Page 1

Page 2

Introduction /

Specifications

Sub-Assemblies

Technical Description

Disassembly Procedures

Maintenance, Testing

and Calibration

®

Troubleshooting

Spare Parts

Rounding Off

Appendix 1Circuits

Appendix 2 PCB Layout

Blood and

Fluid Warmer

Appendix 3 Symbols Glossary

Appendix 4 Frequently Asked Questions

Information Bulletins

Page 3

Welcome...

Who are we?

medical devices for treating critically ill patients. These devices may

be used in high-risk situations, and include ambulatory and hospital

PREFACE

Welcome...

... to one of

Smiths Medical’s

Technical Service Packs

Smiths Medical is a global manufacturer and supplier of

infusion pumps, neo-natal and paediatric monitors, blood and fluid

warmers, and convective warming systems for patients.

Figure P - 1: A selection of Smiths Products - old and new

HOTLINE® Blood and Fluid Warmer Technical Service Pack i

Page 4

Smiths Medical has a long history, bringing many well known

brands to the market, such as Portex®, Level 1®, BCI®, Graseby®,

Wallace®, Bivona®, Pneupac®, Deltec®, DHD® and Medex® . It is part

of the Smiths Group, a British engineering consortium founded in

1851.

Now all of these formerly independent business units have

been merged into one Global company — Smiths Medical. Smiths

Medical is a world leader in the design, manufacture and

distribution of medical devices.

What about Level 1®?

The Level 1® range of products is synonymous with a high

PREFACE

Welcome...

quality, cost effective range of temperature management products.

The range includes blood and fluid warming products for both

gravity flow and fast flow intravenous or irrigation applications, and

convective (hot air) warming systems. These products help to

prevent hypothermia and maintain normothermia in patients

undergoing surgery in the operating theatre, recovery ward and in

the casualty departments in emergency situations.

Why is Temperature Management important?

Patients undergoing surgical procedures are exposed to a

variety of influences that have a effect on their ability to maintain

their normal body temperature (Normothermia). If these factors

persist for a prolonged period of time, the patient will become

hypothermic, i.e., their body temperature drops below 36°C. Even

mild hypothermia (34°-36°C) puts patients at risk. Trauma cases and

extensive procedures present well-known temperature

management challenges. But so can routine operations. Clinical

evidence shows that warming is important in any case lasting more

than an hour and/or using more than one litre of fluid.

HOTLINE® Blood and Fluid Warmer Technical Service Pack ii

Page 5

PREFACE

What hypothermia does to the patient

■ Cardiovascular instability

■ Vasoconstriction, decreased cardiac output, and changes in

electrical conduction can contribute to an increased incidence of

cardiac ischemia, arrhythmias, and arrest.

■ Increased coagulopathy

■ Coagulopathy may result in increased bleeding, possibly

necessitating blood transfusions.

■ Altered action and reduced clearance of anesthetics

■ Hypothermia decreases a patient’s metabolism, resulting in a

need for higher amounts of anesthetics. It also contributes to

delayed emergence from anesthesia and longer recovery room

stays.

Welcome...

■ Increased risk of wound infection

■ Wound infection and delayed wound healing result in longer

hospital stays. Wound infection can prolong hospitalization.

■ Postoperative discomfort

■ Thermal discomfort, shivering, and fatigue can occur when core

temperature decreases by 1°C .

The HOTLINE® Blood and Fluid Warmer

The HOTLINE® Blood and Fluid Warmer uses a special

disposable that totally encloses the patient’s end of the IV

administration set in a bath of warmed recirculating fluid. This

means that the IV fluid is introduced at or above core body

temperature, rather than in the chilled state that it may have been

stored at.

This simple solution eliminates the chill being passed to the

patient, and assists the patient’s own efforts at maintaining

normothermia.

HOTLINE® Blood and Fluid Warmer Technical Service Pack iii

Page 6

Published by:

Smiths Medical ASD, Inc.

160 Weymouth St, Rockland, MA 02370, USA

■ For assistance or further information, contact Smiths Medical

USA/ Canada

■ Smiths Medical ASD, Inc.

■ USA/Canada 1-800-258-5361

PREFACE

ASD, Inc., Technical Service Department or your Smiths Medical

ASD, Inc., distributor at:

160 Weymouth Street, Rockland, MA 02370 USA

International +1-781-878-8011

Welcome...

European Representative

■ 6PLWKV«0HGLFDO«,QWHUQDWLRQDO«/WG

%UREKA0ARK,OWER0EMBERTON

!SHFORD+ENT4."&5+

5HJLVWHUHG«LQ«(QJODQG«1XPEHU««

■ 7HO««««

Australian Representative

■ Smiths Medical Australasia Pty. Ltd.

61 Brandl Street, Brisbane Technology Park

Eight Mile Plains, QLD 4113, Australia

■ Tel +61 (0) 7 3340 1300

Fax +61 (0) 7 3340 1399

World WideWeb:

■ www.smiths-medical.com

HOTLINE® Blood and Fluid Warmer Technical Service Pack iv

Page 7

PREFACE É Welcome...

■ All possible care has been taken in the preparation and production

of this publication, but Smiths Medical accepts no liability for any

inaccuracies that may be found.

■ This publication may be subject to revision and it is the user’s

responsibility

appropriate to the intended use.

■ Users of the equipment must ensure that they have read and

understood the contents of the complete manual including the

warnings and cautions and have been trained in the correct use of

the product.

■ This publication has been compiled and approved by Smiths

Medical for use with their respective products.

■ It may be supplied in a format that permits users to access the text

and illustrations for their own use (e.g., training and educational

purposes). Smiths Medical cannot be held responsible for the

accuracy of, nor any resulting incident arising from, information

that has been extracted from this publication and compiled into the

user’s documentation.

to ensure that the correct version is used

■ Other than as herein noted, no part of this publication may be

reproduced, transmitted, transcribed, or stored in a retrieval

system or translated into any human or computer language in any

form or by any means without the prior permission of Smiths

Medical.

■ “Graseby

trademarks of the Smiths Medical family of companies. All other

trademarks are acknowledged as the property of their respective

owners.

■ The symbol

Trademarks Office and in certain other countries.

®

” “Smiths” “HOTLINE®” and “LEVEL 1®” are all

® indicates it is registered in the U.S. Patents and

© 2011 Smiths Medical family of companies.

All rights reserved.

HOTLINE® Blood and Fluid Warmer Technical Service Pack v

Page 8

Revision History

PREFACE É Revision History

Issue

No:

000 New Revision - First Release All July 2006

001 Updated EU Rep address iv, v, vi, 6,

Reason for Change Pages

Affected

front and

back covers

Date

October 2011

HOTLINE® Blood and Fluid Warmer Technical Service Pack vi

Page 9

Aims

PREFACE Aims

To provide technical engineering support staff with the

practical and theoretical knowledge necessary to ...

■ ... diagnose,

■ maintain,

■ repair,

■ and update ...

... Smiths Medical products as appropriate to meet the needs

of your healthcare establishment’s equipment management

protocols.

HOTLINE® Blood and Fluid Warmer Technical Service Pack vii

Page 10

Objectives

a qualified Biomedical Engineer or Technician with appropriate

experience to successfully tackle any repair or component

replacement required, and recalibrate the unit either routinely or

post-repair work.

training course that can be held either at Smiths Medical’s premises,

or at your own establishment if that would be more convenient.

Successful training course attendees may be certified by

Smiths Medical, an option not open to non-attendees. Please

PREFACE Objectives

This manual will give you the necessary information to enable

The material covered by this manual is also offered as part of a

contact your local Smiths Medical distributor for more details. We

strongly recommend course attendance wherever possible, to

ensure the highest standards of maintenance for your HOTLINE®

units.

On completion of the program, delegates will have knowledge

of the following:

■ General functionality and device application.

■ Principles of operation of electronic and mechanical systems.

■ Access to, and use of, the menu systems as appropriate.

■ Appropriate methods of testing and the equipment required.

■ Essential safety features and verification of performance.

■ Routine maintenance requirements.

■ Analysis of faults, fault codes and download software as

appropriate.

