DCR-TRV38/TRV38E/TRV39

RMT-814

SERVICE MANUAL

Ver 1.2 2003. 11

Revision History

Revision History

Photo : DCR-TRV38

Z MECHANISM

Link

Link

SPECIFICATIONS

BLOCK DIAGRAMS

BLOCK DIAGRAMS

LEVEL 2

US Model

Canadian Model

DCR-TRV38/TRV39

E Model

Hong Kong Model

Tourist Model

DCR-TRV38/TRV38E

K orea Model

DCR-TRV38

Chinese Model

DCR-TRV38E

PRINTED WIRING BOARDS

PRINTED WIRING BOARDSSPECIFICATIONS

SERVICE NOTE

SERVICE NOTE

DISASSEMBLY

DISASSEMBLY

• For ADJUSTMENTS (SECTION 6), refer to SERVICE MANUAL, ADJ (987623051.pdf).

• For INSTRUCTION MANUAL, refer to SERVICE MANUAL, LEVEL 1 (987623041.pdf).

• For MECHANISM ADJUSTMENTS, refer to the “DV MECHANICAL ADJUSTMENT MANUAL

Z MECHANISM ” (9-876-210-11).

• Reference No. search on printed wiring boards is available.

On the VC-315 board

This service manual provides the information that is premised the circuit board replacement service and not intended repair

inside the VC-315 board.

Therefore, schematic diagram, printed wiring board, waveforms, mounted parts location and electrical parts list of the

board is not shown.

The following pages are not shown.

Schematic diagram .............................Pages 4-33 to 4-66

Printed wiring board............................Pages 4-87 to 4-94 Electrical parts list ......................... Pages 5-19 to 5-27

Waveforms ...........................................

FRAME SCHEMATIC DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

Mounted parts location ..................

Pages 4-97 to 4-98

REPAIR PARTS LIST

REPAIR PARTS LIST

Pages 4-101 to 4-102

VC-315

DIGITAL VIDEO CAMERA RECORDER

DCR-TRV38/TRV38E/TRV39

COVER

COVER

Video camera

recorder

System

Video recording system

2 rotary heads

Helical scanning system

Audio recording system

Rotary heads, PCM system

Quantization: 12 bits (Fs 32 kHz,

stereo 1, stereo 2), 16 bits

(Fs 48 kHz, stereo)

Video signal

DCR-TRV38/TRV39:

NTSC color, EIA standards

DCR-TRV38E:

PAL colour, CCIR standards

Usable cassette

Mini DV cassette with the

mark printed

Tape speed

SP: Approx. 18.81 mm/s

LP: Approx. 12.56 mm/s

Recording/playback time

(using cassette DVM60)

SP: 1 hour

LP: 1.5 hours

Fastforward/rewind time

(using cassette DVM60)

Approx. 2 min. and 40 seconds

Viewfinder

Electric viewfinder (color)

Image device

3.8 mm (1/4.7 type) CCD (Charge

Coupled Device)

Gross: Approx. 1 070 000 pixels

Effective (still):

Approx. 1 000 000 pixels

Effective (moving):

Approx. 690 000 pixels

Lens

Carl Zeiss Vario-Sonnar

Combined power zoom lens

Filter diameter: 30 mm

(1 3/16 in)

10× (Optical), 120× (Digital)

F = 1.8 – 2.0

Focal length

3.7 – 37 mm (5/32 – 1 1/2 in.)

When converted to a 35 mm still

camera

In CAMERA:

50 – 500 mm (2 – 19 3/4 in.)

In MEMORY:

42 – 420 mm (1 11/16 – 16 5/8 in.)

Color temperature

Auto, HOLD, INDOOR (3 200 K),

OUTDOOR (5 800 K)

Minimum illumination

7 lx (lux) (F 1.8)

0 lx (lux) (in NightShot)*

* Objects unable to be seen due to

the dark can be shot with

infrared lighting.

Input/Output connectors

S video input/output

4-pin mini DIN

Luminance signal: 1 Vp-p,

75

DCR-TRV38/TRV39:

Chrominance signal: 0.286 Vp-p,

75 Ω (ohms), unbalanced

DCR-TRV38E:

Chrominance signal: 0.3 Vp-p,

75 Ω (ohms), unbalanced

Audio/Video input/output

AV MINI JACK, 1 Vp-p,

75 Ω (ohms), unbalanced

327 mV, (at output impedance

more than 47 kΩ (kilohms))

Output impedance with less than

2.2 kΩ (kilohms)/Stereo minijack

(ø 3.5 mm)

Input impedance more than

47 kΩ (kilohms)

DV input/output

4-pin connector

Headphone jack

Stereo minijack (ø 3.5 mm)

LANC jack

Stereo mini-minijack (ø 2.5 mm)

USB jack

DCR-TRV38/TRV38E:

mini-B

DCR-TRV39:

mini-AB

MIC jack

Minijack, 0.388 mV low impedance

with 2.5 to 3.0 V DC, output

impedance 6.8 k Ω (kilohms)

(ø 3.5 mm)

Stereo type

LCD screen

Picture

8.8 cm (3.5 type)

Total dot number

184 000 (840 × 220)

Ω (ohms), unbalanced

SPECIFICATIONS

General

Power requirements

7.2 V (battery pack)

8.4 V (AC Adaptor)

Average power consumption

(when using the battery pack)

During camera recording using

LCD

DCR-TRV38/TRV38E: 4.3 W

DCR-TRV39: 4.4 W

Viewfinder

DCR-TRV38/TRV38E: 3.2 W

DCR-TRV39: 3.3 W

Operating temperature

0°C to 40°C (32°F to 104°F)

Storage temperature

–20°C to + 60°C

(–4°F to + 140°F)

Dimensions (approx.)

72 × 91 × 161 mm

(2 7/8 × 3 5/8 × 6 3/8 in.) (w/h/d)

Mass (approx.)

660 g (1 lb 7 oz)

main unit only

750 g (1 lb 10 oz)

including the rechargeable battery

pack NP-FM30, cassette DVM60

and lens cap

Supplied accessories

See page 3.

AC Adaptor

AC-L15A/L15B

Power requirements

100 – 240 V AC, 50/60 Hz

Current consumption

0.35 – 0.18 A

Power consumption

18 W

Output voltage

DC OUT: 8.4 V, 1.5 A

Operating temperature

0°C to 40°C (32°F to 104°F)

Storage temperature

–20°C to + 60°C

(–4°F to + 140°F)

Dimensions (approx.)

56 × 31 × 100 mm

(2 1/4 × 1 1/4 × 4 in.) (w/h/d)

excluding projecting parts

Mass (approx.)

190 g (6.7 oz)

excluding power cord

Rechargeable

battery pack

NP-FM30

Maximum output voltage

DC 8.4 V

Output voltage

DC 7.2 V

Capacity

5.0 Wh (700 mAh)

Dimensions (approx.)

38.2 × 20.5 × 55.6 mm

(1 9/16 × 13/16 × 2 1/4 in.)

(w/h/d)

Mass (approx.)

65 g (2.3 oz)

Type

Lithium ion

“Memory Stick”

Memory

Flash memory

8MB: MSA-8A

Operating voltage

2.7 – 3.6 V

Power consumption

Approx. 45 mA during operation

mode

Approx. 130 µA during tape

recording standby

Dimensions (approx.)

50 × 2.8 × 21.5 mm

(2 × 1/8 × 7/8 in.) (w/h/d)

Mass (approx.)

4 g (0.14 oz)

Design and specifications are

subject to change without notice.

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

— 2 —

• SUPPLIED ACCESSORIES

Make sure that the following accessories are supplied with your camcorder .

DCR-TRV38/TRV38E/TRV39

1 4

6

qa qf qg

1 AC-L15A/L15B AC Adaptor (1), Power cord (1)

2 NP-FM30 rechargeable battery pack (1)

3 A/V connecting cable (1.5m) (1)

4 Wireless Remote Commander (RMT-814E) (1)

5 Size AA (R6) battery for Remote Commander (2)

6 Shoulder strap (1)

7 Lens cap (1)

8 “Memory Stick” (MSA-8A) (1)

9 USB cable (1)

qs

7

2

8

qd

0 CD-ROM (USB Driver) (1)

SPVD-010 (DCR-TRV38:E, HK, JE, KR/TRV38E)

SPVD-010 (I) (DCR-TRV38:US, CND/TRV39

qa Cleaning cloth (1)

qs UNA-PSTN Modem Adaptor (1),

Telephone cord (1) (DCR-TRV39 only)

qd Stylus (1) (DCR-TRV39 only)

qf 2-pin conversion adaptor

(DCR-TRV38:JE/TRV38E:JE only)

qg 2-pin conversion adaptor

(DCR-TRV38:E, HK/TRV38E:E, HK)

