Sony DSC-T700 Service Manual

DSC-T700

SERVICE MANUAL

Ver. 1.2 2009.10

Revision History

Revision History

Internal memory

Internal memory

ON BOARD

ON BOARD

Photo: Silver

Link

Link

SPECIFICATIONS

BLOCK DIAGRAMS

LEVEL 2

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Hong Kong Model

Chinese Model

Korea Model

Argentine Model

Brazilian Model

Thai Model

Japanese Model

Tourist Model

PRINTED WIRING BOARDS

SERVICE NOTE

DISASSEMBLY

• Precaution on Replacing the SY-208 Board

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

FRAME SCHEMATIC DIAGRAM

SCHEMATIC DIAGRAMS

REPAIR PARTS LIST

DIGITAL STILL CAMERA

DSC-T700_L2

Sony EMCS Co.

2009J0800-1

© 2009.10

Published by Tokai TEC9-852-607-33

SPECIFICATIONS

Camera

[System]

Image device: 7.7 mm (1/2.3 type) color CCD,

Primary color filter

Total pixel number of camera: Approx. 10.3

Megapixels

Effective pixel number of camera: Approx. 10.1

Megapixels

Lens: Carl Zeiss Vario-Tessar 4× zoom lens

f = 6.18 – 24.7 mm (35 – 140 mm (35 mm

film equivalent))

F3.5 (W) – F4.6 (T)

Exposure control: Automatic exposure, Scene

Selection (11 modes)

White balance: Automatic, Daylight, Cloudy,

Fluorescent 1,2,3, Incandescent, Flash

Underwater White Balance: Auto, Underwater

1,2, Flash

File format (DCF compliant):

Still images: Exif Ver. 2.21 JPEG compliant,

DPOF compatible

Movies: MPEG1 compliant (Monaural)

Recording media: Internal Memory

(approx. 4 GB*), “Memory Stick Duo”

* When measuring media capacity, 1GB equals 1

billion bytes, a porton of which is used for

system management and/or applicaton files.

The capacity that a user can use is

approximately 3.71GB.

Flash: Flash range (ISO sensitivity

(Recommended exposure Index) set to Auto):

Approx. 0.08 to 4.3 m (3 1/4 inches to

14 feet 1 3/8 inches) (W)/

approx. 0.5 to 3.4 m (1 feet 7 3/4 inches to

11 feet 1 7/8 inches) (T)

[Input and Output connectors]

Multi connector:Video output

Audio output (Monaural)

USB communication

USB communication: Hi-Speed USB (USB 2.0

compliant)

[LCD screen]

LCD panel: Wide (16:9), 8.8 cm (3.5 type) TFT

drive

Total number of dots: 921 600 (1920 × 480) dots

[Power, general]

Power: Rechargeable battery pack NP-BD1, 3.6 V

NP-FD1 (not supplied), 3.6 V

AC-LS5K AC Adaptor (not supplied), 4.2 V

Power consumption (during shooting): 1.2 W

Operating temperature: 0 to 40˚C (32 to 104˚F)

Storage temperature: -20 to +60˚C (-4 to +140˚F)

Dimensions: 95.0 × 58.4 × 16.4 mm (3 3/4 × 2 3/8

× 21/32 inches) (W/H/D, excluding

protrusions)

Mass (including NP-BD1 battery pack

and strap etc.): Approx. 160 g (5.6 oz)

Microphone: Monaural

Speaker: Monaural

Exif Print: Compatible

PRINT Image Matching III: Compatible

PictBridge: Compatible

[Password]

Release number: 7669

BC-CSD battery charger

Power requirements: AC 100 V to 240 V,

50/60 Hz, 2.2 W

Output voltage: DC 4.2 V, 0.33 A

Operating temperature: 0 to 40˚C (32 to 104˚F)

Storage temperature: -20 to +60˚C (-4 to +140˚F)

Dimensions: Approx. 62 × 24 × 91 mm (2 1/2 ×

31/32 × 3 5/8 inches) (W/H/D)

Mass: Approx. 75 g (2.7 oz)

Rechargeable battery pack

NP-BD1

Used battery: Lithium-ion battery

Maximum voltage: DC 4.2 V

Nominal voltage: DC 3.6 V

Capacity: 2.4 Wh (680 mAh)

Design and specifications are subject to

change without notice.

DSC-T700_L2

— 2 —

ENGLISH JAPANESE

ENGLISH JAPANESE

Danger of explosion if battery is incorrectly replaced.

CAUTION

Replace only with the same or equivalent type.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

DSC-T700_L2

— 3 —

ENGLISH JAPANESE

ENGLISH JAPANESE

電池の交換は,正しく行わないと破裂する恐れがあり

注意

ます。電池を交換する場合には必ず同じ型名の電池

又は同等品と交換してください。

サービス,点検時には次のことにご注意下さい。

1. 注意事項をお守りください。

サービスのとき特に注意を要する個所については,

キャビネット,シャーシ,部品などにラベルや捺印で

注意事項を表示しています。これらの注意書き及び取

扱説明書等の注意事項を必ずお守り下さい。

2. 指定部品のご使用を

セットの部品は難燃性や耐電圧など安全上の特性を

持ったものとなっています。従って交換部品は,使用

されていたものと同じ特性の部品を使用して下さい。

特に回路図,部品表に0印で指定されている安全上重要

な部品は必ず指定のものをご使用下さい。

3. 部品の取付けや配線の引きまわしはもとどおりに

安全上,チューブやテープなどの絶縁材料を使用した

り,プリント基板から浮かして取付けた部品がありま

す。また内部配線は引きまわしやクランパによって発

熱部品や高圧部品に接近しないよう配慮されています

ので,これらは必ずもとどおりにして下さい。

4. サービス後は安全点検を

サービスのために取外したネジ,部品,配線がもとど

おりになっているか,またサービスした個所の周辺を

劣化させてしまったところがないかなどを点検し,安

全性が確保されていることを確認して下さい。

5. チップ部品交換時の注意

• 取外した部品は再使用しないで下さい。

• タンタルコンデンサのマイナス側は熱に弱いため交

換時は注意して下さい。

6. フレキシブルプリント基板の取扱いについて

• コテ先温度を270℃前後にして行なって下さい。

• 同一パターンに何度もコテ先を当てないで下さい。

(3回以内)

• パターンに力が加わらないよう注意して下さい。

7. 無鉛半田について

無鉛半田を使用している基板には,無鉛(Lead Free)を

意味するレッドフリーマークがプリントされています。

(注意:基板サイズによっては,無鉛半田を使用して

いてもレッドフリーマークがプリントされて

いないものがあります)

:レッドフリーマーク

無鉛半田には,以下の特性があります。

• 融点が従来の半田よりも約40℃高い。

従来の半田こてをそのまま使用することは可能です

が,少し長めにこてを当てる必要があります。

温度調節機能のついた半田こてを使用する場合,約

350℃に設定して下さい。

注意:半田こてを長く当てすぎると,基板のパター

ン(銅箔)がはがれてしまうことがあります

ので,注意して下さい。

• 粘性が強い

従来の半田よりも粘性が強いため,IC端子などが半田

ブリッジしないように注意して下さい。

• 従来の半田と混ぜて使用可能

無鉛半田には無鉛半田を追加するのが最適ですが,

従来の半田を追加しても構いません。

DSC-T700_L2

— 4 —

ENGLISH JAPANESE

1. SERVICE NOTE

ENGLISH JAPANESE

1-1. NOTE FOR THE INTERNAL MEMORY

When a “Memory Stick Duo” is inserted in the camera, images are recorded on the “Memory Stick Duo”.

Note that the camera cannot copy or transfer images directly between the internal memory and a “Memory Stick Duo”. Use the “PMB”.

1-2. PASSWORD LOCK

Once the password is set, images in the internal memory cannot be played back.

In case of needing to read images in the internal memory from the password locked set, release the password locking.

