Page 1

EN

PV Inverter

SUNNY BOY 2500TLSingleTracker

SUNNYBOY3000TLSingleTracker

Installation Manual

SB25-30TLST-21-IA-en-13 | Version 1.3

Page 2

Page 3

SMA Solar Technology AG Table of Contents

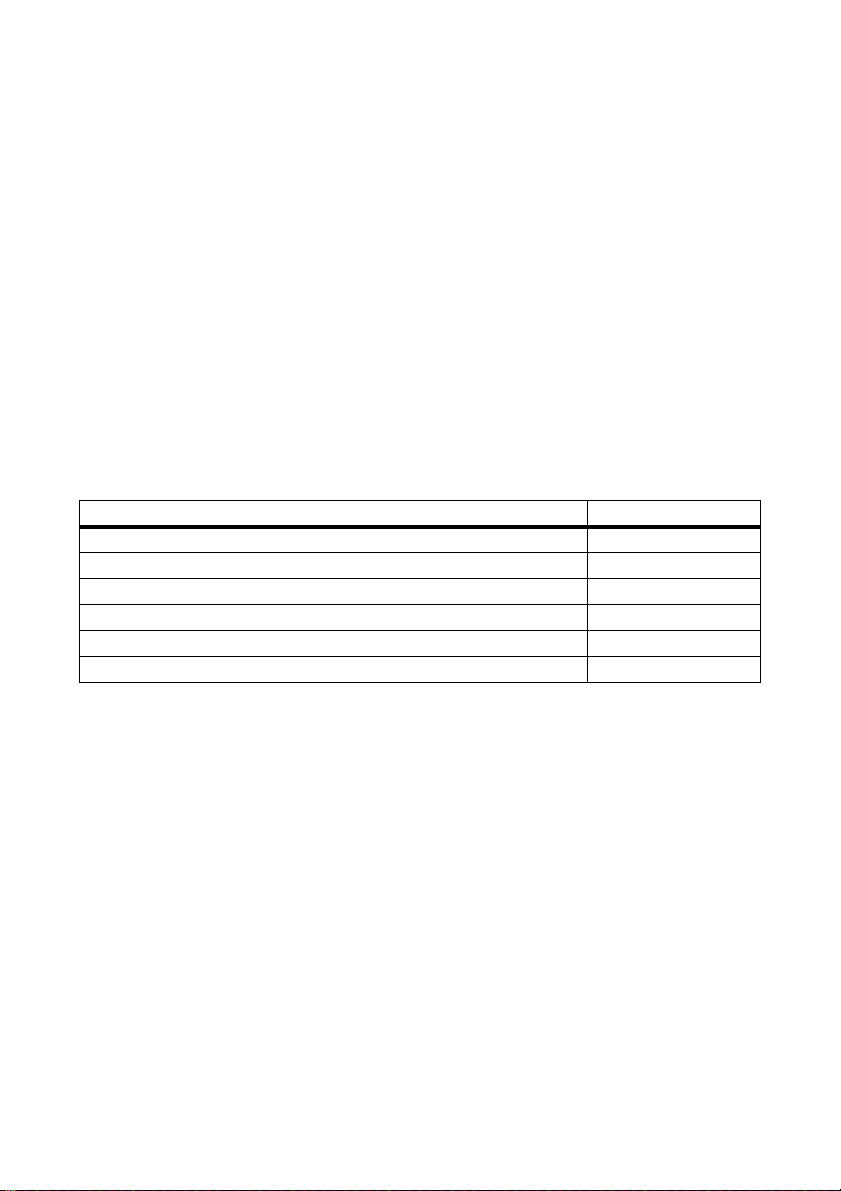

Table of Contents

1 Information on this Document. . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Target Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Symbols Used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Intended Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Qualification of Skilled Persons . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Scope of Delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

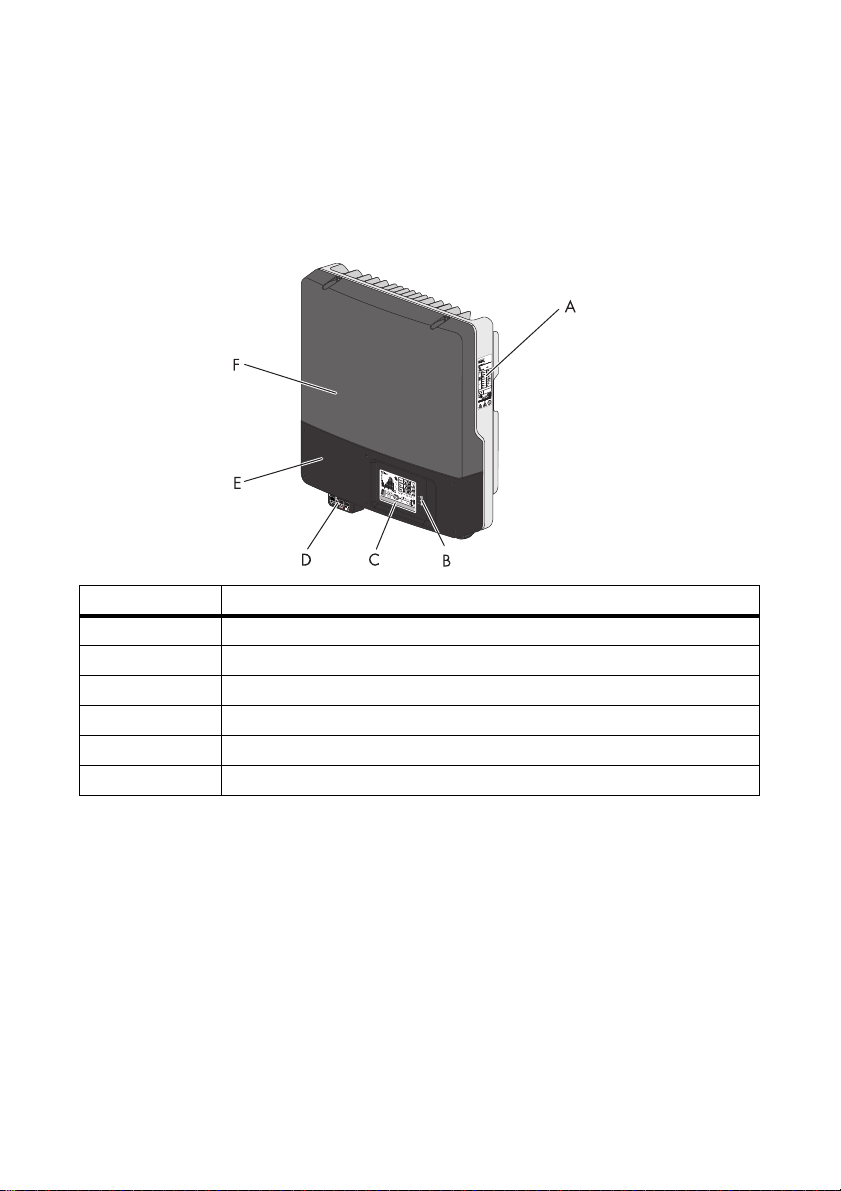

4.1 Sunny Boy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Symbols on the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Type Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5 Electronic Solar Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.6 Bluetooth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.7 Slot for Communication Interface . . . . . . . . . . . . . . . . . . . . . . . 20

4.8 Slot for Multi-Function Interface . . . . . . . . . . . . . . . . . . . . . . . . 21

4.9 Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.10 Grid Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.11 Varistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Selecting the Mounting Location. . . . . . . . . . . . . . . . . . . . . . . . 23

5.3 Mounting the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installation Manual SB25-30TLST-21-IA-en-13 3

Page 4

Table of Contents SMA Solar Technology AG

6 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2 Overview of the Connection Area . . . . . . . . . . . . . . . . . . . . . . 28

6.3 Connection to the Electricity Mains (AC) . . . . . . . . . . . . . . . . . 29

6.3.1 Conditions for the AC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.2 Connecting the Inverter to the Electricity Mains (AC) . . . . . . . . . . . . . . . . . . 32

6.3.3 Additional Earthing of the Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4 Connecting the PV Array (DC) . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4.1 Conditions for DC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4.2 Assembling the DC Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4.3 Disassembling the DC Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4.4 Connecting the PV Array (DC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.5 Setting the Country Standard and Display Language . . . . . . . 43

6.5.1 Checking the Country Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.5.2 Setting the Country Standard and Language using the

Rotary Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.6 Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.6.1 Interface for RS485 Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.6.2 Setting the Bluetooth NetID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.6.3 Multi-Function Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.1 Commissioning the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.2 Display Messages during the Start-Up Phase . . . . . . . . . . . . . . 53

7.3 Self-Test in Accordance with CEI 0-21 for Plants ≤ 6 kW. . . . 54

7.3.1 Starting the Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.3.2 Abortion of the Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.3.3 Restarting the Self-Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.4 Deactivating Protective Conductor Monitoring. . . . . . . . . . . . . 55

4 SB25-30TLST-21-IA-en-13 Installation Manual

Page 5

SMA Solar Technology AG Table of Contents

8 Opening and Closing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.2 Disconnecting the Inverter from Voltage Sources . . . . . . . . . . . 57

8.3 Closing the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9 Maintenance and Cleaning. . . . . . . . . . . . . . . . . . . . . . . . 62

9.1 Cleaning the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.2 Checking Heat Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.3 Checking the Electronic Solar Switch for Wear . . . . . . . . . . . . 62

10 Slot for SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.1 LED Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

11.2 Event Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

11.3 Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

11.4 DC Current after AC-Side Disconnection . . . . . . . . . . . . . . . . . 76

11.5 Checking the PV Array for Earth Faults . . . . . . . . . . . . . . . . . . . 76

11.6 Checking the Function of the Varistors . . . . . . . . . . . . . . . . . . . 78

12 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

12.1 Dismantling the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

12.2 Replacing the Enclosure Lid . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

12.3 Packing the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

12.4 Storing the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

12.5 Disposing of the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

13 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

13.1 DC/AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

13.1.1 Sunny Boy 2500TL Single Tracker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

13.1.2 Sunny Boy 3000TL Single Tracker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

13.2 General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Installation Manual SB25-30TLST-21-IA-en-13 5

Page 6

Table of Contents SMA Solar Technology AG

13.3 Protective Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

13.4 Climatic Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

13.5 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

13.6 Electronic Solar Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

13.7 Torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

13.8 Grid Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

13.9 Data Storage Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

14 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

15 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

6 SB25-30TLST-21-IA-en-13 Installation Manual

Page 7

SMA Solar Technology AG Information on this Document

1 Information on this Document

1.1 Validity

This document is valid for the following device types:

• SB 2500TLST-21

• SB 3000TLST-21

1.2 Target Group

This document is for skilled persons. Only skilled persons with appropriate qualification are allowed

to perform the tasks set forth in this document (see Section 2.2 "Qualification of Skilled Persons"

(page10)).

1.3 Additional Information

Additional information is available at www.SMA.de/en.

Title Document type

Miniature Circuit-Breaker Technical information

Parameters and Measured Values Technical description

SMA Bluetooth ‒ SMA Bluetooth

SMA Bluetooth

Module Technology Technical information

Capacitive Leakage Currents Technical information

®

Wireless Technology Technical description

®

Wireless Technology in Practice Technical information

Installation Manual SB25-30TLST-21-IA-en-13 7

Page 8

Information on this Document SMA Solar Technology AG

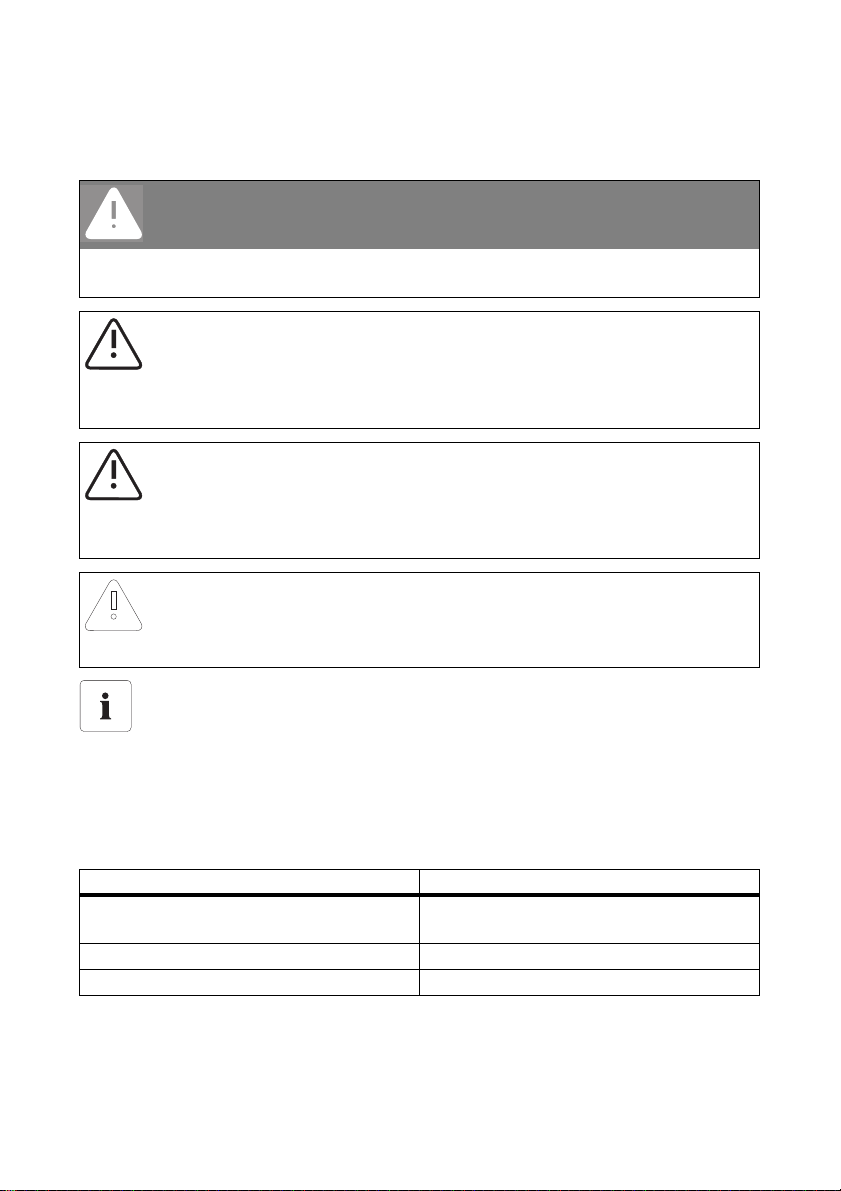

1.4 Symbols Used

The following types of safety precautions and general information appear in this document:

DANGER!

DANGER indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING!

WARNING indicates a safety precaution which, if not avoided, could result in death or

serious injury.

CAUTION!

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE!

NOTICE indicates a situation which, if not avoided, could result in property damage.

