Page 1

www.soehnle

-

professional.com

Operation Manual

Terminal

3025

Page 2

2

Thank you for purchasing the Soehnle Professional Terminal 3025. This terminal was developed according to

the requirements of operational practice and offers you numerous possibilities to individually adapt the

weighing process to your needs in order to make your processes rational and cost-effective.

Please read the operating instructions carefully before use. Improper use could result in damage to you or

the terminal.

If you have any questions or have problems with your terminal that are not covered in this manual, please

contact your Soehnle Industrial Solutions service center or Soehnle Industrial Solutions Customer Service.

Telephone: +49 7191 3453-220

Fax: +49 7191 3453-211

E-Mail: info@sis.gmbh

For more information and documentation, see:

https://www.soehnle-professional.com/en/site/documents

Please go to the customer centre on our website www.soehnle-professional.com and select Terminal 3025

under Downloads / Industrial scales / Terminals.

Page 3

3

TABLE OF CONTENTS PAGE

1. GENERAL INFORMATION ........................................................................................................... 6

1.1 Purpose of use ..................................................................................................................................... 6

1.2 Safety instructions............................................................................................................................... 6

1.3 Cleaning ............................................................................................................................................... 6

1.4 Maintenance and service .................................................................................................................... 7

1.5 Warranty/Liability ................................................................................................................................ 7

1.6 Installation instructions ...................................................................................................................... 8

2. DEVICE DESCRIPTION ................................................................................................................ 9

2.1 Connection and device description .................................................................................................... 9

2.2 Technical data ..................................................................................................................................... 9

2.3 Symbols in the display ...................................................................................................................... 10

2.4 Calibration notes ............................................................................................................................... 11

2.4.1 Nameplate.................................................................................................................................. 11

2.4.2 Calibration counter .................................................................................................................... 11

2.5 Switching on / off .............................................................................................................................. 12

3. OPERATING CONCEPT ............................................................................................................. 13

3.1 Setting mode ...................................................................................................................................... 13

3.2 Program mode ................................................................................................................................... 14

3.3 Function keys ..................................................................................................................................... 14

3.4 Input and control keys ....................................................................................................................... 14

4. SETTING MODE ......................................................................................................................... 16

4.1 Calling up the setting mode .............................................................................................................. 17

4.2 Program settings ............................................................................................................................... 18

4.3 Setting mode – Terminal settings .................................................................................................... 19

4.4 Setting mode – Scale settings.......................................................................................................... 25

4.5 Setting mode – Communication settings ........................................................................................ 28

4.6 Setting mode – Service settings ...................................................................................................... 37

4.7 Reset terminal .................................................................................................................................... 37

5. BASIC FUNCTIONS ................................................................................................................... 38

5.1 Switch on............................................................................................................................................ 38

5.2 Switch off ........................................................................................................................................... 38

5.3 Program selection ............................................................................................................................. 38

5.4 Set to zero .......................................................................................................................................... 38

5.5 Tare function ...................................................................................................................................... 39

5.6 Gross display ..................................................................................................................................... 39

5.7 Scale switching .................................................................................................................................. 39

5.8 Tenfold display x10 ........................................................................................................................... 40

5.9 Hold function ..................................................................................................................................... 41

5.10 Auxiliary display ............................................................................................................................... 42

5.10.1 Second unit .............................................................................................................................. 44

5.11 Organisation data (Identifier) ......................................................................................................... 46

5.12 Alphanumeric input ......................................................................................................................... 49

5.13 Key lock ............................................................................................................................................ 50

5.14 User password ................................................................................................................................. 51

5.15 Login function / Process start function ......................................................................................... 51

5.16 SD - card data backup ..................................................................................................................... 56

6 APPLICATION PROGRAMS ....................................................................................................... 57

6.1 Selection of application programs ................................................................................................... 57

6.2 Function keys ..................................................................................................................................... 57

Page 4

4

6.3 Navigation in the application programs ........................................................................................... 58

6.4 Special programs............................................................................................................................... 58

6.5 Weighing and Taring ......................................................................................................................... 59

6.5.1 Function keys ............................................................................................................................. 59

6.5.2 Display view ............................................................................................................................... 59

6.5.3 Display information field ........................................................................................................... 60

6.5.4 Weighing without taring ............................................................................................................ 61

6.5.5 Manual taring ............................................................................................................................. 61

6.5.6 Taring with manual tare input ................................................................................................... 61

6.5.7 Multiplicative tare ...................................................................................................................... 62

6.5.8 Additive tare ............................................................................................................................... 62

6.5.9 Provisional tare .......................................................................................................................... 63

6.5.10 Automatic taring ...................................................................................................................... 63

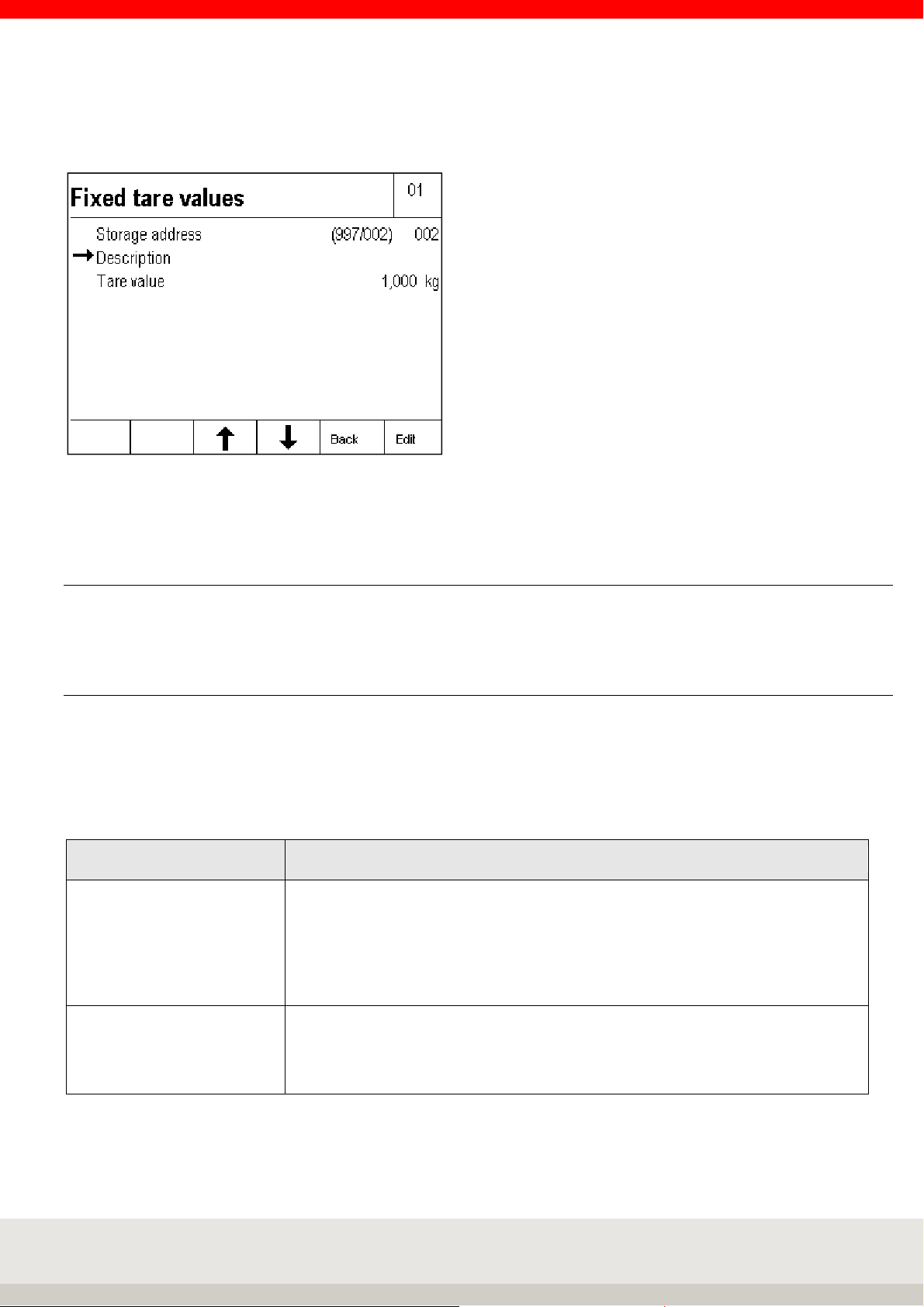

6.5.11 Fixed tare memory .................................................................................................................. 64

6.5.12 Error messages during taring ................................................................................................. 65

6.5.13 Display options with the Info key ............................................................................................ 65

6.5.14 Transfer of current values to the fixed memory .................................................................... 66

6.5.15 Organizational data (Identifier)............................................................................................... 66

6.5.16 Settings in the Setting Mode .................................................................................................. 67

6.6 Totalising and picking ....................................................................................................................... 69

6.6.1 Function keys ............................................................................................................................. 69

6.6.2 Display view ............................................................................................................................... 70

6.6.3 Display information field ........................................................................................................... 71

6.6.4 Tare function .............................................................................................................................. 71

6.6.5 Operating the totalising function .............................................................................................. 72

6.6.6 Selection options for the totals display.................................................................................... 73

6.6.7 Relief factor for totalising ......................................................................................................... 73

6.6.8 Auto total / pick ......................................................................................................................... 73

6.6.9 Reference scale for totalisation................................................................................................ 73

6.6.10 Assigning and deleting the sequential number ..................................................................... 74

6.6.11 Item counter ............................................................................................................................ 74

6.6.12 Print-triggering keys ................................................................................................................ 74

