Sony BKDS9470 INSTALLATION MANUAL

SWITCHER PROCESSOR PACK

DVS-9000-C

DVS9000SF-C

PRODUCTION SWITCHER PROCESSOR

DVS-9000

DVS-9000SF

HK-PSU04

BKDS-9160

BKDS-9161

BKDS-9162

BKDS-9210

BKDS-9470

MKS-8110SD

MKS-8111SD

BZS-9250

BZS-9420

INSTALLATION MANUAL

1st Edition (Revised 2)

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

DVS-9000 Serial No. 10001 and Higher

DVS-9000SF Serial No. 10001 and Higher

BKDS-9160 Serial No. 10001 and Higher

BKDS-9161 Serial No. 10001 and Higher

BKDS-9162 Serial No. 10001 and Higher

BKDS-9210 Serial No. 10001 and Higher

BKDS-9470 Serial No. 10001 and Higher

MKS-8110SD Serial No. 10001 and Higher

MKS-8111SD Serial No. 10001 and Higher

HK-PSU04 Serial No. 10001 and Higher

BZS-9250

BZS-9420

DVS-9000/9000SF

Attention-when the product is installed in Rack:

1. Prevention against overloading of branch circuit

When this product is installed in a rack and is

supplied power from an outlet on the rack, please

make sure that the rack does not overload the supply

circuit.

2. Providing protective earth

When this product is installed in a rack and is

supplied power from an outlet on the rack, please

confirm that the outlet is provided with a suitable

protective earth connection.

3. Internal air ambient temperature of the rack

When this product is installed in a rack, please make

sure that the internal air ambient temperature of the

rack is within the specified limit of this product.

4. Prevention against achieving hazardous

condition due to uneven mechanical loading

When this product is installed in a rack, please make

sure that the rack does not achieve hazardous

condition due to uneven mechanical loading.

5. Install the equipment while taking the operating

temperature of the equipment into consideration

For the operating temperature of the equipment, refer

to the specifications of the Operation Manual.

6. When performing the installation, keep the rear of

the unit 10 cm (4 inches) or more away from walls

in order to obtain proper exhaust and radiation of

heat.

When using a LAN cable:

For safety,do not connect to the connector for

peripheral device wiring that might have excessive

voltage.

DVS-9000/9000SF

1 (P)

Table of Contents

Manual Structure

Purpose of this manual .............................................................................................. 3

Related manuals......................................................................................................... 3

Contents ..................................................................................................................... 3

1. Installation

1-1. Operating Environment ...............................................................................1-1

1-2. Power Supply .............................................................................................. 1-1

1-2-1. Power Specifications ..................................................................1-1

1-2-2. Recommended Power Cord ........................................................ 1-1

1-3. Installation Space (External dimensions) .................................................... 1-2

1-3-1. DVS-9000 .................................................................................. 1-2

1-3-2. DVS-9000SF .............................................................................. 1-3

1-4. Installing the Options .................................................................................. 1-4

1-4-1. Installing the Plug-in Boards ...................................................... 1-4

1-4-2. Installing the Connector Board ..................................................1-6

1-4-3. Installing the HK-PSU04 ...........................................................1-7

1-4-4. Installing the BZS-9250/9420 .................................................... 1-8

1-5. Rack Mounting ............................................................................................ 1-9

1-6. Matching Connectors ................................................................................ 1-11

1-7. Input/Output Signals of Connectors .......................................................... 1-12

1-8. Checks on Completion of Installation ....................................................... 1-14

1-8-1. Description of On-board Switches and LEDs ..........................1-14

1-8-2. Checks on the Switch Setting the Number of Power Supply

Units ......................................................................................... 1-33

1-9. System Connection.................................................................................... 1-34

DVS-9000/9000SF

2. Service Overview

2-1. Troubleshooting .......................................................................................... 2-1

2-2. Periodic Inspection and Maintenance ......................................................... 2-2

2-2-1. Cleaning .....................................................................................2-2

2-3. About the Data Backup Capacitor ............................................................... 2-3

1

Purpose of this manual

Related manuals

Manual Structure

This manual is the installation manual of Switcher Processor Pack DVS-9000-C/

DVS9000SF-C and their optional boards and units.

This manual is intended for use by trained system and service engineers, and

describes the information on installing the DVS-9000-C/DVS9000SF-C system.

The following manuals are prepared for DVS-9000-C/DVS9000SF-C and their

optional boards and units.

..

. Operation Manual (Supplied with DVS-9000-C/DVS9000SF-C)

..

This manual describes the application and operation of DVS-9000-C/

DVS9000SF-C system.

..

. Maintenance Manual (Available on request)

..

This manual describes the detailed service information.

If this manual is required, please contact your local Sony Sales Office/Service

Center.

