Page 1

InstallationManual

SMA CLUSTER CONTROLLER

ClusterController-IA-en-15 | Version 1.5

ENGLISH

Page 2

Legal Provisions

SMA Solar Technology AG

Legal Provisions

The information contained in these documents is property of SMA Solar Technology AG. Any

publication, whether in whole or in part, requires prior written approval by SMA Solar Technology

AG. Internal reproduction used solely for the purpose of product evaluation or other proper use is

allowed and does not require prior approval.

SMA Warranty

You can download the current warranty conditions from the Internet at www.SMA-Solar.com.

Software Licenses

The licenses for the software modules used with this product can be found on the supplied CD.

Trademarks

All trademarks are recognized, even if not explicitly identified as such. A lack of identification does

not mean that a product or symbol is not trademarked.

The BLUETOOTH® word mark and logos are registered trademarks of BluetoothSIG,Inc. and any

use of these marks by SMASolarTechnologyAG is under license.

Modbus® is a registered trademark of Schneider Electric and is licensed by the Modbus

Organization, Inc.

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

Phillips® and Pozidriv® are registered trademarks of Phillips Screw Company.

Torx® is a registered trademark of Acument Global Technologies, Inc.

SMASolarTechnologyAG

Sonnenallee 1

34266 Niestetal

Germany

Tel. +49 561 9522-0

Fax +49 561 9522-100

www.SMA.de

E-mail: info@SMA.de

© 2004 to 2015SMASolarTechnologyAG. All rights reserved.

Installation ManualClusterController-IA-en-152

Page 3

SMA Solar Technology AG

Table of Contents

Table of Contents

1 Information on this Document ................................................. 6

1.1 Validity................................................................................................ 6

1.2 Target group....................................................................................... 6

1.3 Additional Information....................................................................... 6

1.4 Symbols .............................................................................................. 6

1.5 Typographies...................................................................................... 7

1.6 Nomenclature..................................................................................... 7

2 Safety......................................................................................... 8

2.1 Intended Use ...................................................................................... 8

2.2 Safety Information.............................................................................. 8

2.3 Supported Products............................................................................ 9

2.4 System Requirements ......................................................................... 10

3 Scope of Delivery...................................................................... 11

4 Product Description................................................................... 12

4.1 Cluster Controller ............................................................................... 12

4.2 Type Label .......................................................................................... 17

4.3 LEDs..................................................................................................... 18

4.4 Display................................................................................................ 19

4.5 Keypad ............................................................................................... 20

5 Mounting ................................................................................... 22

5.1 Requirements for Mounting ............................................................... 22

5.2 Mounting the Cluster Controller........................................................ 23

6 Connection and Commissioning .............................................. 25

6.1 Overview of the Connection Area .................................................... 25

6.2 Functions of the Terminals and Pin Groups ...................................... 26

6.3 Cable Requirements........................................................................... 28

6.4 Performing Pin Coding....................................................................... 29

6.5 Preparing Connection Cables for Connection to Multipole Plugs .. 30

6.6 Connecting the Cluster Controller to the Voltage Supply................ 32

Installation Manual 3ClusterController-IA-en-15

Page 4

Table of Contents

SMA Solar Technology AG

6.7 Checking and Setting the Cluster Controller System Time............... 35

6.8 Connecting the Cluster Controller to a Speedwire Network .......... 36

6.9 Connecting the Cluster Controller to the LAN.................................. 38

6.10 Connecting USB Data Carriers to the Cluster Controller................. 39

6.11 Connecting Sensors to the Cluster Controller................................... 40

6.11.1 Connecting the Temperature Sensor............................................. 40

6.11.2 Connecting an Irradiation Sensor................................................. 43

6.11.3 Connecting Additional Sensors..................................................... 44

6.12 Connections for Grid Management Services................................... 47

6.12.1 Options for Implementing Grid Management Service Setpoints 47

6.12.2 Digital Setpoint Signal ................................................................... 48

6.12.2.1 Connection Options ................................................................ 48

6.12.2.2 Connecting a Signal Source to a Digital Input for Active

Power Limitation.......................................................................

6.12.2.3 Connecting a Signal Source to a Digital Input for Reactive

Power Setpoint.........................................................................

6.12.2.4 Digital Signal Setpoint when Using Multiple Cluster

Controllers................................................................................

6.12.3 Analog Setpoint Signal.................................................................. 54

6.12.3.1 Connecting a Signal Source to an Analog Input for Active

Power Limitation.......................................................................

6.12.3.2 Connecting a Signal Source to an Analog Input for

Reactive Power Setpoint..........................................................

6.12.3.3 Analog Setpoint Signal when Using Multiple Cluster

Controllers................................................................................

6.12.4 Setpoint via Modbus Client........................................................... 57

6.12.5 Feedback of the Cluster Controller ............................................... 57

6.12.5.1 Feedback Options................................................................... 57

6.12.5.2 Connecting a Remote Terminal for Feedback via Digital

Signal .......................................................................................

6.12.5.3 Connecting a Remote Terminal for Feedback via Analog

Signal .......................................................................................

6.12.5.4 Feedback When Using Multiple Cluster Controllers............. 63

6.13 Checking the Connections via the Display....................................... 64

6.14 Configuring a Static LAN................................................................... 65

6.15 Setting Up a Modbus Data Connection........................................... 65

49

51

53

54

55

56

58

59

7 Troubleshooting ........................................................................ 66

Installation ManualClusterController-IA-en-154

Page 5

SMA Solar Technology AG

Table of Contents

7.1 LED States........................................................................................... 66

7.1.1 Operation LEDs.............................................................................. 66

7.1.2 Network Port LEDs ......................................................................... 69

7.2 Errors in the Cluster Controller or the Connected Devices .............. 70

7.3 Resetting the Cluster Controller ......................................................... 74

8 Decommissioning...................................................................... 76

8.1 Disassembling the Cluster Controller ................................................ 76

8.2 Packing the Product for Shipment ..................................................... 76

8.3 Disposing of the Product.................................................................... 77

9 Technical Data........................................................................... 78

10 Accessories................................................................................ 82

11 Contact....................................................................................... 83

Installation Manual 5ClusterController-IA-en-15

Page 6

1 Information on this Document

SMA Solar Technology AG

1 Information on this Document

1.1 Validity

This document is valid for the SMAClusterController (models "CLCON-10" and "CLCON-S-10")

from hardware versionA1 and from firmware version1.03.xx.R.

1.2 Target group

The tasks described in this document must only be performed by qualified persons. Qualified

persons must have the following skills:

• Training in the installation and configuration of IT systems

• Knowledge of how an inverter works and is operated

• Training in how to deal with the dangers and risks associated with installing and using

electrical devices and installations

• Training in the installation and commissioning of electrical devices and installations

• Knowledge of the applicable standards and directives

• Knowledge of and compliance with this document and all safety information

1.3 Additional Information

Links to additional information can be found at www.SMA-Solar.com:

