Page 1

®

HOTLINE

Blood and Fluid Warmer

HL-90

OPERATOR’S MANUAL

PN 4534005-GB Rev D

Page 2

General Information

HOTLINE® Blood and Fluid Warmer

Part Number: 4534005-GB Rev. D (2005-07)

This revision supercedes all previous revisions.

Every effort has been made to ensure that the information in this manual is accurate and details provided

are correct at the time of printing. The company, however, reserves the right to improve the equipment

shown. Mention of third-party products is for informational purposes only and constitutes neither an

endorsement nor a recommendation. Smiths Medical ASD, Inc. (“Smiths Medical”) assumes no responsibility with regard to the performance or use of these products.

Level 1, HOTLINE, and Smiths design mark are trademarks of the Smiths Medical family of companies.

The symbol ® indicates the trademark is registered in the U.S. Patent and Trademark office and certain

other countries.

All other names and marks mentioned are the trade names, trademarks, or service marks of the respective

owners.

The products described are covered by one or more of the following U.S. Patent Nos., 5,063,994;

5,097,898; other patent(s) pending; foreign patent(s) pending.

For further information, please call the local Smiths Medical representative or Smiths Medical direct at

1-800-258-5361 or +1-781-878-8011.

©2005 Smiths Medical family of companies. All rights reserved.

ii HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual

Page 3

Contents

1 About this Manual 1

Indications for Use 1

Conventions Used in this Manual 1

2 Description 2

Components 2

HOTLINE® Fluid Warming Set 4

3 Important Safety Information 5

Additional WARNINGS and CAUTIONS for Accessories 8

4 Assembly Instructions 9

Step 1 - Unpack the HOTLINE® Warmer 9

Step 2 - Clamp the HOTLINE® Warmer to the I.V. Pole 9

Step 3 - Disinfect the Reservoir 10

Step 4 - Fill the Reservoir With Recirculating Solution 11

Step 5 - Perform the Electrical Safety Tests 12

5 Principle of Operation 13

Infusate Delivery Temperatures 13

6Operation 14

Controls and Displays 14

Display Panel 14

Power and Alarm Test Panel 15

Reservoir Level Display 15

Modes of Operation 16

OFF Mode 16

ON/Operating Mode 16

Check Disposables Mode 16

Add Recirculating Solution Mode 17

Over Temperature Alarm Mode 17

7 Operating Instructions 18

Step 1 - Set Up the HOTLINE

Step 2 - Set Up the HOTLINE

Step 3 - Connect the Intravenous Administration Set 20

Step 4 - Using the HOTLINE

Step 5 - After Use 21

Storage 21

8Troubleshooting 22

®

Warmer 18

®

Fluid Warming Set 18

®

Warmer 20

Contents

HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual iii

Page 4

Contents

9 Testing 24

Alarm Signal Test 24

Over Temperature Test 25

Add Recirculating Solution Test 25

Check Disposables Test 26

Temperature Verification of the Recirculating Solution 26

Periodic Electrical Testing 28

Leakage Current 28

Ground Bond Test 28

10 Maintenance 29

Maintenance Performed with Every Use 29

Clean the Exterior 29

General Inspection 29

Disinfect the Reservoir and Change the Recirculating Solution 30

Disinfect the Reservoir 30

Add Recirculating Solution 31

Maintenance Performed Every 30 Days 31

Disinfect the Reservoir and Change Recirculating Solution for Sterile

Distilled Water and 35% Isopropyl Alcohol Solution 31

Lubricate O-Ring Seals 32

Maintenance Performed Every 12 Months 32

Disinfect the Reservoir and Change Recirculating Solution for

0.3% Hydrogen Peroxide Solution 32

Replace O-Rings 32

Testing HOTLINE

Maintenance Log 33

®

Warmer Operation 32

11 Limited Warranty 34

12 Service 36

Warranty Service 36

Non-Warranty Work 36

Additional Documentation 36

Disposal Information 37

Service Contacts 37

USA/Canada 37

European Representative 37

Australian Representative 37

13 Specifications and Accessories 38

System Specifications 38

Electromagnetic Compliance 39

Electromagnetic Environmental Recommendations 40

Accessories 40

14 Symbols 41

iv HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual

Page 5

SECTION 1 • About this Manual

SECTION 1

About this Manual

This operator’s manual describes the assembly, use, and maintenance of

®

the HOTLINE

Blood and Fluid Warmer. This manual is intended for use

by individuals trained in the healthcare and biomedical professions.

These instructions contain important information for safe use of the

product. Read the entire operator’s manual, including Warnings and

Cautions, before using the HOTLINE

®

Warmer. Failure to properly follow

warnings, cautions, and instructions could result in death or serious injury

to the patient.

Indications for Use

The HOTLINE® Blood and Fluid Warmer is designed for use with the

HOTLINE

fluids and deliver them to the patient's intravenous access site at

normothermic temperatures under gravity flow conditions. The

HOTLINE

provide routine flow of warmed I.V. fluid.

®

Fluid Warming Set to warm blood and intravenous (I.V.)

®

Warmer is intended for use by trained medical personnel to

Conventions Used in this Manual

• The HOTLINE® Blood and Fluid Warmer will be referred to as the

HOTLINE

®

Warmer.

• The L Series Fluid Warming Sets (L-70, L-70NI, L-80) will be

®

referred to as the HOTLINE

Convention Description

CONTRAINDICATION A Contraindication statement alerts the user to

CAUTION A Caution statement alerts the user to conditions

WARNING A Warning statement alerts the user to conditions

®

HOTLINE

Blood and Fluid Warmer | Operator’s Manual 1

Fluid Warming Set.

conditions when the device should not be used.

that may cause physical injury and/or an adverse

effect on the device or its performance.

that may cause serious personal injury or death

to the user or patient.

Page 6

SECTION 2 • Description

o

SECTION 2

Description

The HOTLINE® Warmer delivers blood and intravenous fluid at

normothermic temperatures by surrounding the sterile intravenous line

with a layer of warmed recirculating solution. An onboard recirculating

solution supply is heated to 41.5°C ± 0.5 and circulated through the outer

lumen of the HOTLINE

intravenous line.

®

Fluid Warming Set, which surrounds the

The HOTLINE

®

Warmer employs a safe, recirculating solution heating

system, inherently free of “hot spots,” to actively warm the patient line.

Electronic circuitry continuously monitors the recirculating solution

temperature. The primary temperature control circuit limits the

recirculating solution to 42°C maximum. In the unlikely event of a

malfunction of this circuit, a second “watchdog” circuit will visually and

audibly alarm and stop the recirculating solution pump if the temperature

reaches 43.1°C. Fluid in the HOTLINE

®

Fluid Warming Set is never

exposed to any damaging or dangerous temperatures while the

HOTLINE

®

Warmer is operating.

The recirculating solution temperature and visual alarms are indicated on

the Display Panel on the front of the HOTLINE

Operating light illuminates on this panel when the HOTLINE

®

Warmer. A green

®

Warmer is

set up and operating correctly.

Components

The HOTLINE® components are called-out in the following series of

figures.

Front View

1 Socket for HOTLINE

place

®

Fluid Warming Set with the reflux plug in

o

C

HOTLINE

Fluid Warmer

1

2

2 Display Panel

2 HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual

Page 7

SECTION 2 • Description

Right Side View

1 Socket with the reflux plug removed

o

C

HOTLINE

Fluid Warmer

1

2

3

2 Clamp for I.V. pole

3 Drain tube in tube holder

4 Reflux plug

5 Power cord

4

5

Rear View

1

1

2

3

1 Fill-port plug

2 Drain tube in tube holder

3 Clamp for I.V. pole

4

5

4 Protective earth terminal

5 Auxiliary electrical outlet

1

2

3

1.4 LITERS

Left Side View

1 Power and Alarm Test Panel

2 Fill-port plug

4

3 Reservoir, contains recirculating solution

4 Float switch (inside reservoir)

®

HOTLINE

Blood and Fluid Warmer | Operator’s Manual 3

Page 8

SECTION 2 • Description

HOTLINE® Fluid Warming Set

HOTLINE® Fluid Warming Sets (L-70, L-70NI, L-80) are individually

packed, single-use disposables with a Sterile Fluid Path. The priming

volume is 20 ml for the L-70 and L-70NI, and 21 ml for the L-80. The

HOTLINE

into the socket on the right side of the HOTLINE

only connection necessary to provide the warming function. The

HOTLINE

Warmer and discarded.

