Page 1

Service

System

250

Manual

Fluid

Warmer

:

Unpacking

Filling

Electricat

Alarm

Performance

Maintenance

Troubleshooting

Limited

Service

Specifications...

Electrical

Parts

Mechanical

and

with

Distilled

Safety

Power

Leakage

Testing

Testnd

Inoperable

Flow

Restriction,

Warranty

Schematics

List,

Maintenance

Parts

Set-Up

Reguirement.

Current

.

List

..

Water

ii

System

and

.

Test.

250

|.V.

Disposable

User

Sets

Replaceable

Parts

6

…

Revised

REV

A

May

1993

215)

Page 2

Purpose

The

Level 1 System

patients.

The

Minimum

are

Level 1 1.V.

board

infusion

warming

Disposable

standard

delivery

delivered

safety

of

for

250

sets

Disposable

temperature

near

37°C.

Sets,

and

and

monitoring

normothermic

and

|.C.U.

is

designed

specifically

Set

allows

at

Blood

and

will

be

delivered

systems

fluids.

Emergency

for

designed

infusion

these

packed

make

Typical

Room

safe

and

for

of

6°C

flow rates

RBCs

near 37°C.

the

Level 1 System

uses

of

use.

rapid

various

blood

is

35°C.

from

ail

High

the

system

in-line

warming

infusion

up

to

At

the

auto

warming

of

rates

are

100

ml/min.

somewhat

transfusion

and

flow

250

the ideal

include

all

|.V.

fluids

available.

or

6°C

crystalloid

lower

flow rates

systems

capacity,

choice

routine

surgery

as

may

simple

for

they

are

generally

be

infused

all

procedures

and

_

administered

up

to

150

used,

through

operation,

blood

to

mMmin.

fluids

the

and

on-

requiring

and

fluid

Messages

improper

results.

Messages

cause

improper

Messages

cause

improper

Concept

The

Level 1 System

makes

used

The

rapidly

rapid

System

Taking

very

available

in

the

System

circulated

water

250.

advantage

cold

blood.

that

are

headed

that

are

headed

results

that

are

headed

results,

to

all

Open

Heart

250

employs a Disposable

counter-flow

circulation,

of

The

Filter

and

250

other

the

by

by

damage

by

damage

is

the

areas

Suite

for

and

counter-flow

high

Holder

“NOTE:"

indicate

“CAUTION:"

to

the

“WARNING:"

to

the

equipment,

first

significant

of

the

on-pump

through

warming

of

an

capacity,

the

System

information

indicate

equipment.

indicate

advance

hospital

warming

Heat

Exchanger.

anodized

warming

the

250

or

information

information

injury

to

personnel,

in

routine

the

same

for

over

25

As

aluminum

all

contribute

Disposable

is

warmed

procedures

or

procedures

or

procedures

or

blood

fluid

warming

years.

with

extracorporeal

tube.

The

to

the

Sets

allow

to

help

maintain

that

if

not

that i not

`

that

serious

and

use

excellent

patient

fluid

technology

of a thermal

increased

peak

followed

followed

if

not

followed

harm.

warming

Perfusionists

warming,

conductor

high

warming

fluid

efficiency

correctly

correctly can

correctly

in

over

warmed

capacity

flow

rates,

at

low

can

cause

can

20

years.

have

water

It

safety

is

(aluminum),

of

the

even

with

flow

rates.

The

Hardware

and

easy

to

use.

the

system

safely

Safety

FILTER

The

released

delivered

WITH

Level 1 Disposable

from

to

the

and

Disposables

By

following

set-up

GAS

VENT

fluids

as

patient

and

Sets

they

along

of

the

Level 1 System

the

1-2-3

instructions

operating

employ a unique

are

with

within

warmed.

the

warmed

seconds.

In

many

fluids.

Gas

found

Vent

other

250

on

which

warming

are

integrated

the

unit,

vents

into

properly

micro-bubbles

systems,

the

design

trained

these

to

be

highly

users

can

confidently

of

gas

which

micro-bubbles

effective

are

always

are

actually

have

Page 3

The

ability

Gas

Vent

with

luer-locks

Fitter

vent

replacement

For

D-50

For

D-100

with

of

in

gas

Set

Set

the

the

and

vent

order

order

Gas

Vent

I.V.

Sets

is

easily

should

fitters

are

replacement

replacement

to

quickly

contains a 170-micron

changed

be

changed

available

fitter

without

as

F-10

filter

F-10

vent

air

every

follows:

patient

three

also

screen

permits

hours

rapid

filter

to

trap

disconnection

to

maintain

priming

of

the

macro-aggregates.

or

repriming

efficient

system

Disposable

This

of

the

entire

performance.

Set.

The

filter

is

disposable

Fitter

Fitter

with

connected

set.

he

with

gas

TEMPERATURE

The

System

temperature

this

circuit, a second

temperature

Fluid

present

temperatures.

ELECTRICAL

A

special

through

low

the

power

CONTROL

250

employs a safe

control

reaches

in

the

circuit

“watchdog”

about

heat

SAFETY

leakage

cord

limits

41°C.

exchanger

immersion

providing

circulating

the

circulating

circuit

will

while

heater

an

is

extra

Unpacking

The

Level 1 System

Contents

water

water

visually

the

unit

used

measure

heating

to a 40°C

and

audibly

is

operating

in

the

Level 1 System

of

patient

and

Set-Up

250

system,

maximum.

alarm

is

and

is

packaged

inherently

and

never

exposed

250.

operator

and

tn

the

stop

This

safety.

partially

Quantity

free

of

unlikely

the

circulating

to

any

heater

assembied.

"hot

spots".

event

of a malfunction

water

damaging

is

electrically

The

primary

pump

or

dangerous

grounded

if

of

the

Figure

UNIT

PACKAGING

Power

Rolling

ACCESSORY

Service

Operators

Casters

ГУ

IV.

Fill

Set

Level 1 Video

Hitch

1

Вад

Pole

Plug

Up

Pin

Unit

Base

Manual

Manual

Напдег

Knob

Card

1

1

PACK

a

da

一

一 一

一

一

一

Page 4

WARNING

This

unit

prior

to

1,

With

wheels.

2.

Slide

base

as

3.

insert

must

placing

the

Rolling

the

Power

shown

the

PIN

be

assembled

the

device

base

Unit

in

Figure

through

into

on

Pole

1.

the

and

service.

its

side,

down

holes

tested

push

over

in

the

by

Level 1 technical

the

four

the

vertical

bottom

of

casters

square

the

pole

FULLY

base

and

personnel

into

their

tube

with

vertical

or

sockets.

Power

base

an

authorized

Unit

tube,

Place

facing

locking

distributor

the

base

the

longer

them

together.

of

Level

upright

side

of

on

1

its

the

Filling

Set-Up

CAUTION

For

WATER

water

operating

DO

creates

A.

B.

port

in

Figure

way

port

proper

in

the

NOT

an

Unscrew

Fil

with

exits

3.

to

be

and

fill

with

system

should

unit

efficiency.

FILL

air

and

1.3

at

the

This

sure

the

Distilled

operation

be

used

will

build

the

unit

lock

preventing

remove

liters

of

bottom

vent

port

the

reservoir

reservoir

Water

and

in

the

up

mineral

with a DISPOSABLE

proper

the

Fillport

Distilled

of

the

also

is

until

water

component

water

Plug.

Water.

Power

serves

full

is

begins

life,

reservoir.

scale

and

SET

filling.

Note: A water

Module

as

to

at

an

overflow

place a cup

to

exit

only

DISTILLED

The

use

seriously

IN

PLACE

reservoir

the

location

tube.

under

the

port.

of

reduce

as

this

vent

shown

An

easy

this

vent

tap

its

Fillport

Plug

Figure

2

C.