Contents

..

. User’s Guide (Supplied with CCP-8000/9000)

..

This manual is required for detailed application and operation of the DVS-9000-C/

DVS9000SF-C system.

For the installation procedure of the software options BZS-9250/9420, refer to this

manual.

..

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in B&P Company equipment.

Semiconductors that cannot be searched for on this CD-ROM are listed in the

maintenance manual for the corresponding unit. The maintenance manual contains

a complete list of all semiconductors and their ID Nos., and thus should be used

together with the CD-ROM.

Part number: 9-968-546-XX

This manual is organized by following sections.

Section 1 Installation

This section describes the operating environment, power supply, installation space,

installation of optional boards and units, rack mounting, connectors, input and

output signals of connectors, checking upon completion of installation, and system

configuration.

DVS-9000/9000SF

Section 2 Service Overview

This section describes the troubleshooting and periodic inspection and maintenance.

3

Section 1

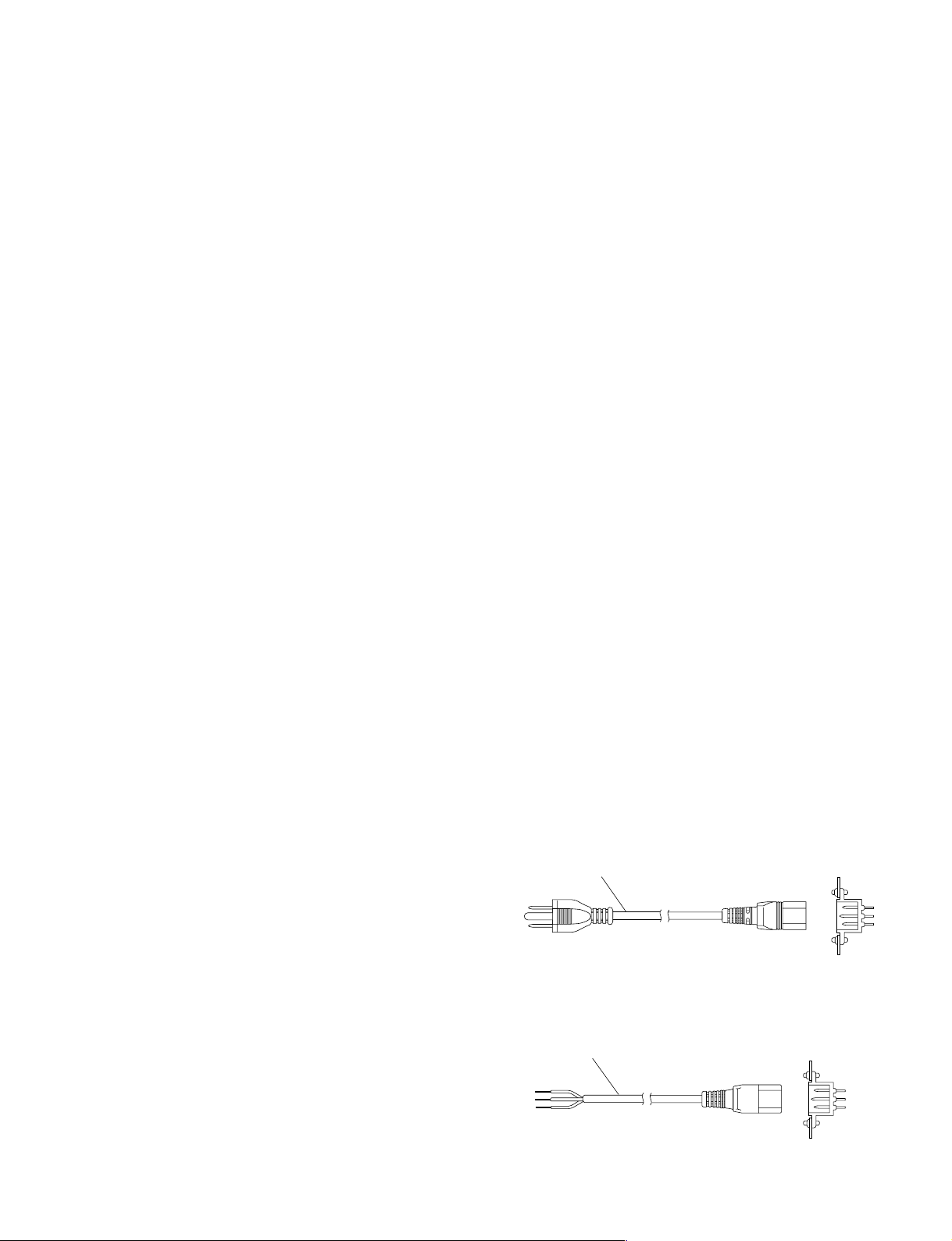

For customers in the U.S.A. and Canada

1 Power cord, 125 V 10 A (2.4 m) : ! 1-557-377-11

AC inlet

1

Installation

1-1. Operating Environment

Operating guaranteed temperature : +5 dC to +40 dC

Performance guaranteed temperature : +10 dC to +35 dC

Operating humidity : 10 % to 90 %

(relative humidity)

Storage temperature : _20 dC to +60 dC

Mass (when all options are installed) :

DVS-9000 : Approx. 43 kg

DVS-9000SF : Approx. 25 kg

Prohibited locations for installation

. Areas where the unit will be exposed do direct sunlight

or any other strong lights.