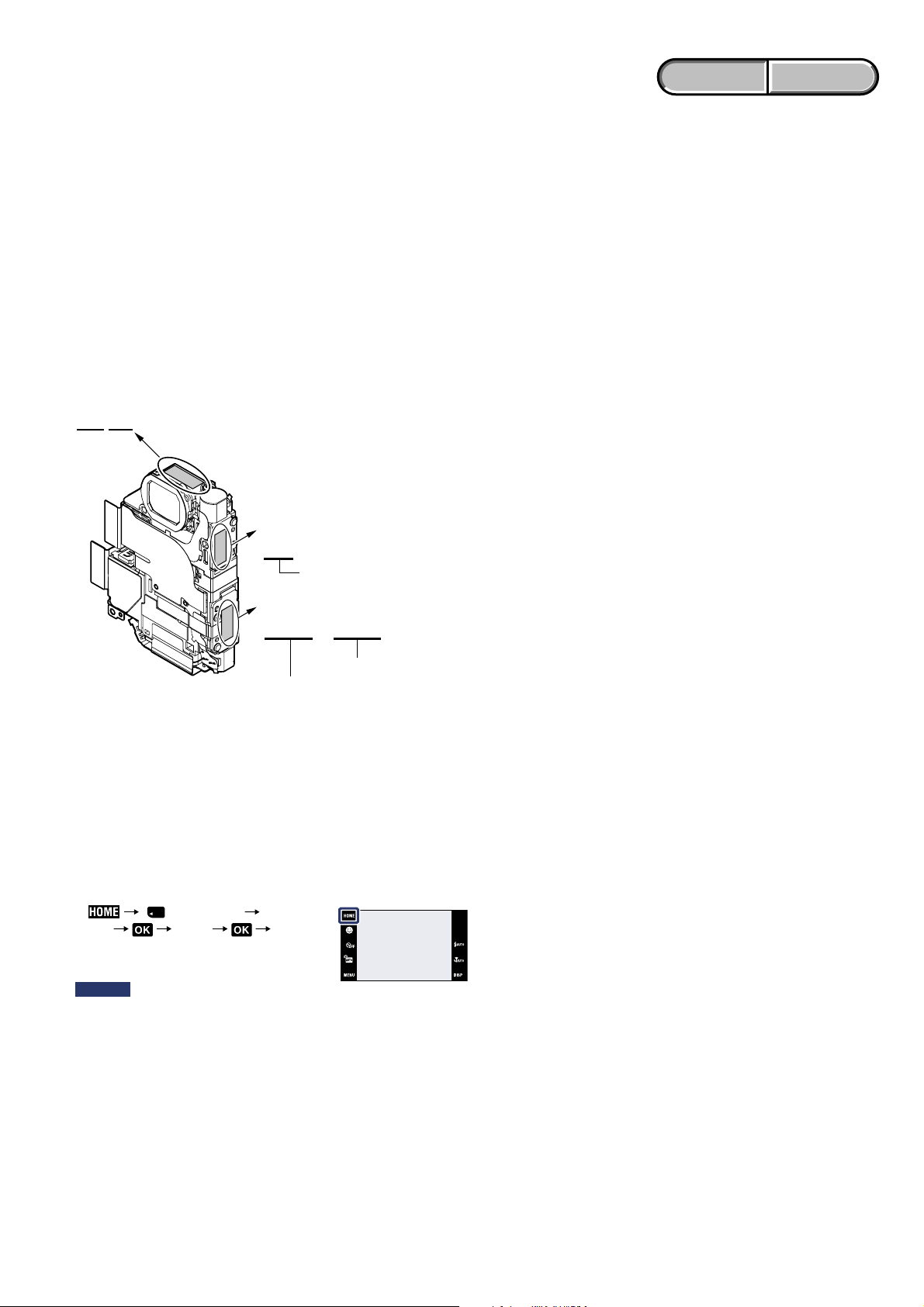

Releasing the Password Lock

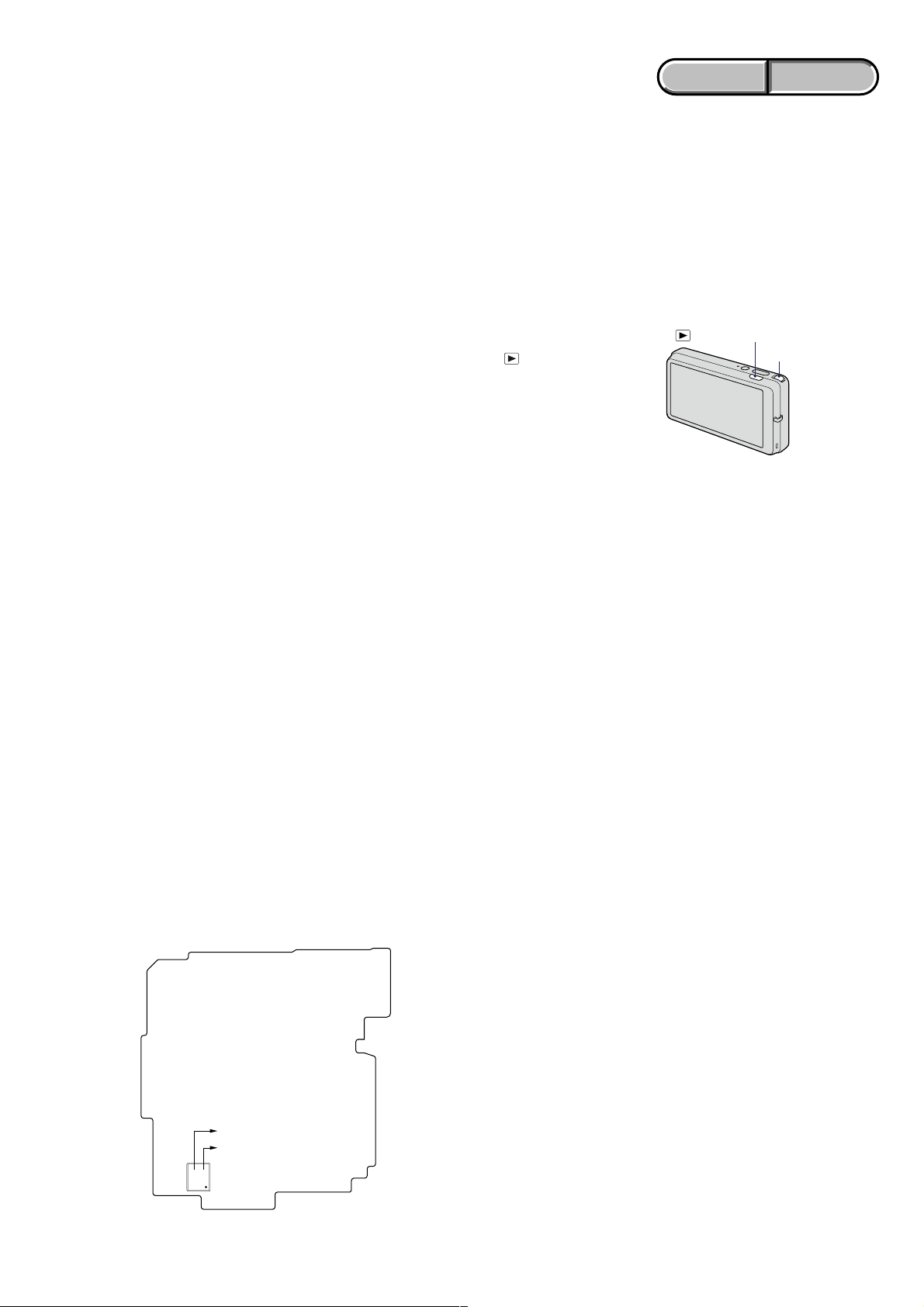

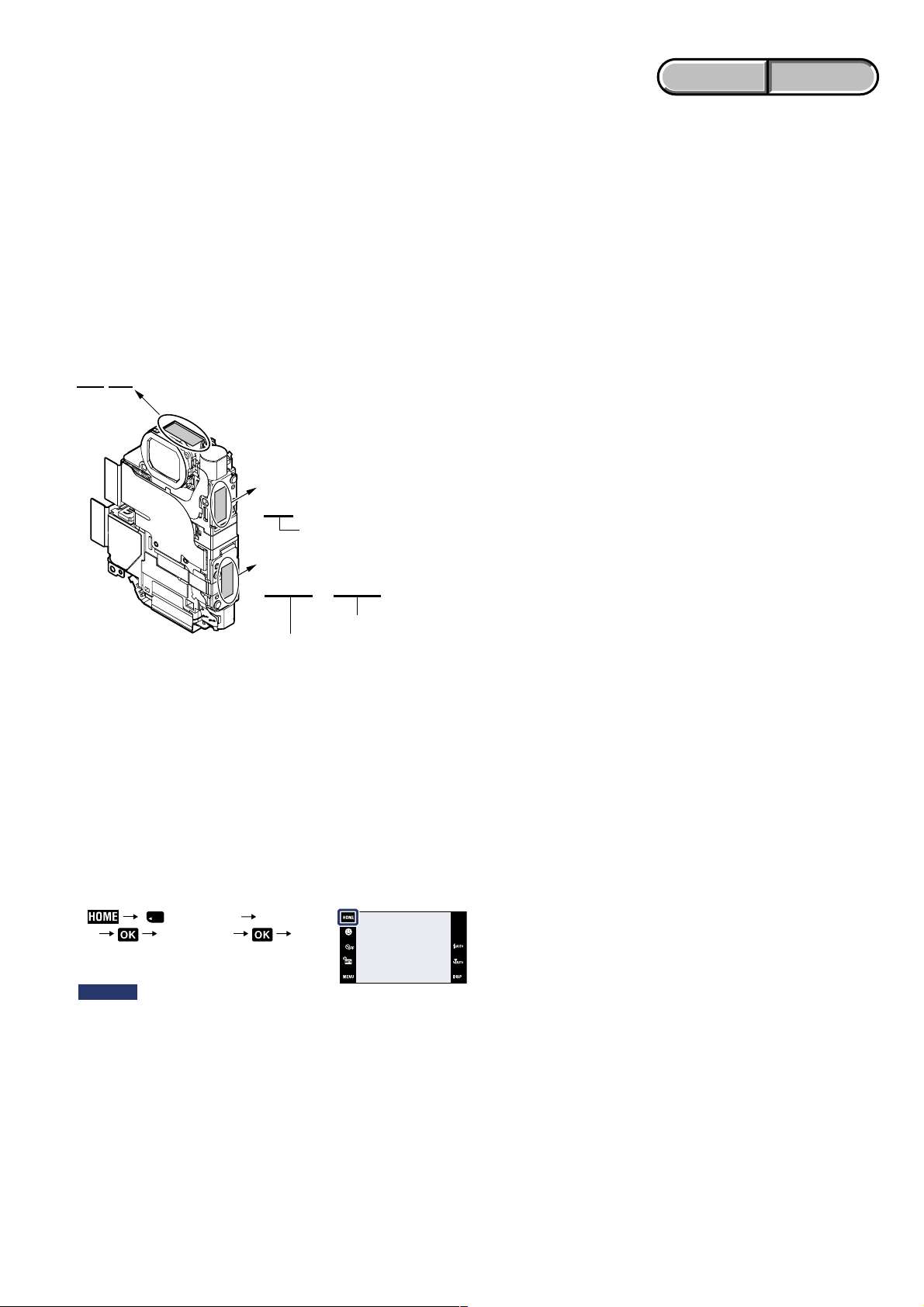

1. First turn off the camera’s power. Then press (Playback) button while moving the zoom (W/T) lever to the W side.

2. The power is now turned on, and the password release screen apears t touch [OK]

3. Enter the password release number ‘7669’ t touch [OK] t [OK]

(Playback) button

Zoom (W/T) lever

1-3. PMB PORTABLE

The application “PMB Portable” has already built in the internal memory.

