Page 1

ServiceManual

SUNNY BOY 3600 / 5000 SMART ENERGY

BATTERY PACK SMART ENERGY

SB36-50SE-SG-en-10 | Version 1.0

AMERICAN ENGLISH

Page 2

Legal Provisions

SMA Solar Technology AG

Legal Provisions

The information contained in these documents is property of SMA Solar Technology AG. Any

publication, whether in whole or in part, requires prior written approval by SMA Solar Technology

AG. Internal reproduction used solely for the purpose of product evaluation or other proper use is

allowed and does not require prior approval.

SMA Warranty

The current warranty regulations are included with your device. You can download the version on

the Internet at www.SMA-Solar.com or obtain a printed version from the regular distribution

channels.

Trademarks

All trademarks are recognized, even if not explicitly identified as such. A lack of identification does

not mean that a product or symbol is not trademarked.

The BLUETOOTH® word mark and logos are registered trademarks of Bluetooth SIG, Inc. and any

use of these marks by SMA Solar Technology AG is under license.

Modbus® is a registered trademark of Schneider Electric and is licensed by the Modbus

Organization, Inc.

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

Phillips® and Pozidriv® are registered trademarks of Phillips Screw Company.

Torx® is a registered trademark of Acument Global Technologies, Inc.

SMA Solar Technology AG

Sonnenallee 1

34266 Niestetal

Germany

Tel. +49 561 9522-0

Fax +49 561 9522-100

www.SMA.de

E-mail: info@SMA.de

© 2004 to 2014 SMA Solar Technology AG. All rights reserved.

Service ManualSB36-50SE-SG-en-102

Page 3

SMA Solar Technology AG

Table of Contents

Table of Contents

1 Information on this Document ................................................. 4

2 Safety......................................................................................... 6

2.1 Skills of Qualified Persons .................................................................. 6

2.2 Safety Precautions ............................................................................... 6

2.3 Disconnecting the Inverter from Voltage Sources ............................. 8

3 Cleaning the Inverter................................................................ 11

4 Troubleshooting ........................................................................ 12

4.1 LED Signals .......................................................................................... 12

4.2 Event Messages................................................................................... 12

4.3 Error Messages ................................................................................... 13

5 Checking the PV System for Ground Faults............................ 26

6 Checking the Function of the Varistors.................................... 29

7 Replacing the Varistors ............................................................ 31

8 Testing the Function of the Battery Pack ................................. 32

9 Recommissioning the Inverter.................................................. 33

10 Decommissioning the Inverter ................................................. 35

11 Spare Parts................................................................................ 38

12 Contact....................................................................................... 39

Service Manual 3SB36-50SE-SG-en-10

Page 4

1 Information on this Document

SMA Solar Technology AG

1 Information on this Document

This document describes how to rectify certain errors and how to replace defective components.

This document supplements the documents that are enclosed with each product and does not

replace any locally applicable standards or directives. Read and observe all documents supplied

with the product.

Validity

This document is valid for the following device types from firmware version 2.02.17.R:

• SB 3600SE-10 (Sunny Boy 3600 Smart Energy)

• SB 5000SE-10 (Sunny Boy 5000 Smart Energy)

Target Group

This document is intended for qualified persons. Only persons with the appropriate skills are

allowed to perform the tasks described in this document (see Section2.1 "Skills of Qualified

Persons", page6).

Links to additional information can be found at www.SMA-Solar.com:

Document title Document type

SUNNY BOY 3600 / 5000 SMART ENERGY

BATTERY PACK SMART ENERGY

BATTERY PACK SMART ENERGY Technical Information

Inverter Replacement in PV Systems with Com-

munication Products and Replacement of the

SMAEnergyMeter

Parameter List Technical Information

Order Form for the SMAGridGuardCode Certificate

Webconnect Systems in SunnyPortal User Manual

SunnyHomeManager in SunnyPortal User Manual

Operating Manual

Installation Manual

Symbols

Symbol Explanation

Indicates a hazardous situation which, if not

avoided, will result in death or serious injury

Indicates a hazardous situation which, if not

avoided, can result in death or serious injury

Indicates a hazardous situation which, if not

avoided, can result in minor or moderate injury

Indicates a situation which, if not avoided, can result in property damage

Service ManualSB36-50SE-SG-en-104

Page 5

SMA Solar Technology AG

1 Information on this Document

Symbol Explanation

Sections describing activities to be performed by

qualified persons only

Information that is important for a specific topic or

goal, but is not safety-relevant

Indicates a requirement for meeting a specific goal

Desired result

A problem that might occur

Nomenclature

Complete designation Designation in this document

Battery Pack Smart Energy BatteryPack

Sunny Boy 3600 / 5000 Smart Energy Inverter, product

Service Manual 5SB36-50SE-SG-en-10

Page 6

2 Safety

SMA Solar Technology AG

2 Safety

2.1 Skills of Qualified Persons

The tasks described in this document must only be performed by qualified persons. Qualified

persons must have the following skills:

• Knowledge of how an inverter works and is operated

• Training in how to deal with the dangers and risks associated with installing and using

electrical devices, batteries and systems

• Training in the installation and commissioning of electrical devices and systems

• Knowledge of the applicable standards and directives

• Knowledge of and compliance with this document and all safety precautions

• Knowledge of and compliance with the documents of the battery manufacturer and all safety

precautions

• Knowledge of and compliance with the regulations of the European Agreement concerning

the International Carriage of Dangerous Goods by Road (ADR) for packaging, transport and

labeling of dangerous goods

• Training in accordance with Section 1.3 ADR for packaging and transport of the Battery Pack

Smart Energy

2.2 Safety Precautions

This section contains safety precautions that must be observed at all times when working on or with

the product.

To prevent personal injury and property damage and to ensure long-term operation of the product,

read this section carefully and follow all safety precautions at all times.

Danger to life due to high voltages of the PV array

When exposed to sunlight, the PV array generates dangerous DC voltage which is present in the

DC conductors and the live components of the inverter. Touching the DC conductors or the live

components can lead to lethal electric shocks. If you disconnect the DC connectors from the

inverter under load, an electric arc may occur leading to electric shock and burns.

• Do not touch uninsulated cable ends.

• Do not touch the DC conductors.

• Do not touch any live components of the inverter.

• Have the inverter mounted, installed and commissioned by qualified persons with the

appropriate skills only.

• If an error occurs, have it rectified by qualified persons only.

• Prior to performing any work on the inverter, disconnect it from all voltage sources as

described in this document (see Section2.3, page8).

Service ManualSB36-50SE-SG-en-106

Page 7

SMA Solar Technology AG

Danger to life due to high voltages on the BatteryPack

Lethal voltage is present at the pin connector for the power cable. Reaching into the pin

connector for the power cable can result in lethal electric shock.

• Do not open the BatteryPack.

• Do not wipe over the Battery Pack with a damp cloth.

• Leave the protective caps on the pin connectors for the power cable and the data cable until

the inverter cables are connected to the Battery Pack.

• Only operate the BatteryPack with its protective cover. The protective cover is separately

packed.

• Prior to performing any work on the inverter or the Battery Pack, disconnect the inverter from

all voltage sources as described in this document (see Section2.3, page8).

Danger to life due to electric shock

Touching an ungrounded PV module or an array frame can cause a fatal electric shock.

• Connect and ground the PV modules, array frame and electrically conductive surfaces so

that there is continuous conduction. Observe the applicable local regulations.

Risk of chemical burns from electrolyte or toxic gases

During normal operation, no electrolyte can leak from the Battery Pack and no toxic gases can

form. Despite careful construction, if the Battery Pack is damaged or a fault occurs, it is possible

that electrolyte may be leaked or toxic gases formed.

• Store the Battery Pack in a cool and dry place.

• Do not drop the Battery Pack or damage it with sharp objects.

• Only set the Battery Pack down on its back, i.e., on the side with the mounting lugs.

• Do not open the BatteryPack.

• Only operate the Battery Pack at ambient temperatures between 0°C and +40°C.

