Sony CFMA-50 Service manual

CFM-A50

SERVICE MANUAL

Ver. 1.2 2005.06

SPECIFICATIONS

Radio section

Frequency range

FM 87.6 – 108MHz (US model)

FM 87.6 – 107MHz (AEP, UK model)

AM 530 – 1,710kHz (US model)

MW 531 – 1,602kHz (AEP, UK model)

LW 153 – 279kHz (AEP, UK model)

Aerials

FM : Telescopic aerial

AM : Built-in ferrite bar aerial

Cassette-corder section

Recording system

2-track 1channel monaural

Fast winding time

Approx. 120 s (sec.) with Sony cassette C-60

Frequency response

TYPE I (normal) : 100 – 8,000Hz

General

Speaker

Full range : 9.2cm dia.,4 ohms, cone type (1)

Output

Earphone jack (minijack)

For 32 ohms impedance earphone

US Model

AEP Model

UK Model

Model Name Using Similar Machanism NEW

Tape Transport Mechanism Type MF-A50-117

Maximum power output

2.3 W

Power requirements

120V AC, 60Hz (US model)

230V AC, 50Hz (AEP, UK model)

6V DC, four R20 (size D) batteries

Power consumption

AC 6W

Battery life

FM recording

Sony R20P : approx. 13h

Sony alkaline LR20 : approx. 35h

Tape playback

Sony R20P : approx. 7h

Sony alkaline LR20 : approx. 20h

Dimensions

Approx. 289 x 200 x 123 mm (w/h/d)

(111/2 x 7 7/8 x 4 7/8 inches) (incl. projecting parts)

Mass

Approx. 2.4 kg (5 lb. 5 oz) (incl. batteries)

Supplied accessory

AC power cord (1)

Earphone (1)

Design and specifications are subject to change without notice.

9-923-167-14

2005F02-1

© 2005.06

RADIO CASSETTE-CORDER

Sony Corporation

Personal Audio Group

Published by Sony Engineering Corporation

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. GENERAL

Location and Function of Controls .................................... 3

2. DISASSEMBLY

2-1. Cabinet (Rear) Removal ............................................. 4

2-2. ISS SW Board, Battery Case,

BATTERY Board, POWER Board Removal ............. 4

2-3. Main Board, TUN LED Board,

TACT SW Board Removal ........................................ 5

2-4. H/P JACK Board, Door Ear (PH),

Box Ear (PH) Removal ............................................... 5

2-5. Mechanism Deck, DECK CONTROL Board

Volume Board Removal .............................................. 6

3. DIAL POINTER SETTING......................................... 7

4. ADJUSTMENTS

4-1. Mechanical Adjustment .............................................. 8

4-2. Electrical Adjustment ................................................. 8

5. DIAGRAMS

5-1. Schematic Diagram (AEP,UK Model)...................... 12

5-2. Printed Wiring Boards (AEP,UK Model) ................. 15

5-3. Printed Wiring Boards (US Model).......................... 19

5-4. Schematic Diagram (US Model) .............................. 23

HOW TO CHANGED THE CERAMIC FILTERS

This model is used three ceramic filters of CF2, CF4 and CF3.

You must used same type of color marked ceramic filters in order

to meet same specifications.

Therefore, the ceramic filter must changed three pieces together

since it's supply three pieces in one package as a spare parts.

mark

CF2, 4

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

mark

CF3

Mark

red

blue

orange

black

white

Center

fequency

10.70MHz

10.67MHz

10.73MHz

10.64MHz

10.76MHz

6. EXPLODED VIEWS

6-1. Cabinet (Rear) Section.............................................. 28

6-2. Cabinet (Front) Section ............................................ 29

6-3. Mechanism Deck Section-1 (MF-A50-117)............. 30

6-4. Mechanism Deck Section-2 (MF-A50-117)............. 31

7. ELECTRICAL PARTS LIST.................................... 32

– 2 –

SECTION 1

GENERAL

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer :

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5mA (500 microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is

0.75V , so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

µ

0.15 F

Fig. A. Using an AC voltmeter to check AC leakage.