HOTLINE® Blood and Fluid Warmer Technical Service Pack viii

Page 11

Contents

Section 1 - Introduction and Specifications

Superior Performance - - - - - - - - - - - - - - - - - 2

Ease of Use - - - - - - - - - - - - - - - - - - - - - - 2

Features - - - - - - - - - - - - - - - - - - - - - - - 3

Specifications - - - - - - - - - - - - - - - - - - - - - 4

Contra-Indications - - - - - - - - - - - - - - - - - - - 6

Section 2 - Sub-assemblies

CONTENTS

Environmental - - - - - - - - - - - - - - - - - - - 5

Miscellaneous - - - - - - - - - - - - - - - - - - - 5

Enclosure - - - - - - - - - - - - - - - - - - - - - - 9-11

Recirculating Solution Path - - - - - - - - - - - - - - - 12

Interlock Block - - - - - - - - - - - - - - - - - - - - 13

PCB Mounting - - - - - - - - - - - - - - - - - - - - 14

Section 3 - Technical Description

General - - - - - - - - - - - - - - - - - - - - - - - - 16

Mechanical - - - - - - - - - - - - - - - - - - - - - - 16

Controls and Indicators - - - - - - - - - - - - - - - - 17

Side Panel - - - - - - - - - - - - - - - - - - - - - 17

Electrical - - - - - - - - - - - - - - - - - - - - - - - 19

Power Circuits - - - - - - - - - - - - - - - - - - 19

Control Circuit - - - - - - - - - - - - - - - - - - 20

Digital Display - - - - - - - - - - - - - - - - - - - 22

Thermistor Loss - - - - - - - - - - - - - - - - - 23

Over Temperature Alarm - - - - - - - - - - - - - - 25

Flasher - - - - - - - - - - - - - - - - - - - - - 27

Interlock Alarm - - - - - - - - - - - - - - - - - - 29

Recirculating Solution Level Alarm - - - - - - - - - 30

HOTLINE® Blood and Fluid Warmer Technical Service Pack

ix

Page 12

CONTENTS

Section 4 - Disassembly Procedure

Tools you will need - - - - - - - - - - - - - - - - - - - 33

Disassembly - - - - - - - - - - - - - - - - - - - - - 34

Step 1: Open the case - - - - - - - - - - - - - - - - 34

Step 2: Remove the PCB - - - - - - - - - - - - - - 36

Step 3: Release the Earth Stud - - - - - - - - - - - 40

Step 4: The Recirculating Solution Return Pipe - - - - 41

Step 5: Removing the Chassis - - - - - - - - - - - - 42

Reassembly - - - - - - - - - - - - - - - - - - - - - - 44

Section 5 - Maintenance, Testing and Calibration

Before each use - - - - - - - - - - - - - - - - - - - - 46

Lubrication of O-Ring Seals - - - - - - - - - - - - - 46

After each use - - - - - - - - - - - - - - - - - - - - - 46

Routine Maintenance Tasks - - - - - - - - - - - - - - - 47

Every 30 days - - - - - - - - - - - - - - - - - - - - - 48

Every 12 months - - - - - - - - - - - - - - - - - - - - 49

Maintenance Solutions - - - - - - - - - - - - - - - - - 54

Changing the Recirculating Solution - - - - - - - - - - - 54

Sterile Distilled Water - - - - - - - - - - - - - - - 54

Isopropyl Alcohol Solution - - - - - - - - - - - - - - 56

Hydrogen Peroxide Solution - - - - - - - - - - - - - 57

Routine Maintenance Checklists - - - - - - - - - - - - - 60

Full Service Test Procedure - - - - - - - - - - - - - - - 64

Things you will need - - - - - - - - - - - - - - - - 64

HL-90 Service Test Specification - - - - - - - - - - - 65

Section 6 - Troubleshooting

Troubleshooting Hints - - - - - - - - - - - - - - - - - 71

Over Temperature Alarm always ON - - - - - - - - 71

Over Temperature Alarm not working - - - - - - - - 72

Fluid Warming Set Interlock Alarm always ON - - - - 72

Fluid Warming Set Interlock Alarm not working - - - 72

Low Recirculating Solution Level Alarm always ON - - 73

Low Recirculating Solution Level Alarm not working - 73

Non-Alarm related Faults - - - - - - - - - - - - - 74

HOTLINE® Blood and Fluid Warmer Technical Service Pack

x

Page 13

Section 7 - Spare Parts

Enclosure Parts for two-part case - - - - - - - - - - - 76

Enclosure Parts for single-part case - - - - - - - - - - 77

Float Switch and related parts - - - - - - - - - - - - - - 77

Parts in the Recirculating Solution Path - - - - - - - - - 78

P.C.B and mounting accessories - - - - - - - - - - - - - 79

Water pump and related parts - - - - - - - - - - - - - - 79

Interlock Block and related parts - - - - - - - - - - - - 80

External Parts, Rear of case - - - - - - - - - - - - - - - 81

Poleclamp parts - - - - - - - - - - - - - - - - - - - - 82

Section 8 - Rounding Off

Updates - - - - - - - - - - - - - - - - - - - - - - - - 84

Modifications - - - - - - - - - - - - - - - - - - - - - 84

GRI Pump - - - - - - - - - - - - - - - - - - - - - - - 86

Float Switch Sealing Washer- - - - - - - - - - - - - - - 87

CONTENTS

Appendix 1- Circuits

Appendix 2 - PCB Layout

PCB layout - - - - - - - - - - - - - - - - - - - - A2 - 2

Component Listing - - - - - - - - - - - - - - - - - A2 - 3

Appendix 3 - Symbols Glossary

Appendix 4 - Customer Information Bulletins

HOTLINE® Frequently Asked Questions - - - - - - - A4 - 2

General Advisement - - - - - - - - - - - - - - - - A4 - 6

®

HOTLINE

- Specific Announcements - - - - - - - - A4 - 7

HOTLINE® Blood and Fluid Warmer Technical Service Pack

xi

Page 14

Introduction /

Specifications

Blood and

Fluid Warmer

®

Page 15

HOTLINE® HL-90

Blood and Fluid Warmer

The HOTLINE® HL-90 Blood and Fluid Warmer is designed for

use with the HOTLINE® Warming Set to warm blood and IV fluids,

and deliver them to the patient’s intravenous access site at normo-

thermic temperatures under gravity flow conditions.

By jacketing the sterile patient IV line with a layer of precisely

controlled warmed recirculating solution, HOTLINE® provides active

warming of the patient line all the way down to the patient connec-

tion, thus eliminating “patient line cool-down.”

SECTION 1 HOTLINE® HL-90

Superior Performance

■ The HOTLINE® innovative tubing design eliminates “patient

line cool-down,” and delivers warm intravenous fluids to pa-

tients

Ease of Use

■ Simple, 1-step plug-in disposable for fast setup and start

■ A 2.4 m (8 foot) patient line allows convenient positioning of

unit

■ Requires 60 - 70% less priming volume (20 ml)

■ Compatible with standard IV sets, infusion pumps and in-line

hand pumps

HOTLINE® Blood and Fluid Warmer Technical Service Pack

2

Page 16

Features

y

SECTION 1 HOTLINE® HL-90

■ Integrated, highly effective design gives unparalleled ease of

use

■ Can be set up and operated in seconds

■ Warmed Intravenous Fluid delivery at up to 4750 ml/hr

■ Digital display of recirculating solution temperature

■ Electronic circuitry continuously monitors recirculating solu-

tion temperature

■ Green “Warming” operating LED

■ Red fault indicator LEDs identify 3 common fault conditions

■ Audible alarm indication

■ Alarm test facility

Fault Condition LEDs

Disposable Interlock

Temperature Displa

Operating LED

Recirculating Solution Level

Over Temperature

HOTLINE® Blood and Fluid Warmer Technical Service Pack

GM-0163-8102-GB-A

Figure 1 - 1: HOTLINE® Front Panel

3

Page 17

Specifications

Dimensions inch cm

Height 9.5 24.1

Length 8.3 21.0

Width 7.0 17.8

Weights lbs kg

Weight (dry) 7.6 3.5

Weight (full) 11.0 5.0

Weight (as Shipped) 7.95 3.6

SECTION 1 Specifications

Electrical HL-90 US HL-90 UK

Supply Voltage 115 V AC 230 V AC

Supply Current 3.0 A 1.5 A

Supply Frequency 50-60 Hz 50-60 Hz

Classification Class 1 Class 1

Safety Rating Type BF applied part Type BF applied part

Power Cord 0.75mm x 3.6 m 0.75mm x 3.6 m

HOTLINE® Blood and Fluid Warmer Technical Service Pack

4

Page 18

Environmental

Temperature

Operating Range 10oC — 45oC,

Transport / Storage -20oC — 70oC

Water Resistance

Enclosure Protection IEC 60529, IP Code: IPX1

Miscellaneous

SECTION 1 Specifications

10 — 95% RH, (non-condensing)

5 — 95% RH, (non-condensing)

Standards Compliance

Fluid Warmers ASTM F2172-02

Product Safety EN60601-1, UL2601-1

EMC EN60601-1-2; FCC 47

Performance

Recirculating Solution temperature display will reach 37oC

from ambient in about 4 minutes.

Operating Temp. Set Point 41.5oC ± 0.5oC

Over Temp. Set Point 42.6oC ± 0.5oC

Max Height on IV pole 107 cm (42 inch)

CFR part 15, Class B

Recirculating Solution 1.4 litres Capacity

HOTLINE® Blood and Fluid Warmer Technical Service Pack

5

Page 19

Contra-indications

■ Not Suitable for use in the presence of flammable anaesthetic

mixtures with air or oxygen or with nitrous oxide.

SECTION 1 Contra-indications

■ HOTLINE

devices generating over 300 mmHg.

®

disposables are not suitable for use with pressure

HOTLINE® Blood and Fluid Warmer Technical Service Pack

6

Page 20

Sub-Assemblies

Blood and

Fluid Warmer

®

Page 21

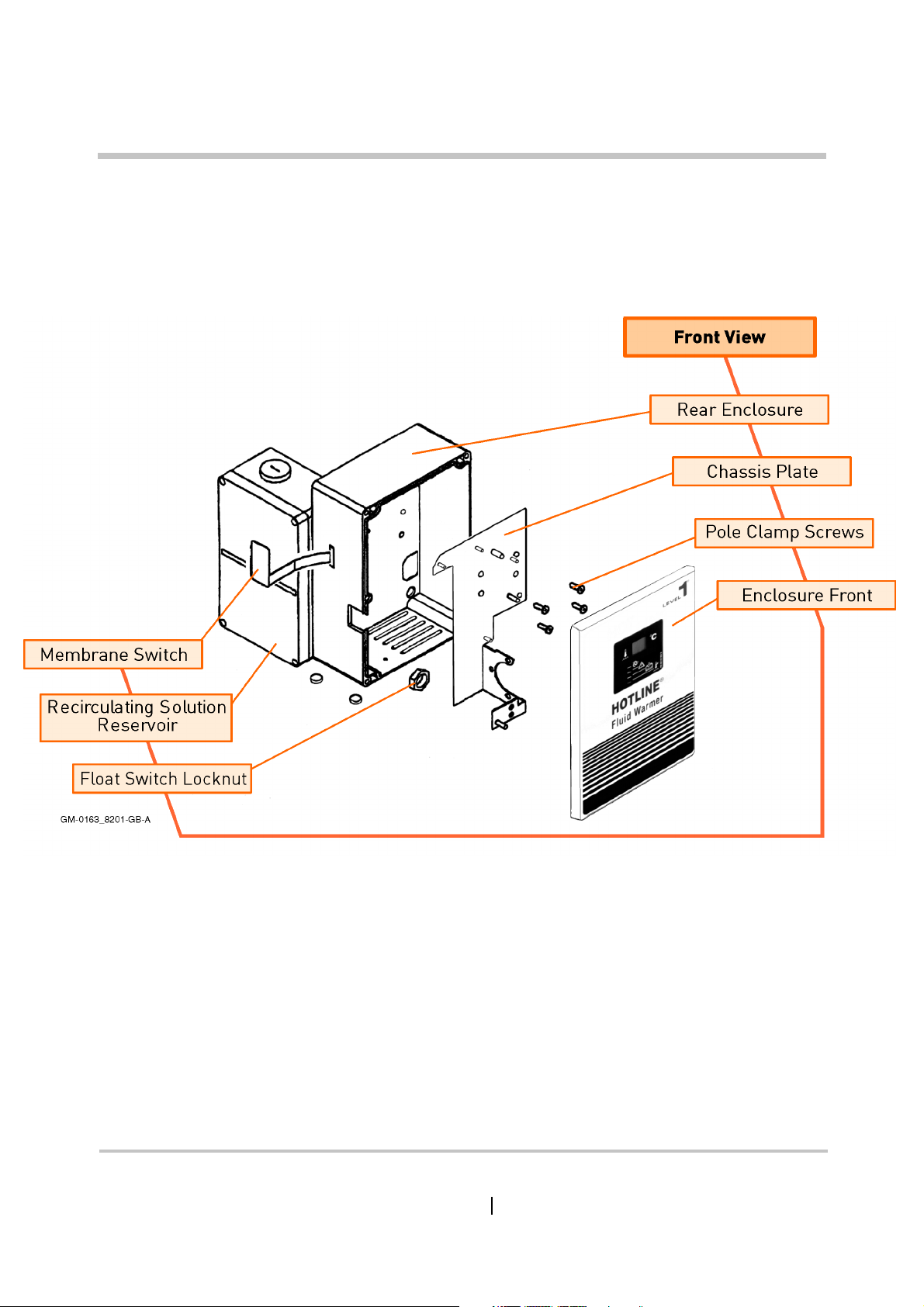

Sub-assemblies

The principal sub-assemblies to be found in the HOTLINE®

HL-90 are:

■ The enclosure and chassis parts

■ The recirculating solution path components

■ The PCB and its mountings

SECTION 2 Sub-assemblies

These are detailed on the following pages.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

8

Page 22

Enclosure (1)

SECTION 2 Enclosure (1)

