CFS-515S

SERVICE MANUAL

Ver. 1.0 1998.07

SPECIFICATIONS

Frequency range FM :

Saudi Arabia model : 87.6 – 107MHz

EXCEPT Saudi Arabia model : 87.6 – 108MHz

MW : 530 – 1,605kHz

SW1 : 2.3 – 7 MHz

SW2 : 7 – 22MHz

IF FM : 10.7MHz

MW/SW : 455kHz

Aerials FM/SW : Telescope

MW : Built-in ferrite bar

Recording system 4-track, 2-channel stereo

Frequency response 70 – 13,000Hz

Speakers Full range : 10cm (4 inches) dia., 6ohms,

cone type/Tweeter : 2cm (13/16 inches) dia.

Output Headphones jack (stereo minijack), for

16 – 68 ohms impedance headphones

Maximum Power output

5W+5W

Battery life FM Recording : Sony R20P : Approx. 10hours/

Sony LR20 alkaline : Approx. 20hours

Playback : Sony R20P : Approx. 3.5hours/

Sony LR20 alkaline : Approx. 8hours

Power requirements 110 – 120V/220 – 240V AC selectable, 50/60Hz

9V DC, six R20 (size D) batteries

Power consumption AC 18 W

Dimensions Approx. 697 x 211 x 201.5 mm (w/h/d)

(27 1/2 x 8 3/8 x 8 inches) incl. projecting parts and

controls, not incl. handle

Mass Approx. 6.2 kg (13 lb 10 oz) incl. batteries

Supplied accessories

AC power cord (1),

E Model

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type MF-W495-1 17

MICROFILM

Design and specifications are subject to change without notice.

RADIO CASSETTE-CORDER

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. GENERAL

Looking at the Controls ..................................................... 3

2. DISASSEMBLY

2-1. Cabinet (Front) Section, Cabinet (Rear) Section....... 4

2-2. BATT (–) Board, BATT (+) Board ............................. 4

2-3. Power (AC) Board, Power (DC) Board...................... 4

2-4. Mechanism Deck, REC SW Board............................. 5

2-5. Chassis Sub Assy, Belt................................................ 5

2-6. VOL Board, Main Board, ECM Board....................... 6

2-7. Tuner Board ................................................................ 6

3. DIAL POINTER INSTALLATION ............................ 7

4. ADJUSTMENTS

4-1. Mechanical Adjustments ............................................ 8

4-2. Electrical Adjustments................................................ 8

5. DIAGRAMS

5-1. Block Diagram...........................................................11

5-2. Printed Wiring Boards – Main Section –.................. 14

5-3. Schematic Diagram – Main Section – ...................... 17

5-4. Printed Wiring Boards – Tuner Section –................. 20

5-5. Schematic Diagram – Tuner Section – ..................... 21

6. EXPLODED VIEWS

6-1. Cabinet (Rear) Section.............................................. 25

6-2. Cabinet (Front) Section ............................................ 26

6-3. Mechanism Deck Section -1..................................... 27

6-4. Mechanism Deck Section -2..................................... 28

6-5. Speaker Section ........................................................ 29

7. ELECTRICAL PARTS LIST.................................... 30

• HOW TO CHANGED THE CERAMIC FILTERS

This model is used two ceramic filters of CF1 and CF2.

You must used same type of color marked ceramic filters in

order to meet same specifications.

Therefore, the ceramic filter must changed two pieces together

since it’s supply two pieces in one package as a spare parts.

