Sony DVPK-800-D Service manual

DVP-K800D

RMT-D106E

SERVICE MANUAL

• Refer to the OPERATION MANUAL (9-921-669-21) and

DVD MECHANISM OPERA TION MANUAL (9-921-669-31)

for DVD mechanism.

SPECIFICATIONS

Chinese Model

E Model

Hong kong Model

Spanish Model

Taiwan Model

MICROFILM

CD/DVD PLAYER

WARNING!!

WHEN SERVICING, DO NOT APPROACH THE LASER

EXIT WITH THE EYE TOO CLOSELY. IN CASE IT IS

NECESSARY T O CONFIRM LASER BEAM EMISSION,

BE SURE TO OBSERVE FROM A DIST ANCE OF MORE

THAN 25 cm FROM THE SURFACE OF THE OBJECTIVE

LENS ON THE OPTICAL PICK-UP BLOCK.

CAUTION:

The use of optical instrument with this product will increase eye

hazard.

CAUTION

Use of controls or adjustments or performance procedures other

than those specified herein may result in hazardous radiation

exposure.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replace-ment.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

— 2 —

T ABLE OF CONTENTS

SERVICE NOTE

1. DISK REMOVAL PROCEDURE (at POWER OFF).................... 4

2. NOTE ON MOUNTING SLED MOTOR ................................. 4

3. REPLACING OPTICAL PICK-UP ............................................... 5

3-1. Handling .......................................................................................... 5

4. NOTE ON ASSEMBLING MECHANICAL DECK.................. 6

4-1. Application of Grease ..................................................................... 6

4-2. Cleaning Spindle Motor Turntable................................................. 7

4-3. Aligning Phase of Cam Gear and Drive Gear ................................ 7

4-4. Deformation of Insulator................................................................ 7

4-5. Note on connecting OPT Harness .................................................. 7

4-6. Note on Mounting FG-43 Board .................................................... 8

4-7. Note on Mounting TK-47 Board.................................................... 8

5. EMERGENCY CODE INDICATION ........................................... 8

5-1. Users are expected to take of the followings by thermselves

--- “C” code .................................................................................... 8

5-2. Consult Sony Service --- “E” code, E : YY: ZZ ............................. 8

1. GENERAL

Getting Started

Unpacking...........................................................................................................1-1

Hooking Up the System......................................................................................1-1

Necessary Setup Before Using the Player .......................................................... 1-1

Selecting the Language for On-screen Display .................................................. 1-1

Basic Operations

Playing a DVD....................................................................................................1-2

Playing a CD/VIDEO CD .................................................................................. 1-3

Enjouing Karaoke

Using Karaoke .................................................................................................... 1-4

Reserving Karaoke .............................................................................................1-4

Additing Richness to Your Voice (Karaoke Star) ...............................................1-5

Plaing Karaoke with Any Stereo Disc (Karaoke Pon) ........................................1-5

Using the On-Screem Dosplay ........................................................................... 1-5

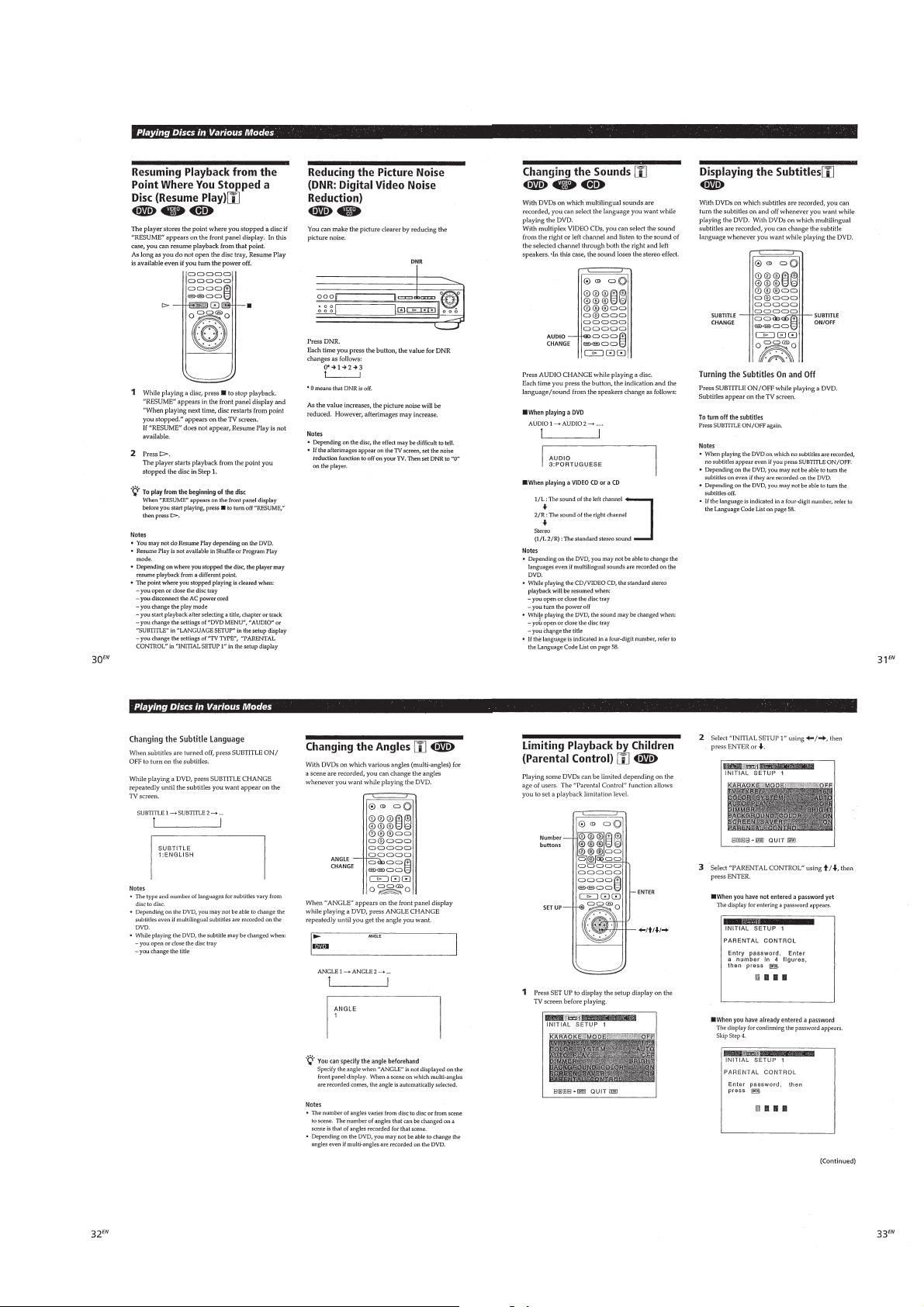

Playing Discs in Various Modes

Using the On-Screen Display ............................................................................. 1-4

Using the Front Panel Display ............................................................................1-5

Playing Repeatedly (Repeat Play) ...................................................................... 1-6

Playing in Random Order (Shuffle Play) ...........................................................1-5

Creating Your Own Program (Program Play) ..................................................... 1-6

Resuming Playback from the Point Where

You Stopped a Disc (Resume Play) ....................................................................1-7

Reducing the Picture Noise

(DNR: Digital Video Noise Reduction)..............................................................1-7

Changing the Sounds .......................................................................................... 1-7

Displaying the Subtitles......................................................................................1-7

Changing the Angles...........................................................................................1-7

Limiting Playback by Children (Parental Control) ............................................ 1-7

Controlling the TV or the amplifier with

the Supplied Remote........................................................................................... 1-8

Settings and Adjustments

Using the Setup Display ..................................................................................... 1-8

Setting the Language for Displaying and Sound (LANGUAGE SETUP) .........1-9

Settings for Display (INITIAL SETUP 1).......................................................... 1-9

Settings for Sound (INITIAL SETUP 2) ............................................................1-9