1.5kΩ

Earth Ground

AC

voltmeter

(0.75V)

This section is extracted from

instruction manual.

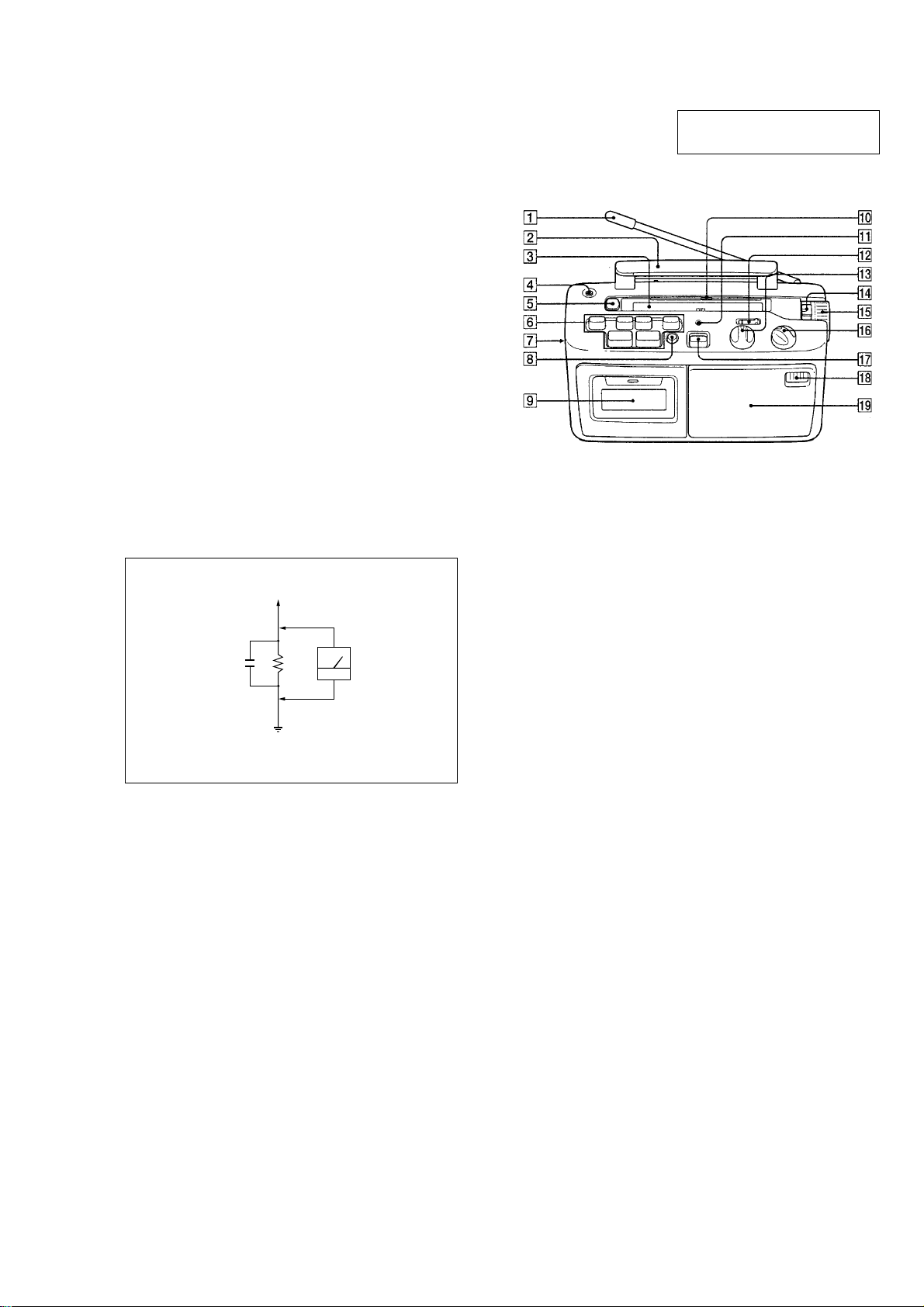

LOCATION AND FUNCTION OF CONTROLS

1 FM telescopic aerial

2 Carrying handle

3 Dial scale

4 @ (earphone) jack (mini jack)