mark

CF1, 2

Mark Center fequency

red

blue

orange

10.70MHz

10.67MHz

10.73MHz

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

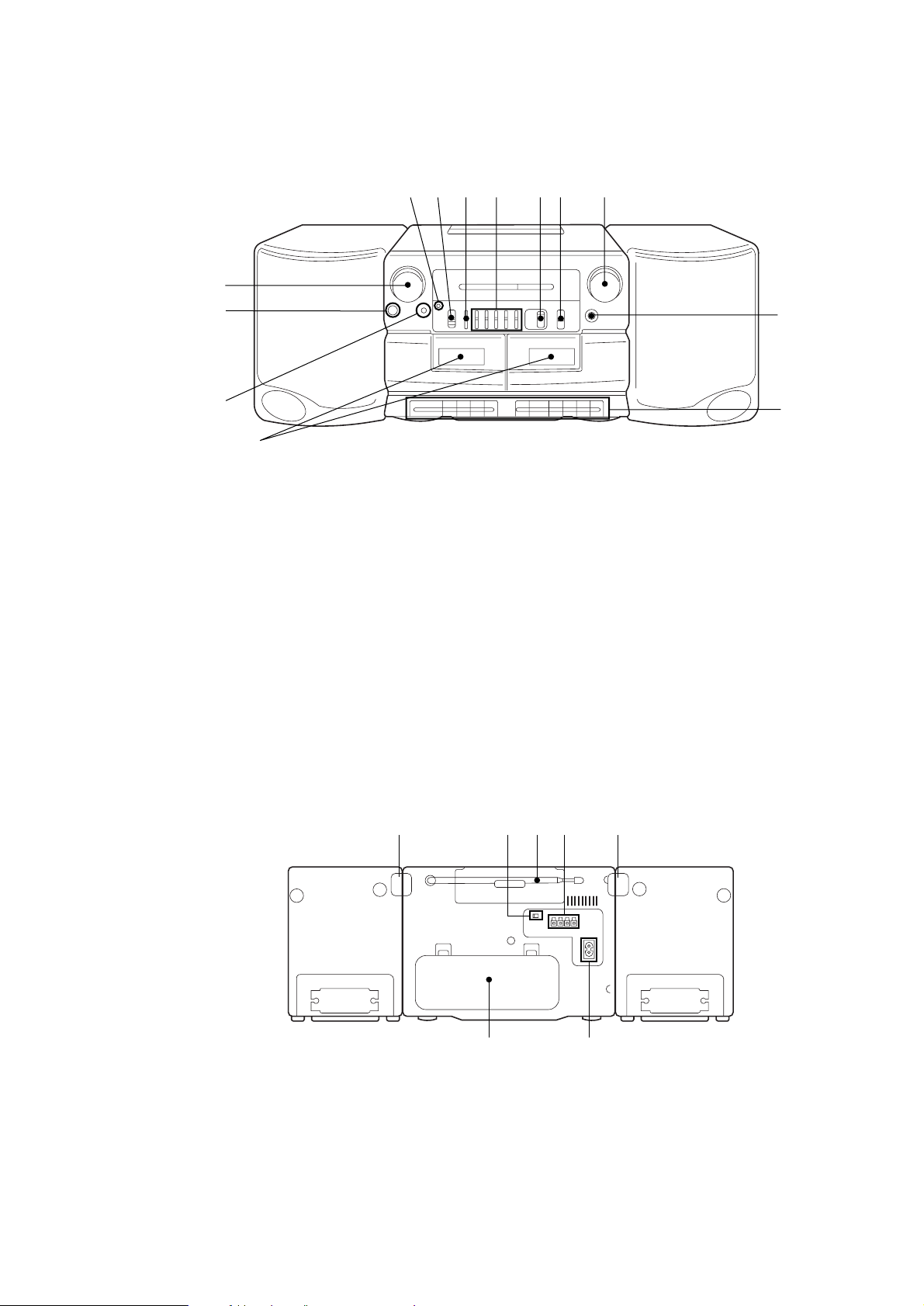

LOOKING AT THE CONTROLS

FRONT PANEL

4

3

SECTION 1

GENERAL

5

67

!¡89!º

!™

REAR PANEL

2

1

1Cassette compartments

2 MIC (microphone)

3 PHONES (headphones) jack (stereo mini-jack)

4 VOLUME control

5 OPR/BATT (operation/battery) indicators

6 FUNCTION selector

RADIO

DUBBING HIGH

DUBBING NORM

TAPE/RADIO OFF

7 BALANCE control

8 5 BAND GRAPHIC EQUALIZER controls

1234

!£

9 PRESET MODE selector

!º BAND selector

!¡ TUNING control

!™ FINE TUNING control

!£ Tape operating buttons

r REC (record) button : Deck B only

( PLA Y (playback) button

0 REW (rewind) button

) FF (fast-forward) button

p6 STOP/EJECT button

P PAUSE button

5

67

1 LOCK tab (right side)

2 FM MODE switch

3 Telescopic aerial

4 SPEAKER terminals

5 LOCK tab (Left side)