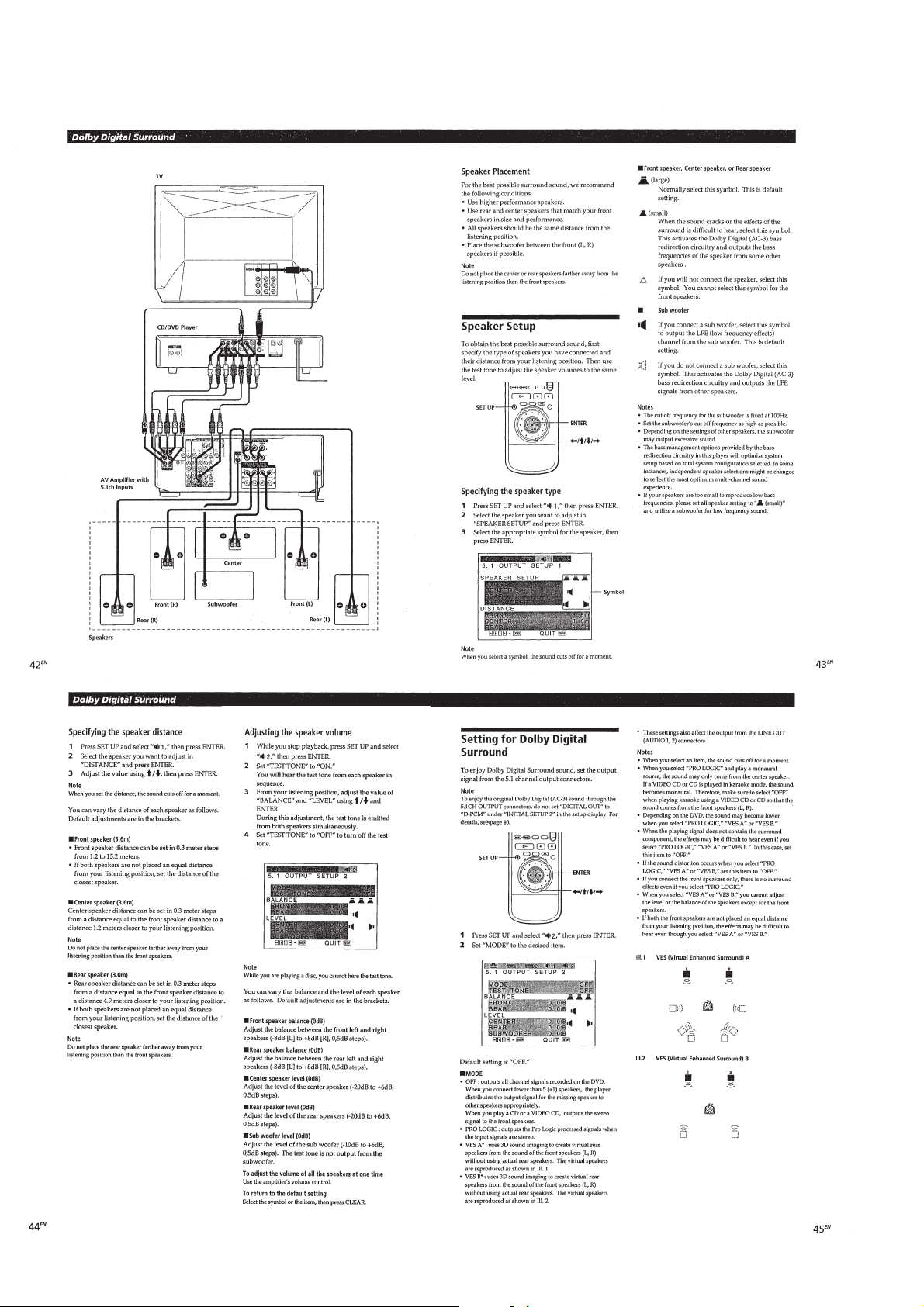

Dolby Digital Surround

What is Dolby Digital Surround? ....................................................................... 1-9

Speaker System Hookups ................................................................................... 1-9

Speaker Setup ................................................................................................... 1-10

Setting for Dolby Digital Surround .................................................................. 1-10

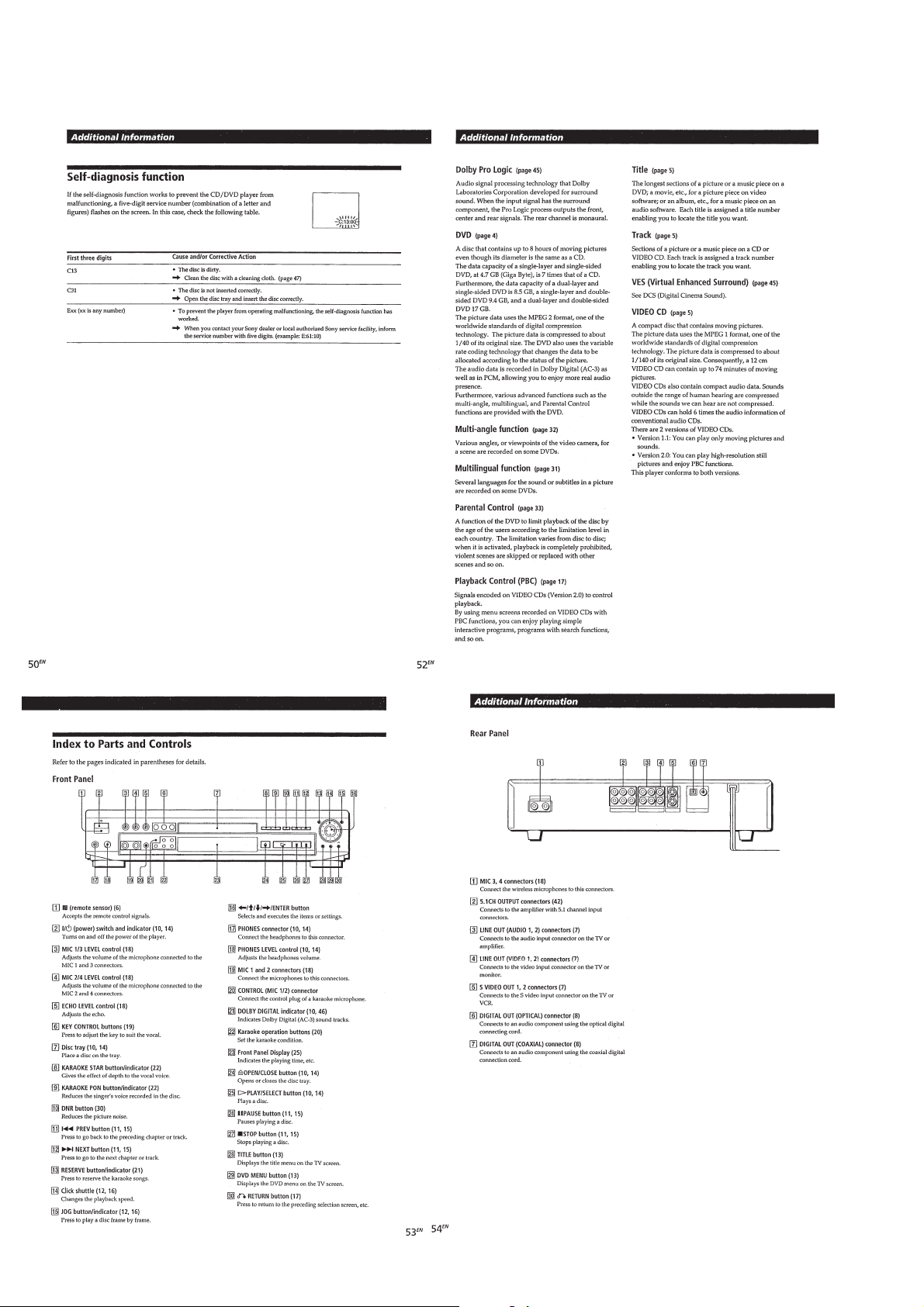

Additional Information

Precautions ....................................................................................................... 1-11

Notes on Discs .................................................................................................. 1-11

Troubleshooting................................................................................................ 1-11

Self-diagnosis Function .................................................................................... 1-12

Index to Parts and Controls ..............................................................................1-12

Setup Display Item List .................................................................................... 1-13

Language Code List.......................................................................................... 1-13

2. DISASSEMBLY

2-1. UPPER CASE ............................................................................. 2-1

2-2. FRONT PANEL BLOCK ASSEMBLY ...................................... 2-1

2-3. AU-217 BOARD ......................................................................... 2-2

2-4. MB-78 BOARD ..........................................................................2-2

2-5. KR-35 BOARD ........................................................................... 2-3

2-6. POWER BLOCK ........................................................................2-3

2-7. TK-47 BOARD ........................................................................... 2-4

2-8. HP-116 BOARD, MC-115/VR-68 BOARD BLOCK,

FL-106 BOARD, FR-156 BOARD ............................................. 2-4

2-9. CIRCUIT BOARDS LOCATION ............................................... 2-5

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM ................................................ 3-1

3-2. RF/SERVO BLOCK DIAGRAM................................................ 3-3

3-3. AUDIO BLOCK DIAGRAM ..................................................... 3-5

3-4. VIDEO BLOCK DIAGRAM...................................................... 3-7

3-5. SYSTEM CONTROL BLOCK DIAGRAM............................... 3-9

3-6. MODE CONTROL BLOCK DIAGRAM................................. 3-11

3-7. AC3 BLOCK DIAGRAM......................................................... 3-13

3-8. POWER SUPPLY BLOCK DIAGRAM ................................... 3-15

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM ...........................................4-1

4-2. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS........................................................ 4-3

• TK-47 (RF, SERVO) PRINTED WIRING BOARD ................ 4-4

• TK-47 (RF, SERVO) SCHEMATIC DIAGRAM ..................... 4-7

• MB-78 (VIDEO, SERVO/SYSTEM CONTROL, AUDIO)

PRINTED WIRING BOARD ...................................... 4-12

• MB-78 (DSP) SCHEMATIC DIAGRAM .............................. 4-17

• MB-78 (AV DECODER) SCHEMATIC DIAGRAM ............ 4-20

• MB-78 (VIDEO ENCODER) SCHEMATIC DIAGRAM ..... 4-23

• MB-78 (INTERFACE) SCHEMATIC DIAGRAM ................ 4-26

• MB-78 (MOTOR DRIVE) SCHEMATIC DIAGRAM .......... 4-29

• MB-78 (POWER SUPPLY) SCHEMATIC DIAGRAM ........4-31

• MB-78 (DIGITAL PROCESS 1)

SCHEMATIC DIAGRAM ...........................................4-33

• MB-78 (DIGITAL PROCESS 2)

SCHEMATIC DIAGRAM ...........................................4-37

• MB-78 (AC3 DECODER)

SCHEMATIC DIAGRAM ...........................................4-41

• AU-217 (VIDEO/AUDIO INPUT/OUTPUT)

SCHEMATIC DIAGRAM ...........................................4-44

• AU-217 (VIDEO/AUDIO INPUT/OUTPUT)

PRINTED WIRING BOARD ...................................... 4-47

• FL-106 (DISPLAY, OPERATION SWITCHES)

PRINTED WIRING BOARDS ....................................4-49

• FL-106 (DISPLAY, OPERATION SWITCHES)

SCHEMATIC DIAGRAM ...........................................4-51

• FG-43 (SLED MOTOR)

