Page 1

FOR MEASUREABLE SUCCESS

Basic Terminal 3010

Operating Manual

www.soehnle-professional.com

Page 2

English

Contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..Page 3

1.1 Operating manual notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 3

1.2 Description of the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 3

1.3. Putting into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 4

1.4. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 4

1.5 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..Page 5

1.6 Description of the nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 5

1.7 Control keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 6

1.8 Electronic nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 7

2.0 Basic functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 8

2.1 Power-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 8

2.2 Switching off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 8

2.3 Zeroing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 8

2.4 Switching over the weight unit kg <> lb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 8

2.5 Taring function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 9

2.6 Ten times resolution X10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 10

2.7 Switching over the scales (measuring points) . . . . . . . . . . . . . . . . . . . . . . . . .Page 10

2.8 Alibi memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 10

2.9 Hold function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 11

2.10 Measuring point inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..Page 12

2.11 LED lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 12

3.0 Application programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 13

3.1 Weighing and taring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 13

3.2 Counting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..Page 13

3.3 Totalising . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..Page 14

3.4 Batching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 15

3.5 Withdrawal weighing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 15

3.6 Switching point programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 16

3.7 Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 16

3.8 Dosing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 16

4. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 18

22

Page 3

English

Thank you for choosing this Soehnle Professional product. All the features of this product were

designed to the state of the art and are optimised for simple and straightforward use.

If you have any queries or experience any problems with the appliance that are not addressed in

the operating instructions, please contact your Soehnle Professional service partner or visit us on

the web at www.soehnle-professional.com.

1.1 Operating manual notes

This operating manual describes all the standard functions and settings of the Basic Terminal 3010.

Further information on the Setting mode is provided on the enclosed CD.

All the information is based on the standard version of the Basic Terminal 3010.

There may be deviations on special-purposes versions.

