Page 1

DSC-H1

SERVICE MANUAL

Ver. 1.4 2006. 06

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Internal memory

Internal memory

ON BOARD

ON BOARD

Link

Link

SPECIFICATIONS

SPECIFICATIONS

BLOCK DIAGRAMS

BLOCK DIAGRAMS

LEVEL 2

DSC-H1

US Model

Canadian Model

AEP Model

UK Model

Hong Kong Model

Australian Model

Japanese Model

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

E Model

Chinese Model

Korea Model

Tourist Model

SERVICE NOTE

SERVICE NOTE

DISASSEMBLY

DISASSEMBLY

• For ADJUSTMENTS (SECTION 6), refer to SERVICE MANUAL, ADJ (9-876-880-51).

• For INSTRUCTION MANUAL, refer to SERVICE MANUAL, LEVEL 1 (9-876-880-41).

• Reference number search on printed wiring boards is available.

On the CH-169 and SY-127 board

This service manual provides the information that is premised the circuit board replacement service and not intended repair

inside the SY-127 board.

Therefore, schematic diagram, printed wiring board, mounted parts location and electrical parts list of the

shown.

The following pages are not shown.

Schematic diagram .............................Pages 4-21 to 4-44

Printed wiring board ............................Pages 4-55 to 4-60

Waveforms ........................................... Page 4-62

FRAME SCHEMATIC DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

Mounted parts location .............................

Electrical parts list ................................... Pages 5-14 to 5-18

REPAIR PARTS LIST

REPAIR PARTS LIST

SY-127

Page 4-64

board are not

DIGITAL STILL CAMERA

DSC-H1

9-876-880-31

Sony EMCS Co.

2006F1600-1

©2006.06

Published by Kohda TEC

Page 2

SPECIFICATIONS

Camera

[System]

Image device 7.19 mm (1/2.5 type) color

CCD, Primary color filter

Total pixel number of camera

Approx. 5 255 000 pixels

Effective pixel number of camera

Approx. 5 127 000 pixels

Lens 12 zoom lens

f = 6.0 - 72.0 mm (36 - 432 mm

when converted to a 35 mm still

camera)

F2.8 - 3.7

Exposure control Automatic exposure, Shutter

speed priority, Aperture

priority, Manual exposure,

Scene Selection (7 modes)

White balance Automatic, Daylight, Cloudy,

Fluorescent, Incandescent,

Flash, One push

File format (DCF compliant)

Still images: Exif Ver. 2.2

JPEG compliant, DPOF

compatible

Movies: MPEG1 compliant

(Monaural)

Recording media Internal memory 32 MB

“Memory Stick”

Flash Recommended distance (ISO

set to Auto): 0.3 m to 6.8 m

(11 26/32 inches to 22 feet

3 23/32 inches) (W)/0.9 m to

5.2 m (2 feet 11 14/32 inches to

17 feet 23/32 inches) (T)

Viewfinder Electric viewfinder (color)

[Input and Output connectors]

A/V OUT (MONO) jack (Monaural)

Minijack

Video: 1 Vp-p, 75 ,

unbalanced, sync negative

Audio: 327 mV (at a 47 k

load)

Output impedance 2.2 k

USB jack mini-B

USB communication

Hi-Speed USB (USB 2.0

compliant)

[LCD screen]

LCD panel 6.2 cm (2.5 type) TFT drive

Total number of dots

115 200 (480x240) dots

[Finder]

LCD panel 0.75 cm (0.3 type) TFT drive

Total number of dots

115 200 (480x240) dots

[Power, general]

Power HR 15/51:HR6 (size AA)

Nickel-Metal Hydride batteries

(2), 2.4 V

ZR6 (size AA) Oxy Nickel

Primary Battery (2, not

supplied), 3 V

AC-LS5K AC Adaptor (not

supplied), 4.2 V

Power consumption

(during shooting with the LCD screen)

1.8 W

Operating temperature

0°C to +40°C (+32°F to

+104°F)

Storage temperature

–20°C to +60°C (–4°F to

+140°F)

Dimensions 108x81.4x91.2 mm

(4 1/4x 31/4x 35/8 inches)

(W/H/D, excluding maximum

protrusions)

Mass Approx. 590.8 g (1 lb 20.8 oz)

(including two batterries,

shoulder strap, adaptor ring,

lens hood, lens cap, etc.)

Microphone Electret condenser microphone

Speaker Dynamic speaker

Exif Print Compatible

PRINT Image Matching III

Compatible

PictBridge Compatible

BC-CS2A/CS2B Ni-MH battery charger

Power requirements

AC 100 to 240 V, 50/60 Hz,

3 W

Output voltage AA: DC 1.4V 400 mAx 2

AAA: DC 1.4 V 160 mAx2

Operating temperature

0°C to +40°C (+32°F to

+104°F)

Storage temperature

–20°C to +60°C (–4°F to

+140°F)

Dimensions Approx. 71x30x91 mm

(2 7/8x 13/16x 35/8 inches)

(W/H/D)

Mass Approx. 90 g (3 oz)

Design and specifications are subject to change

without notice.

DSC-H1

— 2 —

Page 3

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky , less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

DSC-H1

— 3 —

Page 4

TABLE OF CONTENTS

1. SERVICE NOTE ........................................................ 1-1

2. DISASSEMBLY

2-1. DISASSEMBLY······························································2-1

2-2. SERVICE POSITION ·····················································2-5

2-3. CIRCUIT BOARDS LOCATION ···································2-7

2-4. FLEXIBLE BOARDS LOCATION ································2-8

HELP (List of caution points is shown here.)

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/2) ··························· 3-1

3-2. OVERALL BLOCK DIAGRAM (2/2) ··························· 3-3

3-3. POWER BLOCK DIAGRAM (1/2) ································ 3-5

3-4. POWER BLOCK DIAGRAM (2/2) ································ 3-7

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM································4-1

4-2. SCHEMATIC DIAGRAMS

• CD-576 (CCD IMAGER)

SCHEMATIC DIAGRAM ······························4-5

• MS-275 (MEMORY STICK, LI BATTERY)

SCHEMATIC DIAGRAM ······························4-7

• ST-123 (FLASH DRIVE)

SCHEMATIC DIAGRAM ······························4-9

• ST-124 (FLASH)

SCHEMATIC DIAGRAM ····························4-17

• PL-039 (PLUNGER)

SCHEMATIC DIAGRAM ······························4-8

• SW-447 (1/2) (FUNCTION SW)

SCHEMATIC DIAGRAM ····························4-11

• SW-447 (2/2) (PITCH/YAW SENSOR AMP)

SCHEMATIC DIAGRAM ····························4-13

• EV-016 (EVF, BACK LIGHT)

SCHEMATIC DIAGRAM ······························4-7

• AF-102 FLEXIBLE (AF LED, LENS COVER SW)

SCHEMATIC DIAGRAM ····························4-15

• SW-006 FLEXIBLE (SY-SW RELAY)

SCHEMATIC DIAGRAM ····························4-18

• MS-029 FLEXIBLE (SY-MS RELAY)

SCHEMATIC DIAGRAM ····························4-15

• ST-001 FLEXIBLE (SY-ST RELAY)

SCHEMATIC DIAGRAM ····························4-17

• FP-224 FLEXIBLE (SY-CD RELAY)

SCHEMATIC DIAGRAM ····························4-16

• CONTROL SWITCH BLOCK (SW51780)

SCHEMATIC DIAGRAM ····························4-19

Shematic diagram of the CH-169 and SY-127 board

are not shown.

Pages from 4-21 to 4-44 are not shown.

4-3. PRINTED WIRING BOARDS

• CD-576 (CCD IMAGER)

PRINTED WIRING BOARD ·······················4-49

• MS-275 (MEMORY STICK, LI BATTERY)

PRINTED WIRING BOARD ·······················4-47

• ST-123 (FLASH DRIVE)

PRINTED WIRING BOARD ·······················4-51

• ST-124 (FLASH)

PRINTED WIRING BOARD ·······················4-52

• PL-039 (PLUNGER)

PRINTED WIRING BOARD ·······················4-51

• SW-447 (FUNCTION SW, PITCH/YAW SENSOR AMP)

PRINTED WIRING BOARD ·······················4-53

• EV-016 (EVF, BACK LIGHT)

PRINTED WIRING BOARD ·······················4-49

• AF-102 FLEXIBLE (AF LED, LENS COVER SW)

PRINTED WIRING BOARD ·······················4-47

Printed wiring board of the CH-169 and SY-127 board

are not shown.

Pages from 4-55 to 4-60 are not shown.

4-4. WAVEFORMS ······························································4-61

Wav eforms of the SY -127 board are not shown.

Page 4-62 is not shown.

4-5. MOUNTED PARTS LOCATION ·································4-63

Mounted parts location of the SY-127 board is not

shown.

Page 4-64 is not shown.

5. REPAIR PARTS LIST

5-1. EXPLODED VIEWS ······················································ 5-3

5-1-1. OVERALL SECTION····················································5-3

5-1-2. LED SECTION, CABINET(REAR) SECTION ············5-4

5-1-3. MAIN SECTION ···························································5-5

5-1-4. EVF SECTON ·······························································5-6

5-1-5. LENS SECTION ···························································5-7

5-1-6. CABINET(FRONT) SECTION·····································5-8

5-1-7. ST SECTION ·································································5-9

Checking supplied accessories ················································5-10

5-2. ELECTRICAL PARTS LIST ········································5-11

Electrical parts list of the SY-127 board are not

shown.

Pages from 5-14 to 5-18 are not shown.

DSC-H1

— 4 —

Page 5

• NOTE FOR REPAIR

1. SERVICE NOTE

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Take care that there are

some pieces of gilt left inside)

When remove a connector, don't pull at wire of connector.

Be in danger of the snapping of a wire.

When installing a connector, don't press down at wire of connector.

Be in danger of the snapping of a wire.

[Discharging of the FLASH unit’s charging capacitor]

The charging capacitor of the FLASH unit is charged up to the

maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by the

charged voltage which is kept without discharging when the main

power of the DSC-H1 is simply turned off. Therefore, the remaining

voltage must be discharged as described below.

Preparing the Short Jig

To preparing the short jig. a small clip is attached to each end of a

resistor of 1 kΩ /1 W (1-215-869-11)

Wrap insulating tape fully around the leads of the resistor to prevent

electrical shock.

Discharging the Capacitor

1 Remove the main section.

2 Discharge the capacitor on the ST -123 board for about 10 seconds

by using the short jig.

Caution

1

Discharging the capacitor

Capacitor

1 kΩ/1 W

Wrap insulating tape.

