Sony DDS-4, SDT-10000, SDT-11000 Product Description Manual

PRODUCT DESCRIPTION MANUAL

DDS-4 Tape Drive

Model : SDT-10000

: SDT-11000

Ver. 1.2 July, 1999

Sony Corporation

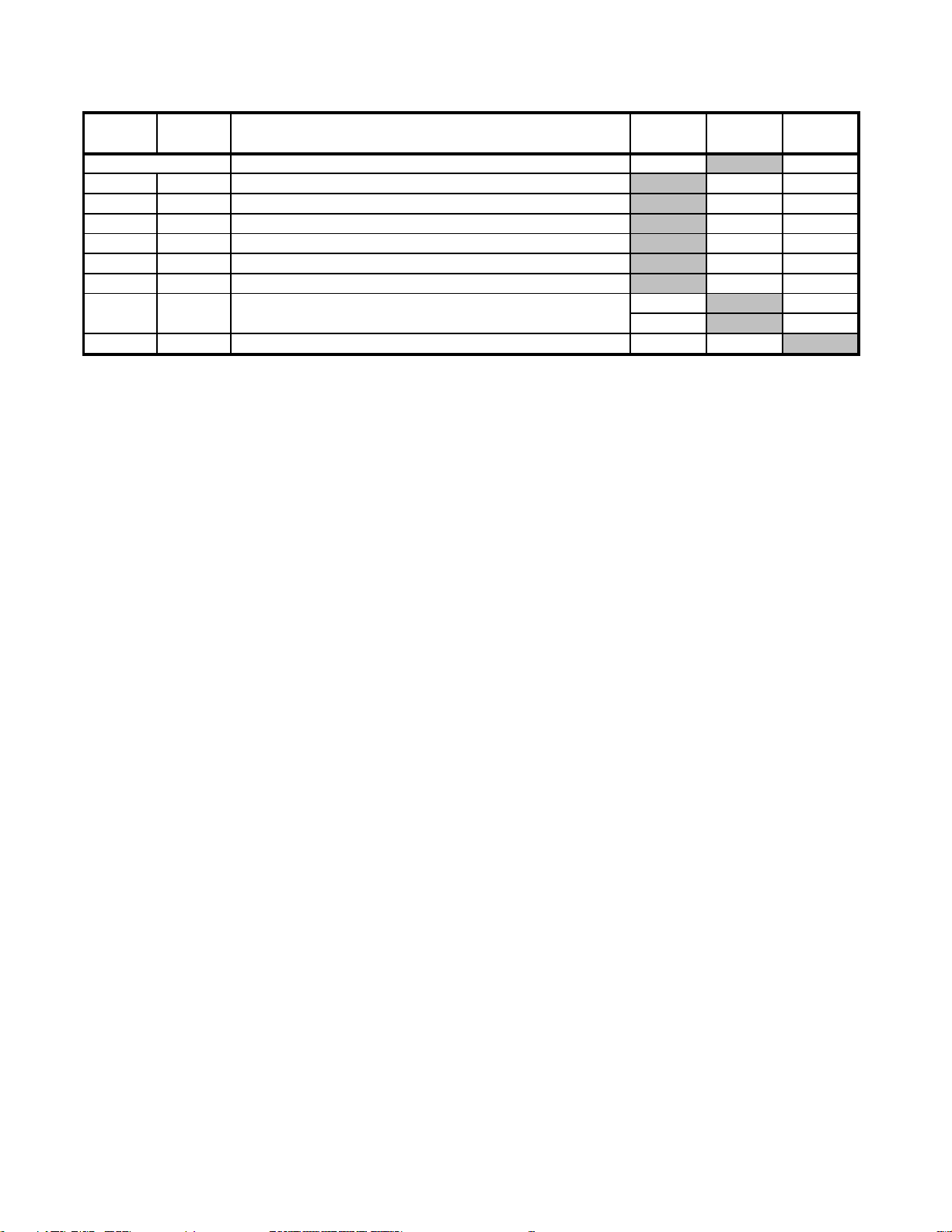

Difference List ( From Ver.1.1 To Ver.1.2 )

SDT-11000 SCSI Signals ( Low-Voltage-Differential

1-11Introduction

1-2

1.1

Feature of the drive

2-3

2.1.3

Connectors

2-3

2.13.1

SCSI Cables and Terminators

2-6

2.3.2.2

Burst Data Transfer Rate To and From the SCSI Bus

3-3/3-4

3.1.4

SCSI 68 Pin Connector

3-3

Table 3-1

SDT-11000 SCSI Signals ( Low-Voltage-Differential

Type Bus P Cable Signal Assignment)

7-8

Error Set 2

13h: DDS Controller SRAM TEST FAILURE

Model Name

Page Clause Title Modify Add Delete

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

1. Introduction

234

234

234

234

234

234

234

2. Specification

3. Installation

4. Operation

5. SCSI Interface

6. Command Specificaiton

7. Drive Diagnostics

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

234

APPENDIX

1. INTRODUCTION

12345

1

5

1

5

1

5

1

5

1

5

1

5

1

5

12345

1 INTRODUCTION ............................................................................................................. 1-1

1. 1 Features of the drive ........................................................................................ 1-2

1. 2 Reference ......................................................................................................... 1-3

234

234

234

234

234

234

234

1. Introduction

1. INTRODUCTION

This manual provides information about the Sony SDT-10000/SDT-11000 Digital Data Storage (DDS) Tape Drives

which is necessary to integrate the drives into OEM products.

This manual describes the specifications, SCSI Interface, diagnostics, operation and installation of Sony DDS Tape

Drives. This drive is:

• SDT-10000/SDT-11000 20 to 40 GB capacity, 2.36 to 4.72 MBytes/Second Transfer Rate, Ultra/WIDE, Singleended or Low Voltage differential, 3.5"FH

*1, *2 This is assuming 2:1 Compression ratio.

The degree of data compression attained while recording data varies according to system environment and data

type.

Note: The SDT-10000/SDT-11000 drive uses data compression to achieve high capacity and high transfer rates. Ac-

tual capacity and transfer rate depends on the source file type.

Note: The capacity ratings listed above are based on a 150 meter DDS-4 tape cassette.

The Sony SDT-10000/SDT-11000 drive is a high capacity data storage device using 4 mm DAT (Digital Audio Tape)

technology. The SDT-10000/SDT-11000 drive achieves high data reliability through read-after-write, an additional

level of Error Correction Code, and other features.

The Sony SDT-10000/SDT-11000 drive stores data on tape using a standard format called DDS (Digital Data Storage),

DDS-DC, DDS-2, DDS-3 and DDS-4. This format is used by numerous other DDS tape drive manufacturers, providing

a broad range of compatible tape drives.

The Sony SDT-10000/SDT-11000 is fully READ and WRITE compatible with the DDS-4, DDS-3, DDS-2, DDS and

DDS-DC format tapes.

*1

*2

SONY SDT-10000/SDT-11000 DDS Tape Drive

1 - 1

1. Introduction

1.1 FEATURES OF THE DRIVE

Major features of the Sony SDT-10000/SDT-11000 include:

• 20 GB capacity

• Sustained transfer rate - 2,360 KB/sec

• Supported Format: DDS-4, DDS-3, DDS-2, DDS , DDS-DC and DCLZ

• Fully READ and WRITE compatible with the DDS-4, DDS-3, DDS-2, DDS and DDS-DC format tapes

• Burst transfer rate

• Large 10 MB Buffer

• 3 1/2 inch form factor

• Embedded SCSI interface (Ultra/WIDE, Single-ended or Low Voltage differential)

• Supports Variable or Fixed record length

• Supports SCSI Disconnection/Arbitration

• Read After Write (RAW)

• Frame rewrite function

• Three levels of Error Correction Code (ECC)

• High Speed search (100 times normal Read/Write speed)

• Random read

• N-Group write option (DDS-2, DDS and DDS-DC only)

• Dual Partition option

(20GB to 40 GB with Data Compression) *1

(approximately 2.36 MB/s to 4.72 MB/s with Data Compression) *2

*1, *2 This is assuming 2:1 Compression ratio.

The degree of data compression attained while recording data varies according to system environment

and data type.

- 14 MB/sec Asynchronous

- 40 MB/sec Synchronous

1 - 2

SONY SDT-10000/SDT-11000 DDS Tape Drive

1. Introduction

1.2 REFERENCE

Please refer to the following documents for additional information:

• Helical-Scan Digital Computer Tape Cartridge for Information Interchange (3.81 mm (0.150 in) Digital Data Stor-

age (DDS) Recorded Format)

ANSI X3.203

• Proposed Final Test Unrecorded Helical-Scan Digital Computer Tape Cartridge

ANSI ASC TC X3B5 Document 92-251

• 3,81 mm Wide Magnetic Tape Cartridge For Information Interchange

Helical Scan Recording, DDS Format, June 1990

European Computer Manufacturers Association (ECMA-139)

1

• 3,81 mm Wide Magnetic Tape Cartridge For Information Interchange

Helical Scan Recording, DDS-DC Format, June 1991

European Computer Manufacturers Association (ECMA-150)

1

• Data Compression For Information Interchange

Adaptive Coding with Embedded Dictionary, DCLZ Algorithm, June 1991

European Computer Manufacturers Association (ECMA-151)

1

• 3.81mm Wide Magnetic Tape Cartridge For Information Interchange

Helical Scan Recording, DDS-2 Format Using 120m Length Tapes,

December 1993

European Computer Manufacturers Association (ECMA-198)

1

• 3.81mm Wide Magnetic Tape Cartridge For Information Interchange

Helical Scan Recording, DDS-3 Format Using 125m Length Tapes

European Computer Manufacturers Association(ECMA XXX)

1

• Designing a Data Storage Format for Digital Audio Tape (DAT)

DDS Manufacturers Group

• Small Computer System Interface (SCSI-1), ANSI X3.131-1986

The ANSI authorized standard for SCSI implementation, available through ANSI

2

• Enhanced Small Computer Systems Interface (SCSI-2)

ANSI X3T9.2/86-109 (Revision 10H, or above), available through ANSI

2

• Parallel Small Computer Systems Interface (SCSI-3)

ANSI X3T10/855D (Revision 15a, or above) available through ANSI.

