Page 1

DSC-F505

SERVICE MANUAL

Level 2

Ver 1.1 1999.10

This service manual contains information for Japanese model as well.

On the PS-427, SY-56 board

This service manual provides the information that is premised the circuit

board replacement service and not intended repair inside the PS-427,

SY-56 board.

Therefore, schematic diagram, printed wiring board and electrical parts

list of the PS-427, SY-56 board are not shown.

The following pages are not shown.

SPECIFICATIONS

System

Recording format

Digital (JPEG based)/Field

recording

Video signal

NTSC color, EIA standards

PAL color CCIR standards

Image device

1/2-inch CCD (total number

of square pixels : 1636 x 1236),

square grid, primary color filter

Interface format

Lens

ƒ = 7.1 - 35.5 mm (38 - 190 mm, when

converted into a 35 mm still camera)

0.5 m - ∞ (“W” side)

0.08 m - ∞ (Macro, “W” side)

F = 2.8 - 3.3

Photometric system

TTL system

Exposure control

Automatic exposure

White balance

Automatic, Indoor, Outdoor,

One-push

Data compression system

Movie : MPEG-1

Still : JPEG

Audio (with still image) :

MPEG AUDIO (Monaural)

Data format

Still :1600 x 1200

1024 x 768

640 x 480

320 x 240 (E-mail)

Movie : 320 x 240, 160 x 112

Memory

“Memory stick”

Flash

Recording distance

limitations : 11 7/8 inches to 8 1/3 feet

(0.3 m to 2.5 m), automatic flash

control system

Shutter speed

NTSC : 1/8 - 1/725

PAL : 1/6 - 1/600

LCD screen

Screen size

2 inches

LCD panel

TFT

Total dot number

122,980 (559 x 220) dots

Input and output connectors

A/V out (Monaural)

Minijack

Video : 1Vp-p, 75 ohms,

unbalanced, sync negative

Audio : monaural, 327 mV

(at output, impedance more than

47 kilohms)

Output impedance with less than

2.2 kilohms

Digital I/O (serial)

Minijack

RS-232C based, 9.6 Kbps to

115.2 Kbps

Digital I/O (USB)

Special minijack

USB 1.0 based

General

Power consumption

Operation temperature

32°F to 104°F (0°C to 40°C)

Storage temperature

-4°F to 140°F (-20°C to 60°C)

Dimensions

Approx. 4 1/4 x 2 1/2 x 5 3/8 in.

(107.2 x 62.2 135.9 mm)

(w / h / d)

Mass

Approx. 15 oz (435 g)

(excluding batteries)

Approx. 1 lb (475 g)

(including battery,

“Memory stick” (4 MB),

wrist strap and lens cap etc.)

AC-VF10 AC power adaptor/

charger

Power requirements

100 to 240 V AC, 50/60 Hz

Power consumption

13 W

US Model

Canadian Model

AEP Model

UK Model

E Model

Hong Kong Model

Australian Model

Chinese Model

Korea Model

Tourist Model

PS-427 board

Schematic diagram...............................Pages4-15 to 4-18

Printed wiring board..............................Page 4-11

Electrical parts list.................................Pages6-12 to 6-13

SY-56 board

Schematic diagram...............................Pages4-23 to 4-33

Printed wiring board..............................Pages4-19 to 4-22

Electrical parts list.................................Pages6-13 to 6-14

Output voltage

Using the AC power

adaptor/charger :

Recording : 3.6 W

Playback : 3.1 W

Using the rechargeable

NP-FS11 lithium ion battery :

Recording : 3.3 W

Playback : 2.7 W

DC OUT : 4.2 V, 1.8 A in operating

mode

Battery charge terminal :

4.2 V, 1.5 A in charge mode

Operation temperature

32°F to 104°F (0°C to 40°C)

Storage temperature

-4°F to 140°F (-20°C to 60°C)

Approx. 1 15/16 x 1 9/16 x 3 3/8 in.

(49 x 39 x 85 mm) (w / h / d)

Mass

Approx. 4.2 oz. (120 g)

(excluding batteries)

NP-FS11 battery pack

Voltage

DC 3.6 V

Capacity

4.1 Wh

Type

Lithium ion type

Design and specifications are subject

to change without notice.

DIGITAL STILL CAMERA

MICROFILM

– 1 –

Page 2

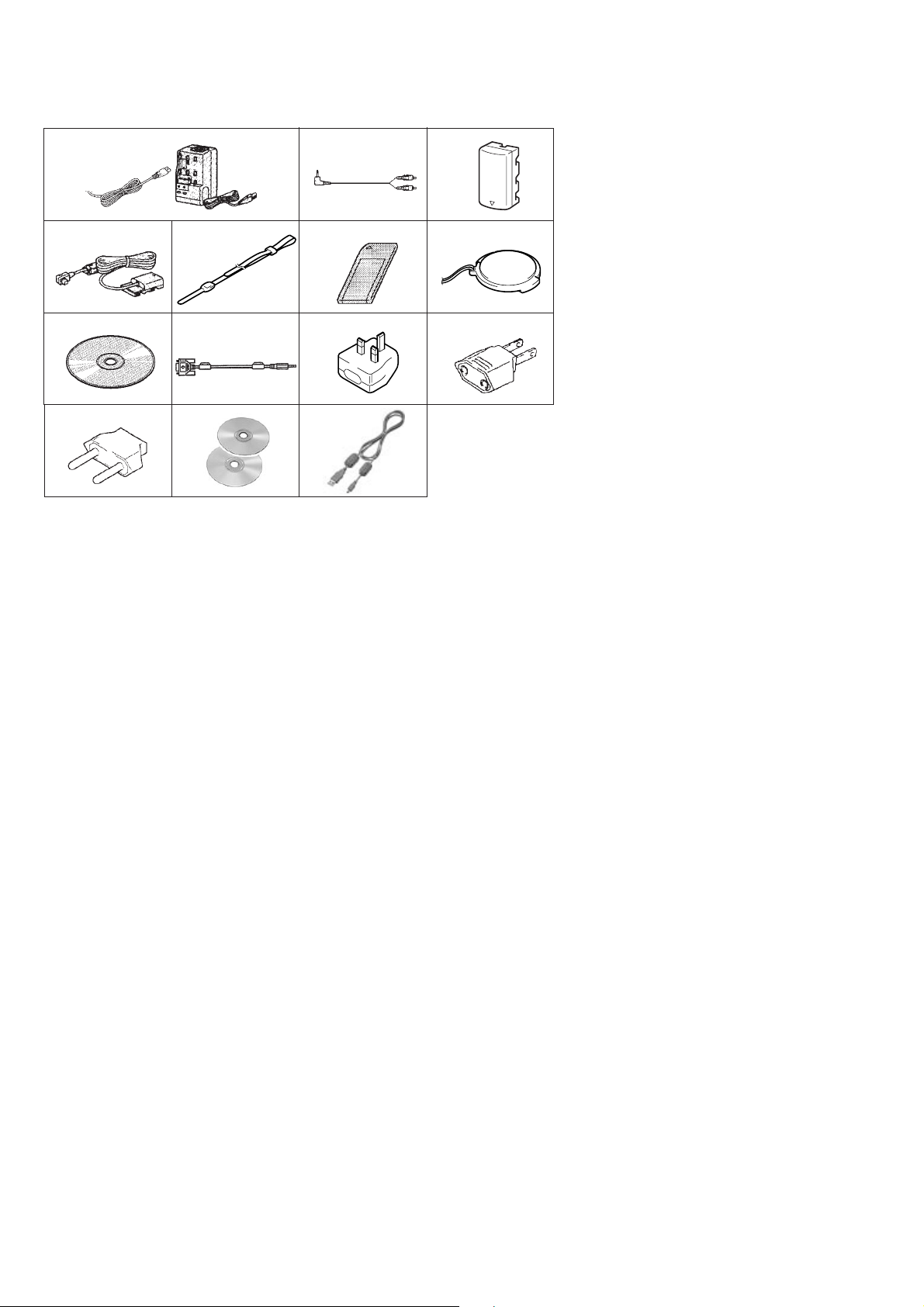

Supplied accessories

123

4567

89!º!¡

!™ !£ !¢

1 AC-VF10 AC power adaptor/charger,

Power cord (1)

2 A/V connecting cable (1)

3 NP-FS11 Battery pack (1)

4 DK-115 DC connecting cable (1)

5 Wrist strap (1)

6 Memory Stick (4MB) (1)

7 Lens cap/Lens cap strap (1)

8 Sony Picture Gear 3.2Lite (1)

(Compact Disk)

9 PC serial cable (1)

!º Conversion plug 3P adaptor (1)

UK, Hong Kong model

!¡ 2-pin conversion adaptor (1)

E model

!™ 2-pin conversion adaptor (1)

Tourist model

!£ USB driver software (1)

!¢ USB cable (1)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

– 2 –

Page 3

TABLE OF CONTENTS

1. GENERAL ...................................................................1-1

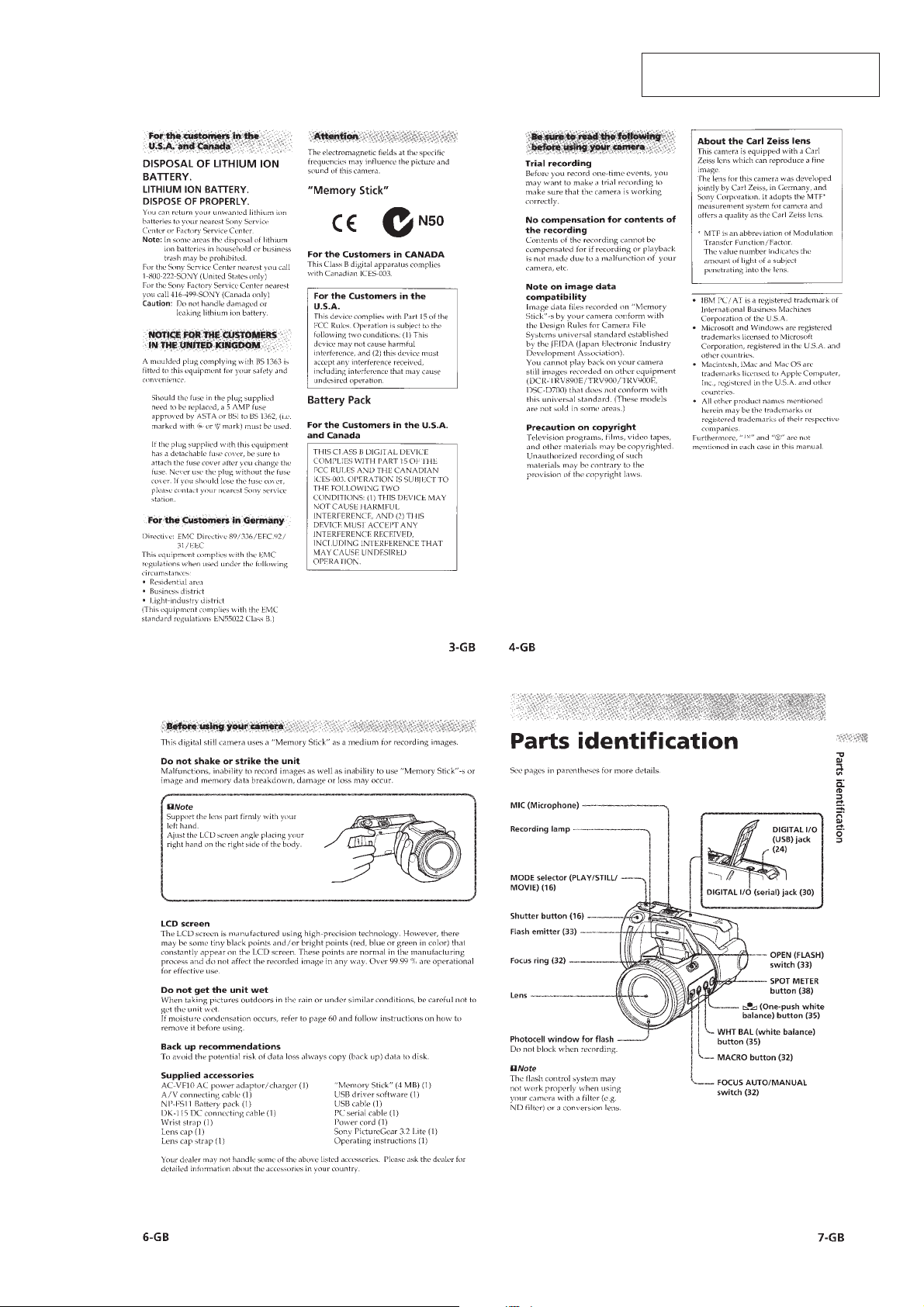

Parts identification.....................................................................1-1

