Page 1

DIGITAL BETACAM CAMCORDER

DVW-707/707P

D VW-709WS/709WSP

/

D VW-790WS

SDI OUTPUT BOARD

BKDW-702

PICTURE CACHE BOARD

BKDW-703

IMAGE INVERTER BOARD

BKDW-704

790WSP

MAINTENANCE MANUAL Part 1

1st Edition (Revised 1)

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

DVW-707 (SY) Serial No. 10001 and Higher

DVW-707P (SY) Serial No. 40001 and Higher

DVW-709WS (SY) Serial No. 10001 and Higher

DVW-709WSP (SY) Serial No. 40001 and Higher

DVW-790WS (SY) Serial No. 10001 and Higher

DVW-790WSP (SY) Serial No. 40001 and Higher

Page 3

CAUTION

Danger of explosion if battery is incorrectly

replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer’s instructions.

Vorsicht!

Explosionsgefahr bei unsachgemäßem

Austausch der Batterie.

For the customers in the U.S.A. and Canada

RECYCLING NICKEL-CADMIUM

BATTERIES

Nickel Cadmium batteries are

recyclable. You can help preserve our

environment by returning your unwanted

batteries to your nearest point for

collection, recycling or proper disposal.

Note: In some areas the disposal of

nickel cadmium batteries in household or business trash

may be prohibited.

RBRC (Rechargeable Battery Recycling Corporation)

advises you about spent battery collection by the

following phone number.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ.

Entsorgung gebrauchter Batterien nach Angaben

des Herstellers.

ATTENTION

Il y a danger d’explosion s’il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du

même type ou d’un type équivalent recommandé

par le constructeur.

Mettre au rebut les batteries usagées

conformément aux instructions du fabricant.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

Call toll free number: 1-800-822-8837

(United States and Canada only)

Caution: Do not handle damaged or leaking nickelcadmium batteries.

Voor de klanten in Nederland

Dit apparaat bevat een MnO

back-up.

Raadpleeg uw leverancier over de verwijdering van de

batterij op het moment dat u het apparaat bij einde

levensduur afdankt.

Gooi de batterij niet weg. maar lever hem in als KCA.

Bij dit produkt zijn batterijen geleverd.

Wanneer deze leeg zijn, moet u ze niet

weggooien maar inleveren als KCA.

2-Li batterij voor memory

Page 4

Page 5

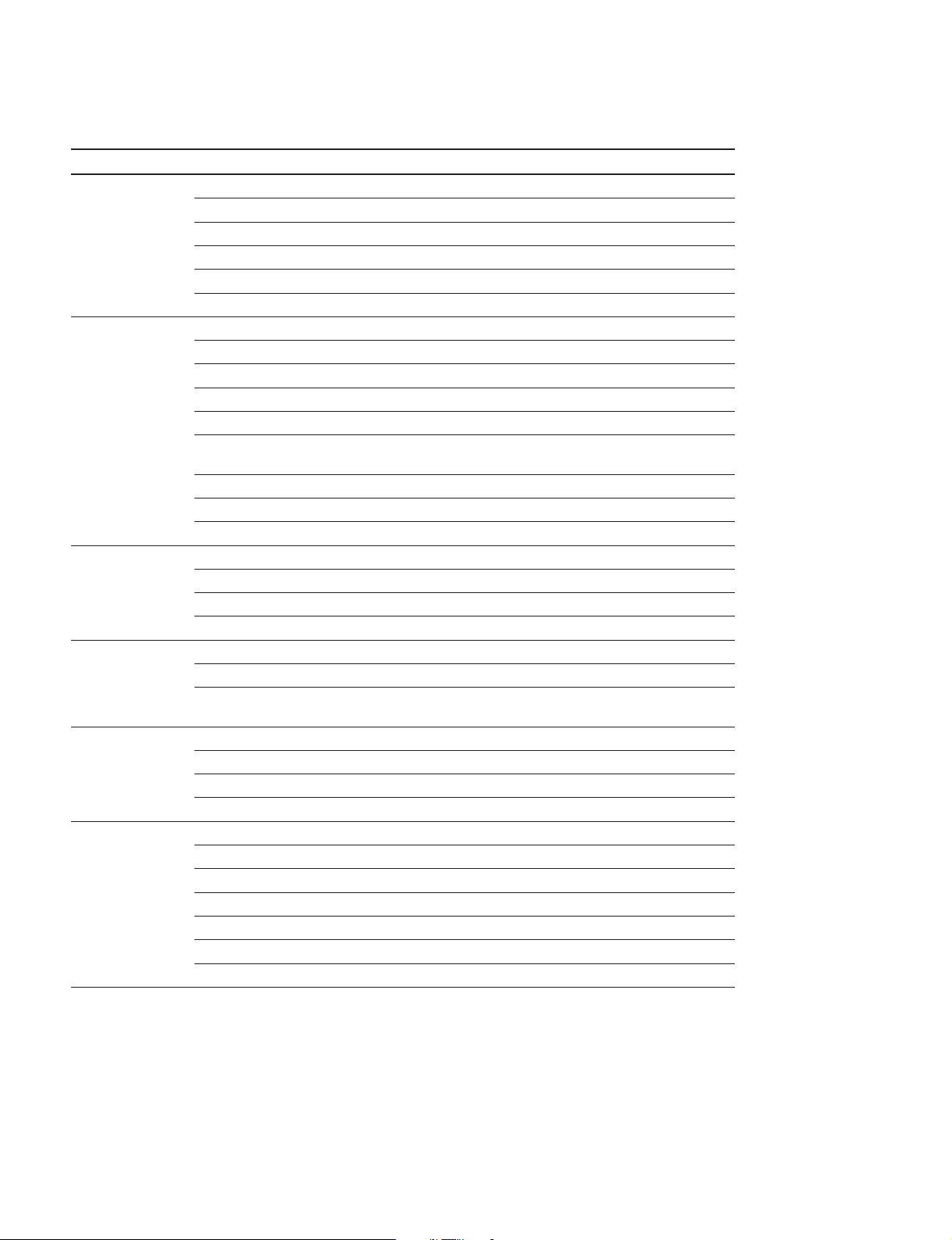

Table of Contents

Manual Structure

Purpose of this manual .............................................................................................. 5

Contents .....................................................................................................................6

Related manuals......................................................................................................... 6

1. Service Overview

1-1. Operating Conditions ..................................................................................1-1

1-2. Supplied Accessories ..................................................................................1-1

1-3. Main Part Locations and Circuit Functions ................................................1-2

1-3-1. Printed Circuit Board Locations................................................. 1-2

1-3-2. Circuit Functions ........................................................................ 1-4

1-3-3. Mechanical Part Locations ......................................................... 1-6

1-3-4. Sensor Locations and Functions................................................. 1-8

1-4. Matching Connectors ................................................................................1-10

1-5. Signal Inputs and Outputs .........................................................................1-11

1-6. Removing/Reinstalling Outside Panel ...................................................... 1-14

1-7. Opening/Closing Inside Panel...................................................................1-15

1-8. Removing/Reinstalling Cassette Compartment ........................................ 1-15

1-9. Removing/Reinstalling Plug-in Boards.....................................................1-17

1-9-1. DCP/DVP Board Assembly .....................................................1-17

1-9-2. SV-210 Board........................................................................... 1-17

1-10. Switch/Slit Land Settings and LED Functions on the Boards .................. 1-18

1-10-1. AXM-21 Board ........................................................................1-18

1-10-2. CNB-11 Board .........................................................................1-19

1-10-3. DCP-17 Board .......................................................................... 1-20

1-10-4. DVP-17 Board..........................................................................1-21

1-10-5. HN-260 Board .......................................................................... 1-22

1-10-6. TC-101 Board........................................................................... 1-23

1-10-7. TG-207 Board

(for DVW-790WS/790WSP/709WS/709WSP only)............... 1-24

1-10-8. DIF-75 Board (BKDW-702) ....................................................1-25

1-11. Ejecting the Cassette Tape Manually ........................................................1-26

1-12. Inserting the Cassette Tape With Outside Panel Removed....................... 1-27

1-13. Cleaning When the Heads are Clogged ....................................................1-27

1-14. Fixtures and Adjustment Equipment......................................................... 1-28

1-15. Battery for Memory Backup ..................................................................... 1-28

1-16. Replacing the DC-DC Converter ..............................................................1-28

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

1

Page 6

2. Diagnostics

2-1. Error Code ...................................................................................................2-1

2-1-1. Warning Indicators .....................................................................2-1

2-1-2. Error Codes ................................................................................2-1

2-2. Error Messages............................................................................................2-2

2-3. Display Panel and Lamp Operation Check .................................................2-2

2-4. Displaying the Servo Adjustment Data.......................................................2-3

2-5. Displaying the Slack Information in the Past.............................................. 2-4

3. Setup Menu

3-1. Engineer Mode (Setup Menu) .....................................................................3-1

3-1-1. Fundamental Operation of the Setup Menu ............................... 3-2

3-1-2. Contents of Setup Menu .............................................................3-3

3-1-3. Setup Menu List .......................................................................3-16

3-2. VTR (DIAG) Menu...................................................................................3-25

4. Camera System Electrical Alignment

(Only for DVW-790WS/790WSP/709WS/709WSP)

4-1. General Information for Electrical Adjustment .......................................... 4-1

4-1-1. Note for Adjustment...................................................................4-1

4-1-2. Equipment/Fixtures .................................................................... 4-1

4-1-3. Initial Setting for Switches .........................................................4-1

4-1-4. Maintaining the Grayscale Chart ...............................................4-3

4-2. ENC Level Adjustment ............................................................................... 4-5

4-3. TEST OUT Level Adjustment ....................................................................4-6

4-4. VA Gain Adjustment...................................................................................4-7

4-5. White Shading Adjustment .........................................................................4-8

4-6. Gamma Correction Adjustment .................................................................. 4-9

4-7. Black Set Adjustment................................................................................ 4-10

4-8. Flare Adjustment .......................................................................................4-11

4-9. Manual Knee and White Clip Adjustments ..............................................4-12

4-10. Crispening Adjustment (16:9)...................................................................4-13

4-11. Level Depandent Adjustment (16:9) .........................................................4-13

4-12. H/V Ratio Adjustment (16:9)....................................................................4-14

4-13. Detail Level Adjustment (16:9) ................................................................4-14

4-14. Crispening Adjustment (4:3).....................................................................4-15

4-15. Level Depandent Adjustment (4:3) ...........................................................4-15

4-16. H/V Ratio Adjustment (4:3)......................................................................4-16

4-17. Detail Level Adjustment (4:3) ..................................................................4-16

4-18. Skin Tone Adjustment...............................................................................4-17

4-19. Zebra Adjustment......................................................................................4-18

4-20. Automatic Iris Adjustment ........................................................................4-19

2

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 7

5. Camera System Electrical Alignment

(Only for DVW-707/707P)

5-1. General Information for Electrical Adjustment .......................................... 5-1

5-1-1. Note for Adjustment...................................................................5-1

5-1-2. Equipment/Fixtures .................................................................... 5-1

5-1-3. Initial Setting for Switches .........................................................5-1

5-1-4. Maintaining the Grayscale Chart ...............................................5-2

5-2. ENC Level Adjustment ............................................................................... 5-4

5-3. TEST OUT Adjustment .............................................................................. 5-4

5-4. VA Gain Adjustment...................................................................................5-5

5-5. White Shading Adjustment .........................................................................5-6

5-6. Gamma Correction Adjustment .................................................................. 5-7

5-7. Black Set Adjustment.................................................................................. 5-8

5-8. Flare Adjustment .........................................................................................5-8

5-9. Manual Knee and White Clip Adjustments ................................................5-9

5-10. Crispening Adjustment...............................................................................5-10

5-11. Level Depandent Adjustment.....................................................................5-10

5-12. H/V Ratio Adjustment................................................................................5-11

5-13. Detail Level Adjustment ............................................................................5-11

5-14. Skin Tone Adjustment................................................................................5-12

5-15. Zebra Adjustment.......................................................................................5-13

5-16. Automatic Iris Adjustment .........................................................................5-14

6. Block Diagrams and Circuit Description

6-1. Circuit Description ...................................................................................... 6-1

6-2. Camera Overall Block Diagram..................................................................6-6

6-3. VTR Overall Block Diagrams..................................................................... 6-8

7. Periodic Maintenance and Inspection

7-1. Cleaning ...................................................................................................... 7-1

7-1-1. General Information for Cleaning .............................................. 7-1

7-1-2. Cleaning of Tape Running Surface of Upper Drum and

Video Heads ............................................................................... 7-3

7-1-3. Cleaning of Tape Running Surface of Lower Drum and

Lead Surface............................................................................... 7-4

7-1-4. Stationary Heads Cleaning ......................................................... 7-5

7-1-5. Cleaning of Tape Running System and Tape Cleaner ............... 7-6

7-1-6. Cares After Using at Special Environment ................................7-7

7-2. Periodic Check ............................................................................................7-8

7-2-1. Hours Meter ...............................................................................7-8

7-2-2. Periodic Check List .................................................................... 7-9

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

3

Page 8

8. Spare Parts

8-1. Notes on Repair Parts..................................................................................8-1

8-2. Recommended Replacement Parts ..............................................................8-2

9. Optional Boards Installation

9-1. BKDW-702 (DIF-75 board)........................................................................ 9-1

9-2. BKDW-703 (MY-93 board)........................................................................ 9-2

9-3. BKDW-704 (FM-65 board) ........................................................................ 9-4

4

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 9

Purpose of this manual

Contents

Manual Structure

This manual is the Maintenance Manual Part 1 of the following models:

Digital Camcorder DVW-790WS/709WS/707,

DVW-790WSP/709WSP/707P

Sony SDI Output Board BKDW-702

Sony Picture Cache Board BKDW-703

Sony Image Inverter Board BKDW-704 (For DVW-790WS/790WSP/709WS/

709WSP only)

This manual is intended for use by trained system and service engineers, and

provides the information that is required to the primary services, maintenance of this

unit and installation of the optional boards (BKDW-702/703/704) .

This manual is organized by the following sections:

Section 1 Service Overview

Explains the locations of main parts, the functions of printed circuit boards, the

removal and reinstallation of cabinet, and the measures against troubles.

Section 2 Diagnostics

Explains the error messages and self-diagnostics.

Section 3 Setup Menu

Explains the setup menu (engineering mode) and VTR (DIAG) menu of this unit.

Section 4 Camera System Electrical Alignment

(Only for DVW-790WS/790WSP/709WS/709WSP)

Explains the electrical adjustments after installing/replacing the lens to/of the DVW790WS/790WSP/709WS/709WSP.