Replace

CAUTION

The

Distilled

manual.

sure

there

The

are

the

Fillport

Water

System

no

in

250

large

Plug

the

reservoir

draws a maximum

power

consumers

should

on

be

of

7.5

that

changed

Amps.

circuit.

every

It

should

30

days.

be

plugged

See

the

Maintenance

into a 10

to

20

section

Amp

of

circuit,

being

this

Page 5

Electrical

Safety

Power

Requirement

Most

of

the

current

600

Watt

immersion

turned

temperatures

full

proportional

proportionally

water

Leakage

on

and

ON

condition.

nears

controller

the

Current

drawn

the

digital

below

Beyond

shorter

40°C

heater.

30°C,

cycles

target

Test

NOTE

This

device

device

the

Parts

WARNING

DO

NOT

WITHOUT A DISPOSABLE

and

is

equipped

perform

List

section

DEFEAT

leakage

of

THE

΄

by

the

System

When

display

the

shows

600

approximately

the

heater

ON

times

temperature.

with

disposable

current

this

manual.

DISPOSABLE

HEAT

250

the

device

rapidly

Watt

heater

30°C,

ON/OFF

as

the

circulating

sensing

testing.

EXCHANGER

Non-Sterile

SENSING

is

for

its

is

first

rising

is in

a

the

with

interlocks. A Level 1 Heat

Test

Sets

are

INTERLOCKS

IN

PLACE.

Exchanger

available

OR TRY

Figure

from

Level 1 for

TO

Air

intake

3

is

required

this

OPERATIVE

Vent

Port

Slots

to

operate

purpose.

THE

the

See

UNIT

Power

in

be

warms

Although

less

Units

repair.

On

order

performed

up

than

exceeding

Alarm

NOTE

Alarm

avatlable

testing

Leakage

to

be

quickly,

the

specifications

50

microamps.

sure

on

100

Current

the

immersion

units

test

readings

microamps

which

Testing

requires a Level 1 Heat

from

Level 1 for

this

Tests

have

should

claim

purpose.

should

heater

less

electrical

circuit

been

be

than

Exchanger

See

be

allowed

taken

100

・

leakage

the

performed

is

in a full

to

stand

within 1 minute

microamps

should

to

be

Parts

List

with

the

ON

condition,

until

electrical

be

removed

in

place

in

this

immersion

Power

close

to

of

startup.

leakage,

from

on

the

manual.

heater

On

room

temperature.

units

service

System

circuit

Leakage

leaving

and

250.

Non-sterile

in

the

full

Current

As

the

the

factory

returned

ON

condition.

Tests

should

System

are

usually

to

Level 1 for

Test

Sets

250

are

Page 6

Add

Water

The

System

water

level

condition

Alarm

250

is

too

the

circulating

is

equipped

low, a RED

pump

with a float

L.E.D.

should

on

not

switch

the

Display

be

running.

which

senses

Panel

the

water

illuminates

level

in

the

and a sonic

on-board

alarm

reservoir,

sounds.

In

When

the

the

alarm

With a Test

tube

on

the

Replace

Check

Two

and

running,

1.

2.

Over

any

Disposables

interlocks

the

Power

each

Top

Heat

Heat

Exchanger

Temperature

With a Test

the

water

Fil/Drain

DISTILLED

this

manual.)

illuminate

above,

normal

and

turn

operation.

Heat

Exchanger

back

of

the

Power

water

drained

Alarm

sense a property

Switch

interlock

Exchanger

is

may

Socket - Pull

Guide - Bend

Alarm

Heat

Exchanger

tube

on

WATER

the

Turn

the

Power

which

the

Sonic

Switch

Power

Alarm

in

place,

Unit

with

DISTILLED

installed

ON,

the

RED

be

independently

tube

in

place and

the

back

has

been

Switch

should

OFF

and

the

ADD

and

tilting

Heat

indicator

Release

portion

the

of

the

heated

ON.

sound.

allow

WATER

it

down

WATER.

Exchanger.

tested:

knob

of

Heat

Power

Power

to

45°C

The

Over

The

the

unit

ALARM

to

See

will

illuminate

and

slide

Exchanger

Switch

Unit

and

to

48°C.

temperature

water

circulating

to

cool

may

allow

some

the

Filling

If a properly

and a pulsed

up.

out

OFF,

drain

tilting

it

(See

FILLING

pump

to

room

be

tested

of

the

water

with

Distilled

installed

of

Guide

down

RED

groove.

the

water

to a container.

WITH

L.E.D.

should

temperature.

by

releasing

to

drain

Water

Heat

Exchanger

alarm

will

out

of

the

DISTILLED

on

the

not

be

Restart

the

out

section

sound.

reservoir

Fill

WATER

Display

running.

the

water

Fil/Drain

into a container.

of

this

manual.

is

not

in

place

With

the

unit

by

releasing

with

1.3

liters

of

section

Panel

Confirming

unit

and

of

should

the

confirm

NOTE

The

sonic

alarm

Performance

NOTE

Performance

Disposable

THREE

1.

COLD

Store

in

piace,

Rapidly

minutes

simpie

the

rising

on

Test

START

System

note

an

and

all

RED

Testing

testing

the

numbers

efficiently

requires a Level 1 0-50

Sets

are

tests

allow

TEST

250

unit

time

and

will

operating

L.E.D.s

available

periodic

in a room

turn

checking

the

appear

unit.

may

from

Level 1 for

where

Power

on

be

the

tested

Disposable

of

the

the

room

Switch

Water

by

pressing

Set

this

purpose.

overall

operating

temperature

ON.

The

Temperature

the

to

See

Green

alarm

test

be

in

place

the

Parts

efficiency

is

approximately

System

display.

37°C

button

of

on

List

the

21°C

on

the

System

section

System

Operational

will

appear

the

back

250.

in

this

250.

(70°F).

With a D-50

indicator

in

approximately

of

the

cabinet.

Non-sterile

manual.

will

illuminate.

Set

3

Page 7

2.

SYSTEM

RECOVERY

TEST

Chill a 1

allow

the

place

the

Pole

so

at

250

mUmin.

Note

the

display.

not

read

3.

STEADY

Thermal

For

use

NOTE

Use

of

this

accurate

liter

bag

of

unit

to

reach

Male

Luer

the

fluid

bag

(This

time

and

OPEN

The

fluid

bag

below

37°C.

STATE

Calibration

with:

within

Level 1 Fluid

unit

requires a digital

0.1°C.

Normal

in a container

may

RUN

Well

at

least

outlet

be

the

should

TEST:

(TCW)

Saline

39.5°C.

is

4"

confirmed

clamp

empty

Warmers

thermometer

to

10°C

to

Remove

on

the

floor.

above

the

level

with a graduated

below

the

in

about 4 minutes,

'.

Model

15°C.

the

Close

of

bag,

P/N

H-500

H-500

H-250

H-250

NIST

With a D-50

cap from

the

Bag

the

Heat

Exchanger

beaker

allowing

80-03-002

traceable

and

INT

INT

the

the

and

Test

the

Spike

and

fluid

digital

Set

in

place,

Male

Luer

clamps,

inlet.

stopwatch.)

to

flow

freely.

display

at

and

With

in

the

spike

an

turn

the

Power

end

of

the

the

fluid

all

clamps

Watch

the

efficiently

Switch

Patient

bag.

open,

fluid

Water

Temperature

operating

Set

ON

Line

the

will

unit

and

and

LV.

flow

will

Required

Short

a.

Install

(sockets 1 &

“For

b.

Turn

thermometer

Compare

Unit

correctly

Examples

Thermometer

Level 1 Unit

probe

checklist

TCW

H:500 & H-500

the

temperatures.

display

calibrated

size:

to

verify

in

machine

2).

machine

probe

will

be

39.750

WITHIN

0.099"

0.50" - 1.50"

displayed

INT,

on

and

fully

into

within

unit.

