Page 1

Technical Information

SMA CLUSTER CONTROLLER Modbus® Interface

ClusterController_Modbus-TI-en-18 | Version 1.8 ENGLISH

Page 2

Legal Provisions SMA Solar Technology AG

Legal Provisions

The information contained in these documents is the property of SMA Solar Technology AG.

Any publication, whether in whole or in part, requires prior written approval by

SMA Solar Technology AG. Internal reproduction used solely for the purpose of product evaluation

or other proper use is allowed and does not require prior approval.

Trademarks

All trademarks are recognized, even if not explicitly identified as such. Missing designations do not

mean that a product or brand is not a registered trademark.

Modbus® is a registered trademark of Schneider Electric and is licensed by the Modbus Organization, Inc.

SMA SOLAR TECHNOLOGY AG

Sonnenallee 1

34266 Niestetal

Germany

Tel. +49 561 9522-0

Fax +49 561 9522-100

www.SMA.de

E-Mail: info@SMA.de

Copyright © 2017 SMA Solar Technology AG. All rights reserved.

2 ClusterController_Modbus-TI-en-18 Technical Information

Page 3

SMA Solar Technology AG Table of Contents

Table of Contents

1 Information on this Document ................................................................. 5

2 Safety .......................................................................................................... 7

2.1 Intended Use ............................................................................................................... 7

2.2 Skills of Qualified Persons ......................................................................................... 7

2.3 Safety Information ...................................................................................................... 7

2.4 Information on Data Security .................................................................................... 8

3 Product Description ................................................................................... 9

3.1 Modbus Protocol ........................................................................................................ 9

3.2 SMA Modbus Profile ................................................................................................. 9

3.3 User-Defined Modbus Profile .................................................................................... 9

3.4 PV System Topology................................................................................................... 9

3.5 Addressing and Data Transmission in the Modbus Protocol ............................. 12

3.5.1 Unit IDs ................................................................................................................. 12

3.5.2 Assignment of the Modbus Register to Unit IDs ................................................. 13

3.5.3 Modbus Register Address, Register Width and Data Block ............................. 13

3.5.4 Address Range for Modbus Register .................................................................. 13

3.5.5 Data Transmission ................................................................................................ 13

3.6 Reading and Writing of Data ................................................................................ 14

3.7 SMA Data Types and NaN Values ...................................................................... 15

3.8 SMA Data Formats .................................................................................................. 15

4 Commissioning and Configuration .......................................................17

4.1 Commissioning Steps and Requirements .............................................................. 17

4.2 Information on Changing Unit IDs ........................................................................ 17

4.3 Changing Unit IDs via the Gateway ..................................................................... 18

4.3.1 Reading Out the Gateway .................................................................................. 18

4.3.2 Changing A Unit ID in the Gateway .................................................................. 19

4.4 Changing Unit IDs via the XML File usrplant.xml ................................................ 20

4.4.1 Overview .............................................................................................................. 20

4.4.2 Structure of the XML File usrplant.xml ................................................................. 20

4.4.3 Activating and Deactivating usrplant.xml ........................................................... 21

Technical Information ClusterController_Modbus-TI-en-18 3

Page 4

Table of Contents SMA Solar Technology AG

4.5 Resetting the Cluster Controller to the Default Settings ...................................... 22

5 SMA Modbus Profile—Assignment Tables ...........................................23

5.1 Information on the Assignment Tables .................................................................. 23

5.2 Gateway (Unit ID = 1) ........................................................................................... 24

5.3 System Parameters (Unit ID = 2) ........................................................................... 26

6 User-Defined Modbus Profile ................................................................30

6.1 Structure of the XML File for the User-Defined Modbus Profile ......................... 30

6.2 Example of a User-Defined Modbus Profile ........................................................ 31

6.3 Activating and Deactivating User-Defined Modbus Profile ............................... 32

7 Troubleshooting .......................................................................................33

8 Technical Data .........................................................................................34

8.1 Supported SMA Inverters ....................................................................................... 34

8.2 Number of SMA Devices ....................................................................................... 34

8.3 Modbus Communication Ports............................................................................... 34

8.4 Data Processing and Time Behavior ..................................................................... 35

8.5 Number Codes of the Time Zones ........................................................................ 36

8.6 Frequently Used Number Codes (ENUM) .......................................................... 38

9 Contact ......................................................................................................39

4 ClusterController_Modbus-TI-en-18 Technical Information

Page 5

SMA Solar Technology AG Information on this Document

Icon

Explanation

Indicates a hazardous situation that, if not avoided, will result in

death or serious injury.

Indicates a hazardous situation that, if not avoided, can result in

death or serious injury.

Indicates a hazardous situation that, if not avoided, can result in

minor or moderate injury.

Indicates a situation that, if not avoided, can result in property damage.

Information that is important for a specific topic or goal, but is not

safety-relevant.

◻

Indicates a requirement for meeting a specific goal.

1 Information on this Document

Validity

This document is applicable for device type "CLCON-10" and device type "CLCON-S-10"*

(SMA Cluster Controller). It describes the Modbus interface of the SMA Cluster Controller, the

variant of the "Modbus® Application Protocol" implemented by SMA, and the corresponding parameters, measured values and data exchange formats.

* Not available in all countries (see the SMA Cluster Controller product page at

www.SMA-Solar.com)

This document does not contain any information on software which can communicate with the

Modbus interface (see the software manufacturer's manual).

Target Group

This document is intended for qualified persons. Only persons with appropriate skills are allowed to

perform the tasks described in this document (see Section 2.2 "Skills of Qualified Persons", page 7)

Symbols

Technical Information ClusterController_Modbus-TI-en-18 5

Page 6

Information on this Document SMA Solar Technology AG

Typography

Application

Example

bold

• Elements to be selected

• Elements on a user interface

• File names

• Parameters

• Select Settings.

• Control via communication.

• The file usrprofile.xml

• The values Major and Minor

Complete designation

Designation in this document

Modbus register

Register

Photovoltaic system

PV system

SMA Cluster Controller

Cluster Controller

Abbreviation

Designation

Explanation

GFDI

Ground-Fault Detection and

Interruption

Detection of the grounding error and subsequent interruption of the electric circuit.

PMAX

Set active power limit

The device can generate active power up to

this limit.

Power Balancer

-

The Power Balancer is a function in

Sunny Mini Central devices for controlling

three-phase grid feed-in, for example, to avoid

unbalanced loads.

SMA fieldbus

-

Hardware interface for communication between SMA devices (e.g. Speedwire). For

information on the supported communication

interfaces, refer to the datasheet of the SMA

device being used.

SUSy ID

SMA update system ID

Numeric value that identifies a specific

SMA device type, e.g.

128 = STP nn000TL-10.

Typographies

Nomenclature

Abbreviations

6 ClusterController_Modbus-TI-en-18 Technical Information

Page 7

SMA Solar Technology AG Safety

Damage to SMA inverters

The parameters of the SMA inverters that can be changed with writable Modbus registers (RW)

are intended for long-term storage of device settings. Cyclical changing of these parameters leads

to destruction of the flash memory of the devices.

• Device parameters must not be changed cyclically.

Contact the SMA Service Line if you would like to automate the remote control of your PV system

(see Section 9 "Contact", page 39).

2 Safety

2.1 Intended Use

The Modbus interface of the SMA Cluster Controller is designed for industrial use and has the

following tasks:

• Remote control of the grid management services of a PV system.

• Remote-controlled querying of the measured values of a PV system.

• Remote-controlled changing of the parameters of a PV system.

The Modbus interface can be used via the protocol Modbus TCP and

by the protocol Modbus UDP.

The enclosed documentation is an integral part of this product:

• Read and observe the documentation.

• Keep the documentation in a convenient place for future reference.

2.2 Skills of Qualified Persons

The activities described in this document must only be performed by qualified persons.

