Page 1

DSC-P9

SERVICE MANUAL

Ver 1.0 2002. 04

Revision History

Revision History

Link

Link

SPECIFICATIONS

SPECIFICATIONS

BLOCK DIAGRAMS

BLOCK DIAGRAMS

LEVEL 2

US Model

Canadian Model

AEP Model

UK Model

E Model

Hong Kong Model

Australian Model

Chinese Model

Korea Model

Tourist Model

Japanese Model

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

SERVICE NOTE

SERVICE NOTE

DISASSEMBLY

DISASSEMBLY

•For INSTRUCTION MANUAL, refer to SERVICE MANUAL, LEVEL 1 (992997341.pdf).

• This service manual contains information for Japanese model as well.

• Note in Lens Frame Installation.

On the JK-226, JK-227, SY-77 boards

This service manual procides the information that is premised

the circuit board replacement service and not intended repair

inside the JK-226, JK-227, SY-77 boards.

Therefore, schematic diagram, printed wiring board and

electrical parts list of the JK-226, JK-227, SY-77 boards are not

shown.

The following pages are not shown.

FRAME SCHEMATIC DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

SY-77 board

Schematic diagram ......................... Pages 4-9 to 4-28

Printed wiring board ........................ Pages 4-43 to 4-46

Electrical parts list ........................... Pages 6-9 to 6-13

JK-226, JK-227 boards

Schematic diagram ......................... Pages 4-33 to 4-34

Printed wiring board ........................ Pages 4-49 to 4-50

Electrical parts list ........................... Pages 6-6

The above-described information is shown in service

manual Level 3.

ADJUSTMENTS

ADJUSTMENTS

REPAIR PARTS LIST

REPAIR PARTS LIST

DIGITAL STILL CAMERA

Page 2

DSC-P9

COVER

COVER

SPECIFICATIONS

System

Image device 8.98 mm (1/1.8 type) color

Total pixels number of camera

Lens 3× zoom lens

CCD

Primary color filter

Approx. 4 130 000 pixels

17

/

−

32

15

/16 inches)

−

16

4 19/32 inches))

f=8

24.0 mm (5/

−

(35 mm camera conversion: 39 to

117mm (1

5.6

F2.8

−

Camera

Effective pixels number of camera

Exposure control

White balance

Data formats Movies: MPEG1 (M onaural)

Recording media

Flash Recommended distance

Approx. 3 950 000 pixels

Automatic,

Scene selection (three modes)

Automatic, Daylight, Cloudy,

Fluorescent, Incandescent

Still images: JP EG, GIF (for Clip

Motion)

Audio with still image: MPEG1

(Monaural)

“Memory Stick”

0.5 to 3.8 m (1.6 to 12.5 ft) (W)

0.6 to 2.4 m (2 to 7.9 ft) (T)

(when ISO sens itivity is set to Auto)

Output connectors

A/V OUT (MONO) jack

USB jack mini-B

Minijack

Video: 1 Vp-p, 75

sync negative

Audio: 327 mV (at a 47 k

Output impedance 2.2 k

Ω

, unbalanced,

Ω

load)

Ω

LCD screen

LCD panel used

Total number of do ts

3.8 cm (1.5 type) TFT drive

123 200 (560×220) dots

Power, general

Used battery pack

Power requireme nts

Power consumption (when shooting)

Operating temperature range

Storage temperature range

Dimensions 114 × 51.5 × 35.8 mm

Mass 206 g (7 oz) (NP-FC10 battery pack,

Microphone Electret condenser microphone

Speaker Dynamic speaker

NP-FC10

3.6 V

1.9W

+

40°C (32° to +104°F)

0° to

20° to +60°C (4° to +140°F)

1

/2 × 2 × 1 3/8 inches)

(4

(W/H/D, protruding portions not

included)

“Memory Stick” and wrist strap

included)

AC-LS1A AC power adaptor

Power requirement s

Rated output voltage

Operating temperature range

Storage temperature range

Dimensions 105 × 36 × 56 mm (4

Mass Approx. 180 g (6 oz)

AC 100 – 240 V, 50/60 Hz

DC 4.2 V, 1.5 A

+

40°C (32° to +104°F)

0° to

20° to +60°C (4° to +140°F)

1

/4 inches) (W/H/D, protruding

2

parts not included)

(adaptor only)

1

/4 × 1 7/16 ×

NP-FC10 battery pack

Used battery Lithium ion battery

Maximum voltage

Nominal voltage

Capacity 2.4 Wh (675 mAh)

DC 4.2 V

DC 3.6 V

Accessories

•A/V connecting cable (1)

•NP-FC10 battery pack (1)

•AC-LS1A AC power adaptor (1)

•Power cord (mains lead) (1)

•USB cable (1)

•Wrist strap (1)

•“Memory Stick” (16MB) (1)

•CD-ROM (USB driver: SPVD-008) (1)

•Operating Instructions (1)

Design and specifications are subject to change

without notice.

— 2 —

Page 3

DSC-P9

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show ob vious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

— 3 —

Page 4

DSC-P9

TABLE OF CONTENTS

Section Title Page Section Title Page

1. SERVICE NOTE ························································1-1

Self-diagnosis Display····················································· 1-3

2. DISASSEMBLY

2-1. BT Lid ·············································································2-2

2-2. Cabinet (Front) Assembly ···············································2-2

2-3. Cabinet (Rear) Assembly················································· 2-3

2-4. LCD Module····································································2-3

2-5. Cabinet (Bottom) Assembly ············································2-4

2-6. Lens Block Assembly······················································2-4

Service Position (SY-77 Board: Side A)··························2-5

2-7. Control Switch Block ······················································2-5

2-8. SY-77 Board ···································································· 2-6

2-9. Memory Stick Connector ················································2-6

2-10. ST-70 Board·····································································2-7

2-11. SW-368 Board ································································· 2-7

2-12. JK-227 Board ··································································2-8

Service Position (SY-77 Board: Side B)··························2-8

2-13. Circuit Boards Location ·················································· 2-9

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram ···················································3-1

3-8. Power Block Diagram 1 ················································3-15

3-9. Power Block Diagram 2 ················································3-17

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagrams·············································4-1

Frame Schematic Diagram (1/2) ·····································4-1

Frame Schematic Diagram (2/2) ·····································4-3

4-2. Schematic Diagrams························································4-5

CD-397 (CCD IMAGER) ···············································4-7

SW-368 (1/2) (CONTROL SWITCH) ··························4-29

SW-368 (2/2)

(LCD DRIVE, TIMING GENERATOR) ·····················4-31

ST-70 (FLASH DRIVE) ···············································4-35

4-3. Printed Wiring Boards ···················································4-39

CD-397 ··········································································4-41

SW-368··········································································4-47

ST-70 ·············································································4-51

4-4. Waveforms·····································································4-54

4-5. Parts Location································································4-57

5. ADJUSTMENTS

Before Starting Adjustment ·······················································5-1

1-1. Adjusting Items when Replacing

Main Parts and Boards ····················································5-2

5-1. Camera Section Adjustments···········································5-3

1-1. Preparations Before Adjustment······································5-3

1-1-1.List of Service Tools ························································5-3

1-1-2.Preparations ·····································································5-4

1-1-3.Discharging of the Flashlight Power Supply··················· 5-4

1-1-4.Precautions ······································································5-6

1. Setting the Switch···························································· 5-6

2. Order of Adjustments ······················································5-6

3. Subjects ···········································································5-6

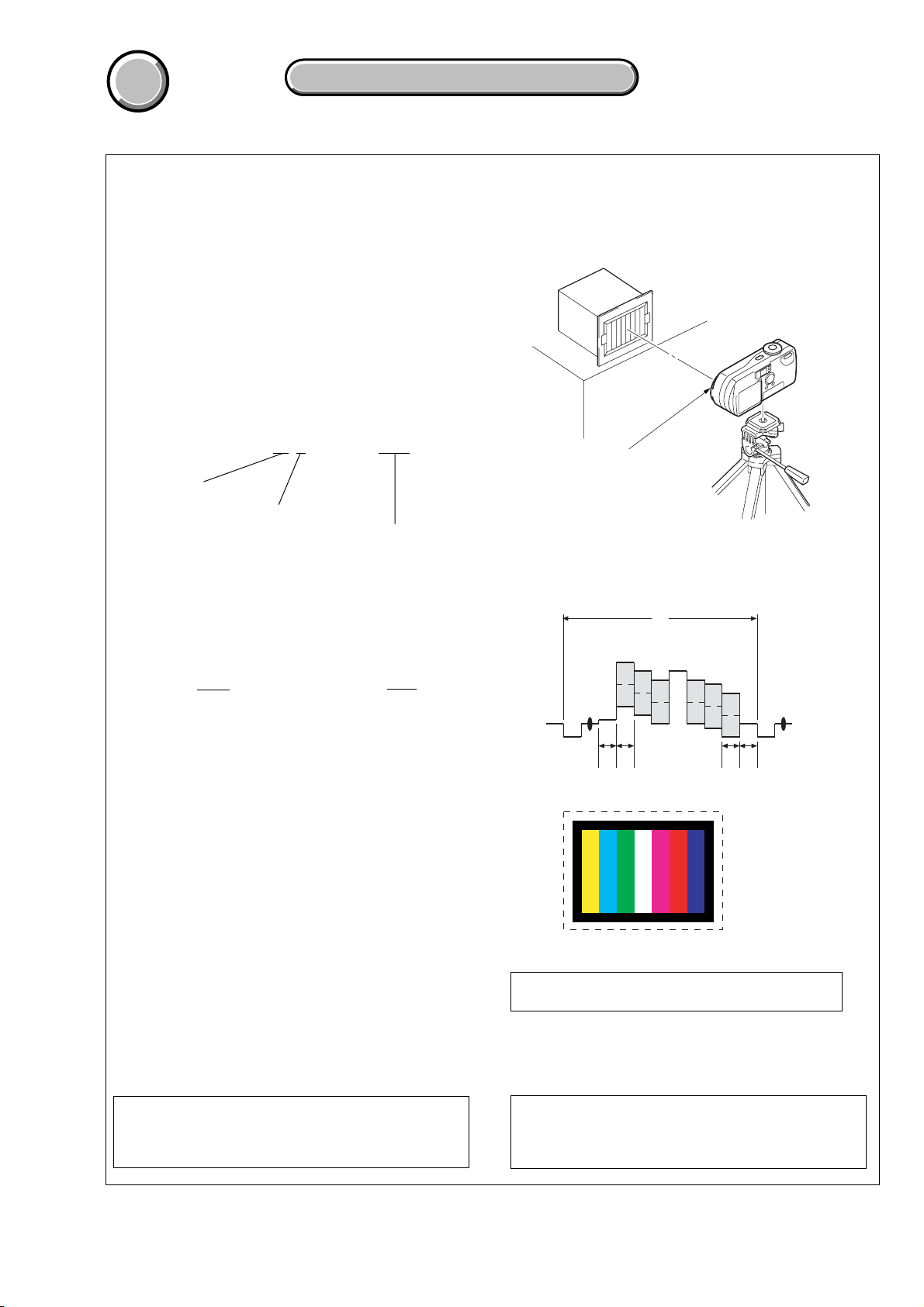

4. Preparing the Flash Adjustment Box·······························5-7

1-2. Initialization of A, B, D, E, F, 7, 9 Page Data ················· 5-8

1-2-1.Initialization of A, D Page Data ······································ 5-8

1. Initializing A, D Page Data ··············································5-8

2. Modification of A, D Page Data ······································ 5-8

3. A Page Table····································································5-8

4. D Page Table····································································5-8

1-2-2.Initialization of B, E, F, 7, 9 Page Data ···························5-9

1. Initializing B, E, F, 7, 9 Page Data ··································5-9

2. Modification of B, E, F, 7, 9 Page Data.··························5-9

3. B Page Table ····································································5-9

4. E Page Table ····································································5-9

5. F Page Table ··································································5-10

6. 7 Page Table···································································5-12

7. 9 Page Table···································································5-12

1-3. Video System Adjustments············································ 5-13

1. Video Sync Level Adjustment ·······································5-13

2. Video Burst Level Check···············································5-13

1-4. Camera System Adjustments·········································5-14

Data Setting During Camera System Adjustments········5-14

Picture Frame Setting ····················································5-15

Check on the Oscilloscope ············································5-15

1. Flange Back Adjustment

(Using the minipattern box) ··········································5-16

2. Flange Back Adjustment

(Using the flange back adjustment chart)······················5-17

3. Flange Back Check························································ 5-17

4. F No. Compensation ······················································ 5-18

5. Mechanical Shutter Adjustment ····································5-18

6. Light V alue Adjustment ·················································5-19

7. Mixed Color Cancel Adjustment··································· 5-19

8. Auto White Balance 3200K Standard Data Input 1 ······5-20

9. Auto White Balance 3200K Standard Data Input 2 ······5-21

10. Auto White Balance 3200K Standard Data Input 3 ······ 5-21

11. Auto White Balance 3200K Check ·······························5-22

12. Auto White Balance 5800K Standard Data Input 1 ······ 5-23

13. Auto White Balance 5800K Standard Data Input 2 ······ 5-24

14. Auto White Balance 5800K Standard Data Input 3 ······ 5-24

15. Auto White Balance 5800K Check ·······························5-25

16. CCD Linearity Check ····················································5-26

17. Color Reproduction Adjustment····································5-27

18. CCD White Defect Compensation ································5-28

19. CCD Black Defect Compensation·································5-29

20. Strobe White Balance Adjustment·································5-30

21. AF Illumination Check ··················································5-32

1-5. LCD System Adjustments ·············································5-33

1. LCD Initial Data Input ··················································5-34

2. VCO Adjustment (SW-368 Board)································5-34

3. Black Limit Adjustment (SW-368 Board) ·····················5-35

4. Bright Adjustment (SW-368 Board) ······························5-35

5. Contrast Adjustment (SW-368 Board) ··························5-36

6. VG Center Adjustment (SW-368 Board)·······················5-36

7. PSIG Gray Adjustment (SW-368 Board) ······················5-37

8. V-COM Adjustment (SW-368 Board) ··························· 5-37

9. White Balance Adjustment (SW-368 Board) ················5-38

5-2. Service Mode·································································5-39

2-1. Adjusting Remote Commander ·····································5-39

1. Used the Adjusting Remote Commander ······················5-39

2. Precautions upon Using the Adjusting

Remote Commander······················································5-39

2-2. Data Process ··································································5-40

2-3. Service Mode·································································5-41

1. Setting the Test Mode ····················································5-41

2. Bit V alue Discrimination ···············································5-41

3. Mode Dial Check (1) ·····················································5-41

4. Mode Dial Check (2) ·····················································5-41

5. Switch Check (1) ···························································5-41

6. Switch Check (2) ···························································5-42

7. LED Check ····································································5-42

8. Self Diagnosis Code ······················································5-42

— 4 —

Page 5

Section Title Page

6. REPAIR PARTS LIST

6-1. Exploded Vie ws ·······························································6-1

6-1-1.Cabinet (Front) Section ···················································6-1

6-1-2.Cabinet (Rear) Assembly·················································6-2

6-1-3.Lens Block and LCD Section ··········································6-3

6-1-4.Battery Holder Assembly ················································6-4

6-2. Electrical Parts List ·························································6-5

* The color reproduction frame is shown on page 113.