®

Fluid Warming Set has a Twin-Tube Connector that plugs

®

Fluid Warming Set is easily unplugged from the HOTLINE®

®

Warmer. This is the

4 HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual

Page 9

SECTION 3 • Important Safety Information

SECTION 3

Important Safety Information

This section covers information for prescribers and guidelines for safe use

of the HOTLINE

®

Warmer.

CONTRAINDICATIONS

• Not for use in warming platelets, cryo-precipitates, or

granulocyte suspensions.

WARNINGS

WARNINGS

Death or serious injury may occur to the patient or user if these

warnings are not followed.

• Read and follow all instructions, labeling, and accompanying

documents supplied with this medical device. Failure to follow

instructions, including all warnings and cautions, could lead to

misuse of the device or device malfunction.

•The HOTLINE

®

Fluid Warming Set is a single-use device and is

not intended for re-sterilization.

• Do not use HOTLINE

®

Fluid Warming Set if the caps are not

securely in place, else the I.V. flow path may not be sterile.

•The HOTLINE

®

Warmer is for use only with Smiths Medical

supplied or approved parts, accessories, and Disposable Sets.

The device may not function as intended with the use of

unapproved parts, accessories, or Disposable Sets.

• Do not fill the HOTLINE

Warming Set in place. Failure to remove the HOTLINE

®

reservoir with a HOTLINE® Fluid

®

Fluid

Warming Set before the fill procedure may result in an air lock

in the HOTLINE

®

Warmer.

• Blood and blood products could contain pathogenic organisms.

Failure to follow institutional policy and procedures for

biomedical-hazardous materials could lead to exposure to

harmful pathogens.

Continued

®

HOTLINE

Blood and Fluid Warmer | Operator’s Manual 5

Page 10

SECTION 3 • Important Safety Information

Continued from previous page

WARNINGS

WARNINGS

• Set-up, priming, and use require aseptic technique as per

applicable institutional policies and procedures.

• Prime the recirculating solution path before connecting to the

intravenous extension set. This is to confirm that there is not a

breach between the recirculating solution path and intravenous

path. If fluid exits the patient end of the HOTLINE

®

Fluid

Warming Set before connecting to the intravenous

administration set, remove and replace HOTLINE

®

Fluid

Warming Set.

• Remove all air from the intravenous fluid lines before

connecting to the patient. Failure to do so may result in

introduction of air to the patient.

• Do not stick the HOTLINE

®

Fluid Warming Set with needles, as

this will breach the I.V. path and compromise the integrity of the

patient intravenous line. If a Disposable Set with a breached

recirculating solution path/intravenous path is used, then

patient illness may occur because of the HOTLINE

®

Warmer's

recirculating solution entering the patient's bloodstream.

• Activation of the Over Temperature warning signal indicates

that warming has stopped and immediate operator intervention

is required to clear the over temperature condition or to remove

the device from service.

• If any visual indicator does not illuminate or the audible signal

does not sound, do not use the HOTLINE

®

Warmer. Remove the

device from service immediately.

• Do not operate the HOTLINE

®

Warmer in the presence of a

flammable anesthetic mixture with air, oxygen, or nitrous oxide.

The risk of explosion exists if the HOTLINE

®

Warmer is operated

in a potentially explosive environment.

• Do not use the HOTLINE

®

Warmer in high-energy fields such

as: MRI, X-RAY, portable and mobile RF communications

equipment, and other such devices. The HOTLINE

®

Warmer

may act as a projectile in a strong magnetic field, cause image

artifacts, or not function as intended.

6 HOTLINE

Continued

®

Blood and Fluid Warmer | Operator’s Manual

Page 11

SECTION 3 • Important Safety Information

Continued from previous page

WARNINGS

WARNINGS

• Exposed conductor on MAINS power cord can cause an

electrocution hazard. Remove device from service if the MAINS

power cord has exposed wires.

• Grounding reliability can only be achieved when the MAINS

power cord is connected to a properly grounded receptacle.

Risk of electrical shock exists if the equipment is not connected

to a properly grounded receptacle.

• No user-serviceable parts. All service must be performed by

Smiths Medical or an authorized representative.

CAUTIONS

• Federal Law (USA) restricts this device to sale by or on the order

of a physician.

• Do not mount the HOTLINE

®

Warmer more than 107cm (42")

above the floor. For convenience, 107cm (42") is indicated on

the HOTLINE

the HOTLINE

®

Warmer power cord by a black mark. Mounting

®

Warmer above 107cm (42") may result in

instability of the pole and tipping.

• Do not autoclave or immerse any part of the HOTLINE

®

Warmer

in liquids, which may cause damage and improper functioning.

• Ensure that the HOTLINE

onto the I.V. pole. Failure to securely mount the HOTLINE

Warmer onto the I.V. pole may cause the HOTLINE

®

Warmer clamp is screwed tightly

®

to slide

®

down the I.V. pole.

• Do not use the HOTLINE

®

Warmer if equipment or Disposable

Set malfunction is evident.

• Not for use with pressure devices generating over 300 mmHg.

Pressure greater than 300 mmHg may compromise the integrity

of the HOTLINE

®

Fluid Warming Set.

• This device is cooled by convection. Be sure the air vents on the

bottom and the back of the device are kept clear.

HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual 7

Page 12

SECTION 3 • Important Safety Information

Additional WARNINGS and CAUTIONS for Accessories

WARNINGS for the L-10 Gas Vent

• Do not tape over vents, else air will not be vented.

• Not for use with volumetric infusion pumps, hand pumps, or

syringes. These may compromise the integrity of the L-10 Gas

Vent or HOTLINE

®

Fluid Warming Set.

• When the L-10 Gas Vent is in use, it should be placed at or

below the heart level. Do not raise the gas vent above the

patient’s heart level. If the gas vent is raised above heart level,

air may be entrained into the infusion line, possibly causing air

embolism, resulting in serious injury or death.

CAUTIONS for the L-10 Gas Vent

• Contains natural rubber latex, which may cause allergic

reactions.

8 HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual

Page 13

SECTION 4 • Assembly Instructions

SECTION 4

Assembly Instructions

Read through the instructions completely prior to setting up the

HOTLINE

®

Warmer.

Step 1 - Unpack the HOTLINE® Warmer

1 Open the shipping carton and remove the HOTLINE® Warm e r.

2 Check the contents of the package to verify the following

components are present:

•HOTLINE® Warmer

• Operator’s Manual

3 Examine the HOTLINE® Warmer for damage. If any components

appear damaged, do not use the HOTLINE

®

Warmer. Contact

Smiths Medical for a replacement.

Note: After unpacking the HOTLINE® Warmer, recycle packaging

material according to hospital policy for recyclable materials.

Step 2 - Clamp the HOTLINE® Warmer to the I.V. Pole

CAUTIONS

• Insure that the HOTLINE® Warmer pole clamp is screwed tightly

onto the I.V. pole. Failure to securely mount the HOTLINE

Warmer onto the I.V. pole may cause the HOTLINE

®

®

Warmer to

slide down the pole.

• Do not mount the HOTLINE

®

Warmer more than 107cm (42”)

above the floor. For convenience, 107cm (42") is indicated on

the HOTLINE

HOTLINE

®

Warmer line cord by a black mark. Mounting the

®

Warmer above 107cm (42”) may result in instability

of the pole and tipping.

• This device is cooled by convection. Be sure the air vents on the

bottom and the back of the device are kept clear.

®

HOTLINE

Blood and Fluid Warmer | Operator’s Manual 9

Page 14

SECTION 4 • Assembly Instructions

o

1 Slide the clamp (a) on the HOTLINE® Warmer over the I.V. pole

(b) and tighten the clamp screw (c) firmly.

2 Check the tightness of the HOTLINE

®

Warmer to ensure it is

securely clamped to the pole.

Step 3 - Disinfect the Reservoir

a

c

b

1 Prepare a 0.3% hydrogen peroxide solution by mixing 140 ml of 3%

hydrogen peroxide solution and 1,260 ml of sterile distilled water.

2 Remove the reflux plug from the socket if required, and then

remove the fill-port plug (

d) and fill the reservoir with 1.4 liters of

0.3% hydrogen peroxide solution.

3 Replace the fill-port plug.

4 Insert a HOTLINE

®

Fluid Warming Set (e) (L-70, L-70 NI, L-80)

into the socket.

