Sony CPD-G420 Service Manual

CPD-G420

[with LCC]

SERVICE MANUAL

S. Hemisphere Model

SPECIFICATIONS

CRT 0.24 mm aperture grille pitch

19 inches measured diagonally

90-degree deflection

FD Trinitron

Viewable image size Approx. 365 × 274 mm (w/h)

Resolution

Maximum Horizontal: 1920 dots

Recommended Horizontal: 1280 dots

Input signal levels Video signal

Standard image area Approx. 352 × 264 mm (w/h)

3

(14

/8 × 107/8 inches)

18.0" viewing image

Vertical: 1440 lines

Vertical: 1024 lines

Analog RGB: 0.700 Vp-p

(positive), 75 Ω

SYNC signal

H/V separate or composite sync:

TTL 2 kΩ, Polarity free

Sync on Green: 0.3 Vp-p

(negative)

7

(13

/8 × 101/2 inches)

or

Approx. 330 × 264 mm (w/h)

(13 × 10

1

/2 inches)

Deflection frequency* Horizontal: 30 to 110 kHz

AC input voltage/current 100 to 240 V, 50 – 60 Hz, 2.0 – 1.0 A

Power consumption Approx. 130 W (with no USB devices

Dimensions Approx. 451 × 471 ×

Mass Approx. 25.5 kg (56 lb 3 oz)

Plug and Play DDC2B/DDC2Bi, GTF**

* Recommended horizontal and vertical timing condition

• Horizontal sync width duty should be more than 4.8% of

total horizontal time or 0.8 µs, whichever is larger.

• Horizontal blanking width should be more than 2.3 µsec.

• Vertical blanking width should be more than 450 µsec.

** If the input signal is Generalized Timing Formula (GTF)

compliant, the GTF feature of the monitor will automatically

provide an optimal image for the screen.

Design and specifications are subject to change without notice.

Equator Model

Chassis No. SCC-L33C-A

CR1

Vertical: 48 to 170 Hz

connected)

7

(17

/8 × 185/8 × 181/4 inches)

CHASSIS

461 mm (w/h/d)

TRINITRON

®

COLOR COMPUTER DISPLAY

1.5 k

Ω

0.15 µF

AC

Voltmeter

(0.75 V)

To Exposed Metal

Parts on Set

Earth Ground

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety

checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that you

have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that

were installed during a previous repair. Point them out to the customer

and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specified values. Make sure your

instruments are accurate; be suspicious of your HV meter if sets always

have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws, and

all other exposed metal parts for AC Leakage. Check leakage as

described below.

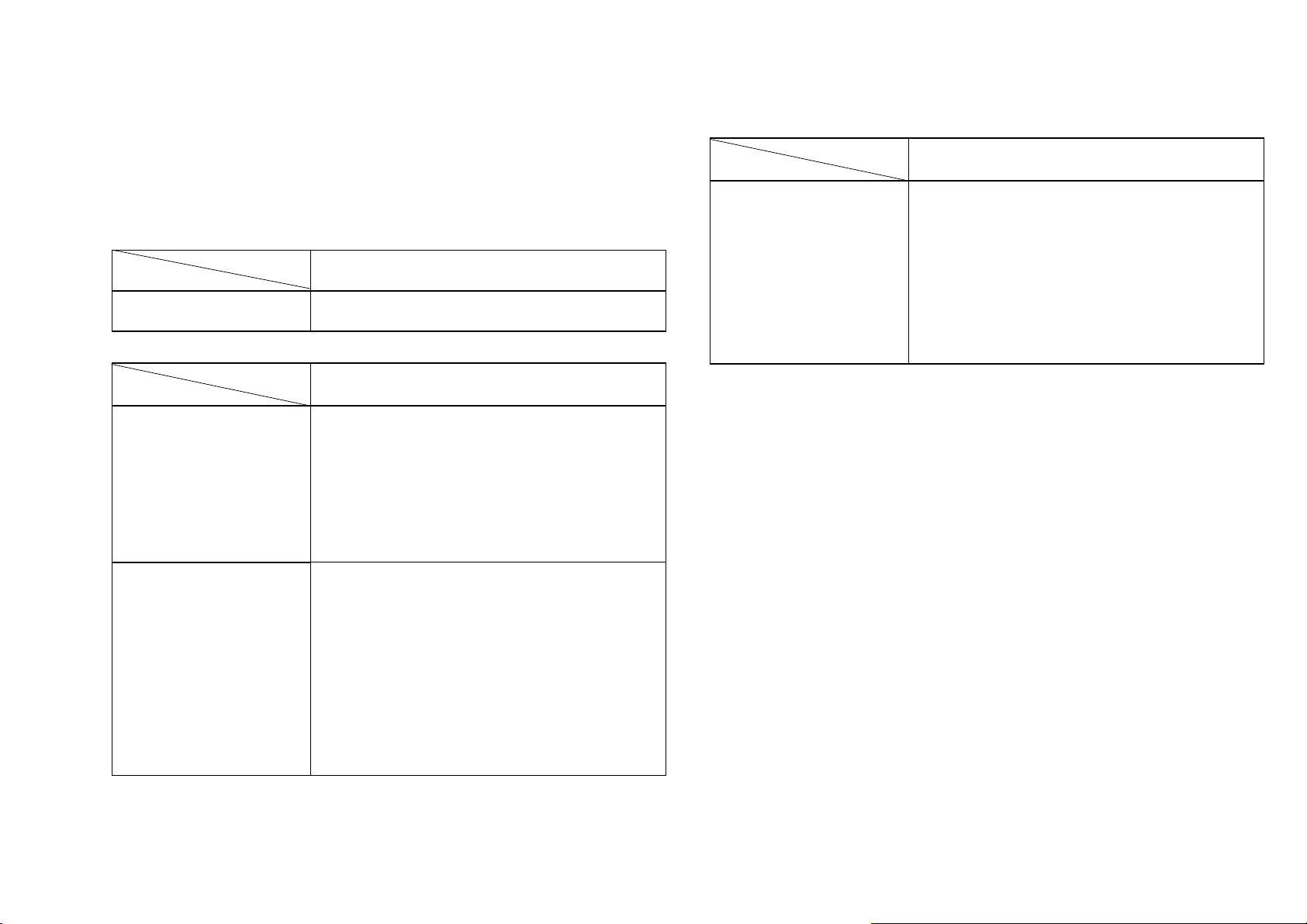

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and from all

exposed metal parts to any exposed metal part having a return to chassis,

must not exceed 0.5 mA (500 microamperes).

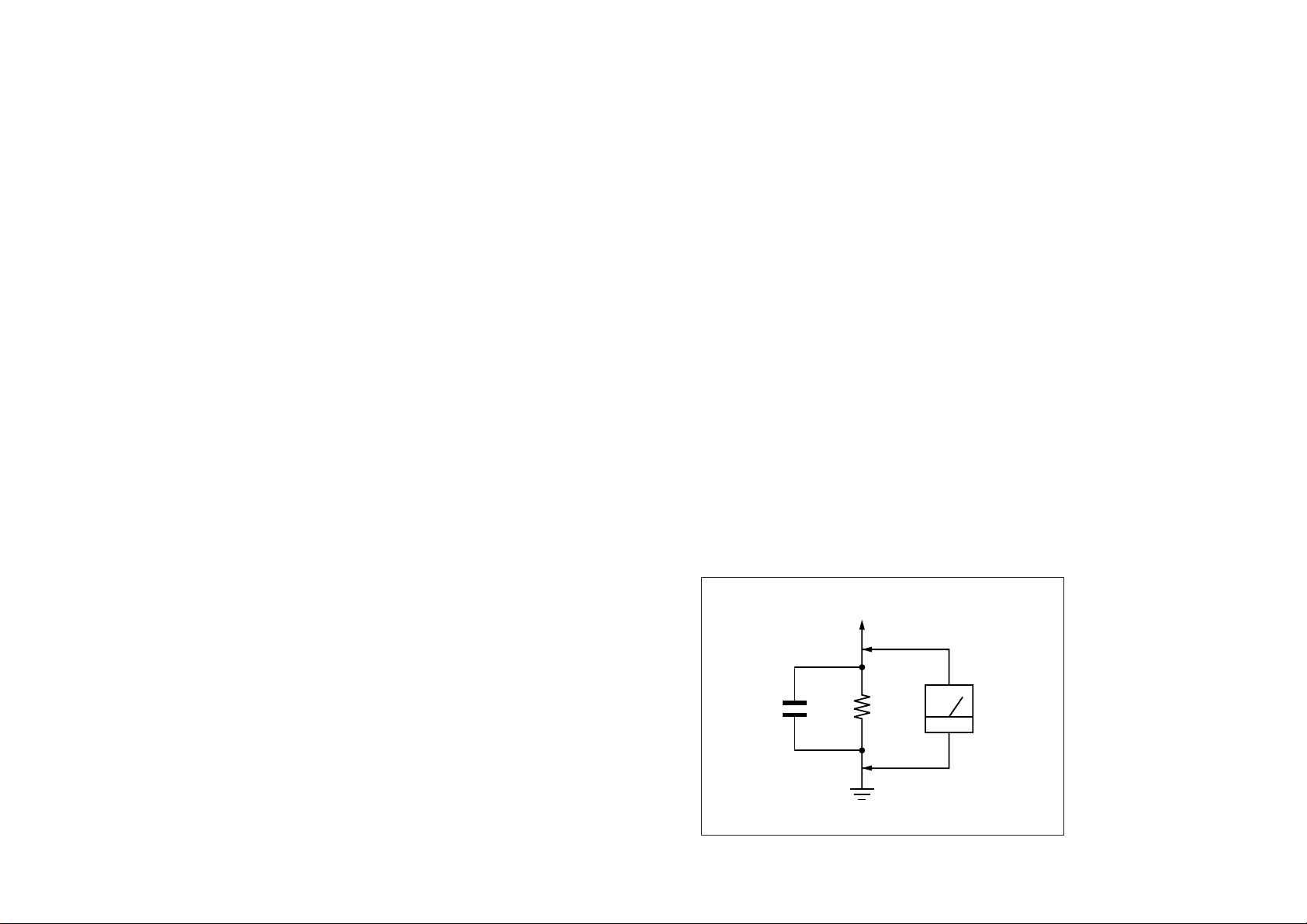

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA WT540A. Follow the manufacturers’ instructions to use these instruments.

2. A battery-operated AC milliammeter. The Data Precision 245 digital

multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM or

battery-operated AC voltmeter. The “limit” indication is 0.75 V, so

analog meters must have an accurate low-voltage scale. The Simpson 250

and Sanwa SH-63Trd are examples of a passive VOMs that are suitable.

Nearly all battery operated digital multimeters that have a 2 V AC range

are suitable. (See Fig. A)

Fig. A. Using an AC voltmeter to check AC leakage.

CPD-G420(E) 2

WARNING!!

NEVER TURN ON THE POWER IN A CONDITION IN WHICH THE

DEGAUSS COIL HAS BEEN REMOVED.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ¡ ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE CRITICAL FOR SAFE OPERATION ARE

IDENTIFIED IN THIS MANUAL. FOLLOW THESE PROCEDURES

WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

CPD-G420(E) 3

POWER SAVING FUNCTION

This monitor meets the power-saving guidelines set by VESA,

ENERGY STAR, and NUTEK. If no signal is input to the

monitor from your computer, the monitor will automatically

reduce power consumption as shown below.