HOTLINE® Blood and Fluid Warmer Technical Service Pack

9

Page 23

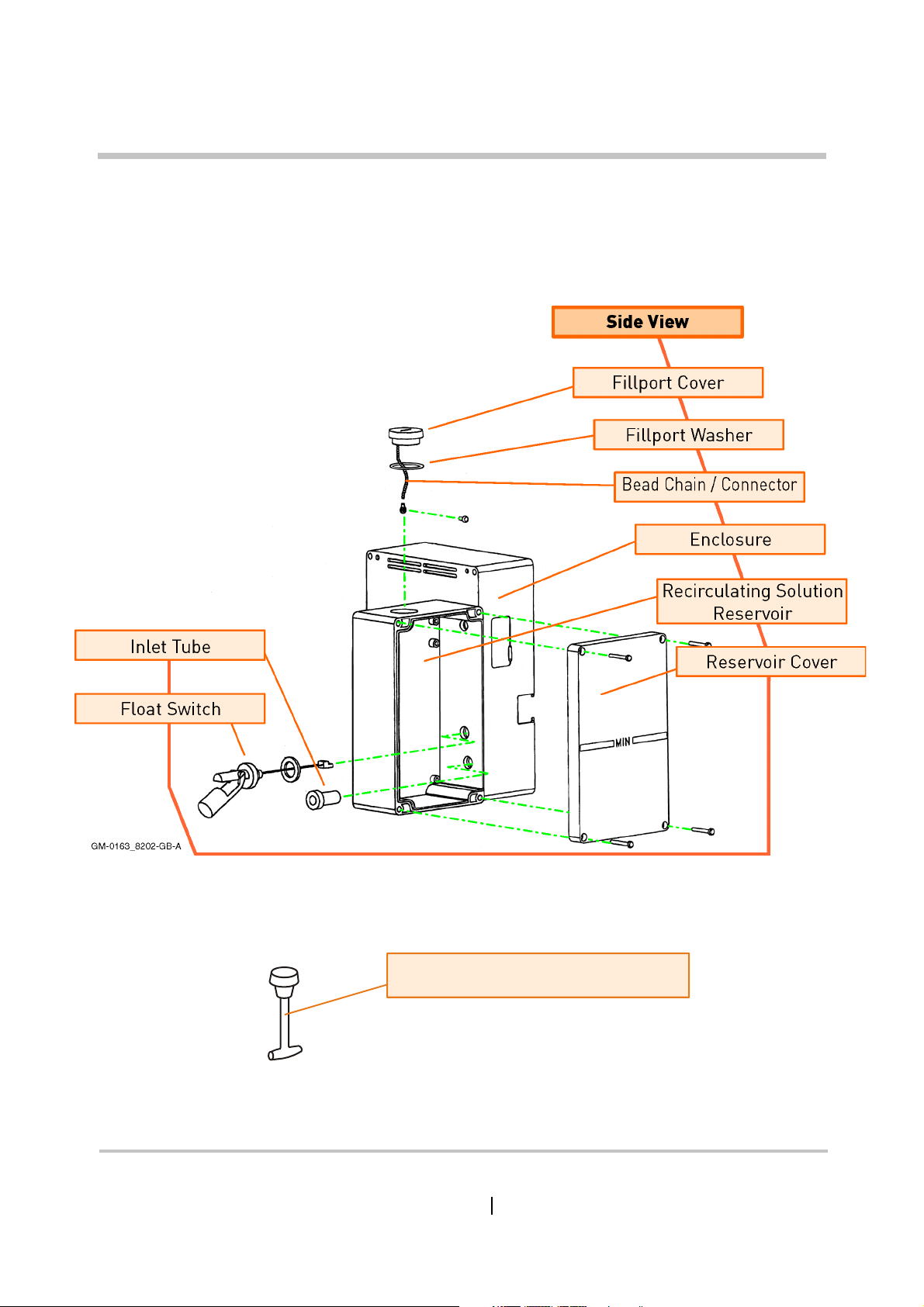

Enclosure (2)

SECTION 2 Enclosure (2)

Newer design Fillport Cover removes

need for chain or retaining screw

HOTLINE® Blood and Fluid Warmer Technical Service Pack

10

Page 24

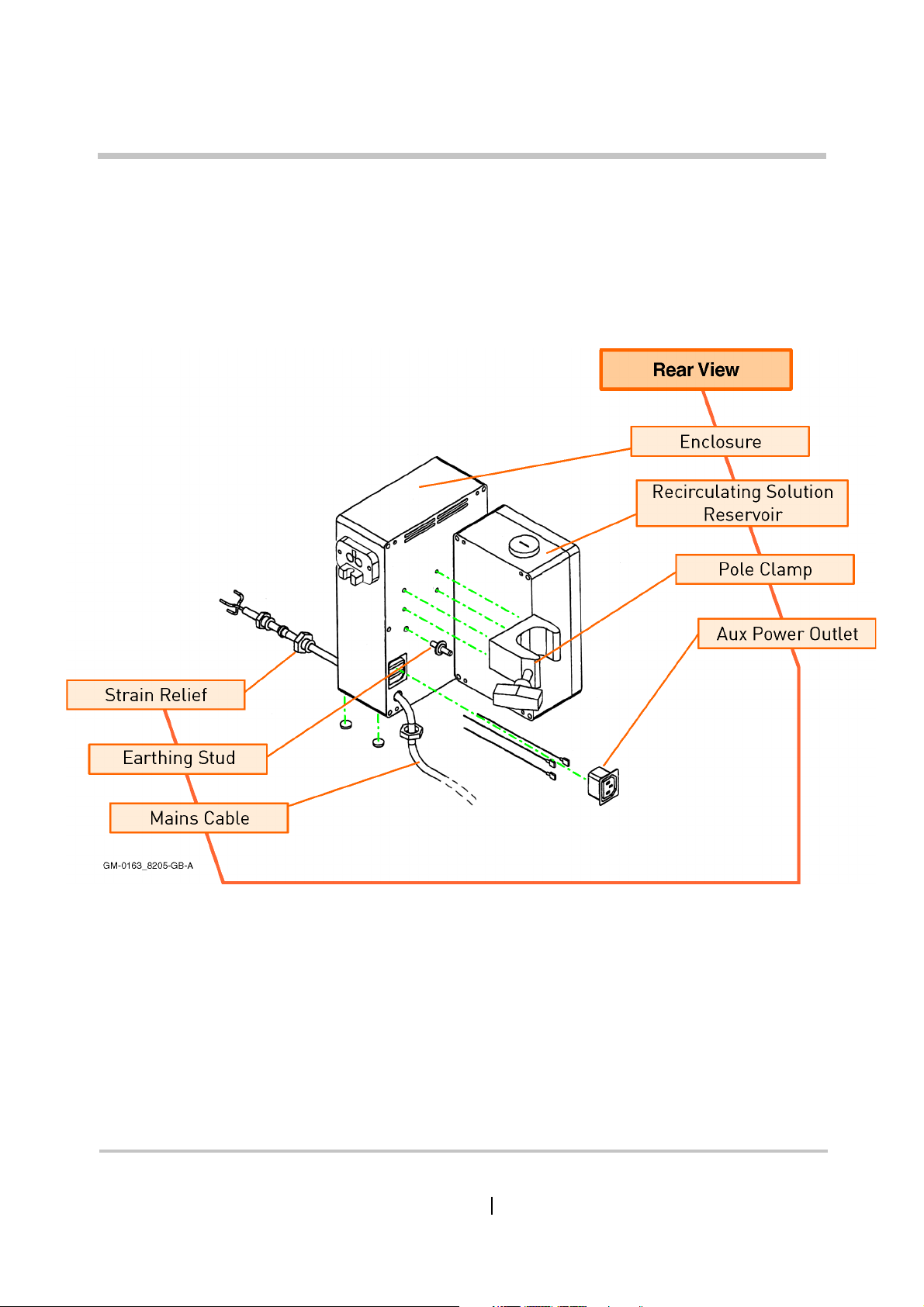

Enclosure (3)

SECTION 2 Enclosure (3)