. Dusty areas

. Areas subject to vibration.

. Areas with strong electric or magnetic fields.

. Areas near heat sources.

. Areas subject to electrical noise.

. Areas subject where is subjected to static electricity.

Ventilation

The inside of the DVS-9000-C/DVS9000SF-C (DVS-9000

series hereafter) is cooled by a fan (both sides).

The power supply can be damaged if the exhaust vent

(both sides) and air intake (front panel) are blocked or the

fan is stopped.

Therefore, leave a blank space of more than 10 cm in the

front and both sides of the DVS-9000 series).

m

. As the inrush current at turn-on is a maximum 60 A (at

100 V)/110 A (at 230 V), the capacity of the AC power

source must be commensurate with this load.

If the capacity of the AC power is not adequately large,

the AC power source braker will operate or the unit will

abnormally operate.

. The DVS-9000 contains the two power supply units as

the standard configuration. A maximum of four power

supply units may be installed. When starting up the

DVS-9000, be sure to turn on the power of two or more

power supply units.

. The DVS-9000SF contains the single power supply unit

as the standard configuration. A maximum of two power

supply units may be installed. When starting up the

DVS-9000, be sure to turn on the power of one or more

power supply units.

1-2-2. Recommended Power Cord

w

. The power cord is not supplied with the DVS-9000

series.

Be sure to use the power cord that is applicable to places

in the area.

To avoid a fire or an electric shock, be sure to use the

designated power cord.

. Do not damage the power cord otherwise a fire or

electric shock may result.

1-2. Power Supply

1-2-1. Power Specifications

A switching regulator is used for the power supply of this

unit. The voltage within the range of 100 V to 240 V can

be used without changing the supply voltage.

Power requirements : AC 100 to 240 V ± 10 %

Power frequency : 50/60 Hz

Current consumption (when all options are installed) :

DVS-9000 : 8.6 to 4.2 A

DVS-9000SF : 5.5 to 2.5 A

DVS-9000/9000SF

For customers in the all European countries

1 Power cord, 250 V 10 A (2.4 m) : ! 1-782-929-21

1

AC inlet

1-1

1-3. Installation Space (External dimensions)

1-3. Installation Space (External dimensions)