DSC-P9

— 5 —

Page 6

DSC-P9

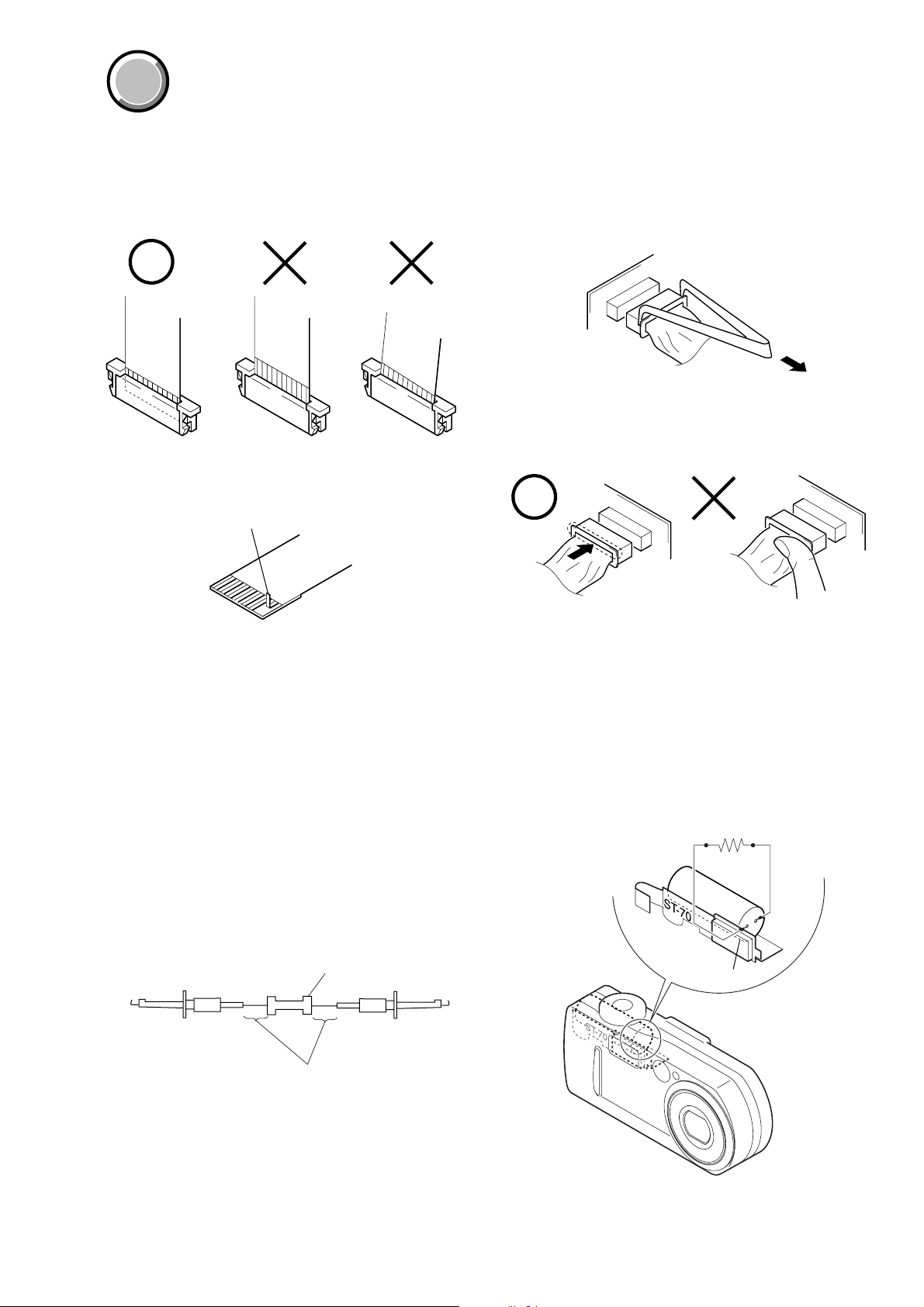

When installing a connector, don’t press down at wire of connector.

It is possible that a wire is snapped.

COVER

COVER

SECTION 1

SERVICE NOTE

• NOTE FOR REPAIR

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

When remove a connector, don’t pull at wire of connector.

It is possible that a wire is snapped.

[Discharging of the ST-70 flexible board’s charging

capacitor (C510)]

The charging capacitor (C003) of the ST -70 flexible board is char ged

up to the maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

battery is handled by hand. The electric shock is caused by the

charged voltage which is kept without discharging when the main

power of the unit is simply turned off. Therefore, the remaining

voltage must be discharged as described below.

Preparing the Short Jig

To preparing the short jig, a small clip is attached to each end of a

resistor of 1 kΩ /1 W (1-215-869-11).

Wrap insulating tape fully around the leads of the resistor to prevent

electrical shock.

1 kΩ/1 W

Wrap insulating tape.

Discharging the Capacitor

Short-circuit between the positive and the negative terminals of

charged capacitor with the short jig about 10 seconds.

R:1 kΩ/1 W

(Part code:

1-215-869-11)

Capacitor

1-1

Page 7

DSC-P9

[Precaution on Replacing the Video Lens or the SY-77

Board]

The DSC-P9 uses the position sensor to detect the zoom position.

Accordingly, the zoom position will v ary if the position data changes

due to the replacement of the video lens or the SY-77 board, thus

causing the video lens to collide against the mechanism end when

the power is turned off.

Though the position data is calibrated at the “Flange Back

Adjustment”, add the following work when making an adjustment

at the replacement of video lens to prevent a collision of video lens.

When Replacing the Video Lens

1) With current video lens assembled, turn the power on, and set

the bit value of Bit0 on Page:9, Address:17 to “0” using the

adjusting remote commander, then turn the power off.

2) Replace the video lens with a new one, turn the power on, and

perform the “Flange Back Adjustment”.

Thus, new position data will be written.

3) After the “Flange Back Adjustment”, return the bit value of Bit0

on Page:9, Address:17 to “1” using the adjusting remote

commander.

When Replacing the SY-77 Board

1) Replace the SY-77 board with a new one, set the mode dial to

“PLAY”, turn the power on, and set the bit value of Bit0 on

Page:9, Address:17 to “0” using the adjusting remote

commander, then turn the power off.

2) Set the mode dial to “CAMERA”, turn the power on, and

perform the “Flange Back Adjustment”.

Thus, new position data will be written.

3) After the “Flange Back Adjustment”, return the bit value of Bit0

on Page:9, Address:17 to “1” using the adjusting remote

commander.

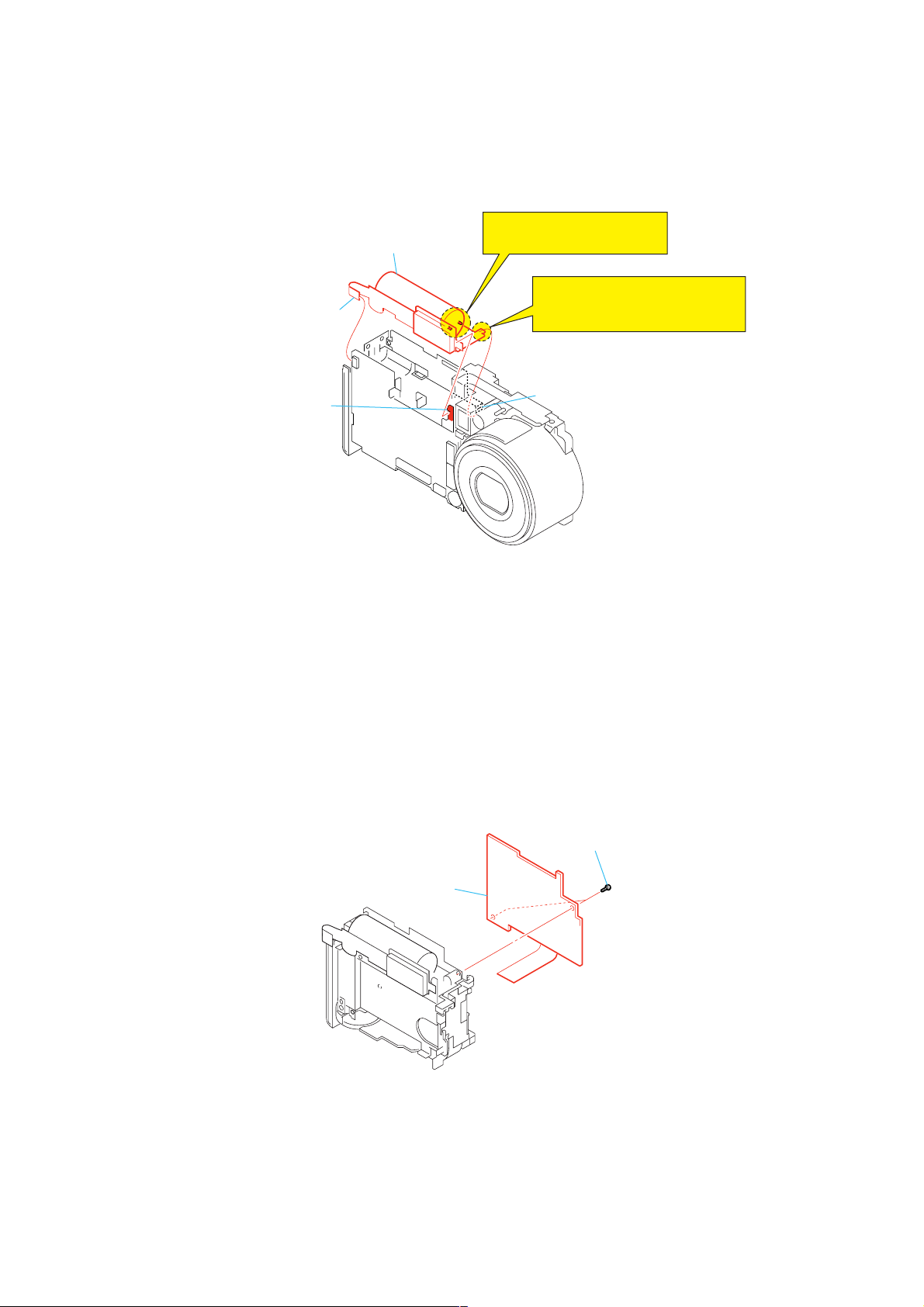

[Note in Lens Frame Installation]

When tightening a screw , have both sides of the lens b lock assemb ly

so as not for the load to depend.

M1.7 × 4

Lens block assembly

Lens frame

M1.7 × 4

1-2

Page 8

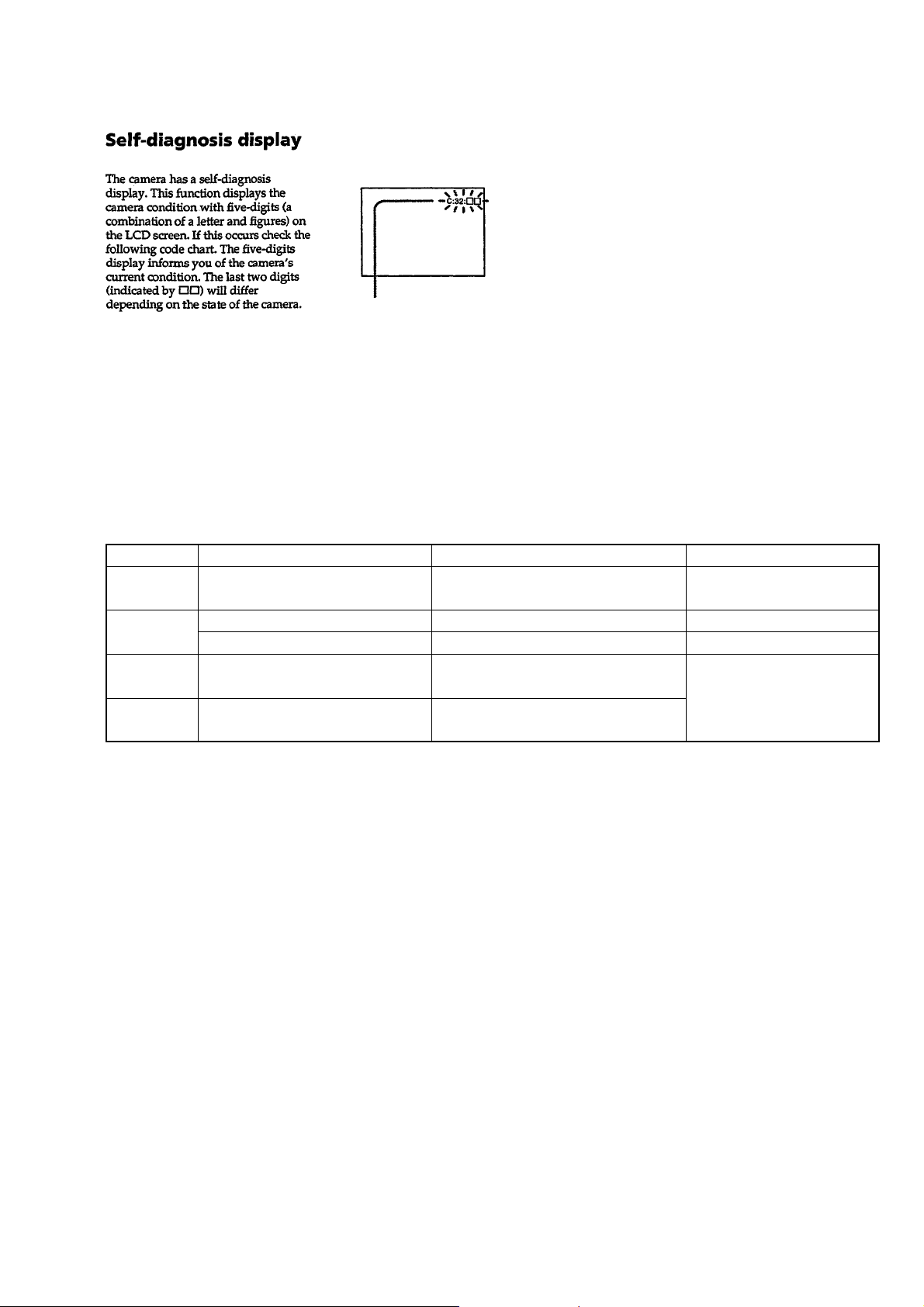

[Description on Self-diagnosis Display]

Self-diagnosis display

• C: ss: ss

You can reverse the camera

malfunction yourself. (However,

contact your Sony dealer or local

authorized Sony service facility

when you cannot recover from the

camera malfunction.)

• E: ss: ss

Contact your Sony dealer or local

authorized Sony service facility.

DSC-P9

Display Code

C:32:ss

C:13:ss

E:61:ss

E:91:ss

Countermeasure

Turn the power off and on again.

Format the “Memory stick”.

Insert a new “Memory Stick”.

Checking of lens drive circuit.

Checking of flash unit or replacement

of flash unit.

Cause

Trouble with hardware.

Unformatted memory stick is inserted.

Memory stick is broken.

When failed in the focus and zoom

initialization.

Abnormality when flash is being

charged.

Caution Display During Error

SYSTEM ERROR

FORMAT ERROR

MEMORY STICK ERROR

—

1-3E

Page 9

DSC-P9

COVER

COVER

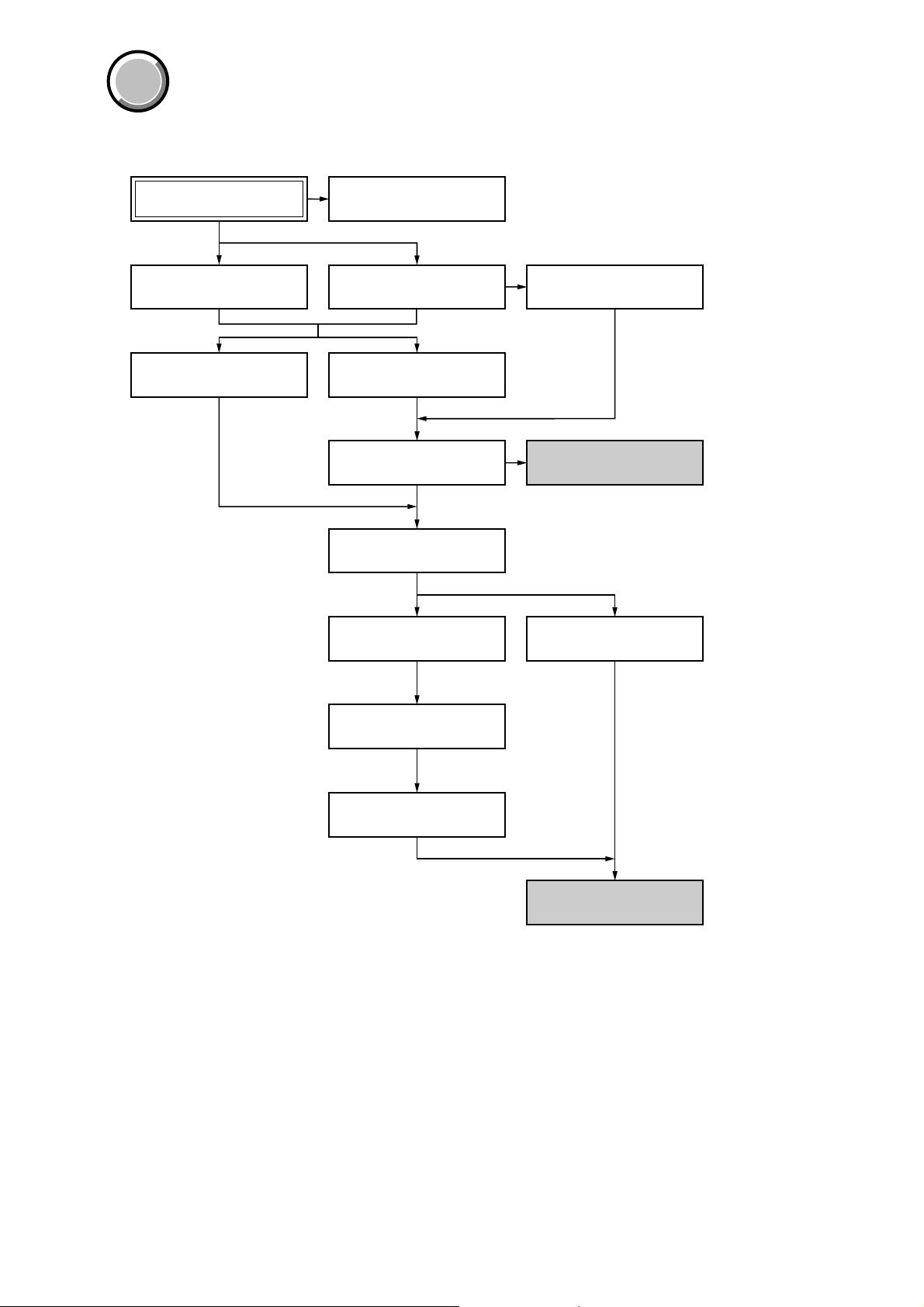

• This set can be disassembled in the order shown below.