• Do not install or operate the Battery Pack in potentially explosive atmospheres or areas of

high humidity.

• If moisture has penetrated the Battery Pack (e.g. due to a damaged enclosure), do not install

or operate the Battery Pack.

• In case of contact with electrolyte, rinse the affected areas immediately with water and

consult a doctor without delay.

2 Safety

Service Manual 7SB36-50SE-SG-en-10

Page 8

2 Safety

Risk of burns due to hot enclosure parts

Some parts of the enclosure can get hot during operation.

• During operation, do not touch any parts other than the enclosure lid of the inverter.

Damage to the inverter due to electrostatic discharge

Touching electronic components can cause damage to or destroy the inverter through

electrostatic discharge.

• Ground yourself before touching any component.

Damage to the display or the type label due to the use of cleaning agents

• If the inverter is dirty, clean the enclosure, the cooling fins, the enclosure lid, the type label,

the display and the LEDs using only water and a cloth.

SMA Solar Technology AG

2.3 Disconnecting the Inverter from Voltage Sources

1. Disconnect the circuit breaker and secure it against reconnection.

2. If the multi-function relay is used, switch off the load supply voltage, if necessary.

3. Turn the DC load-break switch towards OFF until it snaps into place at position O.

4. Wait until all LEDs and the display have gone out.

5.

Danger to life due to high voltages

The capacitors in the inverter take five minutes to discharge.

• Wait five minutes before opening the enclosure lid.

6.

Risk of injury from dropping the enclosure lid

After removing the last screw, the enclosure lid could fall off.

• Remove all screws of the enclosure lid using an Allen key (AF5). When removing the last

screw, support the enclosure lid with one hand. Then remove the enclosure lid by pulling

it forwards and make sure that the conical spring washers are retained.

Service ManualSB36-50SE-SG-en-108

Page 9

SMA Solar Technology AG

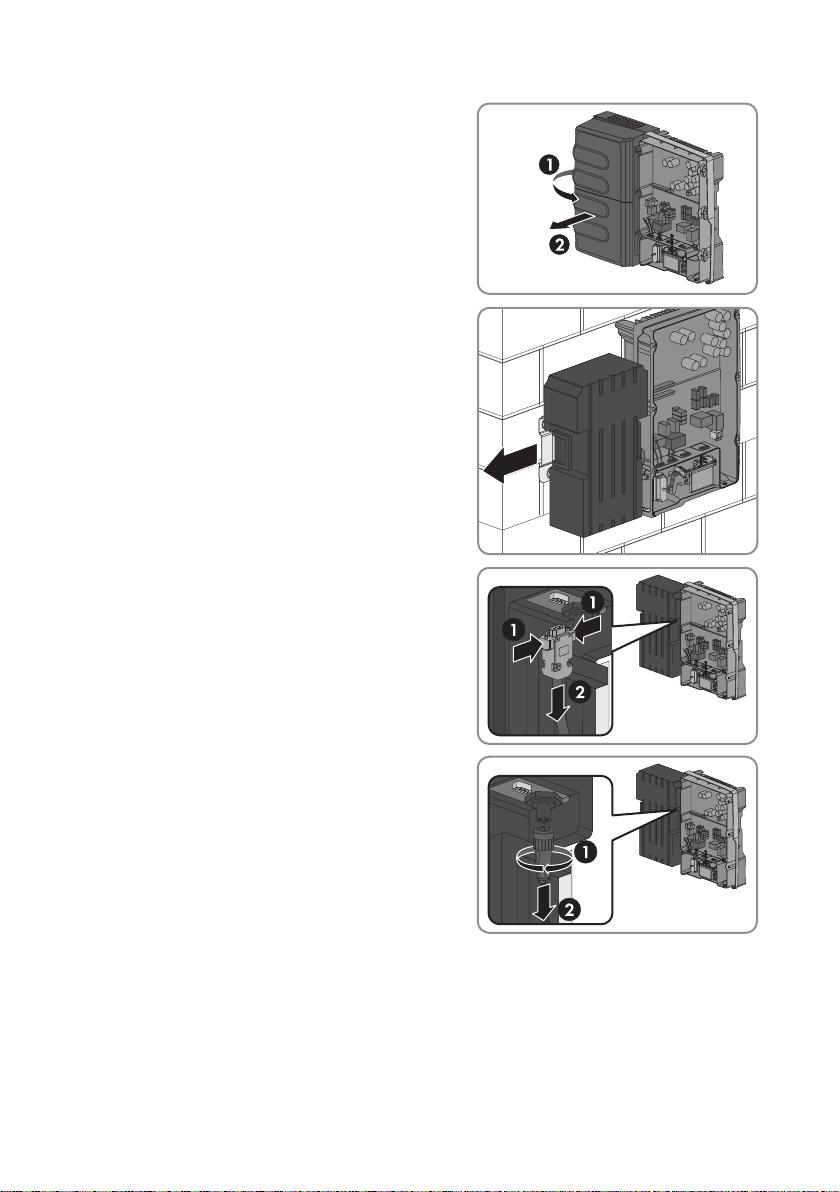

7. Grip behind the left-hand side of the protective

cover and lever it loose. Then lift the protective

cover forwards and off.

8. Hold the Battery Pack by the side handles, and

slide it to the left of the wall mounting plate up to

the stop. This deactivates the lift-off protection of

the Battery Pack and gives you more room to

pull out the cables.

9. Remove the data cable from the BatteryPack.

Press the lateral brackets in and pull the plug out

of the pin connector.

2 Safety

10. Remove the power cable from the BatteryPack.

Turn the mating plug to the left until it releases

and pull it out of the pin connector.

11. If the protective caps of the pin connectors for the data cable and the power cable are

available, use them to cover the corresponding pin connectors of the Battery Pack.