Document title Document type

"SMASPEEDWIRE FIELDBUS" Technical Information

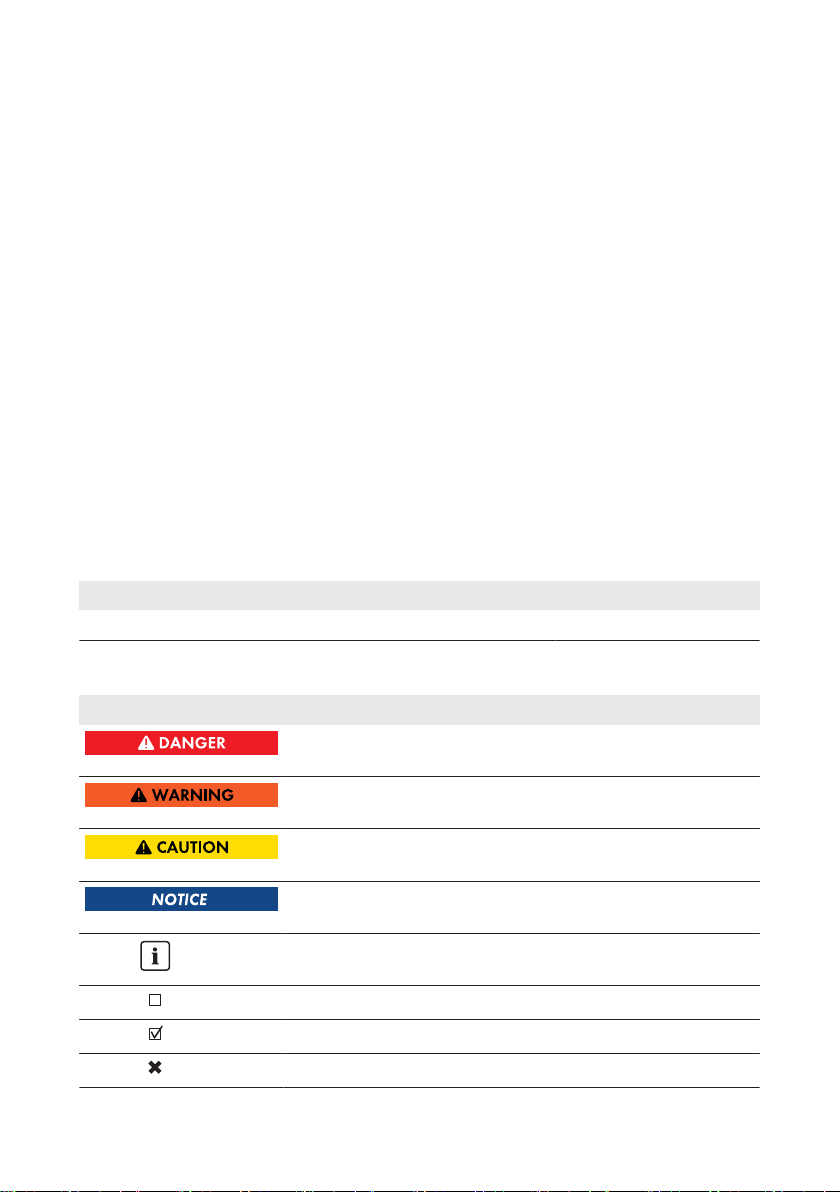

1.4 Symbols

Symbol Explanation

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury

Indicates a hazardous situation which, if not avoided, can result in

death or serious injury

Indicates a hazardous situation which, if not avoided, can result in

minor or moderate injury

Indicates a situation which, if not avoided, can result in property

damage

Information that is important for a specific topic or goal, but is not

safety-relevant

Indicates a requirement for meeting a specific goal

Desired result

A problem that might occur

Installation ManualClusterController-IA-en-156

Page 7

SMA Solar Technology AG

1 Information on this Document

1.5 Typographies

Typography Use Example

bold

>

[Button]

[Key]

• Display texts

• Elements on a user interface

• Terminals

• Elements to be selected

• Elements to be entered

• Connects several elements to be

selected

• Button or key to be selected or

pressed

• The value can be found in

the field Energy.

• Select Settings.

• Enter 10 in the field

Minutes.

• Select Settings > Date.

• Select [Next].

1.6 Nomenclature

Complete designation Designation in this document

Large-scale PV power plant PV system

PV inverter Inverter

SMAClusterController ClusterController

SMA Energy Meter Energy Meter

Installation Manual 7ClusterController-IA-en-15

Page 8

2 Safety

SMA Solar Technology AG

2 Safety

2.1 Intended Use

The ClusterController is a device for monitoring and controlling SMAinverters with Speedwire/

Webconnect interfaces in decentralized PV systems and large-scale PV power plants.

The ClusterController is an ITE classA device as per EN55022 and is designed for industrial use.

The product is designed for indoor use only.

Use this product only in accordance with the information provided in the enclosed documentation

and with the locally applicable standards and directives. Any other application may cause

personal injury or property damage.

Alterations to the product, e.g. changes or modifications, are only permitted with the express written

permission of SMA Solar Technology AG. Unauthorized alterations will void guarantee and

warranty claims and in most cases terminate the operating license. SMA Solar Technology AG

shall not be held liable for any damage caused by such changes.

Any use of the product other than that described in the Intended Use section does not qualify as

appropriate.

The enclosed documentation is an integral part of this product. Keep the documentation in a

convenient place for future reference and observe all instructions contained therein.

The type label must remain permanently attached to the product.

2.2 Safety Information

This section contains safety information that must be observed at all times when working on or with

the product.

To prevent personal injury and property damage and to ensure long-term operation of the product,

read this section carefully and observe all safety information at all times.

Danger to life due to electric shock from touching an ungrounded product

Touching an ungrounded product can cause a lethal electric shock.

• Ensure that the product is integrated in the existing overvoltage protection.

• Ground the enclosure of the product.

Damage to the product due to moisture

The product is not splash-proof (IP20). Moisture can penetrate the product and damage it.

• Only use the product in a dry, indoor environment.

Installation ManualClusterController-IA-en-158

Page 9

SMA Solar Technology AG

2.3 Supported Products

SMA Products

Availability of SMA products in your country

Not all SMA products are available in all countries. For information on whether an SMA

product is available in your country, visit the website of your country's SMA subsidiary at

www.SMA-Solar.com or contact your distributor.

The ClusterController can establish a connection to and display data on the following SMA

products that are equipped with Speedwire communication:

Inverters:

• All inverters with integrated or retrofitted Speedwire/Webconnect interface

Information on whether an inverter has an integrated Speedwire/Webconnect interface or can

be retrofitted with a Speedwire/Webconnect interface can be found on the inverter product

page at www.SMA-Solar.com.

Other products:

• SunnyPortal

• SMA Energy Meter

• SMAFuelSaveController

• SMAGridGate of device type "GRIDGATE-20" from firmware version1.0

• SMAPowerPlantController

Products from Other Manufacturers

2 Safety

Sensors:

• Irradiation sensors that can output a current signal in the range from 0mAto20mA

• Temperature sensors with a Pt100 measuring shunt or a Pt1000 measuring shunt

• Other sensors that can output a current signal in the range from 0mAto20mA or a voltage

signal in the range from −10V to+10V

Signal receivers and digital and analog signal sources:

• Signal sources with relay contacts

• Signal sources that provide digital output signals

• Signal sources that can output current signals in the range from 0mA to 20mA

• Signal sources that can output voltage signals in the range from −10V to+10 V

• Signal receivers that can process current signals in the range from 0mA to 20mA

Routers and network switches:

• Routers and network switches for Fast Ethernet with a data transfer rate of at least 100Mbit/s

All network components used must support the IGMP version 1 protocol (IGMPv1).

Installation Manual 9ClusterController-IA-en-15

Page 10

2 Safety

Power supply units:

In addition to the top-hat rail power supply unit offered as an accessory (see Section10, page82

), the ClusterController supports power supply units with the following properties:

• Maximum output current including short circuit: 8A

• Maximum output apparent power: 100VA

• DC output voltage: 24V

• Nominal current: minimum 1.8A

SMA Solar Technology AG

2.4 System Requirements

Supported web browsers:

☐ MicrosoftInternetExplorer from version8

☐ MozillaFirefox from version3.6

Recommended display resolution:

☐ Minimum 1,024pixelsx768pixels

Installation ManualClusterController-IA-en-1510

Page 11

SMA Solar Technology AG

3 Scope of Delivery

3 Scope of Delivery

Check the scope of delivery for completeness and any externally visible damage. Contact your

distributor if the scope of delivery is incomplete or damaged.

Figure 1: Components included in the scope of delivery

Position Quantity Designation

A 1 ClusterController

B 1 Three-pole plug

C 1 Two-pole plug*

D 2 Five-pole plug

E 8 Six-pole plug**

F 2 Eight-pole plug

G 2 Coding element

H 20 Cable tie with caption field

I 8 Shield clamp with ring terminal lug

K 1 Ring terminal lug

L 1 Fastening screw

M 2 Washer

N 1 Tooth lock washer

O 1 Split lock washer

P 1 CD with product documentation

Q 1 Quick reference guide for commissioning and supplementary sheet

for noting down connected devices

* Reserved for future applications. Keep the plug in a safe place.

** Two of the eight plugs are reserved for future applications. Keep the twoplugs in a safe place.

Installation Manual 11ClusterController-IA-en-15

Page 12

4 Product Description

SMA Solar Technology AG

4 Product Description

4.1 ClusterController

The ClusterController is a device for monitoring and controlling SMAinverters with Speedwire/

Webconnect interfaces in decentralized PV systems and large-scale PV power plants.

