Page 1

Digital A udio Mixer

Automation Operation

DMX-R100

1999 – 2002 Sony Corporation

Page 2

Table of Contents

Automation Operation

System Set-up ...................................................................4

Titles...................................................................................5

To Name a Title ............................................................... 5

To Keep a Title................................................................. 6

To Save a New Title......................................................... 6

To Save a Title ................................................................. 6

Cues ...................................................................................7

To Enter a New Cue at the Current Timecode Point ....... 8

To Revise the Time of a Cue ‘On the Fly’....................... 8

To Revise the Time of a Cue Manually ........................... 8

To Locate to a Cue ........................................................... 8

Cycle All .......................................................................... 8

Cycle Between Two Cues ................................................ 8

Overview of Automation Controls ...................................9

GUI Options for Automation ..........................................12

Automating Faders .........................................................14

To Clear Automation Data ............................................. 14

To Automate Moves on One or More Faders ................ 15

Operation of A and B Buffers ........................................ 16

Automation Drop-out Modes ......................................... 16

To Save a Mix ................................................................ 16

To Trim Moves on One or More Faders ........................ 17

Automating Fader Cut Switches....................................18

To Automate One or More Cut Switches....................... 18

To Automate Cuts Simultaneously ................................ 19

Trimming Cut Switches ................................................. 20

Automating Other Switches ...........................................20

Automating Knobs ..........................................................21

To Automate a Pan Knob ............................................... 21

To Automate a Number of Knobs .................................. 22

Trimming Knob Moves.................................................. 22

Automating Sections of Controls ..................................24

To Automate a Complete EQ Section ............................ 24

Trimming Sections of Knob Moves ............................... 25

To Automate All EQ Sections........................................ 26

(Continued)

Table of Contents 2

Page 3

Table of Contents

Footswitch, Audition & Auto..........................................27

Automation Drop-in Using FOOT SW .......................... 28

Automation Drop-in Using AUDITION ........................ 28

Automation Record Using AUTO ................................. 29

Automation Isolate..........................................................30

Isolating Channels or Sections of All Channels............. 30

Snapshots........................................................................31

To Save a New Snapshot................................................ 31

To Revise a Snapshot ..................................................... 32

To Delete a Snapshot ..................................................... 32

To Recall a Complete Snapshot ..................................... 32

To Recall a Partial Snapshot .......................................... 32

Automating Snapshot & Library Entry Recall ..............33

Automating the Recall of a Snapshot............................. 33

Automating the Recall of a Library Entry...................... 33

Fader Gang Grouping Offsets........................................34

Setting Up a Fader Gang Group..................................... 34

Table of Contents 3

Page 4

Automation Operation

Automation Operation

System Set-up

The descriptions and operational procedures that

follow assume that:

•A multitrack machine, either tape or hard drive, is

connected to the DMX-R100.

•The multitrack has suitable material recorded on it,

and its audio outputs are assigned to input channels

on the mixer.

•The multitrack transport is under the control of the

mixer transport keys.

•A timecode link, either SMPTE or MIDI, exists

between the multitrack and the mixer for location and

synchronisation purposes.

Automation Operation

4

Page 5

Titles

The Title for any project is the heading under which all

related data, such as mixes, snapshots and cue points, is

held. So, although not vital, it is a good idea to have a

Title name for any project right from the start.

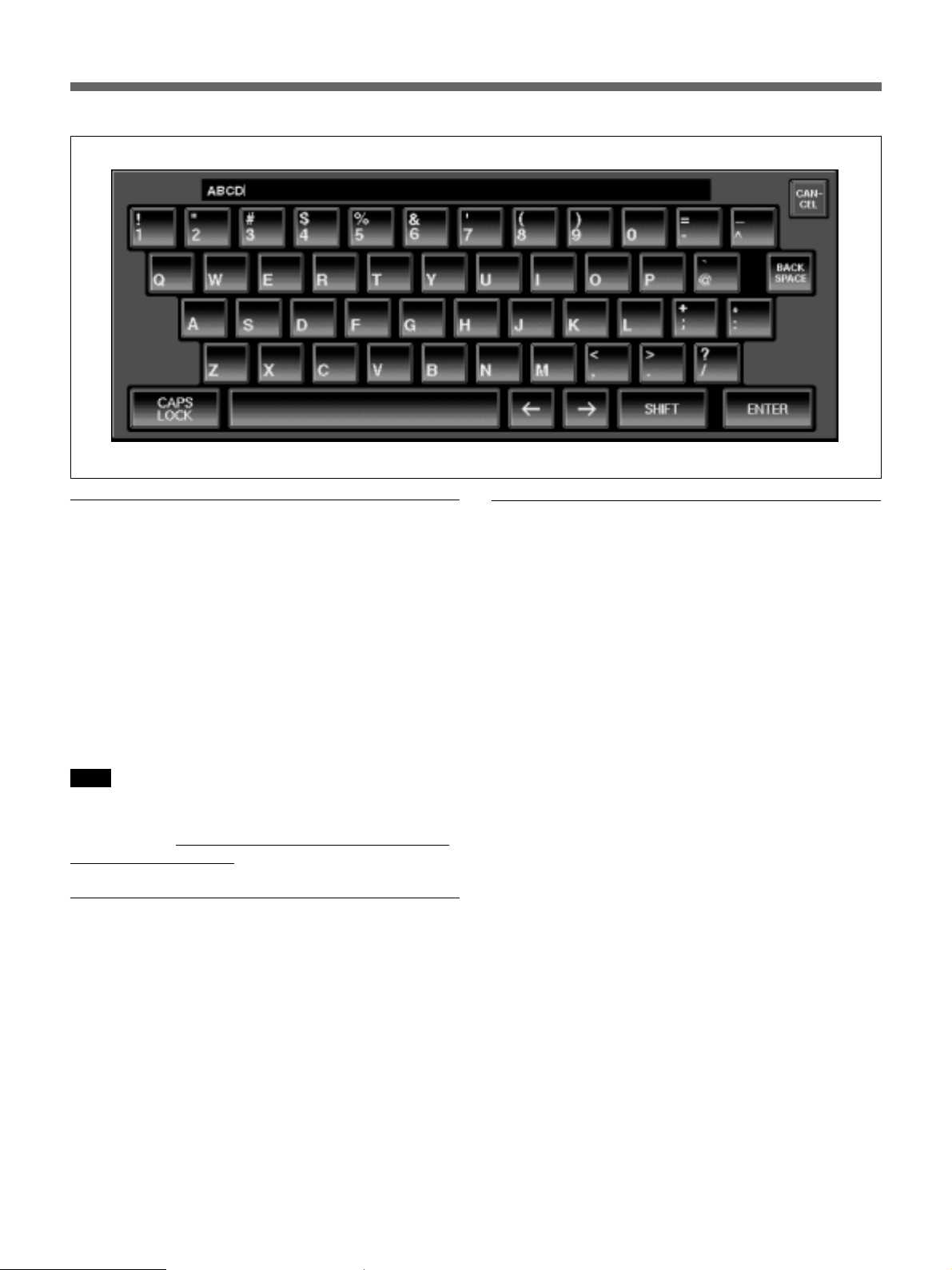

To Name a Title

1 Touch {SYSTEM} for its pop-up and then touch

{TITLEMANAGER} to access the TITLE

MANAGER GUI.

2 Touch the NAME line in the INFORMATION

block in the centre of the GUI, and the QWERTY

Keyboard pop-up appears.

3 ‘UNTITLED’ will be displayed by default in the

upper entry dialogue line for a new system. Either

touch {BACKSPACE} several times to delete it, or

touch and move a finger across it to highlight it.

Then type in a Title name using the touch

QWERTY keyboard. Touch {ENTER} when

finished.

From now on, any changes in settings will relate to

the Current Title which has just been named. The

data for this Title resides in the system Dynamic

RAM.

Note

Data left in RAM will be lost if the system is powered down.

Use KEEP or SAVE to retain it.

Automation Operation

5

Page 6

Automation Operation

To Keep a Title

1 Touch {TITLE} at the very top left of the GUI for its

pop-down.

2 Touch {KEEP} in order to save the current settings

and data into the Flash Memory, where they will

be safely stored.

If the system is turned off and turned on again, the

settings stored using KEEP will be restored.

Note

That having used KEEP for the current Title, recalling a

further Title will overwrite the previously ‘kept’ Title in the

Flash Memory. SAVE or SAVE AS NEW must be used to

permanenty store a Title.

To Save a New Title

1 Touch {SAVEASNEW} and the Current Title will

be saved in the first available slot in the column to

the left of the GUI. The slot number will be

highlighted white and the Title name will appear in

the NAME column.