12. Insert the data cable and power cable into the bracket on the left-hand side of the inverter.

Service Manual 9SB36-50SE-SG-en-10

Page 10

2 Safety

SMA Solar Technology AG

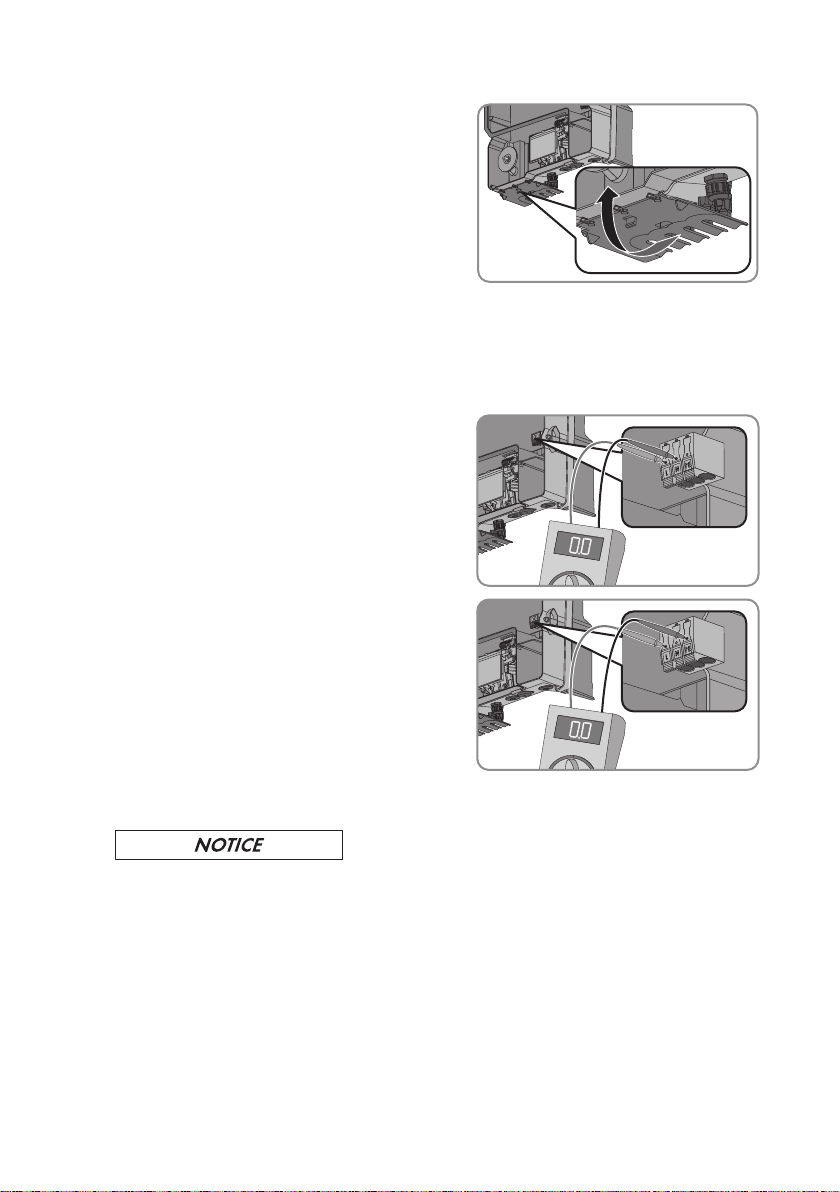

13. Flip the DC contact protection up and press

firmly until it snaps into place.

14. Use a current clamp to ensure that no current is present in the DC cables.

15. Unlock and remove all DC connectors. Insert a flat-blade screwdriver or an angled

screwdriver (blade width: 3.5mm) into one of the side slots and pull the DC connectors

straight out. Do not pull on the cable.

16. Ensure that no voltage is present at the DC inputs on the inverter.

17. Ensure that no voltage is present on the

ACconnecting terminal plate between L and N

using a suitable measuring device. Insert a test

probe in each round opening of the terminal.

18. Ensure that no voltage is present on the

ACconnecting terminal plate between L and PE

using a suitable measuring device. Insert a test

probe in each round opening of the terminal.

19. If you are using the multifunction relay, ensure that no voltage is present between any of the

terminals on the multifunction relay and PE on the AC connecting terminal plate.

20.

Damage to the inverter due to electrostatic discharge

Touching electronic components can cause damage to or destroy the inverter through

electrostatic discharge.

• Ground yourself before touching any component.

Service ManualSB36-50SE-SG-en-1010

Page 11

SMA Solar Technology AG

3 Cleaning the Inverter

3 Cleaning the Inverter

Damage to the display or the type label due to the use of cleaning agents

• If the inverter is dirty, clean the enclosure, the cooling fins, the enclosure lid, the type label,

the display and the LEDs using only water and a cloth.

• If the cooling fins on the rear of the enclosure are dirty, clean them using a soft brush.

• If the air ducts on the top of the inverter are dirty, clean them using a soft brush.

• If the protective cover of the Battery Pack is dirty, clean it with a dry cloth.

• If the Battery Pack is dirty, clean it with a dry cloth.

Service Manual 11SB36-50SE-SG-en-10

Page 12

4 Troubleshooting

SMA Solar Technology AG

4 Troubleshooting

4.1 LED Signals

The LEDs indicate the operating state of the inverter.

LED Status Explanation

Green LED glowing Operation

flashing The requirements for the connection to the utility

grid have not been met.

Red LED glowing Error

The red LED indicates an error (see Section4.3

"Error Messages", page13).

Blue LED - No function

4.2 Event Messages

Display message Cause

Set parameter The parameter change is adopted.

Parameters set success-

fully

Update file OK The update file found is valid.

Memory card is read USB stick (memory card) is searched for the update file and the update

No new update on the

memory card

Update communication The inverter is updating the communication component.

Update main CPU The inverter is updating the inverter component.

Update completed The inverter has successfully completed the update.

Condition test success-

ful

Update transport

started

Update transport suc-

cessful

Update BMS Battery management software (BMS) is updated.

Grid parameter un-

changed

The parameter changes were successfully adopted.

file is checked.

On the USB stick (memory card), there is an update file that has already

been used.

Conditions from the update file have been tested successfully.

Update file is being copied.

Update file was copied successfully to the inverter's internal memory.

The parameters have been locked and cannot be changed.

Service ManualSB36-50SE-SG-en-1012

Page 13

SMA Solar Technology AG

4.3 Error Messages

Error number Display message, cause and corrective measures

101 to 103

202 to 205

Grid fault

The grid voltage or grid impedance at the connection point of the inverter

is too high. The inverter has disconnected from the utility grid.

Corrective measures:

• Check whether the grid voltage at the connection point of the

inverter is permanently in the permissible range. If the grid voltage is

outside the permissible range due to local grid conditions, contact

the grid operator. The grid operator must agree with an adjustment

of the voltage at the feed-in point or with a change of the monitored

operating limits.

If the grid voltage is permanently within the permissible range and

this message is still displayed, contact the SMAServiceLine.

Grid fault

The utility grid has been disconnected, the AC cable is damaged or the

grid voltage at the connection point of the inverter is too low. The inverter

has disconnected from the utility grid.

Corrective measures:

• Make sure that the circuit breaker is switched on.

• Make sure that the AC cable is not damaged.

• Make sure that the AC cable is correctly connected.

• Check whether the grid voltage at the connection point of the

inverter is permanently in the permissible range.

If the grid voltage is outside the permissible range due to local grid

conditions, contact the grid operator. The grid operator must agree

with an adjustment of the voltage at the feed-in point or with a

change of the monitored operating limits.

If the grid voltage is permanently within the permissible range and

this message is still displayed, contact the SMAServiceLine.

4 Troubleshooting

Service Manual 13SB36-50SE-SG-en-10

Page 14

4 Troubleshooting

SMA Solar Technology AG

Error number Display message, cause and corrective measures

301

Grid fault

The ten-minute average value of the grid voltage is no longer within the

permissible range. The grid voltage or grid impedance at the connection

point is too high. The inverter disconnects from the utility grid to comply

with the power quality.

Corrective measures:

• Check whether the grid voltage at the connection point of the

inverter is permanently in the permissible range.

If the grid voltage is outside the permissible range due to local grid

conditions, contact the grid operator. The grid operator must agree

with an adjustment of the voltage at the feed-in point or with a

change of the monitored operating limits.

If the grid voltage is permanently within the permissible range and

this message is still displayed, contact the SMAServiceLine.

401 to 404

Grid fault

The inverter is no longer in grid-parallel operation. The inverter has

stopped feeding into the utility grid.

Corrective measures:

• Check the grid connection for significant, short-term frequency

fluctuations.

501

Grid fault

The power frequency is not within the permissible range. The inverter has

disconnected from the utility grid.

Corrective measures:

• If possible, check the power frequency and observe how often

fluctuations occur.

If fluctuations occur frequently and this message is displayed often,

contact the grid operator and request approval to change the

operating parameters of the inverter.

If the grid operator gives his approval, discuss any changes to the

operating parameters with the SMAServiceLine.

601

Grid fault

The inverter has detected an excessively high proportion of direct current

in the grid current.

Corrective measures:

• Check the grid connection for direct current.

• If this message is displayed frequently, contact the grid operator and

check whether the monitoring threshold on the inverter can be

raised.

Service ManualSB36-50SE-SG-en-1014

Page 15

SMA Solar Technology AG

Error number Display message, cause and corrective measures

701

Frequency not permitted > Check parameter

The power frequency is not within the permissible range. The inverter has

disconnected from the utility grid.

Corrective measures:

• If possible, check the power frequency and observe how often

fluctuations occur.

If fluctuations occur frequently and this message is displayed often,

contact the grid operator and request approval to change the

operating parameters of the inverter.

If the grid operator gives his approval, discuss any changes to the

operating parameters with the SMAServiceLine.

801

Waiting for grid voltage > Grid failure > Check fuse

The AC cable is not correctly connected or the country data set is not correctly configured.

Corrective measures:

• Ensure that the AC cable is correctly connected (see inverter manual

at www.SMA-Solar.com).

• Ensure that the country data set has been configured correctly.