Note 1: Also available from: European Computer Manufacturers Association

114 Rue du Rhone - CH-1204 Geneva(Switzerland)

TEL: (41) 22-735-36-34

FAX: (41) 22-786-52-31

Note 2: Also available from: Global Engineering Documents

2805 McGaw Avenue

Irvine, CA 92714

(800) 854-7179

(714) 261-1455

SONY SDT-10000/SDT-11000 DDS Tape Drive

1 - 3

2. SPECIFICATION

5

5

5

5

5

5

5

2. 1 PHYSICAL SPECIFICATIONS ................................................................................. 2-1

2. 1. 1 Dimensions .................................................................................................. 2-1

2. 1. 2 Weight........................................................................................................... 2-3

2. 1. 3 Connectors................................................................................................... 2-3

2. 2 ENVIRONMENTAL SPECIFICATIONS .................................................................... 2-4

2. 2. 1 Temperature and Humidity Range ............................................................. 2-4

2. 2. 2 Altitude ......................................................................................................... 2-4

2. 2. 3 Dust............................................................................................................... 2-4

2. 2. 4 Vibration ....................................................................................................... 2-4

2. 2. 5 Shock............................................................................................................ 2-4

2. 2. 6 Acoustic Noise............................................................................................. 2-5

2. 2. 7 ESD ............................................................................................................... 2-5

2. 2. 8 Orientation ................................................................................................... 2-5

2. 3 PERFORMANCE SPECIFICATION.......................................................................... 2-6

2. 3. 1 Data Capacity............................................................................................... 2-6

2. 3. 2 Data Transfer Rate....................................................................................... 2-6

2. 3. 3 Initialize Time ............................................................................................... 2-6

2. 3. 4 Load Time..................................................................................................... 2-7

2. 3. 5 Rewind Time ................................................................................................ 2-7

2. 3. 6 Search Time ................................................................................................. 2-7

2. 3. 7 Unload Time ................................................................................................. 2-7

2. 3. 8 Error Rate ..................................................................................................... 2-7

2. 3. 9 Retry Limits on Rewrites ............................................................................ 2-7

2. 3. 10 Definition of Failure................................................................................... 2-7

2. 3. 11 Mean Time Between Failures ................................................................... 2-7

2. 3. 12 Mean Time To Repair ................................................................................ 2-7

2. 3. 13 Component Life ......................................................................................... 2-8

2. 3. 14 Durability .................................................................................................... 2-8

2. 4 SAFETY...................................................................................................................... 2-8

2. 4. 1 Conditions of Acceptability ........................................................................ 2-8

2. 5 INSTALLATION REQUIREMENTS .......................................................................... 2-9

2. 5. 1 Power Requirements................................................................................... 2-9

2. 1. 1. 1 Mounting Holes .......................................................................... 2-2

2. 1. 3. 1 SCSI Cables and Terminators................................................... 2-3

2. 3. 2. 1 Sustained Data Transfer Rate To and From Tape ................... 2-6

2. 3. 2. 2 Burst Data Transfer Rate To and From the SCSI Bus ............ 2-6

234

234

234

234

234

234

234

2. SPECIFICATION

2. SPECIFICATIONS

Physical, environmental and performance specifications for the SDT-10000/SDT-11000

2. 1 PHYSICAL SPECIFICATIONS

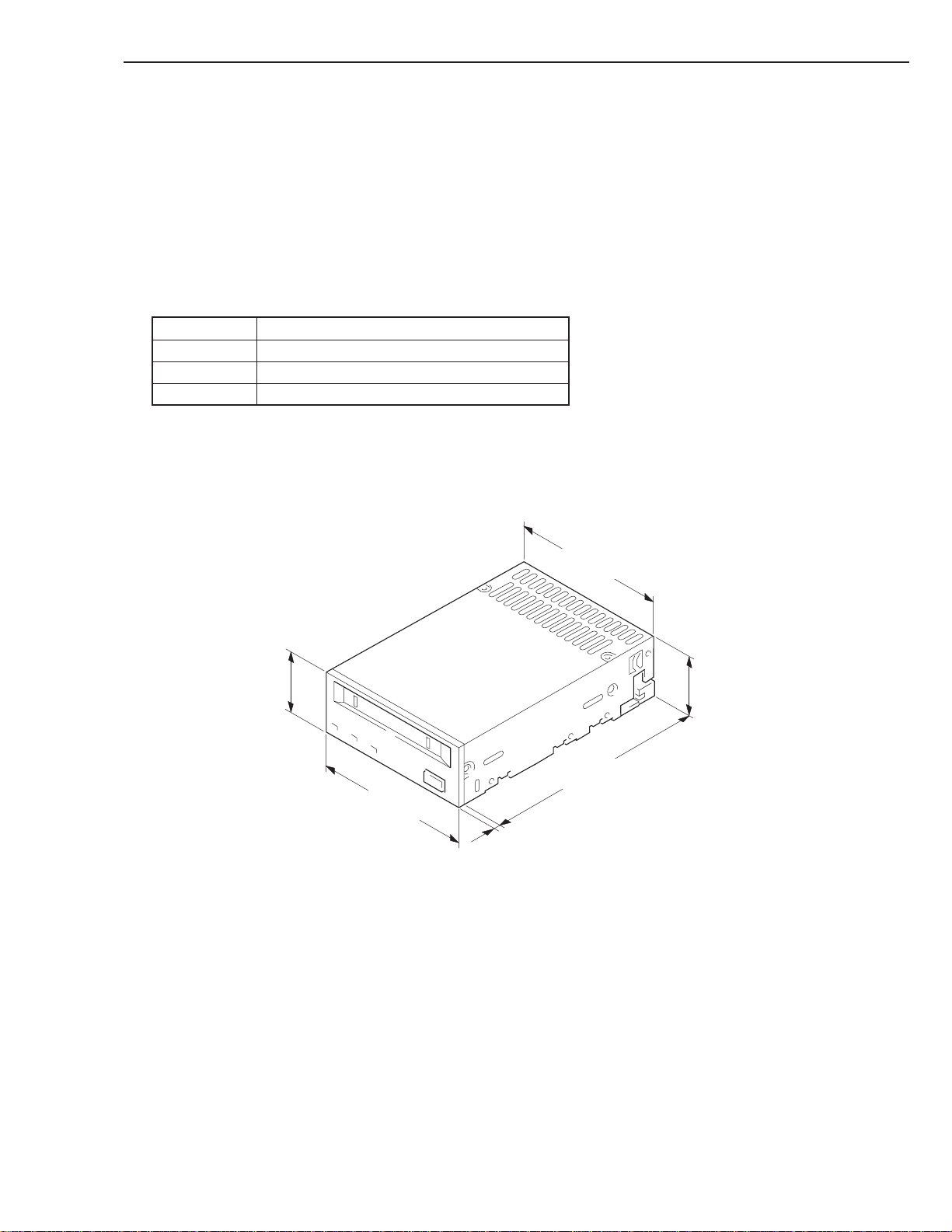

2. 1. 1 Dimensions

The SDT-10000/SDT-11000 conforms to the 3.5 inch standard height form factor.

SDT-10000/SDT-11000

Height 41.2 mm (1.62 in) ± 0.5 mm (0.02 in)

Width 101.6 mm (4.0 in) ± 0.5 mm (0.02 in)

Depth 146.0 mm (5.75 in) ± 0.5 mm (0.02 in)

Note: The above dimensions do not include the front panel thickness, eject button and some projecting.

41.2±0.5 mm

(1.62 inch)

101.6±0.5 mm

(4.00 inch)

101.6±0.5 mm

146±0.5 mm

3.8±0.5 mm

(0.15 inch)

SDT-10000/SDT-11000

Figure 2-1 Dimensions

(4.00 inch)

(5.75 inch)

41.2±0.5 mm

(1.62 inch)

