Page 1

14

1

ZECKOROLL REV ‘A’ OCT 2018

Page 2

IMPORTANT SAFETY INSTRUCTIONS

This document contains important safety and operation instructions for tool storage units. Refer to this information often for safe usage

and operation.

SAVE THESE INSTRUCTIONS

When using electric products, basic precautions should

always be followed, including the following:

Improper assembly can cause unsafe conditions.

Read instructions before using or assembling.

Maintain safety labels. If label is worn or damaged,

replace label.

Unsafe conditions can cause injury.

Particles may y during assembly.

Wear safety goggles. (User and bystanders)

Flying particles can cause eye injury.

To reduce the risk of injury, close supervision is

necessary when this product will be used around

children.

Keep children away.

Unsupervised children can be injured.

To reduce the risk of injury, never overload drawers or

shelves.

Refer to installation and loading instructions.

Overloaded drawers or shelves can cause injury or

damage.

Units can tip or strike you.

• Do not open more than one loaded drawer at a

time

• Do not force open a drawer kept closed by

drawer control slide

• Close lid and lock drawers before moving

• Apply brakes on locking casters when not

moving unit

• If unit begins to tip, stand clear

• Do not open any drawer with swivel caster

positioned inward

• Do not step in or on drawers

• Do not use any open drawer as support or

leverage

• Do not use add-ons as stanalone units

• Units to be used on level ground only

• Secure units together with fasteners

• Disconnect or unplug all power cord and cable

assemblies before moving unit

Tipping of storage unit or unit striking you can cause

injury.

Risk of electric shock and re.

• Refer to loading instructions or markings for

the proper load on receptacles

• Do not remove the ground connection

• Do not expose to rain, snow, or wet conditions

• Do not operate with damaged cord or plug

• Replace damaged cord or plug immediately

Electric shock or re can cause injury.

Risk of explosion.

• Flammable fuel or vapors can ignite

• This equipment should not be located in a re-

cessed area or below oor level

• Powered worksurface and power drawer have

internal arcing or sparking parts

• Do not expose to ammable vapors. Powered

worksurface and power drawer components to

be mounted at least 460 mm (18 inches) or more

above the oor.

Explosion or ame can cause injury.

NOTE: This caution applies to tool storage units that use 120VAC, 60Hz.

For tool storage units that use power other than 120VAC, 60Hz, refer to

owner’s manual supplement for max cumulative load.

Risk of electrical shock and re.

• 12A maximum cumulative load for all recepticles

Electrical shock or re can cause injury.

Risk of tripping.

• Do not use extension cords with power drawer

or powered worksurface outlets

• Do not place any power cord or cable assembly

in walkway

• Disconnect or unplug all power cords and cable

assemblies before moving unit

Tripping can cause injury.

Component edges can cut or pinch.

• Wear gloves when removing and installing

components into power drawer

• Keep ngers clear of edges when working near

or with sheet metal components

• Keep hands and ngers clear of prybar or sharp

objects

Units’ edges or components can cause injury.

14

2

ZECKOROLL REV ‘A’ OCT 2018

Page 3

IMPORTANT SAFETY INSTRUCTIONS CONT

This document contains important safety and operation instructions for tool storage units. Refer to this information often for safe usage

and operation.

SAVE THESE INSTRUCTIONS

INSTRUCTIONS PERTAINING TO

RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS

To reduce the risk of electric shock and re, never overload

receptacles. Refer to the markings at the receptacles for

proper loading of receptacles.

Risk of electric shock and re.

• Do not operate with damaged cord or plug

• Replace damaged cord or plug immediately

Electrical shock or re can cause injury.

Risk of electrical shock and re.

• 12A maximum cumulative load for all recepticles

Electrical shock or re can cause injury.

Periodically inspect all external cords and plugs for damage

or wear. Replace damaged or worn cords immediately.

GROUNDING INSTRUCTIONS

This product must be grounded. If it should malfunction or

break down, grounding provides a path of least resistance

for electric current to reduce the risk of electric shock. This

product is equipped with a cord having an equipmentgrounding conductor and a grounding plug. The plug must be

plugged into an appropriate outlet that is properly installed

and grounded in accordance with all local codes and

ordinances.

Risk of electric shock and re.

• Do not remove the ground connection

Electrical shock or re can cause injury.

Improper connection of the equipment-grounding

conductor is able to result in a risk of electric shock.

Check with a qualied electrician or serviceman if

you are in doubt as to whether the product is properly

grounded. Do not modify the plug provided with the

product – if it will not t the outlet, have a proper outlet

installed by a qualied electrician.