THIS

in

normal

also

install a test

allow

well

0.3°C

of

RANGE

OD

maximum

long

circulating

heat

to

warm

and

allow

the

thermometer

39.4°C - 40.0°C = OK

water

exchanger

filter

at

up

for

15

display

temperature:

position

position

to

display

3.

minutes.

stabilize.

on

Insert

a

7 し

pe

|

一

3

一

一

圖

一

1

Page 8

Thermometer

Levelt

NOTE

IF

SERVICE.

THE

Unit

SYSTEM

Maintenance

40.0°C

WITHIN

250

THIS

DOES

RANGE

NOT

39.7°C - 40.3°C = OK

MEET

1,

2,

or

3,

IT

SHOULD

BE

RETURNED

TO

THE

FACTORY

FOR

CLEAN

Clean

and a soft

discolor

CHANGE

Release

container.

water.

GREASE

Place a small

Rings

sockets

CHANGE

Note:

the

socket

Ring

Caps

EXTERIOR

the

entire

some

DISTILLED

the

See

O-RING

in

the

to

O-RING

An

O-Ring

Parts

List

and

sockets.

and

button

cloth

Replace

FILLING

grease

remove

System

after

of

the

water

amount

bottom

Kit

jn

this

Coat

head

--

EVERY

every

plastics

WATER

Fil/Drain

the

tube

WITH

SEALS

of

and

top

them.

SEALS

containing 2 O-Rings, 1 1/8"

manual.

the

rectanguiar

the

new

screws.

USE

250

with a spray

use.

Cold

on

the

--

tube

by

pushing

DISTILLED

--

EVERY

silicone

heat

--

EVERY

Using a 1/8"

O-Rings

sterilizing

device.

EVERY

behind

firmiy

WATER

30

DAYS

grease

exchanger

on a cotton

12

MONTHS

Socket

with

of

Do

30

the

hex

Caps.

silicone

warm

solutions

not

DAYS

Power

up

into

section

sockets

hex

wrench,

After

grease

soapy

use

Unit

the

swab

of

wrench

unscrew

removing

water

may

be

cleaning

and

tilt

fitting

of

this

or

the

the

Pole

and

and

press

solution

used,

agents

it

down

until

it

bottoms.

manual.

end

of a smali

Assembly.

silicone

the

four

and

discarding

them

or a commercial

but

strong

containing abrasives.

to

allow

It

grease

stainless

into

the

Refill

finger

is

not

is

button

the

their

chemical

non-abrasive

concentrations

water

to

with

1.3

and

apply

necessary

available

head

old

O-Rings,

sockets.

drain

into

liters

of

all

around

to

disassemble

from

Level

screws

clean

Replace

cleaner

may

a

distilled

the

1.

See

of

each

the

O-

the

Socket

O-

the

GENERAL

INSPECTION

--

EVERY

USE

Visually

service

Disposable

This

bottom

Pole

check

which

unit

is

of

mount ( figure

the

shows

Set

cooled

the

cabinet

condition

physical

does

not

by

4)

of

damage

install

convection.

(refer

to

are

not

blocked.

Air

Vent

Figure

4

the

device.

easily.

Be

Figure

or

one

sure

3)

and

Remove

in

which

the

air

air

any

the

intake

vent

below

unit

Test

slots

from

on

the

the

Ι.Ν.

Page 9

Troubleshooting

Inoperable

System

PROBLEM

NO

POWER

NO

GREEN

OPERATIONAL

and

CHECK

ALARM

ADD

WHEN

DISPOSABLES

WATER

UNIT.IS

250

SYSTEM

ALARM

MOVED

LIGHT

CHECK

Unit

is

PLUGGED

Power

Minimum

Note:

from

Switch

will

Heat

properly

Pole

property

Switch

If

power

the

is

GLOW.

Exchanger

installed?

interlocks

engaged

Exchanger?

Add

about

water

to

the

Fill

Port.

ON?

10

AMP

is

wall

and

turned

(2)

150

mt

reservoir

IN?

circuit?

reaching

the

Power

ON,

the

switch

by

the

Heat

distilled

through

the

unit

the

ADD

WHEN

ON

OVER

ALARM

WATER

UNIT

ALARM

IS

TEMPERATURE

TURNED

Fill

with

distilled

alarm

stops.

Manual

filling

Turn

and

service.

or

for

complete

instructions.

off

the

remove

It

must

replaced

by

Technologies,

Note:

Room

above

unusual

off

40°C,

before

situation,

returning

water

until

Refer

to

Service

draining

Power

the

Switch

Unit

be

repaired

Level

from

1

Inc.

temperature

may

cause

turn

the

it

to

service.

above

the

Power

and

40°C

H-250

(104°F)

to

shut

Switch

down

OFF

or

filling

and

and

allow

with

alarm.

the

distilled

In

unit

this

to

water

cool

Page 10

LONG

HOT

POWER

CABINET

WARM

UP

MODULE

Unit

stored

environment?

Blocked

Assembly?

perforated

the

I.V.

air

round

Pole

in

an

vent

on

(The

air

black

mount.)

unusually

Pole

vent

is

disc

cold

the

below

HARD

HEAT

WATER

TO

EXCHANGER

LEAKS

EXCHANGER

INSTALL

AT

SOCKETS

HEAT

Grease

O-Rings

Exchanger

Grease.

Replace

Order

Part

sockets

Order

Part

O-Rings.

No.

80-04-003.

in

Heat

with

Silicone

No.

80-04-002.

10

Page 11

TROUBLESHOOTING

FLOW

RESTRICTION,

1.V.

DISPOSABLE

Many

restnctors

CHECK

OLD

BLOOD

Stored

partially

factors

of

higher

EACH

blood

block

which

OF

begins

fluid

pathways,

SETS

are

insignificant

flow

infusion.

THESE

to

POSSIBLE

develop

in

low

If

you

CAUSES.

particulate

impeding

fluid

encounter

flow.

administration

flow

within 5 to 7 days.

restriction

are

This

may

FULLY

Bag

BAG

40

spike

1.

2.

pre-filttering,

3.

CLAMPS

Check

TUBE

Leaving

Disposable

take a SET

TUBE

Be

Y-set

lowered

TRAPPED

As

and

vent

SPIKED

port

membranes

PORT

micron

Cold,

As

They

sure

when a pressure

noted

tap

out.

FILTER(if

to

of

the

Disposable

viscous

they

are

they

may

PARTLY

to

be

sure

SET

clamps

Set

in

KINK

no

tube

position.

AIR

in

the

against

80

BAG

may

used)

micron

blood

directly

clog quickly.

trap

air

which

ENGAGED

all

clamps

engaged

is

not

in

the

clamped

kinks

are

IN

FILTER

Priming

the

Cabinet

only

be

filters

used

set

may

restrict

does

not

flow

connected

can

block

are

FULLY

for

extended

use

(such

position.

present

cuff

is

employed

Instructions,

to

dislodge

split,

not

between

flow

weil

to

the

source

filter

open.

periods

as

pre-set-up)

anywhere

and

remove

air

completely

the

blood

because:

through

media

the

bubbles

in

the

of

the

t.V.

small

of

particulate

surface

time

will

set,

Filter

and

pierced.

bag and

pore

when

cause

especially

Pole

is

from

allow

filters.

with

area.

the

the

used

the

holder

them

the

bag

no

tubing

in

the

in

a

to

to

CLOGGED

If

good

restriction.

changed.

clogging

with

you

EXTENSION

Use

only

equipped

Y-30.