5 Tu r n t he H OT L IN E

®

Warmer ON and let the solution circulate for

a 30-minute disinfection period.

6 Tu r n t he H O T L I N E

7 Invert the drain tube (

tube. Remove the end cap (

®

Warm e r O F F.

e) and place a container under the end of the

f) and drain the recirculating solution

into the container.

d

o

C

HOTLINE

Fluid Warmer

1.4 LITERS

e

8 When all the recirculating solution has drained from the reservoir,

replace the end cap and insert the drain tube back in the holder.

9 Remove the HOTLINE

to established hospital procedures.

®

Fluid Warming Set and discard according

e

f

10 HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual

Page 15

SECTION 4 • Assembly Instructions

Step 4 - Fill the Reservoir With Recirculating Solution

WARNINGS

WARNINGS

• Set-up, priming, and use require aseptic technique. Follow

applicable institutional policies and procedures.

• Do not fill the HOTLINE

Fluid Warming Set in place. Failure to remove the HOTLINE

Fluid Warming Set before the fill procedure may result in an air

lock in the HOTLINE

Recirculating Solution Protocols

®

Warmer reservoir with a HOTLINE®

®

Warmer.

®

Use one of the following solutions for the reservoir.

Recirculating Solution Preparation Maintenance

0.3% Hydrogen Peroxide

Solution

Sterile Distilled

Water

35% Isopropyl Alcohol

Solution

Note: Use sterile distilled water only, not tap water. Failure to do so may cause

build-up of mineral deposits in the recirculating solution path, which may impair

heater performance.

a

1.4 LITERS

Mix 140 ml of 3% hydrogen

peroxide with 1,260 ml of

sterile distilled water.

Use sterile distilled water. Replace solution and

Mix 700 ml of 70% isopropyl

alcohol with 700 ml of sterile

distilled water.

Replace solution and

disinfect reservoir every

12 months.

disinfect reservoir every

30 days.

Replace solution and

disinfect reservoir every

30 days.

1 Prepare the recirculating solution.

2 Remove the fill-port plug (

a).

3 Fill the reservoir with 1.4 liters of recirculating solution.

4 Replace the fill-port plug.

®

HOTLINE

Blood and Fluid Warmer | Operator’s Manual 11

Page 16

SECTION 4 • Assembly Instructions

Step 5 - Perform the Electrical Safety Tests

Perform all applicable electrical safety tests as required per institutional

Te s t i n g

procedure. Refer to Section 10,

electrical safety testing.

, for more information about

12 HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual

Page 17

SECTION 5 • Principle of Operation

SECTION 5

Principle of Operation

HOTLINE® Warmer delivers blood and intravenous fluid at

normothermic temperatures under routine, gravity flow rates. All other

a

a

patient connection. HOTLINE

providing active warming of the patient line all the way to the patient

connection.

Active warming is achieved by surrounding the sterile intravenous line

with a layer of precisely controlled warm recirculating solution (

protecting the patient line against exposure to cold and eliminating patient

line cool-down.

fluid warming systems suffer from cool-down between the warmer and the

®

Warmer overcomes this problem by

a), thereby

The unique design of the HOTLINE

®

Fluid Warming Set allows blood and

intravenous fluid to be delivered to the patient at normothermic

temperature at gravity flow rates to 50-5,000 ml/hr.

Infusate Delivery Temperatures

The following table shows the typical infusate delivery temperatures

at the patient end of an L-70 HOTLINE

Note: The setpoint temperature of the recirculating solution is

41.9°C.

44.0

42.0

40.0

38.0

36.0

34.0

32.0

30.0

28.0

Temperature ° C

26.0

24.0

22.0

20.0

50 250 500 750 1000 1250 1500 2000 2500 3000 3500 4000 4500 5000

®

Fluid Warming Set.

Ambient Temperature Range: 19.5° C - 20.5° C

®

HOTLINE

Blood and Fluid Warmer | Operator’s Manual 13

Flow Rate (ml / hr)

20° C Infusate

10° C Infusate

Page 18

SECTION 6

Operation

SECTION 6 • Operation

This section describes the controls and displays that monitor and control

the HOTLINE

®

Warmer, and the modes of operation.

Controls and Displays

• Display Panel

• Power and Alarm Test Buttons

• Reservoir Level Display

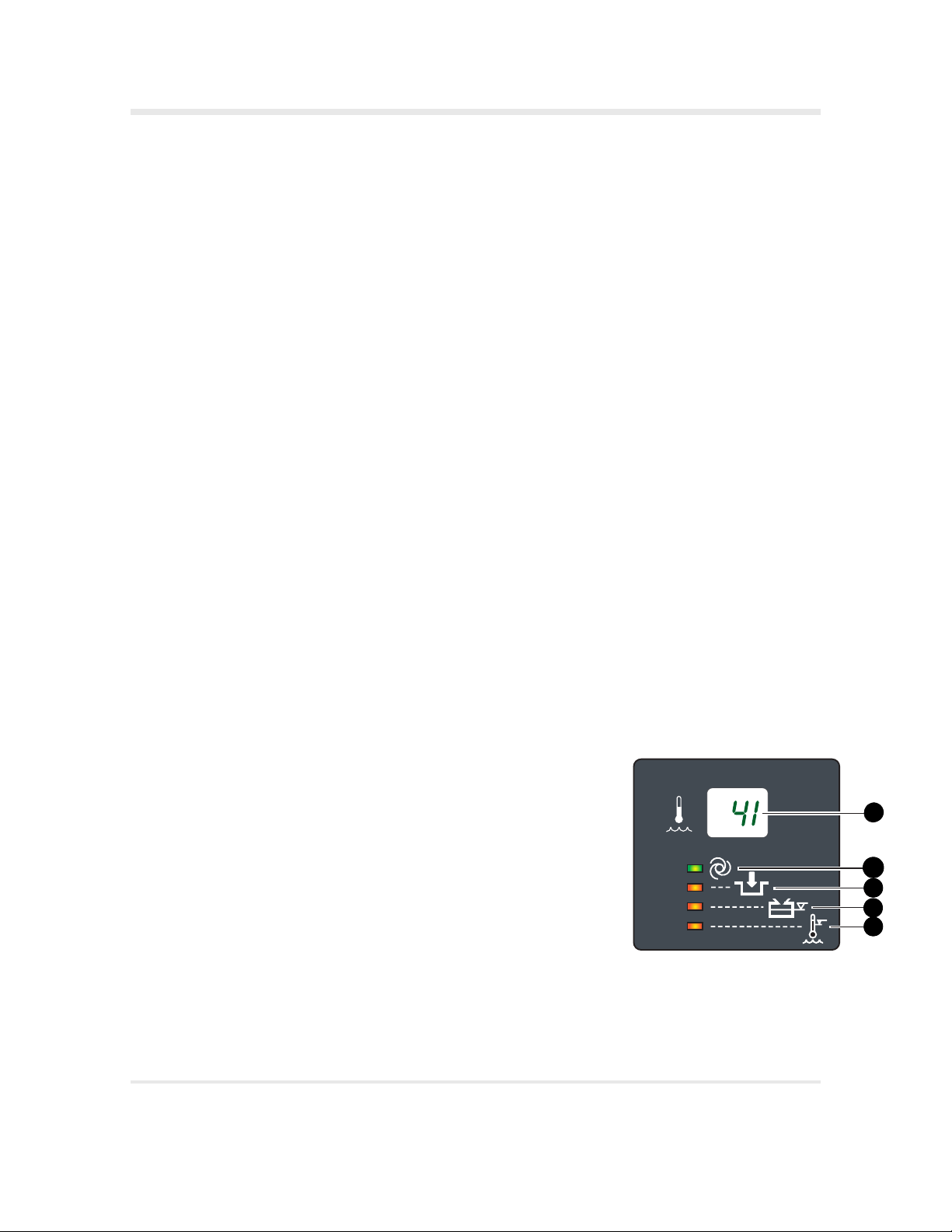

Display Panel

The Display Panel is located on the front of the HOTLINE

and provides continuous information about the operation of the

HOTLINE

®

Warmer. A liquid crystal display (LCD) indicates

recirculating solution temperature. Just below the LCD, four lightemitting diodes (LEDs) indicate operation modes for the HOTLINE

Wa rm e r.

1 Recirculating Solution Temperature - The temperature is displayed

in degrees Celsius.

2 Operating - The green LED illuminates when the power is turned

on and the HOTLINE

®

Fluid Warming set is properly installed.