SONY SDT-10000/SDT-11000 DDS Tape Drive

2 - 1

2. SPECIFICATION

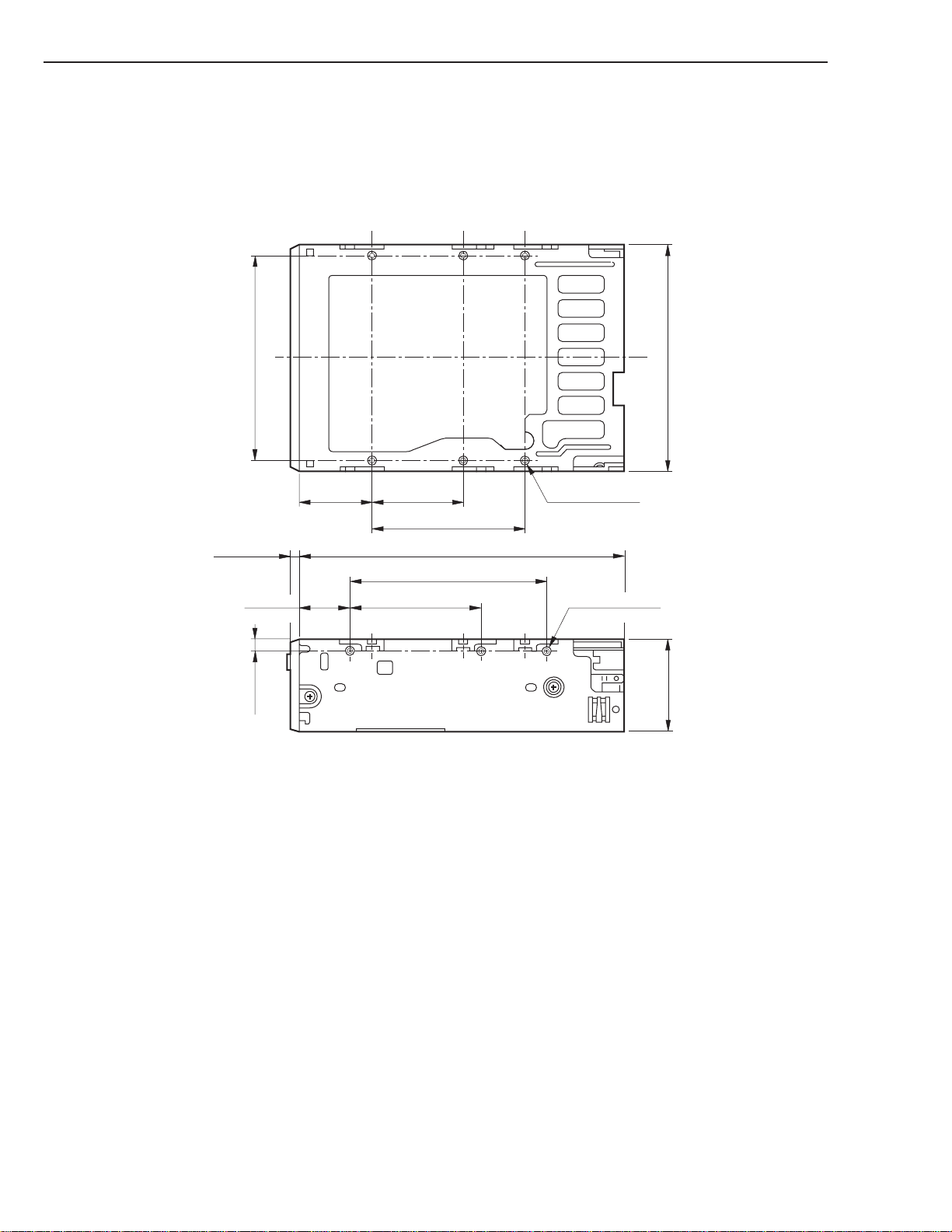

2. 1. 1. 1 Mounting Holes

Figure 2-2 gives details of the mounting holes for the drive.

94 ± 0.3 mm

3.8 ± 0.5 mm

(0.15 in)

21 ± 0.3 mm

(0.83 in)

5 ± 0.3 mm

(3.70 in)

(0.20 in)

31 ± 0.3 mm

(1.22 in)

42 ± 0.3 mm

(1.65 in)

70 ± 0.3 mm

(2.76 in)

146 ± 0.5 mm

(5.75 in)

90 ± 0.3 mm

(3.45 in)

60 ± 0.3 mm

(2.36 in)

SDT-10000/SDT-11000

Figure 2-2 Mounting Holes

6-M3 (DEPTH 3mm)

(DEPTH 0.12 in)

3-M3 (DEPTH 3mm)

(DEPTH 0.12 in)

(4.00 in)

101.6 ± 0.5 mm

(1.62 in)

41.2 ± 0.5 mm

2 - 2

Note: Mounting Screw Thread Length 2.5 mm. If the mounting screw thread length is exceeded, damage to the drive

may occur.

SONY SDT-10000/SDT-11000 DDS Tape Drive

2. SPECIFICATION

2. 1. 2 Weight

• SDT-10000/SDT-11000 - 600 grams (1 lb 5 oz), without a cassette

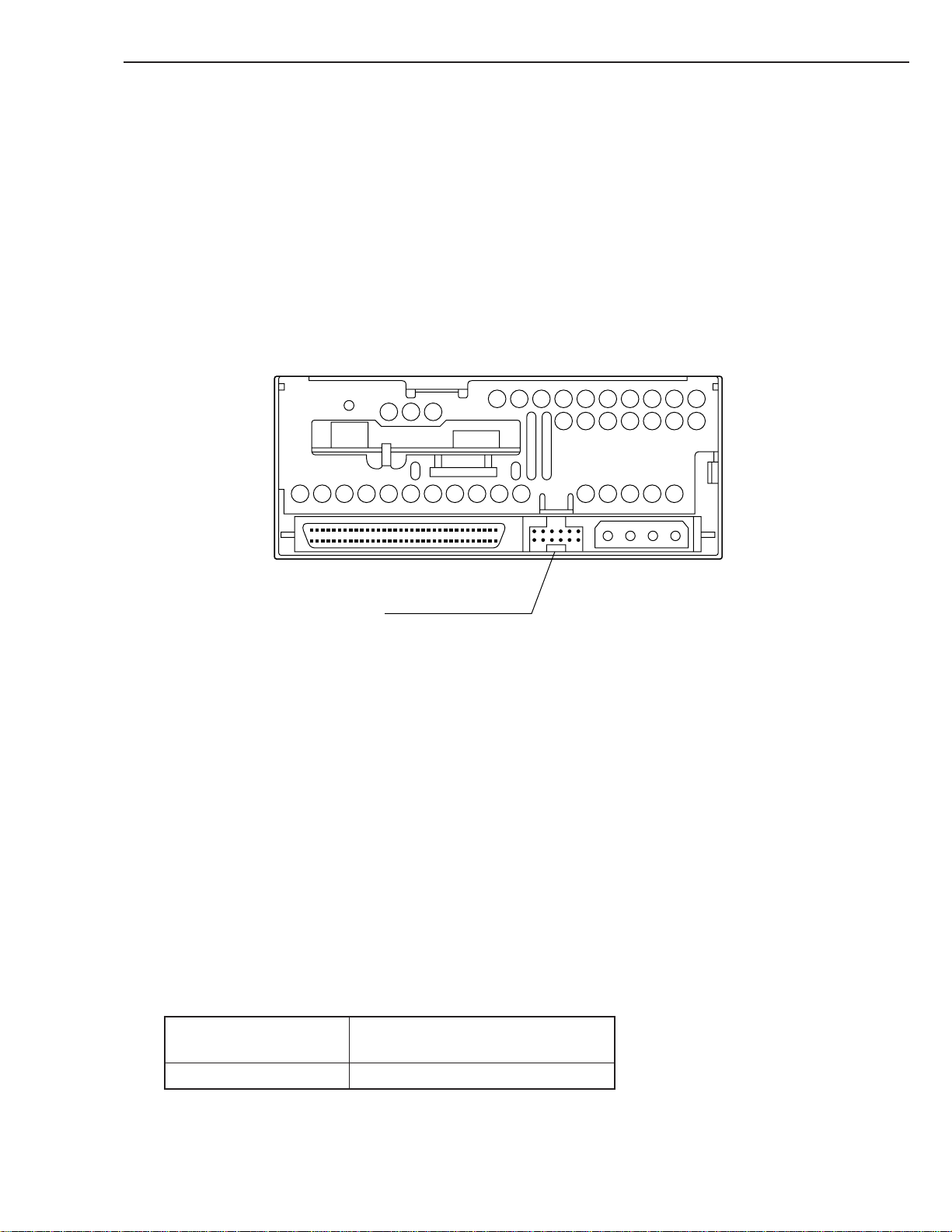

2. 1. 3 Connectors

The SDT-10000/SDT-11000 has a SCSI connector with a power connector at the positions shown in Figure 2-3. All

other connectors are for use by Sony’s manufacturing and service facilities only.

SCSI & Power Connector

SDT-10000/SDT-11000

Figure 2-3 Connector Positions

2. 1. 3. 1 SCSI Cables and Terminators

The Single-Ended SCSI configuration is supported by SDT-10000 and SDT-11000.

The Low-Voltage-Differential SCSI configuration is supported by SDT-11000. The hardware specification of this interface can be found in Clause 3. Physical Characteristics, of the X3T10/1142D (SCSI Parallel Interface2) standard. Only

unshielded connectors are supported. Possible cable and connector sources are listed below. This does not imply that

these are the only sources for SCSI accessories.

Note: When using high speed data transfer with the SDT-10000/SDT-11000, it is recommended that total length of the

SCSI data cable not exceeded 1.5m for Single Ended SCSI configuration. As for Low-Voltage-differential SCSI

configuration for SDT-11000, less than 12m is recommended.

Cable 30 AWG Ribbon

Hitachi UL 20818 (or equivalent)

Connector AMP 1-786090-7 (or equivalent)

SONY SDT-10000/SDT-11000 DDS Tape Drive

2 - 3

2. SPECIFICATION

2. 2 ENVIRONMENTAL SPECIFICATIONS

Note: The specifications which apply when a medium is present may be different than these.

2. 2. 1 Temperature and Humidity Range

Temperature

Operating: 5°C to 40°C ( T<10°C/h)

Non-operating(mech): -40°C to 70°C ( T<20°C/h)

Non-operating(tape): -40°C to 45°C ( T<20°C/h)

Humidity

Operating: 20 to 80% RH, non-condensing

Non-operating(mech): 5 to 95% RH ( RH<30%/h)

Non-operating(tape): 20 to 80% RH ( RH<30%/h)

Maximum wet bulb temperature=26°C

2. 2. 2 Altitude

Operating: 0 to 2133 m (0 to 7000 feet)

2. 2. 3 Dust

Operating: Less than 150 microgram/m

Based Sampling period 24 hours

2. 2. 4 Vibration

Operating: Swept Sine 5 to 500 Hz

@ 0.25 G Peak 1 Octave/min.

3 axis, 3 directions

Non-operating: Swept Sine 5 to 500 Hz

@ 0.5 G Peak 1 Octave/min.

3 axis, 3 directions

2. 2. 5 Shock

Operating: No Data Loss

Half Sine

5 G Peak 3 ms

3 axes, 3 directions

Interval 10 seconds

3

2 - 4

Non-operating: No Device Damage

Half Sine

90 G Peak 3 ms

(30 G Peak 11 ms)

3 axes, 3 directions

SONY SDT-10000/SDT-11000 DDS Tape Drive

2. SPECIFICATION

2. 2. 6 Acoustic Noise

The ambient noise level is no greater than 25db (A). The sound-meter on (A) scale is located 1m in front of the center

of the unit front panel.