6 ⁄ AC IN (AC power input) socket

7 Battery compartment

– 3 –

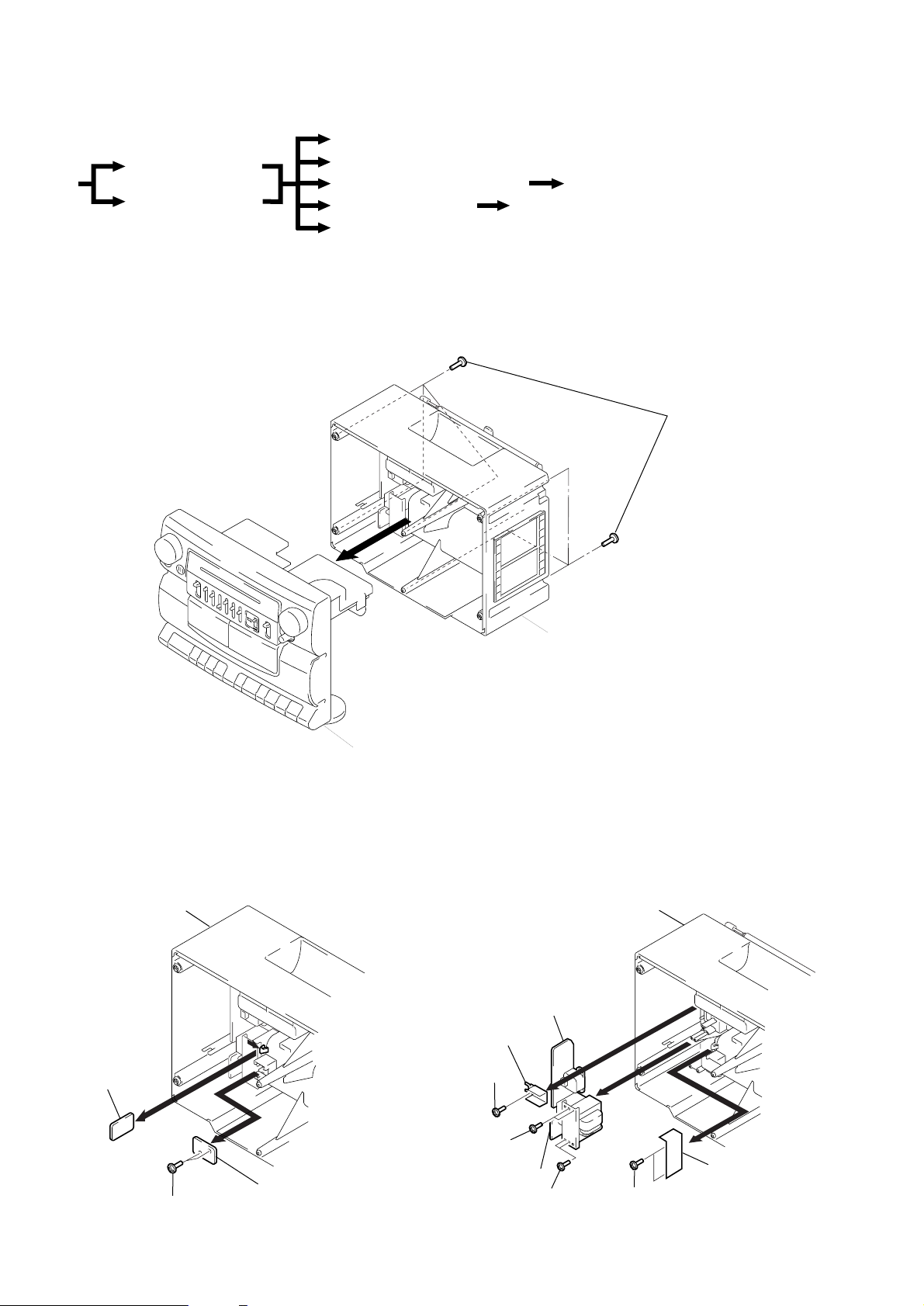

SECTION 2

DISASSEMBLY

r

The equipment can be removed using the following procedure.

BATT (–) board, BATT (+) board

Cabinet (Front) section

Set

Cabinet (Rear) section

Note : Follow the disassembly procedure in the numerical order given.

2-1. CABINET (FRONT) SECTION, CABINET (REAR) SECTION

Power (AC) board, Power (DC) board

Mechanism deck, REC SW board Chassis sub assy, Belt

VOL board, Main board ECM board

Tuner board

1

Screws

(+BTP 3x14)

2-2. BATT (–) BOARD, BATT (+) BOARD

Cabinet (Rear) section

2

Cabinet (Rear) section

Cabinet (Front) section

2-3. POWER (AC) BOARD, POWER (DC) BOARD

Cabinet (Rear) section

BATT (+) board

4

1

Screws (+BTP 3x10)

3

2

BATT (–) board

Bracket (AC)

1

Screw

(+BTP 3x10)

3

Screws

(+BTP 3x10)

Power (DC) board

– 4 –

Power (AC) board

3

Screws

(+BTP 3x10)

2

4

5

Screws (+BTP 3x10)

6

Shield plate (T)

