Page 1

User Manual

August 2012

EAZ0077L00A Rev. B

Page 2

Trademarks

IMPORTANT:

Snap-on, ShopStre am, and ShopStream Connect, are trademarks of Snap-on Incorporated.

All other marks are trademarks or registered tr ademarks of th eir resp ective hold ers.

Copyright Information

©2012 Snap-on Incorporated. All rights rese rved.

Disclaimer of Warranties and Limitation of Liabilities

The information, specifications and illustrations in this manual are based on the latest information available at the

time of printing. While the authors have taken due care in the p rep ara tion of this manua l, nothing con t ained he rein:

• Modifies or alters in any way the standard terms and cond itions of the purchase, lea se, or rent al agre ement

under the terms of which the equipment to which this m anual relate s was acquired.

• Increases in any way the liability to the customer or to third parties.

Snap-on reserves the right to make changes at any time without notice.

Before operating or maintaining this u nit, please read this ma nual carefully paying extra attention to the safety

warnings and precautions.

Visit our websites at:

http://diagnostics.snapon.com (North America)

www1.snapon.com/diagnostics/uk (United Kingdom)

snapontools.com.au (Australia and New Zealand)

For Technical Assistance Call

1-800-424-7226 (North America)

CALL +44 (0) 845 601 4736 (United Kingdom)

E-mail DiagnosticsUKproductsupport@snapon.com (United King dom)

For technical assistance in all other markets, cont act your selling agent.

ii

Page 3

Safety Information

'$1*( 5

:$51 ,1*

&$87,21

For your own safety and the safety of others, and to prevent damage to the equipment an d

vehicles upon which it is used, it is important that the accompanying Important Safety Instructions

be read and understood by all persons operating, or coming into contact with, the equipment. We

suggest you store a copy near the unit in sight of the operator.

This product is intended for use by properly trained and ski lled pro fessional automo tive

technicians. The safety messages presented throughout this manual are reminders to the

operator to exercise extreme care when using this test instrument.

There are many variations in procedures, techniques, tools, and p art s for servicing vehicles, as

well as in the skill of the individual doing the work. Because of the vast number of test applications

and variations in the products that can be tested with this instrument, we cannot possibly

anticipate or provide advice or safety messages to cover every situation. It is the responsibility of

the automotive technician to be knowledgeable of the system being tested. It is essential to use

proper service methods and test procedures. It is import ant to perform tests in an appropriate and

acceptable manner that does not endanger your sa fety, the safety of others in the work area, the

equipment being used, or the vehicle being tested.

It is assumed that the operator has a thorough underst anding of vehicle systems before using this

product. Understanding of these system principl es and oper ating th eories is nece ssary for

competent, safe and accurate use of this instrument.

Before using the equipment, always refer to and follow the safety messages and app licable te st

procedures provided by the manufacturer of the vehicle or equipment being tested. Use the

equipment only as described in this manual.

Read, understand and follow all safety messag es and instructio ns in this manual, the

accompanying Important Safety Instr uction s, an d on the test equipm ent.

Safety Message Conventions

Safety messages are provided to help prevent personal injury and equipm ent damage. All safety

messages are introduced by a signal word indicating the haza rd level.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury to the operator or to bystanders.

Indicates a potentially hazardous situation which, if n ot avoided, could result in death o r serious

injury to the operator or to bystanders.

Indicates a potentially hazardous situation which, if not a voided, may r esult in modera te or mino r

injury to the operator or to bystanders.

iii

Page 4

Safety Information Important Safety Instructio ns

:$51 ,1*

Safety messages contain three different type styles.

• Normal type states the hazard.

• Bold type states how to avoid the hazard.

• Italic type states the possible consequences of not avoid ing th e hazard.

An icon, when present, gives a graphical description of the potential hazard.

Example:

Risk of unexpected vehicle movement.

• Block drive wheels before performing a test with engine running.

A moving vehicle can cause injury.

Important Safety Instructions

For a complete list of safety messages, refer to the accomp anyin g Important Safety Instructions.

SAVE THESE INSTRUCTIONS

iv

Page 5

Contents

Safety Information..................................................................................................................... iii

Contents....................................................................................................................................... i

Chapter 1: Using This Manual................................................................................................... 1

Conventions.................................................................................................................................. 1

Bold Text................................................................................................................................ 1

Symbols ................................................................................................................................. 1

Terminology ........................................................................................................................... 1

Notes and Important Messages............................................................................................. 2

Hyperlinks .............................................................................................................................. 2

Procedures............................................................................................................................. 2

Chapter 2: Introduction.............................................................................................................. 3

Display Device............................................................................................................................. 3

Functional Description ......................... ... ... .... ... ... ....................................... ... ... ... .... ... ... ... ..... 3

Technical Specifications ........................................................................................................5

Power Sources....................................................................................................................... 6

Scan Module..................... ... ....................................... ... .... ... ... ... .......................................... ... ..... 7

Functional description.................................... ... ....................................... ... ... ... ... .... ... ........... 7

Technical Specifications ........................................................................................................8

Power Sources....................................................................................................................... 8

Scope Multimeter Module............................................................................................................. 9

Functional Description ......................... ... ... .... ... ... ....................................... ... ... ... .... ... ... ... ..... 9

Technical Specifications ...................................................................................................... 10

Power Sources..................................................................................................................... 10

Chapter 3: Getting Started....................................................................................................... 11

Powering Up............................................................................................................................... 11

Module Buttons.................................................................................................................... 11

Toolbar................................................................................................................................. 13

Windows Toolbar .................................................................................................................16

Powering Down .......................................................................................................................... 17

Emergency Shutdown.......... ... ... ... .... ... ... ... ....................................... ... .... ... ... ... ... ................ 17

Chapter 4: Navigation .............................................................................................................. 18

Controls and Features................................................................................................................ 18

Control Buttons .................................................................................................................... 18

LEDs .................................................................................................................................... 19

The Stand ........................................................................................................................... 19

Camera Operation...................................................... ... .... ...................................... ... .... ... ......... 19

Chapter 5: Scanner Operations............................................................................................... 21

Getting Started ........................................................................................................................... 21

The Demonstration Program................................................................................................ 21

Disconnecting the Diagnostic Platform From a Vehicle....................................................... 22

i

Page 6

Contents

Vehicle Identification................................................................................................................... 23

Alternative Vehicle Identification.......................................................................................... 25

Connecting to a Vehicle.............................................................................................................. 26

Cables.................................................................................................................................. 26

No Communication Message............................................................................................... 27

Navigation................................................................................................................................... 27

Scanner Screen Layout ............................. .... ... ... ... ....................................... ... ... .... ... ... ... ... 27

Screen Messages ................................................................................................................ 30

Making Selections................................................................................................................ 30

Operations.................................................................................................................................. 30

Data Display......................................................................................................................... 32

Codes Menu..... .... ...................................... .... ... ... ... .... ... ...................................... .... ... ... ...... 36

Functional Tests... ... ... ... .... ... ... ... ....................................... ... ... .... ... ... ... ................................ 39

Generic Functions................................................................................................................ 40

Troubleshooter..................................................................................................................... 41

Scanner Toolbar Operations......... .... ... ... ... .... ... ....................................... ... ... ... ... .... ... ......... 42

Exiting the Scanner .................................................................................................................... 48

Downloading Firmware...............................................................................................................49

Chapter 6: OBD Direct Operations.......................................................................................... 52

OBD Health Check..................................................................................................................... 52

Global OBD II Code Check..................................... ....................................... ... ... .... ... ... ... ... 53

Global OBD II Clear Codes........... .... ... ... ....................................... ... ... .... ... ... ... ................... 54

Readiness Monitors ............................................................................................................. 54

MIL Status............................................................................................................................ 54

OBD Diagnose............................................................................................................................ 55

Start Communication ........................................................................................................... 55

Select Communication Protocol........................................................................................... 58

Connector Information ......................... ... ... .... ... ....................................... ... ... ... ... .... ... ......... 59

Chapter 7: Component Test Operations ................................................................................ 60

Vehicle Identification................................................................................................................... 60

Creating a Favorites List................................... ... ... .... ...................................... ... .... ... ......... 61

Identifying a Test Vehicle..................................................................................................... 62

Operations.................................................................................................................................. 64

Component Information ....................................................................................................... 64

Tests .................................................................................................................................... 65

Chapter 8: Scope Multimeter Operations............................................................................... 69

Remote Scope Multimeter Setup................................................................................................ 69

Getting Started ........................................................................................................................... 70

Capabilities .......................................................................................................................... 71

Leads, Probes and Adapters ............................................................................................... 72

Navigation................................................................................................................................... 75

Screen Layout...................................................................................................................... 75

Making Selections................................................................................................................ 79

Operations.................................................................................................................................. 79

Starting the Scope and Multimeter....................................................................................... 79

Scope and Multimeter Setup................................................................................................ 81

ii

Page 7

Contents

Chapter 9: Ask-a-Tech Operations ......................................................................................... 93

Ask-a-Tech Tips ...................................... ... ... ... .... ... ... ... ....................................... ... ... .... ............ 93

Launching Ask-a-Tech................... ... ... .... ...................................... .... ... ... ... .... ... ......................... 94

Ask-a-Tech Home Page.......................... ... ... ... .... ... ... ... ....................................... ... ... .... ... ... ... ... 94

Ask-a-Tech Pulse . ... ... ....................................... ... ... .... ... ... ... ....................................... ... ... ... 95

What Do You Want To Do? ................................................................................................. 96

Chapter 10: Information Operations..................................................................................... 100

Chapter 11: Vehicle History Operations............................................................................... 101

Screen Layout .......................................................................................................................... 101

Vehicle History Main Body................................................................................................. 101

Vehicle History Toolbar...................................................................................................... 102

Chapter 12: Data Manager Operations ................................................................................. 106

Screen Layout .......................................................................................................................... 106

Navigation................................................................................................................................. 107

Operations................................................................................................................................ 107

My Data.............................................................................................................................. 107

Up ...................................................................................................................................... 108

Open .................................................................................................................................. 108

New.................................................................................................................................... 108

Delete................................................................................................................................. 109

Rename ............................................................................................................................. 110

Save................................................................................................................................... 111

Properties........................................................................................................................... 111

More................................................................................................................................... 112

Saved File Structure................................................................................................................. 112

Chapter 13: Help Operations................................................................................................. 113

Using the Help Toolbar.................................. ....................................... ... ... .... ... ... ... ................. 113

Chapter 14: System Settings Operations............................................................................. 114

Paired Devices ........................................... ....................................... ... ... ... .... ... ... .................... 114

Pairing the Scan Module.................................................................................................... 115

Shop Information...................................................................................................................... 116

Chapter 15: Maintenance....................................................................................................... 118

Display Device.......................................................................................................................... 118

Cleaning the Touch Screen ............................................................................................... 118

Calibrating the Touch Screen ............................................................................................ 118

Cleaning and Inspecting the Display Device...................................................................... 121

Battery Service...................................................................................................................121

Operating System Restore ... ... ... ....................................... ... ... .... ... ... ... .............................. 124

Scan Module..................... ... ....................................... ... .... ... ... ... ... ........................................... 125

Cleaning and Inspecting the Scan Module ........................................................................ 125

Replacing the Protective Handgrip.......................................... .... ... ... ... .... ... ...... ... .... ... ... ... . 125

Software License Agreement, North America ................................. ... ... .... .......................... 126

Index............................. ....................................... ... ....................................... ... ....................... 131

iii

Page 8

Chapter 1 Using This Manual

This manual contains tool usage instructions.

