedance 47 kΩ

10,000 Hz; rated

240 V, 50/60 Hz (European,

240 V, 50/60 Hz (Other models)

iPod/iPhone section

iPod/iPhone connector:

Output voltage: DC 5 V

Maximum output current: 1 A

Compatible iPod/iPhone models:

iPod touch 4th generation

iPod touch 3rd generation

iPod touch 2nd generation

iPod nano 6th generation

iPod nano 5th generation (video camera)

iPod nano 4th generation (video)

iPod nano 3rd generation (video)

iPod classic

iPhone 4S

iPhone 4

iPhone 3GS

iPhone 3G

“Made for iPod,” and “Made for iPhone” mean that an electronic accessory has

been designed to connect specically to iPod or iPhone, respectively, and has

been certied by the developer to meet Apple performance standards. Apple

is not responsible for the operation of this device or its compliance with safety

and regulatory standards. Please note that the use of this accessory with iPod

or iPhone may aect wireless performance.

USB section

Supported bit rates:

MP3 (MPEG 1 Audio Layer-3): 32 kbps

WMA: 48 kbps

192 kbps, VBR

320 kbps

AAC: 48 kbps

Sampling frequencies:

MP3 (MPEG 1 Audio Layer-3): 32/44.1/48 kHz

WMA: 44.1 kHz

AAC: 44.1 kHz

(USB) port: Type A, maximum current 500 mA

320 kbps, VBR

Saudi Arabia Model

Tuner section

FM stereo, FM/AM superheterodyne tuner

Antenna:

FM lead antenna

AM loop antenna

FM tuner section:

Tuning range:

87.5 MHz

108.0 MHz (100 kHz step) (US model)

87.5 MHz

108.0 MHz (50 kHz step) (Except US model)

AM tuner section:

Tuning range:

European, Russian and Saudi Arabian models:

531 kHz

1,602 kHz (9 kHz step)

US and Latin American models:

530 kHz

1,710 kHz (10 kHz step)

1,710 kHz (9 kHz step)

531 kHz

Australian model:

531 kHz

1,710 kHz (9 kHz step)

530 kHz

1,710 kHz (10 kHz step)

Other models:

531 kHz

1,602 kHz (9 kHz step)

530 kHz

1,610 kHz (10 kHz step)

General

Power requirements:

US model:

AC 120 V, 60 Hz

Latin American models (except for Mexican and Argentine models):

240 V, 50/60 Hz

AC

120 V

Mexican model:

AC 127 V, 60 Hz

European, Russian, Australian and Argentine models:

240 V, 50/60 Hz

AC 220 V

Other models:

240 V, 50/60 Hz

AC 120 V

Power consumption:

FST-GTK33iP/RDH-GTK33iP: 75 W (0.5 W at the Power Saving mode)

FST-GTK11iP/RDH-GTK11iP: 45 W (0.5 W at the Power Saving mode)

Dimensions (W/H/D):

FST-GTK33iP/RDH-GTK33iP: Approx. 768.5 mm × 323 mm × 385 mm

FST-GTK11iP/RDH-GTK11iP: Approx. 678.5 mm × 323 mm × 385 mm

Mass:

FST-GTK33iP/RDH-GTK33iP: Approx. 14.0 kg

FST-GTK11iP/RDH-GTK11iP: Approx. 12.5 kg

Quantity of the unit: 1 piece

Supplied accessories: Remote Commander (1), R6 (Size AA) batteries (2),

FM lead/AM loop antenna (1)

Design and specications are subject to change without notice.

US Model

RDH-GTK33iP

AEP Model

UK Model

Singapore Model

Malaysia Model

RDH-GTK11iP

E Model

FST-GTK11iP/GTK33iP

Australian Model

RDH-GTK11iP/GTK33iP

Chilean Model

Peruvian Model

FST-GTK33iP

License and Trademark Notice

iPhone, iPod, iPod classic, iPod nano, and iPod touch

are trademarks of Apple Inc., registered in the U.S. and

other countries.

MPEG Layer-3 audio coding technology and patents

licensed from Fraunhofer IIS and omson.

Windows Media is either a registered trademark or

trademark of Microso Corporation in the United

States and/or other countries.

is product contains technology subject to certain

intellectual property rights of Microso. Use or

distribution of this technology outside of this product

is prohibited without the appropriate license(s) from

Microso.

All other trademarks and registered trademarks are of

their respective holders. In this manual,

are not specied.

and ® marks

™

9-893-451-01

2012C33-1

2012.03

©

HOME AUDIO DOCKING SYSTEM

Sony Corporation

Published by Sony Techno Create Corporation

Page 2

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

NOTES ON CHIP COMPONENT REPLACEMENT

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

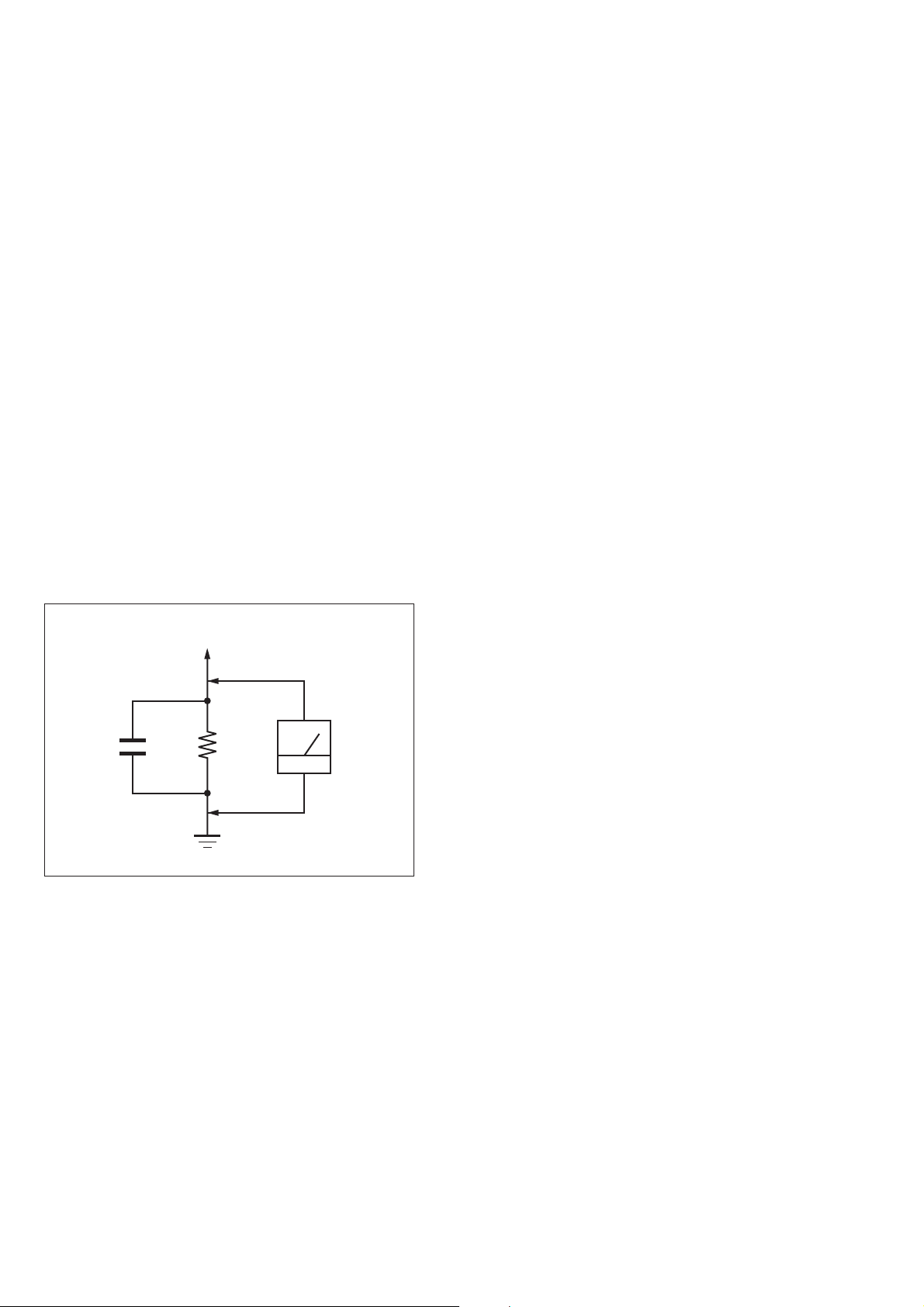

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

AC

1.5 kΩ0.15 μF

Earth Ground

voltmeter

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

Page 3

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

TABLE OF CONTENTS

1. SERVICING NOTES ............................................. 4

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 12

2-2. Side Panel (R) ................................................................. 13

2-3. Side Panel (L-base) ......................................................... 14

2-4. Cover (Back) Block ........................................................ 15

2-5. Back Panel Block (GTK11iP) ......................................... 16

2-6. Back Panel Block (GTK33iP) ......................................... 17

2-7. Shield (Main) Block ........................................................ 18

2-8. Panel Right Assy ............................................................. 19

2-9. USB Board ...................................................................... 20

2-10. Stage (Bottom-i-ph) Block .............................................. 20

2-11. Spring (PWB) ................................................................. 21

2-12. IP Board .......................................................................... 21

2-13. Spring (Lock 2) ............................................................... 22

2-14. MAIN Board ................................................................... 23

2-15. Shield (Power) Block ...................................................... 24

2-16. Power Cord (AC1) .......................................................... 25

2-17. GTK11-SMPS Board (GTK11iP) /

GTK33-SMPS Board (GTK33iP) ................................... 26

2-18. Chassis Block, Reinforcement (Back Panel) Block ....... 27

2-19. Ornament Base Block ..................................................... 27

2-20. Front Panel Assy ............................................................. 28

2-21. Loudspeaker (16 cm) (SP1, AP2) (GTK11iP) ................ 29

2-22. Loudspeaker (20 cm) (SP1, AP2) (GTK33iP) ................ 30

3. TEST MODE ............................................................ 31

4. ELECTRICAL CHECK ......................................... 32

5. DIAGRAMS

5-1. Block Diagram - MAIN Section - ................................... 33

5-2. Block Diagram - AMP Section - ..................................... 34

5-3. Block Diagram - REGULATOR Section - ...................... 35

5-4. Block Diagram - POWER SUPPLY Section - ................ 36

5-5. Printed Wiring Board

- MAIN Board (Component Side) - ................................ 38

5-6. Printed Wiring Board

- MAIN Board (Conductor Side) - .................................. 39

5-7. Schematic Diagram - MAIN Board (1/4) - ..................... 40

5-8. Schematic Diagram - MAIN Board (2/4) - ..................... 41

5-9. Schematic Diagram - MAIN Board (3/4) - ..................... 42

5-10. Schematic Diagram - MAIN Board (4/4) - ..................... 43

5-11. Printed Wiring Boards - AUDIO INPUT Section - ........ 44

5-12. Schematic Diagram - AUDIO INPUT Section - ............. 45

5-13. Printed Wiring Boards - PANEL Section - ..................... 46

5-14. Schematic Diagram - PANEL Section - .......................... 47

5-15. Printed Wiring Board

- GTK11-SMPS Board - (GTK11iP) .............................. 48

5-16. Schematic Diagram

- GTK11-SMPS Board - (GTK11iP) .............................. 49

5-17. Printed Wiring Board

- GTK33-SMPS Board - (GTK33iP) .............................. 50

5-18. Schematic Diagram

- GTK33-SMPS Board - (GTK33iP) .............................. 51

6. EXPLODED VIEWS

6-1. Side Panel Section .......................................................... 61

6-2. Back Cover Section ........................................................ 62

6-3. Back Panel Section (GTK11iP) ...................................... 63

6-4. Back Panel Section (GTK33iP) ...................................... 64

6-5. Ornament Section ........................................................... 65

6-6. Top Panel Section ........................................................... 66

6-7. Front Panel Section ......................................................... 67

6-8. DC Fan Section ............................................................... 68

6-9. MAIN Board Section ...................................................... 69

6-10. Chassis Section ............................................................... 70

6-11. SPK Box Section (GTK11iP) ......................................... 71

6-12. SPK Box Section (GTK33iP) ......................................... 72

6-13. LED Board Section ......................................................... 73

7. ELECTRICAL PARTS LIST .............................. 74

Accessories are given in the last of the electrical parts list.

3

Page 4

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

SECTION 1

SERVICING NOTES

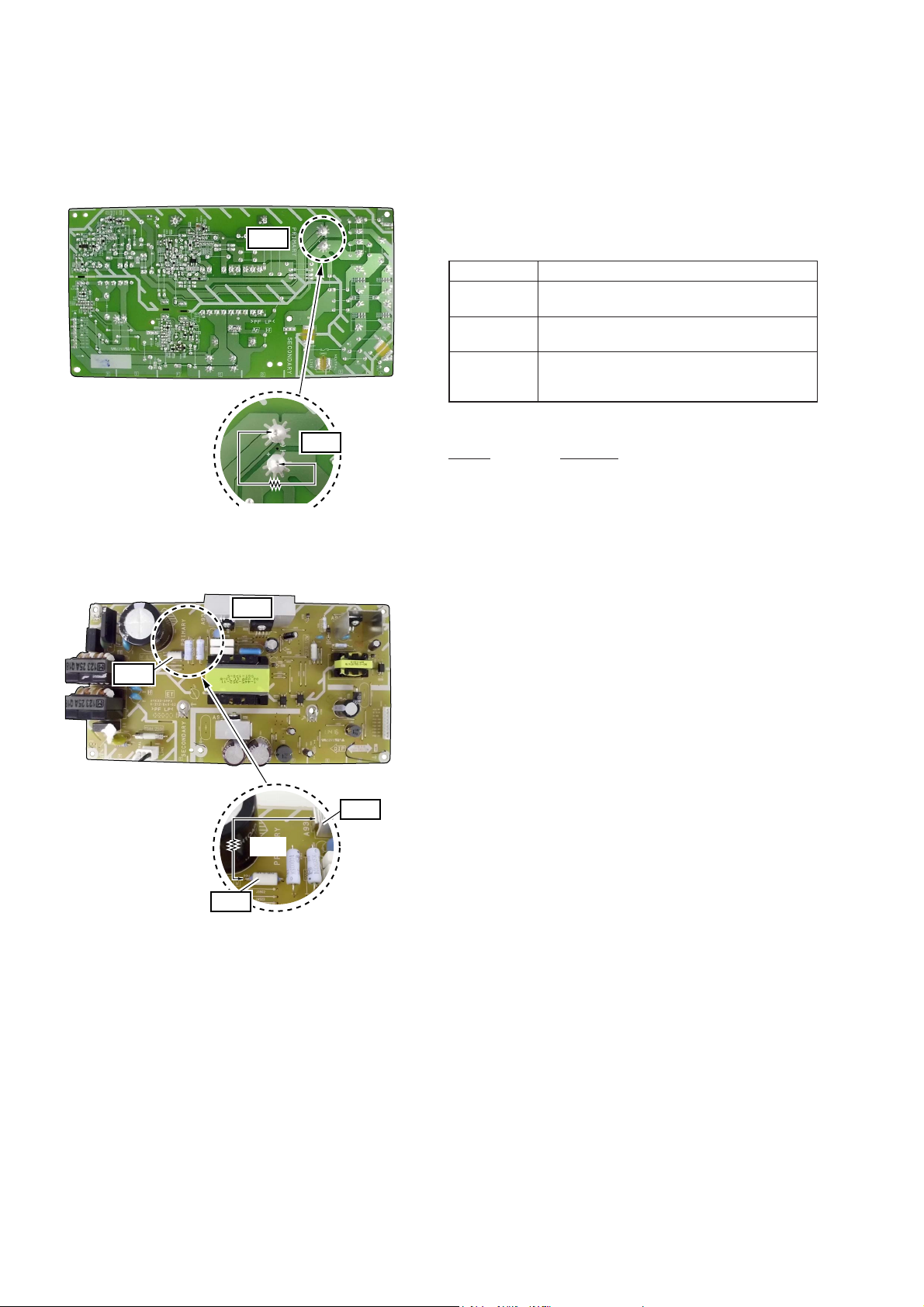

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

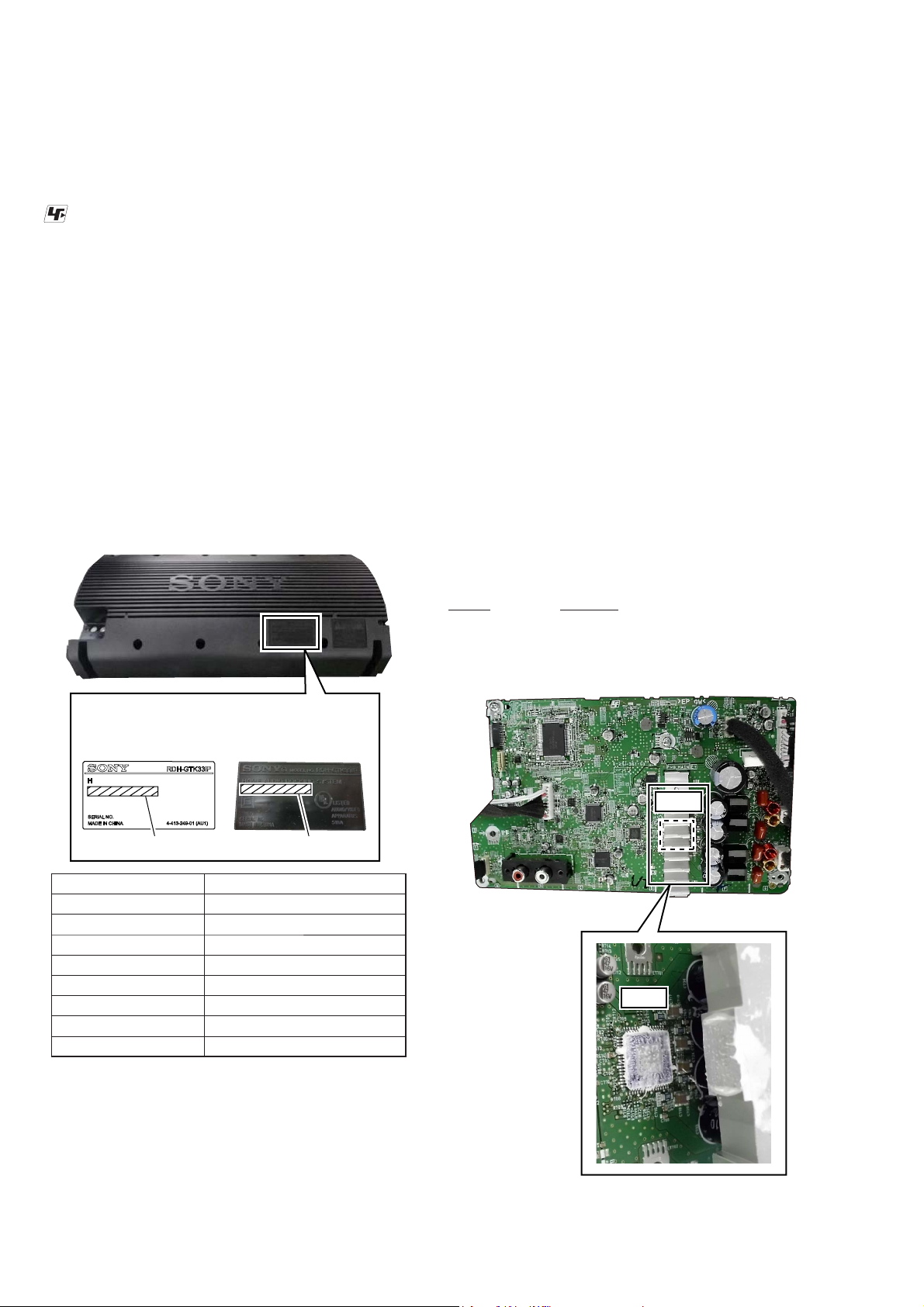

MODEL IDENTIFICATION

– Bottom side view –

NOTE THE D009 AND D010 ON THE LED (L) BOARD

REPLACING

D009 and D010 on the LED (L) board cannot exchange with

single. When these parts are damaged, exchange the complete

mounted board.