Section 5 Camera System Electrical Alignment

(Only for DVW-707/707P)

Explains the electrical adjustments after installing/replacing the lens to/of the DVW707/707P.

Section 6 Block Diagrams and Circuit Description

Describes the overall block diagrams and circuit description.

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Section 7 Periodic Maintenance and Inspection

Explains the cleaning procedures and periodic checks.

5

Page 10

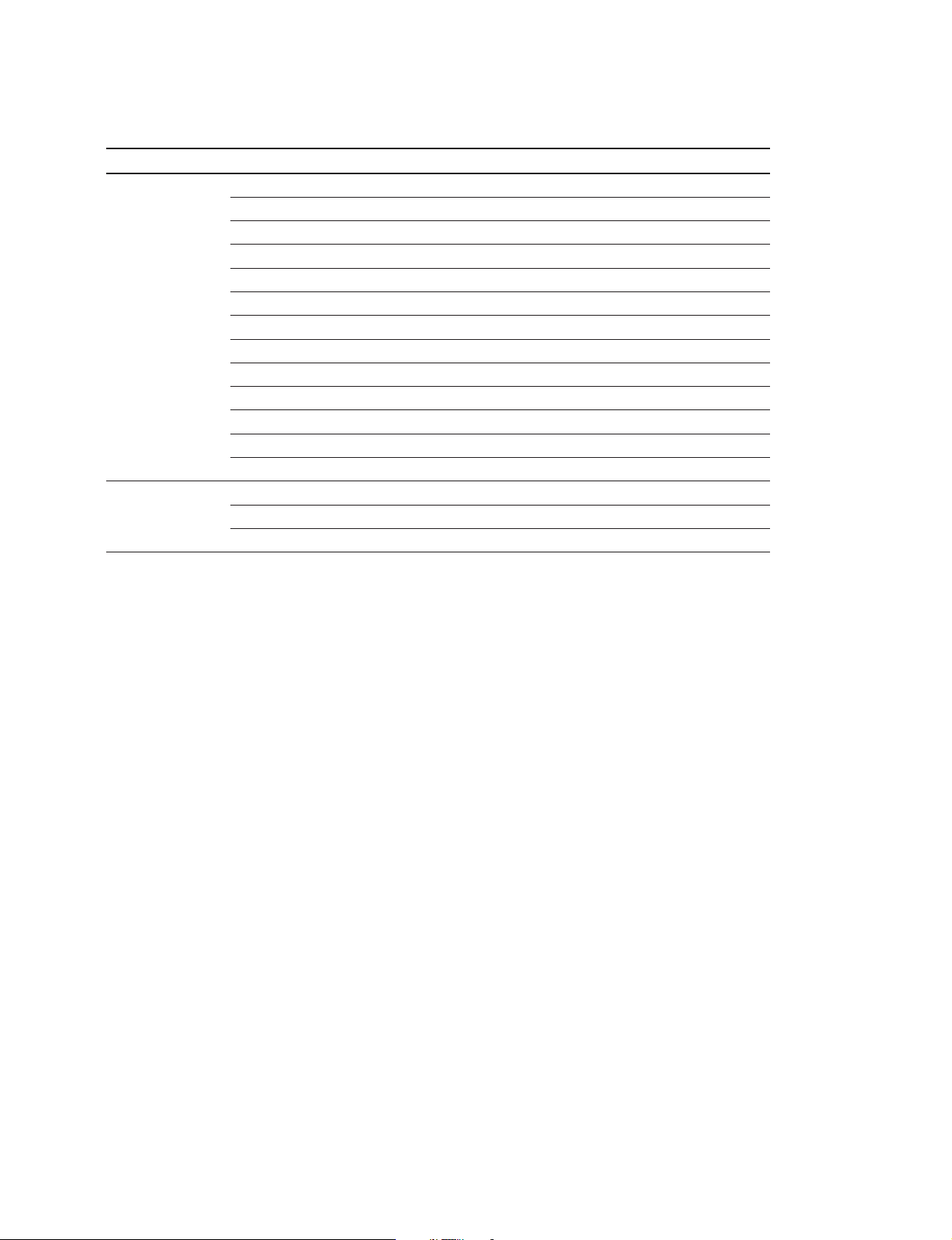

Related manuals

Section 8 Spare Parts

Describes the notes on spare parts and list of parts which need the periodic maintenance.

Section 9 Optional Boards Installation

Explains the installation procedure of optional boards (BKDW-702/703/704) to this

unit.

Besides this “Maintenance Manual Part 1”, the following manuals are available for

this unit:

..

. Operation Manual (Supplied with this unit)

..

This manual is necessary for application and operation of this unit.

..

. Maintenance Manual Part 2 (available on request)

..

Volume-1 : Service Instructions

Volume-2 : Parts List and Diagrams

These manuals describe the information that premises the parts level service

(adjustments, board layouts, schematic diagrams, detailed parts list, etc.) for this

unit.

If these manuals are required, contact your local Sony Sales Office/Service

Center.

..

. BVF-V10/V10CE or BVF-V20W/V20WCE

..

Maintenance Manual (available on request)

This manual describes the service information of the supplied viewfinder.

If this manual is required, contact your local Sony Sales Office/Service Center.

6

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 11

Section 1

Service Overview

1-1. Operating Conditions

Operating temperature : 0 to 40 dC

Humidity : 25 to 85 % (Relative humidity)

Storage temperature : _20 to 60 dC

User under special environment (Measure for cold area) :

The unit is guaranteed its operation under the temperature

of 0 to 40 dC. When the unit is used under 0 dC, covercloth (part No. : 3-191-775-01) against the cold is recommended to use.

1-2. Supplied Accessories

Description Part No. Q’ty

Shoulder Belt Assembly A-6772-374-B 1

Microphone 1-542-295-11 1

Window Screen 3-709-104-01 1

XLR Cap (1) 3-741-727-01 2

XLR Cap (2) 3-741-726-03 2

Operation Manual _ 1

Maintenance Manual Part 1 _ 1

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

1-1

Page 12

1-3. Main Part Locations and Circuit Functions

1-3. Main Part Locations and Circuit Functions

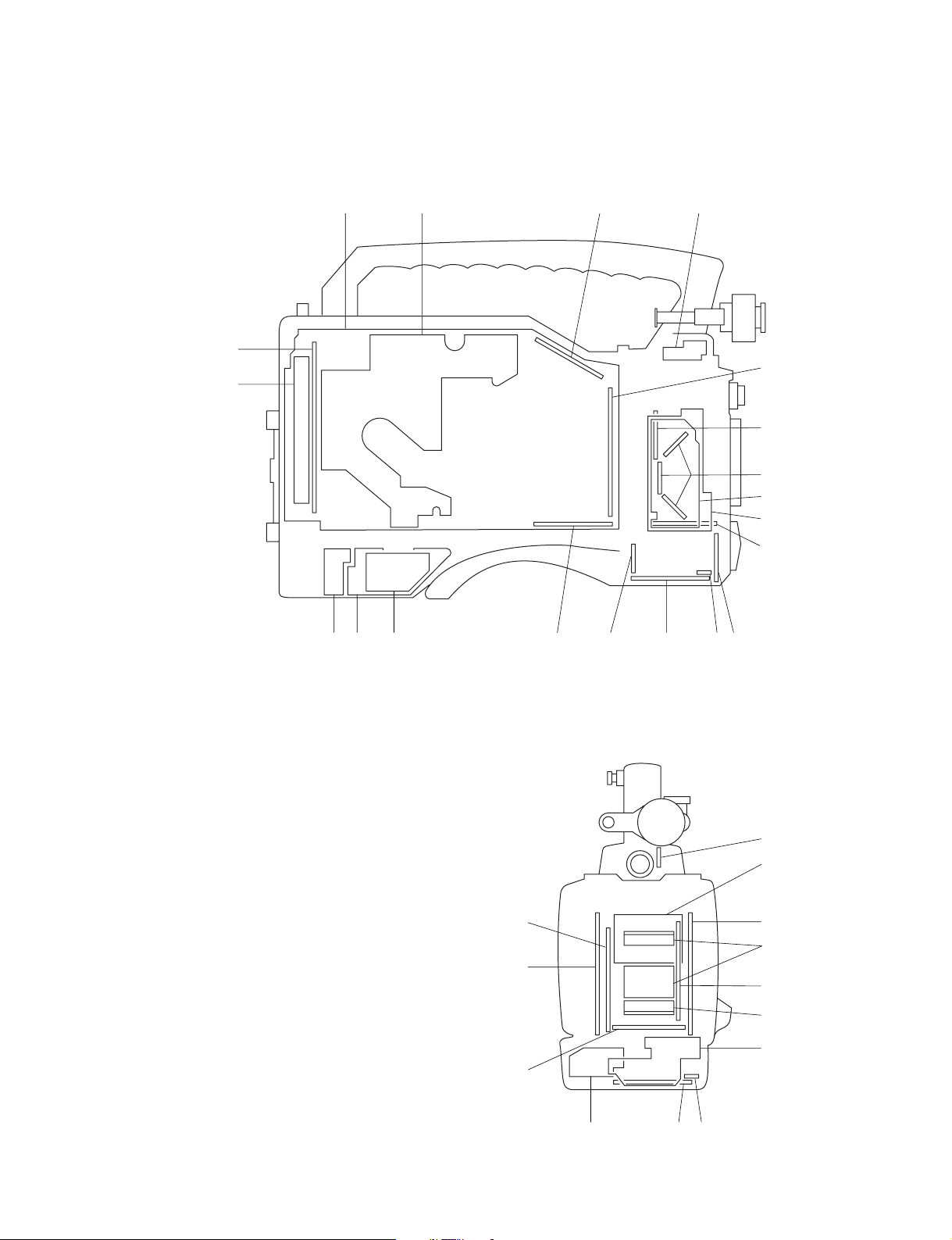

1-3-1. Printed Circuit Board Locations

AD-155 ........ 3

AXM-21 ......!]

BC-31*1........#;

BC-32*2........#;

BF-74 ........... 5

BI-96............#[

CI-20............!-

CI-21............0

CN-1183 ...... $,

CN-1573*1....!.

CNB-11........ !'

CP-329 ......... @[

CTL-10 ........ @.

CUE-2..........$-

DC-101 ........ !=

DC-106 ........ ![

DCP-17 ........ @=

DIF-75 ......... 9 (BKDW-702)

DR-387 ........ $'

DVP-14........@]

DVP-17........@\

ES-23 ...........@/

FM-65*3.......5 (BKDW-704)

HN-260 ........ #-

HP-93........... !;

IF-716 .......... #.

IO-178.......... $[

KY-293 ........ 4

LP-109 .........6

LP-111 .........!\

MA-94 ......... $/

MB-810........ !,

MB-811........ @;

MY-93 ......... @' (BKDW-703)

PA-228......... #]

PS-533 ......... 7

RC-69*2........!.

RC-75*2........!.

RE-160......... $;

RE-161......... $\

RM-180........ $]

SE-275 .........@,

SV-210......... 8

@[

SW-971........#'

SW-972........2

SW-973........#/

SW-983........#,

TC-101......... @-

TG-206*1......#=

TG-207*2......#=

VA-191 ........ #\

VR-248 ........ 1

VSE-32 ........ $=

3412

@= @-

< Inside Panel View >

5

!.

@-

5

!,

@/ !' !; !\!\!]

4

@=

!.

6

6

7

8

9

0

!-

!=

![

7

@]

@\

@;

@'

!=

!'

*1 : For DVW-707/707P only

*2 : For DVW-790WS/790WSP/709WS/709WSP only

*3 : Dedicated optional board for DVW-790WS/790WSP/709WS/709WSP

1-2

!;

![

< Rear Panel View >

!]

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 13

#;

#;

#]

#\

#-

#/

#[

$,

#[

#'

$/ #. #,

#=

#/

$'

@.@; @,

$-

$/ #. #,

#'

$] $[ $=

$;

$\

#=

#[

#]

#\

1-3. Main Part Locations and Circuit Functions

Inside Panel View : 1 through @[

(Some boards are also indicated in

the Rear Panel View.)

Rear Panel View : @] through @'

Outside Panel View :@, through $;

(Some boards are also indicated in

the Front Panel View.)

Front Panel View : $' and $,

< Outside Panel View >

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

< Front Panel View >

1-3

Page 14

1-3. Main Part Locations and Circuit Functions

1-3-2. Circuit Functions

System Board Function

CCD BLOCK BI-96 CCD Imager (R, G, B)

CN-1183 Connector for BI-96

DR-387 CCD Driver

PA-228 Pre-amp (Sample & Hold)

TG-206*1/TG-207

VA-191 Video Amp

CAMERA/VIDEO AD-155 A/D Converter

BF-74 Connector for DCP-17

CN-1573

RC-69*2+RC-75

DCP-17 Camera Processor

DVP-14 Digital Bit Reduction Decoder, Digital Encoder, Digital Decoder,

DVP-17 RF, Digital Audio Processor, System Controller for VTR Block

ES-23 Composite Encoder

TC-101 Analog Audio Processor, Time Code Generator

HEAD/SERVO CTL-10 CTL/Erase Head Amp

CUE-2 CUE Head Amp

HN-260 Harness, Head Amp (REC Head PB)

SV-210 Servo Controller

MICROPHONE IF-716 Lens Control, Mic Amp

MA-94 Camera Mic Pre-amp

SW-971 Mic Level, Auto White/Black SW, VTR Start/Stop SW,

POWER SUPPLY DC-101 Battery DC Filter

PS-533 Power Supply (Light)

RE-160 Regulator

RE-161 Regulator, Switching Control

CONNECTOR BOX AXM-21 Connector (AUDIO IN/OUT), Audio Pre-amp

CNB-11 Circuit Breaker

DC-106 External DC Filter

IO-178 Connector (GEN LOCK IN, TEST OUT, TC IN, TC OUT)

LP-111 Rear Tally

RM-180 Connector (RM)

VSE-32 GENLOCK IN Filter

*1 : For DVW-707/707P only

*2 : For DVW-790WS/790WSP/709WS/709WSP only

*2

*1

*2

Timing Generator

Connector for DCP-17

Rate (16:9 to 4:3) Converter

Timing Clock Generator

Shutter On/Off Select SW

1-4

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 15

System Board Function

OTHERS CI-20 Connector (40-pin)

CI-21 40-pin Adaptor Interface

CP-329 Switch Panel

HP-93 Earphone

KY-293 Function Key

LP-109 Back Tally, Back Tally Switch

MB-810 Motherboard

MB-811 Motherboard

SE-275 Sensor

SW-972 Turbo Gain Switch

SW-973 Menu and Light Auto/Manual Switch

SW-983 Rotary Encoder Switch

VR-248 Memory Card, Audio Select Switch, Alarm Level, Monitor Level

OPTION FM-65*3 (BKDW-704) Image Inverter Board

DIF-75 (BKDW-702) SDI Output Board

MY-93 (BKDW-703) Picture Cache Board

*3 : Dedicated optional board for DVW-790WS/790WSP/709WS/709WSP.