To Save a Title

1 Touch {SAVE} to overwrite the data in the Title that

has its number highlighted white. A pop-up will

appear, requiring confirmation. Touch {YES} to

complete the save.

2 To save in a different slot, touch its number to

highlight it, and then touch {SAVE}. A pop-up will

appear, requiring confirmation. Touch {YES} to

complete the save.

Automation Operation

6

Page 7

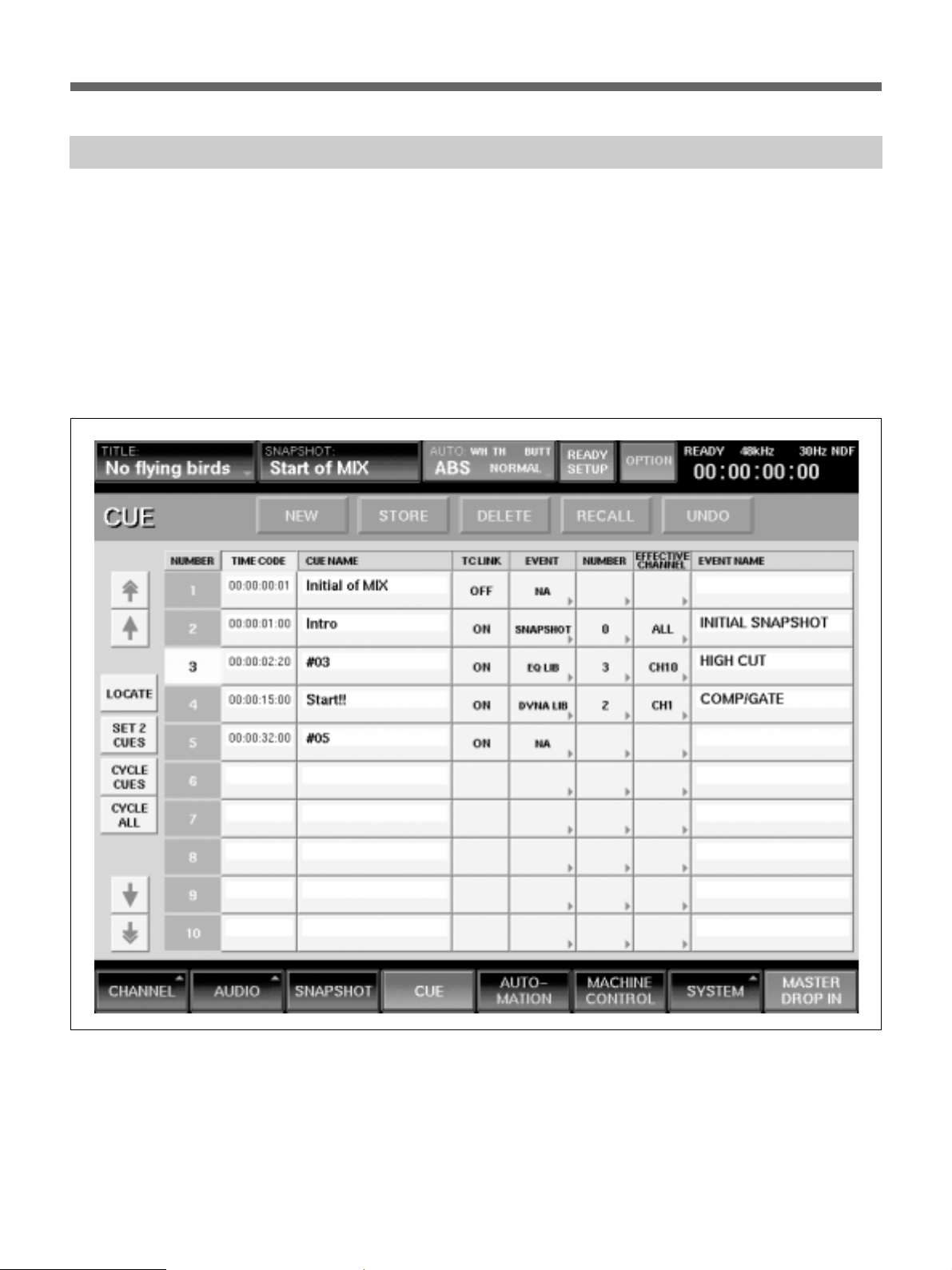

Cues

The Cues GUI allows Cue Points, in the form of

timecode markers, to be set along with a name entry.

It is often extremely useful to set Cues for the crucial

points in any piece of material to be worked on. These

include the start and end, verses and choruses for

music, and scene changes in post production projects.

Once set, Cues can be used for a number of purposes,

including locate and cycling between specified Cues.

General

Cue timecode points can be set in a number of ways:

•From the current time point whilst the material is

rolling (‘on the fly’).

•From the current time point whilst the material is

stationary.

• Manual entry using the jog wheel.

• Manual entry using the ten-number key pad.

Cues can be linked to fire events at their timecode

points. Events include Snapshots, EQ and Dynamics

library settings.

Automation Operation

7

Page 8

Automation Operation

To Enter a New Cue at the Current Timecode

Point

To enter a Cue for the start of the material, for

example:

1 Whilst the material is either stationary or moving,

touch {NEW} in the CUE GUI, and a new entry will

appear in the TIMECODE column. A default

number will be entered automatically in the CUE

NAME column.

2 To change the default number to an appropriate

name, touch the default in the CUE NAME

column, and the QWERTY Keyboard pop-up

appears.

3 The default will be displayed in the upper entry

dialogue line. Either touch {BACKSPACE} several

times to delete it, or touch and move a finger

across it to highlight it. Then type in a suitable

name, such as ‘START OF TITLE’ in this case,

using the touch QWERTY keyboard. Touch

{ENTER} when finished.

To Locate to a Cue

1 Under the NUMBER column, touch the Cue

number that is to be the locate point, to highlight it

white.

2 Touch {LOCATE} in the CUE GUI and the system

will locate to the timecode point for the highlighted

Cue.

3 To locate to the same Cue, either touch {LOCATE}

or press the LOCATE button above the transport

keys on the panel.

Note

The front panel LOCATE button will always cause a locate

operation to the point set by touching {LOCATE} in the GUI,

even if another Cue number is touched and highlighted

white in the GUI. However, touching {LOCATE} in the GUI

will always locate to the Cue which is highlighted. In other

words, touching {LOCATE} in the GUI sets the Cue to which

the front panel LOCATE button will operate.

Cycle All

To Revise the Time of a Cue ‘On the Fly’

1 Under the NUMBER column, touch the Cue

number to be revised. It highlights white.

2 Whilst the material is either stationary or moving,

touch {STORE} in the CUE GUI, and the current

timecode point will appear in the TIMECODE

column.

To Revise the Time of a Cue Manually

1 Under the TIMECODE column, touch the

timecode number to be revised. It highlights

white.

2 Then adjust the timecode number using the jog

wheel or the ten-number key pad. Press {ENTER}

at the bottom right of the number key pad when

finished.

To play the source material from beginning to end and

have it repeat until the stop transport key p is pressed:

1 Touch {CYCLEALL} in the CUE GUI and it turns

green. The LOCATE button above the transport

keys on the panel also lights green.

2 Press the LOCATE button and the system will play

from the first Cue to the last Cue and repeat until

the p transport key is pressed.

3 After pressing p, press {LOCATE} again to

continue Cycle All.

4 De-select {CYCLEALL} when finished.

Note

When {LOCATE} in GUI is pressed for the first time or Cycle

All is continued, the system will always play from CUE 1.

Press the z transport key to continue from the current point.

Cycle Between Two Cues

To play the source material from one Cue to another

and have it repeat until the stop transport key p is

pressed:

Automation Operation

8

Page 9

1 Touch {SET2CUES} in the CUE GUI and it turns

green.

2 Under the NUMBER column, touch the first Cue

number and it highlights white.

3 Touch the Cue number for a second Cue, later than

the first. {SET2CUES} will return to grey,

indicating that the two Cues have been accepted.

4 Touch {CYCLECUES} in the CUE GUI and it turns

green. The LOCATE button above the transport

keys on the panel also lights green.

Overview of Automation of Controls

5 Press the front panel LOCATE button and the

system will play between Cues set up in step 3, and

repeat until the p transport key is pressed.

6 After pressing p, press LOCATE again to

continue Cycle Cues.

7 De-select {CYCLECUES} when finished.

Note

When LOCATE is pressed for the first time or to continue

Cycle Cues, the system will always play from the beginning.

Press the z transport key to continue from the current point.

General

The DMX-R100 allows virtually all controls and

switches to be automated. That is to say, movements

of faders, knobs and switch operations can be recorded

and replayed with reference to timecode. Snapshots of

the controls can also be restored with reference to

timecode.