The ClusterController primarily performs the following tasks:

• Set-up of the Speedwire network

• Reading out, provision and administration of PV system data

• Configuring device parameters

• Feedback on current total active power of the system

• Implementation and feedback of grid operator setpoints for active power limitation and

reactive power operation under grid management services

• Implementation and feedback of setpoints for active power limitation when PV electricity is

directly marketed

• Sending e-mail alarms in the event of critical system statuses

• Sending the system data to an FTP server and/or the SunnyPortal Internet portal

• Performing updates for the ClusterController and the inverters

Figure 2: Design of the ClusterController

Position Designation

A LEDs

B Connection areas

C Keypad

D Display

Reading out, provision and administration of PV system data

The ClusterController is the central communication unit for the system and continuously reads out

the data of the devices in the system (e.g. inverters, sensors). The ClusterController then makes this

system data available via the display, user interface and Modbus data interface. In addition, the PV

system data can be displayed, evaluated and managed using Sunny Portal.

Installation ManualClusterController-IA-en-1512

Page 13

SMA Solar Technology AG

4 Product Description

Configuring device parameters

You can configure specific parameters of individual devices or entire device classes via the user

interface of the ClusterController. You must be logged into the user group Installer on the

ClusterController. The device parameters that can be configured, if any, depend on the device and

the rights of the user group. You may only change grid-sensitive device parameters

(SMAGridGuard parameters) with the approval of the grid operator and using your personal

SMAGridGuard code.

Sending e-mail alarms in the event of critical system statuses

You have the option of receiving prompt information on critical system statuses via e-mail. The

ClusterController automatically sends a notification if alarm-related events occur in the system.

Feedback on current total active power of the system

You have the option of being informed of the total active power currently generated by the system

via an analog current output signal.

Implementation and feedback of grid operator setpoints for active power

limitation and reactive power operation under grid management services

With the ClusterController, as part of grid management services you can implement different grid

operator setpoints for active power limitation and reactive power operation of your system. The

ClusterController can implement the setpoints using open-loop control or closed-loop control.

For ClusterController systems without self-consumption and with direct limitation of active power

feed-in, the operating mode Open-loop control is used. In this operating mode, the

ClusterController can receive the setpoints either in the form of digital or analog signals, or via

Modbus. The different types of signal source can be combined so that, for example, the setpoints

for the active power limitation are received as digital signals and the reactive power setpoints are

received as analog signals: For ClusterController systems with self-consumption, the operating

mode Closed-loop control is used. In this operating mode, you can regulate the active power fed

in by the system at the grid-connection point and limit it e.g. to a fixed percentage value. In

agreement with your grid operator, you can use the user interface of the ClusterController to

configure which setpoints of the ClusterController are to be transmitted to the connected inverters

depending on the respective signal. In addition, you can use a digital response contact or an

analog current output signal to inform the grid operator of the setpoints (if any) for active power

limitation and reactive power operation that are currently being used in the system.

Implementation and feedback of setpoints for active power limitation when PV

electricity is directly marketed

The PV current generated by your system can be directly marketed. The ClusterController can

receive setpoints for active power limitation from the direct marketer as digital or analog signals or

via Modbus. The "CLCON-S-10" model provides a Modbus register for sending setpoints via

Modbus. The model "CLCON-10" provides two Modbus registers.

The ClusterController can provide feedback about the current feed-in power of the system to the

direct marketer via digital or analog signals. To avoid conflicts when different setpoints are used by

the grid operator and the direct marketer, the ClusterController always implements the setpoint that

more strongly limits the active power of the system.

Installation Manual 13ClusterController-IA-en-15

Page 14

4 Product Description

SMA Solar Technology AG

Sending the system data to an FTP server and/or the SunnyPortal Internet

portal

The ClusterController can automatically send the system data that has been read out to an

arbitrary FTP server and/or the SunnyPortal Internet portal via the Internet. The ClusterController

establishes the connection to the FTP server and/or SunnyPortal e.g. via a router.

Performing updates for the ClusterController and the inverters

You have the option of performing updates for the Cluster Controller and the inverters in the system.

You can perform the updates automatically or manually. The update source can be the

SMAUpdate Portal or a USB data carrier with update files downloaded from the Internet.

Alternatively, you can also upload the update files directly from the computer via the user interface

of the ClusterController.

Figure 3: Decentralized large-scale PV power plant with ClusterController and implementation of grid operator

setpoints via open-loop control (example)

Position Designation

A PV Modules

B Module temperature sensor

C Inverter

D Outside temperature sensor

Installation ManualClusterController-IA-en-1514

Page 15

SMA Solar Technology AG

Position Designation

E Irradiation sensor

F ClusterController

G SunnyPortal

H Router

I Ripple control receiver or remote terminal unit

K Grid station

L Control room

M Grid control room

N Utility grid

4 Product Description

Installation Manual 15ClusterController-IA-en-15

Page 16

4 Product Description

SMA Solar Technology AG

Figure 4: Decentralized large-scale PV power plant with ClusterController and implementation of grid operator

setpoints via closed-loop control (example)

Position Designation

A PV Modules

B Module temperature sensor

C Inverter

D Outside temperature sensor

E Irradiation sensor

F ClusterController

G Industrial load

H SunnyPortal

I Router

K Ripple control receiver or remote terminal unit

Installation ManualClusterController-IA-en-1516

Page 17

SMA Solar Technology AG

Position Designation

L Energy meter

M Control room

N Grid control room

O Grid station

P Utility grid

4 Product Description

4.2 Type Label

The type label clearly identifies the product. The type label can be found on the back of the

enclosure. You can read off the following data from the type label:

• Device type (Type)

• Serial Number

• Hardware version (Version)

• Model

• Device-specific characteristics

You will require the information on the type label to use the product safely and when seeking

customer support from Service (see Section11 "Contact", page83).

Symbols on the Type Label

Symbol Designation Explanation

C-Tick The product complies with the require-

ments of the applicable Australian

EMC standards.

CANICES-3(A)/

NMB-3(A)

IC marking The product complies with the require-

ments of the applicable Canadian

EMC standards.

Indoors The product is only suitable for indoor

installation.

FCC designation The product complies with the require-

ments of the applicable FCC standards.

CE marking The product complies with the require-

ments of the applicable EU directives.

Installation Manual 17ClusterController-IA-en-15

Page 18

4 Product Description

Symbol Designation Explanation

WEEE designation Do not dispose of the product together

with household waste but in accordance with the locally applicable disposal regulations for electronic waste.

Data matrix code 2Dcode for device-specific character-

istics

4.3 LEDs

Operation LEDs

LED Designation Explanation

Power LED Shows whether the ClusterController is starting or is in op-

eration (see Section7.1 "LED States", page66)

Status LED Shows the status of the ClusterController and the con-

nected devices as well as the communication status of the

system and the status of the grid management services

(see Section7.1 "LED States", page66)

Data carrier status

LED

Shows the status of the connected USB data carrier (see

Section7.1 "LED States", page66)

SMA Solar Technology AG

Network Port LEDs

Colors and functionality of the network port LEDs are not standardized

The colors and functionalities of the network port LEDs are not standardized. The colors used

by SMA for the link/activity LED and the speed LED as well as the corresponding

functionalities can deviate in products supplied by third-party manufacturers.

Installation ManualClusterController-IA-en-1518

Page 19

SMA Solar Technology AG

Figure 5: Network port LEDs

4 Product Description

Position Designation Color Explanation

A Link/activity LED Green Shows the status and the activity of the network

connection (see Section7.1.2 "Network Port

LEDs", page69)

B Speed LED Yellow Shows the network connection speed (see Sec-

tion7.1.2 "Network Port LEDs", page69)

4.4 Display

The display shows information on the ClusterController and the connected devices as well as the

system status and the system configuration. The display contrast can be configured. The display

languages are "German" and "English". You can change the display language via the

ClusterController user interface.

Figure 6: ClusterController display (example)

Position Designation Explanation

A Title line Displays the title of the display view

The system time is always displayed.

B Data lines Displays text and numeric values

The numeric values for measurement or yield data are displayed with units.

Overview of the Display Views

Display view Explanation

Start view Displayed when the ClusterController starts up; includes the current

firmware version of the ClusterController

Installation Manual 19ClusterController-IA-en-15

Page 20

4 Product Description

Display view Explanation

System overview Displays the system status, the current daily yield, the nominal sys-

tem power and the current setpoints for active power and reactive

power

If no button on the keypad is pressed within five minutes, the Clus-

terController switches to the display view System overview.