1-3. Main Part Locations and Circuit Functions

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

1-5

Page 16

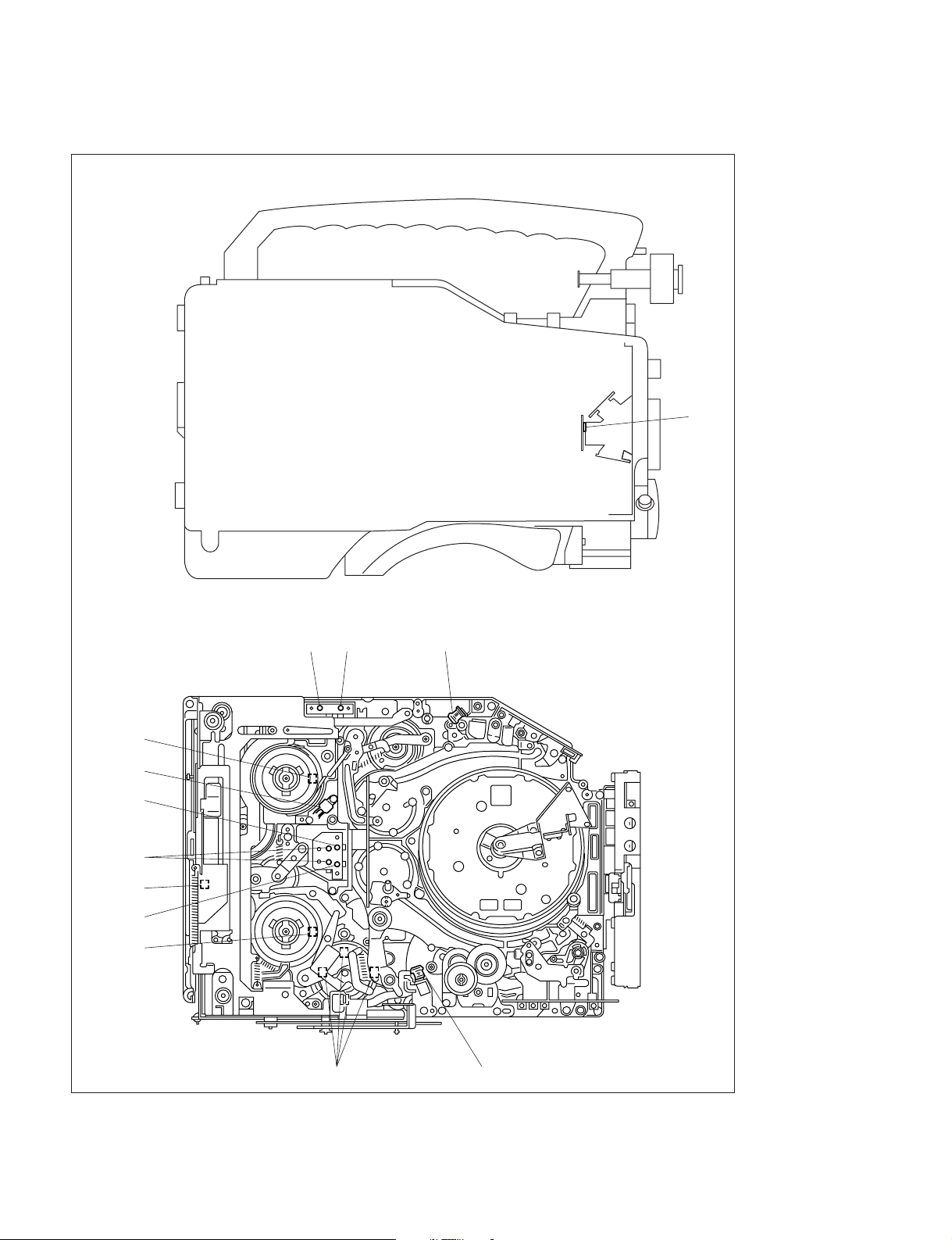

1-3. Main Part Locations and Circuit Functions

1-3-3. Mechanical Part Locations

2

1

Mechanical Deck

#=

#-

#/

@.

@,

34567890!-

!=

![

!]

!\

1-6

@' @; @\ @] @[ @= @- @/ !. !, !' !;

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 17

1 CCD block

2 DC fan motor

3 Tension regulator arm

4 S1 tape guide (on S slider)

5 S2 tape guide (on S slider)

6 Tension regulator guide (S4 tape guide)

7 S5 tape guide

8 S3 tape guide

9 Full erase head

0 Tape cleaner

!- CTL head

!= Brush

![ Slip ring

!] Video head cleaner

!\ Upper drum

!; Lower drum

!' CUE head cleaner

!, CUE/TC head

!. Manual eject knob

@/ Threading motor

@- Capstan motor

@= T3 tape guide

@[ T drawer guide

@] Pinch roller

@\ T2 tape guide (on T slider)

@; T1 tape guide (on T slider)

@' T soft brake

@, T reel table

@. Timing belt

#/ Gear

#- S reel table

#= Brake band

1-3. Main Part Locations and Circuit Functions

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

1-7

Page 18

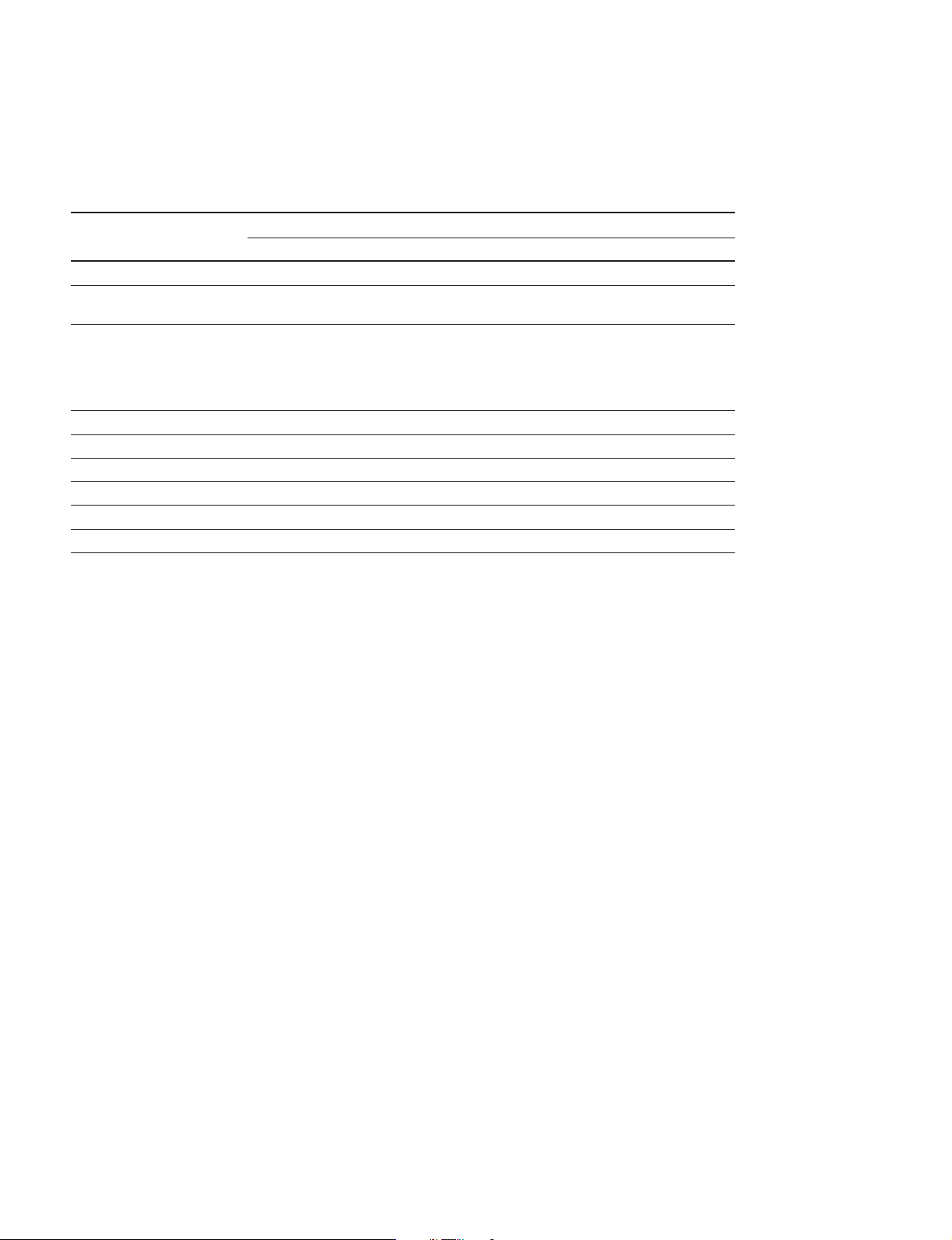

1-3. Main Part Locations and Circuit Functions

1-3-4. Sensor Locations and Functions

1

Mechanical Deck

!=

!-

0

(Spare)

8

9

7

6

32

4

5

1-8

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 19

1-3. Main Part Locations and Circuit Functions

1 Temperature Detection Sensor

Detects the temperature, to perform the black correction.

2 Cassette-in Sensor

Detects the existence of a cassette.

3 REC INHIBIT Sensor

Detects the REC inhibiting plug of the cassette tape.

4 Tape End Sensor

Detects the end of the tape that runs in the forward direction.

5 Tape Top Sensor

Detects the end of the tape that runs in the reverse direction.

6 Function Cam Sensor

Detects the rotation position of a cam.

7 Take-up Reel Table Rotating Sensor

Detects the rotation of the take-up reel table. The FG output signal of this sensor is input to a servo

circuit so as to calculate the winding diameter of the tape.

8 Cassette Lock Sensor (Switch)

Detects that the cassette compartment was locked.

9 Tape Thickness Sensor

Using a tub on the back side of the cassette tape, this sensor detects the thickness of the tape wound

on a cassette tape that is being inserted into the unit.

0 Reel Hub Diameter Sensor

The reel hub diameter of a cassette tape varies depending on the length of the tape wound on the

cassette tape. The reel hub diameter sensor detects the reel hub diameter by the tab on the back side

of the cassette tape. The output signal of this sensor is input to a servo circuit so as to calculate the

winding diameter of the tape.

!- Condensation Sensor

Detects whether the dew condensation occurs in the unit.

!= Supply Reel Table Rotating Sensor

Detects the rotation of the supply reel table. The FG output signal of this sensor is input to a servo

circuit so as to calculate the winding diameter of the tape.

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

1-9

Page 20

1-4. Matching Connectors

1-4. Matching Connectors

When external cables are connected to the connector during maintenance, the hardware listed below (or

the equivalents) must be used:

Panel Indication Matching Connector/Cable

Name Part No.

AUDIO IN CH-1/CH-2 XLR 3-pin, male 1-508-084-00

AUDIO OUT Audio cable SONY CCXA-53 or equivalent

GENLOCK IN BNC 1-569-370-12

TC IN

TC OUT

TEST OUT

VIDEO OUT

DC IN XLR 4-pin, female 1-508-362-00

DC OUT 12 V DIN 4-pin, male 1-566-425-11

MIC IN +48 V XLR 3-pin, male 1-508-084-00

REMOTE 6-pin, male 1-560-078-00

EARPHONE Mini jack Available separately

LIGHT Power tap [OE] ANTONBAUER 33710 or equivalent

(XLR 5-pin _ XLR 3-pin, 2 m)

1-10

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 21

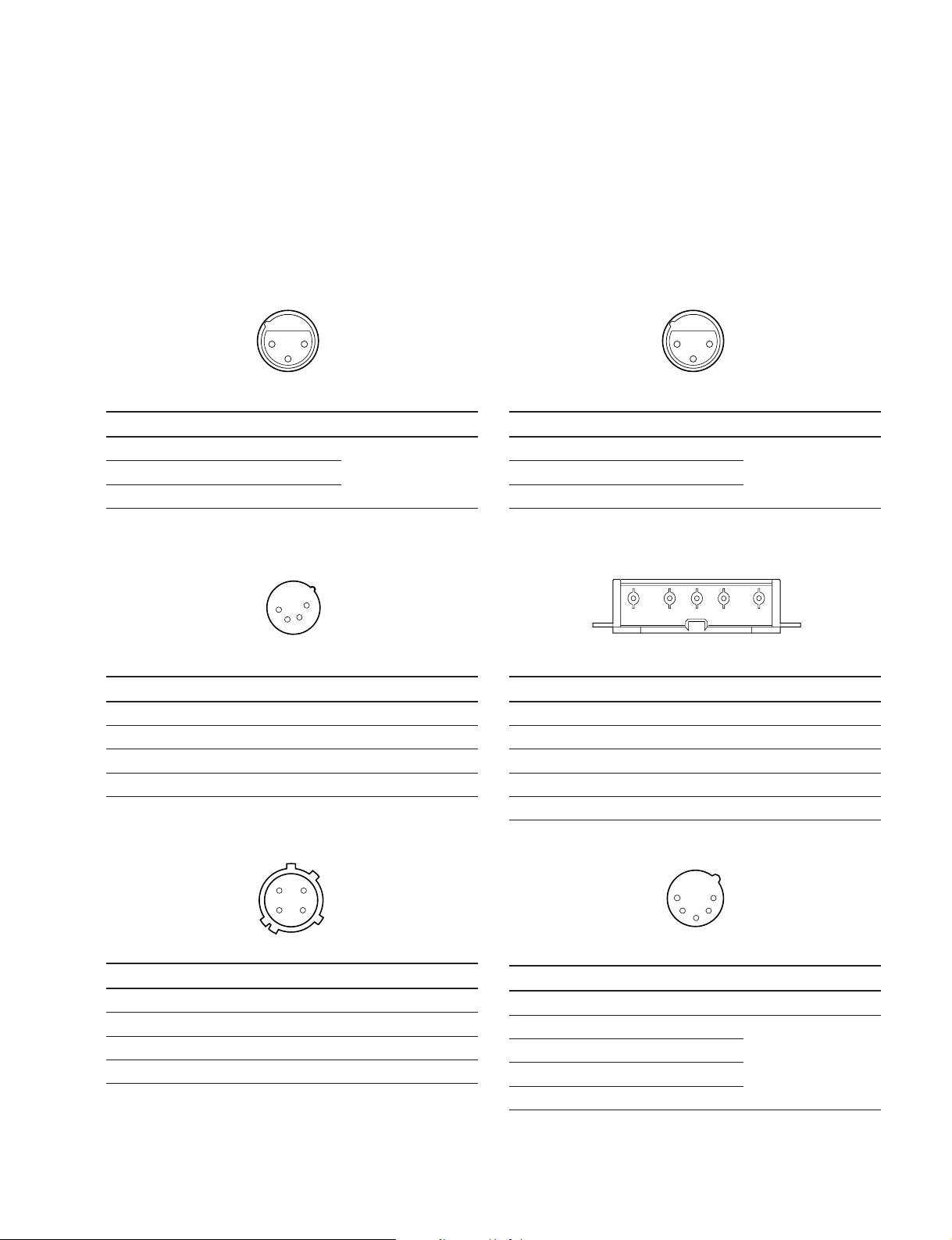

1-5. Signal Inputs and Outputs

12345

1-5. Signal Inputs and Outputs

Inputs

GENLOCK IN 1.0 V p-p, 75 Z

TC IN 0.5 V to 18 V p-p, 10 kZ

MIC IN : XLR 3-pin, female

2

1

3

<External View>

Pin No. Signal Specification

1 MIC IN (G) _60 dBu High

2 MIC IN (X)

impedance balance

3 MIC IN (Y)

(0 dBu=0.775 Vrms)