DSC-P9

2-2. CABINET (FRONT)

ASSEMBLY (Page 2-2)

2-7. CONTROL SWITCH

BLOCK (Page 2-5)

2-1. BT LID

(Page 2-2)

2-3. CABINET (REAR)

ASSEMBLY (Page 2-3)

2-5. CABINET (BOTTOM)

ASSEMBLY (Page 2-4)

2-6. LENS BLOCK ASSEMBLY

(Page 2-4)

SECTION 2

DISASSEMBLY

2-4. LCD MODULE

(Page 2-3)

SERVICE POSITION

(SY-77 BOARD: side A)

(Page 2-5)

2-8. SY-77 BOARD

(Page 2-6)

2-9. MEMORY STICK

CONNECTOR (Page 2-6)

2-11. SW-368 BOARD

(Page 2-7)

2-12. JK-227 BOARD

(Page 2-8)

2-10. ST-70 BOARD

(Page 2-7)

SERVICE POSITION

(SY-77 BOARD: side B)

(Page 2-8)

2-1

Page 10

DSC-P9

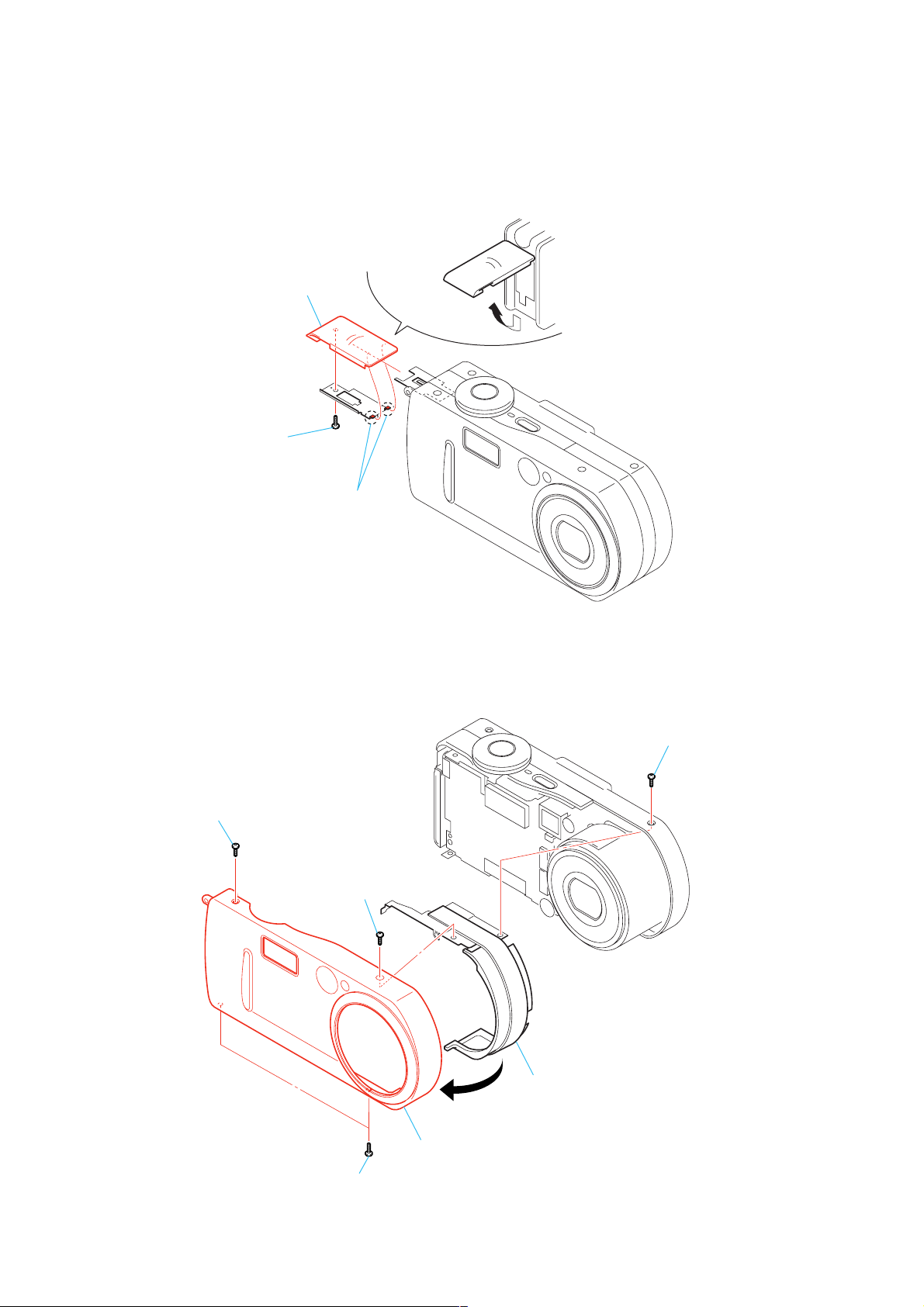

Note: Follow the disassembly procedure in the numerical order given.

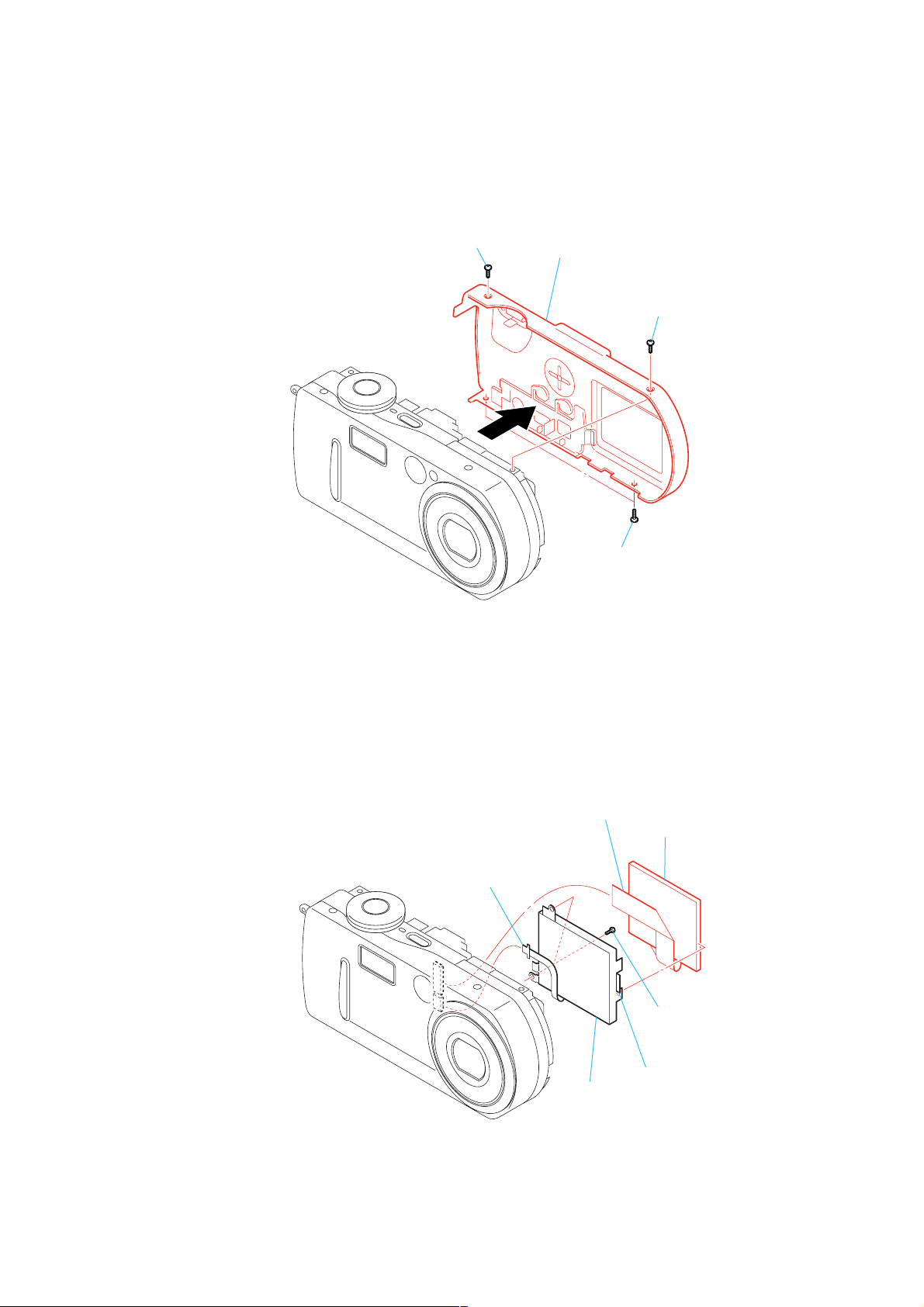

2-1. BT LID

1 Open the BT lid.

4 BT lid

2 Screw

(1.7 × 3)

3 Two claws

2-2. CABINET (FRONT) ASSEMBLY

1 Screw

(M1.7)

2 Screw

(M1.7)

6 Screw

(M1.7)

3 Two screws

(M1.7)

7 Center cabinet

4

5 Cabinet (front)

assembly

2-2

Page 11

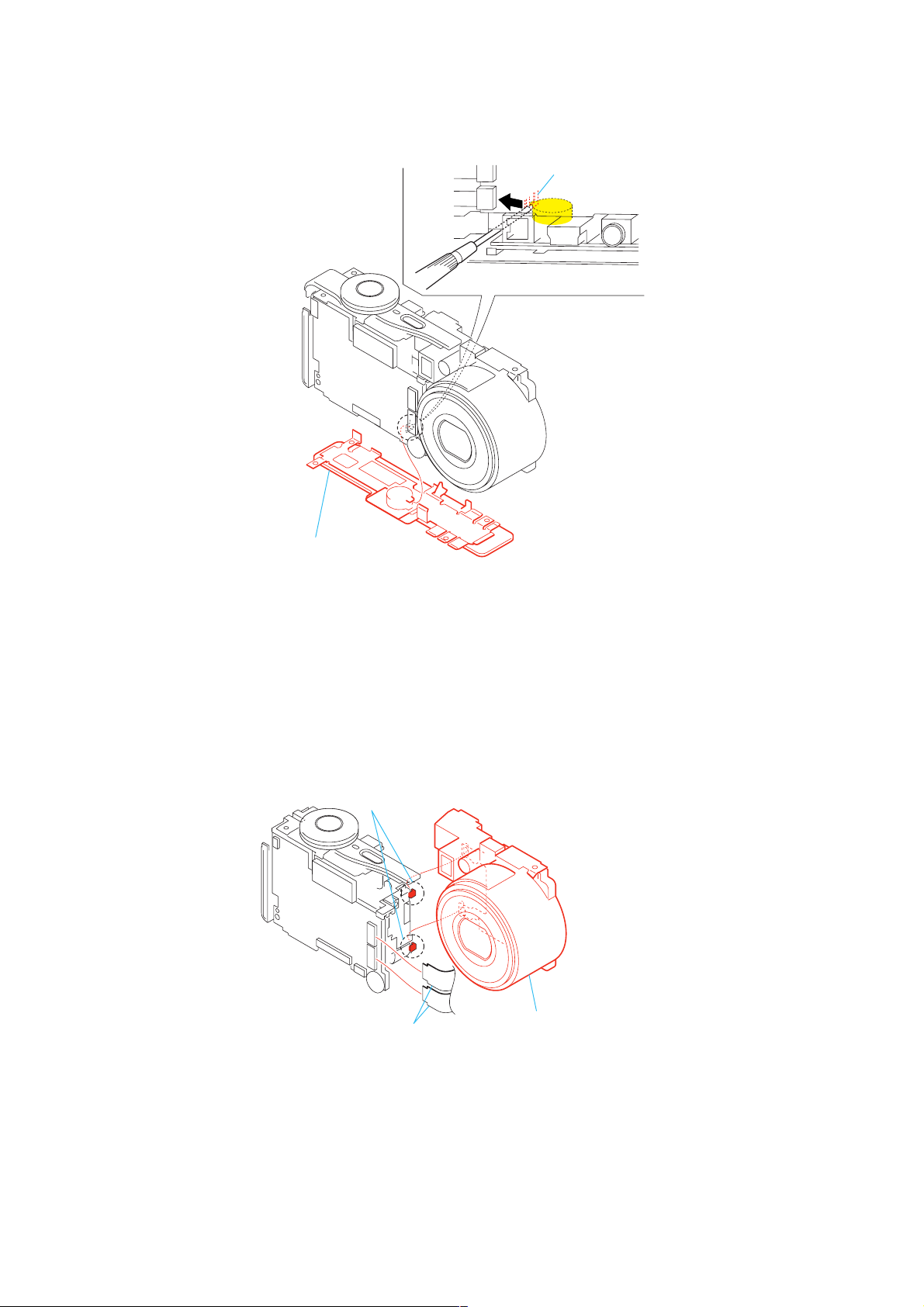

2-3. CABINET (REAR) ASSEMBLY

DSC-P9

2 Screw

(M1.7)

5 Cabinet (rear)

assembly

1 Screw

(M1.7)

4

3 Two screws

(M1.7)

2-4. LCD MODULE

1 Flexible board

(CN102)

6 LCD module

2 Flexible board

(CN101)

3 Two screws

(M1.7)

4 Four claws

5 Back light unit

2-3

Page 12

DSC-P9

2-5. CABINET (BOTTOM) ASSEMBLY

1 Claw

Rear side

2 Cabinet (bottom) assembly

2-6. LENS BLOCK ASSEMBLY

2 Two claws

1 Two flexible board

(CN001, 301)