INSTALLATION INSTRUCTIONS

Do not install or store this product where it will be exposed to rain,

snow, or wet conditions.

Risk of electric shock and re.

• Do not expose to rain, snow, or wet conditions

Electrical shock or re can cause injury.

Do not expose this unit to ammable fuel or vapors. This unit

contains internal parts that arc or spark, which could cause fuel or

vapors to ignite. Do not install or store this equipment in a recessed

area or below oor level, where vapors can accumulate. Locate all

electrical components stored within this equipment at least 460 mm

(18 inches) or more above oor level.

Risk of explosion.

• Flammable fuel or vapors can ignite

• This equipment should not be located in a recessed area

or below oor level

• Powered worksurface and power drawer have internal

arcing or sparking parts

• Do not expose to ammable vapors. Powered worksurface

and power drawer components to be mounted at least 460

mm (18 inches) or more above the oor.

Explosion or ame can cause injury.

LOADING INSTRUCTIONS

Drawers are designed to support heavy loads. Care should be

taken to uniformly load your tool storage unit. When adding tools

and other items to the drawers, load each drawer with no more

than 15 lbs at a time. After adding up to a 15 lb load, close drawer

and proceed to the next one. Repeat this process until all drawers

have been uniformly loaded with the desired contents. Items that

weigh more than 15 lbs should be added after all other drawers are

loaded and closed.

Units can tip or strike you.

• Do not open more than one drawer at a time

• Apply tool load in up to 15 lb (max) increments.

• Before adding more than 15 lbs to any drawer, all other

drawers should be loaded and closed.

• Load items weighing more than 15 lbs last.

• Apply brakes on locking casters.

• Do not open any drawer with swivel caster positioned

inward.

Tipping of storage unit or unit striking you can cause injury.