DC IN : XLR 4-pin, male

4

1

3

2

Outputs

TEST OUT 1.0 V p-p, 75 Z, unbalanced

TC OUT 1.0 V p-p, 75 Z

VIDEO OUT 1.0 V p-p, 75 Z, unbalanced

EARPHONE

_∞ to _18 dBu, adjustable, 8 Z

AUDIO IN CH1/CH2 : XLR 3-pin, female

2

1

3

<External View>

Pin No. Signal Specification

1 LINE/MIC IN (G)

2 LINE/MIC IN (X)

+4 dBu/_60 dBu High

impedance balance

3 LINE/MIC IN (Y)

(0 dBu=0.775 Vrms)

BATT IN : 5-pin, male

<External View>

Pin No. Signal Specification

1 GND

2 _

3 _

4 EXT DC IN DC 11 to 17 V

DC OUT 12V : DIN 4-pin, female

4

1

2

3

<External View>

Pin No. Signal Specification

1 UNREG GND

2 _

3 _

4 UNREG +12 V OUT 0.1 A MAX

<External View>

Pin No. Signal Specifications

1 BATT IN (_)

2 BATT IND IN

3 BATT REM IN

4 LIGHT CONT OUT

5 BATT IN (+) DC11 to 17 V

AUDIO OUT : XLR 5-pin, male

1

5

2

4

3

<External View>

Pin No. Signal Specifications

1 GND

2 CH1 (X) OUT 0 dBm

3 CH1 (Y) OUT

4 CH2 (X) OUT

5 CH2 (Y) OUT

(Terminated in 600 Z)

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

1-11

Page 22

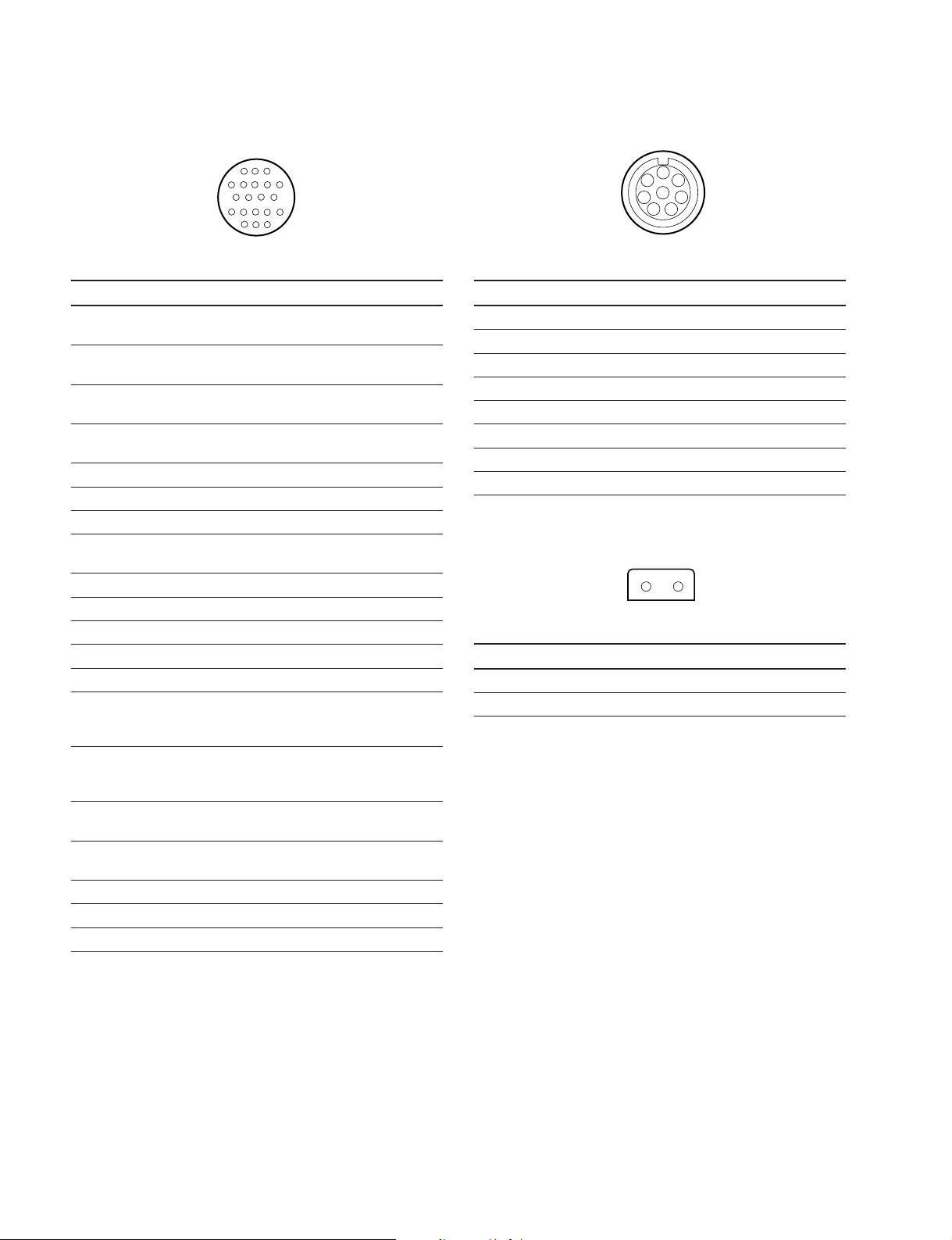

1-5. Signal Inputs and Outputs

VF : 20-pin, female

3

1

4

9

13

18

<External View>

Pin No. Signal Specifications

1 VTR SAVE OUT L : Light on,

2 ABNORMAL OUT L : Light on,

3 16:9/4:3 OUT H : NORMAL (4:3)

4 REC (L) OUT H : Light on,

5 COLOR VF DET IN H : Color, L : B/W

6 CCIR/EIA OUT H : CCIR, L : EIA

7 DISPLAY ON IN OPEN : ON, L : OFF

8 G TALLY OUT H : Light on,

9 _

10 Y (X) OUT 1 Vp-p, VF : Zi=1 kZ

11 ZEBRA ON IN H : OFF, L : ON

12 VIDEO (X) OUT 1 Vp-p, VF : Zi=1 kZ

13 AUDIO CTL IN

14 B-Y (Y) OUT 700 mVp-p,

15 R-Y (X) OUT 700 mVp-p,

16 BATT IND OUT H : Light on,

17 REC/TALLY OUT H : Light on,

18 +9.3 OUT REG +9.3 V

19 GND

20 UNREG OUT +11 V to 17 V

8

12

17

20

OPEN : Light off

OPEN : Light off

L : WIDE (16:9)

L : Light off

L : Light off

VF : Zi=1 kZ,

75% color-bars

VF : Zi=1 kZ,

75% color-bars

L : Light off

L : Light off

REMOTE : 8-pin, female

1

7

2

8

6

3

4

5

<External View>

Pin No. Signal Specifications

1 RM TX (+) OUT

2 RM TX (_) OUT

3 RM RX (+) IN

4 RM RX (_) IN

5 UNREG GND

6 UNREG +12 V OUT +11 V to 17 V

7 RM TEST (G) OUT

8 RM TEST (X) OUT 1 Vp-p, Zo=75 Z

LIGHT : 2-pin, female

2

<External View>

Pin No. Signal Specifications

1 LIGHT +12 V OUT 50 W MAX

2 GND

1

1-12

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 23

LENS: 12-pin, female

9

1

2

3

4

<External View>

Pin No. Signal Specifications

1 RET(SW) IN L : ON, OPEN : OFF

2 VTR TRIG IN L : ON

3 LENS GND

4 AUTO +5 V IN AUTO : +5 V

5 IRIS CONT OUT +3.4 V (F16) to

6 UNREG +12 V OUT +11 V to 17 V

7 IRIS POSITION IN +3.4 V (F16) to

8 REMOTE/LOCAL IN

9 EXTENDER IN EX 2 ON : 0 V

10 ZOOM POSITION IN WIDE : 2 V

11 N.C No connection

12 N.C No connection

8

10

12

7

11

6

5

MANU : 0 V or OPEN

+6.2 V (F2.8)

+6.2 V (F2.8)

EX 0.8 ON : +1.8 V

OFF : +4.8 V

TELE : 7 V

1-5. Signal Inputs and Outputs

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

1-13

Page 24

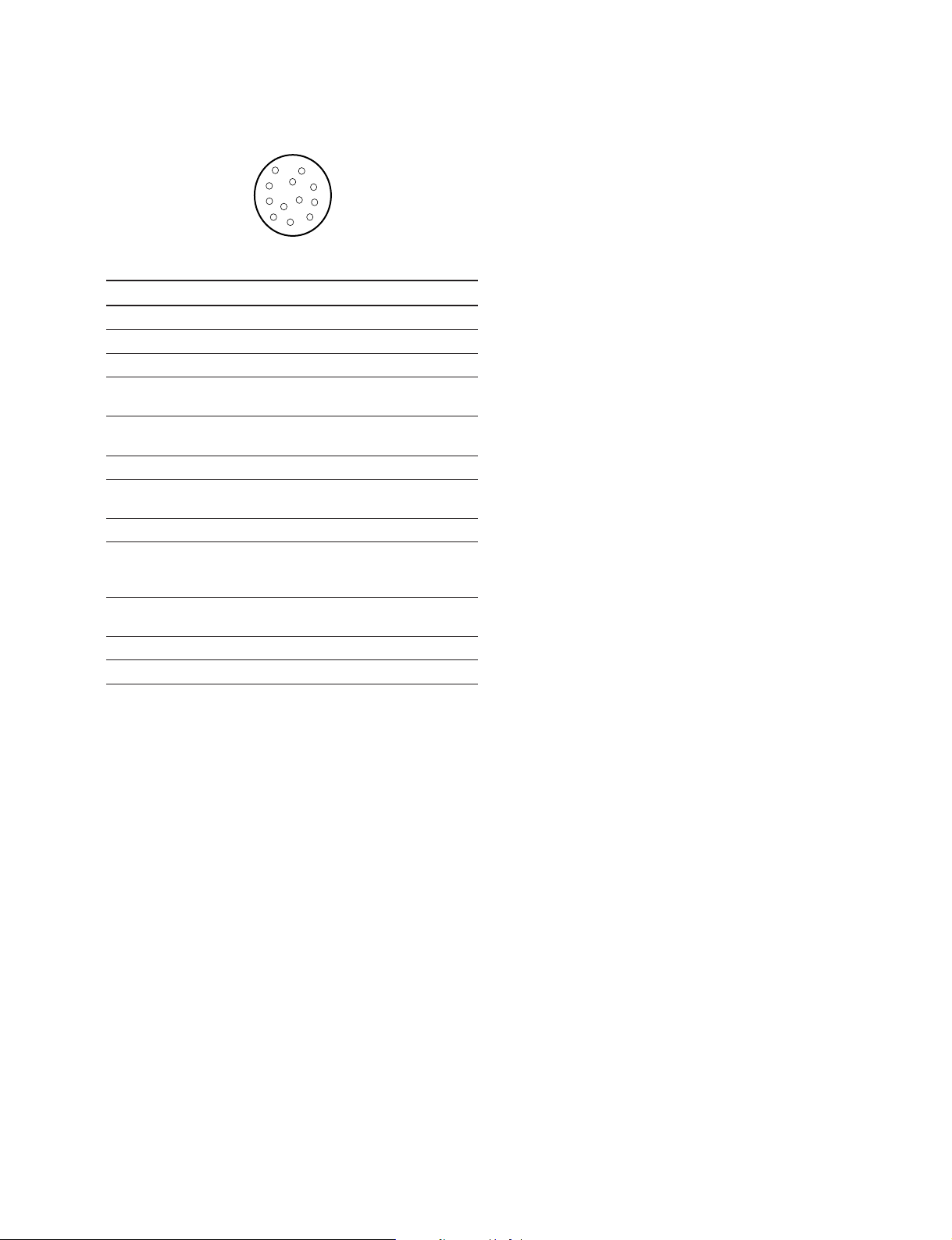

1-6. Removing/Reinstalling Outside Panel

1-6.

Removing/Reinstalling Outside Panel

Removing

n

Be sure to turn off the power, and then disconnect the

power cord and/or battery before performing the following

steps. If not, damage to internal circuit may result.

1. Fully loosen the left screw (with drop-safe) of the front

lid.

2. Fully loosen the four screws of the outside panel to

remove the panel.

Front lid

Outside panel

Reinstalling

1. Sliding the hook of the outside panel onto the guide

shaft of the cassette compartment, install the outside

panel.

