Page 1

Table of Contents

1. PRECAUTIONS FOR SAFETY AND USE ___________________________ 44

2. INSTALLING THE APPLIANCE ___________________________________ 46

3. ADAPTATION TO DIFFERENT TYPES OF GAS______________________ 50

4. FINAL OPERATIONS ___________________________________________ 52

5. DESCRIPTION OF CONTROLS___________________________________ 53

6. USING THE HOB ______________________________________________ 60

7. USING THE OVENS ____________________________________________ 61

8. USING THE "PIZZA" FUNCTION __________________________________ 63

9. ACCESSORIES AVAILABLE _____________________________________ 65

10. COOKING ADVICE _____________________________________________ 67

11. CLEANING AND MAINTENANCE _________________________________ 73

12. EXTRAORDINARY MAINTENANCE _______________________________ 79

THESE INSTRUCTIONS ONLY APPLY TO THE COUNTRIES OF DESTINATION WHOSE

IDENTIFICATION SYMBOLS ARE LISTED ON THE COVER OF THIS MANUAL.

INSTRUCTIONS FOR THE INSTALLER: these are intended for the

qualified engineer who is to check the gas supply system and install,

commission and test the appliance.

INSTRUCTIONS FOR THE USER: these provide recommendations for

use, a description of the controls and the correct procedures for

cleaning and maintaining the appliance.

43

Page 2

Presentation

1. PRECAUTIONS FOR SAFETY AND USE

THIS MANUAL IS AN INTEGRAL PART OF THE APPLIANCE. TAKE GOOD

CARE OF IT AND KEEP IT TO HAND THROUGHOUT THE COOKER'S LIFE

CYCLE. USERS ARE ADVISED TO READ THIS MANUAL AND ALL THE

INSTRUCTIONS IT CONTAINS BEFORE USING THE COOKER. ALSO KEEP

THE SET OF NOZZLES PROVIDED IN A SAFE PLACE. INSTALLATION MUST

BE CARRIED OUT BY QUALIFIED STAFF IN COMPLIANCE WITH THE

RELEVANT REGULATIONS. THIS APPLIANCE IS INTENDED FOR

HOUSEHOLD USE AND COMPLIES WITH THE EEC DIRECTIVES CURRENTLY

IN FORCE. THE APPLIANCE IS BUILT TO PROVIDE THE FOLLOWING

FUNCTION: COOKING AND HEATING FOODS; ALL OTHER USES ARE TO BE

CONSIDERED IMPROPER.

THE MANUFACTURER DECLINES ALL LIABILITY FOR USES OTHER THAN

THOSE STATED ABOVE.

NEVER LEAVE PACKAGING RESIDUES UNATTENDED IN THE HOME.

SEPARATE WASTE PACKAGING MATERIALS BY TYPE AND CONSIGN THEM

TO THE NEAREST SEPARATE DISPOSAL CENTRE.

THE APPLIANCE MUST BE CONNECTED TO EARTH IN COMPLIANCE WITH

ELECTRICAL SYSTEM SAFETY REGULATIONS.

THE PLUG TO BE CONNECTED TO THE POWER SUPPLY LEAD AND THE

RELATIVE SOCKET MUST BE OF THE SAME TYPE AND COMPLY WITH THE

RELEVANT REGULATIONS.

THE POWER SUPPLY SOCKET MUST BE ACCESSIBLE EVEN AFTER THE

APPLIANCE HAS BEEN BUILT-IN.

NEVER DISCONNECT THE PLUG BY PULLING ON THE POWER SUPPLY

LEAD.

IMMEDIATELY AFTER INSTALLATION, CARRY OUT A QUICK TEST ON THE

APPLIANCE FOLLOWING THE INSTRUCTIONS PROVIDED LATER IN THIS

MANUAL. IF THE APPLIANCE FAILS TO OPERATE, DISCONNECT IT FROM

THE ELECTRICAL MAINS AND CONTACT YOUR NEAREST SERVICE CENTRE.

NEVER ATTEMPT TO REPAIR THE APPLIANCE YOURSELF.

AFTER EACH USE OF THE APPLIACE, ALWAYS CHECK THAT THE CONTROL

KNOBS ARE TURNED TO

NEVER PLACE FLAMMABLE OBJECTS IN THE OVENS: IF THEY SHOULD

ACCIDENTALLY BE SWITCHED ON, THIS MIGHT CAUSE A FIRE.

(OFF).

44

Page 3

Presentation

THE NAMEPLATE WITH THE TECHNICAL DATA, SERIAL NUMBER AND MARK

IS IN A VISIBLE POSITION IN THE STORAGE COMPARTMENT.

THE NAMEPLATE MUST NEVER BE REMOVED.

NEVER PLACE PANS WITH BOTTOMS WHICH ARE NOT PERFECTLY FLAT

AND SMOOTH ON THE HOB PAN STANDS.

THE APPLIANCE BECOMES VERY HOT DURING USE. TAKE CARE NOT TO

TOUCH THE HEATING ELEMENTS INSIDE THE OVEN.

THIS APPLIANCE MUST NEVER BE INSTALLED ON A STAND.

INSTALL THE APPLIANCE SO THAT WHEN DRAWERS OR DOORS OF UNITS

INSTALLED AT HOB HEIGHT ARE OPENED, ACCIDENTAL CONTACT WITH

PANS ON THE HOB IS NOT POSSIBLE.

NEVER USE PANS OR GRIDDLE PLATES WHICH PROJECT BEYOND THE

OUTSIDE EDGE OF THE HOB.

THE APPLIANCE IS INTENDED FOR USE BY ADULTS. KEEP CHILDREN AT A

SAFE DISTANCE AND NEVER ALLOW THEM TO PLAY WITH IT.

THIS APPLIANCE IS TAGGED UNDER EUROPEAN DIRECTIVE 2002/96/EC ON

WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE).

THIS DIRECTIVE CONTAINS THE REGULATIONS GOVERNING THE

COLLECTION AND RECYCLING OF DECOMMISSIONED APPLIANCES

THROUGHOUT THE EUROPEAN UNION.

BEFORE THE APPLIANCE IS PUT INTO OPERATION, ALL THE LABELS AND

PROTECTIVE FILMS APPLIED INSIDE OR OUTSIDE MUST BE REMOVED.

The manufacturer declines all responsibility for injury or damage

caused by failure to comply with the above regulations or deriving from

tampering with even just one part of the appliance and the use of nonoriginal spare parts.

45

Page 4

Instructions for the Installer

2. INSTALLING THE APPLIANCE

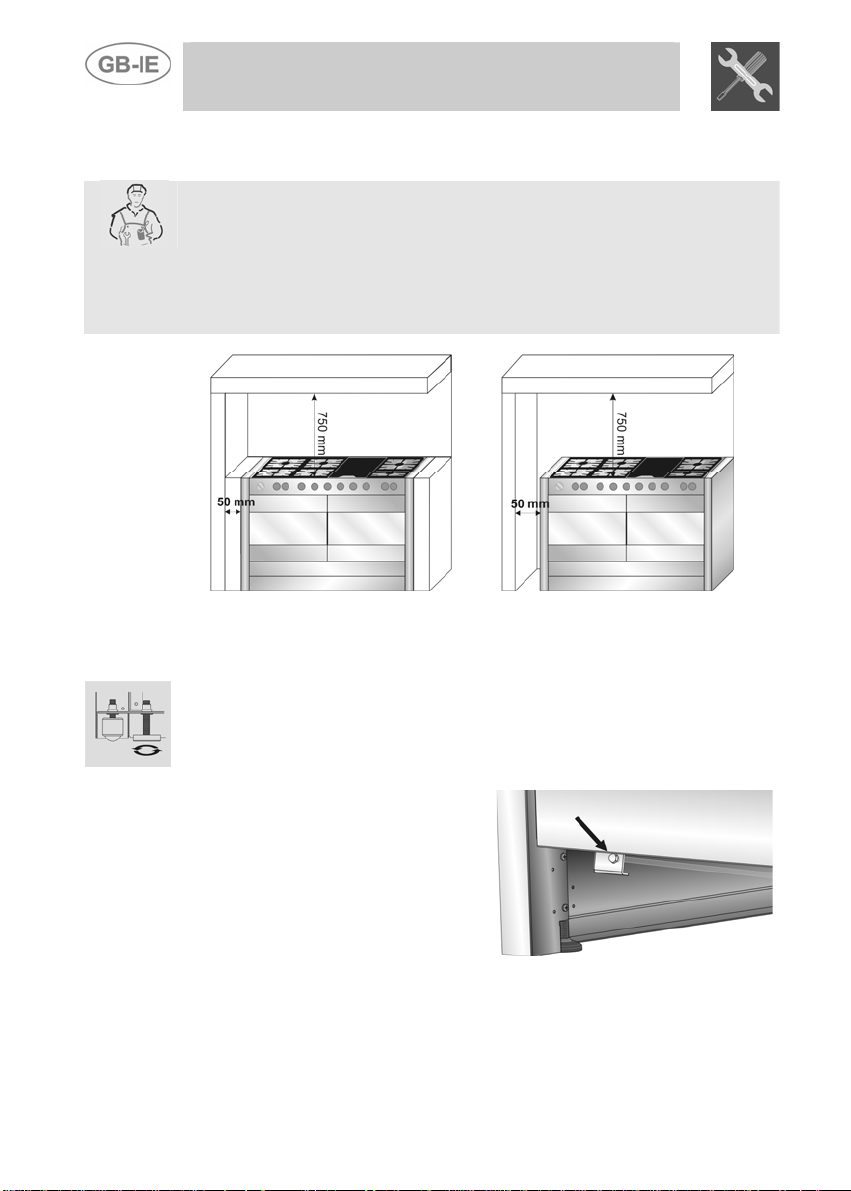

Installation must be carried out by a qualified engineer in compliance

with the relevant regulations.