®

Warmer

®

3 Check Disposables - The red LED illuminates and an audible

attention signal beeps when the HOTLINE

®

Fluid Warming Set is

not properly installed.

4 Add Solution - The red LED illuminates and an audible attention

signal beeps when the level in the reservoir is low and additional

solution must be added.

5 Over Temperature - The red LED illuminates and an audible

warning signal beeps when the recirculating solution is over the

acceptable temperature for safe use.

®

14 HOTLINE

Blood and Fluid Warmer | Operator’s Manual

o

C

1

2

3

4

5

Page 19

SECTION 6 • Operation

1.4 LITERS

Power and Alarm Test Panel

The Power and Alarm Test Panel is located on the left side of the

HOTLINE

®

Warmer next to the reservoir. This panel contains two

pressure-sensitive buttons that are activated when pressed, and the

ON/OFF switch.

1 Over Temperature Test Button - The Over Temperature Test is

used to confirm the proper operation of the Over Temperature

circuitry.

2 Alarm Test Button - The Alarm Signal Test is used to confirm

proper operation of the visual and audible alarms.

3 Power ON/OFF Switch - The black switch toggles to turn power

ON and OFF.

Reservoir Level Display

a

The reservoir for the recirculating solution is located on the left side of

the HOTLINE

®

Warmer, next to the Power and Alarm Test Panel. The

level of the recirculating solution is visible in the reservoir. Two symbols

indicate the maximum (a) and minimum (b) solution level

requirements.

b

HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual 15

Page 20

SECTION 6 • Operation

Modes of Operation

The HOTLINE® Warmer operation is defined in the following modes:

• OFF Mode

•ON/Operating Mode

•Check Disposables Mode

• Add Recirculating Solution Mode

• Over Temperature Alarm Mode

The description of each mode includes a definition of the mode, activation

and/or monitoring of the mode, mode characteristics, and method to clear

the mode state.

OFF Mode

The power switch is in the OFF position (

a) and the HOTLINE

Warmer is turned off.

ON/Operating Mode

The power switch is in the ON position (

b) and the HOTLINE

Warming Set has been properly installed.

Mode Characteristics

• The green Operating LED (c) illuminates.

• The reservoir temperature display will begin to increase.

®

• The recirculating solution path in the HOTLINE

Fluid

Warming Set will automatically prime.

Check Disposables Mode

The Check Disposables mode indicates a missing or improperly

installed HOTLINE

Mode characteristics

®

Fluid Warming Set.

• The green Operating LED on the Display Panel turns off.

®

®

Fluid

a

b

c

d

• Τhe red Check Disposables LED (

d) on the Display Panel

illuminates.

• The audible alarm sounds and repeats approximately every two

seconds.

• The recirculating solution stops circulating.

®

16 HOTLINE

Blood and Fluid Warmer | Operator’s Manual

Page 21

SECTION 6 • Operation

To clear this mode, check that the Twin-Tube Connector on the

HOTLINE

®

Fluid Warming Set is firmly inserted in the socket.

Add Recirculating Solution Mode

The Add Recirculating Solution mode indicates that the solution level

in the reservoir is below its minimum level.

Mode characteristics

• The green Operating LED on the Display Panel turns off.

a

• The red Add Solution LED (

a) on the Display Panel illuminates.

• The audible alarm sounds and repeats approximately every two

seconds.

• The recirculating solution stops circulating.

To clear this mode, add recirculating solution to the reservoir.

Over Temperature Alarm Mode

The Over Temperature Alarm mode indicates that the temperature of

the recirculating solution is at or above 43.1°C.

Mode characteristics

• The green Operating LED on the Display Panel turns off.

• The red Over Temperature LED (

b

illuminates.

b) on the Display Panel

• The audible alarm sounds and repeats approximately every two

seconds.

• The recirculating solution stops circulating.

®

HOTLINE

Blood and Fluid Warmer | Operator’s Manual 17

Page 22

SECTION 7 • Operating Instructions

SECTION 7

Operating Instructions

The Operating Instructions are grouped into five segments. Read through

each segment BEFORE performing a procedure.

WARNINGS

WARNINGS

• Set-up, priming, and use require aseptic technique as per

applicable institutional policies and procedures.

• Grounding reliability can only be achieved when MAINS power

cords are connected to a properly grounded receptacle. Risk of

electrical shock exists if the equipment is not connected to a

properly grounded receptacle.

Step 1 - Set Up the HOTLINE® Warmer

1 Check that the level is above the minimum level mark (a) on the

reservoir. Add recirculating solution to the reservoir through the

fill-port if required.

2 Check the condition of the HOTLINE

®

Warmer with a visual

inspection before using. Remove from service any HOTLINE®

Warm e r t h a t s h o ws physical damage.

3 Plug the

HOTLINE

®

Warmer into properly grounded power outlet.

Step 2 - Set Up the HOTLINE® Fluid Warming Set

WARNINGS

WARNINGS

•The HOTLINE® Fluid Warming Set is a single-use device and is

not intended for re-sterilization.

• Do not use HOTLINE

securely in place, else flow path may not be sterile and may

cause death or serious injury.

®

Fluid Warming Set if the caps are not

a

18 HOTLINE

Continued

®

Blood and Fluid Warmer | Operator’s Manual

Page 23

SECTION 7 • Operating Instructions

o

Continued form previous page

WARNINGS

WARNINGS

• Prime the recirculating solution path before connecting to the

intravenous extension set. This is to confirm that there is not a

breach between the recirculating solution path and intravenous

path. If fluid exits the patient end of the HOTLINE

®

Fluid

Warming Set before connecting to the intravenous extension

set, remove and replace HOTLINE

®

Fluid Warming Set.

To set up the HOTLINE® Fluid Warming Set, you will need the following:

o

C

HOTLINE

Fluid Warmer

•HOTLINE

a

• Intravenous administration set

®

Warmer

• Intravenous fluid or blood

• Extension Set, 20cm (8") or less in length (optional)

1 Remove the reflux plug (if present) from the socket on the right

side of the HOTLINE® Warm e r.

2 Plug the Twin-Tube Connector on the

HOTLINE

®

Fluid Warming

Set (a) into the socket.

3 Turn ON the power switch.

• The green Operating LED on the Display Panel illuminates.

• The recirculating solution temperature display will begin to

increase.

• The recirculating solution path in the HOTLINE

®

Fluid

Warming Set will automatically prime.

4 Remove the end cap and inspect the patient end of the HOTLINE®

Fluid Warming Set for leaks to confirm the integrity of the

intravenous pathway.

®

HOTLINE

Blood and Fluid Warmer | Operator’s Manual 19

Page 24

SECTION 7 • Operating Instructions

Step 3 - Connect the Intravenous Administration Set

WARNINGS

WARNINGS

• Remove all air from the intravenous fluid lines before

connecting to the patient. Failure to do so may result in

introduction of air to the patient, which may contribute to

serious patient injury or death.

• Do not stick the HOTLINE

®

Fluid Warming Set with needles, as

this will breach the I.V. path and compromise the integrity of the

patient intravenous line. If a Disposable Set with a breached

recirculating solution path/intravenous path is used, then

patient illness may occur because of the HOTLINE

®

Warmer's

recirculating solution entering the patient's blood stream.

1 Connect the I.V. fluid and the intravenous administration set to the

HOTLINE

2 Fully prime the intravenous administration set, the

®

Fluid Warming Set.

HOTLINE

Fluid Warming Set, and patient extension set (if used).

3 Connect the distal end of the

HOTLINE

®

Fluid Warming Set to

the patient's intravenous access site without entrapping air.

Step 4 - Using the HOTLINE® Warmer

WARNINGS

WARNINGS

• Activation of the Over Temperature warning signal indicates

that warming has stopped and immediate operator intervention

is required to clear the over temperature condition or to remove

the device from service.

®

1 Wait until the recirculating solution temperature display reaches

41

°C, which indicates the HOTLINE

®

Warmer is ready for use.

2 Adjust the rate of I.V. flow using the clamp on the intravenous

administration set.

Note: Do not kink the Disposable Set. Do not restrict the circulation

of the solution through the tubing.

®

20 HOTLINE

Blood and Fluid Warmer | Operator’s Manual

Page 25

SECTION 7 • Operating Instructions

Step 5 - After Use

WARNINGS

WARNINGS

• Blood and blood products could contain pathogenic organisms.