Check the setting of the rotary switches A and B or select the

operating parameter Set country standard and check the value.

• Check the fuse.

901

PE conn. missing > Check connection

The grounding conductor is not correctly connected.

Corrective measures:

• Ensure that the grounding conductor is correctly connected (see

inverter manual at www.SMA-Solar.com).

1001

L / N swapped > Check connection

The connection of L and N is swapped.

Corrective measures:

• Ensure that L and N are correctly connected (see inverter manual at

www.SMA-Solar.com).

1101

Installation fault > Check connection

A second line conductor is connected to N.

Corrective measures:

• Correct the AC connection (see inverter manual at www.SMASolar.com).

4 Troubleshooting

Service Manual 15SB36-50SE-SG-en-10

Page 16

4 Troubleshooting

SMA Solar Technology AG

Error number Display message, cause and corrective measures

1501

Reconnection fault grid

The changed country data set or the value of a parameter you have set

does not correspond to the local requirements. The inverter cannot connect to the utility grid.

Corrective measures:

• Ensure that the country data set has been configured correctly.

Check the setting of the rotary switches A and B or select the

operating parameter Set country standard and check the value.

3301 to 3303

Unstable operation

The ten-minute average value of the grid voltage is no longer within the

permissible range. The grid voltage or grid impedance at the connection

point is too high. The inverter disconnects from the utility grid to comply

with the power quality.

Corrective measures:

• Check whether the grid voltage at the connection point of the

inverter is permanently in the permissible range.

If the grid voltage is outside the permissible range due to local grid

conditions, contact the grid operator. The grid operator must agree

with an adjustment of the voltage at the feed-in point or with a

change of the monitored operating limits.

If the grid voltage is permanently within the permissible range and

this message is still displayed, contact the SMAServiceLine.

3401 to 3402

DC overvoltage > Disconnect generator

Overvoltage at DC input. This can destroy the inverter.

This message is additionally highlighted by rapid flashing of the back-

light.

Corrective measures:

• Immediately disconnect the inverter from all voltage sources (see

Section2.3, page8).

• Check whether the DC voltage is below the maximum input voltage

of the inverter. If the DC voltage is below the maximum input voltage

of the inverter, reconnect the DC connectors to the inverter.

• If the DC voltage is above the maximum input voltage of the

inverter, ensure that the PV array has been correctly rated or contact

the installer of the PV array.

• If this message is displayed frequently, contact the

SMAServiceLine.

Service ManualSB36-50SE-SG-en-1016

Page 17

SMA Solar Technology AG

Error number Display message, cause and corrective measures

3405

IRE defective > Disconnect the PV array

Corrective measures:

• Immediately disconnect the inverter from all voltage sources (see

Section2.3, page8).

• Check whether the DC voltage is below the maximum input voltage

of the inverter. If the DC voltage is below the maximum input voltage

of the inverter, reconnect the DC connectors to the inverter.

• If the DC voltage is above the maximum input voltage of the

inverter, ensure that the PV array has been correctly rated or contact

the installer of the PV array.

• If this message is displayed frequently, contact the

SMAServiceLine.

3501

Insulation failure > Check generator

The inverter has detected a ground fault in the PV array.

Corrective measures:

• Check the PV system for ground faults (see Section5, page26).

3601

High discharge current > Check generator

The leakage current from the inverter and the PV array is too high. There

is a ground fault, a residual current or a malfunction.

The inverter interrupts feed-in operation immediately after exceeding a

limiting value. When the fault is eliminated, the inverter automatically reconnects to the utility grid.

Corrective measures:

• Check the PV system for ground faults (see Section5, page26).

3701

Residual current too high > Check generator

The inverter has detected a residual current due to temporary grounding

of the PV array.

Corrective measures:

• Check the PV system for ground faults (see Section5, page26).

3801 to 3802

DC overcurrent > Check generator

Overcurrent at the DC input. The inverter briefly interrupts feed-in operation.

Corrective measures:

• If this message is displayed frequently, ensure that the PV array has

been correctly rated and wired.

4 Troubleshooting

Service Manual 17SB36-50SE-SG-en-10

Page 18

4 Troubleshooting

SMA Solar Technology AG

Error number Display message, cause and corrective measures

3901 to 3902

Waiting for DC start conditions > Start conditions not met

The feed-in conditions for the utility grid are not yet fulfilled.

Corrective measures:

• Wait for higher irradiation.

• If this message is displayed frequently in the morning, increase the

voltage limit for starting grid feed-in. Change the parameter Critical

voltage to start feed-in.

• If this message is displayed frequently with medium irradiation,

ensure that the PV array is correctly rated.

6001 to 6462

Self diagnosis > Interference of device

The cause must be determined by the SMAServiceLine.

Corrective measures:

• Contact the SMAServiceLine.

6501 to 6513

Self diagnosis > Overtemperature

The inverter has switched off due to excessive temperature.

Corrective measures:

• Clean the cooling fins on the rear of the enclosure and the air ducts

on the top using a soft brush.

• Ensure that the inverter has sufficient ventilation.

6603 to 6604

Self diagnosis > Overload

The inverter has detected an internal overload and interrupts the feed-in

operation.

Corrective measures:

• Contact the SMAServiceLine.

6607 to 6608

Self-diagnosis > Battery overcurrent

Internal error. The inverter continues to feed into the utility grid.

Corrective measures:

• If this message is displayed frequently, contact the

SMAServiceLine.

6609

Self-diagnosis > Battery undervoltage

Internal error. The inverter continues to feed into the utility grid.

Corrective measures:

• If this message is displayed frequently, contact the

SMAServiceLine.

Service ManualSB36-50SE-SG-en-1018

Page 19

SMA Solar Technology AG

Error number Display message, cause and corrective measures

6610

Self-diagnosis > Battery overvoltage

Corrective measures:

• Turn the DC load-break switch towards OFF until it snaps into place

at position O.

• Contact the SMA Service Line and clarify the next steps.

6701 to 6702

Comm. disturbed

An error has occurred in the internal communication of the inverter. The

inverter continues feeding power into the grid.

Corrective measures:

• If this message is displayed frequently, contact the

SMAServiceLine.

6801 to 6802

Self diagnosis > Input A defective

Input A of the inverter is defective.

Corrective measures:

• Contact the SMAServiceLine.

6901 to 6902

Self diagnosis > Input B defective

Input B of the inverter is defective.

Corrective measures:

• Contact the SMAServiceLine.

7001 to 7002

Sensor fault

A temperature sensor in the inverter is defective and the inverter interrupts

the feed-in operation.

Corrective measures:

• Contact the SMAServiceLine.

7008

Disturbance sensor display temperature

The ambient temperature sensor is defective. The display is not switched

off at temperatures below -25°C and, as a result, it may have been destroyed. The inverter continues feeding power into the grid.

Corrective measures:

• Contact the SMAServiceLine.

7102

Parameter file not found or defective

The parameter file was not found or is defective. The update failed. The

inverter continues feeding power into the grid.

Corrective measures:

• Copy the parameter file to the correct folder again.

4 Troubleshooting

Service Manual 19SB36-50SE-SG-en-10

Page 20

4 Troubleshooting

SMA Solar Technology AG

Error number Display message, cause and corrective measures

7105

Param. setting failed

Parameters could not be set using the memory card. The inverter continues to feed in.

Corrective measures:

• Ensure that the parameters are set correctly.

• Ensure that you have an SMA Grid Guard code.

7106

Update file defect.

Update file on the memory card is defective.

Corrective measures:

• Reformat the memory card.

• Re-save the files to the memory card.

7110

No update file

No update file has been found.

Corrective measures:

• Copy the update file to the memory card folder. Select the folder

\UPDATE.

7112

Update file copied

The update file was successfully copied to the memory of the inverter processor.

7201 to 7202

Data stor. not poss.

Internal error. The inverter continues to feed into the utility grid.

Corrective measures:

• Contact the SMAServiceLine.

7303

Update main CPU failed

The cause must be determined by the SMAServiceLine.