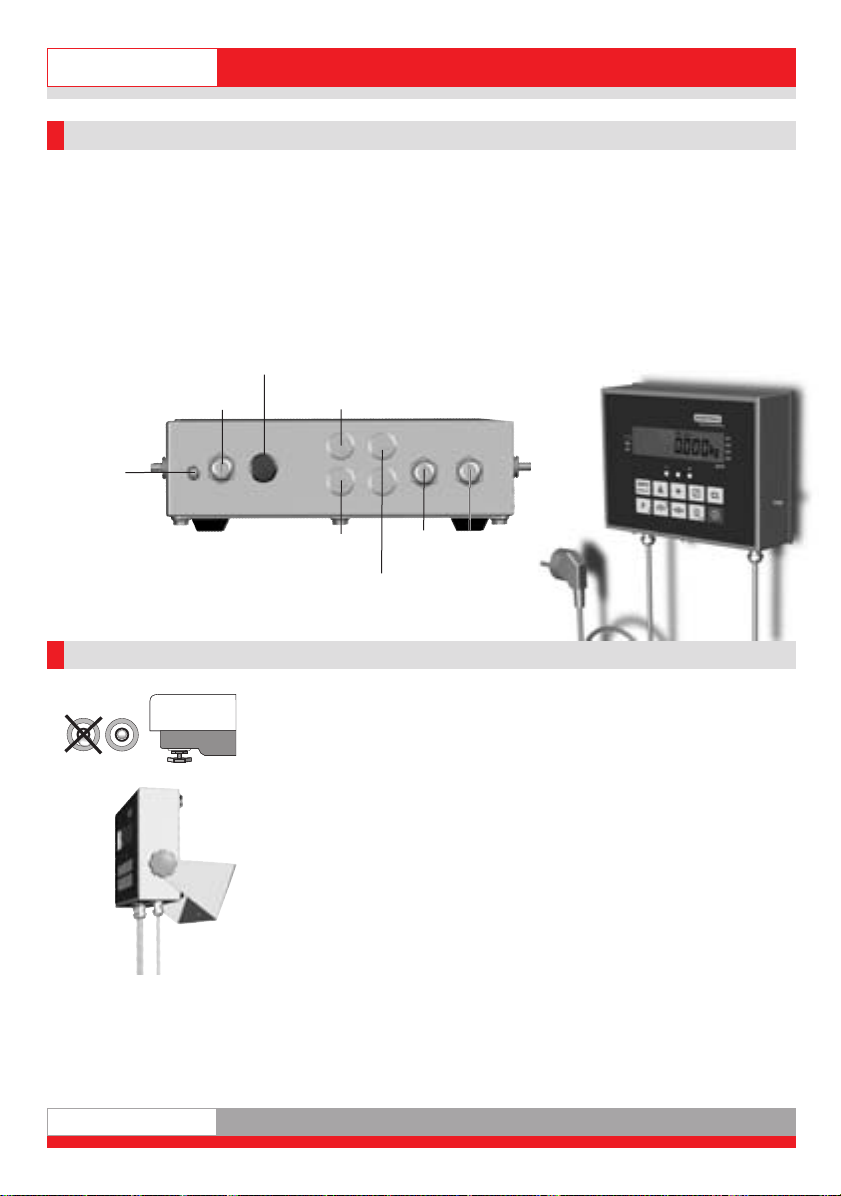

1.2 Appliance description

Technical data

• Housing made of stainless steel, protection class IP 40 or 65, integrated power adapter

100 - 240 VAC, optional DC/DC converter, 12 or 24 V

• 2 measuring points connectable internally

• Membrane keyboard with a total of 10 keys, 1 function key

• Display: 7 digits, 7-segment display, 16 mm digit height, backlit and dimmable

• Operating temperature: -10°C to +40°C

• Calibratable to Precision Class III for n = 8000e for multirange and multidivision scales.

• Approvable weighing range 0.1 kg to 120 t.

• Smallest permissible input signal per calibration value = 0.22 µV.

• Load cell power supply 5 VDC

Optional:

• Alibi memory for min. 2 million inputs

• Interfaces: 2 x RS 232, additional ports optional, including bus, analogue output 0 - 20 mA, USB

33

Page 4

English

1.3 Putting into operation

Before connecting the power plug to the mains, make sure that the power supply specified on the

nameplate and the power plug version comply with local conditions.

Place the connected scales on a level and stable surface. Protect the application by selecting a site of

installation that is not subject to shocks, vibration, intensive heat or cold, draughts, chemicals or moisture.

The appliance may only be opened by trained service technicians. Before carrying out any service

work on the appliance, disconnect the power supply.

After power-on, the measured values stabilise after a warm-up period of 30 minutes.

Pressure compensation membrane on IP 65 housing

Power supply

Ground (GND)

1.4 Installation

Interface 1

Interface 2

e.g. Profibus, Ethernet, etc.

Install the weighing platform at the point of use.

Using a spirit level and the adjustable feet, ensure that the platform is

horizontal.

Install the Basic Terminal or mount it on the wall using the optional bracket.

Provide access to a mains power source or connect the appliance to a

DC power source using a DC/DC converter.

The scale is ready for use.

Scale 1 + 2

Connections

44

Page 5

1.5 Symbols

M1 Active measuring point (scale)

Active weighing range

Zero reading

Net weighing

Tare reading

Manual tare

Hold mode (The reading is fixed to improve legibility)

Total memory

Piece count mode

English

Alibi memory

O1-O4 Switching points (Outputs O1 - O4)

1.6 Description of the nameplate

Max Maximum load of weighing range

Min Minimum load of weighing range

e= Calibration value (resolution)

SNR Serial number of scale (scale type, last digits of year

XXXX

D07-09-011 Number of EU approval

XXXX e.g. 0103, Official Code of "Notified Body"

M

001

Weighing ranges

of manufacture, consecutive number)

EU conformity mark with year of affixing also start of

validity of verification

Precision class

(this body performed the initial calibration)