The SY-208 board for repair is supplied with the built-in application “PMB Portable” .

In case of replacing the internal memory with new one, it is necessory to write the application “PMB Portable” in it.

For writing procedure, please refer to the PMB guide.

1-4. PRECAUTION ON REPLACING THE SY-208 BOARD

Note 1: When replacing the SY-208 board, erase the data in internal memory of the board before replacement.

Note 2: When replacing the SY-208 board, execute formatting and initialize the internal memory after replacement.

DESTINATION DATA

When you replace to the repairing board, the written destination data of repairing board also might be changed to original setting.

Refer to Service Manual ADJ, and perform “DESTINATION DATA WRITE”.

USB SERIAL No.

The set is shipped with a unique ID (USB Serial No.) written in it.

This ID has not been written in a new board for service, and therefore it must be entered after the board replacement.

Refer to Service Manual ADJ, and perform “USB SERIAL No. INPUT”.

Angular Velocity Sensor

When you replace to the reparing board, write down the sensitivity displayed on the angular velocity sensor (SE511).

Refer to Service Manual ADJ, and perform “Angular velocity sensor sensitivity adj”.

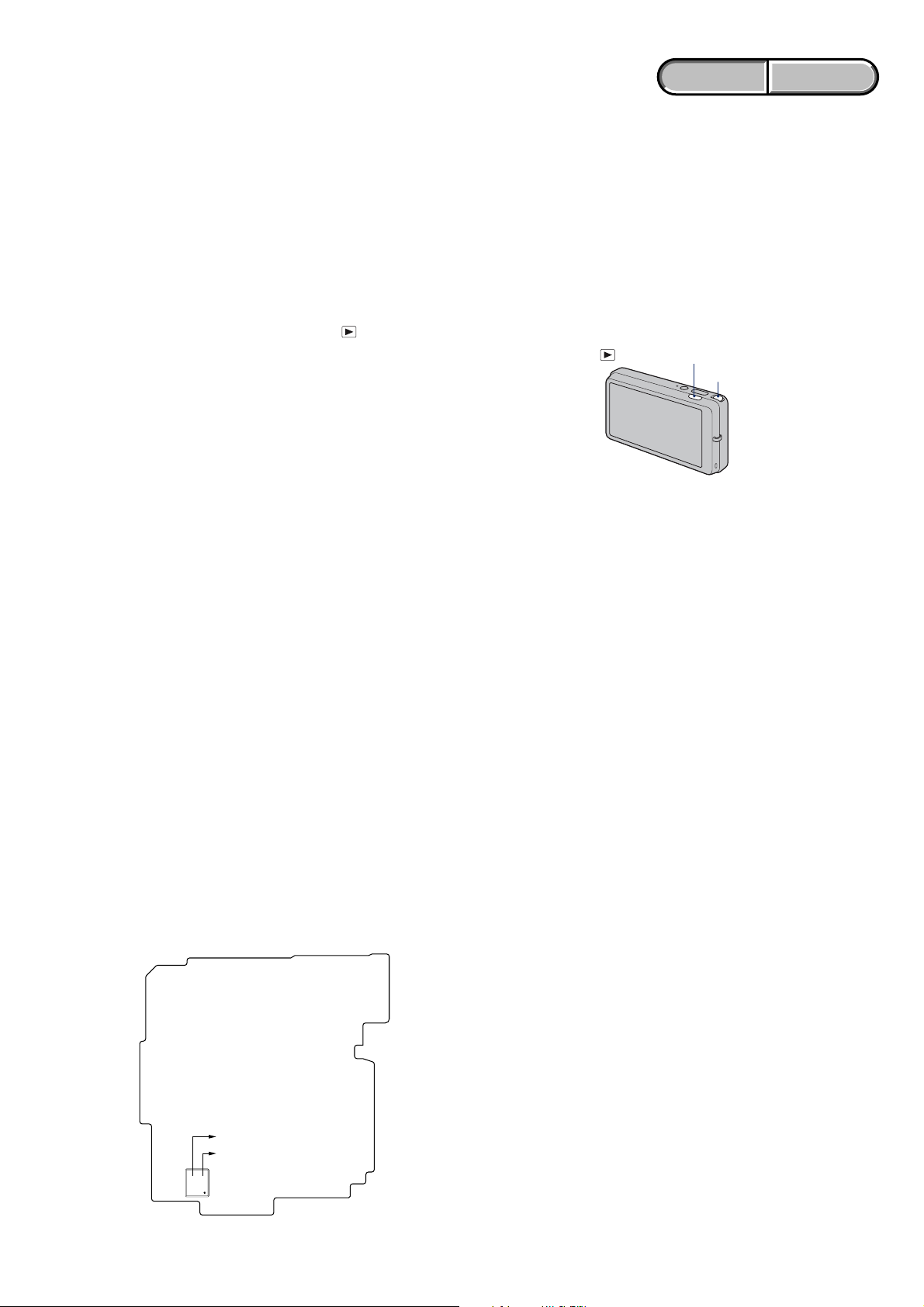

SY-208 BOARD (SIDE B)

PPP: PITCH Sensor sensitivity

YYY: YAW Sensor sensitivity

SE511

Note 3: The sensor sensitivity of SE511 of SY-208 board is written only repair parts.

PPP

YYY

DSC-T700_L2

1-1

ENGLISH JAPANESE

ENGLISH JAPANESE

1-5. NOTE ON REPLACING IC801 (INTERNAL MEMORY)

In case of replacing IC801 (internal memory) with new one, perform followings.

1. Format the internal memory with “INTERNAL MEMORY FORMAT” of the adjustment software.

2. Write the application “PMB Portable” in with “PMB”.

1-6. PRECAUTION ON REPLACING THE LENS

When replacing the lens, write down the PITCH/YAW data, FN data and wide limit data given on the data sheet of the replacement lens for

service.

Refer to Service Manual ADJ, and perform “Wide Limit adj” and “Angular velocity sensor sensitivity adj”.

Wide Limit Data (2-byte data)

XXYY

X

X

Y

Y

FN Data

F

N

XX

FN data

PITCH/YAW Data

L

1

/

L

2

P.PP / Y.YY

YAW data

PITCH data

Note: The PITCH/YAW data, FN data and wide limit data of lens

are written only repair parts.

1-7. METHOD FOR COPYING OR ERASING THE DATA IN INTERNAL MEMORY

Method for Copying the Internal Memory

Note that the camera cannot copy or transfer images directly between the internal memory and a “Memory Stick Duo”. Use the “PMB”.

Method for Formatting the Internal Memory

Formats the “Memory Stick Duo” or the internal memory. A commercially available “Memory

Stick Duo” is already formatted, and can be used immediately.

1 (Manage Memory) [Memory

Tool] [Format] [OK]

Notes

Note that formatting permanently erases all data including even protected images.

Method for Exporting Images to the Internal Memory

Perform [Exporting images to medias] in the program “PMB”.

(In case of moving or copying image files from PC with Explorer, the camera cannot recognize the image files because of the image files

information doesn’t reflect to the album information data folder.)