NOTE THE D009 AND D010 ON THE LED (R) BOARD

REPLACING

D009 and D010 on the LED (R) board cannot exchange with

single. When these parts are damaged, exchange the complete

mounted board.

THE OPERATION CHECK AFTER REPAIR

After repair is completed, connect corresponding “iPhone” etc.

to this unit and perform operation checks (playback, recording,

charging, etc.).

NOTE OF PERFORMING THE OPERATION CHECK

Don’t perform the operation check in the state where the heat sink

was removed from this unit, by any means. When the operation

check is performed, be sure to fi x the heat sink to the board in

advance.

NOTE OF REPLACING THE IC702 ON THE MAIN

BOARD AND THE COMPLETE MAIN BOARD

When IC702 on the MAIN board and the complete MAIN board

are replaced, it is necessary to spread the compound between parts

and heat sink.

The written example of

model number label.

Displayed characters/

values are example.

R

Model No.

OME AUDIO DOCKING SYSTEM

Power requirements

Model Power requirements

GTK11iP: AEP, UK, AUS

GTK11iP: RU

GTK11iP: E2, EA, SP6

GTK11iP: MX

GTK33iP: US

GTK33iP: E2, E51

GTK33iP: MX

GTK33iP: AUS

The written example of

stamp.

Displayed characters/

values are example.

Power requirements

AC:220 - 240V - 50/60Hz 45W

- 220 - 240V 50/60Hz 45W

AC:120 - 240V - 50/60Hz 45W

ca 127 V - 60 Hz 45 W

AC:120V - 60Hz 75W

AC:120 - 240V - 50/60Hz 75W

ca 127 V - 60 Hz 75 W

AC:220 - 240V - 50/60Hz 75W

Part No. Description

J-2501-221-A THERMAL COMPOUND (G747)

Spread the compound referring to the fi gure below.

– MAIN Board (Component Side) –

IC702

IC702

• Abbreviation

AUS : Australian model

E2 : 120V AC area in E model

E51 : Chilean and Peruvian models

EA : Saudi Arabia model

MX : Mexican model

RU : Russian model

SP6 : Singapore and Malaysia models

4

Page 5

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

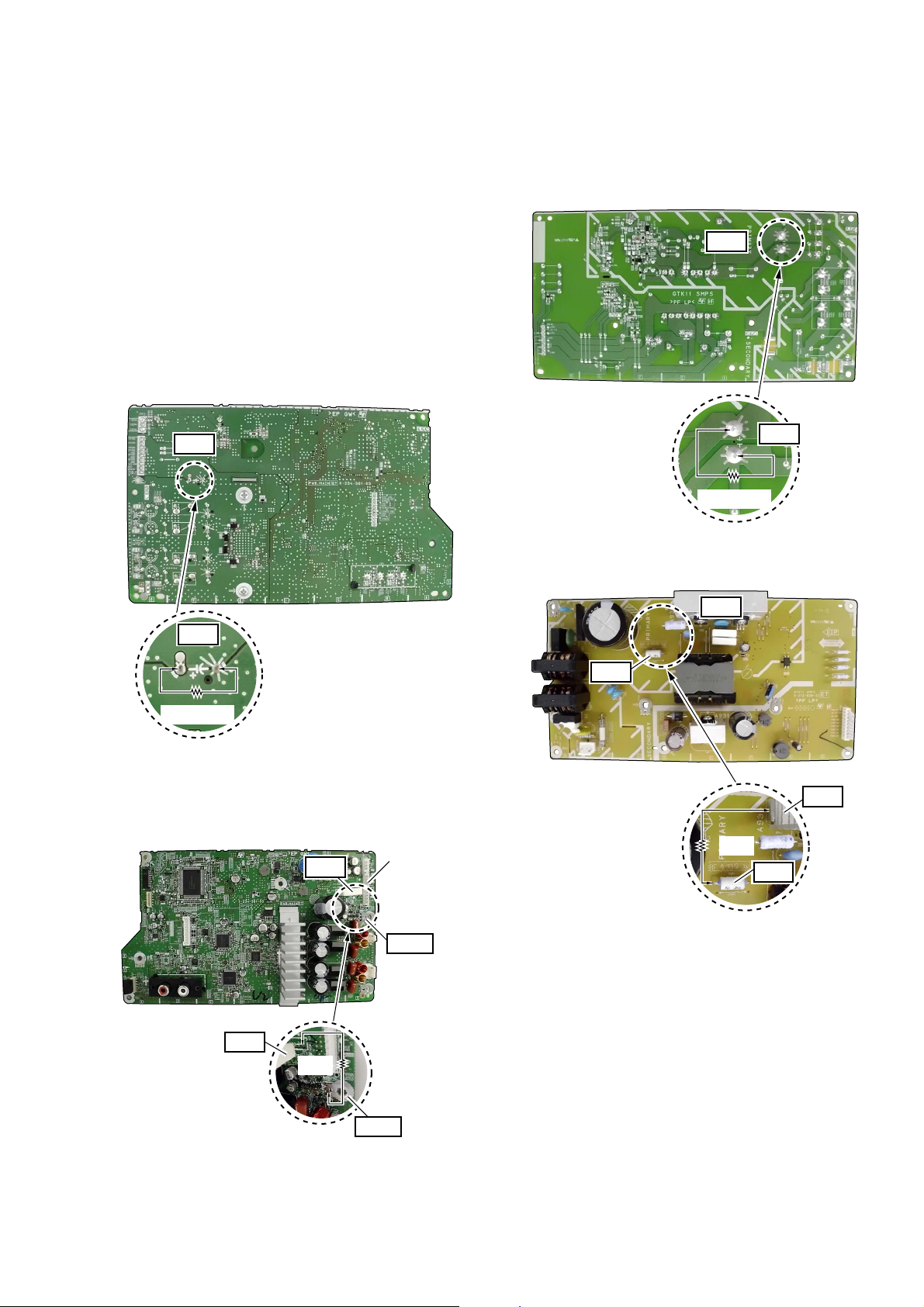

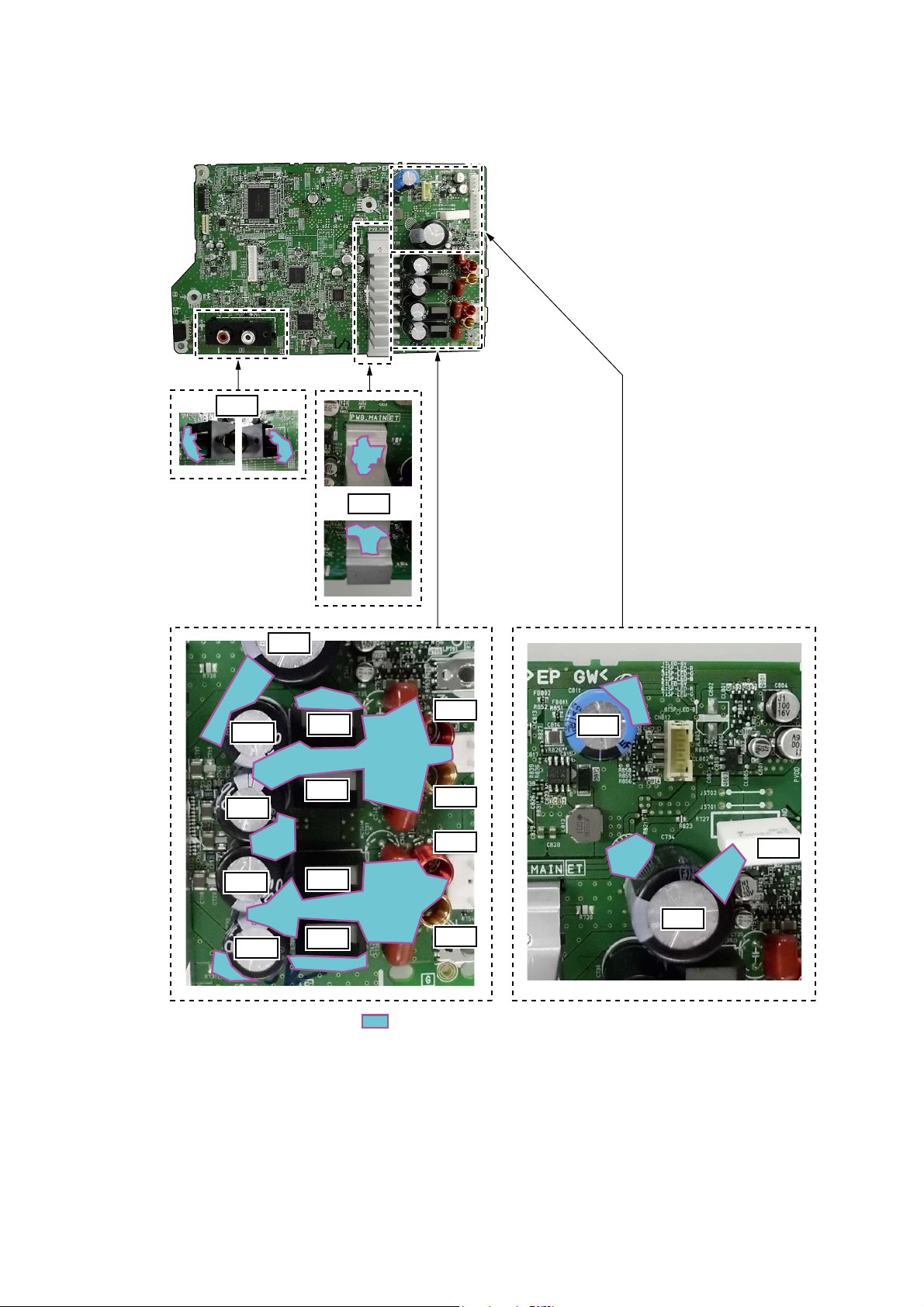

CAPACITOR ELECTRICAL DISCHARGE PROCESSING

When checking the board, the electrical discharge is necessary for

the electric shock prevention.

Connect the resistors referring to the fi gure below.

• Connetion position

1. MAIN board (Ref. No. C734) (page 5)

2. GTK11-SMPS board (Ref. No. C914) (GTK11iP only)

(page 5)

3. GTK33-SMPS board (Ref. No. C914) (GTK33iP only)

(page 6)

1. MAIN board (Ref. No. C734)

The MAIN board can be discharged by two kinds of following

methods.

1. Both ends of C734.

– MAIN Board (Conductor Side) –

C734

2. GTK11-SMPS board (Ref. No. C914) (GTK11iP only)

The GTK11-SMPS board can be discharged by two kinds of following methods.

1. Both ends of C914.

– GTK11-SMPS Board (Conductor Side) –

C914

C914

800 :/2 W

2. Heat sink (A930) and R914.

C734

800 :/2 W

2. Ground terminal (ET703) and R727.

Note: When you use this connection, confi rm that the GTK11-SMPS

board (GTK11iP) or the GTK33-SMPS board (GTK33iP) is not

connected with CN811 on the MAIN board.

– MAIN Board (Component Side) –

R727

CN811

Not connect

ET703

– GTK11-SMPS Board (Component Side) –

A930

R914

A930

0 :

R914

R727

0 :

ET703

5

Page 6

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

3. GTK33-SMPS board (Ref. No. C914) (GTK33iP only)

The GTK33-SMPS board can be discharged by two kinds of following methods.

1. Both ends of C914.

– GTK33-SMPS Board (Conductor Side) –

C914

C914

800 :/2 W

2. Heat sink (A930) and R914.

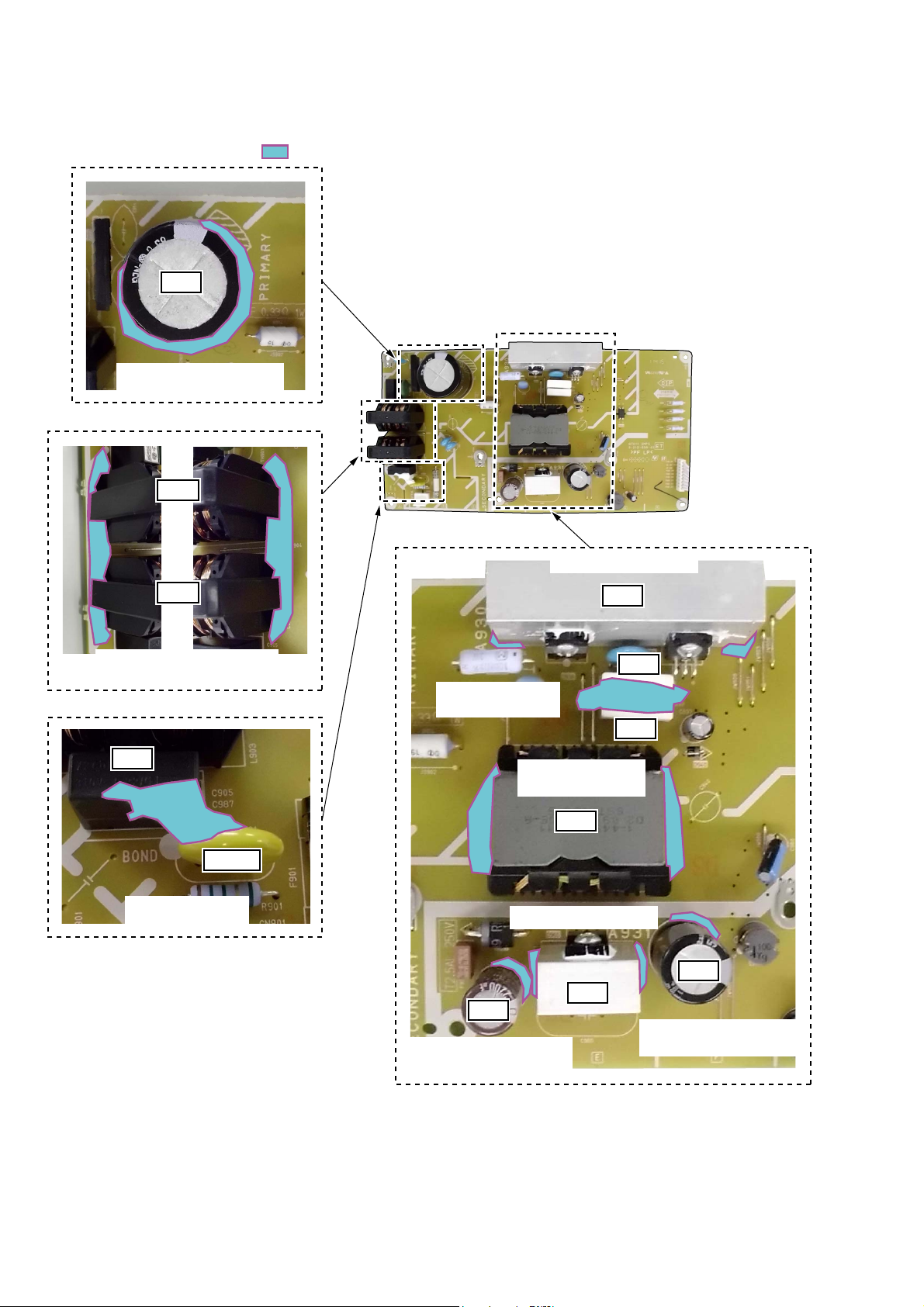

BOND FIXATION OF ELECTRIC PARTS

When MAIN board is replaced or the following object parts are

replaced, it is necessary to fi x parts to the boards by using a speci-

fi ed bond without fail.

• Object boards

Complete MAN board

• Object parts

Board Ref. No.

GTK11-SMPS

GTK33-SMPS

MAIN

C905, C914, C967, C969, L903, L904, R933,

R934, T901, VDR901

C905, C911, C912, C914, C943, C944, C986,

L901, L902, R930, R931, T901, T903, VDR901

C730, C731, C732, C733, C734, C811, L703,

L704, L705, L706, L707, L708, L709, L710,

R727

• Use bond

Part No. Description

7-432-912-52 BOND, SONY (SC-608LV)

• Parts position

1. MAIN board (page 7)

2. GTK11-SMPS board (GTK11iP only) (page 8)

3. GTK33-SMPS board (GTK33iP only) (page 9)

– GTK33-SMPS Board (Component Side) –

A930

R914

A930

0 :

R914

6

Page 7

1. MAIN board

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

– MAIN Board (Component Side) –

J301

C730

C731

C732

C733

C734

L703

L704

L705

L706

HS1

L707

L708

L709

L710

C811

R727

C734

The portion which applies bond:

7

Page 8

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

2. GTK11-SMPS board (GTK11iP only)

The portion which applies bond:

C914

– GTK11-SMPS Board (Component Side) –

Fix the 180-degree or larger

circumferences of C914.

L904

L903

Fix both the sides of

L903 and L904 with the board.

C905

VDR901

Apply bond on

C905 and VDR901.

Fix A930 with the board.

A930

R934

Fix R933 and R934

with the board.

R933

Fix both the sides of

T901 with the board.

T901

Fix A931 with the board.

C967

A931

C969

Fix the 90-degree or larger

Fix the 90-degree or larger

circumferences of C969.

circumferences of C967.