Yield data Displays the yield data of the system

System status Displays the current system status

The number of inverters detected by the ClusterController and the

status of the inverters is displayed here.

ClusterController Displays the status and device information of the ClusterController

When a USB data carrier is inserted into USB port1, information on

the current memory usage of the USB data carrier will be displayed.

SunnyPortal settings Displays the configured upload frequency and the date of the last

successful data upload to SunnyPortal

Analog inputs Displays the analog inputs with the current level value and unit

Digital inputs Displays the digital inputs in binary form

The digital inputs are summarized in two groups here.

Meteorology Displays the measured values of the connected irradiation sensor

and the connected temperature sensors

Active power limitation Displays the current setpoint for active power limitation with the set-

point size and the date of the last configuration change

Reactive power setpoint Displays the current reactive power setpoint and the date of the last

configuration change

Grid management services Displays the setpoint type and the signal sources selected via the

ClusterController user interface for the grid management services

External communication Displays the settings for the LAN

Speedwire Displays the settings for the Speedwire network

Modbus settings Displays the Modbus settings with the activated network protocols

and the corresponding network ports

Settings Enables the display contrast to be changed and the ClusterCon-

troller to be partially or fully reset (see Section7.3, page74)

SMA Solar Technology AG

4.5 Keypad

Designation Explanation

Any button Activates the display illumination

Arrow buttons (◂▸▴▾) Changes display views and selects specific display lines

Installation ManualClusterController-IA-en-1520

Page 21

SMA Solar Technology AG

Designation Explanation

[OK]

[ESC]

ⓘ

Confirms the selected action

Cancels the selected action

Opens the display view System status

4 Product Description

Installation Manual 21ClusterController-IA-en-15

Page 22

5 Mounting

SMA Solar Technology AG

5 Mounting

5.1 Requirements for Mounting

Requirements for the mounting location:

Product can cause radio interference in living areas

The product is a device of ITE class A (EN55022) and can cause radio interference in living

areas.

• Take suitable measures for shielding radio waves when the ClusterController is used in the

vicinity of living areas.

☐ The mounting location must be indoors.

☐ The ambient conditions at the mounting location must be suitable for the operation of the

ClusterController (see Section9, page78).

☐ The mounting location must be protected against dust, moisture and corrosive substances.

Maximum permitted cable lengths:

☐ Observe the maximum cable length of 100 m each between any two nodes in the Speedwire

network and in the LAN.

☐ When connecting a digital or analog signal source (e.g. remote terminal unit, ripple control

receiver), observe the maximum cable length of 30 m from the ClusterController to the signal

source.

☐ When connecting a temperature sensor using the four-conductor connection technology,

observe the maximum cable length of 20 m from the ClusterController to the temperature

sensor.

☐ When connecting a temperature sensor using the two-conductor connection technology,

observe the maximum cable length of 2.5 m from the ClusterController to the temperature

sensor.

Minimum clearances:

☐ The minimum clearances must be maintained to ensure adequate heat dissipation.

Installation ManualClusterController-IA-en-1522

Page 23

SMA Solar Technology AG

Figure 7: Minimum clearances

Permitted and prohibited mounting positions:

☐ The ClusterController must be mounted so that the ventilation slots face upward and

downward. This ensures optimum heat dissipation.

5 Mounting

Figure 8: Permitted and prohibited mounting positions

5.2 Mounting the ClusterController

Requirements:

☐ A top-hat rail must be available.

☐ The top-hat rail must 35 mm wide.

Installation Manual 23ClusterController-IA-en-15

Page 24

5 Mounting

SMA Solar Technology AG

☐ In order to mount the ClusterController, the top-hat rail must be at least 26 cm long. When a

top-hat rail power supply unit is used, the top-hat rail must be correspondingly longer.

☐ The top-hat rail must be securely mounted on the wall or in the switch cabinet.

Procedure:

• Use the rear-side upper retainers to hook the

ClusterController into the upper edge of the tophat rail and press down toward the top-hat rail.

This will hook the spring-mounted top-hat rail

locking mechanism on the ClusterController

onto the lower edge of the top-hat rail.

☑ The top-hat rail locking mechanism snaps into place.

Installation ManualClusterController-IA-en-1524

Page 25

SMA Solar Technology AG

6 Connection and Commissioning

6.1 Overview of the Connection Area

Figure 9: Overview of the connection area

6 Connection and Commissioning

Position Quantity Designation Explanation

A 1 X1 Terminal for the voltage supply

B 1 – Terminal for grounding

C 1 1 USB port for exporting system data

D 1 2 USB port for updates

E 1 X2 Digital outputs

F 1 X3 Reserved for future applications

G 1 X4 Digital inputs

H 1 X5 Digital inputs

I 1 X8 Analog inputs

K 1 X7 Terminals for temperature sensors

L 1 X6 Analog outputs

M 2 X13, X14 Network ports for connecting the LAN

Installation Manual 25ClusterController-IA-en-15

Page 26

6 Connection and Commissioning

Position Quantity Designation Explanation

N 2 X11, X12 Reserved for future applications

O 2 X9, X10 Network ports for connecting the inverters (Speed-

wire)

SMA Solar Technology AG

6.2 Functions of the Terminals and Pin Groups

The digital and analog terminals of the ClusterController are divided into pin groups. Each pin

group forms one of the digital or analog inputs or outputs. On the enclosure, the upper row of

contact pins is marked with A and the lower row is marked with B. The contact pins are counted

from left to right.

The division of terminals into pin groups and the functions of the pin groups are described in the

following table.

For the pin groups of terminals X2 and X6 there are several functions to choose from. You can find

all selectable functions on the user interface of the Cluster Controller. In the following table you can

find the factory-set function.

Terminal Pin group Pin Function

X1 – 1to 3 Voltage supply

X2 Digital output1

Relay A

Digital output2

Relay B

Digital output3

Relay C

X3 – – Reserved for future applications

X4 Digital input1 A1toA3 Signal 1 of 4 for the active power limita-

Digital input2 A4toA6 Signal 2 of 4 for the active power limita-

Digital input3 B1toB3 Signal 3 of 4 for the active power limita-

Digital input4 B4 to B6 Signal 4 of 4 for the active power limita-

A1toA3

A4toA6 Fault indicator contact for the status

B1toB3 Response contact for the current active

Fault indicator contact for the status Er-

ror

Warning or Error

power limitation in grid management services

tion in grid management services

tion in grid management services

tion in grid management services

tion in grid management services

Installation ManualClusterController-IA-en-1526

Page 27

SMA Solar Technology AG

6 Connection and Commissioning

Terminal Pin group Pin Function

X5 Digital input5 A1toA3 Signal 1 of 4 for the reactive power set-

point in grid management services

Digital input6 A4toA6 Signal 2 of 4 for the reactive power set-

point in grid management services

Digital input7 B1toB3 Signal 3 of 4 for the reactive power set-

point in grid management services

Digital input8 B4toB6 Signal 4 of 4 for the reactive power set-

point in grid management services

X6 Analog current output1 A1toA3 Analog current output for feedback on

current active power limitation in grid

management services

Analog current output2 A4toA6 Analog current output for feedback on

current reactive power setpoint in grid

management services

Analog current output3 B1toB3 Analog current output for feedback on

the current total active system power (as

a percentage) based on the maximum

nominal system power

X7 Temperature input1 A1toA5 Analog input for connecting an external

temperature sensor

Temperature input2 B1toB5 Analog input for connecting a module

temperature sensor

X8 Analog current input1 A1toA4 Analog current input for connecting an ir-

radiation sensor or for measuring the active power feed-in at the grid-connection

point

Analog current input2 A5toA8 Analog current input for active power lim-

itation in grid management services or for

measuring the active power feed-in at the

grid-connection point

Analog current input3 B1toB4 Analog current input for reactive power

setpoint in grid management services or

for measuring the active power feed-in at

the grid-connection point

Analog voltage input 4 B5toB8 Analog voltage input for connecting a

sensor

X9, X10 – 1to 8 Network ports for connection to the in-

verters (Speedwire)

Installation Manual 27ClusterController-IA-en-15

Page 28

6 Connection and Commissioning

Terminal Pin group Pin Function

X11, X12 – – Reserved for future applications

X13, X14 – 1to 8 Network ports for connection to LAN

SMA Solar Technology AG

6.3 Cable Requirements

UV resistance of connection cables

Connection cables to be laid outdoors must be UV-resistant or routed in a UV-resistant cable

channel.