STOPCOCK

Any

fittings

should

luer-lock

NEEDLE

If

possible, use a minimum

Smaller

QUALITY

Poorly

FILTER

quality

In

the

See

is

encountered,

Blood

LINES

extension

with

large

or Y ADAPTER

attached

have

large

bore,

or

CATHETER

sizes

will

OF

INFUSION

placed

needles

blood

is

used,

event

of a clogged

REPLACING

Bank.

lines

bore

to

the

bores.

they

are

restrictors

reduce

and

this

filter

FILTERS

discuss

with a bore

fittings,

If

flow

SITE

the

such

male

luer-lock

their

bores

14

Gauge

catheters

should

fitter,

this

section

QUALITY

of

.130"

as

Level 1 Part

at

are

smaller

needie

to

not

allow

never

component

of

this

of

the

(3.3

mm)

the

end

than

or

8.5

high

cause

manual.

blood

or

larger,

No's.

of

the

the

French

infusion

flow

may

be

if

frequent

being

X-36

Patient

male

catheter

rates

used

or

Line

Page 12

Limited

Warranty

LEVEL 1 FLUID

SYSTEM

This

defects

1

reserves

any

repaired

warranty

and

SERIAL

Power

Serial

PROMPT

Level 1 will

proves

requiring

250

Level 1 Fluid

for a period

the

Level 1 H-250

or

replaced.

or

affirmation

Level

1's

liability

NUMBER

Modules

Numbers

DISPOSITION

make a good

to

be

defective

service.

WARMER

MODEL

Warmer

of 1 year

right

to

Fluid

in

LABEL

returned

will

be

H-250

is

replace

Warmer

This

warranty

of

fact,

all

events

for

Warranty

serviced

faith

within

warranted

(12

months)

any

or

found

does

expressed

is

limited

as

Non-Warranty

effort

for

warranty.

by

Level 1 Technologies,

from

all

components

to

be

not

or

implied,

to

the

service

prompt

See

the

the

date

of

purchase,

in

lieu

defective

cover

purchase

must

repairs.

correction

and

misuse,

other

have

Serial

or

than

price

Service Section

of

repair.

shipped

impact

stated

paid

Numbers

other

of

inc.

to

be

abuse

During

to

Level

damage

above,

for

the

intact.

adjustment

the

manual

free

and

impact

the

period

1,

shipping

or

obvious

is

made

device.

Those

with

respect

for

shipping

of

material

or

with

damage

this

abuse

and

workmanship

exciuded.

warranty

costs

prepaid,

of

the

authorized

missing

to

any

or

product

information

Level

is

in

effect,

will

device.

by

Level

altered

which

for

product

be

No

1,

Service

ALL

SERVICE

SERVICE

THE

DEVICE

Contact

will

the

issue

NUMBER

Be

sure

that

NOTE:

FOR

ALL

SERVICE,

LEVEL 1 TECHNOLOGIES

(or

your

local

The

Level 1 System

sent

to

the

UNPACKING

sure

ALL

water

MUST

BY

OTHERS

TO

THE

Level 1 Service

you a Return

of

your

machine

ALL

water

machines

CONTACT:

distributor)

250

factory

AND

is

for

SET-UP

drained

BE

PERFORMED

VOIDS

SERVICING

THE

ORGANIZATION.

Department

Authorization

and a description

is

drained

must

be

from

cleaned

800-553-8351

617-878-8011

is

designed

service.

before

Generally,

section

packing

of

BY

WARRANTY

before

Number

the

unit

and

for

easy

this

manual.

any

LEVEL 1 TECHNOLOGIES

AND

TRANSFERS

shipping

(RAN).

of

the

problem.

before

disinfected

disassembly

disassembly

Power

The

packing

or

Drain

Unit

the

they

is

the

for

unit

Service

it

for

will

so

the

the

water

repair

LIABILITY

to

Level 1 for

Department

shipment.

be

immediately

Power

reverse

from

Unit,

of

the

shipment.

OR

repair.

wilt

1.V.

the

assembly

Power

ITS

AUTHORIZED

FOR

The

want

returned

Pole

or

Unit

before

AGENTS.

MALFUNCTIONS

Service

to

as

Rolling

steps

Department

know

the

received.

Base

found

disassembly.

OF

SERIAL

may

be

in

the

Be

The

the

Power

Rolfing

Unit

Base.

is

secured

to

the

Rolling

Base

by a Hitch

12

Pin.

Remove

the

Pin

to

separate

the

Power

Unit

from

Page 13

For

service

SERVICE

ship

prepaid

DEPARTMENT

LEVEL 1 TECHNOLOGIES,

160

WEYMOUTH

ROCKLAND,

MA

STREET

02370

to:

INC.

Include

Hospital

Address

Telephone

Person

Apparent

WARRANTY

Units

be

NON-WARRANTY

Units

promptly

from

the

Name

to

Contact

Problem

received

promptly

received

inspected

the

hospital

following:

Number

SERVICE

for

repair

repaired

SERVICE

which

consistent

Specifications

which

and

have

have

returned

suffered

and a written

with

the

not

been

at

no

charge.

obvious

estimate

written

obviously

See

abuse

of

repair

estimate.

the

or

impact

costs

abused

Limited

damage

will

be

or

impact

Warranty

and

sent

to

damaged

section

units

of

no

and

this

longer

manual.

you. A purchase

still

under

under

order

warranty

Warranty

will

be

will

will

be

required

PHYSICAL

SPECIFICATIONS

Height,

Height,

Length;

Width,

Weight,

Shipping

ELECTRICAL

SPECIFICATIONS

Input

Operating

Operating

Electrical

Circuit

Power

assembled

1.V.

Pole

overall

overall

assembled,

weight

Voltage

Frequency

Current

leakage

Breaker

Cord

.

dry

。

to

Ground

4'

5“

plus

45-76"

15"

15.2"

32

pounds

40

pounds

I.V.

Pole

(1.35 m)

(1.35 m -

(38.1

(38.6

(14.52

(18.14

120(90-130)

50 - 60

7.5

<100uAmp

8

Molded

Hz

Amp.

Amp.

Line

cm)

cm)

kg)

kg)

VAC

Cord,

2.29

m)