DSC-H1

1-1

Short jig (

ST-123 board

1kΩ/1W

)

Page 6

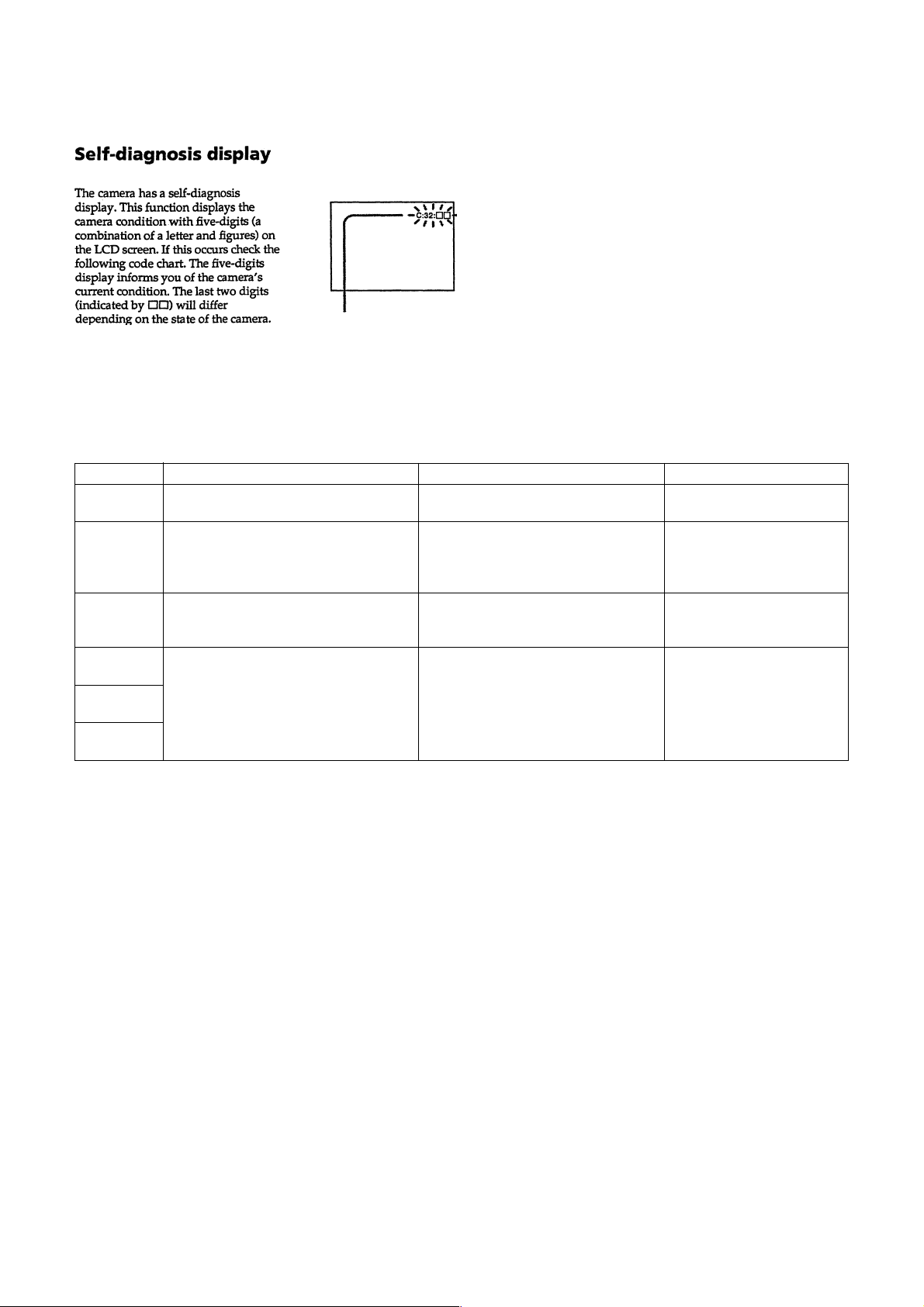

[Description on Self-diagnosis Display]

Self-diagnosis display

• C: ss: ss

The contents which can be handled

by customer, are displayed.

• E: ss: ss

The contents which can be handled

by engineer, are displayed.

Display Code

C:32:01

C:13:01

E:91:01

E:01:XX

E:61:00 *1

E:61:10 *1

Note : The error code is cleared if the battery is removed, except defective flash unit.

*1: The error display is given in two ways.

Turn off the main power then back on.

Replace the memory stick.

Format the memory stick with the DSC-H1.

Checking of flash unit or replacement of

flash unit.

Checking of lens drive circuit

Countermeasure

Trouble with hardware.

• The type of memory stick that cannot be

used by this machine, is inserted.

• Data is damaged.

• Unformatted memory stick is inserted.

Abnormality when flash is being

charged.

When failed in the focus initialization.

Cause

Caution Display During Error

SYSTEM ERROR

MS ERROR

Flash LED

Flash display

Flashing at 3.2 Hz

—

DSC-H1

1-2

Page 7

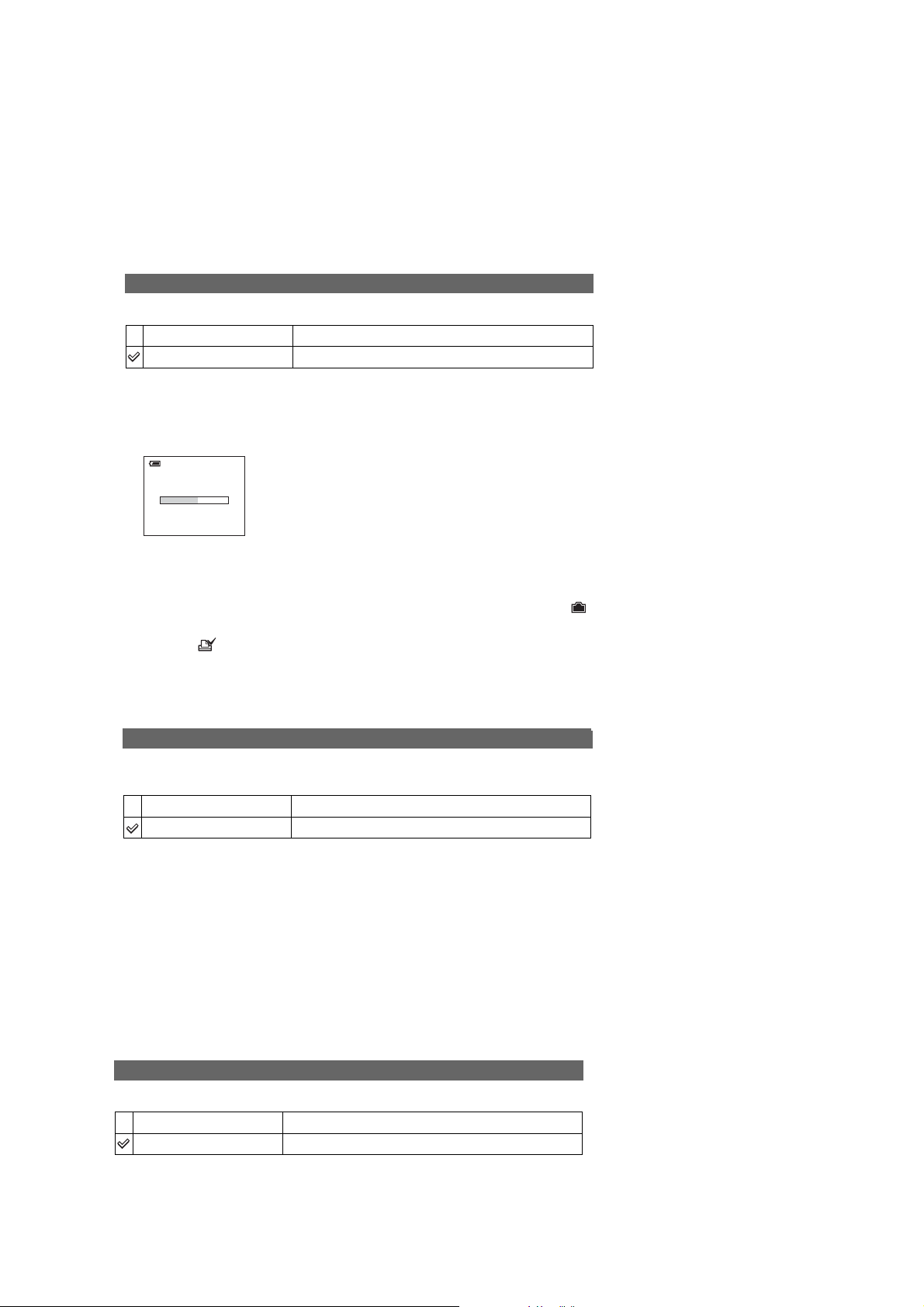

• METHOD FOR COPYING OR ERASING THE DATA IN INTERNAL MEMORY

p

The data can be copied/erased by the operations on the Setup screen. (When erasing the data, execute formatting the internal memory.)

Note: 1 When replacing the SY-127 board, erase the data in internal memory of the board before replacement.

Note: 2 When replacing the SY-127 board or the IC381 on the SY-127 board, execute formatting and initialize the internal memory after

replacement.

Method for Copying the Data in Internal Memory

Copy

Copies all images in the internal memory to a “Memory Stick”.

OK

Cancel

1 Insert a “Memory Stick” having 32 MB or larger capacity.

2 Select [OK] with v on the control button, then press z.

The message “All data in internal memory will be copied Ready?” appears.

3 Select [OK] with v , then pr es s z.

Copying starts.

Copying

102_COPY

Use batteries with enough capacity or the AC Adaptor (not supplied). If you attempt to copy image files

using batteries with little remaining capacity, the batteries may run out, causing copying to fail or possibly

corrupting the data.

You cannot copy individual images.

The original images in the internal memory are retained even after copying. To delete the contents of the

internal memory, remove the “Memory Stick” after copying, then execute the [Format] command in

Internal Memory Tool.

You cannot select a folder copied on a “Memory Stick”.

The setting of (Print order) marks is not copied even when you copy data.

See the following procedure.

Cancels the copying.

Method for Formatting the Internal Memory

Format

Formats the internal memory.

Note that formatting irrevocably erases all data in the internal memory, including even protected images.

OK

Cancel

1 Select [OK] with v on the control button, then press z.

The message “All d ata in internal memory will be erased Ready?” appears.

2 Select [OK] with v, then press z.

The format is com

lete.

See the following procedure.

Cancels the formatting.

• PROCESS AFTER FIXING FLASH ERROR

When “FLASH error” (Self-diagnosis Code E : 91 : ** ) occurs, to prevent any abnormal situation caused by high voltage, setting of the

flash is changed automatically to disabling charge and flash setting.

After fixing, this setting needs to be deactivated. Flash error code can be initialized by the operations on the Setup screen.

Method for Initializing the Flash Error Code

Initialize

Initializes the setting to the default setting.

OK

Cancel

See the following procedure.

Cancels the resetting.

DSC-H1

1 Select [OK] with v on the control button, then press z.

The message “Initialize all settings Ready?” appears.

2 Select [OK] with v, then press z.

The settings are reset to the default setting.

Make sure that the power is not disconnected during resetting.

1-3E

Page 8

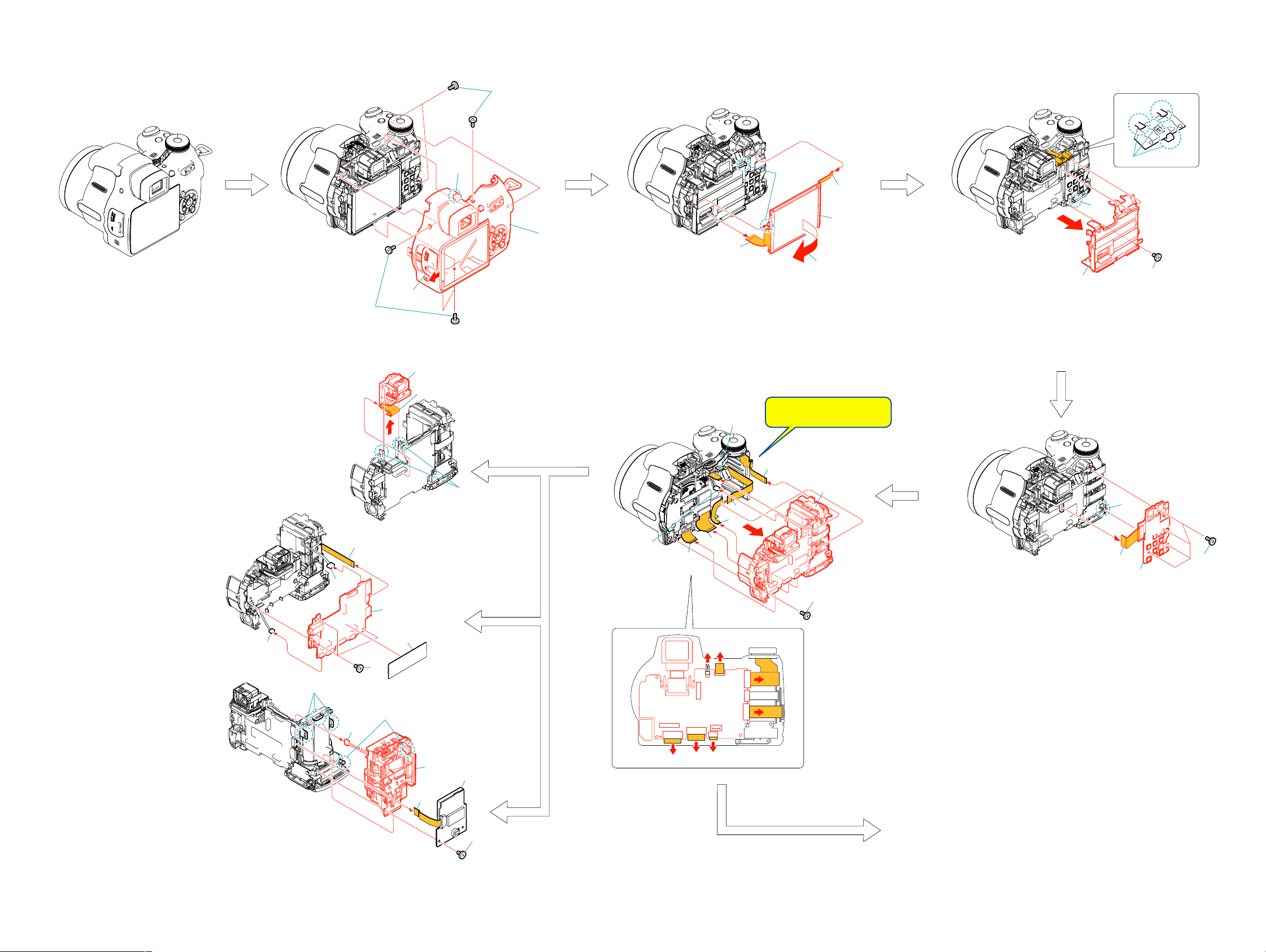

The following flow chart shows the disassembly procedure.