Power mode Power

consumption*

normal

operation

active off**

(deep sleep)***

power off Approx. 0 W off

* Figures reflect power consumption when no USB compatible

peripherals are connected to the monitor.

** When your computer enters power saving mode, the input signal is

cut and NO SIGNAL appears on the screen before the monitor enters

active off mode. After a few seconds, the monitor enters power saving

mode.

*** “Deep sleep” is power saving mode defined by the Environmental

Protection Agency .

≤ 135 W (CPD-G520)

≤ 130 W (CPD-G420)

≤ 3 W orange

! (power)

indicator

green

CPD-G420(E) 4

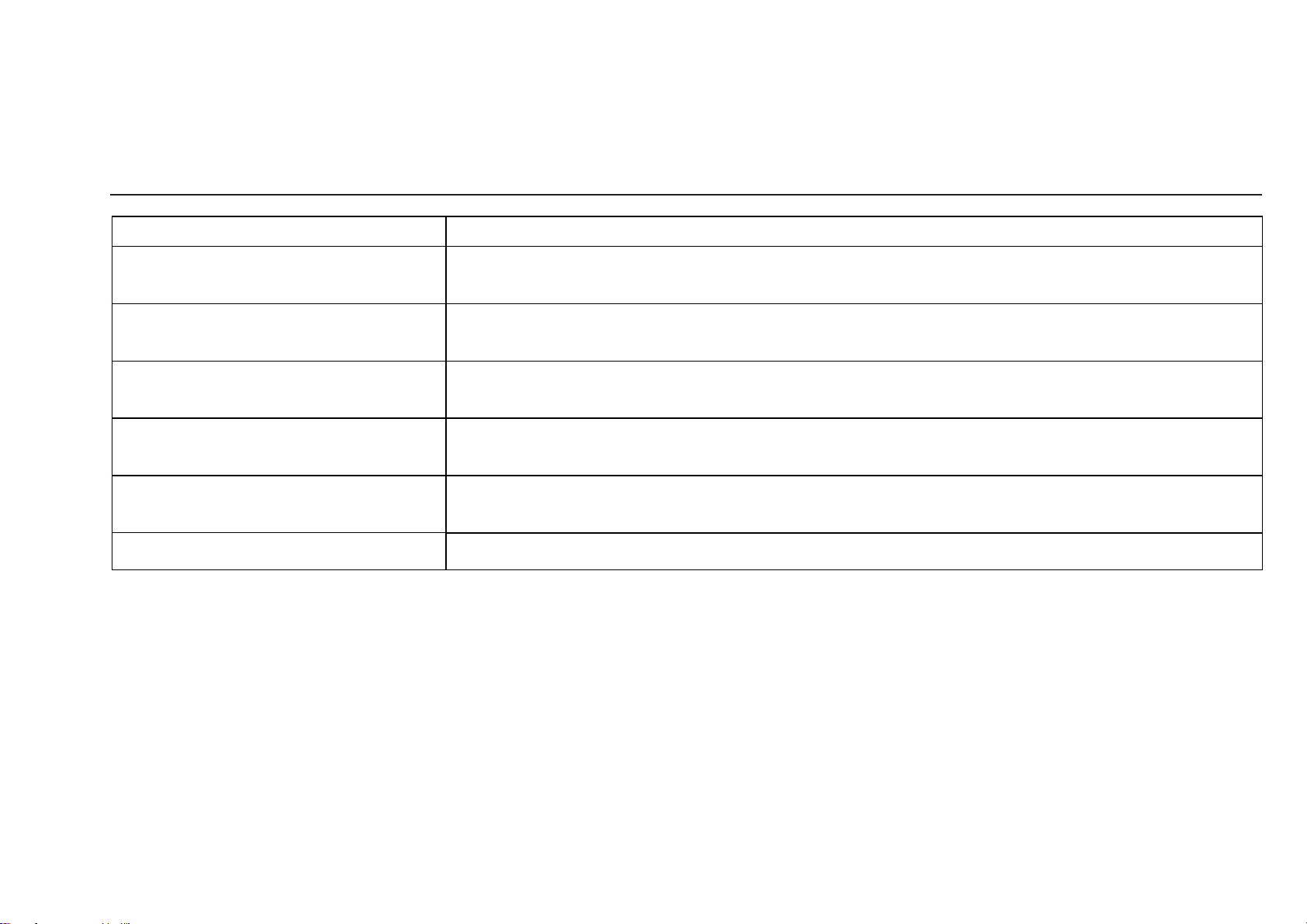

DIAGNOSIS

Failre

+B failure

Horizontal / Vertical Deflection

failure, Thermal protector

ABL protector

HV failure

Aging / Self Test

Out of scan range

Aging Mode (Video Aging) : During Power Save, press MENU button for longer than 2 second.

Self Test (OSD Color Bar) : During Power Save, push up Control button for longer than 2 second.

Reliability Check Mode : During Power Save, push down Control button for longer than 2 second.

Amber → Off

(0.5 sec) (0.5 sec)

Amber → Off

(1.5 sec) (0.5 sec)

Amber → Off

(0.5 sec) (1.5 sec)

Amber → Off → Amber → Off

(0.25 sec) (0.25 sec) (0.25 sec) (1.25 sec)

Amber → Off → Green → Off

(0.5 sec) (0.5 sec) (0.5 sec) (0.5 sec)

Green (OSD indication)

Power LED

CPD-G420(E) 5

TIMING SPECIFICATION

MODE AT PRODUCTION

RESOLUTION

CLOCK

— HORIZONTAL —

H-FREQ

H. TOTAL

H. BLK

H. FP

H. SYNC

H. BP

H. ACTIV

— VERTICAL —

V. FREQ (HZ)

V. TOTAL

V. BLK

V. FP

V. SYNC

V. BP

V. ACTIV

— SYNC —

INT(G)