8

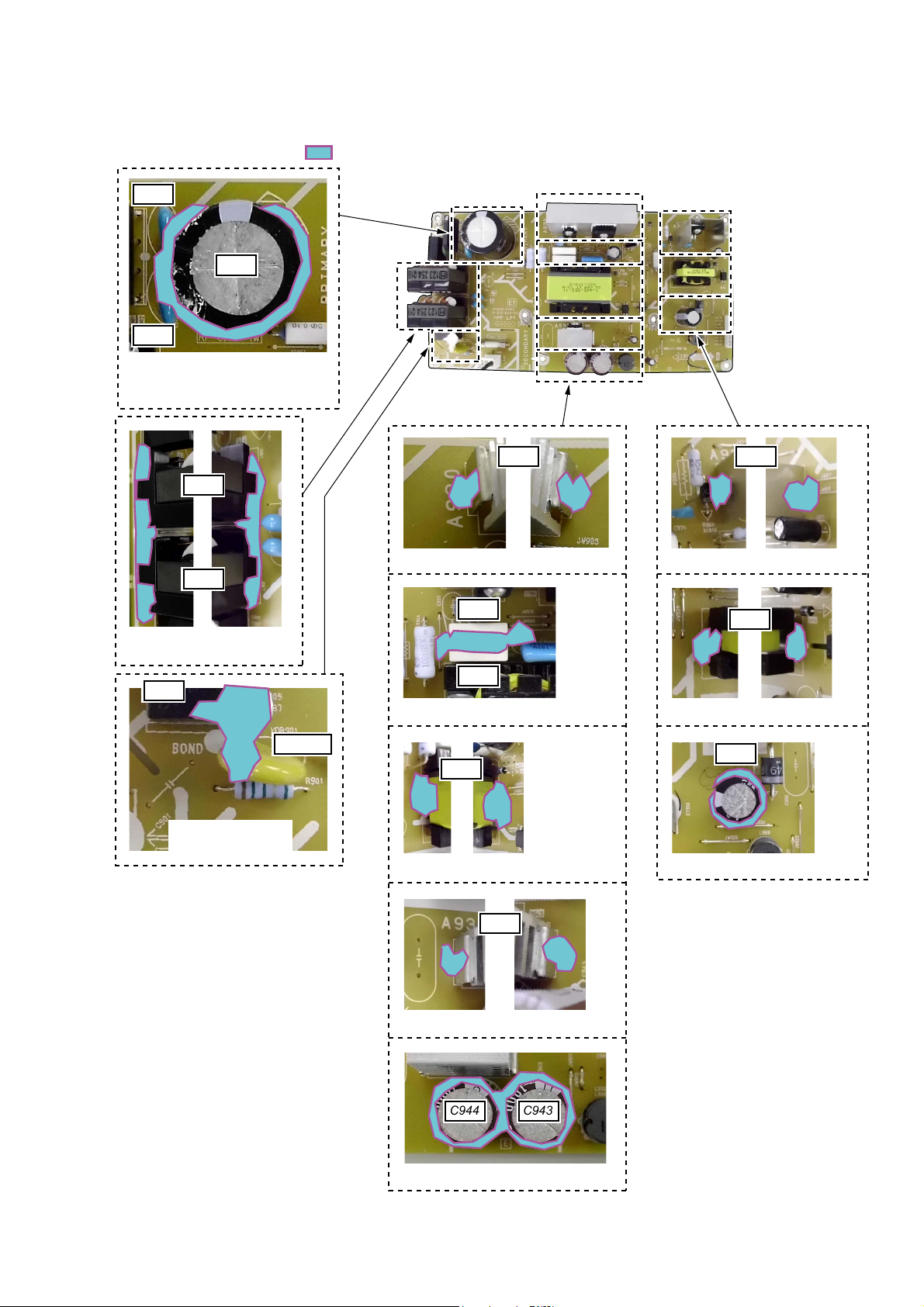

Page 9

3. GTK33-SMPS board (GTK33iP only)

The portion which applies bond:

C911

C914

C912

Fix the 180-degree or larger

circumferences of C914, and

fix C911 and C912 with the board.

L902

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

– GTK33-SMPS Board (Component Side) –

A932A930

L901

Fix both the sides of

L901 and L902 with the board.

C905

VDR901

Apply bond on

C905 and VDR901.

Fix A930 with the board.

R930

R931

T901

Fix T901 with the board.

A931

Fix A932 with the board.

T903

Fix T903 with the board.Fix R930 and R931 with the board.

C986

Fix circumferences of C986.

Fix A931 with the board.

C944 C943

Fix circumferences of C943 and C944.

9

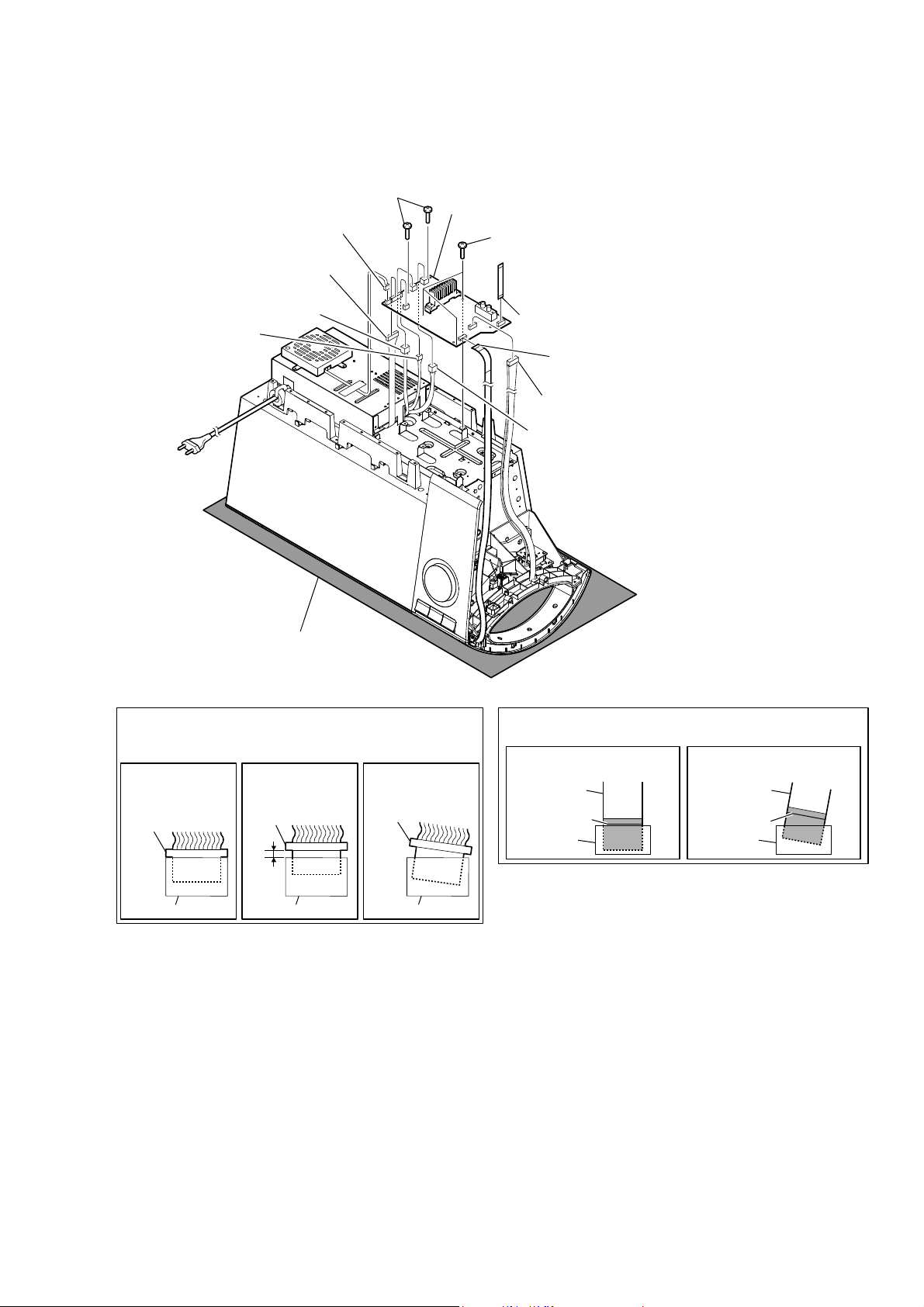

Page 10

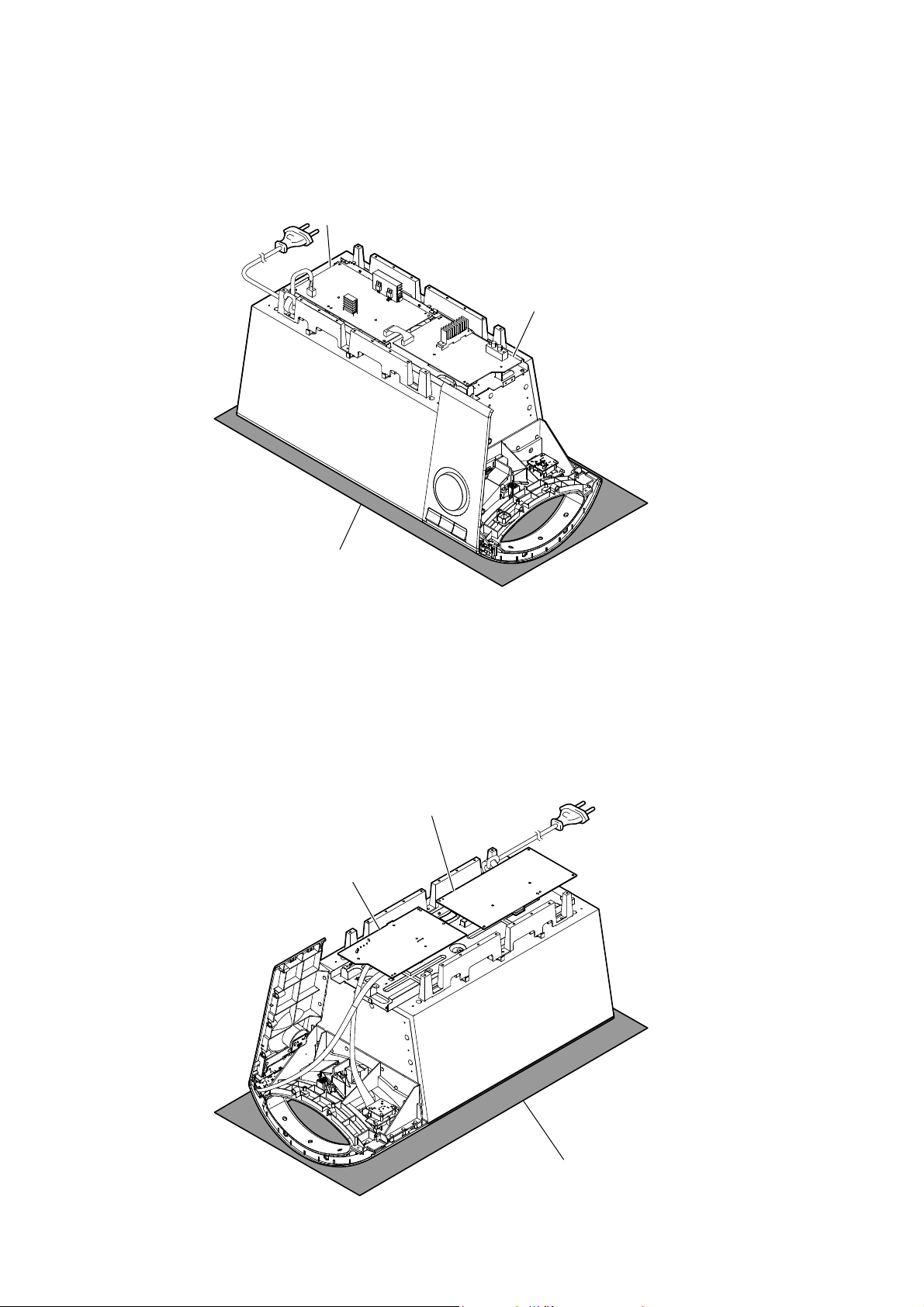

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

t

–

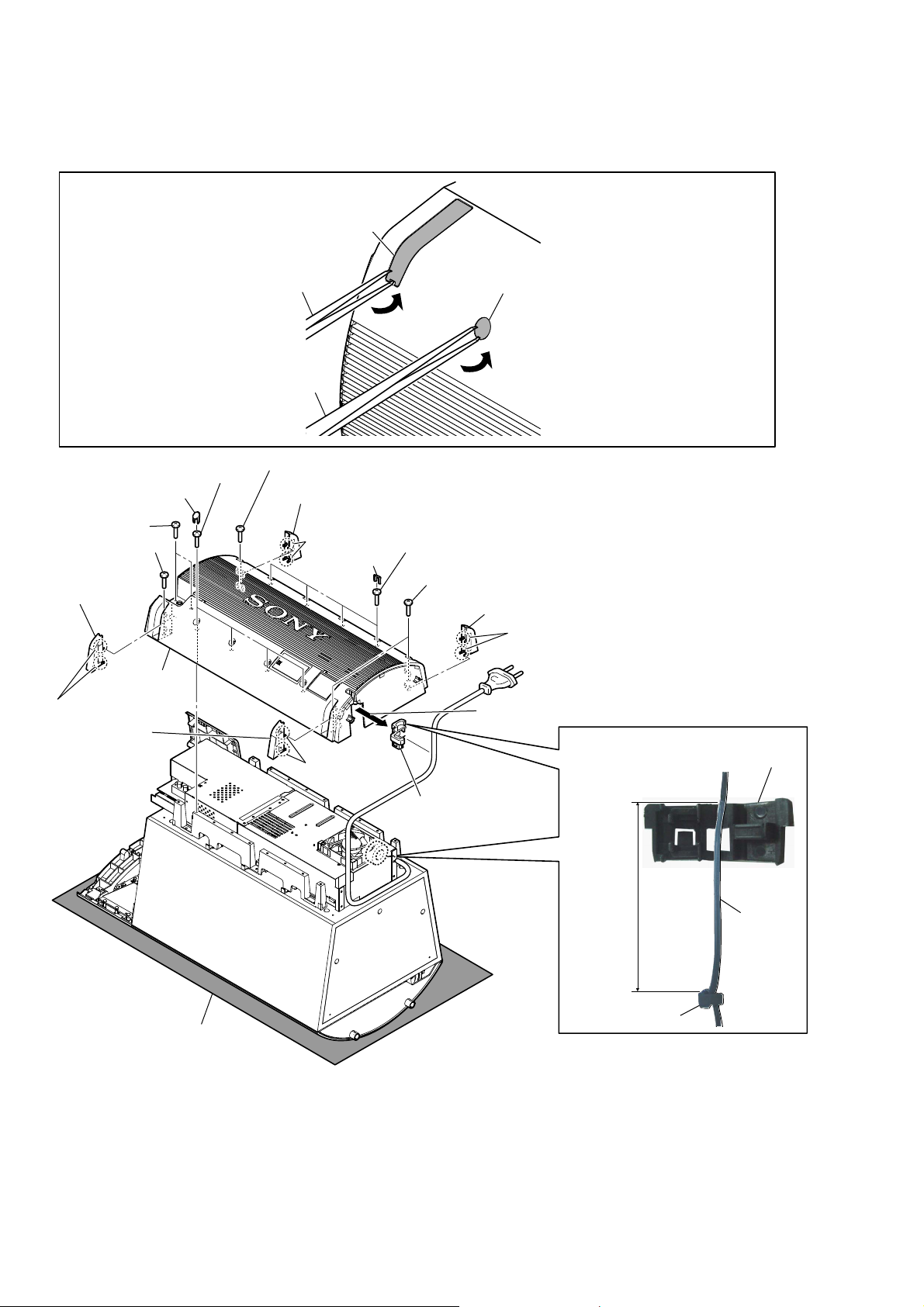

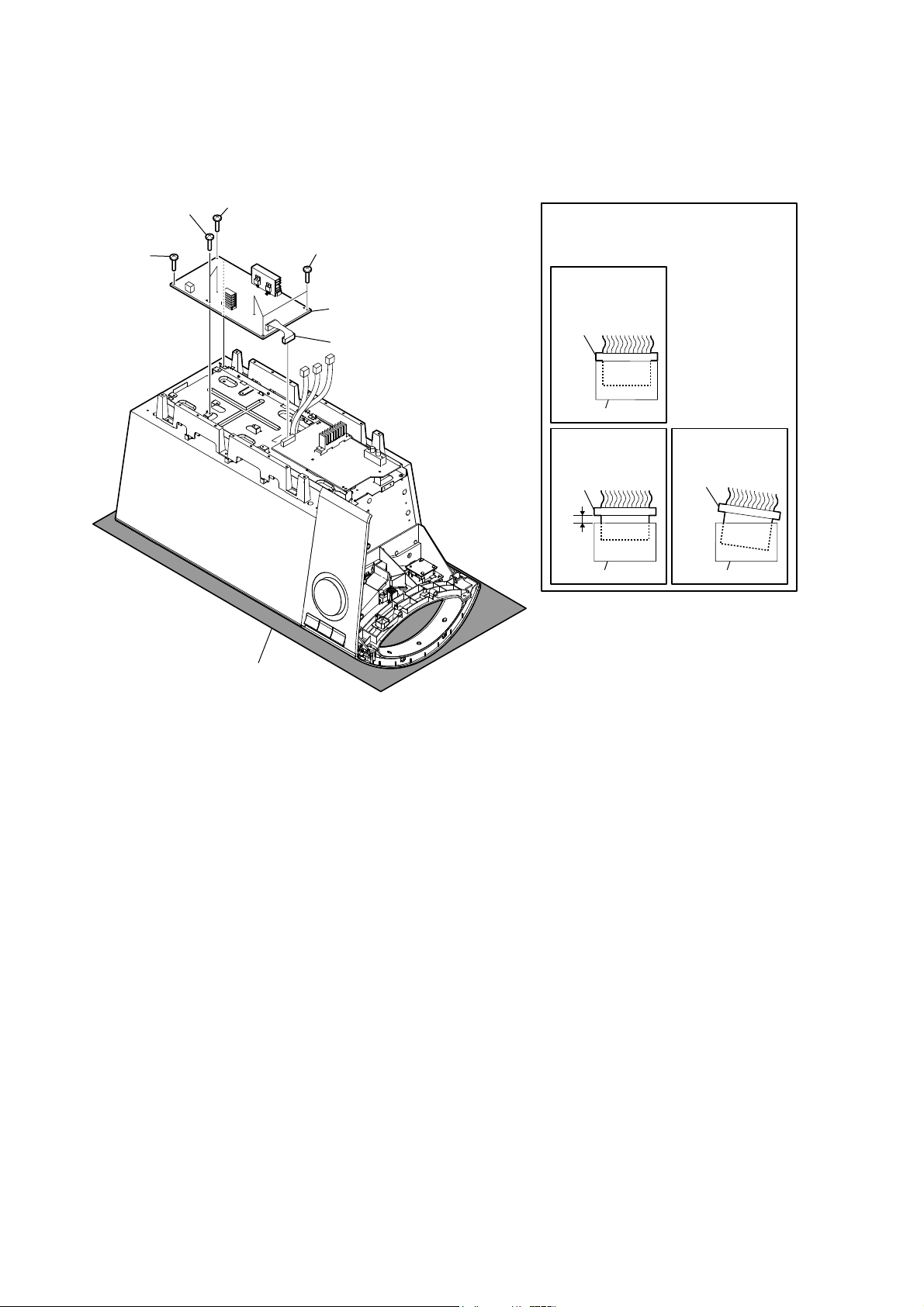

MAIN BOARD SERVICE POSITION

GTK11-SMPS board (GTK11iP)/

GTK33-SMPS board (GTK33iP)

MAIN board

– Top rear view –

Please spread a sheet under a unit

Note:

not to injure front grille.

GTK11-SMPS/GTK33-SMPS BOARD SERVICE POSITION

GTK11-SMPS board (GTK11iP)/

GTK33-SMPS board (GTK33iP)

MAIN board

Please spread a sheet under a uni

Top rear view –

10

Note:

not to injure front grille.