Corrective measures:

• Contact the SMAServiceLine.

7324

Wait for update conditions

The inverter has successfully completed the update.

7330

Condition test failed

The conditions of the update file used for the inverter settings (e.g. country data set, device type) are not fulfilled.

Corrective measures:

• Contact the SMAServiceLine.

Service ManualSB36-50SE-SG-en-1020

Page 21

SMA Solar Technology AG

Error number Display message, cause and corrective measures

7333

Update transport failed

The update was not carried out successfully.

Corrective measures:

• Restart the update.

7337

Update BMS failed

The cause must be determined by the SMAServiceLine.

Corrective measures:

• Contact the SMAServiceLine.

7340

Update communication failed

The cause must be determined by the SMAServiceLine.

Corrective measures:

• Contact the SMAServiceLine.

7401

Varistor defective

At least one of the thermally monitored varistors is defective.

Corrective measures:

• Check the function of the varistors (see Section6, page29).

7701 to 7703

Self diagnosis > Interference of device

The cause must be determined by the SMAServiceLine.

Corrective measures:

• Contact the SMAServiceLine.

8001

Derating occurred

The inverter has reduced its power output for more than ten minutes due

to excessive temperature.

Corrective measures:

• Clean the cooling fins on the rear of the enclosure and the air ducts

on the top using a soft brush.

• Ensure that the inverter has sufficient ventilation.

8902

Self-diagnosis > Battery controller relay defective

The cause must be determined by the SMAServiceLine.

Corrective measures:

• Contact the SMAServiceLine.

8903

Battery controller defective > Disconnect PV array, open DC

switch

The cause must be determined by the SMAServiceLine.

Corrective measures:

• Contact the SMAServiceLine.

4 Troubleshooting

Service Manual 21SB36-50SE-SG-en-10

Page 22

4 Troubleshooting

SMA Solar Technology AG

Error number Display message, cause and corrective measures

8904

Self diagnosis > Interference of device

The cause must be determined by the SMAServiceLine.

Corrective measures:

• Contact the SMAServiceLine.

9002

Grid Guard code invalid

The SMA Grid Guard code entered is incorrect. The operating parameters are still protected and cannot be changed.

Corrective measures:

• Enter the correct SMA Grid Guard code.

9003

Grid parameter locked

The parameters are now locked. You cannot change the parameters.

Corrective measures:

• Unlock the parameters with the SMA Grid Guard code.

9005

Changing grid params not possible > Ensure DC supply

PV power is too low for setting the country data set. As soon as sufficient

irradiation is available, the inverter assumes the setting automatically.

9007

Abort self-test

The self-test (Italy only) was terminated.

Corrective measures:

• Restart the self-test (see inverter manual at www.SMA-Solar.com).

9301

New battery detected

The inverter has detected a new Battery Pack.

9302

Self diagnosis > Interference of device

The cause must be determined by the SMAServiceLine.

Corrective measures:

• Contact the SMAServiceLine.

9303

The service life of the battery is expiring

The state of health of the Battery Pack is 70%.

Corrective measures:

• Replace the Battery Pack with a new one. Contact the SMA Service

Line.

Service ManualSB36-50SE-SG-en-1022

Page 23

SMA Solar Technology AG

Error number Display message, cause and corrective measures

9304

Fault in battery connection > Check battery connection

The connection between the Battery Pack and the inverter is disrupted.

Corrective measures:

• Ensure that the power cable and the data cable are properly

connected to the Battery Pack (see inverter manual at www.SMASolar.com).

• Ensure that the plug contacts of the power cable and the data cable

are not damaged.

9305

Unauthorized battery system

The Battery Pack is not suitable for operation with the inverter.

Corrective measures:

• If the battery has been approved by SMA for operation with the

inverter, contact the SMA Service Line.

9306

Deviation in battery voltage

The cause must be determined by the SMAServiceLine.

Corrective measures:

• Contact the SMAServiceLine.

9307

Battery system defective

The cause must be determined by the SMAServiceLine.

Corrective measures:

• Contact the SMAServiceLine.

9308

Communication fault in battery system > Check battery connection

The connection between the Battery Pack and the inverter is disrupted.

Corrective measures:

• Ensure that the power cable and the data cable are properly

connected to the Battery Pack (see inverter manual at www.SMASolar.com).

• Ensure that the plug contacts of the power cable and the data cable

are not damaged.

9309

Battery system defective

The Battery Pack is defective.

Corrective measures:

• Contact the SMAServiceLine.

4 Troubleshooting

Service Manual 23SB36-50SE-SG-en-10

Page 24

4 Troubleshooting

SMA Solar Technology AG

Error number Display message, cause and corrective measures

9310

Signal fault in battery system > Check battery connection

The connection between the Battery Pack and the inverter is disrupted.

Corrective measures:

• Ensure that the power cable and the data cable are properly

connected to the Battery Pack (see inverter manual at www.SMASolar.com).

• Ensure that the plug contacts of the power cable and the data cable

are not damaged.

9311

Battery cell overvoltage fault

The voltage of at least one cell is outside the threshold.

Corrective measures:

• Immediately disconnect the inverter from all voltage sources (see

Section2.3, page8).

• Contact the SMAServiceLine.

9312

Battery cell undervoltage fault

The cause must be determined by the SMAServiceLine.

Corrective measures:

• Contact the SMAServiceLine.

9313

Low temperature fault in battery > Check installation site

The ambient temperature is below the lowest permitted temperature. The

inverter and the Battery Pack must only be operated at ambient temperatures from 0°C to 40°C.

Corrective measures:

• Ensure that the permitted ambient temperatures are complied with at

the installation site.

• If this message is displayed even though the permitted ambient

temperature is complied with, contact the SMA Service Line.

9314

Overtemperature fault in battery > Check installation site

The ambient temperature is above the highest permitted temperature. The

inverter and the Battery Pack must only be operated at ambient temperatures from 0°C to 40°C.

Corrective measures:

• Ensure that the permitted ambient temperatures are complied with at

the installation site.

• If this message is displayed even though the permitted ambient

temperature is complied with, contact the SMA Service Line.

Service ManualSB36-50SE-SG-en-1024

Page 25

SMA Solar Technology AG

Error number Display message, cause and corrective measures

9315

Battery imbalancing fault

The cause must be determined by the SMAServiceLine.

Corrective measures:

• Contact the SMAServiceLine.

9334

Battery charging test

The function of the Battery Pack is tested. The Battery Pack is charged.

9335

Discharge battery test

The function of the Battery Pack is tested. The Battery Pack is discharged.

9336

Start conditions for battery test not fulfilled

The function of the Battery Pack cannot be tested because the requirements are not fulfilled.

Corrective measures:

• Ensure that the requirements for testing the Battery Pack are

fulfilledTesting the Function of the Battery Pack.

9337

Charge battery test successful

The Battery Pack was charged successfully. The function of the Battery

Pack is ensured.

9338

Battery discharging test successful

The Battery Pack was discharged successfully. The function of the Battery

Pack is ensured.

9339

Battery charging test failed

The Battery Pack could not be charged.

Corrective measures:

• Ensure that the function of the Battery Pack was tested correctly

Testing the Function of the Battery Pack.

9340

Battery discharging test failed

The Battery Pack could not be discharged.

Corrective measures:

• Ensure that the function of the Battery Pack was tested correctly

Testing the Function of the Battery Pack.

4 Troubleshooting

Service Manual 25SB36-50SE-SG-en-10

Page 26

5 Checking the PV System for Ground Faults

SMA Solar Technology AG

5 Checking the PV System for Ground Faults

If the inverter displays the event numbers 3501, 3601 or 3701, there could be a ground fault. The

electrical insulation from the PV system to ground is defective or insufficient.

Danger to life due to electric shock

In the event of a ground fault, high voltages can be present.

• Touch the cables of the PV array on the insulation only.

• Do not touch any parts of the sub-structure or frame of the PV array.

• Do not connect PV strings with ground faults to the inverter.