3

9

q;5

• Abbreviation

CND : Canadian model

HK : Hong Kong model

JE : Tourist model

KR : Korea model

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

— 3 —

DCR-TRV38/TRV38E/TRV39

TABLE OF CONTENTS

1. SERVICE NOTE

1-1. SERVICE NOTE ·····························································1-1

1. POWER SUPPLY DURING REPAIRS ··························1-1

2. TO TAKE OUT A CASSETTE WHEN NOT EJECT

(FORCE EJECT) ····························································· 1-1

1-2. SELF-DIAGNOSIS FUNCTION····································1-2

1. SELF-DIAGNOSIS FUNCTION····································1-2

2. SELF-DIAGNOSIS DISPLAY ·······································1-2

3. SELF-DIAGNOSIS CODE TABLE································1-3

2. DISASSEMBLY

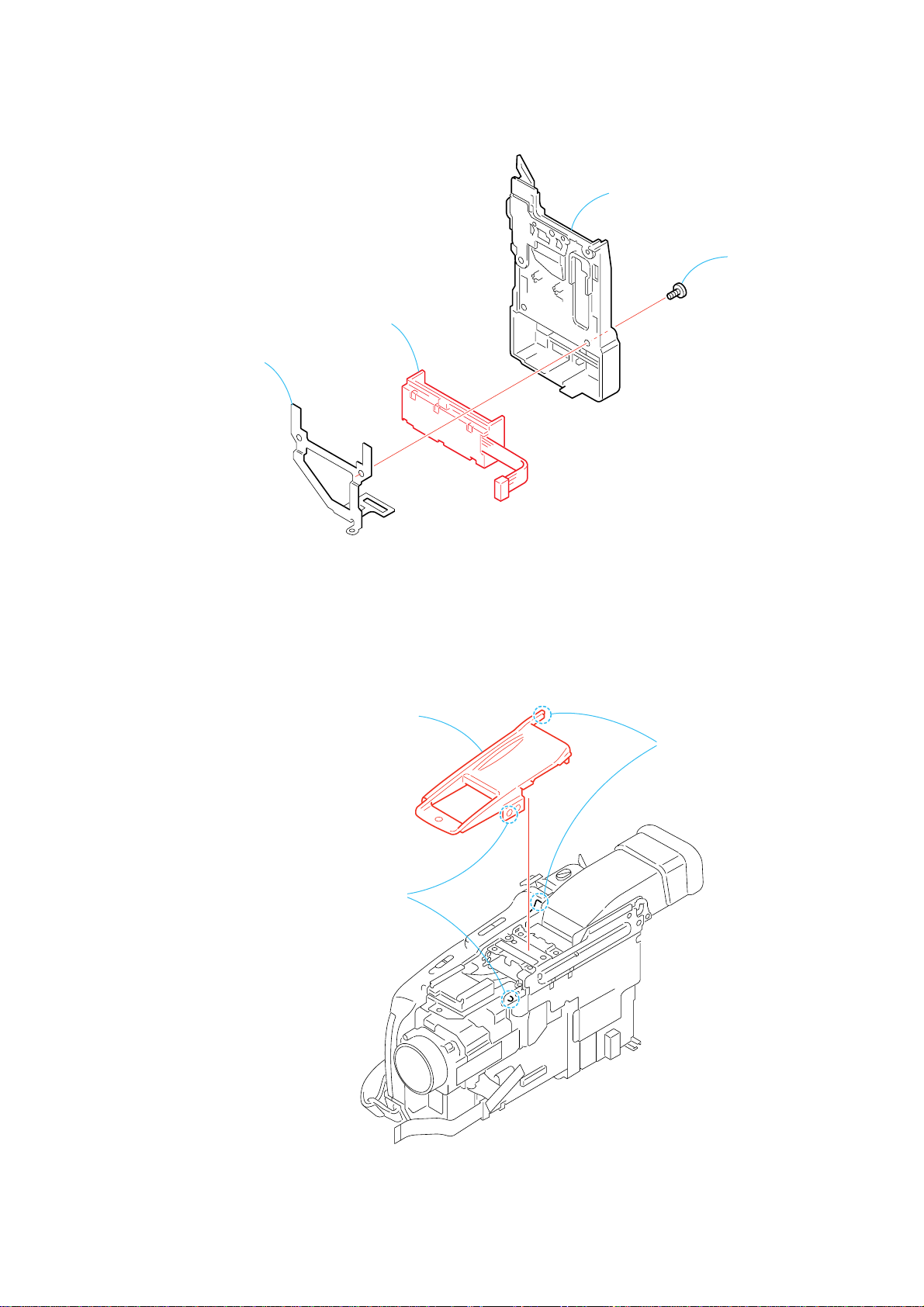

2-1. P CABINET (C) ASSEMBLY ········································ 2-2

2-2. FRONT PANEL SECTION·············································2-3

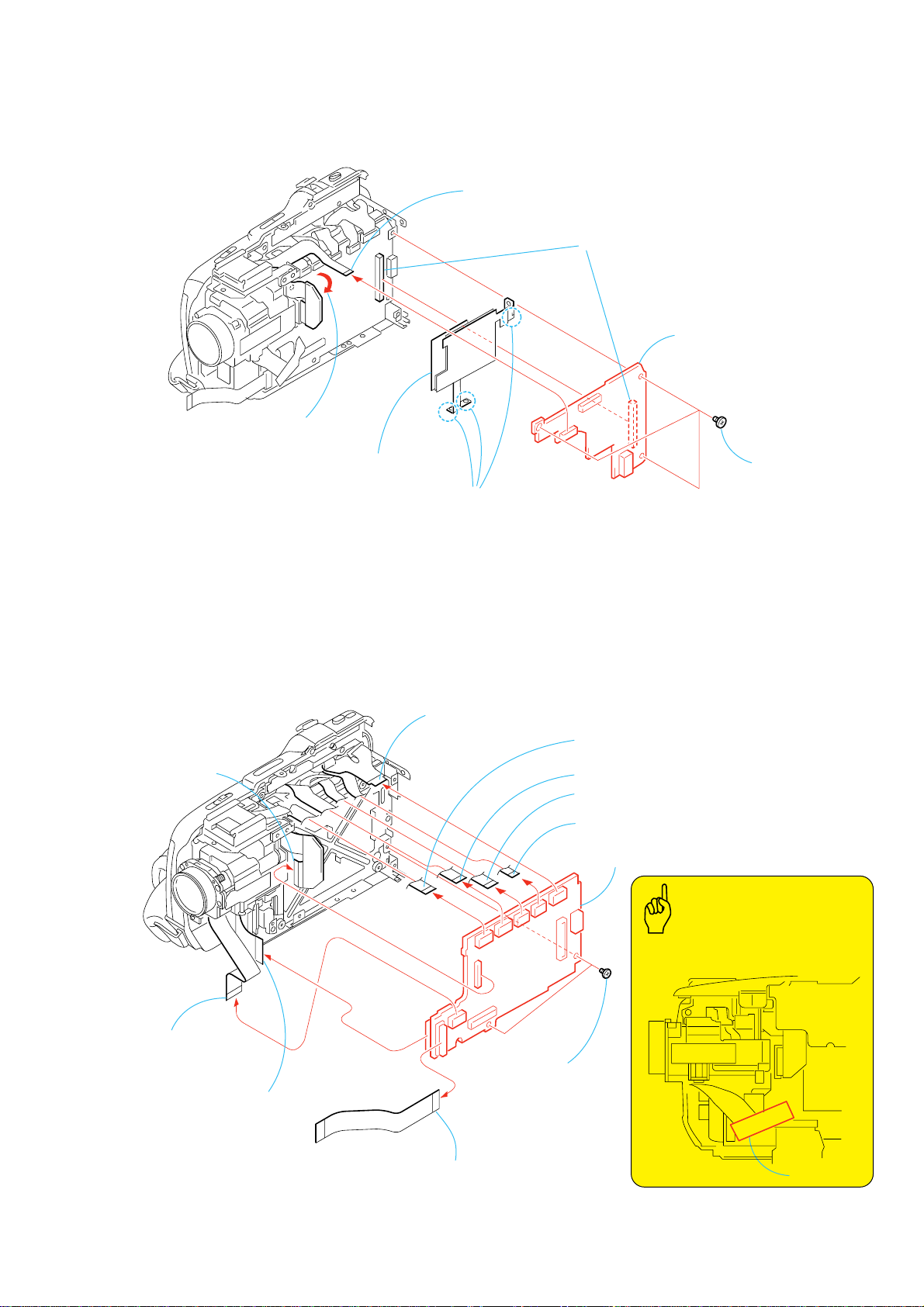

2-3. MA-423, SE-136 BOARD ··············································2-3

2-4. MICROPHONE·······························································2-4

2-5. CABINET (R) SECTION ···············································2-4

2-6. PANEL BLOCK ASSEMBLY ········································2-5

2-7. PD-190 BOARD······························································2-6

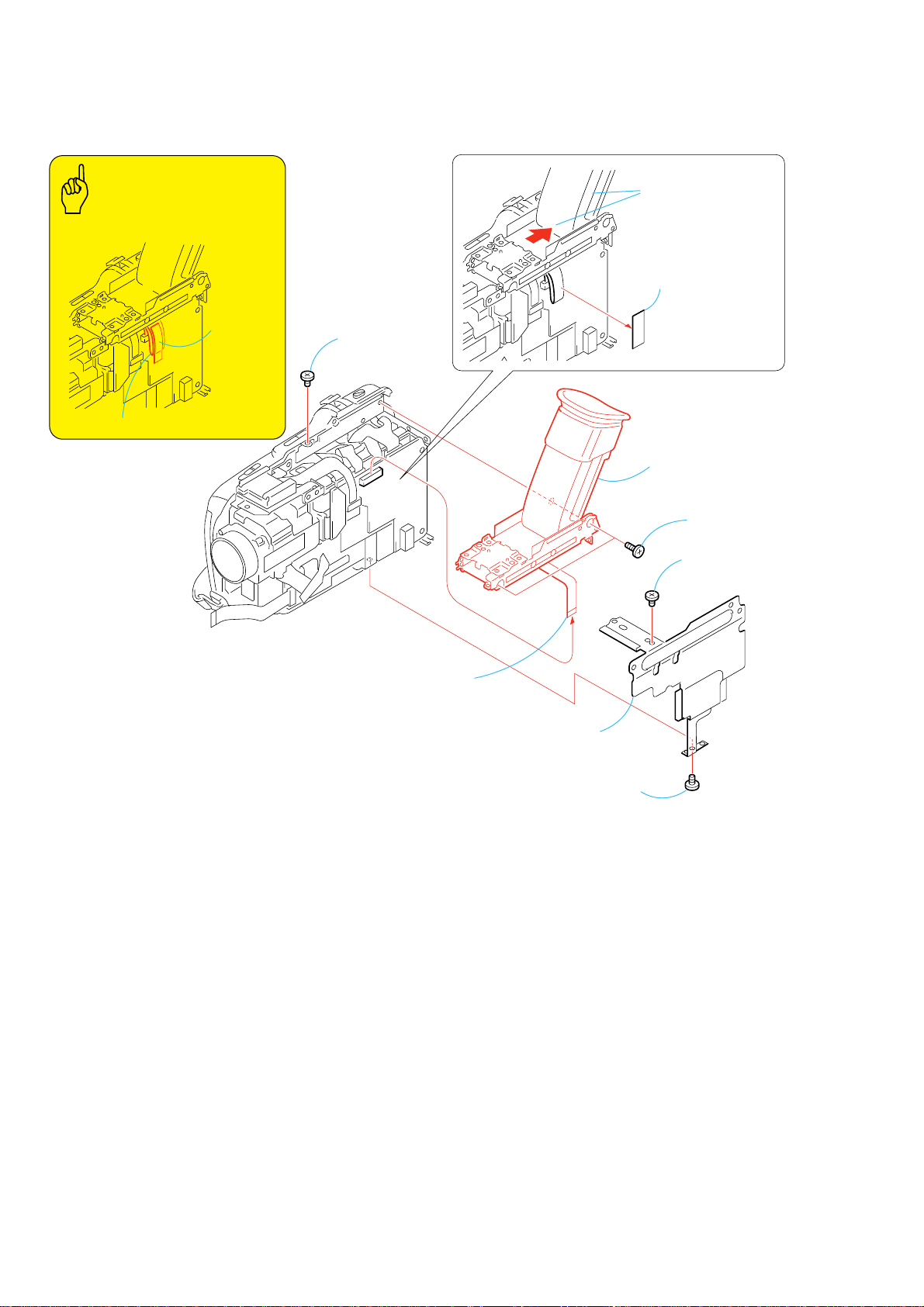

2-8. HINGE ASSEMBL Y·······················································2-7

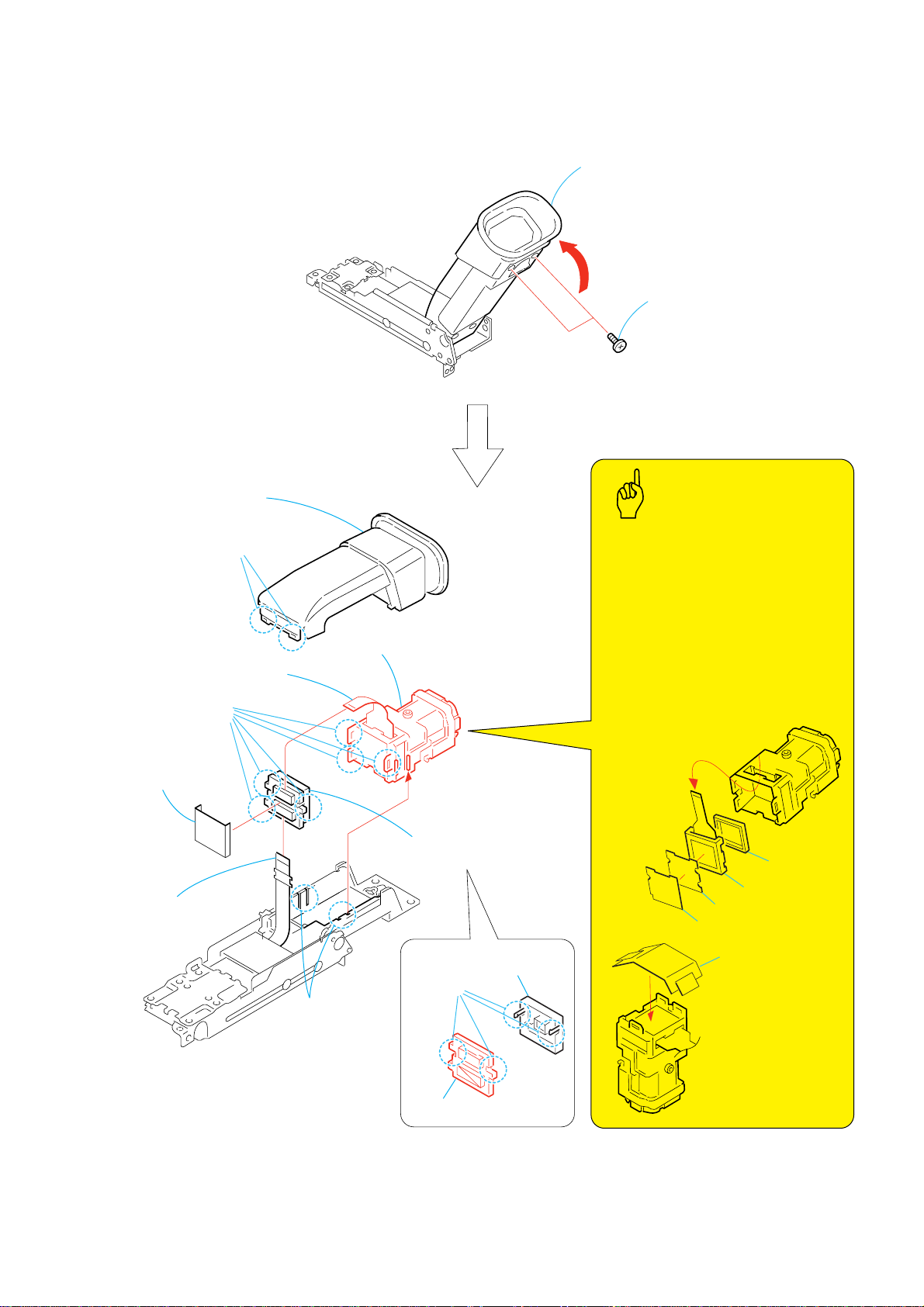

2-9. CK-131 BOARD ·····························································2-7

2-10. LOUD SPEAKER, FP-635 FLEXIBLE BOARD···········2-8

2-11. BATTERY SECTION ·····················································2-8

2-12. BATTERY TERMINAL BOARD ···································2-9

2-13. TOP CABINET ASSEMBLY ·········································2-9

2-14. EVF SECTION······························································2-10

2-15. VF LENS ASSEMBLY ·················································2-11

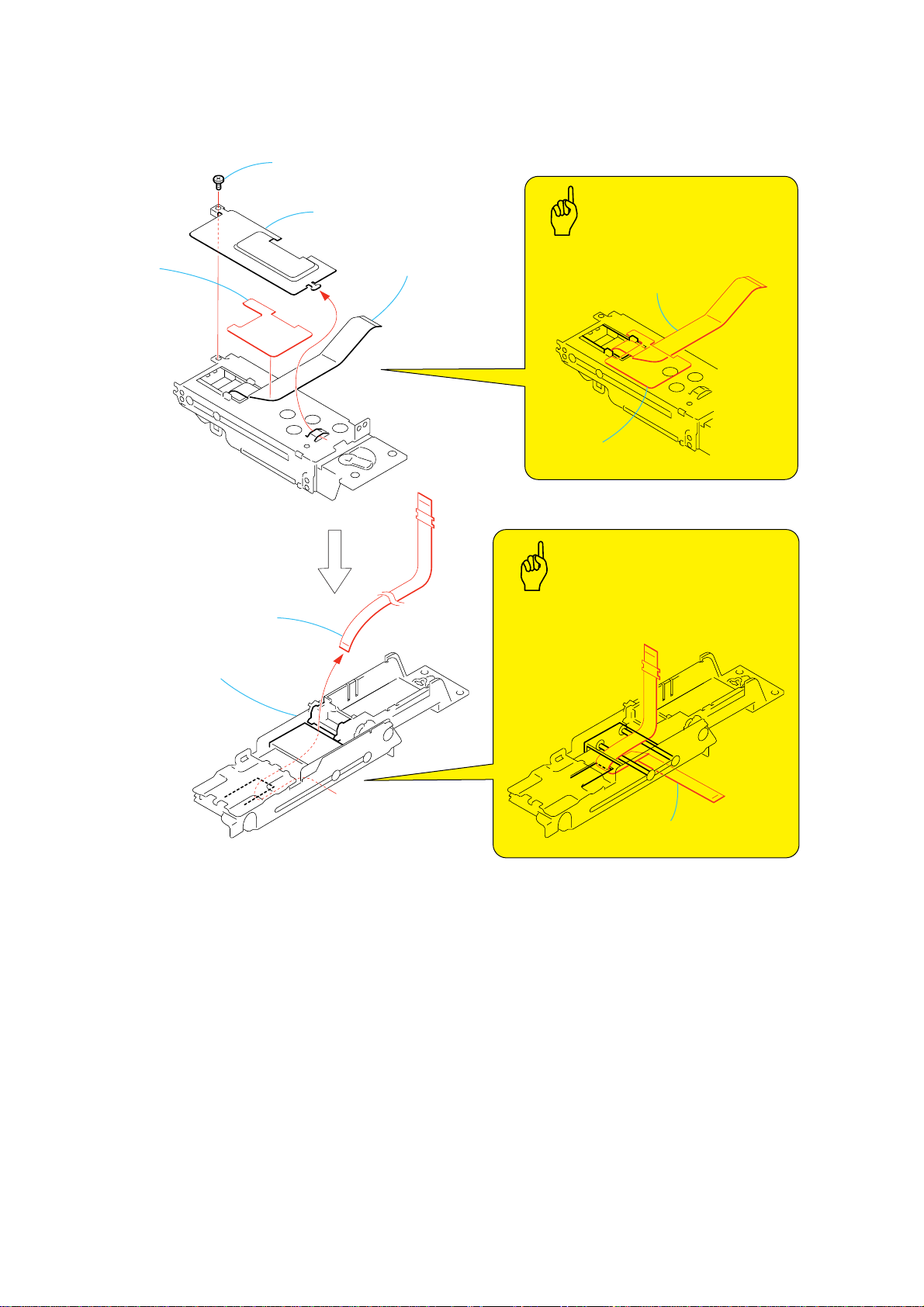

2-16. FP-435 FLEXIBLE BOARD ········································2-12

2-17. DI-089 BOARD·····························································2-13

2-18. VC-315 BOARD ···························································2-13

2-19. MECHANISM DECK···················································2-14

2-20. LENS SECTION ···························································2-14

2-21. JK-248, JK-249 BOARD···············································2-15

2-22. LENS BLOCK ASSEMBLY·········································2-17

2-23. LENS DEVICE (LSV-751A), CD-436 BOARD···········2-17

2-24. GRIP LOCK ASSEMBLY ············································2-18

2-25. CS FRAME ASSEMBLY ··············································2-19

2-26. CONTROL SWITCH BLOCK (PS-2890)····················2-20

2-27. MEMORY STICK CONNECTOR ·······························2-20

2-28. CONTROL SWITCH BLOCK (FK-4300) ···················2-21

2-29. CIRCUIT BOARDS LOCATION ·································2-22

2-30. FLEXIBLE BOARDS LOCATION ······························2-23

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/4) ···························3-1

3-2. OVERALL BLOCK DIAGRAM (2/4) ···························3-3

3-3. OVERALL BLOCK DIAGRAM (3/4) ···························3-5

3-4. OVERALL BLOCK DIAGRAM (4/4) ···························3-7

3-5. POWER BLOCK DIAGRAM (1/2) ································3-9

3-6. POWER BLOCK DIAGRAM (2/2) ······························3-11

• PD-190 (1/2)(LCD DRIVER, TIMING GEN.)

SCHEMATIC DIAGRAM ····························4-17

• PD-190 (2/2)(LCD BACKLIGHT)

SCHEMATIC DIAGRAM ····························4-19

• MA-423 (MIC IN, A/V-IN)

SCHEMATIC DIAGRAM ····························4-21

• JK-248 (P/Y SENSOR, A/V-IN)

SCHEMATIC DIAGRAM ····························4-23

• FP-639 FLEXIBLE

SCHEMATIC DIAGRAM ····························4-23

• JK-249 (MIC IN, DV IN/OUT)

SCHEMATIC DIAGRAM ····························4-25

• CK-131 (FUNCTION KEY)

SCHEMATIC DIAGRAM ····························4-27

• CONTROL SWITCH BLOCK (FK4300)

SCHEMATIC DIAGRAM ····························4-29

• FP-467/468/228 FLEXIBLE (S/T REEL SENSOR,

TAPE SENSOR)

SCHEMATIC DIAGRAM ····························4-31

Shematic diagram of the VC-315 board are not sho wn.

Pages from 4-33 to 4-66 are not shown.

4-3. PRINTED WIRING BOARDS

• CD-436 (CCD IMAGER)

PRINTED WIRING BOARD ·······················4-69

• LB-087 (EVF, BACKLIGHT)

PRINTED WIRING BOARD ·······················4-69

• MA-423 (MIC IN, REMOCON REC)

PRINTED WIRING BOARD ·······················4-69

• DI-089 (CHARGE, POWER IN, EVF DRIVER,

TIMING GEN., DC-DC CONVERTER)

PRINTED WIRING BOARD ·······················4-71

• PD-190 (LCD DRIVER, TIMIN GEN.,

LCD BACKLIGHT)

PRINTED WIRING BOARD ·······················4-75

• MA-423 (MIC IN, REMOCON REC)

PRINTED WIRING BOARD ·······················4-77

• JK-248 (P/Y SENSOR, A/V-IN)

PRINTED WIRING BOARD ·······················4-79

• JK-249 (MIC IN, DV IN/OUT)

PRINTED WIRING BOARD ·······················4-81

• CK-131 (FUNCTION KEY)

PRINTED WIRING BOARD ·······················4-83

• FP-467, FP-468, FP-228

FLEXIBLE BOARD·····································4-83

Printed wiring board of the VC-315 board are not shown.

Pages from 4-87 to 4-94 are not shown.

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM (1/3)·······················4-1

FRAME SCHEMATIC DIAGRAM (2/3)·······················4-3

FRAME SCHEMATIC DIAGRAM (3/3)·······················4-5

4-2. SCHEMATIC DIAGRAMS

• CD-436 (CCD IMAGER)

SCHEMATIC DIAGRAM ······························4-9

• LB-087 (EVF, BACKLIGHT)

SCHEMATIC DIAGRAM ····························4-10

• DI-089 (1/3)(CHARGE, POWER IN)

SCHEMATIC DIAGRAM ····························4-11

• DI-089 (2/3)(EVF DRIVER, TIMING GEN.)

SCHEMATIC DIAGRAM ····························4-13

• DI-089 (3/3)(DC-DC CONVERTER)

SCHEMATIC DIAGRAM ····························4-15

4-4. WAVEFORMS ······························································4-95

Waveforms of the VC-315 board are not shown.

Pages from 4-97 to 4-98 are not shown.

4-5. MOUNTED PARTS LOCATION ·································4-99

Mounted parts location of the VC-315 board is not shown.

Pages from 4-101 to 4-102 are not shown.

— 4 —

5. REPAIR PARTS LIST

5-1. EXPLODED VIEWS ······················································5-1

5-1-1.OVERALL ······································································5-3

5-1-2.CABINET (R) SECTION ···············································5-4

5-1-3.PANEL BLOCK SECTION ············································5-5

5-1-4.CABINET (L) SECTION-1 ············································5-6

5-1-5.CABINET (L) SECTION-2 ············································5-7

5-1-6.EVF SECTION································································5-8

5-1-7.LENS SECTION ·····························································5-9

5-1-8.OVERALL (MECHANISM DECK-Z100) ···················5-10

5-1-9.LS CHASSIS BLOCK ASSEMBLY·····························5-11

5-1-10. MECHANICAL CHASSIS BLOCK ASSEMBLY ····5-12

5-2. ELECTRICAL PARTS LIST ········································5-13

Parts list of the VC-315 board are not shown.

Pages from 5-19 to 5-27 are not shown.

DCR-TRV38/TRV38E/TRV39

— 5 —

DCR-TRV38/TRV38E/TR V39

COVER

COVER

SECTION 1

SERVICE NOTE

1-1. SERVICE NOTE

1. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated power supply (8.4V), the power is shut off so

that the unit cannot operate.

This following two methods are available to prevent this. Take note of which to use during repairs.

Method 1:

Use the AC power adaptor (AC-L15, AC-VQ800 etc.).

Method 1:

Connect the servicing remote commander RM-95 (J-6082-053-B) to the LANC jack, and set the commander switch to the “ADJ” side.

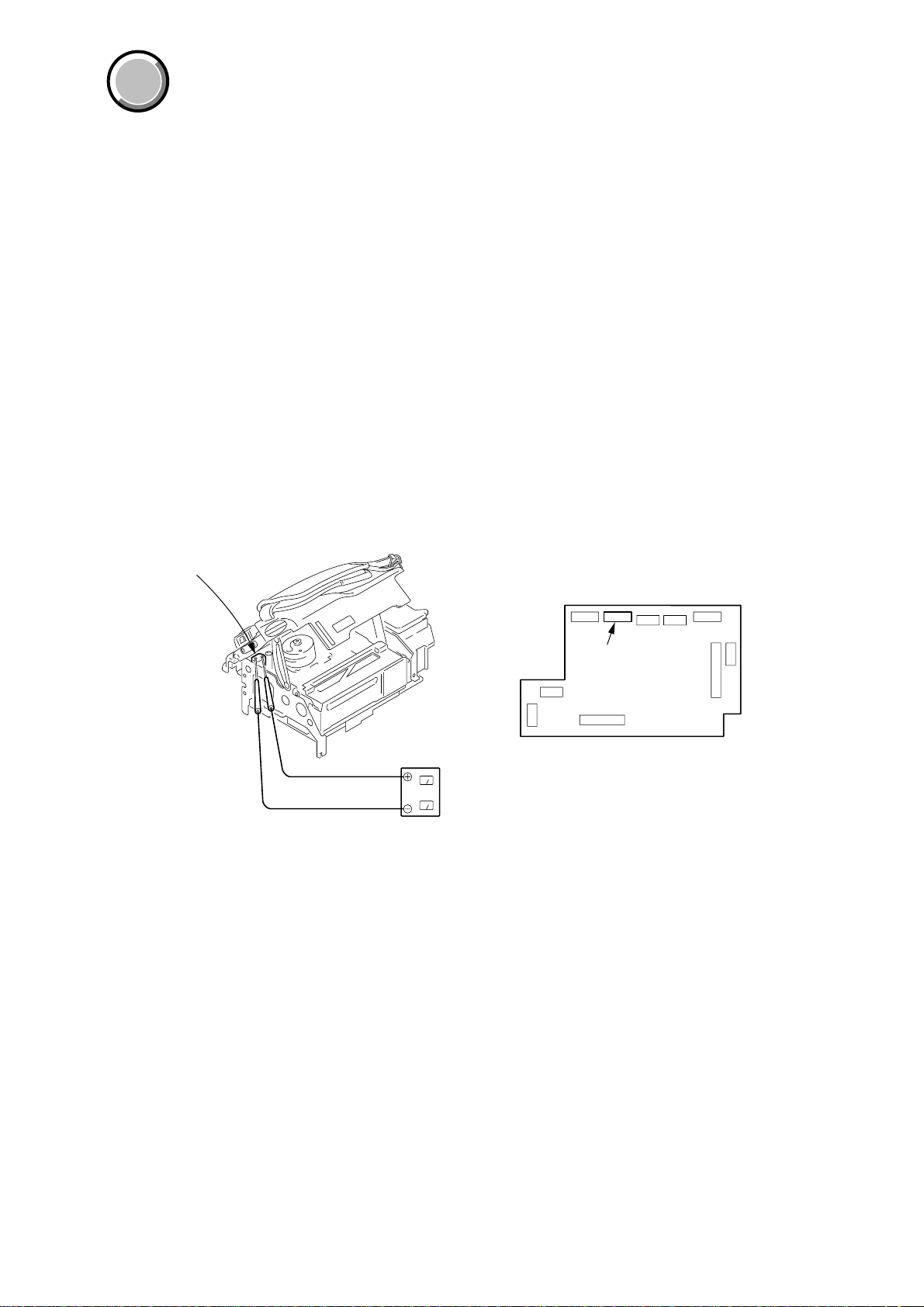

2. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

1 Refer to 2-2 to remove the front panel assembly.

2 Refer to 2-13 to remove the top cabinet assembly.

3 Refer to 2-5 to remove the cabinet (R) assembly.

4 Refer to 2-11 to remove the battery panel section.

5 Remove the EVF block.

6 Open the DI-089 board.

7 Disconnect CN2502 (27P, 0.3mm) of VC-315 board.

8 Open the cassette lid.

9 Supply +4.5V from the DC power supply to the loading motor and unload with a pressing the cassette compartment.

Loading motor

CN2502

VC-315 board

DC power supply

(+ 4.5V)