2-1. DISASSEMBLY

2. DISASSEMBLY

2

1

Three screws (M2x4) silver

2

Three screws (M2x4) silver

3

Remove the JK lid in the

direction of the arrow.

4

Claw

5

Cabinet (rear) section

1

EV-016 board

2

T wo claws

3

EVF section

4

5

4

1

3

1

3

1

Light guide plate (2.5) block

2

T wo claws

3

Remove the LCD, Light guide plate (2.5) block

in the direction of the arrow.

4

LCD unit

5

LCD unit, Light guide plate (2.5) block

6

2

1

5

3

Note:

Be very careful not to

damage the flexible board.

5

SY-127

1

Tapping screw (M1.7x4) black

2

Three claws

3

Claw

4

LCD frame assembly

3

4

2

1

1

Flexible flat cable (MS-029)

2

Battery connector

3

From the loudspeaker

4

Three tapping screws (M1.7x4) black

5

Fuse replacement caution label

6

SY-127 board

1

Flexible flat cable (MS-029)

2

Tapping screw (M1.7x4) black

3

T wo claws

4

MS-275 board

5

Battery connector

6

Three claws

7

Battery terminal board

3

SY-127

9

8

1

From the lens flexible board

2

FP-224 flexible board

3

From the lens flexible board

4

Flexible flat cable (ST-001)

5

Control switch block (SW51780)

6

AF-102 flexible board

7

From the microphone

8

Tapping screw (M1.7x4) black

9

Main section

ST section

(See page 2-3.)

3

SY-127

1

1

Flexible flat cable (SW-006)

2

Four tapping screws (M1.7x4) black

3

Claw

4

SW-447 board

-447

SW

2

4

M

S-275

2

4

3

1

SY-127

2

2

SY-127

6

7

5

4

3

7

1

4

2

SY -127

1

2

6

SY -127

6

5

5

4

3

7

1

DSC-H1

2-1 2-2

Page 9

Caution

1

Discharging the capacitor

Capacitor

Short jig (

ST-123 board

1kΩ/1W

2. DISASSEMBLY

2. DISASSEMBLY

2

2

1

)

1

Two tapping screws (M1.7x4) black

2

Lens section

1

Tapping screw (M1.7x4) black

2

Control switch block (SW51780), Microphone unit

1

6

1

Tapping screw (M1.7x4) black

2

Claw

3

ST-123 board

4

Three harnesses (HA-001) (Red, White, Blue)

5

Open the ST cover in the direction of the arrow.

6

ST section

HELP 02

1

4

5

HELP 01

4

3

3

2

1

2

1

Remove the

AF-102 flexible board

in the direction of the arrow.

2

Three claws

3

Three claws

4

AF-102 flexible board

DSC-H1

2-3 2-4

Page 10

2-2. SERVICE POSITION

2

1

[SERVICE POSITION TO CHECK THE SY-127 BOARD]

From the lens section

SW-447 board

FP-224 flexible board

2

4

2

SW-447

Lens section

5

3

1

1

Flexible flat cable (SW-006)

Monitor TV

Audio/Video jack

CN401

CN502

MS-275

CN101

CN506

SY-127

CN514

CN513

SY-127 board

CN509

Battery terminal board

2

1

5

4

3

Caution

1

ST-123 board

Discharging the capacitor

Capacitor

Short jig (

1kΩ/1W

From the lens section

)

Flexible flat cable (MS-029)

MS-275 board

1

7

2

1

-

Y

3

S

4

3

7

2

1

-

Y

S

1

6

4

3

2

7

1

2

1

7

4

4

-

W

S

2

4

5

9

7

2

1

-

Y

S

8

3

Flexible flat cable (MS-029)

2

7

2

-1

Y

S

3

1

27

-1

Y

S

MS-275 board

6

5

4

Control switch block (SW51780)

Insert the batteries (size AA).

Battery section

Nickel Metal Hydride batteries (x2).