Terminal Cable requirements

Grounding ☐ Conductor cross-section: 2.5mm²

☐ Maximum cable length: 30 cm

Voltage supply ☐ Number of insulated conductors: at least two

☐ Conductor cross-section: 0.2 mm² to 1.5 mm²

☐ Maximum cable length: 3 m

Digital inputs ☐ Number of insulated conductors: at least two

☐ Conductor cross-section: 0.2 mm² to 1.5 mm²

☐ Maximum cable length: 30 m

Digital outputs ☐ Number of insulated conductors: at least two

☐ Conductor cross-section: 0.2 mm² to 1.5 mm²

☐ Maximum cable length: 30 m

Analog inputs, analog outputs and temperature inputs

(conductor)

Analog inputs (connection

cable)

Analog outputs (connection

cable)

☐ Conductor cross-section: 1.5mm²

☐ Cable length: 32 cm

☐ Number of insulated conductors: at least two

☐ Shielding: yes

☐ Conductor cross-section: 0.2 mm² to 1.5 mm²

☐ Maximum cable length: 30 m

☐ Number of insulated conductors: at least two

☐ Shielding: yes

☐ Conductor cross-section: 0.2 mm² to 1.5 mm²

☐ Maximum cable length: 3,000 m

Installation ManualClusterController-IA-en-1528

Page 29

SMA Solar Technology AG

Terminal Cable requirements

Temperature inputs (connection cable)

Inverter (Speedwire) ☐ Number of insulated conductor pairs and insulated conductor

LAN ☐ Number of insulated conductor pairs and insulated conductor

☐ Number of insulated conductors for tolerance ±2°C: at least

two

☐ Number of insulated conductors for tolerance ±0.5°C: at least

four

☐ Conductor cross-section: at least 4 x 0.25 mm²

☐ External cable diameter: 4.5 mm to 7.0 mm

☐ Maximum cable length for four-conductor connection

technology: 20 m

☐ Maximum cable length for two-conductor connection

technology: 2.5 m

cross-section: at least 2 x 2 x 0.22 mm²

☐ External diameter: the maximum external diameter depends on

the size of the cable gland or the conduit (see the installation

manual of the Speedwire/Webconnect interface)

☐ Cable type: 100BaseTx, from Cat5 with shielding S-UTP, F-UTP

or higher

☐ Plug type: RJ45 of Cat5, Cat5e, Cat6, Cat6a

Cat7 plugs cannot be used.

☐ Cable length between two nodes: max. 50 m with patch cable,

max. 100 m with installation cable

cross-section: at least 2 x 2 x 0.22 mm²

☐ Cable type: 100BaseTx, from Cat5 with shielding S-UTP, F-UTP

or higher

☐ Plug type: RJ45 of Cat5, Cat5e, Cat6 or Cat6a. Cat7 plugs

cannot be used.

☐ Cable length between two nodes: max. 50 m with patch cable,

max. 100 m with installation cable

6 Connection and Commissioning

6.4 Performing Pin Coding

Pin coding prevents confusion when using multipole connectors, e.g. in the event of removal and

later re-insertion of a multipole plug. Using the coded pins, you can be sure of inserting a multipole

plug into the correct terminal. Tip: perform pin coding for all multipole connections now, even if you

do not wish to use all multipole connections at this point. Then you will not need to perform pin

coding later for the multipole connections that you are not currently using.

Code the pins correctly

When selecting the pins to be coded, be sure to code different pins for each terminal and for

each pin row.

Installation Manual 29ClusterController-IA-en-15

Page 30

6 Connection and Commissioning

Procedure:

1. Insert one of the coding tabs on the coding

element, parallel to the conductor axis, into the

pin to be coded.

2. Remove the coding tab from the coding element

by snapping it off.

3. On the multipole plug, remove the key from the

conductor entry that will receive the coded pin

when connected to the ClusterController.

SMA Solar Technology AG

6.5 Preparing Connection Cables for Connection to Multipole Plugs

Always proceed as follows to prepare connection cables for connection to multipole plugs.

1. Strip 40 mm of cable sheath from the end of the connection cable to which the multipole plug

is to be attached.

2. Perform the following additional steps for the connection cables for the analog inputs, the

analog outputs and the temperature inputs:

• Trim the cable shield of the connection cable to 15 mm.

• Fold the surplus cable shield back over the

cable sheath.

Installation ManualClusterController-IA-en-1530

Page 31

SMA Solar Technology AG

6 Connection and Commissioning

• Press the shield clamp onto the cable shield.

The cable shield must be clamped under

the shield clamp as completely as possible.

• Depending on the number of connection cables, split the wire required for shielding into

pieces with a length 40 mm.

• Remove 6 mm of the cable sheath and strip

off the insulation by 6 mm at both ends of

the insulated conductor.

• Insert the insulated conductor at one end of

the wire into the ring terminal lug of the

shield clamp and crimp with a crimping

tool.

3. Trim unneeded insulated conductors flush with the cable sheath.

4. Strip off the conductor insulation by 6 mm.

☑ The connection cable is prepared for connection

to the multipole plug.

Installation Manual 31ClusterController-IA-en-15

Page 32

6 Connection and Commissioning

SMA Solar Technology AG

6.6 Connecting the ClusterController to the Voltage

Supply

Danger to life due to electric shock from touching an ungrounded product

Touching an ungrounded product can cause a lethal electric shock.

• Ensure that the product is integrated in the existing overvoltage protection.

• Ground the enclosure of the product.

Damage to the product due to condensation

If the product is moved from a cold environment to a warm environment, condensation may form

in the product.

• When there is a large temperature difference, wait for the product to reach room

temperature before connecting to the voltage supply.

Procedure:

To connect the ClusterController to the voltage supply, perform the following actions in the

specified order. The exact procedure is described in the following sections.

• Connecting the Grounding Conductor to the ClusterController

• Connecting the Power Supply Unit

Connecting the Grounding Conductor to the ClusterController

Additionally required material (not included in the scope of delivery):

☐ 1 grounding conductor (see Section6.3 "Cable Requirements", page28)

Procedure:

1. Remove 10 mm of the cable sheath from the grounding conductor.

2. Insert the insulated conductors into the ring

terminal lug and crimp with a crimping tool.

Installation ManualClusterController-IA-en-1532

Page 33

SMA Solar Technology AG

6 Connection and Commissioning

3. Connect the grounding conductor to the

grounding terminal. Observe the position of the

terminal (see Section6.1, page25). Observe

the order given below and hand-tighten the

fastening screw (torque: 0.8Nm):

• Fastening screw

• Split lock washer

• Washer

• Ring terminal lug with grounding conductor

• Washer

• Tooth lock washer

Connecting the Power Supply Unit

Additionally required material (not included in the scope of delivery):

☐ 1 power supply unit (see Section10 "Accessories", page82)

☐ 1 AC connection cable

☐ 1 cable for connecting the power supply unit to the ClusterController (see Section6.3 "Cable

Requirements", page28)

If you are not using the top-hat rail power supply unit available as an accessory for the

ClusterController, the power supply unit you are using must meet the requirements detailed below.

Requirements for the power supply unit:

☐ Maximum output current including short circuit: 8A

☐ Maximum output apparent power: 100VA

☐ DC output voltage: 24V

☐ Nominal current: minimum 1.8A

Requirement:

☐ The connection cable must be prepared for connection to the multipole plug (see Section6.5,

page30).