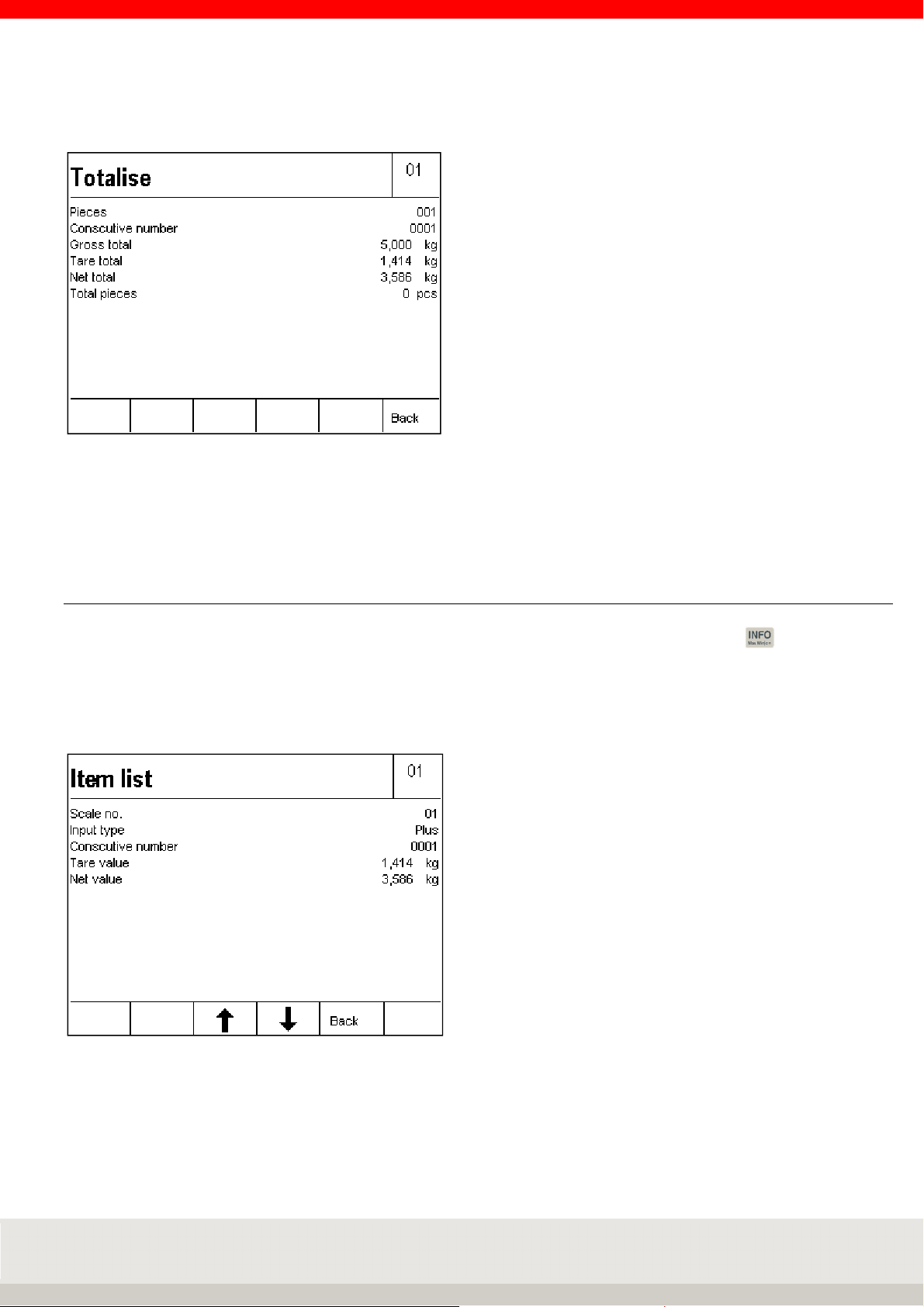

6.6.13 Display of current totals .......................................................................................................... 74

6.6.14 Display individual items .......................................................................................................... 75

6.6.15 Display options with the Info key ............................................................................................ 76

6.6.16 Transfer of current values to the fixed memory .................................................................... 76

6.6.17 Organizational data (Identifier)............................................................................................... 77

6.6.18 Settings in the setting mode ................................................................................................... 77

6.7 Counting ............................................................................................................................................. 79

6.7.1 Function keys ............................................................................................................................. 79

6.7.2 Display view Counting ............................................................................................................... 80

6.7.3 Display information field ........................................................................................................... 81

6.7.4 Tare function .............................................................................................................................. 81

6.7.5 Counting function ...................................................................................................................... 82

6.7.6 Totalising and Picking ............................................................................................................... 84

6.7.7 Reference statistics ................................................................................................................... 88

6.7.8 Piece control .............................................................................................................................. 89

6.7.9 Counting with several weighing bridges .................................................................................. 90

6.7.10 Counting accuracy................................................................................................................... 91

6.7.11 Display options with the Info key ............................................................................................ 93

6.7.12 Transfer of current values to the fixed memory .................................................................... 93

6.7.13 Organizational data (Identifier)............................................................................................... 94

6.7.14 Settings in the setting mode ................................................................................................... 95

Page 5

5

6.8 Checking ............................................................................................................................................ 99

6.8.1 Function keys ............................................................................................................................. 99

6.8.2 Display view ............................................................................................................................. 100

6.8.3 Display information field ......................................................................................................... 101

6.8.4 Tare function ............................................................................................................................ 101

6.8.5 Control function ....................................................................................................................... 101

6.8.6 Totalising and Picking ............................................................................................................. 104

6.8.7 Display options with the Info key ............................................................................................ 108

6.8.8 Transfer of current values to the fixed memory .................................................................... 108

6.8.9 Organizational data (Identifier) ............................................................................................... 109

6.8.10 Settings in the setting mode ................................................................................................. 109

7. ERROR MESSAGES ................................................................................................................. 113

8. ADDITIONAL INFORMATION .................................................................................................. 113

Page 6

6

1. GENERAL INFORMATION

1.1 Purpose of use

The Soehnle Professional Terminal 3025 is a calibratable terminal for use in scales and weighing systems

with standard DMS weighing and load sensors. Up to two analogue measuring points (scales) can be

connected internally at the same time. Another scale can be connected via the serial interface, e.g. as a

reference scale. Additional data can be entered via the keyboard. Various interface options are available for

connecting printers, EDP systems, readers, data storage devices and an external PC keyboard.

The Soehnle Professional Terminal 3025 is designed to work effectively in harsh environments. It is robust,

easy to clean, flexible and fast. Its logical structure and user guidance allow quick familiarisation and

intuitive work at the terminal. Its design adapts to your individual requirements and supports you in your task.

1.2 Safety instructions

Before operating the terminal, please read the information listed in the operating instructions carefully. They

contain important information for the installation, intended use and maintenance of the terminal.

The manufacturer is not liable if the following instructions are not observed:

If electrical components are used under increased safety requirements, the relevant regulations must be

observed. Never service the terminal while it is live. The warranty does not apply in the event of improper

installation.

> The Terminal 3025 must not be used in hazardous or explosion-endangered areas.

> The permissible mains voltage is 100 - 240 volts.

The socket must be earthed and easily accessible.

> The terminal may only be opened by trained Soehnle Industrial Solutions service technicians.

There are no user serviceable parts in the housing. In case of external intervention your warranty

claim expires.

> Repairs and the replacement or installation of parts may only be carried out by a trained

Soehnle Industrial Solutions Service Center.

> If the power cord is damaged, the terminal must not be operated. Interrupt the power supply and

call a Soehnle Industrial Solutions service center.

> If the terminal is used in custody transfer applications, the do not damage the attached safety

markers.

Contact your Soehnle Industrial Solutions service partner if you have any problems.

1.3 Cleaning

A damp cloth and commercially available cleaning agents are sufficient for cleaning.

Do not use abrasive or corrosive agents.

Page 7

7

1.4 Maintenance and service

Note:

These devices comply with the applicable EC Directives 2014/31/EU, 2014/30/EU, 2014/35/EU and

EN45501. However, under extreme electrostatic and electromagnetic influences, e.g. when operating a radio

or mobile phone in the immediate vicinity of the equipment, the scale may be affected.

At the end of the disturbance influence, the product can again be used as intended,

If necessary, a restart is necessary. In case of permanent electrostatic interference, we recommend

grounding the terminal housing and the platform.

The terminal is a measuring instrument. Drafts, vibrations, rapid temperature changes and solar radiation can

affect the weighing result. The terminal complies with protection class IP 67. Very high humidity, vapours,

aggressive liquids and heavy soiling must be avoided.

1.5 Warranty/Liability

Insofar as Soehnle Industrial Solutions is responsible for a defect in the delivered item, Soehnle Industrial

Solutions shall be entitled either to remedy the defect or to deliver a replacement. Replaced parts shall

become the property of Soehnle Industrial Solutions.

If the rectification of the defect or replacement delivery fails, the statutory provisions shall apply.

The warranty period begins on the day of purchase. Please keep the invoice as proof. If service is required,

please contact your dealer or Soehnle Industrial Solutions customer service.

In particular, no warranty is given for damage caused for the following reasons arise:

Unsuitable, improper storage or use, faulty assembly or commissioning by the customer or by third parties,

natural wear and tear, changes or interventions, faulty or negligent treatment, in particular excessive strain,

chemical, electrochemical, electrical influences or moisture, provided that these are not due to a Soehnle

Industrial Solutions' debt.

If operational, climatic or other influences should lead to a significant change in the conditions or the

condition of the material, the warranty for the faultless overall functioning of the equipment is void. Insofar

as Soehnle Industrial Solutions provides a guarantee in individual cases, this means that the delivery item is

free from defects during the guarantee period. Please keep the original packaging for any return transport.

Page 8

8

1.6 Installation instructions

Please check packing and terminal for external damage. Do not operate a visibly damaged terminal, but

inform your dealer. Please keep the packaging for possible shipment.

The terminal is designed for rough commercial use. However, it is a sensitive instrument whose performance

can be affected by unfavourable environmental factors.

After unpacking or transport, acclimatize for 2 hours at room temperature.

The permissible ambient temperature is -10° to +40° C.

The place of installation is a decisive factor for the functioning of your scale.

Protect the terminal as far as possible from shocks, vibration, strong heat or cold, temperature fluctuations,

draughts, chemicals and moisture by selecting the appropriate installation location.

Page 9

9

2. DEVICE DESCRIPTION

2.1 Connection and device description

2.2 Technical data

Passage

membrane

I/O interface

Interface 1

Interface 2

Interface 3

Interface 4

Measuring point 1

Measuring point 2

Ethernet

Grounding Power supply

> Stainless steel housing, protection class IP 67, integrated power supply 100 - 240 V AC, 50/60 Hz

> Membrane keypad with a total of 32 keys, 6 function keys, 4 organisation data keys, alphanumeric

input via numeric keypad

> Connection option for external PC keyboard

> Colour display TFT 3.5" QVGA, dot matrix 320 x 240 pixels dimmable backlit

> Option: Soehnle Professional Micro-SD card (high-quality SLC memory card), memory capacity: fixed

memory for a total of 999 fixed values across programs, alibi memory for 4 million entries and for

software updates

> Interfaces: 1 x RS 232 or USB in the basic version.

> Internal with R232, USB and Ethernet, 2 additional interface slots (RS232).