2

DSC-H1

2-5 2-6

Page 11

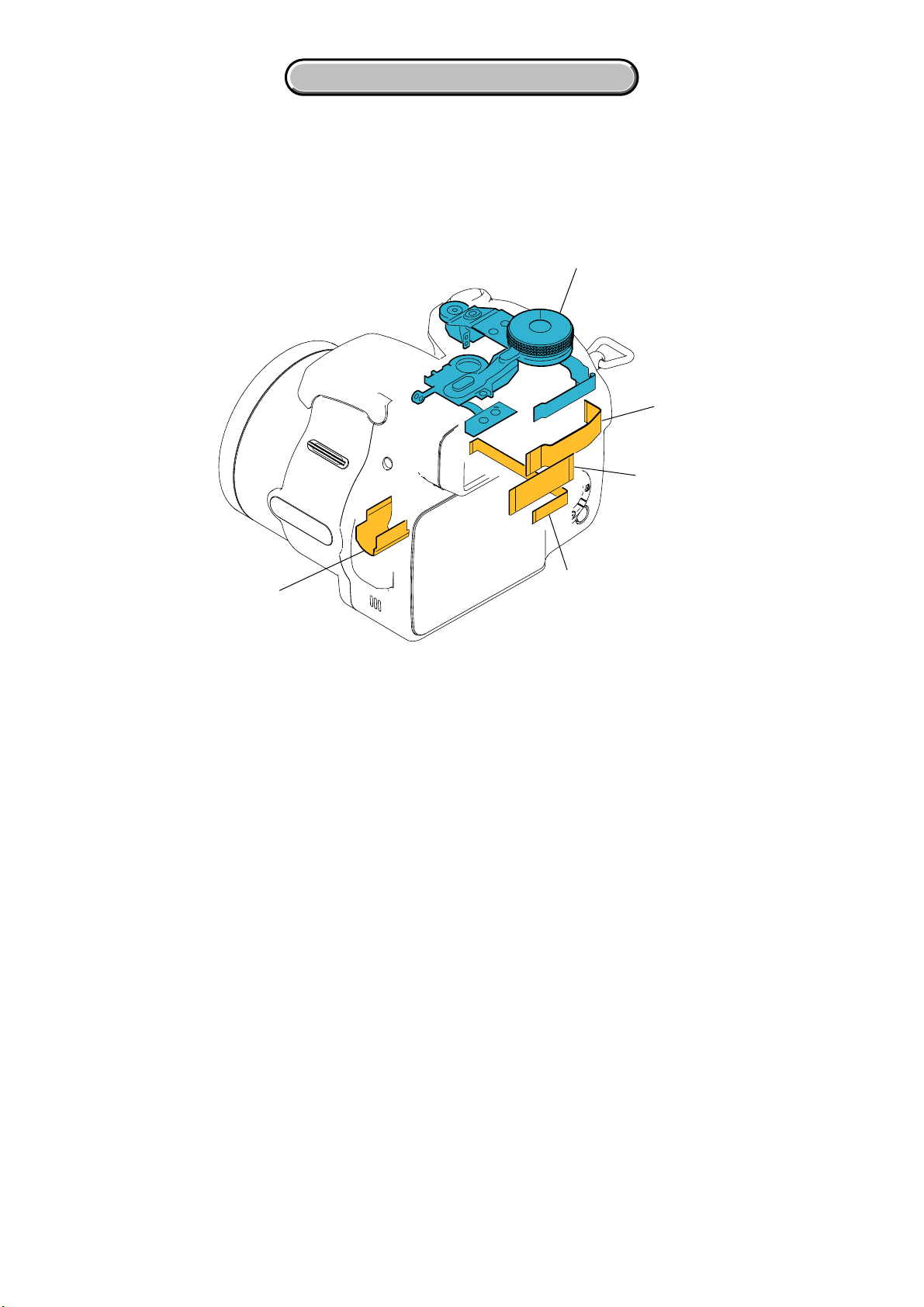

2-3. CIRCUIT BOARDS LOCATION

2. DISASSEMBLY

2. DISASSEMBLY

PL-039

CD-576

ST-124

AF-102

ST-123

MS-275

SW-447

CH-169

SY-127

EV-016

NAME

AF-102 AF LED, LENS COVER SW

CD-576

CH-169

EV-016

MS-275

PL-039

ST-123

ST-124

SW-447

SY-127

CCD IMAGER

CCD SIGNAL PROCESS

EVF, BACK LIGHT

MEMORY STICK, LI BATTERY

PLUNGER

FLASH DRIVE

FLASH

FUNCTION SW, PITCH/YAW SENSOR AMP

LENS DRIVE, CAMERA A/D CONV., TIMING GENERATOR, CAMERA DSP,

SYSTEM CONTROL, 256Mbit SDRAM, FLASH MEMORY, SUPER AND FLASH MEMORY,

A/V AMP, USB/AV JACK, SP, MIC, PANEL DRIVE, STEADY SHOT CONTROL,

LENS SERVO, CONNECTOR, DC/DC CONVERTER

FUNCTION

DSC-H1

2-7

Page 12

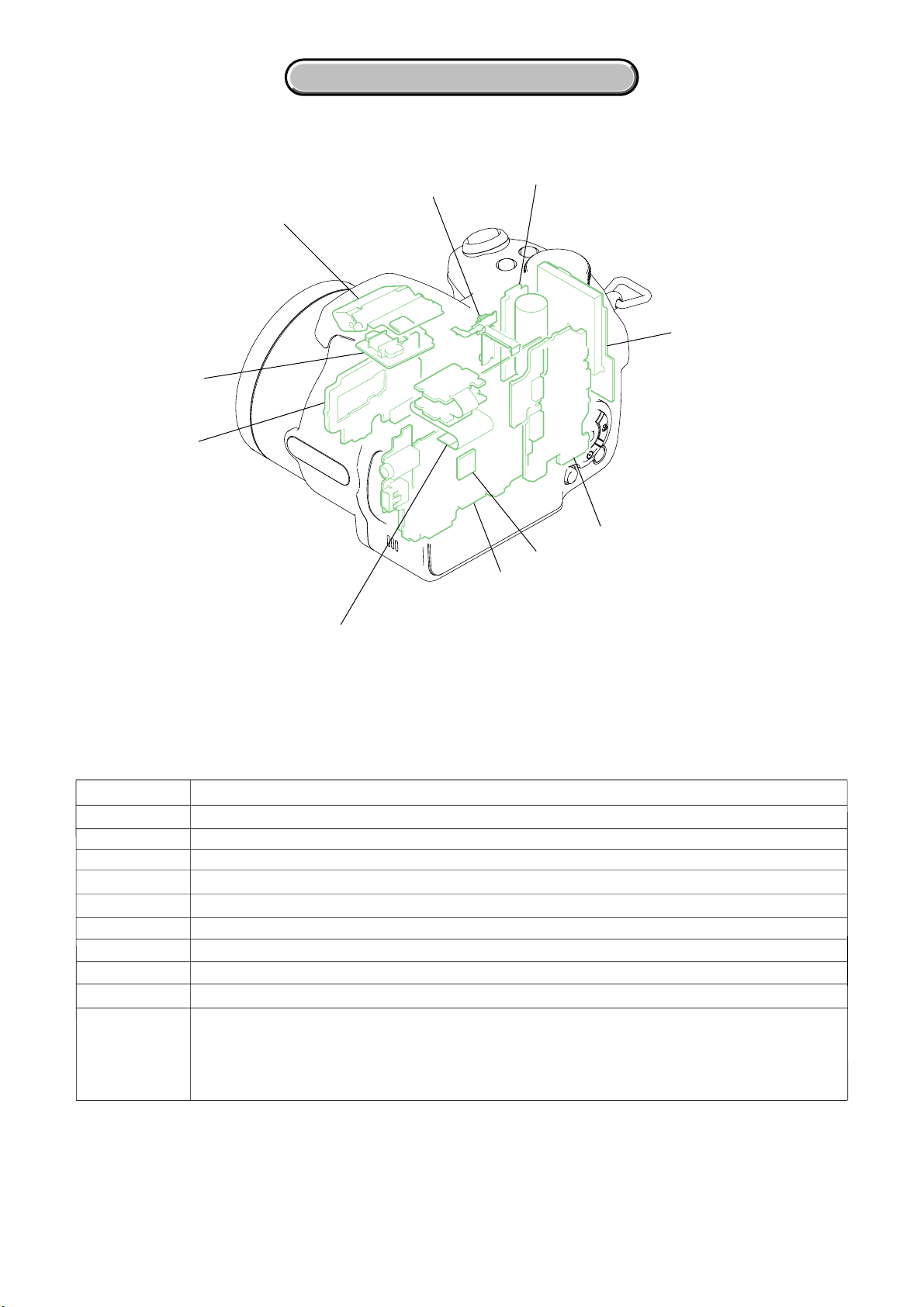

2. DISASSEMBLY

2. DISASSEMBLY

2-4. FLEXIBLE BOARDS LOCATION

The flexible boards contained in the optical unit are not shown.

CONTROL SWITCH BLOCK (SW51780)

MS-029

SW-006

FP-224

ST-001

DSC-H1

2-8E

Page 13

HELP 01

HELP 02

HELP

Disassembling and assembling procedures that require attention are described here.

Harness (HA-001) (Blue)

Harness (HA-001) (White)

Harness (HA-001) (Red)

6

7

2

White

8

1

9

Blue

Red

White

Red

3

Blue

4

5

1

Harness (H-001) (Red)

2

Harness (H-001) (White)

3

Harness (H-001) (

4

Apply the soldering in three points.

5

ST-123 board

6

ST-124 board

7

Four

claws

8

ST cover

9

Tapping screw (M1.7x4) black

0

ST section

0

Blue

)

DSC-H1

HELP

Page 14

Link

Link

3. BLOCK DIAGRAMS

OVERALL BLOCK DIAGRAM (1/2)

OVERALL BLOCK DIAGRAM (2/2)

POWER BLOCK DIAGRAM (1/2)

POWER BLOCK DIAGRAM (2/2)

DSC-H1

Page 15

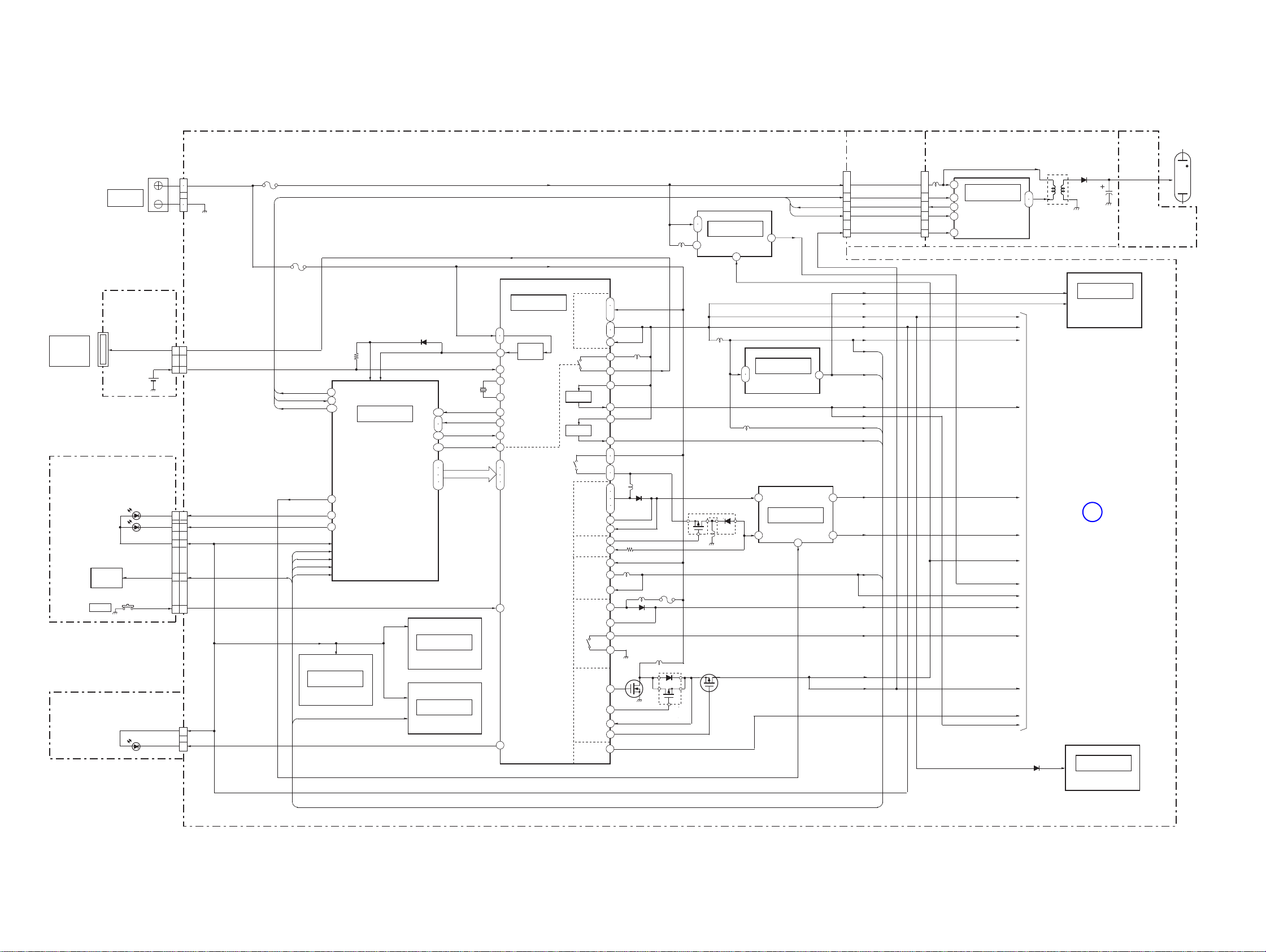

3-1. OVERALL BLOCK DIAGRAM (1/2)

3. BLOCK DIAGRAMS

Ver 1.1 2005. 09

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

LENS UNIT

ACTIVE

LENS

ACTUATOR

PITCH

YAW

SE401

PITCH

SENSOR

SE402

YAW

SENSOR

8

12

P DRIVE A

P DRIVE B

7

6

Y DRIVE A

8

Y DRIVE B

9

2

4

CN101

IC401

PITCH/YAW

SENSOR

AMP

IRIS

SHUTER

IRIS

MOTOR

M

SHUTTER

MOTOR

M

FOCUS

MOTOR

M

ZOOM

MOTOR

M

FOCUS RESET

SENSOR

ZOOM RESET

SENSOR 1ST

ZOOM RESET

SENSOR 2ND

ZOOM DC FG

7

6

7

6

(9/11)

IC103

PITCH DRIVE

(9/11)

IC102

YAW DRIVE

2

18

CN451

CD-576 BOARD

IRIS A

IRIS XA

IRIS B

IRIS XB

1

4

SHUTTER +

8

SHUTTER-

5

FOCUS A

FOCUS XA

FOCUS B

9

FOCUS XB

16

ZOOM +

36

ZOOM -

39

22

24

25

32

31

CN401

PITCH POS AD

YAW POS AD

PITCH AD

9

YAW AD

7

V1A,B

V2

V3A,B

V4

V5A,B

V6

V7A,B

V8,

VST,

VHLD

13

73

IC101

CCD IMAGER

1-14

25-38

25-38

F2

E2

D2

B1

F3

F4

D6

E6

B7

C6

B4

B5

(9/11)

IC104

PRE DRIVE

12

14

CN513

27,28

19-17

CN101

CN502

IC401

SHUTTER DRIVE

FOCUS MOTOR

X902

20MHz

H1A,B

H2A,B

RG

(1/11)

(1/2)

IRIS DRIVE

DRIVE

ZOOM MOTOR

DRIVE

2

FP-224 FLEXIBLE

BOARD

15

1

F5

E5

D3

F1

G1

E4

D5

A6

B6

C5

A2

B2

IC105

LPF LPF

876

131

132

129

130

(8/11)

1

IC901

3

STEADY SHOT

CONTROL

IC102

BUFFER

6

9

3

MSHUT DIR

MSHUT EN

FC DIR A

FC DIR B

ZM DIR A

ZM BRK A

FC SENS

ZM SENS 1ST

ZM SENS 2ND

ZM DC FG 1A

ZM DC FG 1B

7

(9/11)(9/11)

IC106

8

PITCH PWM

95

YAW PWM

96

66

65

63

EVF BL ON

37

EVF BL LEV

38

9

8

184

22

12

10

8

6

18

CN101

DIR2A

BRK2A

DIR2B

BRK2B

FC EN

XDD RST OUT

XSHIFT ON

SY-127 BOARD (1/2)

CCD OUT

6

22

12

10

1

8

|

6

5

18

CN502

7

|

20

(9/11)

IC101

PITCH PWM

3

442

(9/11)

IC107

12

SAN1 SO, SI, SCK

YAW PWM

2

S/H

A/D CONV.

(2/11)

CP201

TIMING

GENERATOR

40 41

SAN1 SO,SCK

D0-D15

22

|

35

47

45

46

42

F4

(5/11)

IC381

SUPER AND

FLASH MEMORY

A20,A21,A25

V LINE OUT

CA AD0 - CA AD13

CLK TGO

CA HD, CA FD

(4/11)

IC353

256Mbit

SDRAM

DIR2A

BRK2A

DIR2B

BRK2B

MSHUT DIR

MSHUT EN

FC DIR A

FC DIR B

FC EN

ZM DIR A

ZM BRK A

FC SENS

ZM SENS 1ST

ZM SENS 2ND

ZM DC FG 1A

ZM DC FG 1B

D0-D15

D0-D15

A01-A21,A25

5

IC802

X301

12MHz

XTAL OSC

(4/11)

IC351

FLASH MEMORY

(6/11)

VIDEO AMP

D0-D31

A0-A11

B5

A01-A21

K5,G4,H4,L5

H2,H1,J1,J2

M5,J4,K4,M6

K2,K1

EXTAL

A6

F2

E1

H5

J5

D21,D22,D20,B22,A22,A23

B23,E20,E21,B24,A24,A25

B25,C25,C26,B26,E10,A10

D10,E11,B10,A11,B11,E12

D11,D12,F12,B12,A12,E13

D17,D18,D16,B18,A19

B19,E16,D19,E19,E17

N4

P6

P4

R2

R25

R5

L2

N5

L4

N6

N2

U4

U5

V4

V5

W4

AB13,AA13,AE13,AF13,AF12

AE12,AA12,AC12,AC11,AB12

AE11,AF11,AE10,AB11,AC10

AF21,AF20,AE20,AB18,AB19

AC19,AB16,AE19,AF19,AF18

AE18,AA15,AC18,AC17,AB15

AE17,AF17,AE16,AB14,AC16

AC15,AE14,

V OUT

H26

3

AB10

D13,D14

B20,A20

(3/11)

IC301

(1/2)