Installation Manual 33ClusterController-IA-en-15

Page 34

6 Connection and Commissioning

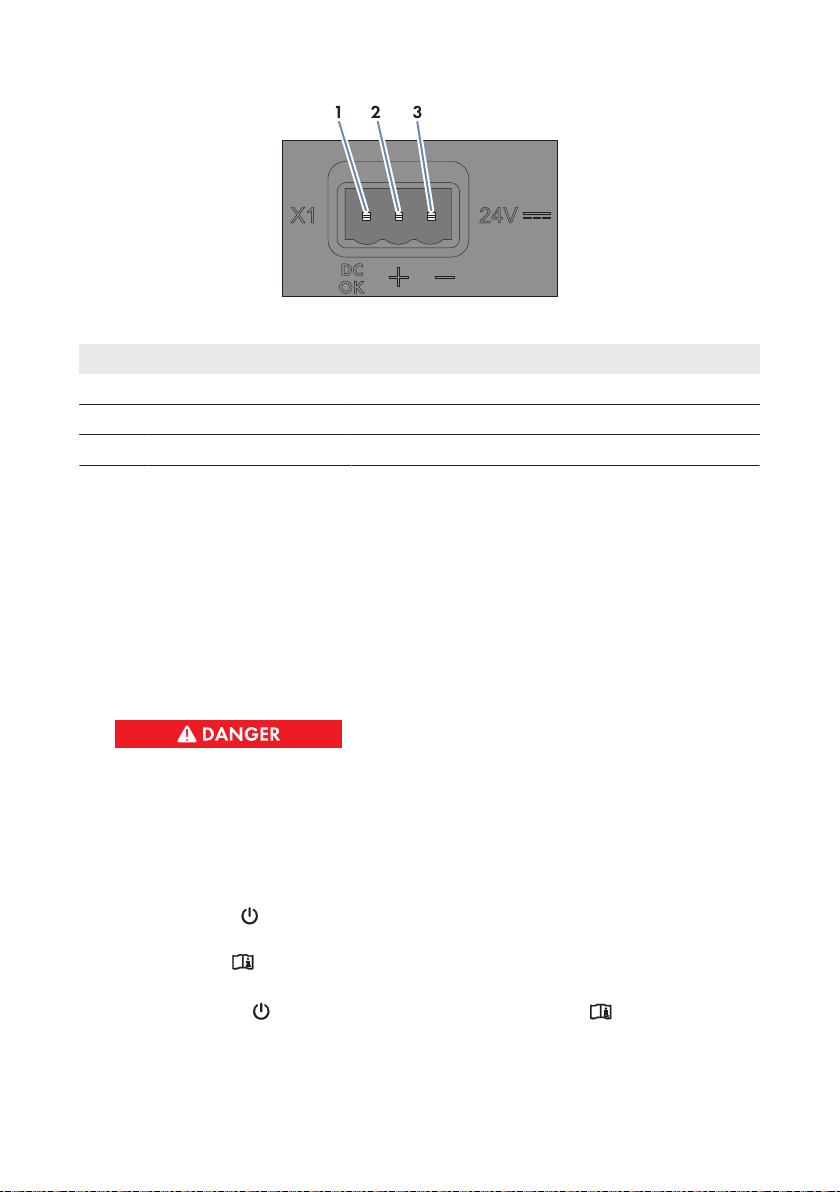

Figure 10: Pin assignment for terminal X1

SMA Solar Technology AG

Pin Signal Explanation

1 Not assigned Reserved for future applications

2 24 V Input voltage 24VDC

3 GND Ground

Procedure:

1. Mount the power supply unit (see manual from manufacturer).

2. Connect the connection cable to the power supply unit (see manual from manufacturer). Trim

the unused insulated conductors up to the cable sheath and write down the conductor colors.

3. Connect the connection cable to the three-pole plug. Unlock conductor entries 2 and 3 with a

screwdriver and insert the insulated conductors into the conductor entries. Observe the pin

assignment.

4. Connect the three-pole plug to terminal X1 on the ClusterController.

5. Connect the AC connection cable to the power supply unit (see the manual from

manufacturer).

6.

Danger to life due to electric shock

Lethal voltages are present at the connection point of the utility grid.

• Disconnect the connection point from voltage sources and ensure that the connection

point is voltage-free.

7. Connect the other end of the AC connection cable to the voltage supply.

8. Connect the connection point to the utility grid.

☑ The power LED ( ) on the ClusterController is glowing red for twoseconds, then it is

permanently glowing green.

The status LED ( ) is glowing corresponding to the current device status (see Section7.1,

page66). The ClusterController is ready for operation after a maximum of one minute.

✖ Is the power LED ( ) glowing permanently red, the status LED ( ) glowing yellow or

red and the ClusterController not starting?

Possible fault cause: the voltage supply is too low.

• Ensure that the voltage supply is sufficient (see Section9, page78).

Installation ManualClusterController-IA-en-1534

Page 35

SMA Solar Technology AG

• If the problem persists, contact the Service (see Section11, page83).

6 Connection and Commissioning

6.7 Checking and Setting the ClusterController System

Time

Before connecting the ClusterController to the Speedwire network and before commissioning the

inverters, you must check the ClusterController display to verify that the correct system time is

displayed on the ClusterController. If the correct system time is not displayed, you must set the

correct system time via the ClusterController user interface. This way, you can avoid inconsistencies

in the time settings of the inverters.

Available display languages

The display languages of the ClusterController are German and English. The default

language is English. You can only change the display language to German via the

ClusterController user interface by selecting German as the user interface language and then

logging in.

Additionally required material (not included in the scope of delivery):

☐ 1 network cable (see Section6.3 "Cable Requirements", page28)

Requirements:

☐ The ClusterController must be connected to the voltage supply and be in operation (see

Section6.6, page32).

☐ A computer must be available for access to the user interface of the ClusterController (see

Section2.4, page10).

Procedure:

1. Connect the computer directly to the ClusterController using the network cable. Connect the

network cable to the network port X13 or X14 on the ClusterController.

2. Select the display view External communication and read and write down the IP address of

the ClusterController from the line IP address. Tip: if you wish to integrate the

ClusterController in a static LAN, you will also need the IP address for the network

configuration (see Section6.14, page65).

3. Call up the IP address of the ClusterController via the web browser.

☑ The login page opens:

✖ The login page does not open?

Possible error cause: you have not written down the IP address correctly or you have not

entered it correctly.

• Enter the correct IP address and confirm the entry with the enter key.

• If the problem persists, read the troubleshooting information(see Section7.2 "Errors

in the ClusterController or the Connected Devices", page70).

4. Select the desired language in the upper area of the login page.

Installation Manual 35ClusterController-IA-en-15

Page 36

6 Connection and Commissioning

5. Log in either as User or as Installer with the corresponding default system password for the

user group. This makes the language change take effect on the user interface and on the

display:

User group Default system password

User 0000

Installer 1111

☑ The user interface opens.

✖ The user interface does not open?

Cause: You have not entered the default system password for the selected user group

correctly.

• On the login page, enter the correct default system password for the selected user

group and confirm the entry with the enter key.

6. Select the ClusterController in the system tree and select the menu Settings in the device

menu.

7. Select the parameter group Device > Time settings.

8. If required, use the drop-down list Standard/daylight saving time conversion on to set

automatic conversion between standard and daylight saving time.

9. In the field Set system time, set the current date and time of the system.

10. In the drop-down list Time zone, select the time zone in which the system is located.

11. Select [Save].

☑ The system time is updated.

12. Select [Logout] in the toolbar.

SMA Solar Technology AG

6.8 Connecting the ClusterController to a Speedwire

Network

Interference in data transmission due to unshielded power cables

If unshielded power cables are used, they generate an electromagnetic field during operation

which may induce interference in network cables during data transmission.

• When laying network cables, observe the following minimum clearances to unshielded

energy cables:

– For installation without separating strip: at least 200 mm

– For installation with aluminum separating strip: at least 100 mm

– For installation with steel separating strip: at least 50 mm

Do not connect the Speedwire network and the LAN

The Speedwire network is a separate network managed by the ClusterController. If the

Speedwire network and the LAN are connected, a disturbance of both networks is likely.

• In order to ensure proper communication, do not connect the Speedwire network and the

LAN (the Speedwire bus and the Ethernet bus of the LAN must not be connected to the

same network switch, for example).

Installation ManualClusterController-IA-en-1536

Page 37

SMA Solar Technology AG

6 Connection and Commissioning

Observe the configuration of the router and the network switch

For the Speedwire connection, the product uses IP addresses from the Unicast range and also

IP addresses from the Multicast range 239/8 (239.0.0.0 to 239.255.255.255).

• When using a router or network switch, ensure that the router and the network switch

forward the Multicast telegrams required for the Speedwire connection to all nodes in the

Speedwire network (for further information on how to configure the router or network

switch, see the manual from the manufacturer).

IGMP protocol version1 must be supported

The product works with multicasts. For correct function of the product, all network components

used must support the IGMP protocol, version1 (IGMPv1).

Requirements:

☐ The nodes in the Speedwire network (e. g. inverters) must be cabled in accordance with one

of the possible network topologies (see the node installation manual and the Technical

Information "SMASPEEDWIRE FIELDBUS").