> Option: IO card for 6 outputs and 4 inputs freely assignable

> Working temperature: -10° C to +40° C

> 1 analogue measuring point in the basic version, 1 additional analogue measuring point can be

connected

internally. Calibratable resolution 10,000,000 e, internal resolution 16,000,000 d

> Verifiable according to accuracy class III and IIII for n = 10 000 e with multi-range and multi-interval

scales

> Smallest permissible input signal per calibration value = 0.2 µV, Load cell impedance 40 Ohm

to 1,245 Ohm

> Connection of a digital reference scale via RS232 interface

Page 10

10

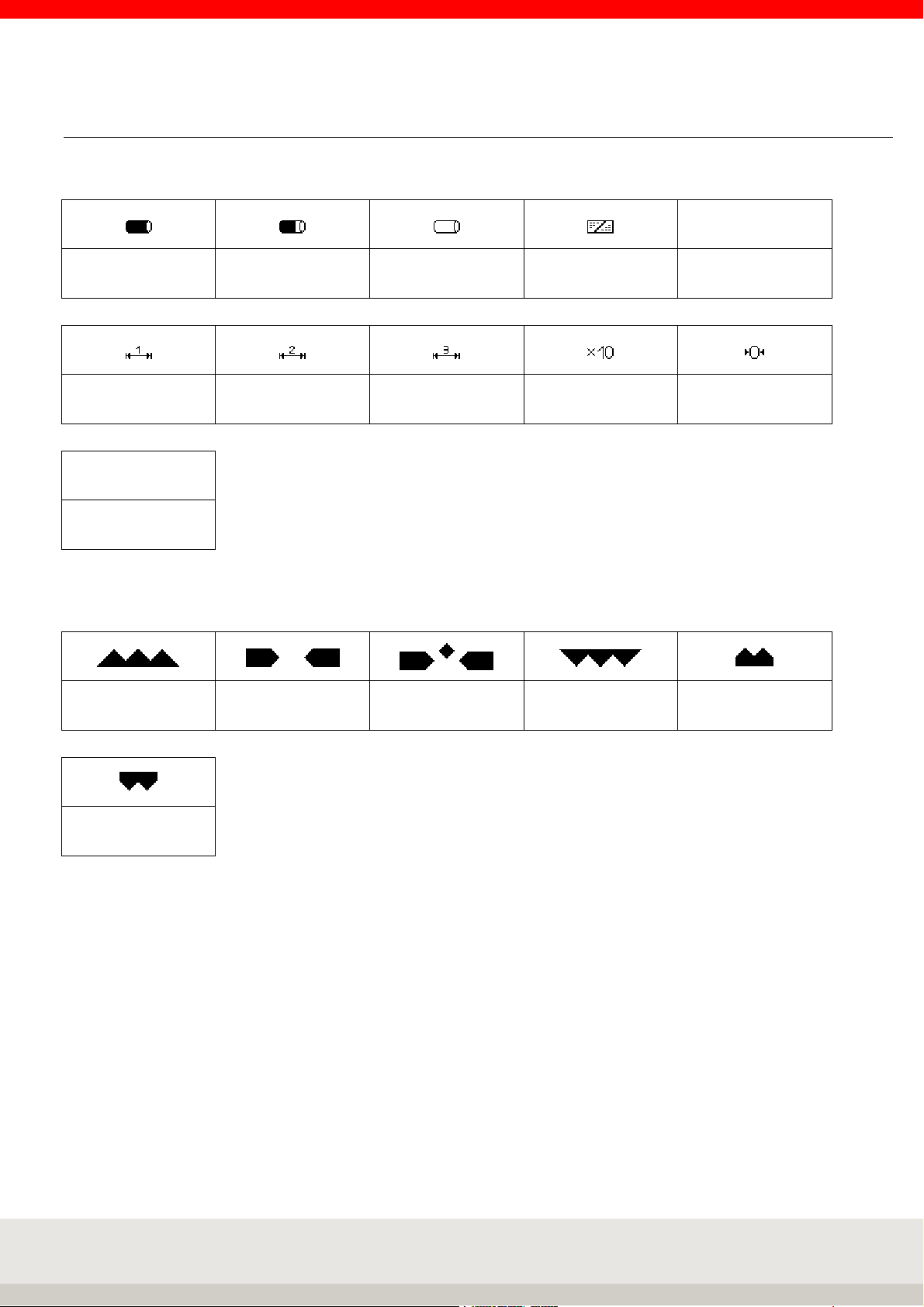

2.3 Symbols in the display

Symbols in the display toolbar

Alibi memory

fill level 100%

Alibi memory

fill level 80%

Alibi memory fill

level empty

Key lock Data logger

Multi range 1 Multi range 2 Multi range 3 Resolution X10 Zero

HLD

Hold function active

Symbols in the information field of the display

LOG

Below tolerance Within tolerance

Setpoint reached

exactly

Above tolerance Under minimum load

Above upper limit

class 5

Symbol for standstill

After the sample has been placed on the scale, it needs time to settle.

As long as no stability has been reached, the dimension symbol (kg, g) is hidden.

If stability has been reached and a stable value is available, this is indicated by the dimension sign fading in.

Page 11

11

2.4 Calibration notes

The scope of this information is Germany. In other countries, conformity with national laws must be checked.

Terminal 3025 is approved within the EU for Class III and IIII custody transfer.

It corresponds to the type described in the type approval as well as to the applicable requirements of

Directives 2014/31/EU, 2014/30/EU, 2014/35/EU and EN 45501.

In accordance with legal requirements, calibrated scales must be recalibrated at regular intervals. Please

contact a Soehnle Industrial Solutions service center or your local calibration office.

Do not under any circumstances damage the official seals, otherwise the calibration validity will expire.

2.4.1 Nameplate

The terminal has an electronic nameplate.

Display after pressing the Info button:

Gross

Brutto/

/Net

Netto

Weight value

Gewichtswert

Max

Min

e=

SNR XXXX/XX-XXXX Eichz: XXXX IDENT-Chip

F 1 F 2 F 3 F 4 F 5 F 6

Dimension

Dimensions-

symbol

zeichen

01

2.4.2 Calibration counter

The calibration counter indicates how often a scale has been calibrated. The stored counter reading must

match the calibration counter reading secured by a sticker. The current calibration counter reading can be

displayed in the setting mode under Scale / Scale parameters for each connected scale.

Page 12

12

2.5 Switching on / off

Switch on:

Press the ON/OFF button .

When switching on, the logo, terminal type 3025, filter type and the detected measuring points are briefly

displayed during the start routine.

The scale is set to zero after power-up.

When the scale is switched on, the last application program used is reactivated.

Switch-on zero setting limits:

Approvable: Switch-on zero range 20 % of the weighing range.

The default value is -5% to +15% of the weighing range. Optional: extended range on request.

Non-approvable: the switch-on zero range can be from -99% to +99% of the weighing range.

If the scale is switched on outside the power-on zero range, an error message is displayed.

If the terminal is not approvable, it then goes directly into weighing mode, while if it is approvable, you can

use the zero key to jump to weighing mode. The current weight value is then displayed with the previously

stored zero point. If you remove the cause of the underload or overload, the scale will go to zero and is ready

for operation without having to be switched on again.

Backlight and colour

Can be adjusted in: Setting mode / Terminal / Display.

The default setting is 80% for the backlight and white for the background colour.

Behaviour in case of power failure

The scale returns to the state it was in when the power was restored.

Switch off

Press the ON/OFF button .

If the connected measuring point is loaded, or if you have called up a menu, the scale does not switch off

until you press the ON/OFF key for 3 seconds.

It is not possible to switch off the scale while it is waiting for an entry in the editing area of the setting mode.

To switch off the scale, you must leave the editing area.

OFF-display

In the setting mode Service (incl. password prompt) /General/OFF display, you can set whether the word

"OFF" appears in the display when the terminal / scale turned off Default setting is "with OFF display".

Page 13

13

3. OPERATING CONCEPT

The operating concept is divided into two functional areas:

• Setting mode

• Program mode

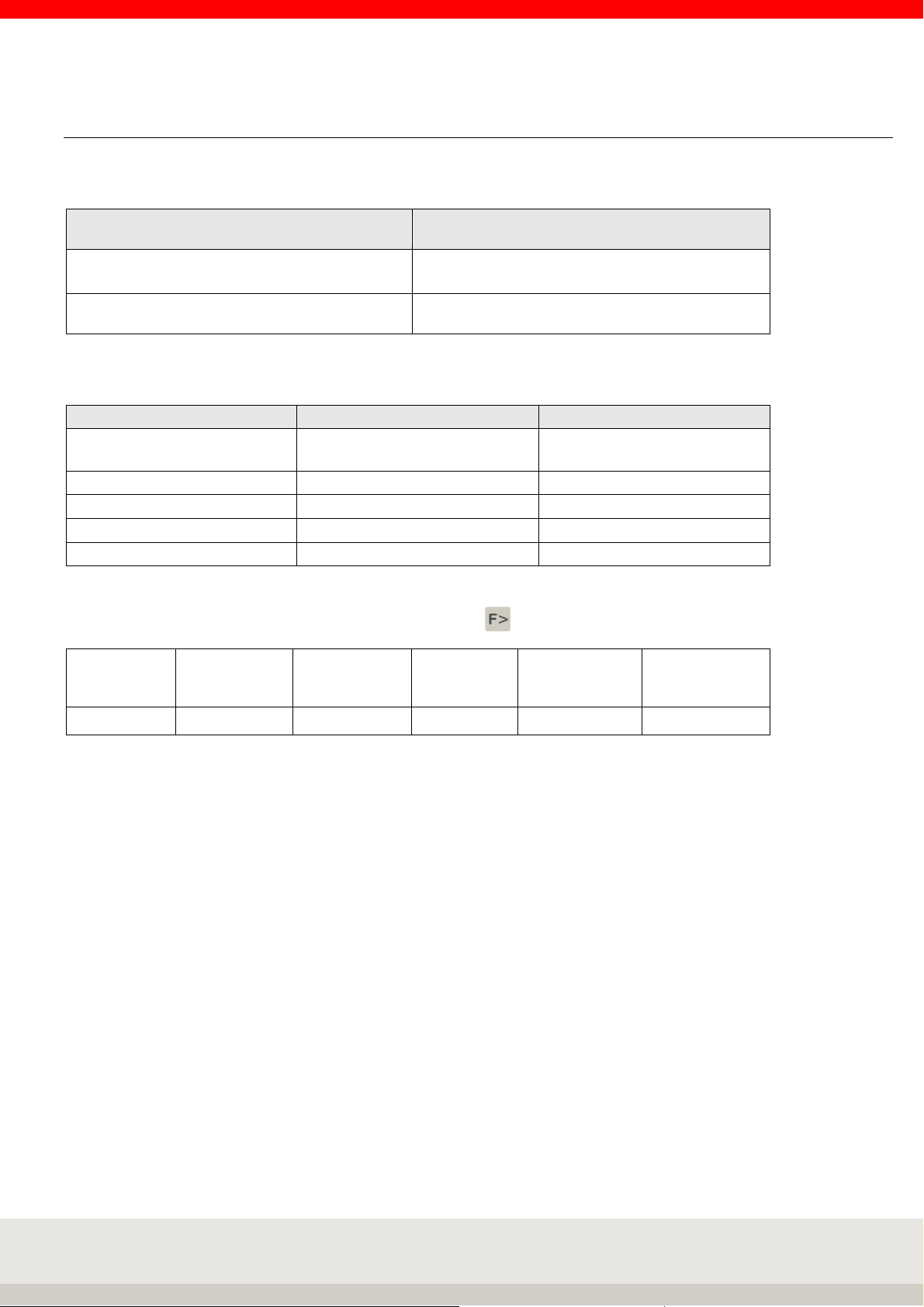

3.1 Setting mode

Here you can make individual settings on the terminal to optimize the scale for your requirements.