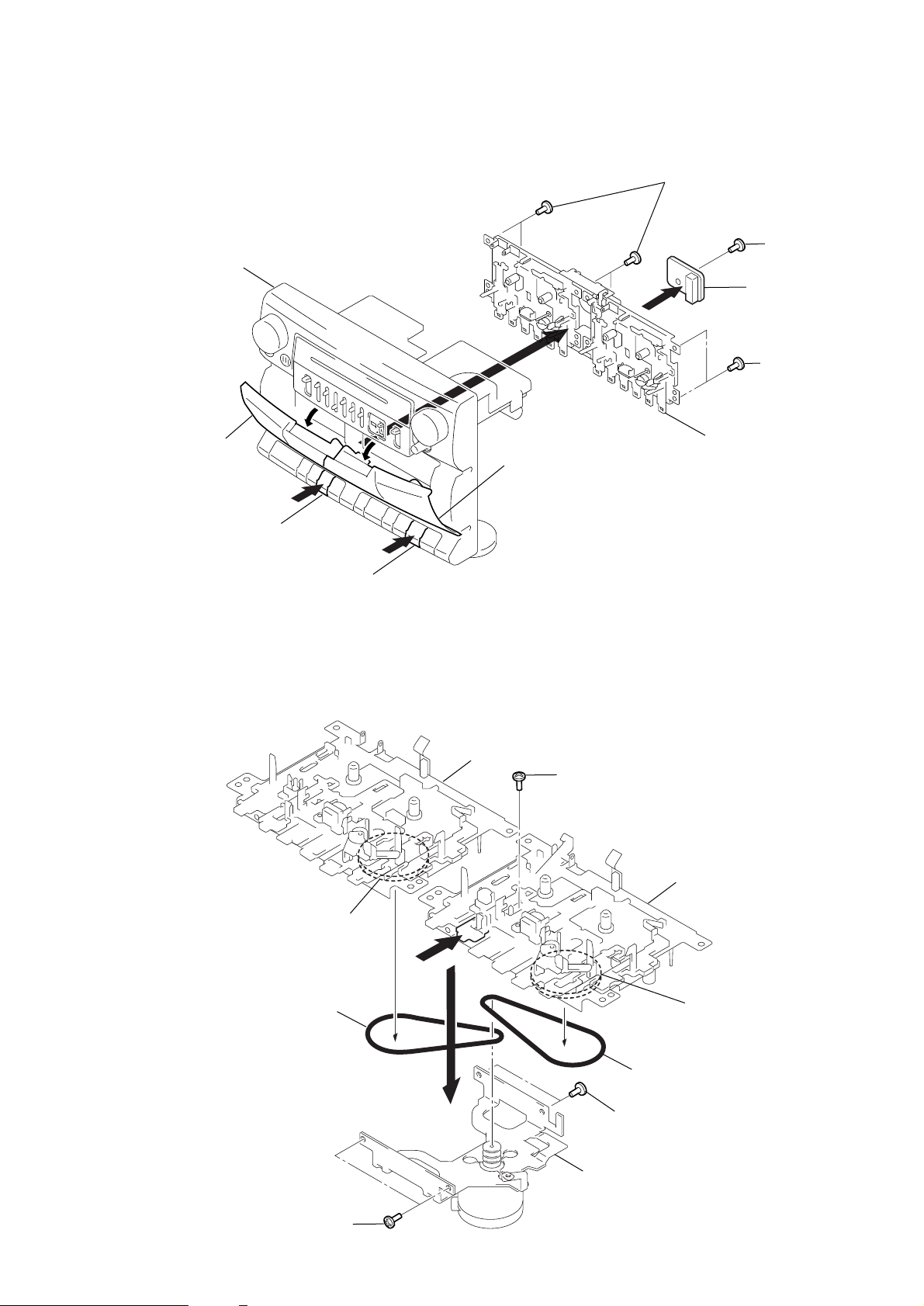

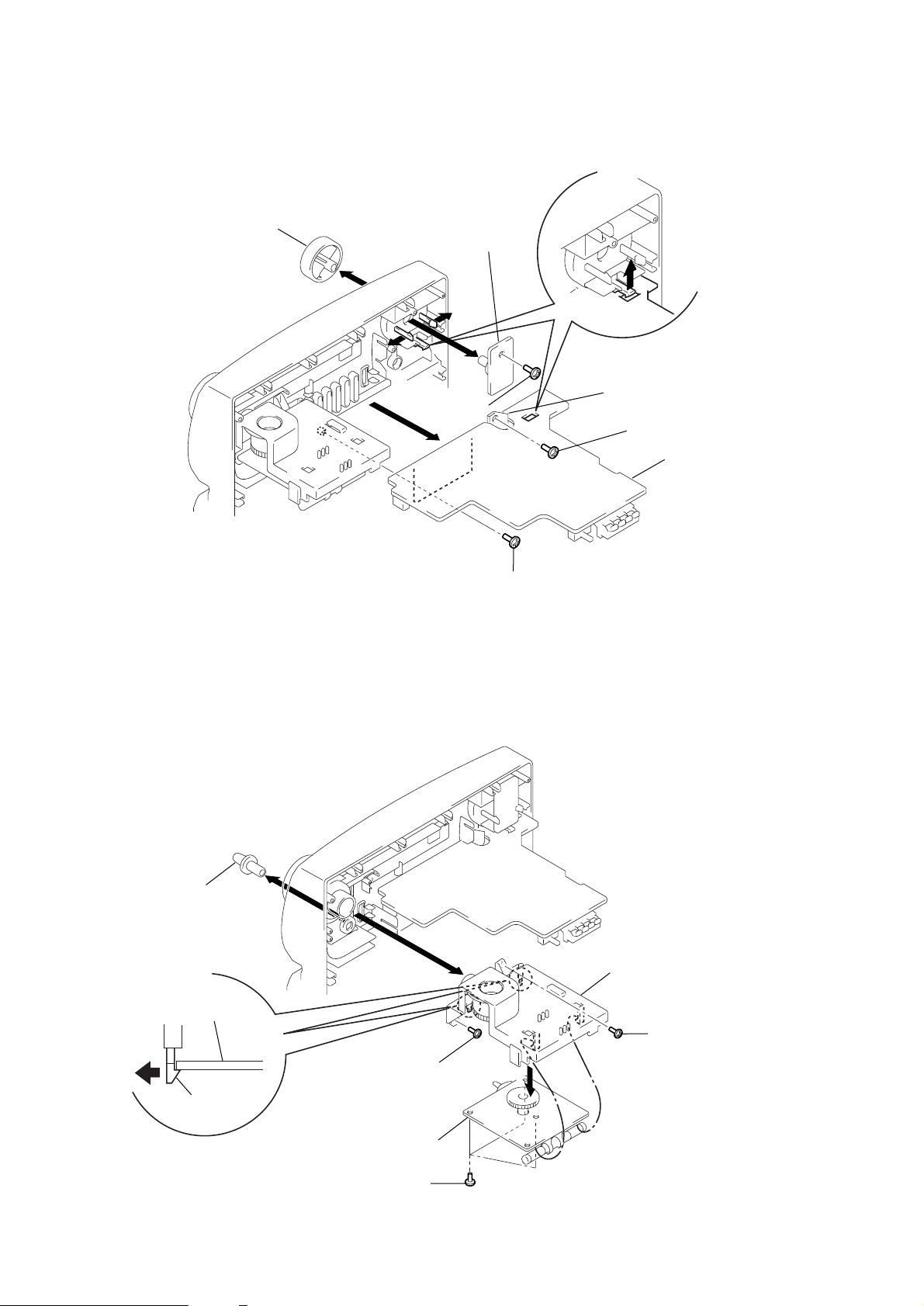

2-4. MECHANISM DECK, REC SW BOARD

y

Cabinet (Front) section

3

Screws

(+BTP 3x10)

5

Screw

(+PTT 2x6)

2

Cassette lid (L)

1

Button (ST/EJ)

Button (ST/EJ)

2-5. CHASSIS SUB ASSY, BELT

1

2

4

Cassette lid (R)

6

REC SW board

3

Screws

(+BTP 3x10)

Mechanism deck section

Flywheel assy

4

Belt

1

3

Deck A

2

Screw (+PTT 2x5)

Chassis sub assy

Deck B

Flywheel ass

4

Belt

2

Screws (+PTT 2x5)

2

Screws (+PTT 2x5)

