Page 1

Quick Reference Guide for Commissioning

SMA CLUSTER CONTROLLER

at

1 INFORMATION ON THIS DOCUMENT

Validity

This document is valid for the SMA Cluster Controller (model: CLCON-10 and CLCON-S-10) from hardware

version A1 and from firmware version 1.0.

Target Group

This document is intended for qualified persons. Only persons with the following skills are allowed to perform the

tasks set forth in this document:

• Training in the installation and commissioning of electrical devices

• Training in how to deal with the dangers and risks associated with i nstall ing an d using electr ical d evices and

systems

• Training in the installation and configuration of IT systems

• Knowledge of how an inverter works and is operated

• Knowledge of all applicable standards and directives

• Knowledge of and compliance with this document and all safety precautions

2 SAFETY

Intended Use

The Cluster Controller* is a device for monitoring and controlling SMA inverters with Speedwire/Webconnect interface

in decentralized PV systems and large-scale PV power plants. The Cluster Controller is an ITE class A device as per

EN 55022 and is designed for industrial use. The Cluster Controller must only be used in an indoor environment and

must only be used with supported products (for a list of the supported products, see the installation manual on the CD

included in the scope of delivery). Use this product only in accordance with the information provided in the enclosed

documentation and with the locally applicable standards and directives. Any other application may cause personal

injury or property damage.

For safety reasons, it is not permitted to modify the product or install components that are not explicitly recommended or

distributed by SMA** for the product. Unauthorized modifications and installations will void all warranty claims and the

operating permission. Any use of the product other than described in the Intended Use section does not qualify as

appropriate.

The type label must remain permanently attached to the product.

The enclosed documentation is an integral part of this product. Before installing or using the product, read and

observe all instructions, safety precautions and warning messages in this document and in the product

documentation on the enclosed CD.

Safety Precautions

ClusterController-IS-en-12 | Version 1.2 ENGLISH

3 SCOPE OF DELIVERY

Check the scope of delivery for completeness and any externally visible damage. Contact your distributor if the

scope of delivery is incomplete or damaged.

%"/(&3

Danger to life due to electric shock

If overvoltage occurs (e. g. due to lightning) or if the enclosure of the Cluster Controller is not grounded, there

is a danger of electric shock.

• Ensure that the Cluster Controller is integrated in the existing lightning protection.

• Ground the enclosure of the Cluster Controller (see Section Connecting the Grounding Conductor

to the Cluster Controller).

/05*$&

Damage to the devices and cables

The Cluster Controller is not splash water-protected (degree of protection: IP20 (NEMA 1)). Consequently, it

is possible that moisture may penetrate the device.

• Only use the Cluster Controller in a dry, indoor environment.

* In this document, the SMA Cluster Controller is referred to as Cluster Controller.

** SMA = SMA Solar Technology AG, SMA America LLC, SMA Solar Technology Canada Inc.

5 CONNECTION AND COMMISSIONING

%"/(&3

Danger to life due to electric shock from faulty connection of the connection cable to the ripple

control receiver

In the event of faulty connection of the connection cable to the ripple control receiver, grid voltage may be

present in the Cluster Controller enclosure.

• Do not connect insulated conductors of the connection cable to line conductors of the ripple control

receiver.

• When connecting, ensure that no bridge is being used in the ripple control receiver.