PRINTED WIRING BOARDS ....................................4-54

• FG-43 (SLED MOTOR)

SCHEMATIC DIAGRAMS ......................................... 4-55

• HP-116 (PHONES JACK)

PRINTED WIRING BOARDS ....................................4-56

• HP-116 (PHONES JACK)

SCHEMATIC DIAGRAMS ......................................... 4-57

• KR-35 (KARAOKE DSP/MIC 3, 4)

SCHEMATIC DIAGRAMS ......................................... 4-59

• KR-35 (KARAOKE DSP/MIC 3, 4)

PRINTED WIRING BOARDS ....................................4-61

• MIC-115 (MIC 1, 2)

SCHEMATIC DIAGRAMS ......................................... 4-63

• MIC-115 (MIC 1, 2)

PRINTED WIRING BOARDS ....................................4-65

• FR-156 (POWER SWITCH)

SCHEMATIC DIAGRAMS ......................................... 4-67

• FR-156 (POWER SWITCH)

PRINTED WIRING BOARDS ....................................4-69

• VR-68 (MIC/ECHO LEVEL)

SCHEMATIC DIAGRAMS ......................................... 4-71

• VR-68 (MIC/ECHO LEVEL)

PRINTED WIRING BOARDS ....................................4-73

• POWER BLOCK HS-930SH (SWITCHING REGULATOR)

PRINTED WIRING BOARD ...................................... 4-75

• POWER BLOCK HS-930SH (SWITCHING REGULATOR)

SCHEMATIC DIAGRAM ...........................................4-77

• POWER BLOCK HS-930SF (SWITCHING REGULATOR)

PRINTED WIRING BOARD ...................................... 4-79

• POWER BLOCK HS-930SF (SWITCHING REGULATOR)

SCHEMATIC DIAGRAM ...........................................4-81

— 3 —

5. TEST MODE

5-1. How to Enter Test Mode ............................................................. 5-1

5-2. System Control Diagnosis........................................................... 5-1

5-2-1. Selection of Check Items ............................................................ 5-2

5-2-1-1. Testing the Selected Item.......................................................... 5-2

5-2-1-2. Testing All Items....................................................................... 5-3

5-2-2. Error Display............................................................................... 5-3

5-2-3. Diagnosis Check Item List.......................................................... 5-4

5-2-4. Brief Description of Check Procedures ......................................5-5

5-2-5. Diagnosis Error Code Table ...................................................... 5-17

5-3. Drive Auto Adjustment ............................................................. 5-18

5-3-1. [0] ALL .....................................................................................5-18

5-3-2. [1] DVD Single Layer Disc....................................................... 5-19

5-3-3. [2] CD disc................................................................................ 5-20

5-3-4. [3] DVD dual layer disc ............................................................5-20

5-4. Drive Manual Operation............................................................ 5-21

5-4-1. Setup Displays In Accordance With

Selected Disc Type .................................................................... 5-21

5-4-2. Manual Control (1).................................................................... 5-22

5-4-3. Manual Control (2).................................................................... 5-22

5-4-4. Manual Control (3).................................................................... 5-23

5-4-5. Manual Adjustment (1) ............................................................. 5-24

5-4-6. Manual Adjustment (2) ............................................................. 5-25

5-4-7. Automatic Adjustment .............................................................. 5-25

5-4-8. Check ........................................................................................5-26

5-5. Mechanism Aging .................................................................... 5-27

5-6. History of Emergencies............................................................. 5-27

5-6-1. Hour Meter Display ..................................................................5-27

5-6-2. History of Emergencies Display ............................................... 5-28

5-6-3. Initialization of Emergency History .......................................... 5-28

5-7. Other Checks ............................................................................. 5-28

5-8. Appendix ................................................................................... 5-29

5-8-1. Emergency Code Table ............................................................. 5-29

5-8-2. Drive Mechanism Mode Table .................................................. 5-30

5-8-3. Disc Status Table....................................................................... 5-30

5-8-4. System Control Microprocessor Operation Mode Table........... 5-30

6. ELECTRICAL ADJUSTMENT

6-1. POWER SUPPLY CHECK (MB-78 board) ...............................6-1

6-2. LEDs, DISPLAY CHECK .......................................................... 6-1

6-3. SYSTEM CONTROL ADJUSTMENT ......................................6-2

6-3-1. 27MHz Free Run (MB-78 board) ............................................... 6-2

6-4. VIDEO SYSTEM ADJUSTMENT ............................................6-2

6-4-1. Video Level Adjustment (AU-217, MB-78 boards).................... 6-2

6-4-2. S-terminal Output Check (AU-217 board) ..................................6-2

6-4-3. Checking Composite Video Output Y (AU-217 board) .............. 6-3

6-4-4. Checking S Video Output S-C (AU-217 board).......................... 6-3

6-4-5. Checking S Video Output DC Level (AU-217 board)................. 6-3

6-5. ADJUSTMENT RELATED PARTS ARRANGEMENT ........... 6-4

7. REPAIR PARTS LIST

7-1. EXPLODED VIEWS

7-1-1. FRONT PANEL BLOCK ASSEMBLY SECTION .................... 7-1

7-1-2. CHASSIS SECTION .................................................................. 7-2

7-1-3. DVD MECHANISM CHASSIS BLOCK ASSEMBLY (1) ....... 7-3

7-1-3. DVD MECHANISM CHASSIS BLOCK ASSEMBLY (2) ....... 7-4

7-2. ELECTRICAL PARTS LIST......................................................7-5

— 4 —

DVP-K800D

A

B

⊕

Screw Driver

1

Cam gear

2

Tray

SERVICE NOTE

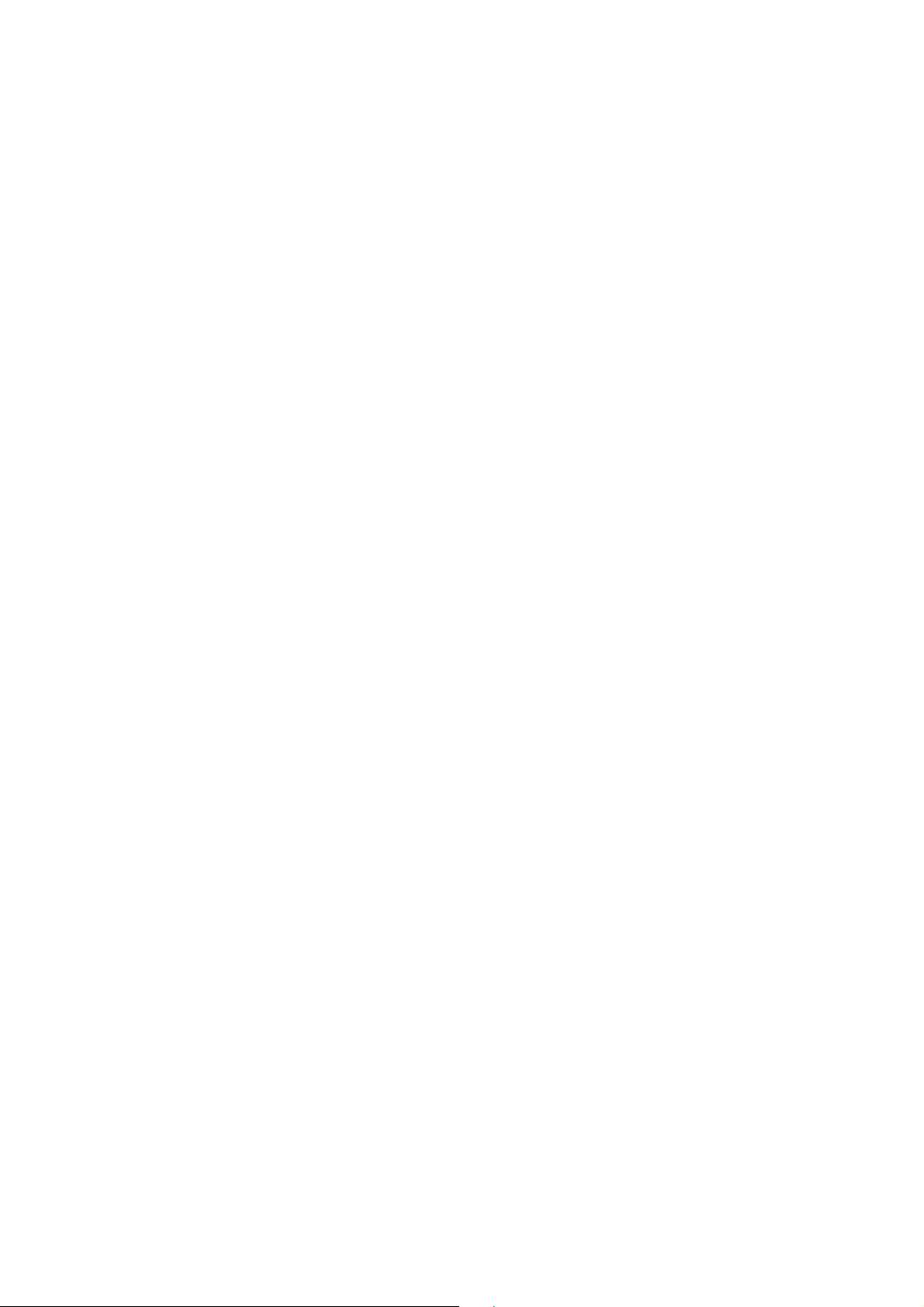

1. DISK REMOV AL PROCEDURE (at POWER OFF)

1) Insert a cross-tip screwdriver into a hole at the bottom, and rotate the cam gear 1 in direction A. (See Fig. 1)

Note: To prevent a damage of cam gear, rotate it in direction A by 1/4 turn.