CAMERA DSP

SAN1 SO, SI, SCK

AC4,AE4

AE5,AC5

AB6,AF6

D8,D7,E8

E7,D6,D5

E6,B4

E9

B8

D9

U2

T2

R6

AF4

L26

K26

AC1

AD1

T5

U25

LCD D0-D7

LCD HD

LCD VD

LCD CK

SAN1 SO, SI, SCK

XSAN RST OUT

AUIN

AUOUT

Q301

XAV JACK IN

MS D0-MS D3, MS BS, MS CLK

SAN1 SO, SCK

XMS IN

XSHIFT ON

XDD RST OUT

USB VBUS

SAN1 SO, SCK

B3,A3,B4

B5,A5,B6

A7,B7

EVF BL ON

EVF BL LEV

F3

E3

E6

C1

E5

A9

C9

A2

B9

A10

C10

IC801

SPEAKER AMP

(7/11)

IC601

RGB DRVE

TIMING

GENERATOR

(7/11)

IC602

EVF BACK LIGHT

DRIVE

TO

OVERALL

BLOCK DIAGRAM

(2/2)

(PAGE 3-4)

(6/11)

MIC AMP

AU OUT AMP

USB DPP, USB DMM

USB VBUS

B6

A5

A2

D1

C2

K2

K3

K1

J6

K4

J4,H1

H2,G1

G2,F1

F2,E2

D1,D2

C2,B1

J7

Q602,603

VR

VG

VB

PANEL COM/CS

PSIG

PANEL REF

XSTB E

PANEL VST

VCK,EN

DWN,XSTB M

PCG,HST

HCK2,HCK1

RGT

1

XMS IN

PANEL REF

PANEL VST

VCK,EN

DWN,XSTB E

PCG,HST

HCK2,HCK1

RGT

M 5V

CN506

PANEL REF

PANEL VST

DWN,XSTB M

PCG,HST

HCK2,HCK1

VR

VG

VB

EVF COM/CS

PSIG

EVF BL L

EVF BL H

V LINE OUT

AU LINE OUT

VCK,EN

CN505

RGT

CN508

CN510

CN511

3,2

6,5,7,

9,4,10

8

4

5

3

24

23

6

22

|

19

14

|

11

8

7

2

5

8

9

3

4

7

21

|

17

14

|

10

6

1

2

2

1

2

1

MS-029 FLEXIBLE

BOARD (1/2)

CN251

7,8,6,

4,9,3

5

MS-275

BOARD

(1/2)

LCD901

2.5 INCH

COLOR LCD

PANEL

CN001

EV-016

FLEXIBLE

BOARD

D001

(EVF BACK LIGHT)

MIC SIG

SP+

SP-

MIC

CN751

(USB)

J751

A/V OUT

MIC901

SP901

SPEAKER

17

18

16

21

19

20

15

|

5

4,3,5,7,2,8

6

LCD902

COLOR EVF

UNIT

CN252

MEMORY

STICK

CONNECTOR

SW-447 BOARD (1/2)

SW-006 FLEXIBLE

FLAT CABLE (1/2)

DSC-H1

3-1 3-2

Page 16

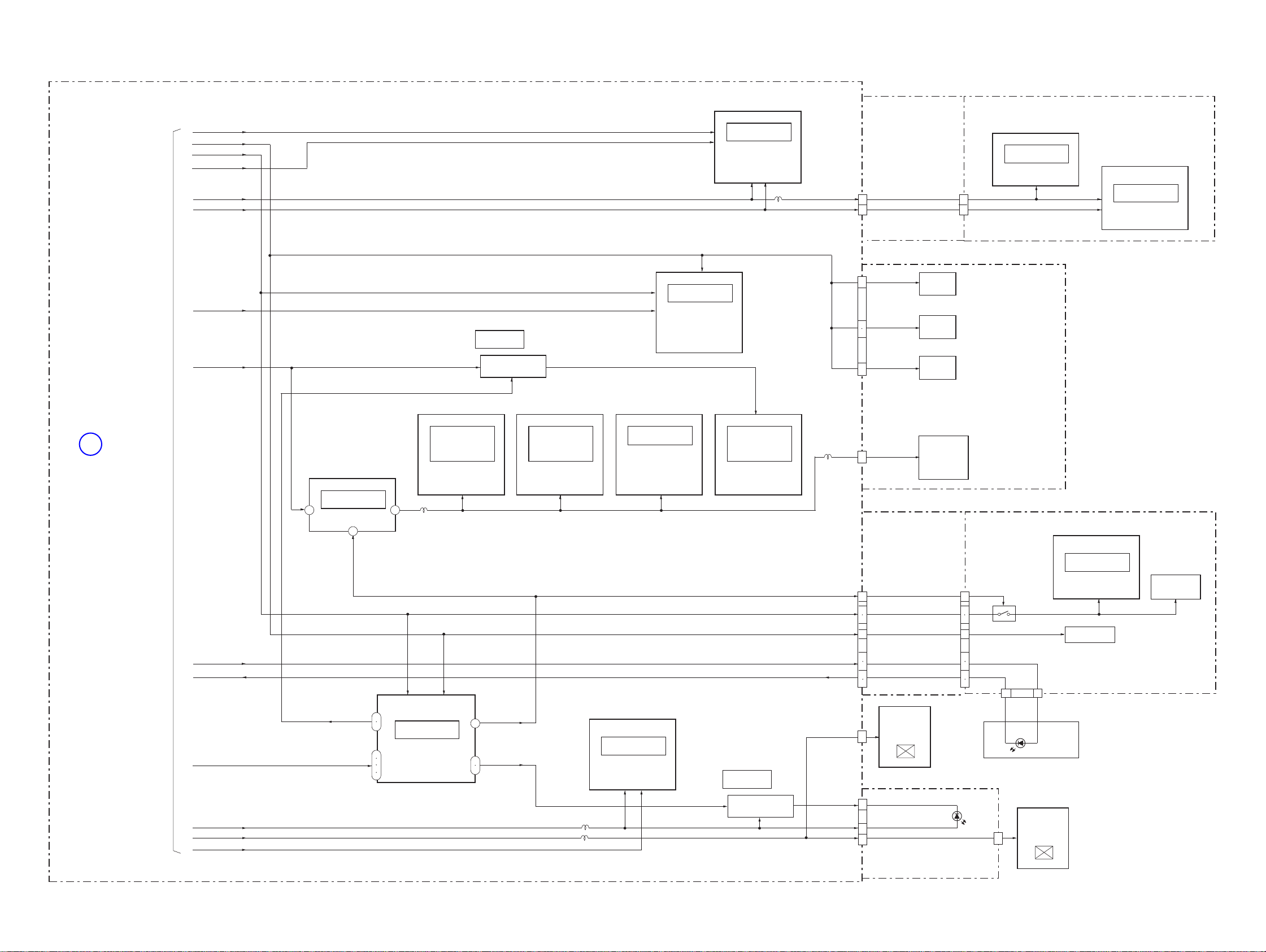

3-2. OVERALL BLOCK DIAGRAM (2/2)

Ver 1.1 2005. 09

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

BATTERY

TERMINAL

4

3

2

1

CN509

UNREG

REG GND

F001

F002

X001

32.768KHz

UNREG

MS-275

BOARD

(2/2)

BT251

LITHIUM

BATTERY

(SECONDARY)

DC/DC CONVERTER

REAL TIME CLOCK

A8

OSC I

OSC O

A9

B8

VL 3V

XPWR ON

C7

USB VBUS

C9

XMS IN

B10

CN251

(11/11)

IC001

(11/11)

IC005

-7,5V/15V REG

(11/11)

IC004

DC/DC CONV.

MS-029

FLEXIBLE

FLAT CABLE

(2/2)

SAN0 SO

SAN0 SI

XSAN0 SCK

BATT SENS

XDD RST OUT

XPWR OFF

VL 3V

C5

C6

B6

G5

A7

B7

A4

CN506

211

EVER 3.1V

EVER 2.8V

D 3.2V

D 3.2V (TO CAM)

D 3.2V (TO SP)

A 3.2V

MS VCC

CAM 2.9V (TO CAM)

CAM 2.9V (TO PANEL)

D 1.8V

M 5V

ST 5V

D 1.2V

PANEL 8.5V

BL H

BL L

XAF LED

CAM 15V

CAM -7.5V

STEADY 5V

SY-127 BOARD (2/2)

VL 3V

ST UNREG

SAN0 SO, SI, SCK

AB5

AA5

Y5

K25

Y4

R26

A23

SAN0 SO

SAN0 SI

XSAN0 SCK

BATT SENS

XDD RST OUT

XPWR OFF

(3/11)

IC301

(2/2)

SYSTEM CONTROL

STRB CHG

XSTRB FULL

STRB CHG CONT

STRB ON

STRB PLUNGER ON

XSTRB POPUP

XLENS COVER SENS

XAE LOCK SW

XSHUTTER SW

MODE DIAL 0

MODE DIAL 1

JOG A

JOG B

KEY AD2

XSTRB LED

XPWR LED

KEY AD0

KEY AD1

XACCESS LED

R22

V23

AB22

R4

AA25

V22

AC23

N21

P23

L22

L25

AB23

W22

G25

E22

D23

K23

L23

E4

1

IC401

A1

(2/2)

STRB PLUNGER DRIVE

TO

OVERALL

BLOCK DIAGRAM

(1/2)

(PAGE 3-2)

(1/11)

B3

XSHIFT ON

USB VBUS

XMS IN

XDD RST OUT

ST-001

FLEXIBLE

FLAT CABLE

12

|

10

STRB CHG

4

XSTRB FULL

5

STRB CHG CONT

6

STRB ON

AF-102 FLEXIBLE BOARD

XAF LED

S103

7

SHUTTER

8

1

MODE DIAL

3

5

6

4

EVF/LCD, FOCUS, BRK

14

12

XPWR ON

11

XSHIFT ON

9

BL H

BL L

CN501

CN507

CN514

CN513

7

8

7

5

1

4

8

7

14

12

10

9

11

1

3

4

6

20

19

1

5

4

3

2

SW-006

FLEXIBLE

FLAT CABLE

(1/2)

ST-123 BOARD FLASH UNIT

1

|

3

9

8

7

6

STRB PLUNGER

S001

(LENS COVER OPEN)

CN001

ST UNREG

15

10

9

6

4

D001 (AF LED)

HIGH VOLTAGE

CHAGER

IC001

IGBT

DRIVE

CN301

RY301

PLUNGER

(STRB POP UP)

4

3

1

PL-039 BOARD

D001

(RECT)

T001

1

2

7

S301

C004

Q001

FLASH

DRIVE

CONTROL SWITCH

BLOCK(SW51780)

S105

JOG DIAL

S106,101,102

STEADY SHOT

S104

POWER

S107

1

2

20

16

17

18

19

EXEC

D101 (FLASH)

D102 (POWER)

S458,460,456,454,457,453

DOWN, RIGHT, UP, LEFT, SET, DUST

S459,455,452,451

ZOOM WIDE, ZOOM TELE, MENU, DISPLAY

D455 (ACCESS)

CN451

CN452

LED901

LCD

BACK

LIGHT

6

4

SW-447 BOARD (2/2)

XE H

XE L

(ST-124

FLEXIBLE

BOARD)

L001

TRIGGER

COIL

D001

XENON

TUBE

DSC-H1

3-3 3-4

Page 17

3-3. POWER BLOCK DIAGRAM (1/2)

Ver 1.1 2005. 09

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

CN252

MEMORY

STICK

CONNECTOR

9

(SECONDARY)

CONTROL SWITCH

BLOCK (SW51780)

D102 (POWER)

D101 (FLASH)

MODE

DIAL

S104

POWER

AF-102 FLEXIBLE

BOARD

D001 (AF LED)

BATTERY

TERMINAL

MS-275

BOARD

MS VCC

BT251

LITHIUM

BATTERY

XPWR ON

VL 3V

D 3.2V

A 3.2V

CN251

D3.2V

XAF LED

SY-127 BOARD (1/2)

UNREG

4

3

REG GND

2

1

CN509

2

21111

CN506

3

12

1

14

2

13

13

2

4

11

CN514

3

4

CN507

F001

F002

STRB CHG

XSTRB FULL

STRB CHG CONT

-7.5V ON

D 3.2V

A 3.2V

AU 3.2V

VI 3.2V

D 1.2V

D 3.2V

R002

R22

V23

AB22

P25

D23

XPWR LED

E22

XSTRB LED

(5/11)

IC381

SUPER AND

FLASH MEMORY

D 1.8V

EVER 2.8V

EVER 3.1V

(3/11)

IC301

CAMERA DSP

SYSTEM CONTROL

D001

XCS DD

SAN0 SO

SAN0 SI

XSAN0 SCK

K25

Y4

R26

AA23

T25

W23

AB5

AA5

Y5

(4/11)

IC353

256Mbit

SDRAM

(4/11)

IC351

FLASH MEMORY

X001

32.768KHz

BATT SENS

XDD RST OUT

XPWR OFF

MS PWR ON

XPWR ON

ST UNREG

MS VCC

UNREG

(11/11)

IC001

DC/DC CONVERTER

REAL TIME CLOCK

J1

UNREG1-1,2

K1

3.1V

LDO1

H1

VL 3V

REG.