Hospital

Grade

13

Page 14

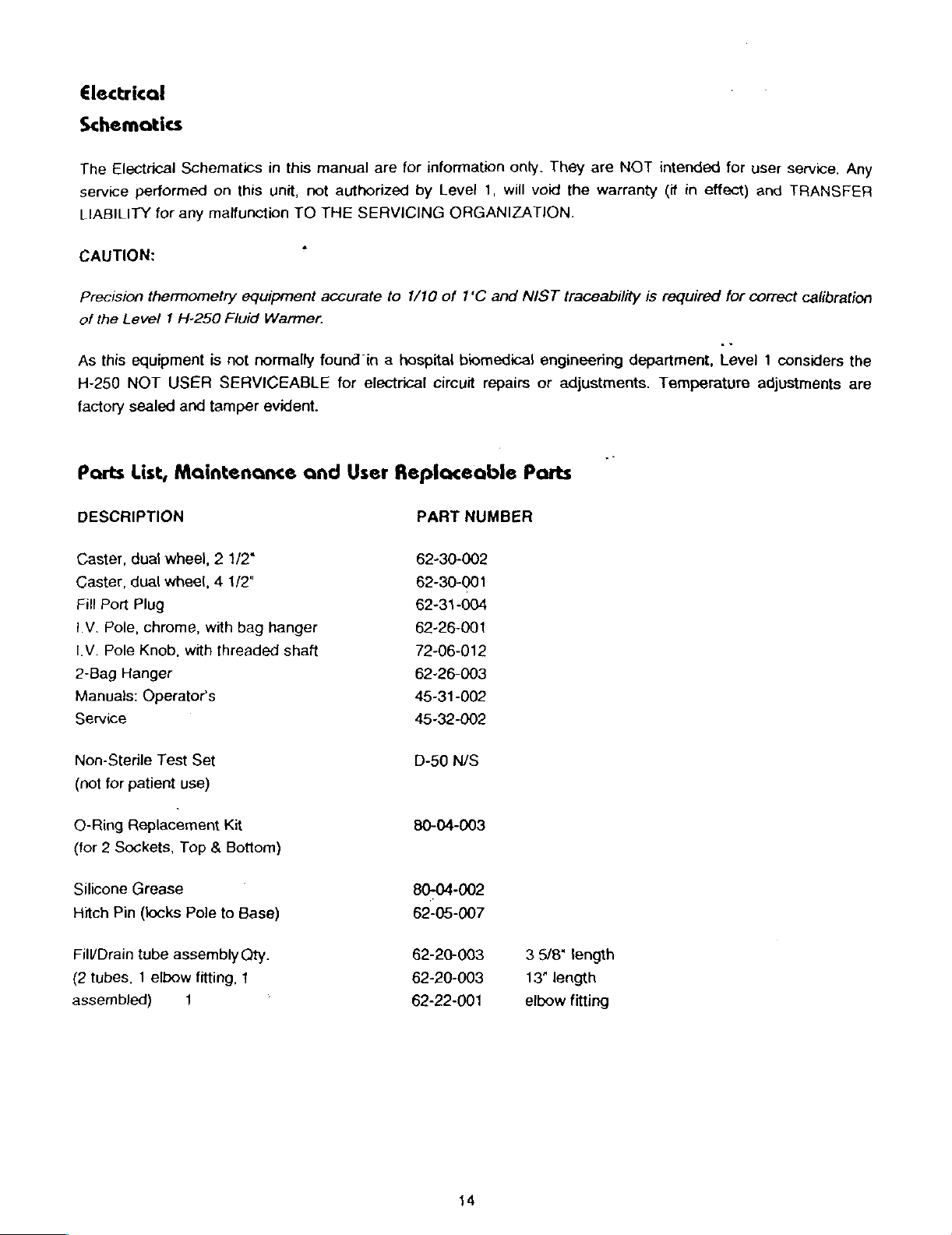

Electrical

Schematics

The

Electrical

service

LIABILITY

performed

for

Schematics

on

this

any

malfunction

in

this

unit,

TO

manual

not

authorized

THE

are

for

by

SERVICING

information

Level

1,

ORGANIZATION.

onty.

will

They

void

the

are

NOT

warranty

intended

(if

in

effect)

for

user

and

service.

TRANSFER

Any

CAUTION:

Precision

of

the

As

H-250

factory

Parts

thermometry

Level 1 H-250

this

equipment

NOT

sealed

List,

DESCRIPTION

Caster,

Caster,

Fill

LV.

IV.

2-Bag

Manuals:

Port

Pole,

Pole

Hanger

dual

dual

Plug

chrome,

Knob,

Operators

Service

equipment

Fluid

is

not

normally

USER

and

tamper

SERVICEABLE

evident.

Maintenance

wheel, 2 1/2"

wheel, 4 1/2"

with

bag

with

threaded

.

Warmer.

and

hanger

shaft

accurate

found

in a hospital

for

electrical

User

to

1/10

of

1*C

biomedical

circuit

repairs

Replaceable

PART

62-30-002

62-30-001

62-31-004

62-26-001

72-06-012

62-26-003

45-31-002

45-32-002

NUMBER

and

NIST

traceability

engineering

or

adjustments.

Parts

is

required

department,

Temperature

for

correct

calibration

Level 1 considers

adjustments

the

are

Non-Sterile

(nat

for

O-Ring

(for 2 Sockets,

Silicone

Hitch

FilVDrain

(2

tubes, 1 elbow

assembled)

Test

patient

Replacement

Grease

Pin

(locks

tube

Set

use)

Kit

Top & Bottom)

Pole

to

Base)

assembly

1

Qty.

fitting,

1

D-50

N/S

80-04-003

80-04-002

62-05-007

62-20-003

62-20-003

62-22-001

14

3

5/8"

13"

length

elbow

tength

fitting

Page 15

mm

一

一

oo

一

—

LHM

MS

LYOU

TAS

一

30d

y]

四

μ

m8

9

ma

isa

nevi

MS

30d

+

トーーーーーーーーーーー

НА

〇

+

a

i

=

라르

я

DAREI

NI

Ov

AMA

一

0d

4

一

|

Na8

чеки

GU

37891

|

-

+

3300

mg

、

-

【

Г

INI

8

vas

SKİ

INI

CAS

Td

|

ㅅ

70005

ong

Z

m

ak|

TU

>>

FE

一

o

a

S

s

一

OA

on

1945

M

SI

TTT

>

VASILE

MOOS

—

TULNON

Mv

Bd

TY

‘

,

TINOON

WO

YSN

OSZ-H

Y

MIGNON

48

NAYYO

TUL

va

Luva

é

06-87-01

0555204

140

—

aNYN

37026

ILIIHS

374

DNI

SJIOOTONHOU

TRAE

08

THA

308

sna

=

OTT

は

TIA/NYO

mu

div

8

LTUNO

oùn3

av

|

(Ha

Эви.

чипа

=

“TBA/NHO

=

ma

ENA)

—

AO-

8

=

Sditv

οςὉ

Za

ya

dna

10H

XY

1

à

è

-

r

EE

o

YINOULNOI

1

ng

a

aA

THA

ON

一

MA/

034

m8

o

AMO

sal

—

504

8

TA

BA

[sue

m8

8-1

IHL

Nag

OL

Zi

35n4

ce/1/€

0300Y

Y

A3Y

IVILN3014NOD

‘AlddNS

2GAOd

M

Page 16

Nte

O

'

Ate

1

MA

038

037

(as

SSSLMI

n

BylrNí

280

u

ry

νι

8

%

i

で

ВЫ

CHI

.03g

cos

037

tu

+39

OLr

gyiyNI

ZI

$

Azı*

Ngo

vas

031

ogy

68

-

VEDOZNIN

гп

gt

Ağlı

so

49001

cod

not

YI0YIH

SOd

Sr

G

08608

2g

OSZ—-H

BOSZH

OSZH

OYYOB

052-01-04

06-61-01

OSZOIOL

TOYLNOD/AUY

x

‘HIBNNN

AB

SAWN

IY

NAVY

13714

1HVd

©

veo

310

3714

NI

S2IDOTONND

EE

31

ow

zla

¿8

vid

2

9la

EM

HE

20021

2326

za

2xzs

ws

NECCRT

δρ

{

|

|

|

-

MOOL

ly

CLAIRE

Lari

|

4

LT

dy

20'0Z

sn

23030

1500

ar

7?

e

と

H3GY3H

I

'SOd

sr

£

vl

ey

za

#30vV3H

‘5092

er

y30Y3H

50d

ir

9

134208

Nid

ых

다

12008

Wa

νι

181

5109

Sx05

205

ID

Nid

8

asx

LMS

1

14205

Ni

art

nx

UJOvaS

dS9n

001

A0

NId

B

LMS

DE

IB

Nid&

GS

DaS

135008

Mee

nx

833005

2590

037

NO

Or-+

INN

sgzxOy-

ャ

io8

вхо

|

135205

мч

TNA

9;

Page 17

H-250

USA

Power

Module

FI

PUMP

AUX

TEMP

TB1

TH1

TH2

P1

K1

H1

SW1

SW2

PCB1

SW3

SW4

J1

J2

J3

J4

8

AMP

115VAC

EURO

CONTROLLER

8

TX1-81

TX1-81

12VDC

SPDT

600W

ALARM

FLOAT

ALARM\CNTRL

POLE

DIS INT

6

4

2

3

5

OUTLET

POS

115VAC

TEST

SW

INT

POS

POS

POS

POS

POS

ETA-R12DB3

PUMP

PWRDY

5CX-376FL

TERMINAL

+

THERMISTOR

THERMISTOR

POWER

RELAY

HEATER

SPDT

FLOAT

H-250

MICROSWITCH

MICROSWITCH

6

4

2

3

5

AC-1C-MD

8121LYZGE

SWITCH

ALARM\CONTROL

POS

AMP

POS

AMP

POS

AMP

POS

AMP

POS

AMP

8.0AMP

115VAC

43R033

BLOCK

SUPPLY

KUHP-5D51-12

600W

CON

CON

CON

CON

CON

MBK

TX1-81

TX1-81

115VAC

115VAC

10-782-PP

FLAT

ROUND

WHT

ILL.