HOTLINE® Blood and Fluid Warmer Technical Service Pack

11

Page 25

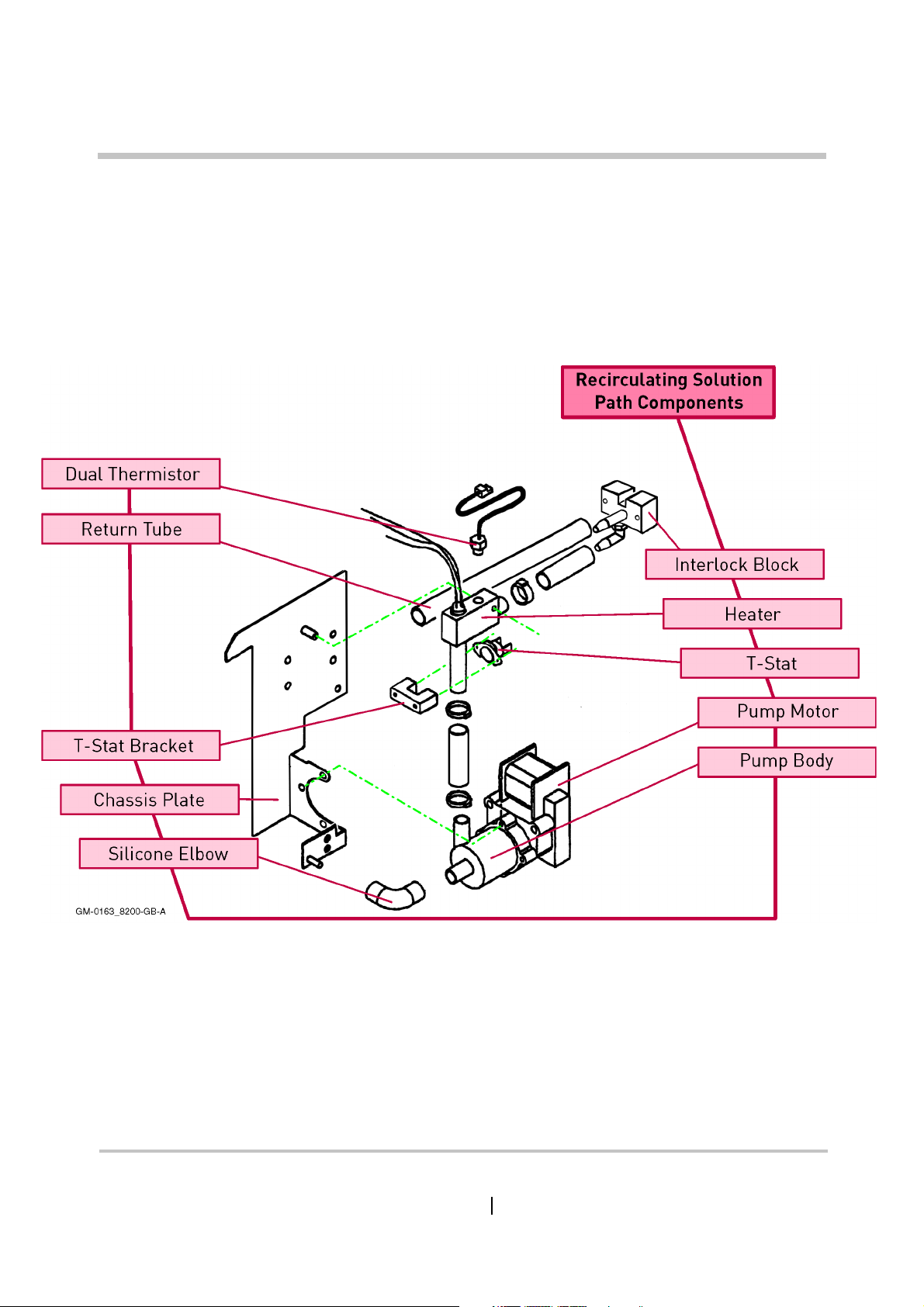

SECTION 2 Recirculating Solution Path

Recirculating Solution Path

HOTLINE® Blood and Fluid Warmer Technical Service Pack

12

Page 26

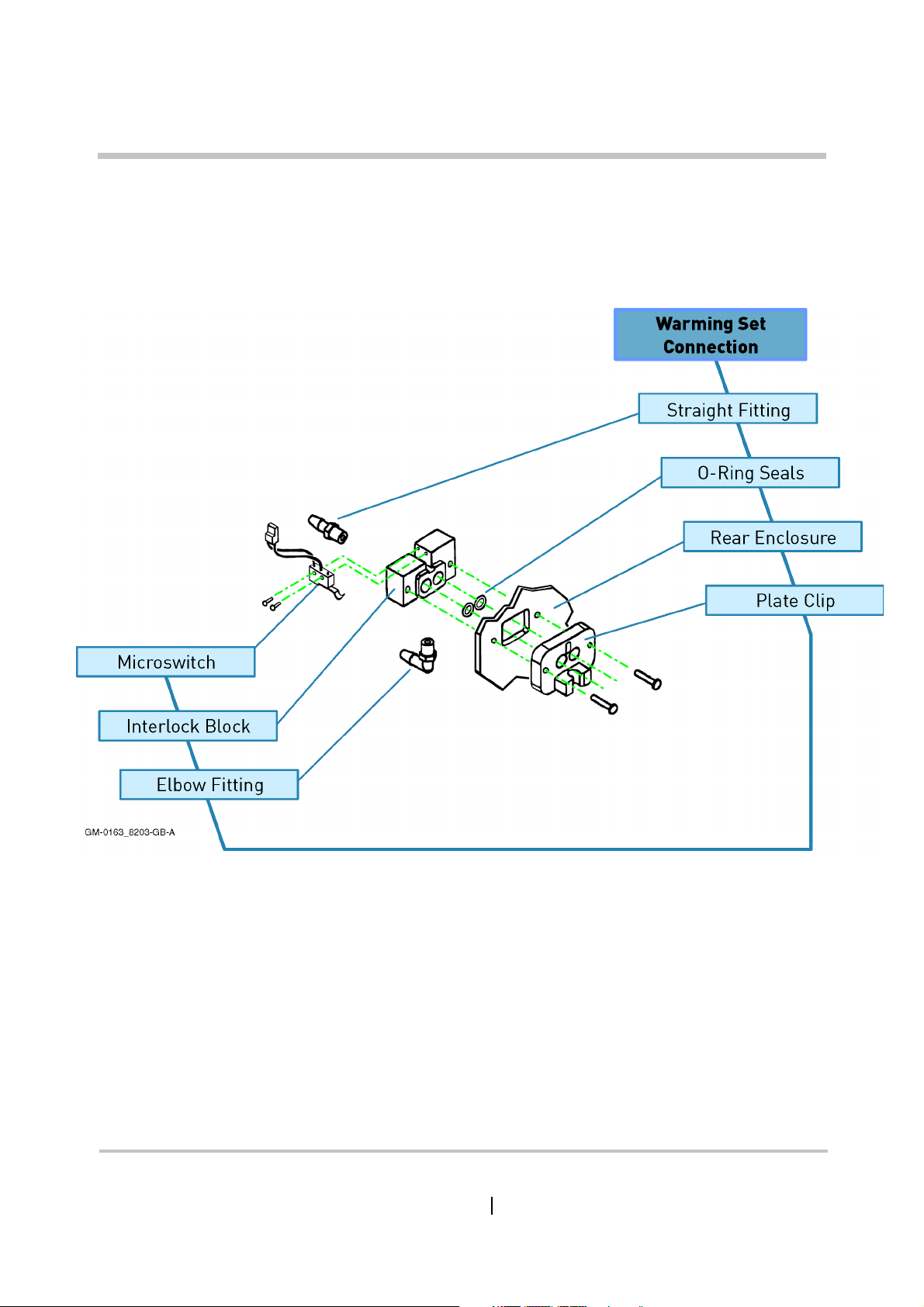

Interlock Block

SECTION 2

Interlock Block

HOTLINE® Blood and Fluid Warmer Technical Service Pack

13

Page 27

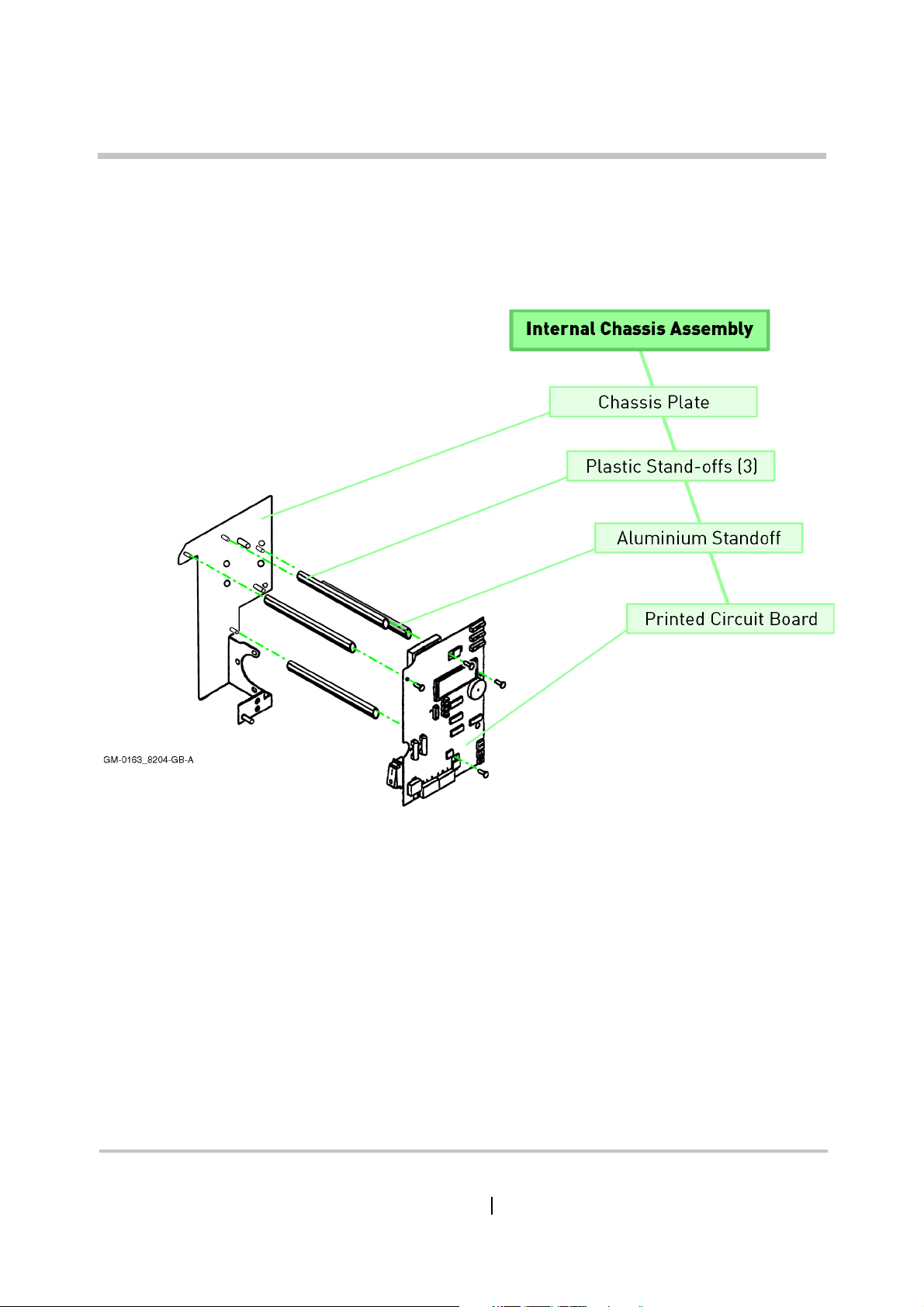

PCB Mounting

SECTION 2 PCB Mounting

HOTLINE® Blood and Fluid Warmer Technical Service Pack

14

Page 28

Technical Description

Blood and

Fluid Warmer

®

Page 29

SECTION 3 Technical Description

Technical Description

General

The HOTLINE® employs a safe recirculating solution heating

system, inherently free of hotspots, to actively warm the HOTLINE

®

Blood and Fluid Warming Set

fluid-filled jacket and sterile IV line. The primary temperature

control circuit limits the recirculating solution to 42oC maximum. In

the unlikely event of a malfunction of this circuit, a second

watchdog circuit will visually and audibly alarm and stop pumping

the recirculating solution if the temperature reaches 43oC.

The heater current is supplied via a thermal cutout, so in the

case of a circulation failure, the heater will be protected against

burn-out; the same cutout will act in the event of catastrophic

breakdown of components in the HOTLINE® circuitry that prevents

the alarm state from disengaging the heater.

These three levels of safety ensure that the IV Fluid in the

HOTLINE® Fluid Warming Set is never exposed to any damaging or

dangerous temperature while the unit is operating.

- a co-axial arrangement of warm

Mechanical

litres of either distilled water or a disinfectant solution. This fluid

will henceforth be referred to as recirculating solution. Do not

confuse recirculating solution with the IV Fluid being dispensed to

the patient.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

The rear left-hand side of the unit is a reservoir, holding 1.4

16

Page 30

SECTION 3 Technical Description

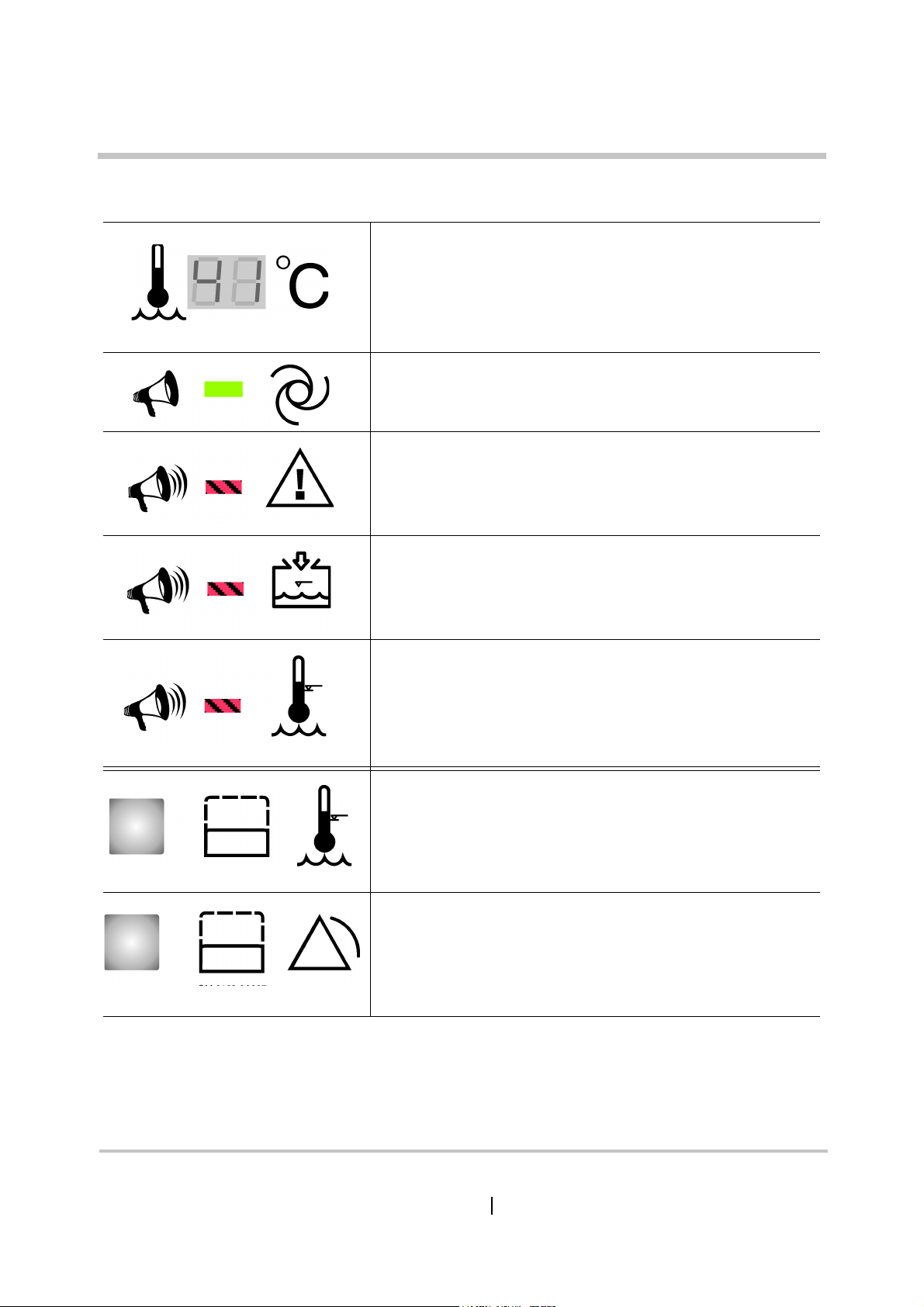

Controls and Indicators

Shows the current temperature of the circulating

warmed recirculating solution.