Qualified persons must have the following skills:

• Knowledge of IP-based network protocols

• Training in the installation and configuration of IT systems

• Knowledge of and compliance with this document and all safety information

2.3 Safety Information

This section contains safety information that must be observed at all times when working on or with

the product. To prevent personal injury and property damage and to ensure long-term operation of

the product, read this section carefully and observe all safety information at all times.

Technical Information ClusterController_Modbus-TI-en-18 7

Page 8

Safety SMA Solar Technology AG

Data security in Ethernet networks

You can connect the Cluster Controller to the Internet. When connecting to the Internet,

there is a risk that unauthorized users can access and manipulate the data of your PV system.

• Take appropriate protective measures, for example:

• Set up a firewall

• Close unnecessary network ports

• Only enable remote access via VPN tunnel

• Do not set up port forwarding at the Modbus port in use

2.4 Information on Data Security

8 ClusterController_Modbus-TI-en-18 Technical Information

Page 9

SMA Solar Technology AG Product Description

3 Product Description

3.1 Modbus Protocol

The Modbus Application Protocol is an industrial communication protocol that is currently used in

the solar sector mainly for system communication in PV power plants.

The Modbus protocol has been developed for reading data from or writing data to clearly defined

data areas. The Modbus specification does not prescribe what data is within which data area. The

data areas must be defined device-specifically in Modbus profiles. With knowledge of the devicespecific Modbus profile, a Modbus master (e.g. SCADA system) can access the data of a Modbus

slave (e.g. SMA Cluster Controller). Information on firmware versions and device-specific Modbus

registers of SMA products can be found on our product pages or Modbus page at

www.SMA-Solar.com.

The special Modbus profile for SMA devices is the SMA Modbus profile.

3.2 SMA Modbus Profile

The SMA Modbus profile contains definitions for SMA devices. A reduction of the available data

on SMA devices was carried out for the definition and this was then assigned to the corresponding

Modbus registers. The SMA Modbus profile contains, for example, the total and daily energy,

current power, voltage and current levels. The assignment between SMA device data and Modbus

addresses is split into ranges in the SMA Modbus profile and these can be addressed via unit IDs

(see Section 3.5 "Addressing and Data Transmission in the Modbus Protocol", page 12).

To enable access to data of an SMA device, a special gateway is required and this is provided by

way of the Cluster Controller.

3.3 User-Defined Modbus Profile

The user-defined Modbus profile enables you to reassign Modbus addresses of the SMA Modbus

profile. One advantage of reassigning Modbus addresses is, for example, that you can arrange

relevant measured values and parameters in sequence for a specific purpose. These addresses can

then be read and written in a single data block.

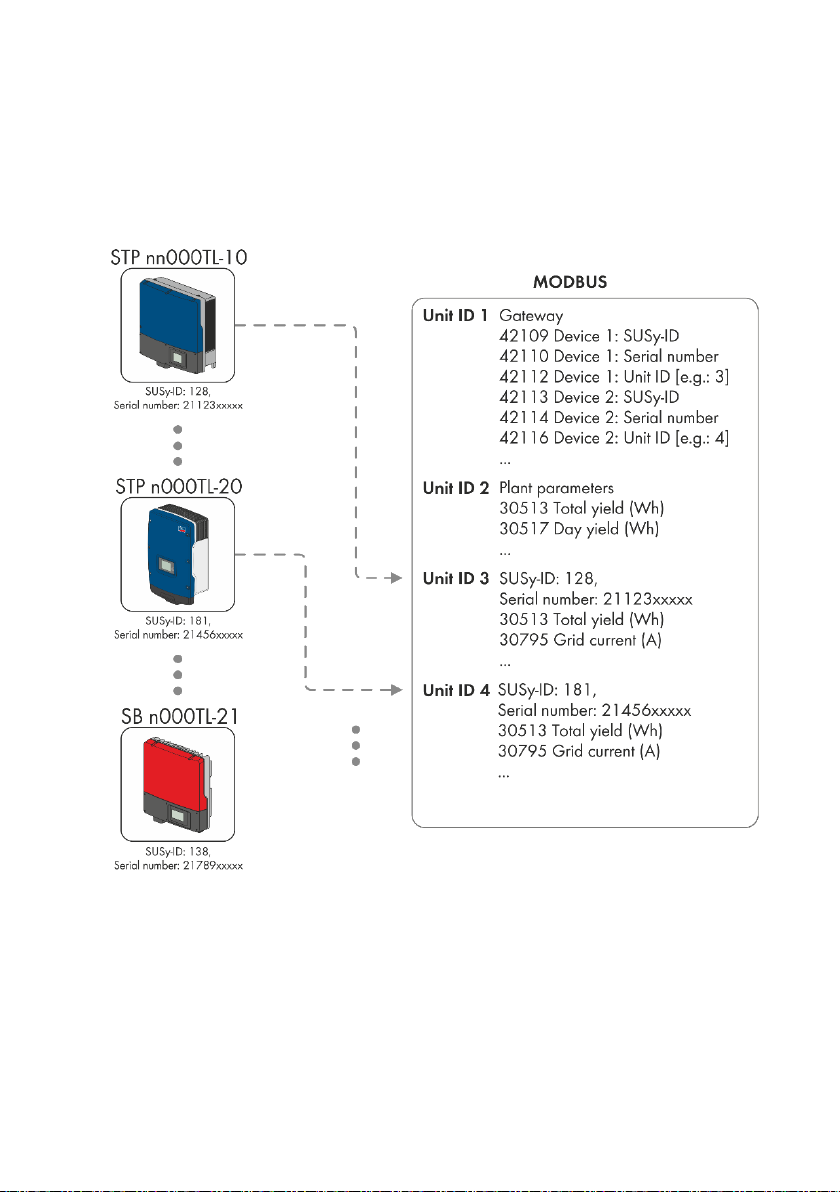

3.4 PV System Topology

The SMA Modbus profile was developed for a hierarchical system structure. In this structure, the

Cluster Controller is a communication device which is equipped with a Modbus TCP/IP and Modbus UDP/IP interface. All additional SMA devices that are connected to the Cluster Controller via

the SMA fieldbus are subordinate to the Cluster Controller. From the perspective of the Modbus

protocol, the Cluster Controller represents a Modbus slave that provides a gateway to SMA devices. The SMA devices can only be addressed using this gateway per unit ID.

Technical Information ClusterController_Modbus-TI-en-18 9

Page 10

Product Description SMA Solar Technology AG

Line

Explanation

IP network connection between SCADA system and Cluster Controller

(PV system router)

SMA fieldbus

Logical assignment of SMA device to unit ID

Example 1: PV System Topology from the Perspective of the SMA Devices

10 ClusterController_Modbus-TI-en-18 Technical Information

Page 11

SMA Solar Technology AG Product Description

Example 2: PV System Topology from the Perspective of the Modbus Protocol

In the following example, an inverter is assigned to a unit ID between 3 and 247 in each case. This

way the inverter data can be addressed in the Modbus protocol. Unit ID 1 represents the gateway

to the Modbus protocol and unit ID 2, the PV system parameters.

Technical Information ClusterController_Modbus-TI-en-18 11

Page 12

Product Description SMA Solar Technology AG

Unit ID

Explanation

1

This unit ID is reserved for the gateway of the Cluster Controller.

2

This unit ID is reserved for the system parameters.

3 to 247

The unit IDs 3 to 247 are used for addressing individual devices and for the userdefined Modbus profile. Information on firmware versions and device-specific Modbus registers of SMA products can be found on our product pages or Modbus page

at www.SMA-Solar.com. You can change the assignment of these unit IDs (see Section 4.2 "Information on Changing Unit IDs", 17).

255

Devices which are assigned to this unit ID, were connected to the Cluster Controller or

replaced after activation of the Modbus server. The devices cannot be addressed with

this unit ID. You must assign unit IDs from the range 3 to 247 to these devices (see

Section 4.2 "Information on Changing Unit IDs", page 17).