Symbol for EU calibration

Calibration counter status

55

Page 6

English

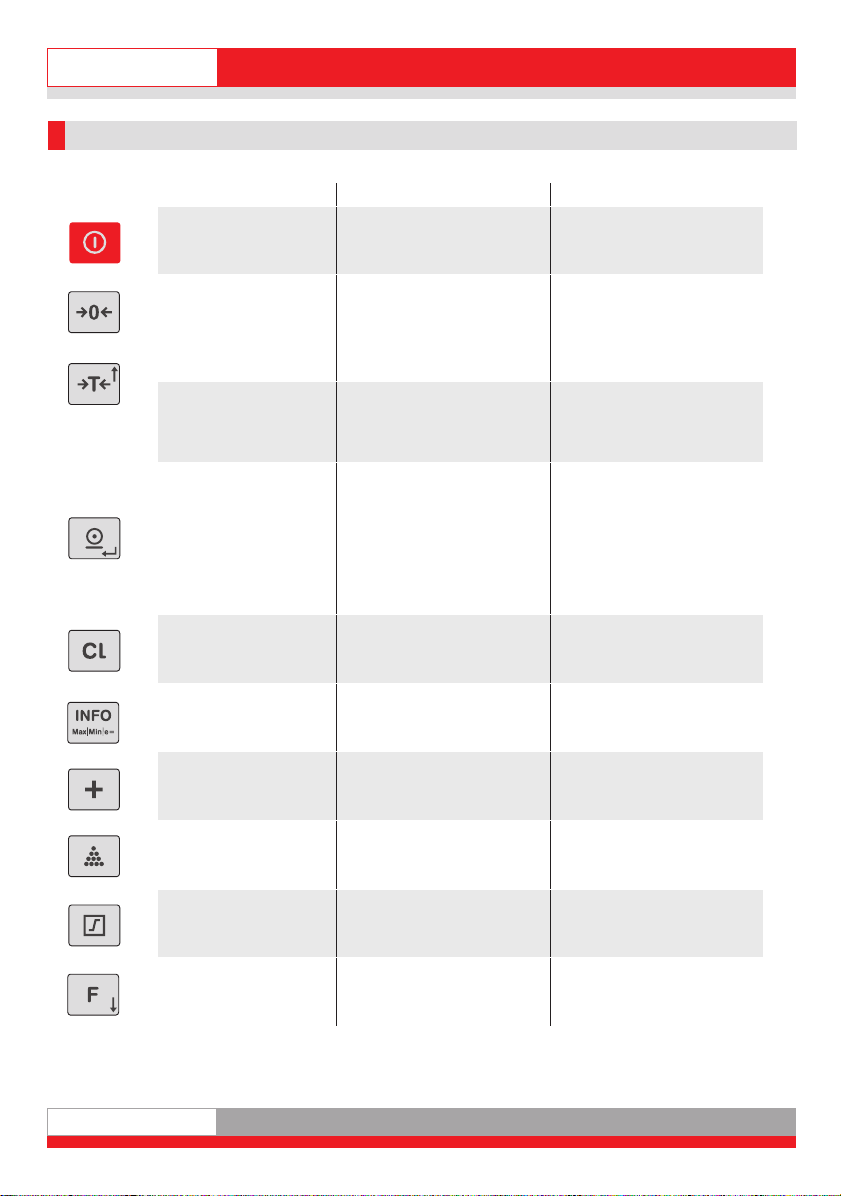

1.7 Control keys

Operating mode Setpoint input Setting mode

On / Off

Zeroing key or Clear

tare

Tare key Increment value

Print key or

Enter key

Clear key or Cancel

key

Info key

Totalise or

Batch

Count

Set input to zero

Cancel key

One menu level back,

or shift an editable decade

from right to left

Next setting step or

increment value

Next setting step or

increment value Access edit

function within setting step

or

save parameter and go to

next setting step

Go back one menu level in

Setting mode

Setpoints or corrected

values

Freely programmable

function key

Accept setpoints or corrected values and continue.

Decrement value

Go back by one setting step

or decrement value

66

Page 7

1.8 Electronic nameplate

Press the Info key twice to display the electronic nameplate. Press the

arrow keys ( / ) to indicate the electronic nameplate, the Serial No.

and the calibration counter of the activated measuring points in the display.

Press the CL key to cancel or end display of the electronic nameplate.

With a 1 or 2-range scale, the parameters of the other ranges disappear.

English

Display

step

1. -

2. Calibration counter

3. Type

4. Year

5. Serial No.

6. ID Chip

7. Max of Range 1 ¯ 10,00kg and symbol for Range 1

8. Min of Range 1 _ 0,20kg and symbol for Range 1

9. e of Range 1 E 0,01kg and symbol for Range 1

10. Max of Range 2 ¯ 20,00kg and symbol for Range 2

11. Min of Range 2 _ 0,40kg and symbol for Range 2

12. e of Range 2 E 0,02kg and symbol for Range 2

13. Max of Range 3 ¯ 30,00kg and symbol for Range 3

14. Min of Range 3 _ 1,00kg and symbol for Range 3

15. e of Range 3 E 0,05kg and symbol for Range 3

On a non-approved scale, "d" is displayed instead of "E".