14

3

ZECKOROLL REV ‘A’ OCT 2018

Page 4

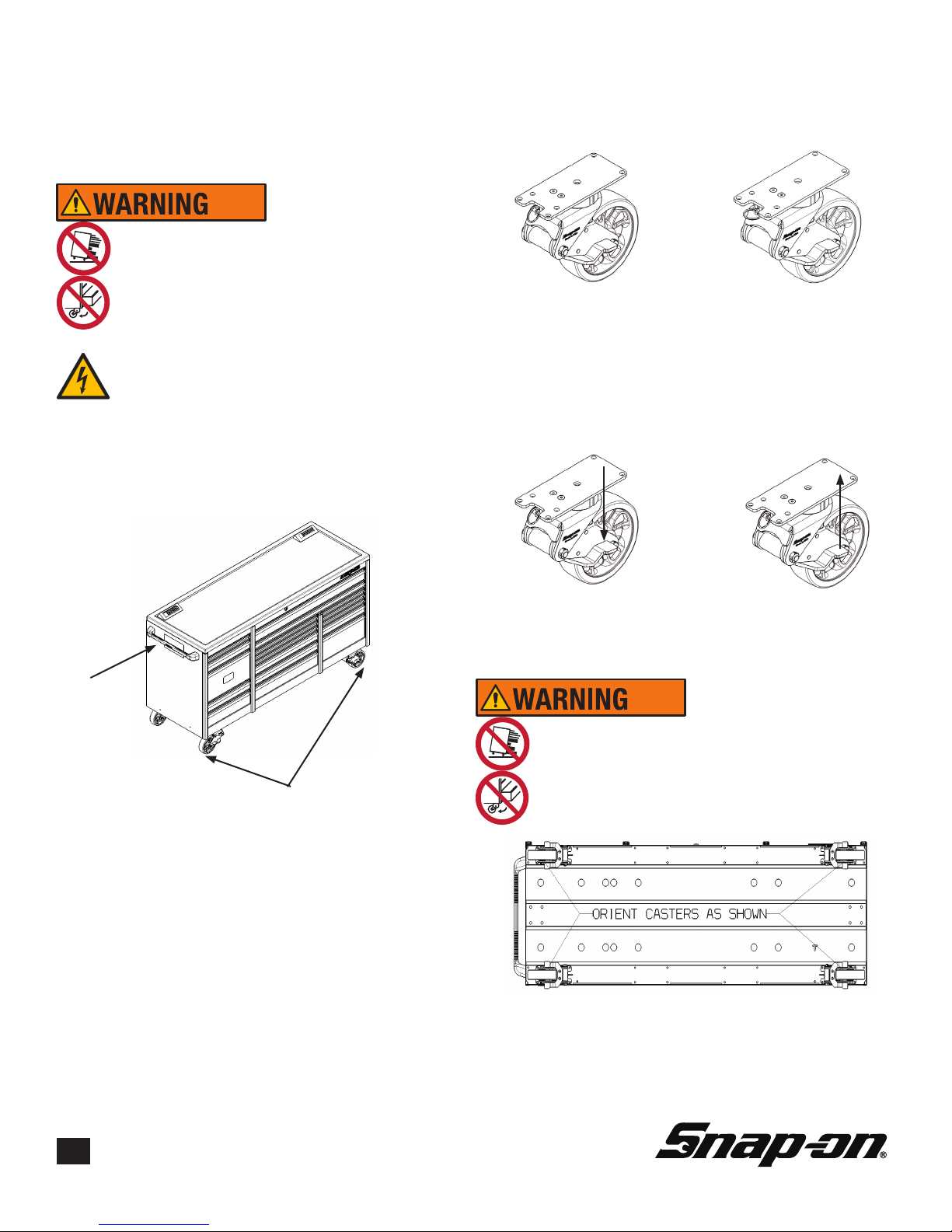

MOVING & STORAGE INSTRUCTIONS

Close and lock all drawers, doors, and lids and lock unit prior to moving.

Disconnect or unplug all power cords and cable assemblies prior to moving

unit. Keep these cables safely stored away from roll cab when moving.

When not moving roll cab, be sure to apply all brakes. Be sure to lock front

caster wheels parallel to the front of the roll cab prior to opening any drawers. Do not open any drawer with swivel caster facing inward.

Units can tip or strike you.

• Close lid and lock drawers before moving

• Apply brakes on casters when not moving unit

• Do not open any drawer with swivel caster positioned

inward

Tipping of storage unit or unit striking you can cause injury.

Risk of electric shock and re.

• Disconnect or unplug all power cords and cable assemblies before moving unit

Electric shock or re can cause injury.

Do not pull. Push to move. If your tool storage unit comes with all

swivel casters, use the swivel-lock pin to lock the two swivel casters opposite the handle as shown before attempting to move. If

your tool storage unit comes with two swivel and two rigid caters,

install handle on the same side as the swivel casters.

MOVING & STORAGE INSTRUCTIONS

CONT.

Casters can be converted from swivel to rigid by pulling and rotating

the swivel lock pin.

Casters will swivel with

swivel lock pin locked in

the outward position as

shown.

Casters can be locked and unlocked by applying pressure to the

caster brake. The brake on the caster stops the caster wheel from

rolling when pressed down in the locked position. When lifted up,

the caster will be unlocked and the wheel will be able to roll.

Casters will not swivel

when swivel lock pin

is locked in the inward

position as shown.

Do not pull.

Push to move.

Rigid casters. If

swivel casters, lock

swivel casters opposite handle prior to

Swivel Casters

moving.

If your tool storage unit has swivel-locks, be sure lock the swivel

caster wheels parallel to the front of the roll cab prior to opening

any drawers. Do not open any drawer with swivel caster positioned inward.

When brake is compressed,

caster wheel will be in the

locked position and will be

unable to roll.

Units can tip or strike you.

• Apply brakes on casters when not moving unit

• Do not open any drawer with swivel caster positioned

inward

Tipping of storage unit or unit striking you can cause injury.

When brake is in the up

position caster wheel will

be in the unlocked position

and will be able to roll.

14

4

ZECKOROLL REV ‘A’ OCT 2018

Page 5

FCC Notice

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference; and (2) This device must accept any interference received,

including interference that may cause undesired operation.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de

licence. L’exploitation est autorisée aux deux conditions suivantes: (1) l’appareil ne doit pas produire de brouillage, et (2) l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d’en compromettre le fonctionnement.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an output or circuit different from that to which the receiver is connected

• Consult the dealer or an experienced radio/TV technician for help

14

5

ZECKOROLL REV ‘A’ OCT 2018

Page 6

Table of Contents

Features.........................................................................................6

Specications.................................................................................6

Manual Locking / Unlocking...........................................................7

Setting Up ECKO Remote Lock.....................................................8

Remote Use...................................................................................8

Maintenance...................................................................................9

Remote Battery Replacement....................................................9

Replacing Remote Lock Module Fuse.......................................9

Remote Pairing........................................................................10

Resetting Remote Lock Receiver Module................................11

Speaker Volume Adjustment....................................................11

Troubleshooting............................................................................12