It may be installed against walls one of which is higher than the worktop

surface, at least 50 mm from the side of the appliance, as shown in the

installation class drawings A and B. Wall units or extractor hoods

installed above the appliance's work-top must be at least 750 mm above

it.

46

A

Built-in Appliance Free-Standing Installation

2.1 Positioning and levelling the appliance

The appliance is equipped with wheels and adjustable feet to simplify the

positioning procedure. To use the front wheels, screw in the foot as

shown here, so that the appliance rests on the front wheels. However, to

allow the appliance to be moved freely it must be lifted at the back. To do

this, proceed as follows:

use a 10 socket wrench to screw in

the 2 hex nuts underneath the oven

compartment: this raises the

appliance either to level it or to

allow it to be moved around.

Once all procedures are complete,

retighten the front feet and the hex

nuts to set the cooker stable and

level.

B

Page 5

Instructions for the Installer

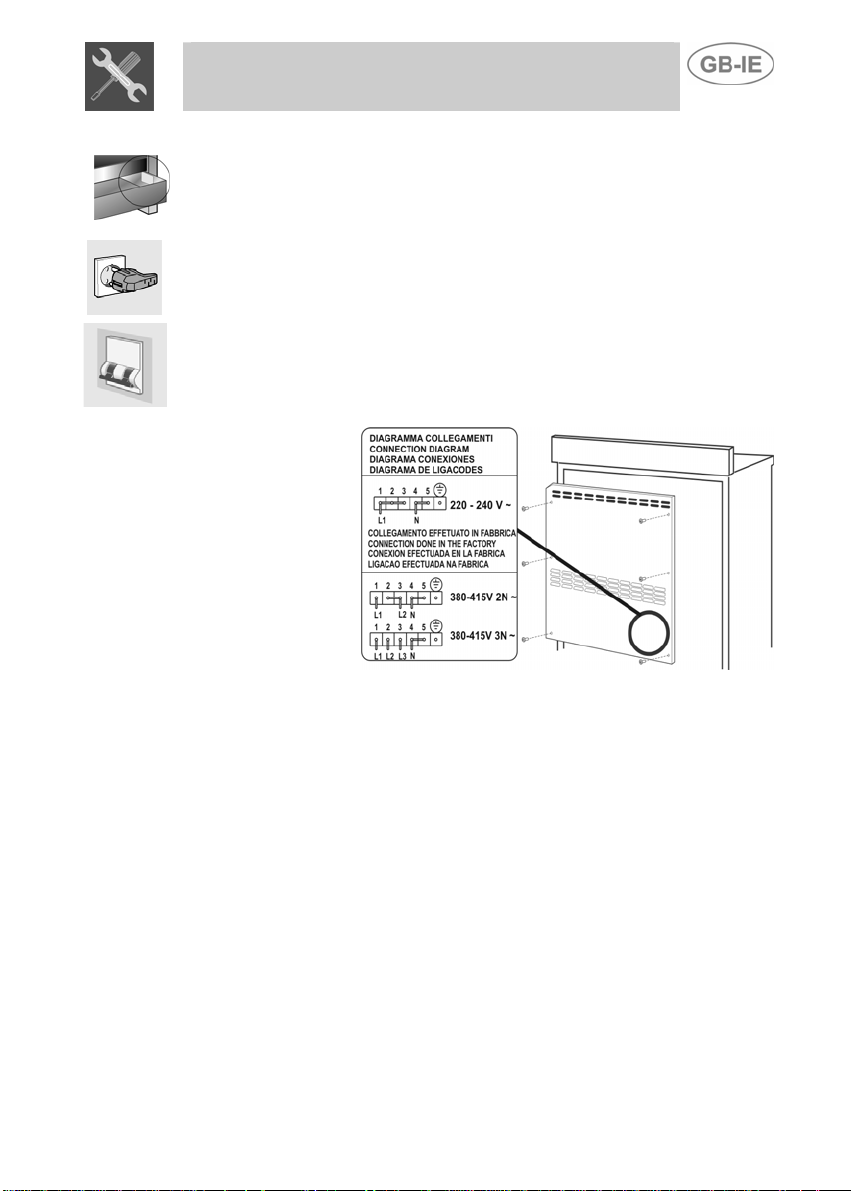

The appliance has a terminal

board on its rear.

To access it, remove the back

cover.

Make the electrical connection

in accordance with the wiring

diagram shown below.

2.2 Electrical connection

Check that the voltage and size of the power supply line are as specified

on the nameplate inside the storage compartment.

This nameplate must never be removed.

The plug on the end of the power supply cable and the wall socket must

be of the same type (in compliance with the relevant national standards).

Check that the power supply line is properly earthed. The use of

reductions, adapters or junctions is not recommended.

The appliance's power supply line must be fitted with an omnipolar

breaking device with contact gap of at least 3 mm, located in an easily

accessible position close to the appliance itself.

47

Page 6

Instructions for the Installer

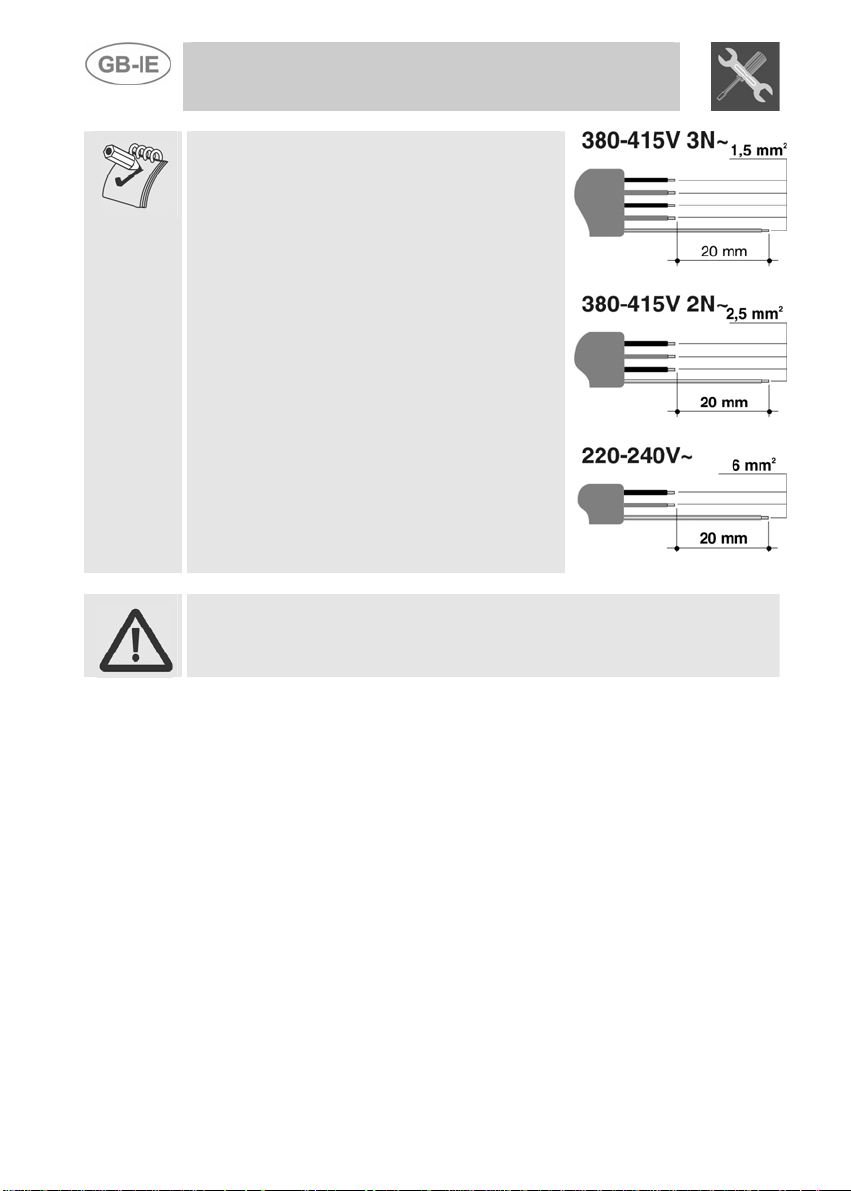

Operation at 380-415V3N~: use a H05RR-F

or H05RN-F five-wire cable (cable of 5 x 1.5

mm2).

Operation at 380-415V2N~: use a H05RR-F

or H05RNF four-wire cable (cable of 4 x 2.5

mm2).