Information

Information provides tips that are valuable for effective installation and operation of the

product.

☑ This symbol indicates the result of an action.

Nomenclature

The following nomenclature is used in this document:

Complete designation Designation in this document

Sunny Boy 2500TL Single Tracker/

Sunny Boy 3000TL Single Tracker

Electronic Solar Switch ESS

®

SMA Bluetooth

8 SB25-30TLST-21-IA-en-13 Installation Manual

Wireless Technology Bluetooth

Inverter, product

Page 9

SMA Solar Technology AG Safety

2 Safety

2.1 Intended Use

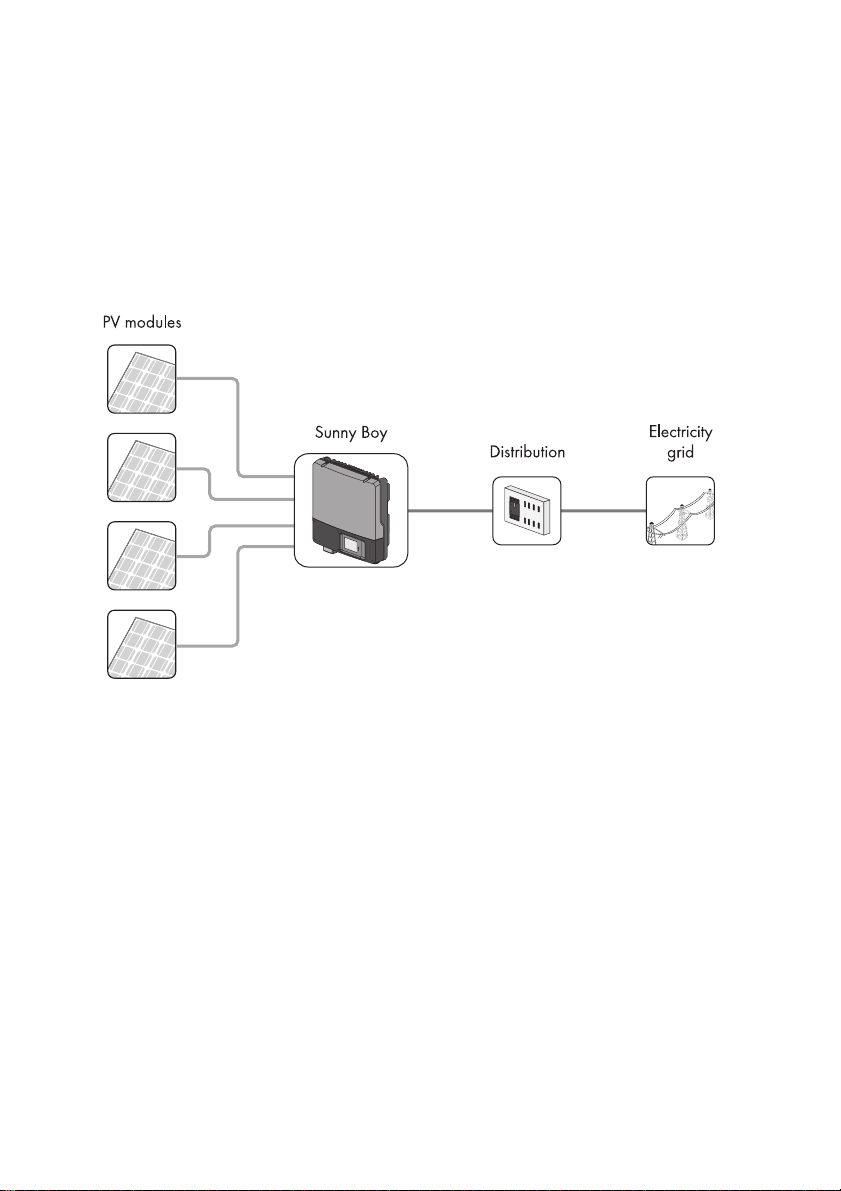

The Sunny Boy is a PV inverter, which converts the direct current of the PV array to grid-compliant

alternating current and feeds it into the electricity grid.

Principle of a PV plant with this Sunny Boy

The Sunny Boy is suitable for indoor and outdoor use.

The Sunny Boy must only be operated with PV arrays of protection class II, in accordance with

IEC 61730, application class A. The PV modules must be suitable for use with the Sunny Boy and

must have been released by the module manufacturer.

It is only permissible to use PV modules with large capacities to earth if their coupling capacity does

not exceed 1.4 μF.

All components must remain within their operating ranges at all times.

For safety reasons, it is not permitted to modify the product or install components that are not explicitly

recommended or distributed by SMA Solar Technology AG for this product.

Only use the Sunny Boy in accordance with the information provided in the enclosed documentation.

Any other use may result in personal injury or property damage.

• Do not mount the inverter on flammable construction materials.

• Do not mount the inverter in areas where highly flammable materials are stored.

• Do not mount the inverter in a potentially explosive atmosphere.

Installation Manual SB25-30TLST-21-IA-en-13 9

Page 10

Safety SMA Solar Technology AG

The enclosed documentation is an integral part of this product.

• Read and observe the documentation.

• Keep the documentation in a convenient place for future reference.

2.2 Qualification of Skilled Persons

The work described in this document must be performed by skilled persons only. Skilled persons must

have the following qualifications:

• Knowledge of how an inverter works and is operated

• Training in how to deal with the dangers and risks associated with installing and using electrical

devices and plants

• Training in the installation and commissioning of electrical devices and plants

• Knowledge of all applicable standards and directives

• Knowledge of and adherence to this document and all safety precautions

2.3 Safety Precautions

DANGER!

Danger to life due to electric shock

When exposed to sunlight, the PV array generates a dangerous DC voltage which is

present in the DC conductors or the live components in the inverter.

• Do not touch the DC conductors.

• Do not touch live components in the inverter.

• Prior to performing any work on the inverter, always disconnect it from any voltage

sources as described in this document (see Section 8.2 "Disconnecting the Inverter

from Voltage Sources" (page57)).

DANGER!

Risk of burns due to electric arc

To prevent arcing when disconnecting cables in the PV array, the ESS and DC connectors

must be removed from the inverter, or the external DC switch-disconnector must be

switched off and the DC connectors must be removed from the inverter before performing

any work on the PV array.

• Before starting work on the PV array, always disconnect the inverter on the AC and

DC sides (see Section 8.2 "Disconnecting the Inverter from Voltage Sources"

(page57)).

• Attach the enclosed warning label "Risk of burns from electric arc" so that it is clearly

visible on the external AC disconnection device.

10 SB25-30TLST-21-IA-en-13 Installation Manual

Page 11

SMA Solar Technology AG Safety

WARNING!

Risk of electric shock if DC connectors are pulled out under load

If you disconnect the DC connectors from the inverter under load, an electric arc may

occur, causing electric shock and burns.

• If the inverter is not equipped with an Electronic Solar Switch and the regulations in

the country of installation require an external DC switch-disconnec tor , yo u mu st i nstall

an external DC switch-disconnector.

• Switch off the AC miniature circuit-breaker and disconnect the inve rte r on the DC side

before pulling out the DC connectors.

CAUTION!

Risk of burns due to hot enclosure parts

Some parts of the enclosure may become hot during operation.

• Do not touch any parts other than the lower enclosure lid of the inverter during

operation.

NOTICE!

Water and dust intrusion can damage the inverter.

If the inv erter is n ot e qui ppe d wi th an E SS, the ele ctr oni cs in the i nve rte r co mpl y wi th deg ree

of protection IP65 when closed. If the inverter is equipped with an ESS, the electronics in

the inverter comply with degree of protection IP65 when the inverter is closed and with the

ESS plugged in. The inverter is then protected against dust and water intrusion. The inverter

connection area complies with degree of protection IP54. It is protected against interior

dust deposits and splash water from all angles.

• When the ESS is not plugged in, measures must be taken to protect the inverter

against dust and water.

• Replug the ESS after carrying out any work on the inverter.

Earthing of the PV array

Comply with local regulations for the earthing of the modules and the PV array.

SMA Solar Technology AG recommends connecting the array frame and other ele ctrical ly

conductive surfaces so that there is continuous conduction, and earthing them in order to

ensure maximum protection for property and persons.

Installation Manual SB25-30TLST-21-IA-en-13 11

Page 12

Scope of Delivery SMA Solar Technology AG

A

B

C

E

H

FG

I

K

_

+

D

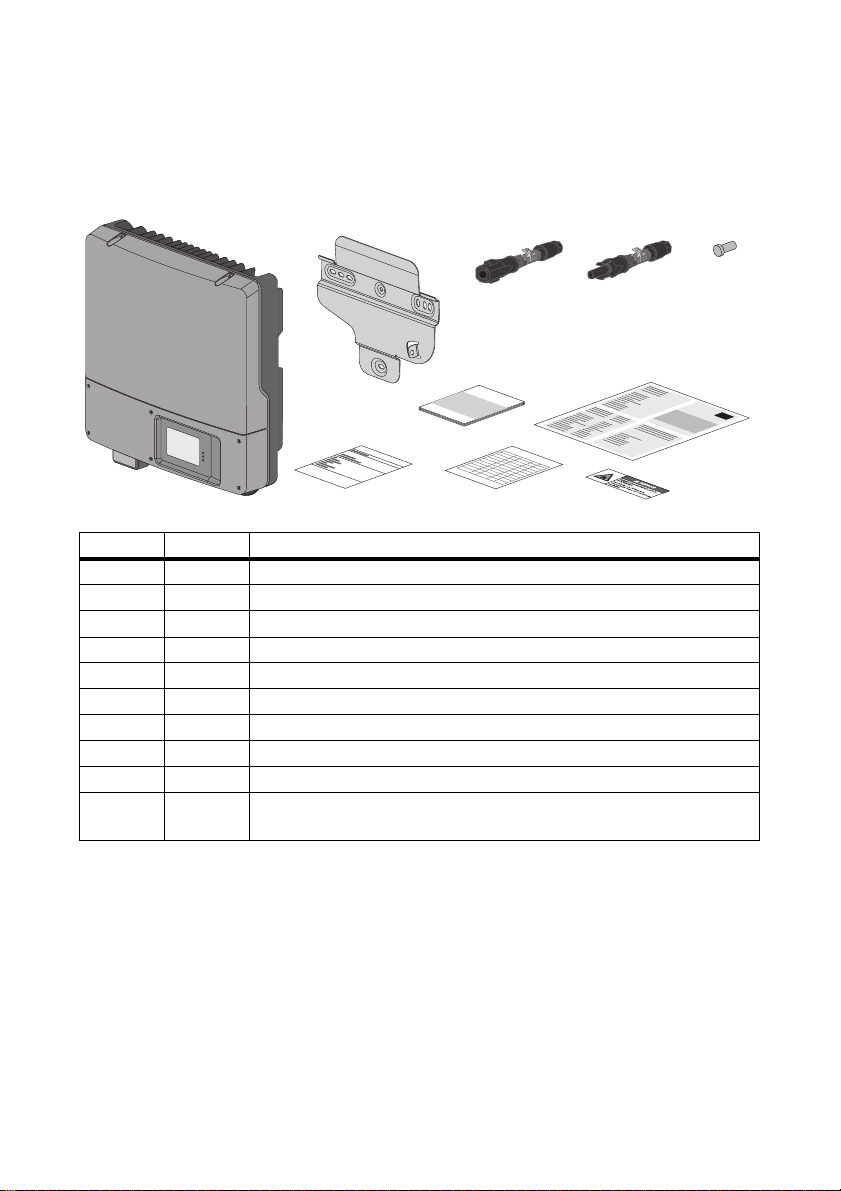

3 Scope of Delivery

Check the scope of delivery for completeness and any externally visible damage. Contact your

specialist dealer if the delivery is incomplete or you find any damage.

Object Quantity Description

A 1 Sunny Boy*

B 1 Wall mounting bracket

C 2 Positive DC connector

D 2 Negative DC connector

E 4 Sealing plugs for the DC connectors

F 1 Installation manual

G 1User manual

H 1 Set of documents with explanations and certificates

I 1 Supplementary sheet with inverter default settings

K 1 Warning label "Risk of burns from electric arc" for the disconnection device

on the AC side.

*Optional without ESS

12 SB25-30TLST-21-IA-en-13 Installation Manual

Page 13

SMA Solar Technology AG Product Description

4 Product Description

4.1 Sunny Boy

The Sunny Boy is a PV inverter, which converts the direct current of the PV array to grid-compliant

alternating current and feeds it into the electricity grid.