1-1

DCR-TRV38/TRV38E/TRV39

1-2. SELF-DIAGNOSIS FUNCTION

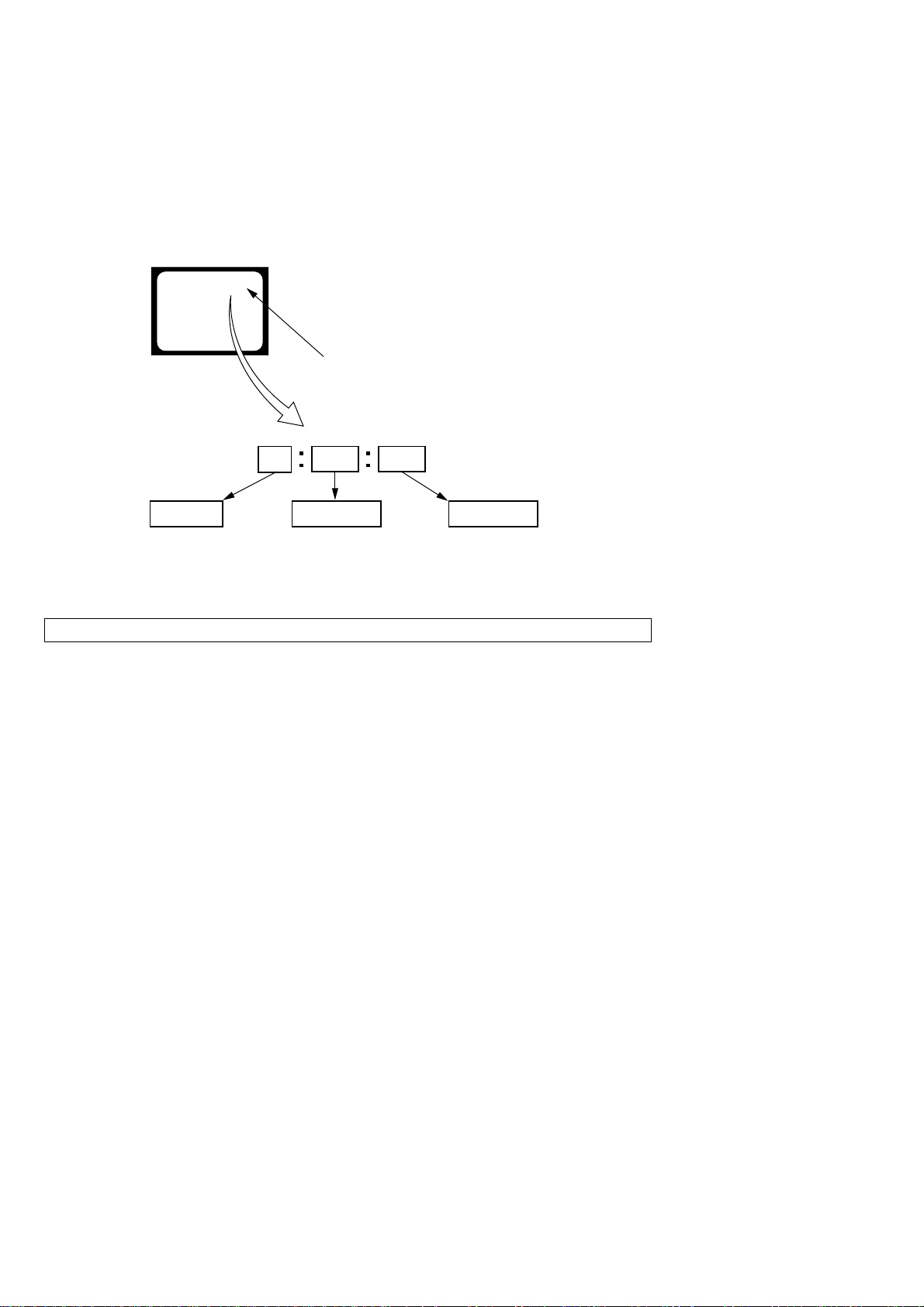

1. SELF-DIAGNOSIS FUNCTION

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewfinder, or LCD

screen what to do. This function consists of two display; selfdiagnosis display and service mode display.

Details of the self-diagnosis functions are provided in the Instruction

manual.

Viewfinder or LCD screen

C : 3 1 : 1 1

Blinks at 3.2Hz

2. SELF-DIAGNOSIS DISPLA Y

When problems occur while the unit is operating, the counter of the

viewfinder or LCD screen consists of an alphabet and 4-digit number,

which blinks at 3.2Hz. This 5-character display indicates the

“repaired by:”, “block” in which the problem occurred, and “detailed

code” of the problem.

3 1C

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

Note: The self-diagnosis display data will be kept even if the lithium battery (BT5201 of CK-131 board) is removed.

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn on power again.

Block

1 1

Detailed Code

Refer to page 1-3.

Self-diagnosis Code Table.

1-2

Ver 1.2 2003. 11

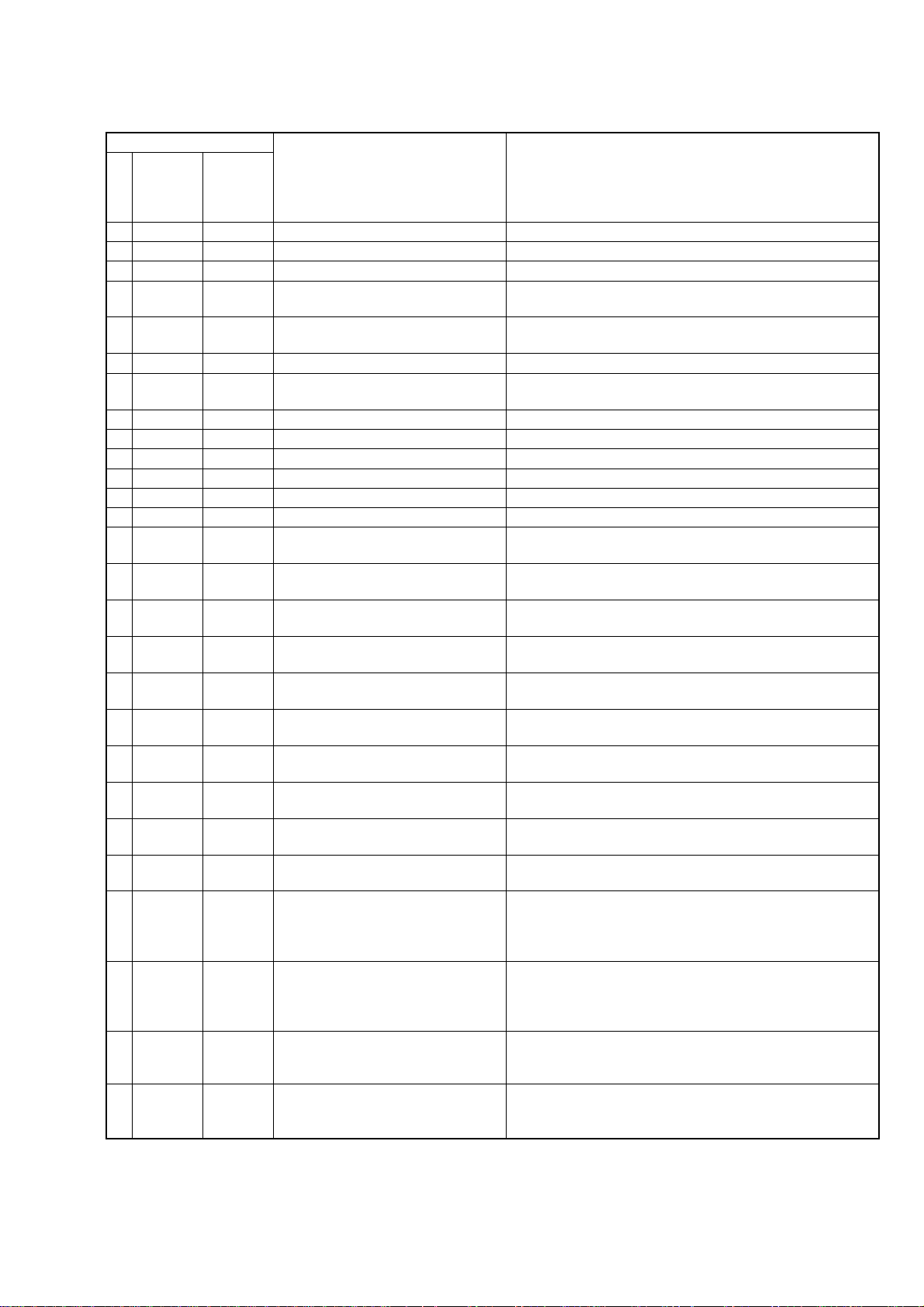

3. SELF-DIAGNOSIS CODE TABLE

Self-diagnosis Code

DCR-TRV38/TRV38E/TRV39

Function

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

E

E

E

E

Block

04

21

22

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

32

32

61

61

62

62

Detailed

Code

00

00

00

10

11

20

21

22

23

24

30

40

42

10

11

20

21

22

23

24

30

40

42

00

10

00

01

Symptom/State

Non-standard battery is used.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum.

FG fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

Winding S reel fault when counting the

rest of tape.

T reel fault.

S reel fault.

T reel fault.

FG fault when starting capstan.

FG fault when starting drum

FG fault during normal drum

operations

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

Steadyshot function does not work well.

(With pitch angular velocity sensor output

stopped.)

Steadyshot function does not work well.

(With yaw angular v elocity sensor output

stopped.)

Correction

Use the info LITHIUM battery.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Inspect the lens block focus MR sensor (Pin ql, w; of CN1301 of

VC-315 board) when focusing is performed when the focus ring is

rotated in the focus manual mode, and the focus motor drive circuit

(IC1301 of VC-315 board) when the focusing is not performed.

Inspect the lens block zoom MR sensor (

VC-315 board

operated and the zoom motor drive circuit (IC1301 of VC-315

board) when zooming is not performed.

Inspect pitch angular velocity sensor (SE5001 of JK-248 board)

peripheral circuits.

Inspect yaw angular velocity sensor (SE5002 of JK-248 board)

peripheral circuits.

) when zooming is performed when the zoom lens is

Pin 8, q; of CN1301 of

1-3E

DCR-TRV38/TRV38E/TRV39

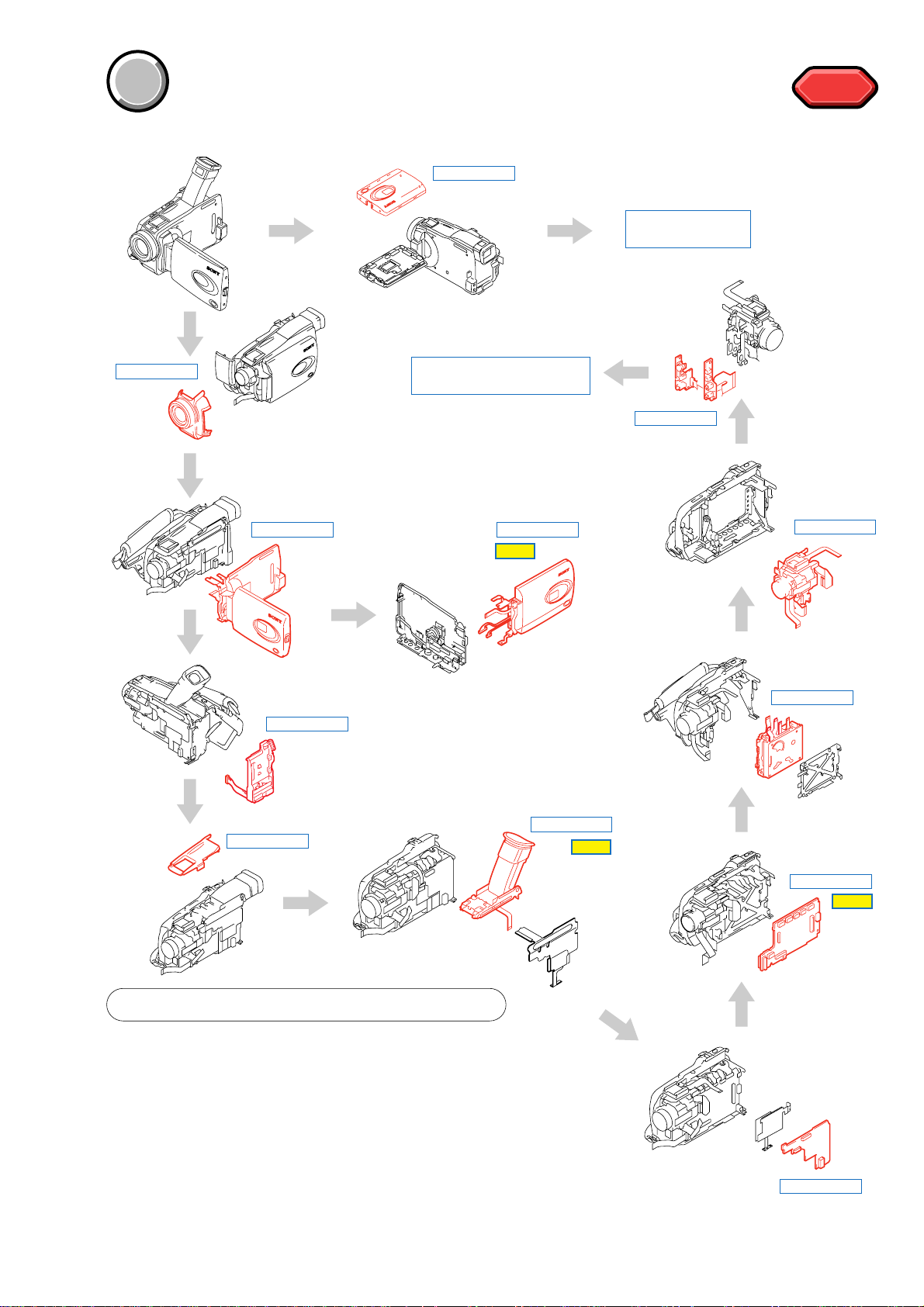

V

C

-

3

1

5

1 2-2. FRONT PANEL SECTION ...............................

2 2-5. CABINET (R) SECTION .................................

3 2-11. BATTERY SECTION ........................................

4 2-13. TOP CABINET ASSEMBLY ...........................

5 2-14. EVF SECTION.................................................

6 2-17. DI-089 BOARD ...............................................

7 2-18. VC-315 BOARD ...............................................

8 2-19. MECHANISM DECK .......................................

9 2-20. LENS SECTION..............................................

0 2-21. JK-248, JK-249 BOARD .................................

qa SERVICE POSITION TO CHECK

THE VTR SECTION................................................

(page 2-3)

(page 2-4)

(page 2-8)

(page 2-9)

(page 2-10)

(page 2-13)

(page 2-13)

(page 2-14)

(page 2-14)

(page 2-15)

(page 2-16)

PROCEDURE OF REMOVING MECHANISM DECK

SERVICE POSITION TO

CHECK THE VTR SECTION

DISASSEMBLY

DISASSEMBLY

DISASSEMBLY DISASSEMBLY

DISASSEMBLY

DISASSEMBLY

DISASSEMBLY

DISASSEMBLY

DISASSEMBLY

DISASSEMBLY

DISASSEMBLY

DISASSEMBLY

HELP

HELP

HELP

PD-190 board

service position

COVER

COVER

SECTION 2

DISASSEMBLY

The following flow chart shows the disassembly procedure.

HELP

HELP

2-1

DCR-TRV38/TRV38E/TRV39

)

NOTE: Follow the disassembly procedure in the numerical order given.

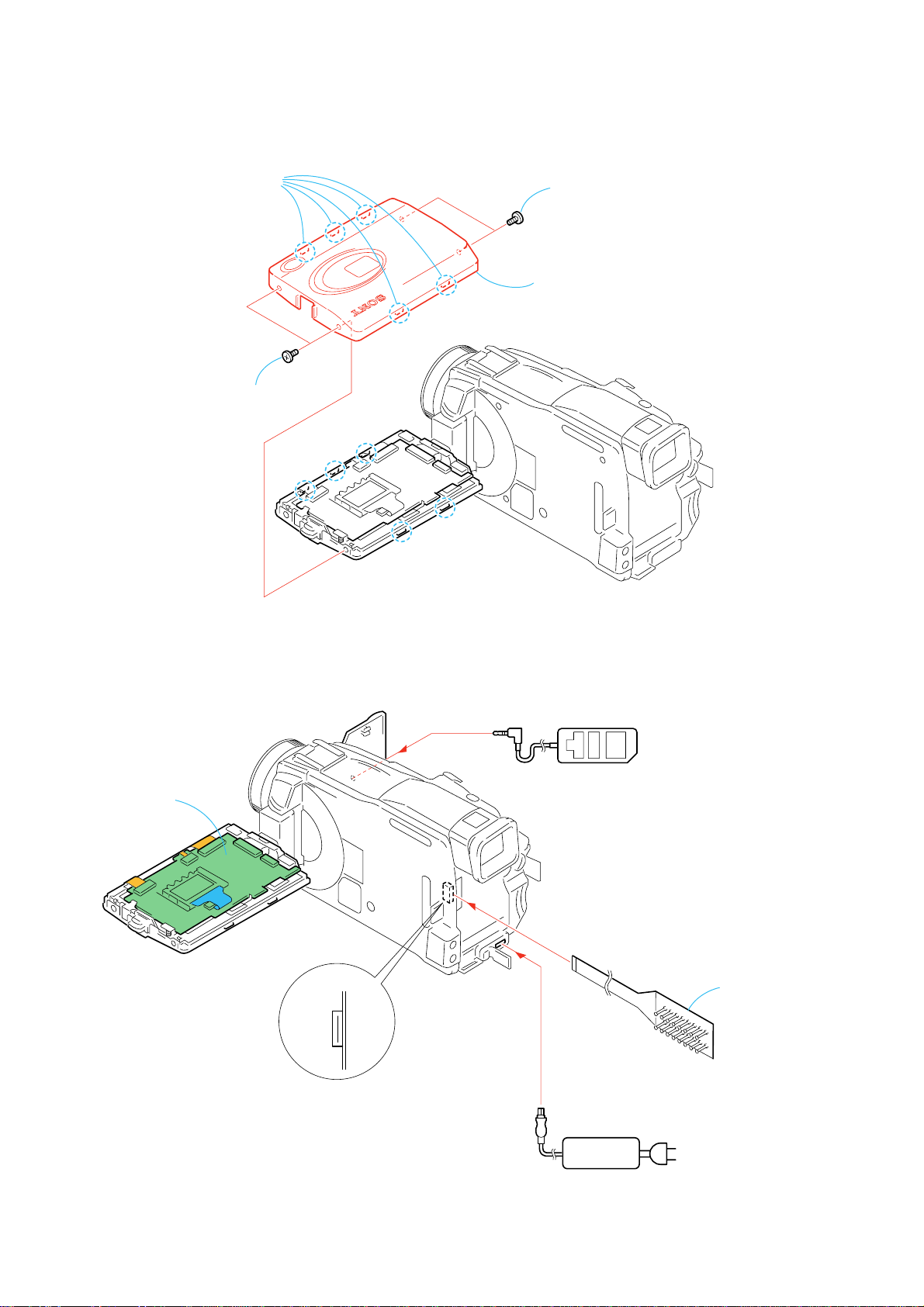

2-1. P CABINET (C) ASSEMBLY

3

Five claws

1

T wo screws

×

(M1.7

lock ace, p2

(silver)

4),

PD-

190

2

T wo screws

(M1.7 × 4),

lock ace, p2

(silver)

4

P cabinet (C) assembly

[PD-190 BOARD SERVICE POSITION]

PD-190 board

PD-

190

CN1004

16

1

Adjustment remote

commander (RM-95)

16

1

CPC-7 jig

(J-6082-382-A

2-2

AC power

adaptor

AC IN

2-2. FRONT PANEL SECTION

4

Screw

(M1.7

lock ace, p2

(silver)

3

Open the jack cover

assembly

DCR-TRV38/TRV38E/TR V39

1

Screw

×

(M1.7

×

4),

lock ace, p2

(silver)

4),

6

FP-640 flexible board (14P)

Caution

Because the 7 Front panel section is

connected to the main unit by the

FP-640 flexible board, the flexible board

may be damaged if you remove the

Front panel section forcibly. Be very

careful not to damage the flexible board.