12VDC

BOARD

.9A

60-23-002

66-01-002

60-45-002

60-13-001-A

60-47-010

60-06-00: で ーー

60-06-001

60-14-001-B

60-20-001

66-03-002-B

60-40-023

60-40-010

70-10-250

60-40-002

60-40-001

60-46-018

60-46-007

60-46-005

60-46-006

60-46-0038

©

ジリ

17

Page 18

|

0

mm

a

m

sa

wm

CI

[Г]

E]

|

m

AVONISSY

151

1081NOI/RYUV

1

Y

A34

mn

001094

ML

S1190

I

ασ]

+

O

の

w

n

TE

[

(Ej

)

on

ῃ

a

CC]

г

er

"C

+

cr

Ca

.

ul

二

и

w

u

y

・

+

a

LK

|

Пл]

1

as

и

u

ti

tl

sı

外

fan

|

re

EI

E

a

E]

a

|

e

NE

a

|

m

CI

NI

59

zf

10RH93」

1

13A31

145

tas

dl

3

“|

Y

-4

10

145

8

|

vos

If

a

ni

fas

=

vas

sn

+

sn

+

"O

ία

]

ta

[

и

ta

o

fay

10

ua

18

Page 19

H-250

R29

Ri

R28

R36

R27

R20

R19

R21

R22

R25

R26

R24

R23

R18

R15

R34

R35

R31

R30

R32

R16

R14

R7

R12

R10

R6

RH

R3

Rg

RS

RS

R4

R33

R2

C3

C2

CI

C5

C6

CR2

CR4

CR3

Qi

SD4

Alarm/Controt

15.4K

3K

11.0K

2K

15.4K

3.32K

3.32K

1.62K

10.0K

7.5K

10,0K

7.5K

10.0K

10.0K

51.1К

127.0K

1.0K

15.4K

2.0K

11.0K

8.2K

B.2K

8.2K

120.0K

8.2K

20.0K

20.0K

2.0K

470

470

470

470

10M

8.2M

10UF

10UF

.1UF

10UF

100РЕ

.

10UF

1N4148

1N4148

1N4148

2N4918

LED

GRN

Board

MF

1/8W

CF

1/4W

MF

1/8W

20

TURN

MF

1/8W

MF

1/8W

MF

1/8W

MF

1/8W

MF

1/8W

MF

1/8W

MF

1/8W

MF

1/8W

MF

1/8W

MF

1/8W

ΜΕ

1/8W

MF

1/8W

MF

1/8W

MF

1/8W

20

TURN

MF

1/8W

CF

1/4W

CF

1/4W

CF

1/4W

CF

1/4W

CF

1/4W

CF

1/4W

5%

CF

1/4W

5%

CF

1/4W

5%

CF

1/4W

5%

CF

1/4W

5%

CF

1/4W

5%

CF

1/4W

5%

CF

1/2W

5%

CF

1/4W

5%

25V

TANTALUM

25V

TANTALUM

POLY

25V

1KV

25V

1N4148

1N4148

1N4148

2N4918

GRN 4 PIN

CW20C104K

TANTALUM

CERAMIC

TANTALUM

PNP

1%

RNS5D

5%

1%

RN55D

SIDE

1%

RNS5D

1%

RN55D

1%

RN55D

1%

RN55D

1%

RN55D

1%

RN55D

1%

RN55D

1%

RN55D

1%

RN55D

1%

RN55D

1%

RNS5D

1%

RN55D

1%

RN55D

1%

RN55D

SIDE

1%

RN55D

5%

5%

5%

5%

5%

DISC

HLMP2500

ADJ.

POT.

ADJ.

POT.

MALLORY

MALLORY

OR

MALLORY

DD101

MALLORY

TDC

TDC

M20R104

TDC

TDC

60-01-001

60-01-022

60-01-019

60-01-024

60-01-001

60-01-004

60-01-004

60-01-010

60-01-003

60-01-002

60-01-003

60-01-002

60-01-003

60-01-003

60-01-007

60-01-005

60-01-006

60-01-001

60-01-024

60-01-019

60-01-011

06-01-011

60-01-011

60-01-013

60-01-011

60-01-014

60-01-014

60-01-023

60-01-025

60-01-025

60-01-025

60-01-025

60-01-017

60-01-021

60-02-001

60-02-001

60-02-003

60-02-001

60-02-002

60-02-001

60-03-001

60-03-001

60-03-001

60-04-002

60-10-006

19

Page 20

SD3

SD2

SD1

U3

U2

U4

US

U1

U6

J4

J2

45

Ji

Q1XN

U6SP

H250B

R17

R13

LS1

J3

Q1XB

U6SP

SDXS

SDXS

XSD

XSD

XU2

XU4

XU3

XU1

XU6

LED

RED

LED

RED

LED

RED

LM339N

ULN2003A

LM324N

MC78LO5CP

CM7555

LCD

3

POS.

HEADER

4

POS.

HEADER

5

POS.

HEADER

6

POS.

HEADER

NUT

4-40

LCD

SPACER

H-250 PC

BOARD

2.49K

10.0K

Al-256K

2

POS.

HEADER

BOLT

4-40X.25

LCD

SPACER

SPC

8PIN

SPC

BPIN

SKT 8 PIN

SKT 8 PIN

16

PIN

SOCKET

14

PIN

SOCKET

14

PIN

SOCKET

8

PIN

SOCKET

13

PIN

SOCKET

.181

.181

DIP

DIP

LED

GRN 4 PIN

LED

RED 4 PIN

LED

RED 4 PIN

LM339N

ULN2003A 7 INPUT

LM324N

MC78L05C0

CM7555

LCD

3

PIN

4

PIN

5

PIN

6

PIN'90

NUT

LCD

H-250

ΜΕ

CF

ALARM

2

PIN

BOLT

LCD

SPACER 8 PIN

SPACER 8 PIN

SOCKET 8 PIN DIP

SOCKET 8 PIN DIP

16

14

14

8

PIN

13

OR

OR

555

MODUTEC

90

AMP

90

AMP

90

AMP

AMP

4-40

HEX

SPACER

ALARM/CONTROL

1/8W

1%

1/4W

5%

AI-256K

90

AMP

4-40X.25

SPACER

PIN

DIP

PIN

DIP

PIN

DIP

DIP

SOCKET

PIN

SIP

HLMP2300

HLMP2300

QUAD

QUAD

5V

REGULATOR

TIMER

640457-3

640457-4

640457-5

640457-6

.395

RNS5D

640457-2

.395

.181.

.181

SOCKET

SOCKET

SOCKET

SOCKET

HLMP2300

MVOLT

COMPARATOR

DRIVER

OP

AMP

ICM

7555IPA

MTR

BIVAR

BIVAR

WIREWRAP

WIREWRAP

WIREWRAP

618-04

PC

618-04

808-187

808-187

WIREWRAP

WIREWRAP

WIREWRAP

BL100-301

BOARD

60-10-005

60-10-005

60-10-005

60-05-001

60-05-002

60-05-003

60-05-004

60-05-005

60-10-004

60-46-014

60-46-015

60-46-016

60-46-017

62-02-004

62-06-013

60-03-002

60-01-052

60-01-012

60-22-003

60-46-013

62-01-010

62-06-013

62-06-014

62-06-014

60-46-003

60-46-003

60-46-001

60-46-002

60-46-002

60-46-003

60-46-004

[Em

PSE

Po

ee

20

Mr”

re

ES

BASS

Foo)

Docoezoor

500.

04

003

©

Wy

So,

Sa

yo

2

>

~

Page 21

POLE

72-03

ASSY

001

-62-22-004

レン

©

62-314001

、

>

<

TT

一

Se

64-04-002

M

6401916 | |

62-01-015

ER

62-22-04

ue

~

、

121

62-01-012

62-01-0413

4

>

:|

©.

oder

—Y

121

com

——

>

6201-01)

‘

45-21-010

|

62-40-01

62-0113

—

17

«

64-10-00)

64-10-00]

-

45-21

-004

$2-30-002

Page 22

К.