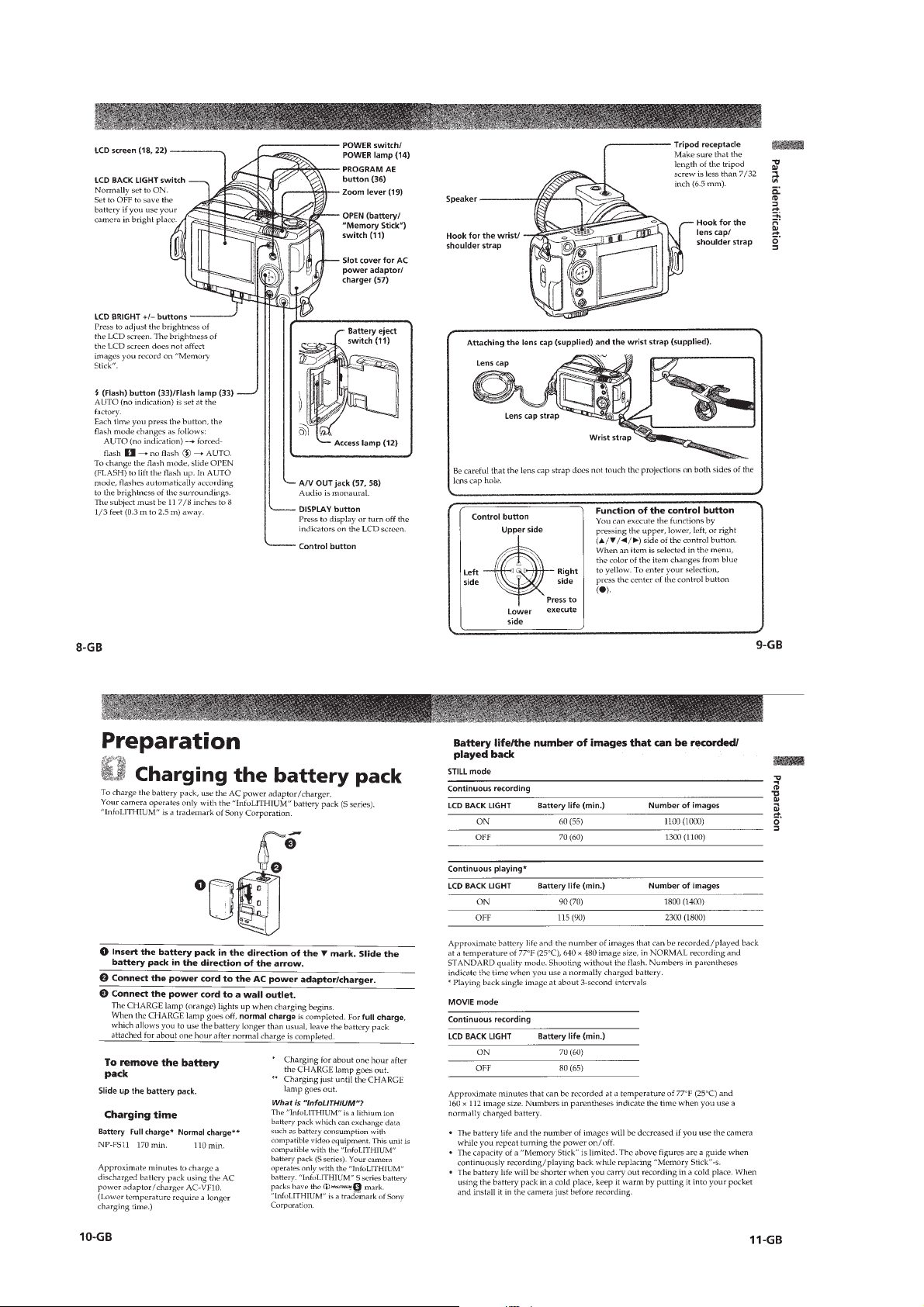

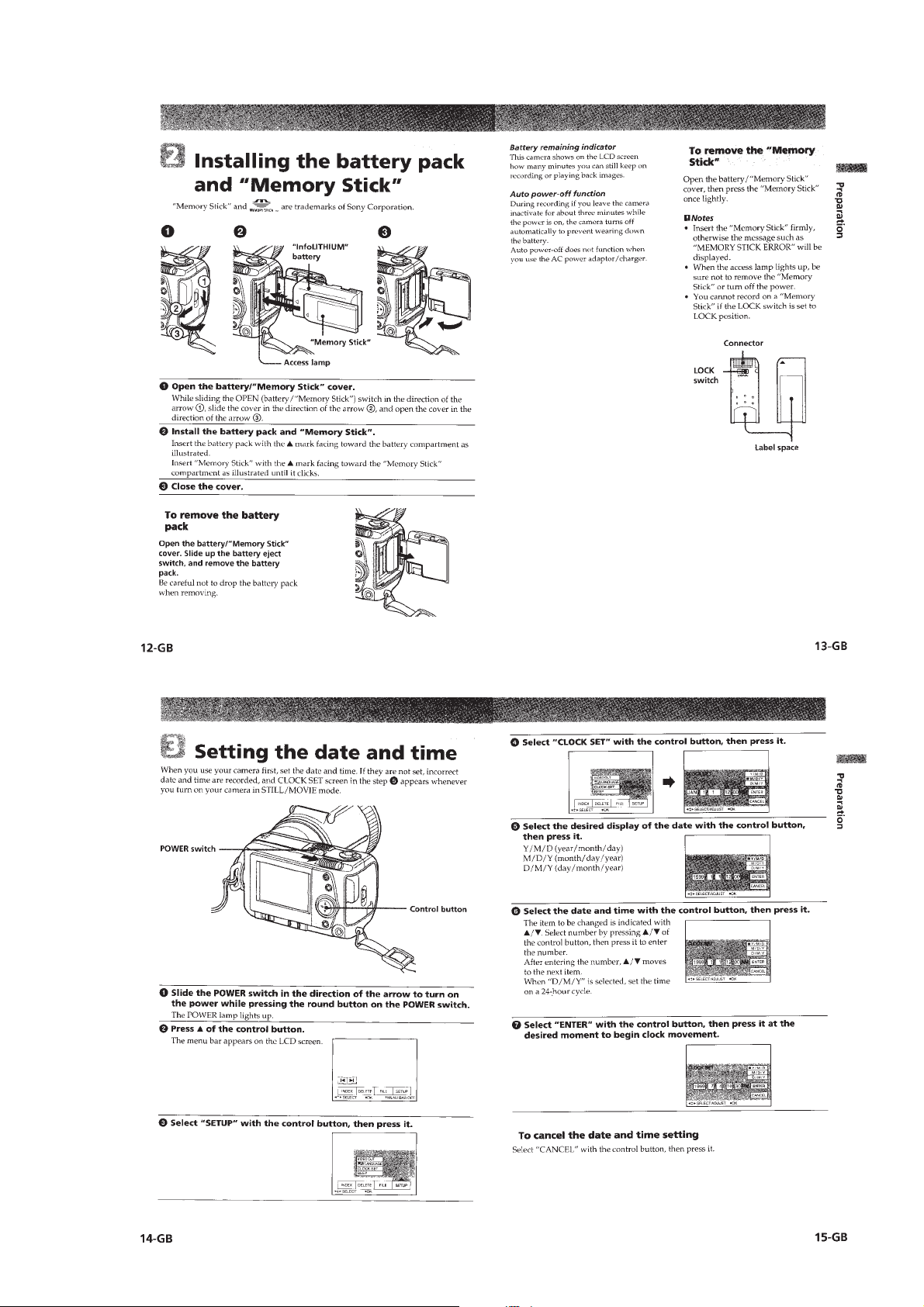

Preparation.................................................................................1-2

1 Charging the battery pack and

“Memory Stick” ...........................................................1-2

2 Installing the battery pack ............................................1-3

3 Setting the date and time ..............................................1-3

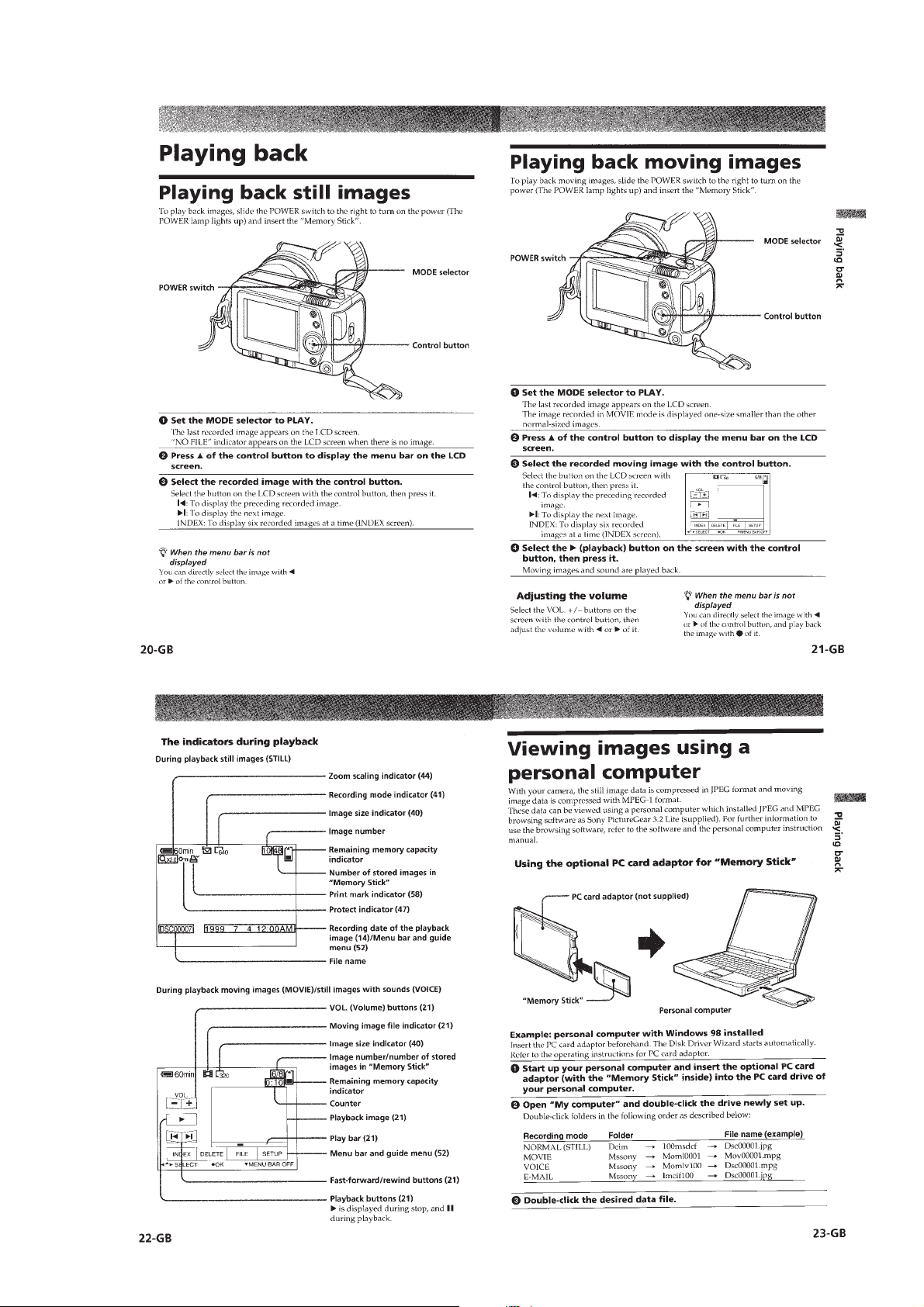

Recording .................................................................................. 1-4

Recording still images ..................................................... 1-4

Recording moving images...............................................1-4

Playing back ..............................................................................1-5

Playing back still images .................................................1-5

Playing back moving images........................................... 1-5

Viewing images using a personal computer....................1-5

Various ways of recording .........................................................1-8

Various ways of playback ........................................................1-10

Changing the menu setting ......................................................1-13

Using image data with other equipment ..................................1-14

Additional information ............................................................1-15

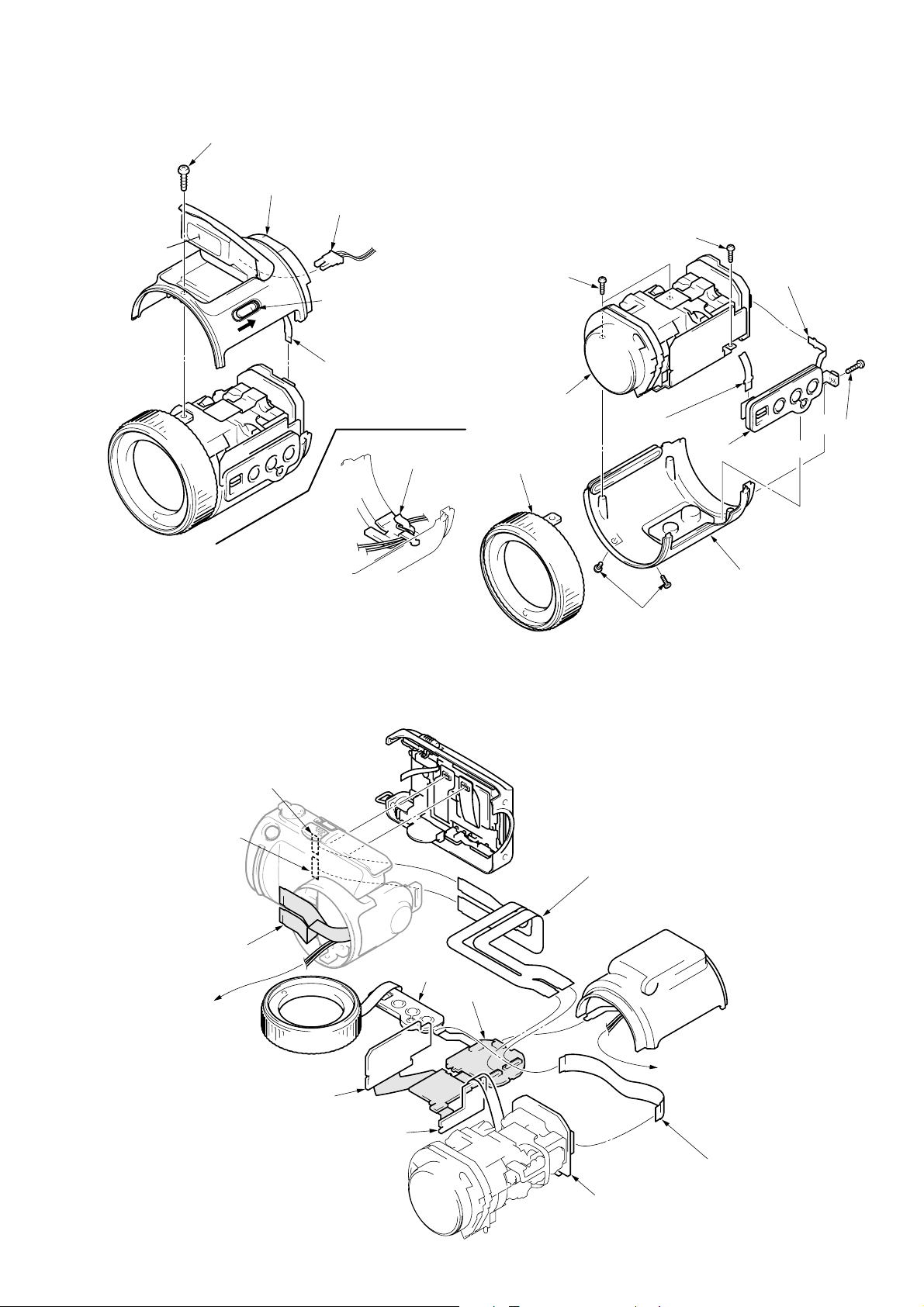

2. DISASSEMBLY

• Attachiment of CPC-9 Jig .......................................................2-1