Failure to follow institutional policy and procedures for

biomedical-hazardous materials could lead to exposure to

harmful pathogens.

1 Turn OFF the power switch.

o

C

HOTLINE

Fluid Warmer

a

2 Remove the

HOTLINE

®

Fluid Warming Set, and insert the reflux

plug (a) into the socket.

3 After use, handle and dispose of the

HOTLINE

®

Fluid Warming

Set as a potential biohazard.

Note: Properly discard the HOTLINE® Fluid Warming Set in containers marked for biohazardous materials. Dispose by incineration, or follow hospital policies and procedures applicable for the disposal of

biohazardous material.

4 Wipe down the external surfaces of the HOTLINE® Warm e r w i t h

mild detergent, water, and a soft cloth. For external disinfection, a

10% bleach solution may be used.

Storage

Store the HOTLINE

extreme temperatures. See Section 13,

®

Warmer in a cool, dry place. Do not expose to

Specifications

, for more details.

HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual 21

Page 26

SECTION 8

Troubleshooting

SECTION 8 • Troubleshooting

Only authorized personnel should perform any routine maintenance and

repairs to the HOTLINE

Problem Check the following

No power

Check Disposables

alarm

Add Recirculating

Solution alarm

Over Temperature

alarm

®

Warmer.

®

1 Confirm that the HOTLINE

Warmer is plugged in

properly.

2 Confirm that the power switch is in the ON position.

®

Note: If the HOTLINE

Warmer is plugged in and the

power switch is turned ON, the green or red LED will

illuminate.

®

Confirm that the HOTLINE

Fluid Warming Set is

properly installed.

• Push the Twin-Tube Connector firmly into the

®

socket on the right side of the HOTLINE

Warmer.

Check the level in the reservoir and add recirculating

solution to the maximum level.

1 Check the HOTLINE

®

Fluid Warming Set for kinks or

other restrictions.

2 Check for air lock:

a Turn the power switch OFF, remove the HOTLINE

Fluid Warming Set, and gently shake HOTLINE®

Warmer to dislodge air.

®

b Plug in the HOTLINE

Fluid Warming Set and turn

power switch ON.

c If there are no restrictions or air present, remove

®

the HOTLINE

Warmer from service and return it

for repair or replacement.

®

Hot cabinet Check for blocked air vents on the bottom or the back of

the HOTLINE

Note: Room temperature above 42

HOTLINE

®

Warmer.

°C may cause the

®

Warmer to shut down and the Over

Temperature alarm to activate. In this unusual

situation, turn the power switch OFF and allow the

®

HOTLINE

Warmer to cool down before returning it

to service.

Difficult to install the

HOTLINE

®

Fluid

Lubricate O-rings in the socket. Refer to Section 10,

Maintenance, for the procedure.

Warming Set

®

22 HOTLINE

Blood and Fluid Warmer | Operator’s Manual

Page 27

SECTION 8 • Troubleshooting

Problem Check the following

Recirculating

solution leaks at the

socket where the

®

HOTLINE

Fluid

Warming Set plugs

into the HOTLINE

®

Warmer

Electrical

interference receiving or

transmitting

Replace O-rings. Use the O-ring Replacement Kit: P/N

80-04-001. Refer to Section 10, Maintenance, for the

procedure.

®

1 Move the HOTLINE

Warmer away from the device in

question.

2Plug the HOTLINE® Warmer into a separate electrical

circuit.

• If the problem continues, notify Smiths Medical or

an authorized representative for assistance.

HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual 23

Page 28

SECTION 9

Te s t i n g

The HOTLINE® Warmer should be tested by hospital biomedical

personnel prior to placing it in service. All testing and maintenance should

be performed by qualified personnel. If qualified personnel are not

available, contact Smiths Medical.

SECTION 9 • Testing

If the HOTLINE

the listed tests, discontinue use of the HOTLINE

®

Warmer and any installed accessories do not pass any of

®

Warmer and remove

from service. Contact Smiths Medical or an authorized representative for

service.

WARNINGS

WARNINGS

• If any visual indicator does not illuminate or the audible signal

does not sound, do not use the Fluid Warmer. Remove the

device from service immediately.

Note: Alarm testing requires a HOTLINE® Fluid Warming Set to be

installed and that the HOTLINE

ating mode.

®

Warmer be turned ON and in the Oper-

Alarm Signal Test

The Alarm Signal Test is used to confirm proper operation of the visual

and audible alarm indicators.

1 Press and hold the Alarm Test button (a).

a

2 Observe the following:

• The green Operating LED turns off.

• Three red LEDs (Check Disposables, Add Solution, and Over

Temperature) illuminate.

• The audible alarm sounds and repeats approximately every two

seconds.

®

24 HOTLINE

Blood and Fluid Warmer | Operator’s Manual

Page 29

Over Temperature Test

SECTION 9 • Testing

a

of approximately 41°C to 42°C.

1 Press and hold the Over Temperature button (a).

2 Observe the following:

• The recirculating solution Over Temperature Alarm activates at

43°C.

The HOTLINE® Warmer should be running at an operating temperature

b

• The green Operating LED turns off.

• The red Over Temperature LED (

b) illuminates.

• The audible alarm sounds and repeats approximately every two

seconds.

3 Stop pressing the Over Temperature Test button to stop the test.

c

Add Recirculating Solution Test

The HOTLINE® Warmer is equipped with a float switch, which senses the

recirculating solution level in the reservoir. When the recirculating

solution is too low, the Add Recirculating Solution Alarm will activate.

d

1 Remove the fill-port plug (c) on the reservoir.

e

2 Gently depress the float switch (

d). (This action will simulate the

low solution condition.)

Note: Use a non-metal tool to depress the float switch because the

float switch contains a magnet.

3 Observe the following:

• The green Operating LED turns off.

• The red Add

Recirculating Solution LED (e) illuminates.

• The audible alarm sounds and repeats approximately every two

seconds.

®

HOTLINE

Blood and Fluid Warmer | Operator’s Manual 25

Page 30

Check Disposables Test

o

SECTION 9 • Testing

An interlock switch/sensor, located in the socket on the right side of the

®

HOTLINE

Warming Set. When the switch does not sense a HOTLINE

Warmer, senses a properly installed HOTLINE® Fluid

®

Fluid

Warming Set, the Check Disposables alarm activates.

1 Slowly remove the HOTLINE® Fluid Warming Set (a) from the

HOTLINE

®

Warmer socket.

2 Observe the following actions:

• The green Operating LED turns off.

• The red Check Disposables LED (

b) illuminates.

• The audible alarm sounds and repeats approximately every two

seconds.

Note: In any alarm condition, the pump should not be running. A

small amount of solution dripping from the disconnection is normal

and should stop in a few seconds.

Temperature Verification of the Recirculating Solution

Use the Level 1® TEMP CHECK Thermometer (HLTA-40) to verify the

displayed recirculating solution temperature. Other methods of

temperature verification may be inaccurate.

HOTLINE

Fluid Warmer

b

a

o

C

TEMP CHECK provides an accurate reading of the highest temperature of

the recirculating solution. Because the temperature of the reservoir is

typically 0.5°C to 2.0°C lower than the temperature from the heater, and

the temperature of the recirculating solution begins to drop due to the

effect of ambient temperature on the HOTLINE

®

Fluid Warming Set, the

highest temperature of the solution is just after it leaves the heater. During

the temperature verification test, the TEMP CHECK is positioned on the

right side of the HOTLINE

solution just after it leaves the heater and before it enters the HOTLINE

®

Warmer attached to the socket and senses the

®

Fluid Warming Set.

Refer to the TEMP CHECK HLTA-40 Thermometer Operator's Manual

for complete Temperature Verification and Calibration Instructions.

®

26 HOTLINE

Blood and Fluid Warmer | Operator’s Manual

Page 31

SECTION 9 • Testing

To verify the recirculating solution temperature, you will need the

following:

• TEMP CHECK (HLTA-40)

•HOTLINE

•HOTLINE

®

Warmer

®

Fluid Warming Set

To Verify the Recirculating Solution Temperature:

1 Plug the HOTLINE® Warmer into a power outlet.

2 Place the TEMP CHECK on the top right corner of the

HOTLINE

the HOTLINE

3 Plug the Twin-Tube Connector on the

®

Warmer and plug it into the socket on the right side of

®

Warme r.

HOTLINE

®

Fluid Warming

Set into the socket on the right side of the TEMP CHECK.