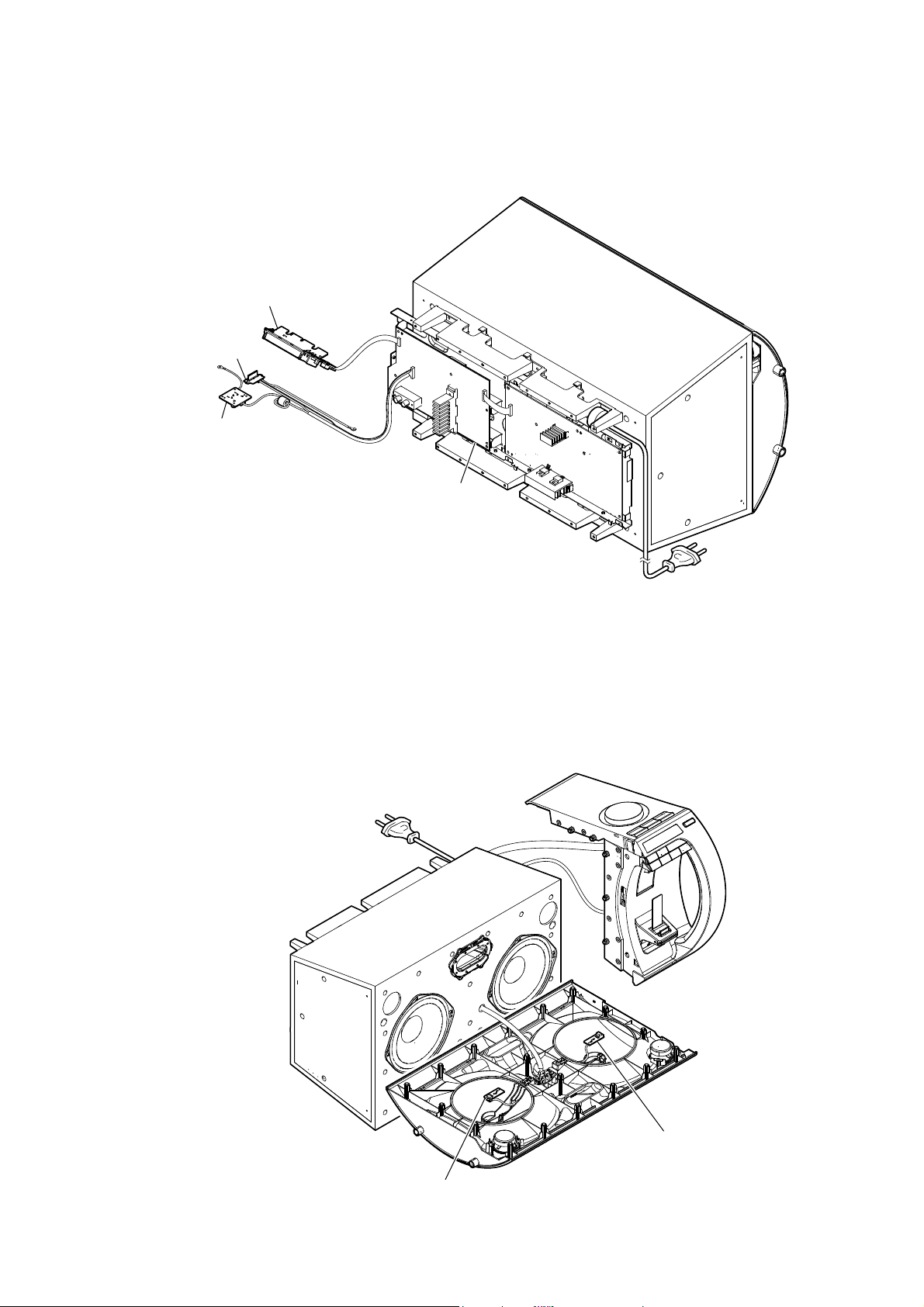

Page 11

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

–

PANEL BOARD, IP BOARD, USB BOARD SERVICE POSITION

PANEL board

IP board

USB board

LED BOARD SERVICE POSITION

MAIN board

– Rear left view –

Front left view –

LED board

LED board

11

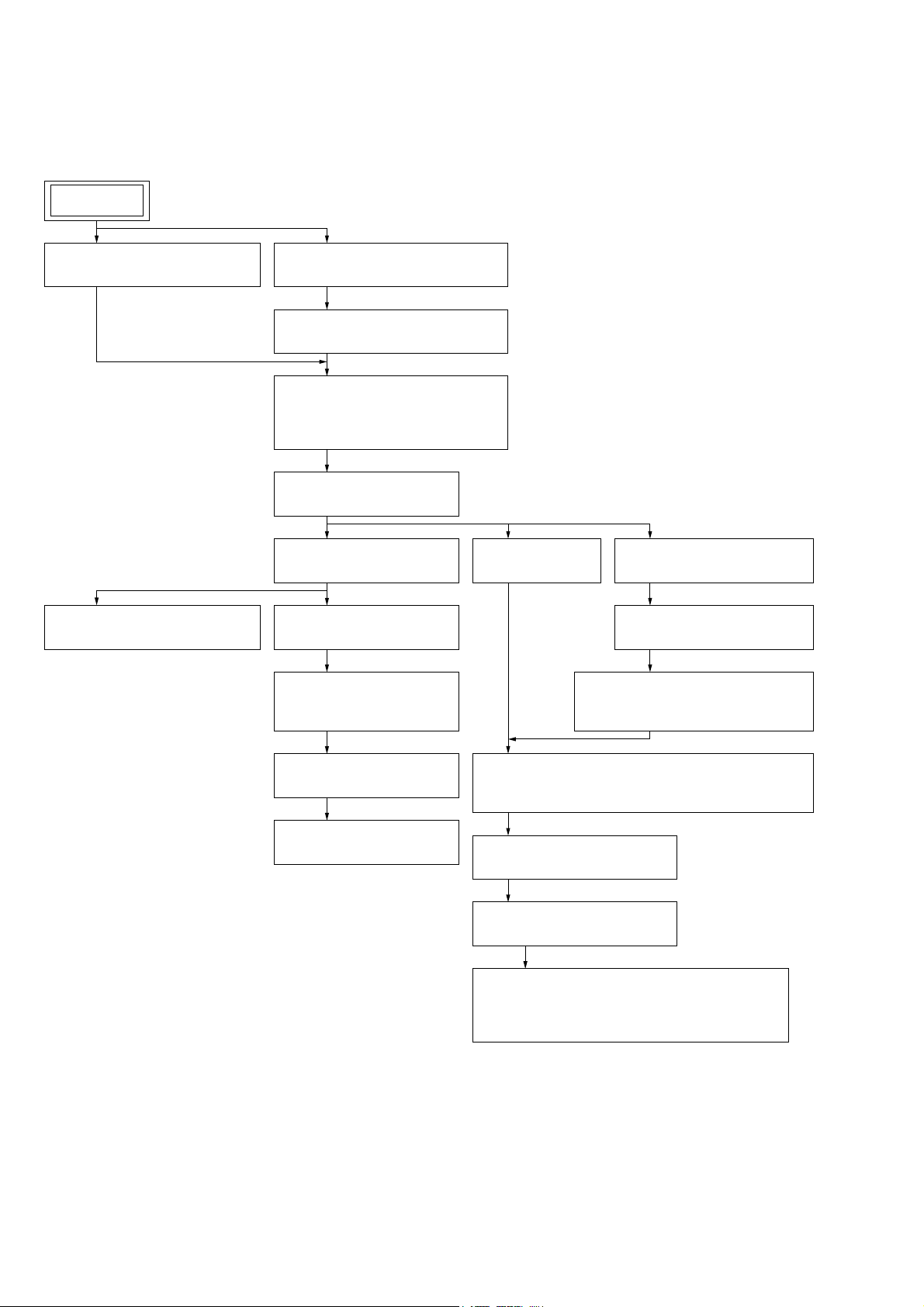

Page 12

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

SECTION 2

DISASSEMBLY

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

SET

2-2. SIDE PANEL (R)

(Page 13)

2-13. SPRING (LOCK 2)

(Page 22)

2-3. SIDE PANEL (L-BASE)

(Page 14)

2-4. COVER (BACK) BLOCK

(Page 15)

2-5. BACK PANEL BLOCK (GTK11iP)

(Page 16)

2-6. BACK PANEL BLOCK (GTK33iP)

(Page 17)

2-7. SHIELD (MAIN) BLOCK

(Page 18)

2-8. PANEL RIGHT ASSY

(Page 19)

2-9. USB BOARD

(Page 20)

2-10. STAGE (BOTTOM-I-PH)

BLOCK

(Page 20)

2-14. MAIN BOARD

(Page 23)

2-15. SHIELD (POWER) BLOCK

(Page 24)

2-16. POWER CORD (AC1)

(Page 25)

2-17. GTK11-SMPS BOARD (GTK11iP)/

GTK33-SMPS BOARD (GTK33iP)

(Page 26)

2-11. SPRING (PWB)

(Page 21)

2-12. IP BOARD

(Page 21)

2-18. CHASSIS BLOCK,

REINFORCEMENT (BACK PANEL) BLOCK

(Page 27)

2-19. ORNAMENT BASE BLOCK

(Page 27)

2-20. FRONT PANEL ASSY

(Page 28)

2-21. LOUDSPEAKER (16 cm) (SP1, AP2) (GTK11iP)

(Page 29)

2-22. LOUDSPEAKER (20 cm) (SP1, AP2) (GTK33iP)

(Page 30)

12

Page 13

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

Note: Follow the disassembly procedure in the numerical order given.

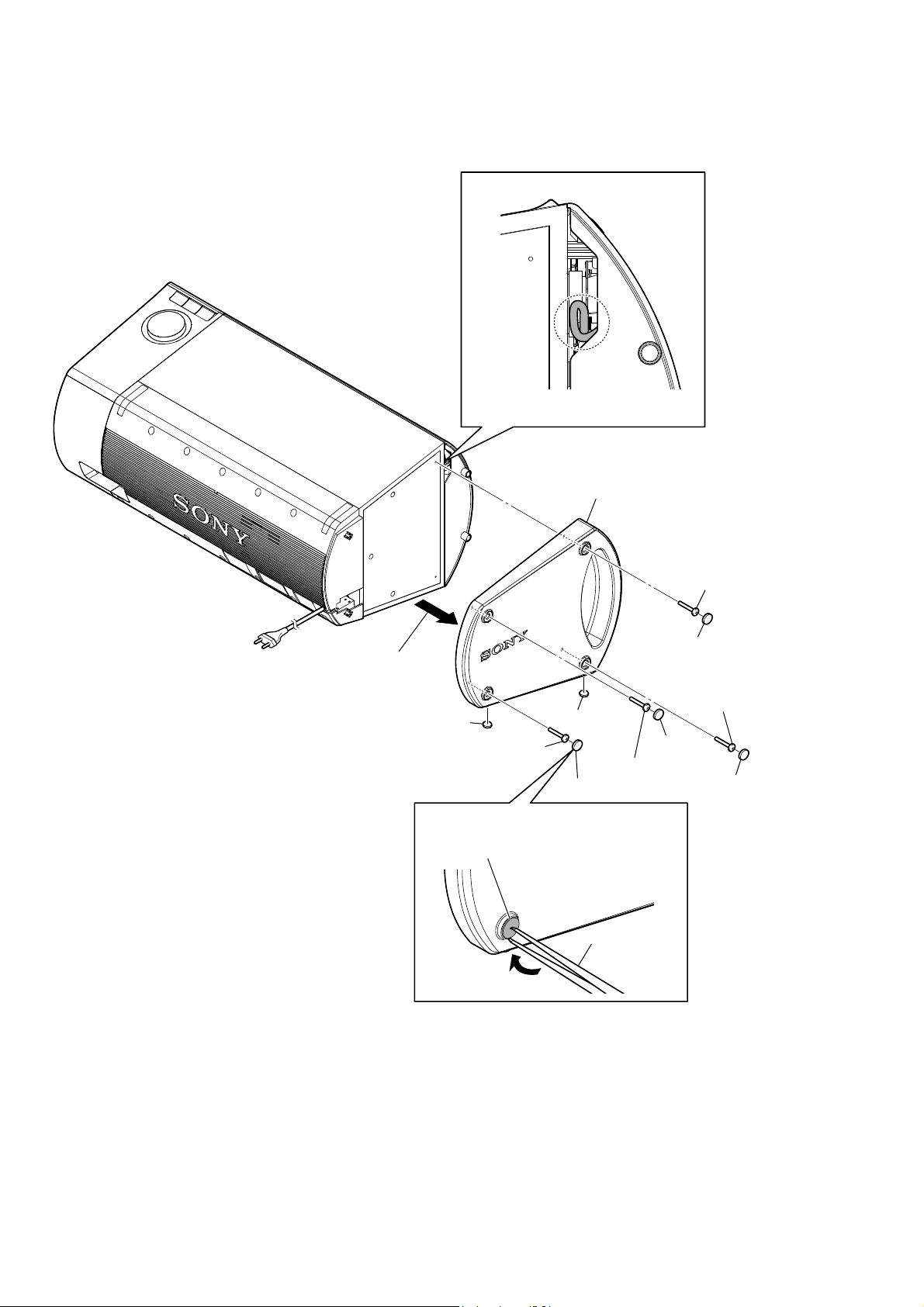

2-2. SIDE PANEL (R)

Insert tweezers etc. in the slot on four cover

1

screws and remove so that it may hollow.

Note:

Do not damage cover screw.

tweezers etc.

3 screw

(BVTP3 u 10)

2 cover screw

:LUHVHWWLQJ

–5LJKWVLGHYLHZ–

&RYHUVFUHZVHWWLQJ

slot

–,QQHUYLHZ––2XWHUYLHZ–

slot

slot

slot

4 Remove the side

panel (R) block in

the direction of an

arrow.

5 two cushions (E)

6 side panel (R)

3 screw

(BVTP3 u 10)

2 cover screw

3 screw

(BVTP3 u 10)

slot

slot

5 two cushions (E)

3 screw

(BVTP3 u 10)

2 cover screw

2 cover screw

slot

–,QQHUYLHZ––2XWHUYLHZ–

slot

–,QQHUYLHZ––2XWHUYLHZ– –,QQHUYLHZ––2XWHUYLHZ–

–5LJKWVLGHYLHZ–

13

Page 14

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

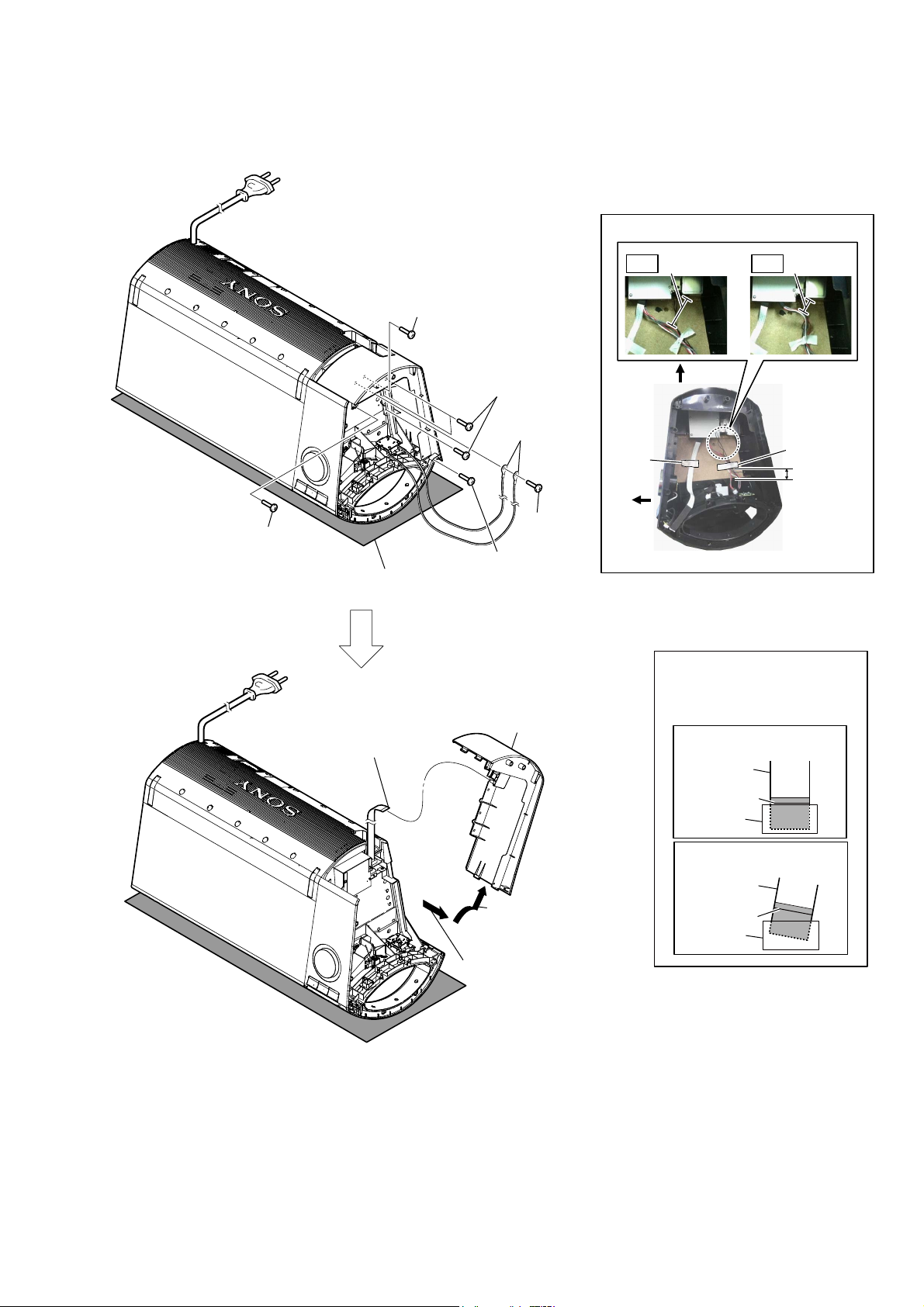

2-3. SIDE PANEL (L-BASE)

:ire settiQJ

– Left side view –

– Rear left view –

4 Remove the side panel (L-base) block

in the direction of an arrow.

5 foot (bottom)

3 tapping screw

(3.5 u 20)

Insert tweezers etc. in the slot on four foots

1

and remove so that it may hollow.

Note:

Do not damage foot.

6 side panel (L-base)

5 foot

(bottom)

3 tapping screw

(3.5 u 20)

2 foot

tweezers etc.

2 foot

3 tapping screw

(3.5 u 20)

2 foot

3 tapping screw

(3.5 u 20)

2 foot

14

Page 15

2-4. COVER (BACK) BLOCK

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

Wire setting

Distance

is near.

2 screw (BV/ring)

Distance

OK NG

is far.

– Top rear view –

4 screw

(BVTP3 u 10)

Note 1:

not to injure front grille.

Please spread a sheet under a unit

7 flexible flat cable (9 core)

(CN101)

1 three tapping screws

(3.5 u 20)

3 two lug wires

2 screw

(BV/ring)

4 screw

(BVTP3 u 10)

8 cover (back) block

rear side

tape

top side

tape

45 ± 5 mm

– Right side view –

When installing the flexible

Note 2:

flat cable, ensure the coloured

line.

No slanting after insertion.

Insert is straight to the interior.

flexible flat

cable

coloured line

connector

OK

6 Remove the cover (back)

block in the direction of

an arrow.

5 Move the cover (back) block

in the direction of an arrow.

NG

Insert is incline

flexible flat

cable

coloured line

connector

15

Page 16

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

2-5. BACK PANEL BLOCK (GTK11iP)

Insert tweezers etc. in the slot on four screw

3

covers (back panel) and remove so that it may hollow.

Note 1:

Do not damage screw cover (back panel).

7 four screw caps

8 two screws

(BVTP3 u 10)

9 tapping screw

(3.5 u 20)

5 screw cover

(back panel)

0 back panel

block

4 four claws

5 screw cover

(back panel)

tweezers etc.