EXT (H/V) /POLARITY

EXT (CS) /POLARITY

INT/NON INT

MODE 1 MODE 2 MODE 3

640 X 480 1280 X 1024 1600 X 1200

25.175 MHz 157.500 MHz 229.500 MHz

31.469 kHz 91.146 kHz 106.250 kHz

usec usec usec

31.778 10.971 9.412

6.356 2.844 2.440

0.636 0.406 0.279

3.813 1.016 0.837

1.907 1.422 1.325

25.422 8.127 6.972

59.940 Hz 85.024 Hz 85.000 Hz

lines lines lines

525 1072 1250

45 48 50

10 1 1

23 3

33 44 46

480 1024 1200

NO NO NO

YES N/N YES P/P YES P/P

NO NO NO

NON INT NON INT NON INT

2000.8.9 VER.

CPD-G420(E) 6

TABLE OF CONTENTS

Section Title Page Section Title Page

1. DISASSEMBLY

1-1. Cabinet Removal ............................................... 1-1

1-2. A1 Board (C BLOCK) Removal ....................... 1-2

1-3. A1 Board, US Board Removal .......................... 1-3

1-4. Bezel Assembly, H1 Board Removal ............... 1-4

1-5. D Board Removal .............................................. 1-5

1-6. Service Position .................................................. 1-6

1-7. Picture Tube Removal ........................................ 1-7

1-8. Harness Location ............................................... 1-9

2. SAFETY RELATED ADJUSTMENT

3. ADJUSTMENTS

..................................................... 3-1

............. 2-1

4. DIAGRAMS

4-4. Schematic Diagrams and Printed Wiring

Boards ................................................................. 4-6

(1) Schematic Diagram of A1 Board ...................... 4-8

(2) Schematic Diagram of US Board ...................... 4-10

(3) Schematic Diagram of DA Board ..................... 4-12

(4) Schematic Diagram of N Board ........................ 4-14

(5) Schematic Diagrams of

D (a, b, c) Board ........................................ 4-16

(6) Schematic Diagram of H1 Board....................... 4-20

(7) Schematic Diagram of L2 Board ....................... 4-22

4-5. Semiconductors ................................................. 4-24

5. EXPLODED VIEWS

5-1. Chassis ............................................................... 5-1

5-2. Picture Tube ...................................................... 5-2

4-1. Block Diagrams .................................................. 4-1

4-2. Frame Schematic Diagram ................................. 4-4

4-3. Circuit Boards Location ..................................... 4-5

5-3. Packing Materials ............................................... 5-3

6. ELECTRICAL PARTS LIST

............................ 6-1

GDM-F420(E) 7

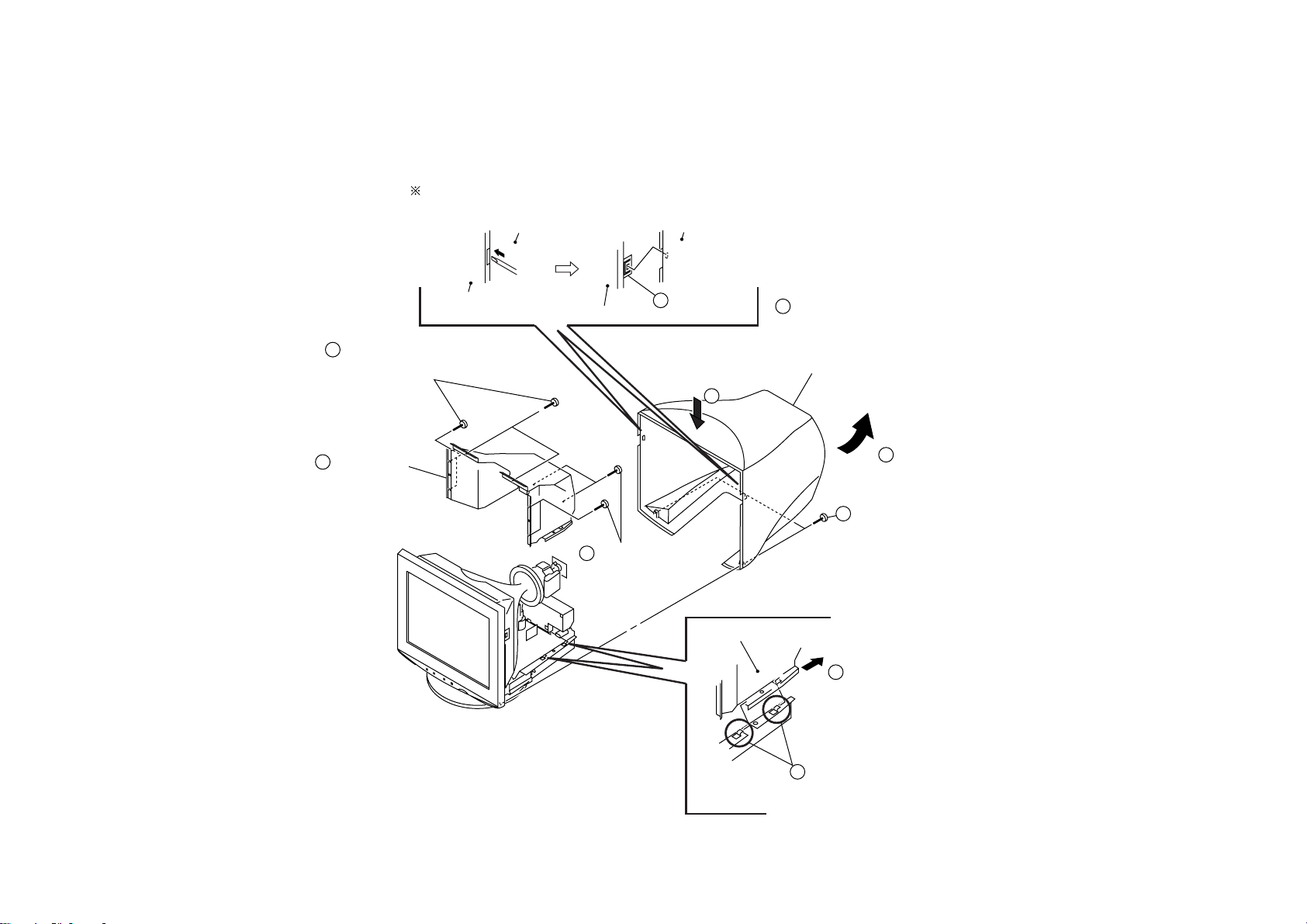

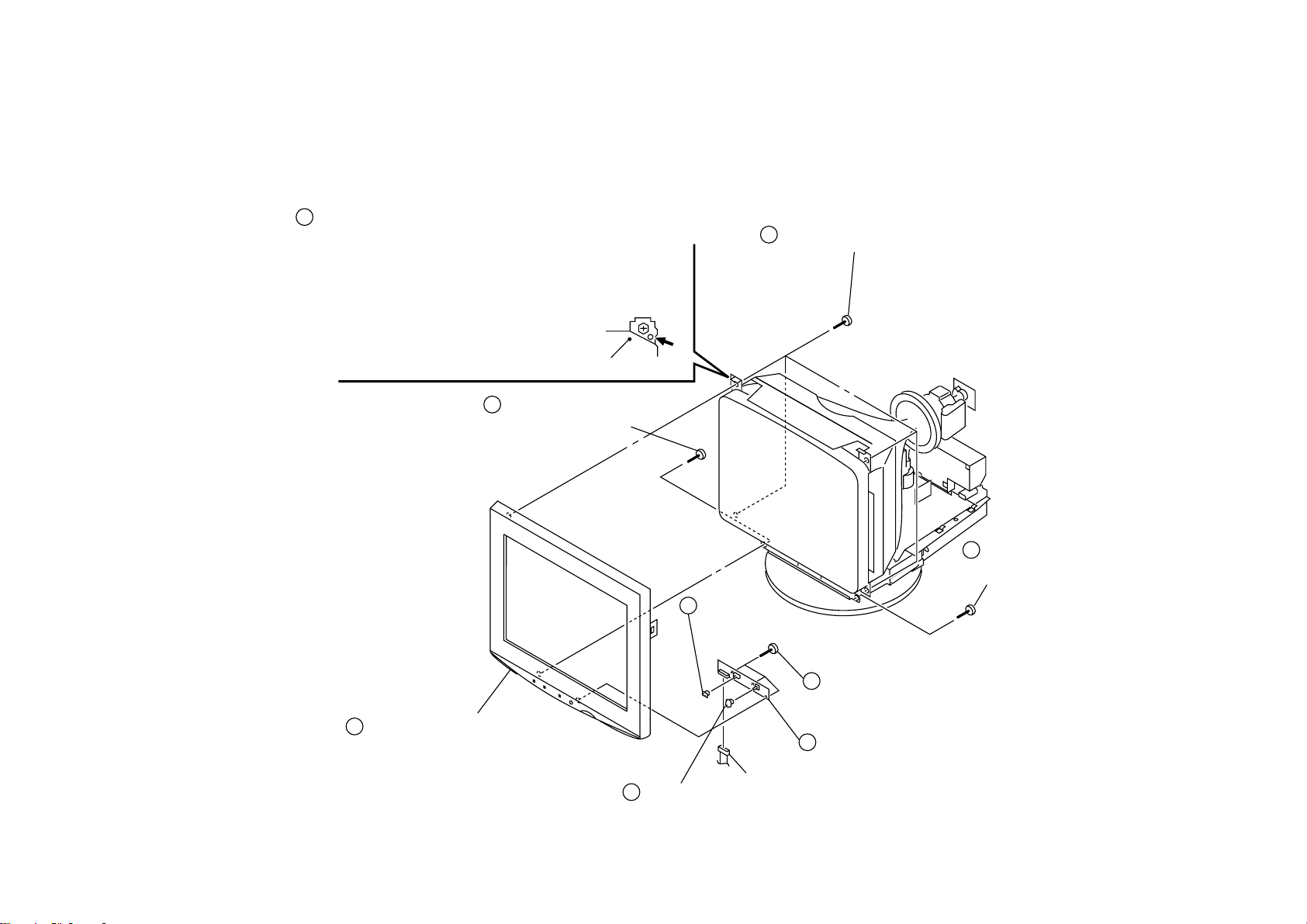

1-1. CABINET REMOVAL

Push in the tip of a screwdriver

about 10mm to unlock the claw.

Cabinet

SECTION 1

DISASSEMBLY

Cabinet

5

Four screws

(+BVTT 4 x 8)

7

EMI shield

Bezel assembly

Bezel assembly

4

Four screws

(+BVTT 4 x 8)

2

Two claws

A

EMI shield

3

Push the upper side of the cabinet

inthe direction of arrow A, disconnect claws,

then remove the cabinet

lifting it up in the direction of arrow B.

B

1

Two screws

(+BVTP 4 x 16)

C

6

Slide the EMI shield in the direction

of arrow C and remove four claws.