2

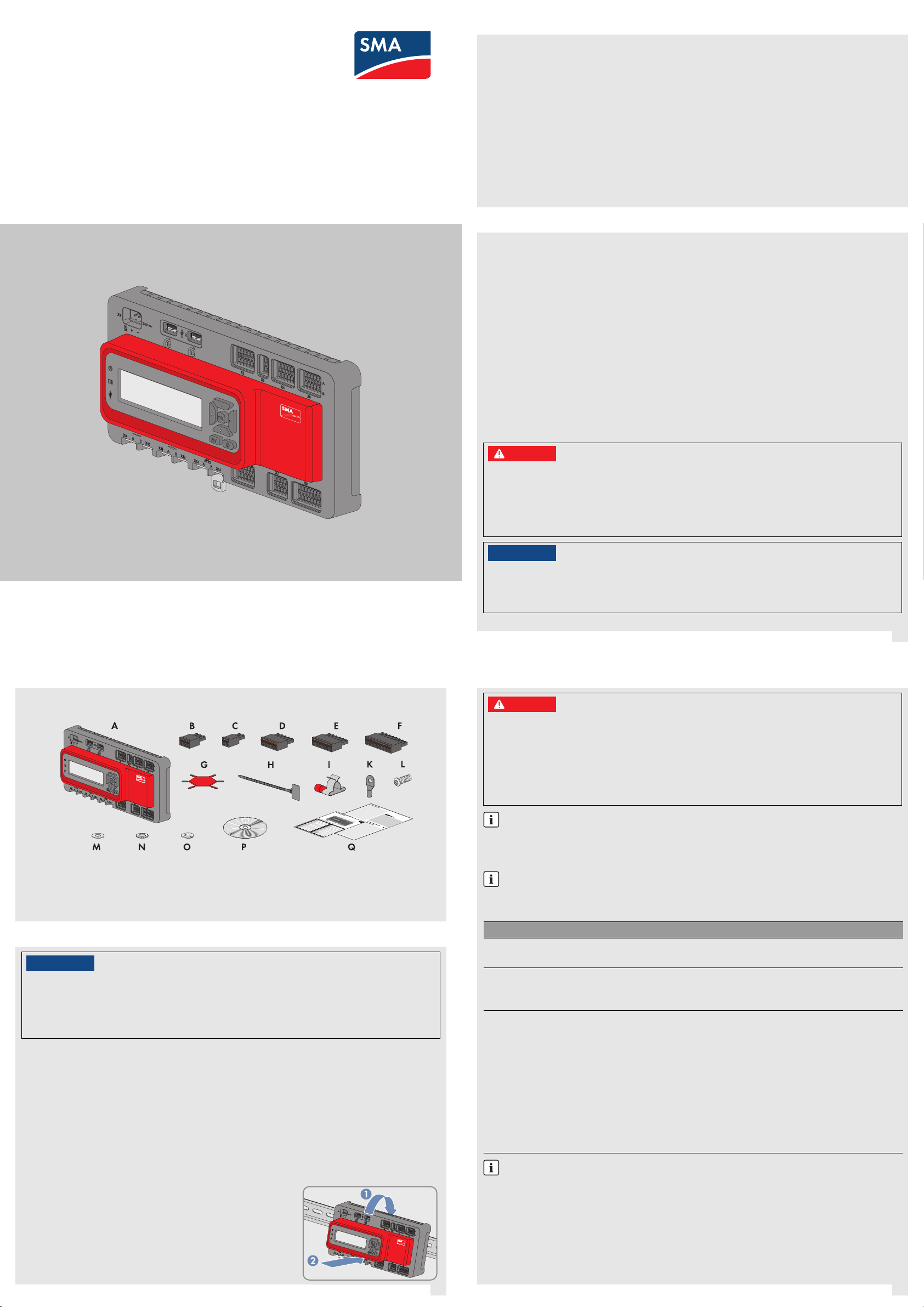

A) 1 x Cluster Controller, B) 1 x three-pole plug, C) 1 x two-pole plug, D) 2 x five-pole plug, E) 8 x six-pole plug,

F) 2 x eight-pole plug, G) 2 x coding element, H) 20 x cable tie with writing field, I) 8 x shield clamp with ring

terminal lug, K) 1 x ring terminal lug, L) 1 x fastening screw, M) 2 x washer, N) 1 x tooth lock washer,

O) 1 x split lock washer, P) 1 x CD with product documentation, Q) 1 x quick reference guide for commissioning

and supplementary sheet for writing down the connected devices

4 MOUNTING

/05*$&

Radio interference in living areas possible due to the Cluster Controller

The Cluster Controller is a device of ITE class A (EN 55022) and can cause radio interference in the living

area.

• Take suitable measures for shielding radio waves when the Cluster Controller is used in the vicinity of

living areas.