Destruction of the measuring device due to overvoltage

• Only use measuring devices with a DC input voltage range of 1,000V or higher.

Procedure

• Check the PV system for ground faults by measuring the voltage.

• If the voltage measurement was not successful, check the PV system via insulation resistance

measurement for ground faults.

Test by Measuring the Voltage

Proceed as follows to check each string in the PV system for ground faults.

Procedure:

1.

Danger to life due to high voltages

• Disconnect the inverter from all voltage sources (see Section2.3, page8).

2. Measure the voltages:

• Measure the voltages between the positive terminal and the ground potential (PE).

• Measure the voltages between the negative terminal and the ground potential (PE).

• Measure the voltages between the positive and negative terminals.

If the following results are present at the same time, there is a ground fault in the PV

system:

☑ All measured voltages are stable.

☑ The sum of the two voltages to ground potential is approximately equal to the

voltage between the positive and negative terminals.

• If a ground fault is present, determine the location of the ground fault via the ratio of the

two measured voltages and eliminate the ground fault.

Service ManualSB36-50SE-SG-en-1026

Page 27

SMA Solar Technology AG

5 Checking the PV System for Ground Faults

Example: Location of the ground fault

The example shows a ground fault between the second and third PV module.

3. If a definite ground fault cannot be measured and the message is still displayed, measure the

insulation resistance.

4. Reconnect the strings without ground fault to the inverter and recommission the inverter (see

Section9, page33).

Test by Measuring the Insulation Resistance

If the voltage measurement does not accurately indicate a ground fault, the insulation resistance

measurement can provide more detailed results.

Figure 1: Schematic diagram of the measurement

Service Manual 27SB36-50SE-SG-en-10

Page 28

total

5 Checking the PV System for Ground Faults

SMA Solar Technology AG

Calculating the insulation resistance

The total resistance of the PV system to be expected or of an individual string can be

calculated using the following formula:

The exact insulation resistance of a PV module can be obtained from the module manufacturer

or the datasheet.

For the resistance of a PV module an average value can be assumed: for thin-film PV modules

approximately 40MOhm and for polycrystalline and monocrystalline PV modules

approximately50MOhm per PV module (for further information on calculating the insulation

resistance see the Technical Information "Insulation Resistance (Riso) of Non-Galvanically

Isolated PV Systems" at www.SMA-Solar.com).

Required devices:

☐ Suitable device for safe disconnection and short-circuiting

☐ Measuring device for insulation resistance

Device required for safe disconnection and short-circuiting of the PV array

The insulation resistance can only be measured with a suitable device for safe disconnection

and short-circuiting of the PV array. If no suitable device is available, the insulation

measurement must not be carried out.

Procedure:

1. Calculate the insulation resistance per string to be expected.

2.

Danger to life due to high voltages

• Disconnect the inverter from all voltage sources (see Section2.3, page8).

3. Install the short circuit device.

4. Connect the measuring device for insulation resistance.

5. Short-circuit the first string.

6. Set the test voltage. The test voltage should be as close as possible to the maximum system

voltage of the PV modules but must not exceed it (see datasheet of the PV modules).

7. Measure the insulation resistance.

8. Eliminate the short circuit.

9. Measure the remaining strings in the same manner.

☑ If the insulation resistance of a string deviates considerably from the theoretically

calculated value, there is a ground fault present in the respective string.

10. Reconnect only those strings to the inverter from which the ground fault was eliminated.

11. Reconnect all other strings to the inverter.

12. Recommission the inverter (see Section9, page33).

13. If the inverter still displays an insulation error, contact the SMAServiceLine. The PV modules

might not be suitable for the inverter in the present quantity.

Service ManualSB36-50SE-SG-en-1028

Page 29

SMA Solar Technology AG

6 Checking the Function of the Varistors

6 Checking the Function of the Varistors

If the inverter displays event number 7401, one of the varistors is probably defective.

Destruction of the inverter due to overvoltage

If varistors are missing, the inverter is no longer protected against overvoltage.

• Do not operate the inverter without varistors in PV systems with a high risk of overvoltages.

• Do not recommission the inverter until the defective varistors have been replaced.

Destruction of the measuring device due to overvoltage

• Only use measuring devices with a DC input voltage range of 1,000V or higher.

Check the function of each varistor as described in the following:

Procedure:

1.

Danger to life due to high voltages

• Disconnect the inverter from all voltage sources and open the enclosure lid (see

Section2.3, page8).

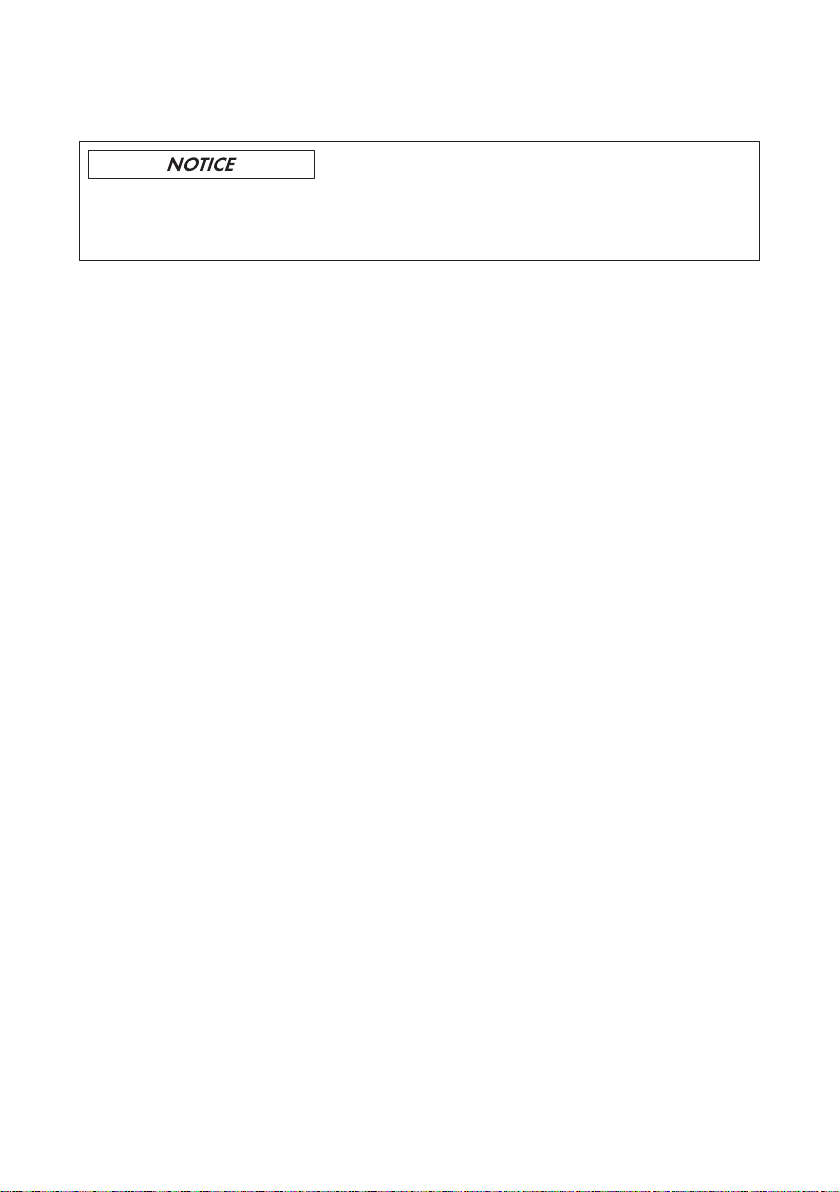

2. Insert the insertion tool in the clamping contacts

of the connecting terminal plate.

3. Remove the varistor from the connecting terminal plate.

4. Use a measuring device to measure whether

there is a conductive connection between the

middle and the right-hand varistor lead. Hold the

varistor with the labeling pointing forward.

If there is no conductive connection, the varistor is defective. SMA Solar Technology AG

recommends replacing all varistors immediately.