Service..........................................................................................13

Features

• Unlock or lock from a distance

• Manual key override

• Remote can be keyed to work several

electronic locks at once

• Spare remote included

• Thermal overload protection

• Maintenance free design

• Small ergonomic remote

• Audible signal of unlock or lock

• On/Off switch

Specications

Remote

Power Lithium CR2032 3 Volt

Battery

Life

Storage Temperatures from -20°F to

2-3 Years

140°F

Remote Lock Module

Power 120V AC to 24V DC Power

Converter

Storage Temperatures from -20°F to

140°F

The ECKO (Electronically Controlled Keyless Operation) remote locking system is designed to give the

user ease of locking and unlocking tool storage units

(TSU’s) without the hindrance of using a key(s). This

TSU is equipped with a receiver module that receives

a coded transmission from the remote transmitter. The

ECKO remote lock receiver module will either lock

or unlock the storage unit. The following service tips

should help in the proper care and maintenance of your

ECKO remote lock equipped TSU.

Manual Locking / Unlocking

ECKO remote lock units use a unique lock with only

one position that the key can be removed. Follow these

instructions to manually unlock your TSU for the rst

time:

Push the key into the lock cylinder and unlock by turning the key to the 9:00 position. Return the key back to

the 12:00 position and remove the key.

The ECKO remote lock unit can also be locked manually. Push the key into the lock cylinder and lock by

turning the key to the 3:00 position. Return the key back

to the 12:00 position and remove the key.

This manual override feature can be used if the batteries in the remote are non-functioning or the remote

is lost. Be sure to store mechanical lock keys in a safe

place outside of your TSU.

14

6

ZECKOROLL REV ‘A’ OCT 2018

Page 7

Setting Up ECKO Remote Lock

Each remote lock equipped TSU comes pre-programmed from the factory with the drawers

locked. Follow these steps to setup your ECKO

remote lock for the rst time:

Maintenance

Remote Battery Replacement

1. Locate keyway location on remote case.

1. Unlock the TSU using the procedure outlined

in the manual unlocking/locking section of this

manual.

2. Locate your AC/DC adapter and plug into

an electrical outlet that is properly installed and

grounded.

3. Plug the round DC end of the adapter into

the jack on the back of the TSU.

4. Use remote to lock or unlock the TSU as

explained in the remote section of the manual.

Remote Use

The remote is a three button design similar to an

automotive remote.

- Press lock key (1) 1-3 seconds to lock - 1 beep

will sound

- Press unlock key (2) 1-3 seconds to unlock - 2

beeps will sound

2. Using small at head screwdriver (or equivalent), separate two halves of remote case.

3. Remove battery (CR2032) out of its holding

bracket.

4. Slide new battery into holding bracket with positive (+) side up.

5. Reassemble remote case by pressing two

halves rmly together.

- Auxiliary (ACC) key is for future use

- If red LED does not turn on when pressing lock

or unlock, battery may be low

14

7

ZECKOROLL REV ‘A’ OCT 2018

Page 8

Remote Pairing

ECKO remotes come from the factory already

paired to the ECKO receiver module. This procedure will only be necessary if your remote has lost

pairing.

Follow these steps to pair the remote(s) with your

TSU:

1. Open top drawer of the TSU and locate the

ECKO receiver module.

2. Hold down the learn button on the module until

it starts to beep. The unit will beep for 1 second.

Release the learn button.

3. After beeping has stopped, pair remote by

pressing and holding the lock or unlock button

on the remote for approximately 3 seconds. The

receiver module will beep once to conrm pairing

was successful.

NOTE: If pairing multiple remotes, press and

holdthe lock button on each remote within the 10

second learn period. The module will end the pairing time period once the second remote is paired.

Only two remotes can be paired to one TSU.

Resetting Remote Lock Receiver Module

Follow these steps to reset the ECKO remote lock receiver module:

1. Open top drawer of the TSU and locate the receiver module.

2. Reset module by removing power cord from the

AC/DC adapter plug. Once removed, wait 5 seconds

before reinstalling power cord

Learn/Volume Button

AC/DC Adapter Plug

*Module view behind front dress plate

Note: If you are unable to reset module with the switch

due to the drawers being locked, unplug TSU from AC/

DC adapter and plug back in after 5 seconds.

Note: The remote(s) will not need to be re-paired to the

receiver module after resetting.

4. After 10 seconds, the receiver module will

beep twice to signify that the pairing time period is over.