Item Description

A Type label

B LEDs

C Display

D Electronic Solar Switch*

E Lower enclosure lid

F Upper enclosure lid

*optional

Installation Manual SB25-30TLST-21-IA-en-13 13

Page 14

Product Description SMA Solar Technology AG

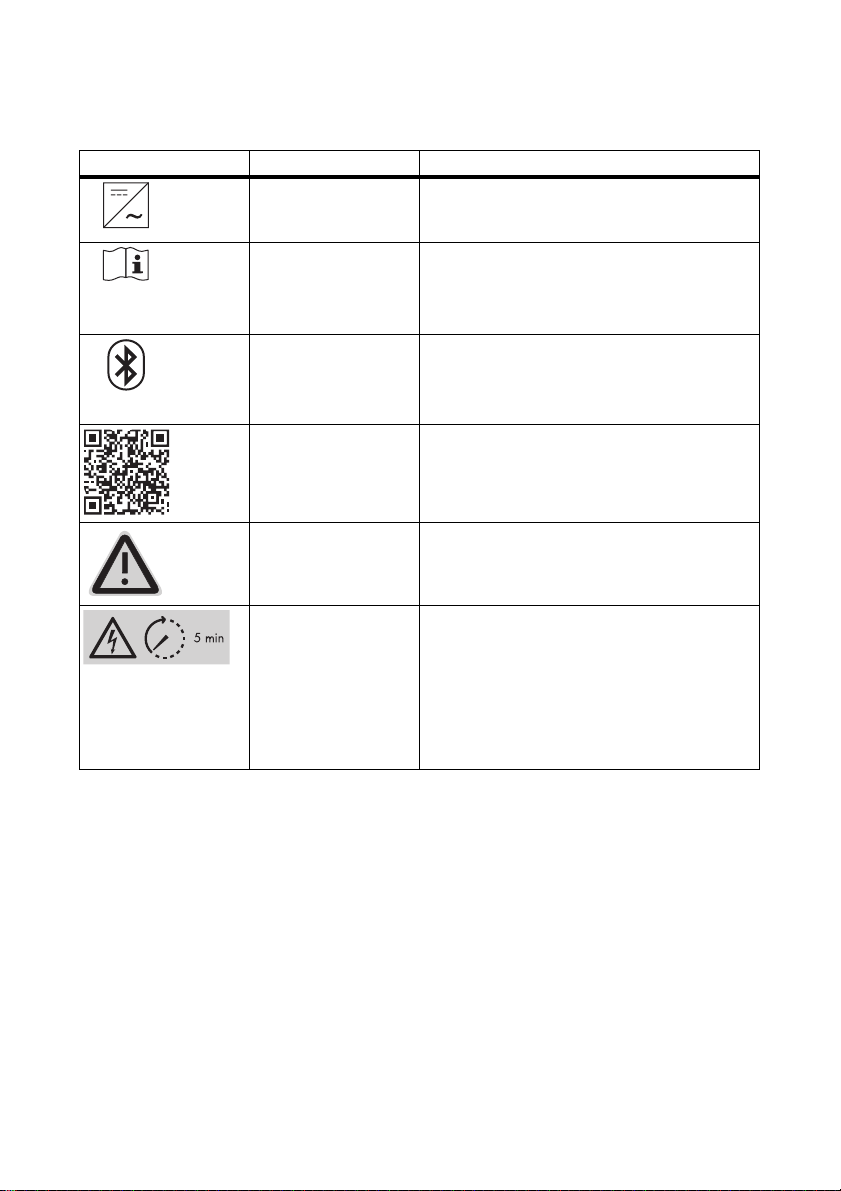

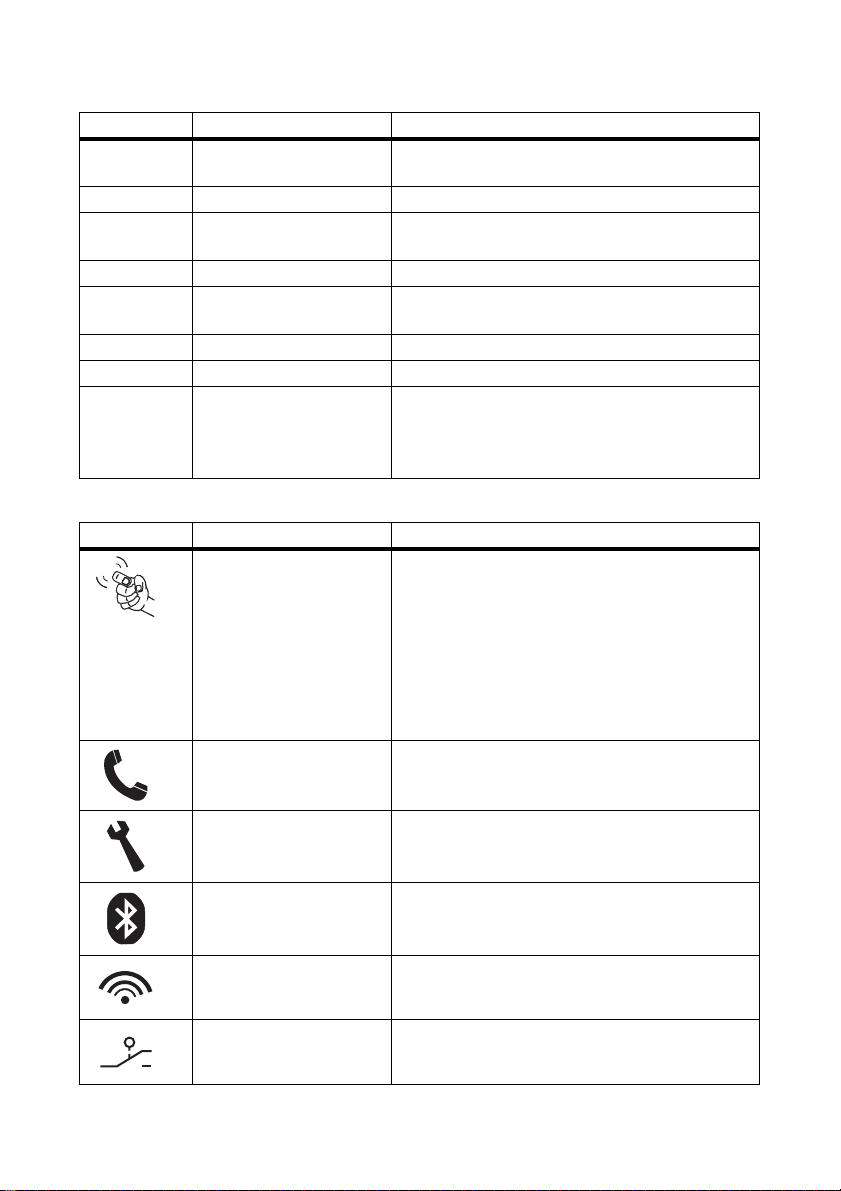

4.2 Symbols on the Inverter

Symbol Description Explanation

Inverter This symbol defines the function of the green LED.

It indicates the operating state of the inverter.

Observe the

documentation.

This symbol defines the function of the red LED.

It in dicat es a faul t or di sturban ce. Please rea d the

manual to find information on how to remedy the

fault or disturbance.

Bluetooth This symbol defines the function of the blue LED.

It indicates that communication via Bluetooth is

activated.

QR Code

®

Links to additional information on the inverter can

be found at www.SMA-Solar.com.

NOTICE, danger! Observe the connection requirements for a

second protective conductor 6.3.1 "Conditions

for the AC Connection" (page29).

Danger to life due to

high voltages in the

inverter

The capacitors in the inverter may be charged

with very high voltages.

• Disconnect the inverter from voltage

sources (see Section 8.2) and wait

five minutes before opening the upper lid,

in order to allow time for the capacitors to

discharge.

14 SB25-30TLST-21-IA-en-13 Installation Manual

Page 15

SMA Solar Technology AG Product Description

IP54

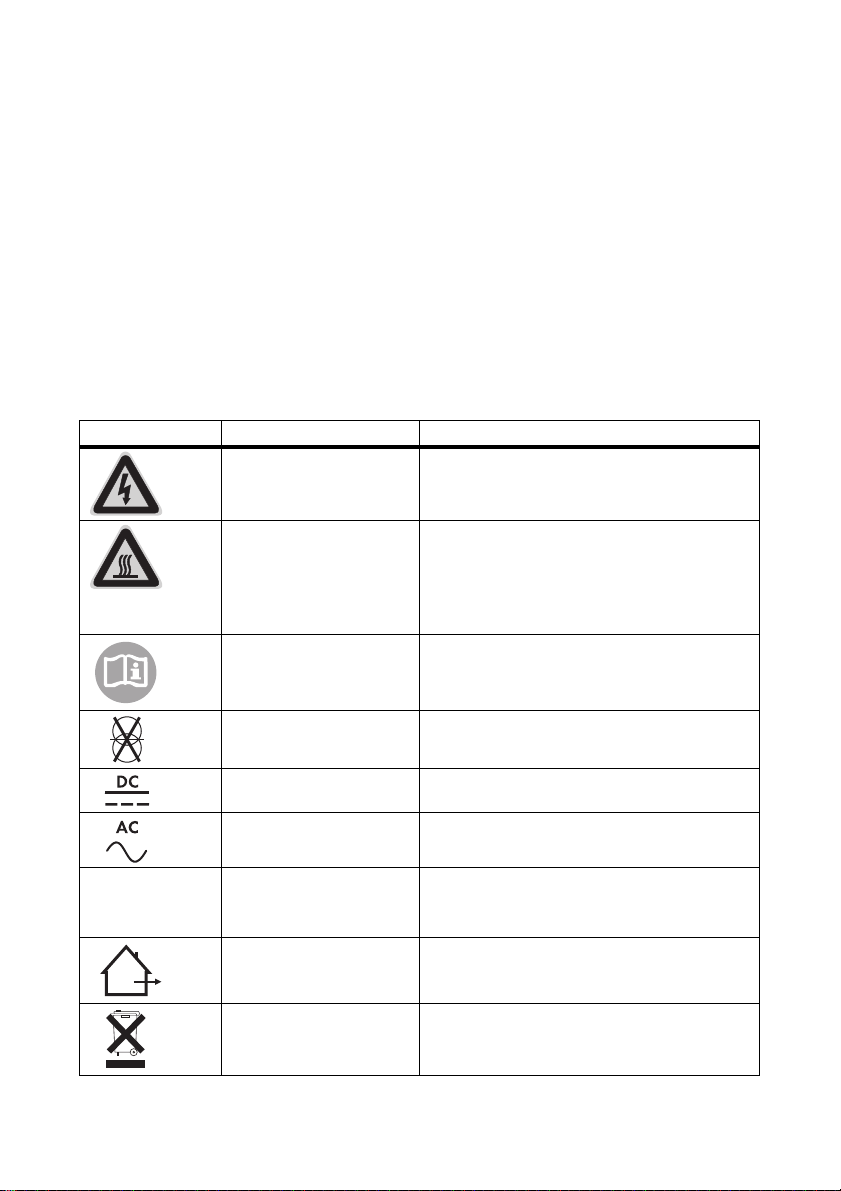

4.3 Type Label

The type label uniquely identifies the inverter. The type label is located on the right-hand side of the

enclosure. You will find the following information on the type label:

• Device type (Model)

•Serial number (Serial No.)

• Date of manufacture

• Device-specific characteristics

The information on the type label is intended to help you use the inverter safely and receive targeted

customer support from the SMA Service Line. The type label must remain permanently attached to the

inverter.

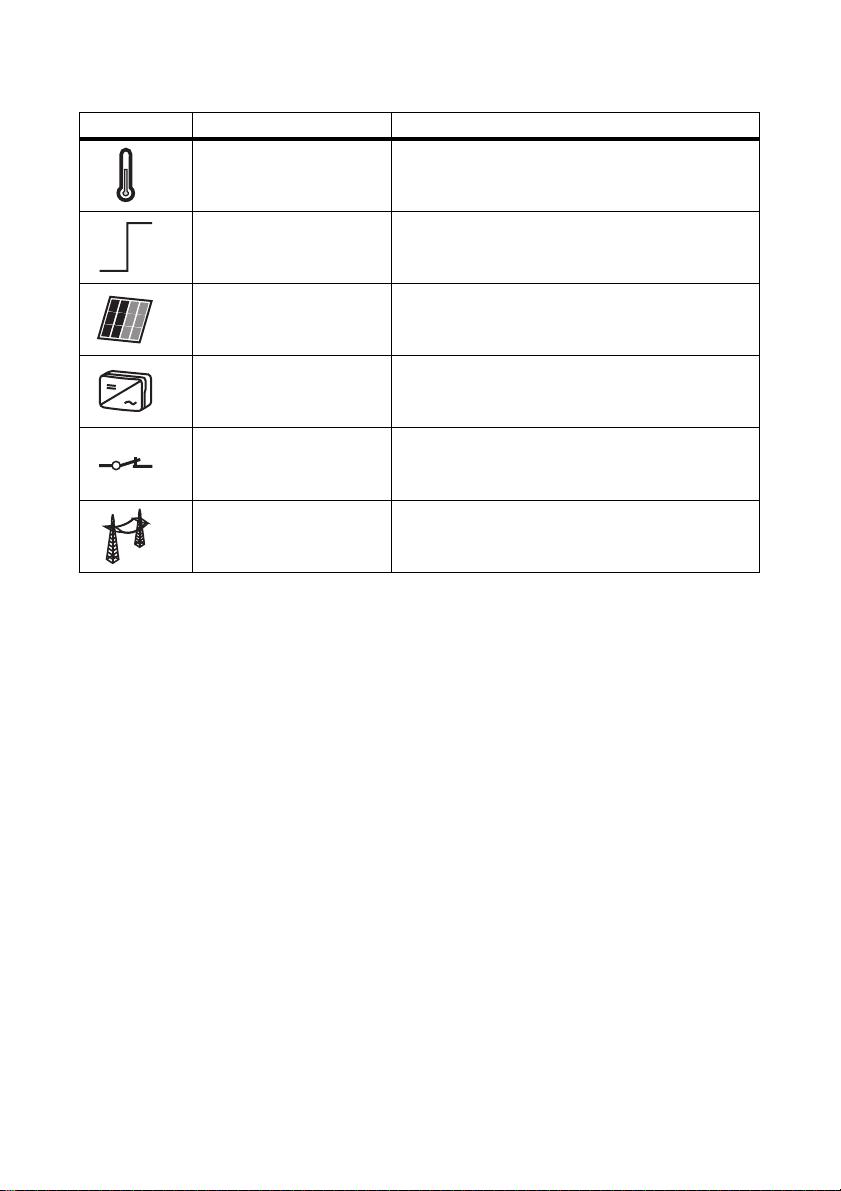

Symbols on the Type Label

Symbol Description Explanation

Danger to life due to high

voltages

Risk of burns from hot

surfaces

Observe the

documentation.

The inverter operates at high voltages. All work

on the inverter must be carried out by skilled

persons only.

The inverter can get hot during operation. Avoid

contact during operation. Allow the inverter to

cool down sufficiently before carrying out any

work. Wear personal protective equipment such

as safety gloves.

Observe all documentation that is supplied with

the inverter.

Without transformer The inverter does not have a transformer.

DC Direct current

AC Alternating current

Degree of protection: IP54 The inverter is protected against interior dust

deposits and against splash water from all

angles.

Outdoor The inverter is suitable for outdoor installation.

Proper disposal The inverter must not be d isp ose d of tog eth er with

the household waste.

Installation Manual SB25-30TLST-21-IA-en-13 15

Page 16

Product Description SMA Solar Technology AG

kVAr

kVArh

kWh

MVArh

MWh

kW

kWh

A

B

C

D

E

F

G

H

K

L

M

I

t/hday

Symbol Description Explanation

CE marking The inverter complies with the requirements of the

applicable EC directives.

Device class label The product is equipped with a wireless

component that complies with the harmonised

standards.

RAL quality mark for solar

products

The inverter complies with the requirements of the

German Institute for Quality Assurance and

Labelling.

Certified safety The inverter complies with the requirements of the

European Equipment and Product Safety Act.

Australian mark of

conformity

The inverter complies with the requirements of the

applicable Australian guidelines.