– 5 –

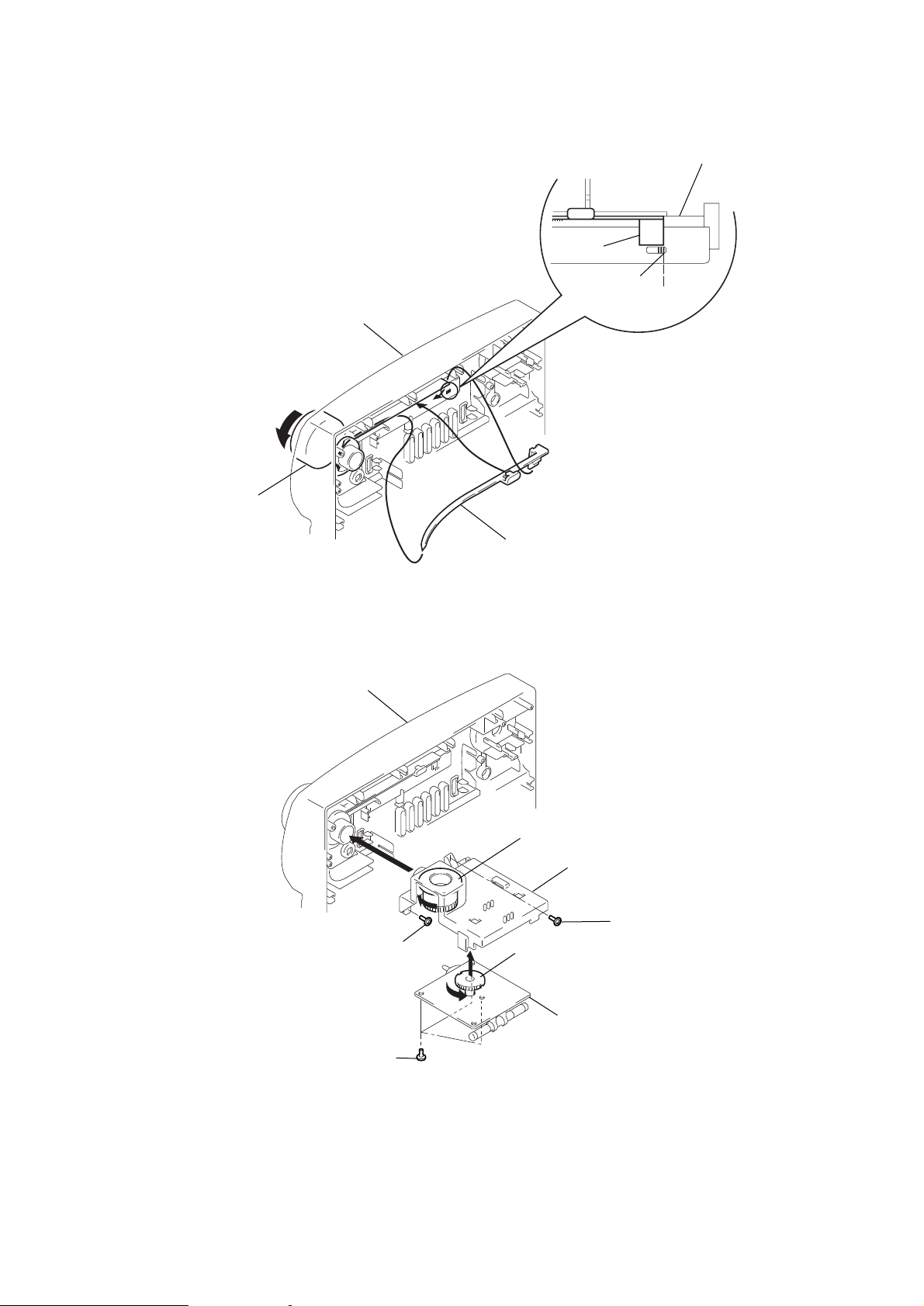

2-6. VOL BOARD, MAIN BOARD, ECM BOARD

)

Knob (VOL)

1

VOL board

7

3

2-7. TUNER BOARD

3

2

Screw

(+BTP 3x10)

8

4

6

Screw (+BVTP 3x6)

ECM board

Screw (+BTP 3x10)

5

Main board

2

Knob (F/T)

5

Tuner board