B8

RTC BAT

A8

OSC I

A9

OSC O

G5

UNREGMON

A7

XRESET

B7

XPWR OFF

MS PWR ON

D3

XCS DD

A6

SAN0 SO

C5

SAN0 SI

C6

XSAN0 SCK

B6

XPWRON1

C7

A4

XAF LED

-7.5V ON

D 3.2V

A 3.2V, AU 3.2V, VI 3.2V, D 1.8V, D 1.2V

2.9V REG

1.8V REG

PWR1-1

PWR1-2

PWR1-3

VO1-1

VO1-2

MS PWR IN

MS PWR

LDO3IN

LDO3

LDO2IN

LDO2

UNREG2

PWR56 OUT

LX5-1

LX5-2

LX5-3

LX5-4

RS3

TG4

PSG4

VO7

ST-001

FLEXIBLE

FLAT CABLE

12

ST UNREG

STRB CHG

XSTRB FULL

STEADY 5V

2

(6/11)

3.2V REG

(11/11)

15V REG

IC005

-7.5V REG

1

-7.5V ON

STRB CHG CONT

(11/11)

6

8

L010

A1

B1

C2

F1

F2

H2VFB1

L011

G1

MS VCC

G2

B2

A2

B3

A3

J6

K6

J7

K7

L006

J9

J10

K9

D003

K10

(RECT)

H10

VO5

H9VFB5

H6GT6

H7VFB6

D10PWR2

L003

C10LX2

D8VFB2

E10LX3

E9VO3

LV3

F9

F8

Q001

SWITCHING

G9BG4

F10

F7VFB4

G8

PANEL 8.5V

K4

L005

D002

(RECT)

Q002

RECT

F003

L008

IC004

DC/DC CONV.

9

L001

Q004

SWITCHING & RECT

L009

BL H

BL L

Q003

SWITCH

1

MT 5V

IC803

4

3

L803

3

|

10

4

5

6

ST 5V

9

CN501

AU 3.2V

D 3.2V (TO SP)

D 3.2V (TO CAM) D 3.2V (TO CAM)

D 3.2V

A 3.2V

AU 3.2V

1

CAM 2.9V

VI 3.2V

D 1.8V

67

4

D 1.2V

M 5V

ST 5V

ST-123 BOARD

1

|

15

3

L001

10

9

8

9

6

7

3

4

CN001

IC001

HIGH VOLTAGE

CHAGER

IGBT DRIVE

CAM 2.9VCAM 2.9V

CAM 15V

CAM -7.5V

M 5V

STEADY 5V

D 1.2V

BL H

BL L

ST 5V

PANEL 8.5V

CAM 2.9V (TO PANEL)

CAM 3.2V

D 3.2V

A 3.2V

T001

1

2

TO

POWER

BLOCK DIAGRAM

(2/2)

(PAGE 3-7)

D821

D001

(RECT)

C004

(6/11)

IC801

MIC AMP

SPEAKER AMP

AU OUT AMP

1

(6/11)

IC802

VIDEO AMP

XE H

FLASH UNIT

(ST-124

FLEXIBLE BOARD)

XENON

TUBE

DSC-H1

3-5 3-6

Page 18

3-4. POWER BLOCK DIAGRAM (2/2)

Ver 1.1 2005. 09

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

SY-127 BOARD (2/2)

1

TO

POWER

BLOCK DIAGRAM

(1/2)

(PAGE 3-6)

D 3.2V

D 3.2V

A 3.2V

CAM 2.9V

CAM 15V

CAM -7.5V

M 5V

STEADY 5V

CD-576 BOARD

IC102

BUFFER

16

14

CN101

LENS UNIT

IC101

CCD IMAGER

FULL PWR

LIM PWR

(9/11)

IC101

IC107

INVERTER

(9/11)

IC110

CURRENT

LIMITER

D 3.2V

(1/11)

IC401

IRIS DRIVE

SHUTTER DRIVE

FOCUS MOTOR DRIVE

ZOOM MOTOR DRIVE

Q107,110

VCC

(9/11) (9/11) (9/11)

IC105

IC104

IC106

LPF

PLUNGER DRIVE

PRE DRIVE

(2/11)

CP201

S/H

A/D CONV.

TIMING GENERATOR

L201

IC102

IC103

PITCH DRIVE

YAW DRIVE

CAM 15V CD

CAM -7.5V

CN401

L101

CN502

CN101

FP-224

FLEXIBLE

BOARD

16

14

21

27

28

33

3

FC RST VCC

ZM RST VCC

ZM FG VCC

A 4.6V

FOCUS

RESET

SENSOR

ZOOM

RESET

SENSOR

ZOOM

DC FG

ACTIVE

LENS

ACTUATOR

(9/11)

IC108

3

4.6V REG

4

A 3.2V

D 3.2V

1

VAP DD ON

L103

A 4.6V

SW-006

FLEXIBLE

FLAT CABLE

10

9

8

18

VAP DD ON

A 3.2V

D 3.2V

SW-447

BOARD

11

12

13

3

Q401,402

(2/2)

IC401

PITCH/YAW

SENSOR AMP

D455

ACCESS LED

SE401, 402

PITCH/YAW

SENSOR

DSC-H1

BL H

BL L

D_1.2V

ST 5V

PANEL 8.5V

CAM_ 2.9V(TO PANEL)

FULL PWR

LIM PWR

5

4

3

2

CN513

154

155

79

36

191

160

(8/11)

IC901

STEADY SHOT

CONTROL

170

37

38

VAP DD ON

EVF BL ON

EVF BL LEV

L603

L602

(7/11)

IC601

RGB DRIVE

TIMING

GENERATOR

EVF BL ON

EVF BL LEV

(7/11)

IC602

BACK LIGHT

DRIVE

Q602, 603

PANEL VDD

EVF BL L

EVF BL H

PANEL VDD

CN505

CN508

18

1

2

16

LCD901

2.5 INCH

COLOR LCD

PANEL

EV-016

BL H

BL L

D001 (EVF BACK LIGHT)

FLEXIBLE BOARD

3-7 3-8E

16

17

18

19

CN451

CN001

46

2

CN452

BACK

LIGHT

LCD902

COLOR EVF

UNIT

LED901

LCD

Page 19

4-1. FRAME SCHEMATIC DIAGRAM

4. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Ver 1.1 2005. 09

RGT

DWN

HCK1

73 198

123456789

N.C.

HST

VDD

HCK2

REG_GND

EVF_VSSG

CN452

1 N.C.

2 N.C.

3 N.C.

4 BL_L

5 N.C.

6 BL_H

6P

1

2

6 14 165

A

B

C

21

D

E

AV

COM

PSIG

COLOR EVF UNIT

B

G

R

CS

EV-016 FLEXIBLE BOARD

EVF,BACK LIGHT

1011121314151617181920

EN

REF

VST

VCK

PCG

XSTB

21PCN001

91213

SW-447 BOARD

(1/2) FUNCTION SWITCH

(2/2) PITCH/YAW SENSOR AMP

1 KEY_AD0

2 KEY_AD1

3 D_3.2V

4 REG_GND

5 VST_C_RESET

6 REG_GND

SW-006

FLEXIBLE FLAT CABLE

SY-SW RELAY

104

20P

CN451

7 YAW_AD

8 REG_GND

9 PITCH_AD

10 REG_GND

11 VAP_DD_ON

12 A_3.2V

13 A_3.2V

14 REG_GND

F

ZM_DC_FG_1B

ZM_DC_FG_1A

123456789

XACCESS_LED

XZM_FG_LED

XZM_FG_TR

ZM_FG_VCC

ZM_DC_MOTOR_+

BL_L

BL_L

BL_H

ZM_DC_MOTOR_-

ZM_DC_MOTOR_-

ZM_DC_MOTOR_+

39

1011121314151617181920

BL_H

A_3.2V

A_3.2V

REG_GND

REG_GND

CN513

REG_GND2CSUB3VSUB4RAMDOM_TRIGGER5REG_GND6H2B7REG_GND8H1B9REG_GND10H2A11REG_GND12H1A13REG_GND14CAM_-7.5V_CD15POWER_SAVE16CAM_15V_CD17REG_GND18RG19REG_GND20REG_GND21REG_GND22CCD_OUT23REG_GND24REG_GND25V5A26V1A27V5B28V1B29VHLD30V231V632V3A33V7A34V3B35V7B36VST37V838V439REG_GND

1

VAP_DD_ON

20P

REG_GND

PITCH_AD

REG_GND

YAW_AD

1234567

COM

EVF_BL_L

EVF_BL_H

G

H

I

LCD BACK LIGHT

2.5 INCH

LCD UNIT

USB

123456789

VB

VG

VR

RGT

PSIG

HCK1

TEST2

HCK2

J

9

8

10111213141516171819202122

EN

VB

CS

VG

VR

101112131415161718192021222324

N.C.

TEST1

PCG

PANEL_REF

VST

PSIG

HST

RGT

HCK2

EVF_VSSG

PANEL_REF

PANEL_VDD

22PCN508

24PCN505

EN

N.C.

REG_GND

PANEL_VDD

VCK

DWN

39PCN401

PCG

XSTB_M

PANEL_VSSG

HST

VCK

DWN

HCK1

XSTB_E

REG_GND

CS

VST

COM

SPEAKER

K

CN511

2 SP_-

1 SP_+

2P

IRIS_XB

IRIS_XA

IRIS_B

IRIS_A

SHUTTER_-

SHUTTER_-

123456789

SHUTTER_+

SHUTTER_+

FOCUS_XB

FOCUS_XB

FOCUS_A

FOCUS_A

FOCUS_B

1011121314151617181920212223242526272829303132333435363738

FOCUS_B

FOCUS_XA

FOCUS_XA

REG_GND

LENS_TMP

XFC_RST_LED

XFC_RST_TR

FC_RST_VCC

FC_SENS

ZM_SENS_1ST

XZM_RST_TR1

XZM_RST_LED1

ZM_SENS_2ND

ZM_RST_VCC2

ZM_RST_VCC1

XZM_RST_LED2

XZM_RST_TR2

11 15

REG_GND

15

REG_GND

16 BL_H

17 BL_H

REG_GND

VST_C_RESET

18 BL_L

D_3.2V

19 BL_L

KEY_AD1

20 XACCESS_LED

KEY_AD0

PL-039 BOARD

PLUNGER

MIC

CN301

6P

XSTRB_POPUP

REG_GND

REG_GND

STRB_PLUNGER

REG_GND

STRB_PLUNGER

12345

6

AF-102 FLEXIBLE BOARD

AF LED,LENS COVER SW

1

2

MIC_GND

MIC_SIG

2PCN510

SY-127 BOARD

(1/11) LENS DRIVE

(2/11) CAMERA A/D CONV. TIMING GENERATOR

(3/11) CAMERA DSP,SYSTEM CONTROL

(4/11) 256Mbit SDRAM,FLASH MEMORY

(5/11) SUPER AND FLASH MEMORY

(6/11) A/V AMP,USB/AV JACK,SP,MIC

(7/11) PANEL DRIVE

(8/11) STEADY SHOT CONTROL

(9/11) LENS SERVO

(10/11) CONNECTOR

(11/11) DC/DC CONVERTER

(CH-169 board) CCD SIGNAL PROCESS

CN502

39P

LENS COVER SW

10

REG_GND

REG_GND

STRB_PLUNGER

D_3.2V

XAF_LED

REG_GND

XSTRB_POPUP

STRB_PLUNGER

10PCN507

P_OUT

A_4.6V

LENS_VC

123456789

AF

123456789

REG_GND

XLENS_COVER_SENSE

10PCN101

Y_OUT

REG_GND

P_DRIV_B

P_DRIV_A

Y_DRIV_A

Y_DRIV_B

4

UNREG

N.C.