3.5 Addressing and Data Transmission in the Modbus Protocol

3.5.1 Unit IDs

The Unit ID is a superordinate addressing type in the Modbus protocol. The SMA Modbus protocol

has 247 unit IDs, of which, 245 can be assigned to individual devices. If a unit ID is assigned to a

device, then the parameters and measured values of this device can be accessed.

The following table shows an overview of the unit IDs in the SMA Modbus profile:

12 ClusterController_Modbus-TI-en-18 Technical Information

Page 13

SMA Solar Technology AG Product Description

3.5.2 Assignment of the Modbus Register to Unit IDs

The assignment of the parameters and measured values of the SMA devices to Modbus register

addresses is achieved using assignment tables and is also shown in this document (see Section 5

"SMA Modbus Profile—Assignment Tables", page 23).

In the assignment table "Gateway (unit ID = 1)", the assignment of SMA devices to individual

unit IDs is saved in the Modbus registers from address 42109. Each assignment has an address

range of four Modbus registers, although only the corresponding register is writable with the

unit ID.

In the assignment table "PV System Parameters (unit ID = 2)", parameters and measured values of

the Cluster Controller and the PV system are stored.

In the assignment table "SMA devices (unit ID = 3 to 247)", the parameters and measured values

intended for all SMA devices are stored. The individual SMA devices use a subset of these for their

device-specific parameters and measured values. Information on firmware versions and devicespecific Modbus registers of SMA products can be found on our product pages or Modbus page

at www.SMA-Solar.com.

3.5.3 Modbus Register Address, Register Width and Data Block

A Modbus register is 16 bits wide. For wider data items, connected Modbus registers are used and

considered as data blocks. The number of connected Modbus registers is indicated in the assignment tables. The address of the first Modbus register in a data block is the start address of the data

block.

3.5.4 Address Range for Modbus Register

For addressing Modbus registers, the address range 0 to 0xFFFF is available with 65536 addresses.

3.5.5 Data Transmission

In accordance with the Modbus specification, only a specific volume of data can be transported in

a single data transmission in a simple protocol data unit (PDU). The data also contains functiondependent parameters such as the function code, start address or number of Modbus registers to

be transmitted. The amount of data depends on the Modbus command used and has to be taken

into account during data transmission. You can find the number of possible Modbus registers per

command in section 3.6.

With data storage in the Motorola format "Big Endian", data transmission begins with the high byte

and then the low byte of the Modbus register.

Technical Information ClusterController_Modbus-TI-en-18 13

Page 14

Product Description SMA Solar Technology AG

Modbus command

Hexadecimal value

Data volume

(number of registers)1

Read Holding Registers

0x03

1 to 125

Read Input Registers

0x04

1 to 125

Write Single Register

0x06

1

Write Multiple Registers

0x10

1 to 123

Read Write Multiple Registers

0x17

Read: 1 to 125, Write: 1 to 121

1

3.6 Reading and Writing of Data

The Modbus interface can be used via the protocol Modbus TCP and by the protocol Modbus

UDP. Using Modbus TCP enables read- and write access (RW) and using Modbus UDP enables

only write access (WO) to the Modbus register.

The following Modbus commands are supported by the implemented Modbus interface:

Error messages on reading or writing individual Modbus registers

If a Modbus register is accessed, which is not contained in a Modbus profile, or if a Modbus command is incorrect, a Modbus exception is generated. Modbus exceptions are also generated when

write access occurs on a read-only Modbus register or read access occurs on a write-only Modbus

register.

Reading or writing of data blocks

To prevent inconsistencies, data blocks of associated registers or register ranges must be read or

written consecutively. The 4 bytes of a 64-bit Modbus register must, for example, be read with an

operation in a 64-bit SMA data type.

Error message on writing multiple Modbus registers as a data block

If multiple registers are written as a data block (Modbus commands 0x10 and 0x17) and an error

occurs during writing, the faulty register as well as all the subsequent registers in the packet will be

rejected. In the event of an error, a Modbus exception will be generated.

Modbus exceptions

For Modbus exceptions, see "Modbus Application Protocol Specification" at

http://www.modbus.org/specs.php.

Number of Modbus registers transferable as data block per command

14 ClusterController_Modbus-TI-en-18 Technical Information

Page 15

SMA Solar Technology AG Product Description

Type

Description

NaN value

S16

A signed word (16-bit).

0x8000

S32

A signed double word (32-bit).

0x8000 0000

STR32

32 byte data field, in UTF8 format.

ZERO

U16

A word (16-bit).

0xFFFF

U32

A double word (32-bit).

0xFFFF FFFF or -1

U32

For status values, only the lower 24 bits of a double word (32bit) are used.

0xFFFF FD or 0xFFFF

FE or -1

U64

A quadruple word (64-bit).

0xFFFF FFFF FFFF

FFFF or -1

Format

Explanation

Duration

Time in seconds, in minutes or in hours, depending on the Modbus register.

DT

Date/time, in accordance with country setting. Transmission as UTC

(seconds since 1970-01-01).

ENUM

Coded numerical values. The breakdown of the possible codes can be found directly

under the designation of the Modbus register in the SMA Modbus profile—assignment

tables (see also Section 8.6 "Frequently Used Number Codes", page 38).

FIX0

Decimal number, commercially rounded, no decimal place.

FIX1

Decimal number, commercially rounded, one decimal place.

3.7 SMA Data Types and NaN Values

The following table shows the data types used in the SMA Modbus profile and compares these to

possible NaN values. The SMA data types are listed in the assignment tables in the Type column.

They describe the data widths of the assigned values:

3.8 SMA Data Formats

The following SMA data formats describe how SMA data is to be interpreted. The data formats are

important, for example, for the display of data or for its further processing. The SMA data formats

are listed in the Format column of the assignment tables.

Technical Information ClusterController_Modbus-TI-en-18 15

Page 16

Product Description SMA Solar Technology AG

FIX2

Decimal number, commercially rounded, two decimal places.

FIX3

Decimal number, commercially rounded, three decimal places.

FW

Firmware version (see "Firmware version extract" below)

IP4

4-byte IP address (IPv4) of the form XXX.XXX.XXX.XXX.

RAW

Text or number. A RAW number has no decimal places and no thousand or other

separation indicators.

REV

Revision number of the form 2.3.4.5.

TEMP

Temperature values are stored in special Modbus registers in degrees Celsius (°C), in

degrees Fahrenheit (°F), or in Kelvin K. The values are commercially rounded, with

one decimal place.

UTF8

Data in UTF8 format.

Release type

Release-type coding

Explanation

0 N No revision number

1 E Experimental release

2 A Alpha release

3 B Beta release

4 R Release

5 S Special release

> 5

As number

No special interpretation

Firmware version extract, format "FW": From the delivered DWORD, four values are extracted. The values Major and Minor are contained BCD-coded in bytes 1 and 2. Byte 3 contains the

Build value (not BCD-coded). Byte 4 contains the Release Type value according to the following

table:

Example:

Firmware version of the product: 1.5.10.R

Values from DWORD: Major: 1, Minor: 5, Build: 10, Release type: 4

(Hex: 0x1 0x5 0xA 0x4)

16 ClusterController_Modbus-TI-en-18 Technical Information

Page 17

SMA Solar Technology AG Commissioning and Configuration

Allocation of unit IDs by activation of the Modbus servers

Upon activation of the Modbus servers of the Cluster Controller, unit IDs are assigned to

the SMA devices already connected to the Cluster Controller. The protocol types TCP/UDP

can be activated individually or together. If one or both of the servers are deactivated and

reactivated, the previously assigned Modbus Unit IDs are maintained.

4 Commissioning and Configuration

4.1 Commissioning Steps and Requirements

Requirements:

☐ The devices of the PV system must be connected to the Cluster Controller and the

Cluster Controller must be commissioned (for information on connection and commissioning,

see the Cluster Controller installation manual).

☐ You must log in as installer to the Cluster Controller (for login to or logout of the

Cluster Controller, see the Cluster Controller user manual).