DSC-T700_L2

1-2

1-8. SELF-DIAGNOSIS FUNCTION

ENGLISH JAPANESE

ENGLISH JAPANESE

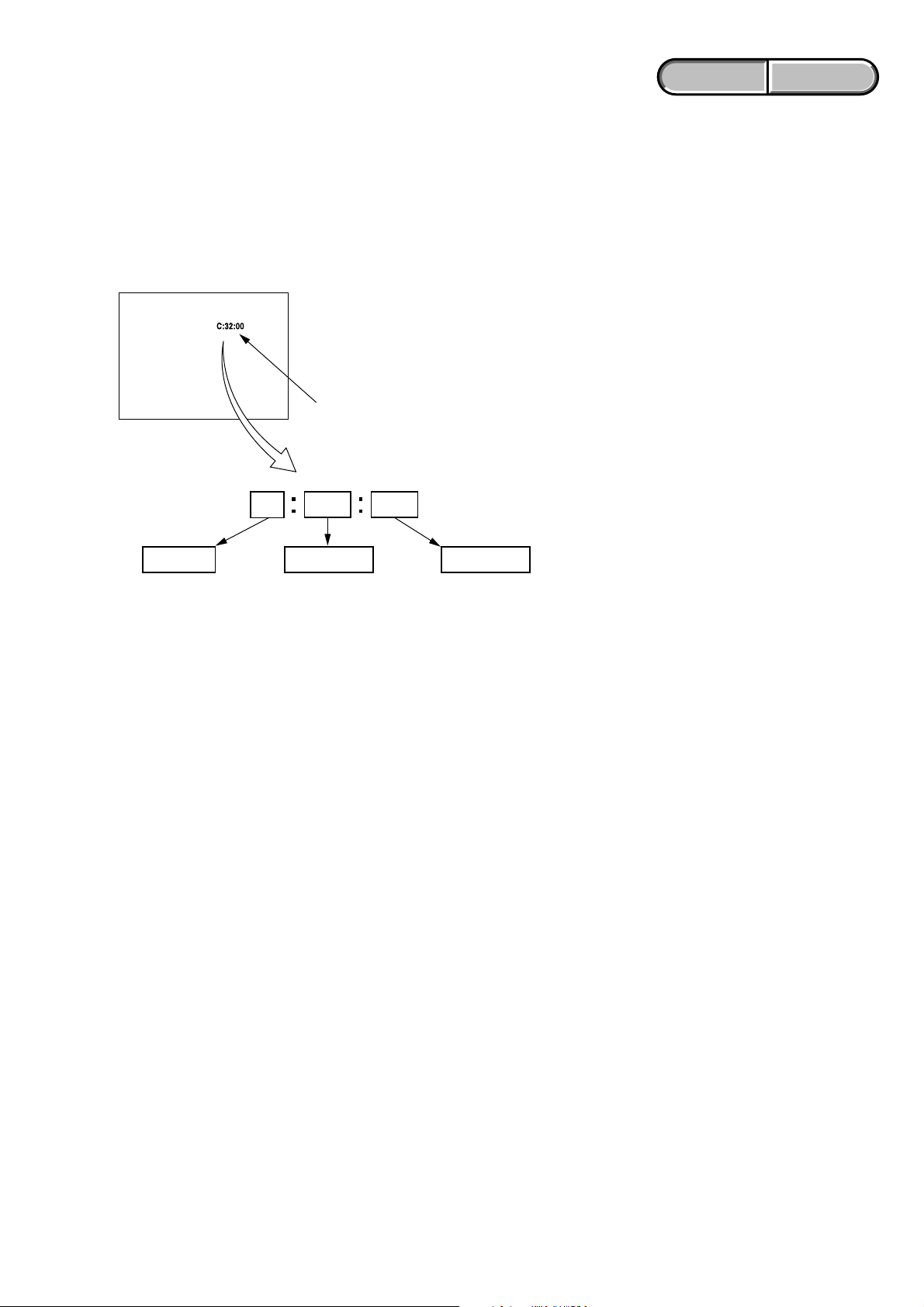

1-8-1. Self-diagnosis Function

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the LCD screen what to

do.

Details of the self-diagnosis functions are provided in the Instruction

manual.

LCD screen

Blinks at 3.2 Hz

0 0

Refer to “1-8-3. Self-diagnosis Code Table”.

Repaired by:

C : Corrected by customer

E : Corrected by service

engineer

3 2C

Block

Indicates the appropriate

step to be taken.

E.g.

13 ....Format the “Memory Stick Duo”.

32 ....Turn on power again.

1-8-2. Self-diagnosis Display

When problems occur while the unit is operating, the LCD screen

shows a 4-digit display consisting of an alphabet and numbers, which

blinks at 3.2 Hz. This 5-character display indicates the “repaired

by:”, “block” in which the problem occurred, and “detailed code”

of the problem.

Detailed Code

DSC-T700_L2

1-3

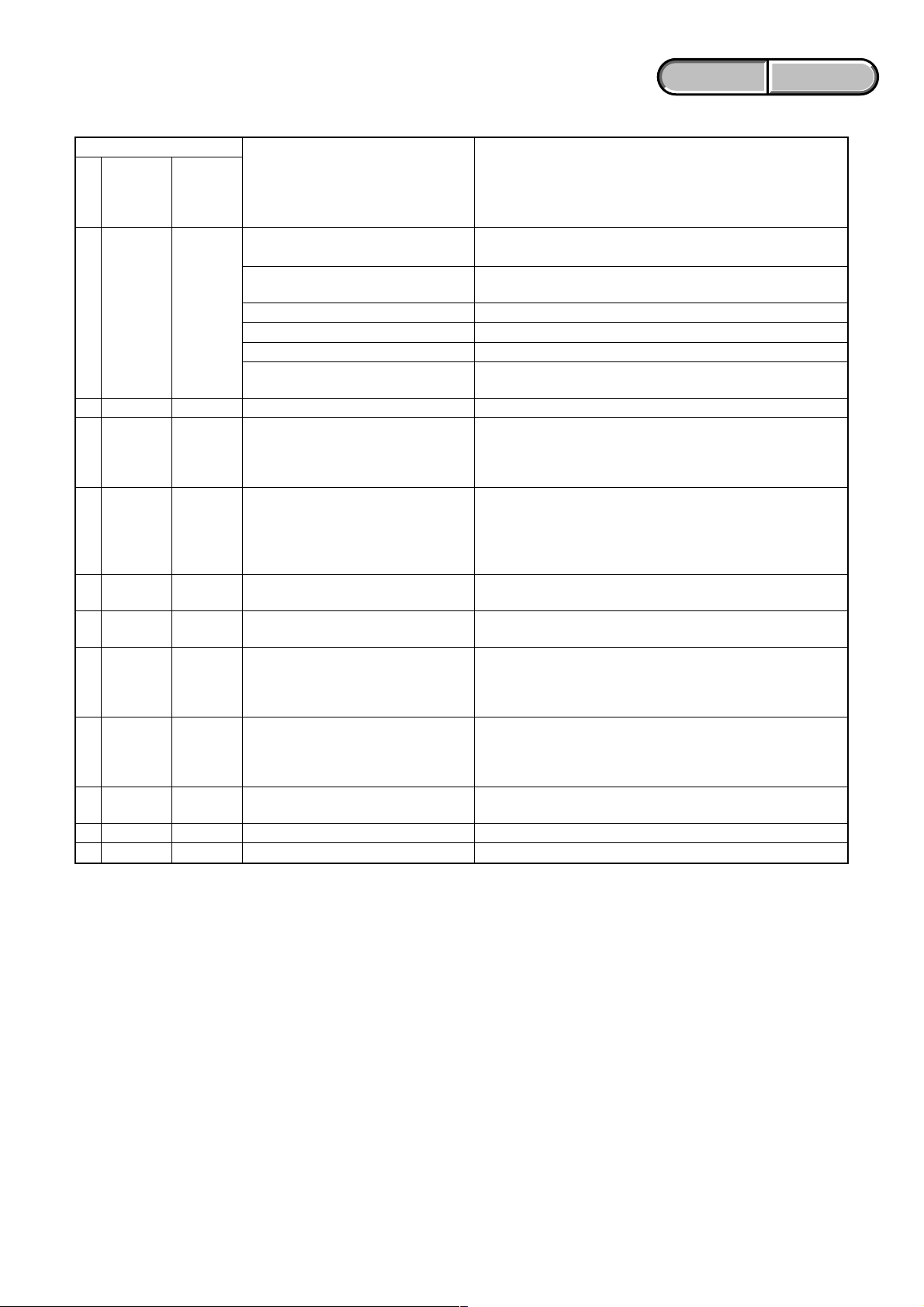

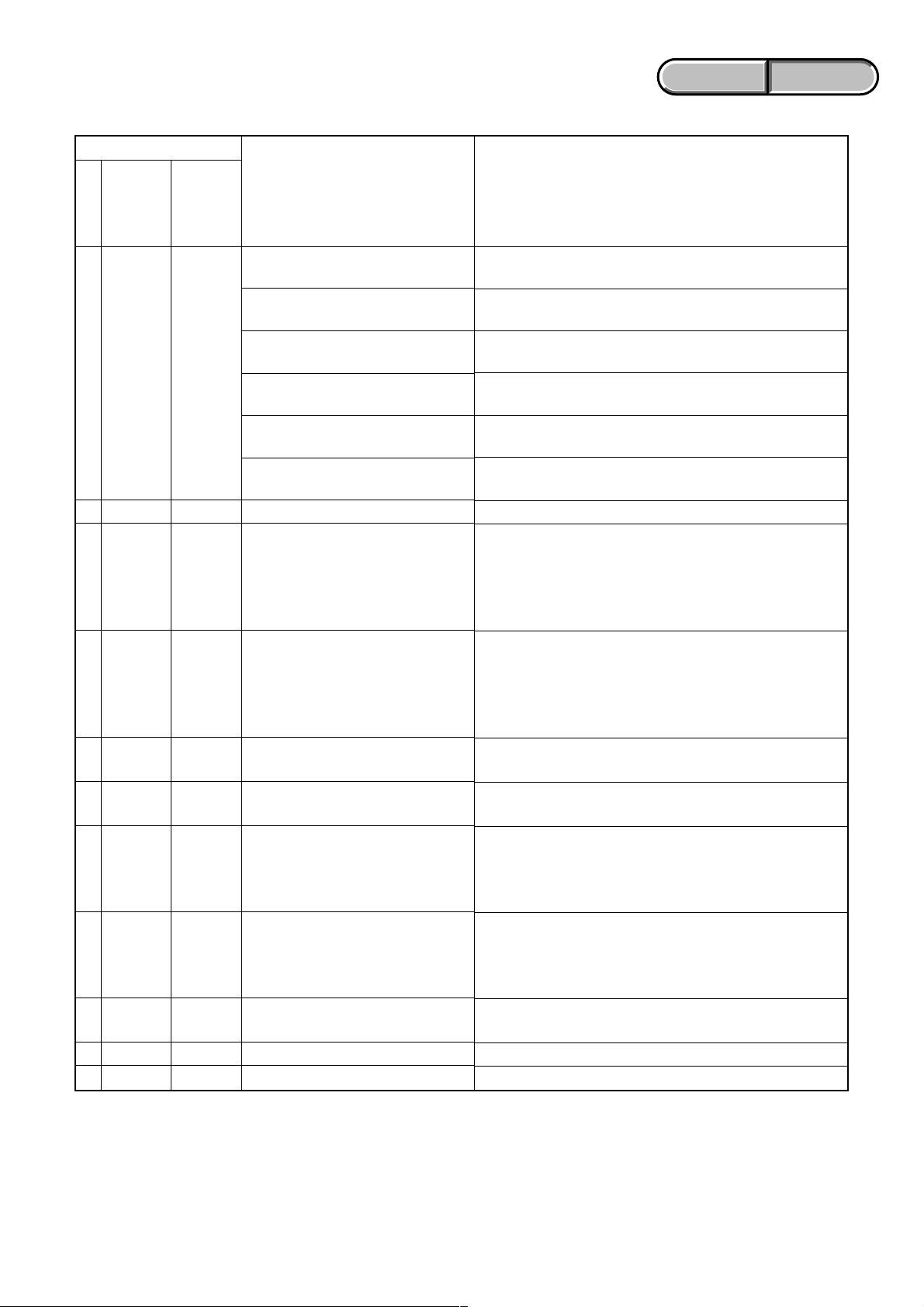

1-8-3. Self-diagnosis Code Table

Self-diagnosis Code

ENGLISH JAPANESE

ENGLISH JAPANESE

Block

Function

Repaired by:

C

13

C

32

E

61

E

61

E

62

E

62

E

62

E

62

E

62

E

91

E

92

Note: After repair, be sure to perform “1-9. PROCESS AFTER FIXING FLASH ERROR”.

Detailed

Code

01

01

00

10

02

10

11

12

20

01

00

Symptom/State

The internal memory has experienced a

media error.

The internal memory has experienced a

format error.

“Memory Stick Duo” is unformatted.

“Memory Stick Duo” is broken.

“Memory Stick Duo” type error

The camera cannot read or write data

on the “Memory Stick Duo”.

Trouble with hardware

Difficult to adjust focus

(Cannot initialize focus)

Zoom operations fault

(Cannot initialize zoom lens.)

Abnormality of IC for steadyshot.

Lens initializing failure.

Lens overheating (PITCH).

Lens overheating (YAW).

Abnormality of thermistor.

Abnormality when flash is being charged.

Non-standard battery is used.

Turn the power off and on again.

Format the internal memory.

Format the “Memory Stick Duo”.

Insert a new “Memory Stick Duo”.

Insert a supported “Memory Stick Duo”.

Turn the power off and on again, or taking out and inserting the

“Memory Stick Duo” several times.

Turn the power off and on again.

Retry turn the power on by the power switch. If it does not

recover, check the focus reset sensor of lens block (pin w; of

CN501 on the SY-208 board). If it is OK, check the focus motor

drive IC (IC503 on the SY-208 board).

Retry turn the power on by the power switch. Check the zoom

reset sensor of lens block (pin wk of CN501 on the SY-208

board), if zooming is performed when the zoom button is

operated. If it is OK, check the zoom motor drive IC (IC503 on

the SY-208 board).

Check or replacement of the IC for steadyshot (IC503 on the SY208 board).

Check or replacement of the IC for steadyshot (IC503 on the SY208 board).

Check the HALL element (PITCH) of optical image stabilizer

(pin q;, qa of CN501 on the SY-208 board). If it is OK, check

PITCH/YAW angular velocity sensor (SE511 on the SY-208

board) peripheral circuits.

Check the HALL element (YAW) of optical image stabilizer (pin

7, qs of CN501 on the SY-208 board). If it is OK, check

PITCH/YAW angular velocity sensor (SE511 on the SY-208

board) peripheral circuits.

Check the OIS temp sensor of optical image stabilizer (pin qk of

CN501 on the SY-208 board).

Checking of flash unit or replacement of flash unit. (Note)

Use the compatible battery only.

Correction

DSC-T700_L2

1-4

ENGLISH JAPANESE

ENGLISH JAPANESE

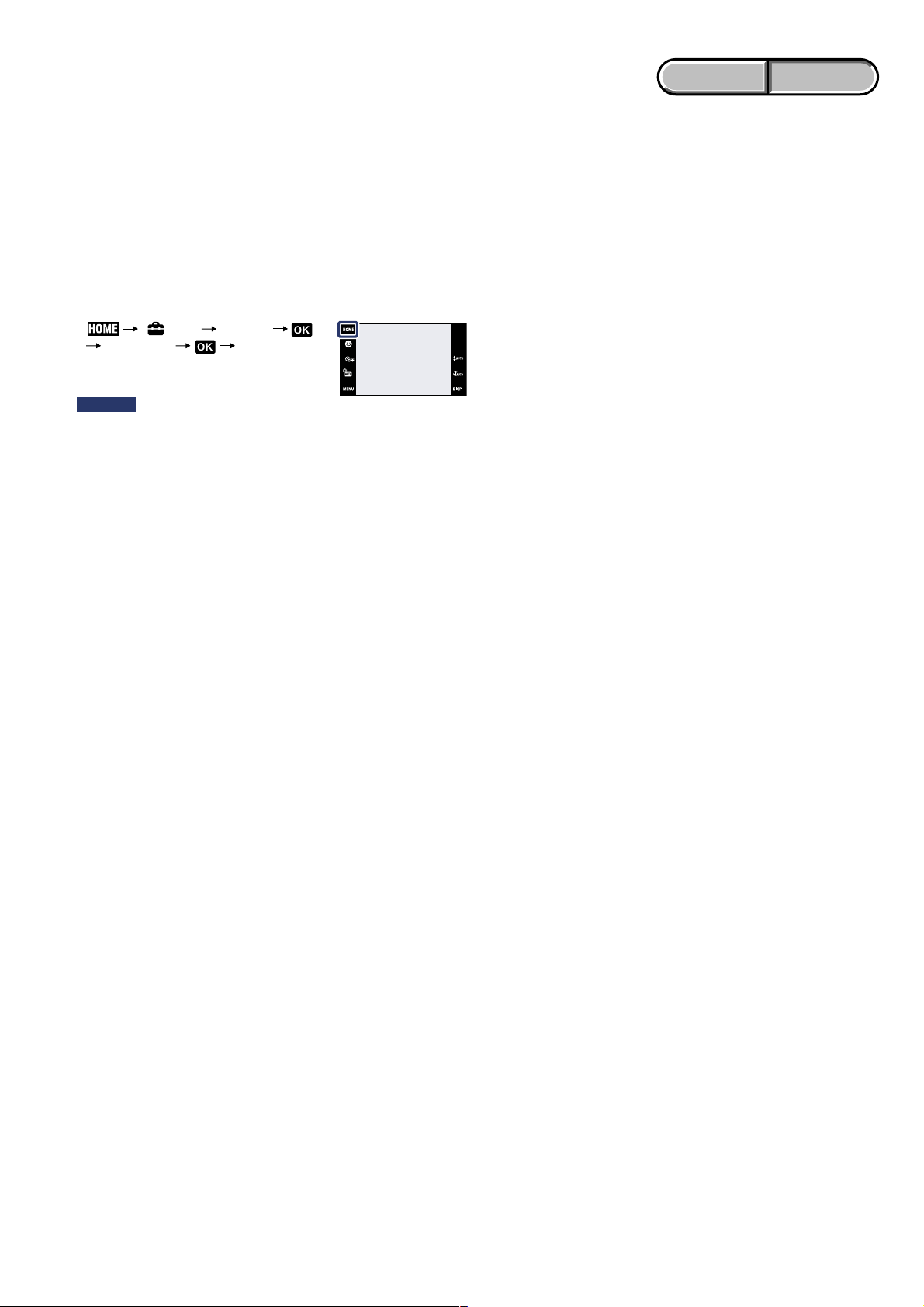

1-9. PROCESS AFTER FIXING FLASH ERROR

When “FLASH error” (Self-diagnosis Code E : 91 : 01) occurs, to prevent any abnormal situation caused by high voltage, setting of the flash

is changed automatically to disabling charge and flash setting.

After fixing, this setting needs to be deactivated. Flash error code can be initialized by the operations on the HOME screen.

Method for Initializing the Flash Error Code

Initializes the setting to the default setting.

Even if you execute this function, the images are retained.

1 (Settings) [Main Settings]

[Initialize] [OK]

Notes

• The Password Lock is not released even if you initialize the settings.

• Be sure not to turn off the camera while initializing.

DSC-T700_L2

1-5

ENGLISH JAPANESE

(再生)ボタン

ー

1. SERVICE NOTE

ENGLISH JAPANESE

1-1. 内蔵メモリーの注意事項について

メモリースティックデュオを本機に挿入しているときは,メモリースティックデュオに画像が記録されます。

本機では,内蔵メモリーとメモリースティックデュオ間での画像コピーや移動はできません。「PMB」をお使いくださ

い。

1-2. パスワードロックについて

パスワードロックを行うと内蔵メモリーの画像を再生できなくなります。

パスワードロックされたセットが入荷した場合で,内蔵メモリー内のデータを読み出す必要がある場合は,パスワードロッ

ク解除を行ってください。

パスワードロックの解除方法について

1.電源を切った状態で,ズーム(W/T)レバーをW側に動かしたまま, (再生ボタン)を押す。

2.電源が入りパスワード解除画面が表示される→ [実行]

3.パスワード解除番号「7669」を入力する→[実行]→[実行]

1-3. PMBPortableについて

・本機の内蔵メモリー内にはPMBPortableが書き込まれています。

・補修用SY-208基板は,PMBPortableが書き込まれた状態で供給されます。

・内蔵メモリーを交換した場合は,PMBPortableを書き込む必要があります。

書き込み方法はPMBガイドを参照してください。

1-4. SY-208基板交換時の注意

Note1:SY-208基板交換の際は,基板交換前に内蔵メモリーのデータを消去して下さい。

Note2:SY-208基板交換の際は,基板交換後に内蔵メモリーのフォーマットおよび初期化を実行して下さい。

仕向けデータ

補修用基板と交換する時,補修用基板に書かれている仕向けデータは元の設定と違っている場合があります。

ADJ編を参照して,「DESTINATIONDATAWRITE」を行ってください。

USBシリアルNo.