2-1. Removal of Rear Cabinet Block......................................2-2

2-2. Removal of Zoom Lens Block .......................................2-2

2-3 Removal of Cabinet (LT) Block ......................................2-3

2-4. Removal of Lens Block ..................................................2-3

• Service Positionn-1 (Lens Block Area : CD-236, LD-98,

PS-427 and SY-56 Boards)..............................................2-3

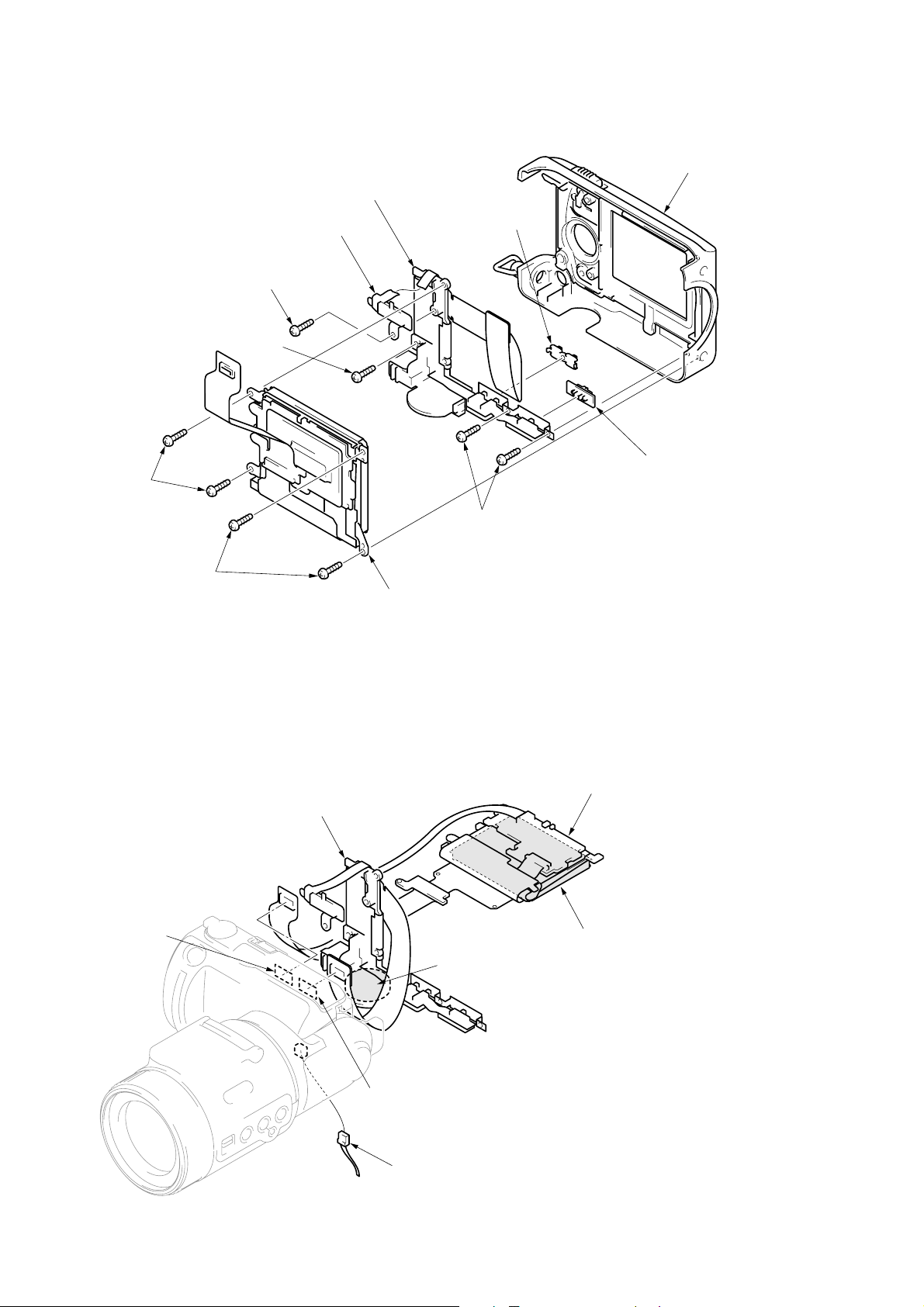

2-5. Removal of LCD Panel Block and

Control Switch Block (FK) .............................................2-4

• Service Positionn-2 (Rear Cabinet Area : LCD Panel and

Control Switch Block (FK)) ............................................ 2-4

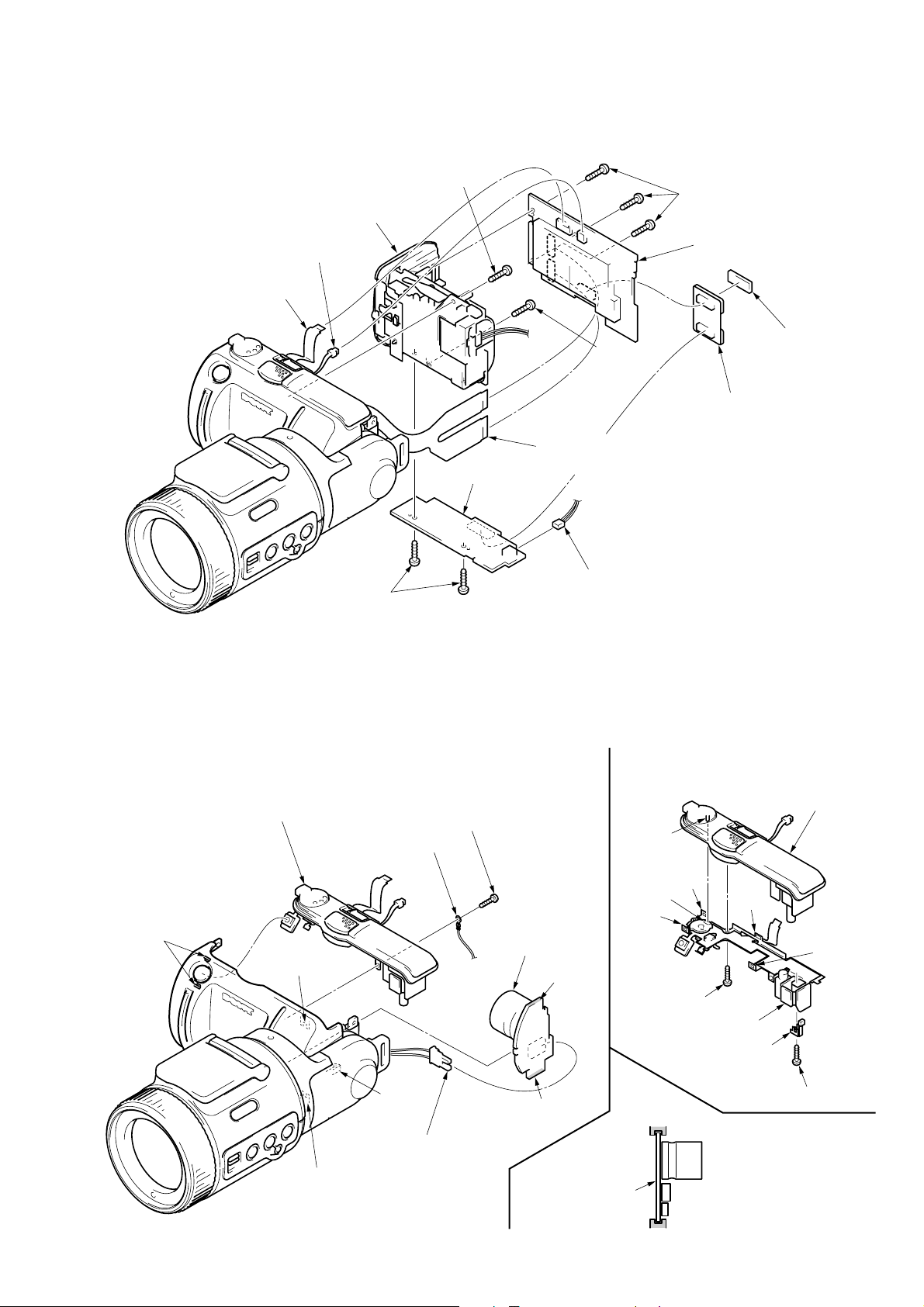

2-6. Removal of HI-70, DD-131 Boards and

Battery Holder Block.......................................................2-5

2-7. Removal of Upper Cabinet Block and Flash Unit (MC) ...2-5

• Service Positionn-3 (HI-70 and DD-131 Boards) ...................2-6

2-8. Removal of Front Cabinet Assembly............................... 2-6

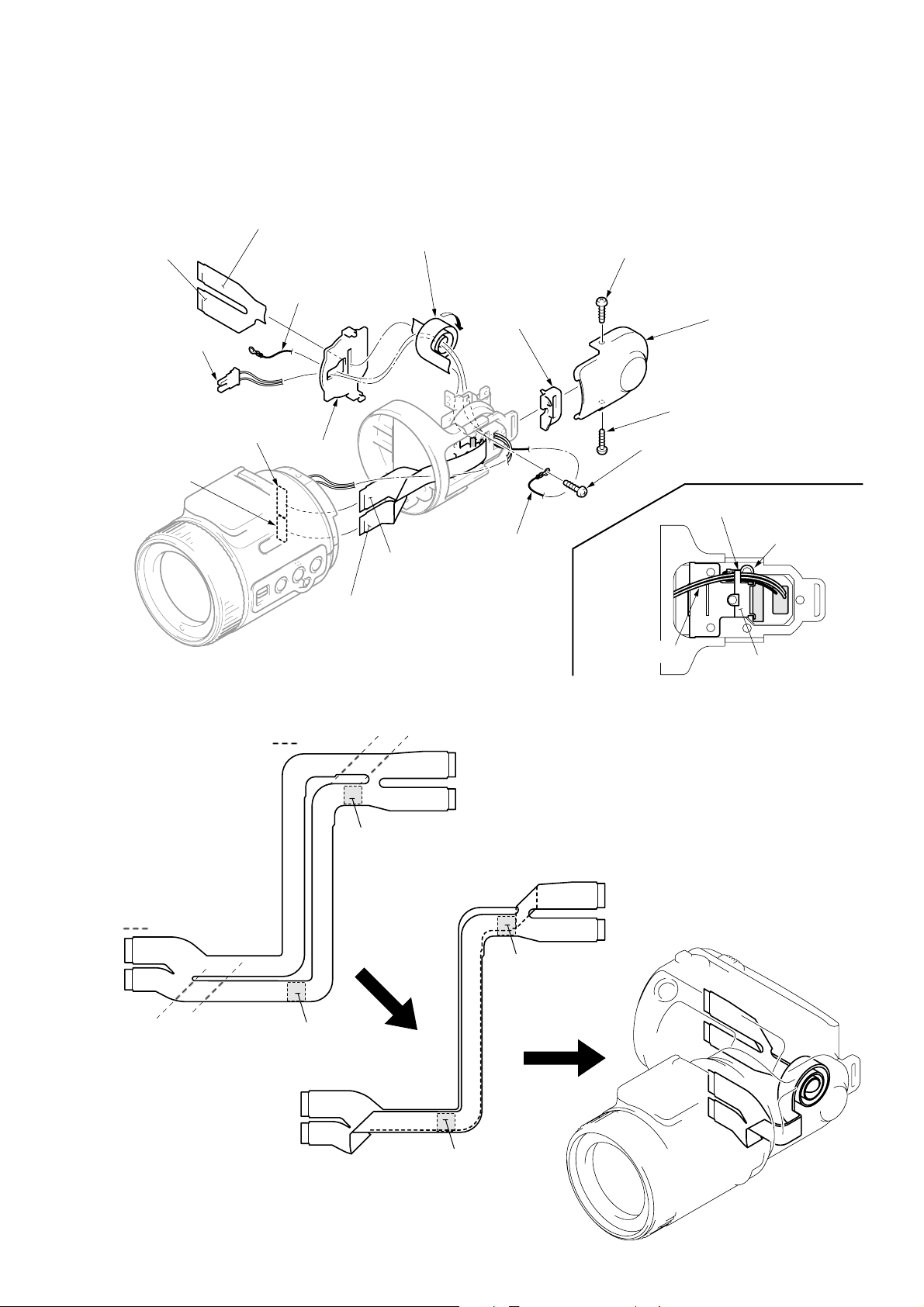

2-9. Removal and Attaciment of FP-133 Flexible Board .......2-7

2-10. To Fold the New FP-133 Flexible Board ........................2-7

2-11. Removal of Crystal Indication Module ...........................2-8

2-12. Removal of Flash Unit (ST)............................................. 2-8

2-13. Circuit Boards Location ..................................................2-9

2-14. Flexible Boards and Control Switch Block Location...... 2-9

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagram (1) ........................................4-3

Frame Schematic Diagram (2) ........................................ 4-5

4-2. Printed Wiring Boards and Schematic Diagram.............. 4-7

• CD-236 (CCD Imager, Camera)

Printed Wiring Board..............................................4-7

• CD-236 (CCD Imager, Camera)

Schematic Diagram.................................................4-9

• LD-98 (Lens Drive)

Printed Wiring Board............................................ 4-12

• MF UNIT

Schematic Diagram...............................................4-33

• CF/PW (Control Switch Block)

Schematic Diagram...............................................4-33

• HI-70 (LCD Drive, Timing Generator, Video,

Audio, Hi Control)

Printed Wiring Board............................................ 4-35

• HI-70 (LCD Drive)

Schematic Diagram...............................................4-39

• HI-70 (Timing Generator)

Schematic Diagram...............................................4-41

• HI-70 (Video)

Schematic Diagram...............................................4-43

• HI-70 (Audio)

Schematic Diagram...............................................4-45

• HI-70 (Hi Control (1/2) )

Schematic Diagram...............................................4-47

• HI-70 (Hi Control (2/2) )

Schematic Diagram...............................................4-49

• DD-131 (DC/DC Converter)

Printed Wiring Board............................................ 4-51

• DD-131 (DC/DC Converter)

Schematic Diagram...............................................4-53

• FK (Control Switch Block)

Schematic Diagram...............................................4-55

4-3. Waveforms.....................................................................4-57

4-4. Printed Parts Location ...................................................4-59

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram ...................................................3-1

– 3 –

Page 4

5. ADJUSTMENTS

1. Before starting adjustment...............................................5-1

1-1. Adjusting items when replacing main parts and boards..5-2

5-1. Adjustments.....................................................................5-3

1-1. Preparations Before Adjustment......................................5-3

1-1-1.List of Service Tools........................................................5-3

1-1-2.Preparations .....................................................................5-4

1-1-3.Discharging of the strobe power supply ..........................5-4

1-1-4.Precaution ........................................................................5-6

1. Setting the Switch............................................................ 5-6

2. Order of Adjustments ......................................................5-6

3. Subjects ........................................................................... 5-6

4. Preparing the Flash Adjustment Box...............................5-7

1-2. Initialization of B, D, E, F, 7 Page Data .......................... 5-8

1-2-1.Initialization of D Page Data ...........................................5-8

1. Initializing the D Page Data ............................................5-8

2. Modification of D Page Data...........................................5-8

3. D Page Table....................................................................5-8

1-2-2.Initializing the B, E, F, 7 Page Data .............................. 5-11

1. Initializing the B, E, F, 7 Page Data ..............................5-11

2. Modification of B, E, F, 7 Page Data ............................ 5-11

3. F Page table ...................................................................5-11

4. E Page Table .................................................................. 5-14

5. B Page Table..................................................................5-16

6. 7 Page Table ..................................................................5-19

1-3. Video System Adjustments............................................5-21

1. Video Sync Level Adjustment.......................................5-21

(Control Switch Block (FK) )........................................5-21

2. Video Burst Level Adjustment ......................................5-21

(Control Switch Block (FK) )........................................5-21

3. Video Y Level Check..................................................... 5-21

(Control Switch Block (FK) )........................................5-21

1-4. Camera System Adjustments.........................................5-22

1. HALL Adjustment .........................................................5-22

2. Flange Back Adjustment (Using Minipattern Box).......5-23

3. Flange Back Adjustment ...............................................5-24

(Using Flange Back Adjustment Chart) ........................5-24

4. Flange Back Check........................................................5-24

5. Picture Frame Setting ....................................................5-25

6. F No. Standard Data Input.............................................5-25

7. Mechanical Shutter Adjustment ....................................5-26

8. AGC Standard Gain and Max Gain Adjustment ...........5-26

9. Light Level Adjustment and ND SHUTTER CHECK..5-26

10. Auto White Balance Standard Data Input .....................5-27

11. Auto White Balance ND Filter Compensation

Adjustment ....................................................................5-27

12. Auto White Balance Adjustment ...................................5-28

13. Color Reproduction Adjustment....................................5-29

13-1. Color Reproduction Adjustment (Without ND Filter)...5-29

13-2. Color Reproduction Adjustment (With ND Filter)........ 5-29

13-3. Color Reproduction Check ............................................5-30

14. White Balance Check ....................................................5-31

15. Strobe White Balance Adjustment ................................5-31

16. Strobe Light Level and White Balance Check ..............5-32

17. CCD Black Defect Compensation.................................5-32

18. CCD Black Defect Compensation Check ..................... 5-33

19. CCD White Defect Compensation ................................5-34

20. CCD White Defect Compensation Check ..................... 5-34

1-5. LCD SYSTEM ADJUSTMENT ................................... 5-35

1. LCD Initial Data Input .................................................. 5-35

2. VCO Adjustment (Control Switch Block (FK) )...........5-36

3. D Range Adjustment (Control Switch Block (FK) ) .....5-36

4. Bright Adjustment (Control Switch Block (FK) ).........5-37

5. Contrast Adjustment (Control Switch Block (FK) )......5-37

6. Color Adjustment (Control Switch Block (FK) ) ..........5-38

7. V-COM Level Adjustment (Control Switch Block

(FK) ) .............................................................................5-38

8. V -COM Adjustment....................................................... 5-39

9. White Balance Adjustment (HI-70 board).....................5-39

1-6. System Control System Adjustment..............................5-40

1. Battery End Adjustment (SY-54 board) .........................5-40

5-2. Service Mode.................................................................5-41

2-1. Adjustment Remote Commander ..................................5-41

1. Using the adjustment remote commander .....................5-41

2. Precautions upon using the adjustment remote

commander ....................................................................5-41

2-2. Data Process ..................................................................5-42

2-3. Service Mode.................................................................5-43

1. Setting the Test Mode ....................................................5-43

2. Bit value discrimination ................................................5-43

3. Switch check (1) ............................................................5-44

4. Switch check (2) ............................................................5-44

5. LED check .....................................................................5-44

5-3. System Control Adjustment...........................................5-45

1. Initializing the data of pages B, C, D, E, F, 7 ................5-45

2. Inputting the serial No. ..................................................5-45

2-1. Inputting the serial No. ..................................................5-45

6. REPAIR PARTS LIST

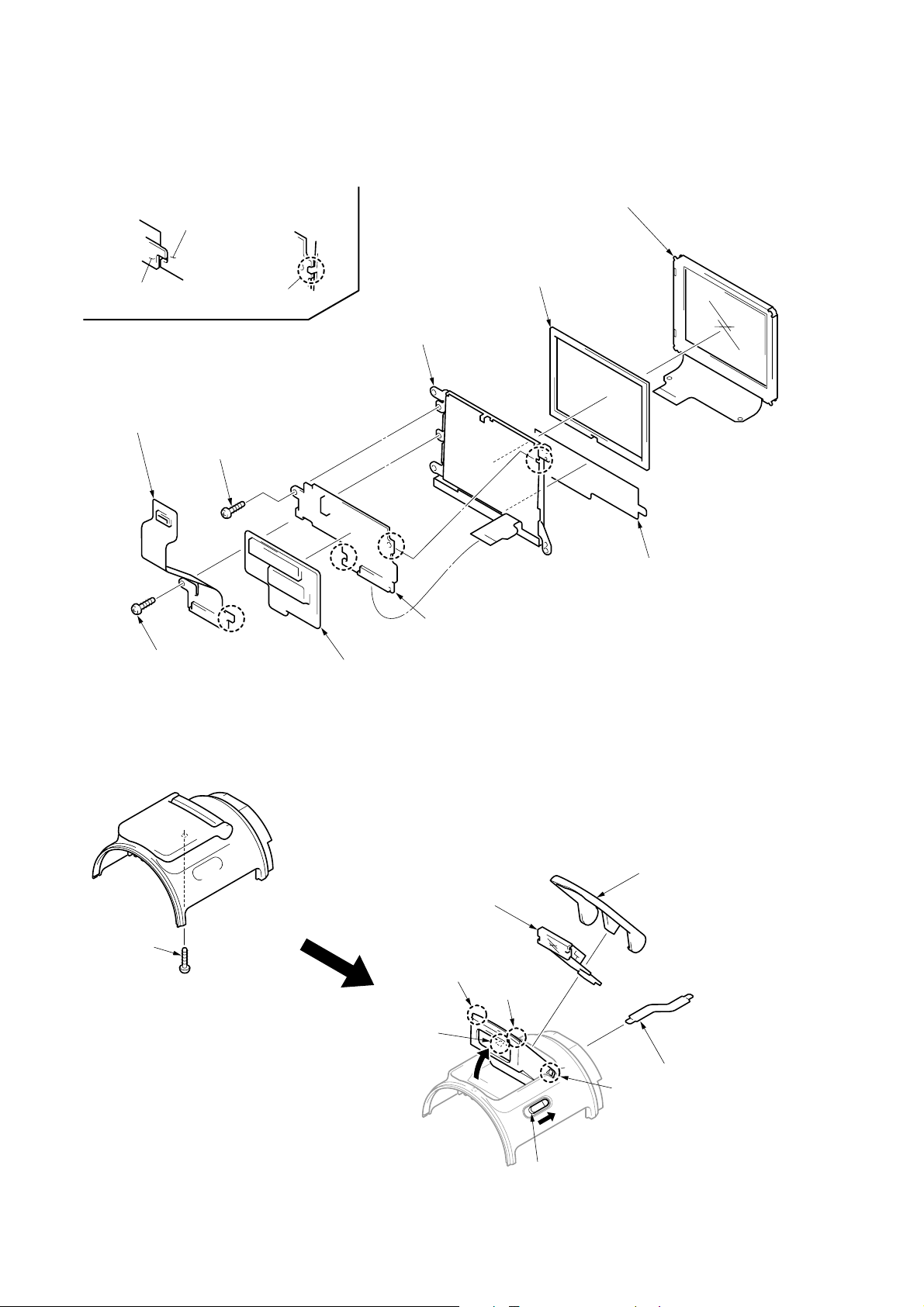

6-1. Exploded Views...............................................................6-1

6-1-1.Battery Holder Assembly ................................................6-1

6-1-2.Front Cabinet Assembly .................................................. 6-2

6-1-3.Rear Cabinet Assembly ...................................................6-3

6-1-4.Lens Cabinet Assembly ...................................................6-4

6-1-5.Lens Assembly ................................................................6-5

6-2. Electrical Parts List ......................................................... 6-6

* The color reproduction frame is shown on page 141.

– 4 –

Page 5

SERVICE NOTE

g

[Discharging of the FLASH unit’s charging capacitor]

The charging capacitor of the FLASH unit is charged up to the

maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by the

charged voltage which is kept without discharging when the main

power of the DSC-F505 is simply turned off. Therefore, the

remaining voltage must be discharged as described below.