2. Fasten the screws of the outside panel.

n

Tightening Torque : 140 x 10

_2

N.m {14.3 kgf.cm}

Screws

(with drop-safe)

Screws (with drop-safe)

Screws

(with drop-safe)

Guide shaft of the

cassette compartment

Screws (with drop-safe)

Hook of the outside panel

1-14

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 25

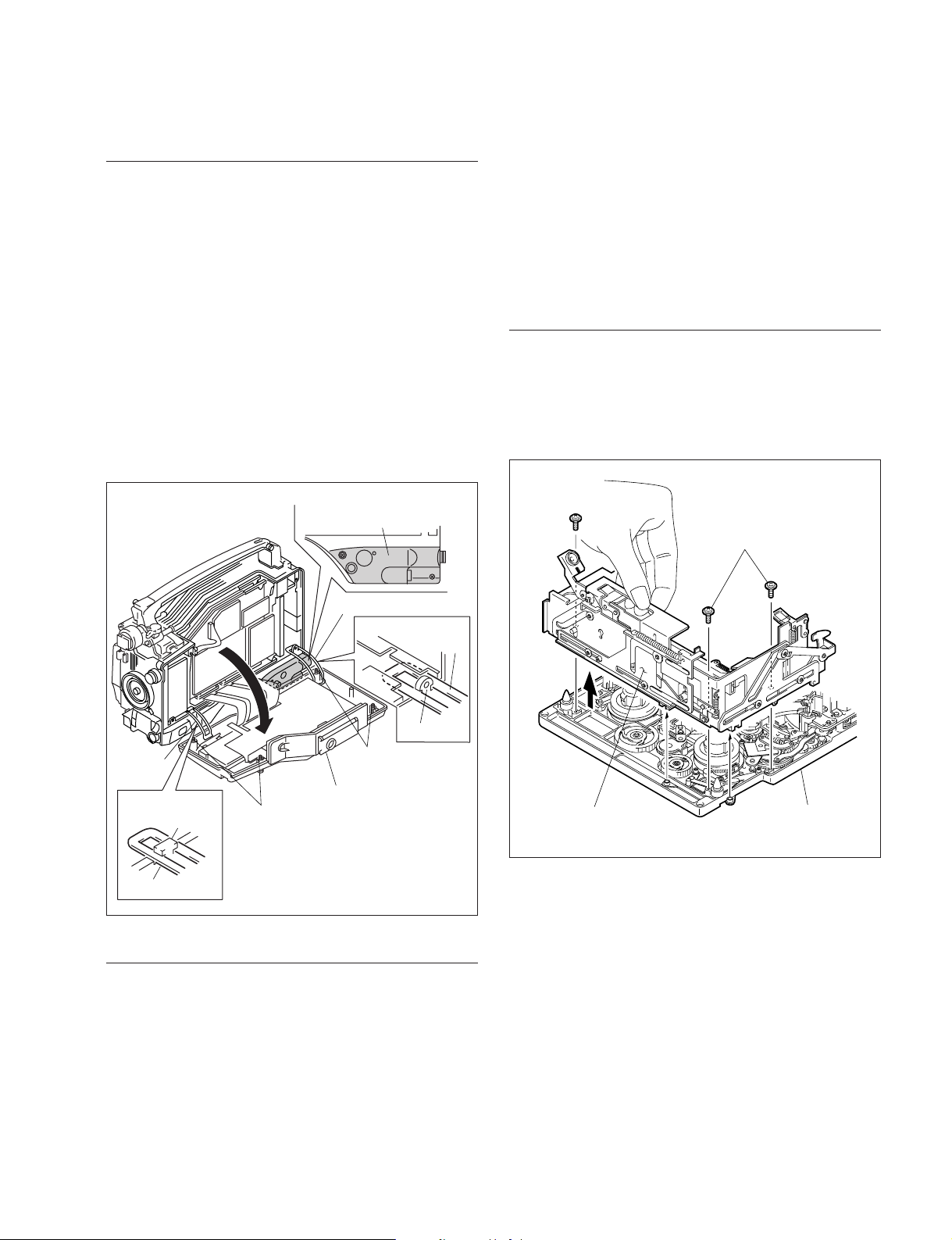

1-8. Removing/Reinstalling Cassette Compartment

1-7. Opening/Closing Inside Panel

1-7. Opening/Closing Inside Panel

Opening

m

. To avoid damage to internal circuit, be sure to turn off

the power, and then disconnect the power cord and/or

battery before following the steps below.

. To protect the connector box from a damage by rubbing

against the hinge, slip in a sheet of paper between the

box and hinge when opening the inside panel.

1. Fully loosen the four screws (with drop-safe), and then

open the inside panel in the direction of the arrow.

n

Be careful not to bend the flexible wires connected to

the TC-101 board intentionally.

Cover here

(with a sheet of paper).

1-8. Removing/Reinstalling Cassette

Compartment

m

. To avoid damage to internal circuit, be sure to turn off

the power, and then disconnect the power cord and/or

battery before following the steps below.

. The cassette compartment is removable in either of up or

down position.

Removing

1. Remove the outside panel. (Refer to Section 1-6.)

2. Remove the three screws of the cassette compartment.

3. Grasp the cassette compartment by the portion shown

in the figure and lift it out.

Screws

(

M 1.4x2.5

)

Screws

(

M 1.4x2.5

)

Hinge (R)

Closing (step 1)

Hinge (R)

Hook

Hinge (F)

Closing (step 1)

Hook

Hinge (F)

Screws

(with drop-safe)

Screws

(with drop-safe)

Inside panel

Closing

1. Ensure that the hinges (F) and (R) are properly hitched

on the hooks of chassis.

2. Close the inside panel, and then fasten the four screws

(with drop-safe) to install the panel.

m

. Tightening Torque : 140 x 10

_2

N.m {14.3 kgf.cm}

. Be careful not to pinch harnesses between the inside

panel and chassis.

Cassette compartment

Mechanical deck

assembly

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

1-15

Page 26

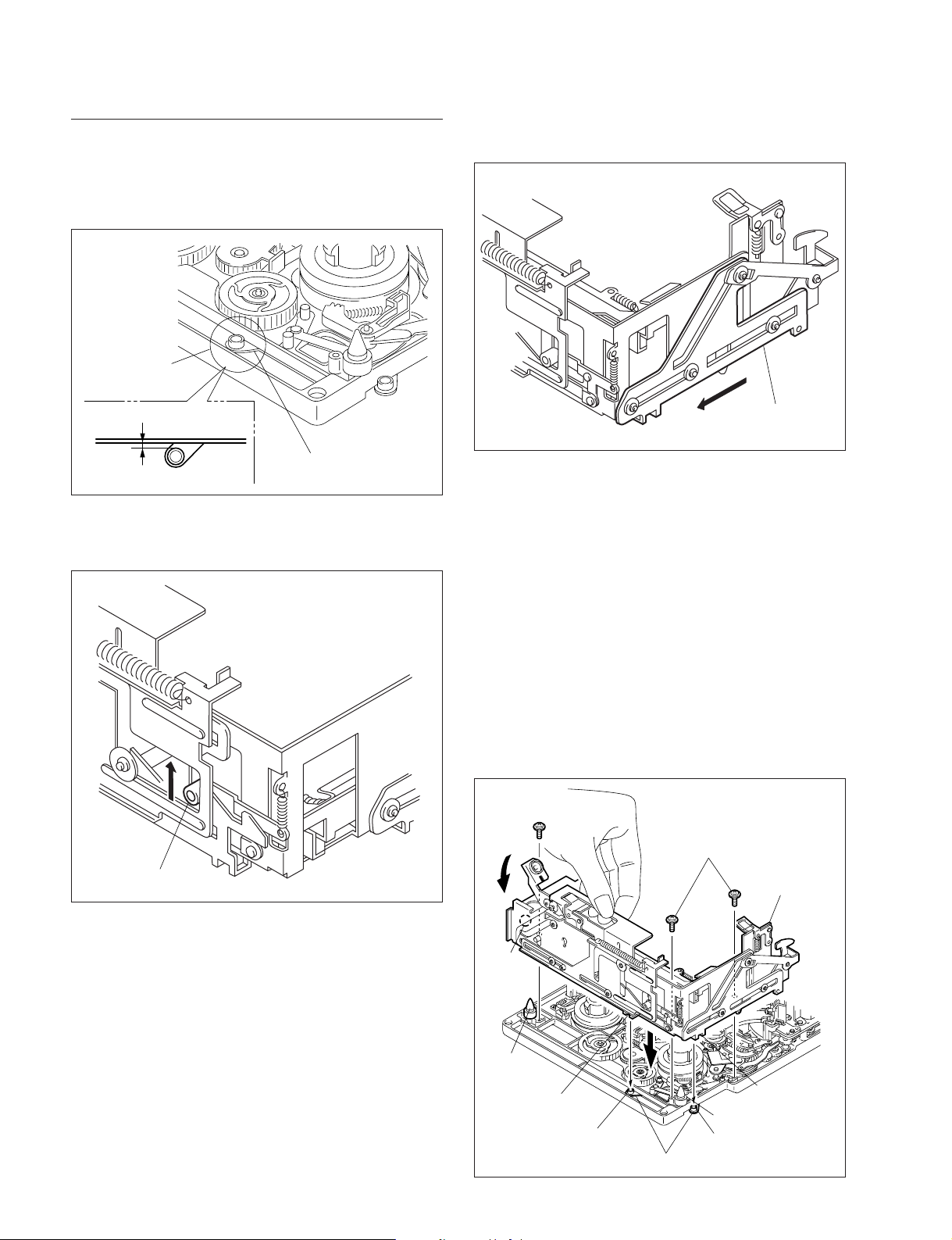

1-8. Removing/Reinstalling Cassette Compartment

Reinstalling

1. To create a clearance of 0.5 mm between the white

roller of joint arm and the end face of mechanical

deck, adjust the position of the joint arm.

Roller (white)

End face of mechanical deck

0.5 mm

Outside surface of roller

Joint arm

2. Slide the white lock-roller of cassette compartment in

an upward direction.

3. Slide the cam plate (A) on the right of the cassette

compartment all the way of the arrow until it stops.

Cam plate (A)

4. Grasp the cassette compartment by the portion shown

in the figure and set it on the stage to insert the two

cassette-guide-pins onto the round hole of the stage.

Check that the other white-roller of joint arm positioned in step 1 is put in the notch of the cam plate (A)

on the right side.

5. Push down the lever of the cassette compartment and

check to see that the stage smoothly moves up and

down. If not moved smoothly, recheck the steps 1

through 4.

6. Fasten the cassette compartment using the three

screws.

n

Tightening Torque : 9 x 10

_2

N.m {0.9 kgf.cm}

Lock-roller (white)

1-16

Screw

(

M 1.4x2.5

Lever

Round

hole of

the stage

Cassetteguide-pin

Notch

White-roller in step 1

)

Screws

Joint arm

(

M 1.4x2.5

)

Stage

Notch of the

cam plate (A)

Cassette-guide-pin

Other white-roller

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 27

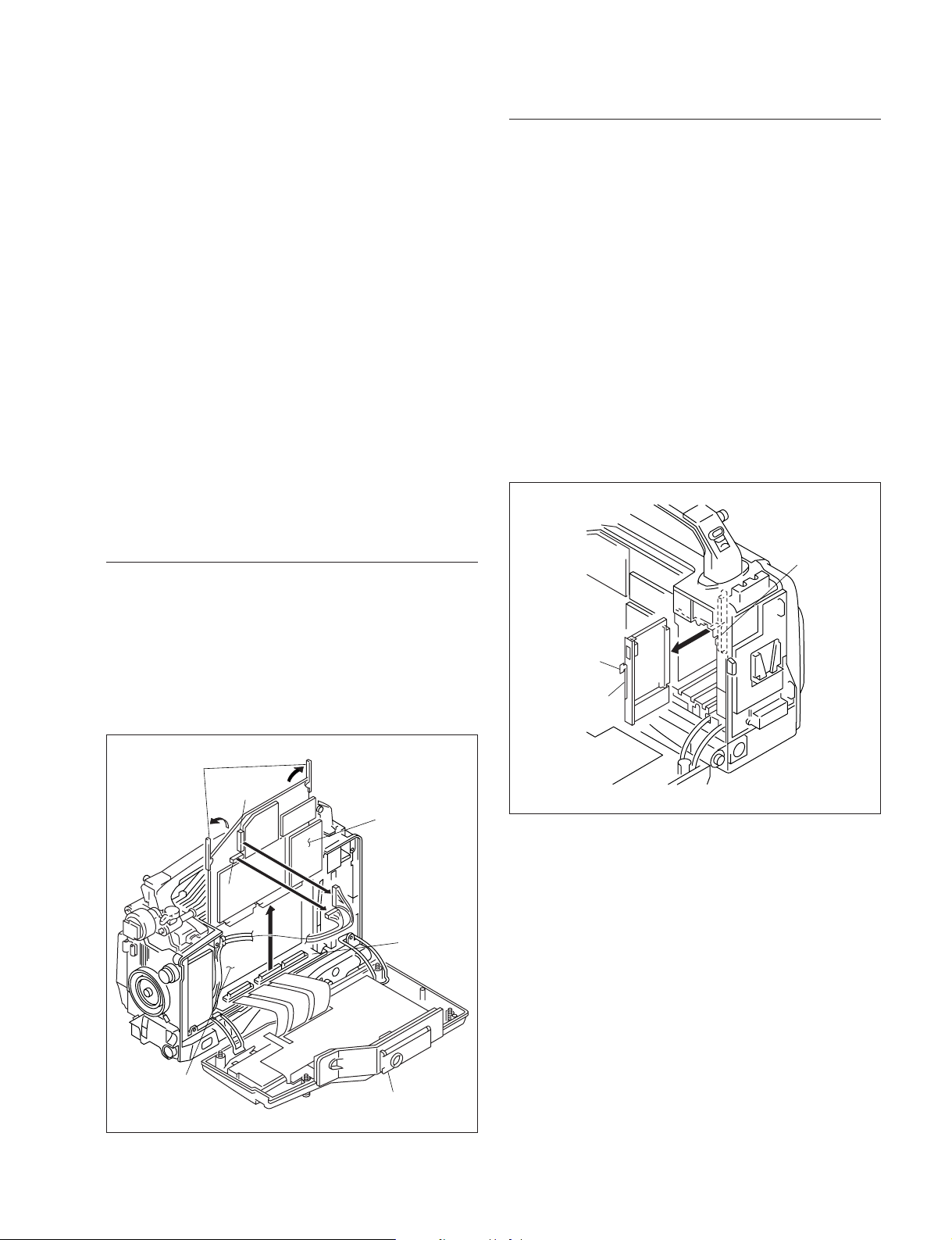

1-9. Removing/Reinstalling Plug-in Boards

1-9.

Removing/Reinstalling Plug-in Boards

Be careful not to damage the board and to position and

orient the board correctly when removing/reinstalling the

plug-in boards.

1-9-1. DCP/DVP Board Assembly

m

. When replacing the board, set the switches on the new

board.