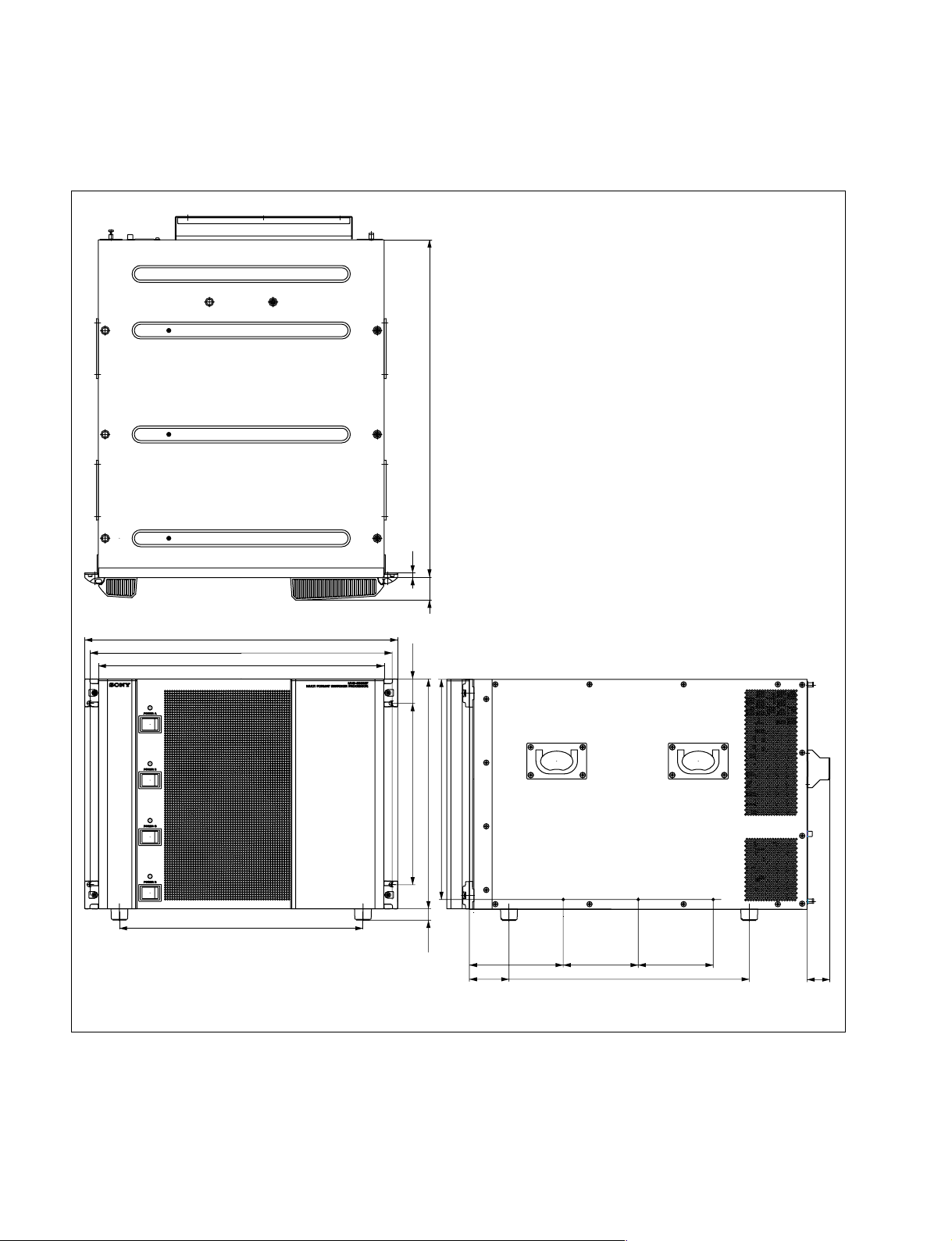

1-3-1. DVS-9000

520

482

465

440

375

7

35

37.6

279.4

354(8U)