Controls first have to be set or armed into an

automation ‘ready’ mode, much like arming the tracks

of a recorder in readiness for recording audio material.

Once armed, they can be ‘dropped in’ to record

automation data, control by control individually, on a

channel basis, or all ‘ready’ controls simultaneously.

This process will be described in more detail later in

this supplement.

Automatable Controls

Dynamic automation is possible on the following

controls and groups of controls that can be automated:

•Channel Faders, Cuts & Pans

• M/T Faders, Cuts & Pans

• Aux Send Levels & Cuts

• Routing Assignment Buttons

•Equaliser Knobs & Switches

• Dynamics Knobs & Switches

• Master Faders

Static settings and I/O assignments will be stored when

a Title is saved, independent of automation operations.

Saved static settings do not include the CR MONITOR

level knob and SELECT MACHINE buttons.

Automation set-up

The following section describes how to turn the

automation functions on, and the options included.

The actual operation varies according to control type

and therefore the detail will be described in separate

sections later.

Automation data is recorded in two basic modes: ABS

(absolute) where the exact settings are recorded for the

first time or overwrite previous data, and TRIM, which

allows previous data to be trimmed and modified.

The way controls are dropped into automation record

varies according to control type. The following brief

summary assumes controls are already set to

automation ready:

•FADERS

Individual faders drop into automation record when

they are touched and drop out when released. (This

applies so long as ‘Touch Hold’ and ‘Write Hold’ are

not enabled.)

•SWITCHES

An individual switch drops into automation record

when it is pressed and remains so until automation

timecode ceases.

•KNOBS

An individual rotary knob drops into automation

record when its numeric indicator in the CHANNEL

Automation Operation

9

Page 10

Automation Operation

4165

TC AUTOMA TION SNAPSHOT

2

3

A B SAFE

ABS

HOURS

TRIM OFF

MINUTES SECONDS

BARS SETLTC

789

456

TO LINK DELETE SETUP

STORE RECALL UNDO

FRAMES SNAPSHOT

LOCATE

– +

SET

SHUTTLE

TC AUTOMATION buttons

GUI is touched (changing its colour from yellow to

red). Touching it once more will drop it out.

•INDIVIDUAL CHANNELS

Any controls set to ready on an individual channel

will drop into automation record when the {WRITE}

button for that channel is pressed, and drop out when

it is pressed once more.

•ALL CHANNELS

Any controls set to ready on all channels will drop

into automation record when {MASTERDROPIN}, at

123

CLEAR

0

ENTER

the bottom right of the LCD, is touched. Touching it

once more will drop all channels out.

Refer to the illustration ‘TC AUTOMATION buttons’

above for the following sections describing the

functionality of buttons related to automation.

11

1 OFF button

11

{OFF} is set as the system fire-up default. When this

button is lit, the recording and replaying of automation

data is prevented. All functions remain as manual

operations.

Automation Operation

10

Page 11

The upper central indicator block in the GUI will be

black, displaying OFF, when this button is lit. {OFF},

{ABS} and {TRIM} inter-cancel.

Note

Although automation cannot be recorded or replayed when

OFF is lit, controls can still be set into automation ‘ready’.

22

2 ABS button

22

Pressing {ABS} allows ‘absolute’ settings and

movements to be recorded as automation data for any

controls set to automation ‘ready’, i.e. the exact

settings or movements of faders and knobs will be

recorded once dropped in.

A ‘ready’ status is indicated with a yellow marker or

display for each individual control. Red markers or

displays indicate automation record status.

The upper central indicator block in the GUI will be

red, displaying ABS, when this button is lit. {ABS},

{TRIM} and {OFF} inter-cancel.

Automation data can be copied from one buffer to the

other. Press and hold the button, {A} or {B}, for the

source data until its button flashes. Then press the

button for the other buffer. A pop-up will appear,

requiring confirmation before the copy operation can

be completed.

66

6 SAFE button

66

When {SAFE} is set to on, automation data will not be

updated. In other words, automation operations can be

performed whilst {SAFE} is on but previous data is safe.

{SAFE} functions in other ways too:

•Whilst {SAFE} is off, if a mistake is made during an

automation operation, press {SAFE} before stopping

the tape or material rolling, to prevent updating the

automation data.

•Whilst {SAFE} is on, if an automation operation is

performed that should be stored, press SAFE before

stopping the tape or material rolling, to update the

automation data.

33

3 TRIM button

33

Pressing {TRIM} allows previously recorded

automation data to be trimmed for any controls set to

automation ‘ready’. So, as an example, a fader may

have certain movements recorded using the ‘ABS’

function and TRIM allows those movements to be

globally adjusted. In other words, the original moves

are retained but are at a higher or lower level overall.

TRIM can also be dynamic in operation.

To make this operation easy for faders, they will all

jump to their 0dB scale points. This is the reference

point from which any trimming moves are made.

The upper central automation status indicator block in

the GUI will be green, displaying ‘TRIM’, when this

button is lit. {TRIM}, {ABS} and {OFF} inter-cancel.

44

4 A button

44

The {A} button will be lit as the system fire-up default

and indicates that automation data will be stored and

recalled to and from the ‘A’ buffer. The {A} and {B}

buttons inter-cancel.

Note

The {SAFE} button is also used for the AUDITION function

described later in this document.

55

5 B button

55

Pressing the {B} button will cause automation data to

be stored and recalled to and from the ‘B’ buffer. The

{B} and {A} buttons inter-cancel.

Automation Operation

11

Page 12

Automation Operation

GUI Options for Automation

AUTO button

The button in the centre at the top of the GUI (with

AUTO legend at top left) displays the current

automation status. It is crucial to keep an eye on this

area during automation operations.

To the lower left of this button is a larger legend which

reflects the settings of the {ABS}, {TRIM} and {OFF}

buttons.

Touch AUTO legend for a pop-down of automation

options; what follows is a brief explanation of each.

They will be described with practical examples later in

this supplement.

Operational modes

The upper four operational modes inter-cancel with

each other and are displayed in the lower right corner

of the AUTO button:

NORMAL

This option is the fire-up default and is the setting for

the majority of automation operations.

FOOT

This option allows the automation record drop-in and

drop-out to be operated via a foot switch plugged into

the rear of the mixer. This mode can also be activated

in the AUTOMATION GUI by touching {FOOTSW}.

AUTO

This option allows controls that are set ready to write

automation data, to have their settings recorded

between specified timecode points. This mode can

also be activated in the AUTOMATION GUI by

touching {AUTO}.

Automation Operation

12

Page 13

AUDITION

This option allows a preset level to be found which

does not overwrite previous automation data. This

new setting can then be dropped in and out of

automation record at the appropriate times. New

moves can also be made during the drop-in period.

This mode can also be activated in the

AUTOMATION GUI by touching {AUDITION}.

Note

FOOT, AUTO and AUDITION require that automation data

is already present for the time period they are to operate

over.

Automation drop-out modes

The four modes in the middle section of the pop-down

inter-cancel with each other and are displayed in the

upper right corner of the AUTO button, but only whilst

{ABS} or {TRIM} is selected.

Automation drop-in and drop-out can be achieved in a

number of ways depending on the options set. The

options also vary according to control types. They

include:

GUI Operations

•Touch {MASTERDROP-IN} to drop all ready controls

into automation record.

•Touch individual controls, in the GUI, that are set

ready for automation record.

BUTT

This option is the fire-up default. Where a new section

of automation moves is recorded over previous moves,

having BUTT selected causes a jump between the old

and new data, if they are different at the drop-out

point. BUTT can also be found under ‘AUTO

RETURN TIME’ in the AUTOMATION GUI.

RAMP (# FRAMES)

This option allows the mix data to return to the

previous data over a specified time as a ramp between

the new and old values at the drop-out point. The

ramp time, in frames, can be set under ‘AUTO

RETURN TIME’ in the AUTOMATION GUI.

HOLD TO END

This option causes the setting at the automation ‘dropout to’ point to be recorded to the end of the title.

HOLD TO END can also be found under ‘AUTO

RETURN TIME’ in the AUTOMATION GUI.

HOLD TO NEXT

The system stores automation data only when changes

to settings occur, in order to save storage space. These

changes are known as events. Using HOLD TO

NEXT causes the setting at the automation drop-out

point to be recorded until the next event. HOLD TO

NEXT can also be found under ‘AUTO RETURN

TIME’ in the AUTOMATION GUI.

WRITE Buttons

•Press {WRITE} directly above the knob in each fader

strip to drop all the ready controls into automation

record for that channel.

Fader Knobs

•Touch a fader knob for a fader that is set ready for

automation record.

Buttons

•Press an individual button that is set ready for

automation record. It will simultaneously change

state and drop into automation record.