3 Lens block assembly

2-4

Page 13

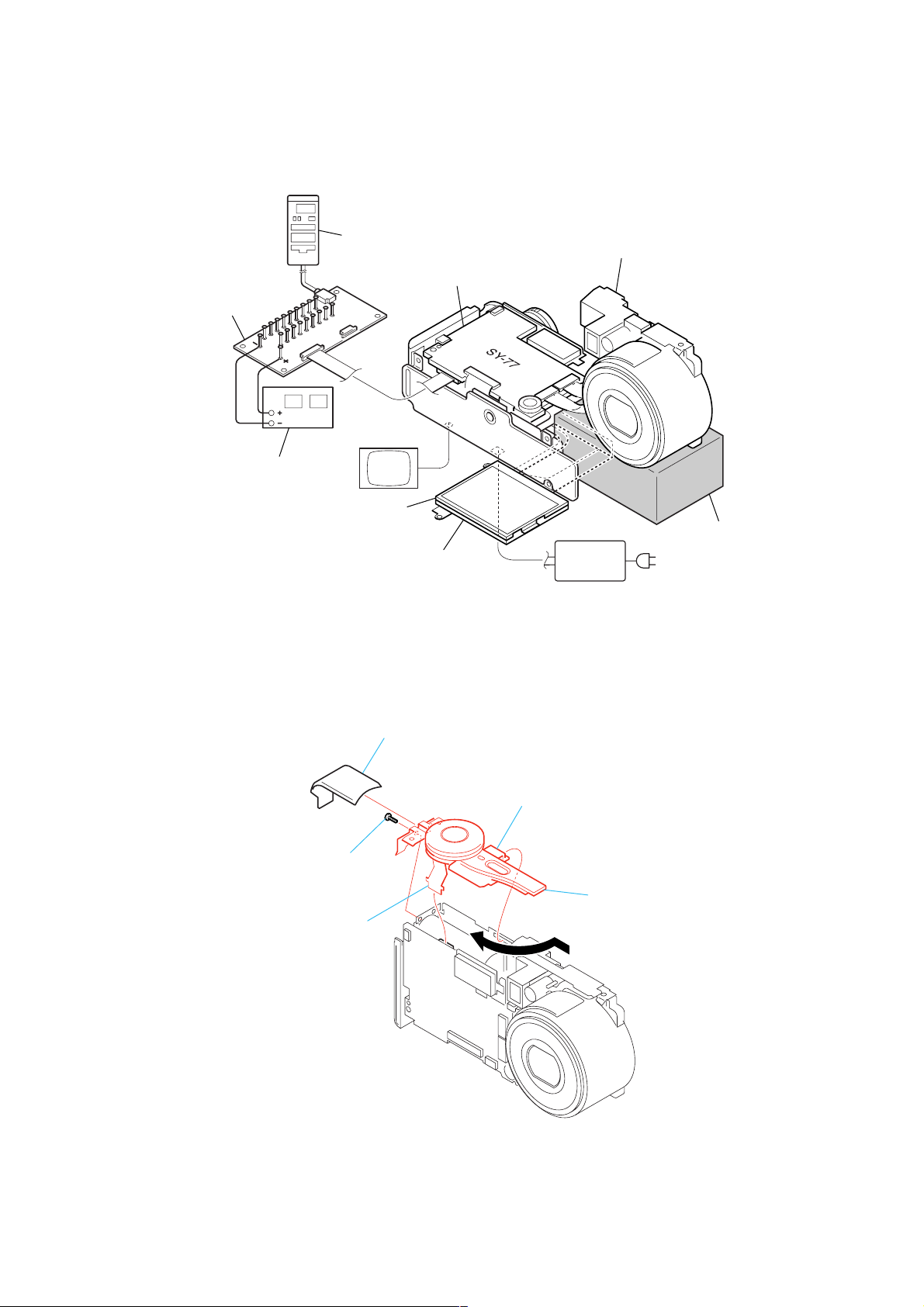

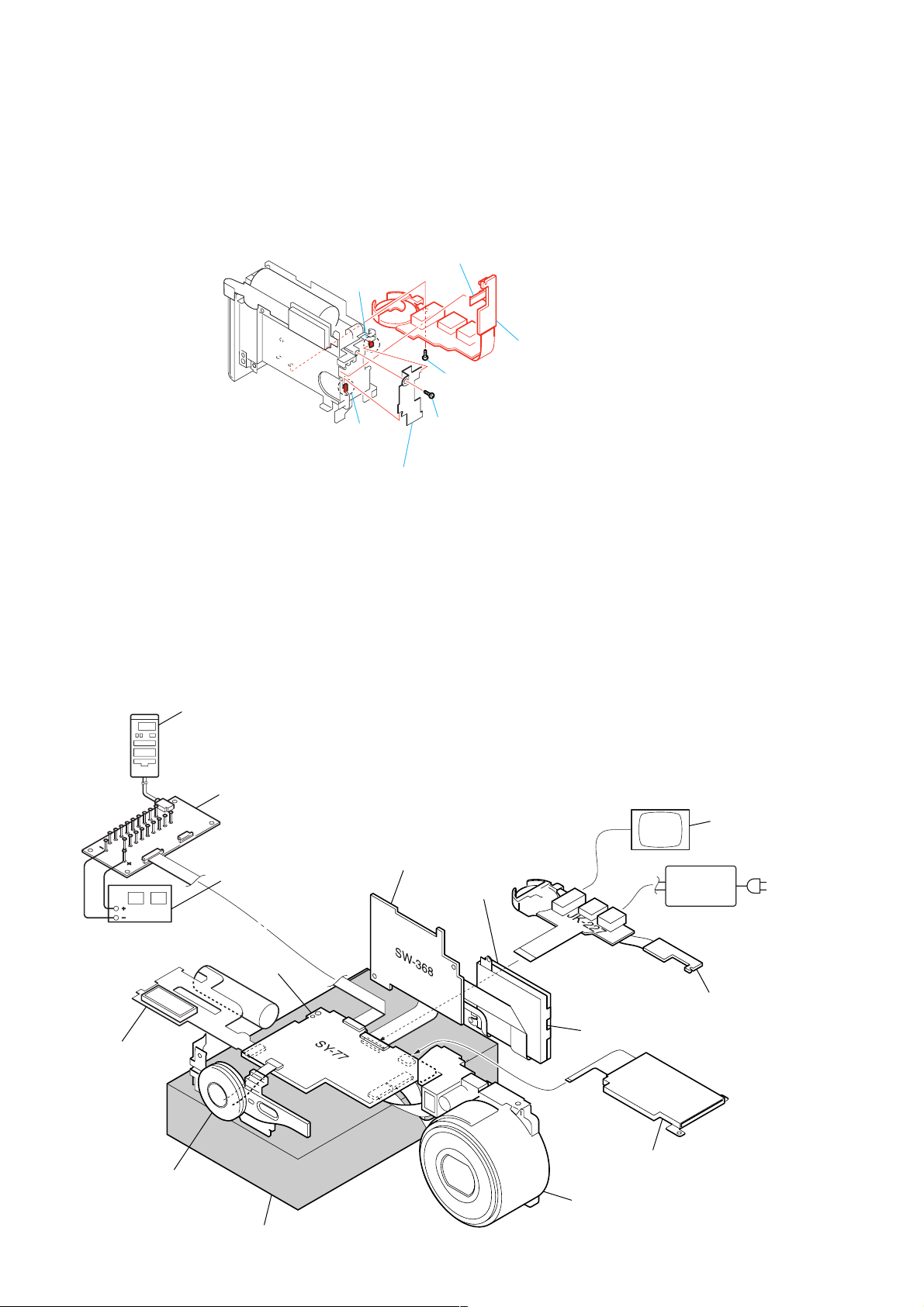

[SERVICE POSITION (SY-77 BOARD: SIDE A)]

DSC-P9

CPC-9 jig

(J-6082-393-C)

Regulated power supply

(6.0 to 7.2 Vdc)

Note 1: Don’t use the 12 pin flexible board of CPC-9 jig.

Note 2: The old CPC-9 jig (Parts code: J-6082-393-B)

Adjusting remote

commander

SY-77 board

18

1

Color monitor

LCD module

Back light unit

18

1

It causes damage to the unit.

cannot be used, because it cannot operate

the adjustment remote commander.

Lens block assembly

Base

AC power

adaptor

AC IN

2-7. CONTROL SWITCH BLOCK

1 Mode dial cover

2 Screw

(M1.7)

5 Flexible board

(CN704)

3 Claw

6 Control swith block

4

2-5

Page 14

DSC-P9

2-8. SY-77 BOARD

5 Claw

1 Connector

(CN351)

7 SY-77 board

4 Screw

(M1.7 × 4)

2 Flexible board

(CN703)

6 Flexible board

2-9. MEMORY STICK CONNECTOR

1 Two screws

(M1.7 × 4)

(CN701)

3 Three flexible boards

(CN001, 301, 702)

2 Claw

3 Memory stick connector

2-6

Page 15

2-10.ST-70 BOARD

1 Connector

(CN351)

3 ST-70 board

DSC-P9

Note: High-voltage cautions

(See page 1-1).

Note: When installing ST-70 board,

the claw is put into the bottom

the BT main frame.

2-11.SW-368 BOARD

2 Claw

BT main frame

1 Two screws

(M1.7 × 4)

2 SW-368 board

2-7

Page 16

DSC-P9

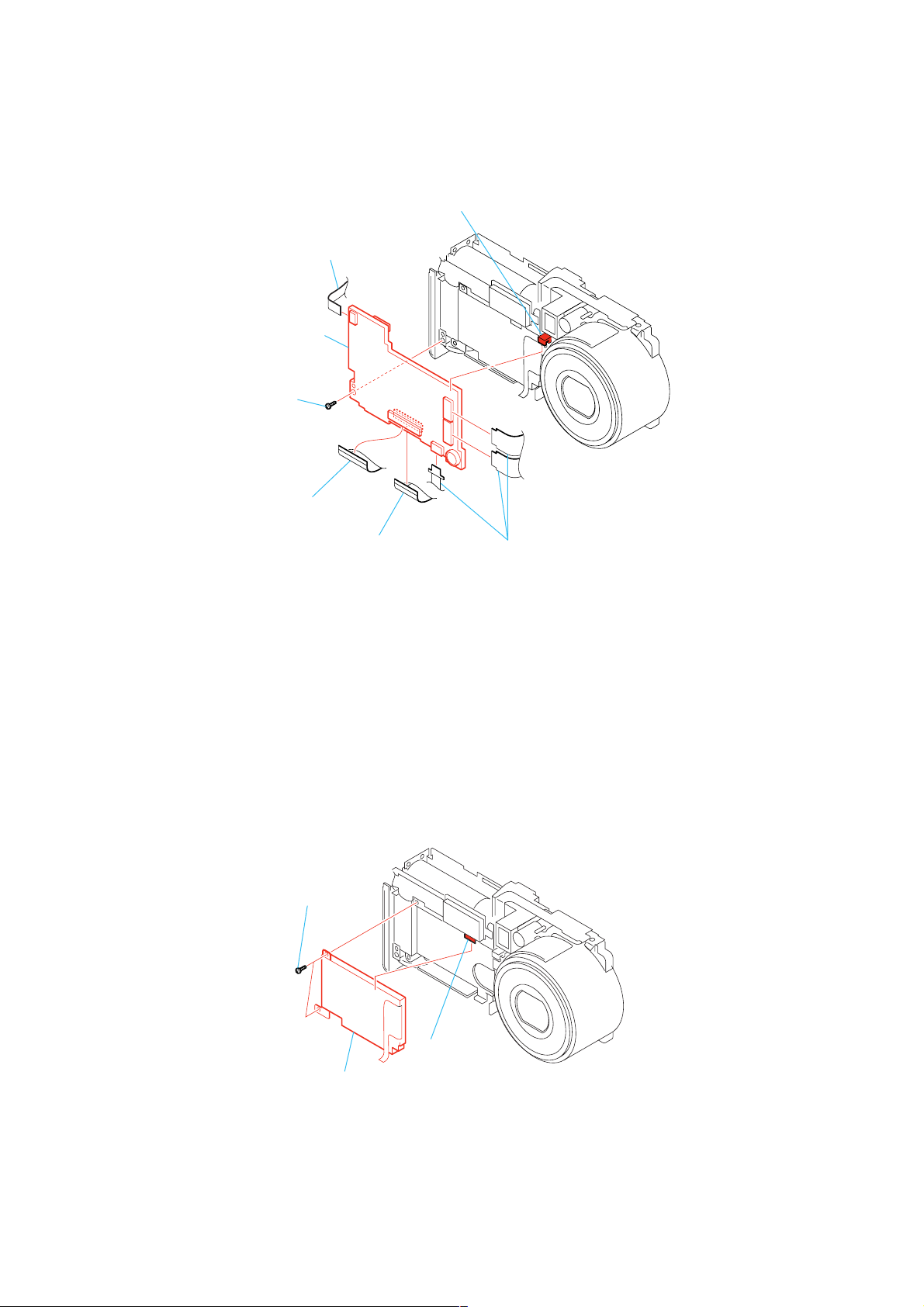

2-12.JK-227 BOARD

6 Claw

2 Claw

7 JK-227 board

(including JK-226)

5 Screw

(M1.7)

3 Claw

4 DD sheet metal

1 Screw

(M1.7 × 4)

[SERVICE POSITION (SY-77 BOARD: SIDE B)]

Adjusting remote

commander

CPC-9 jig

(J-6082-393-C)

18

1

Regulated power supply

(6.0 to 7.2 Vdc)

Note 1: Don’t use the 12 pin flexible board of CPC-9 jig.

It causes damage to the unit.

Note 2: The old CPC-9 jig (Parts code: J-6082-393-B)

cannot be used, because it cannot operate

the adjustment remote commander.

SW-368 board

LCD module

Color monitor

AC power

adaptor

AC IN

ST-70 board

Mode dial block assembly

SY-77 board

Base

18

JK-227 board

1

Back light unit

Memory stick connector

Lens block assembly

2-8

Page 17

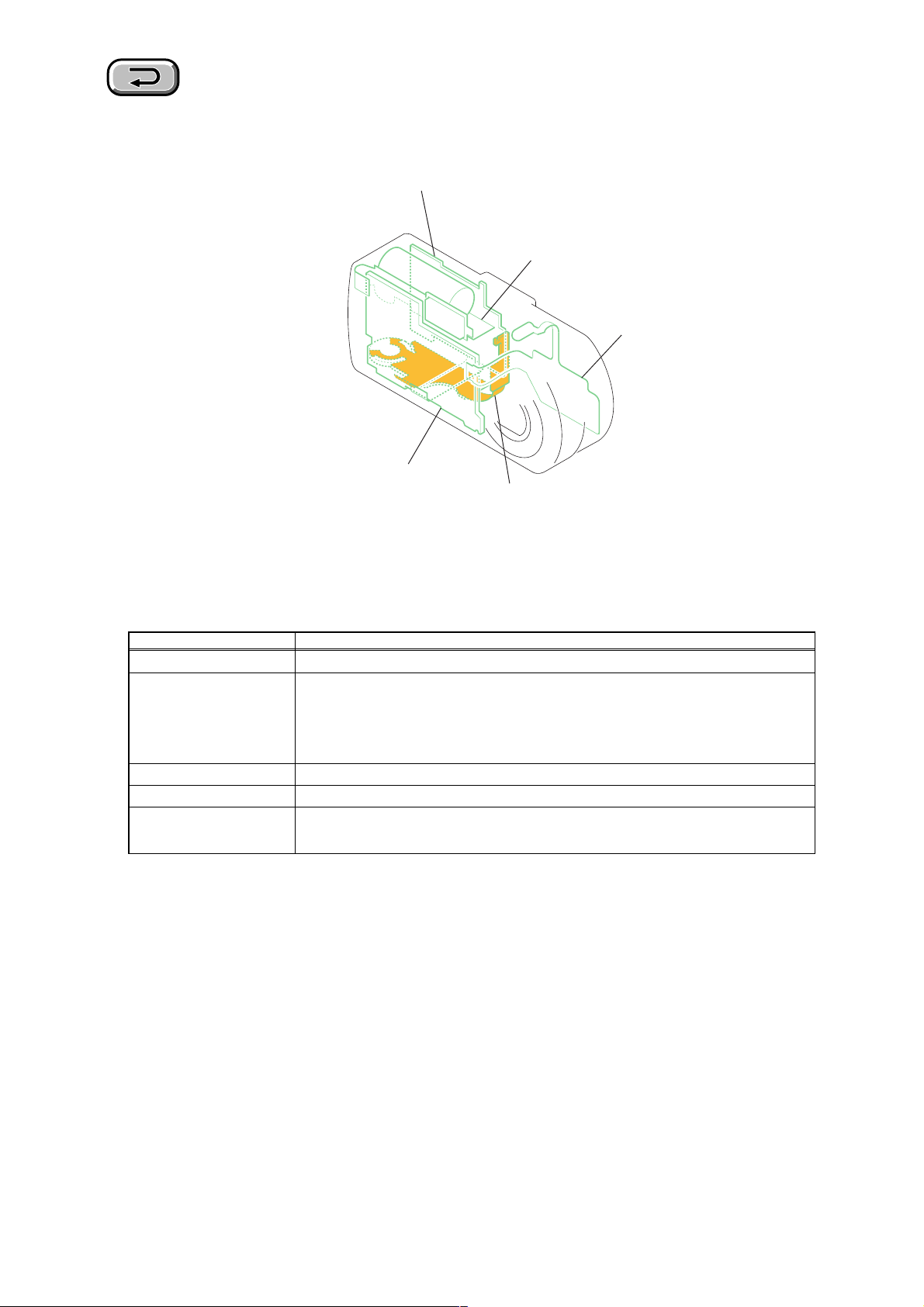

2-13.CIRCUIT BOARDS LOCATION

SW-368

SY-77

DSC-P9

ST-70

CD-397

JK-227

(including JK-226)

Board Name Function

CD-397 CCD IMAGER

SY-77 CAMERA MODULE, CAMERA DSP, VIDEO, MEMORY,

LENS DRIVE, SH DSP, FLASH MEMORY, FRONT CONTROL,

AUDIO, CLOCK GENERATOR, FLASH CONTROL,

DC/DC CONVERTER, CAMERA PROCESS

ST-70 FLASH DRIVE

SW-368 CONTROL SWITCH, LCD DRIVE, TIMING GENERATOR

JK-227 JACK

(including JK-226)