17.5

339

144.5 115.5 115.5

61

370

35

1-2

Unit : mm

DVS-9000/9000SF

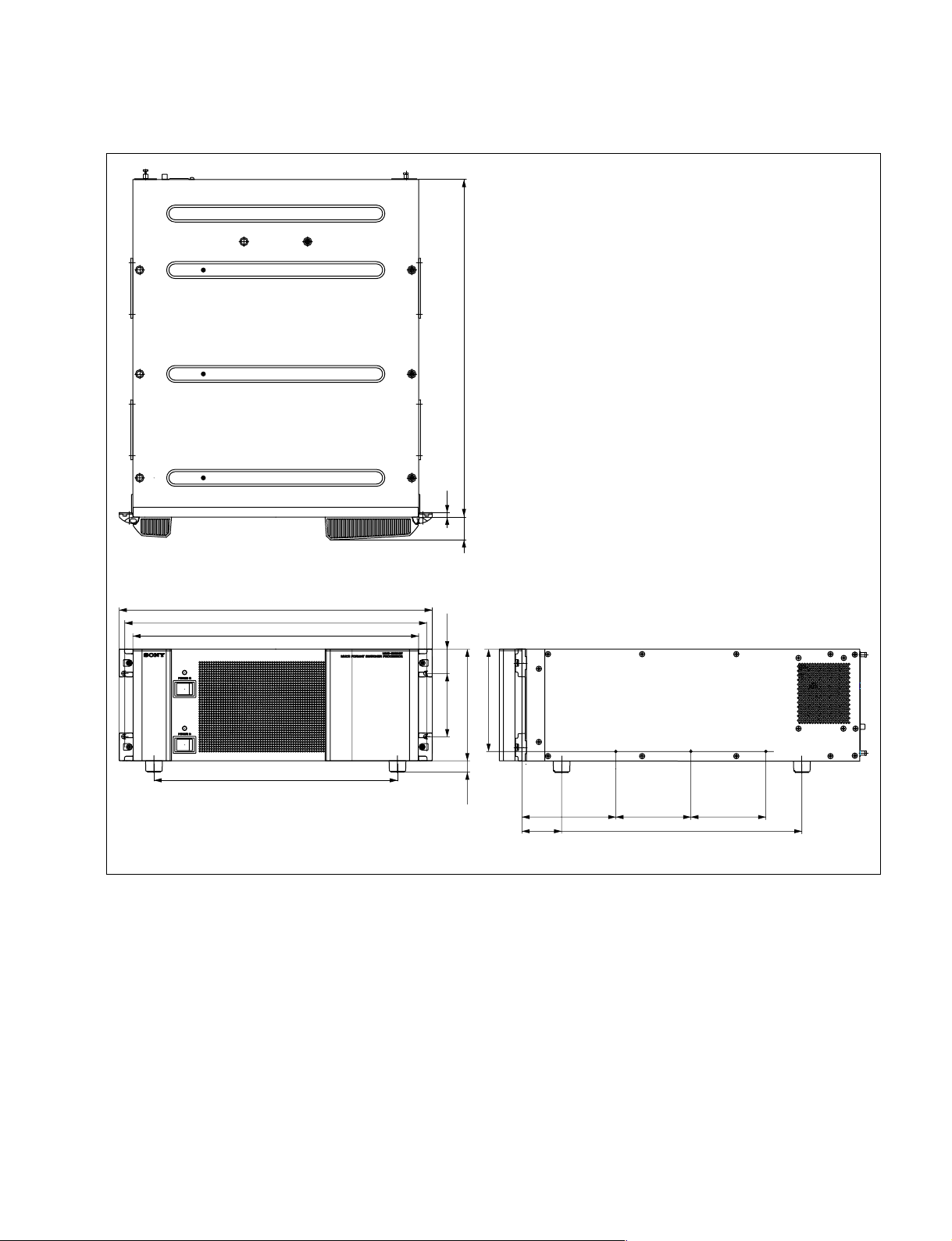

1-3-2. DVS-9000SF

1-3. Installation Space (External dimensions)

520

7

482

465

440

375

35

37.2

101.6

176(4U)

17.5

161

144.5 115.5 115.5

61

380

Unit : mm

DVS-9000/9000SF

1-3

1-4. Installing the Options

1-4. Installing the Options

The DVS-9000-C/DVS9000SF-C is shipped from the

factory with the necessary option boards (refer to the

following table) already installed in accordance with the

specified system configuration.

The following options are available for the DVS-9000/

9000SF.

DVS-9000/9000SF Option List

Model name

Plug-in board

BKDS-9160 (DVS-9000 only) OUT-26 board CNO-19 board

24 Output Board Set

BKDS-9161 (DVS-9000 only) _ CNO-20 board

8 Monitor Output Board

BKDS-9162 (DVS-9000SF only) _ CNO-19 board

12 Output Board

BKDS-9210 MIX-46 board _

Mix/Effect Board

BKDS-9470 DVP-24 board CN-2354 board

DME Board Set CA-54 board

MKS-8110SD _ CNI-10 board

17 Input Board

MKS-8111SD (DVS-9000 only) _ CNI-17 board

Additional 12 Input Board

HK-PSU04 __

Power Supply Unit

BZS-9250

Simple P/P Software

BZS-9420

Color Corrector Software

* : BZS-9250 and BZS-9420 are the software options.

*

*

__

__

Connector board

CN-2132C board

1-4-1. Installing the Plug-in Boards

Each plug-in board of the Production Switcher Processor

DVS-9000/9000SF is allocated to a specific slot into which

they must be installed. Check to see that the respective

plug-in boards are installed in their respective slots.

The name of the board is shown near the eject lever at the

left-most end of each plug-in board.

Names of the plug-in boards and the slot numbers, to

which the plug-in boards are allocated, are shown on the

Extract PWB stopper assembly inside the front panel of the

DVS-9000/9000SF. Install the respective plug-in boards

according to this instruction.

n

Check to see that connectors of the plug-in boards are

securely inserted into the mother board (DVS-9000 : MB985 board, DVS-9000SF : MB-986 board) without loose

contact.

If any plug-in board is inserted into the incorrect slot, it

causes a system error and the system will not work correctly.

c

Be sure to turn off the POWER switch before starting

installation work.

If installation work is started with the POWER switch left

on, it may cause electrical shock or damage to printed

circuit boards.