Knobs

•In the CHANNEL GUI touch the numeric indicator

above any knob that is set ready for automation

record. Its numeric indicator will change colour from

yellow red.

TOP TO END

This option causes the setting at the automation ‘dropout point’ to be recorded from the beginning to the end

of the title. TOP TO END can also be found under

‘AUTO RETURN TIME’ in the AUTOMATION

GUI.

WRITE HOLD

Any controls set into automation record during normal

operations will drop out, returning to ready status, if

the source material is stopped or rewound. The system

monitors timecode in order to operate this way.

WRITE HOLD retains the record status without

reference to timecode.

TOUCH HOLD

This option applies to faders. Normally, any faders set

to automation record will have data written only when

contact is made with their touch sensitive fader knobs.

Using TOUCH HOLD, touching any fader will cause

it to latch into automation record.

Automation Operation

13

Page 14

Automation Operation

Automating Faders

AUTOMATION GUI displaying MAKE STATIC option

General

Before using the automation on any control for the first

time, it is wise to clear automation data which may be

resident in memory if the system has been in use by

others. The following assumes that all important

project data has been saved in an open slot in the Title

Manager.

To Clear Automation Data

1 Touch the {AUTOMATION} label in the middle at

the bottom of the GUI to display the

AUTOMATION GUI.

2 Touch the {MAKESTATIC} tab in the upper part of

the GUI.

3 Touch the {ALLON} button to highlight all channel

and signal paths green. Or touch individual

buttons relating to channels and outputs, if more

appropriate, to highlight them green.

4 Touch {EXECUTE} under the MAKE STATIC

label. A confirmation pop-up will appear. Touch

{YES} to complete the operation

Dynamic and Snapshot automation

It is important to note that it is possible to dynamically

automate individual controls as well as to restore

snapshots, both to timecode. This could cause conflict

when, for example, the same control is restored from a

snapshot whilst also being controlled dynamically.

Therefore it is advisable to isolate controls from

dynamic automation when they are included in

Automation Operation

14

Page 15

snapshots using AUTOMATION ISOLATE, which is

described later. For now, make sure {TCLINK} under

the SNAPSHOT heading, is turned off.

To Automate Moves on One or More

Faders

1 Press {ABS} (short for absolute) on the panel under

the TC AUTOMATION heading above the

timecode display. The AUTO button in the middle

at the top of the GUI turns red and indicates ‘ABS’

at the lower left. In this mode the exact fader

positions and moves will be recorded.

2 Make sure the defaults, ‘BUTT’ and ‘NORMAL’

are displayed in the AUTO button. If not, touch it

for a pop-down, that requires an individual

operation for each selection.

3 Touch {READYSETUP} to the right of the AUTO

button and it highlights.

4 Touch the knobs of the faders to be automated.

Their {WRITE} buttons flash on and off red with a

fast double flash in the red part of the cycle. This

indicates that the faders are ready to have any

moves recorded by the automation system. The

fast double flash serves as a reminder that

{READYSETUP} is selected. If a fader is moved

when it is touched, it will not matter as, during the

ready set-up mode, faders spring back and the level

setting will remain.

Note

Please note that it takes just one touch to set a fader ready

for automation record, and that a second touch will take it

out of ready mode!

The ready status of any fader is displayed in the

CHANNEL GUI. Either touch {CHANNEL} at the

bottom left of the LCD or press the {ACCESS}

button for the channel to be viewed. The dB level

display above the fader icon, to the right of the

GUI, will change colour from green to yellow to

indicate its automation ready status.

The {FADER} button in the READY SETUP

column will also highlight orange when the fader is

ready. In fact, touching the {FADER} button or the

dB legend is another way of setting a fader in and

out of automation ready.

But please note that touching {FADER} in the GUI

sets both the channel and multrack faders into

automation ready mode simultaneously.

5 Then touch {READYSETUP} to de-select it, or roll

the material, when it will be de-selected

automatically. When {READYSETUP} is off, the

{WRITE} buttons will flash regularly without the

double flash. The regular flashing indicates the

normal automation ready mode.

6 Then, whilst the material is playing, touch any

fader knob and its {WRITE} button will light

solidly, indicating that automation data is being

recorded. The dB level display above the fader

icon in the CHANNEL GUI will also turn red.

Make some fader moves and the exact fader

positions and moves will be recorded. The dB

level display will indicate changes and moves.

7 If a mistake is made or changes are required to

what has just been recorded, simply wind back the

material and overwrite by touching and moving

faders. When overwriting a previous pass, the two

small cyan arrows either side of the fader knob

icon will indicate the last mix settings.

Automation Operation

15

Page 16

Automation Operation

How to wind back

There are various ways to locate to points within the

material; these depend on the source storage media:

Quick Rollback

•Press and hold the p transport key. Then press the

0 for every 5 seconds to be rolled back. Then

release p and the system will rewind and play again

from the specified point.

Locate

•Press the LOCATE button

above the transport keys to locate the last locate point

set via the CUE GUI.

•In the CUE GUI, touch one of the Cues in the

NUMBERS column to highlight it, and touch

{LOCATE} in the same GUI. Then press the ”

transport key.

Rewind

•Applies to tape recorders or hard disk systems that

simulate a tape recorder. Press the 0 transport key

and then the ” key when the system has rewound to

an appropriate location.

Note

For secondary automation functions, such as TRIM, to

operate correctly, automation data must already be present

ahead of any points where these are carried out.

Operation of A and B Buffers

If the source material is stopped or rewound, {B} will

light as the next destination. This alternating process

will continue while {AUTO} is selected.

Copying buffers

To copy the data from one buffer to the other, press

and hold {A} or {B} for the source data until its

button flashes. Then press the button for the other

buffer. A pop-up will appear requiring confirmation

before the copy operation can be completed.

Automation Drop-out Modes

When changes are made to just a section over previous

moves, the new fader settings may not match the old at

the end of the new section where the previous and new

join. The default return mode is butt, where a jump

will occur. As described earlier there are other

options, summarised below:

•BUTT

•RAMP (# FRAMES)

(Set time in frames in AUTOMATION GUI)

• HOLD TO END

•HOLD TO NEXT

• TOP TO END

Touch {AUTO} in the top centre of the GUI in order to

select the automation drop-out return modes listed

above.

Automation data is first stored in the A and B buffers.

If the system is powered down, the data in these

buffers will be lost. So automation data must be stored

more permanently using the SAVE or KEEP functions.

However, the A and B buffers do serve a useful

purpose as holding places for data before it is saved

permanently.

The A and B buffers have two modes of operation,

Manual and Auto. These touch button options are

found in the upper left of the AUTOMATION GUI:

Manual

Select the front panel {A} or {B} button under the TC

AUTOMATION heading and all automation data is

stored and replayed from that buffer.

Auto

The default fire-up is the A buffer, indicated by {A}

being lit. So automation data will be stored there first.

To Save a Mix

1 Press {TITLE} at the very top left of the GUI for its

pop-down.

2 Then touch {SAVE} to save the data in the current

Title. Touching {SAVEASNEW} will save the data

in the next available Titles slot.

3 If the work is complete, touch {READYSETUP} to

highlight it, and then {OPTIONS} next to it for a

pop-down. Touch {CANCELALL} in the pop-down

and {CLOSE} to finish with the pop-down menu.

All ready indications will cease. Finally touch

{READYSETUP} once more to turn it off. The

system is now completely ‘safe’ and automation

data cannot be overwritten.

Automation Operation

16

Page 17

To Trim Moves on One or More Faders

A/B buffer rotation

When it comes to using the trim function, it is often a

good idea to set the automation ‘A’ and ‘B’ buffer

rotation to manual. This allows a source mix which is

‘safe’ to be kept close at hand. Otherwise, if a

correction is required, confusion may result from

further trimming of an already trimmed mix.

To set the rotation to manual, touch {AUTOMATION} at

the base of the LCD to display the AUTOMATION

GUI. Then touch {MANUAL} beneath the A/B

BUFFER ROTATION heading.

To save a copy of a mix in the ‘A’ buffer for safety,

press and hold {A} under the TC AUTOMATION

heading until it flashes, then press {B}. A pop-up will

appear requiring confirmation before the copy

operation can be completed. Then continue to work on

the mix in the ‘A’ buffer, which stays lit.

Note

Automation data must already be present ahead of any

points where TRIM operations might be carried out.

4 Then touch {READYSETUP} to de-select it, or roll

the material, in which case it will be de-selected

automatically. When {READYSETUP} is off, the

{WRITE} buttons will flash regularly without the

double flash. The regular flashing indicates the

normal automation ready mode.