CPD-G420(E) 1-1

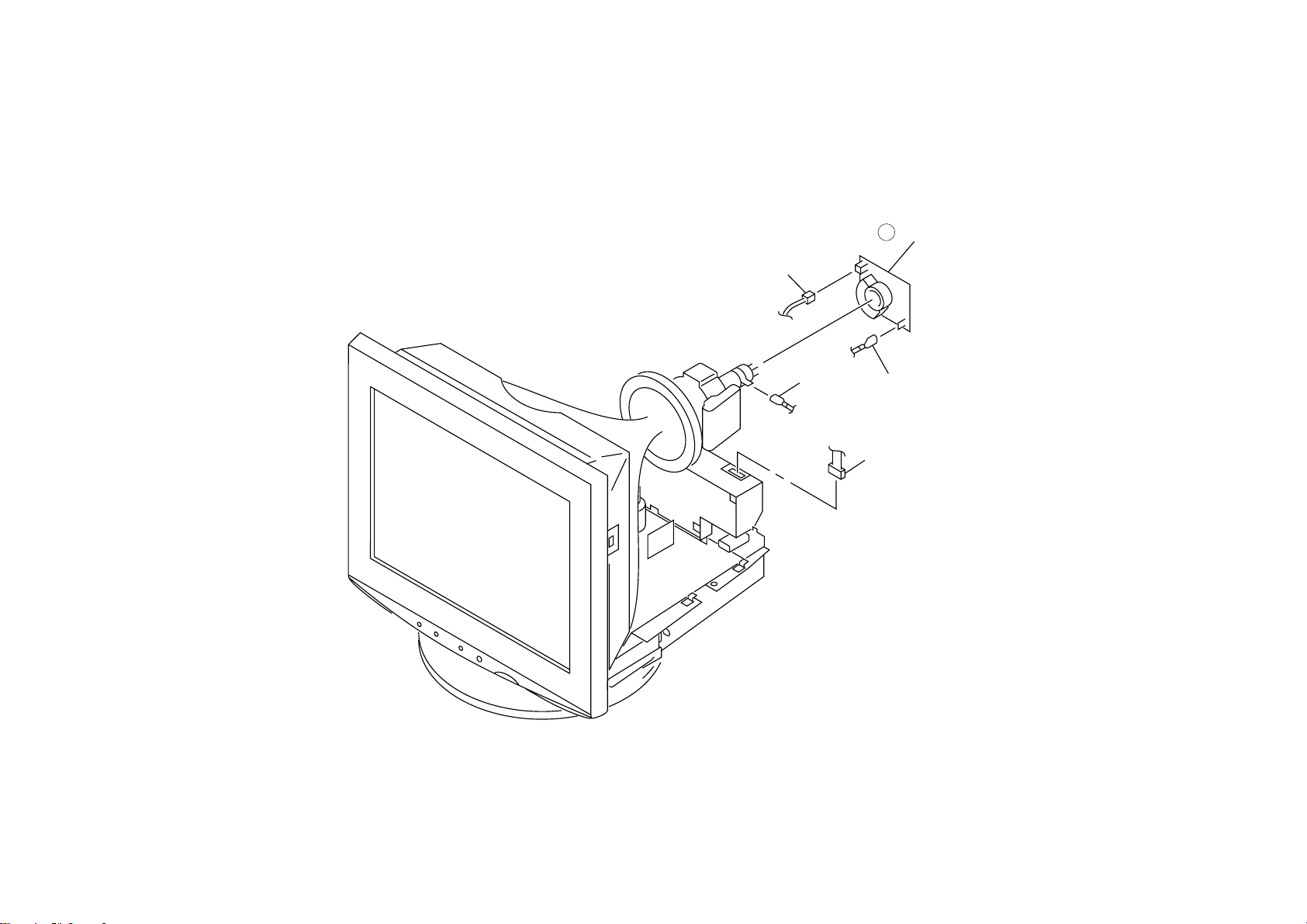

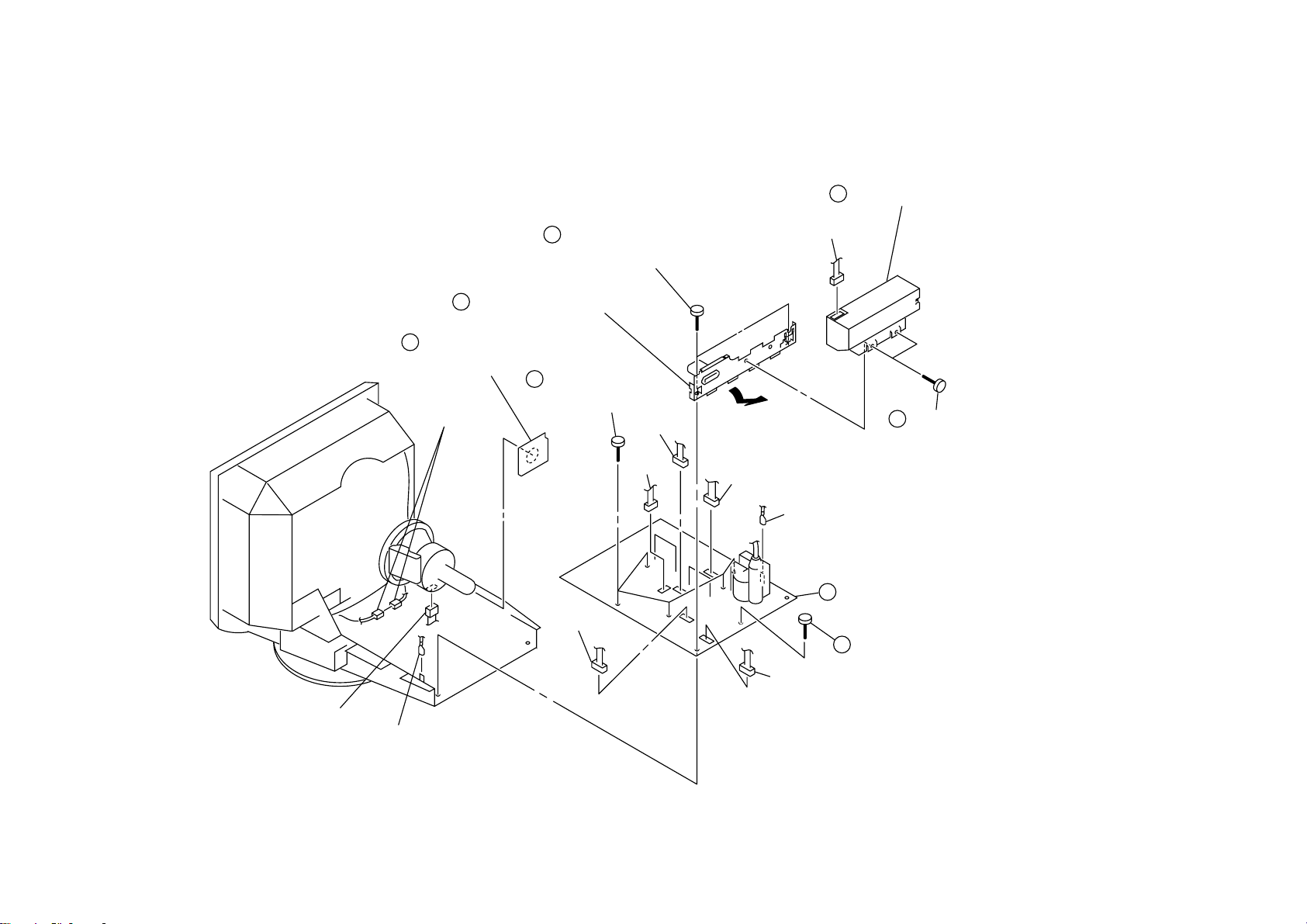

1-2. A1 BOARD (C BLOCK) REMOVAL

CN318

1

A1 board

GND

GND

CN315

CPD-G420(E) 1-2

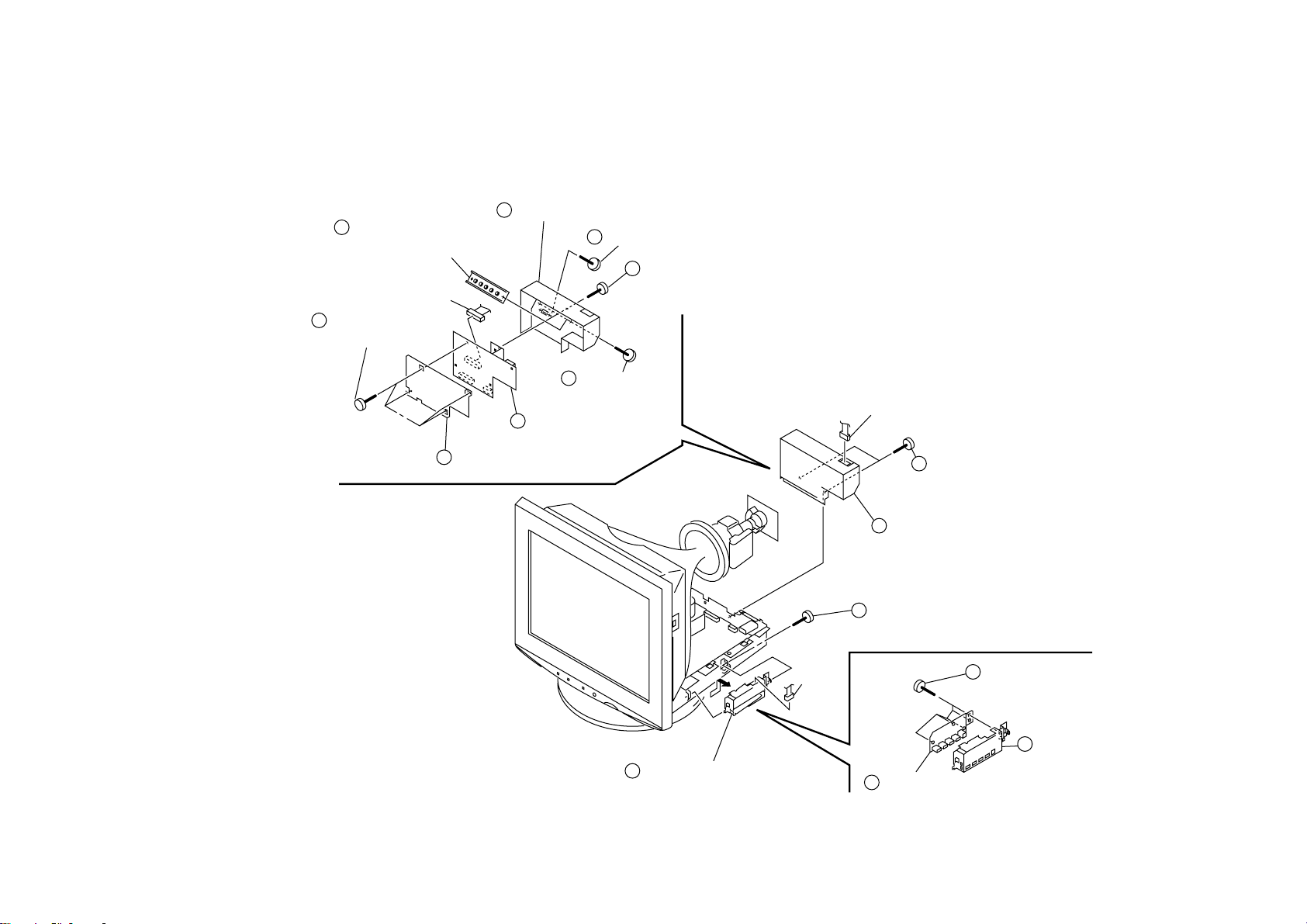

1-3. A1 BOARD, US BOARD REMOVAL

9

Video case

8

Input/out

terminal board assembly

CN313

3

Four screws

(+BVTP 3 x 8)

7

10

A1 board

4

Video shield

5

Two screws (HEX)

6

Screw

(+BVTP 3 X 10)

Two screws

(+BVTP 3 X 8)

CN315

1

Two screws

(+BVTT 4 x 6)

2

Video block assembly

12

USB block assembly

CN2601

11

Screw (+BVTT 4 x 6)

13

15

US board

Five screws

(+BVTT 3 x 8)

14

USB case

CPD-G420(E) 1-3

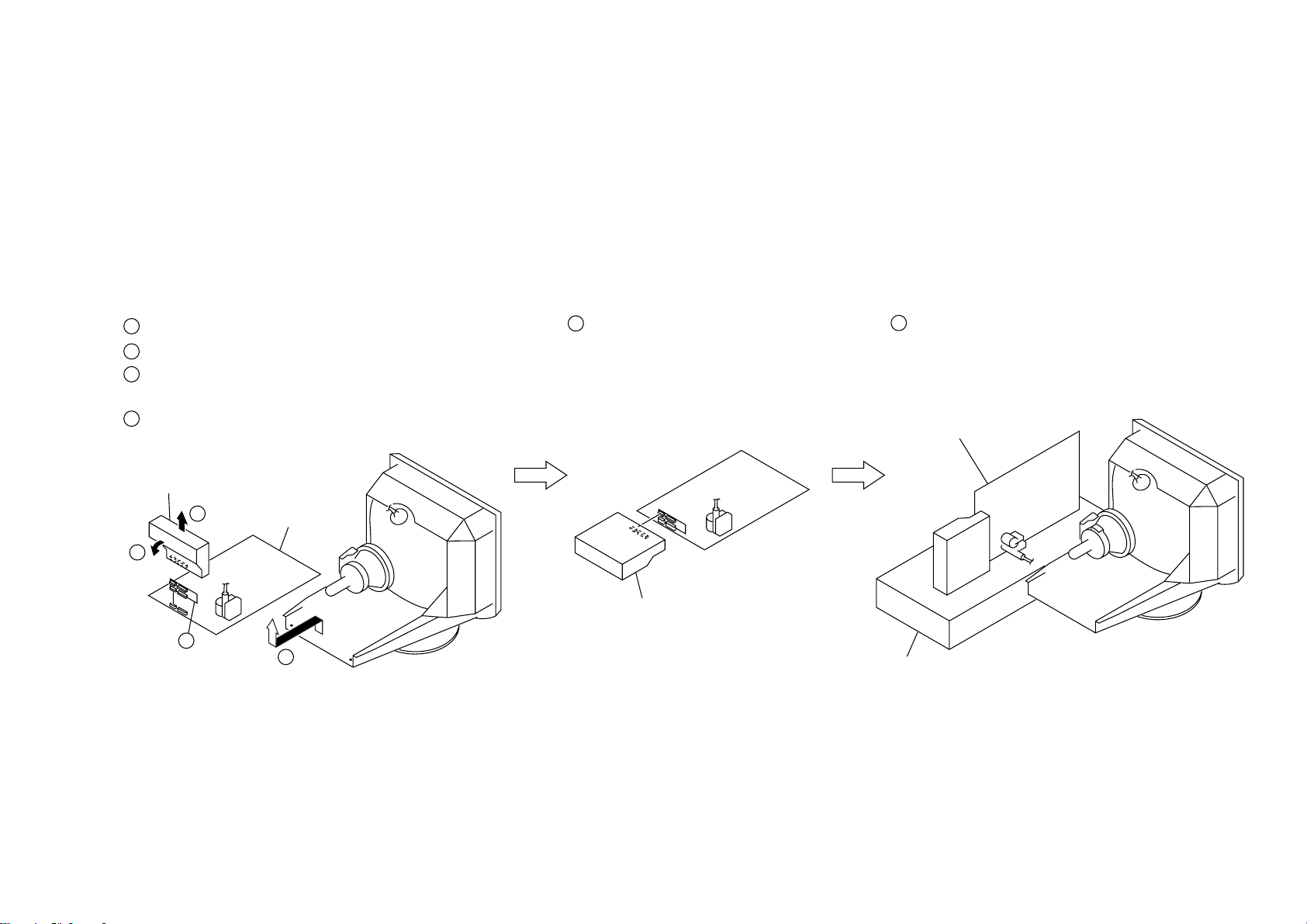

1-4. BEZEL ASSEMBLY, H1 BOARD REMOVAL

Before removing the bezel assembly, secure

1

the picture tube by attaching two screws to

the picture tube shield at the positions shown

with an arrow (diagonal two places) to prevent

the picture tube from falling.

(Use the screws +BVTT 4 x 8 that fix EMI shield.)

Picture tube shield

3

Screw

(+BVTP 4 x 16)

2

Four tapping screws (5)

4

Screw

(+BVTP 4 x 16)

5

Bezel assembly

8

Joy stick

7

Input

selection button

CN1400

6

Three screws

(+BVTP 3 x 10)

9

H1 board

CPD-G420(E) 1-4

1-5. D BOARD REMOVAL

3

Video block assembly

5

Rear plate assembly

1

A1 board

(C block)

Connector (2P)

4

Two screws

(+BVTP 3 x 8)

6

Five screws

(+BVTP 3 x 10)

CN601

CN1103

CN605

CN501

GND

CN602

CN315

2

Two screws

(+BVTT 4 x 6)

8

D board

7

Screw (+BVTT 3 x 8)

CN

GND

CPD-G420(E) 1-5

1-6. SERVICE POSITION

1

Remove the D board.