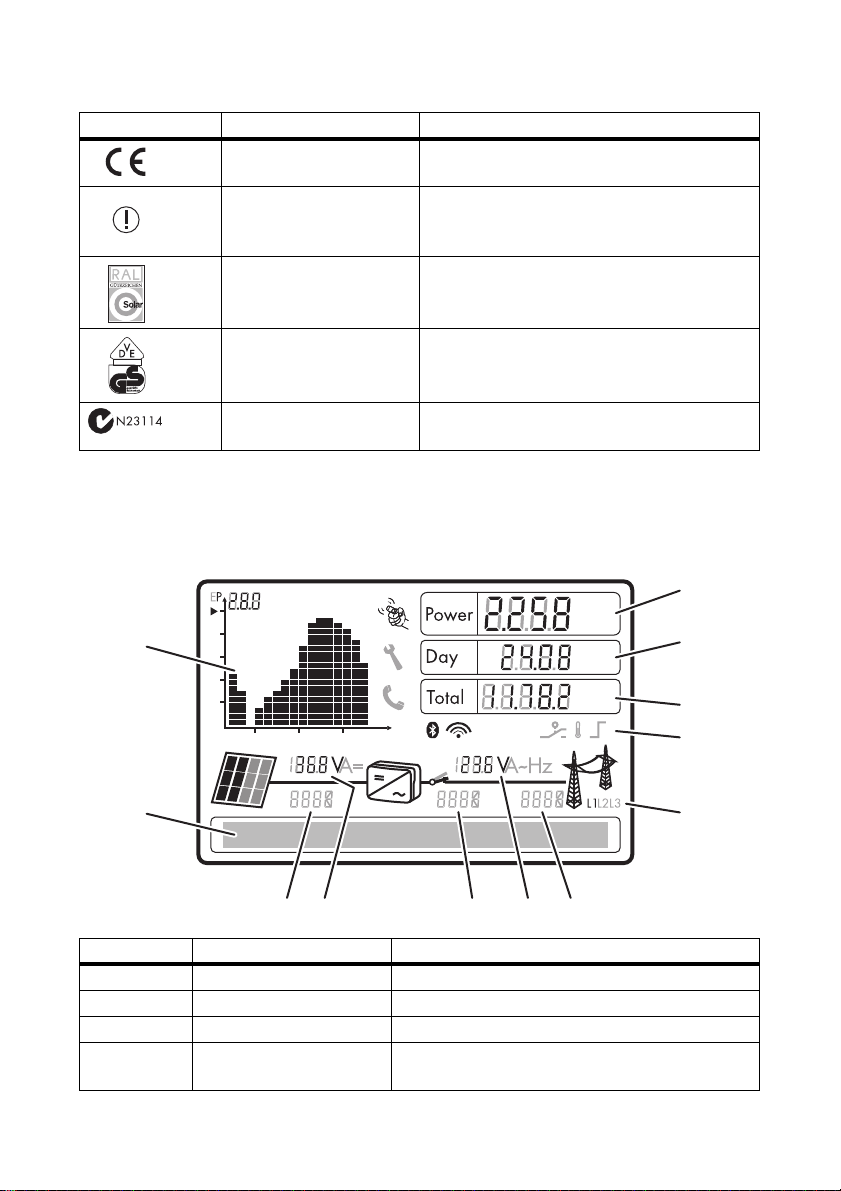

4.4 Display

The display shows the current operating data of the inverter (e.g. status, power, input voltage) as well

as faults and disturbances.

Item Description Explanation

A Power Displays the current power

B Day Displays the amount of energy fed in so far today

C Total Total amount of energy fed in until now

D Active functions The symbols indicate which communication or power

regulation functions are enabled.

16 SB25-30TLST-21-IA-en-13 Installation Manual

Page 17

SMA Solar Technology AG Product Description

Item Description Explanation

E Phase assignment Shows assignment of the inverter to a phase. It is also

used to indicate external power limitation.

F Electricity grid event number Event number of a disturbance in the electricity grid

G Output voltage/output

current

The display alternately shows the output voltage and

the output current of the inverter.

H Inverter event number Event number of a device disturbance

I Input voltage/input current The display alternately shows the input voltage and

the input current of the inverter.

K PV array event number Event number of a disturbance in the PV array

L Text line The text line shows event messages or instructions.

M Power and yield curve The diagram shows the changes in power over the

last 16 feed-in hours or the energy yields over the last

16 days. Tap the display once to switch between

views.

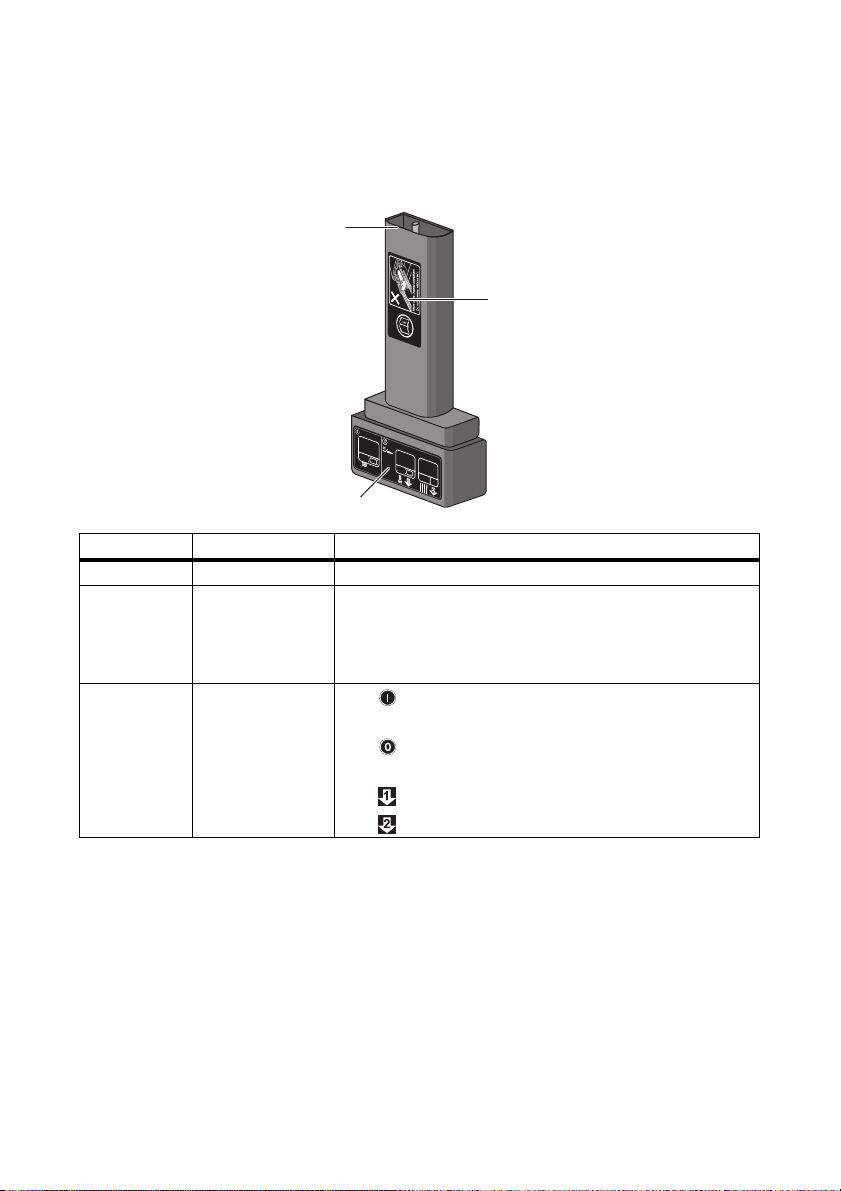

Symbols on the Display

Symbol Designation Explanation

Tap symbol You can operate the display by tapping it:

• Tapping once: the backlight switches on or the

display scrolls to the next display message.

• Tapping twice: the display shows, in succession,

the firmware version, the serial number or

description of the inverter, the Bluetooth NetID,

the set country standard and the display

language.

Telephone receiver Device disturbance present. Contact the

SMA Service Line.

Spanner Disturbance which can be resolved on-site.

Bluetooth Bluetooth communication is enabled.

Bluetooth connection Bluetooth connection to other devices is active.

Multi-function relay The multi-function relay is active.

Installation Manual SB25-30TLST-21-IA-en-13 17

Page 18

Product Description SMA Solar Technology AG

Symbol Designation Explanation

Temperature symbol The power of the inverter is limited due to excessive

temperature.

Power limitation External active power limitation via the

Power Reducer Box is active.

PV array ‒

Inverter ‒

Gr id rel ay If the grid r ela y is clo sed , the i nve rte r fe eds pow er into

the grid. If the grid relay is open, the inverter is

disconnected from the grid.

Electricity grid ‒

18 SB25-30TLST-21-IA-en-13 Installation Manual

Page 19

SMA Solar Technology AG Product Description

B

A

C

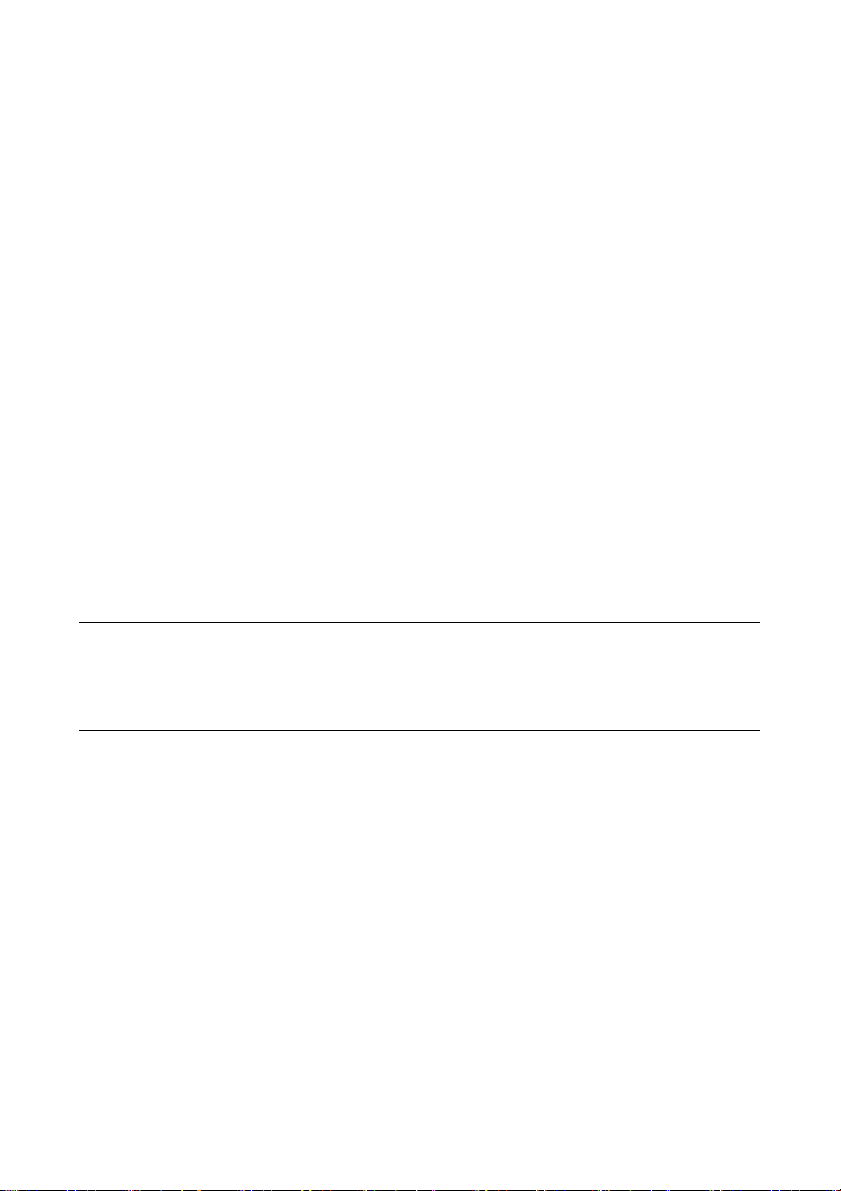

4.5 Electronic Solar Switch

The ESS is an optional DC load disconnect unit. The ESS prevents electric arcs from forming when you

remove the DC connector.

Item Description Explanation

A Plug ‒

B Safety precautions

sticker

C ESS sticker • When the ESS is plugged in, the DC electric circuit

• Never operate the inverter without the lower enclosure

lid in place.

• Observe all documentation that accompanies the

inverter.

remains closed.

• To interrupt the DC electric circuit, you first need to

perform steps 1 and 2.

• Remove the ESS.

• Remove all DC connectors.

When plugged in, the ESS forms a conductive path between the PV array and the inverter. Removing

the ESS interrupts the electric circuit and allows you to safely disconnect the DC connectors from the

inverter.

Installation Manual SB25-30TLST-21-IA-en-13 19

Page 20

Product Description SMA Solar Technology AG

4.6 Bluetooth

The inverter is equipped with a Bluetooth interface as standard and can consequently communicate

with other Bluetooth devices (for information on supported SMA products, see www.SMA-Solar.com).

If you wish to communicate via Bluetooth, you can protect the inverter with one plant password for

the user and one plant password for the installer.

All inverters are delivered with a default plant password for the user (0000) and a default plant

password for the installer (1111). To protect the plant from unauthorised access, you must change

the plant passwords using a communication product (for information on changing the plant password,

refer to the manual of the communication product).

If you do not wish to communicate via Bluetooth, deactivate the Bluetooth communication

(see Section 6.6.2 "Setting the Bluetooth NetID" (page50)).

4.7 Slot for Communication Interface

The inverter can optionally be fitted with an extra communication interface (e.g., RS485 or Speedwire/

Webconnect). This communication interface will enable the inverter to communicate with specific

SMA communication products (for information on supported products, see www.SMA-Solar.com).

The communication interface can either be retrofitted or installed ex works if specified in the

corresponding order.

Depending on the type of communication, RS485, Bluetooth or Speedwire/Webconnect, the

parameters and messages are displayed differently in the communication products.

Example: How the country data set parameter is displayed

• For communication via RS 485: parameter CntrySet

• For communication via Bluetooth or Speedwire/Webconnect: parameter Set country

standard

20 SB25-30TLST-21-IA-en-13 Installation Manual

Page 21

SMA Solar Technology AG Product Description

4.8 Slot for Multi-Function Interface

The inverter is equipped with a slot for multi-function interfaces. This slot is designed to connect a

simple multi-function relay, an SMA Power Control Module or a fan retrofit kit. The multi-function

interface can be retrofitted or installed at the factory according to a specific order.

Multi-Function Relay

You can configure the multi-function relay for various operating modes. The multi-function relay is

used, for example, to switch on or off operation or fault indicators which are required by standards

in some countries, e.g. IEC 62109-2 (for information on installation and configuration, see installation

manual of the multi-function relay). In order to meet the requirements of IEC 62109-2, either the

multi-function relay must be used as fault indicator and configured accordingly or a connection to

Sunny Portal must be available and the fault alarm via e-mail must be activated in Sunny Portal

(for information on fault alarm via e-mail, see the Sunny Portal user manula at www.SMA-Solar.com).

SMA Power Control Module

The SMA Power Control Module enables the inverter to implement grid management services and is

equipped with an additional multi-function relay (for information on installation and configuration, see

installation manual of the SMA Power Control Module).

Fan Retrofit Kit

The fan retrofit kit is used for additional inverter cooling at high ambient temperatures and also has a

multi-function relay (for information on installation and configuration, see the fan retrofit kit installation

manual). The fan retrofit kit and the SMA Power Control Module cannot be operated in parallel.