5 Then, whilst the material is playing, although the

physical fader knobs will not move unless touched,

the knob in the fader icon and the dB display will

reflect the previous mix. The previous mix will be

heard, including the fader moves.

Touch any fader knob and its {WRITE} button will

light solidly, indicating that automation data is

being recorded. The dB level display above the

fader icon will also turn red and continue to

display the levels from the underlying mix, along

with the knob in the fader icon.

1 Press {TRIM} on the panel under the TC

AUTOMATION heading above the timecode

display. The AUTO button in the middle at the top

of the GUI turns green and indicates ‘TRIM’ at the

lower left. All faders move to their 0dB setting

which is the reference point about which any

trimming moves can be made.

2 Touch {READYSETUP} to the right of the AUTO

button and it highlights.

3 Touch the knobs of the fader to be automated.

Their {WRITE} buttons flash on and off red with a

fast double flash in the red part of the cycle. This

indicates that the faders are ready to have any

moves recorded by the automation system. The

fast double flash serves as a reminder that

{READYSETUP} is selected.

As with automation using ABS mode, the

CHANNEL GUI reflects the ready status in the dB

level display above the fader icon as well as the

{FADER} button at the bottom of the READY

SETUP column, in the CHANNEL GUI.

Moving any fader above the 0dB point will trim

the mix, increasing the level. Adjusting the fader

below 0dB will trim to a lower level. Meanwhile

as the physical fader is moved, the two small cyan

arrows either side of the fader knob icon will

reflect the underlying mix. The dB display will

indicate the combined result of trimming the

underlying mix.

This function allows relative adjustment on

previous automated moves whilst those moves are

retained exactly as they were, but at a higher or

lower level.

All trimming adjustments will be heard and if a

fader knob is released it will behave according to

the current automation drop-out mode. If the

return mode is RAMP for example, then a fader

Automation Operation

17

Page 18

Automation Operation

will glide back to the 0dB marker according to the

Ramp Time setting.

6 If a mistake is made or changes are required to

what has just been recorded, the situation may be

tackled in one of several ways:

• Press {SAFE} before pressing the p transport key

to stop the material rolling. Release {SAFE}

afterwards. In this case, the new automation data

is not stored, so rewind and start again.

• Simply wind back the material and re-trim by

touching and moving faders. But remember that

this method causes trim data to be further modified

in trim mode.

• Copy the ‘safe’ mix from the ‘B’ buffer into ‘A’

in order to redo the trim operation completely. In

this case, press and hold {B}, under the TC

Automating Fader Cut Switches

AUTOMATION heading, until it flashes, then

press {A}. A pop-up will appear requiring

confirmation before the copy operation can be

completed. Then continue to work on the restored

‘safe’ mix in the ‘A’ buffer, which stays lit.

7 If the work is complete, touch {READYSETUP} to

highlight it, and then {OPTIONS} next to it for a

pop-down. Touch {CANCELALL} in the pop-down

and {CLOSE} to finish with the pop-down menu.

All ready indications will cease. Finally touch

{READYSETUP} once more to turn it off. The

system is now completely ‘safe’ and automation

data cannot be overwritten.

Note

Fader moves can be viewed on the AUDIO FADER GUI,

including trim offsets. Touch {AUDIO} at the lower left of

the LCD screen for its pop-up, and then touch {FADER} to

view all faders.

General

Before using the automation for cuts or other switches

for the first time, clear automation data which may be

resident in memory if the system has been in use by

others. Clearing automation data is described at the

beginning of the section ‘Automating Faders’.

To Automate One or More Cut Switches

The setting up for automating cut switches works on

exactly the same principles as for faders. There are

differences in actual operation which relate to the

physical differences between faders and switches.

1 Press {ABS} (short for absolute) on the panel under

the TC AUTOMATION heading above the

timecode display. The AUTO button in the middle

at the top of the GUI turns red and indicates ‘ABS’

at the lower left.

2 Make sure the defaults ‘BUTT’ and ‘NORMAL’

are displayed in the AUTO button. If not touch it

for a pop-down, which requires an individual

operation for each selection.

3 Touch {READYSETUP} to the right of the AUTO

button and it highlights.

4 Press each {CUT} button to be automated and note

that they do not change state. Their channel

{WRITE} buttons flash on and off red with a fast

double flash in the red part of the cycle. This

indicates that the cuts are ready to have any switch

operations recorded by the automation system.

The fast double flash serves as a reminder that

{READYSETUP} is selected.

The ready status of any switch is also displayed in

the CHANNEL GUI. Either touch {CHANNEL} at

the bottom left of the LCD or press the {ACCESS}

button for the channel to be viewed. A yellow bar,

indicating automation ready status, will appear

beneath the fader cut switch situated above the

fader icon to the right in the GUI.

The {CUT} button in the READY SETUP column

will also highlight orange when the cut is ready.

Touching this {CUT} button is another way of

setting a fader cuts in and out of automation ready.

But please note that touching {CUT} in the GUI sets

both the channel and multrack cut buttons into

automation ready mode simultaneously.

Automation Operation

18

Page 19

8 If the work is complete, touch {READYSETUP} to

highlight it, and then {OPTIONS} next to it for a

pop-down. Touch {CANCELALL} in the pop-down

and {CLOSE} to finish with the pop-down menu.

All ready indications will cease. Finally touch

{READYSETUP} once more to turn it off. The

system is now completely ‘safe’ and automation

data cannot be overwritten.

To Automate Cuts Simultaneously

A method for dropping a number of cuts into

automation record simultaneously is to set them into a

‘CUT GROUP’:

1 Touch {AUDIO} at the bottom left of the LCD for

its pop-up and touch {FADERGROUP} to display

the AUDIO FADER/CUT GROUPING GUI.

2 Touch one of the GROUP panels to the left of the

GUI in order to set up the CUT GROUP.

5 Then touch {READYSETUP} to de-select it, or roll

the material in which case it will be de-selected

automatically. When {READYSETUP} is off, the

{WRITE} buttons will flash regularly without the

double flash. The regular flashing indicates the

normal automation ready mode.

6 Then, whilst the material is playing, pressing any

cut button will drop it into automation record and

its {WRITE} button will light solidly. The cut will

simultaneously change state and drop into

automation record . The yellow bar beneath the

fader cut in the CHANNEL GUI will also turn red.

Pressing cuts individually drops them into

automation record one at a time.

7 If a mistake is made or some changes are required

to what has just been recorded, simply wind back

the material and overwrite by pressing the cuts

again. As soon as the material is stopped, the cuts

will drop back to their ready state. Pressing any

cut will drop it into automation record again whilst

the material is rolling forward once more.

3 Touch the button immediately to the right of the

GROUP # legend, to cycle through the options

until {CUT} is displayed.

4 Select the channels that are to have their cuts in the

group by touching each individual button in the

channels field occupying most of the GUI.

5 Make sure that {ON} is displayed for the group, set

by the on/off button in the GROUP # panel.

6 Use the procedure described for automating a

single cut. All automation functions carried out on

any individual cut in the group will apply to all

cuts in that group. Automation data is stored for

individual channels, which allows the CUT

GROUP to be disbanded at any time.

Automation Operation

19

Page 20

Automation Operation

Trimming Cut Switches

The trim functions for cut switches allow individual

cut transactions to be time-shifted earlier or later, or

erased.

Note

Automation data must already be present ahead of any

points where TRIM operations might be carried out.

1 Press {TRIM} on the panel under the TC

AUTOMATION heading above the timecode

display. The AUTO button in the middle at the top

of the GUI turns green and indicates ‘TRIM’ at the

lower left.

2 Touch {READYSETUP} to the right of the AUTO

button and it highlights.

3 Press each {CUT} button to be trimmed and note

that they do not change state. Their channel

{WRITE} buttons flash on and off red with a fast

double flash in the red part of the cycle. This

indicates that the cuts are ready to have any switch

operations recorded by the automation system.

The fast double flash serves as a reminder that

{READYSETUP} is selected.

CUT button ON/OFF:

release

ORIGINAL CUT ACTIONS

CUT ON

LATER

A

CUT

B

push

ON OFF

ON

Signal

CUT ON

EARLIER

C

press, hold

& release

Previous cut data

New cut operations

CUT OFF

EARLIER

CUT OFF

LATER

press, hold

& release

The ready status of any switch is also displayed in

the CHANNEL GUI in the same way as when

using the ‘ABS’ mode for automating cuts.

4 Then touch {READYSETUP} to de-select it, or roll

the material in which case it will be de-selected

automatically. When {READYSETUP} is off, the

{WRITE} buttons will flash regularly without the

double flash. The regular flashing indicates the

normal automation ready mode.

5 Once the material is rolling, cuts can be adjusted in

a number ways according to the illustrations that

follow:

A - Shows the original cut actions.