Streaming Write/Read 35 db (A)

Insert/Eject 60 db (A)

(A): A curve weight

2. 2. 7 ESD

Discharge Voltage

Less than 15kV: No operation failure

Less than 20kV: No drive damage

2. 2. 8 Orientation

The SDT-10000/SDT-11000 can be installed in three different mounting positions as shown in the figure below. Each

position has a maximum tolerance of +/– 10 degrees.

10°10

°

10

°

10

10°10

°

°

10°10

°

Figure 2-4 Mounting Attitude and Tolerance

SONY SDT-10000/SDT-11000 DDS Tape Drive

2 - 5

2. SPECIFICATION

2. 3 PERFORMANCE SPECIFICATION

The data capacity, data transfer rate and data reliability specifications in this chapter require the media to conform to the

DDS-4 Media Specification and also require the drive and media to remain within their respective operating and nonoperating environmental specifications. The specifications below also assume that the C3 ECC frame is generated on

writing and used as necessary on reading, and further assumes that read-after-write rewrites are used as necessary on

writing.

2. 3. 1 Data Capacity

The native (uncompressed) capacities of different length cartridges are as follows. Note that 60 m and 90 m cartridges

are automatically written in DDS-1 format, only 120 m cartridges are written in DDS-2 format, and only 125 m cartridges are written in DDS-3 format, and only 150 m cartridges are written in DDS-4 format

Length Format Native Capacity

60 m DDS-1 1.3 GB typical

90 m DDS-1 2.0 GB typical

120 m DDS-2 4.0 GB typical

125 m DDS-3 12.0 GB typical

150 m DDS-4 20.0 GB typical

The SDT-10000/SDT-11000 includes a data compression capability. When data compression is enabled that the drive

capacity can increase typically twice. The efficiency of the data compression depends on the actual data that is being

compressed and cannot be predicted precisely prior to compression.

Sustained transfer rate

Format W/O Compression W/Compression *1

DDS-1 778 KB/S 1556 KB/S

DDS-2 778 KB/S 1556 KB/S

DDS-3 2360 KB/S 4720 KB/S

DDS-4 2360 KB/S 4720 KB/S

2. 3. 2 Data Transfer Rate

2. 3. 2. 1 Sustained Data Transfer Rate To and From Tape

The sustained transfer rates to and from the tape are as follows. For this sustained rate to be achieved, the drive must be

streaming. There may be some dependency on the host for this to be achieved.

*1 This is assuming 2:1 Compression ratio.

The degree of data compression attained while recording data varies according to system environment and data type.

2. 3. 2. 2 Burst Data Transfer Rate To and From the SCSI Bus

The SDT-10000/SDT-11000 will transmit and receive data bursts to and from the SCSI bus at a maximum burst rate of

14 megabytes per second, using WIDE SCSI asynchronous transfers and 40 megabytes per second, using WIDE SCSI

synchronous transfers.

2 - 6

2. 3. 3 Initialize Time

Initialize Time means the period from the time the drive is powered on to the time when the drive is ready and waiting

for a SCSI command such as INQUIRY or TEST UNIT READY.

Initialize Time is less than 1 seconds.

Note: The drive will respond with BUSY status until the completion of the Initialize Time.

Note: The Initialize Time does not include the time necessary for drive diagnostics to complete and the drive to become

ready for tape insertion.

SONY SDT-10000/SDT-11000 DDS Tape Drive

2. SPECIFICATION

2. 3. 4 Load Time

Load Time means the period from the time when the operator inserts a cassette into the drive to the time when the drive

is ready.

Load Time is less than 24 seconds (for a single partition tape).

2. 3. 5 Rewind Time

Rewind Time means the period from the beginning to the end of rewinding sequence. This value depends on the tape

length and the position of the head along the tape.

Rewind Time is less than 80 seconds, when a 150 meter tape is loaded.

2. 3. 6 Search Time

Search Time means the period for the drive to find the position that is required by a command. This time also depends

on the tape length and the position of the head along the tape.

Search Time is less than 90 seconds, when a 150 meter tape is loaded.

2. 3. 7 Unload Time

Unload Time means the period from the beginning of the unload sequence caused by Unload Command or Eject button

to the time when a cassette is ejected from the slot.

Unload Time does not include Rewind time.

Unload Time is less than 20 seconds (for a single partition tape).

2. 3. 8 Error Rate

The uncorrectable bit error rate is expected to be less than 10

-15

. For further details, refer to “Designing a Data Storage

Format for Digital Audio Tape (DAT)”, produced by the DDS Manufacturers Group.

2. 3. 9 Retry Limits on Rewrites

For Read-After-Write error correction, each frame can be rewritten up to a maximum of 255 times giving 256 writes of

the frame. With N-Group writing, where every group is written a fixed number of times, the upper limit is 8.

N-Group writing is not supported by DDS-3 and DDS-4.

2. 3. 10 Definition of Failure

A failure is defined as any permanent malfunction of the drive that prevents the user from retrieving data from tape. This

includes failure to power up, failure to unload or eject a cassette, or failure to write and read data to and from the tape,

providing that both the drive and tape are being used within specification.

Faults are not considered failures when they are related to operator error, mishandling and abuse, system-related faults

(cabling problems, unsupported systems, operating software, and so on), no trouble found, and transportation damage.

2. 3. 11 Mean Time Between Failures

The Mean Time Between Failures (MTBF) for the SDT-10000/SDT-11000 is 250,000 power-on hours, assuming a duty

cycle of 40%, where:

Duty cycle = × 100

Tape Motion Time

Power-on Time

12.5% is assumed as a typical usage level.

2. 3. 12 Mean Time To Repair

The Mean Time To Repair (MTTR) of the SDT-10000/SDT-11000 is 30 minutes. Since at the field level the entire drive

is considered a Field Replaceable Unit (FRU) the time to replace the drive with a new one is less that 30 minutes.

SONY SDT-10000/SDT-11000 DDS Tape Drive

2 - 7

2. SPECIFICATION

2. 3. 13 Component Life

The specified life of the SDT-10000/SDT-11000 is 8 years average.

The usage model for this specification is as follows.

3 hours tape pulling time per day

6 days usage per week

The SDT-10000/SDT-11000 is equivalent to 7,500 hours tape-pulling life.

2. 3. 14 Durability

The durability of the components in the SDT-10000/SDT-11000 will exceed the number of operations listed on the

following table:

Start/Stop 400,000 times

Reposition 3,000,000 times

Thread/Unthread 10,000 times

Load/Eject 10,000 times

2. 4 SAFETY

The SDT-10000/SDT-11000 conforms to the following safety standards:

• Underwriters Laboratories, Inc.

UL 1950 (Third Edition), Safety of Information Technology Equipment, Including Electrical Business Equipment.

• Canadian Standards Association

CSA-C22.2 No. 950 (CUL), Safety of Information Technology Equipment, Including Electrical Business Equipment.

• TUV

EN 60950: 1992 + A1 + A2 + A3 + A4 + A11 Safety of Information Technology Equipment, Including Electrical

Business Equipment.

• CE Mark

2. 4. 1 Conditions of Acceptability

The SDT-10000/SDT-11000 is for use only in equipment where the suitability of the combination has been determined

by an appropriate certification organization (for example, Underwriters Laboratories, Inc. or the Canadian Standards

Association in North America, and the British Standards Institution or Verband Deutscher Elektrotechniker in Europe).

Other considerations include the following:

1. An enclosure must be supplied to limit the operator’s access to live parts, to provide system stability, and to

furnish the drive with the necessary grounding integrity.

2. The necessary voltage supplies must be provided. These supplies are Extra Low Voltage SEC for UL and CSA,

or Safety Extra Low Voltage for BSI, VDE, and so on, of +5V and +12V DC.

2 - 8

SONY SDT-10000/SDT-11000 DDS Tape Drive

2. SPECIFICATION

2. 5 INSTALLATION REQUIREMENTS

2. 5. 1 Power Requirements

SDT-10000/SDT-11000

Voltage

5V +/-5%

12V +/-10%

Max Ripple

100 mV p-p

100 mV p-p

Current

Maximum

(Load/Unload)

2.0 A

1.6 A

Typical

(Write/Read)

1.0 A

0.3 A

SONY SDT-10000/SDT-11000 DDS Tape Drive

2 - 9

3. INSTALLATION

5

5

5

5

5

5

5

3. 1 SCSI Connection/Setting the SCSI ID ..................................................................... 3-1

3. 1. 1 SCSI ID Number Jumper ............................................................................. 3-2

3. 1. 2 Parity Enable Jumper.................................................................................. 3-2

3. 1. 3 Power Connector......................................................................................... 3-2

3. 1. 4 SCSI 68 pin Connector................................................................................ 3-3

3. 2 Option Switches (DIP Switch).................................................................................. 3-4

3. 2. 1 Termination Power Switch.......................................................................... 3-4

3. 2. 2 Data Compression ON switch .................................................................... 3-5