This steady GREEN indicator illuminates when power is

ON and the Warming Set is correctly installed. The

recirculating solution is being warmed and circulated.

This flashing RED indicator with audible alarm shows

that warming and circulating has been stopped

because the Warming Set is not fitted properly.

Reattach the Warming Set and continue.

This flashing RED indicator with audible alarm shows

that warming and circulating has stopped because

there is not enough recirculating solution in the unit to

operate the float switch. Refill, and continue.

This flashing RED indicator with alarm shows that

warming and circulating has been stopped because the

recirculating solution reached a temperature above the

set point. The unit must be removed from service, and

repairs effected before returning to service.

SIDE PANEL BUTTON

Simulates triggering of the Over Temperature

watchdog alarm for testing.

SIDE PANEL BUTTON

General Alarm Test

Simulates triggering of all alarms for testing.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

17

Page 31

Mechanical (contd)

The outer face of the reservoir is transparent so the

recirculating solution level and flow can both be observed. A float

switch is fitted in the tank, so that the unit cannot operate if there is

insufficient recirculating solution to properly circulate.

Recirculating solution is drawn from the bottom of the reservoir, via

a silicone rubber elbow into a centrifugal pump driven by a 60VA

synchronous electric motor in the main enclosure.

The pump outlet is vertically upwards, and feeds into the

heater assembly via another short length of silicone rubber piping.

The heater asembly is a solid cast L-shaped unit that, in the vertical

leg, incorporates a 300 watt heater element, able to warm the

SECTION 3 Technical Description

recirculating solution from room temperature to 37oC in 4 minutes.

In the horizontal leg of the heater assembly, a special dual

thermistor unit is submerged in the flow, to monitor and control the

warmed recirculating solution temperature.

Clamped to the external surface of the heater assembly is the

T - Stat, a thermally-operated bi-metallic cutout that breaks the

circuit at temperatures above 50oC. The cutout only self-resets

when the temperature has dropped significantly (10oC - 15oC)

below its nominal operating temperature.

The warmed recirculating solution leaving the heater

assembly now enters the interlock block, at the top right-hand side

of the HOTLINE®. This interfaces to the Fluid Warming Set that

contains the sterile line for the patient’s IV fluid. The Fluid Warming

Set needs to be in place so as to operate a microswitch that would

otherwise raise an alarm and cut off the pump. Running back from

the interlock block is the recirculating solution return line, which

leads directly throught the rear of the main enclosure and into the

top of the reservoir.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

18

Page 32

SECTION 3 Technical Description

Electrical Power Circuits

VU

10

C501

10F

U501

R501

453R

µ

GM-HL90_8A103

R502

3.16k

C 2

220F

+

µ

13

U1

1

1

T1

3

4

OPTO

6

CR1

F3 375mA

12

10

9

7

C

C100

100pF

14

R502

3.16k

Figure 3 - 1: HOTLINE® Power Circuits

J6

F1 1.5A

LF1

Filter

J7

6

1

U3

4

2

R4

1k

R3

270R

U2

TRIAC

Gate

F2 1.5A

Contacts

MT2

MT1

SW1

DPST

K1

26

22

TB1

3

4

TB1

5

6

TB1

8

7

38

30

Thermofuse

TB1

56 C

1

2

o

Water

Heater

Input

Pump

Motor

Earth Stud

Line

L

N

E

J10

AUX

Outlet

Power circuitry is conventional, and is constructed on the PCB.

There are three fuses, F1 and F2 (both 1.5A) for the Mains input, and

F3 (375 mA) for the low voltage circuits. F3 is wire-ended device,

soldered into place at the top edge of the PCB.

On the Mains side, the power normally passes through a line

filter to reduce susceptibility to interference (this filter is not always

required for domestic US units.) The pump motor is switched by a

PCB-mounted relay K1, and the heater element is controlled by a

triac. The heater can only be energised when the pump is powered

on, since without recirculating solution flow, the heater element

would quickly overheat.

The heater triac is triggered via an optical isolator, and all the

Mains voltage circuits are physically distanced from the low-voltage

circuits for safety reasons. The low-voltage control circuits are

HOTLINE® Blood and Fluid Warmer Technical Service Pack

19

Page 33

SECTION 3 Technical Description

derived from a conventional step-down transformer. After

rectification and smoothing, the supply is regulated to a nominal 10

volts by U501, an LM317T integrated regulator. Resistors R501 and

R502 set the exact output voltage level.

NOTE: The HOTLINE® is NOT a Class 2 double-insulated device, and

must be connected with a good earth connection to ensure

patient and operator safety.

Control Circuit

R607

178k

O'temp

Test

Alarm

Test

Display

Sensor

-t

-t

Control

Sensor

GM-HL90_8305-A

10

1

R02/4

15k

U3.1

C201

22 F

R207

15.4k

µ

10

VU

CR202

Green

15

CR201

1N4001

R206

3.15k

C

Q1

U1.4

R01/6

78L05

4

14

11

R504

15.4k

6

U1.2

5

15k

7

U3.7

12345678910111213

5

R603

R605

15.4k

15.4k

2

U1.1

3

R602

15.4k

R03/5

5

OT Setp oint

R106

5k

U3.6

15k

R606

11k

11

7

10

R601

11k

R03/3

15k

J1

1

2

3

4

J4

1

2

3

4

13

12

LCD Cal

R102

5k

R01/1

15k

4

AA

LCD Module

J101

R104

1k

R103

105k

11

1

R107

34k

R108

10M

10 10

88

U1.3

99

8

C101

µ

47 F

S

2

U2.1

3

Heat Control

R202

5k

6

R203

154k

R01/7

15k

J201

R01/9

R03/8

15k

R204

1M

9

6

1

15k

R201

16.5k

U2.3

U2.2

5

7

R01/8

15k

7

X

Figure 3 - 2: HOTLINE® Temperature Control Circuits

The control sensor is one of a “siamese twin” pair of

thermistors submerged in the recirculating so luti on flow a s it leav es

the heater. At normal operating temperatures, the thermistors each

have a resistance of about 15k, and this decreases roughly linearly

with increasing temperature.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

20

Page 34

SECTION 3 Technical Description

As a result, the current through the chain [control thermistor -

R202 - R01/9] is roughly proportional to the recirculating solution

temperature, and thus, so is the voltage sample at R202 slider. This

is buffered by U2.1, part of an LP324N quad op-amp, and passed to

U2.2, which is configured as a comparator. At pin 5 of U2.2, a

reference voltage of about 5 volts is created by the voltage divider

resistors R03/8 and R01/8.

If the temperature-dependent sample at pin 6 is less than the

reference level set at pin 5, then pin 7 will go high, which switches

on the darlington driver U3.1, and so turning on the opto/triac/

heater combination. However, this also grounds R207 via CR201,

which starts discharging C201, and so reducing the reference

voltage at U2.2/5. Unless the recirculating solution is very cold, the

reference voltage will soon dip below the sample voltage, so

turning off the heater circuit.

As soon as U3.1 turns off, C201 can start recharging to 5 volts,

and at some point the reference voltage overtakes the sample

voltage, and the heater turns on again, repeating the cycle. R204

provides a modest amout of positive feedback, ensuring that the

switch transitions are snap-action.

You can see that the repetition rate of the circuit depends both

on the RC time constants around C201, and also on the temperature

of the recirculating solution in the reservoir. If this is still some

distance from the desired temperature, the sampled voltage will

“sag” very quickly when the heater turns off, and fresh cold

recirculating solution is pumped through the heater unit.

If, however, the HOTLINE® has been running some while, all the

recirculating solution in the circulation loop will be at, or close to,

the desired temperature, so the sample voltage will hardly move at

all.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

21

Page 35

Digital Display

The temperature control thermistor is one of a pair, siamesed

together in the heater housing. The other of these provides a user

display of the recirculating solution temperature and, as we will see

later, protection in case of failure by the first thermistor.

SECTION 3 Technical Description

R607

178k

O'temp

Test

1

2

3

4

Alarm

Test

Display

Sensor

-t

1

2

3

-t

4

Control

Sensor

GM-HL90_8306-A

R601

11k

R03/3

15k

J1

J4

13

12

LCD Cal

R102

R01/1

15k

78L05

4

14

U1.4

11

5k

R504

15.4k

6

U1.2

4

5

R01/6

15k

7

U3.7

12345678910111213

5

R603

R605

15.4k

15.4k

2

U1.1

3

R602

15.4k

R03/5

5

OT Setpoint

R106

U3.6

15k

5k

R606

11k

11

7

10

AA

LCD Module

J101

R104

1k

R103

105k

11

1

R107

34k

6

R108

10M

10 10

88

U1.3

99

8

C101

47 F

µ

S

Q1

Figure 3 - 3: HOTLINE® Temperature Monitoring Circuits

The output from the display sensor thermistor is buffered by

2

U2.1

3

Heat Control

R202

R203

154k

R01/7

15k

5k

J201

R01/9

15k

10

R03/8

15k

C

15k

U3.1

C201

22 F

R207

15.4k

µ

VU

CR202

Green

15

R206

3.15k

CR201

1N4001

R204

1M

9

1

U2.3

R201

16.5k

10

6

U2.2

5

7

R02/4

1

R01/8

15k

7

X

U1.2, another LP324 quad op-amp device. It passes to U1.1, which is

a summing amplifier, combining the sensed voltage with the

buffered output from U1.4. This allows a degree of offset,

determined by R102, to be introduced for calibration purposes.

The buffered and calibrated voltage is scaled by R103/R104,

and presented to the digital LCD millivolt-meter module for display.