2-9E

Page 18

COVER

COVER

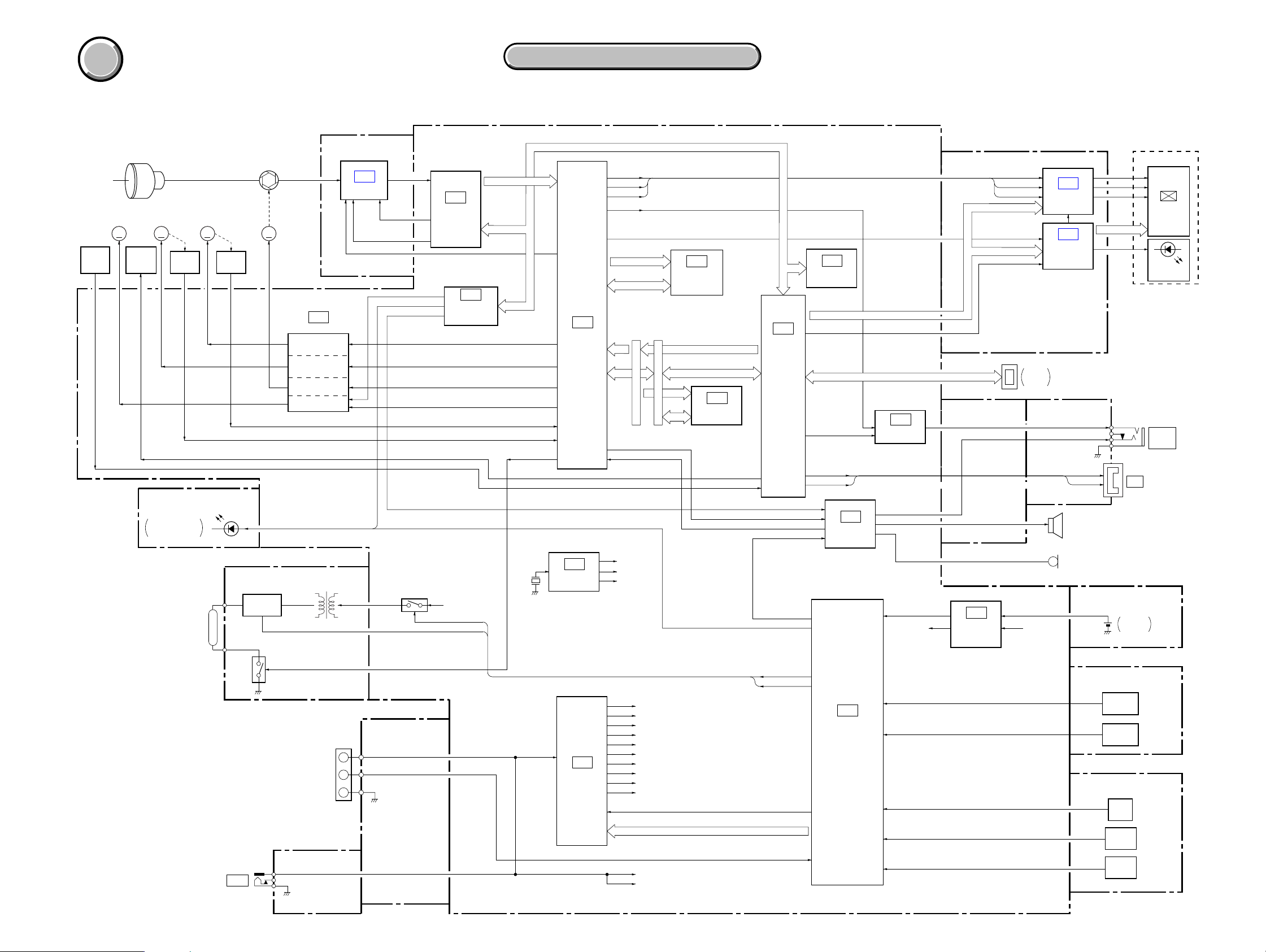

3. BLOCK DIAGRAMS

Link

Link

OVERALL BLOCK DIAGRAM POWER BLOCK DIAGRAM 2

OVERALL BLOCK DIAGRAM POWER BLOCK DIAGRAM 2

POWER BLOCK DIAGRAM 1

POWER BLOCK DIAGRAM 1

DSC-P9

Page 19

DSC-P9

COVER

COVER

BLOCK DIAGRAMS

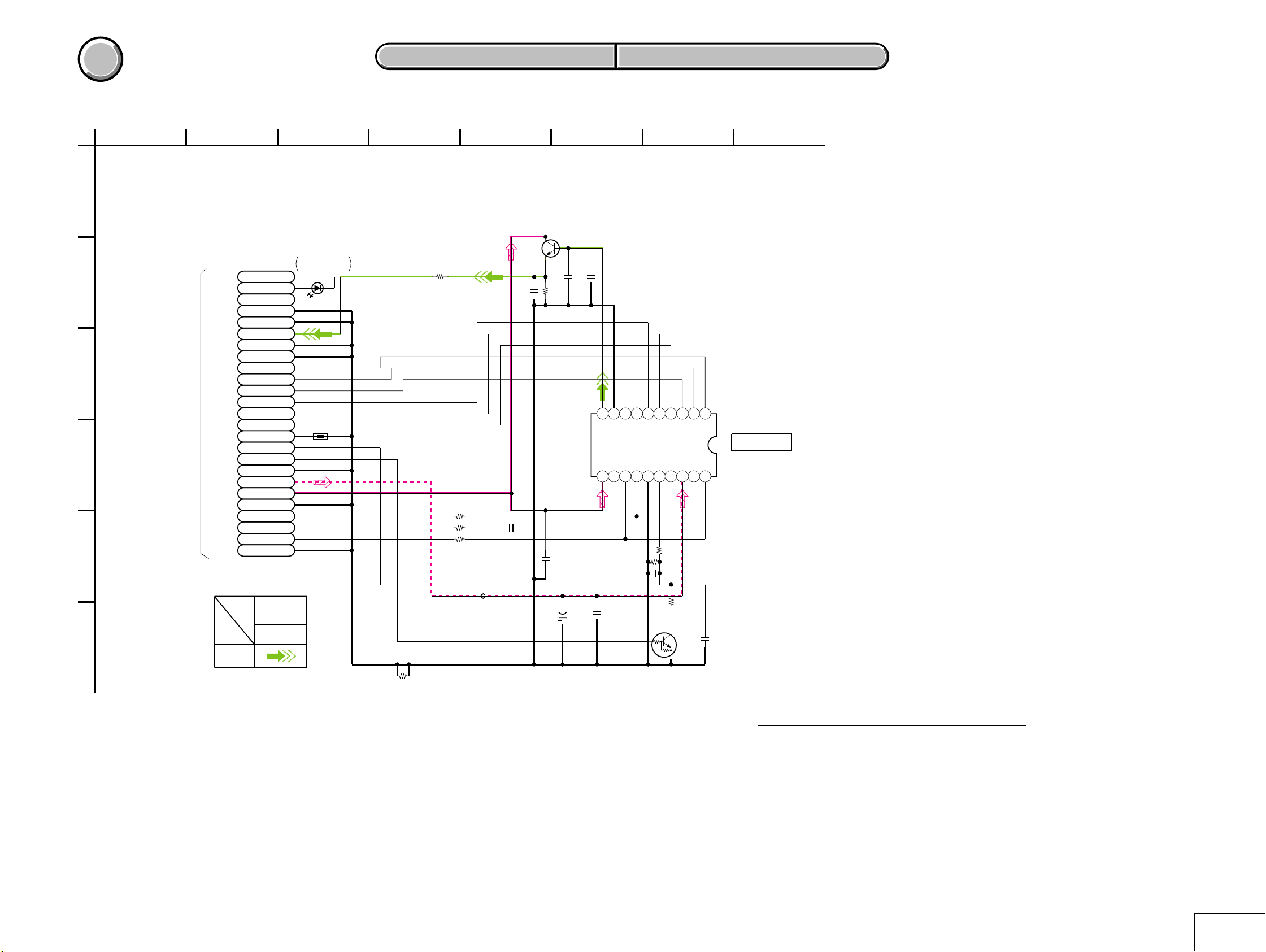

3-1. OVERALL BLOCK DIAGRAM

LENS

TEMP

SENSOR

SHUTTER

MOTOR

LENS

ZOOM

MOTOR

MM

ZOOM

POSITION

SENSOR

SENSOR

CD-397 BOARD (2/2)

D101

SELF TIMER/

AF ILLUMINATOR

ZOOM

FOCUS

MOTOR

M

FOCUS

SENSOR

IRIS

MOTOR

IRIS

METER

M

SECTION 3

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

CCD OUT

SY-77 BOARD

IC151

CAMERA

MODULE

(1/10)

(D/A CONVERTER)

ZOOM POS

LENS TEMP

SELF TIMER LED

DATA BUS 14

IC508

EVR

(6/10)

HR DIR0A, HR DIR0B, HR EN0

HR DIR1A, HR DIR1B, HR EN1

IRIS M IN, IRIS M EN,

IRIS S IN, IRIS S EN

MSHUT ON

MSHUT EN

XFC RST SENS

XZM RST SENS

STRB ON

CAM SO, XCAM SCK

IC601

CAMERA

DSP

(2/10)

PANEL R

PANEL G

PANEL B

CV OUT

ADDRESS BUS14

DATA BUS 32

25

16

ADDRESS BUS

AU AINL

AU AOUT

25

16

20

DATA BUS

16

IC602

256M

SDRAM

(3/10)

IC504

16M FLASH

(6/10)

ZOOM POS

LENS TEMP

IC501

MC CAM,

SH DSP

(5/10)

BEEP, BEEP ON

CD-397 BOARD (1/2)

IC302

(4/10)

FOCUS MOTOR

DRIVER

ZOOM MOTOR

DRIVER

IRIS

DRIVER

SHUTTER DRIVER

IC101

CCD IMAGER

V1A, V1B, V2

V3A, V3B, V4

VSUB CONT

H1, H2

PRELAMP AF ON

CAM SO, XCAM SCK

SP VOL

AU AINL

AU AOUT

IC505

EEPROM

(6/10)

VAMP ON

USB D+

USB D

LCD SO, XLCD SCK

CV OUT

−

IC201

AUDIO AMP

(8/10)

MS DIO, MS BS, MS SCLK

IC101

VIDEO AMP

(3/10)

SW-368 BOARD (1/2)

PANEL R

PANEL G

PANEL B

LCD SO, XLCD SCK

V OUT

AU OUT

MS

SOCKET

JK-226 BOARD (2/2)JK-227 BOARD (2/2)

IC101

LCD DRIVE

(2/2)

IC102

LCD TIMING

GENERATOR

(2/2)

USB D+

USB D–

SP901

SPEAKER

PANEL UNIT

VR

VG

VB

CN002

USB

LCD901

COLOR

LCD

MONITOR

D901

BACK LIGHT

J002

A/V OUT

(MONO)

FLASH

UNIT

ST-70 BOARD (1/2)

CHARGING

CAPACITOR

Q002

J001

DC IN

JK-226 BOARD (1/2)

T001

BT901

BATTERY

TERMINAL

JK-227 BOARD (1/2)

+

S

–

Q360, 361

ACV UNREG

STB CHARGE

XSTB FULL

X501

27MHz

IC507

CLOCK GEN.

(6/10)

IC001

DC/DC

CONTROL

(10/10)

TG CLK

USB CLK

MC CLK

CAM 15V

CAM 3.2V

CAM –7.5V

A 4.9V

A 2.9V

D 1.5V

D 2.9V

PANEL 2.9V

BL VO–

FR 5V

AVC UNREG

BATT UNREG

UNREG SCK, UNREG SO

BEEP, BEEP ON

SELF TIMER LED

STB CHG

XSTB FULL

SYS DD ON

BATT SIG

IC401

FRONT CONTROLLER

(7/10)

RESET

KEY AD0, 1

KEY AD3

MODE DIAL, XPB ON, XSET UP ON

XPWR ON

XAE LOCK SW, XSHTR ON

IC403

INITIAL RESET,

BACK UP VCC

(7/10)

MIC901

MICROPHONE

ST-70 BOARD (2/2)

BT001

LITHIUM

FR 5VEVER 3.0V

BATTERY

SW-368 BOARD (2/2)

FUNCTION

SWITCH

ZOOM

SWITCH

CONTROL SWITCH BLOCK

MODE

DIAL

POWER

ON/OFF

SHUTTER

SWITCH

05

3-1 3-2

Page 20

DSC-P9

COVER

COVER

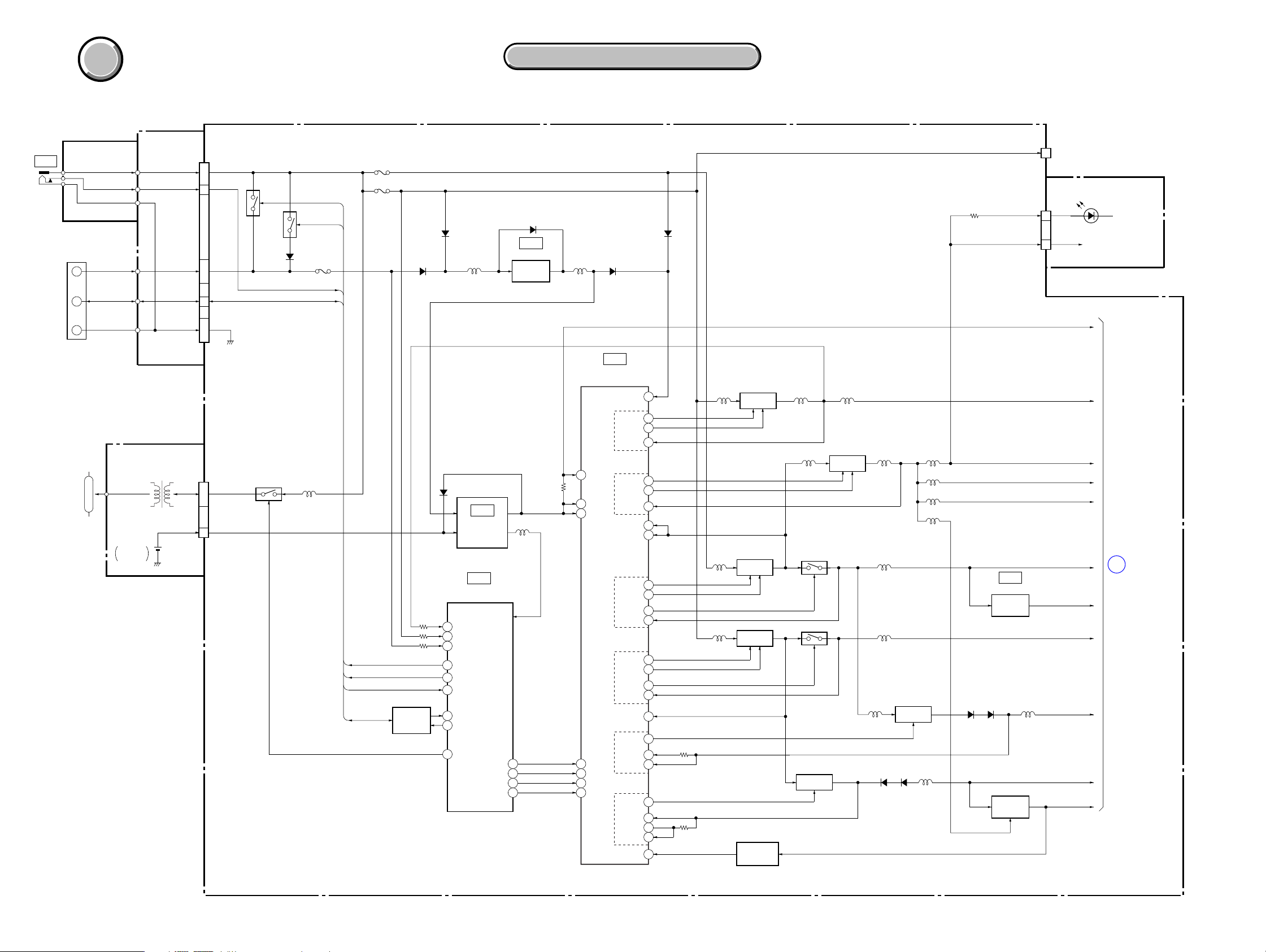

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

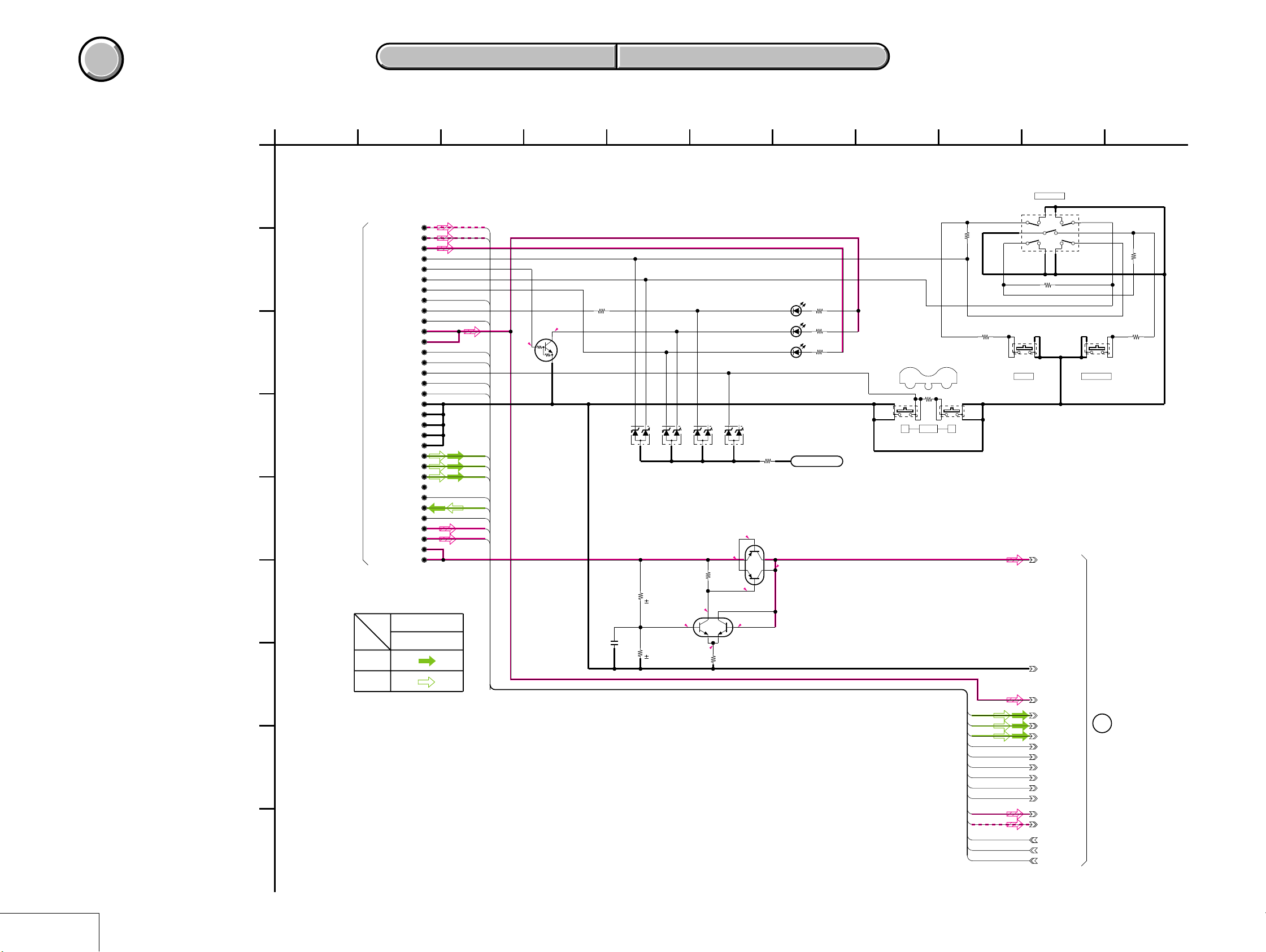

3-8. POWER BLOCK DIAGRAM 1

SY-77 BOARD (1/2)