234

234

234

234

234

234

234

3. Installation

3 INSTALLATION

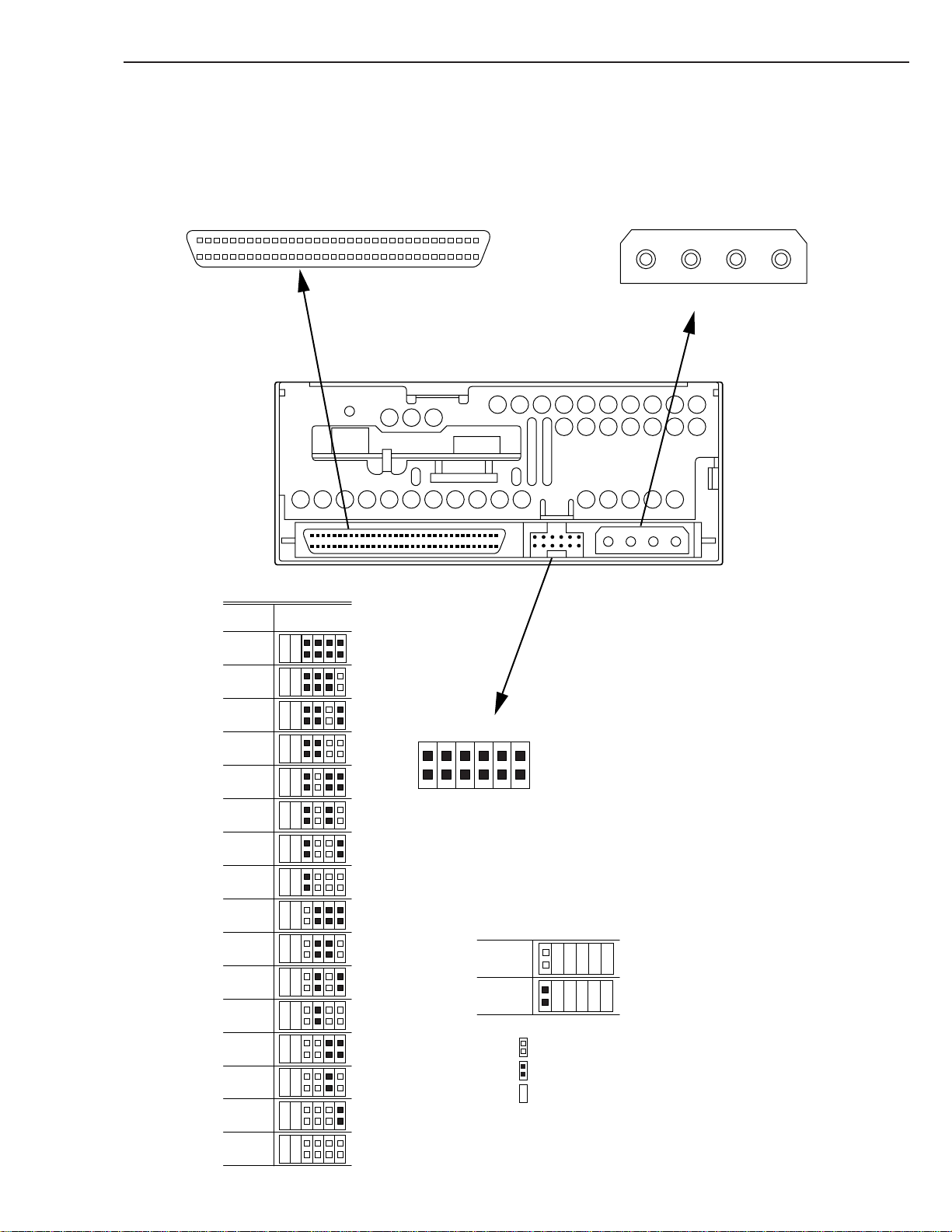

3. 1 SCSI CONNECTION/SETTING THE SCSI ID

Pin 34

Pin 68

SCSI 68 pin connector (Non-Shielded)

SCSI ID

321

SCSI ID

0

P.E.

R.

0

35

1

power connector

4321

GND GND 12V5V

10

11

12

13

14

1

2

3

4

5

6

7

8

9

Parity Enable

Jumpers

Reserved

SCSI ID 3

Parity

Disable

Note :

SCSI ID 2

SCSI ID 1

Enable

SCSI ID 0

= CLOSE/Jumper

= OPEN/Jumper not installed

Don’t care

15

SONY SDT-10000/SDT-11000 DDS Tape Drive

3 - 1

3. Installation

3. 1. 1 SCSI ID Number Jumper

The SCSI ID number of the SDT-10000/SDT-11000 is selected by the SCSI ID number jumpers. The figure below

shows the jumper configuration for each of the possible SCSI IDs.

SCSI ID ID3 ID2 ID1 ID0

0 ::::

1 :::|

2 ::|:

3 ::||

4 :|::

5 :|:|

6 :||:

7 :|||

8 |:::

9 |::|

10 |:|:

11 |:||

12 ||::

13 ||:|

14 |||:

15 ||||

: = OPEN Jumper not installed

| = CLOSED Jumper installed

3. 1. 2 Party Enable Jumper

Parity check function can be disabled by jumper. Parity check is disabled while left end jumper is installed. Parity

generate function is always enabled.

Parity Setting

Enable |

Disable :

: = OPEN Jumper not installed

| = CLOSED Jumper installed

3. 1. 3 Power Connector

The power connector is illustrated as Figure 3-1

4321

3 - 2

GND GND 12V5V

Figure 3-1: Power Connector

SONY SDT-10000/SDT-11000 DDS Tape Drive

3. Installation

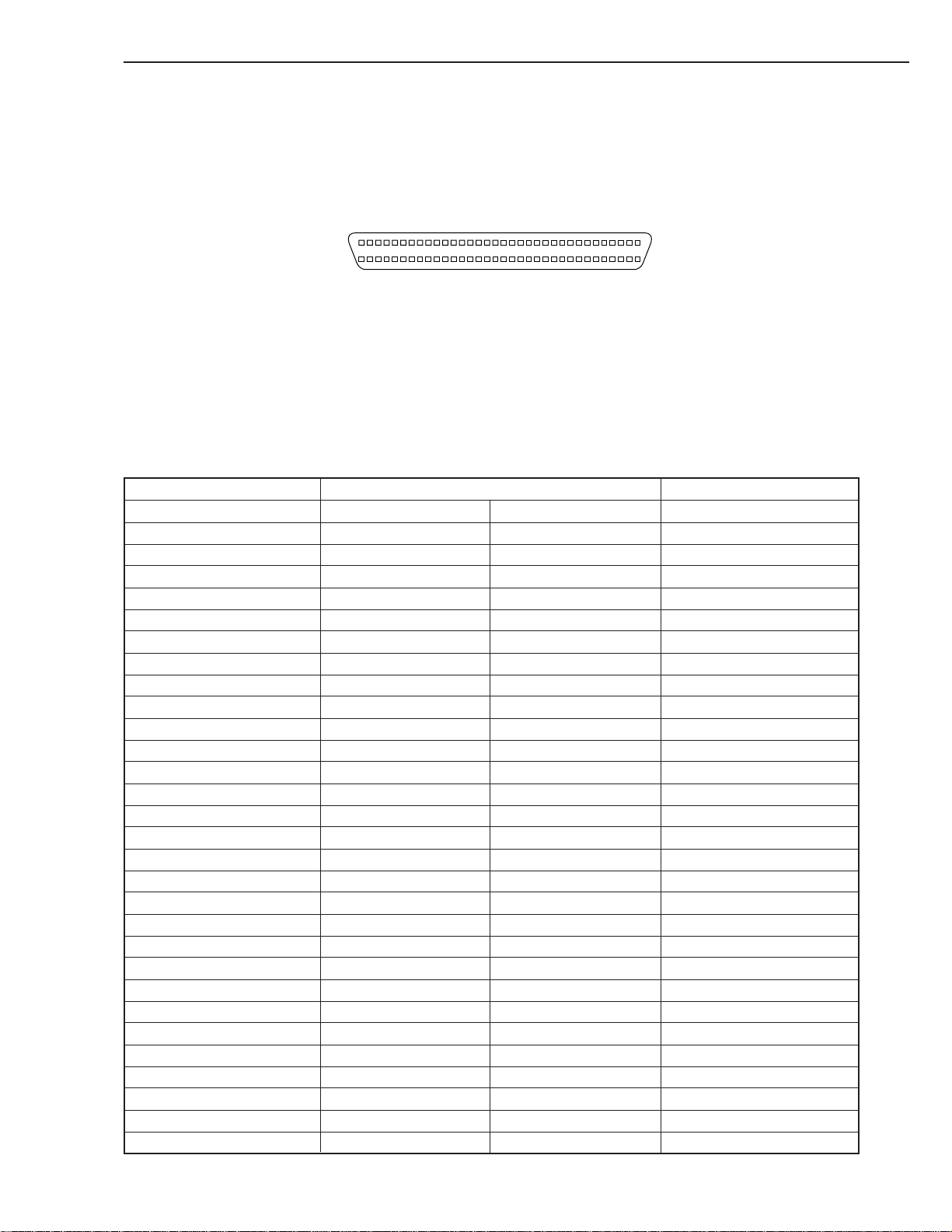

3. 1. 4 SCSI 68 pin Connector

Figure 3-2 illustrates SCSI 68 pin connector, and table 3-1 shows the assignments for the pins of the connector.

Pin 34

Pin 68

1

35

Figure 3-2: Non-shielded SCSI Device Connector

SDT-11000 supports Low-Voltage-Differential SCSI configuration as shown table 3-1. SDT-10000 and SDT-11000

support Single-Ended SCSI configuration as shown table 3-2. SDT-11000 detects and switches SCSI configuration

between Low-Voltage-Differential and Signal-ended modes by monitoring DIFSENS signal assigned pin 16 SCSI bus.