Some illustrations shown in this manual may contain modules and optional equipment that are not

included on your system. Contact your sales representative for availability of other modules and

optional equipment.

1.1 Conventions

The following conventions are used.

1.1.1 Bold Text

Bold emphasis is used to highlight selectable items such as buttons and menu options.

Example:

• Press the OK button.

1.1.2 Symbols

Different types of arrows are used. The “gre ater than” arrow ( >) indicates an abbrevia ted set of

selection instructions.

Example:

• Select Utilities > T ool Setup > Date.

The example statement abbreviates the followin g procedur e:

1. Navigate to the Utilities screen.

2. Highlight the Tool Setup submenu.

3. Highlight the Date option from the submenu.

4. Press OK to confirm the selection.

The solid arrows (

Example:

• Press the down arrow.

1.1.3 Terminology

The term “select” means highlighting a button or menu item and pre ssing the Accept, OK, Y es, or

other similar button to confirm the selection.

Example:

• Select Reset.

, , , ) refer to the four directions of th e dire ctional arr ow keys.

1

Page 9

Using This Manual Conventions

NOTE:

IMPORTANT:

IMPORTANT:

The above statement abbreviates the following procedu re:

1. Navigate to and highlight the Reset selection.

2. Press the OK, or similar, button.

1.1.4 Notes and Important Messages

The following messages are used.

Notes

A NOTE provides helpful information such as additional explanations, tips, and comment s.

Example:

i For additional information refer to...

Important

IMPORTANT indicates a situation which, if not avoided, may result in damage to the test

equipment or vehicle.

Example:

Do not disconnect the data cable while the Scanner is commun icating with the ECM.

1.1.5 Hyperlinks

Hyperlinks, or links, that take you to other related articles, procedures, and illustrations are

available in electronic documents. Blue colore d text indicates a select ab le hyperli nk.

Example:

Read all applicable Safety Information before using this tool!

1.1.6 Procedures

An arrow icon indicates a procedure.

Example:

z To change screen views:

1. Select the View button.

The dropdown menu displays.

2. Select an option from the menu.

The screen layout changes to the format selected.

2

Page 10

Chapter 2 Introduction

The Diagnostic Platform is a specialized personal automotive d iagnostic solution tha t combines

information with test instrumentation to help you diagno se symptoms, co des, and complain t s

quickly and efficiently. There are three main components to the system:

•

Display Device—the central processor and monitor for the system

•

Scan Module—the device for accessing vehicle data

•

Scope Multimeter Module—the device for sampling circuit s and sign als

This manual describes the construction and operation of th ese three devic es and how th ey work

together to deliver diagnostic solutions.

2.1 Display Device

2.1.1 Functional Description

1— Audio Speaker

2— Power Indicator LED (light emitting diode)

3— Microphone

4— Hard Drive Activity LED

5— Directional Buttons; left (

6— S Button (special functions)

7— Enter Button

8— Camera (shutter) Button

9— Virtual Keyboard Button

10—Brightness Button

11—Power Button

), right (), up (), down ()

Figure 2-1 Model D10 front view

3

Page 11

Introduction Display Device

/HIW6LGHRI8QLW

1— Hinged Cover

2— USB (universal serial bus) Ports (2)

3— Head Phone Jack

4— Microphone Jack

5— DC Power Supply Input Port

Figure 2-2 Model D10 side view

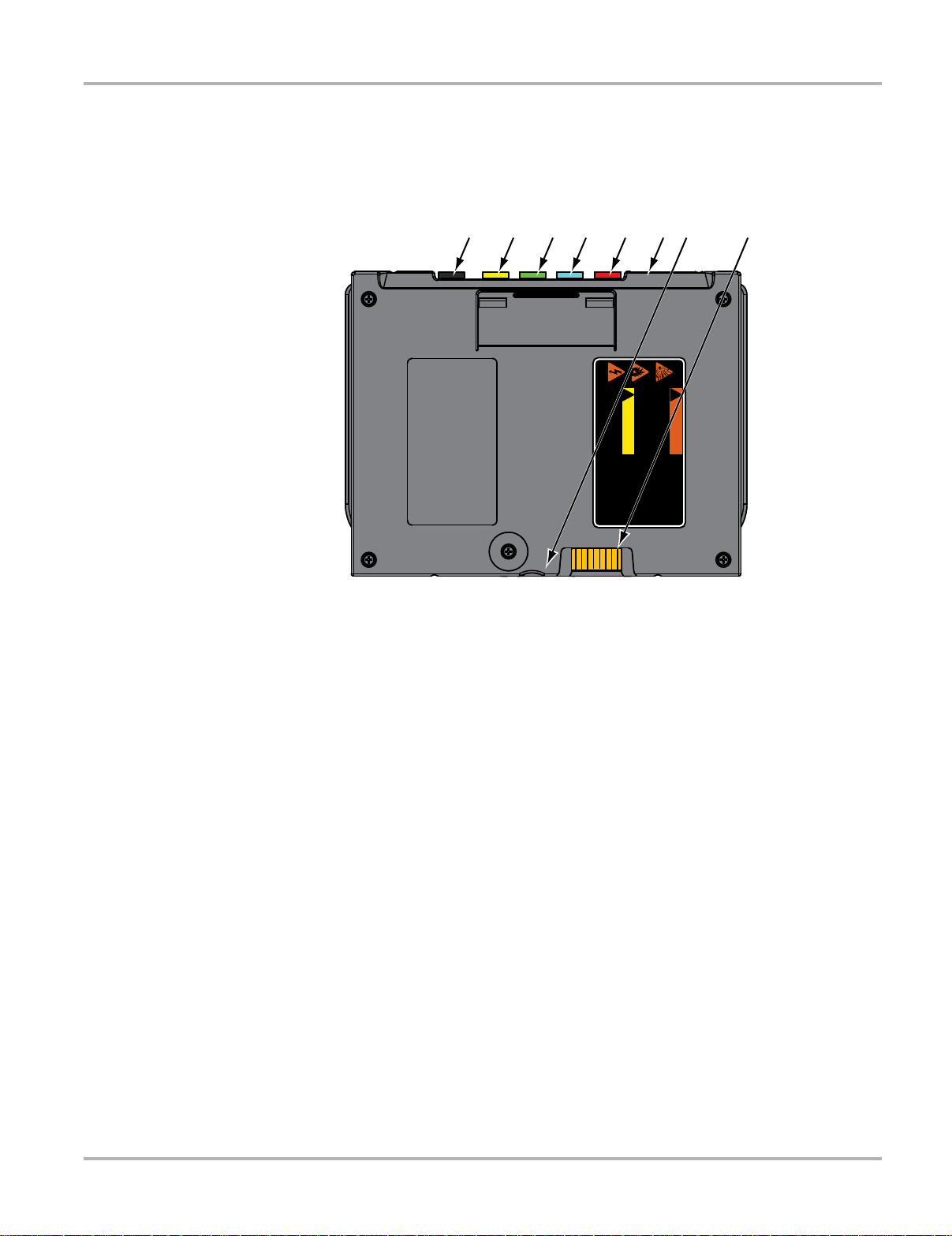

1— Kennsington Lock (standard security device connection, device not included)

2— Battery Compar tment Cove r

3— Collapsible S tand (closed)

4— Camera Lens

Figure 2-3 Model D10 back view

4

Page 12

Introduction Display Device

2.1.2 Technical Specifications

Processor:

Intel Atom Z530P 1.6GHz

Operating System

Microsoft Windows Embedded Standard SP3

T ouc h Screen

Resistive Touch Panel

Display:

10.2 inch diagonal, LCD TFT

1024 x 600 resolution WSVGA

16 bit color

Battery:

Lithium Ion Smart Battery Pack

Approximate 4 hour run time

Approximate 4 hour charge time (with or without unit operating)

DC Jack Operating Voltage

10V to 32V DC

Communications:

802.11 b/g/n Wireless

Bluetooth 2.1 + EDR

Dimensions:

Width:

13.23 inches

336.1 mm

Height:

8.07 inches

205 mm

Depth:

2.41 inches

61.3 mm

Weight (including battery pack and Scope Multimeter Module):

5.1 lbs.

2.31 kg

Weight (including battery pack, without Scope Multimeter Module):

4.5 lbs.

2.04 kg

5

Page 13

Introduction Display Device

Operating Temperature Range (ambient):

At 0 to 90% relative humidity (non-condensing)

32 to 113°F

0 to 45°C

Storage Temperature (ambient):

At 0 to 70% relative humidity (non-condensing)

–4 to 140°F

–20 to 60°C

Environmental Conditions:

This product is intended for indoor use only

This product is rated for Pollution Degree 2 (normal conditions)

Power Supply:

Supply Rating; 19 VDC. 3.42A

2.1.3 Power Sources

Your Display Device can receive power from any of the following sources:

Internal Battery Pack

•

• AC/DC Power Supply

• Vehicle Power

• Docking Cradle (Optional)

Internal Battery Pack

The display unit can be powered from the internal rechargeable ba ttery. A fully charged standard

battery provides sufficient power for about 4.5 hours of continuous operation. A LED on the front

of the unit indicates the battery state of charge.