Selecting the Mounting Location

Select the mounting location. Observe the mounting location requirements, the minimum clearances and the

permissible mounting position (see installation manual on the CD provided).

Mounting the Cluster Controller

Requirements:

☐ A 35 mm (1.4 in) wide top-hat rail must be available which is mounted securely on the wall or in the switch

cabinet.

☐ In order to mount the Cluster Controller, the top-hat rail must be at least 26 cm (10.3 in) in length. To mount

the top-hat rail power supply unit, the top-hat rail must be correspondingly longer.

Procedure:

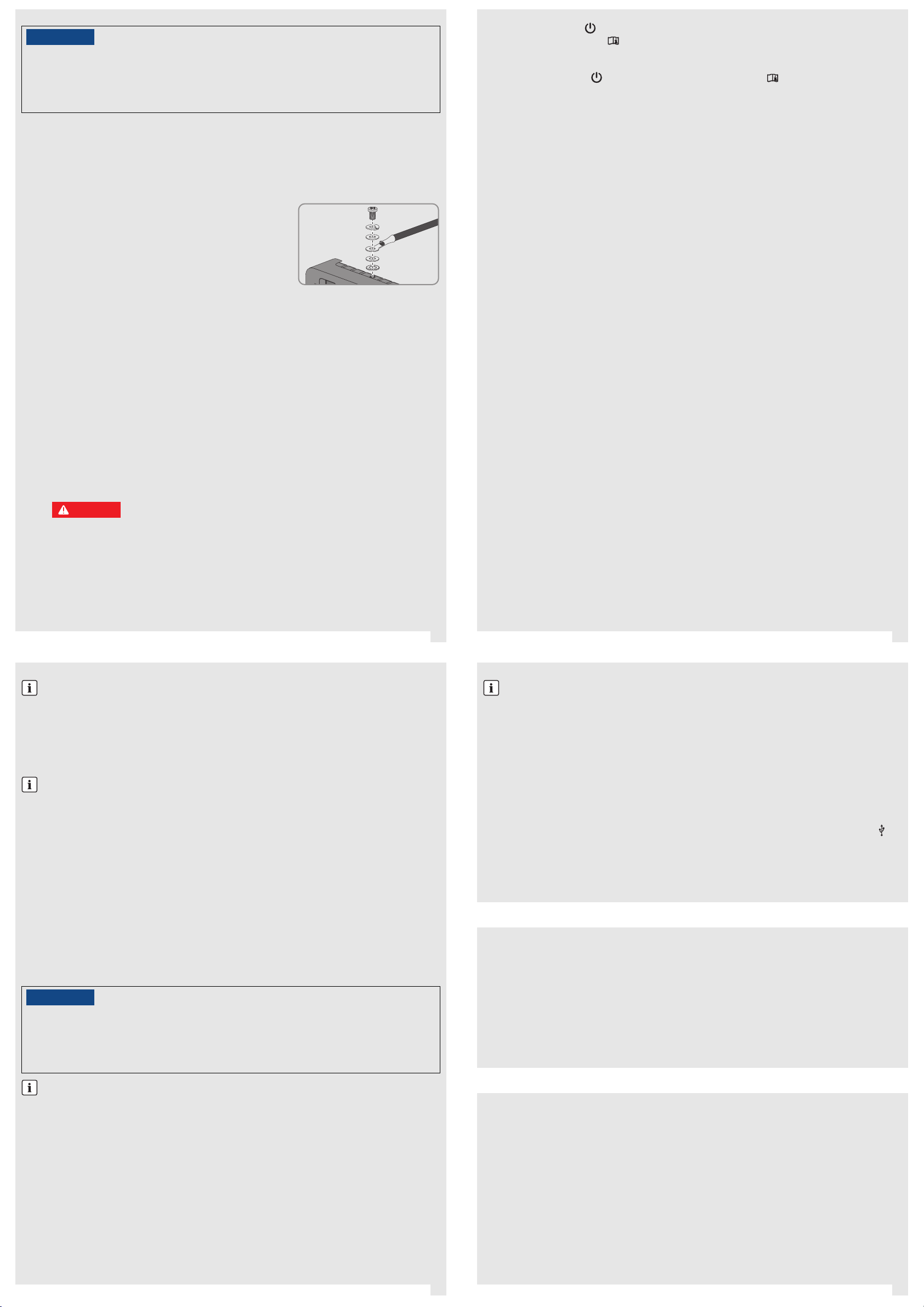

• Use the rear-side upper retainers to hook the Cluster Controller into

the upper edge of the top-hat rail and press down in the direction

of the top-hat rail. This will hook the spring-mounted top-hat rail

locking mechanism of the Cluster Controller onto the lower edge of

the top-hat rail.

For a detailed connection description, see the installation manual

This quick reference guide enables the basic commissioning of the Cluster Controller. A detailed

description of all connection possibilities is contained in the installation manual on the CD included in the

scope of delivery.

Note down the connections on the supplementary sheet

Note down the terminal assignment on the supplementary sheet supplied.

Cable Requirements and Information on Cable Routing

Connection Cable requirements

2

Grounding ☐ Conductor cross-section: 2.5 mm

☐ Maximum cable length: 30 cm (11 in)

Voltage supply ☐ Number of insulated conductors: at least two

☐ Conductor cross-section: 0.2 mm

☐ Maximum cable length: 3 m (9.8 ft)

Inverter (Speedwire) and

local area network (LAN)

Interference in data transmission due to unshielded energy cables

Unshielded energy cables generate an electromagnetic field during operation which may induce

interference in network cables during data transmission.

• When laying network cables, observe the following minimum clearances to unshielded energy

cables:

– For installation without separating strip: at least 200 mm (8 in)

– For installation with aluminum separating strip: at least 100 mm (4 in)

– For installation with steel separating strip: at least 50 mm (2 in)