5 LIGHT (Dial scale light) button

6 Tape operation buttons

7 EARPHONE POCKET box

8 SLOW PLAYBACK button

9 Cassette compartment lid

!º Frequency marker

!¡ OPR/BATT indicator

!™ EASY LISTENING ADJUSTMENT switch

!£ EASY LISTENING ADJUSTMENT control

!¢ BAND switch

!∞ TUNING control

!§ VOLUME control

!¶ FUNCTION switch

!• Built-in microphone

!ª Speaker

– 3 –

e

Ver 1.1 2001.11

SECTION 2

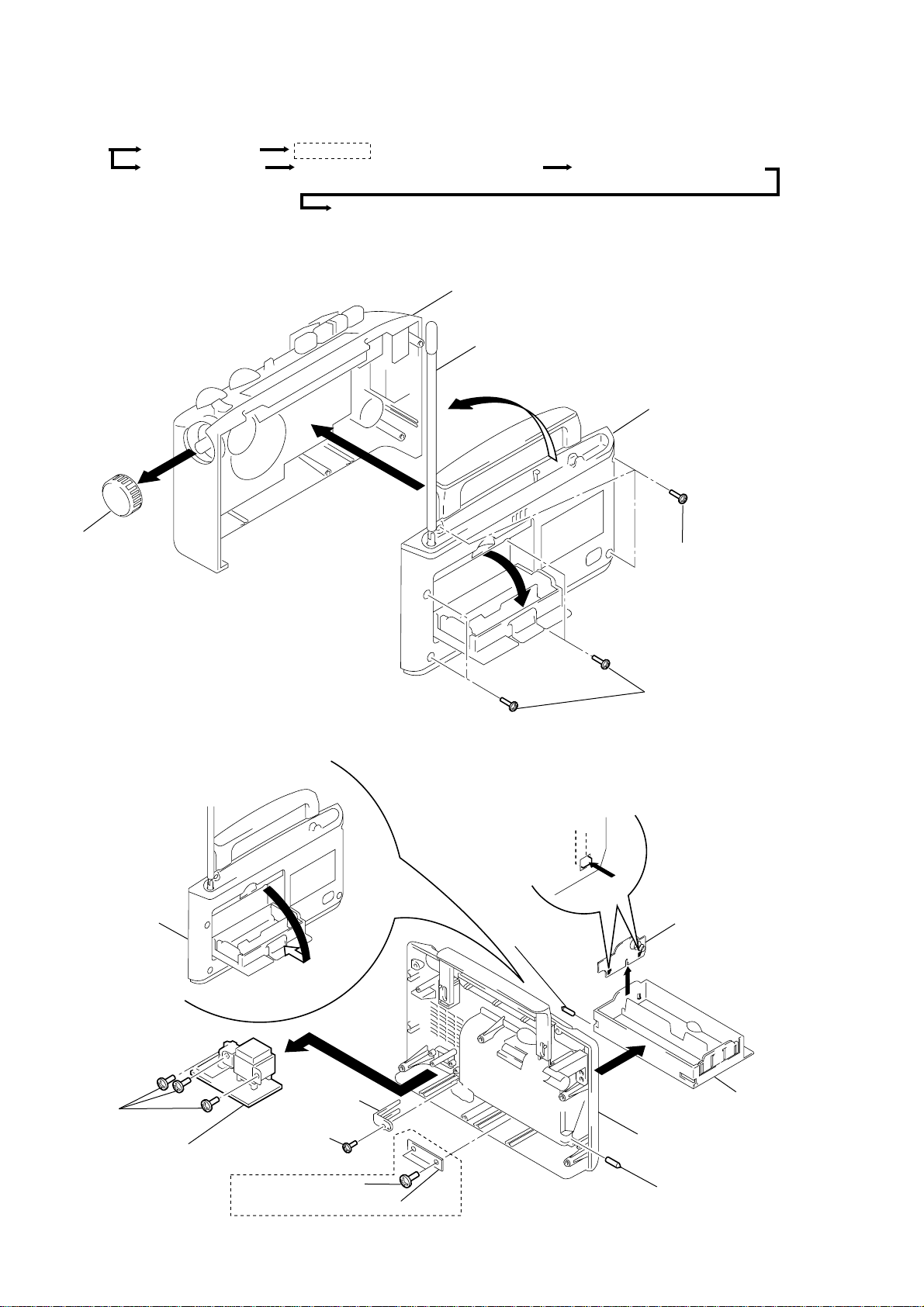

DISASSEMBLY

z

The equipment can be removed using the following procedure.

Set

Cabinet (Rear) assy

Cabinet (Front) assy

Note : Follow the disassembly procedure in the numerical order given.

2-1. CABINET (REAR) REMOVAL

5

AEP, UK model

ISS SW board , BATTERY CASE, BATTERY board, POWER board

Main board, TUN LED board, TACT SW board

Mechanism deck, DECK CONTROL board, VOLUME board

4

H/P JACK board, DOOR EAR (PH),

BOX EAR (PH)