AC/DC Power Supply

The display unit can be powered from a wall socket using the AC/DC power supply. The AC/DC

power supply also powers the internal battery pack charging process.

V ehicle Power

The display unit can be powered from a standar d 12-volt power port on the test vehicle through a

direct cable connection. The vehicle power cable connects to the DC power supp ly port on the left

side of the display unit.

Docking Cradle (Optional)

The display unit can be powered and operated when inst alled on the optional docking cradle. Th e

docking cradle also powers the internal battery pack charging process and allows USB

connectivity for attaching peripherals. Contact your sale represent a tive for addition al det ails.

6

Page 14

Introduction Scan Module

($//%

5

7RS

)URQW

%RWWRP

2.2 Scan Module

2.2.1 Functional description

1— Data cable connector

2— Memory card port (remove protective hand grip f or access)

3— Bluetooth LED (green)

4— Communication issue LED (red)

5— V e hicle power L ED (green)

6— Universal serial bus (USB) port (remove prote ctive hand gr ip for access )

Figure 2-4 Scan Module

Wireless Communication

The Scan Module is a wireless communications device that transmits vehicle dat a to th e disp lay

device without a physical connection. The working range of the transmitter is abo ut 30 feet

(9.14 m). A signal lost due to moving out of range automatically restores itself when the display

unit is brought closer to the Scan Module. The Scanner sounds a tone and the Display Device

shows a warning message when the signal is lost.

7

Page 15

Introduction Scan Module

2.2.2 Technical Specifications

Dimensions:

Length:

8.04 inches

204.3 mm

Height:

3.82 inches

97 mm

Depth:

1.66 inches

42.1 mm

Weight (including protective hand grip):

0.9 lbs.

0.408 kg

Communications:

Bluetooth 2.0 Class 1

USB Power:

5V @ 500mA

Data Cable Connector Power:

8V to 32V, Maximum 12 Watts

Operating Temperature Range (ambient):

At 0 to 90% relative humidity (non-condensing)

32 to 113°F

0 to 45°C

Storage Temperature (ambient):

At 0 to 70% relative humidity (non-condensing)

–4 to 140°F

–20 to 60°C

Environmental Conditions:

This product is intended for indoor use only

This product is rated for Pollution Degree 2 (normal conditions)

2.2.3 Power Sources

The Scan Module operates on 12V or 24V vehicle power , which it r eceives through the data cable

connector. The unit powers o n whenever it i s connected to an OBD-II/EOBD comp liant dat a lin k

connector (DLC). For non OBD-II/EOBD compliant vehicles, the unit can be powered from a

suitable power port on the test vehicle using the auxiliary power cable supplied with your kit.

8

Page 16

Introduction Scope Multimeter Module

:$51,1*

&$87,21

5,6.2)(;3/26,21

)/$0$%/()8(/$1'9$3256&$1,*1,7(

7+,6(48,30(17+$6,17(51$/$5&+,1*2563$5.,1*3$576

'2127(;326(72)/$00$%/(9$3256

/2&$7(7+,6(48,30(17$7/($67PP,1&+(6

$%29(7+()/225

5,6.2)(/(&75,&$/6+2&.

'21275(029(&29(525%$&.

1286(56(59,&$%/(3$576,16,'(

5()(56(59,&,1*7248$/,),('6(59,&(3(56211(/

(;3/26,2125)/$0(&$1&$86(,1-85<

(/(&75,&$/6+2&.&$1&$86(,1-85<

2.3 Scope Multimeter Module

2.3.1 Functional Description

1— Common (Ground) Port

2— Channel 1 Port

3— Channel 2 Port

4— Channel 3 Port

5— Channel 4 Port

6— Auxiliary Port (not visible in illustration)

7— USB Port (under protective co ver)

8— Display Device Connection

Figure 2-5 Scope Multimeter Module, removed from Display Device

Remote Operation

The Scope Multimeter Module installs into the Display Device and is held in place by a lock tab.

Depress the lock tab and the Scope Multimeter Module is easily removed from the Display Device.

A USB cable (supplied with your kit) can then be used to connect the Scop e Multimeter Module to

the Display Device. Now, you can continue to remotely monitor ci rcuit activity while moving the

Display Device around the vehicle.

9

Page 17

Introduction Scope Multimeter Module

2.3.2 Technical Specifications

Dimensions:

Length:

6.75 inches

171.5 mm

Height:

5.1 inches

129.5 mm

Depth:

0.89 inches

22.6 mm

Weight (including protective hand grip):

0.66 lbs.

0.30 kg

Operating Temperature Range (ambient):

At 0 to 90% relative humidity (non-condensing)

32 to 113°F

0 to 45°C

Storage Temperature (ambient):

At 0 to 70% relative humidity (non-condensing)

–4 to 140°F

–20 to 60°C

Environmental Conditions:

This product is intended for indoor use only

This product is rated for Pollution Degree 2 (normal conditions)

2.3.3 Power Sources

The Scope Multimeter Module operates on USB power (5V @ 5 00mA) supplie d by the Display

Device. Power is provided either through direct connection to the Display Device, or through a

USB cable when the Scope Multimeter Module is separated from the Display Device.

10

Page 18

Chapter 3 Getting Started

Make sure the Display Device has a charged battery or is connected to an AC/DC power supply

Power Sources on page 8). It is highly recommended to back up personal and saved data to

(see

a USB mass storage device on a regular basis to prevent loss in the event of system corruption or

hard disk drive failure.

3.1 Powering Up

Press the Display Device Power button to switch the unit on. The system boots up, then opens the

Home screen (

Figure 3-1).

1. Module Buttons

2. Toolbar

3. Windows Toolbar

3.1.1 Module Buttons

The Module buttons configure the Display Device for the type of test to be performed.

page 12 gives brief descriptions of the available Module buttons, which operations ar e available

depends upon the individual configuration of your system. Use the stylus or your finger tip to select

from the Module buttons.