Parameter Reading

77

Page 8

English

2. Basic functions

The basic functions are similar or identical for all application programs.

2.1 Power-on

Only when the scale is not loaded.

After the test routine, the display is set to zero.

The scale is ready for use.

Place the weighing product on the scale.

The display shows the gross weight.

2.2 Switching off

This is immediately possible when the display is "0".

Otherwise hold down the key for 3 seconds.

2.3 Zeroing

Press the Zeroing key to correct minor deviations from zero, e.g. caused by soiling

on the scale.

Zero range approvable and non-approved: -1% to +3% of the weighing range.

2.4 Switching over the weight unit kg <> lb

The option for switching over the weight units must be released in Calibration

mode.

Switch over by pressing the Info key and then the Zeroing key.

If weight unit switchover was also assigned to the F key in Setting mode, you can

also switch over the unit by pressing the F key.

88

Page 9

2.5 Taring function

Manual tare

Place an empty container on the platform and press the -key.

Manual tare input

In Setting mode (see separate description 470.702.078 User Mode), select

"Manual tare input" to assign the key.

Then in operation, press the -key to set the value using the arrow keys

(/).

The set value is accepted by pressing the -key.

Tara info

Press the -key and then the - key to display the currently stored tare

value.

Press the CL key to exit the display.

Clear tare

Press the -key or the - and - keys in succession.

Autotare function

Tares the first weight value on the scale automatically.

Place an empty container on the platform. When the platform is still, the first

weight value in the tare memory is accepted.

After clip off, the tare memory is cleared automatically.

The Autotare function must be selected in Setting mode (see separate description 470.702.078 User Mode).

English

Provisional tare function

A provisional tare function can be assigned to the -key (see separate description 470.702.078 User Mode).

Unknown tare values can be added to the existing tare value without changing

the net reading.

Press the -key. "Hold" appears in the display.

Place additional tare on the platform or remove tare from the platform.

Press the -key to accept the new tare value.

99

Page 10

English

2.6 Ten times resolution X10

The ten times resolution appears by pressing the -key and the Zeroing key

simultaneously.

On approved scales, the high resolution appears for 5 seconds or flashes as

long as you hold down the keys - on non-approved scales, the high resolution

appears as long as you press the -key and the Zeroing key. wird.

2.7 Switching over the scales (measuring points)

The Basic Terminal 3010 can operate 2 analogue measuring points.

Toggle between the measuring points by pressing the INFO key followed by

the -key (in succession).

2.8 Alibi memory

The alibi memory is activated in Setting mode (see separate description

470.702.078 User Mode). When the alibi memory is activated, an arrow points

to the corresponding symbol.

The arrow flashes as soon as the entered limit for full indication is reached.

Press the -key or data request to accept a value to the alibi memory. To

do this, the print template or the data record must be configured accordingly

(see separate description 470.508.059 Data Interface).

1100

Send a request to the alibi memory (view/print entries) in Setting mode:

Press - and -keys for 5 seconds until UCAL I appears.

Press -key repeatedly until UCAL 5 appears.

Press the -key to confirm.

Then press the -key until the Setting step 03 appears.

Press the -key to confirm.

The number of the last data record saved appears. Call each data record by

changing the consecutive number using the arrow keys ( / ) and

display by confirming with the -key.

Page 11

2.9 Hold function

English

The selected data record is displayed in scroll mode as follows:

Display Meaning

I2

2880

07

000I

A I2,34 kg

A 2,98 kg

Scroll by pressing the arrow keys ( / ) up or down.

Quite the View mode by pressing the -key.

Press the -key and then hold down the - and - keys for 5 seconds

to switch back to Weighing mode.

The hold function is activated in Setting mode (see separate description 470.702.078 User Mode).

In weighing mode, activate the Hold function by pressing the F key.

T

Consecutive number of alibi entry

Scale type

Year

Consecutive number

Gross or net with alibi ID

Tare with alibi ID

Serial number of measuring point

The following Hold functions are standard on the Digital Indicator Type 301x

to freeze weight data. Default is "0".

Hold mode Function Clear function

0 Not active

1 Hold at standstill On key

2 Hold at standstill Clip off

3 Max. value On key

4 Max. value Clip off

5 Slave counter On key

6 Slave counter Clip off

1111

Page 12

English

2.10 Inputs and outputs

The optional I/O module has 4 inputs and outputs that can be individually configured in Setting

mode (see (separate description 470.702.078 User Mode).