Cabinet (Front) assy

ANT1

1

Cabinet (Rear) assy

Knob, TU

3

2 Screws (+BV 3X14)

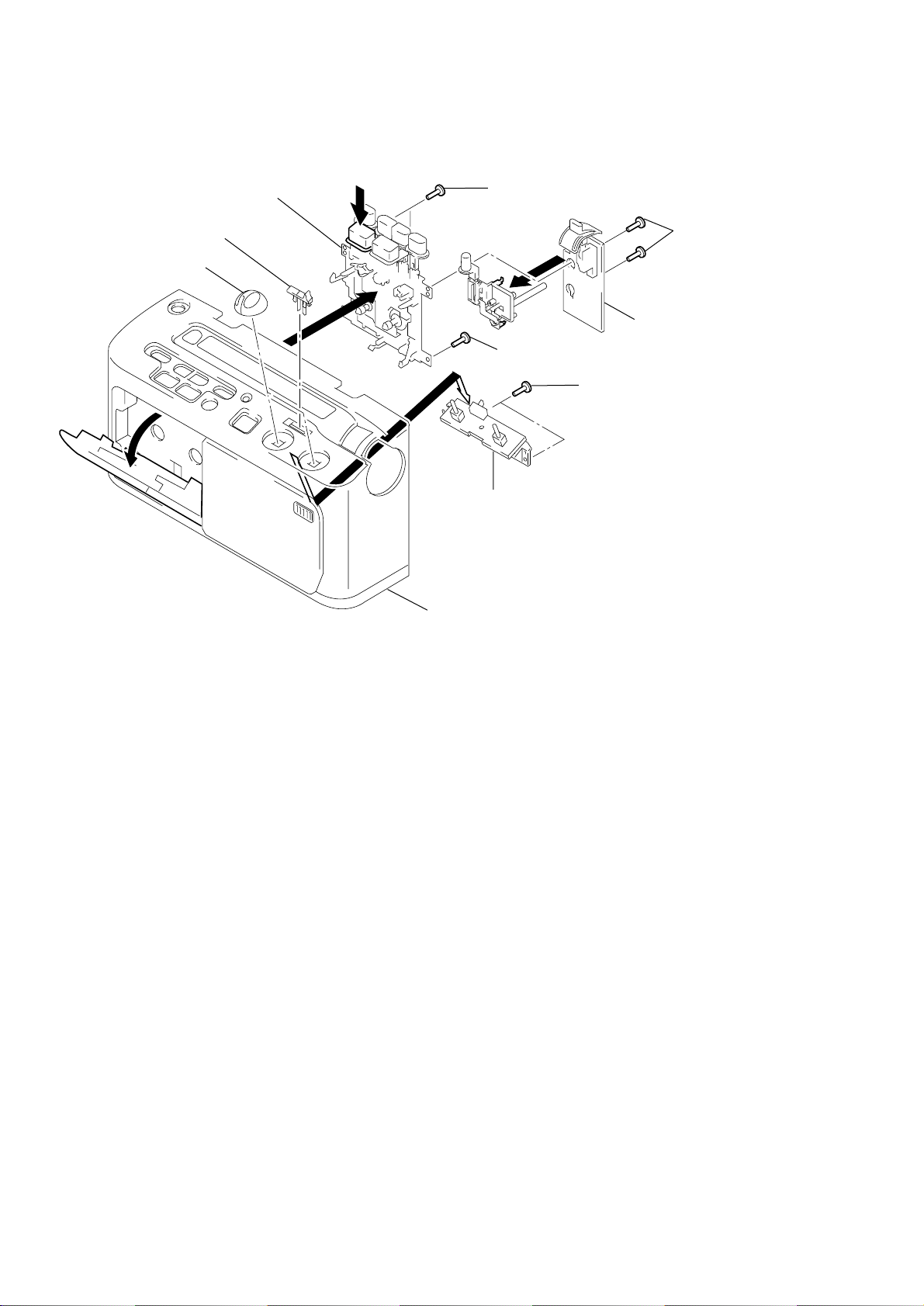

2-2. ISS SW BOARD, BATTERY CASE, BATTERY BOARD, POWER BOARD REMOVAL

7

Cabinet (Rear) assy

2

6 Shaft, handle

8

2 Screws (+BV 3X14)

BATTERY board

9 Screw

(+BV 3x10)

Power board

Stoper, wire

3 Screw

(+BV 3x10)