Procedure:

1. Activate the Modbus server(s) and, if required, configure the communication ports

(for Modbus configuration, see the Cluster Controller user manual).

2. Change the unit IDs if, after activation of the Modbus servers, further SMA devices have

been added to the PV system or SMA devices have been replaced (see the following sections).

4.2 Information on Changing Unit IDs

You can change the unit IDs of SMA devices. A change is required, for example, if additional or

changed SMA devices are connected to the Cluster Controller after activation of the Modbus

servers. By way of the automatic detection of the PV system, additional or changed devices are

assigned the Modbus unit ID = 255 (NaN). On the other hand, it may be necessary to change the

unit IDs if a restructuring of the system topology is required, for example, to better map the physical

arrangement of the devices in the Modbus protocol.

Depending on whether you wish to change individual unit IDs or restructure the entire system topology, you have two options:

• Changing Unit IDs via the gateway (recommended for changing individual Unit IDs)

• Changing Unit IDs via an XML file (recommended for restructuring of the system topology)

Both of these methods are described in separate Sections.

Technical Information ClusterController_Modbus-TI-en-18 17

Page 18

Commissioning and Configuration SMA Solar Technology AG

Accessing the gateway

You access the gateway via the IP address of the Cluster Controller, under the unit ID = 1.

Modbus address

Content

Description

Device #

… … …

42109

158

SUSy-ID

A

42110

2145600972

Serial number

A

42112

3

Unit ID

A

42113

158

SUSy-ID

B

42114

2145600320

Serial number

B

42116

4

Unit ID

B

42117

158

SUSy-ID

C

42118

2145600934

Serial number

C

42120

255

Unit ID

C

… … …

…

4.3 Changing Unit IDs via the Gateway

4.3.1 Reading Out the Gateway

You can read out the individual unit IDs of the SMA devices from the gateway, for example, using

a SCADA system.

The assignment of the system devices for unit IDs 3 to 247 is stored in the Modbus registers from

address 42109. Each assignment has an address range of four Modbus registers. You can find the

Modbus register of the gateway in Section 5.2 "Gateway", page 24.

Example "Read out additional device from the gateway“

Via automatic detection, an additional SMA device was assigned to unit ID = 255 (indicated with

C in column "Device #" in the following table). The assignments of the gateway were, as follows

here, shown with a SCADA system as a table:

18 ClusterController_Modbus-TI-en-18 Technical Information

Page 19

SMA Solar Technology AG Commissioning and Configuration

Do not assign unit IDs more than once

You must not assign a Unit ID more than once. In the event of a Modbus query with a unit

ID that has been assigned more than once, the data is read out for the device that is entered with this unit ID in the gateway under the lowest Modbus address.

Modbus address

Designation

After detection

Modified

42117

SUSy-ID

158

158

42118

Serial number

2145600934

2145600934

42120

Unit ID

255 (NaN)

5

4.3.2 Changing A Unit ID in the Gateway

You change a unit ID by writing it to the relevant Modbus address. All three of the Modbus registers that belong to a device-unit-ID assignment must be transmitted in a single data block, although

only the register with the unit ID is writable. For the following example, this means that all the data

of the three Modbus addresses 42117, 42118 and 42120 must be contained in the data block.

Example "Changing A Unit ID in the Gateway"

The following table shows an example of assignment of a device to a unit ID. An inverter was

subsequently detected with SUSy ID = 158 and serial number 2145600934, as the third device in

the PV system (Modbus addresses 42117 to 42120). The unit ID of this device was manually set to

5:

Technical Information ClusterController_Modbus-TI-en-18 19

Page 20

Commissioning and Configuration SMA Solar Technology AG

Uploading and downloading XML files

For more information on uploading and downloading XML files via the user interface, see

the SMA Cluster Controller user manual.

XML tag or attribute

Explanation

<device…/>

Within the tag "Device" is the assignment of a device to a unit ID.

regoffs=”aaa“

Number of the device in file sysplant.xml. The number must not necessarily be assigned sequentially. There are four Modbus register addresses between two devices. Regoffs = 0 defines the first device under

the Modbus address 42109, Regoffs = 244 the last device under the

Modbus address 43085.

susyid=”bbb“

SUSy ID of the device

4.4 Changing Unit IDs via the XML File usrplant.xml

4.4.1 Overview

The Cluster Controller stores the assignments of the devices of the PV system to unit IDs in the file

sysplant.xml. This file contains an excerpt of the gateway (see Section 5.2 "Gateway (Unit ID =

1)", page 24). If new SMA devices are added or if SMA devices are replaced, these are respectively added to the available XML structure of this file with unit ID = 255 by the Cluster Controller.

You can define your own variant of this file in the file usrplant.xml. You can use

sysplant.xml as a template for usrplant.xml.

You can download the file sysplant.xml from the Cluster Controller.

The file usrplant.xml must be activated in the Cluster Controller. Once the file usrplant.xml is

activated, the file sysplant.xml is not taken into consideration for the duration of the activation.

4.4.2 Structure of the XML File usrplant.xml

The files sysplant.xml and usrplant.xml have the same tag structure.

The basic structure of the files is as follows:

<?xml version=“1.0“ encoding=“UTF-8“?>

<plant version=“001“>

<device regoffs=“aaa“ susyid=”bbb“ serial=”cccccccccc“ unitid=”ddd“ />

…

</plant>

Legend for XML tags and attributes:

20 ClusterController_Modbus-TI-en-18 Technical Information

Page 21

SMA Solar Technology AG Commissioning and Configuration

serial=”cccccccccc“

Serial number of the device

unitid="ddd"

Unit ID of the device

Example of the file usrplant.xml

The unit IDs of the following two SMA devices are to be changed to unit ID 3 and 4:

• SB 5000 TL-21, SUSy ID = 138, Serial number = 2178909920, current position in

gateway = 7

• STP 15000TL-10, SUSy ID = 128, Serial number = 2112303920, current position in

gateway = 8

The exact appearance of the XML file is then as follows:

<?xml version=“1.0“ encoding=“UTF-8“?>

<plant version=“001“>

<device regoffs=”7“ susyid=”138“ serial=”2178909920“ unitid=”3“ />

<device regoffs=”8“ susyid=”128“ serial=”2112303920“ unitid=”4“ />

</plant>

4.4.3 Activating and Deactivating usrplant.xml

Activating the file usrplant.xml:

To activate the file usrplant.xml, upload the file to the Cluster Controller. All the specifications in

the file are checked. If the file contains no errors, its contents are entered into the system.

A changed usrplant.xml becomes effective a few seconds after it is activated. Once the file

usrplant.xml is activated, the file sysplant.xml is not taken into consideration for the duration of

the activation.

Deactivating the file usrplant.xml:

To deactivate the file usrplant.xml, upload a version of this file containing no device tags to the

Cluster Controller. Both of the following lines show the structure of such a usrplant.xml file:

<?xml version=“1.0“ encoding=“UTF-8“?>

<plant version=“001“></plant>

Without the device tags in the file usrplant.xml, the system returns to the specifications saved in

the file sysplant.xml. A changed usrplant.xml becomes effective a few seconds after it is saved

to the Cluster Controller.

Technical Information ClusterController_Modbus-TI-en-18 21

Page 22

Commissioning and Configuration SMA Solar Technology AG

Save data prior to restoring default settings

By resetting the Cluster Controller to default settings, the user-defined PV system topology

usrplant.xml and the user-defined Modbus profile usrprofile.xml are deleted. Save these files

before resetting.

4.5 Resetting the Cluster Controller to the Default Settings

By resetting the Cluster Controller to the default settings, the previously assigned unit IDs are deleted and reassigned – file sysplant.xml is therefore rewritten. As a result, all connected SMA devices are assigned a new unit ID.

For further information on resetting to default settings and saving XML files, refer to the

SMA Cluster Controller user manual.