8 four screws

(BVTP3 u 10)

tweezers etc.

9 tapping screw

(3.5 u 20)

5 screw cover (back panel)

4 four claws

7 four screw

caps

4 four claws

8 four screws

(BVTP3 u 10)

9 two tapping screws

(3.5 u 20)

5 screw cover (back panel)

1 Remove the power cord.

Insert tweezers etc. in the slot on eight screw

6

caps and remove so that it may hollow.

Note 2:

4 four claws

Do not damage screw cap.

Power cord setting

cord bushing (2104)

– Top rear view –

Please spread a sheet under a unit

Note 3:

not to injure front grille.

2 cord bushing (2104)

290 ± 5 mm

power cord

ferrite core

16

Page 17

2-6. BACK PANEL BLOCK (GTK33iP)

Insert tweezers etc. in the slot on four screw

3

covers (back panel) and remove so that it may hollow.

Note 1:

Do not damage screw cover (back panel).

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

7 five screw caps

8 two screws

(BVTP3 u 10)

9 tapping screw

(3.5 u 20)

5 screw cover

(back panel)

0 back panel

block

4 four claws

5 screw cover

(back panel)

8 five screws

(BVTP3 u 10)

tweezers etc.

tweezers etc.

9 tapping screw

(3.5 u 20)

5 screw cover (back panel)

4 four claws

7 five screw caps

4 four claws

Insert tweezers etc. in the slot on ten screw

6

caps and remove so that it may hollow.

Note 2:

8 five screws

(BVTP3 u 10)

9 two tapping screws

(3.5 u 20)

5 screw cover (back panel)

4 four claws

2 cord bushing (2104)

Do not damage screw cap.

1 Remove the power cord.

Power cord setting

cord bushing (2104)

– Top rear view –

Note 3:

not to injure front grille.

Please spread a sheet under a unit

290 ± 5 mm

power cord

ferrite core

17

Page 18

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

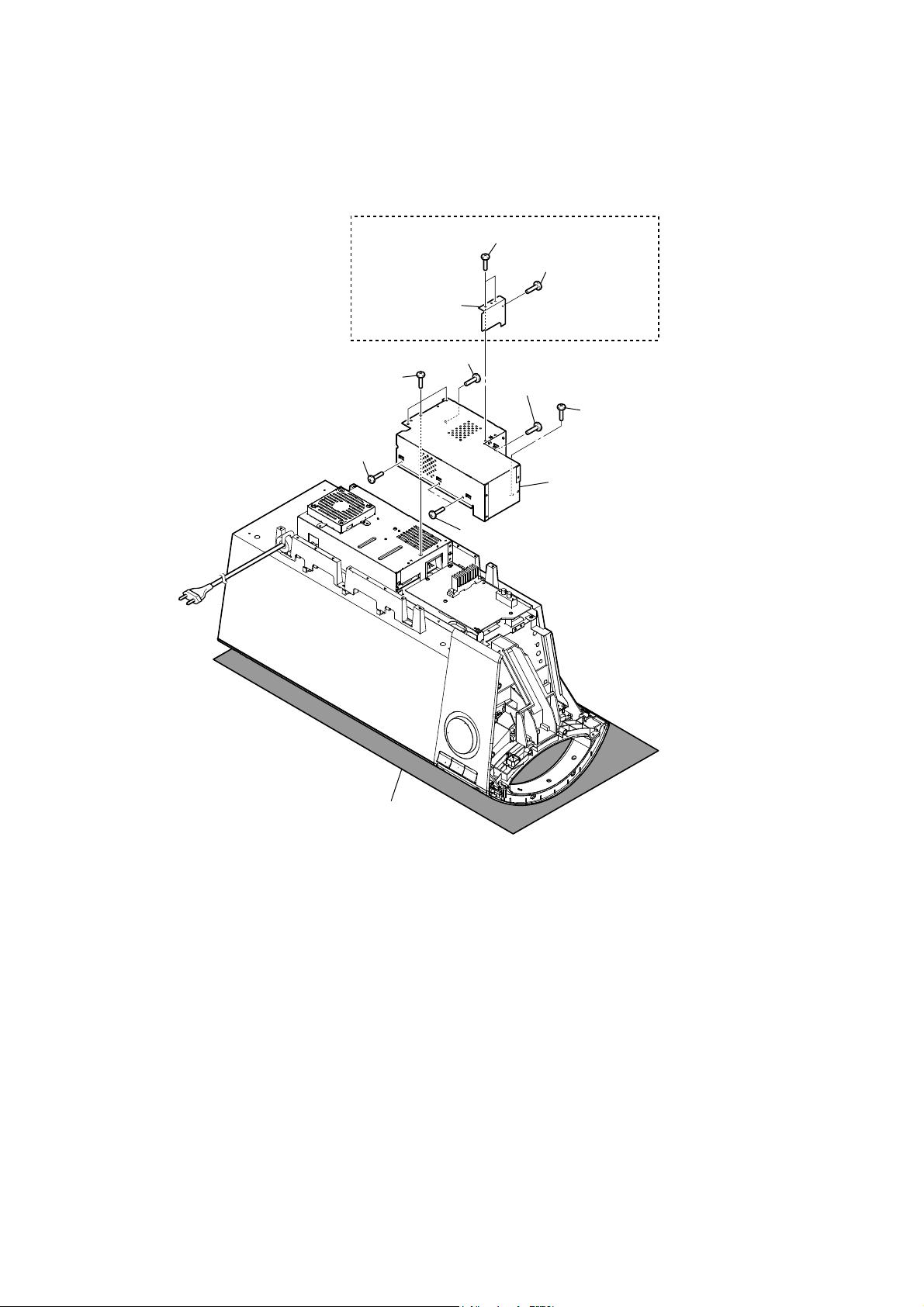

2-7. SHIELD (MAIN) BLOCK

(GTK33iP)

2 shield (main-U)

3 screw (BV/ring)

3 three screws (BV/ring)

3 screw (BV/ring)

1 two screws (BV/ring)

1 screw (BV/ring)

3 screw (BV/ring)

3 screw (BV/ring)

4 shield (main) block

3 two screws (BV/ring)

– Top right view –

Please spread a sheet under a unit

Note:

not to injure front grille.

18

Page 19

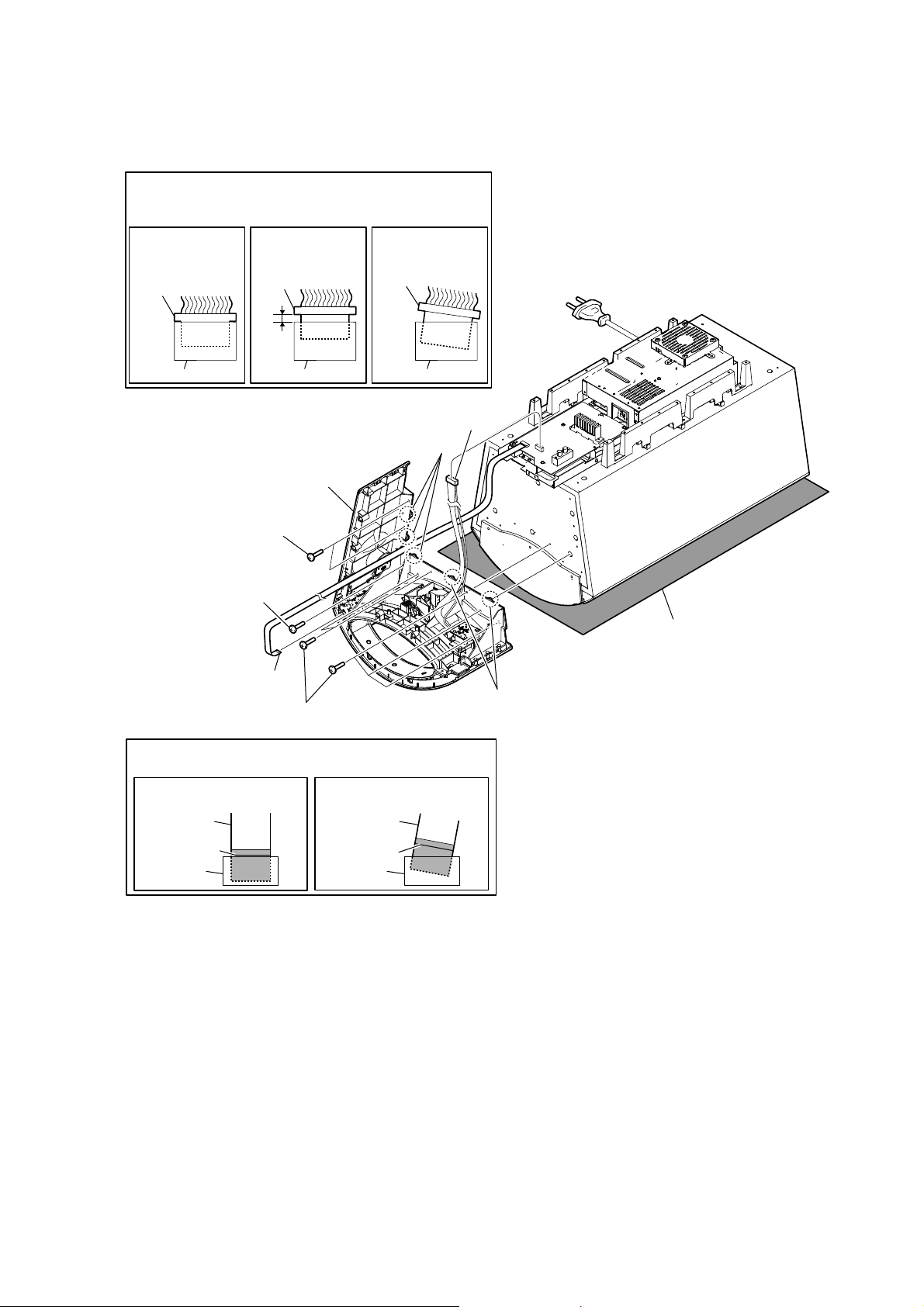

2-8. PANEL RIGHT ASSY

When you install the connector, please install themcorrectly.

Note 2:

There is a possibility that this machine damages when not

correctly installing it.

NGOK NG

Insert is straight

to the interior.

connector

Insert is shallow

connector

Insert is incline

connector

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

connector

5 panel right assy

3 two tapping screws

(3.5 u 20)

3 tapping screw

(3.5 u 20)

1 flexible flat cable (13 core)

(CN501)

When installing the flexible flat cable,

Note 3:

No slanting after insertion.

Insert is straight to the interior. Insert is incline

flexible flat

cable

coloured line

OK

connector connector

4 three bosses

3 five tapping screws

(3.5 u 20)

ensure the coloured line.

NG

flexible flat

cable

coloured line

connectorconnector

2 connector

(CN301)

4 two bosses

– Bottom right view –

Please spread a sheet under a unit

Note 1:

not to injure front grille.

19

Page 20

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

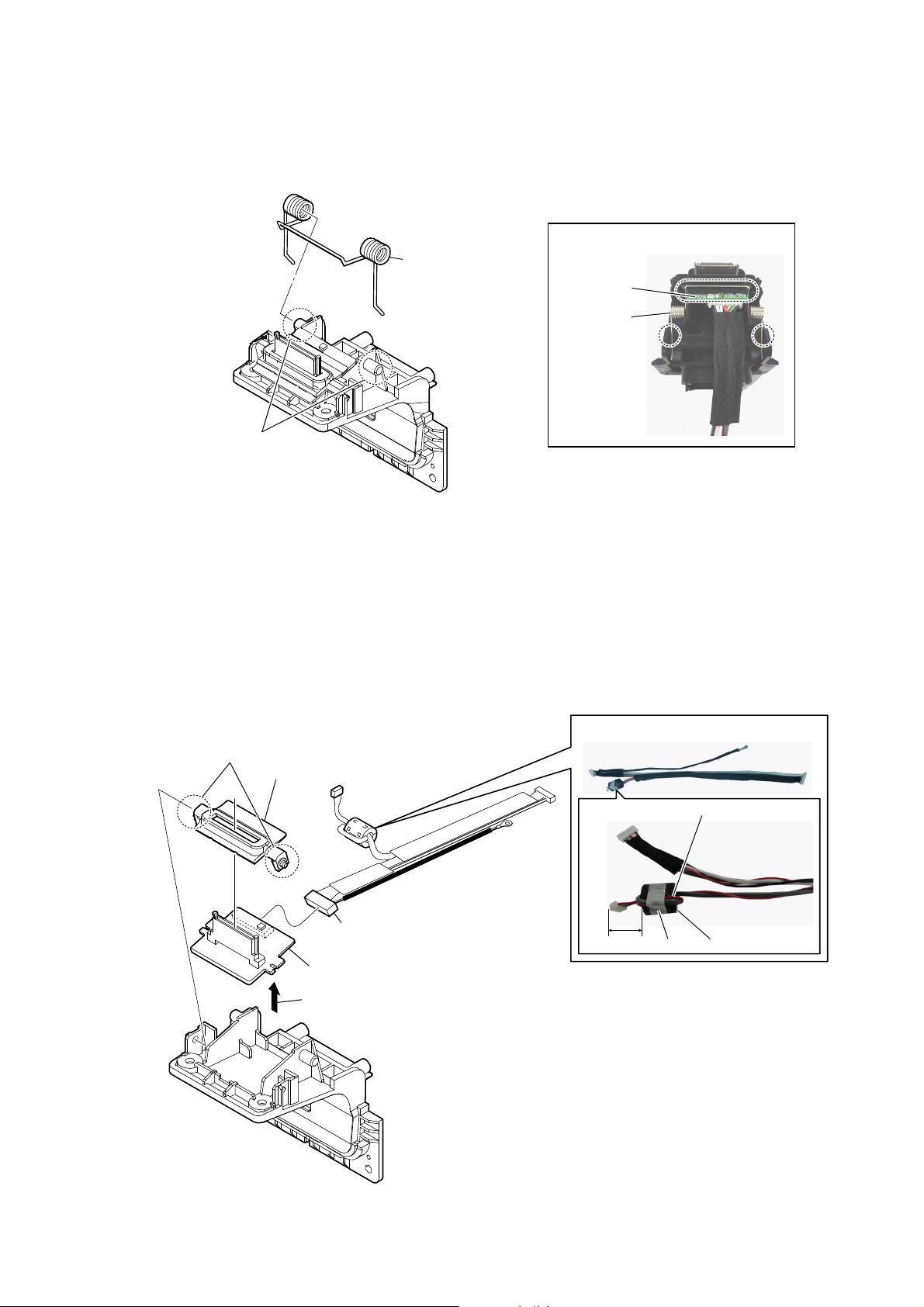

2-9. USB BOARD

3 connector (CN562)

1 two screws

(BVTP2.6)

4 USB board

2 Remove the USB board in

the direction of an arrow.

When you install the connector, please install themcorrectly.

Note:

There is a possibility that this machine damages when not

correctly installing it.

Insert is straight

to the interior.

connector

NGOK NG

Insert is shallow

connector

Insert is incline

connector

– Panel right assy rear view –

2-10. STAGE (BOTTOM-I-PH) BLOCK

connector

2 two screws

(BVTP2.6)

3 stage (bottom-I-PH) block

1 two screws

(BTP2.6 u 8)