AEP, UK model

1 Screws (+BV 3x10)

0

ISS SW board

– 4 –

5

Cabinet (Rear) assy

4 Shaft, handle

Battery cas

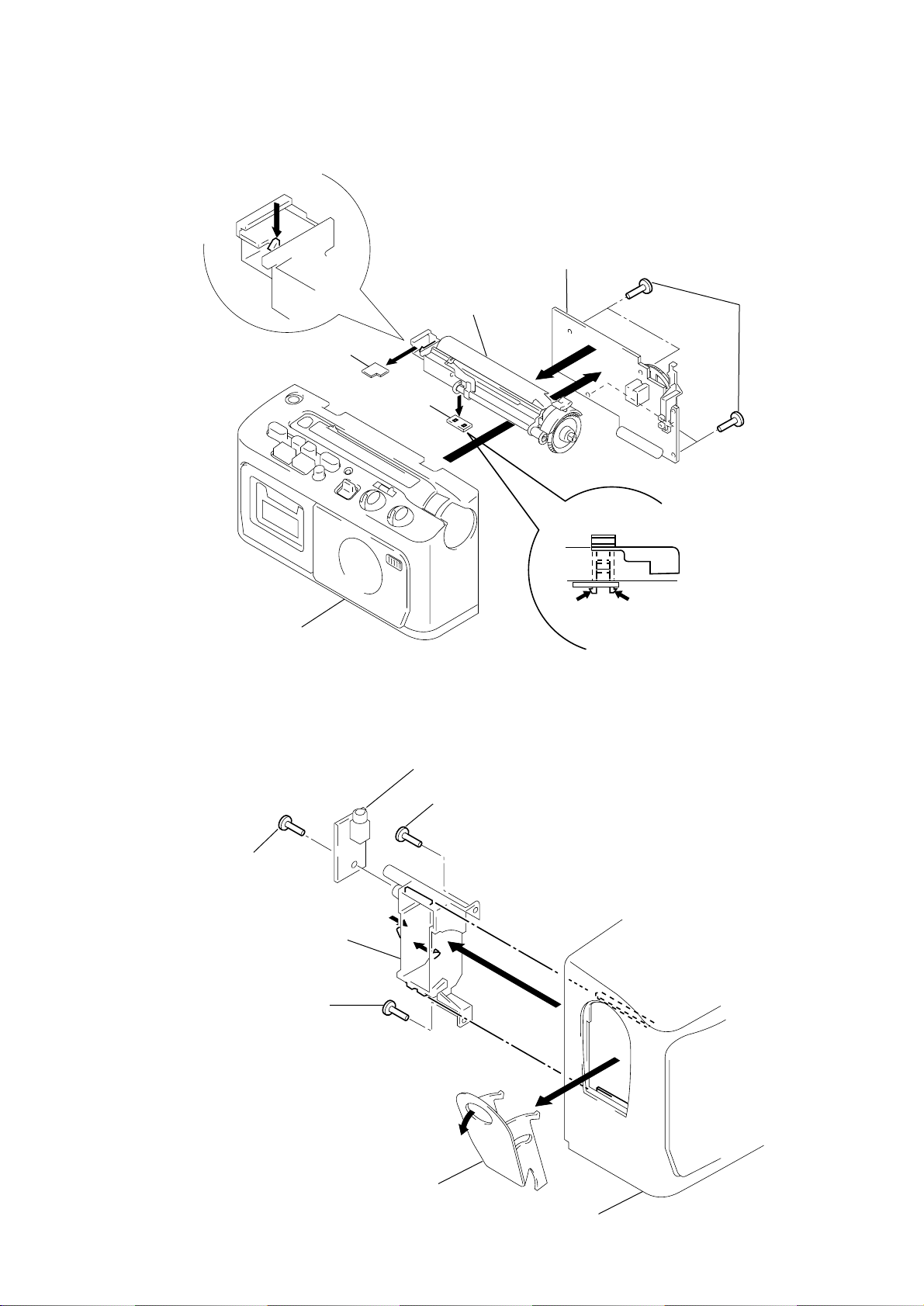

2-3. MAIN BOARD, TUN LED BOARD, TACT SW BOARD REMOVAL

5

2

4

4

3

7

6

1

Screws (+BV 3x10)

Cabinet (Front) assy

Main board

Chassis, TU

TACT SW board

TUN LED board

2-4. H/P JACK BOARD, DOOR EAR (PH), BOX EAR (PH) REMOVAL

H/P JACK board

4

Screw (+BV 3x10)

6

Screw

(+BV 3x10)

1

1

5

2

4

Screw (+BV 3x10)

Box, ear(PH)

3

DOOR, ear(PH)

Cabinet (Front) assy

– 5 –

2-5. MECHANISM DECK, DECK CONTROL BOARD, VOLUME BOARD REMOVAL

)

1

Mechanism deck

7

Knob (TONE SW)

7

Knob (VOL)

3

Screws (+BV 3x10)

6

5

Screws (+BV 3x10

2

4

3

Screw +BV (3x10)

9

Volume board

Cabinet (Front) assy

8

DECK CONTROL board

Screws (+BV 3x10)