DCP-17 board : Refer to Section 1-10-3.

DVP-17 board : Refer to Section 1-10-4.

. After replacing the board, see the Maintenance Manual

Part 2 Vol.1 and perform adjustments as follows :

DCP-17 board : Sec. 7. Camera System Electrical

Alignment

DVP-17 board : Sec. 6-5. Video System Adjustment

(Automatic Equalizer Adjustment and

REC Current Adjustment)

Removing

Reinstalling

1. Stay opens the levers of the board in advance.

2. Insert the DCP or DVP board assembly along the

board guide rails.

3. After the shafts of levers get into the chassis, close the

levers and press in the board to firmly connect it to the

connector of the MB-810 board.

4. Reconnect the harnesses to the connectors CN12 and

CN13 on the DCP board assembly.

1-9-2. SV-210 Board

1. Open the inside panel. (Refer to Section 1-7.)

2. Grasp the board by the pull ring and pull it out to

disconnect the SV-210 board from the connectors of

MB-811 board.

MB-811 board

1. Open the inside panel. (Refer to Section 1-7.)

2. Remove the harnesses from the connectors CN12 and

CN13 on the DCP board assembly.

3. Open the levers to disconnect the DCP or DVP board

assembly from the connectors on the MB-810 board.

4. Lift the DCP or DVP board assembly out.

Levers

CN12

DCP board

assembly

CN13

MB-810

board

Pull ring

SV-210 board

DVP board

assembly

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Inside panel

1-17

Page 28

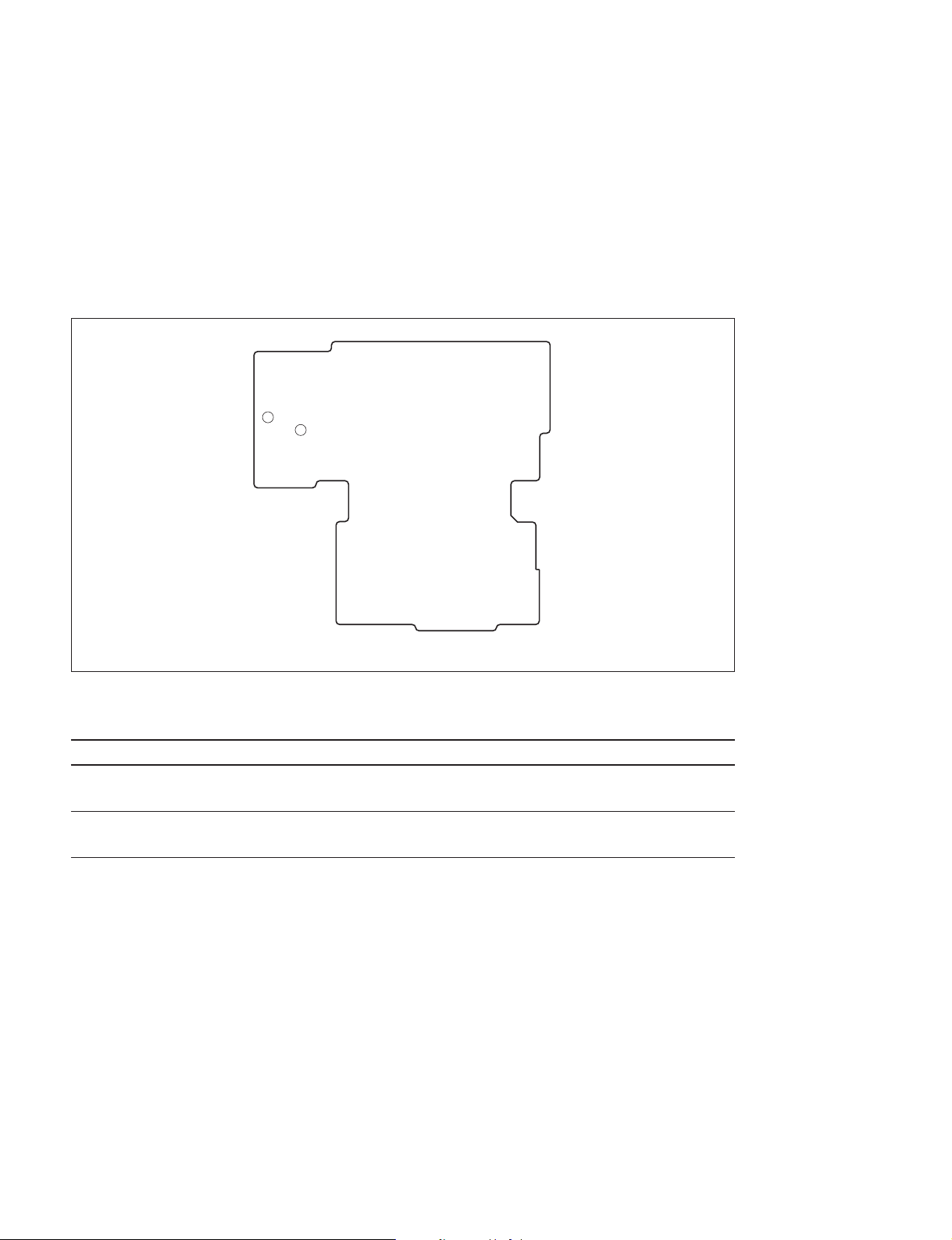

1-10. Switch/Slit Land Settings and LED Functions on the Boards

1-10. Switch/Slit Land Settings and LED Functions on the Boards

As for the external-switch settings, see Section “2. Locations and Functions of the Parts and Controls” in

the Operation Manual.

n

Never change the settings of switches specified “Factory use”.

1-10-1. AXM-21 Board

SL301

SL300

AXM-21 B side

Slit Lands

Ref. No. Name Description Factory setting

SL300 AUDIO OUT Select OPEN : Output from the XLR 5-pin connector OPEN

SHORT : Output from the XLR 3-pin connector

SL301 AUDIO OUT Select OPEN : Output from the XLR 3-pin connector

SHORT : Output from the XLR 5-pin connector

*1 : If the AUDIO OUT connector (XLR 5-pin) is converted to XLR 3-pin connectors, set the slit lands as specified above. (The XLR 3-pin

connectors are not supplied. Ready them separately.)

*2 : This slit land is short-circuited by the traces on the board. Therefore, the traces must be cut using a knife when the setting is

changed.

*1

*1

SHORT

*2

1-18

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 29

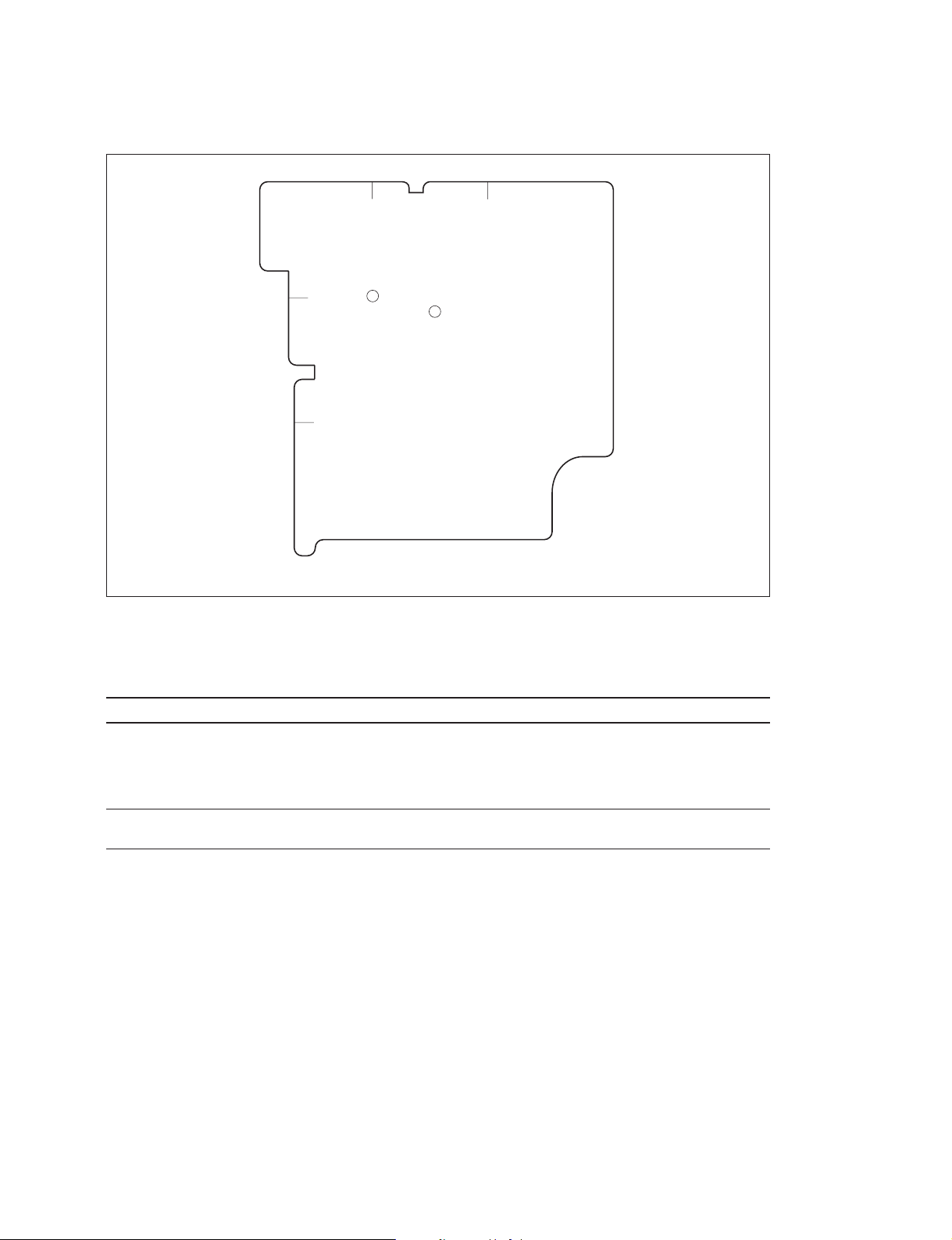

1-10-2. CNB-11 Board

1-10. Switch/Slit Land Settings and LED Functions on the Boards

A

1

SL1

2

3

BC

SL401

CNB-11 A side

Slit Lands

n

Set SL1 according to the destination when replacing the board.

Ref. No. Description Factory setting

SL1 Selects how the power is derived when the battery and external power supply OPEN

SL401 Destination Select OPEN : For the area except Japan

are used simultaneously :

OPEN : Always derived power from the external power supply.

SHORT : Automatically derived power from either of the battery or external

power supply which is in higher input-voltage.

OPEN (for except Japan)

SHORT : For Japan SHORT (for Japan)

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

1-19

Page 30

1-10. Switch/Slit Land Settings and LED Functions on the Boards

1-10-3. DCP-17 Board

S1

EDC

B

A

S4

DCP-17 B side

F

1

2

3

4

5

6

Switches

Ref. No. Name Description Factory

setting

S1 ENG Disable Select Switching ON/OFF of engineer mode OFF

S4-1 SVC Enable Select Switching ON/OFF of service mode OFF

S4-2 _ Factory use OFF

S4-3 VF CAM Select Output signal selection when the OUTPUT/DCC switch OFF

S4-4 CA Mode Function selection of the VTR START button OFF

S4-5 to 7 _ Not used OFF

S4-8 Data reset ON : Resets the setting menu when the power is OFF

ON : Disables

OFF : Enables

ON : Enables

OFF : Disables

is set to BARS

ON : Outputs the camera signal on the viewfinder.

OFF : Outputs the color bars signal on the viewfinder.

ON : Uses the VTR START button as the RET 2 button.

(The VTR SAVE/STBY switch is used as the

INCOM TALK ON button.)

OFF : Uses the VTR START button as the INCOM TALK

ON button.

turned on.

OFF : Not resets. (under normal use)

1-20

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 31

1-10-4. DVP-17 Board

1-10. Switch/Slit Land Settings and LED Functions on the Boards

DE FGHJ

C

B

A

DVP-17 A side

S20

K

1

2

3

4

5

6

7

8

9

K

1

2

D22

3

4

5

6

7

8

9

DVP-17 B side

Switches

n

Set the switches S20-7 and S20-8 according to your own unit when replacing the board.

Ref.No. Name Description Factory setting

S20-1 to 2 _ Factory use OFF

S20-3 _ Not used OFF

S20-4 EQ Adjust Mode Set this switch to ON when adjusting OFF

S20-5 to 6 _ Factory use OFF

S20-7 Model Select OFF : DVW-707/707P OFF (for DVW-707/707P)

S20-8 N/P Select OFF : NTSC OFF (for NTSC)

equalizer and REC current.

ON : DVW-790WS/790WSP/ ON (for DVW-790WS/790WSP/

709WS/709WSP 709WS/709WSP)

ON : PAL ON (for PAL)

DEFGHJ

C

B

A

LED

Ref.No. Name Description Always

D22 _ Not used OFF

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

1-21

Page 32

1-10. Switch/Slit Land Settings and LED Functions on the Boards

1-10-5. HN-260 Board

S4

1

2

A BCD

D7

1

S1-1

D8

S1-2

S2

2

S3

D10

D11

D12

A BCD

D13

HN-260 A side HN-260 B side

Switches

Ref.No. Name Description Factory setting

S1-1 ADJ Switching ON/OFF of the adjustment mode OFF

S1-2 TRK

S2 SET Execution of the automatic servo adjustment _

S3 NUMBER Selection of the automatic servo adjustment _

S4 REC HEAD PB SEL Selection of NORMAL REC or REC HEAD PB (TEST) REC

Switching ON/OFF of the tracking adjustment by tracking VR OFF

(Refer to the Maintenance Manual Part 2 Vol.1,

Sec.6 Servo System Adjustment.)

(Refer to the Maintenance Manual Part 2 Vol.1,

Sec.6 Servo System Adjustment.)

LEDs

Ref. No. Name Description Normal state

D7 _ Lights when S1-1 is turned on. OFF

D8 _ Lights when S1-2 is turned on. OFF

D10 _ Lights when the tape is slacked. OFF

D11 _ Lights when the S1-1 is turned on OFF

D10 to D13 _ Indicates the status of the automatic servo adjustment. OFF

Lights when the S1-1 is turned on

(in the automatic servo adjustment mode).

(in the PG adjustment mode).

(Refer to the Maintenance Manual Part 2 Vol.1,

Sec. 6 Servo System Adjustment.)