4 Remove the black label from the auxiliary outlet on the back of the

HOTLINE

®

and plug in the TEMP CHECK power cord.

Note: The auxiliary outlet is for use only with Smiths Medical

accessories.

5 Tu r n O N t h e HOTLINE® Warmer. Allow 15 minutes for the

temperature to stabilize.

6 If the TEMP CHECK display indicates a temperature between 41

°C

and 42°C, and the HOTLINE® Warmer display equals the TEMP

CHECK display, recirculating solution verification is complete.

Refer to the TEMP CHECK Manual for OVERTEMP ALARM

verification.

7 If the TEMP CHECK display does not indicate a temperature

between 41

°C and 42°C, refer to the TEMP CHECK Manual for

calibration instructions.

HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual 27

Page 32

Periodic Electrical Testing

Electrical Safety Tests must be performed by qualified personnel authorized

by the institution to perform such testing. The Safety Tests must be

performed and documented at least once per year, or according to

institutional policy. These tests include but are not limited to:

• Leakage current

•Ground bond test

Leakage Current

Leakage current must be tested according to methods and pass/fail

criteria described in UL 2601-1 or EN 60601-1. Leakage current must be

performed with the heater circuit in the full ON condition. To achieve

this condition, perform the test when the reservoir is at room

temperature. When the HOTLINE

temperature is rapidly rising, but still below 41°C, the heater circuit is in

a full ON condition.

®

Warmer is first turned on and the

SECTION 9 • Testing

Note: The HOTLINE

HOTLINE

HOTLINE

®

Fluid Warming Set is required to correctly operate the

®

Warmer and perform leakage current testing. Do not defeat

the sensing interlocks or try to operate the HOTLINE

HOTLINE

®

Fluid Warming Set in place.

®

Warmer is equipped with sensing interlocks. A

®

without a

Ground Bond Test

Ground bond test must be tested according to methods and pass/fail

criteria described in UL 2601-1 or EN 60601-1.

28 HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual

Page 33

SECTION 10

Maintenance

SECTION 10 • Maintenance

Only authorized personnel should perform any routine maintenance and

repairs to the HOTLINE

®

Warmer. Maintenance is scheduled with each

use, every 30 days, and every 12 months. The tasks are described below.

Maintenance Performed with Every Use

CAUTIONS

• Do not autoclave.

• Do not immerse any part of the HOTLINE

Clean and inspect the HOTLINE® Warmer.

Clean the Exterior

• Clean the entire HOTLINE

®

Warmer after every use. Use only

mild detergents, water, and a soft cloth.

Note: Do not use abrasive cleaning agents, solvents, or cold

sterilants. These agents will cause the device to crack.

®

Warmer in liquids.

• For disinfecting external surfaces, use a 10% bleach solution.

General Inspection

• Check the condition of the HOTLINE

®

Warmer with a visual

inspection before using. Remove from service any HOTLINE

Warmer that shows physical damage.

•If the HOTLINE

®

Fluid Warming Set does not install easily,

lubricate the O-Rings as directed in the following section.

®

HOTLINE

Blood and Fluid Warmer | Operator’s Manual 29

®

Page 34

SECTION 10 • Maintenance

Disinfect the Reservoir and Change the Recirculating Solution

Disinfect the reservoir and change the recirculating solution every 30 days

or every 12 months based on the recirculating solution used for the

HOTLINE® Warmer. Refer to the following table for the maintenance

schedule

Recirculating Solution Preparation Maintenance

.

0.3% Hydrogen Peroxide

Solution

Sterile Distilled

Water

35% Isopropyl Alcohol

Solution

Note: Use sterile distilled water only, not tap water. Failure to do so may cause

build-up of mineral deposits in the recirculating solution path, which may impair

heater performance.

Mix 140 ml of 3% hydrogen

peroxide with 1,260 ml of

sterile distilled water.

Use sterile distilled water. Replace solution and

Mix 700 ml of 70% isopropyl

alcohol with 700 ml of sterile

distilled water.

Replace solution and

disinfect reservoir every

12 months.

disinfect reservoir every

30 days.

Replace solution and

disinfect reservoir every

30 days.

Disinfect the Reservoir

1 Unplug the HOTLINE® Warmer before servicing.

2 Remove the drain tube from the holder on the rear of the

HOTLINE

3 In

vert the drain tube (a) and place a container under the end of the

tube

®

Warm e r.

. Remove the end cap (b) and drain the recirculating solution

into the container.

c

4 When all the recirculating solution has drained from the reservoir,

replace the end cap and insert the drain tube back in the holder.

5 Prepare a 0.3% hydrogen peroxide solution by mixing 140 ml of 3%

hydrogen peroxide solution and 1,260 ml of sterile distilled water.

6 Remove the fill-port plug (

c), fill the reservoir with the hydrogen

peroxide solution, and replace the fill-port plug.

®

30 HOTLINE

Blood and Fluid Warmer | Operator’s Manual

a

b

Page 35

SECTION 10 • Maintenance

o

o

C

HOTLINE

Fluid Warmer

a

7 Remove the reflux plug from the socket if required, and insert a

HOTLINE

®

Fluid Warming Set (a) (L-70, L-70NI, L-80) into the

socket.

8 Tu r n t h e H O T L I N E

®

Warmer ON, and let the recirculating

solution circulate for a 30-minute disinfection period.

9 Tu r n t h e H O T L I N E

®

Warmer OFF and unplug the power cord.

10 Empty the reservoir.

11 Remove the HOTLINE

®

Fluid Warming Set and discard

according to established hospital procedures.

These suggested instructions are designed to be used in conjunction

with established hospital procedures.

Add Recirculating Solution

CAUTIONS

• Do not fill the HOTLINE® Warmer reservoir with a HOTLINE®

Fluid Warming Set or a TEMP CHECK in place. Failure to

remove the HOTLINE

procedure may result in an air lock in the HOTLINE

®

Fluid Warming Set before the fill

®

Warmer.

1 Prepare the recirculating solution.

2 Remove the fill-port plug.

3

Fill the reservoir with 1.4 liters of recirculating solution.

4 Replace the fill-port plug.

Maintenance Performed Every 30 Days

Disinfect the Reservoir and Change Recirculating Solution for

Sterile Distilled Water and 35% Isopropyl Alcohol Solution

Refer to

procedure in this section.

HOTLINE

Disinfect the Reservoir and Change the Recirculating Solution

®

Blood and Fluid Warmer | Operator’s Manual 31

Page 36

Lubricate O-Ring Seals

SECTION 10 • Maintenance

1 Place a small amount of silicone grease on a cotton swab.

2 Apply silicone grease along the O-Rings inside the socket (

located on the right side of the

HOTLINE

®

Warmer.

a)

Silicone lubricant is available from Smiths Medical, (Silicone

lubricant P/N 80-04-002).

Maintenance Performed Every 12 Months

Disinfect the Reservoir and Change Recirculating Solution for

0.3% Hydrogen Peroxide Solution

Refer to

procedure in this section.

Replace O-Rings

1 Remove the socket head screws (b) with a 0.31cm (1/8") hex

2 Remove the faceplate, being careful not to damage the micro-switch

Disinfect the Reservoir and Change the Recirculating Solution

wrench.

lever.

o

C

HOTLINE

Fluid Warmer

o

C

HOTLINE

Fluid Warmer

a

b

3 Remove the old O-rings and clean the sockets with a cotton swab.

4 Apply silicone lubricant to two new O-rings and install into the

sockets.

5 Reassemble in reverse order, being careful not to damage the micro-

switch lever. (O-Ring Kit: P/N 80-04-001)

Testi n g HOTLI N E® Warmer Operation

Perform all the tests described in the testing section of this manual. See

Te s t i n g

Section 10,

the tests.

32 HOTLINE

. The Scheduled Maintenance Checklist below also lists

®

Blood and Fluid Warmer | Operator’s Manual

Page 37

SECTION 10 • Maintenance

Maintenance Log

All maintenance and testing should be done by qualified personnel.

Regularly scheduled maintenance ensures proper functioning of the

equipment. Refer to the table below for required tasks and frequency of

routine maintenance.