セットは,1台毎に異なる固有のID(USBSerialNo.)を書き込んだ後,出荷されています。

新品の補修用基板には,このIDが書き込まれていないので,基板交換後にIDを入力する必要があります。

ADJ編を参照して,「USBSERIALNo.INPUT」を行ってください。

ズーム(W/T)レバ

角速度センサ

補修用基板と交換する時,角速度センサ(SE511)の感度表示を書き留めてください。

ADJ編を参照して,「角速度センサ感度調整」を行ってください。

Note3:SY-208基板のSE511感度表示は補修用基板にしか記載されておりません。

DSC-T700_L2

SY-208 BOARD (SIDE B)

PPP: PITCH Sensor sensitivity

YYY: YAW Sensor sensitivity

SE511

PPP

YYY

1-6

ENGLISH JAPANESE

メモリースティックデュオまたは内蔵メモリーをフォーマット(初期化)します。市

。

ENGLISH JAPANESE

1-5. IC801(内蔵メモリー)交換時の注意

IC801(内蔵メモリー)を交換した際は,下記の作業を行ってください。

1. 調整ソフトの「INTERNALMEMORYFORMAT」を使用して,内蔵メモリーのフォーマットを実行する。

2. PMBを使用して,PMBPortableを書き込む。

1-6.レンズ交換時の注意

レンズ交換時,補修用レンズ添付データシート掲載のPITCH/YAWデータ,FNデータおよびW端調整データを書き留めてください。

ADJ編を参照して,「W端調整」,「角速度センサ感度調整」を行ってください。

Wide Limit Data (2-byte data)

XXYY

X

X

Y

Y

FN Data

F

N

XX

FN data

PITCH/YAW Data

L

1

/

L

2

P.PP / Y.YY

YAW data

PITCH data

Note:PITCH/YAWデータ,FNデータおよびW端調整データは,

補修用部品にのみ記載されています。

1-7. 内蔵メモリーのデータコピーおよび消去方法

内蔵メモリーのコピー方法

本機では,内蔵メモリーとメモリースティックデュオ間での画像コピーや移動はできません。「PMB」をお使いください。

内蔵メモリーのフォーマット方法

販のメモリースティックデュオはフォーマット済みのため,フォーマットの必要は

ありません。

1(メモリー管理)[メモリーツー

ル][フォーマット][実行]

ご注意

フォーマットすると,プロテクトしてある画像も含めて,すべてのデータが消去され,元に戻せません

内蔵メモリーへデータを書き戻す方法

PMBから[メディアへ書き出し]を行ってください。

(エクスプローラーで画像ファイルをPCから移動しても,アルバム情報のデータフォルダに反映されない為,画像ファイル

を認識しません。)

DSC-T700_L2

1-7

1-8. 自己診断機能

」

LCD画面

1-8-1. 自己診断機能について

本機の動作に不具合が生じたとき,自己診断機能が働き,

L C D 画面に,どう処置したらよいか判断できる表示を行い

ます。自己診断機能については取扱説明書にも掲載されて

います。

C : 3 2 : 00

3.2Hz点滅

ENGLISH JAPANESE

ENGLISH JAPANESE

1-8-2. 自己診断表示

本機の動作に不具合が生じたとき,LCD画面にアルファベッ

トと4桁の数字が表示され,3.2Hzで点滅します。この5文字

の表示によって対応者分類および不具合の生じたブロックの

分類,不具合の詳細コードを示します。

3 2C

対応者分類

C :お客さま自身で対応

E :サービスエンジニア

で対応 デュオ”をフォーマッ

ブロック分類

対応方法の違いにより分類

例 13・・・“メモリースティック

トする

32・・・電源を入れ直す

0 0

詳細コード

「1-8-3 .自己診断コード表

を参照

DSC-T700_L2

1-8

1-8-3. 自己診断コード表

自己診断コード

対

ブロック

応

機能

者

C

13

C

32

E

61

E

61

E

62

E

62

E

62

E

62

E

62

E

91

E

92

Note:交換後は,必ず「1-9.フラッシュエラー発生時の対処法」を行って下さい。

詳細

コード

01

01

00

10

02

10

11

12

20

01

00

症状/状態

内蔵メモリーにメディアエラーが

あった。

内蔵メモリーにフォーマットエ

ラーがあった。

フォーマットしていないメモリー

スティックデュオを入れた。

メモリースティックデュオが

壊れている。

メモリースティックデュオの

タイプエラーを検出した。

メモリースティックデュオが

読み/書きできない。

ハードウェアトラブルを検出した。

フォーカスが合いにくい。

(フォーカスの初期化ができない)

ズーム動作の異常。

(ズームレンズの初期化ができな

い)

手振れ補正用ICの異常。

手振れ補正用ICの異常。

(レンズ初期化異常)

レンズオーバーヒート(PITCH)

レンズオーバーヒート(YAW)

サーミスタの異常。

フラッシュの充電異常。

規定外の充電池が使用された。

電源を入れ直す。

内蔵メモリーをフォーマットする。

メモリースティックデュオをフォーマットする。

新しいメモリースティックデュオに交換する。

規格内のメモリースティックデュオを挿入する。

電源の入れ直し,またはメモリースティックデュオ

の挿し/外しを数回試す。

電源を入れ直す。

操作スイッチの電源を入れ直す。

復帰しない場合はレンズブロックのフォーカスリセットセ

ンサ(SY-208基板CN501w;ピン)を点検する。異常なけ

ればフォーカスモータ駆動IC(SY-208基板IC503)を点検

する。

操作スイッチの電源を入れ直す。

ズームボタンを操作したときにズーム動作をすればレンズ

ブロックのズームリセットセンサ(SY-208基板CN501wk

ピン)を点検する。異常なければズームモータ駆動IC

(SY-208基板IC503)を点検する。

手振れ補正用IC(SY-208基板IC503)を点検または交換す

る。

手振れ補正用IC(SY-208基板IC503)を点検または交換す

る。

光学手振れ補正ブロックのホール素子(PITCH)(SY-208

基板CN501q;,qaピン)を点検する。異常なければ

PITCH/YAW角速度センサ(SY-208基板SE511)周辺の回

路を点検する。

光学手振れ補正ブロックのホール素子(YAW)(SY-208

基板CN5017,qsピン)を点検する。異常なければ

PITCH/YAW角速度センサ(SY-208基板SE511)周辺の回

路を点検する。

光学手振れ補正ブロックのサーミスタ(SY-208基板

CN501qkピン)を点検する。

フラッシュユニットを点検または交換する。(Note)

規定の充電池を使用する。

ENGLISH JAPANESE

ENGLISH JAPANESE

対応/方法

DSC-T700_L2

1-9

ENGLISH JAPANESE

お買い上げ時の設定に戻します。

。

ENGLISH JAPANESE

1-9. フラッシュエラー発生時の対処法

本機はフラッシュエラー(自己診断コードE:91:01)が発生した場合,高電圧による異常を防止するために自動的にフラッシュ

充電および発光禁止の設定になります。

フラッシュエラー発生後はエラーの解除を行う必要があります。エラーの解除はホーム画面から初期化操作を実行することによ

り行います。

フラッシュエラーの解除方法

[設定リセット]を実行しても,画像は削除されません。

1(設定)[本体設定]

[設定リセット][実行]

ご注意

・設定リセットを実行しても,[パスワードロック]は解除されません

・設定リセット中は電源が切れないようにご注意ください。

DSC-T700_L2

1-10E

NOTE FOR REPAIR

2. DISASSEMBLY

• Make sure that the flat cable and flexible board are not cracked of bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

• When remove a connector, don’t pull at wire of connector. It is possible that a wire is snapped.

• When installing a connector, don’t press down at wire of connector.

It is possible that a wire is snapped.