Figure 3-1 Sample Home screen

Table 3-1 on

11

Page 19

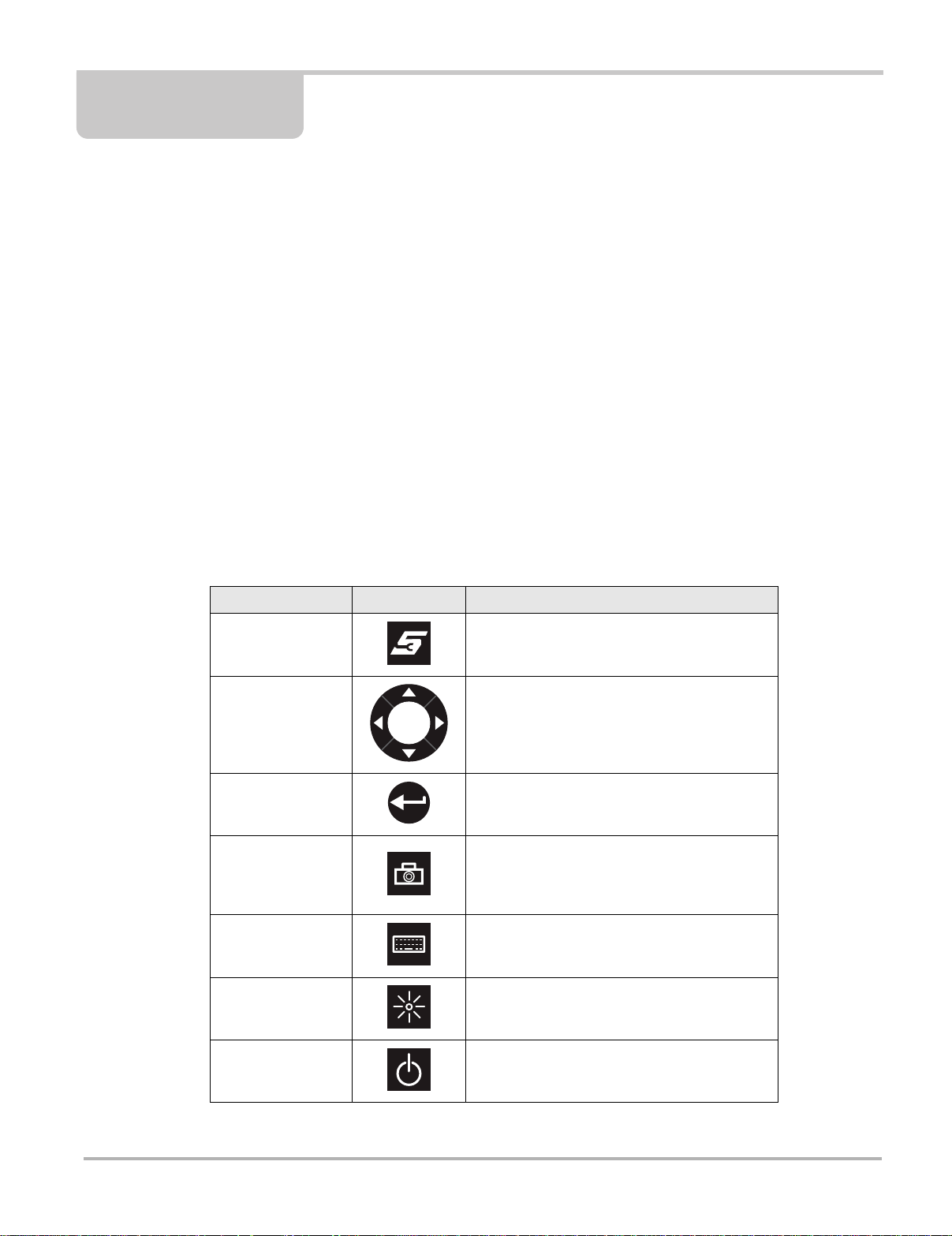

Getting Started Powering Up

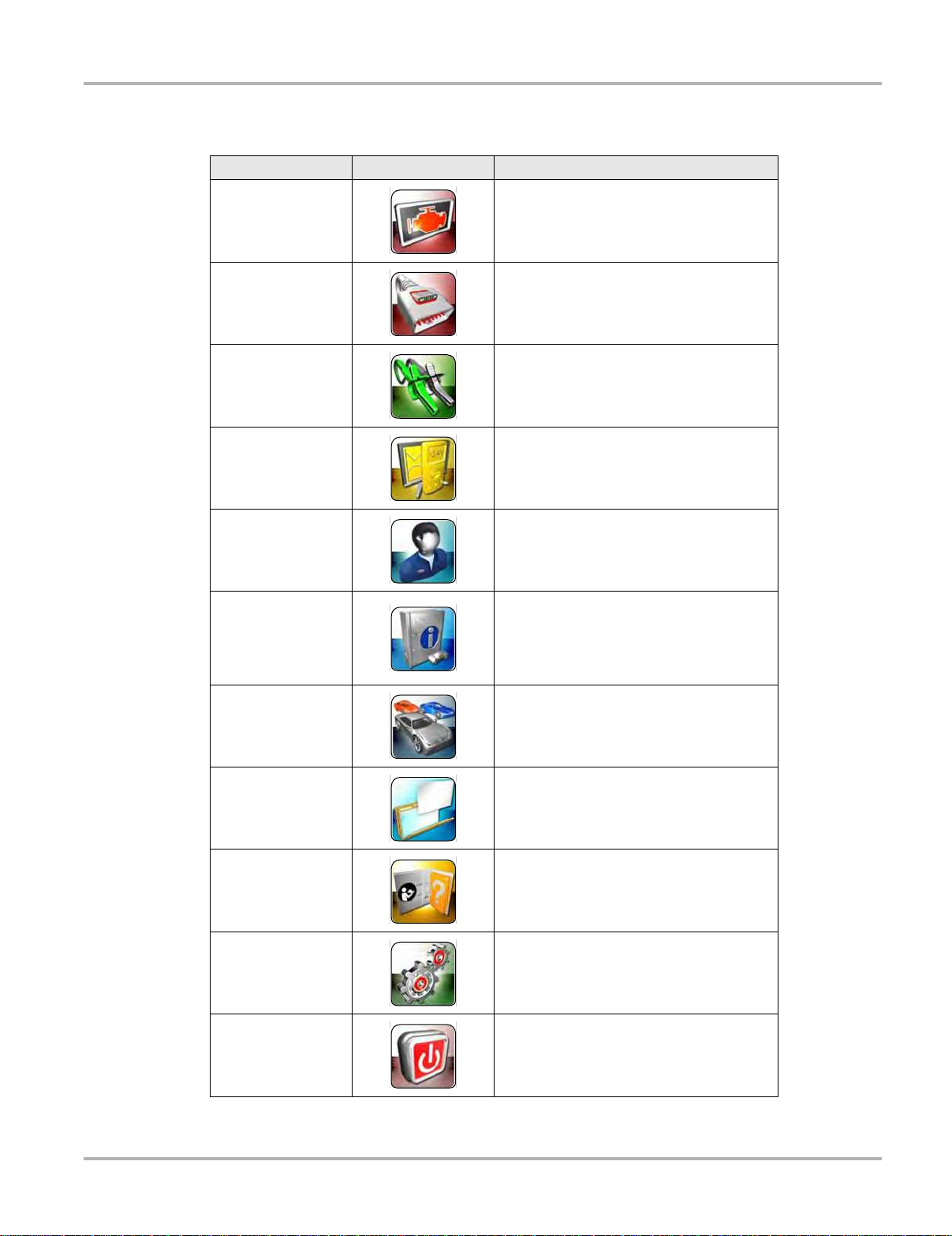

Table 3-1 Module buttons

Name

Button

Description

Scanner

OBD Direct

Component Test

Scope Multimeter

Ask-a-Tech

Information

Configures the unit to operate as a scan

tool. See

Scanner Operations on page 21.

Allows you to perform generic OBD-II or

EOBD system tests without identifying the

specific vehicle. See

Operations

on page 52.

OBD Direct

Opens a diagnostic database of specific

tests for the identified vehicle. See

Component Test Operations on page 60.

Configures the unit to operate as a lab

scope, graphing multimeter, or digital

multimeter. See

Operations

Scope Multimeter

on page 69.

Launches the Ask-a-Tech website. See

Ask-a-Tech Operations on page 93.

Provides the information needed to make

repairs once you have made your

diagnosis. The linked program varies by

region. See

Information Operations on

page 100.

Vehicle History

Data Manager

Help

System Settings

Exit

Identifies the test vehicle and organizes and

manages work in progress and service

records. See

Vehicle History Operations on

page 101.

Opens the organization system for saved

data files. See

Data Manager Operations on

page 106.

Opens the on-line help for the system. See

Help Operations on page 113.

Establishes and manages wireless

connections to peripheral devices, such as

the Scan Module. See

Operations

on page 114.

System Settings

Closes the diagnostic Platform software and

returns the display to the Windows desktop.

See

Powering Down on page 17.