2

Remove the Video block assembly.

3

Install the Adaptor board

(XT MOUNT) (A-1391-123-A).

4

Lay the Video block assembly.

Video block assembly

2

4

3

D board

1

5

Install the video block assembly.

Video block assembly

6

Put a box which is about 15cm in height

under the D board to fix it.

(Please disconnect the CN 701 first.)

D board

Box

CPD-G420(E) 1-6

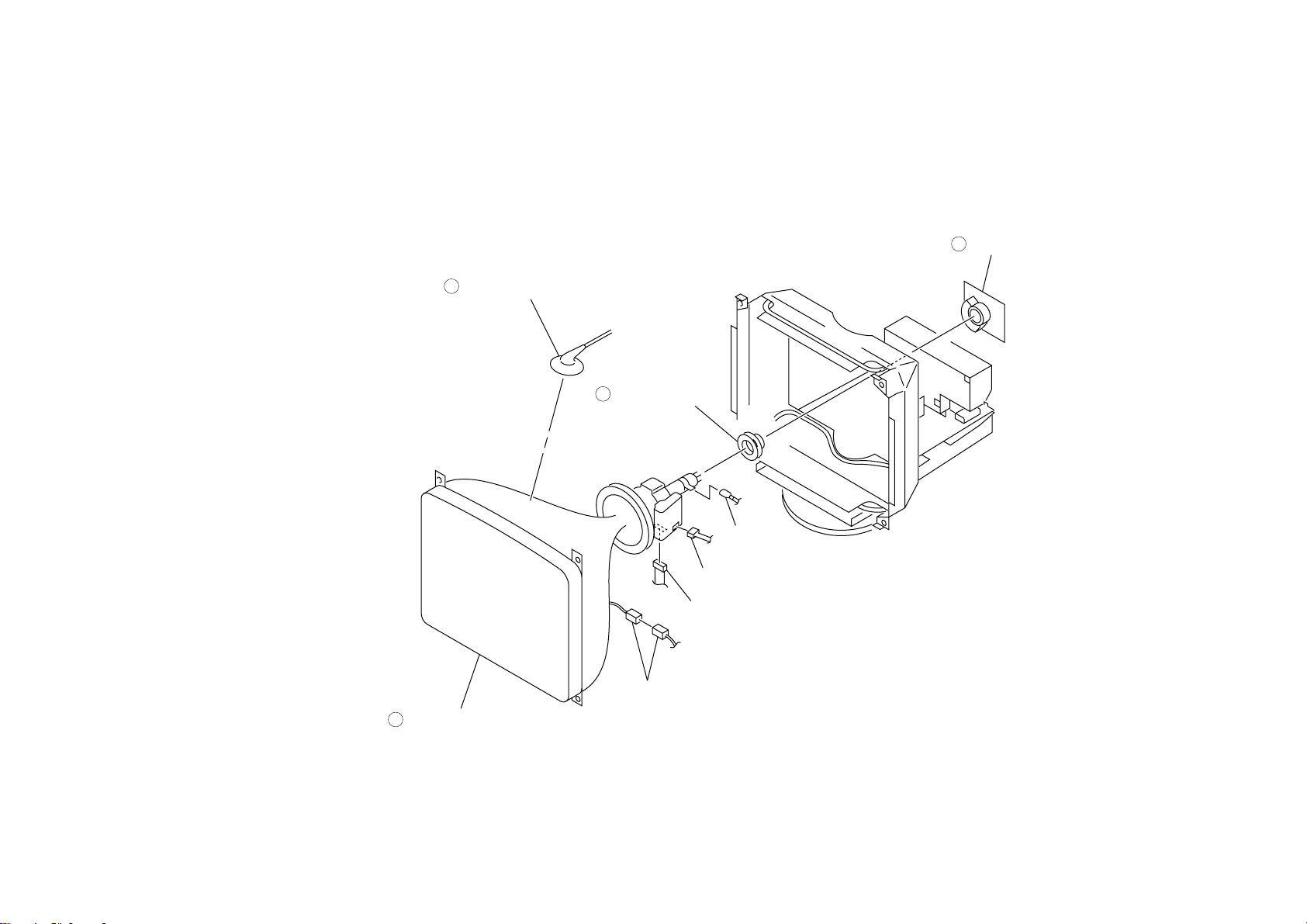

1-7. PICTURE TUBE REMOVAL

1

Anode cap (Refer to 1-8)

3

Neck assembly

CN1

GND

2

A1 board (C block)

4

Picture tube

CN

Connector (2p)

CPD-G420(E) 1-7

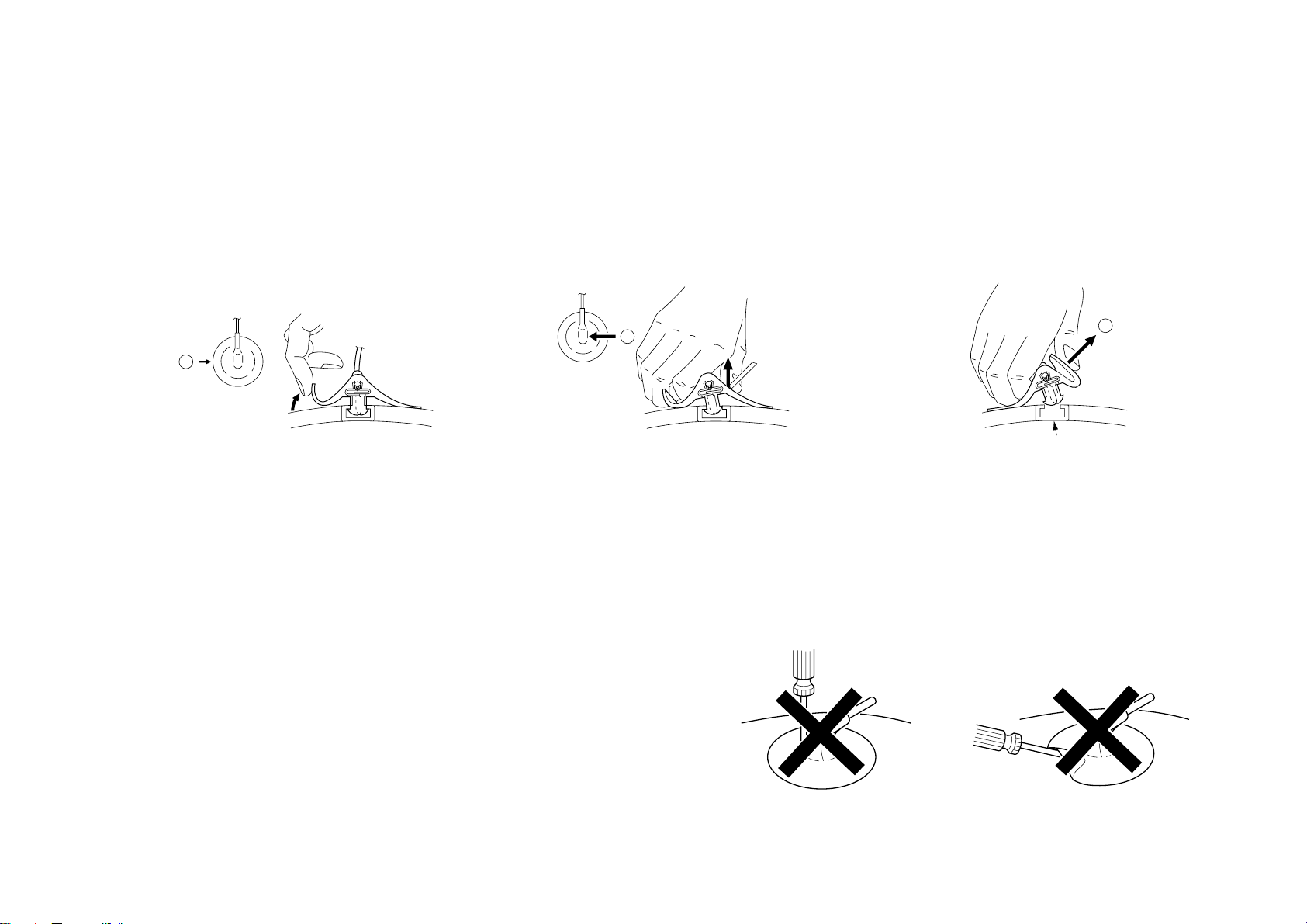

•REMOVAL OF ANODE-CAP

NOTE: Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield or carbon painted on the CRT, after

removing the anode.

•REMOVING PROCEDURES

b

a

1Turn up one side of the rubber cap in the

direction indicated by the arrow a.

2Using a thumb pull up the rubber cap

firmly in the direction indicated by the

arrow b.

•HOW TO HANDLE AN ANODE-CAP

1Don’t scratch the surface of anode-caps with sharp shaped

material!

2Don’t press the rubber hardly not to damage inside of anode-

caps!

A material fitting called as shatter-hook terminal is built in the

rubber.

3Don’t turn the foot of rubber over hardly!

The shatter-hook terminal will stick out or damage the rubber.

c

Anode Button

3When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning up

the rubber cap and pulling up it in the

direction of the arrow c.