Maintenance Checklist

Task Every Use Every 30 Days Every 12 Months

Clean the Exterior

General Inspection

Disinfect the Reservoir and

Change Sterile Distilled

Water or Isopropyl Alcohol

solution

Lubricate the O-Rings

Disinfect the Reservoir and

Change the Hydrogen

Peroxide Solution

Replace the O-Rings

Alarm Test

Add Solution Test

Check Disposables Test

Over Temperature Test

Verify Temperature

Calibration

Electrical Safety Tests

®

HOTLINE

Blood and Fluid Warmer | Operator’s Manual 33

Page 38

SECTION 11

Limited Warranty

SECTION 11 • Limited Warranty

Smiths Medical ASD, Inc. (the “Manufacturer”) warrants to the Original

Purchaser that the HOTLINE

“HOTLINE

®

Warmer”), not including accessories, shall be free from

®

Blood and Fluid Warmer (the

defects in materials and workmanship under normal use, if used in

accordance with this Operator’s Manual, for a period of one year from the

actual date of sale to the Original Purchaser. THERE ARE NO OTHER

WARRANTIES.

This warranty does not cover normal wear and tear and maintenance

items, and excludes any accessory items or equipment used with the

HOTLINE

®

Warmer.

Subject to the conditions of and upon compliance with this Limited

Warranty, the Manufacturer will repair or replace at its option without

charge (except for a minimal charge for postage and handling) any

HOTLINE

®

Warmer (not including accessories) which is defective if a

claim is made during such one-year period.

The following conditions, procedures, and limitations apply to the

Manufacturer's obligation under this warranty:

A. Parties Covered by this Warranty: This warranty extends only to the

Original Purchaser of the HOTLINE

®

Warmer. This warranty does

not extend to subsequent purchasers. The Original Purchaser may be

medical personnel, a hospital, or institution which purchases

HOTLINE

®

Warmers for treatment of patients. The Original

Purchaser should retain the invoice or sales receipt as proof as to the

actual date of purchase.

B. Warranty Performance Procedure: Notice of the claimed defect must

be made in writing or by telephone to the Manufacturer as follows:

Customer Service Department, Smiths Medical ASD, Inc., 160

Weymouth Street, Rockland, MA 02370, (800) 258-5361. Notice to

the Manufacturer must include date of purchase, model and serial

number, and a description of the claimed defect in sufficient detail to

allow the Manufacturer to determine and facilitate any repairs which

may be necessary. AUTHORIZATION MUST BE OBTAINED

PRIOR TO RETURNING THE HOTLINE

authorized, the HOTLINE

34 HOTLINE

®

Warmer must be properly and carefully

®

Blood and Fluid Warmer | Operator’s Manual

®

WARMER . If

Page 39

SECTION 11 • Limited Warranty

packaged and returned to the Manufacturer, postage prepaid. Any

loss or damage during shipment is at the risk of the sender.

C. Conditions of Warranty: The warranty is void if the HOTLINE

Warmer has been 1) repaired by someone other than the

Manufacturer or its authorized agent; 2) altered so that its stability

or reliability is affected; 3) misused; or 4) damaged by negligence or

accident. Misuse includes, but is not limited to, use not in

compliance with the Operator's Manual or use with non-approved

accessories. Removal or damage to the HOTLINE

®

Warmer’s serial

number will invalidate this warranty.

D. Limitations and Exclusions: Repair or replacement of the

HOTLINE

®

Warmer or any component part thereof is the

EXCLUSIVE remedy offered by the Manufacturer. The following

exclusions and limitations shall apply:

1. No agent, representative, or employee of the Manufacturer has

authority to bind the Manufacturer to any representation or

warranty, expressed or implied.

2. THERE IS NO WARRANTY OF MERCHANTABILITY OR

FITNESS OR USE OF THE HOTLINE

®

WARMER FOR ANY

PARTIC ULA R PU RPOS E.

3. The HOTLINE

®

Warmer can only be used under the supervision

of medical personnel whose skill and judgment determine the

suitability of the HOTLINE

®

Warmer for any particular medical

treatment.

®

4. All recommendations, information, and descriptive literature

supplied by the Manufacturer or its agents are believed to be

accurate and reliable, but do not constitute warranties.

The Manufacturer disclaims responsibility for the suitability of the

HOTLINE

medical complications resulting from the use of the HOTLINE

®

Warmer for any particular medical treatment or for any

®

Warmer.

The Manufacturer shall not be responsible for any incidental damages or

consequential damages to property, loss of profits, or loss of use caused by

any defect or malfunction of the HOTLINE

®

Warmer.

This warranty gives the Original Purchaser specific legal rights, and the

Original Purchaser may have other legal rights which may vary from state

to state.

®

HOTLINE

Blood and Fluid Warmer | Operator’s Manual 35

Page 40

SECTION 12

Service

All service must be performed by Smiths Medical or an authorized service

representative. Service by any other person or organization voids the

warranty and transfers liability for malfunctions of the device to the

servicing organization.

Warranty Service

Devices received for repair that have not been obviously abused or impact

damaged and are still under warranty will be promptly repaired and

returned at no charge. See the limited warranty section of this manual. A

no-charge purchase order is requested for tracking.

Non-Warranty Work

SECTION 12 • Service

Devices received that have suffered obvious abuse or impact damage and

devices no longer under warranty will be promptly inspected and a verbal

estimate of repair cost will be provided. A purchase order will be required

from the hospital consistent with the verbal estimate. A written estimate

will be provided upon request.

Before returning the HOTLINE

Medical for Returned Goods Authorization. Be sure that ALL recirculating

solution is drained from the device before packing the HOTLINE

Warmer for shipment.

Note: The HOTLINE

shipment or it will be immediately returned as received.

®

Warmer must be cleaned and disinfected for repair

®

Warmer for service, contact Smiths

®

Additional Documentation

Upon request Smiths Medical will provide the following documentation:

• Circuit diagrams

• Components parts list(s)

• Description of function

• Service and calibration instructions

36 HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual

Page 41

SECTION 12 • Service

Disposal Information

The HOTLINE® Warmer contains lead that is used in solder of electric

assembly. When you are ready to dispose of the device, observe federal,

state, and local codes or requirements for disposal of hazardous materials

and for recycling of solid waste materials that may impact the

environment.

Service Contacts

Contact your Smiths Medical Technical Service Department or Smiths

Medical distributor at:

USA/Canada

Smiths Medical ASD, Inc.

Anesthesia and Safety Devices Division

160 Weymouth Street

Rockland, MA 02370 USA

USA/Canada 1-800-258-5361

International +1-781-878-8011

European Representative

Smiths Medical International Ltd

Watford, Herts, WD24 4LG, UK

Tel +44 (0) 1923 246434

Fax +44 (0) 1923 240273

Australian Representative

Smiths Medical Australasia Pty. Ltd.

61 Brandl Street,

Eight Mile Plains, QLD 4113, Australia

Tel +61 (0) 7 3340 1300

Fax +61 (0) 7 3340 1399

HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual 37

Page 42

SECTION 13 • Specifications and Accessories

SECTION 13

Specifications and Accessories

System Specifications

Standard Compliance Guidelines

Product Safety EN 60601-1, UL 2601-1

EMC EN 60601-1-2, FCC 47 CFR Part 15,

Class B

Enclosure Protection IEC 60529 IP Code: IPX1

Fluid Warmers ASTM F2172-02

Physical Dimensions

Height, Overall 24.1 cm (9.5 inches)

Width, Overall 21.0 cm (8.3 inches)

Depth, Overall 17.8 cm (7.0 inches)

Weight, Dry 3.5 Kg (7.6 lbs)

Weight, Wet (with recirculating

solution)

Weight, Shipping 3.6 Kg (7.95 lbs)

Recirculating Solution

Capacity

Maximum Height on I.V. Pole 107 cm (42 inches)

Environmental Temperature Humidity [%]

Operation

Transportation

Storage

Thermal Temperature

Temperature Set Point

Over Temperature Set Point

Electrical Type

MAINS Power Input:

100V 100VAC, 50/60 H

115V 115VAC, 50/60 HZ, 3.0 Amps

230V 230VAC, 50/60 H

MAINS Auxiliary Supply Power

Output:

100V 100VAC, 50/60 H

115V 115VAC, 50/60 H

230V 230VAC, 50/60 HZ, 0.5 Amps

5.0 Kg (11.0 lbs)

1.4 L (0.37 gallons)

o

C to 45oC 10 to 95

10

o

C to 70oC 10 to 95

-20

-20oC to 70oC 10 to 95

o

C ± 0.1oC

41.9

o

C

43.1

Z, 3.8 Amps

Z, 1.5 Amps

Z, 1.0 Amps

Z, 1.0 Amps

38 HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual

Page 43

SECTION 13 • Specifications and Accessories

Electrical Type

Protection Against Electrical

Shock

Mode of Operation Continuous

Type of Current Alternating

Ingress Protection Rating IPX1

Performance

Recirculating Solution

Te mper at u r e

Normothermic Flow Rates At gravity flow rates to 5,000 ml per hour

Class 1 Equipment, Type BF

Recirculating solution temperature reaches

37oC from ambient in about 4 minutes

The HOTLINE® Warmer is manufactured to be in compliance with UL

2601-1 (HL-90 115V) and EN 60601-1 (HL-90 230V).