10

17

18

BATTERY

123

UNREG

REG_GND

REG_GND

4P

CN509

MODE_DIAL0

MODE_DIAL1

KEY_AD2

XAE_LOCK_SW

XSHUTTER_SW

XSHIFT_ON

REG_GND

XPWR_ON

XPWR_LED

XSTRB_LED

REG_GND

MS_VCC

MS_CLK

XMS_IN

REG_GND

REG_GND

CN501

ST_UNREG

ST_UNREG

ST_UNREG

REG_GND

STRB_ON

STRB_CHG_CONT

XSTRB_FULL

STRB_CHG

REG_GND

REG_GND

REG_GND

A_3.2V

D_3.2V

JOG_A

JOG_B

MS_D3

MS_D2

MS_D0

MS_D1

MS_BS

VL_3V

14PCN514

14

13

12

11

10

9

8

7

6

5

4

3

2

1

12PCN506

12

11

10

9

8

7

6

5

4

3

MS-029

FLEXIBLE

2

1

12P

12

11

10

ST_5V

9

8

7

6

5

4

3

ST-001

2

1

CONTROL SWITCH BLOCK

(SW51780)

14P

1

MODE_DIAL0

2

A_3.2V

3

MODE_DIAL1

4

KEY_AD2

5

JOG_A

6

JOG_B

7

XAE_LOCK_SW

XSHUTTER_SW

8

9

XSHIFT_ON

10

REG_GND

11

XPWR_ON

12

XPWR_LED

D_3.2V

13

XSTRB_LED

14

CN251

12P

REG_GND

1

MS_VCC

2

MS_CLK

3

MS_D3

4

XMS_IN

5

MS_D2

6

MS_D0

7

MS_D1

8

MS_BS

9

REG_GND

10

FLAT CABLE

SY-MS RELAY

VL_3V

11

REG_GND

12

CN001

12P

ST_UNREG

1

ST_UNREG

2

ST_UNREG

3

ST_5V

4

REG_GND

5

STRB_ON

6

STRB_CHG_CONT

7

XSTRB_FULL

8

9

STRB_CHG

10

REG_GND

FLEXIBLE

FLAT CABLE

SY-ST RELAY

11

REG_GND

12

REG_GND

ST-123 BOARD

FLASH DRIVE

20

MS-275

BOARD

MEMORY STICK,

LI BATTERY

(LITHIUM BATTERY)

(SECONDARY)

21

10P

VSS

MS_BS

DATA1

SDIO/DATA0

DATA2

INT

DATA3

SCLK

VCC

VSS

10

ST-124

FLEXIBLE BOARD

FLASH

22

1

2

3

CN252

4

MEMORY

5

STICK

CONNECTOR

6

7

8

9

L

M

N

16

DSC-H1

4-1

LENS UNIT

1

2

4

5

CSUB3VSUB

REG_GND

REG_GND

RAMDOM_TRIGGER

CD-576 BOARD

CCD IMAGER

FP-224 FLEXIBLE BOARD

SY-CD RELAY

6

7

8

9

10

11

12

13

14

15

16

17

18RG19

22

23

25

29

30V231V632

H2B

H1B

H2A

H1A

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND20REG_GND21REG_GND

CAM_15V_CD

POWER_SAVE

CAM_-7.5V_CD

39PCN101

CCD_OUT

REG_GND24REG_GND

V5A26V1A27V5B28V1B

VHLD

37V838V439

V3A33V7A34V3B35V7B36VST

REG_GND

CCD IMAGER

4-2

FRAME SCHEMATIC DIAGRAM

Page 20

4-2. SCHEMATIC DIAGRAMS

Link

Link

CD-576 BOARD (CCD IMAGER) EV-016 FLEXIBLE BOARD (EVF, BACK LIGHT)

CD-576 BOARD (CCD IMAGER) EV-016 FLEXIBLE BOARD (EVF, BACK LIGHT)

AF-102 FLEXIBLE BOARD

MS-275 BOARD (MEMORY STICK, LI BATTERY)

MS-275 BOARD (MEMORY STICK, LI BATTERY)

AF-102 FLEXIBLE BOARD

(AF LED, LENS COVER SW)

(AF LED, LENS COVER SW)

ST-123 BOARD (FLASH DRIVE)

ST-123 BOARD (FLASH DRIVE)

ST-124 FLEXIBLE BOARD (FLASH)

ST-124 FLEXIBLE BOARD (FLASH)

PL-039 BOARD (PLUNGER)

PL-039 BOARD (PLUNGER)

SW-447 BOARD (1/2) (FUNCTION SW)

SW-447 BOARD (1/2) (FUNCTION SW)

SW-447 BOARD (2/2)

SW-447 BOARD (2/2)

(PITCH/YAW SENSOR AMP)

(PITCH/YAW SENSOR AMP)

SW-006 FLEXIBLE BOARD (SY-SW RELAY)

SW-006 FLEXIBLE BOARD (SY-SW RELAY)

MS-029 FLEXIBLE BOARD (SY-MS RELAY)

MS-029 FLEXIBLE BOARD (SY-MS RELAY)

ST-001 FLEXIBLE BOARD (SY-ST RELAY)

ST-001 FLEXIBLE BOARD (SY-ST RELAY)

FP-224 FLEXIBLE BOARD (SY-CD RELAY)

FP-224 FLEXIBLE BOARD (SY-CD RELAY)

CONTROL SWITCH BLOCK

CONTROL SWITCH BLOCK

WAVEFORMSCOMMON NOTE FOR SCHEMATIC DIAGRAMS

WAVEFORMSCOMMON NOTE FOR SCHEMATIC DIAGRAMS

(SW51780)

(SW51780)

DSC-H1

Page 21

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µ

Link

µF. 50 V or less are not indicated except f or electrolytics

and tantalums.

• Chip resistors are 1/10 W unless otherwise noted.

kΩ=1000 Ω, MΩ=1000 kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum

capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

Temperature characteristics

External dimensions (mm)

• Constants of resistors, capacitors, ICs and etc with XX

indicate that they are not used.

In such cases, the unused circuits may be indicated.

• Parts with * differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors have characteristic

curve B, unless otherwise noted.

• Signal name

XEDIT→ EDIT PB/XREC → PB/REC

• 2: non flammable resistor

• 5: fusible resistor

• C: panel designation

• A: B+ Line

• B: B– Line

• J : IN/OUT direction of (+,–) B LINE.

• C: adjustment for repair.

• A: VIDEO SIGNAL (ANALOG)

• A: AUDIO SIGNAL (ANALOG)

• A: VIDEO/AUDIO SIGNAL (ANALOG)

• A: VIDEO/AUDIO/SER V O SIGNAL

• A: SERVO SIGNAL

• Circled numbers refer to waveforms.

(Measuring conditions voltage and waveform)

• Voltages and waveforms are measured between the

measurement points and ground when camera shoots

color bar chart of pattern box. They are reference v alues

and reference waveforms.

(VOM of DC 10 MΩ input impedance is used)

• Voltage values change depending upon input

impedance of VOM used.)

1. Connection

Pattern box Color bar chart

Pattern box PTB-450

J-6082-200-A

or

Small pattern box

PTB-1450

J-6082-557-A

Pattern box

100 cm (PTB-450)

40 cm (PTB-1450)

Front of the lens

For PTB-450:

J-6020-250-A

For PTB-1450:

J-6082-559-A

2. Adjust the distance so that the output waveform of

Fig. a and the Fig. b can be obtain.

H

Yellow

Cyan

White

Magenta

Green

AABBA=B

Fig. a (Video output terminal output waveform)

Red

Blue

Electronic beam

scanning frame

CRT picture frame

Precautions Upon Replacing CCD imager

• The CD-576 board mounted as a repair part is not equipped

with a CCD imager.

When replacing this board, remove the CCD imager from

the old one and mount it onto the new one.

• If the CCD imager has been replaced, carry out all the

adjustments for the camera section.

• As the CCD imager may be damaged by static electricity

from its structure, handle it carefully like for the MOS IC.

In addition, ensure that the receiver is not covered with

dusts nor exposed to strong light.

DSC-H1

Fig.b (Picture on monitor TV)

When indicating parts by reference number, please

include the board name.

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

4-3

Page 22

4-2. SCHEMATIC DIAGRAMS

For Schematic Diagram

• Refer to page 4-49 for printed wiring board. • Refer to page 4-61 for waveforms

A

B

C

D

E

F

1

CD-576 BOARD

CCD IMAGER

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

R :REC MODE

P :PB MODE

TO

FP-224

FLEXIBLE BOARD

(PAGE 4-16)

CN101

REG_GND

REG_GND

REG_GND

CCD_OUT

REG_GND

REG_GND

REG_GND

REG_GND

CAM_15V_CD

POWER_SAVE

CAM_-7.5V_CD

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

RAMDOM_TRIGGER

REG_GND

VST

V7B

V3B

V7A

V3A

VHLD

V1B

V5B

V1A

V5A

H1A

H2A

H1B

H2B

VSUB

CSUB

3

39P

39

38

V4

V8

37

36

35

34

33

32

31

V6

30

V2

29

28

27

26

25

24

23

22

21

20

19

18

RG

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

VST

V7B

V3B

V7A

V3A

VHLD

V1B

V5B

V1A

V5A

V4

V8

V6

V2

R108

0

Note:IC101 is not included in this

complete board of CD-576 board.

CXA3691EN-T9

R11.7

P0

1

2

R11.7

P0

3

R2.9

P0

2

Q104

DTC144EMT2L

VSUB

IC102

BUFFER

IC102

ISF

IN

GND

VCC

IDRV

OUT

R109

1

270k

0

R110

3

542

6

V1A

V1B

V2

V3A

V3B

VST

V4

V5A

V5B

VHLD

V6

V7A

V7B

V8

4

IC101

CCD IMAGER

Note

5

1M

6

R15.1

P0

5

R4.1

P0

4

C108

XX

C101

0.01u

R106

220k

C103

XX

R3.5

P0

Q102

DTC144EMT2L

SWITCH

1

2

3

7

P0

R-0.3

R-7.3P0R-0.3P0R-0.3P0R-0.3P0R-6.2P0R-0.4P0R-0.4P0R-0.3P0R-0.5P0R-0.5

CL113

9

10

11V612

13

14

V8

V7A

V7B

R-6.6/P0

R-6.5/P0

R-6.5/P0

3

6

R11.7/P0

R15.1/P0

CCD_OUT16VDD17RG18H1B19H2B20GND21GND22GND23SUB24CSUB25N.C.26VL27H1A28H2A

15

P0.3

R2.0

R13.3

C102

R104

1500

0

R105

1200

16V

0.1u

C107

B

V5B

VHLD

ICX495BQF

77

P0.1

P0.1

R1.2

0.1u

CL109

V5A

IC101

8

CL108

7V48

R11.0P0R11.3

6

VST

2

P0

CL123

CL124

CL104

P0

1

2

3V24

5

V1A

V1B

V3A

V3B

P0

P0.1

P0.1

R2.0

R1.2

R-7.6

BC109

B

16V0.1u

0.1u 16VC105

9

1

1

CL101

G

DSC-H1

16

4-5

4-6

CD-576

Page 23

For Schematic Diagram

• Refer to page 4-49 for printed wiring board.

For Schematic Diagram

• Refer to page 4-51 for printed wiring board.