(refer to table 3-1)

Table 3-1: SDT-11000 SCSI Signals (Low-Voltage-Differential Type BUS P Cable Signal Assignment)

Signal Name Cable Conductor Number Signal Name

-DB(12) 35 1 +DB(12)

-DB(13) 36 2 +DB(13)

-DB(14) 37 3 +DB(14)

-DB(15) 38 4 +DB(15)

-DB(P1) 39 5 +DB(P1)

-DB(0) 40 6 +DB(0)

-DB(1) 41 7 +DB(1)

-DB(2) 42 8 +DB(2)

-DB(3) 43 9 +DB(3)

-DB(4) 44 10 +DB(4)

-DB(5) 45 11 +DB(5)

-DB(6) 46 12 +DB(6)

-DB(7) 47 13 +DB(7)

-DB(P) 48 14 +DB(P)

GROUND 49 15 GROUND

GROUND 50 16 DIFFSENS

TERMPWR 51 17 TERMPWR

TERMPWR 52 18 TERMPWR

RESERVED 53 19 RESERVED

GROUND 54 20 GROUND

-ATN 55 21 +ATN

GROUND 56 22 GROUND

-BSY 57 23 +BSY

-ACK 58 24 +ACK

-RST 59 25 +RST

-MSG 60 26 +MSG

-SEL 61 27 +SEL

-C/D 62 28 +C/D

-REQ 63 29 +REQ

-I/O 64 30 +I/O

SONY SDT-10000/SDT-11000 DDS Tape Drive

3 - 3

3. Installation

Table 3-2: SDT-10000/SDT-11000 SCSI Signals (Signal Ended Type BUS P Cable Signal Assignment)

Signal Name Cable Conductor Number Signal Name

-DB(8) 65 31 +DB(8)

-DB(9) 66 32 +DB(9)

-DB(10) 67 33 +DB(10)

-DB(11) 68 34 +DB(11)

Signal Name Cable Conductor Number Signal Name

-DB(12) 35 1 GROUND

-DB(13) 36 2 GROUND

-DB(14) 37 3 GROUND

-DB(15) 38 4 GROUND

-DB(P1) 39 5 GROUND

-DB(0) 40 6 GROUND

-DB(1) 41 7 GROUND

-DB(2) 42 8 GROUND

-DB(3) 43 9 GROUND

-DB(4) 44 10 GROUND

-DB(5) 45 11 GROUND

-DB(6) 46 12 GROUND

-DB(7) 47 13 GROUND

-DB(P) 48 14 GROUND

GROUND 49 15 GROUND

GROUND 50 16 GROUND

TERMPWR 51 17 TERMPWR

TERMPWR 52 18 TERMPWR

RESERVED 53 19 RESERVED

GROUND 54 20 GROUND

-ATN 55 21 GROUND

GROUND 56 22 GROUND

-BSY 57 23 GROUND

-ACK 58 24 GROUND

-RST 59 25 GROUND

-MSG 60 26 GROUND

-SEL 61 27 GROUND

-C/D 62 28 GROUND

-REQ 63 29 GROUND

-I/O 64 30 GROUND

-DB(8) 65 31 GROUND

-DB(9) 66 32 GROUND

-DB(10) 67 33 GROUND

-DB(11) 68 34 GROUND

3 - 4

SONY SDT-10000/SDT-11000 DDS Tape Drive

3. Installation

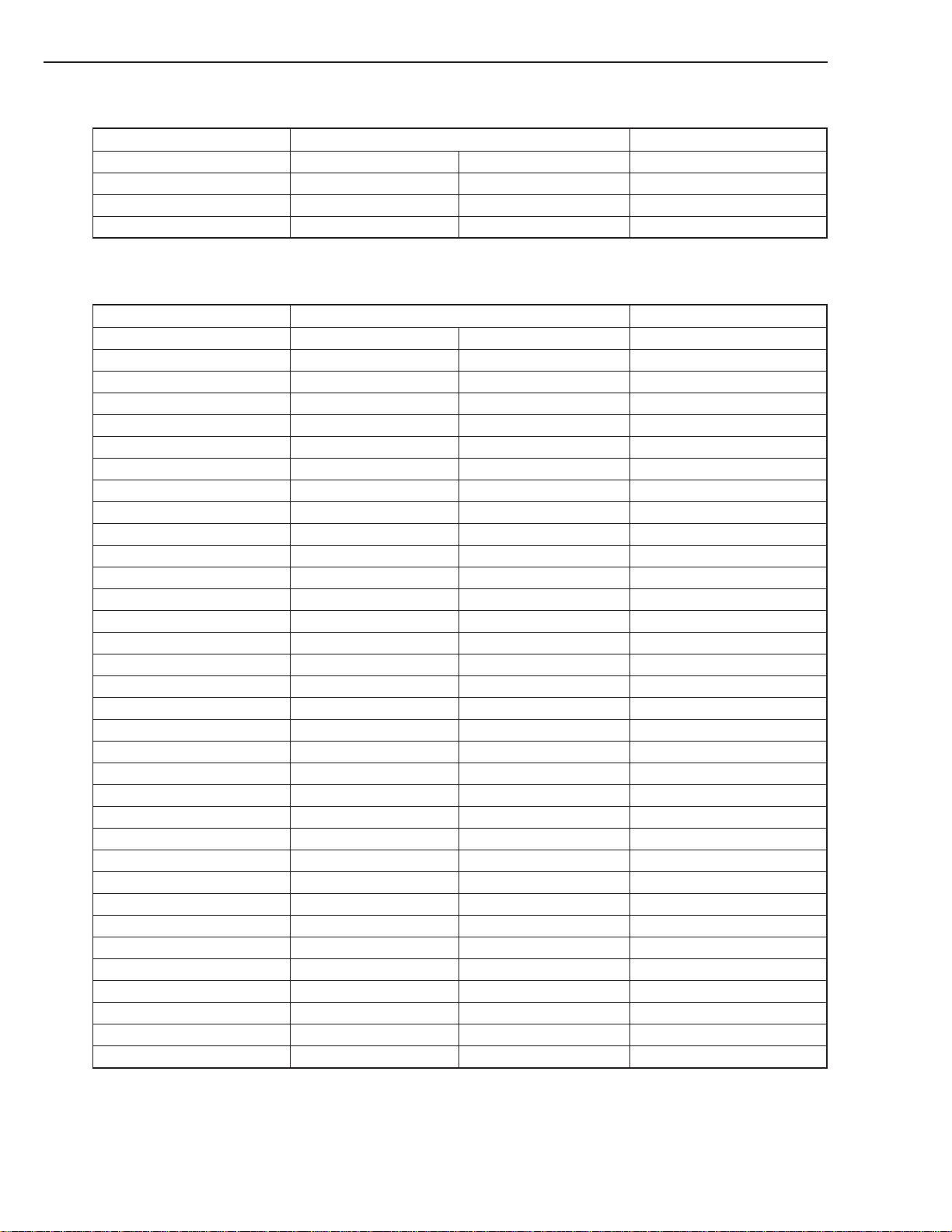

3. 2 OPTION SWITCHES (DIP SWITCH)

UNLOAD

N

O

1234567

3. 2. 1 Termination Power Switch

N

O

1234567

8

1 Reserved (OFF)

2 Reserved (OFF)

3 Reserved (OFF)

8

4 Reserved (OFF)

5 Terminator Power (ON)

6 Reserved (OFF)

7 DC Control-1 (ON)

8 DC Control-2 (OFF)

( ) …default setting

Position 5 of DIP switch is used to set whether SDT-10000/SDT-11000 provides the termination power to pin 17, 18, 51,

52 on SCSI bus, or not.

SONY SDT-10000/SDT-11000 DDS Tape Drive

3 - 5

3. Installation

3. 2. 2 Data Compression ON switch

Data compression can be selected by DIP switch.

DC Control-1 DC Control-2

OFF OFF

OFF ON

ON OFF

ON ON

Table 3-2: Data Compression Switches

Definition

Compression disabled at power-on. The host is allowed to control

compression.

Compression disabled at power-on. The host is not allowed to control compression.

Compression enabled at power-on. The host is allowed to control

compression.

Compression enabled at power-on. The host is not allowed to control compression.

3 - 6

SONY SDT-10000/SDT-11000 DDS Tape Drive

4. OPERATION

5

5

5

5

5

5

5

4. 1 SUMMARY OF LED INDICATIONS........................................................................... 4-1

4. 2 OPERATOR ACTION................................................................................................. 4-3

4. 3 INTERNAL FUNCTION ............................................................................................. 4-4

4. 4 TAPE FORMAT......................................................................................................... 4-7

4. 5 MAINTENANCE, TROUBLESHOOTING AND SERVICE ....................................... 4-8

4. 6 DATA COMPRESSION........................................................................................... 4-11

4. 2. 1 Powering up the SDT-10000/SDT-11000.................................................... 4-3

4. 2. 2 Inserting Cassettes ..................................................................................... 4-3

4. 2. 3 Removing Cassettes ................................................................................... 4-3

4. 2. 4 Write-Protecting Cassettes......................................................................... 4-3

4. 3. 1 The Load Sequence..................................................................................... 4-4

4. 3. 2 The Unload Sequence ................................................................................. 4-4

4. 3. 3 Power-Fail Handling .................................................................................... 4-4

4. 3. 4 Diagnostic and Normal Status Displays.................................................... 4-4

4. 3. 4. 1 Diagnostic Status Display ......................................................... 4-4

4. 3. 4. 1. 1 Front Panel Test.................................................... 4-5

4. 3. 4. 1. 2 Kernel Test ............................................................ 4-5

4. 3. 4. 2 Normal Status Display ............................................................... 4-6

4. 3. 4. 3 Media Warning............................................................................ 4-6

4. 4. 1 Tape Partitions............................................................................................. 4-7

4. 4. 1. 1 Formatting Partitions................................................................. 4-7

4. 5. 1 Head Cleaning.............................................................................................. 4-8

4. 5. 2 Troubleshooting Guide ............................................................................... 4-8

4. 5. 2. 1 Operational Problems ................................................................ 4-8

4. 5. 2. 2 Read/Write Problems ............................................................... 4-10

4. 5. 3 Clearance for Service................................................................................ 4-10

4. 5. 4 Packaging for Return to Sony .................................................................. 4-10