1-22

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 33

1-10-6. TC-101 Board

1-10. Switch/Slit Land Settings and LED Functions on the Boards

S602

C

S601

S603

S802

3

4

5

BA

1

2

E

D825

S106

D824

D

S101

S107

TC-101 B side

Switches

Ref. No. Name Description Factory setting

S101 CH-1 Front MIC Enables to control the audio level of the AUDIO IN OFF

S106 CH-2 Limiter Switching ON/OFF of CH-2 Limiter OFF

S107 CH-1 Limiter Switching ON/OFF of CH-1 Limiter OFF

S601 CUE ONLY Factory use OFF

S602 CH-1 Output Limiter Switching ON/OFF of CH-1 Output Limiter ON

S603 CH-2 Output Limiter Switching ON/OFF of CH-2 Output Limiter ON

S802-1 NTSC/PAL SEL NP Select OFF (for NTSC)

S802-2 _ Factory use OFF

LEVEL Control CH-1 connector on the rear input with MIC LEVEL

volume of the front panel.

ON : Enables.

OFF : Disables.

(The CUE tone is output to AUDIO OUT all the time

during playback.)

(+10 dB limit)

(+10 dB limit)

OFF : NTSC ON (for PAL)

ON : PAL

Slit Lands

All the slit lands on the TC-101 board are “Factory use”. Never change the settings.

(Factory setting : OPEN)

LEDs

Ref. No. Name Description Always

D824 _ Factory use OFF

D825 _ Factory use OFF

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

1-23

Page 34

1-10. Switch/Slit Land Settings and LED Functions on the Boards

1-10-7. TG-207 Board (for DVW-790WS/790WSP/709WS/709WSP only)

BC

S1

S2

TG-207 B side

A

1

2

Switches

n

When replacing the board, set the S2 according to your own unit.

Ref. No. Name Description Factory setting

S1 Model Select 4:3 (No DVW Model) 16:9

S2 Model Select FIT : DVW-790WS/790WSP FIT : (For DVW-790WS/790WSP)

16:9 (DVW-790WS/790WSP/

709WS/709WSP)

IT : DVW-709WS/709WSP IT : (For DVW-709WS/709WSP)

1-24

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 35

1-10-8. DIF-75 Board (BKDW-702)

1-10. Switch/Slit Land Settings and LED Functions on the Boards

A

1

2

3

BC D

DIF-75 B side

E

S1

Switches

Ref. No. Name Description Factory setting

S1-1 VCO ADJ Set to ON in the free-running adjustment. OFF

S1-2 _ Reserved OFF

LEDs

Ref. No. Name Description Normal state

D7 _ Lights when S1-1 is turned on. OFF

D8 _ Lights when S1-2 is turned on. OFF

D10 _ Lights when the tape is slacked. OFF

Lights when the S1-1 is turned on

(in the automatic servo adjustment mode).

D11 _ Lights when the S1-1 is turned on OFF

(in the PG adjustment mode).

D10 to D13 _ Indicates the status of the automatic servo adjustment. OFF

(Refer to the Maintenance Manual Part 2 Vol.1,

Sec. 6 Servo System Adjustment.)

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

1-25

Page 36

1-11. Ejecting the Cassette Tape Manually

1-11.

Ejecting the Cassette Tape Manually

n

To avoid damage to internal circuit, be sure to turn off the

power, and then disconnect the power cord and/or battery

before following the steps below.

1. Open the ME cover of the outside panel in the direction of the arrow.

2. Press in the gear and turn it counterclockwise with a

Philips screwdriver while pressing the gear in.

n

Check that the tape is taken up the cassette reel while

turning the gear.

3. Turn the gear until the front lid opens, and then eject

the cassette tape.

m

. Never turn the gear no further after the front lid opened.

If the gear is turned moreover, gear phase will be out of

order, and the operation timing of the cleaning roller will

be shifted.

When adjusting the phase of the gear, refer to Section

“4-2-12. Timing Belt (Threading) Replacement” of the

Maintenance Manual Part 2 Vol.1.

. Closing the front lid

If the gear is turned moreover after the front lid opened,

the front lid cannot be closed and locked. To close the

front lid, turn on the power and close the lid.

If the front lid cannot be opened by turning the gear :

1. Remove the outside panel. (Refer to Section 1-6.)

2. Put the cassette compartment into the up position as

the cassette lid of the cassette tape opened.

(As for the moving up the cassette compartment, refer

to Section 1-8.)

3. Being careful not to damage the tape, eject the cassette

tape.

Front lid

Outside

panel

Gear

Turn while pressing

(counterclockwise)

ME cover

1-26

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 37

1-12. Inserting the Cassette Tape With Outside Panel Removed

1-13. Cleaning When the Heads are Clogged

1-12. Inserting the Cassette Tape With

Outside Panel Removed

1. Put the cassette compartment into the up position.

(Refer to Section 1-8.)

2. Insert the cassette tape into the cassette compartment.

3. Insert a screwdriver blade into the hole of the cassette

compartment, and then slide it in the direction of the

arrow until it locks to put the cassette compartment

into the down position.

n

To avoid deformation of the lid arm (L), never press the lid

arm (L) to put the cassette compartment into the down

position.

If the lid arm (L) is deformed, the front lid will not be

locked when installing the outside panel.

Lid arm (L)

(Do not use now.)

Screwdriver

1-13. Cleaning When the Heads are

Clogged

If the video heads are clogged, firstly clean them with a

cleaning tape as following “Cleaning by a Cleaning Tape”.

If it does not help, see Section “6. Cleaning” and clean

them with a cleaning cloth.

Cleaning by a Cleaning Tape

Tool

. Cleaning Tape BCT-D12CL

n

Be sure to use the cleaning tape BCT-D12CL.

The use of other cleaning tape may cause unusual wearing

or damage of the video heads.

1. Insert the cleaning tape BCT-D12CL into the unit.

2. Press the PLAY button to start the head cleaning.

3. After the five seconds, press the EJECT button to eject

the cleaning tape.

n

To avoid damage to the video heads, be sure to take

the cleaning tape out after cleaning.

4. Check to see that the head clog is clear.

Hole

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Cassette compartment

1-27

Page 38

1-14. Fixtures and Adjustment Equipment 1-15. Battery for Memory Backup 1-16. Replacing the DC-DC Converter

1-14.

Fixtures and Adjustment Equipment

As for the required fixtures and adjustment equipment for

the maintenance of this unit, refer to Section “1-1. Fixtures

and Adjustment Equipment” in the Maintenance Manual

Part 2 Vol.1.

1-15. Battery for Memory Backup

c

When replacing the battery, ensure that the battery is

installed with “+” and “_” poles connected to the correct

terminals.

An improper connection may cause an explosion or

leakage of fluid.

The unit is equipped with a battery (BT801) for the

memory backup on the TC-101 board. When replacing, be

sure to use the specified part.

Ref. No. : BT801 (B-2/TC-101 board)

Description : CR-2450 (lithium-ion battery)

Part No. : 1-528-229-11

Recommended Replacement Period : Every five years

1-16. Replacing the DC-DC Converter

1. Remove the outside panel. (Refer to Section 1-6.)

2. Disconnect the DC-DC converter from the connector

of the MB-811 board to remove it.

MB-811 board

DC-DC converter

The memory IC stores the data such as date and time.

If the backup battery is dead or replaced, these data are all

cleared.

See Section “4-10. VTR Menu Display in the Display

Panel” in the Operation Manual to reset the data.

1-28

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 39

2-1. Error Code

Section 2

Diagnostics

OVER EMPH OVER

V

H

PEAK dB

0

10

20

30

40

21

Error code

Warning indicators

DIAG PB VITC NDF EXT-LK HOLD

H MIN SEC FRM

TAPE

EB

BATT

EF

RF SERVO HUMID SLACK

Display panel

2-1-1. Warning Indicators

The warning indicator on the display panel lights if any fault occurs during the power-on sequence or

normal operation. And the tally indicator on the viewfinder, back tally and warning indicators blink at the

same time.

RF : Lights if video heads are clogged

SERVO : Lights if the servo fails

Lights if the communication error is occurred between system control IC (DVP-13 board)

and servo IC (SV-210 board)

HUMID : Lights if there is condensation in the unit

SLACK : Lights if the tape is not winding properly or the following troubles

(shown in “Section 2-1-2”) are occurred

2-1-2. Error Codes

When “SLACK” of the warning indicator lights, error causes and its operating status are displayed on the

display panel.

E-XXX

MODE

0: POWER ON

1: REC

2: REC PAUSE

3: THREAD

4: UNTHREAD

5: STOP

8: PLAY

9:FF

A: REW

b: REC REVIEW

C: CUE UP

E: FF SEARCH

F: REW SEARCH

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

ERROR CAUSE

10:Drum drive voltage abnormality

11:Detects no drum FG

12:Detects no drum PG

20:Capstan drive voltage abnormality

21:Detects no capstan FG-A

22:Detects no capstan FG-B

23:Capstan rotation abnormality in forward

and reverse directions

24:Capstan speed abnormality (high speed)

32:Detects no S reel FG

42:Detects no T reel FG

61:Fuction cam rotation overtime in the forward

direction

62:Fuction cam rotation overtime in the reverse

direction

63:Tape top sensor overtime

64:Full top sensor overtime

65:End sensor overtime

70:Servo NVRAM checksum error

71:Communication error between servo CPUs

2-1

Page 40

2-2. Error Messages

2-3. Display Panel and Lamp Operation Check

2-2. Error Messages

The error message is superimposed on the viewfinder screen if any fault occurs during the power-on

sequence or normal operation.

Error message Operation Remedy

STORED DATA:NG Blinks on the viewfinder screen during the The white and/or black balance memory data

CAM? Displayed during the power-on sequence or A fault has been detected in the camera

VTR? Displayed during the power-on sequence or A fault (HUMID or SLACK) has been detected

power-on sequence have been lost. Adjust the white and black

balance again

normal operation Contact your local Sony Sales Office/

Service Center

normal operation in the VTR

Check the warning indicators on the display

panel

2-3. Display Panel and Lamp Operation Check

The display panel and all lamps can be checked for all on and all off using the VTR (DIAG) menu of the

unit.

Refer to Section “3-2. VTR (DIAG) menu” for details of the VTR (DIAG) menu. Perform the check as

follows.

1 Select the page DIAG-8 of the DIAG menu (VF screen : VTR MENU-12 page).

2 Check all on and all off of the display panel and the following lamps.

Every pressing of the SHIFT button toggles between all on and all off. It also toggles between the

messages “ALL OFF” and “ALL ON” on the VF screen.

. REW button

. F. FWD button

. PLAY button

. WARNING lamp (on side of display panel)

. Tally lamp (VF)

. Camera-man tally lamp (VF)

. Back tally lamp (VF)

. Rear tally lamp (rear panel)

. Green tally lamp (in VF)

. TALLY/REC lamp (in VF)

. BATT lamp (in VF)

. “!” (error status warning) lamp (in VF)

. Spare lamp (in VF)

. VTR SAVE lamp (in VF)

2-2

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 41

2-4. Displaying the Servo Adjustment Data

2-4. Displaying the Servo Adjustment Data

The servo adjustment data can be displayed, using the VTR menu of the unit. (It can not be displayed on

the DIAG menu.)

Refer to Section “3-2. VTR (DIAG) menu” for details of the VTR menu. Display the servo adjustment

data as follows.

1. Select the page VTR MENU-13 of the VTR menu.

VF screen

VTR MENU-13

SERVO MEMORY

1. CAP FREE SP

2. PG PHASE-1

3. PG PHASE-2

4. CFGA DUTY

5. CFGB DUTY

6. EDIT DELAY

7. SLACK

XXXX XXXX XXXX XXXX

XX

XX

XX

XX

XX

XX

1. Displays the capstan free speed adjustment data

2. Displays the low-order bit of drum PG phase adjustment data

3. Displays the high-order bit of drum PG phase adjustment data

If the most significant bit is “0” in binary, the PG phase adjustment

data including high and low-order bits ranges from 0 to 255. if it is

“1”, the PG phase adjustment data range from 256 to 511

4. Displays the capstan FGA offset adjustment data

5. Displays the capstan FGB offset adjustment data

6. Displays the delay adjustment data during back-space editing

7. Slack information (Refer to Section 2-5.)

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

2-3

Page 42

2-5. Displaying the Slack Information in the Past

2-5. Displaying the Slack Information in the Past

The slack information indicating a maximum of four slacks that have occurred in the past, can be displayed, using the VTR (DIAG) menu of the unit.

Refer to Section “3-2. VTR (DIAG) menu” for details of the VTR (DIAG) menu. Display the slack

information as follows.

1 Select the page DIAG-9 of the DIAG menu (VF screen : VTR MENU-13 page, 7. SLACK).

2 Select the SLACK DATA 1 to SLACK DATA 4. (The SLACK DATA 1 is the newest information.)

Display panel

9X XXXX

STATE CODE

TROUBLE CODE

1. SLACK DATA 1

2. SLACK DATA 2

3. SLACK DATA 3

4. SLACK DATA 4

VF screen

VTR MENU-13

SERVO MEMORY

1. CAP FREE SP

2. PG PHASE-1

3. PG PHASE-2

4. CFGA DUTY

5. CFGB DUTY

6. EDIT DELAY

7. SLACK

XXXX XXXX XXXX XXXX

SLACK

DATA

1234

XX

XX

XX

XX

XX

XX

Contents of slack trouble

code

10 : Abnormal drum drive voltage

11 : No drum FG output

12 : No drum PG output

20 : Abnormal capstan drive

voltage

21 : No capstan FG-A output

22 : No capstan FG-B output

Abnormal forward/reverse

23 :

rotation of capstan

24 : Abnormal capstan speed

(high-speed)

32 : No S reel FG output

42 : No T reel FG output

61 : Time over the forward

rotation time of function cam

62 : Time over the reverse

rotation time of function cam

63 : Time over the tape top

sensor

64 : Time over the full top sensor

65 : Time over the end sensor

time

70 : Servo NVRAM checksum

error

71 : Communication error

between servo CPUs

Contents of slack state code

00 : Power-on initialization

1x : No cassette and standby state

2x : Record

3x : Stop

4x : FF/REW

5x : Playback

6x : REC PAUSE

7x : REC REVIEW

8x : Threading/unthreading

2-4

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 43

Section 3

Setup Menu

This section describes details of the engineer mode of the setup menu that is displayed on the viewfinder.

It also describes the VTR (DIAG) menu that is displayed inside the display panel.

3-1. Engineer Mode (Setup Menu)

When you enter the engineer mode of the setup menu, the engineer-oriented menu appears. Using the

engineer-oriented menu, selection of user mode, various setting up and camera system adjustment can be

executed.