Table setting mode:

Program settings

Weighing + taring

Totalising and picking Display

Counting

Checking

I/O port programming Organizational data USB

Terminal

Version

Keypad

Date/Time

Error memory

User password

Log in function

Reset terminal

Setting mode

Scale Communication

Scale parameter Alibi memory

Allocation table

measuring points

Reference points

for calibration

Internal measuring

point

Ethernet

Print template

Data processing settings

Barcode

Interface 1 RS232 (internal) service-

Interface Port 2

Interface Port 3

Service

for

Specialists

only

SD card

data backup

Batch processing

IO control

Page 14

14

3.2 Program mode

Select the desired weighing application program here. Once you have selected the application program and

called it up, the scale is ready to weigh.

3.3 Function keys

The function keys F1 to F6 are available for calling the functions.

These assume different functions depending on the program and situation. The respective function is shown

in the display in the function bar above the key.

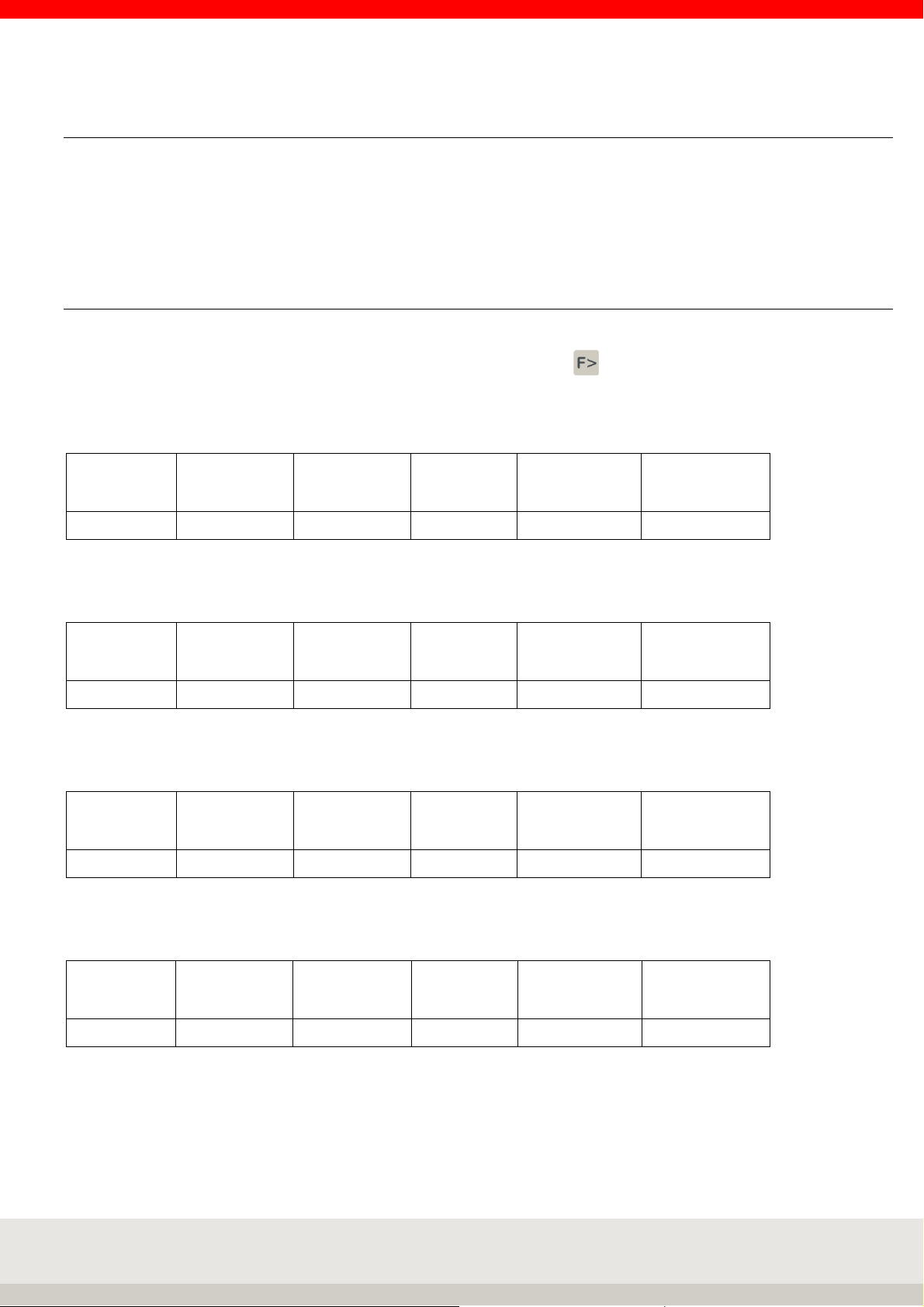

Depending on the program, the function keys are assigned in up to 4 levels, the change through the levels

takes place rolling with the function change key .

Navigation with the function keys

↑ Move the marker up in the list.

↓ Move the marker down in the list.

End Exiting the setting mode

Continue Call of the marked menu item

Back Return to superordinate level

Cancel Return without accepting a change

Delete Deleting an item with a return jump

Accept Acceptance of an entry or change

→ Cursor to the right

← Cursor to the left

3.4 Input and control keys

The following additional keys are available for input and control:

Numeric keys for entering numerical values,

Multiple assignment of the number keys for entering letters

Call organizational data

Delete the complete input or reset the functions

Delete the last digit

Page 15

15

Auxiliary

display

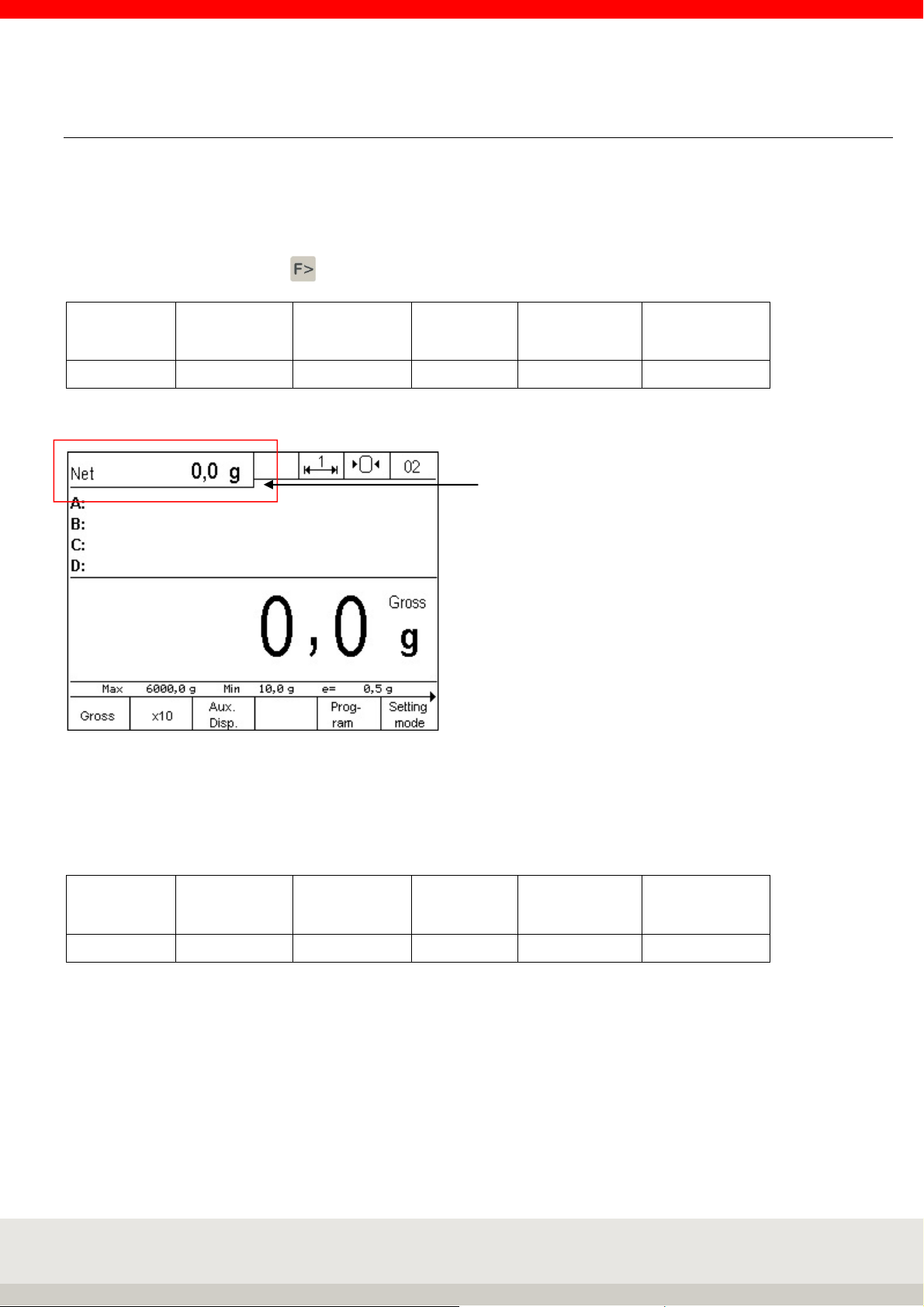

Symbol bar

Display field

Range display

Info key, electronic nameplate with approval data,

Calling information about the application programs

Function change key

Scale change key

Tare key

Zero setting key / delete tare

Enter key

Print key

On / Off

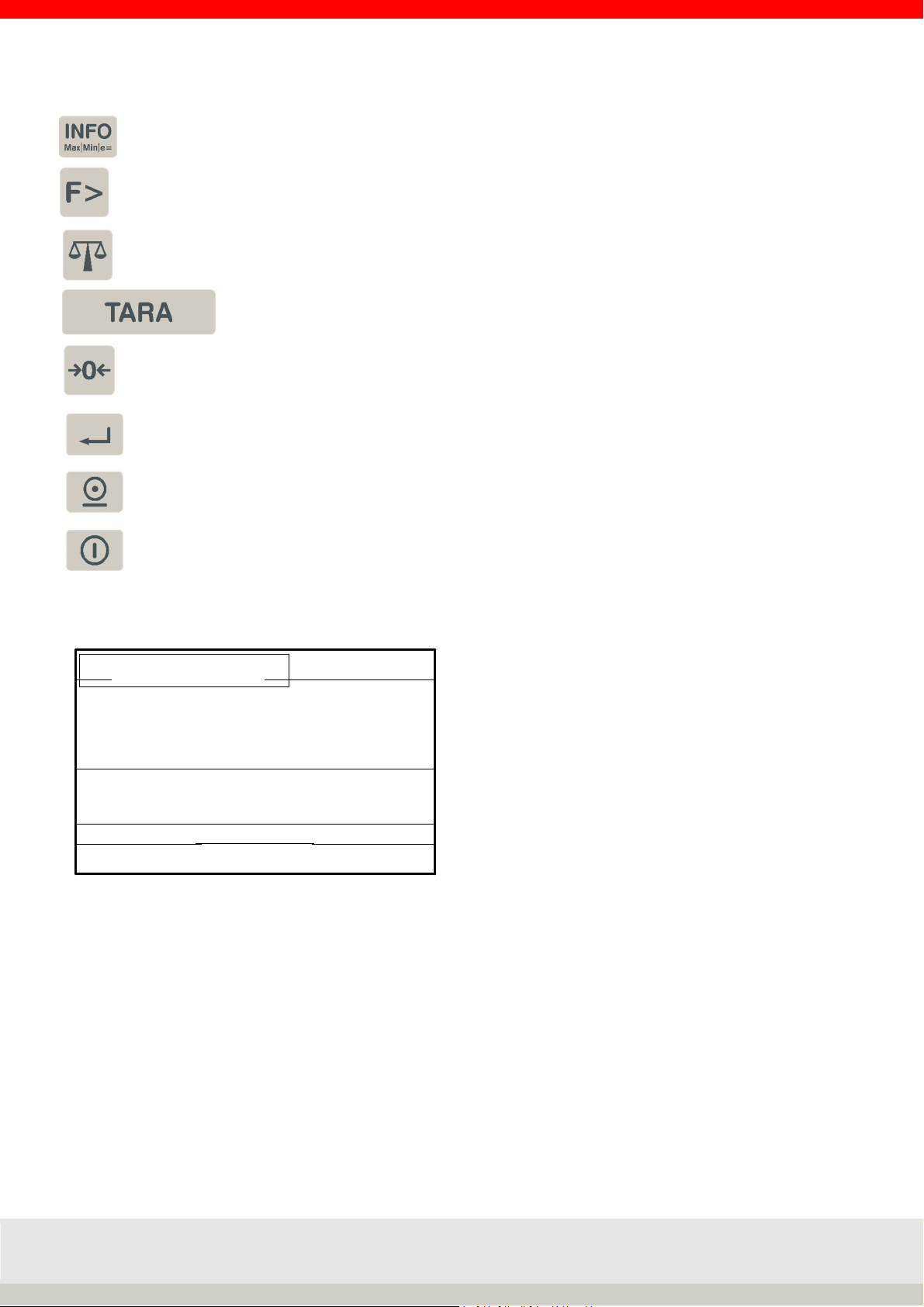

Display:

The display shows different views depending on the situation.

It is divided into the following display fields:

NEBENANZEIGE

INFORMATIONSFELD

Information field

ANZEIGEFELD

BEREICHSANZEIGE

FUNKTIONSLEISTE

SYMBOLLEISTE

Auxiliary display:

Displays additional information and can be set individually under Terminal / Display.

Can be switched on and off by pressing the F3 key.

Symbol bar:

Shows information on the status of the connected measurement loop.

Information field:

Shows organizational data, totals during totalising, special control characters, classes during classification,

operator guidance, switching points depending on situation or individually adjustable.

Display field:

Displays weight value, number of pieces, dimension indicator

Range display:

Displays the current weighing range with Max / Min / e (d).

Function bar:

Functions of the 6 situation-dependent assigned function keys

Page 16

16

4. SETTING MODE

The setting mode stores program and weighing parameters that can be called up and individually configured.

Adjustment can be made by entering data or selecting from predefined parameters.

The individual parameters are stored in logical groups within a multi-level family tree structure.

Note:

Setting Mode structure:

The modification options may be limited in the legal metrology sector.

Program settings

Weighing + taring

Totalising and picking Display

Counting

Checking

I/O port programming Organisation data

Terminal

Version

Keypad

Date/Time

Error memory

User password

Log in function

Reset terminal

Setting mode

Scale Communication

Scale parameter Alibi memory

Assignment table for

measuring points

Reference points

for calibration

internal measuring

point

USB

Ethernet

Print template

Data processing settings

Barcode

Interface 1 RS232 (internal) service-

Interface Port 2

Interface Port 3

Service

for

Specialists

only

SD card

data backup

Batch processing

IO control

Page 17

17

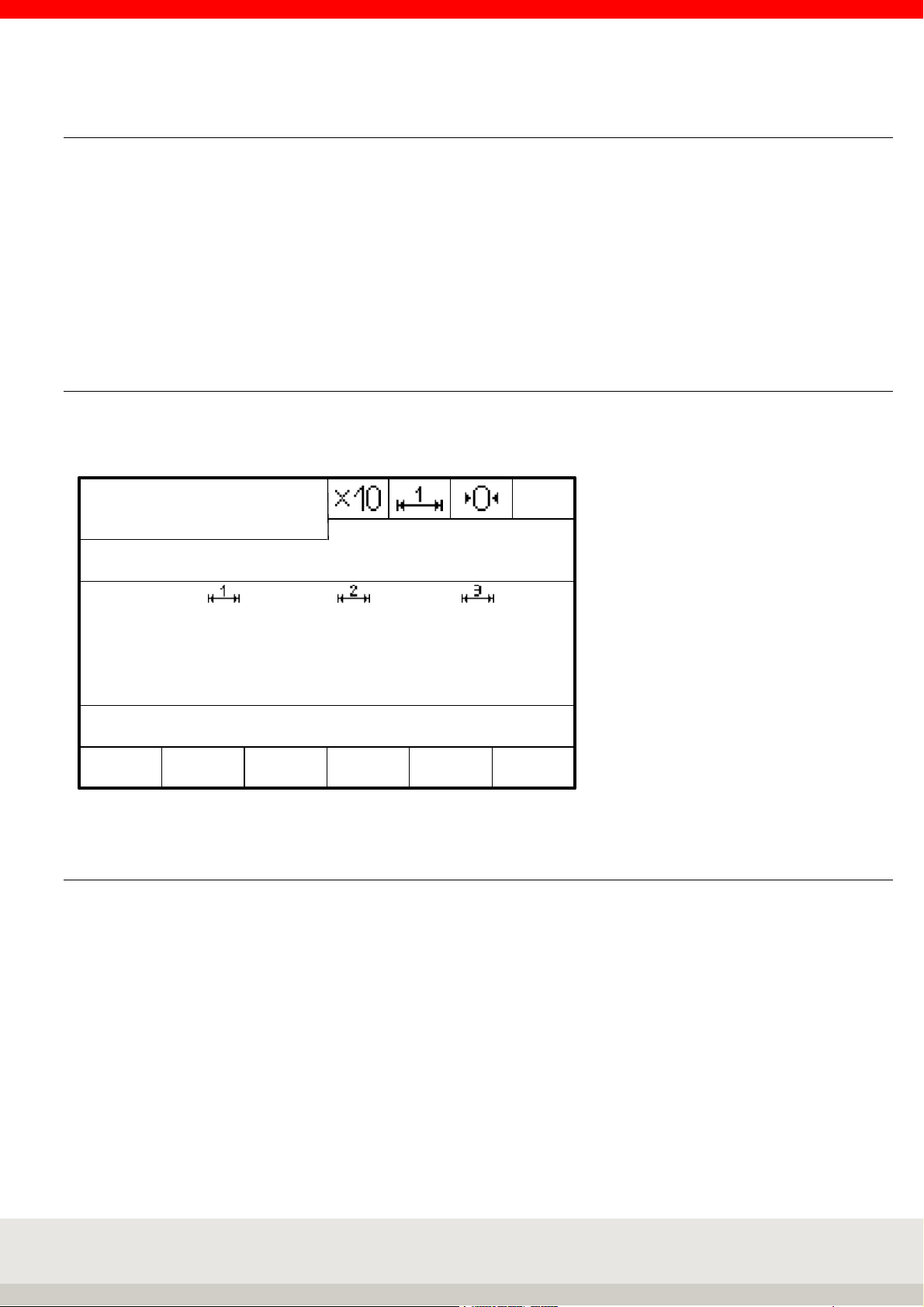

4.1 Calling up the setting mode

Switch on the terminal.

After the power-on routine, the terminal will automatically start the application program that was last

activated. To call up the setting mode, use the function change key to switch to the setting functions

level.

Function keys:

Level Setting functions

Gross x 10

F 1 F 2 F 3 F 4 F 5 F 6

Auxiliary

display

Program

Press the F6 Setting Mode key.

You are now in the selection menu Setting mode.

Navigation in Setting Mode:

The function keys F1 to F6 are available for controlling the functions.

They assume different functions depending on the program and situation.

The respective function is shown on the display in the function bar.

Meaning of the function keys:

↑ Move the marker up in the list.

↓ Move the marker down in the list.

End Exiting the setting mode

Continue Call of the marked menu item

Back Return to superordinate level

Cancel Return without accepting a change

Delete Deleting an item with a return jump

Accept Acceptance of an entry or change

→ Cursor to the right

← Cursor to the left

Setting

Mode

Page 18

18

Entries in the setting mode:

In most cases, you make a selection from the various settings offered.

For editable values, numeric or alphanumeric input is possible via the keyboard.

Service area:

The Service area is protected by a password.

The contained parameters can only be maintained by trained service personnel.

Please contact your Soehnle Industrial Solutions service center.