2) Draw out the tray 2 in direction B by hand, and remove a disk. (See Fig. 1)

Fig. 1

2. NOTE ON MOUNTING SLED MOTOR

1) Push the sled motor assy 1 toward direction A. (See Fig. 2)

2) Tighten two screws 2 (M1.7 × 2.5).

1

Sled motor assy

2

Two screws (M1.7 × 2.5)

Fig. 2

3) Raising the MD block assy 3 90 º with the side down. confirm that the optical pick-up 4 falls by self weight. (See Fig. 3)

4) Further, with the front side of MD block assy 3 up, confirm that the optical pick-up falls by self weight.

Upper

3

MD block assy

Upper

Front side

Lower

Front side

4

Optical pick-up

Fig. 3

— 5 —

Lower

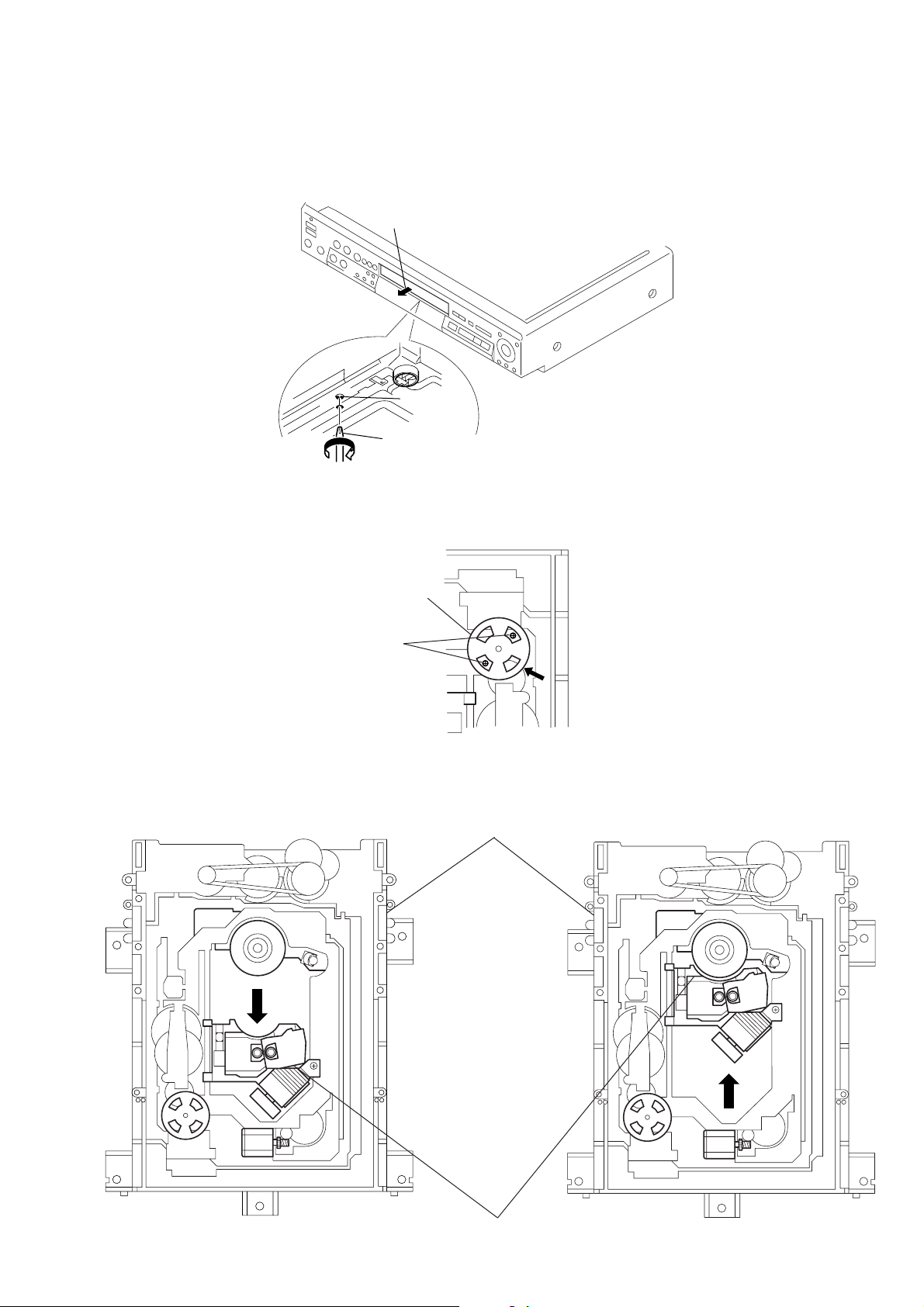

3. REPLACING OPTICAL PICK-UP

s

r

3-1. Handling

1) A red laser diode for DVD r equires more attention to static

electricity than general infrared laser diodes for CD.

Because its durability to static electricity is far weaker than

that of infrared laser diodes, always use an earth band when

handling the optical pick-up block as service parts.

2) As for the flexible board KHS-180A (RP) packed as service

parts, the short lands have been soldered to protect from static

electricity . Accordingly , remo ve solders when replacing optical

pick-up. (See Fig. 4)

DVD short land

3) In handling the KHS-180A (RP), do not touch inhibited parts

shown in Fig. 5, but grip the slide base bearing and U-shaped

guide.

Laser holder

Slide base bearing

Skew sensor

Lens actuator

covers

Objective lense

U-shaped guide

CD short land

Fig. 4 Flexible board

OEIC

Touch inhibited parts

• Objective lens

• Skew sensor

• Laser holder

• Laser coupler

• Flexible board

• OEIC

• Lens actuator covers

Flexible board

Connecto

Laser coupler

Fig. 5 KHS-180A (RP)