☐ Number of insulated conductor pairs and insulated conductor

cross-section: at least 2 x 2 x 0.22 mm2 (at least 2 x 2 x 24 AWG)

☐ External diameter: the maximum external diameter depends on the size

of the cable gland or the conduit (see installation manual of the

Speedwire/Webconnect interface)

☐ Cable type: 100BaseTx, from CAT5 with shielding S-UTP, F-UTP or

higher

☐ Plug type: RJ45 for Cat5, Cat5e, Cat6, Cat6a

Cat7 plugs cannot be used.

☐ Cable length between two nodes: max. 50 m (164 ft) with patch

cable, max. 100 m (328 ft) with installation cable

(14 AWG)

2

to 2.5 mm2 (32 AWG to 14 AWG)

3 4

Page 2

Connecting the Cluster Controller to the Voltage Supply

/05*$&

Damage to the Cluster Controller due to condensation water

If the Cluster Controller is moved from a cold environment to a warm environment, condensation water may

form in the Cluster Controller.

• In the event of large temperature differences, only supply voltage to the Cluster Controller once the

Cluster Controller has reached room temperature.

Connecting the Grounding Conductor to the Cluster Controller

Additionally required material (not included in the scope of delivery):

☐ 1 grounding conductor (see Section Cable Requirements)

Procedure:

1. Remove 10 mm (0.39 in) of the cable sheath from the grounding conductor.

2. Insert the insulated conductors into the ring terminal lug and crimp with a crimping tool.

3. Attach the grounding conductor at the terminal for grounding

(for the position of the terminal, see installation manual on the CD

included in scope of delivery). Observe the following sequence

and hand-tighten the fastening screws (torque: 0.8 Nm

(7.08 in-lb)):

– Fastening screw, split lock washer, washer, ring terminal lug

with grounding conductor, washer, tooth lock washer

Connecting the Power Supply Unit

Additionally required material (not included in the scope of delivery):

☐ 1 power supply unit (available as an accessory). If the power supply unit available as an accessory is not

used, observe the requirements for the power supply unit (see installation manual on the CD included in the

scope of delivery).

☐1 AC connection cable

☐ 1 connection cable for the connection of the power supply unit to the Cluster Controller (see Section Cable

Requirements).