The window in the front case allows two digits to be seen by the

user, although the third digit (tenths of a degree) may be seen by

the technician when the case front is removed.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

22

Page 36

Thermistor Loss

SECTION 3 Technical Description

R607

178k

O'temp

Test

1

2

3

4

Alarm

Test

Display

Sensor

-t

1

2

3

-t

4

Control

Sensor

GM-HL90_8307-A

Q1

U1.4

R01/6

15k

7

78L05

4

14

11

R504

15.4k

6

U1.2

5

U3.7

12345678910111213

5

R603

R605

15.4k

15.4k

2

U1.1

3

R602

15.4k

R03/5

5

OT Setpo int

R106

U3.6

15k

5k

R606

11k

11

7

10

R601

11k

R03/3

15k

J1

J4

13

12

LCD Cal

R102

5k

R01/1

15k

4

LCD Module

J101

R104

1k

R103

105k

11

1

R107

34k

R108

10M

10 10

88

U1.3

99

8

C101

µ

47 F

S

2

3

Heat Control

6

R203

154k

R01/7

R01/7

15k

15k

AA

Figure 3 - 4: HOTLINE® Thermistor Loss Monitoring

U2.1

R202

5k

J201

R01/9

15k

10

R03/8

15k

C

15k

U3.1

C201

22 F

R207

15.4k

µ

VU

CR202

Green

15

R206

3.15k

CR201

1N4001

R204

1M

9

1

U2.3

R201

16.5k

10

6

U2.2

5

7

R02/4

1

R01/8

15k

7

X

Since both control and display thermistors are NTC devices,

their resistance DECREASES with increasing temperature. This

means that if the thermistor or its wiring were damaged somehow,

an open circuit sensor would potentially be a dangerous situation.

The infinitely HIGH resistance of an open circuit would be

interpreted as a very LOW temperature, and so the HOTLINE® would

fail with the heater powered permanently ON.

To prevent this, U2.3 detects that there is a reasonable voltage

being fed to the temperature controller circuit. If the thermistor

circuit ever achieved an effective resistance of some 150K or more,

then U2.3 will turn on sending signal X high. Needless to say, there

is no place on earth cold enough to get this much resistance from

the thermistor through natural causes!

HOTLINE® Blood and Fluid Warmer Technical Service Pack

23

Page 37

SECTION 3 Technical Description

Float

Switch

Interlock

Switch

AA

R03/6

15k

C301

0.1 F

µ

R03/9

R02/3

15k

15k

R01/2

R307

15.4k

15k

J2

1

2

3

J3

1

2

S

X

GM-HL90_8308-A

R302

8.2M

13

U2.4

12

R02/2

15k

Piezo

3

14

U3.3

CR302 Red

15

2

U3.2

CR301 Red

4

13

U3.4

CR303 Red

R03/2

3

14

R301

722R

Float

Interlock

Overtemp

R03/1

15k

15k

Figure 3 - 5: HOTLINE® Thermistor Loss Alarm

R308

15.4k

C302

10 F

12

R304

100k

3

6

U4.2

7

µ

4

U4.1

5

8

14

U4.3

9

10

13

U4.4

11

12

R305

100k

R306

15.4k

10

R03/7

15k

1

2

CR 401

Green

9

5

U3.5

8

R401

1k

12

System

Normal

VU

R 2

270R

Relay

K1

15

Following signal X onto the next page, we see that it reaches

U4.4. U4 is an LP339 - a low-power version of an industry standard

quad comparator with open-collector outputs. Taking signal X high

turns on U4.4’s output, which starves darlington driver U3.5’s input

of current. This was being held on by R03/7, but now it turns off, so

cutting off the relay K1, which in turn removes power from the

pump motor and heater mains circuits, thereby rendering the

HOTLINE® (and any patients it may be attached to) safe.

This arrangement of open-collector devices feeding a

common input effectively creates an OR-gate, allowing multiple

inputs to control the output relay.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

24

Page 38

SECTION 3 Technical Description

Over Temperature Alarm

Earlier, we looked at how the display was generated from the

second thermistor in the siamesed package. There is another good

reason for having a double thermistor arrangement - as safety

watchdog in case of failure.

In this part of the circuit, we take the buffered and calibrated

display signal through R107, and using another quarter of the op-

amp U1, compare it to a pre-selected over temperature set point,

set by R106. If the temperature has got too warm, perhaps because

the primary thermistor has given up, then signal S will be activated.

R607

178k

O'temp

Test

1

2

3

4

Alarm

Test

Display

Sensor

-t

1

2

3

-t

4

Control

Sensor

GM-HL90_8309-A

R601

11k

R03/3

15k

J1

J4

13

12

LCD Cal

R102

R01/1

15k

78L05

4

14

U1.4

11

5k

R504

15.4k

6

U1.2

4

5

R01/6

15k

7

U3.7

12345678910111213

5

R603

R605

15.4k

15.4k

2

U1.1

3

R602

15.4k

R03/5

5

U3.6

15k

OT Setpoint

R106

5k

R606

11k

11

7

10

AA

LCD Module

R104

1k

R103

105k

11

1

R107

34k

R108

10M

10 10

U1.3

99

C101

47 F

µ

Q1

Figure 3 - 6: HOTLINE® Over Temperature Monitoring

10

R03/8

15k

R207

15.4k

µ

VU

CR202

Green

15

R206

3.15k

CR201

1N4001

C

J101

9

2

U2.1

3

1

Heat Control

R202

5k

6

R203

154k

88

R01/7

15k

8

S

J201

R01/9

15k

U2.3

R201

16.5k

R204

1M

10

6

U2.2

5

7

R02/4

15k

U3.1

1

R01/8

15k

7

C201

22 F

X

Since failure of this part of the circuit could be quite

catastrophic, there are two separate methods of verifying that it is

working OK.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

25

Page 39

SECTION 3 Technical Description

Pressing the Alarm Test button artificially lowers the set point

by making U3.6 short out R606. Since the set point is lowered to

below room temperature, this should set off the alarm whatever the

actual fluid temperature.

The second test mechanism is operated by the Over

Temperature Alarm Test button. This overrides the display

thermistor to fake an over temperature situation. You should see

the display rise to an artificially simulated temperature of 43oC -

44oC. Because of the delay (C101 and R107) you need to hold the

button for 2 - 3 seconds to activate the test.

R607

178k

O'temp

Test

1

2

3

4

Alarm

Test

Display

Sensor

-t

1

2

3

-t

4

Control

Sensor

GM-HL90_8314-A

R601

11k

R03/3

15k

J1

J4

13

12

LCD Cal

R102

R01/1

15k

78L05

4

14

U1.4

11

5k

R504

15.4k

6

U1.2

4

5

R01/6

15k

7

U3.7

12345678910111213

5

R603

R605

15.4k

15.4k

2

U1.1

3

R602

15.4k

R03/5

5

U3.6

15k

OT Setp oint

R106

5k

R606

11k

11

7

10

AA

LCD Module

J101

R104

1k

9

R103

105k

11

1

R107

34k

R108

10M

10 10

88

U1.3

99

8

C101

µ

47 F

S

2

U2.1

1

3

Heat Control

R202

5k

6

R203

154k

J201

R01/9

15k

U2.3

R201

16.5k

R01/7

15k

Q1

Figure 3 - 7: HOTLINE® Over Temperature Alarm Test

Signal S operates in much the same way as signal X did

R03/8

15k

6

5

R204

U2.2

7

1M

R01/8

X

10

C

R206

3.15k

VU

10

CR202

Green

7

R02/4

15k

15

U3.1

1

R207

CR201

15.4k

C201

22 F

1N4001

µ

15k

previously, using U4.3 to cut off the pump and heater circuits. In

addition however, there is a LED, driven by U3.4, visible from the

case exterior to warn the operator that this fault situation has

occurred.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

26

Page 40

SECTION 3 Technical Description

Interlock

Flasher

R03/6

15k

C301

0.1 F

R03/9

R02/3

15k

15k

R01/2

R307

15.4k

15k

Float

Switch

Switch

AA

J2

1

2

3

J3

1

2

S

X

GM-HL90_8310-A

Figure 3 - 8: HOTLINE

R302

8.2M

µ

13

U2.4

12

R02/2

15k

Piezo

14

3

U3.3

CR302 Red

15

2

U3.2

CR301 Red

4

13

U3.4

CR303 Red

®

Over Temperature Alarm

R03/2

3

15k

14

R301

722R

Float

Interlock

Overtemp

R03/1

15k

R308

15.4k

C302

10 F

12

R304

100k

3

6

U4.2

7

µ

4

U4.1

5

8

14

U4.3

9

10

13

U4.4

11

12

R305

100k

R306

15.4k

10

R03/7

15k

1

2

CR 401

Green

9

5

U3.5

8

R401

System

Normal

1k

12

VU

R 2

270R

Relay

K1

15

Float

Switch

Interlock

Switch

AA

R03/6

15k

C301

µ

0.1 F

R03/9

R02/3

15k

15k

R01/2

R307

15.4k

15k

J2

1

2

3

J3

1

2

S

X

GM-HL90_8311-A

R302

8.2M

13

U2.4

12

R02/2

15k

Piezo

3

14

U3.3

CR302 Red

15

2

U3.2

CR301 Red

4

13

U3.4

CR303 Red

R03/2

3

14

R301

722R

Float

Interlock

Overtemp

Figure 3 - 9: HOTLINE® Alarm Flasher

12

R03/1

15k

15k

R308

15.4k

C302

10 F

R304

100k

3

6

U4.2

7

µ

4

U4.1

5

8

14

U4.3

9

10

13

U4.4

11

12

R305

100k

R306

15.4k

10

R03/7

15k

1

2

CR 401

Green

9

5

U3.5

8

System

Normal

R401

1k

12

VU

R 2

270R

Relay

K1

15

HOTLINE® Blood and Fluid Warmer Technical Service Pack

27

Page 41

SECTION 3 Technical Description

The alarm LED does not return directly to the positive rail, as

you might expect. Instead it gets its power from U2.4, which is

configured as a low-frequency square-wave oscillator. This means

that the LED can only light up when U2.4’s output is high - so it

flashes on and off to attract attention.

Whenever the LED is ON the piezo-sounder is powered by the

volt-drop across the LED’s current-limiting resistor R301, so it beeps

in synchronism with the flashing of the alarm LED.

Exercise: If more than one alarm happened at once, then two or

more LEDs would be flashed by this circuit. The extra current drain

should increase the volt-drop across R301, so you would expect the

Piezo-sounder to increase in power and volume for every extra alarm

condition.

QUESTION...

Guess how much percentage increase in beep volume results

from ALL alarms simultaneously, compared to a single alarm?

Now try to justify your answer!

HOTLINE® Blood and Fluid Warmer Technical Service Pack

28

Page 42

Interlock Alarm

SECTION 3 Technical Description

Float

Switch

Interlock

Switch

AA

12

R03/6

15k

C301

0.1 F

µ

R03/9

R02/3

15k

15k

R01/2

R307

15.4k

15k

J2

1

2

3

J3

1

2

S

X

GM-HL90_8312-A

R302

8.2M

13

U2.4

12

R02/2

15k

Piezo

3

14

U3.3

CR302 Red

15

2

U3.2

CR301 Red

4

13

U3.4

CR303 Red

R03/2

3

14

R301

722R

Float

Interlock

Overtemp

R03/1

15k

15k

R308

15.4k

C302

10 F

R304

100k

3

6

U4.2

7

µ

4

U4.1

5

8

14

U4.3

9

10

13

U4.4

11

12

R305

100k

R306

15.4k

10

R03/7

15k

1

2

CR 401

Green

9

5

U3.5

8

System

R401

1k

12

Normal

VU

R 2

270R

Relay

K1

15

Figure 3 - 10: HOTLINE® Warming Set Interlock Alarm

The interlock switch is a simple microswitch which is operated

by the insertion of the warming set into the twin socket. If you were

to switch the pump on with no warming set connected, the results

would not be catastrophic, nor particularly dangerous, but they

could be awfully messy!

Therefore, if the Interlock Switch is not made, the pump (and

heater) will not run. The flashing LED lets you know why the

HOTLINE® is refusing to co-operate.