B - Press and release {CUT} before original cut

point to advance the cut on-point. Press and

release {CUT} before the original off-point to

advance the cut off-point. These operations can be

performed independently in one or two passes.

C - Press and hold {CUT} from before the original

cut point, and release after to delay the cut

ERASE CUT TRANSACTION COMPLETELY

D

press & hold release

on-point. Press and hold {CUT} from before the

original off-point, and release after to delay the cut

off-point. These operations can be performed

independently in one or two passes.

D - Press and hold {CUT} from before the original

cut point, and release after the original cut

off-point to erase a cut transaction completely.

Automating Other Switches

The principles of operation for cut switches apply

equally to all other types of switches. They can be set

into automation ready by pressing switches on the

panel, or by touching buttons on the zoomed GUIs.

Automation Operation

20

Page 21

Automating Knobs

General

The principles for automating knobs are very similar to

those for faders. Note that most level control can be

assigned to the row of knobs above the faders. They

can be automated using knobs or faders, provided that

they are assigned to the chosen control type.

Before using the automation for knobs for the first

time, clear all automation data which may be resident

in memory if the system has been in use by others.

Confusion may result if previous automation moves

are replayed whilst learing the system. Clearing

automation data is described at the beginning of the

section ‘Automating Faders’.

To Automate a Pan Knob

1 Make sure no panel buttons are selected under the

‘PANS’ heading to the right of the row of knobs

above the faders. Their default function is pan

unless a button is selected for any other function.

The ready status of any knob is also displayed in

the CHANNEL GUI. Either touch {CHANNEL} at

the bottom left of the LCD or press the {ACCESS}

button for the channel to be viewed. The

positional readout, below the CH PAN legend to

the right of the GUI, will change colour from green

to yellow, indicating automation ready status.

2 Press {ABS} (short for absolute) on the panel under

the TC AUTOMATION heading above the

timecode display. The AUTO button in the middle

at the top of the GUI turns red and indicates ‘ABS’

at the lower left.

3 Make sure the defaults ‘BUTT’ and ‘NORMAL’

are displayed in the AUTO button. If not, touch it

for a pop-down, which requires an individual

operation for each selection.

4 Touch {READYSETUP} to the right of the AUTO

button and it highlights.

5 Turn a pan knob to the right (clockwise) and note

that its surrounding LED position indicator does

not follow when {READYSETUP} is selected. This

sets it into automation ready, indicated by the

channel {WRITE} button above it flashing on and

off red, with a fast double flash in the red part of

the cycle. The fast double flash serves as a

reminder that {READYSETUP} is selected. Turning

the knob to the left (anti clockwise) will take the

pan out of automation ready, at which time the

{WRITE} button will cease flashing. In ‘ABS’

mode, the exact moves and settings will be

recorded by the automation system.

The {PAN} button in the READY SETUP column

will also highlight orange when the fader is ready.

Touching this {PAN} button is another way of

setting a channel pan in and out of automation

ready. But please note that touching {PAN} in the

GUI sets both the channel and multrack pans into

automation ready mode simultaneously.

6 Then touch {READYSETUP} to de-select it, or roll

the material in which case it will be de-selected

automatically. When {READYSETUP} is off, the

{WRITE} buttons will flash regularly without the

double flash. The regular flashing indicates the

normal automation ready mode.

7 Then, either before or whilst the material is

playing, touch the CH PAN positional readout,

touch {MASTERDROPIN} or press the {WRITE}

Automation Operation

21

Page 22

Automation Operation

button to drop into automation record. The readout

will change colour from yellow to red and its

{WRITE} button will light solidly indicating

automation record in progress.

8 Make sure {PANON} is highlighted in green and

then make panning moves and adjustments as

required. They will be reflected in the LED

position indicator and the GUI readout and bar.

For a larger display of the pan readout, either touch

the pan area in the GUI or touch {CHANNEL} at the

bottom left of the LCD for its pop-up, then touch

{INPUT/PAN/ASSIGN}. The INPUT/PAN/ASSIGN

GUI, which has a larger area devoted to the

channel pan at the lower right, will be displayed.

The pan readout in this GUI can also be used for

the ready set-up and automation drop-in.

9 If a mistake is made or changes are required to

what has just been recorded, simply wind back the

material and overwrite. After locating back, either

before or after rolling the material again, drop into

automation record, by touching the CH PAN

positional readout, {MASTERDROPIN} or pressing

{WRITE}.

To set the rotation to manual, touch {AUTOMATION} at

the bottom of the LCD to display the AUTOMATION

GUI. Then touch {MANUAL} beneath the A/B

BUFFER ROTATION heading.

To save a copy of a mix in the ‘A’ buffer for safety,

press and hold {A} under the TC AUTOMATION

heading until it flashes, then press {B}. A pop-up will

appear requiring confirmation before the copy

operation can be completed. Then continue to work on

the mix in the ‘A’ buffer, which stays lit. Using the

trim function for knobs allows previous settings and

moves to be offset or dynamically trimmed.

Note

Automation data must already be present ahead of any

points where TRIM operations might be carried out.

1 Press {TRIM} on the panel under the TC

AUTOMATION heading above the timecode

display. The AUTO button in the middle at the top

of the GUI turns green and indicates ‘TRIM’ at the

lower left.

2 Touch {READYSETUP} to the right of the AUTO

button and it highlights.

When overwriting a previous pass, the two small

cyan dots above and below the pan bar indicator,

will reflect the settings for the previous mix as a

reference.

To Automate a Number of Knobs

1 Use the set-up procedure described in the previous

section.

2 Drop into automation record using

{MASTERDROPIN} to set all knobs to write

simultaneously, or press individual {WRITE}

buttons.

Trimming Knob Moves

A/B buffer rotation

When it comes to using the trim function, it is often a

good idea to set the automation ‘A’ and ‘B’ buffer

rotation to manual. This allows a source mix which is

‘safe’ to be kept close at hand. Otherwise, if a

correction is required, confusion may result from

further trimming of an already trimmed mix.

3 Turn each knob to be trimmed to the right

(clockwise). This sets them into automation ready,

indicated by the channel {WRITE} buttons flashing

on and off red, with a fast double flash in the red

part of the cycle. The fast double flash serves as a

reminder that {READYSETUP} is selected. Turning

knobs to the left (anti clockwise) will take them

out of automation ready, at which time their

{WRITE} buttons will cease flashing.

In ‘TRIM’ mode the system records any knob

changes and moves as differences or offsets from

the underlying mix with reference to the knob

position at the automation drop-in point.

The ready status of any knob is also displayed in

the CHANNEL GUI in the same manner when

using ‘ABS’ mode.

4 Touch {READYSETUP} to de-select it, or roll the

material when it will be de-selected automatically.

When {READYSETUP} is off, the {WRITE} buttons

will flash regularly without the double flash. The

regular flashing indicates the normal automation

ready mode.

Automation Operation

22

Page 23

5 Roll the material and make any adjustments as

required. Although changes will be heard from the

underlying mix, the LED knob position indicators

will only display changes being made for the

current pass. Any knobs being automated, which

are displayed on the LCD, will indicate a

combination of the previous mix and the actions in

the current pass. The two cyan dots, above and

below the pan bar, indicate the settings for the

previous underlying mix. The bar and the position

readout indicate the result of combining the

underlying mix and the new trim operations.

This function allows relative adjustment on

previous automated moves whilst those moves are

retained exactly as they were, but at a higher or

lower level.

6 If a mistake is made or changes are required to

what has just been recorded, the situation may be

tackled in one of several ways:

• Press {SAFE} before pressing the p transport key

to stop the material rolling. Release {SAFE}

afterwards. In this case, the new automation data

is not stored, so rewind and start again.

• Simply wind back the material and re-trim by

touching and moving faders. But remember this

method means that trim data is being further

modified in trim mode.

• Copy the ‘safe’ mix from the ‘B’ buffer into ‘A’

in order to redo the trim operation completely. In

this case, press and hold {B} under the TC

AUTOMATION heading until it flashes, then

press {A}. A pop-up will appear requiring

confirmation before the copy operation can be

completed. Then continue to work on the restored

‘safe’ mix in the ‘A’ buffer, which stays lit.

7 If the work is complete, touch {READYSETUP} to

highlight it, and then {OPTIONS} next to it for a

pop-down. Touch {CANCELALL} in the pop-down

and {CLOSE} to finish with the pop-down menu.

All ready indications will cease. Finally touch

{READYSETUP} once more to turn it off. The

system is now completely ‘safe’ and automation

data cannot be overwritten.