Preparing the Short Jig

To preparing the short jig. a small clip is attached to each end of a

resistor of 1kΩ /1W (1-215-869-11)

Wrap insulating tape fully around the leads of the resistor to prevent

electrical shock.

1kΩ/1W

Wrap insulating tape.

Discharging the Capacitor

Short circuits between the positive and the negative terminals of

charged capacitor with the short jig about 10 seconds.

Capacitor

Short ji

Flash unit (MC)

– 5 –

Page 6

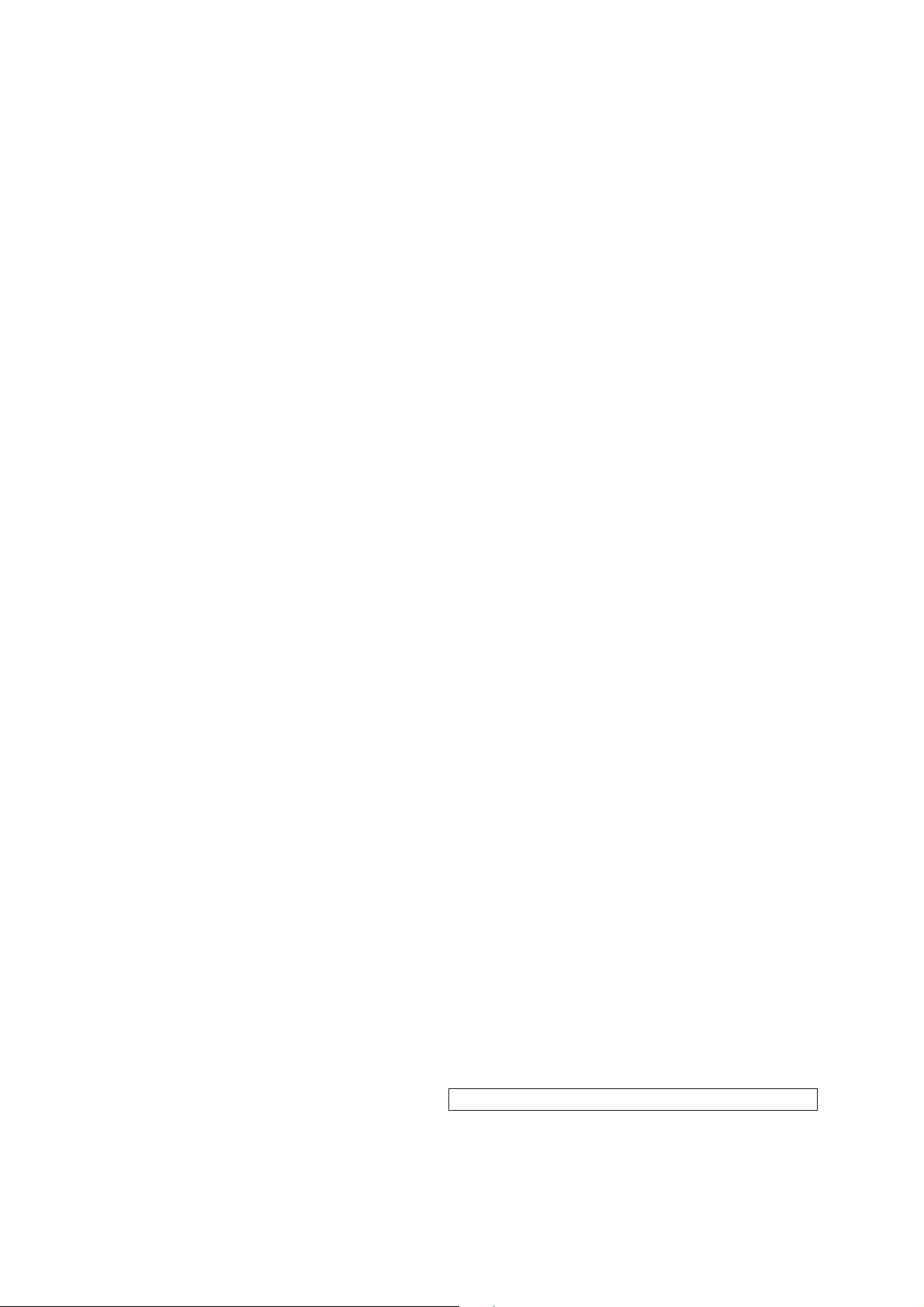

[Description on Self-diagnosis Display]

Self-diagnosis display

• C: ππ: ππ

You can reverse the camera

malfunction yourself. (However,

contact your Sony dealer or local

authorized Sony service facility

when you cannot recover from the

camera malfunction.)

• E: ππ: ππ

Contact your Sony dealer or local

authorized Sony service facility.

Display Code

C:04:ππ

C:32:ππ

C:13:ππ

E:61:ππ

E:91:ππ

Note : The error code is cleared if the battery is removed, except defective

flash, unit.

*1 : The error display is given in two ways.

*2 : When the flash charging failed, Page:D, Address:C7, Data:04 are

written.

After repair, be sure to write Page:D, Address:C7, Data:00.

Use a NP-FS11/F10 battery pack.

Turn the power off and on again.

Format the “Memory stick”.

Insert a new “Memory Stick”.

Checking of lens drive circuit.

*1

Checking of flash unit or replacement

of flash unit.

Countermeasure

You are using a basttery pack that is not an

“InfoLITHIUM” battery pack.

Trouble with hardware.

Unformatted memory stick is inserted.

Memory stick is broken.

When failed in the focus and zoom

initialization.

Abnormality when flash is being

charged.