12

Page 20

Getting Started Powering Up

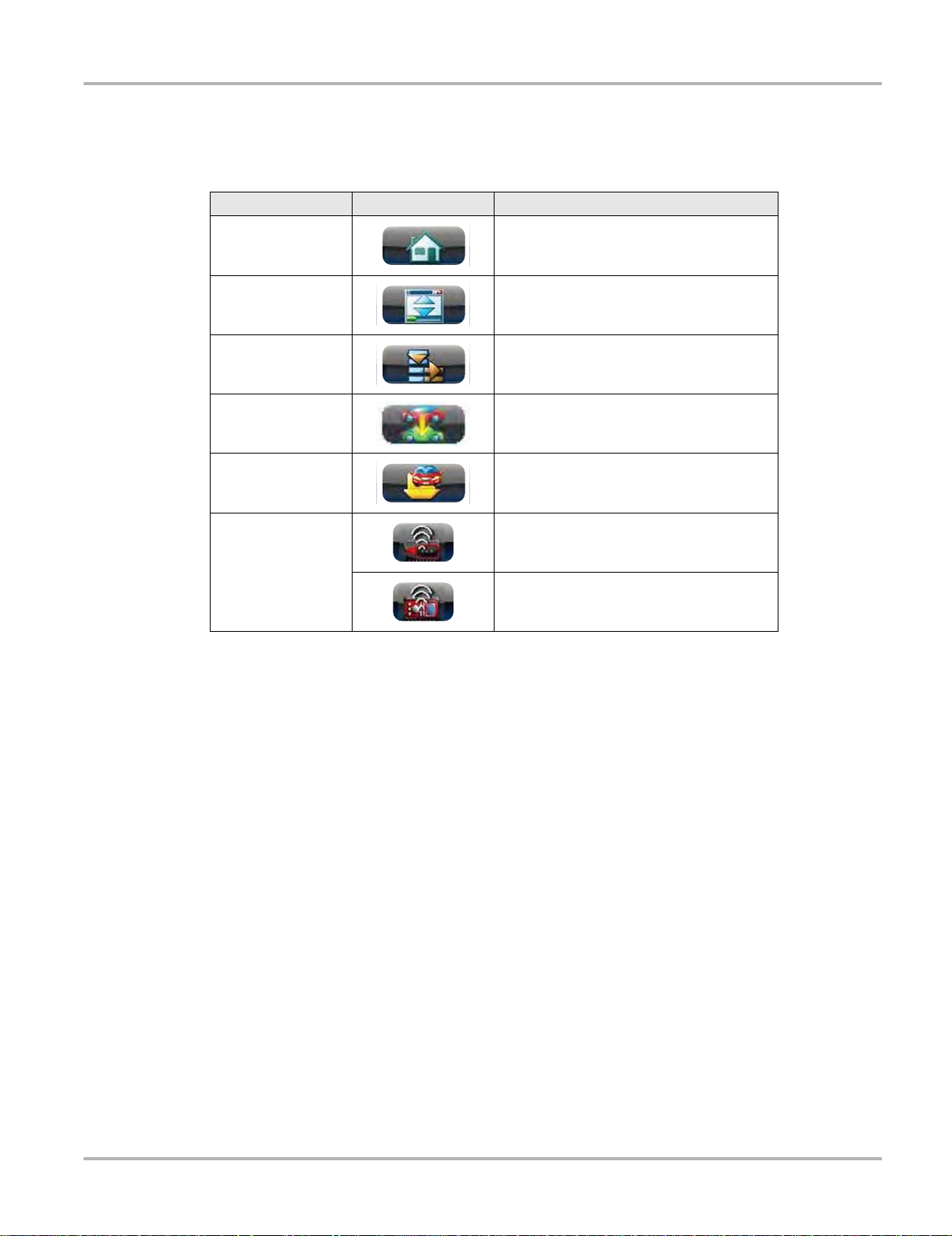

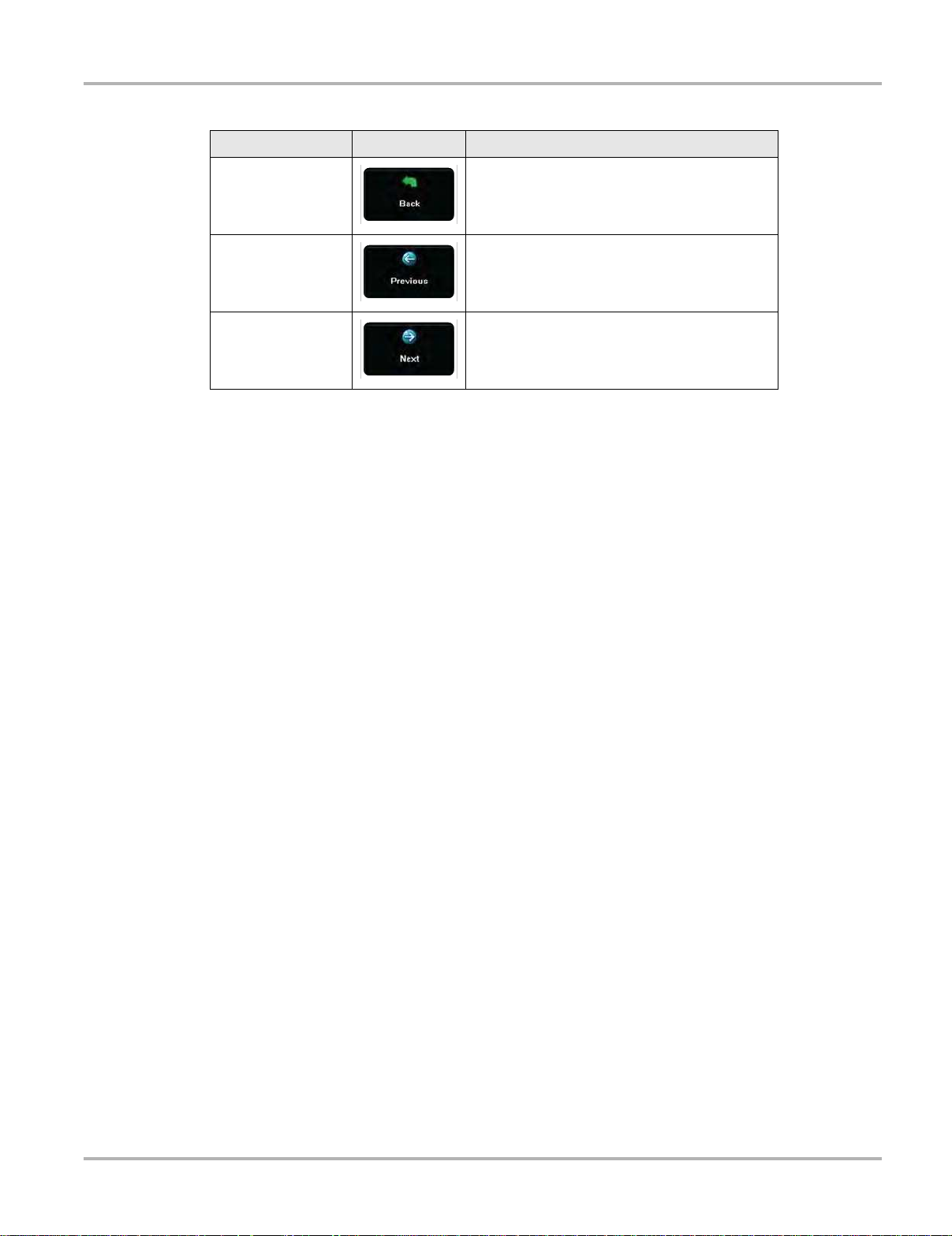

3.1.2 Toolbar

Operation of the buttons located on the toolbar are describe d in the t ab le below:

Table 3-2 Module buttons

Name

Button

Description

Home

Windows Toolbar

Menu

Change Vehicle

View Record

Hardware Status

Menu Button Options

Touching this button returns you to the

Home screen from any test.

Touching this button opens and closes the

standard Windows toolbars at the top and

bottom of the screen.

Touching this button opens a menu that

provides information and basic operations

and features for the current screen.

The currently identified vehicle is shown to

the right of the buttons, touching allows you

to change the identified test vehicle.

Touching the button opens an editable

worksheet of vehicle records.

Indicates the wireless connectivity status of

the Scan Module.

Indicates the wireless connectivity status of

the Scope Multimeter.

The Menu button on the Toolbar at the base of the display screen opens a list of basic operations

and features. Menu options vary by module and may include:

• Safety Information—opens the Important Safety Instructions document, which should be

read and understood prior to using the Diagnosti c Plat fo rm.

• File—allows you to print or save the data being viewed.

• Edit—allows you to configure alarms when viewing Scanner data.

• Setup—allows you to adjust tool settings.

• Help—allows you to view supporting documentation.

Selecting a menu item opens a submenu of choices, and some submenus also open a n additional

menu. A right arrowhead (

) indicates additional choices are available. Touch an item to select it.

File

Use to print or save a copy of the data currently being viewed. Selecting opens a submenu:

• Save—available from the Scan Module, opens an additional submenu with these options:

– Screenshot—saves a graphic image of the current screen

– Collected Data—saves a recording of all the data currently in the buf fer plus the number

of frames designated after the trigger event (see

13

Properties on page 44).

Page 21

Getting Started Powering Up

• Print—available from the Scan Module, opens an additional submenu with these options:

– Screen—sends the current screen image to a printer.

– Troubleshooter—prints the full text of the troubleshooter topic shown in the main body.

• Print Article—available from the Component Test module, has one of the following results:

– If connected to a printer, the file is sent to the printer.

– If not connected to a printer, the article is saved as a .xps file, which can be retrieved,

moved, or copied and printed at a later time.

• Print Preview—available from the Component T est module, displays how the selected article

will appear when printed.

• Page Setup—available from the Component Test module, opens a dialog box that allows you

to adjust the format (orientation and margins) of th e p ages to be prin ted.

Selecting a print option opens a standard Windows Prin t dialog bo x, which allows yo u to print or

save the file.

Edit

This Scan Module option performs the same function as the Alarms bu tton on the Scann er

Toolbar. (For more information refer to

Alarms on page 43).

Setup

This Scan Module option allows you to adjust tool settings to your personal preferences. Selecting

Tools opens a submenu that includes the following:

Graph Properties

•

• Unit Setup

• Download Firmware

• Display BEN

Graph Properties

Selecting opens the General Graph Properties dialog box, which is similar to what is available

from the Properties button on the Scanner Toolbar (see

here apply to all of the graphs. Graph properties options allow you to :

Properties on page 44). Changes made

• Change the background and plot colors of the graphs.

• Switch graph grid lines on and off.

• Adjust how much data is captured after a triggering event.

• Adjust the sweep time of the graphs.

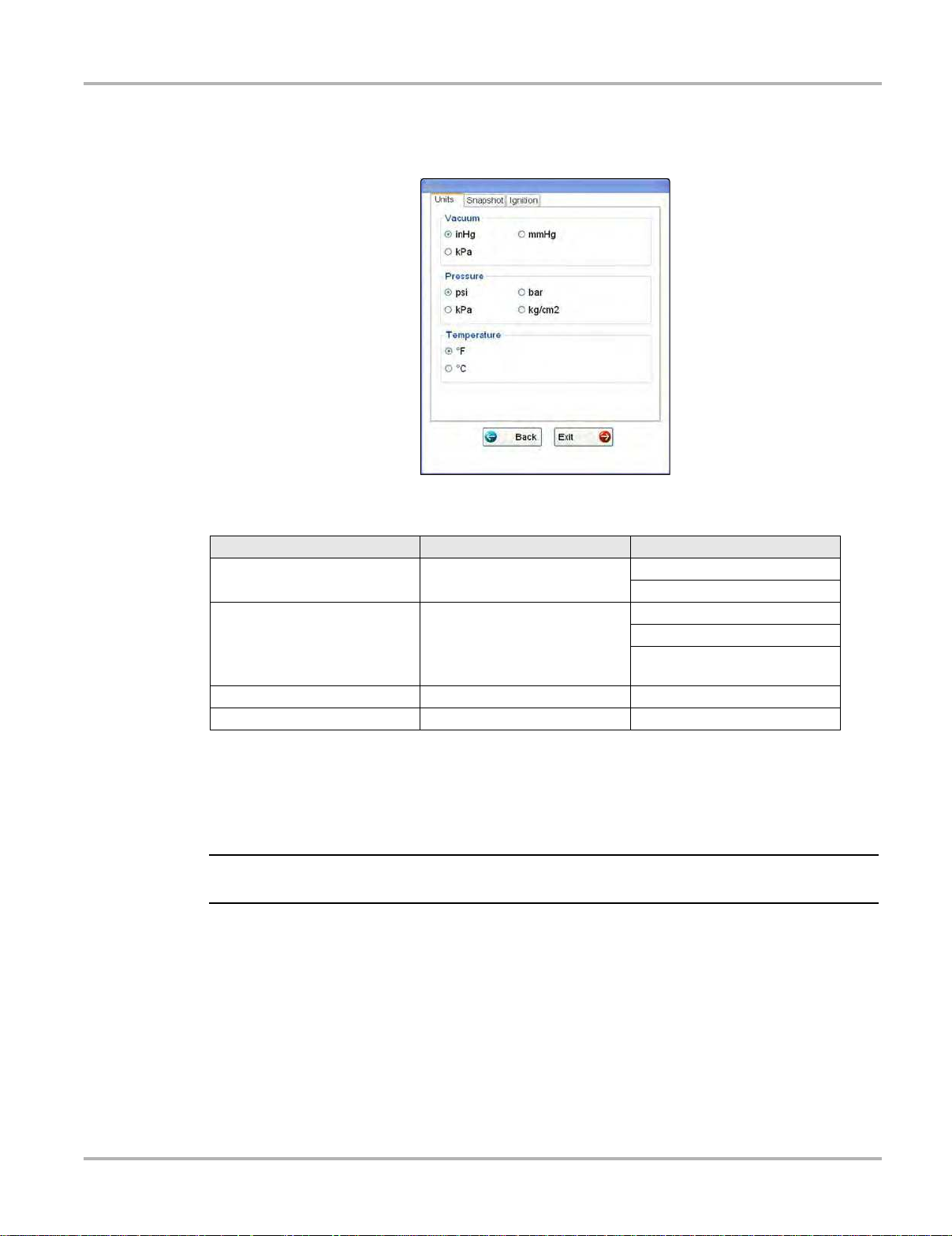

Unit Setup

Selecting opens a dialog box that allows you to choose between US customary or metric units of

measure for temperature, vehicle speed, and pressure read ings.

z To change the units setup:

1. From the Toolbar select Setup > Unit Setup.

The Setup dialog box opens to the Units t ab (

Figure 3-2).

14

Page 22

Getting Started Powering Up

NOTE:

2. Tap the values to select each item, the “radio knob” indicates the selected setting .

3. Tap Back or Exit to close the dialog box and apply the changes.

Figure 3-2 Sample view options

Table 3-3 Scan tool units of measurement

Setting

Vacuum

(manifold pressure)

Pressure kPa (kilopascal)

Temperature °C (degrees Celsius) °F (degrees Fahrenheit)

Vehicle Speed kph (kilometers per hour) mph (miles per hour)

kPa (kilopascal)

Default

inHg (inches of mercury)

mmHg (millimeters of mercury)

psi (pounds per square inch)

bar (atmosphere)

kg/cm2 (kilograms per

centimeter squared)

Option

Download Firmware

This option is used to update the firmware on your Dis pl ay De vi ce. F or firmware information,

contact your sales representative or Customer Ca re. While do wnloading the firmware , do not

interrupt the download process. Connection interruption may result in da mage to the unit.

i It is recommended to connect the unit to an AC power source when downloading firmware.

Display BEN

This option shows the BEN of the currently identified vehicle in the Scanner toolbar. The BEN is a

unique identifier that is used internally for data coor dination a nd communica tion.