22 ClusterController_Modbus-TI-en-18 Technical Information

Page 23

SMA Solar Technology AG SMA Modbus Profile—Assignment Tables

Information

Explanation

ADR (DEC)

Decimal Modbus address (see Section 3.5.3 "Modbus Register Address,

Register Width and Data Block", page 13 onwards)

Description/

number code(s)

Short description of the Modbus register and the number codes used.

CNT

Number of assigned Modbus registers.

Type

Data type, e.g. V32 = 32 bits without prefix (see Section 3.7 "SMA Data

Types and NaN Values", page 15).

Format

Data format of saved value, e.g. DT = date, FIX n = output with n decimal

places, TEMP = output as temperature (see Section 3.8 "SMA Data Formats", page 15).

Access

Access type:

RO: Read only (only Modbus TCP)

RW: Read and write (only Modbus TCP). With Modbus UDP, all RW

registers are write-only (WO register).

WO: Write only (Modbus TCP and Modbus UDP)

If an access type is not allowed, a Modbus exception is generated in the

event of access with an access type that is not allowed.

5 SMA Modbus Profile—Assignment Tables

5.1 Information on the Assignment Tables

The following subsections are sorted by unit ID. Each contains a table of the Modbus addresses

which can be accessed using this unit ID. The tables present the following information:

Technical Information ClusterController_Modbus-TI-en-18 23

Page 24

SMA Modbus Profile—Assignment Tables SMA Solar Technology AG

ADR (DEC)

Description/number code(s)

CNT (WORD) Type Format Access

30001

Version number of the SMA Modbus profile

2

U32

RAW

RO

30003

SUSy ID (of the Cluster Controller)

2

U32

RAW

RO

30005

Serial number (of the Cluster Controller)

2

U32

RAW

RO

30007

Modbus data change: meter value is increased by

the Cluster Controller if new data is available.

2

U32

RAW

RO

30051

Device class:

8000 = All devices

8001 = PV inverter

8002 = Wind power inverter

8007 = Battery inverter

8033 = Load

8064 = Sensor technology general

8065 = Energy meter

8128 = Communication products

2

U32

ENUM

RO

30193

UTC system time (s)

2

U32

DT

RO

30513

Total energy fed in across all line conductors, in Wh

(accumulated values of the inverters)

4

U64

FIX0

RO

30517

Energy fed in on current day across all line conductors, in Wh (accumulated values of the inverters)

4

U64

FIX0

RO

30775

Current active power on all line conductors (W),

accumulated values of the inverters

2

S32

FIX0

RO

30805

Reactive power on all line conductors (var),

accumulated values of the inverters

2

S32

FIX0

RO

5.2 Gateway (Unit ID = 1)

In the following table you can find the parameters and measured values provided by the gateway,

which you can access under unit ID = 1as well as the assignment of the SMA devices to the

unit IDs. You can access the gateway via the IP address of the Cluster Controller:

24 ClusterController_Modbus-TI-en-18 Technical Information

Page 25

SMA Solar Technology AG SMA Modbus Profile—Assignment Tables

34653

Digital input group 1, coded

as status:

311 = Open

2055 = DI1

2056 = DI1 DI2

2057 = DI1 DI2 DI3

2058= DI1 DI2 DI3 DI4

2059 = DI1 DI2 DI4

2060 = DI1 DI3

2061 = DI1 DI3 DI4

2062 = DI1 DI4

2063 = DI2

2064 = DI2 DI3

2065 = DI2 DI3 DI4

2066 = DI2 DI4

2067 = DI3

2068 = DI3 DI4

2069 = DI4

2

U32

ENUM

RO

34655

Digital input group 2, coded

as status:

311 = Open

2070 = DI5

2071 = DI5 DI6

2072 = DI5 DI6 DI7

2073 = DI5 DI6 DI7 DI8

2074 = DI5 DI6 DI8

2075 = DI5 DI7

2076 = DI5 DI7 DI8

2077 = DI5 DI8

2078 = DI6

2079 = DI6 DI7

2080 = DI6 DI7 DI8

2081 = DI6 DI8

2082 = DI7

2083 = DI7 DI8

2084 = DI8

2

U32

ENUM

RO

40001

Set UTC system time, in s

2

U32

DT

RW

Unit ID assignment – SMA devices:

42109

Device 1: SUSy ID

1

U16

RAW

RO

42110

Device 1: Serial number

2

U32

RAW

RO

42112

Device 1: Unit ID (e.g. 3)

1

U16

RAW

RW

42113

Device 2: SUSy ID

1

U16

RAW

RO

42114

Device 2: Serial number

2

U32

RAW

RO

42116

Device 2: Unit ID (e.g. 4)

1

U16

RAW

RW

… … … … …

…

43085

Device 245: SUSy ID

1

U16

RAW

RO

43086

Device 245: Serial number

2

U32

RAW

RO

43088

Device 245: Unit ID (e.g. 247)

1

U16

RAW

RW

Technical Information ClusterController_Modbus-TI-en-18 25

Page 26

SMA Modbus Profile—Assignment Tables SMA Solar Technology AG

Unit ID = 255

For unit ID = 255, observe Section 4.3 "Changing Unit IDs via the Gateway", page 18.

Modbus exception on accessing empty assignments

If, in the address range 42109 to 43088, individual Modbus registers or a data block are

accessed which do not contain any assignment of unit IDs to SMA devices, a Modbus exception is generated.

ADR (DEC)

Description/number code(s)

CNT (WORD) Type Format Access

30193

UTC system time, in s

2

U32

DT

RO

30513

Total energy fed in across all line conductors, in Wh

(accumulated values of the inverters)

4

U64

FIX0

RO

30517

Energy fed in on current day across all line conductors, in Wh (accumulated values of the inverters)

4

U64

FIX0

RO

30775

Current active power on all line conductors (W),

accumulated values of the inverters

2

S32

FIX0

RO

30805

Reactive power across all line conductors (VAr)

(accumulated values of the inverters)

2

S32

FIX0

RO

31235

Active power setpoint Digital I/O in %

2

U32

FIX2

RO

31237

Active power setpoint Analog input in %

2

U32

FIX2

RO

31239

Active power setpoint in %s

2

U32

FIX2

RO

5.3 System Parameters (Unit ID = 2)

In the following table , you can find the PV system parameters that you can access using unit ID =

2. The system parameters represent measured values and parameters of the Cluster Controller and

also PV system devices that are connected via the Modbus protocol. Parameters such as time

settings are transferred by the Cluster Controller to the devices of the PV system and there, depending on the device type, processed further. Measured values such as energy meter values are queried by the devices and made available as accumulated values:

26 ClusterController_Modbus-TI-en-18 Technical Information

Page 27

SMA Solar Technology AG SMA Modbus Profile—Assignment Tables

Specification Modbus Electric utility company

31241

Active power setpoint in %s

Specification Modbus Direct marketing

2

U32

FIX2

RO

31243

Resulting setpoint in %

(minimum value definition of all specifications)

2

U32

FIX2

RO

31249

Current utility grid export active power P in W (actual

value of the active power fed in at the grid-connection

point; measured with an external measuring device).

2

S32

FIX0

RO

31251

Current utility grid export reactive power Q in VAr

(actual value of the reactive power fed in at the gridconnection point; measured with an external measuring device).