• Do not apply excessive load to the gilded flexible board.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

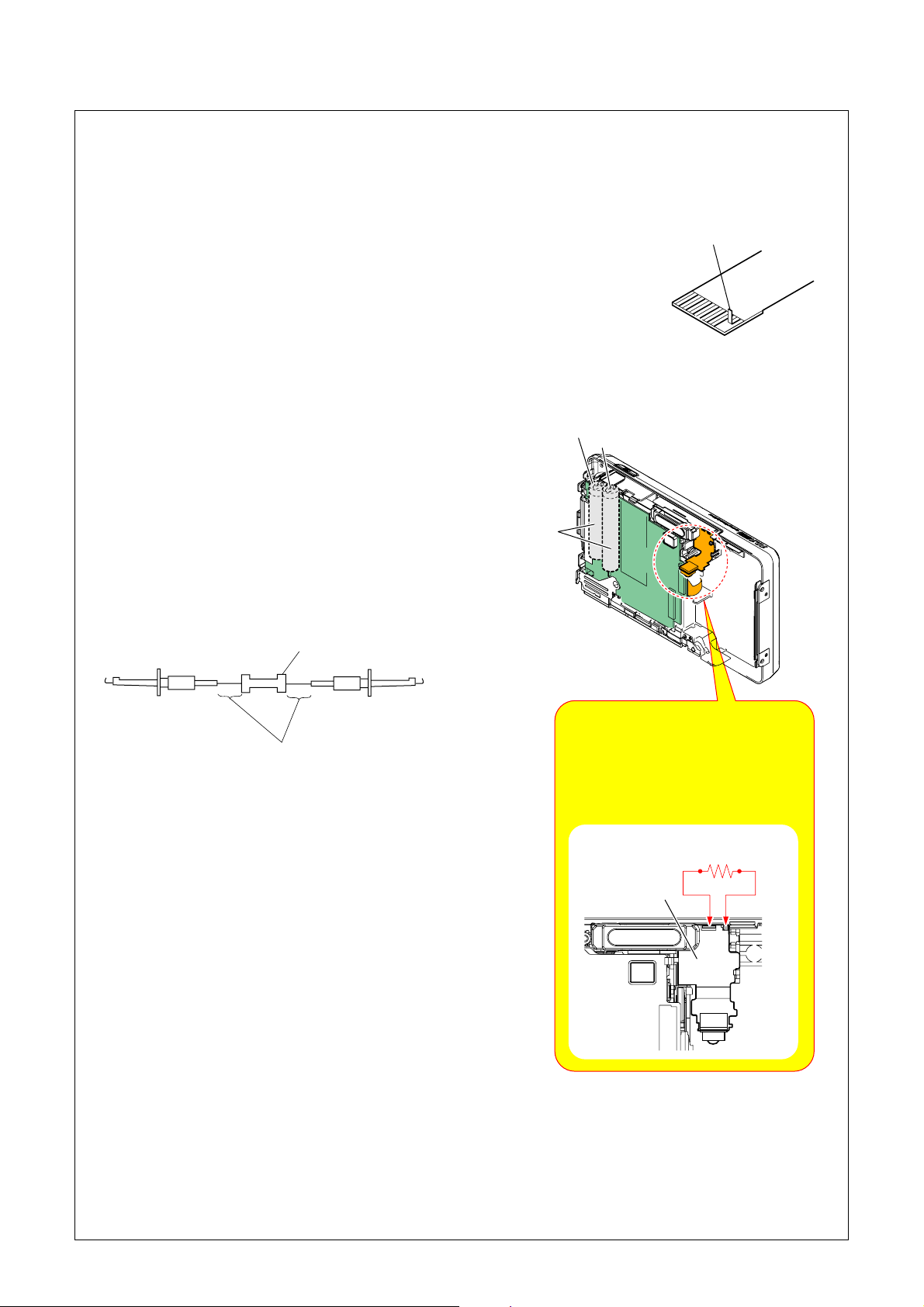

DISCHARGING OF THE ST-203 FLEXIBLE BOARD’S CHARGING CAPACITOR

(C901, C902)

The charging capacitor (C901, C902) of the ST-203 flexible board

is charged up to the maximum 315 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by

the charged voltage which is kept without discharging when the

main power of the unit is simply turned off. Therefore, the

remaining voltage must be discharged as described below.

Preparing the Short Jig

To preparing the short jig, a small clip is attached to each end of

a resistor of 1 kΩ /1 W (1-215-869-11).

Wrap insulating tape fully around the leads of the resistor to

prevent electrical shock.

Capacitors

C901

C902

SY-208

1 kΩ/1 W

Wrap insulating tape.

Note: High-voltage cautions

Discharging the Capacitor

Short-circuit between the two points

with the short jig about 10 seconds.

To avoid the spark with the metal plate,

wrap the short jig with the insulation tape.

R:1 kΩ/1 W

(Part code: 1-215-869-11)

ST-203 Flexible

Board

DSC-T700_L2

2-1

2-1. IDENTIFYING PARTS

Cabinet (Rear)

SY-208 Board

RL Block Assy

Loudspeaker

(1.0cm)

LCD Block

Frame Assy

⋅ BT-046 Flexible Board

ST-203 Flexible

Board

Front Block

- DISASSEMBLY FLOW -

2-2-1. OVERALL SECTION

- Front Block

- Lens Block

2-2-2. MAIN SECTION

- SY-208 Board

- ST-203 Flexible Board

- Rear Section

2-2-3. REAR SECTION

- LCD Block

BT Lid Assy

Lens Block

⋅ CD-743 Flexible Board

DSC-T700_L2

2-2

HELP

EXPLODED VIEW

HELP

2-2. DISASSEMBLY

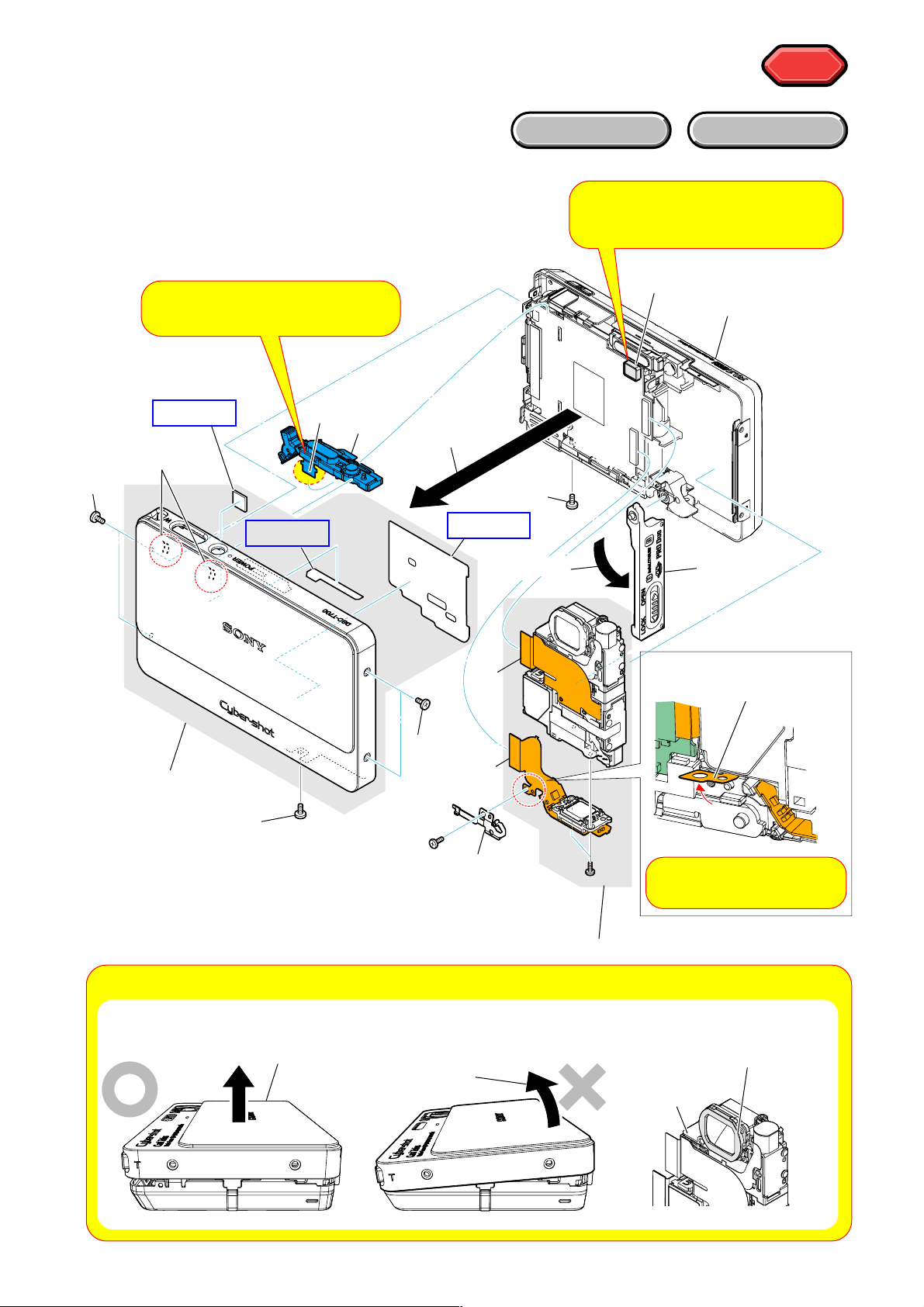

2-2-1. OVERALL SECTION

Follow the disassembly in the numerical order given.

1 Front Block (1-1 to 1-9)

2 Lens Block (2-1 to 2-6)

When removing the Front block,

be careful not to damage the flexible board.

1-1

(#145/

#146)

HELP02

1-8

(Claws)

HELP01

1-7

1-9

1-6

HELP02

1-5

(#27)

1-4 (Open)

HARDWARE LIST

Note: Microphone holder caution

There are some cases the microphone holder

is caught on the front block.

Microphone

Holder

Main Section

(See Page 2-4)

2-3

1

Front Block

1-3

(#145/

#146)

Note: Front Block caution

Raise up Front Block holizontally.

2-5

1-2

(#145/

#146)

2-1 (#27)

2-6

2-2

2 Lens Block

Do not raise up Front Block

at a tilt. (Causes damaging the

ornamental plate of Lens Unit

(LSV-1300A).)

2-4

(Peel off the flexible cable.)

On assembling, note that do not

forget to attach the flexible cable.