Electromagnetic Compliance

HOTLINE® Warmer is certified to be in compliance with the European

Communities Council Directive relating to Electromagnetic Compatibility

(EMC): (89/336/EEC). Test methods and acceptance criteria as specified

in EN 60601-1-2 demonstrate conformance.

HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual 39

Page 44

SECTION 13 • Specifications and Accessories

Electromagnetic Environmental Recommendations

Recommended separation distances between portable and mobile RF communications

®

equipment and the HOTLINE

Warmer

The HOTLINE® Warmer is intended for use in an electromagnetic environment in which radiated RF

®

disturbances are controlled. The customer or the user of the HOTLINE

Warmer can help prevent

electromagnetic interference by maintaining a minimum distance between portable and mobile RF

®

communications equipment (transmitters) and the HOTLINE

Warmer as recommended below, according

to the maximum output power of the communications equipment.

Rated maximum

output power of

transmitter

Separation distance according to frequency of transmitter m

150 kHz to 80 MHz

d=[3.5/V1]√P

80 MHz to 800 MHz

d=[3.5/E1]√P

800 MHz to 2.5 GHz

d=[7/E1]√P

W

0.01 0.116 0.116 0.233

0.1 0.368 0.368 0.737

1 1.16 1.16 2.33

10 3.69 3.69 7.38

100 11.66 11.66 23.33

For transmitters rated at a maximum output power not listed above, the recommended separation distance

d in metres (m) can be estimated using the equation applicable to the frequency of the transmitter, where P

is the maximum output power rating of the transmitter in watts (W) according to the transmitter

manufacturer.

NOTE 1 At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from

structures, objects and people

.

Accessories

Product Description

L-70

L-70NI

L-80

HOTLINE

HOTLINE

HOTLINE

L-10 Gas Vent

PC-8 T-Connector, 8” Patient Lead with Injection Port

YC-8 Y-Connector, 8” Patient Lead with Injection Port

40 HOTLINE

®

Fluid Warming Set with Injection Port

®

Fluid Warming Set without Injection Port

®

Warming Set with L-10 Gas Vent

®

Blood and Fluid Warmer | Operator’s Manual

Page 45

SECTION 14

o

Symbols

Symbols Definitions

Power switch in the ON position

Power switch in the OFF position.

ON/Operation

SECTION 14 • Symbols

o

Reservoir Temperature Display

C

Add Recirculating Solution

Check Disposables

Over Temperature

Maximum Reservoir Level

Minimum Reservoir Level

Alarm Test

Type BF Equipment

®

HOTLINE

Blood and Fluid Warmer | Operator’s Manual 41

Page 46

Symbols Definitions

Protected Against Dripping Water

Catalog Number

Serial Number

Part Number

Batch Code

Authorized Representative in the European

Community

SECTION 14 • Symbols

Manufacturer

Date of Manufacture

Quantity

Protective Earth [Ground]

Alternating Current

Do Not Reuse

Attention, see instructions for use

Electric Shock Hazard

42 HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual

Page 47

Symbols Definitions

Latex Free

Caution: Federal (U.S.A.) law restricts this

device to sale by or on the order of a physician.

SECTION 14 • Symbols

CLASS 1

Device is class type 1 equipment

Protective earth terminal

Do not use if package is damaged.

Sterilized using ethylene oxide

Temperature Limitation

Humidity Limitation

Use by

Recyclable Product

HOTLINE

Device has been tested by National Technical

Systems, a nationally recognized technical

laboratory, to meet U.S. requirements for safety.

Collect separately for electrical and electronic

equipment.

CE Mark and Notified Body number (0473

indicates AMTAC)

®

Blood and Fluid Warmer | Operator’s Manual 43

Page 48

Index

Numerics

0.3% Hydrogen peroxide solution

maintenance schedule

preparation

35% Isopropyl alcohol solution

maintenance schedule

preparation

11, 30

11, 30

30

30

A

Accessories list 40

Add Recirculating Solution mode

Add Recirculating Solution test

Add Solution LED

Additional documentation

After Use

Alarm signal test

Alarm Test button

Alcohol (isopropyl) solution

Anesthetic use warning

Assembly instructions

Australian representative

Auxiliary electrical outlet

21

17

24

15

6

9

37

3

17

25

36

11, 30

B

Biohazardous material

disposal information

21

C

Canada service contact 37

Cautions

Change the recirculating solution

Check Disposables mode

Check Disposables Test

Clamp for I.V. pole

Clean exterior surfaces

Components

Connect the intravenous administration set

Contents

Contraindications

Controls

Conventions used in manual

7

L-10 Gas Vent

2

description

list

9

2

14

8

30

16

26

3

29

5

1

20

D

Description

components

HOTLINE Fluid Warming Sets

HOTLINE Warmer

Disinfect the reservoir

Display Panel

description

Disposal information

biohazardous materials

electrical device

Drain tube

2

4

2

10, 30

2, 14

14

37

21

37

3

E

Electrical safety tests 12, 28

Electrical specifications

Electromagnetic compliance

Electromagnetic environmental

recommendations

Environmental specifications

European representative

38

39

40

38

37

F

Fill-port plug 3

Float switch

3

G

Grounding reliability 7, 18

Guidelines for safe use

5

H

HOTLINE Fluid Warming Sets

description

priming volume

Hydrogen peroxide solution

preparation

4

4

10, 11, 30

I

I.V. pole mounting height restrictions 9

Important safety information

Indications for use

Infusate delivery temperatures

1

5

13

44 HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual

Page 49

Index

Intravenous administration set

connect

Isopropyl alcohol solution

20

11, 30

L

L-10 Gas Vent

warnings and cautions

LCD

14

LEDs

14

Light-emitting diodes (LEDs)

Liquid crystal display (LCD)

8

14

14

M

Maintenance 29

performed every 12 months

performed every 30 days

performed with every use

Maintenance schedule

recirculating solution

Modes of operation

Mounting to I.V. pole

16

31

29

11, 30

9

N

Non-Warranty work 36

O

OFF mode 16

ON/Operating mode

Operating LED

Operation modes

O-Rings

lubricate seals

replace

32

Over Temperature Alarm mode

Over Temperature LED

Over Temperature test

Over Temperature Test button

16

16

14, 16

32

17

25

P

Performance specifications 39

Physical specifications

Power and Alarm Test Panel

Power cord

Power ON/OFF switch

3

38

15

15

32

17

15

priming volume

HOTLINE Fluid Warming Sets

Principle of operation

13

4

R

Recirculating solution

change

30

maintenance schedule

preparation

protocols

Reflux plug

Replace

O-Rings

Reservoir

fill with recirculating solution

Reservoir level display

11, 30

11

3

32

3

11, 30

11

15

S

Service 36

Service contacts

Set Up the HOTLINE Fluid Warming Set

Set Up the HOTLINE Warmer

Socket

2

Specifications

electrical

environmental

performance

physical

thermal

Standard compliance guidelines

Sterile distilled water

maintenance schedule

Storage

Symbols

System specifications

21

41

37

18

18

38

38

38

39

38

38

38

30

38

T

Temperature

display

14

Over Temperature Alarm

Temperature verification of the recirculating

solution

Testing

Thermal specifications

26

24

38

17

HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual 45

Page 50

Troubleshooting 22

Add Recirculating Solution alarm

Check Disposables alarm

electrical interference

hot cabinet

install HOTLINE Fluid Warming Set

no power

Over Temperature alarm

recirculating solution leaks

22

22

22

23

22

23

U

USA service contact 37

Using the HOTLINE Warmer

20

W

Warnings 5

L-10 Gas Vent

Warranty

Warranty service

34

8

36

Index

22

22

46 HOTLINE

®

Blood and Fluid Warmer | Operator’s Manual

Loading...

Loading...