• Order new varistors and insertion tools (see Section11 "Spare Parts", page38).

Service Manual 29SB36-50SE-SG-en-10

Page 30

6 Checking the Function of the Varistors

SMA Solar Technology AG

• Reinsert old varistors and leave them in place until new varistors and insertion tools are

available.

• If new varistors are available, replace all varistors (see Section7, page31).

If a conductive connection is present, contact the SMAServiceLine.

Service ManualSB36-50SE-SG-en-1030

Page 31

SMA Solar Technology AG

7 Replacing the Varistors

Proceed as follows to replace each varistor.

1.

Danger to life due to high voltages

• Disconnect the inverter from all voltage sources and open the enclosure lid (see

Section2.3, page8).

2. Insert the insertion tool in the clamping contacts

of the connecting terminal plate.

3. Remove the varistor from the connecting terminal plate.

4. Insert the new varistor in the connecting terminal

plate. The labeling on the varistor must face

downwards.

7 Replacing the Varistors

5. Remove the insertion tool from the clamping contacts of the connecting terminal plate.

6. Recommission the inverter (see Section9, page33).

Service Manual 31SB36-50SE-SG-en-10

Page 32

8 Testing the Function of the Battery Pack

SMA Solar Technology AG

8 Testing the Function of the Battery Pack

You can test the function of the Battery Pack by manually charging and discharging. The sequence

for charging and discharging depends on the current state of charge of the Battery Pack.

Procedure:

• If the current state of charge of the Battery Pack is lower than 10%, first charge the Battery

Pack until the state of charge has increased to more than 10% and then discharge the Battery

Pack.

• If the current state of charge of the Battery Pack is higher than 95%, first discharge the Battery

Pack until the state of charge has dropped to below 90% and then charge the Battery Pack.

Requirements:

☐ The inverter must be in feed-in operation.

☐ The current PV power must be at least 200W.

☐ The current feed-in AC power must not exceed 90% of the maximum AC power of the inverter.

Charging the Battery Pack

• Select parameter Battery installation mode and set to Charge battery.

☑ The message Charge battery test appears in the display.

☑ The message Battery charging test successful appears in the display. The Battery Pack was

charged successfully.

✖ Does the message Charge battery test failed appear in the display?

The Battery Pack was not charged successfully. The requirements are probably not fulfilled.

• Ensure that the requirements are fulfilled.

• Ensure that the Battery Pack and the inverter are connected correctly.

• Ensure that the Battery Pack is not defective.

• Ensure that the inverter does not display any other error messages.

Discharging the Battery Pack

• Select parameter Battery installation mode and set to Discharge battery.

☑ The message Battery discharging test appears in the display.

☑ The message Battery discharging test successful appears in the display. The Battery Pack

was discharged successfully.

✖ The message Battery discharging test failed appears in the display.

The Battery Pack was not discharged successfully. The requirements are probably not fulfilled.

• Ensure that the requirements are fulfilled.

• Ensure that the Battery Pack and the inverter are connected correctly.

• Ensure that the Battery Pack is not defective.

• Ensure that the inverter does not display any other error messages.

Service ManualSB36-50SE-SG-en-1032

Page 33

SMA Solar Technology AG

9 Recommissioning the Inverter

9 Recommissioning the Inverter

If you have disconnected the inverter from all voltage sources (e.g. for configuration purposes) and

want to recommission it, proceed as follows.

Requirements:

☐ The circuit breaker must be correctly rated.

☐ The inverter and the battery must be correctly mounted.

Procedure:

1. Connect the DC connectors to the inverter.

☑ The DC connectors snap into place.

2. Seal all unused DC inputs using the DC connectors with sealing plugs.

3. Ensure that all DC connectors are securely in place.

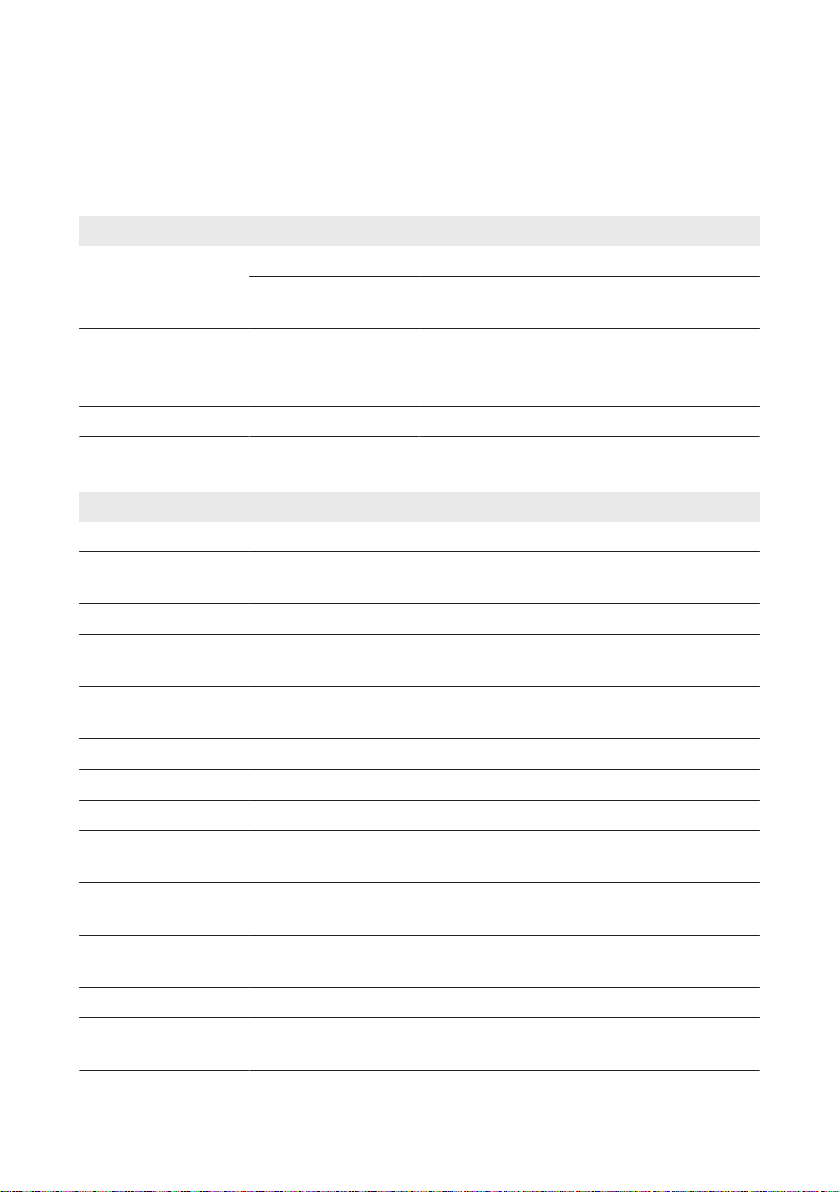

4. Flip the DC contact protection down until it

snaps into place.

5. Connect the inverter and the Battery Pack (see inverter manual at www.SMA-Solar.com).

6. Slide the protective cover across the Battery

Pack and push the brackets on the right of the

protective cover into the guides on the left of the

inverter enclosure. Then, press the left side of the

protective cover down onto the Battery Pack until

it snaps into place.

7. Ensure that the DC load-break switch is turned to position OFF. This makes it possible to fit the

enclosure lid to the enclosure.

8. Attach the enclosure lid:

• Attach one conical spring washer to each

screw. The grooved side of the conical

spring washer must point to the screw head.

• Position the enclosure lid on the enclosure using the six screws and tighten all screws

diagonally to each other using an Allen key (AF5) (torque: 6Nm ± 0.5Nm).

Service Manual 33SB36-50SE-SG-en-10

Page 34

9 Recommissioning the Inverter

SMA Solar Technology AG

9. Switch on the circuit breaker.

10. Turn the DC load-break switch towards ON until it snaps into place at position I.

☑ The start-up phase begins.