4.9 Operating Parameters

Various operating parameters control the functionality of the inverter. Apart from the country data set,

the operating parameters of the inverter can only be adjusted using an SMA communication product

(information on the parameters can be found in the Technical Description "Measured Values, Operating

Parameters and Event Messages" at www.SMA-Solar.com). You can adjust the country data set before

commissioning or within the first ten feed-in hours via two rotary switches in the inverter (see Section

6.5.2 "Setting the Country Standard and Language using the Rotary Switches" (page49)).

4.10 Grid Management

The inverter is equipped with grid management functions.

Depending on the requirements of the network operator, you can activate and configure these

functions (e.g. provision of reactive power, active power limitation) via operating parameters.

For detailed information on the parameters of these functions, see the Technical Description

"Measured Values, Operating Parameters and Event Messages" at www.SMA.de/en in the

"Technical Description" category of the respective inverter.

Installation Manual SB25-30TLST-21-IA-en-13 21

Page 22

Product Description SMA Solar Technology AG

4.11 Varistors

Varistors are voltage-dependent resistors to protect the inverter against overvoltage. The inverter is

equipped with two thermally-monitored varistors.

The function of the varistors can diminish with age or repeated strain as a result of overvoltage. This

can cause varistors to wear. The inverter detects if one of the varistors is defective and indicates a

disturbance.

The varistors are specially manufactured for use in the inverter and are not commercially available.

You must order new varistors directly from SMA Solar Technology AG.

22 SB25-30TLST-21-IA-en-13 Installation Manual

Page 23

SMA Solar Technology AG Mounting

5 Mounting

5.1 Safety

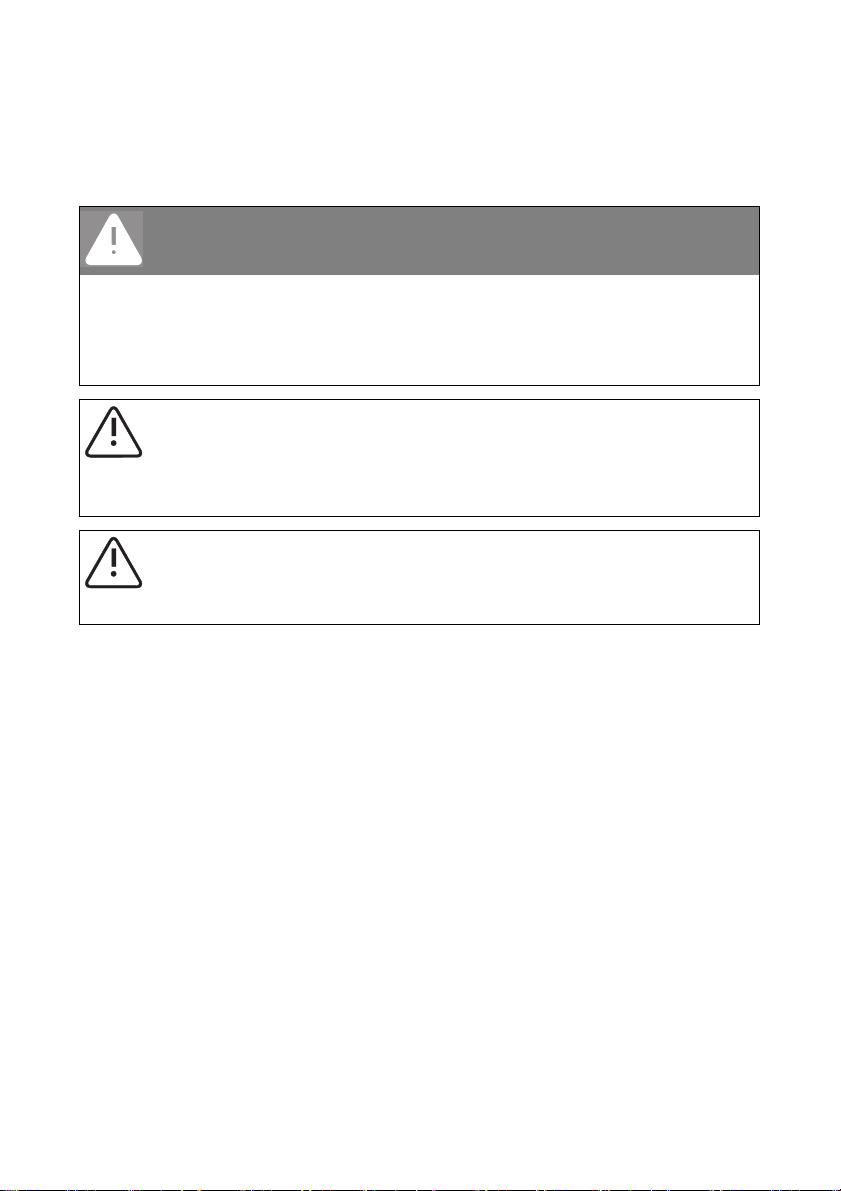

DANGER!

Danger to life due to fire or explosions

Despite careful construction, electrical devices can cause fires.

• Do not mount the inverter on flammable construction materials.

• Do not mount the inverter in areas where highly flammable materials are stored.

• Do not mount the inverter in a potentially explosive atmosphere.

CAUTION!

Risk of burns due to hot enclosure parts

• Mount the inverter in such a way that it cannot be touched inadvertently during

operation.

CAUTION!

Risk of injury due to the heavy weight of the inverter

• When mounting, bear in mind that the inverter weighs approx. 23 kg.

5.2 Selecting the Mounting Location

Take the following requirements into consideration when selecting the mounting location:

• The mounting location must be inaccessible to children.

• The mounting method and location must be suitable for the weight and dimensions of the

inverter (see Section 13 "Technical Data" (page85)).

• Mount on a solid surface.

• The mounting location must be clear and safely accessible at all times without the use of

additional aids such as scaffolding or lifting platforms. Non-fulfillment of these criteria may

restrict execution of servicing.

Installation Manual SB25-30TLST-21-IA-en-13 23

Page 24

500 mm

100 mm

100 mm

50 mm

300 mm

Mounting SMA Solar Technology AG

• Mount vertically or tilted backwards by max. 15°.

• The connection area must face downwards.

• Never mount the device with a forward tilt.

• Never mount the device with a sideways tilt.

• Do not mount horizontally.

• Mount at eye level in order that operating states can be read at all times.

• The ambient temperature should be below 40°C to ensure optimum operation.

• Do not expose the inverter to direct solar irradiation as this can cause excessive heating and

thus power reduction.

• In living areas, do not mount the unit on plasterboard walls or similar in order to avoid audible

vibrations. When in use, the inverter emits noises which may be perceived as a nuisance in a

living area.

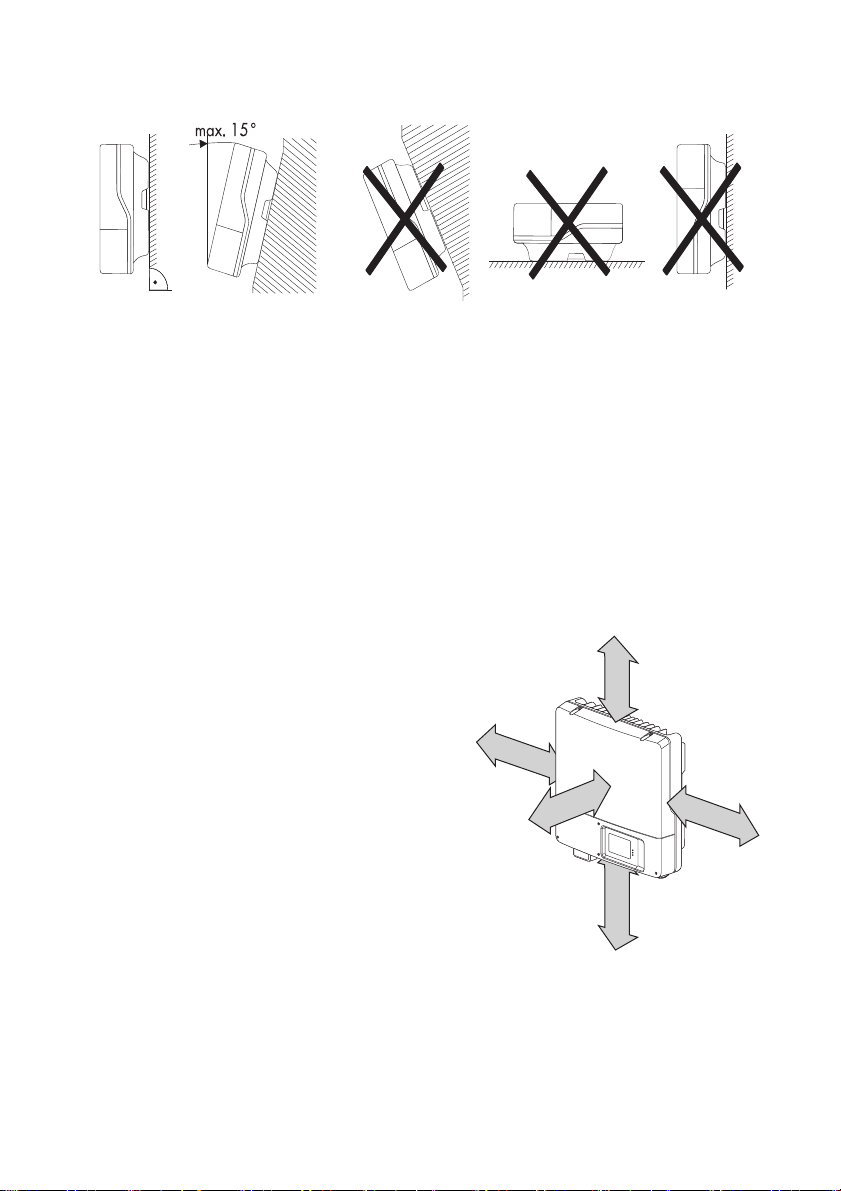

• Obs erve t he recom mended minimu m cleara nces t o

the walls as well as to other inverters and objects as

shown in the diagram. This will ensure sufficient

heat dissipation and gives you enough space to

unplug the ESS.

• If multiple inverters are mounted in areas with high

ambient temperatures, increase the clearances

between the inverters and ensure an adequate

fresh-air supply. This will prevent a reduction in

inverter power as a result of high temperatures

(details on temperature derating can be found in

the Technical Information "Temperature Derating"

at www.SMA.de/en). A fan for connection to the

inverter is available as an accessory

(see Section 14 "Accessories" (page91)).

24 SB25-30TLST-21-IA-en-13 Installation Manual

Page 25

SMA Solar Technology AG Mounting

490 mm

335 mm

175 mm

80 mm

55 mm

33 mm

175 mm

65 mm

45 mm

30 mm

9 mm

9 mm x 18 mm

70 mm

70 mm

31

mm

25

mm

57mm

98 mm

133 mm

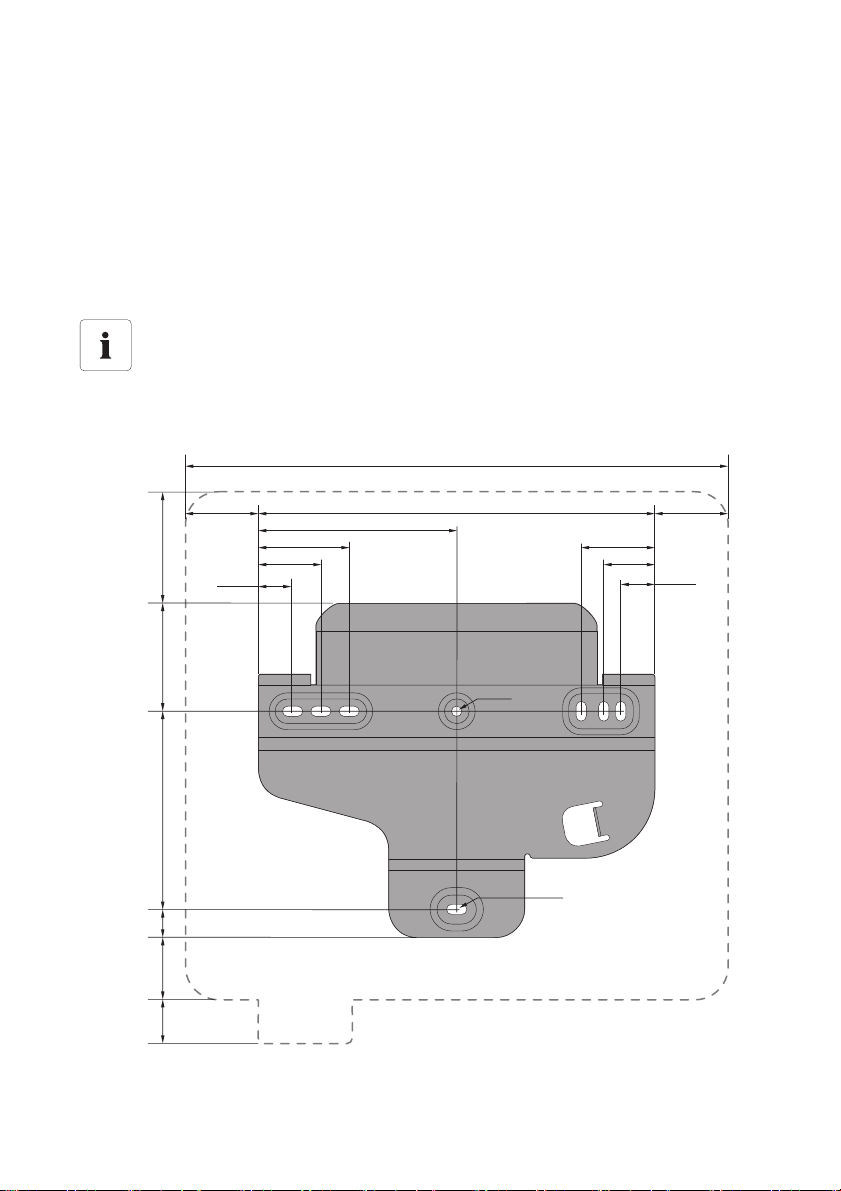

5.3 Mounting the Inverter

Additionally required mounting material (not included in the scope of delivery):

– 3 screws (diameter: at least 6 mm)

– 3 wall plugs

– 3 washers (external diameter: at least 18 mm)

1. Use the wall mounting bracket as a drilling template and mark the positions of the drill holes.

Number of drill holes to use

• When mounting onto the wall, use at least two of the horizontal holes and the lower

centre hole.

• Use the two holes in the centre when mounting the device on a pillar.