Operation at 220-240 V~: use a H05RR-F /

H05RNF three-wire cable (cable of 3 x 6

mm2).

The earth wire (yellow-green) must be at

least 20 mm longer than the other wires at

the end for connection to the appliance.

48

The manufacturer declines all responsibility for injury or damage

caused by failure to comply with the above regulations or deriving from

tampering with even just one part of the appliance.

Page 7

Instructions for the Installer

2.3 Ventilation requirements

The room containing the appliance should have an air supply in accordance with

B.S. 5440 part 2 1989.

1. All rooms require an opening window or equivalent, and some rooms will

require a permanent vent as well.

2. For room volumes up to 5 m

3. If the room has a door that opens directly to the outside, and the room

exceeds 1 m3 no air vent is required.

4. For room volumes between 5 m

5. If there are other fuel burning appliances in the same room B.S. 5440 part 2

1989 should be consulted to determine the air vent requirements.

6. This appliance must not be installed in a bed sitting room of less than 20 m

or in a bathroom or shower room.

Windows and permanent vents should therefore not be blocked or removed

without first consulting a Corgi gas installer.

Failure to install appliances correctly is dangerous and could lead to

prosecution.

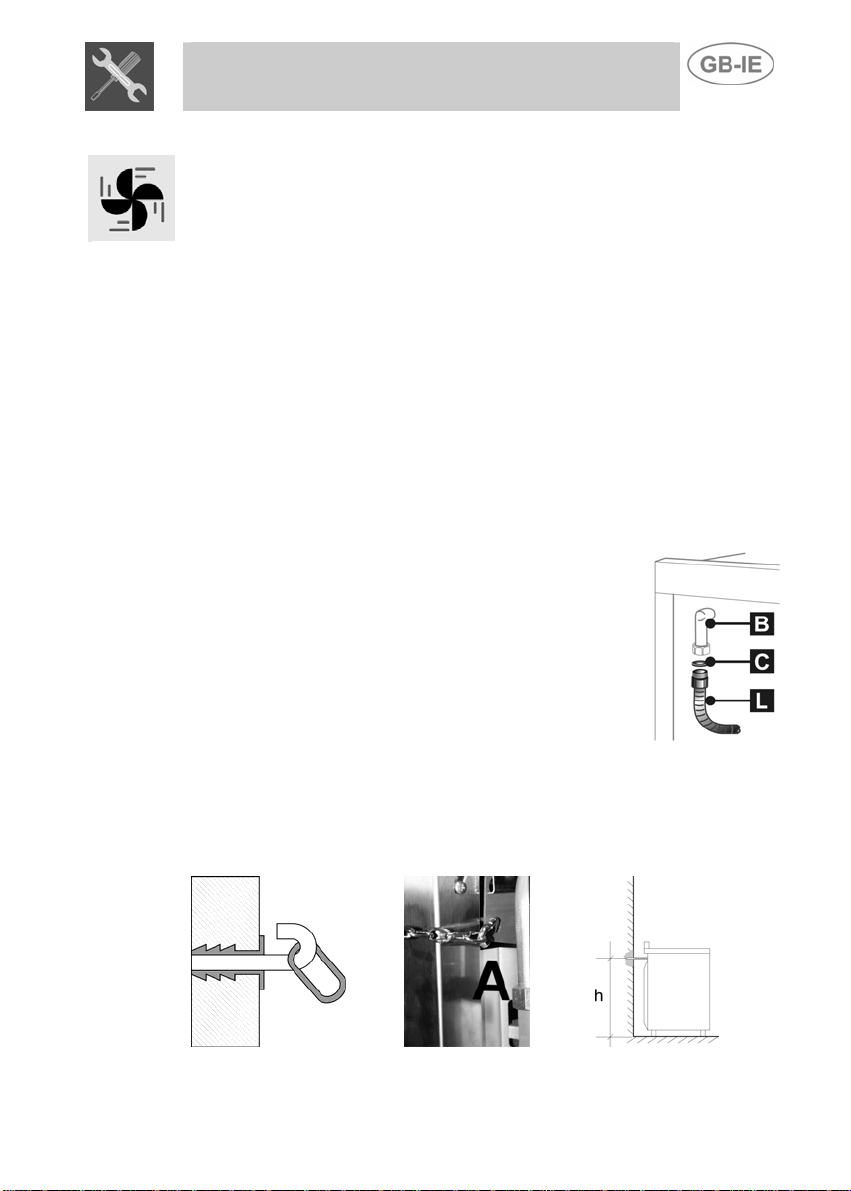

Connecting to natural and LPG gas (Please see connection

2.4

diagram)

Make the connection to the appliance using flexible bayonet

style hose in accordance to B.S. 669. The hose connection at

the rear of the appliance has a 1/2" BSP internal thread.

Please use seal C between the flexible connection L and the

appliance supply tube B. When making the connection, make

sure that no stress of any kind is applied to the cooker and

that the hose does not touch any sharp edges.

If connecting to LPG the bayonet hose must have red

bands on it.

3

an air vent of 100 cm2 is required.

3

and 10 m3 an air vent of 50 cm2 is required.

3

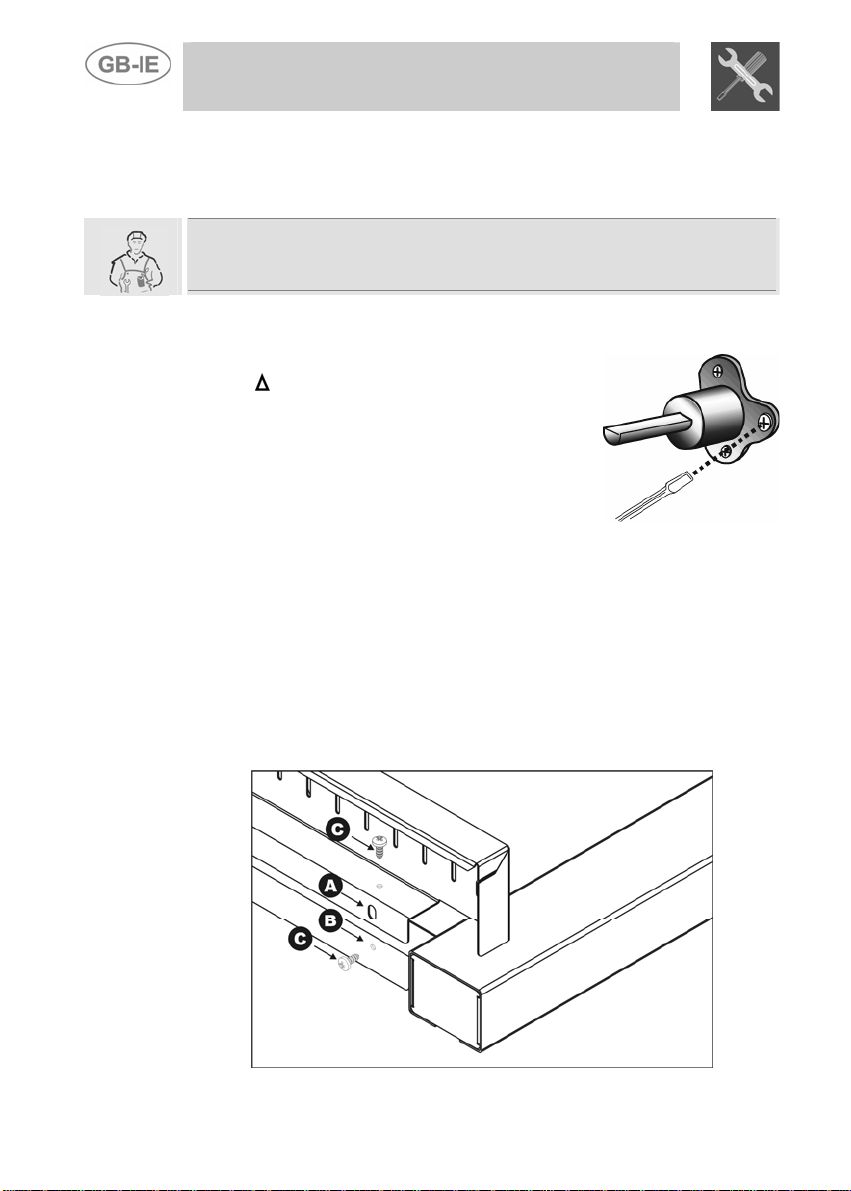

Instruction for wall fixing (only on some models) 2.5

1) Fix the screw to the wall and hook the chain (B);

2) Hook the chain to the hole positioned at the rear of the cooker by the gas

pipe (A);

3) Once the chain is in position, push the cooker against the wall;

4) The height of the screw hole from floor level must not exceed 800 mm (C).

A

B

C

49

Page 8

Instructions for the Installer

3. ADAPTATION TO DIFFERENT TYPES OF GAS

Before performing any cleaning or maintenance work, switch off the

power supply to the appliance.

The cooking hob of the cooker is preset for G20 natural gas at a

pressure of 20 mbar. In the case of functioning with other types of gas the

burner nozzles must be changed and the minimum flame adjusted on the

gas taps. Replace the burner nozzles as indicated in the table of the gas

to be used.