— 6 —

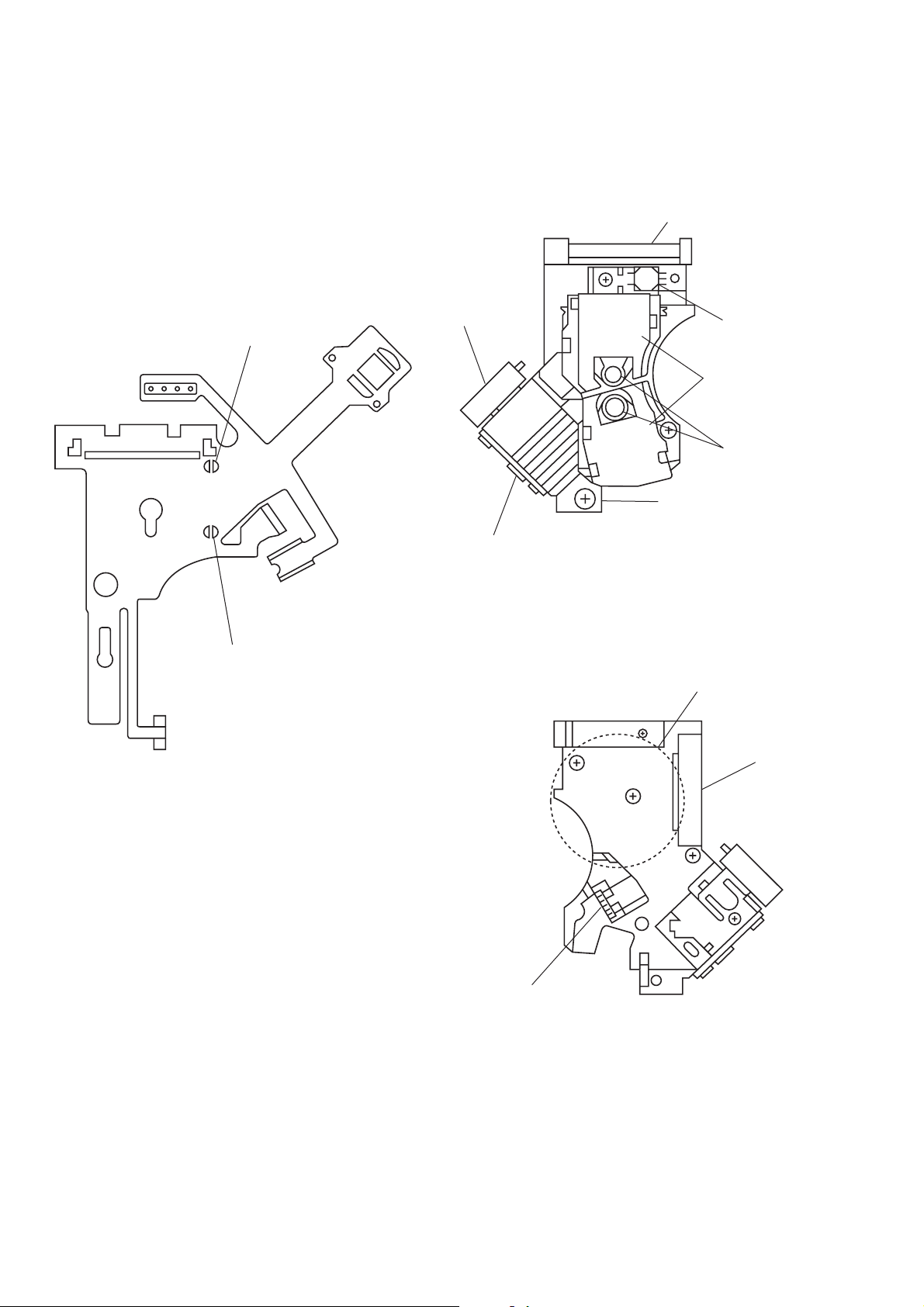

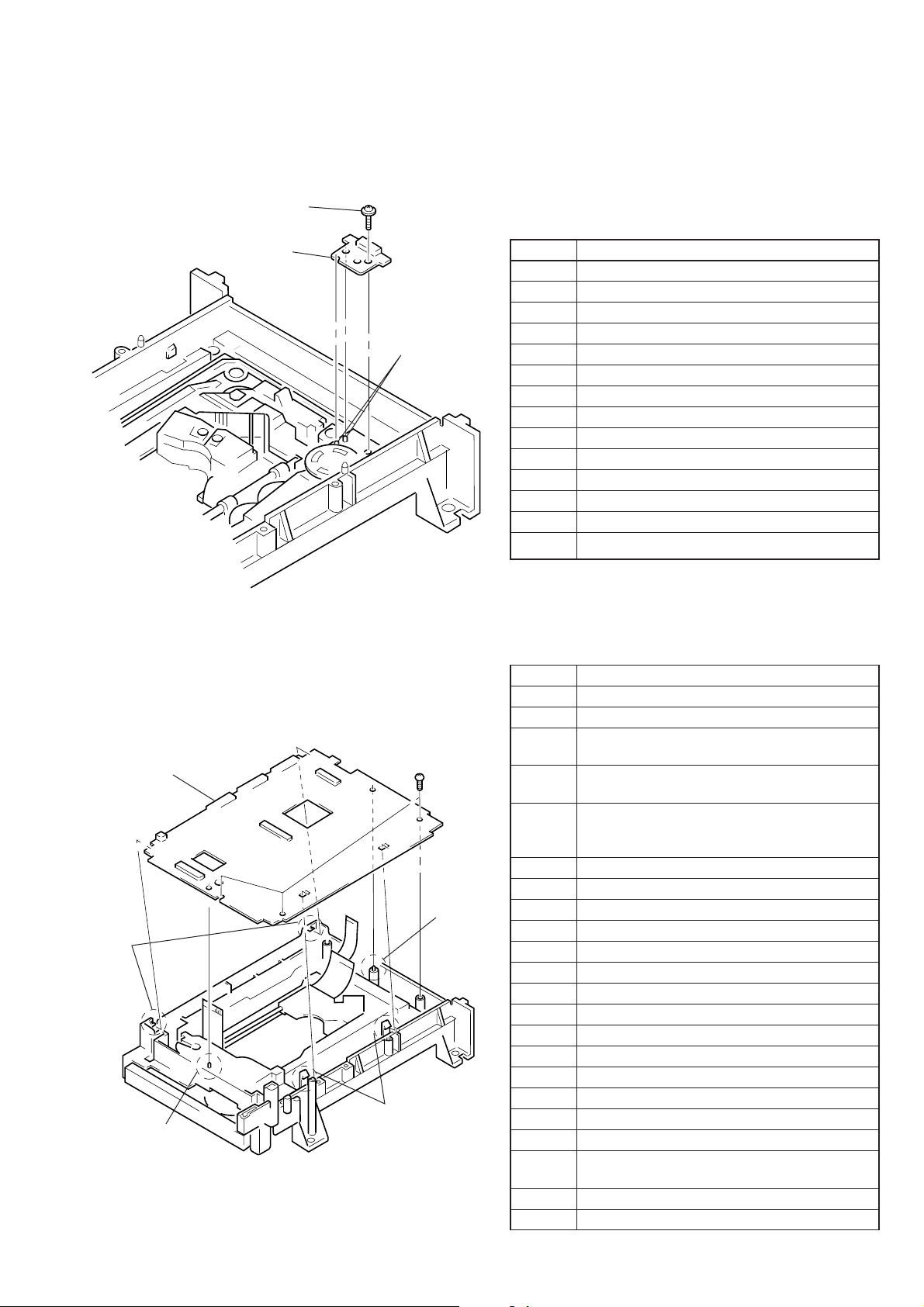

4. NOTE ON ASSEMBLING MECHANICAL DECK

4-1. Application of Grease

1) Grease must be applied if the following parts are replaced. (See Fig. 6)

Note 1: Recommended grease is Foil KG-70MP.

Note 2: In applying grease, take care not to allow grease to stick to other parts (particularly, rubber belt, spindle motor, and optical pick-up).

Base unit holder

2 bosses

Skew cam

Slide base

Tray 3 grooves

NOTE:Add grease if tray

moves slowly.

Cam gear

Loading pulley shaft

NOTE:Add grease if tray

generates noise

periodically.

Fig. 6

— 7 —

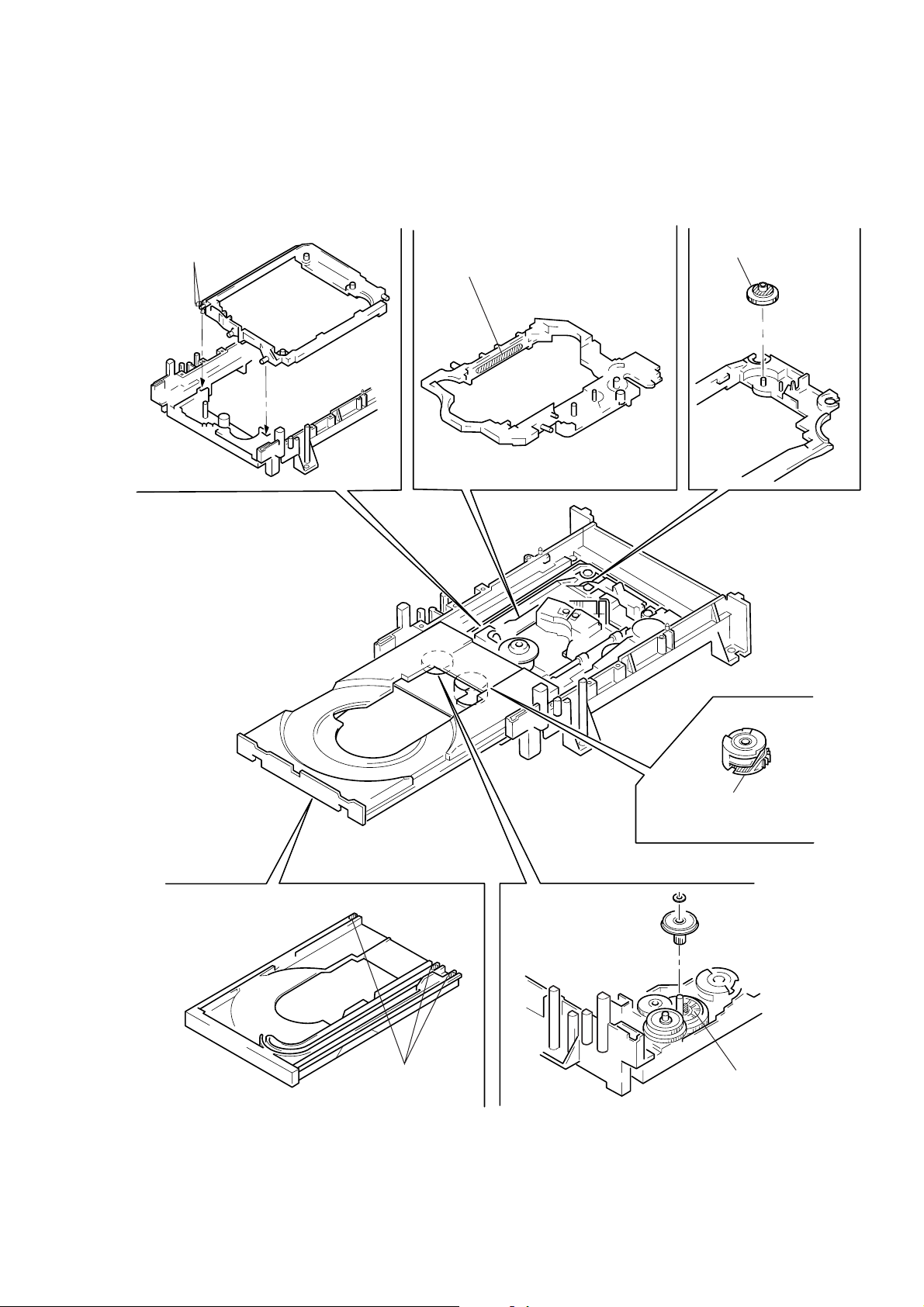

4-2. Cleaning Spindle Motor T urntable

1) Remove the tray. (Refer to 2-2)

2) Clean the spindle motor turntable if disc antiskid rubber (black)

is dirty. (See Fig.7)

Spindle motor

Turntable

4-4. Deformation of Insulator

1) Assemble the spindle base into the base unit.

2) Lock with 4 shoulder screws. (See Fig. 9)

3) Check if 4 insulators deformed. (See Fig. 9)

Four step screws

Two insulators

Fig. 7

4-3. Aligning Phase of Cam Gear and Drive Gear

1) Align triangle marks when assembling the cam gear and dri v e

gear. (See Fig. 8)

Drive gear

Align triangle marks.

Cam gear

Fig. 8

Good

Insulator

NG

Two insulators

Fig. 9

4-5. Note on Connecting OPT Harness

1) The optical pick-up could be destroyed unless the OPT harness

is connected normally to the connector. (See Fig. 10)

OPT harness

Good

Connector

NG

— 8 —

Fig. 10

4-6. Note on Mounting FG-43 Board

1) Align two bosses. (See Fig.11)

2) Fix the board securely with scre ws (PTPWH 2 × 5). (The sensor

will not function normally if the board floats up.)