Installation Manual SB25-30TLST-21-IA-en-13 25

Page 26

Mounting SMA Solar Technology AG

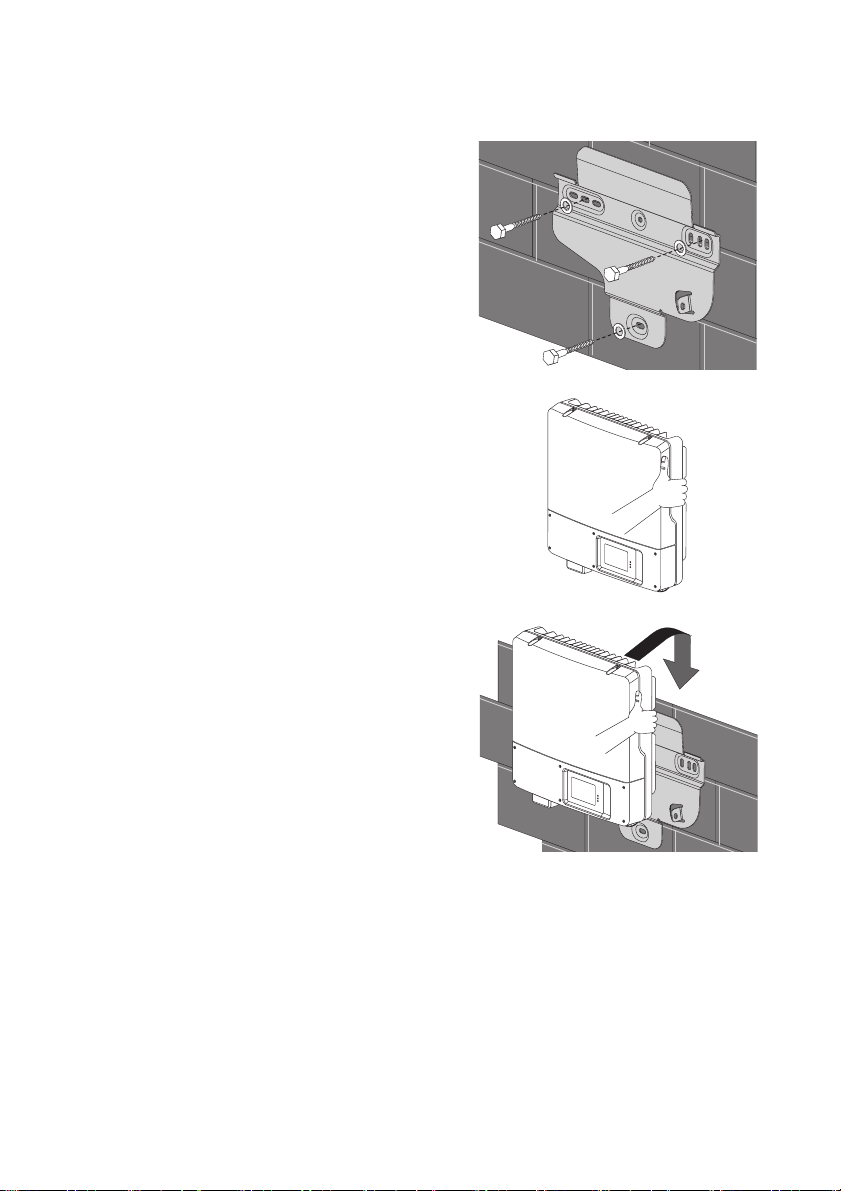

2. Drill the holes.

3. At tac h the w all mou nti ng bra cke t us ing appro pri ate

screws (diameter min. 6 mm) and washers

(outer diameter min. 18 mm).

4. Transport the inverter using the recessed grips on

the sides.

5. Hook the inverter into the mounting bracket from

above.

6. Check both sides of the inverter to make sure it is correctly in place.

26 SB25-30TLST-21-IA-en-13 Installation Manual

Page 27

SMA Solar Technology AG Mounting

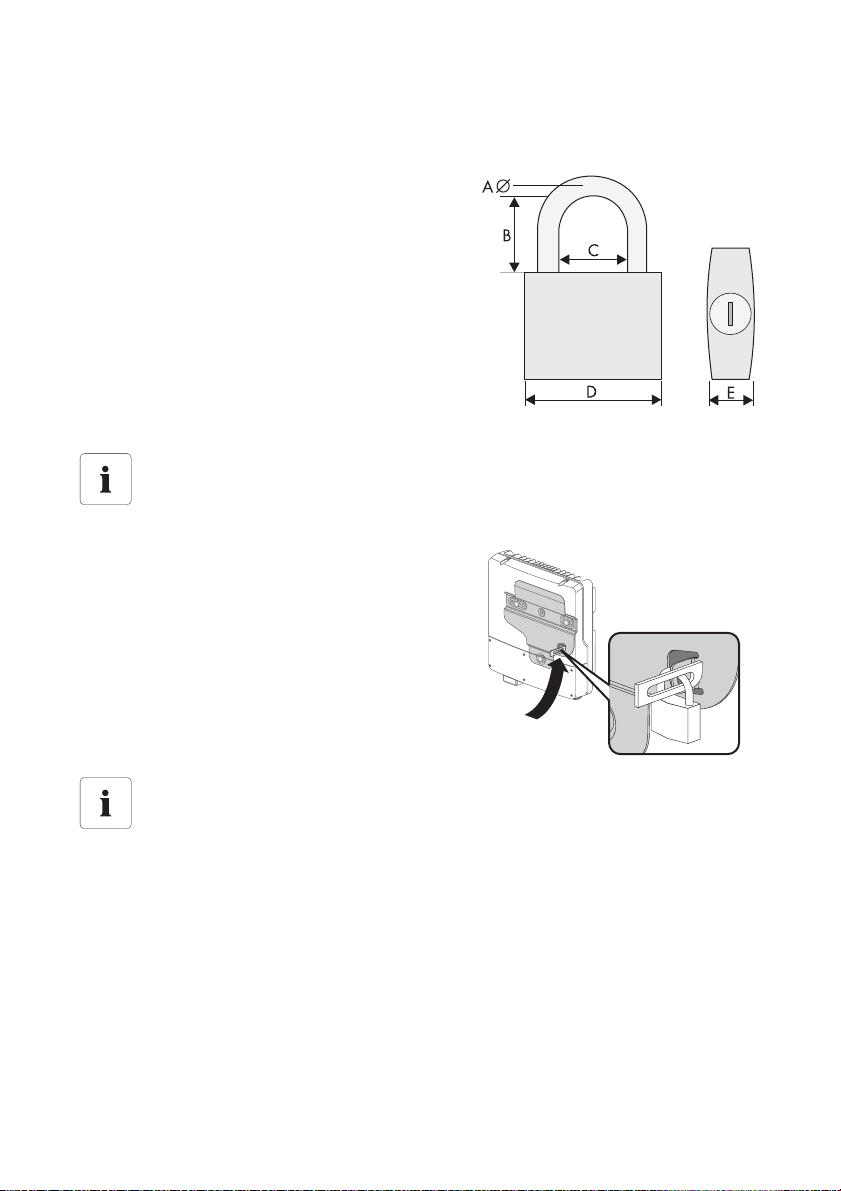

Optional Anti-Theft Protection

To protect the inverter from theft, you can lock it to the wall mounting bracket using a padlock.

The padlock must meet the following requirements:

–Size:

A: 6 mm to 8 mm diameter

B: 23 mm to 29 mm

C: 23mm to 28mm

D: 39 mm to 50 mm

E: 13 mm to 18 mm

–stainless

– hardened shackle

– protected lock cylinder

Outdoor installation

Always use a lock suitable for outdoor applications. Check regularly that the padlock is

working properly.

• Thread the padlock shackle from the centre of the

device outwards through the metal clip on the wall

mounting bracket and the slot on the inverter, and

close the padlock.

Storage of the key

Keep the key in a safe place in case it is needed for service purposes.

Installation Manual SB25-30TLST-21-IA-en-13 27

Page 28

Electrical Connection SMA Solar Technology AG

6 Electrical Connection

6.1 Safety

NOTICE!

Electrostatic discharge can damage the inverter

Internal components of the inverter can be irreparably damaged by electrostatic

discharge.

• Earth yourself before touching any components.

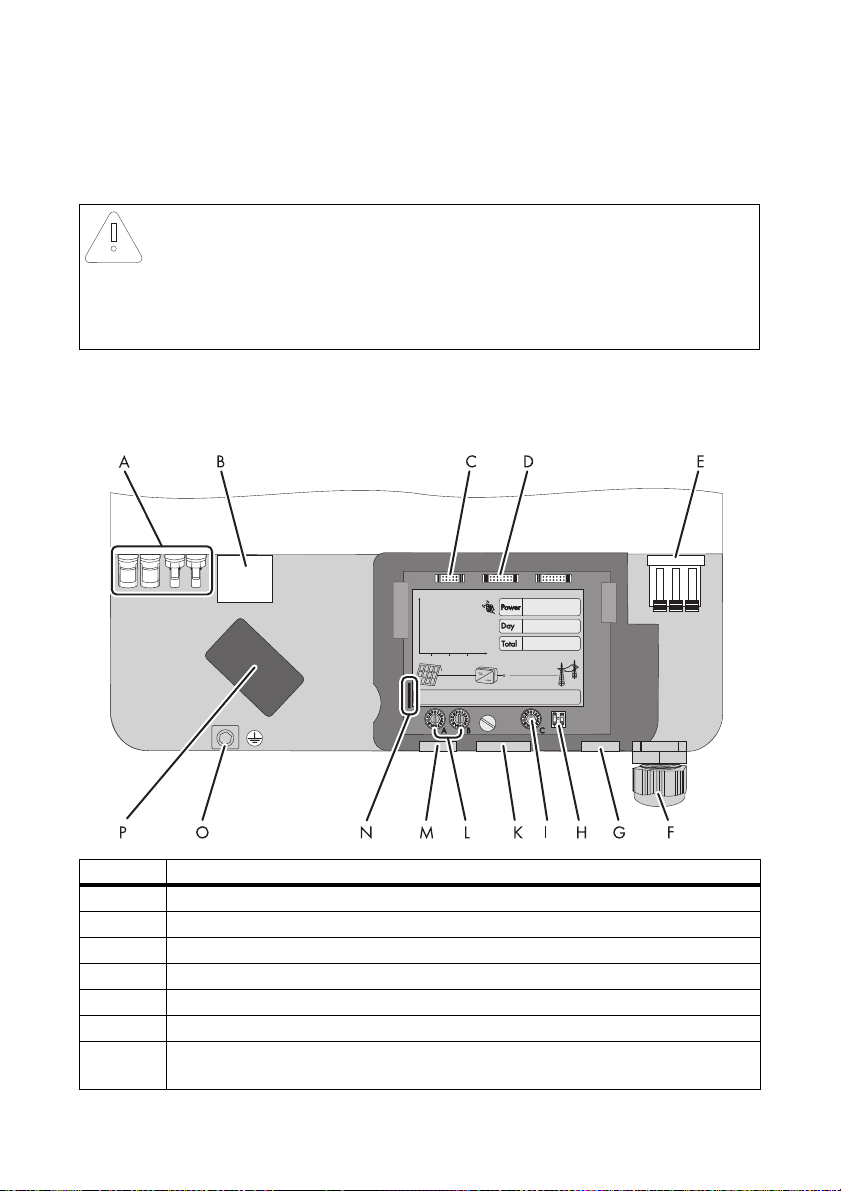

6.2 Overview of the Connection Area

The following figure shows the inverter connection area with the lower enclosure lid open.

Item Description

A DC connectors for connecting the strings

B Socket for connecting the ESS*

C Plug for connecting the optional multi-function relay or additional fan kit

D Plug for optional communication via RS485

E Terminal for the AC cable

F Cable gland (12 mm to 21 mm) for routing the AC cable

G Enclosure opening for connecting the optional multi-function relay or additional fan kit

or optional communication via RS485

28 SB25-30TLST-21-IA-en-13 Installation Manual

Page 29

SMA Solar Technology AG Electrical Connection

Item Description

H Switch for temporarily changing the display language to English (for service purposes)

I Rotary switch for the configuration of Bluetooth communication

K Enclosure opening for optional communication via RS485

L Rotary switches for setting the country standard and display language

M Enclosure opening for connecting the optional multi-function relay or additional fan kit

N Slot for SD Card

O Earth terminal for additional earthing of the inverter

P Enclosure opening for installing a fan (available as an additional fan kit)

*optional

6.3 Connection to the Electricity Mains (AC)

6.3.1 Conditions for the AC Connection

• Comply with the connection requirements of your network operator.

Residual-Current Device

The inverter is equipped with an integrated all-pole-sensitive residual-current monitoring unit. The

inverter can automatically differentiate between residual currents and normal capacitive leakage

currents. If the network operator stipulates a residual-current protective device, you must use a

residual-current protective device that triggers in the event of a residual current of 100 mA or more.

Further information on the use of a residual-current protective device can be found in the Technical

Information "Criteria for Selecting an RCD" at www.SMA.de/en.

Overvoltage Category

The inverter can be deployed in grids of installation category III or lower, as defined under

IEC 60664-1. This means that it can be permanently connected at the grid-connection point in a

building. In installations involving long cable routes outdoors, additional overvoltage-reducing

measures must be taken so that the overvoltage category is reduced from IV to III (for further

information, see the Technical Information "Overvoltage Protection" at www.SMA-Solar.com).

Cable Dimensioning

Use Sunny Design Version 2.0 or higher for sizing the conductor cross-sections (see Sunny Design

program at www.SMA.de/en).

Installation Manual SB25-30TLST-21-IA-en-13 29

Page 30

Electrical Connection SMA Solar Technology AG

Cable Requirements

Object Description Value

A External diameter 12 mm to 21 mm

B Conductor cross-section maximum 10 mm²

C Stripping length approx. 12 mm

Connection of a Second Protective Conductor

The inverter is equipped with a protective conductor monitoring device. This protective conductor

monitoring device detects when there is no protective conductor connected and disconnects the inverter

from the electricity grid if this is the case. Depending on the installation site and earthing system, it may

be advisable to deactivate the protective conductor monitoring. This would apply, for instance, if there

is no neutral conductor and you intend to install the inverter between two line conductors. If you are

uncertain about this, ask your network operator or SMA Solar Technology AG to advise.

• Depending on the earthing system, deactivate the protective conductor monitoring device

(see Section 7.4).

• To ensure safety in accordance with IEC 62109 when the protective conductor monitoring is

deactivated, connect a protective conductor to the connecting terminal plate for the AC cable

(minimum cross-section: 10 mm², copper wire).

or

• Connect a second protective conductor with the same cross-section as the original protective

conductor (see Section 6.3.3 "Additional Earthing of the Enclosure" (page35)). This will

prevent touch current if the original protective conductor fails.

Connection of a second protective conductor

In some countries a second protective conductor is required as a matter of principle. In

each case, observe the applicable regulations for the site.

Load Disconnection Unit

Attach the warning labels on the load disconnect unit on the AC side

To prevent arcing, always disconnect the inverter from the AC and DC side before starting

work on the PV array.