☐ If your system uses an Energy Meter to measure the active power feed-in at the grid-

connection point, then the Energy Meter must be connected either to the router or network

switch of the Speedwire network or directly to terminal X9 or X10 of the ClusterController,

depending on the network topology of the system.

Additionally required material (not included in the scope of delivery):

☐ Depending on the network topology: network cable (see Section6.3 "Cable Requirements",

page28)

Figure 11: Pin assignment for network ports X9, X10, X13 and X14

Pin Designation Explanation

1 TX+ Data Out +

2 TX − Data Out −

3 RX+ Data In +

4 Not assigned Not assigned

5 Not assigned Not assigned

6 RX− Data In −

7 Not assigned Not assigned

8 Not assigned Not assigned

Installation Manual 37ClusterController-IA-en-15

Page 38

6 Connection and Commissioning

SMA Solar Technology AG

Procedure:

1. Connect the ClusterController to the Speedwire network. Take the desired network topology

into account:

• When using a preassembled network cable, connect the network cable to network port

X9 or X10.

• When using a network cable that is to be assembled by the user, connect the RJ45

connector to the network cable (see the manual from manufacturer) and connect the

network cable to network port X9 or X10 on the ClusterController.

2. Write down the terminal assignment on the supplied supplementary sheet.

3. Deactivate the Webconnect function on the inverters after completion of ClusterController

commissioning (see the ClusterController user manual).

6.9 Connecting the ClusterController to the LAN

Additionally required material (not included in the scope of delivery):

☐ 1 network cable (see Section6.3 "Cable Requirements", page28)

Figure 12: Pin assignment for network ports X9, X10, X13 and X14

Pin Designation Explanation

1 TX+ Data Out +

2 TX − Data Out −

3 RX+ Data In +

4 Not assigned Not assigned

5 Not assigned Not assigned

6 RX− Data In −

7 Not assigned Not assigned

8 Not assigned Not assigned

High costs possible due to inappropriate Internet tariff

Depending on use, the data volume transferred by the ClusterController via the Internet can be

more than 1GB per month. The data volume depends, among other things, on the number of

inverters, the frequency of device updates, the frequency of data transfer to SunnyPortal and the

use of FTP push.

• SMA recommends using an Internet flat rate.

Installation ManualClusterController-IA-en-1538

Page 39

SMA Solar Technology AG

Different IP address ranges required for Speedwire network and LAN

In order for an unambiguous assignment of the IP addresses in the Speedwire network and in

the LAN to be possible from the perspective of the ClusterController, the IP address ranges of

both networks must be different. By default, the ClusterController uses address range

172.22/16 (172.22.0.1 to 172.22.255.255) for the Speedwire network.

• Ensure that different IP address ranges are used for the Speedwire network and the LAN.

Observe the configuration of the router and the network switch

For the Speedwire connection, the product uses IP addresses from the Unicast range and also

IP addresses from the Multicast range 239/8 (239.0.0.0 to 239.255.255.255).

• When using a router or network switch, ensure that the router and the network switch

forward the Multicast telegrams required for the Speedwire connection to all nodes in the

Speedwire network (for further information on how to configure the router or network

switch, see the manual from the manufacturer).

IGMP protocol version1 must be supported

The product works with multicasts. For correct function of the product, all network components

used must support the IGMP protocol, version1 (IGMPv1).

Procedure:

1. Connect the network cable to the ClusterController:

• When using a preassembled network cable, connect the network cable to network port

X13 or X14.

• When using a network cable that is to be assembled by the user, connect the two RJ45

connectors to both ends of the network cable (see the manual from manufacturer) and

connect the network cable to network port X13 or X14.

2. Connect the other end of the network cable to the desired node in the LAN.

3. Write down the terminal assignment on the supplied supplementary sheet.

6 Connection and Commissioning

6.10 Connecting USB Data Carriers to the ClusterController

In order to save system data or perform an update, you can connect up to two USB data carriers to

the ClusterController (for information on updates, see the the ClusterController user manual).

Use of USB hubs not possible

The product does not support USB hubs. You must connect the USB data carrier directly to the

desired USB port on the product.

Additionally required material (not included in the scope of delivery):

☐ Up to two USB data carriers, e.g. two USB flash drives (see Section10 "Accessories", page82

)

If you use a USB data carrier other than that offered by SMA as an accessory, the USB data

carrier must meet the requirements stated below.

Installation Manual 39ClusterController-IA-en-15

Page 40

6 Connection and Commissioning

Requirements for USB data carriers:

☐ Maximum storage capacity: 2TB

☐ Supported file systems: FAT16 or FAT32

Use of USB hard disks with external power supply is recommended

In the case of USB hard disks with power supply via the USB interface, malfunctions can occur

if the connected USB hard disk temporarily has a greater electricity demand than that

provided for by the USB2.0 standard.

• To avoid malfunctions as a result of excessive power demand when using USB hard

disks, use only USB hard disks with external power supply.

Archival periods:

Depending on the available storage capacity of the USB data carrier and the configuration of your

system, the following approximate archival periods for the system data are possible:

Number of connected inverters

5 10 years 20 years

10 5 years 10 years

25 2 years 4 years

50 1 year 2 years

75 9 months 18 months

4GB storage capacity 8GB storage capacity

Approximate archival period

SMA Solar Technology AG

Procedure:

1. To protect the USB data carrier against loss, attach the USB data carrier to the eyelets located

on the underside of the USB port, for example with a loop attached to the USB data carrier.

2. Connect the USB data carrier to the desired USB port:

• To export system data, connect the USB data carrier to USB port 1.

• To transfer update files to the ClusterController, connect the USB data carrier to USB port

2.

3. If the USB data carrier is permanently inserted into the ClusterController, note the terminal

assignment on the supplied supplementary sheet.

4. If the USB data carrier is to be removed from the ClusterController, wait until the data carrier

status LED ( ) stops flashing.

6.11 Connecting Sensors to the ClusterController

6.11.1 Connecting the Temperature Sensor

You can connect one outside temperature sensor and one module temperature sensor to the

ClusterController. The measured values from the temperature sensors are shown on the display

and the user interface of the ClusterController and transmitted to SunnyPortal. In SunnyPortal, the

measured values from the module temperature sensor are used to calculate the performanceratio.

Installation ManualClusterController-IA-en-1540

Page 41

SMA Solar Technology AG

6 Connection and Commissioning

Connecting the Outside Temperature Sensor

Additionally required material (not included in the scope of delivery):

☐ 1 outside temperature sensor

☐ 1 connection cable (see Section6.3 "Cable Requirements", page28)

Requirements:

☐ The sensor must be technically suitable for connection to the temperature inputs (see Section9,

page78).

☐ The connection cable must be prepared for connection to the multipole plug (see Section6.5,

page30).

Figure 13: Pin assignment for pin group Temperature input1

Pin Signal Explanation

A1 GND Shield ground

A2 I+ Current input

A3 V+ Voltage input

A4 V− Voltage return

A5 I− Current return

Procedure:

1. Connect the connection cable to the outside temperature sensor (see the manual from

manufacturer). Trim the unneeded insulated conductors up to the cable shield and note down

the conductor colors.

2. For connection to the ClusterController using two-conductor connection technology, perform

the following steps:

• On the five-pole plug, unlock conductor entry 1 using a screwdriver and insert the

insulated conductor of the wire into the conductor entry.

• On the five-pole plug, unlock conductor entries 3 and 4 using a screwdriver and insert the

insulated conductors of the connection cable into the conductor entries. Observe the pin

assignment.

• At terminal X7 in pin row A, place a bridge between pin2 and pin3 and between pin4

and pin5.

Installation Manual 41ClusterController-IA-en-15

Page 42

6 Connection and Commissioning

SMA Solar Technology AG

3. For connection to the ClusterController using four-conductor connection technology, perform

the following steps:

• On the five-pole plug, unlock conductor entry 1 using a screwdriver and insert the

insulated conductor of the wire into the conductor entry.

• On the five-pole plug, unlock conductor entries 2, 3, 4 and 5 using a screwdriver and

insert the insulated conductors of the connection cable into the conductor entries.

Observe the pin assignment.

4. Insert the five-pole plug into pin row A in terminal X7.

5. On the connection cable, mark the terminal and the pin row to which the connection cable is

assigned. Use the supplied cable tie with caption field.