2.11 LED lamps

The appliance has integrated LED lamps. The functionality can be set and activated individually for

each application program in Setting mode (see separate description 470.702.078 User Mode).

1122

Page 13

English

3.0 Application programs

The various application programs on the Soehnle Basic Terminal 3010 offer you a wide range of

solutions for weighing operations.

You can modify the application programs to your specific requirements in Setting mode

(see separate description 470.702.078 User Mode).

Below is a list of application programs available to you:

3.1. Weighing and taring

3.2. Counting

3.3. Totalising

3.4 Batching

3.5 Withdrawal weighing

3.6. Switching point programming

3.7. Checking

3.8 Dosing

3.1 Weighing and taring

Weighing

The appliance starts in Weighing mode after power-on.

Place weighing product on platform and read weight

Weighing with tare

Refer to 2.5.

An active tare weight is indicated by the letter "N" appearing in the display.

3.2 Counting

The counting function is activated by pressing the Counting key.

The message "Add XXX" (XXX=number of reference parts) requests you to

place one or several reference parts on the platform. By pressing the Counting

key repeatedly, you can change the reference quantity for lightweight reference

parts in steps of 1/2/5/10/25/50.

Place the reference parts on the platform and confirm by pressing the -key.

Then place the countable parts on the platform and read off the countable

parts.

Change to Weighing mode by pressing the CL key.

Counting with tare

Refer to 2.5.

An active tare weight is indicated by the letter "N" appearing in the display.

1133

Page 14

English

3.3 Totalising

Displaying the piece weight

Press the Info key and then the counting key to display the piece weight.

Press the CL key to go back.

Place weighing product on the platform in Weighing mode and accept the

weight value in the total memory by pressing the + key.

Remove the weighing product from the platform or - dependent on the previous

setting - clip off. In Setting mode (see separate description 470.702.078 User

Mode), define whether the scale must be clipped off each time you place an

individual piece on the platform by increments of 1 to 30.

If the scale is not clipped off, the weight unit is not accepted in the total memory. This prevents operations such as saving an item twice.

Place the next weighing product on the platform and press the + key to accept

the weight value in the total memory, etc.

A full total memory is recognised by the totalising character (Σ).

Call up the total value

by pressing the Info key and then the + key.

The display then scrolls: Gross, Tare, Net and Quantity.

Cancel or end by pressing the CL key.

1144

Clear the total memory

by pressing the CL key and then the + key.

Totalising with tare

Refer to 2.5.

An active tare weight is indicated by the letter "N" appearing in the display

Autototalising (select function in Setting mode)

Place weighing product on the platform in Weighing mode and accept the

weight value in the total memory by pressing the + key.

Remove weighing product from the platform.

Place the next weighing product on the scale.

The weight value is automatically accepted in the total memory.

Remove the weighing product from the platform and place the next weighing

product, etc.

Carry out a complete configuration of the totalising functions in Setting mode

(see separate description 470.702.078 User Mode).

Page 15

3.4 Batching

English

Place weighing product on the platform in Weighing mode and accept the

weight value in the batch memory by pressing the + key.

Place the next weighing product on the platform and press the + key to

accept the weight value in the batch memory, etc.

A full batch memory is recognised by the totalising character (Σ) in the

display.

Call up the total value

by pressing the Info key and then the + key.

The display then scrolls: Gross, Tare, Net and Quantity.

Cancel or end by pressing the CL key.

Clear the batch memory

by pressing the CL key and then the + key.

Batching with tare

Refer to 2.5.

An active tare weight is indicated by the letter "N" appearing in the display.

Autobatching (select function in Setting mode)

Place weighing product on the platform in Weighing mode and accept the

weight value in the batch memory by pressing the + key.

Place the next weighing product on the scale. The weight value is

automatically accepted in batch memory.Place the next weighing product on

the scale, etc.

Carry out a complete configuration of the batching function in

Setting mode (see separate description 470.702.078 User Mode).

3.5 Withdrawal weighing

Place a container with the weighing product on the platform.

Press the tare key.

Remove part of the weighing product.

The removed weight value is displayed with a negative sign.

Press the tare key again, etc.