Attach the warning label "Risk of burns from electric arc" so that it is clearly visible on the

external AC disconnection device.

30 SB25-30TLST-21-IA-en-13 Installation Manual

Page 31

SMA Solar Technology AG Electrical Connection

You must install a separate miniature circuit-breaker for each inverter in order to ensure that the

inverter can be securely disconnected under load. The maximum permissible fuse protection can be

found in Section 13 "Technical Data" (page85).

For detailed information and examples of miniature circuit-breaker design, see the Technical

Information "Miniature Circuit-Breaker" at www.SMA.de/en.

DANGER!

Danger to life due to fire

When more than one inverter is connected in parallel to the same miniature circuit-breaker,

the protective function of the miniature circuit-breaker is no longer guaranteed. This could

result in a cable fire or destruction of the inverter.

• Never connect several inverters to the same miniature circuit-breaker.

• Observe the maximum permissible fuse protection of the inverter when selecting the

miniature circuit-breaker.

DANGER!

Danger to life due to fire

When a generator (inverter) and a load are connected to the same miniature circuitbreaker, the protective function of the miniature circuit-breaker is no longer guaranteed.

The currents from the inverter and the electricity grid can accumulate to form overcurrents

which are not detected by the miniature circuit-breaker.

• Never connect loads between the

inverter and the miniature circuit-breaker

without fuse protection.

• Always fuse loads separately.

NOTICE!

Damage to the inverter by using screw-type fuses as a load disconnection unit

A s cre w-t ype fus e, e .g. DIA ZED fus e or NEO ZED fus e, i s no t a s witch-disconnector and thus

may not be used as a load disconnection unit. A screw-type fuse only acts as cable

protection.

If the inverter is disconnected under load using a screw-type fuse, the inverter may be

damaged.

• Use only a switch- disconn ector or a mini ature circuit -breaker as a l oad disconnec tion

unit.

Installation Manual SB25-30TLST-21-IA-en-13 31

Page 32

Electrical Connection SMA Solar Technology AG

6.3.2 Connecting the Inverter to the Electricity Mains (AC)

1. Make sure that the mains voltage is within the permissible voltage range.

The exact operating range of the inverter is specified in the operating parameters. The

corresponding documents are available in the download area at www.SMA.de/en, in the

"Technical Description" category of the respective inverter.

2. Shut down the miniature circuit-breaker and secure it to prevent reactivation.

3. If an external DC switch-disconnector is in use, disconnect it.

4. If an ESS is in use, disconnect the ESS.

5. Loosen all six captive screws and remove the lower

enclosure lid. Use an Allen key (AF 3) to do this.

6. Check that the country setting of the inverter is correct using the supplementary sheet with the

default settings provided.

If the inverter is not set to the desired country standard, then adjust the country standard

(see Section 6.5.2 "Setting the Country Standard and Language using the Rotary Switches"

(page49)).

32 SB25-30TLST-21-IA-en-13 Installation Manual

Page 33

SMA Solar Technology AG Electrical Connection

7

9

O

N

E

7

9

O

N

7. For ease of connection, loosen the display screw

until the display can be flipped up.

8. Flip the display up until it clicks into place.

9. Undo the swivel nut of the AC cable gland and

remove the filler-plug from the cable gland.

Seal in the AC cable gland

There is a two-part seal in the cable gland.

Remove the internal ring insert if necessary,

e.g. to introduce a thicker cable.

The following guideline values apply:

• Cable diameter with seal and insert: 12 mm to 16 mm

• Cable diameter with seal only and without insert: 15 mm to 21 mm

10. Pull the cable through.

11. Raise all 3 terminals of the AC terminal as far as they will go.

NOTICE!

Risk of fire when connecting two conductors to a single terminal

If two conductors are connected to one terminal, this may result in a poor electrical contact

which could pose a risk of overheating or fire.

• Never connect more than one conductor per terminal.

Installation Manual SB25-30TLST-21-IA-en-13 33

Page 34

Electrical Connection SMA Solar Technology AG

12. Connect L, N and the protective conductor (PE) to

the AC terminal in accordance with the label.

Th e pr ote cti ve conduc tor mus t be 5 m m lo nge r th an

the insulated L and N wires.

L and N must not be swapped.

CAUTION!

Danger of crushing when terminals snap shut

The terminals close by snapping down fast and hard.

• Press the terminals down with your thumb, do not grip the sides of the terminal

between fingers and thumb.

• Keep fingers away from the terminals.

13. Close all terminals of the AC terminal until they snap into place.

14. Check that the cable ends are firmly secured.

15. Fold down the display and fasten the screw hand-tight.

16. Hand-tighten the swivel nut firmly to the cable gland. Ensure that the cable is securely in place.

DANGER!

Danger to life due to high voltages in the inverter

• Do not switch on the miniature circuit-breaker until the PV array has been connected

and the inverter is securely closed.

17. Attach the enclosed warning label "Risk of burns from electric arc" so that it is clearly visible on

the load disconnect unit on the AC side.

34 SB25-30TLST-21-IA-en-13 Installation Manual

Page 35

SMA Solar Technology AG Electrical Connection

6.3.3 Additional Earthing of the Enclosure

If required in the country of installation, you can use the earth terminal on the enclosure to connect a

second protective conductor or as equipotential bonding.

1. Undo screw (A) half way. Use an Allen key (AF 4)

to do this.

2. Insert the stripped earthing cable (D) under the

clamping bracket (C) (maximum conductor

cross-section 10 mm²).

3. Fasten terminal (C):

– Place the conical spring washer over the screw.

The grooved side of the conical spring washer

must face towards the screw head.

– Tighten the screw (torque: 6 Nm). Use an Allen

key (AF 4) to do this.

☑ The teeth of the conical spring washer press into the clamping bracket. The earthing cable

now has conductive connection to the enclosure.

6.4 Connecting the PV Array (DC)

6.4.1 Conditions for DC Connection

Use of Y adaptors

Y adaptors must not be visible or freely accessible within close proximity of the inverter.

• The DC circuit must not be interrupted by Y adaptors.

• Observe the procedure for disconnecting the inverter (see Section 8.2

"Disconnecting the Inverter from Voltage Sources" (page57)).

• Requirements for the PV modules of the connected strings:

– same type

– same number of in-series-connected PV modules

– identical alignment

– identical tilt

• T he c onn ect ion cab les of t he P V mo dul es m ust be e qui ppe d wi th connectors. The DC connectors

for the DC connection are included in the delivery.

• At the DC input of the inverter, the following limits must not be exceeded:

Maximum input voltage Maximum input current

750 V (DC) 15.0 A (DC)

• On the statistically proven coldest day of the year the open-circuit voltage of the PV array must

never exceed the maximum input voltage of the ivnerter.

Installation Manual SB25-30TLST-21-IA-en-13 35

Page 36

Electrical Connection SMA Solar Technology AG

6.4.2 Assembling the DC Connectors

All PV display module connection cables must be equipped with the DC connectors supplied before

connecting them to the inverter.

Assemble the DC connectors as described below. Be sure to observe the correct polarity.

The DC connectors are marked with the symbols "+" and " − ".

Cable Requirements

• Use a PV1-F cable.

Procedure

1. Lead the stripped cable all the way into the DC

connector.

2. Press the clamping bracket down until it audibly

snaps into place.

3. Ensure that the cable is correctly positioned:

Result Measure

☑ If the stranded wires are visible in the

chamber of the clamping bracket, the cable

is correctly positioned.

36 SB25-30TLST-21-IA-en-13 Installation Manual

• Proceed to step 4.

Page 37

SMA Solar Technology AG Electrical Connection

Result Measure

☑ If the stranded wires are not visible in the

chamber, the cable is not correctly

positioned.

• Release the clamping bracket. To do so,

insert a 3.5 mm screwdriver into the

clamping bracket and lever it open.

• Remove the cable and go back to step 1.

4. Push the swivel nut up to the thread and tighten (torque: 2 Nm).

Installation Manual SB25-30TLST-21-IA-en-13 37

Page 38

Electrical Connection SMA Solar Technology AG

6.4.3 Disassembling the DC Connector

1. Unscrew the swivel nut.

2. To release the DC connector: Insert a 3.5 mm

screwdriver into the snap slot on the side and lever

it open.

3. Carefully pull the DC connector apart.

4. Release the clamping bracket. To do so, insert a

3.5 mm screwdriver into the clamping bracket and

lever it open.

5. Remove the cable.

38 SB25-30TLST-21-IA-en-13 Installation Manual

Page 39

SMA Solar Technology AG Electrical Connection

6.4.4 Connecting the PV Array (DC)

DANGER!

Danger to life due to high voltages in the inverter

• Before connecting the PV array, make sure that the miniature circuit-breaker is

disconnected and cannot be reconnected.

NOTICE!

Excessive voltages can destroy the multimeter

• Only use multimeters with a DC input voltage range up to at least 1,000 V.

1. Check the connection cable of the PV modules for

correct polarity and make sure that the maximum

input voltage of the inverter is not exceeded.

At an ambient temperature above 10°C, the opencircuit voltage of the PV modules must not be more

than 90% of the maximum inverter input voltage. If

this is not the case, review the plant design and the

PV module circuitry. At lower ambient

temperatures, the maximum input voltage of the

inverter could otherwise be exceeded.

NOTICE!

Destruction of the inverter due to overvoltage

If the voltage of the PV modules exceeds the maximum input voltage of the inverter, it c ould

be destroyed by the overvoltage. This will void all warranty claims.

• Do not connect any strings to the inverter which have an open-circuit voltage greater

than the maximum input voltage of the inverter.

• Check the plant design.

2. Check strings for earth faults (see Section 11.5 "Checking the PV Array for Earth Faults" (page76)).

DANGER!

Danger to life due to electric shock.

• Do not connect any strings in which earth faults are present.

• Before connecting the DC cable, rectify the earth fault in the respective string.

Installation Manual SB25-30TLST-21-IA-en-13 39

Page 40

Electrical Connection SMA Solar Technology AG

+

1

2

+

+

3. Check the DC connectors for correct polarity and

connect them.

☑ The DC connectors click audibly into place.

For details on how to release the DC connectors,

see Section 8.2 "Disconnecting the Inverter from

Voltage Sources" (page57).

4. If you do not need all DC inputs on the inverter, seal the enclosure with DC connectors and

sealing plugs:

Sealing plugs

•Do not insert the sealing plugs directly into the DC inputs on the inverter.

– For unused DC connectors, push down the

clamping bracket and push the swivel nut up to

the thread.

– Insert the sealing plug into the DC connector.

– Tighten the swivel nut (torque: 2 Nm).

40 SB25-30TLST-21-IA-en-13 Installation Manual

Page 41

SMA Solar Technology AG Electrical Connection

6

5

3

2

4

1

– Insert the DC connectors with sealing plugs into

the corresponding DC inputs on the inverter.

☑ The DC connectors click audibly into place.

5. Ensure that all DC connectors are securely in place.

6. Close the lower enclosure lid again using the

six screws.

Tighten the screws (2 Nm torque) in the order

shown on the right.

7. If an ESS is used, check it for wear as described in

Section 9.3 "Checking the Electronic Solar Switch

for Wear" (page62) and reattach it firmly.

Installation Manual SB25-30TLST-21-IA-en-13 41

Page 42

Electrical Connection SMA Solar Technology AG

NOTICE!

Damage to the ESS

If it is not connected correctly, the ESS can be damaged.

• Plug the handle firmly onto the jack of the ESS.

• The handle must be flush with the enclosure.

• Make sure that the ESS is securely attached to the inverter.

Currents in DC cabling

After connecting the ESS or switching on the DC switch-disconnector, DC currents may

occur in the DC cabling, even when there is no AC-side supply. This is not an error but

normal behaviour of the inverter when in operation.

☑ The PV array is connected. You can now commission the inverter (see Section 7 "Commissioning"

(page52)). Other connection options are optional (see Section 6.6 "Communication" (page50)).

42 SB25-30TLST-21-IA-en-13 Installation Manual

Page 43

SMA Solar Technology AG Electrical Connection

AB

E

1

2

ON

79

6.5 Setting the Country Standard and Display Language

The inverter can be configured for various countries. This can be done prior to commissioning via

two rotary switches on the display or after commissioning by configuring the "CntrySet" or

"Set country standard" parameter using a communication product (e.g. Sunny WebBox or

Sunny Explorer). For devices ordered without any specified country of installation, the default country

data set is "VDE-AR-N4105-HP" and the display language is set to German.

Both rotary switches are set to 0 upon delivery. If you have ordered the inverter with specific country

settings, they will have already been preset at the factory via a communication product. In this case,

you will not be able to recognise the currently valid setting by the switch position.

If changes are made via the rotary switches or via a communication product, the default grid

parameters are overwritten. They cannot be restored, and must be re-entered via a communication

product.

The display language can be changed at any time using the rotary switches, independent of the grid

parameters. This means that the default grid parameters remain unchanged, but the display messages

are shown in the set language.

Changes will be applied immediately after switching the miniature circuit-breaker on. If an

unprogrammed switch setting is selected, the inverter displays an error message. The last valid setting

is retained.

Installation Manual SB25-30TLST-21-IA-en-13 43

Page 44

Electrical Connection SMA Solar Technology AG

SMA Grid Guard-Protected Country Data Sets

In some countries, the local connection conditions demand a mechanism which prevents the feed-in

parameters from being changed. Therefore, certain country data sets are protected against

unauthorised changes. They can only be unlocked with a personal access code - the

SMA Grid Guard code.

SMA Grid Guard-protected country data sets are automatically locked for ten feed-in hours after

commissioning, or after the last alteration. If the country data set is changed after these ten feed-in

hours, the inverter will not apply the changes but display the error message "Grid param. locked".

If, however, a later change to the country data set only relates to a change of the display language

via the rotary switches in the inverter, this change is immediately applied.

It is also p ossible to configure countr y data se ts (parameter "CntrySet" or "Set country standard"), and

to lock or unlock these manually via a communication product. To lock a data set, enter the digit

sequence "54321" instead of the password in the SMA Grid Guard code field. The data set can only

be unlocked by entering a personal, ten-digit SMA Grid Guard code which is valid for a maximum

of ten feed-in hours. The application form for the personal access code is available at

www.SMA.de/en, in the "Certificate" category of the respective inverter.

The language can be configured without a password, regardless of the country data set.

Changing parameters in SMA Grid Guard-protected country data sets

If the parameters within protected country data sets are changed, these are no longer

protected and instead of the standard "ADJ" or "Special setting" is displayed. In this case,

a change to parameters is not locked automatically after ten feed-in hours, but has to be

locked manually. To manually lock the parameters, set the SMA Grid Guard code to

"54321".

Further information on parameter settings

For detailed information on making adjustments and changing parameters, see the

corresponding user manual for your communication product.