Screw

(PTPWH2

FG-43 board

×

5)

Two bosses

5. EMERGENCY CODE INDICATION

5-1. Users are expected to take care of the

followings by themselves – – – – “C” code

“C : 13 : XX Clean the disc”

“C : 31 : XX Remove and insert the disc again”

XX

00

PON ready

10

Stop

20

Trace

30

Pause

40

Drvcon Unit

50

Mecha Unit

Spin Up

61

Tracking offset

62

Jitter/Gain

63

TOC/Control Data Read

60

Others

70

Spin Down

80

Seek

90

Error Recovery

Fig. 11

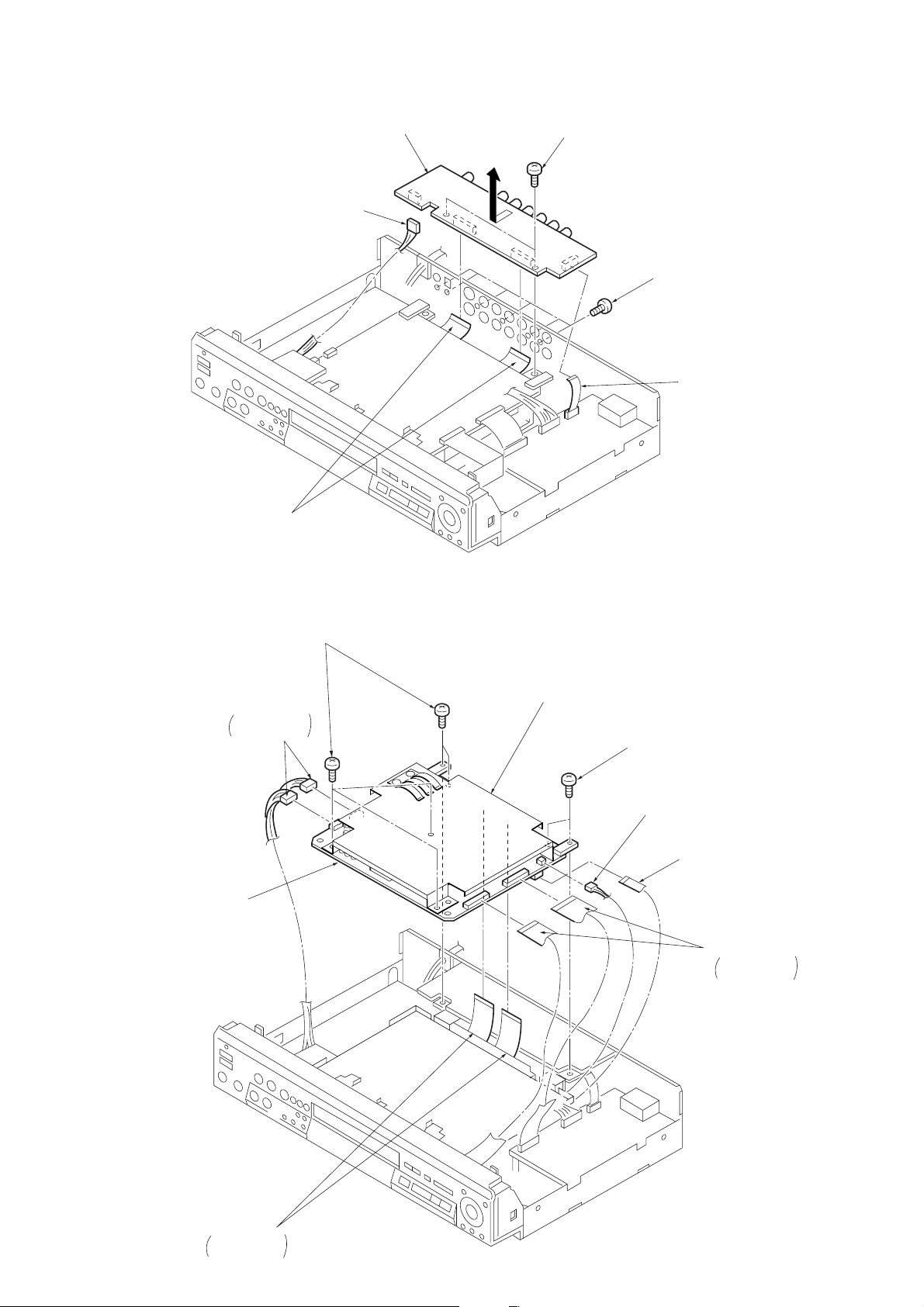

4-7. Note on Mounting TK-47 Board

1) Align two bosses. (See Fig.12)

2) Align four tabs. (See Fig.12)

3) Fix the board securely with 3 screws (BV 3 × 10). (The sensor

will not function normally if the board floats up.)

Three screws

TK-47 board

Two claws

Boss

Fig.12

(BV3

Two claws

× 10

)

Boss

5-2. Consult Sony Service – – – “E” code,

E : YY : ZZ

Refer to the item “5-8. Appendix” for details.

YY

01

EEPROM reading: NG (Check Sum has abnormality)

02

EEPROM writing: NG (Check Sum has abnormality)

EEPROM BUSY is displayed continuously exceeding

03

the specified time.

The pointer that shows the newest Emg History has

04

abnormality.

Communication between the HI microprocessor and

06

the SYS microprocessor is interrupted for a specified

time.

07

HI microprocessor cannot detect V-sync.

10

EEPROM CHECK NG

16

DSP CHECK NG

21

Sled driver has abnormal voltage.

30

Hy Det Level adjustment has abnormality.

31

Sled Offset Cancel adjustment has abnormality.

32

Focus Gain adjustment is faulty.

33

Tracking Offset adjustment is faulty.

34

Tracking Gain adjustment is faulty.

35

JITTER NG (only during the automatic adjustment)

40

Focus Servo does not lock in.

41

Focus Jump failed.

42

DSP Error Code (not used)

60

Mis-chucking when disc is inserted.

When disc started rotation, it did not reach the target

61

speed within 3 seconds.

62

Spindle runs away/does not stop.

63

Lock Check (in the service mode only)

— 9 —

YY

64

65

66

70

71

72

73

80

81

82

83

84

85

86

87

88

89

90

96

97

A0

A1

A2

A3

A4

A5

A6

A7

B0

B1

B2

B3

B4

B5

B6

B7

B8

C0

C1

D0

D1

E0

E1

CL V servo does not lock in within the specif ied time.

FG servo does not reach the target speed within the

specified time.

Spindle is not rotating at x1 speed. (RF Edge)

System control requests address that does not exist.

System control requests time code that is not used.

System control requests track No. that is not used.

The lock-in operation is not completed within the

specified number of times.

Continuity of address has abnormality. (DVD)

Cannot read address even retry is executed. (CD)

TOC read is not completed within the specified period

of time.

Physical Information Read Error ( CTRL DATA ECC

ERR)

Physical Information Read Error ( CTRL DATA

INSA ERR)

Physical Information Read Error ( CTRL DATA

FULL ERR)

Physical Information Read Error ( CTRL DA TA RUN

OVER)

Physical Information Read Error ( CTRL DATA Time

Out)

Layer No has abnormality.

CD Text Data Read Error

Servo recovery has failed when starting a disc.

Auto Sequence Time Out

Auto Sequence has exceeded the specified times.

Stop request from drive microprocessor

Did not return to the mode for a specified time.

Feed error. Retry is impossible.

GetInfo error. Stop

An attempt is made to playback a DVD-R Disc

Failed to execute Decrypt

SlowR. Target address of searching is illegal.

Feed error. Stop

Due to feeder.

Due to video hang-up

Error in DMX

Waiting for data from SlowR

Navi Pack sector address is different during SlowR

mode

Video hang-up during SlowR mode

Time out while waiting for ending of SlowR Gttgt

Waiting for data during FF/FR

Waiting for video data during FF/FR

The installed HI microprocessor ROM does not match

the destination.

HI microprocessor UART1 communication port has

abnormality.

EMG code is not present upon power-of f request from

drive microprocessor

Cannot return t stop mode. Power Off

Drive microprocessor - system error (ST ATUS ERR)

Drive microprocessor - system error (MECHAM

MODE ERR)

ZZ

FF

00

01

02

12

03

13

04

14

05

15

UNKONWN

NO DISC

CD 12 cm

CD 8 cm

SINGLE DVD 12 cm

SINGLE DVD 8 cm

DUAL 12 cm

CDR 12 cm

CDR 8 cm

DVDR 12 cm

DVDR 8 cm

— 10 —

SECTION 1

GENERAL

DVP-K800D

This section is extracted from

instruction manual.

1-1

1-2

1-3

1-4

1-5

1-6

1-7

1-8

1-9

1-10

1-11

1-12

1-13E

SECTION 2

s

)

DISASSEMBLY

NOTE: Follow the disassembly procedure in the numerical order given.