CPD-G420(E) 1-8

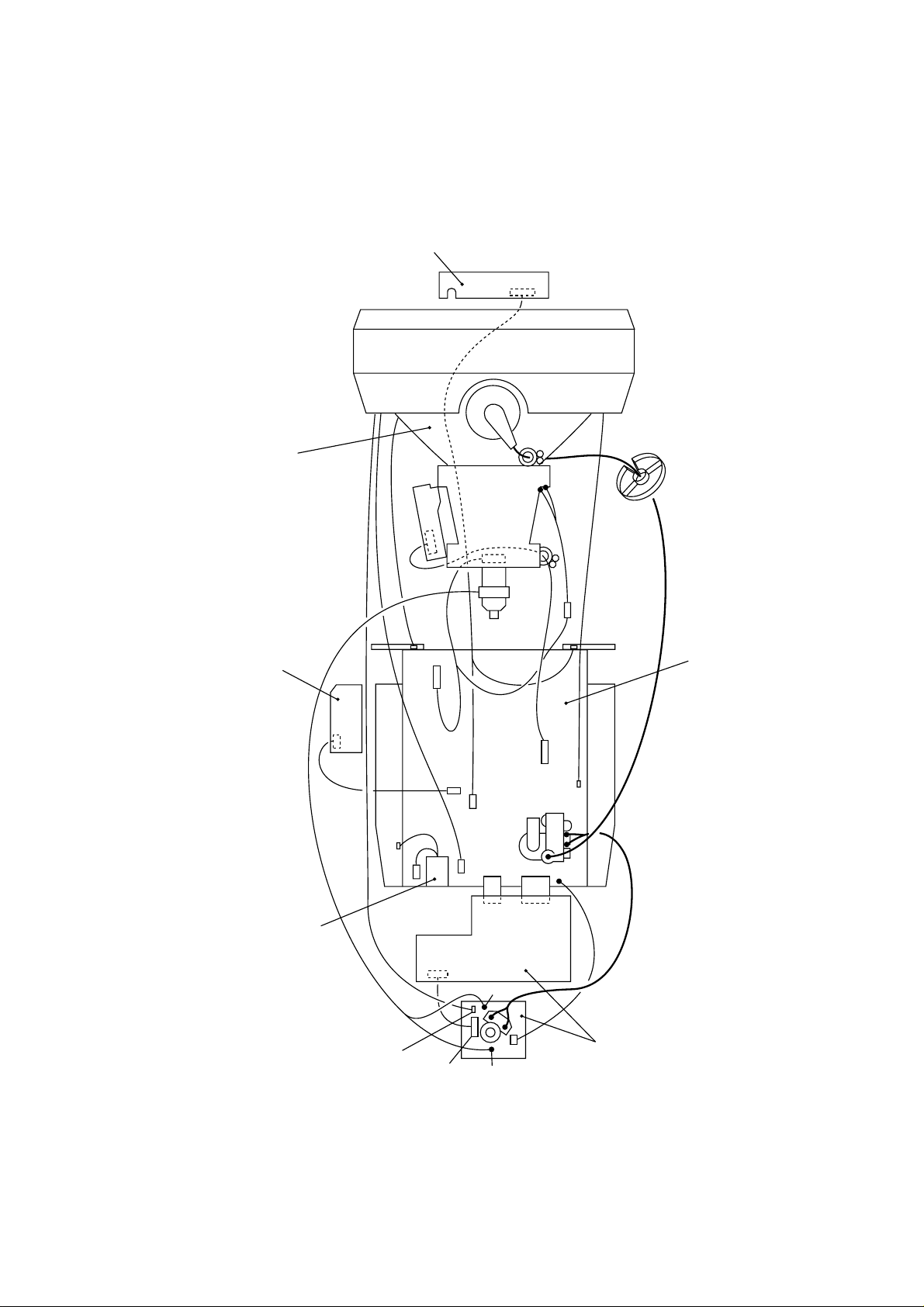

1-8. HARNESS LOCATION

H1 board

Picture tube

CN1400

CN1

CN

US board

AC inlet

CN2601

CN303

CN602

CN701

CN315

CN605

CN316

CN1103

CN601

CN501

CN604 CN1102

CN312 CN311

CN320

CN318

CN319

D board

CN904

A1 board

CPD-G420(E) 1-9

SECTION 2

SAFETY RELATED ADJUSTMENT

When replacing or repairing the shown below table, the

following operational checks must be performed as a

safety precaution against X-rays emissions from the unit.

Part Replaced ([)

HV ADJ

RV901

Part Replaced (])

HV Regulator

Circuit Check

D Board C925, IC901, R901,

R902, R905, R924,

R925, R926, RV901,

T901 (FBT)

• Mounted D Board

HV Protector

Circuit Check

D Board C920, C923, D911,

D912, R903, R917,

Part Replaced (])

Beam Current

Protector Circuit

Check

D Board C930, D917, R921,

R932, R933, R935,

T901 (FBT)

• Mounted D Board

N Board IC1001, RB1001

• Mounted N Board

* Confirm one minute after turning on the power.

a) HV Regulator Circuit Check

1) Turn the RV901 slowly, and adjustment so that high

voltage is in the specified range.

[Specification]: 27.00 ± 0.05 kV

2) Check that the voltage of D912 cathode on the D

board is 17.0 V or more.

R918, R919, R920,

R923, T901 (FBT)

• Mounted D Board

N Board IC1001, RB1001

• Mounted N Board

b) HV Protector Circuit Check

1) Using external DC Power Supply, apply the voltage

shown below between cathode of D912 and GND,

and check that the RASTER disappers.

[Specification]: 19.95 + 0.00/– 0.05 V

CPD-G420(E) 2-1

c) Beam Current Protector Circuit Check

1) Connect constant current source to a section between

T901 (FBT) qa pin and GND, and check that the

RASTER disappers when the specified current flows

to the qa pin.

[Specification]: 2.12 + 0.00/– 0.01 mA

CPD-G420(E) 2-2

SECTION 3

ADJUSTMENTS

•Landing Rough Adjustment

1. Display all white pattern (or black dot pattern).

2. Set contrast to 255.

3. Display green plain pattern.

4. Side back DY and roughly adjust green plain pattern to be centered on

the useful screen with Purity Magnet.

5. Adjust DY tilt.

Note: Set ROTATION to 128 and LCC_NS to 128 when adjusting DY tilt.

6. LIghtly tighten the DY screw.

•Landing Fine Adjustment

Note: (1) After adjust W/B (9300k), measure the average of IK with all

white video input, while CONTRAST is maximum and

BRIGHTNESS is center. And adjustment shall be made so that

the miss-landing become least after aging 2H with the IK 30% of

measured value shown above.

(2) The magnetic field shall be BH = 0.

4. Degauss the iron part of chassis with a hand degausser and degauss coil.

5. Degauss CRT face with a hand degausser again.

6. Input AC 230V to AC IN and turn the monitor off and on. Then autodegauss works.

7. Reset FUNCTION_SW bit1 to 0 (auto-degauss = off)

8. Degauss CRT face with a hand degausser again.

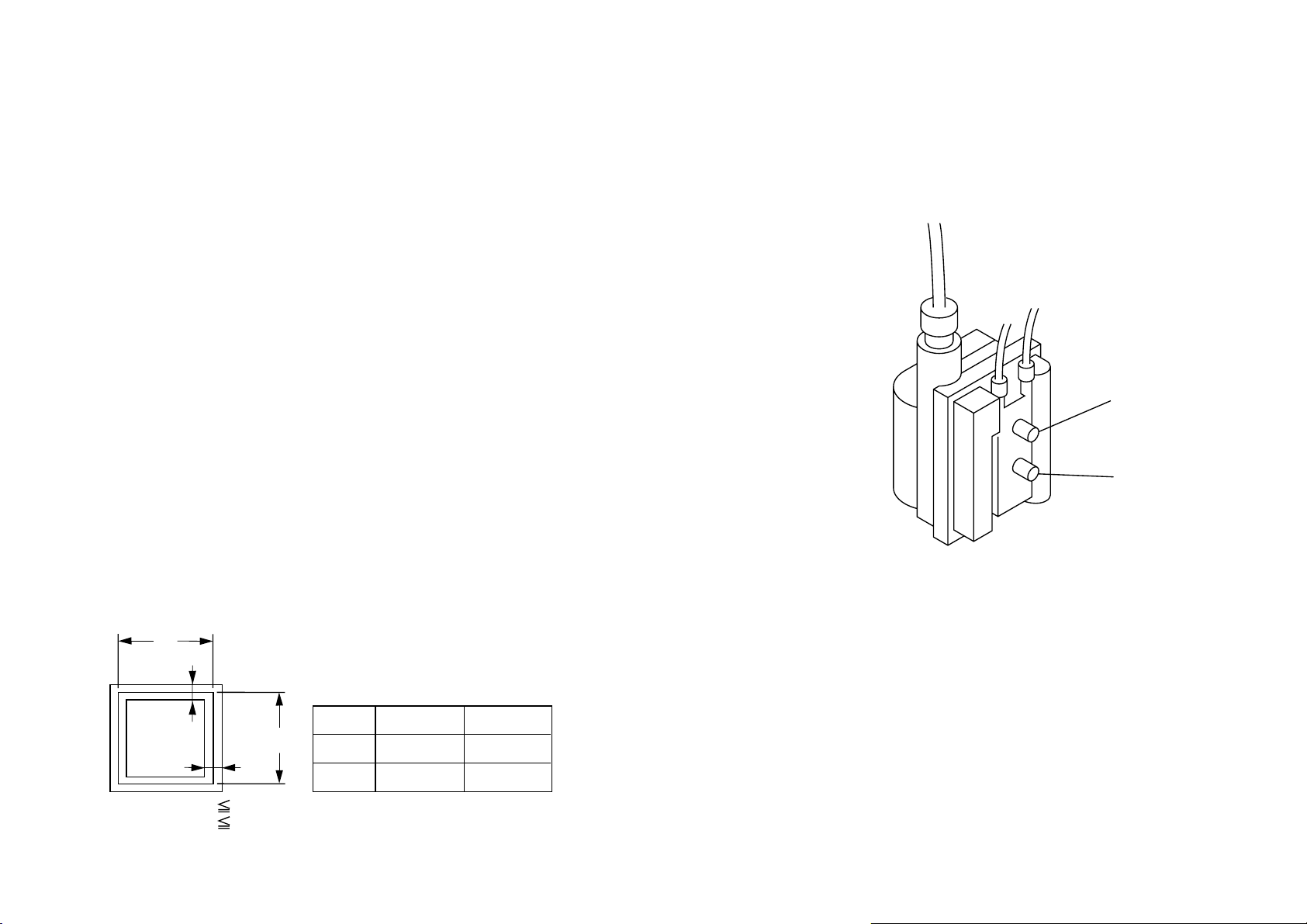

9. Attach wobbling coil to the specified place on CRT neck.

10. Put on landing sensor to CRT face.

11. Set LCC_SW to 12.

12. With landing checker, adjust DY position, purity, DY center and

landing of the 4 corners.

13. Read VX and VY value which are the read out of magnetic sensor, and

write to "LCC_VX_REF" and "LCC_VY_REF".

14. Adjust landing by LCC_NS, LCC_LT, LCC_LB, LCC_RT, and

LCC_RB. Adjustment of registers shall be limited within the following

range.

LCC_NS: 128 ± 15

(3) When adjusting at other than BH = 0, calculate the shifted value

from BH = 0.

1. Put the monitor in helmholz coil.

2. Set as follows;

LCC_SW = 0 (LCC Correction Current = 0)

FUNCTION_SW bit1 = (Auto Degauss = On)

CONTRAST = 255

3. Display green plain pattern.

LCC_LT, LCC_LB, LCC_RT, and LCC_RB: 128 ± 40

<Specifications>

Adjust so that the green is within

the specification given right.

4 corner adjust target : within ± 1

The red and blue must be within the

specification given right with respect to the green.

0 ± 3 0 ± 7.5 0 ± 3

0 ± 3 0 ± 7.5 0 ± 3

0 ± 3 0 ± 7.5 0 ± 3

± 6 ± 6 ± 6

± 6 ± 6 ± 6

± 6 ± 6 ± 6

(µm)

(µm)

CPD-G420(E) 3-1

A difference between red and blue

must be within the specification

given right.

10 10 10

10 7 10

10 10 10

(µm)

17. Adjust top and bottom pins correction VR.

18. Adjust the horizontal trapezoid distortion by DY horizontal trapezoid

correction VR.

Set LCC_SW to 12, and Perform Service Save.

15. Tighten DY screw within specified torque, and auto-degauss.

Note: Torque 22 ± 2 kgcm (2.2 ± 0.2Nm)

16. Adjust the vertical angle of DY to make top and bottom pins equal (a =

b). The horizontal angle shall not be changed (straight). Settle DY

upright without leaning, and insert wedges firmly so that DY shall not

move.

<How to place wedge>

Green plain crosshatch pattern

a

cd

b

Plaster RTV to both sides for the upper wedge.