Procedure:

1. Mount the power supply unit (see the manufacturer manual).

2. Connect the connection cable to the power supply unit (see the manufacturer manual). Trim the unused

insulated conductors up to the cable sheath and note down the conductor colors.

3. Connect the connection cable to the three-pole plug. Release conductor entries 2 and 3 with a screwdriver

and insert the insulated conductors into the conductor entries. Observe the pin assignment.

4. Connect the three-pole plug to terminal X1 of the Cluster Controller.

5. Connect the AC connection cable to the power supply unit (see the manufacturer manual).

6.

7. Connect the other end of the AC connection cable to the voltage supply.

%"/(&3

Danger to life due to electric shock

Lethal voltages are present at the connection point of the utility grid.

• Disconnect the connection point from voltage sources and ensure that the connection point is

voltage-free.

8. Connect the connection point to the utility grid.

☑ The power LED ( ) of the Cluster Controller glows red for two seconds, then it permanently glows

green. The status LED ( ) glows corresponding to the current device status (see Cluster Controller

installation manual on the CD included in the scope of delivery). The Cluster Controller is ready for

operation after a maximum of one minute.

✖ Is the power LED ( ) glowing permanently red, the status LED ( ) glowing yellow or red and the

Cluster Controller is not starting?

Possible fault cause: the voltage supply is too low.

• Ensure that the connected voltage supply is sufficient (for requirements for the voltage supply see

the installation manual on the CD provided). If the problem persists, contact the SMA Service Line

(see Section 7).

Checking and Setting the System Time of the Cluster Controller

Before connecting the Cluster Controller to the Speedwire network and before commissioning the inverters, you

must use the display of the Cluster Controller to check whether the correct system time is displayed on the Cluster

Controller. If the correct system time is not displayed, you must set the correct system time via the user interface of

the Cluster Controller. This avoids inconsistencies in the time settings of the inverters.

Requirement:

☐ The Cluster Controller must be connected to the voltage supply and be in operation (see Section

Connecting the Cluster Controller to the Voltage Supply).

Procedure:

1. Use one network cable to connect the computer to the network port X13 or X14 of the Cluster Controller.

2. Log into the Cluster Controller:

• Select the display view External communication and read off the IP address of the Cluster Controller.

• Enter the IP address in the address bar of the web browser.

• Log in with the default system password (User = "0000", Installer = "1111").

3. Select the Cluster Controller in the system tree and select the Settings menu in the device menu.

4. Select the Device > Time settings parameter group.

5. Select [Edit].

6. If required, use the Standard/Daylight Saving Time conversion on drop-down list to set automatic

conversion between standard and daylight saving time.

7. In the Set PV system time field, set the current date and time of the PV system.

8. In the drop-down list Time zone, select the time zone in which the system is located.

9. Select [Save].

☑ The PV system time is updated.

10. Select [Logout] in the toolbar.

11. Connect the Cluster Controller to the Speedwire network (see Section Connecting the Cluster Controller

to a Speedwire Network) and make any additional required connections.

Connecting the Cluster Controller to a Speedwire Network

Do not connect the Speedwire network and the local area network (LAN)

The Speedwire network is a separate network managed by the Cluster Controller. If the Speedwire

network and the local area network (LAN) are connected, a disturbance of both networks is likely to

occur.

• In order to ensure correct communication, do not connect the Speedwire network and the local

area network (LAN). The Speedwire bus and the Ethernet bus must not be connected to the same

switch.

Observe the configuration of the router and the network switch

For the Speedwire connection, the Cluster Controller uses IP addresses from the Unicast area and also

IP addresses from the Multicast area 239/8 (239.0.0.0 to 239.255.255.255).

• When using a router or network switch, ensure that the router and switch forward the Multicast

telegrams required for the Speedwire connection to all nodes of the Speedwire network

(for information on configuration of the router or switch, see the manufacturer manual).

Requirements:

☐ The nodes in the Speedwire network (e. g. inverters) must be cabled in accordance with one of the possible

network topologies (see the node installation manual and the Technical Information "SMA Speedwire

Fieldbus").