Claw

1

Screw (+BTP 3x10)

Tuner board

Screws (+BVTP 3x10)

4

– 6 –

3

6

Chassis (Tune)

1

Screw (+BTP 3x10

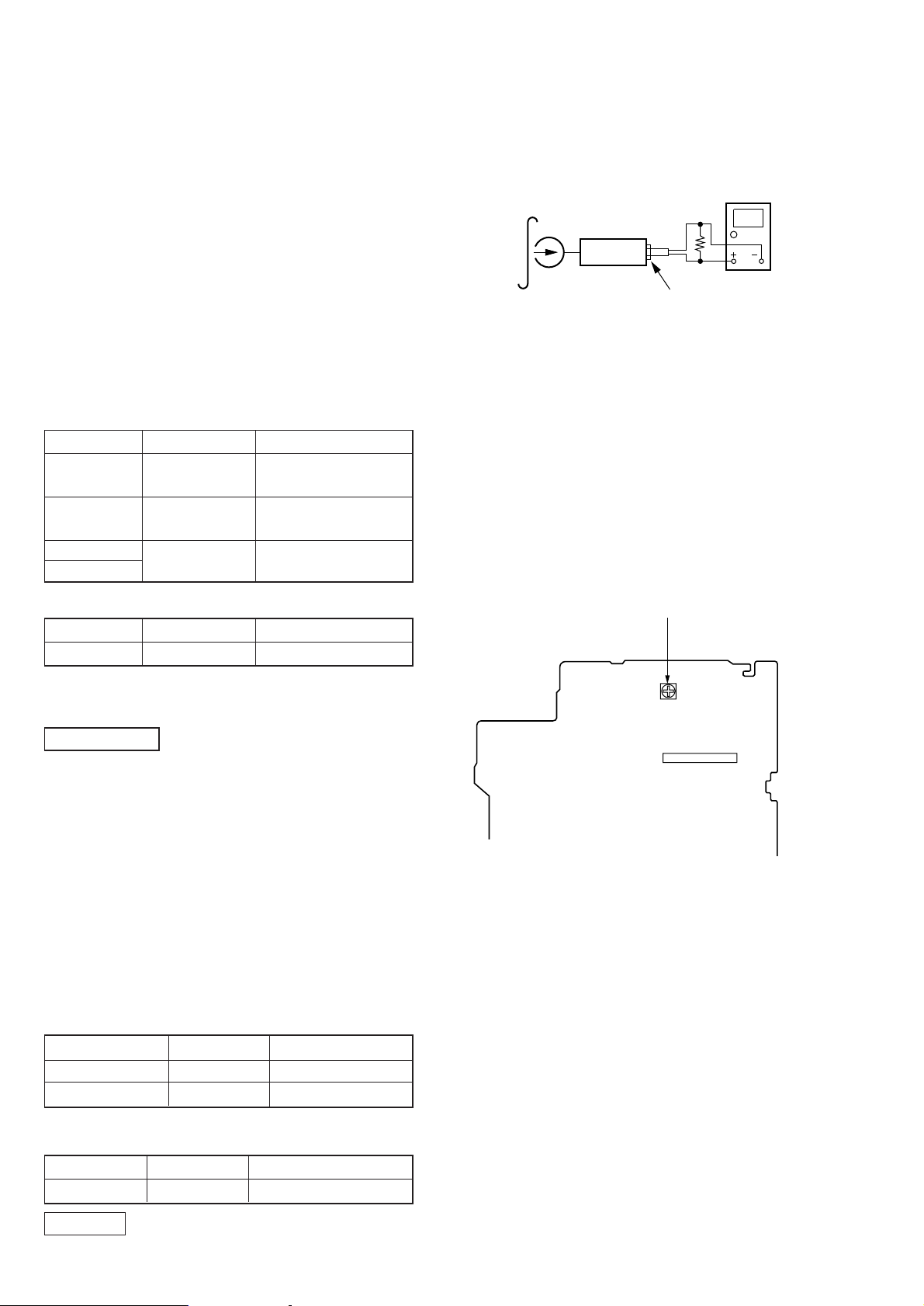

SECTION 3

)

DIAL POINTER INSTALLATION

Note : Follow the installation procedure in the numerical order given.