CN703

17

ı

24

37

1

ı

8

36

9

ı

16

CN351

4

ST UNREG

ı

8

VL 3V

1

J001

DC IN

BT901

BATTERY

TERMINAL

JK-226 BOARD

ACV UNREG

BATT/XEXT

BATT UNREG1

+

BATT SIG

S

BATT GND

–

FLASH

UNIT

GND

ST-70 BOARD

BT001

LITHIUM

BATTERY

JK-227 BOARD

ACV UNREG1

BATT/XEXT

BATT

UNREG1

BATT SIG

GND

T001

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

F004

Q017, 018

Q015, 021

CHARGE

CONTROL

Q360, 361

FAST CHARGE

INIT CHARGE

D008

F001

BATT/XEXT

BATT SIG

L351

STB CHARGE

F003

FAST CHARGE

INIT CHARGE

BATT/EXT

BATT SIG

D009

D007 D001

D006

Q408

BATTERY

CHARGE

DETECTOR

L016

FR 5V

DD CON SENS

D407

IC403

INITIAL RESET,

BACK UP VCC

(7/10)

IC404

FRONT CONTROLLER

(7/10)

66 DD CON SENS

68

ACV SENS

67 BATT SENS

48

FAST CHARGE

INIT CHARGE

47

8

BATT/XEXT

BATT SI

43

BATT SO

42

46 STB CHG

SYS DD ON

XCS DDCON

UNREG SO

UNREG SCK

IC002

(10/10)

DC/DC

CONVERTER

EVER 3.0V

L401

SYS DD ON

76

XCS DDCON

22

UNREG SO

20

UNREG SCK

21

L017

DC/DC CONTROL

47

RST

48

LD ON

56

VCC1

57

CONT

44

XCS

45

DATA

46

CLK

D010

IC001

(10/10)

AMP OUT

VCC2

OUT 1p

OUT 1n

VIN 1–

OUT 4p

OUT 4n

VIN 4–

VCC3

VCC5

OUT 5p

OUT 5n

OUT 5S

VIN 5–

OUT 6p

OUT 6n

OUT 6S

VIN 6–

VCC4

OUT 9

IN 9–

SCP 9

OUT 10

AMP IN

IN 10

SCPIN

41

36

37

55

30

31

53

42

20

38

39

43

52

28

29

18

50

19

23

80

1

22

4

5

−

3

10

L004

L002

SWITCHING

Q008, 010

SWITCHING

Q009, 011

SWITCHING

EMERGENCY

Q002, 005

Q001

DETECT

L005L019 L011

Q003, 006

L020

SWITCHING

Q012

Q013

Q004

SWITCHING

L006

L012

L013

L001

D004 D005

Q007

SWITCHING

L010

L007

L008

L009

L021

D002 D013

CN706

HI UNREG

CN704

PWR LED VCC

D 2.9V

IC003

(10/10)

3.2V

REG

L014

Q019, 020

–7.5V

REG

CPC

10

(FOR CHECK)

CONTROL SWITCH BLOCK

12

3

EVER 3.0V

D 1.5V

D 2.9V

A 2.9V

PANEL 2.9V

A 4.9V

CAM 3.2V

M 5V

CAM 15V

BL VO–

CAM –7.5V

D 2.9V

A

(POWER)

POWER 2

(PAGE 3-17)

05

3-15 3-16

Page 21

COVER

COVER

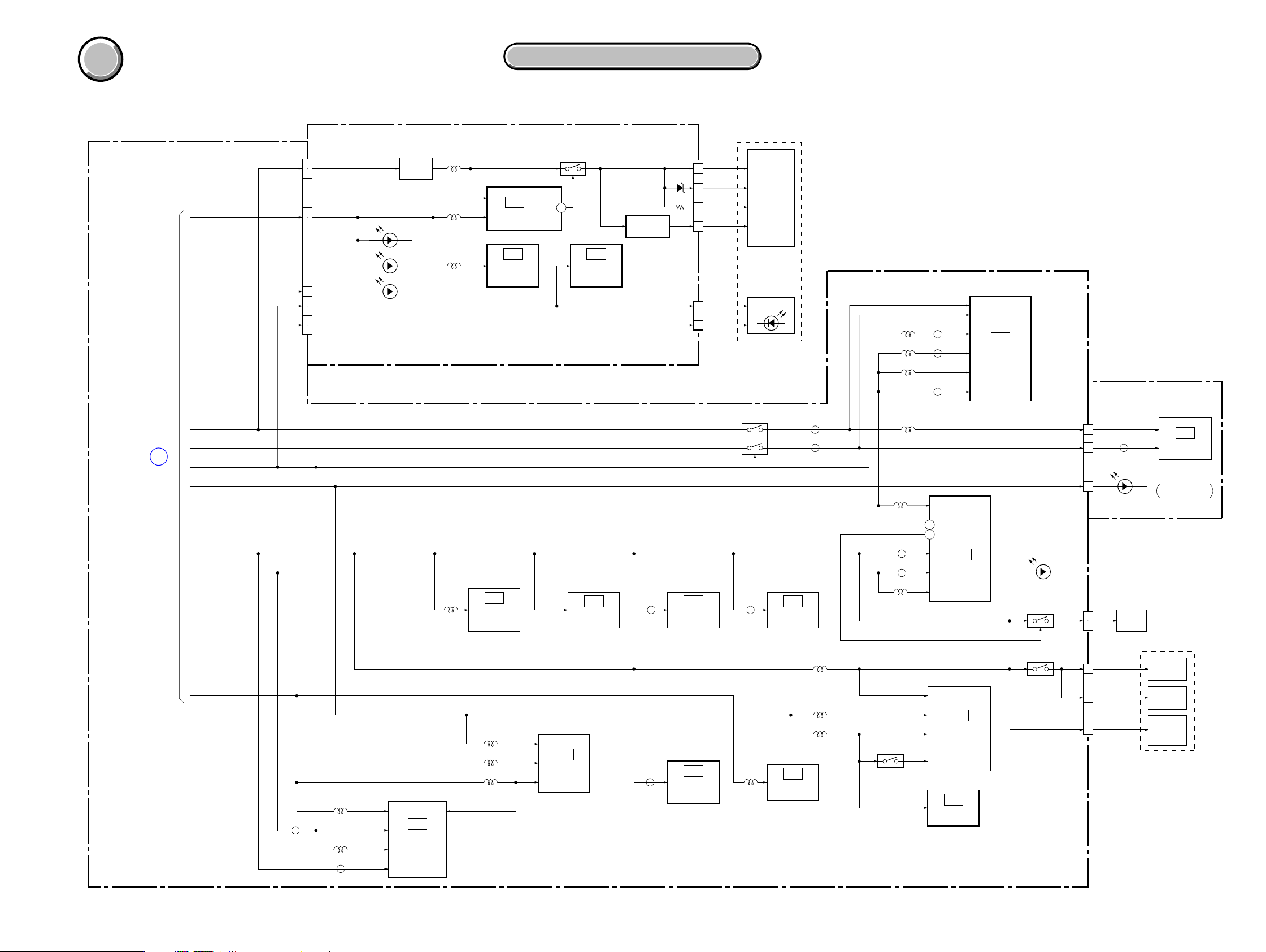

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

DSC-P9

3-9. POWER BLOCK DIAGRAM 2

SY-77 BOARD (2/2)

POWER 1

(PAGE 3-16)

PANEL 2.9V

EVER 3.0V

BL VO–

CAM 15V

CAM −7.5V

A

A 4.9V

M 5V

CAM 3.2V

D 2.9V

D 1.5V

CN701

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

SW-368 BOARD

CAM15V

32

33

PANEL 2.9V

11

12

EVER 3.0V

3

A 4.9V

30

31

BL VO–

1

2

Q002, 003

13.5V

REG

D003

(AE LOCK)

D004

(TALLY)

D002

(FLASH/CHG)

L102

L101

L104

L503

LCD DRIVER

LCD TIMING

GENERATOR

IC508

EVR

(D/A CONV.)

(6/10)

IC101

(2/2)

IC102

(2/2)

XP OFF

Q105, 108

14

CAM 15V

CAM −7.5V

A 4.9V

M 5V

CAM 3.2V

D 2.9V

D 1.5V

IC103

BACK LIGHT

CONTROL

(2/2)

IC505

EEPROM

(6/10)

Q108

REF VOLTAGE

GEN

CN102

18

D102

16

11

CN101

IC507

CLOCK GEN.

(6/10)

9

6

1

VDD

VDDG

CRext

REF

BL THH

BL L

PANEL UNIT

MONITOR

BACK LIGHT

Q152 - 153

FB506FB504

LCD901

COLOR

LCD

D901

CAM DD ON

IC504

16M FLASH

(6/10)

FB155

FB154

MS POWER ON

L504

FB501

FB502

L501

L152

L153

L154

L101

FB151

FB153

FB152

198

PTM (6)

30

D32/PTA (7)

IC501

MC CAM, SH DSP

(5/10)

IC101

CAMERA

MODULE

(1/10)

CAM 15V

CAM −7.5V

D702

(MS ACCESS)

Q701

CN001

M 5V

CN702

CD-397 BOARD

6

FB101

7

24

VCC

MEMORY

2

6

STICK

IC101

CCD IMAGER

D101

SELF TIMER/

AF ILLUMINATOR

LENS BLOCK

CN301

Q301

19

11

14

F RST VCC

Z RST VCC

Z POSI VCC

ZOOM

ZOOM

SENSOR

SENSOR

FOCUS

SENSOR

ZOOM

POSITION

SENSOR

IC101

(3/10)

L303

L302

L301

Q302

IC302

7CH LENS DRIVER

(4/10)

IC301

BUFFER

(4/10)

D 2.9V

A 2.9V

L203

L201

L202

L602

FB601

L601

FB602

05

IC601

CAMERA DSP

(2/10)

A 2.9V

M 5V

IC201

AUDIO AMP

(8/10)

FB603

IC602

256M

SDRAM

(3/10)

L101

VIDEO AMP

3-17 3-18E

Page 22

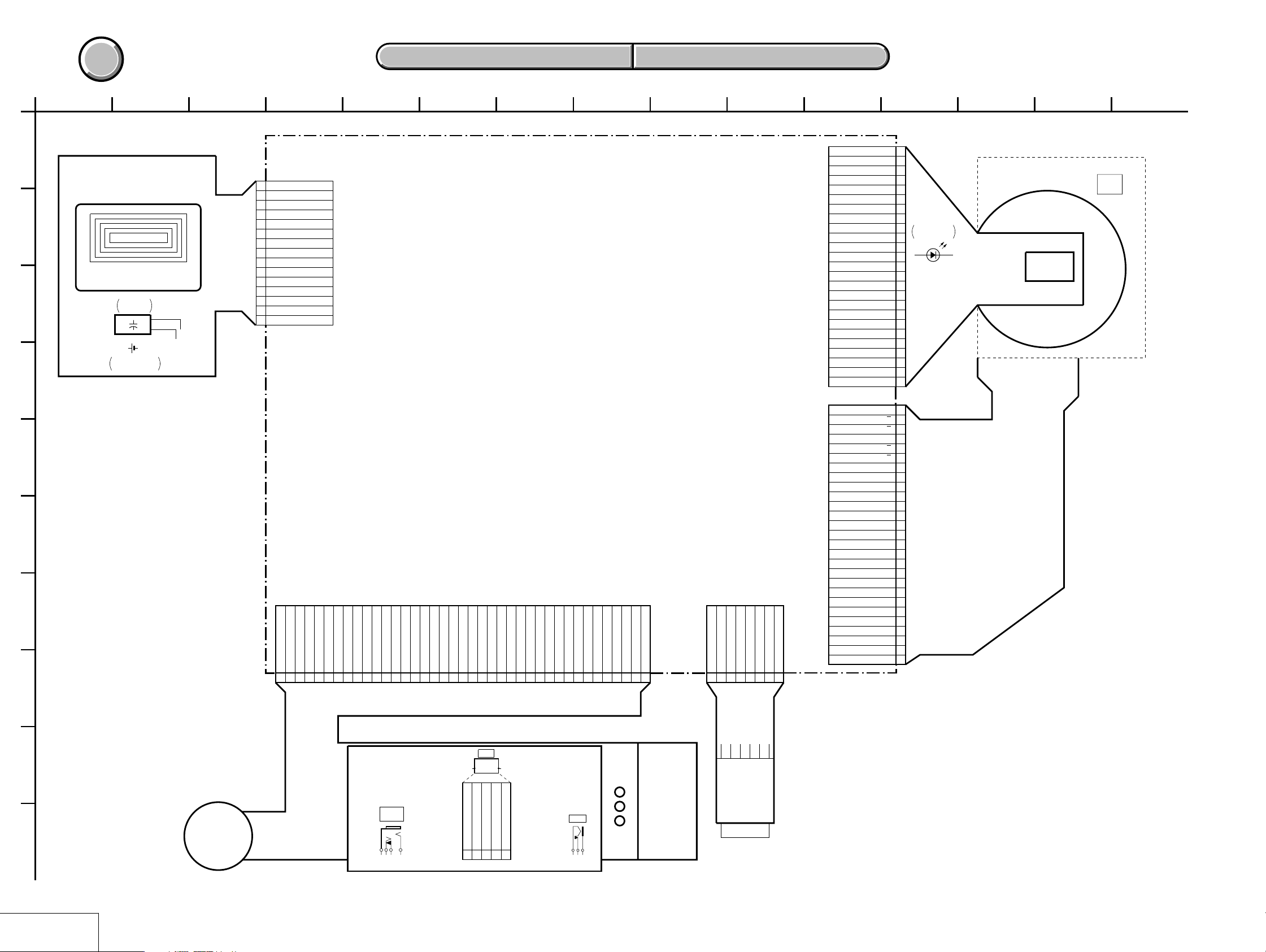

COVER

COVER

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAMS

SECTION 4

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

DSC-P9DSC-P9

1

23

4 138

712

9

10

1165

FRAME (1/2)

A

2

1

8

XPB_ON

CONTROL

SWITCH

BLOCK

(POWER (GREEN))

5

6

7

NC

NC

GND

S004

POWER

D001

3

4

D_2.9V

MODE_DIAL

1

2

XSHTR_SW

XAE_LOCK_SW

PANEL UNIT

B

D901

BACK

LIGHT

LCD901

1.5INCH

COLOR

B

G

6

A

S005

MODE DIAL

LCD UNIT

1

3

S003

(SHUTTER)

2

4

C

BL_THL

BL_H

12345

24

NC

BL_L

TESTL

COM

20EN21

22

23

VST

VCK

19

DWN

18

VDD

16

17

VSS

VSSG

VDDG

11

12

13

14CS15

REF

HST

WIDE

10

SDUT

9

CRext

7

PSIG

HCK18HCK2

1

2

3B4R5G6

RGT

TEST2

CN102 24P

MIC901

MICROPHONE

CN705 2P

1

MIC_SIG

2

REG_GND

14

XPWR_ON

CN704 14P

13

NC

10

11

12

XSET_UP

XPWR_LED

PWR_LED_VCC

9

XMOVIE

6

NC

BL_THH

CN101 6P

D

CN701 33P

1

BL_VO-

2

E

SW-368 BOARD

F

(STROBO/CHARGE_LED (AMBER))

G

H

D002

D003

(AE_LOCK (GREEN))

D004

(TALLY (RED))

S004

CONTROL

MENU DISPLAY

S005S003

ZOOM

S001 S002

TW

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

BL_VO-

EVER_3.0V

KEY_AD0

AE_LOCK_LED

KEY_AD1

XCHARGE_LED

PANEL_HDD

XTALLY_LED

HDO

PANEL_2.9V

PANEL_2.9V

PANEL_V

LCD_SO

KEY_AD3

XCS_PANEL_TG

XLCD_SCK

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

PANEL_R

PANEL_G

PANEL_B

REG_GND

PANEL_COM

PANEL_VG

XRST_SYS

A_4.9V

A_4.9V

CAM_15V

CAM_15V

SY-77 BOARD (1/2)

D702

(MS ACCESS LED (RED))

S401

RESET

I

HSY

CPC_IN

N.C

N.C

REG_GND

N.C

05

CN706 18P

123456789

PANEL_COM

N.C

LANC_OUT

HI_UNREG

VG

LANC_IN

101112131415161718

N.C

N.C

N.C

N.C

N.C

N.C

4-1 4-2

CPC

(FOR CHECK)

FRAME (1/2)

Page 23

DSC-P9

COVER

COVER

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

1

FRAME (2/2)

A

B

C

D

E

F

G

H

23

ST-70 BOARD

FLASH

C003

CHARGING

CAPACITOR

+

BT001

LITHIUM BATTERY

(BACK UP)

4 138

CN351 15P

VL_3V

1

2

STB_ON1

3

STB_FULL

ST_UNREG

4

ST_UNREG

5

ST_UNREG

6

ST_UNREG

7

ST_UNREG

8

REG_GND

9

REG_GND

10

REG_GND

11

REG_GND

12

REG_GND

13

REG_GND

14

REG_GND

15

ACV_UNREG1

SP+

BATT/XEXT

USB_JACK_IN

SP-

CN703 39P

3938373635343332313029282726252423222120191817161514131211

AV_JACK_IN

AU_OUT

N.C.