This part of the circuit has a fail-safe action that might mislead

you if you’re faultfinding. U03.2 is kept turned on by the pull-up

resistor R03/1 so that if there is a fault in the interlock switch

off-board wiring, or the J2 connector isn’t fully connected, the alarm

is defaulted ON. You need a good continuous circuit through J2 to

allow U3.7 to pull U03.2 low and turn the alarm state off.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

29

Page 43

SECTION 3 Technical Description

U3.7 is the Alarm Test circuit; if there is a fault in the alarm test

switch, nothing happens except the unit will be unable to test its

alarms. The integrity of the alarm itself would not be compromised

by alarm test switch failure.

Recirculating Solution Level Alarm

12

Float

Switch

Interlock

Switch

AA

S

X

J2

1

2

3

J3

1

2

R03/9

15k

R01/2

R307

15.4k

GM-HL90_8313-A

R03/6

15k

R02/3

15k

C301

0.1 F

15k

R302

8.2M

µ

13

U2.4

12

R02/2

15k

Piezo

3

14

U3.3

CR302 Red

15

2

U3.2

CR301 Red

13

4

U3.4

CR303 Red

R03/2

3

15k

14

R301

722R

Float

Interlock

Overtemp

R03/1

15k

R308

15.4k

C302

10 F

R304

100k

3

6

U4.2

7

1

µ

4

2

U4.1

5

8

14

U4.3

9

10

13

U4.4

11

12

R305

100k

R306

15.4k

Figure 3 - 11: HOTLINE® Low recirculating solution Level Alarm

R03/7

15k

5

U3.5

10

CR 401

Green

9

8

R401

1k

12

System

Normal

VU

R 2

270R

Relay

K1

15

The recirculating solution level alarm is an almost exact copy

of the interlock alarm arrangements. The starting point for this,

however, is a float switch mounted in the reservoir. The one

significant difference is that the interlock switch acts

instantaneously, whereas the float switch has a time delay element

(R308 and C302) to reduce false alarms due to recirculating solution

just sloshing about.

Both interlock and recirculating solution level alarms will

be exercised by signal AA, which is derived from the general

Alarm Test button (left) mentioned earlier.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

30

Page 44

SECTION 3 Technical Description

Answer to the page 28 Puzzler

As you probably guessed, it’s a bit of a trick question. The fact

is that it really does look like the volume should increase, but this is

apparently not the case. So what’s going on here?

Well, we kind of helped you to think that the current in R301

must increase with every extra LED, but this isn’t necessarily so. All

this current has to come from the Op-amp U2.4, type number

LP324N, which is described by its makers as a MICROPOWER device.

For this reason, its ability to source current is less than you

might have thought. You can see that from this graph:

Not wanting to bore you, we won’t figure out all the voltdrops

across all the various components, but you can see that if the first

LED is taking 12 - 15 mA (a reasonable amount), then the Op-amp is

already pretty much in saturation, and there is no more current

available, no matter how many LEDs you light up.

So maybe the question should have been, did the first LED get

any dimmer as the second and third got added?

HOTLINE® Blood and Fluid Warmer Technical Service Pack

31

Page 45

Disassembly Procedures

Blood and

Fluid Warmer

®

Page 46

Tools you will need

■ Needle-nose pliers

■ Philips head screwdriver

■ Small straight head screwdriver

1

■

■

■

/8 inch A/F Allen key (hex wrench)

7

/8 inch A/F open ended spanner (wrench)

3

/4 inch A/F open ended spanner (wrench)

SECTION 4 Tools you will need

7

■

■

■

/16 inch A/F open ended spanner (wrench)

3

/8 inch A/F deep box spanner OR socket and extension drive

1

/4 inch A/F open ended spanner (wrench)

■ 10 mm A/F open ended spanner (wrench)

Optional

Oetiker Clenching Tool

■

(This will be needed if it is intended to replace the heater ele-

ment or the pump/motor combination)

HOTLINE® Blood and Fluid Warmer Technical Service Pack

33

Page 47

Disassembly

Step 1: Open the case

SECTION 4 Disassembly

WARNING: Ensure that the HOTLINE® is disconnected from the Mains power.

If the HOTLINE

interior components may be hot.

Place the HOTLINE® on a firm surface at a convenient height.

Loosen the front cover screws. Early models have six screws, facing

forward. These screws are tethered to the front panel, so it is neither

necessary or desirable to completely remove them.

®

has been recently used, be aware that some

Figure 4 - 1: The underneath view of a HOTLINE® with the newer (one-part) case.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

34

Page 48

SECTION 4 Disassembly

Later models have only two front cover retaining screws, locat-

ed under the unit. Again, it is not necessary to completely remove

these screws.

Figure 4 - 2: Loosen, but don’t completely remove these screws

WARNING: STATIC-SENSITIVE COMPONENTS.

!

HOTLINE® Blood and Fluid Warmer Technical Service Pack

Ensure that proper antistatic precautions are taken before

attempting any procedure that requires handling the PCB.

35

Page 49

Step 2: Remove the PCB

Remove connectors J2, J3, J4 by gently pulling on them.

SECTION 4 Disassembly

Figure 4 - 3: Disconnecting J3

Do not pull on the wiring, but grasp the connector body itself.

It may be easier to use the needle-nose pliers.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

36

Page 50

SECTION 4 Disassembly

Remove the membrane switch ribbon connection from J1 by

gently pulling it.

Figure 4 - 4: Membrane Switch Connector

Now release the mains input cable from the “Lego brick” termi-

nals at the bottom front of the case.

Figure 4 - 5: Mains Cable Input Terminals

HOTLINE® Blood and Fluid Warmer Technical Service Pack

37

Page 51

SECTION 4 Disassembly

Remove the eight wires from the terminals along the bottom

edge of the PCB. To release the wires, each terminal’s orange tab

must be pressed into the terminal body with pliers.

Figure 4 - 6: Opening the terminal by squeezing the orange release tab

HOTLINE® Blood and Fluid Warmer Technical Service Pack

38

Page 52

SECTION 4 Disassembly

Alternatively, the tabs may be manipulated with a small

straight screwdriver through the slot on the terminal’s top surface.

Remove the four screws indicated.

GM-0163_8408-GB-A

Figure 4 - 7: PCB Mounting Points

1

(Only on older models)

2

4

3

Figure 4 - 8: Older versions have an additional fixing screw, making five in all.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

39

Page 53

SECTION 4 Disassembly

Step 3: Release the Earth Stud

With the PCB removed, you will be able to see the external

Earthing Stud which is attached to the chassis and passes out

through the rear of the case. Undo the 10mm nut holding it in place,

using a spanner on the outside to prevent rotation. Undo the 3/8

inch nut and take off the earth conductors from the internal Earth-

ing Star Point.

Internal

Earthing

Star Point

External

Earthing Stud

Figure 4 - 9: Earthing Arrangements

Notice the order of assembly on this terminal: the crinkle

washers are not there just to prevent unscheduled vibrational dis-

assembly, but also to cut into any corrosion on the ring termina-

tions and ensure good continuity.

GM-0163_8415-GB-A

Figure 4 - 10: Use of Crinkle Washers

HOTLINE® Blood and Fluid Warmer Technical Service Pack

40

Page 54

SECTION 4 Disassembly

Step 4: The Recirculating Solution Return Pipe

The recirculating solution return pipe emerges straight from

the back of the interlock block and crosses the enclosure to the left-

hand side, where it passes into the reservoir.

GM-0163_8410-GB-A

Figure 4 - 11: The Return Pipe

Release it from the interlock block by gentle persuasion. No

tools should be needed.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

41

Page 55

SECTION 4 Disassembly

Step 5: Removing the Chassis

Undo the four

GM-0163_8411-GB-A

poleclamp retaining

screws from the rear

of the chassis. Be

ready to catch the

poleclamp if it

should fall off the

back of the case.

Normally the

silicone sealant will

prevent this.

Figure 4 - 12: The Pole Clamp Retaining Screws also hold the Chassis in place

Figure 4 - 13: Older Pumps have a rigid moulded plastic elbow here

HOTLINE® Blood and Fluid Warmer Technical Service Pack

Gently

pull on the sil-

icone rubber

elbow pump

inlet pipe to

release it from

the spout

leading from

the reservoir.

42

Page 56

SECTION 4 Disassembly

Slide the chassis forward at the left-hand side until you can re-

lease the final silicone tube from the elbow beneath the interlock

block. Once that tube is freed, the entire chassis can be taken out.

Figure 4 - 14: Dissection Complete!

HOTLINE® Blood and Fluid Warmer Technical Service Pack

43

Page 57

Reassembly

Reassembly is a straightforward process, consisting of

following the aforementioned procedures in the reverse order.

Measurements

While you have the chance on a (presumed) good HOTLINE®,

make a note of the following resistance measurements. They may

be useful when fault finding in future.

SECTION 4 Reassembly

■ Pump Motor Coil (Specify March or GRI)

■ Heater Element

■ Transformer Primary

■ Relay K1 Coil

■ Display Thermistor

■ Display Thermistor

■ Control Thermistor

■ Control Thermistor

(J4:1-2) (ambient temp)

(J4:1-2) (operating temp)

(J4: 3-4) (ambient temp)

(J4: 3-4) (operating temp)

HOTLINE® Blood and Fluid Warmer Technical Service Pack

44

Page 58

Maintenance, Testing

and Calibration

Blood and

Fluid Warmer

®

Page 59

Maintenance

Before each use

Carefully inspect the HOTLINE® for signs of damage, cracked or

split case, insecure poleclamp, damaged mains cable, etc.

If the Disposable Set does not install easily, lubricate the O-

Ring Seals.

Lubricating the O-Ring Seals

Using a cotton swab, apply a small amount of silicone grease

(Smiths Medical Part Number EZL 80-04-002) to the O-Rings in the

SECTION 5 Maintenance

Disposable Set connector block.

If this does not solve the problem, reject the unit.

After each use

Wipe all external surfaces of the HOTLINE® with a soft cloth,

using an aqueous solution of mild detergent. If necessary, the

external surfaces may be disinfected using a solution of 10% bleach

in distilled water.

■ Do not autoclave.

■ Do not use alcohol or solvents.

■ Do not use abrasive cleaning agents.

■ Do not use cold sterilants.

■ Do not immerse any part of the HOTLINE

HOTLINE® Blood and Fluid Warmer Technical Service Pack

®

in liquids.

46

Page 60

Routine Maintenance Tasks

Smiths Medical recommends that preventative maintenance

be carried out at specified intervals. Some maintenance tasks need

to be repeated at 30-day intervals and others at annual intervals,

depending on your choice of recirculating solution.

The three approved recirculating solutions and their

associated maintenance protocols are:

SECTION 5 Maintenance

Recirculating

Solution

Sterile

Distilled

Water

Isopropyl

Alcohol

Solution

Hydrogen

Peroxide

Solution

At 30-day Intervals At 12-month Intervals

Visual Inspection

Lubricate O-Ring Seals

Replace Recirculating

Solution

Visual Inspection

Lubricate O-Ring Seals

Replace Recirculating

Solution

Visual Inspection

Lubricate O-Ring Seals

Replace Recirculating Solution

Verify Temperature Calibration

Replace Recirculating Solution

Verify Temperature Calibration

Replace Recirculating Solution

Verify Temperature Calibration

Test All Alarms

Replace O-Ring Seals

Electrical Safety Test

Test All Alarms

Replace O-Ring Seals

Electrical Safety Test

Test All Alarms

Replace O-Ring Seals

Electrical Safety Test

Precise directions for mixing the above solutions to the correct

strength are given on page 54.