6

2-3. MA-423, SE-136 BOARD

2

Loud MIC (4P)

8

SE-136 board

7

T apping

screw (M1.7

1

FP-642

flexible board

×

3.5)

(6P)

(6P)

7

Front panel section

2

Screw

×

(M1.7

lock ace, p2

(silver)

4),

5

Remove the Front panel section

in the direction of the arrow.

Caution

Caution

Routing of the harness (Loud MIC)

3

Screw

(M1.7 × 2.5)

5

Three tapping

screws (M1.7 × 3.5)

4

MA-423 board

6

F&B retainer

metal sheet

2-3

Loud MIC

DCR-TRV38/TRV38E/TRV39

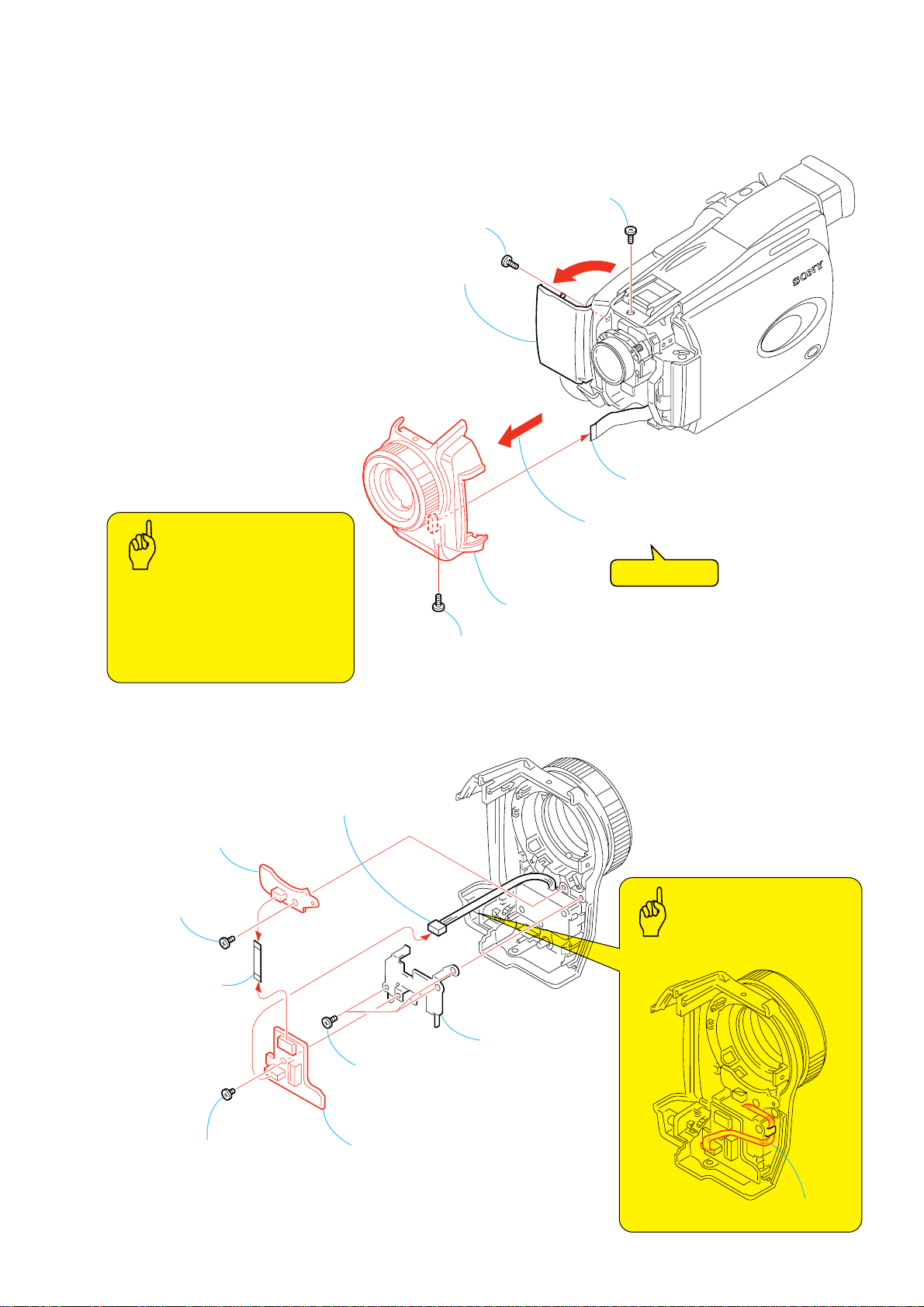

2-4. MICROPHONE

2

1

T apping

screw (M1.7

×

3.5)

6

Microphone

5

Microphone holder

4

Microphone retainder

2-5. CABINET (R) SECTION

5

Open the

cassette lid.

6

Screw

×

(M1.7

lock ace, p2

(black)

4),

1

Screw

(M1.7

lock ace, p2

(black)

9

Cabinet (R) section

T wo claws

3

×

4),

2

Screw

×

(M1.7

(silver)

3

Screw

(M1.7

lock ace, p2

(silver)

2.5)

×

4),

8

FP-668

flexible board (51P)

7

Remove the Cabinet (R)

section in the direction

of the arrow.

Because the 7 Cabinet (R) section is connected

to the main unit using the

Caution

the flexible board may be damaged if you remove

the Cabinet (R) section forcibly. Be very careful not

to damage the flexible board.

2-4

9

FP-668 flexible board,

4

Screw

(M1.7

lock ace, p2

(silver)

×

4),

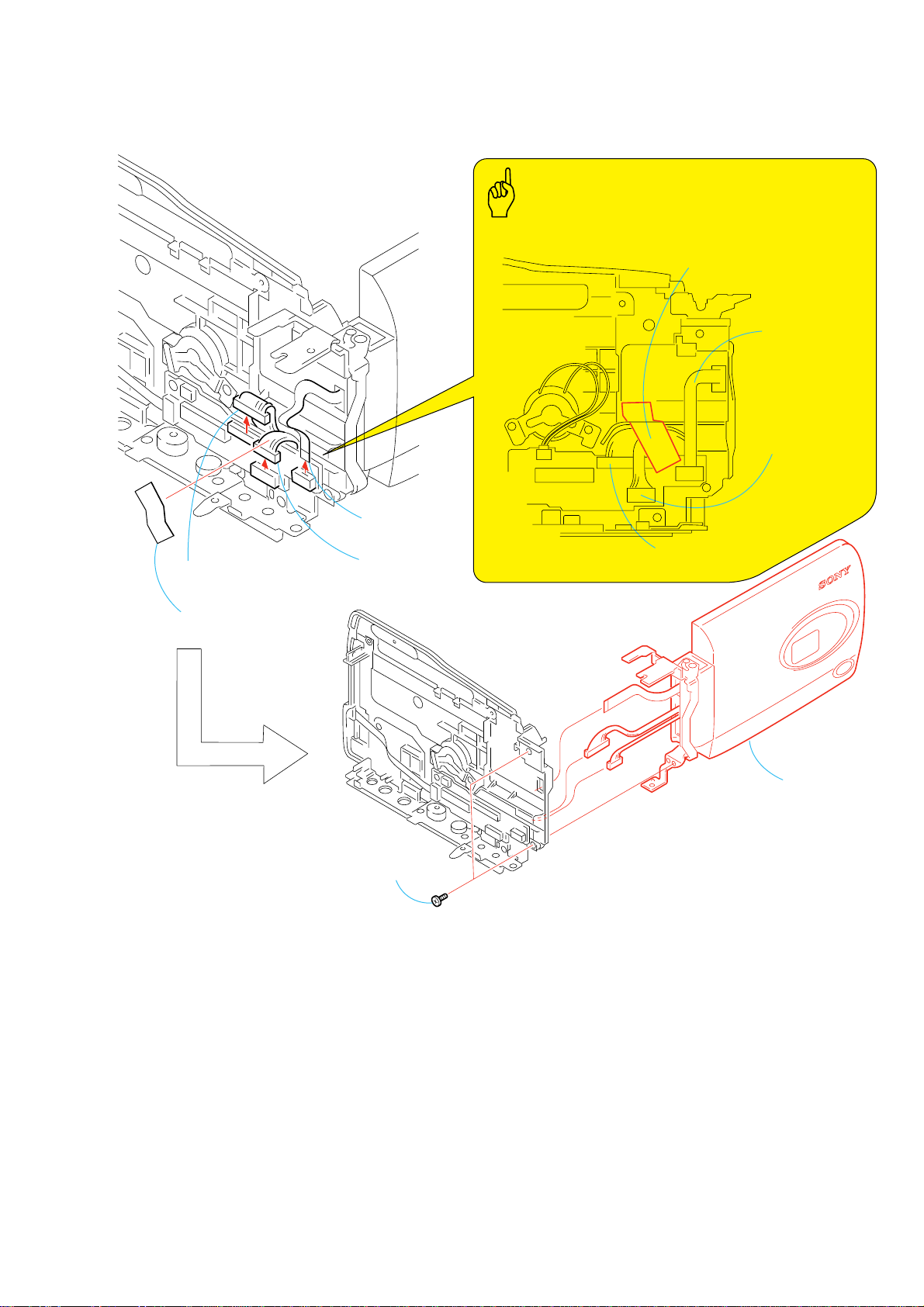

2-6. PANEL BLOCK ASSEMBLY

DCR-TRV38/TRV38E/TR V39

Caution

Attach the Tape (A) as shown in the illustration.

Tape (P)

FP-461 flexible

board (6P)

Harness

(PC-122) (10P)

4

Harness

(PC-121) (20P)

1

T ape (P)

2

FP-461 flexible

board (6P)

3

Harness

(PC-122) (10P)

5

T wo screws

(M1.7 × 4),

lock ace, p2

(silver)

Harness

(PC-121) (20P)

6

Panel block

assembly

2-5

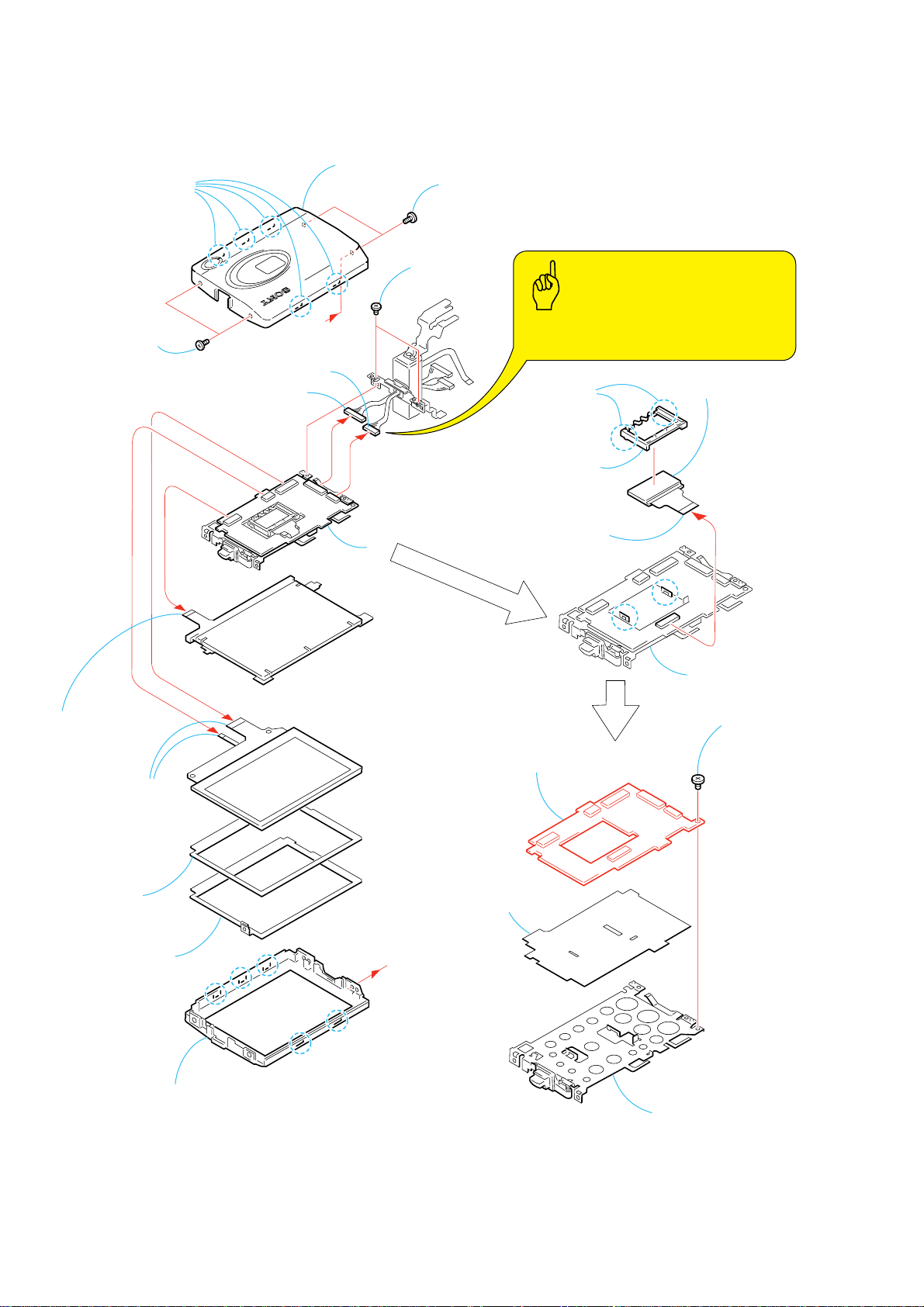

DCR-TRV38/TRV38E/TRV39

2-7. PD-190 BOARD

3

Five claws

1

T wo screws

(M1.7 × 4),

lock ace, p2

(silver)

qs

Harness (PC-122)(10P)

qa

Harness (PC-121)(20P)

4

P cabinet (C) assembly

A

2

T wo screws

(M1.7 × 4),

lock ace, p2

(silver)

q;

T wo screws

(M1.7 × 2.5)

Ver 1.1 2003. 09

Caution

When remove the Harness (PC-121),

be careful to damage the Harness (PC-122).

1

T wo claws

4

LCD holder

5

Indicator module,

liquidcrystal

9

Block light

guide plate (3.5)

(15P)

8

Indicator module,

tp with liqu

6

T ouch

cushion

(6P)

(24P)

PD-

190

qd

2

Indicator module,

liquidcrystal

3

Panel insulating

sheet

2

PD-190 board

PD-

190

PD-

190

3

1

(M1.7 × 2.5)

Screw

7

T ouch plate

ground

5

P cabinet (M)

A

2-6

4

P frame assembly

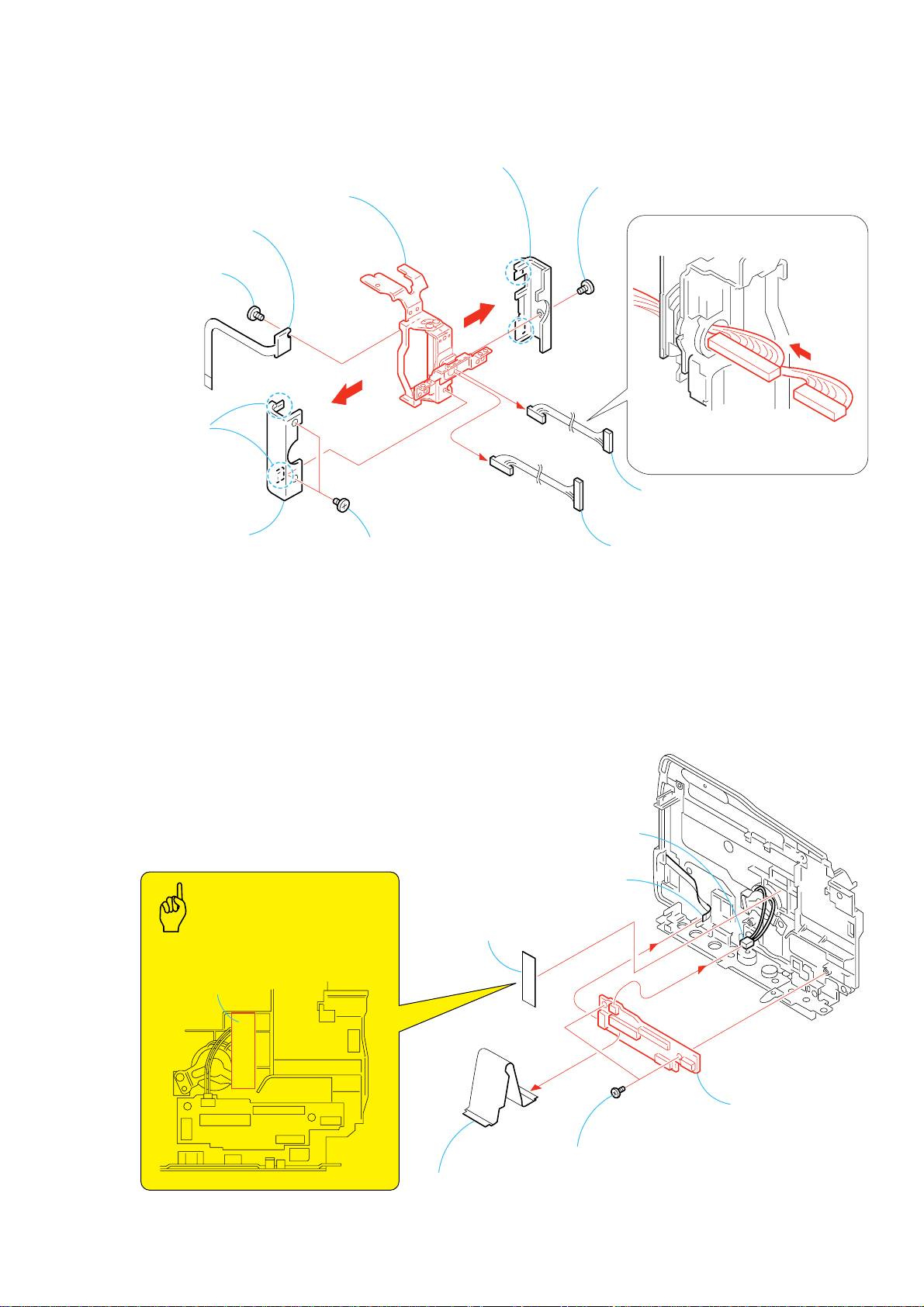

2-8. HINGE ASSEMBLY

q;

Hinge assembly

5

Rear hinge cover

DCR-TRV38/TRV38E/TR V39

2

Screw

(M1.7 × 2.5)

7

FP-461 flexible board

6

Screw

(M1.7 × 2.5)

3

T wo claws

4

Front hinge cover

1

T wo screws

(M1.7 × 2.5)

Remove the Harness (PC-121),

(PC-122) in the direction of the arrow.