234

234

234

234

234

234

234

4. OPERATION

4 OPERATION

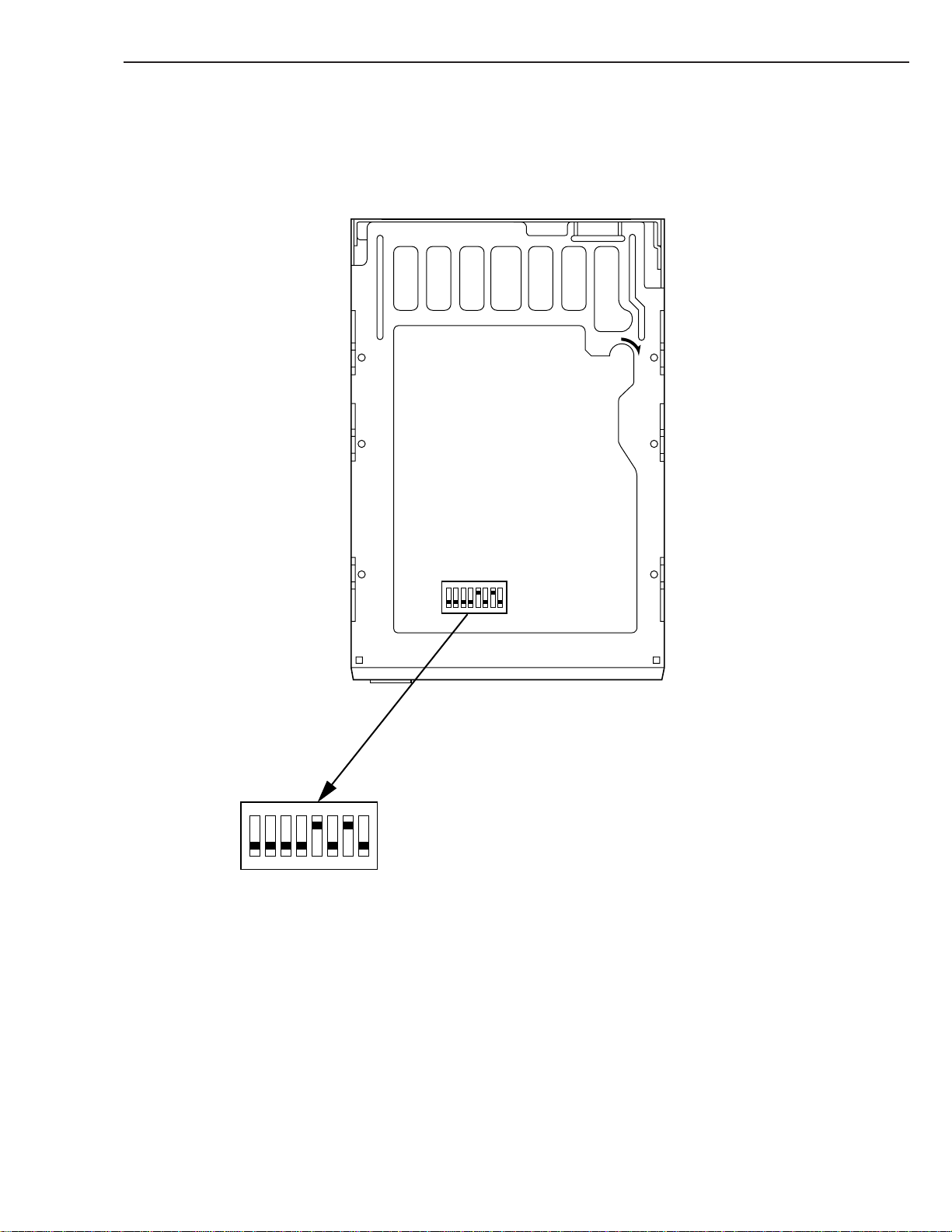

4. 1 SUMMARY OF LED INDICATIONS

The SDT-10000/SDT-11000 LEDs have five (5) different methods of reporting the current status/operation of the drive:

LED function Meaning

Off Not active

On Activity

Flashing-1 Drive Activity

Flashing-2 Warning

Flash code 1, 2 Failure

Table 4-1: Possible LED indication meanings

The following table shows the meaning of each of the possible combinations of LED indications:

LED Busy Tape Status

Off Not Busy Unloaded

On SCSI active Loaded Write Protected

Flashing-1 Drive active Loading/Unloading Cleaning Tape at EOM

Flashing-2 Error Rate Warning Cleaning Request

Flash code 1 Waiting for Reset Waiting for Eject

Flash code 2 Illegal FW Tape Selftest Failure

Table 4-2: Meaning of each LED indications

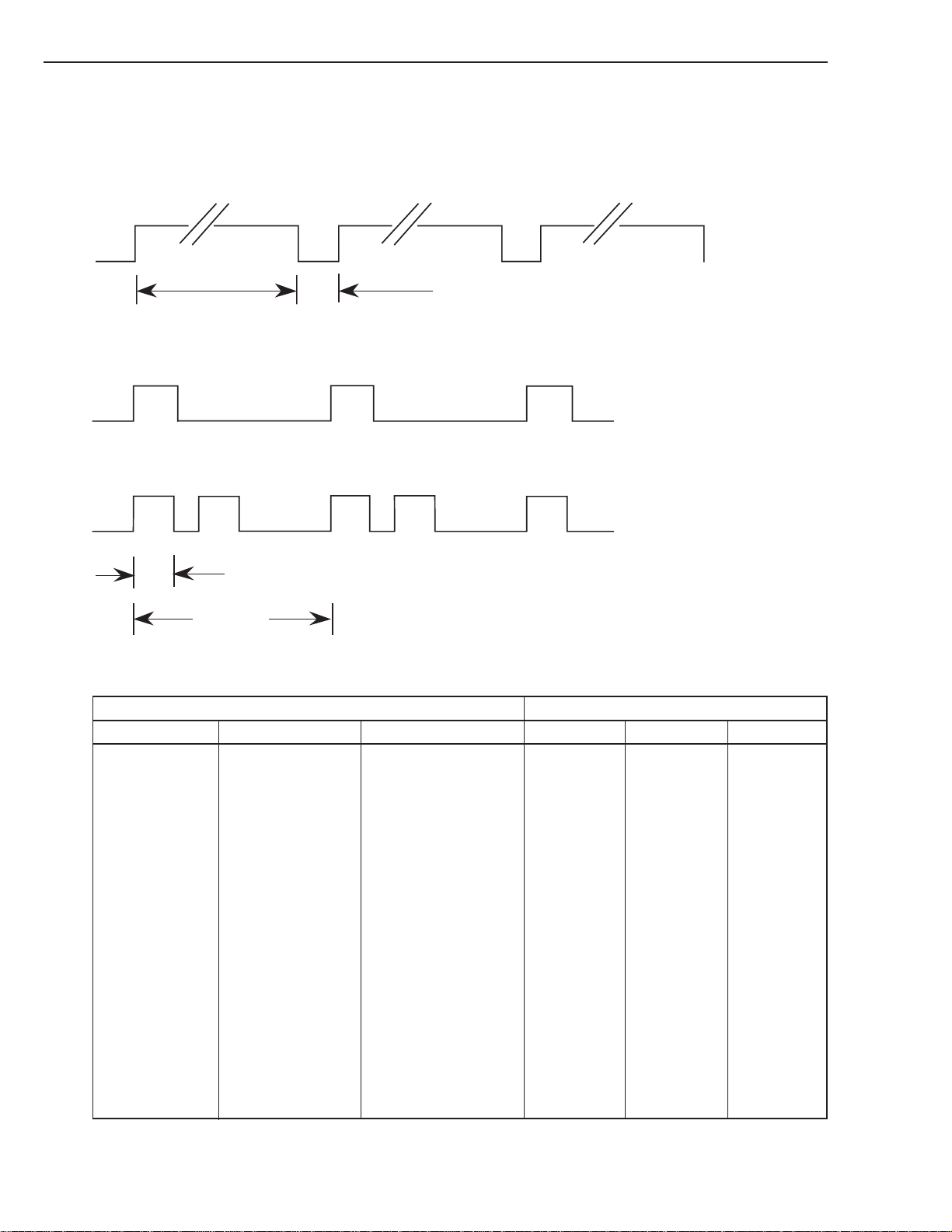

Flashing-1

0.25sec on / 0.25sec off

0.25sec

SONY SDT-10000/SDT-11000 DDS Tape Drive

4 - 1

4. OPERATION

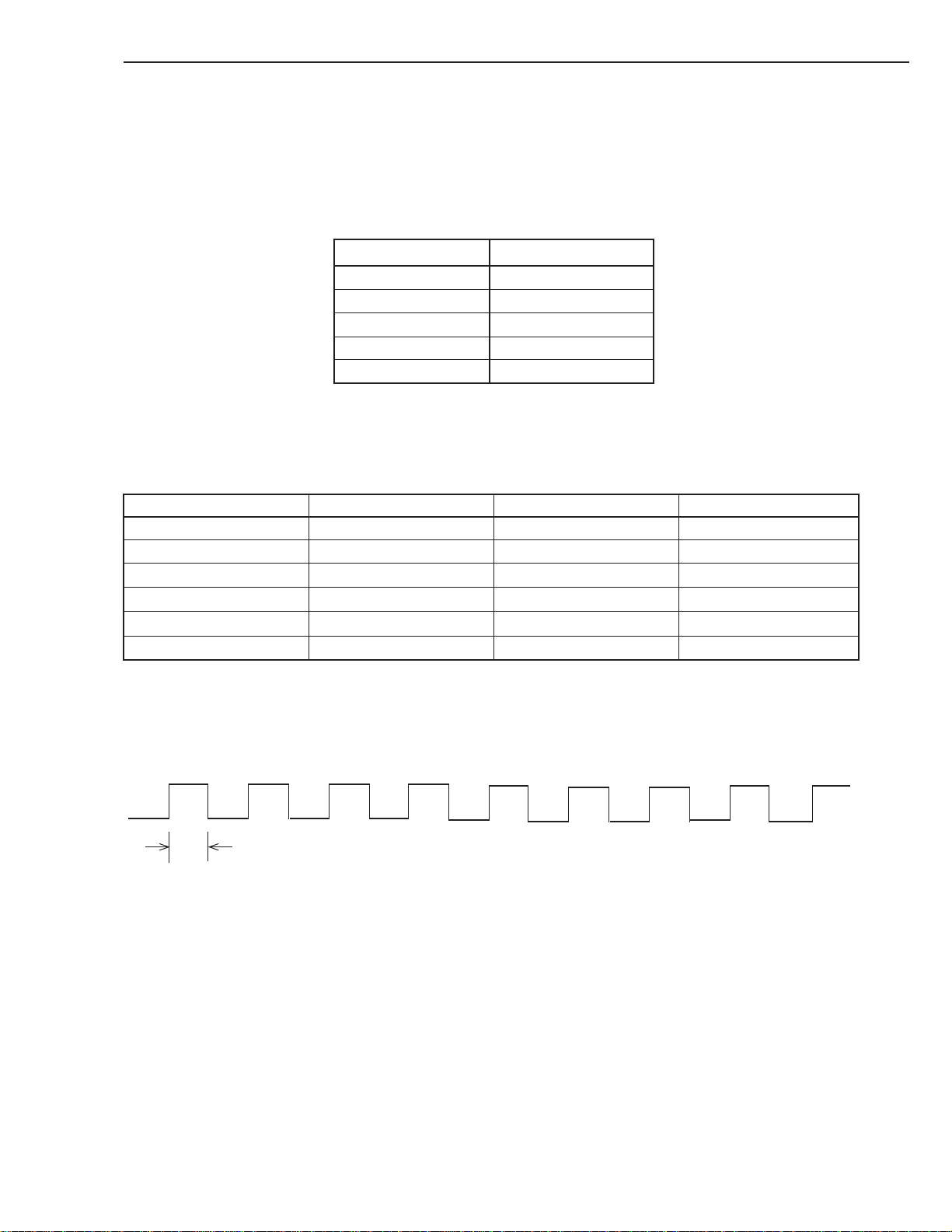

Flashing-2

3.5sec on / 0.5sec off

3.5 sec

0.5 sec

Flash Code LED Indication:

Flash code 1 (one pulse)

Flash code 2 (two pulses)

0.25sec

1.25sec

The following table shows the LED indication for each drive status/condition:

STATE LED

Activity Cartridge Other Busy Tape Status

None None None off off off

SCSI None None on off off

Drive Loading/Unloading None Flashing-1 Flashing-1 off

Drive Loading/Unloading Write Protected Flashing-1 Flashing-1 on

None Loaded Cleaning Tape off on Flashing-1

at EOM

None Loaded None off on off

SCSI Loaded None on on off

SCSI/Drive Loaded None Flashing-1 on off

* Loaded Write Protected * on on

* Loaded Error Rate Warning * Flashing-2

* * Cleaning Request * * Flashing-2

* * Selftest Failure * * Flash code 2

* * Waiting for Reset Flash code 1 * *

* * Waiting for Eject * Flash code 1 *

Illegal FW Tape * Flash code 2 *

Front Panel Test See 4.3.5.1

4 - 2

Table 4-3: LEDs indications for each state

SONY SDT-10000/SDT-11000 DDS Tape Drive

4. OPERATION

4. 2 OPERATOR ACTION

4. 2. 1 Powering up the SDT-10000/SDT-11000

After the initial installation of the SDT-10000/SDT-11000 has been verified, power can be applied to the unit. The

+12V and +5V power must be applied simultaneously. The SDT-10000/SDT-11000 will execute a power-up diagnostic

and then comes ready.

Once the tape has been loaded the SDT-10000/SDT-11000 sends a CHECK CONDITION response on receipt of the

next SCSI command from the host. The UNIT ATTENTION key is set in the returned REQUEST SENSE data to

indicate that the tape may have been changed. (Sense Key/ASC/ASCQ = 06/28/00)

4. 2. 2 Inserting Cassettes

The operator inserts a cassette into the slot on the front panel with the arrow on the cassette pointing towards the drive.

As the cassette is inserted, the drive takes it and automatically loads it into the drive mechanism. The SDT-10000/SDT11000 performs a tape load sequence as described in section 4.3.1.

4. 2. 3 Removing Cassettes

The cassette can be removed from the SDT-10000/SDT-11000 either in response to a SCSI UNLOAD command, or by

pressing the Eject button.

The operator uses the Eject button to initiate the unload sequence (see section 4.3.2). The mechanism winds the tape to

Beginning of Media (BOM), unthreads it, and ejects the cassette from the slot.

Note: Operation of the Eject button is disabled if the host has previously sent a SCSI PREVENT ALLOW MEDIA

REMOVAL command with prevent bit set to one. In this case, pressing the Eject button has no effect, and does

not initiate an Unload sequence. The Eject button returns to normal operation following receipt of a PREVENT

ALLOW MEDIA REMOVAL command with prevent bit clear.

4. 2. 4 Write-Protecting Cassettes

Cassettes can be write-protected by sliding the tab on the back of the cassette open. In this state, data can be read from

the tape but not written to it.

When a Write Protected tape is loaded in the drive the Tape and Status LEDs will be lit. The Busy LED will indicate any

activity on the SCSI bus or mechanical motions in the drive itself.

Caution: The Tape Log, which contains a history of usage of the tape, will not be updated when the cassette is write-

protected. It follows that the Tape Log becomes inaccurate if a cassette is used write-protected, and the media

warning cannot be relied on to indicate that the cassette needs to be copied and replaced.

SONY SDT-10000/SDT-11000 DDS Tape Drive

4 - 3

4. OPERATION

4. 3 INTERNAL FUNCTION

4. 3. 1 The Load Sequence

During load sequence, the following occurs:

1. The drive mechanism accepts the cassette, threads the tape and rewinds to Beginning-of-Media (BOM). The tape is

then moved to Beginning-of-Tape (BOT) and the Reference area is checked to find the tape format (DDS-4, DDS3, DDS-2, DDS and DDS-DC, blank, audio, and so on). If the format is not DDS-4, DDS-3, DDS-2, DDS and DDSDC, the drive rewinds the tape to BOT and awaits either a WRITE, Partitioning MODE SELECT or an

UNLOAD command.

2. The System area is then accessed and the System log read into the drive.

3. Finally the drive goes online.

In the case of two partition tape the drive detects that the tape has been formatted as a two partition tape when the

Reference Area is read. The drive will then automatically position to the beginning of partition 0 before coming on-line.

Partition 0 is the partition that begins the furthest from BOM.

4. 3. 2 The Unload Sequence

The drive will always write any buffered data out to tape followed by an EOD prior to initiating the Unload sequence.

During this sequence the tape is rewound to BOT and, if the tape is write-enabled, the copy of the tape log held in RAM

is written back to tape. The tape is then rewound to BOM and the tape unthreaded from the mechanism. At this stage the

tape is either retained in the drive or ejected, depending on media removal is enabled by the PREVENT ALLOW

MEDIA REMOVAL command.

In the case of two partition tape the drive detects that the tape has been formatted as a two partition tape when the

Reference Area is read during the load sequence. When the Unload operation begins the drive will then automatically

update the Tape Log for each partition before unloading the tape.

4. 3. 3 Power-Fail Handling

If there is a power-fail, the SDT-10000/SDT-11000 performs the following actions, and reverts to its default configuration:

1. The drive remains positioned at the point where the power-fail or SCSI Reset occurred.

2. It executes the Power-Up sequence of self-tests. (When power is restored.)

3. If a tape is in the drive, the SDT-10000/SDT-11000 starts a load sequence.

The drive rewinds the tape to BOT and remains on-line.

4. The drive returns CHECK CONDITION status for the first command after the power-fail or Reset. The next

command from the initiator should be a REQUEST SENSE. The drive will return sense data including a sense key

that will indicate that the drive has been reset. (Sense Key / ASC / ASCQ = 06/29/00)

4. 3. 4 Diagnostic and Normal Status Displays

This chapter describes LED displays while the SDT-10000/SDT-11000 is starting up. When power is turned on, the

SDT-10000/SDT-11000 will go through its diagnostics to reach normal status. When a failure is detected during diagnostics, the LEDs show that the SDT-10000/SDT-11000 is out of order and needs to be repaired.

4. 3. 4. 1 Diagnostic Status Display

The SDT-10000/SDT-11000 starts with its Diagnostic function. This is made up of the Front Panel Test and the Kernel

Test.

4 - 4

SONY SDT-10000/SDT-11000 DDS Tape Drive

4. OPERATION

4. 3. 4. 1. 1 Front Panel Test

LED display sequence:

Busy

0.25 sec

0.25 sec

0.25 sec

0.25 sec

0.25 sec

0.25 sec

0.25 sec

0.25 sec

0.25 sec

0.25 sec

0.25 sec

0.25 sec

0.25 sec

Note: This function is for checking BUSY, STATUS and TAPE LEDs and the related circuits. No errors can be gener-

ated as this test is only for operator verification of indicator operation.

on

-

on

-

on

-

-

on

-

-

on

-

-

Tape

on

-

on

-

-

on

-

-

on

-

-

on

-

Status

on

-

on

-

-

-

on

-

-

on

-

-

on

Front Panel

Test

repeat until end of

Power On Diagnostic

4. 3. 4. 1. 2 Kernel Test

After the Front Panel Test, the SDT-10000/SDT-11000 checks its internal units.

Note: If a failure is detected, the SDT-10000/SDT-11000 displays the Failed Unit. Refer to section 4. 3. 4.

When a Diagnostic error occurs, the SDT-10000/SDT-11000 must be powered off. The SDT-10000/SDT-11000 will

not work and should be checked or repaired immediately.

Note: The purpose of the diagnostic firmware is to test the SDT-10000/SDT-11000 electronics for functionality. If the

diagnostic request comes from the host through SCSI, then the results are reported through SCSI.

If the electronics are not functioning, the diagnostic firmware tries to isolate the non-functional area to a specific Failed

Unit. Given a failure, the firmware decides on an hierarchical basis which Unit to designate as the Most Suspect Failed

Unit (MSFU). The confidence in this decision is intended to be 95%. The MSFU is identified and displayed on the front

panel as shown above section 4. 3. 4. For the details of Diagnostics, see section 7.

SONY SDT-10000/SDT-11000 DDS Tape Drive

4 - 5

Loading...

Loading...