Exceptionally, if the unit has had any non-routine servicing or

repair work, it will need to undergo a more thorough test and

recalibration sequence. This is detailed on page 64 and onwards.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

47

Page 61

Every 30 days

■ Perform a Visual Inspection looking for damage to the case,

poleclamp, mains cable, etc.

■ Lubricate O-Ring Seals with a cotton swab, applying a small

amount of silicone grease to the O-Rings.

Either, if using DISTILLED WATER as the

recirculating solution:

■ Drain and replace the recirculating solution as described on

SECTION 5 Every 30 days

page 54.

or, if using ISOPROPYL ALCOHOL as the

recirculating solution:

■ Drain and replace the recirculating solution as described on

page 56.

Finally

■ Fill in, sign, and date the maintenance log record!

HOTLINE® Blood and Fluid Warmer Technical Service Pack

48

Page 62

Every 12 Months

Alarm Testing

Place the HOTLINE® on a suitable firm surface. Visually check

that the recirculating solution level in the reservoir is above the MIN

mark. Attach a Disposable Set, ensuring that it is free from kinks and

twists.

Plug the unit into the electricity supply and switch on. Verify

that the unit is working normally (recirculating solution circulating,

temperature display gradually rising towards 41°C).

SECTION 5 Every 12 Months

General Alarm Test

Press the General Alarm Test button. Observe:

■ the GREEN LED extinguishes.

■ the THREE RED LEDs light up.

■ the AUDIBLE ALARM commences beeping.

■ the RECIRCULATING SOLUTION ceases circulating.

If any of the above responses are missing, the unit must be

removed from service and repaired.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

49

Page 63

SECTION 5 Every 12 Months

Over Temperature Alarm Test

Allow the unit to run for sufficient time to stabilise the

temperature. Press and hold the Over Temperature Alarm Test

button. Observe:

■ the DISPLAY rises to 43°C - 44°C .

■ the GREEN LED extinguishes.

■ the RED Over Temperature LED lights up.

■ the AUDIBLE ALARM commences beeping.

■ the RECIRCULATING SOLUTION ceases circulating.

If any of the above responses are missing, the unit must be

removed from service and repaired.

Recirculating Solution Level Alarm

Remove the Fill Port plug. Using a non-magnetic tool, gently

depress the float switch arm.

Figure 5 - 1: Depressing the float

switch. Here you see an offcut of

scrap Disposable Set performing

excellently as a non-magnetic probe.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

50

Page 64

SECTION 5 Every 12 Months

Observe that:

■ the GREEN LED extinguishes.

■ the RED recirculating Solution Level LED lights up.

■ the AUDIBLE ALARM commences beeping.

■ the RECIRCULATING SOLUTION ceases circulating.

If any of the above responses are missing, the unit must be

removed from service and repaired. The unit should return to

normal operation upon releasing the float switch.

Disposable Set Interlock Alarm

While the unit is working normally, gently ease the Disposable

Set away from the interlock block. Be aware that a small amount of

recirculating solution may escape during this test. Before the

Disposable Set is fully disconnected, the alarm should operate.

Observe that:

■ the GREEN LED extinguishes.

■ the RED Interlock Alarm LED lights up.

■ the AUDIBLE ALARM commences beeping.

■ the recirculating SOLUTION ceases circulating.

If any of the above responses are missing, the unit must be

removed from service and repaired. The unit should return to

normal operation upon correctly reattaching the Disposable Set.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

51

Page 65

Replace O-Ring Seals

GM-0163_8501-GB-A

Figure 5 - 2: Getting access to the O-Ring Seals

SECTION 5 Every 12 Months

■ Remove the socket head screws with an

1

/

-inch Allen key.

8

■ Remove the disposable interface block, being careful of the

microswitch lever.

■ Using a cotton swab, remove the old O-Rings, and clean out

the empty sockets.

Figure 5 - 3: Revealed: the O-Rings in their niches

HOTLINE® Blood and Fluid Warmer Technical Service Pack

52

Page 66

SECTION 5 Every 12 Months

■ Apply a smear of silicone grease (Smiths Medical Part

Number EZL 80-04-002) to two new O-Rings, and locate

them in the sockets.

■ Re-attach the disposable interface block.

■ Re-fit the socket head screws. Again, take care not to

damage or bend the microswitch operating lever.

A kit of parts is available to make this task simpler. Please ask for

part number reference EZL 80-04-001.

Either, if using DISTILLED WATER as the

recirculating solution:

■ Drain and replace the recirculating solution as described on

page 54.

or, if using ISOPROPYL ALCOHOL as the

recirculating solution:

■ Drain and replace the recirculating solution as described on

page 56.

or, if using HYDROGEN PEROXIDE as the

recirculating solution:

■ Drain and replace the recirculating solution as described on

page 57.

Finally

■ Fill in, sign, and date the maintenance log record!

HOTLINE® Blood and Fluid Warmer Technical Service Pack

53

Page 67

SECTION 5 Maintenance Solutions

Maintenance Solutions

At service intervals of either 12-months or 30-days, depending on the

composition of your recirculating solution, you will need supplies of ready mixed

solutions to perform maintenance. To make up a batch (1.4 litres) of solution, you

will need:

Formula 1

140ml of 3% Hydrogen Peroxide PLUS 1260ml distilled water

This may be used as a disinfectant fluid for flushing the recirculating solution

path during routine maintenance, or as a long-life recirculating solution enabling

fluid change intervals to be extended to 12-monthly.

Formula 2

700ml of 70% Isopropyl Alcohol PLUS 700ml distilled water

This may be used as a disinfectant fluid for flushing the recirculating

solution path during routine maintenance, or as a recirculating solution. It is NOT

suitable for long-term use, and must be replaced at 30-day intervals.

Changing Recirculating Solution (Distilled Water)

If using plain distilled water as the recirculating fluid, then this

must be changed at the 30-day service interval, using the procedure

given here. Smiths Medical currently recommends using the

Hydrogen Peroxide based recirculating solution which allows a

12-monthly recirculating solution change protocol, resulting in a

significant reduction of service time.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

54

Page 68

SECTION 5 Maintenance Solutions

■ Unplug the HOTLINE®.

■ (Old case) Remove the Fill Port plug and hold the Unit over a

sink to empty the water.

(New case) Deploy the drain tube to empty the Unit.

Interlock Block

disposable connector

Pole Clamp

GM-HL90-8508-en

Drain Tube End Cap

Fill Port

Stowage Clip

(for drain tube when

not deployed)

Drain Tube

(in deployed posn)

Figure 5 - 4: Rear view of new-style HOTLINE case, showing drain tube

■ Rinse reservoir with distilled water twice.

■ Refill the reservoir with 1.4 litres of disinfectant flushing

solution made to one of the formulae shown in the blue

panel above. Do not fill the HOTLINE® reservoir with a

Disposable Set in place, as this may result in an airlock in the

HOTLINE® warmer.

■ Connect a Disposable Set to the HOTLINE®.

■ Plug the Unit in and switch on.

■ Allow the disinfectant solution to circulate for 30 minutes.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

55

Page 69

SECTION 5 Maintenance Solutions

■ Switch off and disconnect the Unit.

■ Empty the unit once more.

■ Rinse reservoir with distilled water again.

■ Refill the unit with 1.4 litres of sterile distilled water.

■ Replace the Fill Port plug.

NOTE: Unless using one of the approved maintenance solutions, use only

sterile distilled or de-ionised water. Failure to do so may lead to a

build-up of mineral deposits in the recirculating solution path which

may impair heater performance.

Changing Recirculating Solution (Isopropyl Alcohol)

Since the Isopropyl Alcohol solution gradually loses potency,

it must be replaced at the 30-day service interval using the

following procedure:

■ Prepare two batches of 1.4 litres of recirculating solution

according to formula 2 above for 35% Isopropyl Alcohol

maintenance solution.

■ Drain the HOTLINE®, and refill with one of the prepared

batches.

■ Install an L-70 or L-70 NI Disposable Administration Set in

the HOTLINE®’s Disposable Set connector.

■ Turn on the HOTLINE® and allow the fresh fluid to circulate

for 30 minutes.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

56

Page 70

SECTION 5 Maintenance Solutions

■ Switch off the HOTLINE® and dispose of the Disposable Set

in accordance with the usual procedures for your

establishment. Drain the Fluid from the HOTLINE® and

discard.

■ Refill the HOTLINE® with the second of the Isopropyl Alcohol

solution batches you made earlier.

NOTE: If the HOTLINE® requires topping up at any time before the next

routine recirculating solution change, make sure you always use the

correct mix of Isopropyl Alcohol and Distilled water.

Changing Recirculating Solution (Hydrogen Peroxide)

At the annual routine service interval the Hydrogen Peroxide

solution must be replaced as follows:

■ Prepare two batches of 1.4 litres of recirculating solution

according to formula 1 above for 0.3% Hydrogen Peroxide

maintenance solution.

■ Drain the HOTLINE®, and refill with one of the prepared

batches.

■ Install an L-70 or L-70 NI Disposable Administration Set in

the HOTLINE®’s Disposable Set connector.

■ Turn on the HOTLINE® and allow the fresh fluid to circulate

for 30 minutes.

■ Switch off the HOTLINE® and dispose of the Disposable Set

in accordance with the usual procedures for your

HOTLINE® Blood and Fluid Warmer Technical Service Pack

57

Page 71

SECTION 5 Maintenance Solutions

establishment. Drain the fluid from the HOTLINE® and

discard.

■ Refill the HOTLINE® with the second of the recirculating

solution batches you made earlier.

NOTE: If the HOTLINE® requires topping up at any time before the next

routine recirculating solution change, make sure you always use the

correct mix of Hydrogen Peroxide and Distilled water.

Temperature Checking

TEMP

GM-HL90-8502

Figure 5 - 5: A HOTLINE® HLTA-40 TEMP CHECK wet thermometer

CHECK

To accurately verify the displayed recirculating solution

temperature, you will need a HOTLINE® HLTA-40 TEMP CHECK

thermometer. This bespoke unit is inserted into the recirculating

solution flow and reads the temperature directly from the

recirculating solution as it leaves the heater element and internal

thermistor sensors. This is the point at which the recirculating

solution is at its highest temperature.

Measuring the temperature in the recirculating solution

reservoir is less accurate. Typically the temperature here may be

several degrees cooler, dependent on ambient temperature and

other factors.

HOTLINE® Blood and Fluid Warmer Technical Service Pack

58

Page 72

SECTION 5 Maintenance Solutions

If you do not have a HOTLINE® TEMP CHECK thermometer,

units may be returned to Smiths Medical for temperature

verification.

Set up the HOTLINE® ready for use as before. Attach the TEMP

CHECK thermometer to the interlock block of the HOTLINE® and

connect the Disposable Set to the TEMP CHECK.

Carefully unpeel the black sticker from the back of the

HOTLINE®, and loosely attach it in a safe place ready for re-use. Plug

the TEMP CHECK ’s Mains cable into the Auxiliary Outlet socket of

the HOTLINE®.

NOTE: The Auxiliary Outlet is for use only with approved accessories

supplied by your Smiths Medical distributor for that purpose.

Run the HOTLINE® for 15 minutes to allow the temperature to

stabilise. Verify that:

■ the TEMP CHECK indicates a recirculating solution tempera-

ture between 41°C and 42°C

■ The HOTLINE®’s display indicates the same temperature.

If either of these conditions is not met, the unit will require

either recalibration or repairing and recalibration before it can be

returned to active service.

If both conditions are satisfied, dismantle the test assembly,

and replace the black sticker over the Aux socket. Document the

date and results of your tests and return the HOTLINE® to active

service.