Bend the Harness (PC-121), (PC-122)

along with connector

8

Harness (PC-122) (10P)

9

Harness (PC-121) (20P)

2-9. CK-131 BOARD

Caution

Attach the Tape (A) as shown

in the illustration.

Tape (A)

3

Loud speaker (2P)

4

FP-635 flexible

board (6P)

2

T ape (A)

1

FP-668

flexible board (51P)

5

Two tapping screws

×

(M1.7

3.5)

6

CK-131 board

2-7

DCR-TRV38/TRV38E/TRV39

2

2-10.LOUD SPEAKER, FP-635 FLEXIBLE BOARD

6

F&B button

7

5

F&B retainer metal sheet

4

T apping screw

(M1.7 × 3.5)

FP-635

flexible board

1

(M1.7 × 3.5)

2-11.BATTERY SECTION

Two tapping screws

3

Loud speaker

2

Speaker retainer assembly

5

Battery section

4

Battery terminal

board (6P)

2-8

3

T wo screws

(M1.7

lock ace, p2

2

CPC lid

×

4),

1

Screw

(M1.7

lock ace, p

×

4),

2-12.BA TTER Y TERMINAL BOARD

2

4

Battery terminal board

2

Strap bracket

(lower)

DCR-TRV38/TRV38E/TR V39

3

BT panel assembly

1

Screw

(M1.7 × 4),

lock ace, p

2-13.TOP CABINET ASSEMBLY

3

Top cabinet assembly

1

Dowel

2

Claw

2-9

DCR-TRV38/TRV38E/TRV39

s

2-14.EVF SECTION

Caution

Attach the Tape (A) as shown

in the illustration.

6

Slide the EVF slightly

in the direction of the

arrow so that the two

screws

visible.

5

7

become

Peel off the tape.

FP-461 flexible board

Tape (A)

1

Screw

×

(M1.7

2.5)

DI089

8

FP-435 flexible board (20P)

4

DI heat sink

assembly

3

(M1.7

Screw

×

2.5)

9

EVF section

7

(M1.7 × 5)

2

Screw

(M1.7

Two tapping screw

×

2.5)

2-10

2-15.VF LENS ASSEMBLY

4

VF base

assembly

DCR-TRV38/TRV38E/TR V39

1

Raise the EVF in the

direction of the arrow

A

2

Two tapping screws

(M1.7

Caution

×

A

.

5)

3

Two claws

7

LCX033AN-J (16P)

8

Three claws

5

VF electrostatic

sheet

6

FP-435 Flexible

board (20P)

qa

0

Four claws

VF lens assembly

9

LB-087 board,

Lamp guide

qs

T wo claws

qd

Lamp guide

When separating the 9 LB-087 board and

Lamp guide from the

by removing the three

the side of the VF lens assembly on which

the LB-087 board is installed, downwards.

Because the Illuminator and others may fall

out of the VF lens assembly, hold the

illuminator and others using tape or paper

as shown to prevent them from falling.

Be careful on this point especially when

removing the LB-087 board and Lamp guide

because the three claws located in the VF

lens assembly are easy to break.

qs

VF lens assembly

8

claws, do not face

LCX033AN-J

Prism sheet

Illuminator

Hold the illuminator

and others using

tape or paper as

shown to prevent

them from falling.

LCD Cushion

qf

LB-087 board

2-11

DCR-TRV38/TRV38E/TRV39

2-16.FP-435 FLEXIBLE BOARD

1

Screw (M1.4 × 2.5),

lock ace

2

Flexible retainer sheet metal

Caution

3

VF flexible

retainer sheet

4

5

VF base assembly,

VF cabiet (lower) assembly,

FP-435 Flexible board

Routing of the FP-435 flexible board

FP-435 Flexible board

FP-435 Flexible board

VF flexible

retainer sheet

Caution

When installing, pass the FP-435 flexible

board as shown.

2-12

FP-435 Flexible board

2-17.DI-089 BOARD

2

VC315

Turn it over.

7

VC heat sink assembly

1

FP-641 flexible board (10P)

4

Board to board

connector (100P)

DI089

6

Claw and

two dowels

DCR-TRV38/TRV38E/TR V39

5

DI-089 board

3

Three screws

(M1.7

×

2.5)

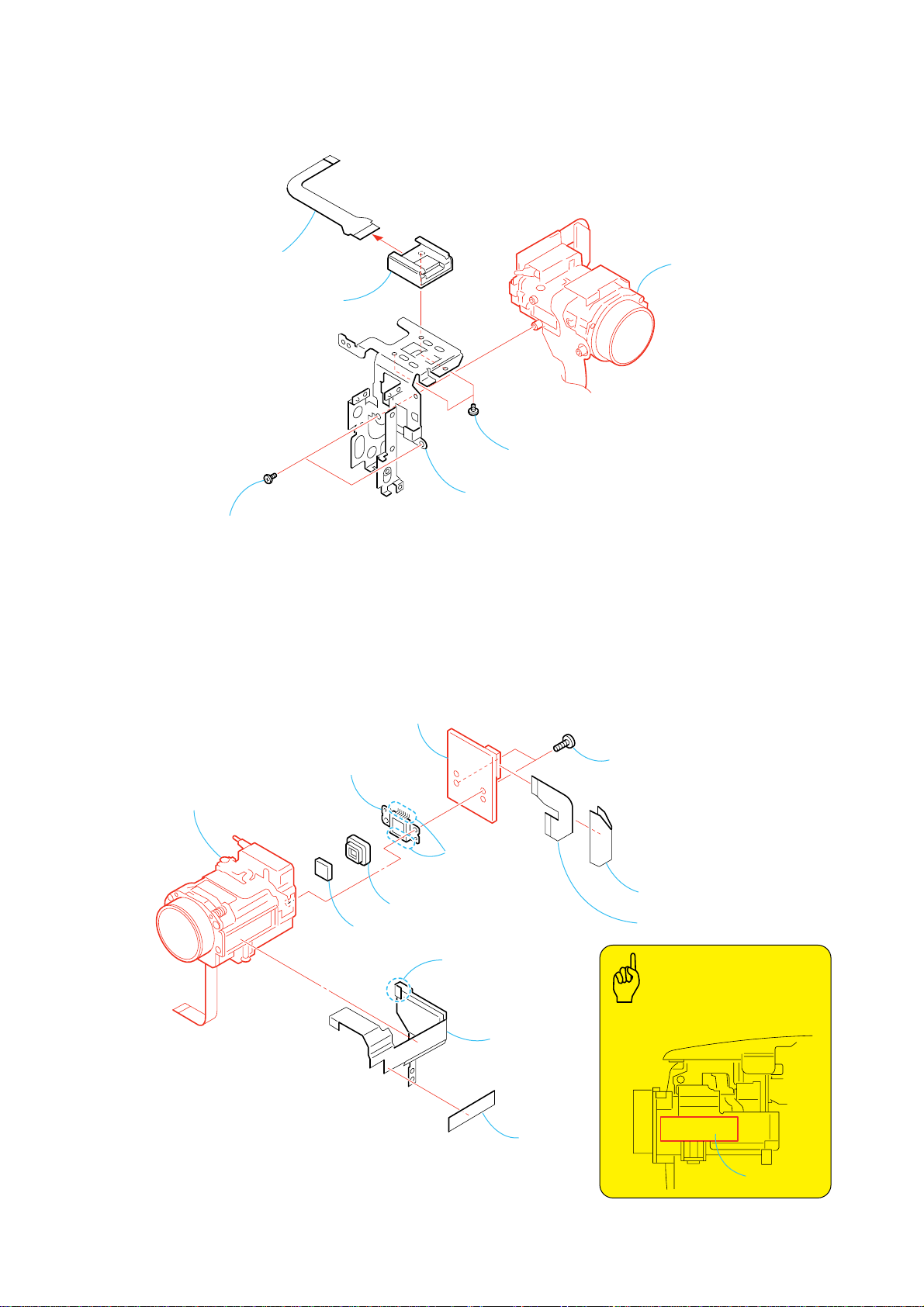

2-18.VC-315 BOARD

3

FP-638 flexible

board (24P)

2

Flexible board

(from lens device)(27P)

q;

FP-639 flexible

board (51P)

4

Control switch block

(FK-4300) (27P)

VC315

9

T wo screws

(M1.7

5

Flexible board

(from the capstan motor)(27P)

6

FP-468 flexible board (27P)

7

Flexible board

(from the drum motor)(10P)

8

Flexible board

(from the video head)(10P)

qa

VC-315 board

Caution

Attach the Tape (A) as shown

in the illustration.

×

2.5)

1

FP-640 flexible board (14P)

2-13

Tape (A)

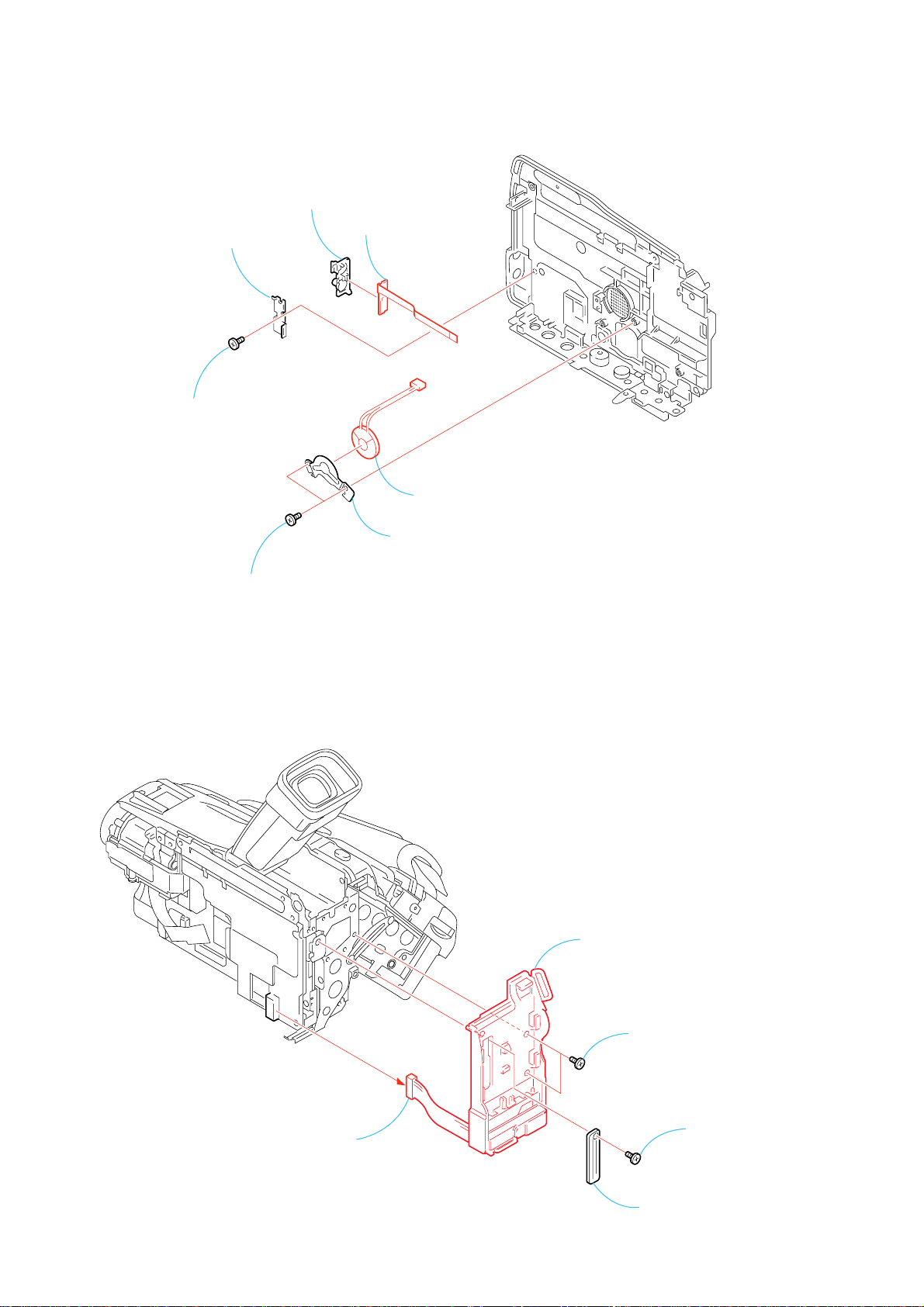

DCR-TRV38/TRV38E/TRV39

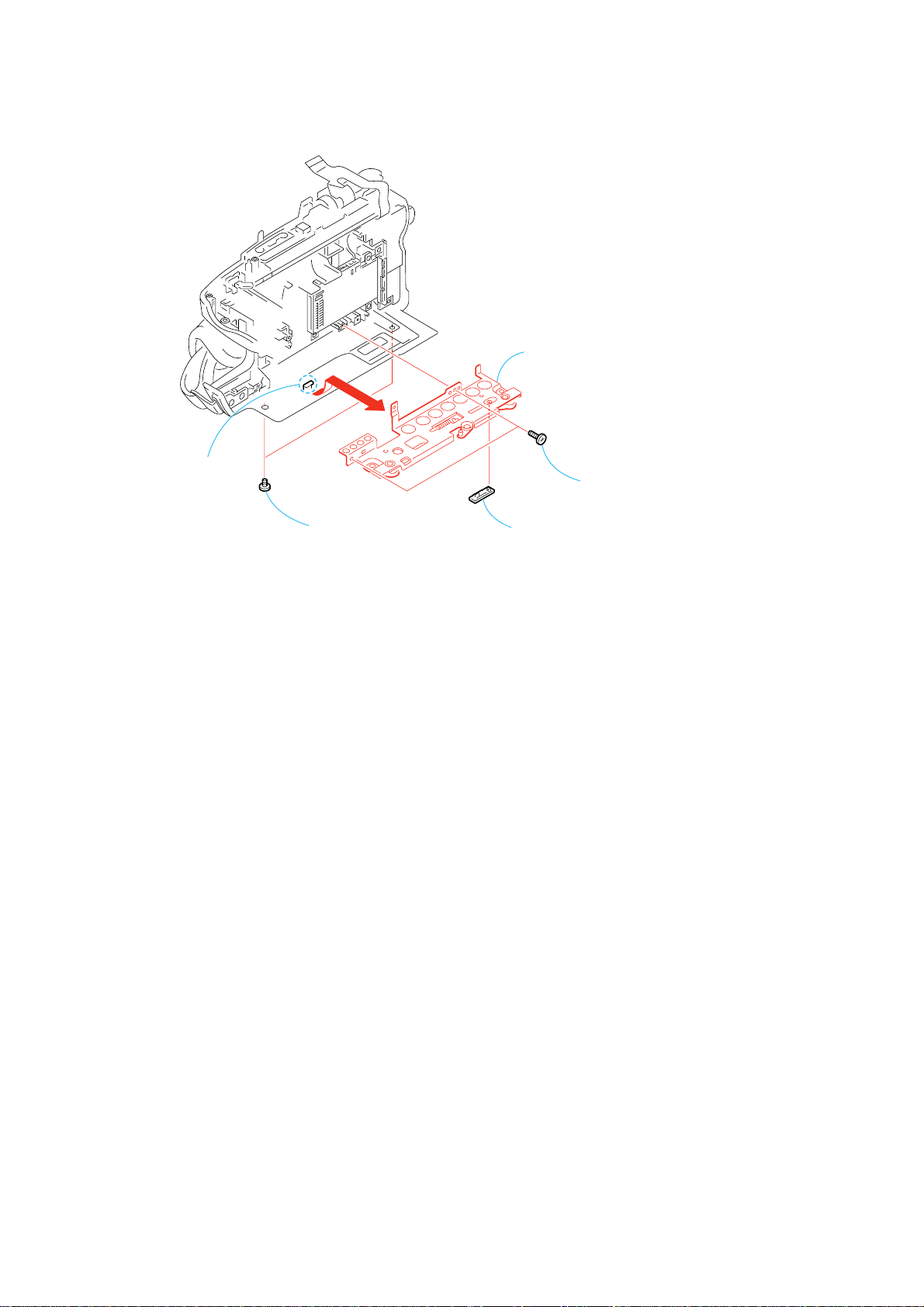

2-19.MECHANISM DECK

2

1

Three screws

(M1.7

×

2.5)

3

Mechanism deck

2

MD frame assembly

2-20.LENS SECTION

1

four special

head screws

(M1.7)

2

Lens section

2-14

1

T apping screw

(M1.7 × 5)

(Silver)

2-21.JK-248, JK-249 BOARD

1

T wo screws

(M1.7

×

2.5)

(22p)

(22p)

3

T wo screws

(M1.7

×

2.5)

2

JK-249 board

4

JK-248 board

5

FP-639 flexible board

DCR-TRV38/TRV38E/TR V39

2-15

DCR-TRV38/TRV38E/TRV39

)

[SERVICE POSITION TO CHECK THE VTR SECTION]

Connection to Check the VTR Section

To check the VTR section, set the VTR to the "Forced VTR power ON" mode.

Operate the VTR functions using the adjustment remote commander (with the HOLD switch set in the OFF position).

Setting the “Forced VTR Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: 0, address: 10, and set data: 00.

3) Select page: D, address: 10, set data: 02, and press

the PAUSE button of the adjustment remote commander.

To eject a cassette, connect the

cabinet (L) assembly.

Mechanism deck

Monitor TV

Exiting the “Forced VTR Power ON” mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: 0, address: 10, and set data: 00.

3) Select page: D, address: 10, set data: 00, and press

the PAUSE button of the adjustment remote commander.