Learn/Volume Button

*Module view behind front dress plate

Speaker Volume Adjustment

Follow these steps adjust the volume of your ECKO remote lock receiver module:

1. Open top drawer of the TSU and locate the receiver module.

2. Press the volume two times to change volume of

speaker.

3. Receiver will beep to conrm volume change.

• 1 Beep – Low Volume

• 2 Beeps – High Volume

• 3 Beeps – Volume Off

14

8

ZECKOROLL REV ‘A’ OCT 2018

Page 9

Troubleshooting

Symptom Possible Cause Solution

Remote battery low

Receiver module not receiv-

ing power

Remote lock does not respond,

remote lights up

Remote not paired with

receiver module

Remote out of range - Move closer to TSU

Reset needed

Self-test start up provides tone

other than 3 rising beeps

Remote does not light up Remote battery low

Response poor or intermittent

Drawer(s) still

unlocked after

locking unit

Receiver module speaker sounds

but unit does not lock/unlock

Receiver failed self-test

Remote battery low

Remote out of range - Move closer to TSU

Drawer(s) not fully closed

before locking

Actuator jammed or not mov-

ing freely

- Remove and reinstall

remote battery

- Replace remote battery

-

Plug AC/DC adapter into outlet and DC jack on rear

of roll cab

- Check blue power LED on AC/DC adapter

-

Check connection between DC

unit (TSU) and receiver module

- See Remote pairing section

of manual

- Unplug and re-plug remote lock cord on back of

ECKO receiver

- Unplug and re-plug remote lock cord on back of

TSU

Check sensor board and sensor board cable to

ensure correct assembly. Sensor board should

be connected to main board If damaged, replace

module

- Remove and reinstall remote battery

- Replace remote battery

- Remove and reinstall

remote battery

- Replace remote battery

- Drawer(s) not fully closed

before locking

- Push in drawer(s)

-

Manually unlock and lock TSU

actuator

- Unplug and re-plug remote lock cord on back of

ECKO receiver

- Unplug and re-plug remote lock cord on back of

TSU

cord in tool storage

to free lock rod and

Sensor board

14

9

ZECKOROLL REV ‘A’ OCT 2018

Main board

Sensor board cable

Page 10

Service – Removing Remote Lock

Module

Follow these steps to remove the ECKO remote

lock receiver module:

1. Remove top two drawers from roll cab.

2. Remove DC jack from remote lock mod-

ule.

Rear of front

dress plate view

3. Disengage snap-t and remove lock cover.

4. Disengage lock rod from cam mechanism.

Lock rod is spring loaded. Push toward back

of case and twist clock wise (with respect to

front) to disengage.

6. Remove nut and lock washer on back of lock.

7. Remove Lock.

8. Rotate remote lock module on mounting bracket.

Pull to right and remove.

5. Remove cam assembly screw. Swing cam

assembly down and out of the way.

14

10

ZECKOROLL REV ‘A’ OCT 2018

9. Reinstall in reverse order. When installing cam,

make sure that at on inner cam aligns with at on

lock.

Page 11

Service – Roll Cab Wiring

Service – Roll Cab Part Numbers

Follow these steps to replace the ECKO receiver

module wiring harness:

1. Remove top two drawers from roll cab.

2. Remove DC jack from remote lock module.

Rear of front

dress plate view

3. Remove wiring harness – disconnect from

plastic wire hangers and remove from rear of

unit.

8-72737BR

Receiver

Module with

Lock Cover

ECKOFOB

Remote

8-72737B-9A

Wiring

Harness

8-72737A-AC

AC/DC

Adapter

8-72737A-5

Lock Cover

4. Replace wire – feed from rear of unit and rein-

stall to plastic wire hangers. Bundle and secure

extra wire in false side gap(s). Make sure that

wire is not in the way of drawers.

5. Reinstall top two drawers

8-72737A-4

Lock Screw

8-72737A-60

Actuator

Assembly

RK1ULCA

Lock Cylinder

RK500KP –

RK699KP

Lock Plug

and 1 Key

RK1LA Lock Assy - 1 Lock, 2 Keys

RK2LA Lock Assy - 2 Locks, 2 Keys

RK3LA Lock Assy - 3 Locks, 3 Keys

RK4LA Lock Assy - 4 Locks, 4 Keys

RK5LA Lock Assy - 5 Locks, 5 Keys

RK6LA Lock Assy - 6 Locks, 6 Keys

RK7LA Lock Assy - 7 Locks, 7 Keys

14

11

ZECKOROLL REV ‘A’ OCT 2018

Loading...

Loading...