4.2 Program settings

In the Program Settings setting mode, you can adapt the user programs of your scale to your specific

requirements. How to activate the application programs and their typical applications are described in Part 6

Application Programs.

1 Weighing + taring

Settings and parameters see chapter 6.5.16

2 Totalising and picking

Settings and parameters see chapter 6.6.18

3 Counting

Settings and parameters see chapter 6.7.14

4 Checking

Settings and parameters see chapter 6.8.10

5 I/O port programming (Dynamic switching)

Settings and parameters see manual chapter 6.9.11

Page 19

19

4.3 Setting mode – Terminal settings

In the setting mode under Terminal you will find the following query and setting options

1 Version

Bootloader Software Query software status

LRS Software Query software status

User software Query software status and filter type

Serial number central board Query the factory-set serial number

Character set Character set (in later version as selection):

- Latin 1

Print parameter Output of all setting parameters of the terminal incl. the currently connected

measuring point via the interface with the use "EDP 2 (unidirectional)".

2 Display

Backlight Input

Setting luminosity, input in percent via numeric keypad

30% is darker, 100% is full luminosity

Factory setting: 80%.

Background colour Selection

Background colour setting

> green

> white

> light blue

> yellow

> blue

> magenta

> red

Factory setting: white

Language Selection

1. language German (factory setting)

2. language English or other languages

can be customized via the Soehnle Professional service program.

Page 20

20

2 Display

Auxiliary display Selection

> Second unit

> Tare value

> x10 Resolution

> Gross/net

> Current weight

> Reference quantity

> Reference weight

> Setpoint

> Difference to setpoint

> Signal light

Factory setting: Second unit

Decimal separator Selection

Comma, dot or none.

Factory setting: Decimal point

Thousands separator Selection

for separators only for counted quantity display

Comma, dot or none.

Factory setting: None

3 Keypad

Keypad key Single, multiple or all keys can be locked on the keyboard.

By pressing the key to be locked, the status of the key can be changed from open

to locked and vice versa.

Press the Enter key to save and exit for 3 seconds.

Key tone Selection off or on

Keyboard confirmation beep

Factory setting: off

Validation tone Selection off or on

Receipt beep (e.g. error message or transfer)

Factory setting: off

Keyboard layout Selection German or French

Layout for PC keyboard assignment and keyboard looping via the USB interface

connection

Factory setting: German

Page 21

21

4 Date / time

Time Input via numeric keypad, clock starts to run Press the Enter key

Date Input via numeric keypad

Date format Selection European or imperial date

Factory setting: European

Use-by period (Days)

Input via numeric keypad in days [d]

Factory setting: 0 d

5 Organisation data

Description ORG A Input

Name of the organizational data memory A

Numbers or plain text via keyboard, e.g. "Article no." max. 12 characters

Description ORG B Input

Name of the organizational data memory B

digits or plain text via keyboard, max. 12 characters

Description ORG C Input

Name of the organizational data memory C

digits or plain text via keyboard, max. 12 characters

Description ORG D Input

Name of the organizational data memory D

digits or plain text via keyboard, max. 12 characters

Page 22

22

5 Organisation data

ORG data A fixed values Selection of existing fixed values from the database

Scroll with the arrow keys F3 and F4.

Call the desired fixed value with F6 Edit.

Editing an existing fixed value from the database

Press F6 to call up editing of the selected fixed value.

Parameter number is marked, call via F6 Edit, input via numeric/alpha keyboard.

Accept the entry with F6.

(Cancel without accepting the entry with F5 Back)

Parameter Entry is highlighted, call via F6 Edit, input via numbers/alpha keyboard.

Accept the entry with F6.

(Cancel without accepting the entry with F5 Back)

Delete an existing fixed value

Scroll with the arrow keys F3 and F4.

Delete the marked fixed value with F2 Delete.

The resulting gap in the consecutive numbering is closed.

Create new fixed value

Press F1 New.

The memory location number is assigned by the terminal. The first number in

brackets indicates the free memory locations, the second number the occupied

memory locations.

Parameter number is marked, call via F6 Edit, input via number/alpha keyboard.

Accept the entry with F6.

(Cancel without accepting the input with F5 Cancel)

Parameter entry is marked, call via F6 Edit, entry of entry 1 to 6 via numbers/alpha

keyboard. Accept the entry with F6.

(Cancel without accepting the entry with F5 Cancel)

Exiting the database

Press F5 back to exit the list.

Note: the optional Micro SD card (Alibi memory) is required to use the fixed values.

ORG data B fixed values As ORG data A fixed values

ORG data C fixed values As ORG data A fixed values

ORG data D fixed values As ORG data A fixed values

Call fixed values Selection of whether the fixed value is called up via consecutive memory location

number or article number.

Factory setting: Article number

Page 23

23

6 Error memory

Error list Request the error list with position, date, time of last error, number of errors, error

number and description. Scroll back using the arrow keys or F5.

Protocol memory Query the list of the download protocol memory with position, date, time, code no.

and description. Scroll back using the arrow keys or F5.

7 User password

New / Edit Input alphanumeric

Password with up to 8 characters via keyboard

After activation, access to the setting mode and the program selection is only

possible by entering the correct password.

If the password is forgotten, the entry CLEAR gives one-time access.

Clear Deletes the password and gives access again

8 Login function

Activation Selection on or off

Factory setting: off

Password request Selection on or off

Factory setting: off

Create/change password Input of the internal terminal password

System alphanumeric via the numeric keypad.

Password with up to 35 characters.

After activation, access is via a password query, e.g. after switching on the

terminal or after logging off by pressing the

C button for 3 seconds.

Delete password Press the F6 Continue key to delete the password.

Enter login text Enter the login query text

Alphanumerically via the numeric keypad.

Text length up to 35 characters.

9 Reset terminal

Reset terminal Selection execute or do not execute

Execute deletes all individual settings of the terminal and resets to factory

settings. Scale parameters, read-only memory and the print image are not reset.

Page 24

24

10 SD card data backup

Import By accepting F6 Next the current user settings are loaded from the micro SD card.

The security prompt Import comes with YES or NO. If NO is selected, no data is

loaded.

Export The current user settings are saved on the micro SD card by accepting F6

Continue.

Export for autom. import The current user settings are saved on the micro SD card and the setting

parameters are automatically reloaded in the event of a software problem.

Page 25

25

4.4 Setting mode – Scale settings

In the first step, select the scale (measuring point) with the scale change key,

for which you want to make settings.

Only connected and active scales (measuring points) are displayed for selection.

The settings and queries are made individually for each scale (measuring point).

All setting and query options are identical for all scales (measuring points).

In the setting mode under Scale, you will find the following query and setting options

1 Scale parameters

Calibration counter Query

of the current value of the calibration counter

Calibratable Query off or on

Note: Approvable can mean limited selection if parameter settings contain options

relevant to approval.

Selection only possible in the service area, subject to approval.

Filter settings Selection

> Service setting (direct modification of filters possible in the service area)

> Livestock scale

> Calm

> Normal

> Troubled

Factory setting: Service setting

The selection function is only possible with the release user filter setting in the

service area.

Hold mode Selection

> not active: no hold function

> Still/key: Hold at stability outside zeroing range,

Cancel by pressing the power button

> Still/empty: Hold at standstill outside zeroing range,

Cancel by relieving the load on the scale

> Max/key: Hold at maximum value reached,

Cancel by pressing the power button

> Max/empty: Hold at maximum value reached,

Cancel by relieving the load on the scale

> Drag/key: Hold when weight is increased and stability is reached,

Cancel by pressing the power button

> Drag/empty: Hold when weight is increased and stability is reached,

Cancel by relieving the load on the scale

Factory setting: not active

Zero tracking Query off or on

off: no zero tracking

on: Correction of drift on scale to zero

Zero tracking verifiable: 0.5 d/s

Zero tracking not verifiable: 2 d/s

Selection only possible in the service area, subject to calibration

Page 26

26

1 Scale parameters

Zero range at power-on Query off or on

When the scale is turned on, it sets the zero range of the weighing range to zero

when the power is turned on.

Selection only possible in the service area, subject to calibration.

Auto tare Selection off or on

off: No auto tare

on: Automatically tares the first weight value above the empty signal after stability

on the scale.

Factory setting: off

Additive tare Selection off or on

off: New tare overwrites old tare

one: New taring adds new tare to the existing tare.

Please note: The function Tare totalising on has an influence on tare sequences

and totals. The description in the manual always refers to the Total tare setting.

Factory setting: off

Second unit Selection

> g

> t

> lb

> mg

> oz.

Can be activated as auxiliary display function in the display via key F3 Auxiliary

display in weighing mode.

In the selection, the adjusted unit is not displayed as the first unit.

Empty message Input

of the percentage of the weighing range in which the empty message is displayed.

Enter the percentage using the numeric keypad.

(Info: Empty message is not shown on the display.)

Factory setting: 0.10 %.

Check mode Query or input off or on

on switches on a 10-fold higher resolution in the display constantly and

deactivates the x10 key.

Only possible with non-verifiable scales.

Serial number MP Query of serial number Measuring point (MP)

Software version MP Query of the software status of the measuring point (MP)

Page 27

27

For the measuring point numbers hardware addressing (system) variable new user - measuring point

numbers (user) can be assigned.

Select the desired system address Sys: xx with the arrow keys, then with F6 Next enter the desired new user

address Use: xx, then accept with F6.

With the user address Use: 00, the system address is automatically used.

Multiple assignment of the same measuring point numbers is possible.

2 Allocation table for measuring points

Sys: 01 Use: 10

Sys: 02 Use: 00

Sys: 00 Use: 00

Sys: 00 Use: 00

Sys: 00 Use: 00

Sys: 00 Use: 00

System No. 01 User No. 10 (new measuring point no. = 10)

System No. 02 User No. 00 (measuring point no. = 02)

System No. 00 User No. 00

System No. 00 User No. 00

System No. 00 User No. 00

System No. 00 User No. 00

Querying the calibration points helps service personnel to check the scale.

3 Reference points for calibration

Zero point raw measured

value

Current raw measured value Query of the current raw measured value (variable depending on the load on the

Reference point 1

weight value

Reference point 1

raw measured value

Query of the adjusted raw measured value from the zero point

scale)

Query of the weight value from the 1st support point

Query of the adjusted raw measured value from the 1st support point

Reference point 2

weight value

Reference point 2

raw measured value

Reference point 3

weight value

Reference point 3

raw measured value

Reference point 4

weight value

Reference point 4

raw measured value

Query of the weight value of the 2nd support point

Query of the adjusted raw measured value from the 2nd support point

Query of the weight value of the 3rd support point

Query of the adjusted raw measured value from the 3rd support point

Query of the weight value of the 4th support point

Query of the adjusted raw measured value from the 4th support point

The internal measuring point is located on the central board of terminal 3025 with measuring point number 01.