4) Select page: 0, address: 01, and set data: 00.

Extension cable (100P)

(J-6082-352-A)

16

CPC-7 jig

(J-6082-382-A

CN4601

DI-089 board

CN1003

CN1006

16

CN4004

CN1004

1

1

DI-089

CN5103

FP-639 flexible board

JK-248 board

AUDIO/VIDEO jack

JK-249 board

CN5001

LANC jack

Adjustment remote

commander (RM-95)

PROCEDURE OF REMOVING MECHANISM DECK

1 2-2. FRONT PANEL SECTION ...............................

2 2-5. CABINET (R) SECTION .................................

3 2-11. BATTERY SECTION ........................................

4 2-13. TOP CABINET ASSEMBLY ...........................

5 2-14. EVF SECTION.................................................

6 2-17. DI-089 BOARD ...............................................

7 2-18. VC-315 BOARD ...............................................

8 2-19. MECHANISM DECK .......................................

9 2-20. LENS SECTION..............................................

0 2-21. JK-248, JK-249 BOARD .................................

(page 2-3)

(page 2-4)

(page 2-8)

(page 2-9)

(page 2-10)

(page 2-13)

(page 2-13)

(page 2-14)

(page 2-14)

(page 2-15)

VC-315

CN1002

VC-315 board

Battery terminal board

(6P)

AC power

adaptor

AC IN

2-16

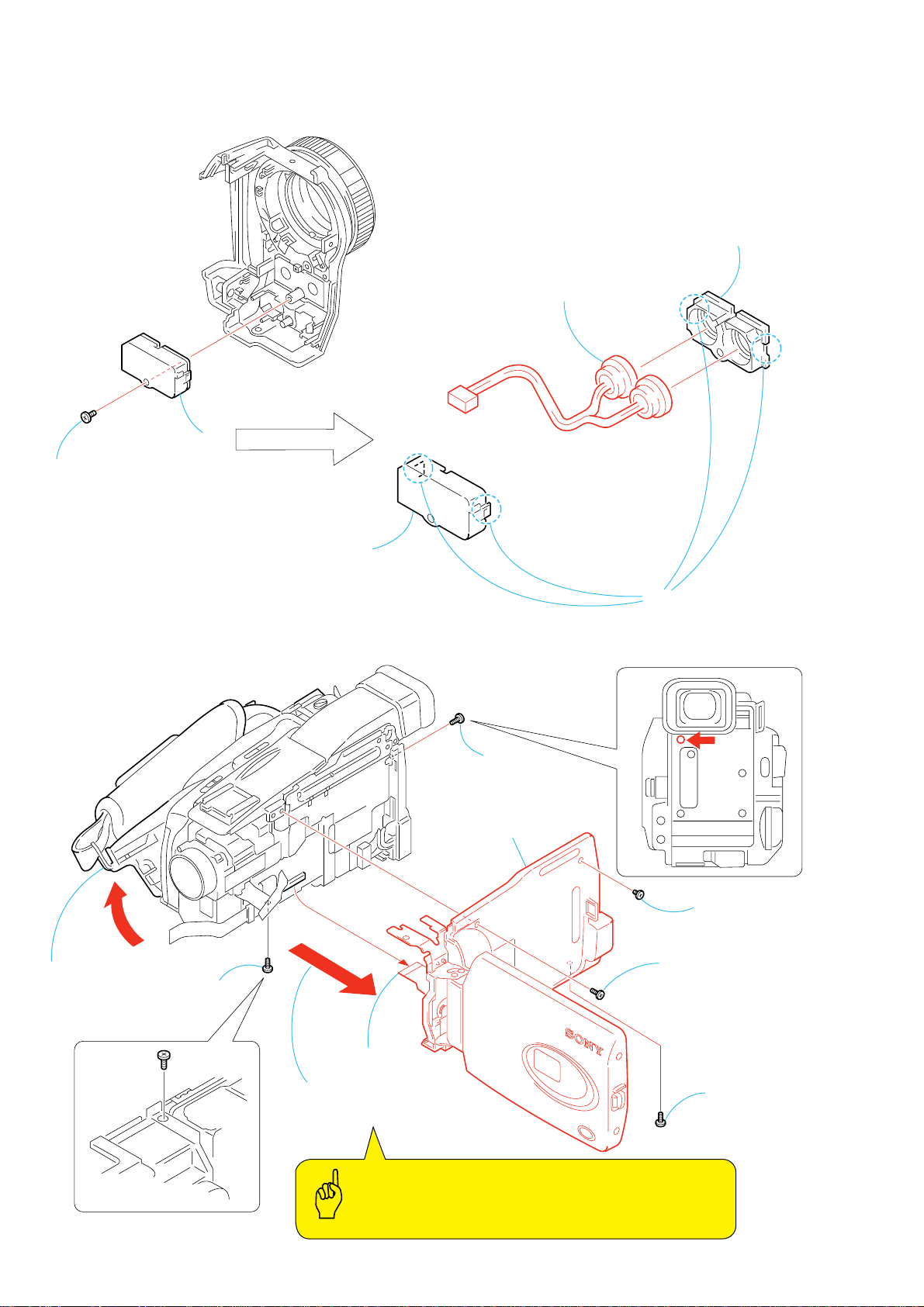

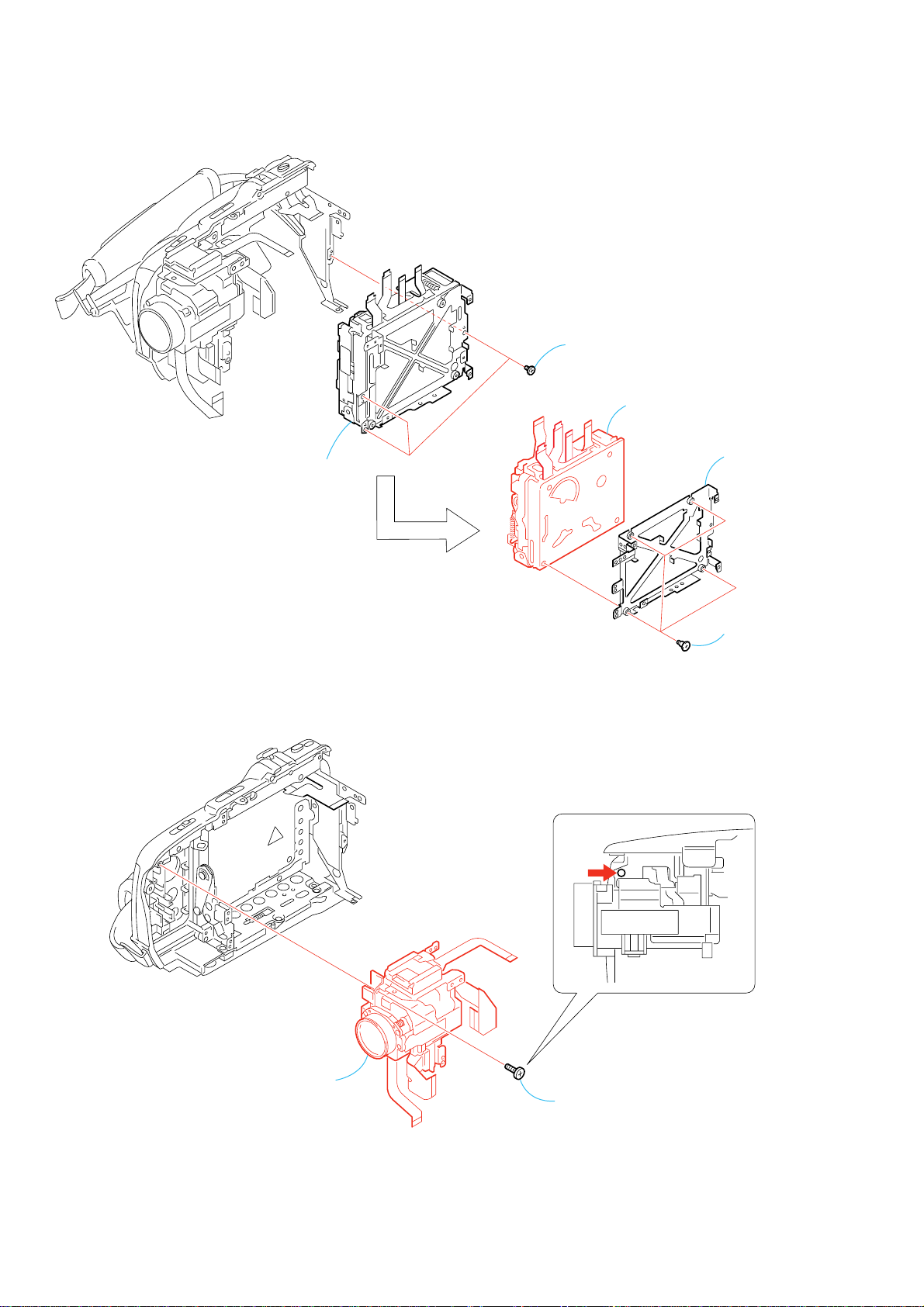

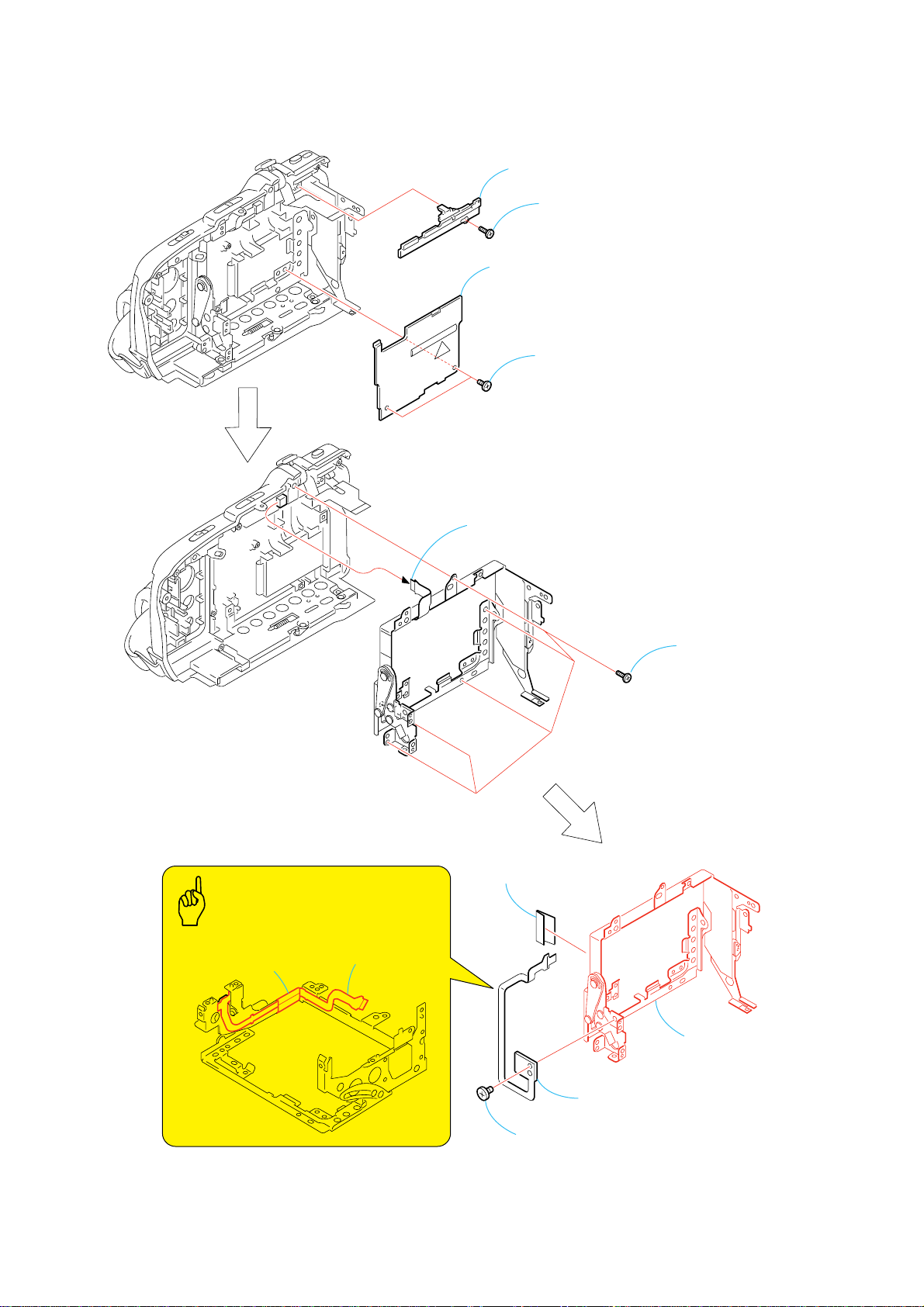

2-22.LENS BLOCK ASSEMBLY

y

1

FP-641 flexible board (10P)

5

External connector

(Hot shoe)

4

T wo screws

(M1.7

×

2.5)

DCR-TRV38/TRV38E/TR V39

3

Lens block assembl

6

Lens frame assembly

2

T wo tapping

screws (M1.7

×

3.5)

2-23.LENS DEVICE (LSV -751A), CD-436 BOARD

qs

CD-436 board

qa

CCD block assembly

7

Lens device

(LSV-751A)

q;

Remove the

solderings

9

Seal rubber (W)

8

Optical filter block

6

T wo tapping

screws (M1.7

4

CD flexible shield sheet

5

FP-638 flexible board

×

5)

2

Claw

3

CD heat sink

2-17

1

T ape (A)

Caution

Attach the Tape (A) as shown

in the illustration.

Tape (A)

DCR-TRV38/TRV38E/TRV39

2-24.GRIP LOCK ASSEMBLY

3

Claw

5

Grip lock assembly

2

Two tapping screws

(M1.7

×

5)

1

T wo screws

(M1.7

lock ace, p2

×

2.5),

4

Eject knob

2-18

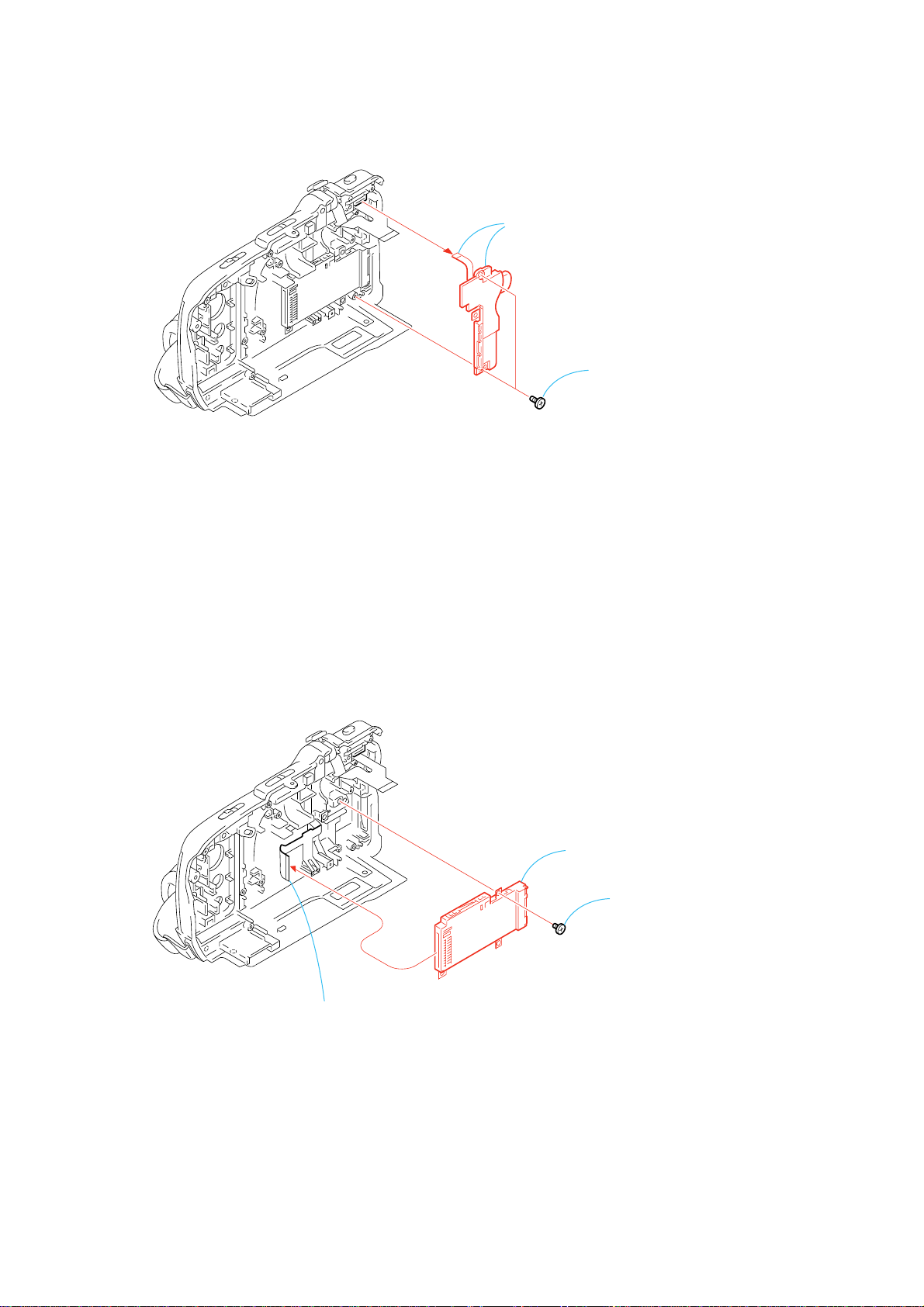

2-25.CS FRAME ASSEMBLY

y

2

Zoom cover

4

Grip cover

1

Two tapping screws

(M1.7 × 5)

3

T wo screws

(M1.7 × 2.5)

DCR-TRV38/TRV38E/TR V39

Caution

Routing of the FP-645 board

L sheet

FP-645 flexible board

5

FP-645 flexible board (15P)

7

L sheet

6

Five tapping screws

(M1.7 × 5)

2-19

9

8

Screw

(M1.7 × 2.5)

FP-645 board

q;