connector connector

20

– Panel right assy rear view –

Page 21

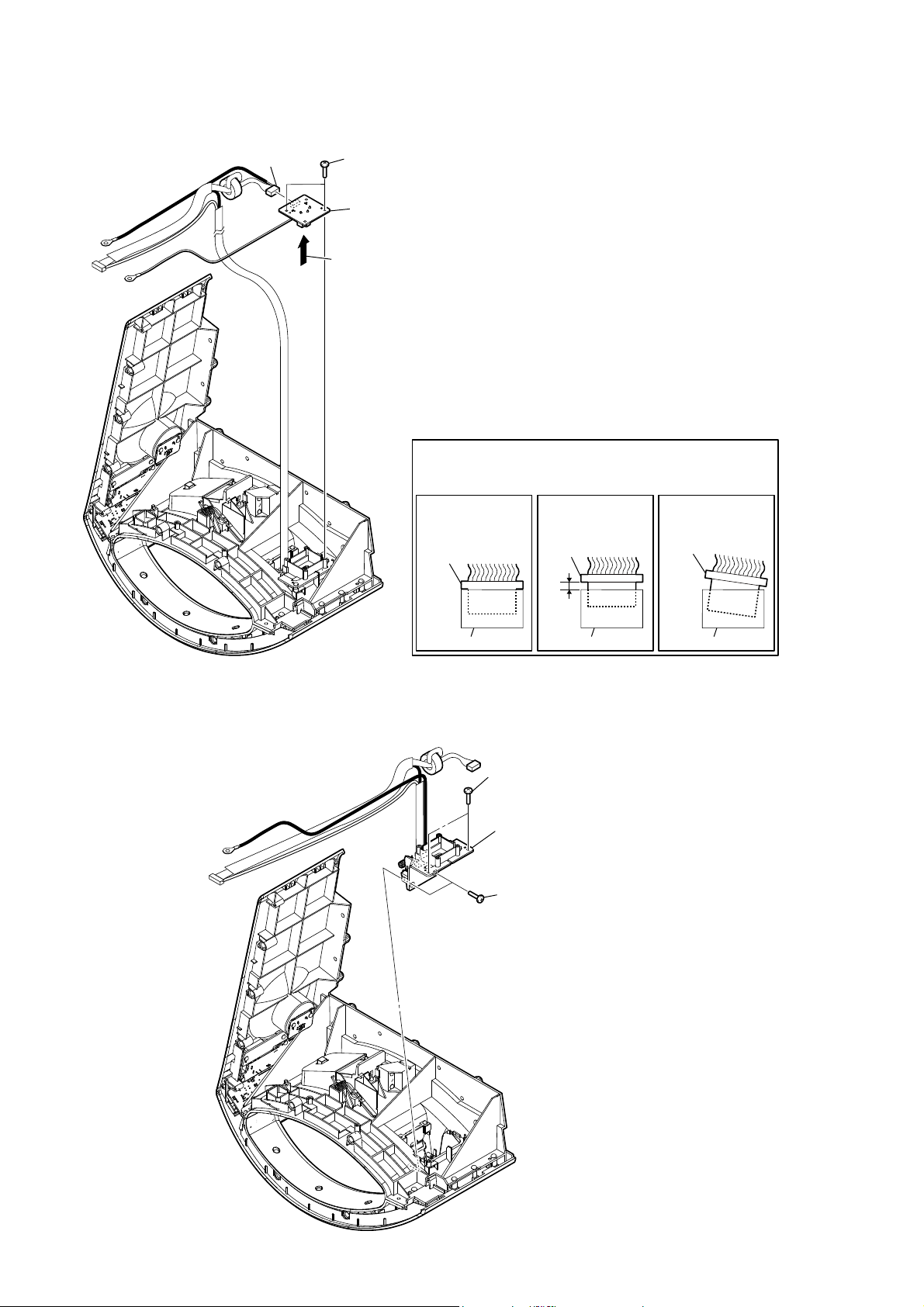

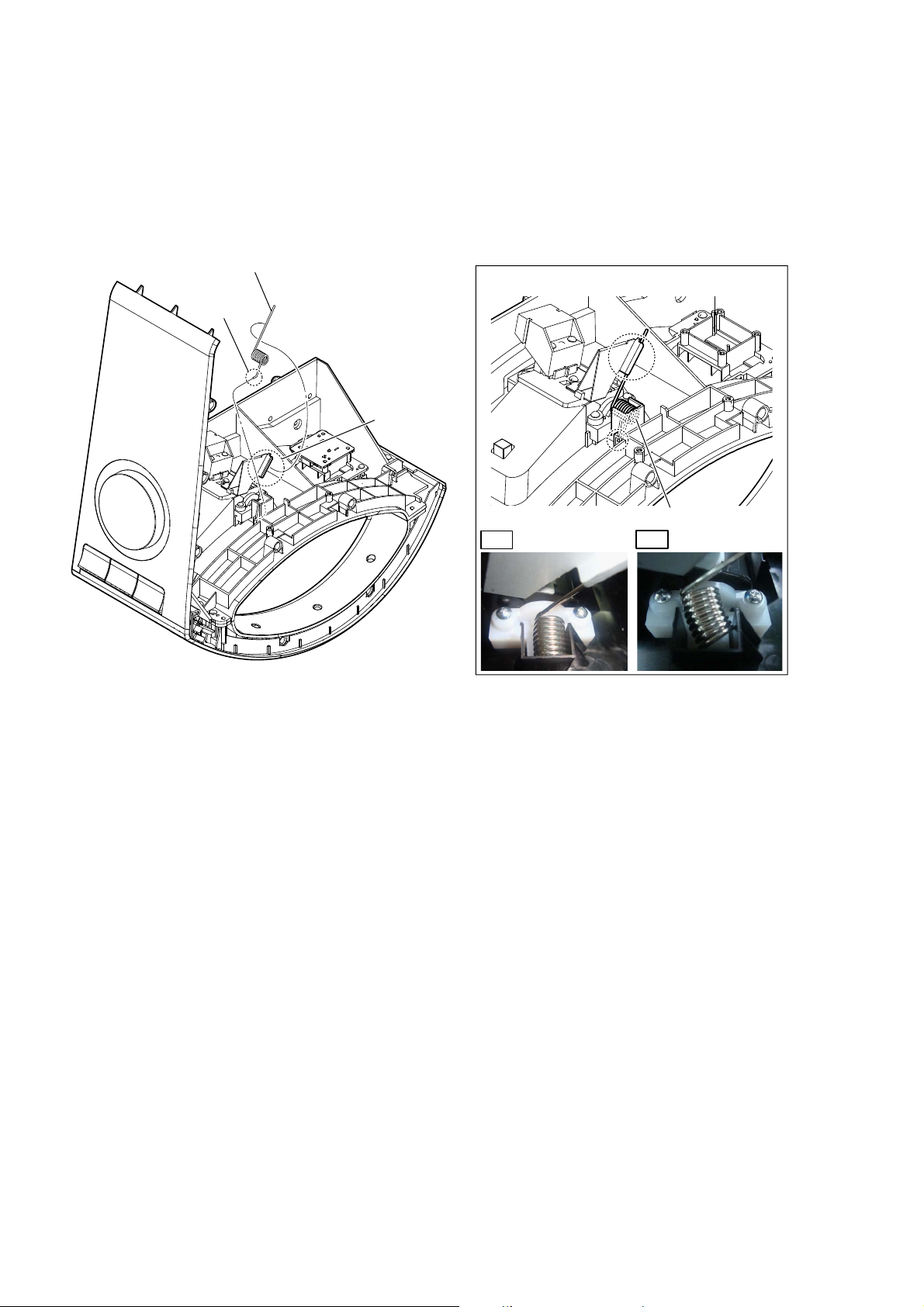

2-11. SPRING (PWB)

1 two shafts

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

6SULQJ3:%VHWWLQJ

2 spring (PWB)

IP board

spring (PWB)

2-12. IP BOARD

1 two shafts

3 escutcheon (I-PH)

4 connector

(CN552)

5 IP board

2 Remove the IP board block

in the direction of an arrow.

WireVeWWiQJ

30 ± 5 mm

Roll the wire once.

tape clamp filter

21

Page 22

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

2-13. SPRING (LOCK 2)

3 spring (lock 2)

2 hook

–3DQHOULJKWDVV\WRSUHDUYLHZ–

1 hook

6SULQJORFNVHWWLQJ

OK

spring (lock 2)

NG

22

Page 23

2-14. MAIN BOARD

4 connector (CN813)

5 connector

(CN812)

8 connector

(CN811)

6 connector

(CN701)

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

9 two screws

(BV/ring)

0 MAIN board

9 three screws

(BV/ring)

1 flexible flat cable (9 core)

(CN302)

3 flexible flat cable (13 core)

(CN101)

2 connector (CN301)

7 connector (CN702)

Please spread a sheet under a unit

Note 1:

not to injure front grille.

When you install the connector, please install themcorrectly.

Note 2:

There is a possibility that this machine damages when not

correctly installing it.

NGOK NG

Insert is straight

to the interior.

connector

connector

Insert is shallow

connector

connector connector

connector

Insert is incline

– Top rear view –

When installing the flexible flat cable,

Note 3:

No slanting after insertion.

Insert is straight to the interior. Insert is incline

flexible flat

cable

coloured line

OK

ensure the coloured line.

NG

flexible flat

cable

coloured line

connectorconnector

23

Page 24

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

2-15. SHIELD (POWER) BLOCK

3 two screws

(BVTP3 u 10)

4 shield (power) block

2 screw

(BV/ring)

2 two screws

(BV/ring)

Note 1:

not to injure front grille.

Please spread a sheet under a unit

2 three screws

(BV/ring)

1 connector

(CN813)

– Top rear view –

When you install the connector, please install themcorrectly.

Note 2:

There is a possibility that this machine damages when not

correctly installing it.

NGOK NG

Insert is straight

to the interior.

connector

connector

Insert is shallow

connector

connector connector

connector

Insert is incline

24

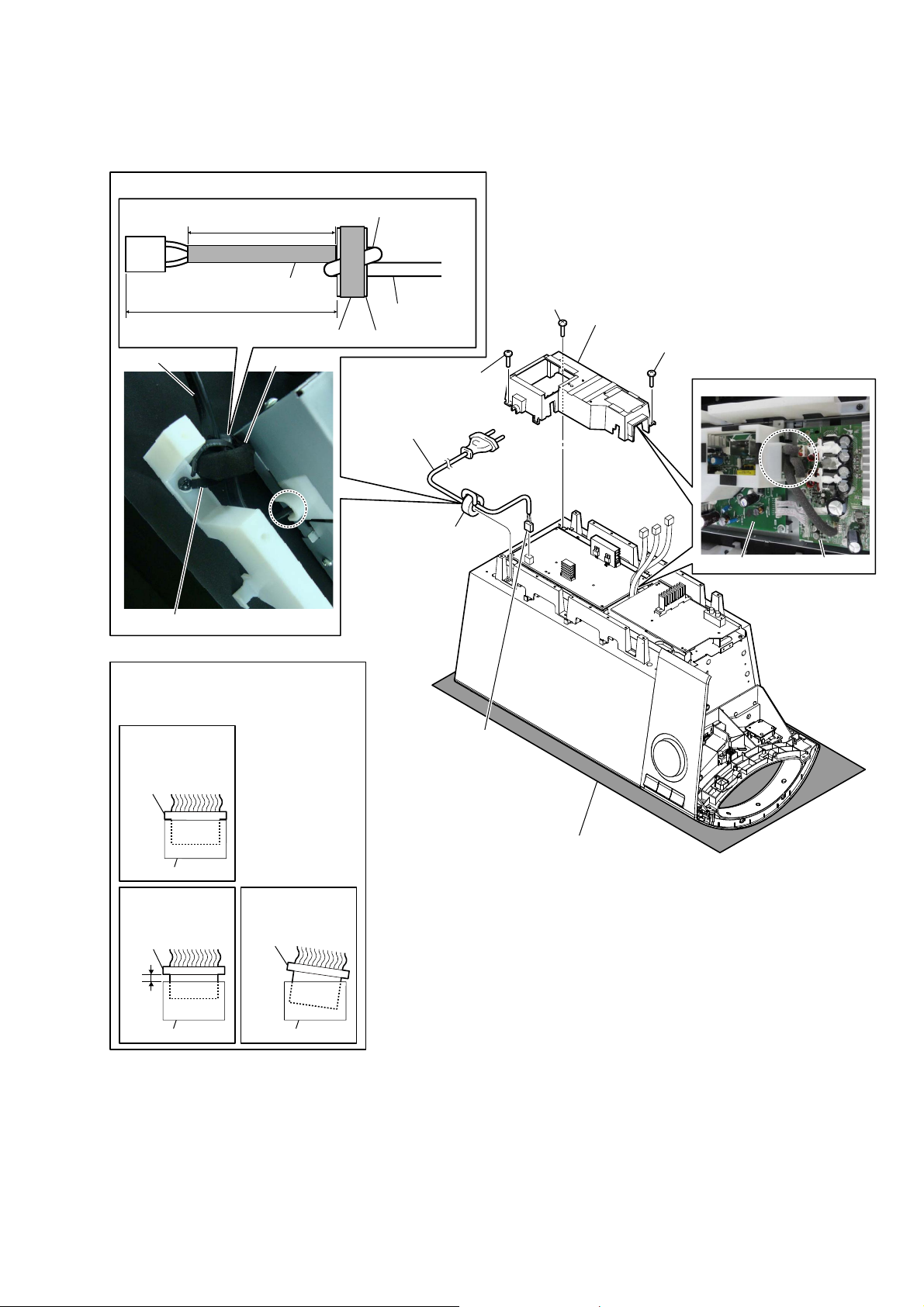

Page 25

2-16. POWER CORD (AC1)

Power cord setting

50 mm

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

Roll the power cord once.

cushion (E)

70 ± 5 mm

power cord (AC1)

coating clip

When you install the connector, please

Note 2:

install themcorrectly.

There is a possibility that this machine

damages when not correctly installing it.

OK

Insert is straight

to the interior.

connector

cushion (E) ferrite core

ferrite core

5 power cord (AC1)

3 Remove the ferrite core

from coating clip.

power cord (AC1)

1 screw

(BV/ring)

4 connector

(CN901)

1 screw

(BV/ring)

2 cover (power-PWB) block

1 screw

(BV/ring)

wire setting

MAIN boardSMPS board

connector

NG

Insert is shallow

connector

connector connector

connector

NG

Insert is incline

Please spread a sheet under a unit

Note 1:

not to injure front grille.

– Top rear view –

25

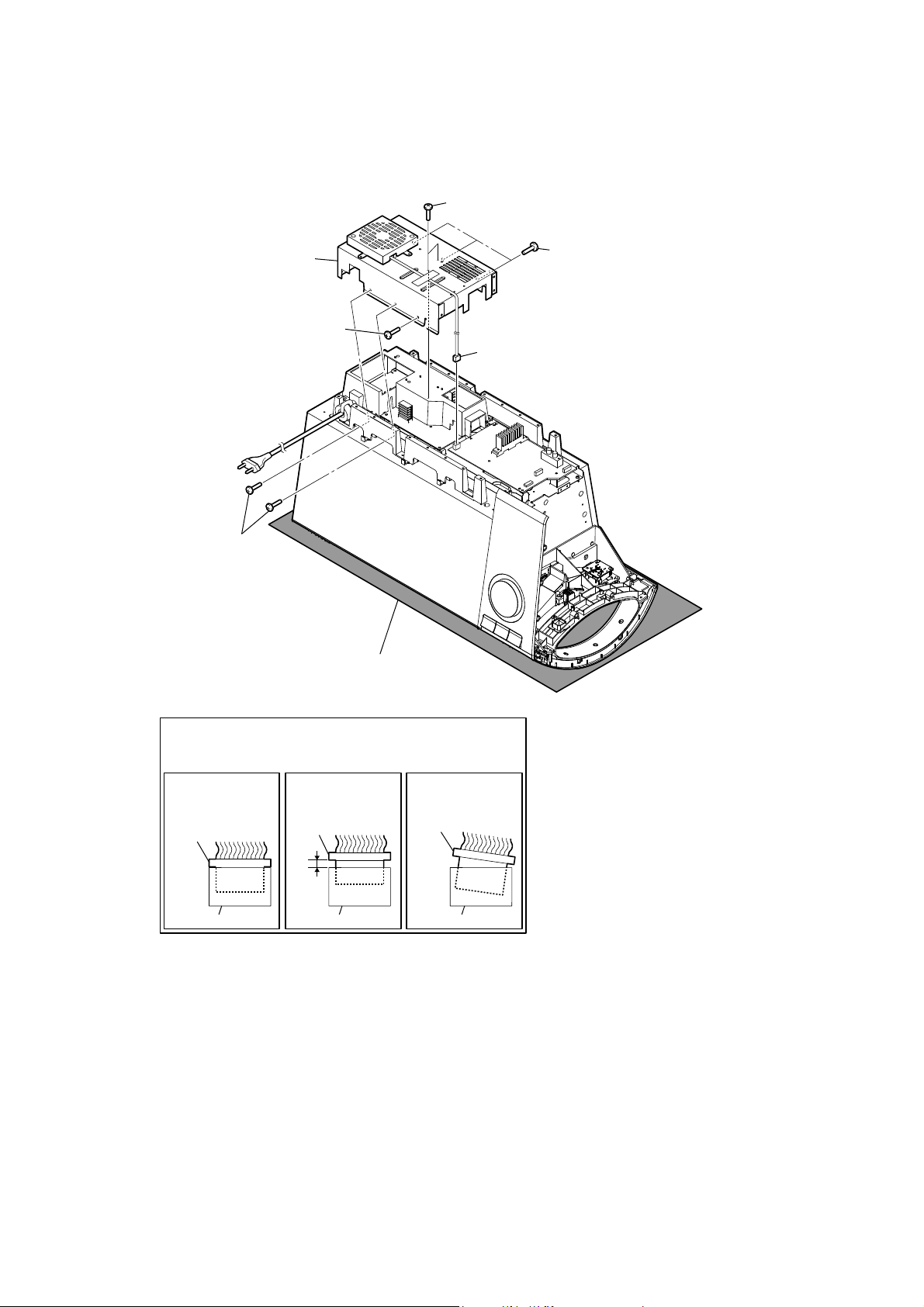

Page 26

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

–

2-17. GTK11-SMPS BOARD (GTK11iP) /GTK33-SMPS BOARD (GTK33iP)

2 two screws

(BV/ring)

2 screw

(BV/ring)

Top rear view –

2 screw

(BV/ring)

2 three screws

(BV/ring)

3 GTK11-SMPS board (GTK11iP)/

GTK33-SMPS board (GTK33iP)

1 connector (CN811)

When you install the connector, please

Note 2:

install themcorrectly.

There is a possibility that this machine

damages when not correctly installing it.

OK

Insert is straight

to the interior.

connector

connector

NG

Insert is shallow

connector

connector connector

NG

Insert is incline

connector

Please spread a sheet under a unit

Note 1:

not to injure front grille.

26

Page 27

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

2-18. CHASSIS BLOCK, REINFORCEMENT (BACK PANEL) BLOCK

3 two tapping screws

(3.5 u 20)

3 tapping screw

(3.5 u 20)

4 chassis block

5 three tapping screws

(3.5 u 20)

7 reinforcement (back panel)

block

5 tapping screw

(3.5 u 20)

6 coating clip

3 two tapping screws

(3.5 u 20)

3 three tapping screws

(3.5 u 20)

(GTK33iP: US)

1 two screws

(BV/ring)

2 shield (main-UB)

5 tapping screw

(3.5 u 20)

7 reinforcement (back panel)

block

5 tapping screw

(3.5 u 20)

2-19. ORNAMENT BASE BLOCK

– Top rear view –

Please spread a sheet under a unit

Note:

not to injure front grille.

2 Peel off four adhessive

sheets.

3 ornament base block

– Bottom front view –

1 three tapping screws

(3.5 u 20)

27

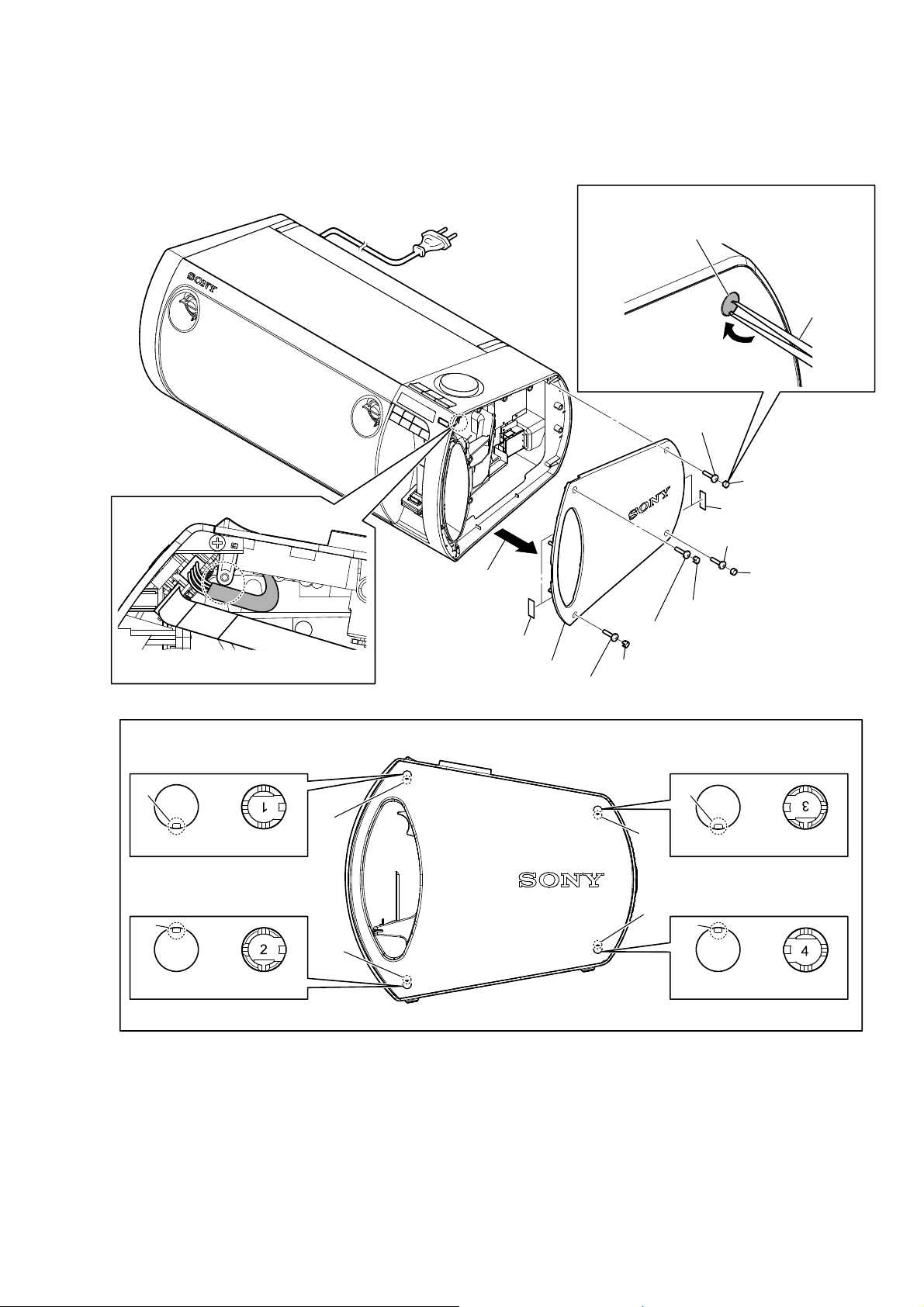

Page 28

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

2-20. FRONT PANEL ASSY

• JIG

When disassembling the set, use the following jig (for speaker

removal).