Page 28

28

4 Internal measuring point

Operating mode Query or selection off or on

With off the internal measuring point is deactivated with on measuring point 01 is

active.

Factory setting: on

4.5 Setting mode – Communication settings

In the setting mode under Communication you will find the following query and setting options

1 Alibi memory

Memory capacity Query

Memory size 4.000.000 = 100%

(Display only with integrated and activated alibi memory)

Memory used Query

of the currently occupied filling level incl. percentage display (e.g. 162 = 0%)

Find (single input) Search

Single entry via input consecutive number

Find function Search

Multiple entries by entering oldest and youngest consecutive number

Search (additional field) Search

Single entry via input contents additional field

Assignment of additional

data

Selection

> None

> Barcode

> Org data A

> Org data B

> Org data C

> Org data D

> Date/Time

> Price labelling (special software)

2

Usage of serial interface Selection

Interface 1 RS232 (internal)

(Further details see also interface description 470.508.090)

> none

> 2795.14

> 2795.12+2795.20

> Data processing

> EDP 2 (unidirectional)

> Barcode

> Second / large display

> Digital scale

If the device is already used via another interface output, this selection position is

displayed with disabled.

Factory setting: 2795.14

Page 29

29

2

Baud rate Selection

Data bits Selection

Parity Selection

Xon/Xoff Selection

Interface 1 RS232 (internal)

(Further details see also interface description 470.508.090)

> 1200

> 2400

> 4800

> 9600

> 19200

> 38400

Factory setting: 9600

> 7

> 8

Factory setting: 8

> none

> even

> odd

Factory setting: none

off or on

Factory setting: off

Factory settings Selection

Do not execute: Individual settings on the interface are retained

Execute: Resets interface to factory setting

3

Usage of serial interface Selection

Baud rate Selection

Interface Port 2

(Further details see also interface description 470.508.090)

> none

> 2795.14

> 2795.12+2795.20

> Data processing

> EDP 2 (unidirectional)

> Barcode

> Second / large display

> Digital scale

If the device is already used via another interface output, this selection position is

displayed with disabled.

Factory setting: none

> 1200

> 2400

> 4800

> 9600

> 19200

> 38400

Factory setting: 9600

Page 30

30

3

Data bits Selection

Parity Selection

Xon/Xoff Selection

Factory settings Selection

Interface Port 2

(Further details see also interface description 470.508.090)

> 7

> 8

Factory settings: 8

> none

> even

> odd

Factory settings: none

off or on

Factory settings: off

Do not execute: Individual settings on the interface are retained

Execute: Resets interface to factory setting

4

Interface Port 3

(Further details see also interface description 470.508.090)

Usage of serial interface Selection

> none

> 2795.14

> 2795.12+2795.20

> Data processing

> EDP 2 (unidirectional)

> Barcode

> Second / large display

> Digital scale

If the device is already used via another interface output, this selection position is

displayed with disabled.

Factory setting: none

Baud rate Selection

> 1200

> 2400

> 4800

> 9600

> 19200

> 38400

Factory setting: 9600

Data bits Selection

> 7

> 8

Factory setting: 8

Parity Selection

> none

> even

> odd

Factory setting: none

Page 31

31

4

Xon/Xoff Selection

Factory settings Selection

Interface Port 3

(Further details see also interface description 470.508.090)

off or on

Factory setting: off

Do not execute: Individual settings on the interface are retained

Execute: Resets interface to factory setting

5

USB mode Selection

USB

(Further details see also interface description 470.508.090)

> none

> 2795.14

> 2795.12+2795.20

> Data processing

> EDP 2 (unidirectional)

> PC keyboard

> Keyboard wedge

> Data logger

If the device is already used via another interface output, this selection position is

displayed with disabled.

Factory setting: none

6

Use of Ethernet Selection

IP Address Input

Subnet Mask Input

Gateway Input

IP Port Input

Ethernet

(Further details see also interface description 470.508.090)

> none

> Data processing

If the device is already used via another interface output, this selection position is

displayed with disabled.

Factory setting: none

IP Address

Factory setting: 010.010.005.005

Subnet Mask

Factory setting: 255.255.255.000

Standard Gateway

Factory setting: 010.010.005.012

IP Port

Factory setting: 23

MAC Address Query

of the MAC Address

Page 32

32

6

Deactivate MAC Addressbypass

Ethernet

(Further details see also interface description 470.508.090)

Selection

off or on

Automatic transmission of UDP-MAB message for recognition of our scale (for

content, see User Mode 470.702.112)

Factory setting: off

7 Print template

Request printout (OK) Selection on or off.

With On, after each printout, you are asked whether the printout was OK.

If this is denied, the printout is repeated until OK is confirmed.

Factory setting: off.

Print when G+T = 0 Selection on or off.

Off: No printout if scale is empty.

Factory setting: on

Decimal separator Selection

Comma, dot or no.

Factory setting: Decimal point

Thousands separator Selection

Comma, dot or no.

Factory setting: none

Hide unit Selection on or off.

Off: Unit is not suppressed.

Factory setting: off

Consecutive number

print key

Clear values after printout Input

Factory settings Selection

Input

The number for the first print image can be entered here. If the value zero is

entered, the function is not active. As of number 1, the value is increased by one

after each output using the print key.

Operation according to interface description 470.508.090

Do not execute: Individual settings for print image settings are retained

Execute: Resets the print image setting to the factory setting.

Page 33

33

for EDP mode unidirectional (terminal automatically triggers the selected

8

Data processing mode Selection for EDP mode (terminal automatically triggers the selected data set)

EDP data set Selection for the format of the EDP data record

EDP data set <I> Selection

Data processing settings

(Further details see also interface description 470.508.090)

> no

> A: Send data record 1 x immediately

> B: Send data record 1 x at standstill + change

> C: Send dataset after change / standstill

> D: Send data record change / standstill / empty

> E: Send data record change / standstill / <>Empty

> F: Send data record continuous

> G: Send data record 3005 continuous

> H: Send data record 1 x at standstill

Factory setting: none

> EDP print template (variable)

> EDP dataset S20

> EDP data set 2790 v2.10

> EDP data set Easylog

Factory setting: EDP print template (variable)

The default setting according to the interface description 470.508.090 or freely

configurable via the service software.

off or on

Factory setting: off

(with one the data record with the print image <I> is sent automatically via the EDP

interface after each standstill, design of print image <I> via service software

required)

EDP mode unidirectional Selection

data set)

> none

> A: Send data record 1 x immediately

> B: Send data record 1 x at standstill + weight change

> C: Send dataset after change/standstill.

> D: Send data record change/standstill/> empty

> E: Send data record change/standstill/<|>empty

> F: Send data record continuously

> G: Send data record 3005 continuously

> H: Send data record 1 x at standstill

Factory setting: none

Data packet time frame Input

Time interval for data packets via interface

Input via numeric keypad in ms

Factory setting: 100 ms

Decimal separator Selection

Comma, dot or none.

Factory setting: Decimal point

Thousands separator Selection

Comma, dot or none.

Factory setting: None

Remote control disable Selection (current without function, conversion in later expansion stage)

off or on

Factory setting: off

Page 34

34

8

EDP with STX-ETX Selection

Factory settings Selection

Data processing settings

(Further details see also interface description 470.508.090)

off or on

Factory setting: off

Do not execute: Individual EDP settings are retained

Execute: Resets EDP settings to factory settings

9 Barcode (further details see also manual 3025 Chapter 7.9)

Decimal separator numerical Selection off or on

Factory setting: on

Show barcode timer Input

Time display barcode numeric via numeric keypad

Factory setting: 2500 ms

Selection filtering number Input

Filter number numeric via numeric keypad

Factory setting: 1

Control character filter no. 01 Input

Code Control character numeric via numeric keypad

Factory setting: 0

First position filter no. 01 Input

Start filter position numeric via numeric keypad

Factory setting: 1

Last position filter no. 01 Input

End of filter position numeric via numeric keypad

Factory setting: 70

Multiscan number Input

of the number of multiple scans from 0 to 4 using the numeric keypad

Factory setting: 0

Code 1.Scan (ORGA) Input

control commands from interface description 3025 (Document 470.508.090D)

Factory setting: 0

Code 2.Scan (ORGB) Input

control commands from interface description 3025 (Document 470.508.090D)

Factory setting: 0

Code 3.Scan (ORGC) Input

control commands from interface description 3025 (Document 470.508.090D)

Factory setting: 0

Code 4.Scan (ORGD) Input

control commands from interface description 3025 (Document 470.508.090D)

Factory setting: 0

Page 35

35

9 Barcode (further details see also manual 3025 Chapter 7.9)

Multiscan timer Input

of the time via the numeric keypad of the multiple scans for the capture of the

barcodes, after exceeding the Multiscan is aborted and no captured barcode

content is set.

Factory setting: 2500 ms

Filter for Scan (ORGA) Input

of the first three positions of the scan content for ORGA scan possible. Filtering

enables the clear allocation to the ORGA memory, so that the order of the scan

processes does not play a role with the Multiscan. Possible entries are A-Z for

letters, 0-9 for numbers and special characters, which can be entered via the

keyboard of the terminal 3025.