Automation Operation

23

Page 24

Automation Operation

Automating Sections of Controls

To Automate a Complete EQ Section

To set up automating of complete sections of channels

on a channel by channel basis, using the EQ section as

an example, first display the CHANNEL GUI, then:

1 Press {ABS} (short for absolute) on the panel under

the TC AUTOMATION heading above the

timecode display. The AUTO button in the middle

at the top of the GUI turns red and indicates ‘ABS’

at the lower left. In this mode the exact fader

positions and moves will be recorded.

2 Make sure the defaults ‘BUTT’ and ‘NORMAL’

are displayed in the AUTO button. If not, touch it

for a pop-down, which requires an individual

operation for each selection.

3 Touch {READYSETUP} to the right of the AUTO

button and it highlights.

4 Touch {EQ/FILT} under the ‘READY SETUP’

heading to the lower right of the GUI. All EQ

knob readouts will turn from green to yellow and

yellow bars will appear beneath all EQ related

switches, indicating that the complete EQ section

is ready for automation data to be recorded. The

channel {WRITE} button will also flash.

Other sections set for automation in the same way:

• {DYNAMICS} button for the full Dynamics

section.

• {ASSIGN} button for all MTR and Program Bus

Assign buttons.

• {AUXSEND} button for all Aux Sends.

Automation Operation

24

Page 25

5 With all controls selected, individual controls can

be de-selected from ready by touching them one at

a time in the CHANNEL GUI. For a larger view

of the EQ section, touch the EQ section avoiding

areas where controls are placed, or touch

{CHANNEL} at the bottom left of the LCD, and then

touch {EQ/FILT}.

2 Make sure the defaults ‘BUTT’ and ‘NORMAL’

are displayed in the AUTO button. If not touch it

for a pop-down, which requires an individual

operation for each selection.

3 Touch {READYSETUP} to the right of the AUTO

button and it highlights.

6 Touch {READYSETUP} to de-select it, or roll the

material when it will be de-selected automatically.

7 Press the {WRITE} buttons for individual channels

or touch {MASTERDROPIN}. All automation

ready controls, knob readouts and bars beneath

switches, in the GUI, will turn from yellow to red,

indicating automation record.

8 If a mistake is made or some changes are required

to what has just been recorded, simply wind back

the material and overwrite. After locating back,

either before or after rolling the material again,

drop into automation record by pressing individual

channel {WRITE} buttons, or touch

{MASTERDROPIN} to have all channels drop into

automation record simultaneously.

9 When the work is complete, touch {READYSETUP}

to highlight it, and then {OPTIONS} next to it for a

pop-down. Touch {CANCELALL} in the pop-down

and {CLOSE} to finish with the pop-down menu.

All ready indications will cease. Finally touch

{READYSETUP} once more to turn it off. The

system is now completely ‘safe’ and automation

data cannot be overwritten.

4 Touch {EQ/FILT} under the ‘READY SETUP’

heading to the lower right of the GUI if not already

highlighted.

5 Touch {READYSETUP} to de-select it, or roll the

material when it will be de-selected automatically.

6 Press the {WRITE} buttons for individual channels

or touch {MASTERDROPIN} in order for any

trimming moves to be recorded by the automation

system.

7 If a mistake is made or some changes are required

to what has just been recorded, the situation may

be tackled in one of several ways:

• Press {SAFE} before pressing the p transport key

to stop the material rolling. Release {SAFE}

afterwards. In this case, the new automation data

is not stored, so rewind and start again.

• Simply wind back the material and re-trim by

touching and moving faders. But remember that

this method means that trim data is being further

modified in trim mode.

• Perform trimming operations on a ‘safe’ mix in

order to redo the trim operation completely.

Trimming Sections of Knob Moves

The trimming of sections of knobs uses the same

procedure described under ‘Trimming knob moves’. It

is described briefly as follows:

Note

Automation data must already be present ahead of any

points where TRIM operations might be performed.

1 Press {TRIM} on the panel under the TC

AUTOMATION heading above the timecode

display. The AUTO button in the middle at the top

of the GUI turns green and indicates ‘TRIM’ at the

lower left.

8 When the work is complete, touch {READYSETUP}

to highlight it, and then {OPTIONS} next to it for a

pop-down. Touch {CANCELALL} in the pop-down

and {CLOSE} to finish with the pop-down menu.

All ready indications will cease. Finally touch

{READYSETUP} once more to turn it off. The

system is now completely ‘safe’ and automation

data cannot be overwritten.

Automation Operation

25

Page 26

Automation Operation

To Automate All EQ Sections

The R100 allows the automation to be set up in order

to record data from sections of all channels and signal

paths on a global basis. Using the EQ section as an

example, first display the CHANNEL GUI, then:

1 Press {ABS} (short for absolute) on the panel under

the TC AUTOMATION heading above the

timecode display. The AUTO button in the middle

at the top of the GUI turns red and indicates ‘ABS’

at the lower left. In this mode the exact fader

positions and moves will be recorded.

2 Make sure the defaults ‘BUTT’ and ‘NORMAL’

are displayed in the AUTO button. If not, touch it

for a pop-down, which requires an individual

operation for each selection.

3 Touch {READYSETUP} to highlight it, and then

{OPTIONS} next to it for a pop-down. Touch

{ALLEQs} in the pop-down and then {CLOSE} to

finish with the pop-down menu. The {WRITE}

buttons for all channels and signal paths which

include EQ processing will flash, indicating

automation ready mode.

Global automation ready set-up exists for other

controls and sections as below. They are selected

using the {OPTIONS} pop-down:

• {ALLDYNAMICSs} for all channels and signal

paths which include Dynamics processing.

• {ALLAUXKNOBS} for the Aux Send Levels for

all channels.

• {ALLAUXBUTTONS} for the Aux Send Cuts for

all Channels and the Aux Returns.

Automation Operation

26

Page 27

• {ALLCUTS} for the Channel Fader and MTR

Fader Cuts for all Channels and the Aux Returns.

• {ALLBUSASSIGNS} for Program and MTR Bus

Assign buttons for all Channels and the Aux

Returns.

• {ALLPANS} for the Channel and MTR Pans for

all Channels.

• {ALLFADERS} for the Channels, MTRs, Aux

Returns, Bus Masters and Program Faders.

Footswitch, Audition & Auto

4 The rest of this procedure follows that described

earlier in this section so please refer to the

beginning of ‘Automating Sections of Controls’.

General

The FOOT SW, AUDITION and AUTO functions

allow the settings for controls in automation record to

be written as automation data over specified periods.

• FOOT SW allows the drop-in time period to be set

using a footswitch.

• AUDITION allows the drop-in time period to be set

manually using the {SAFE} button.

• AUTO allows the drop-in time period to be set by

specifying timecode points.

Automation Operation

27

Page 28

Automation Operation

Note

Automation data must already be present ahead of any

points where the following operation might be performed.

Automation Drop-in Using FOOT SW

Plug a momentary action footswitch into the jack on

the rear panel behind the PGM L and R bar meters.

1 Touch {FOOTSW} to the left of the

AUTOMATION GUI so that it highlights green.

‘FOOT’ will appear in the AUTO button at the top

centre of the LCD.

2 Select the {ABS} or {TRIM} button according to

whether the underlying data is to be overwritten or

trimmed, and make sure {SAFE} is turned off, i.e.

its LED is off.

3 Set the faders to have automation data recorded

into ready and then drop them into automation

record. This will be confirmed by the {WRITE}

buttons being lit solidly for the channels

concerned.

Automation Drop-in Using AUDITION

1 Touch {AUDITION} to the left of the

AUTOMATION GUI so that it highlights green.

The {SAFE} button will light and the AUTO button

at the top centre of the LCD will then display the

following:

• AUDITION

• WH - Write Hold, which means any faders which

are touched will remain armed to write automation

data at all times, including when the material is

rewound.

• TH - Touch Hold, which means that automation

data is being written continuously and not just

when faders are being touched.

• BUTT - Audition can operate only with butt or a

jump at the join between previous and new

auditioned settings.

2 Select the {ABS} or {TRIM} button according to

whether the underlying data is to be overwritten or

trimmed.

4 Play the material over the section where the

settings are to be recorded and adjust the faders to

suitable settings. The underlying mix will not be

overwritten. It is advisable to use a ‘safe’ mix

when performing this kind of operation in case a

complete re-write is necessary.

5 When the fader settings are finally satisfactory, roll

the material again. At the drop-in point, push and

hold the footswitch for the period required for the

drop-in. Pressing the p transport key will also

drop the system out of automation data record.

6 Make sure the channels involved have returned to

ready mode, indicated by their {WRITE} buttons

flashing, then replay the material to check it.