The last change (executed via rotary switch or communication product) is always verified and

activated if applicable. Consequently, the switch position may not necessarily show the actual country

setting.

44 SB25-30TLST-21-IA-en-13 Installation Manual

Page 45

SMA Solar Technology AG Electrical Connection

6.5.1 Checking the Country Standard

Make sure that the inverter is set to the country of installation.

Before commissioning:

• Check that the country standard of the inverter is correct by comparing the default settings of

the inverter listed on the supplementary sheet provided.

After commissioning:

• Check that the country standard is correct on the basis of the display message during

(re-)commissioning (see Section 7 "Commissioning" (page52)).

• Check whether the country standard is correct by tapping the display twice and viewing the

display messages of the start-up phase again.

or

• Check that the country standard is correct using the "SMA grid guard" measuring channel via

a communication product.

Display language

Once you have set the country standard, you can always set the display language later

using rotary switch B. However, you have to then set rotary switch A to "0" in order to keep

the country data set.

The settings of each country data set are specified in the operating parameters. The parameters can

be read using a communication product. The description of the operating parameters is available at

www.SMA.de/en in the category "Technical Description" of the respective inverter.

(A) (B) Country data set Display language Grid Guard

Country

protection

0 0 default setting default setting dependent on

parameter set

0 1 retained English dependent on

parameter set

0 2 retained German dependent on

parameter set

0 3 retained French dependent on

parameter set

0 4 retained Spanish dependent on

parameter set

0 5 retained Italian dependent on

parameter set

0 6 retained Greek dependent on

parameter set

0 7 retained Czech dependent on

parameter set

Installation Manual SB25-30TLST-21-IA-en-13 45

dependent on

parameter set

dependent on

parameter set

dependent on

parameter set

dependent on

parameter set

dependent on

parameter set

dependent on

parameter set

dependent on

parameter set

dependent on

parameter set

Page 46

Electrical Connection SMA Solar Technology AG

(A) (B) Country data set Display language Grid Guard

Country

protection

0 8 retained Korean dependent on

parameter set

0 9 retained Portuguese dependent on

parameter set

0 A retained Dutch dependent on

parameter set

0 B retained Slovenian dependent on

parameter set

0 C retained Bulgarian dependent on

parameter set

0 D retained Polish dependent on

parameter set

dependent on

parameter set

dependent on

parameter set

dependent on

parameter set

dependent on

parameter set

dependent on

parameter set

dependent on

parameter set

1 0 VDE0126-1-1 German yes Germany,

Switzerland,

1 2 VDE-AR-N4105

a)

1 4 VDE-AR-N4105-MP

1 6 VDE-AR-N4105-HP

German yes Germany

b)

German yes Germany

c)

German yes Germany

1 8 VDE0126-1-1 French yes Switzerland,

France

*

1 9 VDE0126-1-1/UTE

French yes France

2 0 VDE0126-1-1 Italian yes Switzerland

3 1 CEI 0-21 intern

3 2 CEI 0-21 extern

d)

e)

Italian yes Italy

Italian yes Italy

4 0 RD1699* Spanish yes Spain

4 1 RD1663/661-A* Spanish yes Spain

4 8 PPC* Greek no Greece

4 9 PPC* English no Greece

5 8 G83/1-1 English no England

5 A G59/2 English no England

6 0 EN50438* German yes various EU

countries

6 1 EN50438* English yes various EU

countries

6 2 EN50438* French yes various EU

countries

6 3 EN50438* Italian yes various EU

countries

46 SB25-30TLST-21-IA-en-13 Installation Manual

Page 47

SMA Solar Technology AG Electrical Connection

(A) (B) Country data set Display language Grid Guard

Country

protection

6 4 EN50438* Spanish yes various EU

countries

6 5 EN50438* Greek yes various EU

countries

6 6 EN50438* Czech yes various EU

countries

6 7 EN50438* Portuguese yes various EU

countries

6 8 EN50438* Bulgarian yes various EU

countries

6 9 EN50438* Polish yes various EU

countries

6 E NEN-EN50438 Dutch yes Netherlands

7 0 EN50438-CZ* Czech yes Czech Republic

7 1 EN50438-CZ* English yes Czech Republic

7 2 EN50438-CZ* German yes Czech Republic

74PPDS* Czech yes Czech Republic

75PPDS* English yes Czech Republic

7 6 PPDS* German yes Czech Republic

7 8 C10/11/2012 French yes Belgium

7 9 C10/11/2012 English yes Belgium

7 A C10/11/2012 German yes Belgium

7 B C10/11/2012 Dutch yes Belgium

C0Customer English no flexible

C 1 Customer German no flexible

C 2 Customer French no flexible

C 3 Customer Spanish no flexible

C4Customer Italian no flexible

C 5 Customer Greek no flexible

C 6 Customer Czech no flexible

D 0 Off-Grid 60 Hz* English no flexible

D 1 Off-Grid 60 Hz* German no flexible

D 2 Off-Grid 60 Hz* French no flexible

D 3 Off-Grid 60 Hz* Spanish no flexible

D 4 Off-Grid 60 Hz* Italian no flexible

D 5 Off-Grid 60 Hz* Greek no flexible

D 6 Off-Grid 60 Hz* Czech no flexible

Installation Manual SB25-30TLST-21-IA-en-13 47

Page 48

Electrical Connection SMA Solar Technology AG

(A) (B) Country data set Display language Grid Guard

Country

protection

E 0 Off-Grid 50 Hz* English no flexible

E 1 Off-Grid 50 Hz* German no flexible

E 2 Off-Grid 50 Hz* French no flexible

E 3 Off-Grid 50 Hz* Spanish no flexible

E 4 Off-Grid 50 Hz* Italian no flexible

E 5 Off-Grid 50 Hz* Greek no flexible

E 6 Off-Grid 50 Hz* Czech no flexible

a) Setting in accordance with VDE-AR-N-4105 for PV plants ≤ 3.68 kVA (Germany)

b) Setting in accordance with VDE-AR-N-4105 for PV plants > 3.68 kVA and < 13.8 kVA (Germany)

c) Setting in accordance with VDE-AR-N-4105 for PV plants > 13.8 kVA (Germany)

d) Setting in accordance with CEI 0-21 for PV plants ≤ 6 kW (Italy)

e) Setting in accordance with CEI 0-21 for plants with external grid and plant protection > 6 kW (Italy)

*Planned

If the inverter is not set to the country of installation, there are several ways of configuring the required

country standard:

• Setting via the two rotary switches (see Section 6.5.2 "Setting the Country Standard and

Language using the Rotary Switches" (page49)).

• Alternatively you can conduct the settings via the "CntrySet" or "Set country standard"

parameters via a communication product, once you have commissioned the inverter.

•If you require adjusted parameter settings for your installation site, you can change these with

the help of a communication product.

48 SB25-30TLST-21-IA-en-13 Installation Manual

Page 49

SMA Solar Technology AG Electrical Connection

E

7

9

O

N

E

7

9

O

N

7

9

ON

E

6.5.2 Setting the Country Standard and Language using the Rotary Switches

1. Disconnect the inverter and open it (see Section 8.2 "Disconnecting the Inverter from Voltage

Sources" (page57)).

DANGER!

Danger to life due to high voltages in the event of electricity grid failure

If you set the inverter to stand-alone grid operation "Off-Grid 50 Hz"/"Off-Grid 60 Hz",

you are not allowed to operate the inverter on the electricity grid, but only on the standalone grid, because the inverter does not satisfy any country-specific standards and

guidelines in this setting. In the event of electricity grid failure, this will prevent the danger

of backfeed.

• If the inverter is set to "Off-Grid 50 Hz" or "Off-Grid 60 Hz", never operate the

inverter directly on the electricity grid.

2. Set the arrows on both rotary switches (A and B) to

the required positions with a screwdriver (see table

in Section 6.5.1 "Checking the Country Standard"

(page45)). Use a screwdriver with blade width

2.5 mm.

Temporarily setting the display language

to English

In addition, it is possible to use a switch to set

the display language to English temporarily,

e.g. for service purposes. This will have no

effect on the inverter parameter settings.

• Push the left switch 1 up until it locks into

pl ace. U se an o bje ct wit h a sma ll tip , e.g.

a ballpoint pen to do this.

• To reset the display language to the

original language, push the left switch 1

back down until it locks into place.

3. Close the inverter (see Section 8.3 "Closing the Inverter" (page60)).

Installation Manual SB25-30TLST-21-IA-en-13 49

Page 50

Electrical Connection SMA Solar Technology AG

E

7

9

O

N

6.6 Communication

6.6.1 Interface for RS485 Communication

If you have ordered an inverter with an interface for wireline communication, the inverter will be

delivered with the interface ready installed.

You can also subsequently order an inte rface for wireline commu nication (see Section 14 "Accessories"

(page91)). You will find a detailed illustration of the wiring principle and instructions for conversion in

the communication interface retrofit kit.

6.6.2 Setting the Bluetooth NetID

Communication with a communication product via Bluetooth is activated by default. Networking with

other inverters via Bluetooth is deactivated by default.

The following configuration settings are possible via a rotary switch (switch C):

Switch position (NetID) Setting

0 Bluetooth communication is deactivated.

1 Communication with a communication product via Bluetooth is activated

and networking with other inverters is deactivated. (default setting)

2 to F Networking via Bluetooth with other inverters is activated.

In order to restrict communication via Bluetooth between the inverters of your PV plant and those of

neighbouring systems, you can assign an individual NetID to the inverters of your PV plant (switch

position 2 to F). However, this is only necessary if neighbouring plants are situated within a radius of

500 m.

For all inverters in your PV plant to be detected by your communication product, they must all have

the same NetID.

1. Disconnect the inverter and open it (see Section 8.2 "Disconnecting the Inverter from Voltage

Sources" (page57)).

2. Set the arrow on the rotary switch (C) to the

required position with a screwdriver. Use a 2.5 mm

screwdriver for this purpose.

3. Close the inverter (see Section 8.3 "Closing the

Inverter" (page60)).

Activation of settings

The Bluetooth settings will only be applied once the inverter has been commissioned.

50 SB25-30TLST-21-IA-en-13 Installation Manual

Page 51

SMA Solar Technology AG Electrical Connection

6.6.3 Multi-Function Relay

If you have ordered an inverter with a multi-function relay, the multi-function relay is installed upon

delivery. You can subsequently order a multi-function relay (for order number, see Section 14

"Accessories" (page91)).

A description of the installation and electrical connection can be found in the installation manual of

the multi-function relay.

You can find detailed information on the configuration of the multi-function relay in the manual of the

multi-function relay at www.SMA.de/en.

Installation Manual SB25-30TLST-21-IA-en-13 51

Page 52

Commissioning SMA Solar Technology AG

7 Commissioning

7.1 Commissioning the Inverter

1. The following conditions must be fulfilled before commissioning:

– Correct mounting (see Section 5.3)

– Correct country setting (see Section 6.5.1)

– AC cable is correctly connected (electricity grid)

– Protective conductor is correctly connected (see Section 6.3.3)

– DC cables (PV strings) are correctly connected

– Unused DC inputs are closed using the corresponding DC connectors and sealing plugs

– All enclosure openings are closed

– The enclosure lid is securely screwed into place

– An external DC switch-disconnector is connected or, if applicable, the ESS is firmly in place

– The AC distribution is correctly installed

– The miniature circuit-breaker is correctly sized

2. Switch the miniature circuit-breaker on.

☑ Green LED is lit: commissioning successful.

or

☑ G reen LED will flash if i rradiat ion is insuffi cient: grid co nnection conditions have not yet been

reached. Wait for sufficient irradiation.

or

☑ Red LED is lit: a disturbance has occurred. Locate and eliminate the fault

(see Section 11 "Troubleshooting" (page64)).

Self-test in accordance with CEI 0-21 during initial start-up (applies to Italy only)

The I talian standard presc ribes that an i nverter can only opera te on the electricity grid after

the disconnection times for overvoltage, undervoltage, minimum frequency and maximum

frequency have been checked.

If you ha ve c onfig ured t he C EI0-2 1 I nt / CE I 0 -21 int ern count ry d ata se t, start t he sel f-t est

(see Section 7.3 "Self-Test in Accordance with CEI 0-21 for Plants ≤ 6 kW" (page54)).

3. If a multi-function relay is connected, switch on the supply voltage to the relay.

4. For communication via Bluetooth, make the following settings:

– Change the plant time (see the manual of the communication product).

– Change the passwords (see the manual of the communication product).

52 SB25-30TLST-21-IA-en-13 Installation Manual

Page 53

SMA Solar Technology AG Commissioning

FW PACK XXXX HP XXXX

SN 2100237148 NetIDA

VDE-AR-N4105-MP

Sprache Deutsch

7.2 Display Messages during the Start-Up Phase

Illustrated display messages

The display messages illustrated in this section serve as examples and, depending on the

country setting, may differ from the actual display messages on your inverter.

• The firmware version of the internal processors

appears first in the text line.

• After five seconds, or after tapping on the display,

the serial number or the description of the inverter

and the NET ID for communication via Bluetooth

will appear. The designation of the inverter can be

changed via a communication product.

• After a further five seconds, or after a further tap,

the configured country standard is displayed

(example: "VDE-AR-N4105-MP").

• After a further five seconds, or after a further tap,

the configured language is displayed

(example: "Sprache Deutsch"

(Language German)).

• D uri ng n orm al o per ati on, the te xt l ine of t he d isp lay wil l be blank . Fo r ev ent mes sag es d isp lay ed

in the text line and their meaning, refer to Section 11 "Troubleshooting" (page64).

Showing display messages again

If you want to view the display messages of the start phase again whilst in normal

operation, double-tap the display.

Installation Manual SB25-30TLST-21-IA-en-13 53

Page 54

Commissioning SMA Solar Technology AG

7.3 Self-Test in Accordance with CEI 0-21 for Plants ≤ 6 kW

7.3.1 Starting the Self-Test

The self-test only applies to inverters that are configured with the country data

set CEI0-21 Int/CEI 0-21 intern.

The self-test is only valid for inverters lic ensed for Ital y and configured with the country data

set CEI0-21 Int/CEI 0-21 intern.

If the inverter is configured to CEI0-21 Ext / CEI 0-21 extern, no self-test is required.

The Italian standard requires that all inverters in plants ≤ 6 kW feeding into the electricity grid

perform a self-test in accordance with CEI 0-21. During the self-test, the inverter will consecutively

check the reaction times for overvoltage, undervoltage, maximum frequency and minimum frequency.

The self-test changes the upper and lower trip-limit values for each protect ive function on a linear b asis

for frequency monitoring and voltage monitoring. As soon as the measured value exceeds the

permitted trip-limit value, the inverter disconnects from the electricity grid. In this way, the inverter

determines the reaction time and checks itself.