Part No. Description

J-2501-238-A JIG FOR SPEAKER REMOVAL

total twenty bosses

3

2 Insert the jig into a space and raise

the front panel assy.

Note 1: When using a jig, please work

so as not to injure front panel

assy and SPK box assy.

3 All bosses are removed while moving jig in the direction

of the arrow, and front panel assy is removed.

– Bottom front view –

2 Insert the jig into a space and raise

the front panel assy.

Note 1: When using a jig, please work

so as not to injure front panel

assy and SPK box assy.

1 Insert the flat-blade driver into a side space

and raise the front panel assy.

When you install the connector, please

Note 2:

install themcorrectly.

There is a possibility that this machine

damages when not correctly installing it.

OK

Insert is straight

to the interior.

connector

6 terminal (red)

6 terminal (black/red)

4 Remove the front panel assy

in the direction of an arrow.

:ire VettinJ

OK

NG

7 front panel assy

5 connector

(CN551)

Insert is shallow

connector

6 terminal (black/red)

6 terminal (red)

:ire VettinJ

OK

NG

connector

NG

connector connector

NG

Insert is incline

connector

28

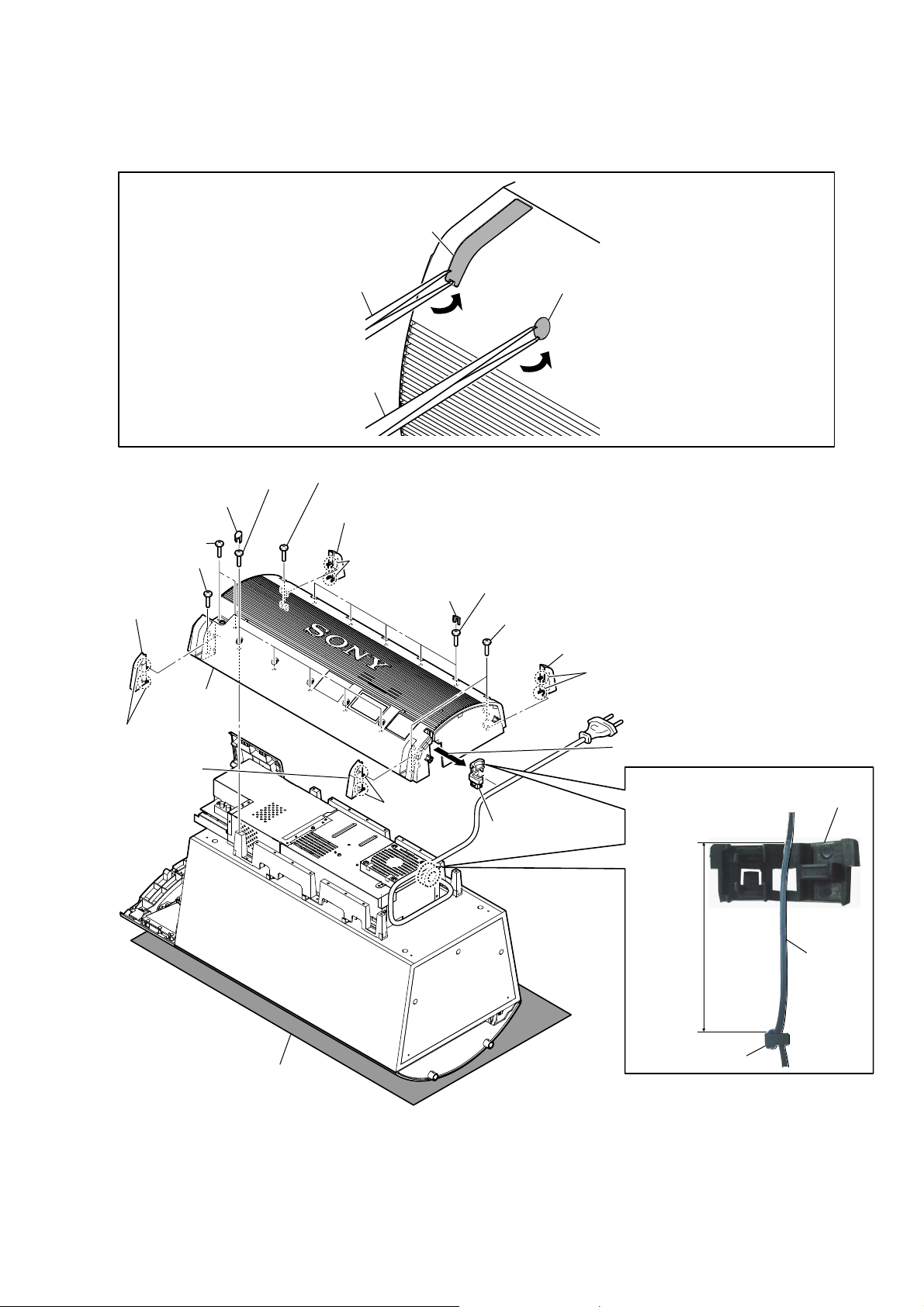

Page 29

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

2-21. LOUDSPEAKER (16 cm) (SP1, AP2) (GTK11iP)

Note: It is possible to also remove ones of Lch and Rch.

1 four tapping screws

(3.5 u 20)

5 four tapping screws

(3.5 u 20)

8 loudspeaker (16 cm) (SP2)

6 Remove the loudspeaker (16 cm) (SP2)

in the direction of an arrow.

7 terminal (red)

7 terminal (black)

4 loudspeaker (16 cm) (SP1)

3 terminal

(black/white)

3 terminal

(red/white)

2 Remove the loudspeaker (16 cm) (SP1)

in the direction of an arrow.

– Top front view –

Loudspeaker (16 cm) setting

loudspeaker (16 cm)

(SP1)

terminal position

loudspeaker (16 cm)

(SP2)

terminal position

29

Page 30

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

2-22. LOUDSPEAKER (20 cm) (SP1, AP2) (GTK33iP)

Note: It is possible to also remove ones of Lch and Rch.

1 four tapping screws

(3.5 u 20)

5 four tapping screws

(3.5 u 20)

8 loudspeaker (20 cm) (SP2)

6 Remove the loudspeaker (20 cm) (SP2)

in the direction of an arrow.

7 terminal (red)

7 terminal (black)

4 loudspeaker (20 cm) (SP1)

3 terminal

(black/white)

3 terminal

(red/white)

2 Remove the loudspeaker (20 cm) (SP1)

in the direction of an arrow.

–7RSIURQWYLHZ–

/RXGVSHDNHUFPVHWWLQJ

loudspeaker (20 cm)

(SP1)

terminal position terminal position

loudspeaker (20 cm)

(SP2)

30

Page 31

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

SECTION 3

TEST MODE

COLD RESET

The cold reset clears all data including preset data stored in the

memory to initial conditions. Execute this mode when returning

the unit to the customer.

Procedure:

1. In the standby status, press the [?/1] button to turn the power

on.

2. Press two buttons of the [u] and [?/1] simultaneously for

three seconds.

3. When “RESET” appears, then becomes standby states.

AUTO STANDBY TEST MODE

It can be confi rmed whether the auto standby function is operating

correctly.

The auto standby function operates in 60 seconds in this mode.

(Usually, it takes 30 minutes)

Procedure:

1. In the standby status, press the [?/1] button to turn the power

on.

2. Press the [FUNCTION] button to select “DVD/PC”, “iPod” or

“USB”.

3. Press two buttons of the [FUNCTION] and [BASS BOOST]

simultaneously for three seconds.

4. The following screen is displayed on the liquid crystal display,

and becomes the auto standby test mode.

In this mode, “MONO ST” on the liquid crystal display panel

continues blinking.

(Displayed characters/values in the following fi gure are ex-

ample)

Screen display of “DVD/PC” or “iPod” function

MONO ST

S 59

AM STEP CHANGE (Except AEP, Russian, UK and Saudi Arabian models)

The step interval of AM channels can be toggled between 9 kHz

and 10 kHz.

Procedure:

1. In the standby status, press the [

on.

2. Press the [FUNCTION] button to select “TUNER AM”.

3. Press the [

4. Press two buttons of the [FUNCTION] and [

ously.

5. “STEP 9 kHz” or “STEP 10 kHz” is displayed on the liquid crystal display panel, and the step interval of AM channels

changed.

PANEL TEST MODE

The liquid crystal display panel, LED, model name, destination,

software version and keys can be confi rmed.

Procedure:

1. In the standby status, press the [?/1] button to turn the power

on.

2. Press two buttons of the [FUNCTION] and [LED SPEAKER]

simultaneously for three seconds.

3. All segments on the liquid crystal display panel and all LEDs

light up, and becomes the panel test mode.

In this mode, “MONO ST” on the liquid crystal display panel

continues blinking.

4. Press the [l m TUNING –] button, the model name and

destination are displayed on the liquid crystal display panel by

turns.

(Displayed characters/values in the following fi gure are ex-

ample)

Screen display

] button to turn the power off.

?/1

MONO ST

] button to turn the power

?/1

] simultane-

?/1

Signal level

(0 to 255)

Screen display of “USB” function

MONO ST

Countdown timer

(60 to 0)

59

Countdown timer

(60 to 0)

5. In the case of the following status, the countdown timer decreases. This unit will become standby status if the countdown

timer decreases to “0”.

• Operation is not performed.

• The signal level is lower than threshold.

(“DVD/PC” or “iPod” function only)

• USB audio is stop status.

(“USB” function only)

Releasing method:

Press two buttons of the [FUNCTION] and [BASS BOOST] simultaneously for three seconds.

GTK33

Model name

MONO ST

LATIN

Destination

Displayed by turns.

31

Page 32

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

SECTION 4

ELECTRICAL CHECK

5. Press the [l m TUNING –] button again, the MC version

is displayed on the liquid crystal display panel. In this state,

whenever the [x] button is pressed, the MC version and the

version date are switched.

(Displayed characters/values in the following fi gure are ex-

ample)

Screen display

MONO ST

MC 1.01

MC version

MONO ST

Press the [x]

button.

120210A

Version date

6. Press the [l m TUNING –] button again, the MCS ver-

sion is displayed on the liquid crystal display panel. In this

state, whenever the [x] button is pressed, the MCS version

and the version date are switched.

(Displayed characters/values in the following fi gure are ex-

ample)

Screen display

MONO ST

FM TUNE LEVEL CHECK

signal

generator

Procedure :

1. Turn the power on.

2. Input the following signal from Signal Generator to FM antenna input directly.

Carrier frequency : A = 87.5 MHz, B = 98 MHz, C = 108 MHz

Deviation : 75 kHz

Modulation : 1 kHz

ANT input : 35 dBu (EMF)

Note: Use 75 ohm coaxial cable to connect signal generator and the unit.

You cannot use video cable for checking.

Use signal generator whose output impedance is 75 ohm.

3. Set to FM tuner function and tune A, B and C signals.

4. Confi rm “TUNED” is lit on the display for A, B and C signals.

When the selected station signal is received in good condition,

“TUNED” is displayed.

unit

MCS 1.01

MCS version

MONO ST

Press the [x]

button.

120210A

7. Whenever the [l m TUNING –] button is pressed, the

state of step 5 and the state of step 6 are switched.

8. In the state of step 3, press the [M L TUNING +] button,

“K 0 V0” is displayed on the liquid crystal display panel.

9. Each time a button is pressed, “K” value increases. However,

once a button is pressed, it is no longer taken into account.

All keys are pressed, display becomes “K11” .

10. “V” value increases 2, 4, 6 ... if turn the [VOLUME] dial

clockwise, or it decreases 8, 6, 4 ... if turn the [VOLUME] dial

counterclockwise.

Releasing method:

Press two buttons of the [FUNCTION] and [LED SPEAKER] simultaneously for three seconds.

Version date

32

Page 33

5-1. BLOCK DIAGRAM - MAIN Section -

CN551

(iPod/iPhone CONNECTOR)

4

USB D+

6

USB D-

VBUS (USB 5V)

DGND

8

30

CN561

VBUS

VBUS POWER

ON/OFF SWITCH

IC311

VBUS

SECTION 5

DIAGRAMS

AUDIO

SELECT

IC309

X302

16.9344MHz

84 USB_IPOD SEL

83 USB_IP_OCP

81 IP_ON

73 IP_DETECT

EEPROM

IC102

35 36 37

iPhone CP IIC SCL

iPhone CP IIC SDA

34 USB_DP

33 USB_DM

40

XIN_PLL

XOUT_PLL

41

iPhone CP RESET

AUDIO DECODER

IC306

IIC SDA

IIC SCL

BUSY

13

12

11

77

78

79

USB SCL

USB SDA

USB BUSY

TUNER_SDA/UCOM_RX

TUNER_SCL/UCOM_TX

IIS DATA

IIS BCK

IIS LRCK

MCHNG

IRPTO

10

8

68

76

USB IRPTO

USB MCHNG

RESETX

1

80

USB RESET

ST POWER

RDS_INT

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

55

54

53

A/D CONVERTER

2 AINL

1 AINR

13

RESET

IC308

SDTO

SCLK

LRCK

MCLK

9

12

10

11

J301

DVD/PC

FM/AM

ANTENNA

31

32

39

38

L

IN

R

TU1

TUNER1AM3RZ ASSY

LRCK/LOUT

BCK/ROUT

DA

CK

CE

IIC/RDSI

R-CH

R-CH

AUDIO

SELECT

IC313

R-CH

Q301

IIS DATA

IIS BCK

IIS LRCK

>001B

(Page 34)

SDTO

SCLK

LRCK

MCLK

2

D+

3

D–

VBUS

(L-SIDE)

(R-SIDE)

VBUS POWER

ON/OFF SWITCH

4

D009 (GTK33iP),

D010 (GTK11iP)

(SPEAKER ILLUMINATION)

D009 (GTK33iP),

D010 (GTK11iP)

(SPEAKER ILLUMINATION)

D556, 557

(iPod/iPhone ILLUMINATION)

IC310

VBUS

+5V

REGULATOR

IC314

(GTK33iP)

+6V

X101

5MHz

X102

32.768kHz

LED DRIVE

Q812

LED DRIVE

Q813

LED DRIVE

Q814

82 USB_ON

Xin

15

Xout

13

Xcin

10

XcOUT

11

SPKLED_RED

28

SPKLED_GREEN

26

SPKLED_BLUE

22

40 IP_LED

SYSTEM CONTROLLER

IC101 (1/4)

KEY_WAKE_UP_POWER

EXT_SEL

ADC_RESET

SIRCS

KEY_2

KEY_1

VOL_JOG

STBY LED

DP INH

43

42

71

74

70

72

75

100

REMOTE

5

CONTROL

RECEIVER

IC501

S505, 506, 511 - 515

(FRONT PANEL KEYS)

S501, 531 - 533

(FRONT PANEL KEYS)

R-ch is omitted due to same as L-ch.

SIGNAL PATH

: TUNER

ROTARY

ENCODER

S521

1DP SDA/SPI DOUT

2DP SCL

48 DI

47 CL

46 CE3DP CS

45 INH (COM)

VOLUME

LIQUID CRYSTAL

DISPLAY DRIVER

IC502

S1 -S33

COM1 -

COM4

35 - 38 1 - 33

D501

\/1

33

ND501

LIQUID

CRYSTAL

4

DISPLAY

PAN EL

: DVD/PC IN

: iPod/iPhone

: USB

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

LED DRIVE

Q501

3333

D502, 503

(LCD BACKLIGHT)

Page 34

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

5-2. BLOCK DIAGRAM - AMP Section -

DSP

IC303

IIS DATA

IIS BCK

IIS LRCK

SDTO

SCLK

LRCK

>001B

(Page 33)

MCLK

DATAI1

43

BCKI1

42

LRCKI1

41

DATAI3

49

BCKI3

48

LRCKI3

47

SDA8SCL7MUTE1B12MUTE2B13MUTE3B14RESETB

DATAMO

BCKO

LRCKO

AMCLKO

AOUTL1

10

17

D301

XO

XI

AOUTL2

22

INPUT_A

INPUT_B

INPUT_C

INPUT_D

/RESET

2

POWER AMP

IC702

/CLIP18READY

/OTW116/OTW2

17

SPB1

SPK BOX ASSY

OUT_A

52, 53

OUT_B

44, 45

OUT_C

36, 37

OUT_D

/SD

19

15

28, 29

OVER LOAD

DETECT

Q706, 707

OVER LOAD

DETECT

Q708, 709

FAN_DET

>002B

SP1

(WOOFER (L-CH))

SP3

(TWEETER (L-CH))

SP2

(WOOFER (L-CH))

SP4

(TWEETER (L-CH))

STREAM PROCESSOR

IC603

27

28

29

30

34

33

X301

24.576MHz

X601

45.184MHz

CLOCK

BUFFER

IC602

31

30

29

36

48

DATA

BCK

LRCK

XFSIIN

XFSOIN

SCDT21SCSHIFT

22

SCLATCH

NSPMUTE18SOFTMUTE

23

19

OUTL1

OUTL2

OUTR1

OUTR2

PGMUTE

20

11

9

6

4

INIT

27

4

5

10

11

(Page 35)

PROTECT

DETECT

Q703, 704

PVDD

SIGNAL PATH

: TUNER

: iPod/iPhone

47

DSP IIC_SDA

48

DSP IIC_CLK

44

45

DSP DOUT_MUTE

D313 D314

66

DSP_RESET

AUDIO LEVEL DET

LEVEL

DETECT

IC312

94

VAC S

65

LED_LEVEL_IN

57

58

59

60

56

55

S-MASTER DATA

S-MASTER SHIFT

S-MASTER LATCH

S-MASTER NSP MUTE

S-MASTER SOFT MUTE

SYSTEM CONTROLLER

IC101 (2/4)

61

S-MASTER_INIT

S-MASTER PG MUTE

52

50

51

54

S-MASTER_CLIP

S-MASTER_OTW1

S-MASTER_OTW2

S-MASTER_RESET

53

49

S-MASTER_SD

S-MASTER_READY

DC DETECT

Q705

67

S-MASTER DCP

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

3434

Page 35

5-3. BLOCK DIAGRAM - REGULATOR Section -

SYSTEM CONTROLLER

IC101 (3/4)

69AC_DET

GVDD +12V

POWER ON/OFF

CONTROL

Q701, 702

+12V

REGULATOR

IC701

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

(GTK11iP)

VOLTAGE DETECT

IC821

VOLTAGE DETECT

IC822

(GTK11iP)

(GTK33iP)

PVDD

GVDD

LEVEL DETECT +12V

VBUS

D302

D813

B+ SWITCH

Q302, 303

POWER ON/OFF

CONTROL

Q817, 818

+5V

REGULATOR

IC811

A/D +3.3V

A/D +5V

TUNER +5V

AMP +1.8V

AMP +3.3V

+3.3V

REGULATOR

IC305

+1.8V

REGULATOR

IC601

+5V

REGULATOR

IC307

+5V

REGULATOR

IC315

+3.3V

REGULATOR

IC302

POWER PROTECT

IC306, IC309 +3.3V

SYSTEM PULL UP +3.3V

86P-ON

E +3.3V

+6V

D814

OVER

VOLTAGE

DETECT

Q811

PROTECT

DETECT

88

Q103

PROTECT

DETECT

Q807

M1

(FAN)

MM

FAN M OTOR

DRIVE

Q801 - 803

OVER LOAD

DETECT

Q710, 816

D707

+3.3V

REGULATOR

IC304

+3.3V

REGULATOR

IC105

+3.3V

REGULATOR

IC10

FAN_DET

>002B

(Page 34)

F801

+6V

REGULATOR

IC812

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

3535

Page 36

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

5-4. BLOCK DIAGRAM - POWER SUPPLY Section -

SYSTEM

CONTROLLER

IC101 (4/4)

POWER

TARNSFORMER

T901

D940

D934

D941

D967

F931

SHUNT

IC932

RECT

D965

RECT

D967

SHUNT

REGULATOR

IC932

RECT

D943

ISOLATOR

PH930

MAIN POWER

TARNSFORMER

T901

PVDD

POWER

85SUB-ON

GVDD

PVDD

ON/OFF

CONTROL

Q970

REGULATOR

RIPPLE

FILTER

Q930

SWITCHING

Q930

B+ SWITCH

Q932

POWER CONTROL

IC930

3 Vcc/OVP

6BD

1D

5FB/OLP

POWER CONTROL

IC931

1D

7 OCP/BD

4Vcc

RECT

D902

TH901

LINE FILTER

L903, 904

F901

(GTK11iP)

AC1

(AC IN)

(GTK33iP)

D985

POWER

ON/OFF

CONTROL

Q934, 935

90PVDD_ON

GVDD

POWER

ON/OFF

CONTROL

Q933

RECT

D981

SHUNT

REGULATOR

IC966

ISOLATOR

PH930

ISOLATOR

PH931

SUB POWER

TARNSFORMER

T903

ISOLATOR

PH965

D970

D972

RIPPLE

FILTER

Q965

6FB

POWER CONTROL

IC965

3 Vcc/OVP

6BD

1D

5FB/OLP

RECT

D901

TH901

LINE FILTER

L901, 902

F901

AC1

(AC IN)

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

3636

Page 37

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

d

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For Printed Wiring Boards.