Cause

Caution Display During Error

for “InfoLITHIUM” BATTERY

ONLY

SYSTEM ERROR

FORMAT ERROR

MEMORY STICK ERROR

—

*2

– 6 –

Page 7

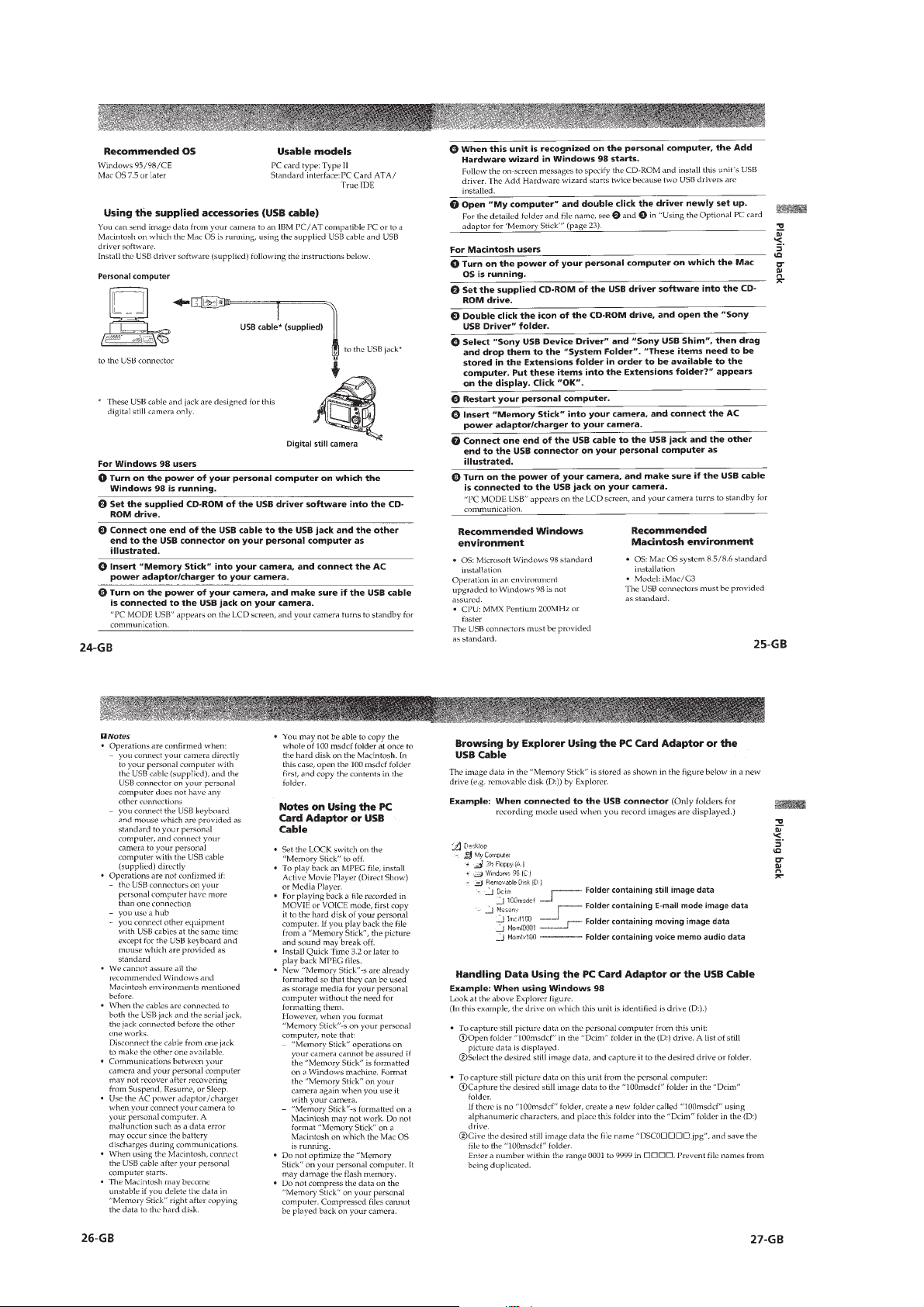

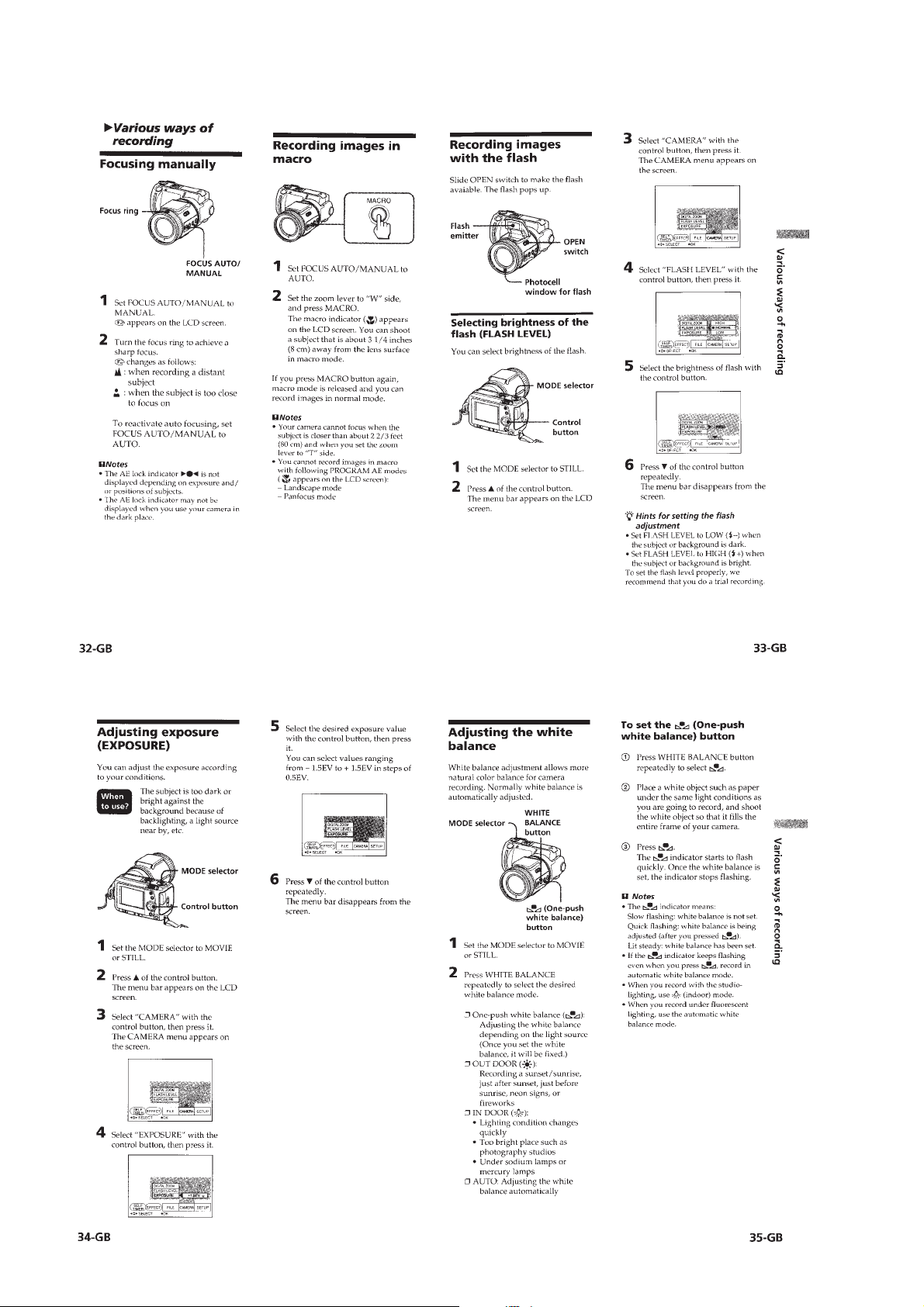

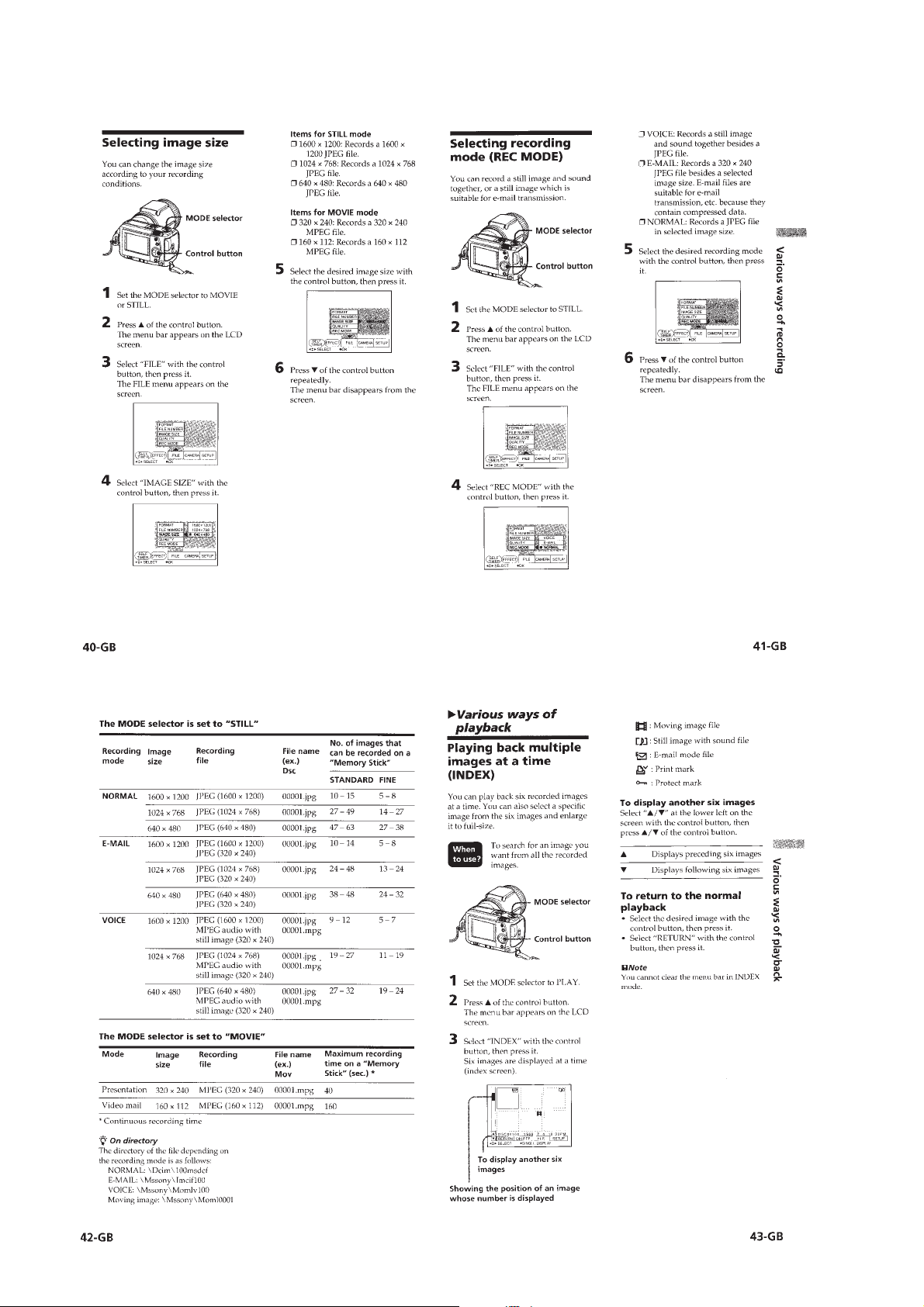

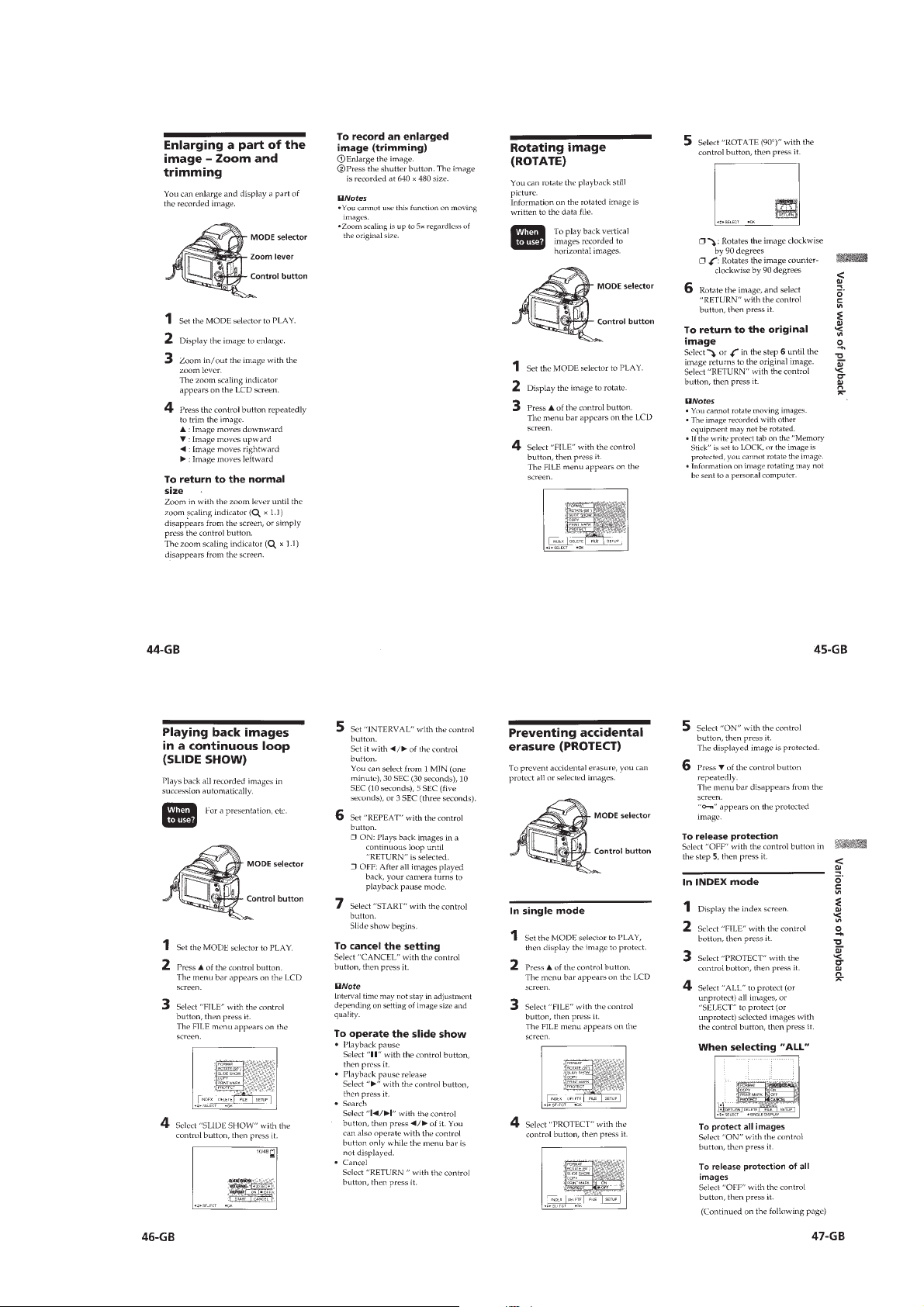

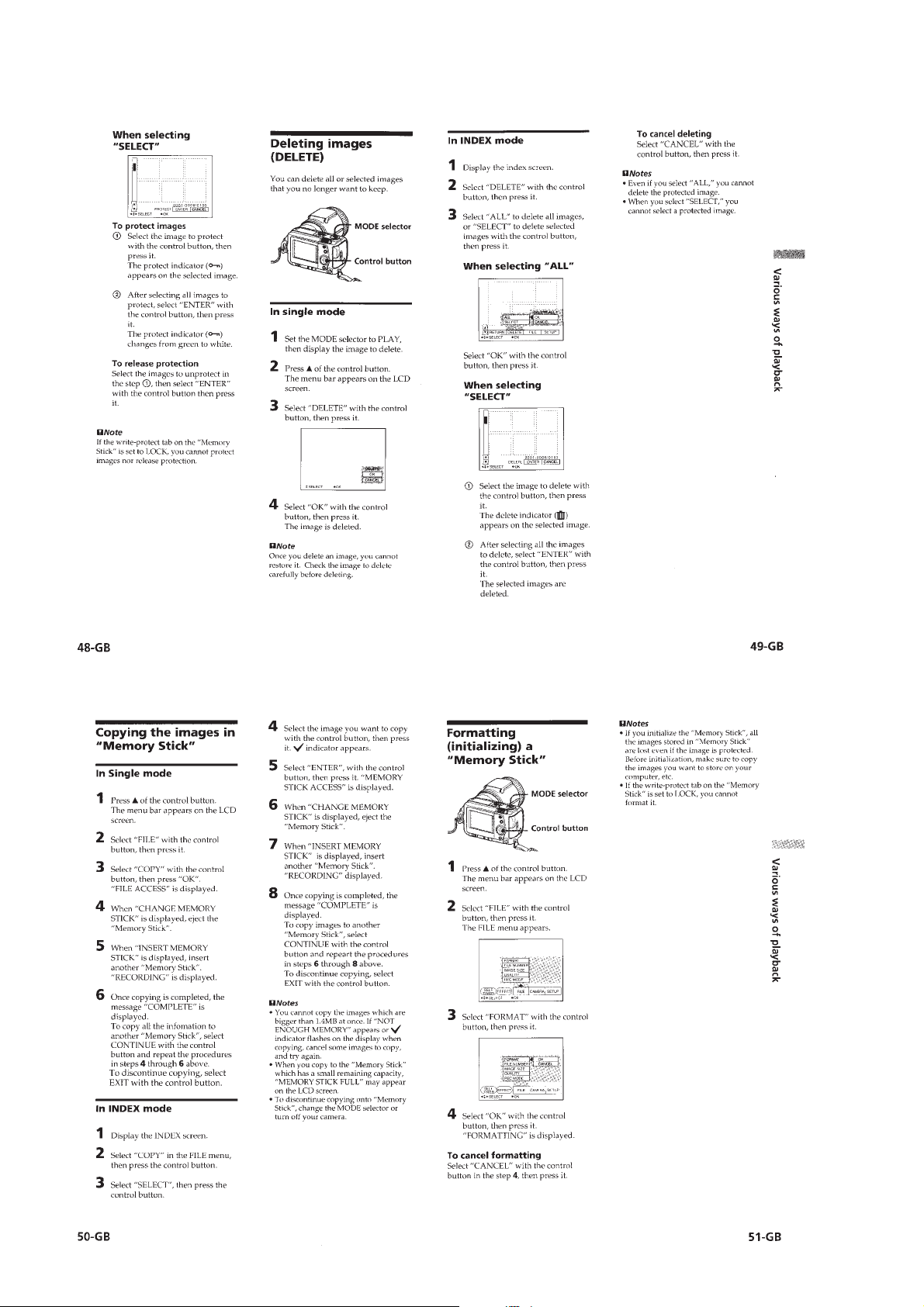

SECTION 1

GENERAL

DSC-F505

This section is extracted from

instruction manual.

1-1

Page 8

1-2

Page 9

1-3

Page 10

1-4

Page 11

1-5

Page 12

1-6

Page 13

1-7

Page 14

1-8

Page 15

1-9

Page 16

1-10

Page 17

1-11

Page 18

1-12

Page 19

1-13

Page 20

1-14

Page 21

1-15E

Page 22

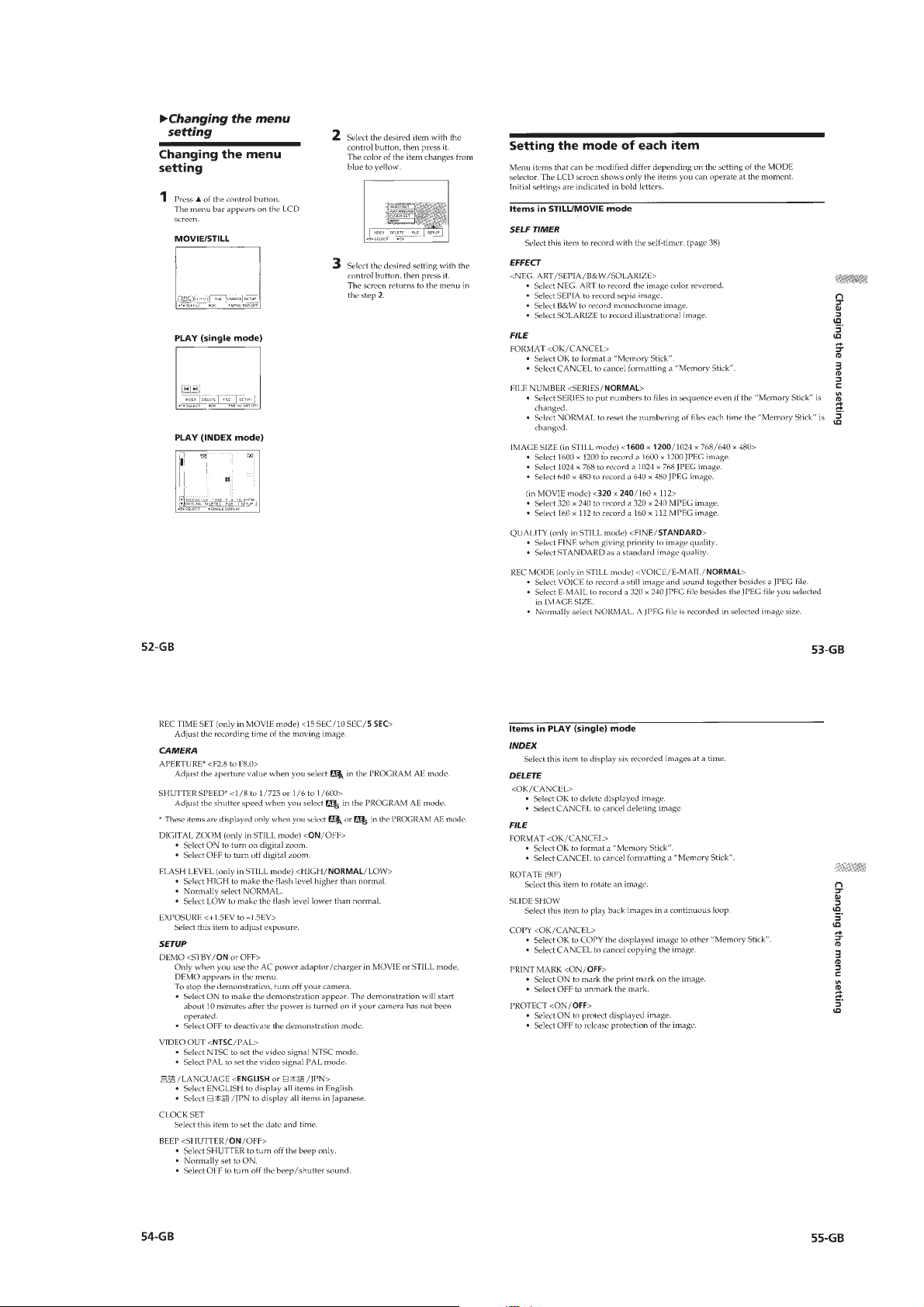

SECTION 2

DISASSEMBLY

The equipment can be removed using the following procedure.

START

2-1. REAR CABINET BLOCK

2-2. ZOOM LENS BLOCK

DSF-F505

2-3. CABINET (LT) BLOCK

2-4. LENS BLOCK

ATTACHMENT OF CPC-9 JIG

AND

SERVICE POSITION-1

· CD-236 BOARD

· LD-98 BOARD

· PS-427 BOARD

· SY-56 BOARD

2-5. LCD PANEL BLOCK

ATTACHMENT OF CPC-9 JIG

SERVICE POSITION-2

2-11. CRYSTAL INDICATION MODULE

2-12. FLASH UNIT (ST)

• ATTACHMENT OF CPC-9 JIG

CONTROL SWITCH BLOCK (FK)

AND

· LCD PANEL BLOCK

· CONTROL SWITCH BLOCK (FK)

AND OTHER

2-6. HI-70 AND DD-131 BOARDS

BATTERY HOLDER BLOCK

2-7. UPPER CABINET BLOCK

CONTROL SW BLOCK (PW)

FLASH UNIT (MC)

ATTACHMENT OF CPC-9 JIG

AND

SERVICE POSITION-3

· HI-70 BOARD

· DD-131 BOARD

2-8. FRONT CABINET ASSEMBLY

ABOUT FP-133 FLEXIBLE BOARD.

(Refer to 2-9. and 2-10.)

Control switch block (FK)

(CN002)

18

1

CPC-9 jig (J-6082-393-C)

(18p flexible board)

Two claws

CPC cover

Note : Don't use the 12 pin flexible board of CPC-9 jig.

It causes damage to the unit

2-1

Slide the Release knob in the direction of arrow

To open the Battery lid.

A

Release knob

A

.

Page 23

d

NOTE : Follow the disassembly procedure in the numerical order given.

2-1. REMOVAL OF REAR CABINET BLOCK

2

T wo screws

(M1.7)

Front cabinet assembly

4

FP-134 flexible board

(HI-70 board, CN901)

5

Flexible board (Control switch block (FK))

(HI-70 board, CN607)

3

Rear cabinet assembly

6

Harness (HB-50)

(HI-70 board, CN605)

1

T wo screws

(M1.7)

7

Harness (SP-163)

(HI-70 board, CN702)

2-2. REMOVAL OF ZOOM LENS BLOCK

4

5

(SY-56 board)

6

Zoom lens block

CN456

(SY-56 board)

CN455

3

Screw (M1.7)

1

Screw (M1.7)

FP-133 flexible boar

7

2-2

MF ornament

2

Screw (M1.7)

Page 24

b

)

2-3 REMOVAL OF CABINET (LT) BLOCK 2-4. REMOVAL OF LENS BLOCK

)

2

Screw (M1.7)

3

Cabinet (LT) block

5

Harness (SM-114)

(Flash unit (ST), 2P)

Flash unit

(Note)

Cabinet (LT) block

(Bottom view)

(Note)

1

Push the Release kno

4

FP-136 flexible board

(SY-56 board, CN454)

Harness clamp

NOTE : Clamp the cables after attaching the Harness (MS-114). If

clamped with the flash unit closed, the flash unit cannot

be opened, Be sure to clamp the cable with the flash unit

opened.

7

T wo screws

(M1.7)

0

Lens block

6

Cabinet (MF)

assembly

8

Screw (M1.7)

3

CN001

(Control switch block)

5

T wo screws

(M1.7)

2

(SY-56 board)

4

Control switch

block (CF)

9

assembly

CN453

1

Cabinet (LB)

Screw (M1.7

• SERVICE POSITION-1 (LENS BLOCK AREA : CD-236, LD-98, PS-427 and SY-56 BOARDS)

CN602

(HI-70 board)

CN603

(HI-70 board)

FP-133 flexible board

(Not used)

Harness (MS-114)

(to Cabinet (LT) block)

Cabinet (MF) assembly

PS-427 board

Control switch block (CF)

LD-98 board

Rear cabinet block

SY-56 board

Extension cable (33, 39P 0.3 mm)

Parts No. : J-6082-447-A

(HI-70 board, CN602, 603)

(SY-56 board, CN455, 456)

Cabinet (LT) block

(Flash unit (ST))

Harness (MS-114)

(from Front cabinet block)

Lens block

2-3

CD-236 board

Extension cable (39P 0.3 mm

Parts No. : J-6082-448-A

(PS-427 board, CN251)

(CD-236 board, CN101)

Page 25

2-5. REMOVAL OF LCD PANEL BLOCK AND CONTROL SWITCH BLOCK (FK)

8

Control switch block (FK)

Rear cabinet assembly

3

T wo screws

(1.7 x 4)

4

Two screws (1.7)

1

Screw (1.7 x 4)

6

Screw (M1.7)

2

Zoom switch

(RV001)

Button (LCD bright)

Knob (LCD back light)

7

Two screws (M1.7)

5

LCD panel block

(Refer to 2-11. for details diagram on removal of LCD section)

• SERVICE POSITION-2 (REAR CABINET AREA : LCD PANEL and CONTROL SWITCH BLOCK (FK))

Cold cathode fluorescent tube (ND901)

(with Inverter transformer unit)

Control switch block (FK)

CN901

(HI-70 board)

SP901

CN607

(HI-70 board)

Crystal indication module (LCD901)

(with FP-134 flexible board)

Harness (From the SP901)

(HI-70 board, CN702)

2-4

Page 26

2-6. REMOVAL OF HI-70, DD-131 BOARDS AND BATTERY HOLDER BLOCK

1

FP-132 flexible board

(HI-70 board, CN601)

(DD-131 board, CN003)

5

Three screws

(1.7 x 4)

!¡

T wo screws

(1.7 x 4)

8

Screw (M1.7)

0

Battery holder block

9

Screw

(M1.7)

!™

DD-131 board

6

HI-70 board

2

FP-133 flexible board

(HI-70 board, CN602,603)

3

Harness (Microphone)

(HI-70 board, CN701)

7

Harness (MD-97)

(DD-131 board, CN002)

4

Control switch block (PW)

(HI-70 board, CN604)

BB fixed sheet

k

2-7. REMOVAL OF UPPER CABINET BLOCK AND FLASH UNIT (MC)

NOTE : When the flash unit (MC) charging failed, Page : D, Address : C7, Data : 04 are written.