6. Write down the terminal assignment on the supplied supplementary sheet.

Connecting the Module Temperature Sensor

Additionally required accessories (not included in scope of delivery):

☐ 1 module temperature sensor

☐ 1 connection cable (see Section6.3, page28)

Requirements:

☐ The sensor must be technically suitable for connection to the temperature inputs (see Section9,

page78).

☐ The connection cable must be prepared for connection to the multipole plug (see Section6.5,

page30).

Figure 14: Pin assignment for pin group Temperature input2

Pin Signal Explanation

B1 GND Shield ground

B2 I+ Current input

B3 V+ Voltage input

B4 V− Voltage return

B5 I− Current return

Installation ManualClusterController-IA-en-1542

Page 43

SMA Solar Technology AG

6 Connection and Commissioning

Procedure:

1. Connect the connection cable to the module temperature sensor (see the manual from

manufacturer). Trim the unneeded insulated conductors up to the cable shield and note down

the conductor colors.

2. For connection to the ClusterController using two-conductor connection technology, perform

the following steps:

• On the five-pole plug, unlock conductor entry 1 using a screwdriver and insert the

insulated conductor of the wire into the conductor entry.

• On the five-pole plug, unlock conductor entries 3 and 4 using a screwdriver and insert the

insulated conductors of the connection cable into the conductor entries. Observe the pin

assignment.

• At terminal X7 in pin rowB, place a bridge between pin2 and pin3 and between pin4

and pin5.

3. For connection to the ClusterController using four-conductor connection technology, perform

the following steps:

• On the five-pole plug, unlock conductor entry 1 using a screwdriver and insert the

insulated conductor of the wire into the conductor entry.

• On the five-pole plug, unlock conductor entries 2, 3, 4 and 5 using a screwdriver and

insert the insulated conductors of the connection cable into the conductor entries.

Observe the pin assignment.

4. Insert the five-pole plug into pin row B in terminal X7.

5. On the connection cable, mark the terminal and the pin row to which the connection cable is

assigned. Use the supplied cable tie with caption field.

6. Write down the terminal assignment on the supplied supplementary sheet.

6.11.2 Connecting an Irradiation Sensor

You can connect one irradiation sensor or pyranometer to the ClusterController. The measured

value from the irradiation sensor or pyranometer is shown on the display and the user interface of

the ClusterController and transmitted to SunnyPortal. In SunnyPortal, the measured values are

used to calculate the performanceratio.

Additionally required material (not included in the scope of delivery):

☐ 1 irradiation sensor

☐ 1 connection cable (see Section6.3 "Cable Requirements", page28)

Requirements:

☐ The sensor must be technically suitable for connection to the analog inputs (see Section9,

page78).

☐ The connection cable must be prepared for connection to the multipole plug (see Section6.5,

page30).

Installation Manual 43ClusterController-IA-en-15

Page 44

6 Connection and Commissioning

Figure 15: Pin assignment for pin group Analog current input1

SMA Solar Technology AG

Pin Signal Explanation

A1 Not assigned Reserved for future applications

A2 I+ Current input

A3 I− Current return

A4 GND Shield ground

Procedure:

1. Connect the connection cable to the irradiation sensor (see the manual from manufacturer).

Trim the unneeded insulated conductors up to the cable shield and note down the conductor

colors.

2. Connect the connection cable to the eight-pole plug:

• Unlock conductor entry4 with a screwdriver and insert the insulated conductor of the

wire into the conductor entry.

• Unlock conductor entries 2 and 3 with a screwdriver and insert the insulated conductors

of the connection cable into the conductor entries. Observe the pin assignment.

3. Insert the eight-pole plug into pin row A in terminal X8.

4. On the connection cable, mark the terminal and the pin row to which the connection cable is

assigned. Use the supplied cable tie with caption field.

5. Write down the terminal assignment on the supplied supplementary sheet.

6. Adjust the characteristic curve of the irradiation sensor or pyranometer via the

ClusterController user interface (see the ClusterController user manual). The measured

irradiation values can then be shown on the display and the ClusterController user interface.

6.11.3 Connecting Additional Sensors

Depending on whether you are using an irradiation sensor (see Section6.11.2, page43), you can

connect a maximum of three sensors to the analog current inputs and one sensor to the analog

voltage input on terminal X8 on the ClusterController.

Installation ManualClusterController-IA-en-1544

Page 45

SMA Solar Technology AG

6 Connection and Commissioning

Display of measured values from pin group Analog voltage input4

If no sensor is connected to the pin group Analog voltage input4, a measured value for this

pin group of up to 2.2V will nevertheless be shown on the display and the user interface of

the ClusterController.

• In order for a measured value of 0V to be displayed for the pin group Analog voltage

input4 when it is not connected, place a jumper wire between pins B5 and B7 in

terminal X8.

Connecting a Sensor to an Analog Current Input

Additionally required material (not included in the scope of delivery):

☐ Up to three sensors

☐ Up to three connection cables (see Section6.3 "Cable Requirements", page28)

Requirements:

☐ The sensor must be technically suitable for connection to the analog inputs (see Section9,

page78).

☐ The connection cable must be prepared for connection to the multipole plug (see Section6.5,

page30).

Figure 16: Pin assignment for the pin groups Analog current input1, Analog current input2 and Analog

current input3

Pin group Pin Signal Explanation

Analog current input1 A1 Not assigned Reserved for future applications

A2 I+ Current input

A3 I− Current return

A4 GND Shield ground

Installation Manual 45ClusterController-IA-en-15

Page 46

6 Connection and Commissioning

SMA Solar Technology AG

Pin group Pin Signal Explanation

Analog current input2 A5 Not assigned Reserved for future applications

A6 I+ Current input

A7 I− Current return

A8 GND Shield ground

Analog current input3 B1 Not assigned Reserved for future applications

B2 I+ Current input

B3 I− Current return

B4 GND Shield ground

Procedure:

1. Connect the connection cable to the sensor (see the manual from manufacturer). Trim the

unneeded insulated conductors up to the cable shield and note down the conductor colors.

2. For connection to the pin group Analog current input1, perform the following steps:

• Unlock conductor entry4 with a screwdriver and insert the insulated conductor of the

wire into the conductor entry.

• Unlock conductor entries 2 and 3 with a screwdriver and insert the insulated conductors

of the connection cable into the conductor entries. Observe the pin assignment.

• Insert the eight-pole plug into pin row A in terminal X8.

3. For connection to the pin group Analog current input2, perform the following steps:

• Unlock conductor entry8 with a screwdriver and insert the insulated conductor of the

wire into the conductor entry.

• Unlock conductor entries 6 and 7 with a screwdriver and insert the insulated conductors

of the connection cable into the conductor entries. Observe the pin assignment.

• Insert the eight-pole plug into pin row A in terminal X8.

4. For connection to the pin group Analog current input3, perform the following steps:

• Unlock conductor entry4 with a screwdriver and insert the insulated conductor of the

wire into the conductor entry.

• Unlock conductor entries 2 and 3 with a screwdriver and insert the insulated conductors

of the connection cable into the conductor entries. Observe the pin assignment.

• Insert the eight-pole plug into pin row B in terminal X8.

5. On the connection cable, mark the terminal and the pin row to which the connection cable is

assigned. Use the supplied cable tie with caption field.

6. Write down the terminal assignment on the supplied supplementary sheet.

Connecting a Sensor to the Analog Voltage Input

Additionally required material (not included in the scope of delivery):

☐ 1 sensor

☐ 1 connection cable (see Section6.3 "Cable Requirements", page28)

Installation ManualClusterController-IA-en-1546

Page 47

SMA Solar Technology AG

Requirements:

☐ The sensor must be technically suitable for connection to the analog inputs (see Section9,

page78).

☐ The connection cable must be prepared for connection to the multipole plug (see Section6.5,

page30).

Figure 17: Pin assignment for pin group Analog voltage input4

Pin Signal Explanation

B5 V+ Voltage input

B6 Not assigned Reserved for future applications

B7 V− Voltage return

B8 GND Shield ground

6 Connection and Commissioning

Procedure:

1. Connect the connection cable to the sensor (see the manual from manufacturer). Trim the

unneeded insulated conductors up to the cable shield and note down the conductor colors.

2. Connect the connection cable to the eight-pole plug:

• Unlock conductor entry8 with a screwdriver and insert the insulated conductor of the

wire into the conductor entry.

• Unlock conductor entries 5 and 7 with a screwdriver and insert the insulated conductors

of the connection cable into the conductor entries. Observe the pin assignment.