USB_DATA+

V_OUT

USB_DATA-

BATT SIG

USB_GND

USB_GND

AV_GND

AV_GND

ACV_UNREG1

ACV_UNREG1

ACV_UNREG1

ACV_UNREG1

ACV_UNREG1

ACV_UNREG1

ACV_UNREG1

JK-227 BOARD

SY-77 BOARD (2/2)

GND

GND

GND

GND

GND

GND

GND

BATT_UNREG1

GND

987654321

10

BATT_UNREG1

BATT_UNREG1

BATT_UNREG1

BATT_UNREG1

BATT_UNREG1

BATT_UNREG1

BATT_UNREG1

9

CN702 8P

10 14

SCLK

INT

VCC

FP-478

FLEXIBLE

BOARD

DIO

VCC

VSS

1234567

1165

CN001 25P

PRE_LAMP

CCD_TEMP_AD

VSUB_CONT

CN301 27P

F_RST_VCC

F_RST_GND

F_RST_SENS

Z_POSI_OUT

Z_POSI_GND

Z_POSI_VCC

TEMP_OUT

TEMP_GND

Z_RST_VCC

Z_RST_SENS

Z_RST_GND

BS

VSS

8

CCD_OUT

VSHUT

CAM_-7.5V

CAM_15V

ZOOM_A

ZOOM_A

ZOOM_B

ZOOM_B

FOCUS_A

FOCUS_B

FOCUS_A

FOCUS_B

IRIS_S-

IRIS_S+

IRIS_M-

IRIS_M+

SHUTTER-

SHUTTER-

SHUTTER+

SUTTEER+

M_5V

25

24

23

GND

22

GND

21

GND

20

19

GND

18

GND

V4

V3A

V3B

V1B

V1A

V2

GND

GND

H1

RG

H2

GND

D101

SELF TIMER/

17

AF ILLUMINATOR

16

15

14

13

12

CD-397 BOARD

11

10

9

8

7

6

5

4

3

2

1

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

LENZ UNIT

LENZ

CCD

OPTICAL

VIEW

FINDER

15712

I

J

05

FRAME (2/2)

SP901

SPEAKER

USB

JK-226 BOARD

MS

SOCKET

A/V OUT

(MONO)

J002

GND

CN002 5P

5

BT901

DC IN

VCC2D-3D+

4ID

1

J001

BATTERY

TERMINAL

4-3 4-4

Page 24

4-2. SCHEMATIC DIAGRAMS

COVER

COVER

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

DSC-P9

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µ

Link

µF. 50 V or less are not indicated e xcept for electrolytics

and tantalums.

• Chip resistors are 1/10 W unless otherwise noted.

kΩ=1000 Ω, MΩ=1000 kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum

capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

Temperature characteristics

External dimensions (mm)

• Constants of resistors, capacitors, ICs and etc with XX

indicate that they are not used.

In such cases, the unused circuits may be indicated.

•Parts with ★ differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors have characteristic

curve B, unless otherwise noted.

• Signal name

XEDIT→ EDIT PB/XREC → PB/REC

• 2: non flammable resistor

• 5: fusible resistor

• C: panel designation

• A: B+ Line

• B: B– Line

• J : IN/OUT direction of (+,–) B LINE.

• C: adjustment for repair.

• A: VIDEO SIGNAL (ANALOG)

• A: AUDIO SIGNAL (ANALOG)

• A: VIDEO/AUDIO SIGNAL

• A: VIDEO/AUDIO/SERVO SIGNAL

• A: SERVO SIGNAL

• Circled numbers refer to waveforms.

(Measuring conditions voltage and waveform)

•Voltages and waveforms are measured between the

measurement points and ground when camera shoots

color bar chart of pattern box. They are reference values

and reference waveforms.

(VOM of DC 10 MΩ input impedance is used)

•Voltage values change depending upon input

impedance of VOM used.)

1. Connection

Pattern box

L

Front of the lens

L = About 30 cm

2. Adjust the distance so that the output waveform of

Fig. a and the Fig. b can be obtain.

H

Yellow

Cyan

White

Magenta

Green

AABBA=B

Fig. a (Video output terminal output waveform)

Fig.b (Picture on monitor TV)

When indicating parts by reference number, please

include the board name.

Red

Blue

Note : The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

Note : Les composants identifiés par une marque

0 sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifie.

4-5

Page 25

COVER

COVER

Link

Link

DSC-P9

4-2. SCHEMATIC DIAGRAMS

CD-397 BOARD

CD-397 BOARD

SW-368 BOARD (1/2) (CONTROL SWITCH)

SW-368 BOARD (1/2) (CONTROL SWITCH)

SW-368 BOARD (2/2)

SW-368 BOARD (2/2)

(LCD DRIVE, TIMING GENERATOR)

(LCD DRIVE, TIMING GENERATOR)

COMMON NOTE FOR SCHEMATIC DIAGRAMS WAVEFORMS

COMMON NOTE FOR SCHEMATIC DIAGRAMS WAVEFORMS

(CCD IMAGER)

(CCD IMAGER)

ST-70 BOARD (FLASH DRIVE)

ST-70 BOARD (FLASH DRIVE)

CONTROL SWITCH BLOCK

CONTROL SWITCH BLOCK

Page 26

COVER

COVER

4-2. SCHEMATIC DIAGRAMS CD-397 PRINTED WIRING BOARD

4-2. SCHEMATIC DIAGRAMS CD-397 PRINTED WIRING BOARD

DSC-P9DSC-P9

4-2. SCHEMATIC DIAGRAMS

1

2

CD-397 BOARD

A

B

C

D

E

F

CCD IMAGER(CCD BLOCK)

XX MARK:NO MOUNT

LND125

LND124

LND123

LND122

LND121

LND120

LND119

LND118

LND117

LND116

LND115

LND114

LND113

LND112

LND111

LND110

LND109

LND108

LND107

LND106

LND105

LND104

LND103

LND102

LND101

SIGNAL PATH

REC

05

SY-77 (1/10)

CN001

( PAGE 4-9)

25

PRE_LAMP

24

23

22

21

20

19

18

17

16

15

14

13

12

11

CCD_TEMP

10

9

VSUB_CONT

8

7

CAM_-7.5V

6

5

4

3

2

1

Y/CHROMA

For Schematic Diagram

• Refer to page 4-41 for printed wiring board.

3

Note: voltage and waveform of mounted on CD-397 board

can not be measured, because they are (mounted)

by the side of the lens.

D101

TLOH20TP(SONY2)

SELF TIMER/

AF ILLUMINATOR

M_5V

CCD_GND

CCD_GND

CCD_GND

CCD_OUT

CCD_GND

CCD_GND

V4

V3A

V3B

V1B

V1A

VSHUT

CAM_15V

VIDEO

SIGNAL

V2

TH101

GND

GND

H1

RG

H2

GND

(CCD TEMP SENSOR)

R109

XX

4

Q101

2SC4250(T5LSONY1)

BUFFER

R101

C101

C102

0.1u

XX

R105

0

R103

0

68

R102

R104

0

FB101

3300

C104

10u

16V

C103

0.1u

C106

0.1u

16V

C105

10p

7

8

9

10

GND

TEST

TEST

VOUT

VDD12RG13H214H115GND16VSHT17CSUB18VL19H120H2

11

R107

16V

C107

0.1u

220k

C108

2200p

DTC144EHT2L

SWITCH

Q102

7

R108

2700

1V42

V3A3V3B

IC101

ICX406AQF-13

IC101

C109

0.1u

4V25

V1A6V1B

22

R106

865

CCD IMAGER

Precautions for Replacement of CCD Imager

• The CD-397 board mounted as a repair part is not equipped

with a CCD imager.

When replacing this board, remove the CCD imager from the

old one and mount it onto the new one.

• If the CCD imager has been replaced, carry out all the

adjustments for the camera section.

• As the CCD imager may be damaged by static electricity from

its structure, handle it carefully like for the MOS IC.

In addition, ensure that the receiver is not covered with dusts

nor exposed to strong light.

4-7 4-8

CD-397

Page 27

DSC-P9

COVER

COVER

4-2. SCHEMATIC DIAGRAMS SW-368 PRINTED WIRING BOARD

4-2. SCHEMATIC DIAGRAMS SW-368 PRINTED WIRING BOARD

For Schematic Diagram

• Refer to page 4-47 for printed wiring board.

1

3

5

9116842

107

SW-368 BOARD (1/2)

A

CONTROL SWITCH(KEY BLOCK)

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

CL001

BL_VO-

CL002

BL_VO-

CL003

EVER_3.0V

CL004

KEY_AD0

KEY_AD1

PANEL_V

LCD_SO

KEY_AD3

XLCD_SCK

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

PANEL_R

PANEL_G

PANEL_B

REG_GND

PANEL_VG

XRST_SYS

A_4.9V

A_4.9V

CAM_15V

CAM_15V

HDO

CL005

CL006

CL007

CL008

CL009

CL010

CL011

CL012

CL013

CL014

CL015

CL016

CL017

CL018

CL019

CL020

CL021

CL022

CL023

CL024

CL025

CL026

CL027

CL028

CL029

CL030

CL031

CL032

CL033

B

AE_LOCK_LED

XCHARGE_LED

PANEL_HDO

XTALLY_LED

PANEL_2.9V

PANEL_2.9V

C

SY-77 (6/10)

CN701

(SEE PAGE 4-20)

XCS_PANEL_TG

D

PANEL_COM

E

F

SIGNAL PATH

VIDEO SIGNAL

CHROMA

REC

G

PB

H

I

BL_VO-

BL_VO-

PANEL_HDO

PANEL_V

LCD_SO

XCS_PANEL_TG

XLCD_SCK

PANEL_R

PANEL_G

PANEL_B

PANEL_COM

PANEL_VG

XRST_SYS

A_4.9V

A_4.9V

HDO

R012

1200

LEFT

13.4

R009

820

R008

330

R007

560

LND001

STATIC_GND

D004

TALLY(RED)

D003

AE_LOCK(GREEN)

STROBO/CHARGE_LED(YELLOW)

D002

(YELLOW)

W

W ZOOM T

R010

1200

R011

1500

B1

T

S002S001

PANEL_R

PANEL_G

PANEL_B

XRST_SYS

HDO

PANEL_V

LCD_SO

XLCD_SCK

XCS_PANEL_TG

A_4.9V

BL_VO-

PANEL_HDO

PANEL_VG

PANEL_COM

B2

R018

470

2.2

0

Q004

UN9213J-(K8).SO

LED DRIVE

D001

MAZT082H08S0

D006

C002

0.22u

MAZT082H08S0

R002

33k

0.5%

R003

240k

0.5%

13.3

D005

MAZT082H08S0

R005

100k

14.1

2

14

12.9

R006

100k

15.2

36

HN1C01FU-TE85R

D004

CL-196HR-CD-T

D003

CL-196YG-CD-T

D002

SML-310YTT86

MAZT082H08S0

Q003

HN1A01FU-TE85R

B+ SWITCH

14.5

2

1

4

14.1

5

13.4

5

Q002

B+ SWITCH

D007

R004

XX

6

3

S004

CONTROL

1200

RIGHT

SET

DOWN

B1

2

4

B2

DISPLAY

S005

R015

1500

R014

3300

A1

1

3

A2

(2/2)

1

UP

R013

A1

2

1

4

3

A2

S003

MENU

PANEL_13.5V

REG_GND

PANEL_2.9V

PANEL_R

PANEL_G

PANEL_B

XRST_SYS

HDO

PANEL_V

LCD_SO

XLCD_SCK

XCS_PANEL_TG

A_4.9V

BL_VO-

PANEL_HDO

PANEL_VG

PANEL_COM

SW-368 (1/2)

05

4-29 4-30

Page 28

COVER

COVER

For Schematic Diagram

• Refer to page 4-47 for printed wiring board.

• Refer to page 4-54 for waveforms.

4-2. SCHEMATIC DIAGRAMS SW-368 PRINTED WIRING BOARD

4-2. SCHEMATIC DIAGRAMS SW-368 PRINTED WIRING BOARD

DSC-P9DSC-P9

1

3

SW-368 BOARD (2/2)

A

LCD DRIVE,TIMING GENERATOR(RGB/TG BLOCK)

NO MARK:REC/PB MODE

B

C

PANEL_13.5V

PANEL_2.9V

D

PANEL_B

PANEL_G

E

F

1

PANEL_R

PANEL_V

LCD_SO

XLCD_SCK

XCS_PANEL_TG

HDO

(1/2)

REG_GND

G

H

A_4.9V

BL_VO-

XRST_SYS

PANEL_HDO

PANEL_VG

PANEL_COM

I

J

K

C101

L101

47u

47uH

6.3V

R135

150k

D102

MA8036-TX

R134

56k

1.5

Q108

2SB1462JQR(K8).SO

REF VOLTAGE GEN

68

0.5%

Q106

DRIVE

3.4

1510

R136

68

0.5%

4.0

2SB1462JQR(K8).SO

BACK LIGHT

0.9

C123

0.1u

Q109

DRIVE

TEST

24

COM

23

VST

22

VCK

21

EN

20

DWN

19

VDD

18

VSS

17

VDDG

16

VSSG

15

CS

14

WIDE

13

HST

12

REF

11

SDUT

10

9

CRext

HCK2

8

HCK1

7

PSIG

6

5

G

4

R

3

B

2

RGT

1

TEST2

CN101 6P

6

BL_THH

5

N.C.

4

BL_THL

3

BL_H

2

N.C.

BL_L

1

24PCN102

PANEL UNIT

LCD901

COLOR

LCD

MONITOR

D901

BACK LIGHT

5

C108

0.01u

1.2

37

XC.SAVE

XLCD_SCK

R106

470k

C103

0.01u

C102

0.1u

R104

33k

R105

33k

XTG_SO

XCS_PANEL_TG

C104

0.01u

XP.SAVE

C105

0.01u

C106

0.01u

C107

0.01u

2.9

38

2.9

39

2.2

40

2.9

41

2.9

42

1.2

43

1.2

44

2.9

45

1.8

46

1.8

47

1.8

48

N.C./C_BG

XC.SAVE

XSCK

SI

XCS

Vcc1

TRAP_ADJ

LPF_ADJ

XP.SAVE

B_IN

G_IN

R_IN

R107

15k

684 172

36

N.C./R_INJECT

5

6

35

EXT_DA

34

N.C

7

L102

10uH

C110

C111

0.1u

4.7u

20V

BLK

FRP

BGP

PRG

PFRP

13.41.77.12.91.51.42.902.80.50.7

26

27VP28

29

30

31

32

33

FRP

BGP

PRG

IC101

LCD DRIVER

IC101

RB5P004AM1

PFRP

BLACK_IN

25

XVP.SAVE

Vcc2

P_DC_DET

4

3

B_DC_DET

2

G_DC_DET

1

R_DC_DET

GND2/N.C.