Changing nozzles 3.1

1. Extract the grids and remove all the caps and flame-spreader

crowns;

2. unscrew the burner nozzles with a 7 mm socket wrench;

3. proceed with replacing the burner nozzles in accordance with the

table for the gas in question.

50

Page 9

Instructions for the Installer

Burner

Nozzle

Auxiliary 1.05 50 30 360 76 75

Semi rapid 1.8 65 33 450 131 129

Rapid 3.0 85 45 750 218 215

Fish Burner 1.9 68 45 800 138 136

Ultra rapid 3.9 100 68 1600 262 257

Burner

Nozzle diameter

Auxiliary 1.05 72 (X) 360

Semi rapid 1.8 97 (Z) 450

Rapid 3.0 115 (Y) 750

Fish Burner 1.9 94 (X) 800

Ultra rapid 3.9 135 (K) 1600

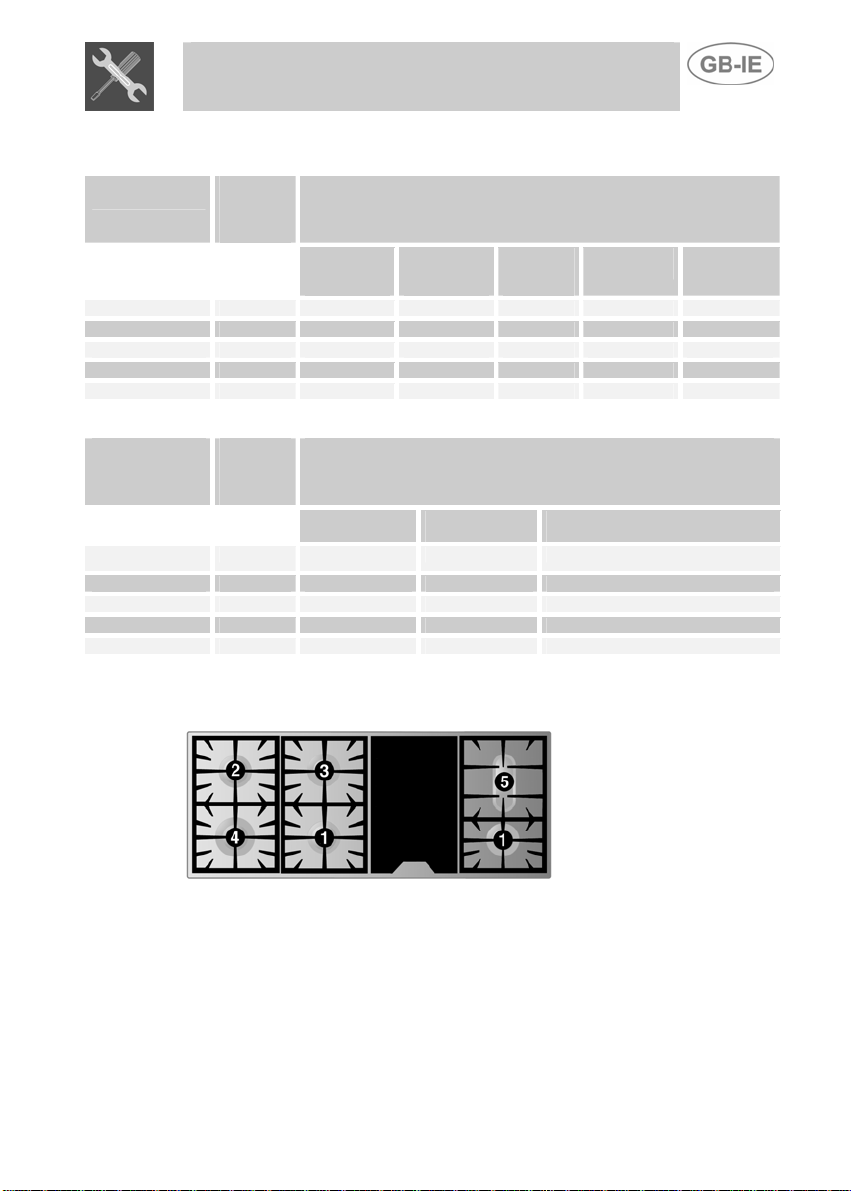

3.2 Burner and nozzle characteristics table

Rated

heating

capacity

(kW)

diameter

1/100 mm

Rated

heating

capacity

(kW)

1/100 mm

3.3 Hob burner layout

LPG – G30/G31 28/37 mbar

(drawing ref. X238)

By-pass

Mm

1/100

NATURAL GAS – G20 20 mbar

Drawing

Ref.

Reduced

flowrate

(W)

Flowrate

g/h G30

Reduced flowrate

(W)

BURNERS

1 Auxiliary

2 Semi rapid

3 Rapid

4 Ultra rapid

5 Fish

Flowrate

g/h G31

51

Page 10

4. FINAL OPERATIONS

After changing the nozzles, put the pan stands, the burner caps and

flame diffuser rings back in place.

After adjusting for use of a gas other than the gas used for testing the

appliance, replace the gas setting label on the appliance with the label

for the new gas. The label is supplied in the bag with the nozzles.

4.1 Adjusting the minimum setting for town gas and natural

gas

Light the burner and turn it to the minimum

setting

regulator screw inside or beside the tap rod

(depending on the model) until an even minimum

flame is obtained. Put the knob back in place and

check the stability of the burner flame (the flame

must not go out when the knob is turned quickly

from the maximum to the minimum setting). Repeat

the operation on all the gas taps.

4.2

To adjust the minimum level when using bottled gas, the adjuster screw

inside or beside the tap rod must be turned fully clockwise (depending on

the models).

The diameters of the bypasses for each individual burner are stated in

point "3.2 Burner and Nozzle Data Tables".

4.3

• Place the splash-back on the hob, aligning the holes A with the holes

B.

• Fix the splash-back to the hob by tightening the screws C.

Instructions for the Installer

Remove the gas tap knob and adjust the

Adjusting the minimum for bottled gas

Fitting the rear splash-back

52

Page 11

Instructions for the User

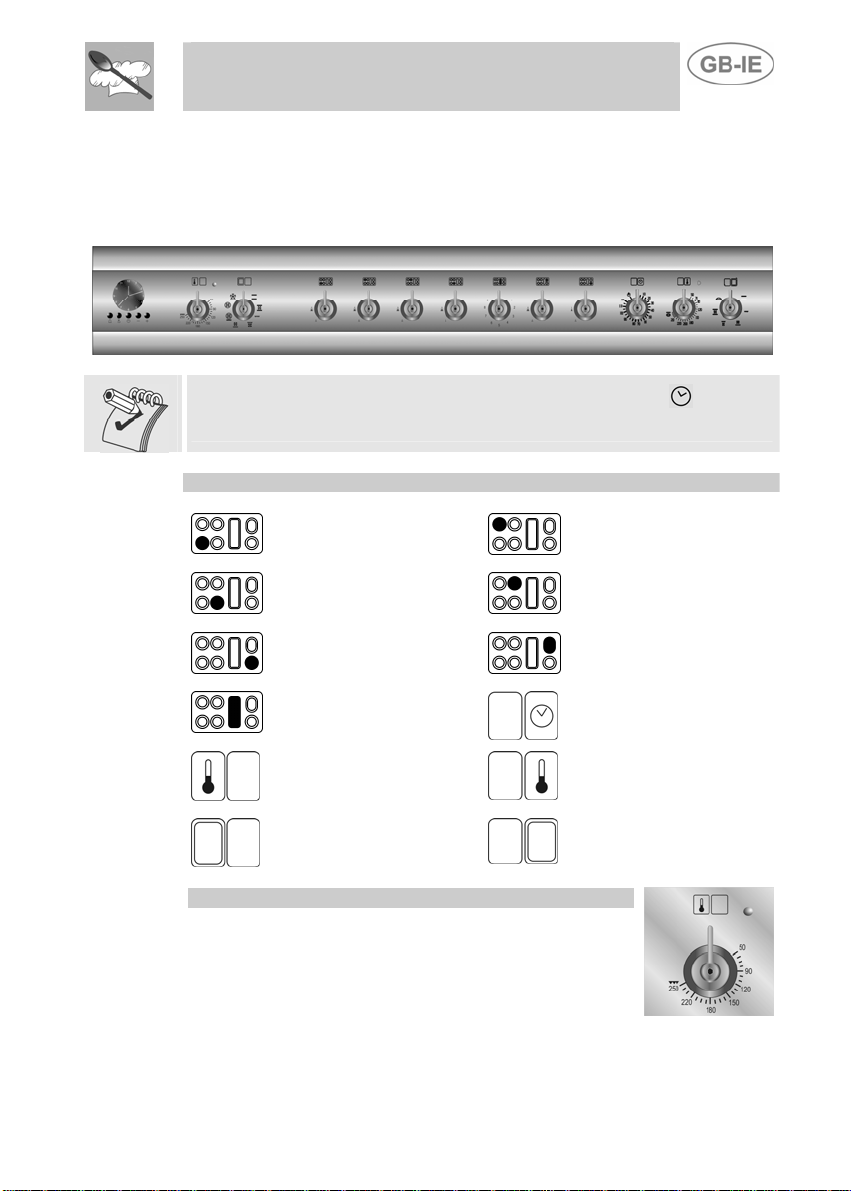

5. DESCRIPTION OF CONTROLS

5.1

The front panel

All the cooker's control and monitoring devices are placed together on the

front panel.