Two claws

After repair, be sure to write Page : D, Address : C7, Data : 00.

3

Upper cabinet block

(Take note of two claws

A

Groove

A

Groove

)

2

Harness (GN-52)

Claw

B

4

Harness (MS-114)

1

Screw (M1.7)

5

Flash unit (MC)

(Take note of claw B)

Details diagram on removal and attachment

of Control switch block (PW)

Claw

(Note)

Edge

Control switch block (PW)

Edge

Flash unit (MC)

Pin

Claw

Hole

Screw (1.7 x 4)

JK retainer assembly

Groove

Claw

Should be fit to the Front

cabinet groove.

Upper cabinet bloc

Claw

Screw (1.7 x 4)

Note for installation of

Flash unit (MC)

2-5

Groove

Page 27

• SERVICE POSITION-3 (HI-70 and DD-131 BOARDS)

)

Control switch block (PW)

Front cabinet block

DD-131 board

FP-133 flexible board

(Not used)

CN456

(SY-56 board)

CN455

(SY-56 board)

CN605

HI-70 board

CN602

CN702

Rear cabinet block

CN603

Harness (HB-50)

Harness (SP-163)

Battery holder block

(To AC power adaptor)

Zoom lens block

2-8. REMOVAL OF FRONT CABINET ASSEMBLY

4

Front cabinet assembly

Extension cable (33, 39P 0.3 mm

Parts No. : J-6082-447-A

(HI-70 board, CN602, 603)

(SY-56 board, CN455, 456)

1

Lift up the Zoom lens block.

3

Screw (M2 x 4)

2

Screw (M2 x 4)

2-6

Page 28

2-9. REMOVAL AND ATTACHIMENT OF FP-133 FLEXIBLE BOARD

NOTE : For folding new FP-133 flexible board, refer to “2-10. To

fold the new FP-133 flexible board” .

FP-133 flexible board

(39P side)

Harness (MS-114)

CN456

(SY-56 board)

CN455

(SY-56 board)

FP-133 flexible board

(33P side)

Harness (GN-52)

FP holder

FP-133 flexible board

(33P side)

When attaching, coil in the direction of

arrow

A

with two and a half revolutions.

(FP-133 flexible board )

A

Hook cover

Harness (GN-52)

FP-133 flexible board

(39P side)

Screw (M1.7)

Screw (M1.7)

Screw (M2 x 4)

Hook the claw of harness

Harness (MS-114)

Hinge cover

Harness (GN-52)

FP guard

2-10. TO FOLD THE NEW FP-133 FLEXIBLE BOARD

: Fold

Adhesive tape

: Fold

1-675-590-xx

FP-133

Adhesive tape

1-675-590-xx

FP-133

Adhesive tape

NOTE : For attaching new FP-133 flexible board, refer to “2-9.

Removal and attachment of FP-133 flexible board” .

Adhesive tape

2-7

Page 29

2-11. REMOVAL OF CRYSTAL INDICATION MODULE

Note for installation

Portion

A

3

FP-134 flexible board

Portion

B

Portion C and

5

(Inverter transformer unit)

4

Screw (M1.7)

1

Crystal indication module (LCD901)

(FP-134 flexible board, 24P)

D

Cold cathode fluorescent tube (ND901)

C

B

A

6

Inverter transformer unit

BL cushion

D

BL light interception sheet

2

Screw (M1.7)

2-12. REMOVAL OF FLASH UNIT (ST)

1

Screw

(M1.7 x 4)

BL insulating sheet

5

Flash unit (ST)

Claw

Claw

Claw

4

Cabinet (ST)

(Take note of four claws)

2

FP-136 flexible board

Claw

(Flash unit ST)

2-8

3

Push the Release knob

Page 30

2-13. CIRCUIT BOARDS LOCATION

t

CD-236

(CCD imager, Camera)

LD-98

(Lens drive)

PS-427

(Camera DSP, Memory control)

SY-56

(SH DSP, Memory, Serial I / O, Connector, Digital I / O, )

HI-70

(LCD drive, Timing generator, Video, Audio, HI control)

Flash unit (MC)

Flash unit (ST)

Inverter transformer uni

DD-131

(DC / DC Converter)

2-14. FLEXIBLE BOARDS AND CONTROL SWITCH BLOCK LOCATION

Control switch block (PW)

Control switch block (FK)

FP-132

FP-136

FP-135

Control switch block (CF)

FP-134

FP-133

Lens block

Manual focus block

2-9

E

Page 31

Ver 1.1 1999.10

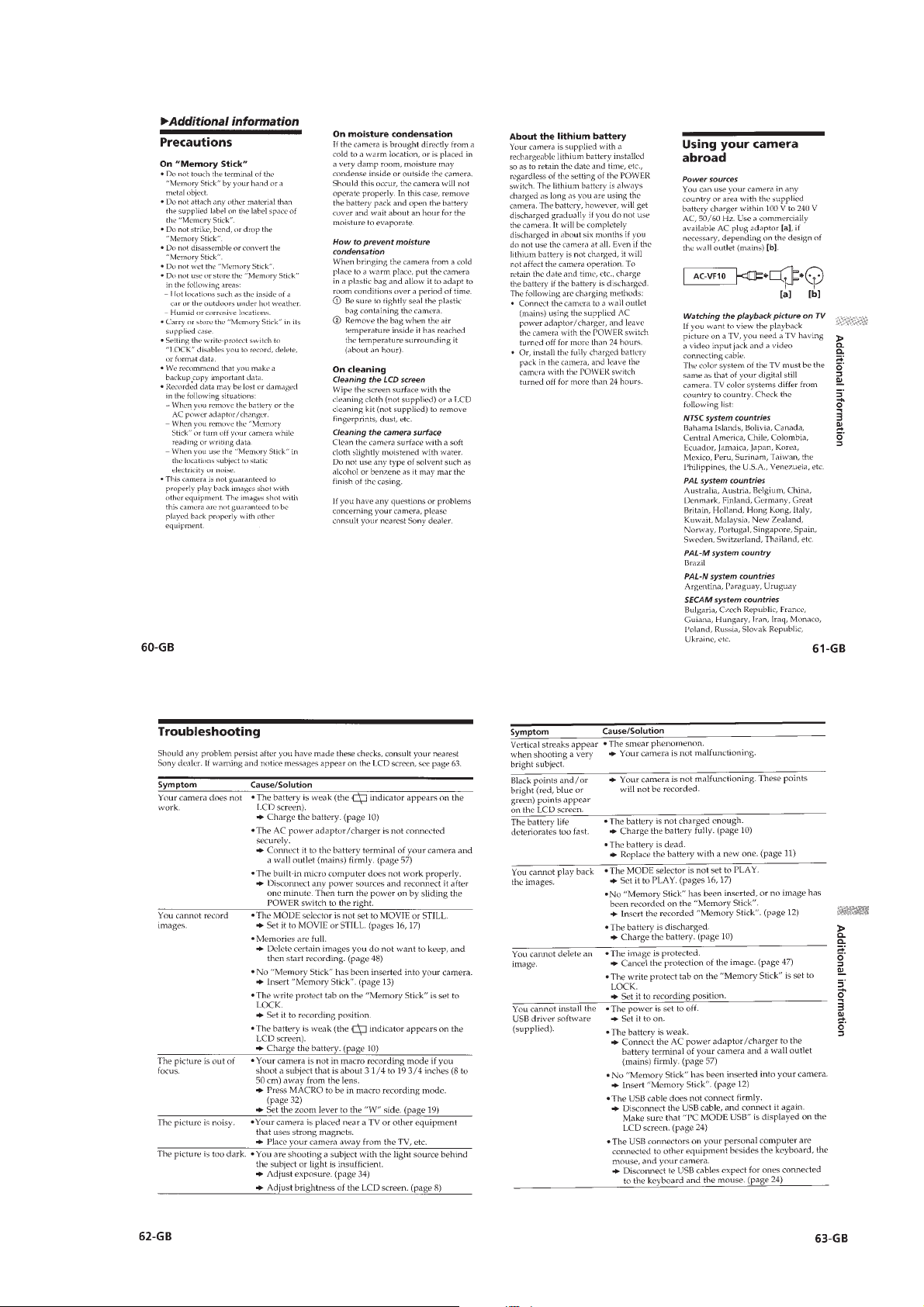

3-1. OVERALL BLOCK DIAGRAM

DSC-F505

SECTION 3

BLOCK DIAGRAMS

M902

FOCUS

MOTOR

M

FOCUS

RESET

SENSOR

IC402

(SEE PAGE 4-13)

FOCUS

MOTOR

DRIVE

IC406

(SEE PAGE 4-13)

FOCUS, ZOOM

MOTOR

PREDRIVE

M901

ZOOM

MOTOR

ZOOM

MOTOR

DRIVE

TERMINAL

09

M

BT901

BATTERY

S

ZOOM

MOTOR

SENSOR

LENS

HALL

H

IRIS

METER

DRIVE (+)

DRIVE (–)

CAM SO, CAM SI, XCAM SCK

FLASH UNIT (ST) (MC)

FLASH UNIT

DD-131 BOARD

IC001

DC/DC

CONVERTER

(SEE PAGE 4-53)

ST UNREG

BATT SIG

IC403

SHUTTER

DRIVE

(SEE PAGE 4-13)

IC404

IC405

(SEE PAGE 4-13)

IRIS

DRIVE

HALL AMP

SYS DD ON

CAM DD ON

LCD DD ON

CD-236 BOARD

IC101

CCD IMAGER

(SEE PAGE 4-9)

H1, H2

CCD OUT

V1A, V1B, V2A

V3A, V3B, V4

RG, VSHT

LD-98 BOARD

M SHUT ON

ZOOM MOTOR SENS

FOCUS MOTOR SENS

IRIS CONT 1, 2

HALL ADHALL (+)

STRB ON

HALL AD

CAM +15VD

CAM –7.5V

A +4.9V

M +5V

D +2.35V

D +3.2V

A +3.2V

PANEL +13.5V

PANEL +6.5V

PANEL +4.9V

PANEL –15V

BL UNREG

IC407

EVR

(D/A CONV.)

(SEE PAGE 4-14)

CNT C

CNT Y

IC103

A/D CONV.

(SEE PAGE 4-9)

IC102

TIMING

GENERATOR

(SEE PAGE 4-9)

DATA BUS IO

MCK12

MCK14

IC252

SDRAM

64Mbit

(SEE PAGE 4-18)

MIC901

MIC

PS-427 BOARD SY-56 BOARD

IC251

CAMERA DSP

MEMORY CONTROL

VIDEO ENCODER

OPD, OSD, HOST IF

RES CONTROL

SG, JPEG, L-MODE

(SEE PAGE 4-16)

DATA

16

ADDRESS

14

ZOOM MOTOR SENS

FOCUS MOTOR SENS

CNT Y/C

16

16

16

MC XCS1

Y

R-Y/C

B-Y/C

M SHUT ON

DATA BUS

ADDRESS BUS

ADDRESS BUS

9

IC456

SERIAL I/O

SHUTTER CONTROL

FLASH CONTROL

(SEE PAGE 4-29)

STRB ON

CAM SO, CAM SI, XCAM SCK

HOST IF

AUDIO OF

HI-70

BOARD

CY

CNT Y

CNT C

BATT SIG

IC301

VIDEO AMP

(SEE PAGE 4-44)

16

MC XCS3

AU SDTO

AU SDTI

IC455

AUDIO AD/DA CONV.

(SEE PAGE 4-29)

HI SO, HI SI, XHI SCK

REC OUT

IC702

LINE/SPEAKER

AMP

(SEE PAGE 4-45)

EVER +3.5V

IC605

REG

(SEE PAGE 4-49)

HI UNREG

SP+, SP–

(SEE PAGE 4-23)

A OUT L

AUDIO

VIDEO

1623

IC301

MC CAM

SH DSP

MC XCS4

MC XCSO

TXD232C/RXD232C

IC308

EEP ROM

(SEE PAGE 4-25)

R-Y

B-Y

IC601

RESET

(SEE PAGE 4-49)

BACK UP VCC

IC606

RESET

(SEE PAGE 4-49)

SYS DD ON

CAM DD ON

LCD DD ON

M CXCS

(SEE PAGE 4-39)

Y

(SEE PAGE 4-40)

(SEE PAGE 4-41)

HALL AD

BATT SIG

16 16 16

12 12 20 3

MC XCS USB

USB D+

USB D–

IC453

SDRAM

16Mbit

(SEE PAGE 4-28)

IC307

FLASH

ROM

8Mbit

(SEE PAGE 4-25)

IC201

USB IF

(SEE PAGE 4-33)

IC302

IC303

IC304

LOGIC

(SEE PAGE 4-24)

MCX CS

MCX CSO

USB D+/USB –

IC607

EEP ROM

(SEE PAGE 4-50)

IC801

EVR

IC802

LCD DRIVE

BL UNREG

R

G

B

ND901

BACK

LIGHT

UNIT

LCD901

LCD

PANEL

BL ON

IC901

TIMING

GENERATOR

AUDIO

HI SI, HI SO, HI XSCK

XPWR SW

IC603

HI

CONTROL

(SEE PAGE 4-49)

XSHTR LOOK SW

XSHTR SW

MOVIE/STILL SW

XCAM/PW SW

KEY AD1

KEY AD2

KEY AD4

ZOOM SW AD

FOCUS A

FOCUS B

BL ON

IC602

(SEE PAGE 4-50)

TIMER

CLOCK

BL ON

VIDEO

BT601

+

LITHIUM

–

BATTERY

MC XCS MS

MCX CS4

IC306

RS232C DRIVE

(SEE PAGE 4-25)

AUDIO

16

IC451

MEMORY

STICK

IF

(SEE PAGE 4-28)

T1 OUT

R1 IN

XPWR SW

XSHTR LOOK SW

XSHTR SW

MOVIE/STILL SW

XCAM/PW SW

KEY AD1

KEY AD2

ZOOM SW AD

FOCUS A

FOCUS B

KEY AD4

SP901

SPEAKER

MC DIO

MC SCK

CONTROL

SWITCH

BLOCK

(CF)

MF

UNIT

CONTROL

SWITCH

BLOCK

(PW)

R1 OUT

T1 OUT

USB D+

USB D–

POWER

SWITCH

SHUTTER

SWITCH

MOVIE/STILL

PLAY SWITCH

CONTROL

SWITCH

(FK)

FUNCTION

KEY

ZOOM

SWITCH

VIDEO

AUDIO

FUNCTION

SWITCH

MANUAL

FOCUS

CN606

MEMORY

STICK

J001

DIGITAL

I/O

(RS232C)

CN002

DIGITAL

I/O

(USB)

A/V OUT

J001

3-1 3-2E

Page 32

Ver 1.1 1999.10

)

SECTION 4

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR WIRING BOARDS AND SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

DSC-F505

(For printed wiring boards)

• b: Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

• Through hole is omitted.

• Circled numbers refer to waveforms.

• There are few cases that the part printed on diagram

isn’t mounted in this model.

• Chip parts.

Transistor Diode

C

5

BE

64

2

13

5

46

2

31

45

2

31

12

4

53

3

21

3

21

3

21

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µµF.

50V or less are not indicated except for electrolytics and

tantalums.

• Chip resistors are 1/10W unless otherwise noted.

kΩ=1000Ω, MΩ=1000kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

Temperature characteristics

External dimensions (mm)

• Constants of resistors, capacitors, ICs and etc with XX indicate

that they are not used.

In such cases, the unused circuits may be indicated.

• Parts with ★ differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors have characteristic curve B,

unless otherwise noted.

• Signal name

XEDIT → EDIT PB/XREC → PB/REC

• 2 : non flammable resistor

• 1 : fusible resistor

• C : panel designation

• A : B+ Line *

• B : B– Line *

• J : IN/OUT direction of (+,–) B LINE. *

• C : adjustment for repair. *

• Circled numbers refer to waveforms. *

*Indicated by the color red.

Note :

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Note :

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

43

12

(Measuring conditions voltage and waveform)

• Voltages and waveforms are measured between the measurement points and ground when camera shoots color bar chart of

pattern box. They are reference values and reference waveforms.

(VOM of DC 10 MΩ input impedance is used.).

• Voltage values change depending upon input impedance of VOM

used.)

1. Connection

Pattern box

About 90 cm

Front of the lens

2. Adjust the distance so that the output waveform of Fig. a and

the Fig. b can be obtain.

H

Yellow

Cyan

White

Magenta

Green

AABBA=B

Fig. a (Video output terminal output waveform

Cyan

White

Green

Yellow

Magenta

Fig.b (Picture on monitor TV)

When indicating parts by reference number, pleas include

the board name.