GND1

VREF

Vcc3

COM_OUT

COM_IN

91411 12 16

R115

10

C116

2.2u

R116

7.1

24

VB

VG

VR

C117

2.2u

1.7

23

7.1

22

C118

2.2u

1.7

21

1.7

20

C119

2.2u

1.7

19

18

17

16

13.4

15

14

13

10

R117

10

R118

10

R119

R120

100k

100k

C120

4.7u

R122

100k

R121

100k

13

Q107

MCH3310-TL-E

SWITCH

13.4

13.4

S

XP_OFF

D

G

0

0

2.9

Q105

UN9213J-

(K8).SO

SWITCHING

VST

VCK

EN

DWN

C122

1u

WIDE

HST

HCK2

HCK1

R127

470k

7

PANEL_V

LCD_SO

XLCD_SCK

XCS_PANEL_TG

HDO

BGP

PRG

BLK

FRP

PFRP

XLCD_SCK

XCS_PANEL_TG

XTG_SO

LCD_SO

PANEL_V

L104

47uH

R139

1k

C126

2200p

C124

0.01u

XSH.SAVE2SH_R3SH_G4SH_B5SH_A6GND/N.C.7BIAS8OP_IN+9OP_IN-10OP_OUT11VCO12COM_DC

1

2.9 2.90.9 0.9 0.9 1.4 1.4 1.4 1.5 2.9 6.7

SH_R

SH_A

SH_B

SH_G

C109

1u

2.8

37

XCLP

2.9

38

PRG

0

39

SBLK

1.4

40

FRP

1.4

41

PFRP

2.9

42

XSCK

2.9

43

VDD

2.3

44

XCS

2.9

45

SO

2.9

46

SI

47

VDO

2.9

48

XVD

10

2700

R108

R109

47k

R111

22k

SH_R

SH_G

0.9

3.0

34

36

SHG35SHR

XCLR

68k

R110

C112

560p

SH_A

SH_B

0.90.9

31

32

VSS

SHA33SHB

IC102

LCD TIMING GENERATOR

IC102

CXD3512R-T4

RGT

R126

10k

0.1u

C113

R114

R113

100k

1M

R112

68k

2.92.9

29

30

RPD

TEST

D101

1SV290(TPL3)

C115

0.001u

L103

6.8uH

C114

82p

XP.SAVE

XC.SAVE

2.91.41.42.91.4

25

26

27

28

OSCI

OSCO

XC.SAVE

XSTBY

XP_OFF

TSTEN

0

24

VST

1.4

23

VCK

2.6

22

EN

2.9

21

DWN

0.2

20

WIDE

2.9

19

VDD

0

18

HST

1.4

17

HCK2

1.4

16

HCK1

2.9

15

RGT

2.9

14

13

9

VST

VCK

EN

DWN

WIDE

C125

0.01u

HST

HCK2

HCK1

RGT

XP_OFF

C121

1u

7.1

Q101

XP4601-TXE

PSIG DRIVE

R123

8200

Q102

7.7

XP4601-TXE

PSIG DRIVE

7.1

6.5

664

2

331

6.5

R124

10k

R125

2200

R137

10k

7.1

5

5

6.5

3.3

3.3

R138

47k

0.5%

13.4

4

1

7.1

IC103

TC75S55FU(TE85R)

VCC

123

IC103

BACK LIGHT

CONTROL

2

7.7

R131

470k

0.5%

R132

27k

0.5%

4.8

3.9

45

Q103

2SD2216J-

QR(K8).SO

BACK LIGHT

DRIVE

2.9

4.8

R129

3300

Q104

UN9213J-(K8).SO

BACK LIGHT

DRIVE

0.8

R133

R130

10k

0.5%

2SB1462J-

R128

QR(K8).SO

3300

BACK LIGHT

4.0

3.4

0.9

0.1

SIGNAL PATH

VIDEO SIGNAL

L

05

REC

CHROMA

HDO

PB

8

4-31

HD2HDO3XWRT4BL_ON5DETIN6GND7TST08LED9PWM10TEST11TEST12TEST

1

2.7 0.3 2.9 2.9

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

4-32

Les composants identifiés par une marque 0 sont

critiques pour la sécurité. Ne les remplacer que

par une piéce portant le numéro spécifié.

SW-368 (2/2)

Page 29

COVER

COVER

For Schematic Diagram

• Refer to page 4-51 for printed wiring board.

4-2. SCHEMATIC DIAGRAMS ST-70 PRINTED WIRING BOARD

4-2. SCHEMATIC DIAGRAMS ST-70 PRINTED WIRING BOARD

DSC-P9DSC-P9

A

B

C

D

E

1

ST-70 BOARD

FLASH DRIVE(FL BLOCK)

NO MARK:REC/PB MODE

SY-77 (9/10)

CN351

(PAGE 4-26)

LND001

LND002

LND003

LND004

LND005

LND006

LND007

LND008

LND009

LND010

LND011

LND012

LND013

LND014

LND015

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

VL_3V

STB_ON1

STB_FULL

ST_UNREG

ST_UNREG

ST_UNREG

ST_UNREG

ST_UNREG

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

3 107

D001

MA2S111-(K8).SO

C002

1u

BT001

LITHIUM

BATTERY

(BACK UP)

0

0

R002

27k

0

Q001

2SB1073-R-TX

TRANS DRIVE

R001

47

C001

0.01u

R004

270

R003

2700

5

D002

HAU160C030TP

T001

4

F

3

2

P

1

5

S

6

C003

135uF

CHARGING

CAPACITOR

R005

47

187.6

R006

1M

Q002

CY25AAJ-8-T13

FLASH DRIVE

0

R007

1M

1/10W

C004

0.047u

L001

96842

LND016

XE_A

LND017

TRIGGER

LND018

XE_K

FLASH

UNIT

05

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

4-35

Les composants identifiés par une marque 0 sont

critiques pour la sécurité. Ne les remplacer que

par une piéce portant le numéro spécifié.

4-36

ST-70

Page 30

DSC-P9

COVER

COVER

DSC-P9

COVER

COVER

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

For Schematic Diagram

1

CONTROL SWITCH BLOCK

A

CONTROL SWITCH BLOCK is replaced as a block,

so that PRINTED WIRING BOARD is omitted.

2

B

(1st)

C

D

S003

(SHUTTER)

(2nd)

R001

20k

123456789

14P

XAE_LOCK_SW

D_2.9V

XSHTR_SW

NC

MODE_DIAL

GND

NC

XPB_ON

1011121314

XMOVIE

XSET_UP

XPWR_LED

3

SET_UP

B

G

MOVIE

6

PLAY

A

(5 POSITION MODE_DIAL)

D001

(POWER(GREEN))

NC

XPWR_ON

PWR_LED_VCC

S005

MODE DIAL

45

R003

R002

4000

6000

S004

POWER

SCN

2

P_AUTO

1

E

05

SY-77 (7/10)

CN704

(SEE PAGE 4-21)

CONTROL SWITCH BLOCK

4-38

Page 31

4-3. PRINTED WIRING BOARDS

COVER

COVER

4-3. PRINTED WIRING BOARDS

4-3. PRINTED WIRING BOARDS

THIS NOTE IS COMMON FOR WIRING BOARDS

(In addition to this, the necessary note is printed in each block)

(For printed wiring boards)

• : Uses unleaded solder.

• : Circuit board

: Flexible board

Pattern from the side which enables seeing.

(The other layers’ patterns are not indicated)

• Through hole is omitted.

• Circled numbers refer to waveforms.

• There are a few cases that the part printed on diagram

isn’t mounted in this model.

• C: panel designation

• Chip parts.

Transistor Diode

C

DSC-P9

43

12

3

43

12

31

4625

4

3

12

5

5246

EB

654

123

31

21

12

345

534

54

45

21321321

123

312

43

12

21

34

4-39

Page 32

COVER

COVER

Link

Link

DSC-P9

4-3. PRINTED WIRING BOARDS

CD-397 BOARD

CD-397 BOARD

SW-368 BOARD

SW-368 BOARD

MOUNTED PARTS LOCATION

MOUNTED PARTS LOCATION

ST-70 BOARD

ST-70 BOARD

CIRCUIT BOARDS LOCATION

CIRCUIT BOARDS LOCATION

WAVEFORMSCOMMON NOTE FOR PRINTED WIRING BOARDS

WAVEFORMSCOMMON NOTE FOR PRINTED WIRING BOARDS

Page 33

DSC-P9DSC-P9

SELF TIMER/

AF ILLUMINATOR

COVER

COVER

CD-397 (CCD IMAGER)

• For Printed Wiring Board.

• :Uses unleaded solder.

• There are a few cases that the part isn't mounted in this

model is printed on this diagram.

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

MOUNTED PARTS LOCATION

MOUNTED PARTS LOCATION

4-41 4-42

CD-397

Page 34

DSC-P9

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

COVER

COVER

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

SW-368 (FRONT CONTROL, LCD DRIVE, TIMING GENERATOR, CONTROL SWITCH)

• For Printed Wiring Board.

• :Uses unleaded solder.

• There are a few cases that the part isn't mounted in this

model is printed on this diagram.

• See page 4-57 for printed parts location.

D004

(TALLY (RED))

D003

(AE LOCK (GREEN))

D002

(STROBO/CHARGE LED)

A

KK

KK

A

A

KK

6

7

1

3

5

4

2

ZOOMW T

K

A

K

MOUNTED PARTS LOCATION

MOUNTED PARTS LOCATION

CONTROL

DISPLAY MENU

10

8

9

SW-368

4-47 4-48

Page 35

DSC-P9

COVER

COVER

ST-70 (FLASH DRIVE)

• For Printed Wiring Board.

• :Uses unleaded solder.

• There are a few cases that the part isn't mounted in this

model is printed on this diagram.

FLASH UNIT

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

MOUNTED PARTS LOCATION

MOUNTED PARTS LOCATION

C

BE

6

3

5

A

K

A

1

2

4

BT001

BATTERY,

LITHIUM SECONDARY

11, 12

11, 12

ST-70

4-51 4-52

Page 36

DSC-P9

SW-368 BOARD

COVER

COVER

SW-368 BOARD

SW-368 BOARD

1

2

3

2H

IC101 w; REC/PB

2H

IC101 ws REC/PB

7.8 Vp-p

7.8 Vp-p

6

340 mVp-p

H

IC101 rj REC/PB

7

460 mVp-p

H

IC101 rk REC/PB

8

4

5

2H

2H

IC101 wf REC/PB

2H

IC101 wj REC/PB

7.8 Vp-p

5.1 Vp-p

340 mVp-p

3.0 Vp-p

H

IC102 1 REC/PB

9

4.1 Vp-p

11.28 MHz

IC102 wj REC/PB

q;

3.0 Vp-p

SW-368

H

IC101 rh REC/PB

V

IC102 rk REC/PB

4-54

Page 37

COVER

COVER

SW-368 BOARD

C002 C-2

C101 B-2

C102 B-3

C103 B-4

C104 B-4

C105 B-4

C106 B-3

C107 B-3

C108 B-4

C109 B-2

C110 B-2

C111 C-3

C112 C-3

C113 C-3

C114 B-3

C115 B-3

C116 C-4

C117 C-4

C118 C-4

C119 C-4

C120 C-3

C121 C-3

C122 B-2

C123 A-2

C124 A-3

C125 A-2

C126 B-3

CN101 C-1

CN102 B-1

D001 A-1

D002 A-1

D003 A-1

D004 A-1

D005 A-2

D006 A-2

D007 A-4

D101 B-3

D102

IC101 B-4

IC102 A-3

IC103 C-3

L101 B-2

L102 C-3

L103 B-3

L104 B-2

Q002 C-2

Q003 C-2

Q004 A-2

Q101 B-4

Q102 B-4

Q103 C-2

Q104 C-3

Q105 A-2

Q106 C-2

Q107 A-2

Q108 A-3

Q109 C-2

R002 C-2

R003 C-2

R005 B-2

R006 C-2

R007 A-2

R008 A-2

R009 A-2

R010 A-4

R011 C-2

R012 B-1

R013 B-1

R014 C-1

R015 C-1

R018 A-2

R104 B-4

R105 B-4

R106 B-3

R107 B-4

R108 B-3

R109 B-3

R110 B-3

R111 B-3

R112 C-3

R113 C-3

R114 B-3

R115 C-4

R116 C-4

R117 C-4

R118 C-4

R119 C-4

R120 C-4

R121 C-3

R122 C-4

R123 B-4

R124 B-4

R125 C-3

R126 A-3

R127 A-2

R128 C-1

R129 C-3

R130 C-3

R131 A-3

R132 A-3

R133 C-2

R134 A-3

R135 A-2

R136 C-1

R137 B-4

R138 C-3

R139 C-3

S001 A-3

S002 A-4

S003 C-2

S004 B-1

S005 C-1

4-3. PRINTED WIRING BOARDS

4-3. PRINTED WIRING BOARDS

DSC-P9

4-57

4-57E

SW-368

Page 38

COVER

COVER

Before starting adjustment

EVR Data Re-writing Procedure When Replacing Board

The data that is stored in the repair board, is not necessarily correct.

Perform either procedure 1 or procedure 2 or procedure 3 when replacing board.

Procedure 1

Save the EVR data of the machine in which a board is going to be replaced. Download the saved data after a

board is replaced.

DSC-P9

SECTION 5

ADJUSTMENTS

(Machine before starting repair)

Save the EVR data

to a personal computer.

Procedure 2

Remove the EEPROM from the board of the machine tha t is going to be repaired. Install the removed EEPR OM

to the replaced board.

PC

Remove the EEPROM and install it.

(Former board)

(New board)

PC

Download the saved

data to a machine.

(Machine after a board is replaced)

Procedure 3

When the data cannot be saved due to defective EEPROM, or when the EEPROM cannot be removed or installed, save the data from the same model of the same destination, and download it.

(Machine to be repaired)

Download the data.

Save the data.

(The same model of the same destination)

After the EVR data is saved and downloaded, check the

respective items of the EVR data.

(Refer to page 5-2 for the items to be checked.)

(Machine to be repaired)PC

5-1

Page 39

DSC-P9

1-1. Adjusting items when replacing main parts and boards

When replacing main parts and boards, adjust the items indicated by z in the following table.

Block

replacement

Replaced parts

Mounted parts

replacement

Board

replacement

Adjustment section Adjustment

Initialization of A, B, D,

E, F, 7, 9 page data

Video Video sync level adj.

Camera Flange back adj.

LCD LCD initial data input

Initialization of A, D page data

Initialization of B, E, F, 7, 9, page data

Video burst level check

F No. compensation

Mechanical shutter adj.

Light value adj.

Mixed color cancel adj.

Auto white balance standard data input

CCD linearity check

Color reproduction adj.

CCD (white and black) defect

compensation

Strobe white balance adj.

VCO adj.

Black limit adj.

Bright adj.

Contrast adj.

VG Center adj.

PSIG Gray adj.

V-COM adj.

White balance adj.

(LCD panel)

(Back light unit)

(CCD imager)

(Camera Module)

(EVR)

(CAMERA DSP)

(VIDEO AMP)

(LCD drive)

LCD901

D901

IC101

IC508

IC601

IC101

(LCD Timing generator)

IC101

IC102

(COMPLETE)

EEPROM

(COMPLETE) (Note)

(COMPLETE)

IC505

RadarWRadarWRadarWRadarWRadarWRadarW

Lens block assy (Note)

Flash unit

LCD block

LCD block

CD-397 board

CH-111 board

SY-77 board

SY-77 board

SY-77 board

SW-368 board

SW-368 board

ST-70 board

SY-77 board

SW-368 board

SY-77 board

Supporting

zz

zz

zzz z z

zzz

zz zzz

zz zzz

zz zzz

zzz zzz

zzz zzz

zzz zzz

zz

zzz zzz

zzzzz

z zzz zz zz

zzz

z zzz

z zzz

z zzz

z zzz

z zzz

z zzz

z z zzz

zz z zzz

Table 5-1-1

Note : When replacing the lens block or the SY-77 board, refer to “Precaution on Replacing the Lens Block or the SY-77 board”. (See

page 6)

5-2

Page 40

Ref. No.

J-1

J-2

J-3

J-4

J-5

J-6

J-7

J-8

Name

Filter for color temperature correction (C14)

Pattern box PTB-450

Color bar chart for pattern box

Adjusting remote commander (RM-95 upgraded).

(Note 1)

Siemens star chart

Clear chart for pattern box

CPC-9 jig (Note 2)

Minipattern box

Parts Code

J-6080-058-A

J-6082-200-A

J-6020-250-A

J-6082-053-B

J-6080-875-A

J-6080-621-A

J-6082-393-C

J-6082-353-B

Usage

Auto white balance adjustment/check

White balance adjustment/check

For checking the flange back

For connecting the adjusting remote commander

For adjusting the LCD block

For adjusting the flange back

J-9 Back ground paper J-2501-130-A For adjusting the strobe

5-1. CAMERA SE CTION ADJUSTMENT

1-1. PREPARATIONS BEFORE ADJUSTMENT

1-1-1. List of Service Tools

• Oscilloscope • Color monitor • Vectorscope

• Regulated power supply • Digital voltmeter