ион

ZTE

200-b0-04

59

E”

8-200-20-9

100-40-24

—

|

‘a:

400-10-49

100-10-41

Xx

..

=.

|

юн

8-200-10-99

800-01-58

COBO

SL

210-62-29

Page 23

Mechanical

45-20-001

45-21-004

45-21-005

45-21-006

45-21-009

45-21-010

60-40-001

60-40-002

62-01-009

62-01-011

62-01-012

62-01-013

62-01-015

62-01-016

62-02-005

62-03-008

62-05-002

62-05-007

62-05-008

62-20-003

62-22-001

62-22-004

62-26-001

62-30-002

62-31-001

62-40-001

64-01-013

64-01-016

64-03-002

64-04-002

64-10-001

64-10-002

64-10-003

64-10-004

64-10-005-A

64-10-010

64-10-011

64-10-015

64-10-020

64-11-003-A

72-03-001

45-20-001

45-21-001

45-21-002

45-21-003

Parts

P,

LABEL

P,

LABEL

P,

LABEL,

P,

LABEL,

P,

LABEL

P,

LABEL

E,

SWITCH,

E,

SWITCH,

M,

BOLT

M,

BOLT

M,

BOLT

M,

BOLT

M,

BOLT

M,

BOLT

M,

NUT

M,

WASHER

M,

CLIP,

M,

HITCH

M,

LATCH,

M,

TUBING,

M,

FITTING

M,

FITTING

M,

POLE

M,

CASTER,

M,

CAP,

M,

O-RING

M,

BRACKET,

M,

BRACKET,

M,

BASE,

M,

POLE,

M,

SOCKET,

M,

SOCKET,

M,

SOCKET

M,

POLE

M,

POLE

M,

BALL

M,

DOWEL

M

,

BRACKET,

7M,

INSERT,

M

,

STUD

A,

|.

V.

P,

LABEL

P,

TAPE,

P,

LABEL

P,

LABEL

List

SET

BOTTOM

"SYSTEM

SCREW

FILTER

TOP

MICRO

MICRO

6-32 X .500

10-32 X 1.750

10-32 X 1.500

10-24 X .625

6-32 X .375

4-40 X .750

4-40

ESNA

1/4

BULLET

PIN

3/8 X 2

NO

POLY

SMC

SMC

ASSEMBLY,

DUAL

BASE,

310846

TOP

LATCH

H-250

FIBERGLASS

BOTTOM

TOP

CAP,

CAP,

BLACK

CLAMP

KNOB 1 7/8

PIN

INTERLOCK

POLE

SOLID

POLE

ASSY

SET

H-250

1/4"

ORANGE

DISPLAY

WATER

H-250

SOCKET

250"

COVER

"3"

SOCKET

ROUND

FLAT

FLT

BTN

FLT

FLT

FLAT

MS15795-811

AERO

LOCK-OUT

1/2"

KQL13-00

KQL13-36S

CHROME

WHEEL

BLACK

SWITCH

KEEPER

REV-

H.E.

H.E.,

H.E.

BLACK

DELRIN

BLOCK,

BLACK

1/8 X 5/8

CLAMP

H-250

H-250

LEVEL

-LS

"2"

LVR

HD

SKT

SKT

HD

HD

CLIP

FP321

H-250

BLACK

BLK

SWITCH

BLOCK

H-250

"1°

REV-12/5/88

BLACK

LVR

HDC/S

HD

SKT

UNION

MALE

SM 2 3/8"

2/1/89

BK

H-500/250-LS

V3L-2105-D8

V3L-101-D8

PHIL M/S

C/S

KNRLD

HD

PHIL

W/S

PHIL

WS

(-750DX.311DX.06TH)

ACG

ELBOW

ELBOW

7/8 X 42

REV-

9/9/86

REV-

9/9/86

WAS

2X2X47

DELRIN

DELRIN

DELRIN

3/4

WAS

WAS

WAS

WAS

DELRIN

BK4

WAS

BLK

WAS

„

1/2

1/2 X 3/8

W/RAMSHORN

WAS

WAS

RB0005

REV-A

REV-

REV-

PA0006

REB-B

DELRIN

MM0031

PA0044

NPT

4

PA0017

PA0016

PA0002

PA0003

PA0004

PA0011

WAS

PA0020

..

0687s

Fy

BH

KA

23

Page 24

45-21-0058

45-21-007

45-21-014

60-06-001

60-10-004

60-13-001-A

60-14-001-B

60-20-001

60-23-002

60-40-010

60-40-023

60-45-002

60-45-001

60-47-010

60-47-011

60-50-005

62-01-003

62-01-008

62-01-012

62-01-018

62-01-0719

62-01-020

62-01-022

62-01-027

62-02-001

62-02-005

62-02-006

62-05\010

62-06-003

62-06-015

62-07-005

62-07-006

62-20-001

62-20-003

62-22-001

52-22-010

62-22-012

62-22-020

62-26-001

62-31-004

62-37-001

62-40-007

64-01-001-B

64-01-018

64-02-002-B

64-07-007

64-10-008

P,

LABEL,

P,

LABEL

P,

LABEL,

E,

THERMISTOR

E,

LCD,

E,

TEMP

E,

POWER

E,

RELAY,

E,

CIRCUIT

E,

SWITCH,

E,

SWITCH

E,

OUTLET,

E,

PLUG,

E,

TERMINAL

E,

TERMINAL

E,

WIRE

M,

BOLT

M,

BOLT

M,

BOLT

M,

BOLT

M,

BOLT

M,

BOLT

M,

BOLT

M,

BOLT

M,

NUT

M,

NUT

M,

NUT

M,

BOLT,

M,

STANDOFF

M,

RAIL,

M,

STRAIN

M,

TYWRAP,

M,

TUBING,

M,

TUBING,

M,

FITTING

M,

FITTING

M,

FITTING

M,

FITTING 1/8-27NPT

M,

POLE

M,

PLUG,

M,

GASKET

M,

SEAL

M,

CHASSIS,

M,

BRACKET,

M,

ENCLOSURE,

М,

WATER

M,

FILLPORT

“SYSTEM

POWER

SOCKET

MODUTEC

CONTRLR

SUPPLY,

SPOT

BREAKER

FLOAT | 10-782-PP

C&K

EURO

HOSPITAL

14AWG

10-32 X .375

6-32 X .375

10-32 X 1.500

8-32 Χ .500

#8 X .500

6-32 X .250

10-32 X .750

8-32 X .375

10-32

4-40

ESNA

6-32

ESNA

POLYCARBONATE

TERMINAL

RELIEF,

X-LARGE

1/4 X

POLY

SMC

SMC

SMC

ASSEMBLY,

FILLPORT,

PVC

SW

APM

PWR

PC

TANK,

BLOCK,

250°

OUTLET

AUX.