1155

Page 16

English

3.6 Switching point programming

Four switching points can be set in the Basic Terminal 3010.

The switching points are used for switching and dosing.

Setting the switching points

Press the switching point key.

The first switching point is displayed. This is indicated by the arrow in the

display.

Set the value using the arrow keys ( / ). The value is incremented

individually by tapping the key briefly. When you hold the key down, the

display increments or decrements continuously.

Acknowledge by pressing the -key.

The display jumps to the next switching point.

Set the value using the arrow keys ( / ).

Press the -key to confirm, etc.

Each switching point function is defined in Setting mode (see separate

description 470.702.078 User Mode).

3.7 Checking

The switching points for the internal LED lamps or the external lamps (optional) are used for checking.

Enter the setpoints as check values as follows.

Switching point Value

S1 0

S2 Lower tolerance

S3 Upper tolerance

S4 Upper tolerance

Enter the switching points as described in 3.6.

Activate in Setting mode (470.702.078 User Mode).

3.8 Dosing

1166

The following dosing functions can be set:

• Coarse dosing without correction value

+ fine dosing without correction value

• Coarse dosing with correction value + fine dosing with correction value

• Coarse dosing without correction value + fine dosing with correction value

• Fine dosing without correction value

• Fine dosing with correction value

Page 17

English

Select the dosing function in Setting mode (see separate description

470.702.078 User Mode and 470.051.109 Dosing).

Use the switching points (see 3.6) to set coarse flow, fine flow and correction

value.

Setting the switching points

S1 Setpoint for coarse dosing

S2 Setpoint for fine dosing

S3 Correction value for coarse dosing

S4 Correction value for fine dosing

The greatest possible switching point in the maximum scale load.

Dosing operation

Tare the container as required.

Note: Adosing start interlock with an untared scale must be selected in

Setting mode (see separate description 470.702.078 User Mode).

Start the dosing function by pressing the F key.

The dosing valve open and dosing product flows.

The yellow LED lights up and the display flashes until the set dosing weight is

reached.

The green LED lights up when the dosing weight is reached and is within the

tolerances. The dosing valve closes.

The red LED lights up when the upper dosing weight tolerance is exceeded.

Interrupting the dosing operation

Press the CL key. The yellow LED lights up, the display flashes and waits for

the dosing operation to continue (the same response takes place when the

dosing product is not sufficient for a full dosing operation).

Press the F key to continue the dosing operation.

The dosing operation is also interrupted when the scale is in overload or

underload. When the overload or underload condition is remedied, the dosing

operation continues automatically.

Ending the dosing operation

Press the CL key twice.

The scale is then in standard weighing mode.

Dosing with totalising function

The totalising function during dosing must be selected in Setting mode (see

separate description 470.702.078 User Mode). Presetting: NO totalising.

1177

Page 18

English

4 Troubleshooting

Display Remedy

Please check that you operated the

appliance correctly. If not, interrupt

the command chain by pressing the

CL key.

The scale sets the value zero automatically when it is switched on. If

the scale is outside the set tolerance

band, the display indicates --0--.

Underload: Only the lower horizontal

lines appear in the display pane.

Overload: Only the upper horizontal

lines appear in the display pane. The

maximum weighing range is exceeded.

Part weight too small.

Zeroing limit overshot or undershot.

Not possible to tare an unloaded

scale; not possible in overload.

Not possible to print in underload or

overload.

Switchover kg/lb locked.

Clip off the platform. Possibly remove

any soiling. If the scale fails to

display zero after a few seconds, please inform your service partner

Switch off the scale and switch it

back on again. The zero point is

reset automatically

Remove part of the weighing product

from the scale.

In case of other error messages,

please contact your service partner.

1188

Page 19

English

1199

Page 20

FOR MEASURABLE SUCCESS

Soehnle Professional GmbH & Co. KG

Wilhelm-Soehnle-Straße 2

71540 Murrhardt

Phone +49 (0) 71 92 / 93 19-220

Fax +49 (0) 71 92 / 93 19-211

E-Mail info@soehnle-professional.de

SSccaalleess,, SSyysstteemm SSoolluuttiioonnss aanndd SSppeecciiaall DDeevveellooppmmeennttss

470.051.104 GB Printed in Germany 04/2008 Subject to technical modifications

www.soehnle-professional.com

Loading...

Loading...