Data structure of the setup menu is described as shown below.

Setup values of the setup menu = Fixed data (absolute value) + Service mode setup value (relative value)

+ Engineer mode setup value (relative value) + User mode setup value (relative value)

Setup values of the setup menu

(adjustment value)

User mode data (relative value)

Engineer mode data (relative value)

Service mode data (relative value)

Fixed data (absolute value)

Stored in setup card

Default data when shipped

from factory

. When the MENU/ON/OFF switch is set to ON after turning on the main power, the camcorder enters

the user mode. When you enter the user mode, the page that is selected by the MENU SELECT page of

the engineer mode, and the items that are registered in the camera-man menu registration mode are

displayed in a maximum of five pages. (Refer to the operation manual for details of the user mode and

of the camera-man menu registration mode.)

. When an item is adjusted in the engineer mode, value of this item in the user mode is reset to 0.

. When a setup data is written in a setup card, the setup value in the user mode and the setup value is the

engineer mode are stored separately.

. Refer to the Maintenance Manual, Part 2, Volume 1, Section 2 for details of the service mode.

. When a remote control RM-B150/P9 is selected and the camcorder is operated externally from the

remote control, there are some items that cannot be changed of their setup or some items to which setup

data is not reflected correctly. Refer to Section “3-1-2 Setup Menu List” for more details.

How to Enter the Engineer Mode

1. Turn off the main power.

2. While pressing the rotary encoder, turn ON the POWER switch.

n

If you cannot enter the engineer mode, check the switch setting of the DCP-17 board for the following.

S4-1 → OFF

S1 → OFF

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

3-1

Page 44

3-1. Engineer Mode (Setup Menu)

3-1-1. Fundamental Operation of the Setup Menu

Switch description

MENU ON/OFF/PAGE

switch

ON

GAIN

VTR

CANCEL/PRST

OFF

ON

PAGE ITEM

MENU

POWER

OUTPUT

WHITE BAL

ASSIGNABLE

OFF

Rotary encoder

1. MENU ON/OFF/PAGE switch

The MENU ON/OFF/PAGE switch is used to display the setup menu or to switch the display items in

units of page. When lid is closed, the MENU ON/OFF/PAGE switch is automatically set to the OFF

position.

MENU CANCEL/PRST/ITEM

switch

ON : Displays the setup menu.

OFF : Exits from the setup menu.

PAGE : Selects another page of the setup menu

2. MENU CANCEL/PRST/ITEM switch

The MENU CANCEL/PRST/ITEM switch is used to select the desired item or to cancel setting or to

recover the default setting when the MENU ON/OFF/PAGE switch is ON.

CANCEL/PRST : Cancels the already executed setting, or returns to the default setting.

ITEM : Selects the desired item.

3. Rotary encoder

Rotate: Moves to another page or to another item, or to change the setup value.

Press: Sets the page, or enters the setup value modification mode.

Operation (Using the MENU switch)

1. Set the MENU ON/OFF/PAGE switch to ON position.

2. To move to another page, set the MENU ON/OFF/PAGE switch to PAGE. (Moves to the next page

every time when this switch is set.)

3. To move to another item, set the MENU CANCEL/PRST/ITEM switch to ITEM. (The cursor

moves to the next item every time when this switch is set.)

Press the rotary encoder to enter the setup value modification mode.

4. Rotate the rotary encoder to modify the setup value.

5. To exit from the setup menu, turn OFF the MENU ON/OFF/PAGE switch.

Operation (Using the rotary encoder)

1. Set the MENU ON/OFF/PAGE switch to ON position.

2. To move to another page, rotate the rotary encoder. (A page is set by pressing the rotary encoder.)

3. To move to another item, rotate the rotary encoder. (An item is set by pressing the rotary encoder.)

Press the rotary encoder to enter the setup value modification mode.

4. To modify the setup value, rotate the rotary encoder .

5. To exit from the setup menu, turn OFF the MENU ON/OFF/PAGE switch.

3-2

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 45

3-1. Engineer Mode (Setup Menu)

3-1-2. Contents of Setup Menu

This section describes details of the menu (including the engineer-oriented menu) that appears when the engineer mode is

selected.

(Values in square [|] of the Setup column indicate the default value when shipped from factory.)

No. Page Item Setup Description

1 MARKER 1/3 SAFETY ZONE [ON]/OFF Sets the safety zone marker display to ON or OFF.

SAFETY AREA 80%/ 90% /100% Sets the safety zone area to 80 %, 90 % or 100 %.

CENTER ON/[OFF] Sets the center marker display to ON to OFF.

CENTER H X ([0]) Moves the center marker horizontally.

CENTER V X ([0]) Moves the center marker vertically.

2 MARKER 2/3 BOX CURSOR ON/[OFF] Sets the box cursor display to ON or OFF.

Note : The box cursor does not appear in the following cases.

The WIDE SCREEN page BOX/4:3/14:9 LIMIT is set to

any other item than BOX.

The WIDE SCREEN page BOX/4:3/14:9 MODE is set to

4:3, while the VF ASPECT is set to 16:9A or 16:9B.

BOX WIDTH X ([0]) Changes the width of the box cursor.

BOX HEIGHT X ([0]) Changes the height of the box cursor.

BOX H X ([0]) Moves the box cursor horizontally.

BOX V X ([0]) Moves the box cursor vertically.

3 MARKER 3/3 TEST OUT MIX ON/[OFF]

RET MIX ON/[OFF]

TEST OUT VF DISP ON/[OFF]

TEST OUT MENU ON/[OFF] Turns ON/OFF the function of outputting the menu to TEST OUT

RM VF MENU INH. [ON]/OFF ON : The menu is not displayed even through the MENU switch

4 VF DISP 1/2 DISP MODE 1/2/[3] Set the display mode. (For details, refer to the Operation Manual.)

EXTENDER [ON]/OFF Sets the extender display to ON or OFF.

ZOOM [ON]/OFF Sets the zoom position display to ON or OFF.

5 VF DISP 2/2 FILTER [ON]/OFF Sets the filter display to ON or OFF.

WHITE [ON]/OFF Sets the white balance display to ON or OFF.

GAIN [ON]/OFF Sets the gain selection value display to ON or OFF.

SHUTTER [ON]/OFF Sets the shutter speed/mode display to ON or OFF.

TAPE [ON]/OFF Sets the tape remaining display to ON or OFF.

AUDIO [ON]/OFF Sets the CH-1 audio level display to ON or OFF.

IRIS [ON]/OFF Sets the iris value display to ON or OFF.

Turns ON/OFF the function of outputting the VF marker to TEST OUT.

Turns ON/OFF the function of mixing the VF marker with return video.

Turns ON/OFF the function of outputting the character to TEST OUT

where the character is displayed on VF when the VF DISPLAY

switch is set to ON.

where the menu is displayed on VF when the MENU ON/OFF/PAGE

switch is set to ON.

Note :

When an RM is connected, the menu is forced to be outputted

regardless of this menu setting.

is set to ON when an RM is connected.

OFF : The menu is displayed when the MENU switch is set to ON

even though an RM is connected.

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

3-3

Page 46

3-1. Engineer Mode (Setup Menu)

No. Page Item Setup Description

6 MASTER GAIN LOW _3/[0]/3/6/9/12/18/ Sets the gain corresponding to the LOW, MIDDLE, HIGH and

24/30/36/42/48 dB TURBO positions of the GAIN selector switch.

MID _3/0/3/6/[9]/12/18/ Note : When the gain selection value is changed, the BLACK SET

24/30/36/42/48 dB adjustment is required.

HIGH _3/0/3/6/9/12/[18]/

24/30/36/42/48 dB

TURBO _3/0/3/6/9/12/18/

24/30/36/[42]/48 dB

7 SHOT ID ID-1 Shot ID setting (ID1 to ID4)

ID-2 Sets the shot ID of a maximum of twelve characters using

ID-3

alphanumeric character, symbol, and space.

ID-4

8 SHOT DISP Selects the shot data to be super-imposed on color-bar signal.

DATE ON/[OFF] Date

TIME ON/[OFF] Time

MODEL NAME ON/[OFF] Model name

SERIAL NO. ON/[OFF] Serial No.

CASSTTE NO. ON/[OFF] Cassette No.

SHOT NO. ON/[OFF] Shot No.

ID SELECT [OFF]/ID1/ID2/ The shot ID number that is selected by the SHOT ID page.

ID3/ID4

9 SHUTTER The shutter mode/speed setting that can be selected by the

SHUTTER switch, etc.

EVS [ON]/OFF

Turns ON/OFF the EVS mode. (DVW-709WS/709WSP/707/707P)

Turns ON/OFF the super EVS (Enhanced vertical definition) mode.

(DVW-790WS/790WSP)

CLS [ON]/OFF Turns ON/OFF the CLS (clear scan) mode.

(DVW-709WS/709WSP/707/707P)

Turns ON/OFF the ECS (extended clear scan) mode.

(DVW-790WS/790WSP)

1/100 (NTSC) [ON]/OFF Shutter speed 1/100 (for NTSC) or 1/60 (for PAL) second in the

1/60 (PAL) standard mode

1/125 [ON]/OFF Shutter speed 1/125 second in the standard mode

1/250 [ON]/OFF Shutter speed 1/250 second in the standard mode

1/500 [ON]/OFF Shutter speed 1/500 second in the standard mode

1/1000 [ON]/OFF Shutter speed 1/1000 second in the standard mode

1/2000 [ON]/OFF Shutter speed 1/2000 second in the standard mode

10 !’ LED OFF : The “!” lamp of VF does not turn on.

ON : The “!” lamp of VF turns on when the following conditions

are satisfied.

MASTER GAIN [ON]/OFF The GAIN value is set to any value other than 0 dB.

SHUTTER ON [ON]/OFF The SHUTTER switch is set to ON.

WHITE PRESET ON/[OFF] The WHITE BAL switch is set to PRST.

ATW RUN ON/[OFF] The ATW (automatic tracing white balance) is operating.

EXTENDER ON [ON]/OFF Lens extender is being used.

FILTER 2,3,4 ON/[OFF] Filter is set to any position other than 1.

FILTER A,C,D ON/[OFF] Filter is set to any position other than B.

(DVW-790WS/790WSP/709WS/709WSP only)

A.IRIS OVERRIDE ON/[OFF] Reference value of the automatic iris control is et to any value

other than the standard value.

3-4

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

Page 47

3-1. Engineer Mode (Setup Menu)

No. Page Item Setup Description

11 SETUP CARD READ (→CAM) To be executed by Reads data from the setup card.

pressing the rotary

encoder.

WRITE (→CARD) To be executed by Writes data to the setup card

pressing the rotary

encoder.

ID EDIT The card ID can be set within ten characters using alphanumeric

characters and symbols.

WRITE PROTECT ON/[OFF] Turns ON/OFF the write-inhibit function into the setup card.

WHITE DATA ON/[OFF] Turns ON/OFF the function of reading white balance correction

value from the setup card.

12 FUNCTION 1/2 TEST OUT [ENC]/R/G/B Selection of video signal to be output froth TEST OUT connector.

Note : R-G or B-G can be selected when R-G/B-G SEL on the

first page of OPERATION is set to ON.

DETAIL [ON]/OFF Turns ON/OFF the function of adding detail signal to video for

improving resolution power.

APERTURE [ON]/OFF Sets the aperture correction to ON or OFF.

SKIN TONE DTL ON/[OFF] Turns ON/OFF the skin tone detail function.

MATRIX ON/OFF Turns ON/OFF the linear matrix correction function.

*Default value The highly color saturation can be obtained when this item is set

OFF (J) to ON.

ON (Except J)

GAMMA [ON]/OFF Turns ON/OFF the gamma correction function.

BLACK GAMMA ON/[OFF] Turns ON/OFF the black gamma correction function.

CHROMA [ON]/OFF Turns ON/OFF the function to add chroma signal.

TEST SAW ON/[OFF] Turns ON/OFF the function to add the TEST signal to the video

signal system forcibly. (Used during the video signal adjustment.)

CROSS COLOR FLT

ON/[OFF] Turns ON/OFF the function to reduce the cross-color of video

signal. (NTSC only)

13 FUNCTION 2/2 GENLOCK [ON]/OFF Turns ON/OFF the function of synchronizing the internal reference

signal with the video signal that is input to GENLOCK IN connector.

CAM RET. ON/[OFF] Turns ON/OFF the function of displaying the return video signal

that is input to the GENLOCK IN connector, when the RET button

on the lens is set to ON.

FILTER INH. ON/[OFF] Turns ON/OFF the function of interlocking the filter with the white

balance correction value.

ON : The white balance correction value does not interlock with

the color temperature conversion filter, but is memorized in

the memory A and memory B respectively.

OFF : The white balance correction value is memorized in the

respective memories of memory A (4 memories) and

memory B (4 memories) totaling 8 memories respectively.

FIELD/FRAME [FIELD]/FRAME Sets the CCD read-out method.

FIELD : Reading out in units of field. (Normal setting)

FRAME : Reading out in units of frame.

(Used when the higher vertical resolution is desired)

Note : The FRAME reading has a more residual image than the

FIELD reading.

A.IRIS OVERRIDE ON/[OFF] Turns ON/OFF the iris override function.

When the iris override function is set to ON, reference value of the

AUTO iris adjustment can be modified by the rotary encoder when

the MENU ON/OFF/PAGE switch is set to OFF.

(continued) (5 steps: _1/2, _1/4, 0, +1/4, +1/2 steps of iris stop)

DVW-790WS/709WS/707

DVW-790WSP/709WSP/707P P1

3-5

Page 48

3-1. Engineer Mode (Setup Menu)

No. Page Item Setup Description

13 FUNCTION 2/2 DCC FUNCTION FIX/[DCC]

SEL

Selects the DCC function modes when the DCC switch is set to ON.

DCC : Normal mode

(Dynamic range is set by the DCC ADJUSTMENT page.)

FIX : Knee is corrected by the fixed dynamic range of 600%.

REAR BNC OUT [VBS]/SDI/OFF Selects the signal to be output from the rear panel VIDEO OUT

connector when the SDI output board BKDW-702 is installed.

VBS : Outputs the composite video signal.

SDI : Outputs the SDI signal.

OFF : Set to OFF when power saving is desired.

VTR MODE ON/[OFF] Set to ON when an external VTR is controlled by the VTR START

button as it is interlocked with the DVW, when an external VTR is

connected via the CA-702.

REC INHIBIT [ON]/OFF Set to OFF when the REC control is executed by the VTR START

(CCU) button even though CCU is connected via CA-705/755.