1

EV-016 FLEXIBLE BOARD

EVF,BACK LIGHT

A

B

(PAGE 4-34 OF LEVEL3)

TO

SY-127 BOARD(7/11)

CN508

C

16

265

PANEL_REF

EVF_VSSG

PANEL_VDD

EVF_BL_L

EVF_BL_H

COM

PSIG

HCK2

XSTB_E

DWN

HCK1

REG_GND

PCG

VST

RGT

VCK

HST

22P

3

LND001

1

LND002

2

LND003

3

LND004

4

CS

LND005

5

VR

LND006

6

LND007

7

LND008

8

VG

LND009

9

VB

LND010

10

EN

LND011

11

LND012

12

LND013

13

LND014

14

LND015

15

LND016

16

LND017

17

LND018

18

LND019

19

LND020

20

LND021

21

LND022

22

4

D001

NSCW455T-TC9

(EVF BACK LIGHT)

CN001

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

21P

COM

PSIG

CS

G

R

B

PCG

EN

VCK

VST

XSTB

REF

DWN

RGT

HCK1

HCK2

HST

EVF_VSSG

REG_GND

VDD

N.C.

LCD902

COLOR EVF

UNIT

A

B

1

PL-039 BOARD

PLUNGER

XX MARK:NO MOUNT

TO

AF-102

FLEXIBLE BOARD

(PAGE 4-15)

16

REG_GND

REG_GND

STRB_PLUNGER

STRB_PLUNGER

REG_GND

XSTRB_POPUP

CN301

32

6P

6

5

4

3

2

1

D301

XX

C301

1u

S301

(FLASH POP UP)

D302

1SS355TE-17

4

2

(PLUNGER)

1

LND301

STATIC_GND

RY301

For Schematic Diagram

• Refer to page 4-47 for printed wiring board.

1

MS-275 BOARD

A

B

MEMORY STICK,LI BATTERY

XX MARK:NO MOUNT

TO

MS-029

FLEXIBLE FLAT CABLE

(PAGE 4-15)

C

16

2643

CN251

12P

REG_GND

REG_GND

XMS_IN

MS_CLK

MS_VCC

REG_GND

MS_BS

MS_D1

MS_D0

MS_D2

MS_D3

12

11VL_3V

10

9

8

7

6

5

4

3

2

1

BT251

(LITHIUM BATTERY)

(SECONDARY)

CL251 CL257

R253

R251

1k

0

CL256

C251

XX

FB251

FB252

FB253

FB254

CL262

C252

0.1u

B

LND251

STATIC_GND

0uH

0uH

0uH

0uH

D251

XX

5

10P

VSS

1

MS_BS

2

DATA1

3

4

SDIO

5

DATA2

6

INT

7

DATA3

SCLK

8

VCC

9

VSS

10

CN252

MEMORY

STICK

CONNECTOR

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

DSC-H1

4-7 4-8

EV-016/MS-275/PL-039

Page 24

For Schematic Diagram

• Refer to page 4-51 for printed wiring board.

Ver 1.1 2005. 09

A

B

C

D

1

ST-123 BOARD

FLASH DRIVE

XX MARK:NO MOUNT

TO

ST-001

FLEXIBLE FLAT CABLE

(PAGE 4-17)

NO MARK:REC/PB MODE

R :REC MODE

P :PB MODE

12PCN001

ST_UNREG

ST_UNREG

ST_UNREG

ST_5V

REG_GND

STRB_ON

STRB_CHG_CONT

XSTRB_FULL

STRB_CHG

REG_GND

REG_GND

REG_GND

325

T001

CONVERTER

SW

SW

VCC

F_ON

TRANSFORMER

2

1

4

3

15

16

17

N.C

HGND

IC001

TPS65552RGTR

L001

1

2

3

4

5

6

7

8

9

10

11

12

4.7uH

C001

22u

6.3V

C005

22u

6.3V

IC001

HIGH VOLTAGE

R001

0

CHARGE,

IGBT DRIVE

3.1

1

2

5.1

3

0

4

68

D001

N.C

FT02P80TP

13

N.C

PGND

PGND

CHG

XFULL

6

5

3.1

14

VBATT

94

TO

ST-124 BOARD

10

C004

205u

330V

7

LND003

XE_H

(PAGE 4-17)

12

11

0

10

3.2

9

LND004

REG_GND

R004

XX

C002

1u

C

I_PEAK

G_IGBT

N.C

5

N.C

7

8

6

0

0

R002

4.7M

E

C003

16

XX

5

6

7

8

Q001

CY25BAJ-8F-T23

0

R003

33

FLASH DRIVE

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

LND005

R280.0

1

P13.0

2

3

4

XE_L

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

DSC-H1

4-9 4-10

ST-123

Page 25

For Schematic Diagram

• Refer to page 4-53 for printed wiring board.

A

B

C

D

1

SW-447 BOARD(1/2)

FUNCTION SWITCH

XX MARK:NO MOUNT

R457

5600

2

3

S452

MENU

R456

27k

2

4

2

4

S451

DISP

1

3

1

3

S454

LEFT

2

4

NO

2

S459

1

3

S456

UP

56

R454

5600

36E8

S455

2

4

1234567

2

4

8

RB451

2200X4

1

3

1

3

ZOOM TZOOM W

1st

1

4

2

4

2

4

2

4

NO

2

3

1

3

S457

1

3

R455

27k

S458

1

DOWN

3

1st

1

2nd2nd

4

56

8

47

RB452

2200X4

1234567

3

D452

1

MAZW068H0LS0

S460

RIGHTSET

D451

1SS387-TPL3

S453

DUST

REG_GND

5

A_3.2V

VST_C_RESET

YAW_AD

PITCH_AD

VAP_DD_ON

R453

2

VST_C_RESET

YAW_AD

PITCH_AD

VAP_DD_ON

A_3.2V

330

A_3.2V

VST_C_RESET

YAW_AD

PITCH_AD

VAP_DD_ON

1 N.C.

2 N.C.

3 N.C.

4 BL_L

5 N.C.

6 BL_H

1 KEY_AD0

2 KEY_AD1

3 D_3.2V

4 REG_GND

5 VST_C_RESET

6 REG_GND

7 YAW_AD

8 REG_GND

9 PITCH_AD

10 REG_GND

11 VAP_DD_ON

12

13 A_3.2V

14 REG_GND

15 REG_GND

16 BL_H

17 BL_H

18 BL_L

19 BL_L

20 XACCESS_LED

6PCN452

20PCN451

A_3.2V

@W01

(2/2)

LED901

LCD

BACK LIGHT

TO

SW-006

FLEXIBLE FLAT CABLE

(PAGE 4-18)

DSC-H1

16

LND451

STATIC_GND

D455

SML-310LTT86

(ACCESS)

4-11 4-12

SW-447(1/2)

Page 26

For Schematic Diagram

• Refer to page 4-53 for printed wiring board.

A

B

C

D

1

2

SW-447 BOARD(2/2)

PITCH/YAW SENSOR AMP

XX MARK:NO MOUNT

C401

6.3V

TA

C402

6.3V

TA

22u

A

22u

A

SE401

(PITCH SENSOR)

34

SE402

(YAW SENSOR)

34

C404

0.33u

1

R401

22k

R402

22k

C403

0.1u

C406

2

1

10u

R403

15k

R404

R405

10k

C408

10u

C405

0.047u

1M

C407

0.047u

NO MARK:REC/PB MODE

R :REC MODE

P :PB MODE

IC401

PITCH/YAW SENSOR AMP

IC0401

1

PASS

R1.3

P0

2

OUT1

R1.3

P0

3

AM1

R1.3

P0

4

Vref1

R1.3

P0.2

5

HO1

R1.3

P0

6

HI1

R1.3

R0.9

R0.7

P0

P0

P0

LO1

7

8

LIA1

9

LIB1

10

GND

NJM3230V(TE2)

R3.2/P0.5

C_RESET

OUT2

Vref2

483

VCC

AM2

HO2

HI2

LO2

LIA2

LIB2

R3.2

P0

75

A_3.2V

VAP_DD_ON

@W01

PITCH_AD

VST_C_RESET

YAW_AD

(1/2)

6

Q401,402

A

Q401

Q402

3.2V SWITCH

R3.2

1

P0.5

R2.5

P3.2

R0.1

P3.2

2

1

3

3

R411

1k

R412

47k

3.2

2

L401

10uH

2SA2029T2LQ/R

DTC144EMT2L

C416

TA

22u

6.3V

C411

0.1u

20

R0

P3.1

19

R1.2

P0

18

R1.3

P0

17

R1.3

P0

16

R1.3

P0.2

15

R1.3

P0

14

R1.3

P0

13

R0.8

P0

12

R0.6

P0

11

R406

R407

C410

0.047u

10k

1M

C409

10u

C413

0.047u

R408

15k

R409

22k

C412

10u

C414

0.33u

R410

22k

C415

0.1u

E

DSC-H1

16

2

REG_GND

4-13 4-14

SW-447(2/2)

Page 27

FP-224 FLEXIBLE BOARD is replaced as a block.

So that this PRINTED WIRING BOARD is omitted.

39P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

39P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

1

A

V6

V5A

CAM_-7.5V_CD

REG_GND

REG_GND

VHLD

V4

V3A

V1A

CAM_15V_CD

REG_GND

VSUB

VST

V1B

RG

V2

V8

REG_GND

CCD_OUT

POWER_SAVE

V7B

V7A

V5B

REG_GND

H2A

H1A

REG_GND

H2B

H1B

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

RANDOM_TRIGGER

CSUB

REG_GND

V3B

REG_GND

REG_GND

REG_GND

V6

V7A

V4

CCD_OUT

REG_GND

VSUB

H2A

H1A

RG

V3B

REG_GND

RANDOM_TRIGGER

V3A

V5B

REG_GND

CAM_15V_CD

H1B

VST

V7B

REG_GND

V5A

CAM_-7.5V_CD

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

CSUB

REG_GND

V8

V1B

H2B

REG_GND

POWER_SAVE

VHLD

V1A

V2

TO

SY-127 BOARD

(2/11)

CN502

TO

CD-576 BOARD

CN101

FP-224 FLEXIBLE BOARD

SY-CD RELAY

C

D

16

B

234

F

5

E

(PAGE 4-23

OF LEVEL3)

(PAGE 4-5)

For Schematic Diagram

• Refer to page 4-47for printed wiring board.

Ver 1.1 2005. 09

A

B

DSC-H1

1

AF-102 FLEXIBLE BOARD

AF LED,LENS COVER SW

XLENS_COVER_SENSE

REG_GND

TO

SY-127 BOARD(10/11)

CN507

(PAGE 4-39

OF LEVEL3)

16

XAF_LED

XSTRB_POPUP

REG_GND

STRB_PLUNGER

STRB_PLUNGER

REG_GND

REG_GND

1

MS-029 FLEXIBLE FLAT CABLE

A

SY-MS RELAY

TO

SY-127 BOARD(10/11)

CN506

B

(PAGE 4-39

OF LEVEL3)

C

16

MS-029 FLEXIBLE FLAT CABLE is replaced as a block.

So that this PRINTED WIRING BOARD is omitted.

D_3.2V

2

3

D001

DOR5073

(AF LED)

1

2

3

12P

S001

3

12

11

10

9

8

7

6

5

4

3

2

1

(LENS COVER OPEN)

10P

LND001

1

LND002

2

LND003

3

LND004

4

LND005

5

LND006

6

LND007

7

LND008

8

LND009

9

LND010

10

REG_GND

MS_VCC

MS_CLK

MS_D3

XMS_IN XMS_IN

MS_D2

MS_D0

MS_D1

MS_BS

REG_GND

VL_3V

REG_GND

4-15 4-16

524

6

5

4

LND012

LND013

LND016

LND011

LND020

LND021

6P

XSTRB_POPUP

1

REG_GND

2

3

STRB_PLUNGER

4

STRB_PLUNGER

5

REG_GND

REG_GND

6

45

12P

REG_GND

1

MS_VCC

2

3

MS_CLK

MS_D3

4

5

6

7

8

9

10

11

12

MS_D2

MS_D0

MS_D1

MS_BS

REG_GND

VL_3V

REG_GND

TO

MS-275 BOARD

CN251

(PAGE 4-7)

TO

PL-039 BOARD

CN301

(PAGE 4-8)

AF-102/FP-224/MS-029

Page 28

Ver 1.1 2005. 09

1

ST-001 FLEXIBLE FLAT CABLE

SY-ST RELAY

A

TO

SY-127 BOARD

(10/11)

CN501