2-1. UPPER CASE

1

Tapping screws

1

Tapping screws

DVP-K800D

Case

2

Vertically up

Front panel

2-2. FRONT PANEL BLOCK ASSEMBLY

Case

1

Tapping screw

6

Front panel block

assembly

Remove hooks on both

sides and bottom

5

Screw

+BVTP3 × 8

4

Tray ornamental

plate assembly

a

Connector

1

3

Tray

slides out

CN205

5

Screw

+BVTP3

2

Turn cam gear

from the bottom

Philips screwdriver

or equivalent

×

a

1

Flat cable

(From CN601 on MB-78 board

8

1

Connector

CN501

2-1

2-3. AU-217 BOARD

AU-217 board

1

Connector

(From CN205)

5

Flat cables

(From CN201and CN203)

4

3

Screws

+BVTP 3

×

8

2

Screws

+BVTP 3 × 10

1

(From CN204)

Flat cable

2-4. MB-78 BOARD

5

MB-73 board

2

+BVTP 3 × 8

1

Connectors

From CN001

and CN002

Screws

3

Cover (upper)

2

Screws

+BVTP 3 × 8

1

Connector

(From CN361)

1

Flat cable

(From CN301)

1

From CN601

and CN702

Flat cables

4

Flat cables

From CN101

and CN252

2-2

2-5. KR-35 BOARD

0

1

Flat cable

(From CN502)

1

Connector

(From CN501)

1

Flat cable

(From CN503)

3

Screws

+BVTP 3 × 8

4

KR-35 board

2

Screw

+BVTP 3 × 1

2-6. POWER BLOCK

1

(From CN201)

Connector

2

Screws

+WHD B3

1

Connector

(From CN101)

3

Power block

2-3

2-7. TK-47 BOARD

8

)

3

+BVTP 3 × 8

Screws

1

Screws

+BVTP 3

×

8

2

Chassis bracket (B)

3

Screws

+BVTP 3 × 8

Mechanism deck

4

Flexible board

(From CN001)

4

Flexible board

(From CN002)

5

Screws

+BVTP 3 × 10

2-8. HP-116 BOARD, MC-115/VR-68 BOARD BLOCK,

FL-106 BOARD, FR-156 BOARD

1

Screw

+BVTP 2.6 × 8

3

4

Screws

+BVTP 2.6 × 8

MC-115/VR-68

board block

TK-47 board

4

(From CN004

2

Screws

+BVTP 2.6 × 8

Connector

5

HP-116 board

5

Connector

Front panel assembly

6

Flexible cable

From S1

rotary encoder

2-4

7

Screws

+BVTP 2.6 × 8

9

FR-156 board

0

FL-106 board

7

Screws

+BVTP 2.6

×

2-9. CIRCUIT BOARDS LOCATION

Power Block

AU-217

AUDIO D/A CONVERTER,

LINE OUT

FG-43

(SLED MOTOR)

TK-47

(RF, SERVO)

KR-35

KARAOKE

DSP/

MIC 3, 4 JACKS

FL-106

DISPLAY,

OPERATION SWITCHES

MB-78

VIDEO, SERVO/SYSTEM

CONTROL, AUDIO

MC-115

MIC 1, 2

JACKS

FR-156

POWER

SWITCH

HP-116

PHONES

JACK

VR-68

MIC/ECHO

LEVEL

2-5E

3-1. OVERALL BLOCK DIAGRAM

SECTION 3

DVP-K800D

BLOCK DIAGRAMS

OPTICAL PICK-UP

BLOCK

KHS-180A/JIN

A

B

C

DVD

PD IC

D

RFP

LD

DVD LD

PD

MODULE

IN

SKEW

OUT

SENSOR

CD E

CD F

PD1

CD

LAZER

PD2

COUPLER

LD

PD

FCS+

DVD

FCS-

FOCUS

TRK+

TRACKING

COIL

TRK-

FCS+

FCS-

CD

FOCUS

TRK+

TRACKING

COIL

TRK-

U 1,2

V 1,2

W 1,2

M901

SPINDLE

MOTOR

SP VH+,-

M

U,V,W

TK-47 BOARD

IC006

DVD

DIGITAL

SERVO

IC005

CD

APC RF

IC501

HALL

IC

IC502

M501

SLED

M

MOTOR

FG-43 BOARD

DVD RF

FE

TE

PI

SCKG3

TIE

CD RF

FE

TE

CD RF DC

TE ATT

M903

LOADING

MOTOR

M902

TILT

MOTOR

SSSD

IC011

SW

M

M

HA+,HB+,VH+,-

SLD MT+,-

MB-78 BOARD

16

IC363

FOCUS

TRACKING

COIL

DRIVE

IC303

SPINDLE

MOTOR

DRIVE

IC361

LOADING

TILT

MOTOR

DRIVE

IC302

SLED

MOTOR

DRIVE

IC452

SEL

IC455

OPN/CLS

HY CNTR,SLD FS

IC502

IC502

IC503

IC301

ERROR

SP CTL0,1

SP GC1,2

HYS DET

IC503

IC503

IC501

IC508 IC501

TRINT

DFCTA

RF1

RF2

FE

IC506

TE

DSP

IC806

ARP

SPD IF

CD DATA

CD BCK

CD LRCK

8

ID0-7

IA0-7

IC810

4M

DRAM

33M

27M DSP

XRST

8

F OUT

T OUT

AMP

SL +,-

13.5M

SSSD

SCKG3

SOG3

27M VE

IC804

L G/A

8 8

8

IFSI

OPN/CLS

SPCTL0.1

IFSO

SPGC1,2

IC801

EEPROM

A1

27M DSP

SDP RST

ACK

CLAP SW0,1

ACSI

SOG4,SCKG4,SCKG4

27M GA

M RST

OH SYNC

H SYNC

8 16

SRST

IC802

1M

SRAM

ACK

SDP RST

VSI

AVCK

SCKG2

SIG1

SIG2

SCKG2

1616

IC803

8M

FLASH

1917

XRST

HD0-15

HA0-7,19,20,21

SD0-7

V SYNC

22

M RST

IC805

SH

SOG2

IC205

IC206

DAC RST

8

8

6

IC205

AC3 RST

IC811

DECRYRT

ID0-7

IA0-7

XRST

27M GA

DCR SD0-7

ID0-7

8

IA0-8

9

CD DATA

CD BCK

CD LRCK

MRST

IC807

S G/A

9

8

8

6

IC203

MPEG2 A/V

DOLBY

DIGITAL

DECODER

16M

SDRAM

IC201

IC202

SO

SCLK

IC605

RESET

ACLK

27M VE

R/G/B

IC208

SPDIF AC3

R/G/B

SO

SCLK

13.5M

IC204

AU-217 BOARD

8YC0-7

IC251

DNR

C0-7

MRST

13.5M

OH SYNC

SCKG3

SOG3

27M DNR

H SYNC

V SYNC

H SYNC

V SYNC

VSI

SOG2

AVCK

IC204 IC206

H SYNC

IC207

V SYNC

OSD

M RST

M RST

SOG2,SCKG2

SOG4,SCKG4,SCKG4

ACSI

CLAP SW0,1

AC3 RST

8Y0-7

8

IC206

IC252

VIDEO

ENCODER

SOG3

SCKG3

DAC RST

IC205

768FS

Y

C

V

IC205

IC209

PLL

M RST

SOG4

SCKG4

IC102

DIR

IC104

AC3

DECODER

IC105

256k

SRAM

DATA

BCK

LRCK

SOG2

SCKG2

IC101

M G/A

DAC RST

768FS

HD OUT

AC3 RST

KR DATA

KA DATA

KR BCK

KR LRCK

SCKG3

SOG3

384FS 2CH

DAC DATA

DAC BCK

DAC LRCK

M RST

DD DATA F

DD BCK

DD LRCK

SOG4

SCKG4

M RST

384FS

DD DATA R

DD BCK

DD LRCK

SOG4

SCKG4

M RST

384FS

DD DATA C

DD BCK

DD LRCK

SOG4

SCKG4

384FS

M RST

IC215

2CH

D/A CONV.

IC203

L,R

D/A CONV.

IC204

SL,SR

D/A CONV.

IC205

C,SW

D/A CONV.