15

Page 23

Getting Started Powering Up

Help

A variety of utilities and additional resources are available through the Help menu. Menu options

vary by module and may include:

•

User Manual

• Vers ion Info

• Activation Status

• User’s Manuals

• About Component Test

• About Scanner

User Manual

This option opens this document, which provides overall navigation and oper ation information for

the Diagnostic Platform.

Version Info

This option opens a window showing the version of the software and a co py of the Sof t ware

License Agreement. Tap OK to close the window.

Activation Status

This option opens a dialog box with version and licensing details for the system, and activation

status for the Display device and all other modules.

User’s Manuals

This Scan Module option opens a submenu of support docu ment ation , such as ve hicle

communication software manuals. These manu als provide co nnection an d test inform ation for

specific vehicles. Selecting a menu item opens a printable PDF ve rsion of the docume nt in a

separate window .

About Component Test

This option opens a dialog box that contain s so f tware vers ion and details, copyright data, and

other specific details about the Component Test module.

About Scanner

This option opens a dialog box that contain s so f tware vers ion and details, copyright data, and

other specific details about the Scan Modul e.

3.1.3 Windows Toolbar

This is the standard Windows toolbar. Y our Display Device is a fully functional personal computer

based on the Windows Embedded S t andard ope rating system. Refer to Microsoft documenta tion

for additional information.

16

Page 24

Getting Started Powering Down

3.2 Powering Down

All vehicle communication must be terminated before shutting down the Display Device. A

warning message displays if you attempt to shut down while the Scan Module is communicating

with the vehicle. Forcing a shut down while communicating may lead to ECM proble ms on some

vehicles. Exit the Scan Module before powering down.

z To power down the Display Device:

1. Navigate to the Home screen.

2. Select the Exit button.

3. From the Windows desktop, open the Windows Start menu.

4. Select T urn Off Computer.

5. Select Turn Off in the dialog box.

The open programs close and the power switches of f.

3.2.1 Emergency Shutdown

In case of emergency, press and hold the Power button for 5 seconds to force a shutdown.

17

Page 25

Chapter 4 Navigation

This chapter discusses how to use the hardware controls and features for the Displ ay Device.

There are no external controls on the Scan Module or Scope Multimeter Module , They can only be

operated when used in conjunction with the Display Device.

4.1 Controls and Features

The external controls on the Display Device are simple because most operations are controlled

through the touch screen. Touch screen navigation is menu driven, which allows you to quickly

locate the test, procedure, or data that you need throu gh a series of choices and qu estions.

Detailed descriptions of the menu structures are found in the chapters for the various modules.

The following sections describe the external controls and featur es of the d isplay de vice.

4.1.1 Control Buttons

Name and location of control buttons:

Table 4-1 Display Device control buttons

Name

Button

Description

S Button

Directional Buttons

Enter Button

Camera Button

Keyboard Button Opens or closes the virtual keyboard.

Brightness Button

Power Button Turns the unit on and off.

A function button that provides a shortcut for

capturing a screen image.

Moves the cursor or highlight on the display

screen up, down, right, or left.

Selects a highlighted item or returns the display

to the previous screen.

Operates the built-in camera. Press once to

open the application. The button then acts as a

shutter to take a photograph of what is visible

on the screen.

Increases the screen backlighting in seven

incremental steps, then returns to the lowest

setting and repeats.

All other tool operations are controlled through the touch screen.

18

Page 26

Navigation Camera Operation

4.1.2 LEDs

There are two light-emitting diodes (LEDs) on the front face of the device (see

page 3 for locations):

• Power Indicator LED—this device uses three colors to show the battery and power status as

follows:

– Green indicates a either a battery with a full, or nearly full, charge or DC po we r

– Orange indicates a battery that is charging. An orange LED that fades on and of f at three

second intervals indicates the unit is in Standby mode.

– Red indicates a low battery (15% of capacity or less).

• Hard Drive Activity LED—illuminates when the central processing unit (CPU) is reading or

writing to the hard disk drive (HDD).

4.1.3 The St and

The built-in stand extends from the back of the unit to allow hands- free viewing . The st and clips

into the unit for storage and pivots out so the display is a t a 45 deg ree an gle when in use.

4.2 Camera Operation

A single press of the Camera button on the front of the Dis play Devic e activates the camera. With

the camera active, the touch screen becomes the view finder and is also used for reviewing

photographs that are taken. Buttons on the touch scree n are used to o perate the came ra. Th e

buttons change depending on what camera function is active:

Table 4-2 Camera buttons (part 1 of 2)

Name

Button

Figure 2-1 on

Description

Photo

Gallery

Exit

OK

Delete

Acts as a shutter to take a photograph of what is

visible in the view finder, which is the left-hand

portion of the screen.

Opens a thumbnail gallery of recently taken

pictures.

Closes the camera application and returns to

the previous screen.

Displays after a picture is taken. Selecting

saves the photograph and returns to the view

finder.

Displays after a picture is taken and in Gallery

mode. Selecting discards the photograph and

returns to the previous screen.

19

Page 27

Navigation Camera Operation

Table 4-2 Camera buttons (part 2 of 2)

Name

Button

Description

Back

Previous

Next

Displays in Gallery mode. Selecting returns to

the previously viewed screen.

Displays in Gallery mode. Selecting opens the

picture prior to the current image in the gallery.

Displays in Gallery mode. Selecting opens the

picture after to the current image in the gallery.

z To use the camera:

1. Press the Camera button.

The camera screen opens and the Camera button now controls the shutter.

2. Focus the image to be captured in the view finder.

3. Press the Camera button, or tap the Photo button.

The view finder now shows the captured picture.

4. Select OK to save the image, or Delete to delete it.

The view finder is live and the Camera button is the shutter, repeat steps 2, 3, and 4 to take

additional pictures.

5. Select Exit from the live view to close the camera application.

Photographs are stored on the hard drive and can be r etrieved from the desktop by selectin g

My Documents > ShopStream > Camera Folder.

20

Page 28

Chapter 5 Scanner Operations

The Scanner allows you to establish a dat a lin k to the ele ctronic control systems of the vehicle

being serviced to retrieve diagnostic trouble codes (DTCs), view live data parameters, and

perform tests. The Scanner can access the electro nic control module (ECM) for var ious veh icle

control systems such as engine, transmission, antilock brake system (ABS) and more.

Scanner testing requires connecting the Scan Module to the test vehicle using the data cable and

test adapters. On screen instructions tell you how to connect the Scan Modu le, additiona l

connection information can be found in the appropriate vehicle communication sof tware manual

for the test vehicle, which is available through the Help menu.

5.1 Getting Started

Prior to first use of the Scan Module the unit must be p aired with the Display Device to establish a

wireless communication link. Refer to

A demonstration program allows you to become familiar with Scanner operations and testing

without being connected to an actual vehicle.

Pairing the Scan Module on page 115 for details.

5.1.1 The Demonstration Program

The Scanner demonstration program allows you to become familiar with many of the test

capabilities without connecting to a vehicle. Sample data and mock test results help you learn the

menus and basic operations.

The Scan Module must be paired with the display device to use th e demonstration progra m. See

Pairing the Scan Module on page 1 1 5 for de t ails. Both the Scan Mod ule and the displa y device

must be powered on.

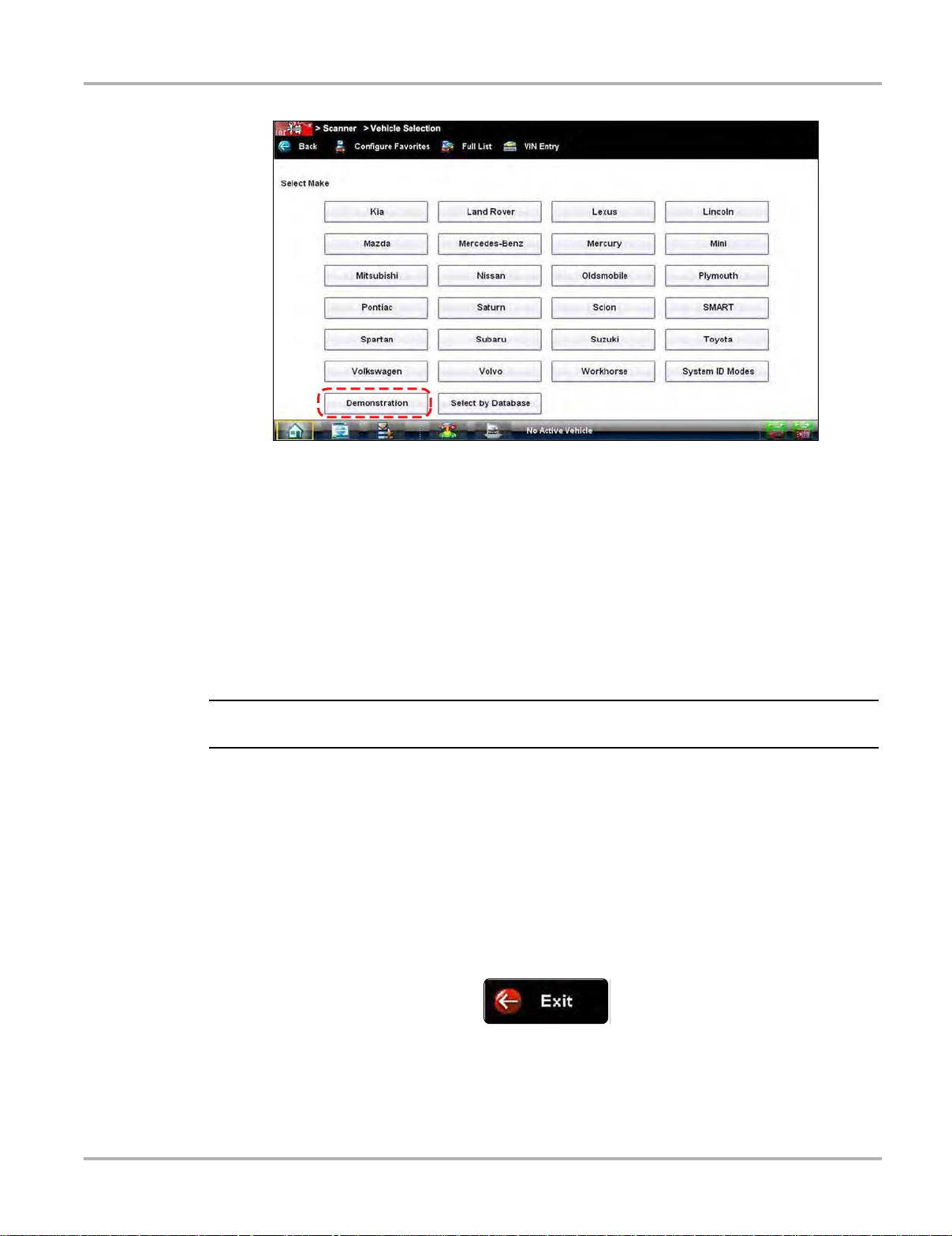

z To start the demonstration program:

1. From the Home screen, tap the Scanner icon.

The manufacturer menu displays. This menu includes all makes that are covered by any of the

Diagnostic Platform modules, not just those for which Sca nner information is available. There

is also a Demonstration button included in the list.