Note:

• X : Parts extracted from the component side.

• Y : Parts extracted from the conductor side.

• f : Internal component.

• : Pattern from the side which enables seeing.

(The other layers’ patterns are not indicated.)

Caution:

Pattern face side:

(Conductor Side)

Parts face side:

(Component Side)

Caution:

Pattern face side:

(SIDE B)

Parts face side:

(SIDE A)

• Indication of transistor.

C

Q

B

E

• Abbreviation

SP6 : Singapore and Malaysia models

Note 1: When the MAIN board is replaced, spread the com-

pound referring to “NOTE OF REPLACING THE

IC702 ON THE MAIN BOARD AND THE COMPLETE MAIN BOARD” on servicing notes (page 4).

Note 2: When the MAIN board is replaced, spread the bond

referring to “BOND FIXATION OF ELECTRIC

PARTS” on servicing notes (page 6).

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

These are omitted.

For Schematic Diagrams.

Note:

• All capacitors are in μF unless otherwise noted. (p: pF) 50

WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and 1/4 W or less unless otherwise

specifi ed.

• f : Internal component.

• 2 : Nonfl ammable resistor.

• 5 : Fusible resistor.

• C : Panel designation.

Note: The components identifi ed by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specifi ed.

• A : B+ Line.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : TUNER

( ) : iPod/iPhone

< > : DVD/PC IN

* : Impossible to measure

• Voltages are taken with VOM (Input impedance 10 M).

Voltage variations may be noted due to normal production

tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : TUNER

L : iPod/iPhone

G : USB

f : DVD/PC IN

• Abbreviation

AUS : Australian model

E2 : 120V AC area in E model

E51 : Chilean and Peruvian models

EA : Saudi Arabia model

MX : Mexican model

RU : Russian model

SP6 : Singapore and Malaysia models

Note 1: When the MAIN board is replaced, spread the com-

pound referring to “NOTE OF REPLACING THE

IC702 ON THE MAIN BOARD AND THE COMPLETE MAIN BOARD” on servicing notes (page 4).

• Circuit Boards Location

LED board

JUNCTION board

LED board

RC board

iPod board

GTK11-SMPS board (GTK11iP)/

GTK33-SMPS board (GTK33iP)

KEY board

MAIN board

VOL JOG boar

tuner (TU1)

IP board

PANEL board

USB board

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

Note 2: When the MAIN board is replaced, spread the bond

referring to “BOND FIXATION OF ELECTRIC

PARTS” on servicing notes (page 6).

3737

Page 38

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

5-5. PRINTED WIRING BOARD - MAIN Board (Component Side) -

1 2 3 4 5 6 7 8 9 10 11 12 13

MAIN BOARD (COMPONENT SIDE)

(EXCEPT AEP, UK)

C110

R111

R113

R115

R117

R210

R129

R130

R131

R389

IC314

C365

1

4

2

C373

C370

C393

R110

R120

CL128

CL133

R358

4

C346

12

IC305

(EXCEPT SP6)

CL202

CL201

1

30

R133

CL134

C304

1

4

3

2

C305

C360

C351

3

R206

E

R207

R297

C198

R295

R197

R195

100 81

IC101

31 50

R138

R134

R135

R136

R304

R413

R410

D307

D305

R407

C383

IC310

C368

C361

CL301

L301

A

SL802

CN101

13

FFC2

B

C

FM/AM

ANTENNA

TUNER1AM3RZ

ASSY

TU1

>01P

PANEL

BOARD

CN501

(Page 46)

(NC)

D302

1

CN102

8

2

9

1

R449

R447

CL127

C423

C112

C109

CL121

CL119

1515

IC102

R448

R446

C422

D

Q303

C302

D314

R445

C416

C417

L401

C307

4

IC315

C435

R439

R438

R442

C390

IC312

C387

148

Q301

C394

C421

C310

R443

ET301

R451

C418

1

2

C391

C308

C312

3

E

(CHASSIS)

F

C434

CN302

9

C424

C413

8

R420

2

R421

1

R414

G

FFC1

R403

C378

D313

R444

R441

5

C389

C377

E

R388

9168

C403

IC313

R406

R401

C392

CL112

1620

106

C309

R440

C106

E

R112

R212

11

R101

R102

R103

R105

X102

C111

X101

CL122

CL126

R231

R232

C114

CL131

C113

R132

CL132

E

Q302

C420

R452

IC307

R402

1

C402

R405

R400

H

• See page 37 for Circuit Boards Location.

SL801

R269

C350

C348

R385

R344

R345

C344

R346

C336

C332

C335

39 27

40

RB303

R333

C333

C331

R386

C343

C382

16

142

43

I

O

R387

R376

R373

R370

R368

R367

R366

R365

R361

1

R353

R351

C345

R324

R325

C330

R330

IC303

52

113

C322

C338

C324

R331

R326

R327

C334

R323

SL304SL305

Q103

(GTK33iP)(GTK11iP)

R139

136

1

IC308

R194

R188

R237

R241

IC311

D308

4

C357

R288

R393

R398

9168

R186

D306

R144

R244

R357

R356

R354

R145

R247

R245

R394

R392

R391

C397

C395

R183

R147

R148

13

R404

IC309

R362

R182

R187

R153

R152

R151

R251

R252

R236

R250

1714

C369

X302

R179

R178

R177

R176

C427

C426

R235

R372

R279

R276

R173

R253

R238

R359

C356

R436

R450

R375

R171

R161

R159

R157

R267

C358

R378

R369

C372

R278

R273

CL187

R283

R277

R268

R168

SL102

RB302

C379

32 17

33

R364

48

49 64

R343

RB301

R336

R335

R334

R342

R341

R340

SL101

IC306

X301

C337

R332

R281

R282

R181

80

R174

R172

R170

R169

R167

R166

R165

C162

R158

51

R150

R149

R246

R248

R249

C384

64

R382

C380

8

C371

C425

C115

IC304

C339

FL302

R363

R322

26

14

R320

C325

IC302

FL301

R321

R319

R313

R314

R311

R318

• : Uses unleaded solder.

R801

R845

C607

L602

R610

JL602

R843

X601

C612

Q701

Q702

D814

1324

4837

R612

C616

L811

E

E

R703

C707

43

12

1

IC603

C610

54

13

C825

C827

C601

C603

12

IC601

JL609

C614

C615

R609

C617

C118

C316

2

I

O

C317

IC105

21

34

C101

21

C103

34

R201

C306

C313

R603

R604

R602

C311

C606

R605

D813

R842

C117

IC10

E

Q811

R846

431

C602

R601

C608

C611

JL605

C604

25

C605

36

JL608

C613

C314

R308

C301

R306

D301

R829

R832

C822

C820

D811

R800

C834

IC701

15

R715

C772

R616

C771

R613

R614

R615

C701

C770

C710

C712

R702

C703

R712

R707

R714

R713

R705

C705

R708

R709

R704

IC602

R835

R833

IC811

R802

JL705

R706

C704

C706

16

C709

1458

ET801

R716

1

R710

(CHASSIS)

C812

C816

R825

R724

C713

C813

R837

F801

HS1

ET701

R723

R827

C817

R839

R831

C715

R826

C762

R836

R838

C826

C823

C763

R852

R851

C814

C815

14

58

C828C829

L812

C717

R760

4964

48

IC812

D812

R761

C721

C765

C764

R859

R860

R857

R858

R855

R856

R821

(GTK33iP)

Q812

E

Q813

E

Q814

E

CN812

1

4

R823

(GTK11iP)

R805

CL802

C809

C803

R804

Q803

E

CL801

R806

Q802

E

Q816

JL803

C750

C744

R803

EE

Q807

E

Q801

R729

JL802

C801

CL805

C804

C807

CL812

Q703

E

R728

Q704

R755

R732

E

R743

D707

Q706 Q707 Q708 Q709

R759

R746

C725

R737

R750

R751

EE EE

C760

C757

R748

C745

E

CL811

R753

R747

R817

Q710

R756

Q705

E

R739

R738

CL806

(GTK11iP)

C773

C774

(GTK11iP) (GTK33iP)

R808

CL815

CL803

E

Q817

Q818

R848

R849

IC821

3

R847

C831

R810

C832

IC822

3

R809

CL814

LP701

R749

R822

E

124

CL813

124

>09P

JUNCTION

BOARD

CN551

(Page

44)

(CHASSIS)

IC702

C722

C768

R763

C769

33

R762

32

C718

C766

C767

64

R711

C714

C716

R725

R726

ET702

C775

C776

R742

R752

R754

1-886-058-

11

(11)

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

(CHASSIS)

Note: When the IC702 on the MAIN board is replaced, spread the compound referring to “NOTE OF REPLACING

THE IC702 ON THE MAIN BOARD AND THE COMPLETE MAIN BOARD” on servicing notes (page 4).

3838

Page 39

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

5-6. PRINTED WIRING BOARD - MAIN Board (Conductor Side) -

1 2 3 4 5 6 7 8 9 10 11 12 13

MAIN BOARD (CONDUCTOR SIDE)

A

CN813

R818

R819

L707

L708

JL706

C743

R820

R824

C735

C736

R727

L703

L704

JL704

C734

C730

C731

M1

(FAN)

M

(GTK11iP)

B

C

D

>04P

GTK11-SMPS

BOARD

NO902

(Page 48)

>05P

GTK33-SMPS

BOARD

NO902

(Page 50)

(GTK33iP)

SPB1

SPK BOX ASSY

SP1

WOOFER

(L-CH)

(CHASSIS)

E

SP3

TWEETER

(L-CH)

1

C808

3

1

CN811

9

ET703

JL707

1

CN701

2

JL708

F

SP2

WOOFER

(R-CH)

SP4

TWEETER

G

(R-CH)

(CHASSIS)

JL709

1

CN702

3

ET704

L709

JL710

L710

C761

C737

L705

C738

L706

C732

C733

• See page 37 for Circuit Boards Location.

C811

C830

C824

R830

D704

D705

C727

C728

C819

D706

D703

C726

C729

R720

R722

JL703

C708

R828

C818

JL701

R718

JL702

C833

C821

D702

JL603

• : Uses unleaded solder.

JL601

C381

C419

CL163

CL190

C415

CL189

CL141

CL192

CL191

C116

R416

C409

CL193

R209

CN301

R418

C132

D103

CL194

CL107

CL118

C131

10

1

CL104

CL125

CL124

CL129

R408

CL106

J301

C414

CL123

CL130

R415

C408

R422R423

R417

C396

JL110

R409

JL106

JL104

JL108

JL102

JL113

R302

JL111

R303

JL101

JL112

ET101

JL105

JL103

JL107

JL109

(CHASSIS)

JL125

BOARD

>03P

CN552

(Page 44)

JL124

JL122

JL123

IP

USB

BOARD

>02P

CN562

(Page 44)

JL127

JL128

JL129

JL126

H

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

11

(11)

1-886-058-

L R

DVD/PC

IN

J301

Note: When the C730, C731, C732, C733, C734, C811, L703, L704, L705, L706, L707, L708, L709, L710 and R727 on the MAIN

board are replaced, spread the bond referring to “BOND FIXATION OF ELECTRIC PARTS” on servicing notes (page 6).

3939

Page 40

FST-GTK11iP/GTK33iP/RDH-GTK11iP/GTK33iP

5-7. SCHEMATIC DIAGRAM - MAIN Board (1/4) -

A

B

C

D

E

F

G

H

J

K

I

1 153

FFC2

>01S

PANE L

BOARD

CN501

(Page 47)

>001S

MAIN

BOARD

(3/4)

(Page 42)

VOL JOG

LCD INH

STBY LED

PVDD_ON

AC_DET

SUB_ON

SP_LED_R

SP_LED_G

SP_LED_B

(CHASSIS)

2

MAIN BOARD (1/4)

CN101

13P

JL101

1

3.3V

JL102

2

LCD DI

D_GND

LCD CL

LCD CE

D_GND

P-MONI

KEY2

KEY1

E3.3V

RMC

P_ON

JL103

3

JL104

4

JL105

5

JL106

6

JL107

7

JL108

8

JL109

9

JL110

10

6V

JL111

11

JL112

12

JL113

13

6V

C101

1

ET101

E

4

1CE2

5.9 5.9

STBY_LED

VDD

LCD_SDA

LCD_SCL

VOL_JOG

LCD_CS

KEY_2

LCD_INH

KEY_1

SIRCS

R206

1k

3.3

3.2

ISA1602AM1TP-1EF

PROTECT DETECT

3.3

3

VOUT

+3.3V REGULATOR

GND

Q103

IC10

IC10

MM3404A33URE

SP_LED_R

SP_LED_G

SP_LED_B

0

C117

C103

1

AC_DET

SUB_ON

R207

10k

R201

1

0

+3.3V REGULATOR

3.1 5.9

1

2

C118

1

IP_ON

USB_ON

USB_IP_OCP

USB_IP_SEL

SUB_ON

VACS

LCD_INH

R197

1k (EA)

1.5k (AUS)

4.7k (US, RU, E2, E51, MX, SP6)

• See page 52 for Waveforms. • See page 52 for IC Block Diagrams. • See page 57 for IC Pin Function Description.

IC105

IC105

MM3404A33URE

CE

GND3VOUT

4

VDD

3.3

R282

10k

R281

10k

R288

10k

(EXCEPT AEP, UK)

(GTK11iP) (GTK33iP)

R186

1k

R188

1k

R194

100

R197

R195

4.7k

C115

220

6.3V

(EXCEPT SP6)

C198

C116

0.1

R283

10k

R187

1k

R181

0

0R182

100R183

CL187

CL190

CL194

R297

R295

4.7k

0.1

R297

150 (RU)

680 (MX)

1k (E2, E51)

2.2k (US)

4.7k (AEP, UK, EA, AUS)

611

P-ON

P-ON

R267

10k

R276

100k

0 (3.2)

0 (3.2)

CL189

CL191

CL192

CL193

X102

32.768kHz

1

34

C110

18p

USB_SCL

USB_RST

USB_BUSY

R278

R277

4.7k

4.7k

R279

100k

100R179

100R177

100R178

3.303.1

7980

7778

USB SCL

81

3.2

82

2.9

83

84

3.3

85

3.1

86

3.3

87

3.2

88

89

3.2

90

91

92

93

0

94

3.1

95

96

2.7

97

3.3

98

3.3

99

3

100

2

C111

22p

USB BUSY

IP_ON

USB RESET

USB_ON

USB_IP_OCP

USB_IPOD SEL

SUB-ON

P-ON

BYPASS

POWER PROTECT

VART D ET ADC_RESET

PVDD_ON

NC

NC

NC

VACS

MODEL-IN

AVss

SPEC-IN

VREF

DP SDA/SPI DOUT

AVcc

DP INH

DP CS

1

345

2

0

0

1.7

R103

R101

R111

220k

100

100

100R102

LCD_SDA

LCD_SCL

LCD_CS

USB_SDA

3.100

USB SDA

DP SCL

NC

CL104

STBY_LED

USB_IRPTO

100R176

USB IRPTO

SIRCS

6789

3.2

R105

100

SIRCS

R268

100k

100R174

2.9

STBY LED

NC

CL106

1

UCON-PGM

CL107

IP_DET

1kR173

2.8

IP_DETECT

KEY_WAKE_UP_POWER

BYTE

NC

85 13

KEY_2

KEY_1

AC_DET

AUTO_POFF

USB_MCHNG

VOL_JOG

100R171

100R170

100R172

1.5

2.9

2.9

7273747576

KEY_2

VOL_JOG

CNVss

Xcin

1011121314

1.7

1.7

1.8

100R169

KEY_1

XcOUT

100R112

S-MASTER_DCP

100R168

100R167

0

68697071

AC_DET

USB MCHNG

IC101

SYSTEM CONTROLLER

R5F364AEDFA

RESET

Xout

1.7

3.2

LED_LEVEL_IN

D103

100R166

100R165

0

0

65

6667

LED_LEVEL_IN

S-MASTER DCP

AUDIO LEVEL DET

IC101

Vcc

Vss

Xin

15 161718 19

1.5

3.3

2

CL112

R110

10M

R209

150k

UCON-RST

X101

R113

5MHz

0

DB2J31000L

R273

10k

R269

10k

Vss

NMI

3.3

R117

10k

R115

1M

S-MASTER_INIT

100R161

CL163

3.3

3.2

NC

Vcc

S-MASTER_INIT

FLASH WRITE MODE IN

TUNER_SCL/UCOM_TX

TUNER_SDA/UCOM_RX

NC

AC-CUT

202122

2

CL118

CL119

R120

47k

C106

0.1

9

S-MASTER_DATA

S-MASTER_SHIFT

S-MASTER_LATCH

S-MASTER_NSP_MUTE

100R158

100R159

100R157

3.2

3.2

3.2

3.2

58596061626364

S-MASTER SHIFT

S-MASTER LATCH

S-MASTER NSP MUTE

S-MASTER_OTW1

S-MASTER_SD

DSP IIC_CLK

DSP IIC_SDA

SOFT_TEST1

SPKLED_BLUENCSOFT_TEST2

NC

24

23

CL123

CL124

CL121

CL122

R210

10k

R212

10k

SP_LED_B

10 171674 14