Cabinet (Front)

2

– 1

Knob (Tune)

c

b

Cabinet (Front)

Pointer

Marked line

2

– 2

1 Set the pointer into the grooves of the cabinet

(Front) in the order of a, b and c.

2 Turn the knob (Tune) in the direction of the arrow ,

then set the pointer by aligning it with the marked

line of the cabinet (Front).

Cabinet (Front)

6

Screw (+BTP 3x10)

a

1

Pointer

4

Gear (Midway)

3

Gear (VC)

Chassis (Tune)

6

Screw (+BTP 3x10

5

Screws (+BVTP 3x10)

– 7 –

Tuner board

3 Turn the gear (VC) fully counterclockwise.

4 Turn the gear (Midway) fully clockwise.

5 Mount the tuner board to the chassis and tighten

with screws.

6 Mount the chassis (Tune) to the cabinet (Front) and

tighten with screws.

SECTION 4

ADJUSTMENTS

4-1. MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback head playback head

pinch roller erase head

rubber belt capstan

2. Demagnetize the record/playback head with a head demagnetizer. (Do not bring the head demagnetizer close to the erase

head.)

3. Do not use a magnetized screwdriver for adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power supply voltage unless otherwise noted.

Torque Measurement

Torque Torque Meter Meter Reading

Playback CQ-102C

Back Tension CQ-102C

Rewind

Fast Forward (0.63 – 1.31 oz• inch)

CQ-201B

18 – 60 g • cm

(0.25 – 0.83 oz• inch)

1 – 5 g • cm

(0.014 – 0.069 oz• inch)

45 – 95 g • cm

Tape Speed Adjustment

Procedure :

Mode : Playback

test tape

WS-48A

(3kHz, 0dB)

set

(Normal speed)

1. Deck A to playback mode.

2. Adjust the RV303 for 2,985 – 3,015Hz reading on digital frequency counter.

3. Frequency difference between the beginning and the end of the

tape should be within 1% (30Hz).

(High speed)

4. Deck B to record mode.

5. Deck A to high speed playback mode.

6. Confirm that the reading of the digital voltmeter becomes 5,500

– 6,500Hz.

7. Frequency difference between the beginning and the end of the

tape should be within 1% (30Hz).

Adjustment Location :

digital frequency

32

Ω

phones jack

counter

T ape Tension Measurement

Mode Tension Meter Meter Reading

FWD CQ-403A more than 60g (2.12 oz)