Red

Blue

Red

Blue

Electron beam

scanned frame

CRT picture frame

4-1

Page 33

DSC-F505

Ver 1.1 1999.10

4-1. FRAME SCHEMATIC DIAGRAM (1)

1

A

MF UNIT

(CARD EDGE)

B

Q004

BRIGHT

LEVEL

SENSOR

C

LENS

UNIT

CCD

IMAGER

D

E

CD-236

F

BOARD

CONTROL SWITCH BLOCK(CF)

D_3.2V

6

FOUCUS_A

5

FOUCUS_B

4

REGGND

3

PHOTOTR_OUT

2

PHOTOTR_5V

1

CN001 6P

CN004

6P

27PCN401

1

ZOOM_A

2

ZOOM_B

3

ZOOM_A

4

ZOOM_B

Z_SENS_VCC

5

6 Z_SENS_RST

7 Z_SENS_GND

8 HALL(-)

9 BIAS(-)

10 HALL(+)

11 BIAS(+)

12 GND

13 GND

14 DRIVE(-)

15 DRIVE(+)

16 FOCUS_A

17 FOCUS_B

18

FOCUS_A

19

FOCUS_B

20

F_SENS_VCC

TH_OUT

21

22 F_SENS_GND

23 F_SENS_RST

24 ND_CONT(+)

25 ND_DRIVE(+)

26 ND_DRIVE(-)

27 ND_CONT(-)

G

GND

GND

39

CAM_15V

38

CAM_-7.5V

37

A_4.9V

36

A_4.9V

35

A_3.2V

H

I

RESET_CAM/PB

XCS_TG_BEAR

J

K

L

A_3.2V

GND

GND

GND

CAM_DD_ON

PAL/XNT

GND

VSUB_CNT

CAM_SO

XCAM_SCK

CLPOB

EAGLE_STBY

CA_FD

CA_HD

GND

MCK12

MCK24

CA_ADO9

CA_ADO8

CA_ADO7

CA_ADO6

CA_ADO5

CA_ADO4

CA_ADO3

CA_ADO2

CA_ADO1

CA_ADO0

GND

GND

AGC_CONT1

AGC_CONT2

39P CN101

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

FLEXIBLE

FP-135

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CAM_15V

CAM_-7.5V

A_4.9V

A_4.9V

A_3.2V

A_3.2V

GND

GND

GND

CAM_DD_ON

PAL/XNT

GND

RESET_CAM/PB

VSUB_CNT

CAM_SO

XCAM_SCK

CLPOB

XCS_TG_BEAR

EAGLE_STBY

CA_FD

CA_HD

GND

MCK12

MCK24

CA_ADO9

CA_ADO8

CA_ADO7

CA_ADO6

CA_ADO5

CA_ADO4

CA_ADO3

CA_ADO2

CA_ADO1

CA_ADO0

GND

GND

AGC_CONT1

AGC_CONT2

39PCN251

5

S001

MACRO

LD-98

BOARD

642

-MOUNT FLEXIBLE-

S002

SPOT

METER

WHT BAL

S003

PE_DAC_LEVEL

AGC_CONT2

LENS_RST_LED

AGC_CONT1

ZM_RST_SENS

FC_RST_SENS

CAM_SCK

CAM_SO

CAM_SI

MC_PB12

MC_PBO9

MC_PBO4

HALL_AD

LENS_TEMP_AD

SP_VOL

MSHUT_ON

30P CN402

A_3.2V

A_3.2V

ND_ON

SYS_V

CNT_Y

CNT_C

MCK12

S004

(W/B SET)

GND

GND

GND

GND

GND

M_5V

M_5V

PS-427

BOARD

1/2 PANEL BLOCK(1/2)

2/2 PANEL BLOCK(2/2)

PANEL_B-Y

Y_OUT

PANEL_R-Y

C_OUT

PANEL_Y

ANS_XIRL4

ANS_XIRL3

ANS_XIRL2

EAGLE_STBY

XCS_TG_BEAR

VSUB_CNT

RESET_CAM/PB

XMACRO_PE

PAL/XNT

MC_A01

MC_A02

MC_A03

MC_A04

MC_A05

MC_A06

MC_A07

CAM_DD_ON

CAM_-7.5V

CAM_15V

MC_XWE1

MC_XWE0

MC_XRD

MC_XCS1

MC_DREQ1

MC_DACK1

XRST_SYS

CAM_SO

XCAM_SCK

FC_RST_SENS

ZM_RST_SENS

LENS_RST_LED

AGC_CONT2

PE_DAC_LEVEL

AGC_CONT1

80P CN252

HDO

CA_FD

MC_A08

MC_A09

MC_A10

MC_A11

MC_A16

MC_A17

MC_A21

MC_A22

MC_A23

MC_D00

MC_D01

MC_D02

MC_D03

MC_D04

MC_D05

MC_D06

MC_D07

MC_D08

MC_D09

MC_D10

MC_D11

MC_D12

MC_D13

MC_D14

MC_D15

D_2.35V

A_3.2V

A_3.2V

A_4.9V

A_4.9V

MCK12

SYS_V

ND_ON

10

GND

D3.2V

D3.2V

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

Board TO

51

50

Board

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

GND

23

22

21

20

GND

19

18

17

16

15

14

13

12

11

10

9

8

7

6

GND

5

4

3

2

1

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

8

CN002 10P

S005

FOCUS

AUTO

MANUAL

30

29

28

27

26

25

24

23

22

21

20

19

18

Board TO

17

Board

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1 KEY_AD4

2 D_3.2V

3 REG_GND

4 PHOTOTR_5V

5 PHOTOTR_OUT

6 REG_GND

7 REG_GND

8 FOCUS_B

9 FOCUS_A

10 D3.2V

30

A_3.2V

29

A_3.2V

PE_DAC_LEVEL

28

AGC_CONT2

27

26

LENS_RST_LED

25

AGC_CONT1

24

ND_ON

23

ZM_RST_SENS

22

FC_RST_SENS

21

GND

GND

20

19

GND

SYS_V

18

CAM_SCK

17

16

CAM_SO

CAM_SI

15

14

MC_PB12

13

MC_PBO9

MC_PBO4

12

HALL_AD

11

10

LENS_TEMP_AD

9

CNT_Y

8

CNT_C

7

GND

SP_VOL

6

MCK12

5

4

MSHUT_ON

3

GND

2

M_5V

M_5V

1

10PCN453

30PCN452

PANEL_B-Y

Y_OUT

PANEL_R-Y

C_OUT

PANEL_Y

HDO

CA_FD

ANS_XIRL4

ANS_XIRL3

ANS_XIRL2

EAGLE_STBY

XCS_TG_BEAR

VSUB_CNT

RESET_CAM/PB

GND

XMACRO_PE

PAL/XNT

MC_A01

MC_A02

MC_A03

MC_A04

MC_A05

MC_A06

MC_A07

MC_A08

MC_A09

MC_A10

MC_A11

MC_A16

MC_A17

MC_A21

MC_A22

MC_A23

MC_D00

MC_D01

MC_D02

MC_D03

MC_D04

MC_D05

MC_D06

MC_D07

MC_D08

MC_D09

MC_D10

MC_D11

MC_D12

MC_D13

MC_D14

MC_D15

D_2.35V

D3.2V

D3.2V

A_3.2V

A_3.2V

A_4.9V

A_4.9V

CAM_DD_ON

GND

CAM_-7.5V

MCK12

CAM_15V

GND

MC_XWE1

MC_XWE0

MC_XRD

MC_XCS1

MC_DREQ1

MC_DACK1

XRST_SYS

SYS_V

CAM_SO

XCAM_SCK

FC_RST_SENS

ZM_RST_SENS

ND_ON

GND

LENS_RST_LED

AGC_CONT2

PE_DAC_LEVEL

AGC_CONT1

12

13 15

14711 163

2P

FLASH UNIT

(ST)

XSTB_OPEN

1

XSTB_OPEN

2

GND

FP-136

3

GND

FLEXIBLE

4

STB_ON

5

A_4.9V

6

A_4.9V

6P CN454

CN456

39P

SY-56

BOARD

1/6 SH BLOCK(1/2)

2/6 SH BLOCK(2/2)

3/6 MM BLOCK(1/2)

4/6 MM BLOCK(2/2)

5/6 CN BLOCK

6/6 USB BLOCK

80PCN451

LENS_TEMP_AD

33P CN455

REG_GND

REG_GND

CAM_15V

CAM_-7.5V

A_4.9V

A_4.9V

A_3.2V

A_3.2V

D_3.2V

D_3.2V

D.2.35V

D.2.35V

KEY_AD4

PAL/XNT

CAM_DD_ON

HALL_AD

FOCUS_A

FOCUS_B

REG_GND

REG_GND

SP_VOL

CNT_C

CNT_Y

REG_GND

AOUT_L

REG_GND

REC_OUT

REG_GND

PANEL_Y

PANEL_R-Y

PANEL_B-Y

REG_GND

C_OUT

REG_GND

Y_OUT

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

XSTB_OPEN

MC_HELP

ACCES_LED

MC_XFLRST

XRST_SYS

REG_GND

MC_VCC

MC_BS

MC_DIO

MC_SCLK

MC_INT

MC_MS_IN

SYS_V

XMC_CS

XHI_SCK

REG_GND

MCK12

REG_GND

X232C_DET

R1_OUT

T1_OUT

REG_GND

USB_+

REG_GND

HI_SO

USB_-

1

2

3

4

5

M_5V

6

M_5V

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

HDO

19

20

21

HI_SI

22

23

24

25

26

27

28

29

30

31

32

33

1

GND

2

GND

3

STB_ON

4

A_4.9V

5

A_4.9V

6

FLEXIBLE

FP-133

6P

179 18

1REG_GND

2DC_300V

MS-114 HARNESS

TO FRAME SCHEMATIC DIAGRAM(2/2)

09

FRAME SCHEMATIC DIAGRAM

4-3 4-4

Page 34

Ver 1.1 1999.10

FRAME SCHEMATIC DIAGRAM (2)

DSC-F505

19

FLASH UNIT(MC)

TO FRAME SCHEMATIC DIAGRAM (1/2)

09

20

4P

MS-114

HARNESS

FLEXIBLE

FP-133

2 REG_GND

1 DC_300V

2P

1ST_GND

2ST UNREG

3STB_CHARGE

4XSTB_FULL

MD-97

HARNESS

39

REG_GND

38

REG_GND

37

CAM_15V

36

CAM_-7.5V

35

M_5V

34

M_5V

A_4.9V

33

32

A_4.9V

31

A_3.2V

30

A_3.2V

29

D_3.2V

28

D_3.2V

27

D.2.35V

D.2.35V

26

25

KEY_AD4

24

PAL/XNT

23

CAM_DD_ON

22

LENS_TEMP_AD

HALL_AD

21

20

FOCUS_A

19

FOCUS_B

18

REG_GND

17

REG_GND

16

SP_VOL

15

CNT_C

14

CNT_Y

13

REG_GND

12

AOUT_L

11

REG_GND

10

REC_OUT

9

REG_GND

PANEL_Y

8

7

PANEL_R-Y

PANEL_B-Y

6

5

REG_GND

4

C_OUT

3

REG_GND

2

Y_OUT

1

REG_GND

33

REG_GND

32

REG_GND

31

REG_GND

30

REG_GND

29

REG_GND

28

XSTB_OPEN

27

MC_HELP

26

ACCES_LED

25

MC_XFLRST

24

XRST_SYS

23

REG_GND

22

MC_VCC

21

MC_BS

20

MC_DIO

19

MC_SCLK

18

MC_INT

17

MC_MS_IN

16

SYS_V

15

HDO

14

XMC_CS

13

XHI_SCK

12

HI_SI

11

HI_SO

10

REG_GND

9

MCK12

8

REG_GND

7

X232C_DET

6

R1_OUT

5

T1_OUT

4

REG_GND

3

USB_+

2

USB_-

1

REG_GND

21

22

23

24

25

27

28

29

3026

31

32

33

34

35

36

A

+

s

-

18P

REG_GND

PANEL_COM

HI_UNREG

LANC_IN

LANC_OUT

BT901

BATTERY

TERMINAL BOARD

SYS_V

HSY

VG

RF7

TXD

RXD

RESET

VDD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

CPC

(FOR CHECK)

11

13

15

17

19

21

23

25

27

29

J001

A/V OUT

(MONO)

21P CN604

REG_GND

1

CONTROL SWITCH BLOCK(PW)

REG_GND

2

D+

REG_GND

USB_DET

REG_GND

REG_GND

POWER_LED

SELF_LED

XPWER_SW

REG_GND

XSHTR_LOCK_SW

XSHTR_SW

MOVIE/XSTILL_SW

XCAM/PB_SW

2P

3

-MOUNT FLEXIBLE-

D-

4

5

6

7

R1_IN

8

T1_OUT

9

10

11

12

D_3.2V

13

14

15

16

17

18

19

N.C

20

N.C

21

CN001 21P

CN701

1MIC SIG

2MIC GND

MOVIE

STILL

MIC

S003

POWER

ON/OFF

D007

(POWER LED)

(GREEN)

S002

(SHUTTER)

PLAY

S001

(MODE)

MIC901

D004

(REC LED)

(RED)

CN002

4P

1vcc

2D-

3D+

4GND

J001

DIGITAL

I/O

(SERIAL)

DIGITAL

I/O

(USB)

B

C

D

BACK-LIGHT

CN605

5P

1BL UNREG

2BL GND

HB-50

3BL ON

4BL PWM

HARNESS

5BL LED ON

24 CLD

23 SPD

22 CTR

30PCN901

EX3

1

CTR

3

SPD

5

CLD

7

N.C

9

N.C

N.C

N.C

N.C

N.C

N.C

VGH

VSH

VCC

CLS

EX2

2

VB12

4

RES

6

VR

8

VG

10

VB

12

GND

14

VSH

16

COM

18

VGL

20

VSS

22

MO2

24

MO1

26

EX1

28

SPS

30

21 EX3

20 EX2

19 VB12

18 RES

17

16

15

14

13 GND

12 YSH

COM

11

10

9

FLEXIBLE

FP-134

8 MO2

7 MO1

6

5 SPS

4 CLS

3 VCC

2 VSH

1 VGH

VR

VG

VB

VGL

VSS

EX1

TST (N.C)

24P

UNIT

1 BL UNREG

2 BL GND

3 BL ON

4 BL PWM

5 BL LED ON

5P

LCD901

COLOR

LCD UNIT

ND901

BACK-LIGHT

E

F

G

H

I

J

K

L

M

CN001

GND

GND

2

1

2

1

GND

GND

3P

1BATT UNREG

2BATT SIG

3BATT GND

HI-70

CN002

1 ST_GND

2 ST UNREG

3 STB_CHARGE

4 XSTB_FULL

4P

DD-131

BOARD

CN003 40P

GND

40

40

GND

40P CN601

GND

GND

GND

GND

39

37

38

A_3.2V

GND

GND

GND

36

33

32

35

34

FP-132

33

37

38

39

GND

GND

GND

32

35

34

36

GND

GND

GND

GND

A_3.2V

A_3.2V

31

31

A_3.2V

D_3.2V

30

30

D_3.2V

D_3.2V

29

29

D_3.2V

28

28

D_3.2V

D_3.2V

D_3.2V

27

27

D_3.2V

D_2.35V

26

26

D_2.35V

D_2.35V

CAM+15V

24

FLEXIBLE

25

24

D_2.35V

CAM+15V

CAM-7.5V

23

23

CAM-7.5V

M+5V

22

22

M+5V

PANEL_-15V

M+5V

21

21

M+5V

PANEL_-15V

20

20

GND

CAM_DD_ON

182516

19

18

19

GND

CAM_DD_ON

PANEL+4.9V

LCD_DD_ON

A+4.9V

15

15

A+4.9V

PANEL+6.5V

14

14

PANEL+6.5V

13

12

13

12

PANEL+4.9V

LCD_DD_ON

SYS_DD_ON

PANEL+13.5V

11

10

10

11

SYS_DD_ON

PANEL+13.5V

STB_CHARGE

9

9

STB_CHARGE

GND

A+4.9V

17

17

16

GND

A+4.9V

EVER_3.5V

8

8

EVER_3.5V

HI_UNREG

XSTB_FULL

6

7

7

6

HI_UNREG

XSTB_FULL

55

BAT_SIG

BAT_SIG

BL_UNREG

4

4

BL_UNREG

BL_UNREG

3

3

BL_UNREG

BOARD

1/6 RGB BLOCK

2/6 TG BLOCK

3/6 VI BLOCK

4/6 AU BLOCK

5/6 HI BLOCK(1/2)

6/6 HI BLOCK(2/2)

1Vss

2P

REG_GND

PANEL_COM

KEY_AD3

HI_UNREG

LANC_IN

LANC_OUT

AV_JACK_IN

SYS_V

RESET

CN702

2BS

3NC

10

4DIO

5NC

6INT

7NC

1

8SCLK

9Vcc

10Vss

1SP_OUT-

2SP_OUT+

30PCN607

CN001

2

30P

4

6

HSY

8

10

VG

12

14

16

18

20

RF7

TXD

22

RXD

24

26

VDD

28

30

MEMORY STICK

SP901

SPEAKER

CONTROL SWITCH BLOCK(FK)

-MOUNT FLEXIBLE-

ON

OFF

S006

LCD

BACK LIGHT

ON OFF

S005

LCD

BRIGHT(+)

S007

LCD

BRIGHT(-)

W

T

RV001

(ZOOM)

S002

(FLASH)

D006

(FLASH LAMP)

S003

PROGRAM AE

S001

MENU

(CONTROL BUTTON)

S004

DISPLAY

CN002

BT601

+

LITHIUM

BATTERY

10PCN606

D607

(ACSSES)