☑ The green LED is glowing and the display alternates between the firmware version, the serial

number or designation of the inverter, the IP address, the subnet mask, the serial number of the

BatteryPack, the configured country data set and the display language.

✖ The green LED is flashing?

Possible cause of error: the DC input voltage is still too low or the inverter is monitoring the

utility grid.

• Once the DC input voltage is sufficiently high and the grid connection conditions are met,

the inverter will start operation.

✖ The red LED is glowing and an error message and event number appear in the display?

• Eliminate the error (see Section4 "Troubleshooting", page12).

Service ManualSB36-50SE-SG-en-1034

Page 35

SMA Solar Technology AG

10 Decommissioning the Inverter

10 Decommissioning the Inverter

Risk of injury through lifting or dropping the inverter or Battery Pack

The inverter and the Battery Pack are heavy (for weight, see operating manual at www.SMASolar.com). There is risk of injury if the inverter or Battery Pack are lifted incorrectly or dropped

during transport or when attaching or removing it from the wall.

• Hold the inverter by the right-hand and lefthand recessed grips, and lift and transport it to

the mounting position horizontally.

• Lift and transport the Battery Pack by the

lateral handles.

1.

Danger to life due to high voltages

• Disconnect the inverter from all voltage sources (see Section2.3, page8).

2. Remove the AC cable from the inverter. Also push the locking levers right up to the top and

pull out the cables.

3. Press down the locking levers of the connecting terminal plate for the AC cable.

4. If an Ethernet cable is connected for Speedwire communication, remove the cable from the

inverter.

5. If other cables are connected to the inverter, remove the connection cables from the inverter.

Service Manual 35SB36-50SE-SG-en-10

Page 36

10 Decommissioning the Inverter

SMA Solar Technology AG

6. If an additional grounding or equipotential bonding is connected, loosen the cylindrical screw

M6x16 and remove the screw, conical spring washer, clamping bracket and grounding

conductor.

7. Position the enclosure lid on the enclosure using the six screws and tighten all screws

diagonally to each other using an Allen key (AF5) (torque: 6Nm ± 0.5Nm).

8. Remove the battery by lifting it vertically up and

off the wall mounting bracket.

9. Remove the inverter by lifting it vertically up and

off the wall mounting bracket.

10. If the inverter is to be stored or shipped, pack the inverter and the protective cover of the

battery. Use the original packaging or packaging that is suitable for the weight and

dimensions of the inverter and the protective cover.

11. Dispose of the inverter in accordance with the locally applicable disposal regulations for

electronic waste.

12.

Danger to life due to incorrect packaging and transport of the Battery Pack

The Battery Pack is considered to be dangerous goods. If the Battery Pack is to be transported,

special regulations must be complied with for packaging and transport.

• When packaging and transporting the Battery Pack, observe the regulations of the

European Agreement concerning the International Carriage of Dangerous Goods by

Road (ADR).

• Packaging and transport of the Battery Pack may only be carried out by persons who

have been trained in accordance with Section 1.3 ADR and whose training has been

documented.

Service ManualSB36-50SE-SG-en-1036

Page 37

SMA Solar Technology AG

10 Decommissioning the Inverter

13. If the Battery Pack is not damaged and it is to be disposed of, dispose of it in accordance with

the SMA Solar Technology AG regulations.

14. If the Battery Pack is damaged and it is to be disposed of, contact the SMA Service Line and

clarify the procedure for its disposal.

Service Manual 37SB36-50SE-SG-en-10

Page 38

11 Spare Parts

SMA Solar Technology AG

11 Spare Parts

You will find the spare parts for your product in the following overview. If required, these can be

ordered from SMA Solar Technology AG or your distributor.

Designation Brief description SMA order number

Replacement varistors Set with three thermally-moni-

tored varistors incl. insertion

tool

Insertion tool for replacing

varistors

SUNCLIX DC connector Field plug for conductor cross-

Insertion tool for varistors SB-TVWZ

sections of 2.5mm²to6mm²

STP-TV10

SUNCLIX-FC6-SET

Service ManualSB36-50SE-SG-en-1038

Page 39

SMA Solar Technology AG

12 Contact

12 Contact

If you have technical problems concerning our products, contact the SMAServiceLine. We need

the following information in order to provide you with the necessary assistance:

• Inverter device type

• Inverter serial number

• Inverter firmware version

• Type of the BatteryPack

• Serial number of the BatteryPack

• Manufacturing code of the Battery Pack

• Firmware version of the BatteryPack

• Hardware version of the BatteryPack

• Manufacturing week of the Battery Pack

• Special country-specific settings of the inverter (if applicable)

• Type and number of PV modules connected

• Mounting location and mounting altitude of the inverter

• Three-digit or four-digit event number and display message of the inverter

• Optional equipment, e.g. communication products

• Use of the multifunction relay (if present)

Australia SMA Australia Pty Ltd.

Sydney

Belgien/Belgique/België

Brasil Vide España (Espanha)

Česko SMA Central & Eastern Europes.r.o.

Chile Ver España

Danmark Se Deutschland (Tyskland)

SMA Benelux BVBA/SPRL

Mecheln

Praha

Toll free for Australia: 1800SMAAUS

(1800762287)

International: +61294914200

+3215286 730

+420235010417

Service Manual 39SB36-50SE-SG-en-10

Page 40

12 Contact

SMA Solar Technology AG

Deutschland SMA Solar Technology AG

Niestetal

Medium Power Solutions

Wechselrichter: +495619522‑1499

Kommunikation: +495619522‑2499

SMA Online Service Center:

www.SMA.de/Service

Hybrid Energy Solutions

Sunny Island: +495619522-399

PV-Diesel Hybridsysteme:

+495619522-3199

Power Plant Solutions

Sunny Central: +495619522-299

España SMA Ibérica Tecnología Solar,

S.L.U.

Barcelona

France SMA France S.A.S.

Lyon

Llamada gratuita en España:

900142222

Internacional: +34902142424

Medium Power Solutions

Onduleurs : +33472090440

Communication : +33472090441

Hybrid Energy Solutions

Sunny Island : +33472090442

Power Plant Solutions

Sunny Central : +33472090443

India SMA Solar India Pvt. Ltd.

+912261713888

Mumbai

Italia SMA Italia S.r.l.

+39028934-7299

Milano

Κύπρος/Kıbrıs Βλέπε Ελλάδα/ Bkz. Ελλάδα (Yunanistan)

Luxemburg/

Luxembourg

Siehe Belgien

Voir Belgique

Magyarország lásd Česko (Csehország)

Nederland zie Belgien (België)

Österreich Siehe Deutschland

Perú Ver España

Polska Patrz Česko (Czechy)

Portugal SMA Solar Technology Portugal,

Unipessoal Lda

Lisboa

Isento de taxas em Portugal:

800208987

Internacional: +351212377860

Service ManualSB36-50SE-SG-en-1040

Page 41

/01,234

9:;

5%6!78%

9:;*<+%,='3)>+%

SMA Solar Technology AG

România Vezi Česko (Cehia)

Schweiz Siehe Deutschland

Slovensko pozri Česko (Česká republika)

South Africa SMA Solar Technology South Africa

Pty Ltd.

Centurion (Pretoria)

United King-

dom

Ελλάδα SMA Hellas AE

България Вижте Ελλάδα (Гърция)

대한민국 SMA Technology Korea Co., Ltd.서울+822508-8599

SMA Solar UK Ltd.

Milton Keynes

Αθήνα

SMA Solar (Thailand) Co., Ltd. +6626706999

08600SUNNY (0860078669)

International: +27(12)6431785

+441908304899

8012229222

International: +302122229222

12 Contact

中国 SMA Beijing Commercial Company

Ltd.

北京

+9712234-6177 SMA Middle East LLC

Other countries International SMA Service Line

Niestetal

+861056701350

Toll free worldwide: 00800SMASERVICE

(+8007627378423)

Service Manual 41SB36-50SE-SG-en-10

Page 42

SMA Solar Technology

www.SMA-Solar.com

Loading...

Loading...