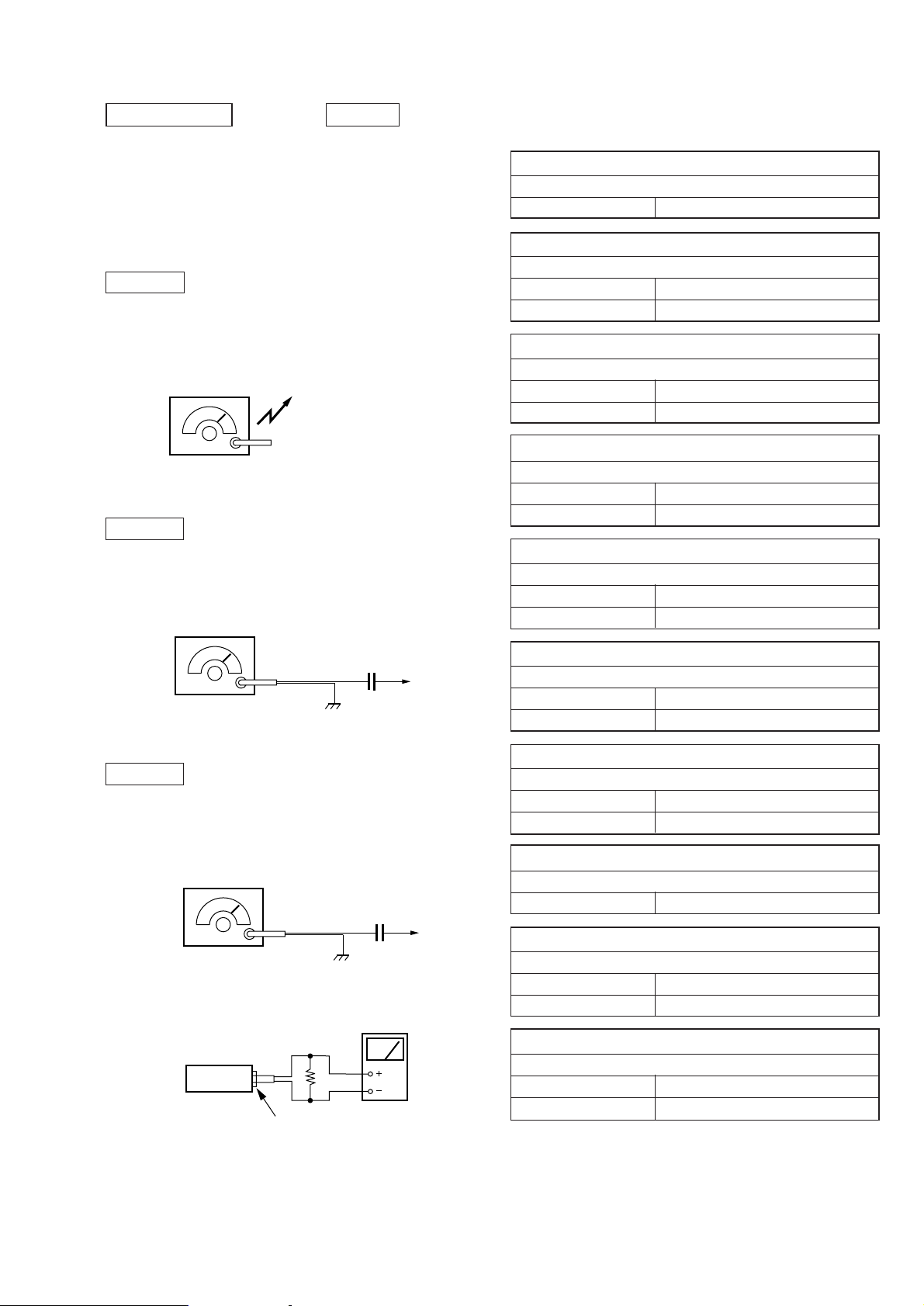

4-2. ELECTRICAL ADJUSTMENTS

TAPE SECTION

1. The adjustments should be performed in the order give in the

service manual. (As a general rule, playbak circuit adjustment

should be completed before performing recording circuit adjustment.)

2. The adjustments should be performed for both L-CH and R-CH

unless otherwise indicated.

• Switch location

FUNCTION switch • • • • • • • • • • • • • • • • • TAPE (RADIO OFF)

PRESET MODE • • • • • • • • • • • • • • • • • • • • • MANUAL

GRAPHIC EQUALIZER • • • • • • • • center click

BALANCE • • • • • • • • • • • • • • • • • • • • • • • • • • • • • center click

VOLUME• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • MAX

MEGA BASS • • • • • • • • • • • • • • • • • • • • • • • • • mechanical center

Standard Output Level

Output terminal PHONES SP (FRONT) OUT

Load impedance 32Ω 6Ω

Output signal level 0.25V (–10dB) 0.775V (0dB)

RV303 : Tape Speed Adjustment

[ MAIN BOARD ]

(Component side)

IC201

Test T ape

Type Signal Used for

WS-48A 3kHz, 0dB Tape Speed Adjustment

0dB=0.775V

– 8 –

TUNER SECTION 0dB=1 µV

c

c

r

• Switch location

FUNCTION switch • • • • • • • • • • • • • • • • • RADIO

PRESET MODE • • • • • • • • • • • • • • • • • • • • • MANUAL

GRAPHIC EQUALIZER • • • • • • • • center click

BALANCE • • • • • • • • • • • • • • • • • • • • • • • • • • • • • center click

VOLUME• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • MAX

MEGA BASS • • • • • • • • • • • • • • • • • • • • • • • • • mechanical center

MW Section

Procedure :

BAND switch : MW

FINE TUNING control : mechanical center

AM RF signal

generator

30% amplitude modulation by 400Hz

signal.

Output level : as low as possible

SW Section

Put the lead-wire

antenna close to

the set.

Procedure :

BAND switch : SW1, SW2

FINE TUNING control : mechanical center

AM RF signal

generator

12PF

30% amplitude modulation

by 400Hz signal.

Output level : as low as possible

FM Section

telescopi

antenna

terminal

Procedure :

BAND switch : FM

FINE TUNING control : mechanical center

FM RF signal

generator

0.01

µ

F

telescopi

antenna

terminal

22.5kHz frequency deviation

by 400Hz signal.

Output level : as low as possible

level mete

32

Ω

set

phones jack

• Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

no mark : COM

< > : Saudi Arabia model

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T1 455kHz

MW FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L4 520kHz < 516kHz >

CT4 1,680kHz < 1,630kHz >

MW TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L3 600kHz

CT3 1,400kHz

SW1 FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L6 2.2MHz

CT6 7.3MHz

SW1 TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L5 2.2MHz

CT5 7.3MHz

SW2 FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L8 6.8MHz

CT8 22.5MHz

SW2 TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L7 6.8MHz

CT7 22.5MHz

FM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T2 10.7MHz

FM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L2 <L21> 86.5MHz < 87.35MHz >

CT2 109.5MHz < 107.8MHz >

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L1 86.5MHz < 87.35MHz >

CT1 109.5MHz < 107.8MHz >

Adjustment Location : Tuner board (page 10)

– 9 –

Loading...

Loading...