2

S32

FIX0

RO

34609

Ambient temperature (°C)

2

S32

TEMP

RO

34611

Highest measured ambient temperature (°C)

2

S32

TEMP

RO

34613

Total irradiation on the sensor surface (W/m²)

2

U32

FIX0

RO

34615

Wind speed (m/s)

2

U32

FIX1

RO

34617

Humidity (%)

2

U32

FIX2

RO

34619

Air pressure (Pa)

2

U32

FIX2

RO

34621

PV module temperature (°C)

2

S32

TEMP

RO

34623

Total irradiation on the external irradiation sensor/pyranometer (W/m²)

2

U32

FIX0

RO

34625

Ambient temperature (°F)

2

S32

TEMP

RO

34627

Ambient temperature (K)

2

S32

TEMP

RO

34629

PV module temperature (°F)

2

S32

TEMP

RO

34631

PV module temperature (K)

2

S32

TEMP

RO

34633

Wind speed (km/h)

2

U32

FIX1

RO

34635

Wind speed (mph)

2

U32

FIX1

RO

34637

Analog current input 1 (mA)

2

S32

FIX2

RO

34639

Analog current input 2 (mA)

2

S32

FIX2

RO

Technical Information ClusterController_Modbus-TI-en-18 27

Page 28

SMA Modbus Profile—Assignment Tables SMA Solar Technology AG

34641

Analog current input 3 (mA)

2

S32

FIX2

RO

34643

Analog current input 4 (mA)

2

S32

FIX2

RO

34645

Analog voltage input 1 (V)

2

S32

FIX2

RO

34647

Analog voltage input 2 (V)

2

S32

FIX2

RO

34649

Analog voltage input 3 (V)

2

S32

FIX2

RO

34651

Analog voltage input 4 (V)

2

S32

FIX2

RO

34653

Digital input group 1, coded

as status:

311 = Open

2055 = DI1

2056 = DI1 DI2

2057 = DI1 DI2 DI3

2058= DI1 DI2 DI3 DI4

2059 = DI1 DI2 DI4

2060 = DI1 DI3

2061 = DI1 DI3 DI4

2062 = DI1 DI4

2063 = DI2

2064 = DI2 DI3

2065 = DI2 DI3 DI4

2066 = DI2 DI4

2067 = DI3

2068 = DI3 DI4

2069 = DI4

2

U32

ENUM

RO

34655

Digital input group 2, coded

as status:

311 = Open

2070 = DI5

2071 = DI5 DI6

2072 = DI5 DI6 DI7

2073 = DI5 DI6 DI7 DI8

2074 = DI5 DI6 DI8

2075 = DI5 DI7

2076 = DI5 DI7 DI8

2077 = DI5 DI8

2078 = DI6

2079 = DI6 DI7

2080 = DI6 DI7 DI8

2081 = DI6 DI8

2082 = DI7

2083 = DI7 DI8

2084 = DI8

2

U32

ENUM

RO

40001

Reading and setting the UTC system time (s)

2

U32

DT

RW

40003

Reading and setting the time zone (see Section 8.5

"Number Codes of the Time Zones", page 36).

2

U32

ENUM

RW

40005

Automatic daylight saving time conversion active:

1129 = Active

1130 = Not active

2

U32

ENUM

RW

28 ClusterController_Modbus-TI-en-18 Technical Information

Page 29

SMA Solar Technology AG SMA Modbus Profile—Assignment Tables

40493

Direct marketer:

Active power setpoint P, in % of the maximum active

power (PMAX) of the PV plant.

Value range:

-100.00% to < 0% = Load

0% = No active power

< 0% to +100.00% = Generator

1

S16

FIX2

WO

41167

Active power setpoint in % (manual specification)

2

U32

FIX2

RO

Technical Information ClusterController_Modbus-TI-en-18 29

Page 30

User-Defined Modbus Profile SMA Solar Technology AG

XML tag or attribute

Explanation

<virtual_modbusprofile>

</virtual_modbusprofile>

A user-defined Modbus profile is created within this XML structure.

<channel />

Within a channel tag, a Modbus address of a unit ID is redefined:

unitid="aaa"

Specifies the unit ID of the device whose Modbus addresses are to be

used as a source. Possible unit IDs for individual devices are 3 to 247.

source=”bbbbb”

Specifies a Modbus address of the devices selected under "unitid",

whose parameters or measured values are to be used as source (see

Section 5 "SMA Modbus Profile—Assignment Tables", page 23).

6 User-Defined Modbus Profile

With the user-defined Modbus profile, the Modbus addresses that are available in the SMA Modbus profile for the individual unit IDs can be assigned to different Modbus addresses. You can use

the entire Modbus address range from 0 to 65535. One advantage of the user-defined Modbus

profile can be that the measured values and parameters relevant for controlling your system can be

applied to consecutive Modbus addresses. These addresses can then be read or written in a single

data block.

The user-defined Modbus profile can be called up via the gateway like an additional device and

has a separate unit ID which you can define between 3 and 247 (see Section 3.5.1 "Unit IDs",

page 12).

6.1 Structure of the XML File for the User-Defined

Modbus Profile

The user-defined Modbus profile is created in the file usrprofile.xml .

The basic structure of the XML file is as follows:

<?xml version=“1.0“ encoding=“UTF-8“?>

<virtual_modbusprofile>

<channel unitid=”aaa” source=”bbbbb” destination=”ccccc” />

…

<!—End of the instructions-->

</virtual_modbusprofile>

Legend for XML tags and attributes:

30 ClusterController_Modbus-TI-en-18 Technical Information

Page 31

SMA Solar Technology AG User-Defined Modbus Profile

destination="ccccc"

Specifies the new Modbus address at which the parameter or measured

value is to be accessed (0 to 65535). Note the number of Modbus

registers that are stored at the original address. The destination registers

must not overlap. If incomplete Modbus registers are called up later, a

Modbus exception is generated. If register addresses are called up,

which are not filled with values, NaN is returned.

<!--xyz-->

Comments out the range xyz, for example, to deactivate an instruction.

ADR (DEC)

Description/number code(s)

CNT (WORD) Type Format Access

30775

AC active power across all line conductors (W)

2

S32

FIX0

RO

30805

Reactive power across all line conductors (VAr)

2

S32

FIX0

RO

30813

Apparent power across all line conductors (VA)

2

S32

FIX0

RO

Modbus exceptions

For Modbus exceptions, see "Modbus Application Protocol Specification" at

http://www.modbus.org/specs.php.

6.2 Example of a User-Defined Modbus Profile

The Modbus registers for apparent power, active power and reactive power of the devices stored

under unit IDs 3 and 4 are to be retrievable in a user-defined Modbus profile from address 0 at

consecutive Modbus addresses (the following table is an excerpt from the SMA Modbus profile):

The exact appearance of the XML file follows from the example:

<?xml version=“1.0“ encoding=“UTF-8“?>

<virtual_modbusprofile>

<channel unitid=”3” source=”30775” destination=”0” />

<channel unitid=”3” source=”30805” destination=”2” />

<channel unitid=”3” source=”30813” destination=”4” />

<channel unitid=”4” source=”30775” destination=”6” />

<channel unitid=”4” source=”30805” destination=”8” />

<channel unitid=”4” source=”30813” destination=”10” />

</virtual_modbusprofile>

Technical Information ClusterController_Modbus-TI-en-18 31

Page 32

User-Defined Modbus Profile SMA Solar Technology AG

Uploading and downloading XML files

For more information on uploading and downloading XML files via the user interface, see

the SMA Cluster Controller user manual.

6.3 Activating and Deactivating User-Defined Modbus Profile

To activate your user-defined Modbus profile, upload the file usrprofile.xml to the Cluster Controller, restart it, and activate the user-defined Modbus profile as described below.

If the usage of the user-defined Modbus profile on the Cluster Controller is deactivated, the userdefined assignments are lost and only the SMA Modbus profile remains active.

Activating A User-Defined Modbus Profile

You activate a user-defined Modbus profile by creating a device entry with the attribute "susyid=0"

in file usrplant.xml (you can find more information on the file usrplant.xml in Section 4.4

"Changing Unit IDs via the XML File usrplant.xml", page 20).

Example:

The following device entry activates a user-defined Modbus profile that is entered as the tenth

device in the gateway.

<device regoffs=”9“ susyid=”0“ serial=”0“ unitid=”100“ />

Deactivating A User-Defined Modbus profile

You deactivate a user-defined Modbus profile by commenting out in its device line in the file

usrplant.xml and re-uploading this to the Cluster Controller (for more information on the

usrplant.xml file, see Section 4.4 "Changing Unit IDs via the XML File usrplant.xml", page 20).