1-4

DVS-9000/9000SF

1-4. Installing the Options

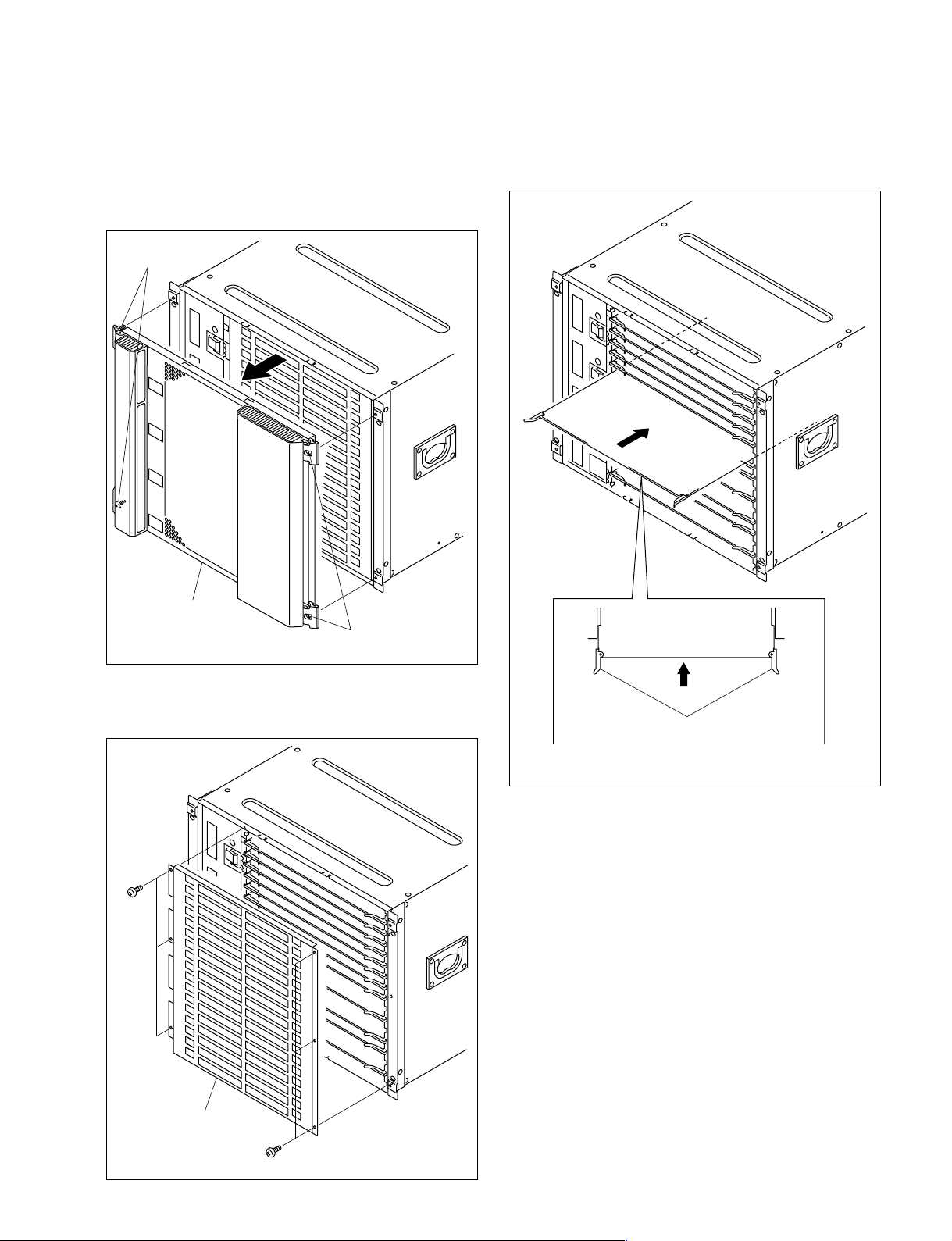

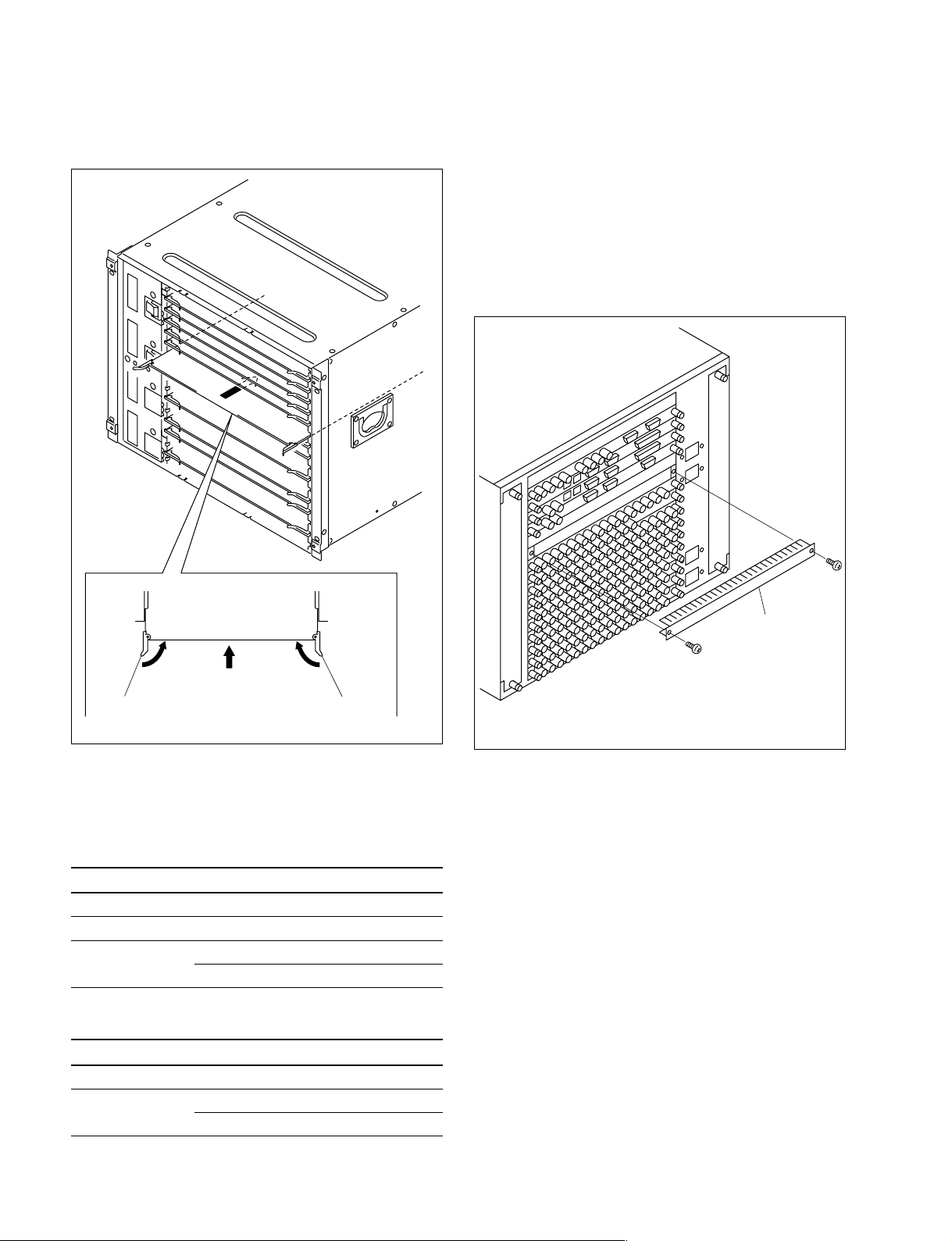

Installation Procedure

1. Turn off the main power of the DVS-9000/9000SF and

disconnect the AC power cord from the wall outlet.

2. Loosen the four screws (with drop-safe) and remove

the front panel to the arrow.

Screws

(with drop-safe)

4. While the eject levers are opened as shown in the

illustration, insert the plug-in board into the board

guide rail.

Front panel

Screws (with drop-safe)

(The illustration shows the DVS-9000.)

3. Remove the screws (DVS-9000: 6 screws, DVS-9000SF:

4 screws) and remove the Extract PWB stopper assembly.

B3 x 5

Eject levers

(The illustration shows the DVS-9000.)

Extract PWB stopper

assembly

DVS-9000/9000SF

B3 x 5

(The illustration shows

the DVS-9000.)

1-5

1-4. Installing the Options

5. While closing the eject levers in the direction of arrow

1, push in the plug-in board.