At first use after a power blackout, press the middle knob for 1 / 2

seconds to enable oven cooking operations.

KEY TO SYMBOLS

FRONT LEFT-HAND

BURNER

FRONT CENTRAL

BURNER

FRONT RIGHT-HAND

BURNER

BARBECUE ELEMENT

LEFT-HAND

OVEN THERMOSTAT

LEFT-HAND OVEN

FUNCTIONS

REAR LEFT-HAND

BURNER

REAR CENTRAL BURNER

REAR RIGHT-HAND

BURNER

RIGHT-HAND OVEN

TIMER

RIGHT-HAND

OVEN THERMOSTAT

RIGHT-HAND OVEN

FUNCTIONS

LEFT-HAND OVEN THERMOSTAT KNOB

The cooking temperature is selected by turning the knob

clockwise to the required setting, between 50° and 250°C.

The light comes on to indicate that the oven is heating up.

This light goes out when the set temperature is reached.

When it flashes at regular intervals, the temperature inside

the oven is being kept constantly at the set level.

53

Page 12

Instructions for the User

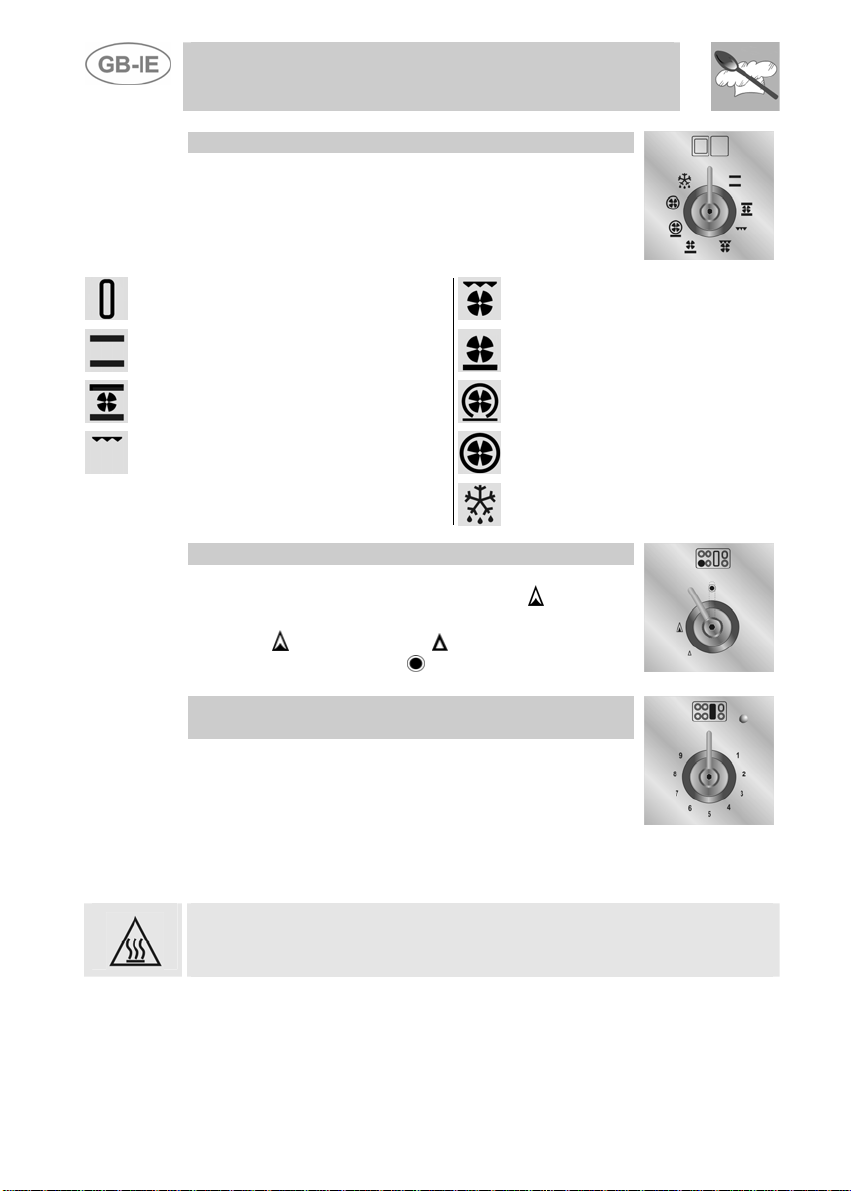

LEFT-HAND OVEN FUNCTION SELECTOR KNOB

Turn the knob to select one of the following functions:

NO FUNCTION SET

TOP AND BOTTOM

HEATING ELEMENTS

TOP AND BOTTOM

HEATING ELEMENTS + FAN

GRILL ELEMENT

GRILL ELEMENT + FAN

BOTTOM HEATING ELEMENT

+ FAN

BOTTOM HEATING ELEMENT +

FAN HEATING ELEMENT

FAN HEATING ELEMENT + FAN

DEFROSTING

HOB BURNER CONTROL KNOB

To light the flame, press the knob and turn it anticlockwise to the maximum flame symbol . To adjust

the flame, turn the knob to the zone between the

maximum and the minimum settings. To turn off the

burner, turn the knob to the position.

BARBECUE ELEMENT POWER REGULATOR

KNOB

This knob is used to set the power of the barbecue

griddle on the hob. Turn the knob to any setting

between “1” and “9” to switch on the heating element.

The light comes on to indicate that the element is

heating up.

To switch off the element, return the knob back to the

“0” setting.

WARNING: after it has been in operation for some time, the griddle

remains hot even after the heating element has been switched off:

keep children at a safe distance.

54

Page 13

Instructions for the User

RIGHT-HAND OVEN THERMOSTAT KNOB

The cooking temperature is set by turning the knob

clockwise to the value required, between 50° and 280°

( )C.

The light comes on to indicate that the oven is heating

up. This light goes out when the set temperature is

reached. When it flashes at regular intervals, the

temperature inside the oven is being kept constantly at

the set level.

RIGHT-HAND OVEN FUNCTION SELECTOR KNOB

Turn the knob to select one of the following functions:

NO FUNCTION SET

TOP AND BOTTOM

HEATING ELEMENTS

GRILL ELEMENT

BOTTOM HEATING ELEMENT

+ FAN

GRILL ELEMENT + FAN

TOP AND BOTTOM

HEATING ELEMENTS + FAN

PIZZA FUNCTION

55

Page 14

Instructions for the User

5.2 Electronic Analogue Clock

LIST OF FUNCTIONS

MINUTE-MINDER BUTTON

END OF COOKING BUTTON

CLOCK ADJUSTMENT AND RESET

VALUE DECREASE BUTTON

VALUE INCREASE BUTTON

5.2.1 Setting the time

When the oven is used for the first time, or after an interruption in the

electricity supply, the display flashes at regular intervals. Press the

key for 1 / 2 seconds to stop the display flashing and start the procedure

for setting the current time. Press the value modification keys

or to

increase or decrease the setting by one minute for each pressure.

Press one of the two value modification keys until the current time

appears. 6/7 seconds after the last key is pressed, the clock will start

from the time set.

At the end of each programmed operation 8 beeps will sound 3/4 times

at intervals of about 1 and a half minutes. This sequence can be stopped

at any time by pressing any key.

56

Page 15

Instructions for the User

5.2.2 Minute-Minder

- This function does not stop cooking; it simply

activates the buzzer. Press the

display will light up as shown in figure 1;

- Within 6/7 seconds, press the

set the minute-minder. Each time a key is

pressed, 1 outside segment, representing 1

minute of cooking time, will light up or go out.

(figure 2 shows a cooking time of 10 minutes).

- 6/7 seconds after the last key is pressed, the

countdown will start; when it finishes, the buzzer

will sound.

- During the countdown, the current time can be

viewed by pressing the

again to return to the minute minder display.

- At the end of the countdown, the oven must

be switched off manually by turning the

thermostat and function selector knob to 0.

key and the

or keys to

key once; press it

1

2

57

Page 16

Instructions for the User

5.2.3 Programming

Cooking duration: the 2nd button

can be pressed to set the cooking

duration. Before it can be set, the thermostat must be turned to the

cooking temperature required and the function selector knob to any

setting. To set the cooking duration, proceed as follows:

- Press the

key for 1 / 2 seconds; the pointer will

locate on 12 (Fig. 1).

- Use the and keys to set the cooking

duration: each pressure on the

key adds 1

minute to the cooking duration, and every 12

minutes a new inside segment will light up (figure

2 shows a cooking duration of 1 hour).

- Once the duration required is obtained, cooking

1

will start about 6 seconds after the last pressure

on

of .

- Once cooking has started the display will show the

current time, represented by the constantly

illuminated segments, and the minutes left to the

end of the cooking time, represented by the

flashing segments (each flashing segment means

2

12 minutes of cooking time left).

- At the end of the cooking time the timer will switch the oven heating

elements off, the beeps will start to sound and the numbers on the

dial will flash.