In the following example, you can see a commenting out applied to the line with the user-defined

Modbus profile:

<!--<device regoffs=”0“ susyid=”128“ serial=”8700654300“ unitid=”3“ />-->

32 ClusterController_Modbus-TI-en-18 Technical Information

Page 33

SMA Solar Technology AG Troubleshooting

The event numbers of the SMA devices cannot be decrypted with the number

codes in this document.

The event numbers of the SMA devices are device-specific and cannot be decrypted with

the number codes in this document.

To decrypt the event numbers of low or medium-power inverters, you require additional

information (operating parameters/measured values, see Technical Description "Measured

Values and Parameters" at www.SMA-Solar.com).

To decrypt the event numbers of central inverters, contact the SMA Service Line (see Section

9 "Contact", page 39).

7 Troubleshooting

You can find information on error analysis of the SMA Modbus profile in Section 3.6 "Reading and

Writing of Data", page 14.

For troubleshooting of the SMA devices, go to Modbus address 30197 and use the event numbers

displayed here.

Technical Information ClusterController_Modbus-TI-en-18 33

Page 34

Technical Data SMA Solar Technology AG

Device type

Maximum number of SMA devices

CLCON-10

75

CLCON-S-10

25

Network protocol

Communication port, default setting

TCP

502

UDP

502

Using free communication ports

You should only use free communication ports. The following range is generally available:

49152 to 65535.

You can find more information on occupied ports in the database "Service Name and

Transport Protocol Port Number Registry" at http://www.iana.org/assignments/servicenames-port-numbers/service-names-port-numbers.xml.

Changing the communication port

If you change one of the communication ports of the Cluster Controller, you must also

change the corresponding communication port of a connected Modbus master system.

Otherwise the Cluster Controller can no longer be accessed via the Modbus protocol.

8 Technical Data

8.1 Supported SMA Inverters

All inverters with integrated or retrofitted Speedwire/Webconnect interfaces are supported.

Information on whether an inverter has an integrated Speedwire/Webconnect interface or can be

retrofitted with a Speedwire/Webconnect interface can be found on the product page of the respective inverter at www.SMA-Solar.com.

8.2 Number of SMA Devices

The following table contains details on the maximum number of SMA devices that can be operated

with the Cluster Controller.

8.3 Modbus Communication Ports

The following table shows the default settings of the supported network protocols:

34 ClusterController_Modbus-TI-en-18 Technical Information

Page 35

SMA Solar Technology AG Technical Data

Damage to SMA inverters

The parameters of the SMA inverters that can be changed with writable Modbus registers (RW)

are intended for long-term storage of device settings. Cyclical changing of these parameters leads

to destruction of the flash memory of the devices.

• Device parameters must not be changed cyclically.

Contact the SMA Service Line if you would like to automate the remote control of your PV system

(see Section 9 "Contact", page 39).

8.4 Data Processing and Time Behavior

In this Section, you can find typical data processing and reaction times of the Cluster Controller

Modbus interface and time details for saving parameters in SMA devices.

Signal run time through the Cluster Controller

The signal run time through the Cluster Controller is a maximum of 100 ms.

The signal run time is the time required by the Cluster Controller to process incoming Modbus

commands and to forward them to the devices in the PV system.

Data transfer interval via the Modbus protocol

For system stability reasons, the time period between data transfers via the Modbus protocol must

be at least ten seconds. No more than 30 parameters and measured values should be transmitted

per inverter. Note the maximum number of SMA devices according to Section 8.2 "Number of

SMA Devices", page 34.

Physical reaction time of the inverters

The physical reaction time of the inverters is typically approximately one second, depending on the

inverters used.

The physical reaction time is the time between the changing of setpoints in the inverters until their

physical implementation. Such a change would be, for example, changing cos φ.

Reaction time of the Modbus interface

The reaction time of the Modbus interface is five to ten seconds.

The reaction time of the Modbus interface is the time between the arrival of the parameter specifica-

tions in the inverters until the corresponding measured values are provided to the Modbus interface

of the Cluster Controller. Due to this reaction time, parameter specifications can only be displayed

via a Modbus master system (e.g. a SCADA system) at a corresponding or larger interval.

Technical Information ClusterController_Modbus-TI-en-18 35

Page 36

Technical Data SMA Solar Technology AG

City/Country

Code

Time zone

Abu Dhabi, Muscat

9503

UTC+04:00

Adelaide

9513

UTC+09:30

Alaska

9501

UTC-09:00

Amman

9542

UTC+02:00

Amsterdam, Berlin, Bern, Rome,

Stockholm, Vienna

9578

UTC+01:00

Arizona

9574

UTC-07:00

Astana, Dhaka

9515

UTC+06:00

Asuncion

9594

UTC-04:00

Athens, Bucharest, Istanbul

9537

UTC+02:00

Atlantic (Canada)

9505

UTC-04:00

Auckland, Wellington

9553

UTC+12:00

Azores

9509

UTC-01:00

Baghdad

9504

UTC+03:00

Baku

9508

UTC+04:00

Bangkok, Hanoi, Jakarta

9566

UTC+07:00

Beirut

9546

UTC+02:00

Belgrade, Bratislava, Budapest,

Ljubljana, Prague

9517

UTC+01:00

Bogotá, Lima, Quito

9563

UTC-05:00

Brasilia

9527

UTC-03:00

Brisbane

9525

UTC+10:00

Brussels, Copenhagen, Madrid,

Paris

9560

UTC+01:00

Buenos Aires

9562

UTC-03:00

Canberra, Melbourne, Sydney

9507

UTC+10:00

Caracas

9564

UTC-04:30

Casablanca

9585

UTC+00:00

Cayenne

9593

UTC-03:00

Chennai, Kolkata, Mumbai, New

Delhi

9539

UTC+05:30

Chicago, Dallas, Kansas City,

Winnipeg

9583

UTC-06:00

Chihuahua, La Paz, Mazatlán

9587

UTC-07:00

Darwin

9506

UTC+09:30

Denver, Salt Lake City, Calgary

9547

UTC-07:00

Dublin, Edinburgh, Lisbon, London

9534

UTC+00:00

Yerevan

9512

UTC+04:00

Fiji, Marshall Islands

9531

UTC+12:00

Georgetown, La Paz, San Juan

9591

UTC-04:00

Greenland

9535

UTC-03:00

Guadalajara, Mexico City,

Monterrey

9584

UTC-06:00

Guam, Port Moresby

9580

UTC+10:00

Harare, Pretoria

9567

UTC+02:00

Hawaii

9538

UTC-10:00

Helsinki, Kiev, Riga, Sofia, Tallinn,

Vilnius

9532

UTC+02:00

Hobart

9570

UTC+10:00

Indiana (East)

9573

UTC-05:00

International Date Line (West)

9523

UTC-12:00

Irkutsk

9555

UTC+08:00

Islamabad, Karachi

9579

UTC+05:00

Yakutsk

9581

UTC+09:00

Yekaterinburg

9530

UTC+05:00

Jerusalem

9541

UTC+02:00

Kabul

9500

UTC+04:30

Cairo

9529

UTC+02:00

Cape Verde Islands

9511

UTC-01:00

Katmandu

9552

UTC+05:45

Caucasus Standard Time

9582

UTC+04:00

Krasnoyarsk

9556

UTC+07:00

Kuala Lumpur, Singapore

9544

UTC+08:00

Kuwait, Riyadh

9502

UTC+03:00

Magadan, Solomon Islands, New

Caledonia

9519

UTC+11:00

Manaus

9516

UTC-04:00

Midway Islands, Samoa

9565

UTC-11:00

Minsk

9526

UTC+02:00

Mid-Atlantic

9545

UTC-02:00

Monrovia, Reykjavík

9536

UTC+00:00

8.5 Number Codes of the Time Zones

The following table contains the most important time zones and their number codes in the SMA

Modbus profile. If the location is known, you can determine the numerical key (code) and the time

zone. In the tables in Section 5 "SMA Modbus Profile—Assignment Tables", from page 23, with

specification of the time zone, this table is referenced.