IC353

Y

IC351

C

VIDEO

D/A

V

IC206

IC207

IC208

IC211

SW

IC209 IC212

IC210

IC213

IC214

IC352

OPTICAL

DIGITAL

OUT

J354

L R

S VIDEO

OUT

VIDEO

L

AUDIO

OUT

R

IC001

HP-116

BOARD

FLONT

REAR

CENTER

WOOFER

J201

5.1CH

OUTPUT

J001

PHONES

FL-106 BOARD

ECHO CONT

MIC2 IN

IC806

MIC1 IN

MIC CONT

MIC

IC503

MROM

KR DATA

KA DATA

KR BCK

KA LRCK

768FS

SOG2

SCKG2

KARAOKE

S101-112

S116,117

S119-123

FUNCTION

KEY

S114,115,118

FUNCTION

KEY

S401

ON/

STANDBY

IC401

REMOTE

CONTROL

RECEIVER

ND101

FLUORESCENT

INDICATOR

TUBE

SW

BLOCK

J103

CONTROL

J102

MIC2

MIC1

IC102

MC-115

BOARD

MIC4

MIC3

CLAP SW0

CLAP SW1

J601

ECHO

IC804

VR-68 BOARD

IC101

DISPLAY

DRIVE

AD3,4-6

SI

SCLK

SI

SCLK

IC604

MIC1,2

I/F

MIC CONT

MYCON

ECHO CONT

IR

SCKG1

D0-7

IC601

SRST

IFSO

IFSI

8 8

BUFFER

BOARD

A0-18

FR-156

8

AD4-6

AD3

AD4

IR

IC603

SOCKET

IC508

DSP

KR-35 BOARD

IC517

IC507

MIC

HAKUSYU

3-1 3-2

DVP-K800D

3-2. RF/SERVO BLOCK DIAGRAM

TK- 47 BOARD

OPTICAL PICK-UP

BLOCK

KHS-180A/JIN

DVD

PD IC

DVD LD

MODULE

SKEW

SENSOR

CD

LAZER

COUPLER

DVD

FOCUS

TRACKING

COIL

CD

FOCUS

TRACKING

COIL

SPINDLE

M901

SPINDLE

MOTOR

M

M903

LOADING

MOTOR

16

RFP

99

RFM

10

A

14

B

13

C

6

D

18

VR

5

DVD LD

3

DVD PD

4

VLD

2

SKEW IN

41

SKEW OUT

42 42

LED

38

CD E

27

CD F

20

PD1

28

PD2

29

AL

19

CD LD

23

MON

26

VR

25

DVD FCS+

34

DVD FCS-

35

DVD TRK+

36

DVD TRK-

37

CD FCS+

30

CD FCS-

31

CD TRK+

33

CD TRK-

32

U IN1

10

U IN2

9

V IN1

8

V IN2

7

W IN1

6

W IN2

5

SP VH+

11

SP VH-

12

U OUT

13

V OUT

14

W OUT

15

LD MT+

1

M

LD MT-

Q010

BUFFER

CN001

10

14

13

6

18

Q004

5

SWITCH

3

4

Q005

SWITCH

2

41

Q001

TILT

38

LED ON

27

20

28

29

19

Q007

SWITCH

23

26

25

34

35

36

37

30

31

33

32

CN002

10

9

8

7

6

5

11

12

13

14

15

CN004

1

22

IC004

3167

D004

IC006

DVD DIGITAL SERVO

SIGO

63

RFP

SDATA

64

RFM

SCLK

10

A

SDEW

B

9

8

C

7

D

1

A2

2

B2

3

C2

4

D2

18

LD

17

PD

PI

20

TI A

TE

TI B21

FE

MIRR

HOLD1

FDCHG

TIOF

TIE

TII

IC005

CD APC RF

MIRR

5

E

6

F

RFO1

3

PD1

4

PD2

9

CE

APC ON

RFO

1

LD

TE

FE

2

PD

TEC

57

44

43

45

16XLDON

37

38

39

30

47

33

19

26

23

19

22

21RFO2

25

32

13

15

12

IC303 !ª@™@£ DVD

6.6 µsec

IC303 !ª@™@£ CD

11 msec

4.6 Vp-p

2.5Vp-p

Q008

SWITCH

S5V

CN451 1 CD

0.5 V/div

0.2 µsec/div

CN451 3 DVD

0.5 V/div

0.1 µsec/div

CN005

PH001

CHUCK

SENSOR

IC011

5

4

3

9

2

15

1

10

13

14

12

11

Q009

CN008

CN501 CN301

IC501

IC502

H

H

M501

SLED

MOTOR

M

FOR CHECK

26

16

19

18

17

3

6

5

21

12

23

15

20

13

22

14

1

9

2

4

10

11

22

20

18

16

23

21

19

17

8

7

6

5

4

3

10

9

11

12

13

14

15

MOTOR

7

8

5

4

6

3

1

2

CHECK

DVD RF+

CD RF

SSSD

SCKG3

SDEN

TILT/H

CHUCK

TRAY

DVD LDON

CD LD ON

DVD PI

CD RFDC

DPD

CD TE

DVD FE

CD FE

MIRR

DFCTS

TE ATT

TI OFS

TI ERR

TIE

DVD FCS+

DVD FCSDVD TRK+

DVD TRK-

CD FCS+

CD FCS-

CD TRK+

CD TRK-

U IN1

U IN2

V IN1

V IN2

W IN1

W IN2

SP VH+

SP VH-

U OUT

V OUT

W OUT

LD MT+

LD MT-

M902

TILT

HA+

HA-

HB+

HBVH+

VH-

SLD MT+

SLD MT-

CN303

FOR

CN451

M

FG-43 BOARD

FE

3

TE

4

PI

1

JIT PWM

5

CD RF

1

DVD RF+

3

CN452

2

12

9

10

11

25

22

23

7

16

5

13

8

15

6

14

27

19

26

24

18

17

CN302

6

8

10

12

5

7

9

11

20

21

22

23

24

25

18

19

17

16

15

14

13

CN361

1

2

2

1

4

5

3

6

8

7

MB-78 BOARD

SSSD IC804

SCKG3 IC804

SDEN IC804

TILT/H IC804

ACHUCK IC804

ATRAY IC804

DVD LDON IC804

CD LDON IC804

IC452

SELECTOR

13

12

1

2

3

5

3,6 1,7

IC455

IC363

FOCUS/TRACKING

COIL DRIVER

16

DF+

15

DF-

17

DT+

18

DT-

13

CF+

14

CF-

12

CT+

11

CT-

IC303

SPINDLE

MOTOR DRIVER

30

U1

31

U2

32

V1

33

V2

34

W1

1

W2

29

VH+

28

VH-

23

U OUT

22

V OUT

19

W OUT

8

OUT2+

9

OUT2-

6

OUT1+

5

OUT1-

34

HA+

33

HA-

30

HB+

29

HB-

23

VH+

22

VH-

2

MTR+

5

MTR-

14

11

15

10

4

9

MUTE1

MUTE2

SPCTL0

SPCTL1

SPGC1

SPGC2

MUTE1

MUTE2

CTRL

HFG

NS+

IN1+

IN2-

TKC

CA+

Q452

IN4

IN3

IN1

IN2

VC

DVI

DVER-

52

46

48

13

TO/FROM

SYSCON

27

(Page 3-9)

28

2

3

26

23

3

6

9

20

27

7

9

8

11

10

13

21

17

2

13

TILT/LOADING

MOTOR DRIVER

MOTOR DRIVER

12

8

11

25

18

17

BLOCK

IC361

IC302

SLED

IC502

12 14

57

10 8

67

IC503

TOFC 1,2 IC804

CD/DVD IC804

HFG IC805

NST IC804

SPCTL0 IC804

SPCTL1 IC804

SPGC1 IC804

SPGC2 IC804

OPN/CLS IC804

S12V OFF IC804

TRAY FREE IC804

IC503

3

1

IC508 IC501

576

21

IC501

2,3

1

IC503

10

8

141

4

97

7

9

8

22

10

5

19

18

Q501

BUFFER

IC503

14

Q371

Q372

142

5

13

FROM

SYSCON

BLOCK

(Page 3-9)

IC806 %ª-^™^¢-^¶ DVD

IC506

DIGITAL SIGNAL

PROCESSOR

63

21

AIN5

7

89

TRINT

7

DFCTA

8

GIO6

24

AIN1

26

AIN0

88

TRREF

12

GIO2

11

GIO3

73

PWM2

22

AIN4

46

AOUT1

49

AOUT2

1

GIO12

2

GIO11

41

AOUT2

38

AOUT3

74

PWM1

75

PWM0

14

GIO0

18

AIN8

19

AIN7

20

AIN6

HD0

8

56

HD7

HLDB

72

CLKIN

65

TCK

79

IC506 ^∞ DVD/CD

4.6 Vp-p

27 MHz

122

IC806

4.8 Vp-p

27 MHz

IC806 (º DVD/CD

3.3 Vp-p

3.375 MHz

106

IC806 CD

1 V/div

0.2 µsec/div

IC806 $• DVD

71HWR

70HRD

ERROR

98

FON

100

BUSY

4

ACK

3

MRST

84

IRS

94

7

56µsec

IC301

ERROR AMP

5

2.5Vp-p

216

52

JITPWM

10

RF IN1

12

RF IN2

122

MCKI

48

MDP0

43

MDS0

SDSP WR IC804

SDSP RD IC804

ERROR IC804

FON IC804

BUSY2 IC804

ACK IC805

SDP RST IC805

2 V/div

0.1 µsec/div

IC806

ARP

77

58

15

17

14

63

MD15

1

SD0

SD7

SDEF

XSAK

XSRQ

XSHD

SDCK

SCKI

D OUT

DATA

BCLK

LRCK

XWR

XRD

DFCT

MUTE

MD2

FWON

XINT

XCS

XWAT

LOCK

MD0

MA0

MA8

XMWR

XCAS

XRAS

XOE

D0

D7

A0

A7

59

62

.

64

67

70

73

.

75

78

96

99

.

101

104

94

93

92

91

90

124

109

106

107

108

56

57

84XRST

51NORF

50

110

112

55

80

81

83

53

156

159

.

161

164

.

166

169

.

171

174

137

139

.

141

.

143

.

145

147

150

151

153

154

TO/FROM

SYSCON

BLOCK

(Page 3-9)

IC807

ID0-7

A1

IA0-7

IC811

DECRYPT

41

SHD0

88

34

SHD7

31

SHA0

IC810

4M DRAM

DQ1

DQ16

6

SHA7

26

74

77

.

79

DTI0

.

8

80

DTI7

.

1

.

3

5

EFLGI

6

ACKI

8

REQO

4

SHDRI

7

DCKI

2

5

.

7

10

.

16

35

38

.

40

43

8

16

18

A0

21

.

9

A8

24

28

15

WE

30

UCAS

31

LCAS

16

RAS

29

DE

DTO1

DTO7

EFLGO

ACKO

REQI

SHDRO

MCK

HCS

WAIT

WRN

RDN

71

68

.

66

64

.

62

60

59

56

61

51

46

INT

43

47

45

44

54XRST

8

8

8DCR SD0-7

DCR SD0-7

ID0-7

41 38

53 52

IA0-7

27M DSP IC206

ERROR IC203

AVALID IC203

AREQ IC203

TOS IC203

27M DNR IC206

DCK IC203

33M IC205

SPDIF IC203

CD DATA IC203

CD BCK IC203

CD LRCK IC203

DCR INT IC804

DCR CS IC804

DCR WT IC804

IWR IC804

IRD IC804

MRST IC805

XRST IC805

NORF IC804

DFCT IC804

MUTE IC804

MD2 IC804

FWON IC804

ARP INT IC804

ARP CS IC804

ARP WT IC804

LOCK IC804

.

36 33

TO/FROM

SYSCON

IC807

.

.

IC203

12 19

50 44

BLOCK

(Page 3-9)

11

24

26

30

21

6

TO/FROM

VIDEO

BLOCK

(Page 3-5)

28

11

102

101

98

99

63

62

64

57

56

54

98

TO/FROM

SYSCON

BLOCK

106

(Page 3-9)

105

104

103

102

60

59

61

16

3-3 3-4

Loading...

Loading...