CS frame assembl

DCR-TRV38/TRV38E/TRV39

s

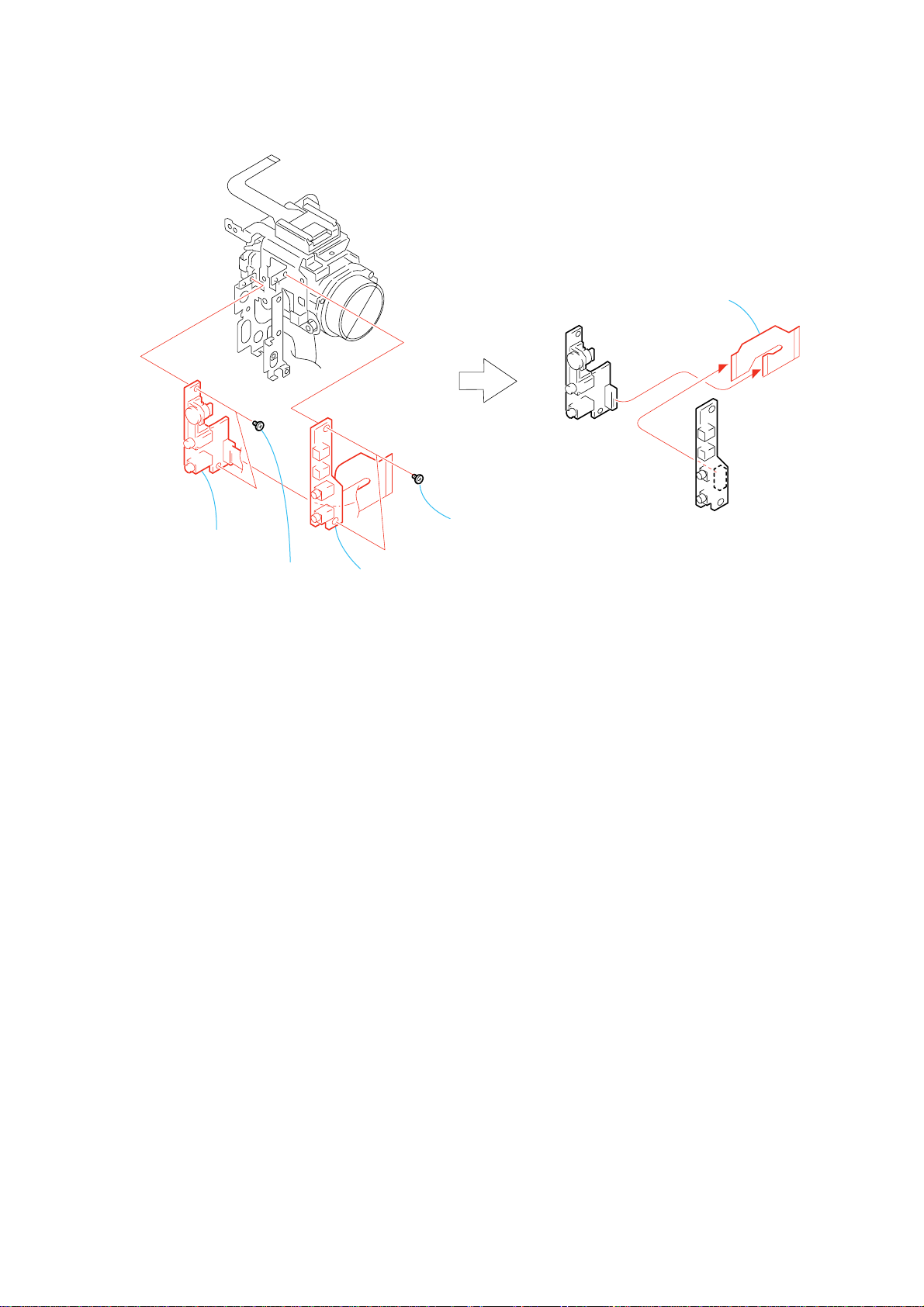

2-26.CONTROL SWITCH BLOCK (PS-2890)

2

Control switch block

(PS-2890) (8P)

1

(M1.7 × 3.5)

Two tapping screw

2-27.MEMORY STICK CONNECTOR

2

Control switch block

(FK-4300) (10P)

3

Memory stick connector

1

T wo screws

×

(M1.7

2.5)

2-20

2-28.CONTROL SWITCH BLOCK (FK-4300)

2

Control switch block (FK-4300)

Caution

Routing of the Control switch block (FK-4300)

DCR-TRV38/TRV38E/TR V39

Two dowels

1

Peel off the

adhesion portion.

Two dowels

Control switch block

(FK-4300)

2-21

DCR-TRV38/TRV38E/TRV39

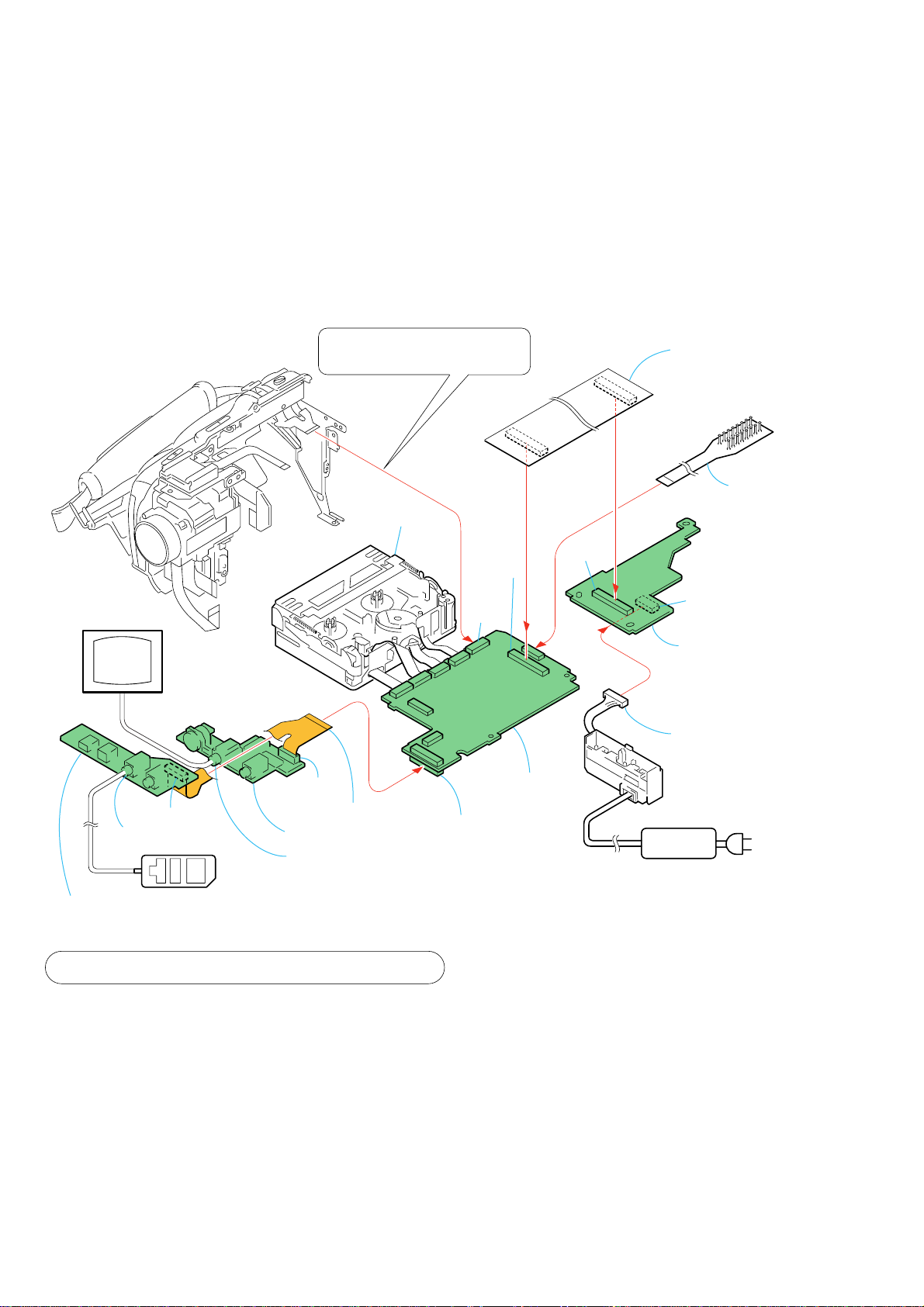

2-29.CIRCUIT BOARDS LOCATION

CD-436

JK-248

LB-087

JK-249

SE-136

DI-089

VC-315

MA-423

CK-131

PD-190

NAME FUNCTION

CD-436

CK-131

DI-089

JK-248

JK-249

LB-087

MA-423

PD-190

SE-136

VC-315

CCD IMAGER

FUNCTION KEY

CHARGE, POWER IN, EVF DRIVER, TIMING GEN., DC-DC CONVERTER

P/Y SENSOR, A/V IN/OUT

DV IN/OUT, MIC IN

EVF, BACK LIGHT

MIC IN, REMOTE CONTROL RECEIVER

LCD DRIVER, TIMING GEN., LCD DRIVER, LCD BACK LIGHT

MF SENSOR

CAMERA PROCESS, MPEG/DIGITAL STILL PROCESS, SERVO PROCESSOR, CAMERA/

MECHA/HI CONTROL, USB SIGNAL PROCESSOR, A/D CONVERTER, TIMING GENE.,

FOCUS/ZOOM/IRIS ND CONTROL, CAMERA/DV SIGNAL/MPEG MOVIE/DIGITAL STILL/

AUDIO SIGNAL PROCESSOR, FLASH MEMORY/SDRAM, DV SIGNAL PROCESSOR,

DV INTERFACE, REC/PB HEAD AMP, VIDEO IN/OUT AGC, AUDIO MIC AMP, AUDIO IN/

OUT INTERFACE, AUDIO A/D-D/A CONVERTER, CONNECTOR

2-22

2-30.FLEXIBLE BOARDS LOCATION

CONTROL SWITCH BLOCK

(PS-2890)

CONTROL SWITCH BLOCK

(FK-4300)

FP-635

FP-639

FP-435

FP-668

FP-641

FP-638

FP-461

FP-640

FP-645

FP-642

The flexible boards contained in the mechanism deck and that in the lens device are not shown.

DCR-TRV38/TRV38E/TR V39

2-23E

DCR-TRV38/TRV38E/TR V39

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

FRONT PANEL SECTION CABINET (R) SECTION

Tape (P)

2003.02.13

Loud MIC

CABINET (L) SECTION

FP-461 flexible board

FP-645 flexible board

L sheet

Tape (A)

Harness (PC-121)

Flexible board

(from lens device)

Two dowels

FP-461 flexible

board (6P)

Harness (PC-122)

VC315

Tape (A)

Two dowels

Control switch block

(FK-4300)

CS frame assembly

HELP

DCR-TRV38/TRV38E/TRV39

CABINET (L) SECTION

VC-315 board

VC shield sheet

EVF SECTION

VF flexible

retainer sheet

CABINET (R) SECTION

Tape (A)

FP-435 Flexible board

FP-435 Flexible board

HELP

Cabinet (R) section

COVER

COVER

Link

Link

DCR-TRV38/TRV38E/TRV39

3. BLOCK DIAGRAMS

OVERALL BLOCK DIAGRAM (1/4)

OVERALL BLOCK DIAGRAM (1/4)

OVERALL BLOCK DIAGRAM (2/4) POWER BLOCK DIAGRAM (2/2)

OVERALL BLOCK DIAGRAM (2/4) POWER BLOCK DIAGRAM (2/2)

OVERALL BLOCK DIAGRAM (3/4)

OVERALL BLOCK DIAGRAM (3/4)

OVERALL BLOCK DIAGRAM (4/4)

OVERALL BLOCK DIAGRAM (4/4)

POWER BLOCK DIAGRAM (1/2)

POWER BLOCK DIAGRAM (1/2)

DCR-TRV38/TRV38E/TRV39

COVER

COVER

BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/4)

LENS ASSY

IRIS

(SHUTTER)

M

H

H

ND FILTER

METER

M

MR

FOCUS

M

MOTOR

M

ZOOM

MOTOR

MR

NIGHT SHOT

SE-136 BOARD

PH6301,6302

MANUAL

FOCUS

PHOTO

SENSOR

JK-248

BOARD(1/2)

SE5002

YAW SENSOR

SE5001

PITCH SENSOR

MEMORY

STICK

CD-436 BOARD

IC7001

1-4 10-12

CN7001

6-9 14-12

21-18

CN1501

IRIS DRIVE

4

+,-

3

IRIS HALL

6

+,-

2

ND HALL

16

+,-

12

ND DRIVE

14

+,-

13

20

FMR A,B

19

26

FOCUS +,-

27

24

ZOOM +,-

25

ZMR A,B

8

10

XNS SW

17

CN1301

MA-423

BOARD(1/3)

CN5902

CN6301

136

4

12

18

5

8

20

3

CN1002

CN5001

JK-249

CN5101

BOARD(1/4)

(USB)

CONTROL SWITCH

BLOCK(FK-4300)(1/2)

CCD

IMAGER

•

V1-V4

RG,H1,H2

13-15

∗1 :

DCR-TRV38/TRV38E

∗2 : DCR-TRV39

MF A

MF B

IC3501

YAW/PITCH

USB D+,USB D-

MS BS,DIO,SCLK

(8/15)

SENSOR

AMP

8

X1501

66MHz(∗1)

54MZ(∗2)

IC7002

11

S/H

IMAGER

13 14 1

XSHD,XSHP,CLPDM

17 16 19

10 11 8

17 16 22

29

(1/17)

30

IC1501

TIMING

40

GENERATOR

44

9

12

13

(3/17)

5

IRIS DRIVE

19

17

ND

FILTER

7

DRIVE

23

FOCUS MOTOR

DRIVE

2

21

ZOOM MOTOR

4

DRIVE

IC1301

CN5903 CN1009

131

3

18

2

CN5103 CN1002

44

6

45

5

CN1006

2

4

6

X2601

20MHz

YAW AD

PITCH AD

CCD OUT

5

•

4

33

34

35

38

25

24

21

1

2

47

13

14

15

16

9

10

11

12

CN1002

1

VC-315 BOARD(1/4)

3

25

+,-

••

2

24

CN1501CN7001

IC1901 Y OUT

HD,VD,FLD HD,VD,FLD

CHCK CHCK

XCHCK

PBLK

CAM SO,SI,SCK

(3/17)

44

IC1302

45

36

ND FILTER

37

CONTROL

IR PWM

10

IR EN

11

ND PWM

8

ND EN

9

FC PWM

14

FC EN

15

EN PWM

12

ZN EN

13

61

60

53

52

(13/17)

41

IC2601

(1/2)

CAMERA CONTROL

210

211

1

3

130

129

TO

OVERALL

BLOCK DIAGRAM

(4/4)

(PAGE 3-8)

SECTION 3

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

FOCUS/

ZOOM/

IRIS/

EXT STROBO

ZOOM VR AD

USB D+

USB D-

136

128

135

77

78

75

73

71

30

•

31

41

40

18

5

6

3

CAM SO,SI,SCK

CH SO,SCK

ND HALL

HALL AD

193420

HALL AD

ND HALL

11

10

(2/15)

SPCK

(IC2101)

(1/17)

IC1503

AGC

A/D CONV.

16

(TRV39 ONLY)

(16/17)

IC3303

USB

I/F

(∗2)

44 45

CH SO,SCK

ADCK 27

(2/17) (4/17)

IC1601

CAMERA

47

48

AD0-AD13

AD0-AD13

1

12

AD0-AD13

EXT STROBO

(13/17)

PROCESS

44

|

57

CLPOBCLPOB

65

64

61

60

95

15

16

13

76

154 133

121 102

A0-A10, A12

IC1701

6

EVR

7

USB D+,USB D-

MS BS,DIO,SCLK

USB VP

USB VM

4

5

24 13

38

40

X2701

48MHz

(16/17)

IC3302

USB

HOST

MS BS

MS DIO

MS SCLK

12031106

6583

USB CLK

DSCK LK

20 26

29

35

IC1602

IC2703

64Mbit

SDRAM

(5/17)

239

238

215

|

213

XTAL

OSC

62 92

SPCK

97

VCK

96 241

3

|

D0-D15A0-A13

213

42

1

175

|

169

7

|

4

8

9

10

53

A0-A13

D0-D15

IFI Y0-Y7

IFI C0-C3

IFI HD

IFI VD

IFI OE

(2/17)

AD4-AD13

CAM SO,SCK

USB D+, USB D-

IC2705

1

4

2

4

(5/17)

IC2704

(1/2)

184

DIGITAL

STILL

CONTROL

A1-A22

D0-D15

60 39

20 26

213

29

35 42

53

(6/17)

IC2802

SDRAM

16Mbit(∗1)

64Mbit(∗2)

(5/17)

USB CLK

DSCK LK

IC2101

216

|

223

224

|

227

228

229

230

185

|

170

215

|

198

252

|

261

IC1901 C OUTIC1901 C OUT

33

ADCK27

245

158

156

28

29

24

USB CLK

119187

A1-A22

D0-D15

MPEG

MOVIE

PROCESS

VIDEO

A/D

CONV.

USB

I/F

DIGITAL

STILL

PROCESS

A1-A19 D0-D15

116 98 121 137

24 16

10 148

(6/17)

IC2803

FLASH MEMORY

16Mbit(∗1)

64Mbit(∗2)

29 36

38

DV

SIGNAL

PROCESS

AUDIO

SIGNAL

PROCESS

45

20

268

269

270

271

279

280

281

282

264

265

266

267

272

273

275

276

284

168

86

169

139

47

46

52

95

96

40

39

45

92

93

53

60

301

302

298

299

82

89

87

151

152

150

FRRV

TRRT

TRRV

SPCK

EVF R

EVF G

EVF B

EVF HD

EVF VD

PANEL R

PANEL G

PANEL B

PANEL HD

PANEL VD

IC2101 Y OUT

IC2101 C OUT

ADATAIN0

ADATAIN1

ADATAOUT0

ADATAOUT1

SFD BCK

DATA FROM SFD

DATA TO SFD

RYO0-RYO3,DEHD,DEVD.DEFLD.SGOUT

RCO0-RCO3,EDHD,EDVD.EDFLD.FRMREF

VSP SO,SI,SCK

RYI0-RYI3,DE0-DE3

RCI0-RCI3,DE4-DE7

DATA TO SFD

SFD BCK

(7/17)

143 79

IC2301

119

162

SIGNAL

120

PROCESS

163

SIGNAL

PROCESS

70

121

71

122

13

72

14

73

123

166

124

125

HY1 PLL 27INHY1 PLL 27IN

12

ADATAIN0

168

ADATAIN1

127

ADATAOUT0

167

ADATAOUT1

126

SFD BCK

21

IC1901 C OUT

(15/17)

9

8

12

IC2901

D/A CONV.

A/D CONV.