Make sure that they settle inside DY.

a and b should be equal.

c and d should be equal.

19. Adjust landing by LCC_NS, LCC_LT, LCC_LB, LCC_RT and

LCC_RB. Adjustment of registers shall be limited within the following

range.

LCC_NS: 128 ± 15

LCC_LT, LCC_LB, LCC_RT, and LCC_RB: 128 ± 40

20. Remove the sensor and wobbling coil.

21. Switch signals to R, G, and B, and then check that the pure colors have

good color purity.

22. Fix purity magnets with white paint.

Plaster RTV to one side for other wedges.

CPD-G420(E) 3-2

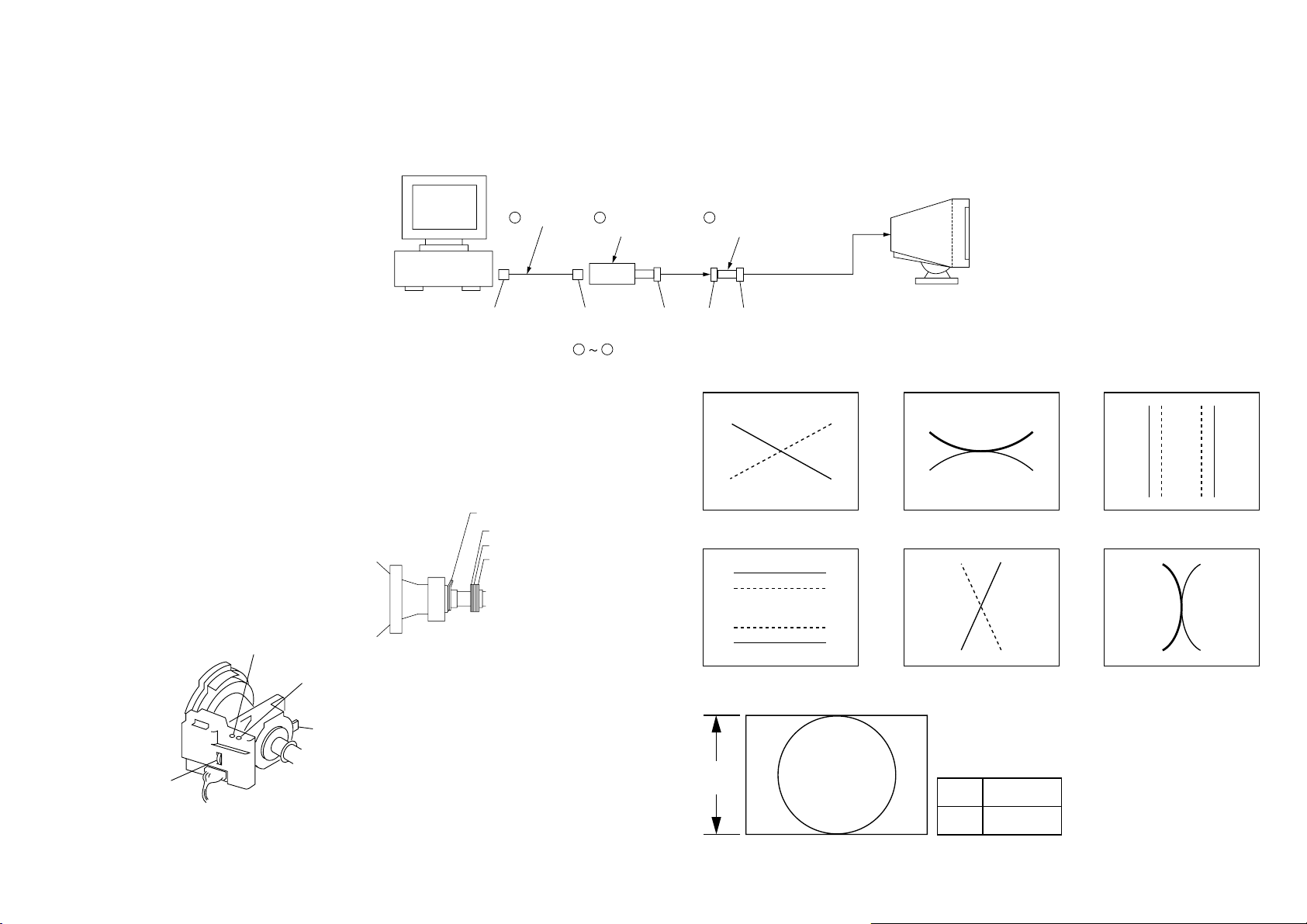

Connect the communication cable of the computer to the connector located on the D board. Run the service software and then follow the instruction.

IBM AT Computer

as a Jig

1-690-391-211A-1500-819-A

D-sub

(9 Pin [female])

*The parts above ( ) are necessary for DAS adjustment.

mini Din

(8Pin)

1

2

Interface Unit

3

•Convergence Rough Adjustment

(1) Display white crosshatch pattern.

(2) Pile the convex parts of 6-pole magnet for convergence together.

(3) Roughly adjust H.CONV and V.CONV with 4-pole magnet.

Purity

4-pole magnet

6-pole magnet

2-pole magnet

H.TRAP

TB-PIN

4 Pin

3-702-691-01

3

Connector Attachment

To BUS CONNECTOR

4 Pin 4 Pin

TLV

XBVXCV

B

R

R

B

TLH

R

BBR

YBHYCH

R

B

B

R

R B

R B

XCV

TLH

•Convergence Specification

B

V

A

A

B

0.20 mm

0.24 mm

CPD-G420(E) 3-3

•White Balance Adjustment Specification

•Focus adjustment

1. 9300 K

x = 0.283 ± 0.005

y = 0.298 ± 0.005

(All White)

2. 6500 K

x = 0.313 ± 0.005

y = 0.329 ± 0.005

(All White)

3. 5000 K

x = 0.346 ± 0.005

y = 0.359 ± 0.005

(All White)

•Vertical and Horizontal Position and Size

Specification

Adjust the focus volume 1 and 2 for the optimum focus.

Focus 1

Focus 2

FBT

A

b

b

a

B

a

a 1.8 mm

b 1.8 mm

MODE

A

B

4 : 3

352 mm

264 mm

5 : 4

330 mm

264 mm

CPD-G420(E) 3-4

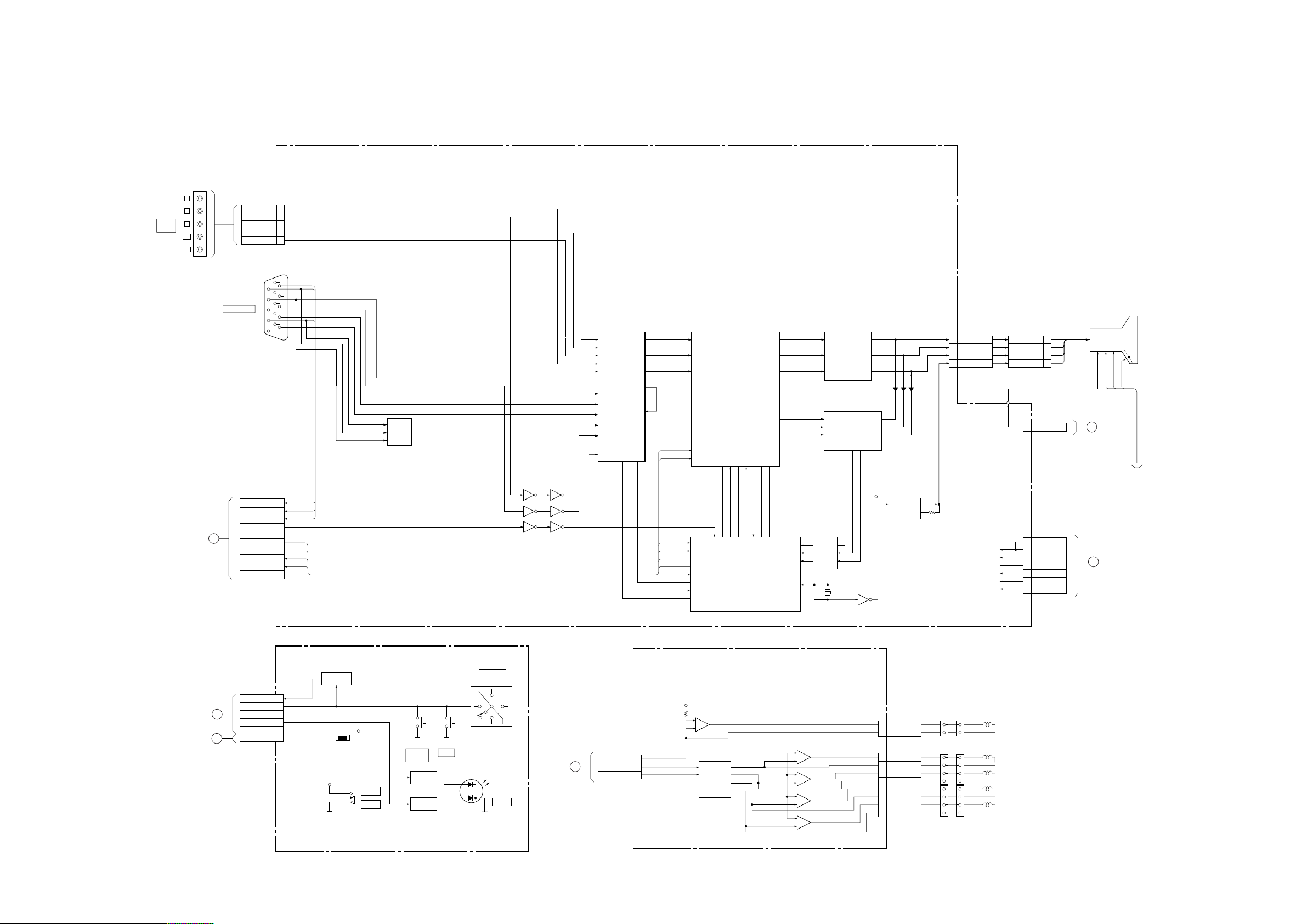

4-1. BLOCK DIAGRAMS

SECTION 4

DIAGRAMS

(VIDEO AMP, RGB OUT)

A1

5BNC

INPUT2

(BNC)

R

G

B

HD

VD

A

TO D BOARD

CN1102

INPUT1(HD15)