- The duration can also be reset by resetting the program selected:

pressing the central key

for 1 or 2 seconds will delete the duration

set and the oven will have to be switched off in manual mode.

Caution: it is not possible to set cooking durations of more than 6

hours.

58

Page 17

Instructions for the User

Starting cooking: as well as setting a cooking duration, the cooking start

time can also be set (with a maximum delay of 12 hours from the current

time). To set the cooking start/end time, proceed as follows:

- Set the cooking duration as described in the previous point.

- Within 6/7 seconds of the last pressure on the

the

key again to set the cooking start time. The current time will

appear on the display with internal segments illuminated to show the

end of cooking time. Use the and keys to set the cooking start

time.

- 6/7 seconds after the last key is pressed, the display will show the

current time and the cooking start and end times, which will be

represented by the illuminated inside segments. The display

segments will be constantly illuminated as long as the current time is

not the same as the cooking start time; as soon as the current time

reaches the set starting time, all the inside segments will start to

flash, indicating that the oven has started cooking.

- At the end of the cooking time the timer will switch the oven heating

elements off, the beeps will start to sound and the numbers on the

dial will flash.

- To reset the whole program set, keep the central key

1 or 2 seconds: if cooking has already started, the oven will have to

be switched off by hand.

- Here we can see a programming example: the

current time is 7:06 and cooking is programmed to

start at 8:00 and end at 9:00.

- At 8 o'clock the inside segments between 8 and 9

will start to flash, while the hours hand will remain

still.

Caution: for the oven to start cooking operations after the

programming procedures just described, the thermostat and

function selector knob must correctly set on the temperature and

function required.

5.2.4 "DEMO" Function

Models with analogue/digital programmer feature a "DEMO" function

which deactivates the heating elements while leaving the other functions

unchanged. To activate it, simply press the

seconds. A confirmation beep will inform the user that the function is

active. To deactivate it, simply repeat the same procedure.

, , and keys for 3/4

or keys, press

pressed for

59

Page 18

Instructions for the User

6. USING THE HOB

6.1

Lighting the hob burners

Before lighting the hob burners check that the flame diffuser rings are

correctly in place with their respective burner caps, making sure that the

holes A in the flame diffusers are aligned with the plugs and thermocouples.

The special pan stand B is for use with woks.

The burner it controls is shown next to each knob. The appliance is

equipped with an electronic ignition device. Simply press the knob and turn

it anti-clockwise to the maximum flame symbol

, until the burner lights.

Keep the knob pressed down for about 2 seconds to allow the thermocouple

to heat up. The burner may go out when the knob is released: this means

that the thermocouple has not warmed up enough. Repeat the operation,

keeping the knob pressed down for longer.

If the burners should go out accidentally a safety device will be tripped

about 20 seconds later, cutting off the gas supply even if the gas tap is

open.

60

Page 19

Instructions for the User

6.2 Practical hints for using the hob burners

For better burner efficiency and to minimise gas consumption, use pans

with lids of suitable size for the burner, so that flames do not reach up

the sides of the pan (see point "6.3 Pan Diameters"). Once the contents

come to the boil, turn down the flame far enough to prevent the liquid

from boiling over. When cooking, to prevent burns or damage to the hob

all pans or griddle plates must be placed inside the perimeter of the hob.

All pans must have smooth, flat bottoms. Take the greatest care when

using fats or oils since they may catch fire if overheated. If the flame

accidentally goes out, turn off the control knob and wait at least 1 minute

before trying to re-light the burner.

6.3 Pan diameters

BURNERS

1 Auxiliary

2 Semi rapid

3 Rapid

4 Ultra rapid

5 Fish

min. and max. Ø

(in cm)

12-14

16-24

18-26

20-26

Special oval pans

6.4 Using the barbecue griddle

This griddle plate has a non-stick (Teflon) coating. The nonstick film is very delicate and may be damaged if metal

utensils are used.

Use only utensils made from wood or plastic resistant

to high temperatures.

7. USING THE OVENS

7.1 Precautions and General Advice

When the oven is used for the first time, it should be heated to the

maximum temperature (250-220°C) for long enough to burn off any oily

residues left by the manufacturing process, which might contaminate

foods with unpleasant smells.

During cooking, do not cover the bottom of the oven with aluminium or

tin foil, and do not place pans or trays on it; this may damage the enamel

coating. If you wish to use greaseproof paper, position it so that it does

not interfere with the hot air circulation inside the oven.

61

Page 20

Instructions for the User

To avoid unpleasant contact with any steam

inside the oven, open the door in two stages:

hold it half-open (about 5 cm) for 4-5 seconds,

then open it completely. If you have to carry out

any procedures on foods, leave the door open

for as short a time as possible to prevent a drop

in the oven temperature which will impair the

cooking results.

7.2

Oven light

It comes on when the function selector is turned to any setting.

7.3

Cooling fan system

The appliance is equipped with a cooling system which comes into

operation as soon as a cooking function is selected. This also applies for

timed cooking processes.

Operation of fans generates a normal air flow which comes out above the

door and may continue for a short time even after the oven is switched

off.

7.4

Storage compartment

The storage compartment is in the bottom of

the cooker, underneath the ovens. To open

it, pull on the top of the door.

Never use it to store flammable materials

such as rags, paper, etc.; it is intended to

take the appliance's metal accessories only.

Caution: when the ovens are in use, the bottom inside surface of the

storage compartment may become hot.

62

Page 21

Instructions for the User

8. USING THE "PIZZA" FUNCTION

This appliance is equipped with a function specially developed for

cooking pizza. This function is identified by the symbol on the oven

functions knob. To cook a pizza, proceed as described below.

Set the oven functions knob on the

on the

Preheat with these settings until the thermostat light goes out, then place

the pizza on the special plate. It does not normally take more than 3-4

minutes to cook a pizza to perfection, although this time may vary

depending on the dough used or individual taste.

8.1.1 Precautions for using the pizza plate

symbol.

• Never use the pizza plate except as described above (for

example, never use it on gas or ceramic hobs, or on ovens not

designed to take this accessory).

• Never use any oven function if the pizza plate is not in position.

• The appliance becomes very hot during use. Oven gloves

should always be worn.

• If you like oil on your pizza, it is best to add it after removal from

the oven since oil stains on the pizza plate are unsightly and

may reduce its efficiency.

symbol and the thermostat knob

63

Page 22

Instructions for the User

8.2 Attention

• Grilling processes must never last more than 60 minutes.

• The oven door must be closed during grill and grill + rotisserie

cooking operations.

• To prevent hazardous overheating, the appliance's glass lid must

always be raised when using the oven or grill.

• Accessible parts may be very hot during and after use of the grill;

keep children well away from the appliance.

• During rotisserie cooking operations, one of the pans supplied with

the cooker should be placed on the bottom of the oven, on the

bottom runners, to collect any grease and fat produced.

• When using the oven, remove all unused pans and shelves from its

interior.

• During cooking, do not cover the bottom of the oven with aluminium

or tin foil, and do not place pans or trays on it; this may damage the

enamel coating. If you wish to use greaseproof paper, position it so

that it does not interfere with the hot air circulation inside the oven.

8.3 To save energy

The pizza stone acts as a heat reservoir. This allows energy consumption

to be reduced, especially in cooking operations requiring pre-heating or

medium-long times.

In these cases, simply turn the thermostat to zero 10-12 minutes before

the end of the cooking time.

The heat gradually emitted by the refractory stone will ensure that the

cooking temperature is maintained.

64

Page 23

Instructions for the User

9. ACCESSORIES AVAILABLE

The oven is fitted with 4 runners for placing

trays and shelves at different heights.

Oven shelf: for cooking food on plates,

small cakes or roasts or foods requiring light

grilling.

Tray grid: for placing on top of a tray for

cooking foods which may drip.

Oven tray: useful for collecting fat from

foods placed on the grid above.

Baking tray: useful for cooking cakes, pizza

and confectionery.

Rotisserie rod: useful for cooking chicken,

sausages and all foods which require

uniform cooking over their entire surface.

Main oven rotisserie frame: for fitting onto

the oven runners before the rotisserie rod is

used.

Chromium-plated gripper: useful for

removing hot shelves and trays.

Roof liner: remove it to simplify cleaning

inside the oven.

65

Page 24

g

Instructions for the User

Pizza plate: specially designed for cooking

pizza. For use as described in point "8

Using the "pizza" function".

Optional accessories

The bottom plinth and self-cleaning oven liners can be ordered through

our Authorised Service Centres.

Before using accessories, read the accompanying instructions carefully.

Two optional hob cooking accessories can also be ordered through our

Authorised Service Centres:

Gas burner griddle plate: this optional plate

is for fitting on the hob instead of the righthand (fish) pan stand. Take care that the

riddle plate feet are resting firmly on the hob

to avoid all risk of tipping.

Barbecue grill: this grill is for fitting on the

barbecue element instead of the aluminium

griddle plate.

66

Page 25

Instructions for the User

10. COOKING ADVICE

The oven should always be preheated in fan mode to 30/40°C above the

cooking temperature. This considerably shortens cooking times and

reduces electricity consumption, as well as giving better results.

The oven door must be closed during cooking operations.