2. Tap the Demonstration button.

21

Page 29

Scanner Operations Getting Started

IMPORTANT:

Figure 5-1 Sample demonstration selection

A screen with two choices now displays:

– US Domestic—contains actual data captured while driving a 2001 Chevrolet T ahoe. Look

for the throttle position (TP) sensor dropout while analyzing the data in Graphing mode.

– OBD Training Mode—provides simulated data for an OBD-II/EOBD vehicle that allows

you to access any of the standard functions.

3. Select either option and a confirmation message di splays.

4. Select Ok to load the selected database.

5. Follow the on-screen instructions and select as needed until the Systems menu displays.

6. Select from any of the systems listed, then select from the submenus.

Do not connect a vehicle to the Scan Module while in the Demonstration mode .

5.1.2 Disconnecting the Diagnostic Platform From a Vehicle

When disconnecting the Diagnostic Platform from the vehicle, make sure the Scanner software is

not communicating with the vehicle.

z To exit Scanner and disconnect from a vehicle:

1. From a codes or data display screen, tap the Exit button on the upper toolbar.

Figure 5-2 Sample upper toolbar Exit button

The screen goes to the codes or data menu.

2. Tap the Back button on the upper toolbar.

22

Page 30

Scanner Operations Vehicle Identification

NOTE:

Figure 5-3 Sample upper toolbar Back button

The screen goes to the system menu.

3. Tap the Back button on the upper toolbar.

A “stopping communication” briefly displays followed by the systems menu.

4. Tap the Change Vehicle button on the Toolbar.

Figure 5-4 Sample Toolbar Change Vehicle button

The vehicle description on the toolbar should now read “No Active Vehicle”.

5. Tap the Home button on the Toolbar.

Figure 5-5 Sample Toolbar Home button

The Home screen displays.

6. Disconnect the test adapter from the vehicle connector.

i Damage to the electronic control module (ECM) of the vehicle can occur if communica tion is

disrupted. Ensure that the vehicle communication cable is pr operly connected a t all times during

testing. Exit all active tests before removing the test cable or powering down.

5.2 V ehicle Identification

The Scanner information presented is provided by a direct lin k to the ECM of th e test vehicle.

Therefore, certain attributes of the test vehicle must be entered into the Diagnostic Platform so

that the data displays correctly. V ehicle identification information is carried over if you enter the

Scan Module either from the Component Test module or from one of the records stored in the

Vehicle History mod ule. However, you may need to enter additional attributes in some instances.

The vehicle identification sequence is menu driven, you simply follo w the scree n prompts and

make a series of choices. Each selection you make advances to the next screen. A Back button

in the upper left corner of the screen re turns you to the previo us screen. Exa ct procedur es may

vary somewhat by vehicle.

z To identify a vehicle for Scanner testing:

1. Tap the Scanner module button from the Home screen.

A list of manufactures displays (

Figure 5-6).

23

Page 31

Scanner Operations Vehicle Identification

NOTE:

Figure 5-6 Sample manufacturer list

2. Select the manufacturer of the test vehicle from the list.

A model year menu displays.

i You can limit the number of manufacturers that appear on the list by selecting Configure Favorites

from the toolbar. See Creating a Favorites List on page 61 for details.

3. Select the year of the test vehicle from the menu.

A list of vehicle types or models displays. Several selections may be required to identify the

vehicle type and model, follow the screen prompt s and enter the required information.

A confirmation dialog box displays once all the required dat a has been en tered (

Figure 5-7).

Figure 5-7 Sample confirmation dialog box

24

Page 32

Scanner Operations Vehicle Identification

NOTE:

4. From the Confirm vehicle details dialog box, sele ct:

a. OK to continue.

b. Cancel to return to the engine list.

When Yes is selected a list of systems available for testing on the identified vehicle displays.

5. Select a test to continue (

Figure 5-8).

Figure 5-8 Sample available tests list

The identification sequence is now complete, refer to

navigate through the Scanner dat a and

tests.

Operations on page 30 for information on how to perform

Navigation on page 27 for details on how to

i If you return to the Home screen and select Component Test, Information, or another module the

vehicle identification entered here is carried over . However , additional information may be needed

in some instances.

5.2.1 Alternative V ehicle Identification

Occasionally , you m ay identify a test vehicle th at the Scanner does not r ecognize, the d at abase

does not support, or has some unique characterist ics that prevent it from co mmunicating with the

Scanner through the normal channels. In these instances, a menu of alternate choices that allow

you to establish communication with the vehicle by other means displays. In add ition to being able

to identify a different manufacturer, the following alternatives are available:

• OBDII/EOBD—allows you to perform generic OBD-II or EOBD tests, see

Operations

on page 52 for additional information.

• System ID Modes—allows you to begin the vehicle identification by first selecting the system

to be tested. Selecting opens a menu of manufacturers that support this mode.

• Select by Database—allows you to begin the vehicle i dentification by fir st selecting which

manufacturer database to load. Selecting ope ns a menu of available databases.

OBD Direct

25

Page 33

Scanner Operations Connecting to a Vehicle

5.3 Connecting to a V ehicle

Make a selection from the systems available for testing list a nd instructions for co nnectin g the

Scanner to the vehicle with the data cable display on the scree n (

Figure 5-9).

5.3.1 Cables

One of two data cables, one for OBD-II/EOBD compliant vehicles and one for no n-OBD-II/EOBD

models, are used to connect the Scan Module to the test vehicle. The 26-pin end of either cab le

attaches to the data cable port on the Scan Module and is secured with two captive screws. The

16-pin end of the OBD-II cable plugs directly into the data link connector (DLC) of the test vehicle.

The 15-pin end of the non-OBD-II cable att aches to a ca ble adapter and is secu red with ca ptive

screws, the adapter then plugs into the diagnostic connector on the test vehicle.

A replaceable 7.5 amp blade-type fuse is inst alled in the vehicle conne ctor end of the cable to

protect the unit from high circuit voltage and current. A green LED, also on the vehicle connector

end of the cable, illuminates whenever there is power supplied to the cable. An LED that fails to

illuminate indicates either a problem on the vehicle power circuit or a blown data cable fuse.

All OBD-II/EOBD vehicles have vehicle battery power (B+) available on the DLC, so th e Scan

Module should power on as soon as the cable is connected to the vehicle. The auxiliary power

cable supplies power for testing models that do not have B+ available on the diagnostic connector .

An OBD-I Data Cable and adapters (optional in some markets) are required for testing models that

are not OBD-II or EOBD compliant.

The large end of the auxiliary power cable plugs into the vehicle accessory port. The small end of

the cable fits into a power port built into the side of the cable adapter. An in-line fuse on the

auxiliary cable provides circuit protection.

Figure 5-9 Sample vehicle connection message

On-screen instructions on the display device screen tell you which cable, and adapter if needed,

to use once a test vehicle has been identified. The screen message also includ es the loca tion of

the vehicle diagnostic connector. Follow the on-screen instructions for connecting to the vehicle.

26

Page 34

Scanner Operations Navigation

5.3.2 No Communication Message

If the Scanner is unable to establish a communication s link, a “n o communications” me ssage

displays. A “no communication” message, means the Scan Module and the vehicle control

module cannot communicate with each other for some reason.

The following conditions cause a “no communication” message to disp lay:

• The Scanner is unable to establish a communication link with the veh icle.

• You selected a system for testing that the vehicle is not equipped with (such as ABS).

• There is a loose connection.

• There is a blown vehicle fuse.

• There is a wiring fault on the vehicle, or in the data cable or ada pter.

• There is a circuit fault in the data cable, Persona lity Key, or adapter.

• Incorrect vehicle identification was entered.

Refer to the Vehicle Com municati on Software manuals for manufacturer-specific problems.

5.4 Navigation

This section describes how to navigate the Scanner interface and sele ct scanner test s.

5.4.1 Scanner Screen Layout

The Scanner screens typically include three sections (

Figure 5-10):

1— Scanner Toolbar

2— Main Body

3— Data Buffer Toolbar

Figure 5-10 Scanner screen layout

27

Page 35

Scanner Operations Navigation

Scanner T oolbar

The Scanner toolbar contains a number of bu ttons that allow you to con figure the disp layed d at a

and to exit. The table below provides a brief explanation of the Scanner toolbar button operations:

Table 5-1 Scanner toolbar buttons

Name

Button

Description

Exit

Back

Custom

Alarms

Properties

Graph View

Save

Closes the current test and returns you

to the menu.

When available, returns to the

previously viewed screen.

Allows you to select which parameters

are displayed on the screen.

Allows you to set an alarm on certain

data parameters when the signal goes

above or below the alarm setting.

Allows you to adjust the display

characteristics for all of the data

screens.

Allows you to simultaneously view up

to 16 data graphs at a time.

Saves a copy of the current frame of

data that can be viewed on the tool or

in ShopStream Connect.

Opens a standard Windows Print

Print

More

Scale

Sweep

dialog box for saving a print copy of the

current frame of data.

Opens a dropdown menu of the

additional options shown below.

Switches the scale values, displayed

along the left-hand side of the graphs,

on and off.

Switches the sweep values, displayed

at the base of the graphs, on and off.

Main Body

The main body of the screen varies depending on the st age of operation. The main body can show

vehicle identification selections, the main menu, test data, instructions, troubleshooting

information, controls, and other diagnostic information.