DDC GND1

DDC SCL1

DDC SDA1

H BLK

INPUT SW

IIC SCL

IIC SDA

HS OUT

VS OUT

ECO SW

CN313

BLUE2

GREEN2

CN307

HD15

CN311

VD2

HD2

RED2

8

9

2

4

6

5

15

10

14

4

9

3

13

8

2

12

7

1

11

6

5

SDA

6

SCL

7

VCLK

IC007

ROM

IC006

INVERTER

985 6

10

11

12

15

16

13

1

4

2

3

SCL

SDA

HS OUT

VS OUT

ECO SW

3 4 11 10

1 2 13 12

2

4

6

7

8

10

12

14

15

16

13

IC008

INPUT SELECT

B1

G1

R1

V1

H1

B2

G2

R2

V2

H2

SW

18 19 21

R OUT

G OUT

B OUT

SOG

SYNC IN

H OUT

V OUT

25

28

31

23

22

G.SYNC

SCL

SDA

SCL

SDA

HS OUT

VS OUT

ECO SW

11

15

14

13

BUFFER

8

9

Q101,

Q201,

Q301

R IN

G IN

B IN

RIN

GIN

BIN

24.5MHz

RGB AMP

12 11 10

X001

IC002

R OUT

G OUT

B OUT

IC004

CUT OFF AMP

R_IK

G_IK

B_IK

24

IC005

INVERTER

ROUT

GOUT

BOUT

5

3

1

7V

3

5

7

HEATER REG

2

Vcc OUT

IC011

VADJ

CN315

KR

5

KG

3

KB

1

HEATER+

7

4

5

+B

+80V

+12V

7V

3.3V

5V

G2

CN318

KR

KG

KB

HEATER+

1

1

2

4

6

7

8

9

G2

+B

+B

+80V

+12V

7V

3.3V

5V

5

3

1

7

CN318

CN312

PICTURE TUBE

FVFCHV

B

C

TO D BOARD

CN604

V901

TO D BOARD

FBT

IC001

R IN

G IN

B IN

SCL

SDA

SCL

SDA

HS OUT

VS OUT

ECO SW

HS IN

VS IN

CS IN

15 14 13 12

18 20 19 21

2

H FLY

RGB PRE-AMP

OSD R

OSD G

OSD B

OSD BLK

101718

OSD B

OSD R

OSD G

OSD BLK

IC003

OSD

7

7

4

2

22

23

4

3

12

13

27

25

24

23

V_DET

11

AV

R OUT

G OUT

B OUT

COF R

COF G

COF B

BLK

10

BLK

CLAMP

CLP

26

28

30

22

23

24

RCI

GCI

BCI

XTAL IN

32

31

30

14

TO D BOARD

CN1103

TO N BOARD

CN1003

S1402

CONTROL /

CN1400

2

WAKE UP

3

KEY SCAN

4

D

E

LED1

LED2

INPUT SW

T_AMB

5

8

12

H1

Q1402

5V

TH1400

5V

S1403

INPUT1

INPUT2

(USER CONTROL)

S1401

PICTURE

MODE

LED DRIVE

Q1400

LED DRIVE

Q1401

S1400

MENU

CONTRAST

5V

IC1603

1

4

+

2

–

CN1603

6

LCC NS

7

F

G

D1400

A

POWER

TO D BOARD

CN1106

IIC SDA

IIC SCL

8

L2

(CY, LCC)

IC1602

DAC

SDA

SCL

AO2

AO1

AO4

AO3

2

1

4

3

21

20

IC1601

4

2

+

(1/2)

3

–

IC1601

6

8

+

(2/2)

7

–

IC1604

4

2

+

(1/2)

3

–

IC1604

6

8

+

(2/2)

7

–

B-SS3540<SH.> -BD1-EPS05

CN1600

12LCC-NS (+)

LCC-NS (–)

CN1602

LCC-LT (+)

1

LCC-LT (–)

2

LCC-LB (+)

3

LCC-LB (–)

4

LCC-RT (+)

5

LCC-RT (–)

6

LCC-RB (+)

7

LCC-RB (–)

8

LCC-NS

LCC-LT

LCC-LB

LCC-RT

LCC-RB

CPD-G420(E) 4-1

POWER SW

Q2601

IC2602

IC2603

POWER SW

Q2602

POWER SW

Q2603

POWER SW

Q2604

1

2

3

V BUS

D–

D+

CN2901

41

40

37

42

43

3

2

2

6

1

5

10

15

9

14

31

32

10

11

12

12

17

4

8

13

35

36

4

5

7

6

25

24

IVCO

G

DP1

DM1

DM2

DP2

DM0

DP0

DP3

DM3

DM4

DP4

IC2601

5V-REG

O

I

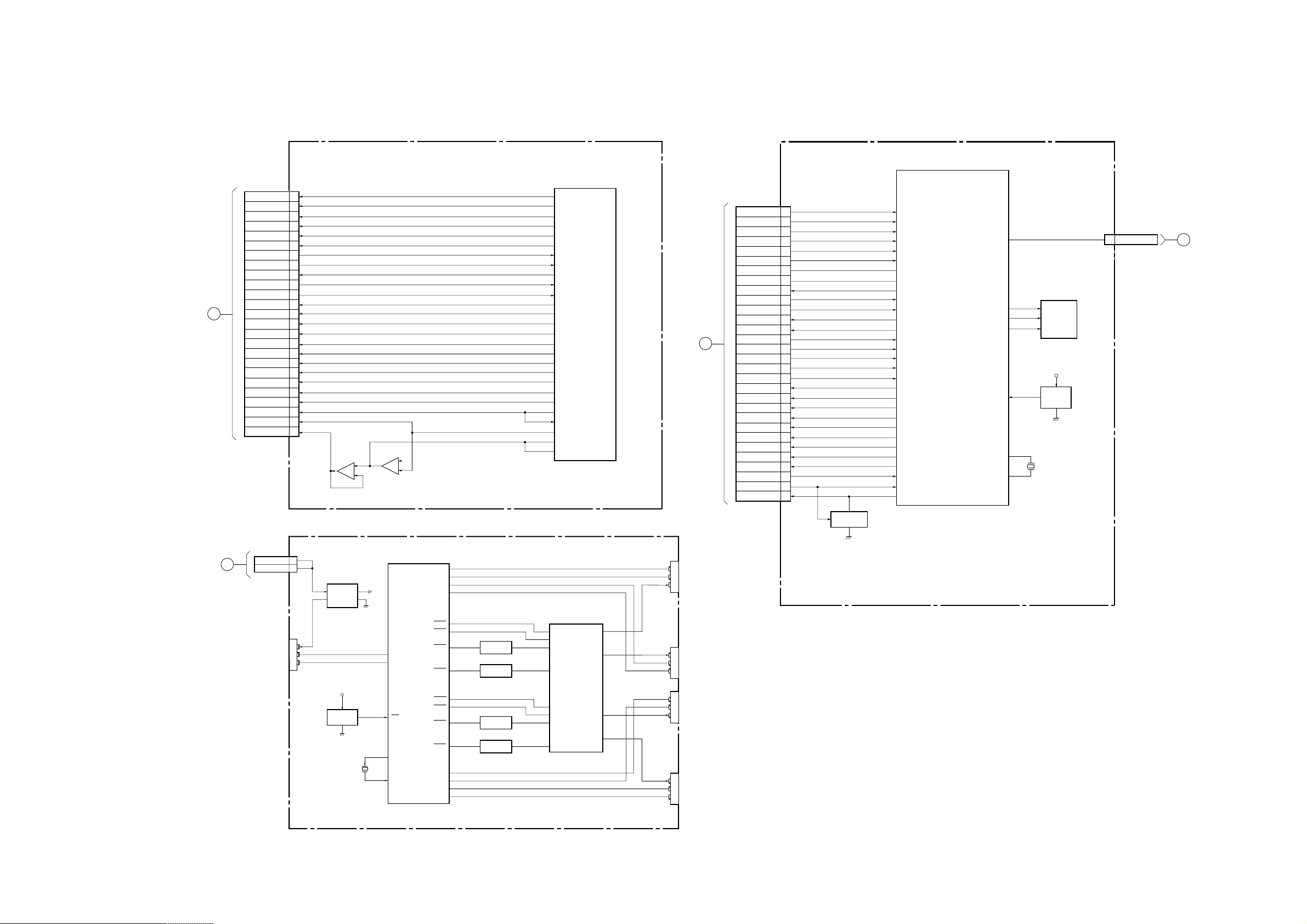

G

IC2902

RESET

X2901

12MHz

5V

IC2901

USB CONT

IC2602

4 OUTPUT VOLTAGE REGULATOR

5V

3

2

1

D+1

D–1

V BUS1

CN2902

D+3

D–3

V BUS3

CN2904

1

2

3

3

2

1

1

2

3

OVR-1

OVR-2

POW-1

POW-2

POW-3

POW-4

OVR-3

OVR-4

V BUS2

C–2

D+2

CN2903

V BUS4

C–4

D+4

CN2905

B-SS3540<SH.>-BD2-EPS05

US

(USB CONTROL)

RST

XIN

XOUT

7V

7V

CN2601

1

2

FLG1

FLG2

VC1

VC2

VOUT1

VOUT2

FLG3

FLG4

VC1

VC2

VOUT3

VOUT4

H

TO D BOARD

CN605

G

TO D BOARD

CN502

1

33

37

34

36

15

11

13

7

20

19

22

24

16

21

23

2

38

39

40

32

35

5

12

10

H.DF

REFDC

XDC

HD OUT

HFBP

H BLK

VS OUT

HS OUT

PLL LOCK

IIC SDA

IIC SCL

LCC_NS(NC)

HSAW_SW

H.LINBAL

GYSC

GXSC

V.DF

D.TILT

YSC

XSC

HSHAPE

YDC

POC

DCC2

VSAWN

CN1101

7

5

6

+

–

2

3

4

+

–

IC1102

AMP

DA

(DPU)

N

(

µ-COM

)

IC1001

CPU

1

2

3

21

23

35

36

38

39

40

41

43

44

45

48

49

50

51

52

53

54

63

27

26

64

58

59

IC1101

DPU

HDF1

DCC2

XDC

HDOUT

FBP-IN

H BLK

V-IN

H-IN

LOCK-DET

SDA

SCL

LCC_NS

HSAW_SW

PWM2

GYSC

GXSC

VDF

VKEY

YSC

XSC

HSHAPE

YDC

POC-OUT

POC-IN

DCC

ASW1

ASW2

P12/A10/AD10

P11/A9/AD9

P10/A8/AD8

RESET

X2

X1

64

63

62

46

7

6

5

IC1003

ROM

WC

SCL

SDA

5V

IC1002

RESET

I

G

O

41

43

X1001

16.9344MHz

INVERTER

Q1001

CN1001

I

TO D BOARD

CN1104

34

32

7

9

11

29

1

3

2

4

35

33

31

39

40

6

8

10

12

14

16

18

24

26

28

23

25

30

36

5

IK SIGMA

LB DET

DDC SDA1

DDC SCL1

DDC GND1

INPUT SW

IIC SDA

IIC SCL

TXD

RXD

KEY SCAN

LED1

LED2

PLL LOCK

POC

HV DET

ABL DET

G2

S6

S5

S4

S3

S2

S1

S0

PWR SW

DGC SW

V.FBP

WAKE UP

ECO SW

P41/AN09

P42/AN10

P86/SDA1

P87/SCL1

P21/A1/A17

P27/A7/A23

P80/SDA0/SI0

P81/SCL0/SO0

P82/TXD0

P83/RXD0

P42/AN11

P26/A6/A22

P25/A5/A21

P76/SCK0/INT3

P73/TB01N0/IN5

P57/AN07

P40/AN08

P70/TA1OUT

P36/TA7OUT

P35/TA61N

P34

P33/MAIT

P32/HWR

P31/WR

P30/RD

P04/AD4

P06/AD6

P61/CTS0

P51/AN01

P60/INT0

22

21

51

52

71

80

35

36

37

38

23

79

78

34

31

19

20

28

7

6

5

4

3

2

1

58

60

10

13

9

CN1003

4

T_AMB

E

TO H2 BOARD

CN1400

P54/AN04

16

CPD-G420(E) 4-2

Loading...

Loading...