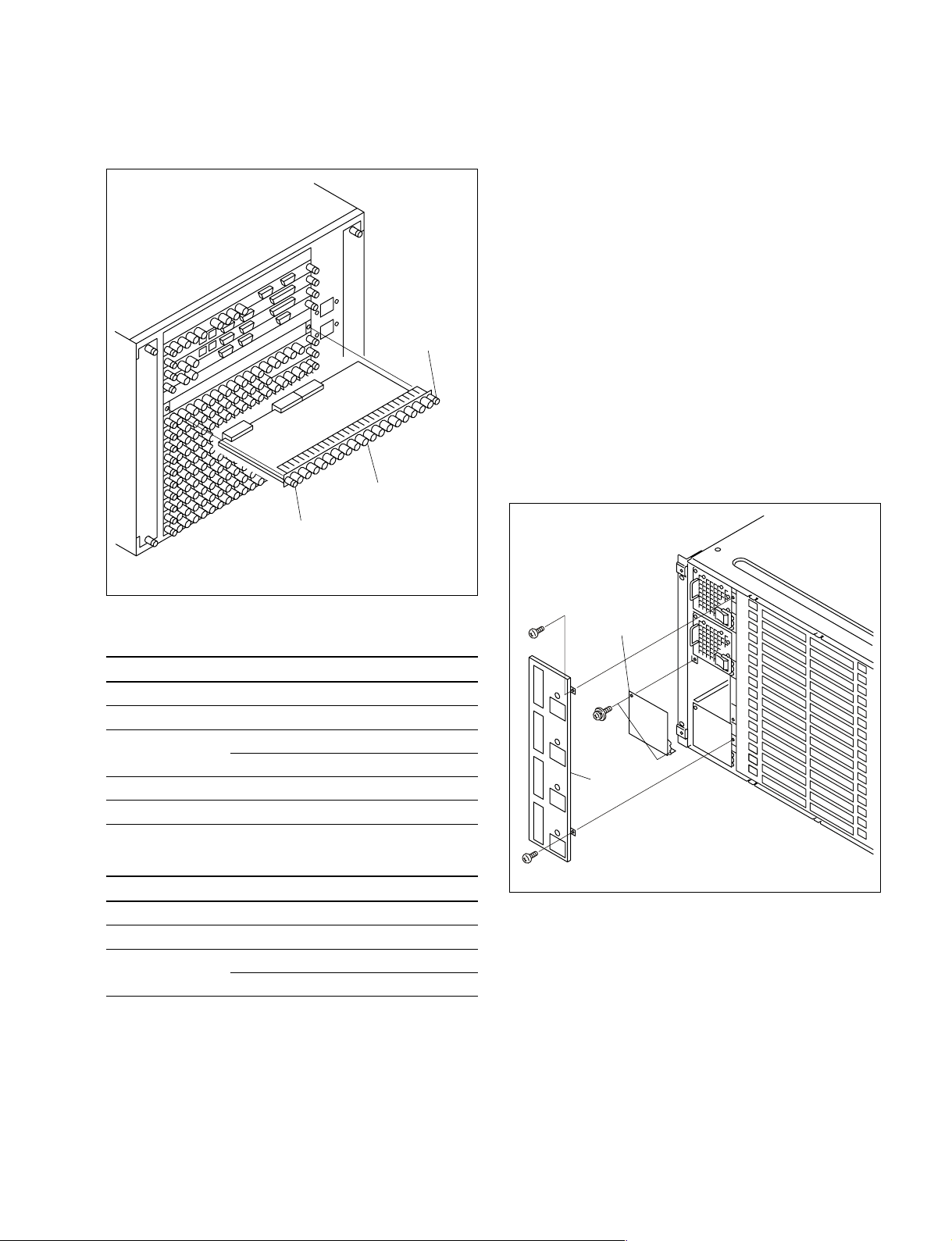

1-4-2. Installing the Connector Board

1. Remove the two screws and remove the blank panel.

m

. To install the connector board into the slot in which

the other board is installed already, loosen the two

fixing screws and remove the connector board that is

installed already.

. Store the removed blank panel in a safe place.

B3 x 5

1

Eject lever Eject lever

(The illustration shows the DVS-9000.)

1

6. Attach the plug-in board loose-proof assembly and the

front panel by reversing the installation steps of 2, 3.

DVS-9000 option

Name of option Name of board

BKDS-9160 OUT-26 board 16

BKDS-9210 MIX-46 board 6, 7

BKDS-9470 DVP-24 board 2

CA-54 board 3

Slot on the front side

DVS-9000SF option

Name of option Name of board

BKDS-9210 MIX-46 board 6

BKDS-9470 DVP-24 board 1

CA-54 board 2

Slot on the front side

Blank panel

B3 x 5

(The illustration shows the DVS-9000.)

1-6

DVS-9000/9000SF

1-4. Installing the Options

2. Insert the connector board horizontally level and

secure it with the two fixing screws.

Screws

(with drop-safe)

Connector board

Screws

(with drop-safe)

(The illustration shows the DVS-9000.)

1-4-3. Installing the HK-PSU04

The HK-PSU04 is used after it is installed in the DVS9000/9000SF.

n

Before installing the HK-PSU04, be sure to turn off the

main power. If the HK-PSU04 is installed while the main

power is turned on, it can result in electrical shock or

damage to printed circuit boards.

Installation procedure

1. Remove the front panel of the DVS-9000/9000SF.

(Refer to Section 1-4-1.)

2. Remove the two screws (B3 x 5) fixing the PS cover,

and remove the PS cover.

3. Remove the two screws (PSW3 x 6) fixing the blank

panel to the location where the HK-PSU04 is going to

be installed. Then remove the blank panel.

DVS-9000 option

Name of option Name of board

BKDS-9160 CNO-19 board 16, 17

BKDS-9161 CNO-20 board 8

BKDS-9470 CN-2354 board 2

CN-2132C board 3

MKS-8110SD CNI-10 board 11, 12, 13

MKS-8111SD CNI-17 board 9

Slot on the rear side

DVS-9000SF option

Name of option Name of board

MKS-8110SD CNI-10 board 8

BKDS-9162 CNO-19 board 6

BKDS-9470 CN-2354 board 1

CN-2132C board 2

Slot on the rear side

Blank panel

B3 x 5

PSW

3 x 6

PS cover

B3 x 5

(The illustration shows the DVS-9000.)

n

Store the removed blank panel in a safe place.

DVS-9000/9000SF

1-7

Loading...

Loading...