36 ClusterController_Modbus-TI-en-18 Technical Information

Page 37

SMA Solar Technology AG Technical Data

Montevideo

9588

UTC-03:00

Moscow, St. Petersburg, Volgograd

9561

UTC+03:00

Nairobi

9524

UTC+03:00

Newfoundland

9554

UTC-03:30

New York, Miami, Atlanta, Detroit,

Toronto

9528

UTC-05:00

Novosibirsk

9550

UTC+06:00

Nuku'alofa

9572

UTC+13:00

Osaka, Sapporo, Tokyo

9571

UTC+09:00

Pacific (U.S., Canada)

9558

UTC-08:00

Beijing, Chongqing, Hong Kong,

Ürümqi

9522

UTC+08:00

Perth

9576

UTC+08:00

Petropavlovsk-Kamchatsky

9595

UTC+12:00

Port Louis

9586

UTC+04:00

Santiago

9557

UTC-04:00

Sarajevo, Skopje, Warsaw, Zagreb

9518

UTC+01:00

Saskatchewan

9510

UTC-06:00

Seoul

9543

UTC+09:00

Sri Jayawardenepura

9568

UTC+05:30

Taipei

9569

UTC+08:00

Tashkent

9589

UTC+05:00

Teheran

9540

UTC+03:30

Tbilisi

9533

UTC+04:00

Tijuana, Lower California (Mexico)

9559

UTC-08:00

Ulan Bator

9592

UTC+08:00

West-Central Africa

9577

UTC+01:00

Windhoek

9551

UTC+02:00

Vladivostok

9575

UTC+10:00

Yangon (Rangoon)

9549

UTC+06:30

Central America

9520

UTC-06:00

Technical Information ClusterController_Modbus-TI-en-18 37

Page 38

Technical Data SMA Solar Technology AG

Event Numbers

The event numbers displayed by the inverters under the Modbus address 30197 are devicespecific. You cannot decrypt the event numbers with the number codes in this document (see

Section 7 "Troubleshooting", page 33).

Code

Meaning

51

Closed

276

Instantaneous value

295

MPP

303

Off

308

On

309

Operation

311

Open

336

Contact the manufacturer

337

Contact the installer

338

Invalid

381

Stop

455

Warning

461

SMA (manufacturer specification)

1041

Leading

1042

Lagging

1069

Reactive power/voltage characteristic curve Q(V)

1070

Reactive power Q, direct setpoint

1071

Reactive power const. Q (kVAr)

1072

Reactive power Q, setpoint via system control

1073

Reactive power Q(P)

1074

cos φ, direct setpoint

1075

cos φ, setpoint via system control

1076

cos φ(P) characteristic curve

1077

Active power limitation P, in W

1078

Active power limitation P (%) of PMAX

1079

Active power limitation P via system control

1387

Reactive power Q, setpoint via analog input

1388

cos φ, setpoint via analog input

1389

Reactive power/voltage characteristic curve Q(U)

with hysteresis and deadband

1390

Active power limitation P via analog input

1391

Active power limitation P via digital inputs

1392

Error

1393

Wait for PV voltage

1394

Wait for valid AC grid

1395

DC section

1396

AC grid

1455

Emergency switch

1466

Waiting

1467

Starting

1468

MPP search

1469

Shutdown

1470

Disturbance

1471

Warning/error e-mail OK

1472

Warning/error e-mail not OK

1473

System info e-mail OK

1474

System info e-mail not OK

1475

Error e-mail OK

1476

Error e-mail not OK

1477

Warning e-mail OK

1478

Warning e-mail not OK

1479

Wait after grid interruption

1480

Wait for electric utility company

8.6 Frequently Used Number Codes (ENUM)

The following table contains number codes which, as function coding in data format ENUM, are

frequently used in the SMA Modbus profile.

38 ClusterController_Modbus-TI-en-18 Technical Information

Page 39

SMA Solar Technology AG Contact

Danmark

Deutschland

Österreich

Schweiz

SMA Solar Technology AG

Niestetal

Sunny Boy, Sunny Mini Central,

Sunny Tripower:

+49 561 9522-1499

Monitoring Systems

(Kommunikationsprodukte):

+49 561 9522-2499

Fuel Save Controller

(PV-Diesel-Hybridsysteme):

+49 561 9522-3199

Sunny Island, Sunny Boy Storage,

Sunny Backup, Hydro Boy:

+49 561 9522-399

Sunny Central,

Sunny Central Storage:

+49 561 9522-299

SMA Online Service Center

www.SMA-Service.com

Belgium

Belgique

België

Luxemburg

Luxembourg

Nederland

SMA Benelux

BVBA/SPRL

Mechelen

+32 15 286 730

SMA Online Service

Center

www.SMA-Service.com

Česko

Magyarország

Slovensko

SMA Service Partner

TERMS a.s.

+420 387 6 85 111

SMA Online Service

Center

www.SMA-Service.com

Türkiye

SMA Service Partner

DEKOM Ltd. Şti.

+90 24 22430605

SMA Online Service

Center

www.SMA-Service.com

9 Contact

If you have technical problems with our products, please contact the SMA Service Line. We require

the following information in order to provide you with the necessary assistance:

• Modbus master software or hardware used

• Software version of your SMA Cluster Controller

• Type of communication interface between the SMA Cluster Controller and the inverters

• Type, serial numbers, and software version of the inverters connected to your PV system

Technical Information ClusterController_Modbus-TI-en-18 39

Page 40

Contact SMA Solar Technology AG

France

SMA France S.A.S.

Lyon

+33 472 22 97 00

SMA Online Service Center :

www.SMA-Service.com

Ελλάδα

Κύπρος

SMA Service Partner

AKTOR FM.

Αθήνα

+30 210 8184550

SMA Online Service Center

www.SMA-Service.com

España

Portugal

SMA Ibérica Tecnología Solar,

S.L.U.

Barcelona

+34 935 63 50 99

SMA Online Service Center

www.SMA-Service.com

United

Kingdom

SMA Solar UK Ltd.

Milton Keynes

+44 1908 304899

SMA Online Service Center

www.SMA-Service.com

Italia

SMA Italia S.r.l.

Milano

+39 02 8934-7299

SMA Online Service Center

www.SMA-Service.com

Bulgaria

România

Slovenija

Hrvatska

SMA Service Partner

Renovatio Solar

+40 372 756 599

SMA Online Service Center

www.SMA-Service.com

United Arab

Emirates

SMA Middle East LLC

Abu Dhabi

+971 2234 6177

SMA Online Service Center

www.SMA-Service.com

India

SMA Solar India Pvt. Ltd.

Mumbai

+91 22 61713888

SMA Solar (Thailand) Co., Ltd.

+66 2 670 6999

대한민국

SMA Technology Korea Co.,

Ltd.

서울

+82-2-520-2666

40 ClusterController_Modbus-TI-en-18 Technical Information

Page 41

SMA Solar Technology AG Contact

South Africa

SMA Solar Technology

South Africa Pty Ltd.

Cape Town

08600SUNNY

(08600 78669)

International:

+27 (0)21 826 0600

SMA Online Service Center

www.SMA-Service.com

Argentina

Brasil

Chile

Perú

SMA South America SPA

Santiago de Chile

+562 2820 2101

Australia

SMA Australia Pty. Ltd.

Sydney

Toll free for Australia:

1800 SMA AUS

(1800 762 287)

International:

+61 2 9491 4200

Other countries

International

SMA Service Line

Niestetal

00800 SMA SERVICE

(+800 762 7378423)

Technical Information ClusterController_Modbus-TI-en-18 41

Page 42

SMA Solar Technology

www.SMA-Solar.com

Loading...

Loading...