10.1 Conventional cooking (left/right oven)

FUNCTION SELECTOR

THERMOSTAT SET AT 50 - 250°C

THERMOSTAT SET AT 50 -220°C

This conventional cooking method, with heat from above and below, is

suitable for cooking food on just one shelf. The oven must be preheated

to the preset temperature. Do not place the food in the oven until the

thermostat light goes out. Very fatty meats can be placed inside the oven

when it is still cold. Place frozen meat in the oven directly, without

thawing. The only precaution required is to set temperatures about 20°C

lower and cooking times about 1/4 longer than for fresh meat.

Use deep containers to prevent splashes from

dirtying the sides of the oven.

67

Page 26

Instructions for the User

10.2 Hot air cooking (left-hand oven)

FUNCTION SELECTOR

THERMOSTAT SET AT 50 - 250°C

This system is suitable for cooking on several shelves, even with foods

of different kinds (fish, meat, etc.) without cross-contamination of

flavours or smells. The air circulation inside the oven ensures uniform

heat distribution. Preheating is not necessary.

Multiple cooking is possible provided that all foods require the same

temperature.

10.3 Grilling (left/right oven)

FUNCTION SELECTOR

THERMOSTAT AT MAXIMUM SETTING

THERMOSTAT AT MAXIMUM SETTING

68

Used for quick browning of foods. The tray should be placed on the top

runner. For short processes and small amounts, place the shelf on the third

runner from the bottom. For longer cooking times and grilling, place the shelf

on lower runners, depending on the size of the food.

The oven door must be close while cooking is in progress.

Page 27

Instructions for the User

Hot-air grilling (left/right oven)

FUNCTION SELECTOR

THERMOSTAT FROM 50° C TO 250°C

THERMOSTAT FROM 50° TO 280°C ( )

Allows uniform heat distribution with better penetration to the core of

foods. Foods are lightly browned on the outside but still soft on the

inside.

During cooking the oven door must be closed, and the maximum

heating time must not exceed 60 minutes

10.4 Defrosting (left-hand oven)

FUNCTION SELECTOR

THERMOSTAT SET ON 0

The air movement provided by the fan alone thaws foods more quickly.

The air circulating inside the oven is at room temperature.

Defrosting at room temperature has the advantage that the food's flavour

and appearance are retained intact.

69

Page 28

Instructions for the User

10.5 Rotisserie cooking (left-hand oven)

FUNCTION SELECTOR

THERMOSTAT SET AT 50 -200°C

Recommended for small pieces of meat.

Prepare the rotisserie rod with the food, tightening the screws A of the

prongs. Fit the shelf B onto the third runners from the bottom. Remove

the handle D and position the rotisserie rod so that the pulley E is still in

the guides on the shelf B. Push the shelf B fully in until the tip of the

rotisserie rod enters the hole C on the rear of the oven. Place a drip tray

F on the bottom shelf and pour a little water into it to prevent smoke from

forming.

It is normal for the thermostat light to switch on and off at regular

intervals during cooking; it indicates that the temperature inside the oven

is being kept constant.

70

Page 29

Instructions for the User

10.6 Recommended cooking tables

Cooking times, for meat in particular, vary depending on the food's

thickness and quality and personal preference.

RUNNER HEIGHT

PASTA

LASAGNE

PASTA BAKES

MEAT

ROAST VEAL

ROAST BEEF

ROAST PORK

CHICKEN

DUCK

GOOSE-TURKEY

RABBIT

LEG OF LAMB

ROAST FISH 1 - 2 170 - 200 DEPENDING ON

PIZZA 1 - 2 210 - 240 40 - 45

CONFECTIONERY

MERINGUES

PASTRY

SPONGE CAKE

BISCUITS

CROISSANTS

FRUIT CAKE

CONVENTIONAL COOKING

FROM BOTTOM

2 - 3

2 - 3

2

2

2

2

2

2

2

1

1 - 2

1 - 2

1 - 2

1 - 2

1 - 2

1 - 2

TEMPERATURE

(°C)

210 - 230

210 - 230

170 - 200

210 - 240

170 - 200

170 - 200

170 - 200

140 - 170

170 - 200

170 - 200

50 - 70

170 - 200

165

150

170 - 200

170 - 200

IN MINUTES (*)

30 - 40 PER KG.

30 - 40 PER KG.

30 - 40 PER KG.

45 - 60

45 - 60

45 - 60

50 - 60

15 PER KG.

60 - 90

15 - 20

35 - 45

30 - 50

40 - 45

20 - 30

TIME

30

40

SIZE

(*) = WITH OVEN PREHEATED

RUNNER POSITION

1ST SIDE 2ND SIDE

PORK CUTLET

PORK FILLET

FILLET STEAK

SLICED LIVER

VEAL ESCALOPE

HALF CHICKEN

SAUSAGE

MEATBALLS

FISH FILLET

TOASTED SANDWICHES

FROM THE BOTTOM

4

3

3

4

4

3

4

4

4

4

GRILLING

TIME IN MINUTES

7 - 9

9 - 11

9 - 11

2 - 3

7 - 9

9 - 14

7 - 9

7 - 9

5 - 6

2 - 4

5 - 7

5 - 9

9 - 11

2 - 3

5 - 7

9 - 11

5 - 6

5 - 6

3 - 4

2 - 3

71

Page 30

Instructions for the User

RUNNER HEIGHT

PASTA

LASAGNE

PASTA BAKES

CREOLE RICE

MEAT

ROAST VEAL

ROAST PORK

ROAST BEEF

FILLET STEAK

ROAST LAMB

RARE ROAST BEEF

ROAST CHICKEN

ROAST DUCK

ROAST TURKEY

ROAST RABBIT

ROAST HARE

ROAST PIGEON

FISH 2 - 3 150 - 170 DEPENDING ON

PIZZA 2 - 3 210 - 240 30 - 50

SWEETS (CONFECTIONERY)

SPONGE CAKE

FRUIT CAKE

LIGHT SPONGE CAKE

CROISSANTS

APPLE TART

BISCUIT PUDDING

BREAD

TOASTED SANDWICHES

FROM BOTTOM

HOT-AIR COOKING

TEMPERATURE

(°C)

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2 - 3

2 - 3

2 - 3

2 - 3

1 - 2

2 - 3

2 - 3

1 - 2

190 - 210

190 - 210

190 - 220

150 - 170

150 - 160

160 - 170

160 - 180

130 - 150

170 - 180

170

160 - 170

150 - 160

150 - 160

160 - 170

140 - 170

150 - 170

170 - 190

190 - 220

160 - 170

150

160 - 170

190 - 210

220 - 240

TIME

IN MINUTES

20 - 25

25 - 30

20 - 25

65 - 90

70 - 100

65 - 90

35 - 45

100 - 130

40 - 45

70 - 90

100 - 160

160 - 240

80 - 100

30 - 50

15 - 25

SIZE

35 - 45

40 - 50

25 - 35

40 - 60

25 - 35

30 - 40

40

7

For barbecue cooking, preheating of about 15 minutes is recommended.

72

Page 31

Instructions for the User

11. CLEANING AND MAINTENANCE

Never use a jet of steam for cleaning the inside of the oven.

11.1 Cleaning stainless steel

To keep stainless steel in good condition, it must be cleaned regularly,

after each use, first allowing it to cool.

11.1.1 Routine daily cleaning

When cleaning and caring for stainless steel surfaces, always use only

specific products which do not contain abrasives or chlorine-based acids.

Instructions for use: pour the product onto a damp cloth and wipe over

the surface, then rinse thoroughly and dry with a soft cloth or chamois

leather.

11.1.2 Food stains or spills

Never use metal scouring pads or sharp scrapers; they will

damage surfaces.

Use ordinary non-abrasive products for steel, with the aid of

wooden or plastic utensils if necessary.

Rinse thoroughly and dry with a soft cloth or chamois leather.

Do not allow spills of foods with high sugar content (e.g. jam) to

dry inside the oven. If they dry for too long, they might damage

the enamel coating of the inside of the oven.

73

Page 32

Instructions for the User

11.2 Cleaning the hob components

Before carrying out any operation involving access to live parts,

disconnect the appliance from the electricity supply.

11.2.1 Barbecue griddle plate

After leaving it to cool, remove the

barbecue plate by lifting it from the front as

shown here, taking care not to spill the

residues that have collected in the

channels at the sides. Clean it with an

ordinary detergent and a non-abrasive

sponge.

Take care not to spill the residues that

collect in the channel.

11.2.2 Basin

To remove the basin underneath the

barbecue heating element:

1. Remove the griddle plate as

described in point 10.2.1;

2. Lift the heating element and

secure it by sliding the retainer to

the right (as shown here);

3. Remove the basin using the two

handles and clean it with a

specific stainless steel detergent

and non-abrasive sponge.

11.2.3 The pan stands

Remove the right-hand pan stands (griddle+fish burner) as shown here.

The left-hand pan stands do not have to be removed in any particular

order. Wash them in warm water with a non-abrasive detergent, taking

care to remove all deposits. Replace fitting first the side pan stand then

the griddle plate.