7 When the work is complete, release {FOOTSW}.

Touch {READYSETUP} to highlight it, and then

{OPTIONS} next to it for a pop-down. Touch

{CANCELALL} in the pop-down and {CLOSE} to

finish with the pop-down menu. All ready

indications will cease. Finally touch

{READYSETUP} once more to turn it off. The

system is now completely ‘safe’ and automation

data cannot be overwritten.

3 Set the faders to have automation data recorded

into ready and then drop them into automation

record. This will be confirmed by the {WRITE}

buttons being lit solidly for the channels

concerned.

4 Play the material over the section where the

settings are to be recorded and adjust the faders to

suitable settings. The underlying mix will not be

overwritten. It is advisable to use a ‘safe’ mix

when performing this kind of operation in case a

complete re-write is necessary.

5 When the fader settings are finally satisfactory, roll

the material again. At the drop-in point, release

{SAFE} so that its LED is no longer lit, when

automation data will be recorded. At the drop-out

point press {SAFE} again.

6 When the work is complete, release {AUDITION}

and the automation will resume ‘NORMAL’ mode.

Check that the automation is in ready mode,

indicated by the {WRITE} buttons flashing. Then

replay the material to check that the revised

automation data is satisfactory.

Automation Operation

28

Page 29

7 When finally complete, touch {READYSETUP} to

highlight it, and then {OPTIONS} next to it for a

pop-down. Touch {CANCELALL} in the pop-down

and {CLOSE} to finish with the pop-down menu.

All ready indications will cease. Finally touch

{READYSETUP} once more to turn it off. The

system is now completely ‘safe’ and automation

data cannot be overwritten.

Note

If a return mode other than BUTT was selected before

touching {AUDITION}, it must re-selected manually. The

mode being used previously will not be returned

automatically when AUDITION is turned off.

Automation Record Using AUTO

Static settings using AUTO

This procedure allows static settings to be recorded as

automation data between fixed time points.

1 Touch {AUTO} towards the left of the

AUTOMATION GUI so that it highlights green.

‘AUTO’ will appear in the AUTO button at the top

centre of the LCD.

2 Set the time when automation data will start to be

recorded. This can be done in two ways:

• Touch {PUNCHINTIME} and the current timecode

point will be set.

• Touch the timecode display to highlight its

background. Then adjust the timecode number

using the jog wheel or the ten-number key pad.

Press {ENTER} at the bottom right of the number

key pad when finished.

5 Set the faders to have automation data recorded

into ready and then drop them into automation

record. This will be confirmed by the {WRITE}

buttons being lit solidly for the channels

concerned.

6 Play the material over the section where the

settings are to be recorded and adjust the faders to

suitable settings. The underlying mix will not be

overwritten. It is advisable to use a ‘safe’ mix

when performing this kind of operation in case a

complete re-write is necessary.

7 When the fader settings are finally satisfactory

press the p transport key. Then press

{WRITENOW}. A pop-up will appear requesting

confirmation in order to finalise the operation.

8 Rewind and check that the automation is in ready

mode, indicated by the {WRITE} buttons flashing.

Then replay the material to check that the revised

automation data is satisfactory.

9 When the work is complete, release {AUTO}.

Touch {READYSETUP} to highlight it, and then

{OPTIONS} next to it for a pop-down. Touch

{CANCELALL} in the pop-down and {CLOSE} to

finish with the pop-down menu. All ready

indications will cease. Finally touch

{READYSETUP} once more to turn it off. The

system is now completely ‘safe’ and automation

data cannot be overwritten.

Dynamic settings using AUTO

This procedure allows dynamic settings to be recorded

as automation data between fixed time points.

3 Set the time when automation data will finish

being recorded. This can be done in two ways:

• Touch {PUNCHOUTTIME} and the current

timecode point will be set.

• Touch the timecode display to highlight its

background. Then adjust the timecode number

using the jog wheel or the ten-number key pad.

Press {ENTER} at the bottom right of the number

key pad when finished.

4 Select the {ABS} or {TRIM} button according to

whether the underlying data is to be overwritten or

trimmed.

1 Repeat steps 1-5 as described in the ‘Static settings

using AUTO’ to set the start and finish times.

2 Play the material from before the ‘punch in time’

set in step 2, to the ‘punch out time’ set in step 3.

3 Make adjustments to any of the controls set in

automation record whilst the material is rolling.

Automation data will only be recorded between the

in and out time points set.

4 Rewind and check that the automation is in ready

mode, indicated by the {WRITE} buttons flashing.

Then replay the material to check that the revised

automation data is satisfactory.

Automation Operation

29

Page 30

Automation Operation

Automation Isolate

General

Complete channels or sections of channels can be set

into an isolate mode in order that automation data will

not affect control settings.

Isolating Channels or Sections of All

Channels

1 Touch the {AUTOMATION} label in the middle at

the bottom of the GUI to display the

AUTOMATION GUI.

2 The {AUTOMATIONISOLATE} tab in the upper part

of the GUI is the default and should already be

selected.

3 Touch the {ALLON} button to highlight all channel

and signal paths green. Or touch individual

buttons relating to channels and outputs, if more

appropriate, to highlight them green. The

automation data will be isolated from all

highlighted channels, leaving their controls free for

adjustment.

4 Alternatively, under the FUNCTION heading,

touch ‘section’ buttons according to what is to be

isolated on a mixer-wide basis:

• {EQ/FILT} for all Equaliser and Filter sections.

• {DYN} for all Dynamics sections.

• {AUXSND} for all Aux Send controls.

• {CUT} for all Channel, MTR and Aux Return

Fader Cuts.

Automation Operation

30

Page 31

• {ASSIGN} for all MTR and Program Bus Assign

buttons.

• {PAN} for all Channel and MTR Pans.

• {FADER} for all Channel, MTR and Aux Return

Faders.

Snapshots

General

The Snapshots GUI allows static control settings to be

stored and recalled. The settings for the whole mixer

are saved for every Store operation whereas an Isolate

function allows snapshots to be recalled on a selective

basis.

To Save a New Snapshot

1 Touch {SNAPSHOT} at the bottom towards the left

of the LCD for the SNAPSHOT GUI.

2 Whilst the material is either stationary or moving,

touch {NEW} and a new entry will appear in the

SNAPSHOT NAME column. A default number

will be entered automatically.

Automation Operation

31

Page 32

Automation Operation

3 To change the default number to an appropriate

name, touch the default in the CUE NAME

column, and the QWERTY Keyboard pop-up

appears.

4 The default will be displayed in the upper entry

dialogue line. Either touch {BACKSPACE} several

times to delete it, or touch and move a finger

across it to highlight it. Then type in a suitable

name, such as ‘START OF TITLE’ in this case,

using the touch QWERTY keyboard. Touch

{ENTER} when finished.

To Revise a Snapshot

1 Under the NUMBER column, touch the Snapshot

number to be revised. It highlights white.

2 Whilst the material is either stationary or moving,

touch {STORE} in the SNAPSHOT GUI, and the

Snapshot location will be overwritten with the

current settings.

To Recall a Partial Snapshot

1 Under the NUMBER column, touch the Snapshot

number to be recalled. It highlights white.

2 Under the ISOLATE heading, touch individual

buttons relating to channels and outputs to

highlight them green. The data for these channels

will not be restored. Or, if more convenient, touch

the {ALLON} button to highlight all and then deselect individual channels.

3 Alternatively, under the FUNCTION heading,

touch ‘section’ buttons according to what is to be

isolated on a mixer-wide basis:

• {INROUT} for all Input Routing assignments.

• {EQ/FILT} for all Equaliser and Filter sections.

• {DYN} for all Dynamics sections.

• {AUXSND} for all Aux Send controls.

• {CUT} for all Channel, MTR and Aux Return

Fader Cuts.

To Delete a Snapshot

1 Under the NUMBER column, touch the Snapshot

number to be deleted. It highlights white.

2 Whilst the material is either stationary or moving,

touch {DELETE} in the SNAPSHOT GUI. A popup requesting confirmation will appear. Touch

{YES} to complete the operation.

This Snapshot location is now available for storing

a New Snapshot by touching {NEW} in the GUI.

To Recall a Complete Snapshot

1 Under the NUMBER column, touch the Snapshot

number to be recalled. It highlights white.

2 Whilst the material is either stationary or moving,

touch {RECALL} in the SNAPSHOT GUI and the

settings will be restored. Touch {UNDO} to reverse

the operation.

• {ASSIGN} for all MTR and Program Bus Assign

buttons.

• {PAN} for all Channel and MTR Pans.

• {FADER} for all Channel, MTR and Aux Return

Faders.

• {INPUT} for all Input Trim and Delay settings.

4 Whilst the material is either stationary or moving,

touch {RECALL} in the SNAPSHOT GUI and the

settings will be restored. Touch {UNDO} to reverse

the operation.

Automation Operation

32

Page 33