Factory setting: - | - | - -

Filter for scan (ORGB) Like filter for scan (ORGA) valid for filter for scan (ORGB)

Filter for scan (ORGC) Like filter for scan (ORGA) valid for filter for scan (ORGC)

Filter for scan (ORGD) Like filter for scan (ORGA) valid for filter for scan (ORGD)

10 Batch processing (further details see also manual 3025 Chapter 7.10)

Batch code 1 Input

Control commands from interface description 3025 (document 470.508.090D)

Factory setting: 0

Batch code 2 Input

Control commands from interface description 3025 (document 470.508.090D)

Factory setting: 0

Batch code 3 Input

Control commands from interface description 3025 (document 470.508.090D)

Factory setting: 0

Batch code 4 Input

Control commands from interface description 3025 (document 470.508.090D)

Factory setting: 0

Batch code 5 Input

Control commands from interface description 3025 (document 470.508.090D)

Factory setting: 0

Batch code 1 parameter

source

Selection

> No parameter

> ORGA-memory

> ORGB-memory

> ORGC-memory

> ORGD-memory

> Barcode-memory

> Barcode-buffer memory

Factory setting: no parameter

Batch code 2 parameter

source

Batch code 3 parameter

source

as Batch code 1 parameter source

as Batch code 1 parameter source

Page 36

36

10 Batch processing (further details see also manual 3025 Chapter 7.10)

Batch code 4 parameter

source

Batch code 5 parameter

source

Batch activation key Selection

Pause between

batch code 1 - 2

Pause between

batch code 2 - 3

Pause between

batch code 3 - 4

Pause between

batch code 4 - 5

as Batch code 1 parameter source

as Batch code 1 parameter source

> No key

> Print key

> Enter key

Factory setting: No key

Input

Time for the pause between the batch codes, numeric via numeric keypad

Factory setting: 100 ms

Input

Time for the pause between the batch codes, numeric via numeric keypad

Factory setting: 100 ms

Input

Time for the pause between the batch codes, numeric via numeric keypad

Factory setting: 100 ms

Input

Time for the pause between the batch codes, numeric via numeric keypad

Factory setting: 100 ms

Pause after end Input

Time for the pause at the end, numeric via numeric keypad

Factory setting: 100 ms

11 IO-control (further details see also manual 3025 Chapter 7.11)

IO - mode Selection

> off

> on

> on, safety function

Factory setting: off

Outputs Selection for the assignment of the individual switching points

> Switching point S1

> Switching point S2

> Switching point S3

> Switching point S4

> Switching point S5

> Switching point S6

Factory setting: all not active

Inputs Selection for the assignment of the individual inputs

> Input E1

> Input E2

> Input E3

> Input E4

Factory setting: all not active

Page 37

37

4.6 Setting mode – Service settings

The Service area is protected by a password.

The contained parameters can only be maintained by trained service personnel.

4.7 Reset terminal

To reset all settings (except scale parameters and service area) of the terminal back to the factory settings,

you can perform a reset of the terminal with the selection in the Setting mode / Terminal / Reset Terminal

and press the function key F6 Continue.

Page 38

38

5. BASIC FUNCTIONS

5.1 Switch on

The detailed description for switching on the terminal can be found in chapter 2.5 on page 12..

5.2 Switch off

The detailed description for switching off the terminal can be found in chapter 2.5 on page 12.

5.3 Program selection

Selection from the available application programs.

Use the function change key to switch to the setting functions level.

Gross x 10

F 1 F 2 F 3 F 4 F 5 F 6

Auxiliary

display

Prog-

ram

Setting

mode

Press the F5 Program key.

You now have a choice of 6 different application programs.

Select the program: F3 up arrow key / F4 down arrow key

Start the selected program: Press F6 to confirm.

For information on all user programs, see Chapter 6.

5.4 Set to zero

Zeroing corrects small deviations from the zero point, e.g. due to contamination of the scale.

Press the zeroing key .

The following character appears in the toolbar when zero is displayed:

Zero range calibratable and non-calibratable: -1 to +3% of weighing range.

If zeroing is not possible, the error message "Above zero range" or "Below zero range" appears for two

seconds.

Zero tracking

Zero tracking automatically corrects small deviations from the zero display.

In the setting mode, you can activate or deactivate zero tracking under

Setting mode / Scale / Scale parameters / Zero tracking

(on = 0.5 d/sec verifiable and 2d/sec not verifiable).

Page 39

39

5.5 Tare function

Tare is the delta of gross and net weights.

For a detailed description of taring, refer to the Weighing and Taring application program on page 59, section

6.5.

5.6 Gross display

Display of gross weight with tared scale

Use the function change key to switch to the setting functions level.

Gross x 10

F 1 F 2 F 3 F 4 F 5 F 6

Auxiliary

display

Prog-

ram

Setting

mode

Press the F1 Gross key.

As long as you hold down the key, the gross weight appears in the display with the message Gross.

5.7 Scale switching

Switch between several connected scales.

Up to two analogue measuring points can be installed in the 3025 display unit. It is also possible to connect a

digital scale via the RS232 interface with measuring point no. 30. Switching between the connected

measuring points can be done manually or automatically.

Manual switching:

Press the button briefly. The connected measuring points are connected one after the other.

Press and hold the button long .

An input field opens, the measuring point number can be directly entered and accepted.

Automatic switchover: For description see program Counting in chapter 6.7.9.

The display shows the number of the connected measuring point in the toolbar on the right.

The Info key sequence can be used to display the data of the connected measurement loop. By pressing the

key combination Info/ scale changeover, the data of other connected measuring points can be viewed one

after the other.

The following data are displayed:

> Max, Min, e (d)

> Serial number measuring point (additionally if activated)

> Calibration counter

> Ident- Chip (additionally if activated)

Page 40

40

5.8 Tenfold display x10

Displays the weight value with another decimal value in 10 times higher resolution.

Use the Function Change key to switch to the Setting Functions level.

Gross x 10

F 1 F 2 F 3 F 4 F 5 F 6

Auxiliary

display

Prog-

ram

Setting

mode

Press the key F2 x10.

Approvable scale

If the scale has been calibrated for legal metrology, the resolution is ten times higher as long as the x10 key

is held down. After the key is released, the x10 display switches to the following position 5 seconds.

Non-approvable scale

If the scale is not calibrated for legal metrology, the resolution is ten times higher and appears constantly in

the display. Pressing a key switches on the tenfold higher resolution. Pressing the key again switches the

tenfold higher display off again.

As long as the tenfold higher display is active, X10 appears in the toolbar. The function is deactivated when

the device is switched off.

In the setting mode, you can constantly switch on the tenfold higher display for a weighbridge.

The function Setting mode / Scale / Scale parameters / Check mode / on constantly activates the x10

display and deactivates the x10 key.

Prerequisite: The scale cannot be calibrated. The factory setting is "off".

Page 41

41

5.9 Hold function

In setting mode, a hold function can be activated separately for each connected measuring point

Setting mode / Scale / Scale parameters / Hold mode.

The following hold functions are available for selection:

> Not active: Hold is deactivated.

> Still/key: Hold at standstill outside empty message,

Cancel by pressing the power button

> Still/empty: Hold at standstill outside empty message,

Cancel by relieving the load on the scale

> Max/key: Hold at maximum reached value with stability outside empty signal,

higher weight sets new hold, cancel by switch-on button

> Max/empty: Hold at maximum reached value with stability outside empty signal,

higher weight sets new Hold, lift by relieving the scale

> Drag/key: Hold at each increase of the weight without stability outside empty message,

higher weight sets new hold,

Cancel by pressing the power button

> Drag/Empty: Hold at every increase of the weight without stability outside empty signal,

higher weight sets new hold,

Cancel by relieving the scale.

This function is effective in all application programs.

To activate the selected setting of the hold function, the terminal must first be restarted.

When the hold function is activated, holding a weight value in the toolbar is indicated by the HLD symbol in

the toolbar.

Page 42

42

Auxiliary

display activated

.

5.10 Auxiliary display

Displays additional information, such as second units, weight values when counting, differences from the

target value, etc.

Activating and deactivating the auxiliary display

Use the function change key to switch to the setting functions level.

Gross x 10

F 1 F 2 F 3 F 4 F 5 F 6

Auxiliary

display

Prog-

ram

Setting

mode

Press the F3 key for the auxiliary display.

Setting the auxiliary display

To set the function of the auxiliary display, first switch to the setting functions level with the function change

key.

Gross x 10

F 1 F 2 F 3 F 4 F 5 F 6

Press the F6 Setting Mode key.

Use the arrow keys F3 and F4 to move to the Terminal item in the list and select it by pressing the F6 "

Continue " key.

Now move to Display with the arrow keys and select it with the F6 " Continue " key.

Now select the submenu Auxiliary display by pressing the arrow keys and the F6 " Continue " key.

Auxiliary

display

Prog-

ram

Setting

mode

Page 43

43

When you call the submenu Auxiliary display, the system displays a list of possible applications:

You can move in the list with the arrow keys F3 and F4.

Functions of the auxiliary display

The following function states can be set in the submenu auxiliary display:

> Second unit

> Tare value

> x10 Resolution

> Gross/net

> Current weight

> Reference quantity

> Reference weight

> Setpoints

> Difference to setpoint

> Signal light

Note: the setting of the function must correspond to the user program!

The factory setting of the auxiliary display is the second unit.

Page 44

44

5.10.1 Second unit

The second unit is defined in the setting mode for each connected scale. The following second units are

stored as standard:

Calibrated unit Second unit

kg g

g kg

The following units are available:

Unit Abbreviation Conversion to g

Gram /

Kilogram

Tons t 1.000.000 g

Pound lb 453,59237 g

Milligram mg 0,001 g

Ounce oz. 28,349523125 g

To select the second unit, use the Function change key to switch to the setting functions level.

g /

kg

1 g /

1.000 g

Gross x 10

F 1 F 2 F 3 F 4 F 5 F 6

Auxiliary

display

Prog-

ram

Setting

mode

Press the F6 Setting Mode key.

Use the arrow keys F3 and F4 to move to Scale in the list and select "Continue" by pressing the F6 key.

Then press the F6 Continue key to select Scale parameters.

Use the arrow keys F3 and F4 to move to Second unit in the list and select it by pressing the F6 „Continue "

key.

Page 45

45

You can move in the list with the arrow keys F3 and F4. Press F6 "Apply" to define the second unit.

After selecting the second unit, press F1 "End" to return to the weighing mode.

Page 46

46

5.11 Organisation data (Identifier)

Organizational data is used to assign identification characteristics when documenting weighing operations,

for example, article number, vendor, scale operator.

They are available in all application programs.

The 3025 display unit has 4 organizational data memories.

Each memory has

> a freely selectable designation, e.g. "Article no.". (up to 12 characters, database up to 18 characters).

> a freely selectable content e.g. "1234" (up to 35 characters, database 6x35 characters).

The name is entered in the setting mode, the content in the respective weighing mode. The name and

content can be entered alphanumerically using the numeric keypad.

Four keys to are available for calling up the organizational data memory

Description

Input Designation

First enter the names (max. 12 characters) for the required organizational data memories in the setting

mode:

Call up the setting mode by pressing the F6 key in the Setting functions key level.

Use the arrow key to highlight F4 Terminal, F6 Next.

Use the arrow key F4 to select Organisation data, F6 Continue.

Designation A ORG to D ORG can now be called up and the designation assigned in the input field.

Attention!

An organizational data memory is only activated by assigning a name! Only activated organization data

memories can be called up via the keys A ORG to D ORG.

In the application programs, the names of all activated organizational data memories are then displayed in

the information field under Program settings in the Information field, depending on the setting of the display.

Content

Page 47

47

Input Content

In weighing mode, press the Org button to enter the contents for the organizational data stores. Enter the

content data alphanumerically using the keyboard.

(max. 35 characters). Confirm by pressing the F6 key.