TX1-81

MVOLT

5CX-376FL

12V,

W389CX-2

SPDT

AUXILIARYPWRDY

GRADE

BLOCK

STOP

3CON

PAN

PAN

PAN

PAN

SKT

SKT

ESNA

0.250

BLOCK

STRAIGHT

3/8

CVT

1/2"

KQL13-00

KQL13-35S

KQH13-35S

"T"

CHROME

RED

2X4

VF10212

N5040-R

MOD

BOARD

H-250

H-250

BLACK

-LS

REV-12/5/88

OUTLET

SENSOR

MTR

.9AHA15-0.9-A

MAGNACRAFT

8

AMP

3120-F323-P7T

8121LYZGE

HUBBELL

PHX

MBK

PHX

E/MBK

SJT

ORANGE

SKT

HD

PHIL

SKT

HD

C/S

PHIL M/S

PHIL

S/M/S

PHIL M/S

HD

C/S

HD

HEAD

SSL

1/4

FR

PHX

THRU

TY29M

OVERFLOW

UNION

MALE

MALE

W/BARBS,

7/8 X 42

THREADED

FOR

H-250

REV-B12/18/89

H250REV-

REV-B

ROSE

REV-B

DELRIN

H-500/250-LS

BL100-301

43R033121-250

8215-C

LINE

HD

M/S

KNRLD

FOR

ROSE

NS

15

SR7L-2

ELBOW

ELBOW

CONNECTOR

BLACK

W/

1/2

C&K

SWITCH

2/1/89

WAS

MM0031

1-R12DB3

CORD

ENC

HEYCO

1/2

1/2 X 1/4

NYLON

RAMSHORN

NPT

WAS

WAS

PM0046

86333-1

64-02-002

#1250

NPT

1/2X1/4NPT

4

P-48B

MM0005

MM0006

BH

24

Page 25

4

“So

64-10-012

64-10-013

64-10-014-B

64-10-016

6601-002

66-03-002-B

70-01-004

70-01-005

70-02-002

70-03-002

70-04-002

70-04-003

72-05-002

72-06-007

72-06-017

72-07-001

72-08-003

=

74-01:008—

74-02-002

74-05-002

M,

FILTER

-

M,

BRACKET,

M,

THERMISTER

M,

MOUNT,

E,

PUMP

E,

HEATER

A,

CIRCUIT

A,

LINE

A,

ALARM/CONTROL

A,

POWER

`

A,

FLOAT

A,

ALARM

A,

WATER

A,

TERMINAL

À,

FILTER

À,

CABINET

A,

FILLPORT

A,

PUMP

A,

HEATER

A,

POWER

BLOCK,

ALUMINUM

BACKING

BLOCK

FLOAT

AC-1C-MD

120V

SWITCH,

115V

600W

BLK

BREAKER HARNESS

CORD

ASSY

BOARD

SUPPLY

SWITCH

SWITCH

TANK

BLOCK

BLOCK

ASSY

BLOCK

ASSY

ASSY

ASSY

ASSY

ASSY

ASSY

H-250

H-250

ASSY

H-250

H-250

H-250

MODU

BLACK

PLATE

1/4NPT

1X1

ANODIZED

DELRIN

H-250

CENTRIFICAL

WHT

GRN

H-250

H-250

H-250

H-250

H-250

H-250

H-250

REV-B9/27/89

25

Page 26

HAAL'YWARE

STANDARD

PROCEDURES

РЕК

ЕСО # 157

‘scription

{-250

(DOM/

CALIBRATION

8.

9.

10.

CHECK

8.1

SET

9.1

9.2

9.3

9.4

COLD

10.1

10.2

10.3

FLOAT

TO

CHECK

ALARM

UNIT

TURN

ASMALL

ALLOW

SET

UNIT

START

TURN

PLACE A CLAMP

NEUTRAL).

TURN

AT

39.2

OPERATING

INT)

SWITCH

FLOAT

SOUNDS.

AT

39.9

TEMP.

TURN

TIME

TO

UNIT

UNIT

CONTROLLER

RUN

OFF.

SET

ON.

+-0.3°C

HSOP#

FINAL

PROCEDURE

SWIT:

REFILL

FOR

DOMESTIC

OF

THE

TO

STABILIZE

AT

39.9°C

REPLACE

CURRENT

METER

THE

UNIT,CURRENT

FOR

DOMESTIC

WATER

AND

POT

POT

IS A LARGE

TEMP.

+-

0.1°C

WARM

METER

ON 6 AMP

AND

002

De

ONNECT

TO

RE-OPERATE.

40.9

CW

TO

BETWEEN

FOR

WATER

AROUND

RANGE.

40.2

BERN

novo“

FILLPORT

FOR

INCREASE

INCREASE

DOMESTIC

SHOULD

+-

Ne

TUBING

INTERNATIONAL;

TEMPERATURE

IN

ADJUSTMENTS.

AND

WITH

COLD.

ONE

CHANGE

OF

ey

TEMP.

40.9°C

THE

FR

ENG:

QC:

МЕС:

07/25/95

AND

+-0.1°C

CIRGUIT

Date

DRAIN

BREAKER

NAL

NAL.

File

Name:

WATER

FOR

INTERNATIONAL.

WIRES

JANT

DRAW

HSOP002.DOC

UNTIL

(LINE

TO

Page

2

of

WATER

OR

PULSE

EV

2

LEVEL

MODE

11.

11.1

IDLE

:21

13.

SEND

CHECK

REMOVE

RATE

CHECK

ALLOW

FOR

UNIT

FLOW

RATE

CALIBRATED

OF

THE

CIRCULATING

UNIT

TO

RUN

INTERNATIONAL.

TO

Q.A.

FOR

ELECTRICAL

T-40

THERMO

WATER,

FOR 1 HOUR

x

Y

V

TESTING

URE

AND

39.9°C

+-

FINAL

A

ALLONS

0.1°C

FOR

INSPECTION.

FLOW

PER

RATE

MINUTE.

DOMESTIC

METER.

AND

40.9°C

THE

+-

FLOW

0.1°C

Page 27

«LARD

OPERATING

PROCEDURES

PER

ECO # 157

scription

250

(DOM/

INT)

CALIBRATION

1

SET

UP

11

2.

3.

1.2

1.3

14

CHECK

2.1

CHECK

3.1

3.2

RECORD

THE

NOTIFY

FILL

INSTALL

RECORD

WORKSHEET.

TURN

PLACE

MEASUREMENT

ADJUST

THE

FOLLOWING

YOUR

UNIT

WITH

THE

THE

FOR

LEAKS

UNIT

POWER

DC

VOLTAGE

POWER

ON.

HSOP#

FINAL

PROCEDU

Qe

RESUL

TEST

PARAMETERS

SUPERVISOR.

TAP

WATER.

CALIBRATED

CALIBRATED

(H.S.O.P.

OBSERVE

SUPPLY

SHOULD

SUPPLY

002.5).“ALSO

VOLTAGE

METER

OUTPUT

Pe

READ

FOLLOWING

T40

THERMOMETER

ALL

FITTINGS

LEADS

002

que"

ass

TAG

THERMOMETER.

RECORD

'

AND

ACROSS

12

VOLTS

IF

NECESSARY.

THE

+-

THE

0.1

À

ON

H.S.O.P.

MACHINE

SERIAL

THE

SEAMS

PCB

VOLTS.

νο

#,

AMBIENT

IN

CONNECTOR

Date

07/25/95

002.5

IF

THE

WITH A DESCRIPTION

YOUR

NAME,

TEMPERATURE.”

THE

CIRCULATING

(J5),

UNIT

AND

BLACK

File

UNDER

THE

WATER

Name:

OF

DATE

AND

HSOP002.

TEST

THE

ON

SYSTEM

RED

Page

Tof

2

DOC

FAILS

TO

FAILURE

THE

CALIBRAT

FOR

WIRES,

MEET

AND

LEAKS

THE

4.

SET

OVER

4.1

WATER

4.2

ADJUST

TEMP.

TEMPERATURE

INTERNATIONAL.

3

ADJUST

..4

ADJUST

AT

4.5

ADJUST

41.5

4.6

REPEAT

5.

SET

CALIBRATION

5.1

COMPARE

5.2

TURN

THERMOMETER

6.

POLE

6.1

CHECK

UNIF

RETURN

6.2

TO

ACTIVATE.

7.

ALARM

7 1 DEPRESS

PL

ASHING

OPERATIONAL.

THE

40.2

+-0.2°C

THE

+-

0.0° C FOR

STEPS,

THR

INTERLOCK

TOP

SHOULD

CHECK

TEST

ALARM

MUST

THE

40

ADJ.

POT

THE

OVERTEMPERATURE

40

ADJ.

POT

FOR

DOMESTI

40

ADJ.

POT

DOMESTI

TWO

TIMES

OF

DISPLAY

UNIT

LCD

TO

40

AN}

POT

ON

LCD