15

16

3

2

DV

RF

IC901 Y OUT

LDATA FROM SFD

R

L

R

19

17

25

23

152 189

190 109

155 192

149

186

150

187

45

41

139

54 107

55 153

60

58

112

111

114

157

3

46

7

34

36

IC3001

LBUS0-LBUS3

TRCK0

SWP

FRRV

TRRT

TRRV

VSP SO,SI,SCK

910

(10/17)

IC1901

VIDEO

IN/OUT

AGC

ACC

15 14

(15/17)

AUDIO

I/O

DO-D15

LCK0LCK0 VCK

VD SO,SCK

54

55

51

53

8

10

64

2

46

49

JK-249

BOARD(2/4)

EVF HD

EVF VD

PANEL R

PANEL G

PANEL B

PANEL HD

PANEL VD

14

CN5102

DV

EVF R

EVF G

EVF B

SP +

SP -

CN5001

3

4

TO

OVERALL

BLOCK DIAGRAM

(2/4)

(DI-089)

(PAGE 3-3)

G

TO

OVERALL

BLOCK DIAGRAM

(2/4)

(CK-131)

(PAGE 3-3)

YC

G

J5002 (1/2)

S VIDEO

TPA

(8/17)

IC2201

45

DV

|

INTERFACE

42

47104

29 37

Y

18

C

14

V

22

Y

39

C

48

V

42

CN1002

NTPA

TPB

9

NTPB

|

6

VSP SO,SI,SCK

MC BUSMC BUS

VD SO,SCK

CN5103

38

10

39

9

35

13

36

12

REC DTREC DT

REC CKREC CK

RF INRF IN

TO

SWP

FRRV

TRRT

TRRV

SPCK

OVERALL

2

BLOCK DIAGRAM

(3/4)

(PAGE 3-5)

CN1003

44

42

40

60

58

5

3

1

24

26

51

50

CN1007

SY I/O

SC I/O

7 916

CN1002

JK-248

BOARD(2/2)

VIDEO I/O

13

L

R

L

R

SP+

SP-

HP L

HP R

MIC L

MIC R

5

TO

OVERALL

BLOCK DIAGRAM

(2/4)

(PAGE 3-3)

AUDIO SIGNAL

VIDEO SIGNAL

VIDEO/AUDIO SIGNAL

AUDIO L I/O

AUDIO R I/O

CN1002

10

15

8

11

12

3

20

1

22

CN5001

J5002 (2/2)

L

AUDIO VIDEO

V

R

J5003

L

HEAD PHONES

R

16

3-1 3-2

DCR-TRV38/TRV38E/TRV39

COVER

COVER

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

3-2. OVERALL BLOCK DIAGRAM (2/4)

TO

4

OVERALL

BLOCK DIAGRAM (1/4)

(VC-315)

(PAGE 3-2)

TO

6

OVERALL

BLOCK DIAGRAM (3/4)

(VC-315)

(PAGE 3-5)

TO OVERALL

7

BLOCK DIAGRAM (4/4)

(VC-315)

(PAGE 3-8)

VC-315 BOARD

(2/4)

CN1004

FOR

ADJUSTMENTS

PANEL VG

18

PANEL COM

10

H START

14

EVF VG

26

EVF VCO

22

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

PD-190 BOARD(1/2)

CN5602

10

10

4

4

4

4

4

3

3

2

2

1

1

9

9

10

10

13

13

14

14

16

16

CN5601

1

2

SP901

SPEAKER

(2/2)

48

47

46

40

39

46

45

42

1

48

HD OUT

IC5701

(1/2)

IC5501

RGB

DRIVE

(1/2)

IC5502

TIMING

GENERATOR

2 58

5 2

1

20

22

24

27

35

12

24

4

VD SO,SCK

CN1007

PANEL R

PANEL G

PANEL B

PANEL HD

PANEL VD

SP+

SP-

BL CONT

HD

VD

VD SO,SCK

BL CONT

CN5206

CN5205

CN5204

CK-131 BOARD(1/2)

CN5201

47

49

51

28

26

1

2

30

32

44

PANEL VG

48

4

2

19

COM OUT

50

XHD OUT

53

PANEL VG

COM OUT

XHD OUT

PANEL R,G,B

VR,VG,VB

COM

DAC

Q5701

ND901

LCD901(1/2)

19

20

3.5 INCH

21

COLOR LCD

VCOM

VGL AC

CN5501

7

6

EP 2.8V

UNIT

11

4

5

|

10

12

|

18

BACKLIGHT

Q5704

LED DRIVE

BL HIGH

BL LOW

(STARTER)

CN5701

14

3

2

DETIN

T5701

Q5702

INVERTER

BACK

LIGHT

DRIVE

3

BL REG

(2/2)

IC5702

CURRENT

DET

4

AUDIO SIGNAL

VIDEO SIGNAL

MIC901

J5101

MIC

(PLUG IN POWER)

MIC

L

MIC

R

16

MA-423 BOARD

(2/3)

CN5901

1

3

JK-249

BOARD

(3/4)

CN5903

CN5103

121412

222023

14

25

CN1009

R

L

CN1002

TO OVERALL

5

BLOCK DIAGRAM

(1/4)

(PAGE 3-2)

35

1

3

33

(14/17)

IC3601

MIC AMP

(3/6)

MIC L

MIC R

22

14

36

48

TO

3

OVERALL

BLOCK DIAGRAM

(1/4)

(VC-315)

(PAGE 3-2)

TO

8

OVERALL

BLOCK DIAGRAM

(3/4)

(VC-315)

(PAGE 3-5)

EVF VG

EVF VCO

CN1003

38

62

66

EVF R

EVF G

EVF B

EVF HD

EVF VD

VD SO,SCK

38

62

66

44

42

40

60

58

74

78

CN4004

DI-089 BOARD (1/3)

EVF R,G,B

VD SO,SCK

VD SO,SCK

HD

VD

VCO

INTELLIGENT

CN4001

9

8

10

7

11

18

4

3

ACCESSORY

SHOE (1/2)

LB-087 BOARD

R,G,B

COM

BCK, HCK1/2, HST, EN, STB, VCK, VST

IC6101

Q6102

BACK LIGHT

CN6101

DRIVE

CN6102

D5602

BACK

LIGHT

LCD903

COLOR

EVF

14

UNIT

15

13

16

12

9

6

3

8

(2/3)

48

47

IC3201

46

RGB

DRIVE

40

39

46

(2/3)

45

IC3202

42

1

TIMING

GENERATOR

48

2 8

CN3201

20

22

24

14

24

14

12

13

11

14

10

3

8

18

3-3 3-4

COVER

COVER

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

DCR-TRV38/TRV38E/TRV39

3-3. OVERALL BLOCK DIAGRAM (3/4)

VC-315 BOARD(3/4)

TO

OVERALL

2

BLOCK DIAGRAM

(1/4)

(PAGE 3-2)

TO

6

OVERALL

BLOCK DIAGRAM

(2/4)

(CK-131)

(PAGE 3-3)

TO

8

OVERALL

BLOCK DIAGRAM

(2/4)

(DI-089)

(PAGE 3-3)

TO

9

OVERALL

BLOCK DIAGRAM

(4/4)

(PAGE 3-8)

16

DIGITAL VIDEO/AUDIO SIGNAL

REC CK

REC DT

RF IN

MC BUS

SPCK

SWP, FRRV, TRRT, TRRV

VSP SO,SI,SCK

VD SO, SCK

CN1007

VD SO, SCK

VD SO, SCK

HI SO,SI,SCK

REC PROOF

CHIME SDA,CHIME SCK,CHIME VDD

XCC DOWN

22

20

74

78

CN1003

SWP

(13/17)

IC2602

EEPROM

5 2 6

VSP SO,SI,SCK

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

CN1004

FOR ADJUSTMENTS

84

41

44

RF MON

(11/17)

IC2501

LPF

LPF

43 676567

(2/2)

45

VSP SO, SCK

65

CN4004 CN4004 CN1003CN1003

CAP ERROR

9

IC4502

DRUM ERROR

6

DI-089 BOARD (2/3)

(3/3)

PWM

DRIVE

REC CK

44

REC DT

46

RF IN

35

RF MON

30

RF SWP

39

SWP

38

SPCK

Q4508

SWITCHING

61

(1/2)

Q4509

SWITCHING

62

61 63

57 59

61 63

57 59

CAP VS

DRUM VS

X2601

20MHz

FRRV

TRRT

TRRV

SWP

172

164

(13/17)

IC2601

(2/2)

52

45

33

32

23

178

179

69

70

67

82

80

66

65

63

MECHA

CONTROL

|

1

3

CAP FG

190

CAP ON,CAP FWD

165

166

CAP PWM

89

DRUM PWM

88

DRUM FG

197

DRUM PG

198

LOAD,UNLOAD

15

13

TREEL FG

192

SREEL FG

193

TAPE END

31

TAPE TOP

30

DEW AD

119

TAPE LED ON

180

106

MODE SW A - MODE SW C

|

108

(9/17)

IC1801

REC/PB

AMP

35

38

36

4

80

1

75

77

64

67

53 52

50

32

LOADING MOTOR

33

29

25

21

TAPE END DETECT

19

TAPE TOP DETECT

CN2501

10

ODD

9

4

EVEN 8

3

(11/17)

IC2501

CAPSTAN

FG AMP

CAPSTAN

MOTOR

DRIVE

DRUM

MOTOR

DRIVE

DRUM FG AMP

DRUM PG AMP

DRIVE MOTOR

REEL FG AMP

Z MECHA DECK

5

6

9

(1/2)

FG 1,2

7@8

74

CAP U,V,W

76

78

63

DRUM U,V,W

65

68

49

69

72

26@27

22

@

23

20

18

CN2503

CN2501

CN2502

LM +, –

DEW AD

T REEL +, –

S REEL +, –

XCC DOWN

DRUM

M903

22

25

20

|

17

4

|

1

11

|

14

5

|

10

1

2

1

|

4

5

26

25

22

23

20

11

18

12

13

|

15

17

7

|

9

CAPSTAN

M

M901

M

DRUM FG

DRUM PG

M

DEW

SENSOR

T REEL

SENSOR

S REEL

SENSOR

Q901

TAPE END SENSOR

Q902

TAPE TOP SENSOR

D901

TAPE LED

REC PROOF

4PIN

CONNECTOR

C. C. DOWN

MODE

SWITCH

S902

FG

CAPSTAN

MOTOR

DRUM

MOTOR

M902

LOADING

H902

H901

S901

MIC902

S903

3-5 3-6

DCR-TRV38/TRV38E/TRV39

COVER

COVER

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

3-4. OVERALL BLOCK DIAGRAM (4/4)

PD-190

BOARD (2/2)

LCD902

LCD

INDICATOR

COM1- 4

SEG1-16

1

-

20

CN5604

TOUCH

PANEL

BT901

BATTERY

TERMINAL

S

DC IN 3

IC5601

11

-

30

2

.

1

.

5

.

4

FP-635

FP-461

(2/2)

LCD

INDICATOR

DRIVE

CN5602CN5603

(FLEXIBLE)

S002

(FLEXIBLE)

PANEL REVERSE SW

S001

DI-089

BOARD (3/3)

VTR DD ON

SHOE ON

BATT/XEXT

FAST CHARGE

BATT SIG

CN4601

6

5

1

4

2

16

8

.

7

18

.

17

.

20

.

19

BACK LIGHT SW

S001

Q4601,

Q4602

FOCUS SW

6

.

7

CN5601

18

17

20

19

2

3

4

5

3

.

4

LI 3V

Q4608,

Q4610

6

.

7

CN5206

.

.

.

CN5203

.

.

CN5202

CK-131

BOARD (2/2)

CN5205

S5201

S5203

51

39

43

38

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

VC-315 BOARD(4/4)

(12/17)

PANEL XCLOSE/OPEN SW

DISPLAY/BATT INFO SW

LANC SIG

3V REG

IC4502

CONVERTER,

S5202

RESET

BT5201

LITHIUM

BATTERY

LANC I/O

(3/3)

DC/DC

RESET,

LANC I/O

TP L

TP R

TP TOP

TP BOT

RESET

IC3102

HI CONTROL

25

.

27

.

.

.

20

.

19

LANC OUT

LANC IN

XRESET

VOUT

27

.

25

11

.

9

.

10

.

12

18

32

.

33

31

30

29

CN1007

LI 3V

EVER 3.0V

BL REG

MT 5V

A 1.5V

D 1.5V

NS 2.8V

AL 2.8V

RP 2.8V

A 2.8V

D 2.8V

AU 2.8V

EP 2.8V

D 1.9V

A 4.6V

AU 4.6V

EP 4.6V

RP 4.6V

EP 13.5V

EP -15.3V

CAM 15V

CAM -7.5V

BATT UNREG

VTR UNREG

SHOE UNREG

30

30

HI EVER SO,SCK

Q3102-3104

TOUCH PANEL

I/F

.

53 51 31

.

20

HI EVER SO

.

21

HI EVER SCK

TOP SEL 1

34

.

TOP SEL 2

48

.

TOP OUT X

70

.

71

TOP OUT Y

.

.

73

XRESET

61

KEY AD2

3

XBATT VIEW SW

65

KEY AD3

CN1003

3153 51

CN4004

LANC OUT

40

41

.

.

45

32

37

17

11

13

15

43

27

BATT SIG

LANC SIG

CN1003

39

14

.

53

.

62

35

37

.

75

74

LANC IN

VCC

VTR DO ON

FAST CHARGE

SHOE ON

BATT/XEXT

CN4004

41

.

45

32

37

17

11

13

15

43

27

CN5201

41

43

42

40

34

21

22

23

50

.

48

45

42

41

27

.

28

BL CONT

(2/2)

XCC DOWN

XCAM MODE SW

XVTR MODE SW

XPHOTO STBY SW

XEJECT SW

XPHOTO FREEZE

SIRCS PWM

X TAL

X TAL

KEY AD7

KEY AD1

IR ON

SIRCS SIG

IB SO

SHOE ID2

SHOE ID1

IB SI

5

23TXD

.

24

RXD

.

25

SCK

X 0A

52

X 1A

51

29

28

2

.

1

.

7

69

4

6

60

Q1005,1006

45

DRIVE

15

41

Q3101

42

.

43

58

.

57

CN1003

70 68 64

CN4004

X3101

32.768KHz

X3102

10MHz

LED

I/F

.

.

TXD,RXD,SCK

SHOE UNREG

6470 68

CN1007

CN1002

CN4001

CN1006

CN1009

XCC DOWN

190 TXD

.

191

.

185

3

REC PROOF

160

CHIME SDA

.

162

CHIME SCK

.

228

CHIME AD0

.

CHIME AD1

229

.

CHIME AD2

(2/2)

HI SO

XHI SCK

EEP TXD

EEP RXD

EEP SCK

HI SI

230

200

.

.

201

.

.

199

207

.

206

.

205

(5/17)

IC2704

RXD

SCK

HI CONTROL

HI SO,SI,SCK

ZOOM VR AD

EXT STROBO

REC PROOF

CHIME SDA

CHIME SCK

CHIME VDD

5

.

2

.

6

(5/17)

IC2702

EEPROM

TO

OVERALL

9

BLOCK DIAGRAM(3/4)

(PAGE 3-5)

TO

OVERALL

1

BLOCK DIAGRAM(1/4)

(PAGE 3-1)

CONTROL SWITCH

BLOCK(PS-2890)

D5901

S001

EJECT SW

XCAM STBY SW

XVTR MODE SW

XPHOTO STBY SW

KEY AD7

PHOTO FREEZE

PHOTO REC

ZOOM AD

IC5901

REMOTE

4

COMMANDER

RECEIVER

S002~004

POWER SW

S001

START/STOP SW

S8003,8004

PHOTO SW

RV8001

ZOOM VR

(FLEXIBLE)

CONTROL

SWITCH

BLOCK

(FK-4300) (2/2)

FP-645

CN8001

24

.

21

.

25

20

16

19

17

12

5

10

CN8002

NS LED K

SIRCS SIG

5

.

2

.

6

1

S8001,8002

EDIT SEARCH SW

.

.

1

5

3

.

7

9

(NIGHT SHOT LED)

5

10

CN5903

MA-423

BOARD (3/3)

8

JK-249

BOARD

(4/4)

30

16

CN5103

EXT STROBO

6

5

SHOE ID1,2

.

4

LANC SIG

3

2

SHOE UNREG

.

1

6

INTELLIGENT

5

.

4

ACCESSORY

SHOE

3

(2/2)

2

.

1

J5103

LANC

BL CONT

TO

OVERALL

7

BLOCK DIAGRAM(2/4)

(CK-131)

(PAGE 3-3)

3-7 3-8

COVER

COVER

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

DCR-TRV38/TRV38E/TRV39

3-5. POWER BLOCK DIAGRAM (1/2)

DI-089 BOARD

BT901

BATTERY

TERMINAL

S

DC IN

CK-131 BOARD

(1/2)

BT5201

LITHIUM

BATTERY

CONTROL SWITCH

BLOCK (FK-4300)

(1/2)

CN8001

POWER

VCR

OFF (CHG)

CAMERA

MEMORY

MEMORY/NETWORK

CONTROL SWITCH BLOCK

(PS-2890) (1/2)

LCD903

COLOR

UNIT

EVF

LB-087 BOARD

1

IC6101

RESET

S5202

CN5201

256

(TRV38/TRV38E)

BACK

LIGHT

DRIVE

6

5

1

4

3

2

CN4601

BATT UNREG

BATT SIG

CN4601

ACV UNREG

BATT/XEXT

20

19

34

S002-004

(TRV39)

LF4601

Q4601,

4602

FAST CHARGE

17 1213 15

17 1213 15

CHARGE

SWITCH

Q4603,

4604

VC-315 BOARD (1/2)

CN1007

32

33

18

21

24

25

CN1006

CN6101CN6102

20

2 19

1

4

20

17

1

LI 3V

XRESET

Q3101

I/F

BATT SIG

CN1003

95 97 99

95 97 99

CN4004

CN3201

FB3202

(2/3) (2/3)

IC3201 IC3202

RGB

DRIVE

LED ON/OFF

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

1

INTELLIGENT

1

ACCESSORY

3

SHOE

Q4528-4530

5V

Q4504

SWITCHING

Q4505

SWITCHING

BL CONT

Q4506

SWITCHING

Q4507

SWITCHING

Q4508

SWITCHING

Q4509

SWITCHING

REG

L4502

L4522

L4508

L4526

Q4511

L4503

L4524

BL REG

BL CONT

L4521

L4511

CAP VS

CAP ERROR

DRUM VS

DRUM ERROR

L4513

L4514

L4515

L4516

L4517

L4518

L4519

L4512

L4510

L4525

L4504

L4505

L4506

L4507

Q4510

SWITCHING

D4504

RECT

(3/3)

IC4502

VCC

DIN

CLK

LD

CTL1

V CONT

LANC DC

3V REG

RESET

DC/DC CONVERTER

RESET,LANC I/O

BATTERY

IN

DETECT

LANC

I/O

56

43

41

40

39

42

45

44

27

28

26

38

49

52

54

VREF

OUT1

VCC1

OUT2

+INE2

OUT3

OUT4

OUT5

+INE5

OUT6

+INE6

OUT7

37

30

RT

57

55

20

IN1

58

14

59

22

IN3

34

VR

60

23

IN4

61

9

62

6

L4501

63

2

IN7

BATT SENS

54

ACV SENS

55

SHOE ON

75

BATT/XEXT

74

INIT CHARGE ON

38

FAST CHARGE

37

IB SO

42

IB SI

43

56

VTR DD SENS

VTR MODE SW

1

CAM MODE SW

2

XPHOTO STBY SW

7

INIT CHARGE ON

HI CONTROL

IC3102

8

F4602

F4605

F4606

F4604

F4603

F4601

XLANC PWR ON

TIMING

GENERATOR

SHOE ON

XRESET

BATT IN

HI EVER SO

HI EVER SCK

XCS DD

VTR DD ON

(12/17)

L4601

EP 13.3V

SHOE UNREG

CN4001

BATT UNREG

UNREG 2.8V 4.6V

UNREG BL

UNREG C/D VS MT 4.9

VTR UNREG VTR UNREG

Q4608,4610

CN4004

11

11

CN1003

D4503

D4502

VOUT

Q4526

REG

VCC

D 2.8V

EP 2.8V

EP 4.6V

14

14

16

16

18

18

30

30

14

53

32 32

62

73

31 31

31

33 33

20

53

53

21

51

51

49

55

55

35

37 37

8

39 39

CN1003

CN4004

Q4524,4525

1.9V REG

Q4517,

4519

LANC DC

49

EVER 3.0V

D 1.5V

A 1.5V

D 1.5V (IC1601)

NS 2.8V

L4523

AL 2.8V

RP 2.8V

A 2.8V

D 2.8V

AU 2.8V

EP 2.8V

(3/3)

1

13.5V

45

REG

LANC DC