Additionally required material (not included in the scope of delivery):

☐ Depending on the network topology: network cable (see Section Cable Requirements).

Procedure:

• Connect the network cable to the network port X9 or X10 of the Cluster Controller.

Connecting the Cluster Controller to the Local Area Network

/05*$&

High costs possible through inappropriate Internet rates

Depending on use, the data volume of the Cluster Controller transferred via the Internet can be more than 1

GB per month. The data volume depends, among other things, on the number of inverters, the frequency of

device updates, the frequency of data transfer to the Sunny Portal and the use of FTP push.

•SMA recommends using an Internet flat rate.

5 6

Connecting USB Data Carriers to the Cluster Controller

Not possible to use USB hubs

The Cluster Controller does not support any USB hubs. You must connect the USB data carrier directly

to the desired USB terminal on the Cluster Controller.

Additionally required material (not included in the scope of delivery):

☐ Up to two USB data carriers, e.g. two USB sticks (available as an accessory). If the USB data carrier available as

an accessory is not used, observe the requirements for USB data carriers (see installation manual on the CD

included in the scope of delivery).

Procedure:

1. Connect the USB data carrier to the desired USB terminal of the Cluster Controller.

• To export system data, connect the USB data carrier to the USB terminal 1.

• To transmit update files to the Cluster Controller, connect the USB data carrier to USB terminal 2.

2. If the USB data carrier is to be removed from the Cluster Controller, wait until the data carrier status LED ( ) is

not flashing anymore.

Checking the Connections via the Display

• You can use the display of the Cluster Controller to check whether the connections have been made correctly and

whether all inverters, sensors and remote terminals have been recorded by the

Cluster Controller (see installation manual on the CD included in the scope of delivery).

6 CONFIGURING THE CLUSTER CONTROLLER

Requirement:

☐ The Cluster Controller and the computer must be located in the same local area network (LAN).

Procedure:

1. Log

into the Cluster Controller:

• Select the External Communication display view and read out the IP address of the Cluster Controller.

• Enter the IP address in the address bar of the web browser.

• Log in with the default system password (User = "0000", Installer = "1111").

2. Deactivate the Webconnect function of the inverters (see user manua l of the Cl uste r Cont roller on the CD included

in the scope of delivery).

3. Make further desired configurations via the user interface (see user manual on the CD included in the scope of

delivery).

Different IP address ranges required for Speedwire network and local network (LAN)

In order to clearly assign the IP addresses in the Speedwire network and in the local network (LAN) from

the perspective of the Cluster Controller to be possible, the IP address ranges of both networks must be

different. By default, the Cluster Controller uses address range 172.22/16 (172.22.0.1 to

172.22.255.255) for the Speedwire network.

• Make sure that different IP address ranges are used for the Speedwire network and the local

network (LAN).

Additionally required material (not included in the scope of delivery):

☐ 1 network cable (see Section Cable Requirements)

Procedure:

1. Connect the network cable to the network port X13 or X14 of the Cluster Controller.

2. Connect the other end of the patch cable to the desired device in the local area network (LAN).

7 CONTACT

If you have technical problems with our products, contact the SMA Service Line. We require the following information

in order to provide you with the necessary assistance:

• Serial number and firmware version of the Cluster Controller

• Type, serial number, and firmware version of the inverter

• When using a retrofitted Speedwire/Webconnect interface:

Serial number and firmware

SMA Solar Technology AG

Niestetal, Germany

International SMA Service Line

Toll free worldwide: 00800 SMA SERVICE

(+800 762 7378423)

* toll free for USA, Canada and Puerto Rico / Llamada gratuita en EE. UU., Canadá y Puerto Rico

** international / internacional

7 8

*** toll free for Canada / gratuit pour le Canada

version of the Speedwire/Webconnect interface

SMA America, LLC

Rocklin, CA, United States/Estados Unidos

+1 877-MY-SMATech (+1 877-697-6283)*

+1 916 625-0870**

SMA Canada, Inc.

Toronto, Canada/Canadá

+1 877-MY-SMATech (+1 877-697-6283)***

Loading...

Loading...