28

Page 36

Scanner Operations Navigation

Data Buffer Toolbar

Whenever communication is established with a vehicle, the Scanner con tinuousl y recor ds dat a

transmitted by the ECM in the data buffer. The toolbar below the main body of the screen contains

the buttons for navigating the buffered da t a (

Table 5-2 Data buffer toolbar buttons

Name

Go To Start Moves to the first frame in the data buffer

Button

Table 5-2).

Description

Pause

Play

Go To End Moves to the last frame in the data buffer

Clear Erases data in the data buffer

Step Back Moves to the previous frame in the data buffer

Frame Counter Indicates the data buffer frame currently displayed

Step Forward Moves to the next frame in the data buffer

Suspends data capture and changes to show the

Play button

Starts or resumes dat a capture and changes to show

the Pause button

Snapshot Arms the software to take a snapshot of vehicle data

Zoom In

Zoom Out

Increases the magnification by decreasing the sweep

of the graph

Decreases the magnification by increasing the

sweep of the graph

Use the slider in the middle of the toolbar to quickly move through paused data.

Figure 5-11 Sample data buffer slider

29

Page 37

Scanner Operations Operations

5.4.2 Screen Messages

Screen messages appear when additional input is n eeded befor e pro ceeding. There are thr ee

types of on-screen messages, confirmations, warnings, and errors.

Confirmation Messages

Confirmation messages inform you when you are about to perform an actio n that cannot be

reversed or when an action has been initiated and your con firmatio n is needed to con tinue.

When a user-response is not required to continue, the message displa ys briefly be fore

automatically disappearing.

Warning Messages

Warning messages inform you wh en co mpleting the selected action may result in an irreversible

change or loss of data.

Error Messages

Error messages inform you when a system or procedural error has occurred. Examples of

possible errors include a disconnected cable or a peripheral, su ch as a prin ter, is powered off.

5.4.3 Making Selections

The Scanner software is a menu driven pro gram that present s a ser ies of choi ces one at a time.

As you select from a menu, the next menu in the series displays. Each selection narrows the focus

and leads to the desired test. Use your fingertip or the stylus to make menu selections.

5.5 Operations

The Scanner allows you to establish a dat a lin k to the ele ctronic control systems of the vehicle

being serviced in order to view live data par ameters and perform tests. You can use selected

functional tests, get troubleshooting tips, and access vehicle-specific trouble codes for various

vehicle control systems such as engine, transmission, antilock brake system (ABS) and more.

The Scanner has two main functions:

1. Scanner—provides access to V e hicle Commun ication So f tware functio ns such as re ading

codes, viewing data, and performing functional tests.

2. Fast-Track Troubleshooter—provides the diagnostic power of Fast-T r ack Troubleshooter, a

database of experience based information developed by master technicians.

After a system is selected and the Scanner est ablishes com munication with the vehicle, a

Scanner Main menu, which lists available tests, displays.

30

Page 38

Scanner Operations Operations

Figure 5-12 Sample Scanner Main menu

Main menu options vary slightly by year, make, and model. The main menu may include:

• Data Display— displays data par ameter information from the vehicle co ntrol mod ule.

Selecting may open a submenu of viewing options.

• Codes Menu—displays diagnostic trouble code (DTC) records from the vehicle control

module. Selecting may open a submenu of viewing options.

• Clear Codes—erases DTC records and other data from the ECM. Th is selection is found on

a Codes submenu for some models.

• Functional Tests—provides specific sub syst em a nd component tests. The tests vary

depending on the manufacturer and model.

• Actuator T ests—similar to functional tests, checks the operation of certain actuators, such as

solenoid valves and relays.

• Memory Resets—allows you to reprogram adaptive valu es for certain components after

making repairs. Selecting opens a su bmenu. These options are found on the Fu nctional Tests

Menu for some models.

• System Tests—provides specific subsystem testing. Performing these tests is similar to

functional tests.

• Generic Functions—lets you access certai n available Gen eric OBD II functions fro m a

proprietary menu (1996 and newe r vehicles only) .

• Troubleshoot er—provide s step-b y-step pr ocedures , integr ating p ara meter da t a and

retrieving trouble codes when appropriate, for specific symptoms of the identified vehicle.

z To perform a Scanner test

1. Launch the Scanner—Tap Scanner on the Home screen.

2. Identify the vehicle—Identify the test vehicle by selecting from the menu option s.

3. Select the system—Select the system to be tested from the systems menu.

4. Connect the data cable to the vehicle—Follo w the on-scree n connection instr uctions to

connect the Scan Module to the test vehicle.

5. Select a test from the Scanner main menu—Select the desired test.

31

Page 39

Scanner Operations Operations

5.5.1 Data Display

Depending upon the test vehicle, this selection may appear as Data, Data Display, Data Only,

Data (No Codes), or something similar . All are similar. Selecting has one of the following results:

• A submenu of data viewing choices displays.

• Vehicle data displays.

A submenu displays when more than one data viewing mode is available on the identified vehicle.

On some models, the engine must be started or cranked before data can be displayed. For these

models, a “Waiting to Co mmunicate” messag e displays if the eng ine was n ot cranke d or st ar ted.

Data Screens

When a Data selection is made, the screen displays the data list for the se lected module. The

items available for any control module vary from one vehicle to another.

Data is presented in a 2-column format. An abbreviated parameter name is at the left of each

column and its value is at the right edge of the column. Parameters display in the order that they

are transmitted by the ECM, so expect variation between vehicles.

Gesture scrolling allows you to quickly move through the data list. Simply touch the screen and

drag your finger up or down to reposition th e parameters being displayed. Position bars

momentarily appear to the right of each column in dicate the po sition of the curr ent screen in

relation to the entire list as you scroll. Each column of parameters scrolls independently of the

other column.

Figure 5-13 shows a typical data screen.

1— Graph button

2— Parameter name

3— Parameter value

Figure 5-13 Sample data screen

32

Page 40

Scanner Operations Operations

Data Graphs

Tap the Graph button to open a data graph for that p ar ameter (

Figure 5-14). Selecting a

parameter for graph view moves it to the top of the list. Tap the Graph button again to close the

graph for that parameter and return to a dat a list view.

Figure 5-14 Sample graph view

The icons that display on each data graph allow you configure settings for the selected graph only:

Table 5-3 Data graph icon operations

Name

Button

Description

Expand/Collapse

Graph Properties

Tap to expand the graph to fill the entire screen, tap

again to collapse the graph to the standard view.

Tap to open the Graph Properties dialog box, which

allows you to set triggers for recording a snapshot

and to adjust the scale.

Triggers

Triggers esta blish threshold values, an upper limit and a lower limit, for recording a data snapshot.

A snapshot allows you to closely evaluate conditions that caused the trigger ing even t.

When a snapshot is taken, the Scanner captures addition al data after the trigger poin t is detected,

data collection pauses, and the buf fered information is automatically saved as a movie. This gives

you a complete picture of what was happening before the fact, what occurred at the trigger po int,

and what happened after the fact.

Data collection is paused following a trigger event. Select the Play button to resume viewing live

data. A vertical line now appears on each of the dat a graphs to ind icate the tr iggering po int. The

trigger line on the parameter that triggered the snap shot is a different color than those on th e other

graphs. This makes it easy to determine which param eter caused the trigger when triggers are set

for multiple parameters.

33

Page 41

Scanner Operations Operations

NOTE:

z To adjust the amount of data collected after a trigger:

1. Tap the Properties button on the Scanner toolbar to open the dialog box.

2. Highlight one of the Samples After Trigger options:

3. Tap the Accept button to close the dialog box.

i You can also ad just the a mount of dat a collected after a triggering event using the Properties

button on the Scanner toolbar. See Properties on page 44 for additional information.

z To set triggers and record a snapshot:

1. Tap the Graph Properties icon on the parameter grap h you wish to set trig gers on.

The Graph Properties dialog box opens.

2. From the Graph Properties dialog box, tap Triggers On.

A check mark appears in the box and the minimum and maximum fields activa te

Figure 5-15).

(

Figure 5-15 Sample Graph Properties dialog box

3. Tap either Max: (maximum) or Min: (minimum) to activate that field and open the ke yboard.

4. Type the desire d trigger valu e into th e field.

5. Tap the other field and enter a trigger value, then close the virtual keyb oard.

6. Tap Save to close the dialog box.

Trigger lines (blue for upp er and re d for lower ) disp lay on th e selected p a rameter gr aph.

The area between the upper and lower tr igger lines establishes the trigg ering condition. Once

the snapshot is armed, any data po int s that register out side of the set trigger conditions

initiates a snapshot. The Scanner continues to reco rd the pr eset amoun t of dat a after the

trigger and includes it in the snapshot.

7. Tap Snapshot on the Data Buffer Toolbar to arm the snapshot.

The Snapshot button changes color to indicate it has been armed (

34

Figure 5-16).

Page 42

Scanner Operations Operations

NOTE:

Figure 5-16 Sample armed Snapshot button

Once all of the data is compiled, data collect ion p ause s and the infor mation is save d as a

movie. A confirmation screen displays to let you know the name au tomatically assigned to the

saved file and where to locate it.

Figure 5-17 Sample saved movie confirmation screen

8. Select OK to close the confirmation screen.

9. Tap the Play button on the toolbar to resume viewing live data.

i Selecting an armed Snapshot button disarms it.

Scale

Scale adjusts the upper and lower values displayed on the vertical axis of a dat a graph. T wo scale

modes are available; auto scale and manual scal e. Auto scale, which is the default setting,

automatically adjusts the graph scale based upon the minimum and maximum values transmitted

by the ECM. Manual scale allows you to set the minimum and maximum valu es.

z To manually set the scale on a graph:

1. Tap the Graph Properties icon to open the dialog box for the graph you wish to scale.

2. From the Graph Properties dialog box, tap Auto Scale On .

35

Page 43

Scanner Operations Operations

Figure 5-18 Sample manual scale selection

The check mark is cleared from the box and the minimum and maximum fields activate

3. Tap either Max: (maximum) or Min: (minimum) to activate that field and open the ke yboard.

4. Type the desire d scale value into the field .

5. Tap the other field and enter a value, then close the virtual keyboard.

6. Tap Save to close the dialog box.

The dialog box closes and the parameter scale is now a t the set value s.

Using Zoom

The zoom options on the Data Buf fer toolbar allow you to change th e magnification level of the

sweep when viewing data graphs. Use the Zoom In (+) b utton to increa se magnification , and the