– 6 –

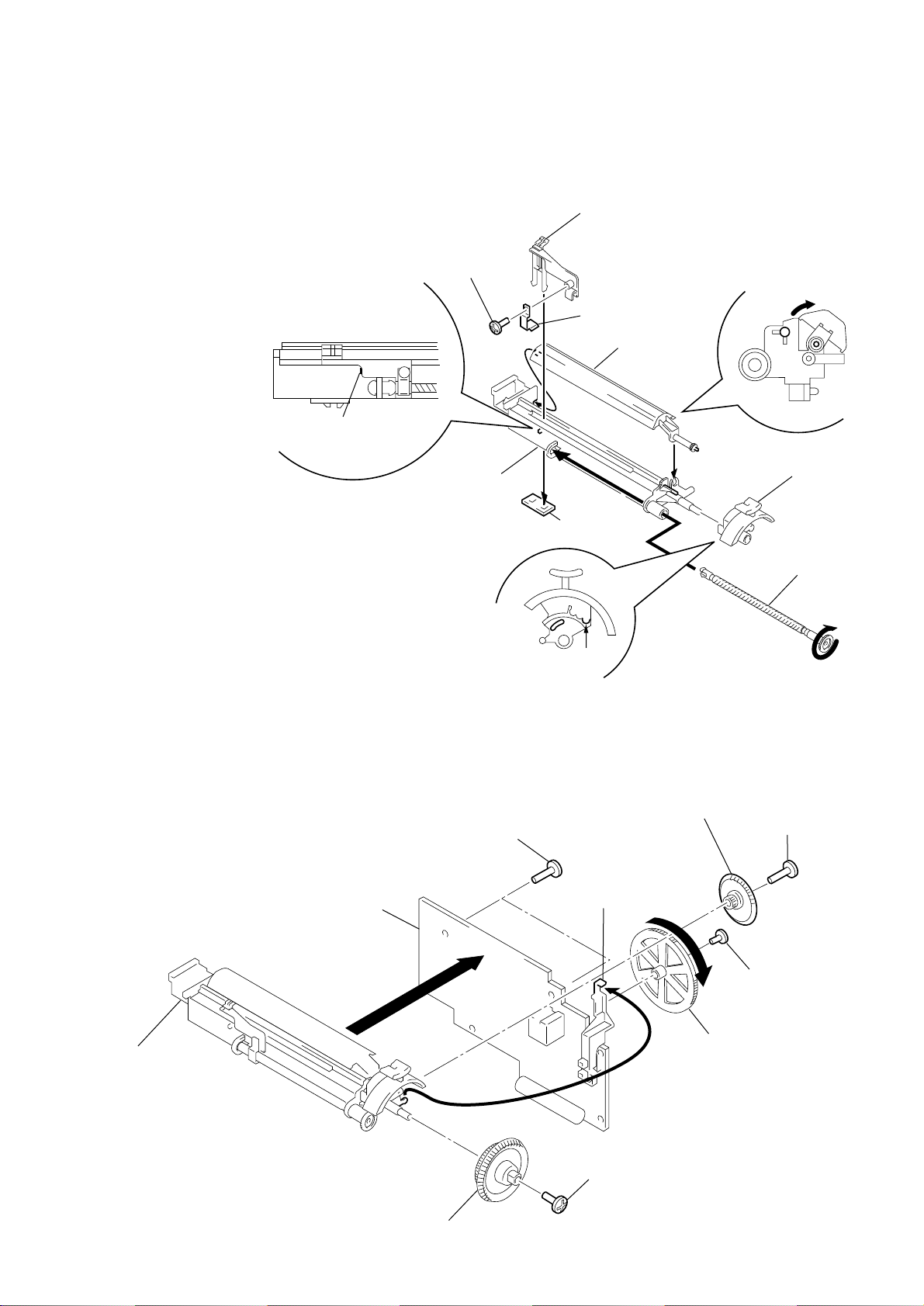

SECTION 3

d

DIAL POINTER SETTING

Note : Follow the instaooation procedure in the numerical order given.

1 Attach TU worm to tuner chassis.

2 Attach needle, tighten needle spring using a bolt, then attach TU

LED board.

3 Rotate TU worm until needle stops at the stopper shown in Fig. A.

Screw (+P 2.6x5)

2

Pointer

Fig. A

Stopper

Chassis, TU

4 Mount PLATE BLIND and position it as shown in Fig. B.

5 Attach the band knob. Make sure that the projected part of the

tuner chassis fits as shown in Fig. C (the arrow).

6 Tighten idler gear, combine projected part of band knob and the

band slider so that they interlock, then mount to main board.

7 Mount VR gear to main board, then turn in the direction of the

arrow until it stops.

8 Fasten the TU gear to the TU chassis with the screw.

Screws (+BV 3x10)

Retainer, Pointer

TUN LED board

Fig. C

4

Plate, blind

8

Gear, TU

Fig. B

5

Knob, ban

1

Worm, TU

3

Screw (+BV 3x10)

Chassis, TU

Main board

6

Gear, idler

– 7 –

Slieder, band

Screw (+BV 3x10)

Screw (+B 2.6x5)

7

Gear, VR

Loading...

Loading...