Ornamental

Plate

Lens Unit

(LSV-1300A)

DSC-T700_L2

2-3

EXPLODED VIEW

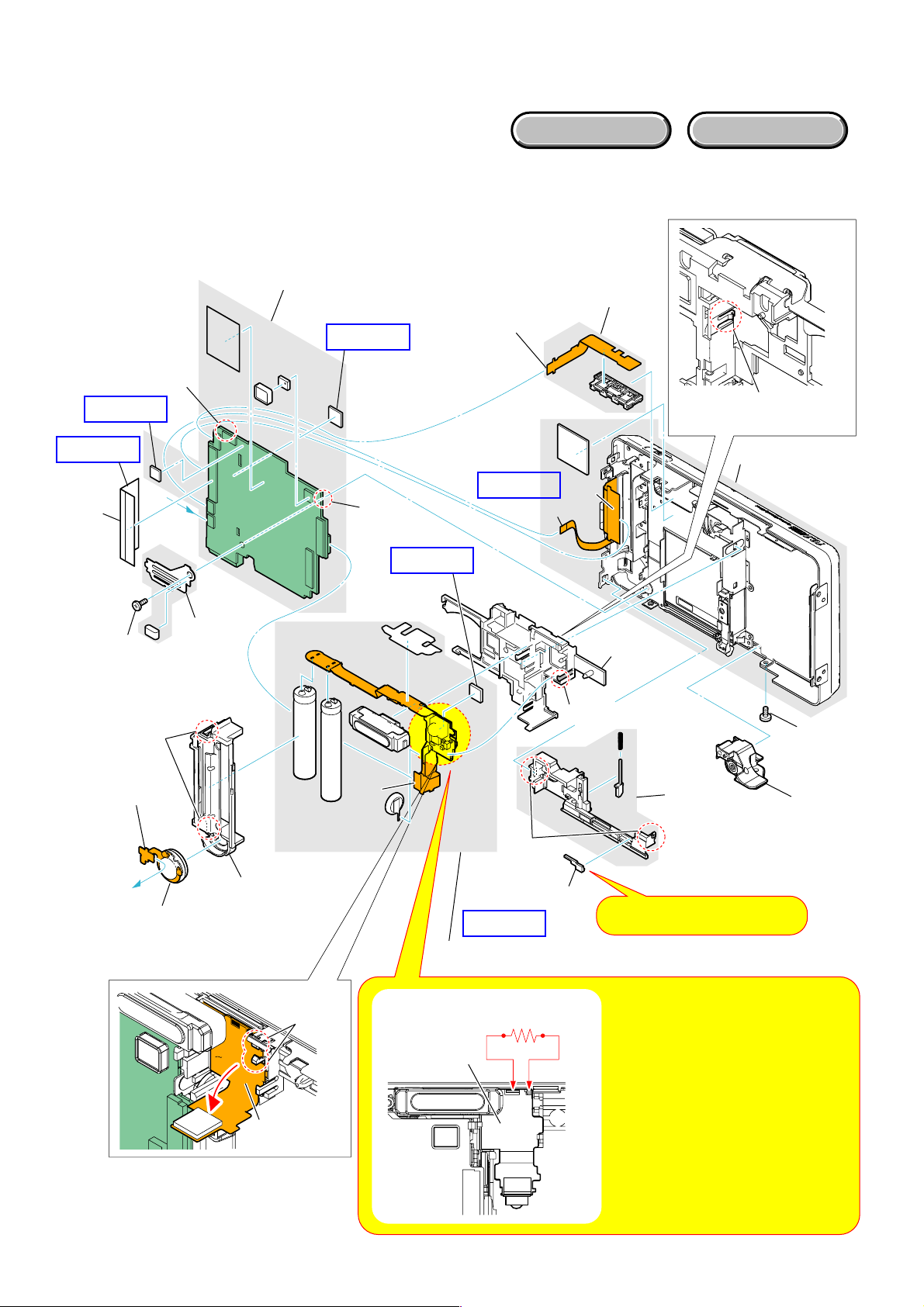

2-2-2. MAIN SECTION

Follow the disassembly in the numerical order given.

1 SY-208 Board (1-1 to 1-11)

2 ST-203 Flexible Board (2-1 to 2-9)

3 Rear Section (3-1 to 3-3)

1 SY-208 Board

HELP04

1-10 (Claw)

HELP03

HARDWARE LIST

3-3

1-3

2-7 (Claw)

Seen from Rear side

HELP05

1-2

2-5

(Claws)

1-6

1-8

(#27)

A

A

2-4

1-9

SY-208

2-6

1-11

(Claw)

1-7

HELP07

HELP06

2-2

(Claws)

HELP08

1-5

2-1

1-4

2-9

2-8 (Claw)

2-3

Be sure not to lose MS light guide.

3

Rear Section

(See Page 2-5)

3-1

(#145/#146)

3-2

DSC-T700_L2

1-1

(Claws)

ST-203 Flexible

Board

ST-203 Flexible Board

2

R:1 kΩ/1 W

(Part code: 1-215-869-11)

ST-203 Flexible

Board

2-4

Note: High-voltage cautions

Discharging the Capacitor

Short-circuit between the two points

with the short jig about 10 seconds.

To avoid the spark with the metal plate,

wrap the short jig with the insulation tape.

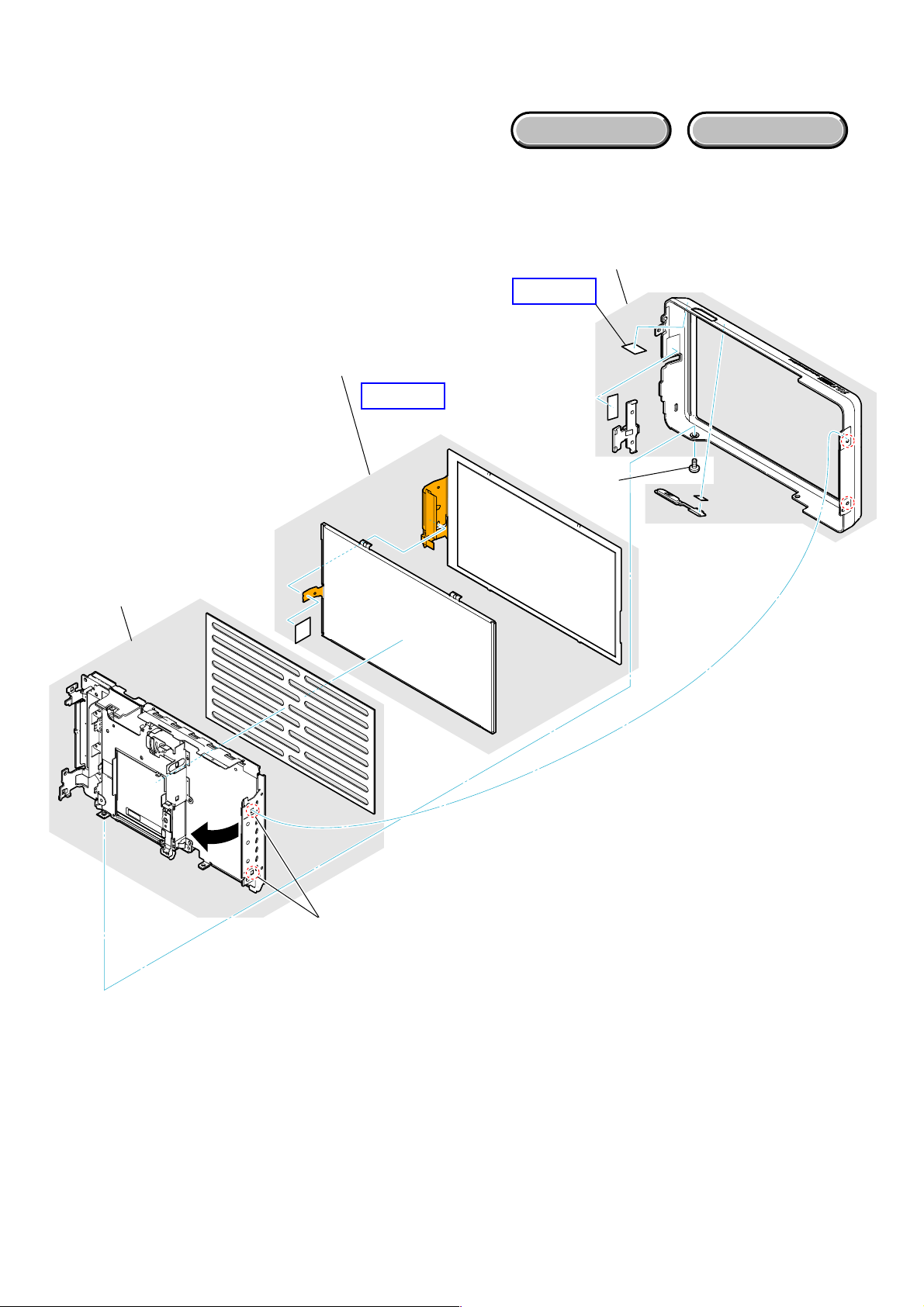

2-2-3. REAR SECTION

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 LCD Block (1-1 to 1-4)

1 LCD Block

HARDWARE LIST

1-3

HELP10

HELP09

1-1

(#27)

1-4

1-2

(Claws)

DSC-T700_L2

2-5E

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

HELP01

INTERCEPTION PROTECTION

SHEET PUTTING POSITION

Cabinet Front Assy

Plate Interception Protection Sheet

HELP02

PROTECTION SHEET (250), FRONT CUSHION (P) PUTTING POSITION

1.0mm

Cabinet Front Assy

Plate

Plate

Edge of rib

Lib

Wall surface

inside

Press is against the wall surface inside.

DSC-T700_L2

Protection Sheet (250)

Front Cushion (P)

HELP

Loading...

Loading...