74

Page 33

Instructions for the User

11.2.4 The burner caps, flame diffuser rings and burners

The burner caps and flame diffuser rings can be

removed for easier cleaning; wash them in hot water

and non-abrasive detergent, taking care to remove

all deposits, and wait for them to dry completely.

Replace the burner caps on their rings, making sure

that the holes A are perfectly centered with the

circular projections B on the burners.

Never wash these components in the dishwasher.

11.2.5 The plugs and thermocouples

For best performance, the ignition plugs and thermocouples

must always be kept thoroughly clean. Check them

frequently and if necessary clean them with a wet cloth.

Remove any dry residues with a wooden toothpick or a

needle.

11.3 Cleaning the ovens (without self-cleaning liners)

To keep the ovens in good condition, they must be cleaned regularly,

after allowing them to cool down. Remove all removable parts.

In the main oven, remove the side runners by unscrewing the ring-nut

"A" and extract them from the guide "B". (Fig. 1)

In the auxiliary oven, remove the side runners by lifting them at the front

and extracting them from the hole at the back. (Fig. 2)

• Clean the oven shelves and side runners with hot water and non-

abrasive detergents, rinse and dry.

• Clean the inside walls of the oven with a soft cloth dipped in an

ammonium solution, rinse and dry. If stains or drippings remain,

place a damp cloth soaked in ammonium on the bottom of the oven,

close the door and after a few hours wash the oven with hot water

and liquid detergent, rinse and dry.

75

Page 34

11.3.1 Oven liners (main oven)

The main oven is fitted with enamelled liners that are continuously selfcleaning.

These liners simplify cleaning of the oven and ensure it continues to

perform well over time.

11.3.2 Using the self-cleaning liners

To keep the inside of the oven clean and free from food residues and

unpleasant smells, it should periodically be operated empty at a

temperature of at least 200° C for a time varying between 30 and 60

minutes. This allows the self-cleaning liners to oxidise any deposits

present, which can then be wiped away with a damp sponge once the

oven has cooled.

11.3.3 Maintenance of self-cleaning liners

The liners should not be cleaned using abrasive creams and ordinary

cleaners. Simply wipe with a damp sponge to avoid damaging the special

enamel coating.

11.3.4 Removing the self-cleaning liners

Remove all accessories from the inside of the oven and proceed as

follows:

1. Remove the side runners (fig.1);

2. Extract the side liners "F" and "G" (fig. 2);

3. Extract the back liner "A" after undoing the threaded ring-nut "C" (fig.

2);

4. Replace the liners in their original positions.

Instructions for the User

76

1)

2)

Page 35

Instructions for the User

11.4

Door glazing

The glass in the door should always be kept thoroughly clean. Use

absorbent kitchen roll; remove stubborn dirt with a damp sponge and

ordinary detergent.

Do not use abrasive or corrosive cleaners for cleaning the door glazing.

(e.g. powder products, oven-cleaner sprays, stain removers and metal

scouring pads).

Do not use rough or abrasive materials or sharp metal scrapers to clean

the oven's glass doors since they may scratch the surface and cause the

glass to shatter.

11.5 Cleaning the oven bottom (right-hand oven)

To clean the bottom of the oven, proceed as follows with the oven

cold.

1)

Remove the pizza plate and then the base to which it is fixed (Fig. 1).

Lift the base a few mm and then extract it from the oven.

Now lift the end of the heating element next to the door of the oven and

clean the bottom. When the operation is complete, damp parts should be

dried thoroughly.

• NEVER USE A JET OF STEAM FOR CLEANING THE INSIDE OF

THE OVEN.

• Clean the oven shelf and side runners with hot water and non-

abrasive detergents, rinse and dry.

• For easier cleaning, the door can be removed (see point 8.3).

• The oven should be operated at the maximum heat setting for 15/20

minutes after use of specific products, to burn off the residues left

inside the oven.

The pizza plate must be washed separately;

2)

77

Page 36

• Before cleaning, remove any dirt burnt onto the stone with the aid of

• For best results, the stone must still be warm; otherwise, wash it in

• Use metal mesh or non-abrasive scouring pads, dipped in lemon or

• Never use detergents;

• Never wash in the dishwasher;

• Never leave the stone to soak;

• The damp stone must not be used for a least 8 hours after the end of

• Over time, slight cracks may appear on the surface of the stone. This

• To put the pizza plate base back in place, push it firmly down against

Instructions for the User

a metal spatula or a scraper of the kind used for cleaning ceramic

hobs;

hot water;

vinegar;

the cleaning procedures;

is due to the normal expansion of the stone's finishing glazes at high

temperatures.

the oven's bottom panel and ensure it engages with the plate of the

pizza heating element (detail A Fig. 2)

78

Page 37

Instructions for the Installer

12. EXTRAORDINARY MAINTENANCE

Occasionally, the ovens will require minor servicing procedures or the

replacement of parts subject to wear and tear, such as gaskets, light

bulbs, etc. The specific operations for each procedure of this kind are

provided below.

Before carrying out any operation involving access to live parts,

disconnect the appliance from the electricity supply.

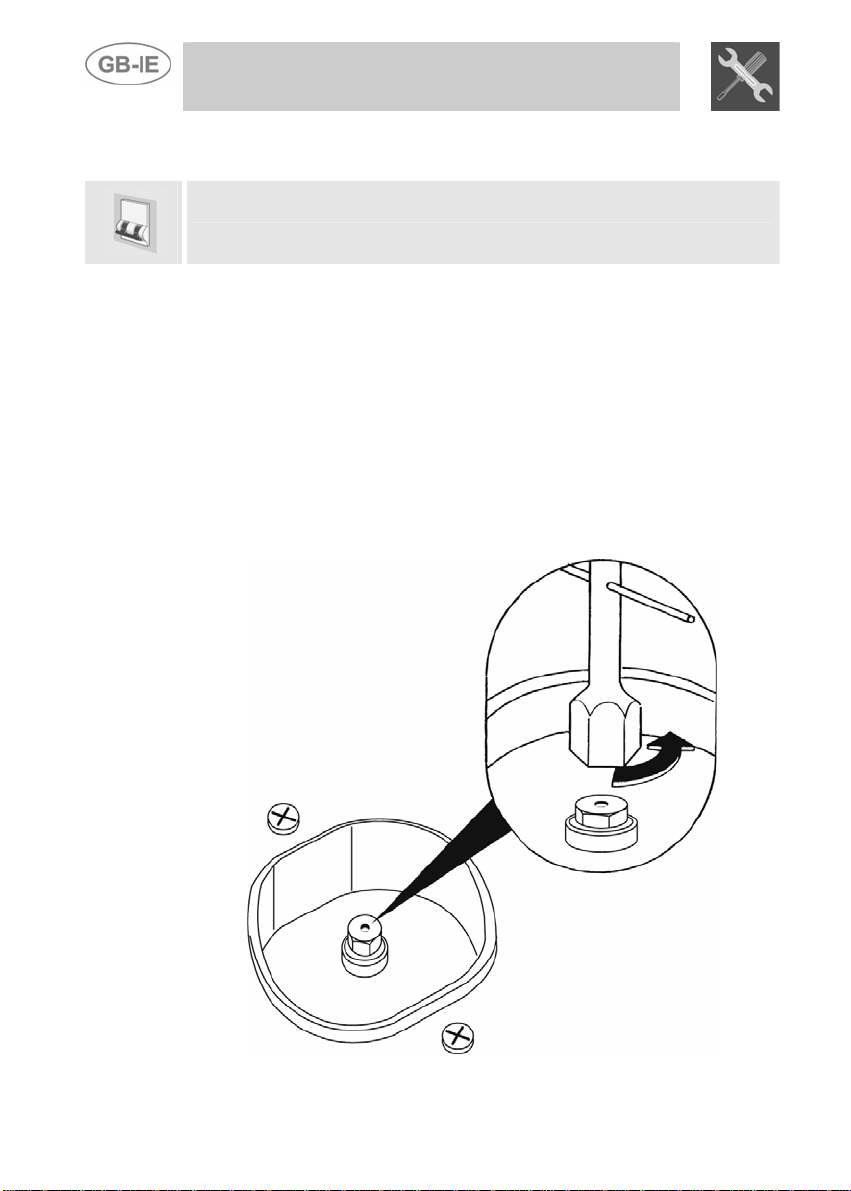

12.1 Changing the light bulbs

Remove the protective cover A by unscrewing it anticlockwise and

replace the bulb B with another of the same type. Replace the protective

cover A.

Use only light bulbs approved for ovens (T 300°C).

79

Page 38

12.2 Removing the door

Instructions for the Installer

Open the door completely and insert the pins (supplied) into the holes from

the inside. Close the door to an angle of about 45° and lift it off. To

reassemble, fit the hinges into their grooves, then lower the door into place

and extract the pins.

12.3 Oven door gaskets

To allow thorough cleaning of the oven, the door

gaskets can be removed. Before removing the

gaskets, remove the oven doors as described above.

Once the doors have been removed, lift the tangs at

the corners as shown on the right.

12.4 Greasing the gas taps

Over time, the gas taps may become stiff or jam. Clean their insides and

change their lubricating grease. This operation must be carried out by

a skilled technician.

80

Loading...

Loading...