39PCN602

1

REG_GND

ZOOM_SW_AD

3

D_3.2V

5

7

STB_LED

REG_GND

9

AU_OUT

11

13

REG_GND

15

REG_GND

REG_GND

17

REG_GND

19

21

V_OUT

REG_GND

23

REG_GND

25

KEY_AD1

27

KEY_AD2

29

33PCN603

4-5 4-6

FRAME SCHEMATIC DIAGRAM

Page 35

DSC-F505

Ver 1.1 1999.10

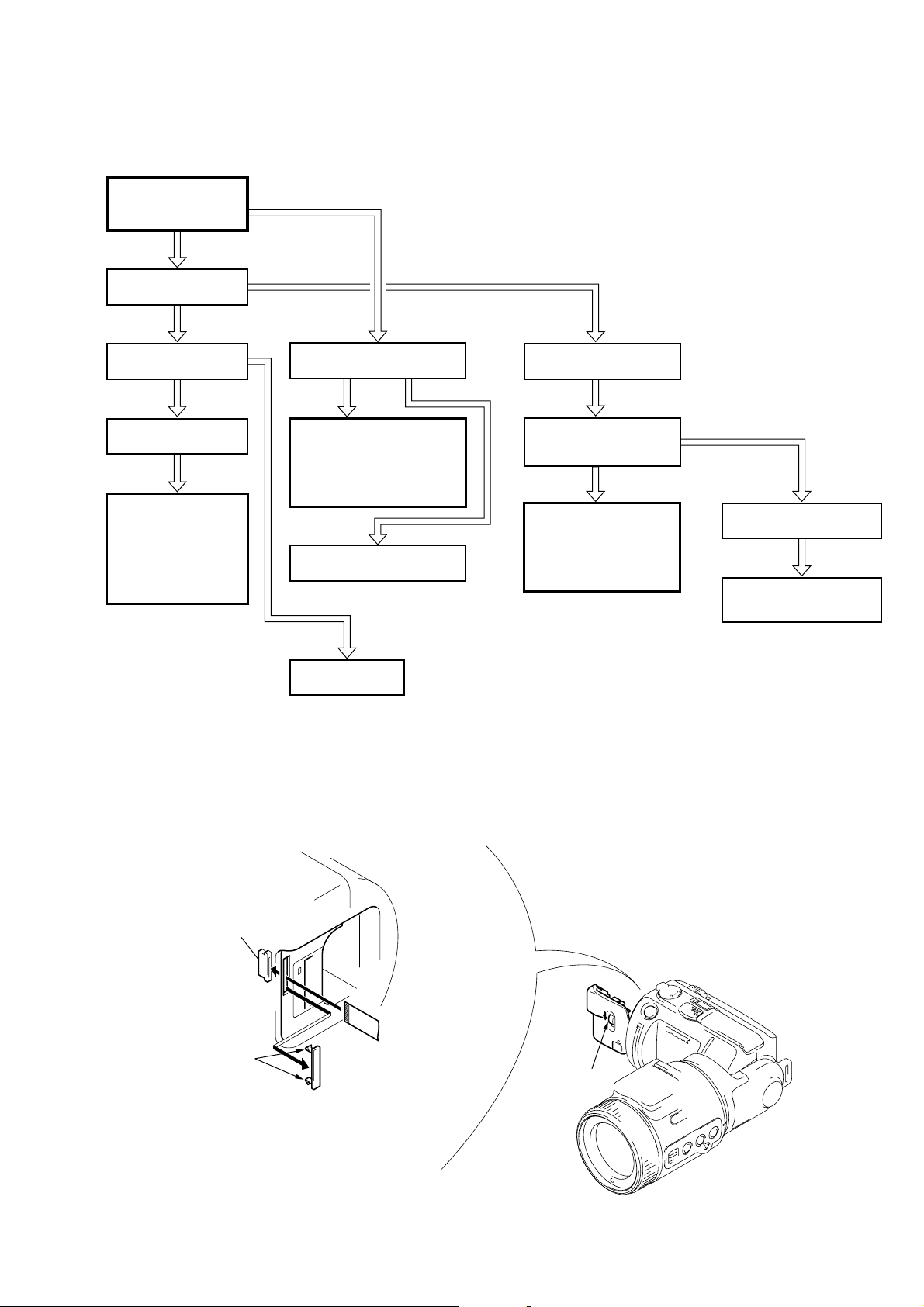

4-2. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAM

CD-236 BOARD (SIDE A) CD-236 BOARD (SIDE B)

C

E

D

B

A

C131

R118

14

R120

R119

FB106

C103

1

12

C134

C108

R117

R116

R123

R115

R122

R114

R121

1

39

R124

CL101

09

12345 76891110

2

38

CN101

FB108

C130

48

IC103

15

10

1113

13 24

C129

C109

FB107

R103 R102

Q102

C106

12

L101

C132

C135

C127

37

C126

C125

C121

C119

C110

R112

C139

C105

C137

C136

C107

C128

C118

C115

C123

R113

R109

37

Q101

Q103

C101

R101

C102

FB105

36

R111

C117

FB103

X102

C122

C113

25

987 6

IC102

48

112

C140

IC104

FB109

C104

R104

FB110

R105

FB111

R106

FB104

24

13

FB101

X101

5

10 1

R110

R108

C114

11 20

C112

C111

36

C120

C116

25

C124

C138

L102

C133

IC101

2

L103

3

4

1

1-675-583-

12

CCD IMAGER, CAMERA

CD-236

For printed wiring boards

• This board is six-layer print board. However, the patterns of layers two to five have not been included in

the diagram.

• Chip parts

Transistor

C

BE

There are few cases that the part printed on this

diagram isn’t mounted in this model.

4-7 4-8

Page 36

Ver 1.1 1999.10

DSC-F505

1

CD-236 BOARD

A

CCD IMAGER,CAMERA

-REF.NO.:3000 SERIESXX MARK : NO MOUNT

Note:Resistor are mounted

to the location where

B

FB109,FB110,FB111 are

printed.

C

D

C101

XX

E

F

G

H

I

J

K

09

10

L102

10uH

R113

C138

22u

16V

B

TA

48

P0

S-7.2

47

P0

S-7.2

46

P0

S-7.2

45

P0

S-7.2

44

P0/S-0.3

43

P0

S14.9

42

P0/S-0.3

41

P0/S-7.2

40

P0/S-0.3

39

38

37

100k

C135

10u

20V

TA

C136

0.1u

C137

0.1u

B

VSHT

V3B

F

V3A

V1B

F

V1A

V4

V2

C139

XX

B

1279

FB107

0uH

FB108

0uH

R124

0

1608

C140

XX

B

1

3

VSS2VIN

VOUT

V2153

IC104

XX

1411

TG_DSGAT

TG_RST

VSUB_CNT

B

VSUB_CNT

VSHT

(Note)

FB110

FB111

(Note)

5

R106

C111

10u

6.3V

C112

1u

B

1608

C114

0.1u

B

FB101

0uH

1608

0

0

R108

C113

0.1u

B

FB103

0uH

C117

0.1u

B

(NTSC)

0 (PAL)

FB104

3.1

13

14

15

16

17

18

19

20

21

22

23

24

P0/S2.7

P0/S1.9

H2

4.8

VDD3

3.2

VDD4

P0/S2.5

XSHP

P0/S2.3

XSHD

XRS

P0/S2.7

PBLK

P0.1/S3.1

CLPDM

VSS4

P0/S3.1

CLPOB

P0/S1.8

ADCLK

VSS5

R110

0uH

22

24.375MHz(PAL)

R109

47k

Q103

UN9213J-(K8).SO

PAL/NTSC

SWITCH

1.8

24.54MHz(NT)

0 (NTSC)/3 (PAL)

R104

22

R105

22

XSHP

0

0

V4

V3A

V3B

XSHD

V2

V1A

V1B

84

C123

0.1u

B

P0/S0.9

8RG9

10

11H112

VSS2

VSS3

TIMING GENRATOR

CXD2470R-T4

3.2

3.2

6

7

VDD1

VDD2

IC102

IC102

5

WEN

EBCKSM

C128

0.1u

B

TG_RST

TG_DSGAT

3.1

3.1

1

2

3ID4

RST

VSS1

DSGAT

TEST2

SUB

V3B

V3A

V1B

V1A

678

TEST1

9

1.6

CKO25CKI26OSCO27OSCI28VDD529MCKO30SSI31SCK32SEN33VDI34HDI35VSS6

1.7

3.2

B

0.01u

C122

X101

R111

X102

47

FB105

0uH

36

0

3.1

3.1

3.2

3.1

C132

47u

6.3V

B

TA

VL

VH

V4

V2

VM

26 13 15

FB109

(Note)

0

C106

C104

0.1u

0.1u

1608

B

1608B

C103

0.1u

1005

1

5

P0

R101

S11.4

3300

C102

10p

CH

P0

S10.5

P0/S11.4

P0/S14.8

2SC4178-F13F14-T1

BUFFER

F

Q101

11

12RG13H214H115

VDD

P0/S14.8

VOUT

10

GND

2

P0/S12.6

C105

0.1u

R102

1M

P0/S2.0

GND

7

8NC9

1608B

3

NO MARK : STILL/PB mode

S : STILL mode

P : PB mode

Q102

UN9213J-(K8).SO

SWITCH

0.1

P0/S9.0

C107

R103

0.01u

4700

2012B

P0/S2.0

17

18VL19H120

CSUB

P0/S8.2

4V25

P0/S8.4

P0/S-7.4

V3A3V3B

2

P0/S-7.1

P0/S-0.2

P0/S-0.2

H2

P0/S2.7

V4

1

GND16SUB

P0/S2.7

V1A6V1B

P0/S-0.2

4

1

3

P0/S-7.1

C108

22u

16V

B

TA

IC101

CCD IMAGER

IC101

ICX224AQ-13

P0/S-7.1

C109

10u

20V

TA

100uH

L101

1112

R112

XX

P0/S2.7

18

STBY

0

17

16

3.2

ADCLK

DVDD1

P0/S1.8

15

C129

0.1u

B

14

DVSS3

XSHD

XSHD

P0/S2.3

XSHP

21

XSHP

P0/S3.1

20

P0/S2.5

19

PBLK

CLPOB

IC103

S/H,AGC,A/D CONVERTER

IC103

CCD1000Y-2/2K

3.2

3.2

3.2

3.2

AVDD239AVDD340MODE1

41

42

MODE2

43

AVDD4

44

AVDD5

3.2

1.2

AVSS4

AVSS5

45

46

47

C127

0.1u

B

13

DRVDD

DRVSS

(MSB)D9

14

(LSB)D0

REFN

48

C130

0.1u

B

DRVSS

DVSS1

1.8

REFP

C131

0.1u

B

C134

1u

B

R114

1608

R118

10uH

FB106

0uH

47R119

47

47

R120

47R115

R121

47

47R116

R122

47

47R117

R123

47

47

Precautions Upon Replacing CCD imager

• The CD-236 board mounted as a repair part is not equipped

L103

with a CCD imager.

When replaching this board, remove the CCD imager from the

old one and mount it onto the new one.

• If the CCD imager has been replaced, carry out all the

adjustments for the camera section.

• As the CCD imager may be damaged by static electricity from

its structure, handle it carefully like for the MOS IC.

In addition, ensure that the receiver is not covered with dusts

nor exposed to strong light.

13

3.2

12

0

11

P3.2/S0.5

D8

10

P3.2/s1.1

9

D7

P3.2/S1.5

8

D6

P0/S1.4

7

D5

P0/S1.8

6

D4

P0/S1.3

5

D3

P3.2/S1.3

4

D2

P3.2/S1.7

3

D1

P3.2/S0

2

1

C133

47u

6.3V

B

TA

•

SIGNAL PATH

CHROMA Y/CHROMAY

REC

PB

VIDEO SIGNAL AUDIO

SIGNAL

C110

0.1u

B1608

C115

0.1u

B

1608

C116

0.1u

C118

0.1u

B

P0/S3.1

C124

1u

10

B

2012

C119

0.1u

B

P0/S0.9

P0/S1.2

B

C120

0.1u

B

C121

0.1u

B

P3.1/S1.0

P0.6/S1.6

1.0

22

23

24

FMC

AVSS1

25

CLPDM

CCD_D

26

15

CCD_R

27

AVSS2

28

AGCCNT1

29

AGCCNT2

30

AVSS3

31

1.8

LCM(1.8V)

32

3.2

AVDD1

33

3.2

COMPVIDEO

34

3.2

CGAINCNT

35

0

CHROMA

36

1.4

2.3

CM(1.5V)

2.4V

37

38

C125

0.1u

B

C126

0.1u

B

CL101

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

GND

CAM_15V

CAM_-7.5V

A_4.9V

A_4.9V

A_3.2V

A_3.2V

GND

GND

GND

CAM_DD_ON

PAL/XNT

GND

RESET_CAM/PB

VSUB_CNT

CAM_SO

XCAM_SCK

CLPOB

XCS_TG_BEAR

EAGLE_STBY

CA_FD

CA_HD

GND

MCK12

MCK24

CA_ADO9

CA_ADO8

CA_ADO7

CA_ADO6

CA_ADO5

CA_ADO4

CA_ADO3

CA_ADO2

CA_ADO1

CA_ADO0

GND

GND

AGC_CONT1

AGC_CONT2

39PCN101

16

TO

PS-427 BOARD

CN251

THROUGH THE

FP135

FLEXIBLE

(SEE PAGE

4-15)

4-9 4-10

CCD IMAGER, CAMERA

CD-236

Page 37

DSC-F505

Ver 1.1 1999.10

LD-98 BOARD (SIDE A)

L401

C411

1426

F

E

L403

30 2

CN402

29 1

D

LD-98 BOARD (SIDE B)

C426

C406

R436

R413

R416

R412

R414

1

4

IC404

C410

8

5

C

R410

C408

C407

B

A

Q401

R415

C409

D401

L404

R406

C424

C423

C412

1

Q405

L402

C420

1

IC406

R432

IC407

11

C425

R438

Q406

C404

2

R437

1

R417

C401

R433

20

1110

R426

C419

R427

D402

R431 R423

CN401

IC402

131

R402

C403

C402

Q403

R434

R435

IC403

C417

C413

C418

C421

110

814

20

R418

C416

R428

R430

R421

IC405

C415 C414

R429

R422

26

27

R425

R424

R419

R420

17

C405

R408

R439

R404

R405

R403

1426

Q402

131

Q404

C422

R409

R411

R407

85

IC401

4

1

09

12345

For printed wiring boards

• This board is six-layer print board. However, the patterns of layers two to five have not been included in

the diagram.

• Chip parts

Transistor

C

BE

64

13

Diode

5

2

3

21

There are few cases that the part printed on this

diagram isn’t mounted in this model.

1-675-586-

12

LENS DRIVE

LD-98

4-11

4-12

Page 38

Ver 1.1 1999.10

DSC-F505

1

LD-98 BOARD

A

LENS DRIVE

-REF.NO.:4000 SERIESXX MARK : NO MOUNT

B

C

D

E

F

G

LENS

UNIT

H

I

J

24

NO MARK : STILL/PB mode

S : STILL mode

P : PB mode

Q406

2SD2216J-QR(K8).SO

ND FILTER DRIVE

4.4

0.70

R438

10

TH_OUT

F_SENS_VCC

FOCUS_B

FOCUS_A

Z_SENS_VCC

ZOOM_B

ZOOM_A

ZOOM_B

ZOOM_A

27P CN401

C404

0.022u

B

27ND_CONT(-)

26ND_DRIVE(-)

25ND_DRIVE(+)

24ND_CONT(+)

23F_SENS_RST

22F_SENS_GND

21

20

19

18

17FOCUS_B

16FOCUS_A

15DRIVE(+)

14DRIVE(-)

13GND

12GND

11BIAS(+)

10HALL(+)

9BIAS(-)

8HALL(-)

7Z_SENS_GND

6Z_SENS_RST

5

4

3

2

1

3 16117 14

C402

1608

B

R403

1u

10k

R402

100k

0.1uBC403

C401

0.01u

IC401

B

4.8

8

NJM2904V(TE2)

IC401

1

0.8

1608

0.8

0.8

0.8

5

6

7

VCC

OUT

IN(-)

IN(+)

OUT

IN(+)

IN(-)

GND

2

3

4

0.8

0.8

S1.1/P4.9

R437

2200

R439

3300

ND FILTER DRIVE

D402

MA111-(K8).S0

5

R404

18k

C405

0.1u

B

1608

2SD2216J-QR(K8).SO

S0.7/P0

R406

10

1608

D401

MA3ZD1200LS0

V2819

25

26

0.3

DGND

UPD16833AGS-9JH

VDD2VM13A1<FA>4PGND15A2<FB>6A3<ZA>7PGND38A4<ZB>9VM410IN111EN112IN213EN2

IC402

1

3.1

4.9

R411

R409

120k

39k

±0.5%

±0.5%

R407

47k

±0.5%

R408

10k

±0.5%

S1.8/P0

Q401

IRIS DRIVE

R410

S1.8/P0

1k

C406

0.022u

B

FOCUS/ZOOM MOTOR DRIVE

21

22

23

24

0

0.3

VM2,3

PGND2

B2<FB>

B1<FA>

B3<ZA>

0.1

0.1

0.1

6

4700

ND FILTER SWITCH

4.8

0

C408

1u

19

20

000

PGND4